Patents

Literature

218results about "Weighing apparatus using fluid action balancing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

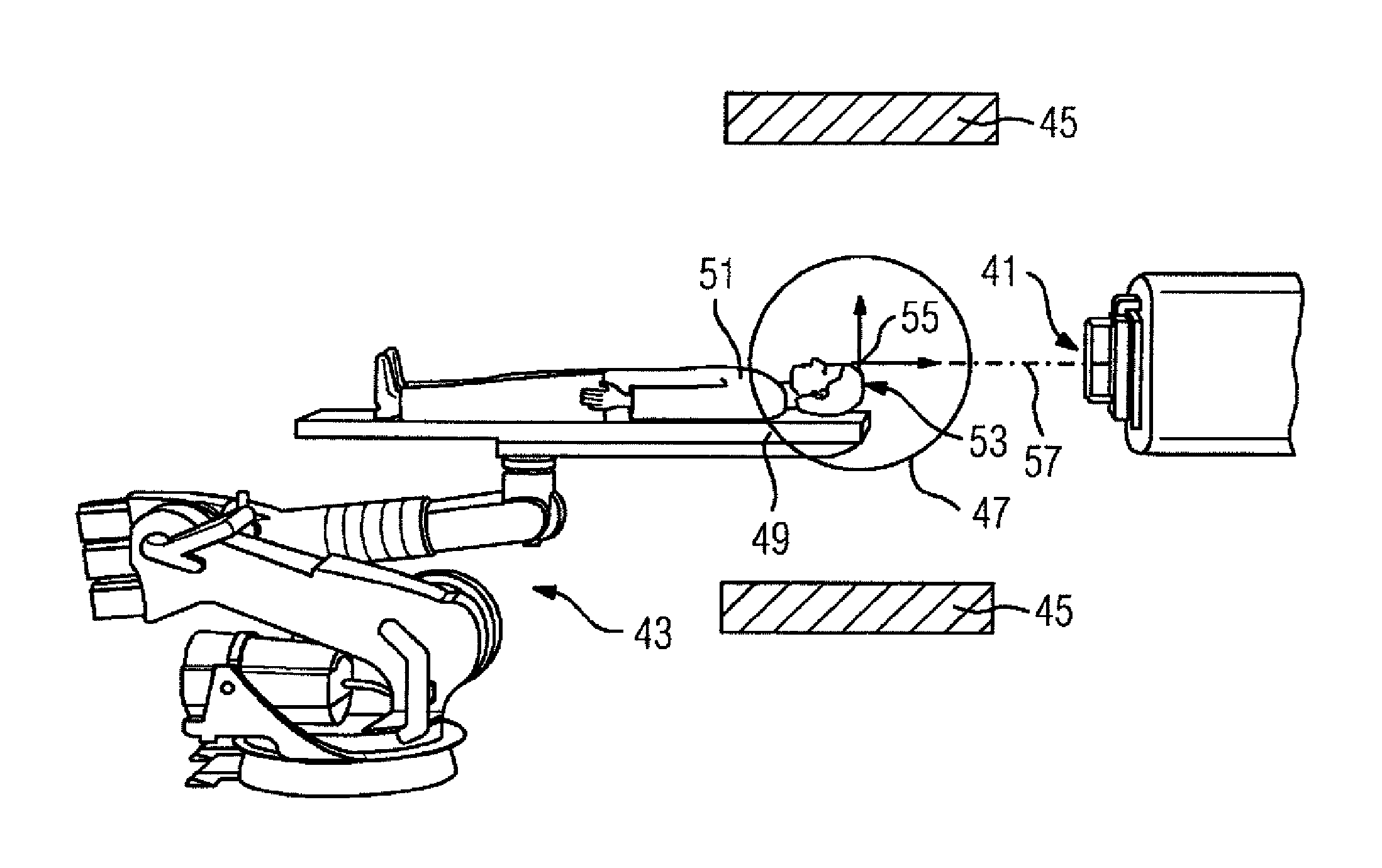

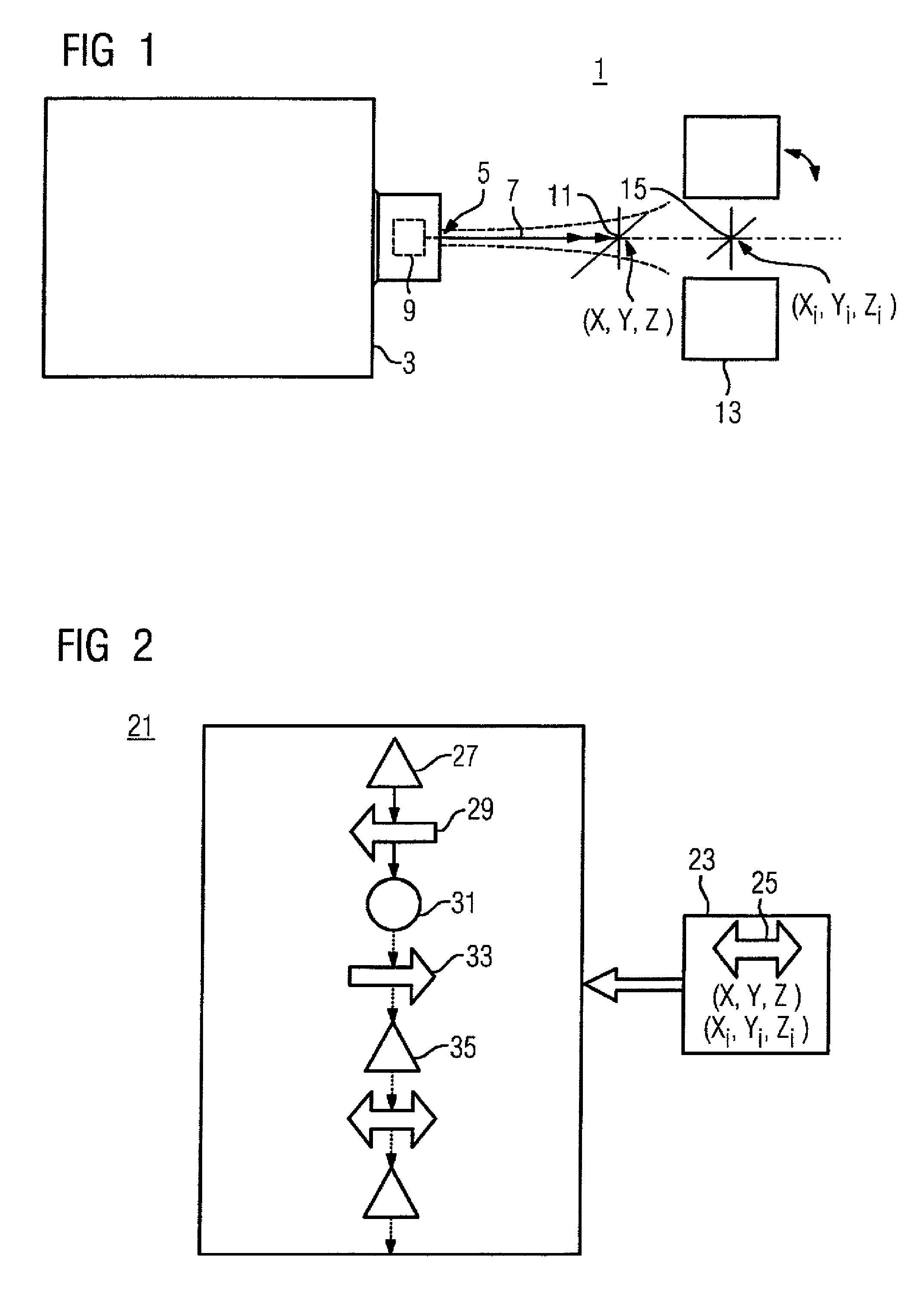

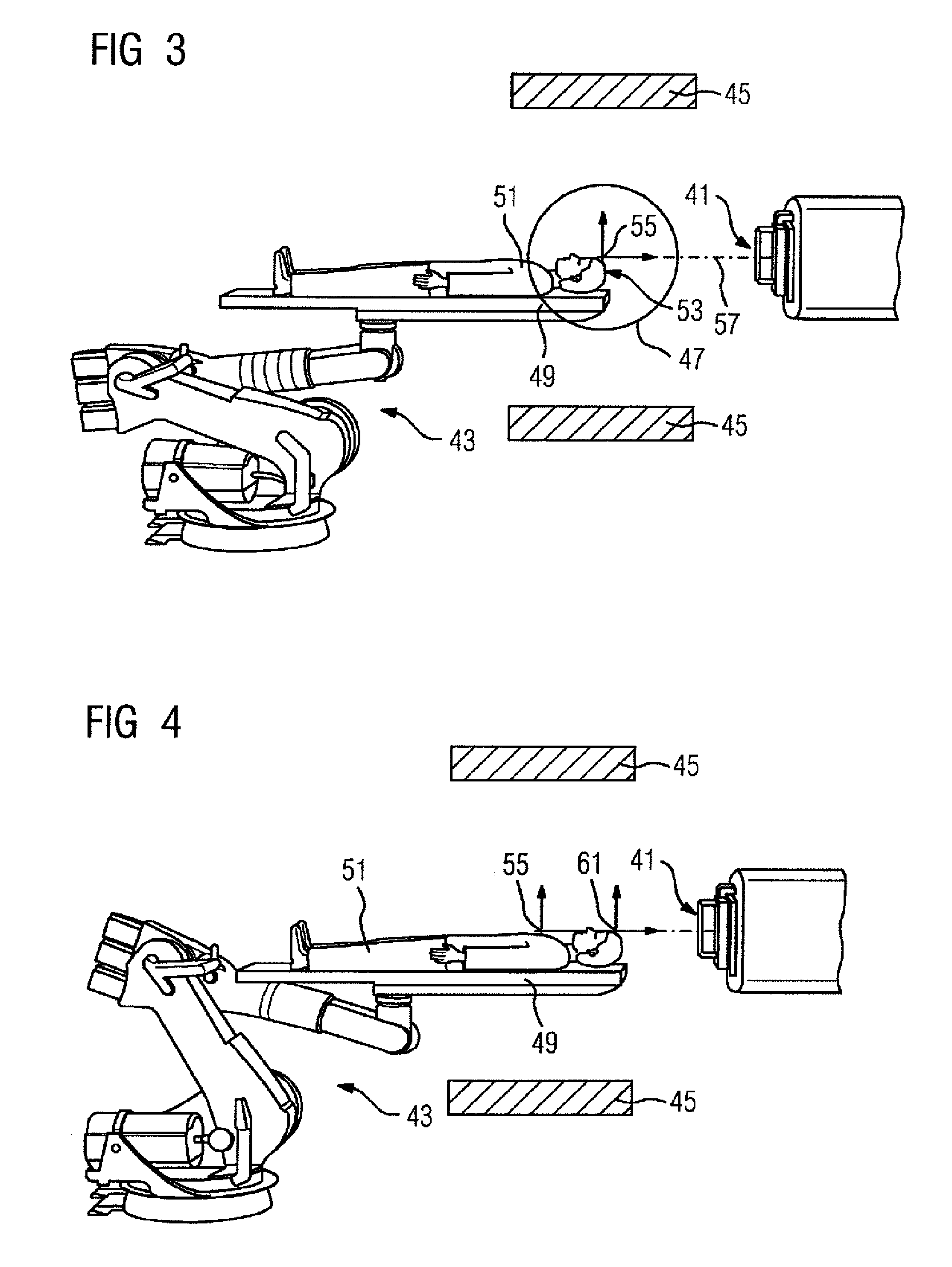

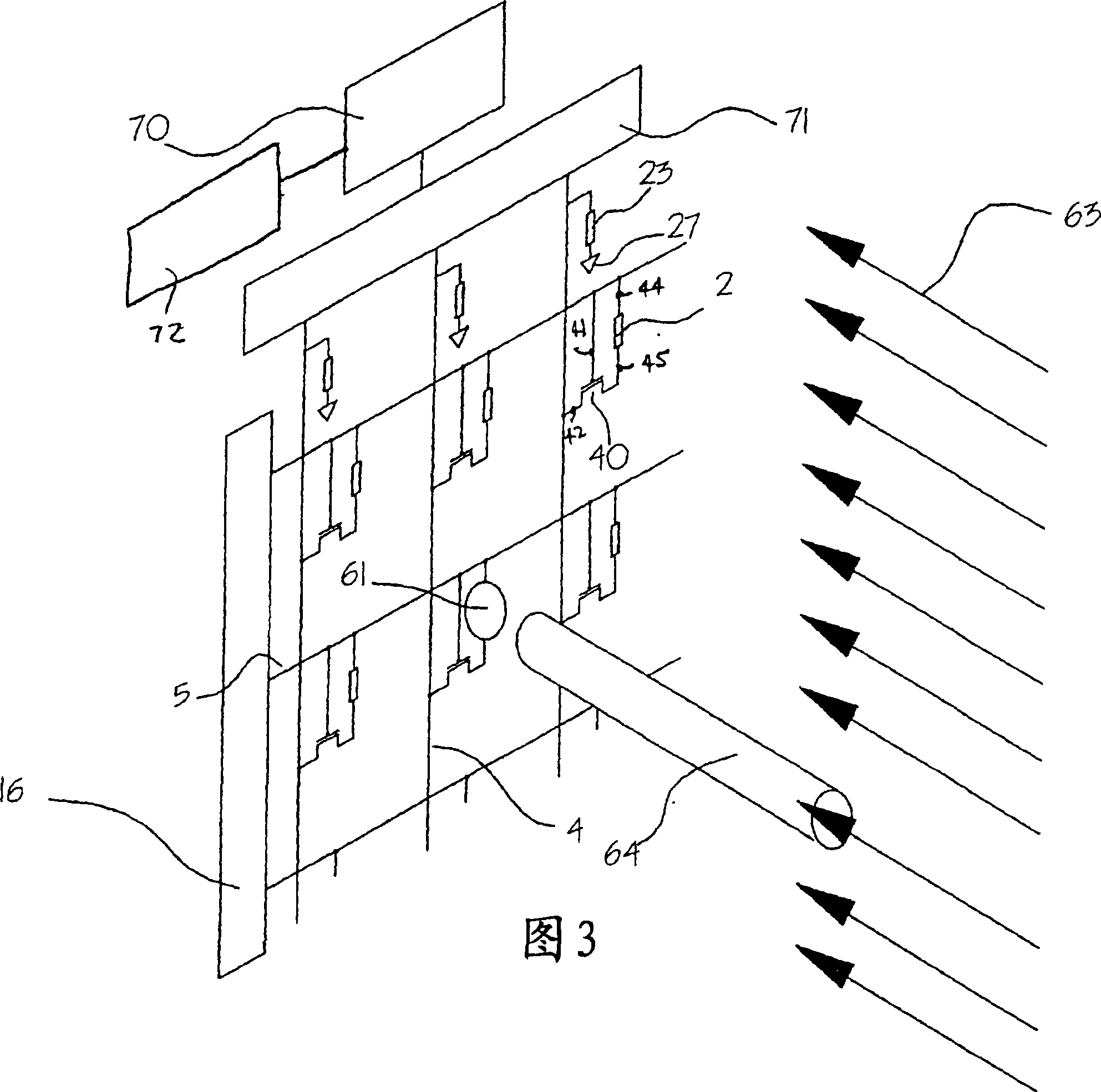

Particle therapy system

InactiveUS7834334B2Weighing apparatus using fluid action balancingMicrowave therapyParticle beamHigh energy

A particle therapy system for irradiating a volume of a patient to be irradiated with high-energy particles is provided. The system includes a radiation outlet of a radiation delivery and acceleration system from which a particle beam exits in order to interact with the patient positioned in an irradiation position; an imaging device for verifying the position of the volume to be irradiated in relation to the particle beam; and a patient-positioning device with which the patient can be brought into the irradiation position for irradiation. The imaging device checks the position of the volume to be irradiated in an imaging position of the patient that is spatially remote from the irradiation position, and the patient-positioning device automatically changes position between imaging position and irradiation position.

Owner:SIEMENS AG

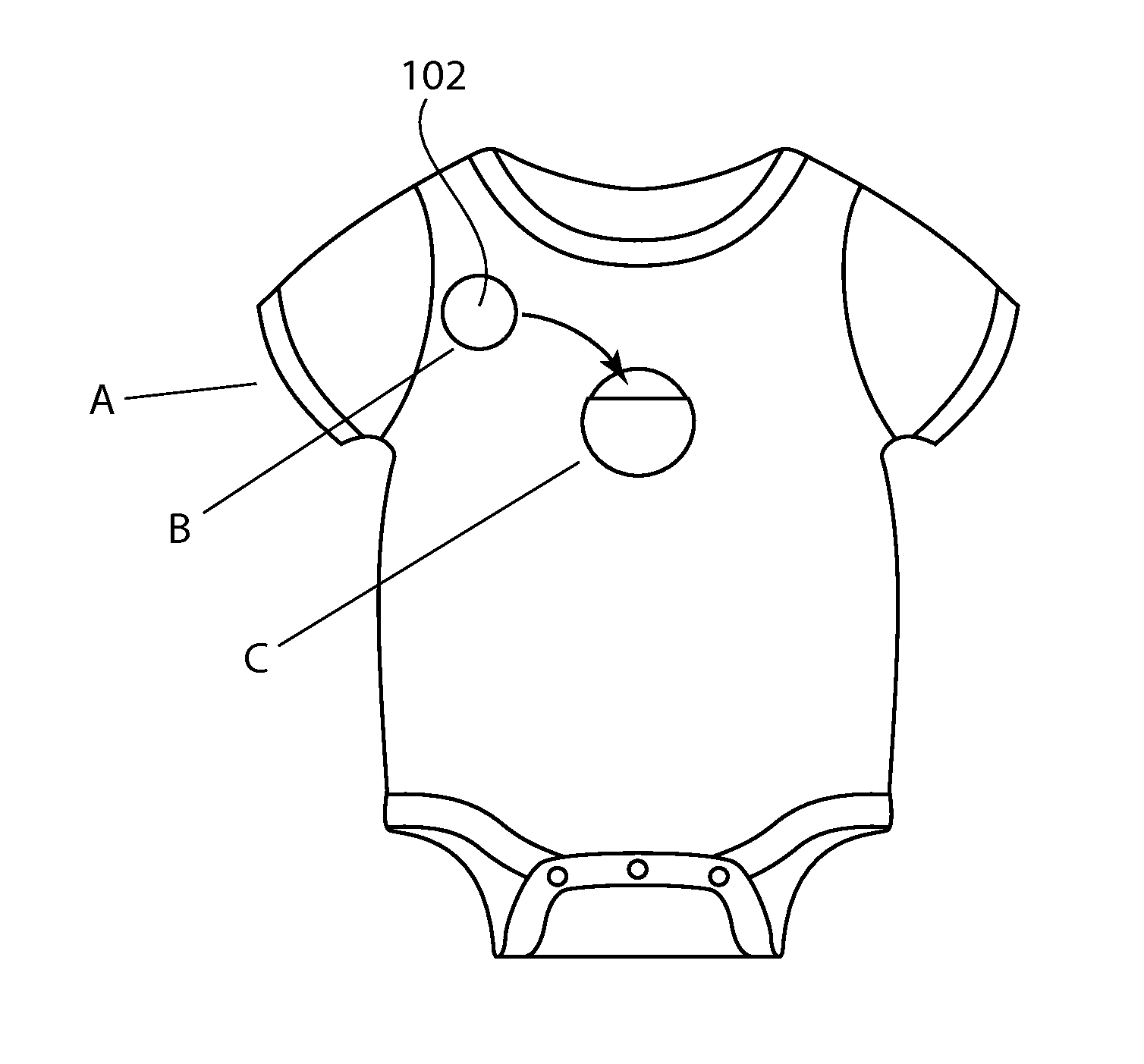

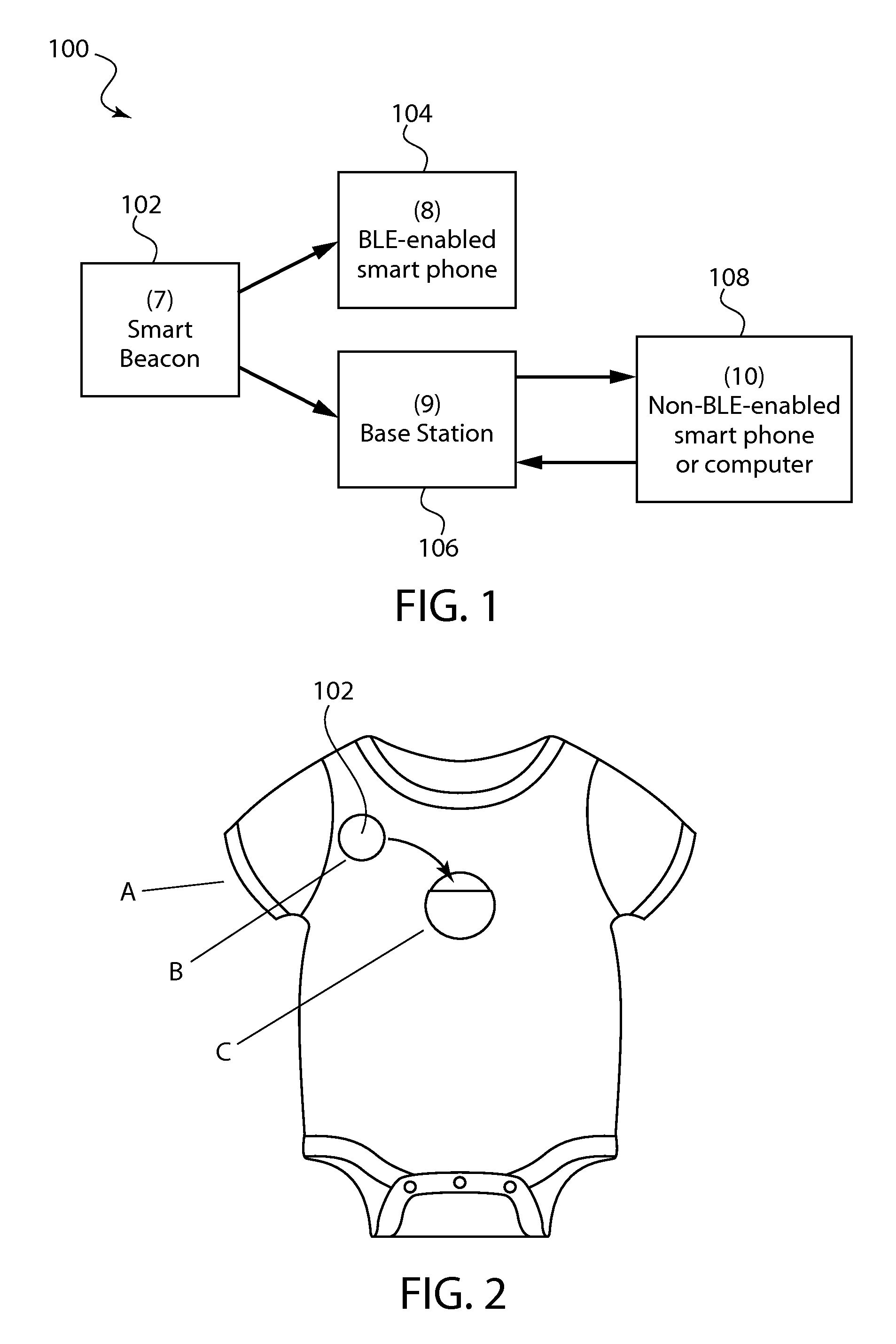

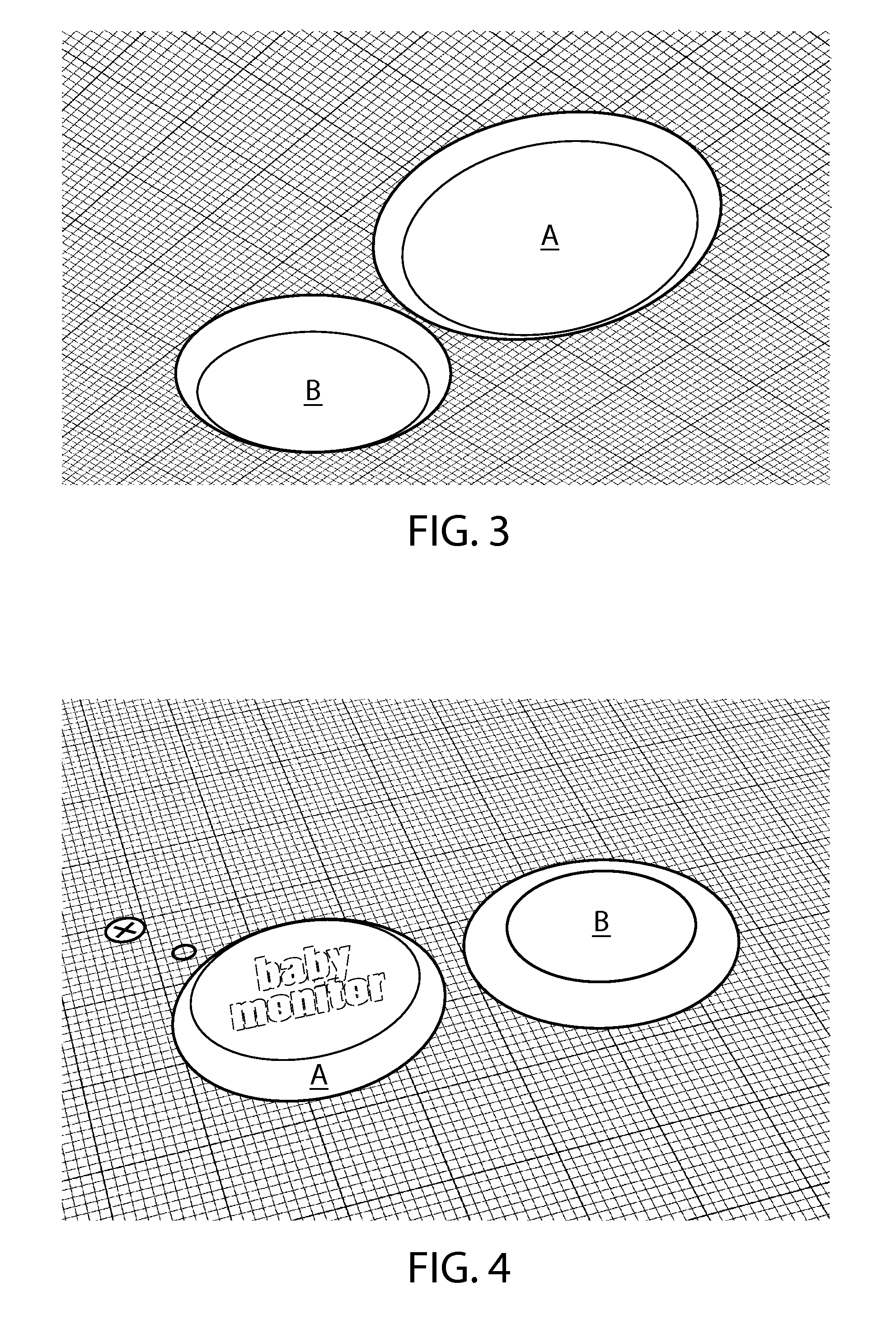

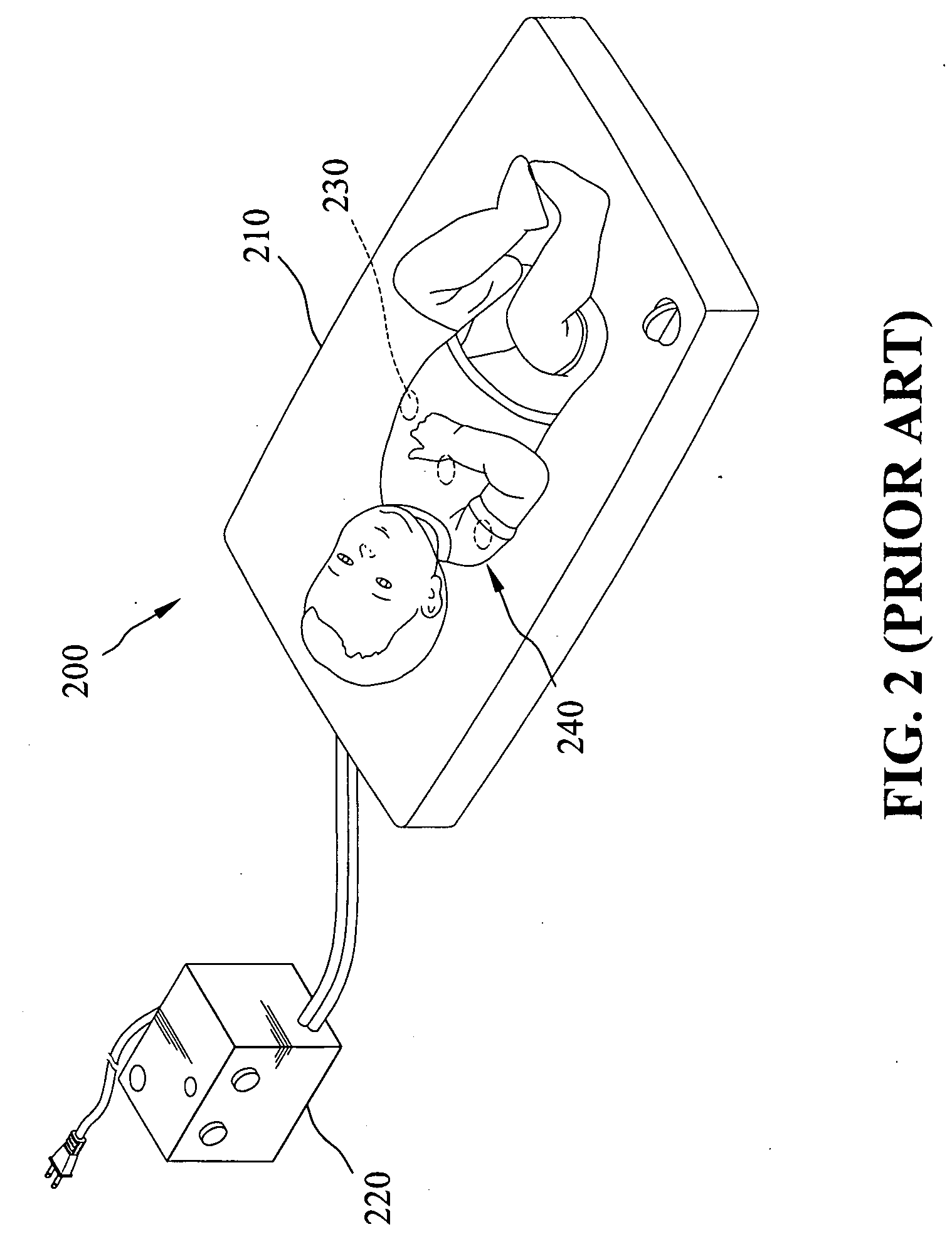

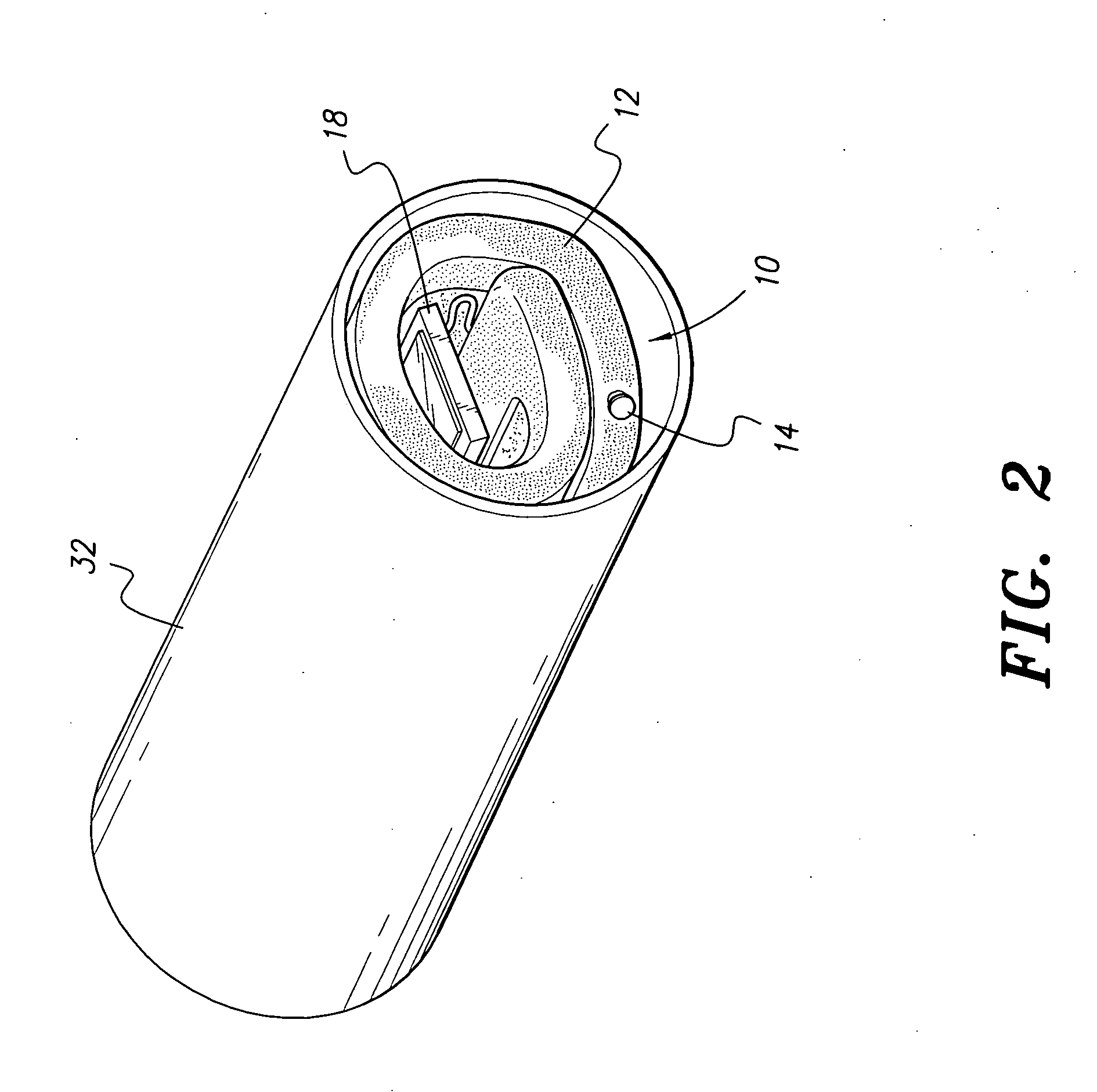

Subject motion monitoring, temperature monitoring, data gathering and analytics system and method

ActiveUS20150250419A1Weighing apparatus using elastically-deformable membersInertial sensorsTransceiverModem device

The monitoring device provides value to parents by assisting with monitoring their infants via a convenient sensor package, straightforward interface, and informative data. With movement, orientation, and temperature data, some strong indicators of general well-being can be monitored and conclusions extracted without the parent needing to be constantly involved. The low-power transceiver technology also means that the device can integrate with smart devices for even more convenience. Such a smart device can in turn communicate with modem large-scale data storage and analysis centers for data logging and analytics, which allows useful analytics to be passed back to the user. The advanced sensing, displaying, and analyzing of data makes the invention stands out in the field of infant monitoring devices.

Owner:MONDEVICES

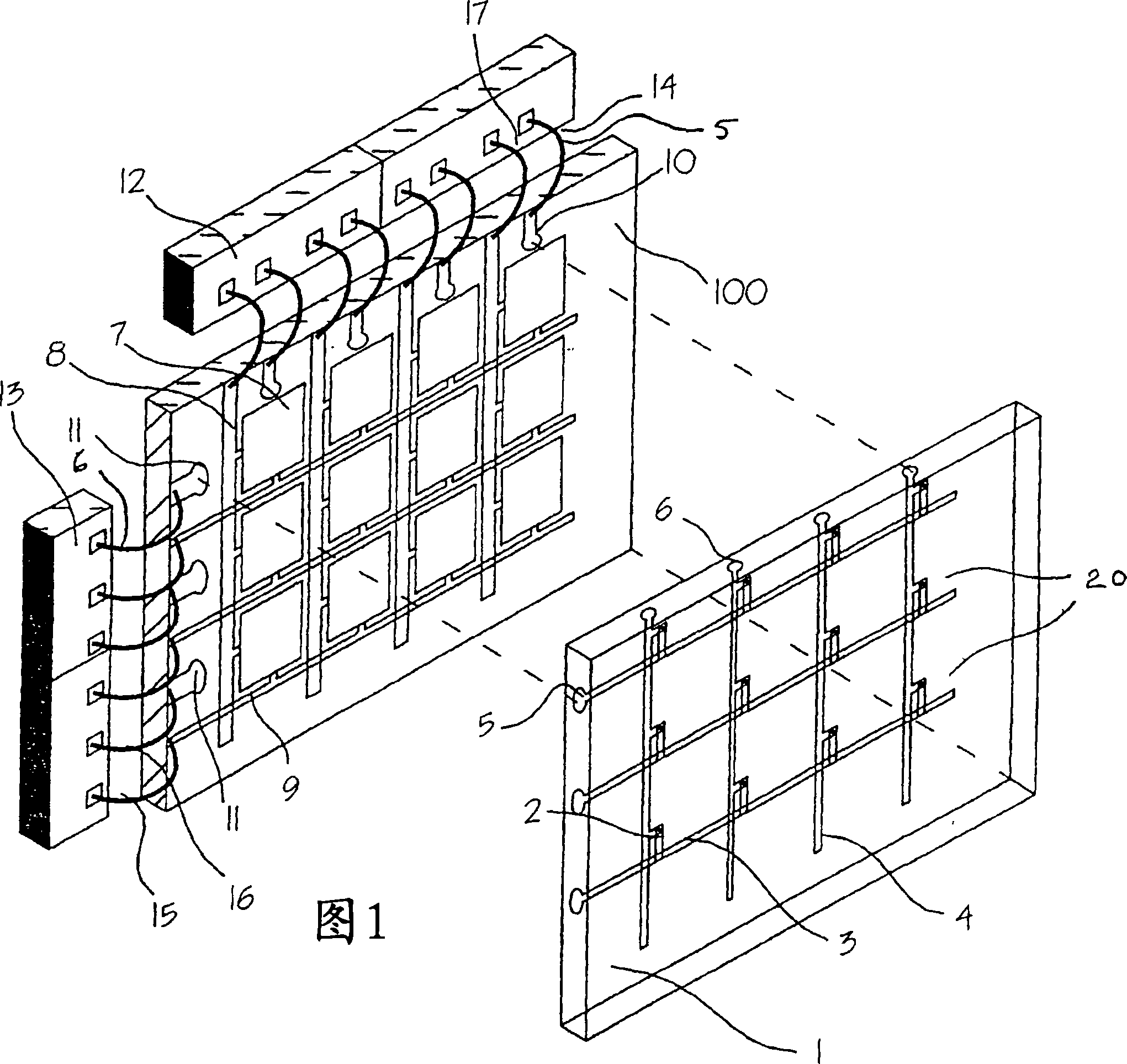

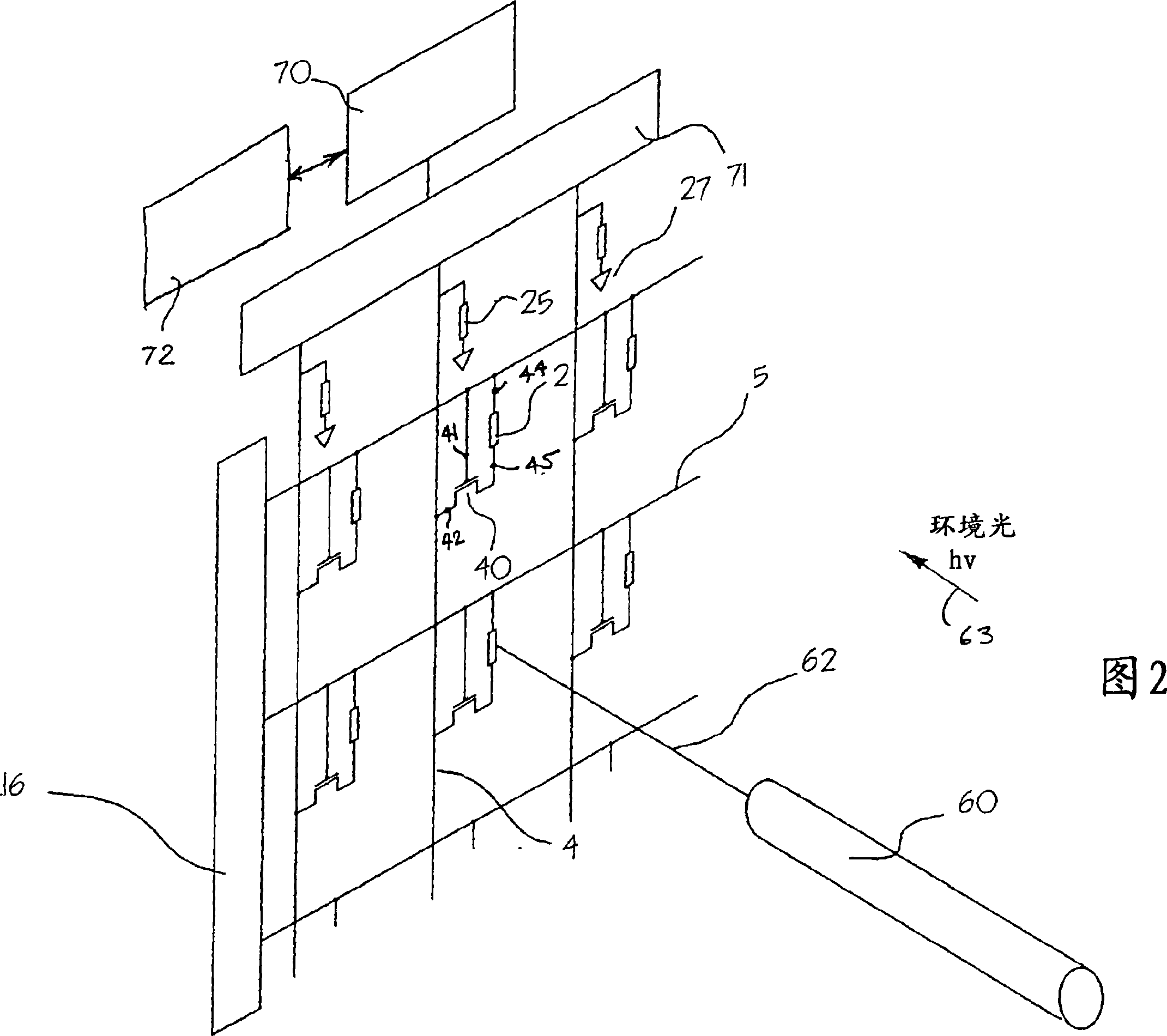

Penlight and touch screen data input system and method for flat panel displays

InactiveCN1922470AWeighing apparatus using fluid action balancingEnergy saving control techniquesTouch panelLight source

System, device, and method for receiving or sensing touch or light input to an emissive display such as to a OLED display using the same or different sensors as are used to sense and maintain a pixel luminance. Penlight and touch screen data input system and method for display. A sidelight illuminated display and touch panel input device. Method and device for reading display pixel emission and ambient luminance levels. Emissive display having sensing for luminance stabilization and user light or touch screen input. Method and device for emissive display using shielded or partially shielded sensors. Emissive pixel display device characterized in that photon sensors are disposed within pixels and operated to sense photons emitted by emitter within pixel and ambient photons emitted by sources outside pixel, sensed internally emitted photons being for luminance feedback control and sensed ambient photons being used to detect external light source or sources.

