Patents

Literature

339results about How to "Improve coating adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

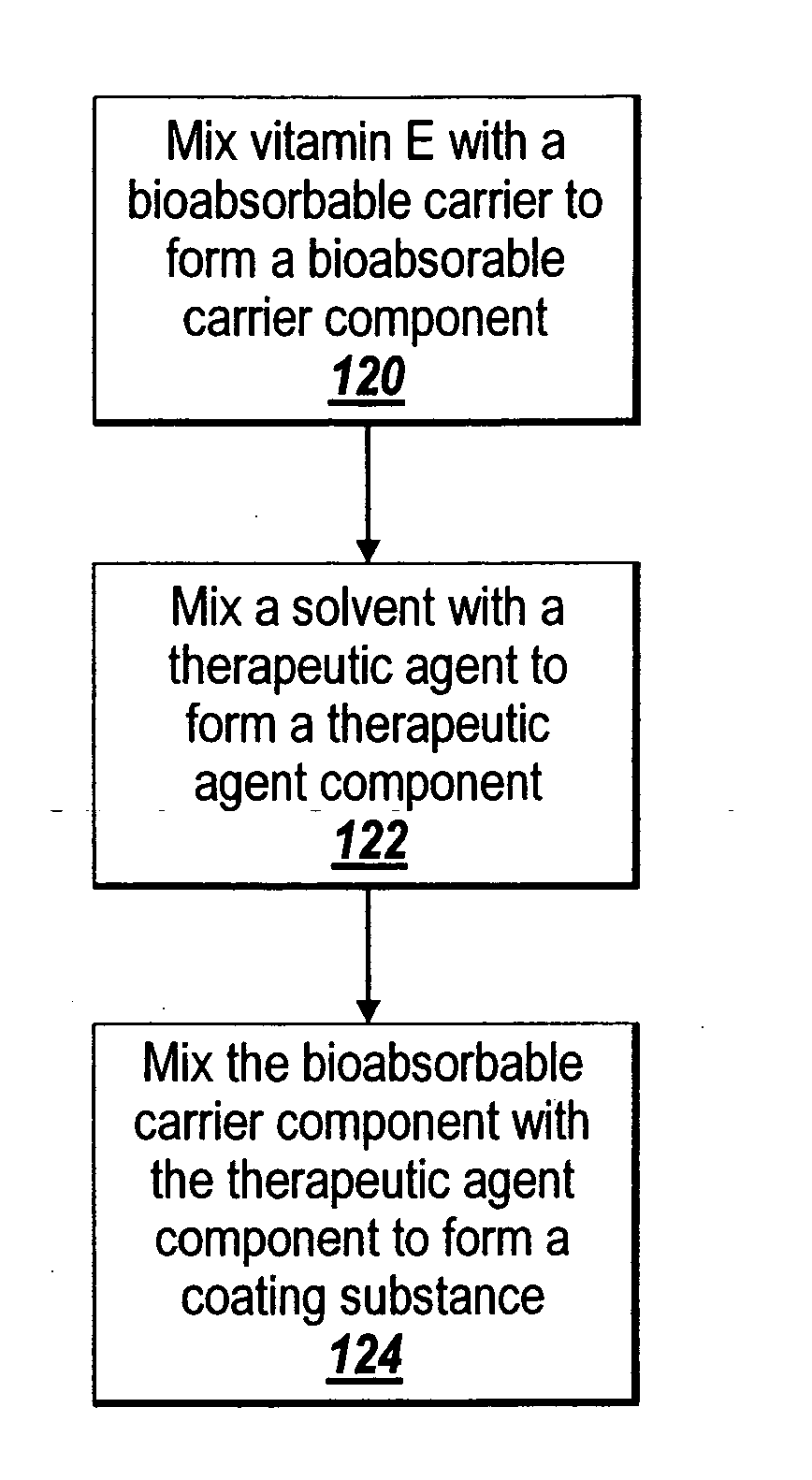

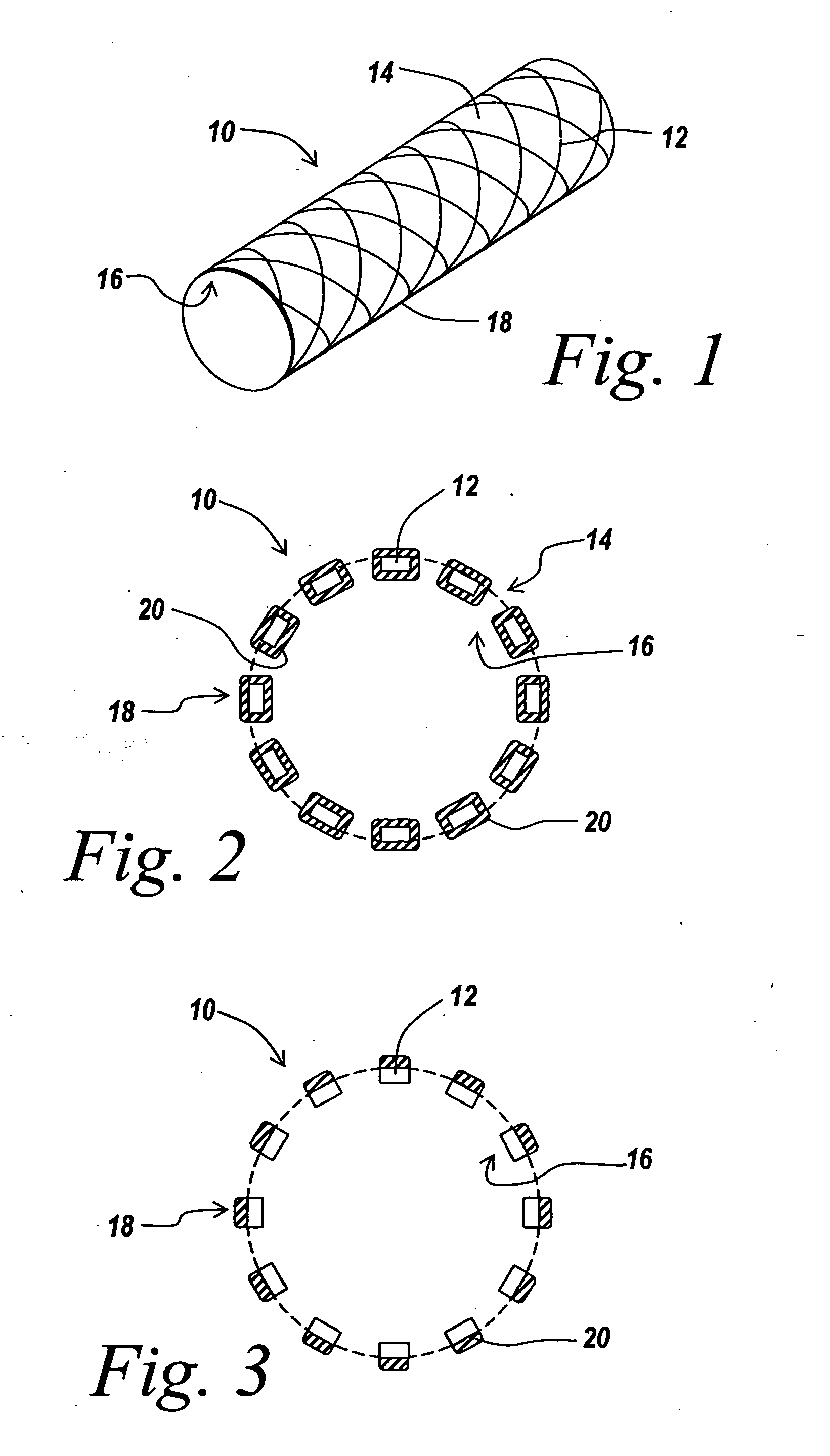

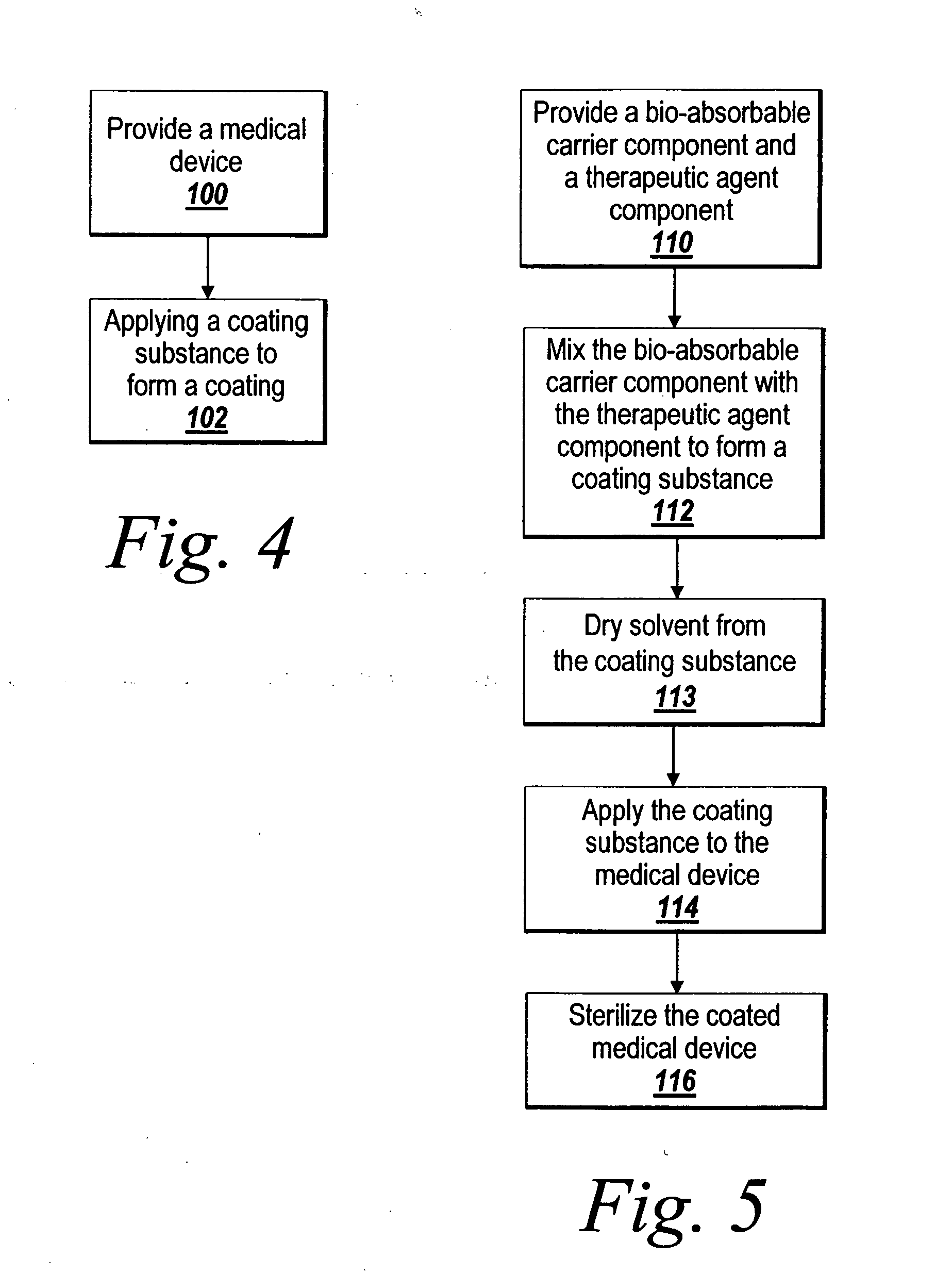

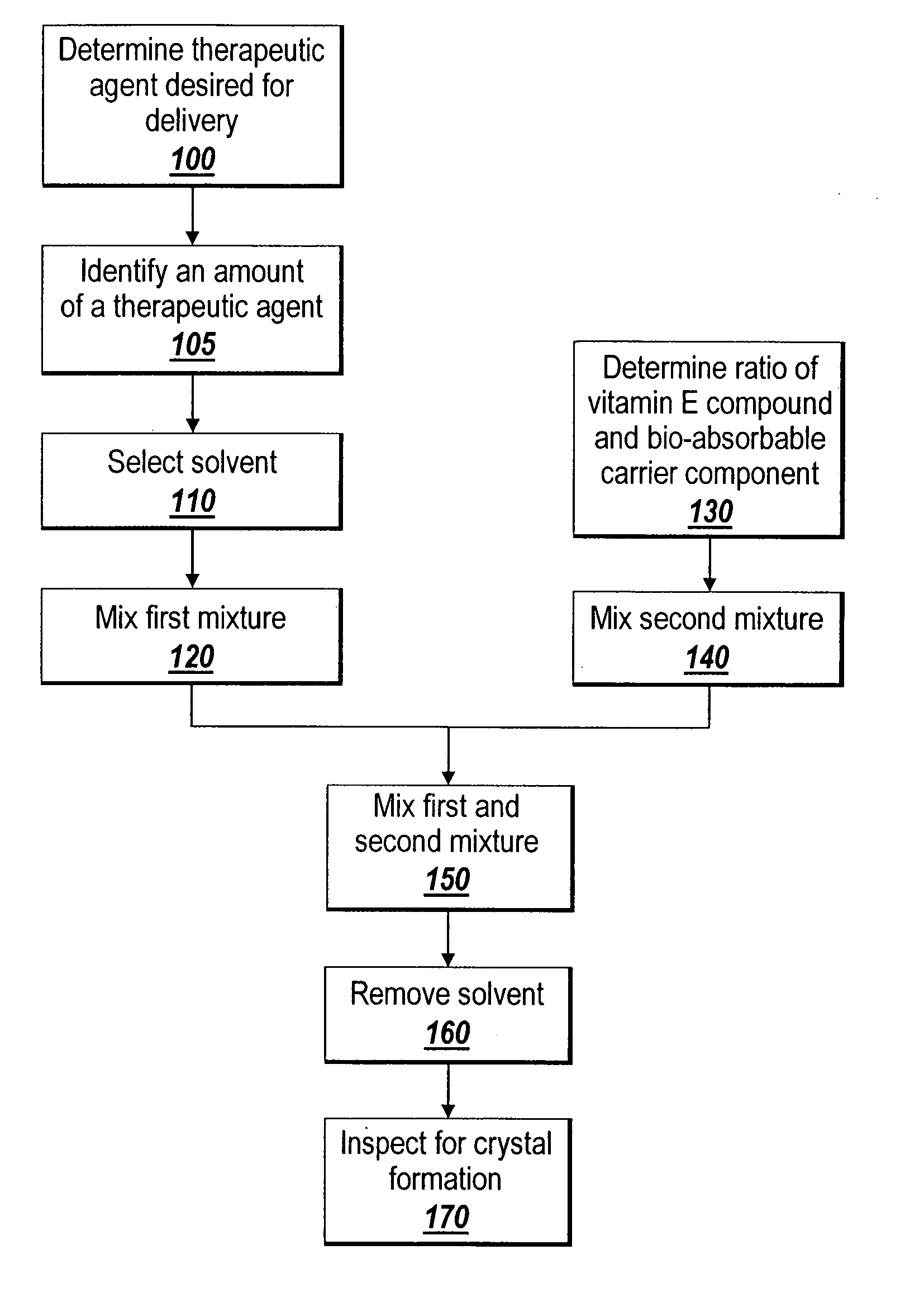

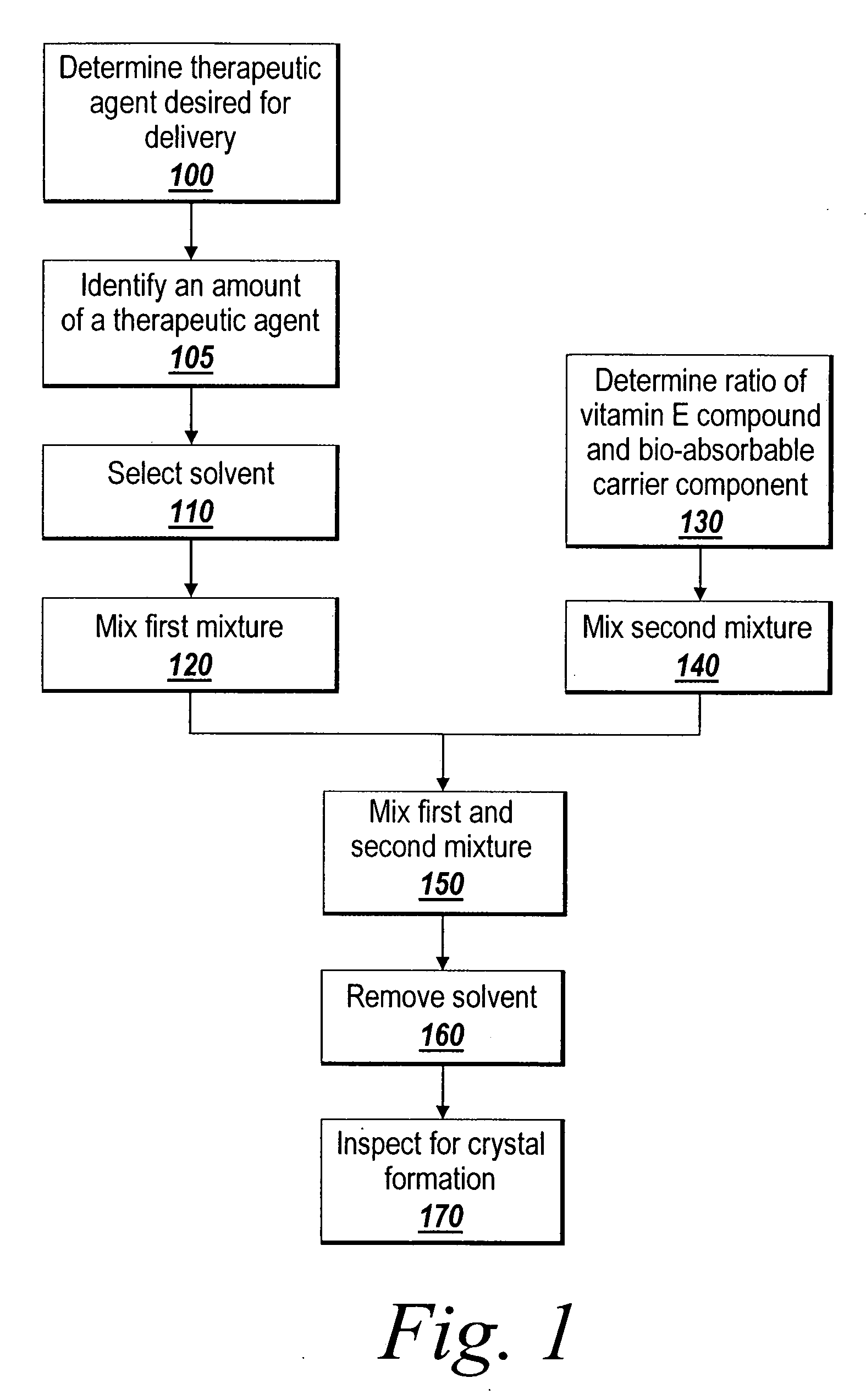

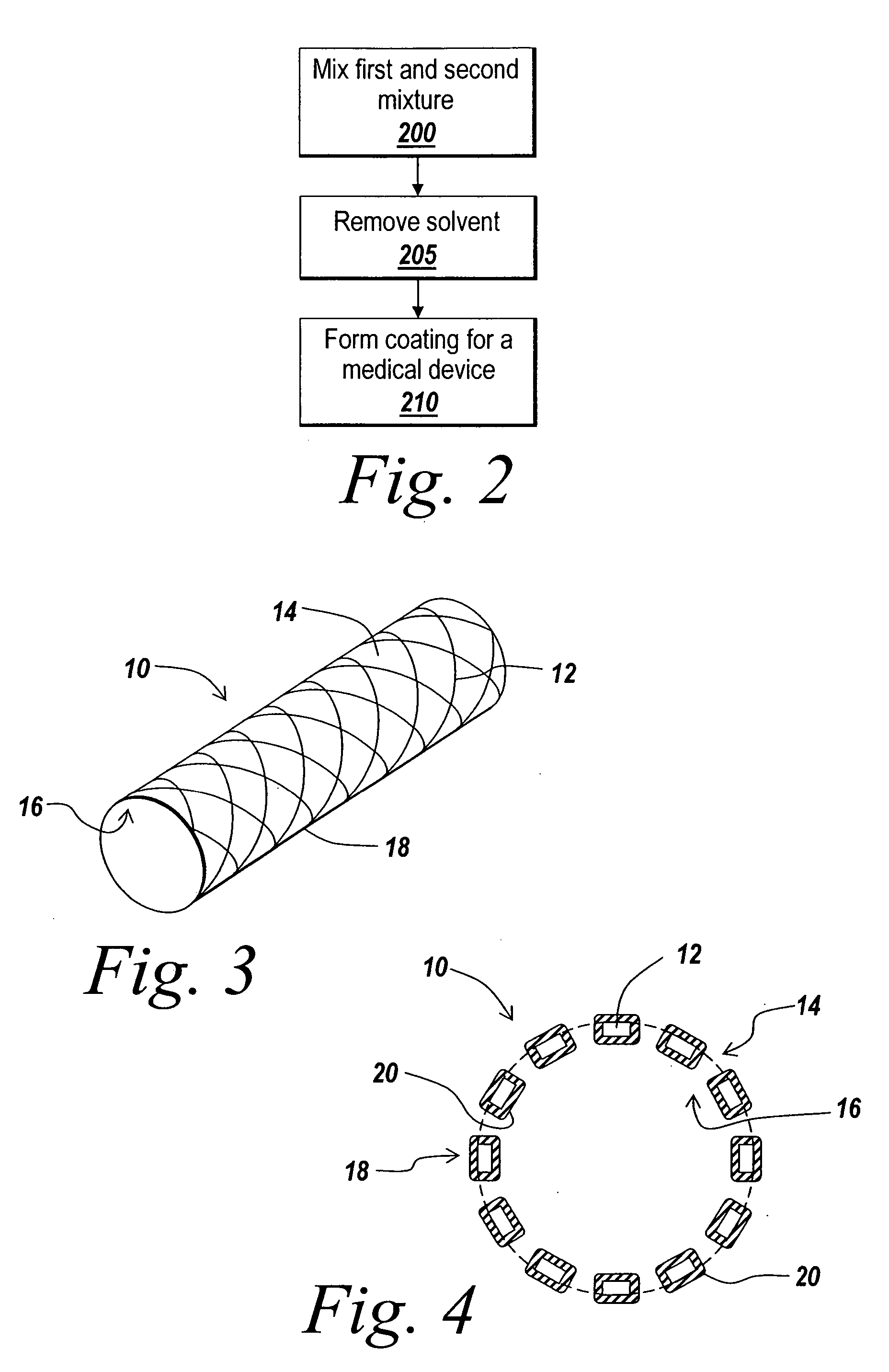

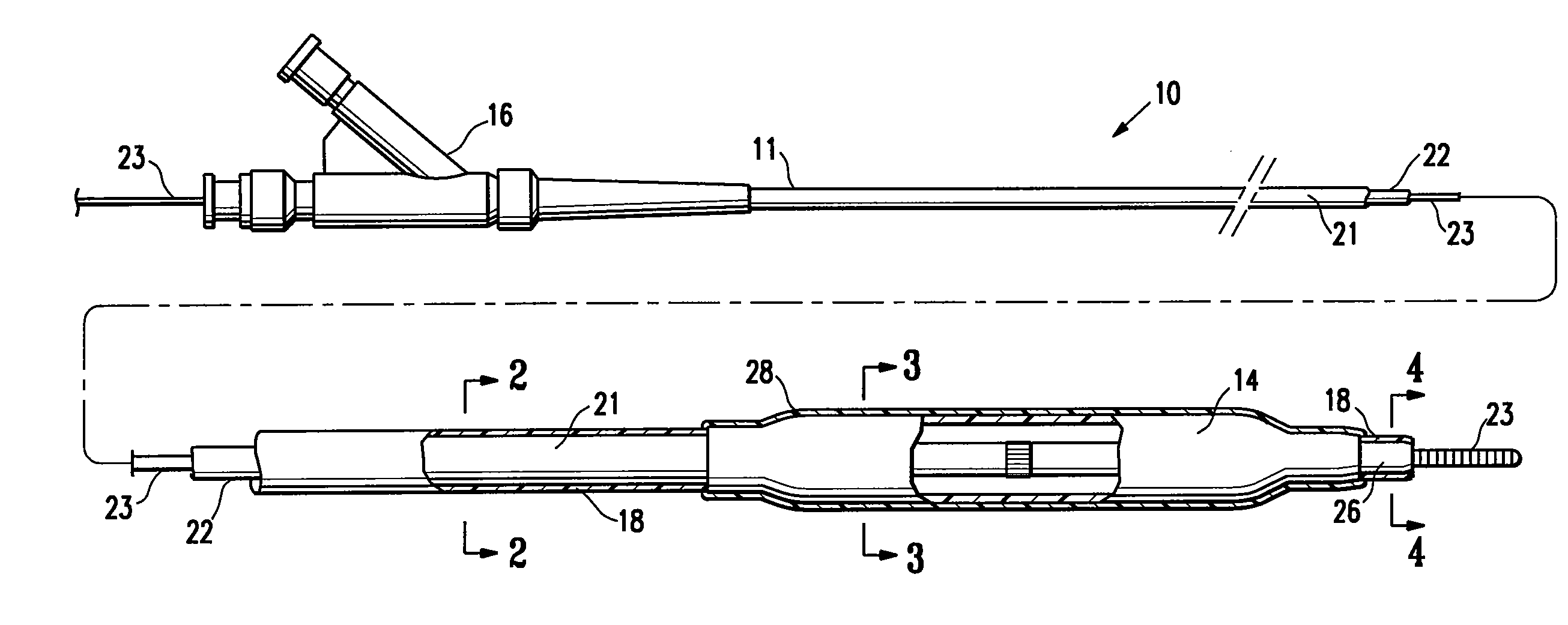

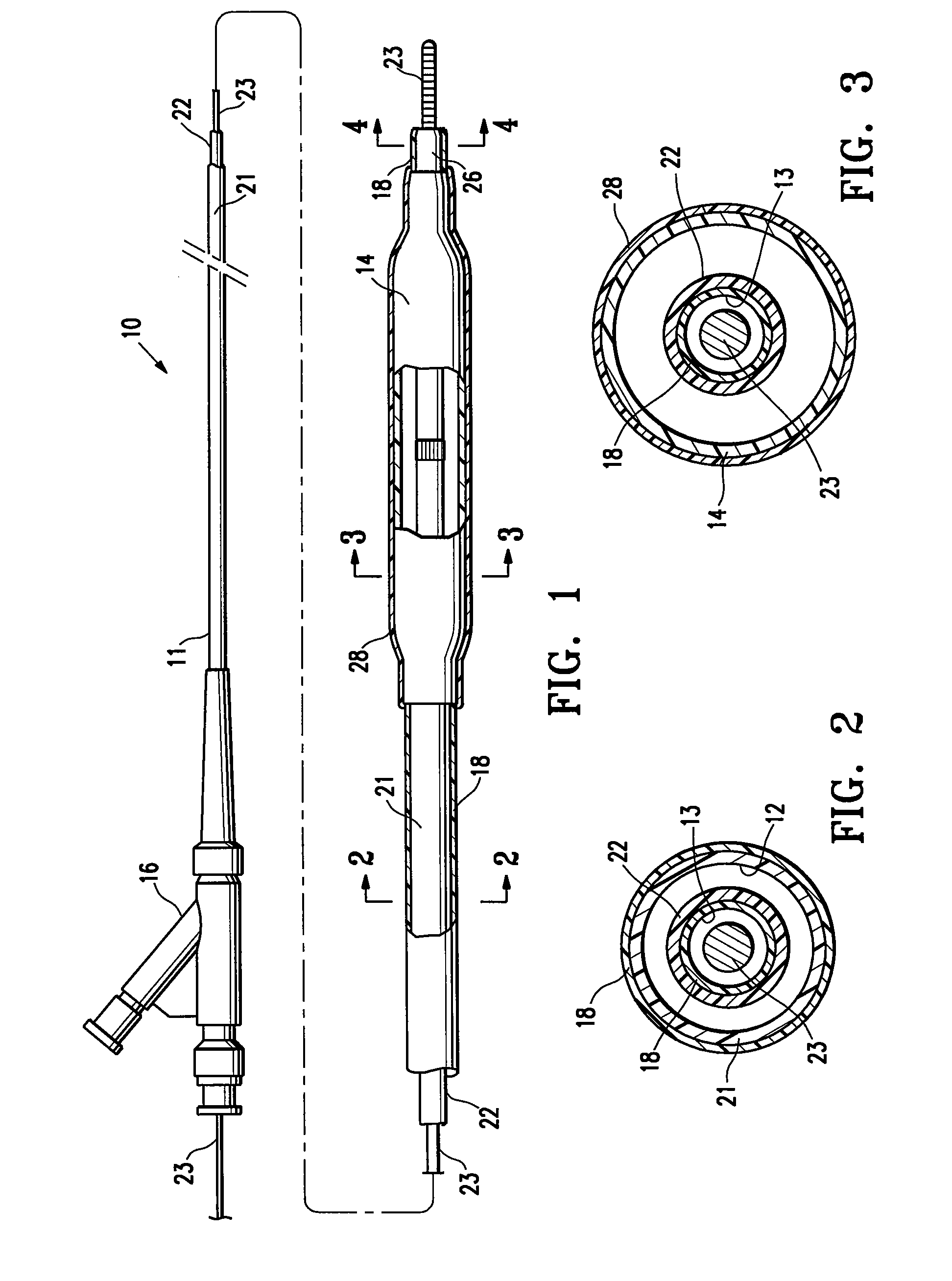

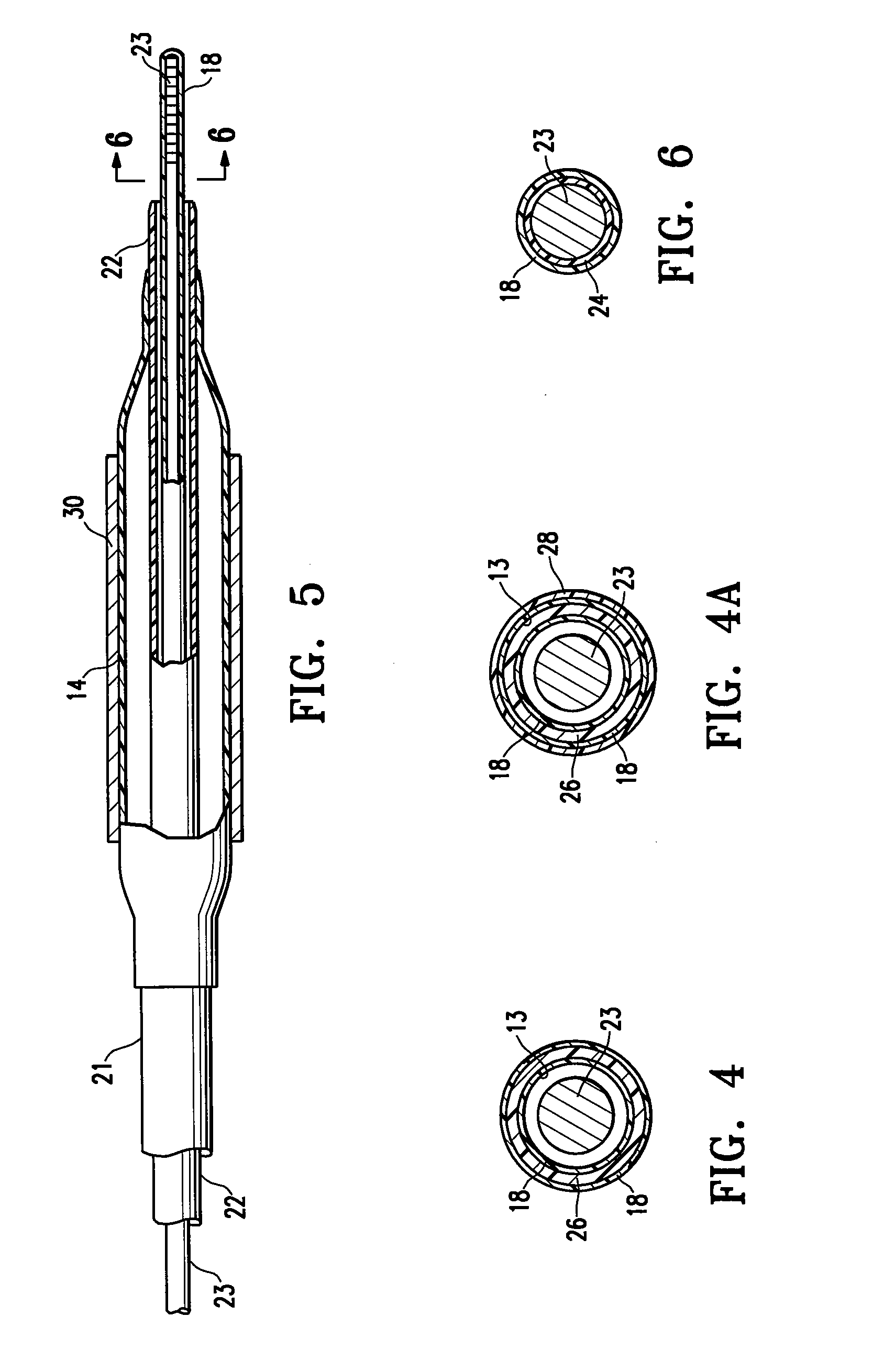

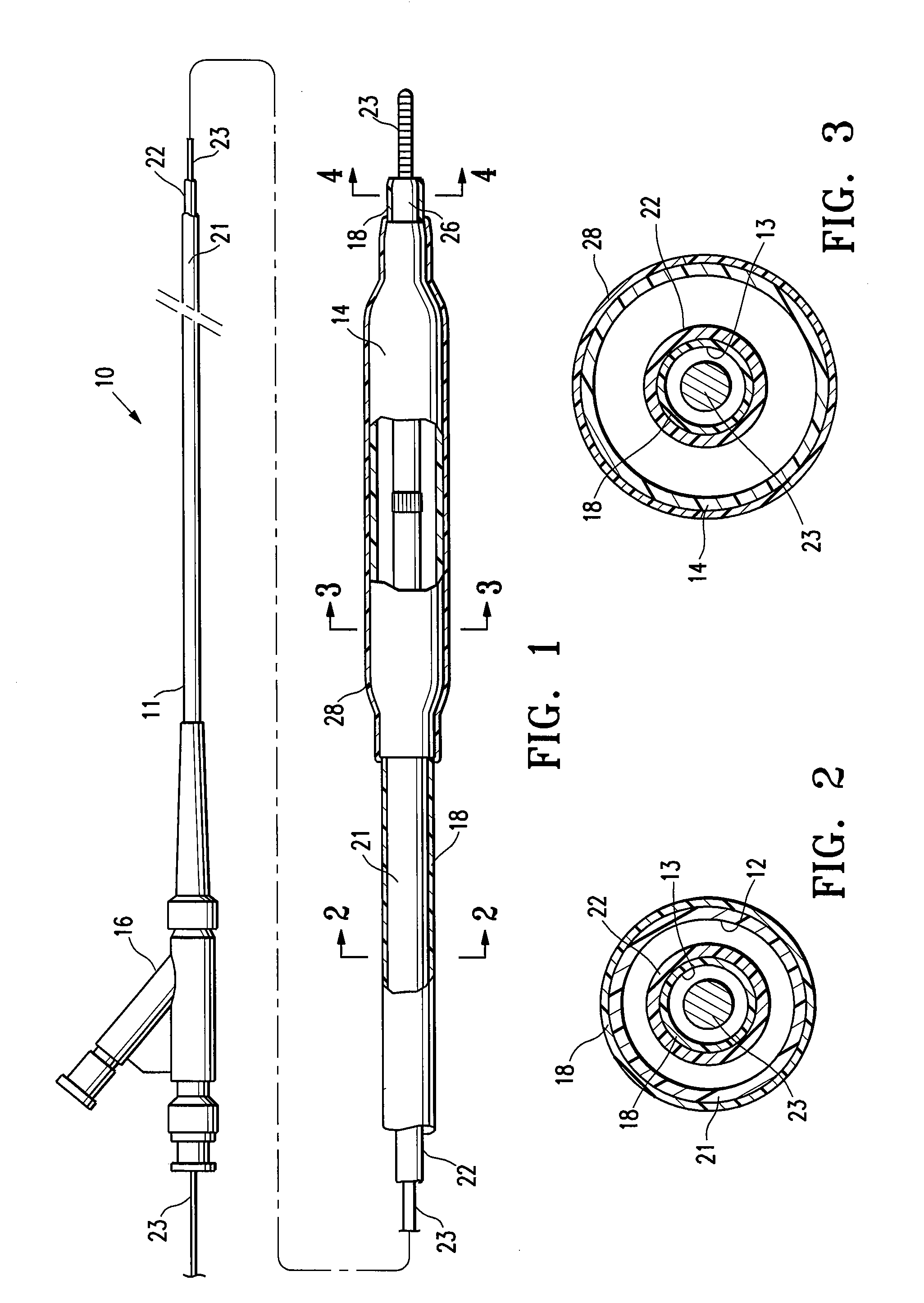

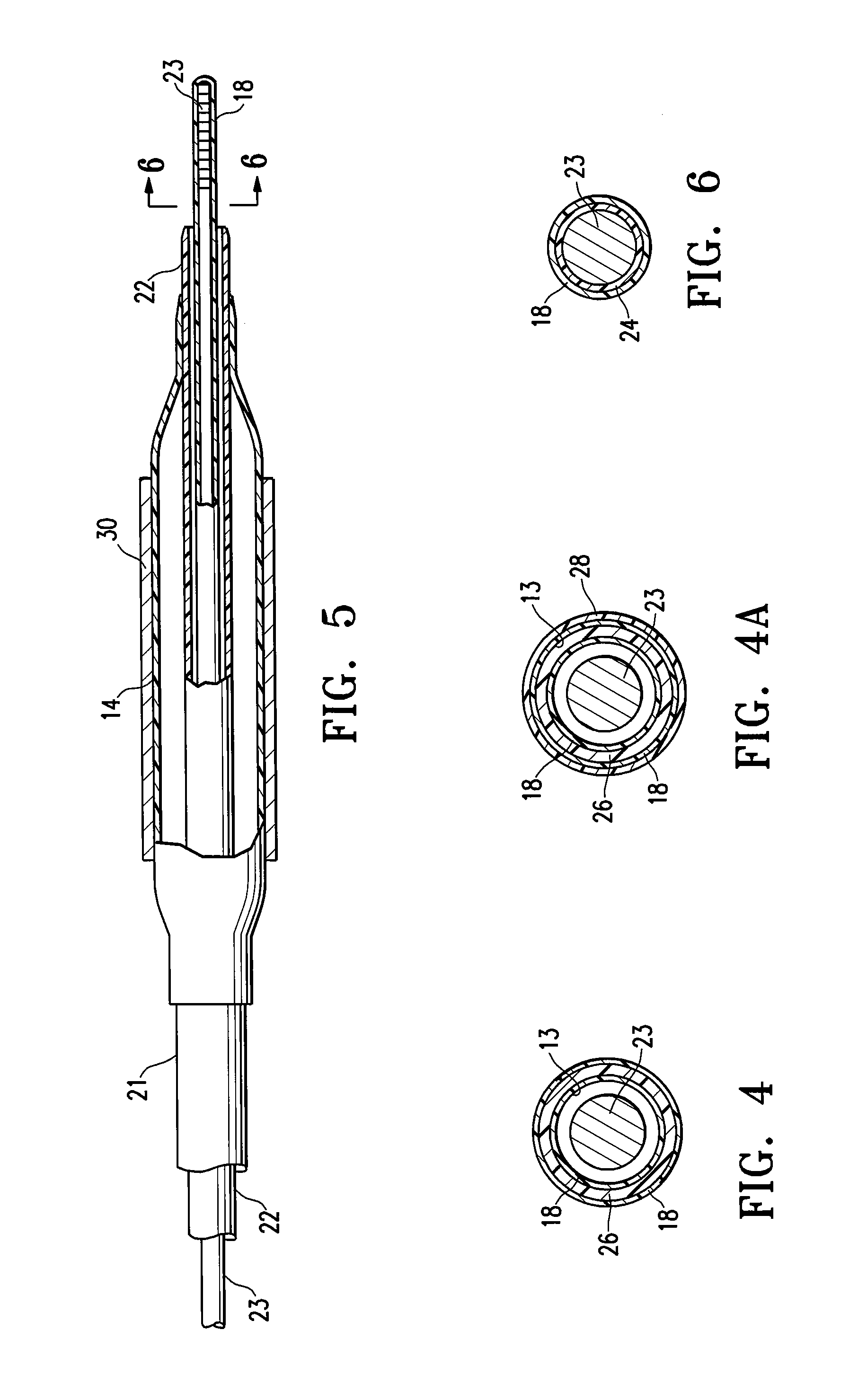

Pre-dried drug delivery coating for use with a stent

InactiveUS20060067977A1Increases rate of solvent evaporationRaise transfer toAntipyreticAnalgesicsInsertion stentSolvent

A method and apparatus for the provision of a coating for application to a medical device results in a medical device having a bio-absorbable coating. The coating includes a bio-absorbable carrier component. In addition to the bio-absorbable carrier component, a therapeutic agent component and solvent can also be provided. The solvent is removed from the coating before the coating is applied to the medical device. The coated medical device is implantable in a patient to effect controlled delivery of the coating, including the therapeutic agent, to the patient.

Owner:ATRIUM MEDICAL

Environmentally-friendly corrosion-resistant chromium-free chemical conversion liquid and method for preparing chemical conversion film

InactiveCN102409325AEasy to store and transportStrong corrosion resistanceAnti-corrosive paintsMetallic material coating processesSolventCorrosion resistant

