Patents

Literature

51results about How to "High melt tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melt-processible thermoplastic fluoropolymers having improved processing characteristics and method of producing same

ActiveUS6927265B2Increased critical shear rateSimple processPlastic/resin/waxes insulatorsFibre treatmentThermoplasticPolymer science

The present invention provides a fluoropolymer that is melt-processible and thermoplastic and that has a melting point between 100° C. and 320° C. The fluoropolymer is derived from (a) one or more gaseous fluorinated monomers, (b) one or more modifiers selected from (i) olefins having a bromine or iodine atom bonded to a carbon of the double bond of the olefin, (ii) olefins corresponding to formula (I):Xa2C═CXa—Rf—Br (I)wherein each Xa independently represents hydrogen, fluorine, bromine, chlorine or iodine, Rf is a perfluoroalkylene group, typically having 1 to 8 carbon atoms, a perfluorooxyalkylene group or a perfluoropolyether group and (iii) mixtures thereof; and (c) optionally one or more comonomers selected from non-gaseous fluorinated monomers and non-fluorinated monomers. The resulting fluoropolymer has long chain branches. The invention further provides a method for making these polymers.

Owner:3M INNOVATIVE PROPERTIES CO

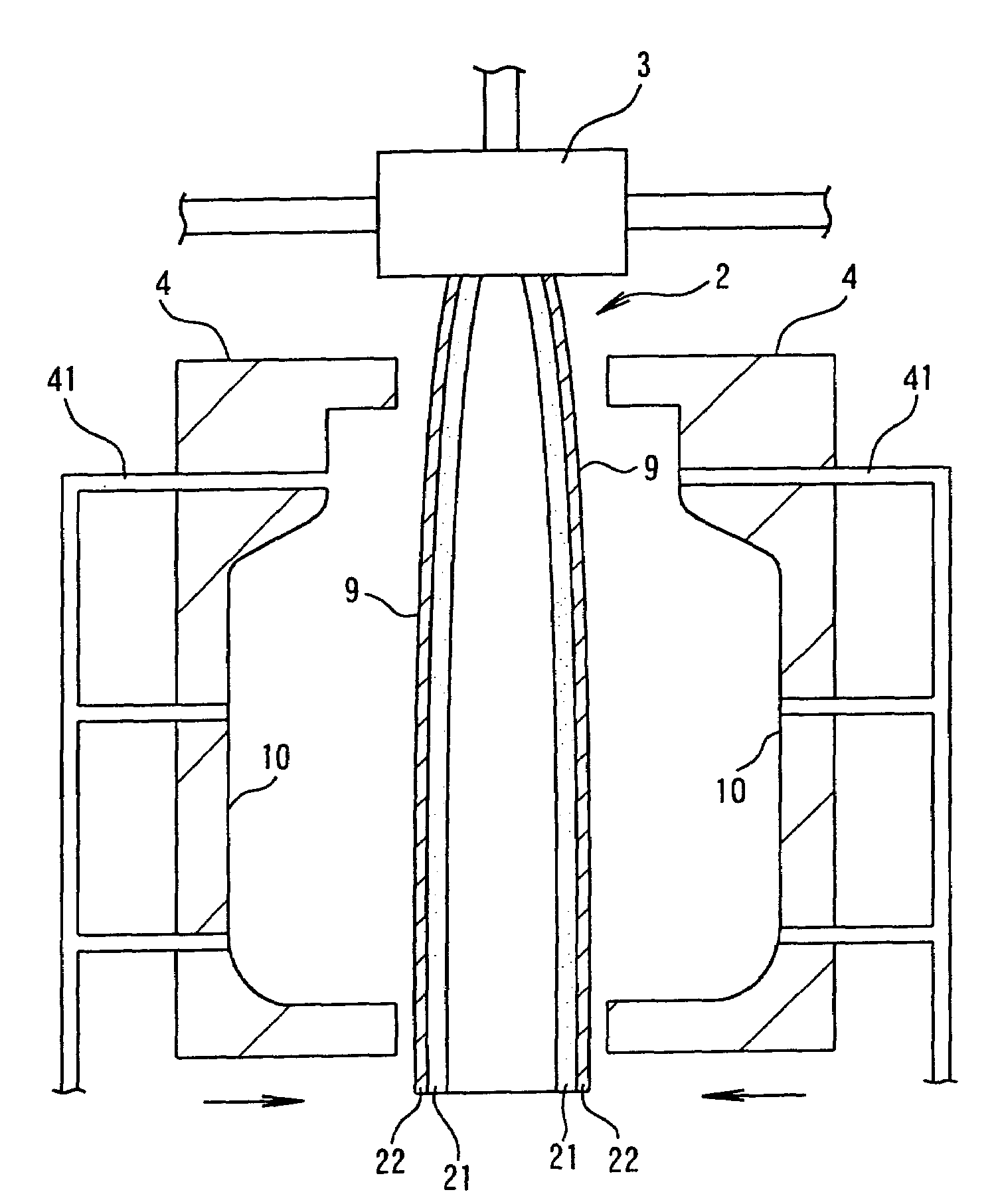

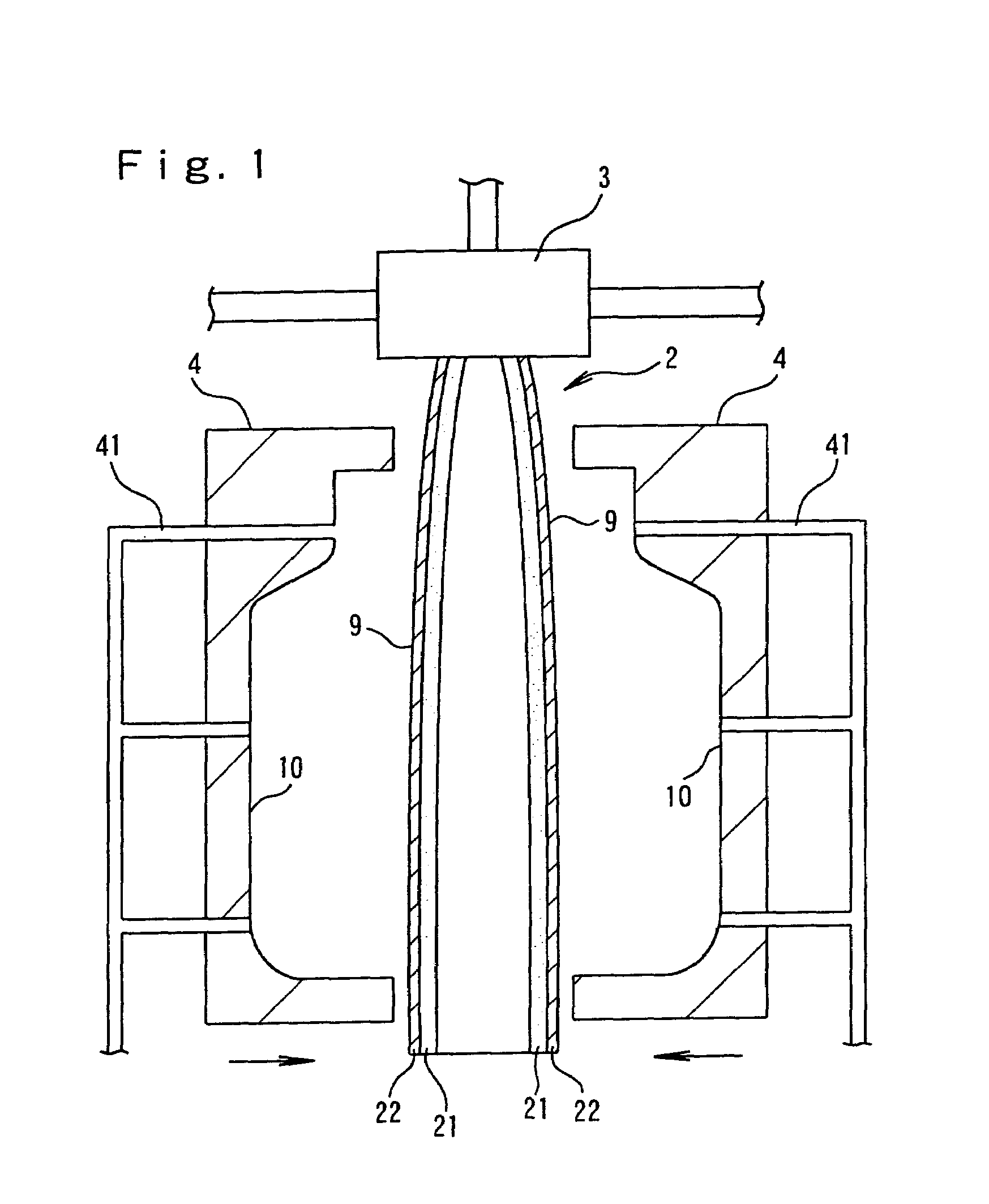

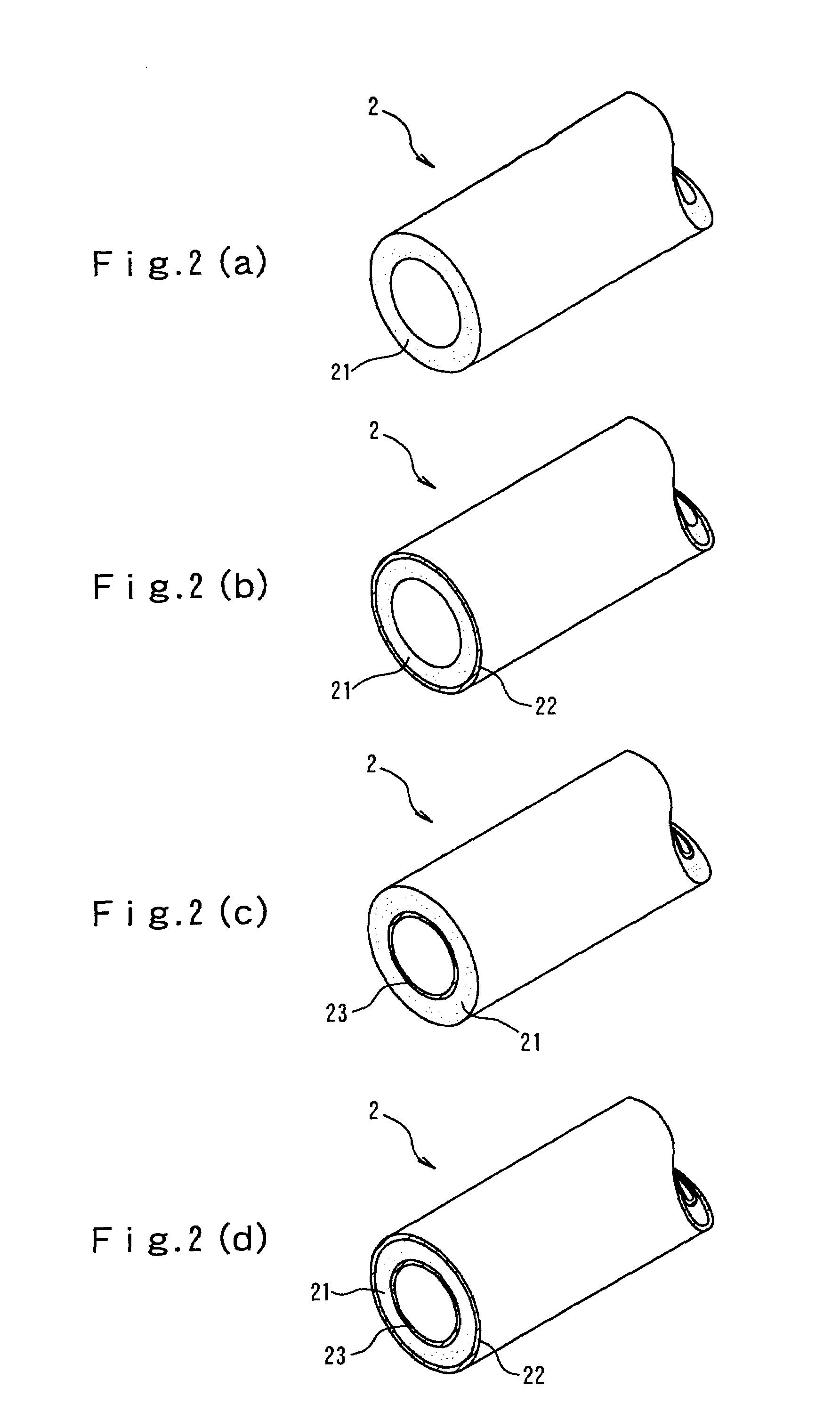

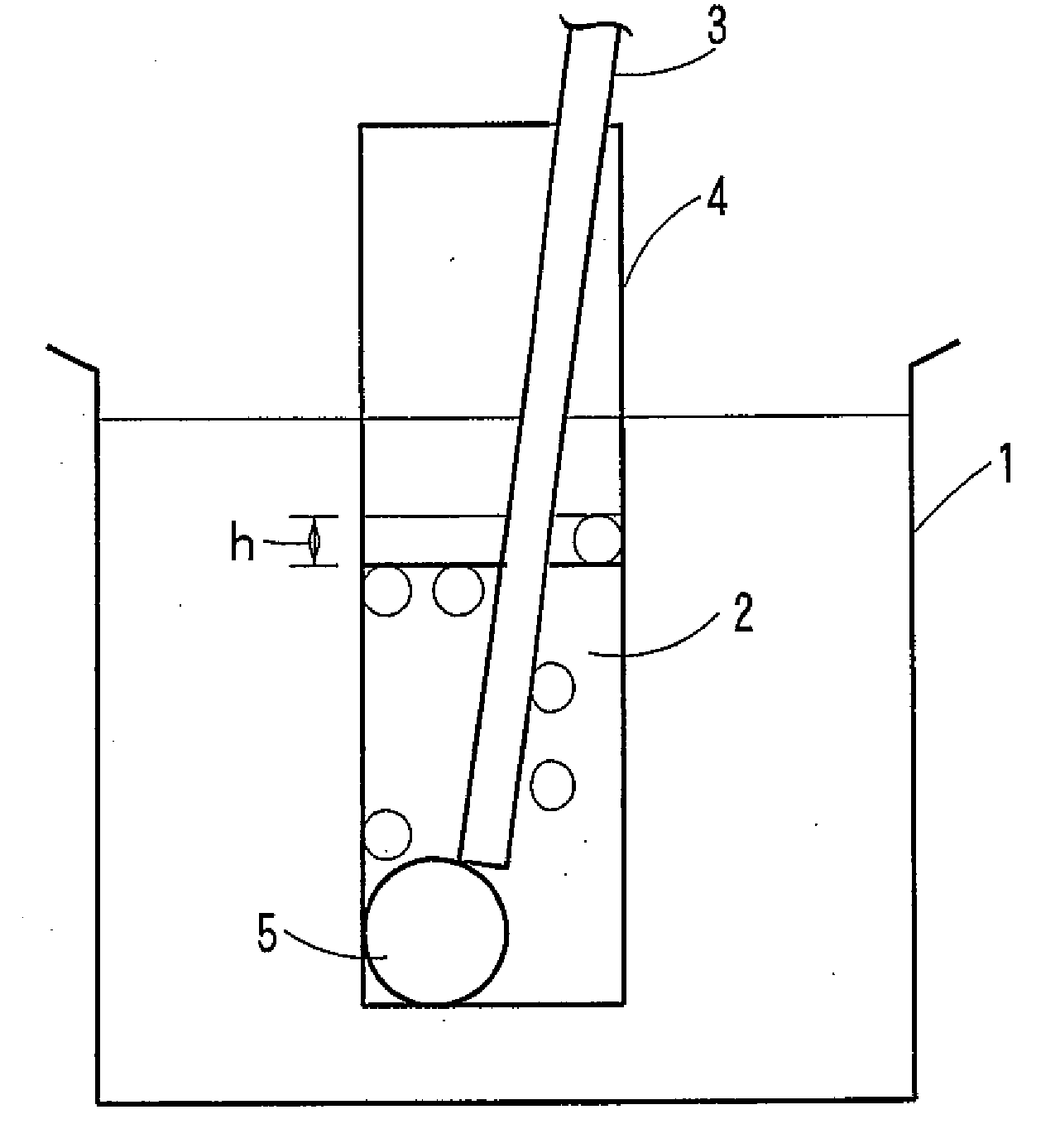

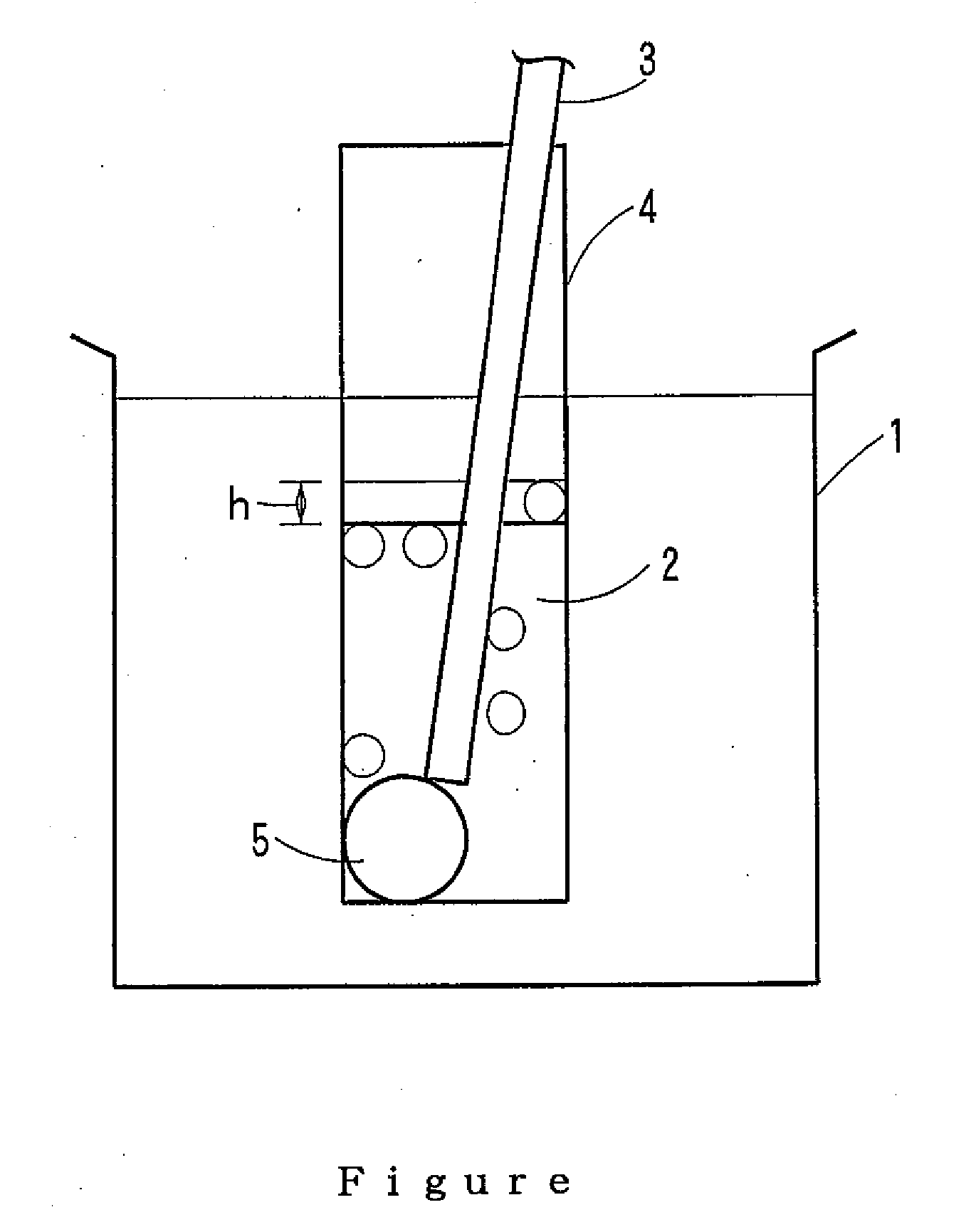

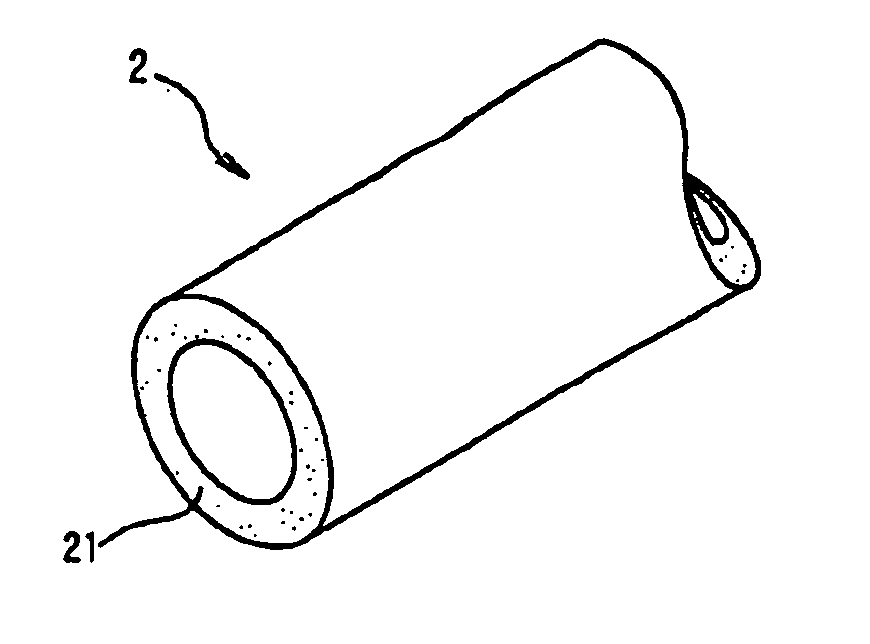

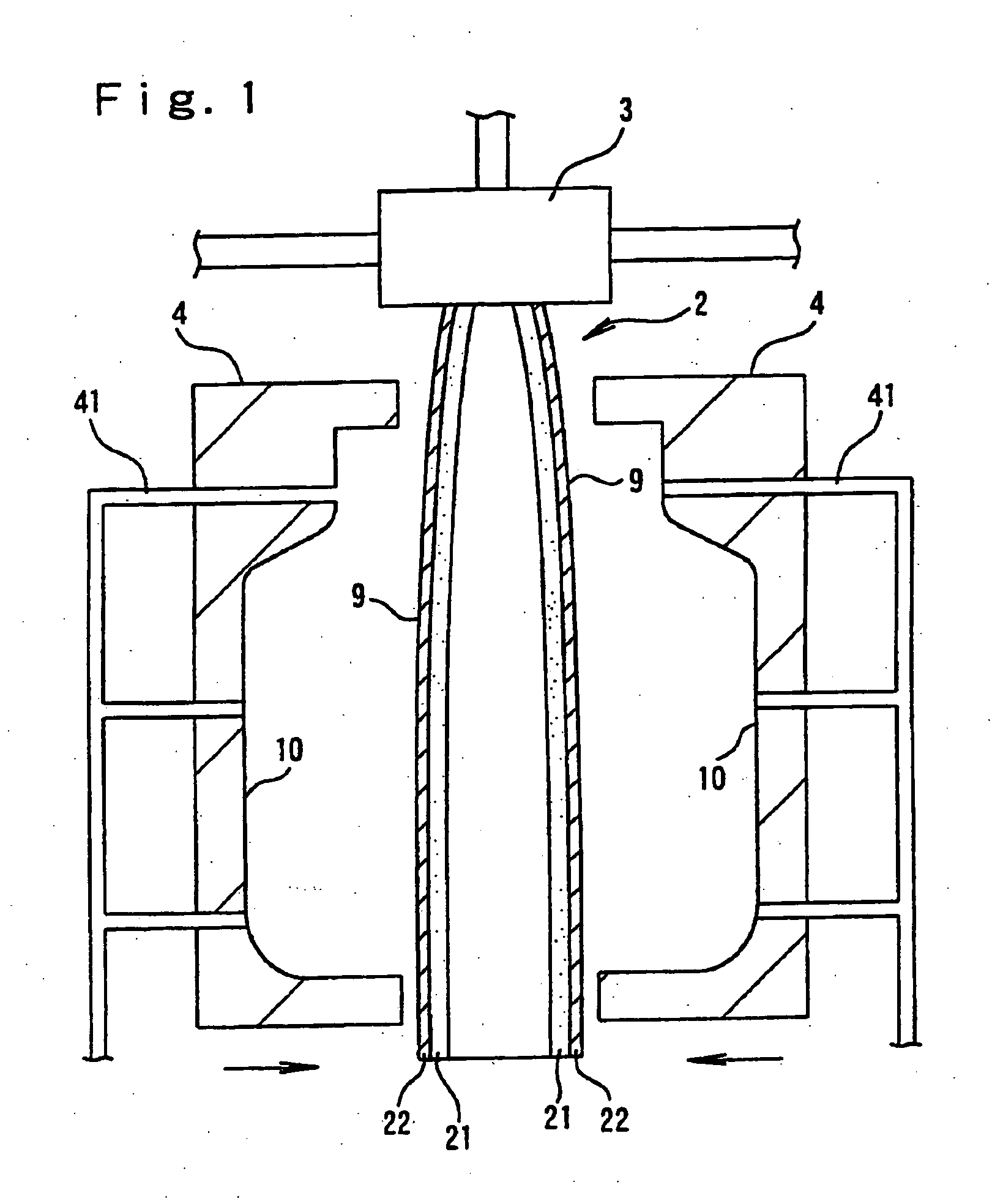

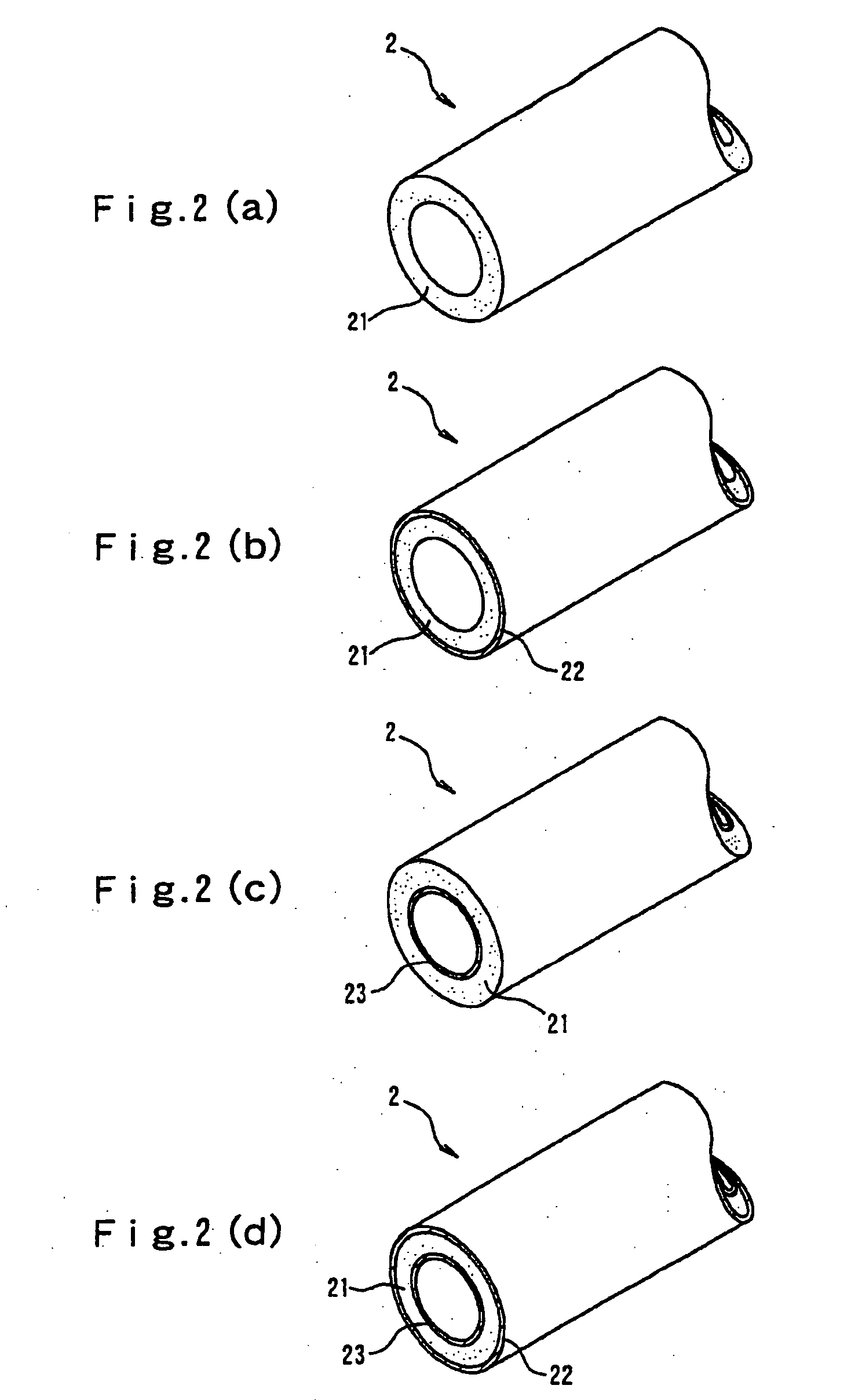

Polypropylene resin hollow molded foam article and a process for the production thereof

ActiveUS7014801B2Low production costHigh expansion rateDomestic articlesFlat articlesApparent densityPolymer science

The present invention relates to a hollow molded foam article in which a plurality of polypropylene resins are used as the base resin, and to a process for the production of this hollow molded foam article. More particularly, the present invention relates to a polypropylene resin hollow molded foam article having a foam layer, in which the base resin comprises (a) a polypropylene resin with a melt tension of at least 98 mN and a melt flow rate of 0.5 to 15 g / 10 minutes, (b) a polypropylene resin with a melt tension of less than 30 mN (excluding O) and a melt flow rate of 2 to 30 g / 10 minutes, and (c) a polypropylene resin with a melt tension of at least 30 mN and less than 98 mN and a melt flow rate of 2 to 15 g / 10 minutes, formed by positioning in a mold a softened cylindrical foam having a foam layer obtained by extruding from the die of an extruder a foamable molten resin composition containing a foaming agent, wherein the melt tension at 230° C. of the polypropylene resin that forms the foam layer is at least 10 mN and less than 49 mN, and the apparent density of the foam layer is no more than 0.3 g / cm3.

Owner:JSP CORP

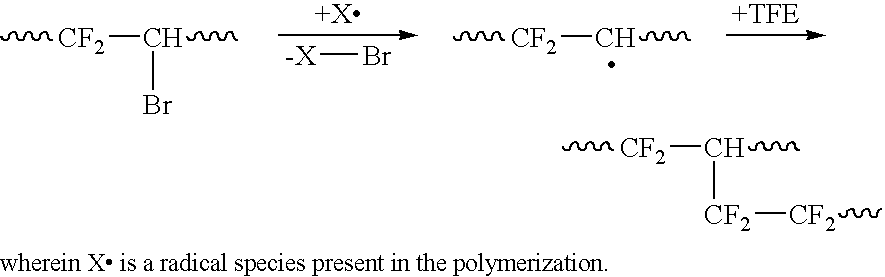

Melt-processible thermoplastic fluoropolymers having improved processing characteristics and method of producing same

ActiveUS20040192868A1Increase the critical shear rateHigh melt tensionPlastic/resin/waxes insulatorsFibre treatmentFluorinated monomersBromine

