Patents

Literature

71results about How to "Sufficiently robust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

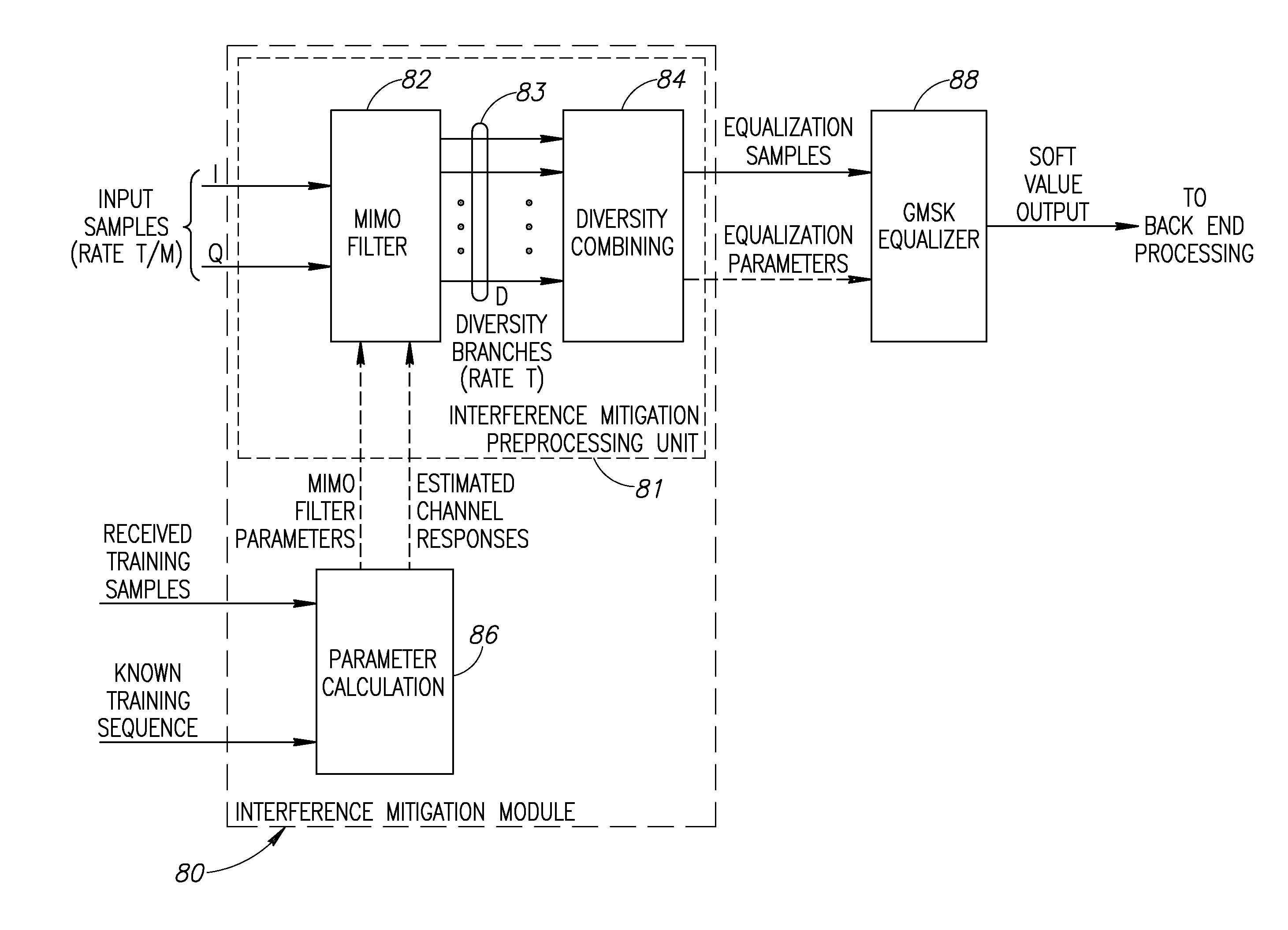

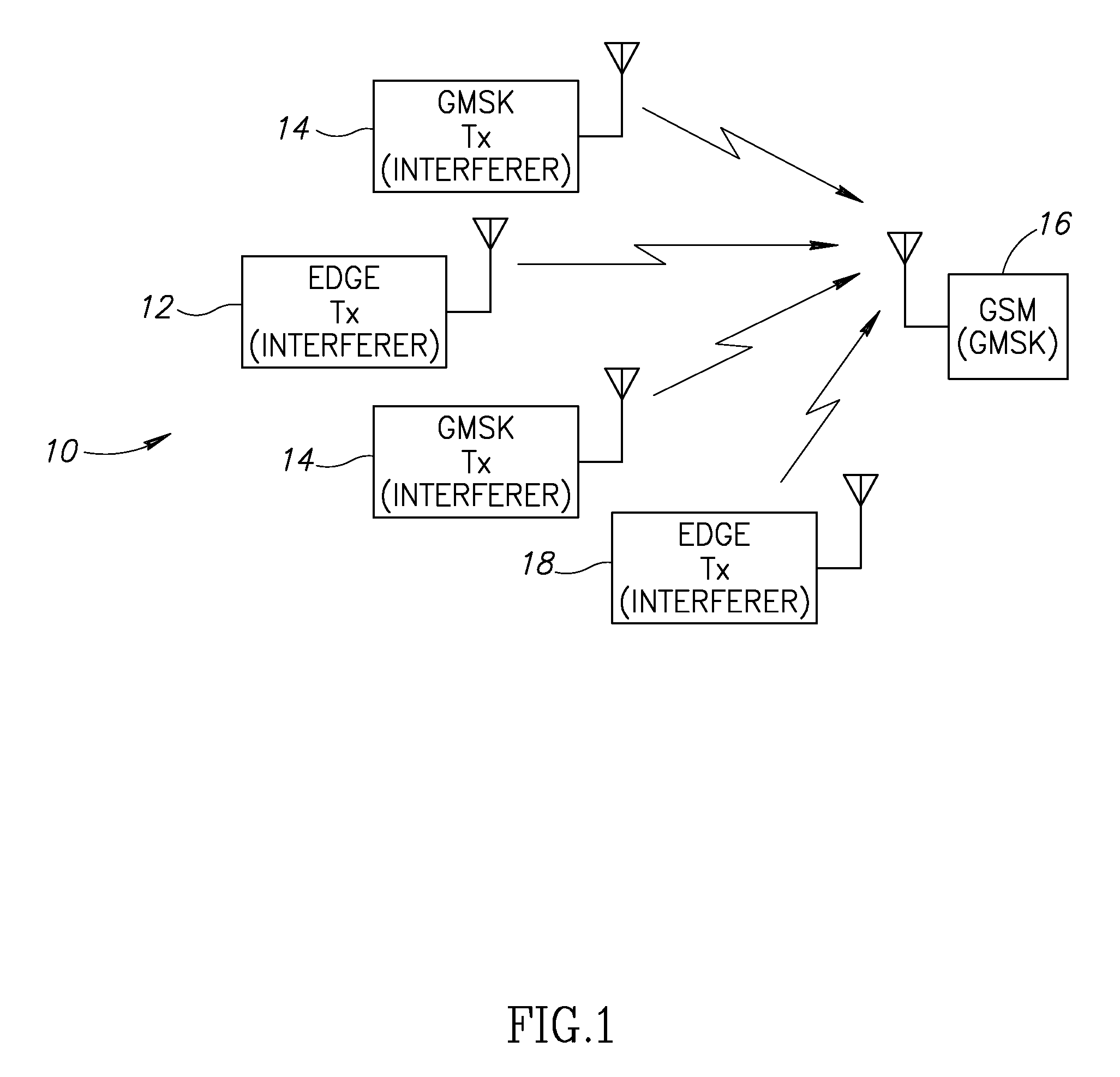

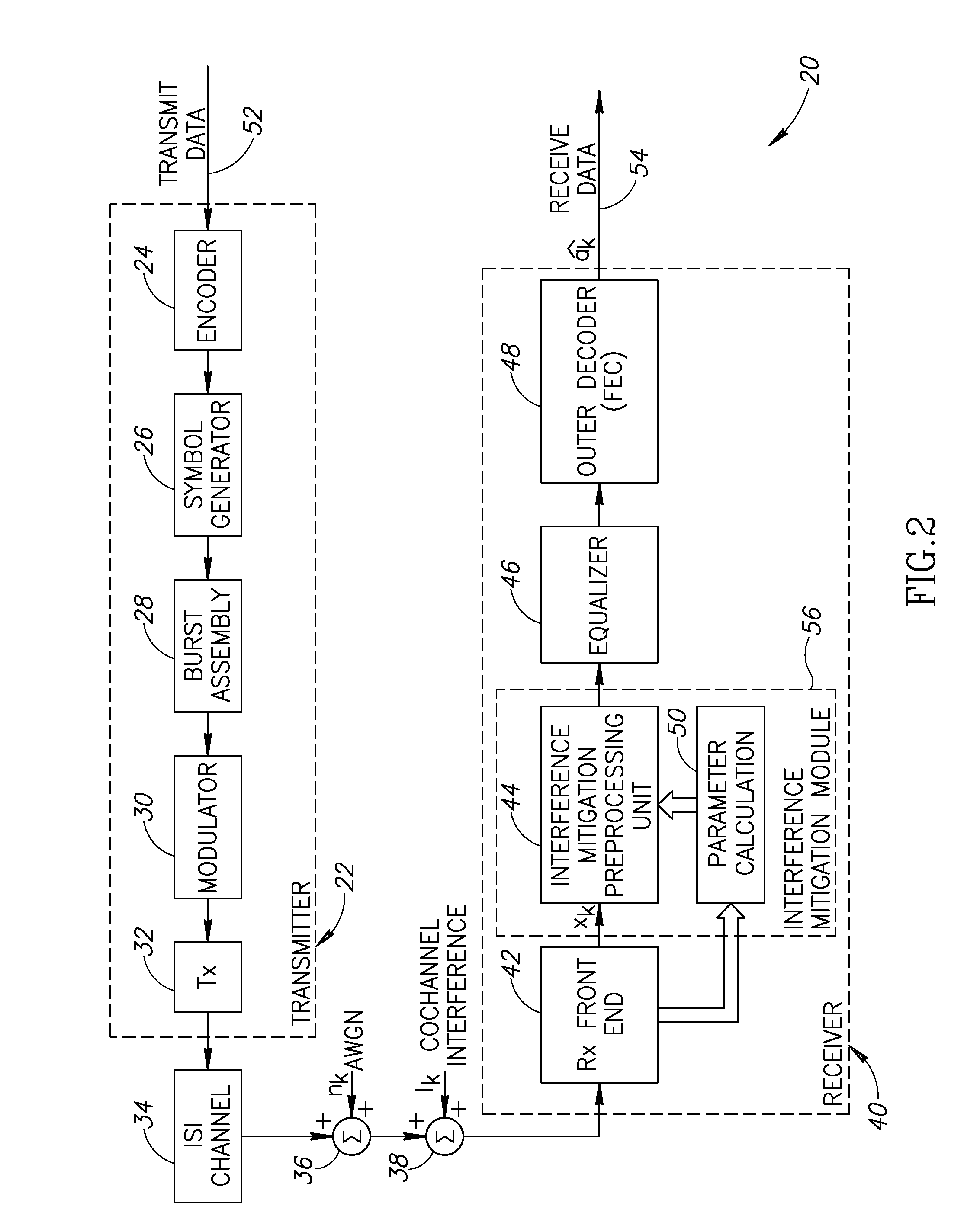

Blind interference mitigation in a digital receiver

InactiveUS20070127608A1Improve acceleration performanceReduce computational complexityError preventionLine-faulsts/interference reductionEngineeringCo-channel interference

A novel and useful apparatus for and method of Gaussian Minimum Shift Keying (GMSK) single antenna interference cancellation (SAIC) for use in a digital receiver. The invention comprises an interference mitigation module that treats the problem of GMSK SAIC in a blind manner. The interference mitigation mechanism is operative to compensate for the co-channel interference added in the communications channel which is subject to multipath propagation and fading, receiver filter and any pre-channel estimation filtering. The interference mitigation module takes advantage of the spatial diversity making up multiple branches of the received signal. The branches comprise the in-phase and quadrature elements of the received signal, the sampling phases if over sampling is applied (i.e. T / m sampling) and / or multiple antennas. The invention utilizes the spatial diversity of these multiple representations of the received signal and combines (i.e. collapses) the information in the plurality of branches into a single branch that is input to the equalizer.

