Multiple plane weigh platter for multiple plane scanning systems

a technology of multiple plane scanning and weigh platter, which is applied in the direction of weighing apparatus details, instruments, sensing record carriers, etc., can solve the problems of increasing the area of the weigh platter, affecting the mechanical stability and affecting the operation of the weighing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

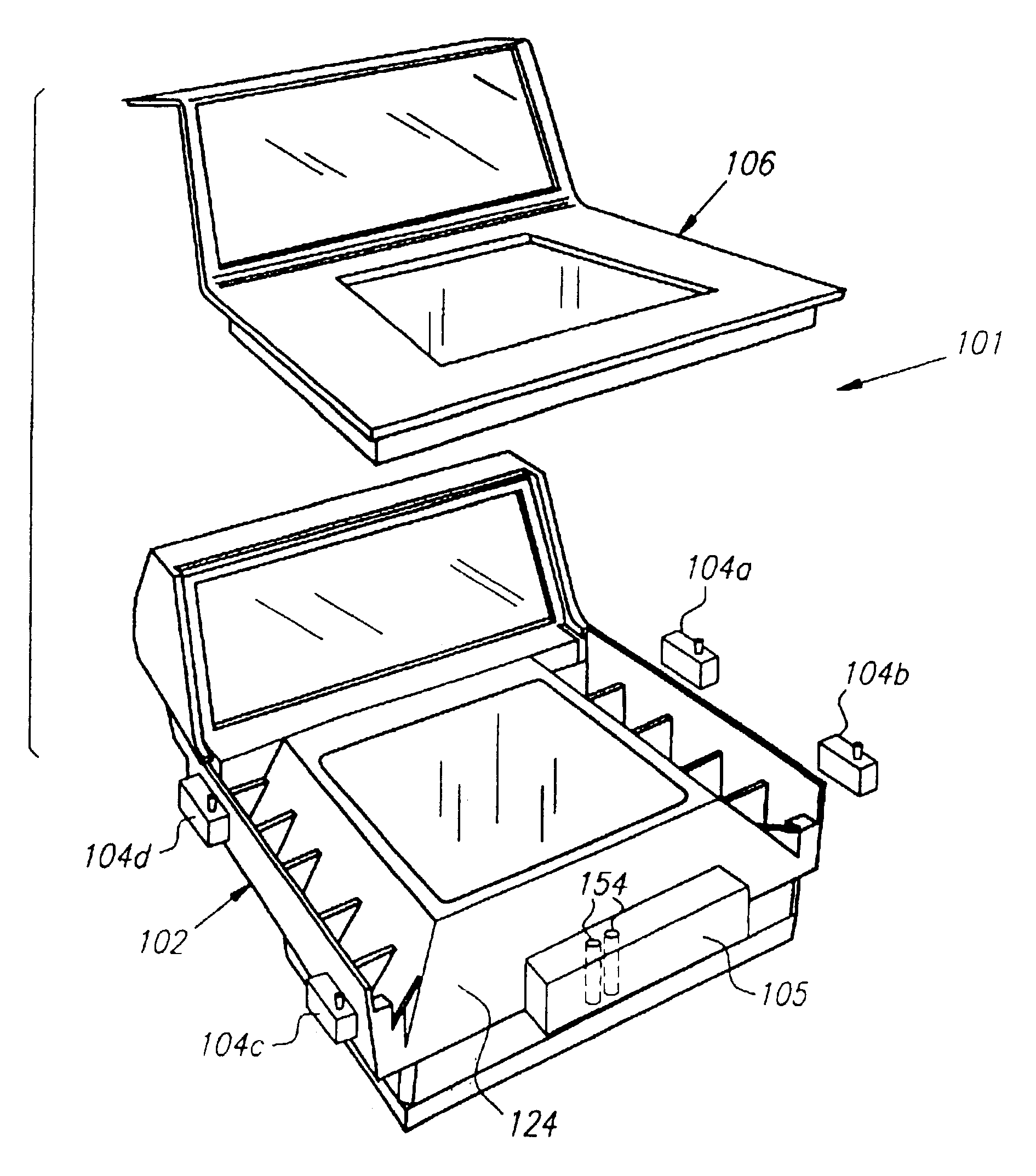

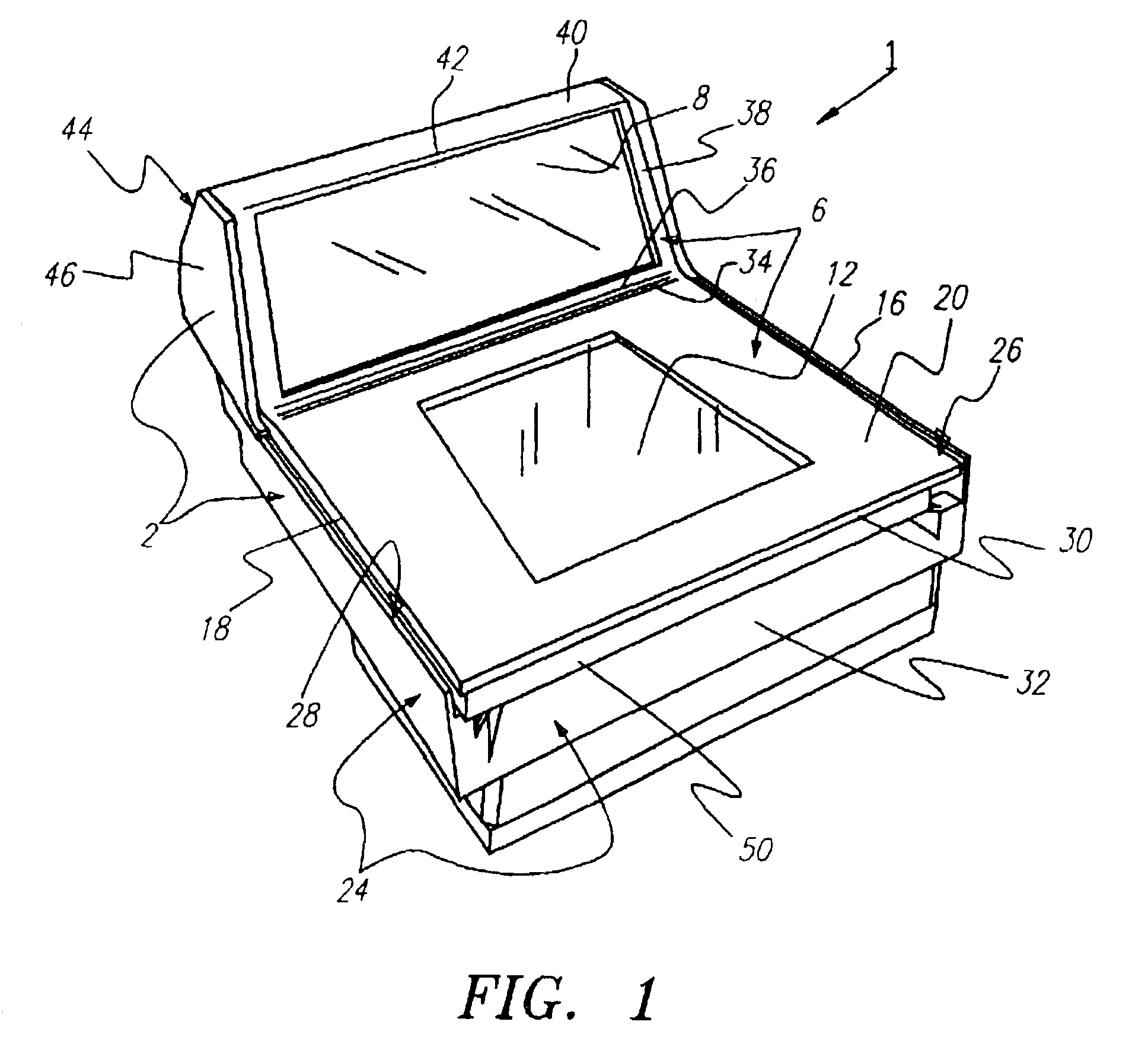

