Patents

Literature

320results about How to "Improve foaming quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

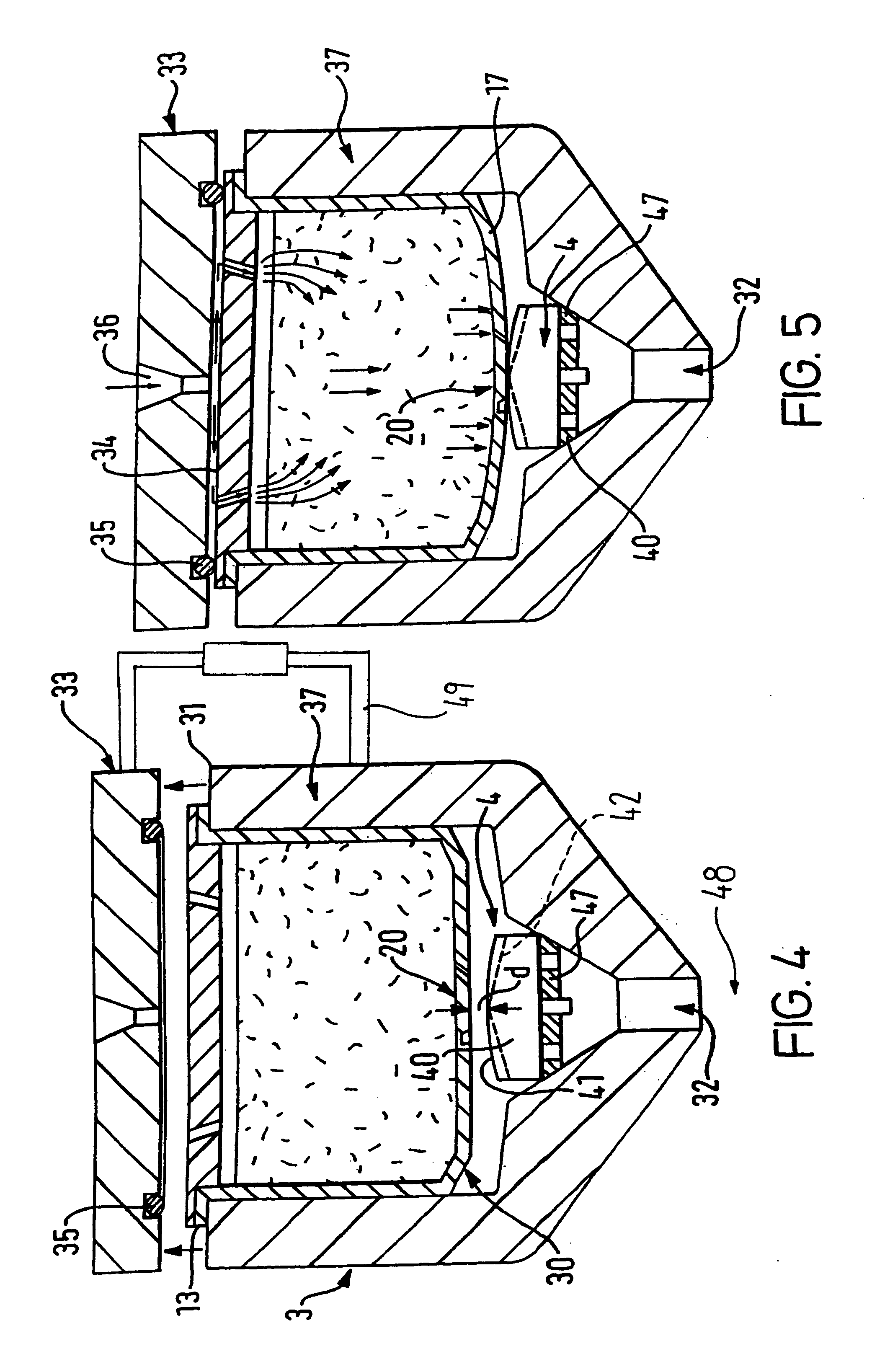

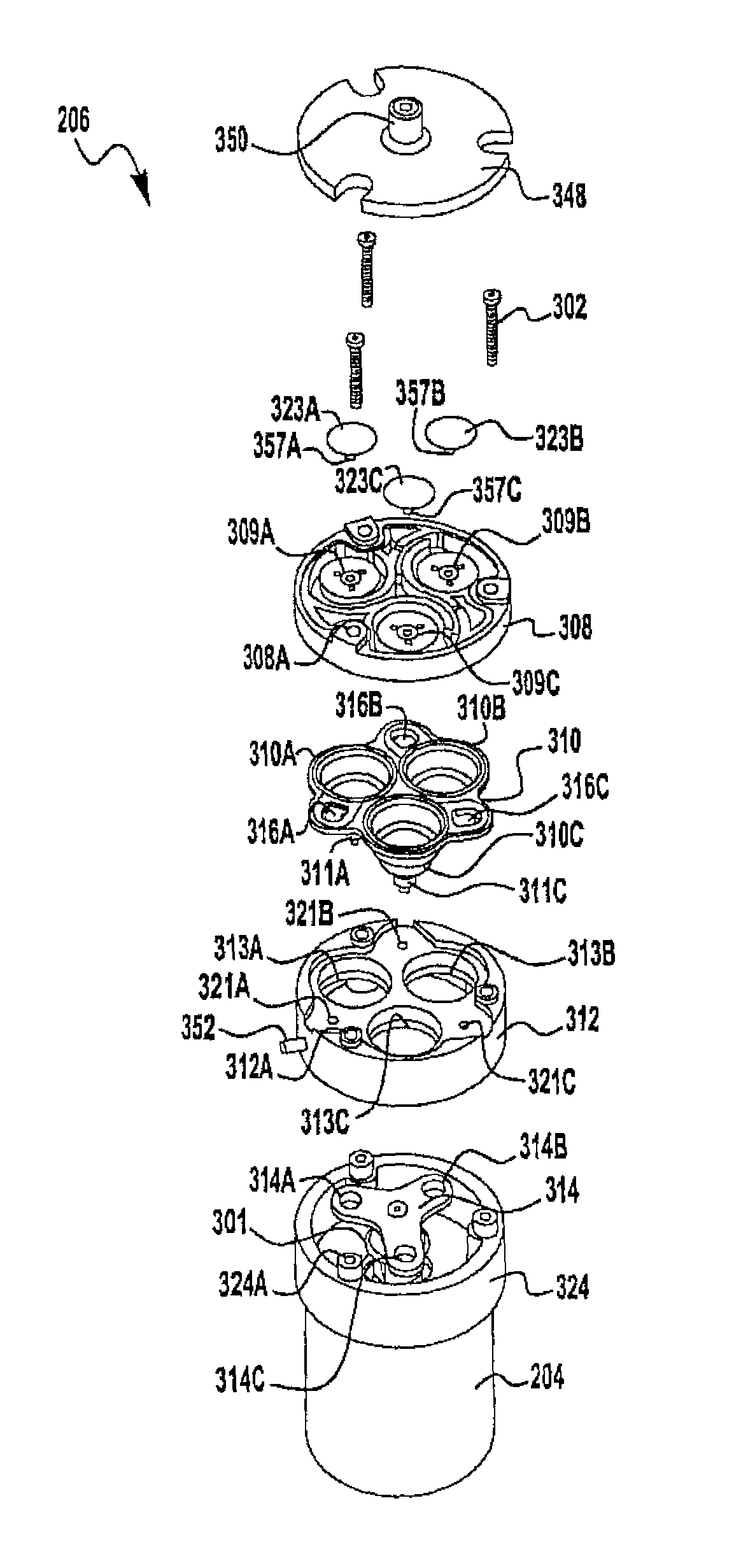

Device for preparing a hot beverage

InactiveUS7412921B2Improve foaming qualityReduce riskReady-for-oven doughsBeverage vesselsInternal pressureWater flow

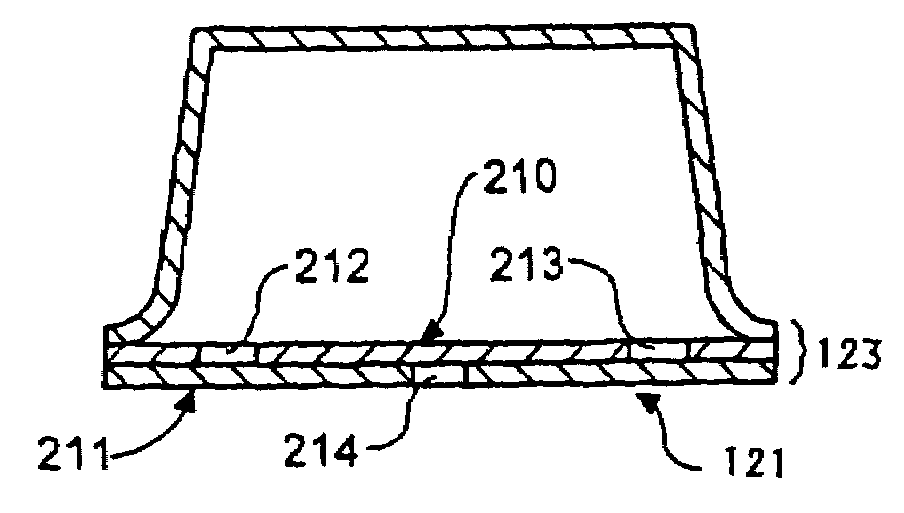

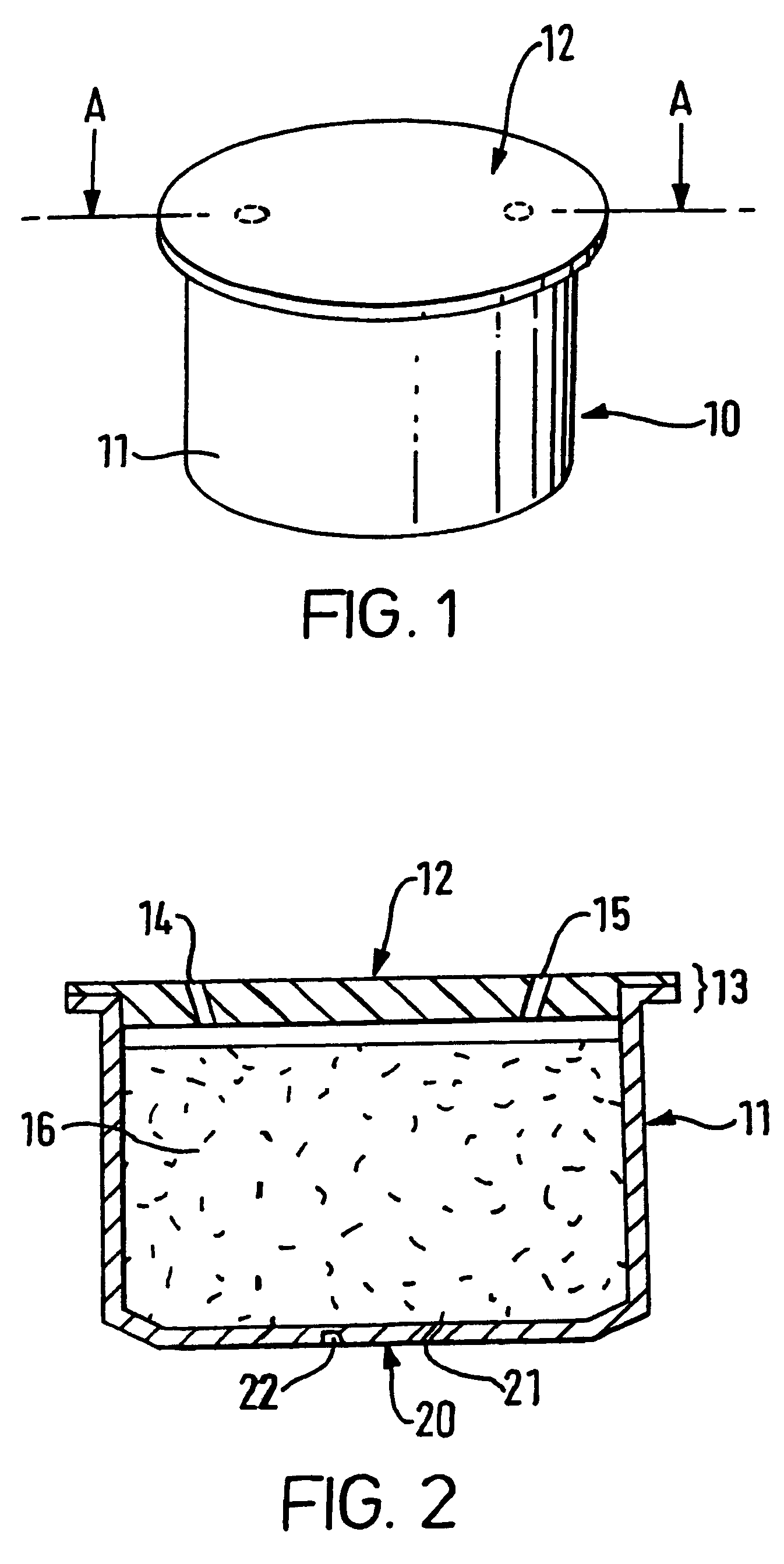

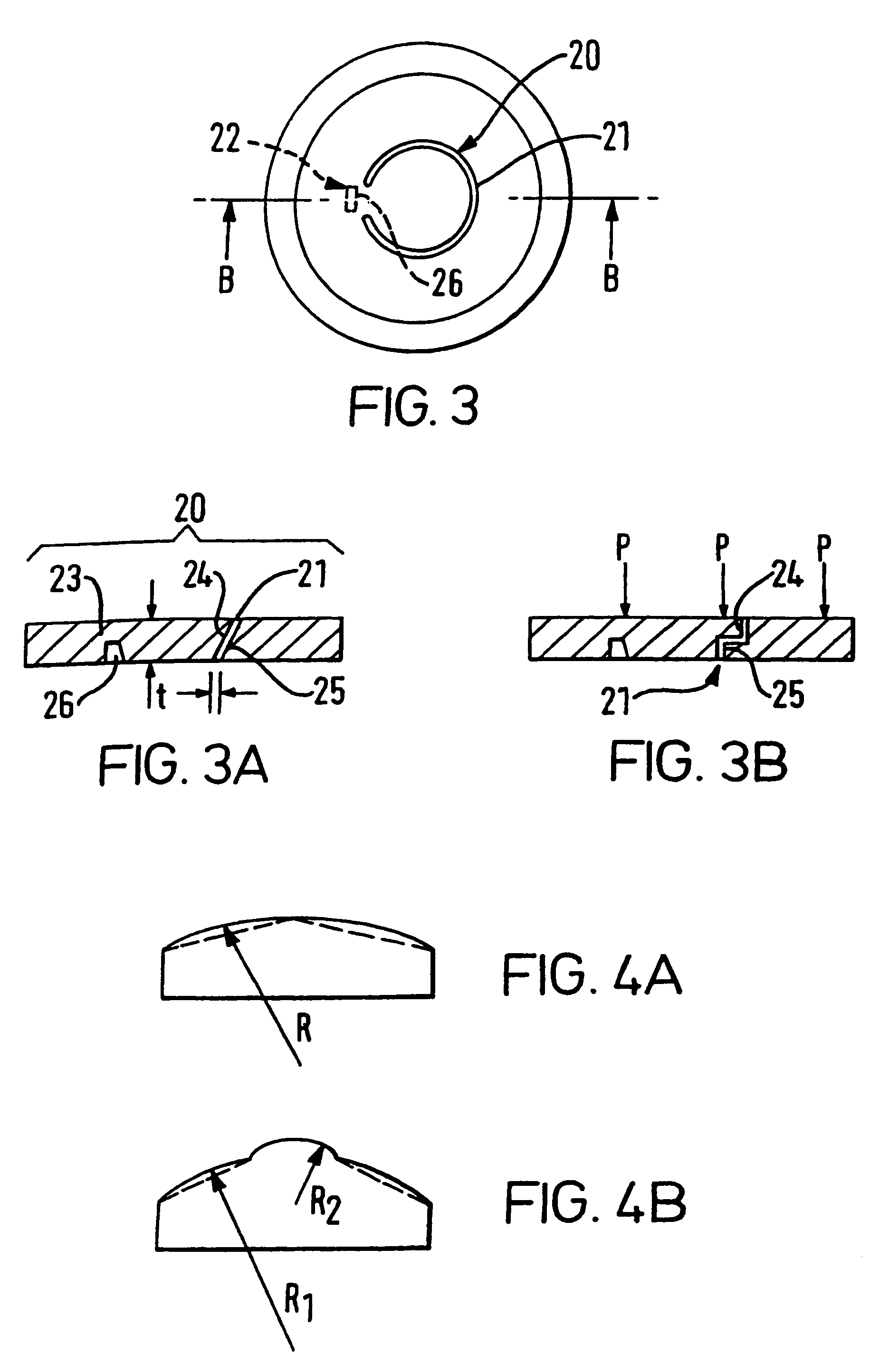

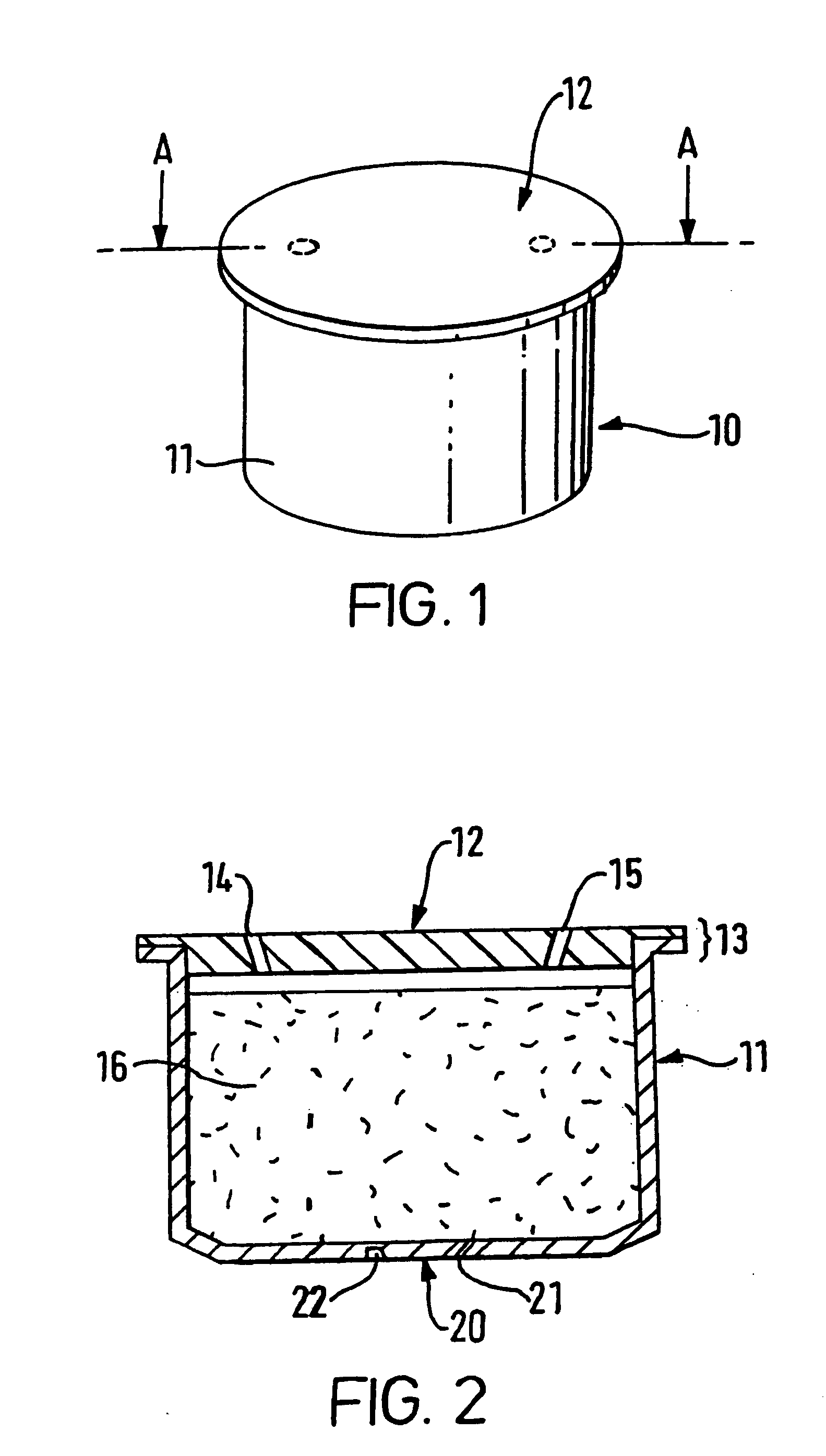

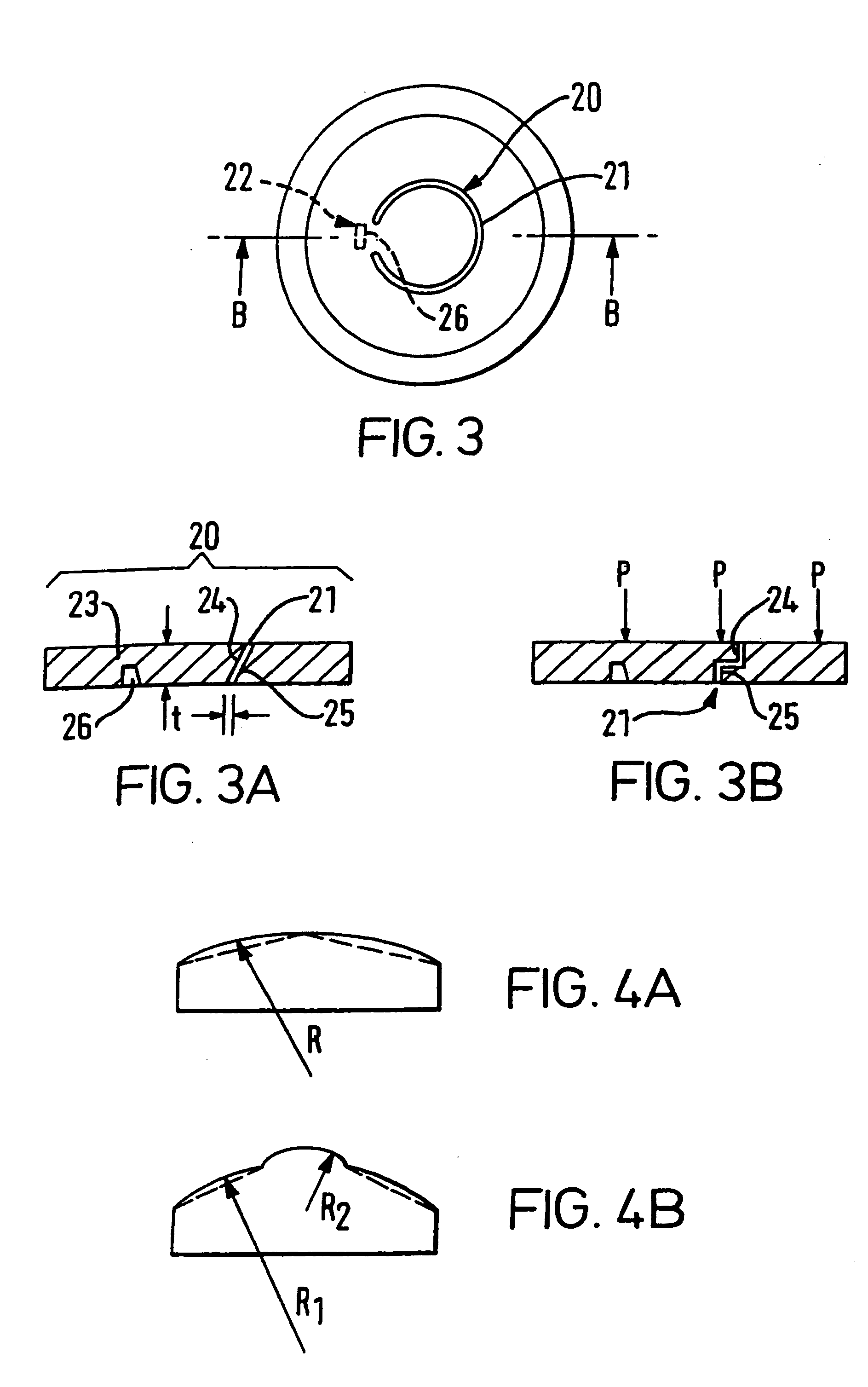

The invention relates to a capsule for the preparation of a beverage obtained by supplying hot water within the capsule under pressure and releasing the beverage from the capsule. The capsule includes a food substance therein, a first surface adapted to be traversed by a flow of water entering the capsule, and a second surface adapted to be traversed by a flow of beverage exiting the capsule. The second surface is adapted to deform outwardly upon action of the inside water pressure thereon. Also, that surface includes at least one opening member capable of deforming inwards the capsule upon a mechanical reaction force applied from outside onto the closure member as a result of the deformation of the second surface due to the build-up of the inside pressure.