Owner:COMSYS COMM & SIGNAL PROC

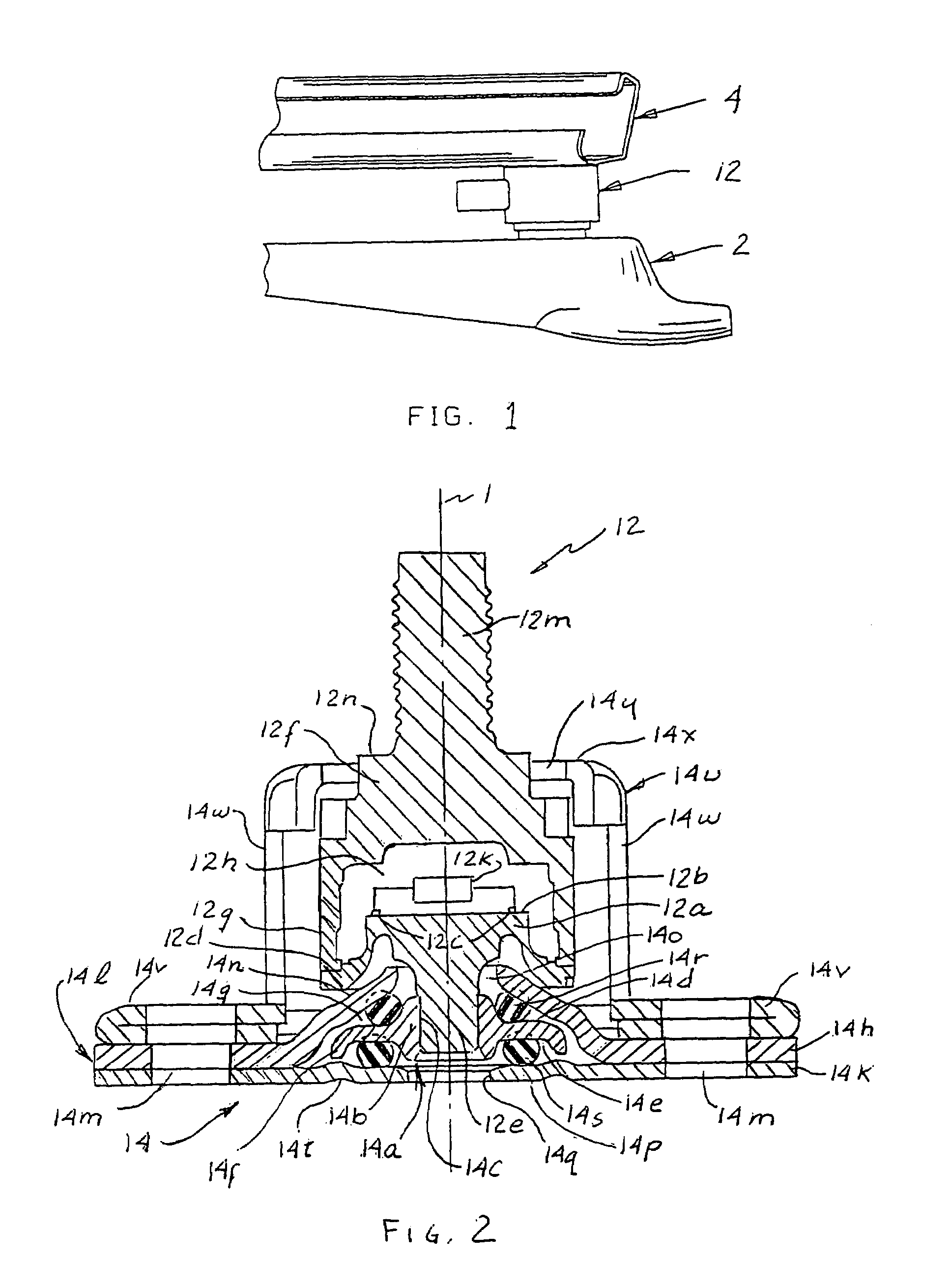

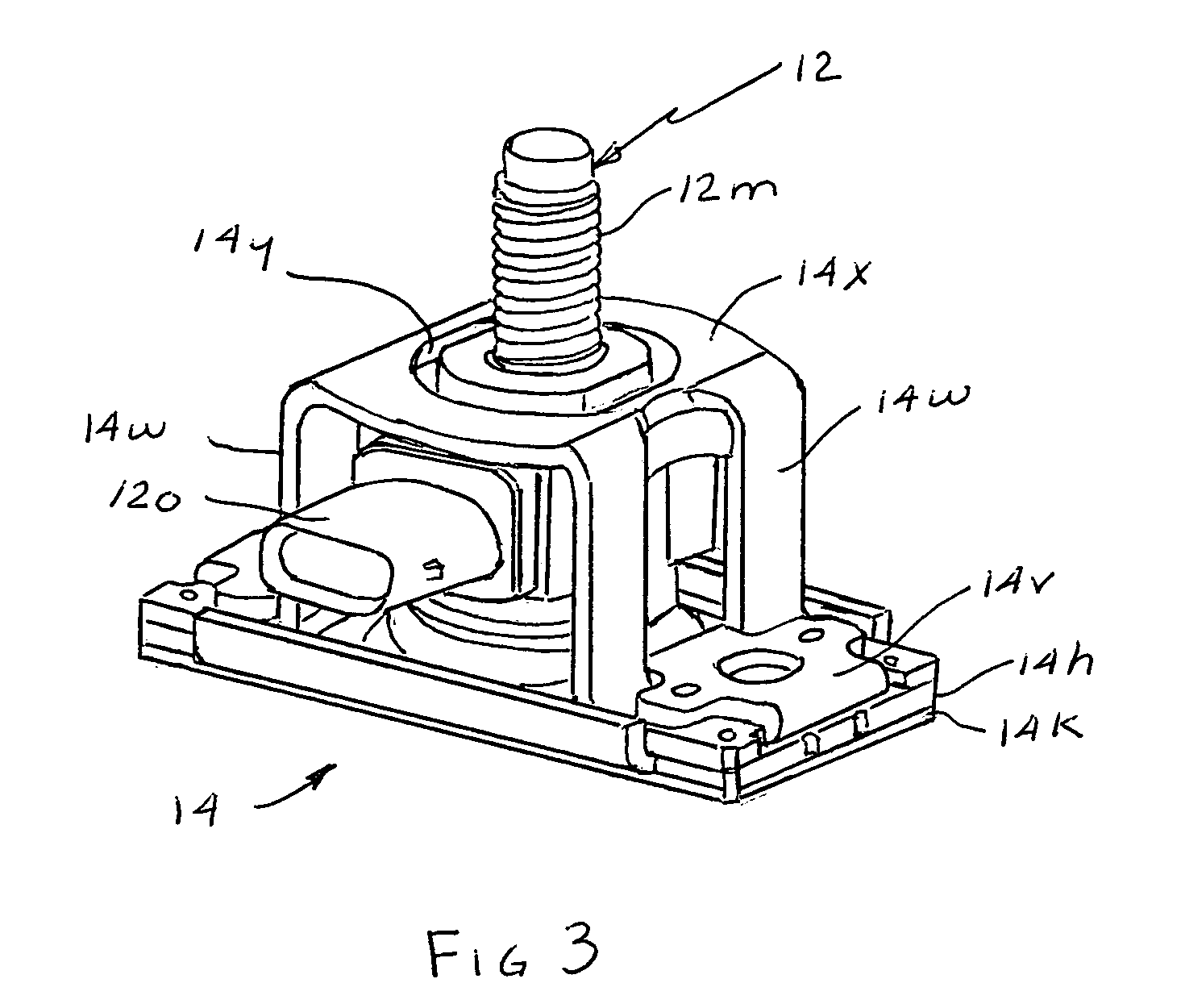

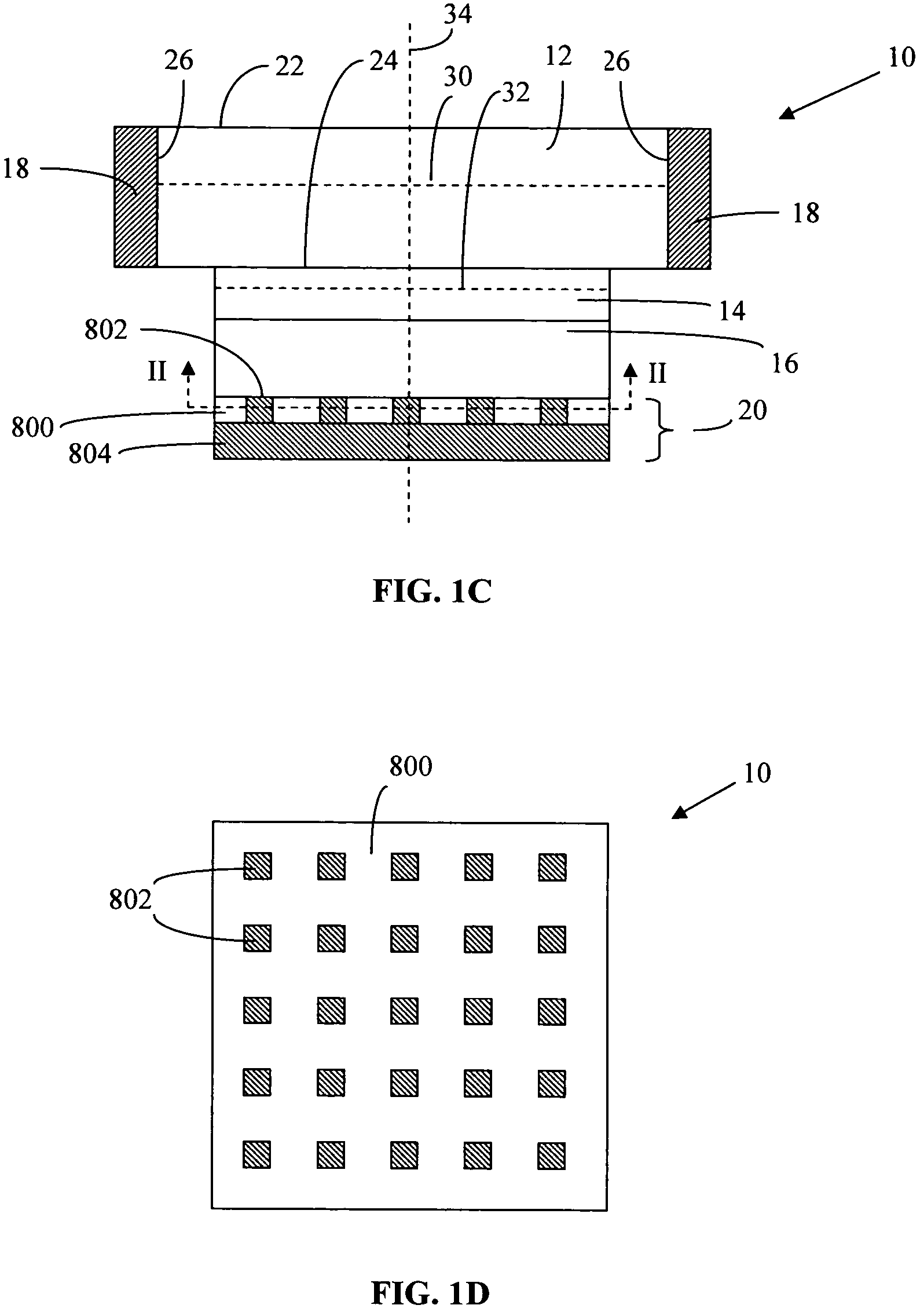

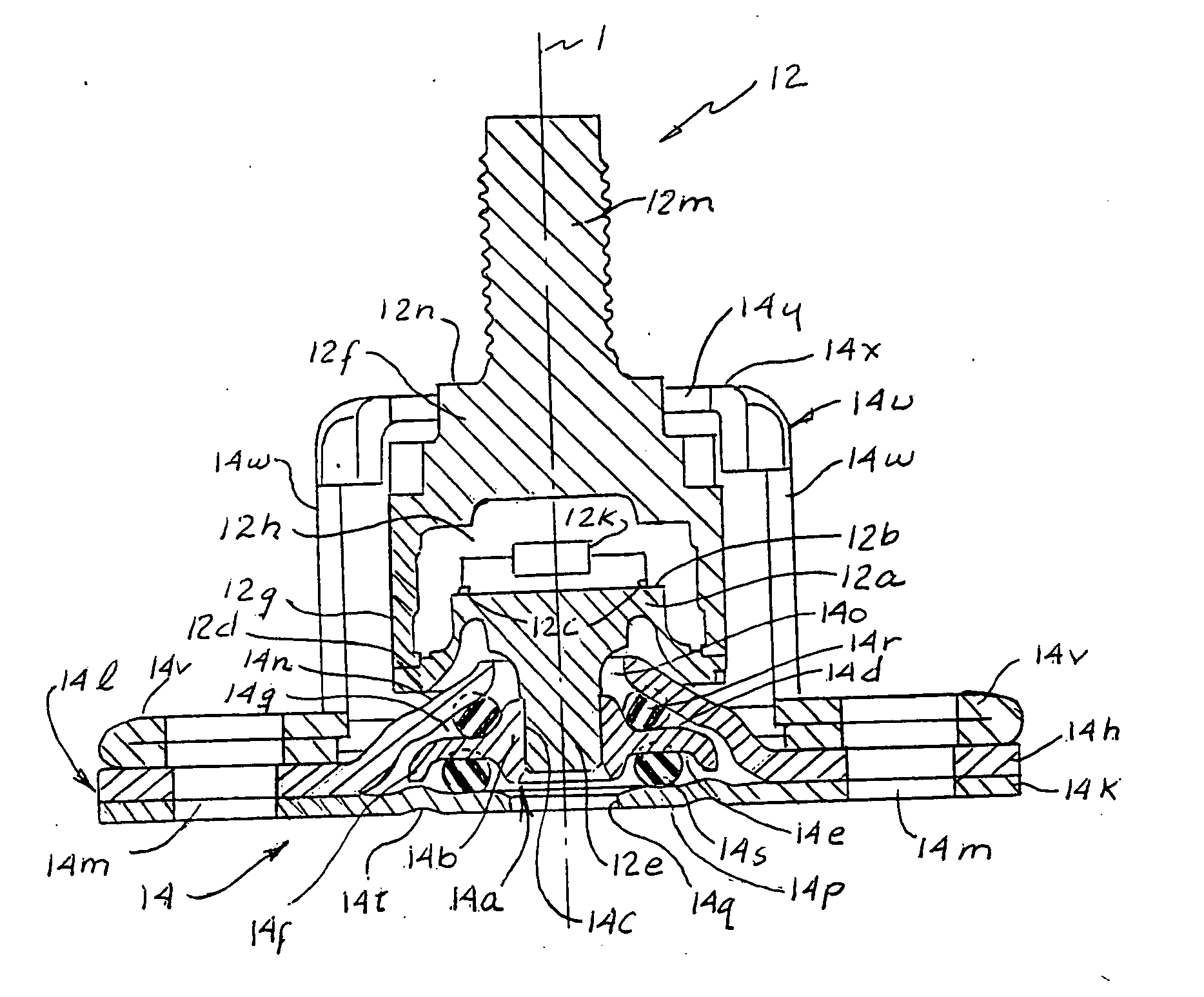

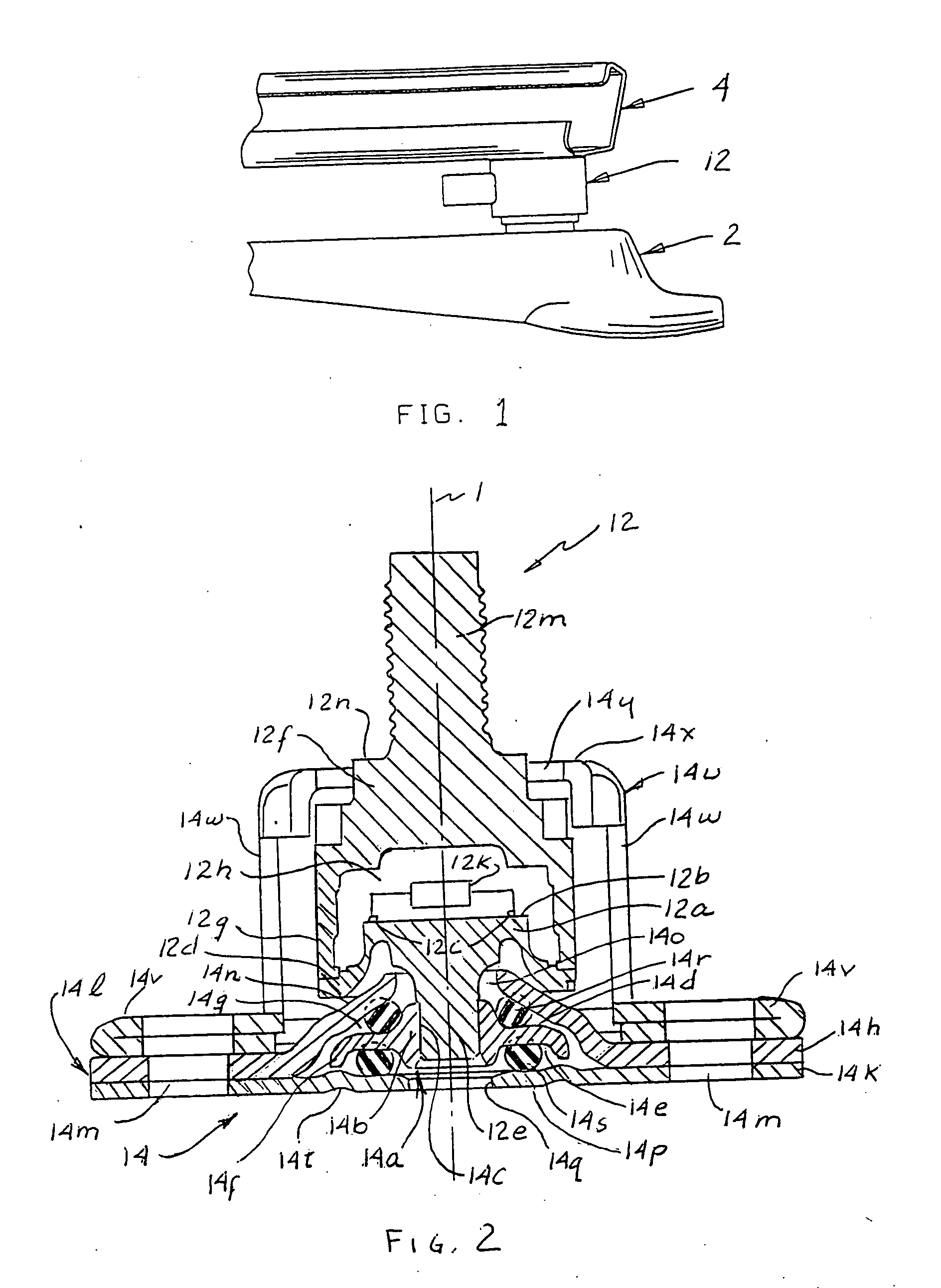

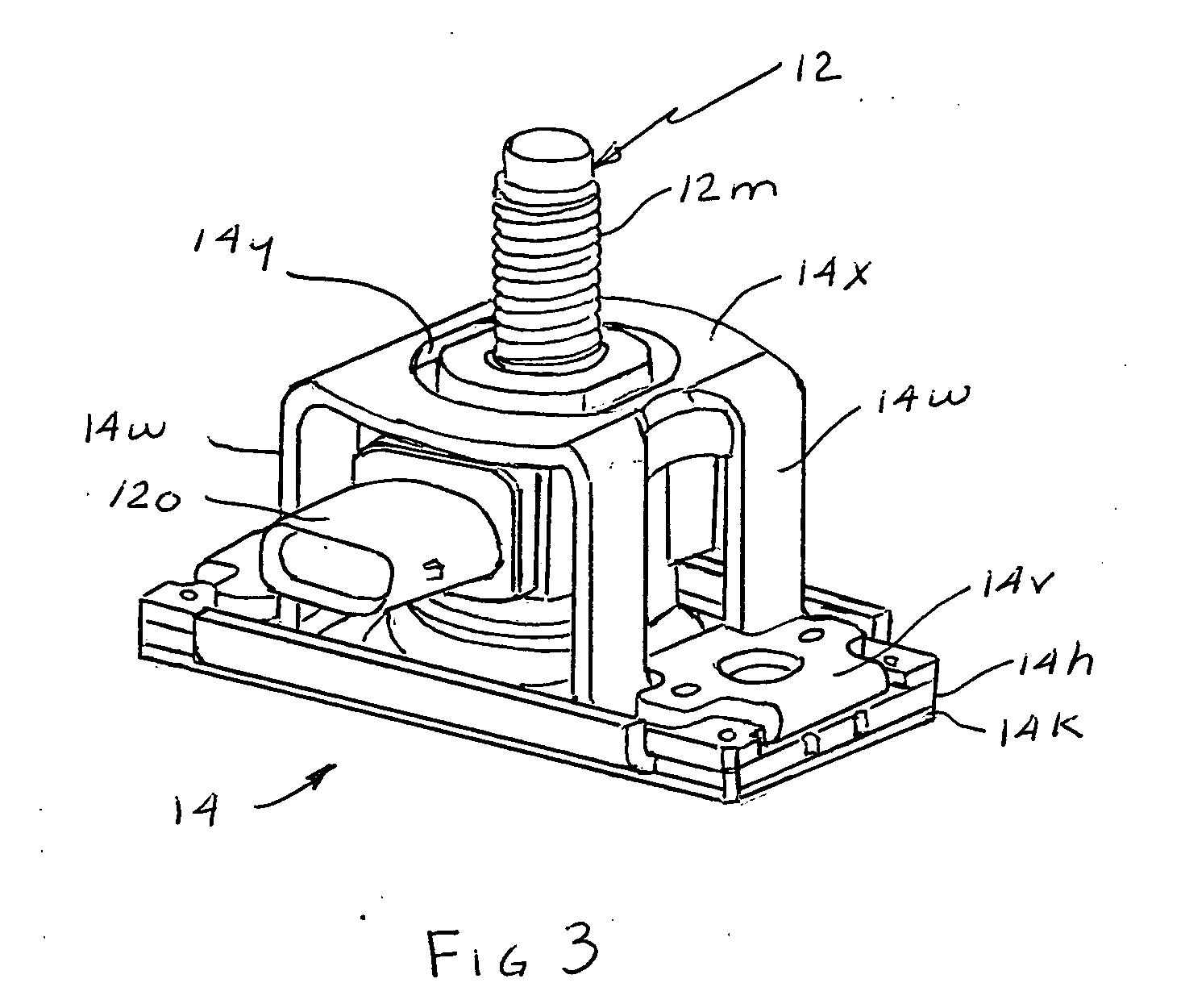

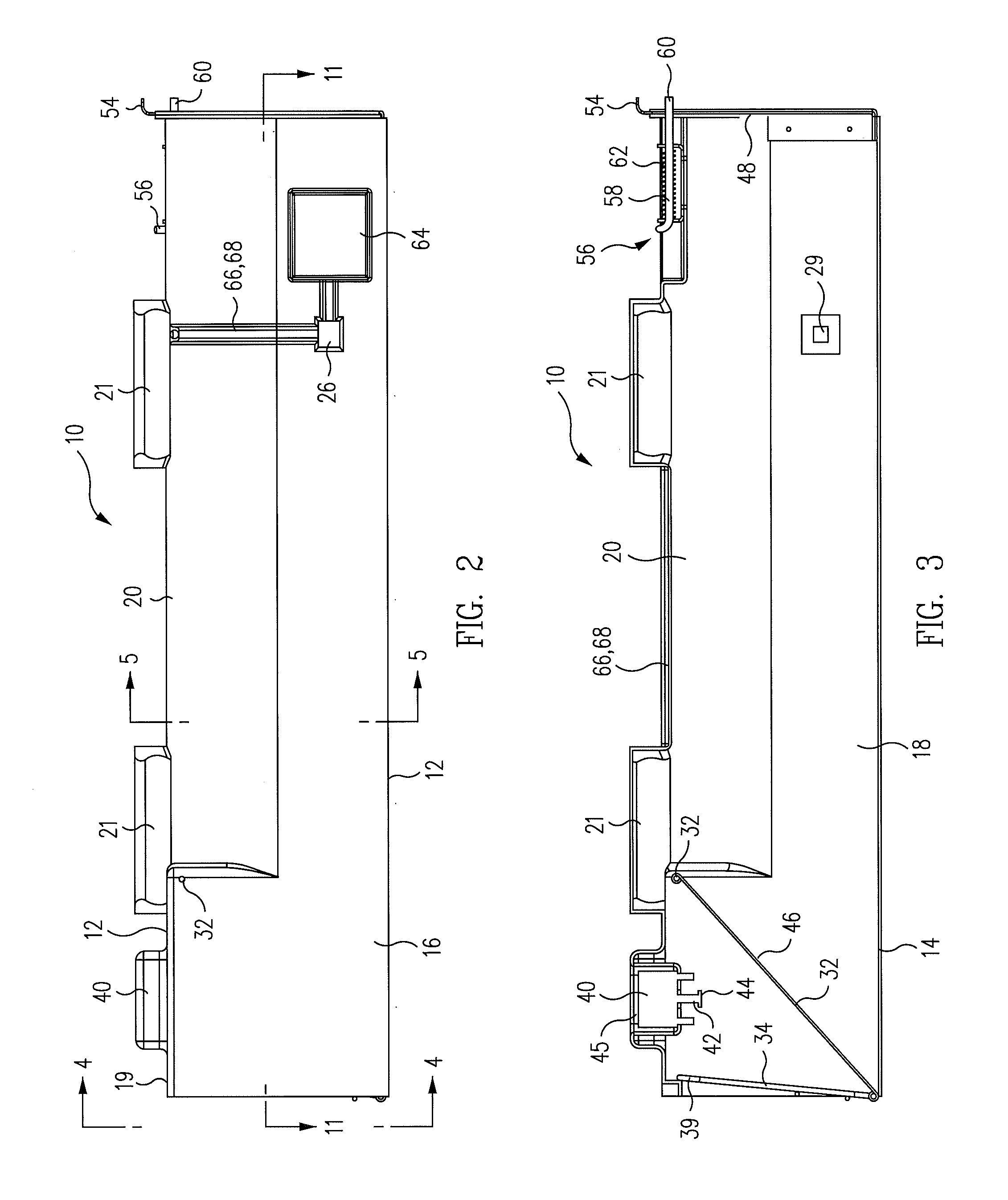

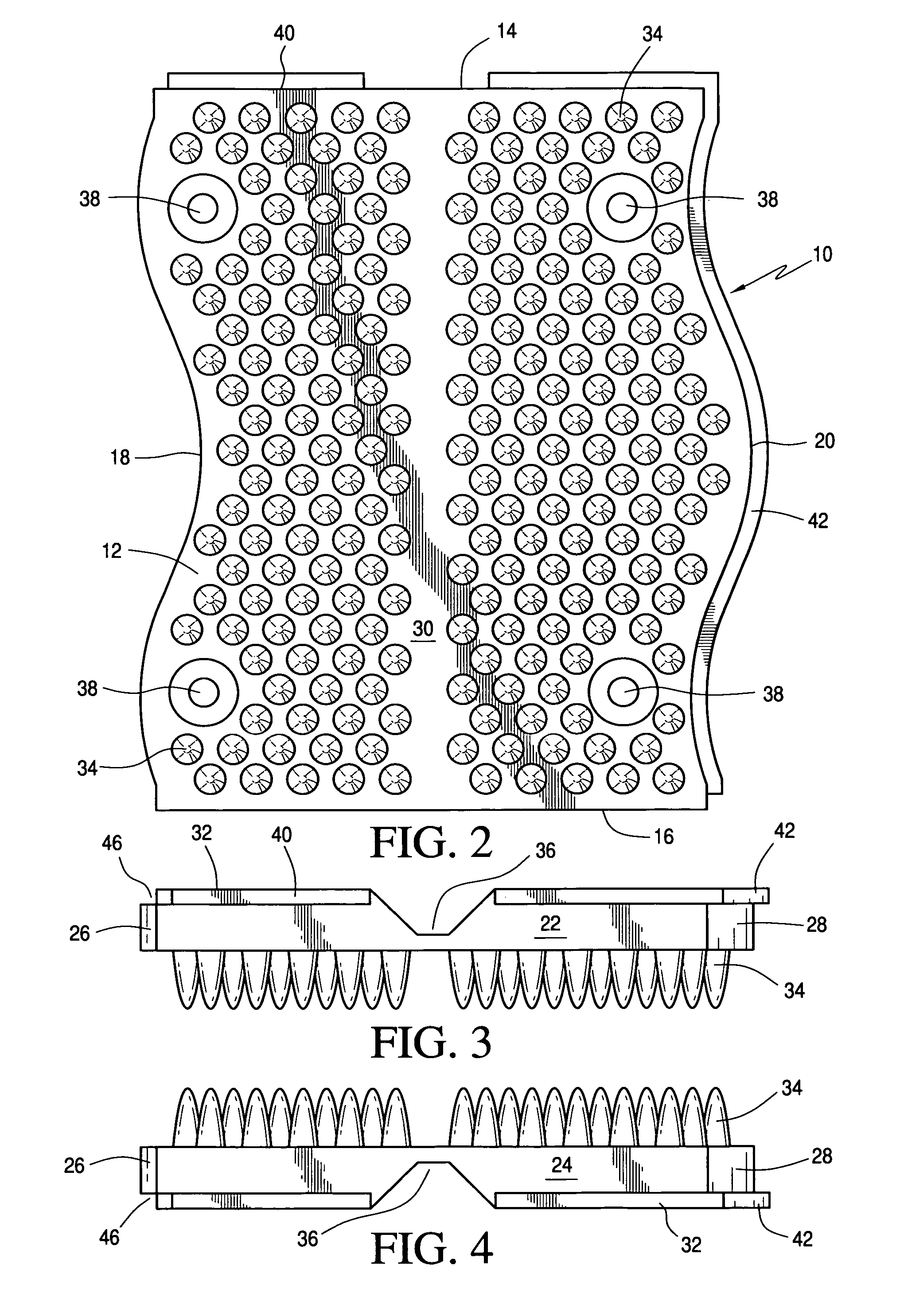

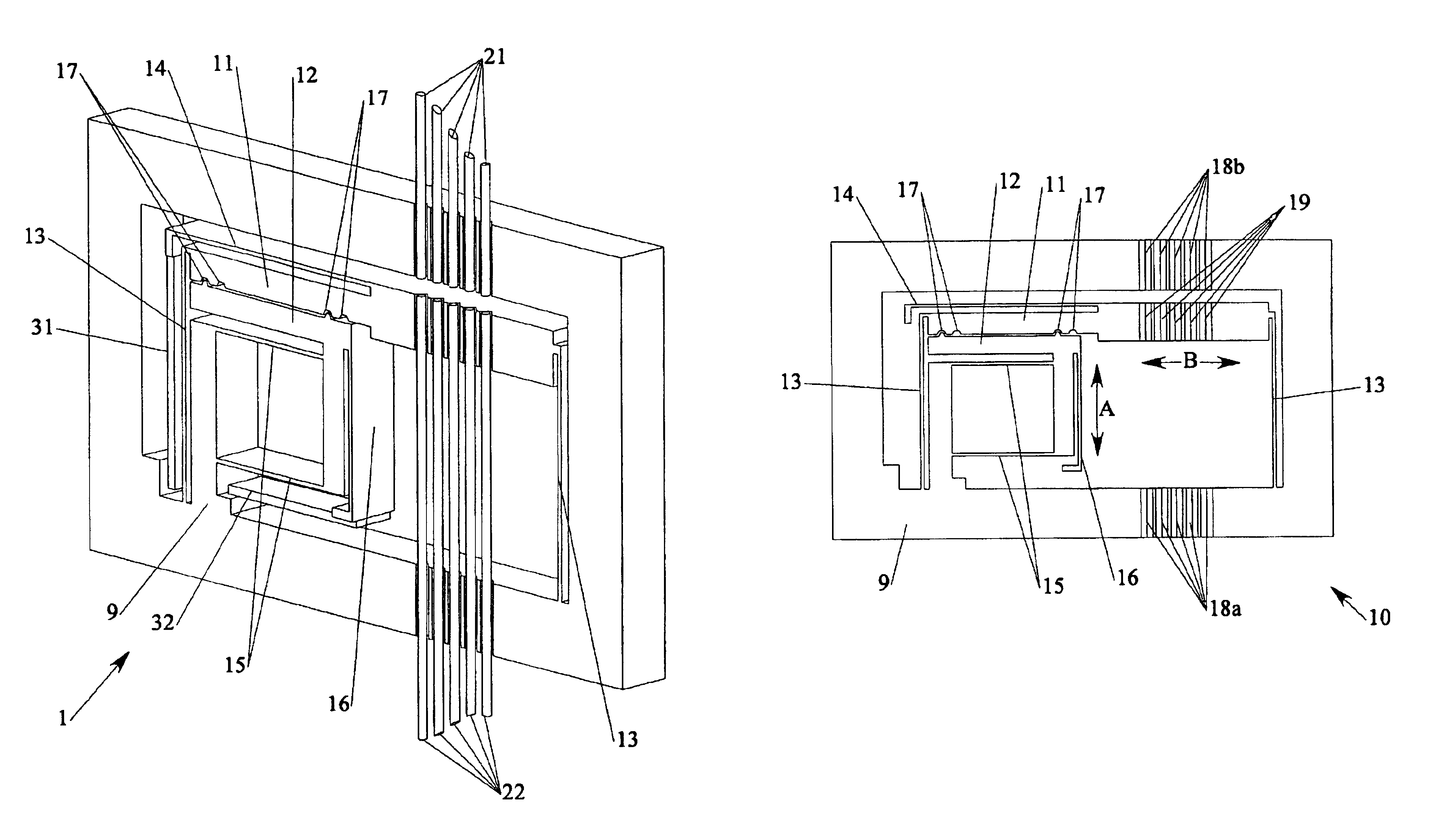

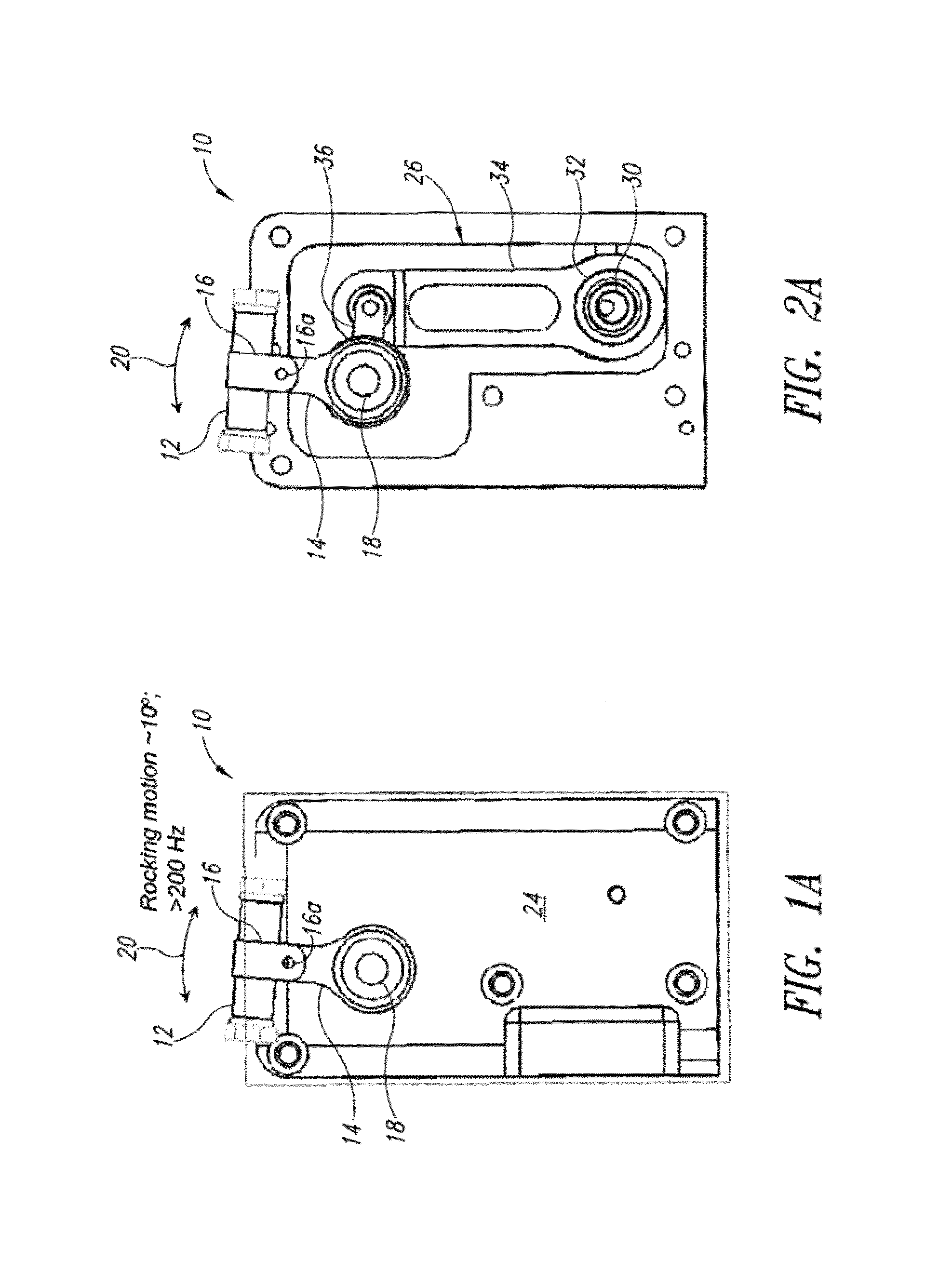

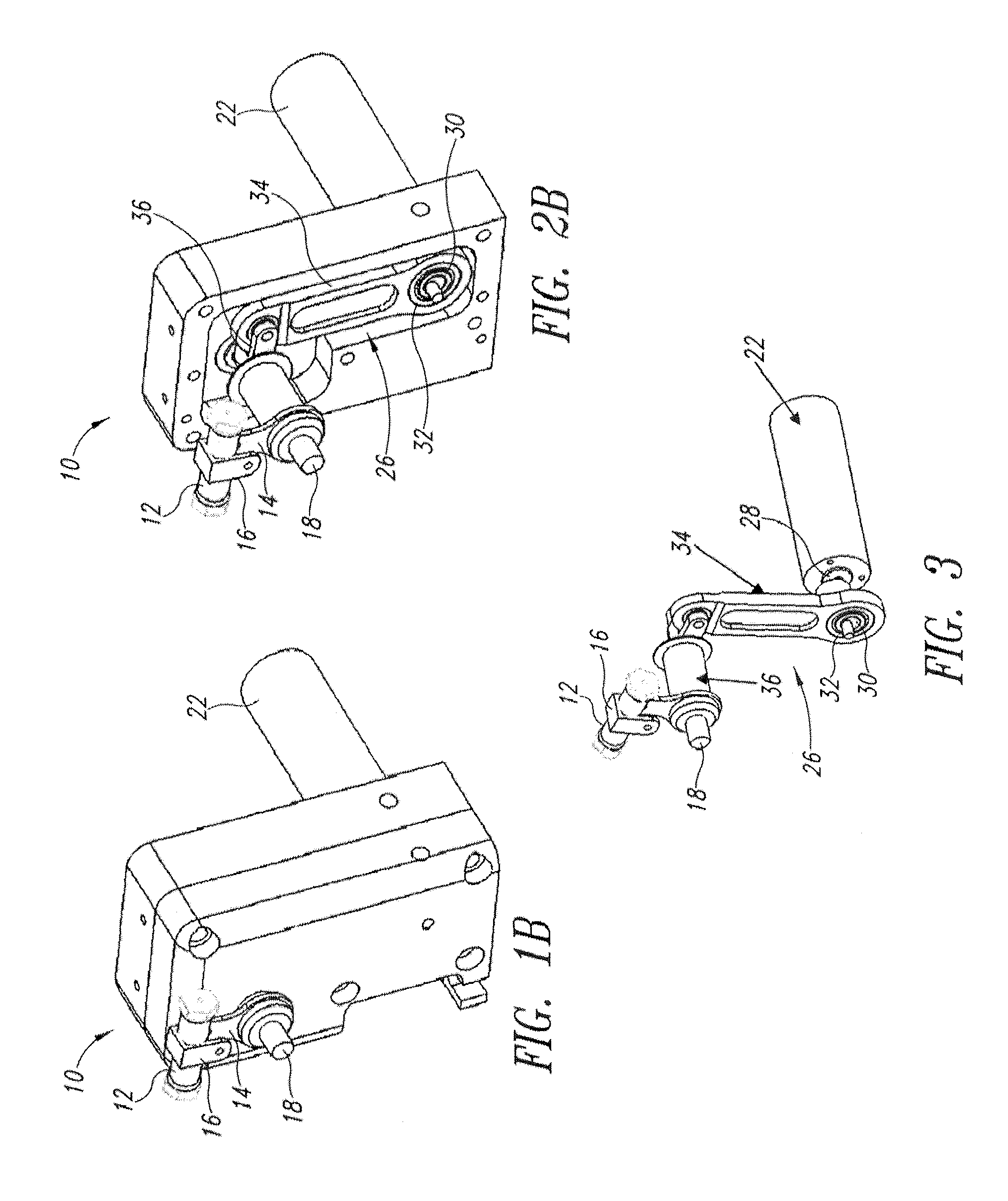

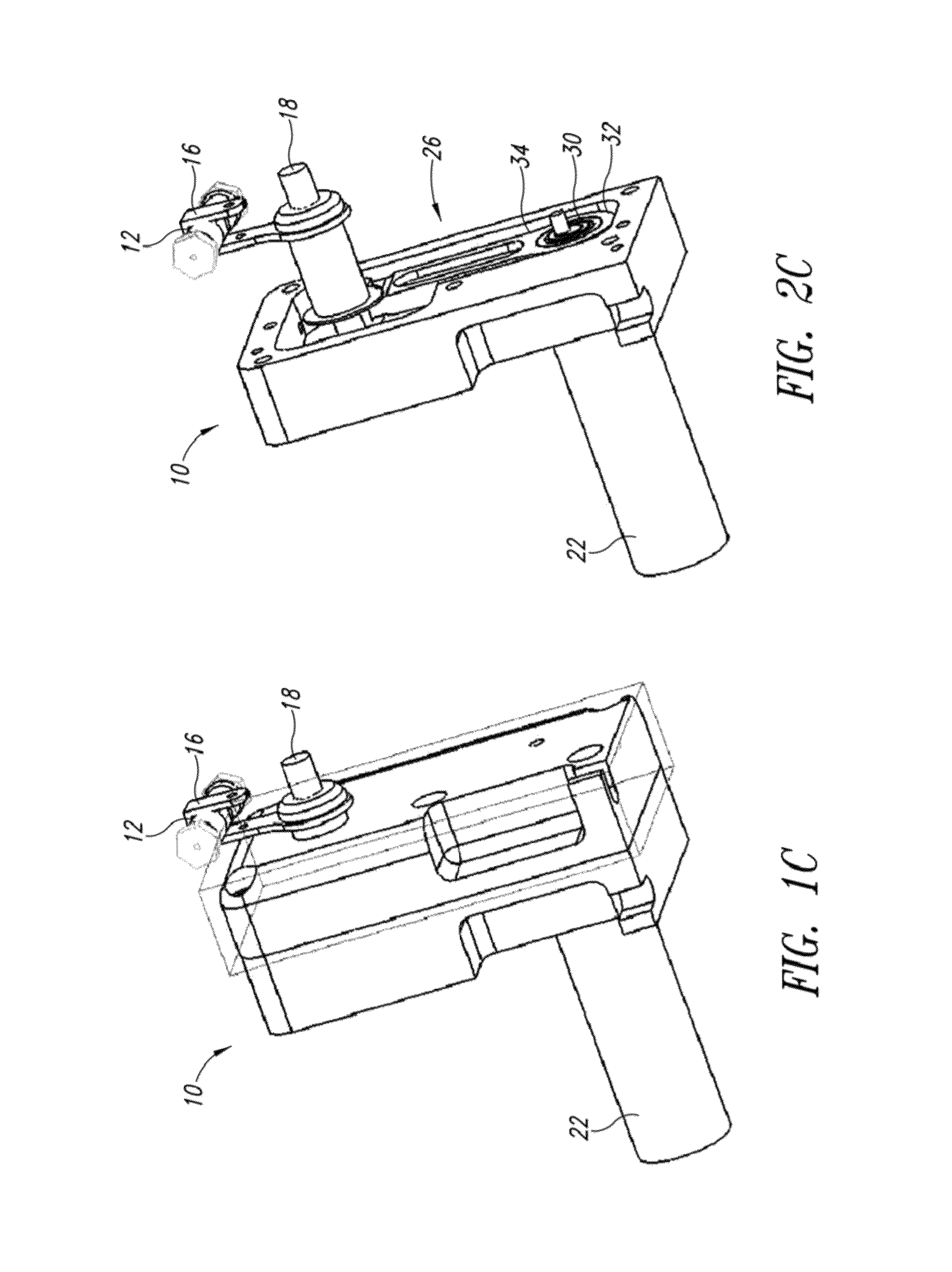

Sensor mounting apparatus for minimizing parasitic stress

ActiveUS7112749B2Minimize parasitic stressSufficiently robustVehicle seatsElectric devicesEngineeringParasitic structure

A compliant interface (14,16) for vehicular seat weight sensors minimizes parasitic stresses affecting sensor output. In one embodiment, an integral compliant interface (14) has an annular flange (14a) attached to a post extending from the sensor body with a first compliant member (14r) disposed between the annular flange and an upper elongated flange (14h) of a mounting bracket (14l) and a second compliant member (14s) disposed between the annular plate and a lower elongated flange (14k) to allow pivotal movement of the sensor limited by a motion stop member (14f) of annular flange (14b) engaging the lower flange. An overload cage (14u) may be placed over the sensor and attached to an additional flange (14l) to contain the sensor in the event of a failure of the mount in a catastrophic high speed crash. According to another preferred embodiment, an interface having upper and lower body members are formed with a sensor post receiving bore (16c) for attachment to the post. The body members are formed with spaced apart, radially extending face surfaces, each formed with an annular recess aligned with each other and with a compliant member received therein and fixed to the respective body members and extending beyond the face surfaces. The interface is received through a bore of a support plate to which the sensor is mounted with the compliant members engaging opposite face surfaces of the support plate allowing limited pivotal motion and with a compliant member limiting lateral movement of the interface relative to the support plate.

Owner:SENSATA TECHNOLOGIES INC

Light emitting diodes with reflective electrode and side electrode

InactiveUS7592637B2High trafficDepth toleranceSolid-state devicesSemiconductor devicesEdge surfaceLight-emitting diode

A light emitting diode includes a first doped semiconductor layer, an active region and a second doped semiconductor layer. The first reflective electrode of the light emitting diode is connected to the edge surfaces of the first doped semiconductor layer. The second reflective electrode includes an optically transparent layer and is connected to the second doped semiconductor layer. The second reflective electrode may include a plurality of electrically conductive contacts extending from a reflective conductive metallic layer through a transparent layer. A method is described for fabricating the light emitting diode.

Owner:GOLDENEYE

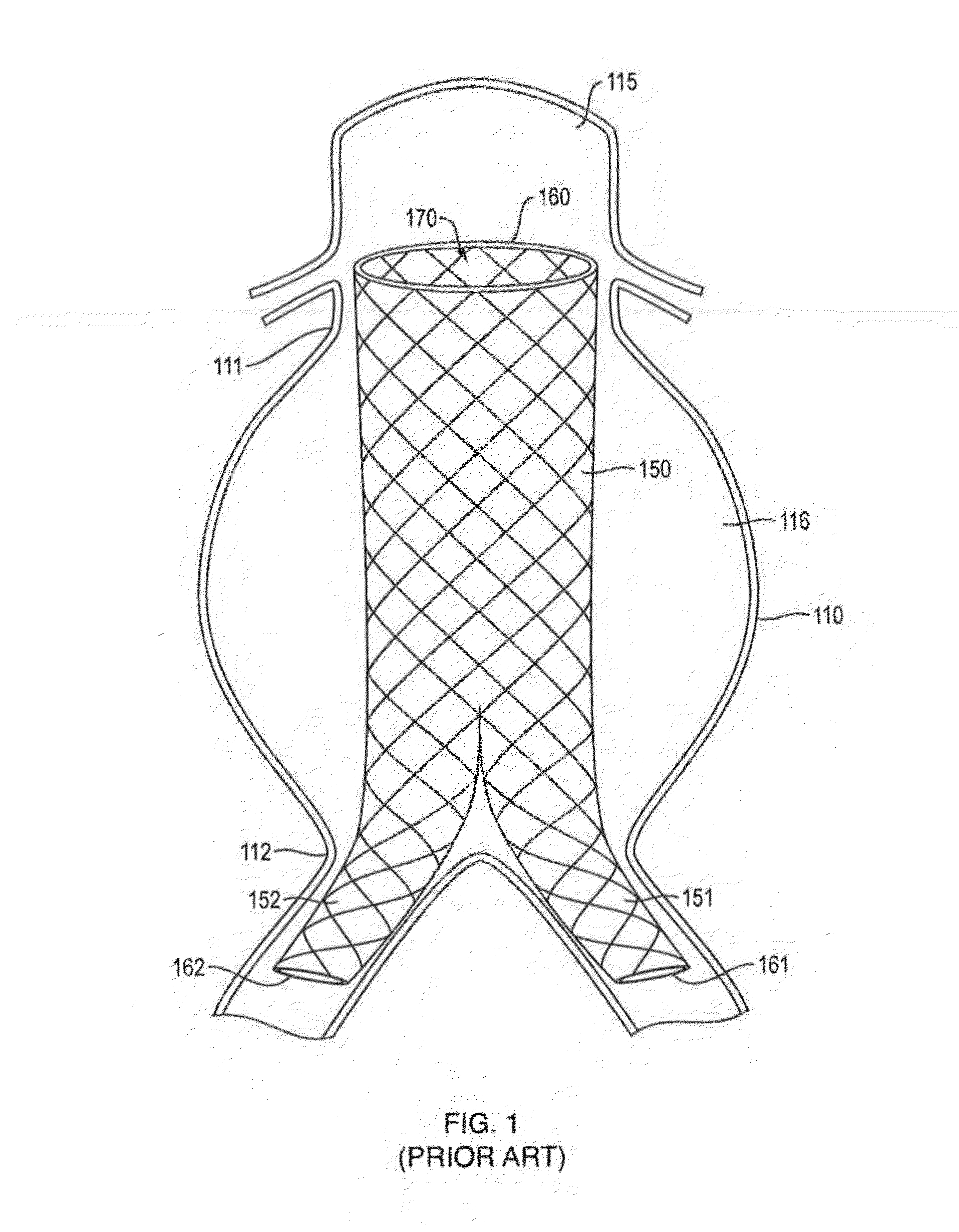

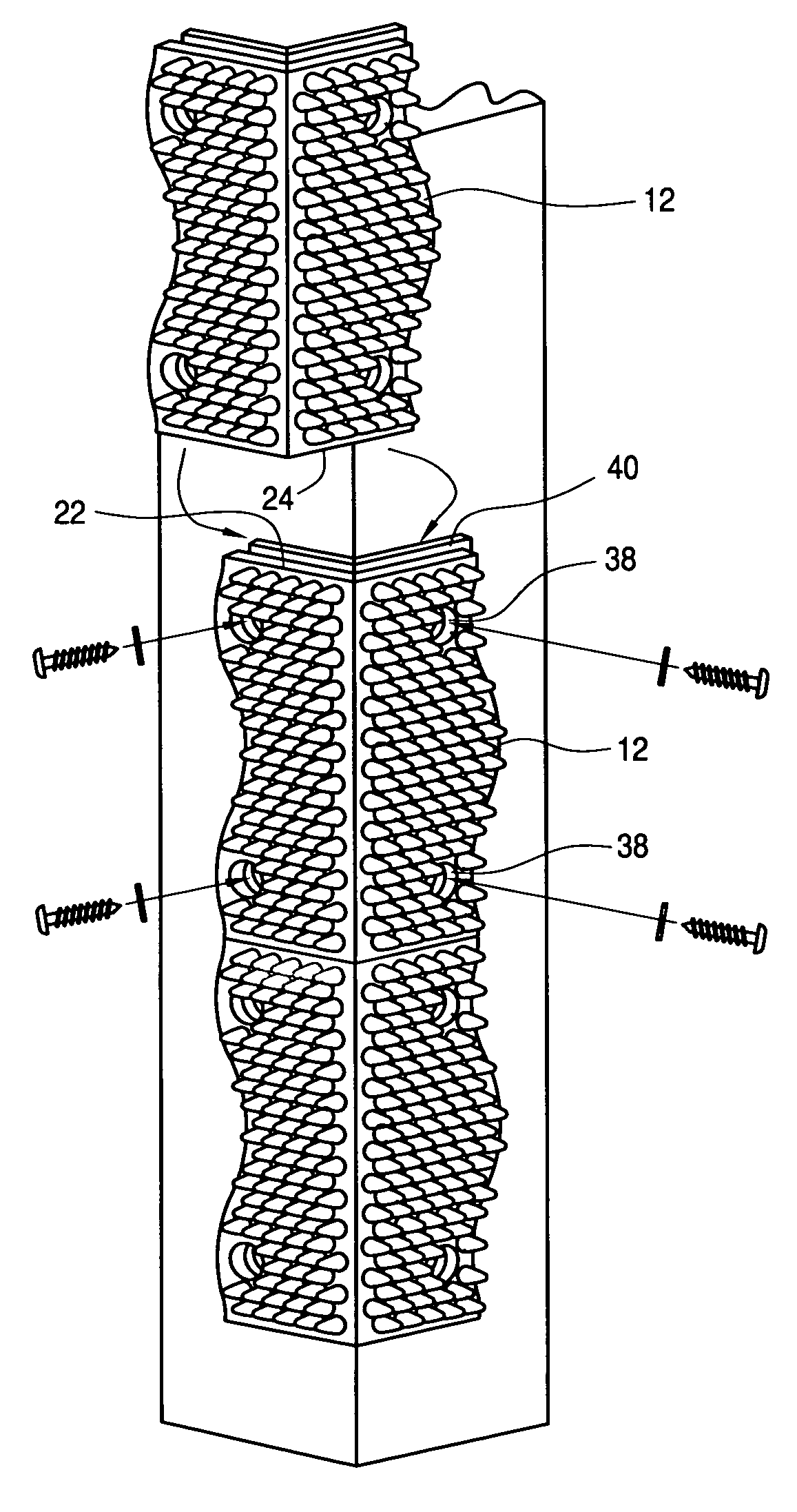

Porous membranes for medical implants and methods of manufacture

Owner:ABBOTT LAB VASCULAR ENTERPRISE

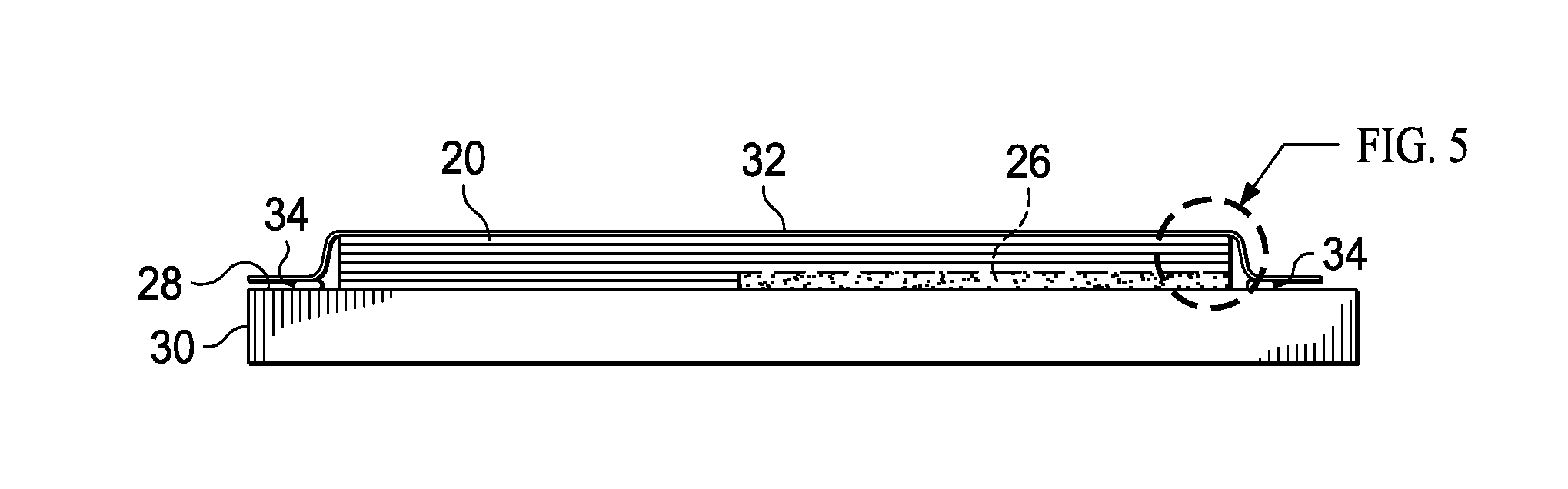

Optical fiber cables

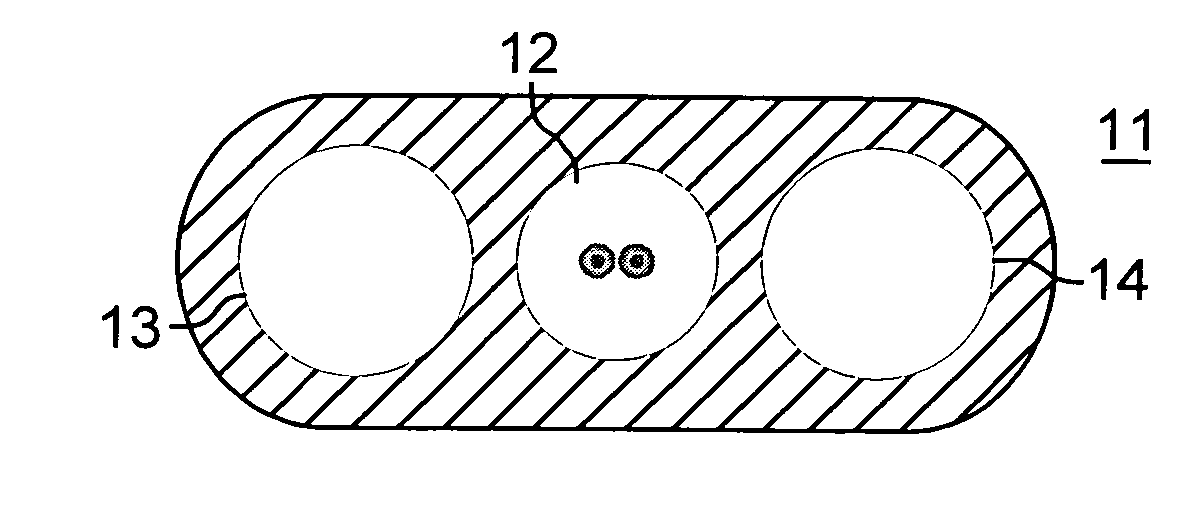

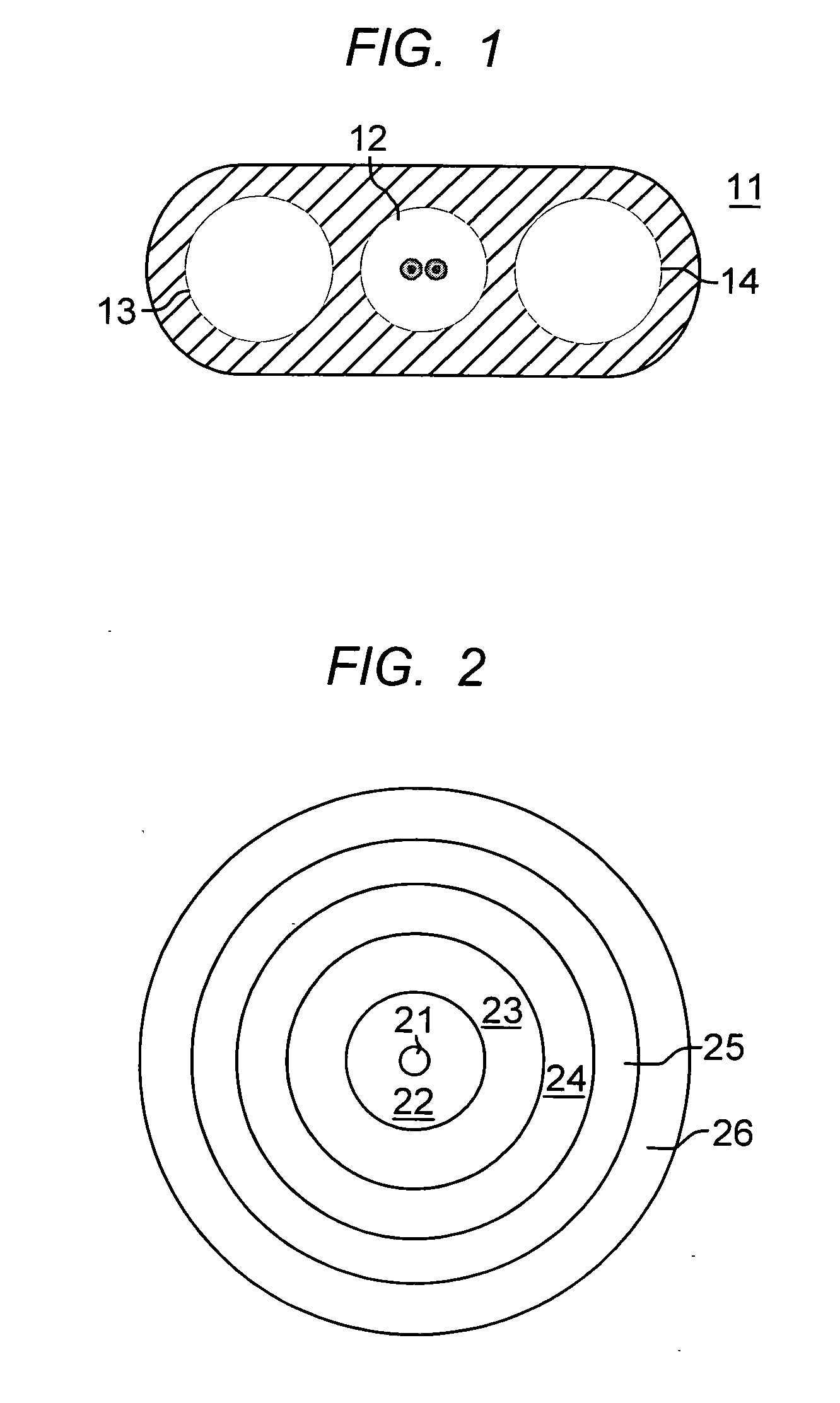

InactiveUS20090087148A1Small sizeLow costCoupling light guidesFibre mechanical structuresFiberEngineering

An optical fiber cable suitable for drop cable applications has a dual jacket, dual reinforcement layers, a round cross section, and a tight buffered construction. The optical fiber cable is a compact unitary coupled fiber assembly that has a small profile, and is light in weight, while still sufficiently robust for many indoor / outdoor drop cable installations. The small profile and round construction make the cable easy to connectorize.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

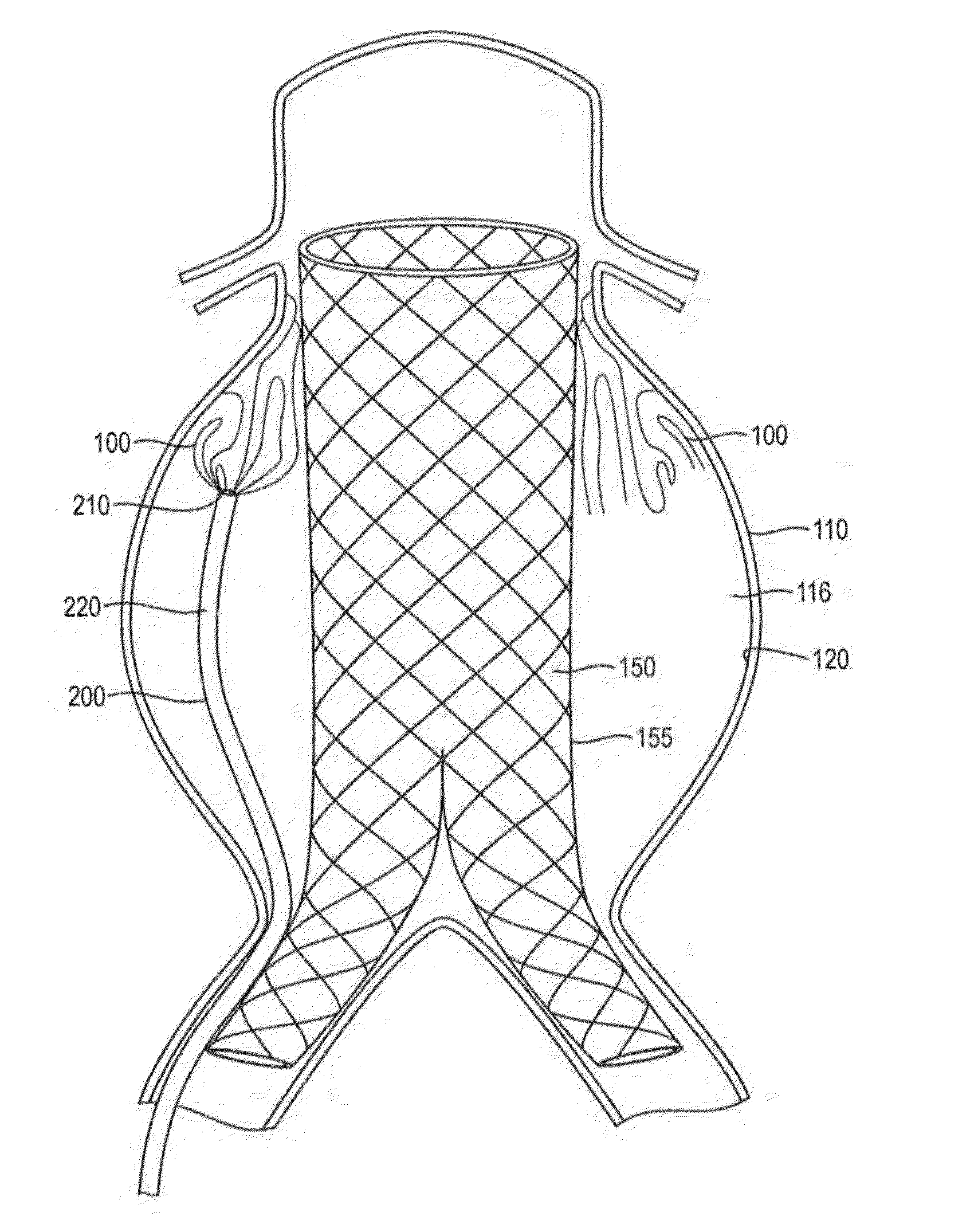

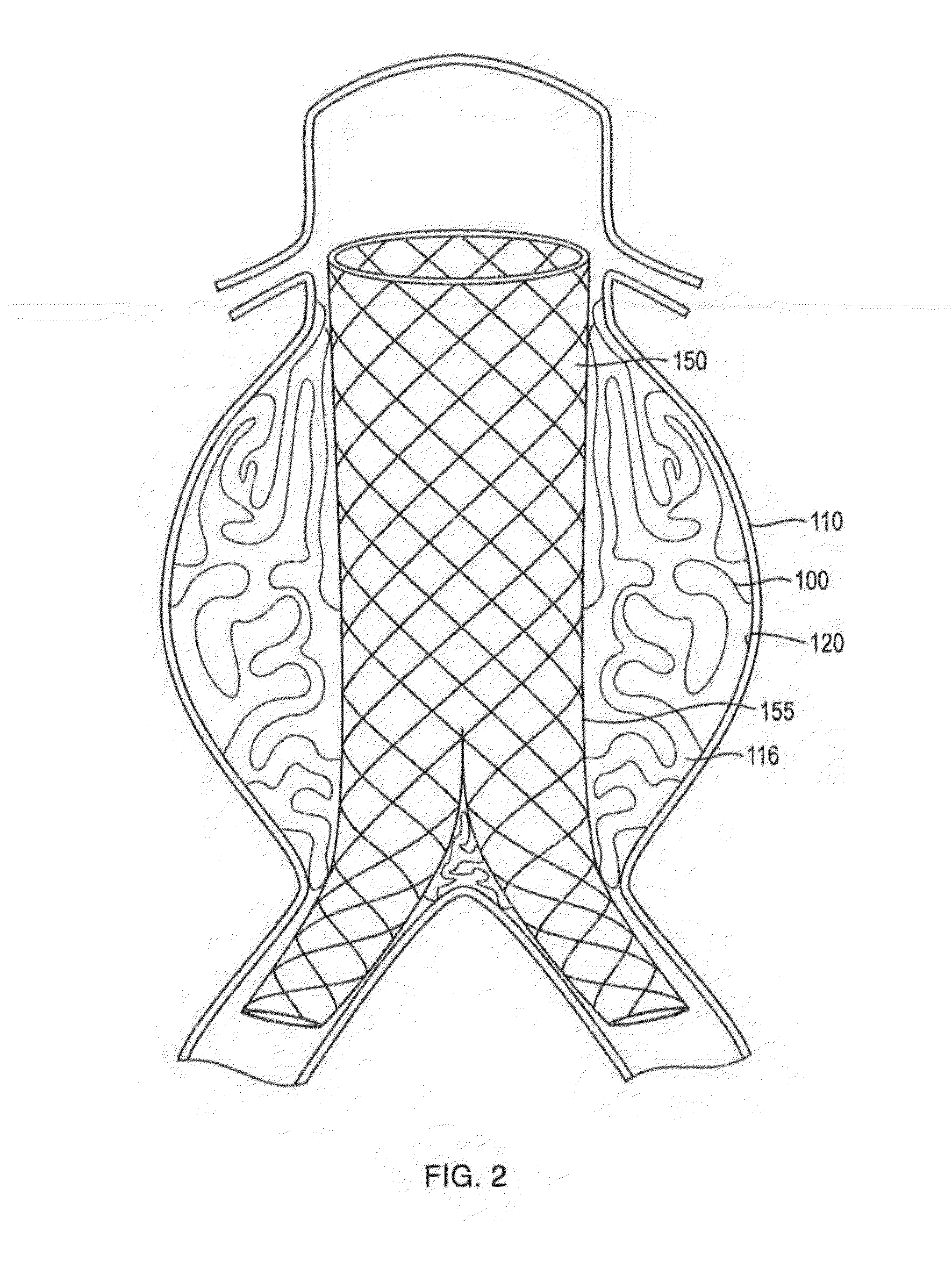

Porous membranes for medical implants and methods of manufacture

The present invention involves porous polymer membranes, suitable for use in medical implants, having controlled pore sizes, pore densities and mechanical properties. Methods of manufacturing such porous membranes are described in which a continuous fiber of polymer is extruded through a reciprocating extrusion head and deposited onto a substrate in a predetermined pattern. When cured, the polymeric material forms a stable, porous membrane suitable for a variety of applications, including reducing emboli release during and after stent delivery, and providing a source for release of bioactive substances to a vessel or organ and surrounding tissue.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

