Patents

Literature

47results about How to "High foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

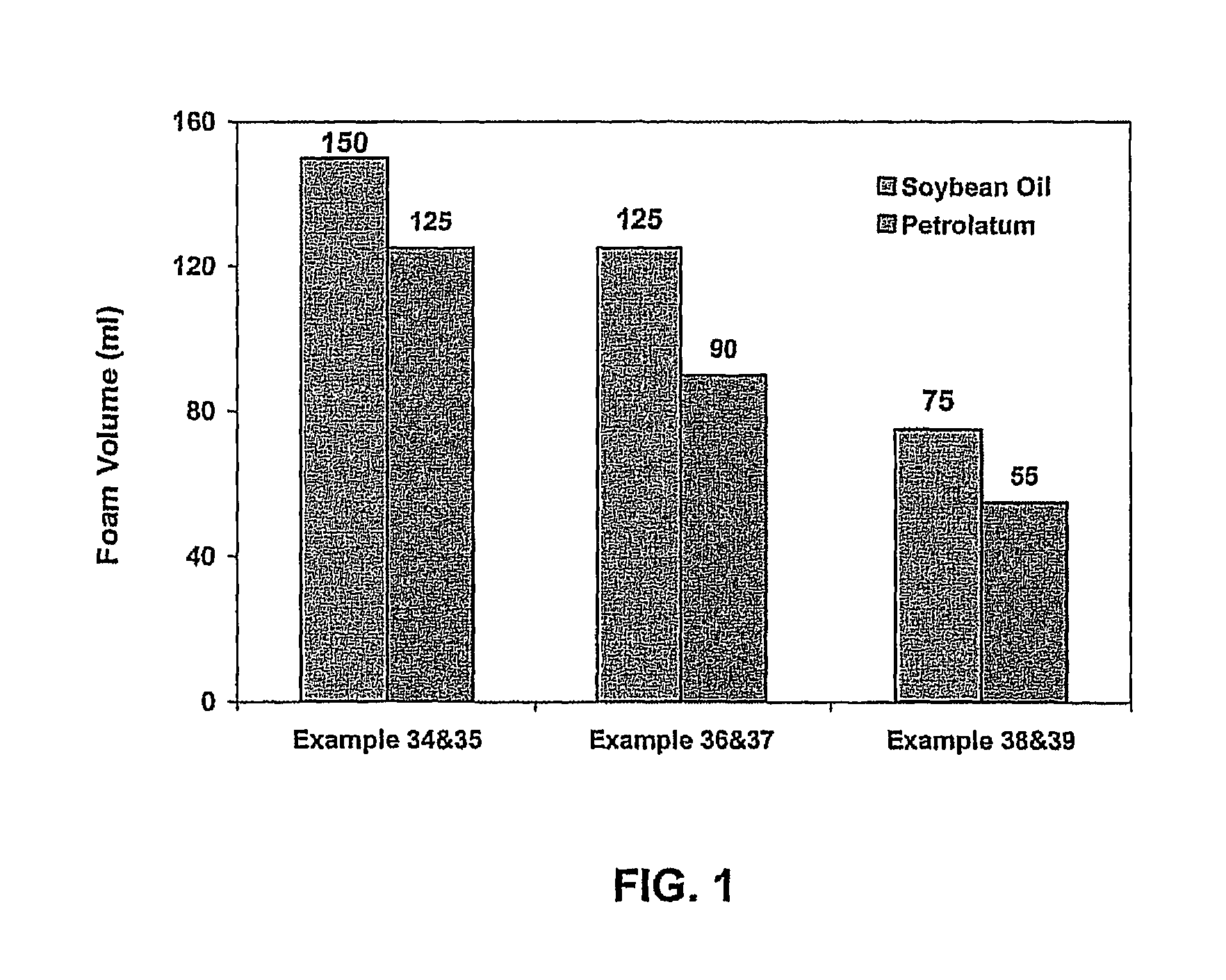

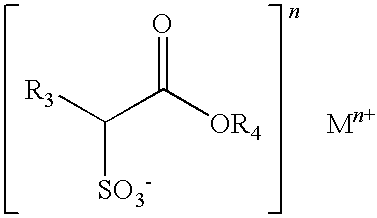

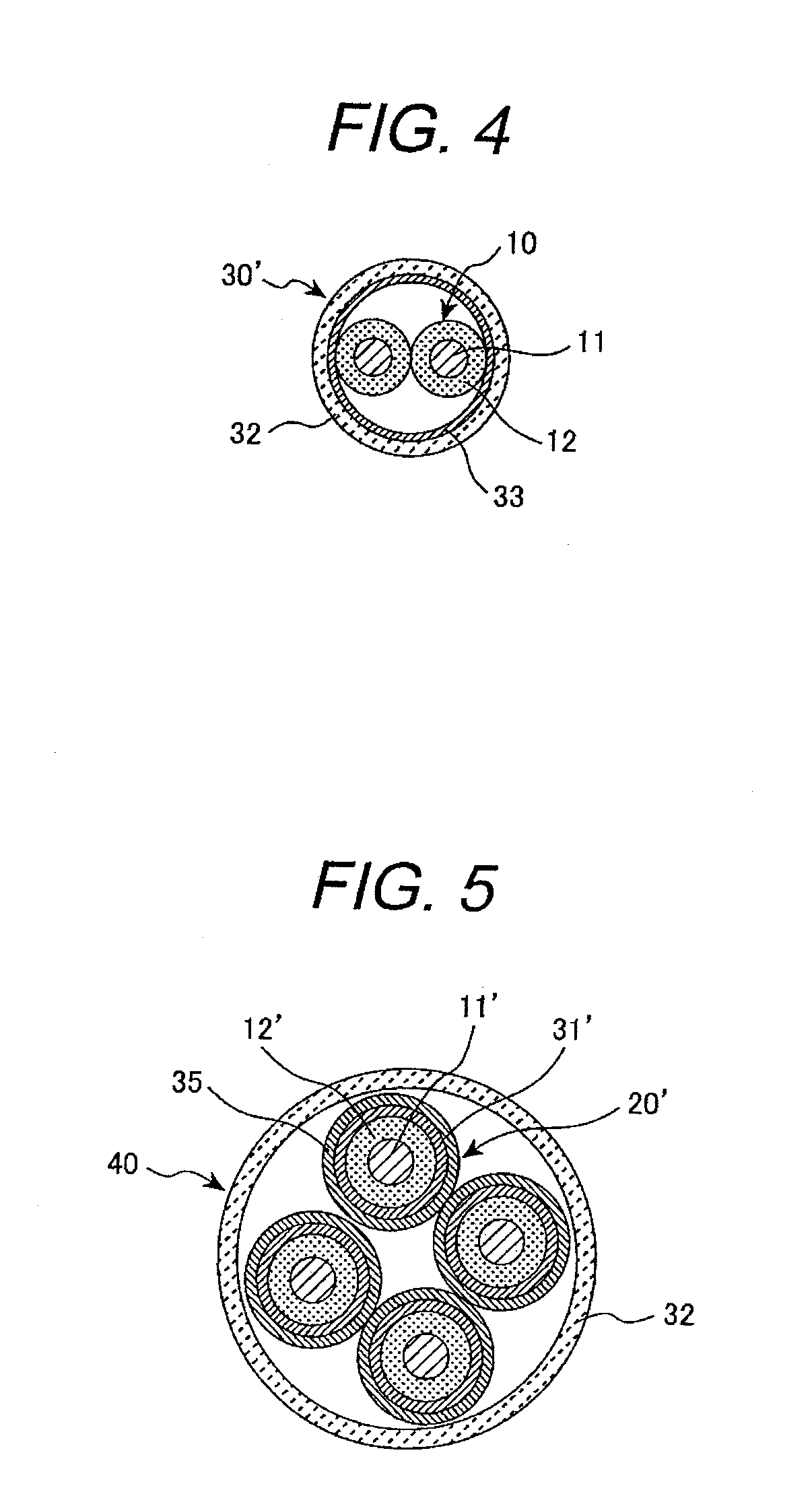

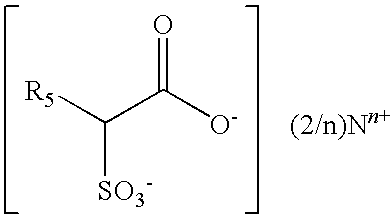

Liquid cleansing composition

A personal cleansing composition exhibiting enhanced skin feel (i.e., enhanced skin softness, reduced skin irritation, reduced residue, and reduced greasy, tacky, or tight skin feel), enhanced foaming and lather, and good cleansing, more specifically, a personal cleansing composition comprising a mixture of alpha sulfonated alkyl esters or sulfonated fatty acids, or salts thereof, with an alkyl sulfoacetate or ethoxylated alkyl sulfoacetate, or salts thereof, secondary surfactants, and optional additives.

Owner:STEPAN COMPANY

Thermally expandable microcapsule,process for producing molded foam, and molded foam

ActiveUS20060063000A1Improve performanceImprove heat resistanceFatty substance preservation using additivesGlass/slag layered productsFoaming agentSide chain

Thermo-expansive microcapsule comprising: a polymeric shell produced by polymerizing 15 to 75 weight % of a nitrile monomer, 10 to 65 weight % of a monomer having a carboxyl group, 0.1 to 20 weight % of a monomer having an amide group and 0.1 to 20 weight % of a monomer having a cyclic structure in its side chain; and a blowing agent encapsulated in the polymeric shell.

Owner:MATSUMOTO YUSHI SEIYAKU

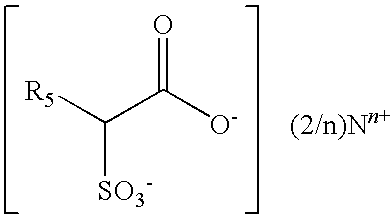

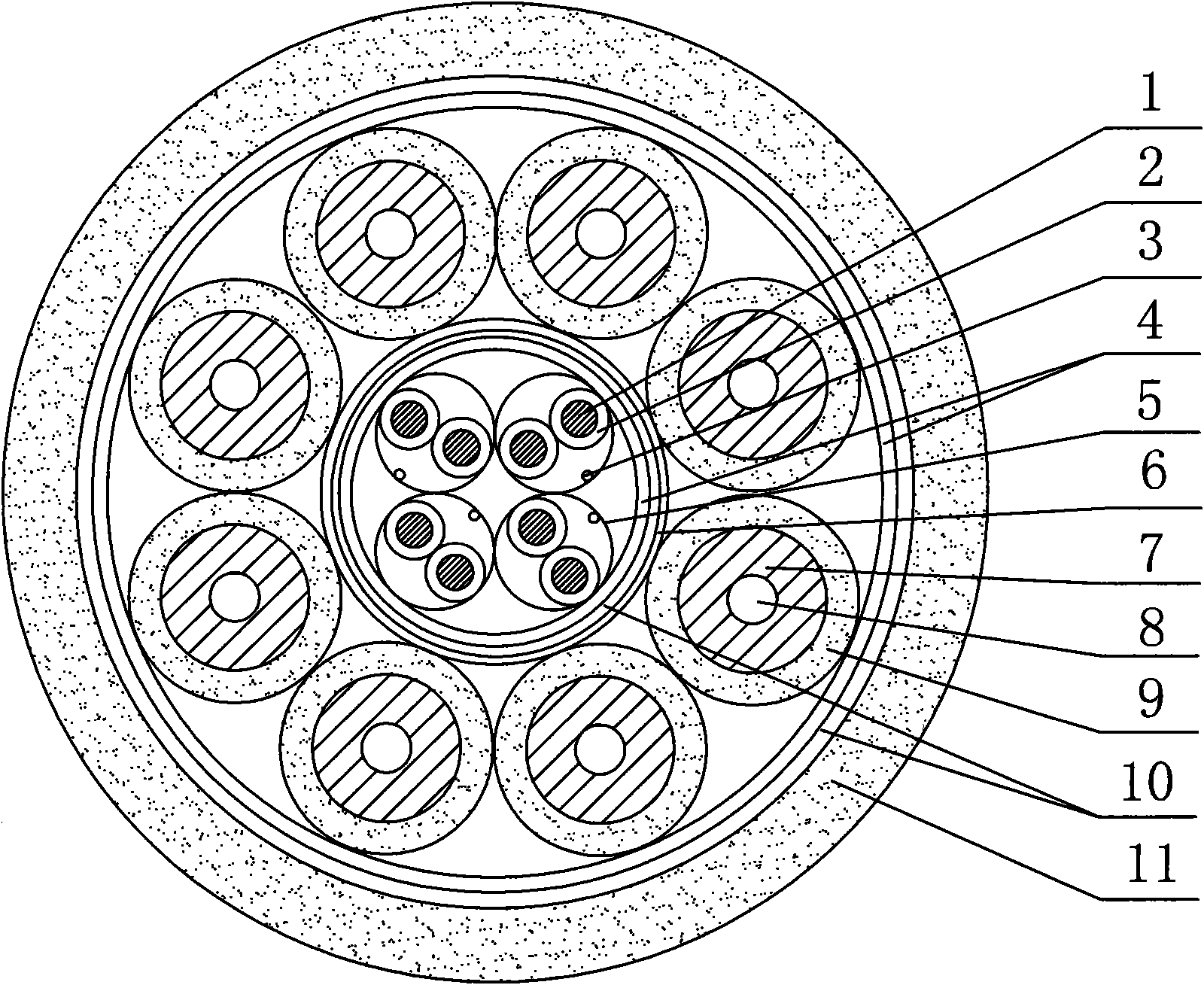

Broad band radiation type leak coaxial cable for subway and its production method

ActiveCN101404350AUniformly foamed poresUniform field strengthCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsInsulation layerElectrical conductor

The invention relates to a broadband radial pattern leaky coaxial cable used for subway and a manufacturing method thereof, and the leaky coaxial cable has the double functions of transmission line of information and duplexer. The structure of the leaky coaxial cable consists of an inner conductor, an insulation layer, an outer conductor and a jacket, wherein, the inner conductor is externally covered with the insulation layer which is externally covered with the outer conductor that is externally sheathed with the jacket, and the insulation layer that covers on the surface of the inner conductor adopts nitrogen or carbon dioxide physical foam to form a foamed polyethylene insulation layer; cambered slotted holes are opened on a clutch gold belt of the outer conductor covered outside the insulation layer. The manufacturing method comprises the steps: (1) a spiral wrinkle inner conductor is manufactured by longitudinal covering welding and embossing by using a copper strip; (2) the nitrogen or the carbon dioxide are adopted to be injected into the smelted polyvinyl plastics, and then the physical foamed polyethylene insulation layer is formed on the surface of the inner conductor by extrusion and cladding; (3) the slotted holes broken out by the clutch gold belt of the outer conductor are the cambered slotted holes; (4) the clutch gold belt of the outer conductor is covered on the insulation layer longitudinally, and the surface of the clutch gold belt of the outer conductor is crowded and covered with the jacket.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

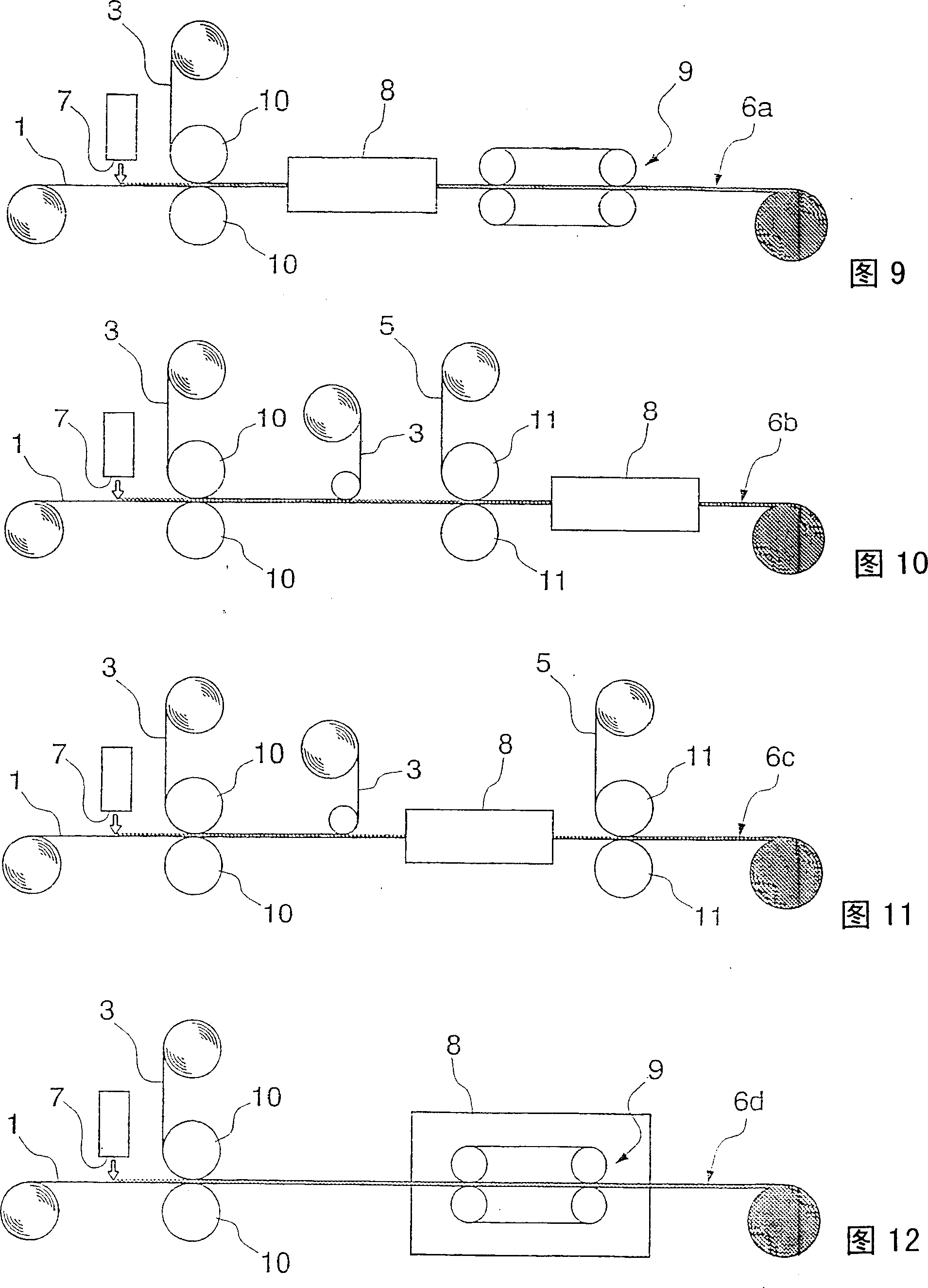

Manufacturing process of polyurethane foam sheet and layered sheet using the same

ActiveCN1732082AControllable shapeUniform shapeSynthetic resin layered productsLaminationWood veneerCushioning

A method of producing a polyurethane foam sheet, and a laminated sheet that uses such a foam sheet, that can be applied to artificial leather, synthetic leather, and cushioning materials used in all manner of applications. A polyurethane foam sheet is produced by applying a liquid mixture, obtained by mixing together a heated and melted hot melt urethane prepolymer (A) containing isocyanate groups at molecular terminals, and a compound (B) containing at least 2 active hydrogen atom-containing groups, onto a substrate in a sheet-like manner, and then water foaming the liquid mixture by bringing the sheet-like liquid mixture into contact with water vapor or moisture (water). A laminated sheet is produced by bonding a third substrate to the polyurethane foam sheet.

Owner:DIC CORP

Polyolefin resin foam and the process for producing the same

An object of the invention is to provide a polyolefin resin foam which is excellent in flexibility, cushioning property and processability, especially excellent in cutting processability. The present invention relates to a polyolefin resin foam obtained by foaming a polyolefin resin composition using carbon dioxide in a supercritical state, wherein the polyolefin resin composition contains at least: (1) a thermoplastic elastomer composition obtained by subjecting to a dynamically heat treatment a mixture of (A) a rubber, and (B) (B-1) an α-olefin crystalline thermoplastic resin and / or (B-2) an α-olefin amorphous thermoplastic resin, each having a melt tension of less than 3.0 cN at a temperature of 210° C. and at a take-up speed of 2.0 m / min, in the presence of (C) a crosslinking agent; (2) a polyolefin resin; and (3) a nucleant agent having an average particle diameter of from 0.1 μm to less than 2.0 μm. The polyolefin resin foam has a density, for example, of 0.2 g / cm2 or less.