Owner:NESTEC SA

Polyurethane Foam Premixes Containing Halogenated Olefin Blowing Agents And Foams Made From Same

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof. More particularly, the invention relates to closed-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and a non-amine catalyst used alone or in combination with an amine catalyst.

Owner:HONEYWELL INT INC

Device for preparing a hot beverage

InactiveUS20050084569A1Improve foaming qualityReduce decreaseReady-for-oven doughsMeat/fish preservationInternal pressureWater flow

The invention relates to a capsule for the preparation of a beverage obtained by supplying hot water within the capsule under pressure and releasing the beverage from the capsule. The capsule includes a food substance therein, a first surface adapted to be traversed by a flow of water entering the capsule, and a second surface adapted to be traversed by a flow of beverage exiting the capsule. The second surface is adapted to deform outwardly upon action of the inside water pressure thereon. Also, that surface includes at least one opening member capable of deforming inwards the capsule upon a mechanical reaction force applied from outside onto the closure member as a result of the deformation of the second surface due to the build-up of the inside pressure.

Owner:NESTEC SA

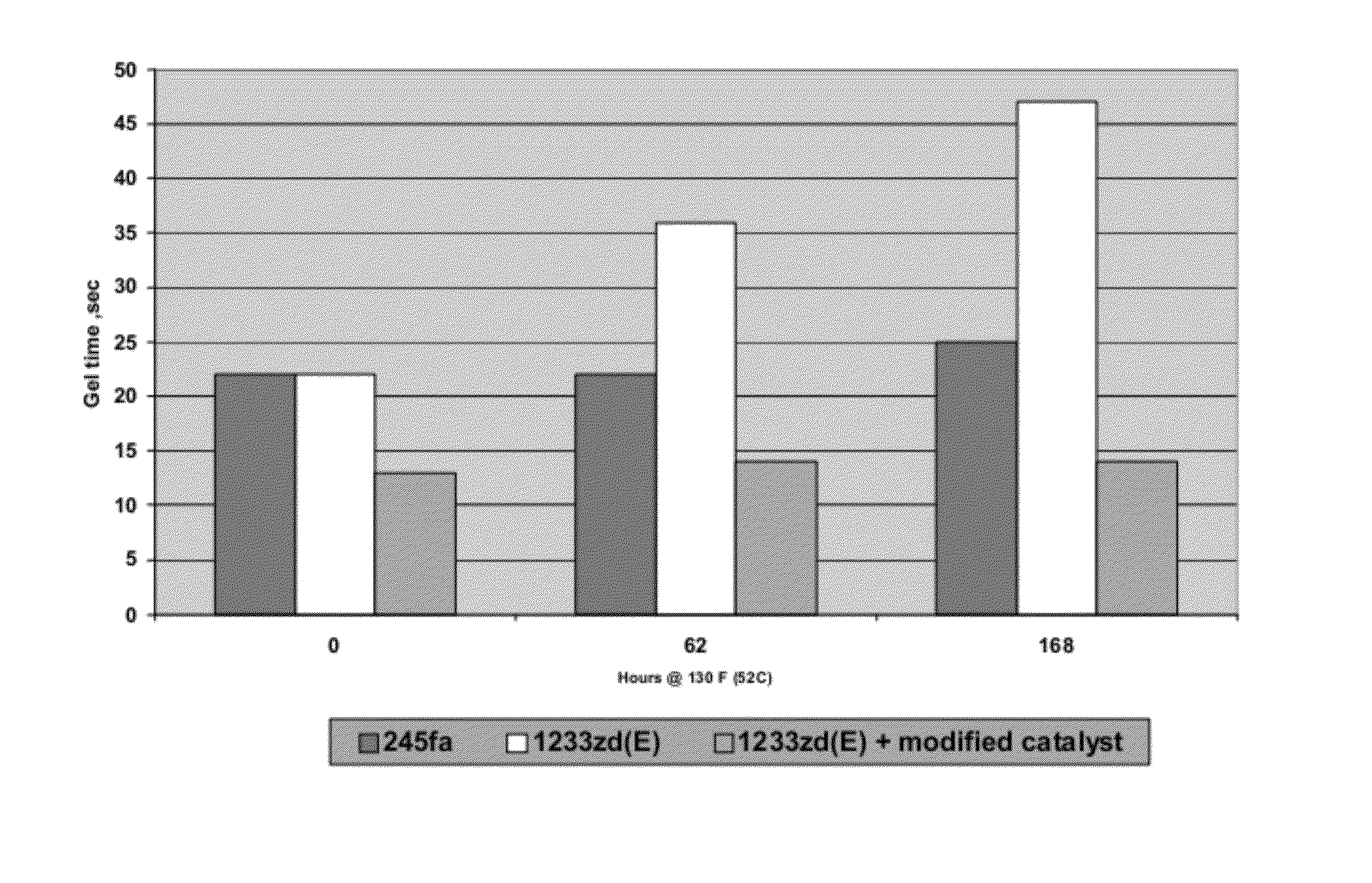

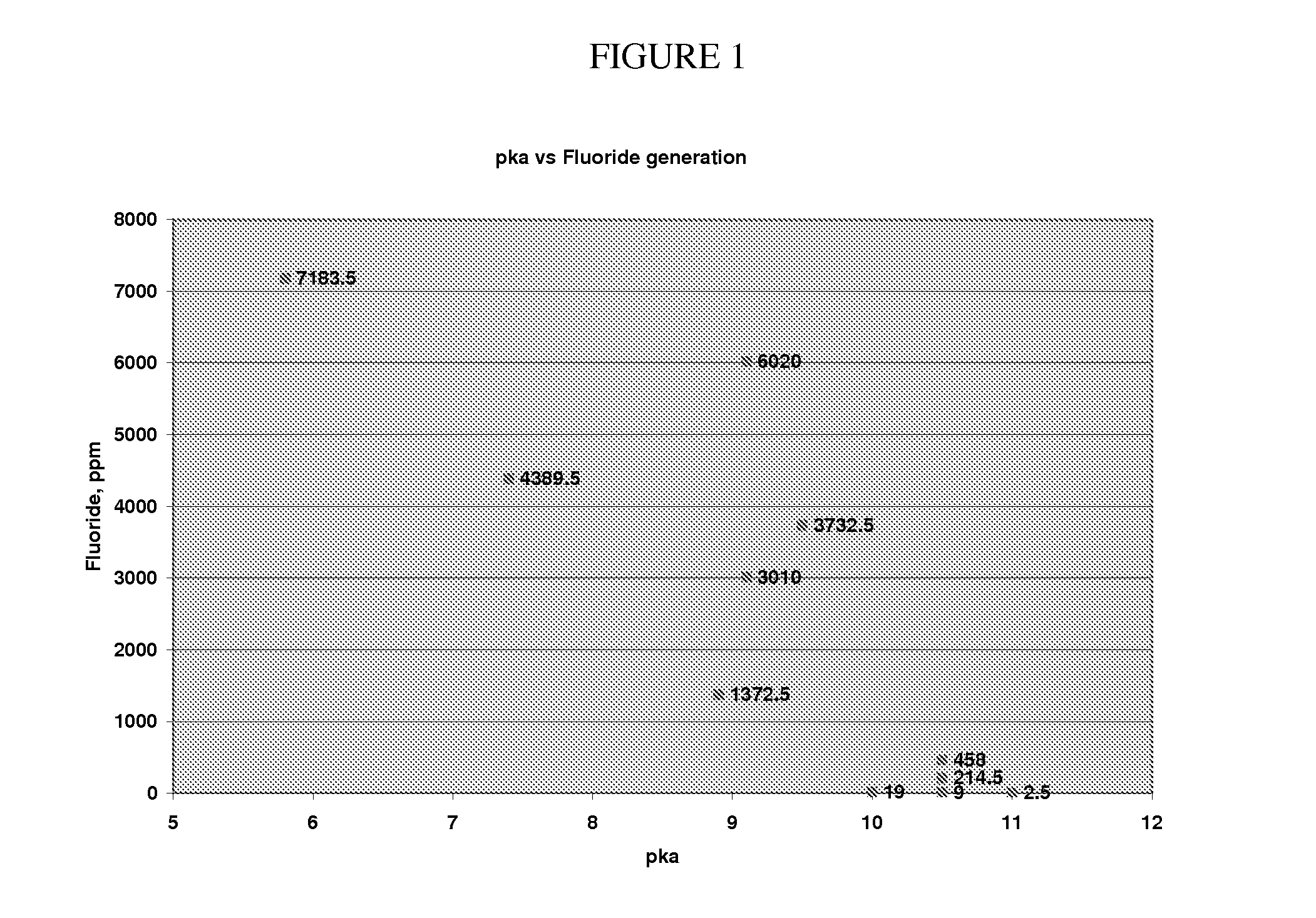

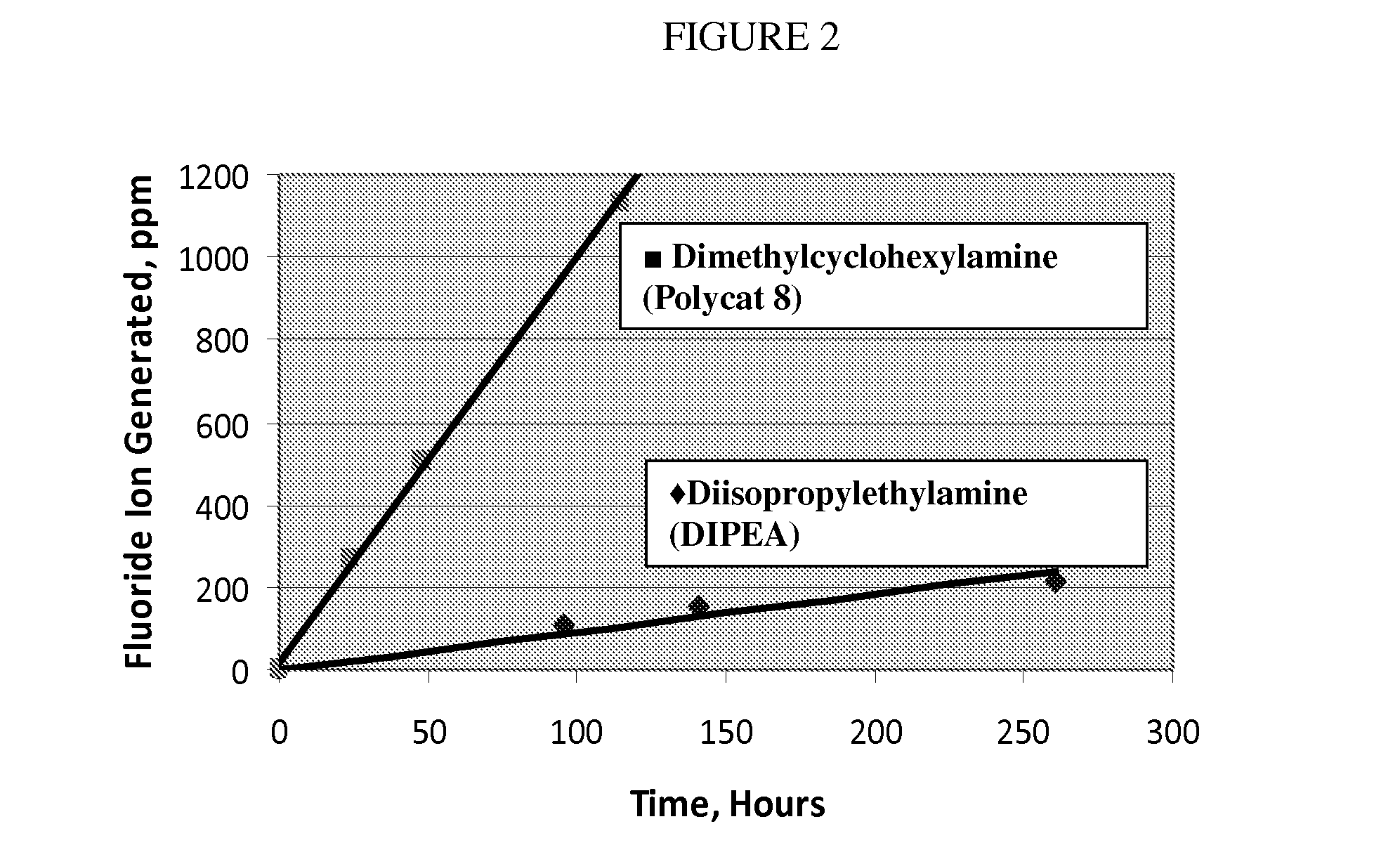

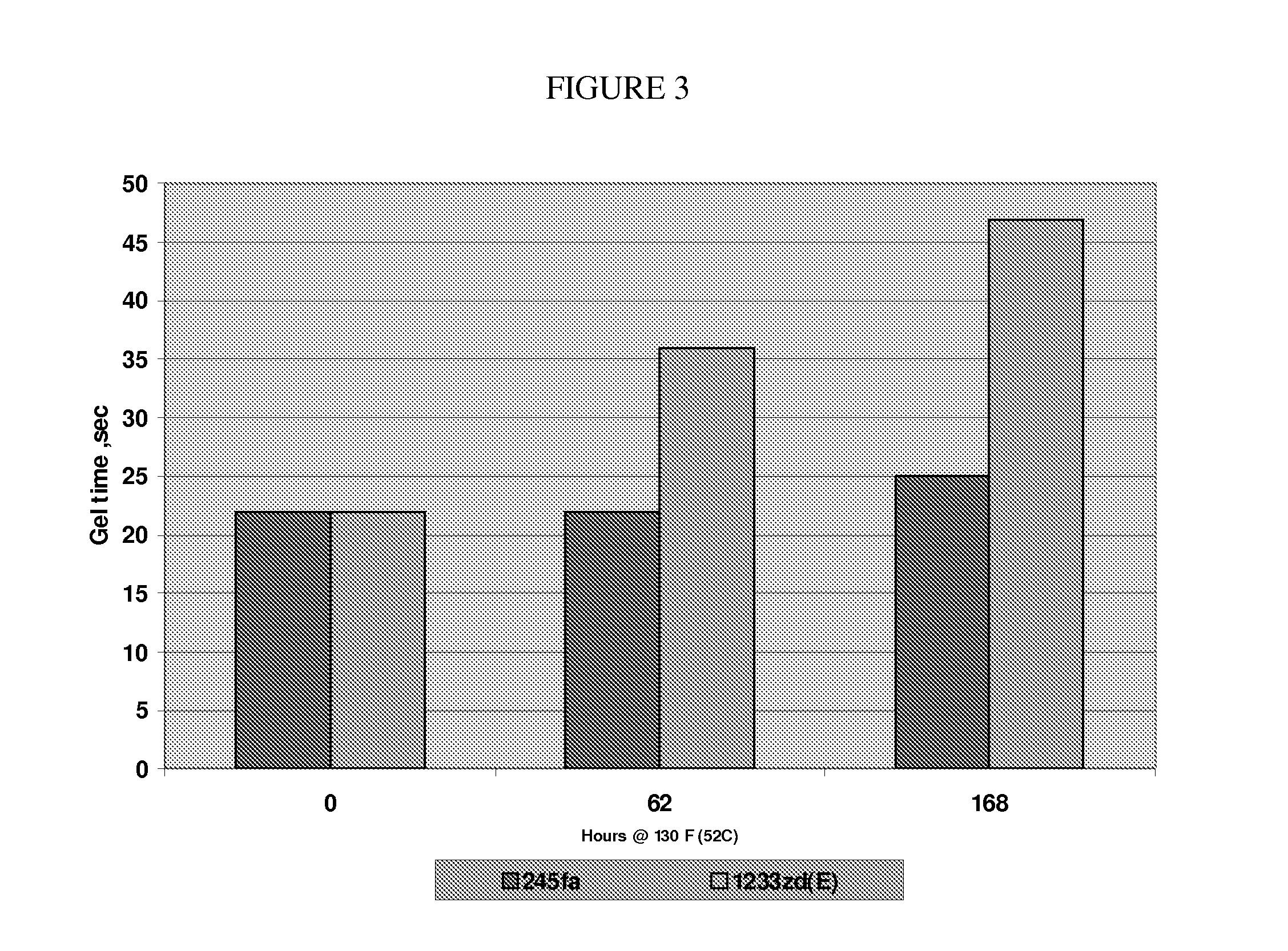

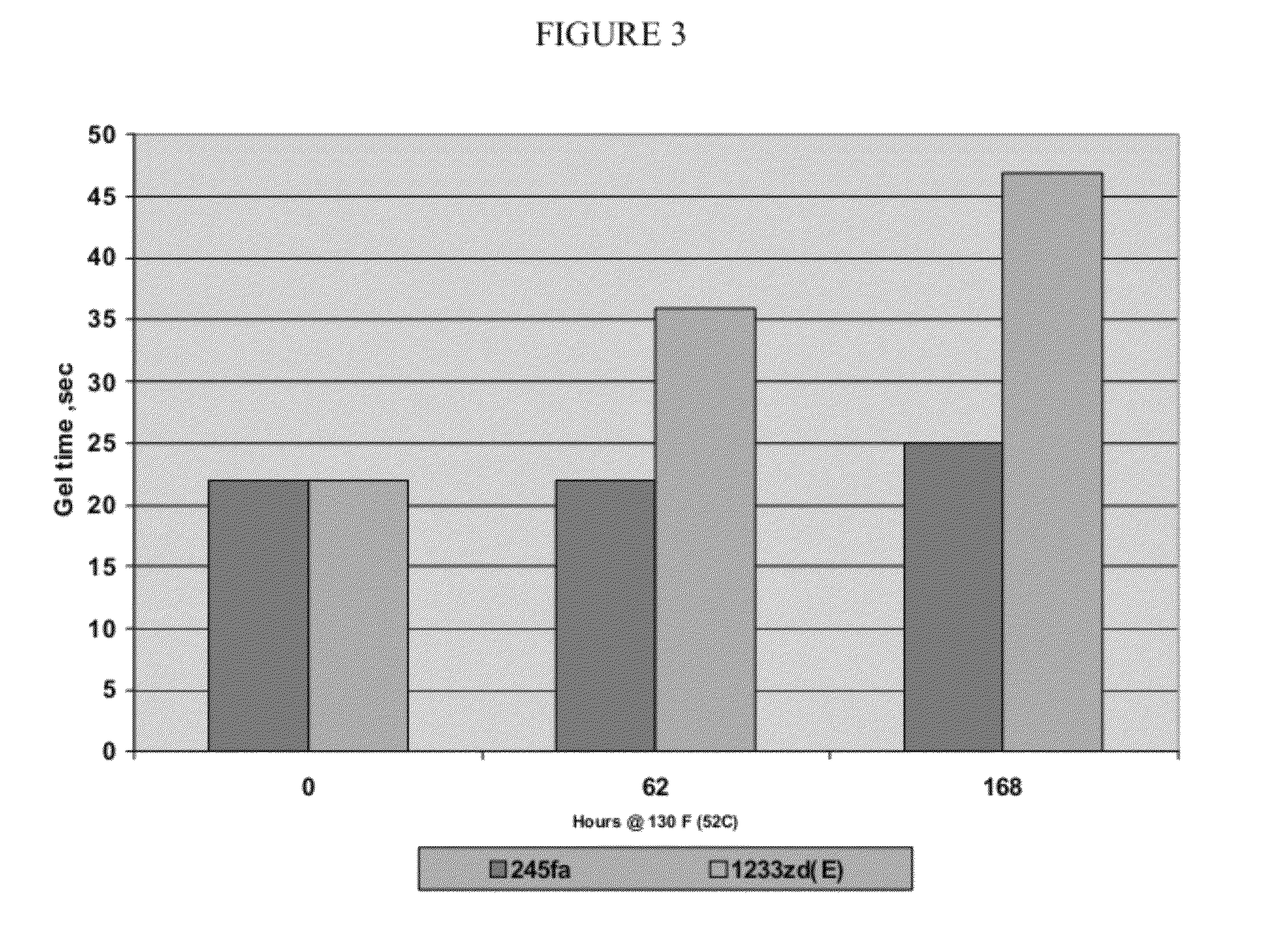

Polyurethane foam premixes containing halogenated olefin blowing agents and foams made from same