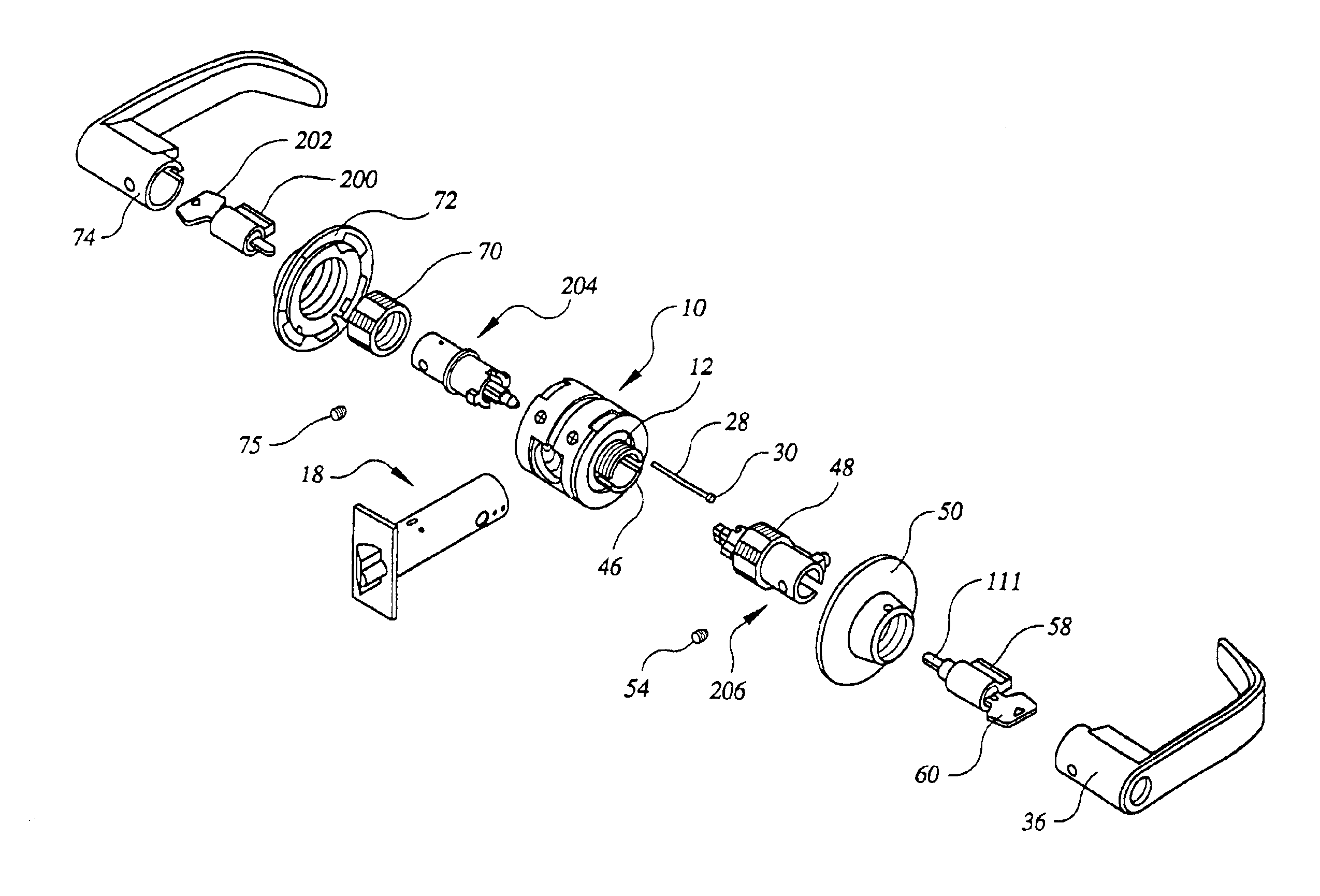

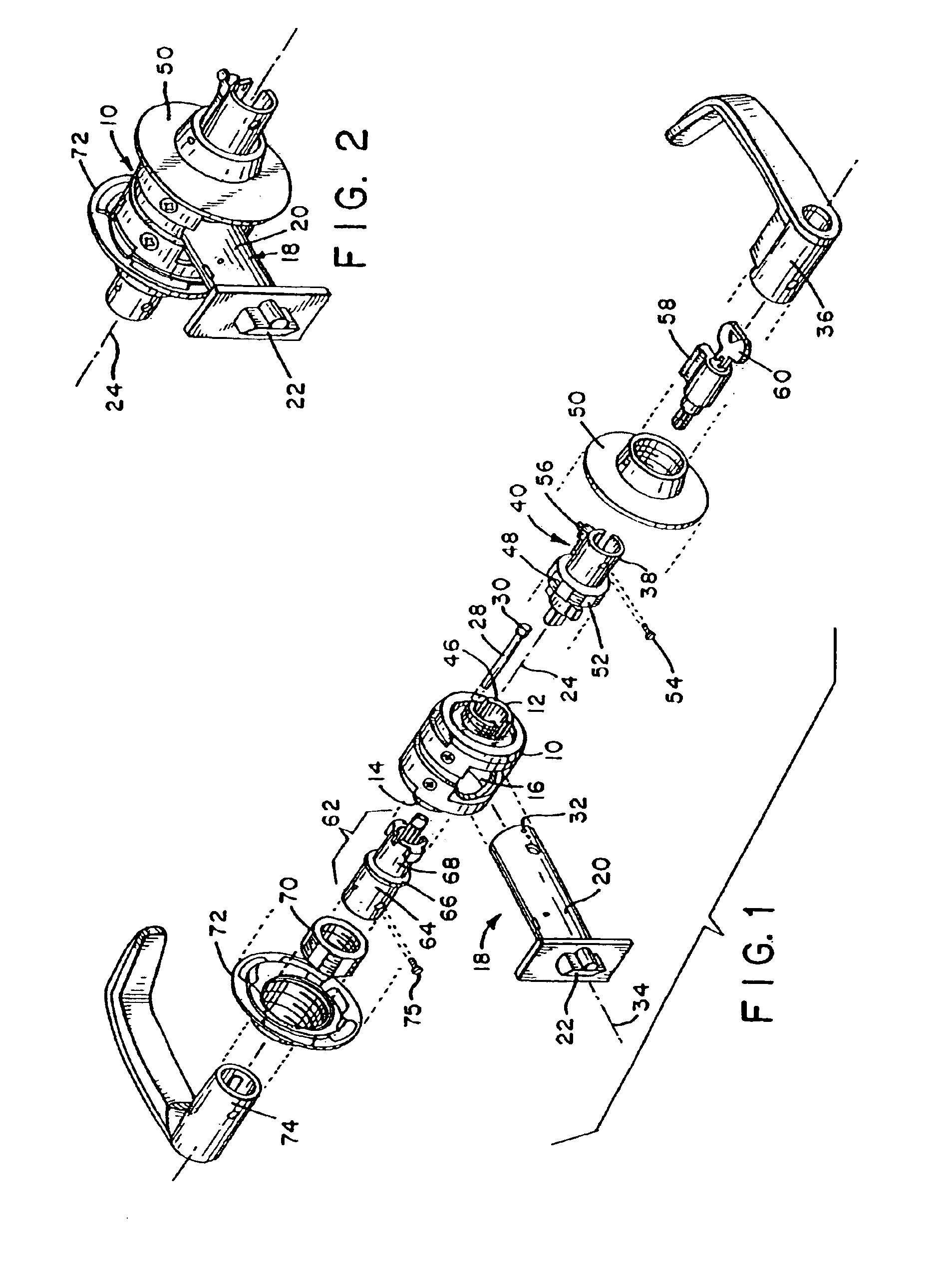

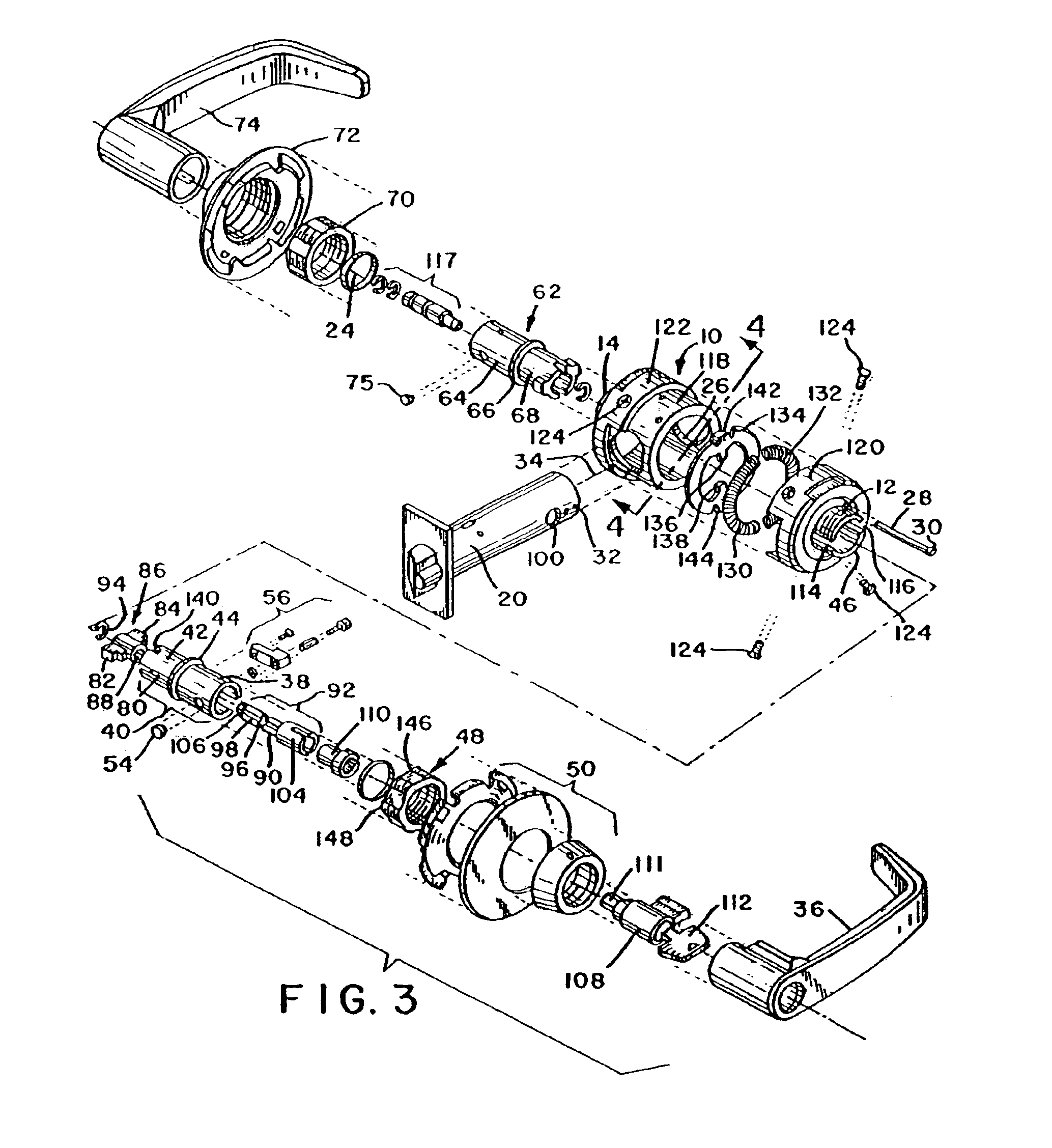

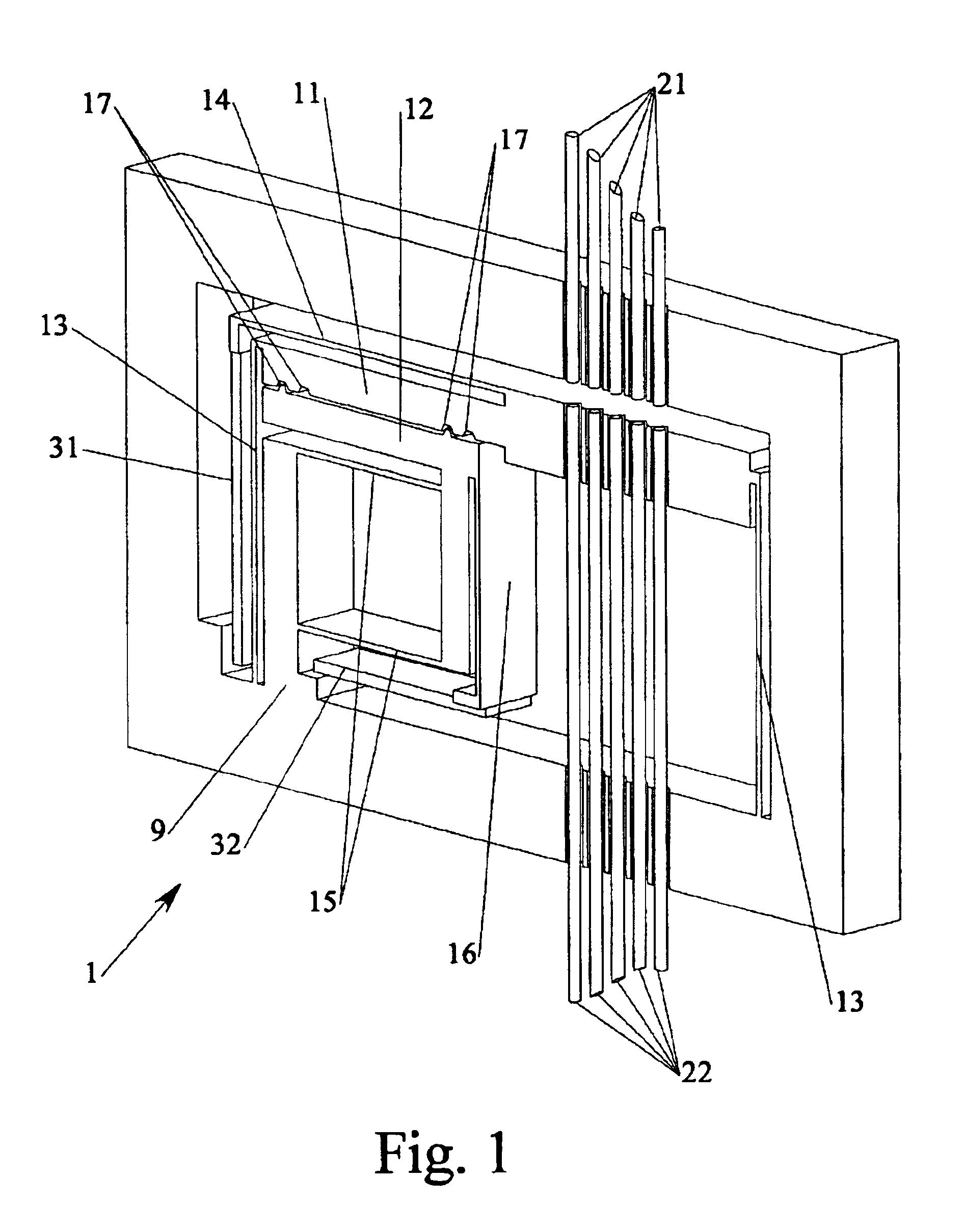

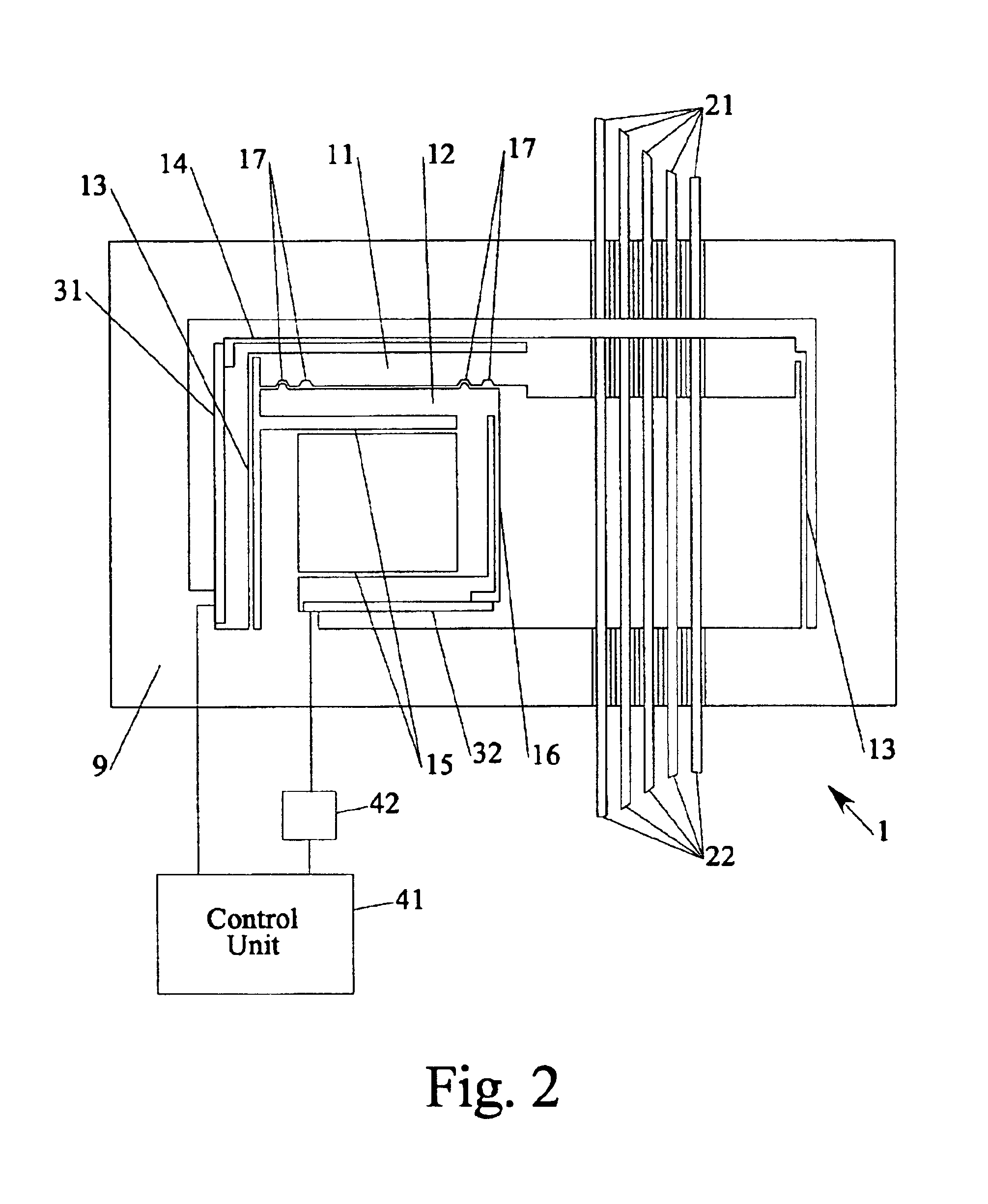

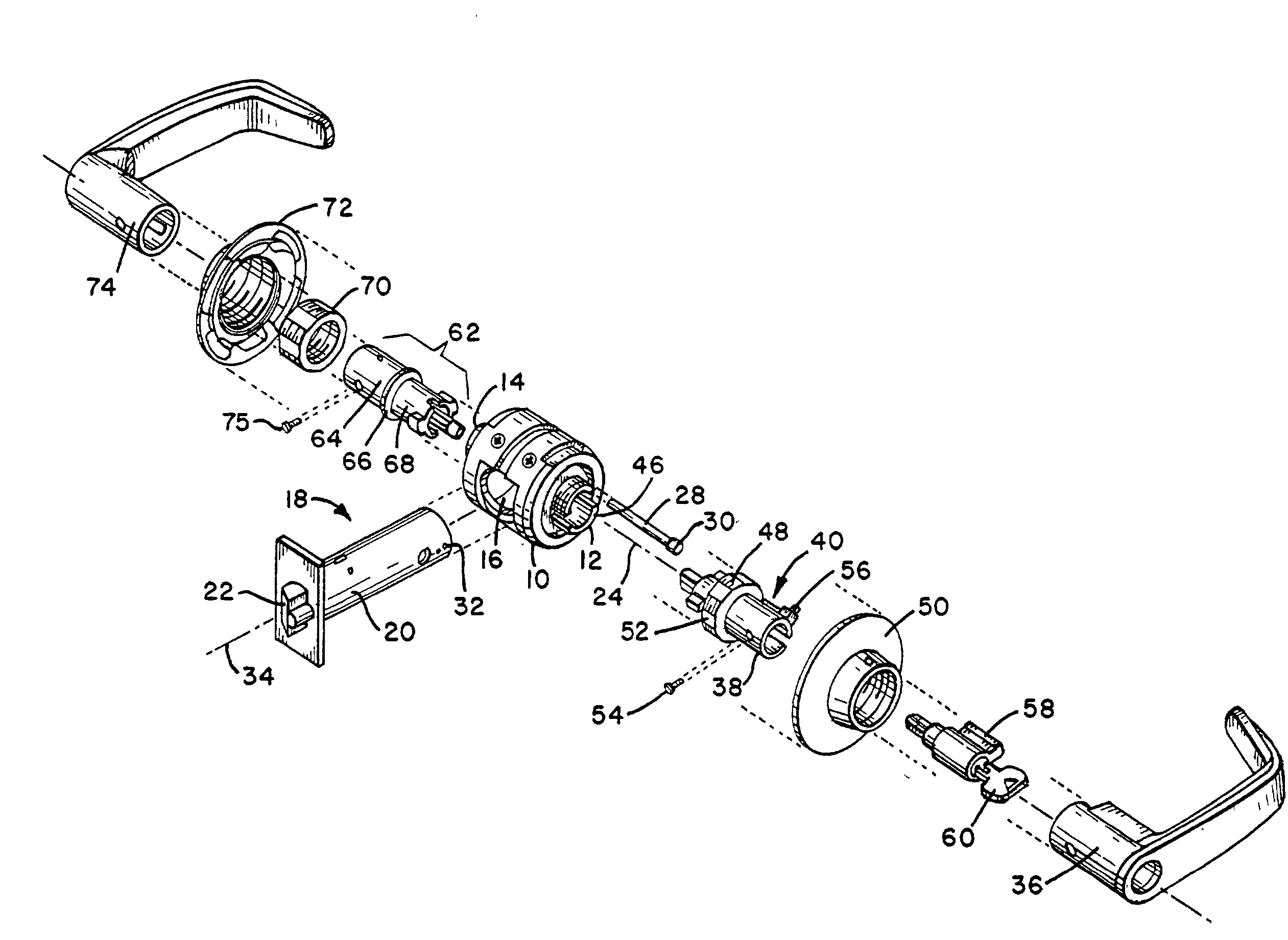

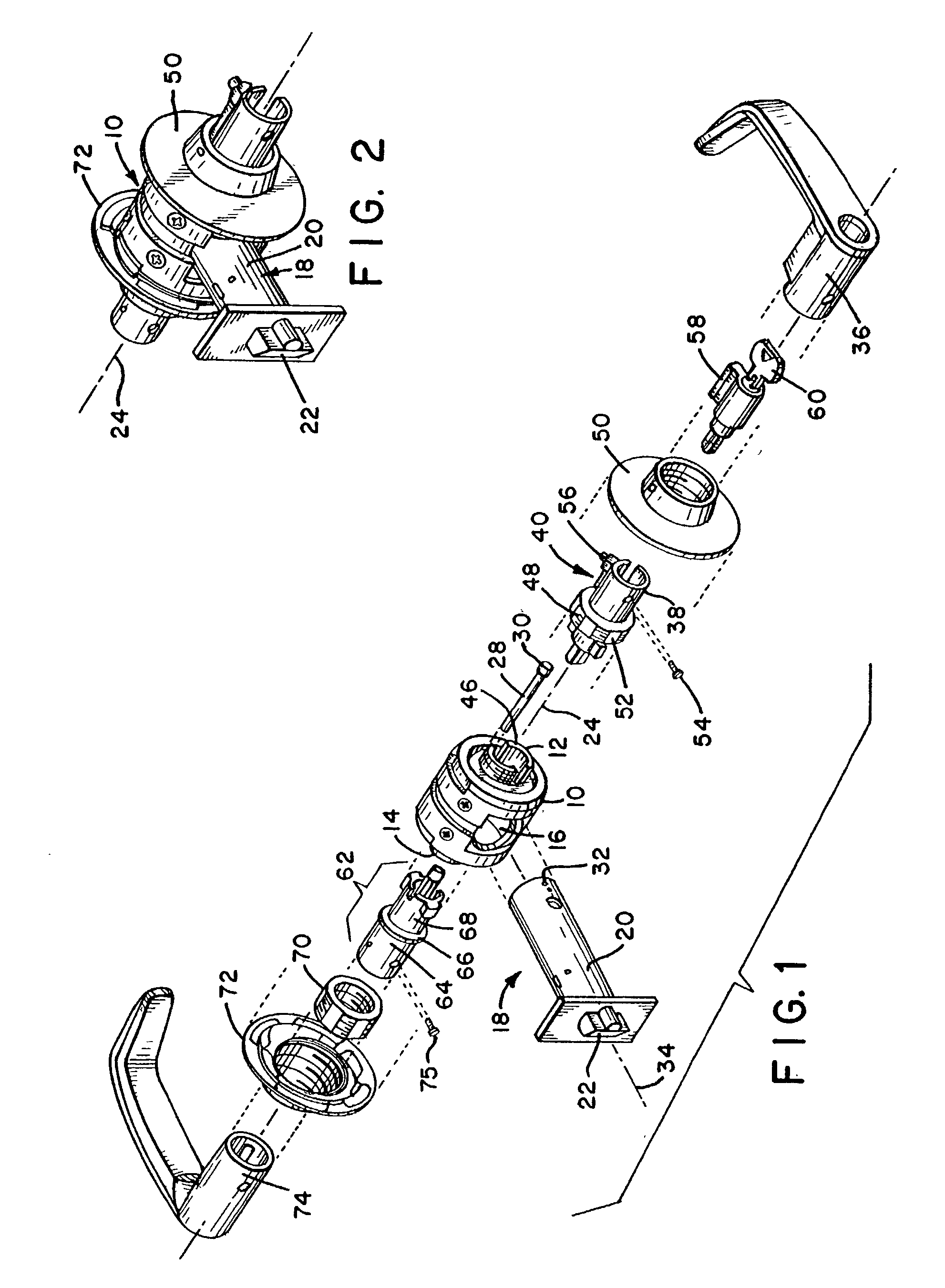

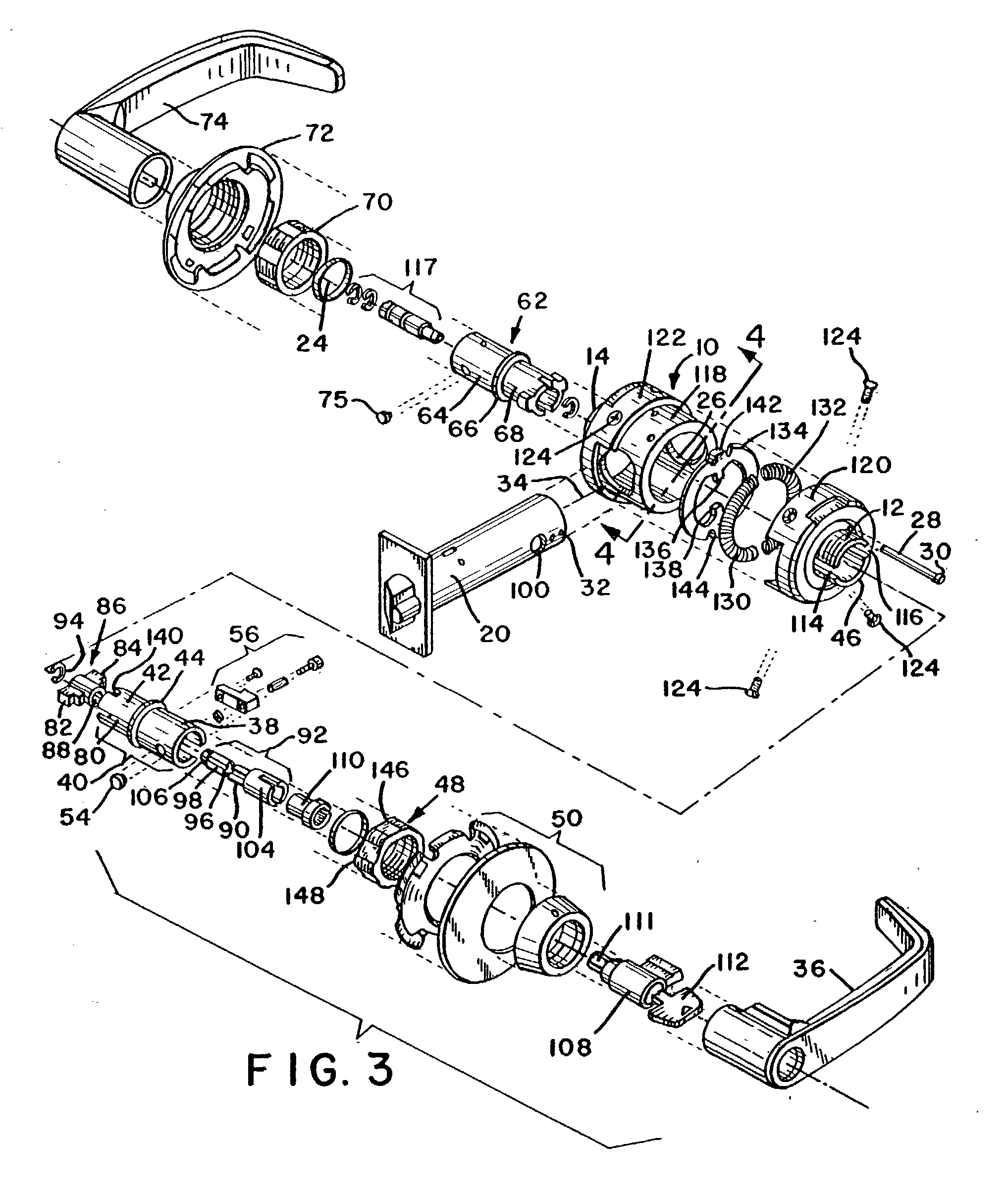

Security classroom function lock mechanism

InactiveUS6860129B2Sufficiently robustPrevent rotationAnti-theft cycle devicesWing handlesPositive controlLocking mechanism