Owner:SAIKO CO LT

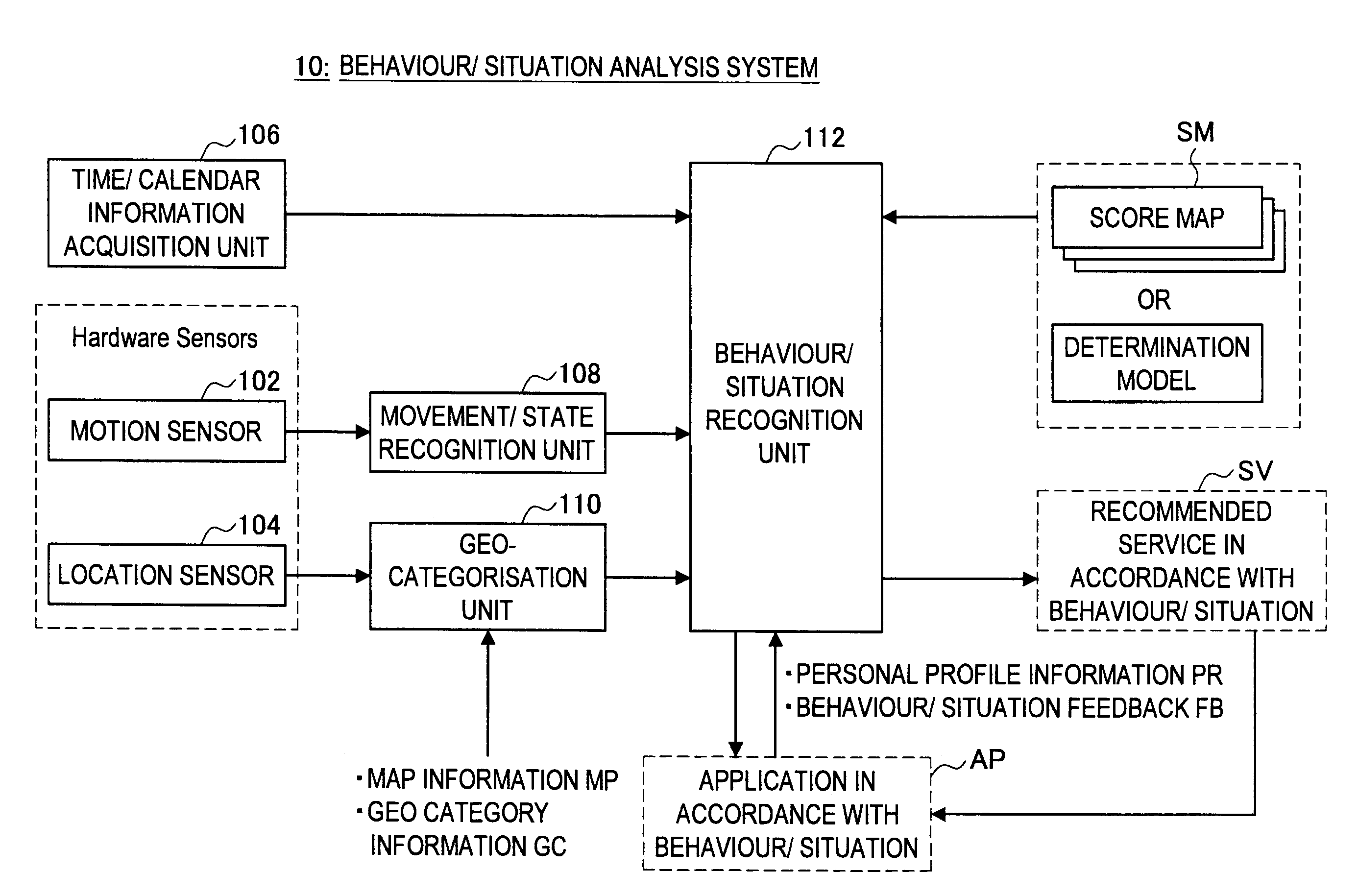

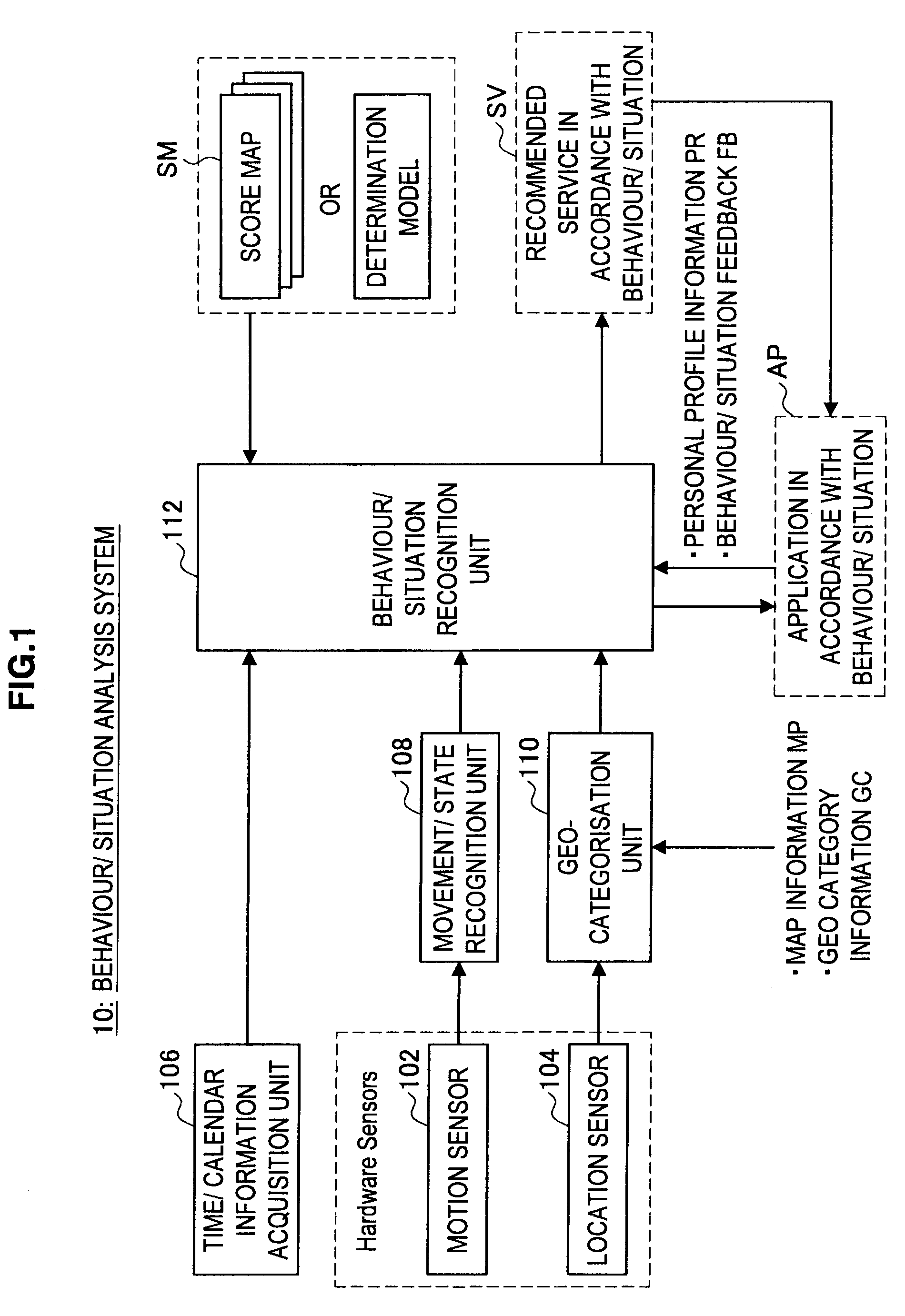

Behaviour pattern analysis system, mobile terminal, behaviour pattern analysis method, and program

Owner:SONY CORP

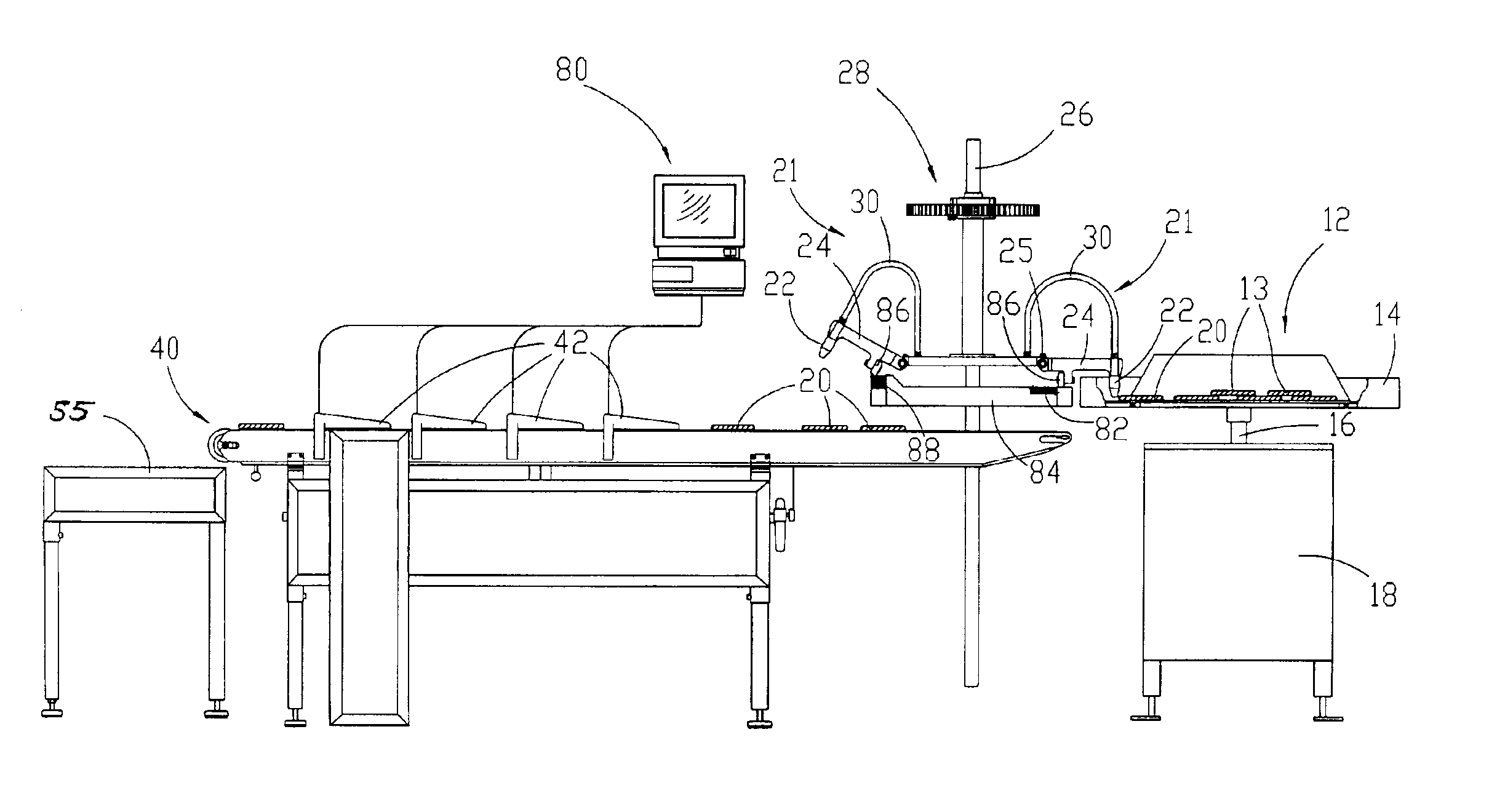

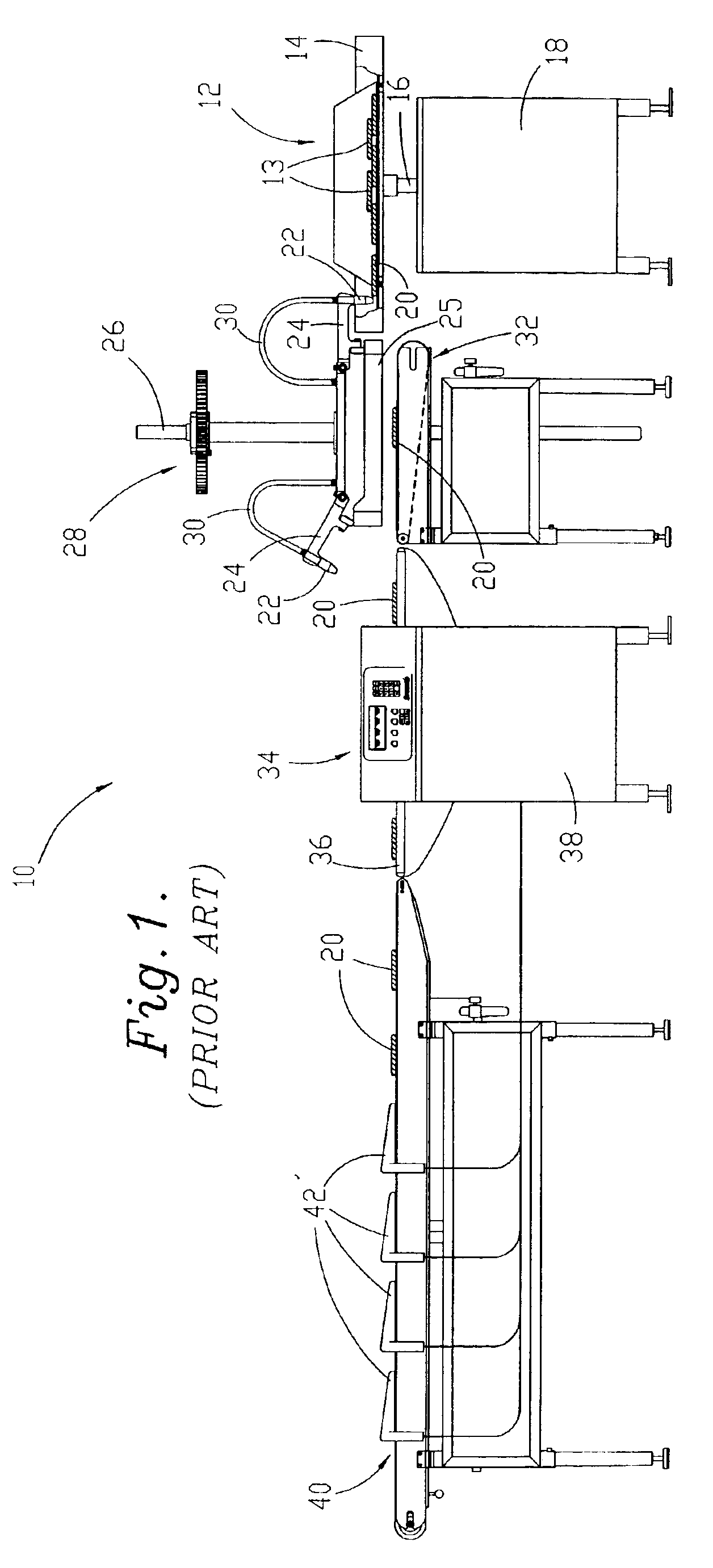

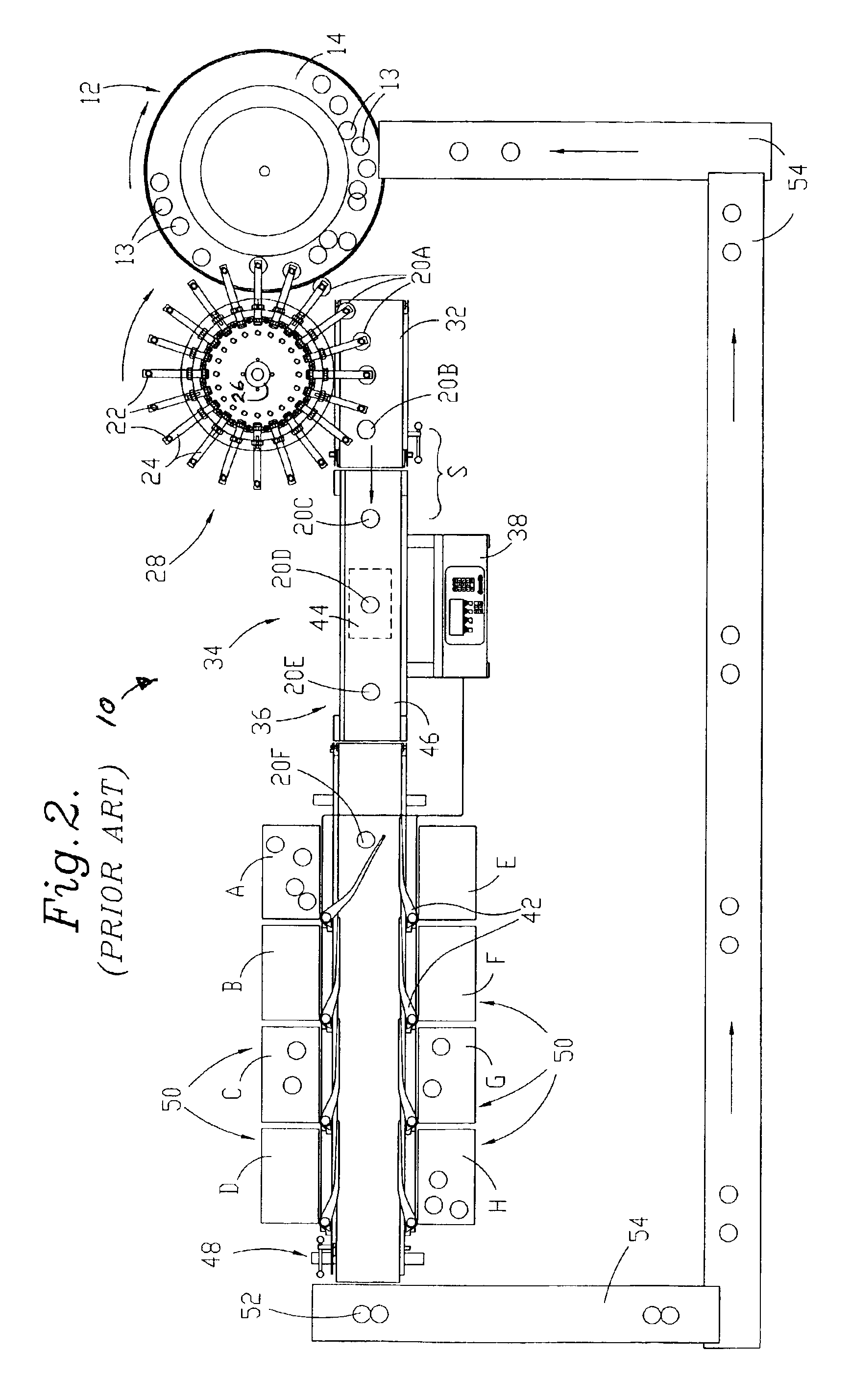

Method and apparatus for product attribute measurement

InactiveUS6881907B2ConveyorsWeighing apparatus using fluid action balancingProduct propertyComputer science

A method and apparatus is provided for determining an attribute of an article during the transfer of the article by an article-feeding machine during the transfer of the article from one location to another location.

Owner:BAADER LINCO INC

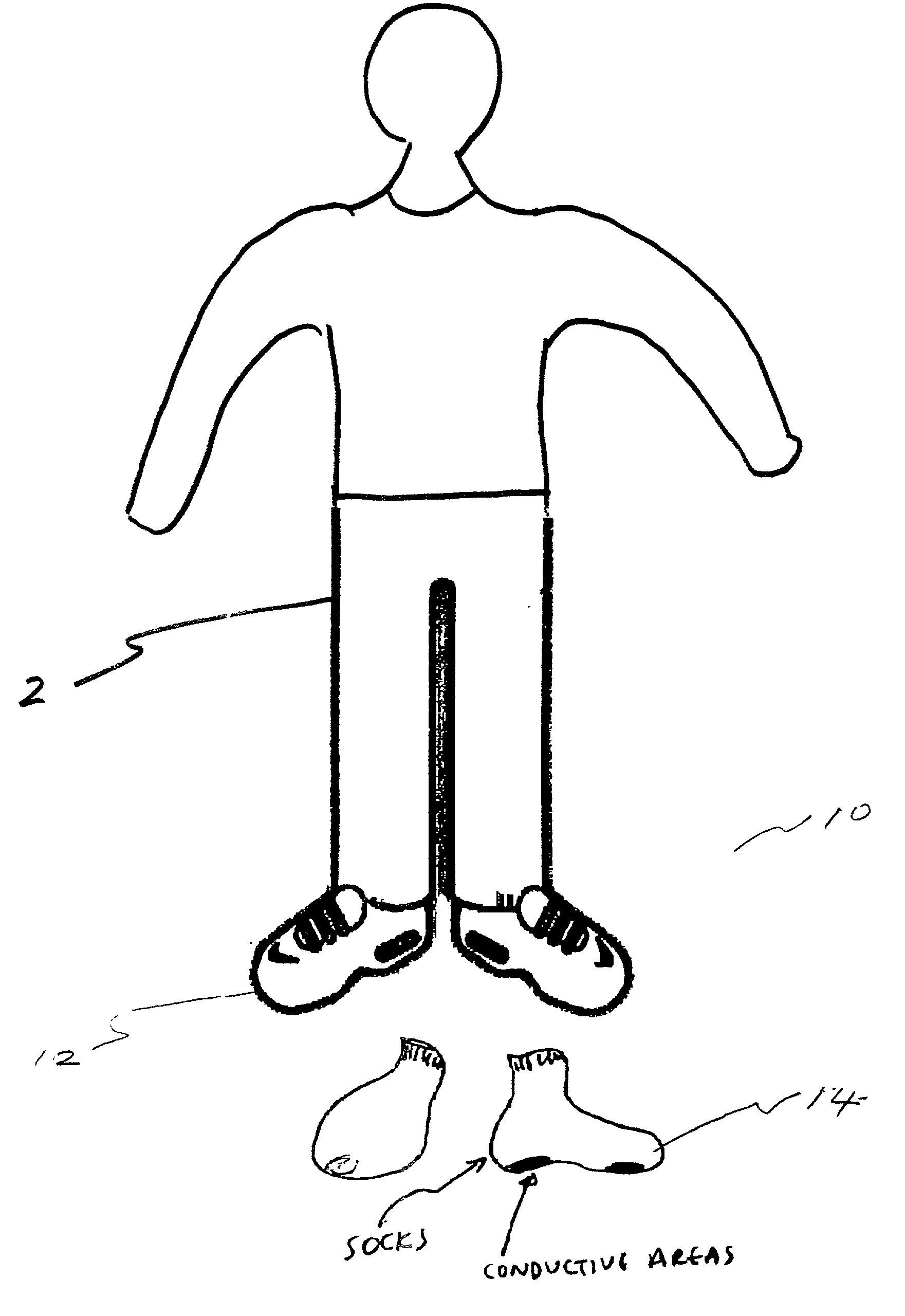

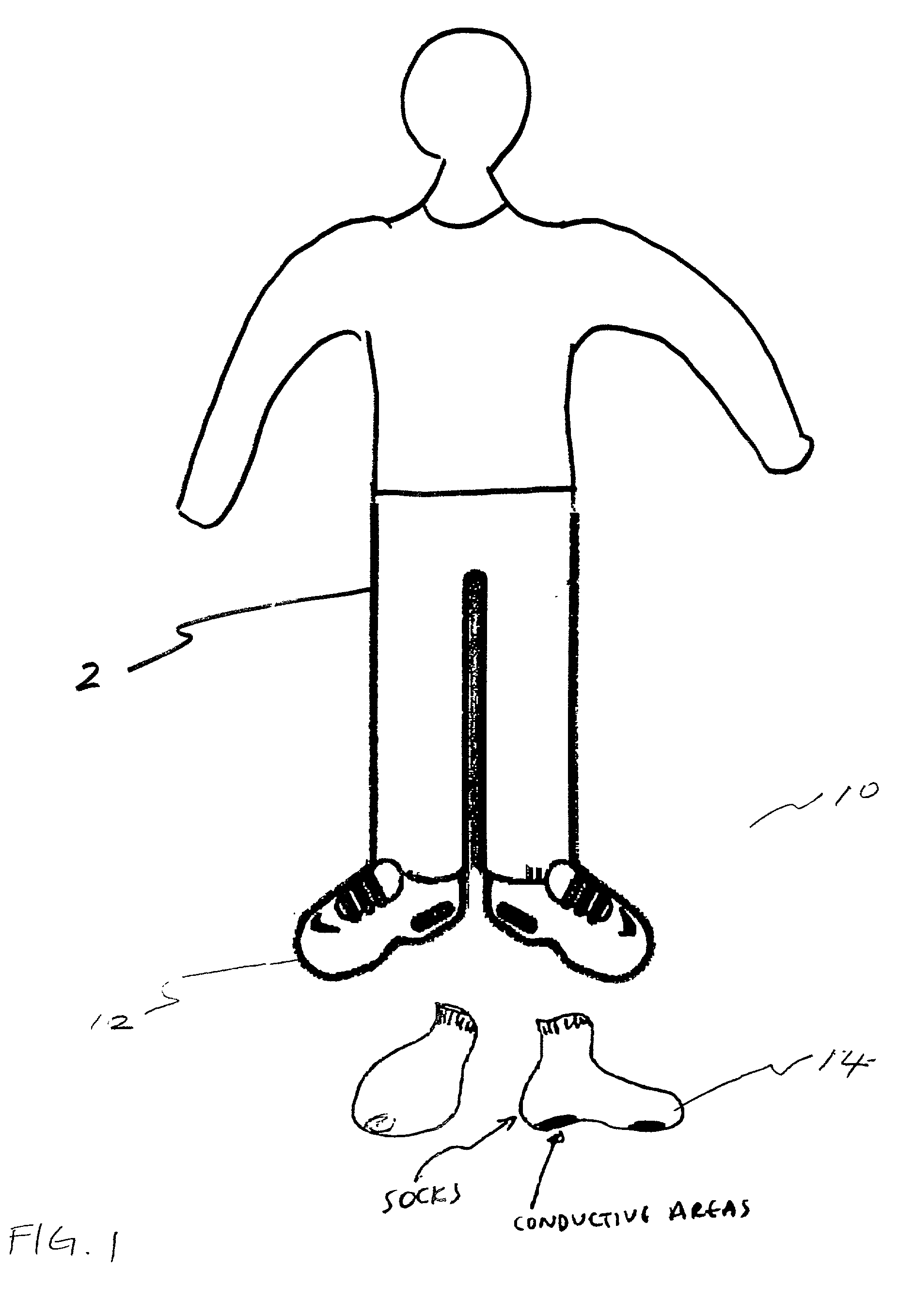

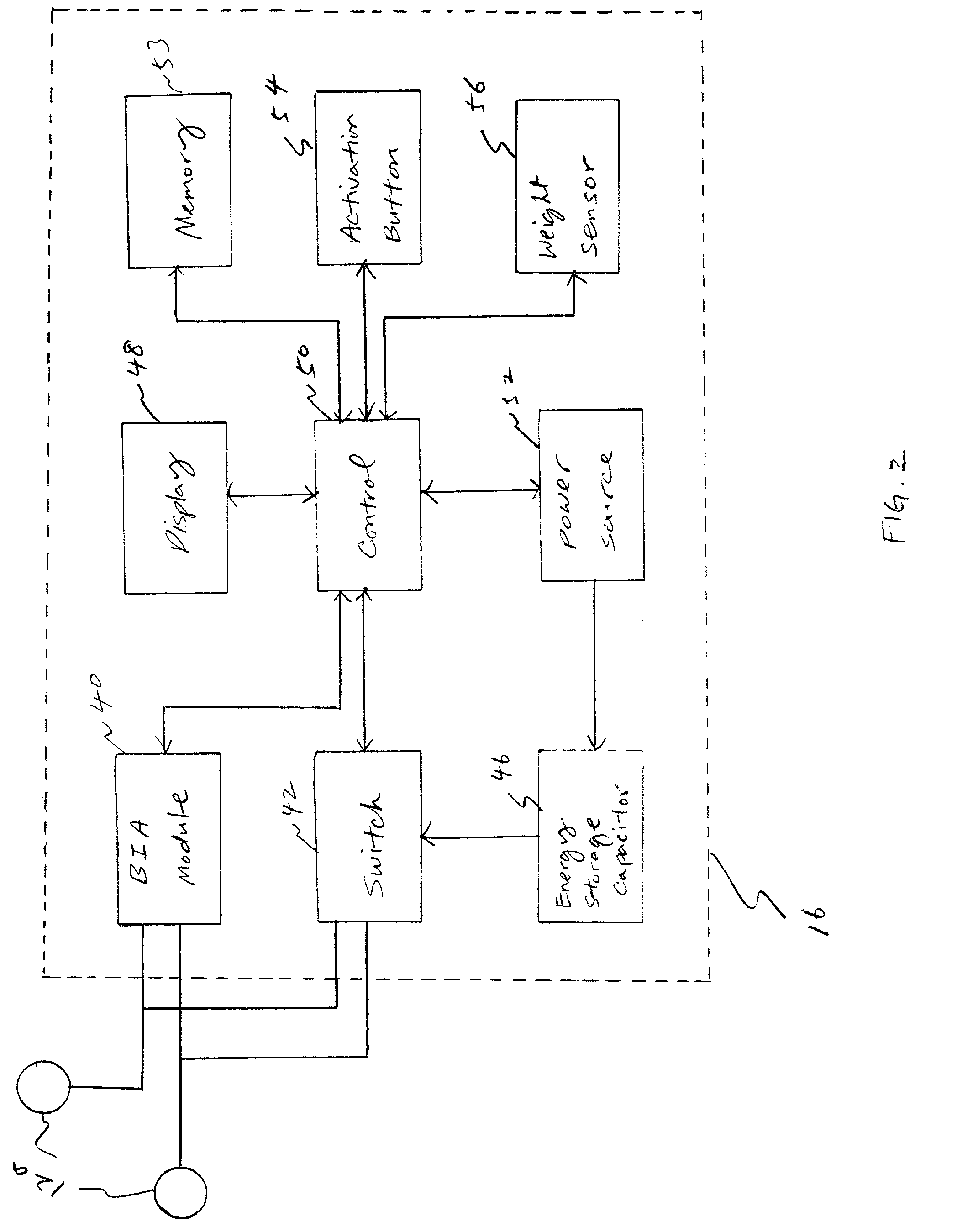

Wearable body-fat sensor

InactiveUS20020169387A1Simple and efficient and reliable implementationPerson identificationWeighing apparatus using fluid action balancingElectrical conductorEngineering

A wearable garment having an electrode and sensors mounted in a predetermined position relative to the wearer's skin provides a quick and efficient way to measure the body-fat composition of the person. The body-fat sensor includes a pair of shoes having a weight-measuring sensor and a wearable body structure, of flexible material, having an inner surface, wherein a flexible electrical conductor is affixed to the inner surface of the wearable body structure. The body-fat sensor further includes an impedance-measuring circuit having at least one pair of electrodes, where the pair of electrodes is being electrically coupled to both ends of the electrical conductor, so that the body-fat composition of the person can be measured based on the data received from the weight sensor and the impedance-measuring circuit.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Airbag sensor deactivator suitable for use in smart airbag system

InactiveUS6431591B1More planarMore brokenElectric devicesPedestrian/occupant safety arrangementPressure transmissionAirbag deployment

Smart airbag systems employ a sensor bag containing an organopolysiloxane gel pressure transmission medium, transmitting pressure to one or more associated pressure sensor devices. The organopolysiloxane gel efficiently transmits pressure without leaking or extruding from the sensor bag when the latter is punctured or ruptured.

Owner:WACKER SILICONES

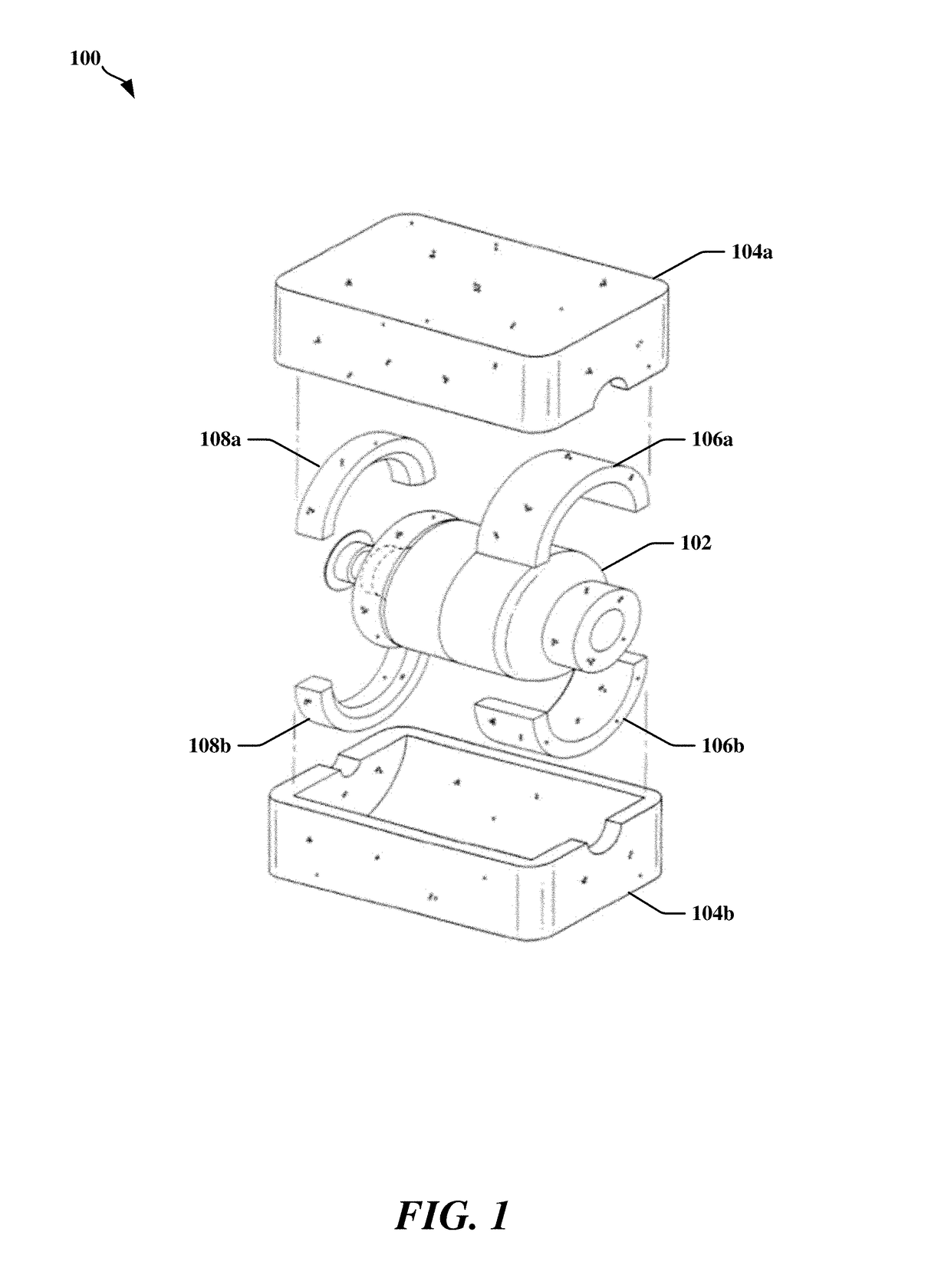

Load cell including angular and lateral decoupling

InactiveUS7005587B2Creating frictionIncrease surface areaVehicle seatsWeighing apparatus using elastically-deformable membersEngineeringLoad cell

A load cell includes a first element, a second element and a sensor measuring force between the first and second elements along a first axis. In some embodiments, lateral and angular decoupling is provided by the provision of a convex surface between the first and second elements. The convex surface is slidable relative to at least one of the first and second elements in a first direction perpendicular to the first axis.