The present invention provides a fluoropolymer that is melt-processible and thermoplastic and that has a melting point between 100° C. and 320° C. The fluoropolymer is derived from (a) one or more gaseous fluorinated monomers, (b) one or more modifiers selected from (i) olefins having a bromine or iodine atom bonded to a carbon of the double bond of the olefin, (ii) olefins corresponding to formula (I): X2C=CX-Rf-Br (I) wherein each Xindependently represents hydrogen, fluorine, bromine, chlorine or iodine, Rf is a perfluoroalkylene group, typically having 1 to 8 carbon atoms, a perfluorooxyalkylene group or a perfluoropolyether group and (iii) mixtures thereof; and (c) optionally one or more comonomers selected from non-gaseous fluorinated monomers and non-fluorinated monomers. The resulting fluoropolymer has long chain branches. The invention further provides a method for making these polymers.

Owner:3M INNOVATIVE PROPERTIES CO

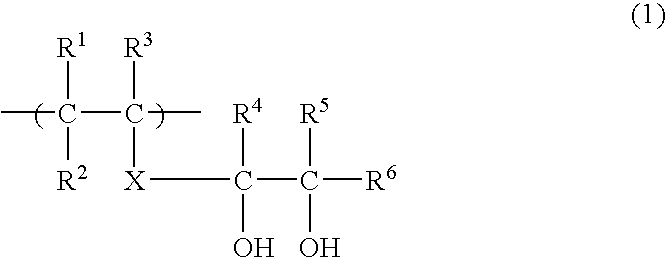

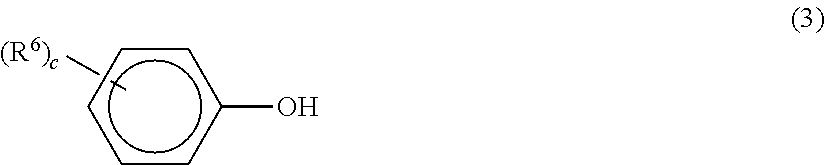

Water-soluble polyvinyl alcohol resin filament and nonwoven fabric made by using the same

InactiveUS20090061719A1Good water solubilityRadiation suppressionLayered productsMonocomponent synthetic polymer artificial filamentSolubilityDissolution

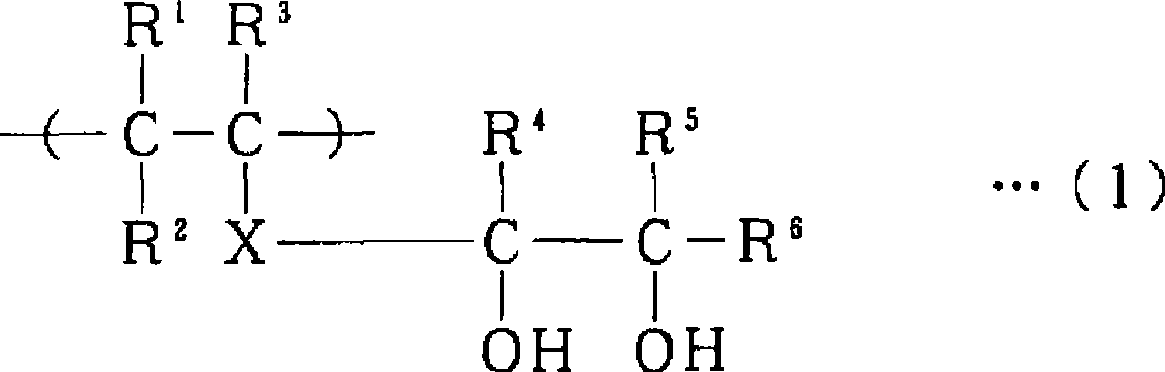

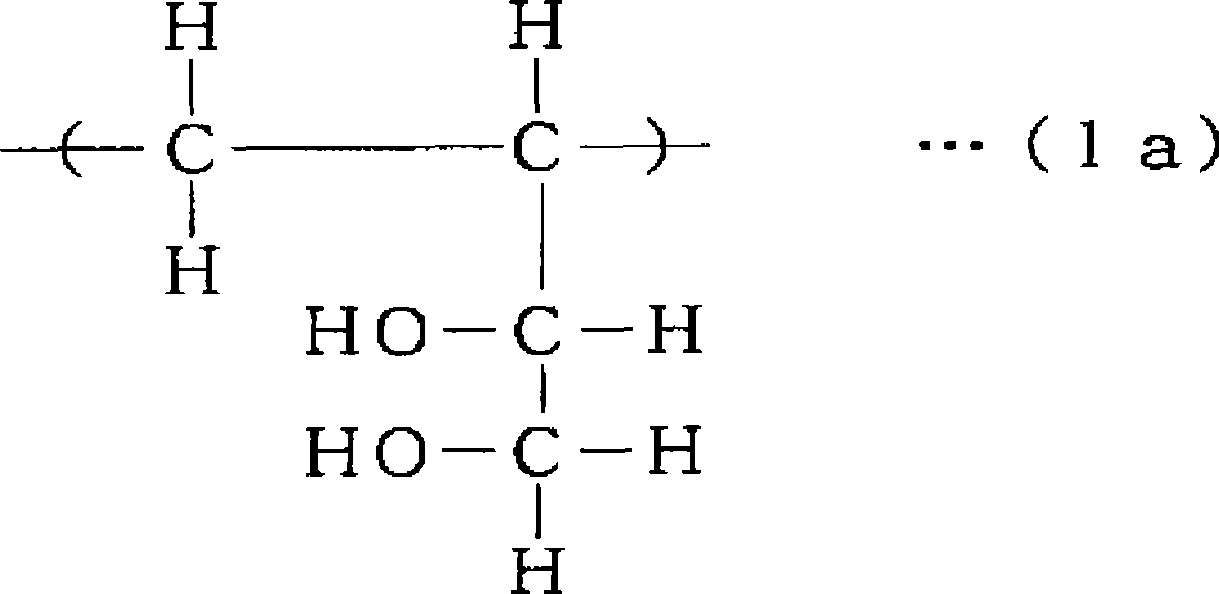

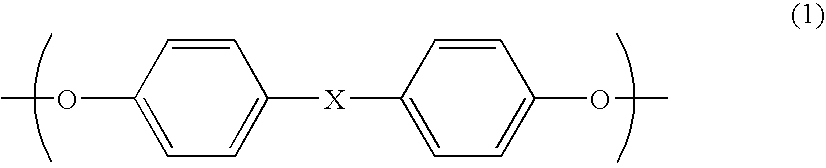

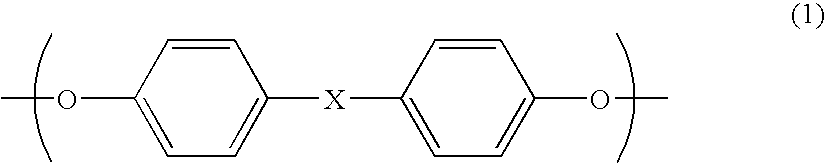

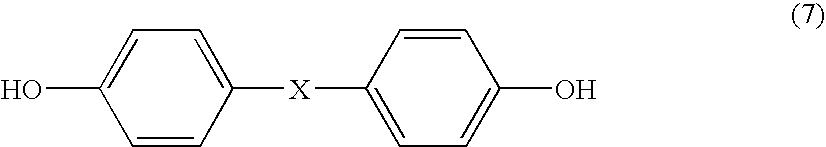

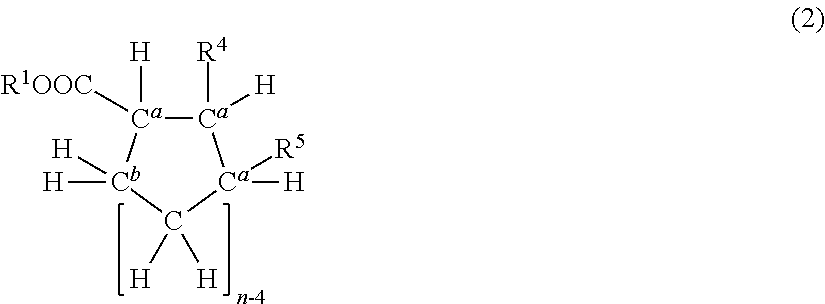

A water-soluble polyvinyl alcohol resin filament is provided, which is formed by melt-spinning a material consisting essentially of a water-soluble polyvinyl alcohol resin having a 1,2-diol structural unit represented by the following general formula (1). A nonwoven fabric is also provided, which is produced by using the water-soluble polyvinyl alcohol resin filament. Therefore, the nonwoven fabric is excellent in water solubility at a lower temperature, and substantially free from bubbling during dissolution thereof in water. In addition, a fully saponified PVA can be used for melt-forming. This suppresses emanation of acetic acid odor, thereby improving the working environment.wherein R1, R2, R3, R4, R5 and R6, which may be the same or different, are each a hydrogen atom or a monovalent organic group, and X is a single bond or a connecting chain.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

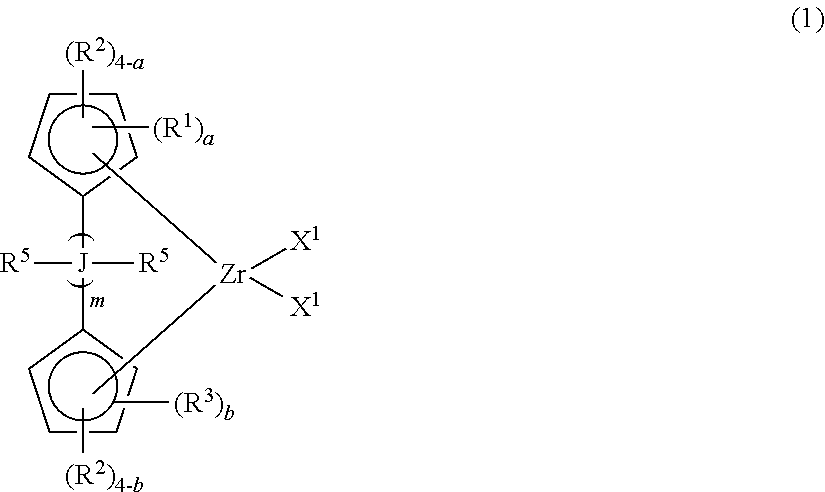

Catalyst component for addition polymerization, process for producing catalyst for addition polymerization and process for producing addition polymer

InactiveUS6870015B2High melt tensionEasy to processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryPolymerization catalysts

There are provided:(I) a catalyst component for addition polymerization comprising:(i) a transition metal compound having (a) two cyclopentadiene type anion skeleton-carrying groups, which are linked with each other directly or through a bridging group, and (b) a hafnium atom as its central metal, and(ii) a transition metal compound having (a) two substituted cyclopentadiene type anion skeleton-carrying groups, which are not linked with each other, and (b) a zirconium atom or a titanium atom as its central atom; and(II) a process for producing a catalyst for addition polymerization, which comprises the step of contacting the above catalyst component with a co-catalyst component for activation.