The invention relates to the field of aluminum alloy surface treatment, in particular relates to an environmentally-friendly corrosion-resistant chromium-free chemical conversion liquid and an application thereof in an environmentally-friendly corrosion-resistant chromium-free chemical conversion film with aluminum alloy coating adhesion for ships, and solves the problems of incapability of meeting the requirements on corrosion resistance and coating adhesion in the current environmentally-friendly chemical conversion treating process. The prepared chemical conversion film has excellent corrosion resistance and coating adhesion, is convenient in construction and can be used for substituting for a traditional chromium-containing chemical conversion and phosphate treatment process. The environmentally-friendly corrosion-resistant chromium-free chemical conversion liquid mainly comprises the components of silane, corrosion inhibition components and a solvent. The chromium-free chemical conversion film construction modes comprise dipping, roller painting and spraying, and the curing modes comprise natural curing and heating curing. The environmentally-friendly corrosion-resistant chromium-free chemical conversion film in the invention has excellent corrosion resistance and coating adhesion, can be used for substituting for a traditional chromium-containing chemical conversion and phosphate treatment process, and is applicable to aluminum alloys for ships such as 5xxx and 6xxx series aluminum alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Coating for medical devices comprising an inorganic or ceramic oxide and a therapeutic agent

InactiveUS20070264303A1Improve coating adhesionGood biocompatibilityStentsHeavy metal active ingredientsIntravascular stentMedical device

The invention relates generally to an implantable medical device for delivering a therapeutic agent to the body tissue of a patient, and a method for making such a medical device. In particular, the invention pertains to an implantable medical device, such as an intravascular stent, having a coating comprising an inorganic or ceramic oxide, such as titanium oxide, and a therapeutic agent.