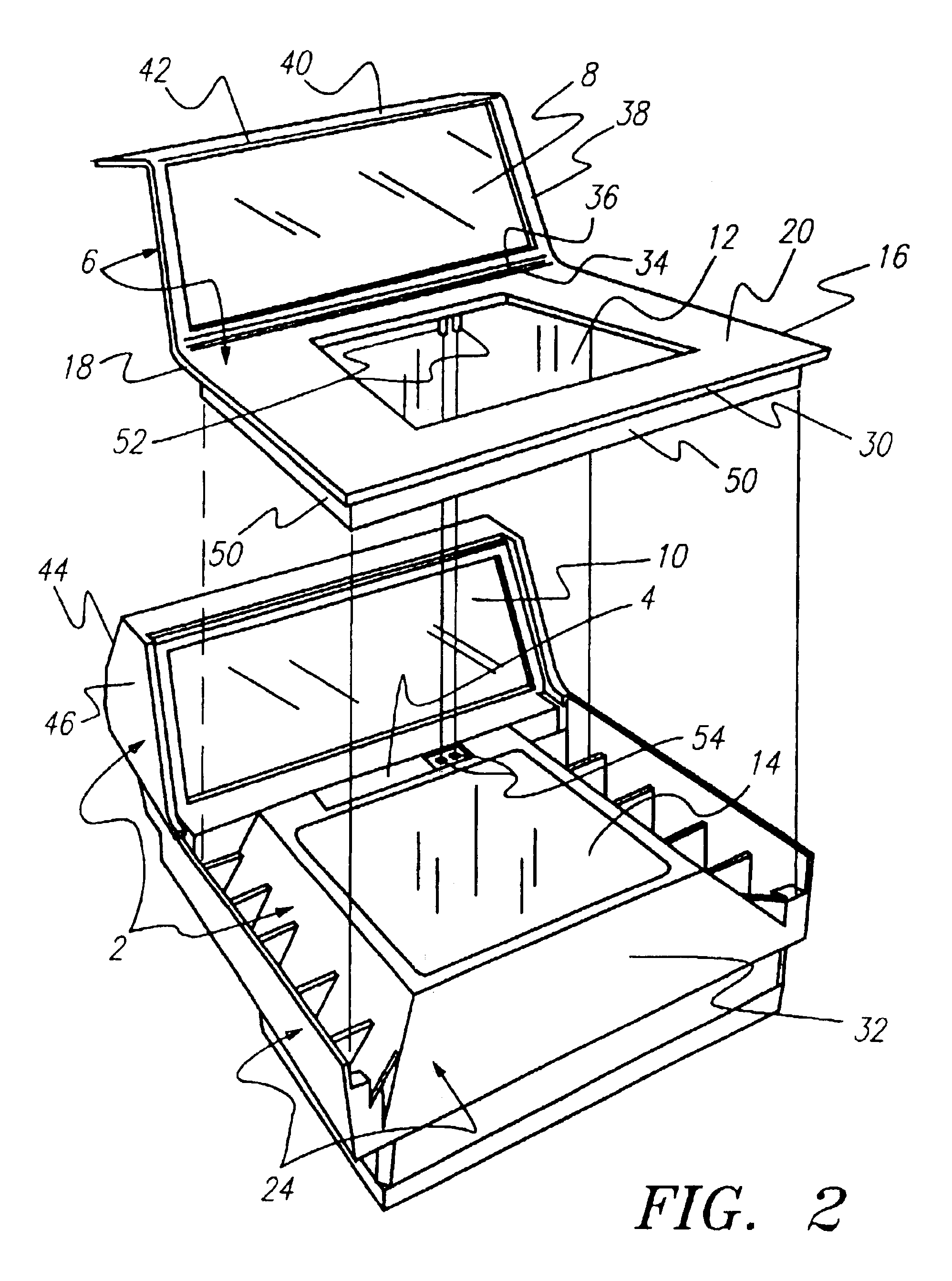

[0022]The preferred embodiments will now be described with reference to the drawings. FIGS. 1-5 illustrate a two-plane scanner / weighing apparatus 1 including a scanner 2 with an integral load cell 4 and a two-plane spiderless weigh platter 6. When assembled the vertical platter window 8 is positioned in front of the vertical scan window 10 and the horizontal platter window 12 is positioned over the horizontal scan window 14. This relative positioning of the platter windows 8, 12 to the scan windows 10, 14 allows optical beams generated by the scan engine(s) to pass out through the scan windows and platter windows, and allows the resulting optical signals from a scanned barcode to pass in through the platter windows and the scan windows for detection and decoding. The window 8 may be oriented perfectly vertical, or it may be angled somewhat from absolute vertical as best shown in FIG. 3.

[0023]The lateral side edges 16, 18 of the horizontal section 20 of the weigh platter 6 and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com