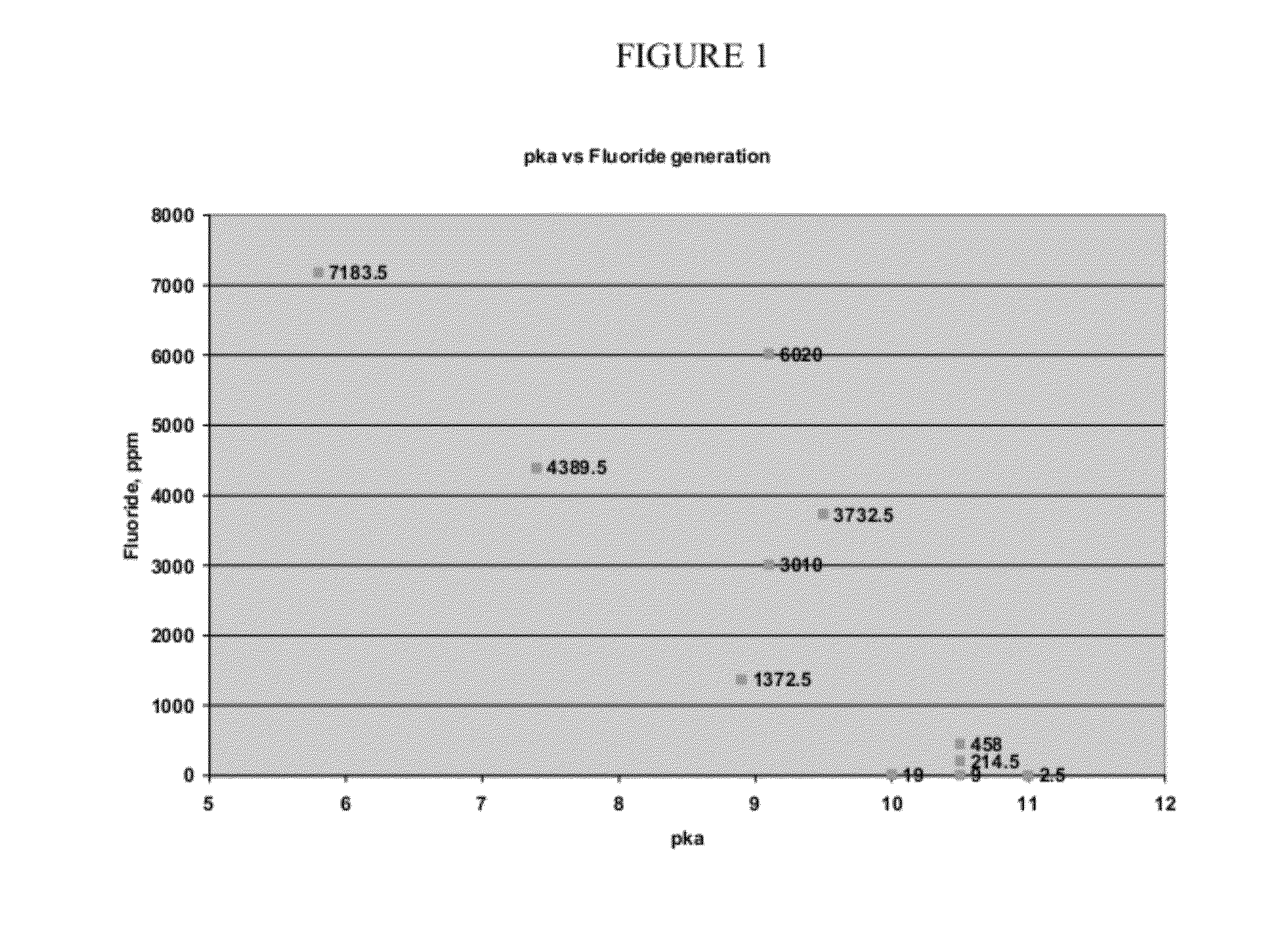

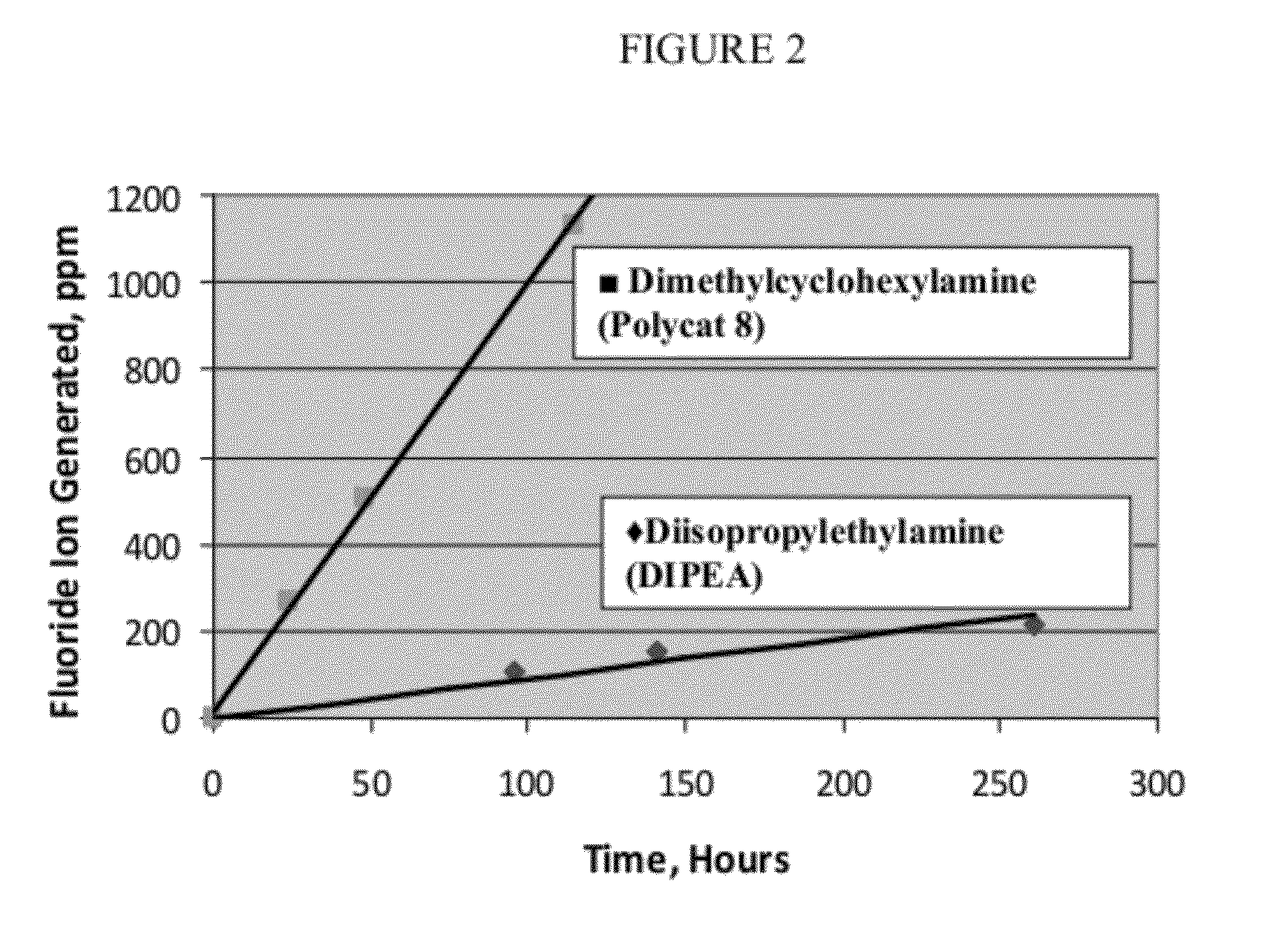

InactiveUS20120313035A1Effect qualityThe effect is timelyOther chemical processesPolymer chemistryPolyisocyanurate

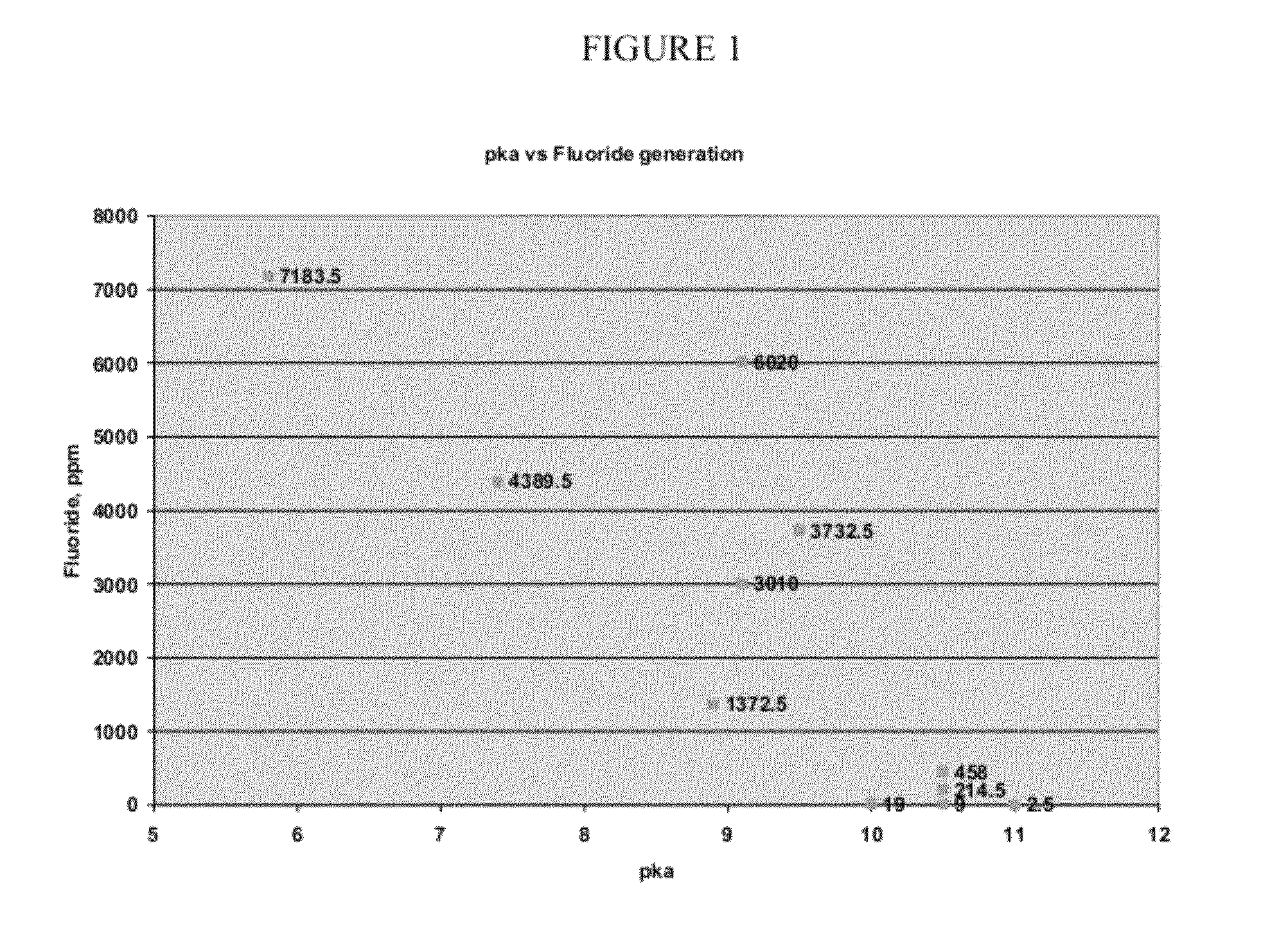

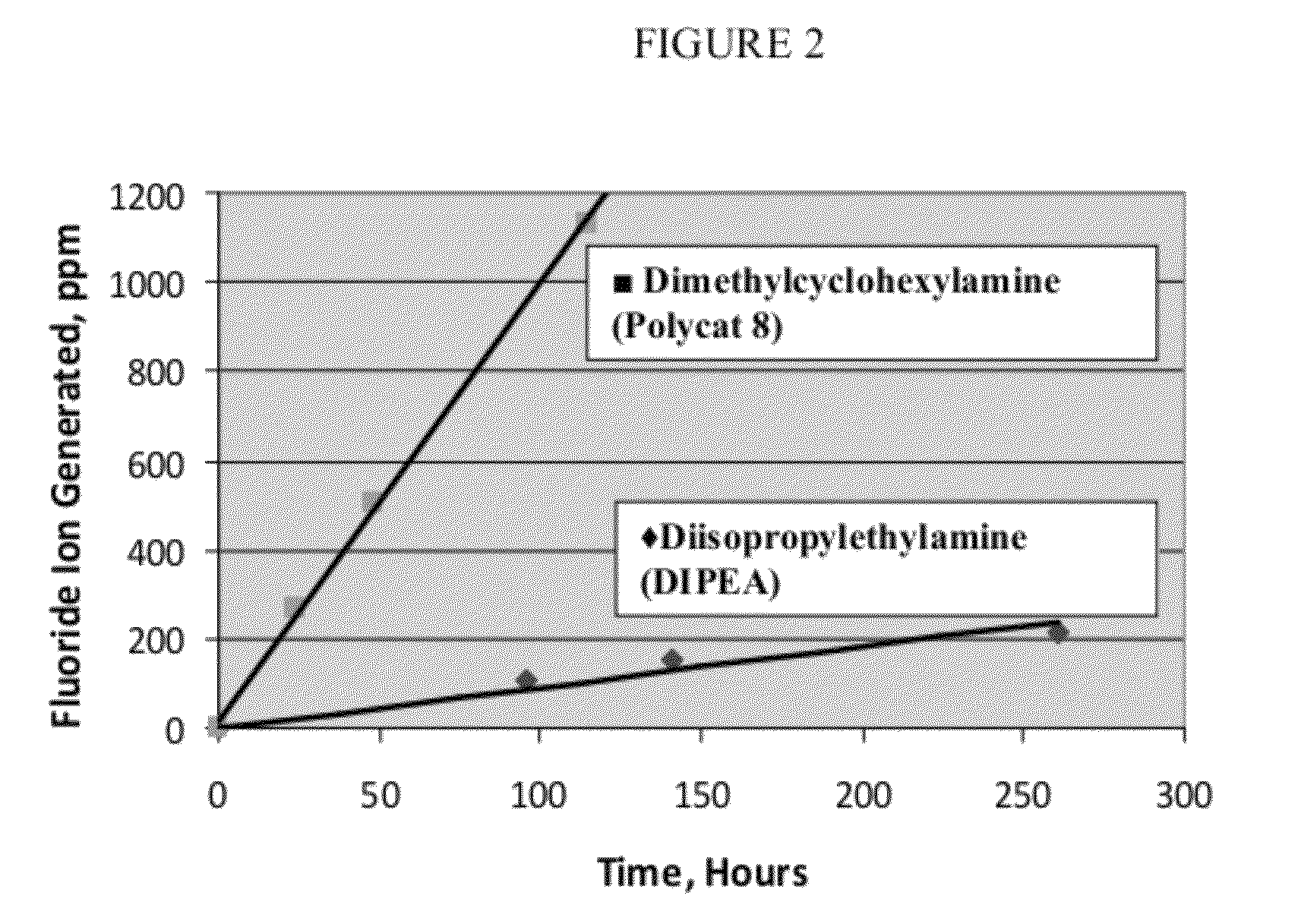

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof. More particularly, the invention relates to closed-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and an-amine catalyst that prefreably has a Fluoride Generation Value of not greater than about 1000 ppm.

Owner:HONEYWELL INT INC

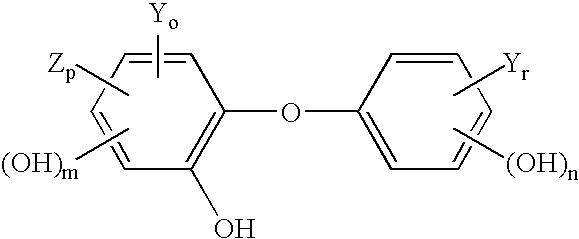

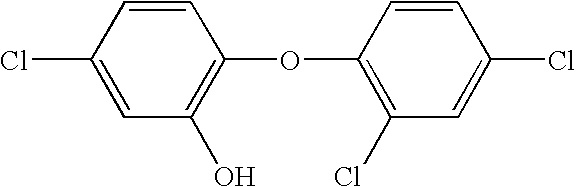

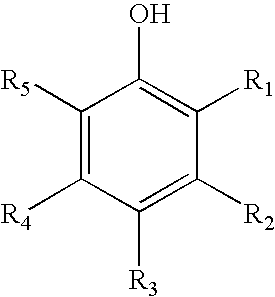

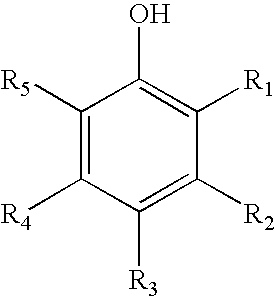

Antimicrobial wash formulations including amidoamine-based cationic surfactants

InactiveUS7517842B2Improve foaming qualityReduce stimulationCosmetic preparationsOrganic detergent compounding agentsBULK ACTIVE INGREDIENTActive ingredient

An antimicrobial hand wash comprises an active ingredient and an amidoamine based cationic surfactant having a fatty chain with from 6 to 24 carbon atoms. These cationic surfactants are compatible with common active ingredients such that antimicrobial efficacy is maintained, while foam quality is improved when the hand wash is dispensed as foam. Other antimicrobial hand washes include specific amidoamine based cationic surfactants that dissolve at least a portion of the active ingredient, thus reducing the amount of solids in the formulation, and, in some instances, making a cold manufacturing process possible.

