Chemical foaming polyethylene composition, preparation method and applications thereof

A chemical foaming, polyethylene technology, used in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of low melt tension and high decomposition heat, achieve good mechanical properties, avoid PE materials Too soft, the effect of improving decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a kind of preparation method of chemical foaming polyethylene composition, comprises the following steps:

[0046] 1) Preparation of composite foaming agent masterbatch: get low-density polyethylene B, foaming agent A, foaming agent B, foaming aid, dispersant, lubricant and antioxidant of formula quantity, join the first mixer Stir in the medium for 3-5 minutes, then add the stirred raw materials into the first reciprocating screw extruder to extrude and granulate to obtain the composite foaming agent masterbatch; wherein, the aspect ratio of the first reciprocating screw extruder For (18-36): 1, the granulation temperature is 120-140°C, and the screw speed is 80-160r / min;

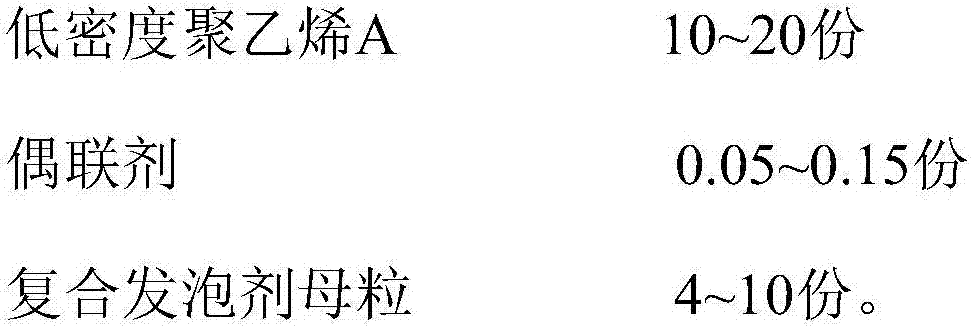

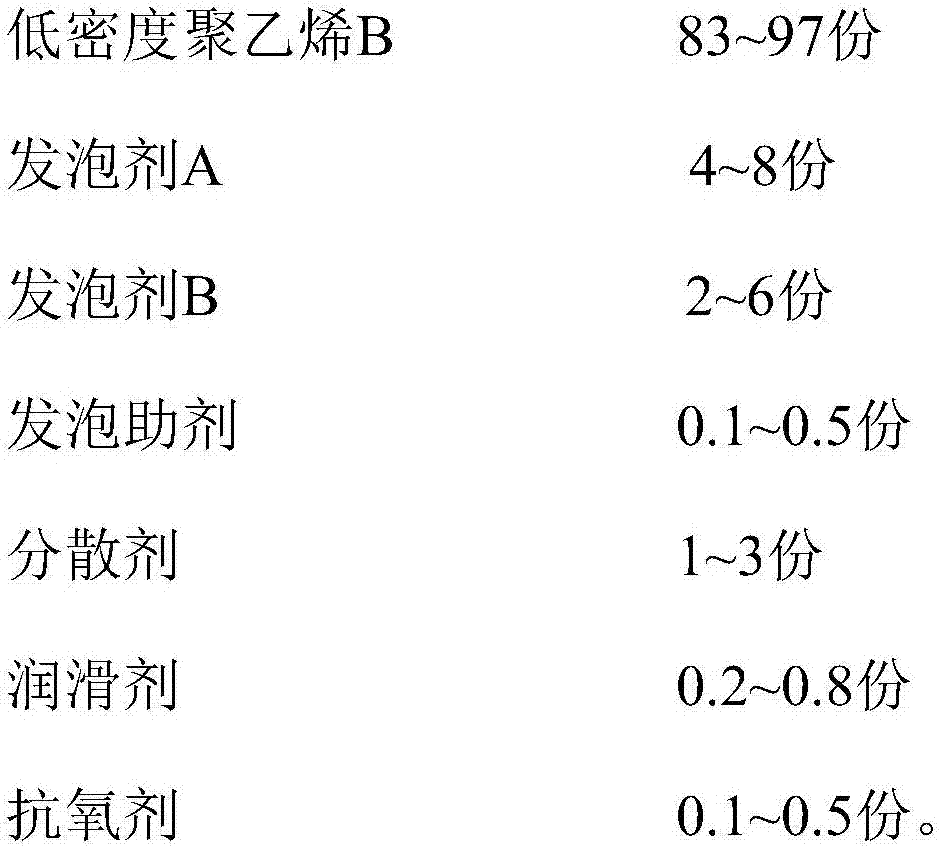

[0047] 2) Preparation of chemically foamed polyethylene composition: take the high-density polyethylene, low-density polyethylene A, coupling agent and the composite foaming agent masterbatch obtained through step 1), add in the second mixer, stir 5-15 minutes, t...

Embodiment 1-5

[0049] The formula of embodiment 1-5 is as shown in the following table, and component is by weight, and unit is part, and in embodiment 1-5, high-density polyethylene is selected as the model that Formosa Plastics produces is 9007 high-density polyethylene, LDPE A is 951-050 low-density polyethylene produced by Maoming Petrochemical Company. The coupling agent is 6040 silane coupling agent produced by Dow Corning. Low-density polyethylene B is produced by Beijing Yanshan Petrochemical Co., Ltd. It is low-density polyethylene of 1C7A, and the foaming agent A is selected from the model ADCA DN-4 foaming powder produced by Jiangsu Thorpe Fine Chemical Co., Ltd., and the foaming agent B is selected from OBSH produced by Hangzhou Haihong Fine Chemical Co., Ltd. The zinc stearate produced by Faji (Chemical) Zhangjiagang Co., Ltd. was selected as the agent, the precipitated silica of Evonik Degussa model Sipernat D10 was selected as the dispersant, and the polyethylene wax produced b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com