Patents

Literature

2108results about "Weighing apparatus details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

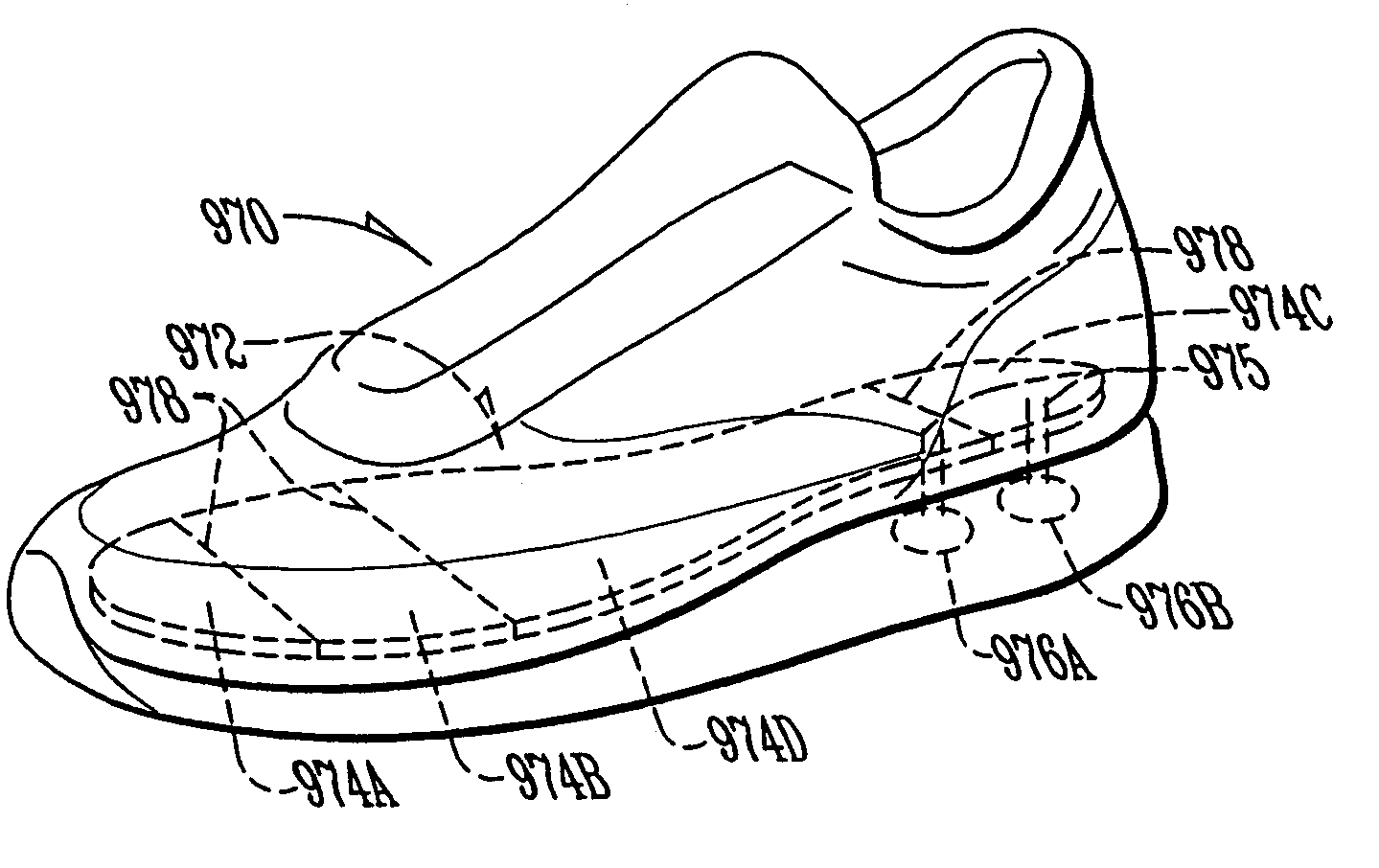

Shoes employing monitoring devices, and associated methods

InactiveUS7171331B2Soften contactAvoid breakingBroadcast transmission systemsLinear/angular speed measurementAccelerometerEngineering

Owner:APPLE INC

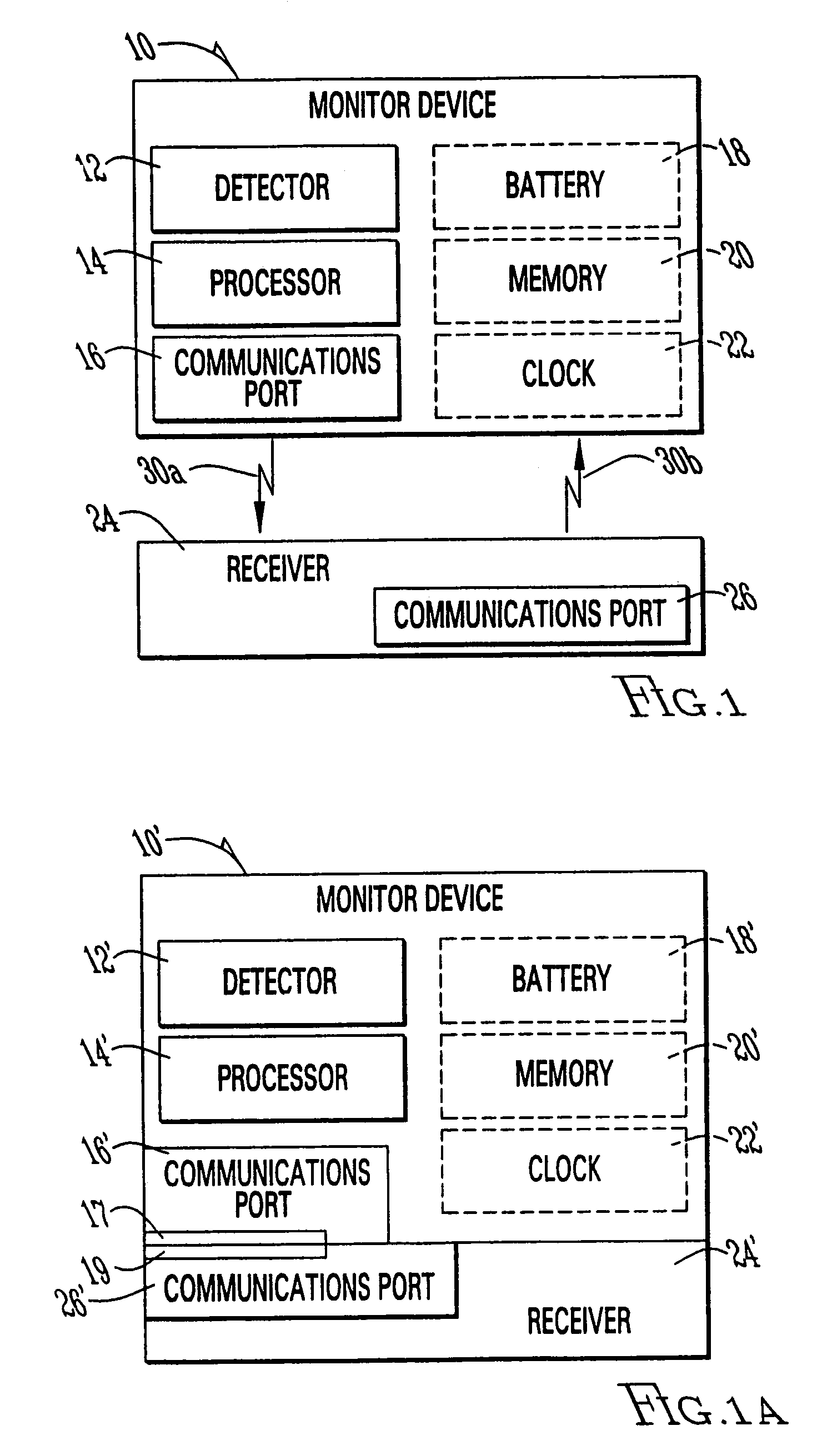

Product integrity systems and associated methods

InactiveUS7174277B2Soften contactAvoid breakingForce measurement using piezo-electric devicesLinear/angular speed measurementAccelerometerData shipping

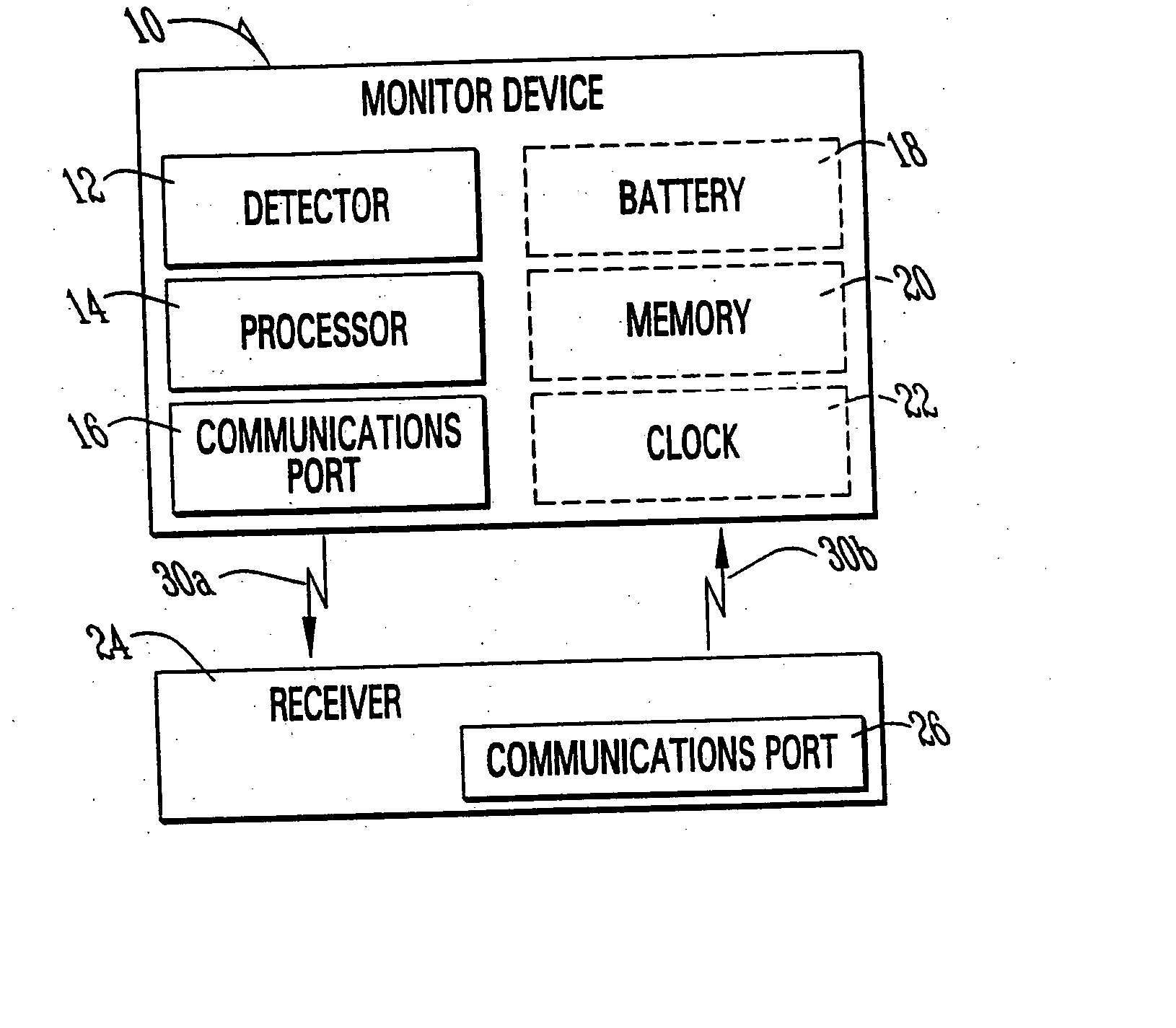

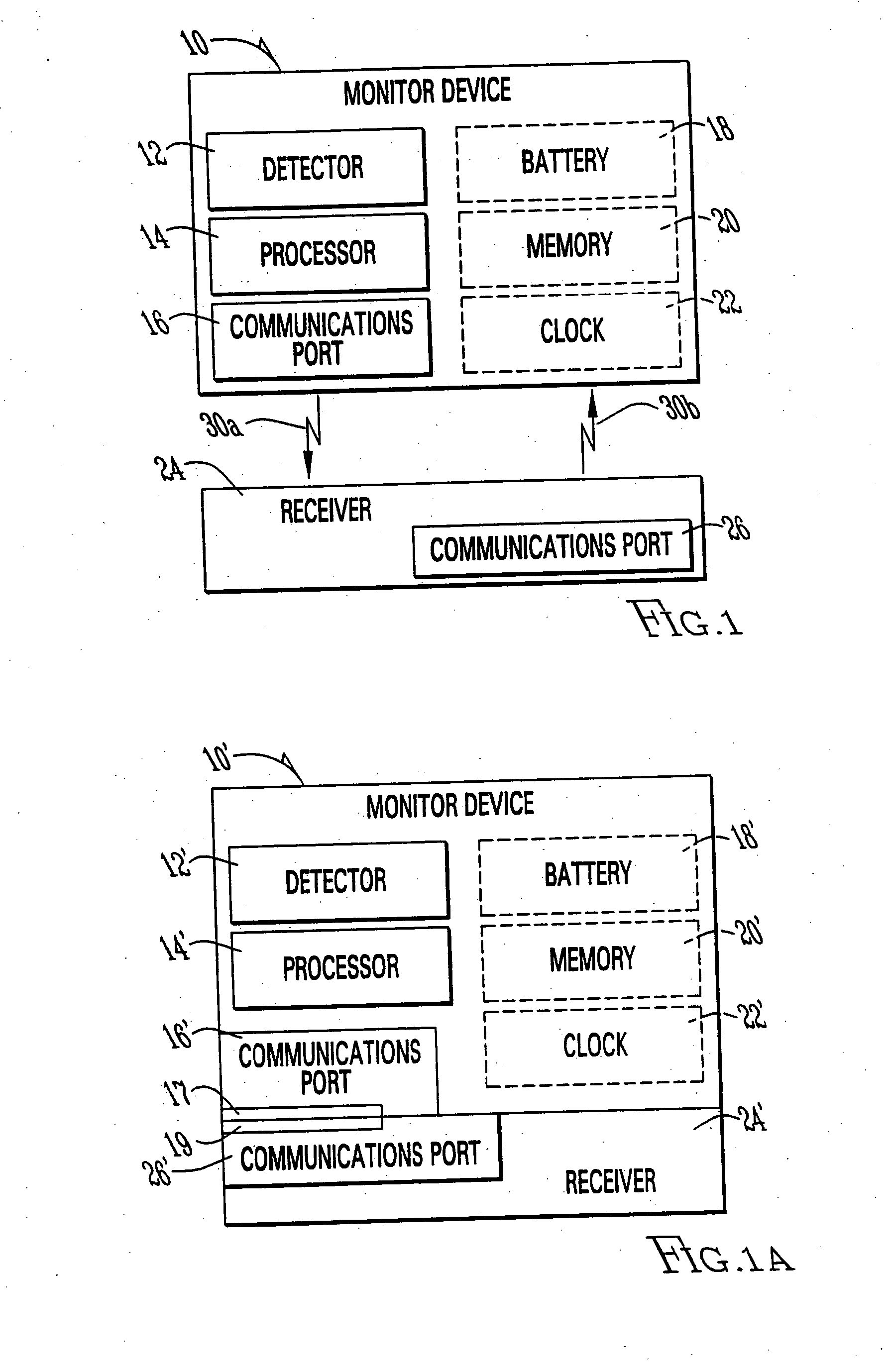

System determines integrity of a product through shipment and has: (a) plurality of identical smart sensors for direct attachment to different locations on the product and (b) interrogating device, the identical smart sensors monitoring like environmental condition of the product during shipment and wirelessly communicating data about the environmental condition to the interrogating device during or after shipment, the interrogating device communicating the environmental condition over a network, wherein the identical smart sensors comprise an accelerometer and the environmental condition comprises acceleration. Method establishes product integrity after shipment from first location to second location by: attaching plurality of identical smart sensors directly to product at first location; monitoring environmental condition of product via the identical smart sensors during shipment; wirelessly communicating the environmental condition from the identical smart sensors to receiver at the second location; and communicating the environmental condition from the receiver to a third location.

Owner:TVIPR

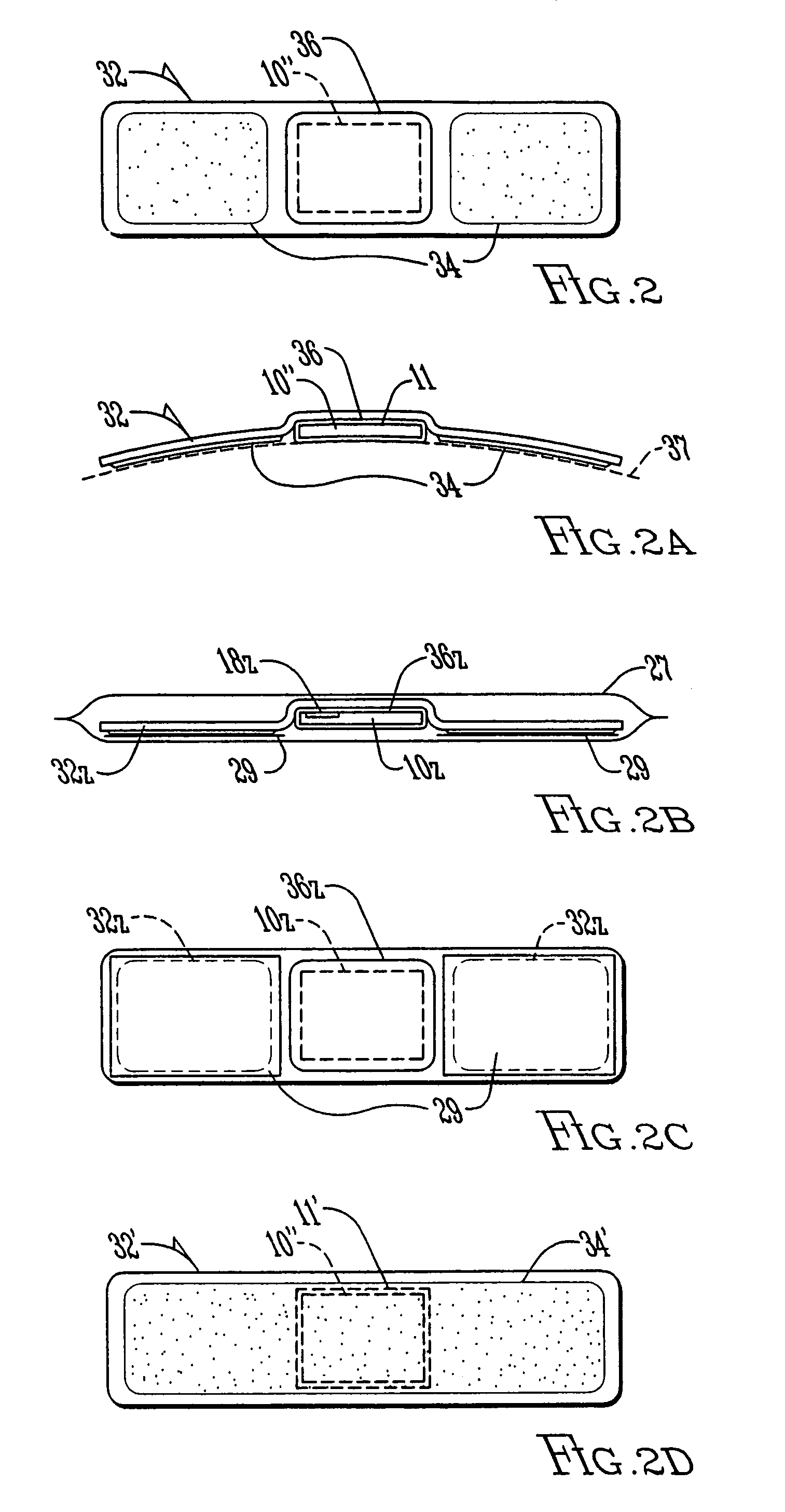

Product integrity systems and associated methods

InactiveUS20050080566A1Soften contactAvoid breakingForce measurement using piezo-electric devicesLinear/angular speed measurementAccelerometerTransceiver