Owner:GOJO IND INC

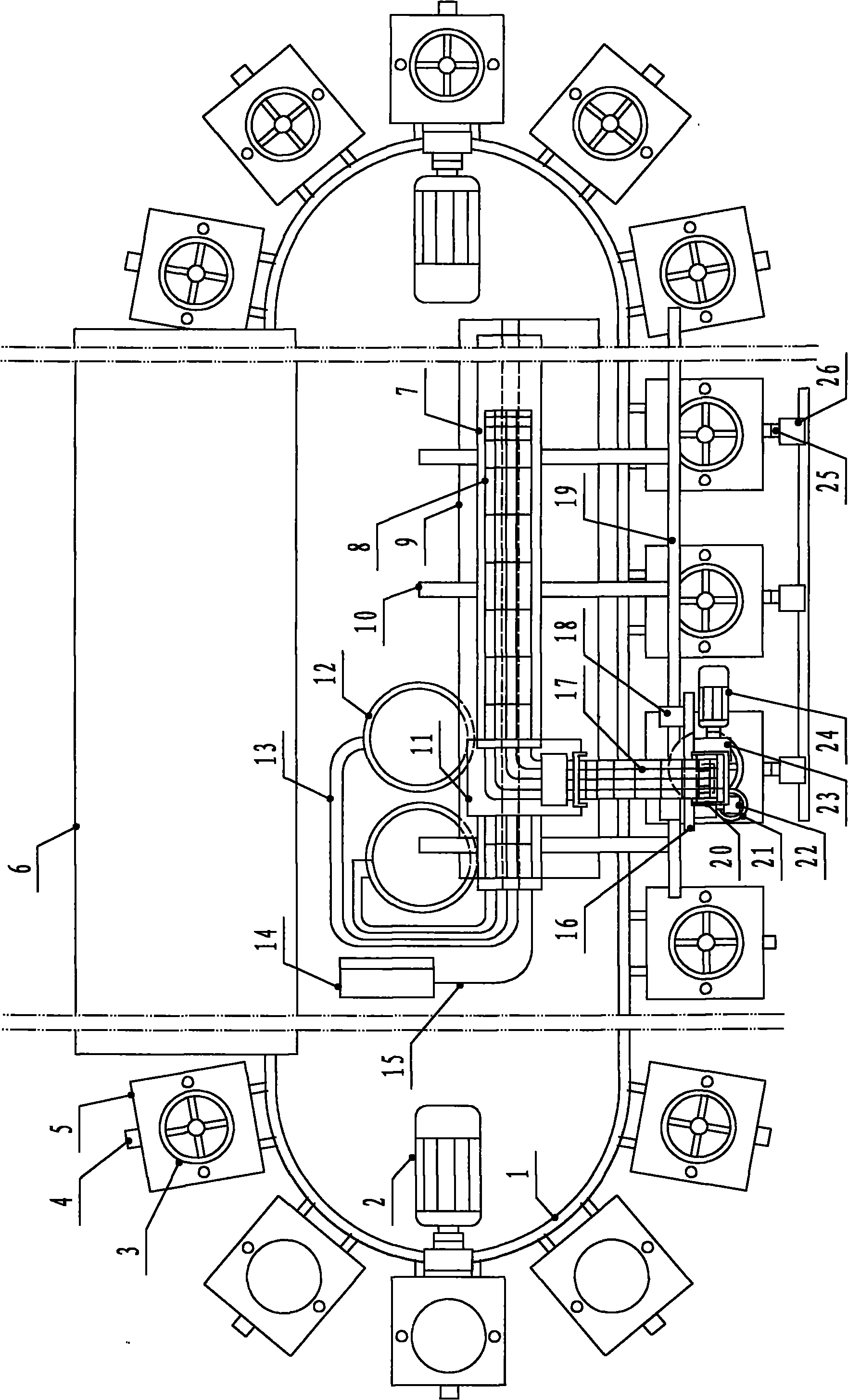

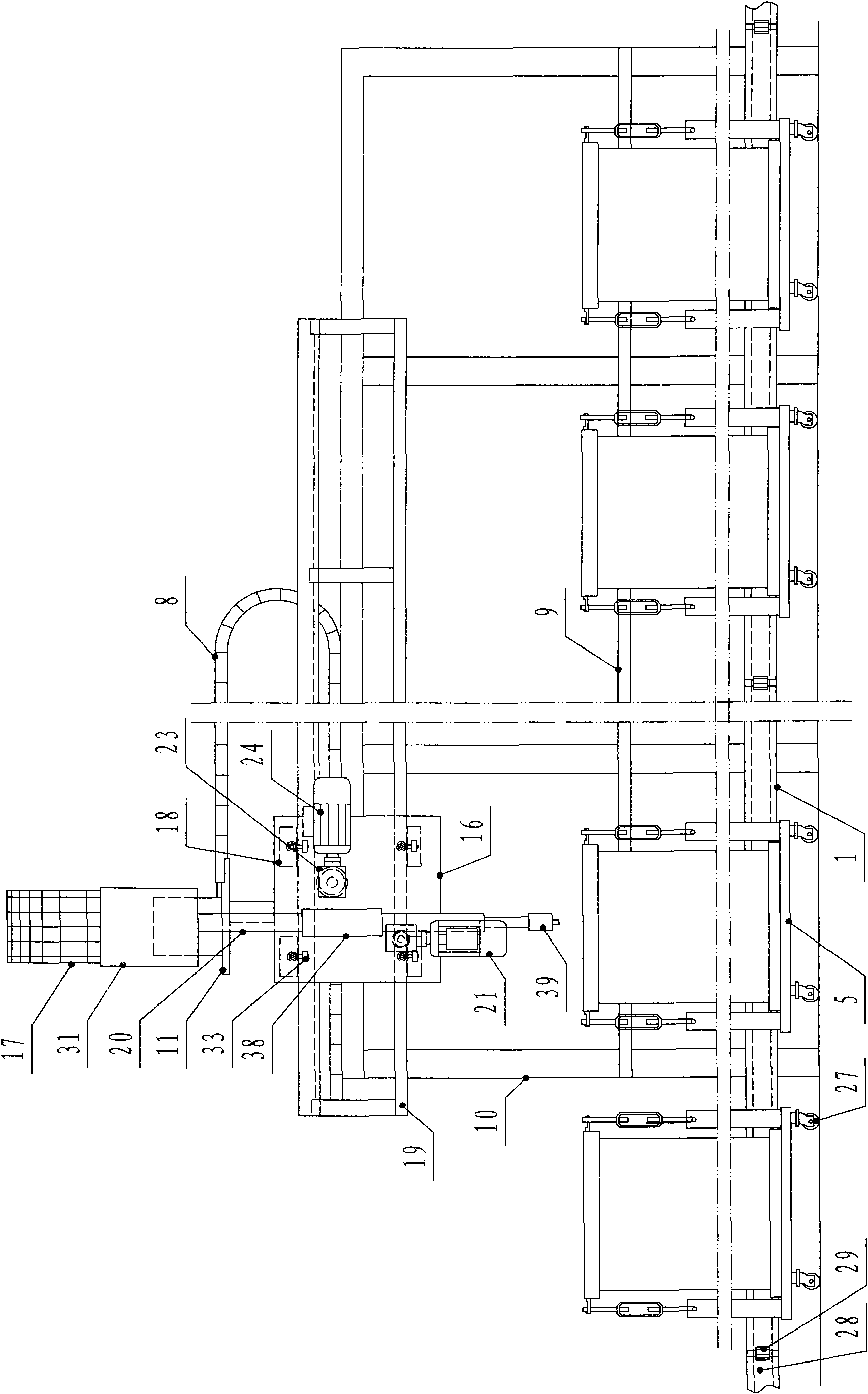

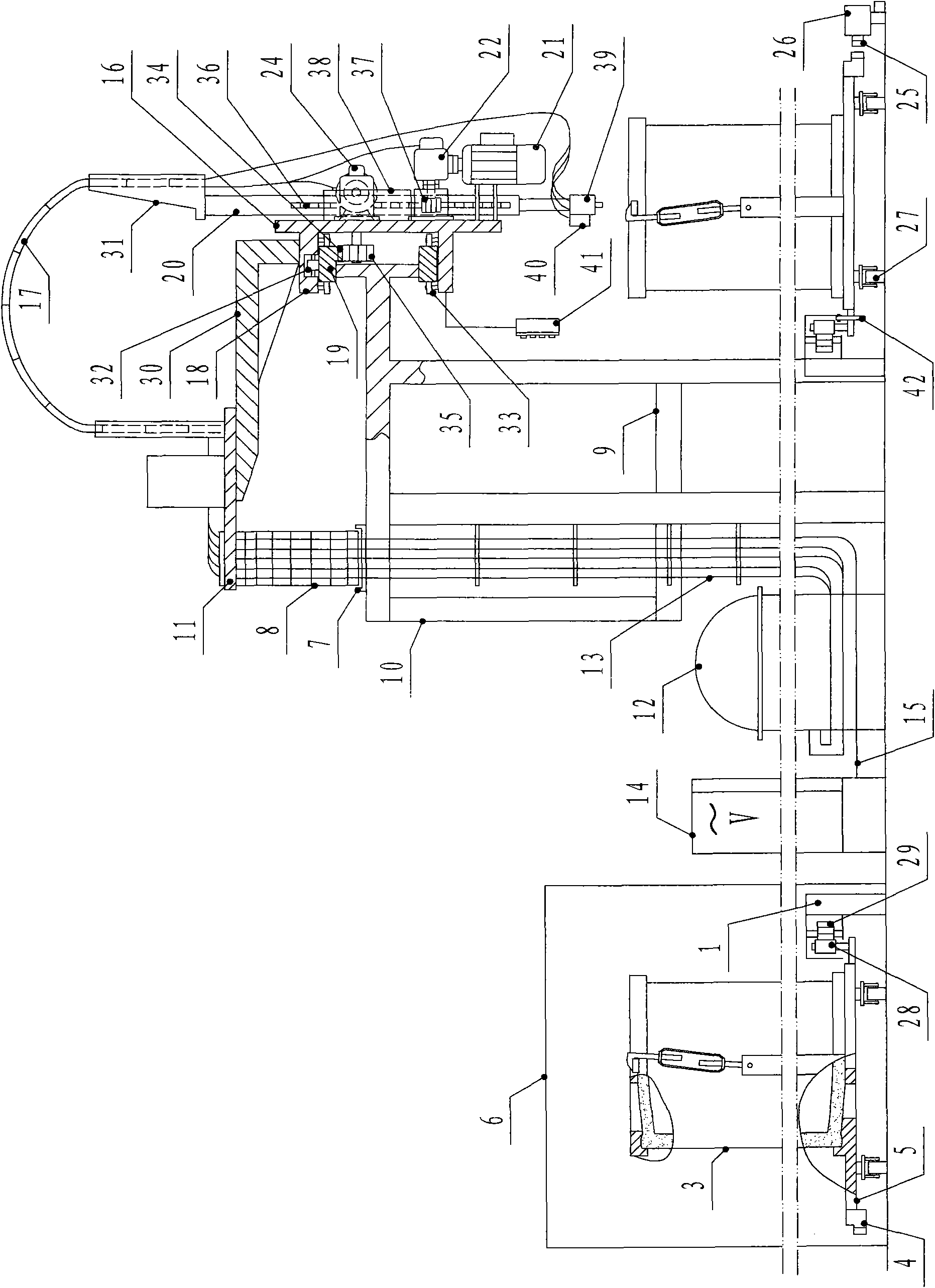

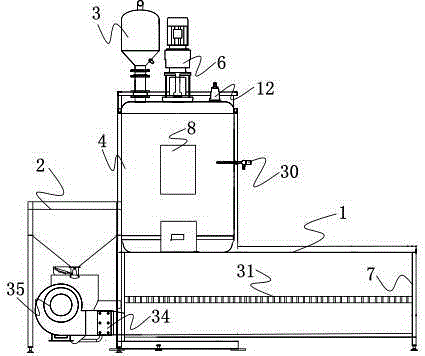

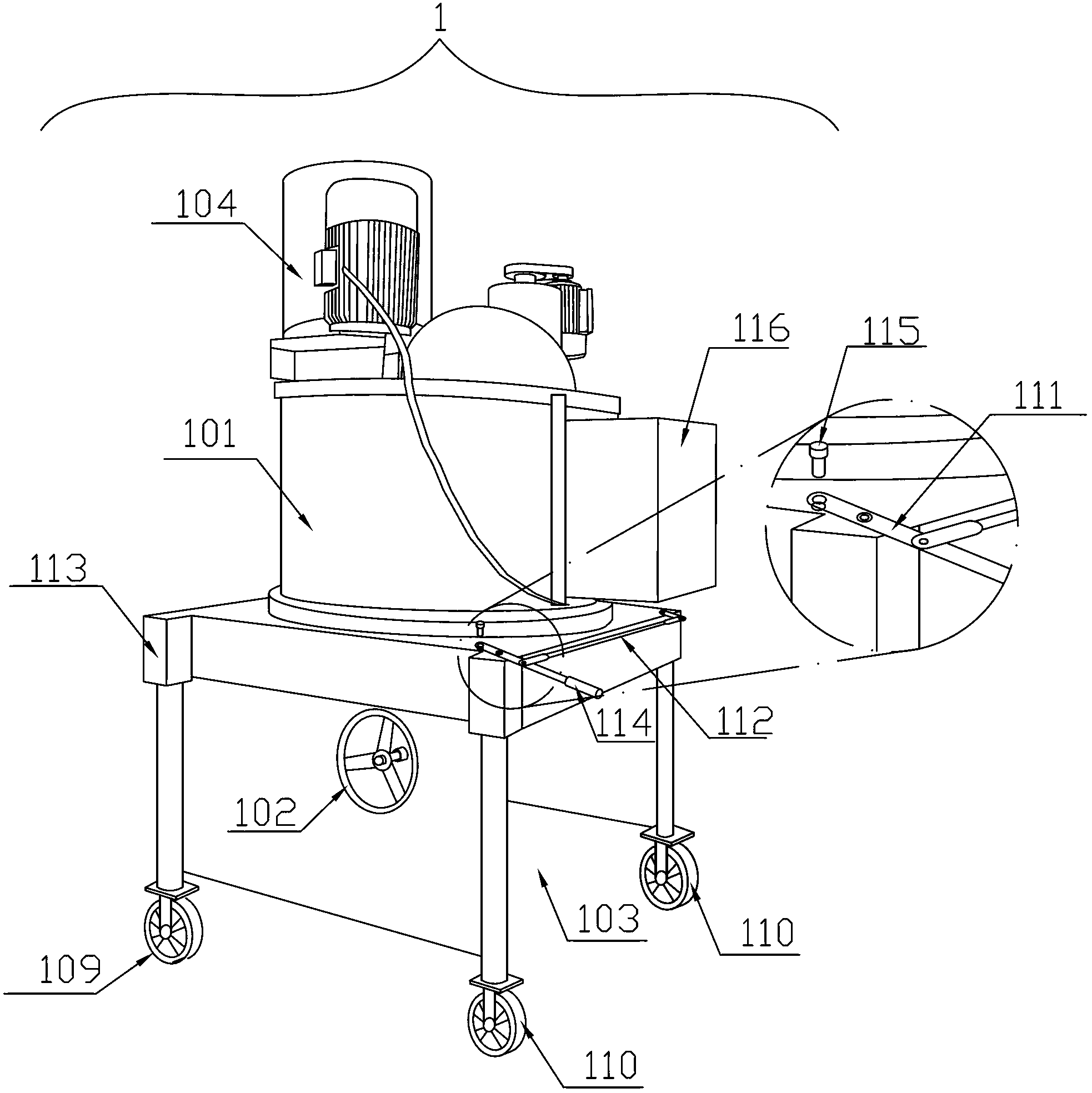

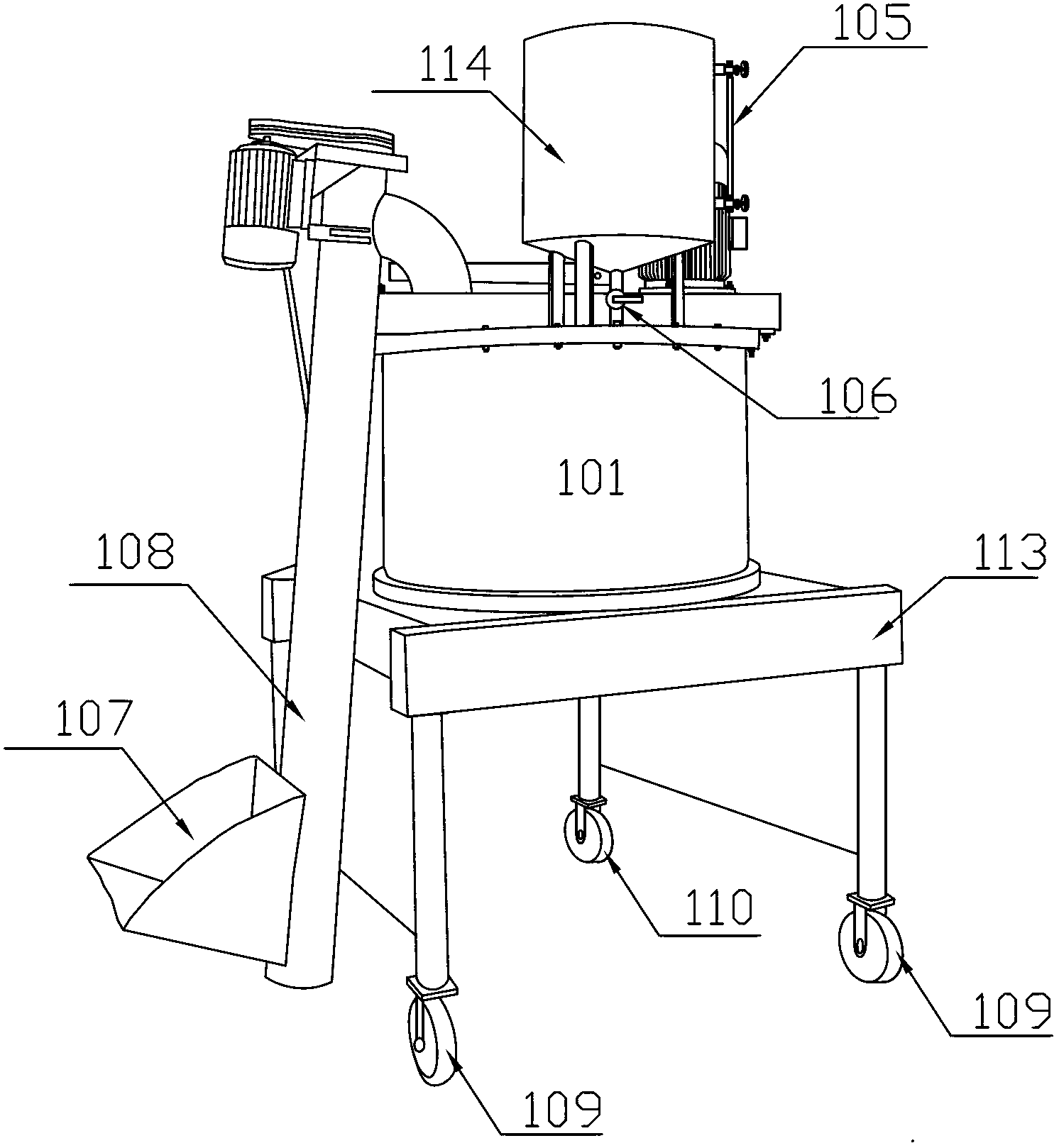

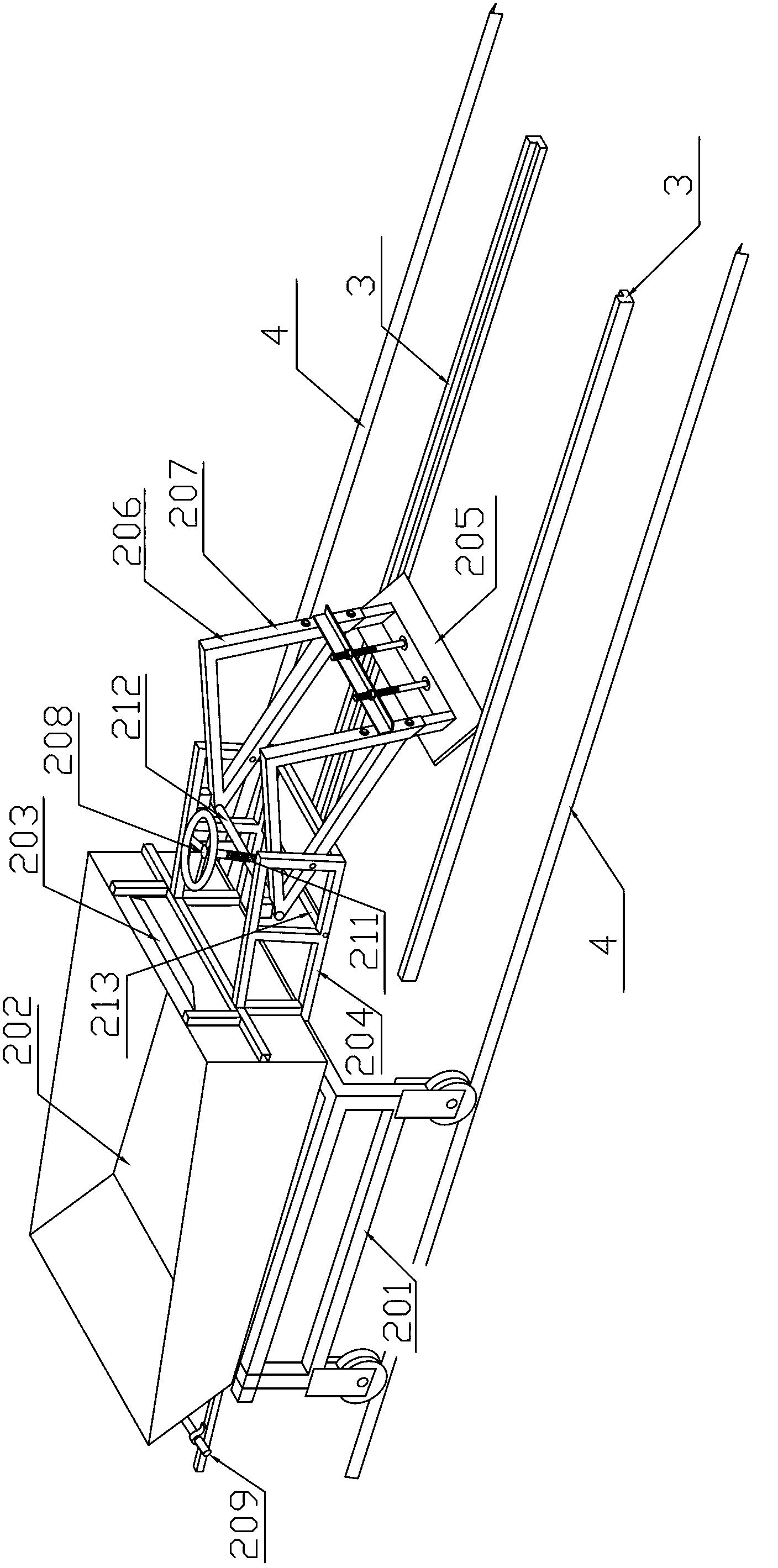

Foaming production line for water tank heat-insulation layers

InactiveCN101786309AAvoid wastingAccurate positioning of the injection siteProduction lineFoaming agent

The invention provides a foaming production line for water tank heat-insulation layers. The production line is designed and arranged on an annular track, and is divided into a water tank assembling area, a foaming work area, a foamed-layer curing area and a finished-product unloading area so as to form an automatic production line. The production line is provided with an electronic control mechanism and a foaming agent injection mechanism of the water tank heat-insulation layers; a water tank conveying mechanism and a positioning-locking mechanism are arranged on the annular track of the production line; a foaming worktable and a foamed-layer curing chamber are arranged on the annular track; the middle part of the foaming worktable is provided with a work channel; a side above the worktable is provided with a fixed track; a bracket is movably arranged on the fixed track; a movable control mechanism of an injection head is arranged on the bracket; and the top part of the foaming worktable is provided with a movable line connecting mechanism for controlling wires and liquid conveying pipes. The production line can effectively raise the automatic production level of the work of foaming the water tank heat-insulation layers so as to improve production efficiency, improve product quality, save production raw materials, reduce labor intensity and reduce production cost.

Owner:YUNNAN YUXI TAIBIAO SOLAR ENERGY EQUIP

Attapulgite composite flame-retardant foaming agent

The invention discloses an attapulgite composite flame-retardant foaming agent. The technical scheme of the attapulgite composite flame-retardant foaming agent has the following key points that the attapulgite composite flame-retardant foaming agent is composed of attapulgite argil powder having an air purifying function, hydrogen peroxide, aluminium hydroxide, sodium polyoxyethylene fatty alcohol ether sulfate, superfine polyvinyl alcohol powder, dimethicone and water, and then the raw materials of the attapulgite composite flame-retardant foaming agent are stirred into a paste, and further stirred into the finished product of the attapulgite composite flame-retardant foaming agent. The attapulgite composite flame-retardant foaming agent is added with water and stirred at a high speed to form porous foamed mud; and the porous foamed mud is capable of quickly isolating a combustible material from air, thereby achieving the purposes of flame retarding and fire extinguishment; the attapulgite composite flame-retardant foaming agent has the effects of flame retarding, heat preservation, heat insulation and sound insulation, and also has the air purification function; and the attapulgite composite flame-retardant foaming agent is suitable for producing flame retarding and fire extinguishing products, light plates, light walls, and sound attenuation and noise reduction products.