Owner:JSR CORPORATIOON +1

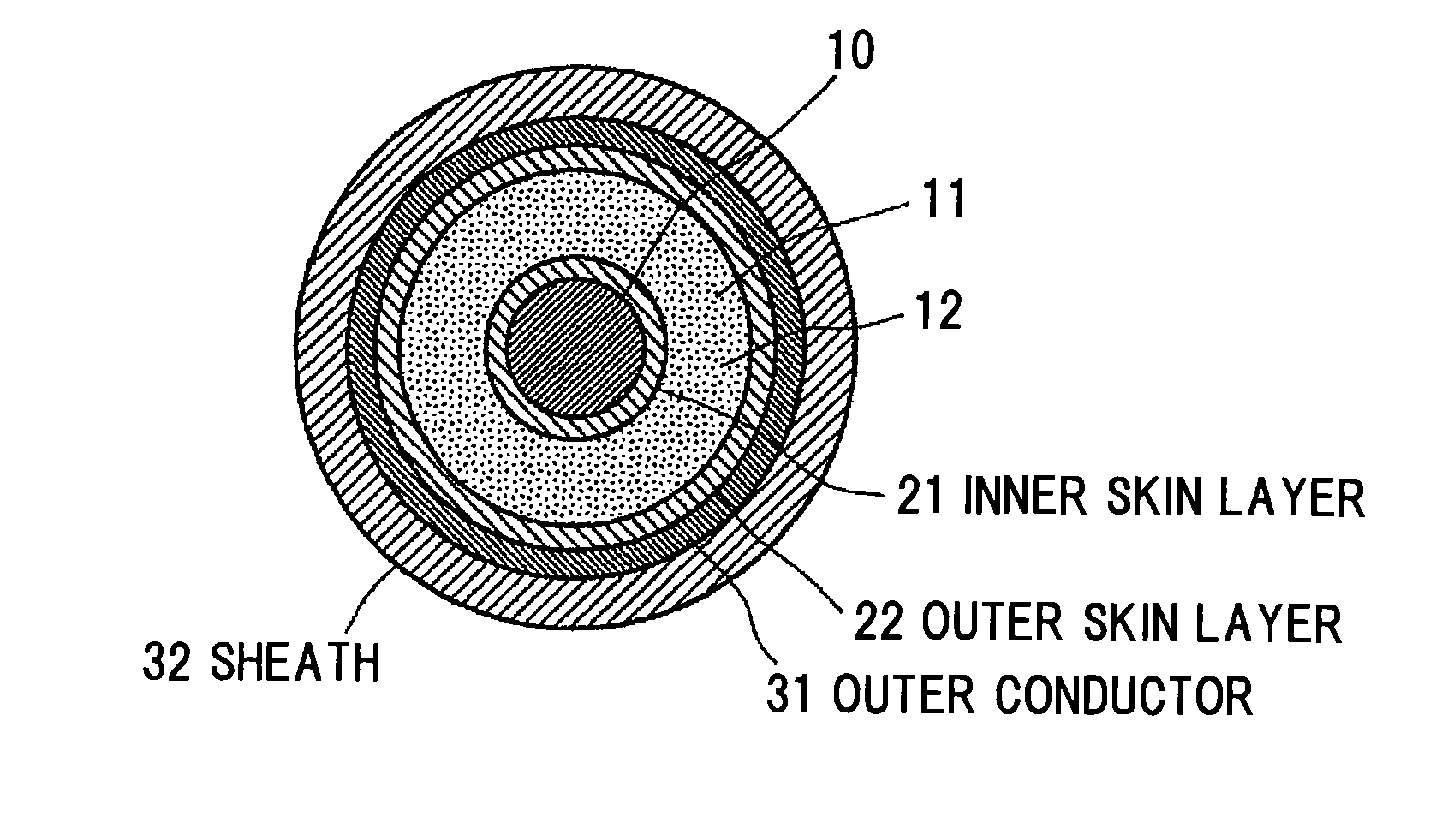

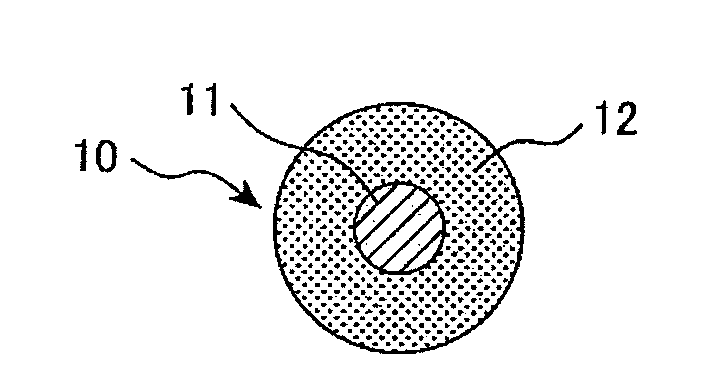

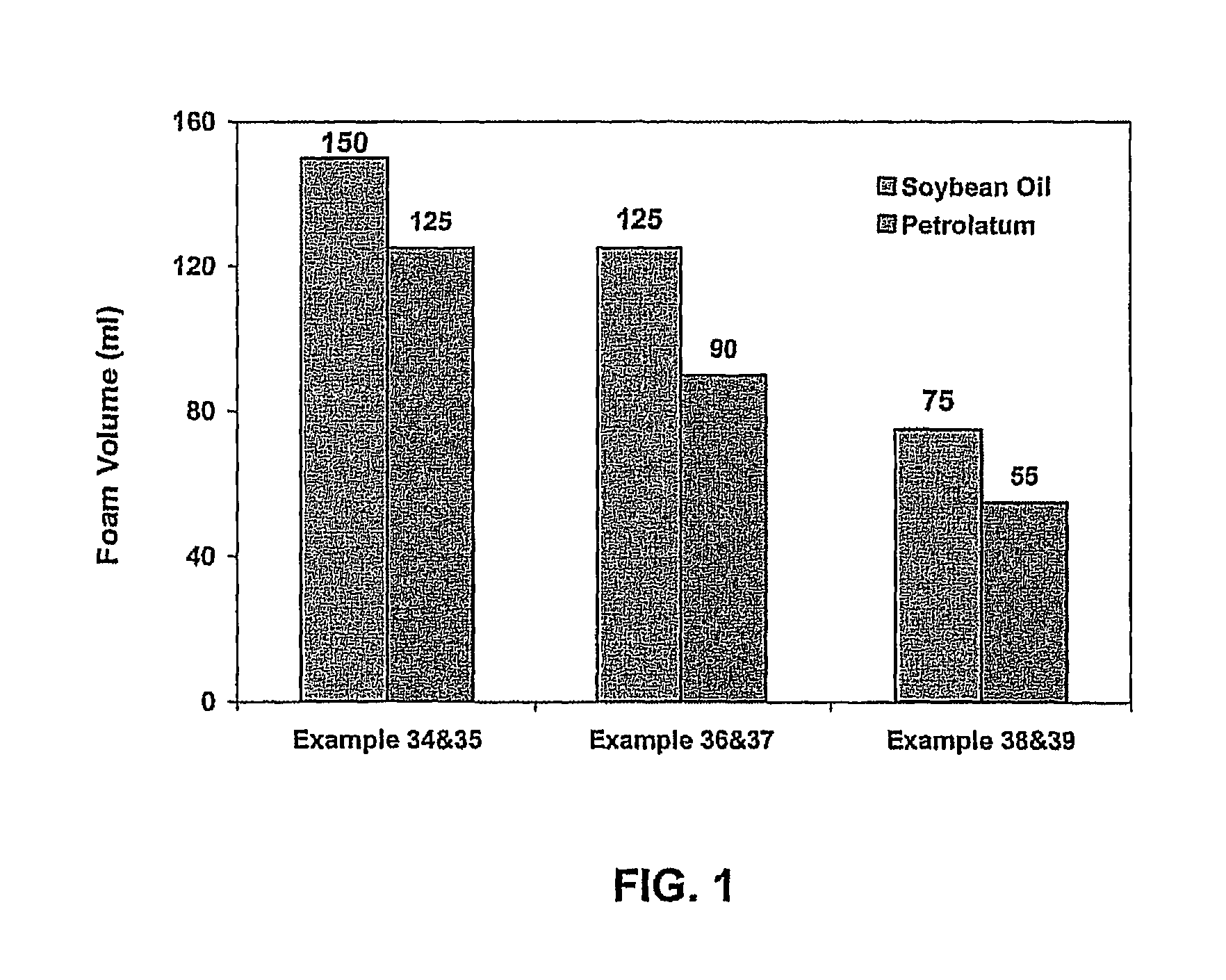

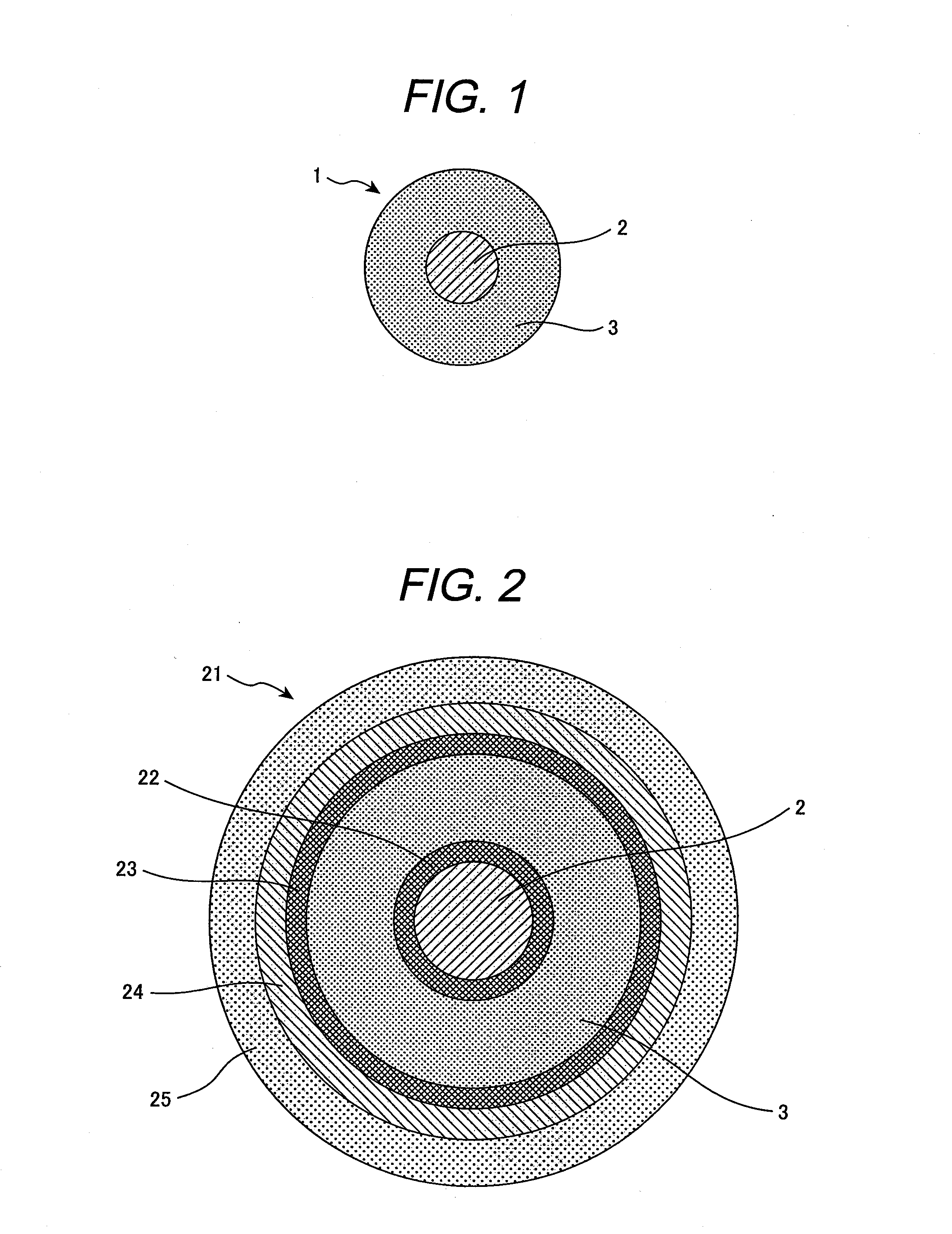

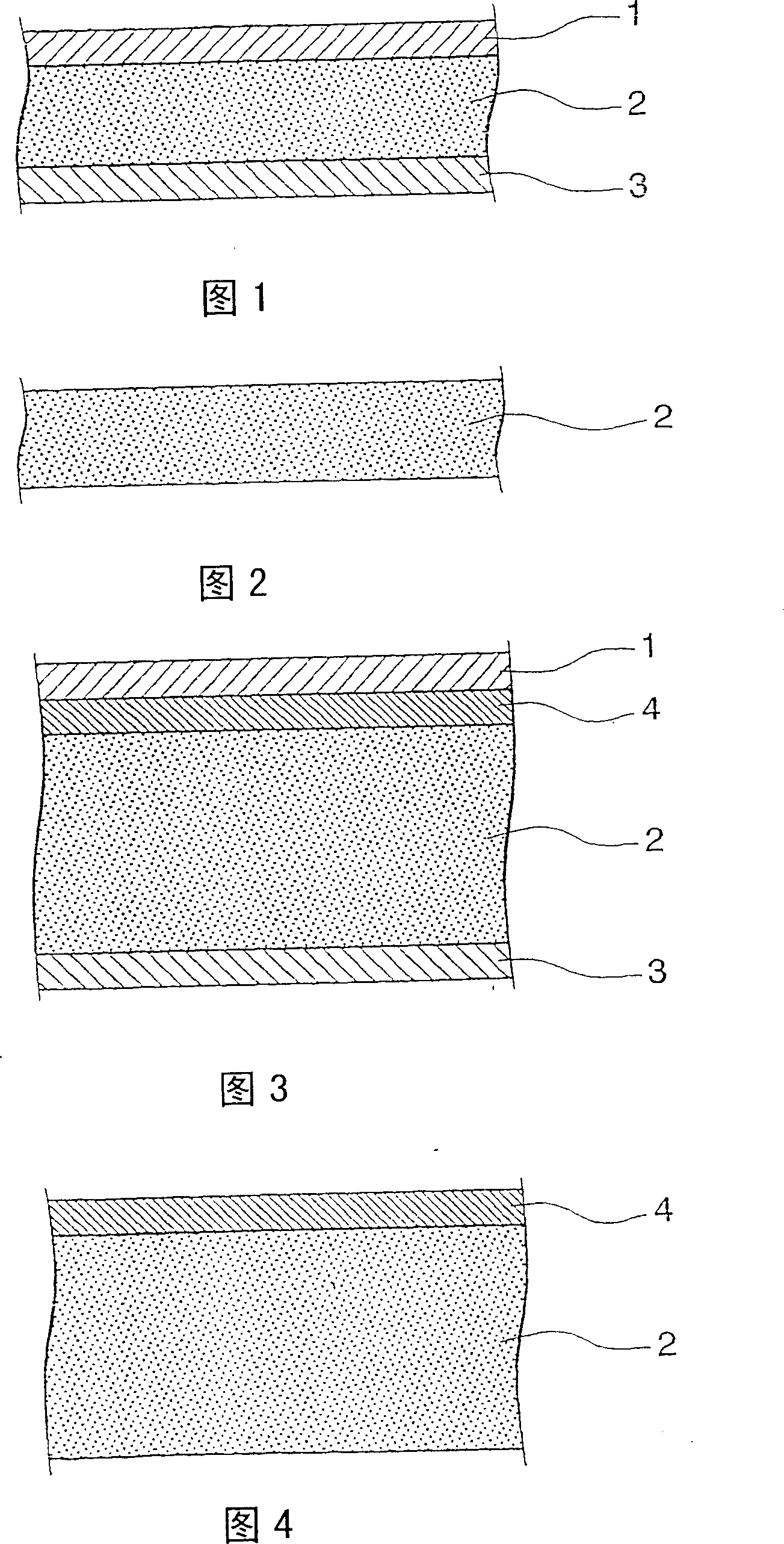

Resin composition, foamed resin using same, and electric wire insulated with foamed resin

InactiveUS20110198106A1High foamingUniform fine bubblePlastic/resin/waxes insulatorsGlass transitionPolyresin

There is provided a resin composition for a foamed resin by generating bubbles, the resin composition made of a blend of a base resin and a polymer material other than the base resin, the polymer material dispersed in the base resin, in which: the bubbles are generated at circumference of the dispersed polymer material by infusing a foaming gas into the resin composition at a predetermined processing temperature; and melting point or glass transition temperature of the polymer material is between melting point of the base resin and the processing temperature.

Owner:HITACHI METALS LTD

Foamed resin composition and wire/cable using the same

A foamed resin composition includes a polyolefin-based resin, and a ring opening polymer of norbornene or a copolymer of norbornene and ethylene or a mixture thereof. The ring opening polymer of norbornene or the copolymer of norbornene and ethylene or the mixture thereof is used as a foam nucleating agent in the foamed resin composition.