Owner:SUMITOMO CHEM CO LTD

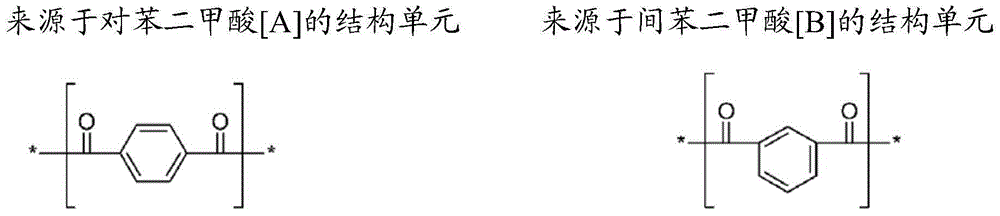

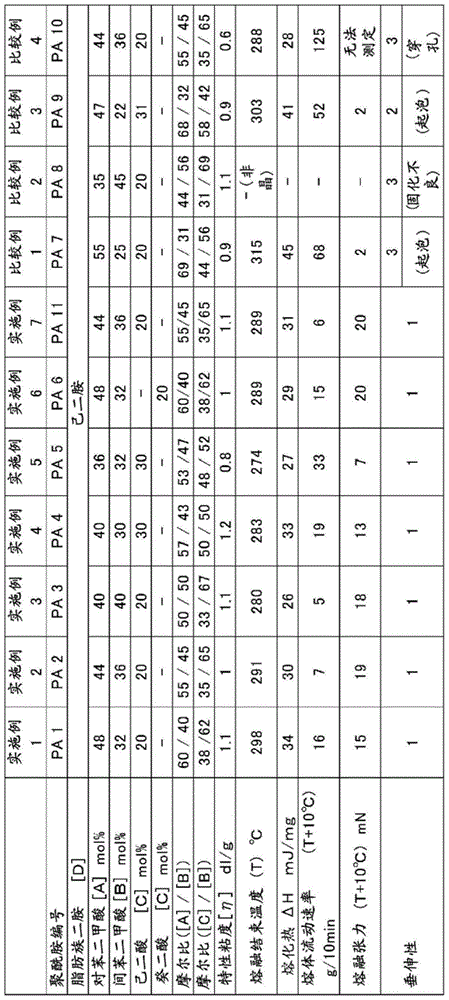

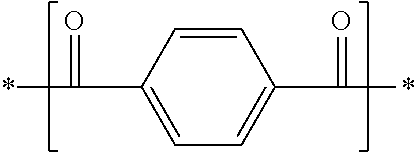

Semiaromatic polyamide, semiaromatic polyamide resin composition, and molded article

The purpose of the present invention is to provide: a semiaromatic polyamide which has excellent heat resistance, chemical resistance and mechanical characteristics, while exhibiting moldability that is suitable for various component materials for automobiles and the like; and a molded article of this semiaromatic polyamide. A semiaromatic polyamide (I) of the present invention contains 35-50% by mole of a structural unit derived from terephthalic acid [A], 25-40% by mole of a structural unit derived from isophthalic acid [B], 15-35% by mole of a structural unit derived from an aliphatic dicarboxylic acid [C] (provided that the total of [A], [B] and [C] is 100% by mole), and a structural unit derived from an aliphatic diamine [D] having 4-12 carbon atoms. The molar ratio ([A] / [B]) is from 65 / 35 to 50 / 50, and the molar ratio ([C] / [B]) is from 30 / 70 to 50 / 50. The melting enthalpy (∆H) of the semiaromatic polyamide (I) as determined by differential scanning calorimetry (DSC) is 20-40 mJ / mg, and the limiting viscosity [η] of the semiaromatic polyamide (I) is 0.7-1.6 dl / g.

Owner:MITSUI CHEM INC

Polypropylene resin hollow molded foam article and a process for the production thereof

InactiveUS20060051543A1Low production costHigh expansion rateSynthetic resin layered productsDomestic articlesApparent densityFoaming agent

The present invention relates to a hollow molded foam article in which a plurality of polypropylene resins are used as the base resin, and to a process for the production of this hollow molded foam article. More particularly, the present invention relates to a polypropylene resin hollow molded foam article having a foam layer, in which the base resin comprises (a) a polypropylene resin with a melt tension of at least 98 mN and a melt flow rate of 0.5 to 15 g / 10 minutes, (b) a polypropylene resin with a melt tension of less than 30 mN (excluding O) and a melt flow rate of 2 to 30 g / 10 minutes, and (c) a polypropylene resin with a melt tension of at least 30 mN and less than 98 mN and a melt flow rate of 2 to 15 g / 10 minutes, formed by positioning in a mold a softened cylindrical foam having a foam layer obtained by extruding from the die of an extruder a foamable molten resin composition containing a foaming agent, wherein the melt tension at 230° C. of the polypropylene resin that forms the foam layer is at least 10 mN and less than 49 mN, and the apparent density of the foam layer is no more than 0.3 g / cm3.

Owner:IMANARI DAISUKE +3

Semiaromatic polyamide, semiaromatic polyamide resin composition, and molded article

ActiveUS20150329670A1High melt tensionReduce crystallinityFilm/foil adhesivesPolyamideCarboxylic acid

To provide: a semiaromatic polyamide which has excellent moldability, heat resistance, chemical resistance and mechanical characteristics; and a molded article of this semiaromatic polyamide. A semiaromatic polyamide (I) of the present invention contains 35-50% by mole of a structural unit derived from terephthalic acid [A], 25-40% by mole of a structural unit derived from isophthalic acid [B], 15-35% by mole of a structural unit derived from an aliphatic dicarboxylic acid [C] (provided that the total of [A], [B] and [C] is 100% by mole), and a structural unit derived from an aliphatic diamine [D] having 4-12 carbon atoms. The molar ratio ([A] / [B]) is from 65 / 35 to 50 / 50, and the molar ratio ([C] / [B]) is from 30 / 70 to 50 / 50. The melting enthalpy ([increment]H) of the semiaromatic polyamide (I) as determined by differential scanning calorimetry (DSC) is 20-40 mJ / mg, and the intrinsic viscosity of the semiaromatic polyamide (I) is 0.7-1.6 dl / g.

Owner:MITSUI CHEM INC

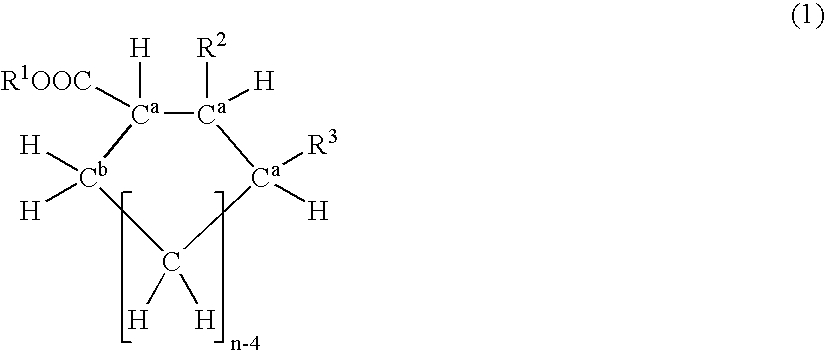

Process for Producing Olefin Polymer and Solid Titanium Catalyst Component

ActiveUS20080306228A1Reduce tensionLow costOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePtru catalyst

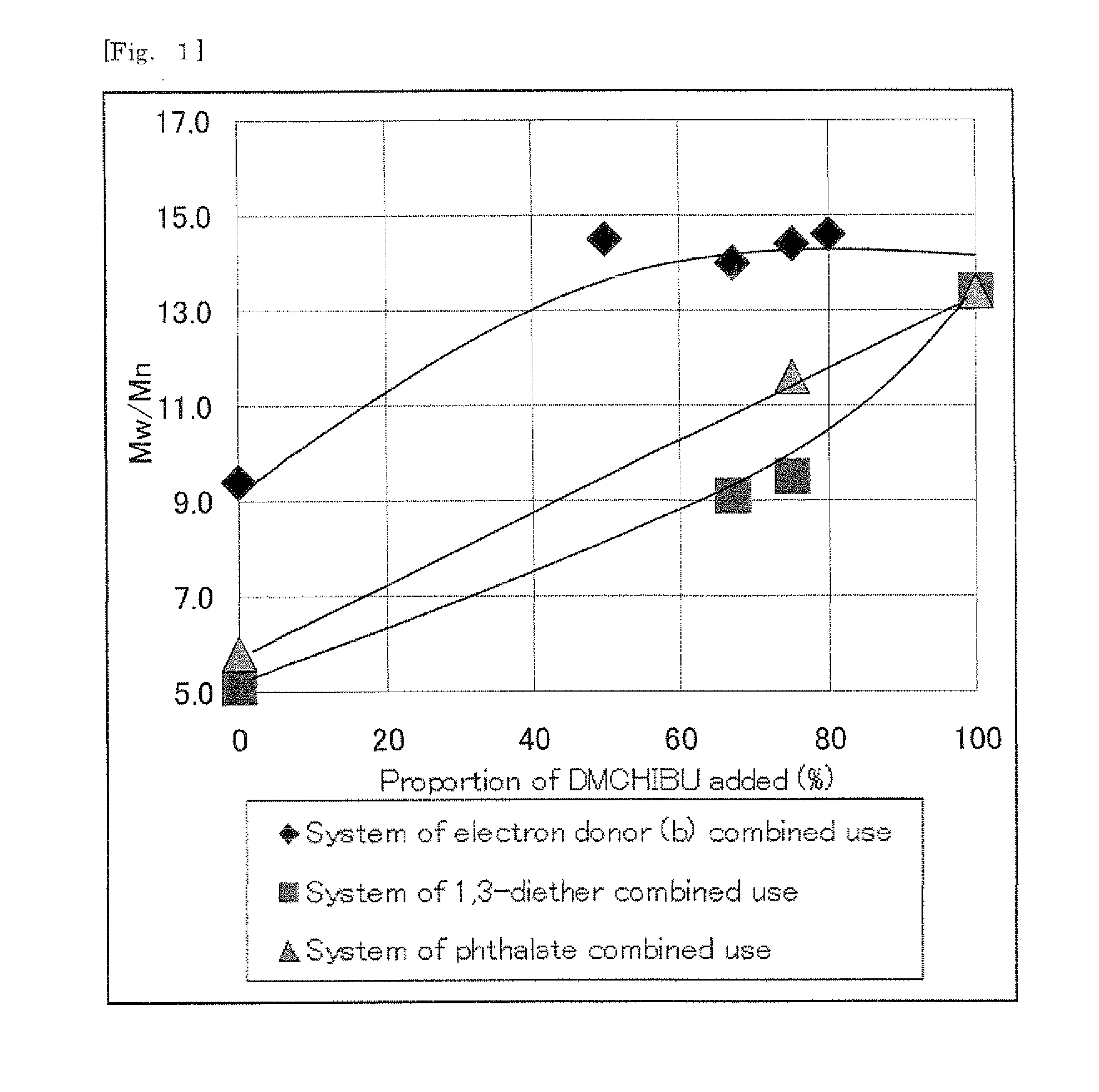

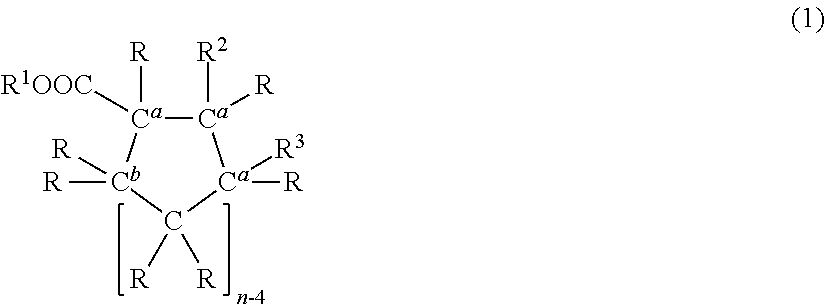

The process for producing an olefin polymer according to the present invention is characterized in that it comprises polymerizing an olefin having 3 or more carbon atoms in the presence of a catalyst for olefin polymerization containing a solid titanium catalyst component (I) which contains titanium, magnesium, halogen, and a cyclic ester compound (a) specified by the following formula (1):wherein n is an integer of 5 to 10,R2 and R3 are each independently COOR1 or a hydrogen atom, and at least one of R2 and R3 is COOR1; and R1's are each independently a monovalent hydrocarbon group having 1 to 20 carbon atoms, anda single bond (excluding Ca—Ca bonds, and a Ca—Cb bond in the case where R3 is a hydrogen atom) in the cyclic backbone may be replaced with a double bond, andan organometallic compound catalyst component (II),at an internal pressure of the polymerization vessel which is 0.25 times or more as high as the saturation vapor pressure of the olefin at a polymerization temperature.According to this process, an olefin polymer having a broad molecular weight distribution can be prepared.

Owner:MITSUI CHEM INC

Polypropylene resin compositions having high melt tension and method for preparing the same

InactiveUS20110245425A1Excellent long side-chain introduction capabilityHigh melt tensionPolymer sciencePolypropylene

Disclosed herein are a polypropylene resin composition having excellent melt tension and a method for preparing the same. More particularly, a high melt tension polypropylene resin composition prepared by stepwise reaction of existing polypropylene resin with at least two organic peroxides having different half-life distributions, as well as a method for preparation thereof are described.

Owner:LOTTE CHEM CORP

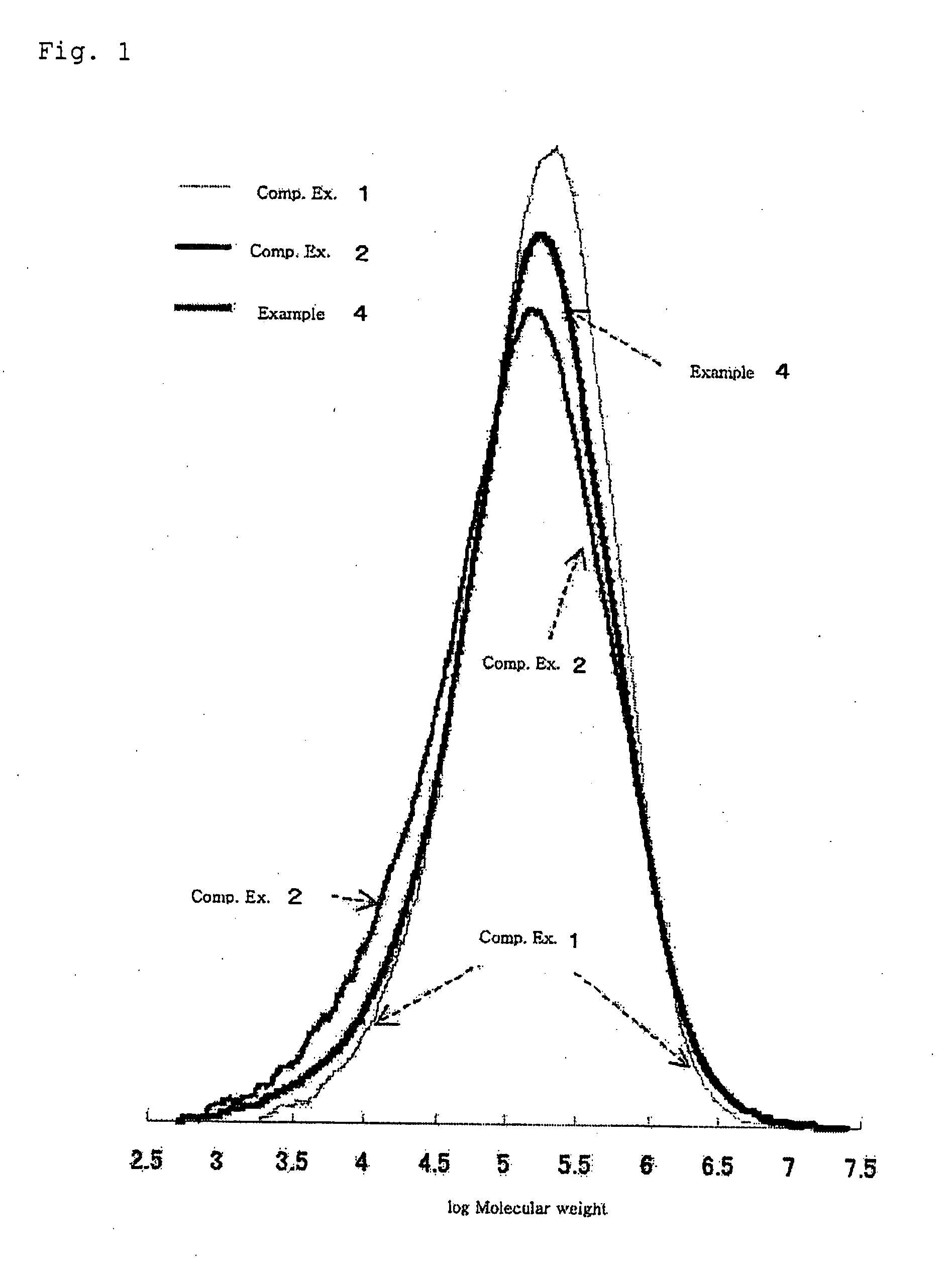

Propylene-based polymer, production method therefor, composition using the same, and application thereof