Owner:INTELLIGENT MECHANTRONIC SYST INC

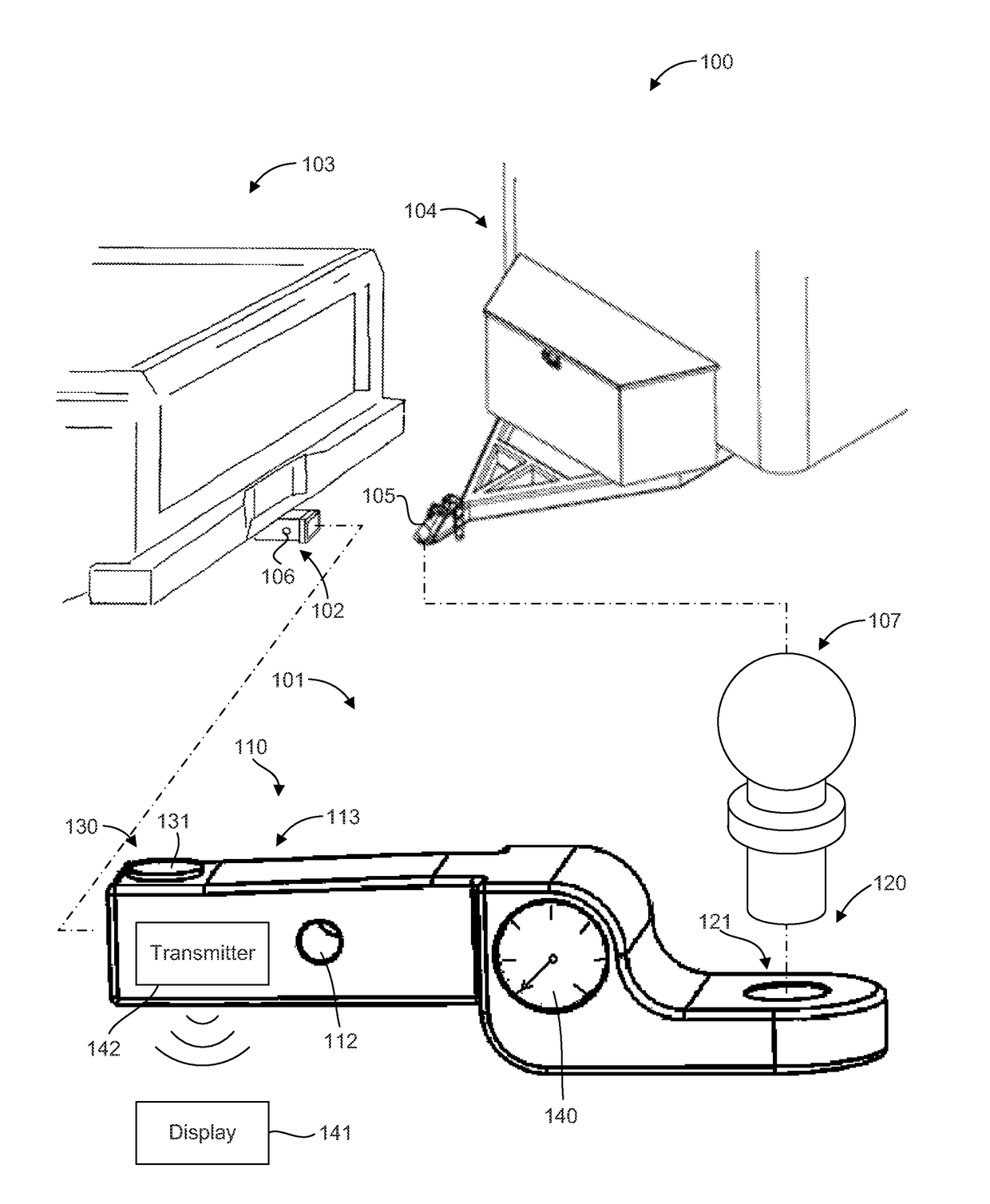

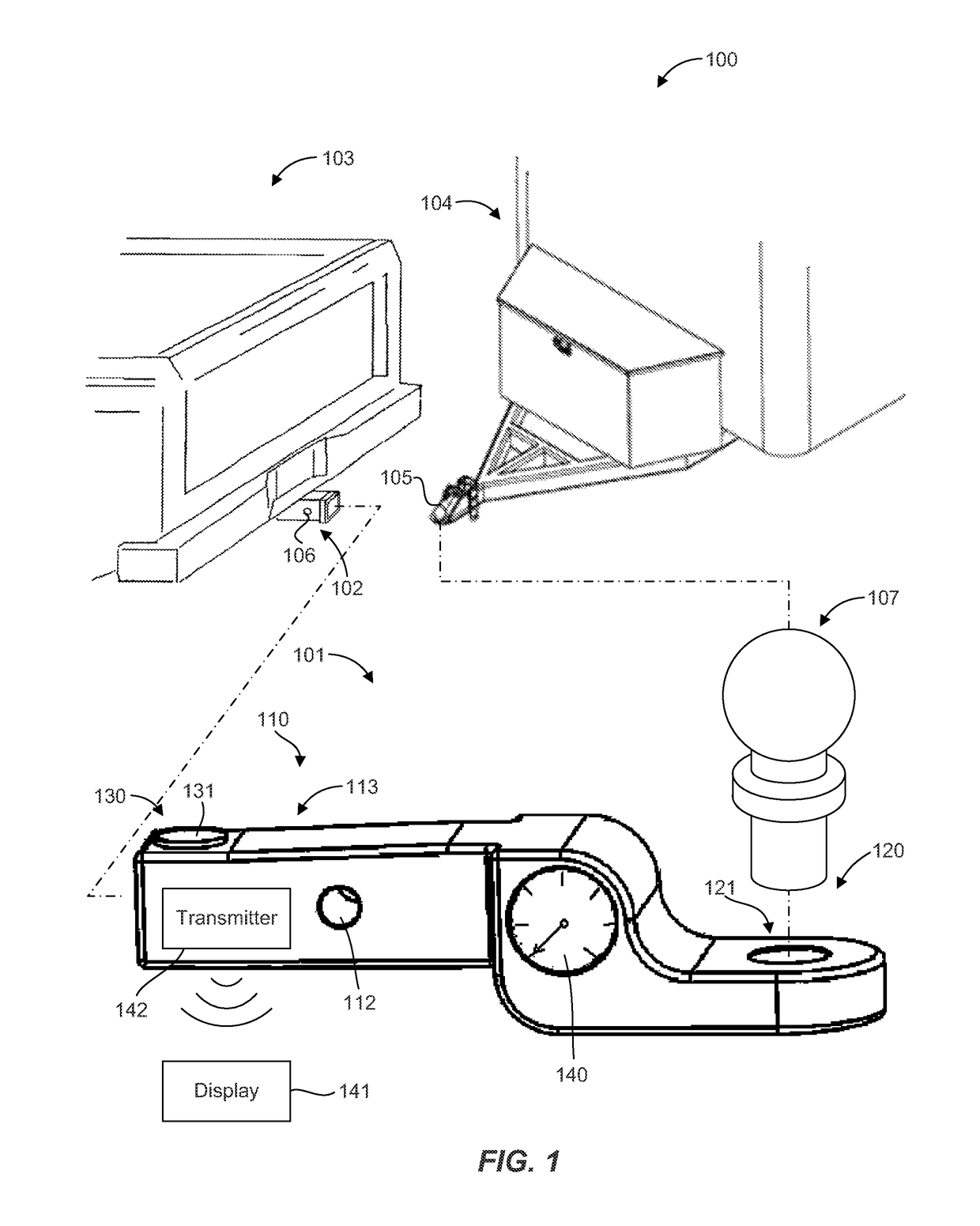

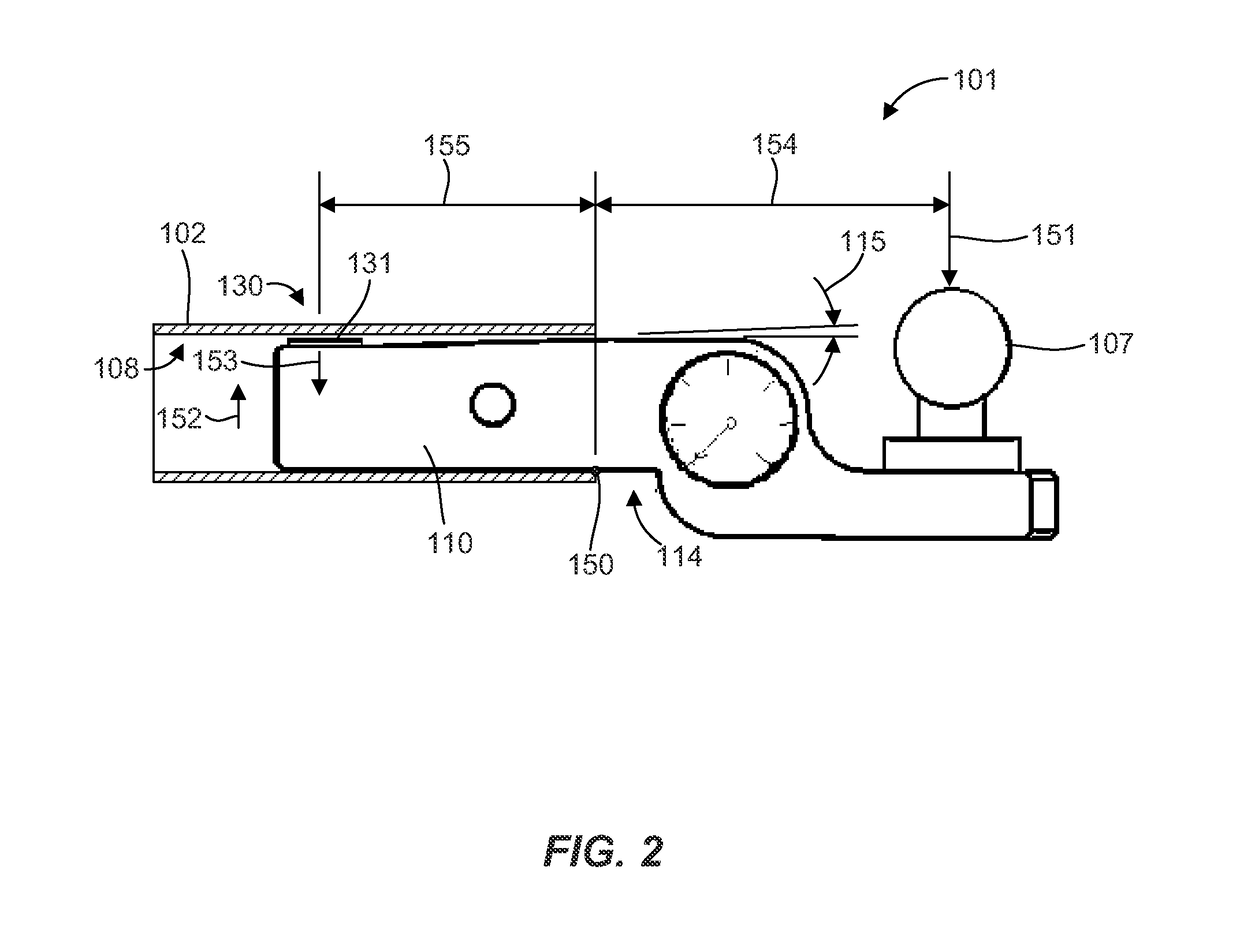

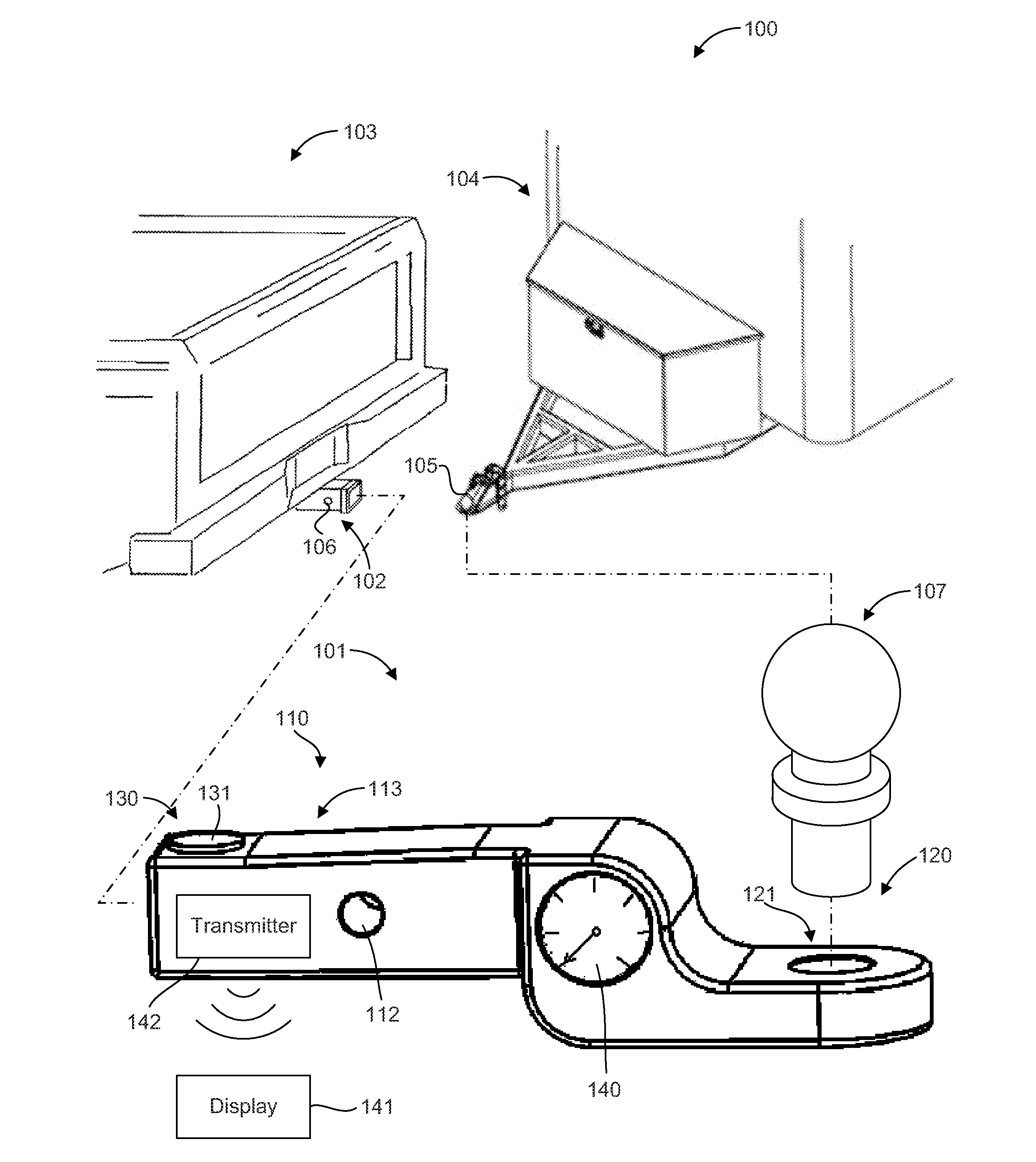

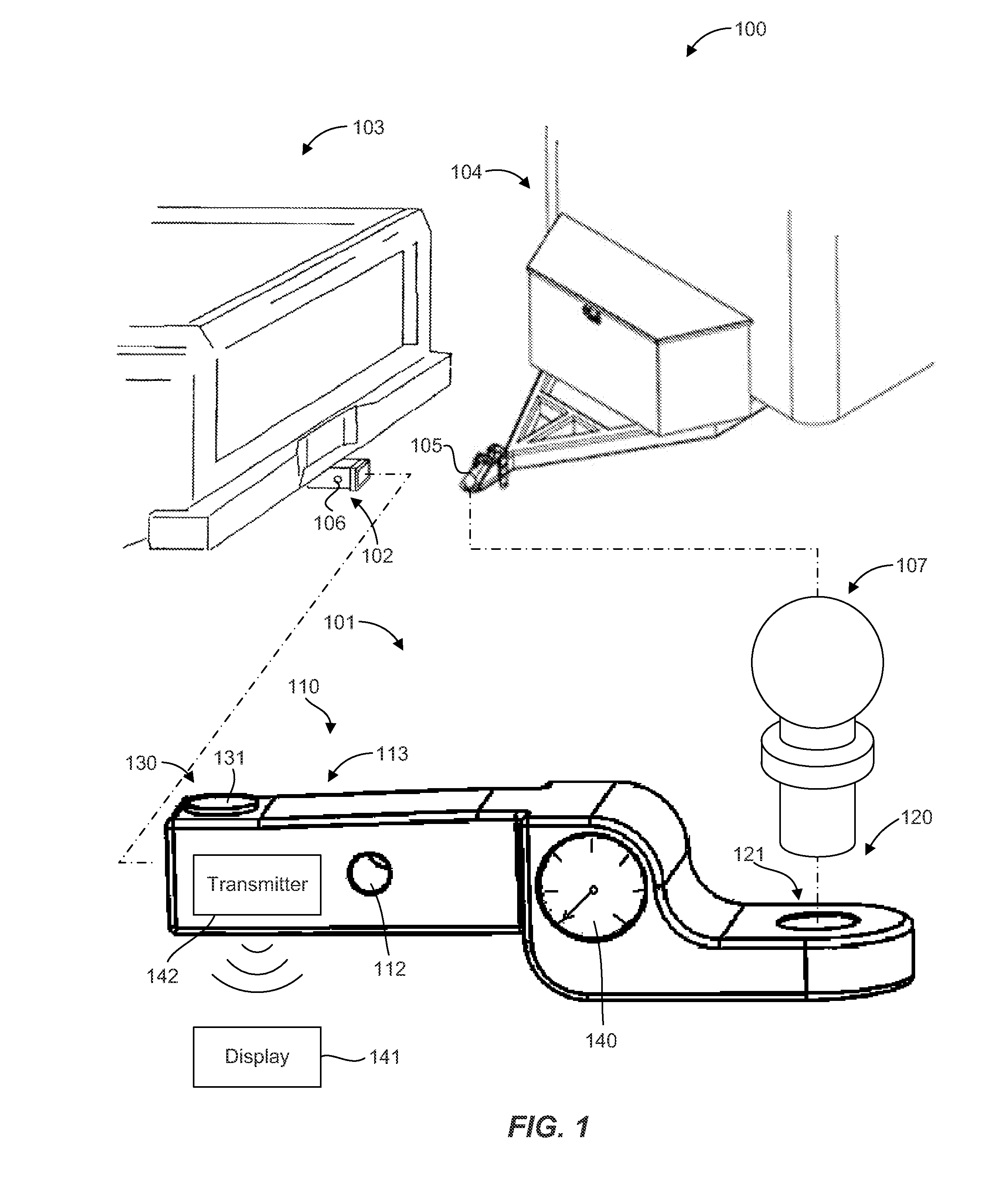

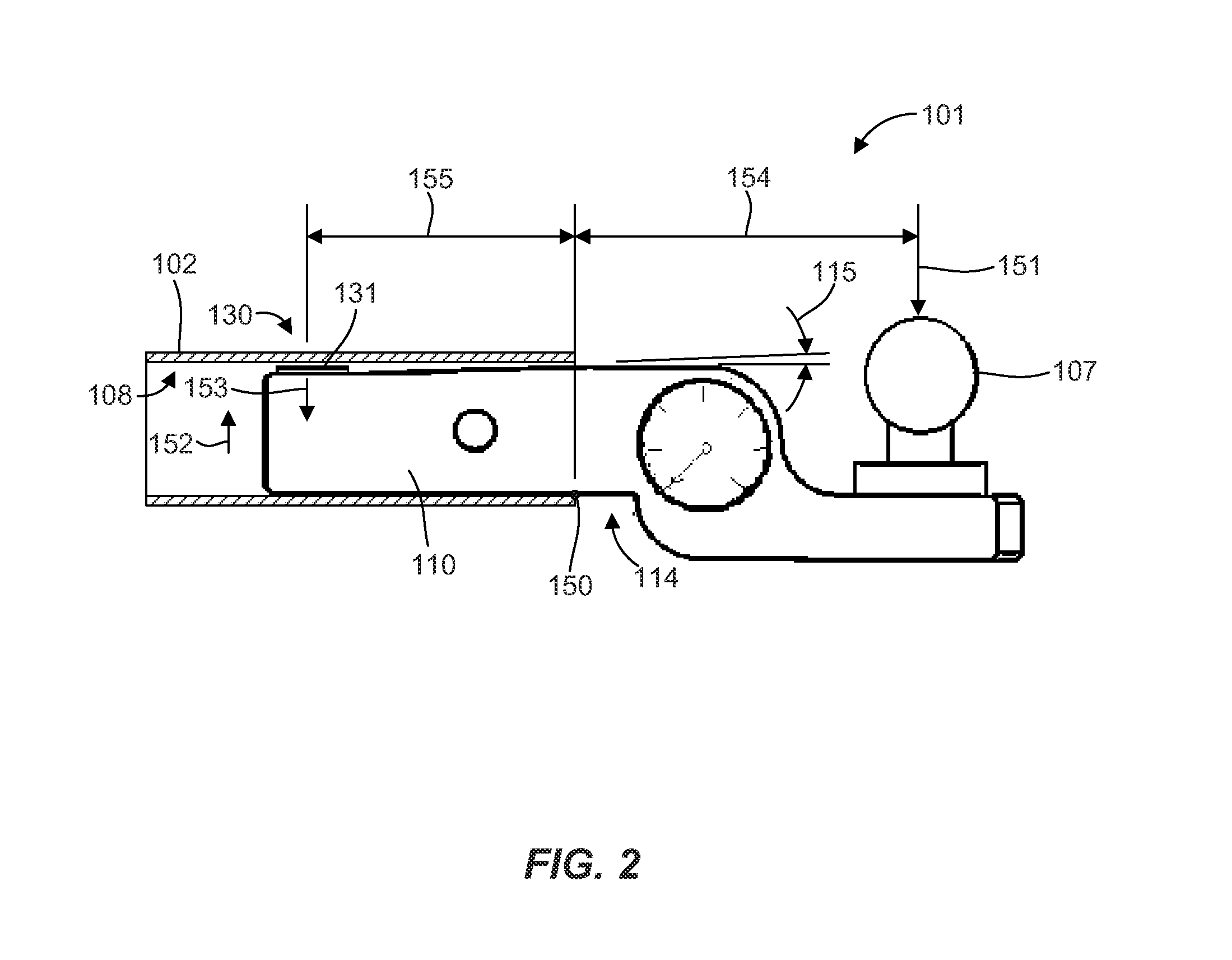

Ball mount for measuring tongue weight of a trailer

A ball mount for measuring tongue weight of a trailer is disclosed. The ball mount can include a ball portion having a hitch ball configured to couple with a tongue of a trailer. The ball mount can also include a hitch portion for interfacing with a hitch receiver associated with a vehicle. In addition, the ball mount can include a load measurement device associated with the ball portion to determine a magnitude of a downward force on the hitch ball. The load measurement device can include a reservoir having a fluid and a piston disposed therein, and a pressure sensor in fluid communication with the reservoir. The hitch ball can be configured to exert a force on the piston, thereby affecting a pressure of the fluid in response to the downward force on the hitch ball.

Owner:WEIGH SAFE LLC

Quantitative weighing system based on buoyant force weighing sensing principle

InactiveCN101464181AIncrease flexibilityCompetitiveWeighing apparatus using counterbalanceWeighing apparatus using fluid action balancingAutomatic controlDigital control

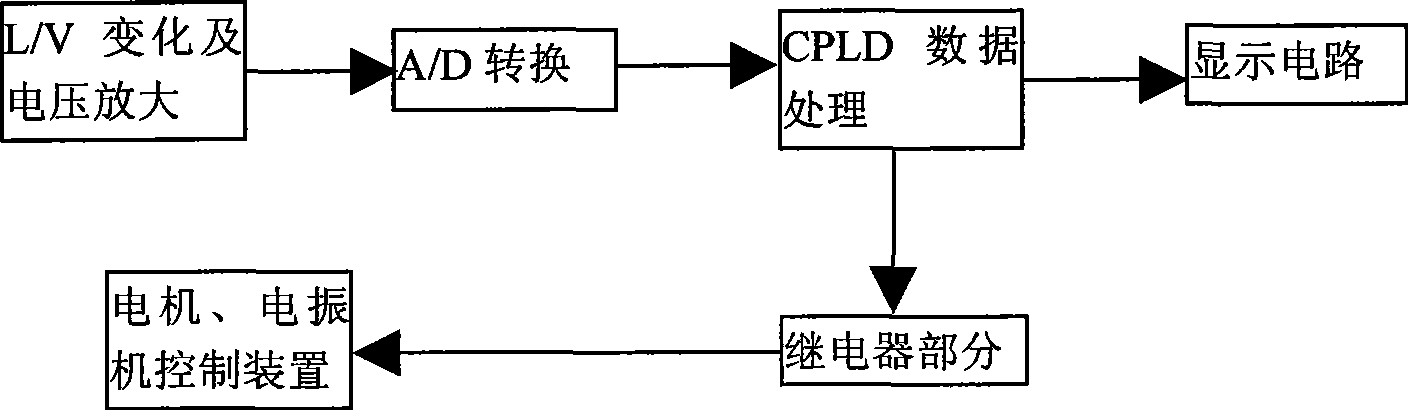

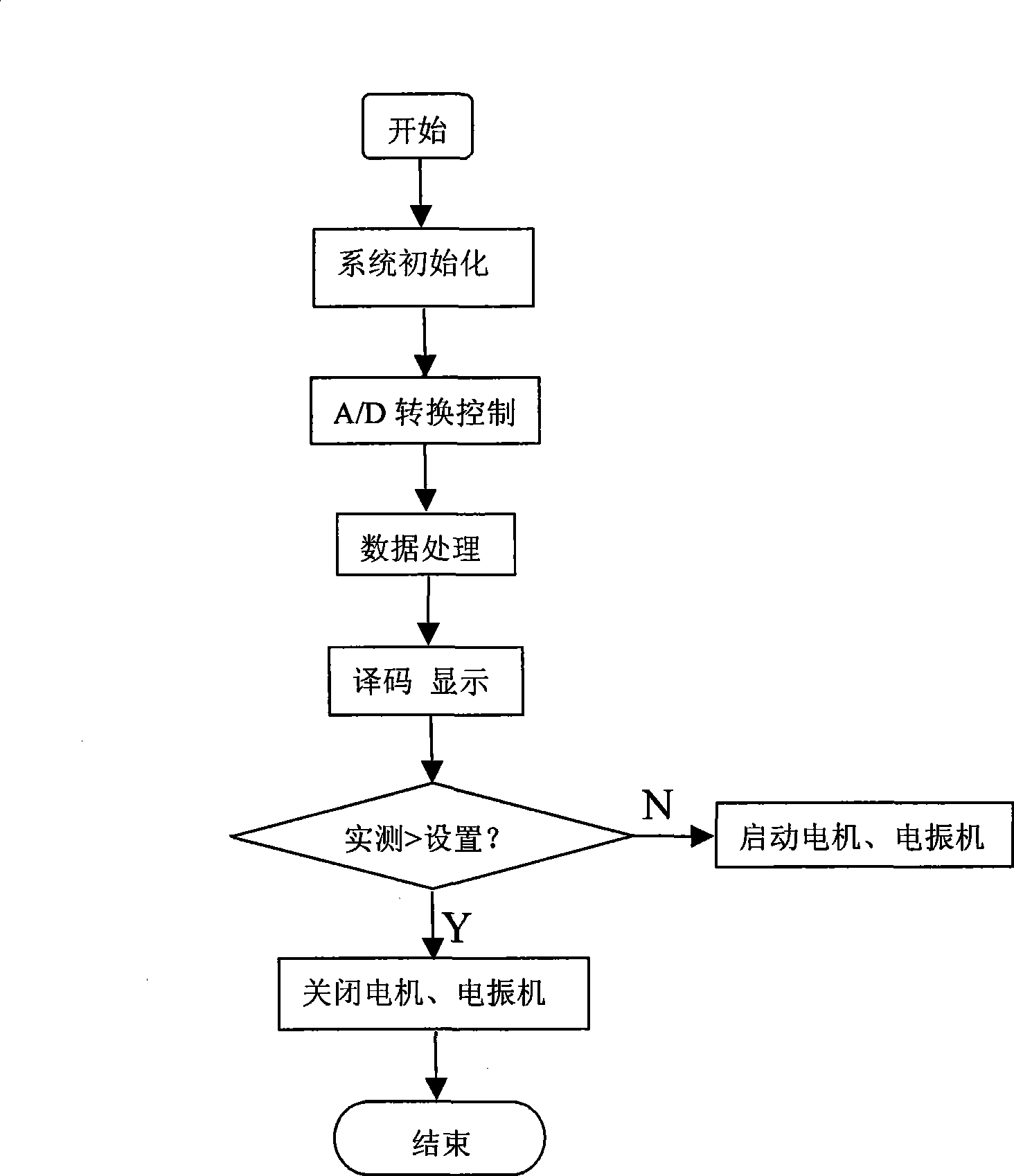

The invention belongs to the field of detection and automatic control. A quantifying-weighing system based on the buoyancy weighing sensing principle comprises a leverage mechanism, a shedding mechanism, a buoyancy sensor and a CPLD control system. According to the liquid buoyancy principle, the buoyancy weighing sensor converts the measured gravity value in the form of linear relation into displacement value which clearly refers to the displacement, and outputs the displacement value in the form of electrical signal. The buoyancy weighing sensor is free of technical defects such as creep deformation, zero point, sensitivity drift and the like. The CPLD control system consists of an R / V change and voltage amplification module, an A / D conversion module, a CPLD data processing module, a display module, a relay part and a motor as well as an electromagnetic vibrating machine control system; and the fundamental controlling principle thereof is that the control system converts a complex digital control logical system into the SOC (design system on chip design) by employing the VHDL language and adopting the top down design method. The invention achieves the effects of reducing the size of the system, enhancing the reliability of the system, shortening the development period, reducing the development cost, and greatly improving the accuracy of the dynamic weighing.

Owner:孔令宇

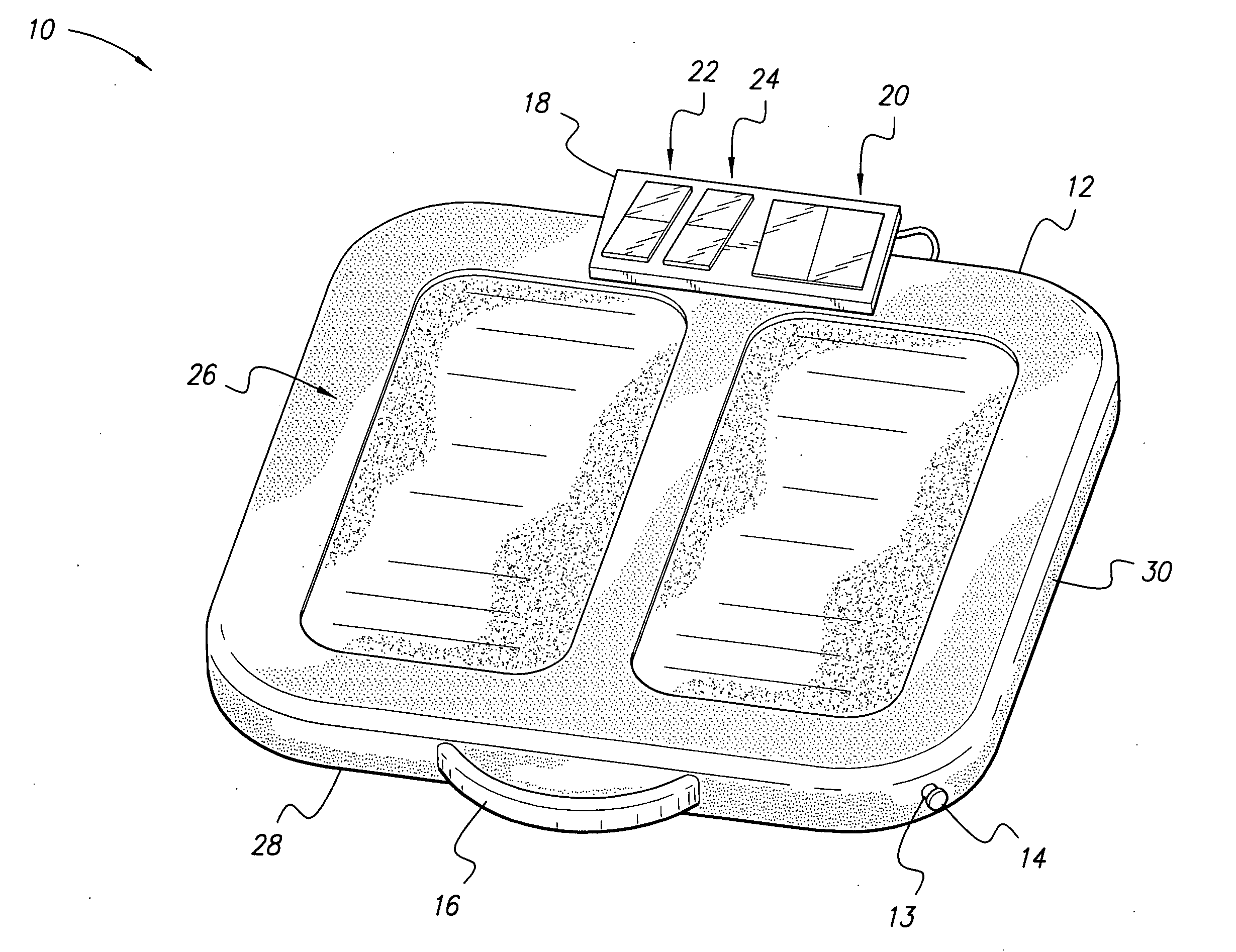

Portable scale

InactiveUS20100300768A1Easy to storeEasy to deflateWeighing apparatus using fluid action balancingWeighing indication devicesBladder baseDisplay device

A portable scale including an inflatable bladder, an inflation port, a pressure sensor, and a display. The display indicates the weight of an object that may be placed upon the bladder based on the pressure inside the bladder that is sensed by the pressure sensor. The bladder may be deflated for easy transport or storage. The portable scale may further include a mechanical or electric pump for inflating the bladder. The pump may be turned off when the pressure inside the bladder reaches a predetermined level.

Owner:PARASH HLDG

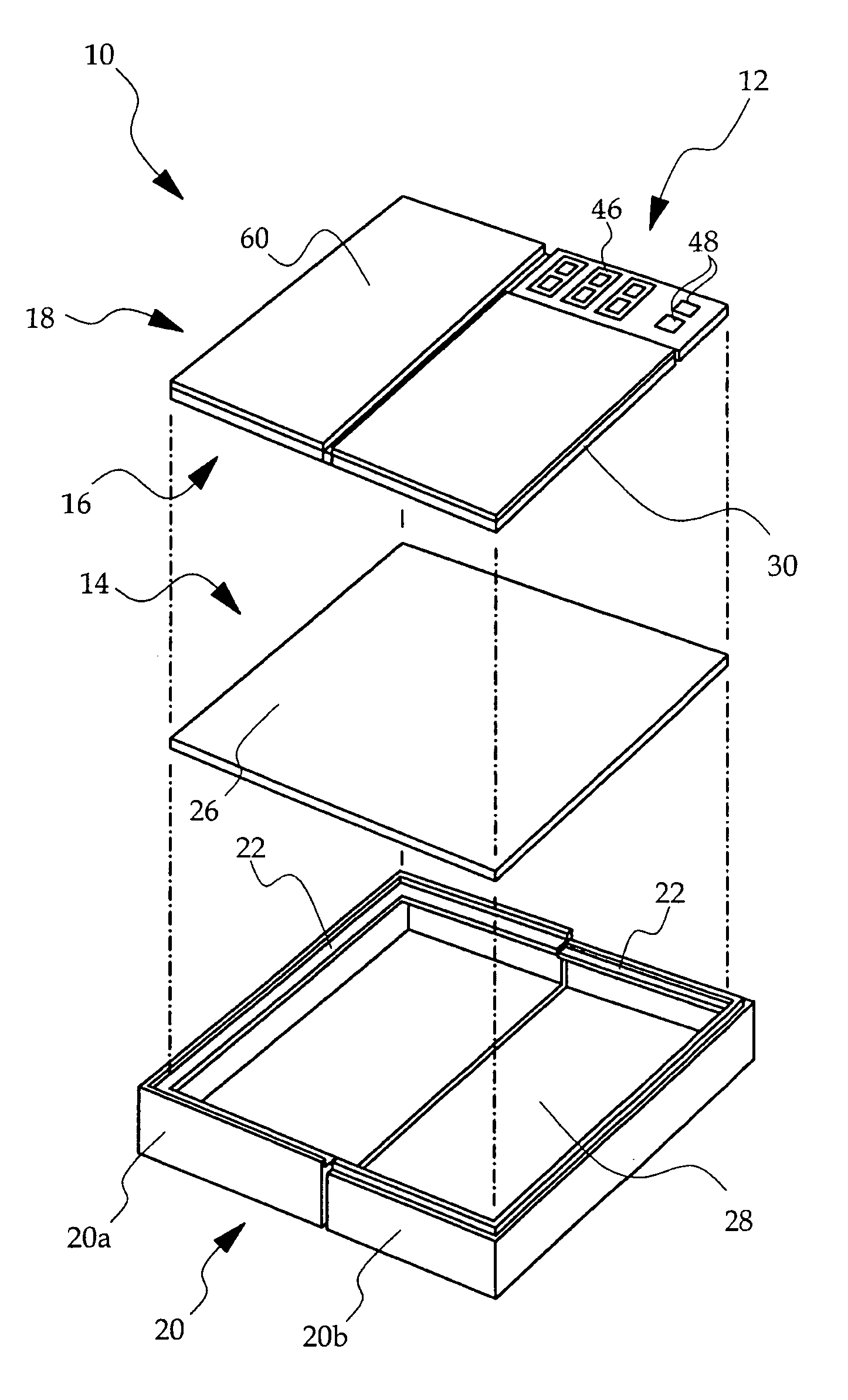

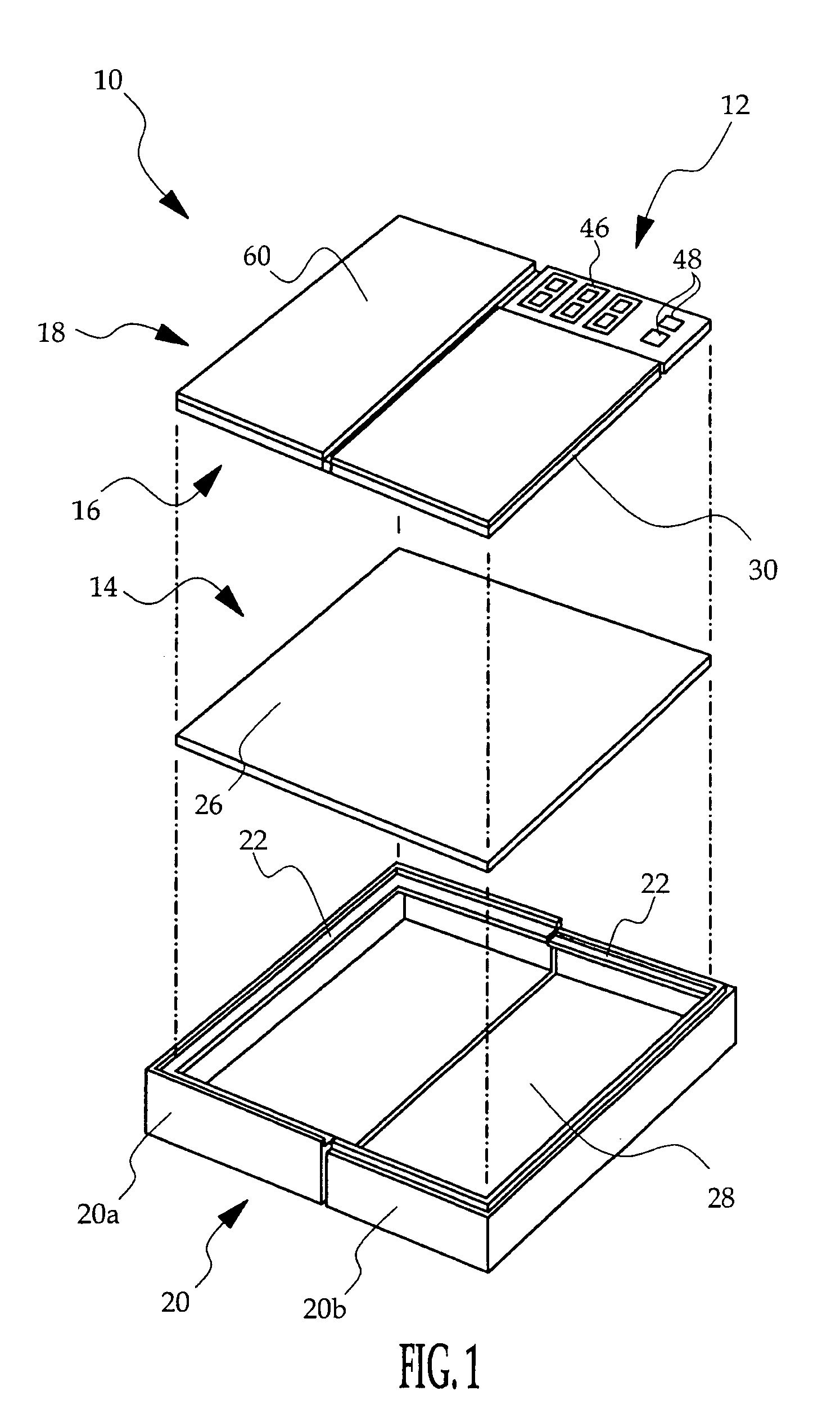

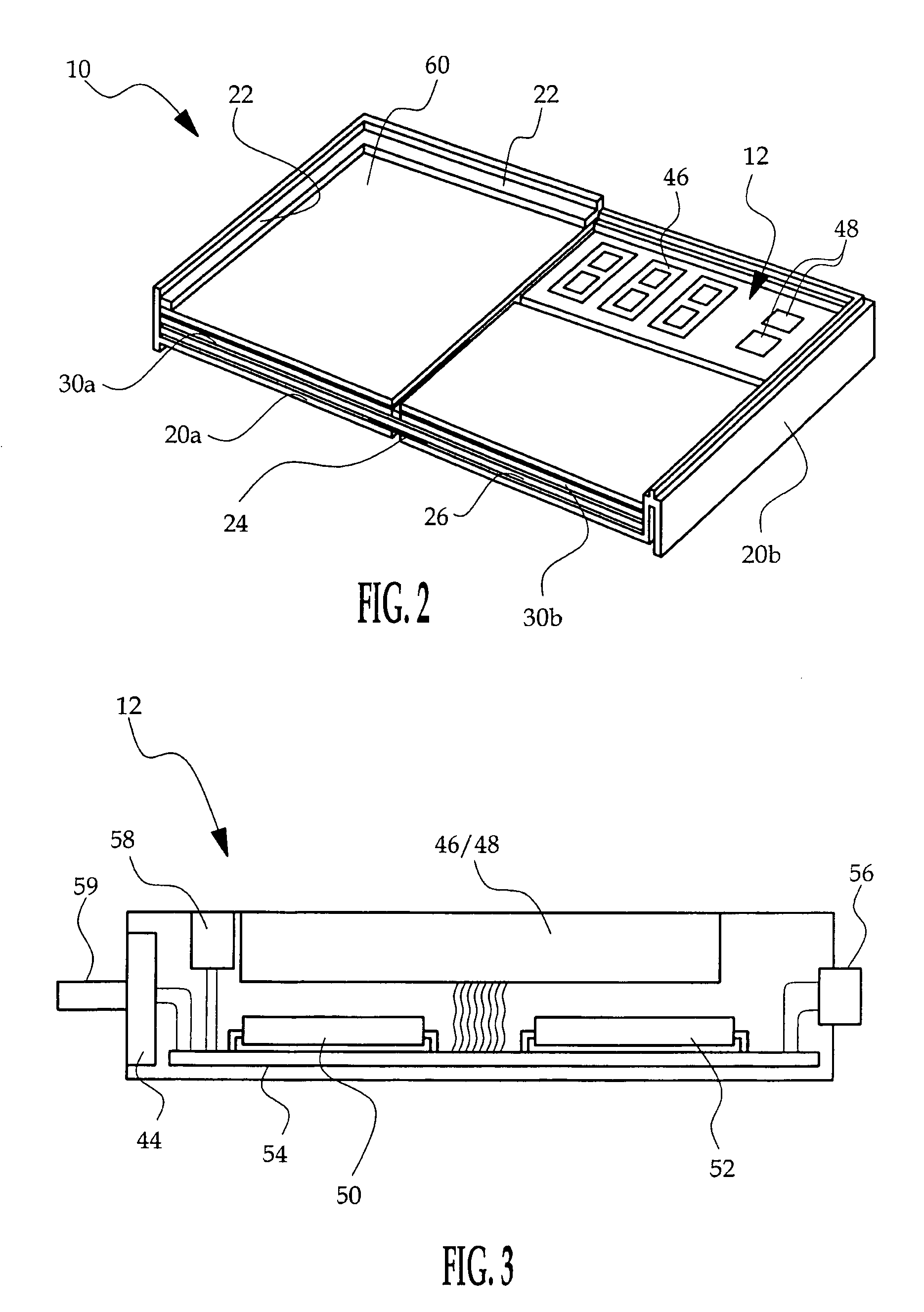

Folding digital scale

ActiveUS7047827B1Easy to storeEasy to transportWeighing apparatus using fluid action balancingFluid pressure measurement by mechanical elementsData portDisplay device

A portable digital scale is foldable for ease of storage and transport. The scale includes a fluid-filled elastomeric bladder and electronic module disposed in a hard-sided case that is opened in use and folded to encase the bladder and electronic module during transport and storage. The electronic module includes a pressure sensor for detecting the fluid pressure in the bladder as a measure of the user's weight, and a user interface and digital display for displaying the weight and / or other parameters requested by the user. Preferably, the electronic module includes a memory device capable of storing multiple weight measurements and a data port for down-loading stored weight data to a personal computer or PDA for tracking weight variation of one or more users over time.