Owner:SARGENT MANUFACTURING CO INC

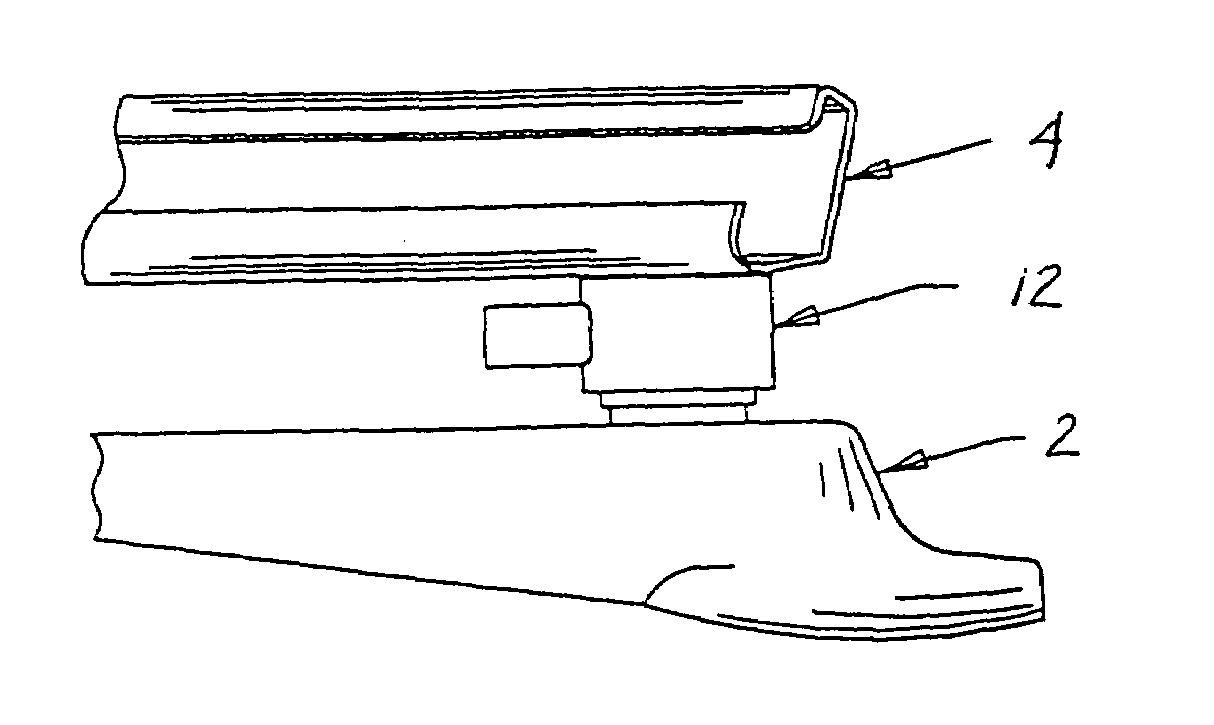

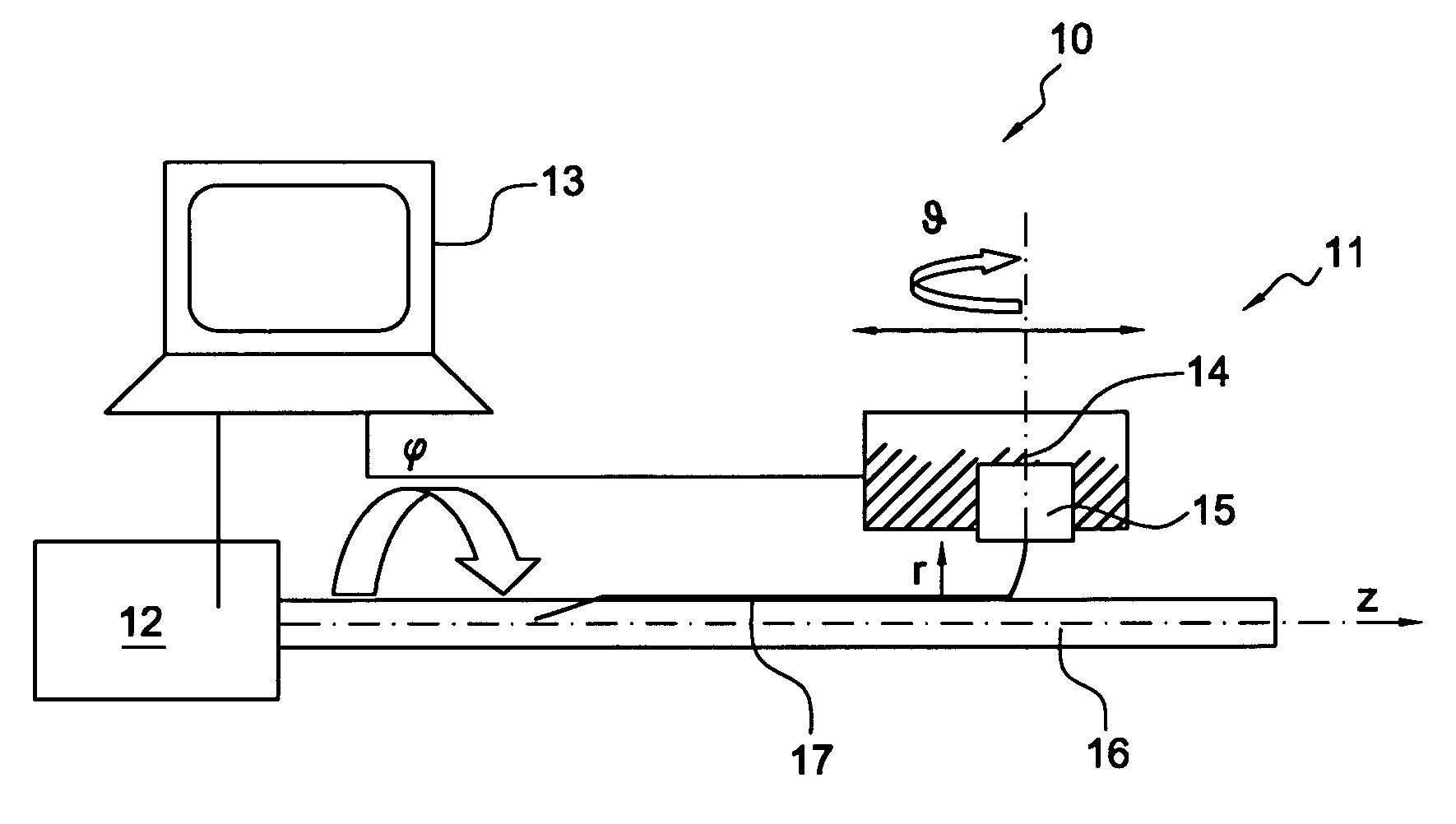

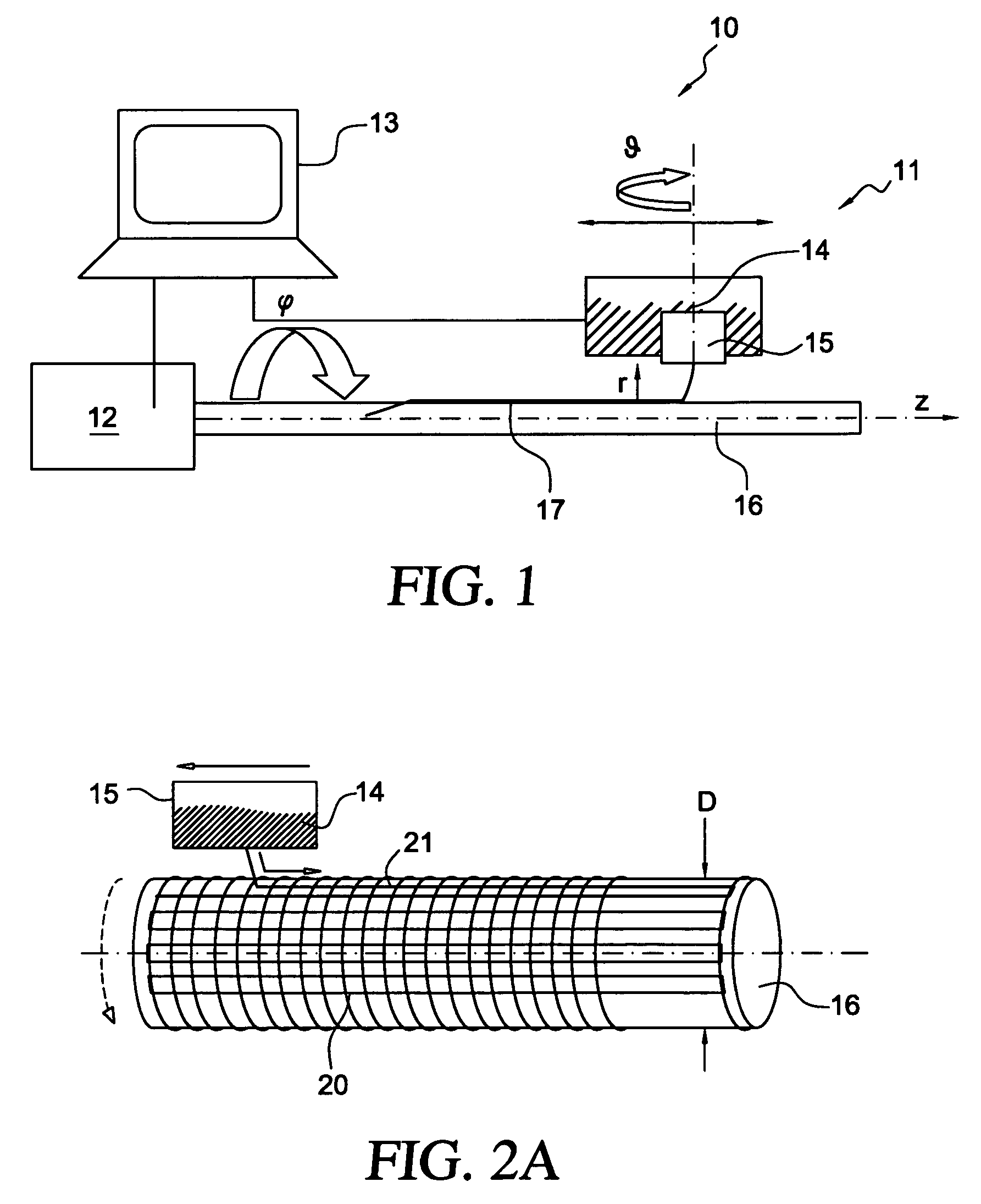

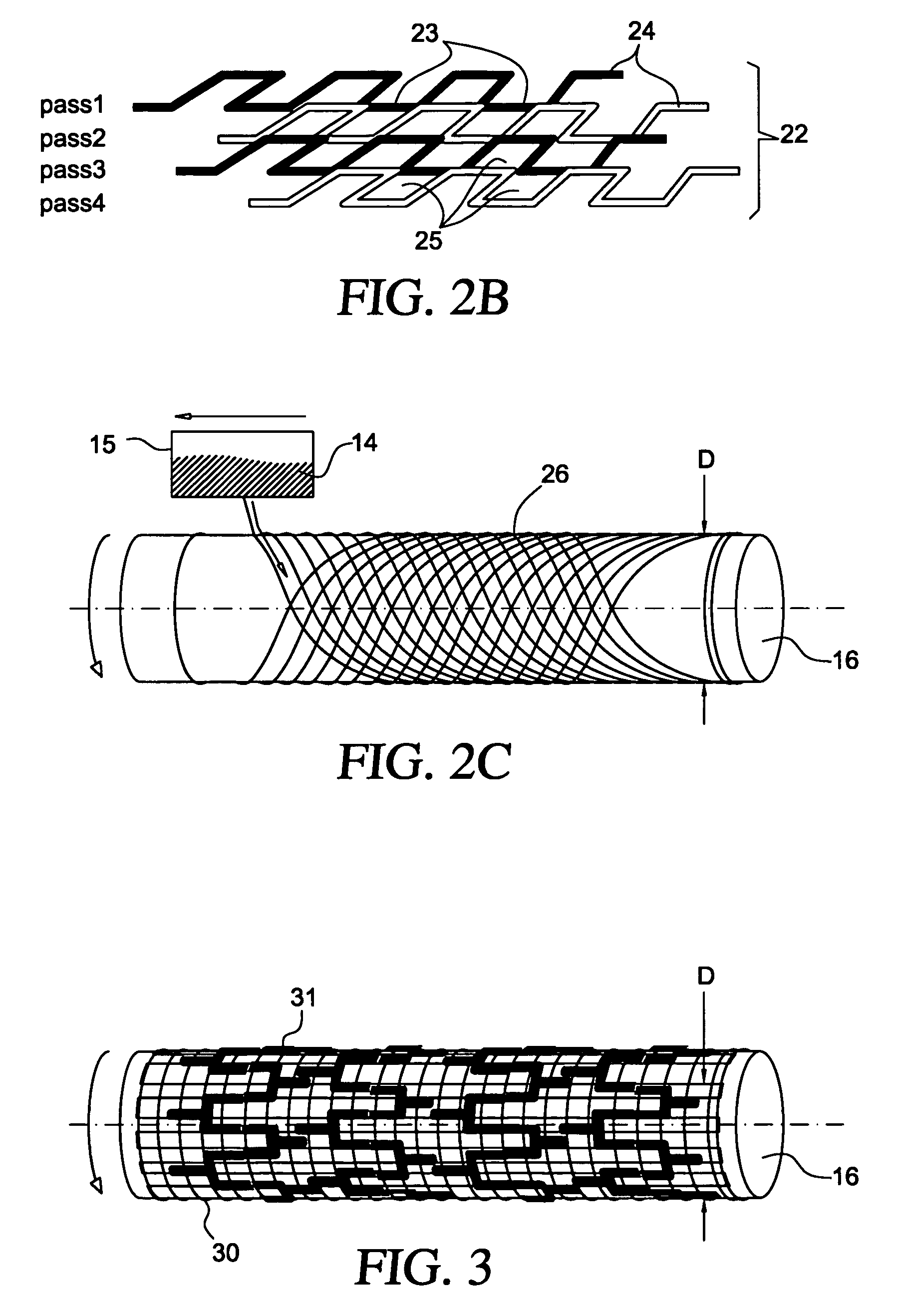

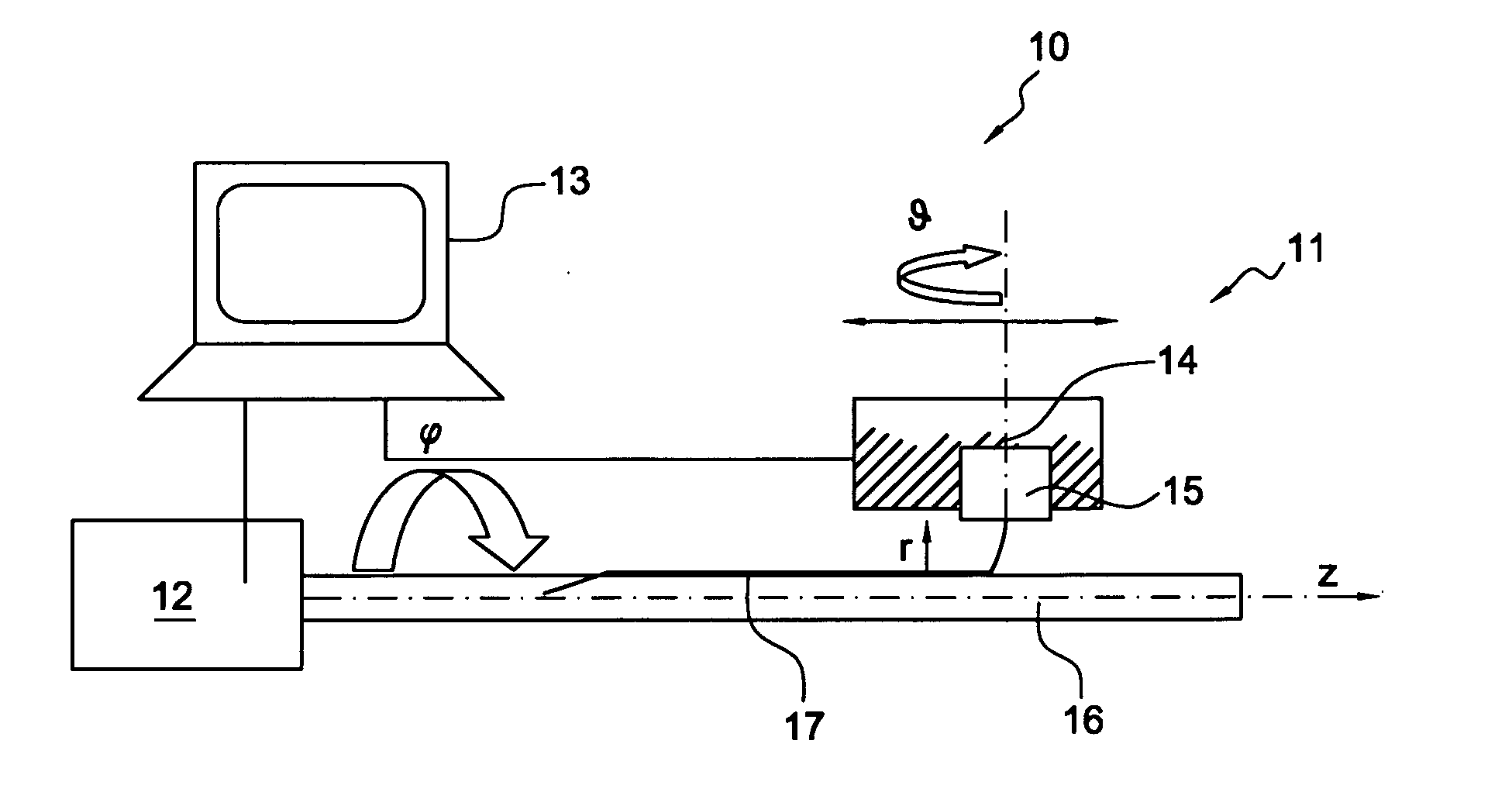

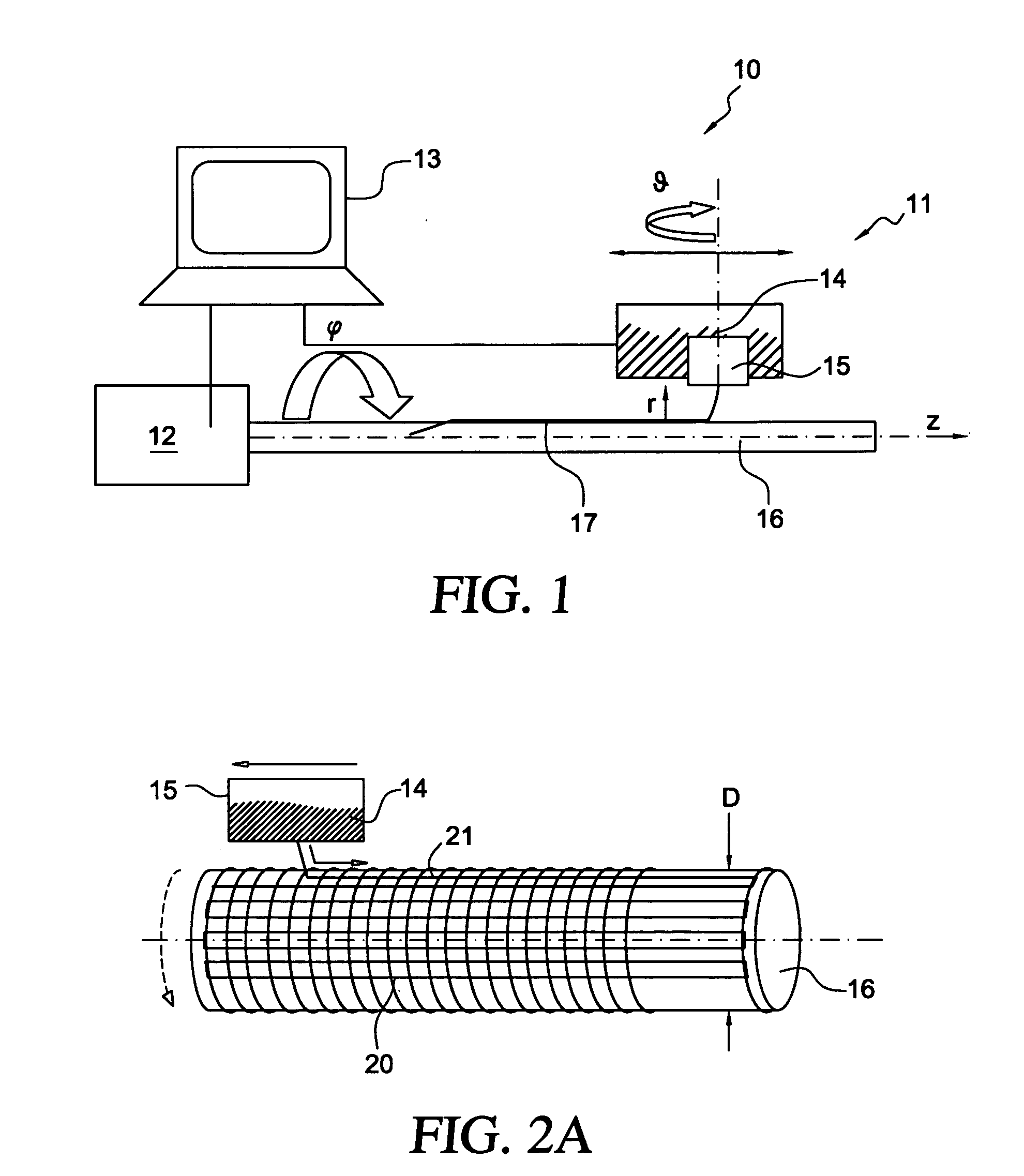

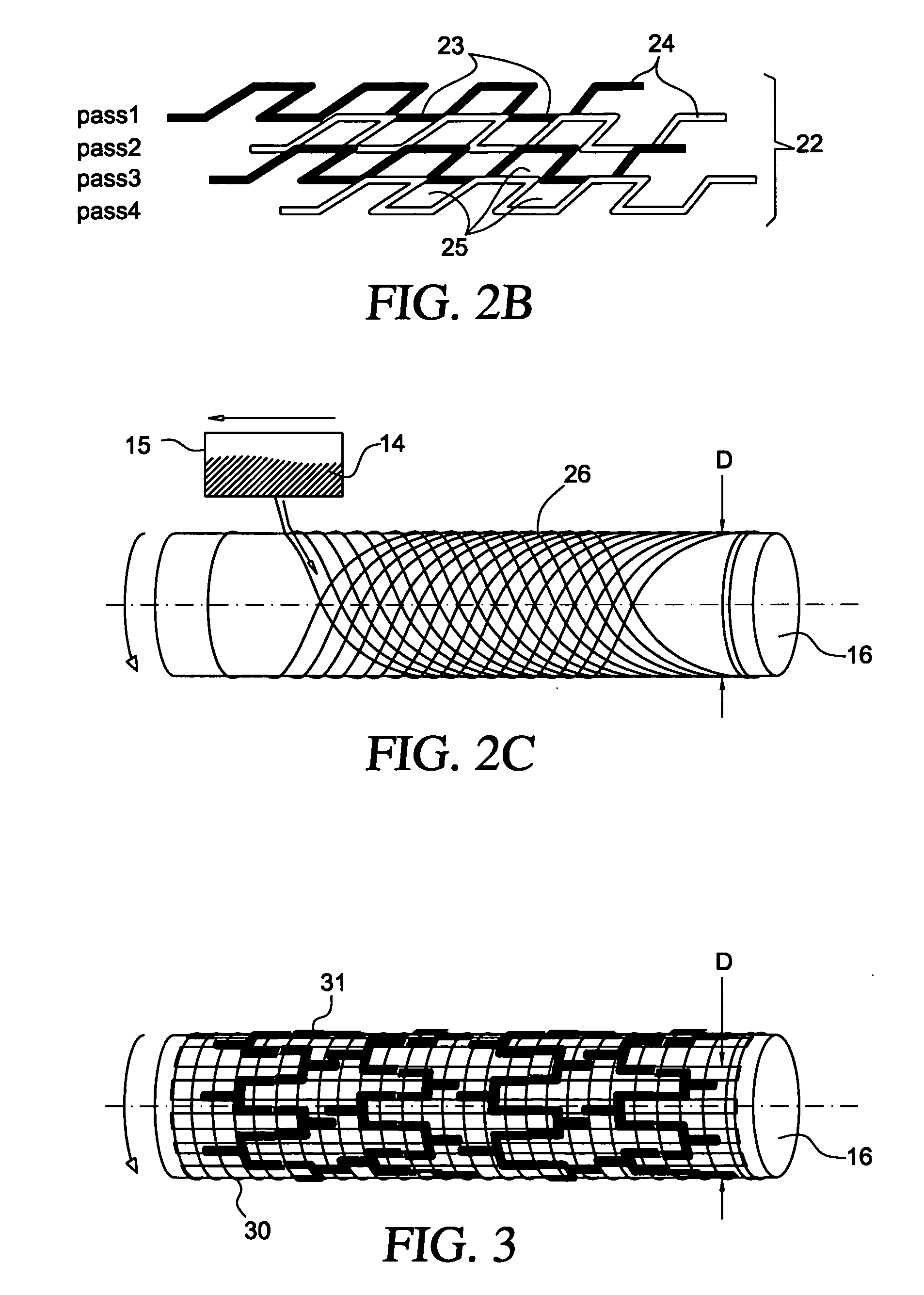

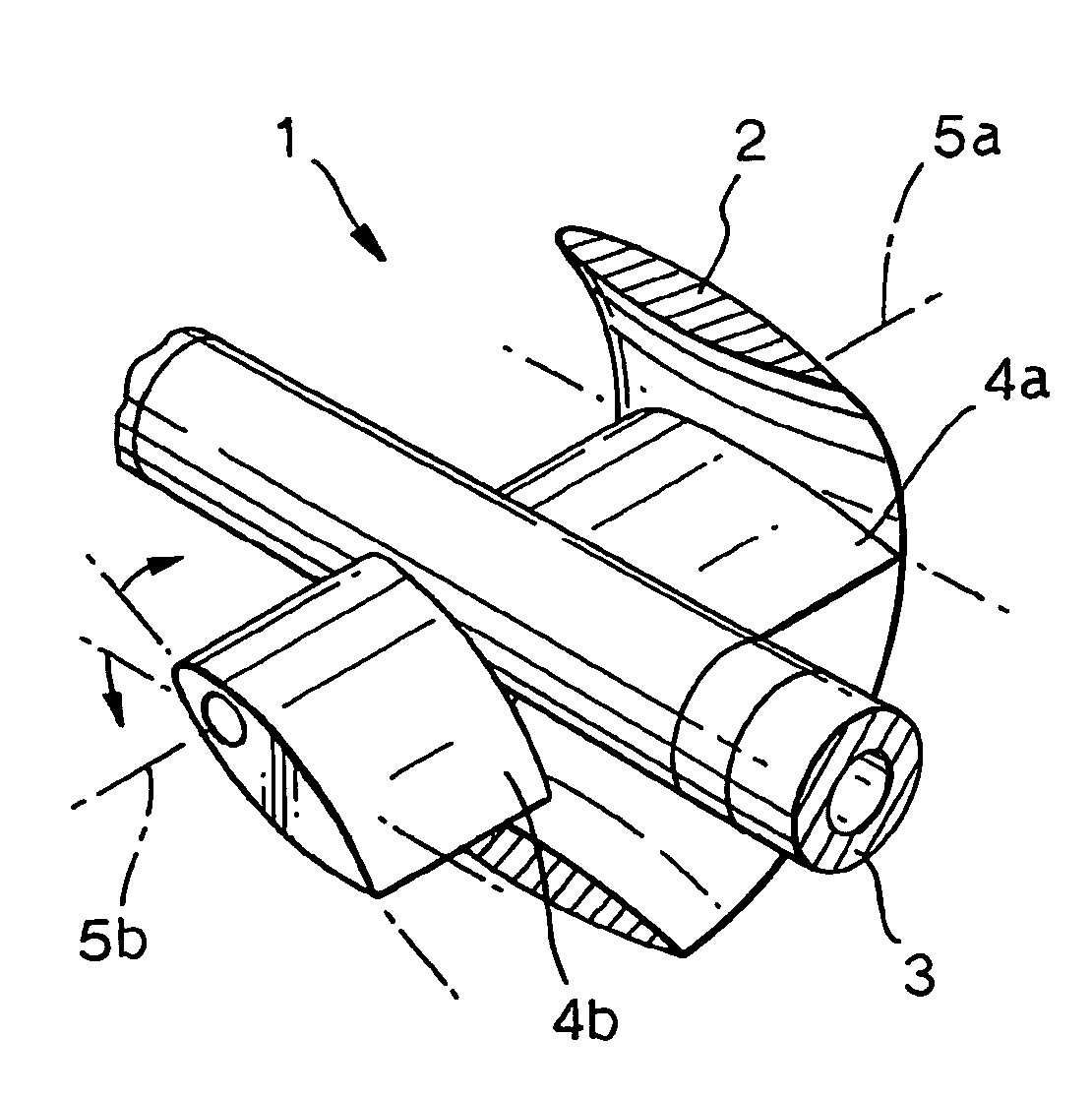

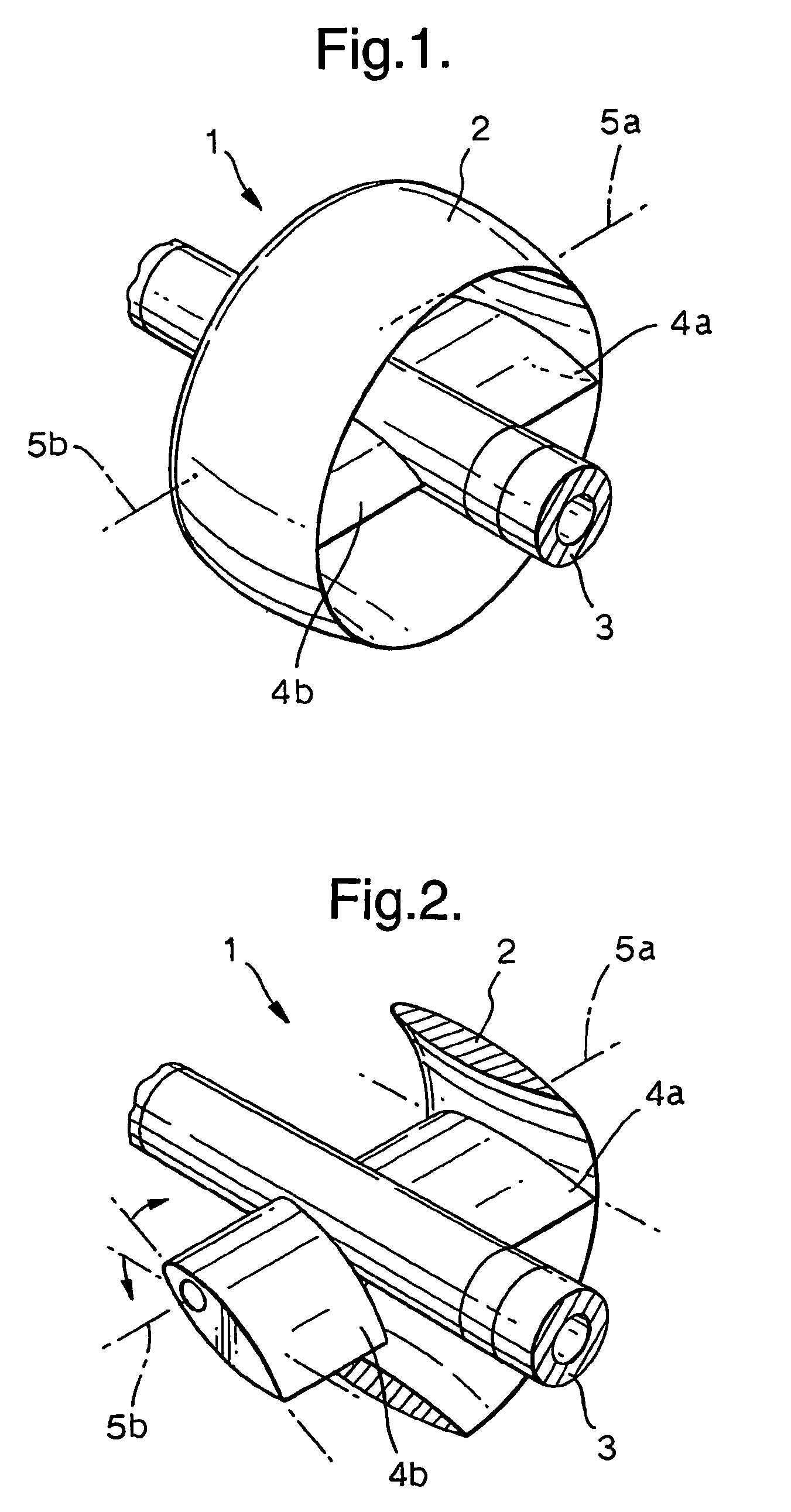

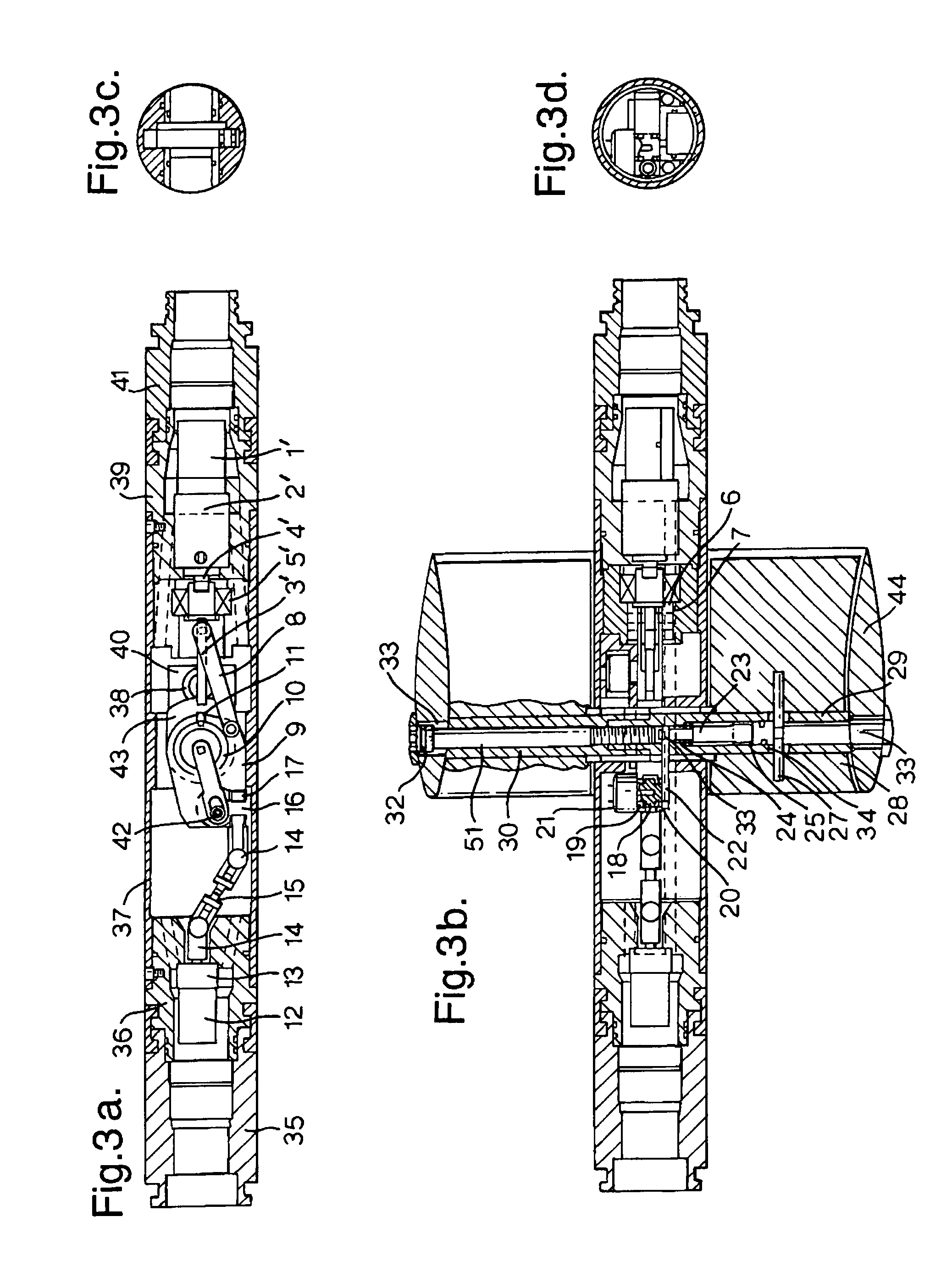

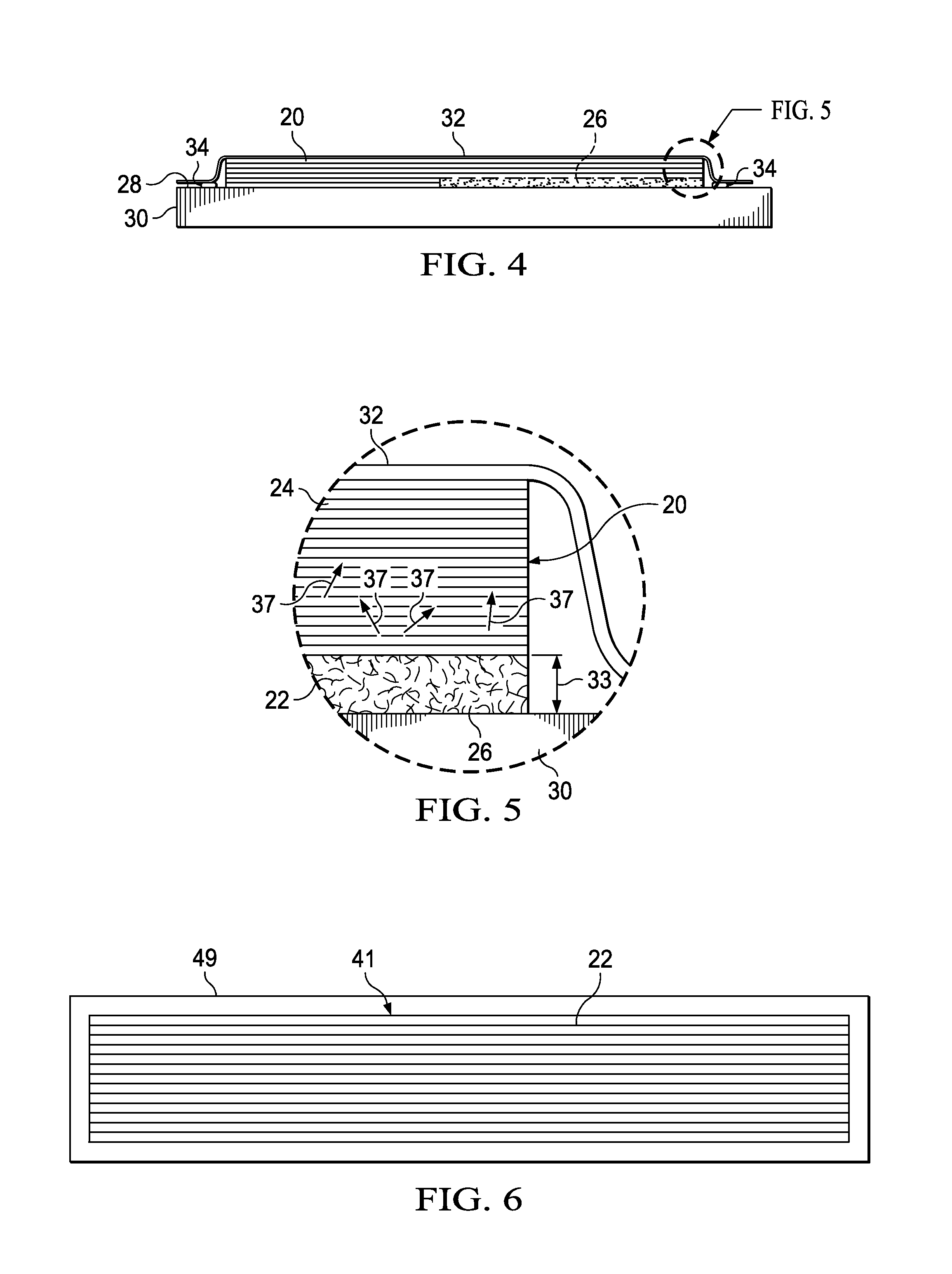

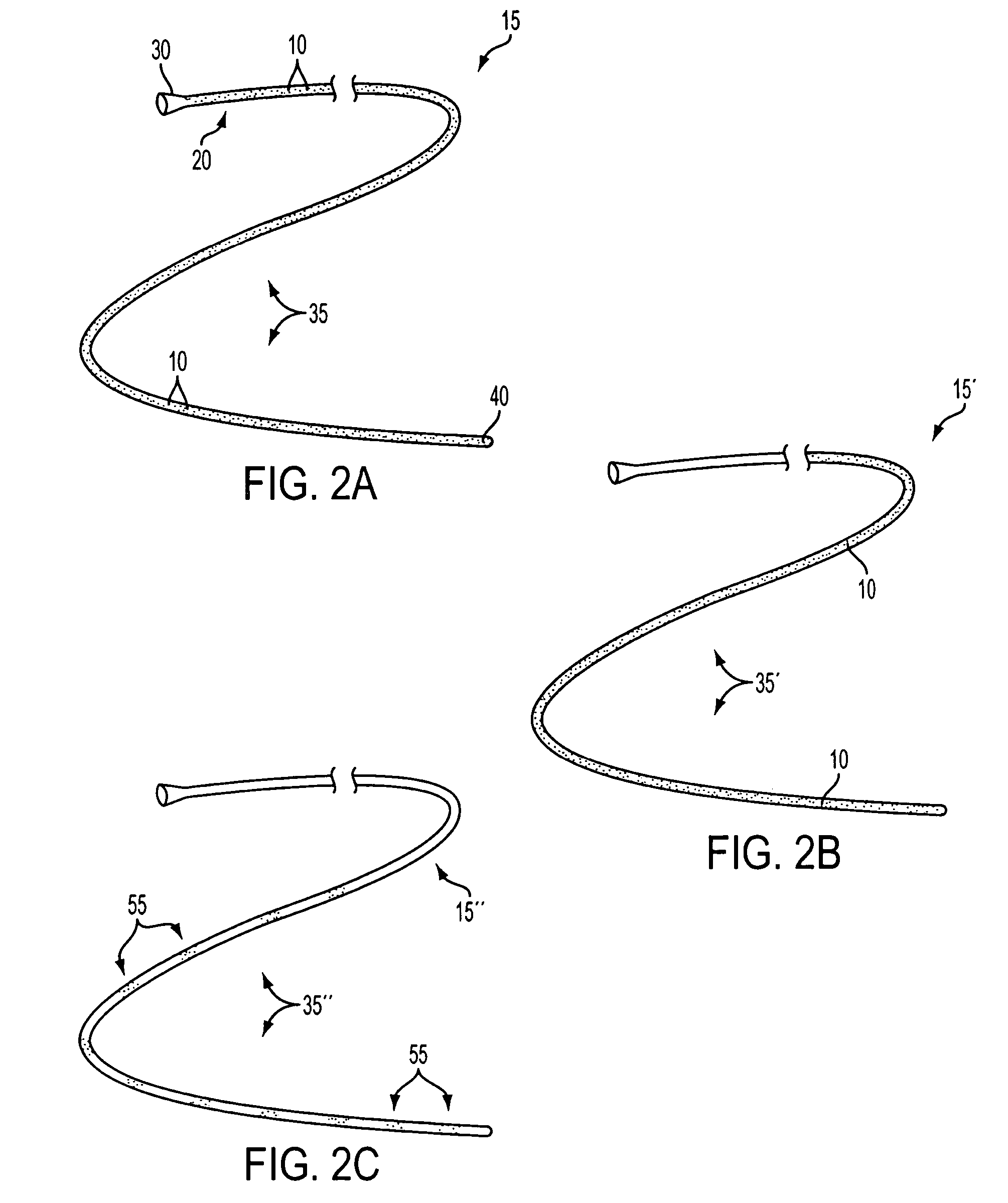

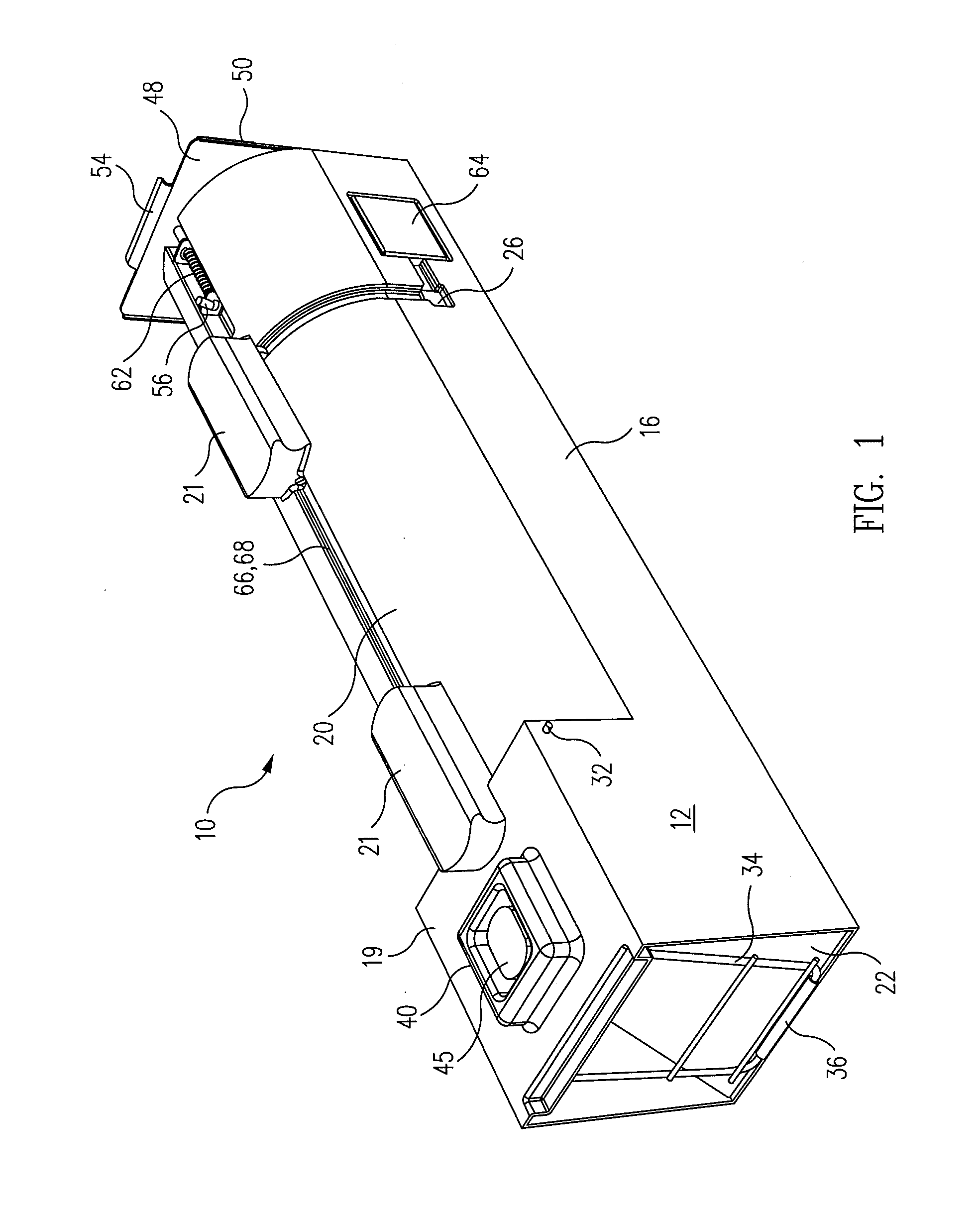

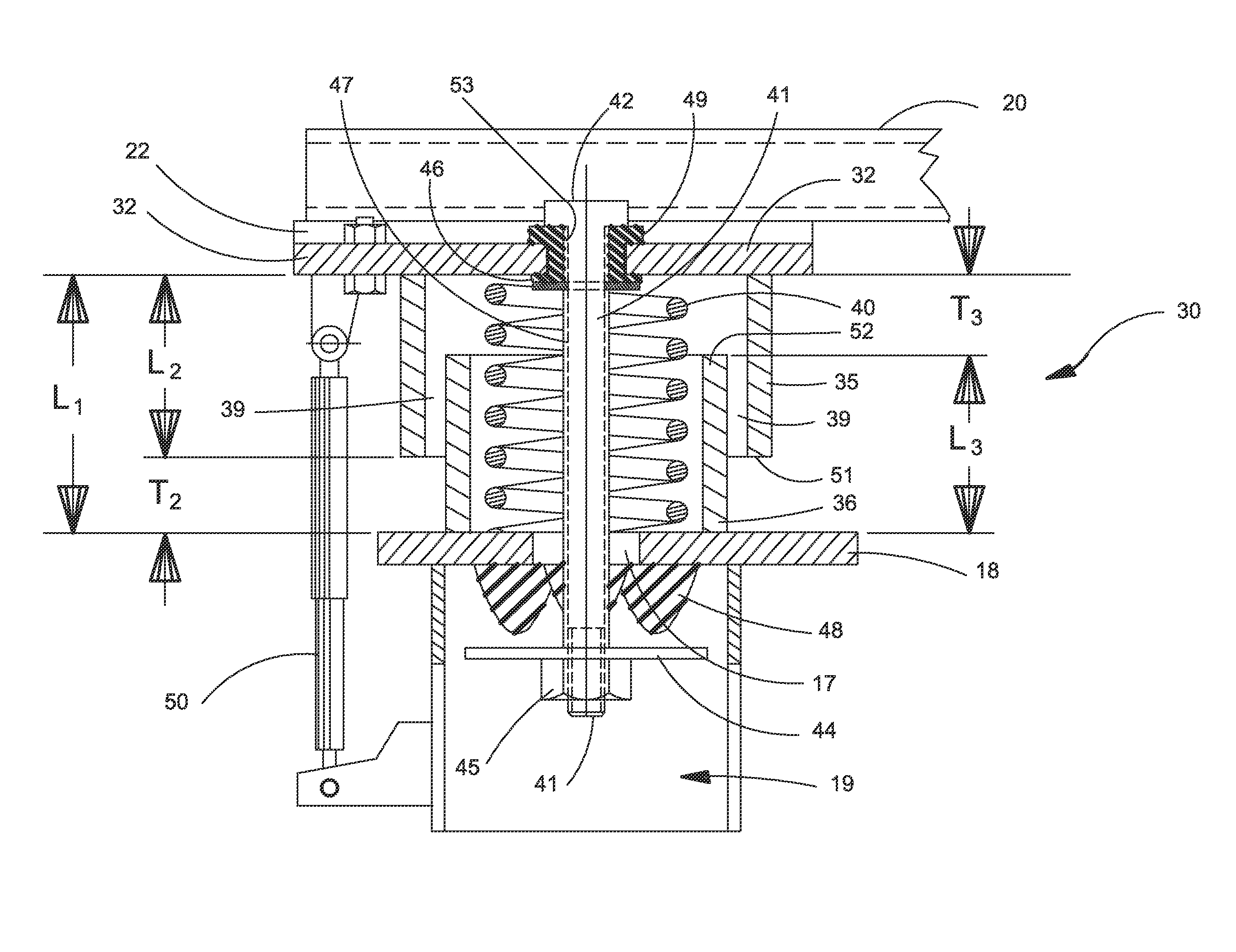

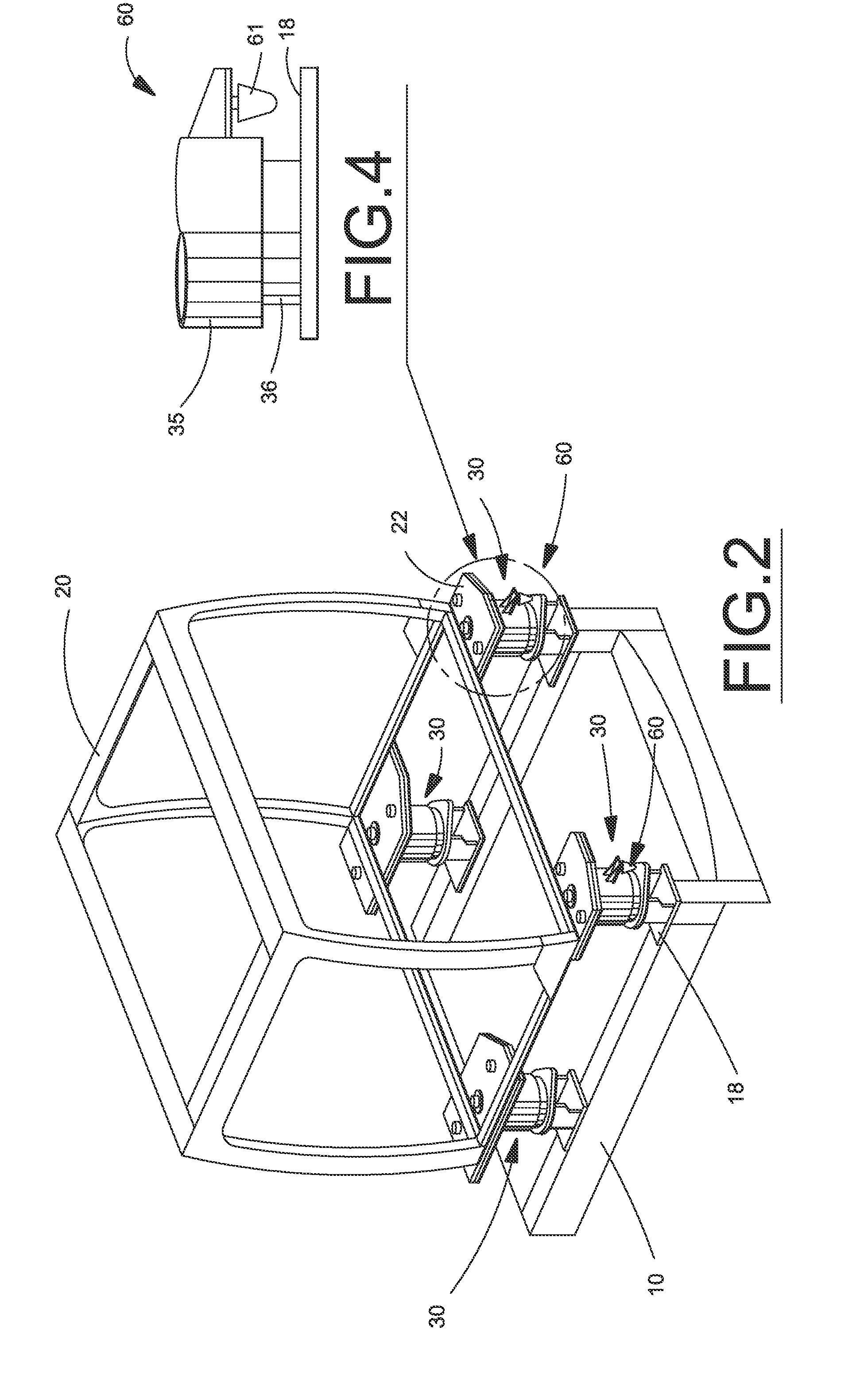

Control device for controlling the position of a marine seismic streamer

InactiveUS6985403B2Minimising the forces required to control its orientationSufficiently compactSeismology for water-covered areasUnderwater vesselsEngineeringControl theory

A control device (1) for controlling the position of a marine streamer comprising; an annular aerofoil (2), a mount (3) for mounting the annular aerofoil onto and around the streamer; and control means (4a, 4b) for controlling the tilt and / or rotation of the annular aerofoil (2) whereby to adjust the lateral position and / or depth of the streamer.