Owner:BOSTON SCI SCIMED INC

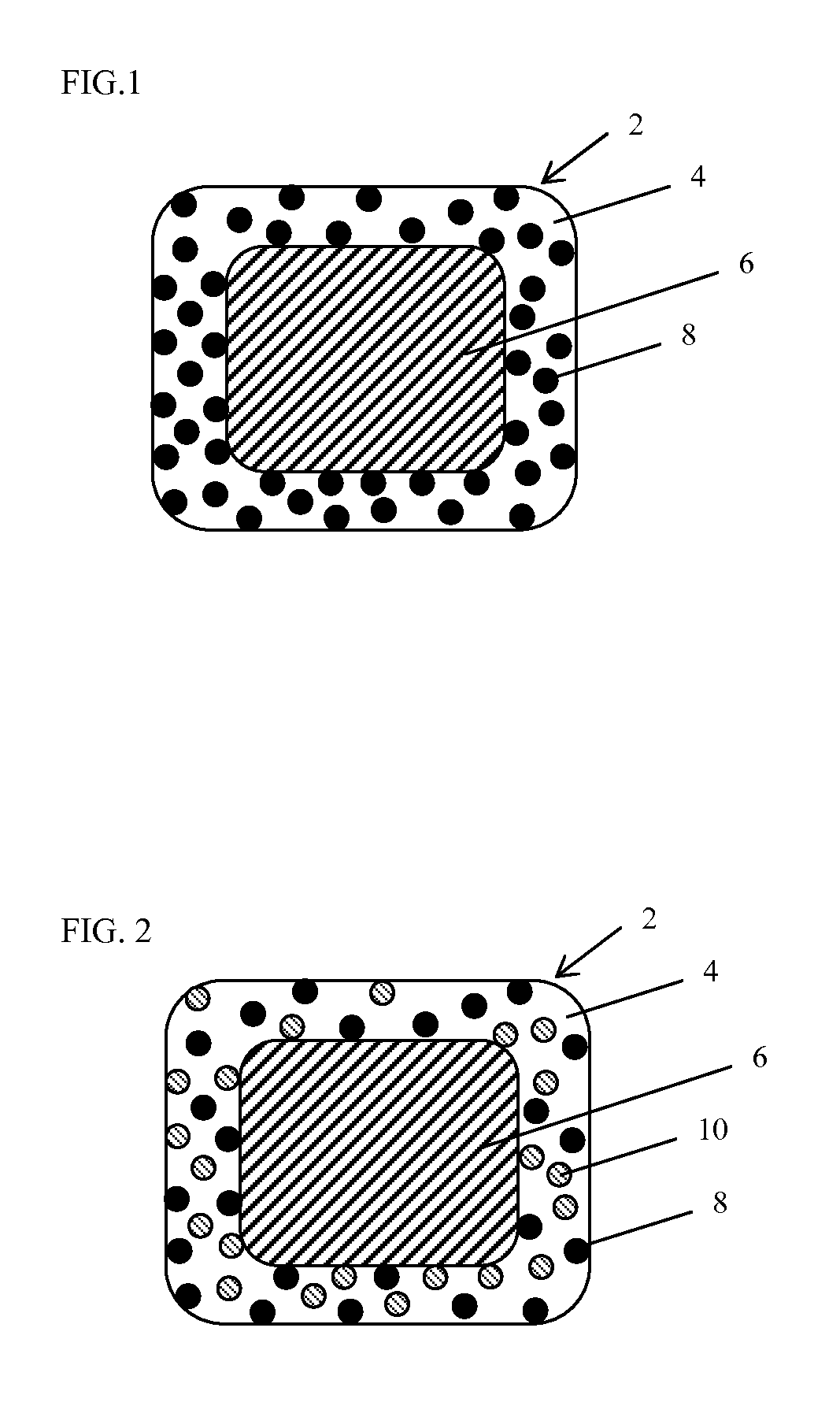

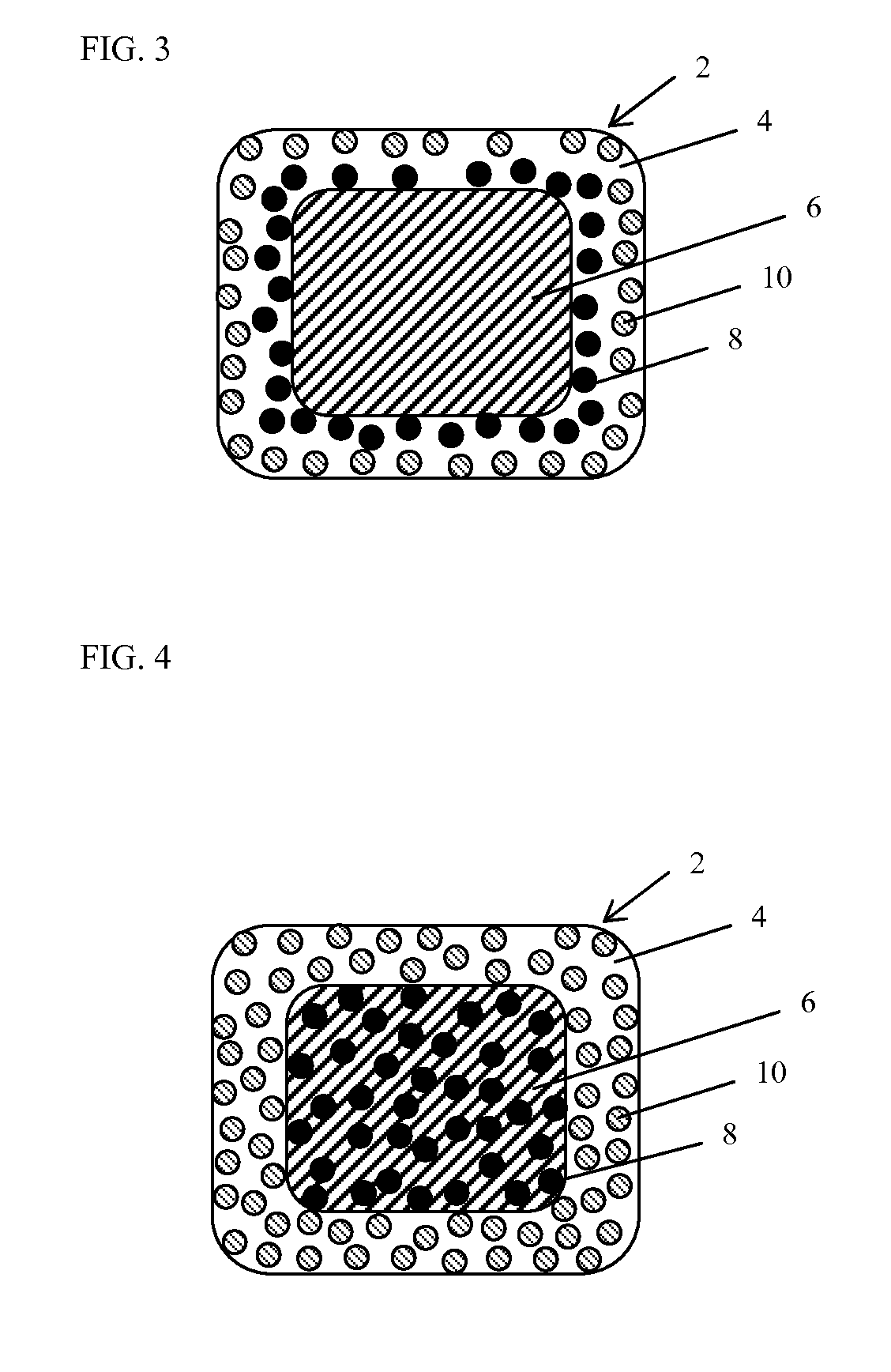

Solubilizing a drug for use in a coating

InactiveUS20060088596A1Improve coating adhesionGood conformabilityAntipyreticAnalgesicsNuclear medicineMedical device

Owner:ATRIUM MEDICAL

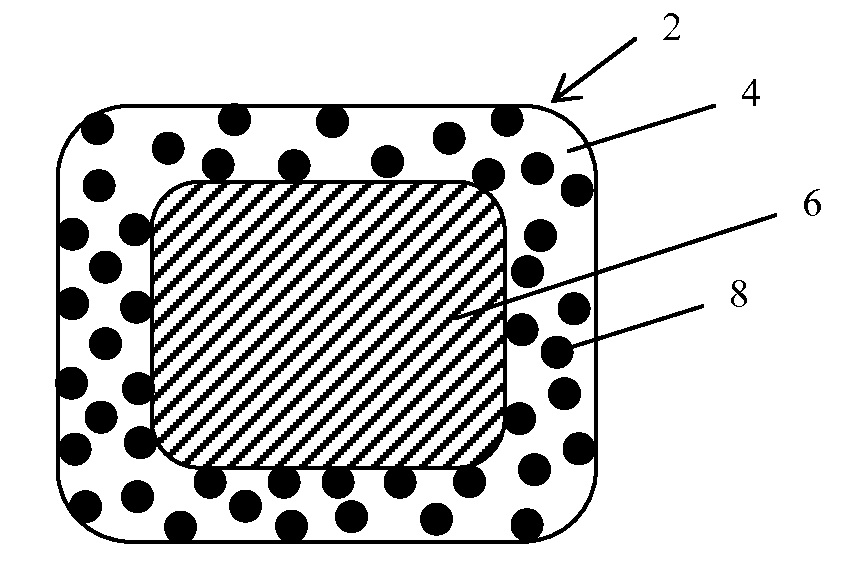

Stents and other devices having extracellular matrix coating

ActiveUS20110264190A1Provide durabilityImprove coating adhesionStentsSurgeryActive agentBiomedical engineering

Provided herein are devices comprising a stent; and a coating on said stent comprising a polymer and an active agent, wherein the active agent comprises at least one of: extracellular matrix and an extracellular matrix component. Provided herein are methods of preparing a device comprising a stent and a coating on said stent; said method comprising: providing a stent; and forming a plurality of layers on said stent; wherein the coating comprises a polymer and at least one of said layers comprises one or more active agents; wherein at least a portion of the active agent comprises at least one of extracellular matrix and an extracellular matrix component.

Primer coating for enhancing adhesion of liquid toner to polymeric substrates

ActiveUS7470736B2Improve adhesionImprove coating adhesionSpecial tyresInksWater basedPolyvinyl chloride

A primer coating is provided for use on polymeric substrates to enhance adhesion of liquid toner to the substrates for printing in an electrophotographic printing device. The primer coating is water-based and includes a dispersion of a copolymer of ethylene and acrylic or methacrylic acid, and a compatible adhesion enhancer selected from an aliphatic polyurethane dispersion, a hydrogenated hydrocarbon rosin or rosin ester dispersion, and an amorphous acrylic polymer dispersion. The coating may also include additives such as wetting agents, antiblocking agents, matting agents, and waxes. The primer coating may be applied to a variety of polymeric substrates including polypropylene, biaxially oriented polpypropylene, polyethylene terephthalate, and polyvinyl chloride.

Owner:MICHELMAN INC

Ceramic substrate for nonstick coating

InactiveUS20030059600A1Improve coating adhesionMore durableSynthetic resin layered productsPretreated surfacesFritAluminized steel

The present invention provides a new and useful nonstick coating for use on pure aluminum, alloys of aluminum, or aluminized steel surfaces. A nonstick coating according to the present invention includes a ceramic substrate disposed on an aluminum surface and a fluorocarbon polymer coating disposed on the ceramic substrate. The ceramic substrate, prior to firing, includes at least two layers: a first or bottom layer applied to the aluminum surface including an enamel ground coat; and a second or top layer applied over the enamel ground coat layer including a blend of one or more glass frits, non-ceramic refractory particles, and non-vitreous inorganic oxide particles. Upon firing, the ceramic substrate includes a continuous layer of vitreous enamel that is bonded to the aluminum surface. The exposed surface of the ceramic substrate has a micro-rough texture that is enriched with bonding sides for binder resins used in a fluorocarbon polymer primer layer. The ceramic substrate protects the aluminum surface from corrosion and mechanical damage and also protects the fluorocarbon polymer coating from abrasive wear.

Owner:FERRO CORP

Metallic composite coating for delivery of therapeutic agents from the surface of implantable devices

InactiveUS20050092615A1Reduced responseImproving device-tissue interfaceSurgeryCatheterActive agentImplanted device

A metallic composite coating, and methods for forming same, for an implantable medical device is disclosed. The composite coating comprises at least one metal or metallic tie layer formed on the surface of the device, followed by an electroless electrochemical cladding of one or more additional layers over the tie layer. One or more therapeutic or biologically active agents are co-deposited with at least one of the electroless electrochemical claddings.

Owner:MEDLOGICS DEVICE CORP

Primer coating for enhancing adhesion of liquid toner to polymeric substrates

ActiveUS20050245651A1Enhanced liquid toner adhesionImprove adhesionSpecial tyresInksWater basedPolymer science

A primer coating is provided for use on polymeric substrates to enhance adhesion of liquid toner to the substrates for printing in an electrophotographic printing device. The primer coating is water-based and includes a dispersion of a copolymer of ethylene and acrylic or methacrylic acid, and a compatible adhesion enhancer selected from an aliphatic polyurethane dispersion, a hydrogenated hydrocarbon rosin or rosin ester dispersion, and an amorphous acrylic polymer dispersion. The coating may also include additives such as wetting agents, antiblocking agents, matting agents, and waxes. The primer coating may be applied to a variety of polymeric substrates including polypropylene, biaxially oriented polpypropylene, polyethylene terephthalate, and polyvinyl chloride.

Owner:MICHELMAN INC

Medical device having a lubricious coating with a hydrophilic compound in an interlocking network

InactiveUS20090041923A1Enhance adhesionImprove lubricityBiocideSalicyclic acid active ingredientsBiomedical engineeringDiagnostic agent

A medical device having a lubricious coating on at least a section of the medical device, and a method of coating a medical device, the lubricious coating being a network of a hydrophilic compound cross-linked to itself and interlocked with a network of a cross-linked polymerized multifunctional monomer or polymer. The coating can include one or more agents which provide enhanced adhesion of the coating on the device, or which provide faster hydration of the coating and / or improved lubricity. Additionally, the lubricious coating can be provided with one or more therapeutic or diagnostic agents, and in one embodiment the agent elutes relatively quickly in a concentrated release from the lubricious coating upon hydration of the coating.

Owner:ABBOTT CARDIOVASCULAR

Method for producing surface antibiotic product using physical gas phase deposition technology

ActiveCN1995442AReduce photocatalysisImprove antibacterial propertiesVacuum evaporation coatingSputtering coatingGas phaseProduct gas

The invention discloses a making method of antibiotic product of surface through physical gas-phase sediment technique, which comprises the following steps: plating antibiotic target or evaporating material on the base surface to form antibiotic coater through physical gas-phase sediment technique; allocating the antibiotic target or evaporated material with one or more component of Ti, Zn, Ca, Si, Mg, Zr, Cd, As, Sb, Se, Ce, Re, Cu, Ag, Pb, Hg, Co, Ni, Al, Fe and their oxide, sulfate, nitride and carbonate; aerating O2, N2, NH3, CH4, C2H6 or H2S as reacting gas.

Owner:JIANGSU TRAUVOR BIOLOGICAL TECH

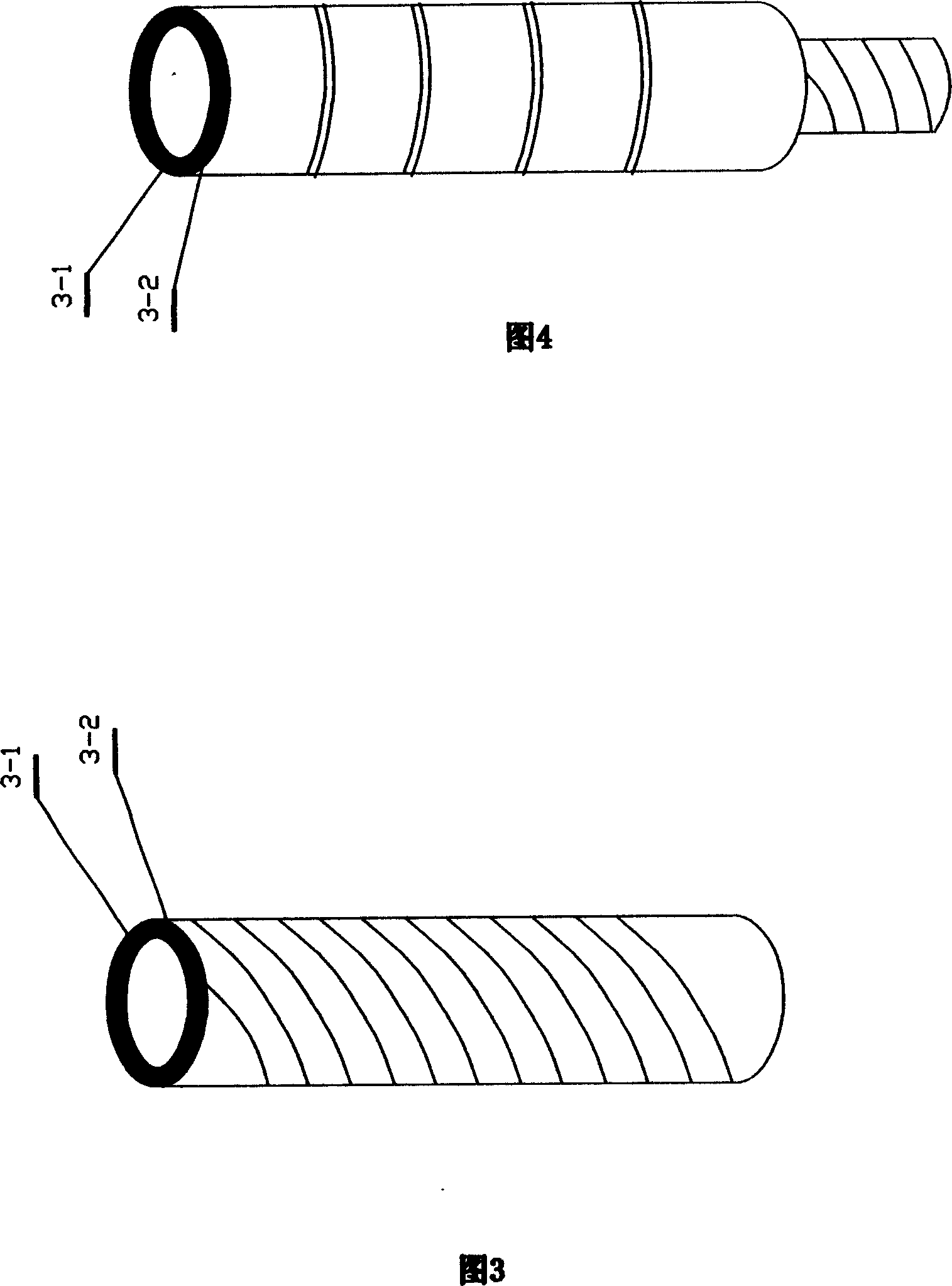

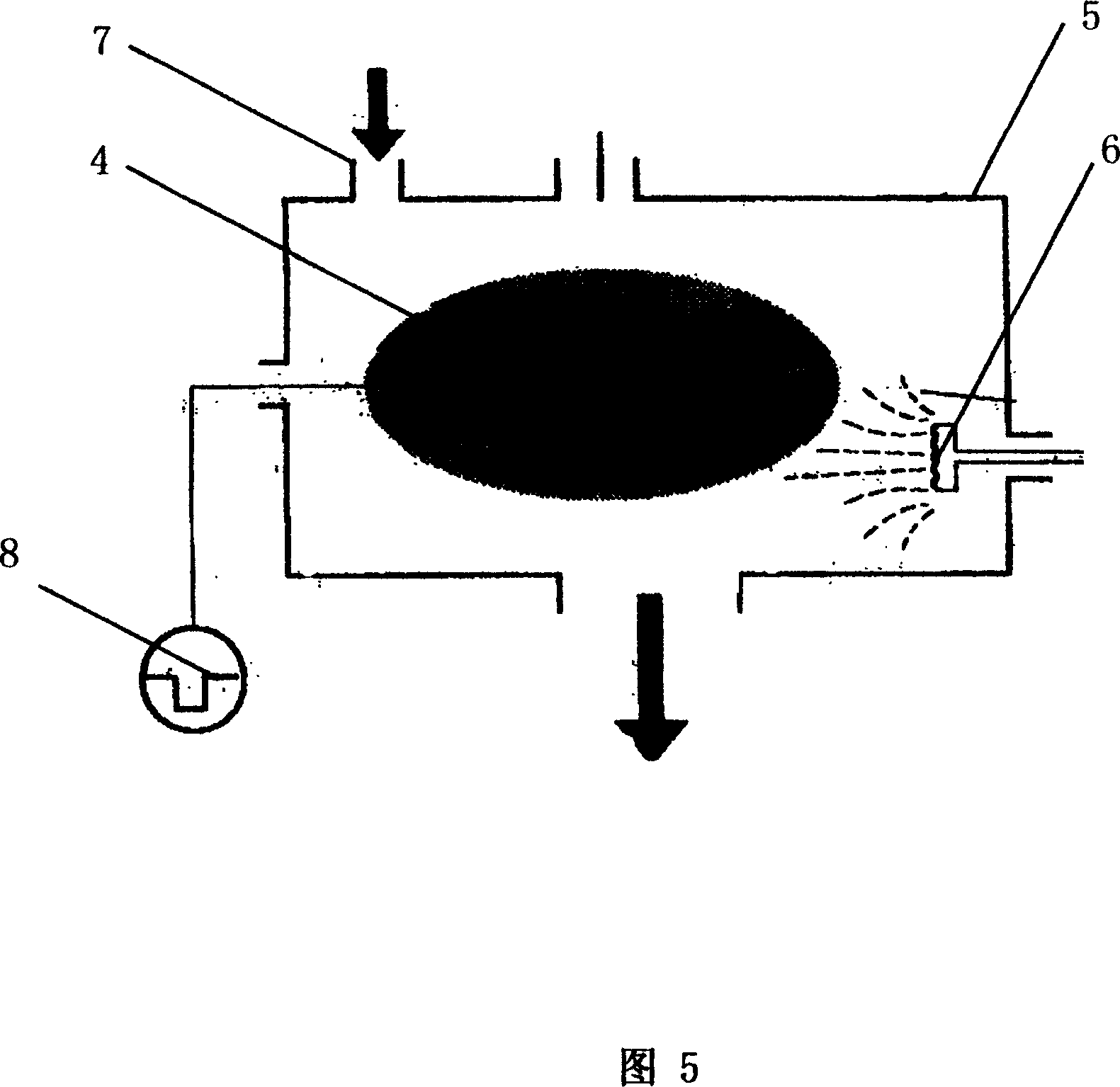

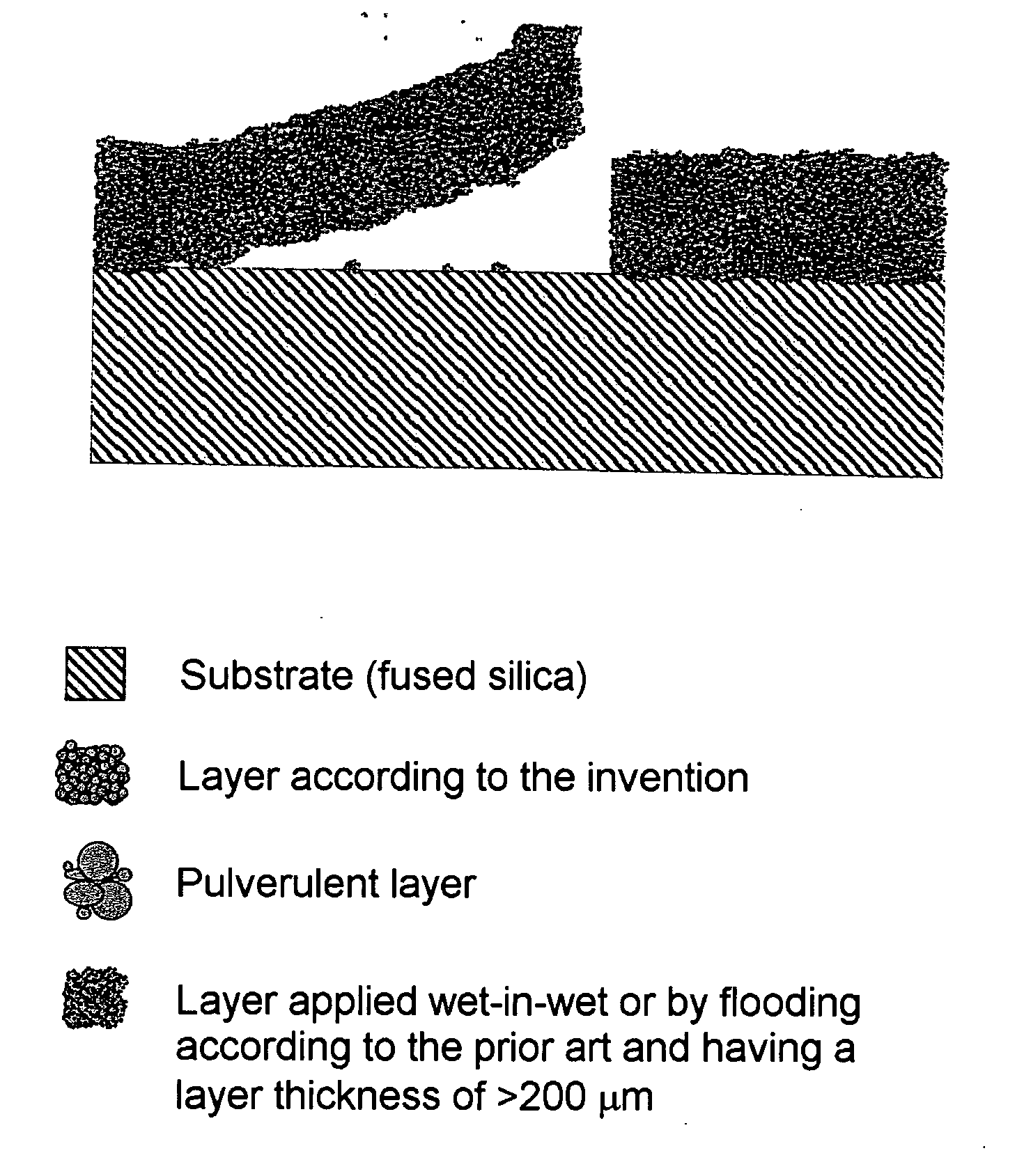

Firmly adhering silicon nitride-containing release layer

InactiveUS20090119882A1Relieve pressureSinter activity is reducedMaterial nanotechnologyBy pulling from meltNonferrous metalSolid particle

The invention relates to a slip for producing a durable, firmly adhering release layer on a substrate, comprising a suspension of solid particles, wherein the solid particles comprise 67-95% by weight of silicon nitride and 5-33% by weight of an SiO2-based high-temperature binder and the SiO2-based high-temperature binder is derived from SiO2 precursors and has been pretreated by heat treatment in a temperature range of 300-1300° C.The invention further provides shaped bodies comprising a substrate having a durable, firmly adhering release layer and also processes for producing them. The shaped bodies of the invention are suitable for use in the field of corrosive nonferrous metal melts.