Owner:江苏世澳非金属应用科技有限公司

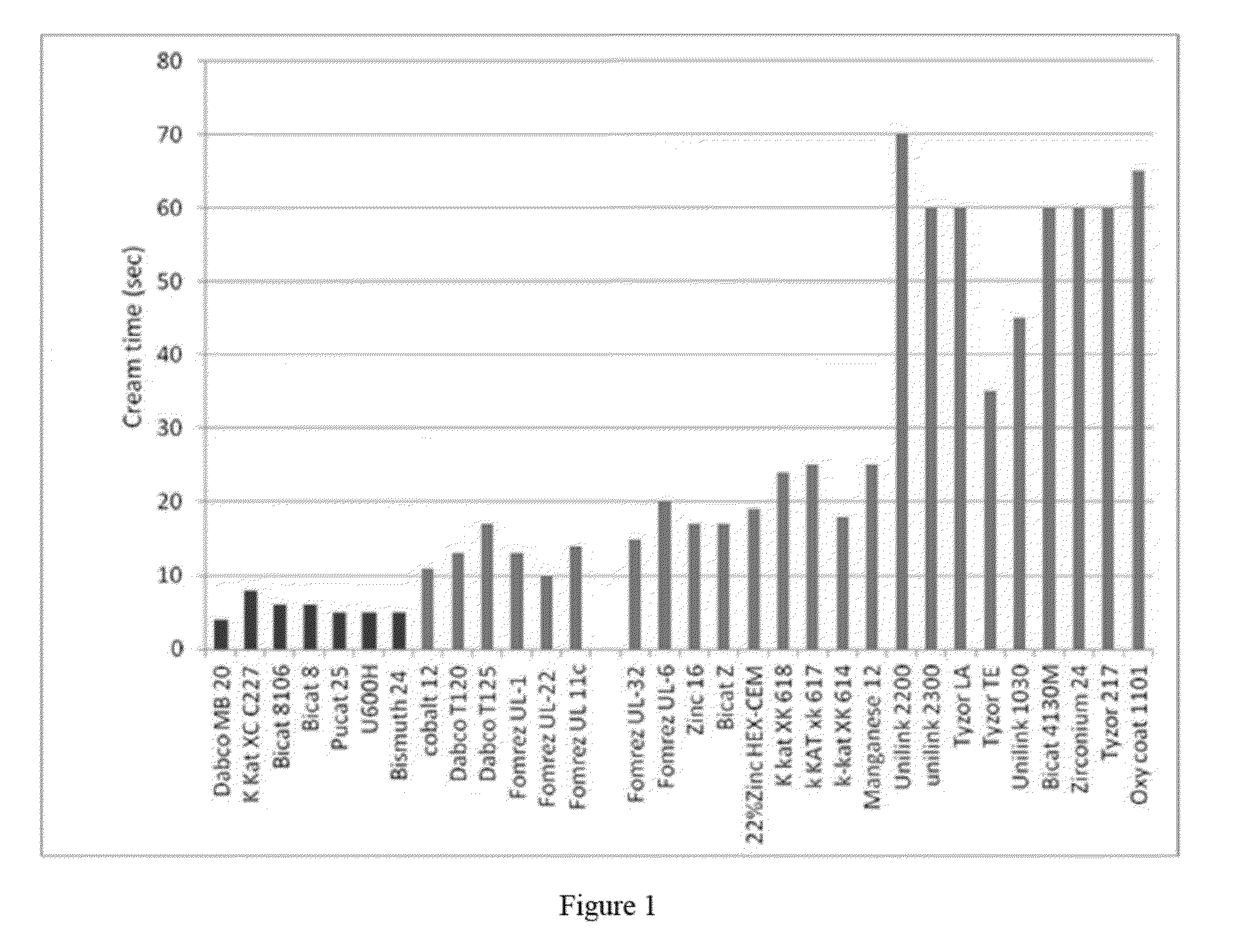

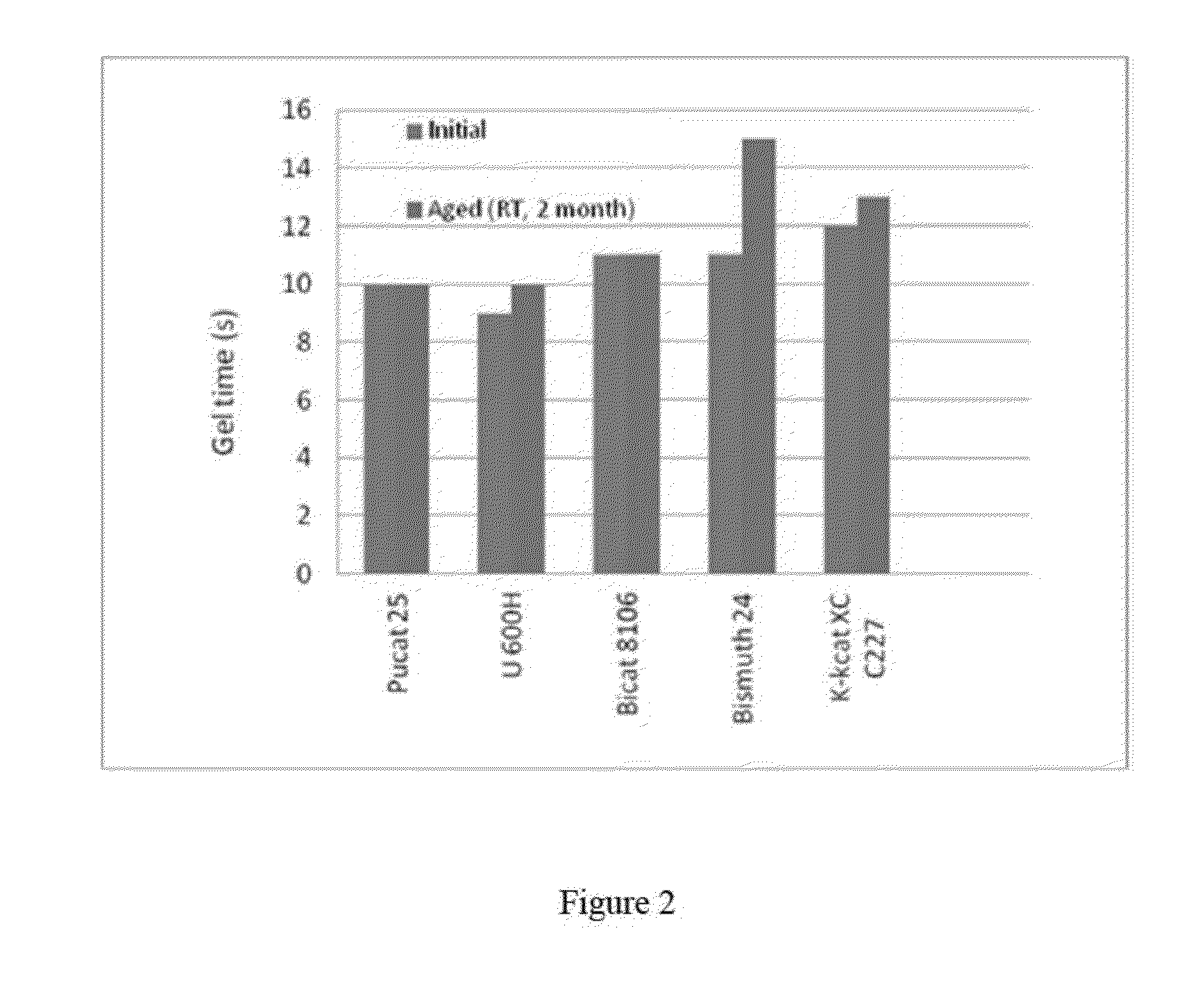

Polyurethane foam premixes containing halogenated olefin blowing agents and foams made from same

InactiveUS20140171525A1Faster and improved front-end catalytic reactivityDecreased cream timePolyolFoaming agent

Disclosed are polyol premix compositions, and foams formed therefrom, which comprise a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and a catalyst system that includes a bismuth-based metal catalyst. Such catalysts may be used alone or in combination with an amine catalyst and / or other non-amine catalysts.

Owner:HONEYWELL INT INC

Polyurethane foam premixes containing halogenated olefin blowing agents and foams made from same

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof. More particularly, the invention relates to closed-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and a non-amine catalyst used alone or in combination with an amine catalyst.

Owner:HONEYWELL INT INC

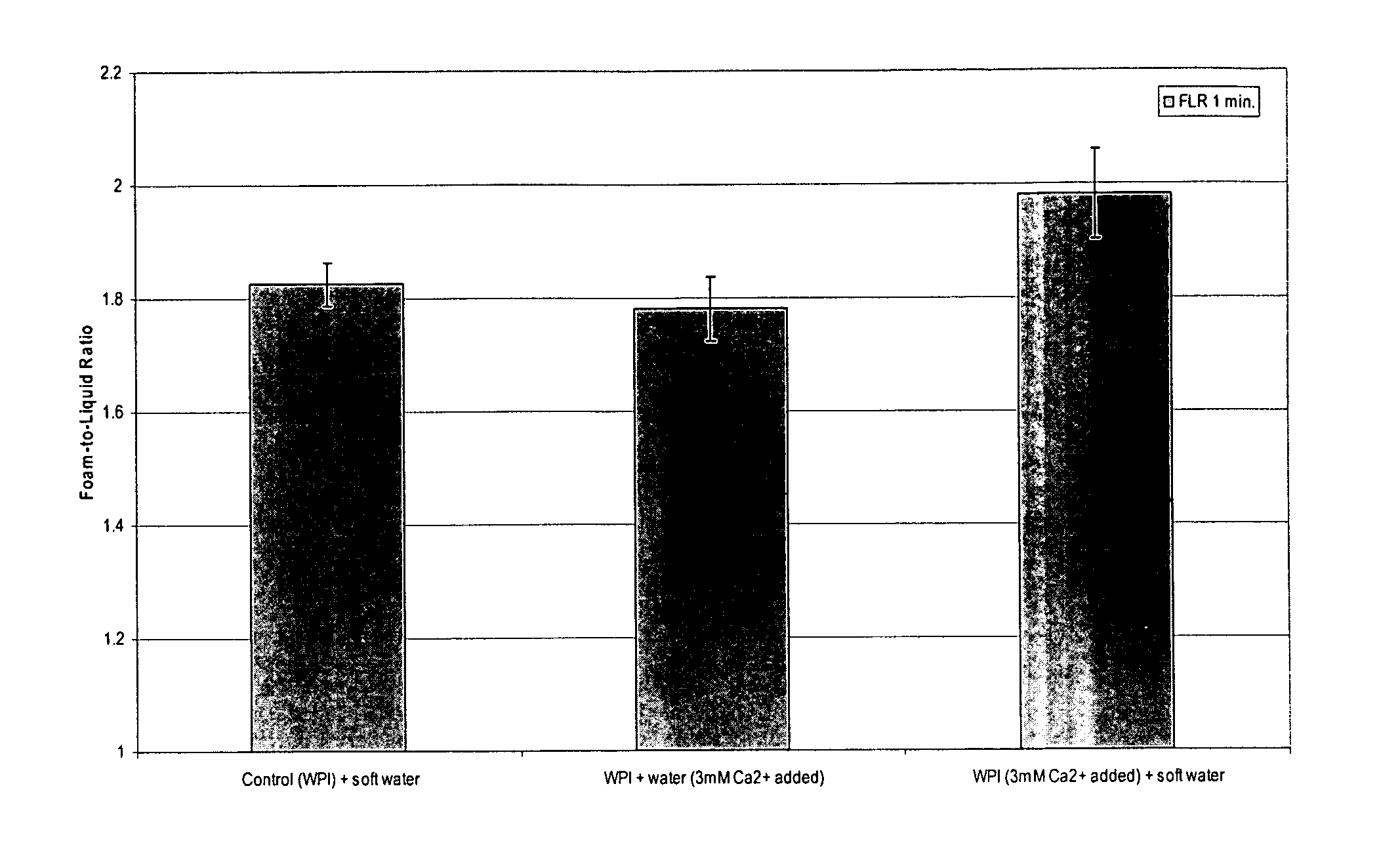

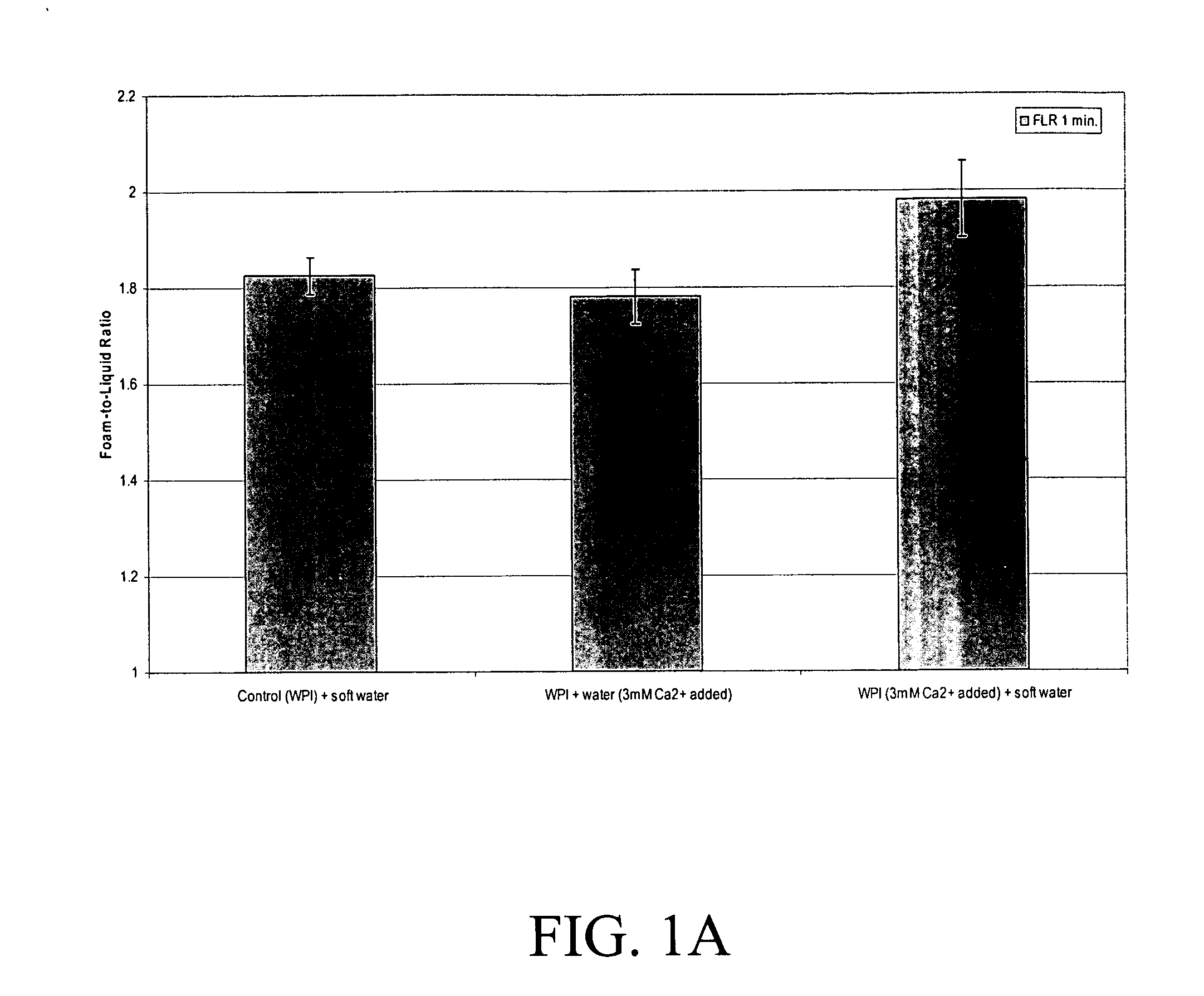

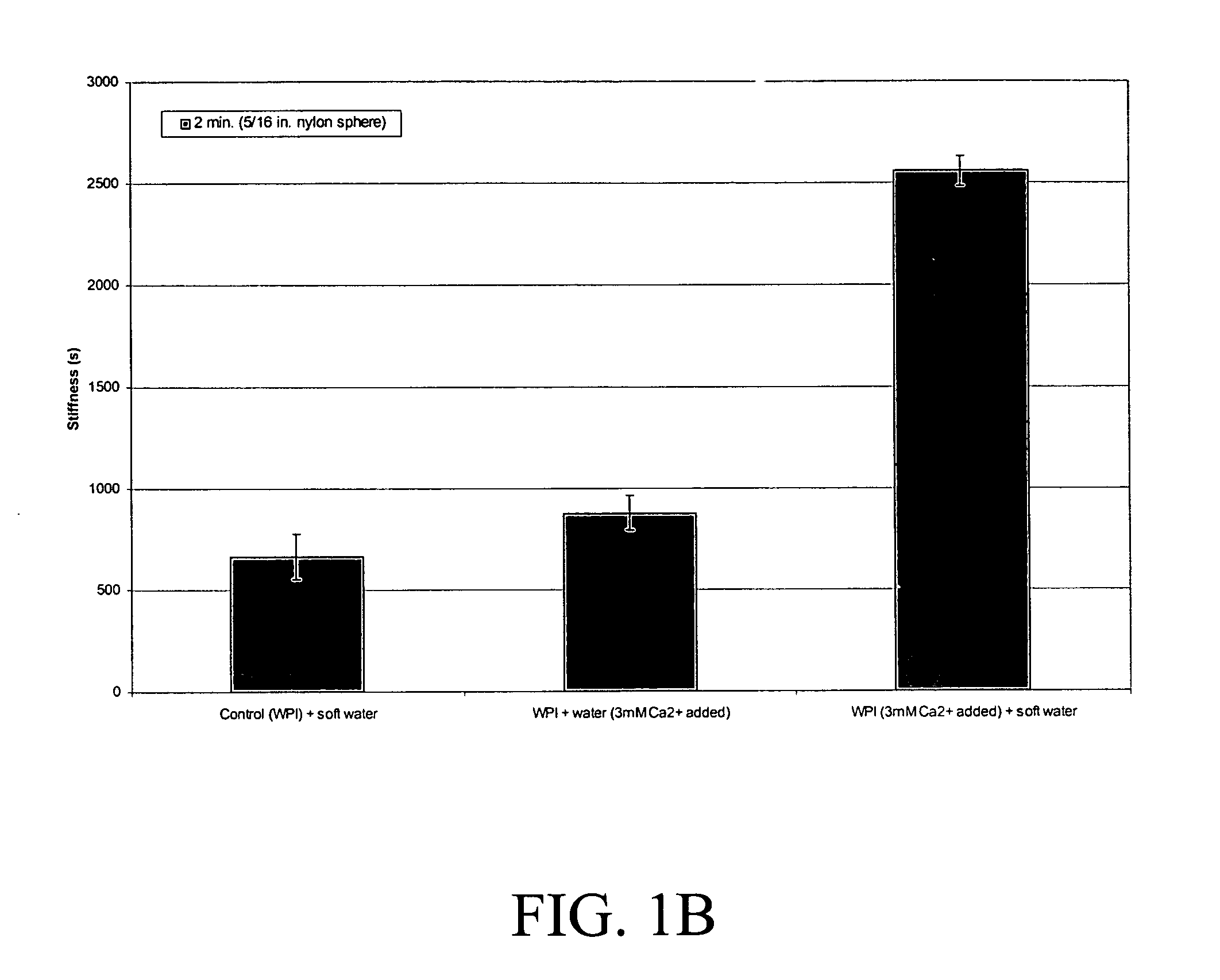

Methods and systems to enhance foam generation and quality through dispenser

InactiveUS20070009636A1Quality improvementImprove sensory qualityWine preparationOther dairy technologyIon sourceChemistry

Methods for generating an improved quality foam for a beverage are presented. In an embodiment, the method comprises providing at least one protein source; providing at least one multivalent ion source; providing a liquid source separate from the multivalent ion source; simultaneously dispensing the protein source and the multivalent ion source with the liquid source; and aerating during the dispensing to produce the stable foam. The foam has an improved stability, texture and mouthfeel.

Owner:NESTEC SA

Composite type kaolin flame-retardant foaming agent

The invention discloses a composite type kaolin flame-retardant foaming agent. The essentials of the technical scheme are as follows: the composite type kaolin flame-retardant foaming agent is prepared from kaolin powder, concave-convex rod argil powder having an air purification function, hydrogen peroxide, aluminium hydroxide, aliphatic alcohol polyoxyethylene ether sodium sulfate, superfine polyvinyl alcohol powder, dimethicone and water. A preparation method of the composite type kaolin flame-retardant foaming agent comprises the following steps of: firstly, stirring a composite type kaolin flame-retardant foaming agent paste-shaped ingredient into a paste; then stirring the composite type kaolin flame-retardant foaming agent ingredient into a finished product of the composite type kaolin flame-retardant foaming agent. After the composite type kaolin flame-retardant foaming agent is stirred at a high speed, porous foamed slurry is formed and the contact between combustible materials and air can be quickly isolated so as to fulfill the aims of flame retardance and extinguishment; by using a product produced by the composite type kaolin flame-retardant foaming agent, the effects of flame retardance, heat preservation, heat insulation and sound insulation are achieved, and a function of purifying the air is also realized; moreover, the composite type kaolin flame-retardant foaming agent is suitable for producing flame-retarding extinguishment products, light slabs, light wall bodies and sound-attenuating and noise-reducing products.

Owner:顾翔

Foaming cartridge

ActiveUS10065199B2Improve foaming qualitySmall sizeFlexible member pumpsHolders and dispensersPorosityWaste management

Foaming cartridge for use with a foam pump, refill unit or foam dispenser includes a housing and a foaming stage disposed within the housing. The foaming stage includes two or more mix media located within the foaming stage. At least two of the mix media are sponges and the sponges have different porosities.

Owner:GOJO IND INC

Amino acid cleansing cream containing multiple plant ingredients

InactiveCN106236690AStable efficacyGood effectCosmetic preparationsToilet preparationsGlycerolDisodium cocoamphodiacetate

The invention discloses amino acid cleansing cream containing multiple plant ingredients. The amino acid cleansing cream is prepared from the following materials in proportion with a common preparation method of the amino acid cleansing cream: 17-19% of glycerol, 10-12% of sodium cocoyl glycinate, 9-11% of alkyl polyglucoside, 8-10% of cocamidopropyl betaine, 4-6% of N-lauroyl-L-sodium glutamate, 2-4% of disodium cocoamphodiacetate, 1.5-2.5% of cholesteryl hydroxystearate, 1.5-2.5% of a macromolecule positive ion conditioner, 0.8-1.2% of glyceryl stearate, 0.7-0.9% of saccharides isomerate, 2-4% of natural plant extract, and the balance of plasma water. Through the strict selection and concentration ratio, the synergistic effect of the various materials is played excellently. The amino acid cleansing cream has the advantages that the amino acid cleansing cream is low in irritation, moderate in cleaning performance and good in skin friendliness, and a user feels comfortable after washing with the amino acid cleansing cream and does not feel dry or tight.