Owner:ATLAS ELEKTRONIK UK

Sensor mounting apparatus for minimizing parasitic stresss

ActiveUS20050284669A1Minimize parasitic stressSufficiently robustVehicle seatsElectric devicesEngineeringFlange

A compliant interface (14,16) for vehicular seat weight sensors minimizes parasitic stresses affecting sensor output. In one embodiment, an integral compliant interface (14) has an annular flange (14a) attached to a post extending from the sensor body with a first compliant member (14r) disposed between the annular flange and an upper elongated flange (14h) of a mounting bracket (14l) and a second compliant member (14s) disposed between the annular plate and a lower elongated flange (14k) to allow pivotal movement of the sensor limited by a motion stop member (14f) of annular flange (14b) engaging the lower flange. An overload cage (14u) may be placed over the sensor and attached to an additional flange (14l) to contain the sensor in the event of a failure of the mount in a catastrophic high speed crash. According to another preferred embodiment, an interface having upper and lower body members are formed with a sensor post receiving bore (16c) for attachment to the post. The body members are formed with spaced apart, radially extending face surfaces, each formed with an annular recess aligned with each other and with a compliant member received therein and fixed to the respective body members and extending beyond the face surfaces. The interface is received through a bore of a support plate to which the sensor is mounted with the compliant members engaging opposite face surfaces of the support plate allowing limited pivotal motion and with a compliant member limiting lateral movement of the interface relative to the support plate.

Owner:SENSATA TECHNOLOGIES INC

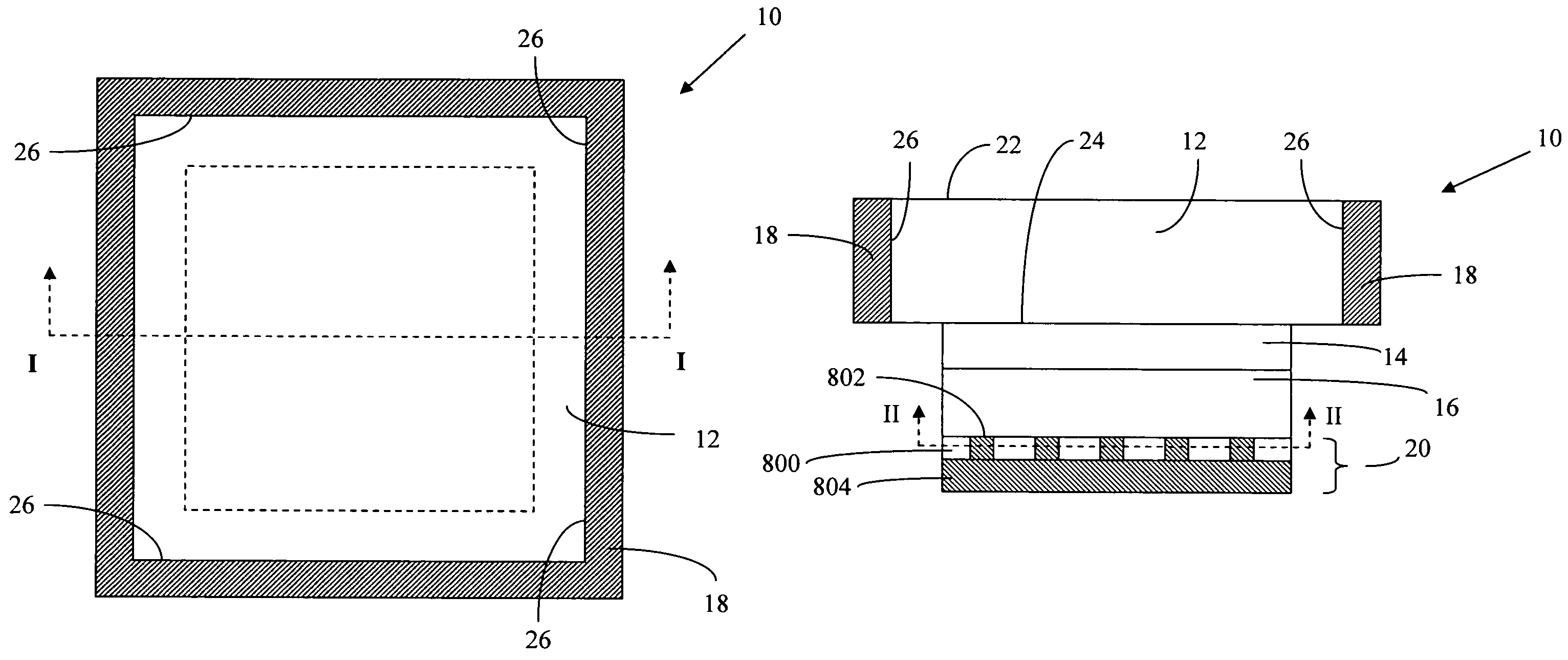

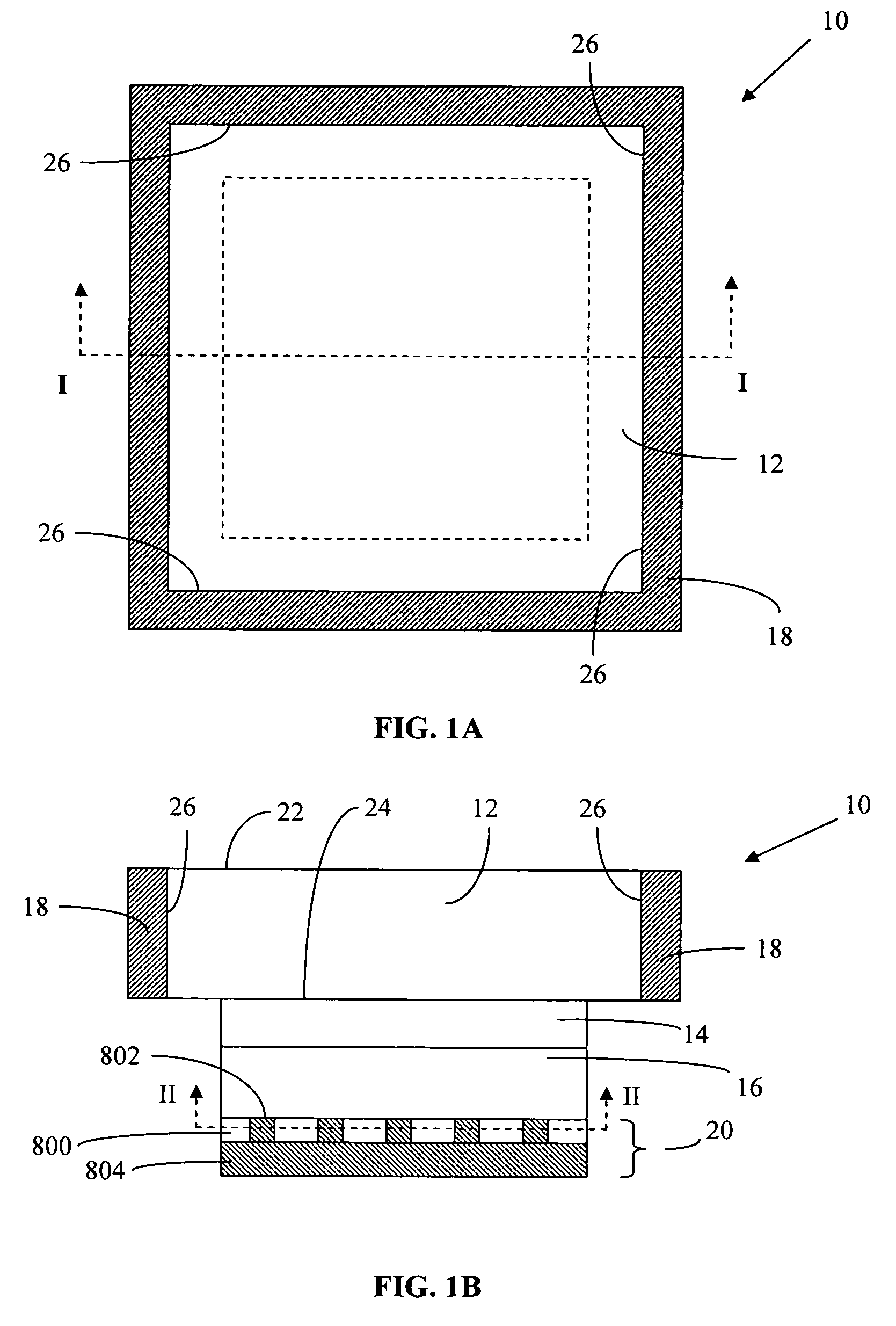

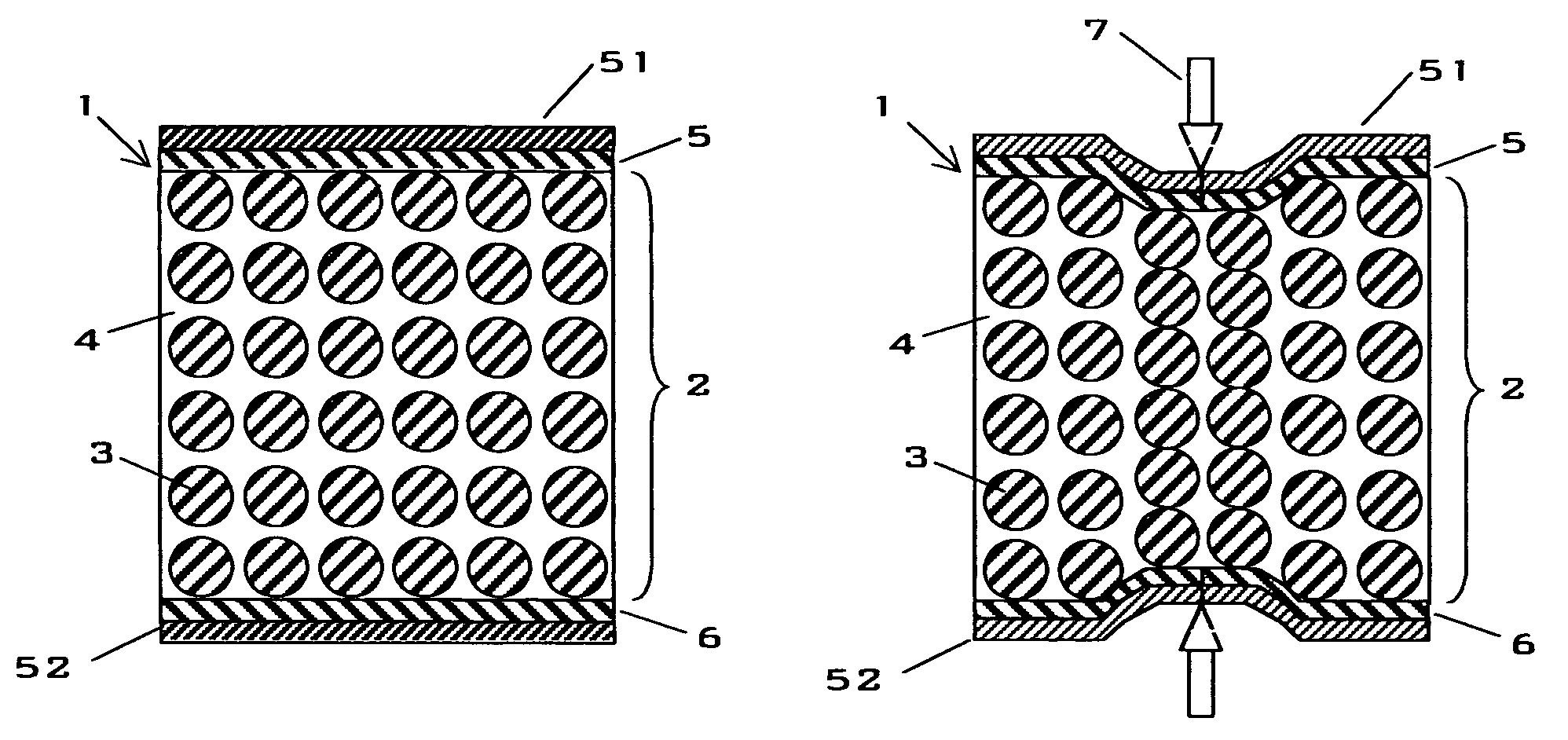

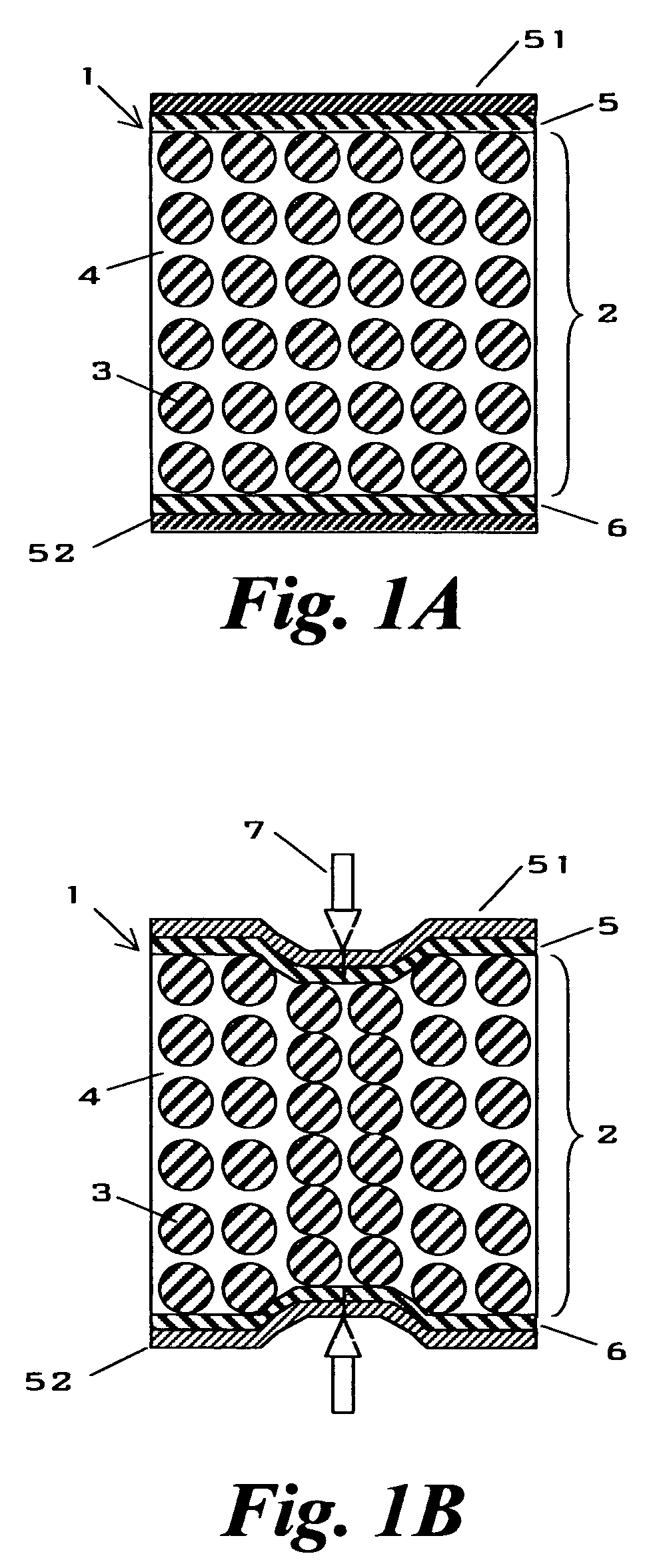

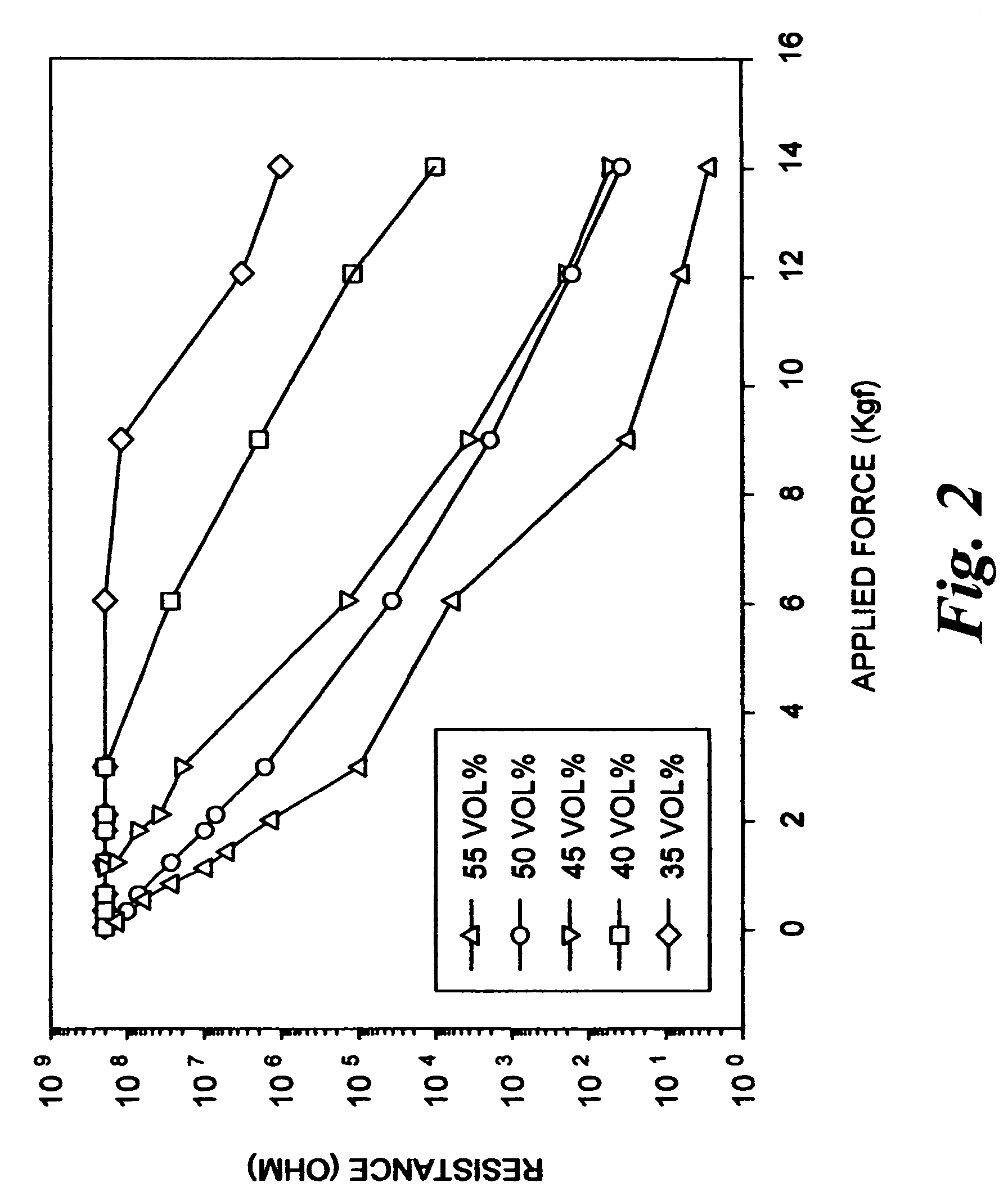

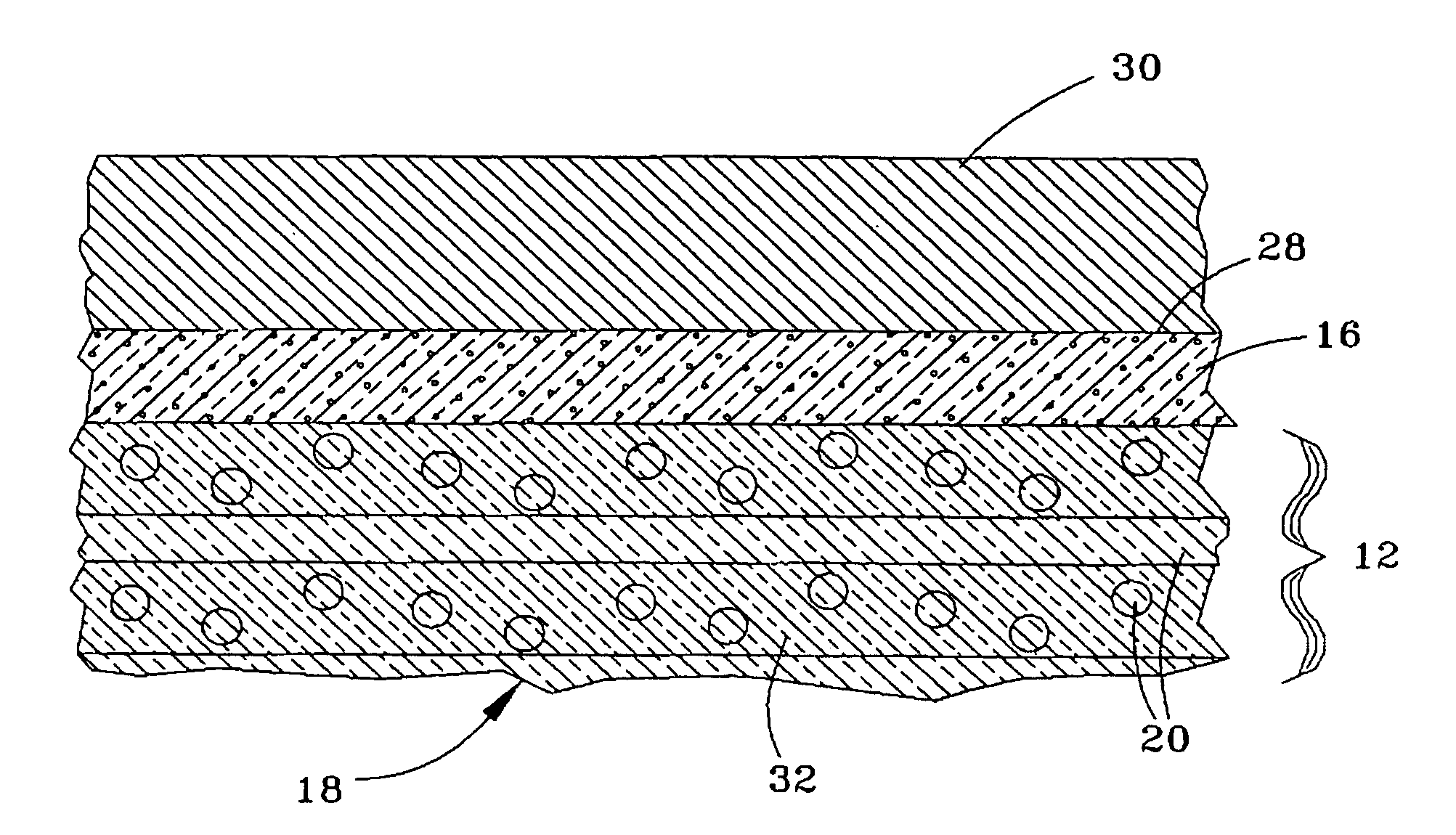

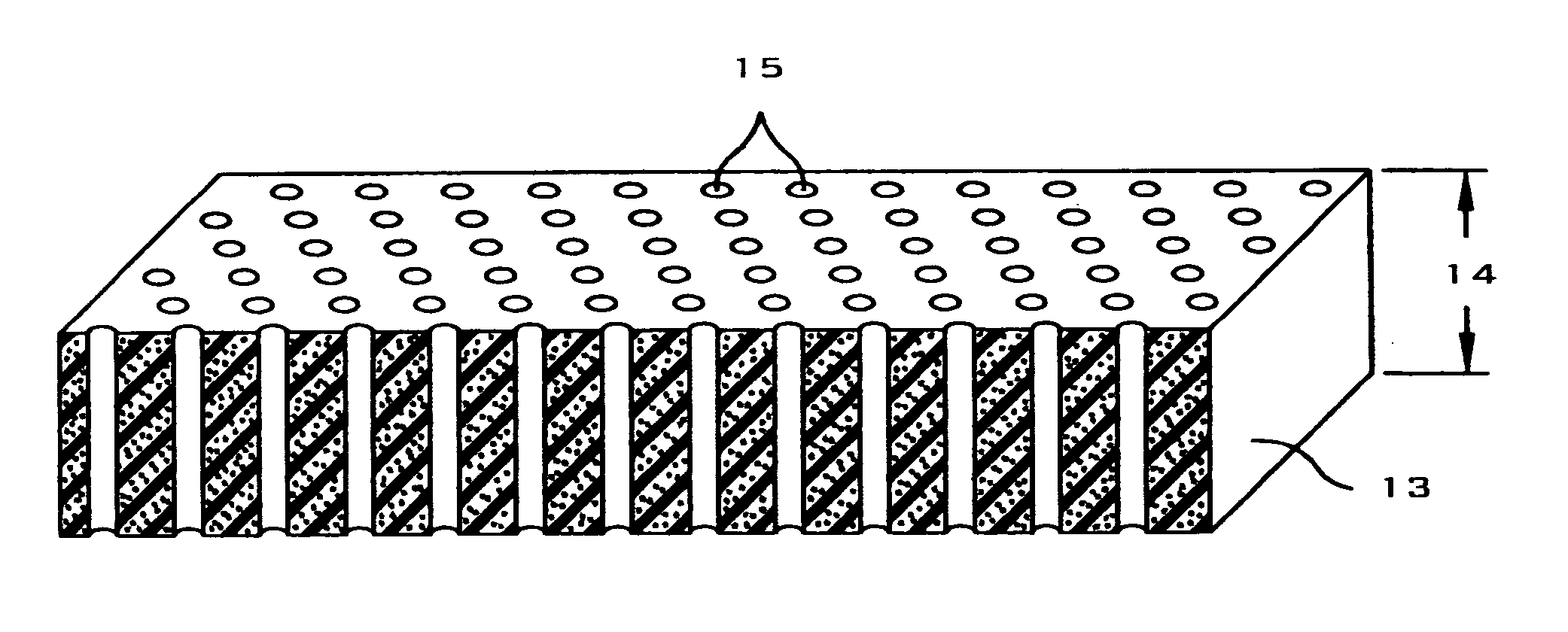

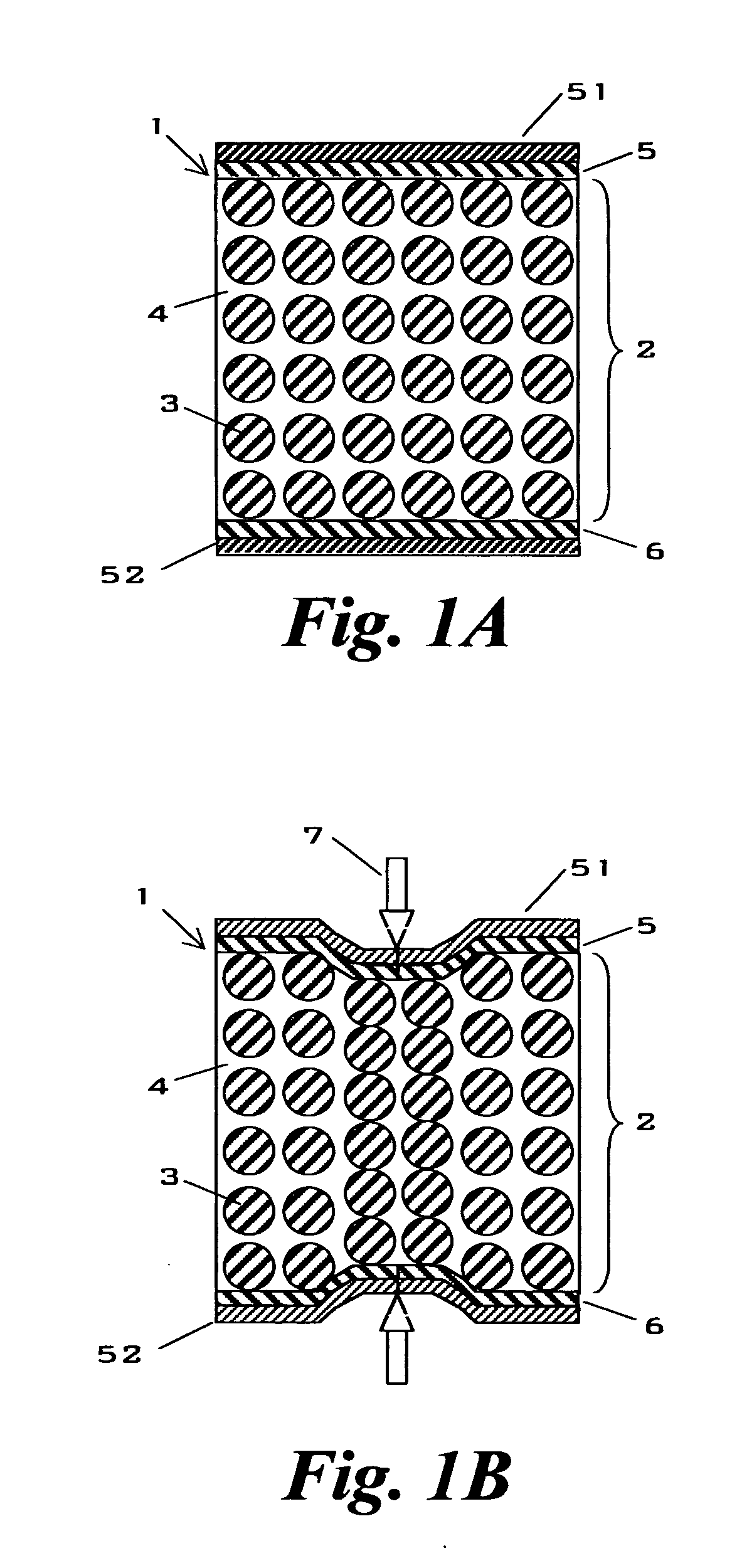

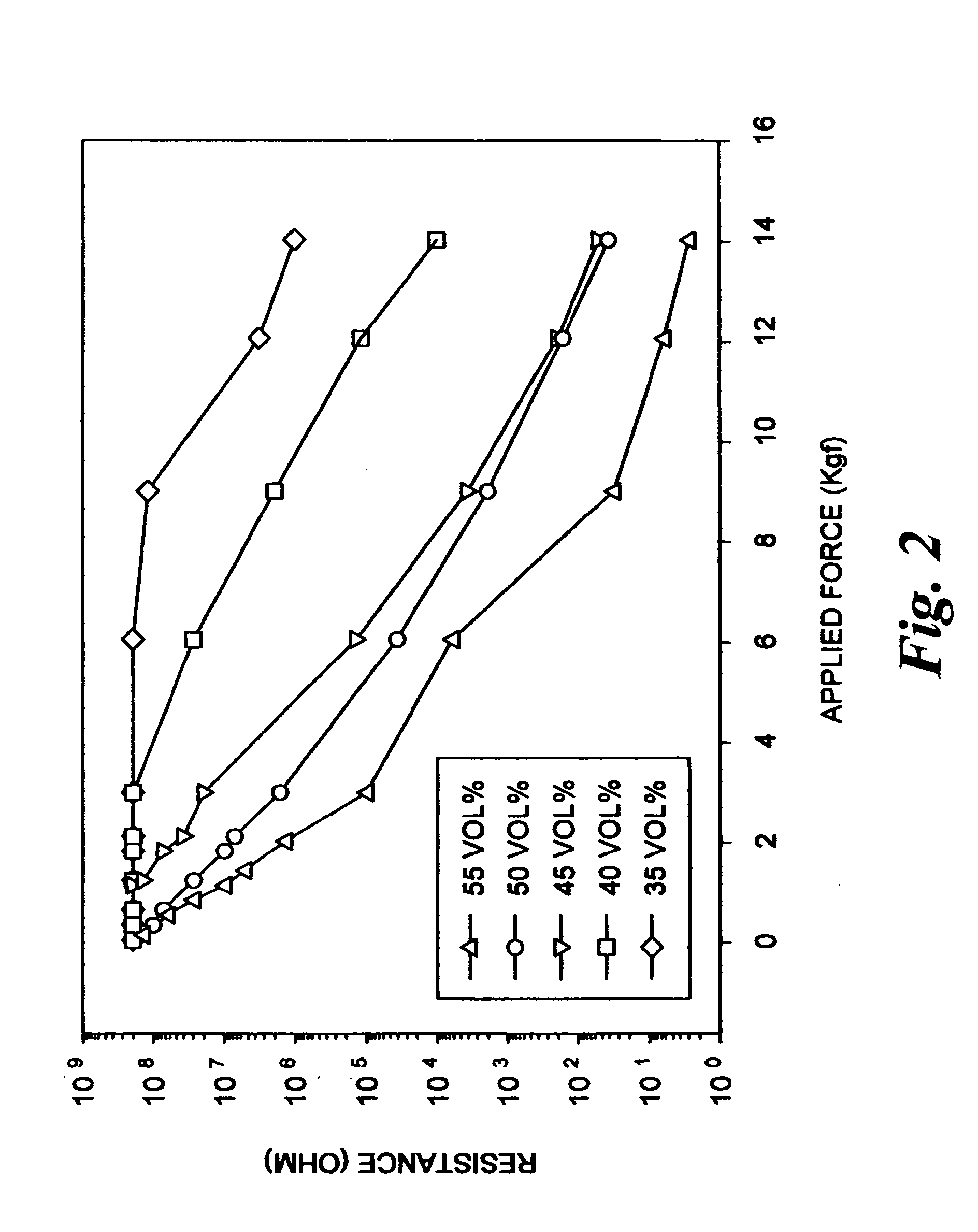

High-sensitivity pressure conduction sensor for localized pressures and stresses

ActiveUS7080562B2Minimizes signal-processing requirementAvoid harmful effectsForce measurementMaterial strength using tensile/compressive forcesElectricityControl system

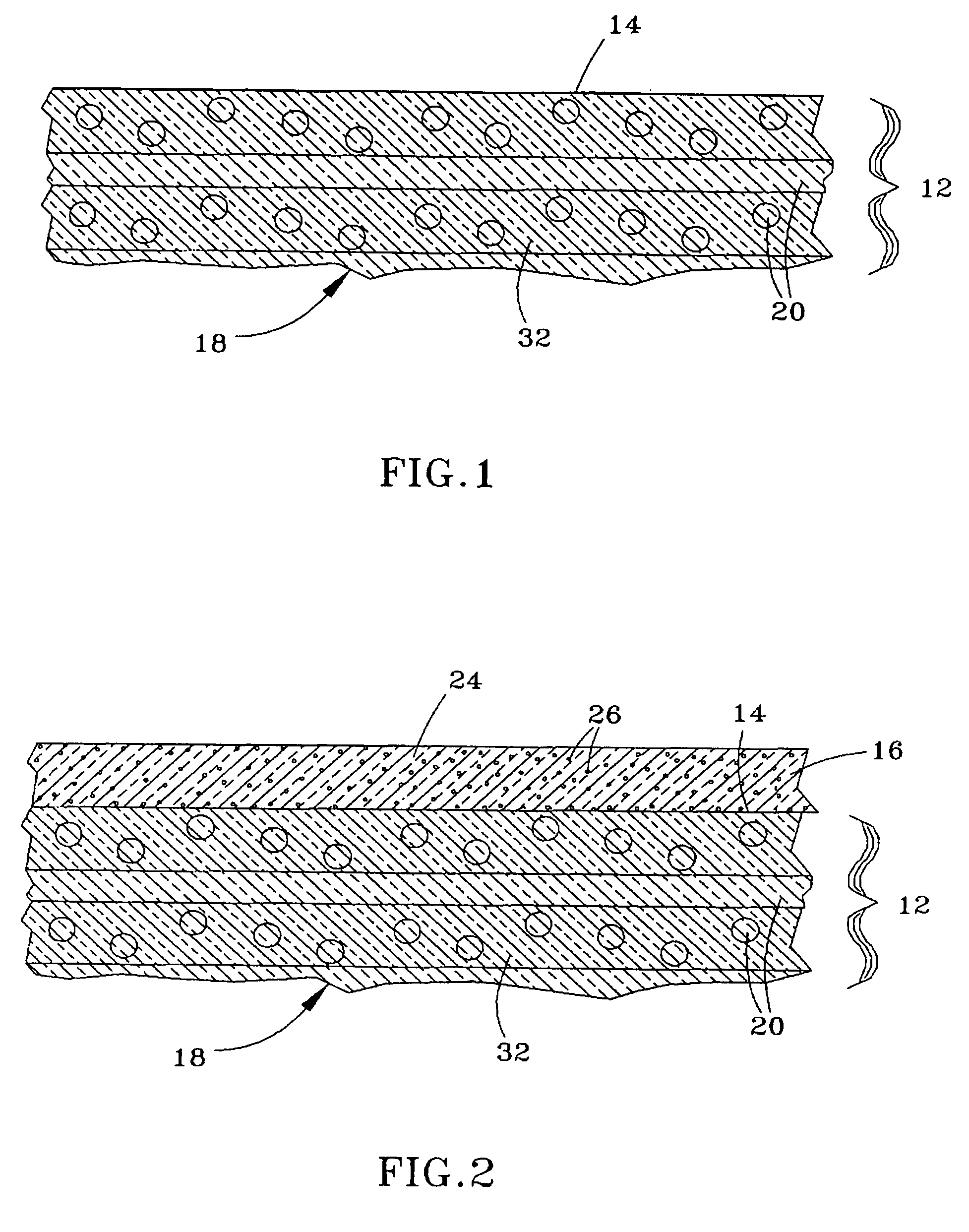

A high-sensitivity pressure conduction sensor is presented. The present invention includes a pair of locally resilient conductive layers and a locally resilient pressure conduction composite disposed between and contacting both conductive layers. Alternate embodiments include at least three locally resilient conductive layers and at least two locally resilient pressure conduction composites, each having a critical percolation threshold. Each composite is disposed between and contacting two conductive layers in a multi-layer fashion. Other embodiments include a locally resilient pressure conduction composite, a flexible substrate completely surrounding the composite so as to seal it therein, and a pair of electrical leads contacting the composite and terminating outside of the flexible substrate. Pressure conduction composites are composed of a plurality of conductive particles electrically isolated within a non-conductive matrix. Conductive particles are loaded so as to have a volume fraction approaching the critical percolation threshold of the material system and exhibit a conductance that greatly increases with pressure. Sensors may be arranged to form one or more arrays including planar and conformal configurations. The present invention has immediate application in keyboards, intrusion systems, control systems, submarines, ships, sonobuoys, doors, and switches.