Owner:3M INNOVATIVE PROPERTIES CO

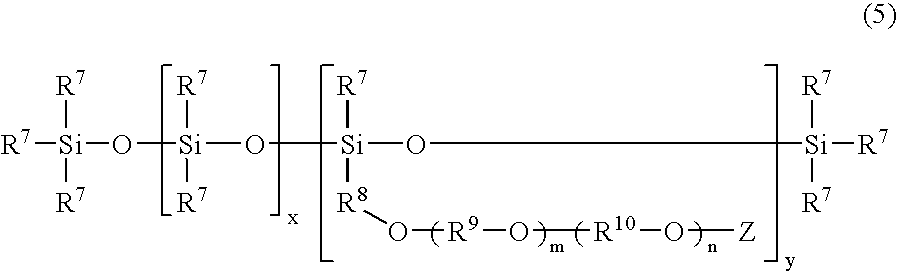

Curable silyl-containing polymer composition containing paint adhesion additive

ActiveUS20090005498A1Improve adhesionImprove coating adhesionPolyurea/polyurethane coatingsFilling pastesAdhesivePolymer composition

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

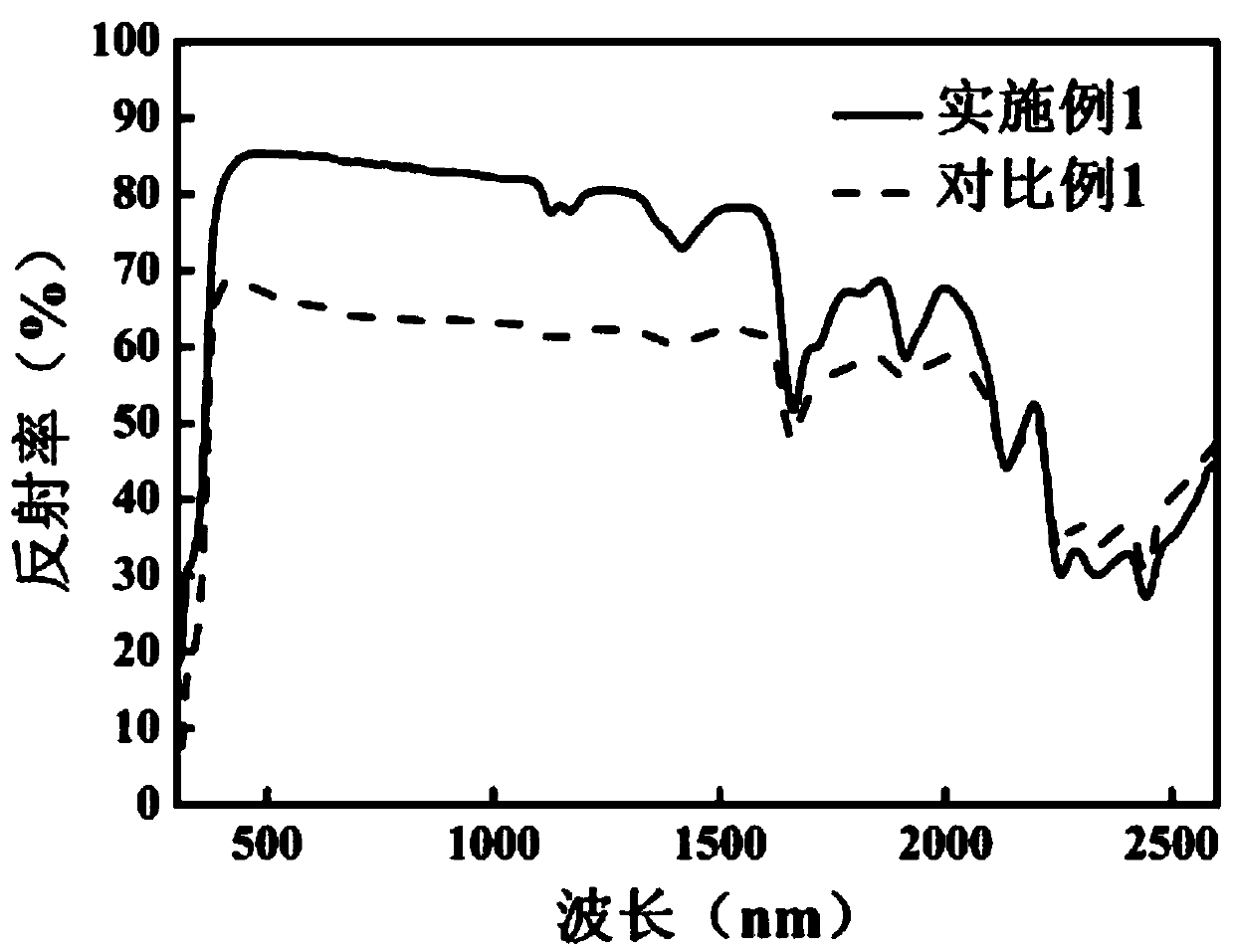

Passive radiation refrigeration composite material layer and preparation method thereof

InactiveCN111393915AImprove Radiation PerformanceImprove mechanical propertiesLiquid surface applicatorsChemical industryPolymer dissolutionNanoparticle

The invention discloses a passive radiation refrigeration composite material layer which coats a substrate to form a composite layer structure of the substrate and a passive radiation refrigeration layer, and the passive radiation refrigeration layer reflects visible light and near-infrared light in sunlight and dissipates heat through an atmospheric window in an infrared radiation form. The invention discloses a preparation method of the passive radiation refrigeration composite material layer, and the method comprises the following steps: dissolving resin in a volatile solvent, dispersing nanoparticles in the volatile solvent, and mixing at normal temperature to form a suspension; dissolving a functional polymer in the suspension, and uniformly mixing to form a coating solution; and coating the substrate with the coating solution to volatilize the solvent so as to form the passive radiation refrigeration layer on the surface of the substrate. The material disclosed by the invention has a simple single-layer structure, can simply coat the surfaces of various substrates like a coating, can reduce the incompatibility among multi-layer structures and reduce the cost, and is simple and convenient in preparation method, easy to operate and low in cost.

Owner:SHANGHAI UNIV

Process of producing a ceramic matrix composite article and article formed thereby

ActiveUS20070092762A1Improve coating adhesionAggressive treatmentLiquid surface applicatorsCeramic layered productsSurface layerMetallurgy

A CMC article and process for producing the article to have a layer on its surface that protects a reinforcement material within the article from damage. The method entails providing a body containing a ceramic reinforcement material in a matrix material that contains a precursor of a ceramic matrix material. A fraction of the reinforcement material is present and possibly exposed at a surface of the body. The body surface is then provided with a surface layer formed of a slurry containing a particulate material but lacking the reinforcement material of the body. The body and surface layer are heated to form the article by converting the precursor within the body to form the ceramic matrix material in which the reinforcement material is contained, and by converting the surface layer to form the protective layer that covers any fraction of the reinforcement material exposed at the body surface.

Owner:GENERAL ELECTRIC CO

Hot press-formed article and a method for its manufacture

ActiveUS20060121305A1Improve corrosion resistanceNot readily peel offAnodisationHot-dipping/immersion processesSolderabilitySolid solution

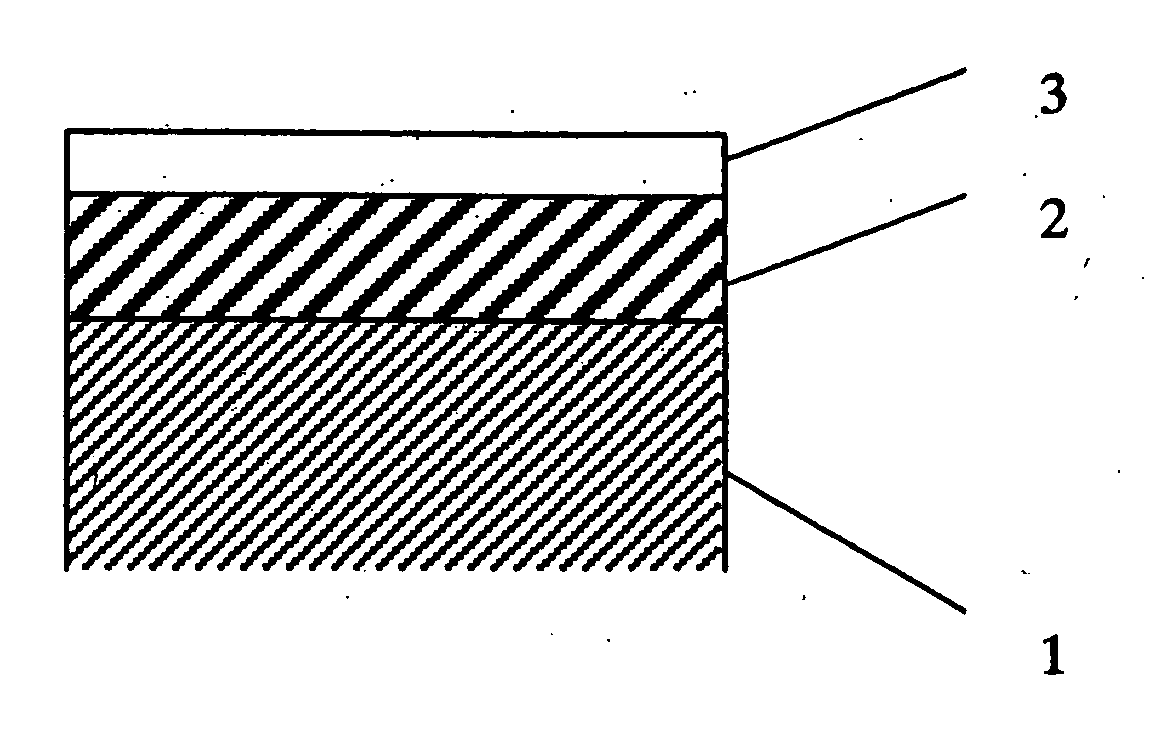

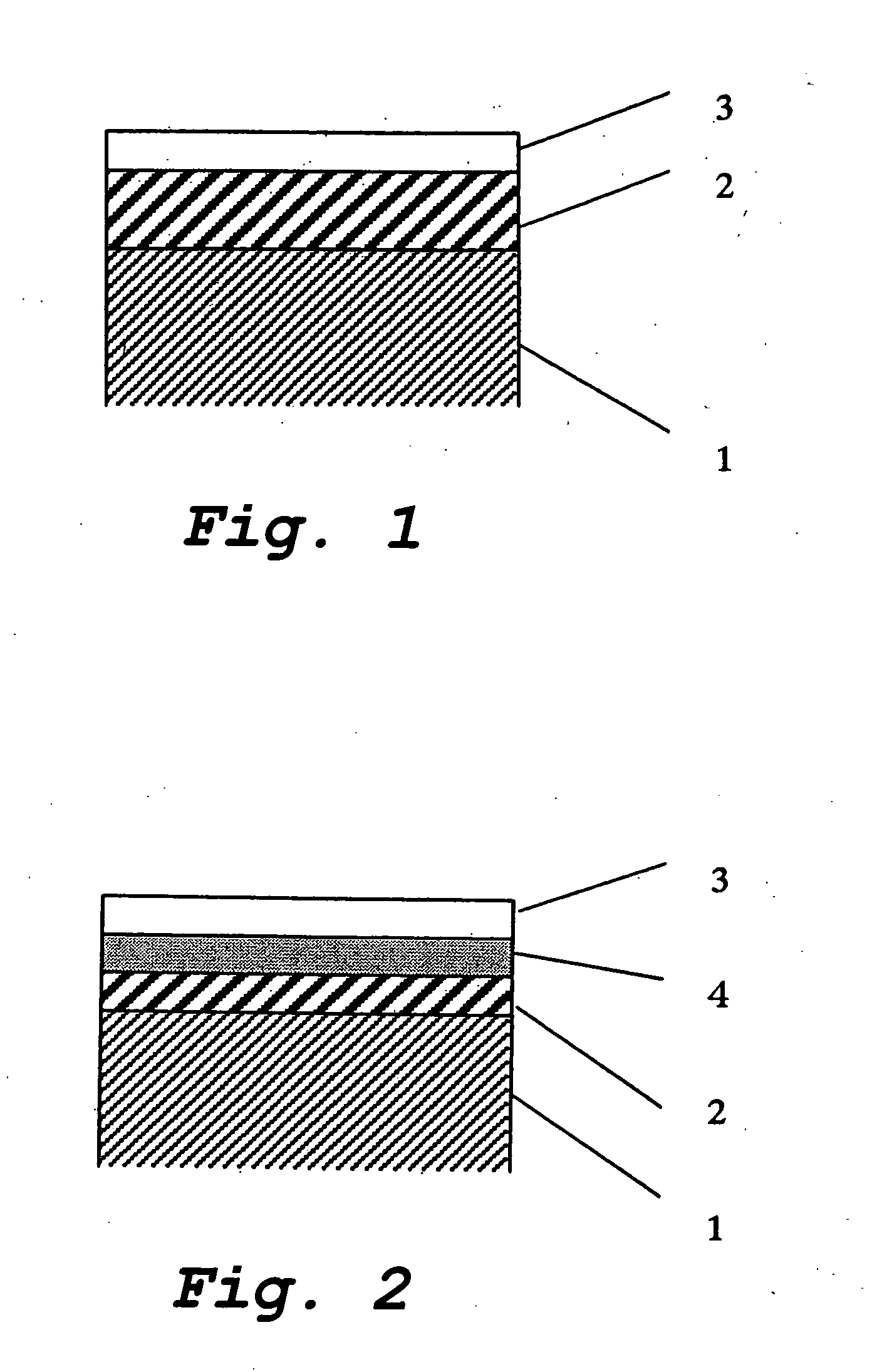

A hot press-formed article having improved corrosion resistance and coating adhesion when coated is obtained by hot press forming of a zinc-based plated steel material. It has a zinc-based plating layer comprising an iron-zinc solid solution phase and atop it a zinc oxide layer. The average thickness of the zinc oxide layer which is the outermost layer is at most 2 μm. A hot press-formed article having a good appearance and excellent corrosion resistance, coating adhesion, post-coating corrosion resistance, and weldability has a layer (2) consisting essentially of an iron-zinc solid solution phase atop a base material steel sheet (1). It also has a zinc oxide layer (3) with an average thickness of at most 5 μm as an uppermost layer, but it does not have a substantial amount of an iron-zinc intermetallic compound phase. The total amount of Al contained in the iron-zinc solid solution layer (2) and the zinc oxide layer (3) is at most 0.5 g / m2, and / or the total amount of Al oxides contained in these layers is at most 5 mg / m2.

Owner:NIPPON STEEL CORP +2

Metal gas separation membrane

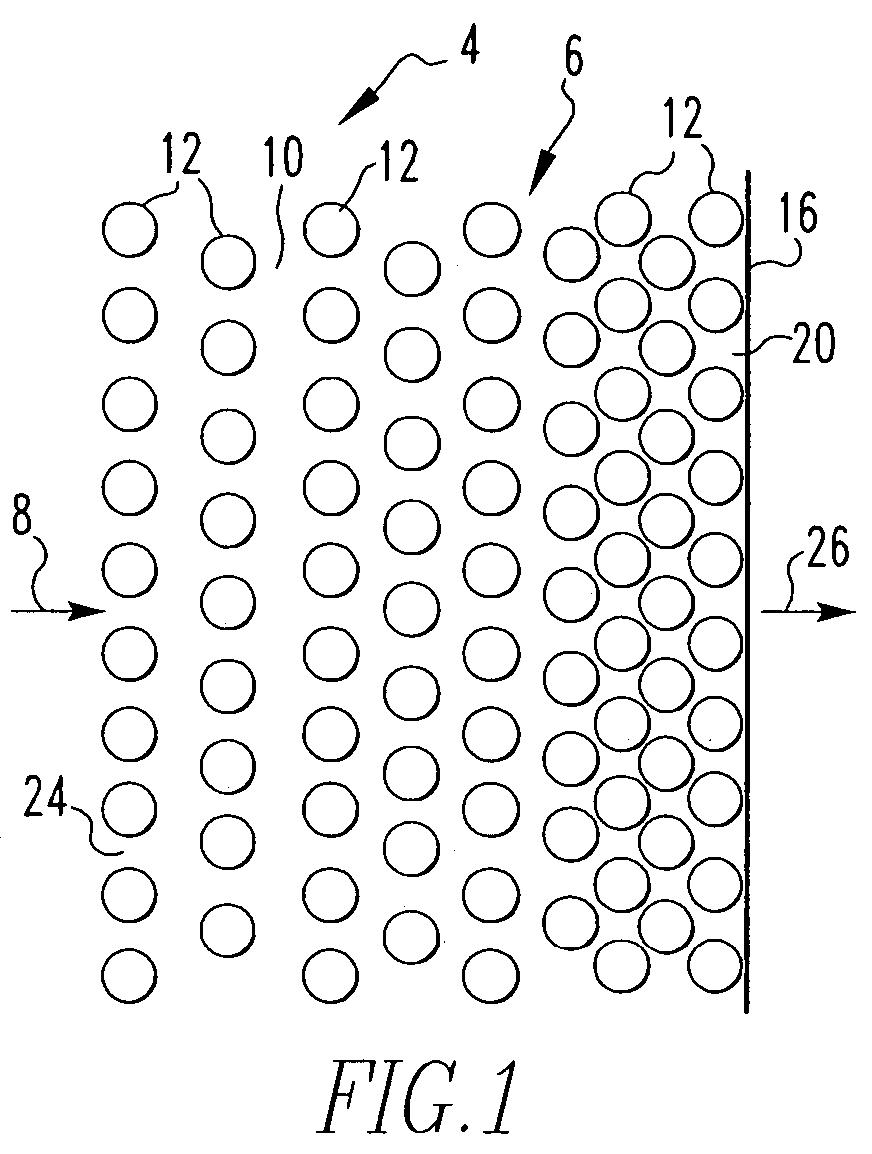

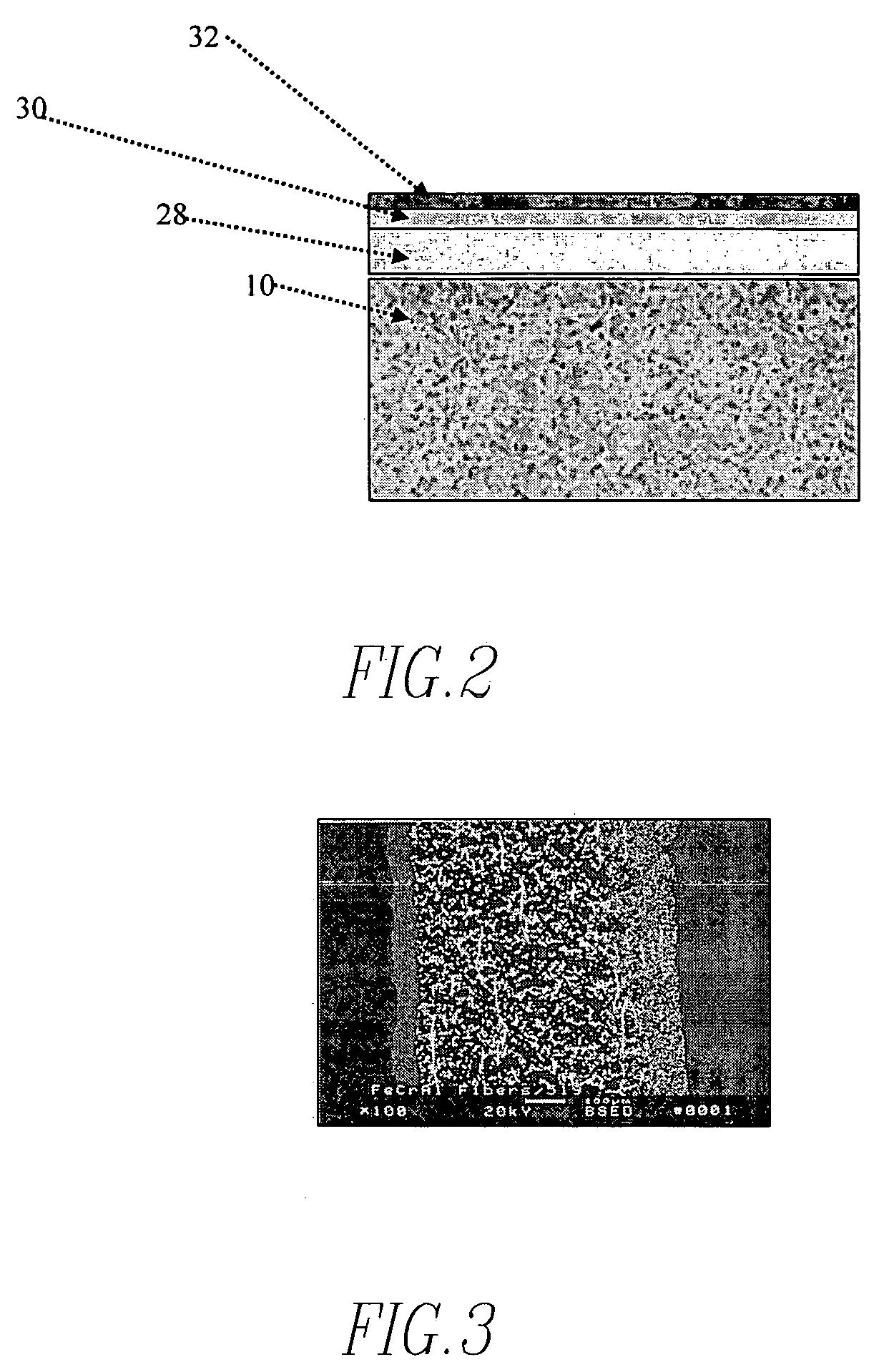

InactiveUS7018446B2Improve coating adhesionIncrease temperatureSemi-permeable membranesIsotope separationHydrogenNiobium

A high temperature hydrogen gas separation membrane employing a physically interlocking barrier layer to form a spinel or intermetallic architecture bonding the metal barrier layer onto the surface of a fibrous metal medial structural support substrate. A tantalum / niobium interface layer is deposited on the barrier layer. The final layer is a precious metal such as palladium, which is deposited on the tantalum / niobium interface layer.