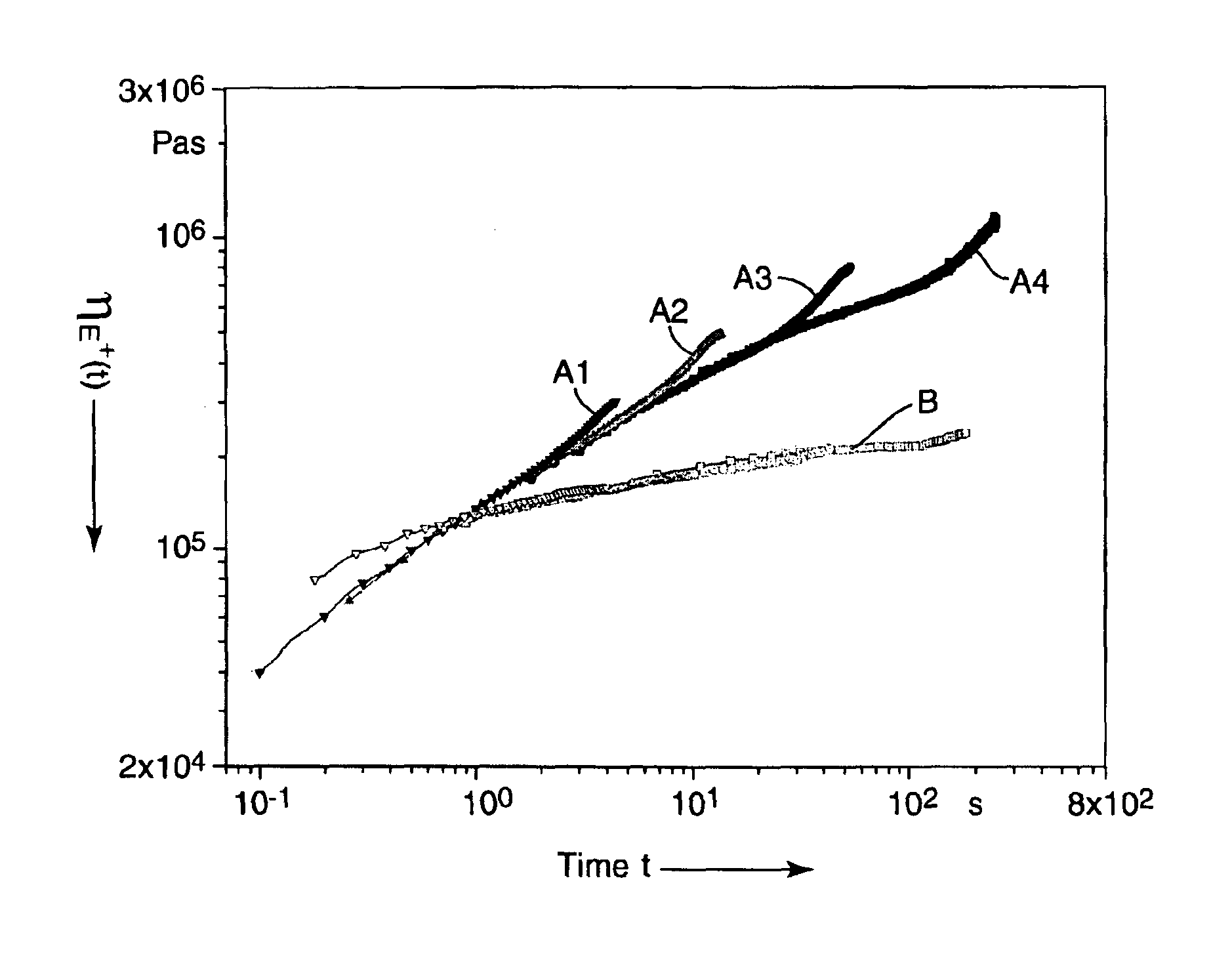

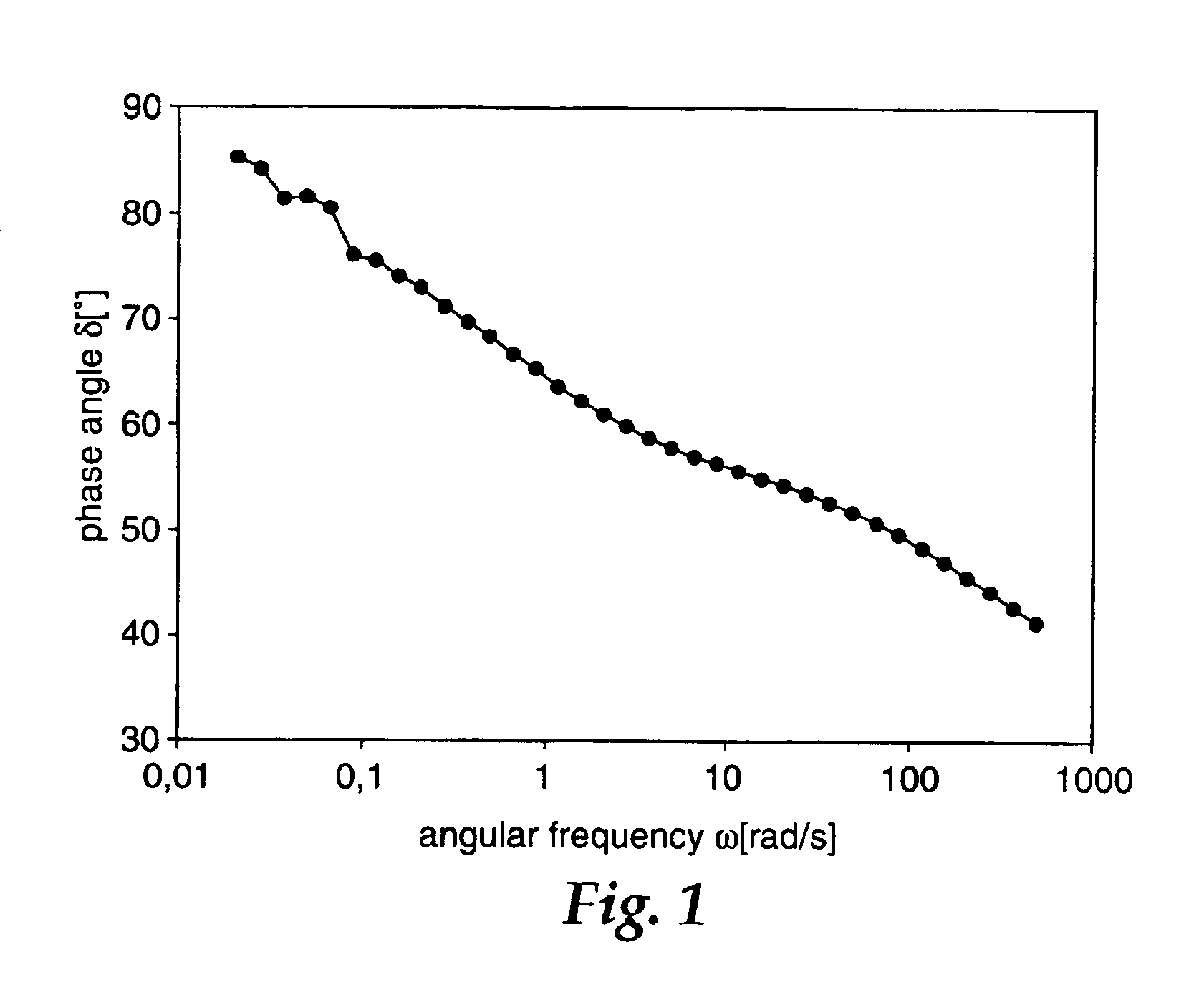

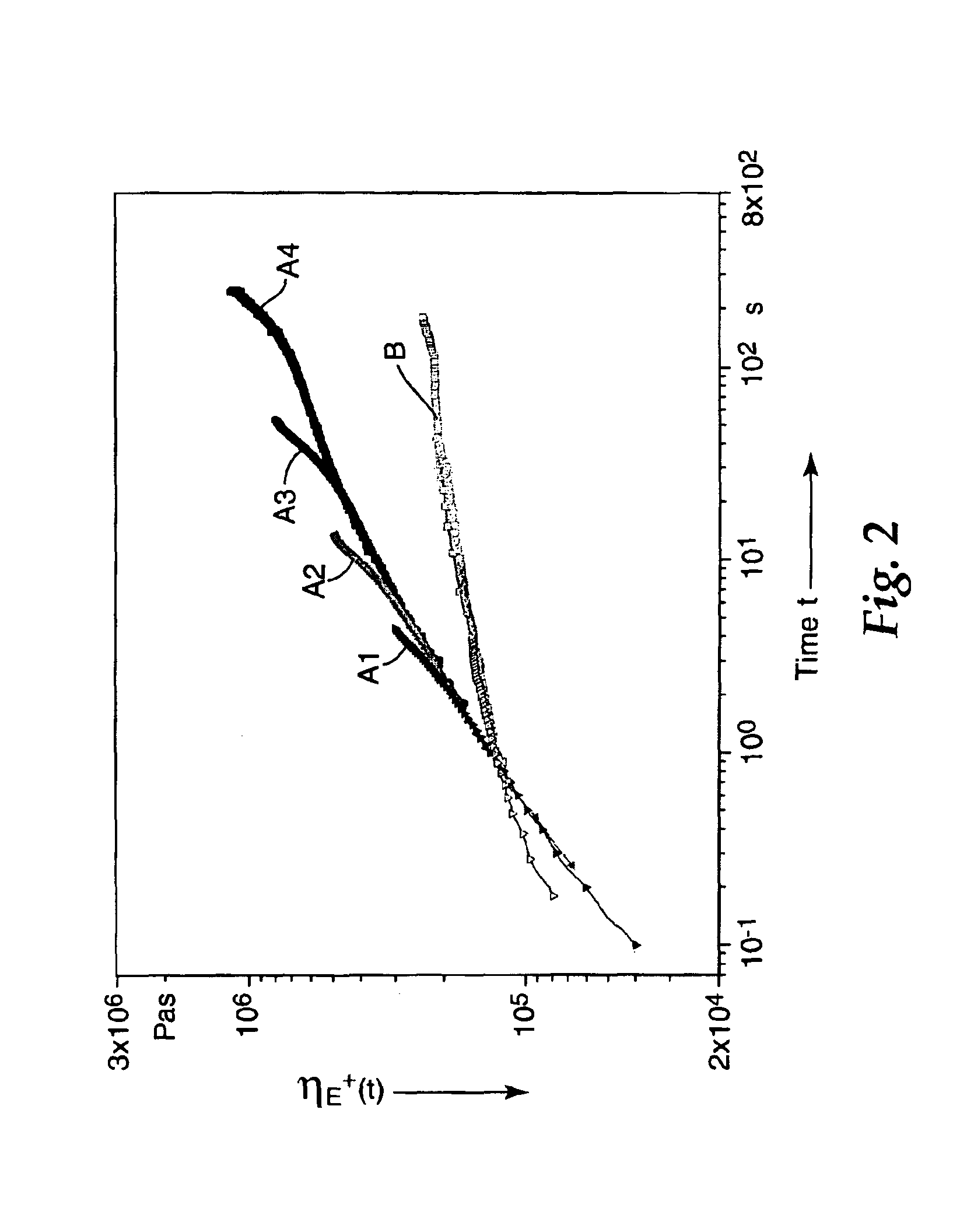

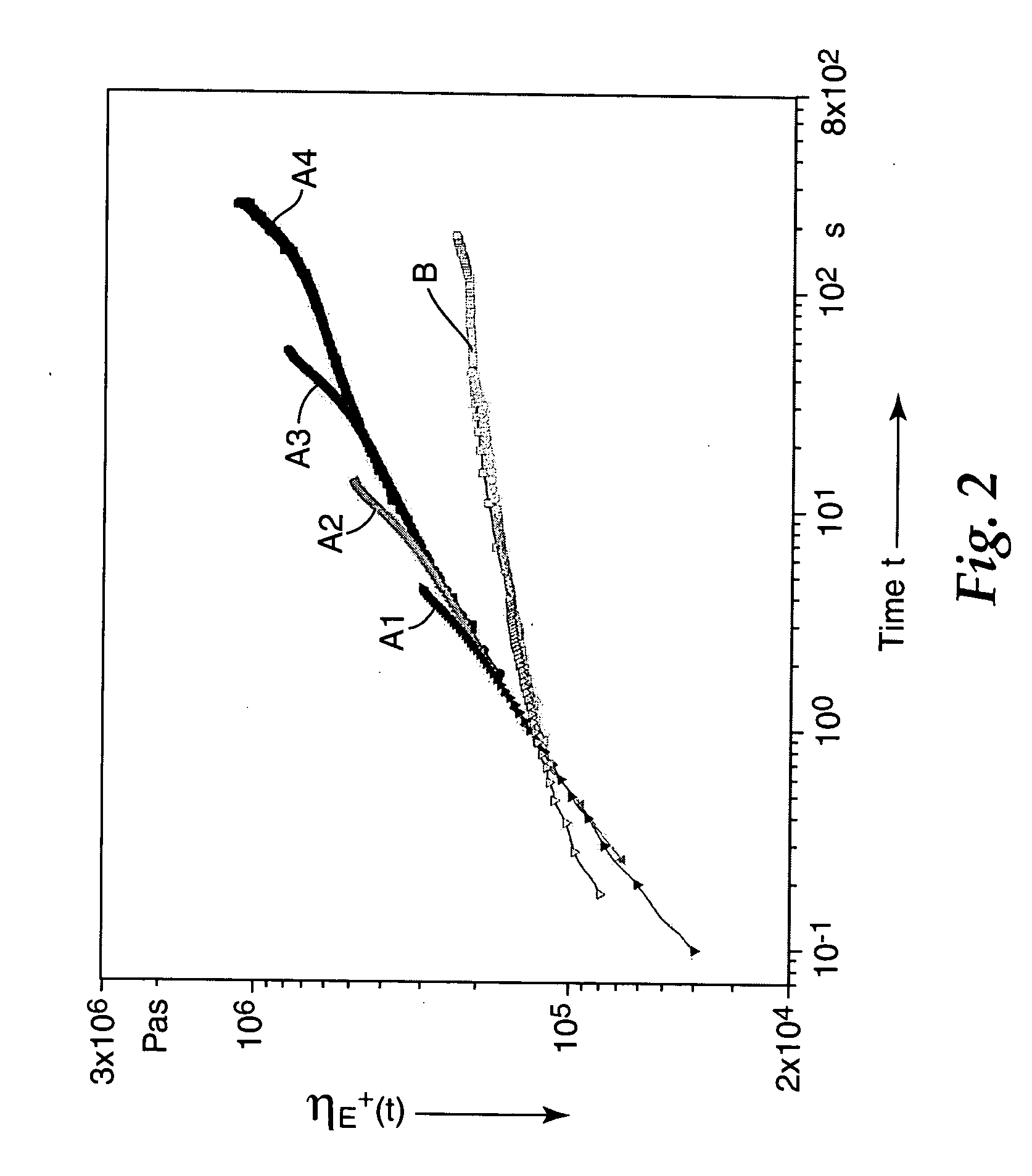

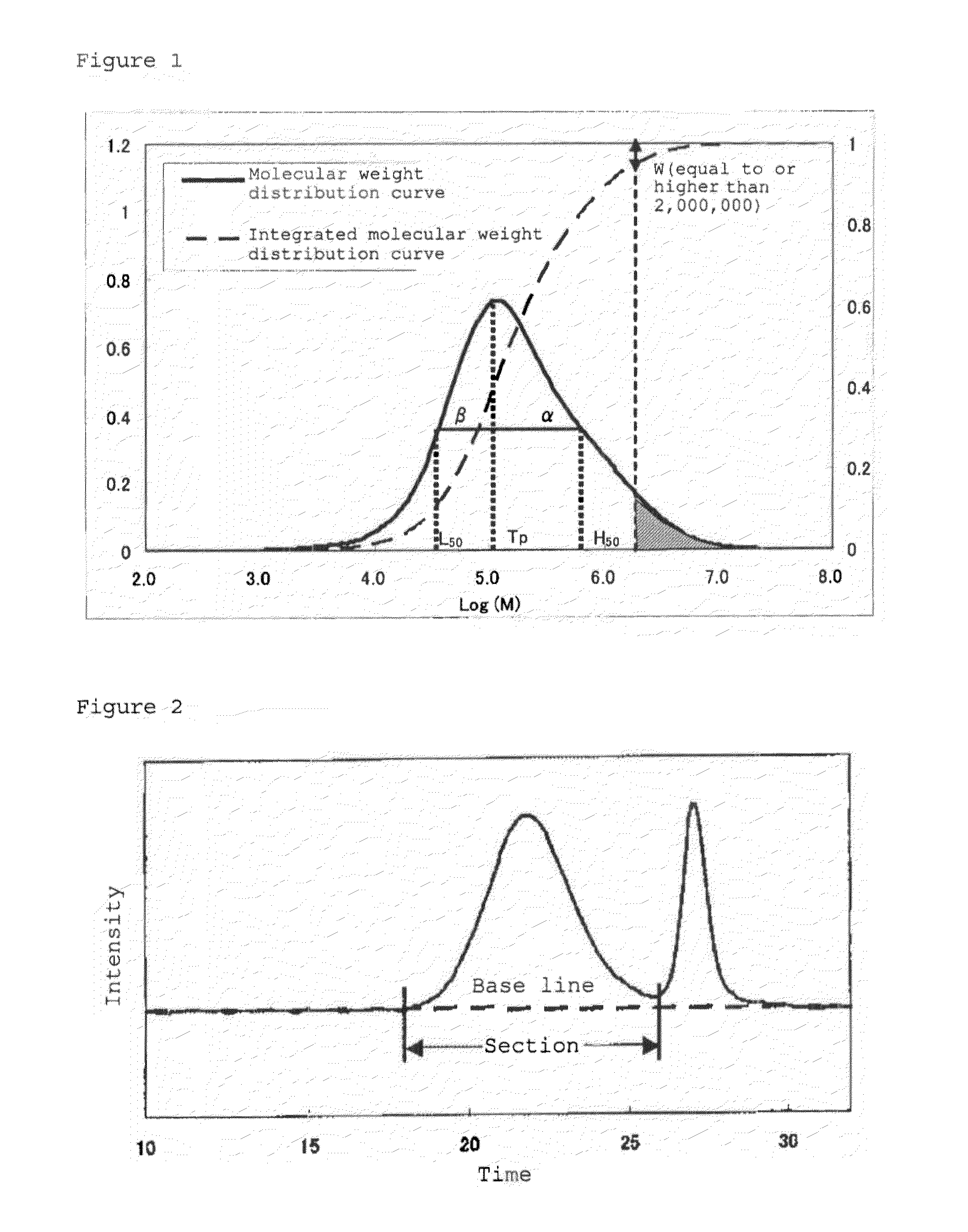

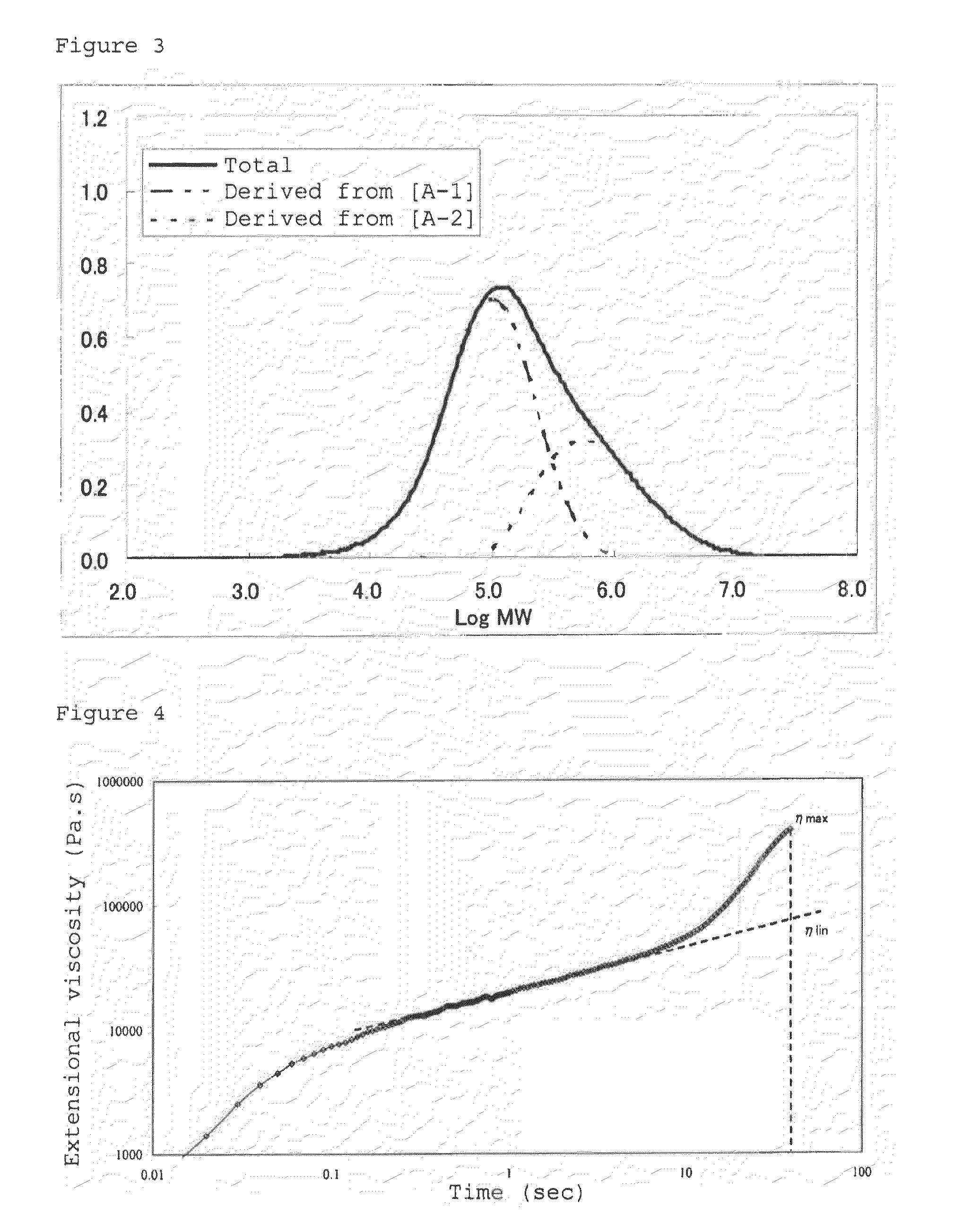

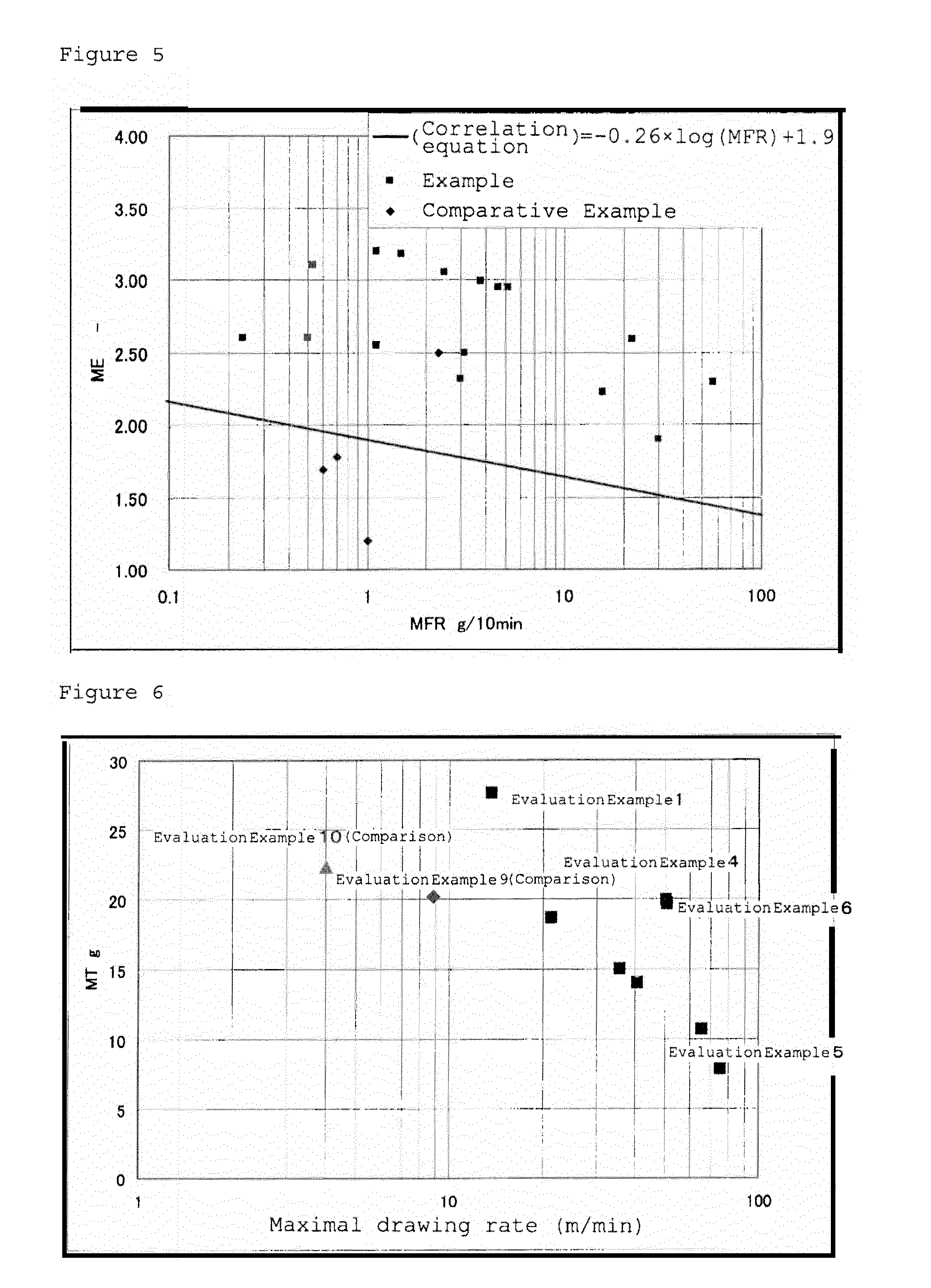

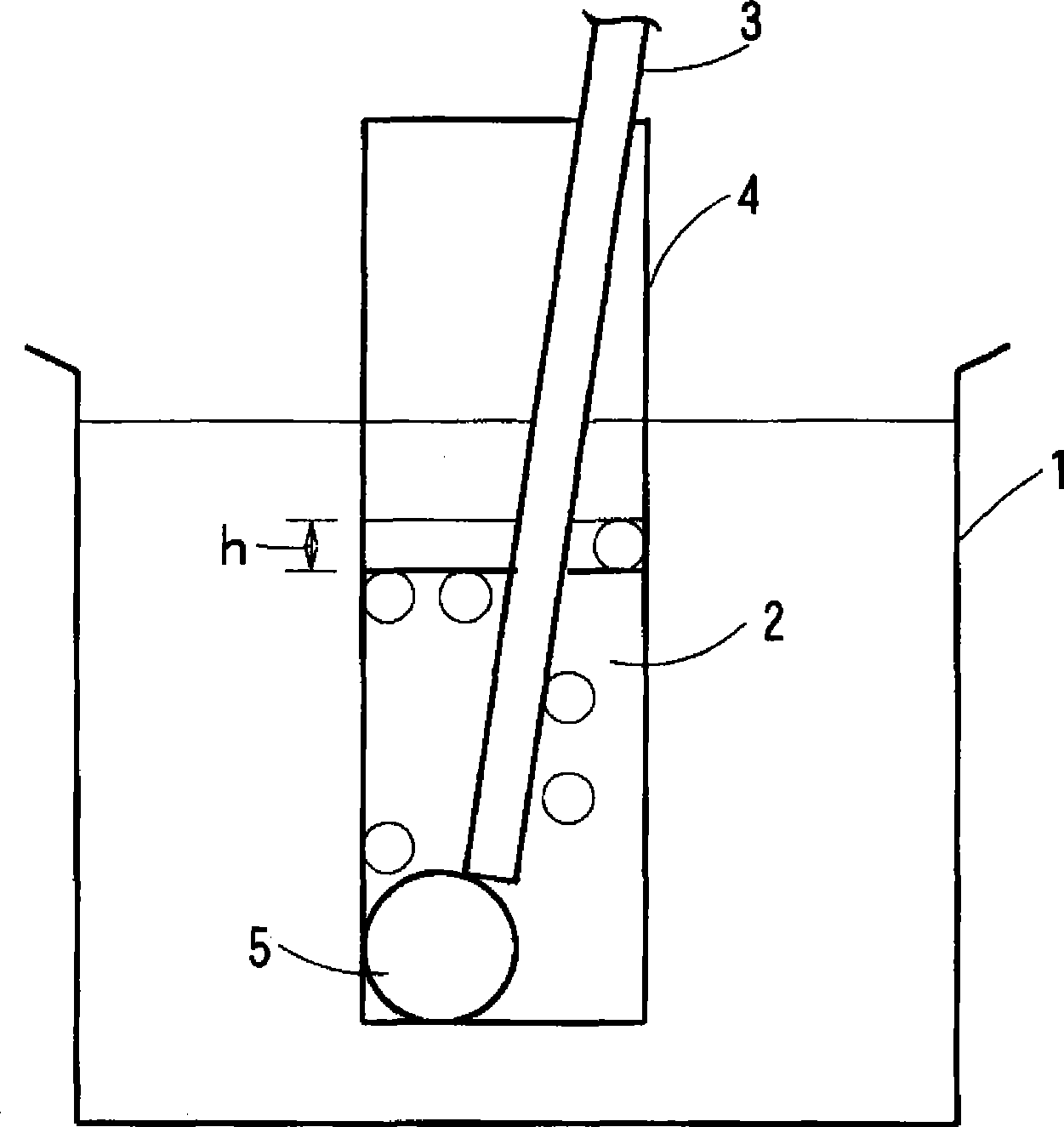

ActiveUS8080624B2High melt tensionImprove liquidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationBlow moldingExtensional viscosity

A propylene-based polymer which is suitably applicable to foam molding, sheet molding, blow molding or the like, because of having good flow characteristics, high melt tension, high swell ratio and thus good molding workability.It is attained by a propylene-based polymer or the like characterized by satisfying the following requirements (i) to (vi).Requirement (i): MFR is 0.1 g / 10 minutes to 100 g / 10 minutes.Requirement (ii): Q value by GPC is 3.5 to 10.5.Requirement (iii): ratio of components with a molecular weight of equal to or higher than 2,000,000, in a molecular weight distribution curve obtained by GPC, is equal to or larger than 0.4% by weight and less than 10% by weight.Requirement (iv): components, which elute at a temperature of equal to or lower than 40° C., are equal to or less than 3.0% by weight, in temperature rising elution fractionation by ODCB.Requirement (v): isotactic triad fraction (mm) measured with 13C-NMR is equal to or higher than 95%.Requirement (vi): strain hardening degree (λmax), in measurement of extensional viscosity, is equal to or higher than 6.0.

Owner:JAPAN POLYPROPYLENE CORP

Ethylene-tetrafluoroethylene copolymer

ActiveUS20100204423A1High melt tensionExcellent in blow moldability moldabilityOrganic compound preparationHalogenated hydrocarbon preparationTetrafluoroethylenePolymer science

To provide an ETFE-type copolymer having a high melt tension and excellent blow moldability.An ethylene-tetrafluoroethylene copolymer which comprises ethylene units, tetrafluoroethylene units and units of a monomer (A) having at least two copolymerizable double bonds and which has a ratio (X / W) of its melt tension (XmN) to a load (Wkg) applied for the measurement of the melt tension being at least 0.8.