Owner:QORTEK

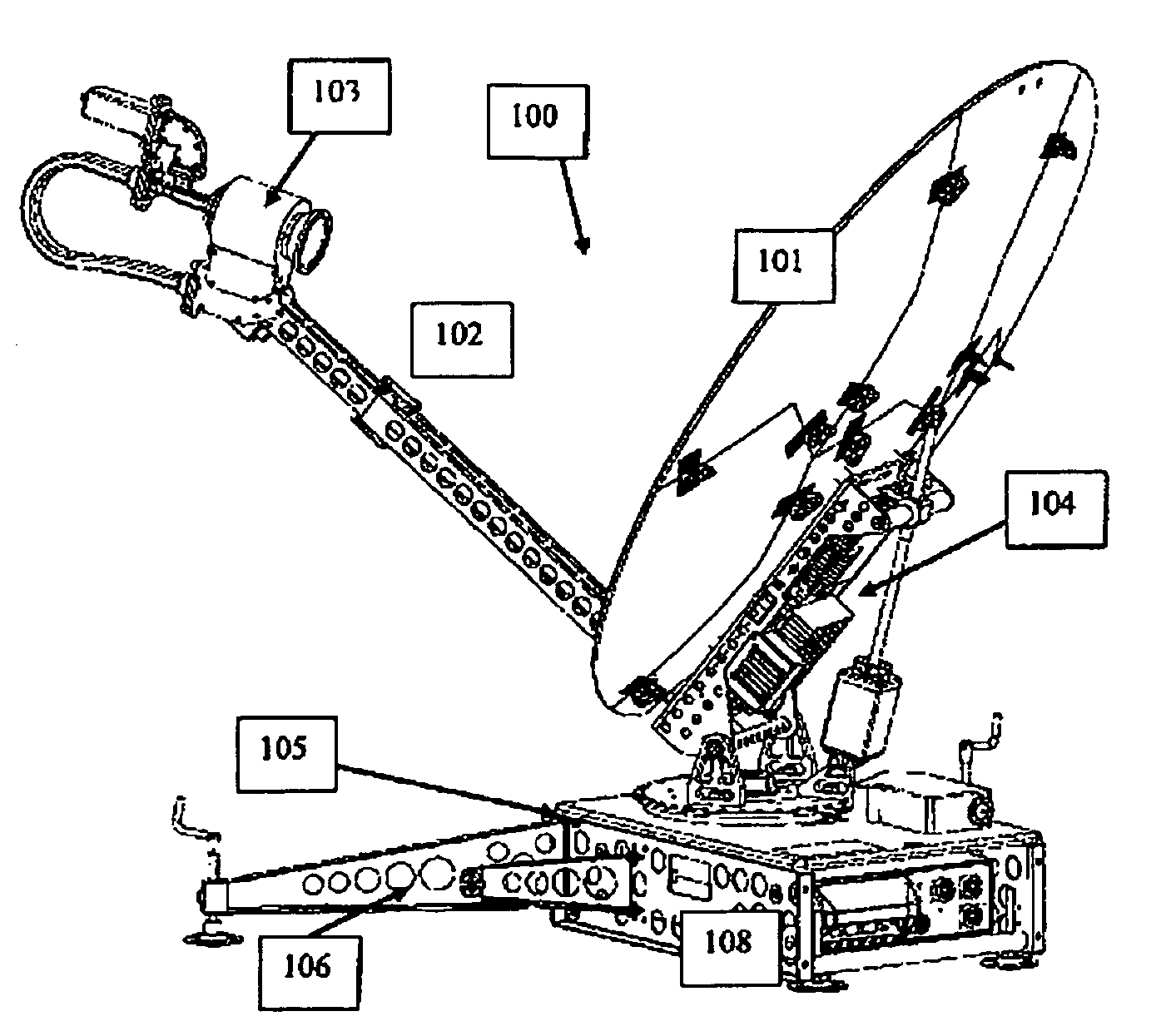

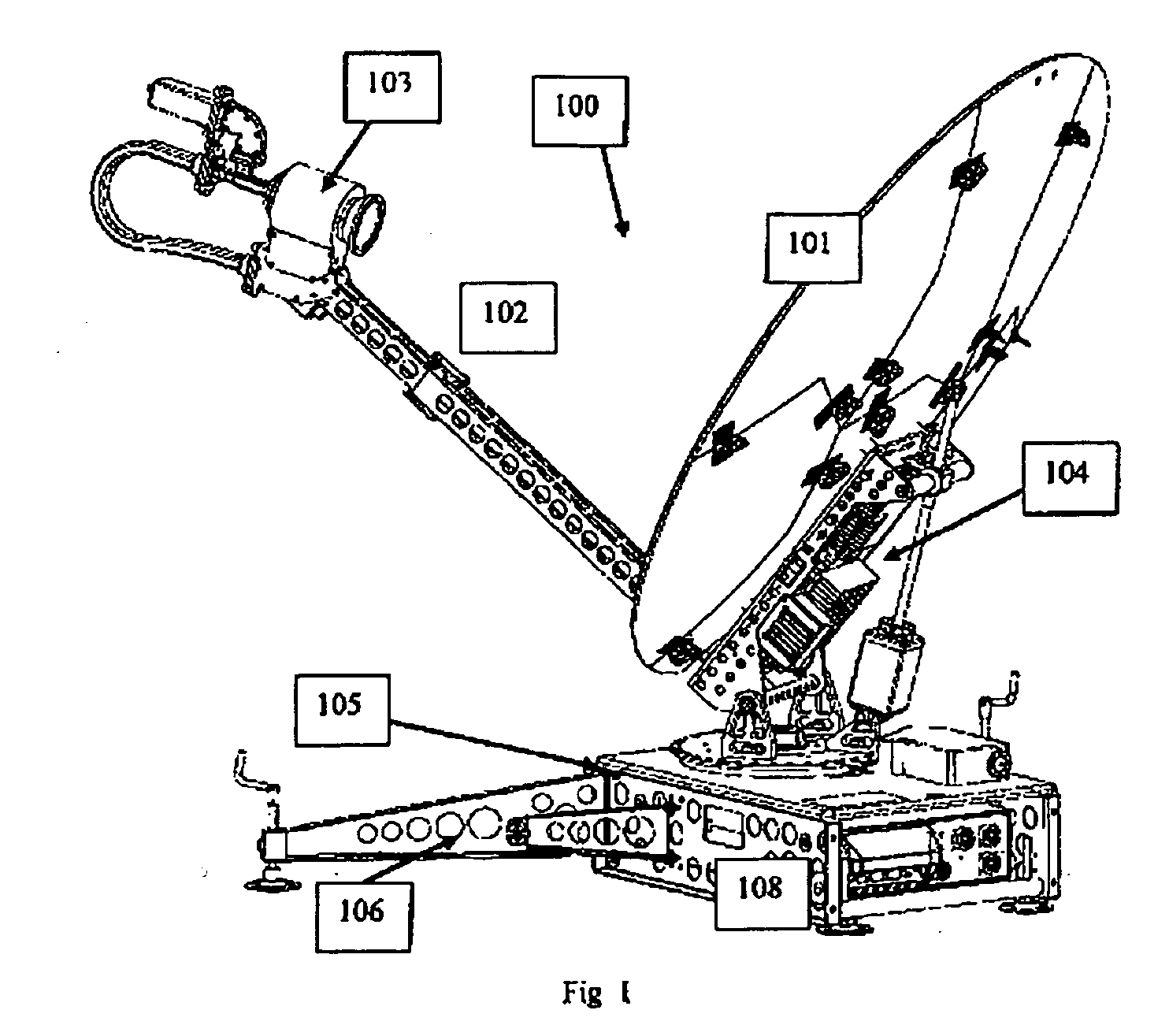

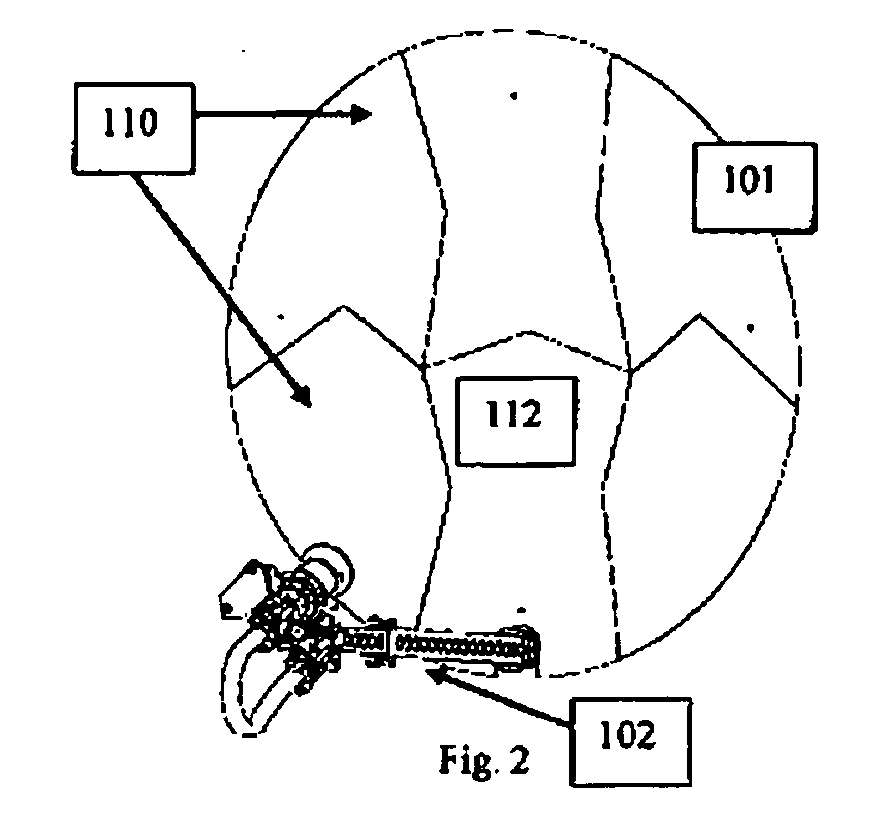

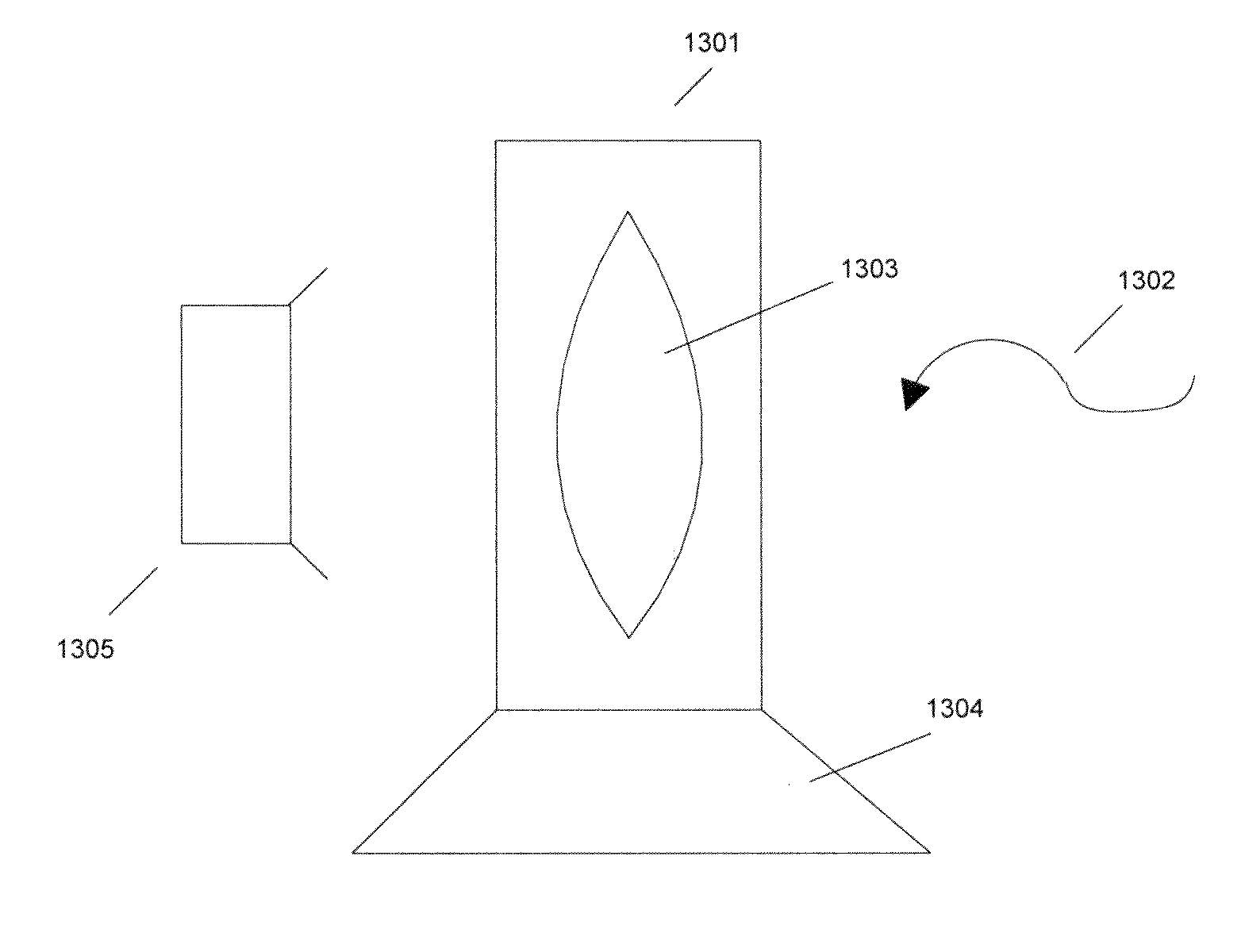

Antenna positioner for portable satellite terminal

InactiveUS20070052607A1Improve accuracyBetter freedomTransmissionAntennasCommunication unitEngineering

A motorized antenna positioning mechanism in a portable microwave communication unit for use as a ground station in a satellite communication system. The antenna positioner has compact and low profile azimuth wire drive mechanics, azimuth and polarization angle sensors that are not affected by slippage and backlash, and an elevation drive mechanism which neutralizes the pressure on the motor axis due to the weight of the parabolic antenna.

Owner:NORSAT INTERNATIONAL

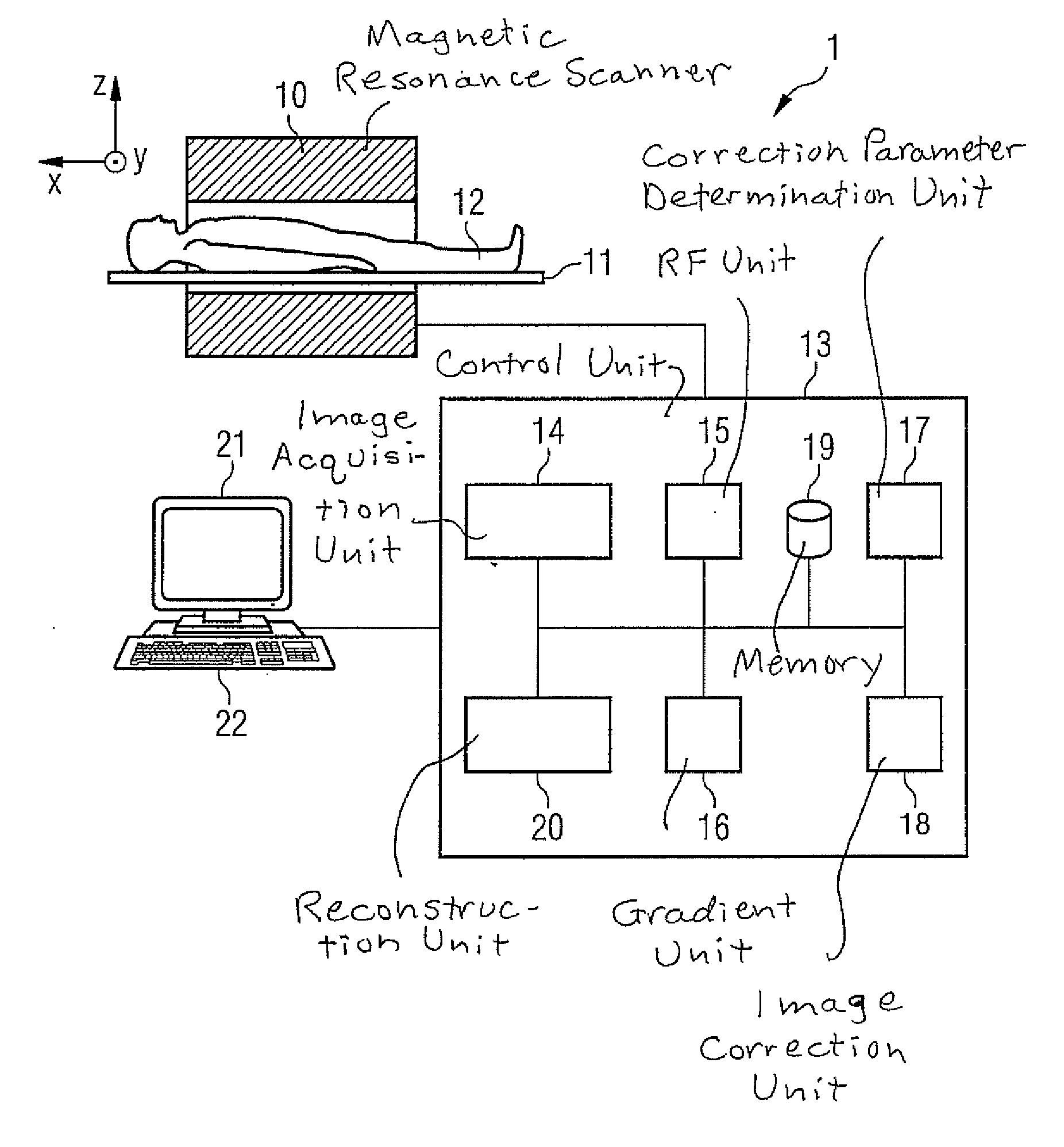

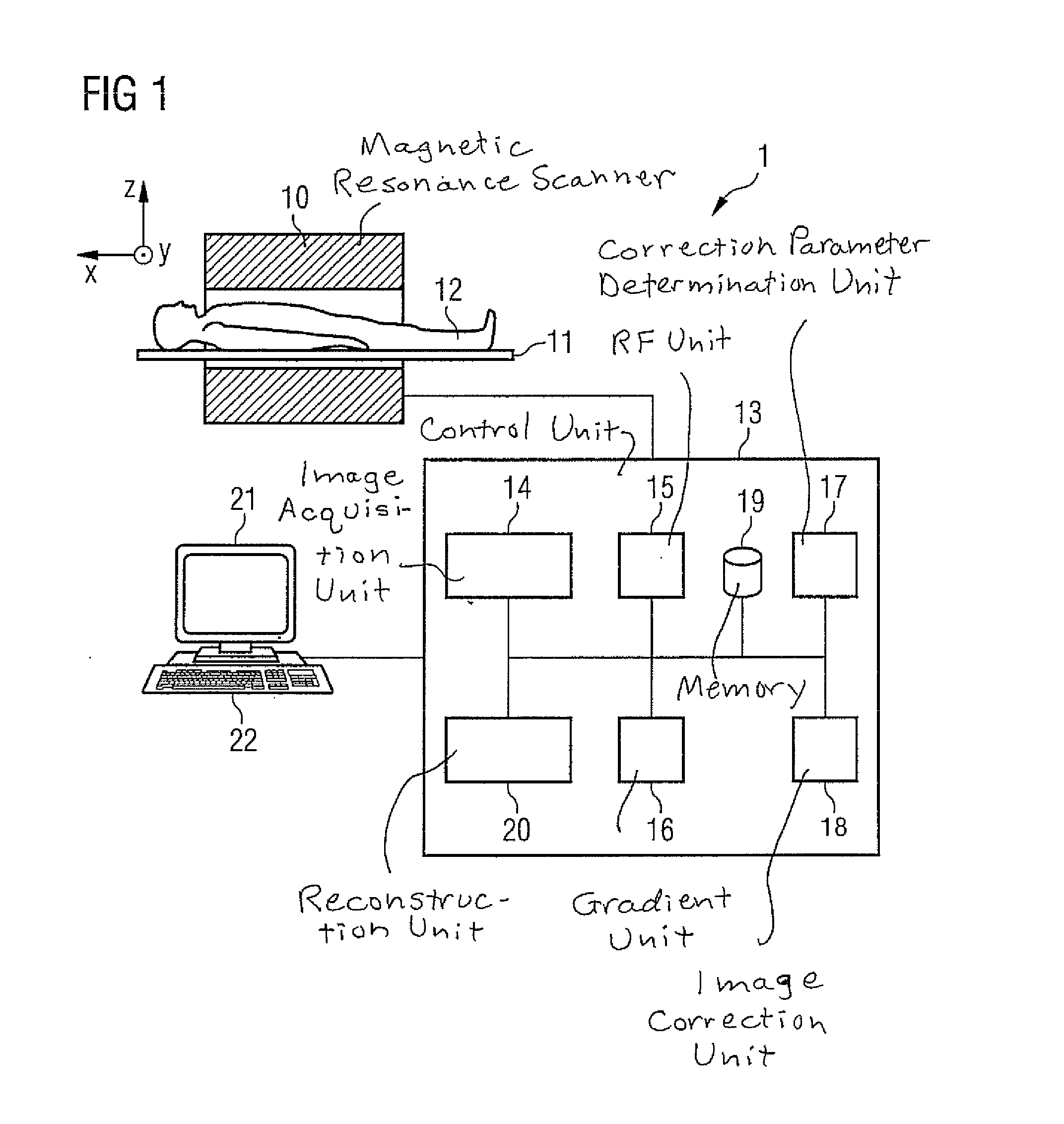

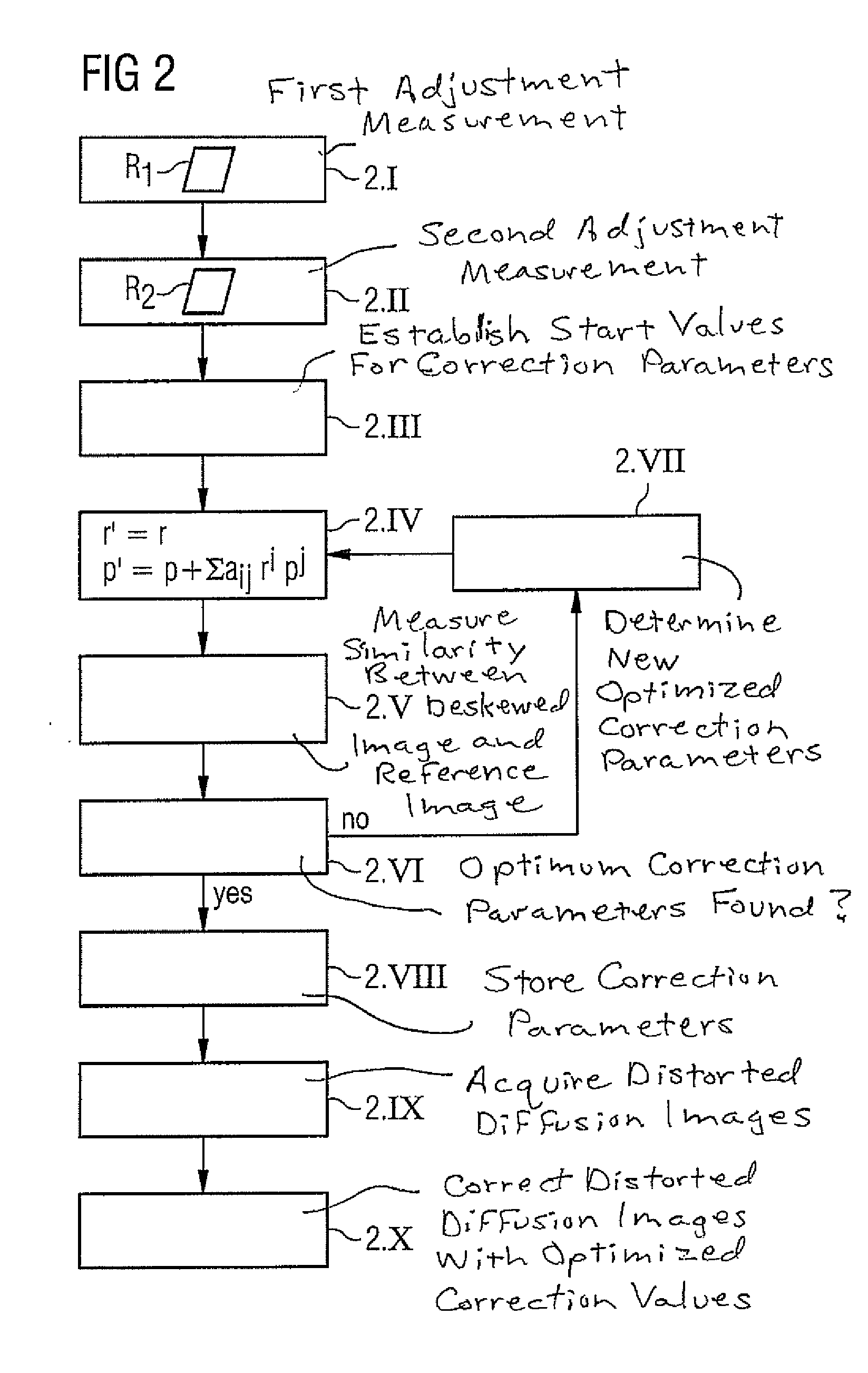

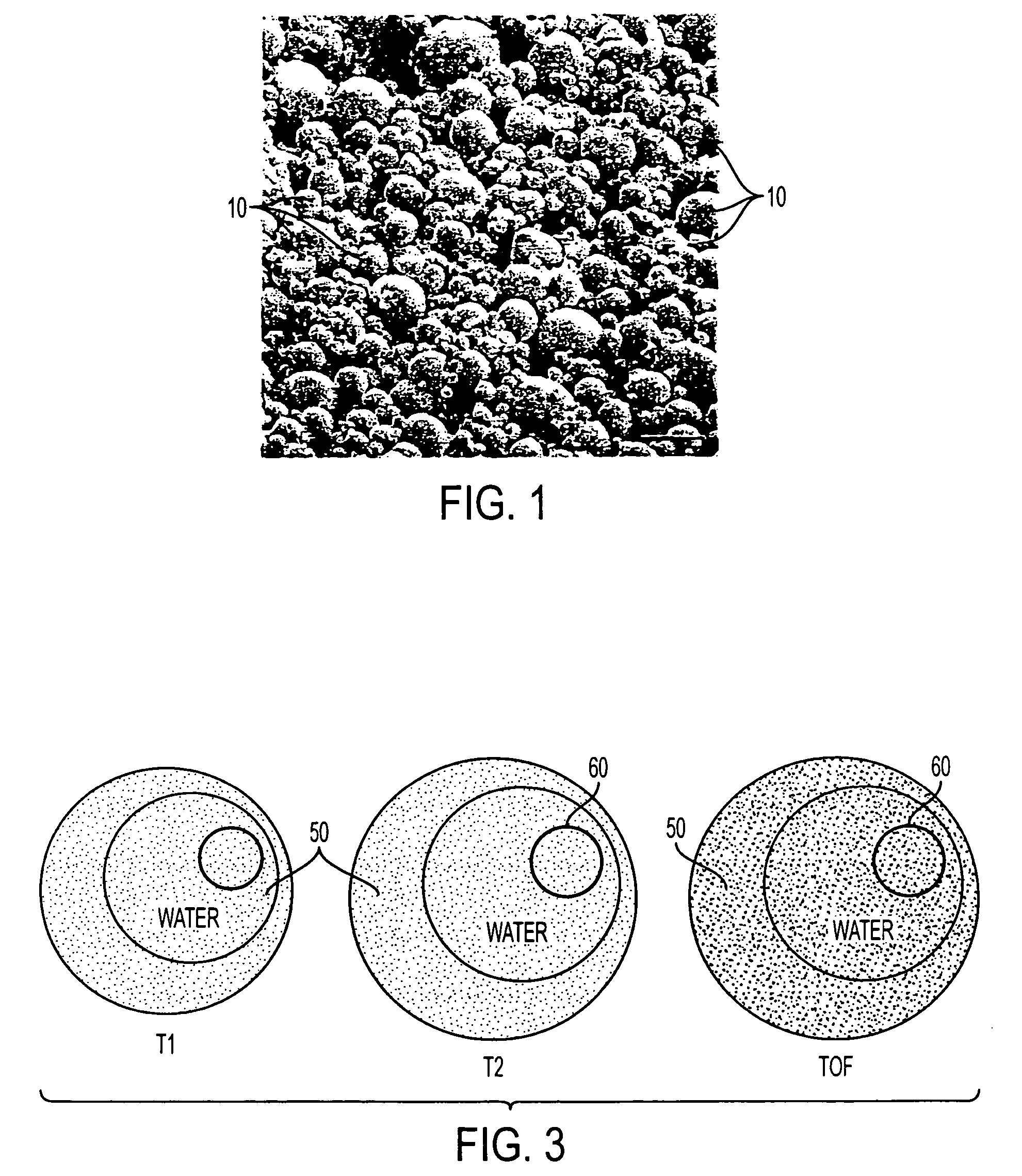

Method and magnetic resonance system to reduce distortions in diffusion imaging

ActiveUS20110187367A1Reduce distortion problemsSufficiently quickElectric/magnetic detectionMeasurements using NMRDiffusionResonance

In a method and magnetic resonance apparatus to reduce distortions in magnetic resonance diffusion imaging, a magnetic resonance data acquisition system is operated to acquire magnetic resonance data in a first measurement with a first diffusion weighting, and to acquire magnetic resonance data in a second measurement with a second, different diffusion weighting. A non-linear, system-specific distortion-correcting function is determined on the basis of system-specific information that is specific to said magnetic resonance data acquisition system. Correction parameters are calculated to correct distortions in subsequently-acquired diffusion-weighted magnetic resonance images, based on the data acquired in the first and second measurements with the system-specific distortion-correcting function applied thereto. The subsequently-acquired diffusion-weighted magnetic resonance images are corrected using the correction parameters to at least reduce distortions therein.

Owner:SIEMENS HEALTHCARE GMBH

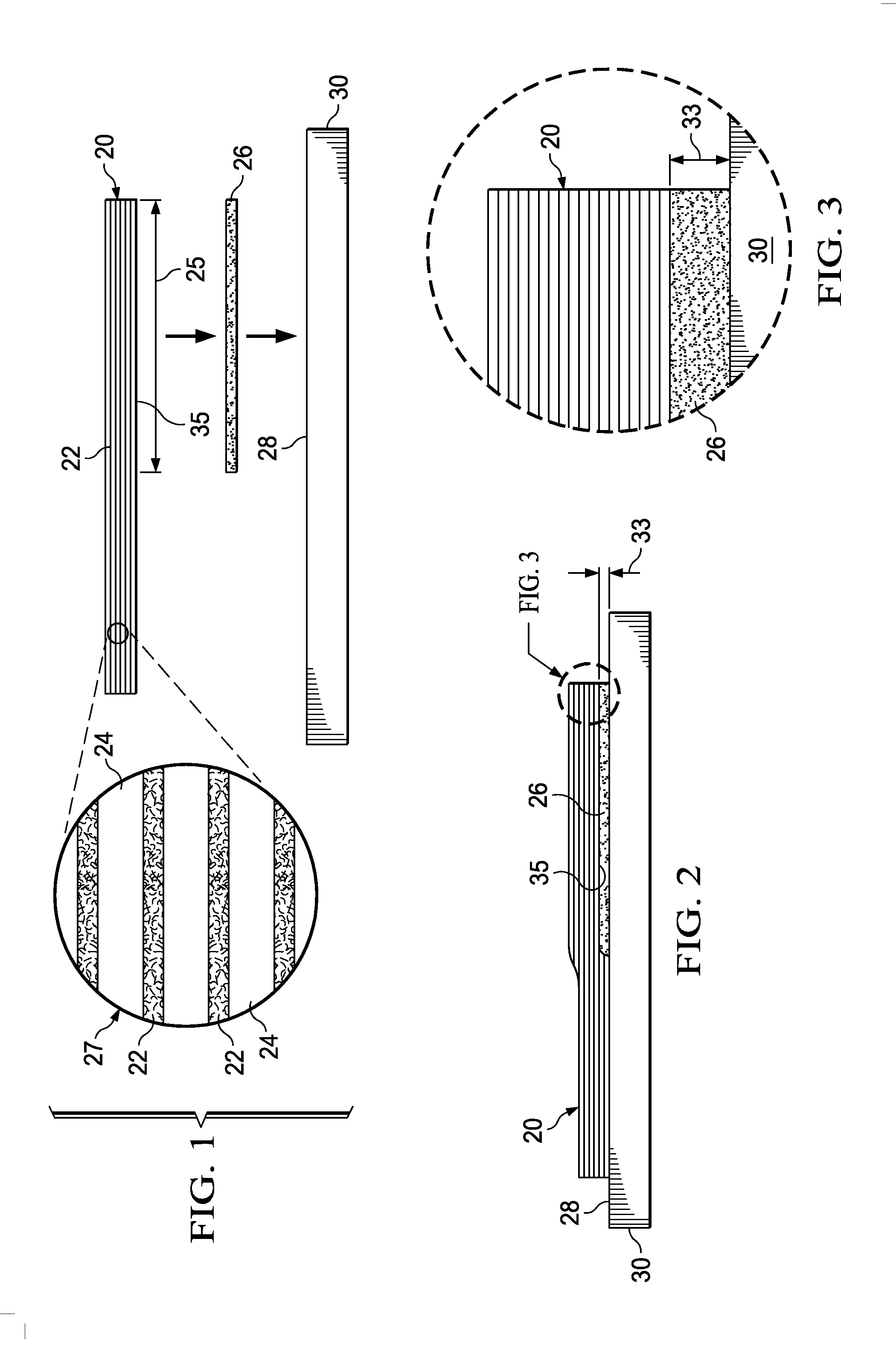

Exposing Fibers in Composite Laminates

ActiveUS20140119813A1High strengthImprove crack resistanceAdhesive processesWood working apparatusFiberComposite laminates

Owner:THE BOEING CO

Medical devices having MRI-enhancing encapsulated fluids

InactiveUS20050171425A1Increase awarenessLimit fluid mobilityDiagnostic recording/measuringSensorsVisibilityMedical treatment

A medical device is described that comprises a polymeric component and a microcapsule additive including a fluid that enhances direct visibility during magnetic resonance imaging of at least a predetermined portion of the polymeric component.

Owner:PHANTOMS BY DESIGN

In-situ Forming foams with outer layer

ActiveUS20130317418A1Improve cohesionResistance to deformationStentsSurgical adhesivesMedical devicePolymer

Systems, methods and kits relating to in-situ forming polymer foams for the treatment of aneurysms or fluid filled spaces are disclosed. The systems include an insertable medical device and an in-situ forming foam of lava like materials with a fast forming outer skin and a slower hardening interior that is formed from a one-, two- or multi-part formulation. When used to treat an aneurysm, the foam is placed into contact with at least a portion of an exterior surface of the medical device and / or the tissue surface of the aneurysm.

Owner:ARSENAL MEDICAL

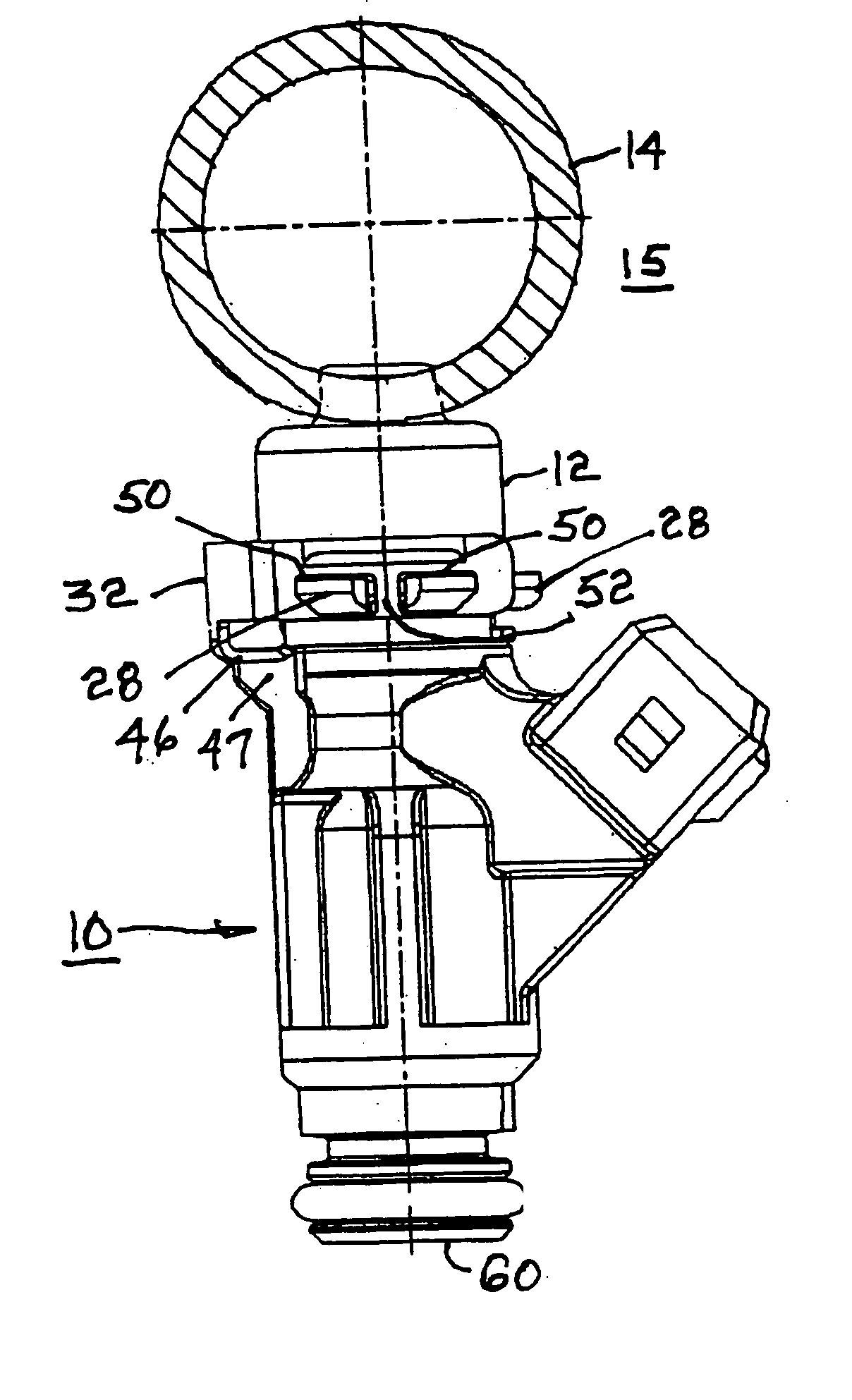

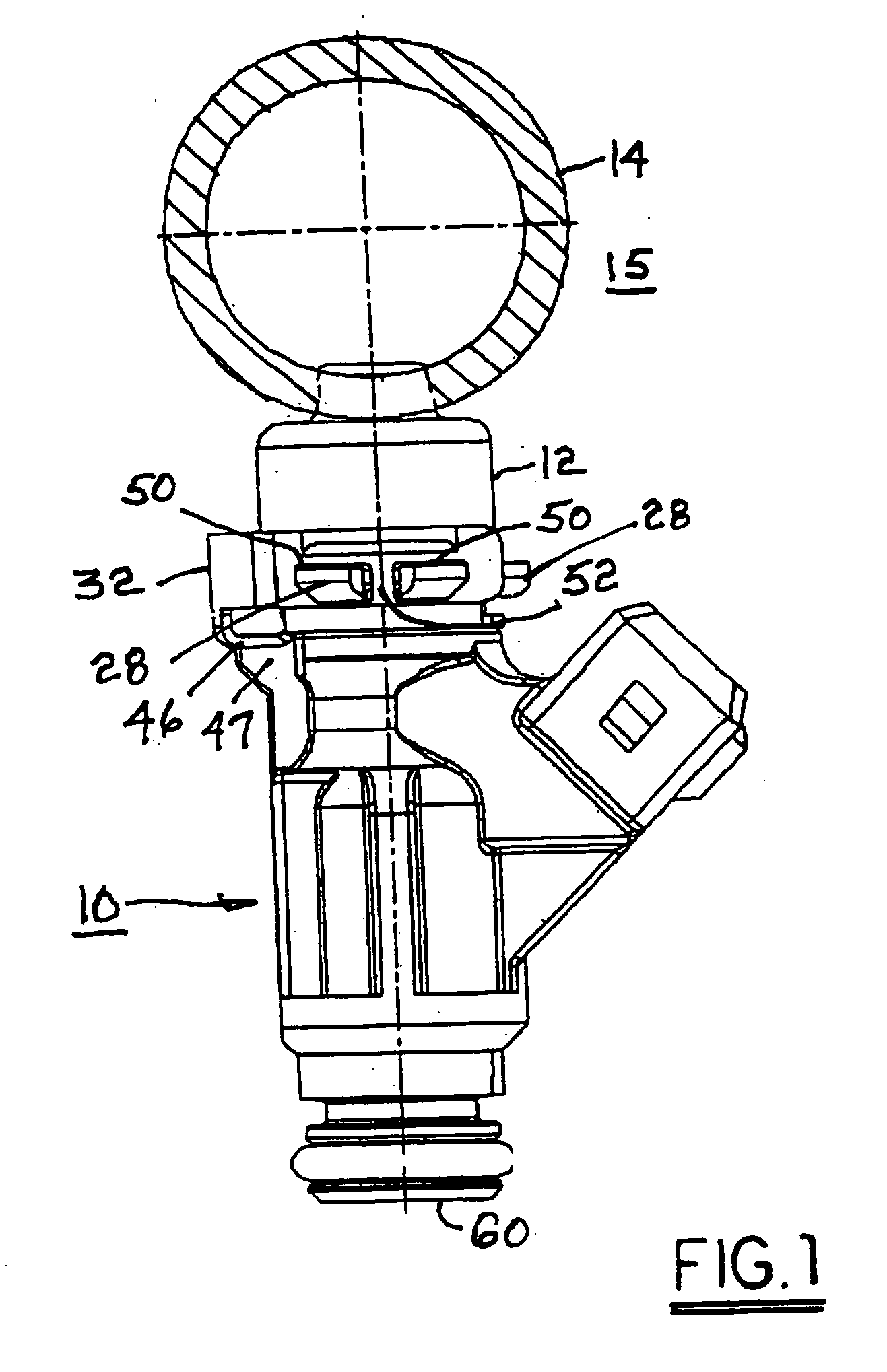

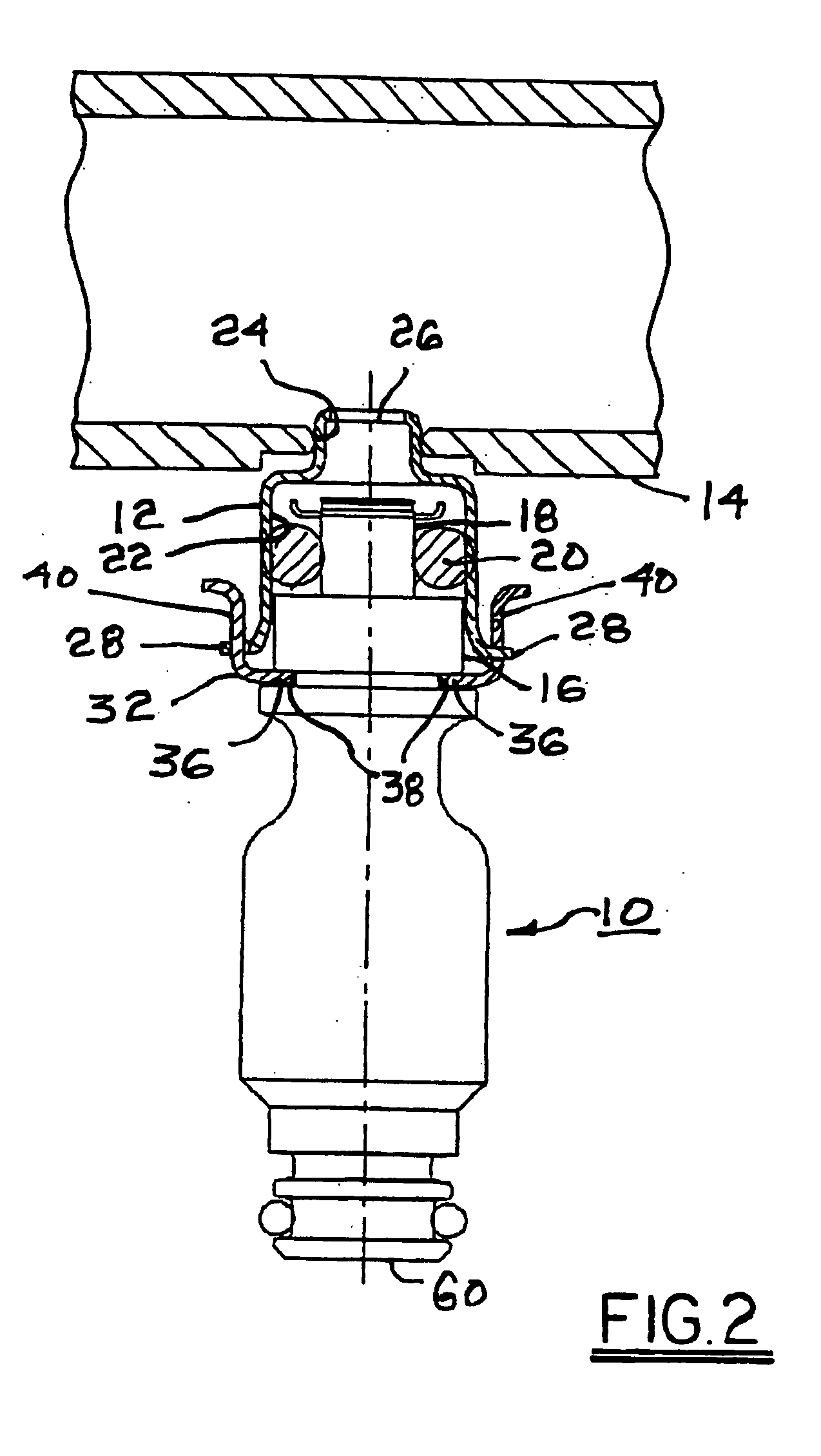

Anti-rotation fuel injector clip

InactiveUS20050161025A1Sufficiently robustCorrect positionFuel injection apparatusMachines/enginesInjectorRadial position

An anti-rotation clip for joining a fuel injector body to a fuel rail socket. A C-shaped base is formed to slide into an annular groove in the injector body. A pair of tangs extend from the base to straddle a rib on the injector body to prevent rotation between the clip and the injector. Opposed sidewalls extending from the base include windows for receiving a radial flange of the fuel rail socket to correctly position the fuel injector axially within the socket. Each window is divided by a locking bar for reception in a notch in the socket flange to prevent rotation between the clip and the socket. The radial positions of the injector rib and flange notch are selected such that the injector will be properly oriented with respect to the engine after installation therein.