Owner:DELPHI TECH IP LTD

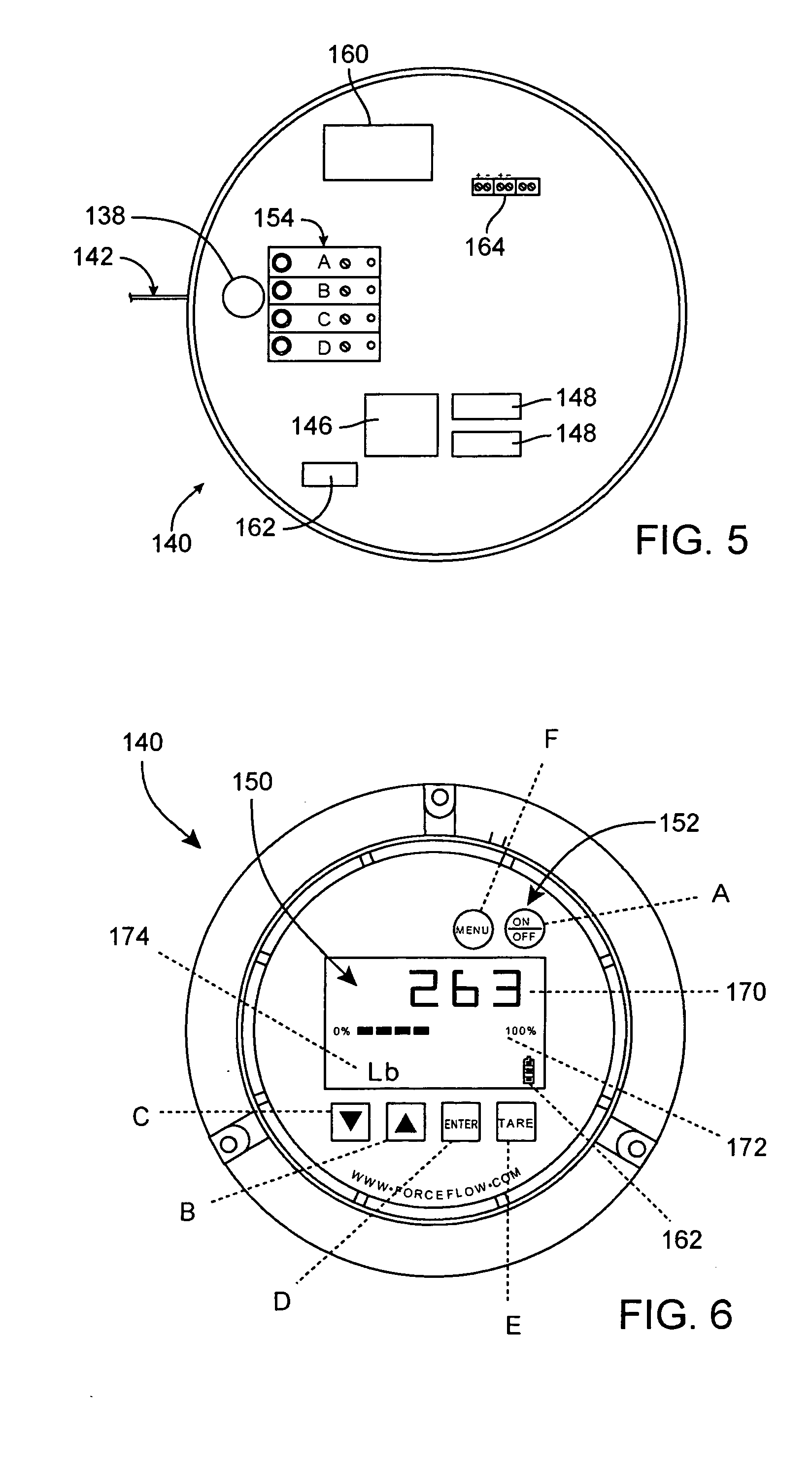

Chemical storage device with integrated load cell

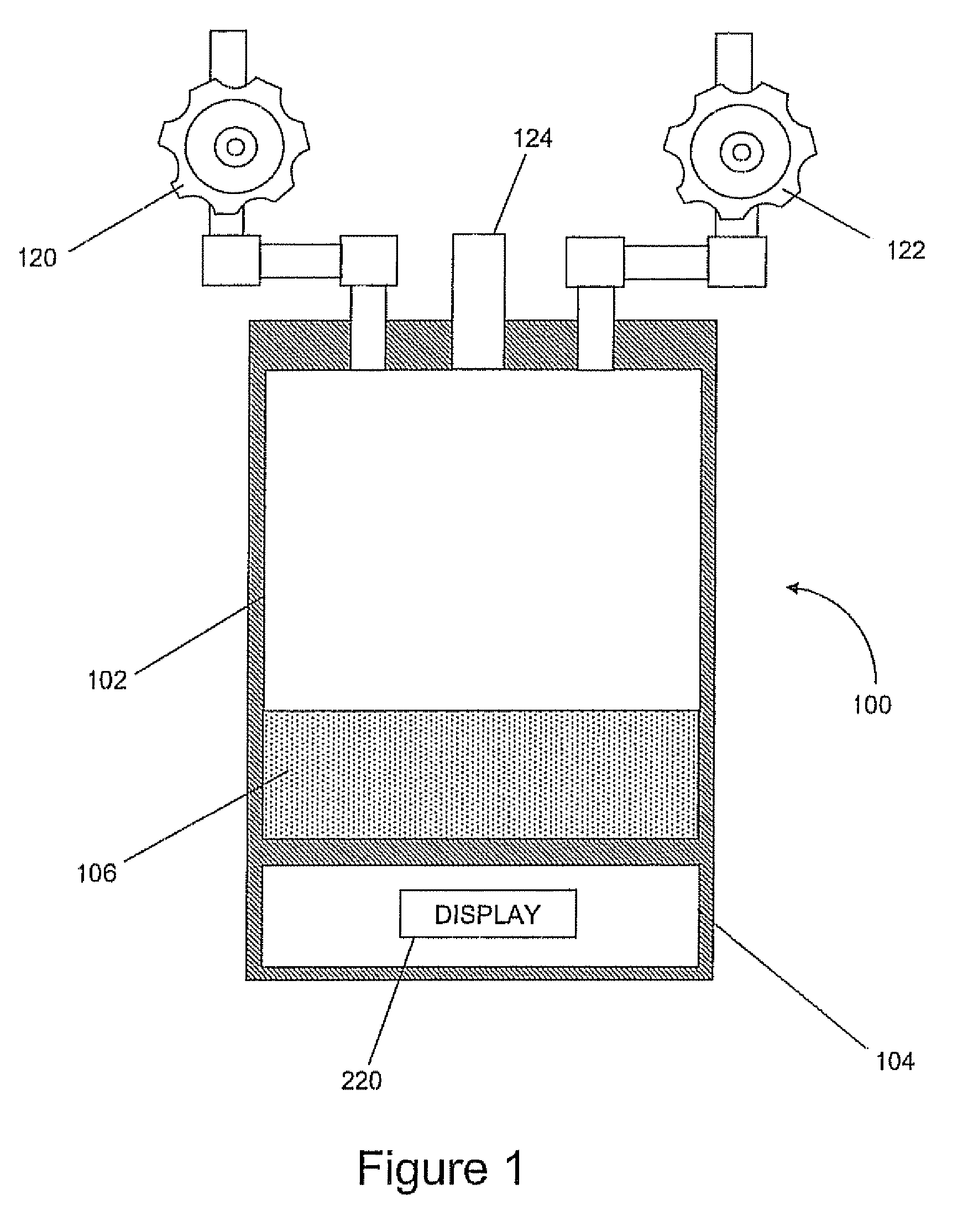

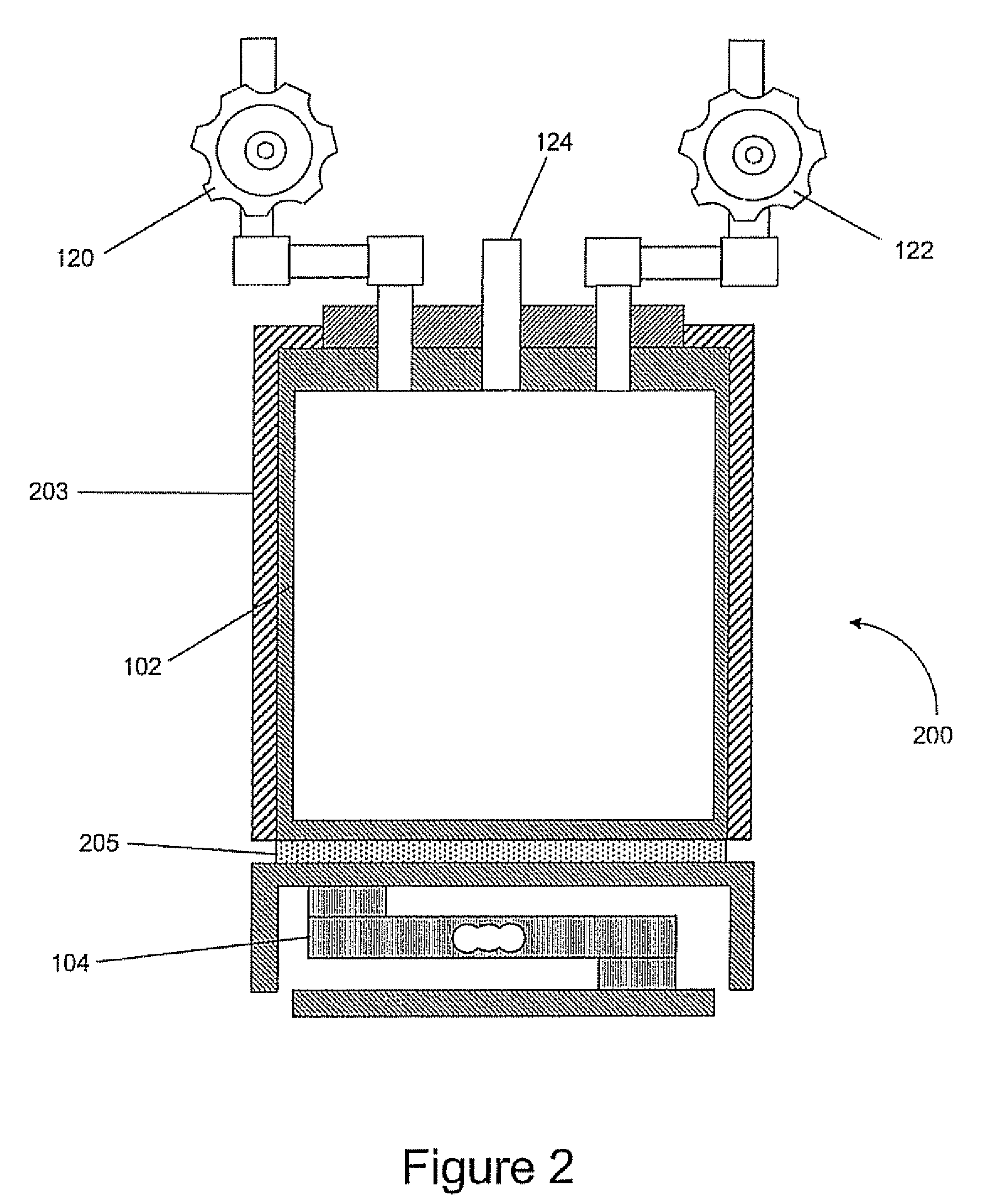

ActiveUS20070062270A1Weight increaseEasy to useWeighing apparatus using fluid action balancingLiquid transferring devicesChemical storageCompound (substance)

A chemical storage device and a method for monitoring chemical usage are described herein. The device and disclosed method utilize a chemical storage canister and a load cell integrated into one transportable unit. The load cell is capable of compensating for the added weight of attached dispensing devices used in the semiconductor industry. Additionally, the load cell continuously displays the weight of the chemicals as they are withdrawn from the chemical storage device. These functionalities are included in the control logic of the load cell which is incorporated into the load cell itself.

Owner:AIR LIQUIDE ELECTRONICS US LP

Chemical storage device with integrated load cell

ActiveUS7770448B2Easy to useWeighing apparatus using fluid action balancingLiquid transferring devicesChemical storageLoad cell

A chemical storage device and a method for monitoring chemical usage are described herein. The device and disclosed method utilize a chemical storage canister and a load cell integrated into one transportable unit. The load cell is capable of compensating for the added weight of attached dispensing devices used in the semiconductor industry. Additionally, the load cell continuously displays the weight of the chemicals as they are withdrawn from the chemical storage device. These functionalities are included in the control logic of the load cell which is incorporated into the load cell itself.

Owner:AIR LIQUIDE ELECTRONICS US LP

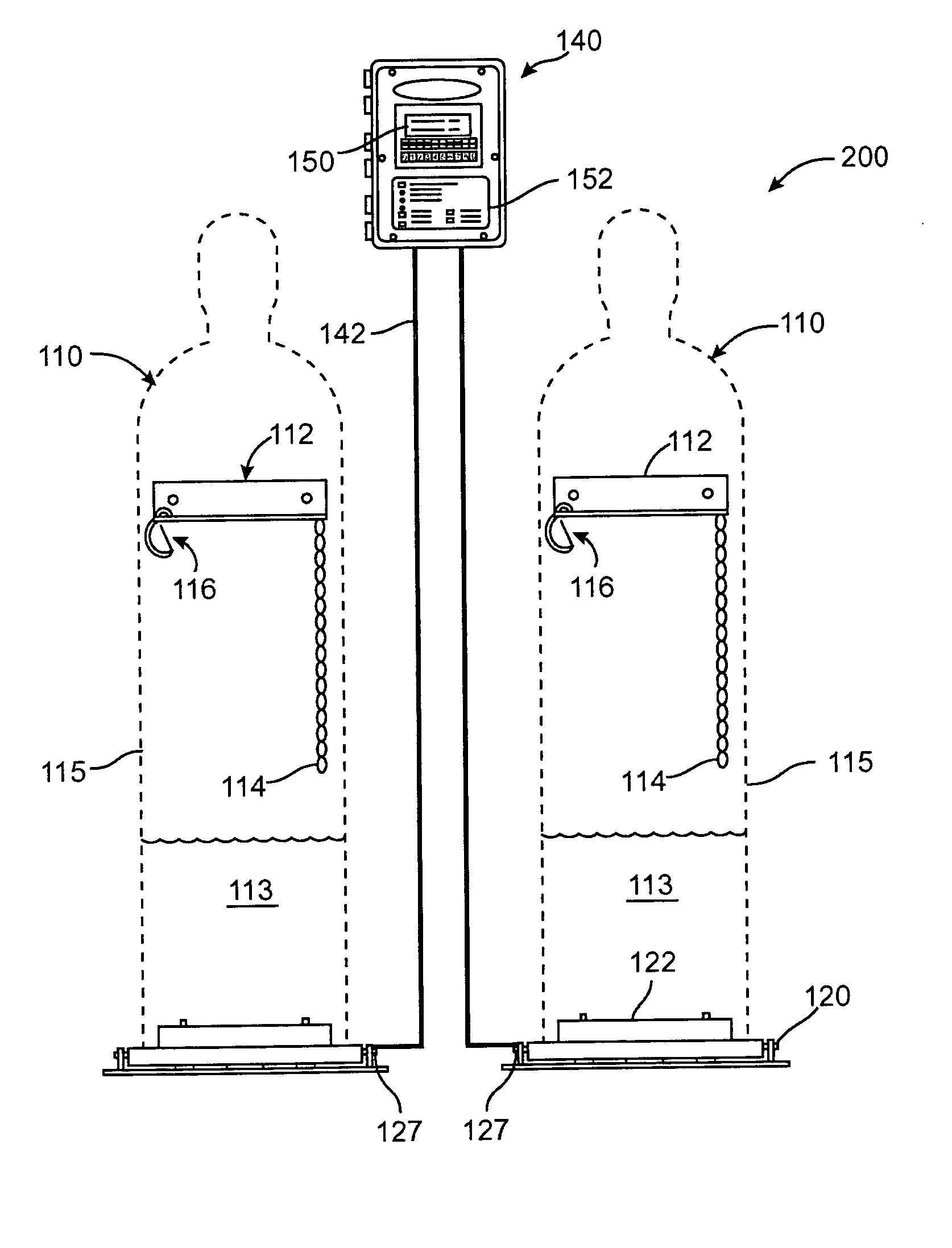

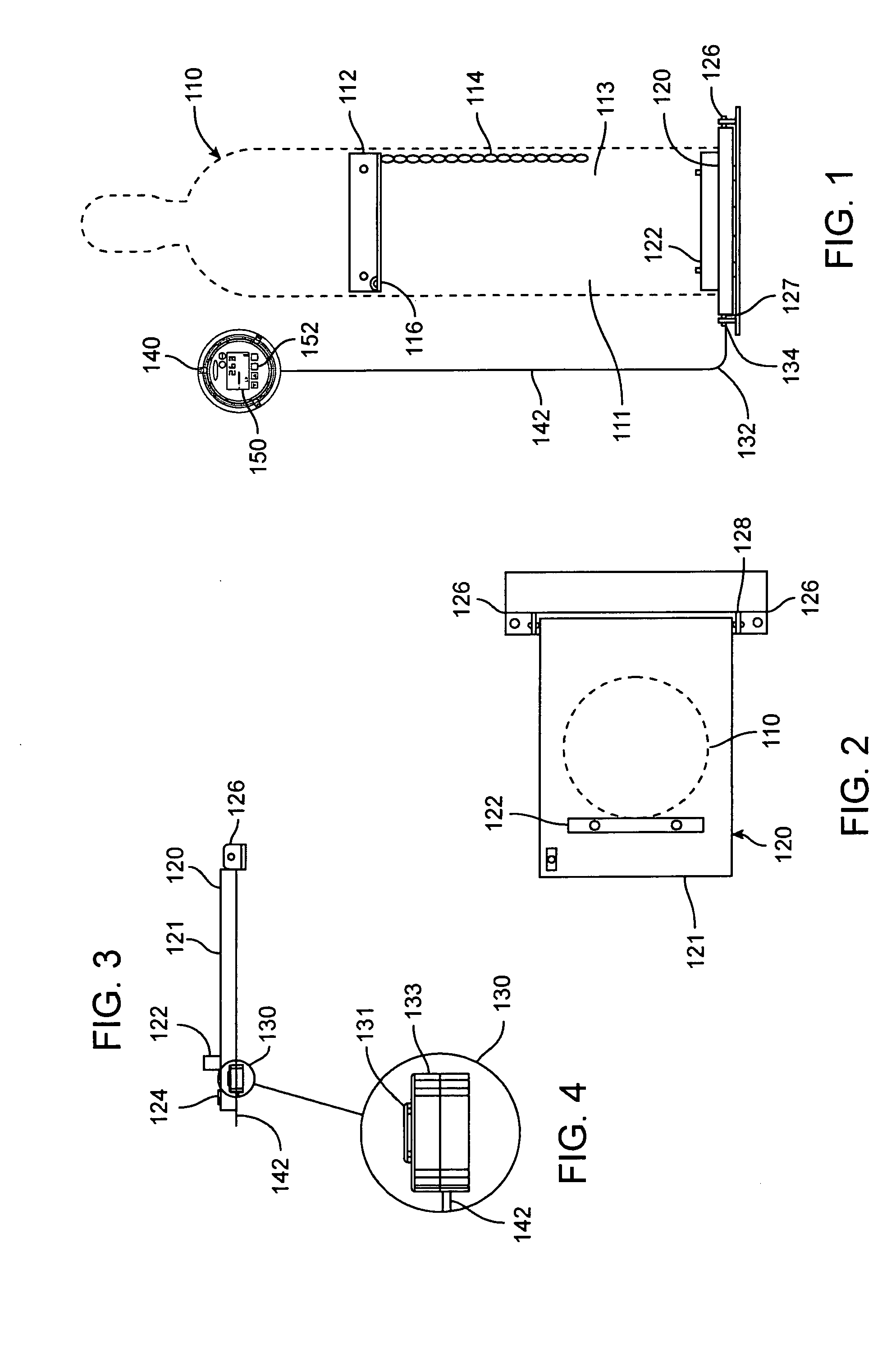

System and method for detecting and displaying an amount of chemical in a cylinder or vessel

ActiveUS20050126277A1Weighing apparatus using fluid action balancingContainer/cavity capacity measurementMarine engineeringTransducer

A system and method for detecting and displaying the amount of chemical in a vessel. The system includes a vessel with a variable quantity of gas supported upon a moveable platform. A hydraulic load cell is positioned under the platform, and generates a hydraulic pressure signal, which is a function of the variable quantity of gas in the vessel. An electrical signal transducer converts the pressure signal to an electrical signal which is transmitted to a battery powered microprocessor / display capable of converting the electrical signal into a displayable signal indicative of an amount of gas remaining in the vessel.

Owner:FORCE FLOW

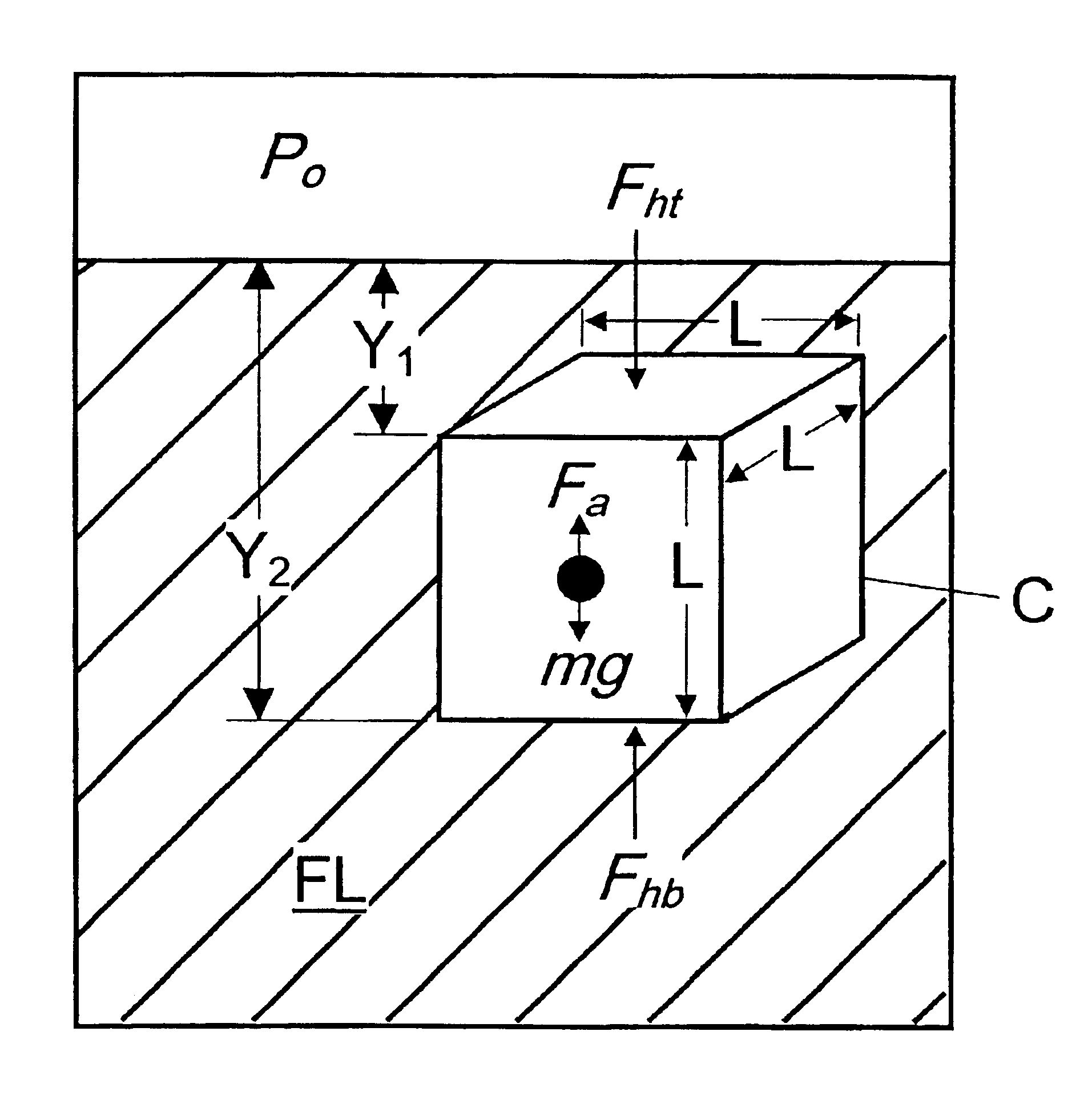

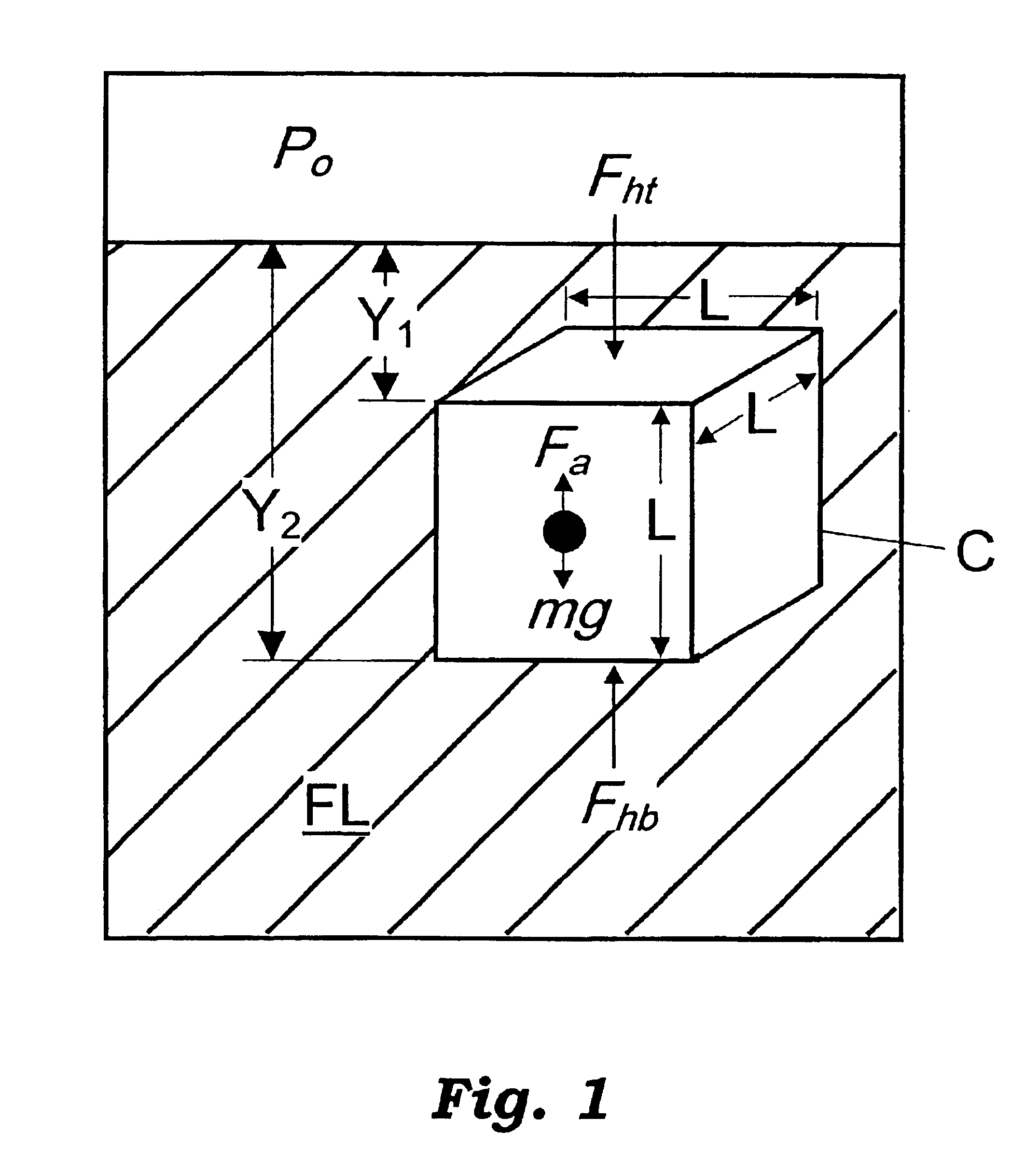

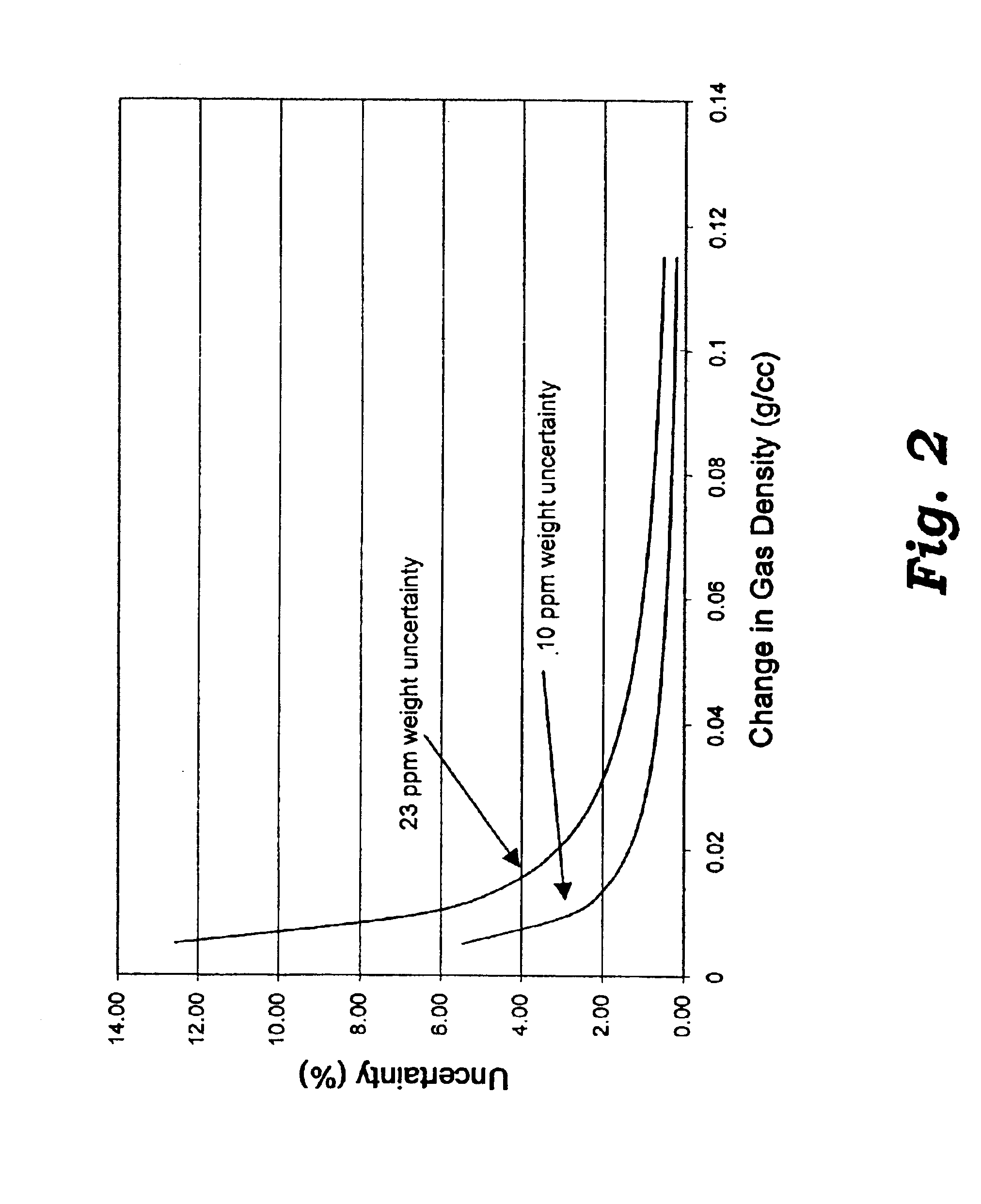

Method and apparatus for measuring physical properties of matter

InactiveUS6860136B1Material analysis by measuring buoyant forcesWave based measurement systemsBeam balanceMagnetic interaction

The invention determines density of a sample while the sample is immersed in a gaseous medium having variable density. The apparatus includes a chamber for containing the gaseous medium and the sample, means for selectively varying the density of the gaseous medium over a range of densities, and means for producing electrical signals related to the density of the gaseous medium. In the chamber is a balance beam having a sample pan at a first end and a coil assembly at an opposing second end. Also at the second end of the beam is a first counter-weight having a volume and mass which is substantially equivalent to the volume and mass of sample pan, and which creates a moment that is substantially equivalent to the moment created by the sample pan. At the first end of the beam is a second counter-weight having a volume and mass which is substantially equivalent to the volume and mass of the coil assembly, and which creates a moment which is substantially equivalent to the moment created by the coil assembly. A magnet assembly is disposed adjacent to and magnetically interacts with the coil assembly. A controller provides a coil current to the coil assembly, thereby generating a magnetic field which interacts with the magnet assembly. According to the invention, the interaction between the magnetic field of the coil assembly and the magnet assembly applies a force to the second end of the beam to keep the beam balanced as the density of the gaseous medium in the chamber is varied over the range of densities. A computing device receives the electrical signals related to the density of the gaseous medium and the electrical signal related to the coil current, and calculates the density of the sample based thereon.

Owner:FAST FORWARD DEVICES

Ball mount for measuring tongue weight of a trailer

ActiveUS20150306929A1Weighing apparatus using fluid action balancingApparatus for force/torque/work measurementEngineeringPiston

A ball mount for measuring tongue weight of a trailer is disclosed. The ball mount can include a ball portion having a hitch ball configured to couple with a tongue of a trailer. The ball mount can also include a hitch portion for interfacing with a hitch receiver associated with a vehicle. In addition, the ball mount can include a load measurement device associated with the ball portion to determine a magnitude of a downward force on the hitch ball. The load measurement device can include a reservoir having a fluid and a piston disposed therein, and a pressure sensor in fluid communication with the reservoir. The hitch ball can be configured to exert a force on the piston, thereby affecting a pressure of the fluid in response to the downward force on the hitch ball.