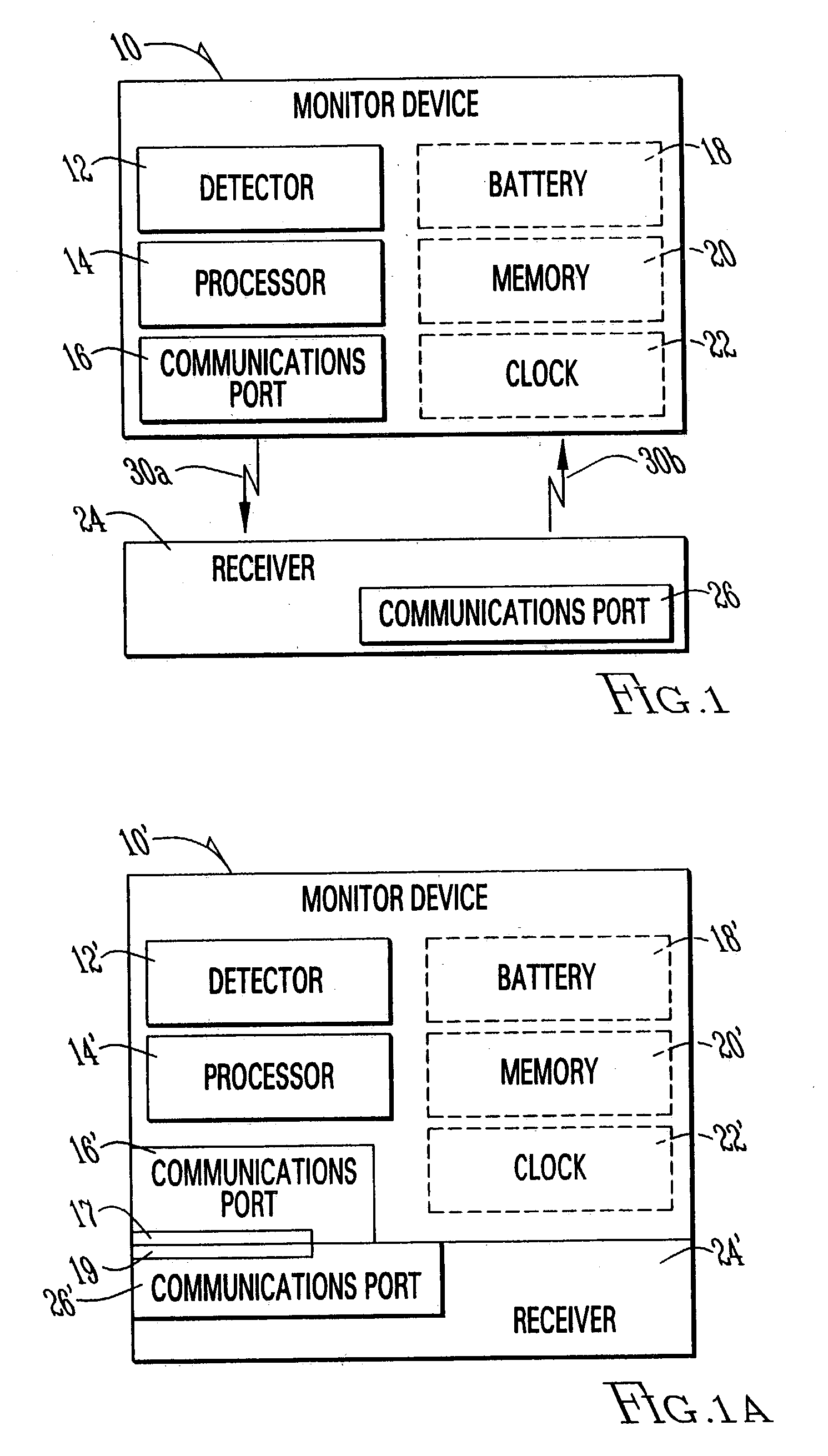

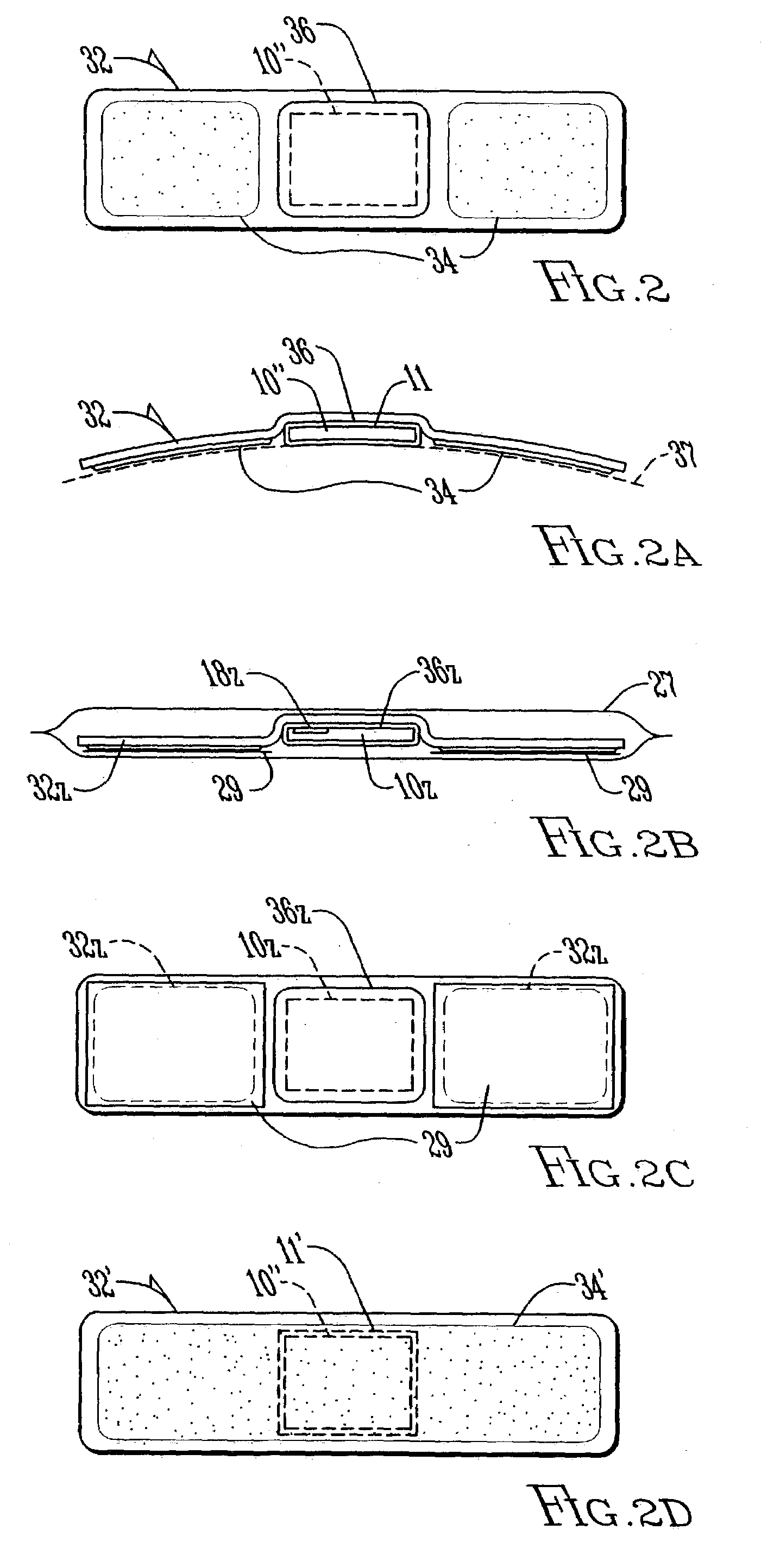

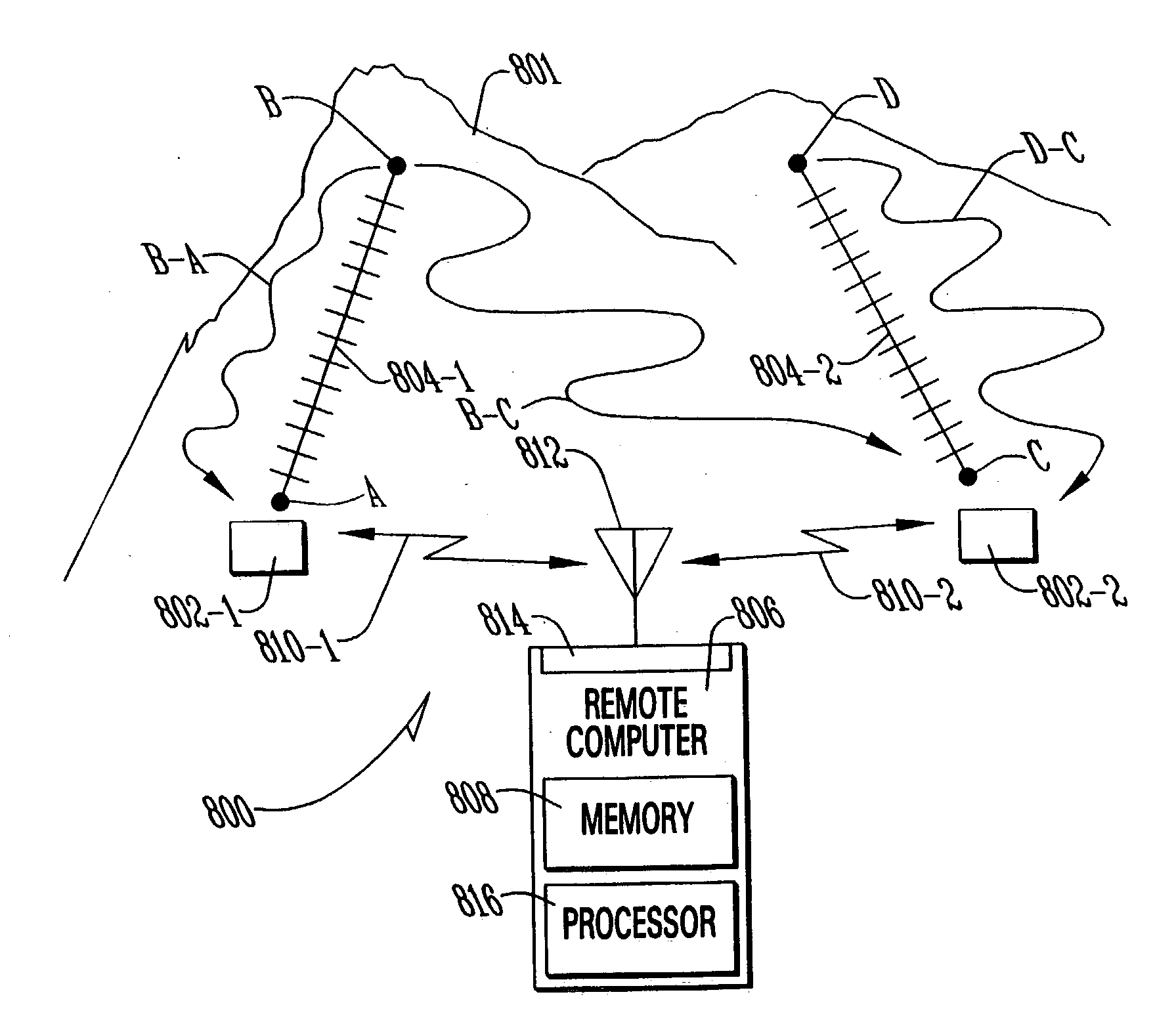

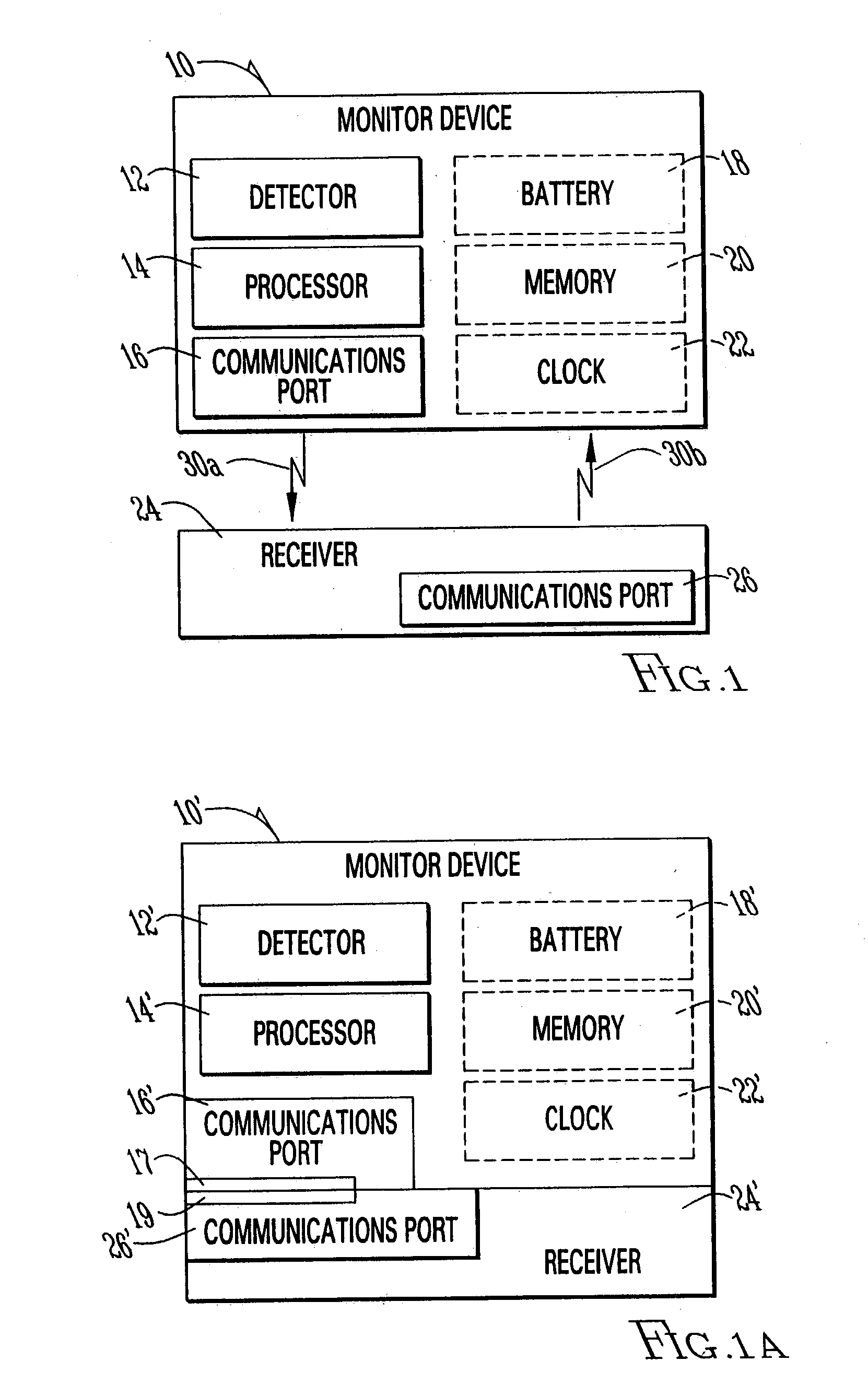

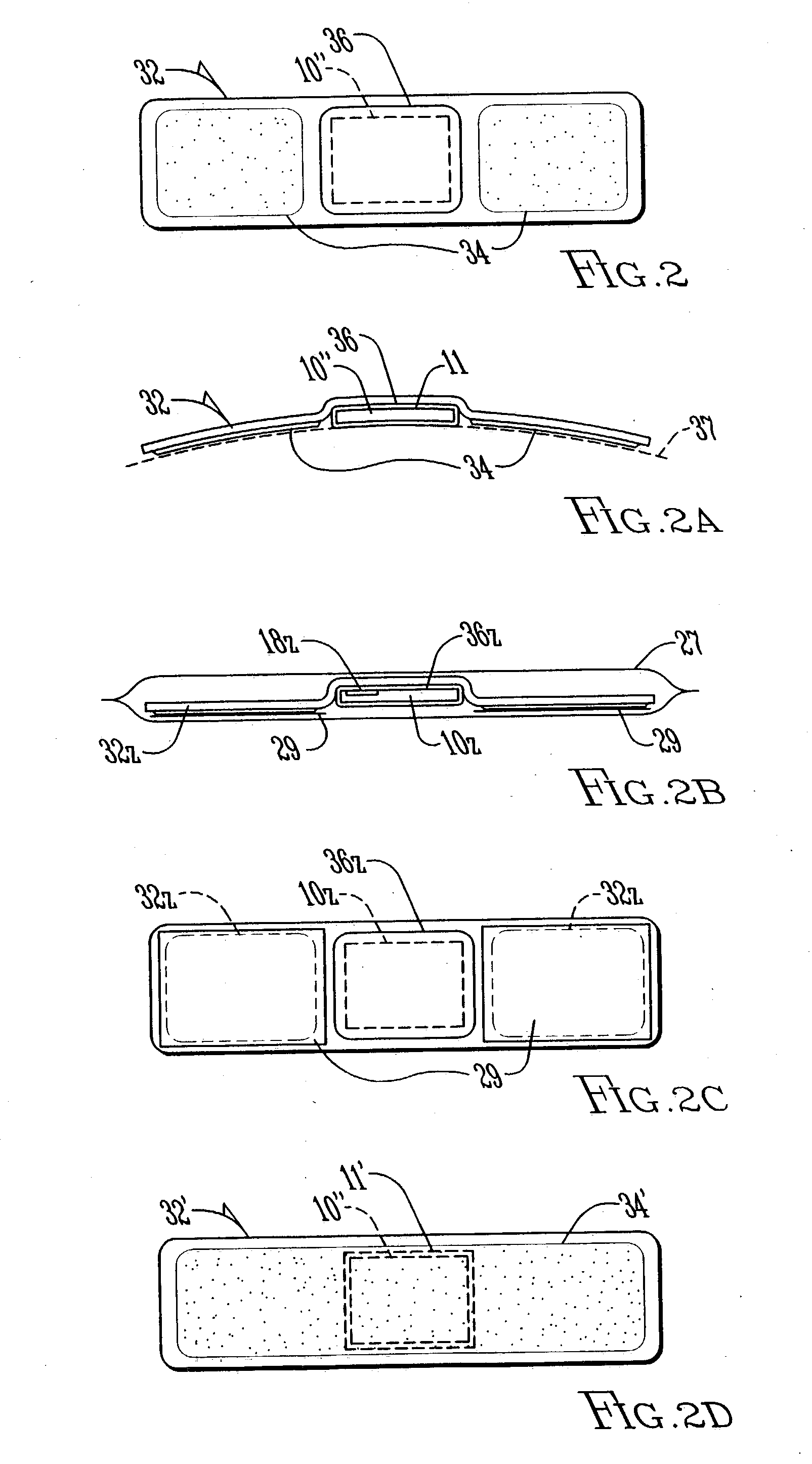

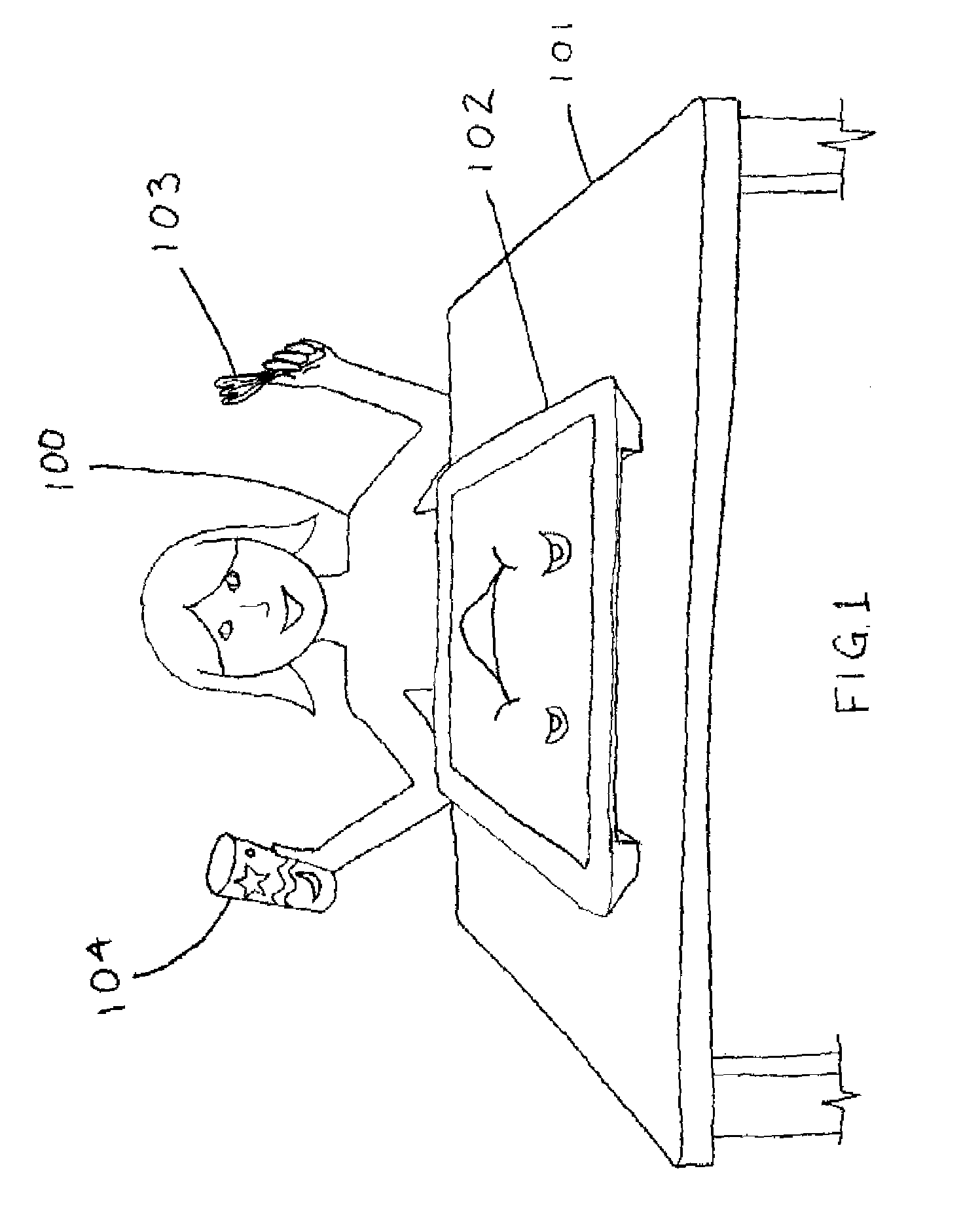

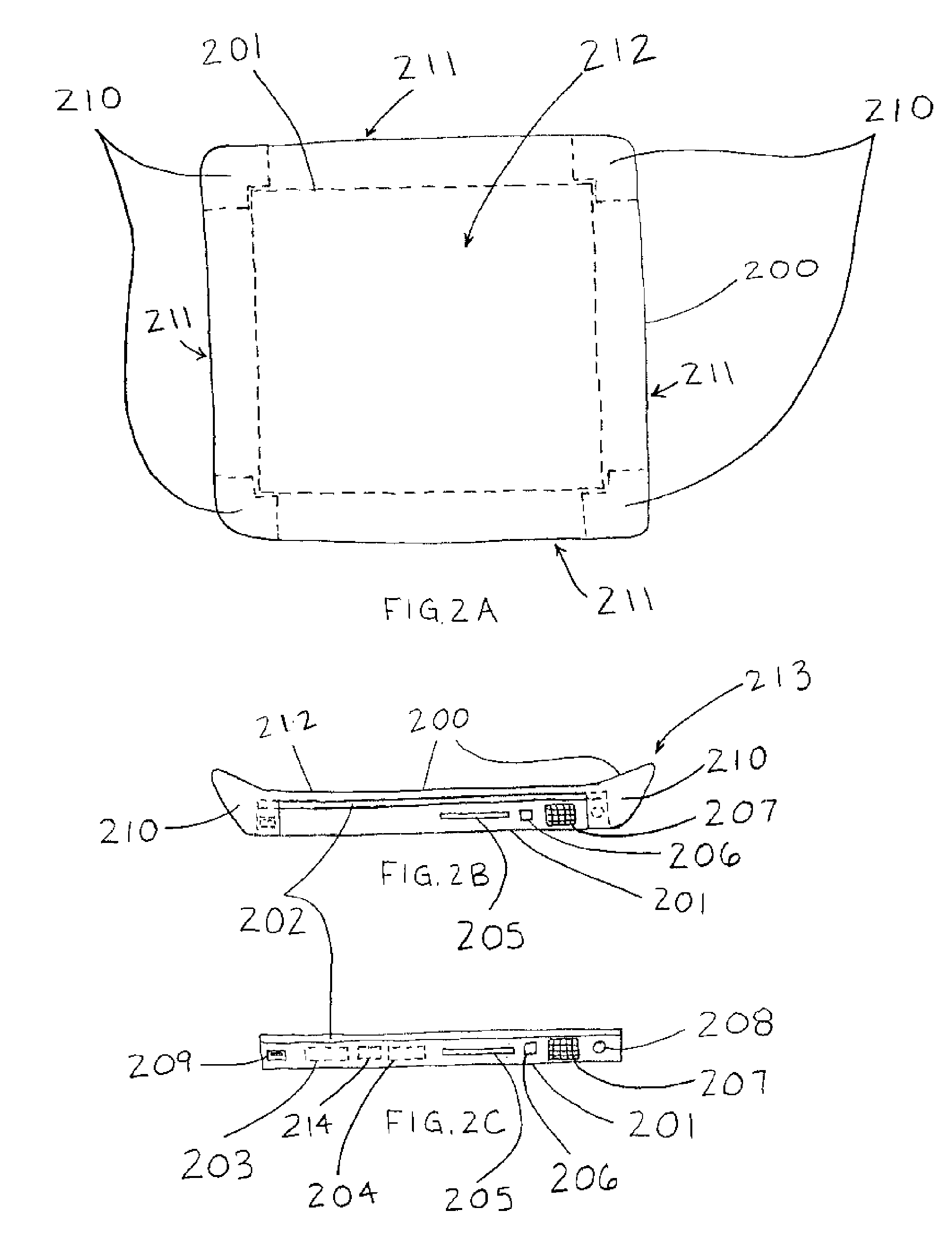

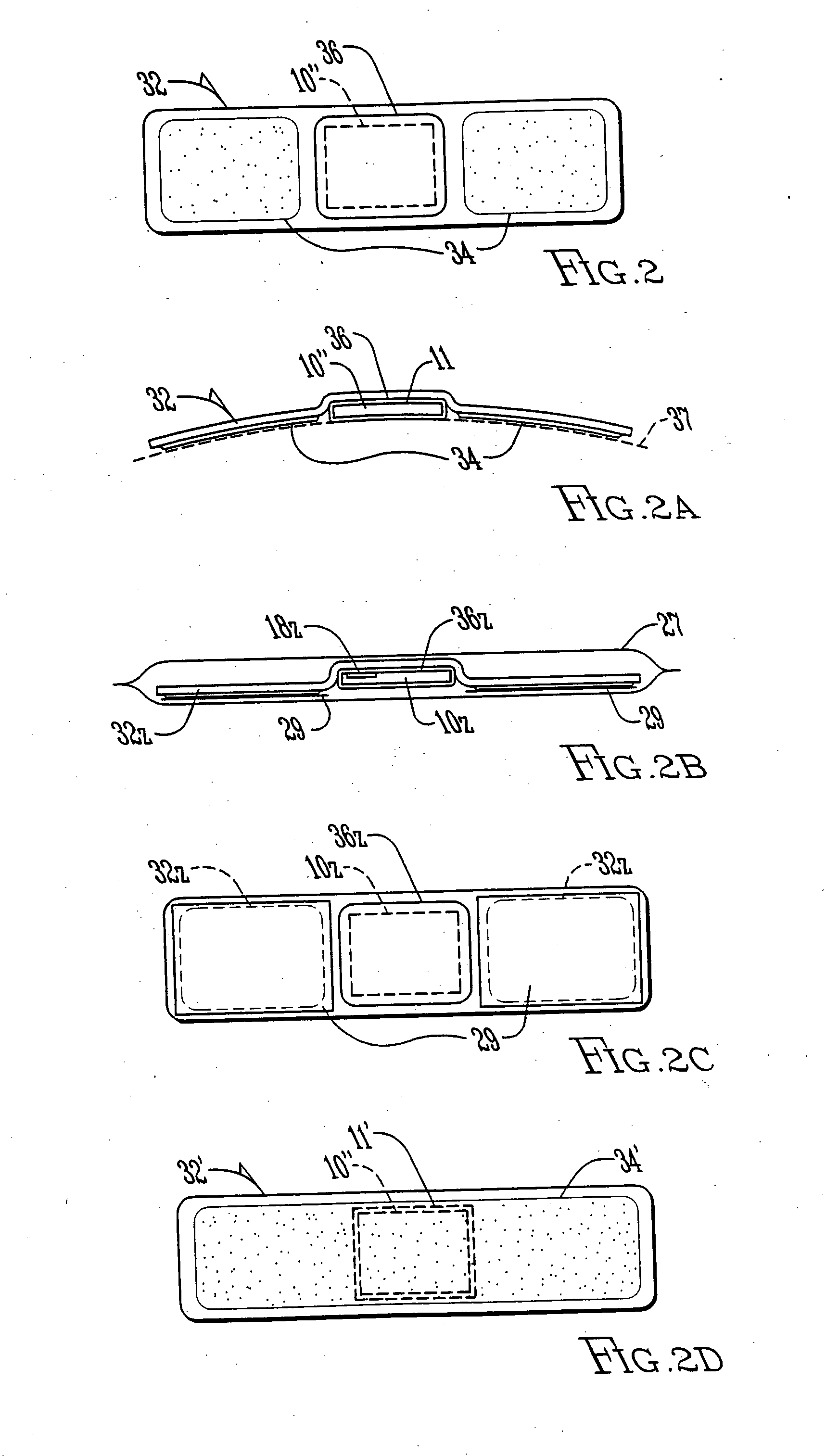

The invention provides a smart sensor in the form of an adhesive bandage. The sensor may be used in many applications such as within sports, the shipping industry and medical and health industries. The sensor sticks to people and objects and wirelessly communicates with remote receivers. Internal detectors sense conditions associated with movement and / or the environment of the sensor. In one example, an accelerometer detects impact and drop distance of a package in transit; the sensor is either within a label or attached to a product within the package. The sensor may also prevent theft and assist in tracking package disposition so as to reduce lost packages. The sensors of the invention may also be used in fitness and health, such as to monitor body functions of heart rate and respiration; these sensors also may initiate immediate wireless warnings for improper functions so that persons may obtain immediate assistance. Sensors of the invention are also useful for sports media broadcasts; multiple sensors may attach to athletes so that wireless performance data is made available, in near real time, to audiences and media observers. Data from sensors of the invention may also change the computer gaming community; that is, certain sensors tracking real performance data may relay information used within gaming so as to govern computer gaming motions. Typically, sensors of the invention communicate by an RF transmitter or transceiver. Groups of sensors may be combined within a common canister that imparts date and time information and “power on” when dispensed.

Owner:TVIPR

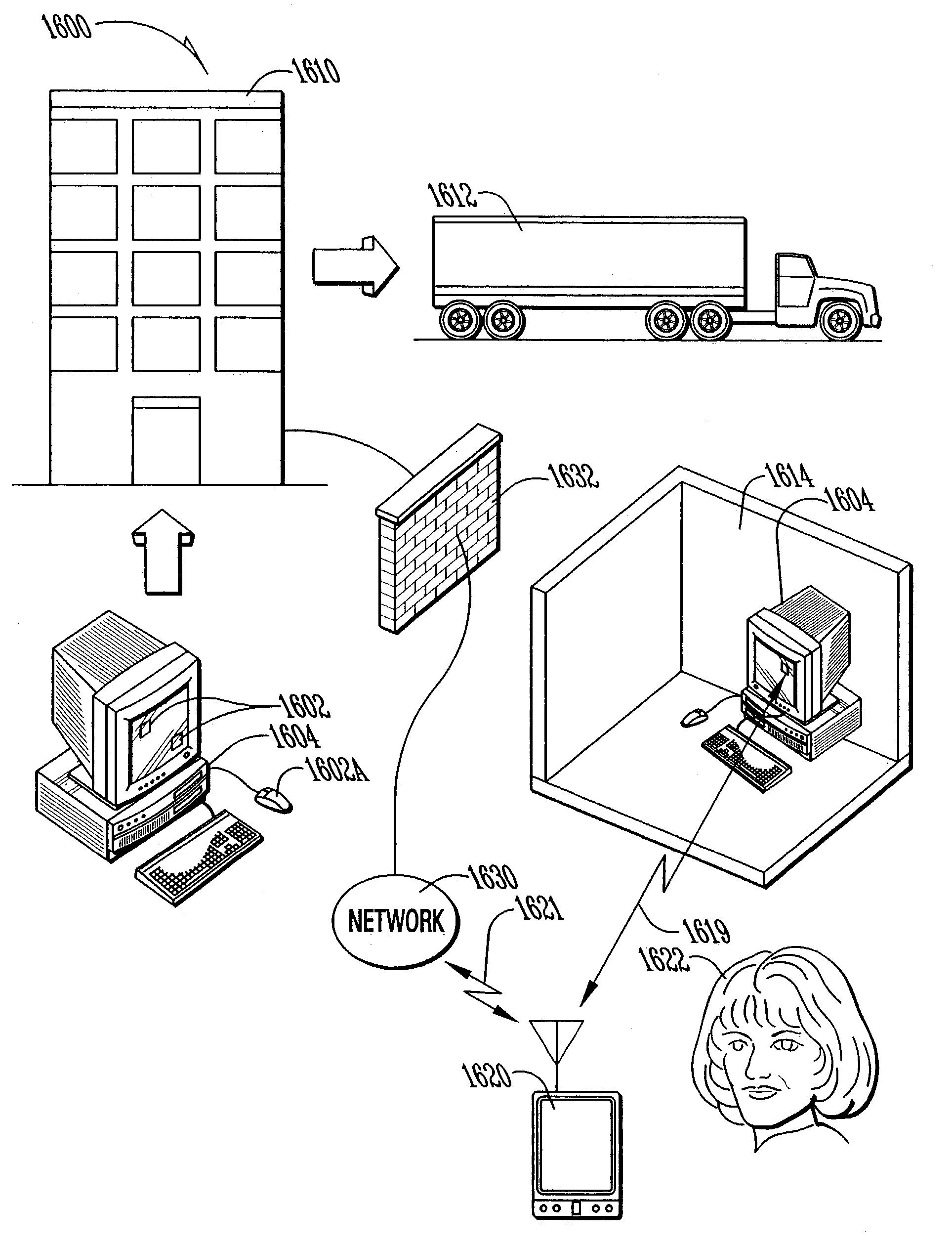

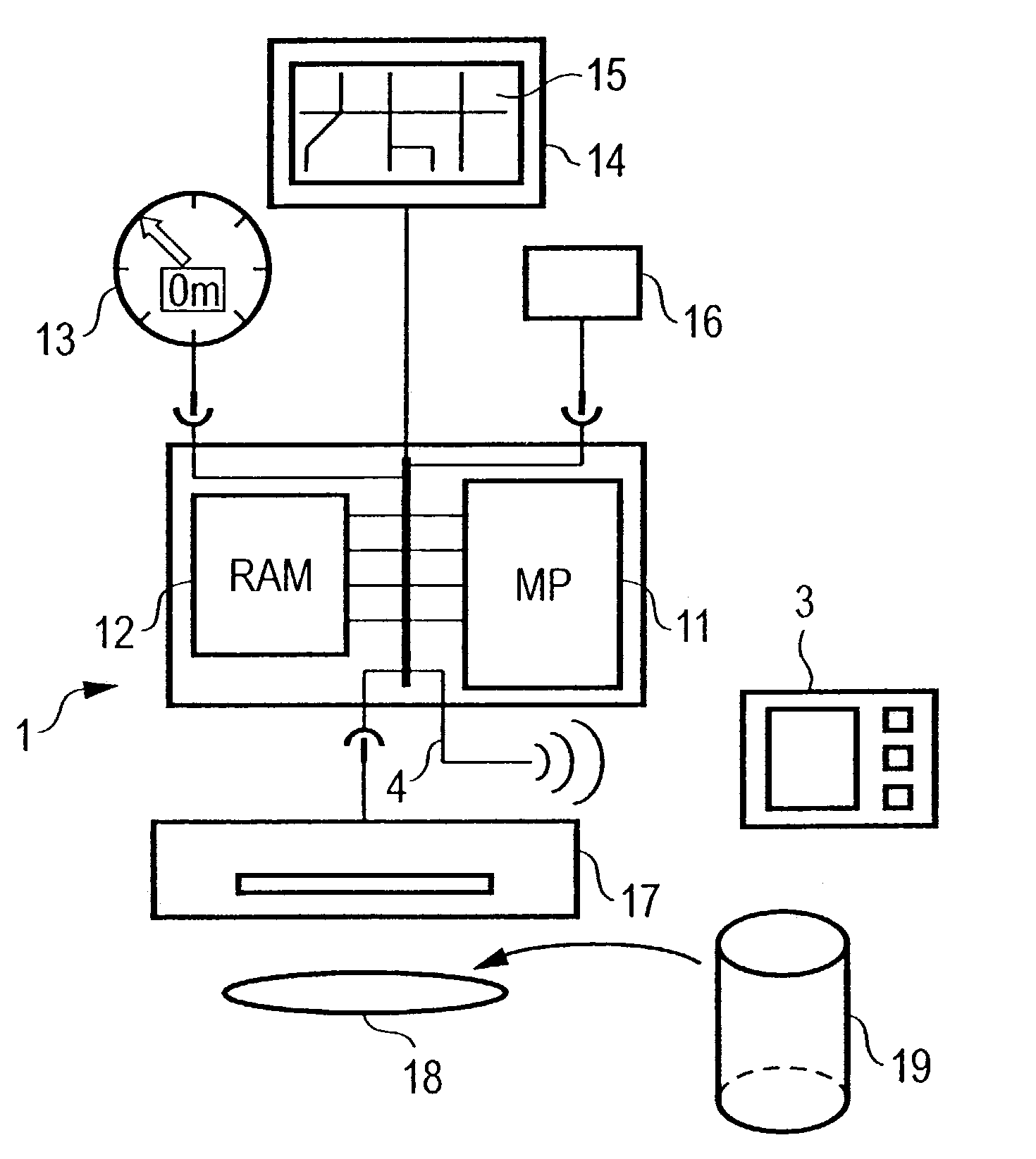

Systems, methods and computer program products for monitoring the behavior, health, and/or characteristics of an animal

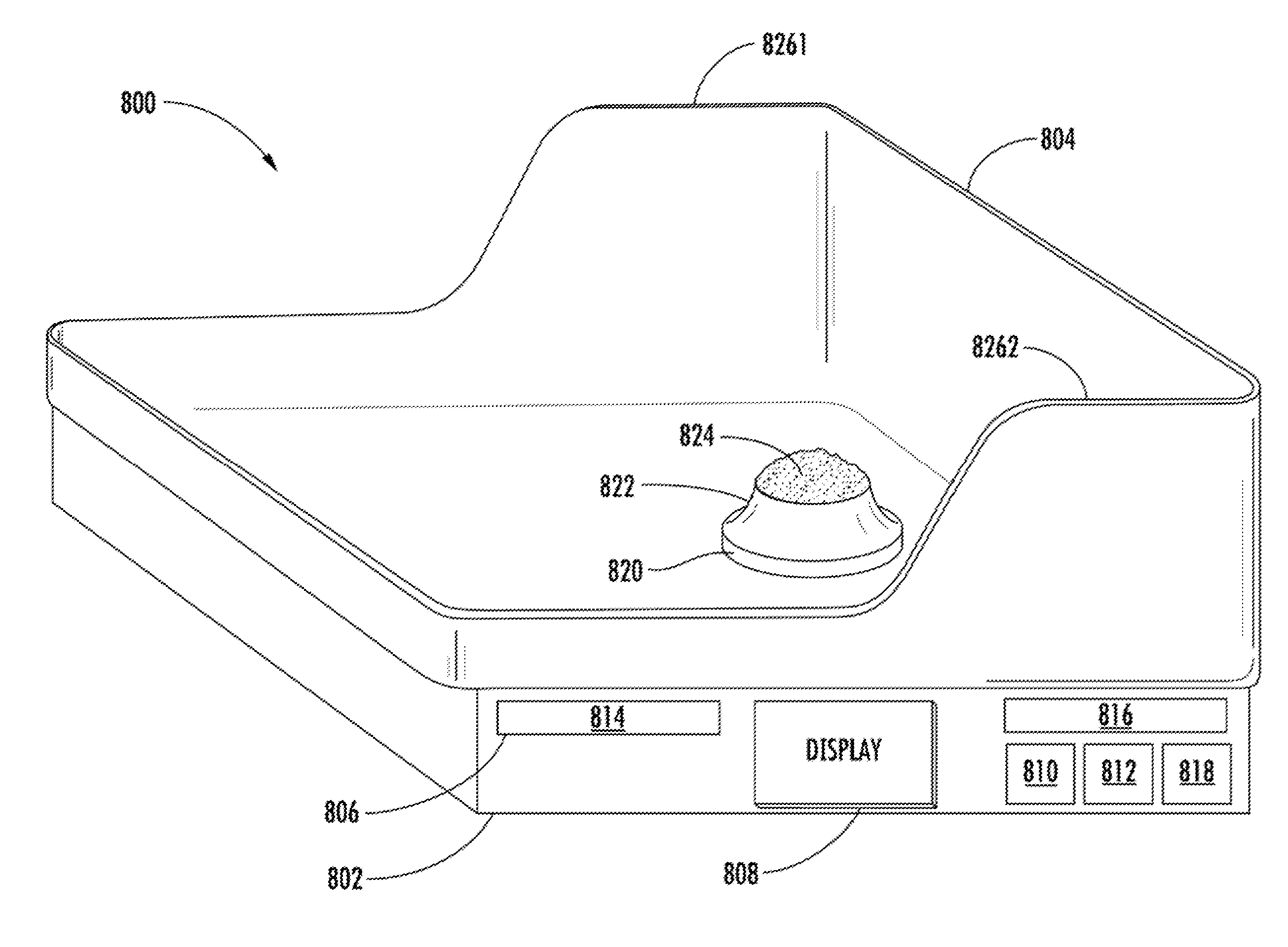

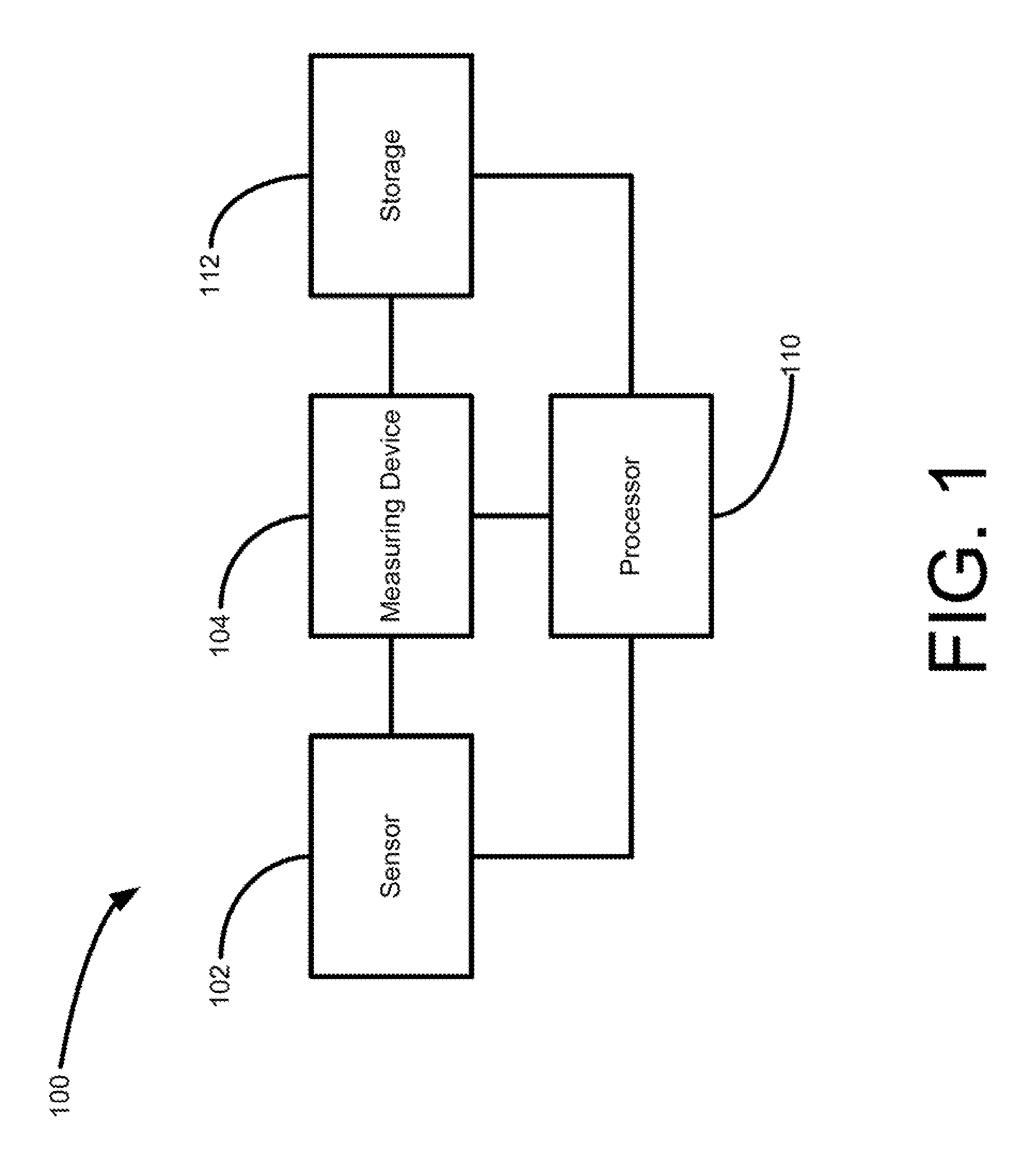

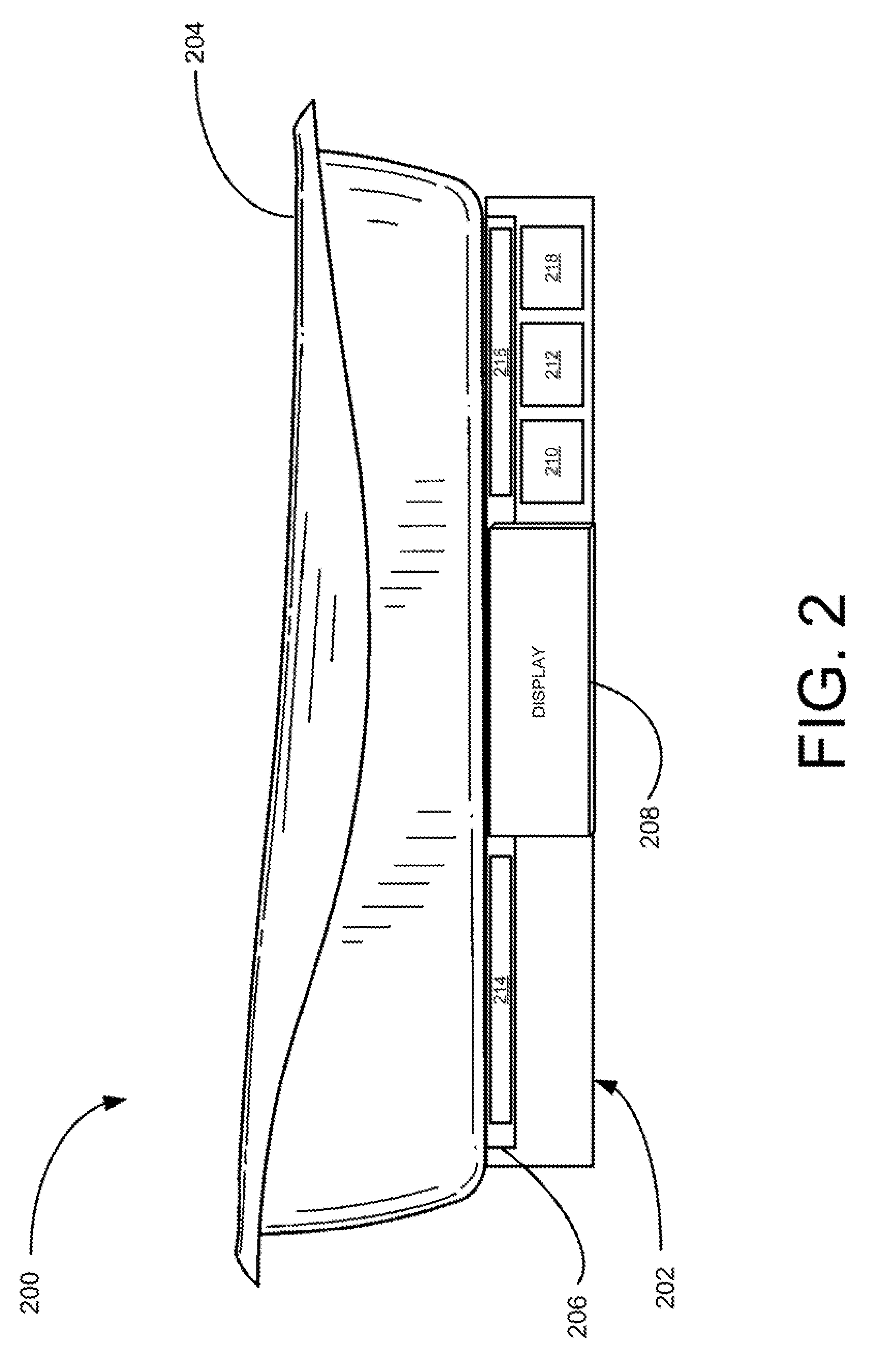

Systems, methods, and computer code products for monitoring the behavior, health, and / or characteristics of an animal are disclosed herein. In one implementation, the animal is positioned inside a waste container placed on a system that is adapted to determine, record and communicate over a network various animal health parameters. These parameters can be processed to determine trends, statistics and changes of animal physiological functions. The results can be used to access animal health conditions and issue warnings, alarms, messages, and other notifications to designated caretakers. These notifications may be displayed using various means such as computers and / or mobile devices. Data retrieval and review capability can provide improved understanding of an animal's health conditions and facilitate early illness detection.