Owner:HITACHI CABLE

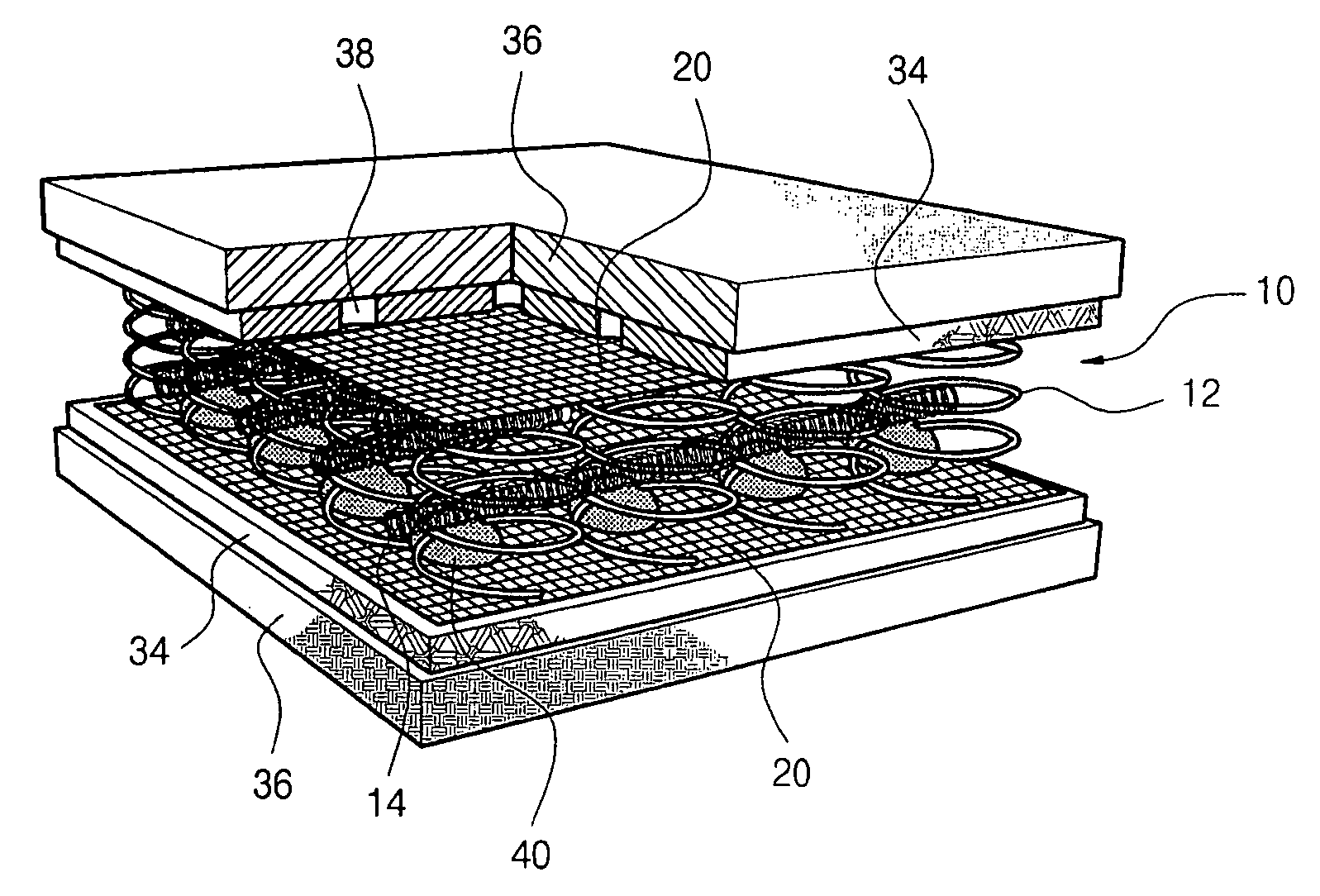

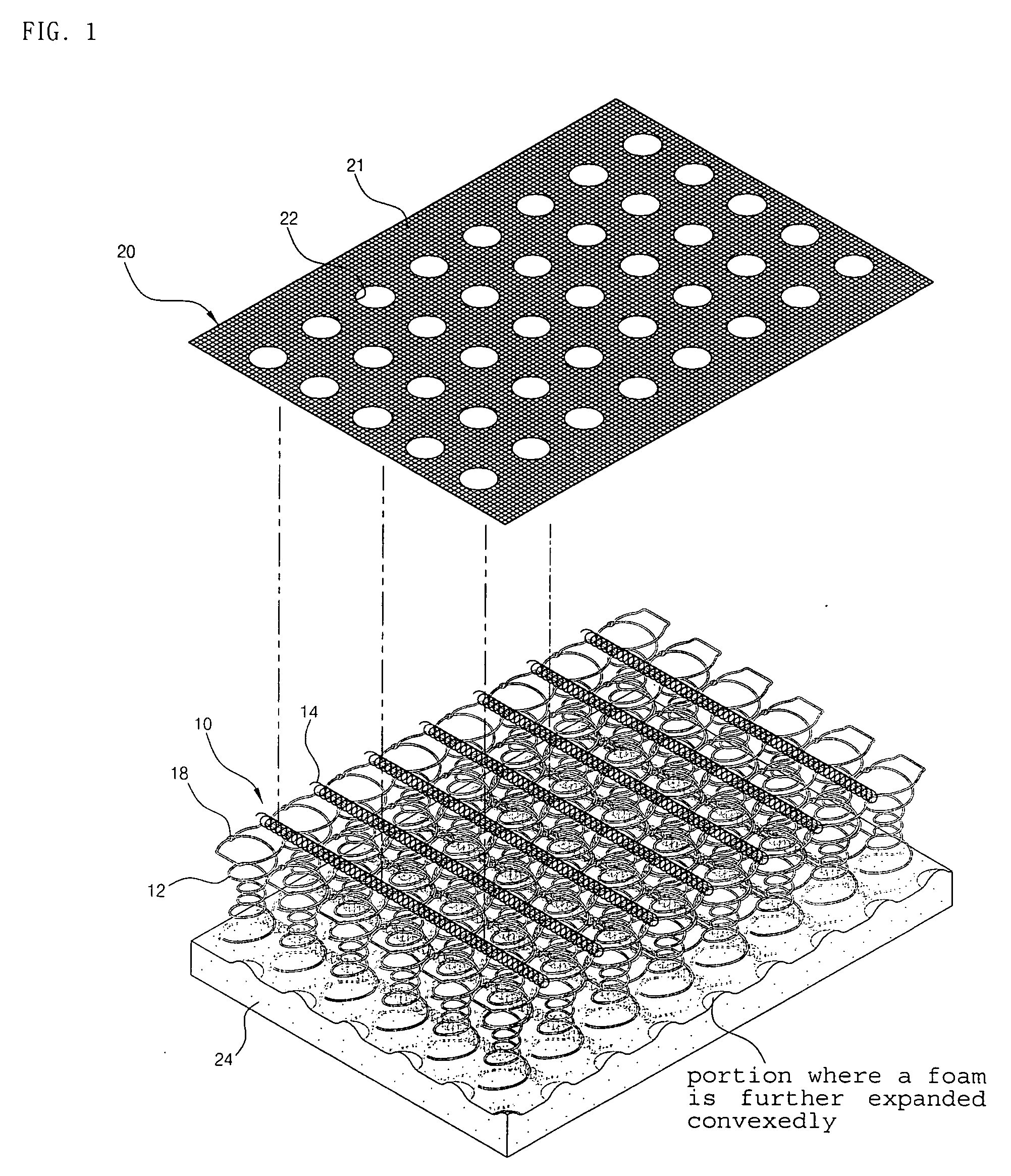

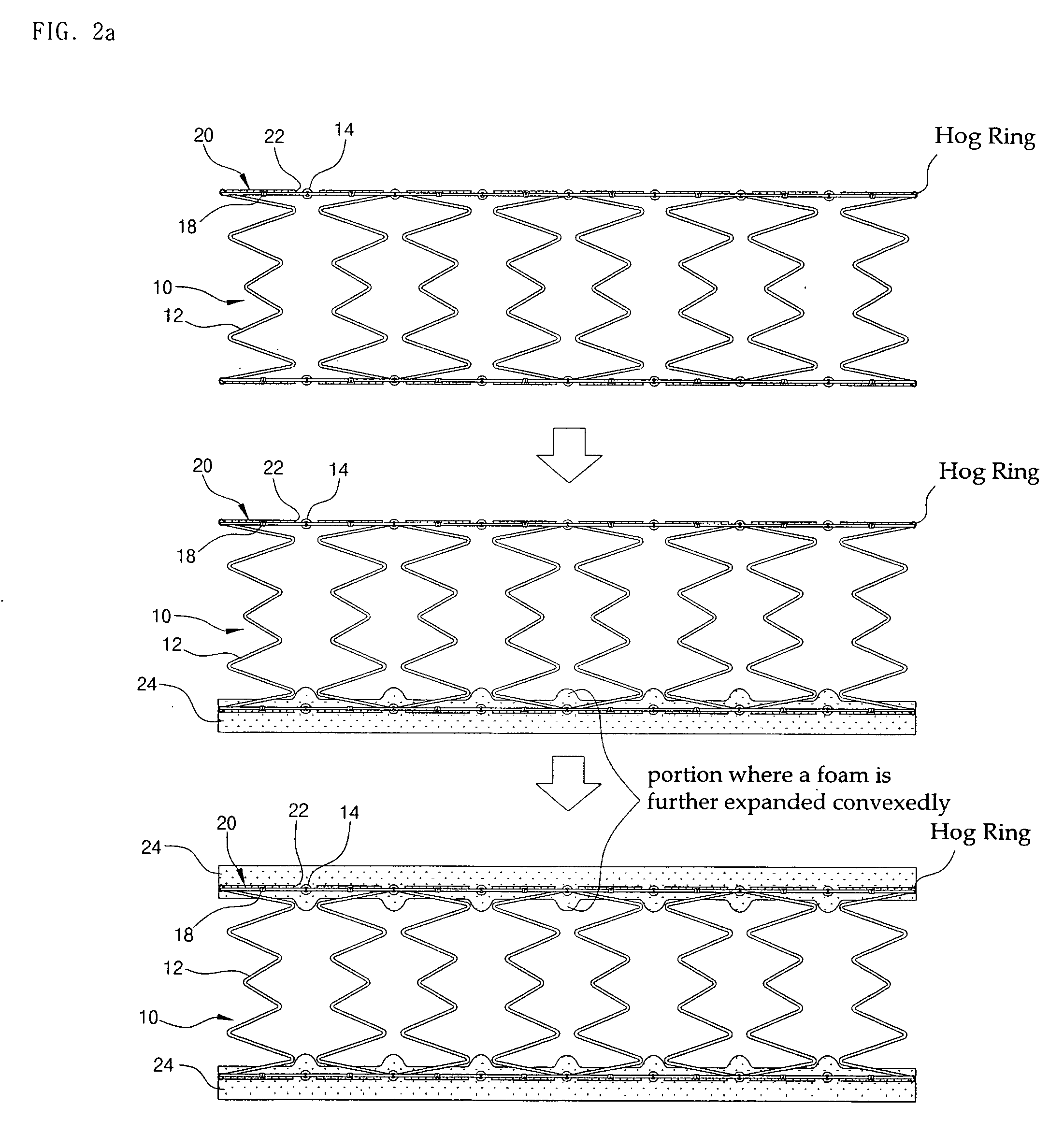

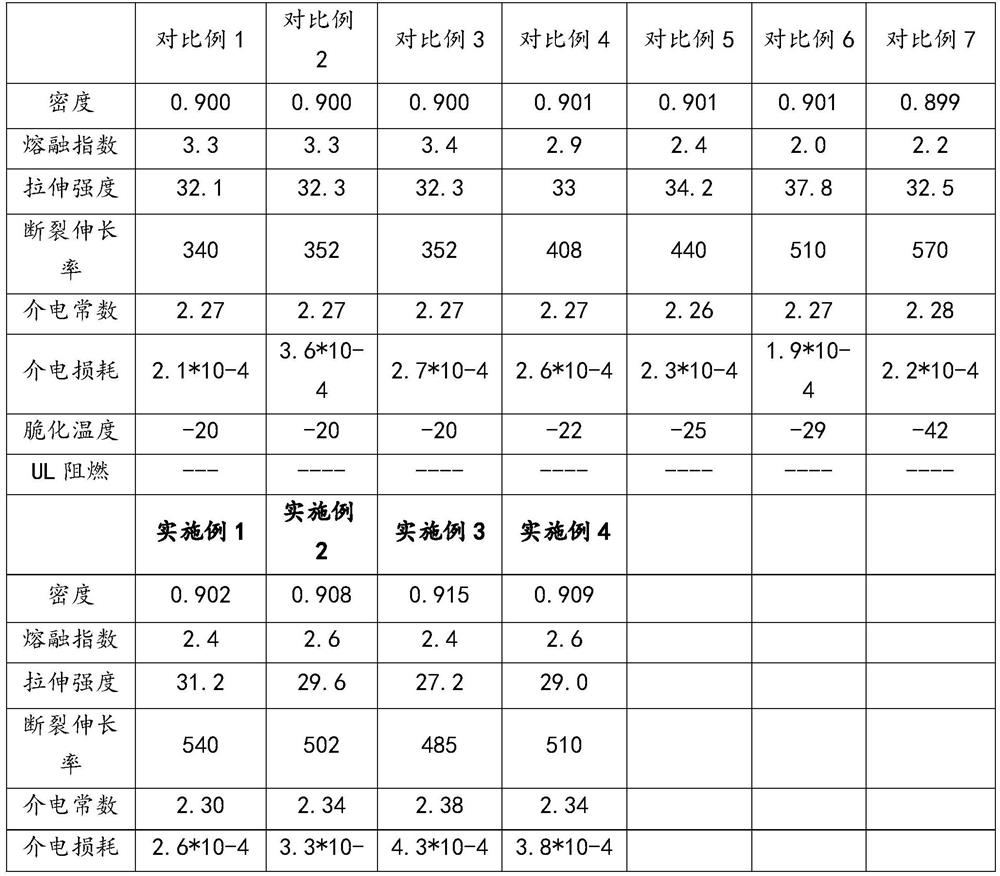

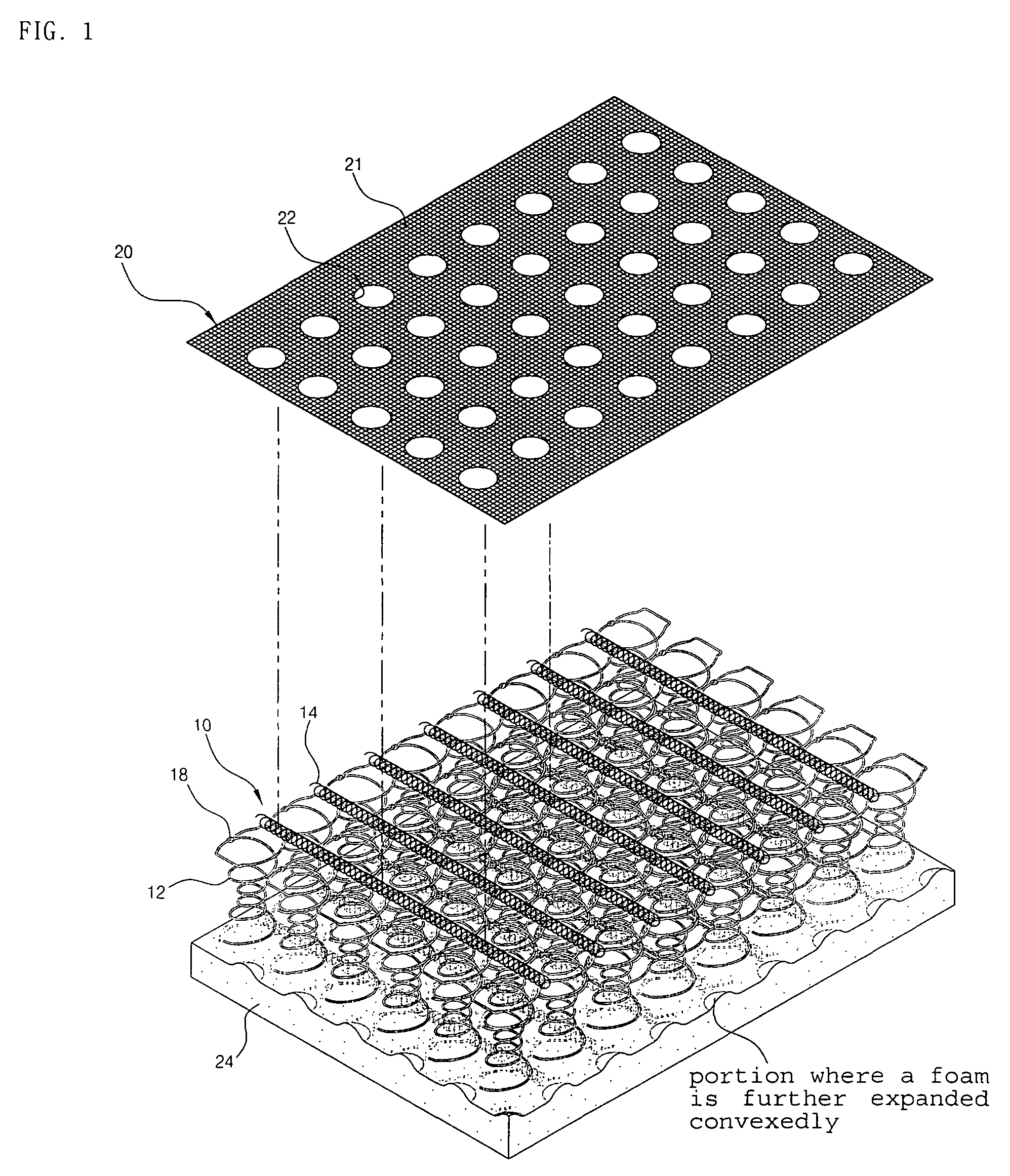

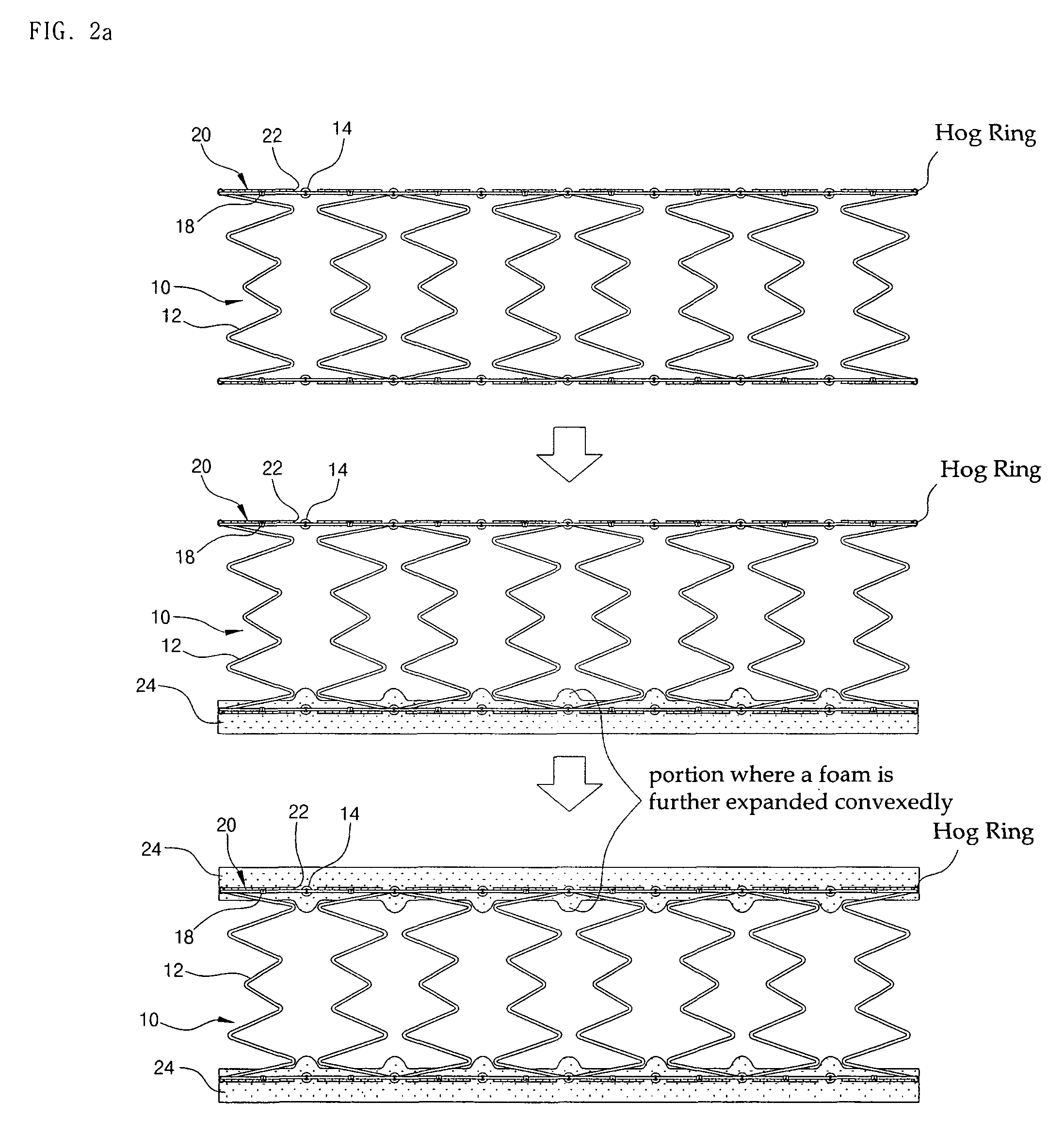

Bed mattress using permeable reinforcing member and foaming material, and method of manufacturing the same

ActiveUS20070044244A1Extend your lifeReduce noiseUpholstery manufactureStuffed mattressesEngineeringMechanical engineering

Disclosed herein is a bed mattress and a method of manufacturing the same, in which a permeable reinforcing member is provided at an upper portion and a lower portion of a spring assembly which is one of frame constituents of the bed mattress, and a foaming material is disposed on the permeable reinforcing member so as to be foamed, so that the spring assembly and the foaming material are integrally formed while the foaming material is expanded through fine holes and / or foam expansion holes of the permeable reinforcing member.