Owner:WEIGH SAFE LLC

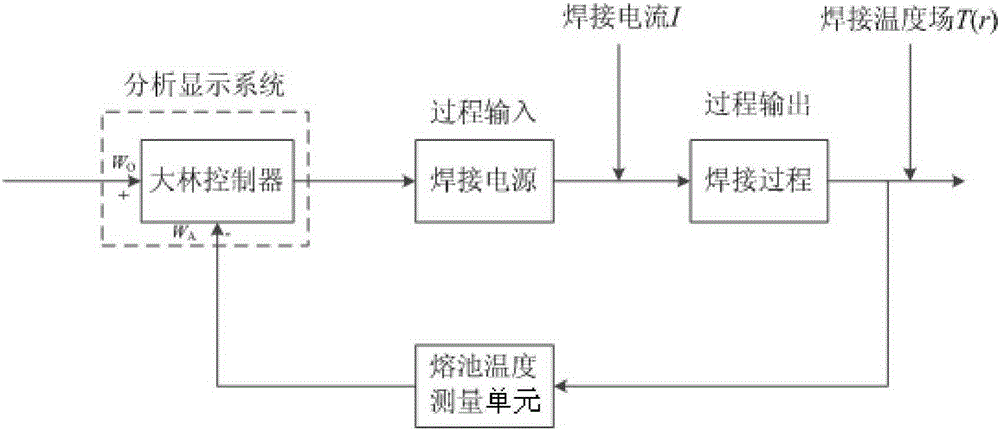

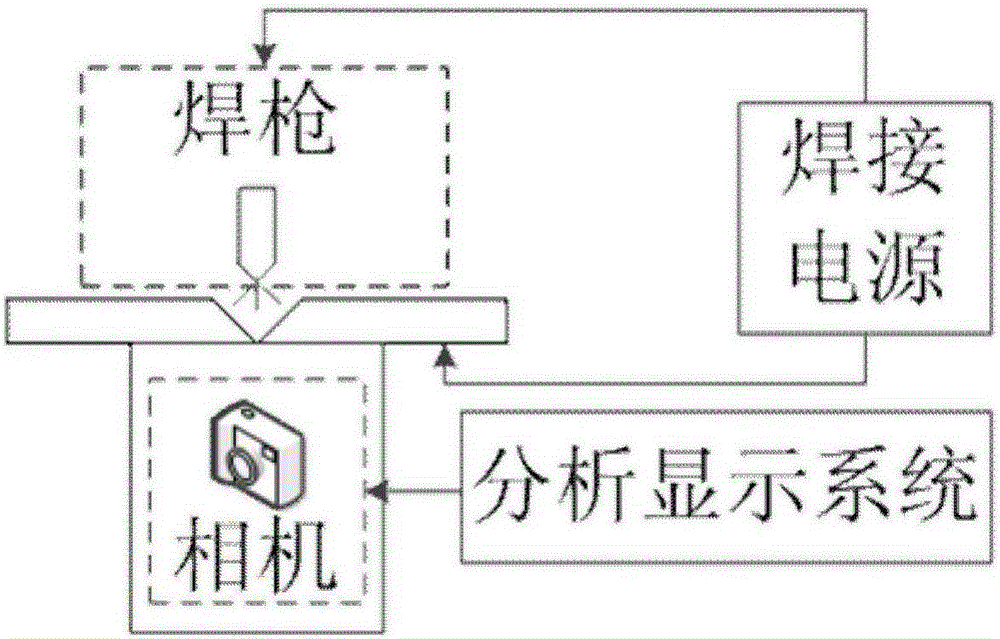

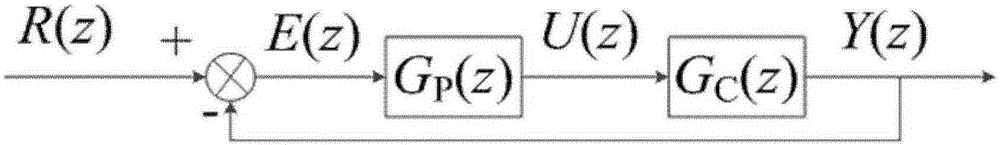

Welding temperature field control system and method

ActiveCN105234599AEliminate residualQuick responseRadiation pyrometryTemperatue controlMelting tankWelding power supply

The invention relates to a welding temperature field control system and method. The output end of a Dahlin controller is connected with a welding power supply of a welding machine system, and a welding pool temperature measuring unit transmits detected welding pool data to the collected signal input end of the Dahlin controller. The method includes the steps that a welding line and heat effect zone is divided into a high-temperature welding zone, a medium-temperature welding zone and a low-temperature welding zone; the welding pool temperature measuring unit acquires an image of a heat radiation field of two wave bands on the back sides of the welding zones through a CCD camera; filtering processing is performed on the collected image of the heat radiation field to obtain the corresponding relation between the grey level and temperature; distribution of the whole welding field temperature is obtained according to the corresponding relation; and the width of an isotherm is calculated, and the Dahlin controller outputs a control value to the welding power supply of the welding machine system. By means of the method, closed-loop control over the width of the isotherm of the back side of the welding line and heat effect zone is achieved, residual errors in automatic welding objects are eliminated, production efficiency is improved, cost is lowered, and rapid, accurate and convenient detection and quality control are achieved.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

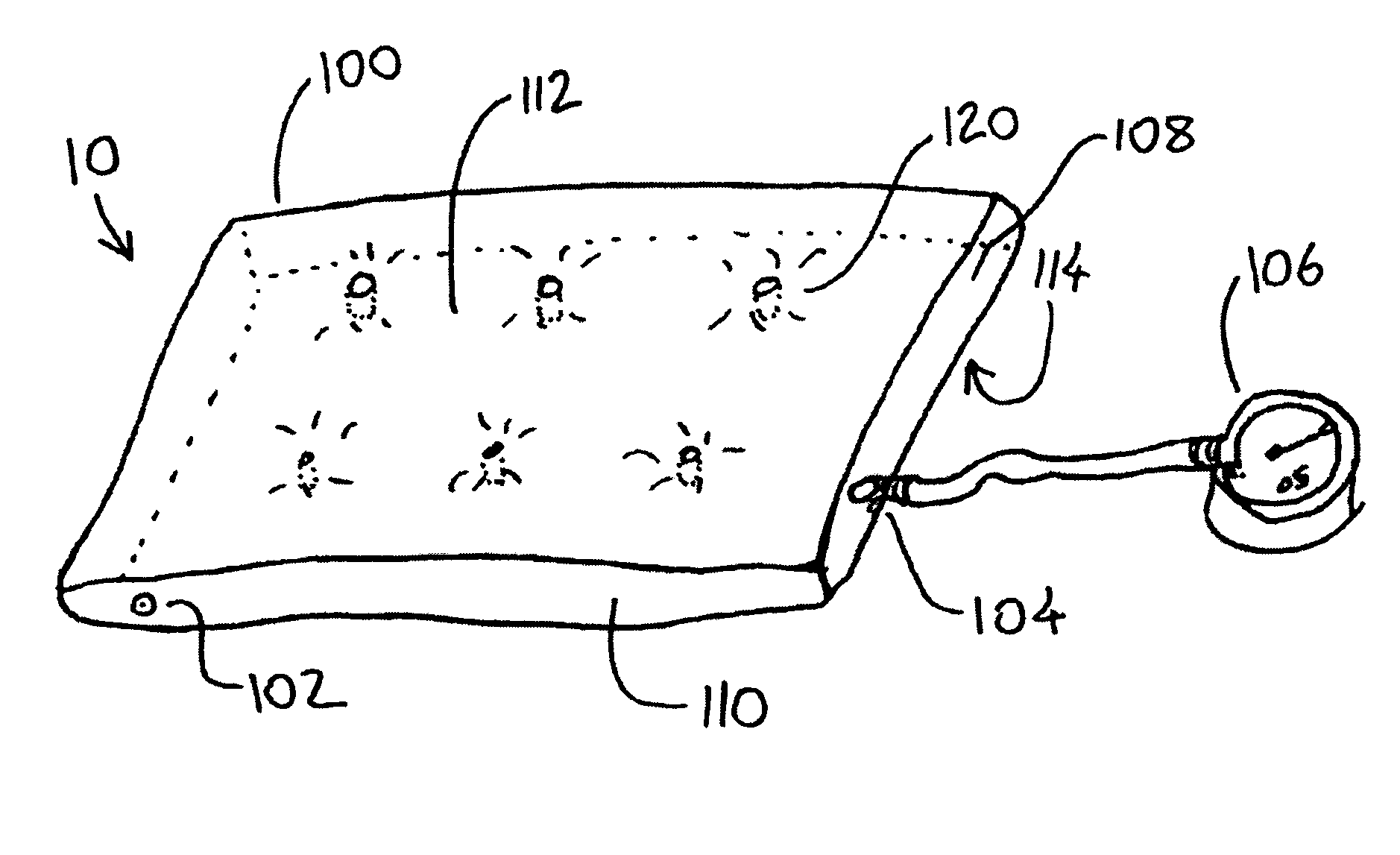

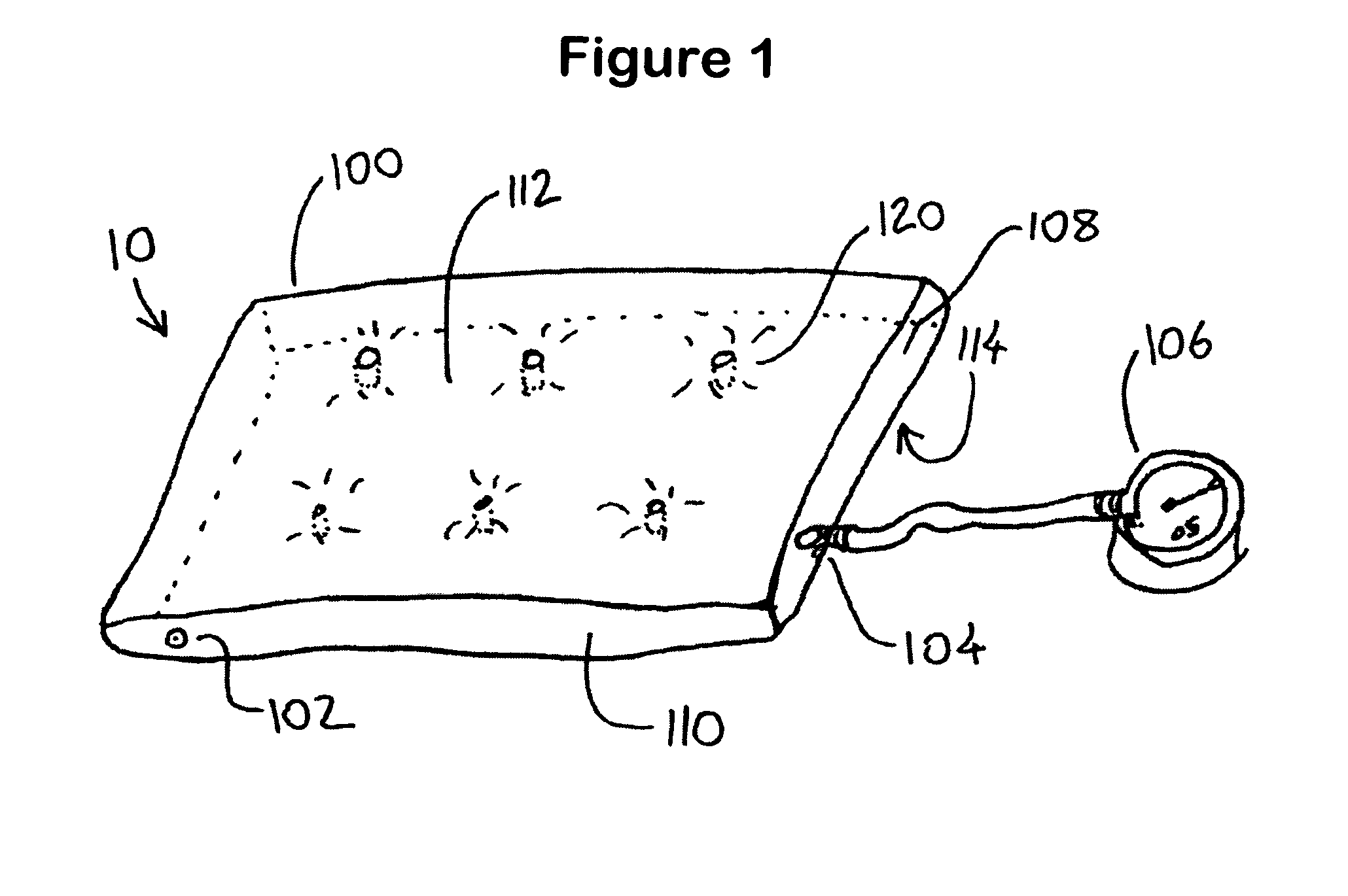

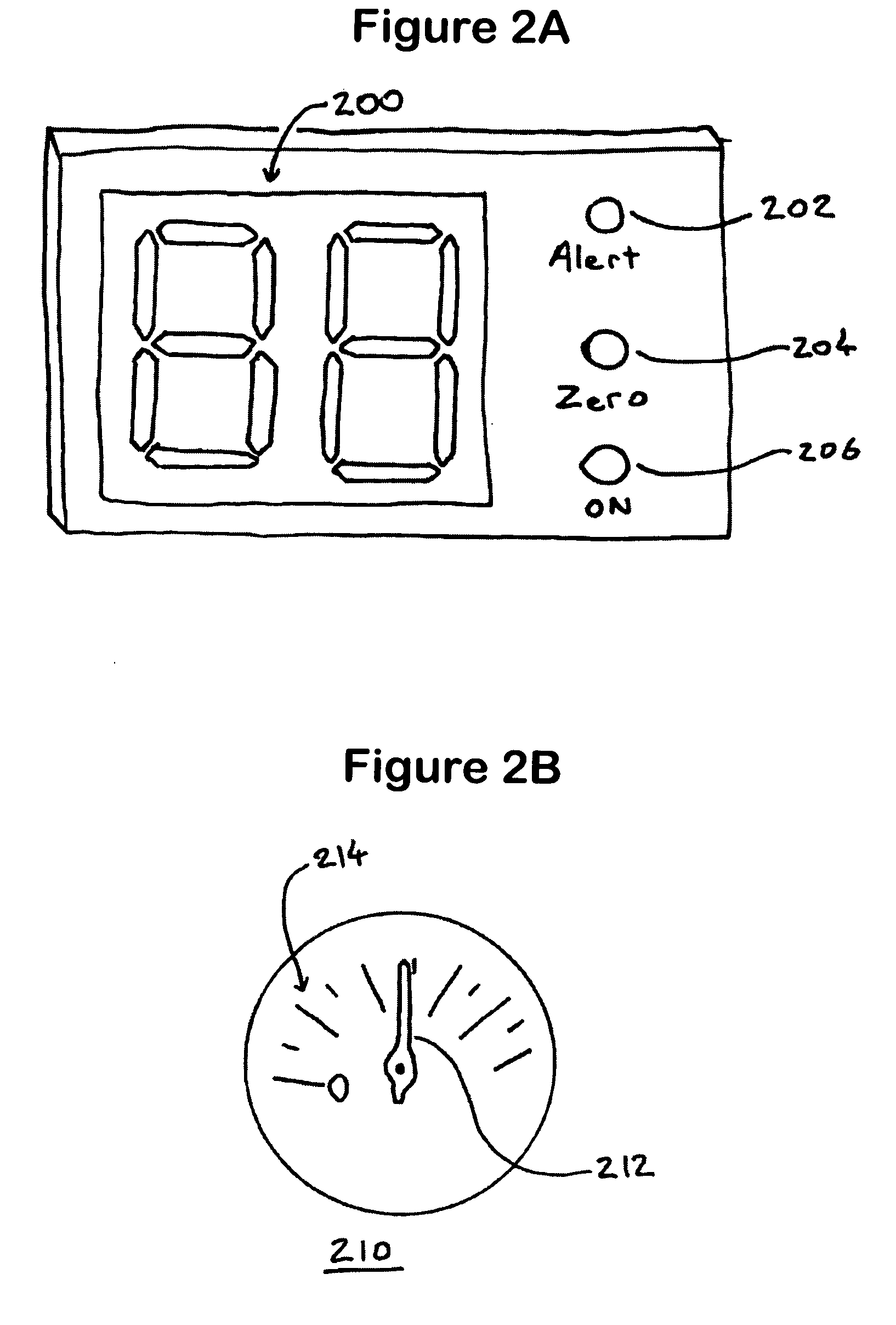

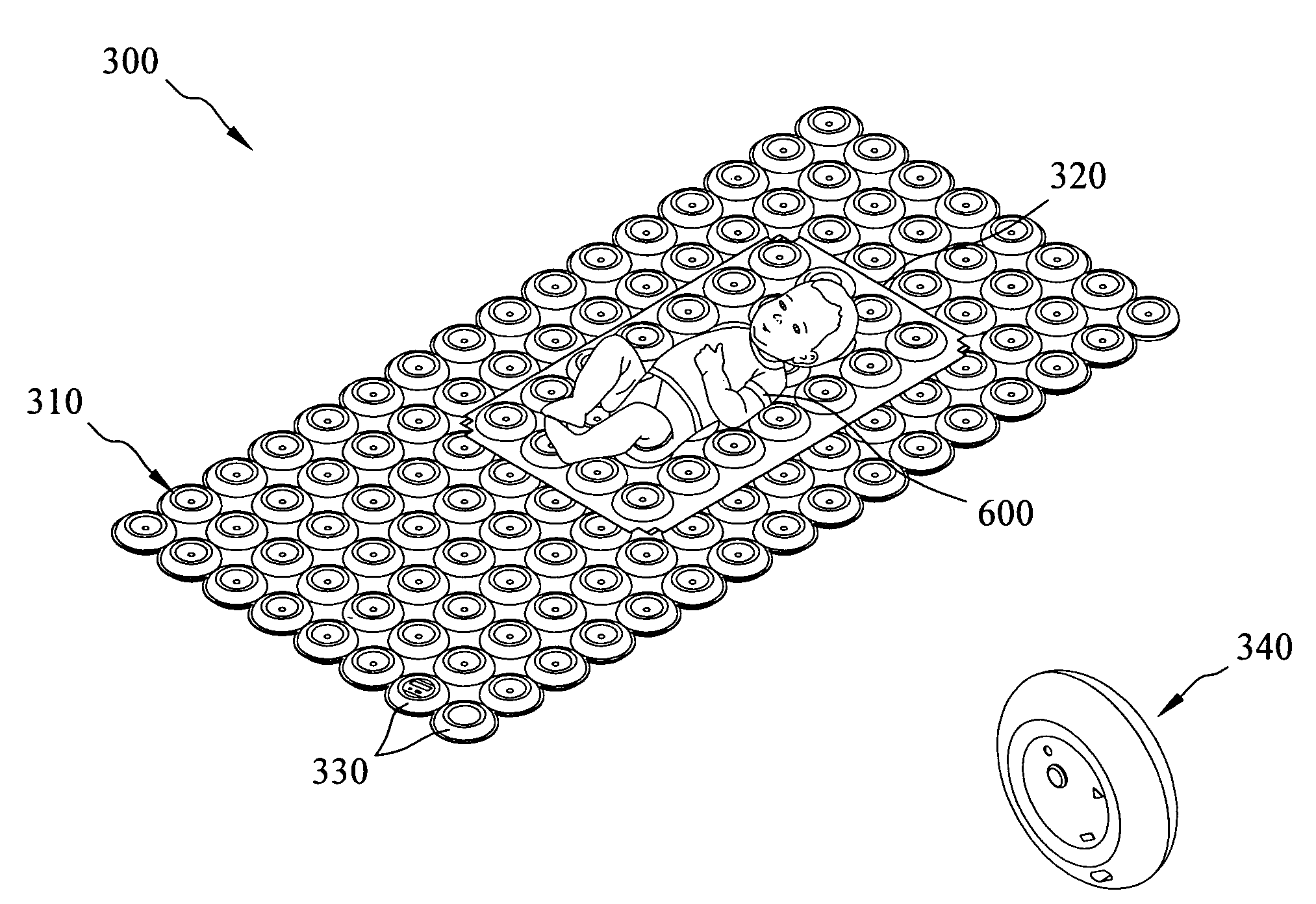

Portable Cushion Device

A portable cushion device is provided, including a first cushion region, a second cushion region, a control interface module, and an alarm unit. The second cushion region includes an inflation inlet. The first cushion region is located on the outside of the second cushion region. The control interface module is connected to the second cushion region, and is able to inflate the second cushion region to a specific pressure through the inflation inlet. When an object is placed on the second cushion region, the control interface module measures the weight of the object and monitors the object continuously. The alarm unit is triggered to issue an alarm when the control interface module detects a sudden increase or decrease of the weight of the monitored object on the second cushion region.

Owner:IND TECH RES INST

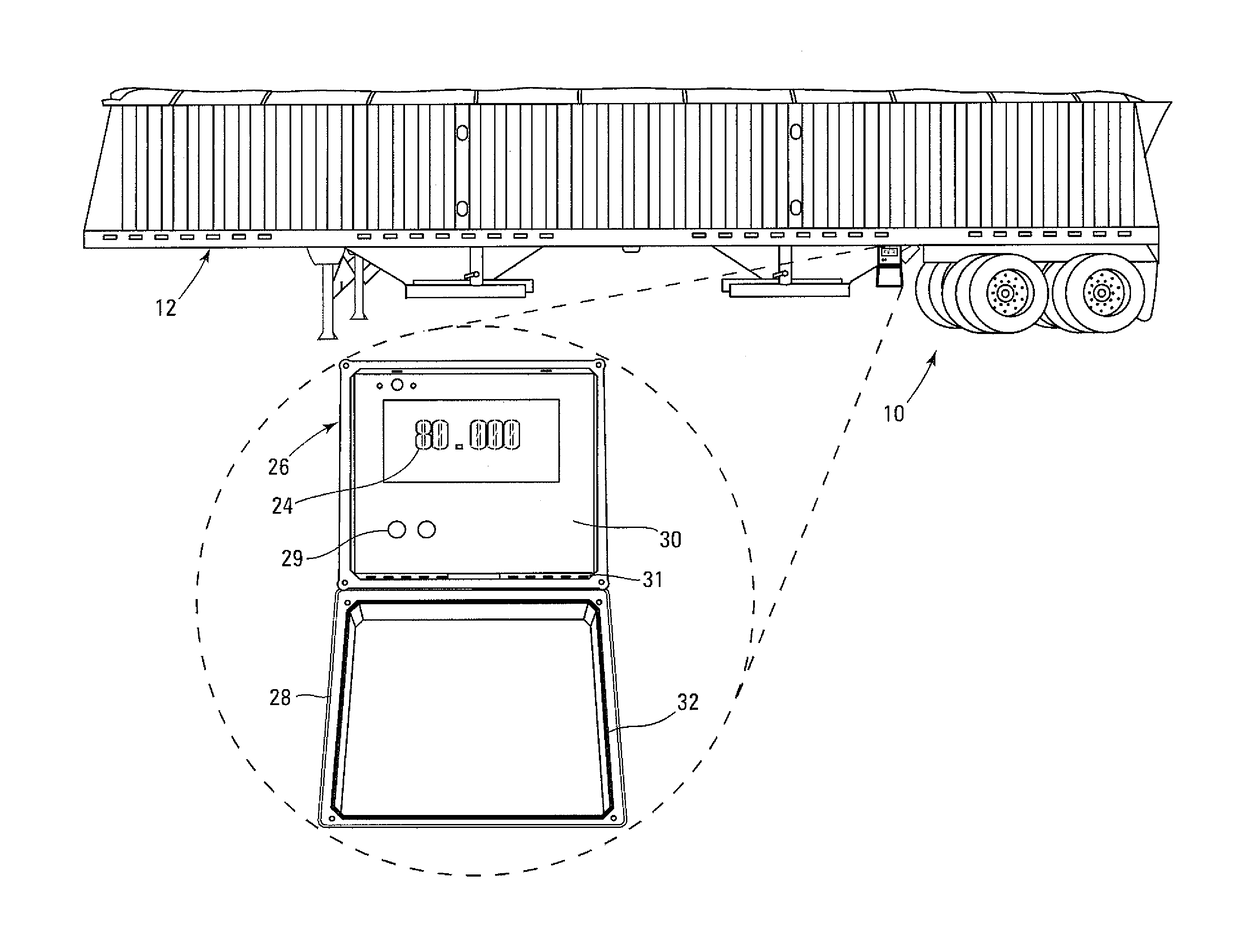

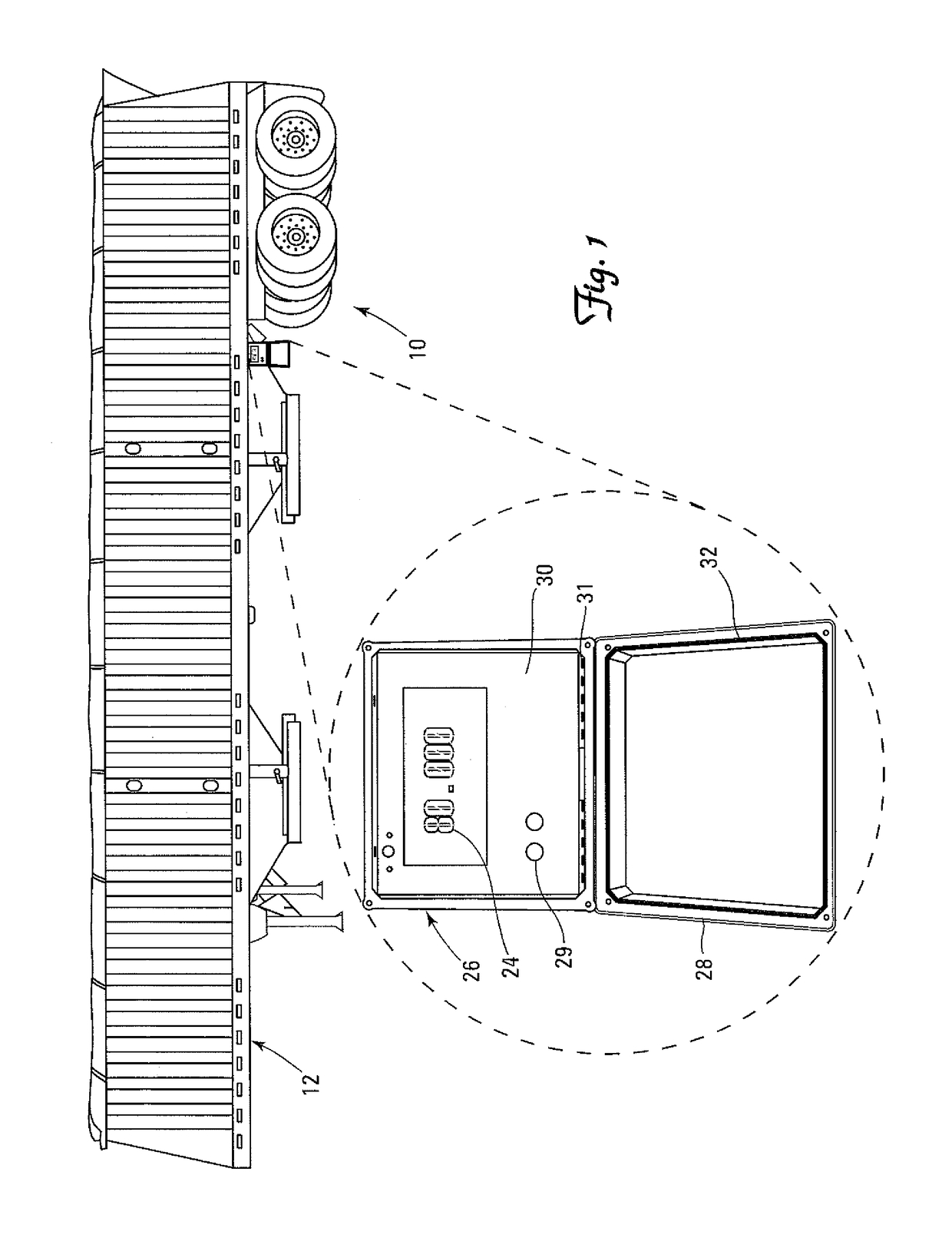

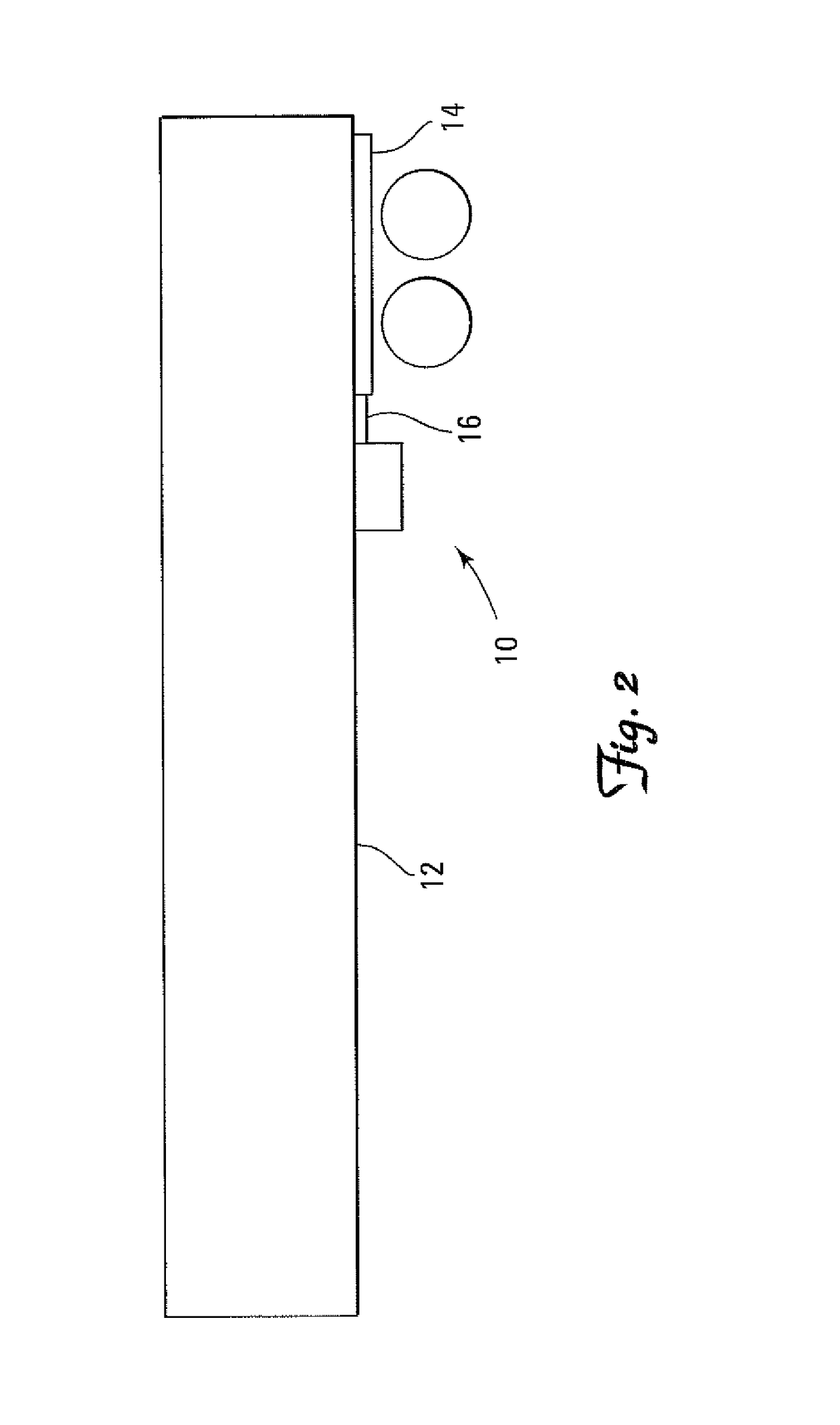

High visibility on board digital, semi-trailer scale

ActiveUS9631969B1Large capacityWeight controlWeighing apparatus using fluid action balancingResilient suspensionsElectricityVisibility

A scale for mounting on a semi-trailer having an air bag in the suspension and an air line connected to the air bag includes a pressure transducer for connecting to the air line and measuring the pressure in the air bag, and to send a signal correlated to the sensed pressure, a process module in electric communication with the pressure transducer and configured to receive the signal therefrom wherein the process module is configured to correlate the signal from the pressure transducer to a weight of a load on the trailer, and a display module configured to receive a signal from the process module indicating the sensed weight and display the sensed weight of the load on the semi-trailer. A method for monitoring weight includes converting pressure in the air line to a weight of the semi-trailer, which can be monitored in real-time.

Owner:WHALEN DENNY

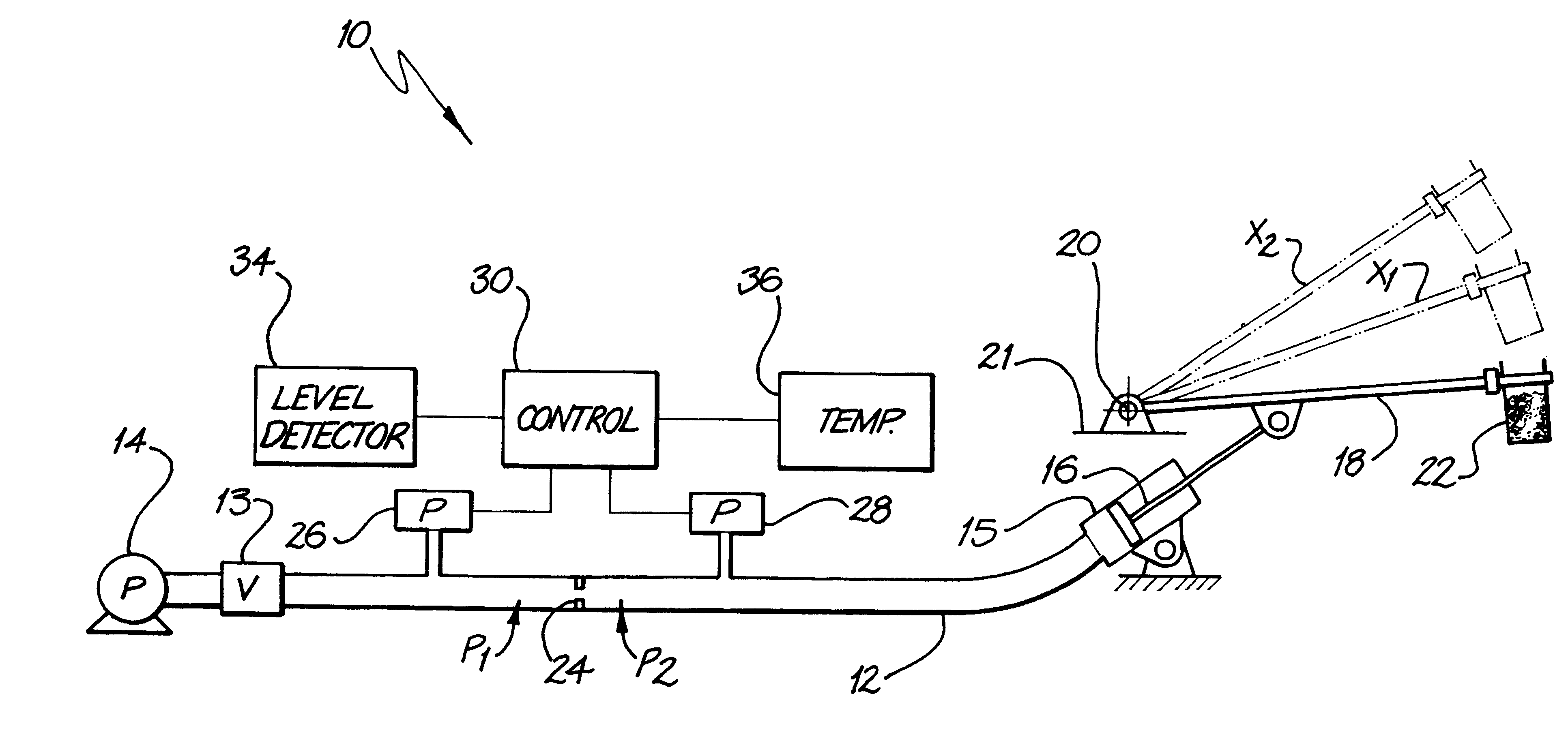

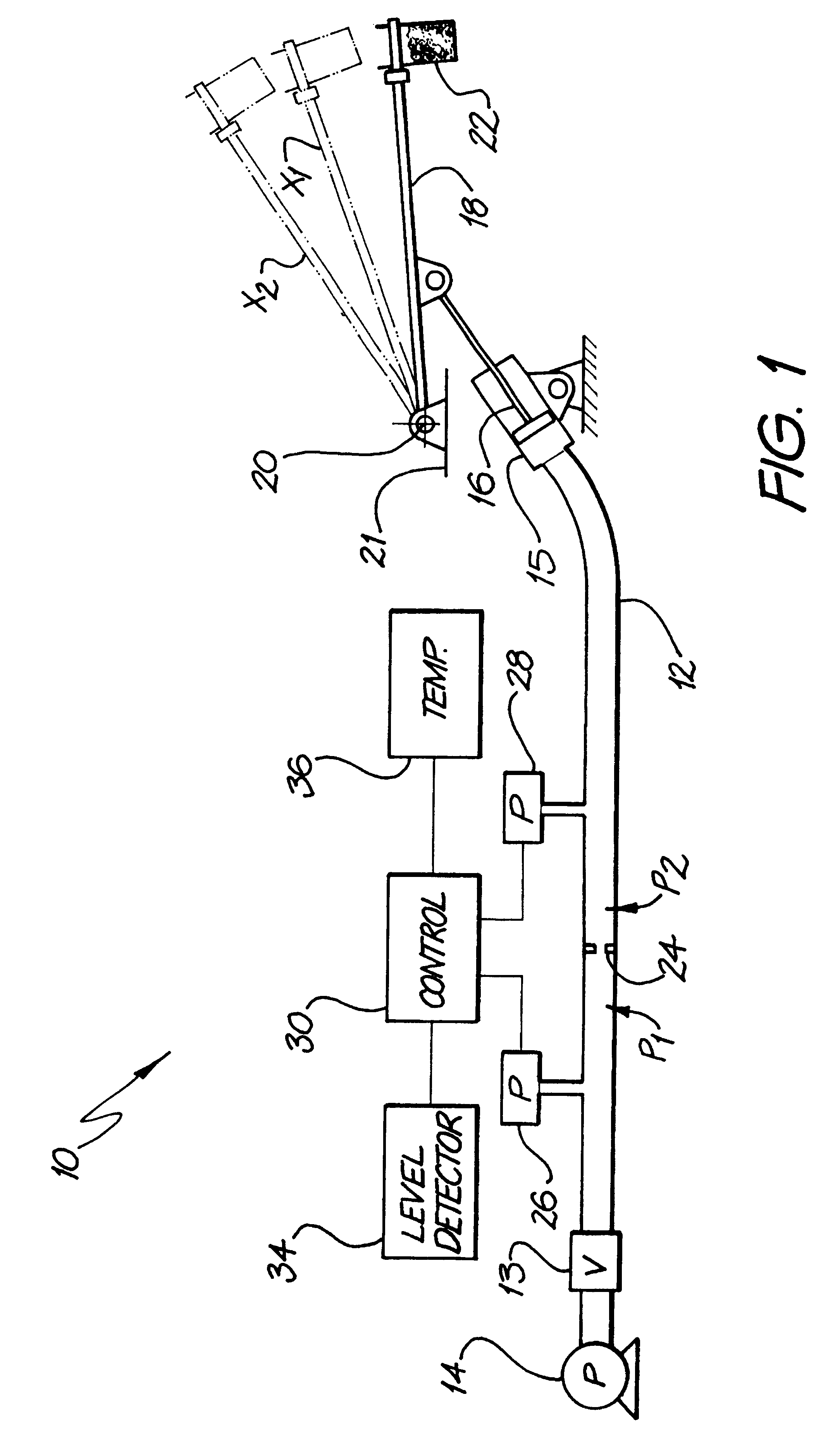

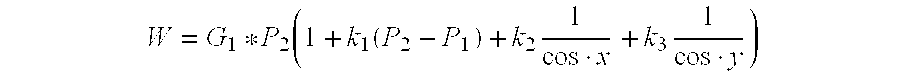

Hydraulic weighing apparatus and method

InactiveUS6627825B1Constant rateForce measurement using counterbalancing forcesWeighing apparatus testing/calibrationRefuse collectionWaste collection

A hydraulic lifting and weighing system particularly for refuse collection vehicles and the like and includes means for dynamically weighing garbage. The system includes a hydraulic actuator operable to move a lifting arm and takes two measurements of the pressure of the hydraulic fluid in the system as the arm raises a waste bin whose weight is to be measured. The weight of the bin is calculated by multiplying the pressure by a factor determined by calibration with known weights. Weights are calculated based on the measurements of pressure and the result averaged. The system compensates for variations in hydraulic flow characteristics. The system includes means for compensating for variations in the inclination of the vehicle.