Owner:SOC DES PROD NESTLE SA

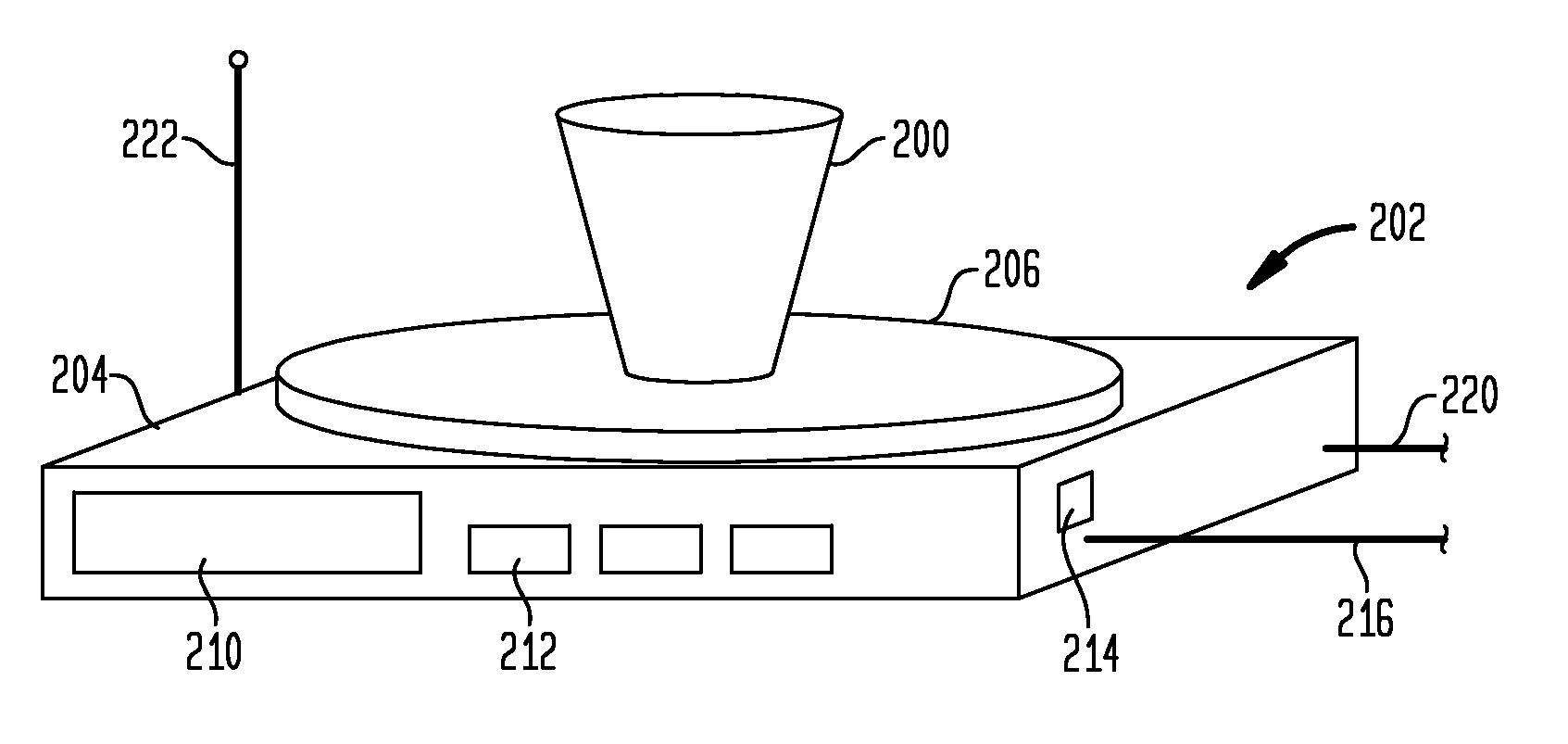

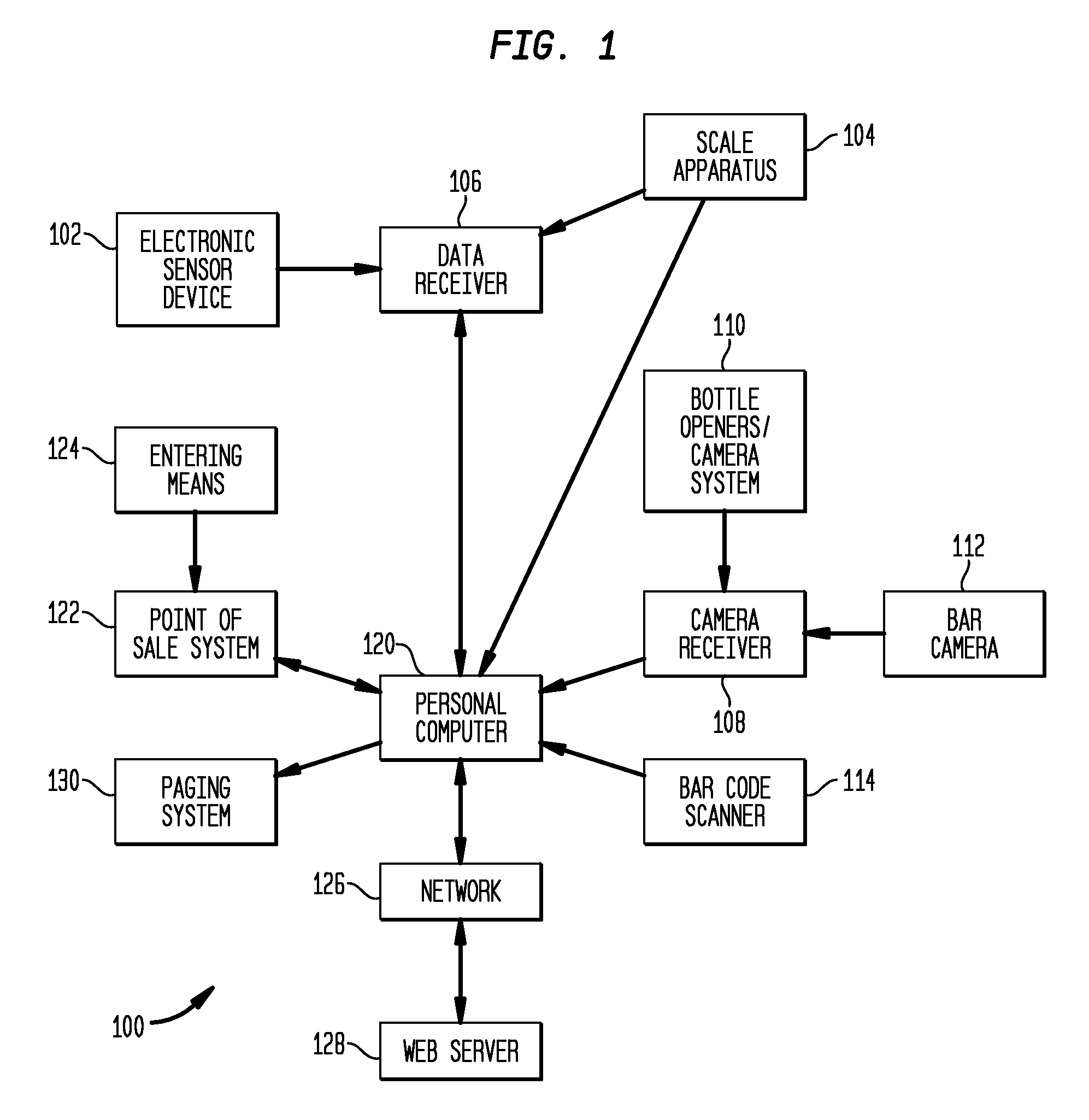

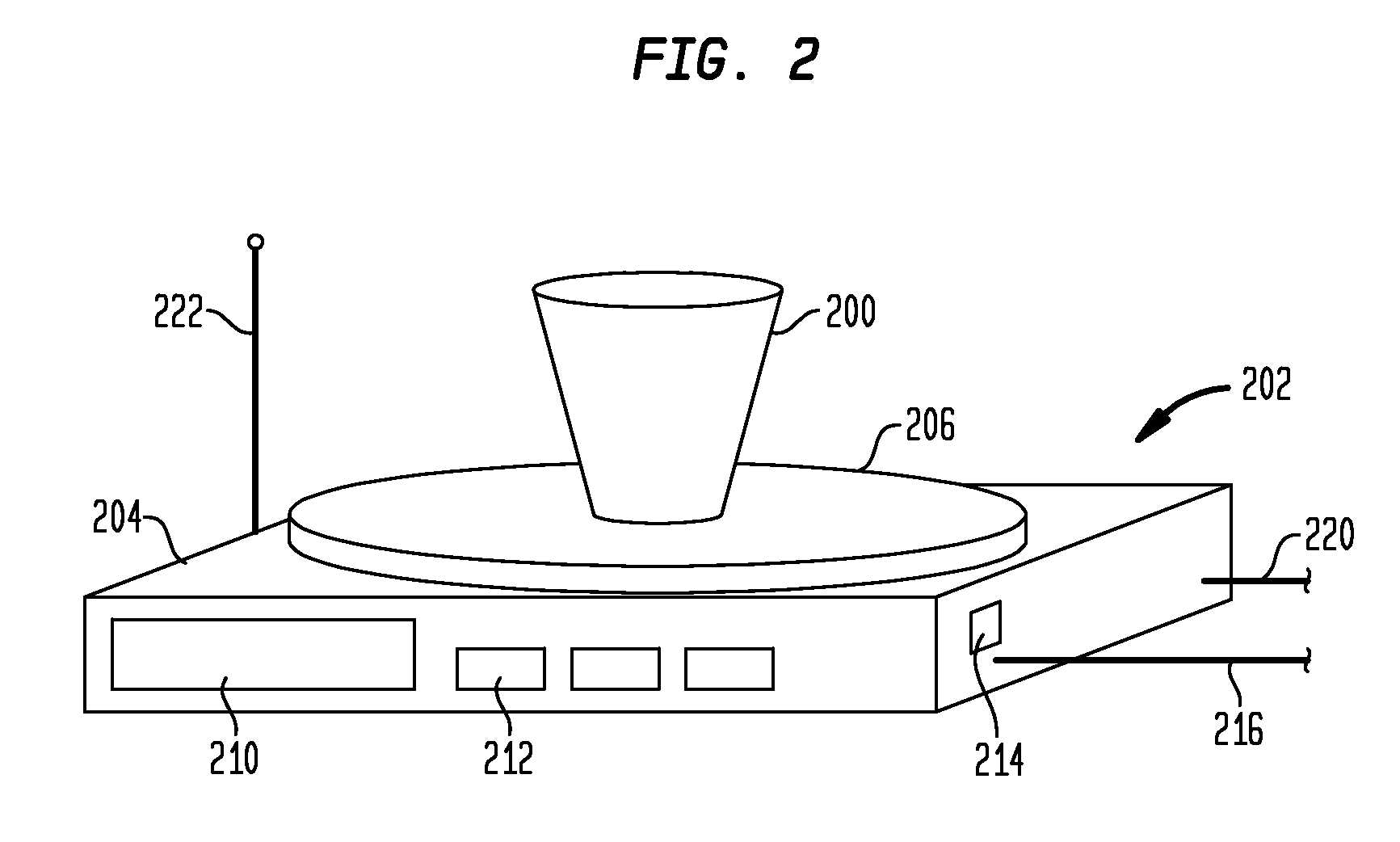

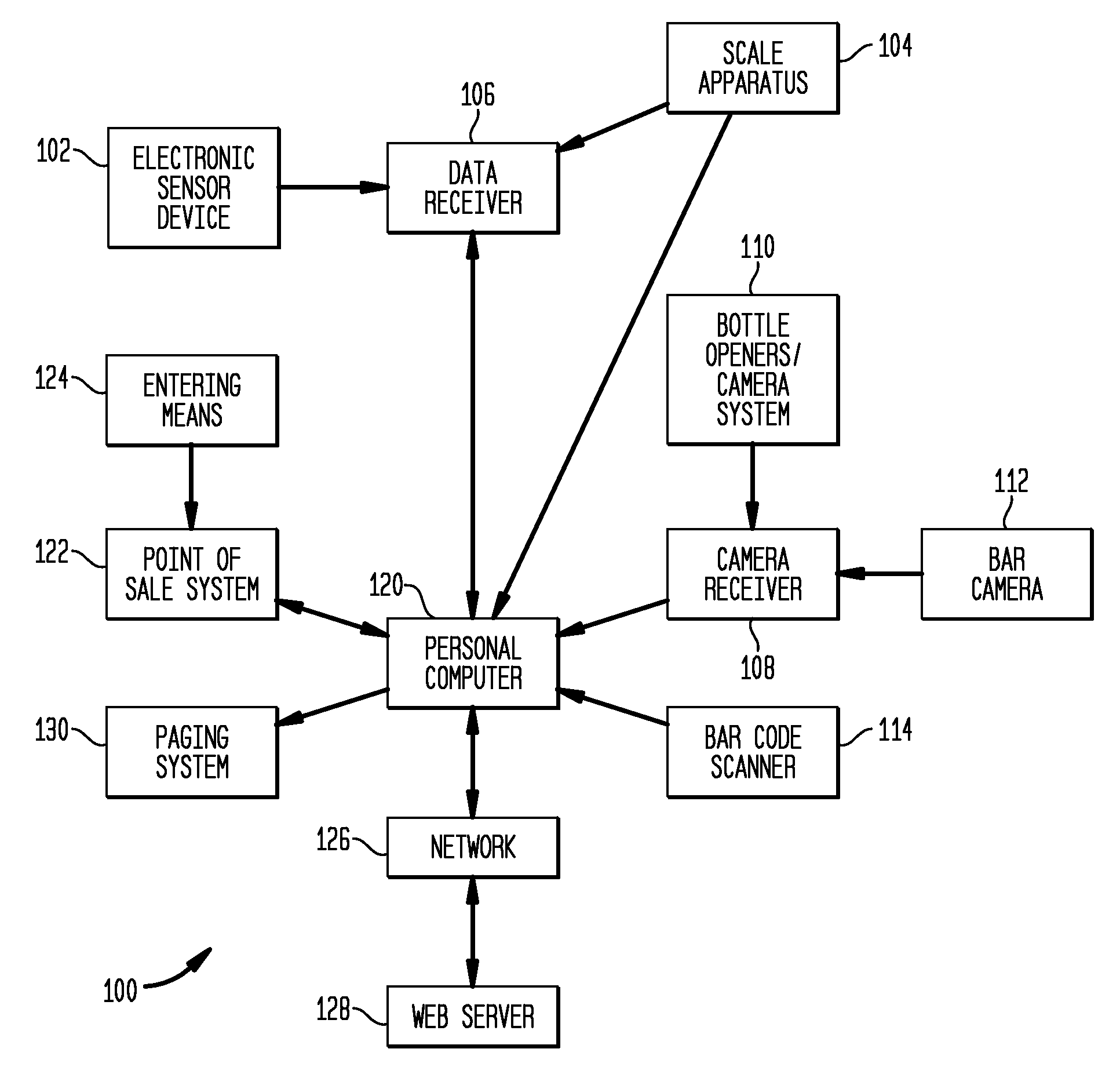

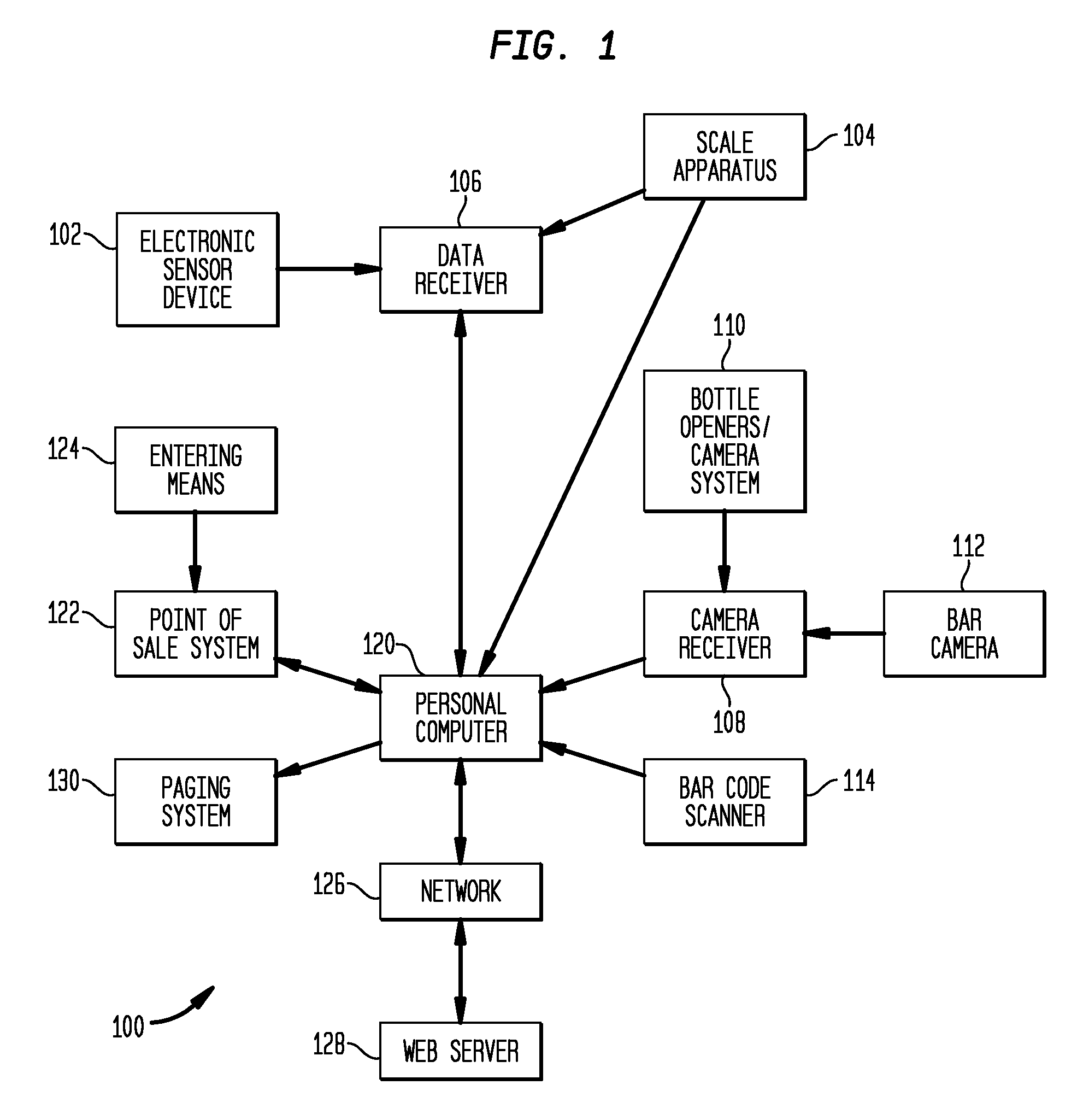

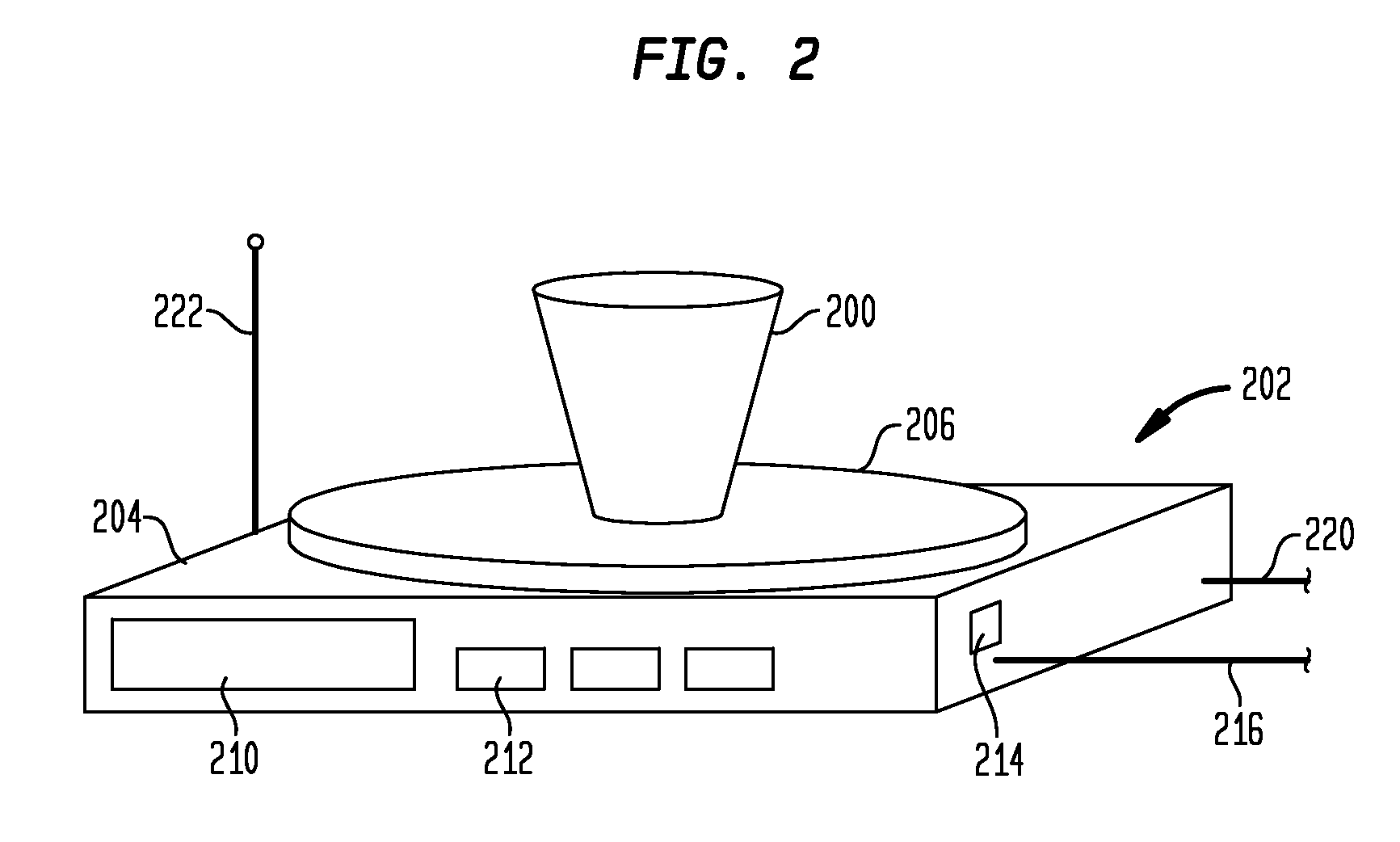

System and Method Using a Scale for Monitoring the Dispensing of a Beverage

Owner:BEVERAGE METRICS HLDG

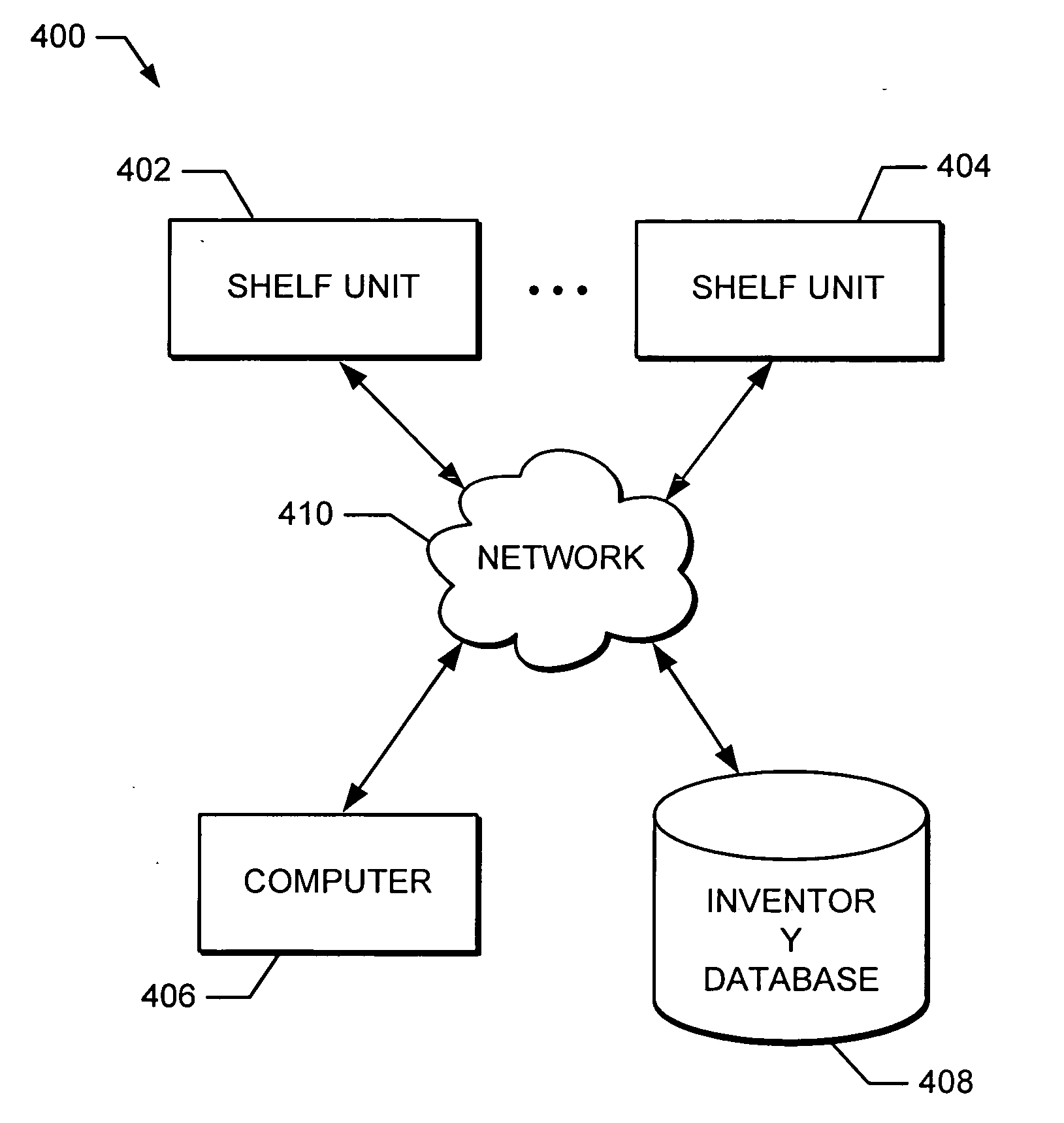

Load sensing inventory tracking method and system

Owner:HEWLETT PACKARD DEV CO LP

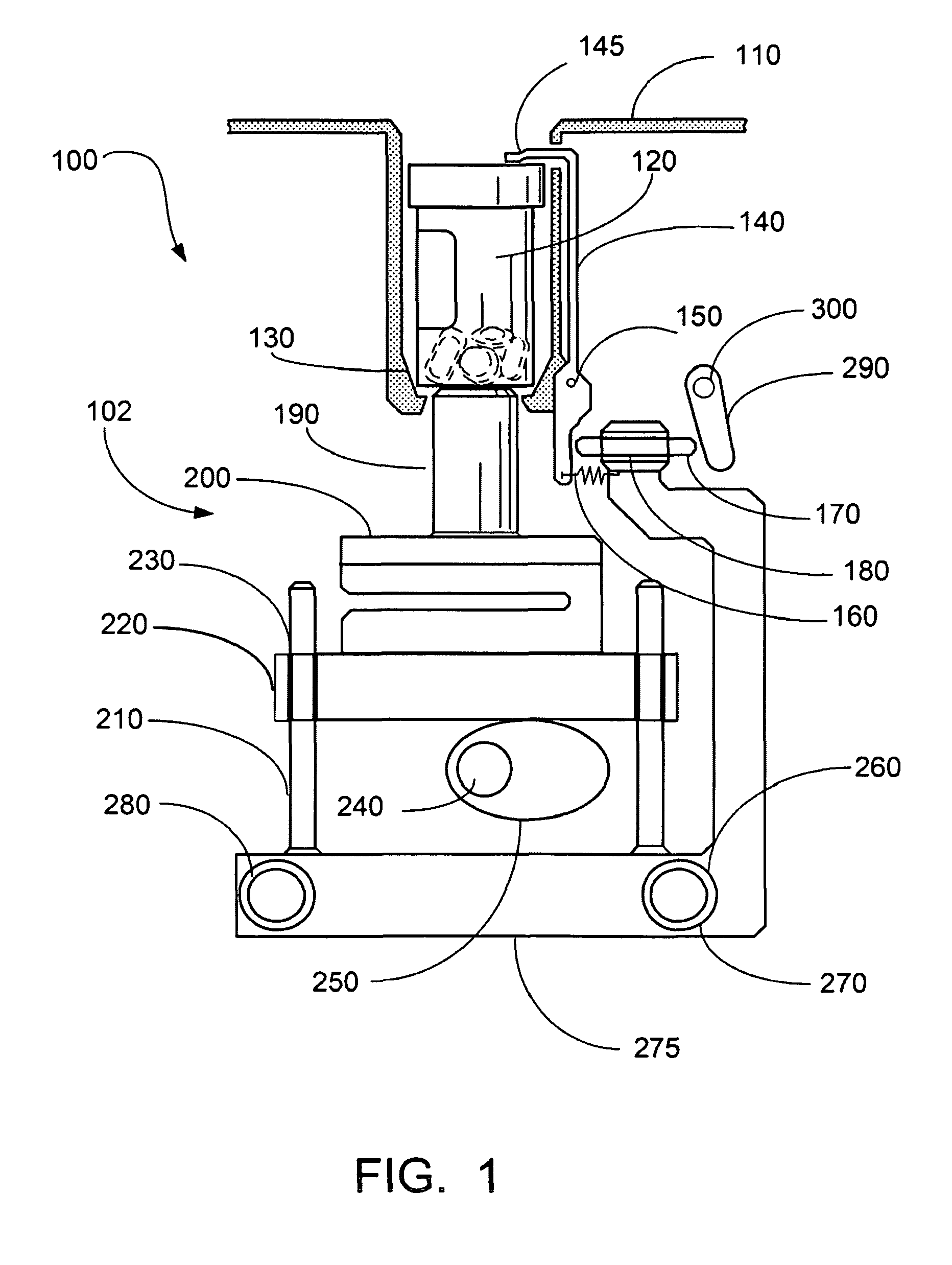

Prescription medication control system and method

ActiveUS8108068B1Reduce random noiseImprove accuracyDrug and medicationsOral administration deviceControl systemDrugs prescriptions

A medication dispensing device comprising a housing having an enclosure configured to provide direct access to a current medication container storing medication to be dispensed. The device includes a plurality of bins, each bin configured to receive and store therein a medication container within a bin seat. Additionally, the device includes a scale assembly, within the housing, configured to automatically lift the medication container from the bin seat, weigh the medication container at least once and lower the medication container into the bin seat during a weighing cycle.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

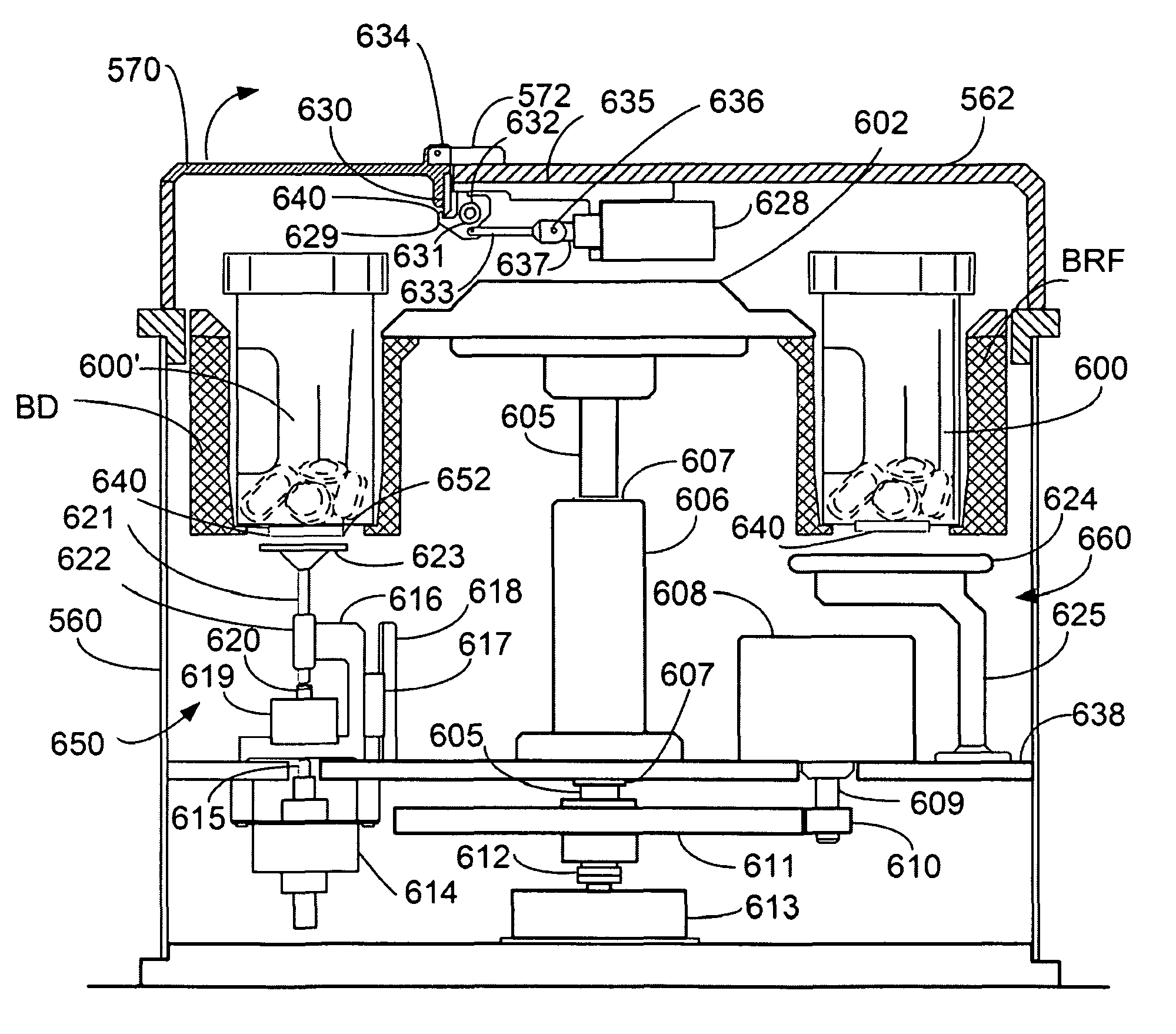

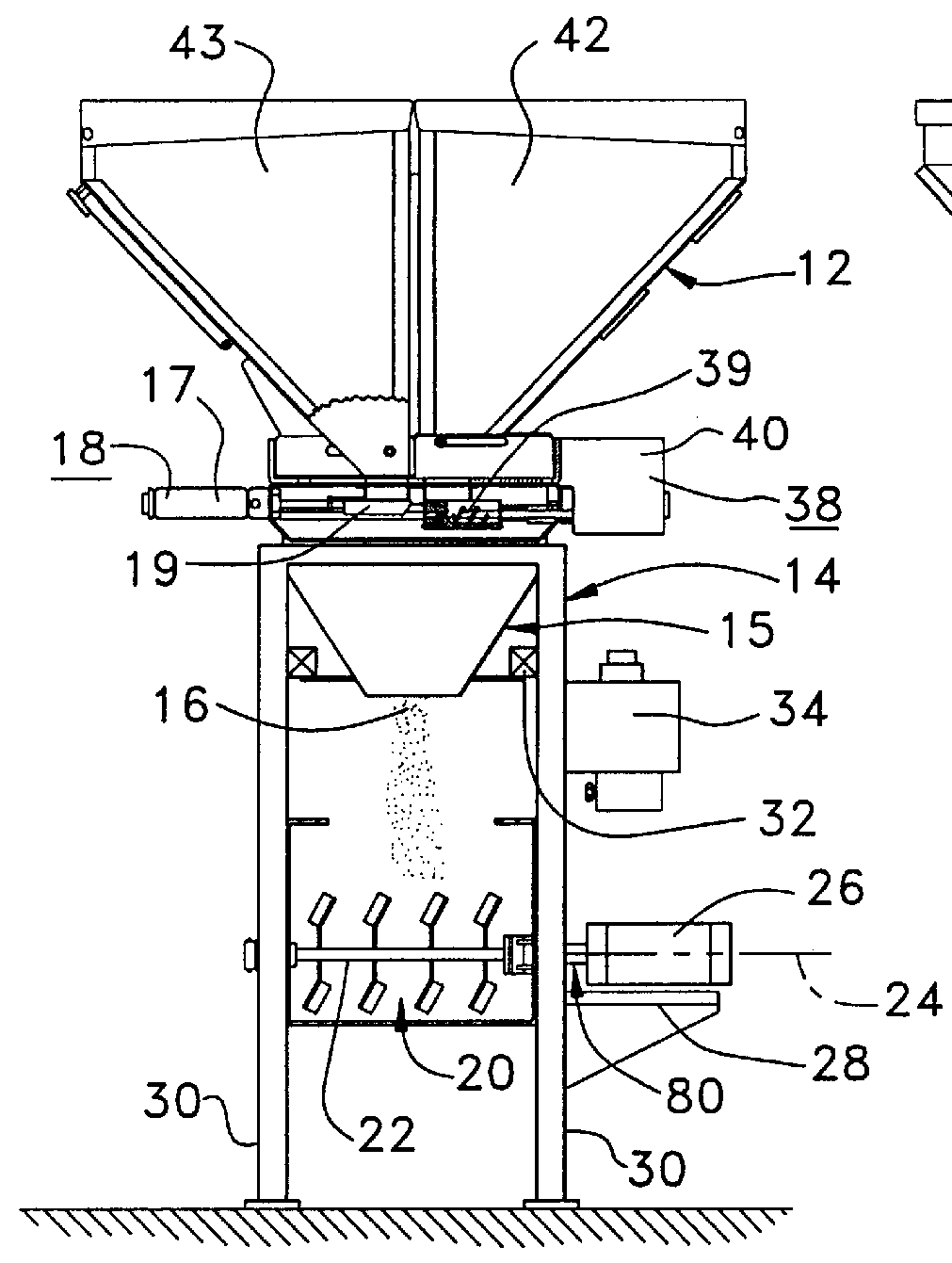

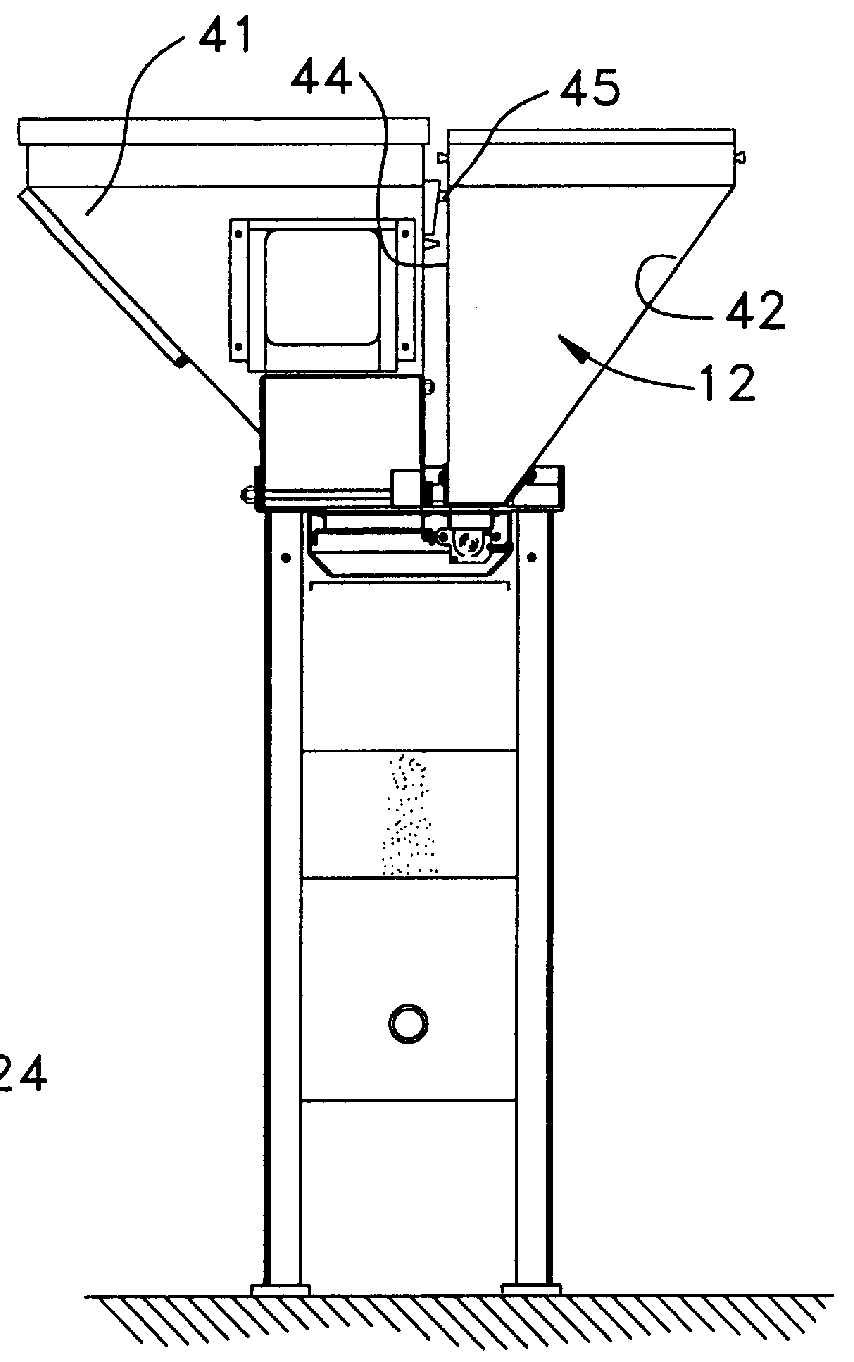

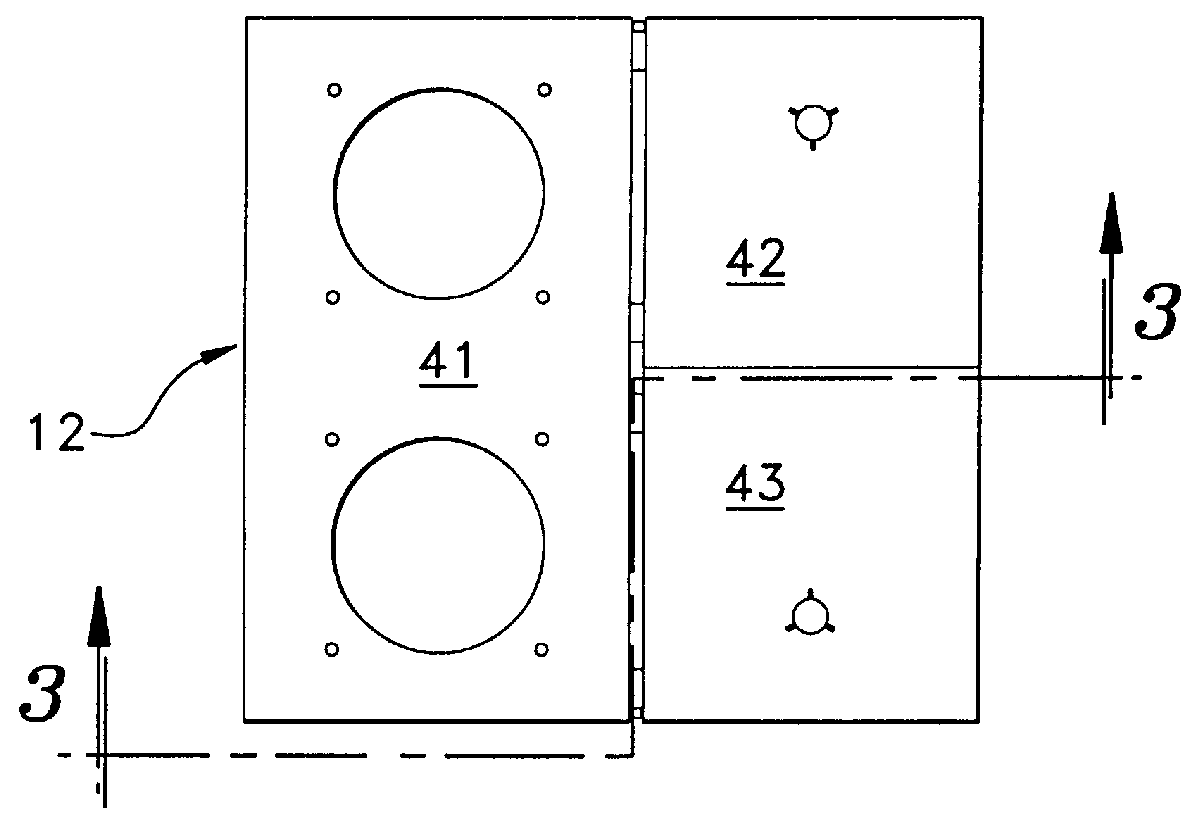

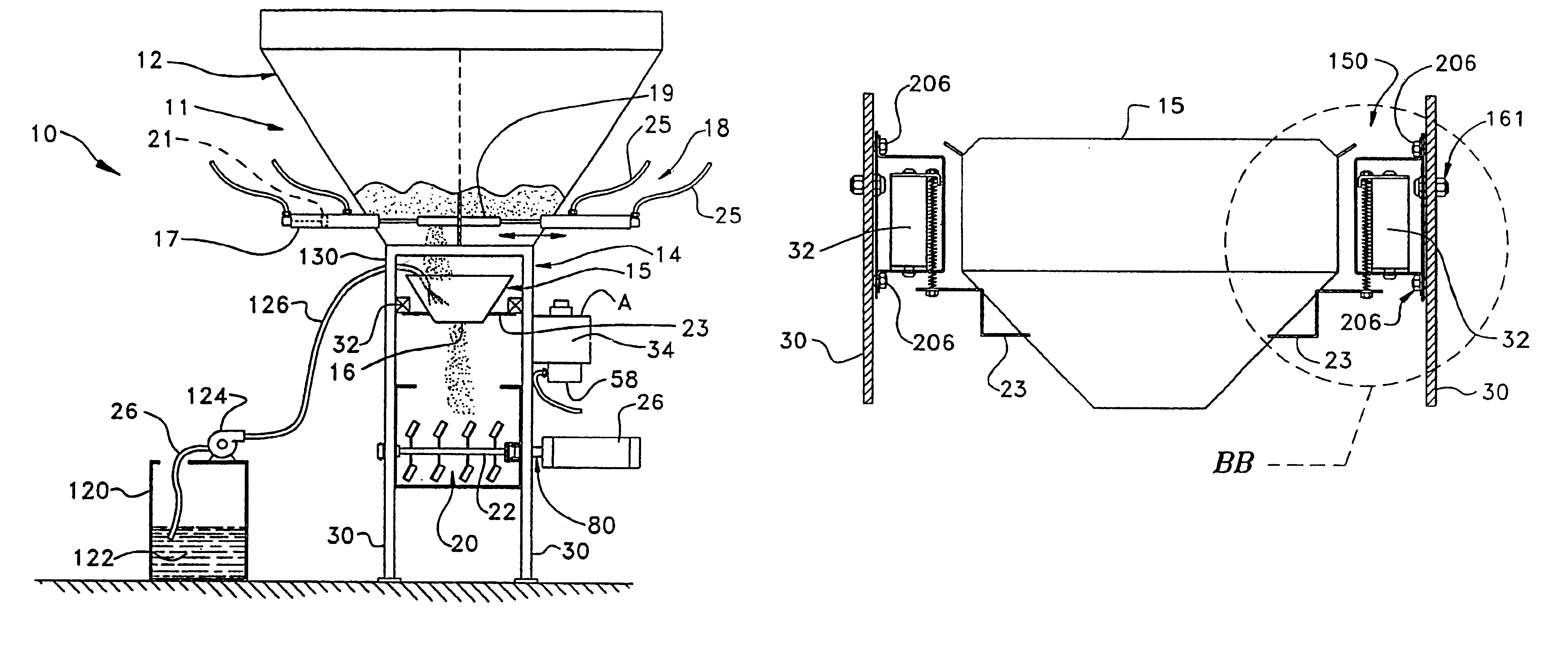

Removable hopper with material shut-off

A gravimetric weigh scale blender having a plurality of hoppers 41, 42 and 43 discharging into a weigh chamber 14. The hoppers are funnel-shaped, each terminating in a discharge opening which permits flow of material from the hopper through a metering device 19 or 38 into a weigh chamber 14. Two of the hoppers are mounted for horizontal sliding displacement in the frame of the blender and a valve is provided at the bottom of each hopper to automatically close the hopper when it is moved horizontally. The valve consists of a shoe 53 slidable on the bottom of the funnel of the hopper to be operated by a saddle 51 on the frame so as to allow flow through the opening when the hopper is in its operating position but is displaced to close the opening when the hopper is moved away from the operating position. An improved metering device is also disclosed which comprises an auger device 70 which includes a trough 71 pivotally mounted under one of the hopper openings for pivotal movement between an operative position adjacent the opening and a clean-out position remote from the opening. An auger is provided in the trough which may be driven at the desired speed to provide a positive metered flow through the trough from the hopper's discharge opening into the weigh chamber.

