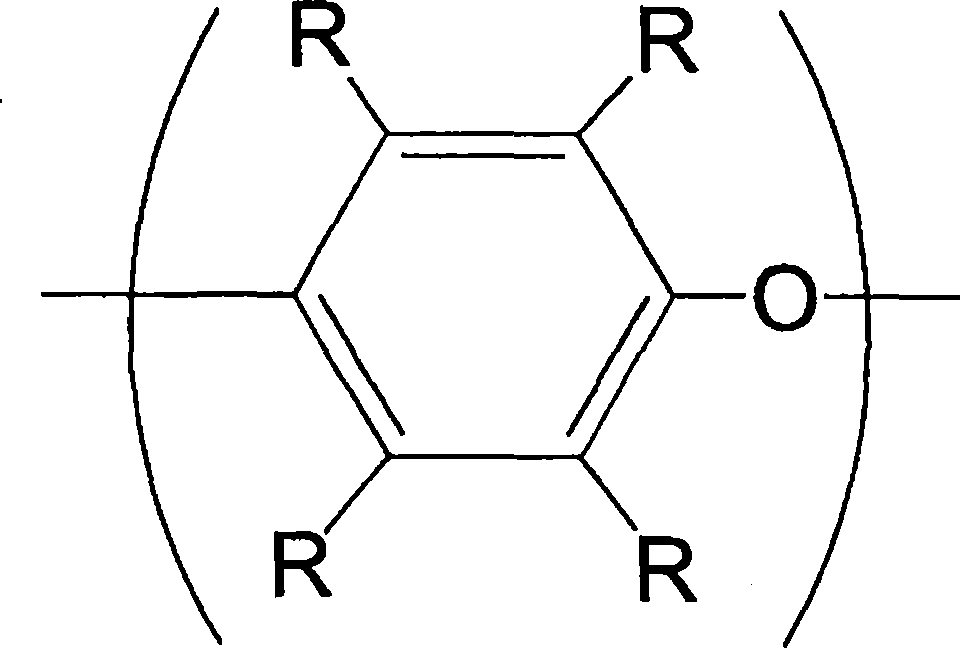

Polyamide-polyphenylene ether resin composition

A technology of resin composition and polyamide, applied in the field of resin composition, can solve problems such as difficulty in controlling fluidity, and achieve the effects of excellent retention stability, improved coating adhesion and less change in MFR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12、 comparative example 1~3

[0266] Using the upstream side supply port in the first barrel from the upstream side of the extruder and the downstream side supply port in the sixth barrel, L / D (extruder barrel length / extruder barrel) Diameter) = 44 (barrel number: 11) twin-screw extruder [ZSK-40: manufactured by Kopelion Co., Ltd. (Germany)], from the supply port on the upstream side to the front of the supply port on the downstream side was set at 320 ° C, from The downstream side supply port to the die is set at 280°C, the screw rotation speed is 300rpm, and the discharge rate is 60kg / hour. According to the ratio described in Table 1, PPE, SEBS, GPPS, and MAH are supplied from the upstream side supply port for melt kneading After that, PA and NaH are supplied from the downstream supply port 2 PO 2 , making resin composition particles. After adjusting the water content of the obtained resin composition, MFR and silver streaks were evaluated. In addition, physical property values are described in Tabl...

Embodiment 13~16、 comparative example 4

[0268] L / D( The length of the barrel of the extruder / the diameter of the barrel of the extruder) = 44 (number of barrels: 11) of the twin-screw extruder [ZSK-40: manufactured by Kopelion (Germany)], will be supplied from the upstream side The mouth to the front of the first supply port on the downstream side is set at 320°C, the distance from the first supply port on the downstream side to the die is set at 280°C, the screw rotation speed is 300rpm, and the discharge rate is 60kg / hour, and the supply is supplied from the upstream side supply port. After melt-kneading PPE, SEBS, and MAH, PA and PA / CB-MB are supplied from the first supply port on the downstream side. Furthermore, GF is supplied from the downstream side 2nd supply port. According to the ratio described in Table 2, resin composition pellets were prepared. After adjusting the water content of the obtained resin composition, MFR and silver streak evaluations were performed. In addition, coating adhesiveness after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com