Owner:TEK SOLUTIONS

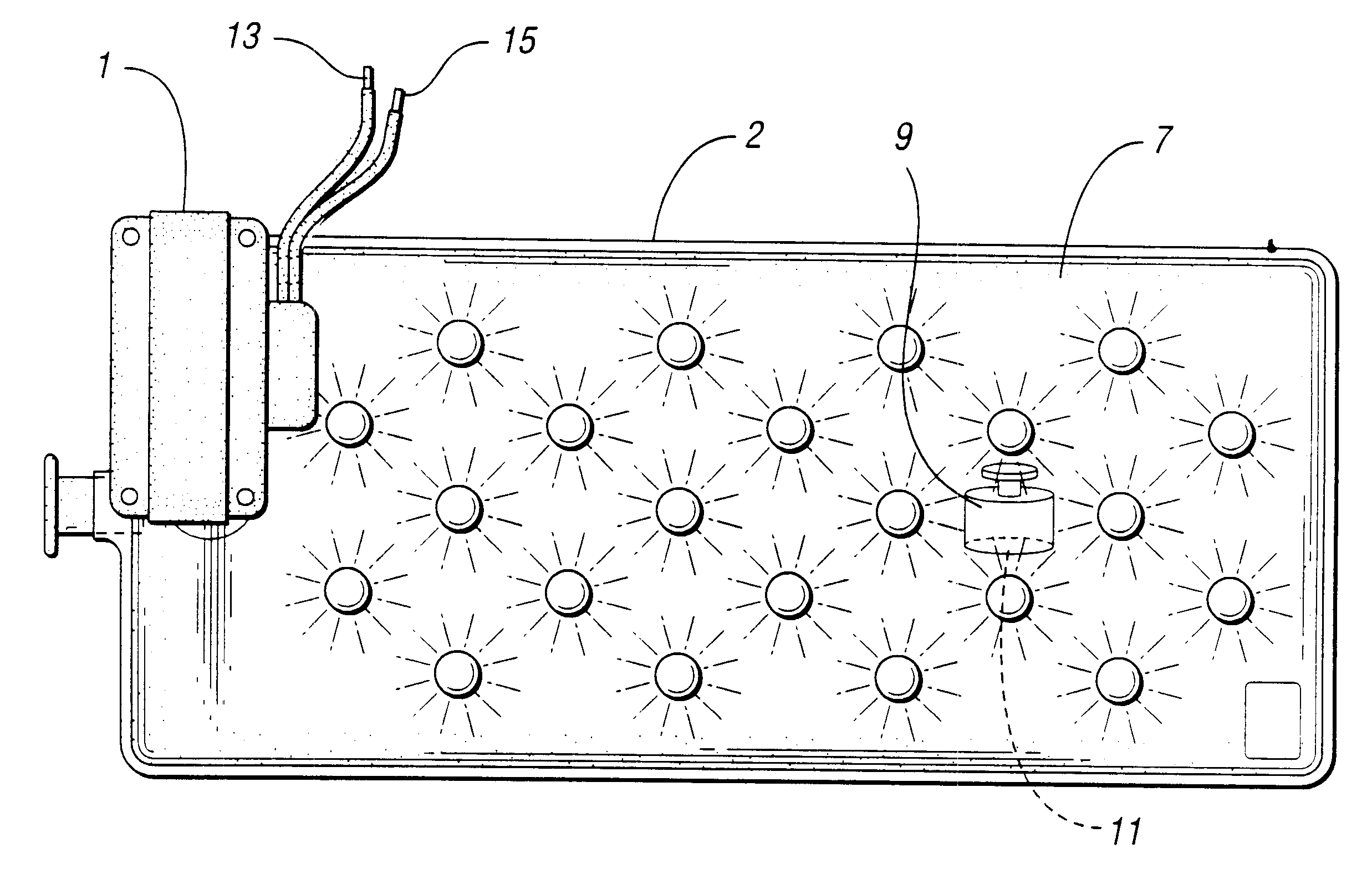

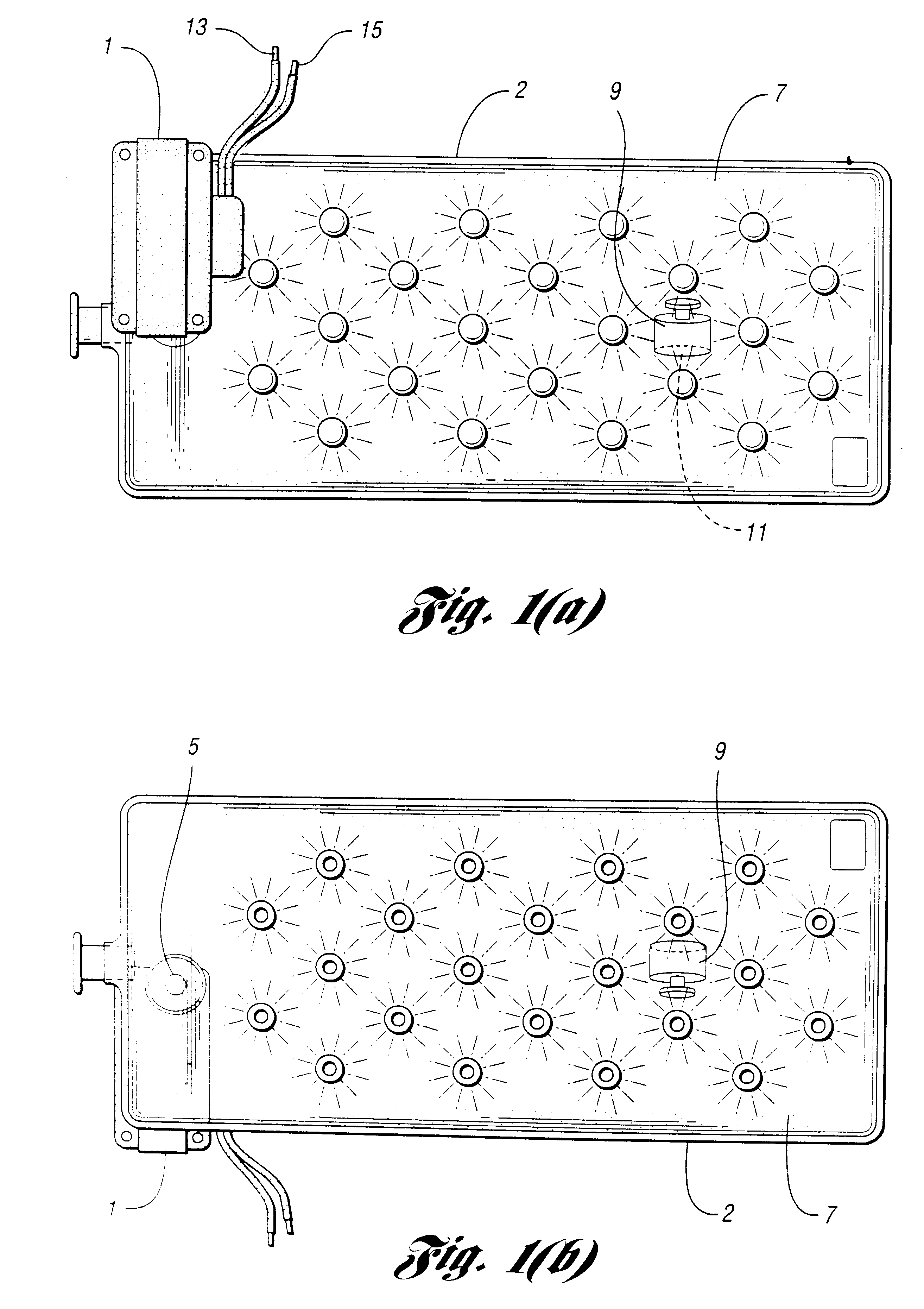

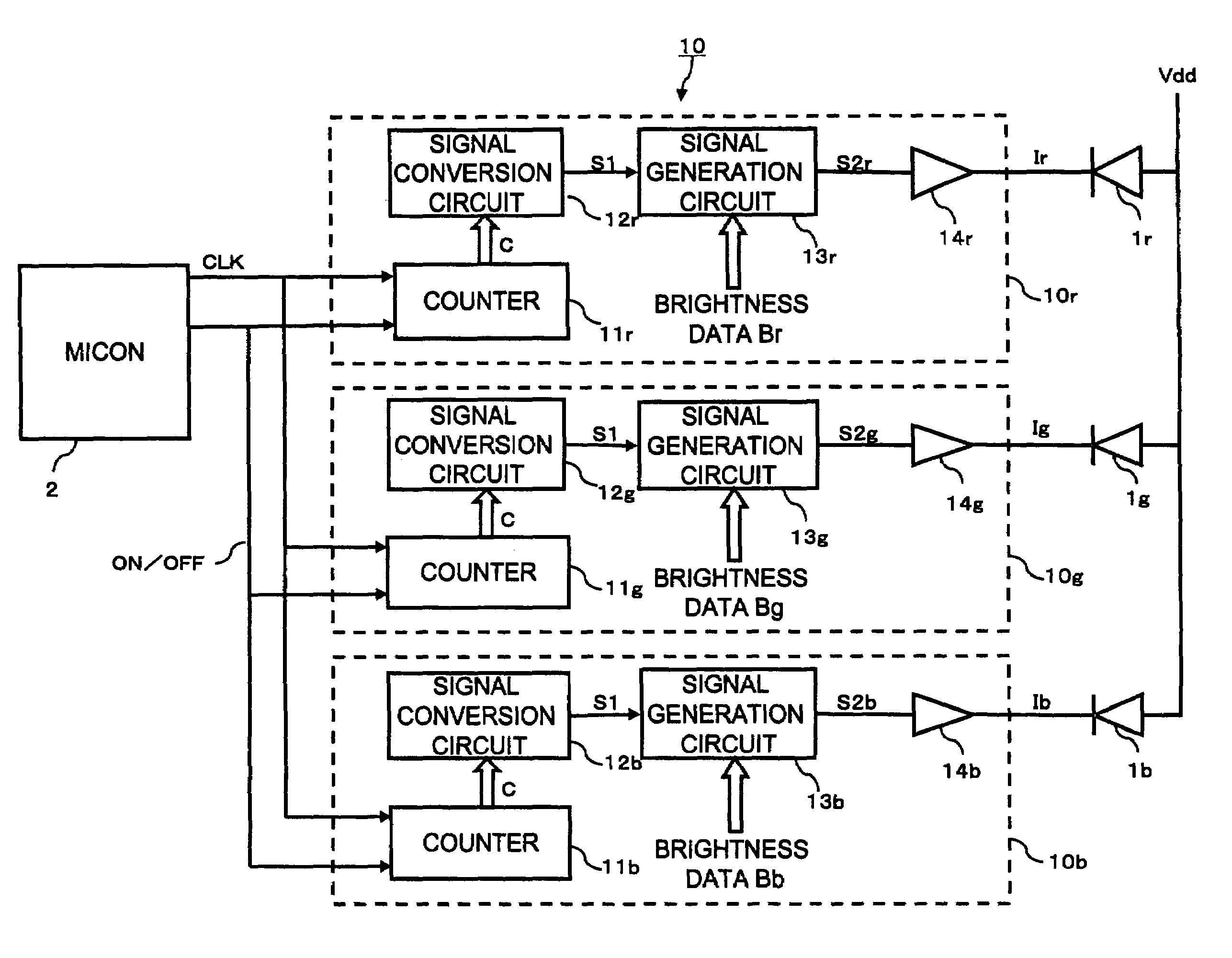

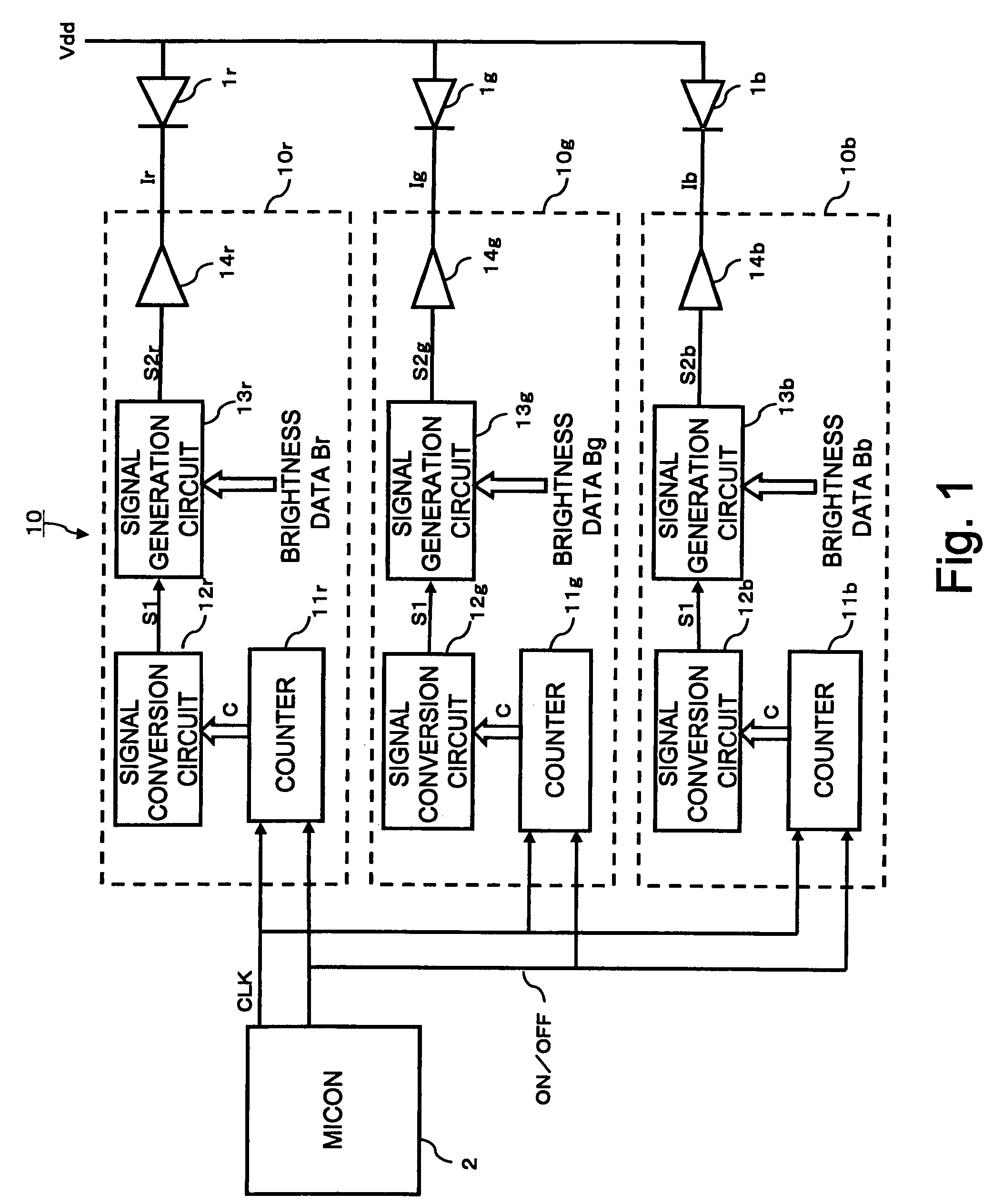

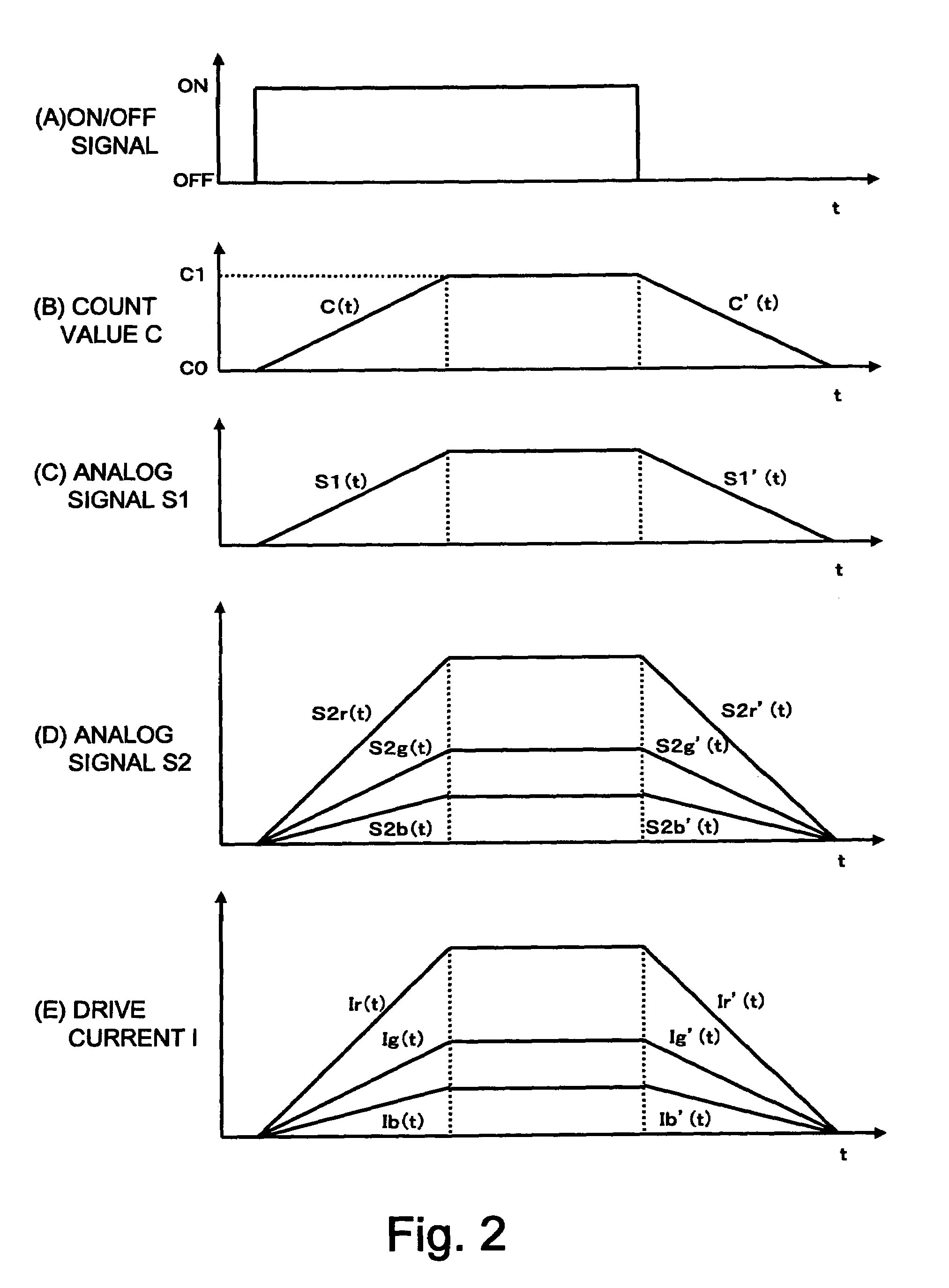

LED control circuit

ActiveUS7256552B2Weighing apparatus using elastically-deformable membersElectroluminescent light sourcesDriver circuitEngineering

An LED control circuit for controlling a plurality of LEDs with different emission colors comprises a counter which increments or decrements a count value at a predetermined clock in response to a count start signal externally supplied, a signal conversion circuit which converts the count value into an analog signal displaying intensity corresponding to the count value and outputs the analog signal as an output signal, a signal generation circuit which generates, based on the output signal from the signal conversion circuit and brightness data externally specified to its corresponding LED, an analog signal displaying intensity corresponding to a product of the output signal and the brightness data, and a driving circuit which drives its corresponding LED according to the analog signal output from the signal generation circuit, to gradually and simultaneously change the brightness of the LEDs in accordance with the count value.

Owner:SEMICON COMPONENTS IND LLC

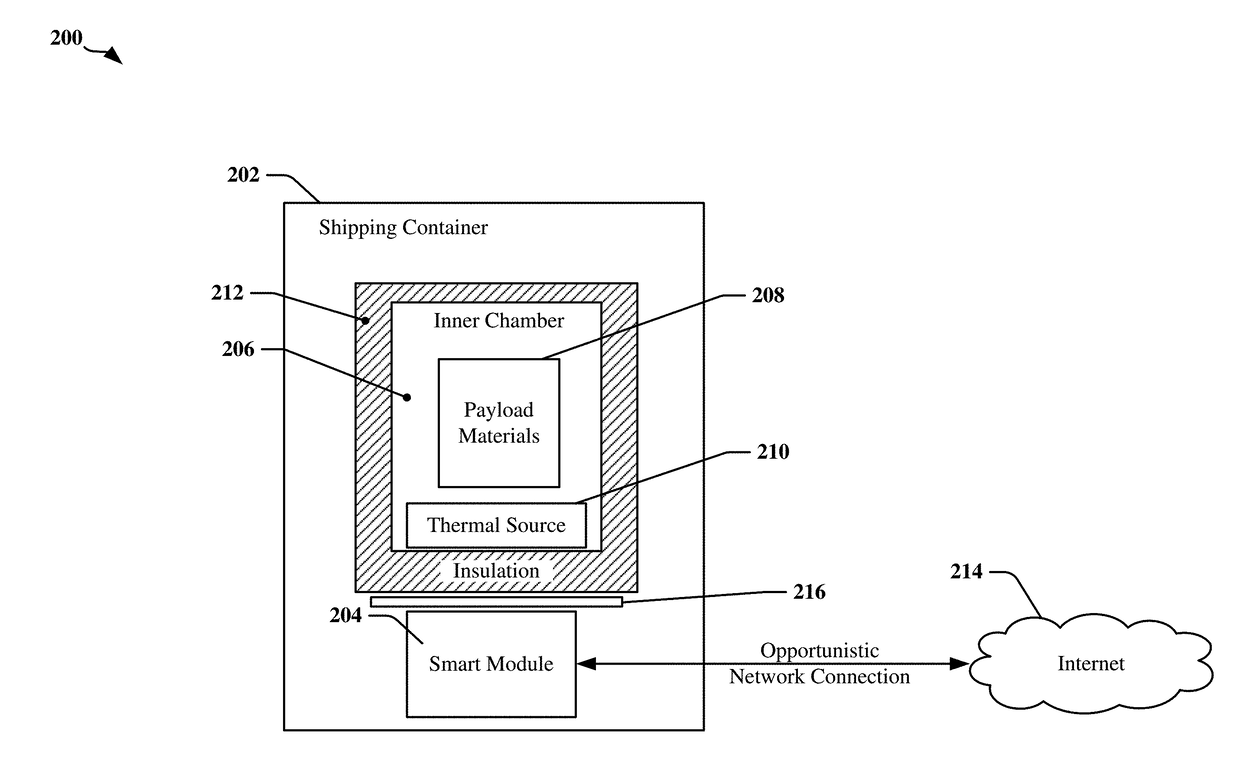

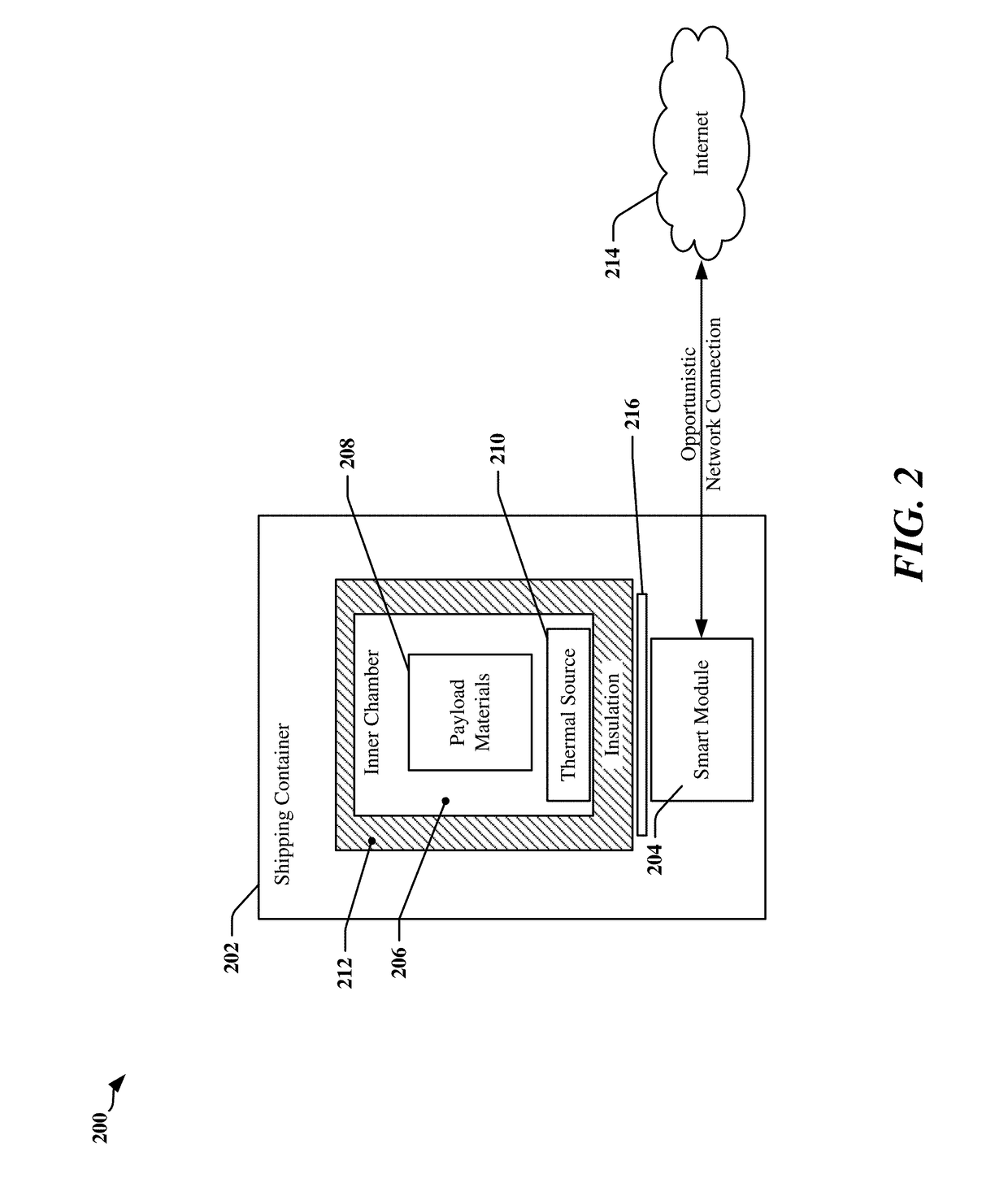

Method for determining the remaining life of a thermal mass in a shipping package while in transit

InactiveUS20170206497A1Domestic cooling apparatusLighting and heating apparatusTemperature controlTransducer

A shipping container is described for use with methods for monitoring and controlling shipment of a temperature controlled material and determining the remaining useful life of a Thermal Source contained within the shipping container. The container comprises an inner enclosure adapted to carry one or more commodities during shipment, a bladder conformed to the inner surface of the inner chamber, or a plate upon which commodities are place, and instrumented with at least one transducer and at least one processing device configured to receive measurements from the at least one transducer. The processing device communicates the measurements to a networked device upon detecting the presence of a network. The networked device may transmit commands to the processing device that causes the processing device to adjust a configuration parameter.

Owner:KLATU NETWORKS

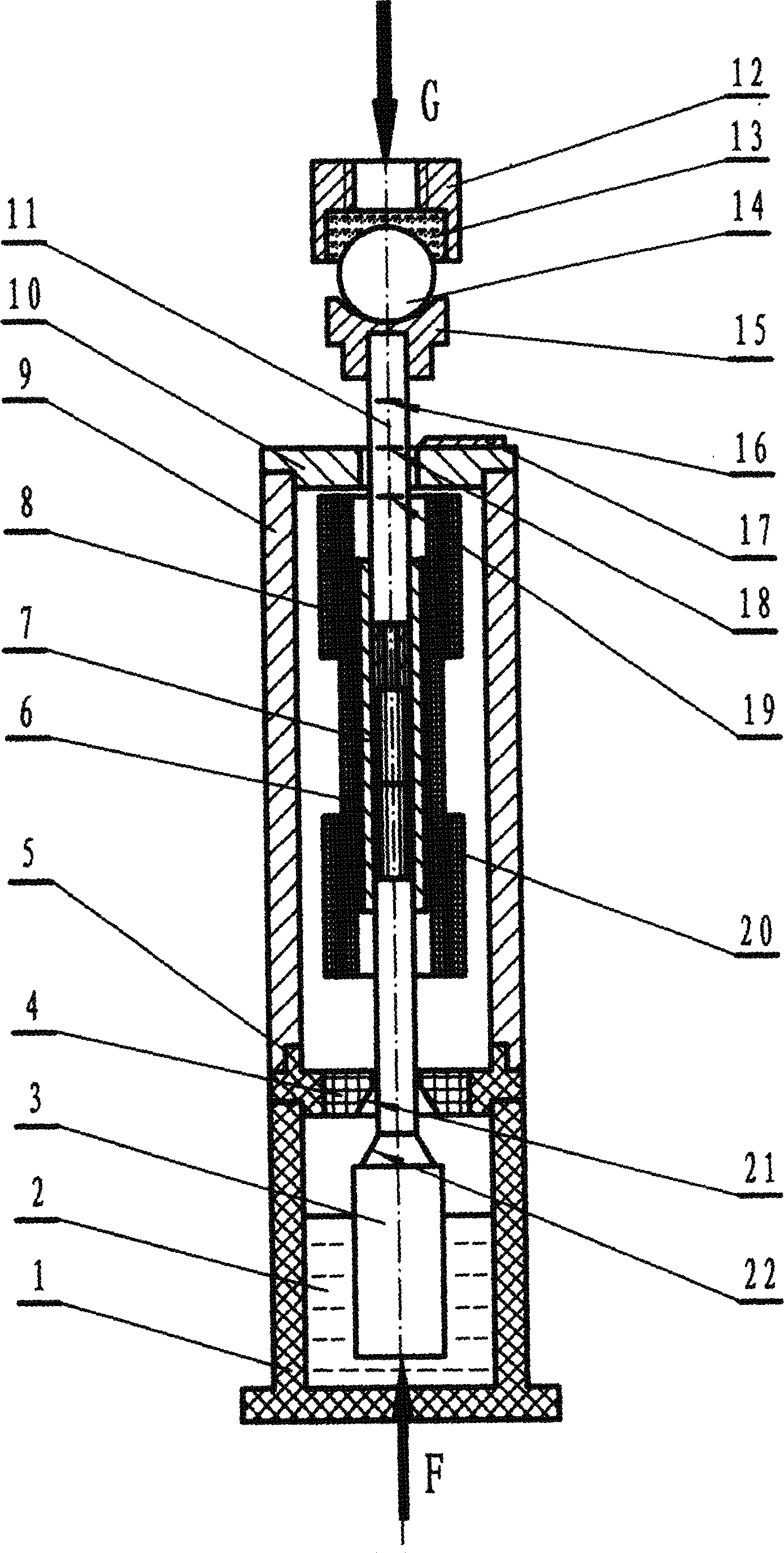

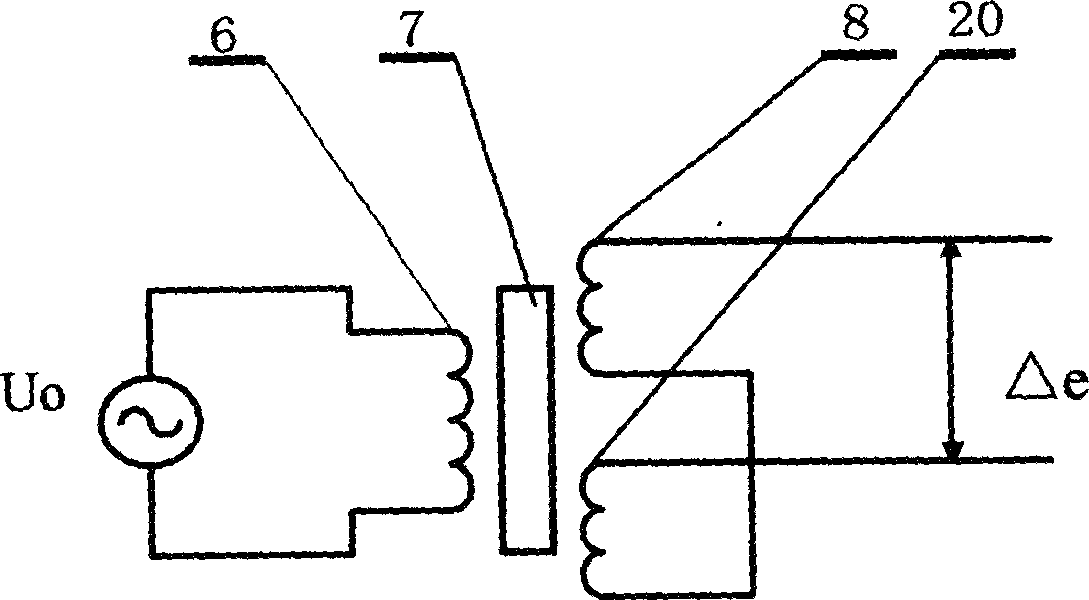

Float weighing sensor and PID deviation control method for dynamic coeighing

InactiveCN1598498AHigh sensitivityImprove weighing accuracyWeighing apparatus using fluid action balancingMechanical pressure/force controlNegative errorEngineering

The invention belongs to weight sensing technology field. The flotage weight sensor is made up of flotage balancer, weighing liquid leakage preventing mechanism, shit signal transmitting device and magnetic centering suspending mechanism. It converts the linear relation of gravity value based on the flotage theory into prominent shift value, and outputs with electric signal. It has no technology deficiencies such as slow change and zero point, and sensitivity excursion. The invention also provides a method for flotage weight sensor in PID error control when in dynamic weight metering. What is detected and controlled by the method is error of the weighted material to the set weight in dynamic weighing process. The positive and negative error value measured by the method, they counteracted in the dynamic weighing process, thus the accuracy of weighing can be upgraded greatly.