Owner:MAGUIRE STEPHEN B

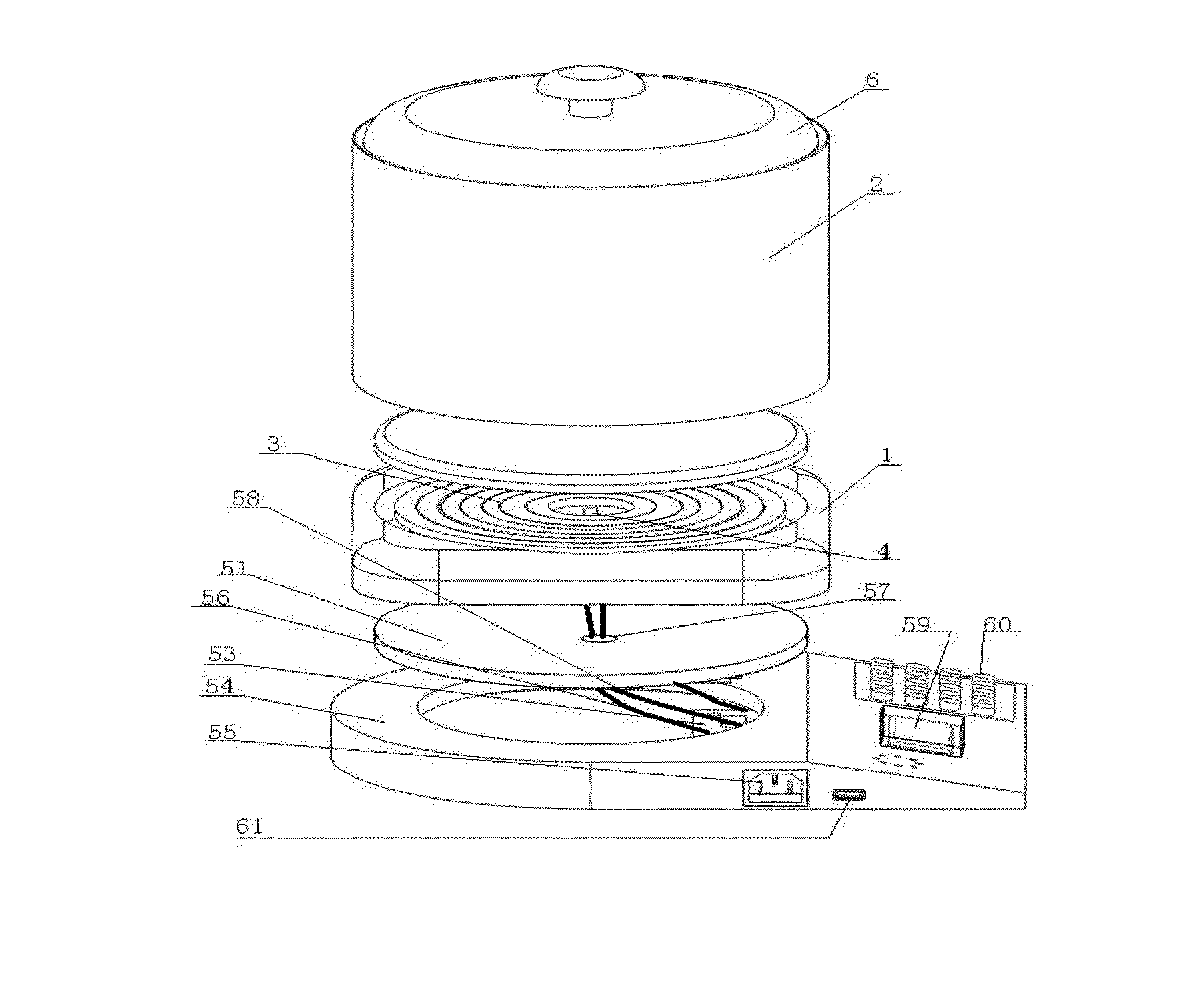

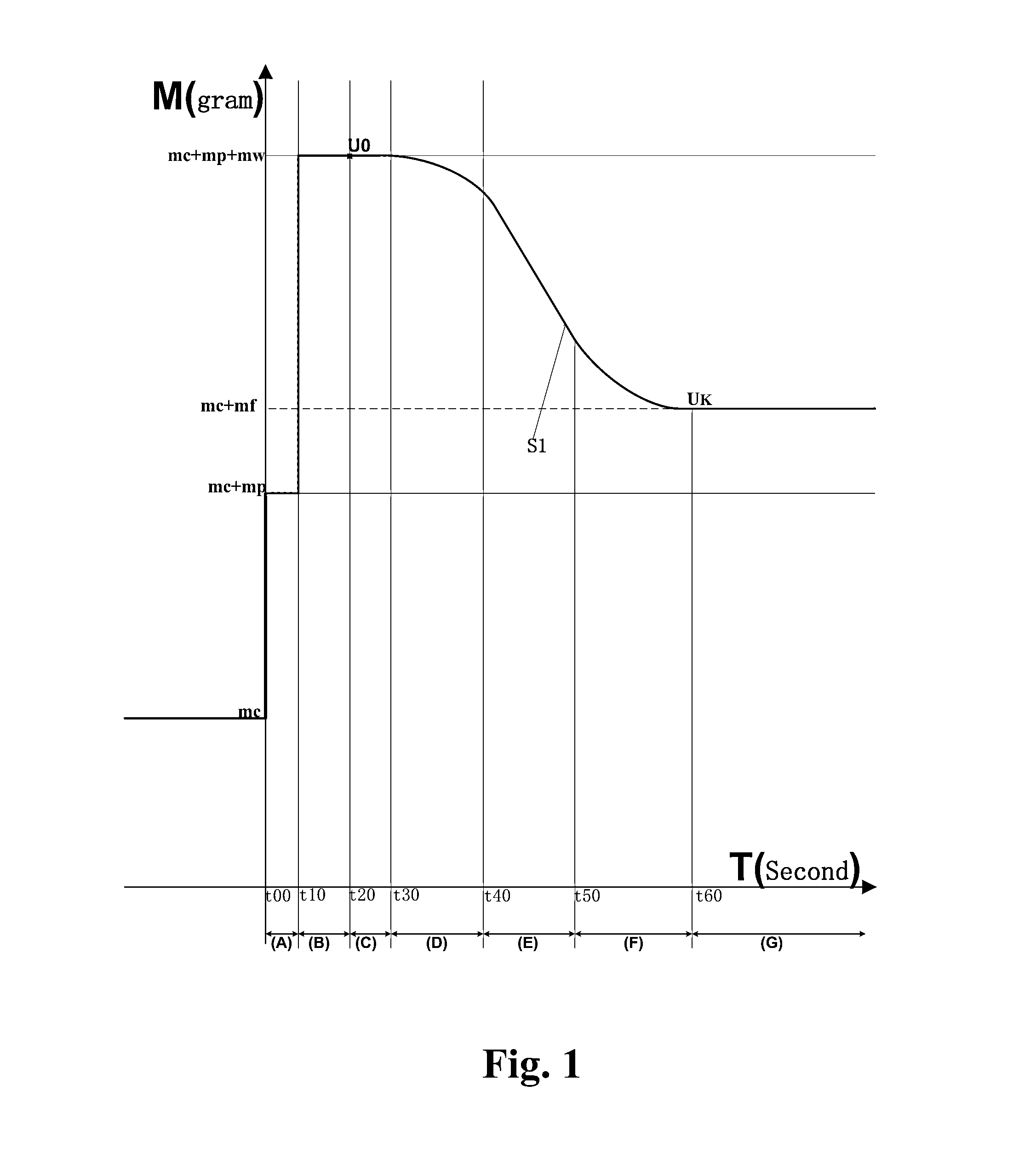

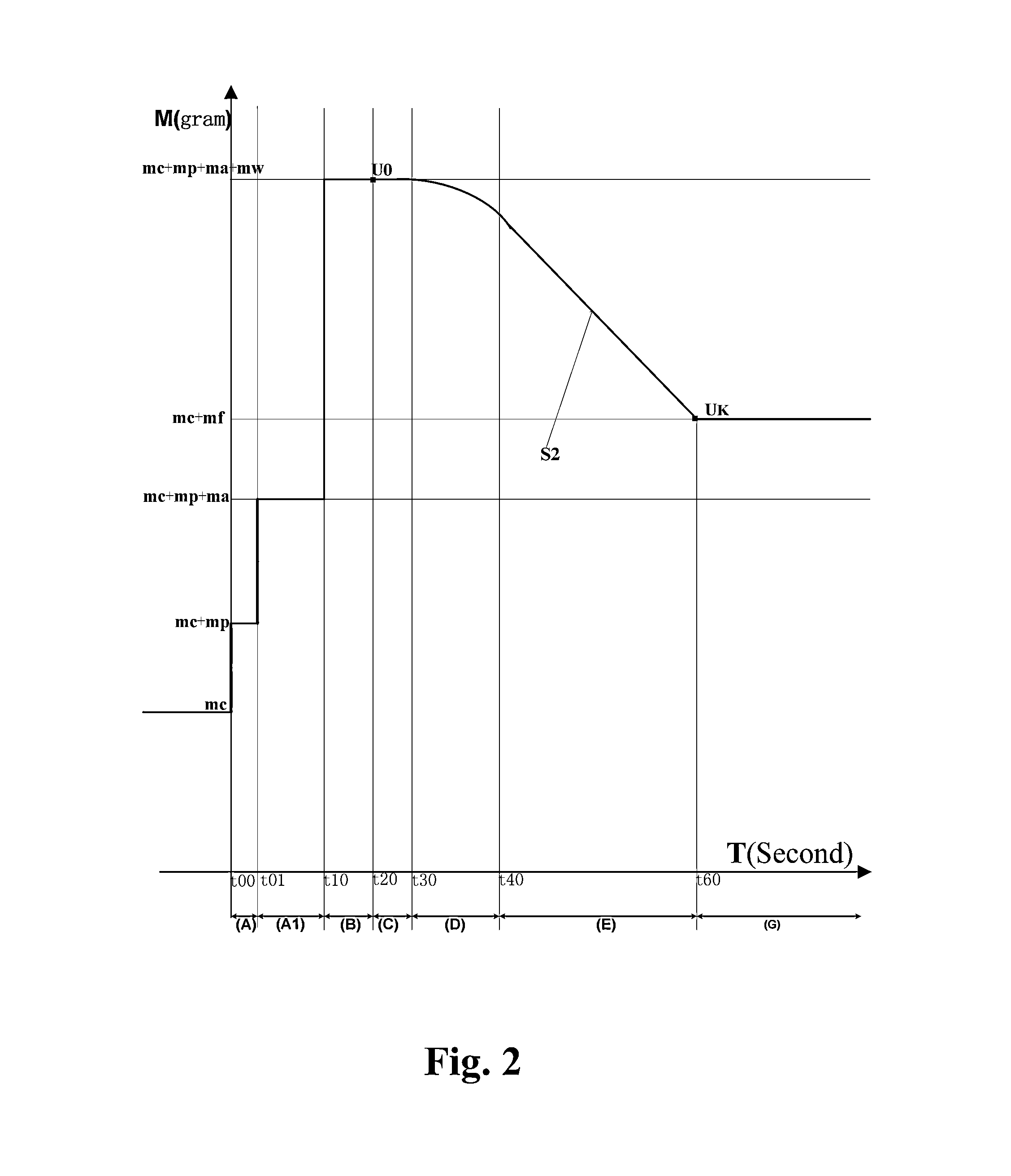

Electric heating cooker with weighing function and weighing control method thereof

ActiveUS9119501B2Increase and decrease valueEasy to controlWeighing apparatus detailsOhmic-resistance heatingCholesterolAdditive ingredient

An electric heating cooker with weighing function and a weighing control method thereof are provided. An electronic scale (5) with weighing function is added under the traditional electric heating cooker and stores cooking experience database and food information database. It solves the problem that users aren't accurate about the amount of water to add for a given weight of ingredient. And experience curve of heating power are designed at different weight points for food such as rice or meat, and also it makes the cooker to intelligently adjust parameters according to the taste feedback of the user so as to be more closer to the user's taste for the cooking next time; additionally it is capable of showing the total and average content of heat quantity, cholesterol, protein, fat, salt and cook oil of various foods in current cooking or if there are unmatched foods.

Owner:DUO AI JIA BEIJING SCI & TECH

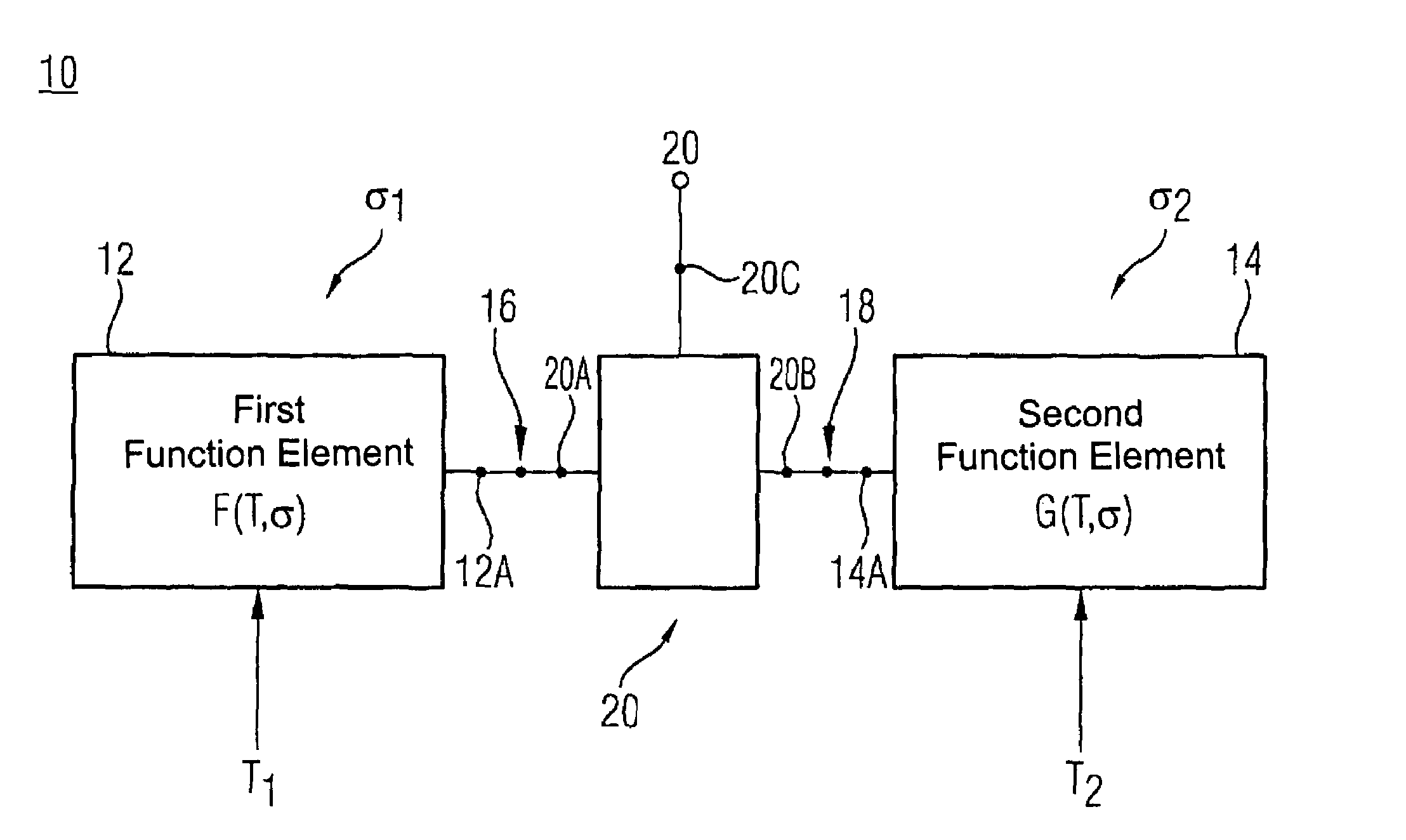

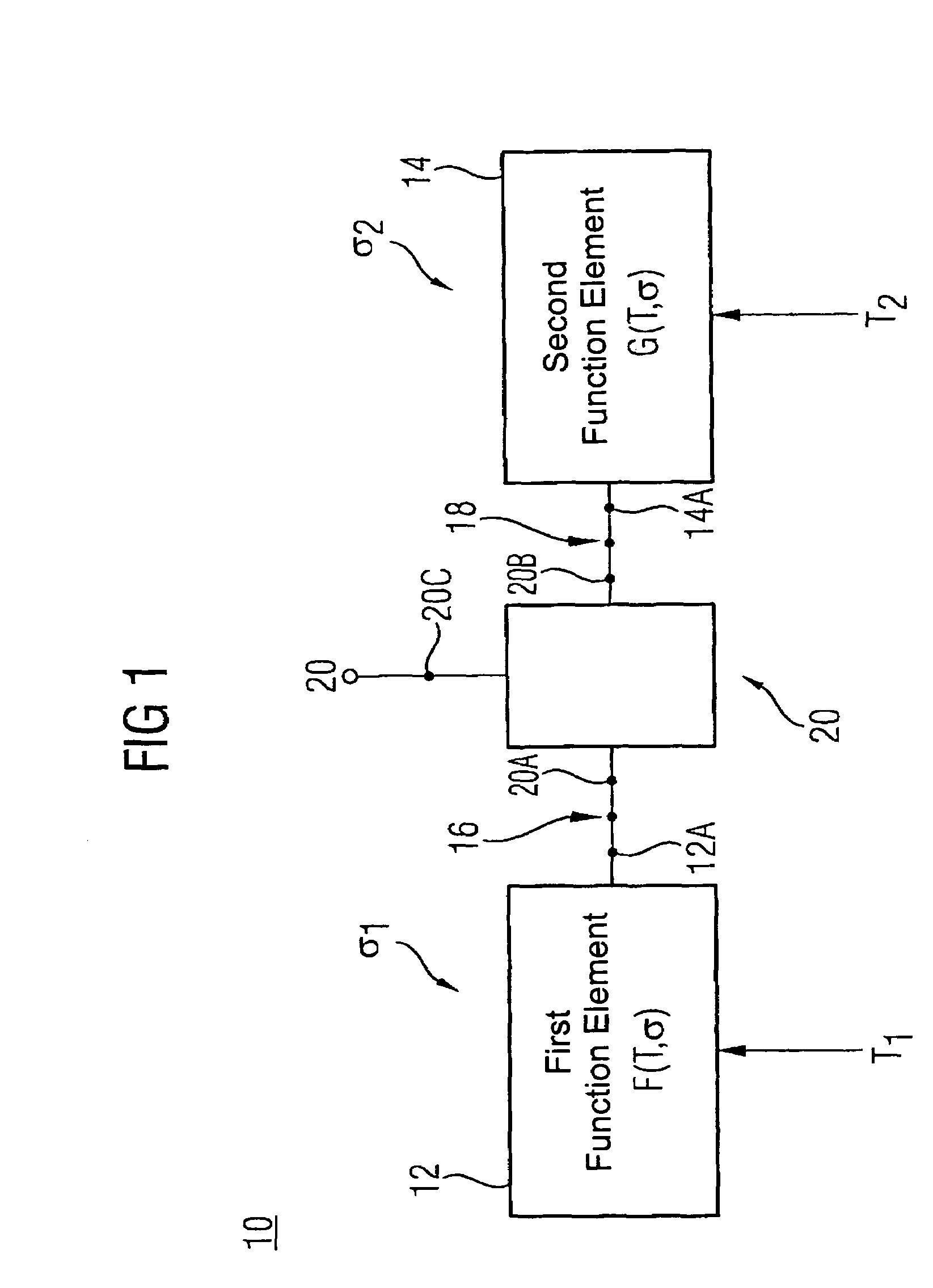

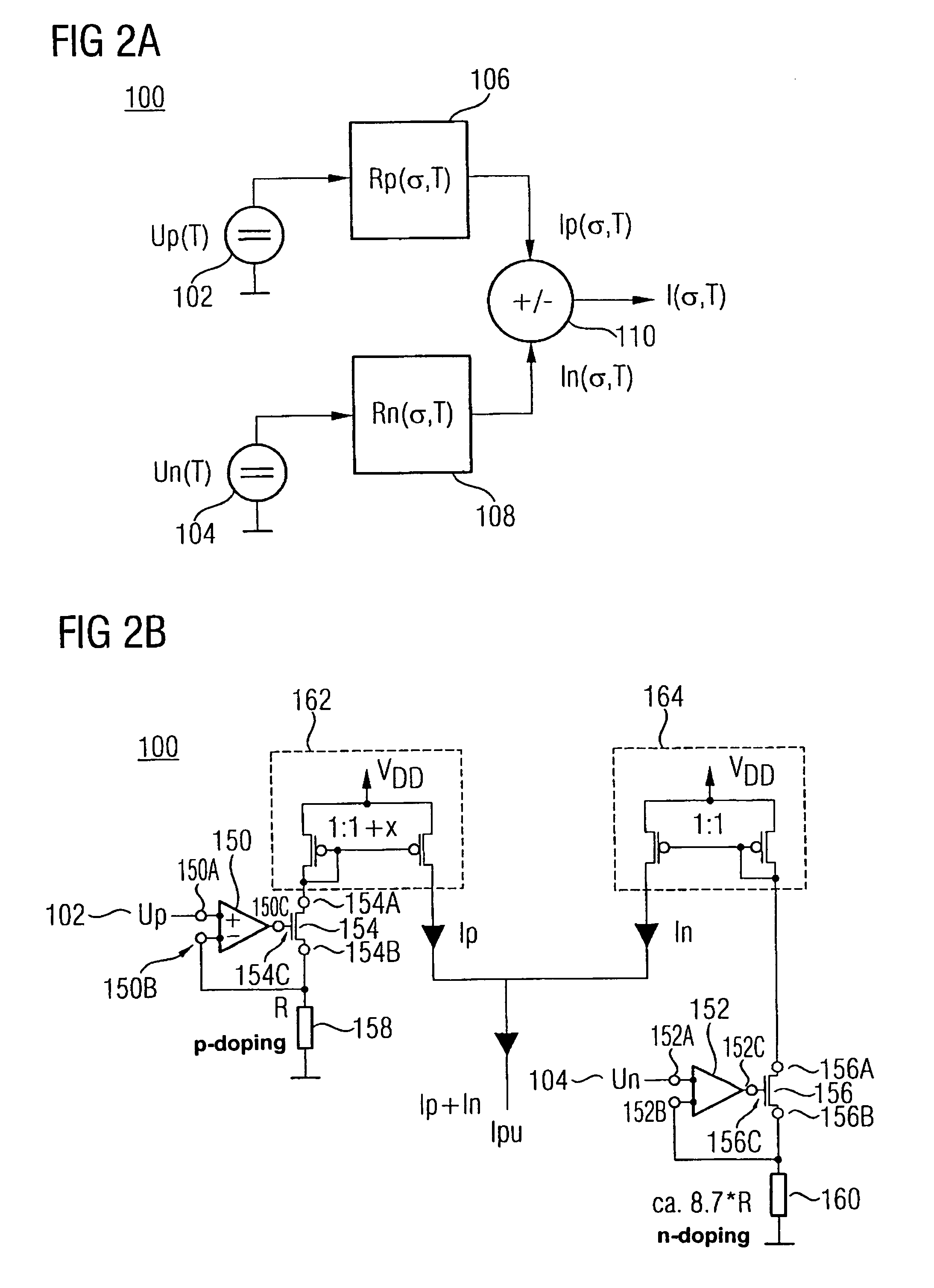

Concept of compensating for piezo influences on integrated circuitry

ActiveUS7437260B2Quality improvementFluid pressure measurement by electric/magnetic elementsSolid-state devicesElectricitySemiconductor chip

A semiconductor chip includes a first functional element having a first electronic functional-element parameter exhibiting a dependence relating to the mechanical stress present in the semiconductor circuit chip, and being configured to provide a first output signal, a second functional element having a second electronic functional-element parameter exhibiting a dependence in relation to the mechanical stress present in the semiconductor circuit chip, and being configured to provide a second output signal in dependence on the second electronic functional-element parameter and the mechanical stress, and a combination means for combining the first and second output signals to obtain a resulting output signal exhibiting a predefined dependence on the mechanical stress present in the semiconductor circuit chip, the first and second functional elements being integrated on the semiconductor circuit chip and arranged, geometrically, such that that the first and second functional-element stress influence functions are identical within a tolerance range.

Owner:INFINEON TECH AG

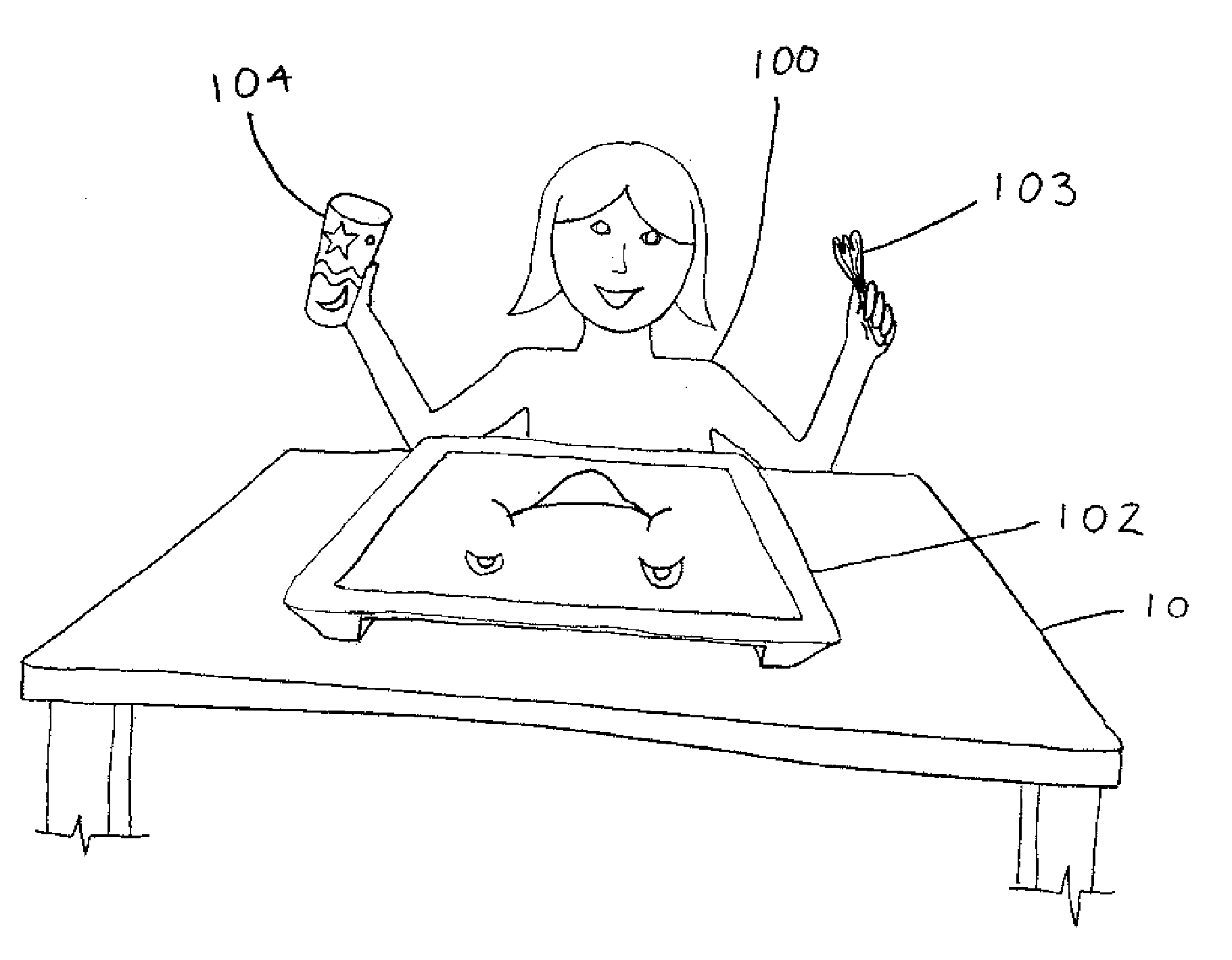

Active Foodware

Active foodware comprises at least a plate unit that provides visual stimuli by having a power source and a visual sensory stimulating component to provide light emanating from the plate. Other devices can provide auditory and haptic stimuli. The plate unit can be a single component where the device and circuitry are all contained in the unit and protected from water or can be two components an upper translucent plate and an underplate comprising the devices and circuitry for directing light through the upper plate.

Owner:KRAMER JAMES F

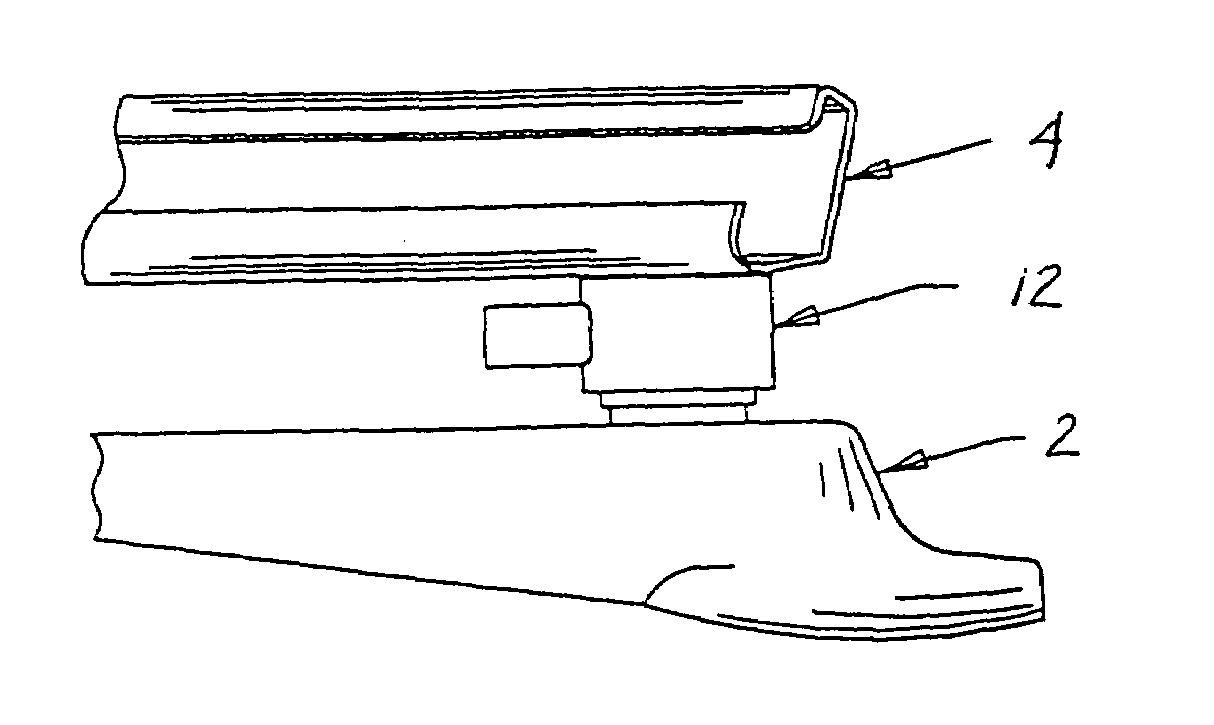

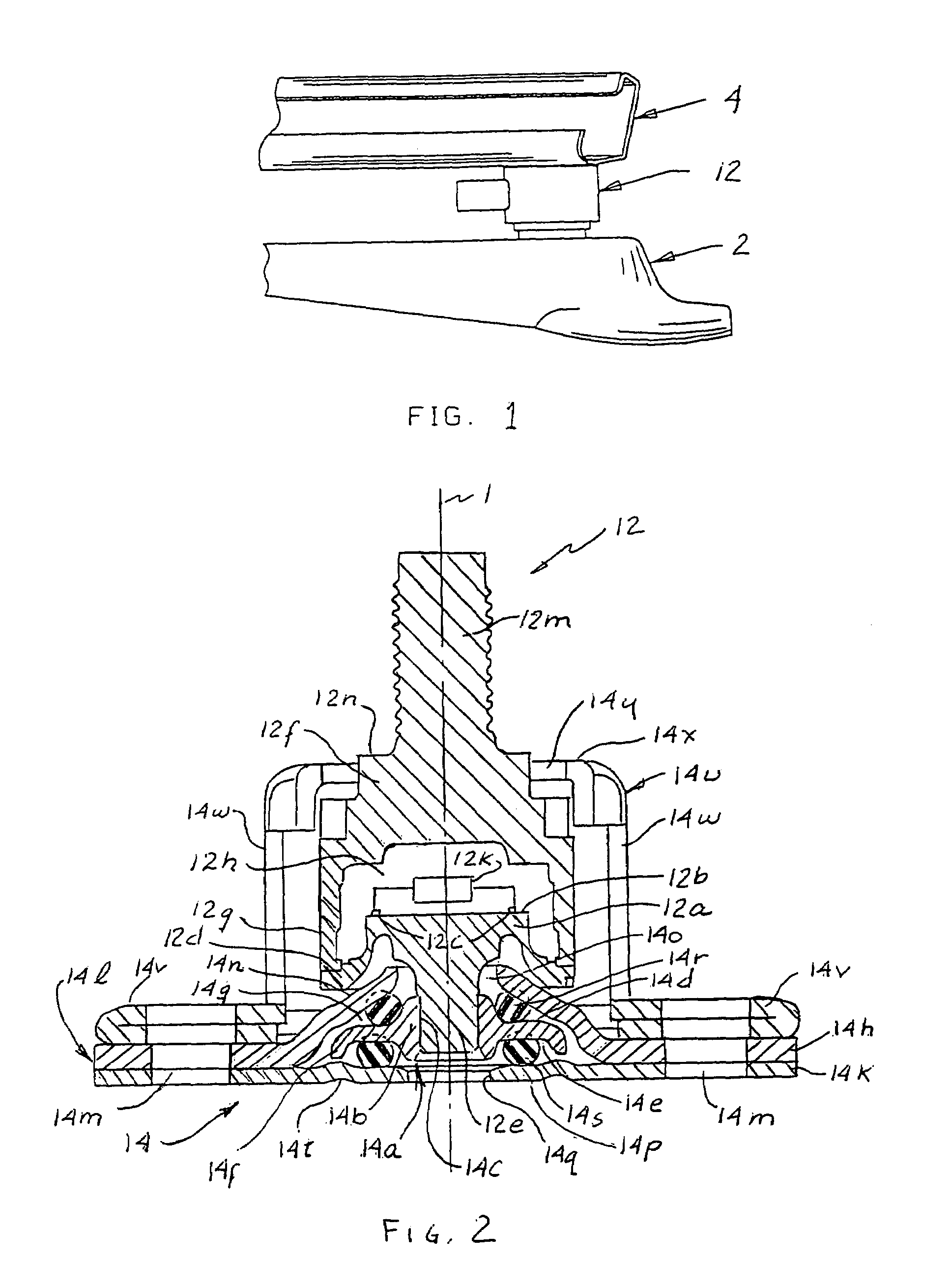

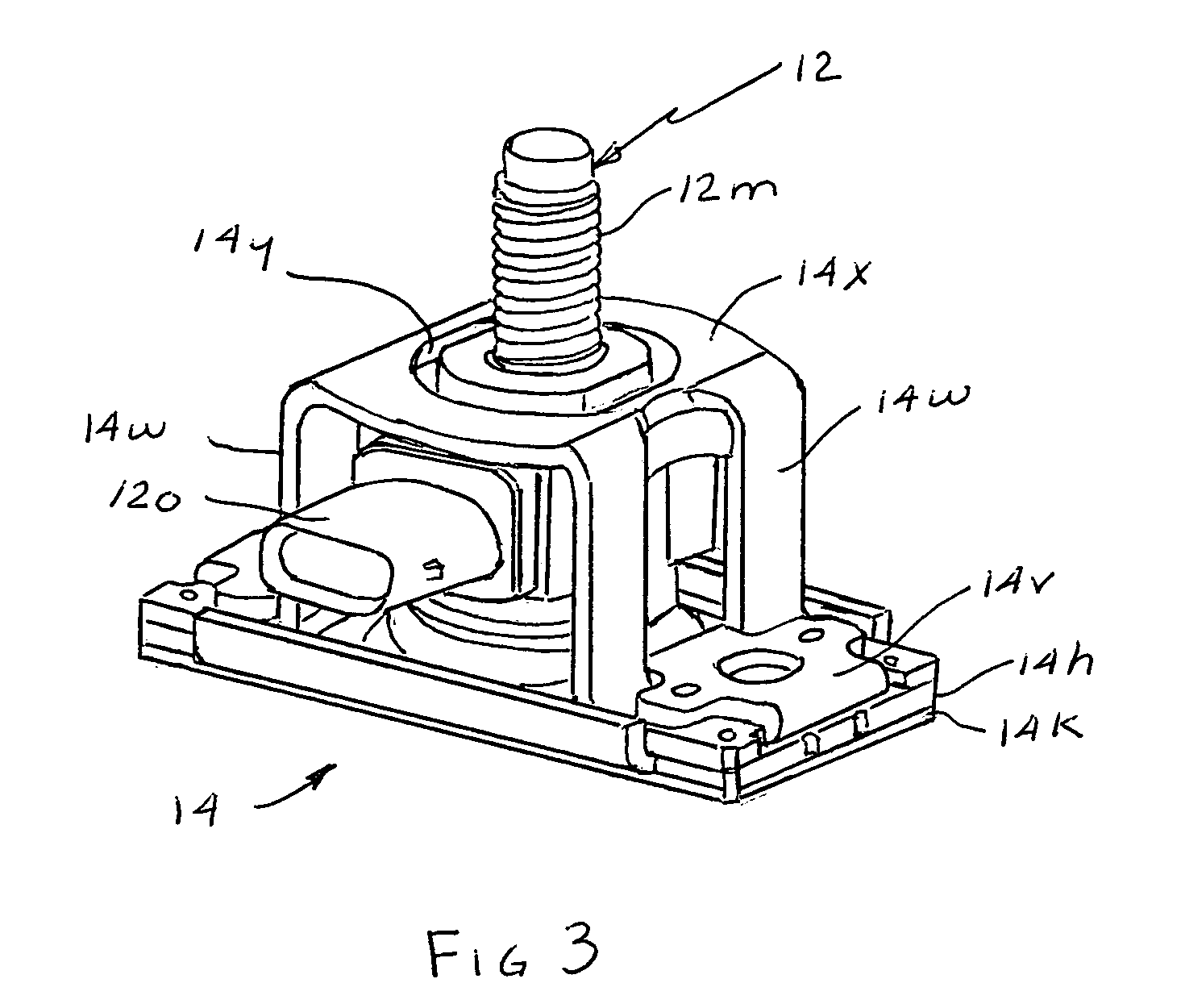

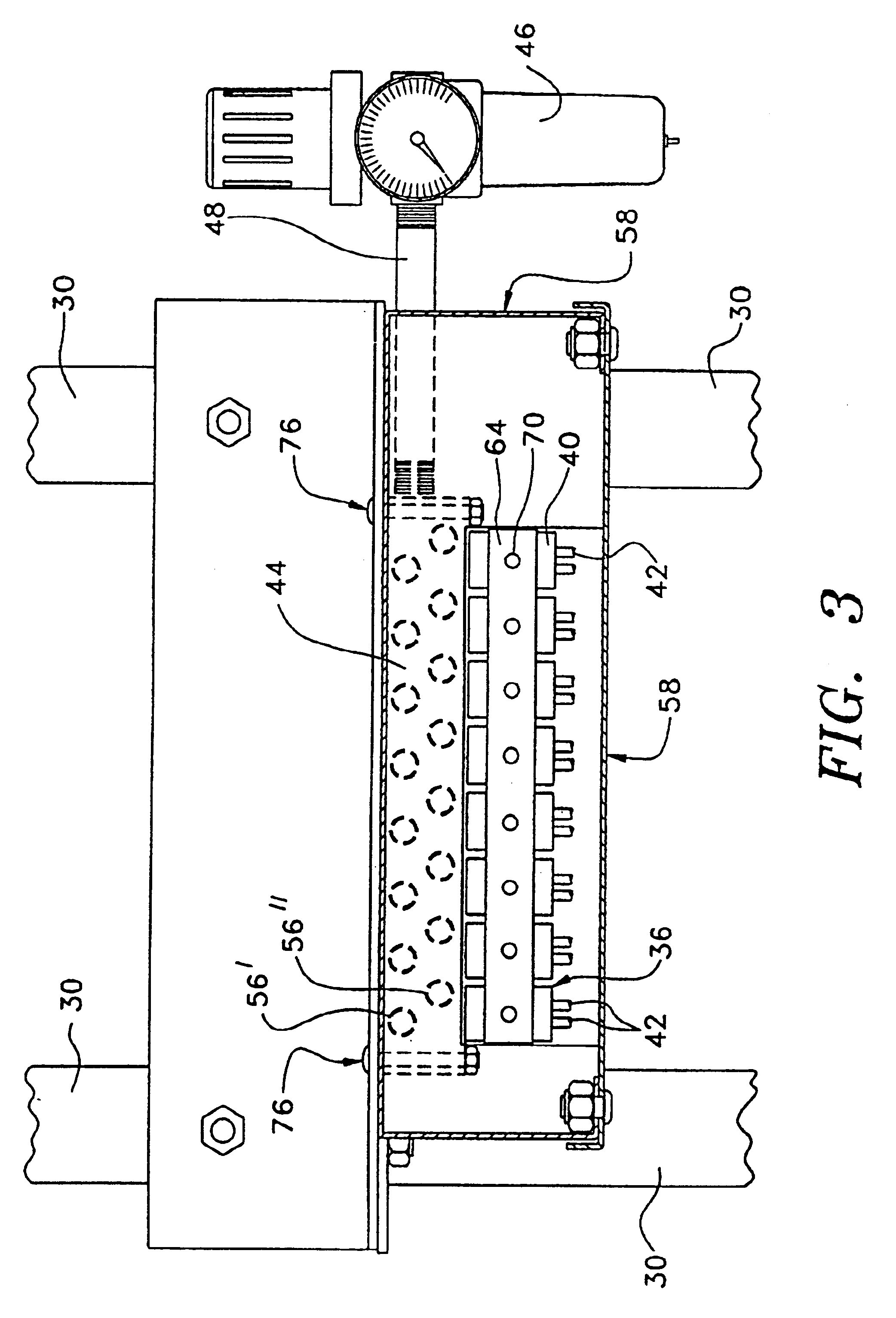

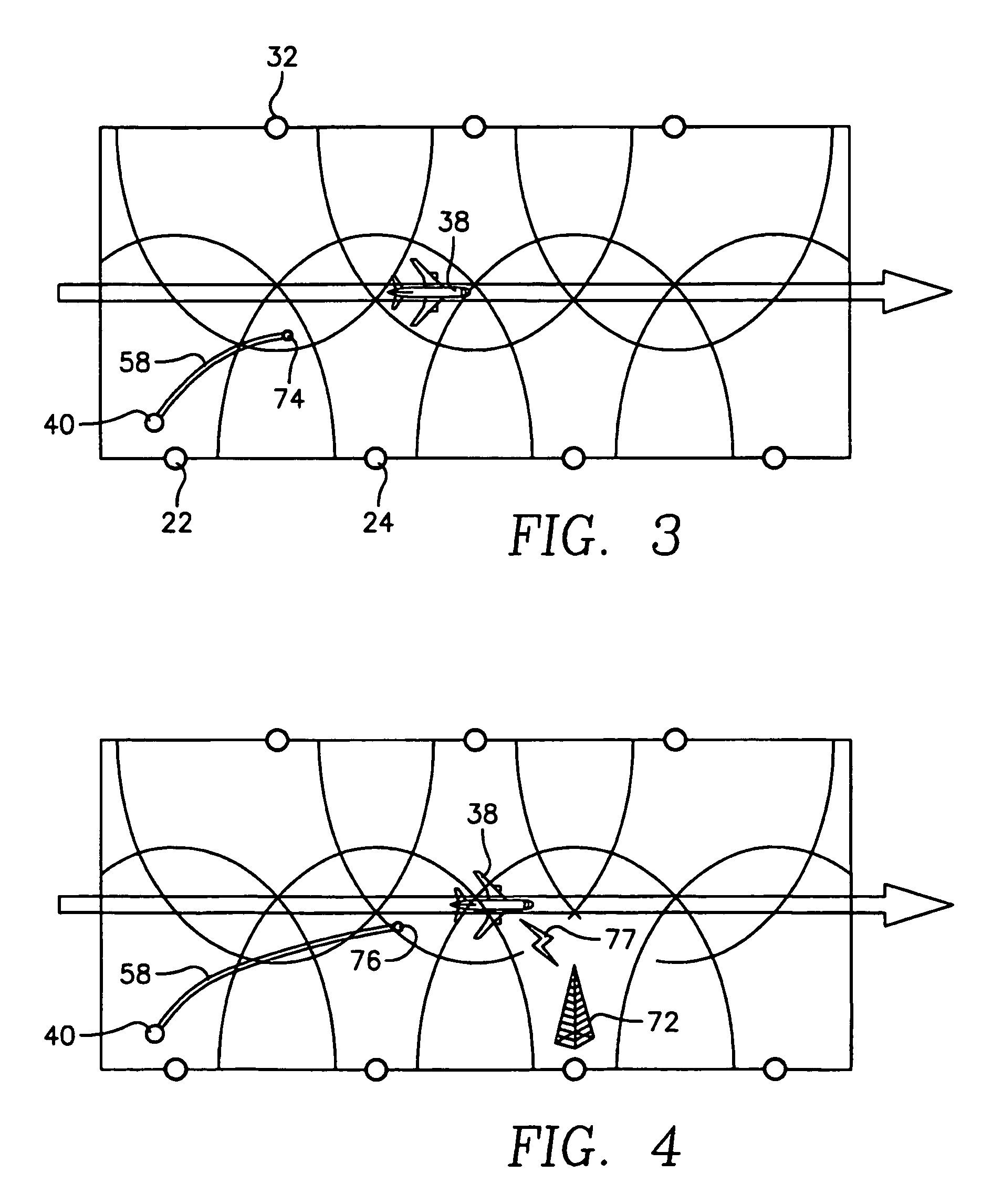

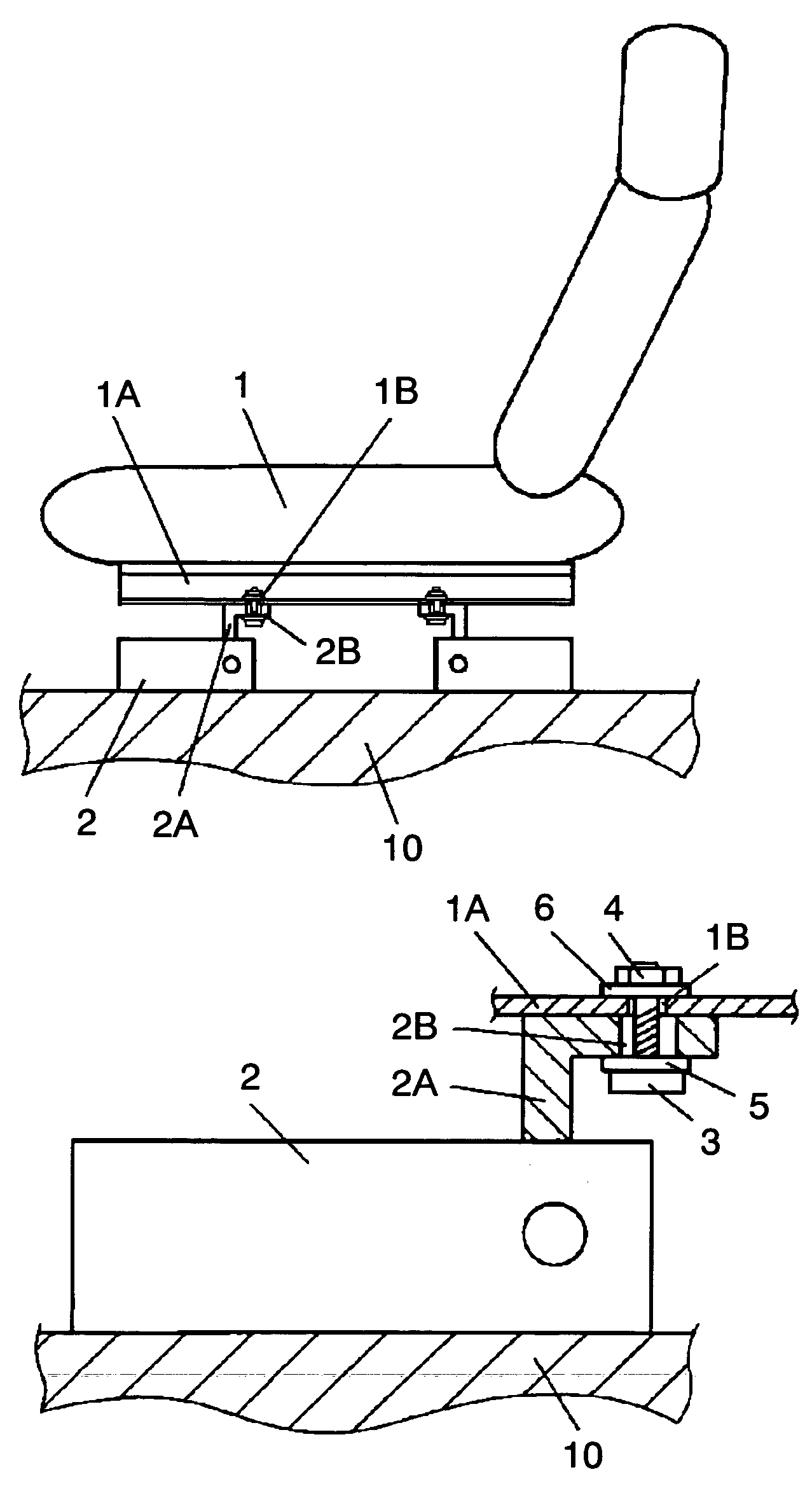

Sensor mounting apparatus for minimizing parasitic stress

ActiveUS7112749B2Minimize parasitic stressSufficiently robustVehicle seatsElectric devicesEngineeringParasitic structure

A compliant interface (14,16) for vehicular seat weight sensors minimizes parasitic stresses affecting sensor output. In one embodiment, an integral compliant interface (14) has an annular flange (14a) attached to a post extending from the sensor body with a first compliant member (14r) disposed between the annular flange and an upper elongated flange (14h) of a mounting bracket (14l) and a second compliant member (14s) disposed between the annular plate and a lower elongated flange (14k) to allow pivotal movement of the sensor limited by a motion stop member (14f) of annular flange (14b) engaging the lower flange. An overload cage (14u) may be placed over the sensor and attached to an additional flange (14l) to contain the sensor in the event of a failure of the mount in a catastrophic high speed crash. According to another preferred embodiment, an interface having upper and lower body members are formed with a sensor post receiving bore (16c) for attachment to the post. The body members are formed with spaced apart, radially extending face surfaces, each formed with an annular recess aligned with each other and with a compliant member received therein and fixed to the respective body members and extending beyond the face surfaces. The interface is received through a bore of a support plate to which the sensor is mounted with the compliant members engaging opposite face surfaces of the support plate allowing limited pivotal motion and with a compliant member limiting lateral movement of the interface relative to the support plate.