Owner:ASAHI GLASS CO LTD

Water-soluble polyvinyl alcohol resin fiber and nonwoven fabric made by using the same

ActiveCN101379230AGood water solubilityInhibitionMonocomponent synthetic polymer artificial filamentWoven fabricsSolubilityPolymer science

Owner:MITSUBISHI CHEM CORP

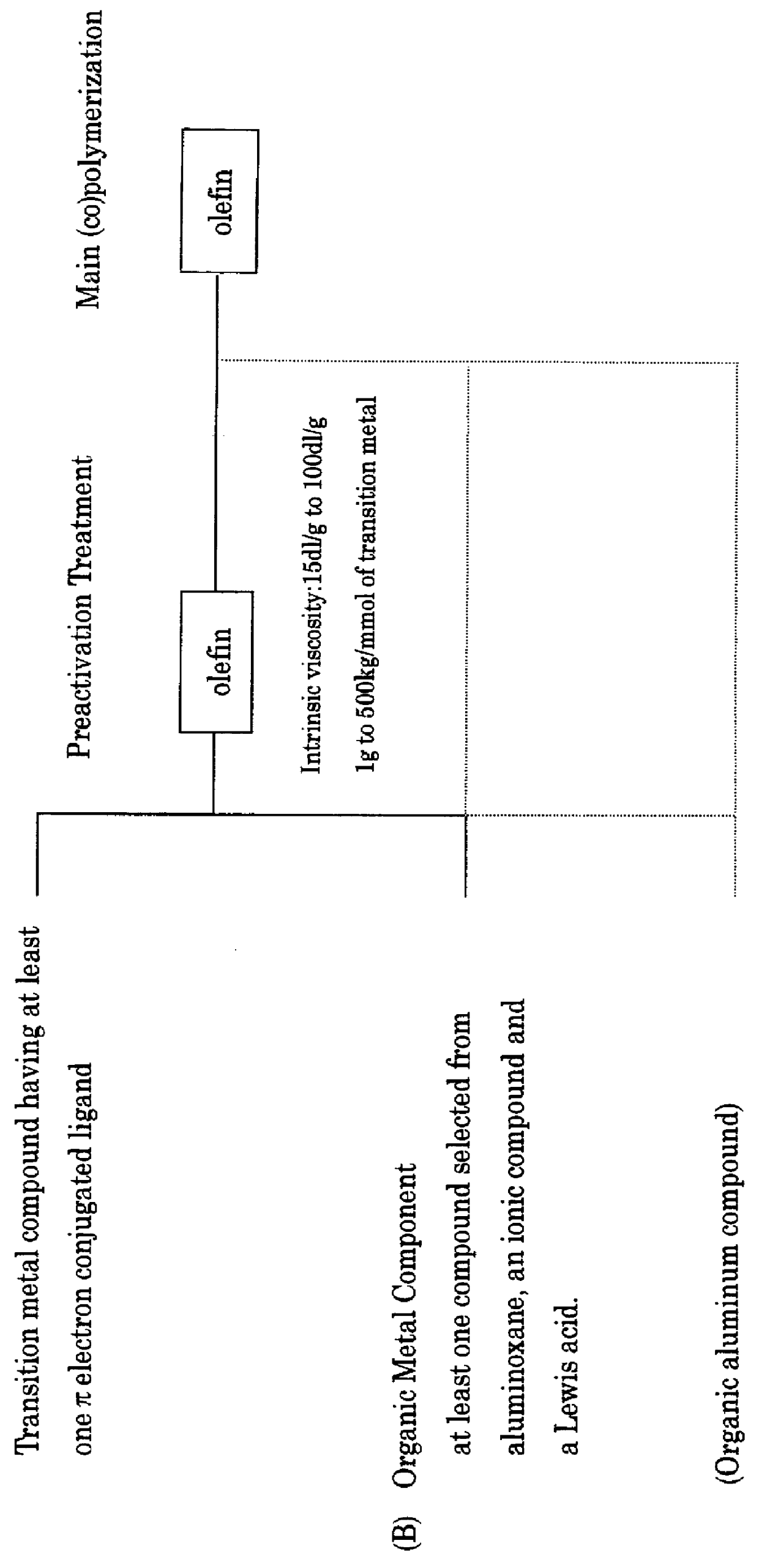

Preactivated catalyst for olefin (CO)polymer, catalyst for olefin (CO)polymerization, olefin (CO)polymer composition, and process for producing the same

InactiveUS6153710AHigh melt tensionImprove thermal stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceTetralin

PCT No. PCT / JP98 / 00534 Sec. 371 Date Sep. 22, 1998 Sec. 102(e) Date Sep. 22, 1998 PCT Filed Feb. 9, 1998 PCT Pub. No. WO98 / 35997 PCT Pub. Date Aug. 20, 1998An olefin (co)polymer composition comprising, as major components, (a) 0.01 to 5 parts by weight of an olefin (co)polymer having an intrinsic viscosity [ eta a] as measured in 135 DEG C. tetralin of 15 to 100 dl / g and (b) 100 parts by weight of an olefin (co)polymer obtained by using a metallocene catalyst and having an intrinsic viscosity [ eta b] as measured in 135 DEG C. tetralin of 0.2 to 10 dl / g. When polyethylene having a high degree of polymerization is produced before a so-called metallocene catalyst is used to polymerize, e.g., propylene in the presence of the polyethylene as a component of a catalyst composition, a polypropylene composition having a high melt tension and a high crystallization temperature is produced.

Owner:JNC CORP

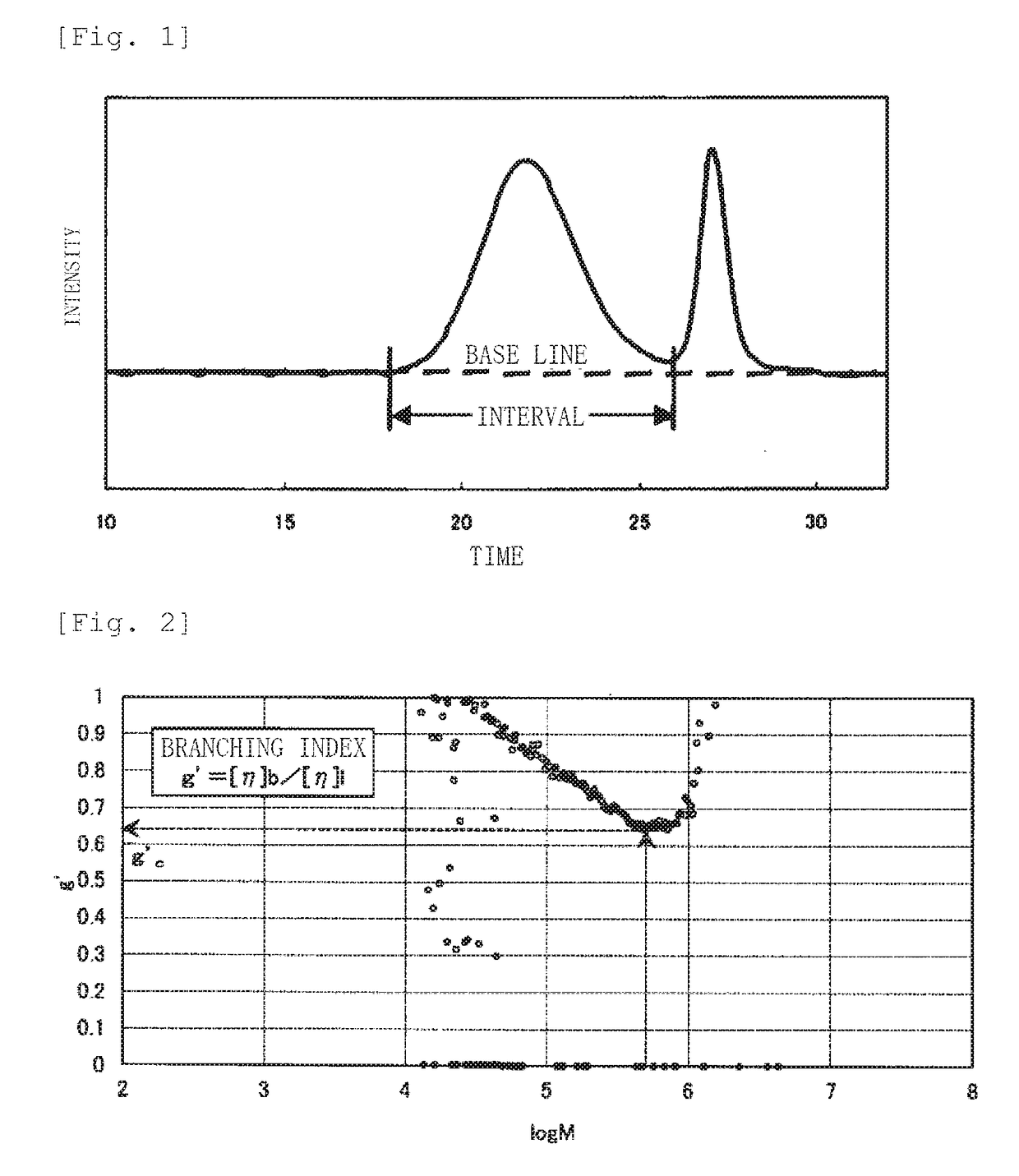

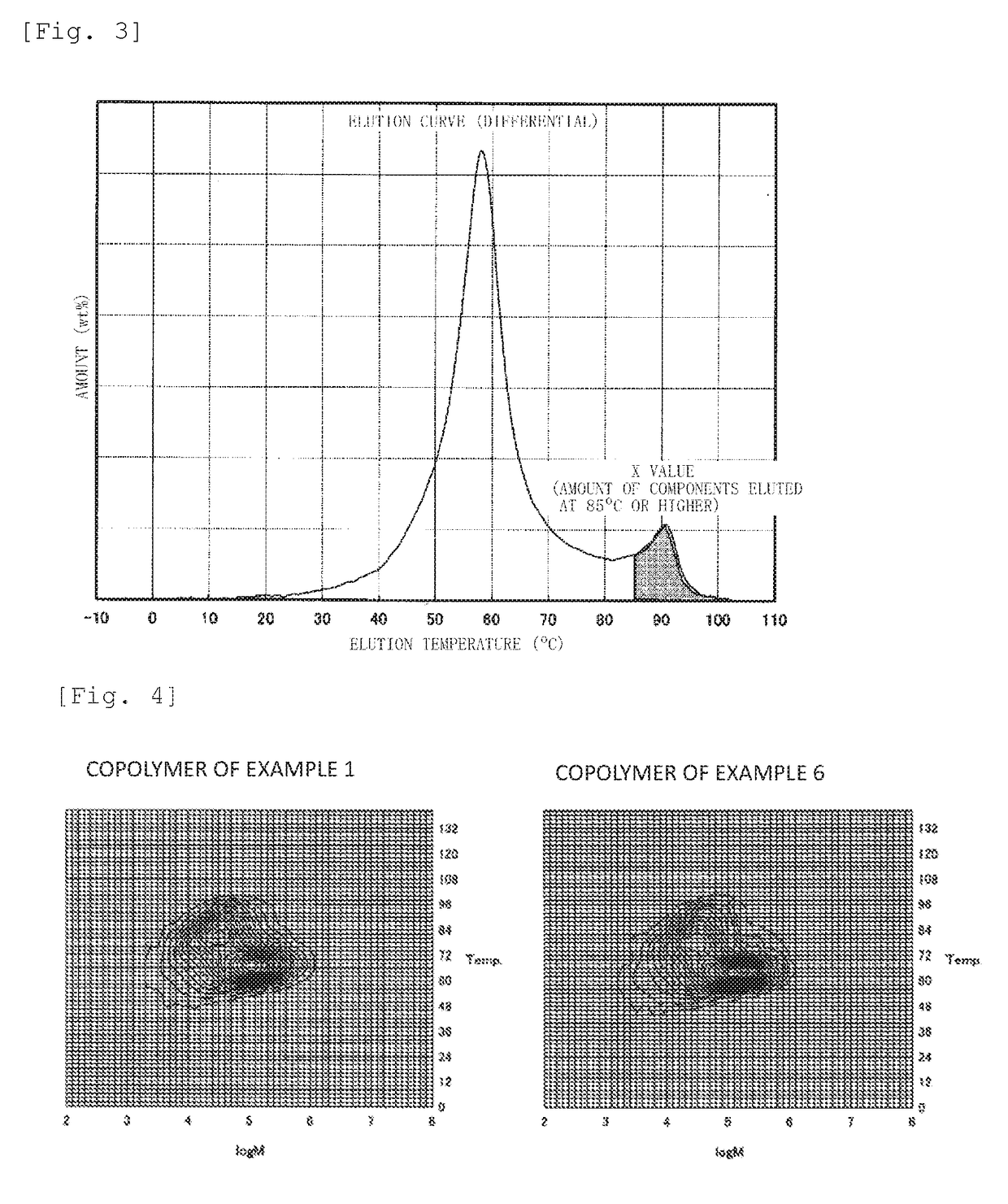

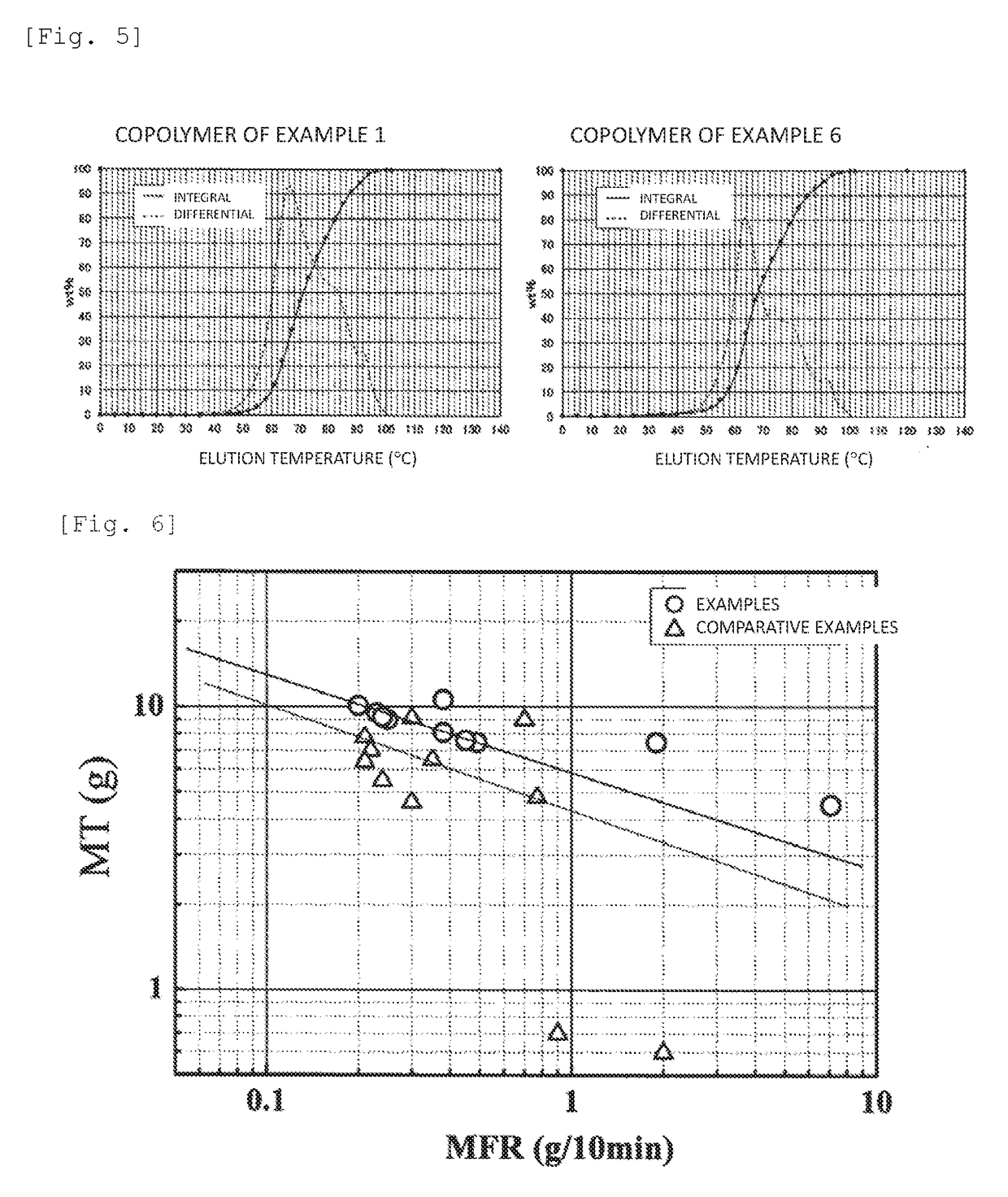

ETHYLENE-a-OLEFIN COPOLYMER AND OLEFIN RESIN COMPOSITION

[Problem] To provide an ethylene-α-olefin copolymer having high mechanical strength and good molding properties.[Solution] Provided is an ethylene-α-olefin copolymer having a specific MFR, a specific density, and a specific molecular weight distribution, containing a suitable amount of a long-chain branching structure characterized by a branching index, and having a specific composition distribution structure characterized by solvent fractionation behavior.