Owner:孔令宇

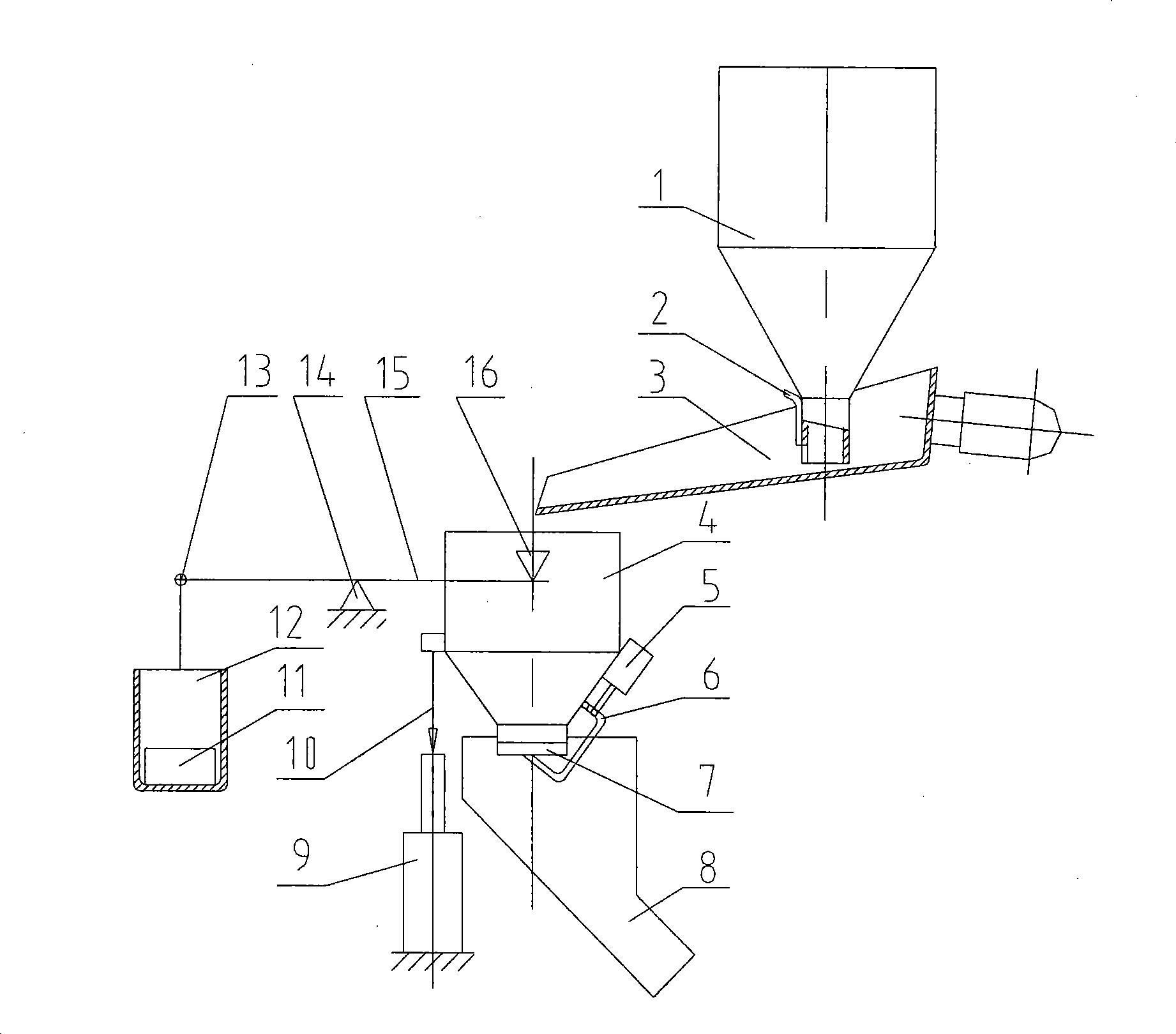

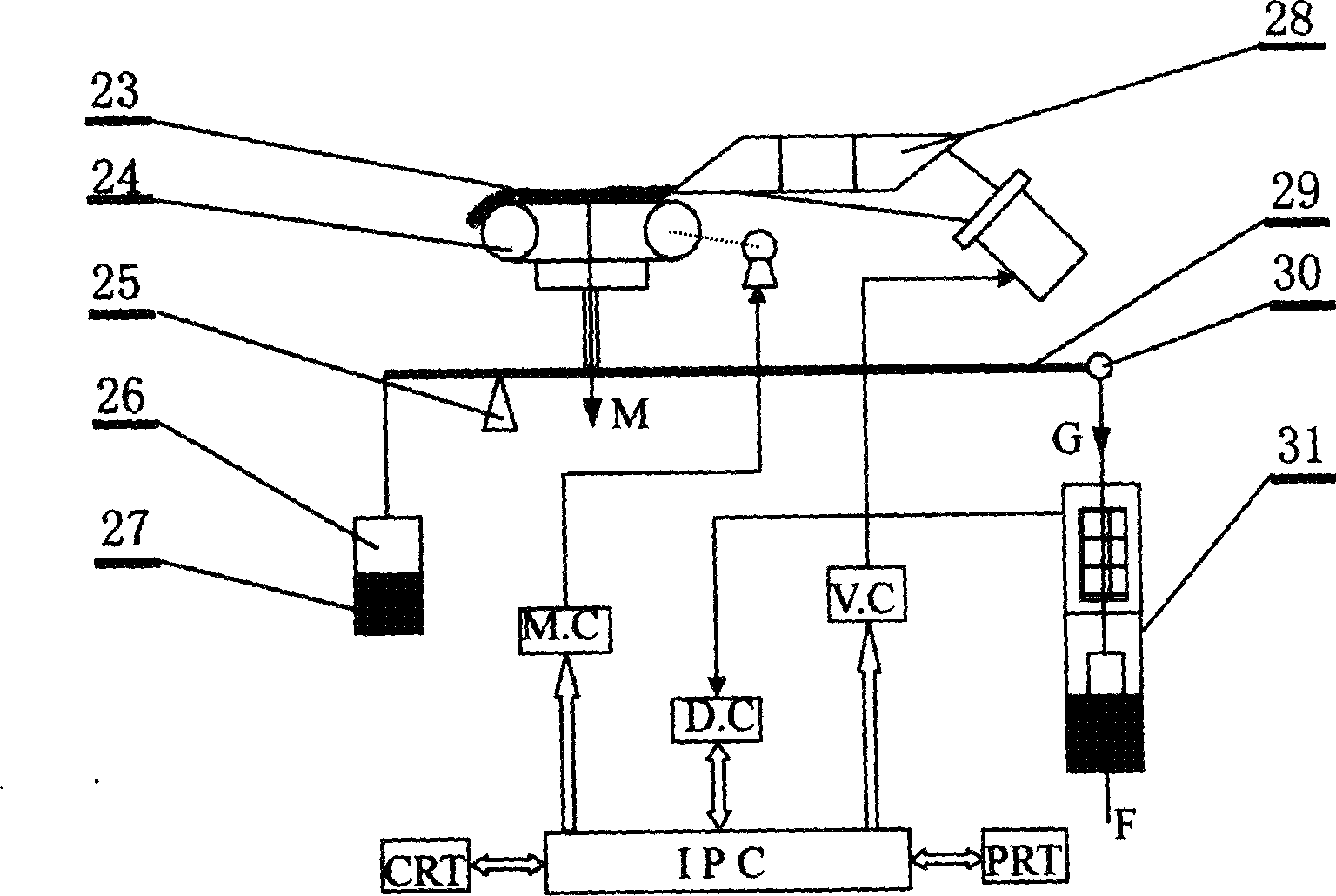

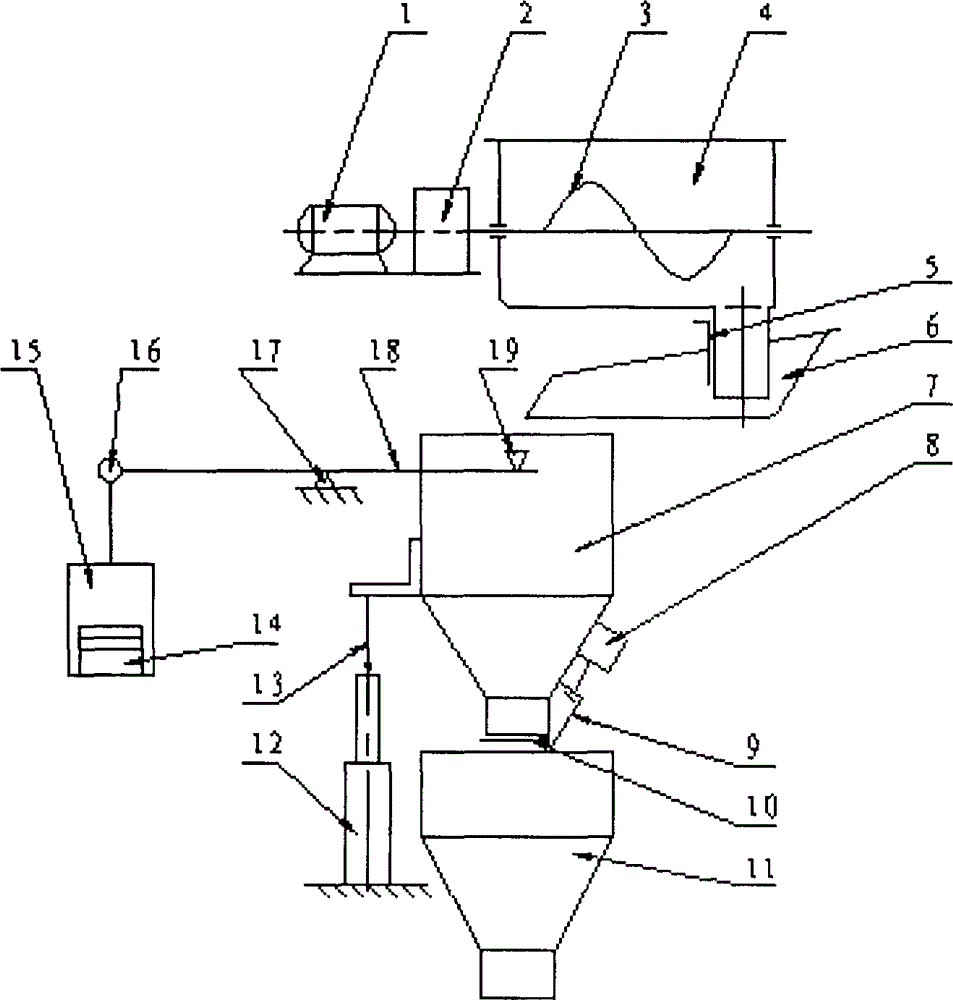

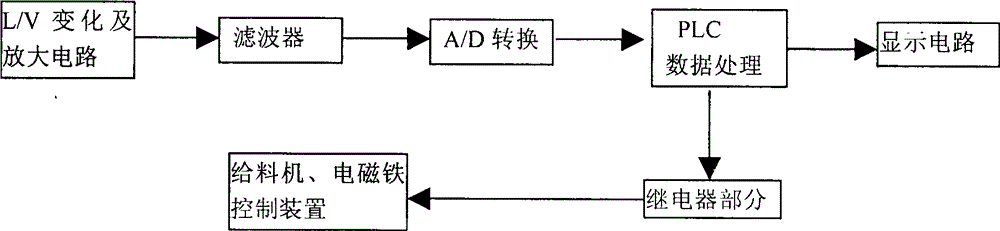

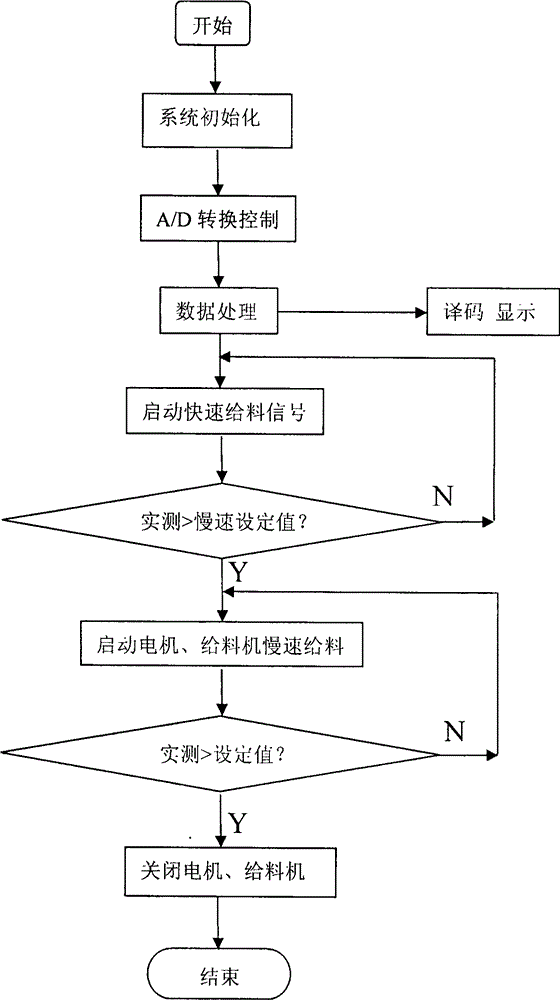

Variable speed feeding quantitative weighing system based on buoyant weighing and sensing principle

InactiveCN102879064AEasy programmingImprove metering accuracyWeighing apparatus using fluid action balancingGraduated cylinderAutomatic control

The invention belongs to the technical field of online quantitative weighing and an automatic control system thereof, and in particular relates to a variable speed feeding quantitative weighing system based on a buoyant weighing and sensing principle. A mechanical system of the variable speed feeding quantitative weighing system consists of a feeding mechanism, a feeding machine, a weighing cylinder mechanism, a leverage which transfers a quantitative weighing force value during the weighing, a discharging mechanism, a discharging cylinder, a dowel bar, a buoyant weighing sensor and weights which can adjust the quantitative weighing value; and a programmable logical control (PLC) measurement and control system of the variable speed feeding quantitative weighing system consists of a chord length (L) / instantaneous velocity (V) variation and voltage amplification module, a filter module, an analog (A) / digital (D) conversion module, a PLC central processing module, a display module, a relay part, a feeding mechanism and an electromagnet control device. The basic principle of the system is that after the buoyant weighing sensor compares the measured weighing value with a preset weighing value range, when the output electrical signal value reaches the preset signal value, the PLC measurement and control system can be used for accelerating and slowing down the feeding machine, and thus, the dual purposes of increasing the production efficiency and improving the weighing accuracy are realized.