Owner:SENSATA TECHNOLOGIES INC

System and method using a scale for monitoring the dispensing of a beverage

Owner:BEVERAGE METRICS HLDG

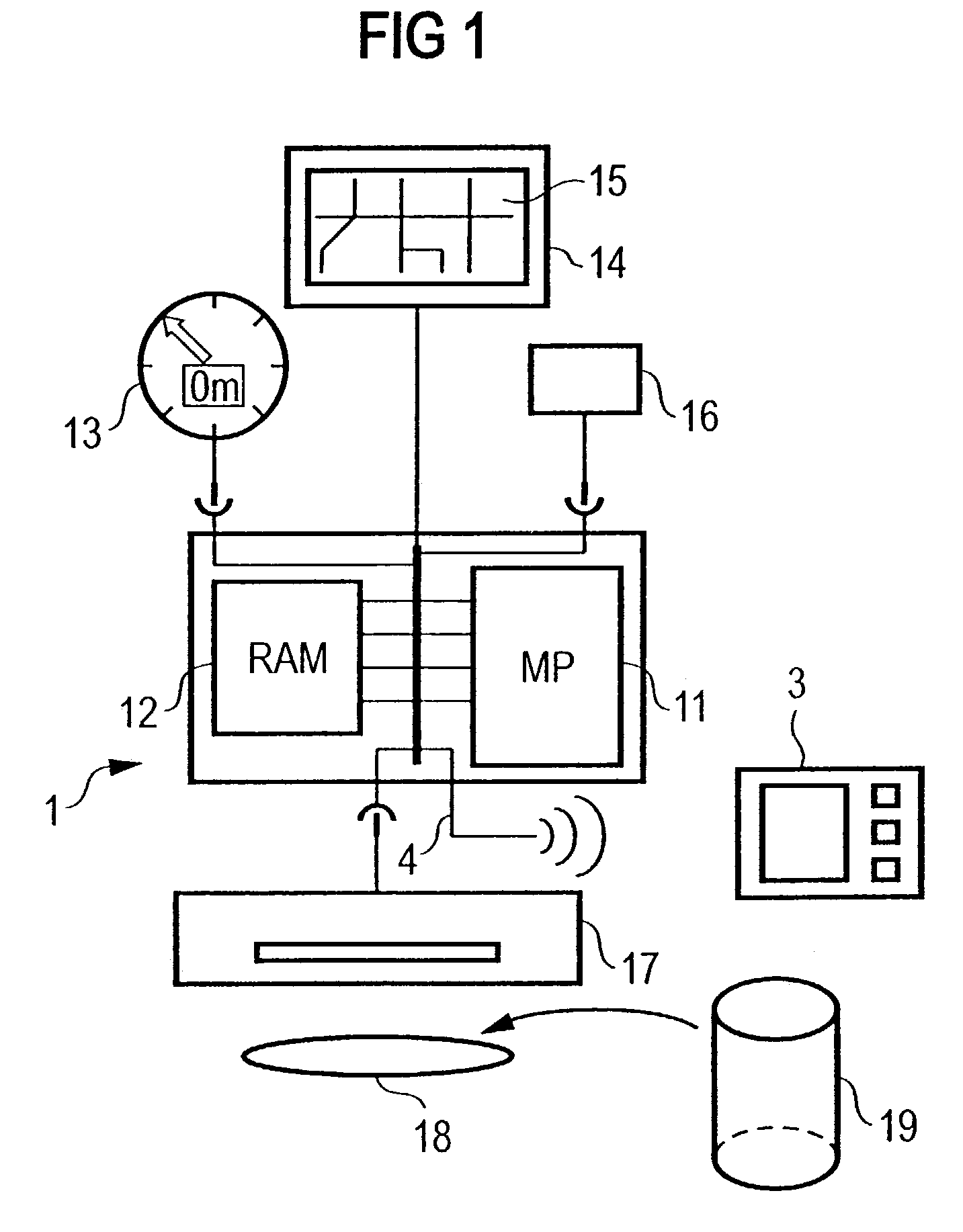

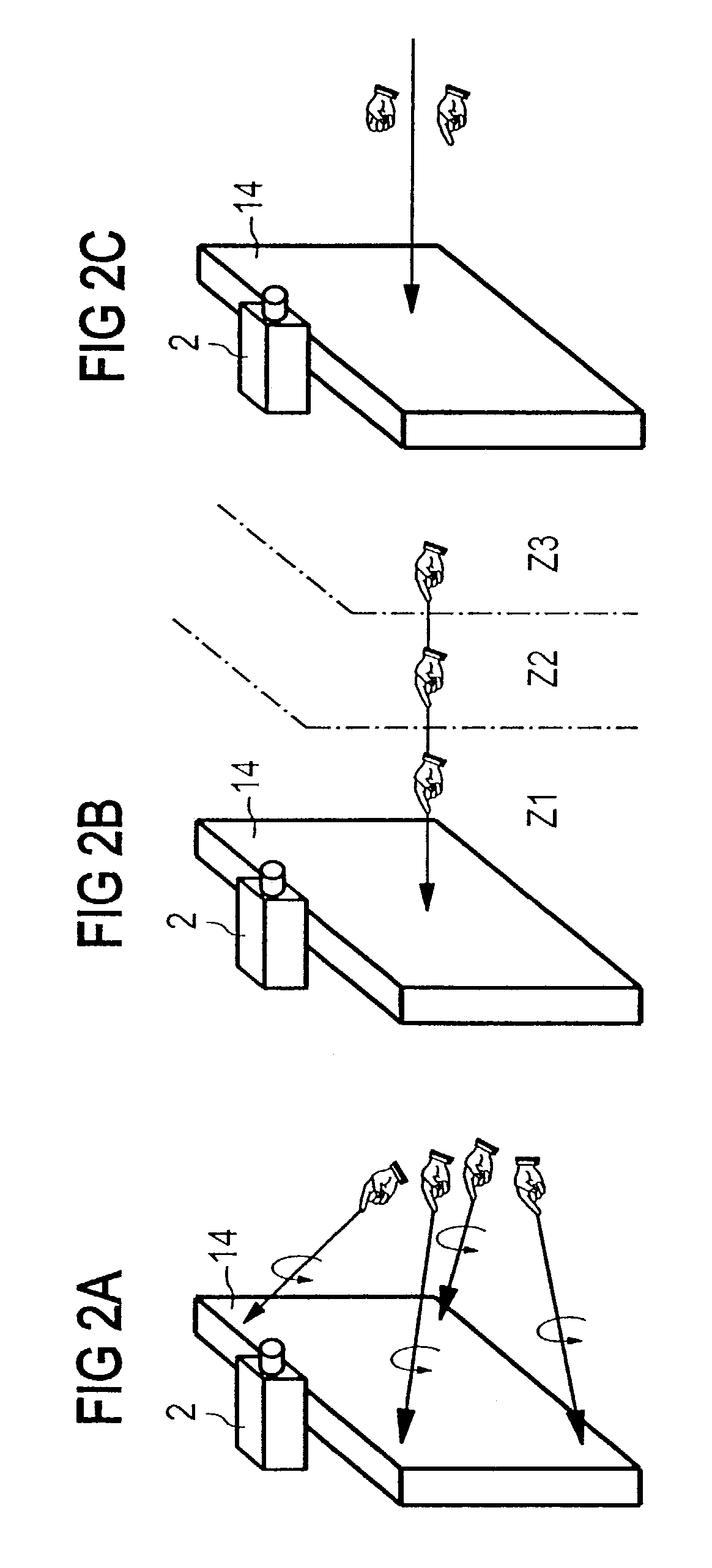

Method for requesting destination information and for navigating in a map view, computer program product and navigation unit

InactiveUS7126579B2Simple and visual orientationInput/output for user-computer interactionInstruments for road network navigationUser inputComputer program

A method for querying target information within a card view (15) is disclosed wherein a three-dimensional object (151) is selected on the basis of a user input and data (152) linked thereto is outputted. Preferably, in order to navigate within the card view (15), the gestures of the user are evaluated. The user can then navigate within a card view in a virtual manner and can easily query target information relating to an object.

Owner:CONTINENTAL AUTOMOTIVE GMBH

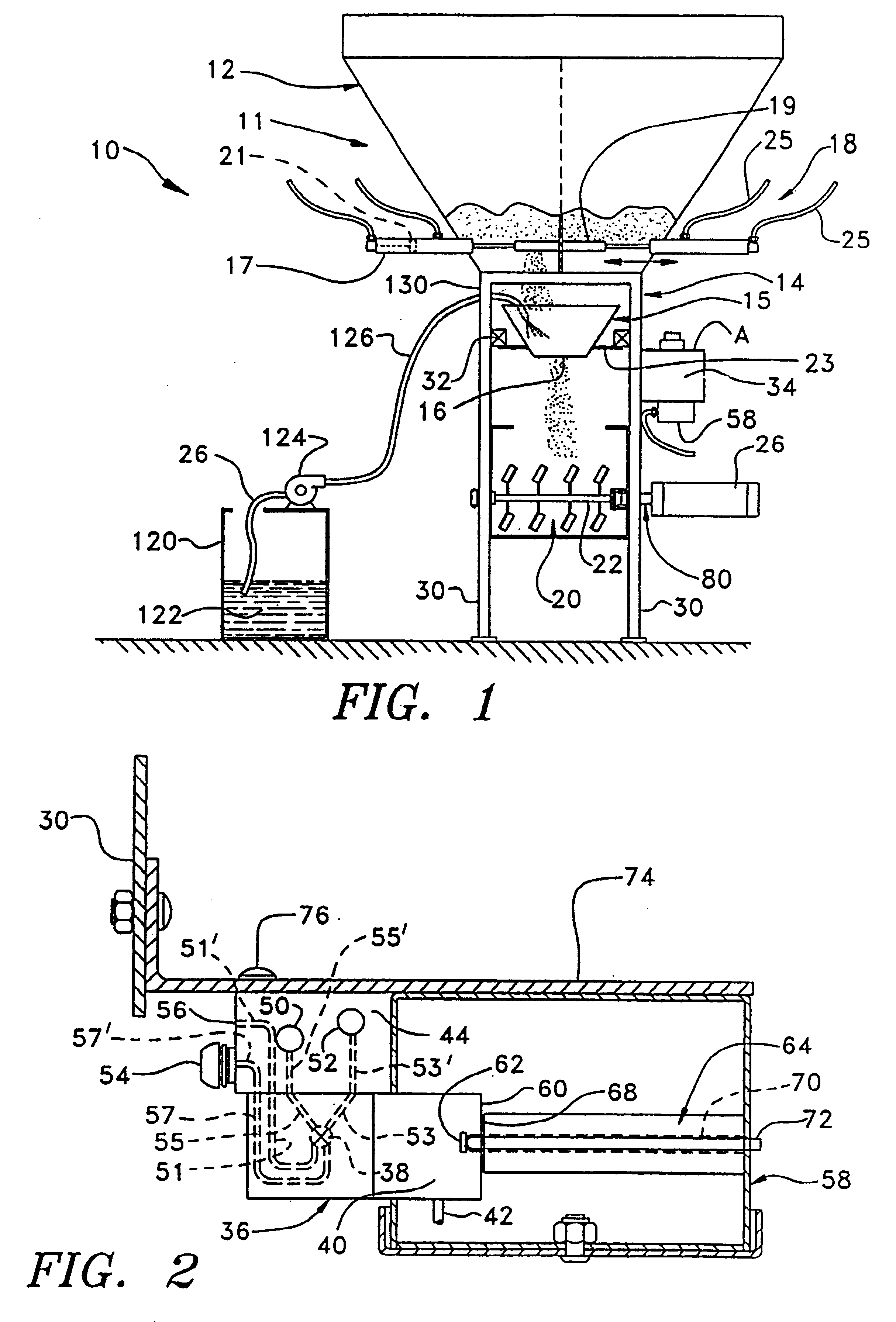

Weigh scale blender

InactiveUS6402363B1Accurate measurementEasy and efficient and accurateControlling ratio of multiple fluid flowsRotary stirring mixersEngineeringLoad cell

A weigh scale blender comprising a frame, a weigh bin, a load cell connected to the frame for sensing weight of the bin and any material contained therein, a mix chamber connected to the frame, including a mixing paddle therewithin, a dump flap for selectably releasing material from the bin into the mix chamber, a bushing intermediate the load cell and the frame for damping transfer of vibration and shock motion therebetween.

Owner:MAGUIRE STEPHEN B

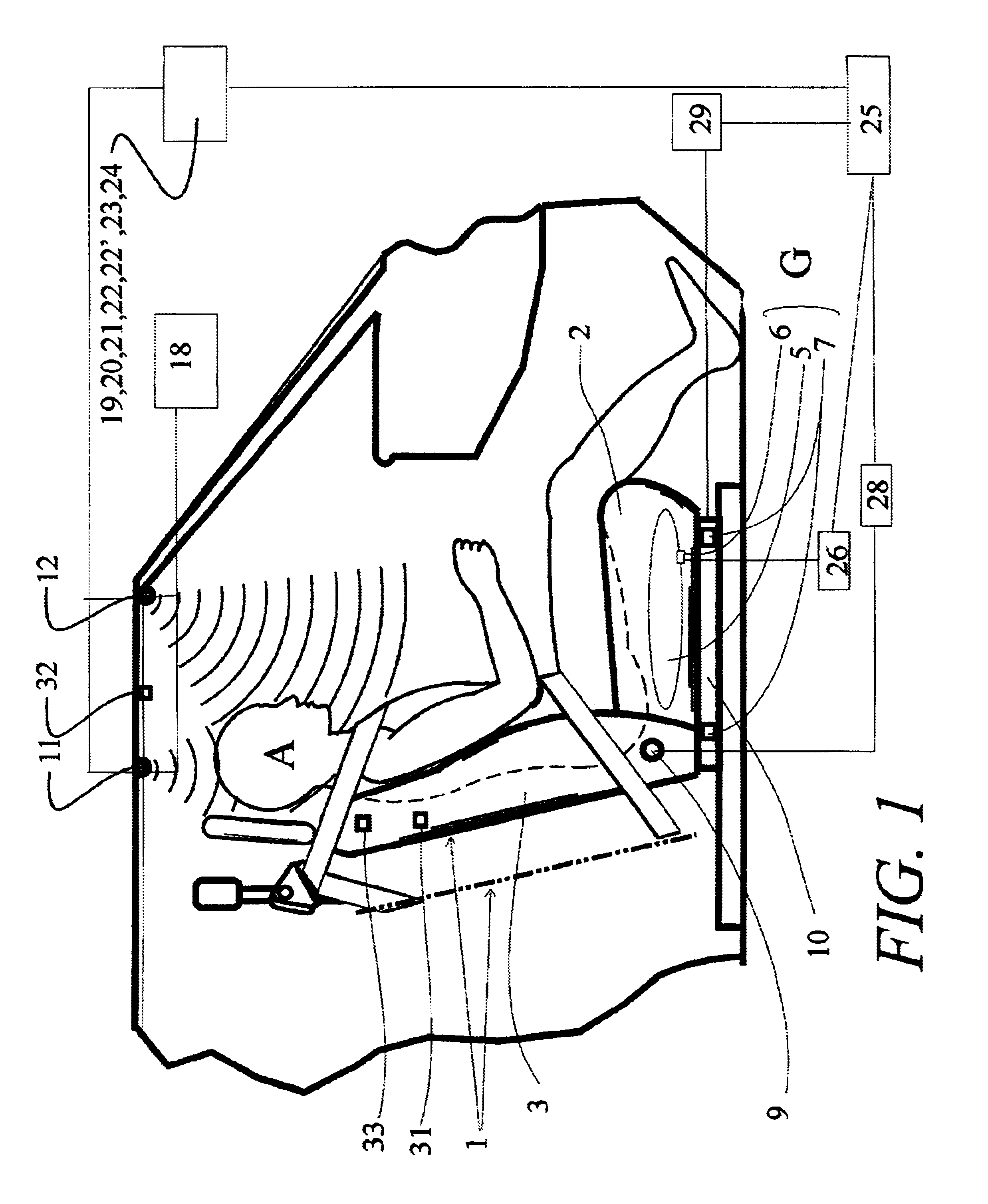

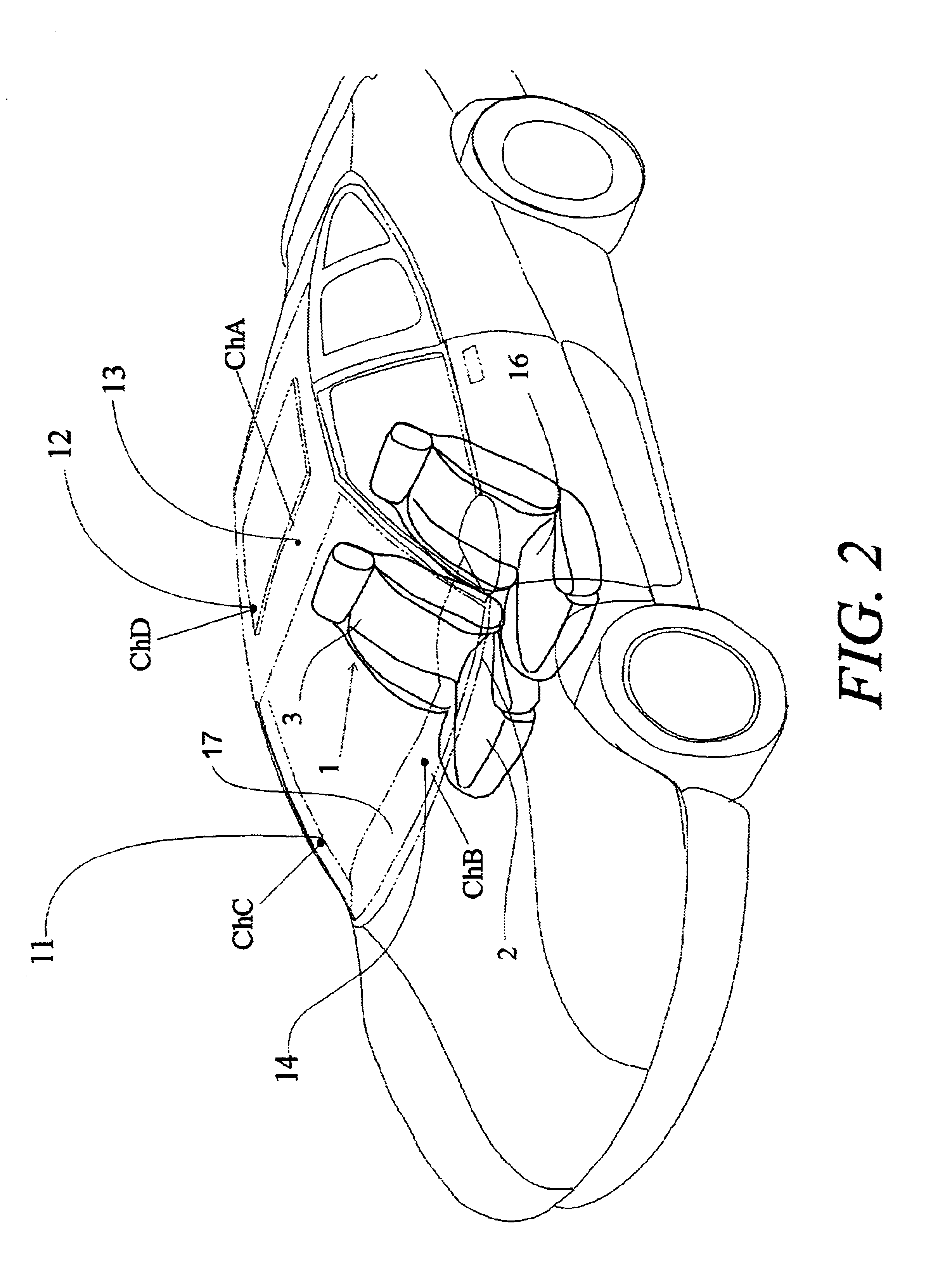

Apparatus and method for measuring weight of an occupying item of a seat

InactiveUS6958451B2Improve performanceReduce crew damageVehicle seatsBelt retractorsAccelerometerRoad surface roughness

Arrangement and method for determining weight of an occupying item in a seat including one or more weight sensors arranged to obtain a measurement of the force applied to the seat, a forcing function determination arrangement for measuring a forcing function of the seat and a processor coupled to the weight sensor(s) and forcing function determination arrangement for receiving the measurement of the force applied to the weight sensor(s) and the measurement of the forcing function from the forcing function measurement system and determining the weight of the occupying item based thereon. The forcing function determination arrangement may include an accelerometer and measures effects on the seat caused by load of a seatbelt associated with the seat and / or effects on the seat of road roughness, steering maneuvers, and a vehicle suspension system.

Owner:AUTOMOTIVE TECH INT

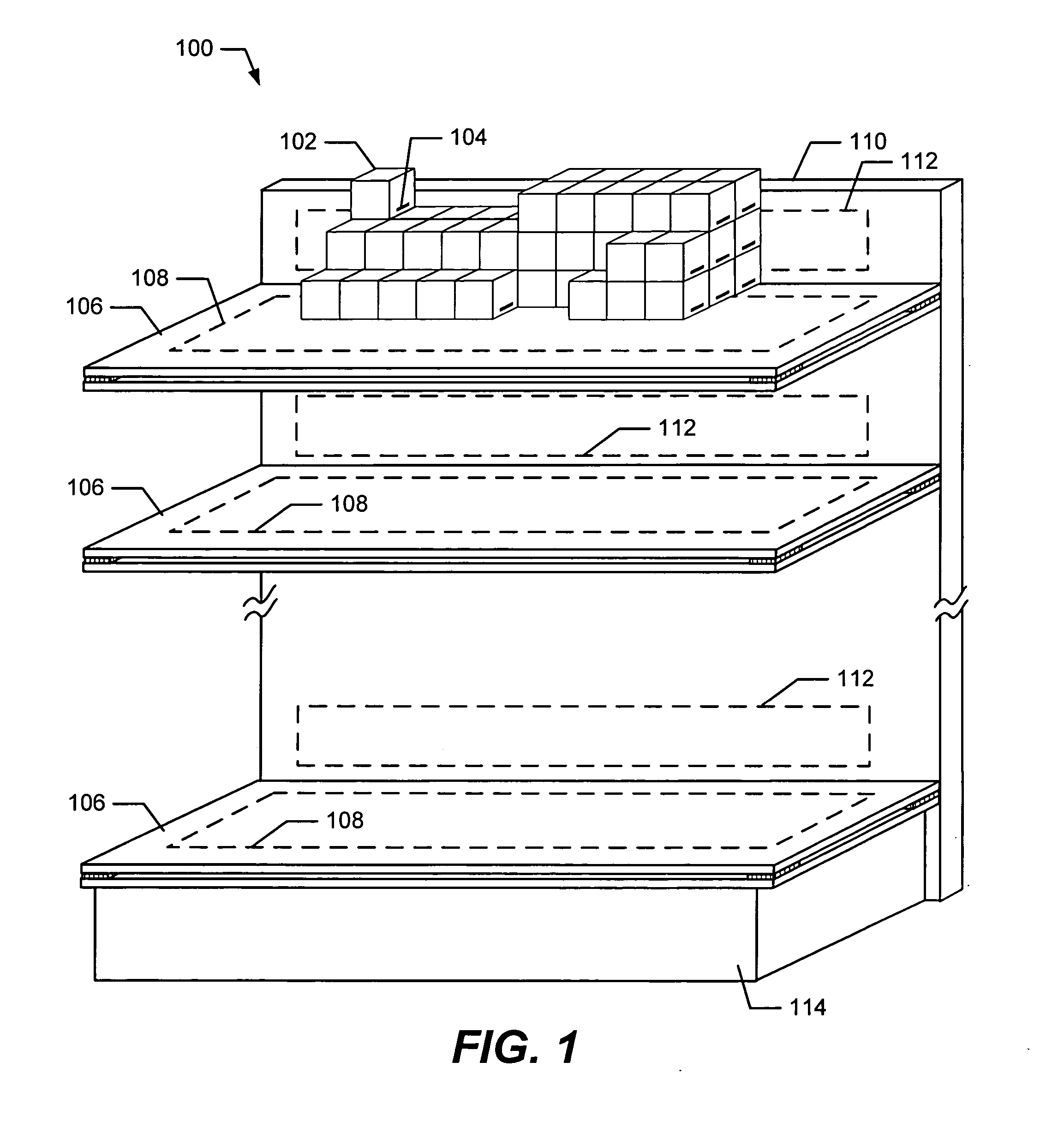

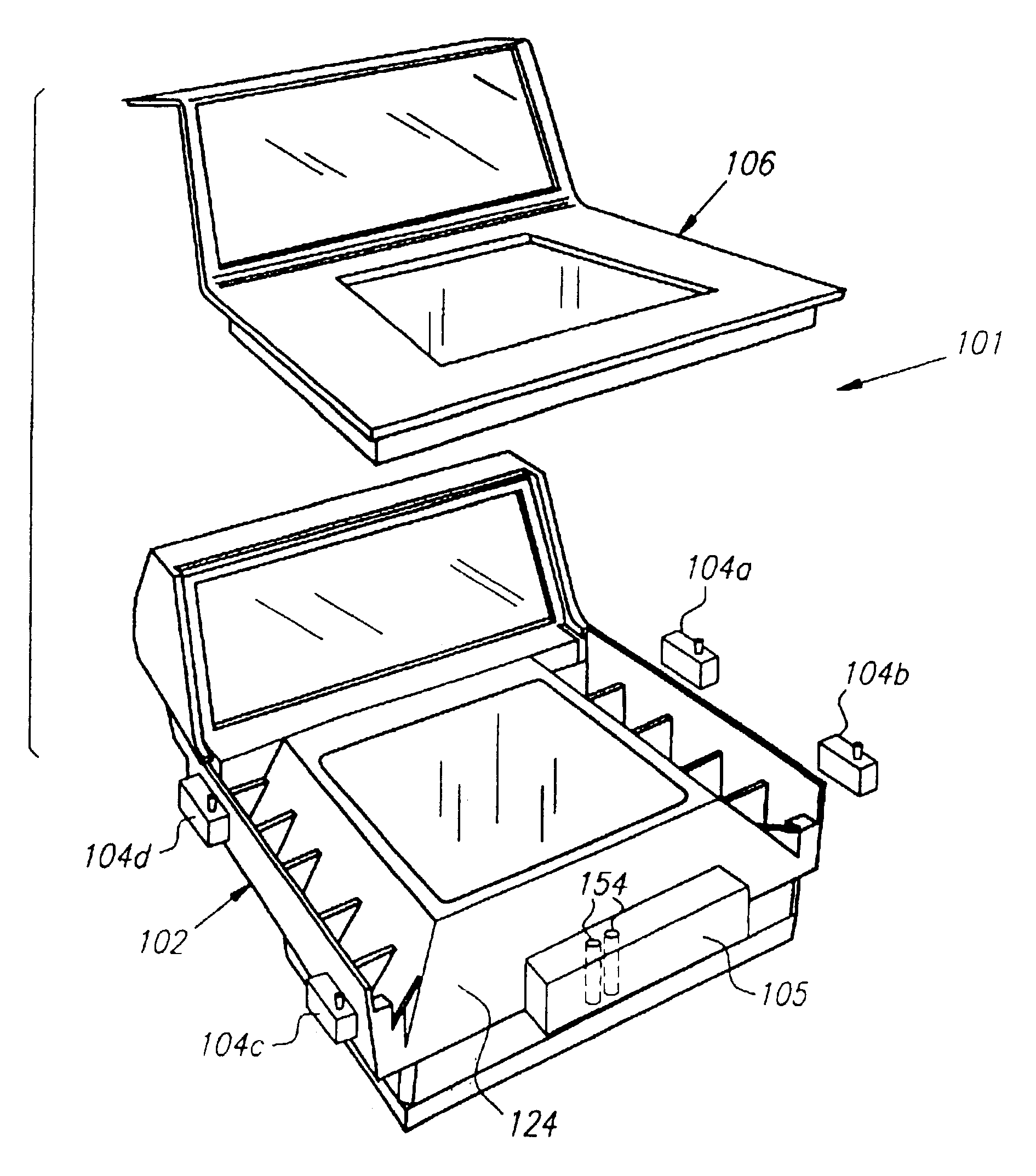

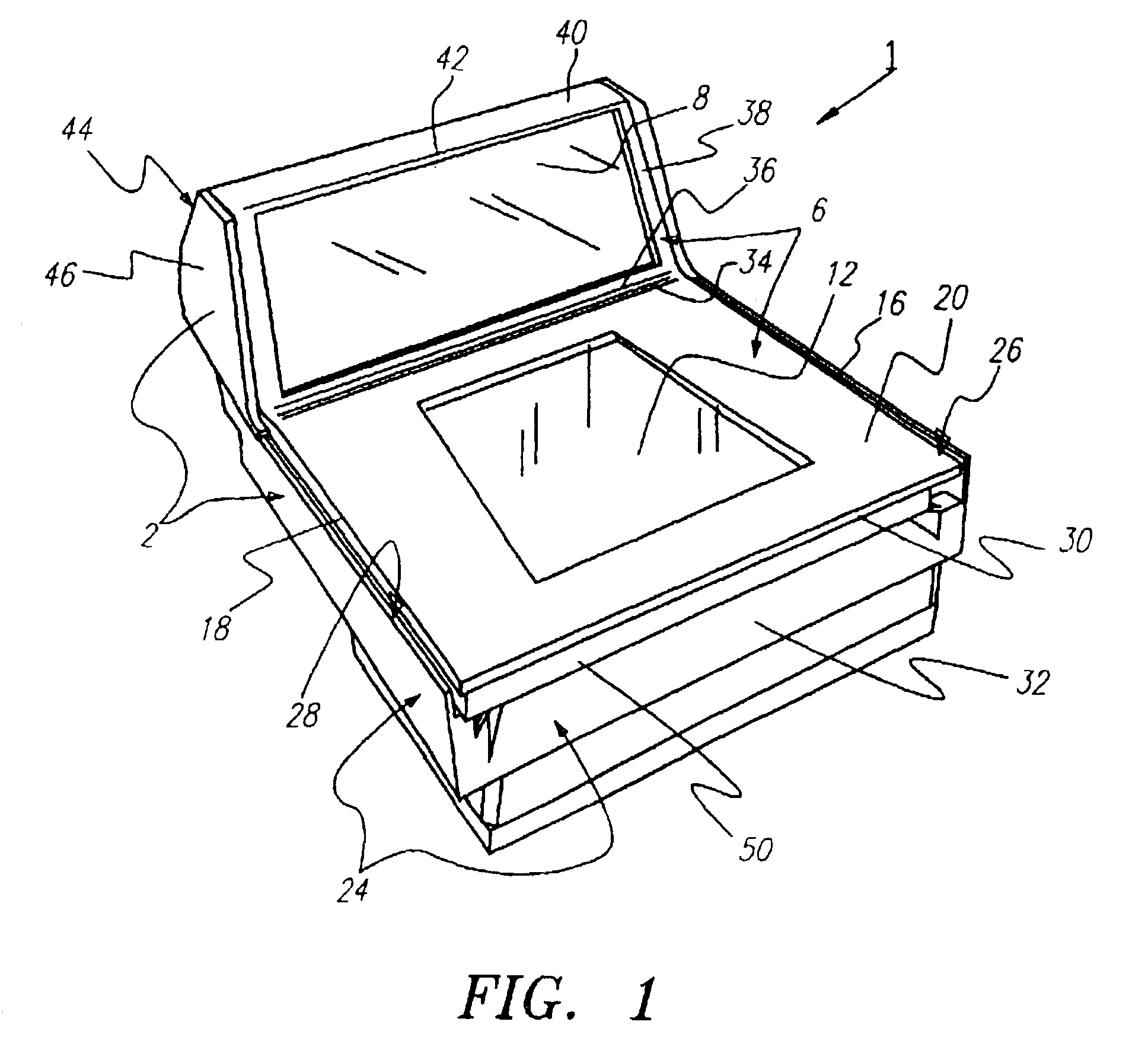

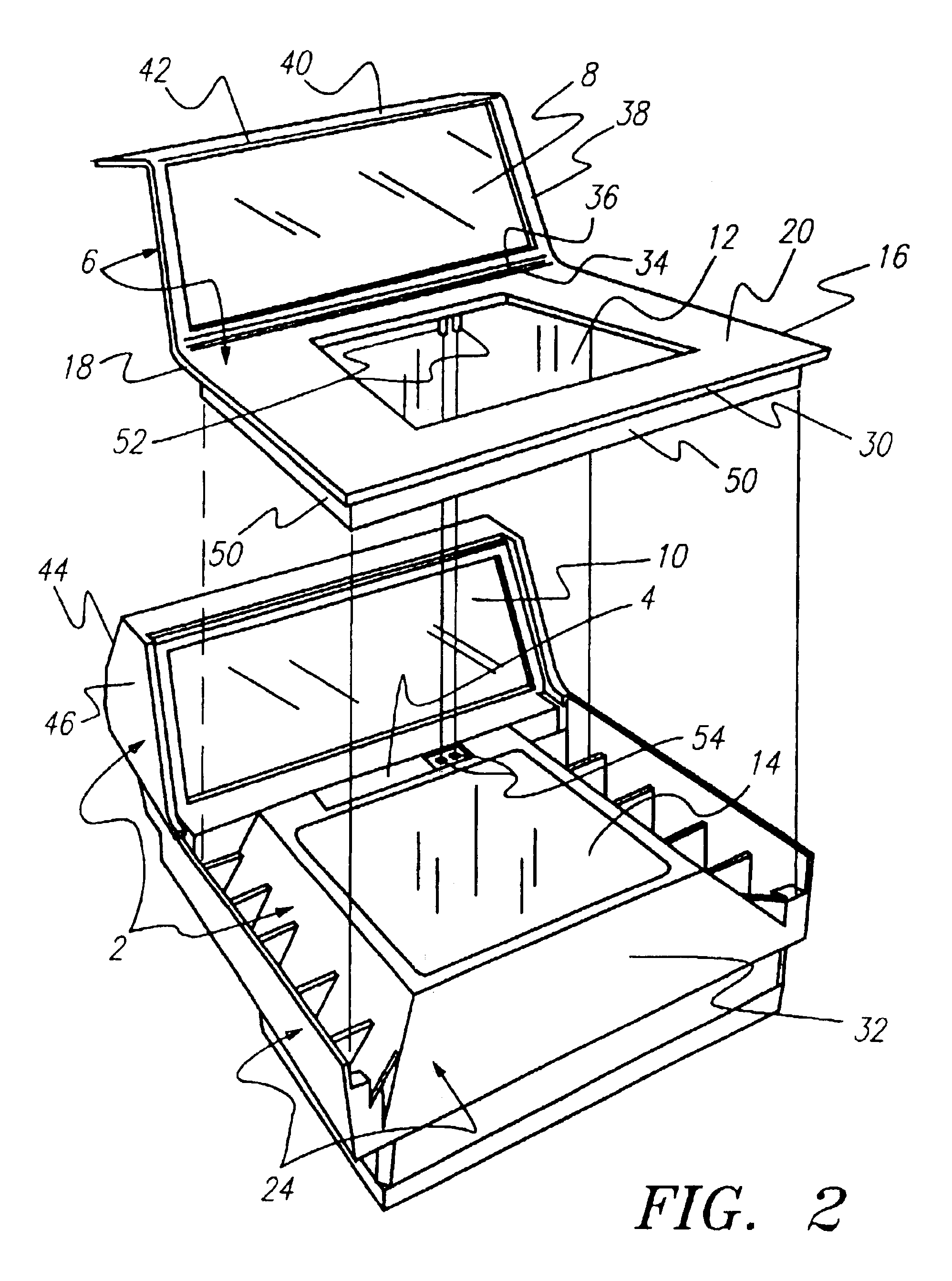

Multiple plane weigh platter for multiple plane scanning systems

A multi-plane scanner having a dual plane scanner with a horizontal window and a vertical window and a load cell / weigh platter weighing apparatus such that the weigh platter itself is a dual plane object with vertical and horizontal sections. The size and orientation of the planes of the weigh platter correspond to the size and orientation of the scan windows of the dual plane scanner, and each plane of the weigh platter has a transparent area (typically central), or “platter window”, corresponding to a respective scan windows of the scanner for allowing transmission of scanned optical beams and optical barcode signals through each of the planes of the weigh platter. The platter is sufficiently rigid to permit accurate weighing whether the object being weighed is placed solely on the horizontal section of the platter or in part on the vertical section. The vertical and horizontal sections of the platter are sealed together to prevent passage of debris therebetween.