Owner:ACE BED CO LTD

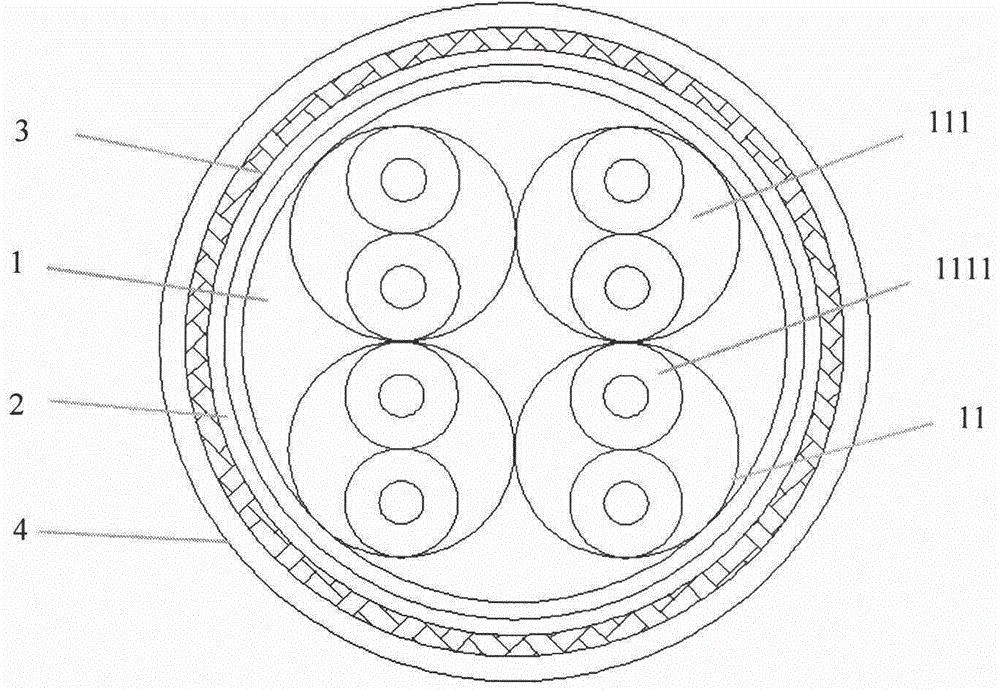

Anti-torsion data power composite cable and manufacturing method thereof

ActiveCN101562062ASimple structureAdvanced technologyPlastic/resin/waxes insulatorsInsulated cablesCapacitanceEngineering

The invention discloses an anti-torsion data power composite cable and a manufacturing method thereof. The composite cable comprises a cable core, an outer jacket, and is provided with a data line core and a power control line core; wherein, the data line core is formed by stranding of quad and positioned in the center of cable, the quad is provided with two insulated cores and drainage lines, and wounded and wrapped with a plastic-aluminum composite strip sub-shielding layer, the data line core is provided with a main shielding layer, the power control line core is formed in a manner that multi-assemble reinforced cores are mounted on the periphery of the data line core, the data line core and the cable core are provided with a composite cushion layer respectively. The invention has the advantages of simple and reasonable structure, advanced technique, high mechanical strength of products, low capacity and low attenuation. The invention is also characterized by strong anti electromagnetic interfere property, shock resistance, fine torsion bending resistance property, oil proofness, chemical solvent resistance, hard wearing, high / low temperature resistance, water erosion resistance, environmental leaching and loss resistance, ensuring stable property of cables in various severe environments so that cable property is reliable and safe.

Owner:BAOSHENG SCI & TECH INNOVATION

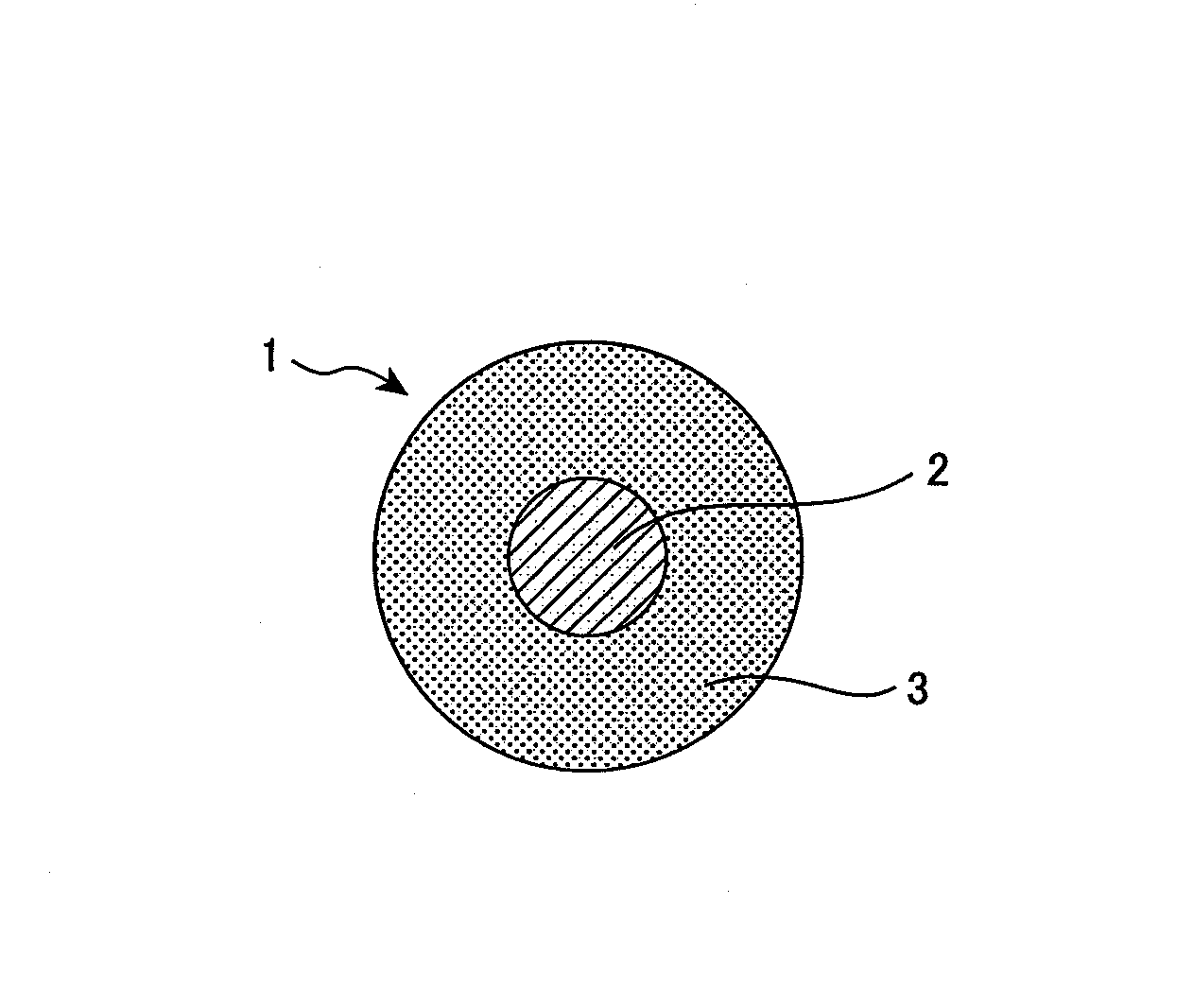

Electric-wire cable equipped with foamed insulator

InactiveUS20100300725A1High foamingLow melting pointRubber insulatorsPlastic/resin/waxes insulatorsVitrificationPolymer science

There is provided an electric-wire cable equipped with a foamed insulator, the foamed insulator molded on an outer periphery of a metal conductor by a physical foaming method, in which: the foamed insulator is made of a blend of crystalline polymer A with polymer B; and the crystal melting point or glass transition temperature of the polymer B is between the crystal melting point of the crystalline polymer A and a temperature 50° C. lower than the crystal melting point of the crystalline polymer A.

Owner:HITACHI METALS LTD

Liquid cleansing composition comprising a ternary mixture of anionic surfactants

ActiveUS8053400B2Improve skinReduce skin problemsCosmetic preparationsMake-upPolymer scienceSKIN SOFTNESS

A personal cleansing composition exhibiting enhanced skin feel (i.e., enhanced skin softness, reduced skin irritation, reduced residue, and reduced greasy, tacky, or tight skin feel), enhanced foaming and lather, and good cleansing, more specifically, a personal cleansing composition comprising a mixture of alpha sulfonated alkyl esters or sulfonated fatty acids, or salts thereof, with an alkyl sulfoacetate or ethoxylated alkyl sulfoacetate, or salts thereof, secondary surfactants, and optional additives.