Owner:DELPHI TECH INC

Method of producing a ceramic matrix composite article

InactiveUS7686990B2Improve coating adhesionSufficiently robustPretreated surfacesCoatingsMetallurgySlurry

A method of producing a CMC article having a net shape, and by which the article can be formed to have an exterior surface with desirable characteristics, such as being free of an imprint pattern of a fiber reinforcement material within the article. The method entails providing a body comprising the fiber reinforcement material, and depositing a coating on a surface of the body. The coating contains a carbonaceous binder and a slurry containing a ceramic particulate material. Following its deposition, the carbonaceous binder within the coating is cured to render the coating machinable, and the coating is then machined to approximately produce the net shape of the article.

Owner:GENERAL ELECTRIC CO

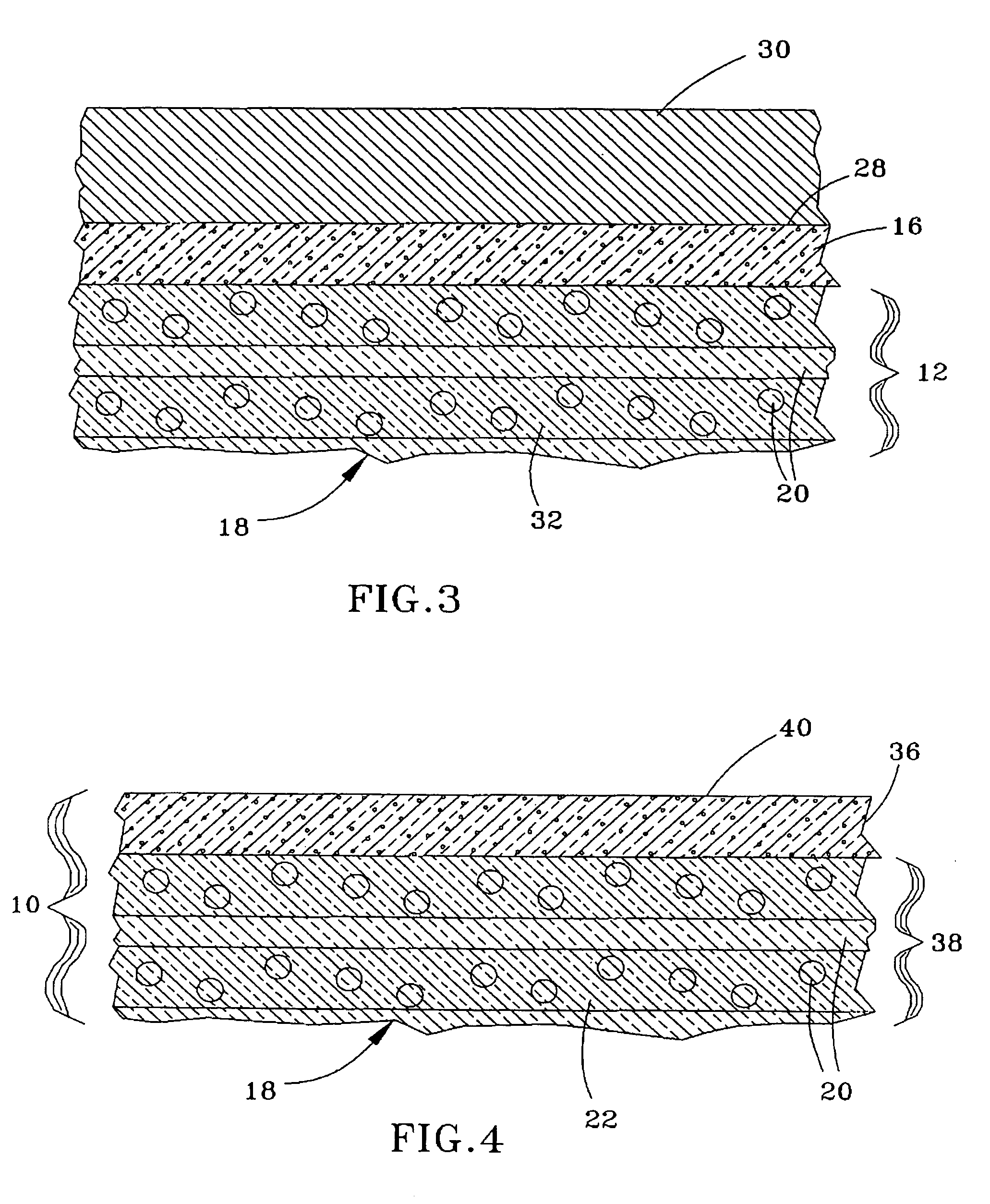

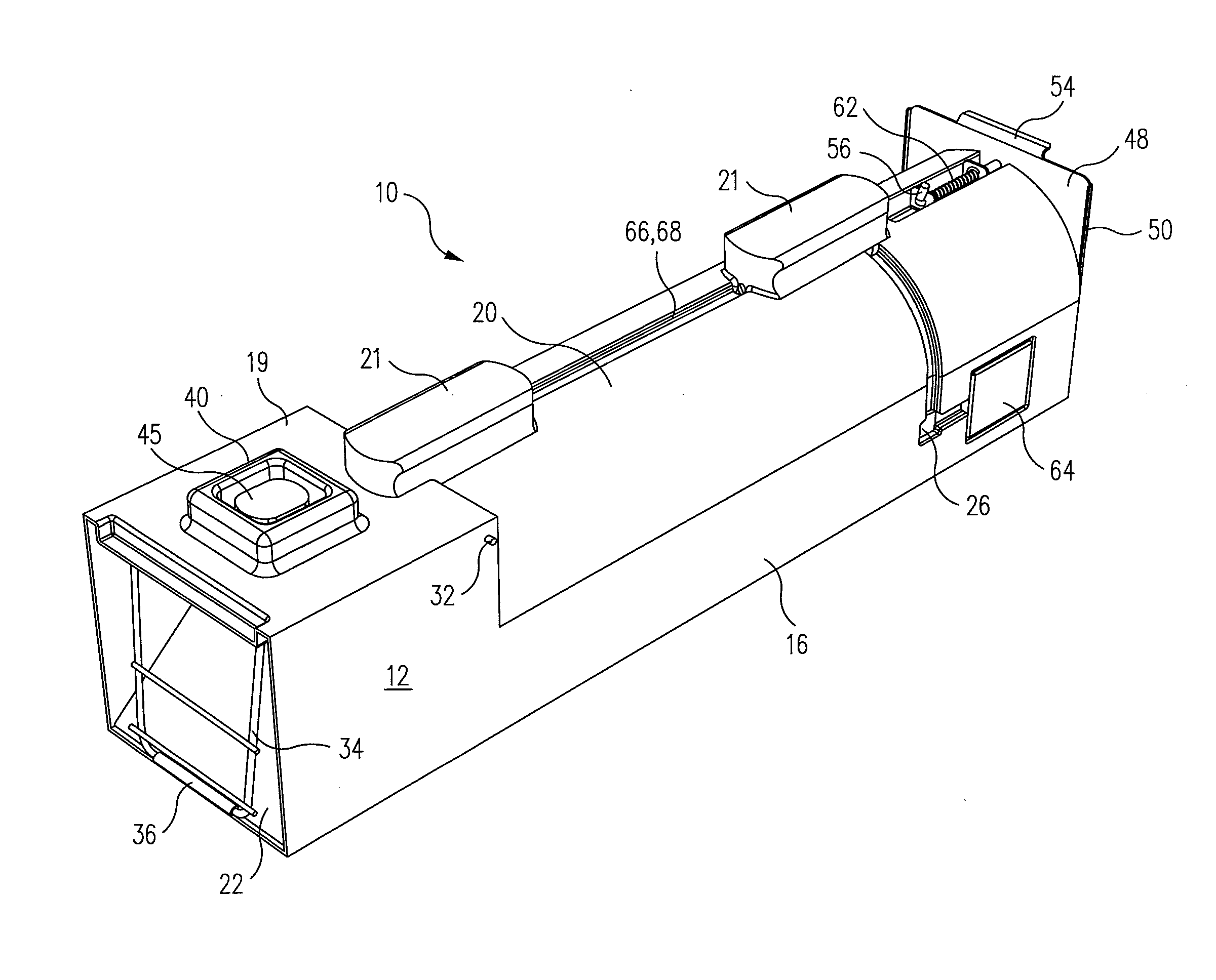

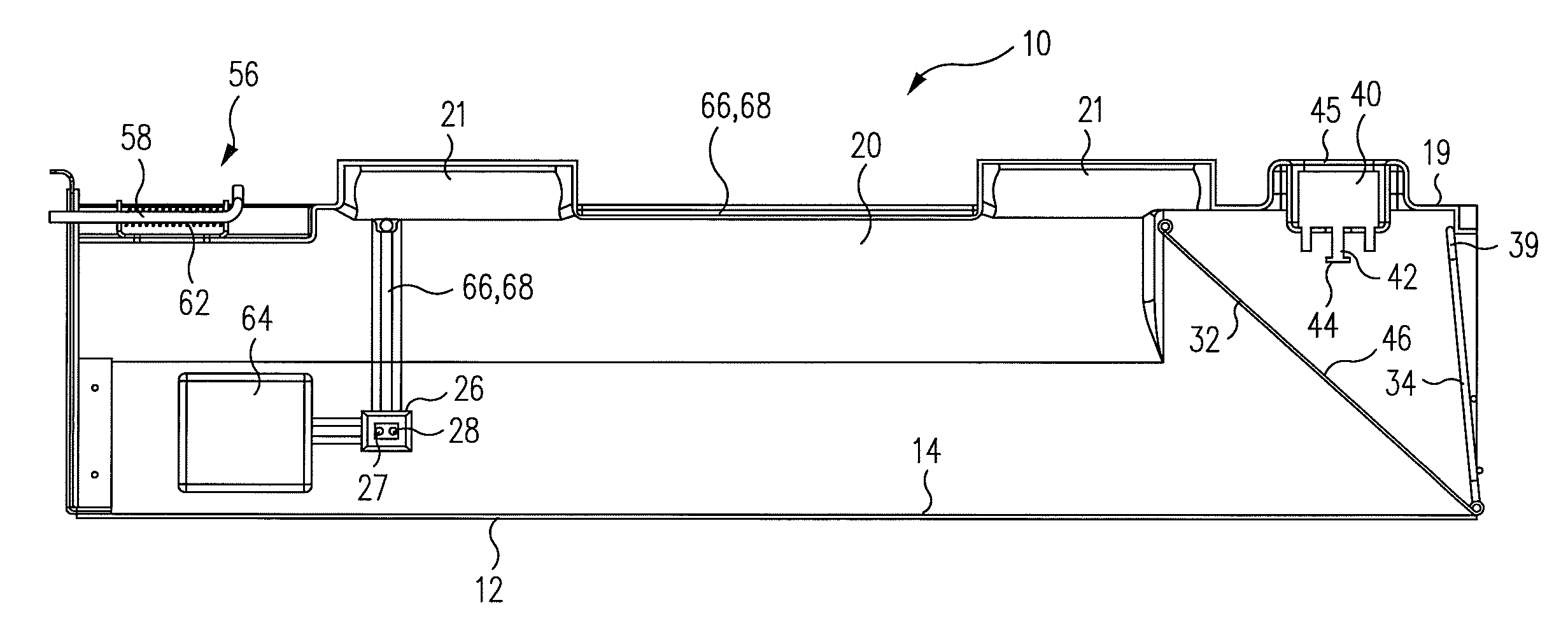

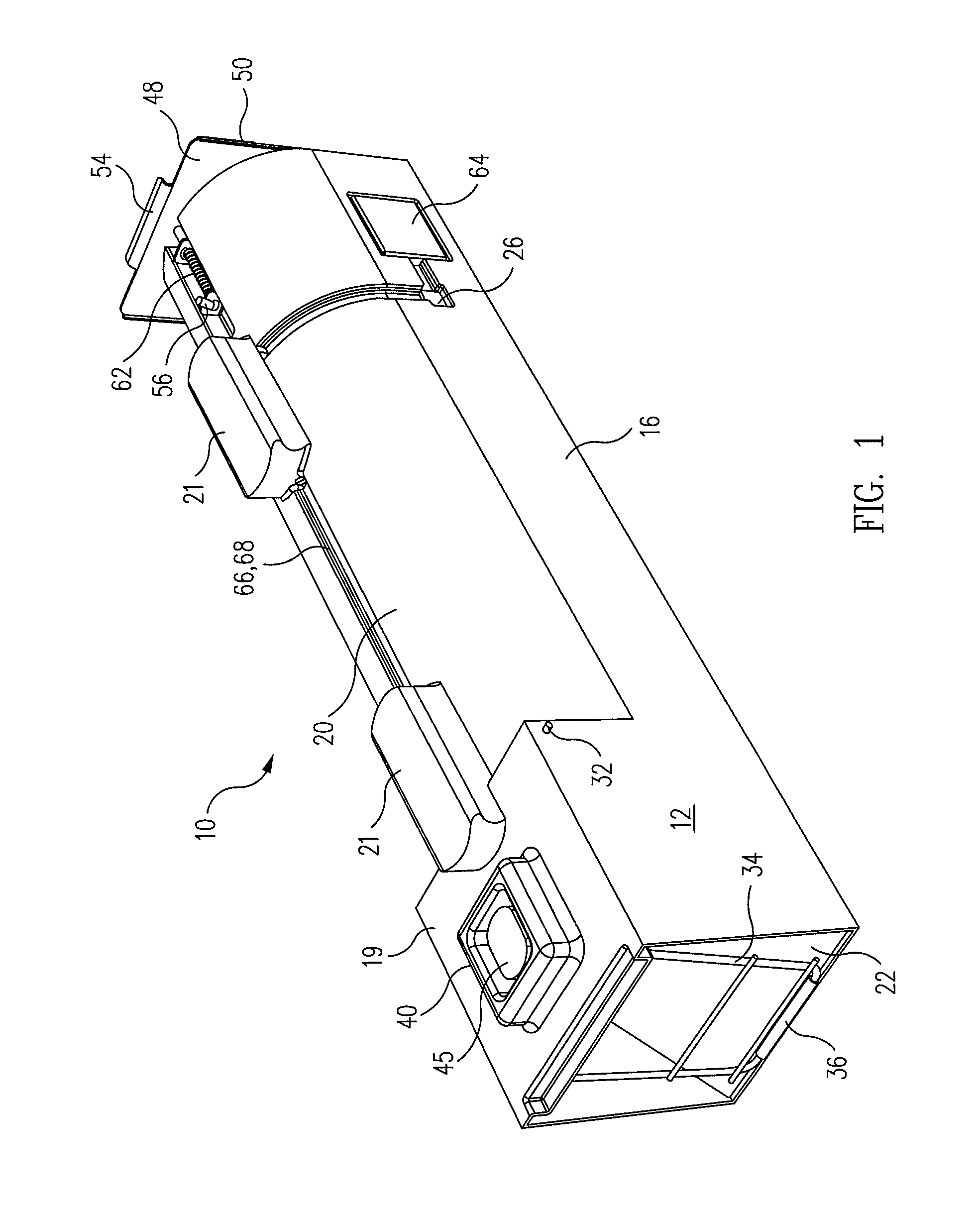

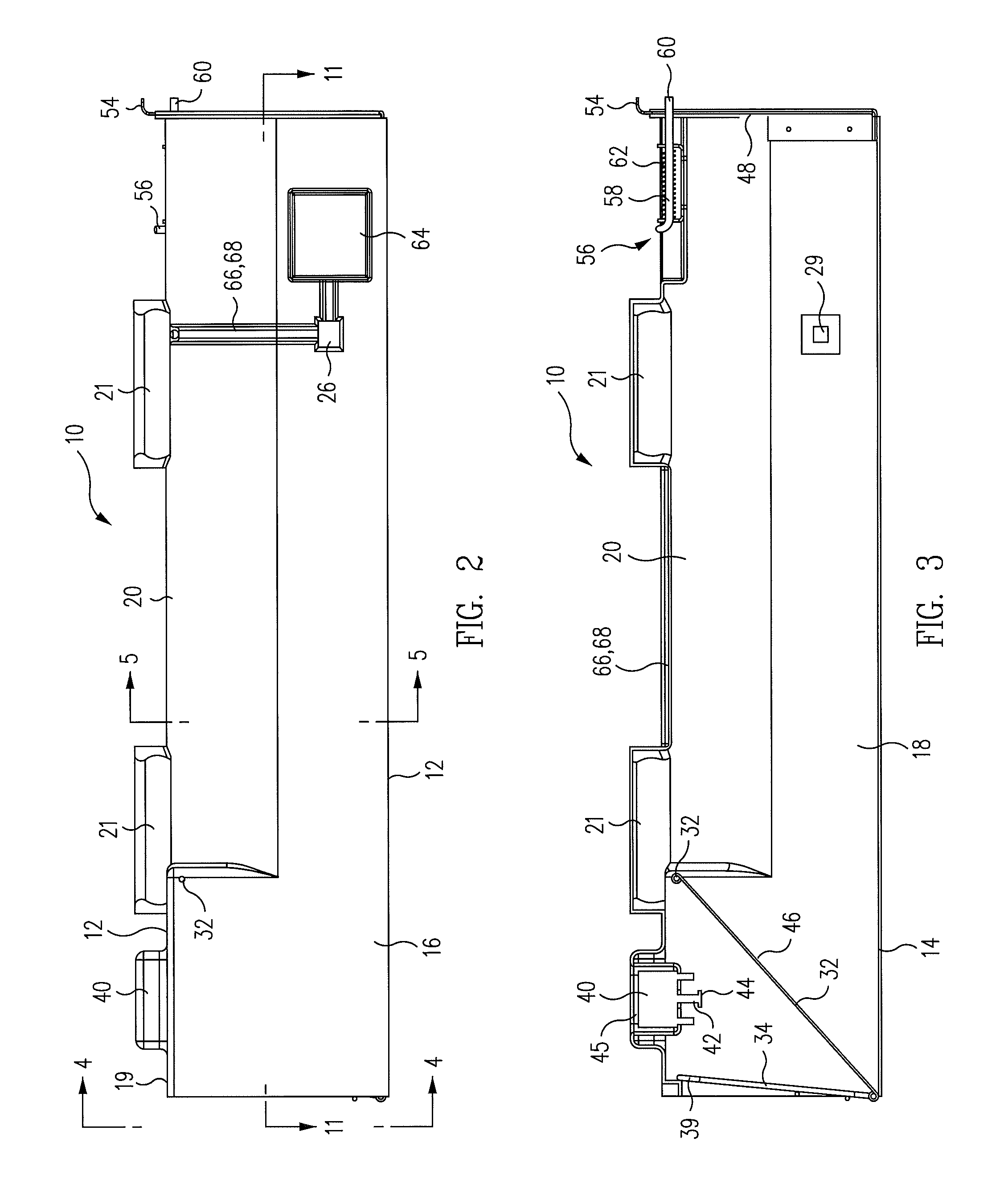

Humane animal trap

InactiveUS20090205244A1Inexpensive to fabricateSolve the complicated settingAnimal huntingAnimal trapsLight beamEngineering

A humane animal trap includes an enclosure having an opening with a door disposed therein. The door is pivotable about an upper edge between open and closed positions, and is biased toward the closed position by a torsion spring. An electrical solenoid is disposed above the door and has a catch that is biased into engagement with a holding feature on the door when the door is in the open position, and is operable to disengage the catch from the holding feature in response to the receipt of an electrical trip signal. An electrical sensor disposed in the enclosure transmits a light beam between opposite sidewalls of the trap, and generates an electrical trip signal and transmits it to the solenoid when the light beam is interrupted by an animal entering the trap so as to close the door behind the animal and thereby capture it unharmed in the enclosure.

Owner:RIZHAO J&J TECH MFG CO LTD

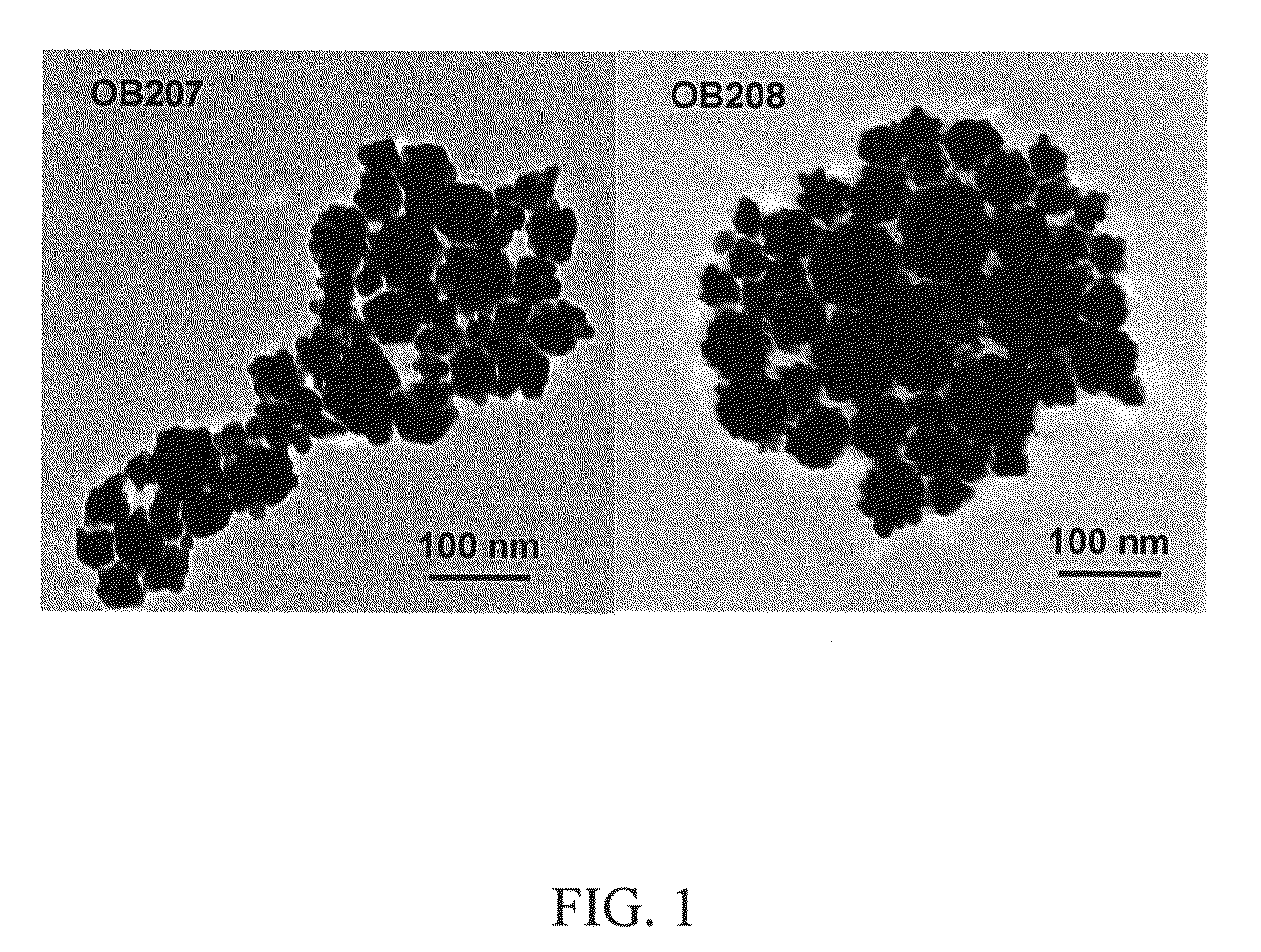

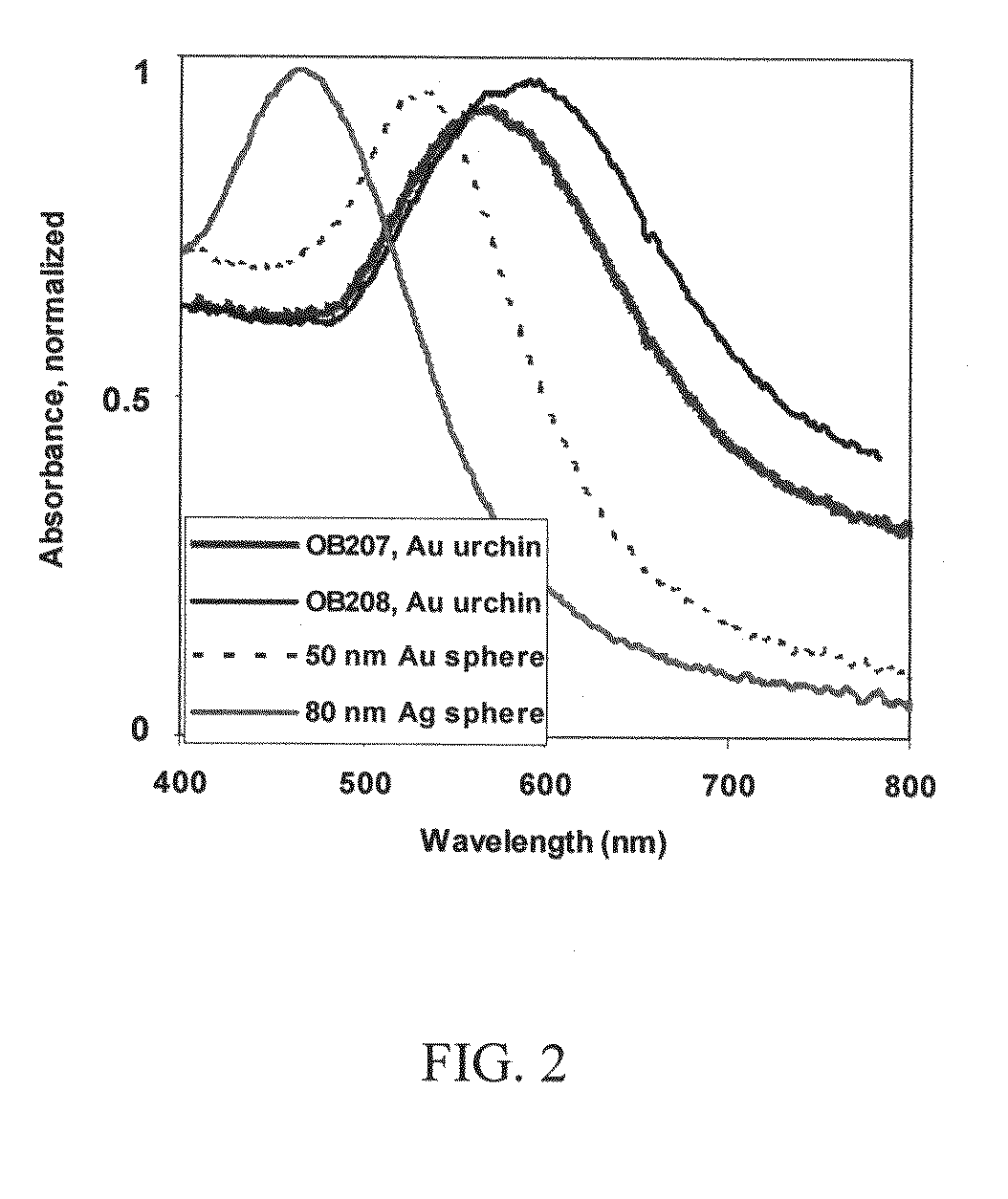

Optical limiting using plasmonically enhancing nanoparticles

There is provided an optical limiter device for protecting an object from incident light having a wavelength in the visible, infrared or ultraviolet spectrum. The device comprises a plurality of nanoparticles of a metallic material including free electrons that undergo collective oscillations when exposed to the incident light. The plurality of nanoparticles of the metallic material include a plurality of nanoparticles of a non-spherical particle geometry, which may include a geometry having a plurality of sharp protrusions on a spherical body. The metallic material may include gold, silver, aluminum, indium or copper. The device further comprises a structurally rigid transparent medium in which the plurality of nanoparticles of the metallic material are embedded; and a mechanical support mounting the transparent medium between the incident light and the object.

Owner:MASSACHUSETTS INST OF TECH

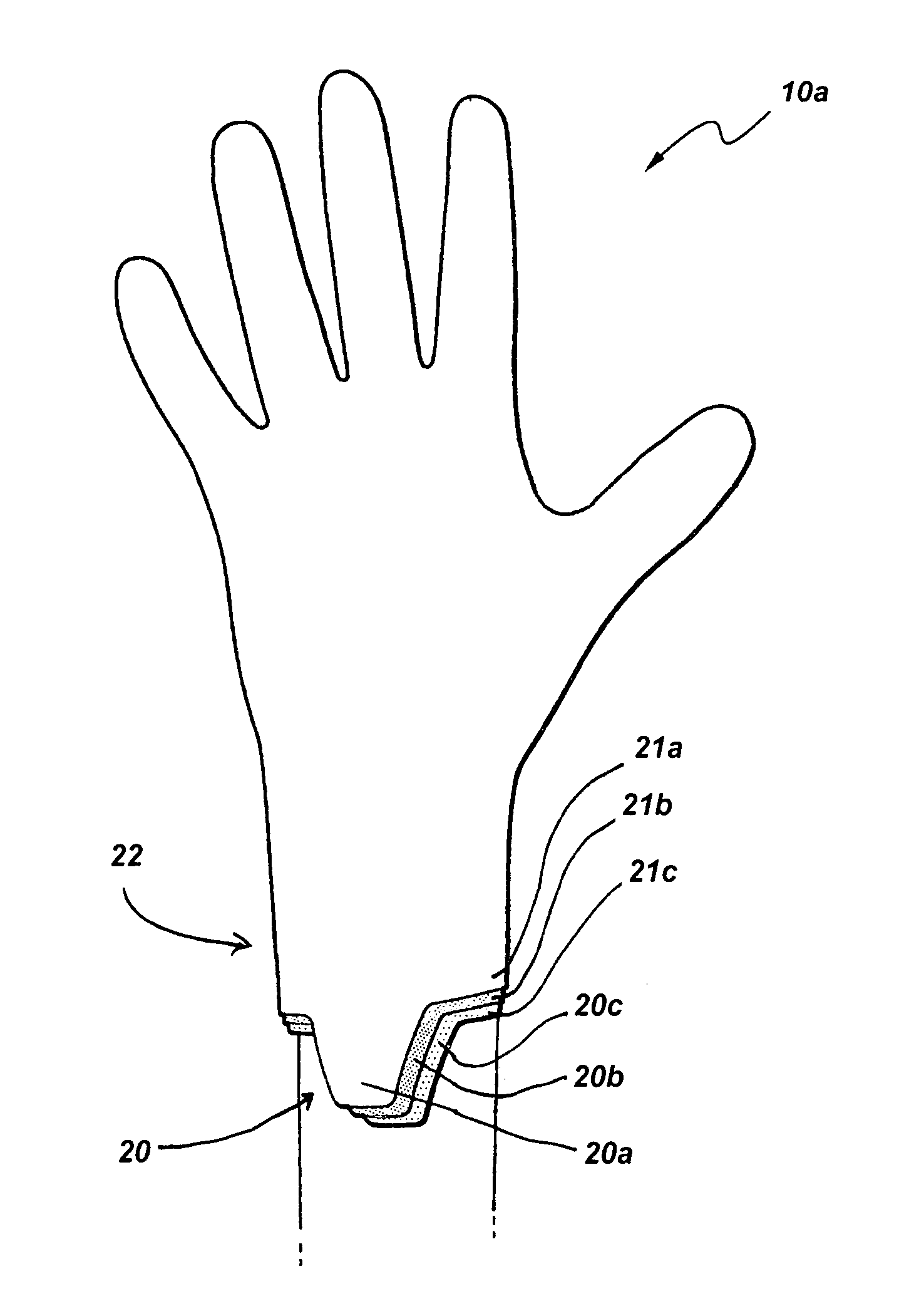

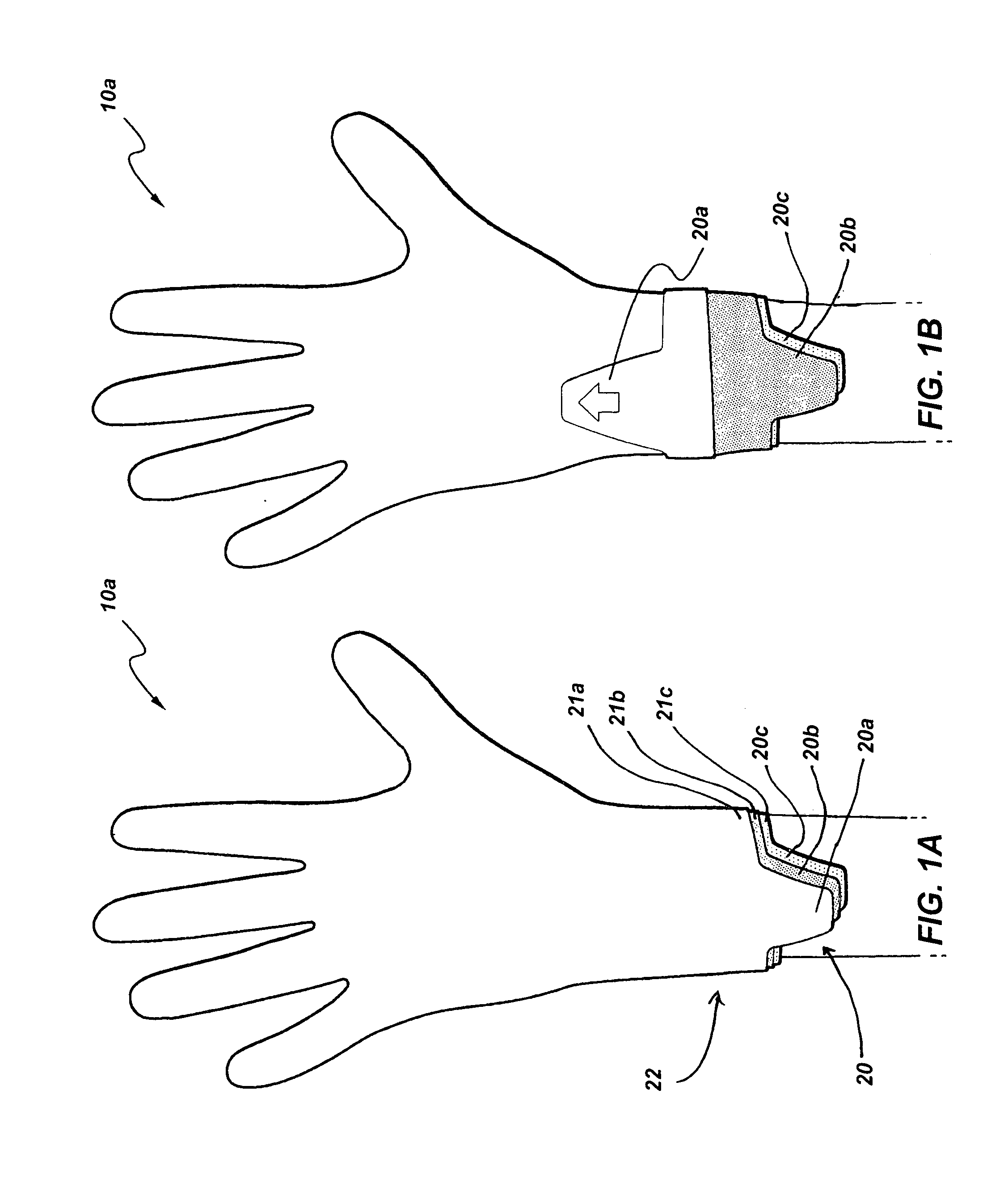

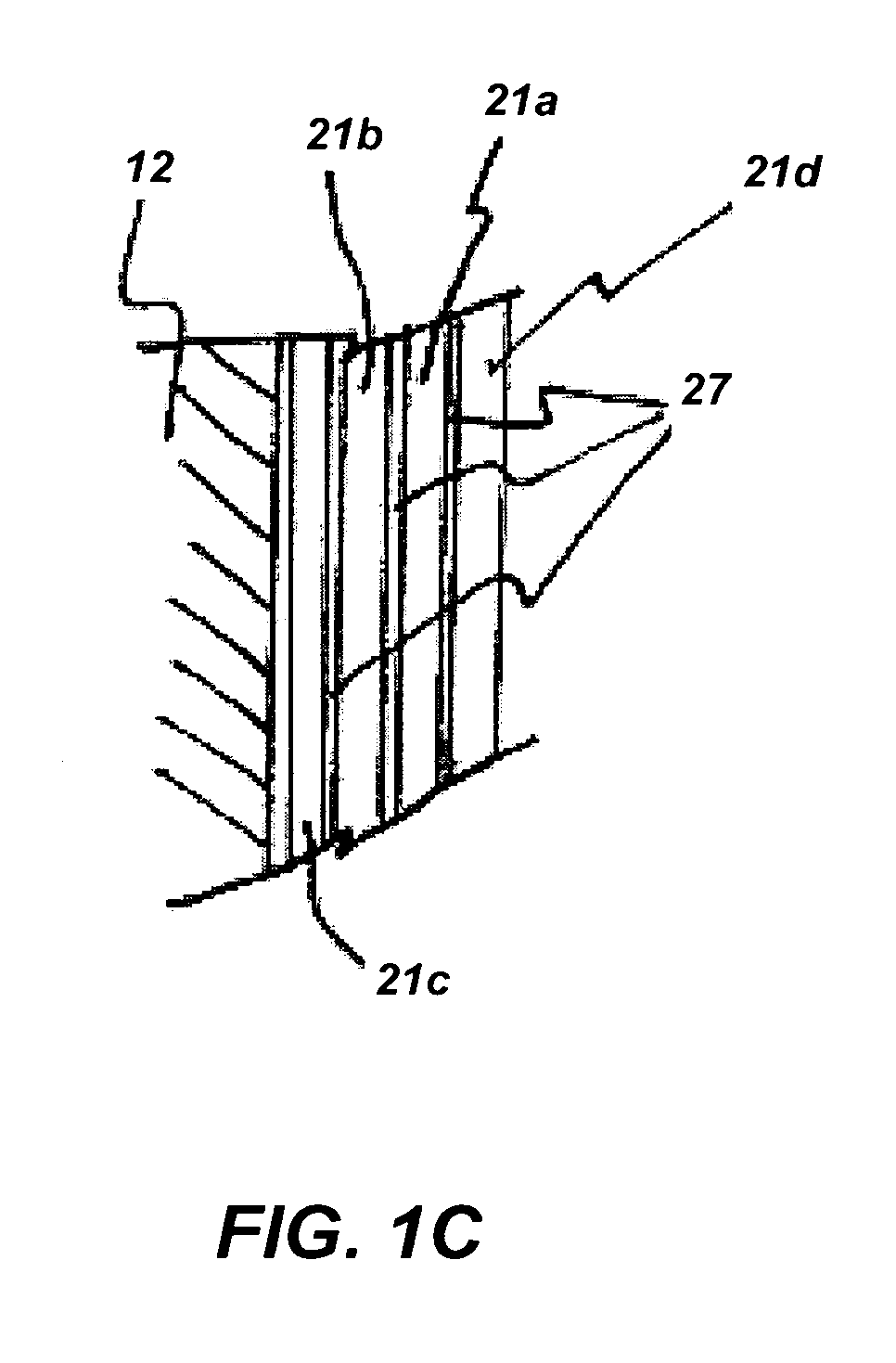

Protective glove

InactiveUS20130067638A1Maintain sensitivitySufficiently robustGlovesProtective garmentMedicineProtective gloves

Owner:PATKOV VASKO

High-sensitivity pressure conduction sensor for localized pressures and stresses

ActiveUS20050081640A1Accurate measurementInexpensive and scalable in and formForce measurementMaterial strength using tensile/compressive forcesElectricityControl system

A high-sensitivity pressure conduction sensor is presented. The present invention includes a pair of locally resilient conductive layers and a locally resilient pressure conduction composite disposed between and contacting both conductive layers. Alternate embodiments include at least three locally resilient conductive layers and at least two locally resilient pressure conduction composites, each having a critical percolation threshold. Each composite is disposed between and contacting two conductive layers in a multi-layer fashion. Other embodiments include a locally resilient pressure conduction composite, a flexible substrate completely surrounding the composite so as to seal it therein, and a pair of electrical leads contacting the composite and terminating outside of the flexible substrate. Pressure conduction composites are composed of a plurality of conductive particles electrically isolated within a non-conductive matrix. Conductive particles are loaded so as to have a volume fraction approaching the critical percolation threshold of the material system and exhibit a conductance that greatly increases with pressure. Sensors may be arranged to form one or more arrays including planar and conformal configurations. The present invention has immediate application in keyboards, intrusion systems, control systems, submarines, ships, sonobuoys, doors, and switches.