Owner:FUJIAN MENGJIAOLAN DAILY CHEM

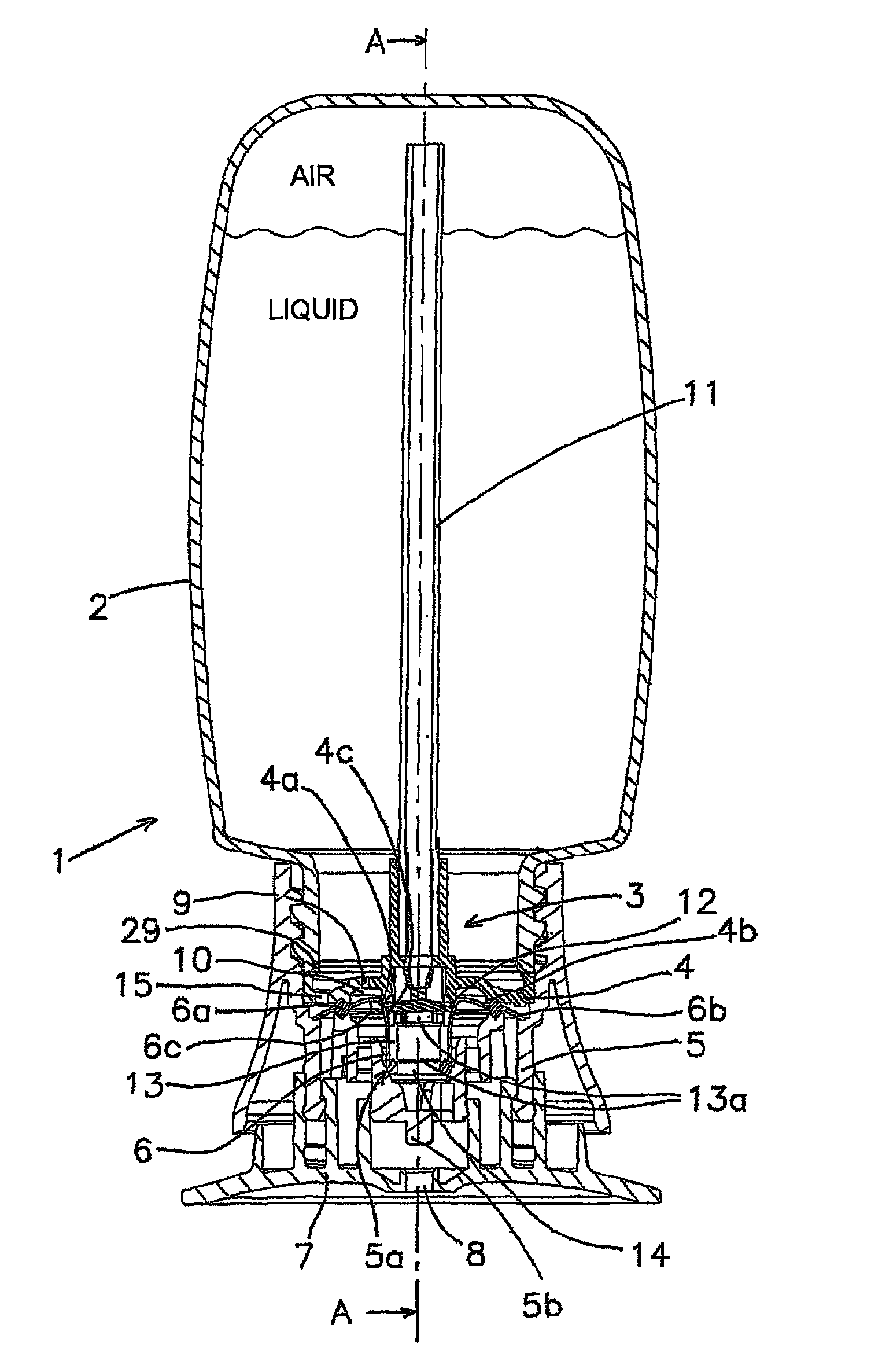

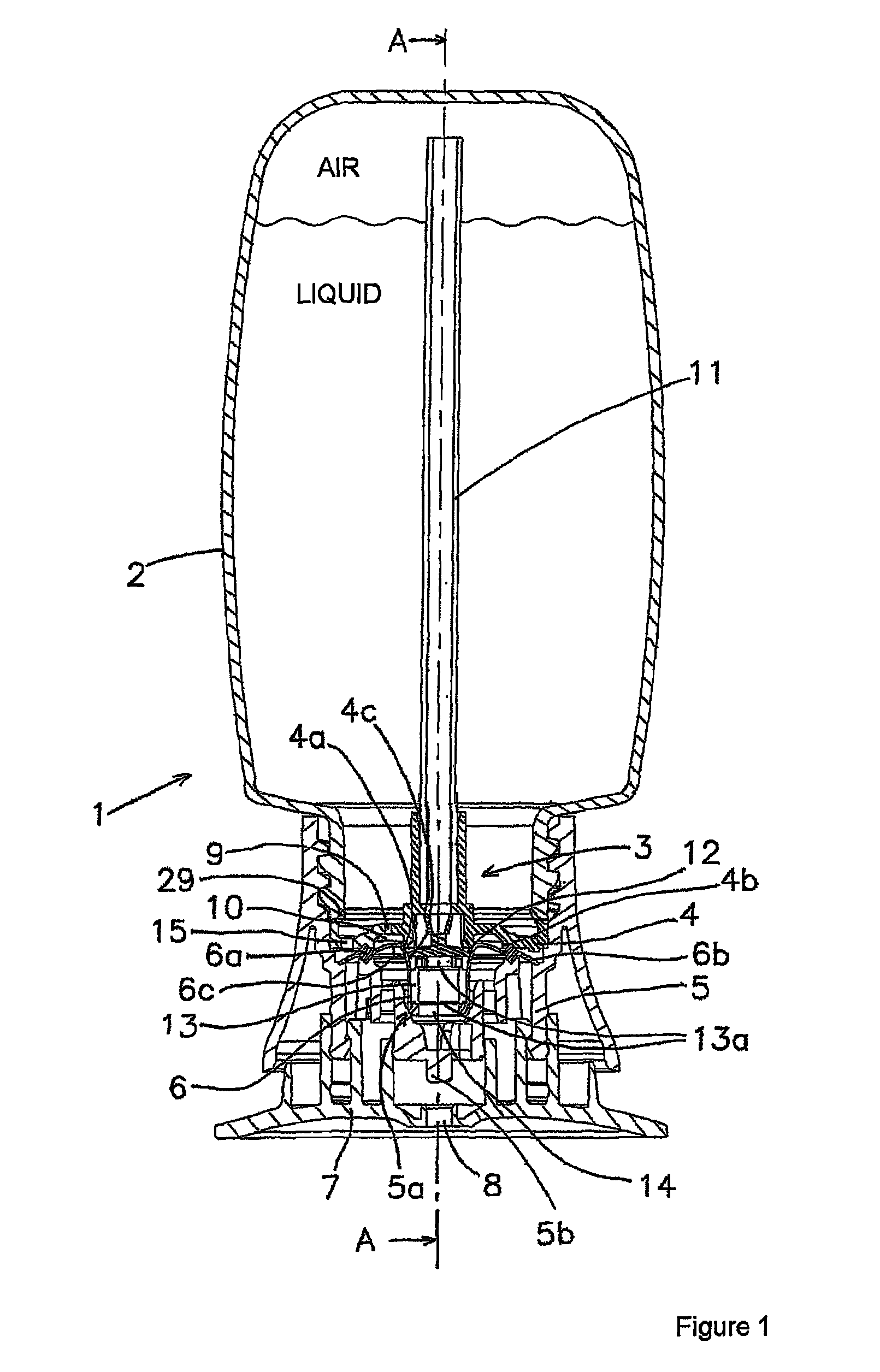

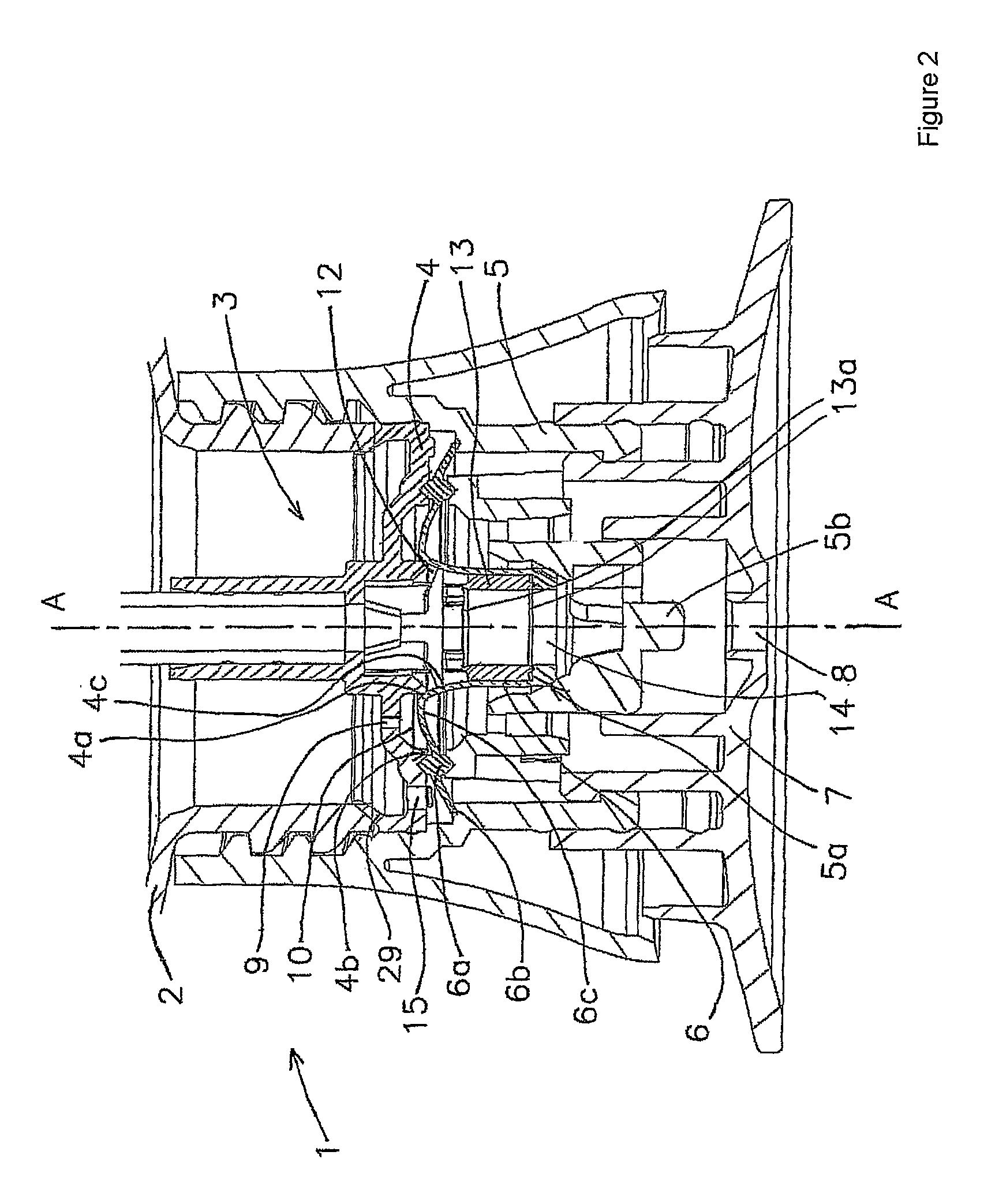

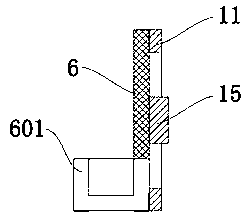

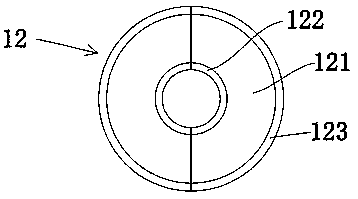

Squeeze foamer

ActiveUS8056769B2Easy constructionWell formedHolders and dispensersLiquid transferring devicesRest position

The invention relates to a dispensing device for dispensing a foam, comprising a manually compressible container (2) for storing a liquid and air, which container comprises an opening (3), a rigid housing (4, 5) to be fitted in or on the opening, the housing comprising an air passage (11, 12) and a liquid passage (9), which are in communication with a dispensing passage (14) which ends in a dispensing opening (8), and a valve body (6) which, in a rest position, covers a mouth of the liquid passage and a mouth of the air passage (10) in a sealing manner in order to prevent a flow from the liquid passage and the air passage to the dispensing passage, and which, during dispensing, opens the mouth of the liquid passage and the mouth of the air passage in order to allow mixing of air and liquid to take place in the dispensing passage. The invention is characterized by the fact that the mouth of the air passage and the mouth of the liquid passage are—substantially annular and are arranged substantially concentrically with respect to one another.

Owner:REXAM AIRSPRAY

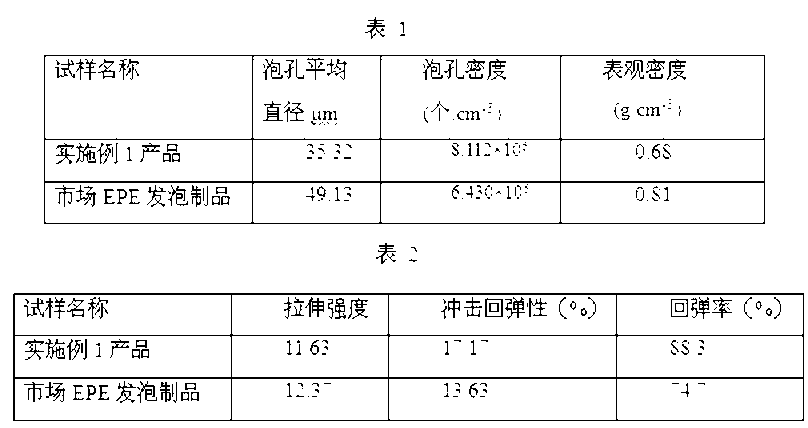

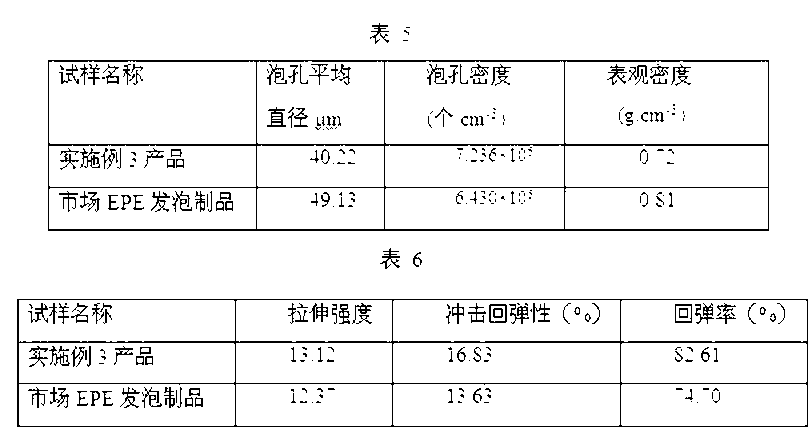

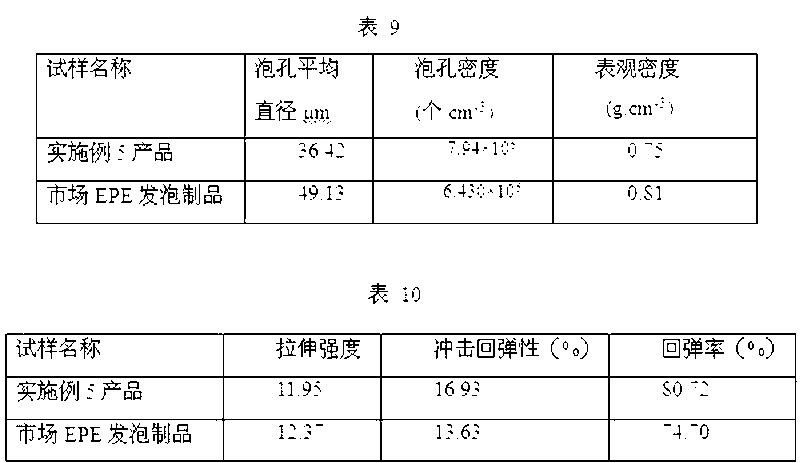

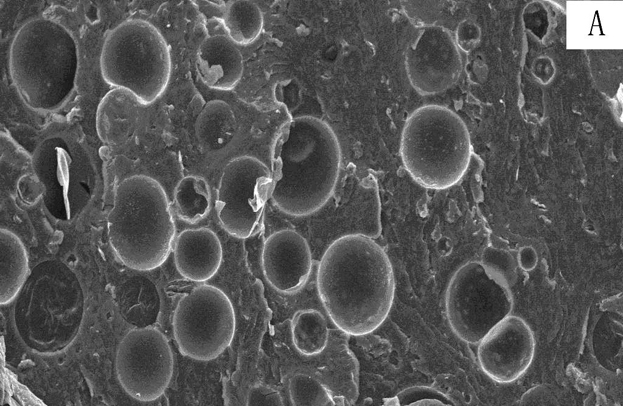

High-elasticity low-density polyethylene foaming composite material and preparation method thereof

ActiveCN103224662AIncreased decomposition temperature rangeBroaden the decomposition temperature rangeLow-density polyethyleneElastomer

The invention discloses a high-elasticity low-density polyethylene foaming composite material and a preparation method thereof. The high-elasticity low-density polyethylene foaming composite material is prepared from the following raw material components in parts by weight: 85-95 parts of low-density polyethylene, 5-15 parts of elastomer, 0.1-0.3 part of crosslinking agent, 1-2 parts of foaming agent and 0.2-0.8 part of blowing promoter. The foaming composite material prepared by the following steps of: burdening, extrusion, drying and injection molding has a high foaming ratio and improved rebound resilience reaching above 16.3%. Compared with present low-density polyethylene foaming sheets on the market, the high-elasticity low-density polyethylene foaming composite material has high cost performance and can be used for solving the problem that the rebound resilience of conventional foaming composite materials prepared by low-density polyethylene (LDPE) generally does not exceed 14%, and as the conventional foaming composite materials cannot reach technical requirements, have high cost and the like, the application of the conventional foaming composite materials in industries is limited.

Owner:GUIZHOU NORMAL UNIVERSITY

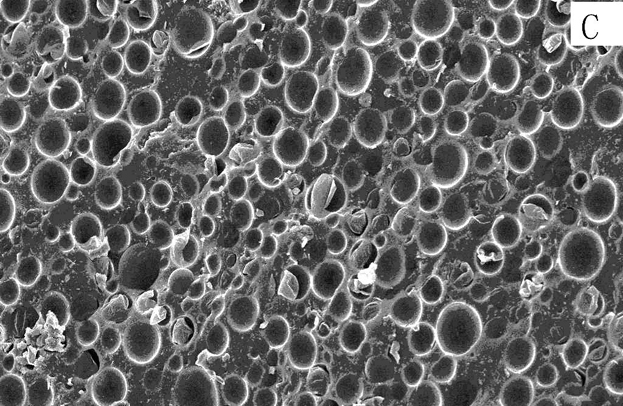

Epoxy resin and nano inorganic particle compounded foam material and preparation method thereof

The invention discloses an epoxy resin and nano inorganic particle compounded foam material and a preparation method thereof. The material comprises epoxy resin, a curing agent, a curing assistant, composite nano inorganic particles and a foaming agent. The preparation method comprises the following steps: mixing the epoxy resin, the curing agent, the composite nano inorganic particles, the curing assistant and the foaming agent, pouring the mixture into a die, curing for 1.5-5.5 hours in an oven at the temperature of 140-160 DEG C, and cooling along with the oven. In the technical scheme of the invention, composite nano inorganic particles are added in epoxy resin, composite inorganic particles can increase the viscosity of the polymer melt in preparing foam material, and the melt viscosity of the foaming system is improved to perform better synchronization of the epoxy resin curing and the cell nucleation and growth, thereby obtaining good foaming effect within wide process scope. Moreover, the prepared foam material has the advantages of small cell average diameter, uniform cell size distribution and high cell density.

Owner:贵州凯科特材料有限公司 +1

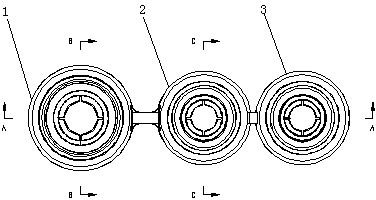

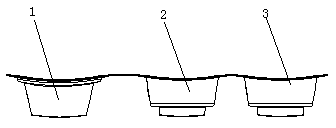

Electric water heater and assembly method of electric water heater using large plastic sleeve

The invention provides an electric water heater and an electric water heater assembly method using a large plastic sleeve. The electric water heater comprises an inner container, an outer shell, a water inlet pipe, a water outlet pipe, a magnesium rod, a water inlet pipe sleeve, a water outlet pipe sleeve and a magnesium rod sleeve. One ends of the various sleeve bodies are narrow-mouthed ends, and the other ends of the various sleeve bodies are flared ends. Each narrow-mouthed end is provided with an inner container follow-shape surface which is characterized that a middle hole edge of the inner container follow-shape surface of each plastic sleeve is provided with a horn-mouth shape elastic cantilever extending inward. The free end of each horn-mouth shape elastic cantilever is a cylindrical installation guide. The water inlet pipe sleeve, the water outlet pipe sleeve and the magnesium rod sleeve are connected into a whole in a sequential and side-by-side mode. The electric water heater is reasonable in structural design, high in installation efficiency and good in tightness. In the electric water heater assembly method using the large plastic sleeve, the separated or integrated large plastic sleeve is firstly clamped on a magnesium rod seat, the water inlet pipe and the water outlet pipe, wherein the magnesium rod seat, the water inlet pipe and the water outlet pipe are arranged outside the inner container. Only once inner container leakage detecting is needed, and thus processing step is simplified, and production efficiency and foaming quality are improved.

Owner:HAIER GRP CORP +1

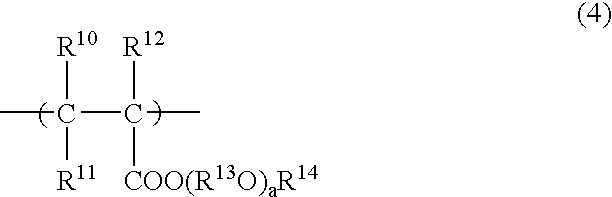

Concrete composition method of producing concrete compositions and cement admixture

The objective of the present invention is to provide a concrete composition in which the amount of air entrained can be maintained stably and which is excellent in strength and durability, a concrete composition which is excellent in freeze-thaw durability owing to the good quality of foams and is excellent in air content stability with time and which can form curing products excellent in strength and durability, a method of producing such concrete composition, and a cement admixture.