Owner:STEPAN COMPANY

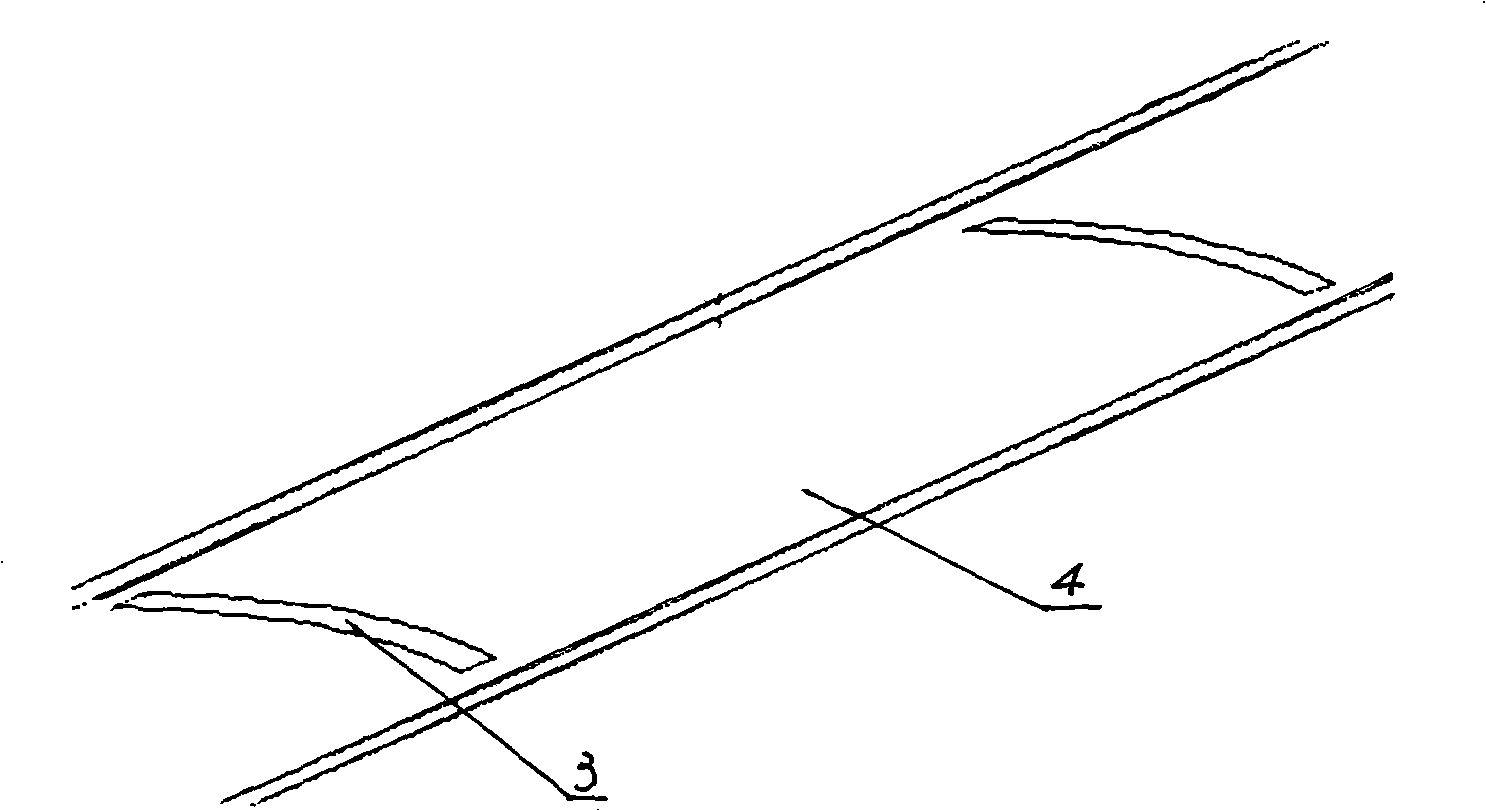

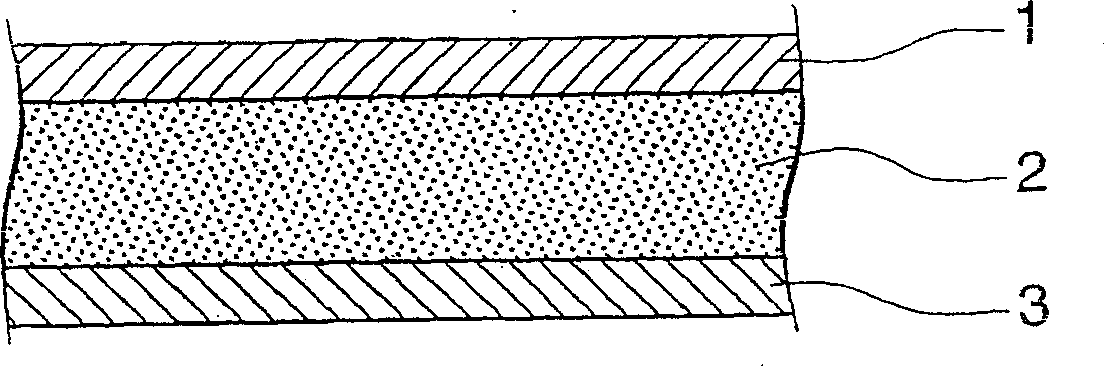

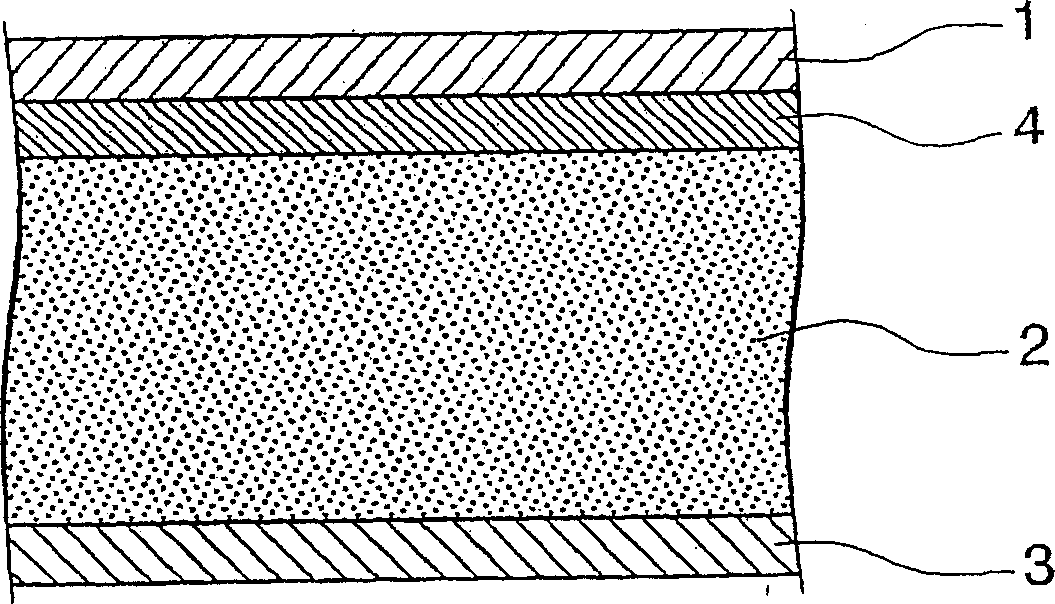

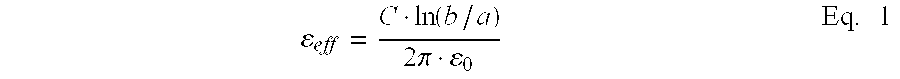

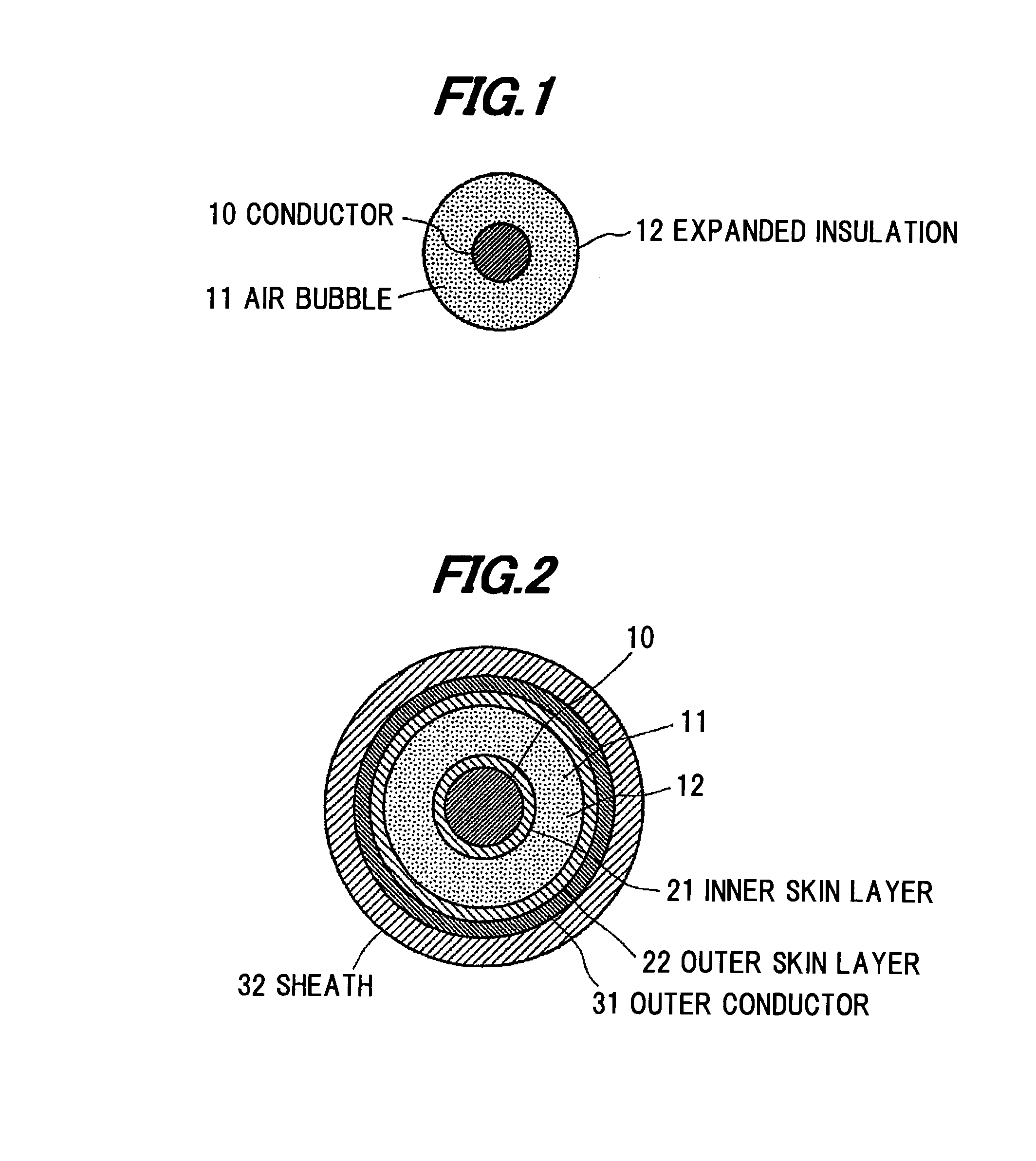

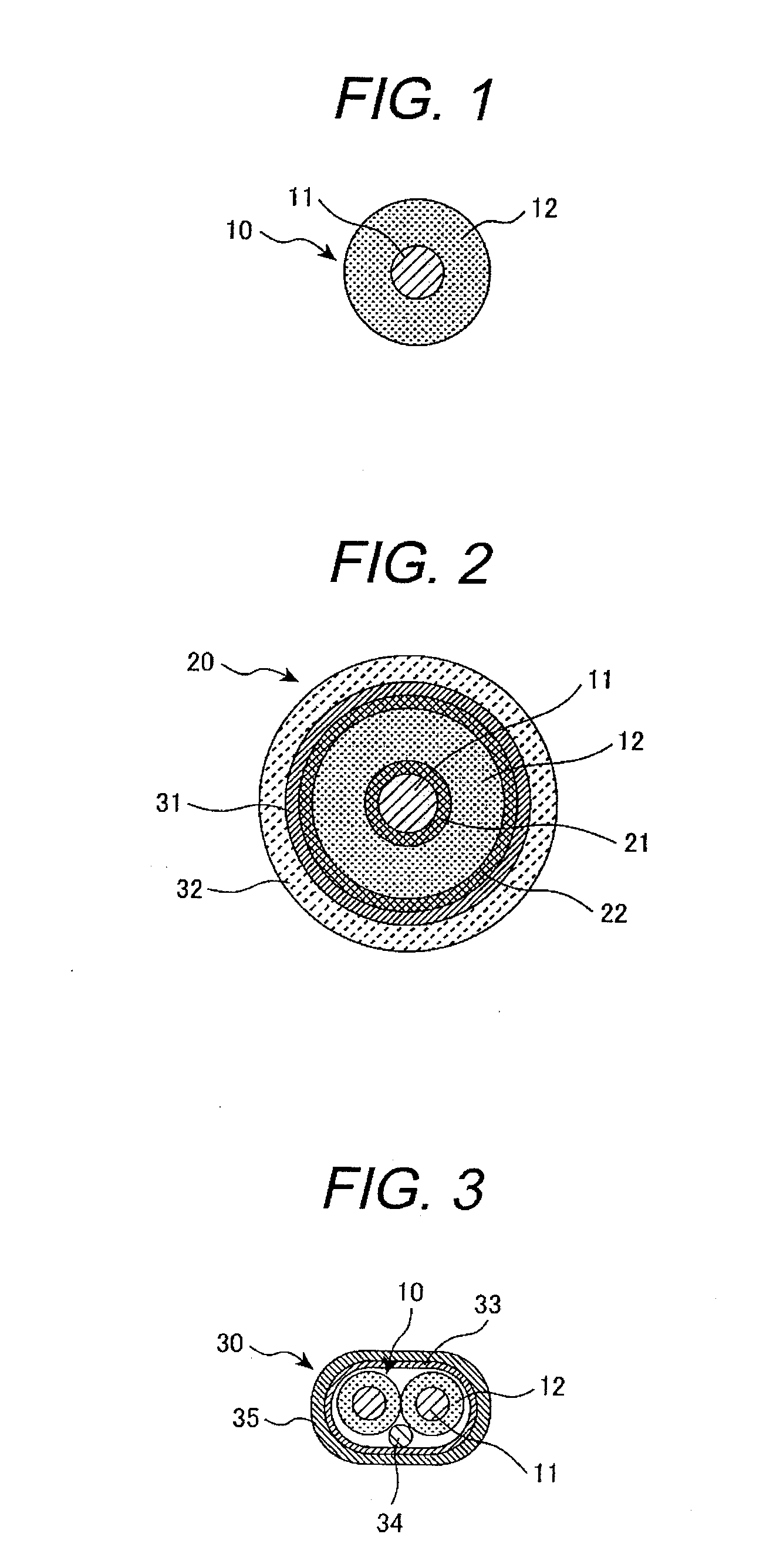

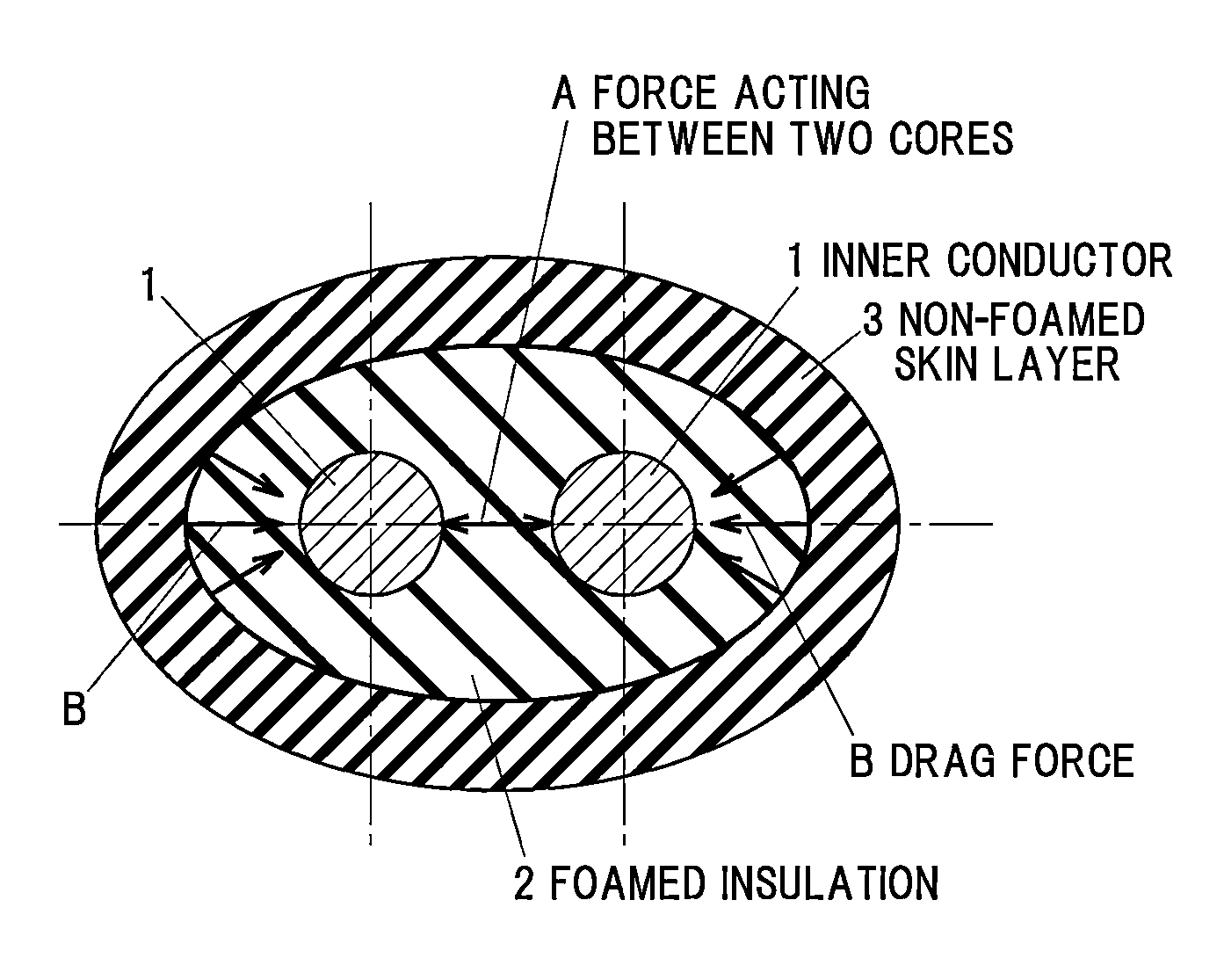

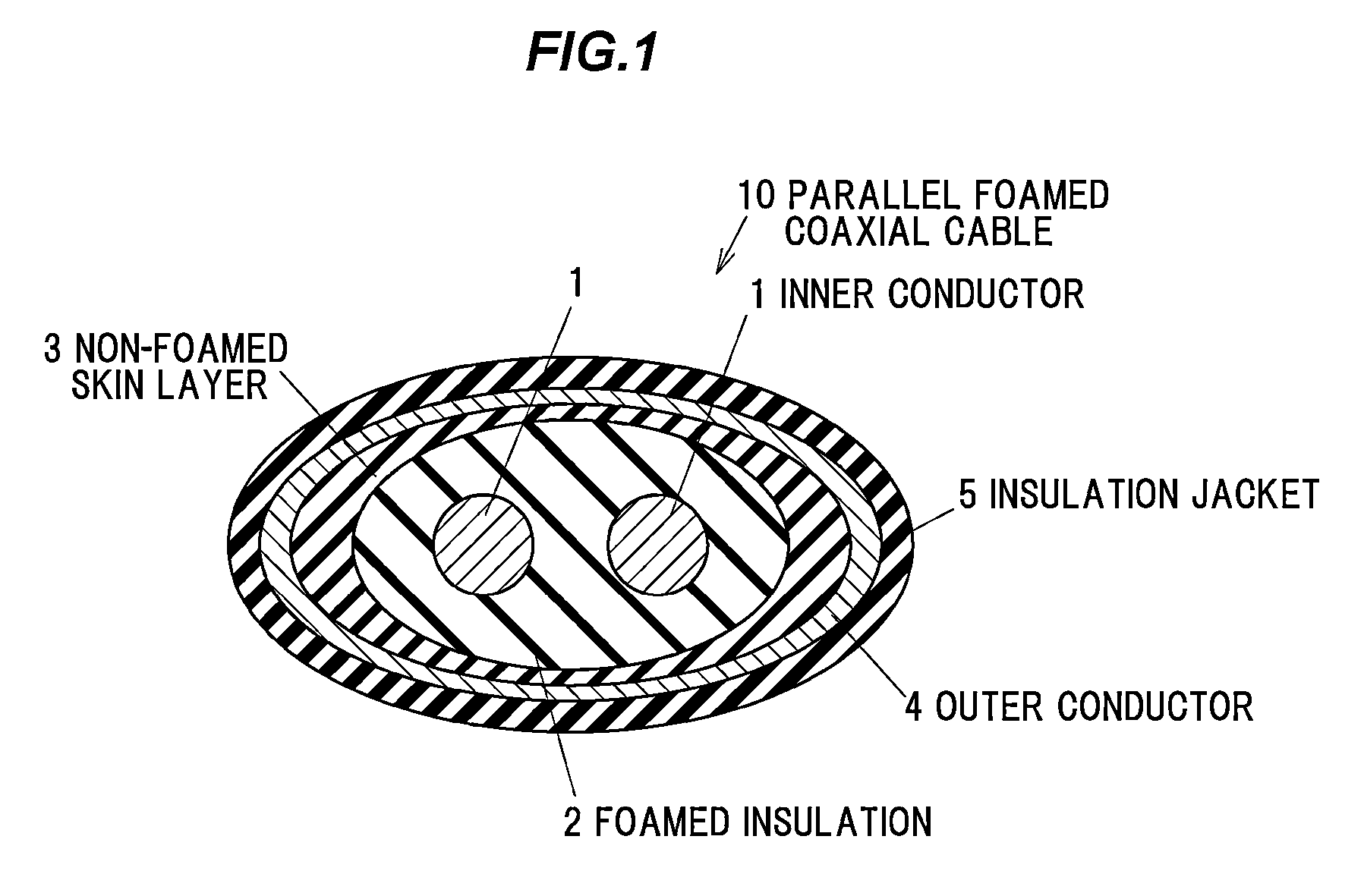

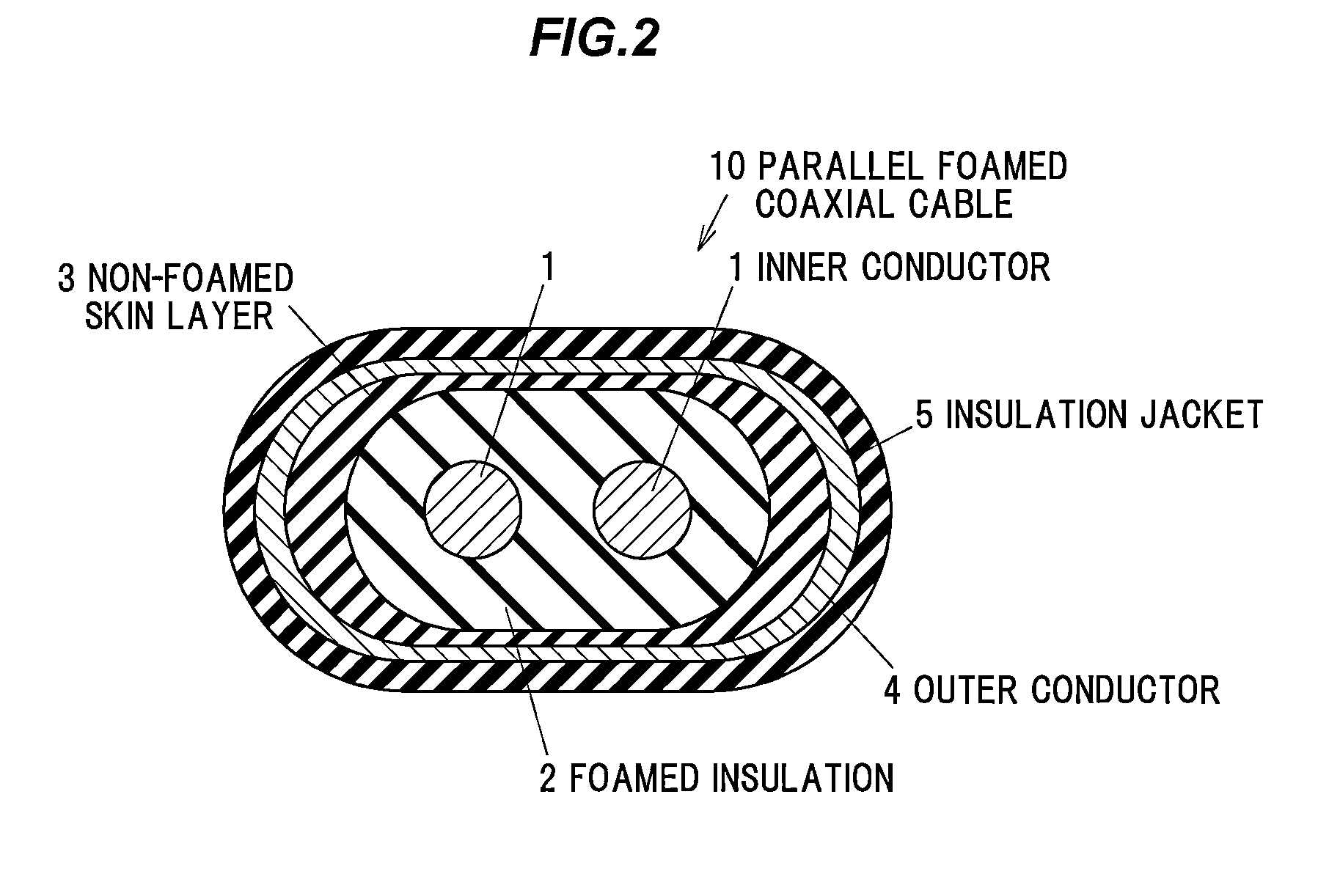

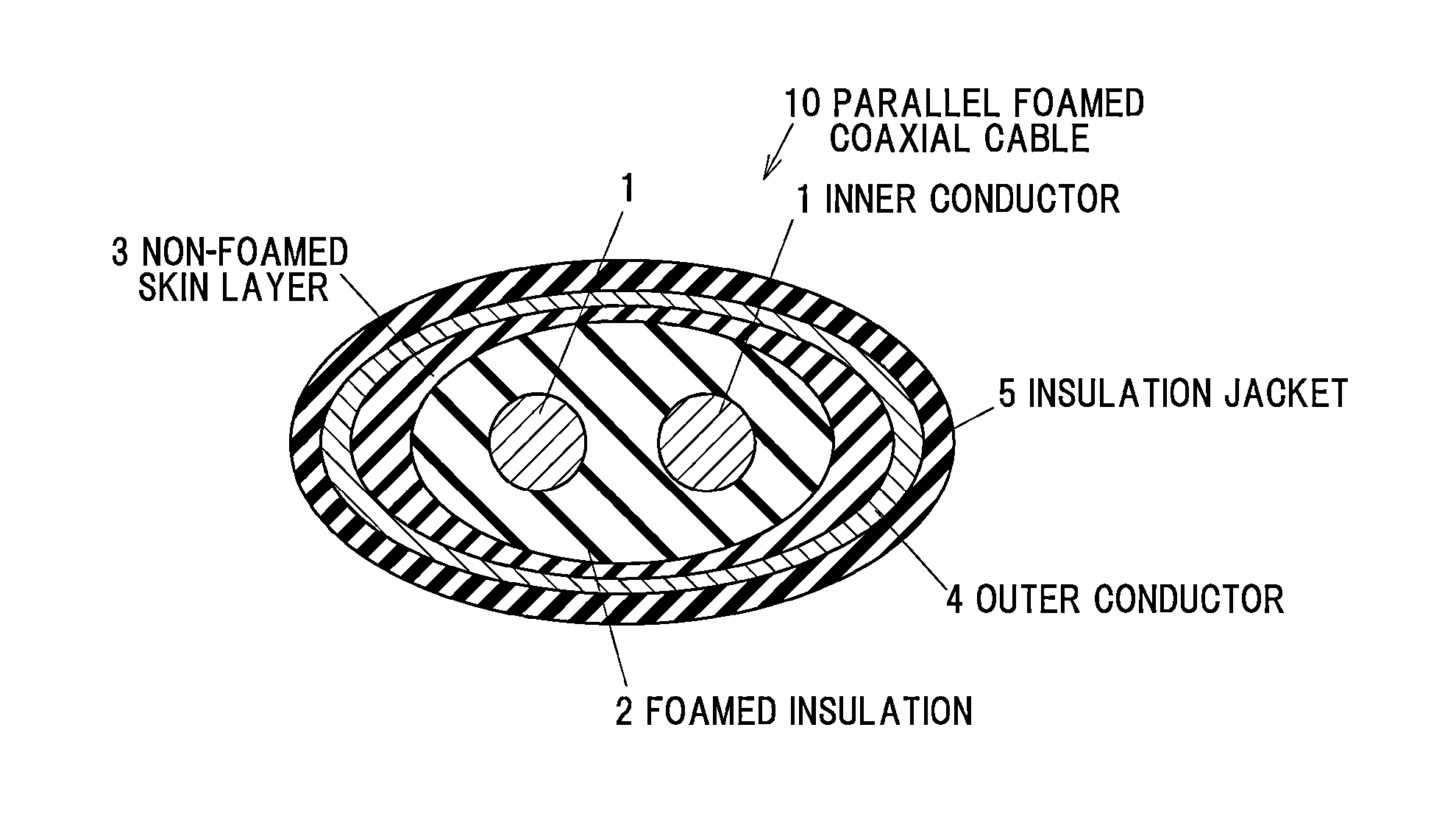

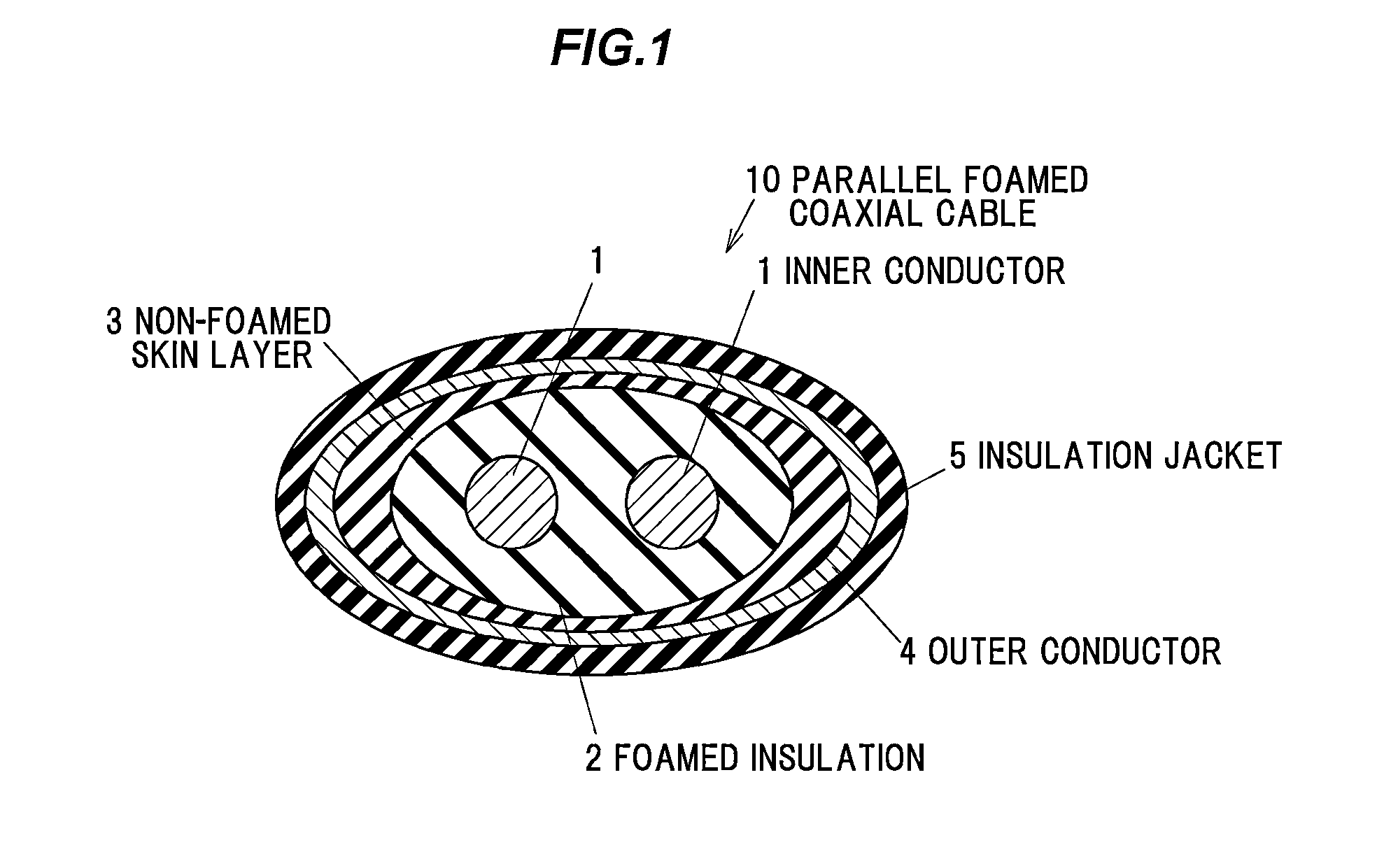

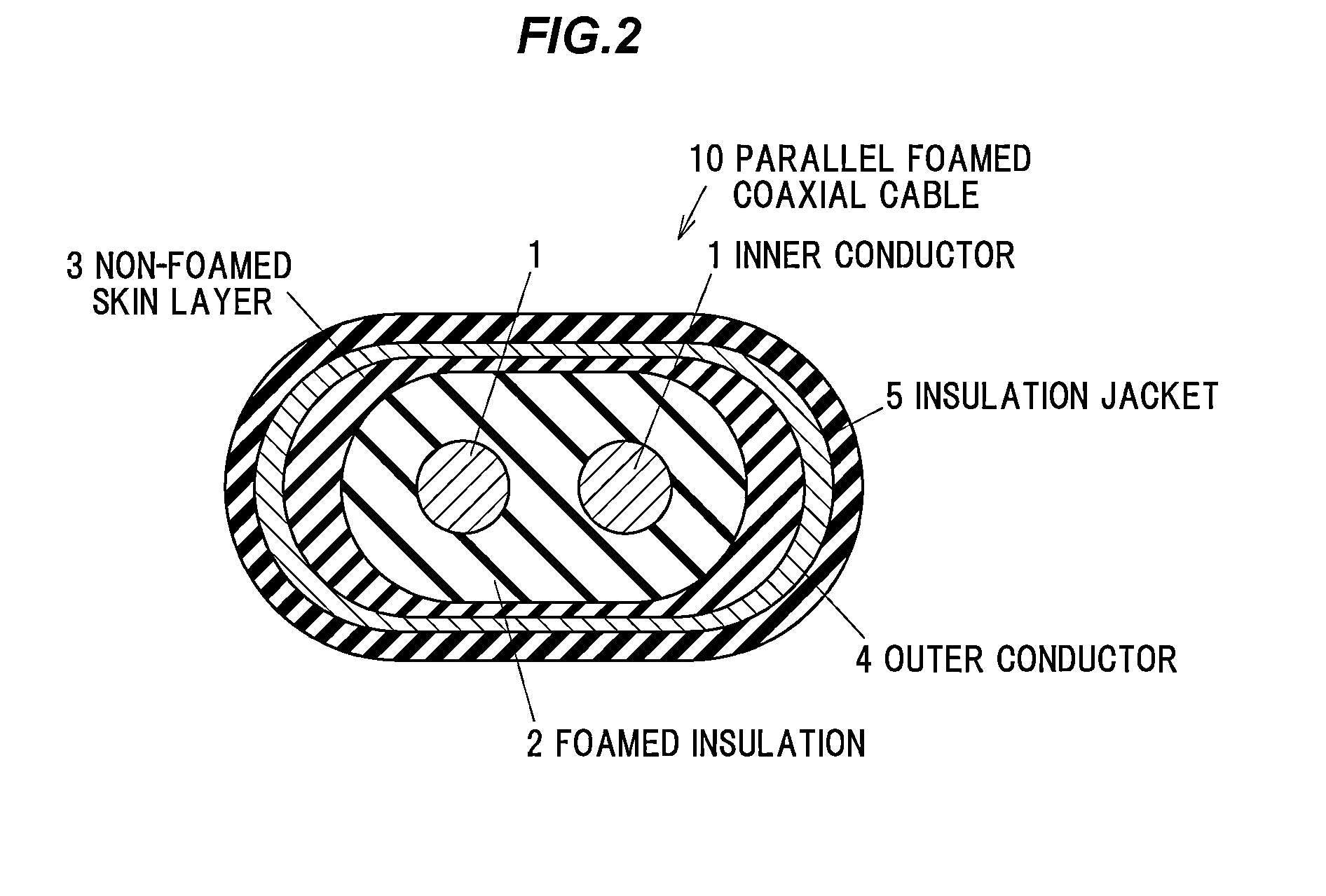

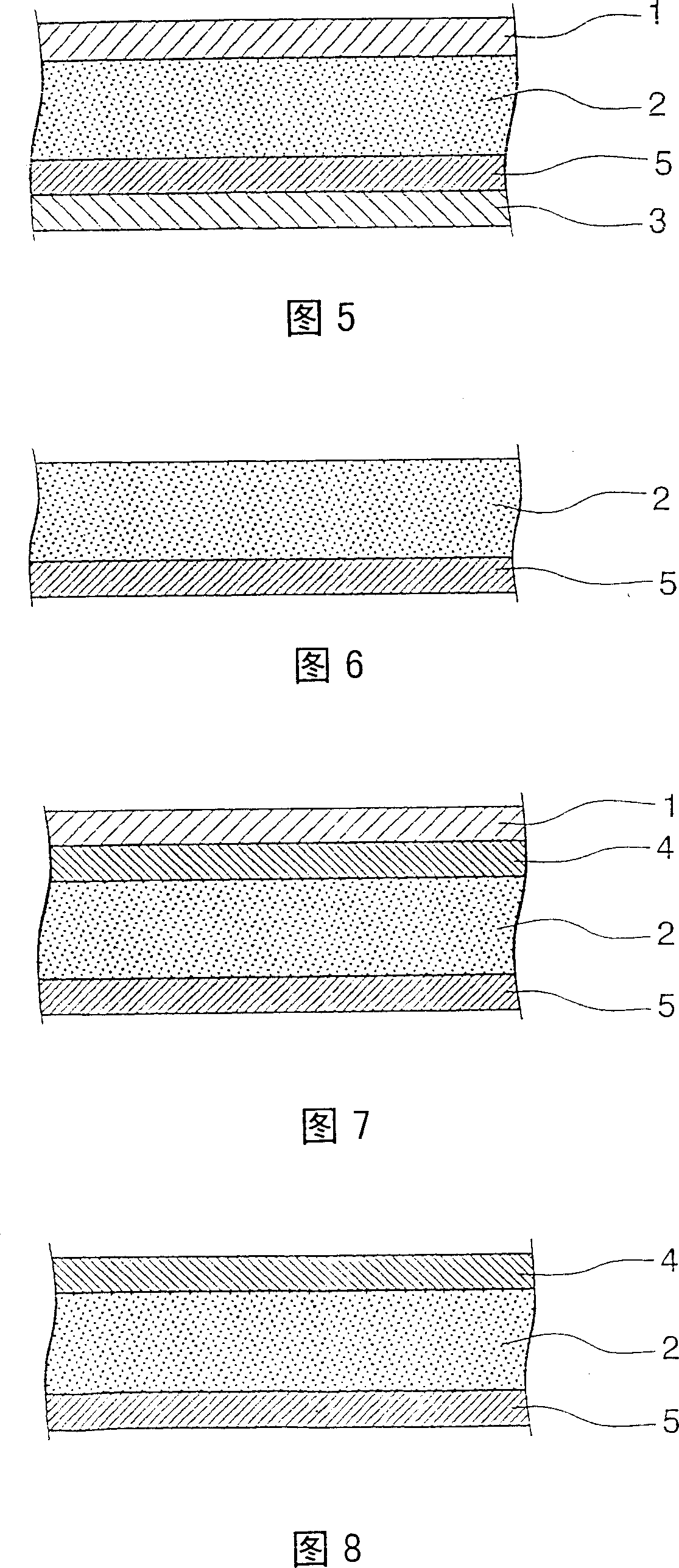

Parallel foamed coaxial cable

ActiveUS9064621B2Stable distanceImprove transfer rateCoaxial cables/analogue cablesPower cables with screens/conductive layersCoaxial cableElectrical conductor

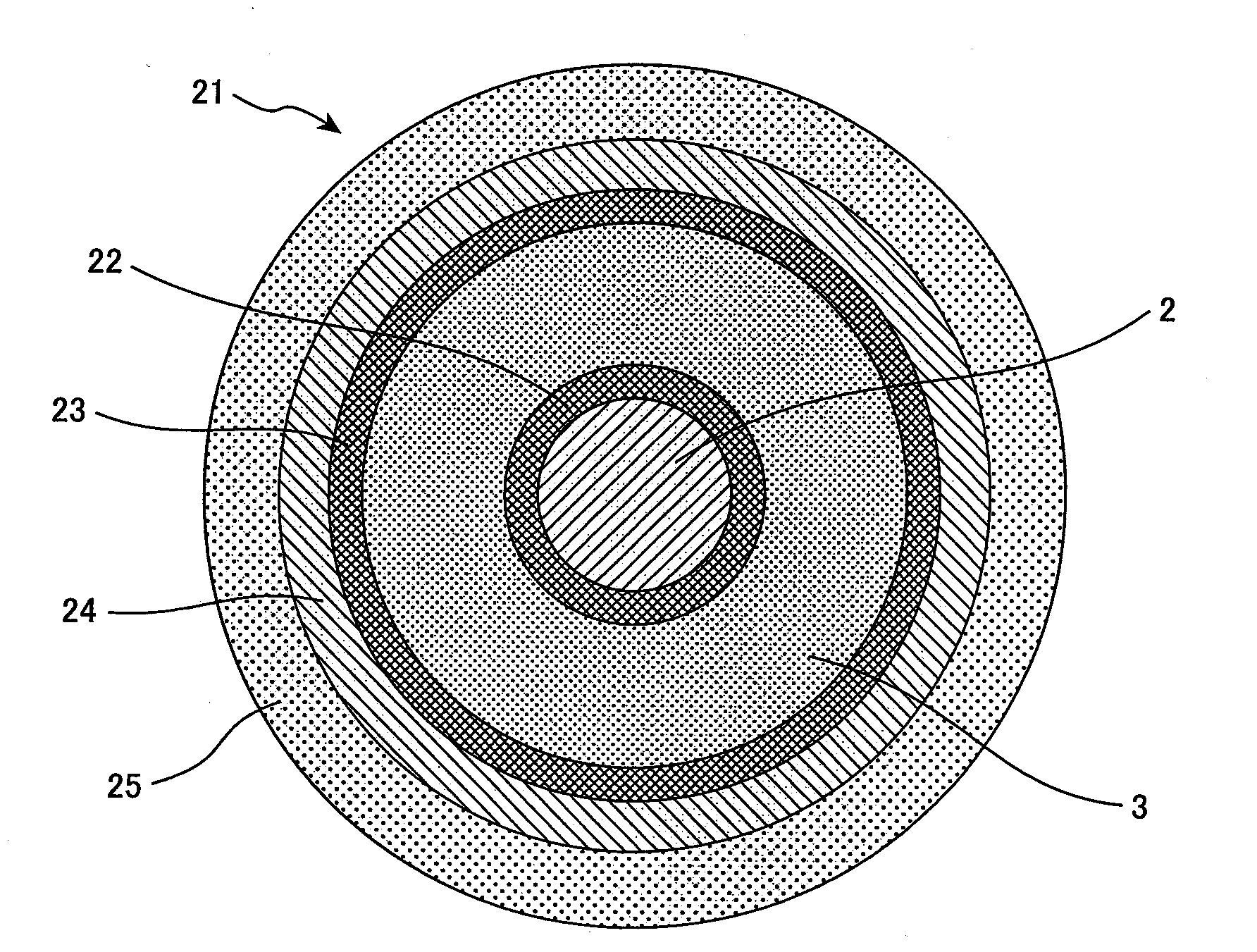

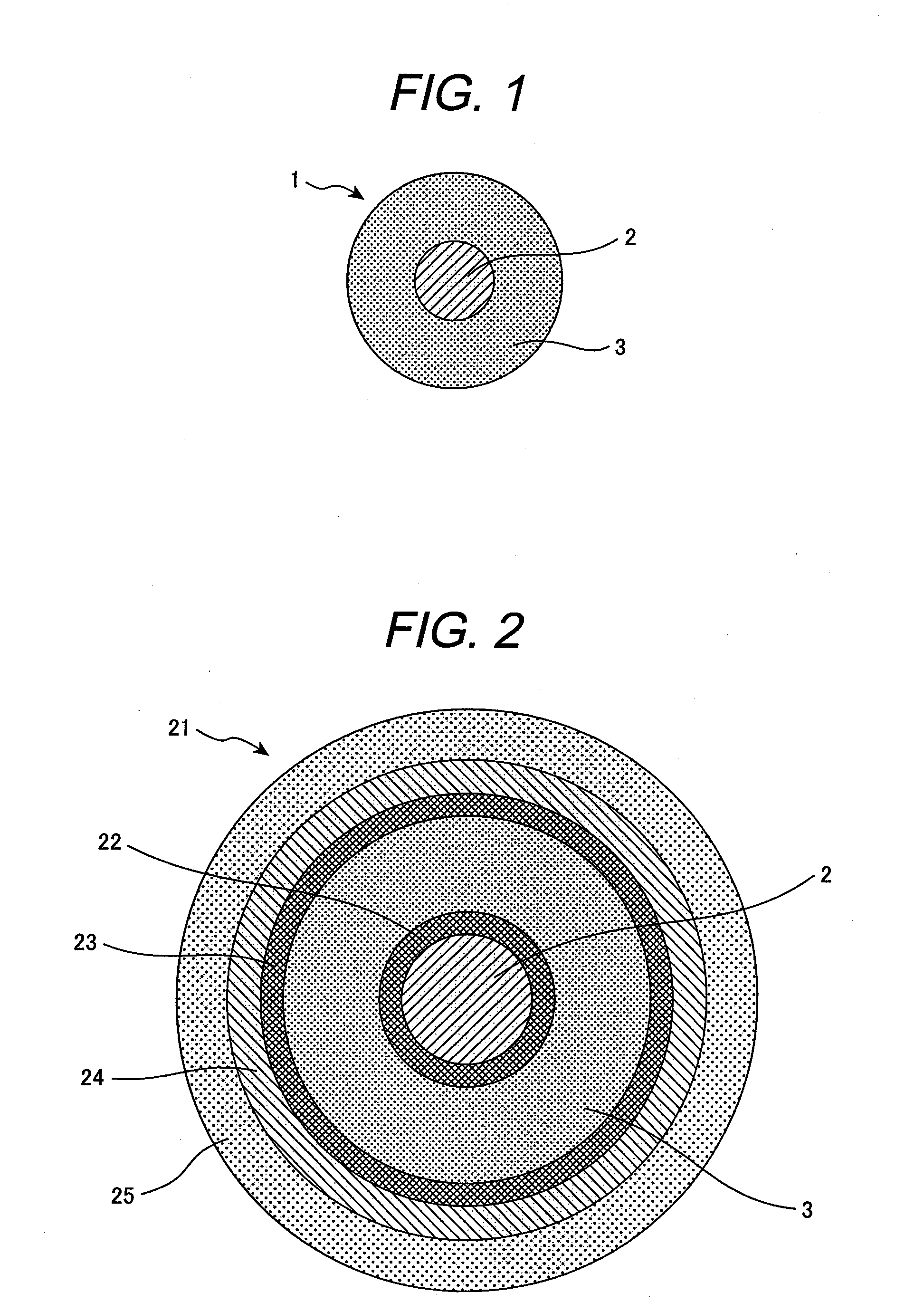

A parallel foamed coaxial cable includes one or more pairs of inner conductors aligned in parallel, a foamed insulation covering together the inner conductors and having a cross sectional shape including an elliptical shape, a rounded-rectangular shape or a quasi-elliptical shape formed by combining a plurality of curved lines, a non-foamed skin layer covering the foamed insulation and having a maximum thickness in a major axis direction of the cross sectional shape of the foamed insulation and a minimum thickness in a minor axis direction of the cross sectional shape of the foamed insulation, an outer conductor covering the non-foamed skin layer, and an insulation jacket covering the outer conductor. The maximum thickness of the non-foamed skin layer is not less than 1% of a major axis of the cross sectional shape of the foamed insulation.

Owner:HITACHI METALS LTD

Parallel foamed coaxial cable

ActiveUS20130180752A1Increase transmission rateReduce skewCoaxial cables/analogue cablesPower cables with screens/conductive layersEngineeringElectrical conductor