Owner:DATALOGIC SCANNING

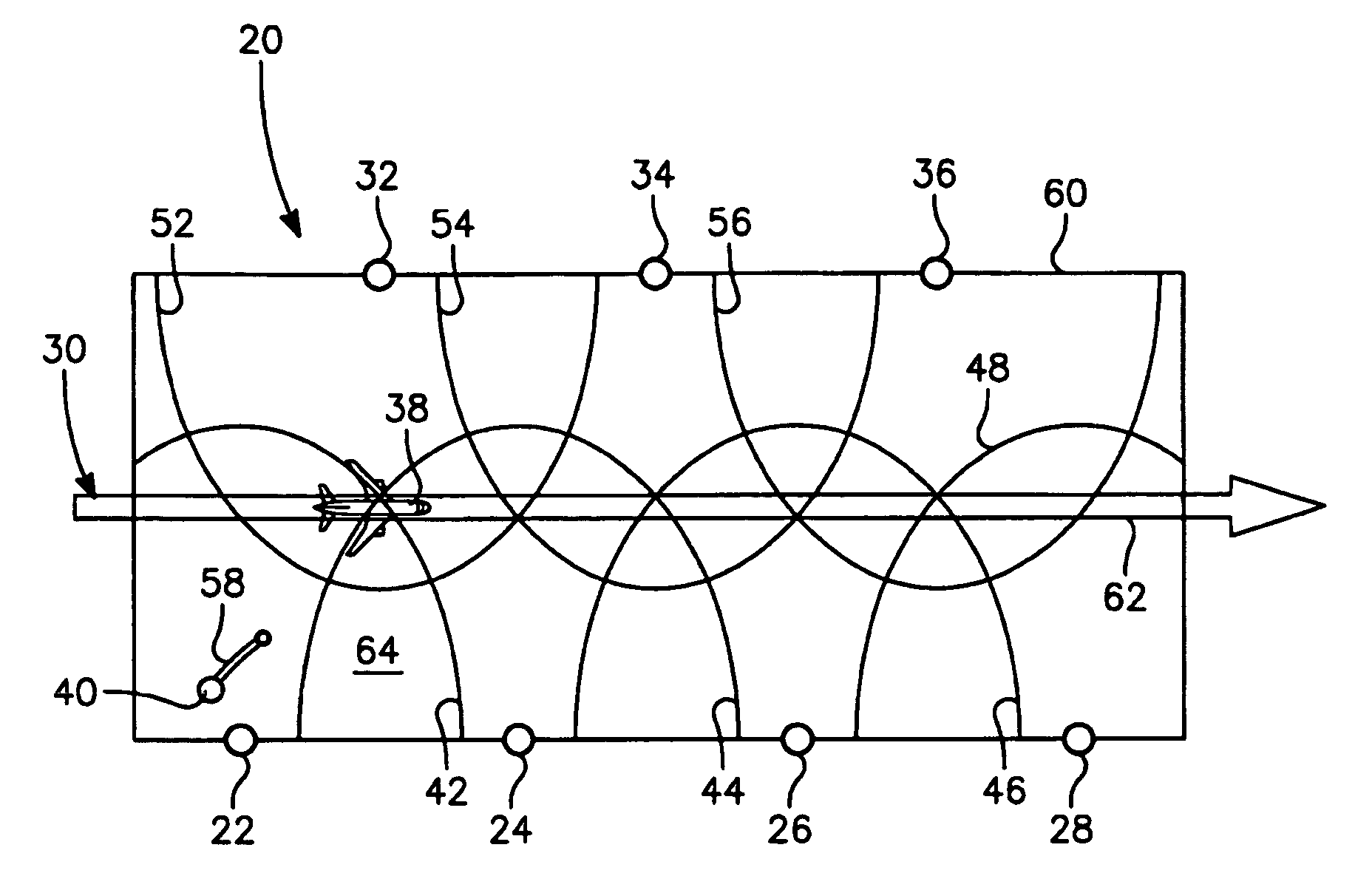

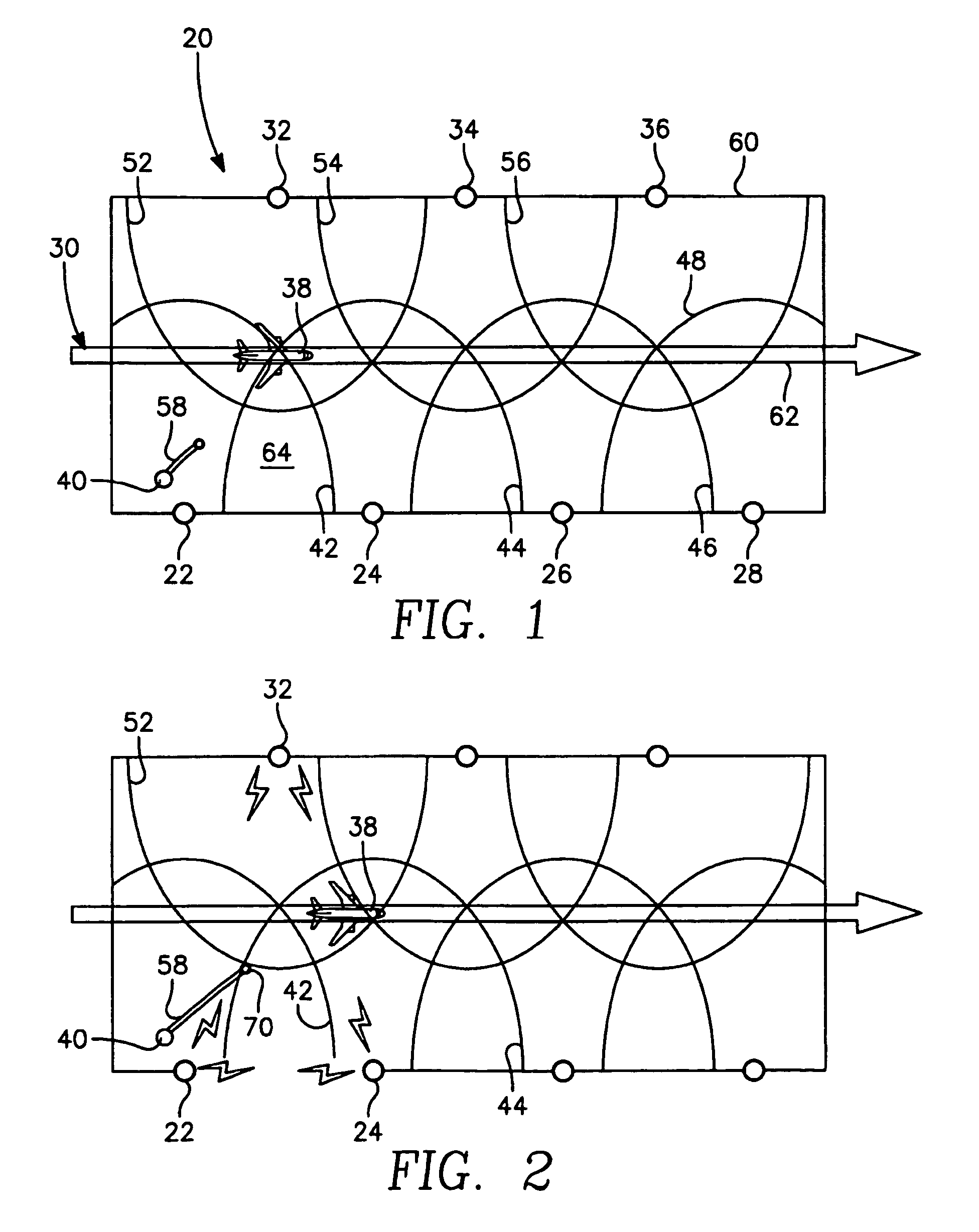

Portable air defense ground based launch detection system

InactiveUS7230221B2Low costAvoid attackPhotometry using reference valueInstruments for comonautical navigationCountermeasureSensor grid

A ground based launch detection system consisting of a sensor grid of electro-optical sensors for detecting the launch of a threat missile which targets commercial aircraft in proximity to a commercial airport or airfield. The electro-optical sensors are configured in a wireless network which broadcast threat lines to neighboring sensors with overlapping field of views. When a threat missile is verified, threat data is sent to a centrally located processing facility which determines which aircraft in the vicinity are targets and send a dispense countermeasure signal to the aircraft.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

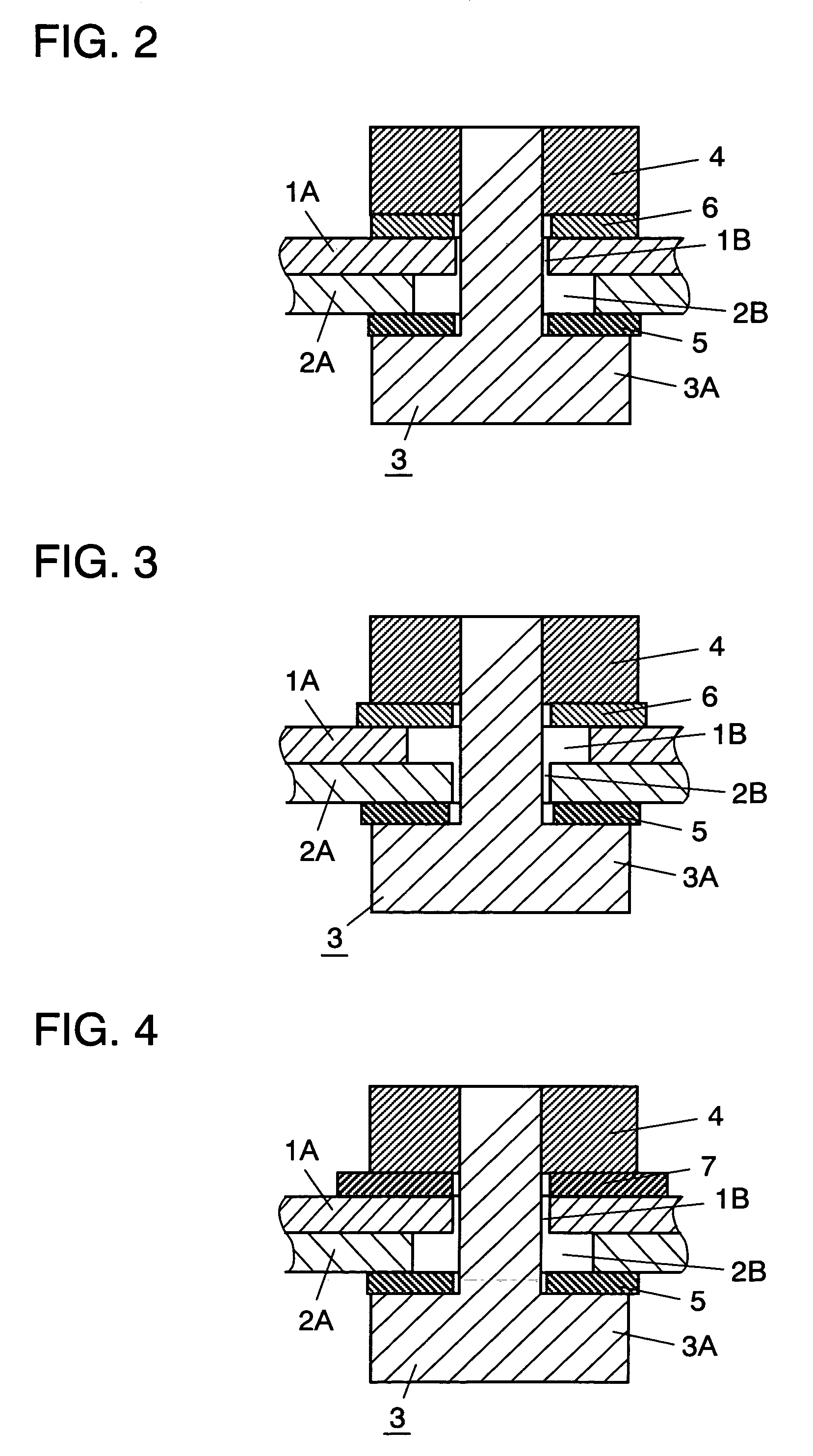

Fixing device including a screw arranged with clearance in a fixing hole, and a weight measuring apparatus using the same

According to a fixing device of the present invention, a screw penetrates through a first fixing hole of a first fixing section and a second fixing hole of a second fixing section to be coupled with a weight measuring machine, and is tightened with a nut, so that the first fixing section is fixed to the second fixing section. In addition, at least one clearance of the first fixing hole and the second fixing hole is configured to be bigger than an assembly tolerance of the two fixing holes. Using this structure, the fixing device, which can accommodate constructive variations of the fixing section of the weight measuring machine and maintain excellent detecting accuracy, and a weight measuring apparatus using the same, can be provided.

Owner:PANASONIC CORP

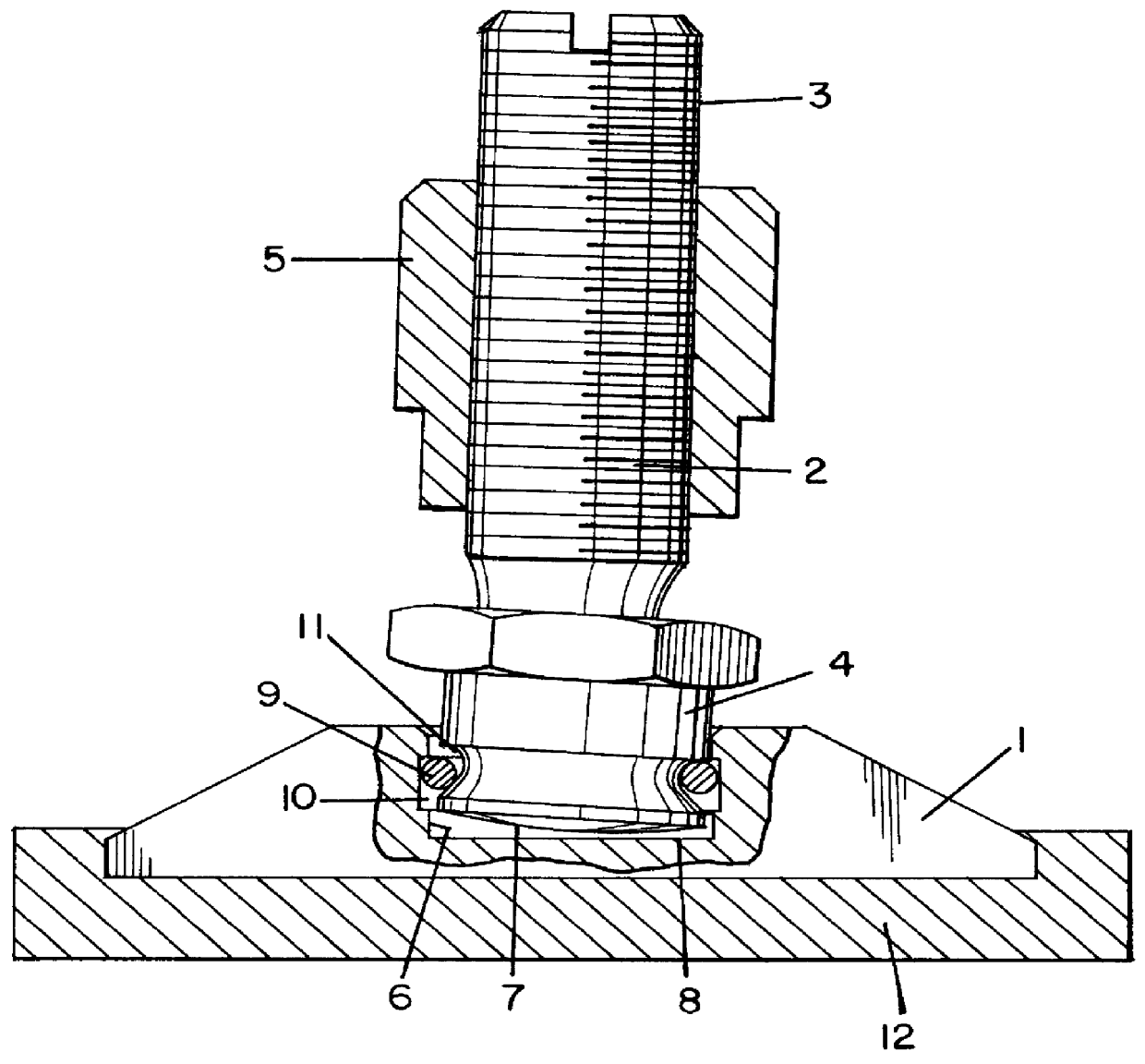

Support base for a measuring cell

InactiveUS6150619AHeavy loadSmall heightWeighing apparatus using counterbalanceWeighing apparatus using elastically-deformable membersEngineeringMechanical engineering

PCT No. PCT / DE97 / 01266 Sec. 371 Date Jan. 29, 1999 Sec. 102(e) Date Jan. 29, 1999 PCT Filed Jun. 20, 1997 PCT Pub. No. WO98 / 00688 PCT Pub. Date Jan. 8, 1998A support base for a measuring cell including a base plate with a bore and an annular groove defined therein, and a planar pressure surface machined therein. A load pin is connected to the base plate to provide articulated support for a load. The load pin has a threaded shank adaptable to adjust its height relative to the measuring cell and terminates in a pressure head with a convex pressure surface and an annular groove defined therein. The pressure head of the load pin is inserted with play into the bore of said base plate. A resilient ring is disposed between the annular grooves to connect the base plate and the pressure head.

Owner:BORNGASSER JOHANNES

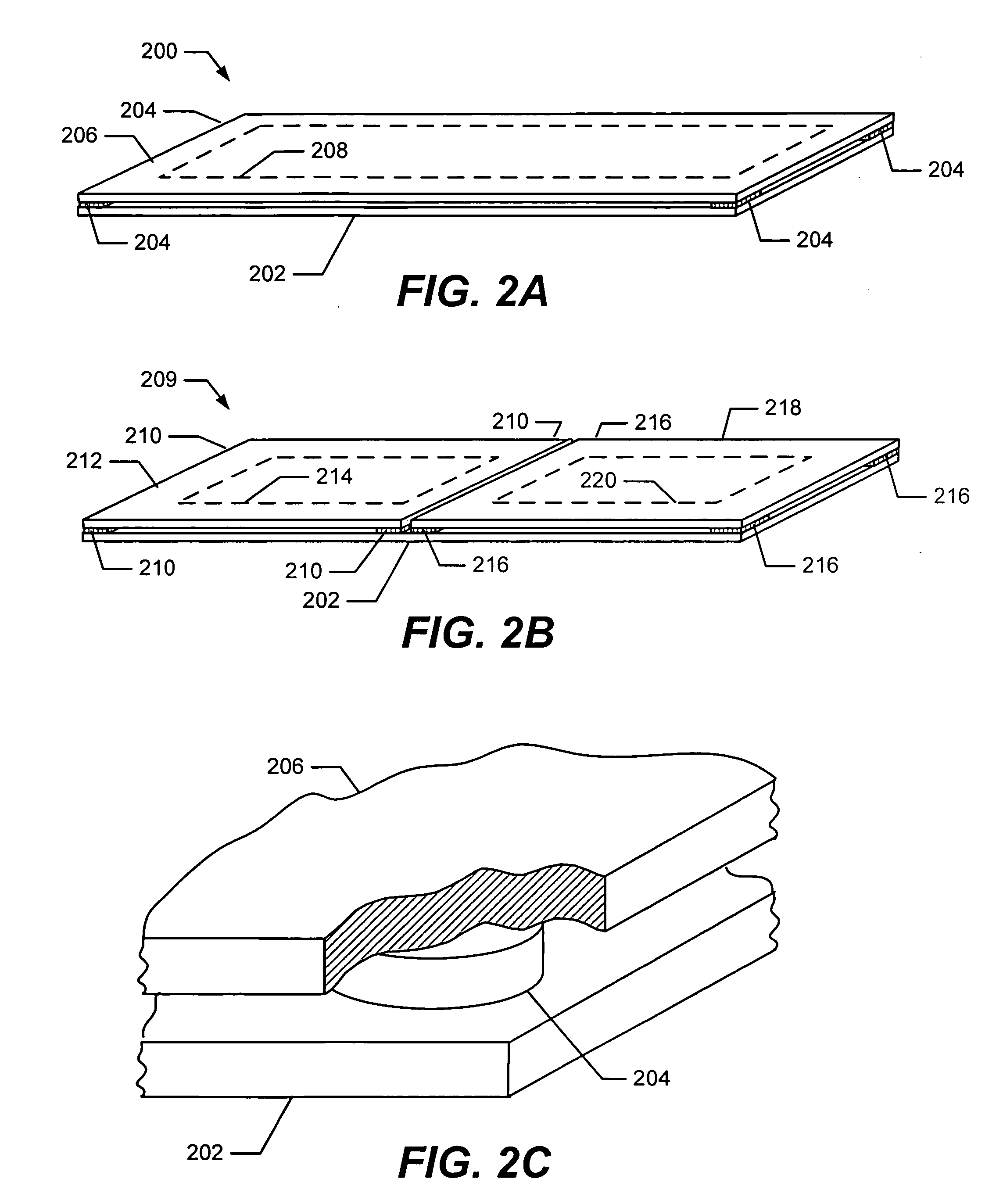

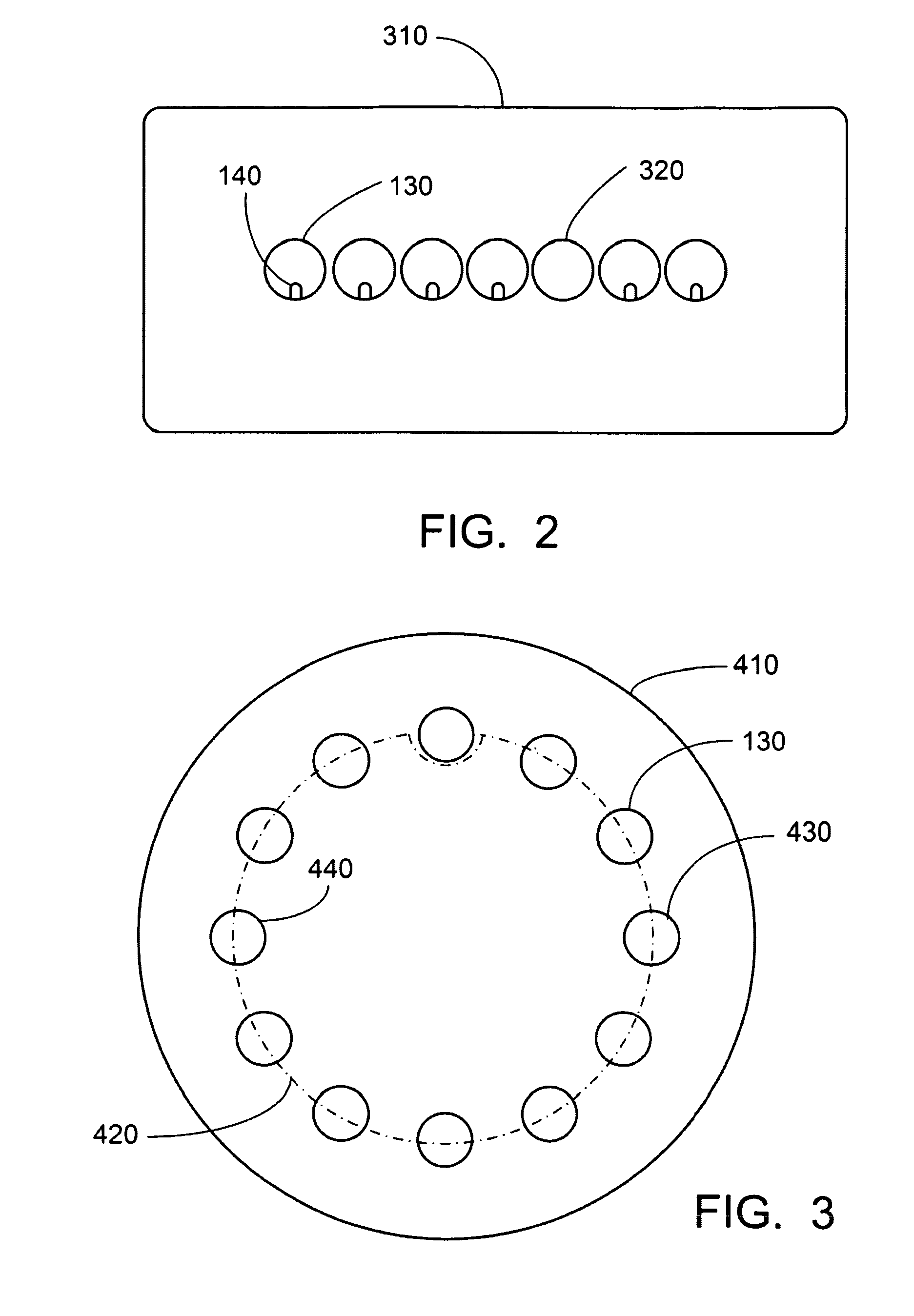

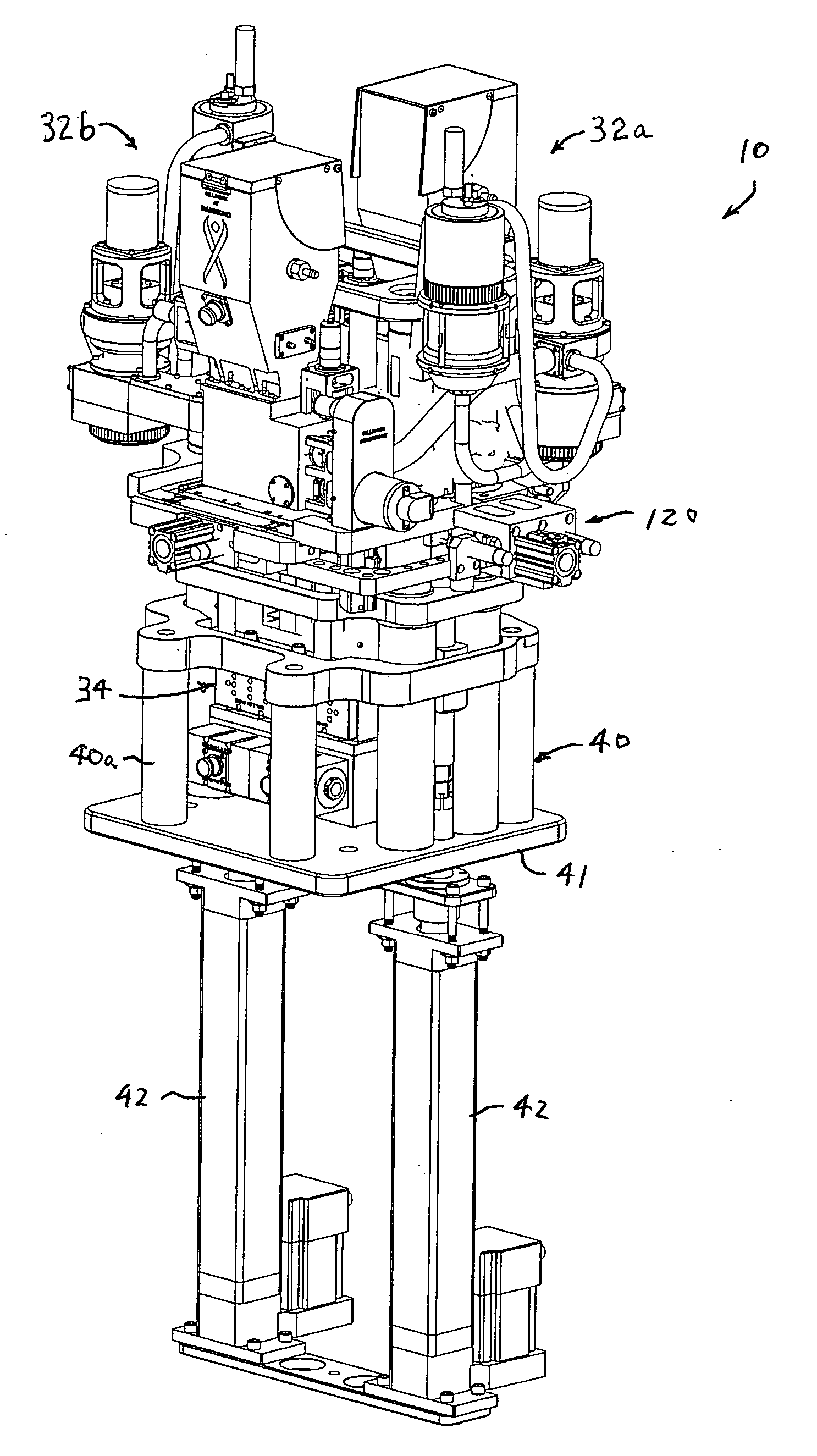

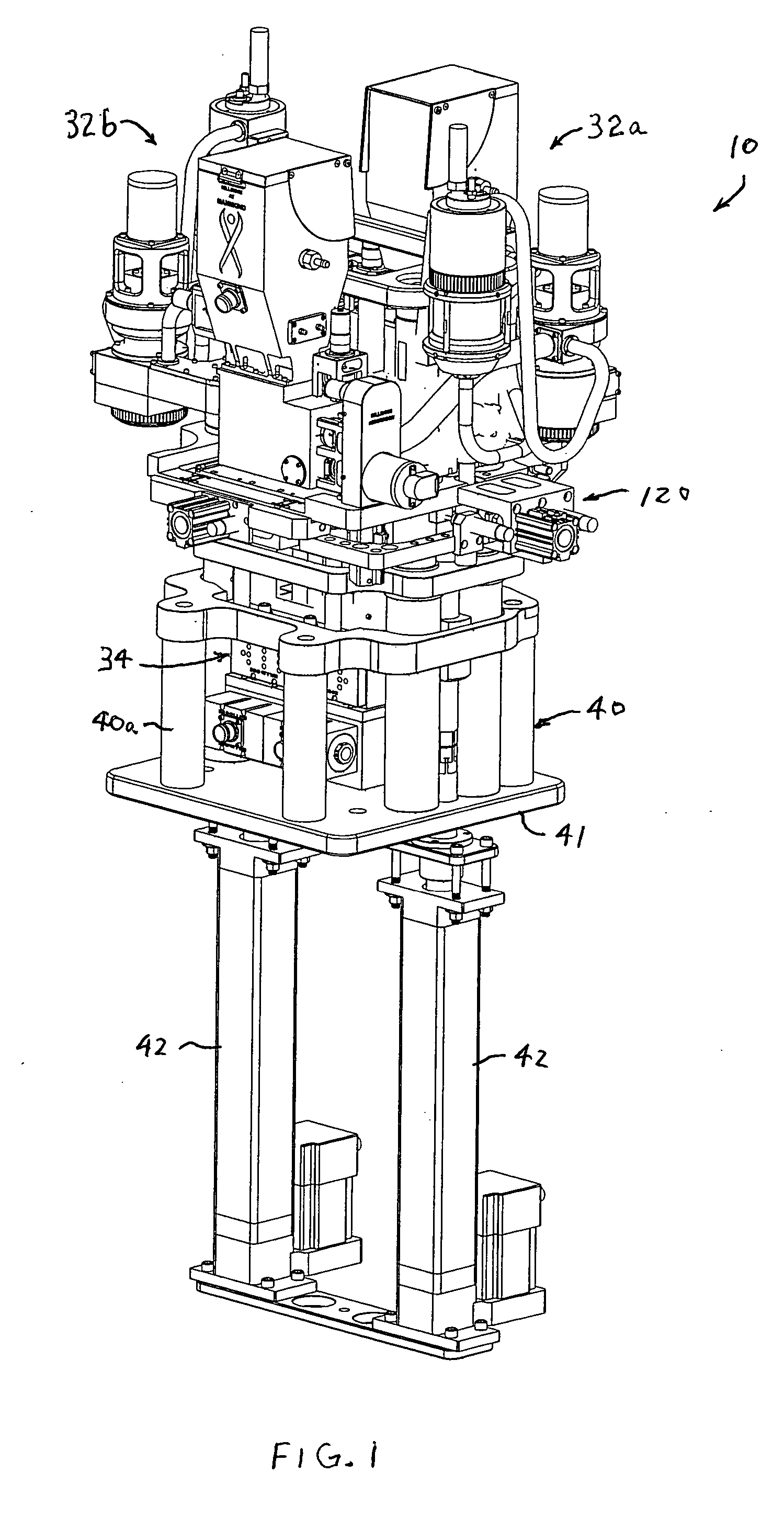

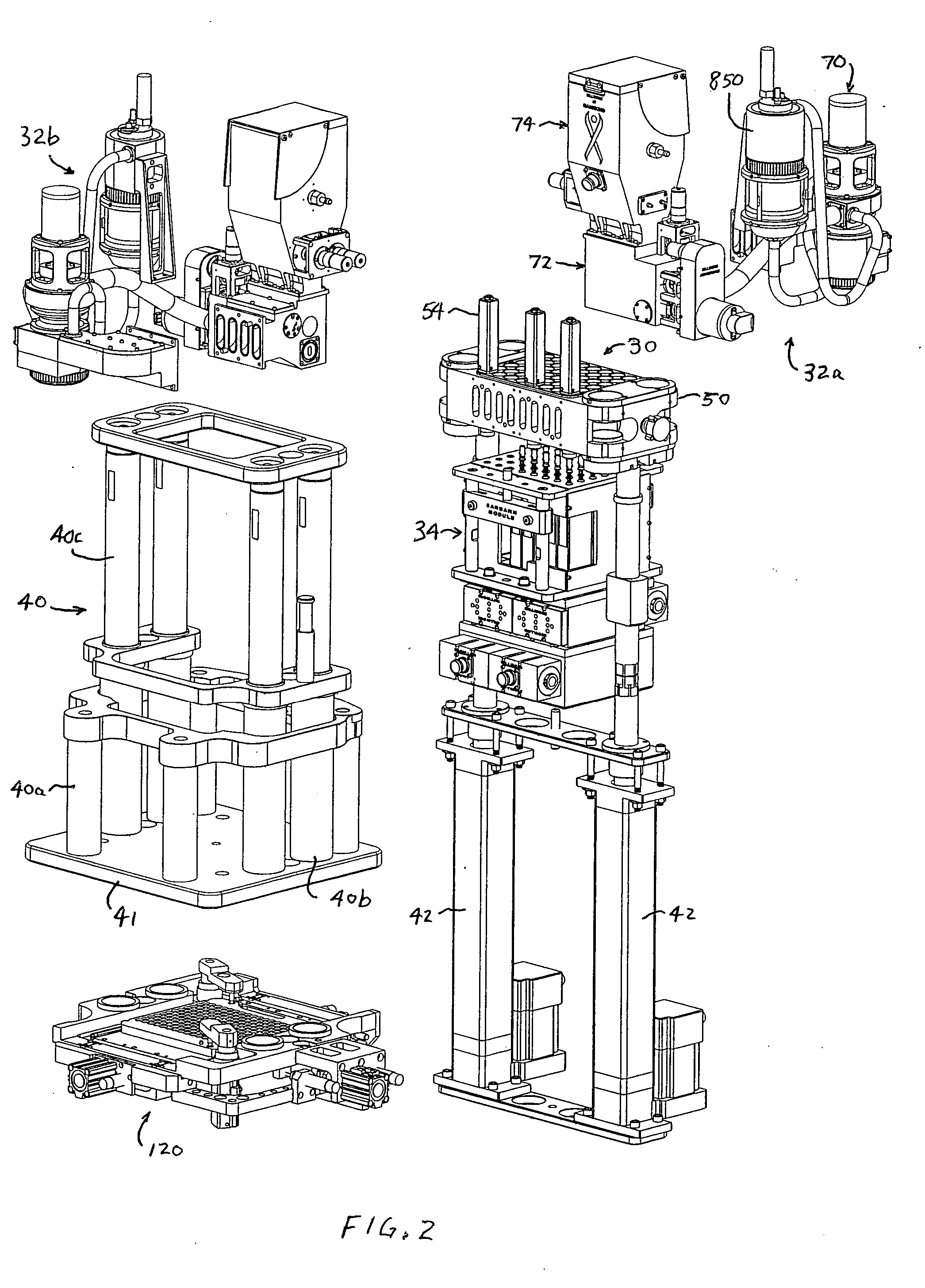

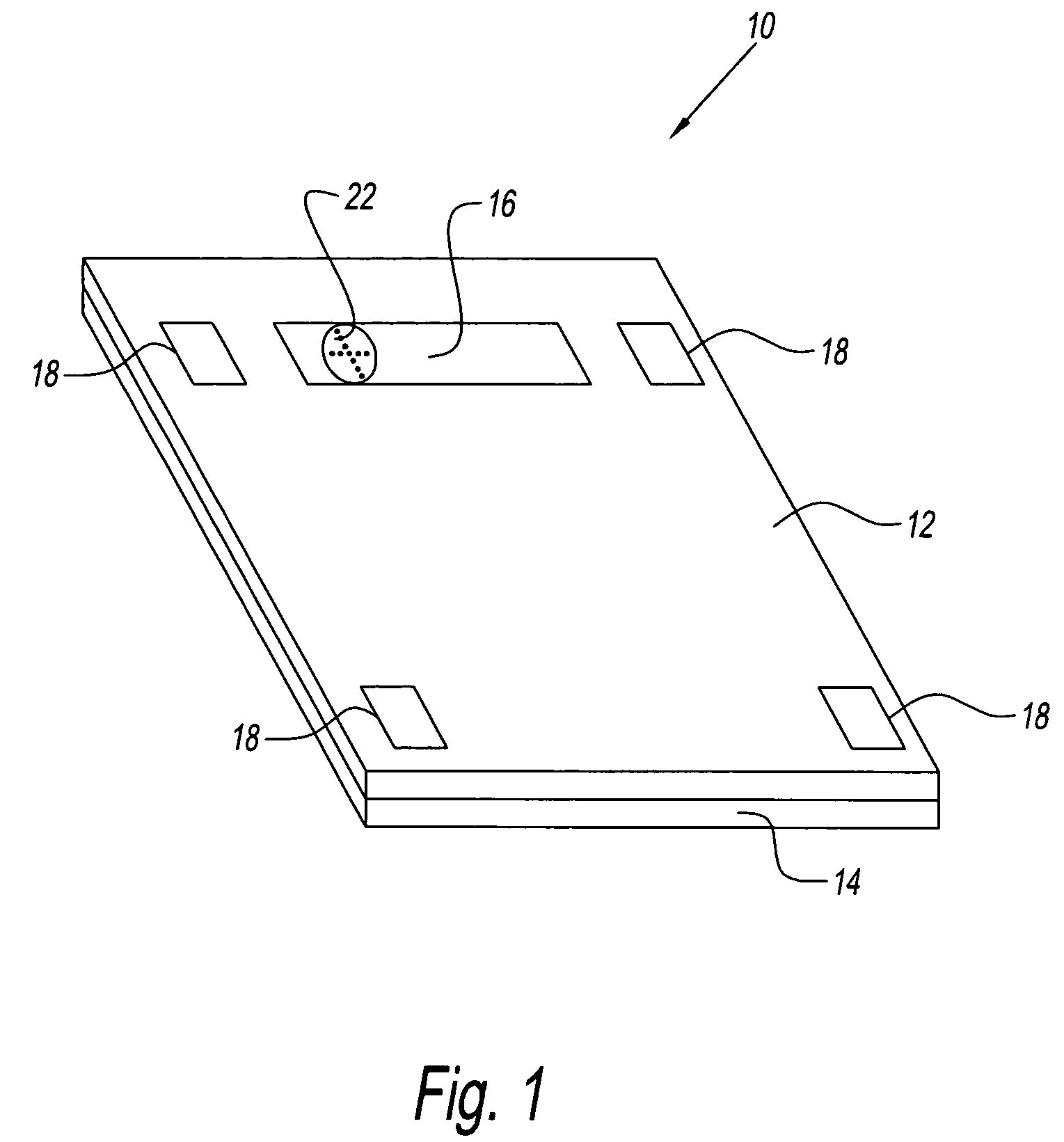

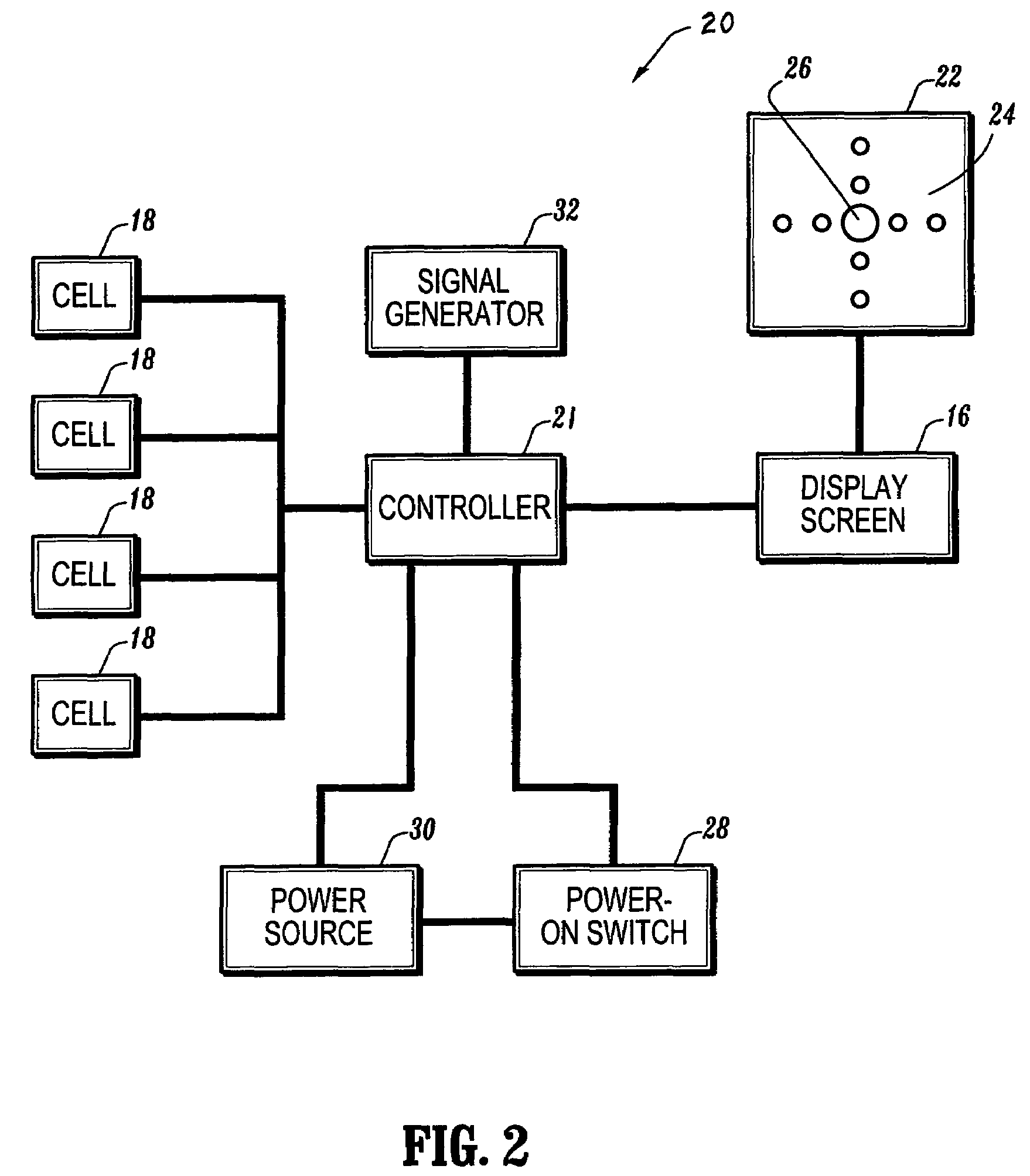

Powder dispenser modules and powder dispensing methods

InactiveUS20070131707A1Facilitates regulatory approvalImprove compactnessBarrels/casks fillingMovable measuring chambersTransport systemControl system

Powder dispensing and sensing apparatus and methods are provided. The powder dispensing and sensing apparatus includes a tray support structure to receive a cartridge tray holding cartridges, a powder dispenser assembly including powder dispenser modules to dispense powder into respective cartridges of a batch of cartridges in the cartridge tray, a powder transport system to deliver powder to the powder dispenser modules, a sensor module including sensor cells to sense respective fill states, such as the weights, of each of the cartridges in the batch of cartridges, and a control system to control the powder dispenser modules in response to the respective sensed fill states of each of the cartridges of the batch of cartridges.