Owner:NIPPON SHOKUBAI CO LTD

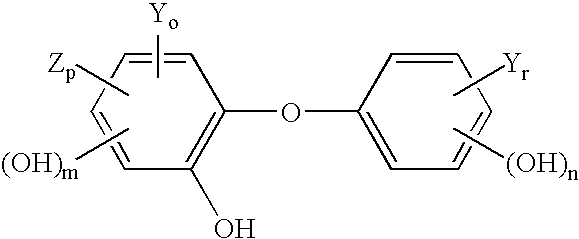

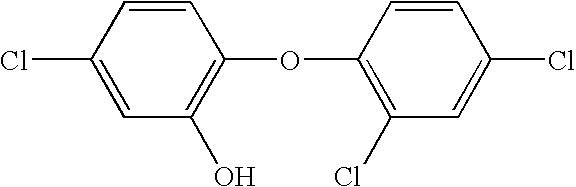

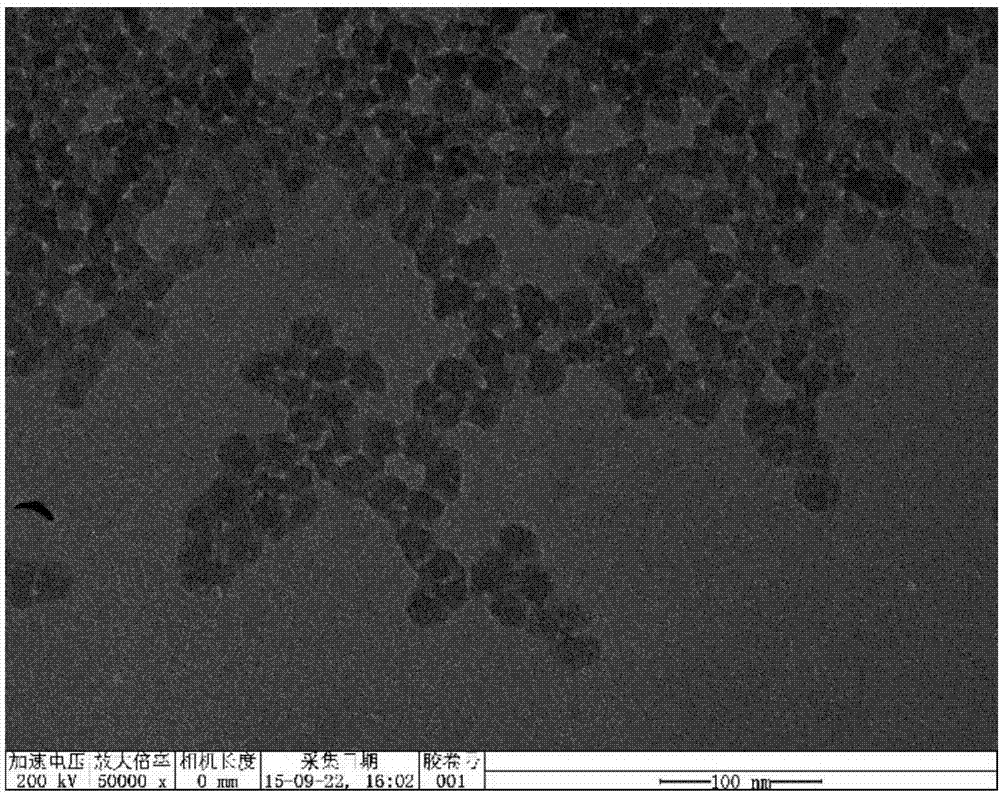

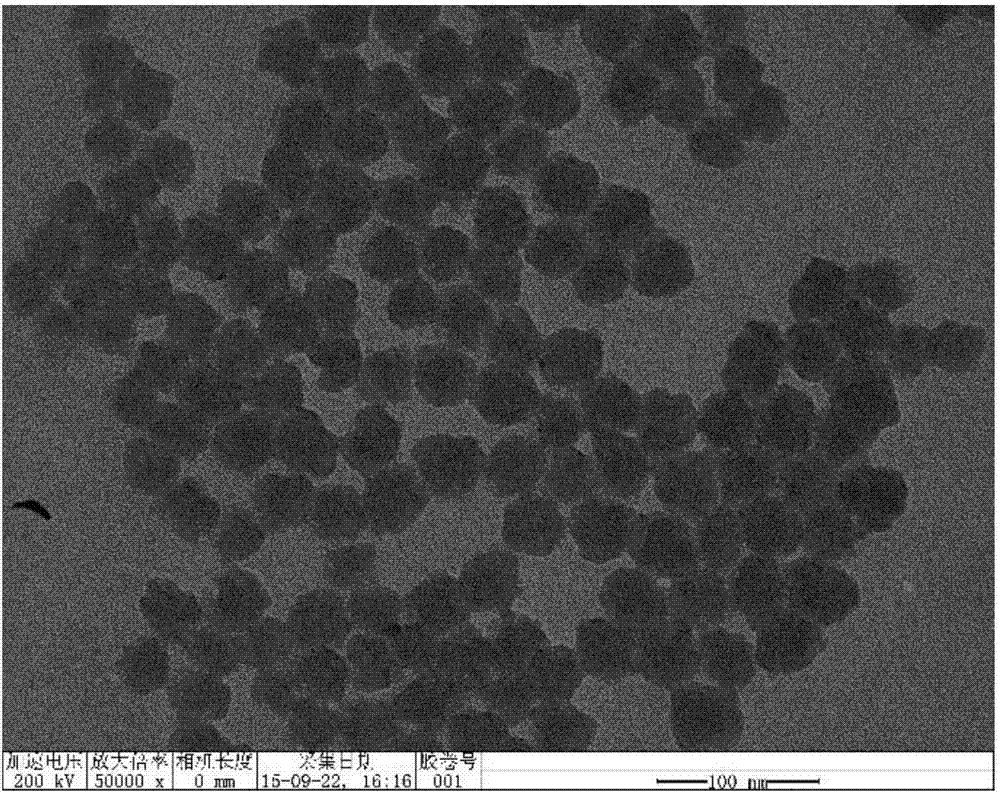

Nano composite foaming agent, foaming product, and preparation method and application thereof

The invention relates to the field of foaming agents, in particular to a nano composite foaming agent, a foaming product, and a preparation method and application thereof. The nano composite foaming agent is characterized in that the nano composite foaming agent is formed by compounding modified mesoporous silica and 4,4'-oxobibenzene sulfonamide, the mass ratio of the modified mesoporous silica to the 4,4'-oxobibenzene sulfonamide is 1: (3-7), and the modified mesoporous silica is obtained by successively carrying out pore expanding and grafted modification on the mesoporous silica. The nano composite foaming agent not only is small in particle size, but also is high in loading amount on a chemical foaming agent, so that micropore foamed plastic with good foaming quality can be obtained, and the application prospect is wide.

Owner:BEIJING UNIV OF CHEM TECH

Compound type foaming agent for infusorial earth

The invention discloses a compound type foaming agent for infusorial earth. The technical scheme of the foaming agent is characterized in that the compound type foaming agent for the infusorial earth comprises infusorial earth powder, attapulgite clay powder with an air purification function, hydrogen peroxide, dodecyl dimethyl amine oxide, coconut oil diethanol amide, a silicon resin polyether emulsion, polyether modified polysiloxane and water. Firstly the compound type foaming agent for the infusorial earth is burdened and stirred, so that a paste is obtained; and then the compound type foaming agent for the infusorial earth is burdened and stirred, so that a finished product of the compound type foaming agent for the infusorial earth is obtained. The compound type foaming agent for the infusorial earth has the characteristics as follows: the foaming capacity is high, the foaming times are high, the bubble producing amount in unit volume is large, the bubble holes are fine, uniform and not prone to be broken, the product demolding speed is high, the surface smoothness is good, and the product later-term strength is high; a product produced by using the compound type foaming agent for the infusorial earth not only has the effects of heat preservation, thermal insulation and sound insulation, but also has the air purification function; and the compound type foaming agent for the infusorial earth is suitable for being used for producing lightweight slabs, lightweight walls and noise reduction products.

Owner:黄万辉

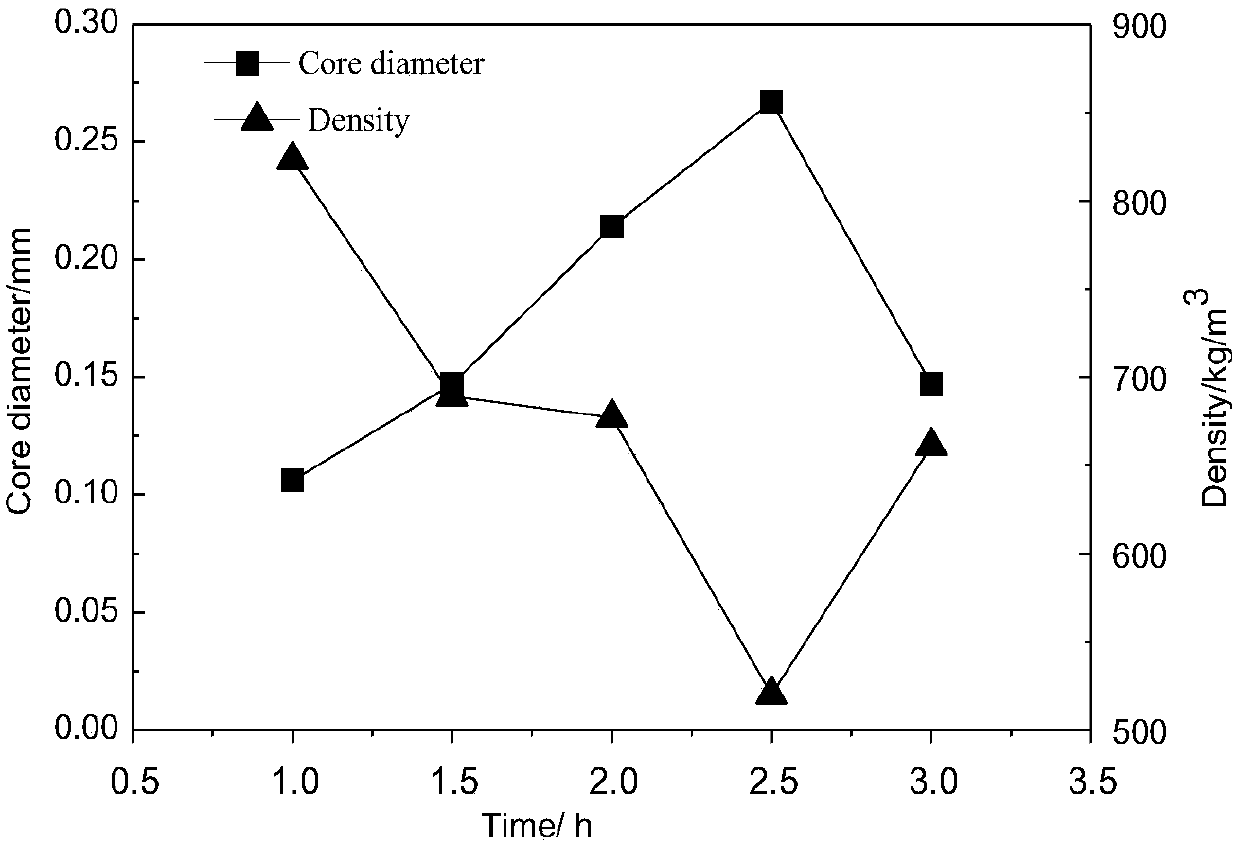

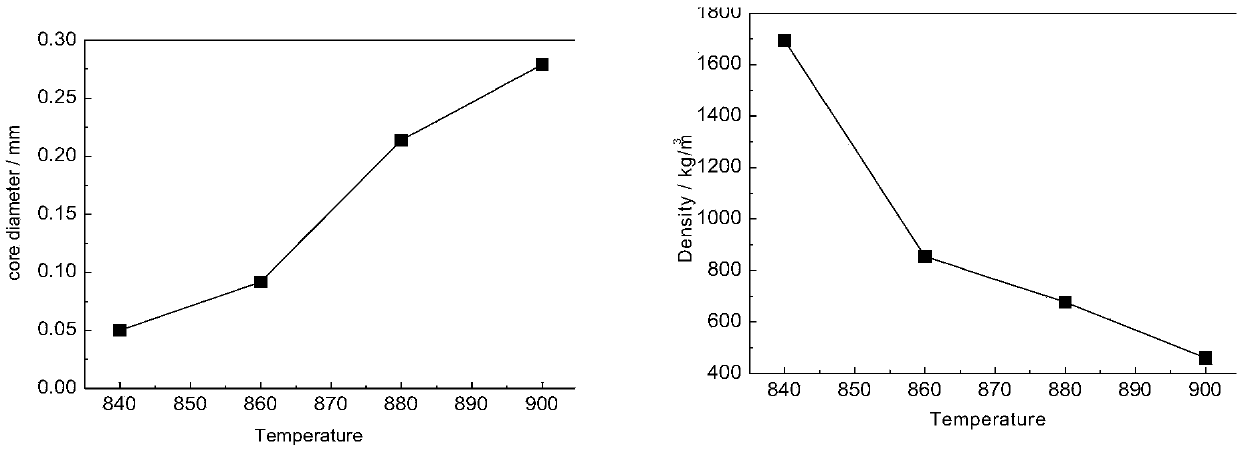

Preparation method of foam glass

InactiveCN107721182AReduce manufacturing costShaolian through holeVolumetric Mass DensityAbsorption rate

The invention discloses a preparation method of foam glass. The preparation method comprises taking graphite powder as a foaming agent, mixing the graphite powder with pretreated glass powder, and performing firing to obtain the foam glass product. Waste glass in daily life is taken as a raw material, and the raw material is cleaned and dried, crushing and ball-milling are performed to prepare glass powder with a particle size smaller than 300 microns, the glass powder is mixed with a proper amount of the graphite powder, ball milling is performed in a ball mill, 50-mesh sieving is performed,a proper amount of the mixture is taken for forming under a certain pressure, the formed mixture is placed into a stainless steel mold coated with a release agent for firing according to a certain process condition, and the foam glass product is obtained. The average pore diameter of the prepared foam glass is about 0.2mm, the product density is 460 kg / m<3>, the water absorption rate is less than3.5%, the foaming is uniform, the volume expansion is obvious, the air holes are small and uniform, the communication holes are less, and the foaming quality is optimum. The foam glass prepared by thepreparation method can be applied to heat-preservation, sound-absorption and heat-insulation materials; and the dual problems of environmental pollution and resource reutilization are effectively solved by the preparation of the foam glass.

Owner:XUZHOU YUANYANG MAGNETIC MATERIAL

Antimicrobial wash formulations including amidoamine-based cationic surfactants

InactiveUS20080113892A1Reduce stimulationLow usage levelCosmetic preparationsOrganic detergent compounding agentsBULK ACTIVE INGREDIENTActive ingredient

An antimicrobial hand wash comprises an active ingredient and an amidoamine based cationic surfactant having a fatty chain with from 6 to 24 carbon atoms. These cationic surfactants are compatible with common active ingredients such that antimicrobial efficacy is maintained, while foam quality is improved when the hand wash is dispensed as foam. Other antimicrobial hand washes include specific amidoamine based cationic surfactants that dissolve at least a portion of the active ingredient, thus reducing the amount of solids in the formulation, and, in some instances, making a cold manufacturing process possible.

Owner:GOJO IND INC

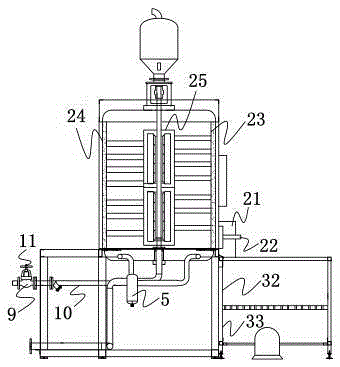

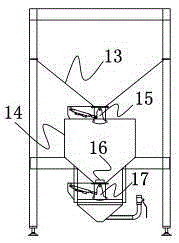

Full-automatic intermittent type pre-foaming machine

The invention discloses a full-automatic intermittent type pre-foaming machine. A steam conveying pipeline is communicated with the bottom end of a pre-foaming machine barrel. A negative-pressure feeding device is connected with a metering weighing device and provided with a vacuum generator used for sucking in raw materials in the metering weighing device. The negative-pressure feeding device is arranged above the pre-foaming machine barrel and communicated with the pre-foaming machine barrel. A stirring device is arranged above the pre-foaming machine barrel. The stirring device is provided with a cross-shaped stirring block used for stirring the raw materials in the pre-foaming machine barrel. A sensor used for detecting the foaming degree is arranged on the inner wall of the pre-foaming machine barrel. The pre-foaming machine barrel is connected with a vulcanization drying device. The steam conveying pipeline, the pre-foaming machine barrel and a control system are installed on a rack. The rack is further provided with a power-off protection device connected with the pre-foaming machine barrel to prevent the raw materials in the pre-foaming machine barrel from being bonded after powering off. The full-automatic intermittent type pre-foaming machine can carry out effective drying, foaming particles are not bonded after powering off, the automation degree is high, stirring is even, and efficiency is high.

Owner:QINGDAO HEINOSKY TECH CO LTD

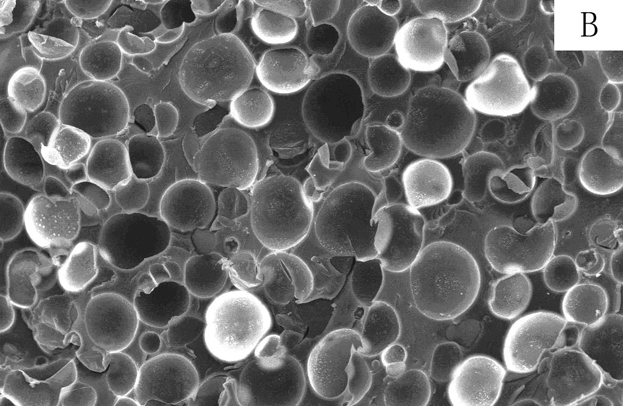

Porous material for tissue engineering stent

InactiveCN103520770AMeet the requirements of growthLower nucleation free energy barrierProsthesisPorosityWater baths

The invention discloses a porous material for a tissue engineering stent. The porous material for the tissue engineering stent is prepared from 25-40% of polycaprolactone, 30-45% of polyethylene oxide and 25-40% of sodium bicarbonate according to a method as follows: uniformly mixing the raw materials; extruding in a twin-screw extruder for granulating; foaming and moulding by a conventional microporous foaming and moulding technology to obtain an intermediate product; leaching the obtained intermediate product in a circulating water bath; and performing vacuum drying to obtain a porous material with the porosity of 68-74.0%, the pore size of 20-200 microns, and the sizes of internal intercommunicating passages of about 20-200 microns. The porous material for the tissue engineering stent has the advantages as follows: in the foaming process, not only supercritical carbon dioxide for microporous foaming and moulding can generate a foaming action, but also gas obtained by decomposing sodium bicarbonate can generate a foaming action, so that by a combined physical and chemical foaming method, the finally obtained porous material can meet a growth requirement of a biological cell.

Owner:ZHENGZHOU UNIV

Production line for fireproof heat-insulating wall plates, and method for on-site processing of fireproof heat-insulating wall plates by utilizing production line

The invention relates to a production line for fireproof heat-insulating wall plates, and a method for on-site processing of the fireproof heat-insulating wall plates by utilizing the production line, and solves the problems that the conventional multi-layer fireproof heat-insulating wall plate processing equipment has a large occupied area, high investment and failure in on-site processing. Therefore, the production line comprises a stirrer, a pouring vehicle, and two lines of pouring molds, wherein the stirrer comprises an agitation tank; a stirring paddle driven by an external motor is arranged in the agitation tank; the agitation tank is provided with a liquid feeding device, a solid feeding device and a baiting valve, and is fixed on four support legs; the pouring vehicle comprises a vehicle body and a wagon box; the wagon box is fixed on the vehicle body; wheels are arranged below the vehicle body; the opening of the wagon box faces upwards; an emptying gate is arranged at the rear part of the wagon box; and a scraping plate is arranged on a fixing bracket behind the emptying gate. The invention further relates to a corresponding processing method. The production line has the advantages of low investment and small occupied area, ensures on-site processing, saves transportation cost, and is an ideal upgrading product for the conventional fireproof heat-insulating wall plate production line.