A parallel foamed coaxial cable includes one or more pairs of inner conductors aligned in parallel, a foamed insulation covering together the inner conductors and having a cross sectional shape including an elliptical shape, a rounded-rectangular shape or a quasi-elliptical shape formed by combining a plurality of curved lines, a non-foamed skin layer covering the foamed insulation and having a maximum thickness in a major axis direction of the cross sectional shape of the foamed insulation and a minimum thickness in a minor axis direction of the cross sectional shape of the foamed insulation, an outer conductor covering the non-foamed skin layer, and an insulation jacket covering the outer conductor. The maximum thickness of the non-foamed skin layer is not less than 1% of a major axis of the cross sectional shape of the foamed insulation.

Owner:HITACHI METALS LTD

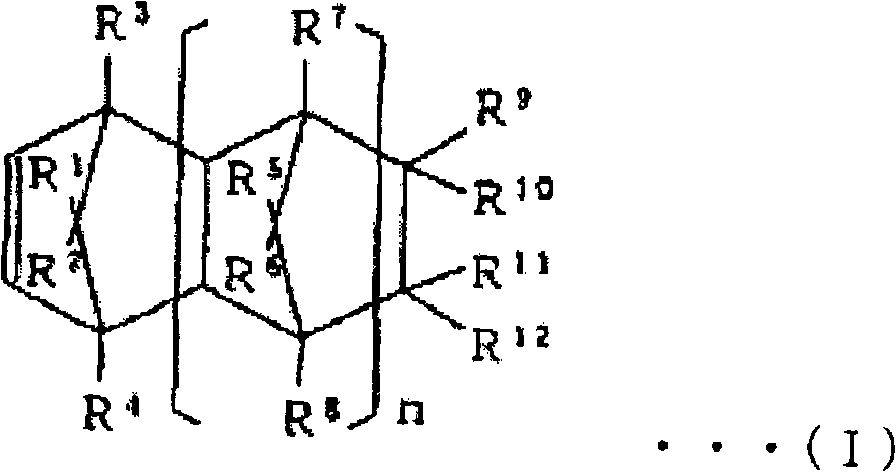

Expanded polyhydroxyalkanoate resin bead, molded object thereof, and process for producing the expanded resin bead

An object of the present invention is to provide expanded polyhydroxyalkanoate resin beads which are satisfactory and have biodegradability, the molded product thereof, and process for producing the expanded resin beads. The object can be achieved by expanded poly(3-hydroxyalkaonate) (abbreviatedtoP3HA) resin beads obtained from a P3HA resin composition comprising: a copolymer which comprises repeating units of one or more kinds represented by the formula (1): [-O-CHR-CH 2 -CO-] (wherein R is alkyl represented by CnH2n+1, provided that n is an integer of 1 to 15) and is yielded by a microorganism (this copolymer is P3HA); and an isocyanate compound, and having a melt viscosity of 500Pas or higher when examined under the conditions of a shear rate of 122 sec -1 and a temperature of from Tm1 to Tm2, wherein Tm1 is the melting temperature of the P3HA resin composition and Tm2=Tm1+20 DEG C, provided that Tm2<180 DEG C.