Owner:孔令宇

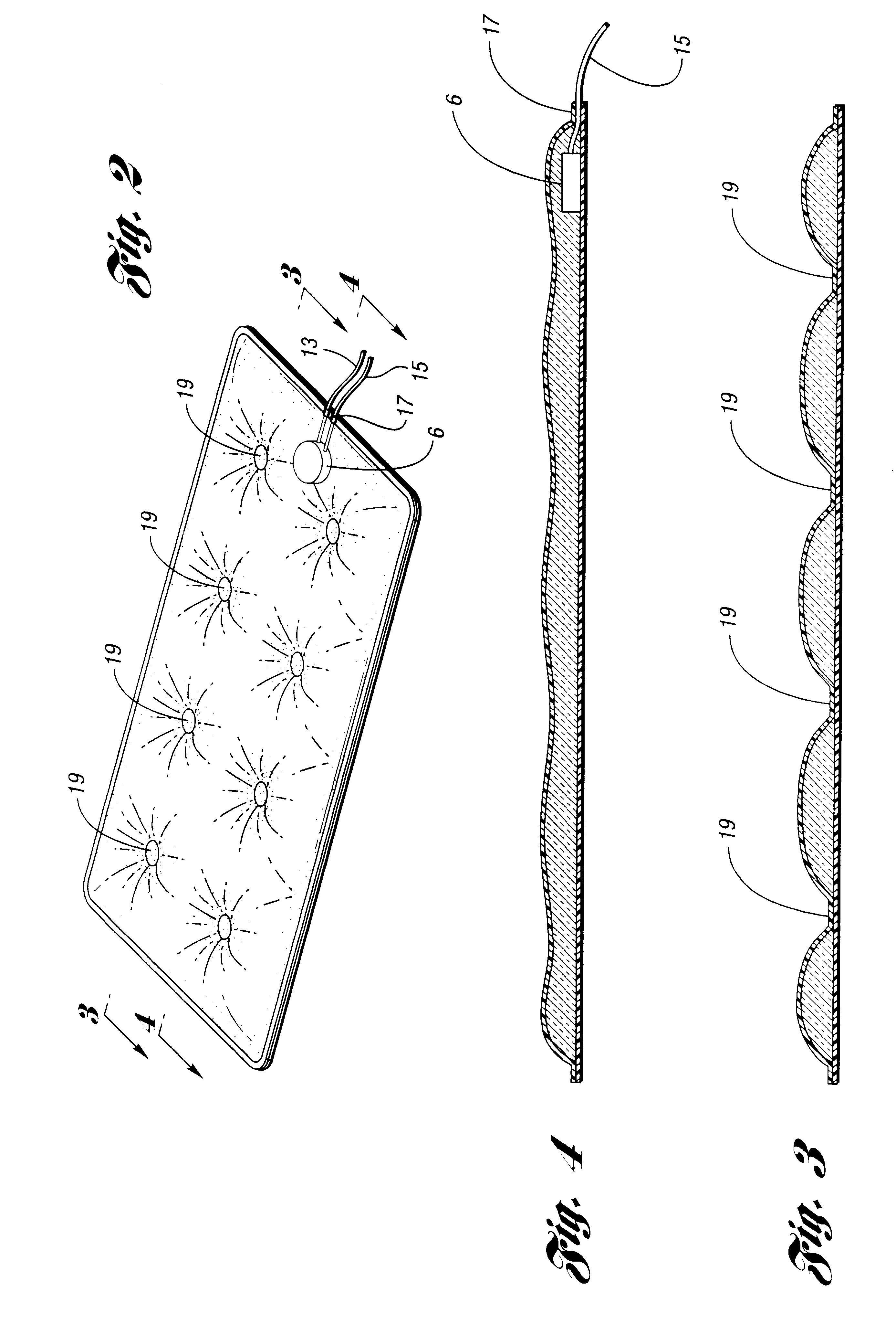

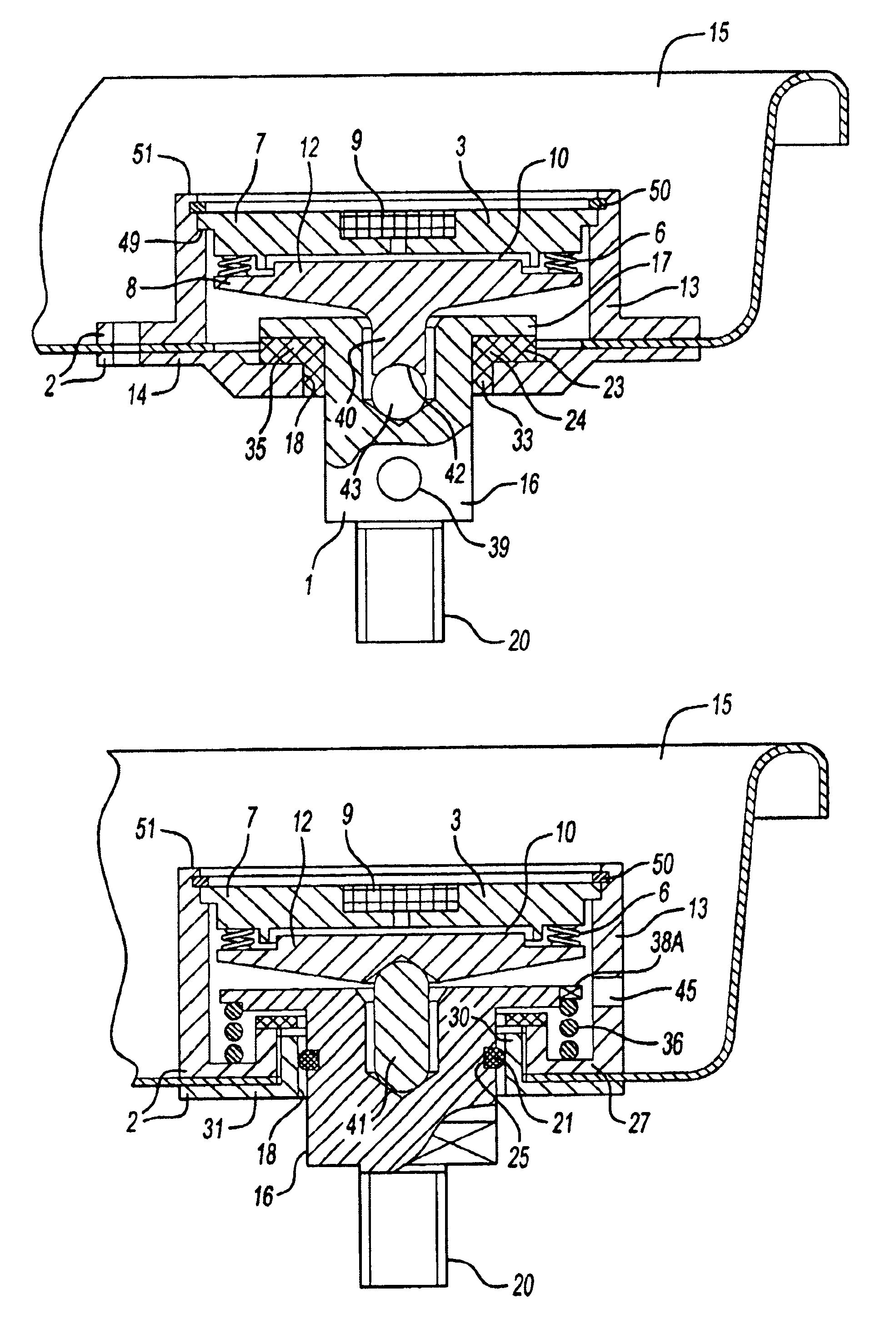

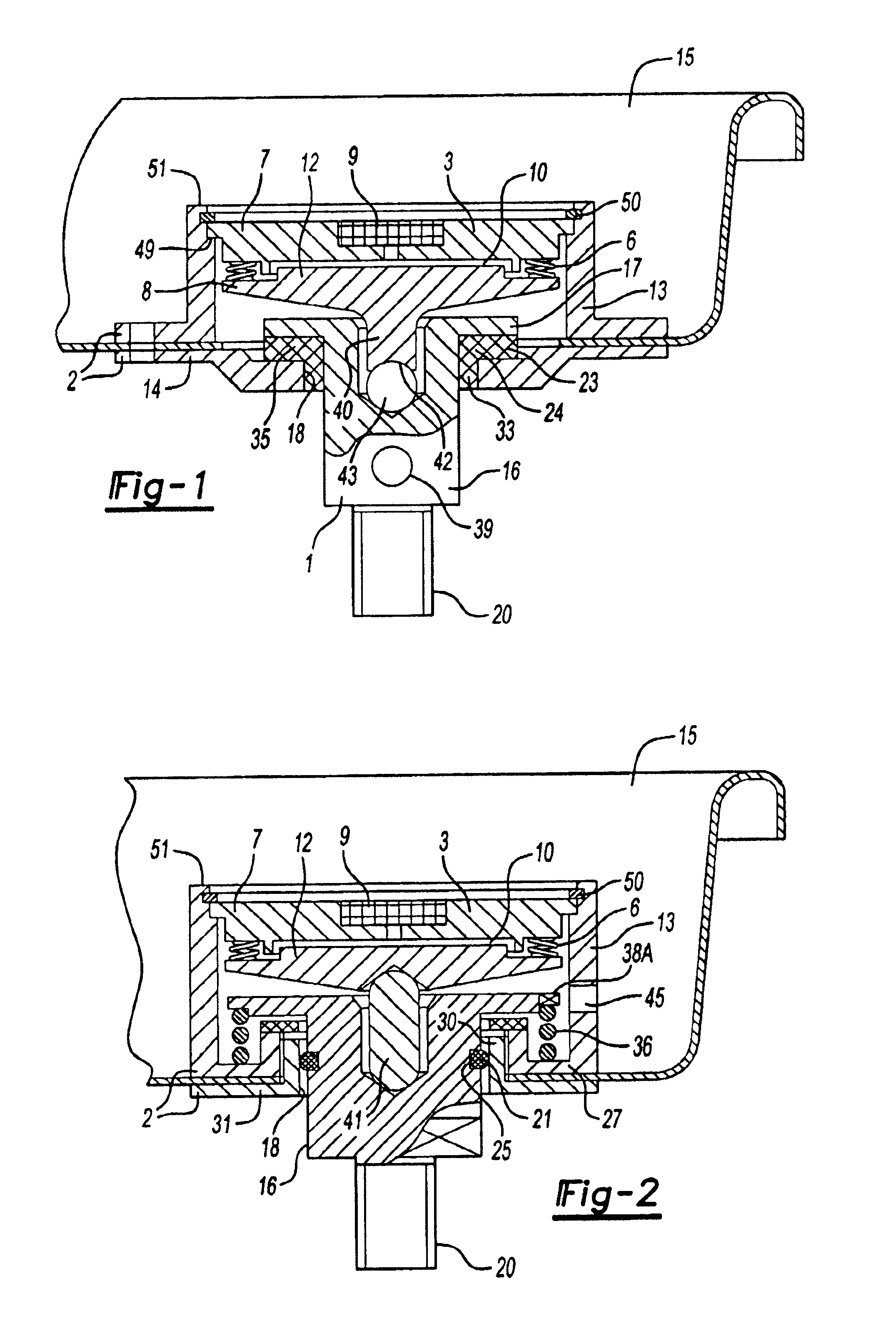

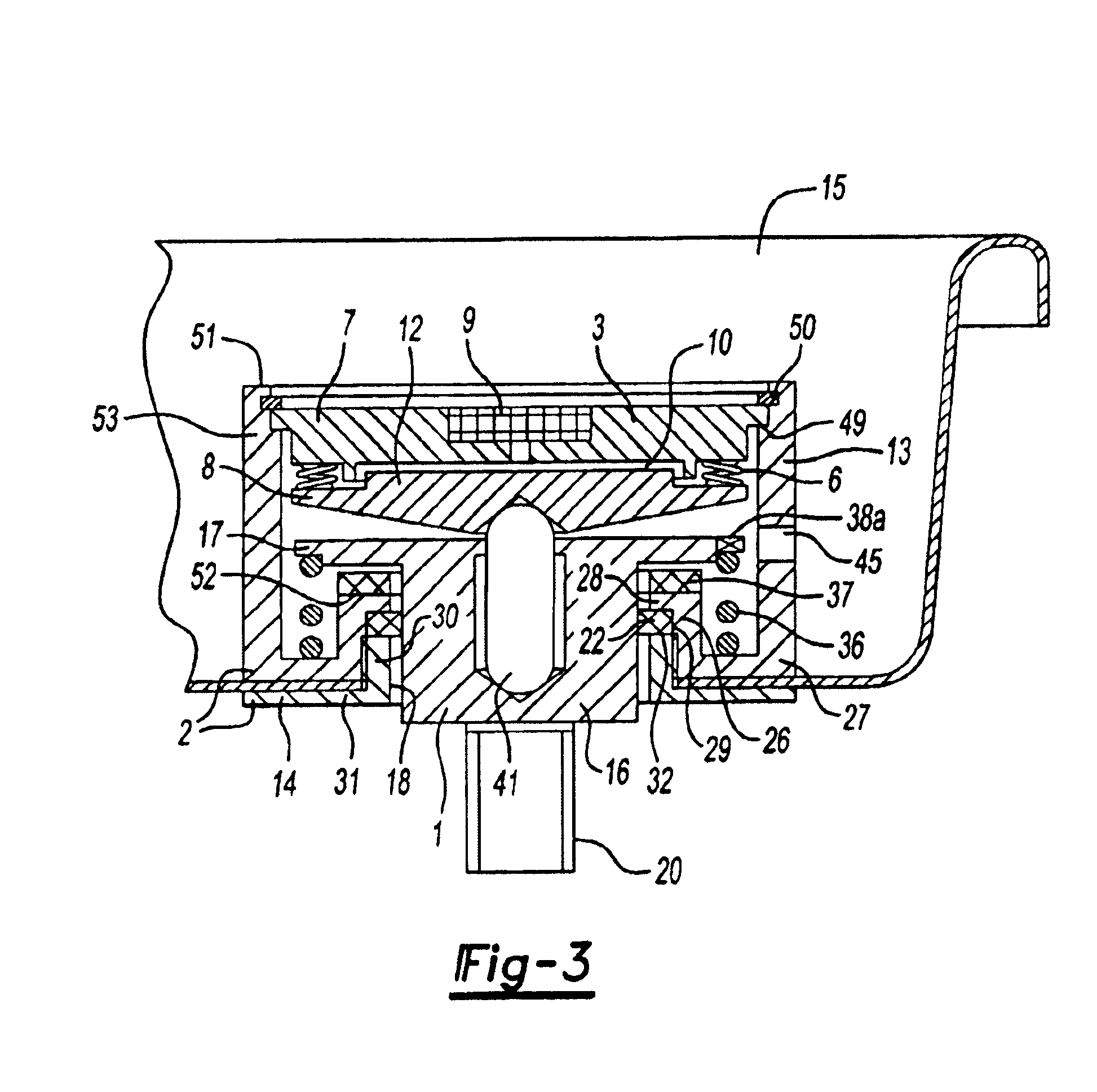

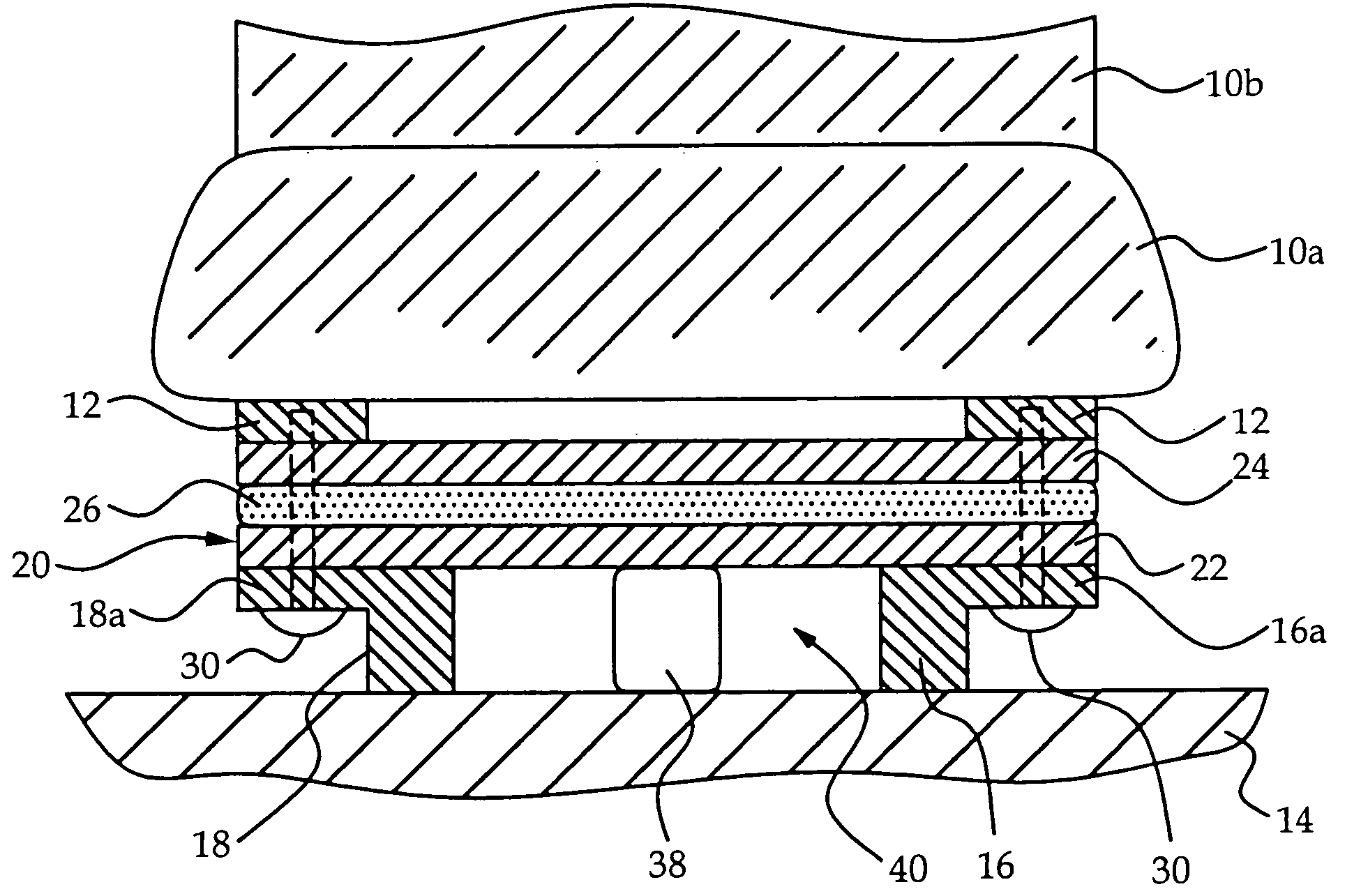

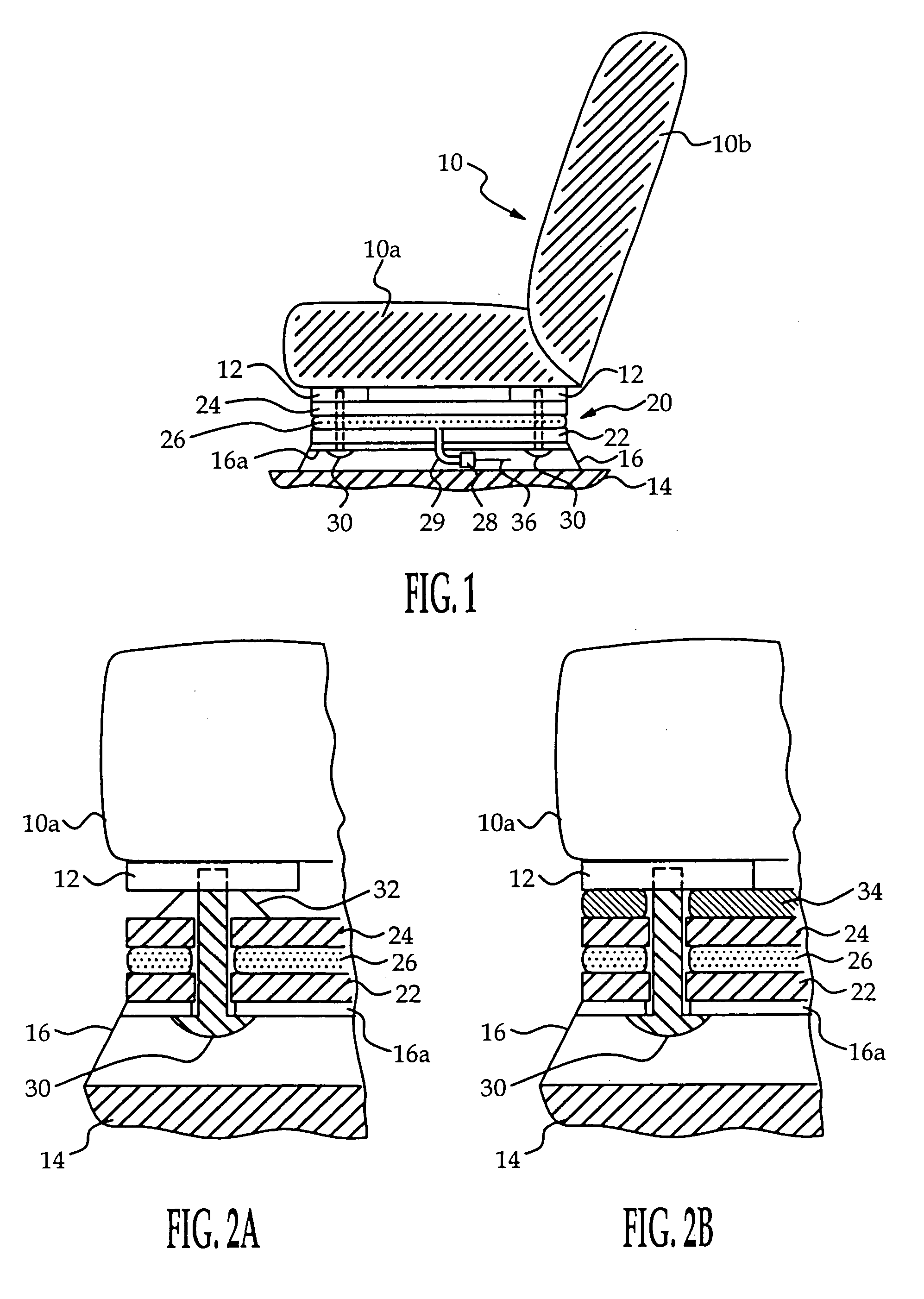

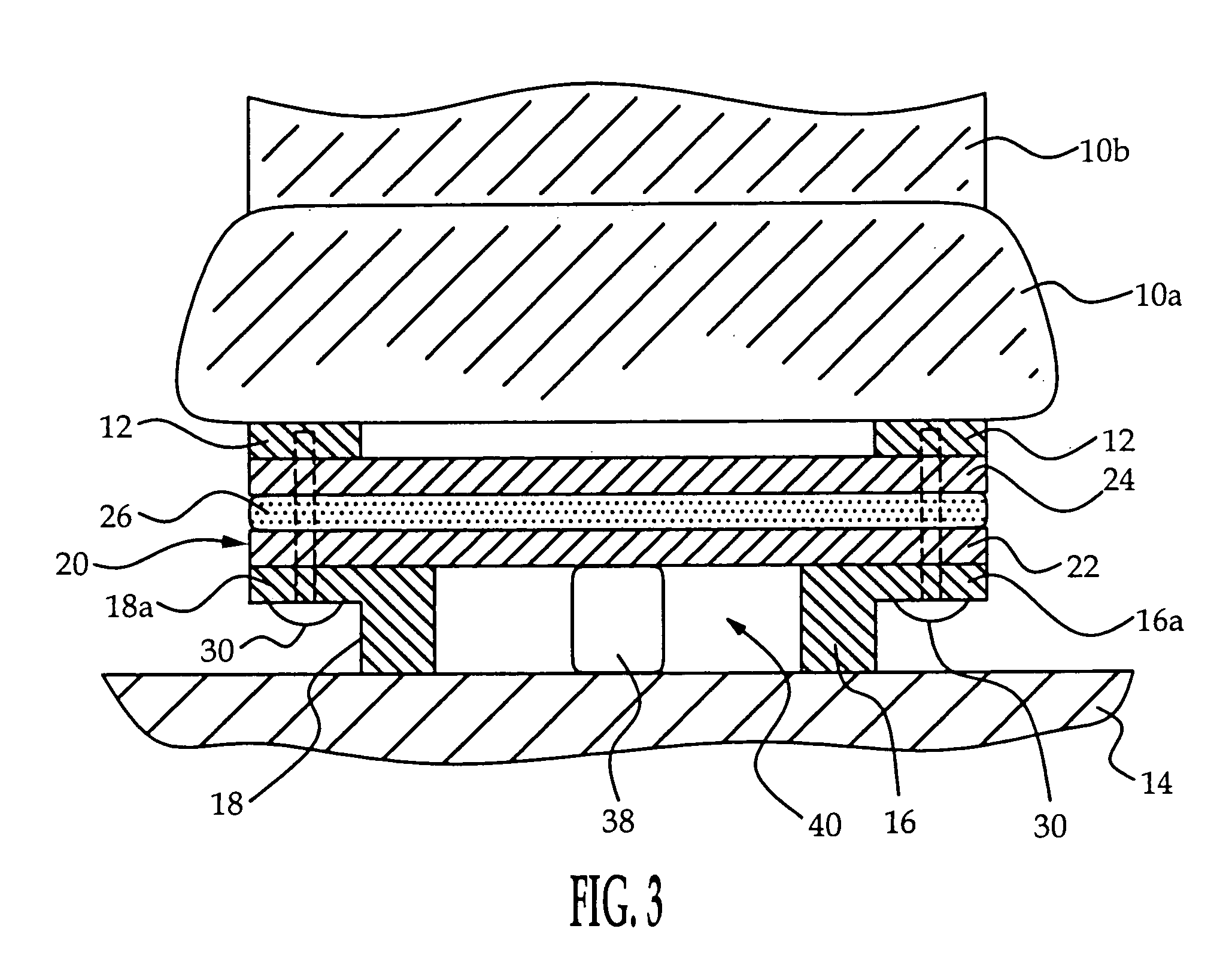

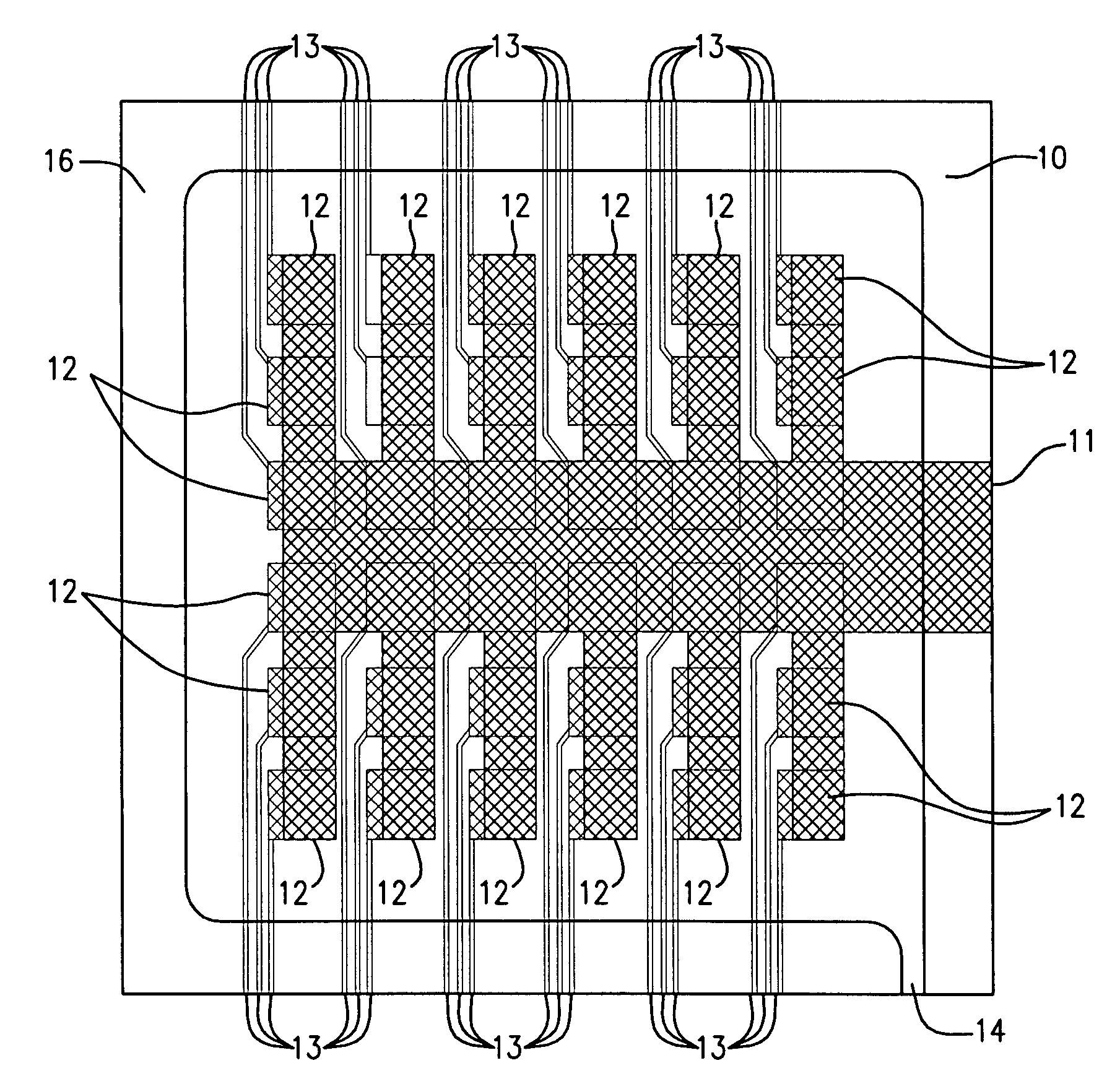

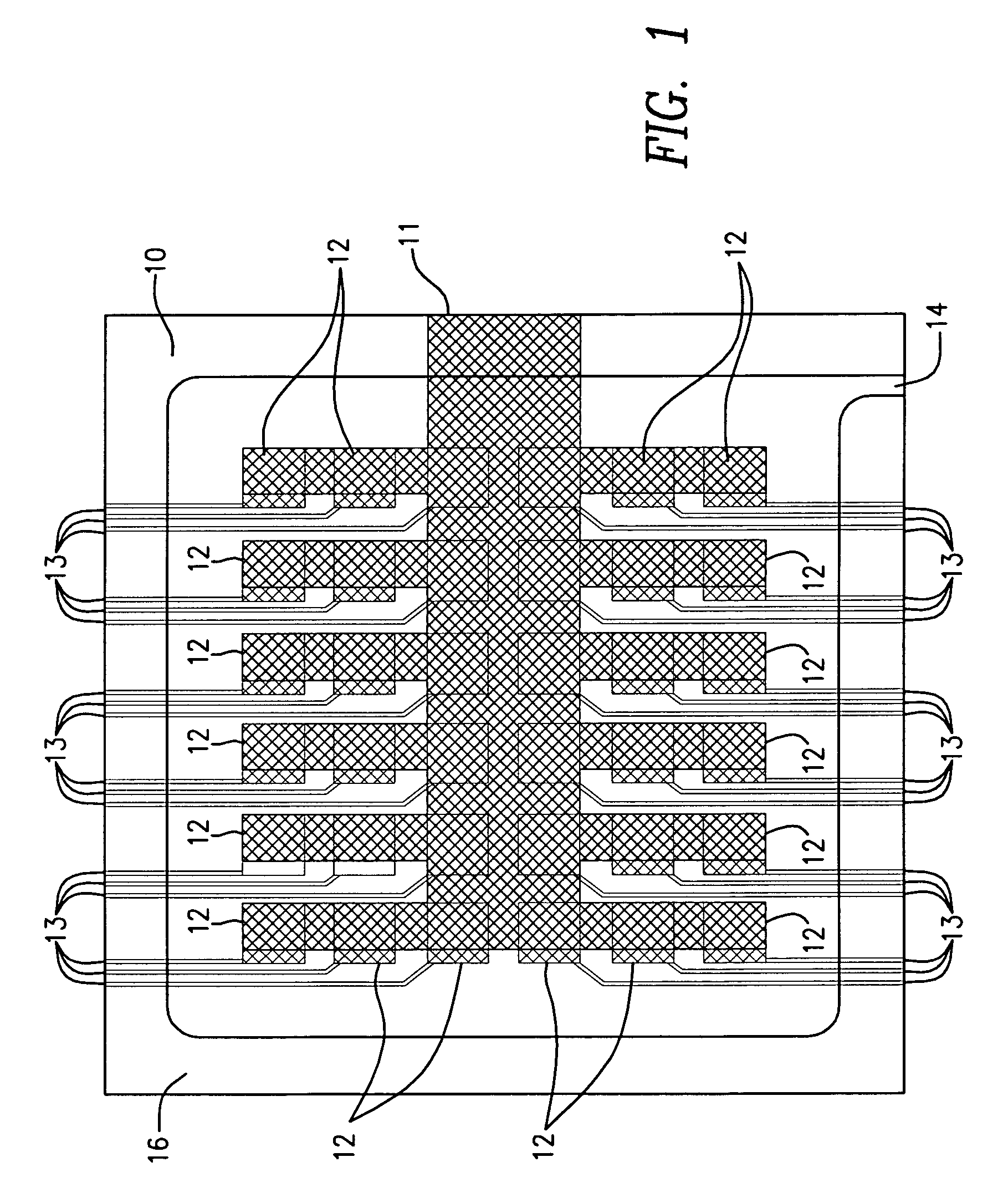

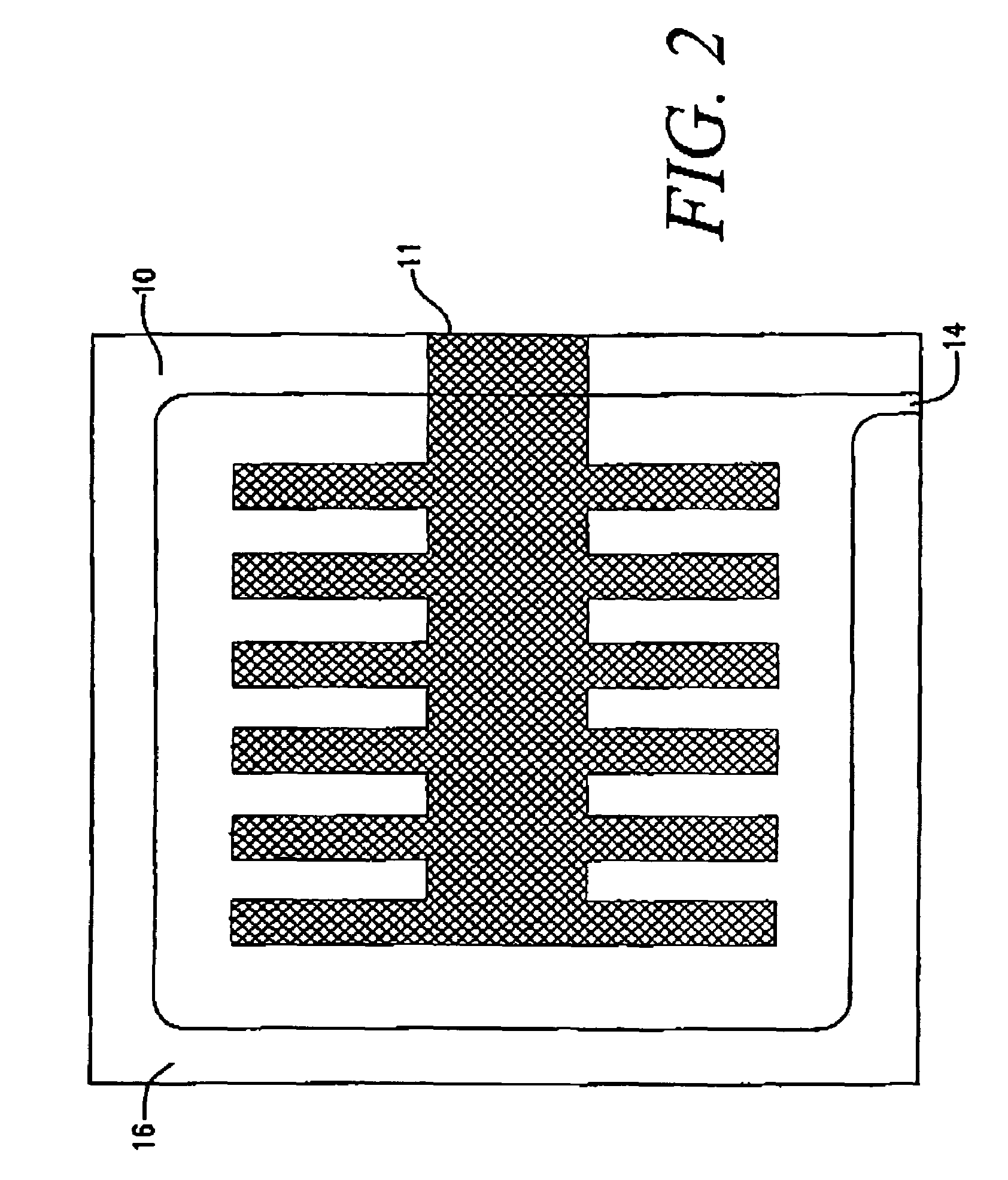

Frame-based bladder apparatus for seat occupant weight estimation

A frame-based occupant weight estimation apparatus for a vehicle seat that is supported by two or more floor brackets secured to the vehicle floor spans an open space between the floor brackets to prevent shunting of the occupant weight through a foreign object lying on the floor between the floor brackets. The weight estimation apparatus includes a fluid filled bladder sandwiched between first and second rigid plates, and is held in place between the seat frame and the floor brackets by a set of fasteners. A spring preloads the bladder so that deviations of the bladder fluid pressure from the preload pressure will be indicative of occupant weight. The first plate spans the open space between the floor brackets so that the fluid pressure is indicative of occupant weight even in cases where a portion of the occupant weight is supported by a foreign object disposed between the floor brackets.

Owner:DELPHI TECH INC

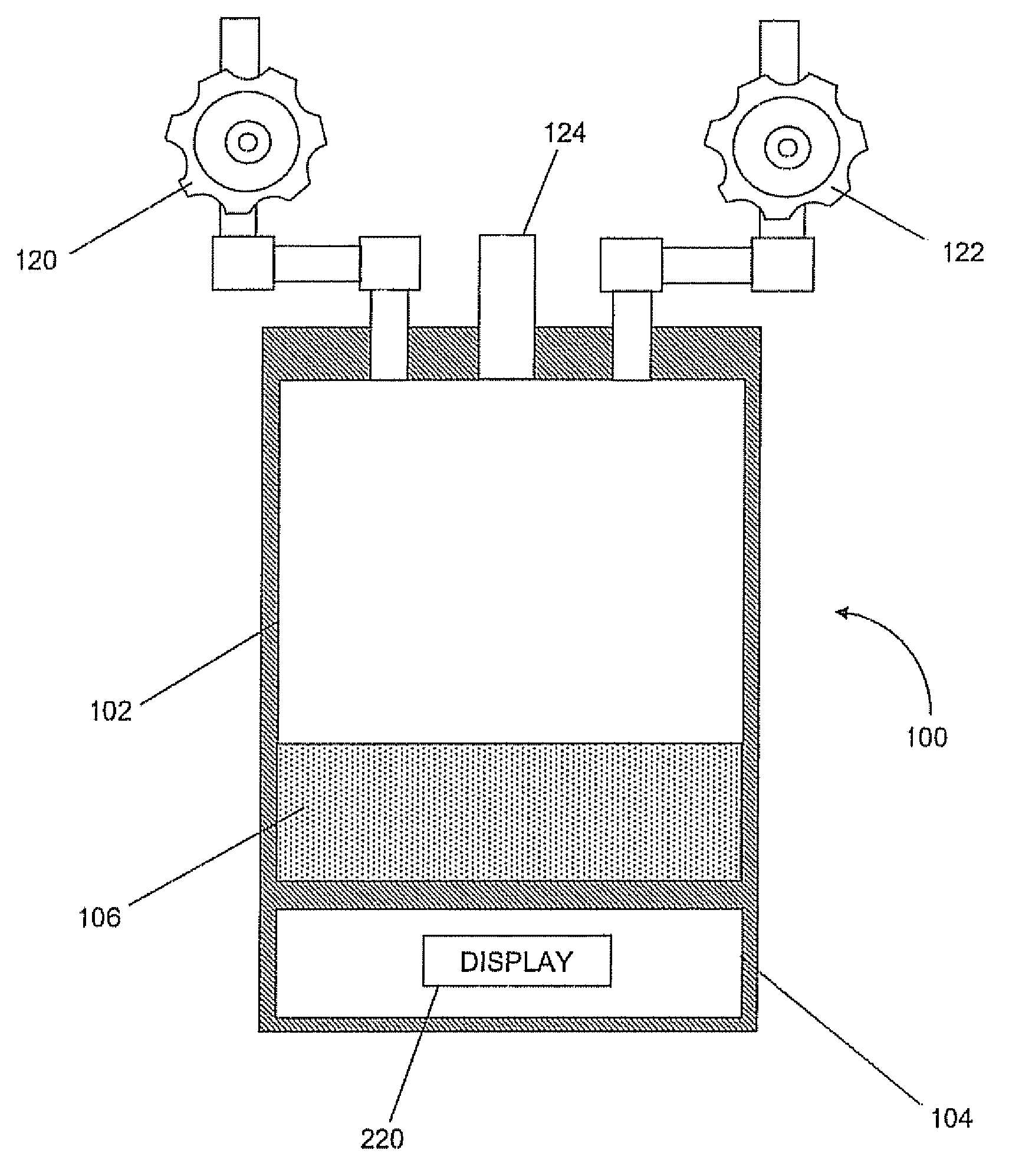

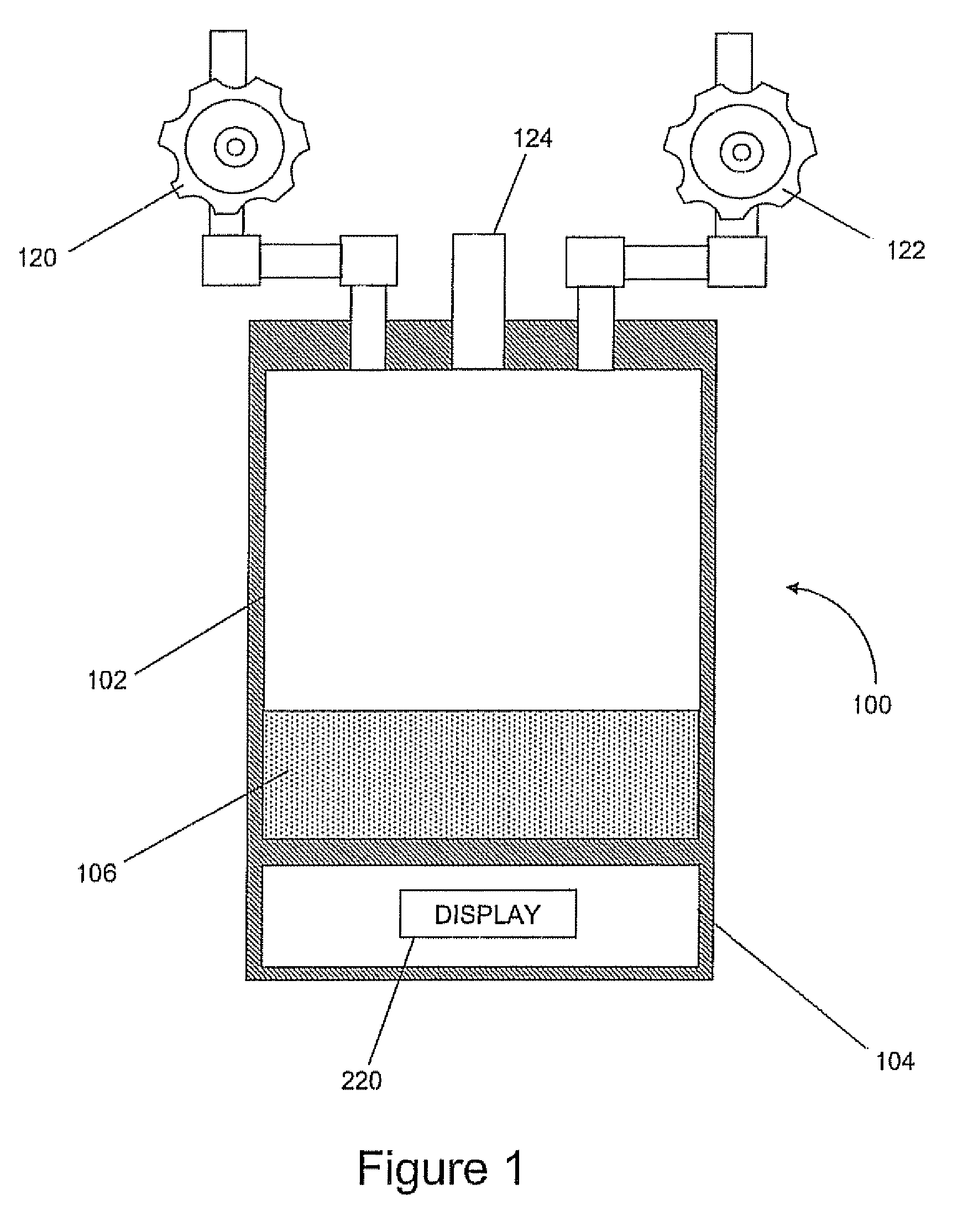

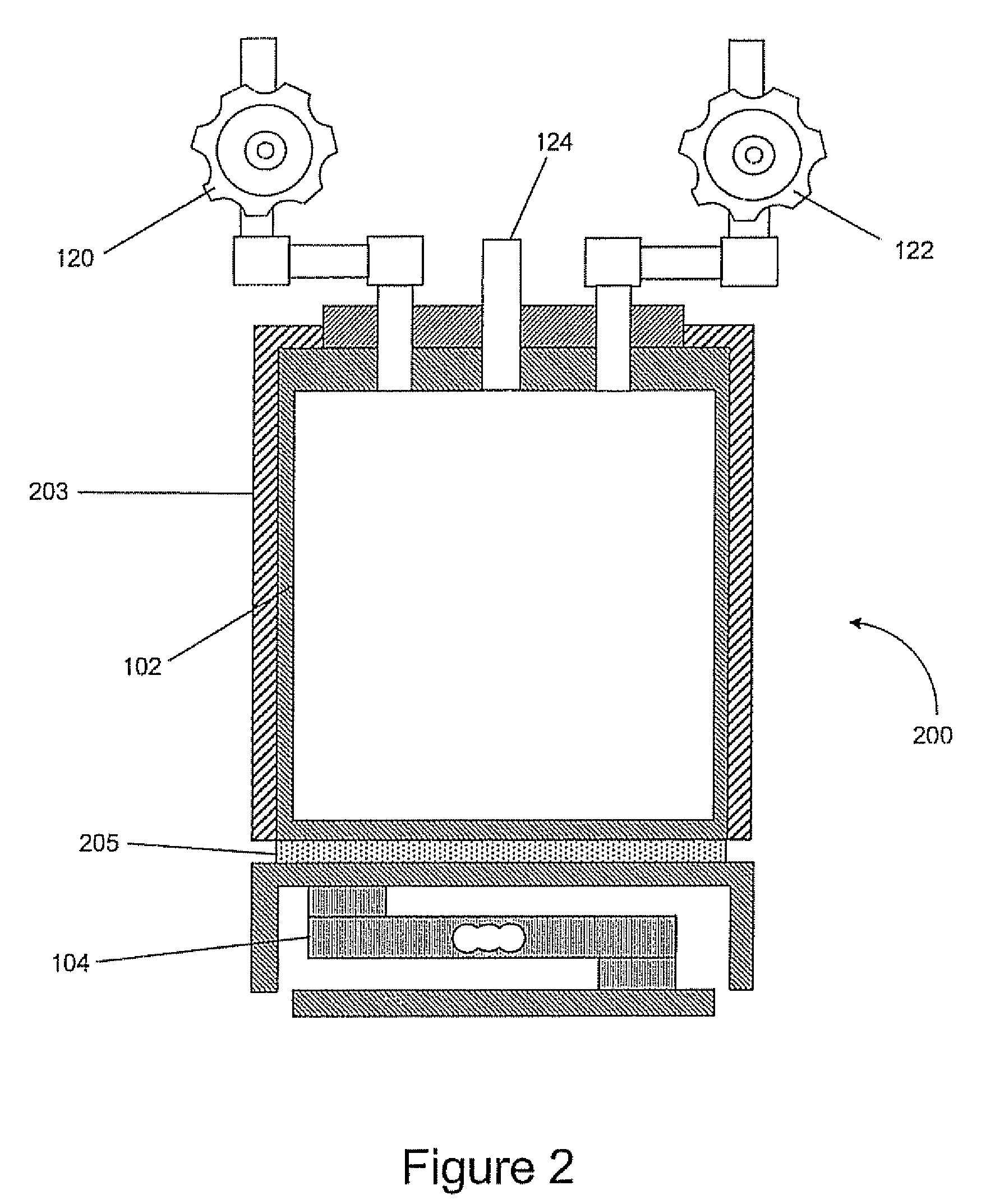

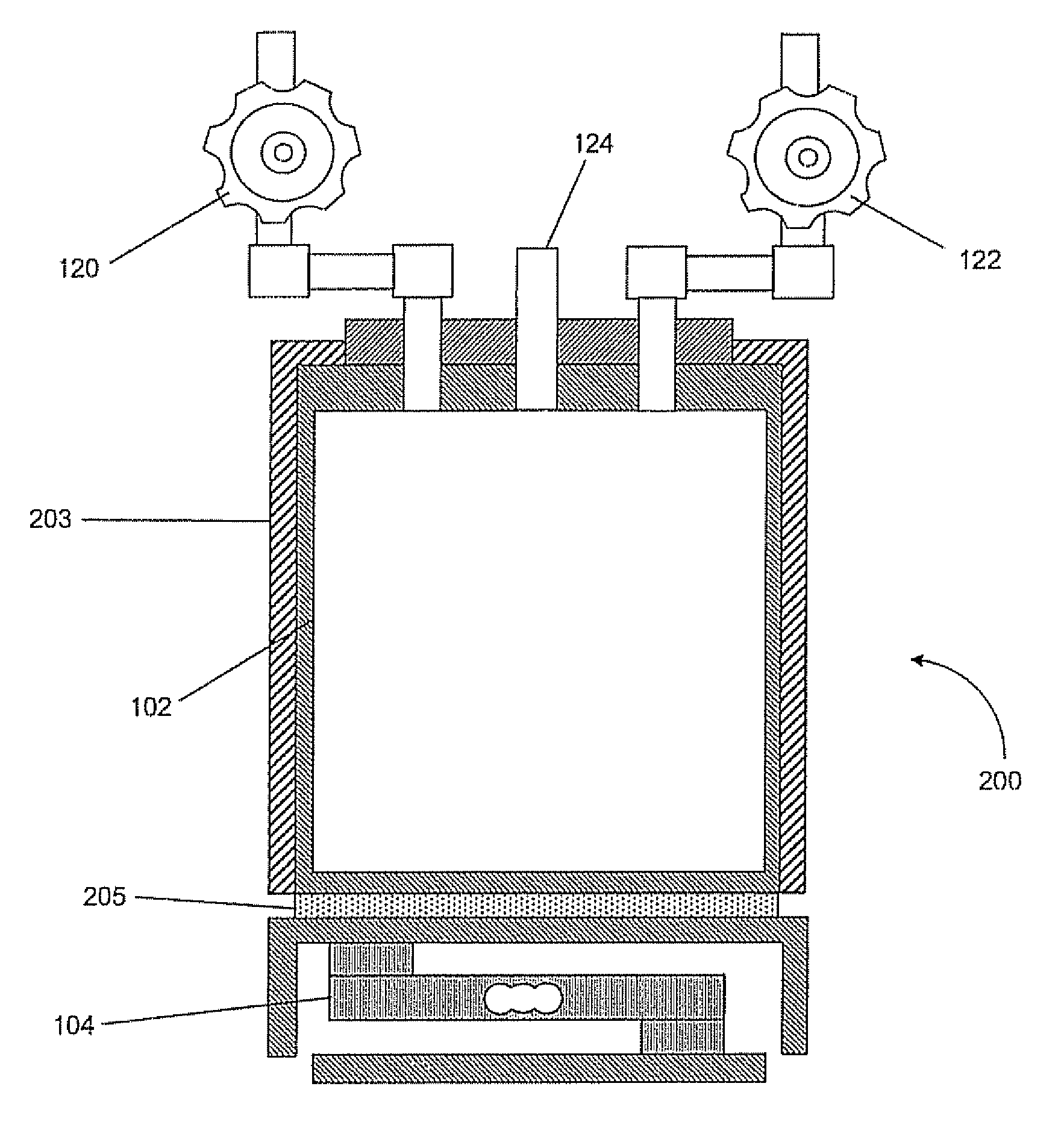

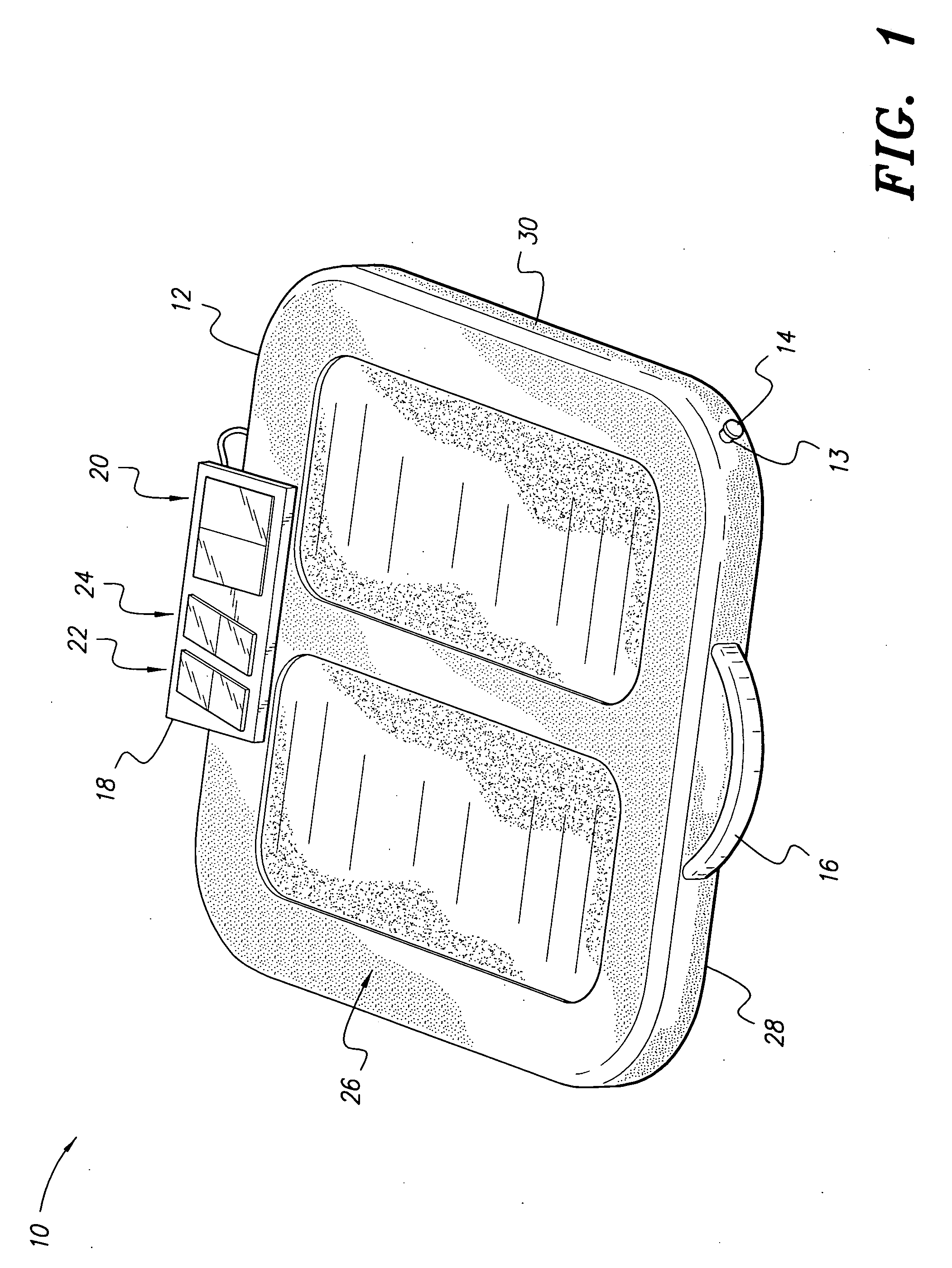

Patient weighing system

InactiveUS7282654B2Contact operating partsWeighing apparatus using fluid action balancingEngineeringUrinary bladder

Owner:PATIENTECH LLC

Portable airbag scale

InactiveUS20110272197A1Readily apparentWeighing apparatus using fluid action balancingWeighing apparatus detailsDisplay deviceEngineering

The portable airbag scale is a scale that measures the weight of a load based upon a difference between measured air pressure in an inflatable bladder, the difference being measured between a first state, where the load is not positioned on the inflatable bladder, and a second state, in which the load is supported on the inflatable bladder. The portable airbag scale includes an inflatable bladder having opposed upper and lower walls and at least one sidewall. A port is formed through the at least one sidewall for selective inflation and deflation of the inflatable bladder. A pressure sensor is mounted within the inflatable bladder for measuring the air pressure therein. A controller selectively calculates the weight of the load based upon the measured difference in air pressure. A display is provided for displaying the weight of the load.

Owner:KING FAHD UNIV OF PETROLEUM & MINERALS INTELLECTUAL ASSETS OFFICE INNOVATION CENT

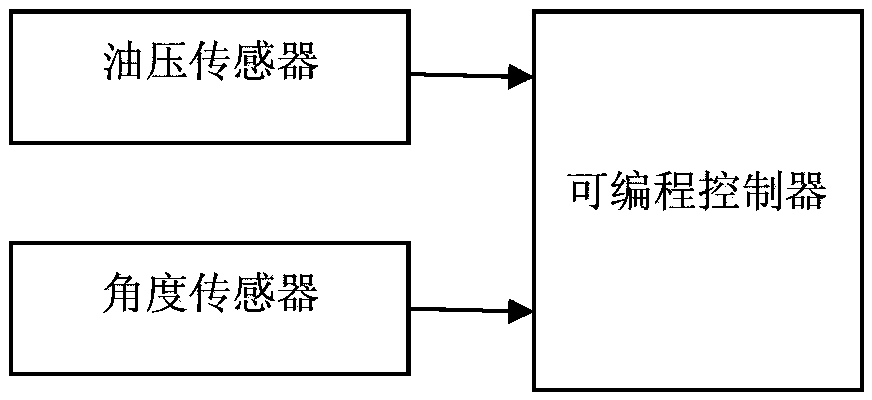

Apparatus and method used for excavator hanging object weighing

ActiveCN103407890AImprove measurement efficiencySave human effortWeighing apparatus using fluid action balancingLoad-engaging elementsOil pressureHeavy load

The invention discloses an apparatus and a method used for excavator hanging object weighing. The apparatus comprises an oil pressure sensor, angle sensors and a programmable controller; the oil pressure sensor is arranged on a movable arm cylinder; the angle sensors are arranged on a movable arm and a bucket respectively; the oil pressure sensor and the angle sensors are connected with the programmable controller respectively. The method comprises following steps: an excavator unloading torque equation is established; a plurality of different movable arm angles and bucket rod angels are input so as to obtain an equation set, and actual unloading torque values under different lazy arm conditions are obtained by calculation of the equation set; actual torque values of the movable arm cylinder is calculated; and the weight of hanging objects is calculated according to the actual torque values and the actual unloading torque values obtained in the steps above, and working radius of the hanging objects measured by the angle sensor. The apparatus and the method are capable of realizing the weight calculation of the excavator hanging objects rapidly and accurately when parameters such as the weights of the excavator movable arm, the bucket rod and the bucket, and the barycentric coordinate are unknown.

Owner:XUZHOU HIRSCHMANN ELECTRONICS

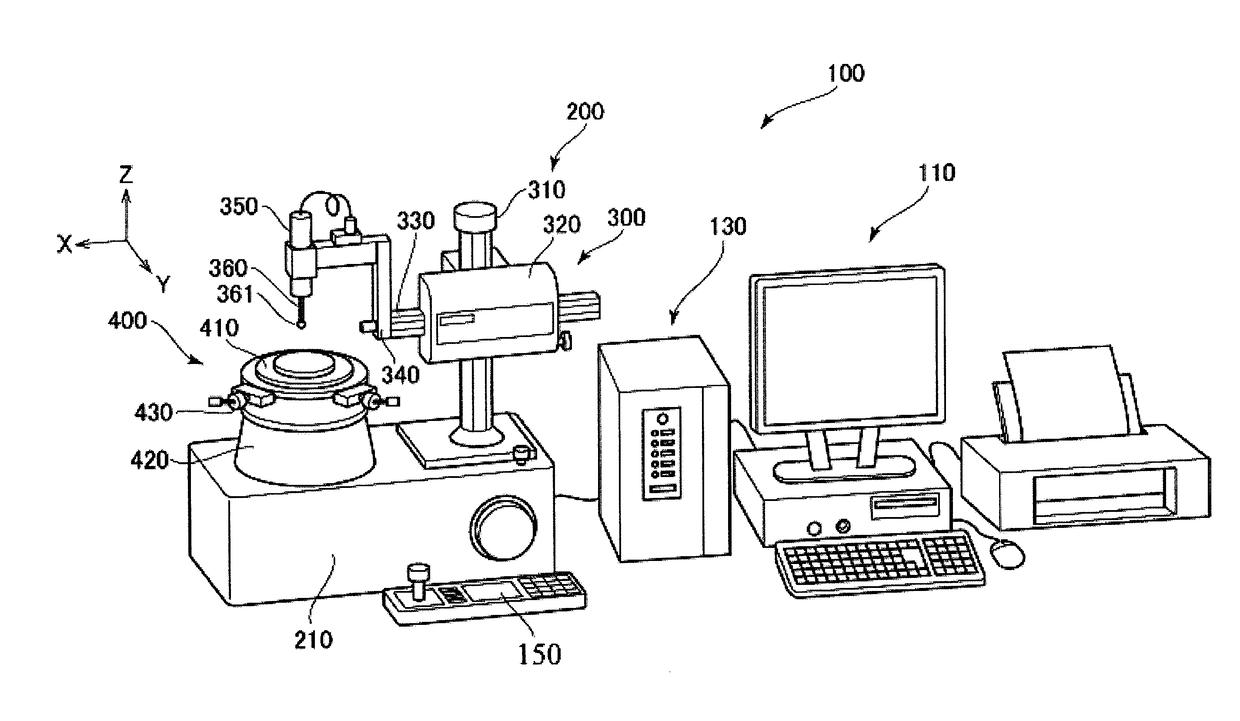

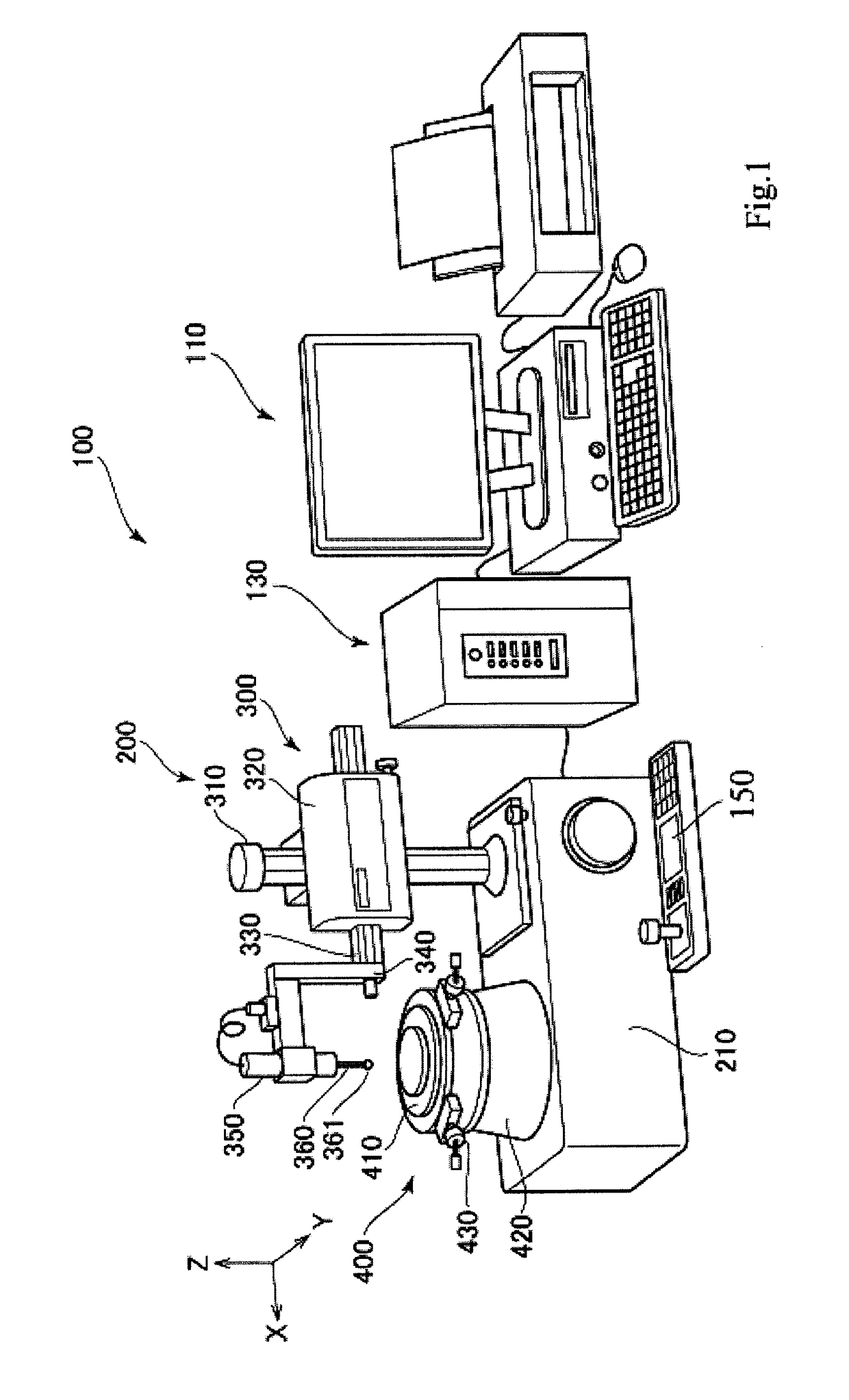

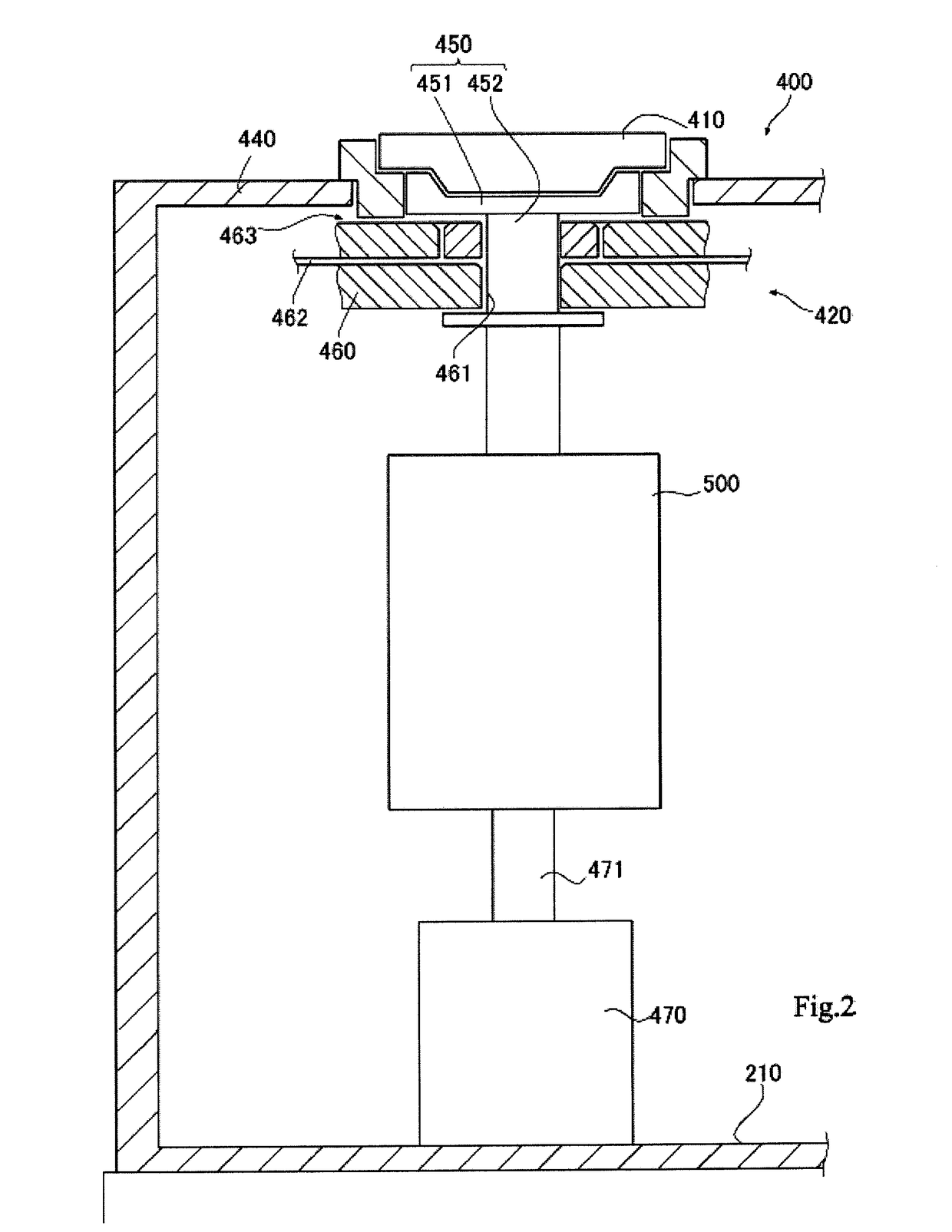

Drive control method of drive stage device

ActiveUS20180299247A1Mechanical counters/curvatures measurementsWeighing apparatus using fluid action balancingAir bearingEngineering

In a control method of a drive stage device, a stage is floated on an air bearing, then a height of the stage while floating on the air bearing is measured as a first height. A work piece is placed on the stage and a height of the stage while holding the work piece is measured as a second height. A difference between the first height and the second height is calculated as a drop amount, and a weight of the work piece is calculated based on the drop amount. An upper limit speed of one of rotational drive and horizontal movement of the stage is determined based on the calculated work piece weight. A speed of the one of the rotational drive and the horizontal movement of the stage is controlled so as to not exceed the upper limit speed.

Owner:MITUTOYO CORP

Popular searches

Chemical conversion by chemical reaction X-ray/gamma-ray/particle-irradiation therapy Medical devices Medical equipment Medical reports Telemetric patient monitoring Sleep inducing/ending devices Special purpose weighing apparatus Sleep/relaxation inducing devices Electric unknown time interval measurement

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com