Owner:山东信发环保科技有限责任公司

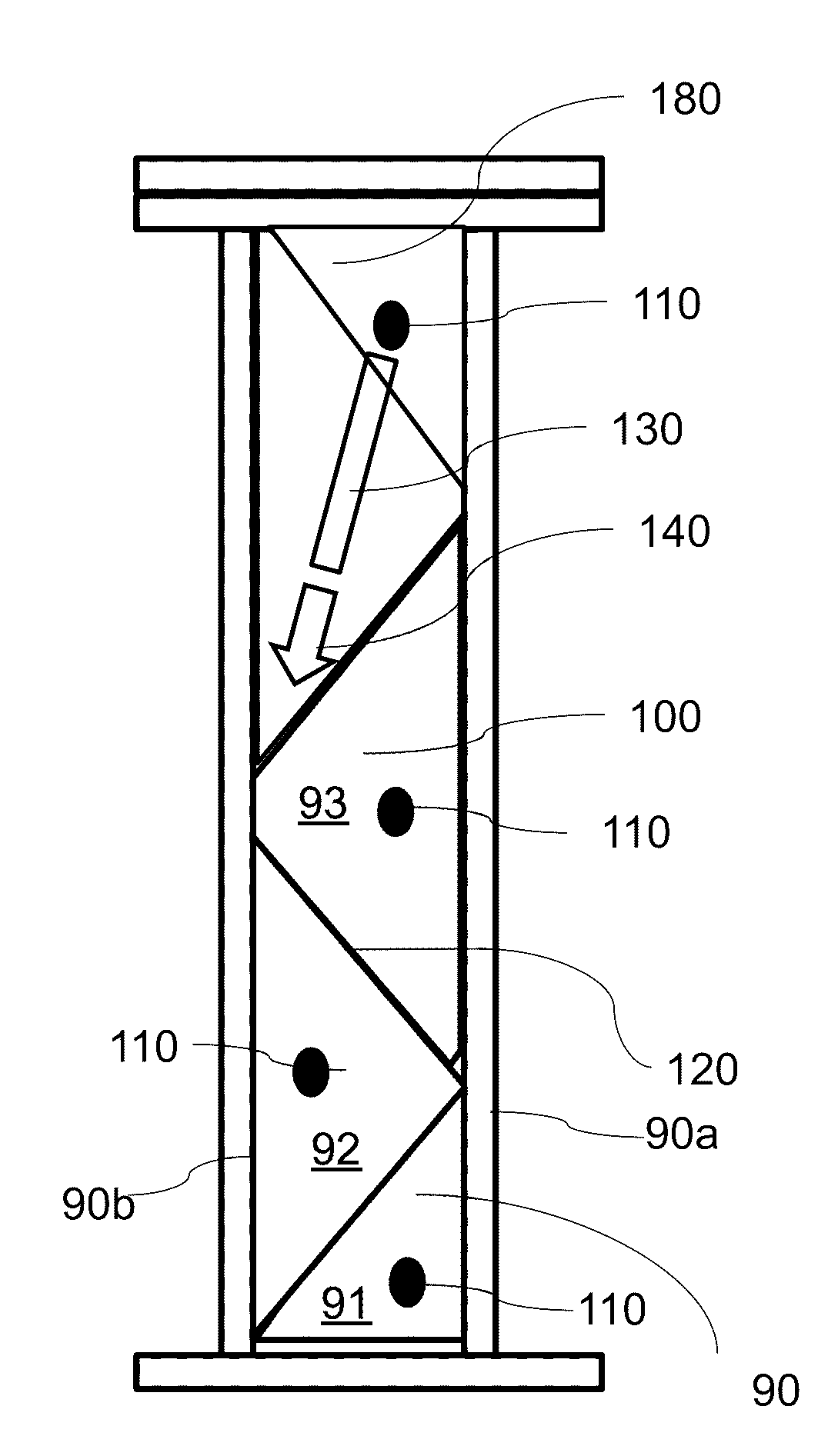

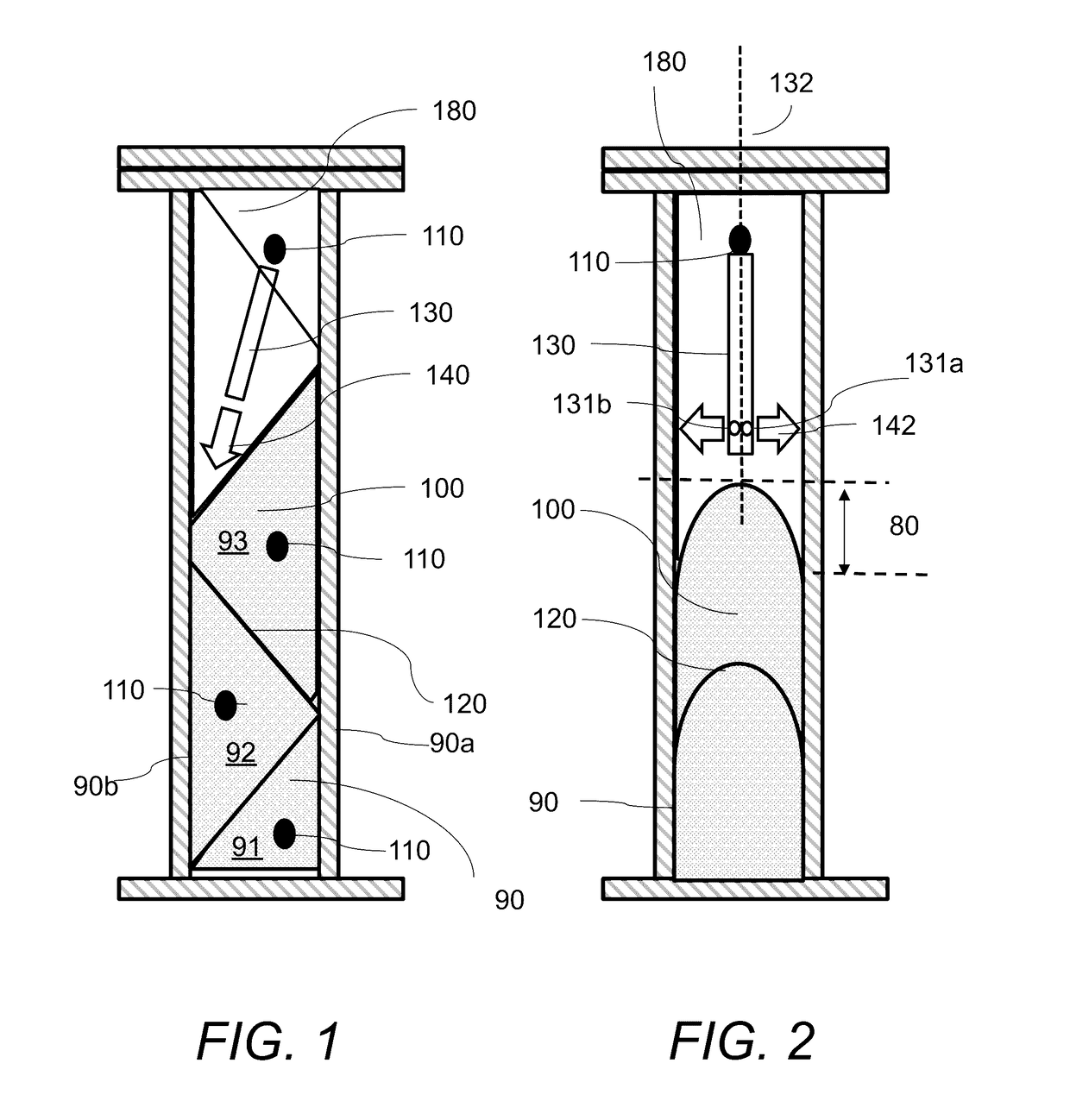

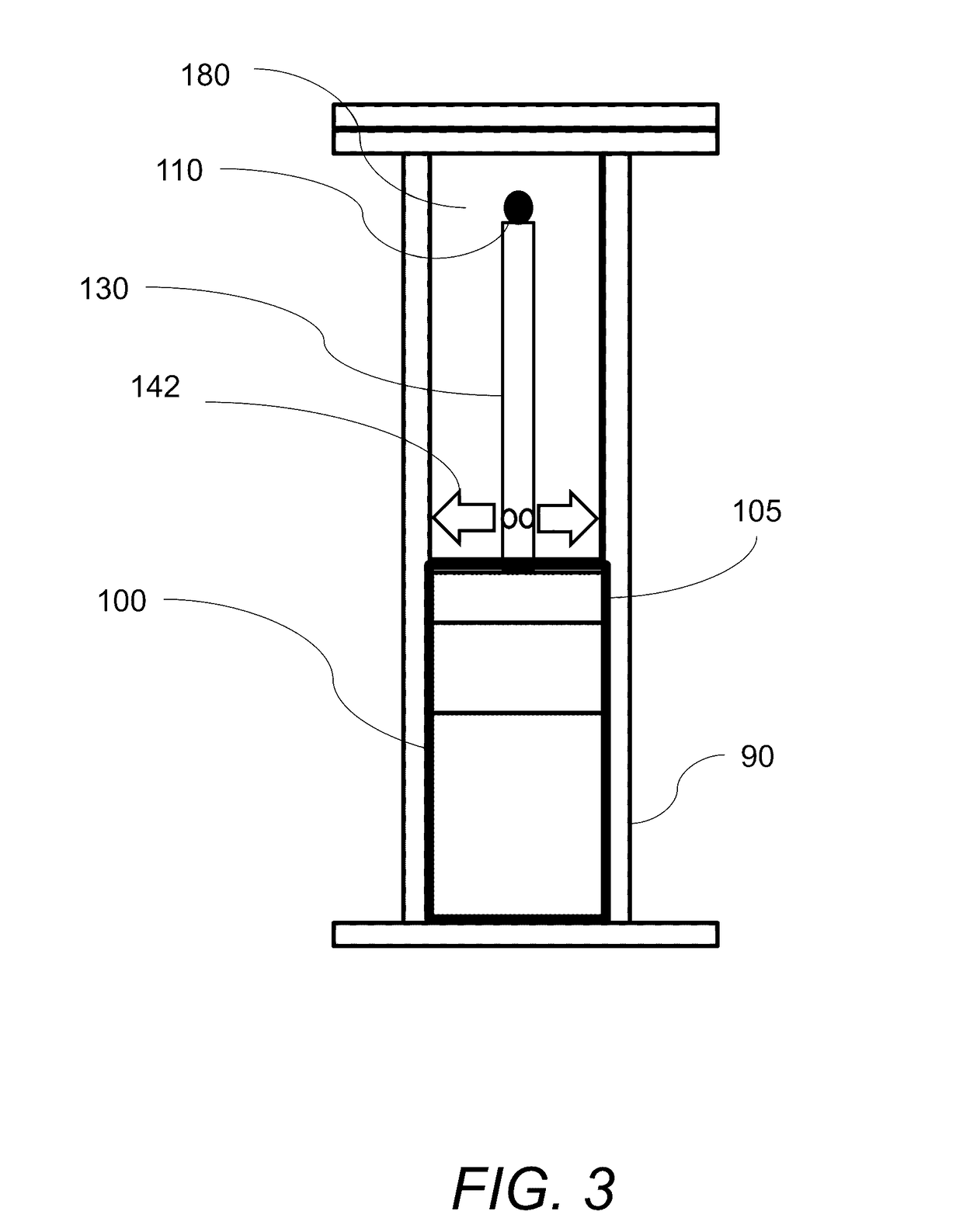

System and method for minimally invasive injection foam

InactiveUS20170080614A1Reduce pressure buildupTraining can be simplifiedHeat proofingDomestic articlesSlope angleEngineering

A method for filling a cavity with an expanding insulating foam component includes the following. First, providing a closed cavity comprising at least one elongated wall surface that extends along a first direction and includes first and second opposite sides, a top side and a bottom side. Next, forming a plurality of openings in the elongated wall surface arranged along the first direction and being alternating close to the first or the second opposite sides. Next, inserting a dispense tube through a first opening of the plurality of openings, and injecting a first portion of the expanding insulating foam into the closed cavity. The first opening is located close to the bottom side and close to the first side of the elongated wall surface. The injected foam expands along the bottom side and the first side and forms a first sloped top surface that has a positive slope angle. Next, inserting the dispense tube through a second opening of the plurality of openings located close and above the first opening and close to the opposite second side, and injecting a second portion of the expanding insulating foam into the closed cavity. The injected foam expands along the first sloped top surface and the second side and forms a second sloped top surface that has a negative slope angle.

Owner:CERTAIN TEED LLC

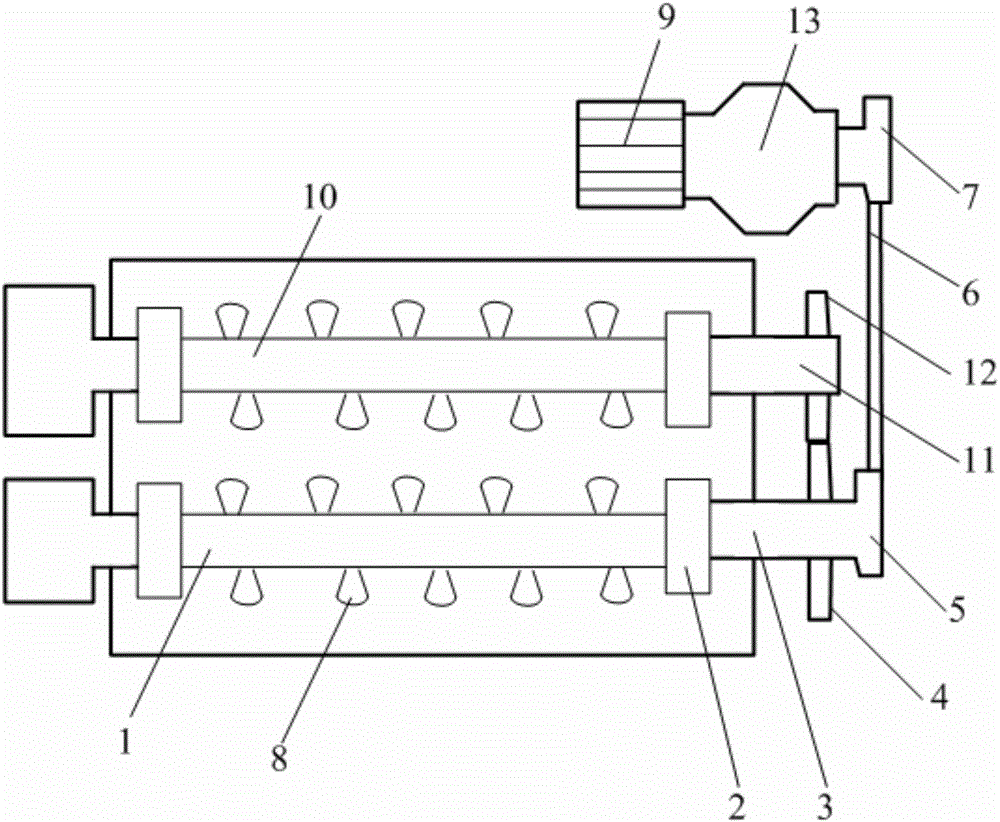

Horizontal type double-shaft stirring cement foaming machine

InactiveCN106079092ACompact structureSimple structureDischarging apparatusCement mixing apparatusGear driveMotor drive

The invention discloses a horizontal type double-shaft stirring cement foaming machine which comprises a horizontal type foaming barrel; two parallel stirring shafts are arranged in the horizontal type foaming barrel; a motor drives a drive sprocket to rotate; the drive sprocket drives a driven sprocket to rotate through a chain; the driven sprocket rotates to drive a driving shaft and a driving gear to rotate; and the driving gear drives a driven gear and a driven shaft to rotate to realize rotating stirring of the two stirring shafts. The horizontal type double-shaft stirring cement foaming machine is compact and simple in structure and small in occupied area; the motor is adopted to drive the two stirring shafts to rotate and stir, so that the production efficiency is improved, and the foaming quality is optimized; and the stirring shafts and a transmission shaft are in split type connection, so that the consumable stirring shafts can be conveniently replaced.

Owner:WUXI LEHUA AUTOMATION TECH

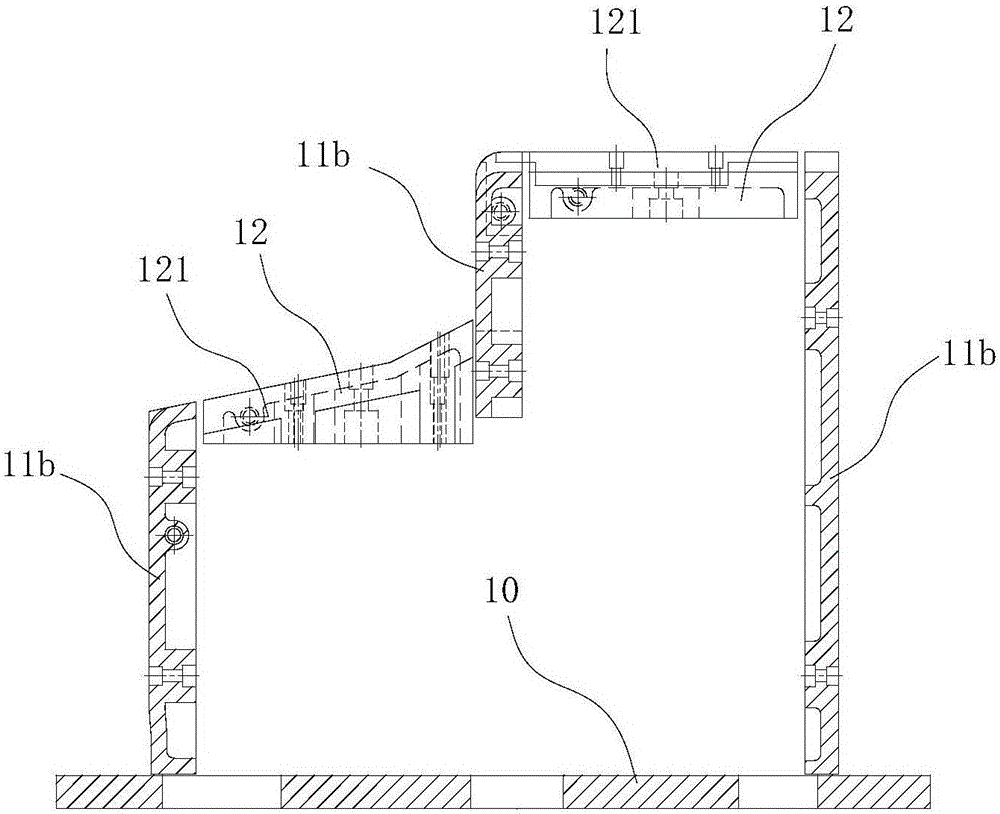

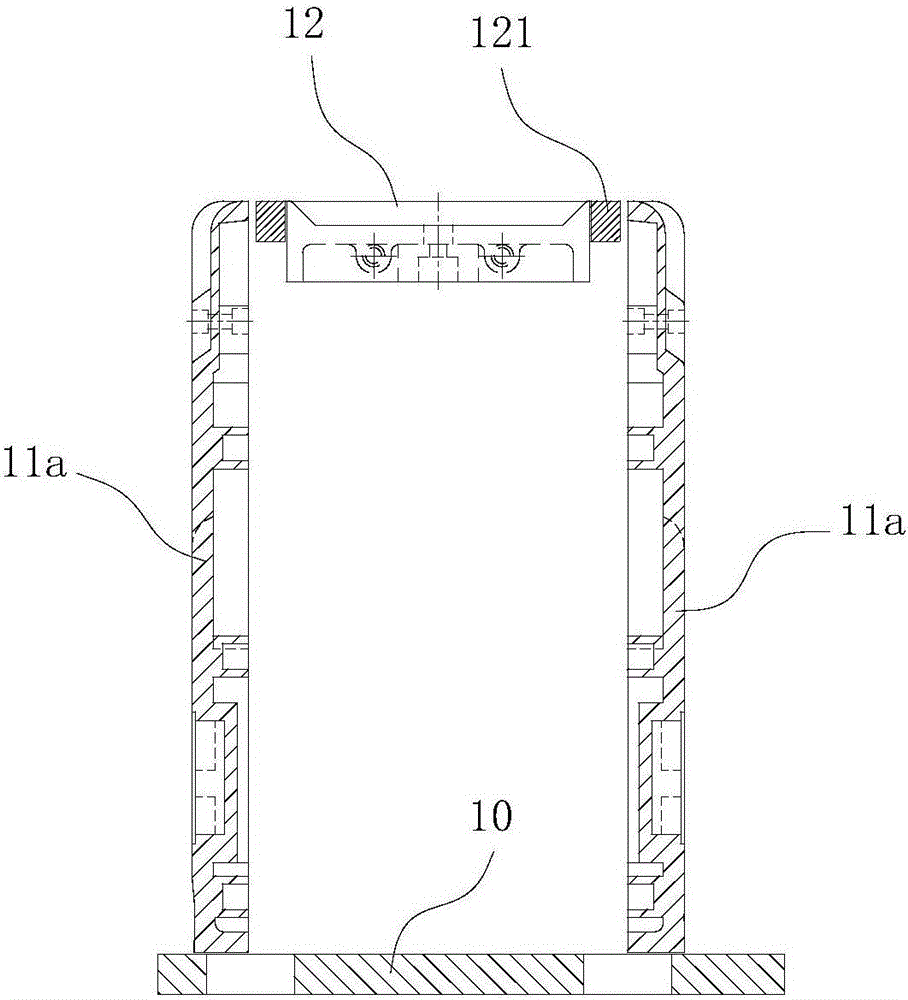

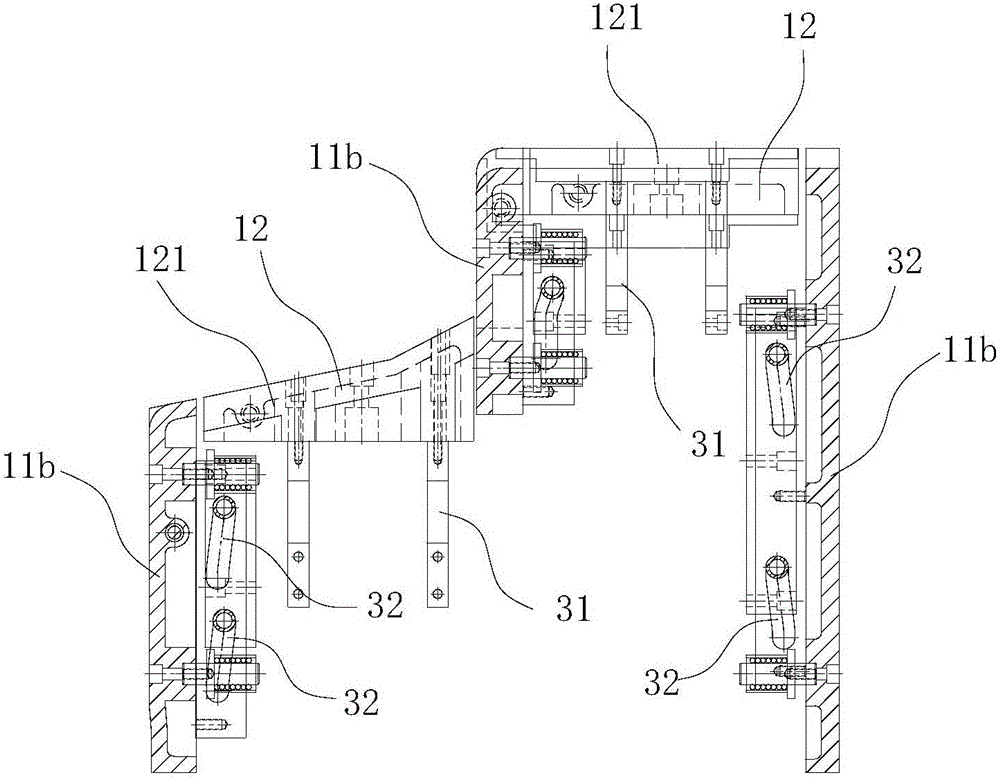

Foaming and expanding-shrinking mold for box body

The invention belongs to the technical field of forming of inner containers of refrigerators and particularly relates to a foaming and expanding-shrinking mold for a box body. The mold comprises a base plate and a convex mold body, wherein the convex mold body is formed by combining top plates, side plates and terminal plates, each top plate, each side plate and each terminal plate are of a split type structure, and each side plate and each terminal plate are arranged to do reciprocating motion along the normal so as to transversely expand or shrink the convex mold body; the top plates are fixedly arranged relative to the base plate, and pulling cores are arranged in crevices between the side plates and the top plates to do up-down reciprocating motion; in a foaming process, the side plates expand outwards, and then the pulling cores are level with the tops of the side plates and the top plates; and in a demolding process, the pulling cores move down, so as to form a space for the horizontal shrinkage of the side plates. According to the foaming and expanding-shrinking mold, the expansion and shrinkage of the top plates and the side wall of the mold are simultaneously driven by virtue of the vertical motion of a movable frame, a transmission structure is compact, and the interference is unlikely to be caused in an operation process, so that the foaming quality of the box body is effectively improved.

Owner:滁州市博精模具设备制造有限公司

Preparation method of monodispersed mesoporous silica, and nano-composite foaming agent as well as preparation method and application thereof

The invention provides a preparation method of monodispersed mesoporous silica, and a nano-composite foaming agent as well as a preparation method and application thereof. The preparation method of the monodispersed mesoporous silica comprises the steps of preparing silica sol by taking monatomic silicon powder as a silicon source, adjusting the particle sizes of the silica sol by supplementing silica powder and a sodium hydroxide solution, synthesizing the silica sol into urea formaldehyde resin / SiO2 composite microspheres by using a polymerization-induced colloid aggregation method, and calcining to obtain the monodispersed mesoporous silica. The nano-composite foaming agent is prepared by compounding the monodispersed mesoporous silica and azodicarbonamide. The composite foaming agent prepared by the method not only is small in particle size, and is high in loading amount of a chemical foaming agent, thus being used for preparing microcellular foam plastics with better foaming quality and having wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

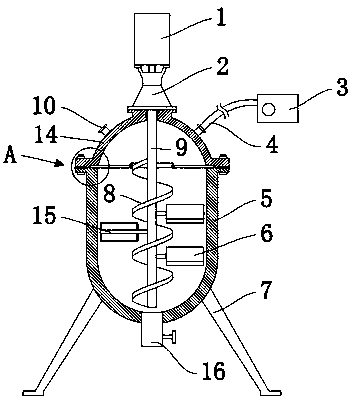

Polyurethane foaming device and using method thereof

The invention discloses a polyurethane foaming device and a using method thereof. The polyurethane foaming device comprises a tank, a disturbance plate and a sieve tray. The top end of the tank is fixedly connected with a top cover through a flange, and the sieve tray is fixed between the tank and the top cover in a pressing joint mode. The power output end of a speed reducer is connected with a stirring shaft, and a spiral blade and a fixing rod are welded and fixed to the stirring shaft. The disturbance plate is welded and fixed to the fixing rod, and the other side of the top cover is connected to a vacuum pump through a connecting pipe. A motor drives the stirring shaft to rotate at a low speed, a foaming raw material is vertically transported from the bottom to the upper portion in the tank through the spiral blade, the foaming raw material is stirred in the horizontal direction through the disturbance plate, the foaming raw material is filtered in the stirring process, the interior of the tank is vacuumized through the vacuum pump, bubbles in the foaming raw material are broken through vacuum, and thus the foaming quality is improved.

Owner:CHUZHOU YULIN POLYURETHANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com