Owner:KANEKA CORP

Expanded polyhydroxyalkanoate resin bead, molded object thereof, and process for producing the expanded resin bead

An object of the present invention is to provide expanded polyhydroxyalkanoate resin beads which are satisfactory and have biodegradability, the molded product thereof, and process for producing the expanded resin beads. The object can be achieved by expanded poly(3-hydroxyalkaonate) (abbreviated to P3HA) resin beads obtained from a P3HA resin composition comprising: a copolymer which comprises repeating units of one or more kinds represented by the formula (1): [—O—CHR—CH2—CO—] (wherein R is alkyl represented by CnH2n+1, provided that n is an integer of 1-15) and is yielded by a microorganism (this copolymer is P3HA); and an isocyanate compound, and having a melt viscosity of 500 Pa·s or higher when examined under the conditions of a shear rate of 122 sec−1 and a temperature of from Tm1 to Tm2, wherein Tm1 is the melting temperature of the P3HA resin composition and Tm2=Tm1+20° C., provided that Tm2<180° C.

Owner:KANEKA CORP

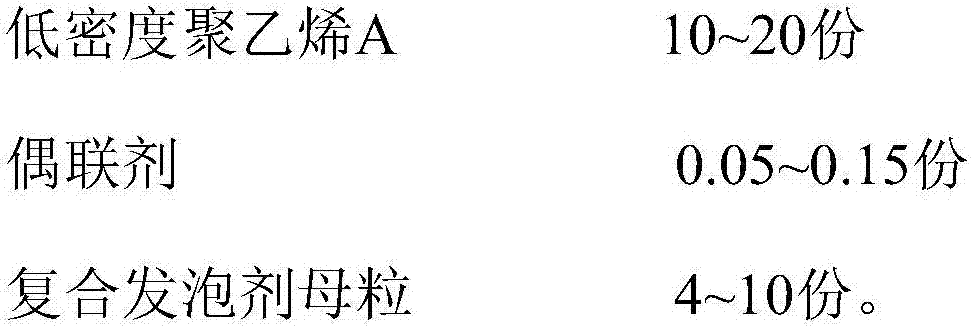

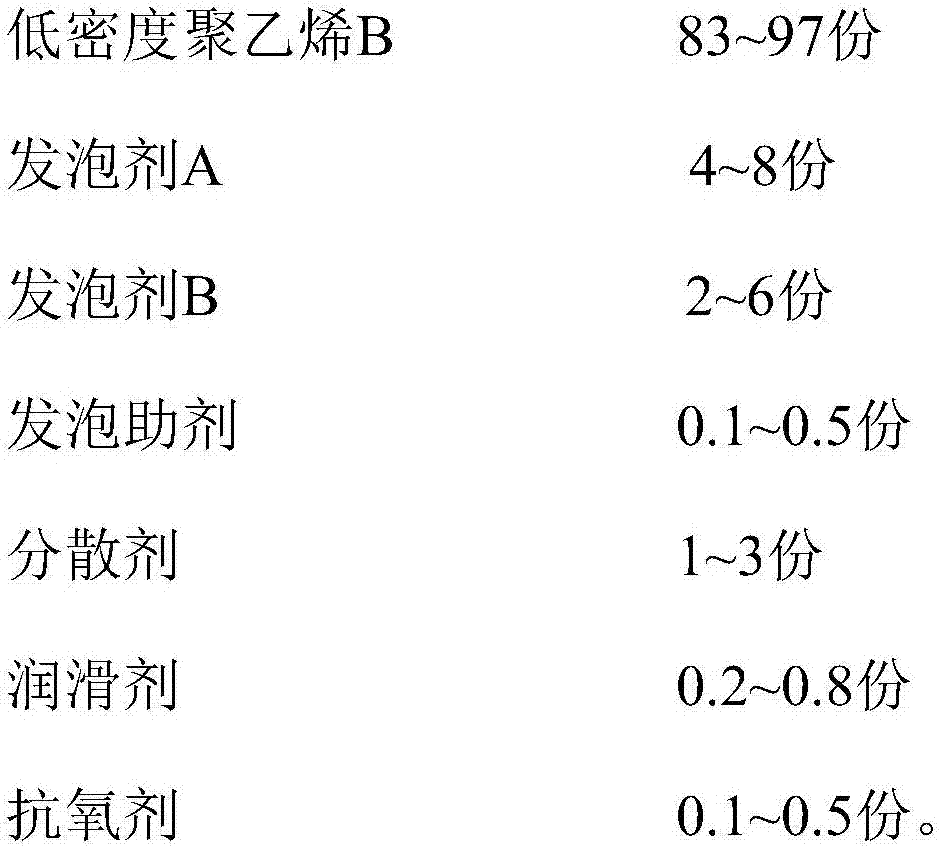

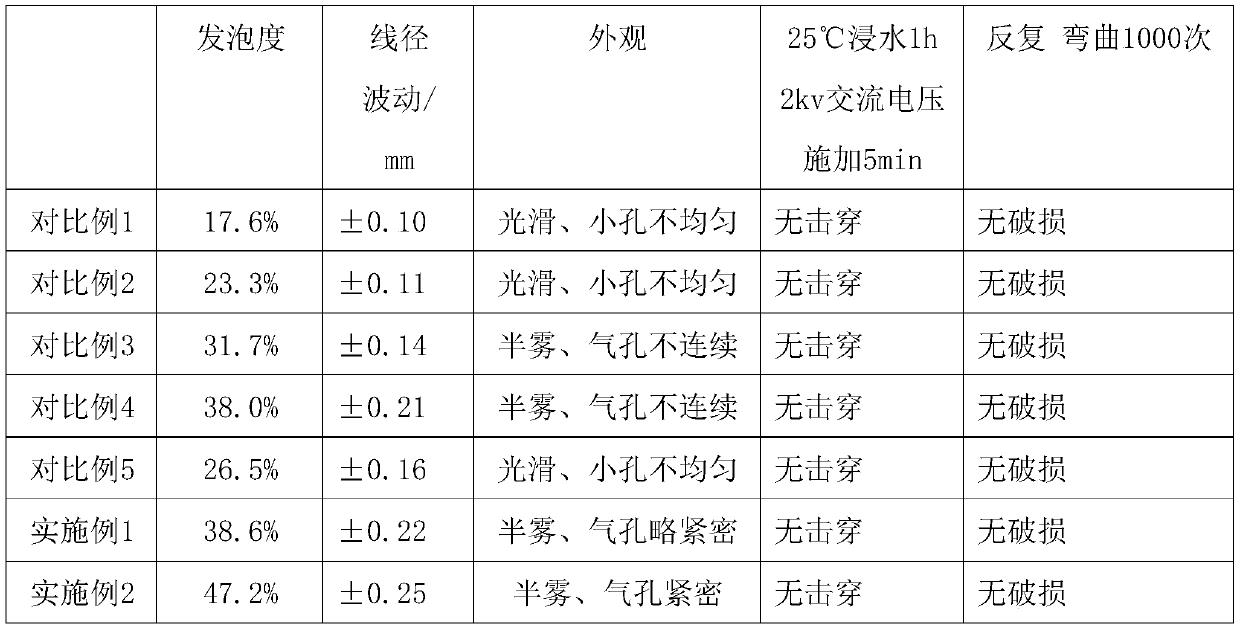

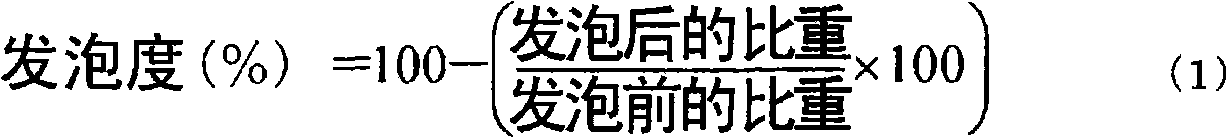

Chemical foaming polyethylene composition, preparation method and applications thereof

InactiveCN106947153AHigh foamingImprove mechanical propertiesPlastic/resin/waxes insulatorsLow-density polyethyleneFoaming agent

The present invention discloses a chemical foaming polyethylene composition, a preparation method and applications thereof, wherein the chemical foaming polyethylene composition is prepared from the following components by weight: 70-86 parts of high-density polyethylene, 10-20 parts of low-density polyethylene A, 0.05-0.15 part of a coupling agent, and 4-10 parts of composite foaming agent master batch. According to the present invention, the chemical foaming polyethylene composition retains the high foaming degree of the low-density polyethylene foaming material and the good mechanical property of the high-density polyethylene chemical foaming material so as to obtain the foaming insulation layer having the good electrical property. Another purpose of the present invention is to provide the preparation method of the chemical foaming polyethylene composition, wherein the preparation method is simple and is easy to operate. The present invention further provides uses of the chemical foaming polyethylene composition in preparation of communication cables.

Owner:广州敬信高聚物科技有限公司

Resin composition, foamed resin using same, and electric wire insulated with foamed resin

InactiveUS9115254B2High foamingUniform fine bubblePlastic/resin/waxes insulatorsGlass transitionPolyresin

Owner:HITACHI METALS LTD

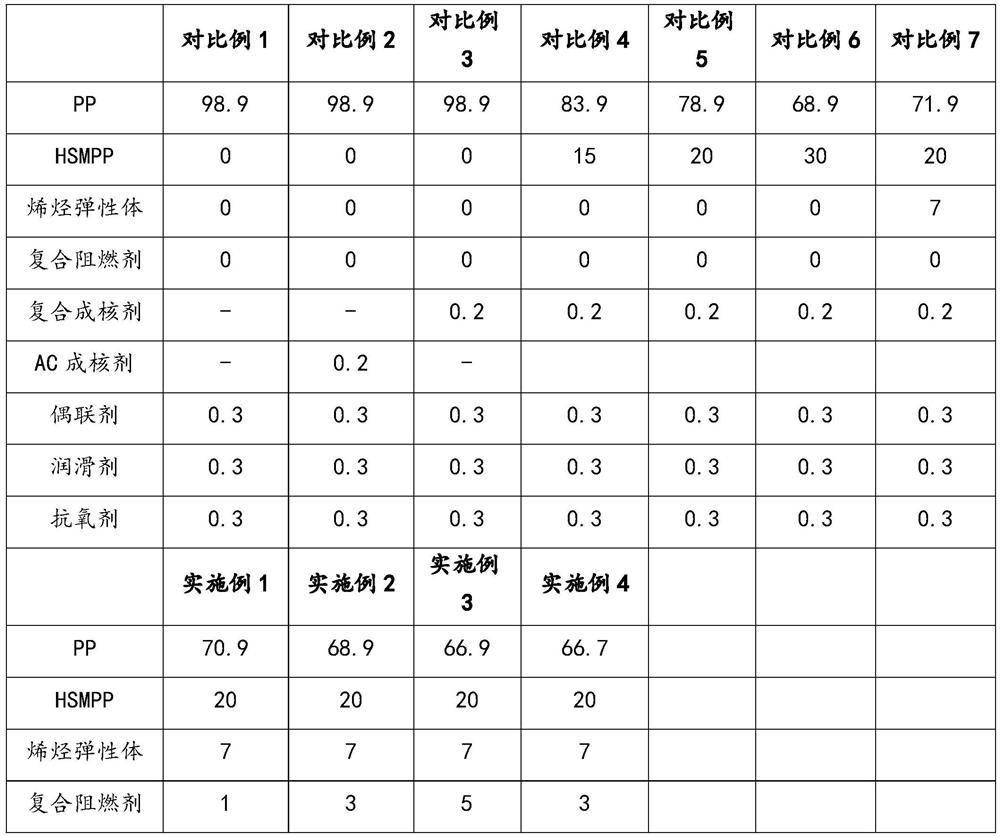

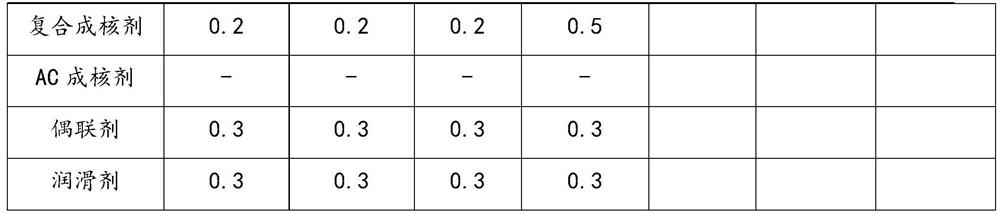

Flame-retardant physical polypropylene foam composition and preparation method thereof

The invention discloses a flame-retardant physical foaming polypropylene composition, which is prepared from the following components in percentage by weight: 36.5 to 85.6 percent of polypropylene, 10 to 40 percent of high melt strength polypropylene, 1 to 5 percent of a composite flame retardant, 3 to 15 percent of an olefin elastomer, 0.1 to 0.5 percent of a composite nucleating agent, 0.1 to 1 percent of an antioxidant, 0.1 to 1 percent of a silane coupling agent and 0.1 to 1 percent of a lubricant, wherein the polypropylene is polypropylene of other types except the polypropylene with high melt strength. The invention also provides a preparation method of the polypropylene foam composition. The polypropylene foam composition disclosed by the invention has the advantages of uniform foam pores, high physical heat resistance, flame retardance and self-extinguishing.

Owner:广州敬信高聚物科技有限公司

Bed mattress using permeable reinforcing member and foaming material, and method of manufacturing the same

ActiveUS7721367B2High foamingImprove the bonding force between layersUpholstery manufactureStuffed mattressesMechanical engineeringMaterials science

Disclosed herein is a bed mattress and a method of manufacturing the same, in which a permeable reinforcing member is provided at an upper portion and a lower portion of a spring assembly which is one of frame constituents of the bed mattress, and a foaming material is disposed on the permeable reinforcing member so as to be foamed, so that the spring assembly and the foaming material are integrally formed while the foaming material is expanded through fine holes and / or foam expansion holes of the permeable reinforcing member.

Owner:ACE BED CO LTD

Physical foaming thermoplastic elastomer composition for floating cable and preparation method thereof

The invention discloses a physical foaming thermoplastic elastomer composition for a floating cable. The physical foaming thermoplastic elastomer composition comprises the following components in parts by weight: 20 to 50 parts of softening plasticizer; 28 to 35 parts of SEBS (styrene-ethylene-butadiene-styrene) 25 to 28 parts of polypropylene, 8 to 12 parts of polyolefin elastomer, 5 to 9 parts of a compatilizer, 1 to 2 parts of silicone master batch, 0.5 to 1 part of a foaming agent and 0.05 to 0.1 part of an antioxidant. The invention also discloses a preparation method of the physical foaming thermoplastic elastomer composition for the floating cable. The physical foaming thermoplastic elastomer composition for the floating cable has the characteristics of uniform foam holes, good mechanical property, low-temperature resistance and good weather resistance; and the floating cable prepared from the composition has the advantages of good mechanical property, fatigue resistance, lightand heat resistance and uniform foaming, and can be well bonded with part of polar materials.

Owner:广州敬信高聚物科技有限公司

Manufacturing process of polyurethane foam sheet and layered sheet using the same

InactiveCN1328037CControllable shapeUniform shapeSynthetic resin layered productsLaminationWood veneerCushioning

A method of producing a polyurethane foam sheet, and a laminated sheet that uses such a foam sheet, that can be applied to artificial leather, synthetic leather, and cushioning materials used in all manner of applications. A polyurethane foam sheet is produced by applying a liquid mixture, obtained by mixing together a heated and melted hot melt urethane prepolymer (A) containing isocyanate groups at molecular terminals, and a compound (B) containing at least 2 active hydrogen atom-containing groups, onto a substrate in a sheet-like manner, and then water foaming the liquid mixture by bringing the sheet-like liquid mixture into contact with water vapor or moisture (water). A laminated sheet is produced by bonding a third substrate to the polyurethane foam sheet.

Owner:DIC CORPORATION

High frequency data cable of 1200 MHz

InactiveCN105448420AHigh foamingLow dielectric constantCable/conductor manufactureCables with twisted pairs/quadsSignal qualityPolyolefin

The present invention discloses a high frequency data cable of 1200 MHz. The high frequency data cable of 1200 MHz comprises a cable core unit, and the cable core unit includes four shielding subunits; each shielding subunit includes a pair of stranded wires with stranding pitches, each pair of stranded wires with stranding pitches consisting of two insulated single lines with different colors and high foaming; a low smoke zero halogen flame retardant polyolefin outer sheath coats a cable core unit; the cable core unit and the low smoke zero halogen flame retardant polyolefin outer sheath coat a single-face plastic-coated aluminum foil shielding layer and a braided prismatic tinned wire shielding layer in turn from the inside out. Through adoption of a copper wire polishing technology and an insulated wire core back-twist technology, the return loss of cables caused during transmission is reduced; through adoption of insulated single lines with high foaming, the transmission loss of cables is reduced, and transmission rate is enhanced, so that the requirement of 1200MHz high frequency transmission is satisfied; and moreover, through adoption of the modes of wire pair shielding, the aluminum foil shielding and tinned wire braiding shielding and the unique shielding technological structure of each shielding layer, the signal quality is improved.

