Apparatus and method used for excavator hanging object weighing

A technology for weighing devices and excavators, applied to measuring devices, weighing equipment using fluid balance, weighing, etc., can solve problems such as lack of measurement conditions, large workload, and time-consuming measurement, so as to reduce manpower, The effect of saving measurement cost and improving measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

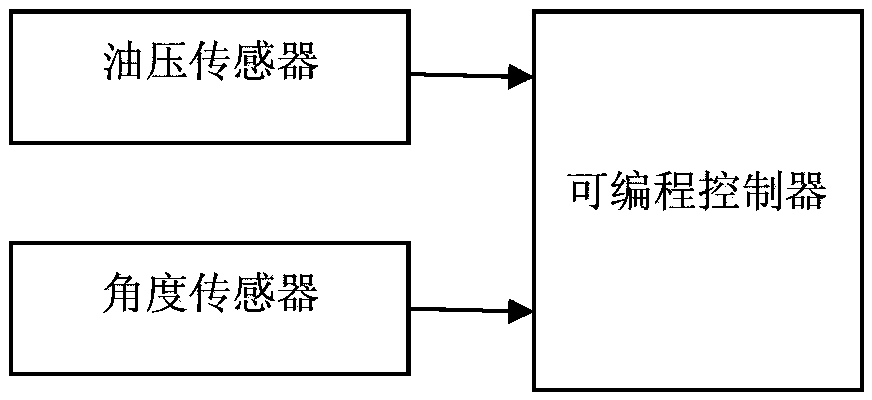

[0041] An excavator hanging object weighing device, including an oil pressure sensor, an angle sensor and a programmable controller, the oil pressure sensor is installed on the boom cylinder, the angle sensor is respectively installed on the boom and the bucket, the oil pressure sensor and the The sensors are respectively connected with the programmable controller.

[0042] Preferably, the oil pressure sensor is a CAN signal oil pressure sensor. The CAN signal oil pressure sensor has a high communication rate, is easy to implement, and is cost-effective.

[0043] Preferably, the angle sensor is a CAN signal angle sensor. The CAN signal angle sensor has a high communication rate, is easy to implement, and has high cost performance.

[0044] A method for weighing an excavator hanging object, comprising the steps of:

[0045] (1) When lifting heavy objects, the attitude of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com