Owner:SIEMENS ENERGY INC

Polyamide-polyphenylene ether resin composition

ActiveCN101163746AExcellent retention stabilitySimplify moisture managementElastomerPhosphoric Acid Esters

A resin composition characterized by containing polyamide (A), polyphenylene ether (B), elastomer (C) and phosphorus compound (D) selected from among phosphoric acids, phosphorous acids, hypophosphorous acids, metal phosphates, metal phosphites, metal hypophosphites and phosphoric esters wherein per 100 mass% of the sum of components (A) to (D), phosphorus element is contained in an amount of 1 to 35 ppm. Further, there is provided a molding of the resin composition. Application can be found in a wide spectrum of fields, such as electrical / electronic parts, OA parts, vehicle parts and mechanical parts. In particular, suitable application can be found in exterior parts of automobile, etc. wherein large moldings are required.

Owner:ASAHI KASEI KK

Coated substrate

InactiveUS6929851B1Improve the environmentImprove wear resistancePigmenting treatmentOther chemical processesOxidation stateSubstrate surface

Method for removing a portion of the binder phase from the surface of a substrate that is composed of particles of at least a first phase joined together by the binder phase, and wherein the surface is etched by contacting it with a gas flow of an etchant gas and a second gas. The second gas is one or more gases that will not react with the substrate or the removed binder phase and will not alter the oxidation state of the substrate during etching.

Owner:KENNAMETAL INC

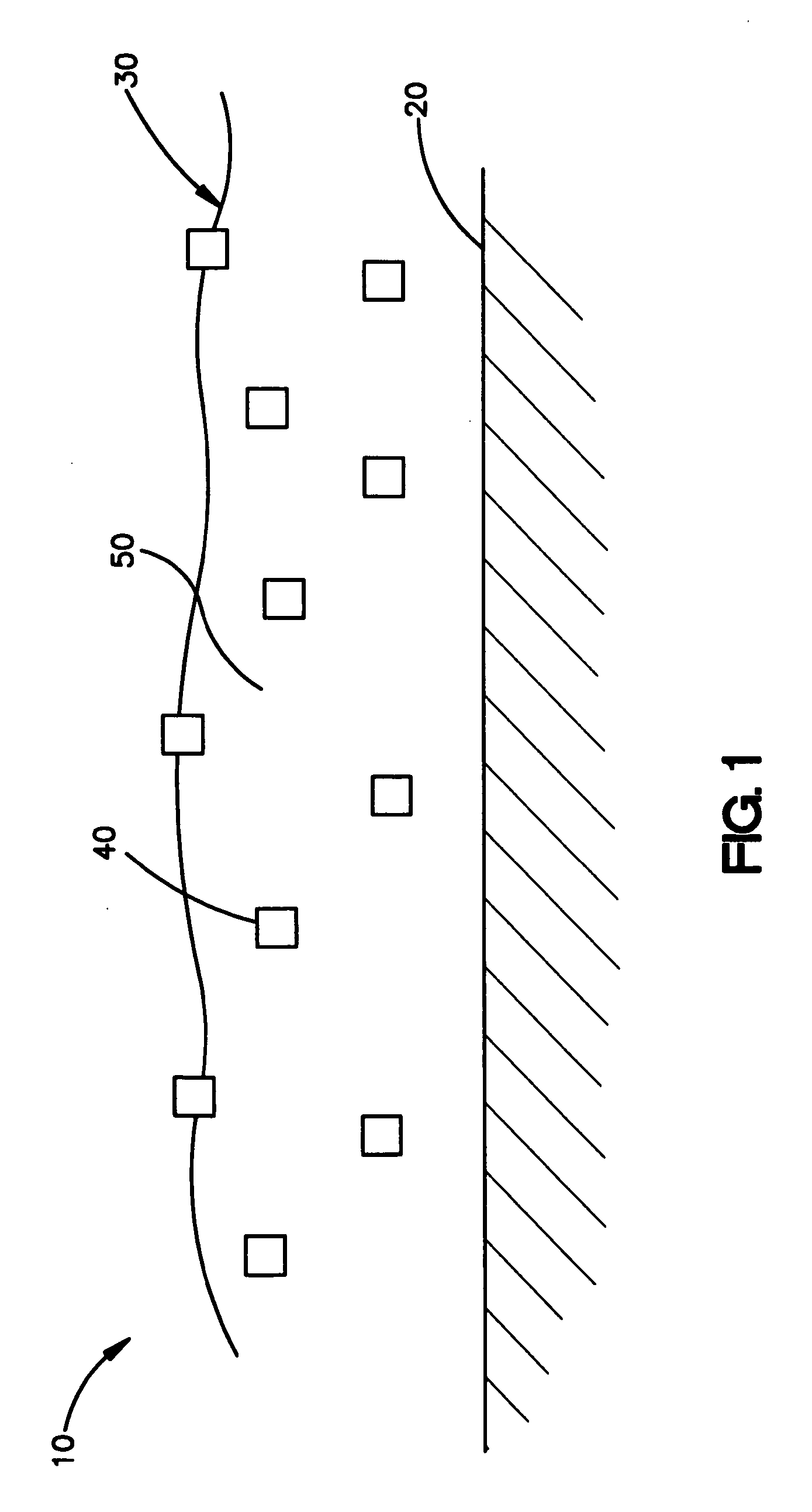

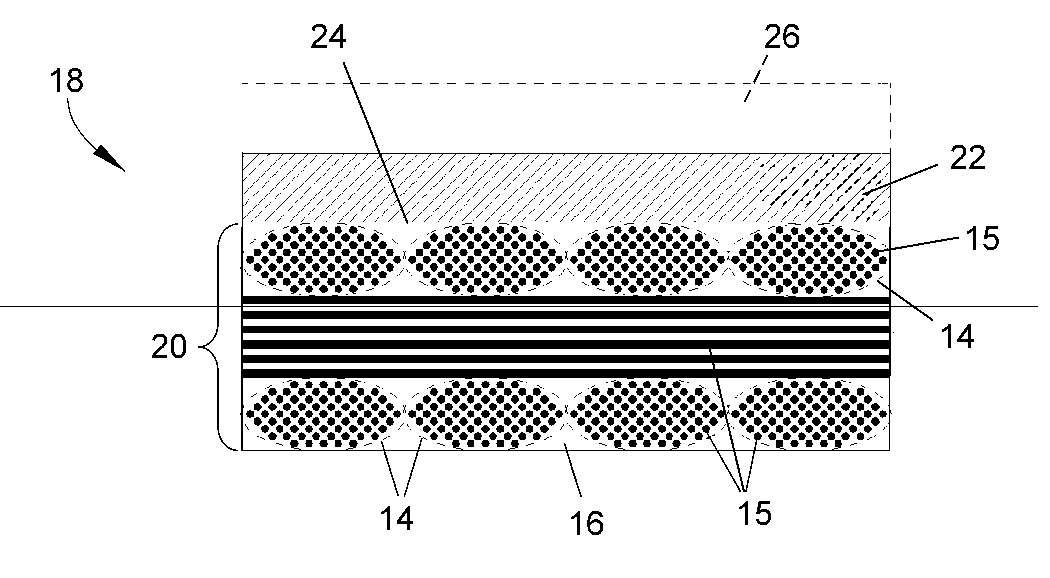

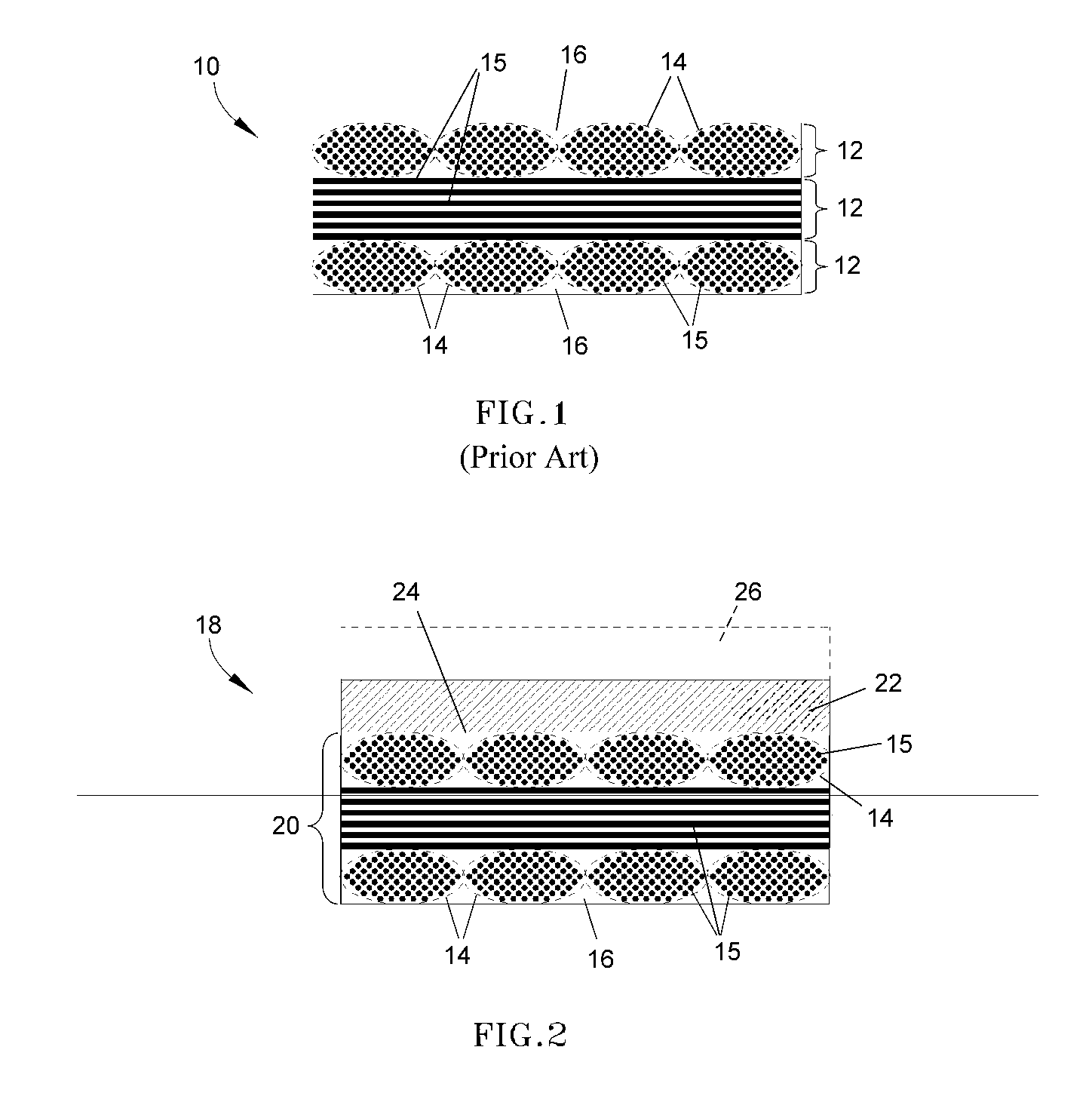

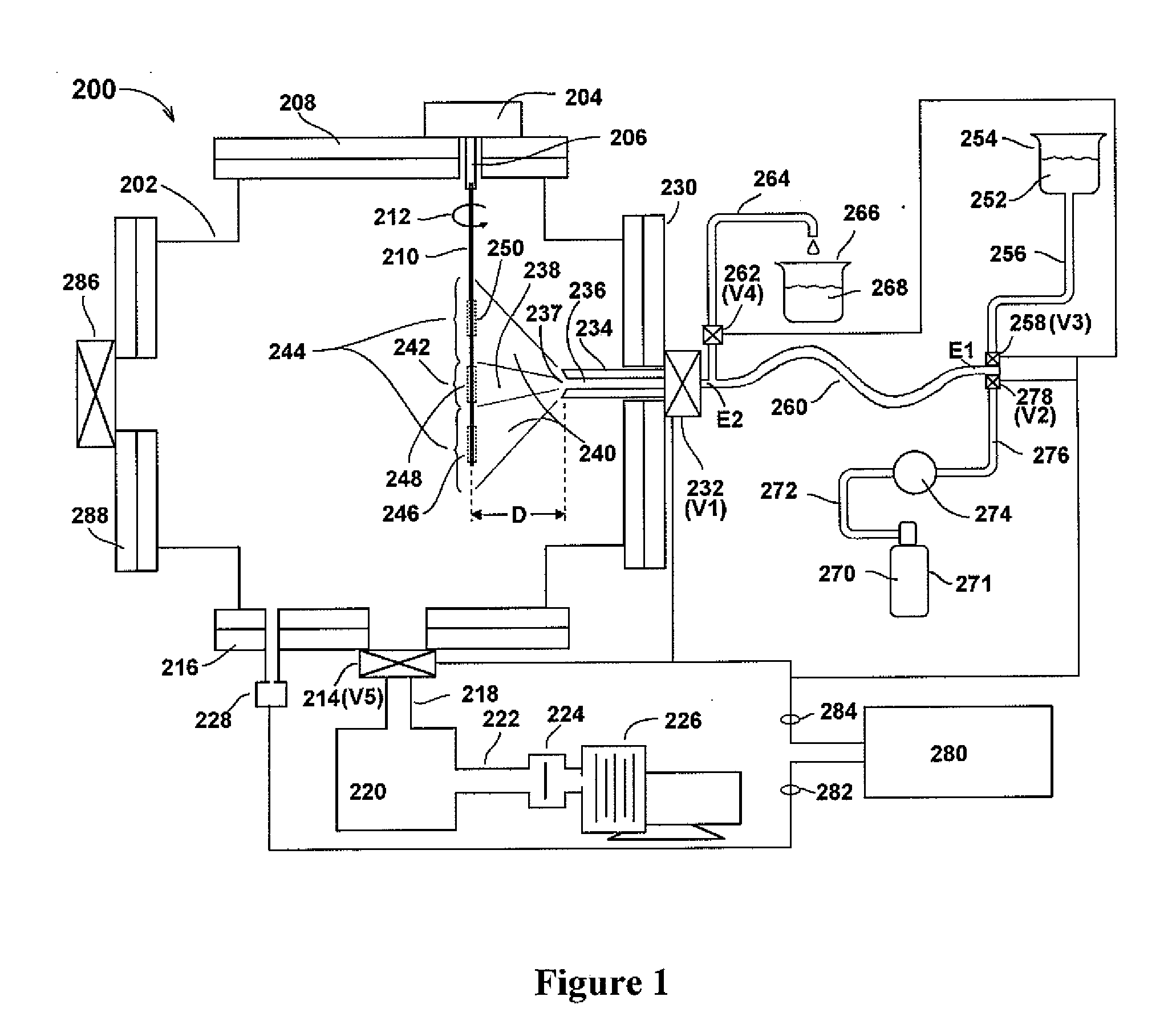

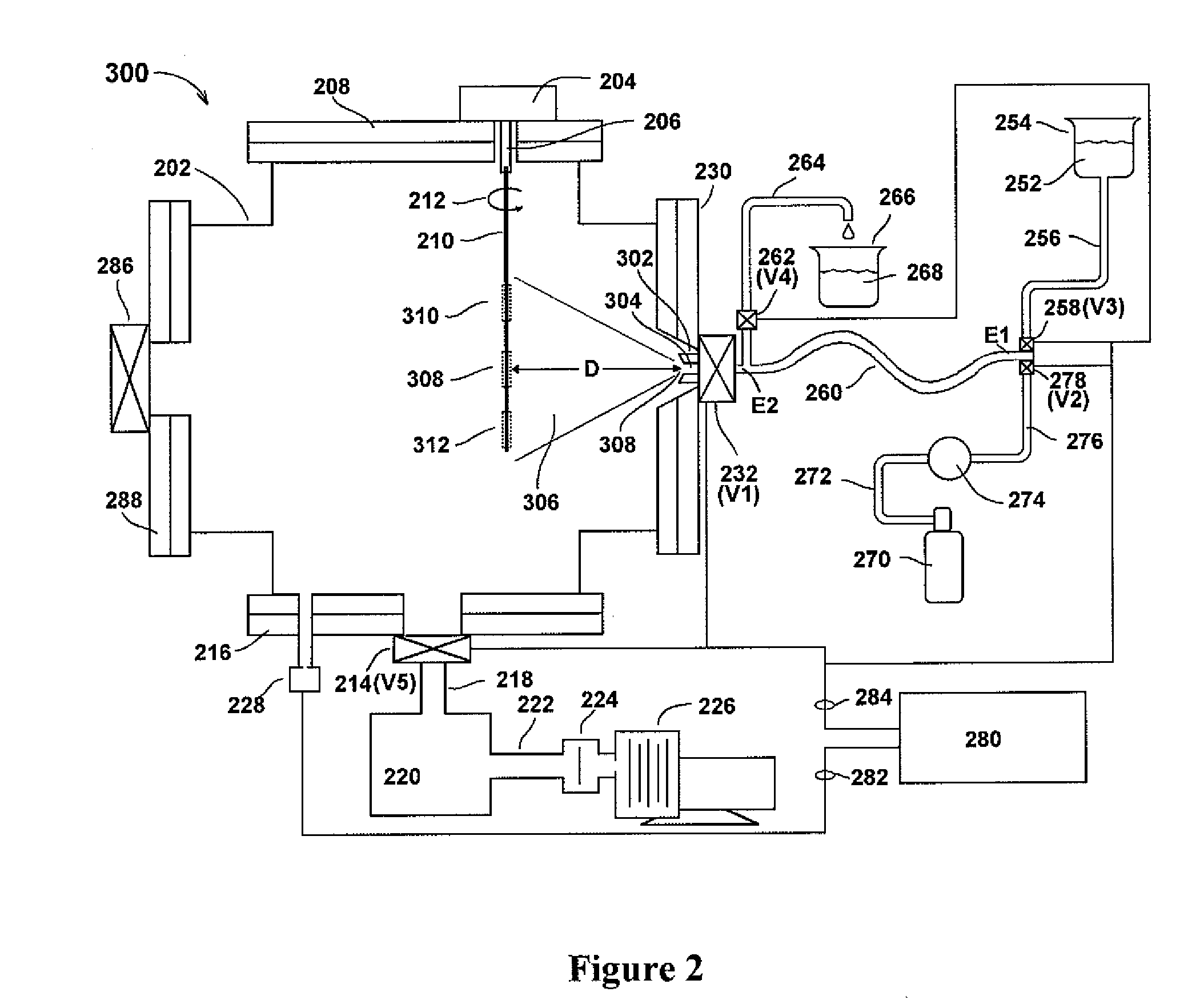

Method and system for coating a surface of a medical device with a therapeutic agent and drug eluting medical devices made thereby

ActiveUS20090098186A1Use be knowImprove coatingVacuum evaporation coatingPretreated surfacesDrug-eluting stentDrug coating

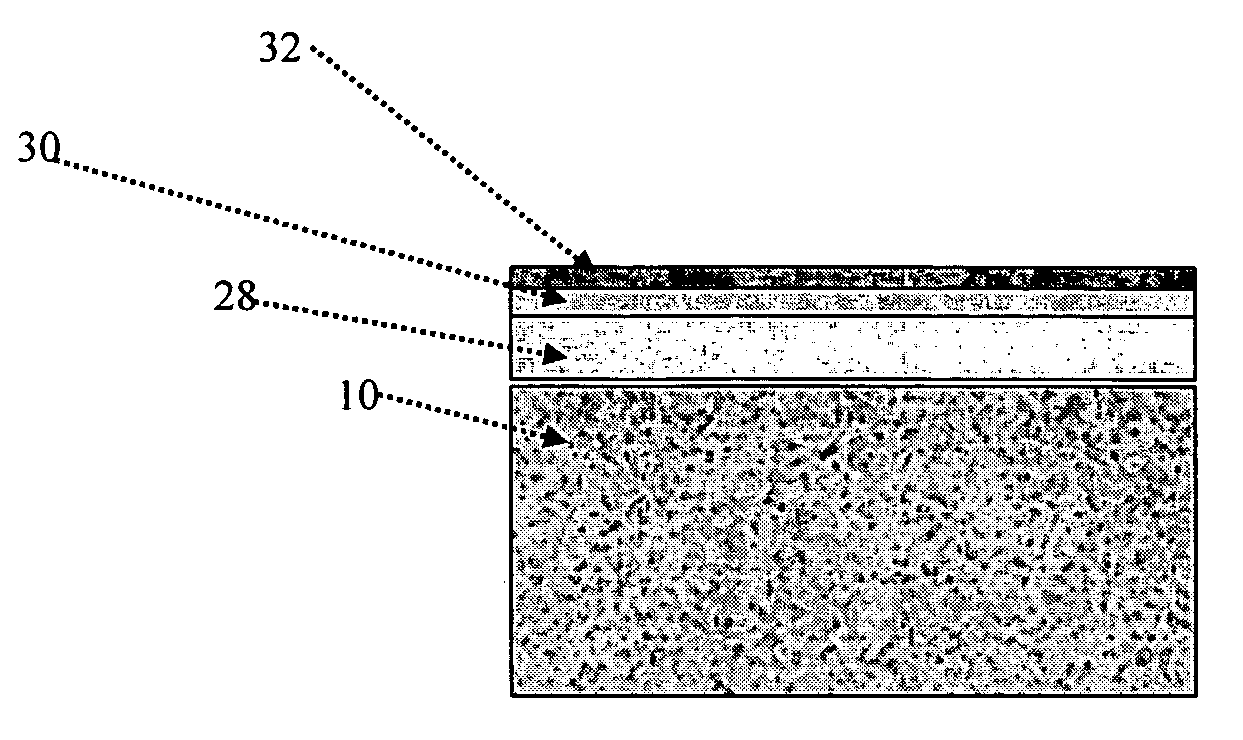

A multi-layer drug coated medical device such as for example an expandable vascular drug eluting stent is formed by vacuum pulse spray techniques wherein each layer is irradiated to improve adhesion and / or drug elution properties prior to formation of subsequent layers. Layers may be homogeneous or of diverse drugs. Layers may incorporate a non-polymer elution-retarding material. Layers may alternate with one or more layers of non-polymer elution-retarding materials. Polymer binders and / or matrices are not used in the formation of the coatings, yet the pure drug coatings have good mechanical and elution rate properties. Systems, methods and medical device articles are disclosed.