Owner:MANNKIND CORP

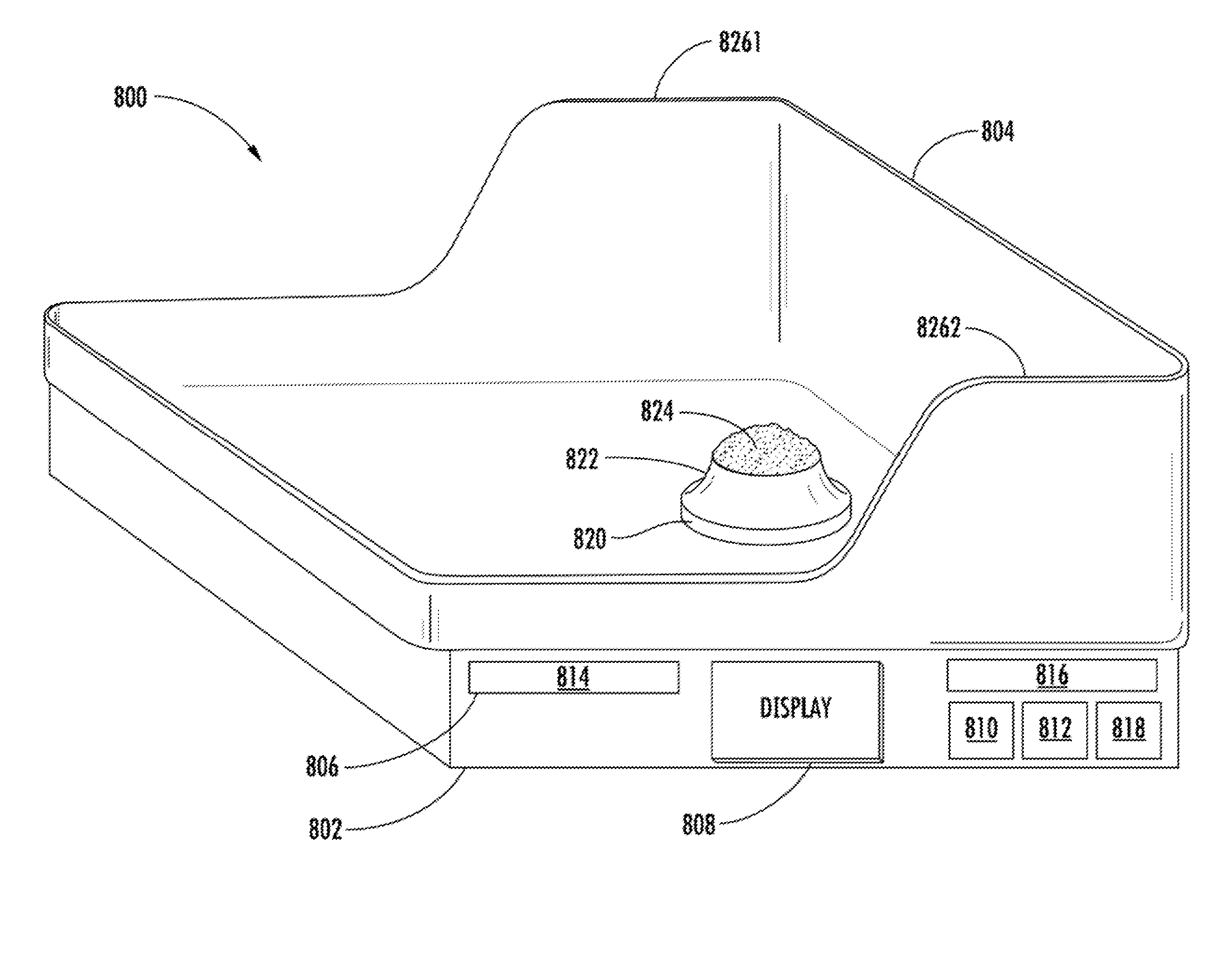

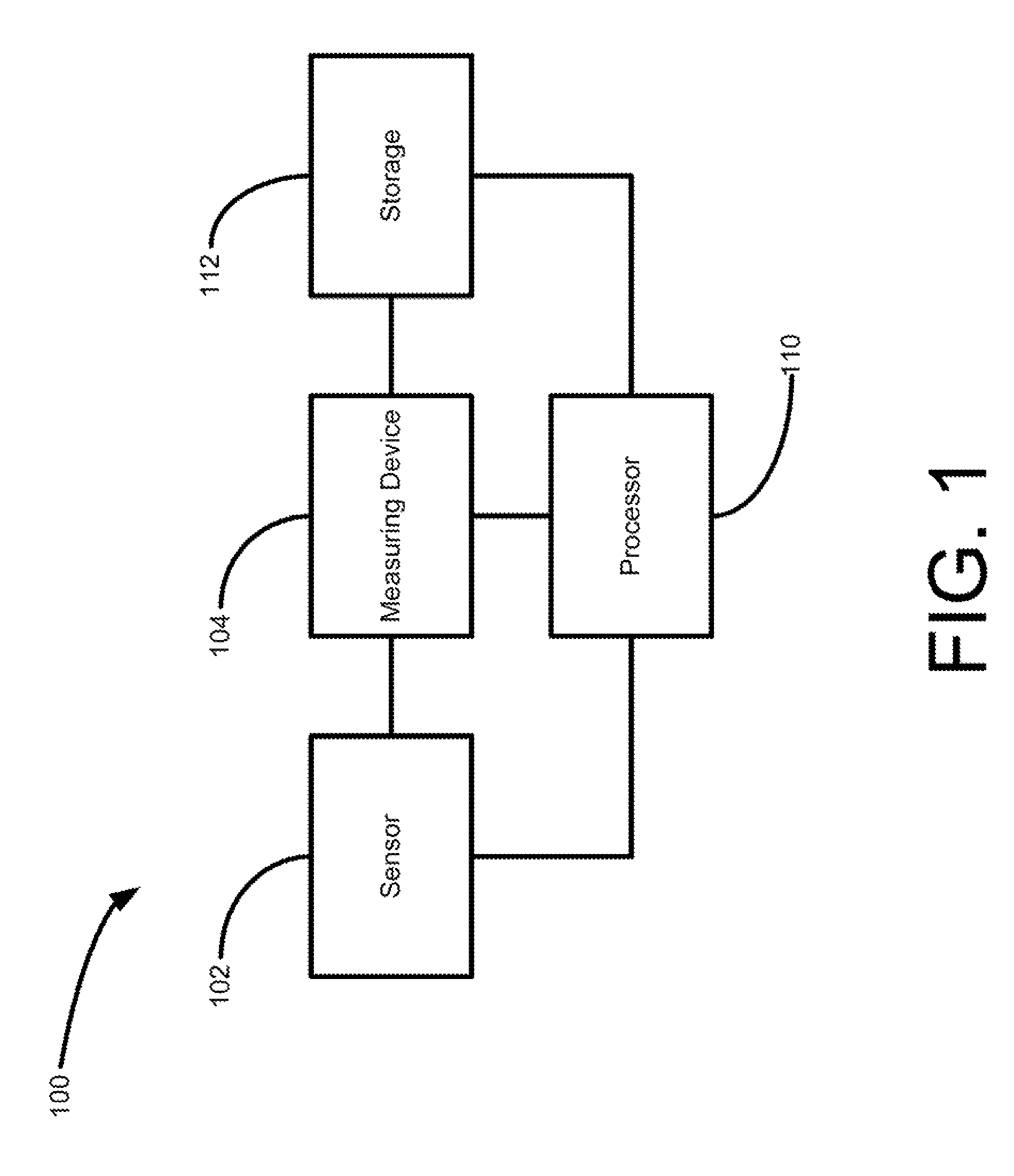

Systems, methods and computer program products for monitoring the behavior, health, and/or characteristics of an animal

Systems, methods, and computer code products for monitoring the behavior, health, and / or characteristics of an animal are disclosed herein. In one implementation, the animal is positioned inside a waste container placed on a system that is adapted to determine, record and communicate over a network various animal health parameters. These parameters can be processed to determine trends, statistics and changes of animal physiological functions. The results can be used to access animal health conditions and issue warnings, alarms, messages, and other notifications to designated caretakers. These notifications may be displayed using various means such as computers and / or mobile devices. Data retrieval and review capability can provide improved understanding of an animal's health conditions and facilitate early illness detection.

Owner:SOC DES PROD NESTLE SA

Prompting and directing users to safety during emergency situations

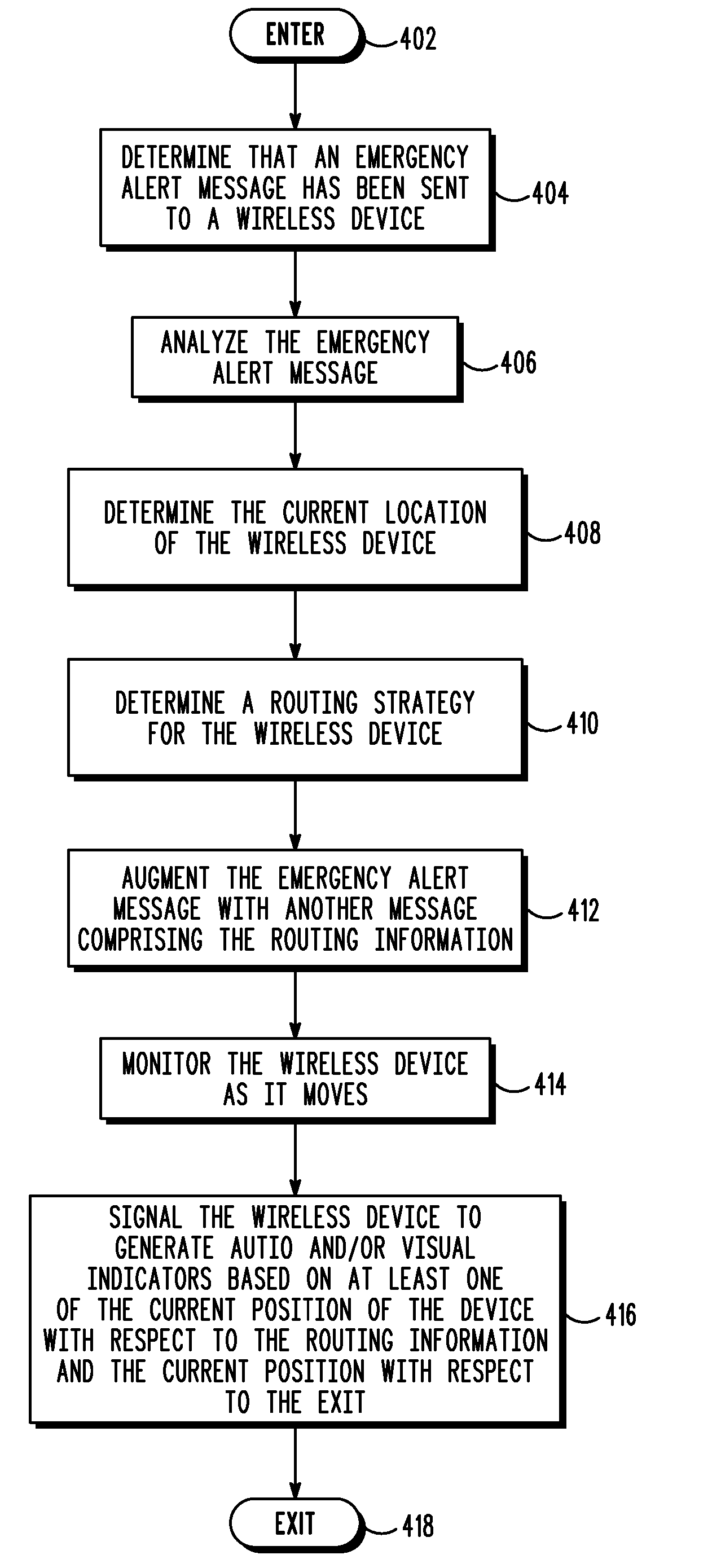

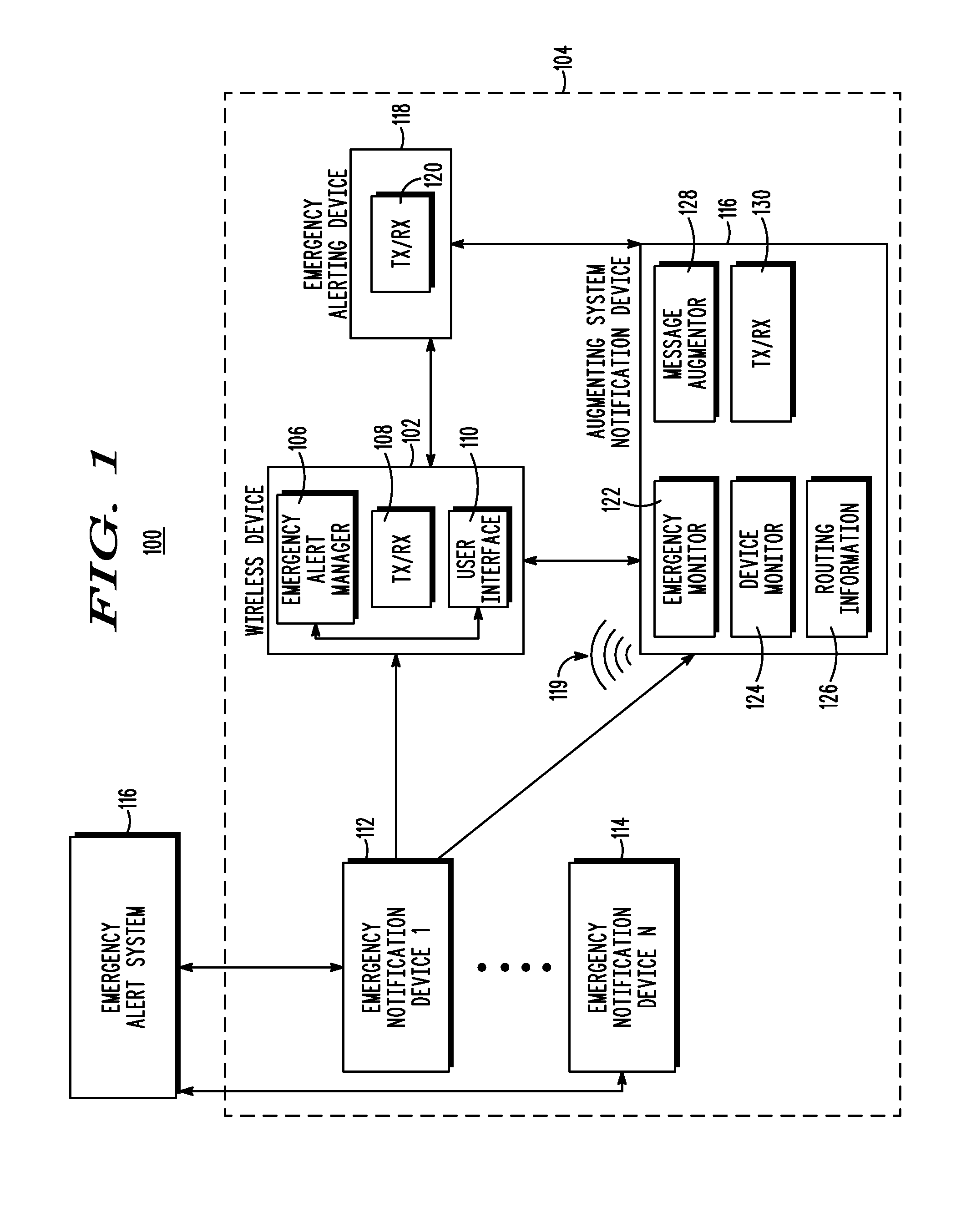

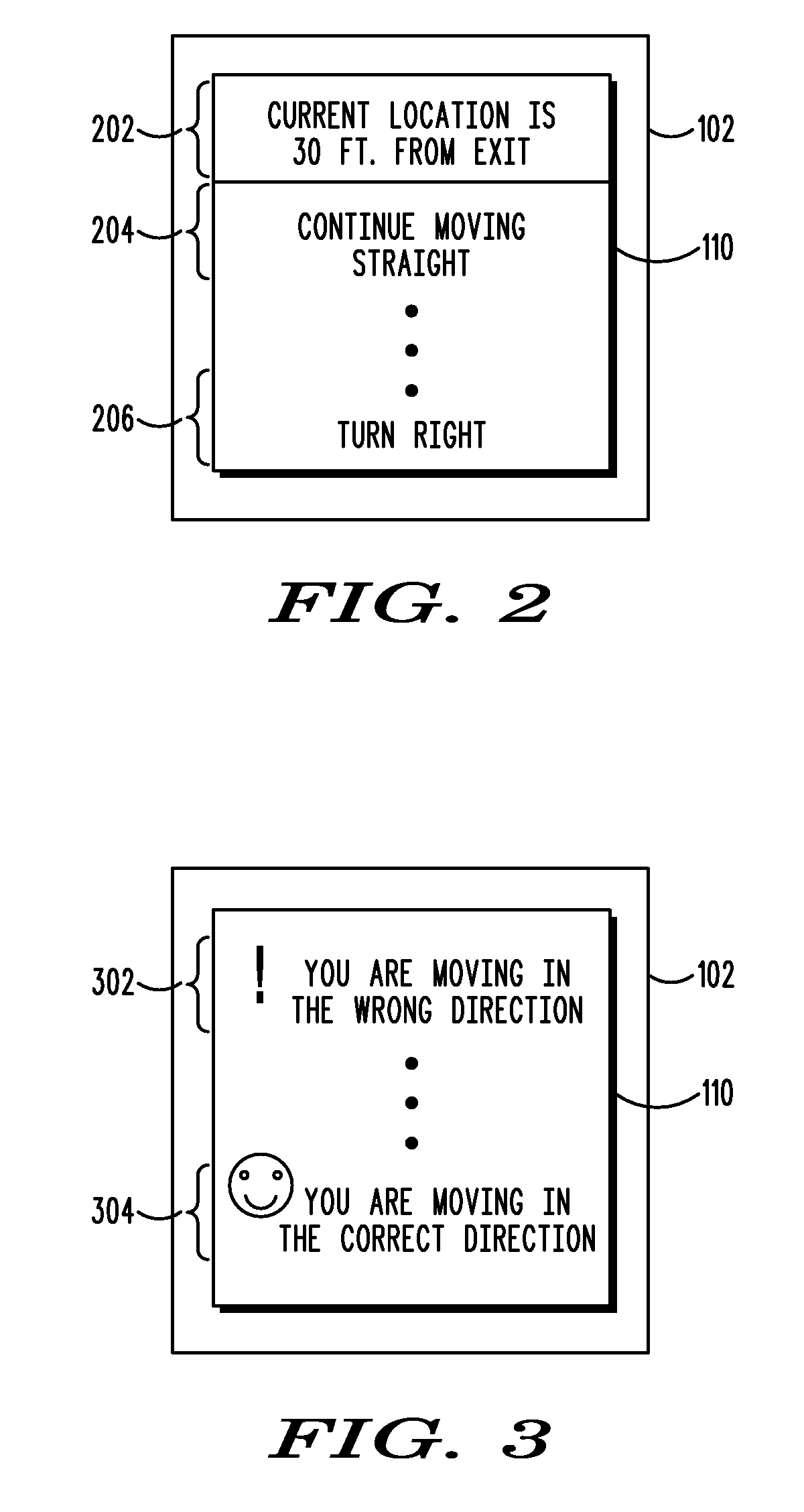

ActiveUS20090170468A1Provide feedbackEmergency connection handlingTelephonic communicationLogistics managementSTI Outpatient

A method and wireless device augment and manage, respectively, emergency alert messages with additional emergency information. An emergency alert message is determined to have been sent (404) to one or more wireless devices (102) in a given area. The emergency alert message is analyzed (406) to determine a type of emergency associated with the emergency alert message. Optionally, a current location of at least one wireless device (102) within the given area is determined. A message is generated (412), based at least in part on the type of emergency and logistics of the given area, including additional emergency information for augmenting the emergency alert message. The message that has been generated is transmitted to the at least one wireless device (102). This message is, optionally, adjusted based on the location of the device and the logistics of the given area.

Owner:MOTOROLA SOLUTIONS INC

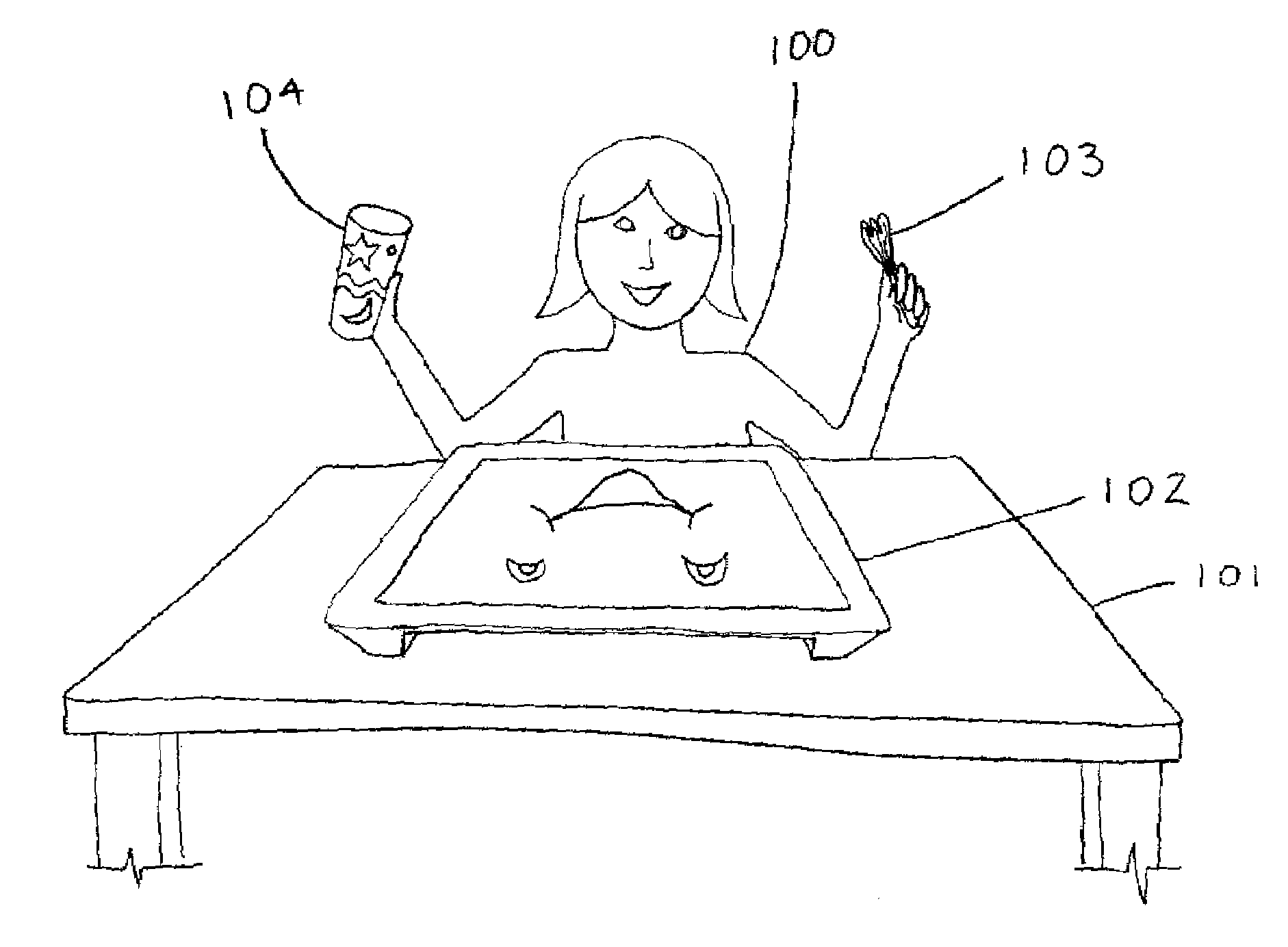

Foodware having visual sensory stimulating or sensing means

Active foodware comprises at least a plate unit that provides visual stimuli by having a power source and a visual sensory stimulating component to provide light emanating from the plate. Other devices can provide auditory and haptic stimuli. The plate unit can be a single component where the device and circuitry are all contained in the unit and protected from water or can be two components an upper translucent plate and an underplate comprising the devices and circuitry for directing light through the upper plate.

Owner:KRAMER JAMES F

Electronic drink coaster

InactiveUS20060052983A1Soften contactAvoid breakingTime indicationSynchronous motors for clocksTelecommunicationsUser input

A system for ordering drink refills, comprising a coaster body with a processor, a wireless transmitter and at least one button, the processor responding to user inputs to activate the wireless transmitter to transmit wireless signals indicative of a desired order.

Owner:TVIPR

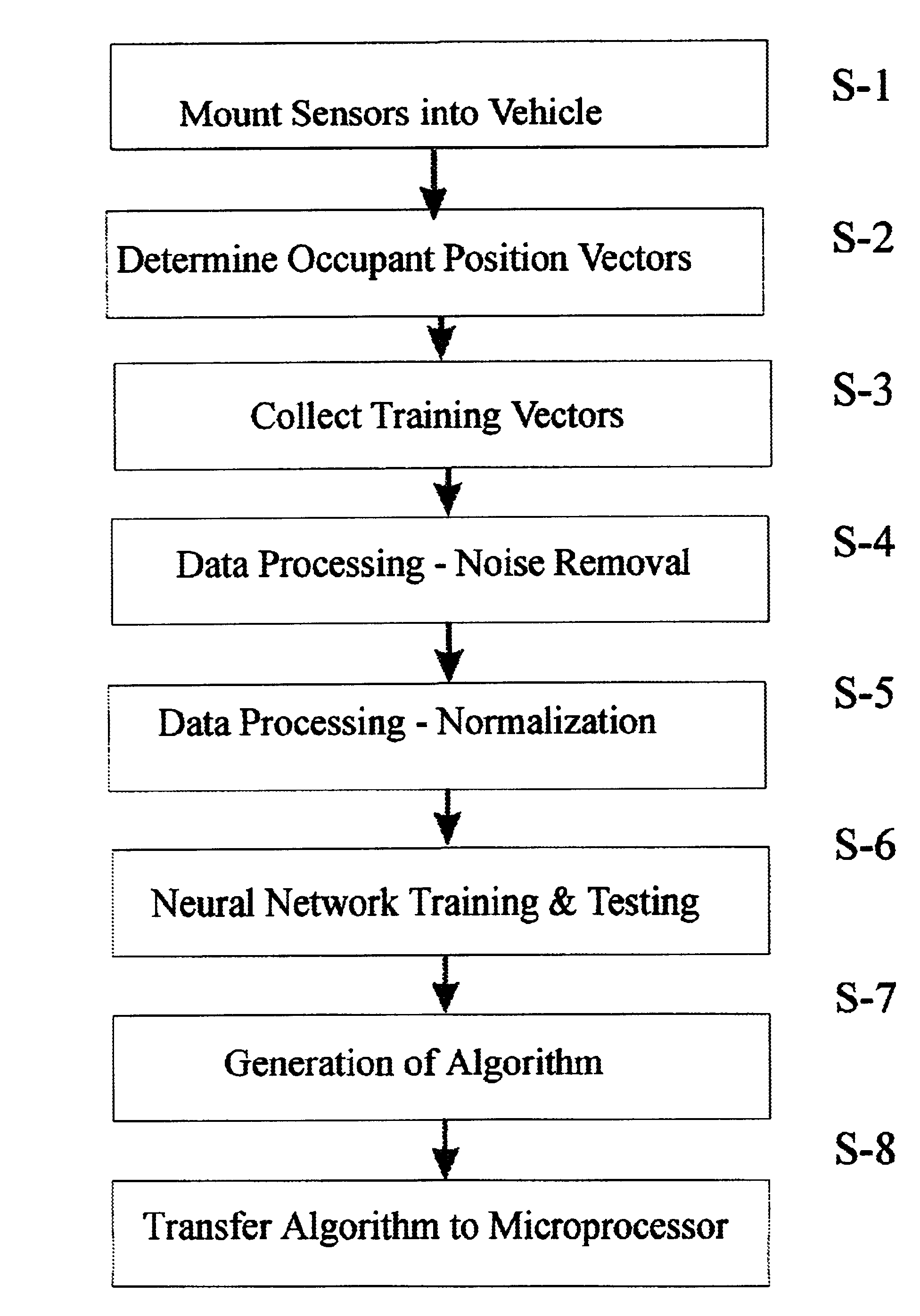

Method and apparatus for sensing seat occupancy

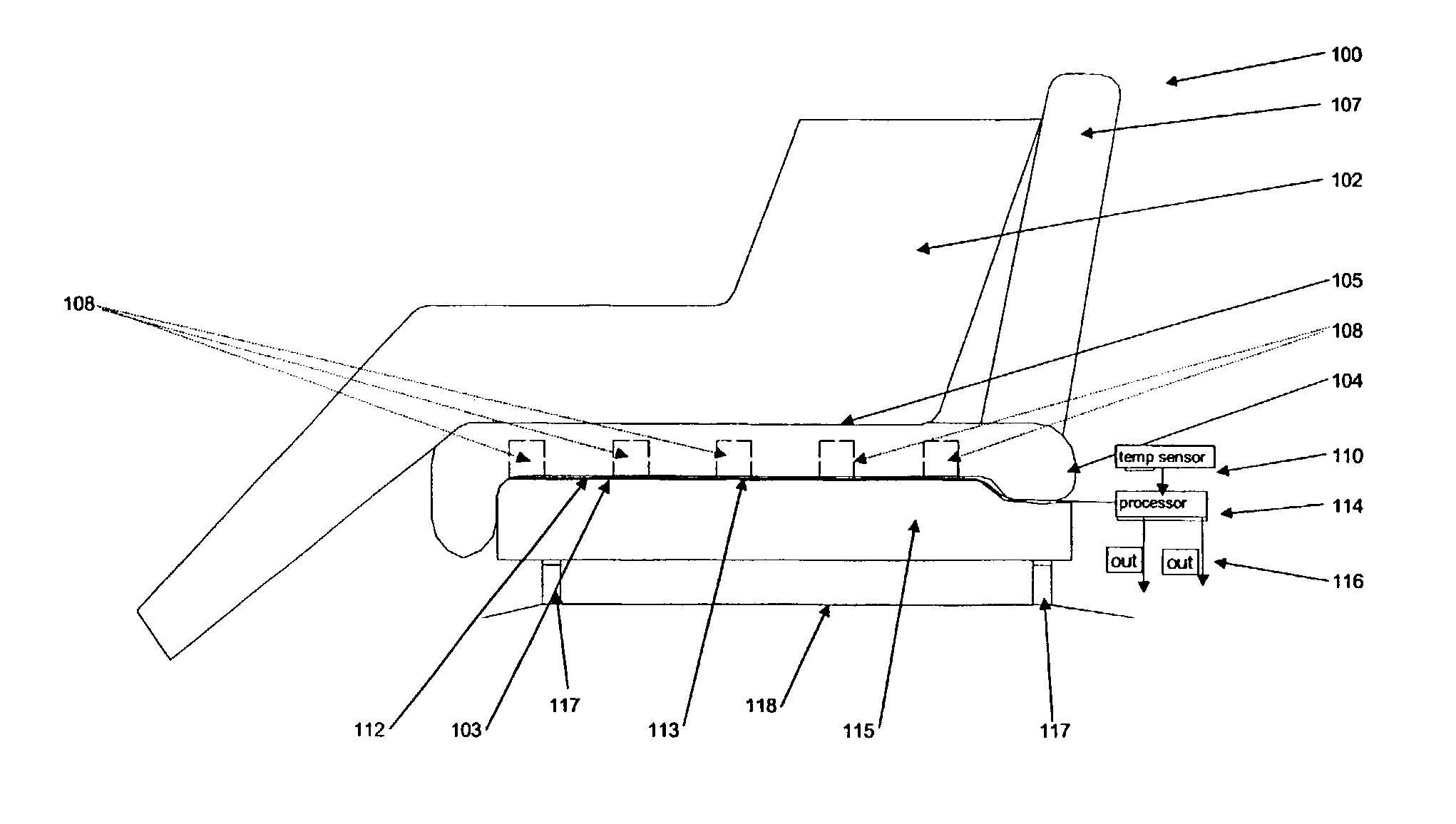

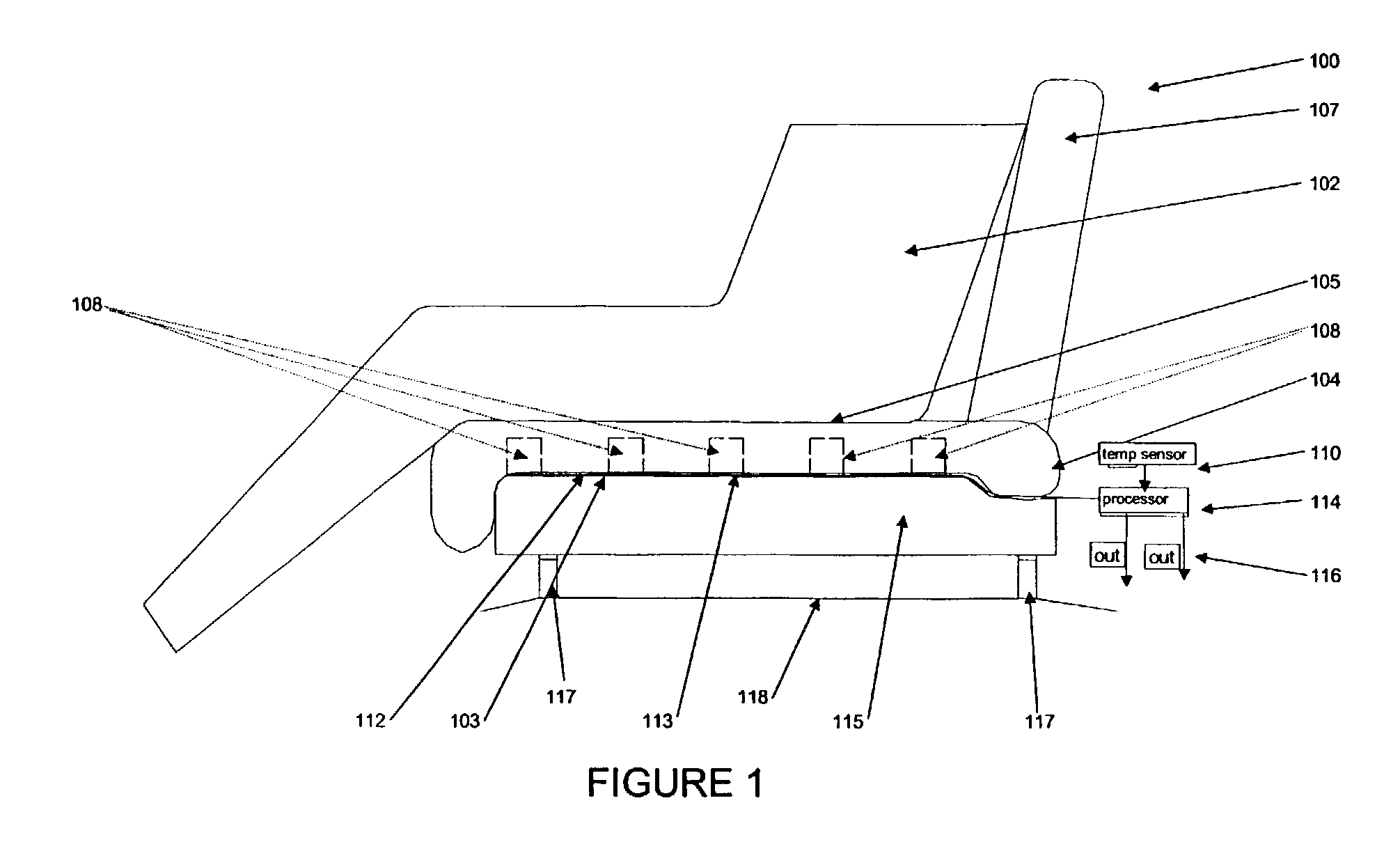

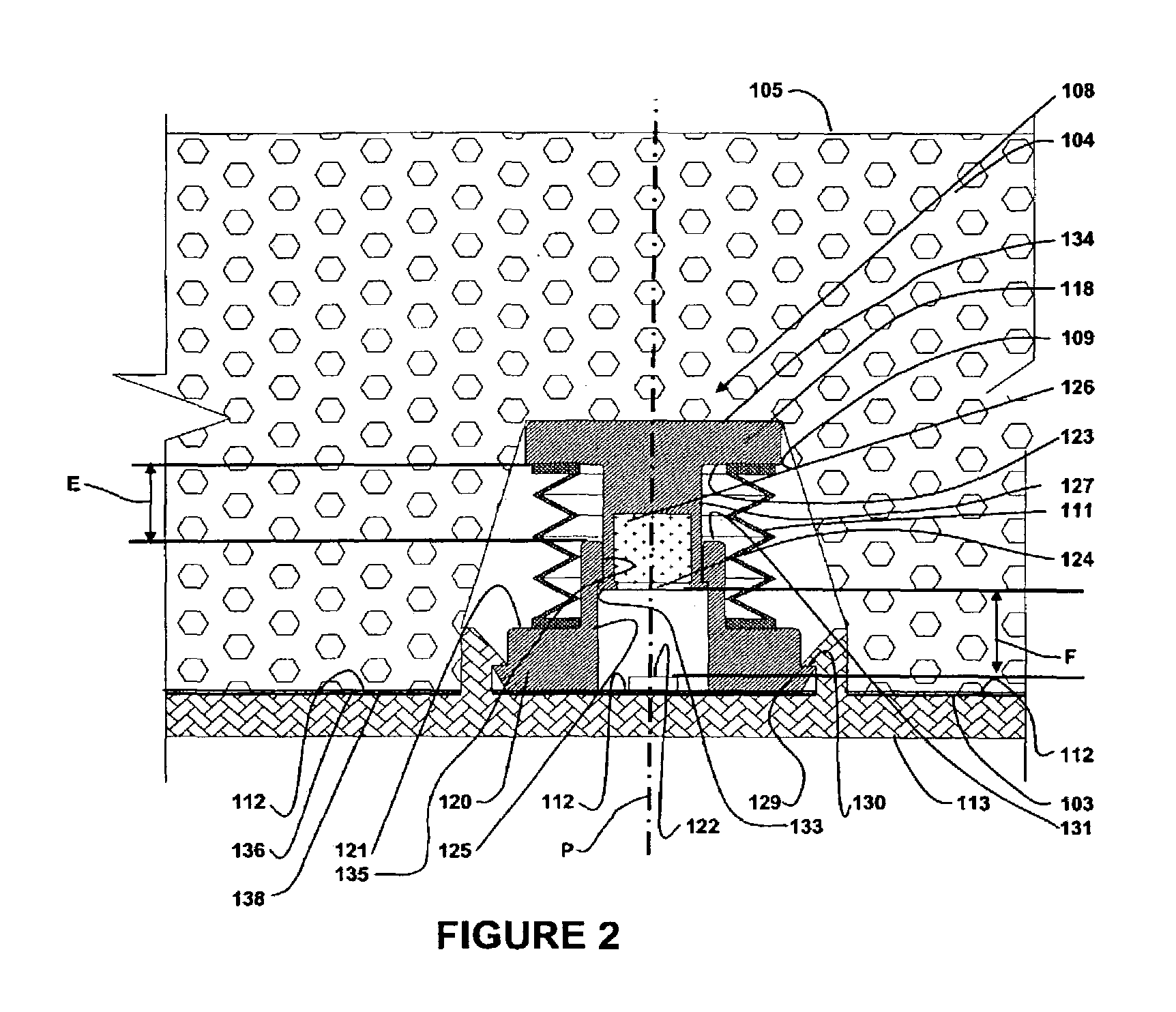

Method and apparatus for identifying and categorizing the weight and characteristics of the occupant currently occupying a vehicle seat. The method for identifying and categorizing the occupant or object involves measuring the deflection of the upper surface of the seat cushion at several points and therefore the weight distribution of the occupant. The system contains multiple weight sensors arrayed for detecting the distribution of the load causing the seat deflection. The system also includes a sensor to measure ambient temperature, preferably for temperature compensation due to the effects extreme temperatures may have on the compression properties of the seat cushion material and the weight sensors. A system processor interprets the data acquired by the sensors, and utilizes an algorithm and weight tables to simulate a neural network in providing an output a control signal indicative of the categorization of the occupant or object.