Owner:JAPAN POLYETHYLENE CORP

Thermoplastic fluororesin and its production process

To provide a process for producing a thermoplastic fluororesin having a high melt tension and being excellent in blow moldability, etc.A process for producing a thermoplastic fluororesin comprising a fluoropolymer having a branched structure, which comprises a step of polymerizing a monomer (A) having a radical generating group (x) and an addition polymerizable double bond, and a monomer (B), under polymerization conditions under which the radical generating group (x) is not decomposed, to produce a fluoropolymer (X), and a step of polymerizing a monomer (C) in the presence of the fluoropolymer (X) under polymerization conditions under which the radical generating group (x) is decomposed, to form a fluoropolymer (Y) having a branched structure (provided that each of the monomer (B) and the monomer (C) comprises one or more monomers having an addition polymerizable double bond, at least one of the monomers having an addition polymerizable double bond being a fluoromonomer, and is such a monomer that a polymer of only the monomer is a crystalline fluoropolymer; and the monomer (B) and the monomer (C) may be the same).

Owner:ASAHI GLASS CO LTD

Polypropylene based resin composition, expanded moldings comprising the same and method for production thereof

ActiveCN1845964AImprove liquidityHigh melt tensionThin material handlingPolypropylenePolymer chemistry

A polypropylene based resin composition for injection expansion molding, which comprises (A) 50 to 95 parts by weight of a linear polypropylene based resin having a melt flow rate of 10 g / 10 min to 100 g / 10 min and a melt tension of 2 cN or less, (B) 5 to 50 parts by weight of a modified polypropylene based resin having a melt flow rate of 0.1 g / 10 min or more and less than 10 g / 10 min and a melt tension of 5 cN or more and exhibiting the strain hardening property (provided that the sun of the linear polypropylene based resin (A) and the linear polypropylene based resin (B) is 100 parts by weight); expanded moldings comprising the resin composition; and a method for producing said expanded moldings. Said expanded moldings are produced along with good injection expansion molding properties and comprises a skin layer having a surface being almost free of silver streaking or the like and an inner core layer being expanded in a high expansion ratio and having uniform and fine pores, and further is excellent in appearance, lightweight property and rigidity.

Owner:KANEKA CORP

Semiaromatic polyamide, semiaromatic polyamide resin composition, and molded article

To provide: a semiaromatic polyamide which has excellent moldability, heat resistance, chemical resistance and mechanical characteristics; and a molded article of this semiaromatic polyamide. A semiaromatic polyamide (I) of the present invention contains 35-50% by mole of a structural unit derived from terephthalic acid [A], 25-40% by mole of a structural unit derived from isophthalic acid [B], 15-35% by mole of a structural unit derived from an aliphatic dicarboxylic acid [C] (provided that the total of [A], [B] and [C] is 100% by mole), and a structural unit derived from an aliphatic diamine [D] having 4-12 carbon atoms. The molar ratio ([A] / [B]) is from 65 / 35 to 50 / 50, and the molar ratio ([C] / [B]) is from 30 / 70 to 50 / 50. The melting enthalpy ([increment]H) of the semiaromatic polyamide (I) as determined by differential scanning calorimetry (DSC) is 20-40 mJ / mg, and the intrinsic viscosity of the semiaromatic polyamide (I) is 0.7-1.6 dl / g.

Owner:MITSUI CHEM INC

Chemical foaming polyethylene composition, preparation method and applications thereof

InactiveCN106947153AHigh foamingImprove mechanical propertiesPlastic/resin/waxes insulatorsLow-density polyethyleneFoaming agent

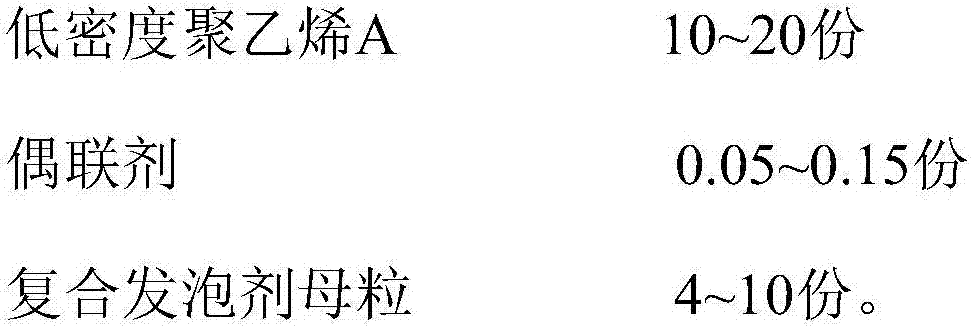

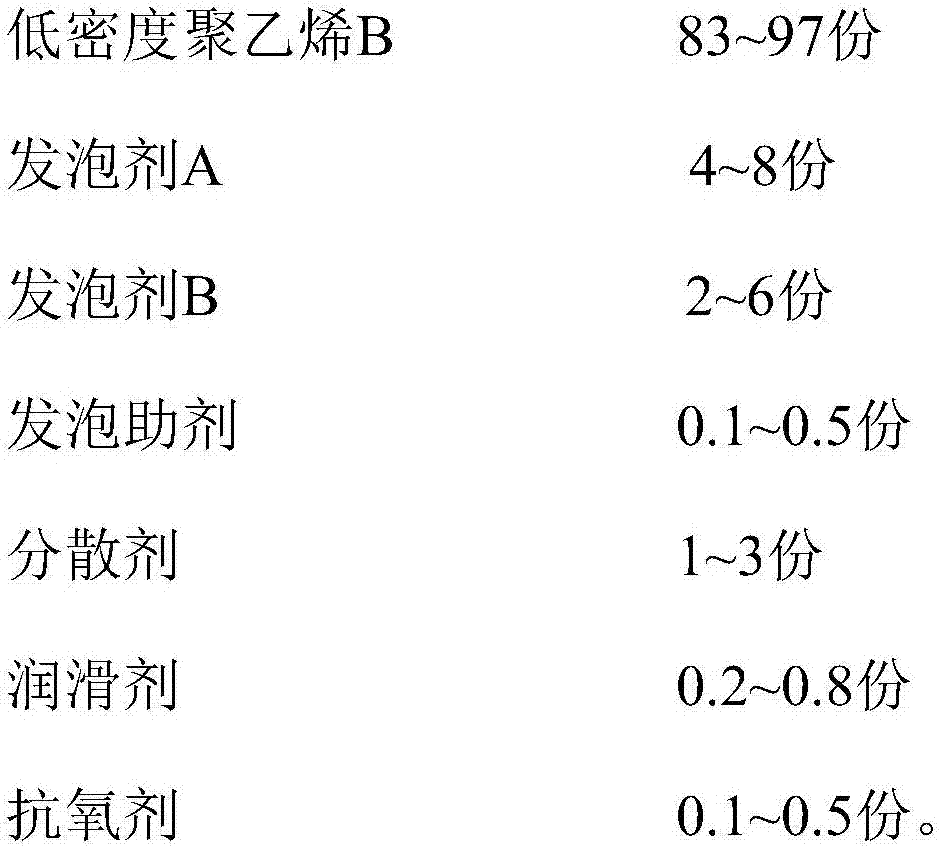

The present invention discloses a chemical foaming polyethylene composition, a preparation method and applications thereof, wherein the chemical foaming polyethylene composition is prepared from the following components by weight: 70-86 parts of high-density polyethylene, 10-20 parts of low-density polyethylene A, 0.05-0.15 part of a coupling agent, and 4-10 parts of composite foaming agent master batch. According to the present invention, the chemical foaming polyethylene composition retains the high foaming degree of the low-density polyethylene foaming material and the good mechanical property of the high-density polyethylene chemical foaming material so as to obtain the foaming insulation layer having the good electrical property. Another purpose of the present invention is to provide the preparation method of the chemical foaming polyethylene composition, wherein the preparation method is simple and is easy to operate. The present invention further provides uses of the chemical foaming polyethylene composition in preparation of communication cables.