Owner:EXOGENESIS CORP

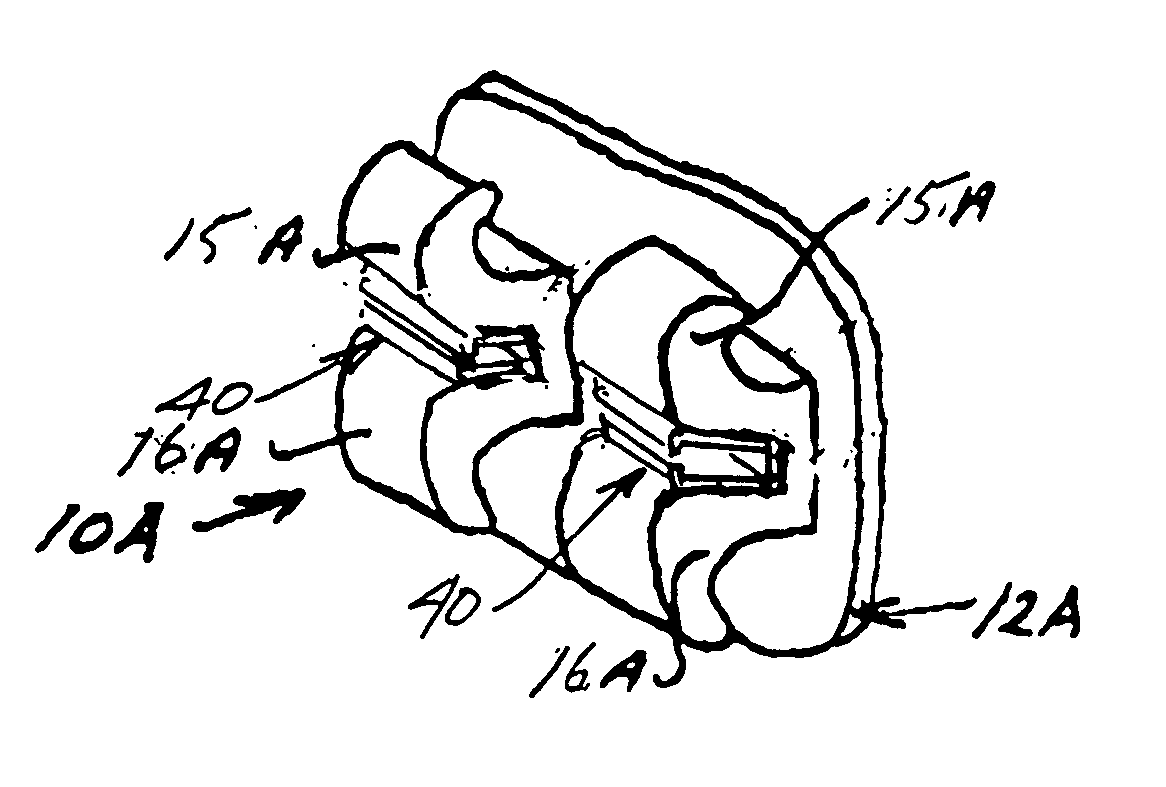

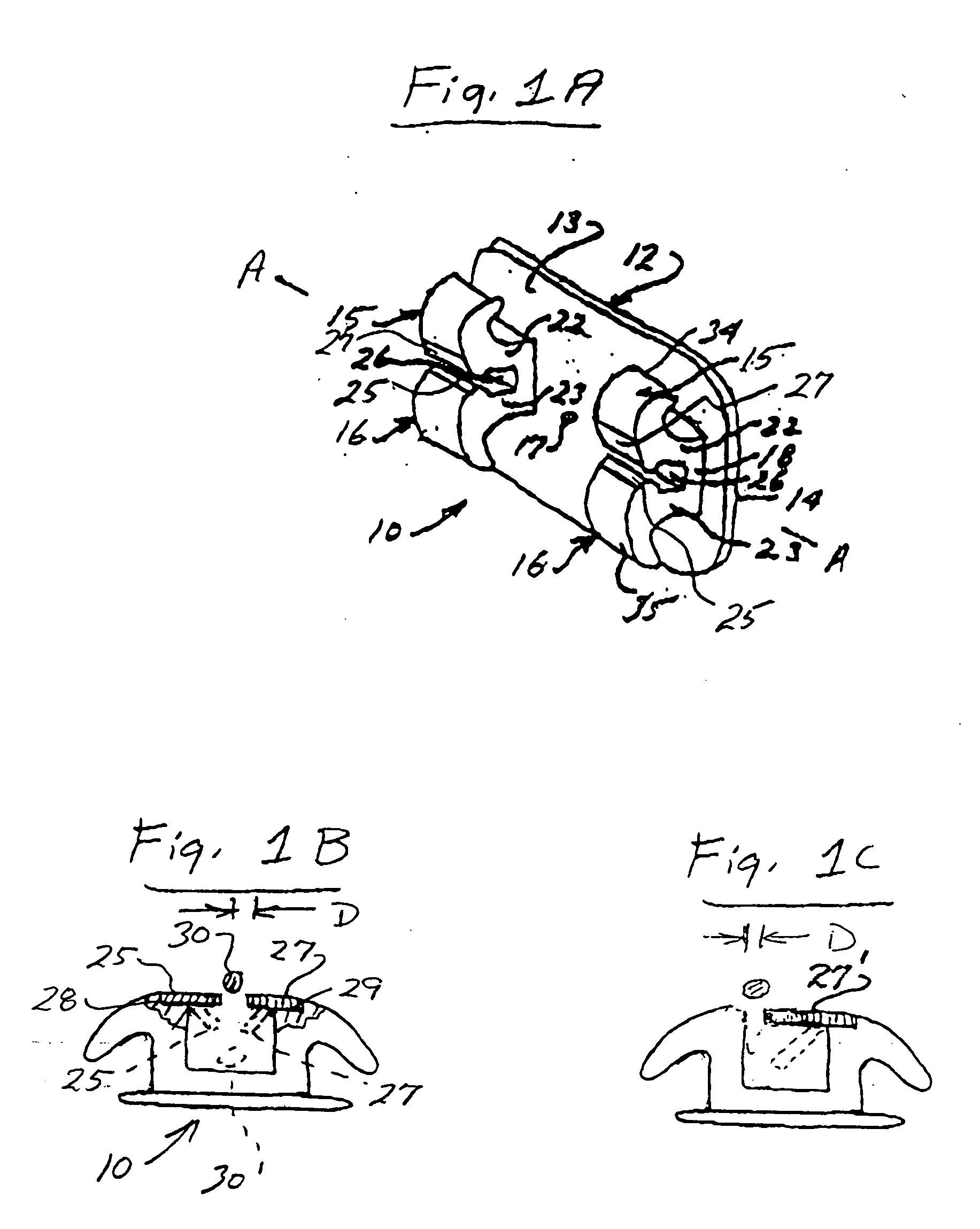

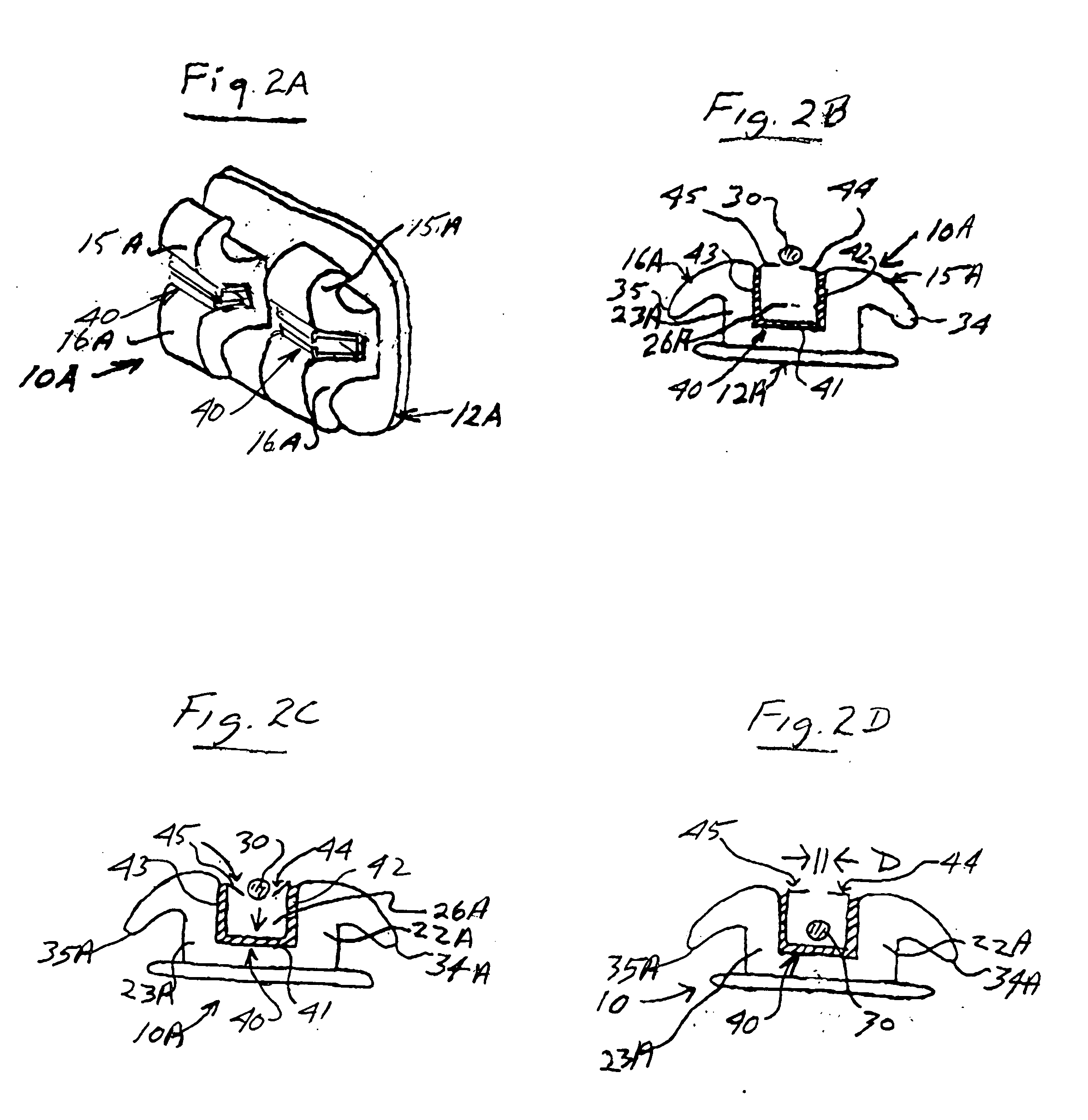

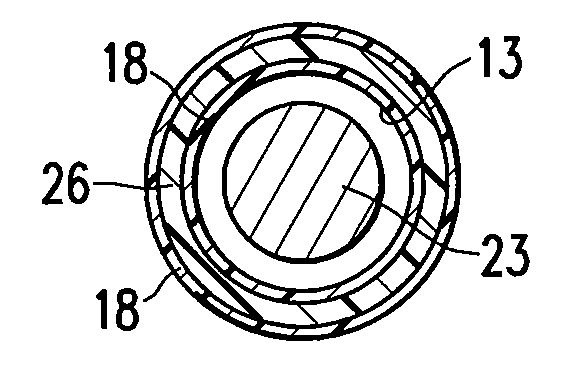

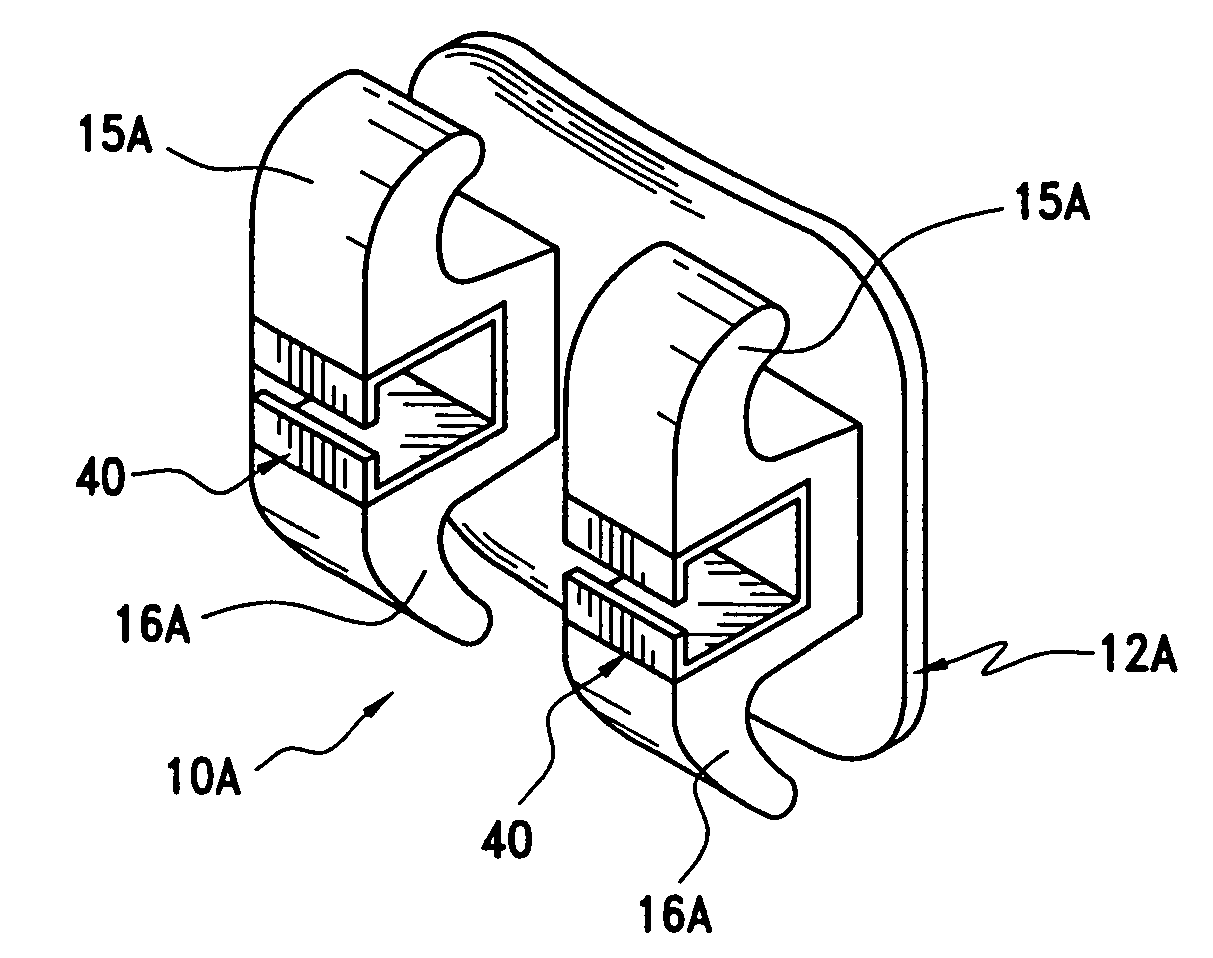

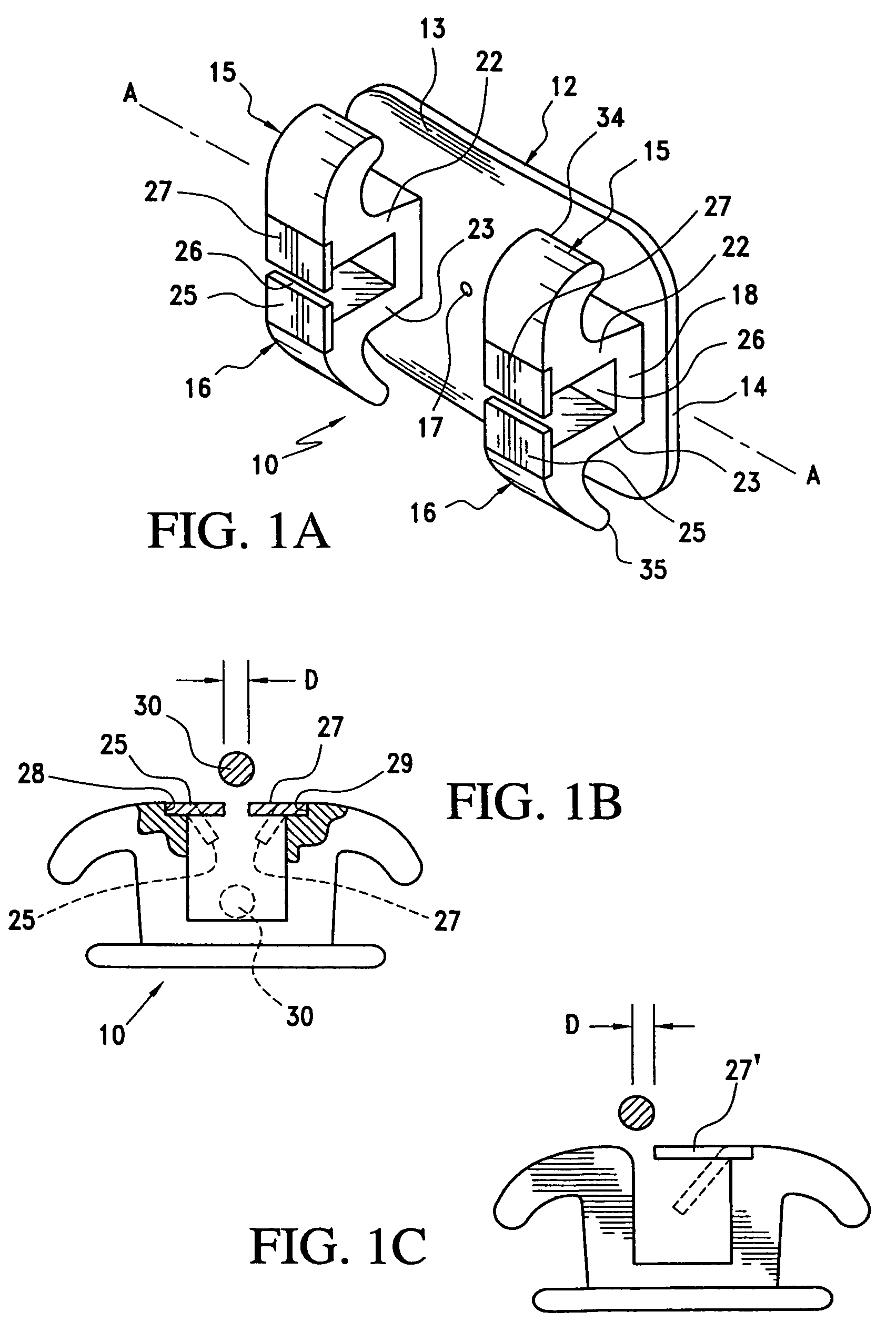

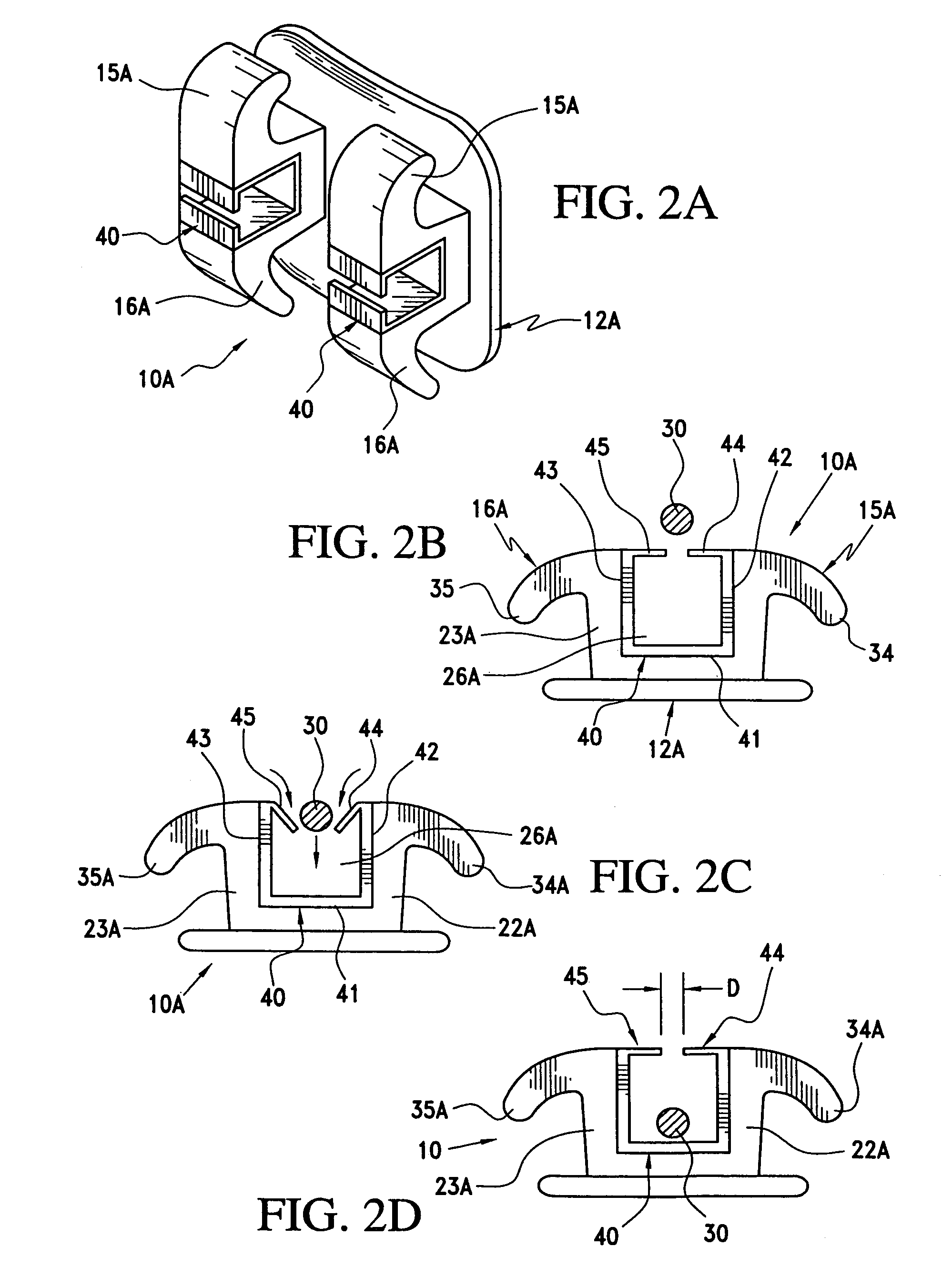

Shape memory self-ligating orthodontic brackets

InactiveUS20060003282A1Reduce frictionFacilitate movementArch wiresBracketsOrthodontic bracketsEngineering

Self-ligating orthodontic brackets with archwire retainers formed of materials exhibiting shape memory. Each bracket which includes a base from which extends two spaced and opposing pairs of tie wings each pair of which define an archwire guide slot therebetween. The retainers include at least one flange to retain an archwire within the archwire guide slot but which is yieldable to permit insertion and / or removal of the archwire relative to the archwire guide slots. Portions of the brackets and / or retainer may be coated to reduce friction between the archwire and the bracket and to promote aesthetics and overall bracket appearance.

Owner:NICHOLSON JAMES A

Medical devices having a lubricious coating with a hydrophilic compound in an interlocking network

InactiveUS20120077049A1Improve adhesionDecreasing lubricitySurgerySynthetic resin layered productsCross-linkDiagnostic agent

A medical device having a lubricious coating on at least a section of the medical device, and a method of coating a medical device, the lubricious coating being applied over a primer coating which is directed applied to the medical device. The coating can include one or more agents which provide enhanced adhesion of the coating on the device. The lubricious coating can be a network of a hydrophilic compound cross-linked to itself and interlocked with a network of a cross-linked polymerized multifunctional monomer or polymer. Additionally, the lubricious coating can be provided with one or more therapeutic or diagnostic agents, and in one embodiment the agentelutes relatively quickly in a concentrated release from the lubricious coating upon hydration of the coating.