Owner:QORTEK

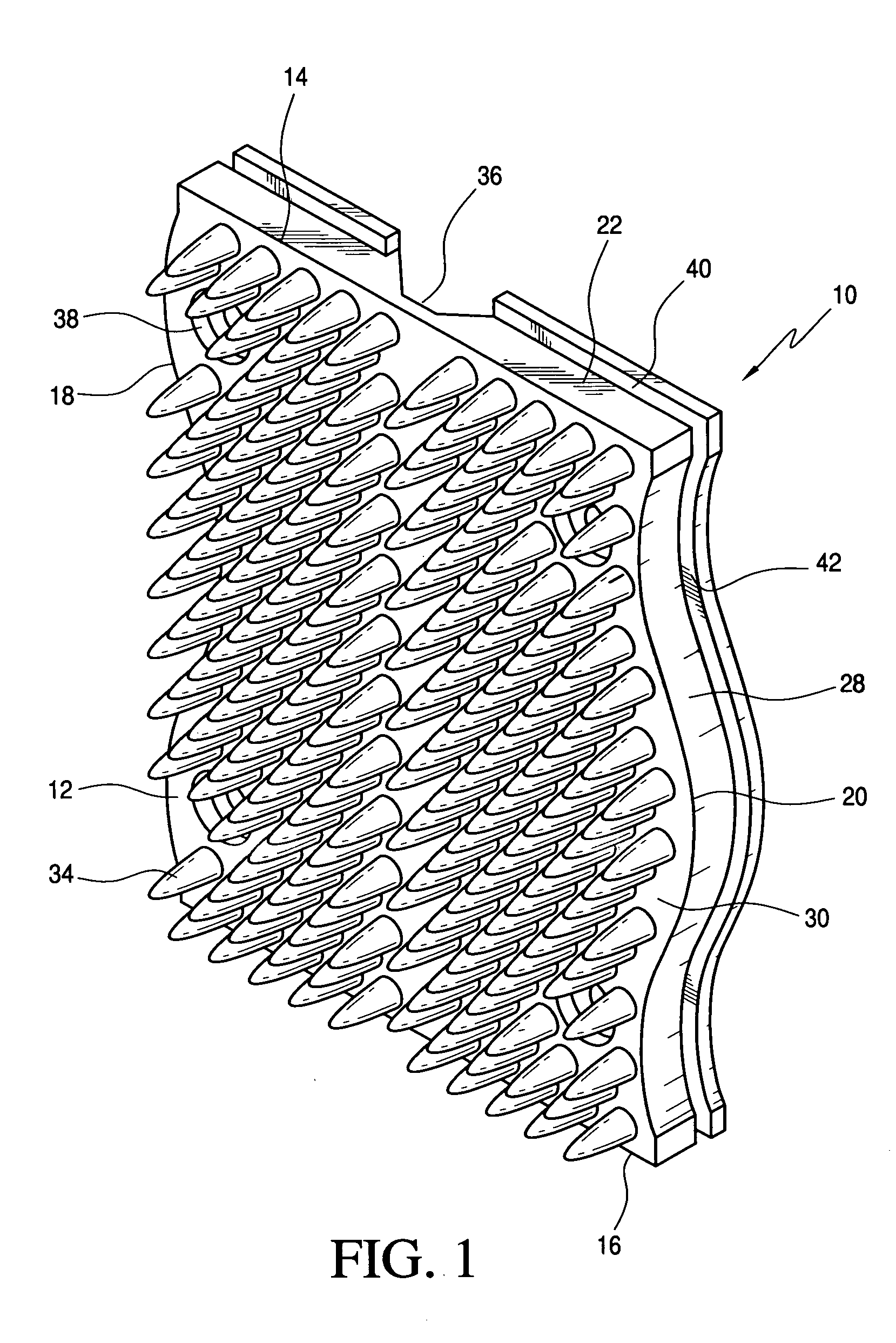

Scratching and self-grooming tool

A self-grooming tool for mammals consists of a quadrilateral pad which has a front face having a plurality of teeth extending therefrom, a rear face and opposed peripheral end and side walls, the opposed peripheral walls having complementary configurations. A recess in the rear face defines two planar areas, the pad being foldable about the recess between a flat position and a folded position. One each of the peripheral end and side walls have laterally projecting flanges, the underside of each flange being co-planar with the rear face of the pad and the flanges having a thickness which is less than about one-half the thickness of the pad. The other of each of the peripheral end and side walls have lengthwise extending undercuts formed therein, having the same shape and dimensions as the flanges, and communicating with the rear face of the pad.

Owner:GARRY CYNTHIA

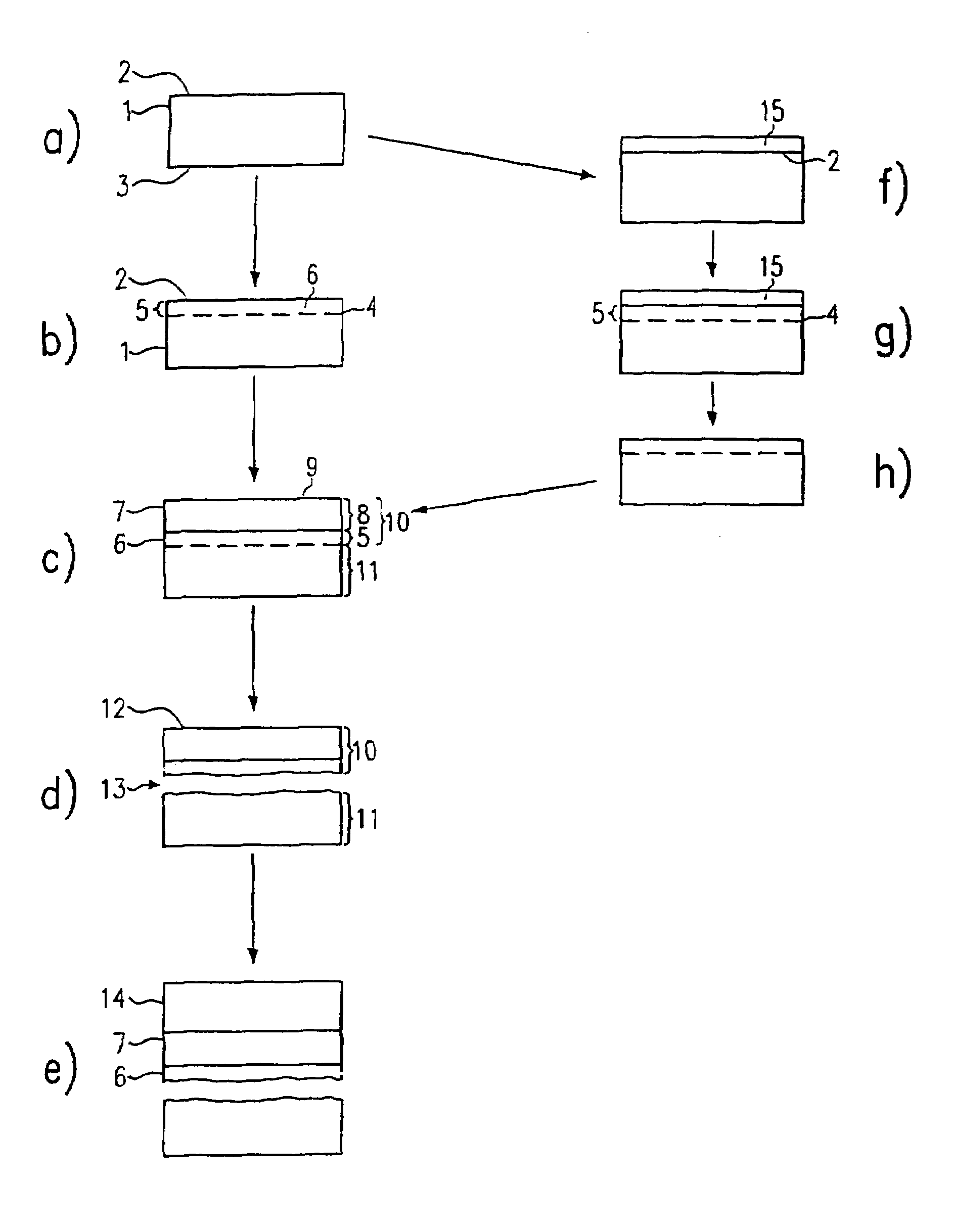

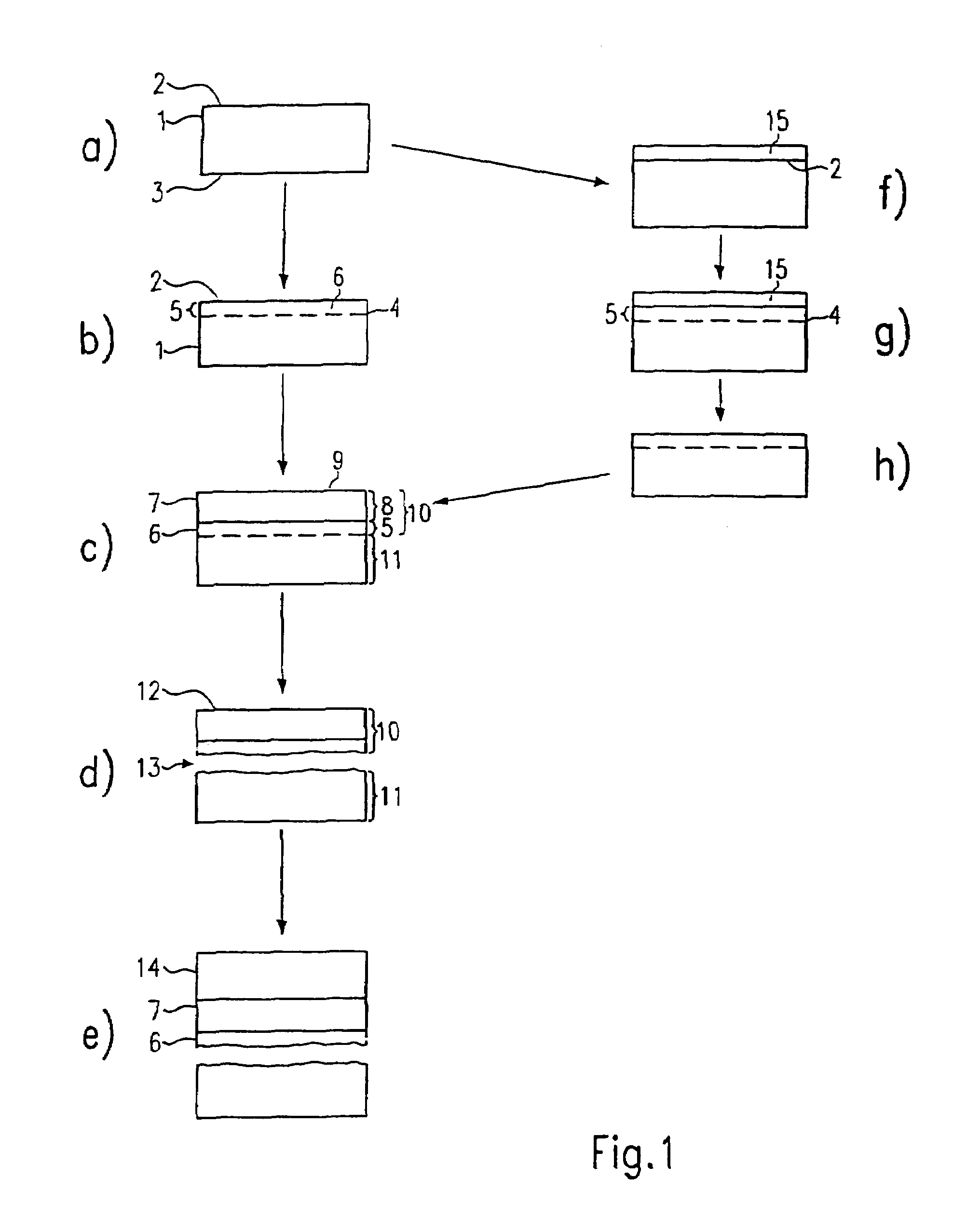

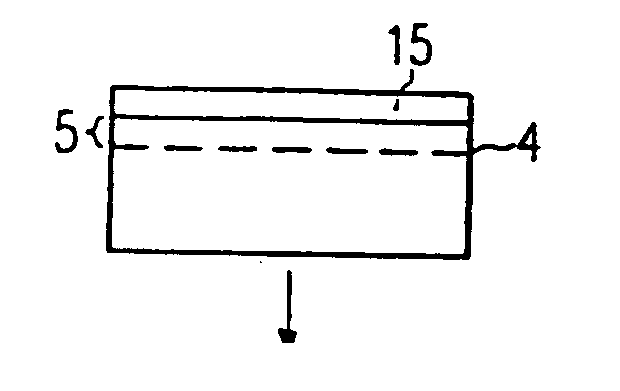

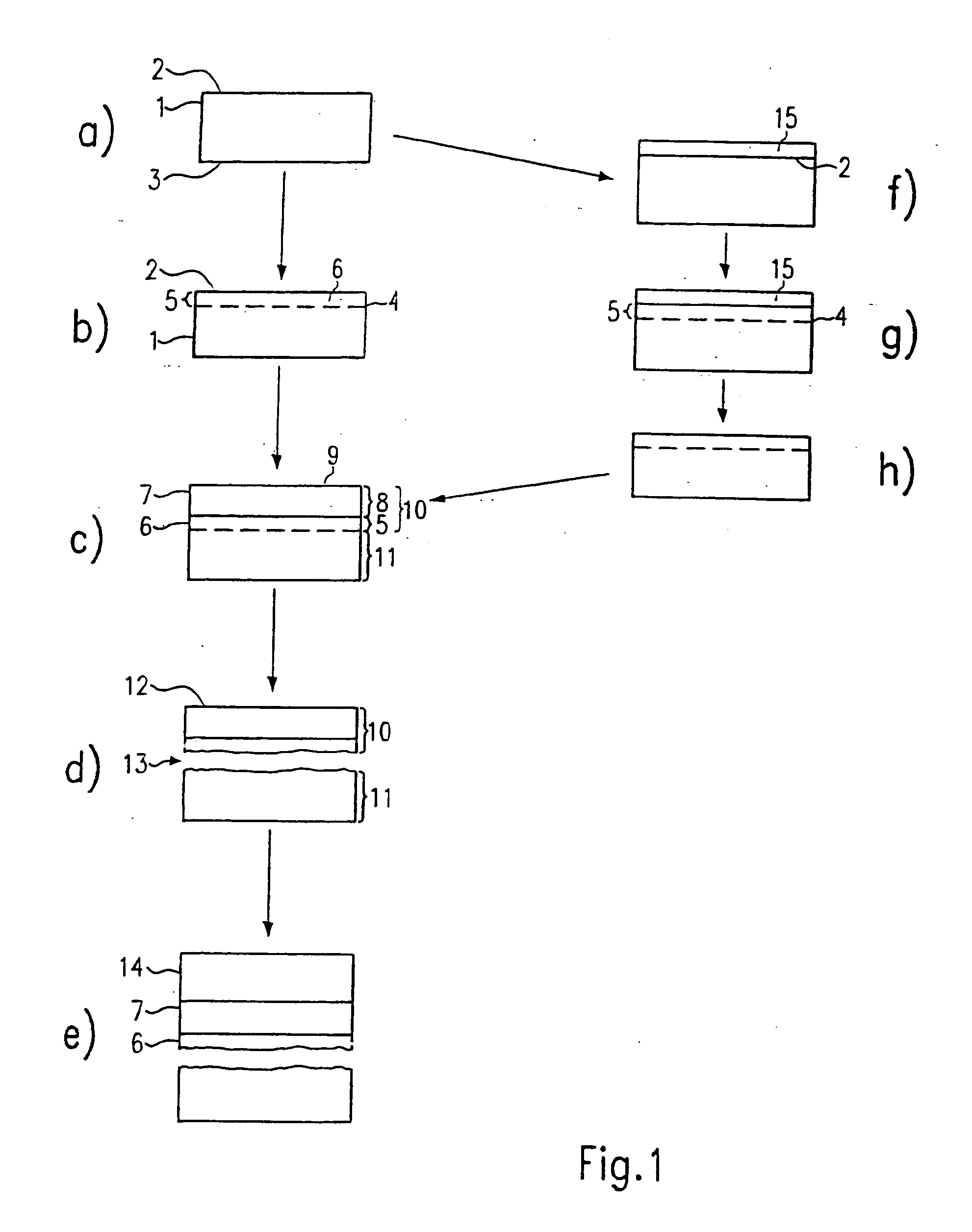

Method for fabricating an epitaxial substrate

ActiveUS7261777B2Sufficiently robustAvoid insufficient thicknessPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalOptoelectronics

Owner:SOITEC SA

Method for fabricating an epitaxial substrate

ActiveUS20050003641A1Sufficiently robustAvoid insufficient thicknessPolycrystalline material growthSemiconductor/solid-state device manufacturingOptoelectronicsSingle crystal

A method for fabricating an epitaxial substrate. The technique includes providing a crystalline or mono-crystalline base substrate, implanting atomic species into a front face of the base substrate to a controlled mean implantation depth to form a zone of weakness within the base substrate that defines a sub-layer, and growing a stiffening layer on a front face of the base substrate by using a thermal treatment in a first temperature range. The stiffening layer has a thickness sufficient to form an epitaxial substrate. In addition, the method includes detaching the stiffening layer and the sub-layer from the base substrate by using a thermal treatment in a second temperature range higher than the first temperature range. An epitaxial substrate and a remainder of the base substrate are obtained. The epitaxial substrate is suitable for use in growing high quality homoepitaxial or heteroepitaxial films thereon.

Owner:SOITEC SA

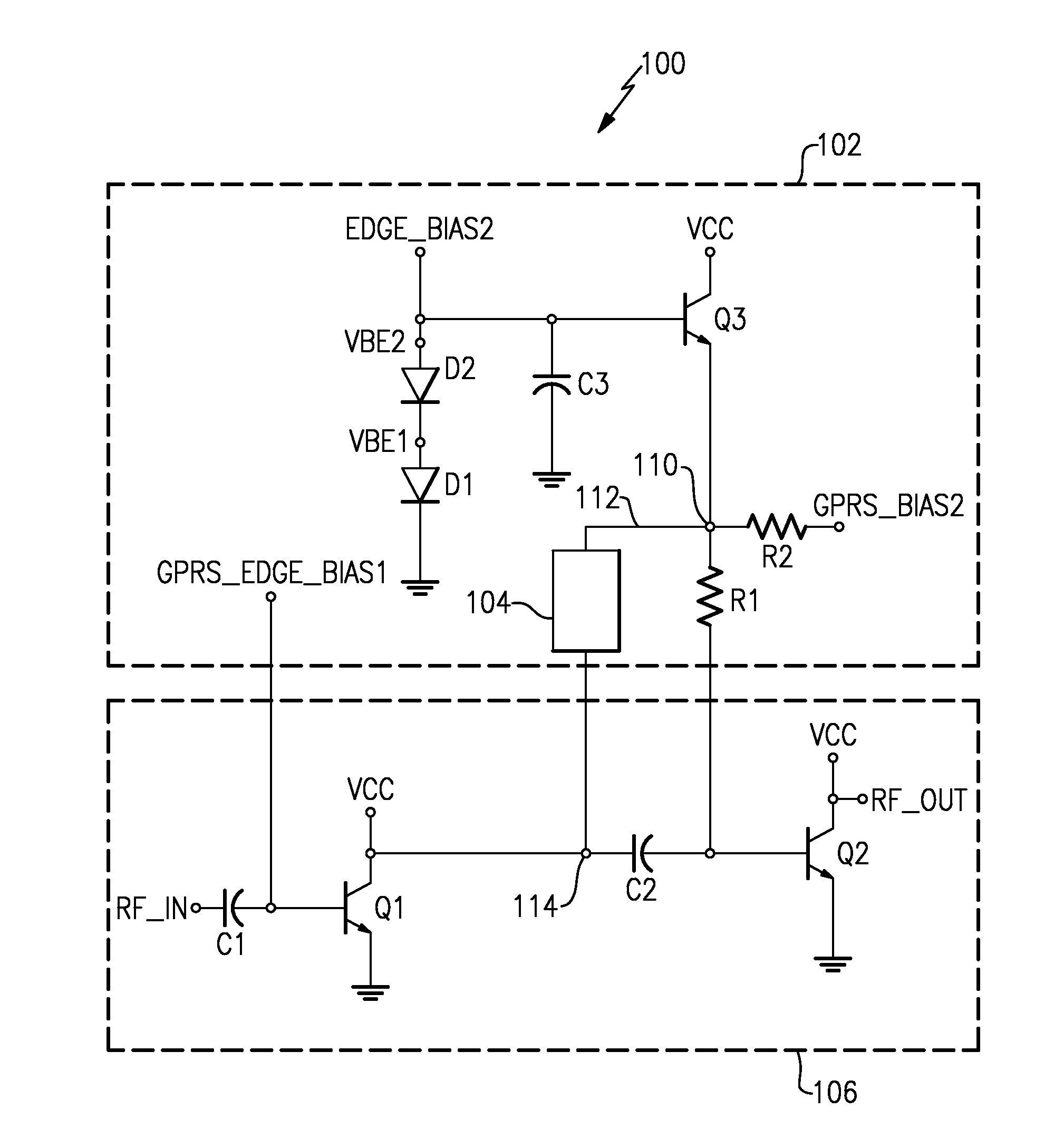

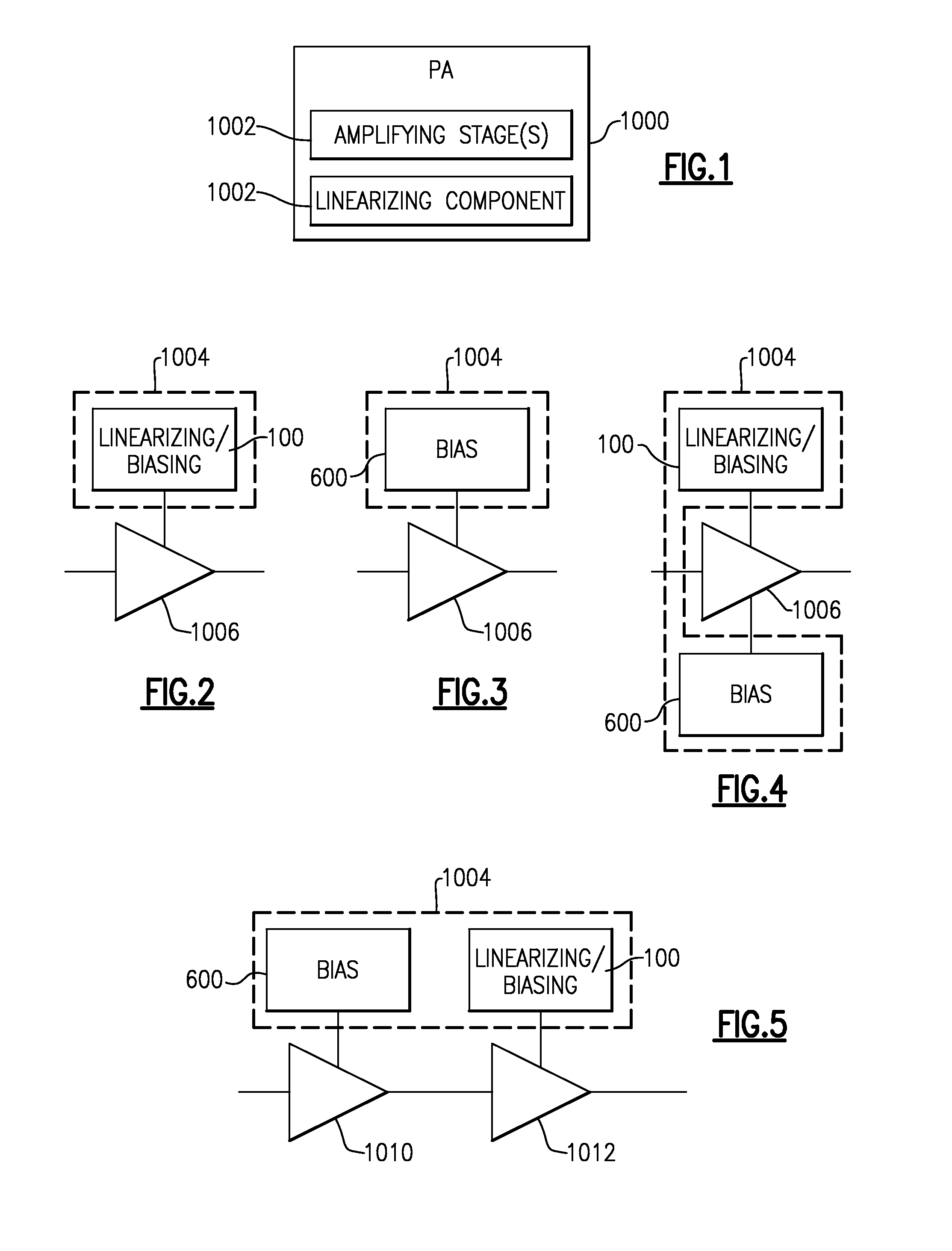

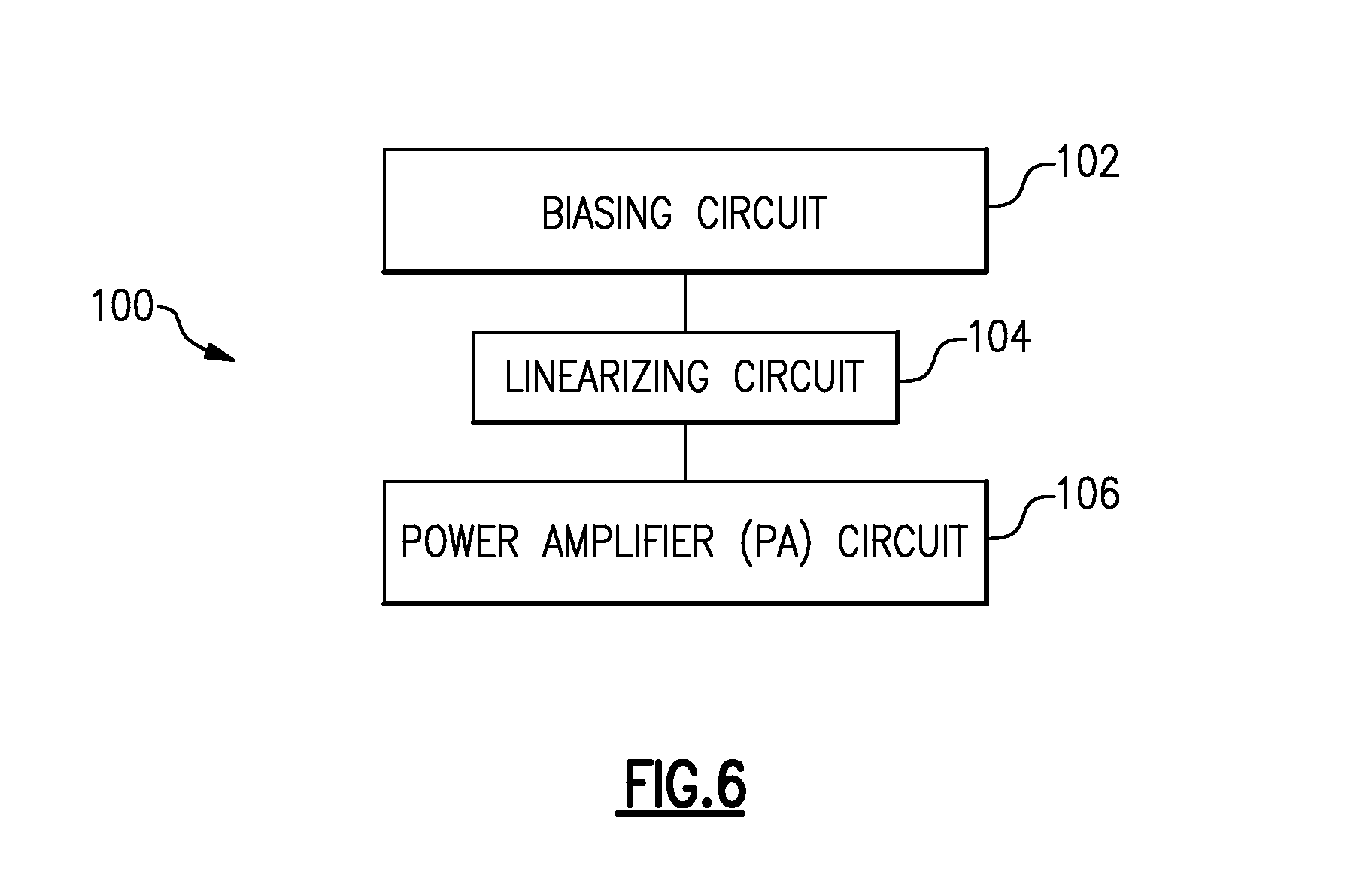

Linearity performance for multi-mode power amplifiers

ActiveUS20150171797A1Improve linearitySufficiently robustAmplifier modifications to reduce non-linear distortionAmplifier details to increase power/efficiencyAudio power amplifierElectrical ballast

Improved linearity performance for multi-mode power amplifiers. A power amplifier (PA) assembly can include a radio-frequency (RF) amplification path having a first stage and a second stage, with each stage including a transistor. The PA assembly can further include a biasing circuit having a first bias path between a supply node and the base of a corresponding transistor. The PA assembly can further include a linearizing circuit implemented as either or both of a second bias path and a coupling path relative to the first bias path. The second bias path can be configured to provide an additional base bias current to the base under a selected condition. The coupling path can be configured to improve linearity of the corresponding transistor operating in a first mode while allowing a ballast resistance to be sufficiently robust for the corresponding transistor operating in a second mode.

Owner:SKYWORKS SOLUTIONS INC

Humane animal trap

InactiveUS7930853B2Inexpensive to fabricateSolve the complicated settingAnimal huntingAnimal trapsLight beamEngineering

A humane animal trap includes an enclosure having an opening with a door disposed therein. The door is pivotable about an upper edge between open and closed positions, and is biased toward the closed position by a torsion spring. An electrical solenoid is disposed above the door and has a catch that is biased into engagement with a holding feature on the door when the door is in the open position, and is operable to disengage the catch from the holding feature in response to the receipt of an electrical trip signal. An electrical sensor disposed in the enclosure transmits a light beam between opposite sidewalls of the trap, and generates an electrical trip signal and transmits it to the solenoid when the light beam is interrupted by an animal entering the trap so as to close the door behind the animal and thereby capture it unharmed in the enclosure.

Owner:RIZHAO J&J TECH MFG CO LTD

Fiber-aligning optical switch

A mechanical optical switch provides an active switching mechanism and an active latching mechanism that are both actuated by piezoelectric elements. The switching mechanism includes a switching frame at which fiber ends are attached to be switched along an opposing array of fixed fiber ends. The active latching mechanism provides for a fast switching of the switching mechanism and a reliable holding of the switching positions. The elements of the switching mechanism and the latching mechanism are monolithically fabricated from a wafer. The piezoelectric elements are integrated by bonding. The switch is substantially free of gliding friction, which reduces switching forces and makes the switch highly reliable over an extended lifetime.

Owner:INTEL CORP

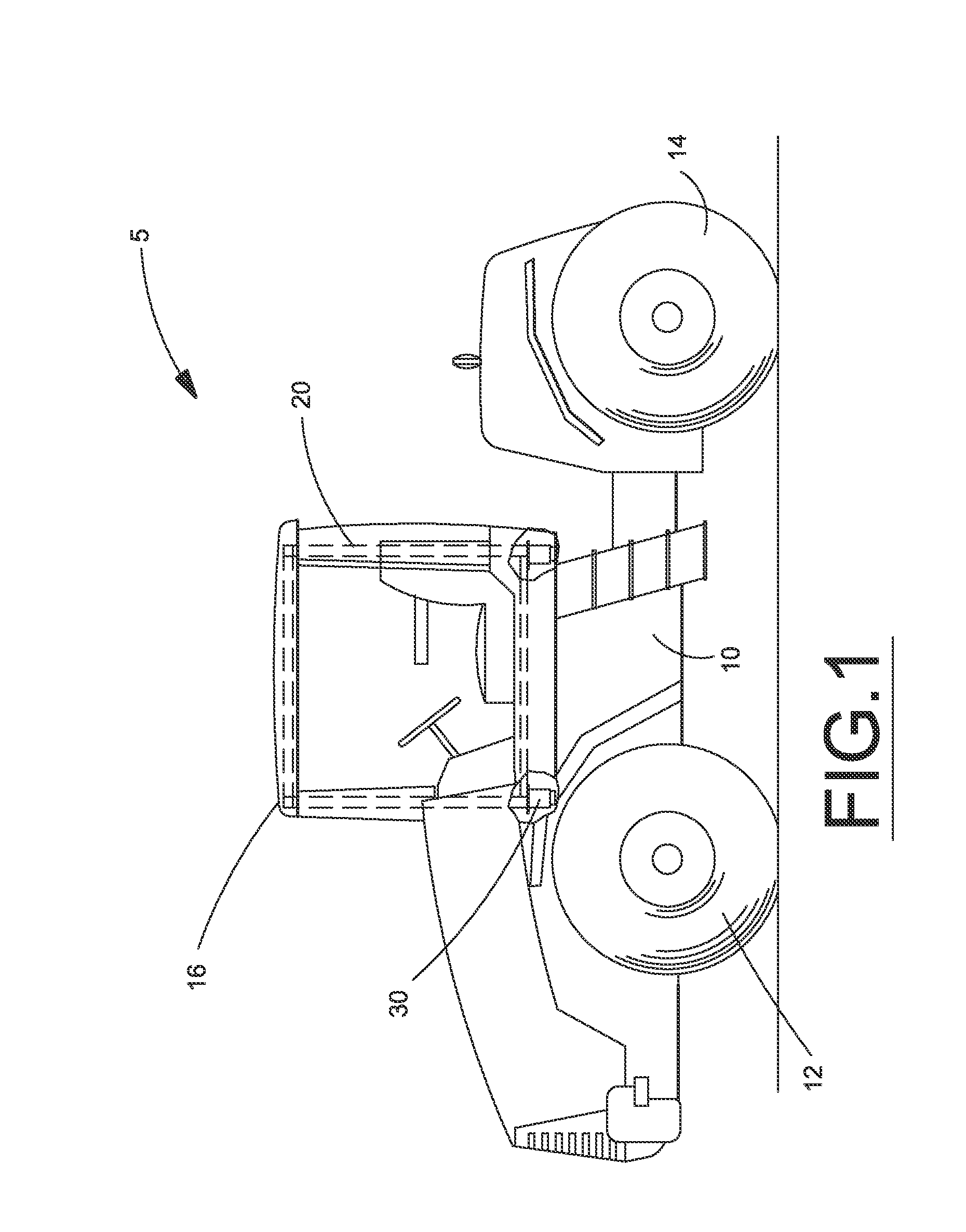

Suspended cab rollover protection system (ROPS) attachment for a 4WD agricultural tractor

ActiveUS8430426B2Minimizes metal-to-metal contactSufficiently robustVehicle seatsPedestrian/occupant safety arrangementRolloverVehicle frame

Owner:CNH IND AMERICA LLC

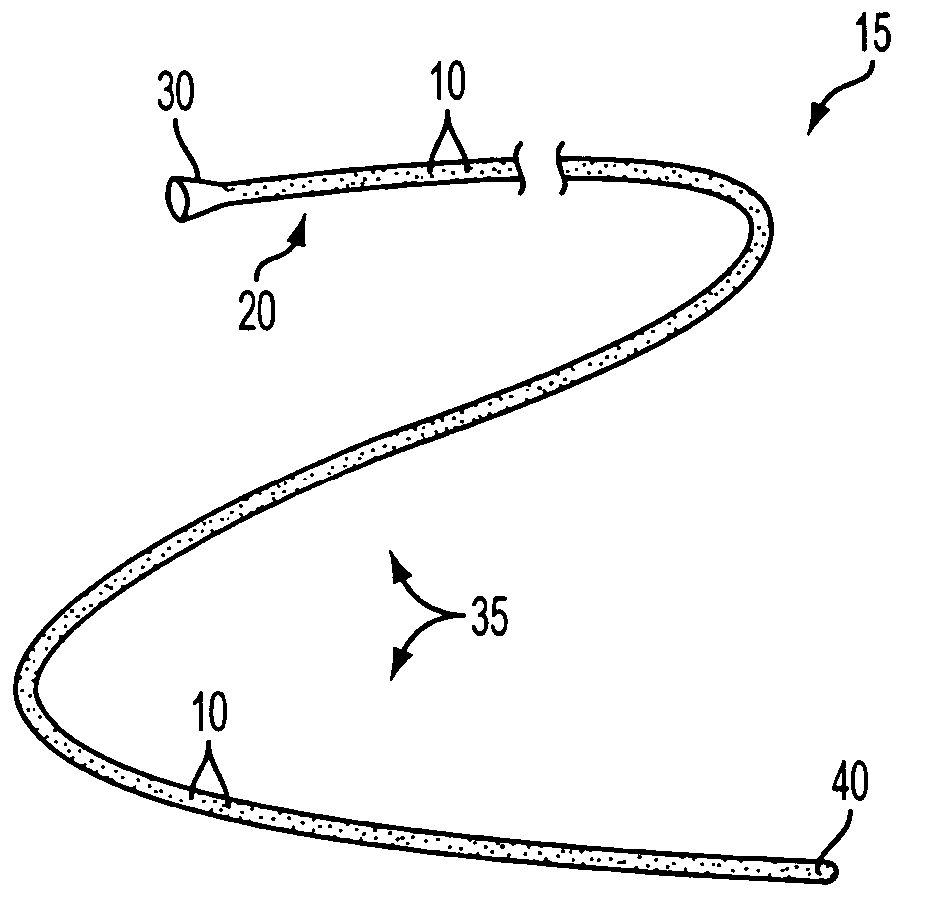

Compositions and methods for capture and elution of biological materials via particulates

ActiveUS8663974B2Efficiently obtainedReduce the amount requiredBioreactor/fermenter combinationsBiological substance pretreatmentsParticulatesElution

Lysing may include agitating a specimen in a chamber along with a medium that includes a particulate lysing material that has an affinity for a biological material. Lysing material may include beads or other material which may be coated that facilitates binding. The medium may include a fluid with a high salt or low pH level. Binding of biological materials to solid surfaces may be induced by particular media. The biological material may be eluted by lowering a concentration of salt or increasing a pH level. Lysing materials with two or more different affinities may be employed. Lysing materials may include particles of different sizes. Heating may be used. Lysing may be performed in a flow through apparatus. Surfaces of solid materials may be modified to capture bacteria with high cell wall lipid content.

Owner:CLAREMONT BIOSOLUTIONS

Security classroom function lock mechanism

InactiveUS20040025548A1Reduce residualExcessive repairWing handlesAnti-theft cycle devicesPositive controlLocking mechanism

A lock mechanism operated by inner and outer lever handles provides a security classroom function and includes inner and outer lock mechanisms that are independently switchable between locked and unlocked states by inner and outer lock cylinders and keys. The inner handle always operates the lock mechanism to retract a latch bolt. The outer handle can only retract the latch bolt when both the inner and outer lock mechanisms are in the unlocked state. The outer key can retract the latch bolt when the inner lock mechanism is in the locked state, but cannot change the inner lock mechanism to the unlocked state or enable the outer handle, thereby ensuring positive control over the locked state of the outer handle from the inner side.

Owner:SARGENT MANUFACTURING CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com