Owner:广州敬信高聚物科技有限公司

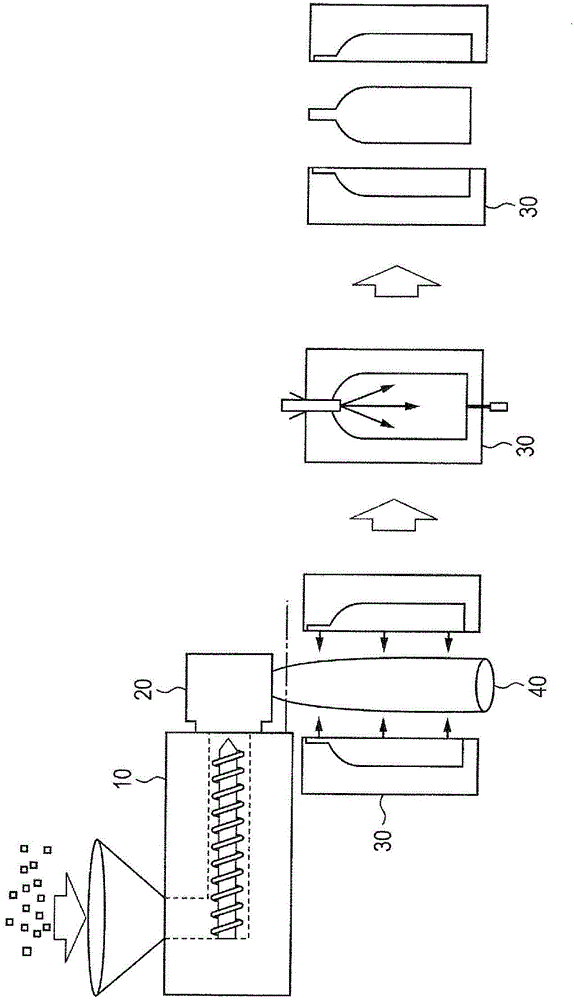

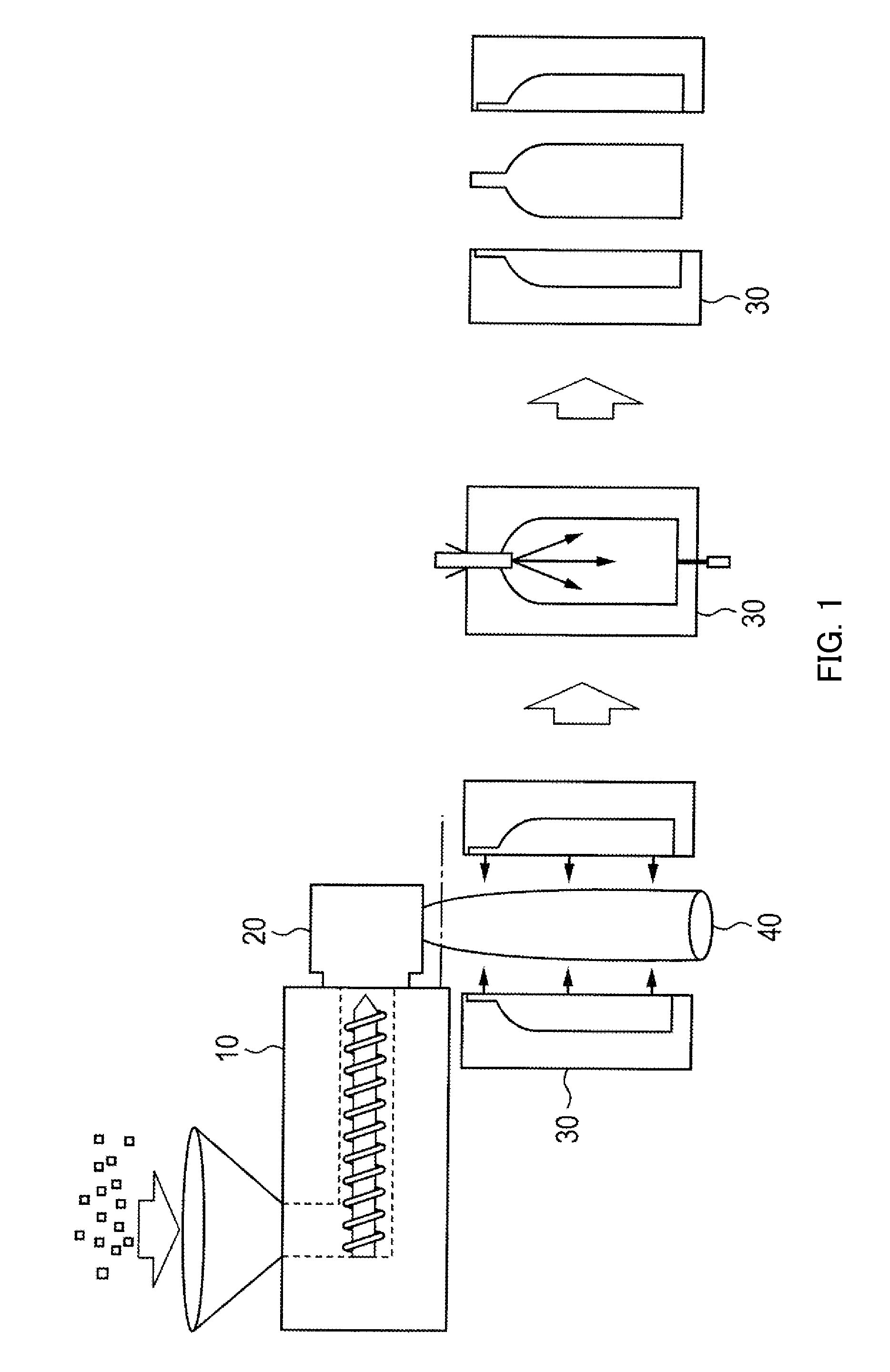

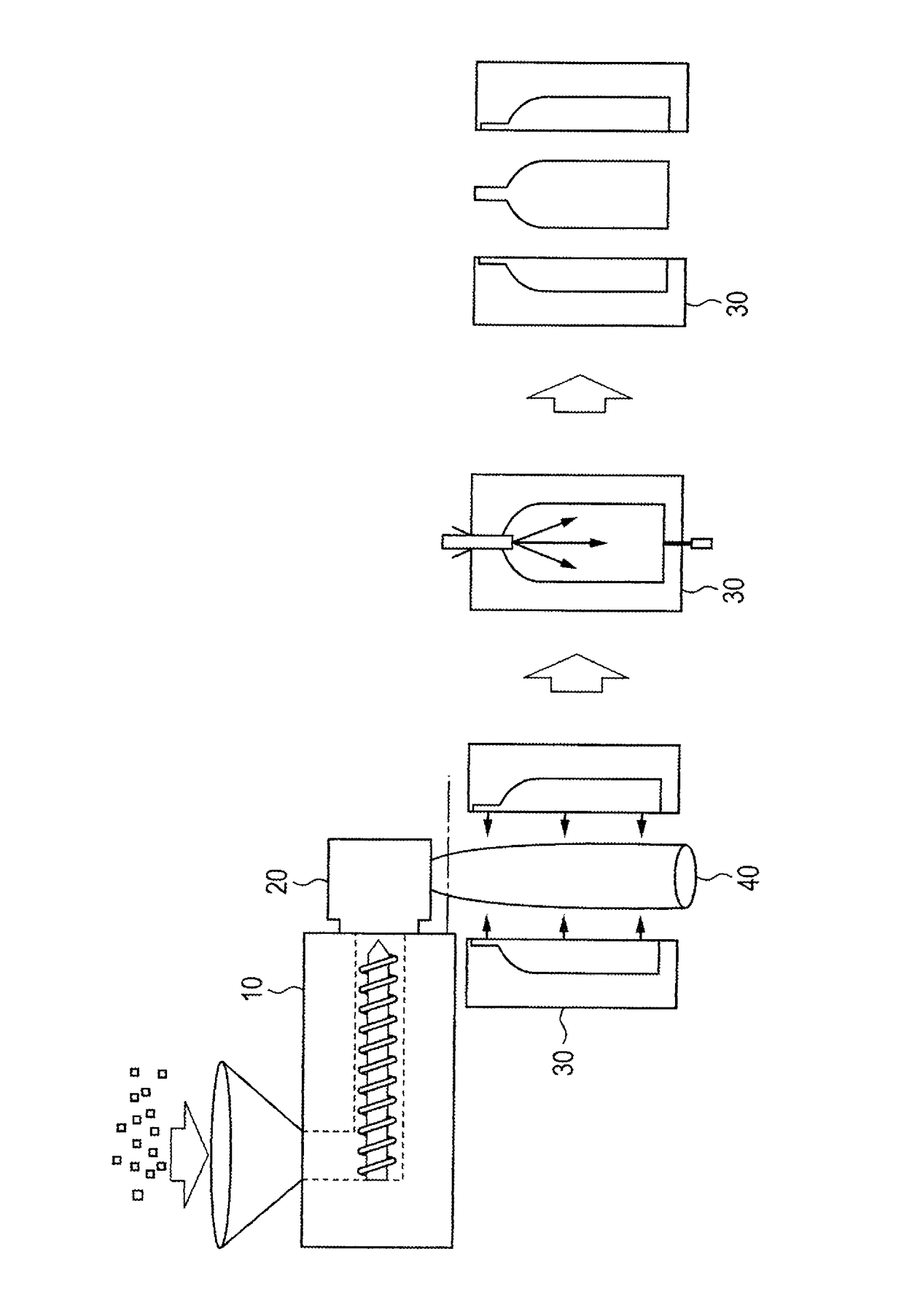

Heat-resistant food container, and manufacturing method for same

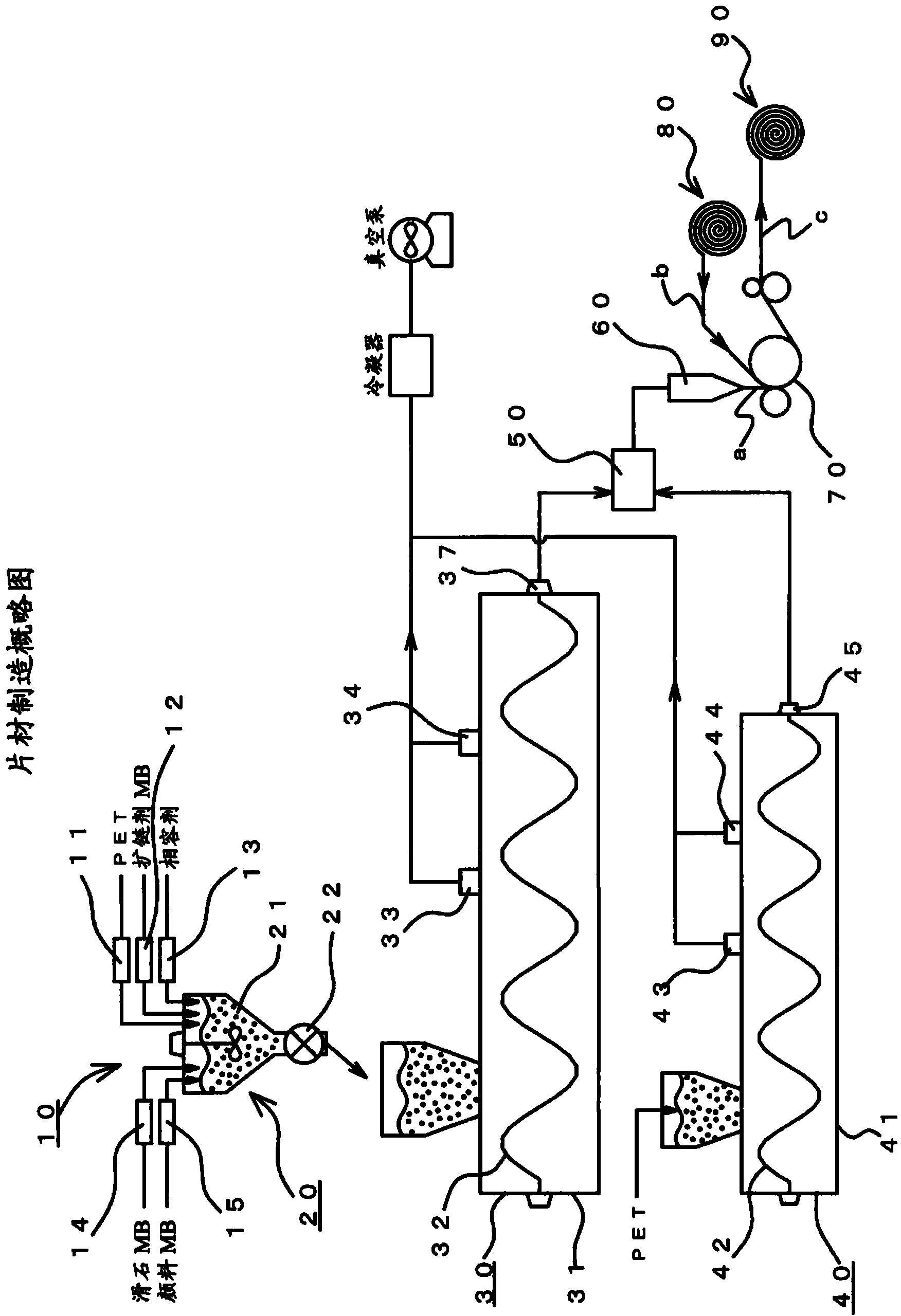

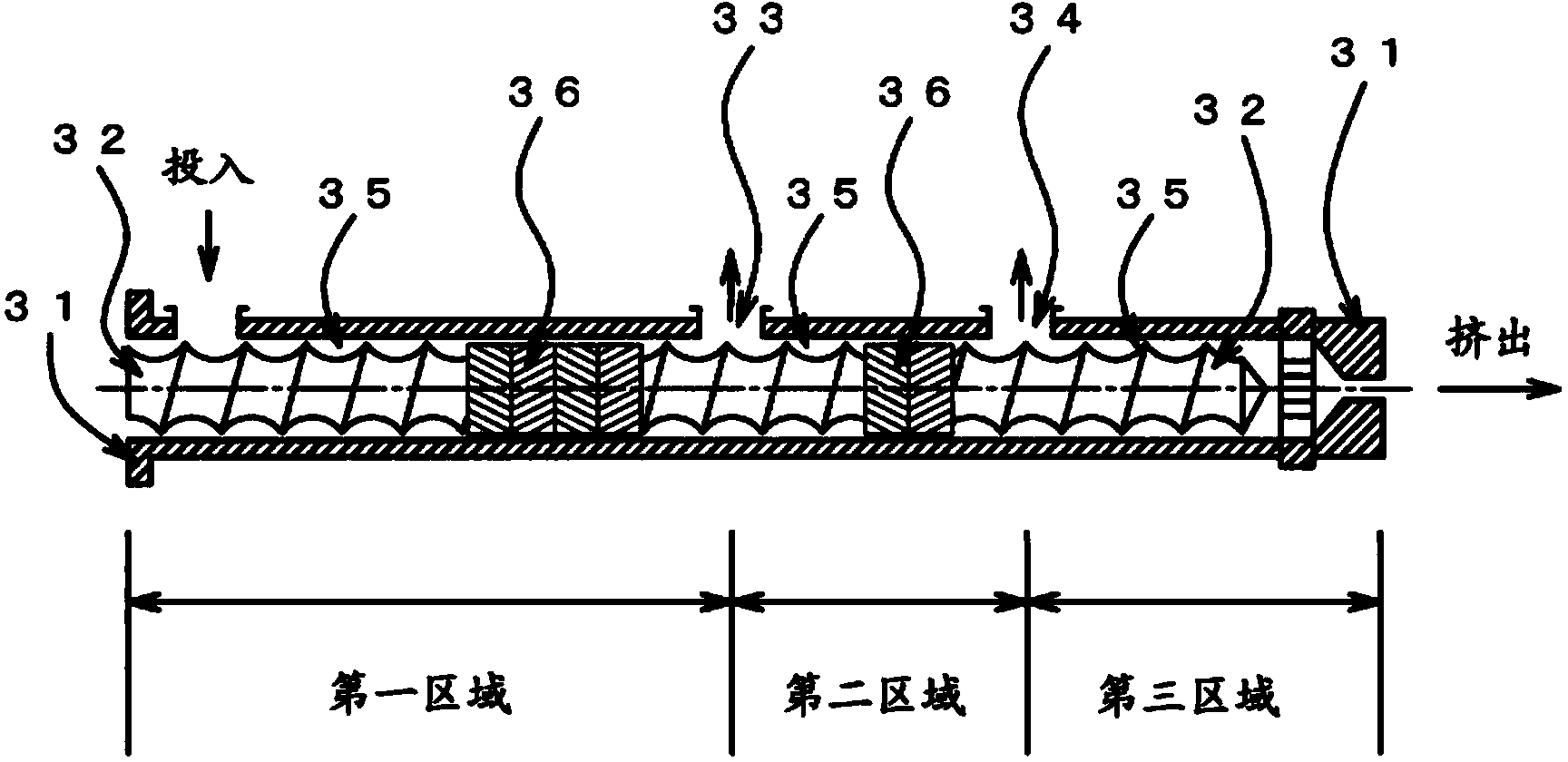

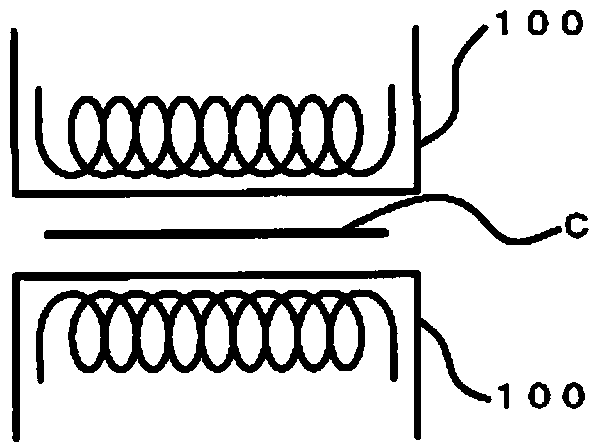

Provided is a heat-resistant food container that exhibits high heat resistance up to 250 DEG C and that can be manufactured inexpensively using low-cost standard PET resin, lower-cost PET resin for fibers and recycled PET flakes. The container is obtained by: adding a chain extender, a compatibilizer and talc to PET resin; introducing the same into an extruder (30) having at least 2 vent holes; suctioning / degassing the heated / molten PET resin using a high vacuum of at least -99.99kPa from the vent holes (33, 34), after which a sheet is formed by extrusion; vacuum / pressure forming the sheet using a thermoforming machine; and forming the container by retaining the formed product in a mold at 100-220 DEG C. The combined amount of the crystalline portion and the talc content of the container is at least 25%.

Owner:NAKAMOTO PAKKUSU

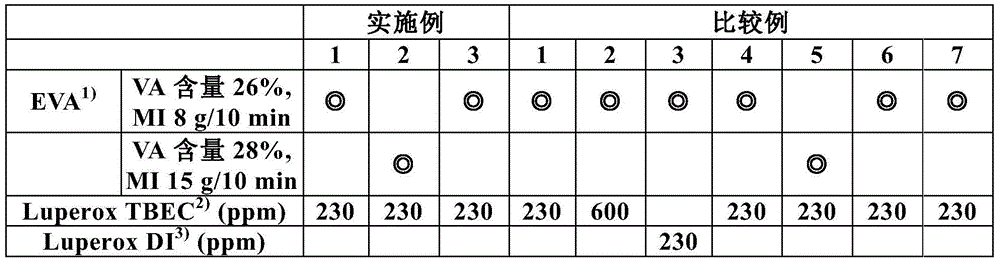

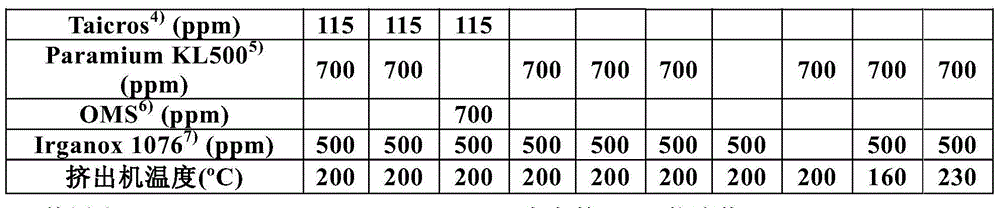

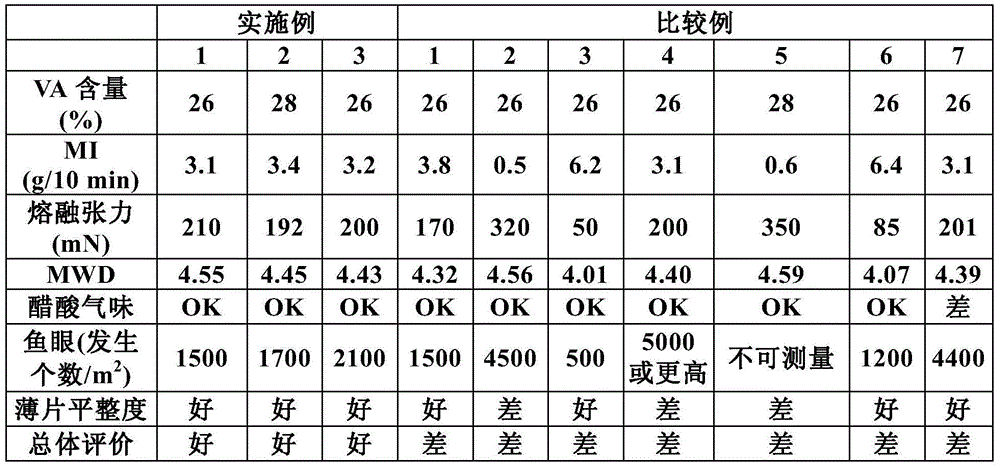

Composition used for preparing EVA copolymer, EVA copolymer and preparation method of EVA copolymer

The invention discloses a composition used for preparing an EVA copolymer cross-linked in trace amount, the EVA copolymer and a preparation method of the EVA copolymer. The composition comprises gel or fisheye which is provided with high fusion tension and lowest probability. The composition comprises 50-500 pm one kind or various kinds of organic peroxides which are selected from dialkyl peroxides crosslinking agent, alkyl group peroxy esters crosslinking agent and peroxy ketals crosslinking agent and have one-minute half-life period temperature of 130 DEG to 190 DEG C. the composition also comprises 50-250 ppm common crosslinking agent, 100-1500 pm diluents and 50-600 ppm antioxidant and ethylene-vinyl acetate (EVA) with melt index (MI) of 8-25g / 10min and with 26%-28wt% of vinyl acetate (VA).

Owner:HANWHA TOTAL ENERGIES PETROCHEMICAL CO LTD

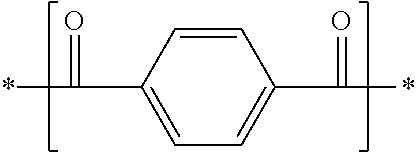

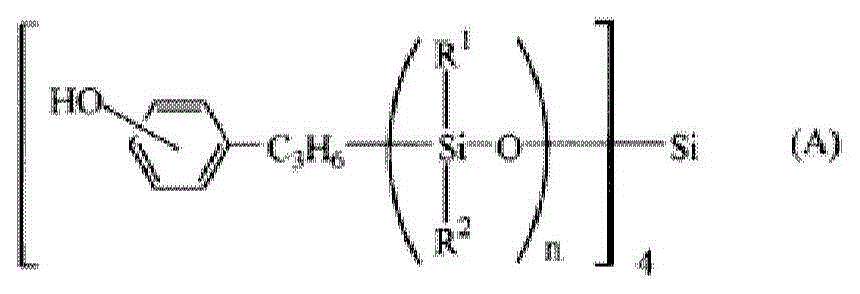

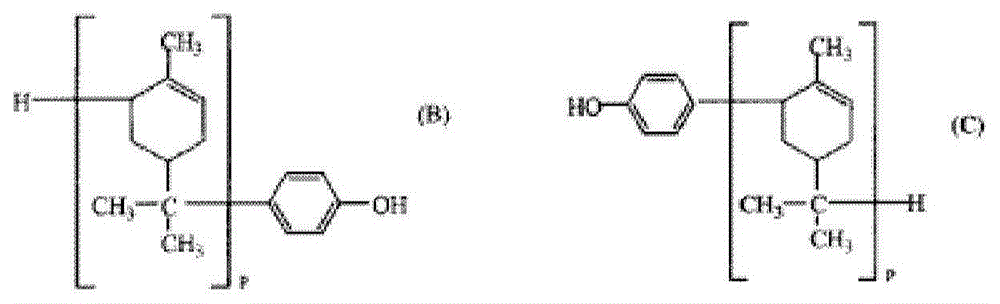

Colored aromatic polycarbonate resin composition, process for producing the same and colored hollow container

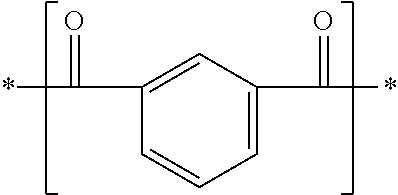

ActiveUS7511114B2High melt tensionImprove hydrolysis resistanceEnvelopes/bags making machinerySynthetic resin layered productsMolten stateHydrogen atom

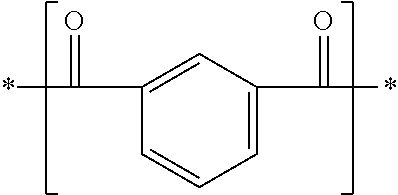

Colored aromatic polycarbonate resin compositions are prepared by dispersing a colorant (b) selected from phthalocyanine-based compounds, anthraquinone-based compounds and ultramarine blue in a polyalkyleneglycol compound (c) having a number-average molecular weight of 62 to 4000 of formula (2):HO—[—CHR1—CHR2—]m—OH (2)where R1, R2, R3 and R4 are independently hydrogen atoms or alkyl groups, and m is not less than 1. The dispersion is added to an aromatic polycarbonate resin (a) kept in a molten state which has a viscosity-average molecular weight of not less than 16000 and contains a branched constitutional unit of formula (1):in an amount of 0.3 to 0.95 mol % where X is a single bond, an alkylene group having 1 to 8 carbon atoms, an alkylidene group having 2 to 8 carbon atoms, a cycloalkylene group having 5 to 15 carbon atoms, a cycloalkylidene group having 5 to 15 carbon atoms, or a divalent connecting group —O—, —S—, —CO—, —SO— and —SO2—.

Owner:MITSUBISHI CHEM CORP

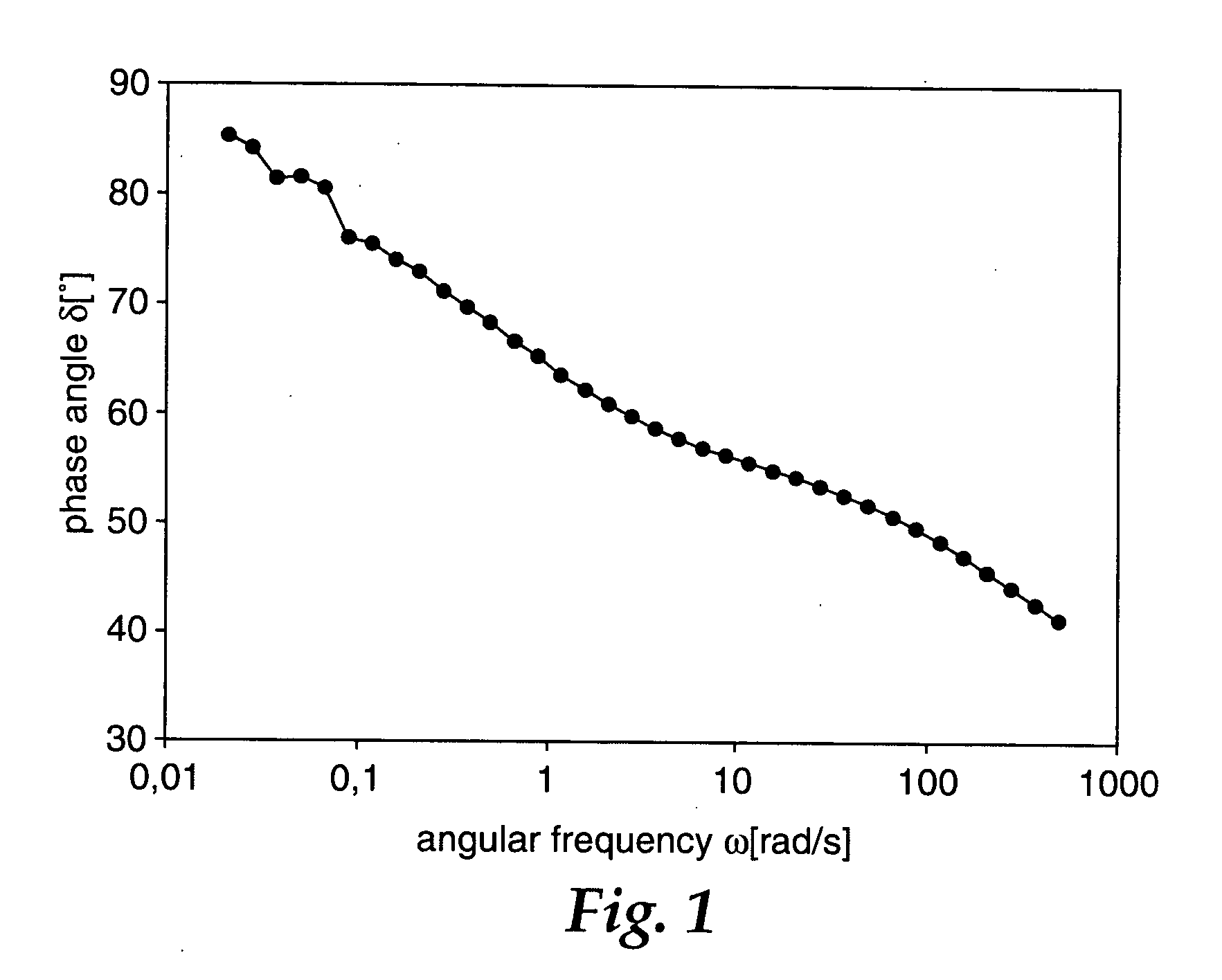

Ethylene-alpha-olefin copolymer and molded object thereof

ActiveUS8436101B2Short relaxation timeHigh melt tensionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSmall neckAlpha-olefin

The purpose of the invention is to provide an ethylene-α-olefin copolymer, which has a high melt tension but a small neck-in, and a molded object produced by extrusion molding of the copolymer. An ethylene-α-olefin copolymer having a monomer unit based on ethylene and a monomer unit based on an α-olefin having 3 to 20 carbon atoms, which has a melt flow rate (MFR) of 0.1 to 100 g / 10 min, a density (d) of 850 to 940 kg / m3, a ratio (Mw / Mn) of weight average molecular weight (Mw) to number average molecular weight (Mn) of 2 to 12, and a value g* defined by the following formula (I) of 0.50 to 0.75:g*=[η] / ([η]GPC×gSCB*) (I).

Owner:SUMITOMO CHEM CO LTD

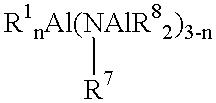

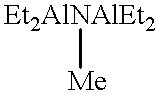

Graft modified ethylene alpha-olefin copolymer obtained by graft copolymerzing an ethylene/alpha-olefin copolymer with a polar monomer

A graft modified ethylene / alpha-olefin copolymer obtained by graft polymerizing an ethylene / alpha-olefin of 3 to 20 carbon atoms copolymerizing with a polar monomer in the presence of a catalyst for olefin polymerization comprising an organoaluminum oxy-compound (a) and at least two kinds of transition metal compounds (b). This ethylene / alpha-olefin copolymer has high melt tension and high flowability. An ethylene copolymer composition comprising the above-mentioned graft modified ethylene / alpha-olefin copolymer and polyolefin. The graft modified ethylene / alpha-olefin copolymer of the invention is excellent in heat stability and moldability. From this copolymer, a film having a high transparency and good adhesion to highly polar materials can be produced. The ethylene copolymer composition of the invention is excellent in heat stability and moldability. From this composition, a film having high transparency and good adhesion to highly polar materials can be produced.