Owner:NORTH AMERICAN RESCUE PRODS

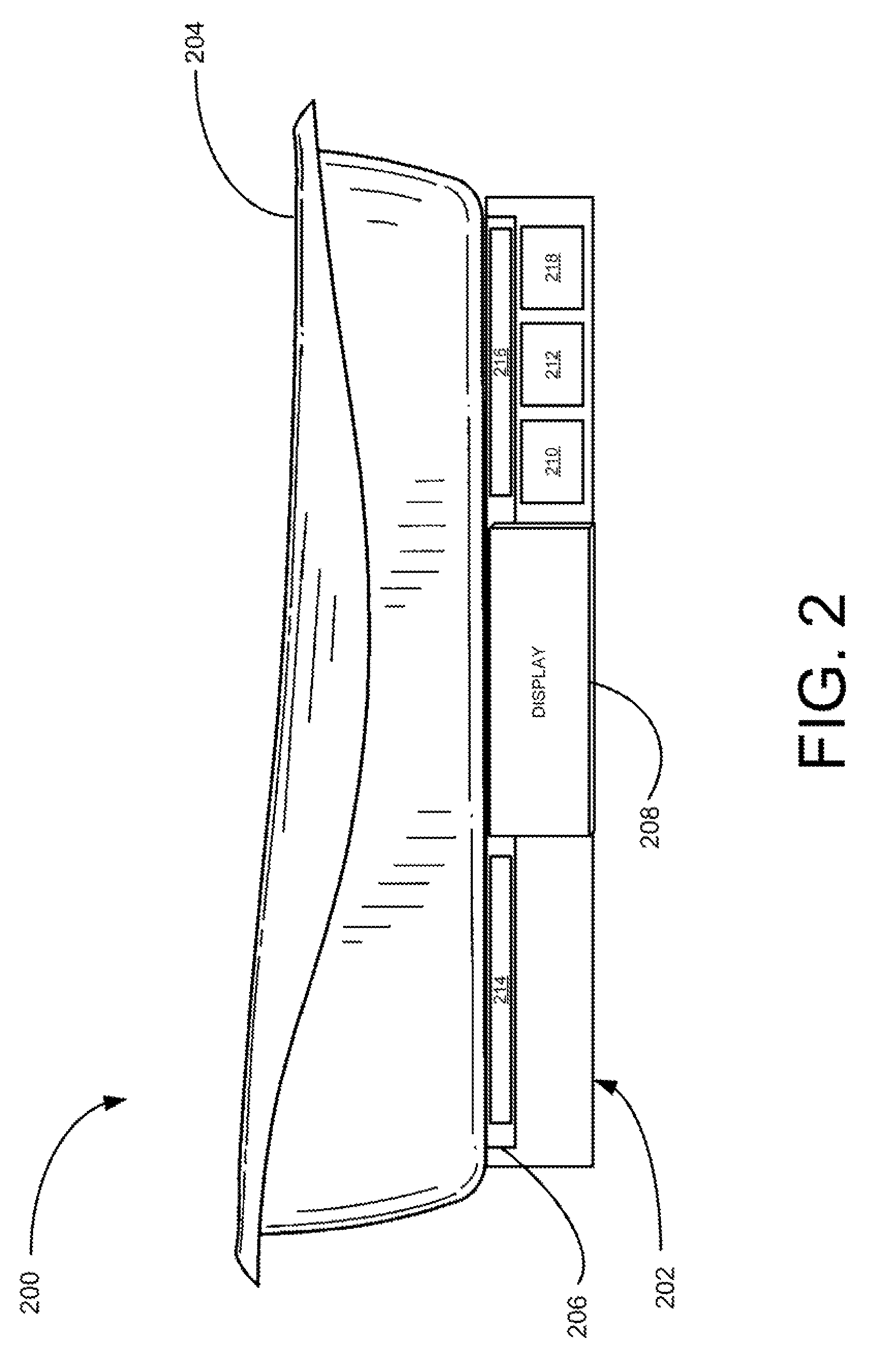

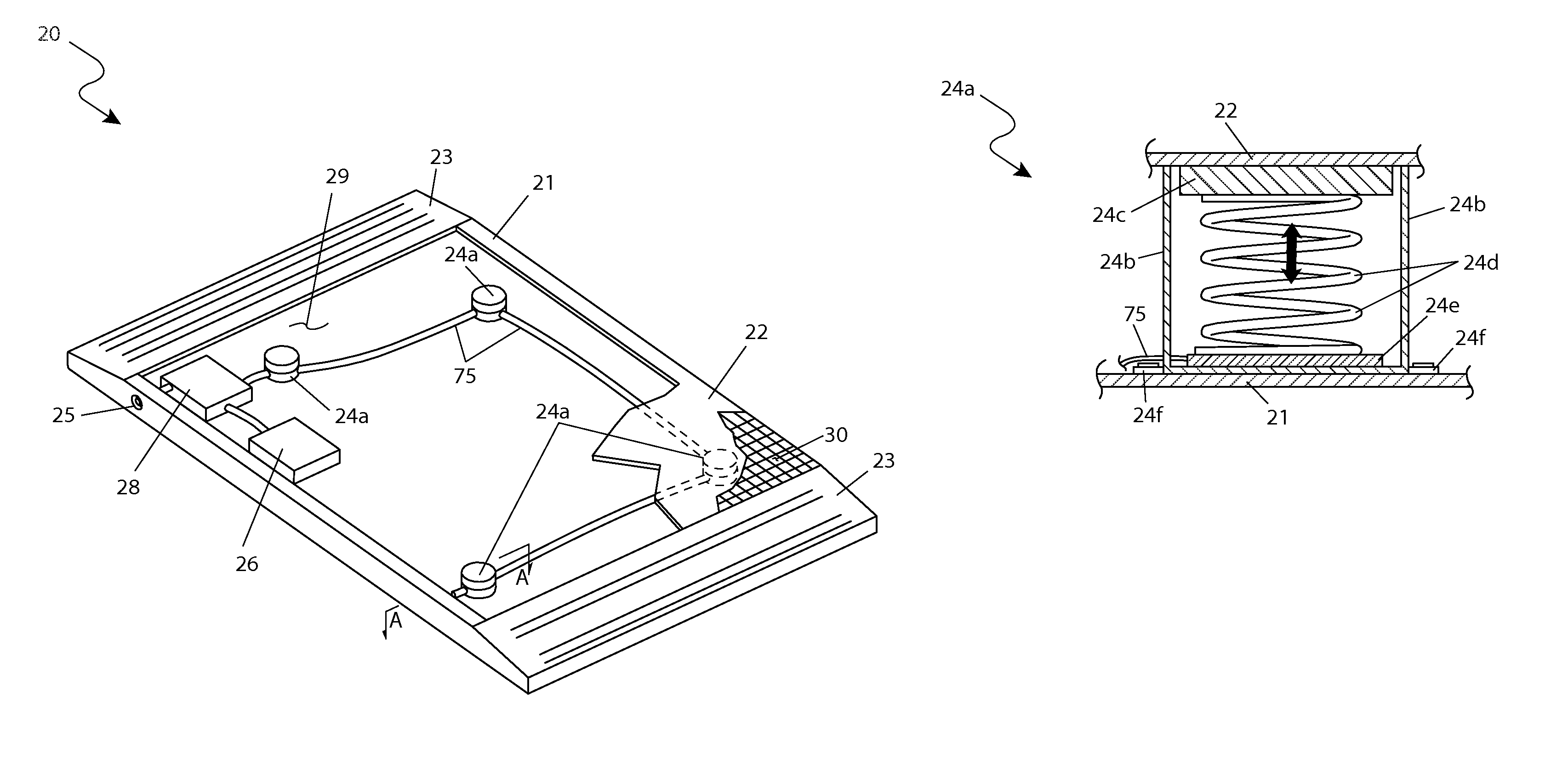

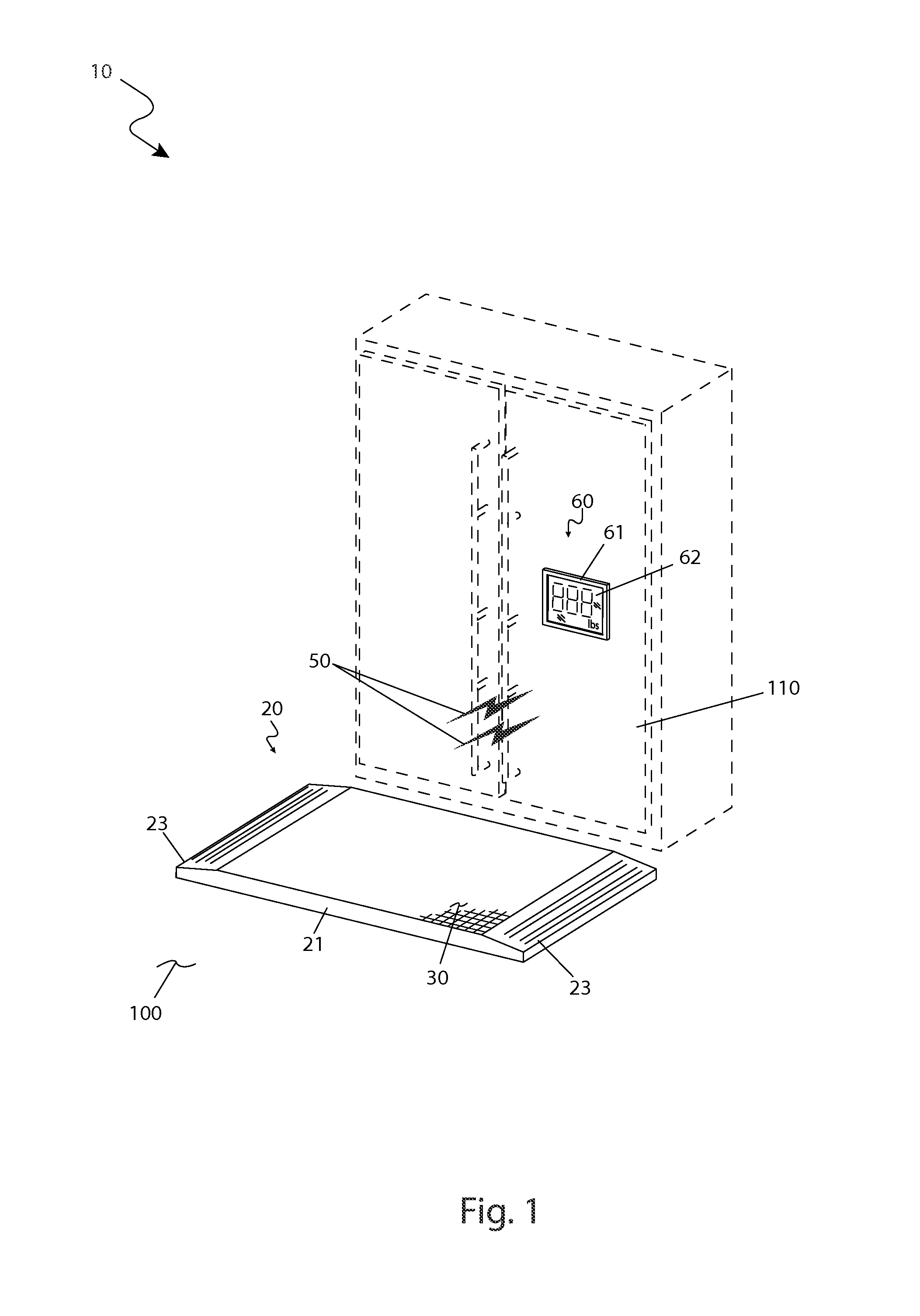

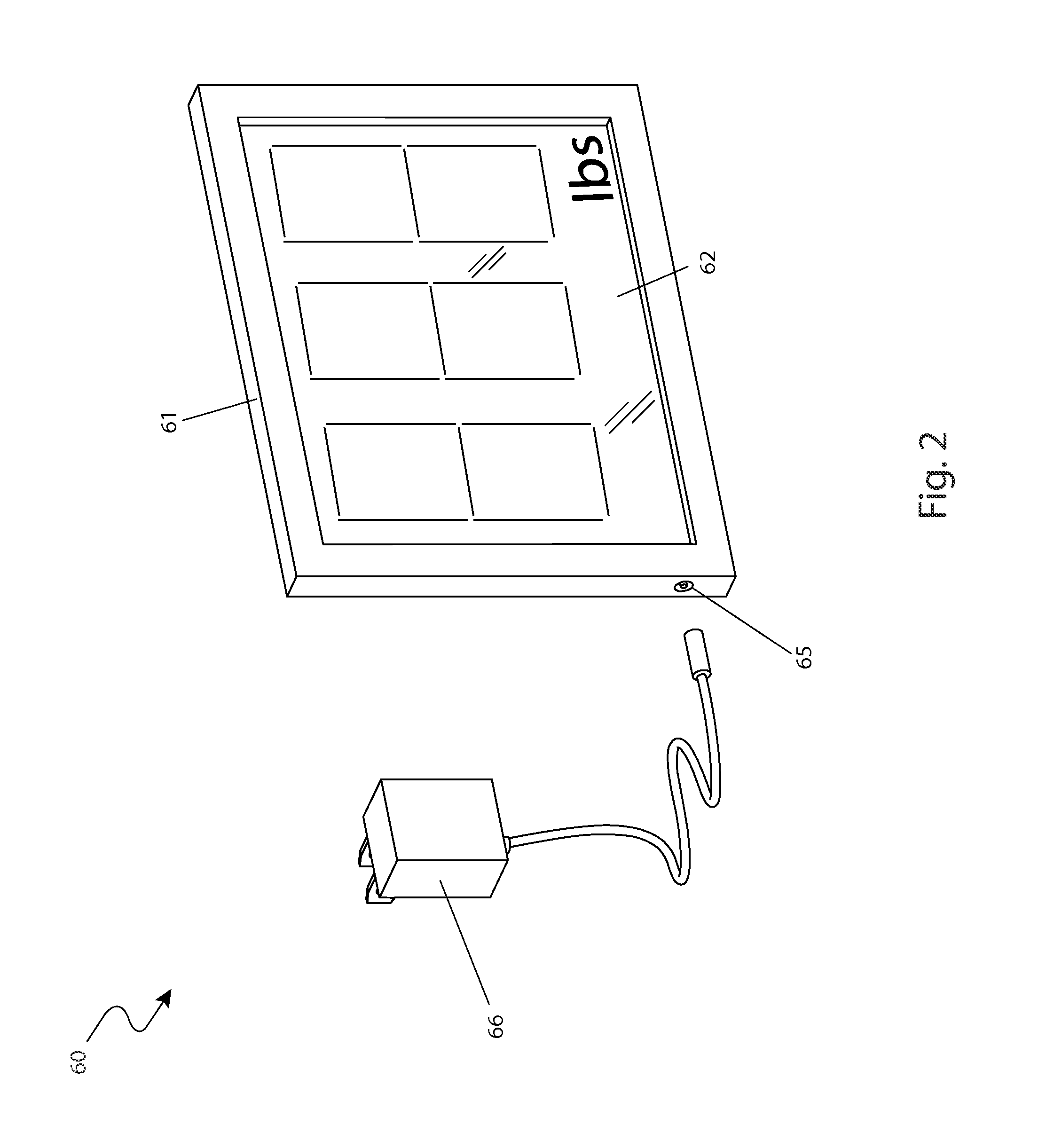

Weight scale with remote readout

InactiveUS8698014B1Place safePrevent trippingWeighing apparatus detailsSpecial purpose weighing apparatusEngineeringRefrigerated temperature

An apparatus that provides for the measurement of a person's weight via a portable remote readout located at eye-level. The weight measuring device comprises a low profile mat with weight sensors that are activated whenever someone steps on the mat. The sensors communicate a sensor weight signal to a transmitter, which in turn communicates the weight signal to a receiver preferably located at eye-level and provided with a variety of mounting means. A preferred embodiment provides for a magnet which enables mounting of the receiver on a refrigerator door. Such a location is envisioned to provide an incentive for those trying to lose weight, by providing one's current weight on the refrigerator door to avoid any unnecessary snacks.

Owner:WALSTAD DAVID M

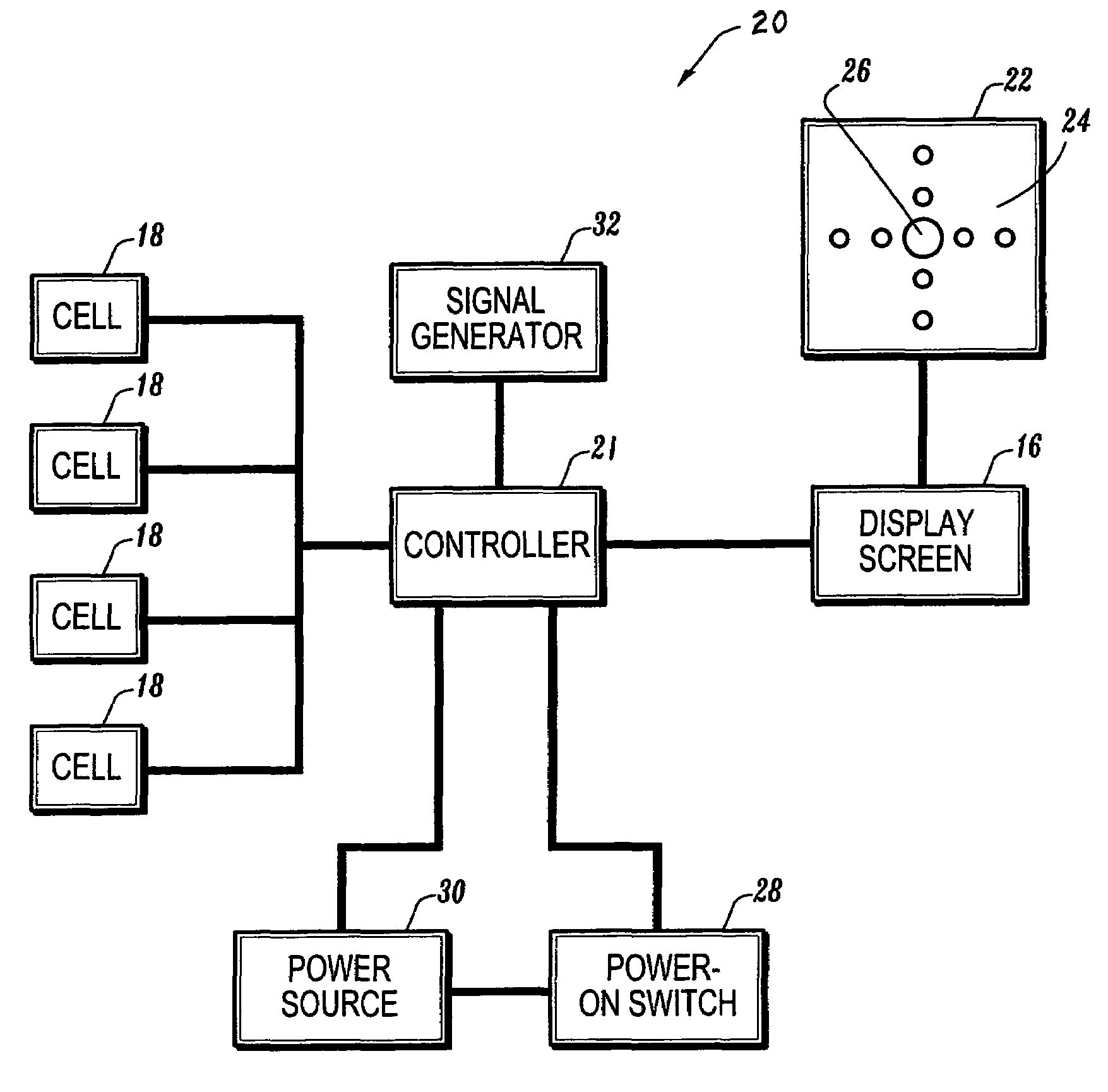

Balance control system for weight scales

InactiveUS7202424B2Evenly distributedImprove accuracyWeighing apparatus detailsDiagnostic recording/measuringControl systemEngineering

The present invention is directed to a weight scale having a balance control system that detects unequal load distribution to the scale's load sensors and produces an output signal that enables the user to re-distribute weight until a predetermined level of balance is achieved. Various load sensors are positioned in an array in the scale and are in communication with a controller that receives signals from the sensors indicative of relative load applied to each sensor. The controller generates a signal that is displayed or emitted to the user indicative of the position of the user's center of gravity relative to the sensors.

Owner:CONAIR CORP

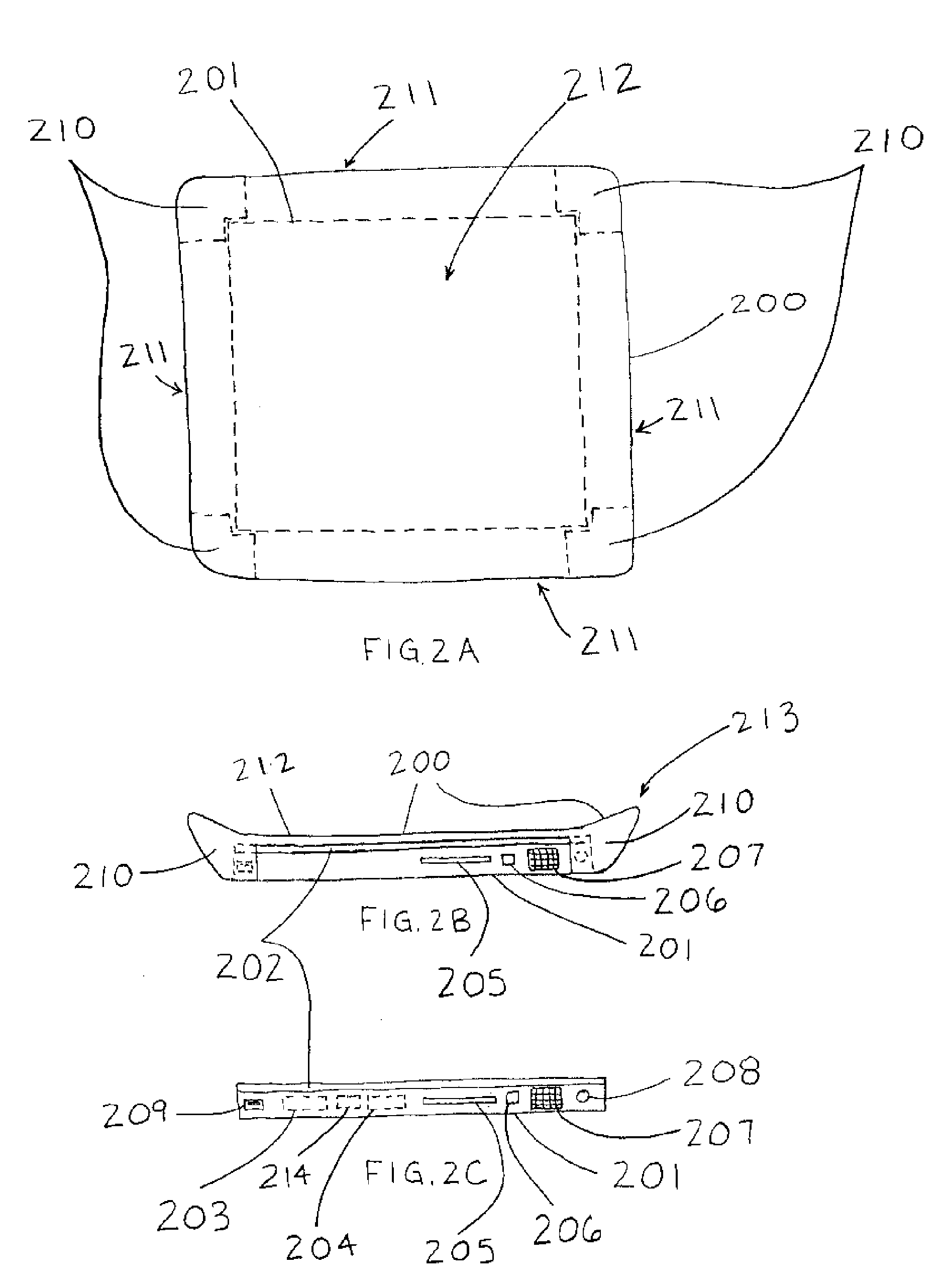

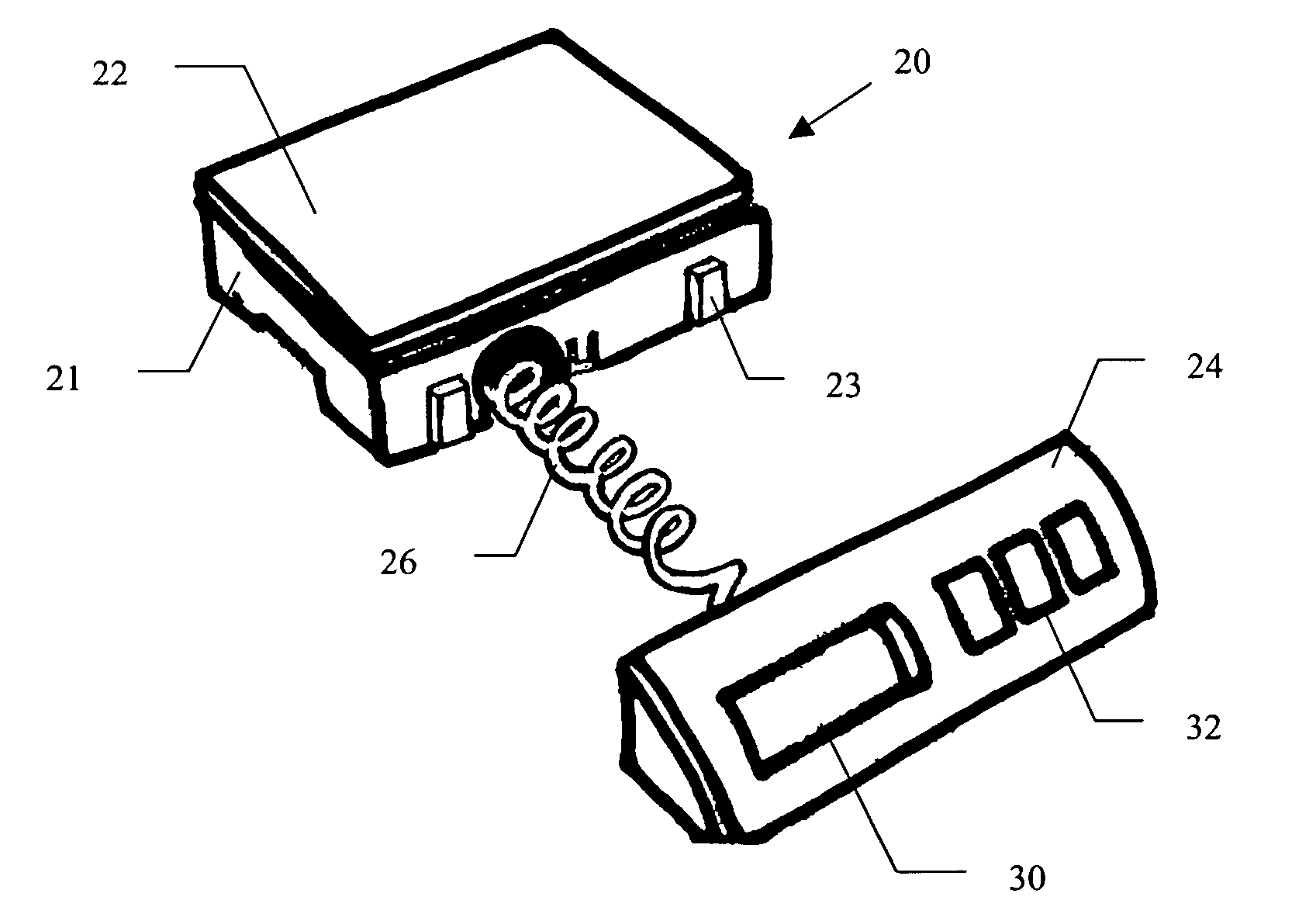

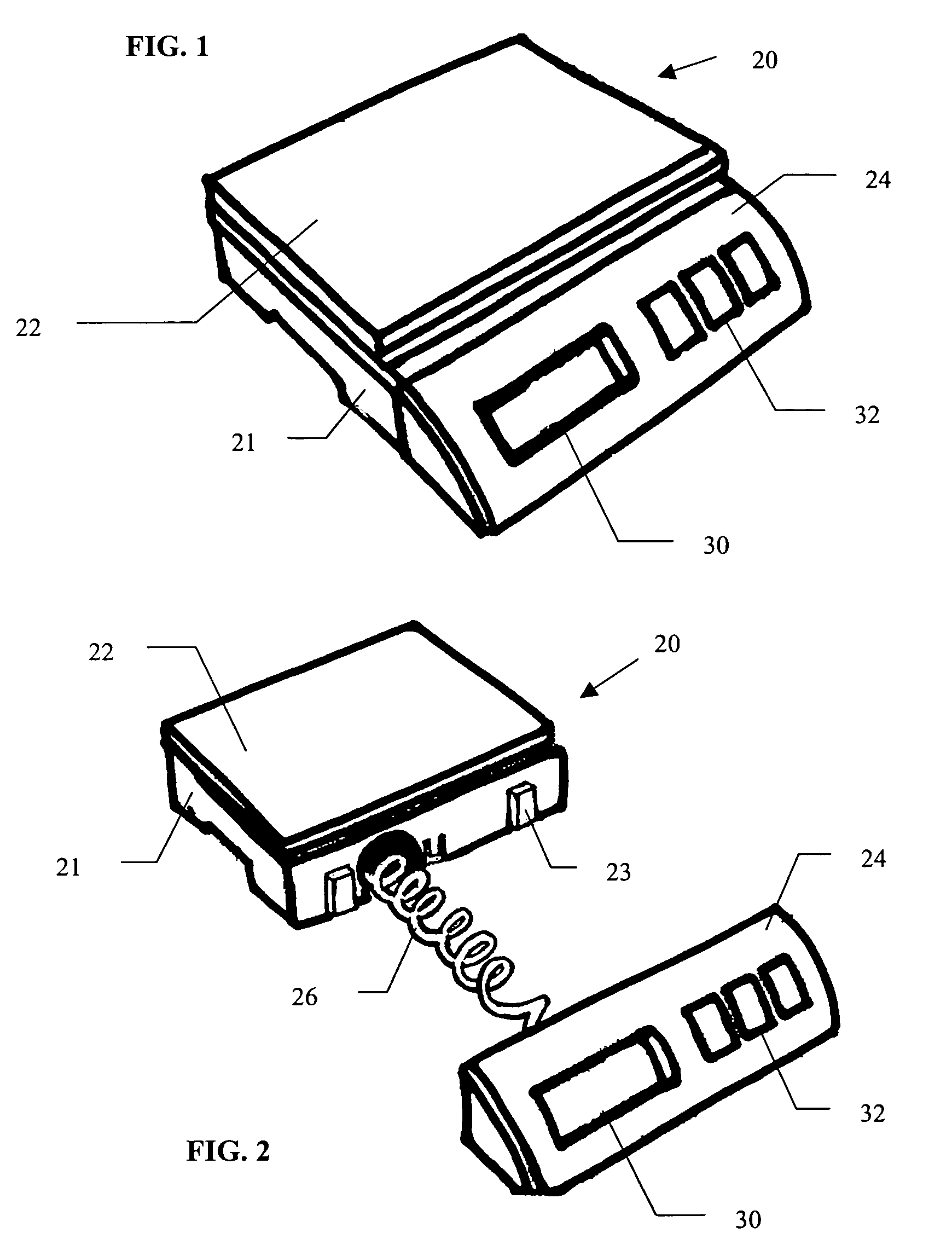

Postal scale with extendable input/output unit

ActiveUS7256357B1Easy to operateAccurate weighingWeighing apparatus detailsSpecial purpose weighing apparatusDisplay deviceEngineering

A postal type scale, such as an electronic scale, capable of weighing a plurality of different size packages is provided. The scale includes a weighing mechanism in its base, a platform for supporting a package thereon in a weighing relationship, and an extendable input / output unit (e.g., weight display and keypad) removeably attached to the scale and extendable therefrom. The input / output unit includes a weight display, such as an LCD display, and an input device such as a keypad or touchscreen or the like. When attached to the scale, weight display and keypad form a compact unitary design. When extended away from the scale, the display and keypad may be located at a position remote from the scale on any plane.

Owner:KESSELMAN JOSHUA D

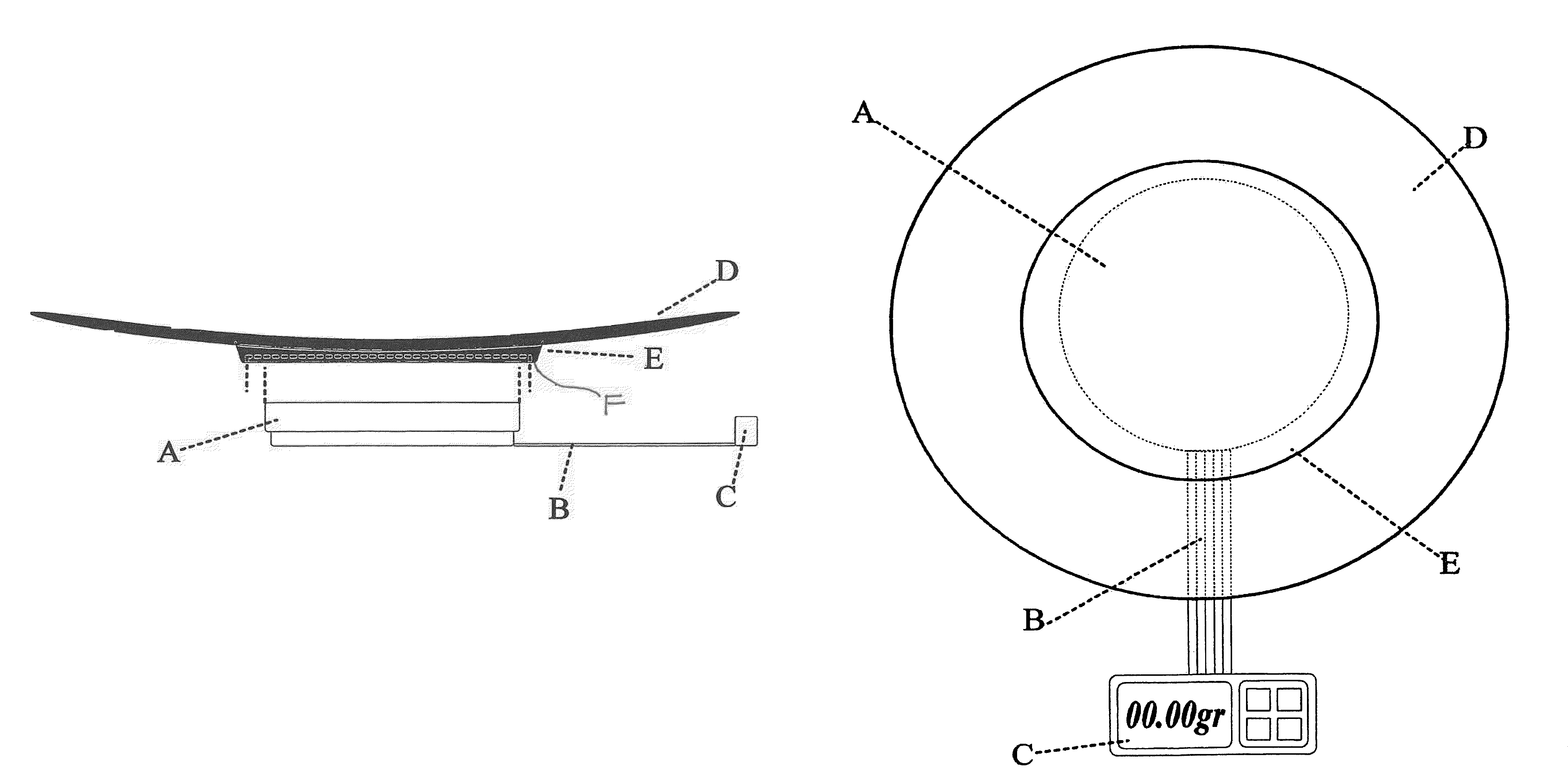

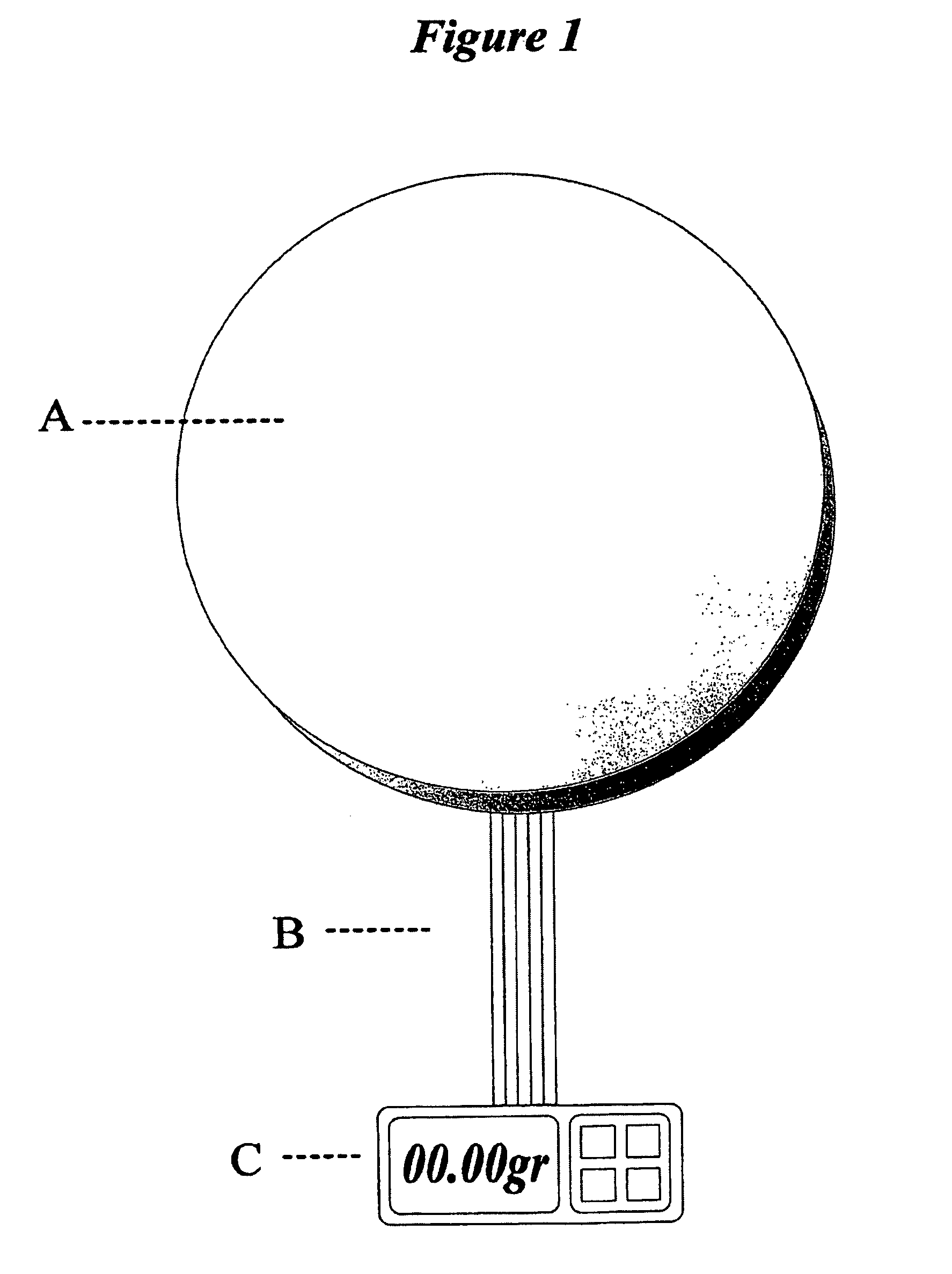

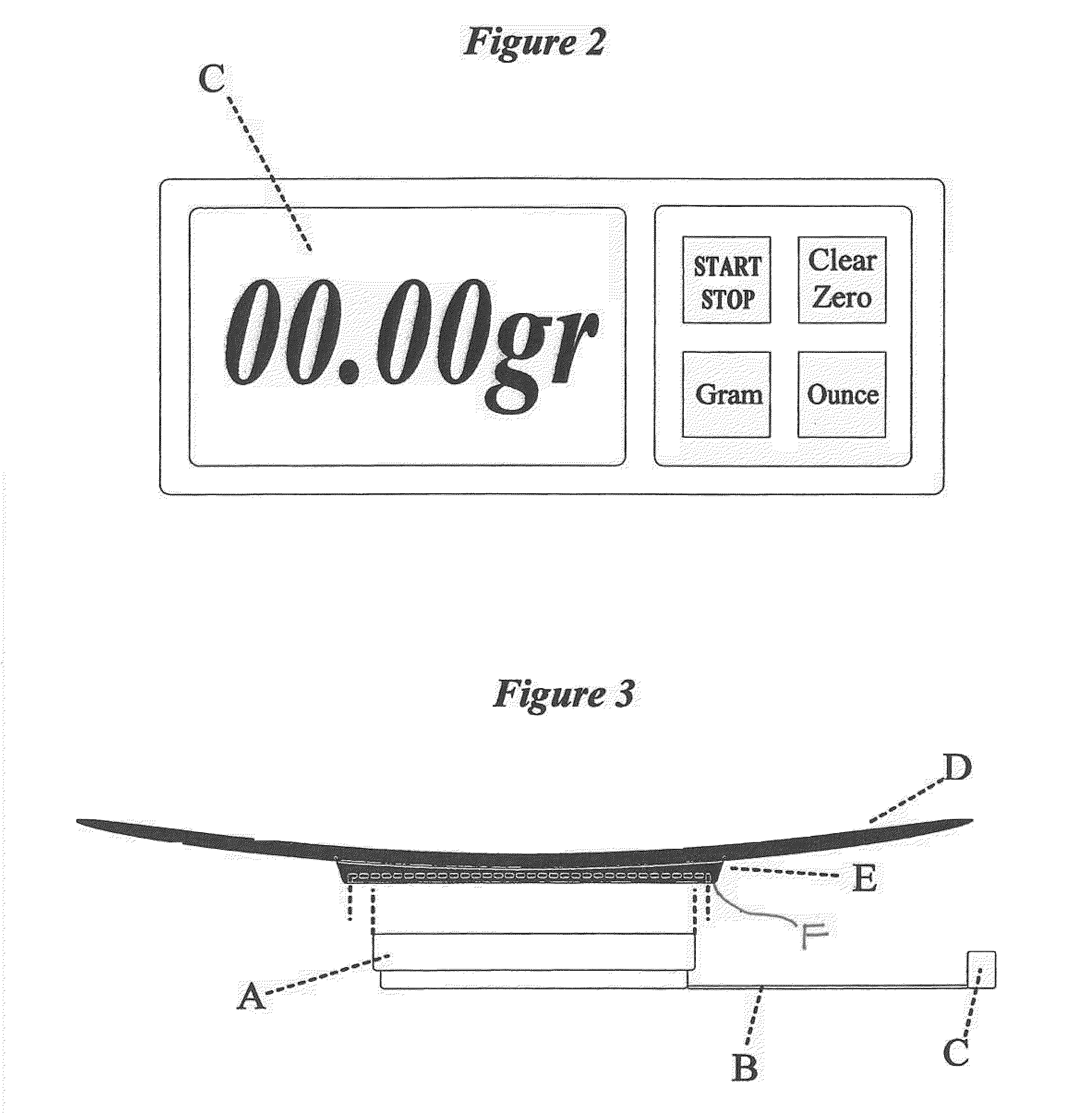

Portable digital plate scale

InactiveUS7550683B2Easily fit with pocketbook and jacketEasy to cleanWeighing apparatus detailsSpecial purpose weighing apparatusDigital interfaceGram

Owner:DAUGHTRY AMANDA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com