Owner:JIANGSU DONGQIANG

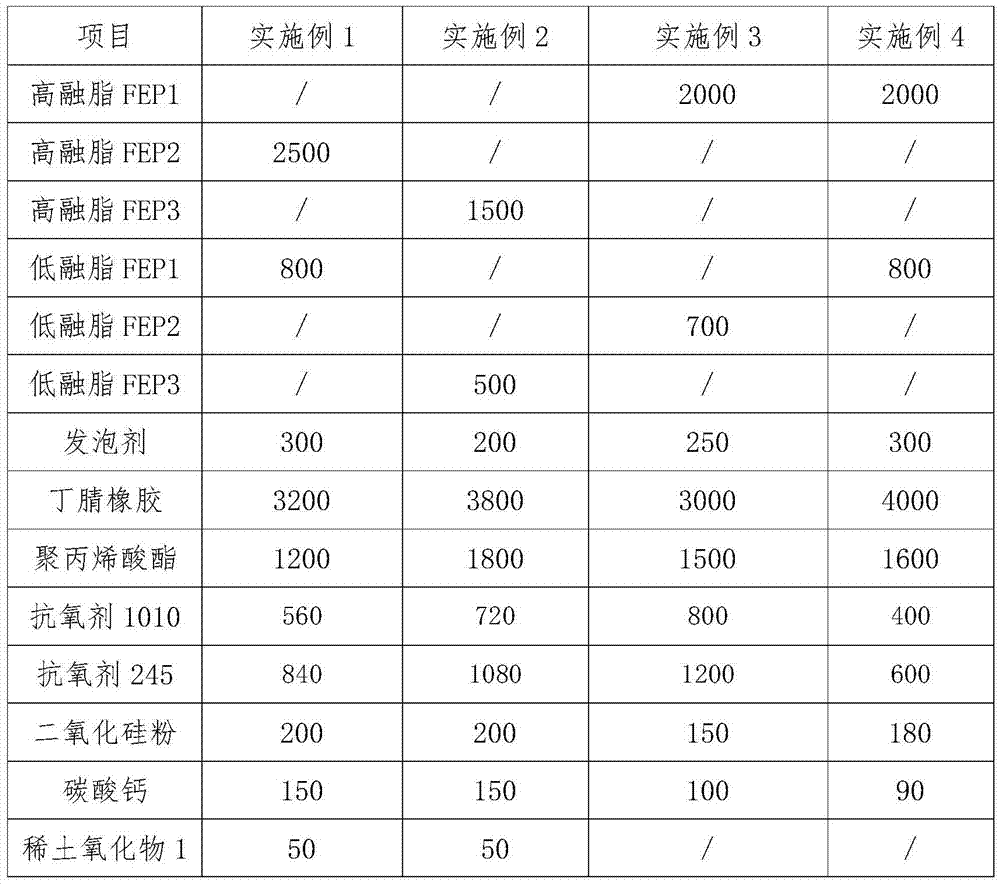

Foamed sheath for foamed FEP (fluorinated ethylene propylene) cables and preparation method thereof

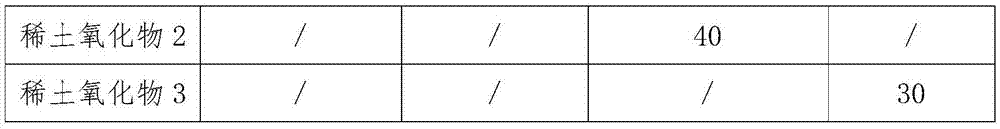

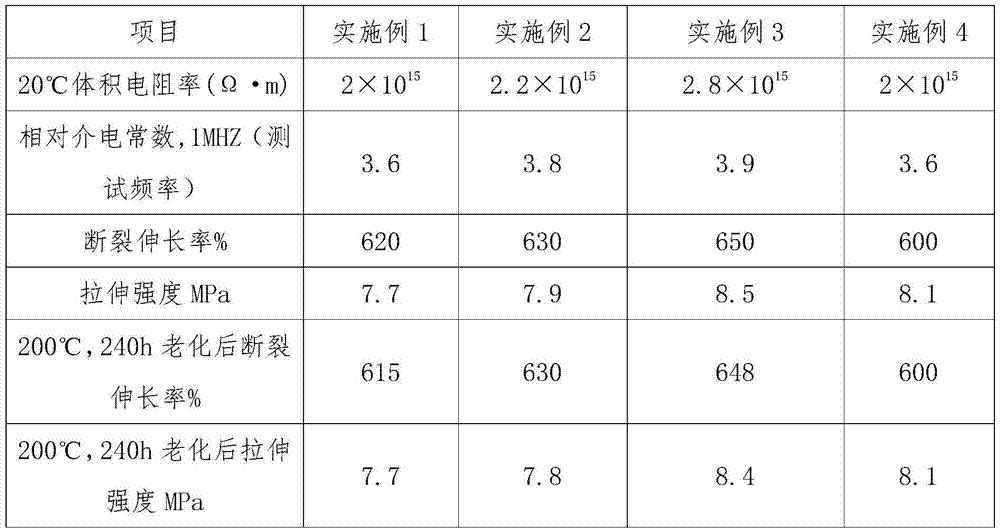

The invention relates to a foamed sheath for foamed FEP (fluorinated ethylene propylene) cables and a preparation method thereof. The foamed sheath for foamed FEP cables comprises the following components in percentage by weight: 15-25% of high-melt-index FEP, 5-8% of low-melt-index FEP, 2-3% of foaming agent, 25-40% of nitrile-butadiene rubber, 12-18% of polyacrylate, 10-20% of composite antioxidant, 1.5-2% of silicon dioxide powder, 0.5-1.5% of calcium carbonate and 0.2-0.5% of rare-earth oxide. The invention also relates to a preparation method of the foamed sheath. Compared with the prior art, the high-melt-index and low-melt-index mixture is adopted to enhance the toughness and foaming degree of the foamed sheath and lower the possibility of melt fracture. Certain amounts of calcium carbonate and silicon dioxide powder are added into the materials to improve the properties of the sheath and lower the cable attenuation and cable echo loss.

Owner:GANZHOU JINXINNUO CABLE TECH

Leakage cable for train ground wireless transmission signal system

ActiveCN104966874AReduce transmission lossLong transmission distanceWaveguidesIsosceles trapezoidCoupling loss

The invention provides a leakage cable for a train ground wireless transmission signal system, which comprises an outer sheath, a longitudinal covering copper strip outer conductor, a physical foaming insulator and a spiral corrugated copper tube inner conductor, wherein multiple profiled gaps are arranged on the longitudinal covering copper strip outer conductor along the axial direction; the profiled gaps are rectangular, the middle part of one long edge of the rectangle extends towards the opposite edge to form an isosceles trapezoid protruding part, the central point of the bottom edge of the isosceles trapezoid protruding part coincides with the central point of the long edge of the rectangle of the isosceles trapezoid protruding part, directions of the isosceles trapezoid protruding parts on adjacent two profiled gaps are opposite, and the multiple profiled gaps are arranged axially along the longitudinal covering copper strip outer conductor. The leakage cable for the train ground wireless transmission signal system can meet requirements of signal transmission of multiple frequency bands of the train ground wireless transmission signal system in the urban rail transit field, can be well applied to the train ground wireless transmission signal system, and has the advantages of little transmission loss, little coupling loss, and long transmission distance.

Owner:JIAOZUO RAILWAY CABLE +2

Foaming agent for oilfield, and preparation method thereof

The invention discloses a foaming agent for oilfield. The foaming agent is prepared from the following raw materials in percentage by mass: 10%-20% of dodecyl dimethyl betaine, 5%-15% of lauramidopropyl betaine, 3%-10% of caprylyl / capryl glucoside, 1%-5% of butanediol, and 55%-80% of deionized water, wherein the sum of weight percentages of the components is 100%. The invention further discloses a preparation method of the foaming agent. The foaming agent for oilfield can be used for oil-gas field development operation of oil-gas well drilling, oil-gas well pigging and washing, gas well cracking, gas well drainage and gas recovery and the like, especially for the ultralow-permeability oil-gas area in the north of Shanxi province, the foaming agent has a good foaming effect in stratum water with the mineralization degree of 20*10<4>mg / L and the stratum with the temperature of 130DEG C, and has obvious commercial effect in practical site use.

Owner:陕西延长石油油田化学科技有限责任公司

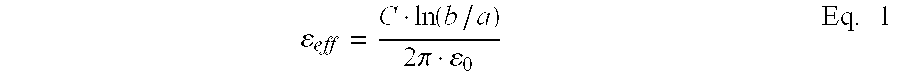

Coaxial cable

InactiveCN101809680ASufficient lateral pressure resistanceReduce lossPlastic/resin/waxes insulatorsCable insulation constructionLow-density polyethyleneLinear low-density polyethylene

This invention provides a high-frequency coaxial cable comprising an inner conductor and an insulator layer covering the surface of the inner conductor. In the coaxial cable, the insulator layer has satisfactory side pressure resistance, and the attenuation level in the transmission is low. An insulating layer having a higher foaming level and a higher mechanical strength as compared with the conventional insulating layer can be formed by foam molding a resin composition comprising a cyclic olefin resin, a high-density polyethylene, and a low-density polyethylene and / or a linear low-density polyethylene. As a result, the insulator layer covered on the inner conductor in the coaxial cable has lowered dielectric loss tangent and lowered permittivity and possesses excellent transmission characteristics and mechanical properties.

Owner:POLYPLASTICS CO LTD

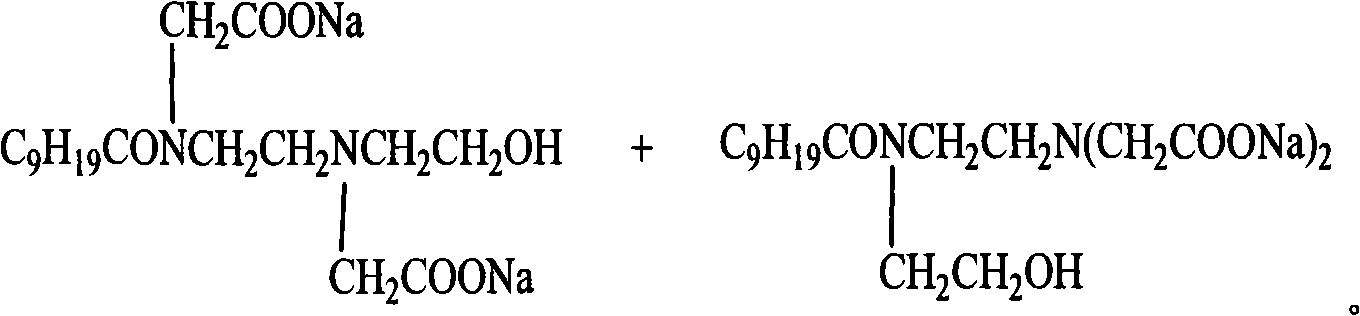

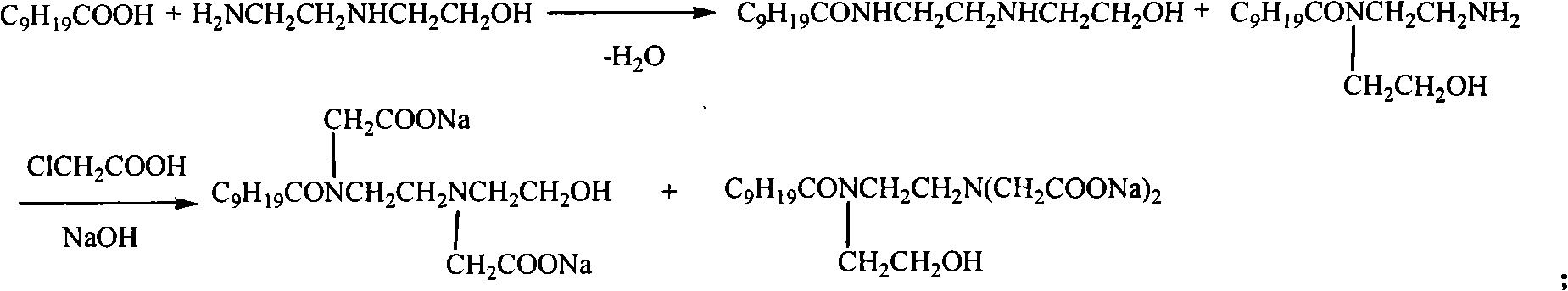

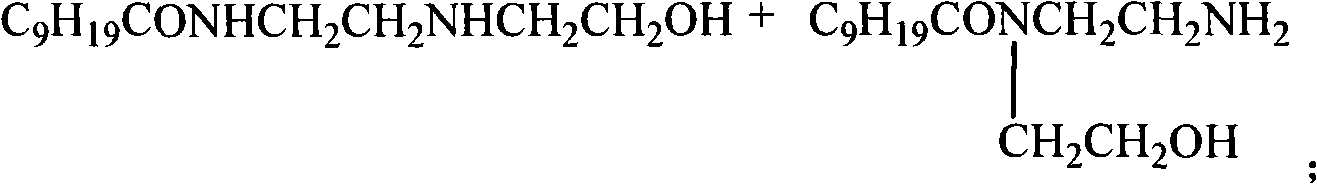

Dicarboxy capric acid acidamide surfactant and synthetic method

InactiveCN101254439AHigh foamingLess irritatingTransportation and packagingMixingChemical industryChloroacetic acids

A dicarboxyl capric amide surfactant and a synthetic method thereof are provided. The inventive dicarboxyl capric amide surfactant has the structural formula as above. The synthetic method is novel in the direct synthesis of amide surfactants by vacuum-amphoteric method without ring closing reactions. The method includes the following steps: synthesizing a dicarboxyl capric amide surfactant intermediate from capric acid and hydroxyethylethylene diamine as raw materials, and then performing amphoteric reaction by 'chloroacetic acid process' to obtain the dicarboxyl capric amide surfactant, wherein the mole ratio of intermediate to chloroacetic acid to NaOH is 1:2-2.6:4-5.2. The inventive dicarboxyl capric amide surfactant has good forming performance, low irritation, and good washing, wetting and penetrating performance, and can be used as a cleaning agent in daily chemical industry, a softening agent in textile industry, a corrosion inhibitor and a foaming agent.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

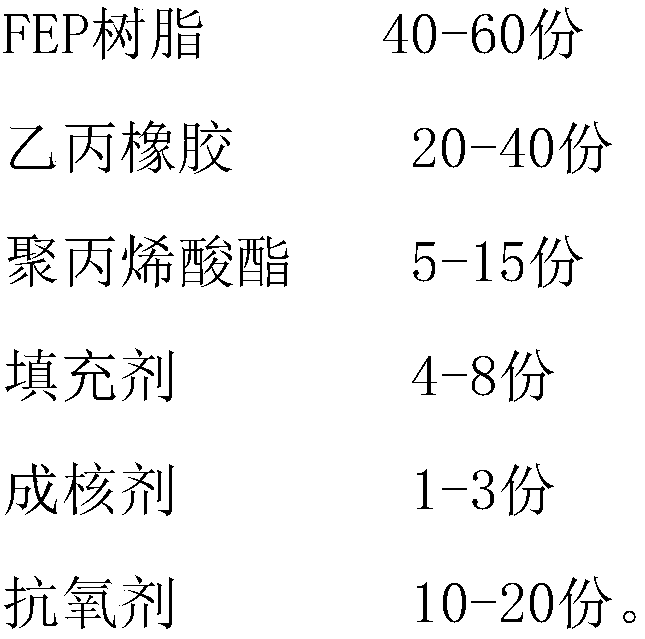

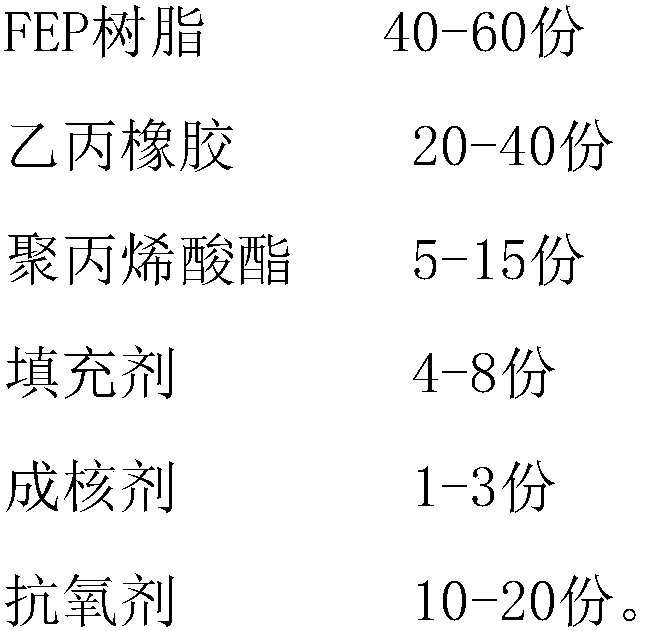

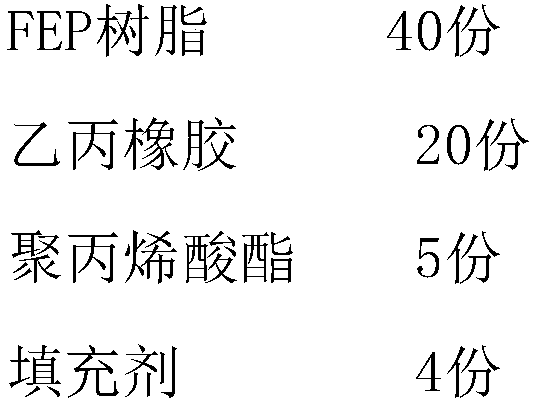

High speed signal transmission cable insulating material with extrusion resistance and foaming technology thereof

The invention relates to the technical field of high speed cables, and more specifically relates to a high speed signal transmission cable insulating material with extrusion resistance and a foaming technology thereof. The high speed signal transmission cable insulating material with extrusion resistance comprises the following raw materials in parts by weight: 40-60 parts of FEP resin, 20-40 parts of EP rubbers, 5-15 parts of polyacrylate, 4-8 parts of a filler, 1-3 parts of a nucleating agent, and 10-20 parts of an anti-oxidant. The high speed signal transmission cable insulating material with extrusion resistance has the advantages of better strength, toughness as well as heatproof and fireproof performances; after the product is extruded by outside force, because the strength is high,the deformation rate is obviously small, and the product also has a certain self-repairing function.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD

Thermo-expansive microcapsule, production process of expanded product and expanded product thereof

ActiveUS7566498B2Improve heat resistanceImprove performanceFatty substance preservation using additivesGlass/slag layered productsSide chainBlowing agent

Owner:MATSUMOTO YUSHI SEIYAKU

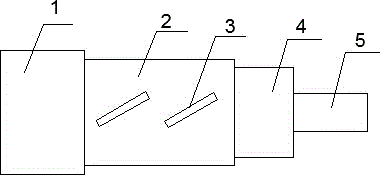

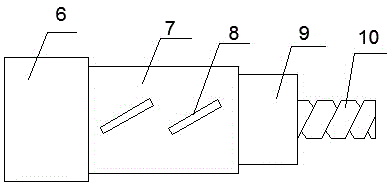

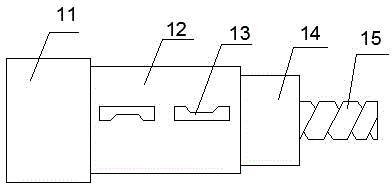

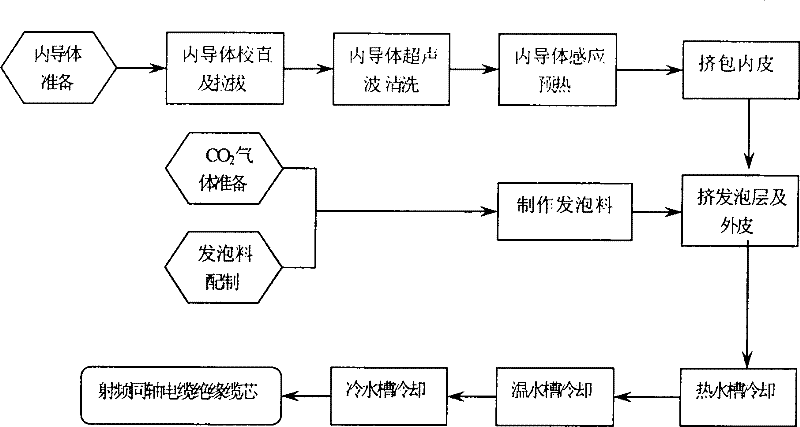

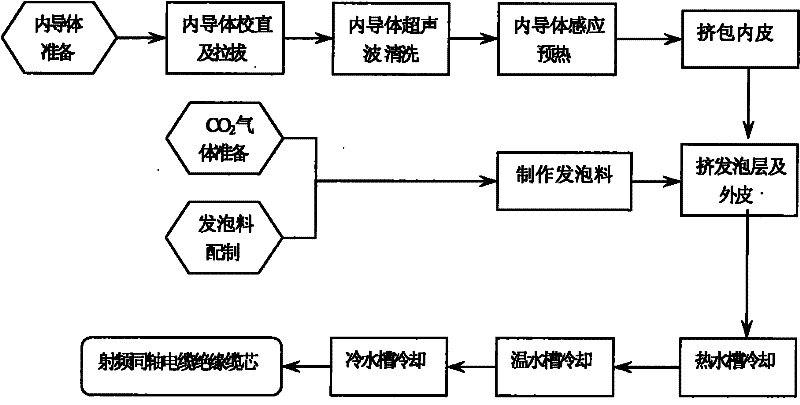

Carbon dioxide physically foamed radio frequency coaxial cable insulation cable core manufacturing method

ActiveCN101640083BImprove the attenuation effectReduce performance degradationManufacturing co-axial cablesInsulating conductors/cablesLow-density polyethyleneElectrical conductor

The invention relates to a method for manufacturing high foaming carbon dioxide physically foamed radio frequency coaxial cable insulating cores, in particular to a production process for radio frequency coaxial cable insulating cores used in the third generation data mobile communication 3G. The production method is as follows: (1) The inner conductor of the insulating cable core is straightened, sized, and ultrasonically cleaned, and after preheating, the inner skin layer is extruded by an extruder; (2) The foaming material is prepared, which is made of high-density polyethylene, Low-density polyethylene and nucleating agent are mixed and melted into a polymer at a high temperature of 180-220°C in the extruder; (3) Liquid carbon dioxide is injected into the melted polymer in the extruder through a small hole gas injection needle under high pressure Carbon dioxide foaming agent; (4) At high temperature, through the rotation of the extruder screw, the molten polymer and carbon dioxide foaming agent are uniformly mixed; (5) The mixture is extruded on the 3G radio frequency coaxial cable through the extruder head The periphery of the inner conductor is foamed to make a foamed insulating cable core; (6) The foamed insulating cable core is made into a carbon dioxide physically foamed radio frequency coaxial cable insulating cable core after three-stage cooling treatment.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com