Owner:MITSUI CHEM INC

Solid titanium catalyst component, olefin polymerization catalyst, and olefin polymerization process

ActiveUS20100305285A1Wide molecular weight distributionHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHalogenOlefin polymerization

A solid titanium catalyst component (I) comprising titanium, magnesium, halogen, a specific cyclic ester compound (a) and a specific cyclic ester compound (b), an olefin polymerization catalyst containing this catalyst component (I), and an olefin polymerization process using this olefin polymerization catalyst are disclosed. According to the solid titanium catalyst component, the olefin polymerization catalyst and the process for preparing an olefin polymer of the invention, an olefin polymer having high stereoregularity and a wide molecular weight distribution can be prepared with high activity, preparation of an olefin polymer excellent not only in molding properties such as high-speed streatchability and high-speed moldability but also in rigidity becomes possible, and besides, production cost can be reduced.

Owner:MITSUI CHEM INC

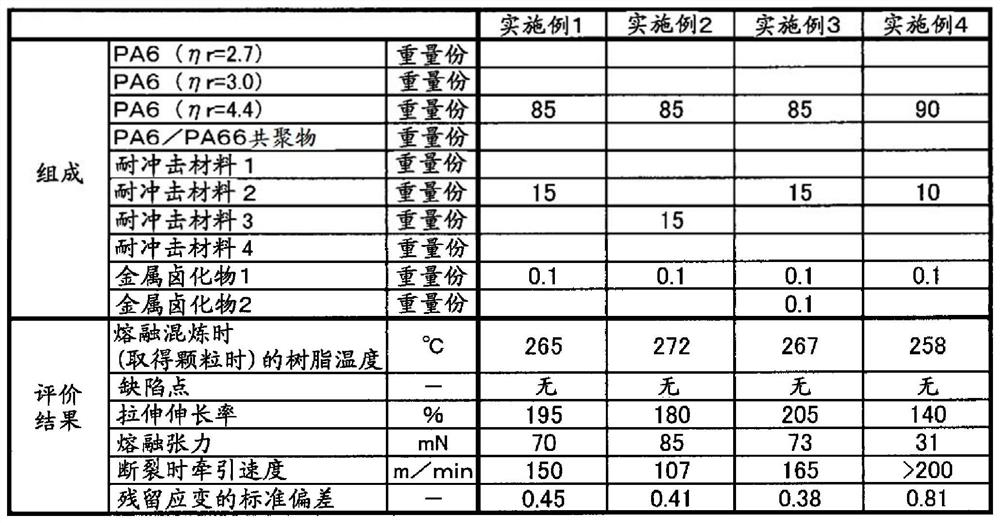

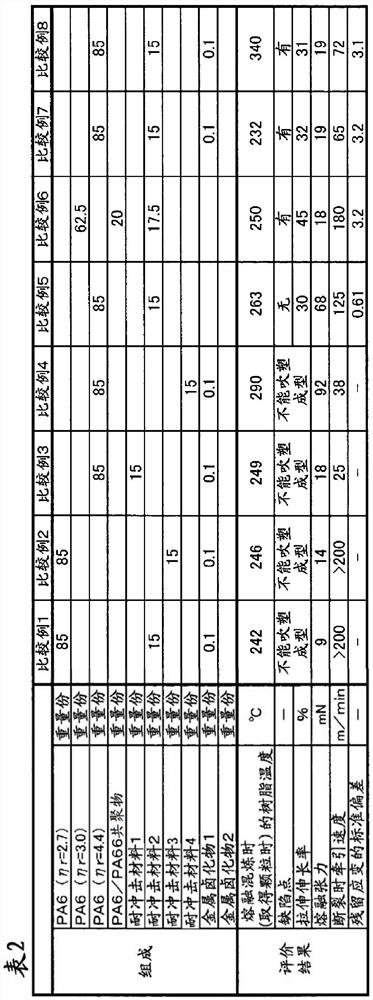

Polyamide resin composition for blow-molded articles in contact with high-pressure hydrogen, and blow-molded article using polyamide resin composition

ActiveCN112424288AHigh melt tensionExcellent retention stabilityVessel manufacturingVessel wallsPolymer scienceHigh pressure hydrogen

The purpose of the present invention is to provide a polyamide resin composition which has excellent blow moldability and retention stability, can suppress the residual strain of a molded product fromlocally increasing, and can be used to obtain a blow-molded product in which the occurrence of defects is suppressed even after repeated charging and release of high-pressure hydrogen. Provided is the polyamide resin composition for blow-molded products exposed to high-pressure hydrogen, the polyamide resin composition is characterized by combining 0.005-1 part by weight of a metal halide (C) with 100 parts by weight in total of 70-99 parts by weight of a polyamide 6 resin (A) and 1-30 parts by weight of an impact resistant material (B), wherein the polyamide resin composition has a molten tension of at least 20 mN as measured at 260 DEG C, and a take-up speed at break of at least 50 m / min as measured at 260 DEG C.

Owner:TORAY IND INC

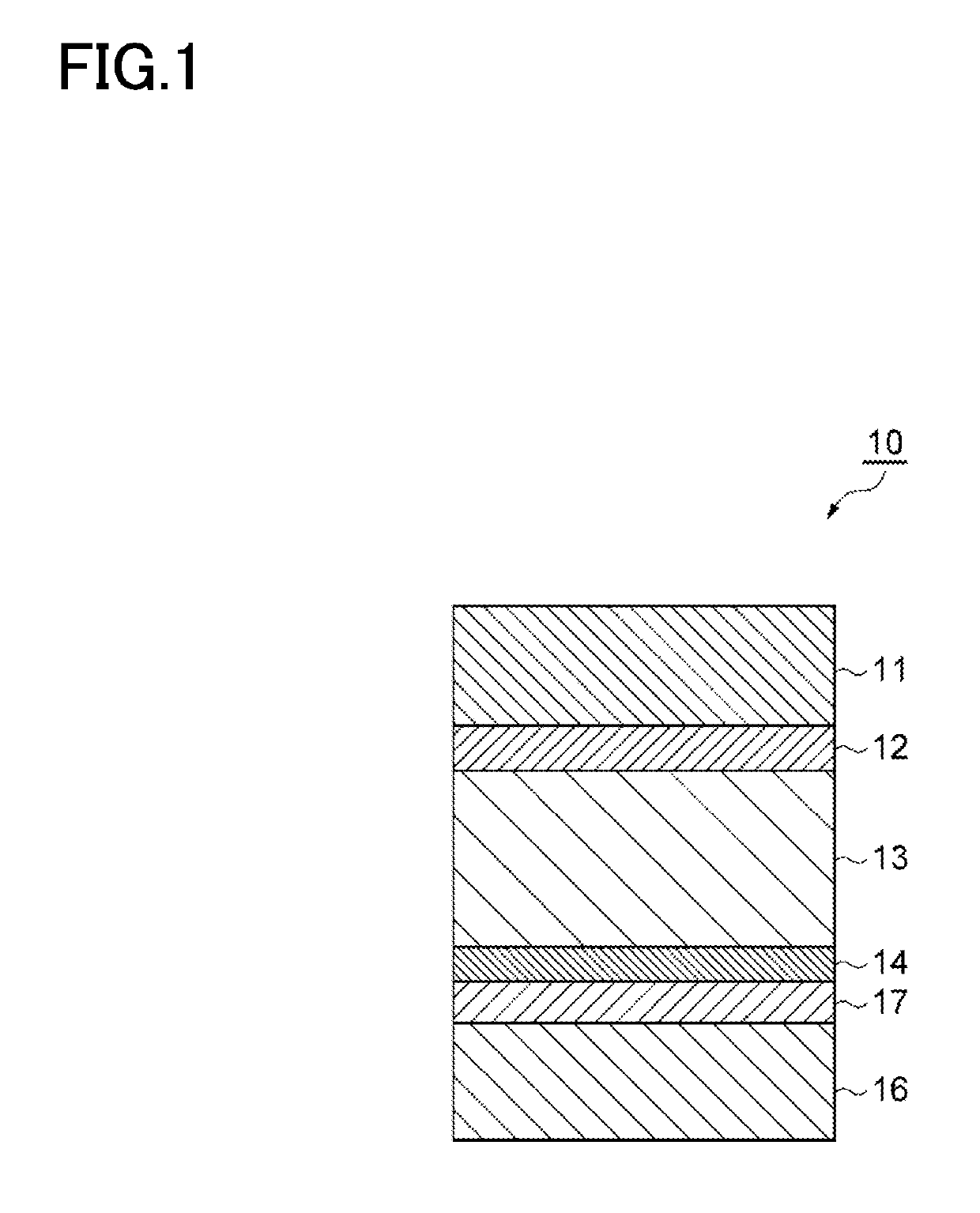

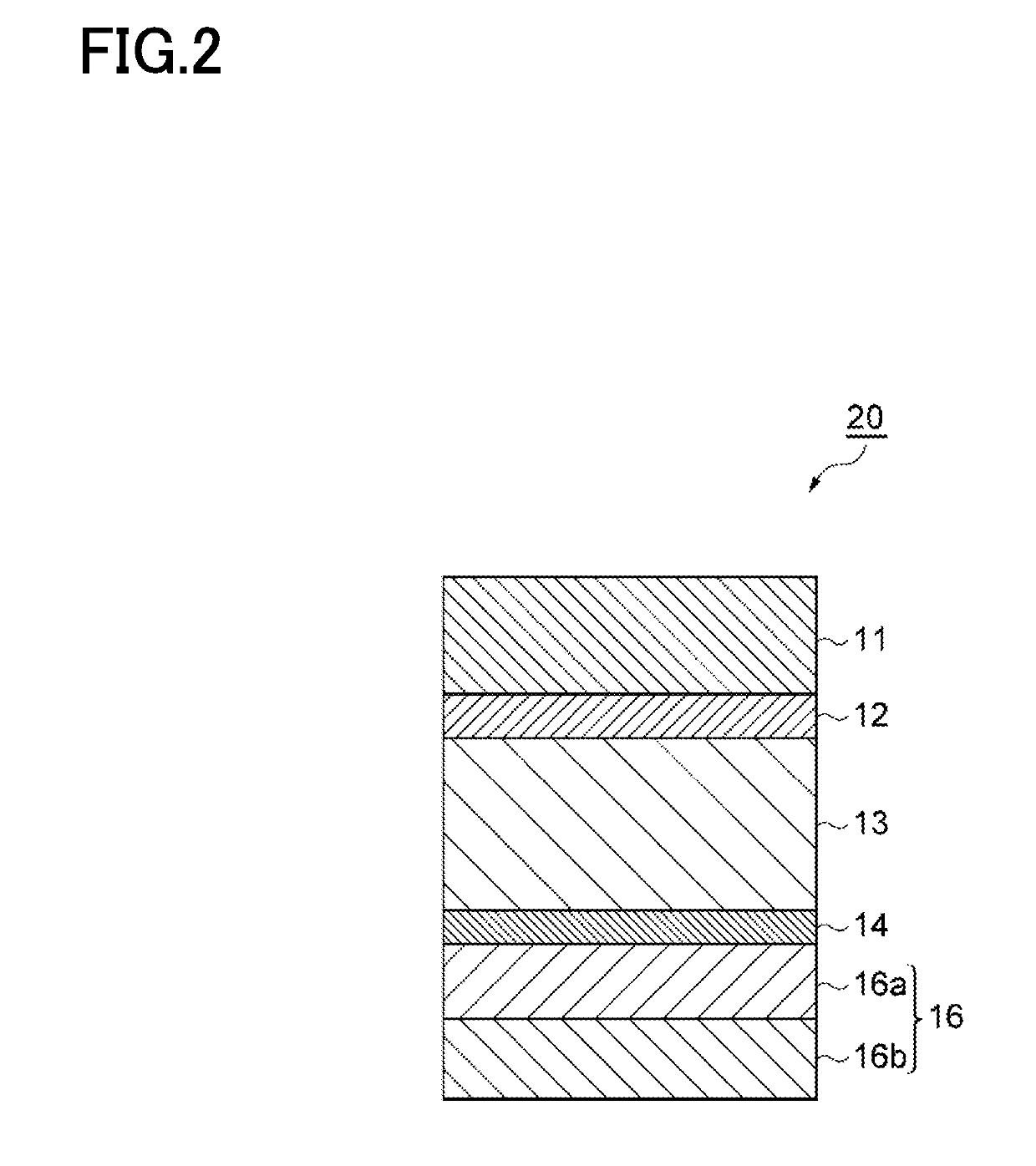

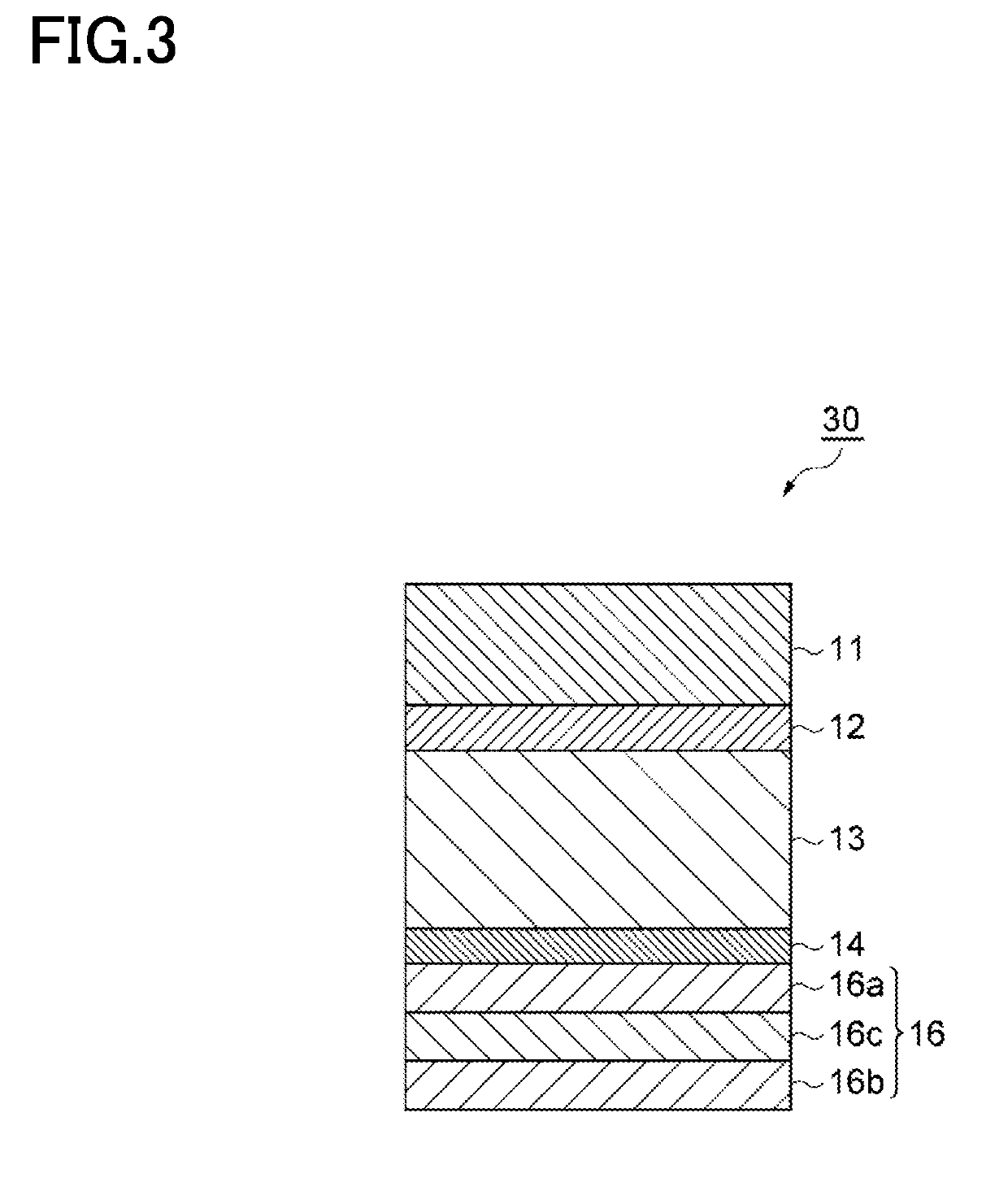

Power storage device packaging material

PendingUS20190143646A1Reduces and prevents defectHigh melt tensionNon-macromolecular adhesive additivesDomestic containersMetallic foilPolymer science

A power storage device packaging material includes at least a substrate layer, a metal foil layer having an anticorrosion treatment layer on one or both sides thereof, and a sealant layer in this order. In the packaging material, the sealant layer includes a propylene-based branched polymer-containing layer that contains a propylene-based branched polymer having branched chains.

Owner:TOPPAN PRINTING CO LTD

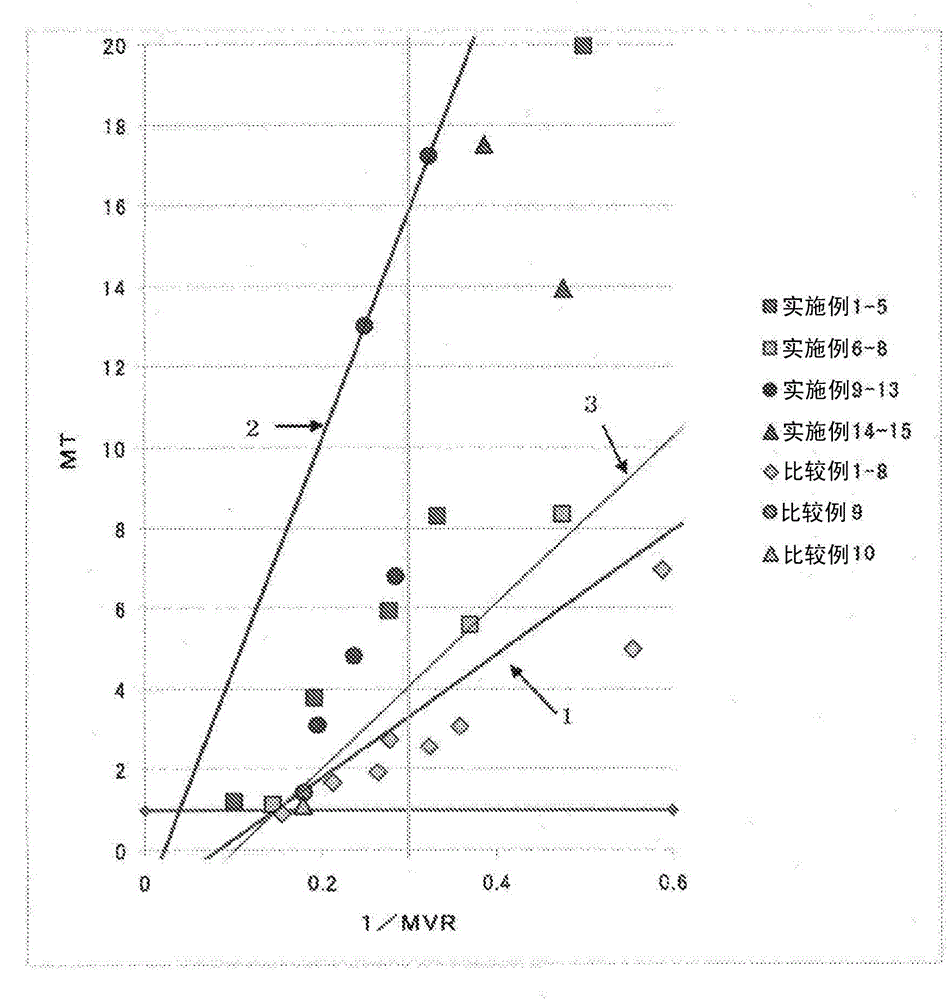

Polycarbonate resin, polycarbonate resin composition and molded article

ActiveCN104812796AHigh melt tensionExcellent resistance to drippingPolymer scienceBisphenol-A-polycarbonate

A polycarbonate resin wherein a relation between the melt tension [MT (g)] at 280°C and melt volume rate [MVR (cm3 / 10 min)] at 280°C satisfies the requirements represented by formulae (1) to (3), and a polycarbonate resin composition and a molded article containing the same. Formula (1): MT≥(15.4 / MVR)-1.3 Formula (2): MT≤(57.4 / MVR)-1.3 Formula (3): MT≥1

Owner:IDEMITSU KOSAN CO LTD

Polypropylene resin compositions having high melt tension and method for preparing the same

InactiveUS20120149845A1Excellent long side-chain introduction capabilityHigh melt tensionPolypropylenePolymer chemistry

Owner:HONAM PETROCHEM

EVA (ethylene-vinyl acetate) copolymer and preparation method thereof

The invention discloses an EVA (ethylene-vinyl acetate) copolymer and a preparation method thereof. The EVA copolymer comprises the following components in percentage by weight: 50-70% of EVA particle, 10-30% of phenolic resin, 10-50% of methyl acrylate, 1-10% of ammonia water, 5-20% of cellulose, 5-20% of calcium carbonate, 5-20% of magnesium carbonate, 0-3.8% of color paste, 3-9% of emulsifier, 0-0.5% of coupling agent, 0.5-5% of accelerator, 1-5% of preservative and 20-40% of deionized water. The EVA copolymer has the advantages of high melting tension and extremely low probability for gel or fisheye formation. Thus, the obtained crosslinked EVA copolymer can be used as a raw material for shoe soles and wires.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com