Owner:ABBOTT CARDIOVASCULAR

Silicone-based low permeability airbag fabric coatings

InactiveUS6846004B2Highly cost-effectiveEasy to handlePreformed elementsThin material handlingHigh pressureGas retention

Owner:MILLIKEN & CO

Concrete structure heavy-duty nano composite coating and protection method

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

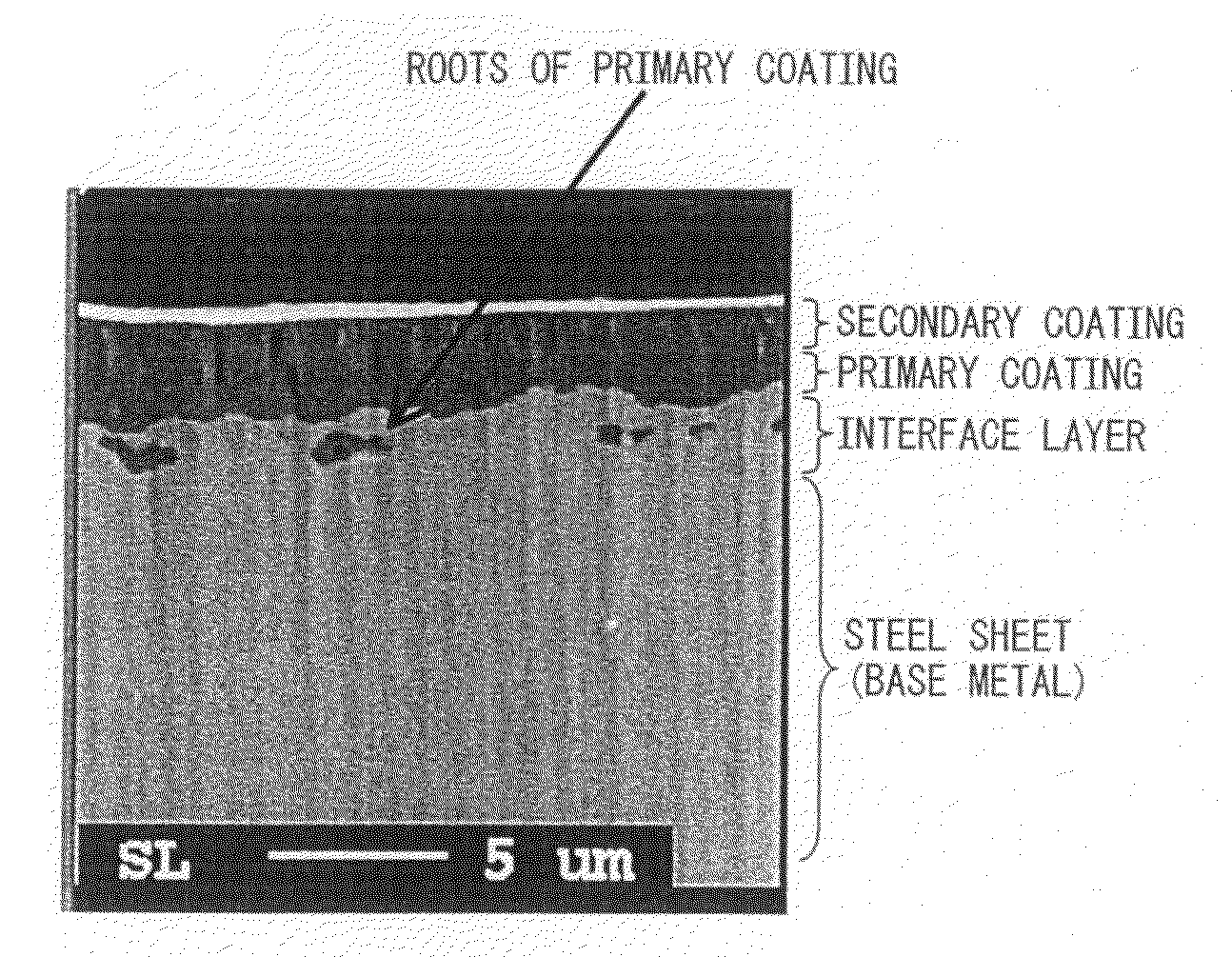

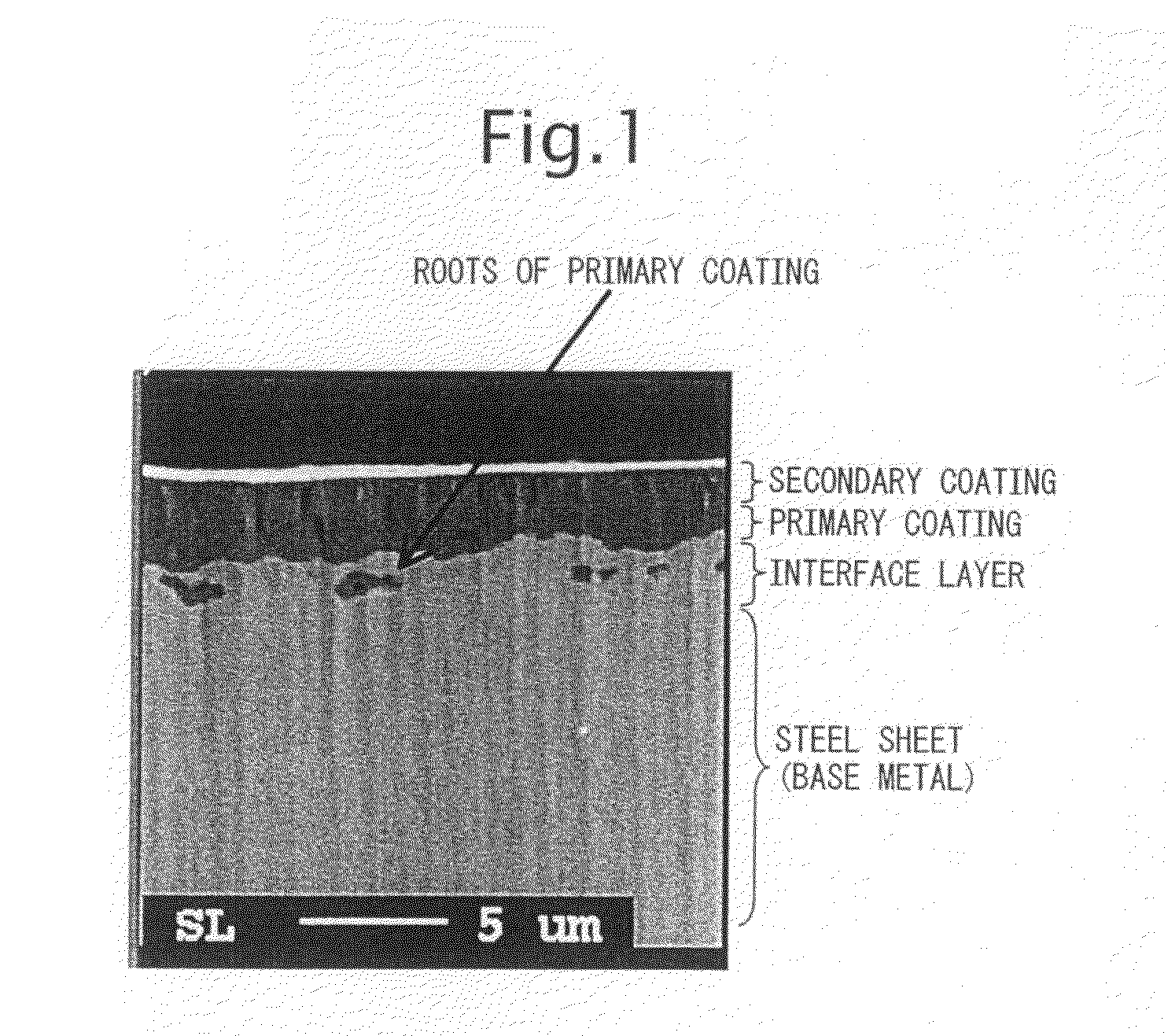

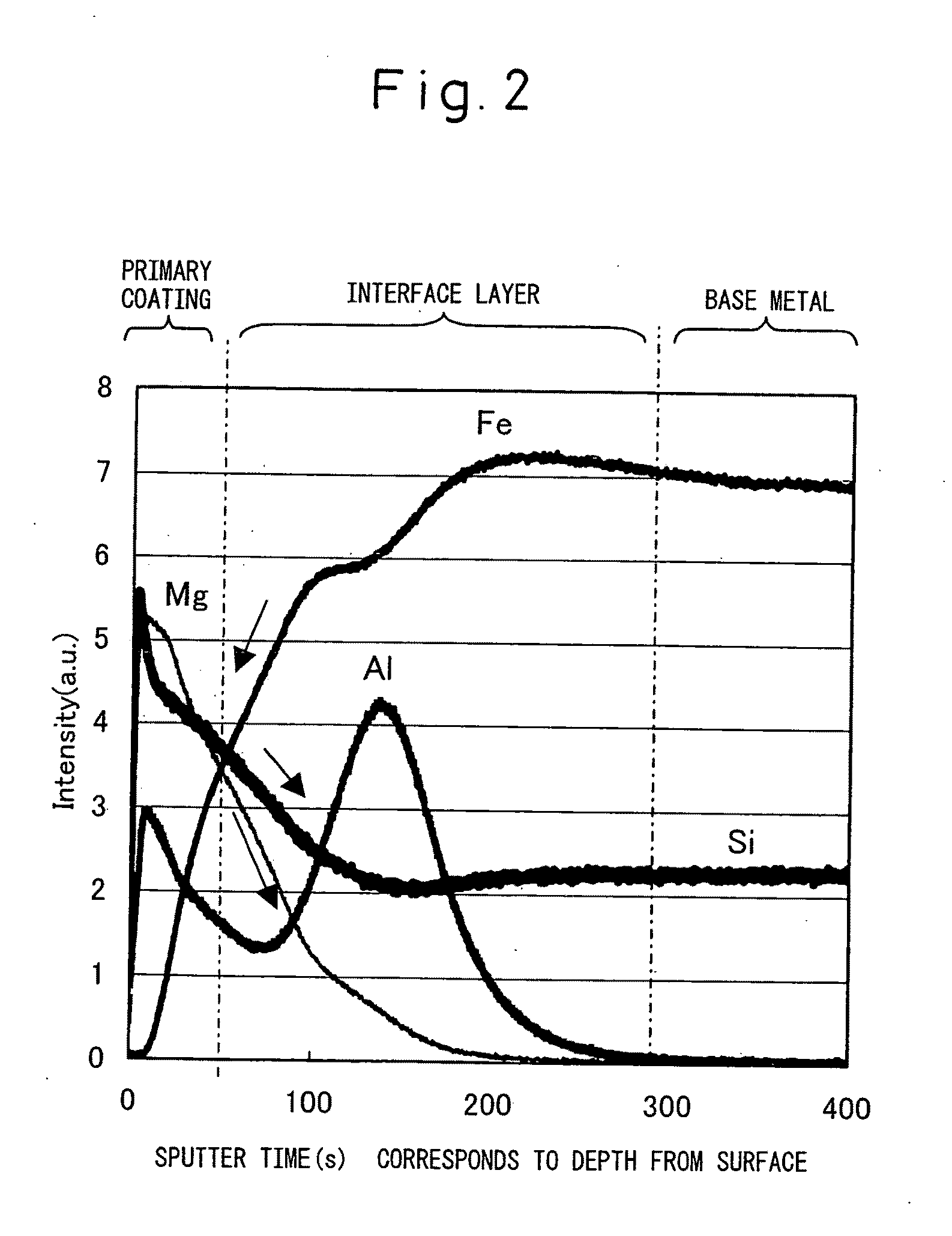

Grain-oriented electrical steel sheet excellent in coating adhesion and method of producing the same

ActiveUS20100055481A1Improve coating adhesionLow coating exfoliation area rateInorganic material magnetismSolid state diffusion coatingElectrical steelTransformer

Grain-oriented electrical steel sheet excellent in coating adhesion is provided. The steel sheet contains Si: 2 to 7% mass % and has a primary coating composed mainly of forsterite on its surface. A compound (A) containing one or more elements selected from among Ca, Sr and Ba, at least one rare earth metal, and sulfur is incorporated in the primary coating so as to reside in the interface layer between the primary coating and the steel sheet. As a result, occurrence of primary coating exfoliation at regions that are strongly worked during manufacture of a wound core transformer or the like is prevented.

Owner:NIPPON STEEL CORP

Shape memory self-ligating orthodontic brackets

InactiveUS7677887B2Reduce frictionImprove coating adhesionArch wiresBracketsArch wiresShape-memory alloy

Self-ligating orthodontic brackets with archwire retainers formed of materials exhibiting shape memory. Each bracket which includes a base from which extends two spaced and opposing pairs of tie wings each pair of which define an archwire guide slot therebetween. The retainers include at least one flange to retain an archwire within the archwire guide slot but which is yieldable to permit insertion and / or removal of the archwire relative to the archwire guide slots. Portions of the brackets and / or retainer may be coated to reduce friction between the archwire and the bracket and to promote aesthetics and overall bracket appearance.

Owner:NICHOLSON JAMES A

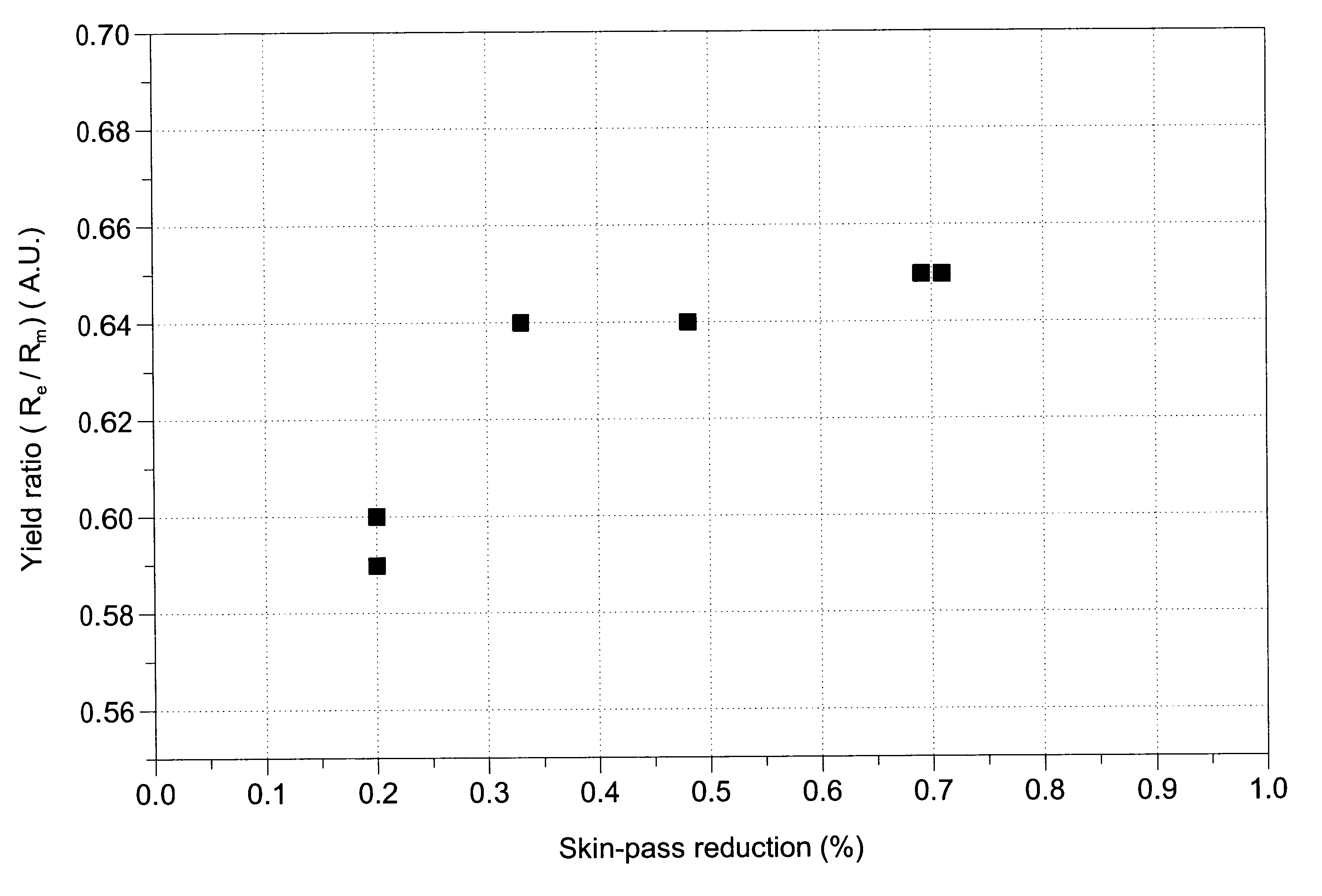

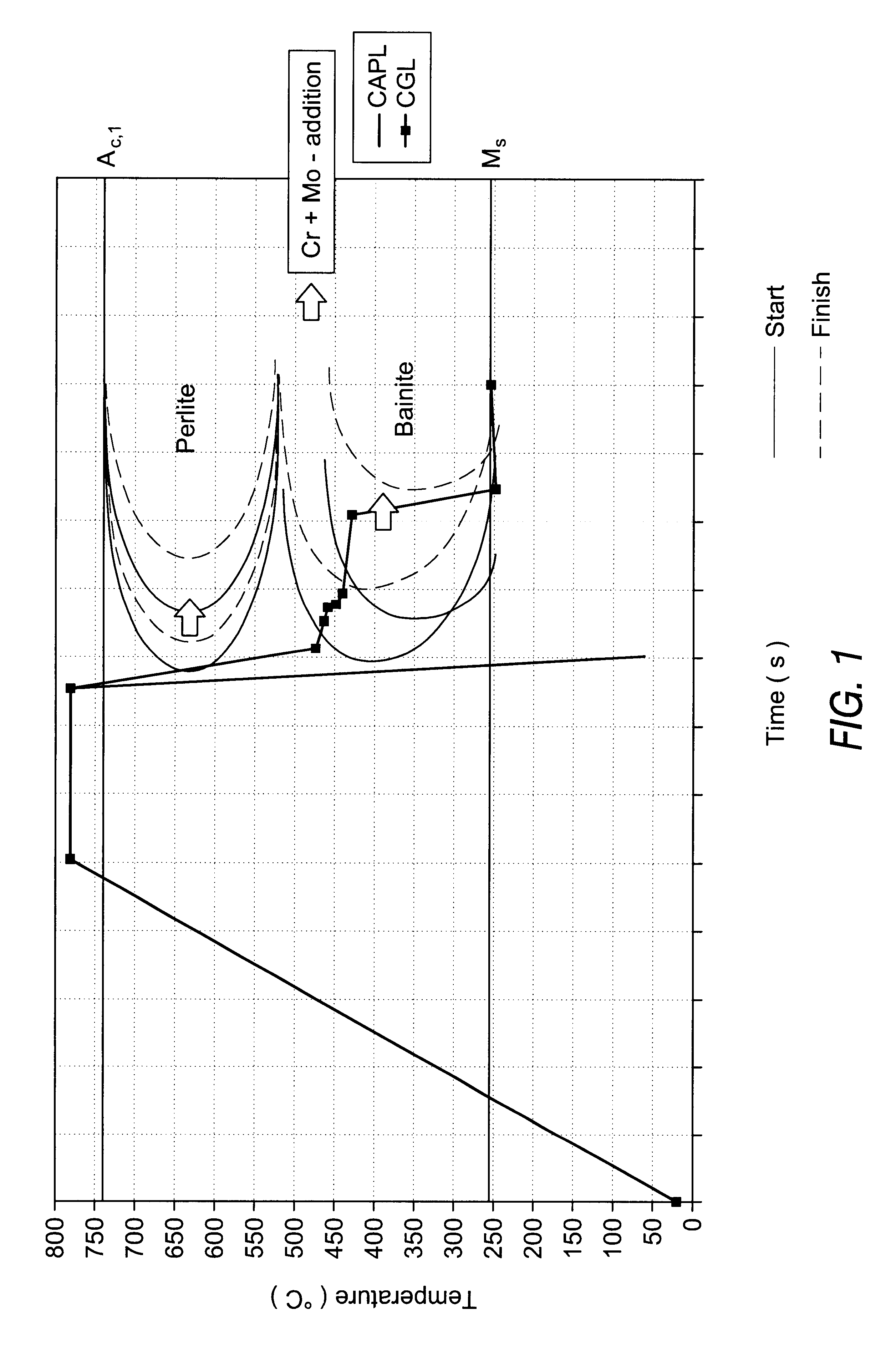

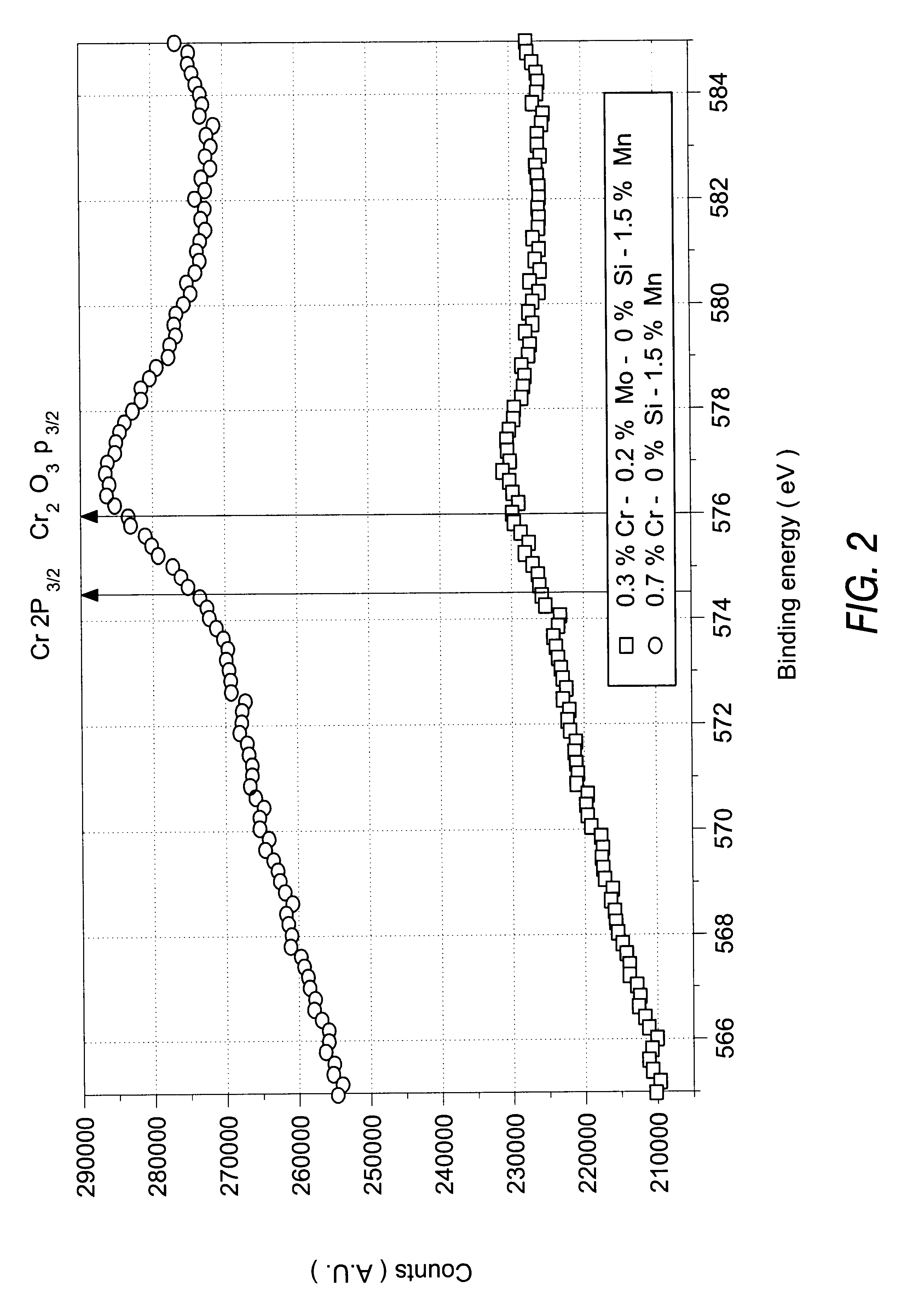

Method of production of cold-rolled metal coated steel products, and the products obtained, having a low yield ratio

InactiveUS6641931B2High strengthGood molding effectHot-dipping/immersion processesFurnace typesManganeseYield ratio

The present invention aims to produce a cold rolled metal coated multi-phase steel, characterized by a tensile strength of at least 500 MPa, a yield ratio (Re / Rm) lower than 0.65 in skinned conditions, lower than 0.60 in unskinned conditions, and with good metal coating adhesion behavior. In the case of the aluminized steel according to the invention, the steel also has superior resistance to temperature corrosion up to 900° C. and excellent mechanical properties at this high temperature. The hot metal coated steel product having a steel composition with a manganese content lower than 1.5%, chrome content between 0.2 and 0.5%, molybdenum content between 0.1 and 0.25%, and a relation between the chrome and molybdenum content as follows Cr+2 Mo higher than or equal to 0.7%, undergoes a thermal treatment in the hot dip metal coating line defined by a soaking temperature between Ac1 and Ac3, a primary cooling speed higher than 25° C. / sec and a secondary cooling speed higher than 4° C. / sec.

Owner:SIDMAR

Method for manufacturing substrates with transparent and color coatings stable at high temperatures and in the presence of ultraviolet rays

InactiveUS6156388AImprove coating adhesionHigh glossTube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersHalogenCrystalline oxide

PCT No. PCT / EP97 / 06006 Sec. 371 Date Apr. 26, 1999 Sec. 102(e) Date Apr. 26, 1999 PCT Filed Oct. 30, 1997 PCT Pub. No. WO98 / 18736 PCT Pub. Date May 7, 1998A method of manufacturing a substrate coated with a transparent, colored coating stable to high temperature and UV includes coating the substrate with a coating composition including at least one element which is able to form a vitreous, crystalline, or partially crystalline oxide, in the form of a compound which on heat treatment yields the oxide and is present as a sol or solution in an at least predominantly aqueous medium, as the matrix-forming component, and at least one member selected from the group consisting of metal colloids, metal compound colloids, metal alloy colloids, and metal compounds which form metal colloids under reducing conditions, as the coloring component; and heat-curing the resulting coating. Particularly suitable substrates are glass substrates, such as (halogen) lamp bulbs and gas discharge tubes.

Owner:INST FUR NEUE MATERIALIEN GEMEINNUTZIGE GMBH

Single-side coated and integrated backplane for photovoltaic modules

InactiveCN106519276AShort manufacturing cycleSimple processSynthetic resin layered productsCoatingsPolyesterCarbon coating

The invention discloses a single-side coated and integrated backplane for photovoltaic(PV) modules. The backplane is obtained through co-extrusion of a polyester basic layer and a modified polyester thin layer. The surface of the polyester basic layer is coated with a fluoro-carbon resin coating. The polyester basic layer is prepared by mixing 1-10 parts by weight of a functional master batch polyester slice and 1 part by weight of a pure polyester slice. The modified polyester layer comprises a dicarboxylic acid, a diol, a fluorine-containing monomer, titanium dioxide powder, a catalyst, a heat stabilizer, a phosphorus compound, an antioxidant, a UV absorber, a light stabilizer, an antistatic agent and an anti-hydrolysis agent. The fluoro-carbon resin coating is obtained by curing a two-component FEVE fluoro-carbon coating under normal temperature. The fluoro-carbon resin coating comprises a polymer matrix, an aliphatic polyisocyanate curing agent, a solvent, an additive and a filler.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

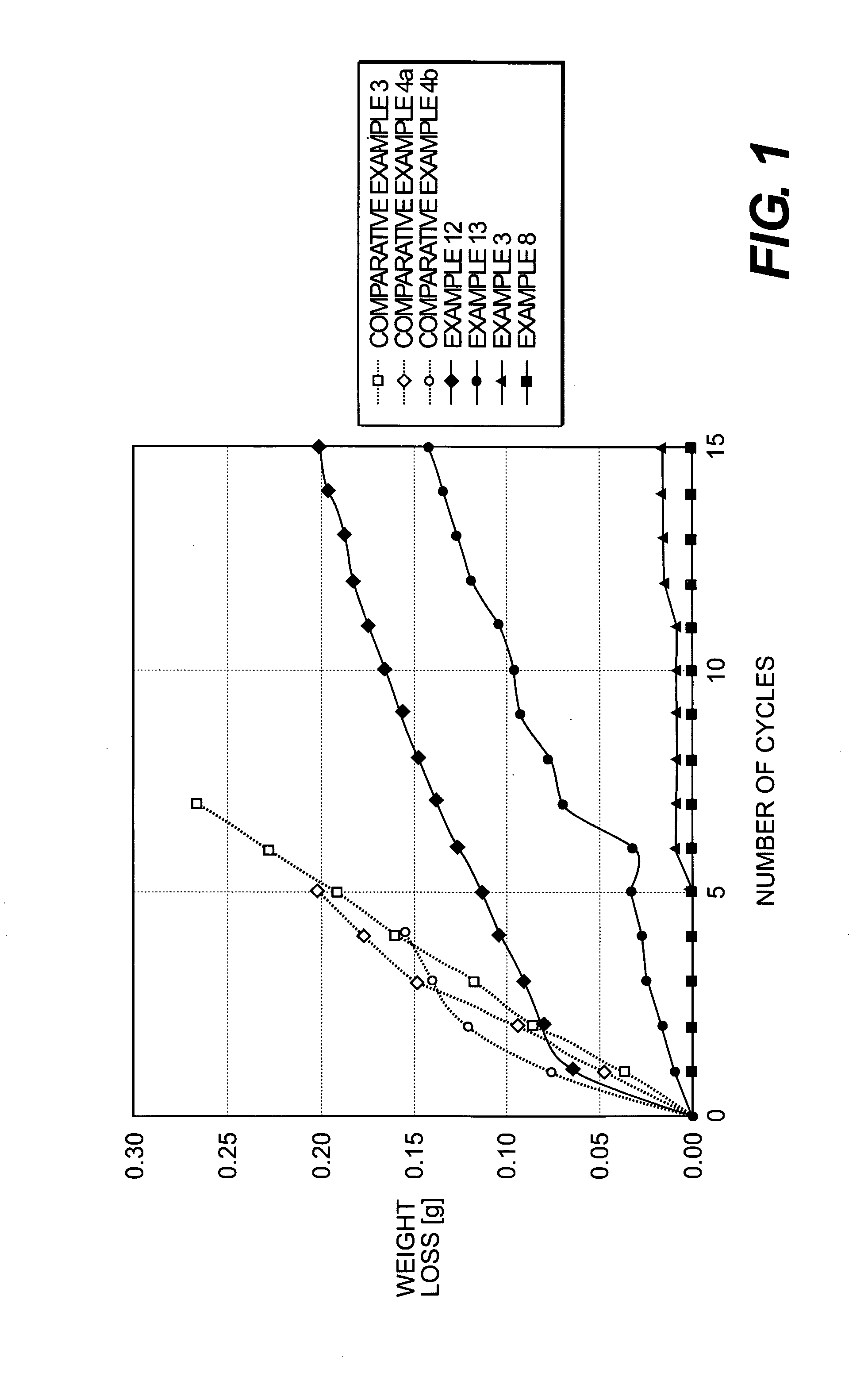

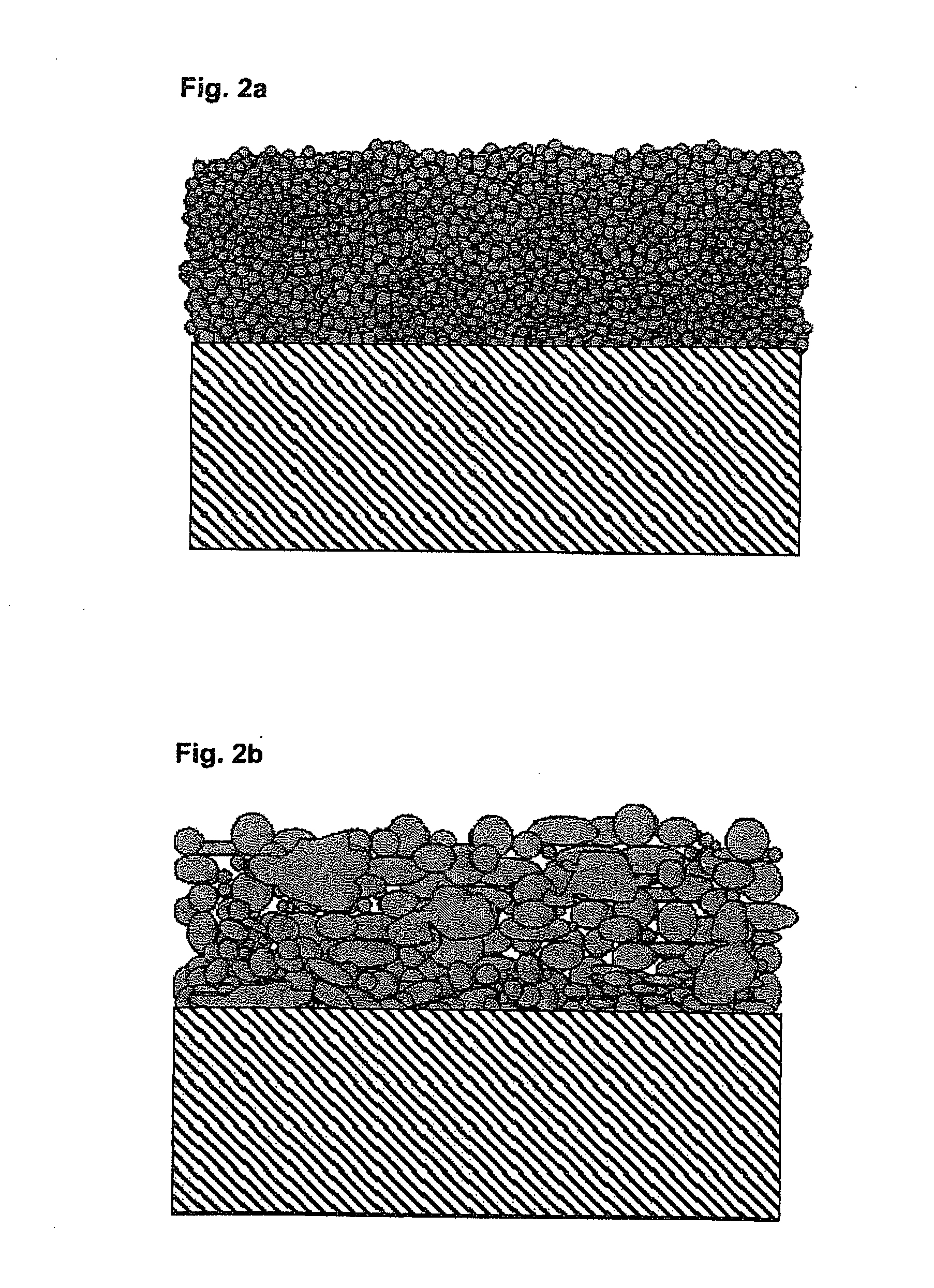

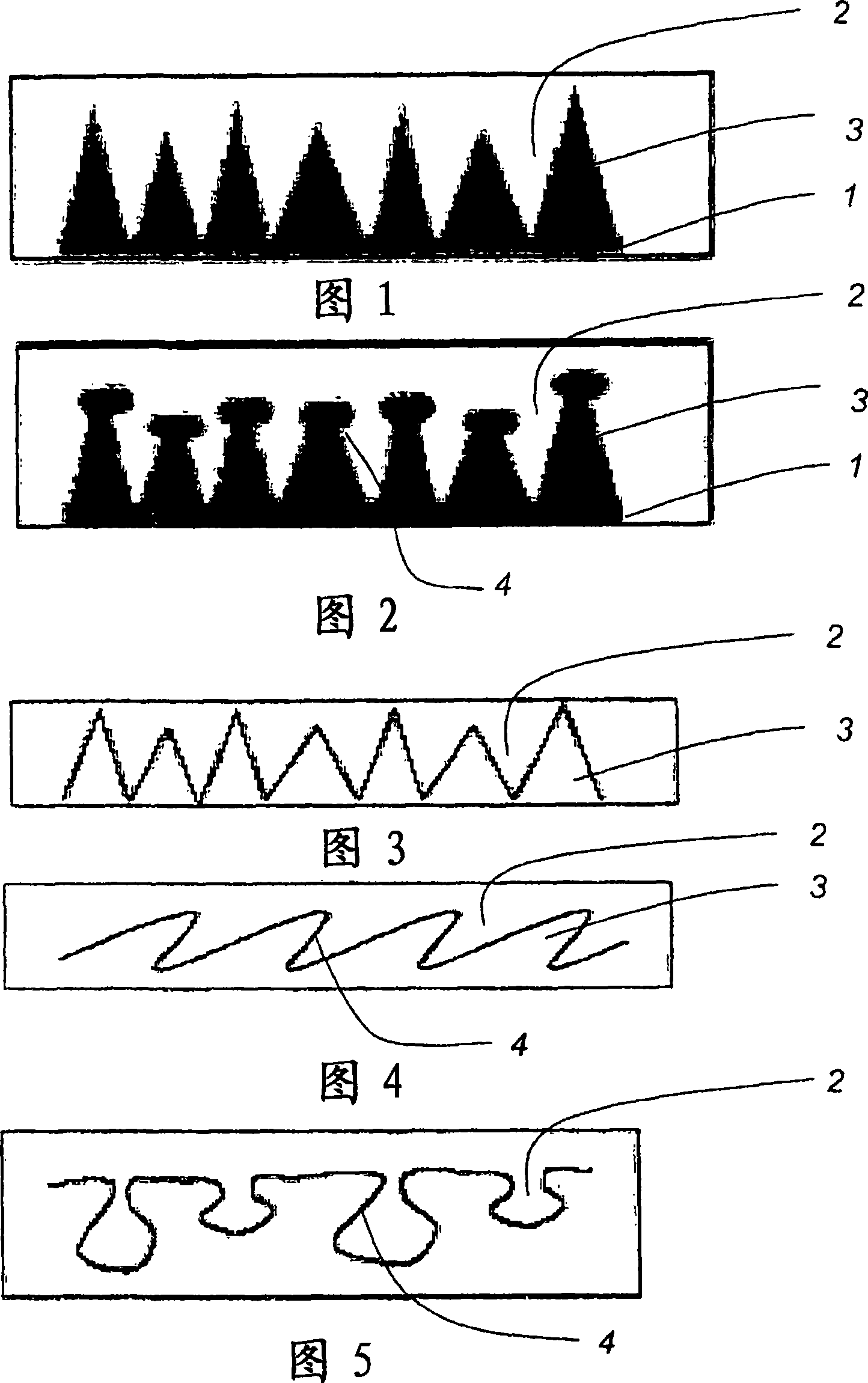

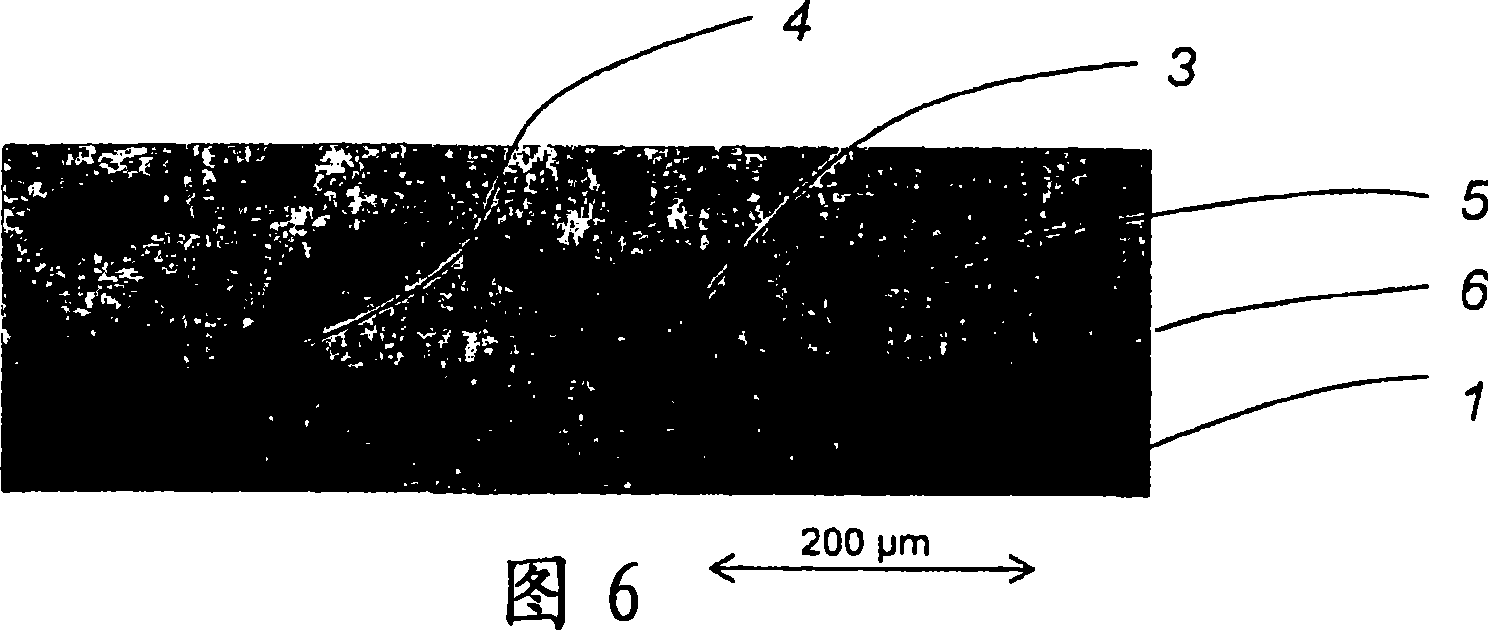

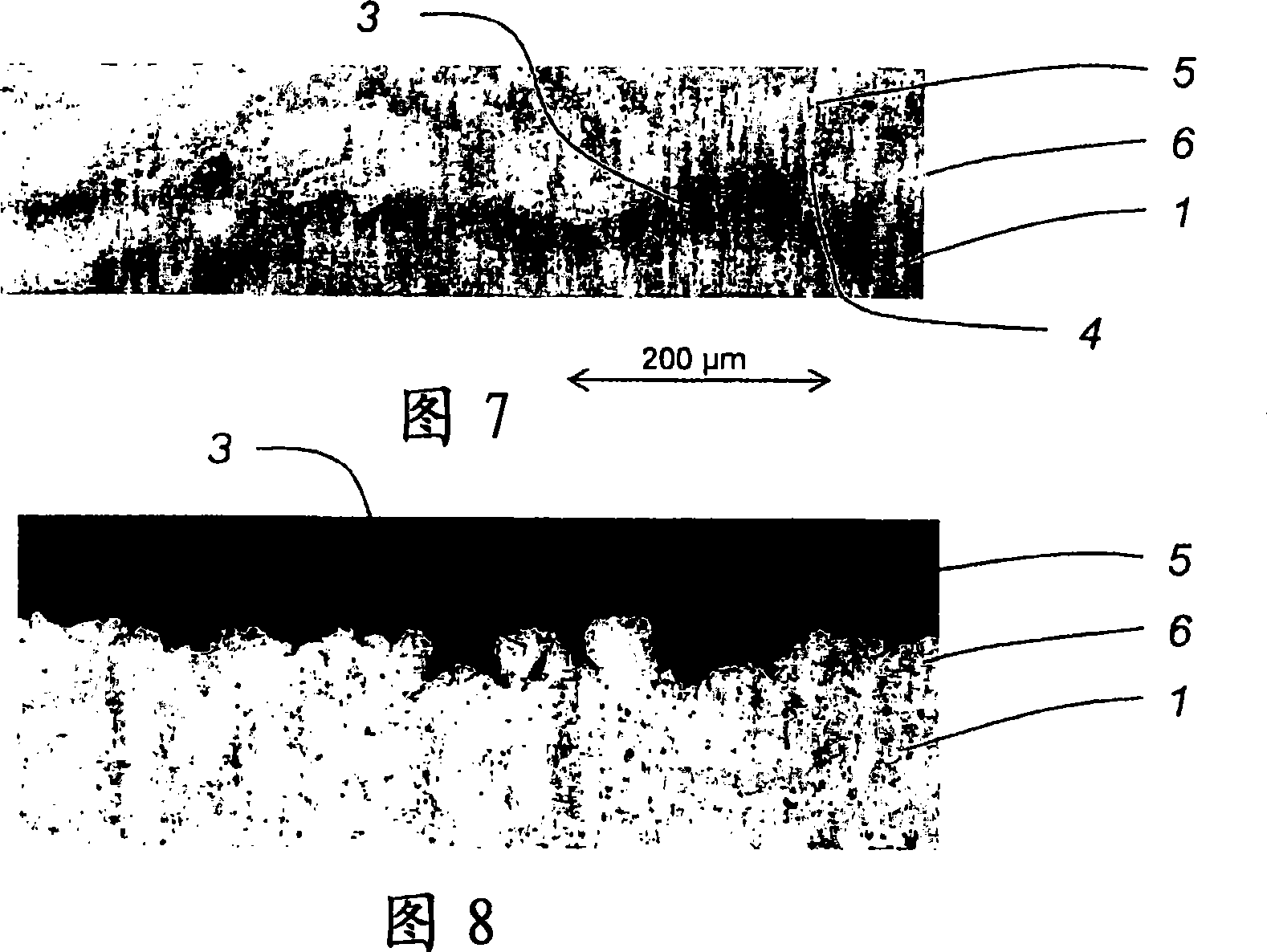

Surface conditioning for thermal spray layers

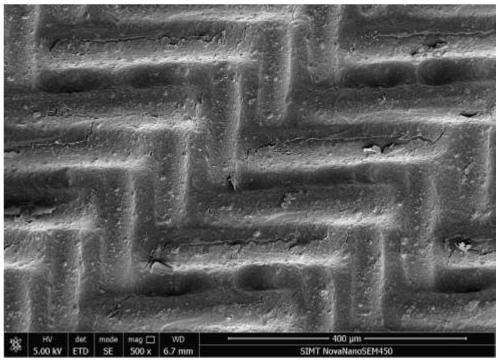

InactiveCN101379212AImprove adhesionImprove coating adhesionMolten spray coatingThin material handlingMaterial removalSurface conditions

The invention relates to a process for roughening metal surfaces to improve adhesion of layers which are thermally sprayed onto the surface, in which, in a first process step, recesses or depressions (2) are introduced into the surface in a material-detaching or material-removing treatment so that the remaining metal of the surface forms raised microstructures (3), in particular projections, ridges, protuberances or bumps, with these microstructures being further worked in at least one further process step by shaping and / or breaking so that a significant proportion of the structures forms undercuts (4) in relation to the surface.

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com