Patents

Literature

174results about How to "Fast demoulding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-imprinting template, system thereof and imprinting method

ActiveCN103926789AReduce volumeLow costNanoinformaticsPhotomechanical apparatusUltraviolet lightsEngineering

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

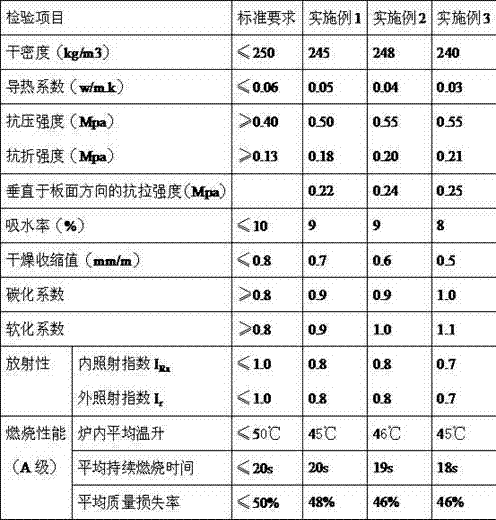

High-strength foam cement insulation board and preparation method thereof

ActiveCN103241997AImprove fire performanceExtended service lifeMould separation apparatusMouldsFiberPolymer science

The invention discloses a high-strength foam cement insulation board. The board is prepared from raw materials including cement, coal ash, water, emulsion, calcium stearate, fiber hair, a foam stabilizer, a water repellent, calcium chloride, aluminium sulfate and a foaming agent which are added in a ratio. The preparation method comprises steps of: first-level stirring: mixing the cement, the coal ash, the water, the emulsion, and calcium stearate according to a ratio, and stirring uniformly; second-level stirring: sequentially adding the fiber hair, the foam stabilizer, the water repellent, the calcium stearate and hydrogen peroxide into the size according to the ratio after first-level stirring, and stirring uniformly; carrying out injection molding, foaming and initial curing; demolding; cutting; and maintaining a finished product. The insulation board is short in production period, high in production efficiency, high in performance index and low in cost.

Owner:HUAIAN RUNCHENG BUILDING ENERGY SAVING MATERIAL CO LTD

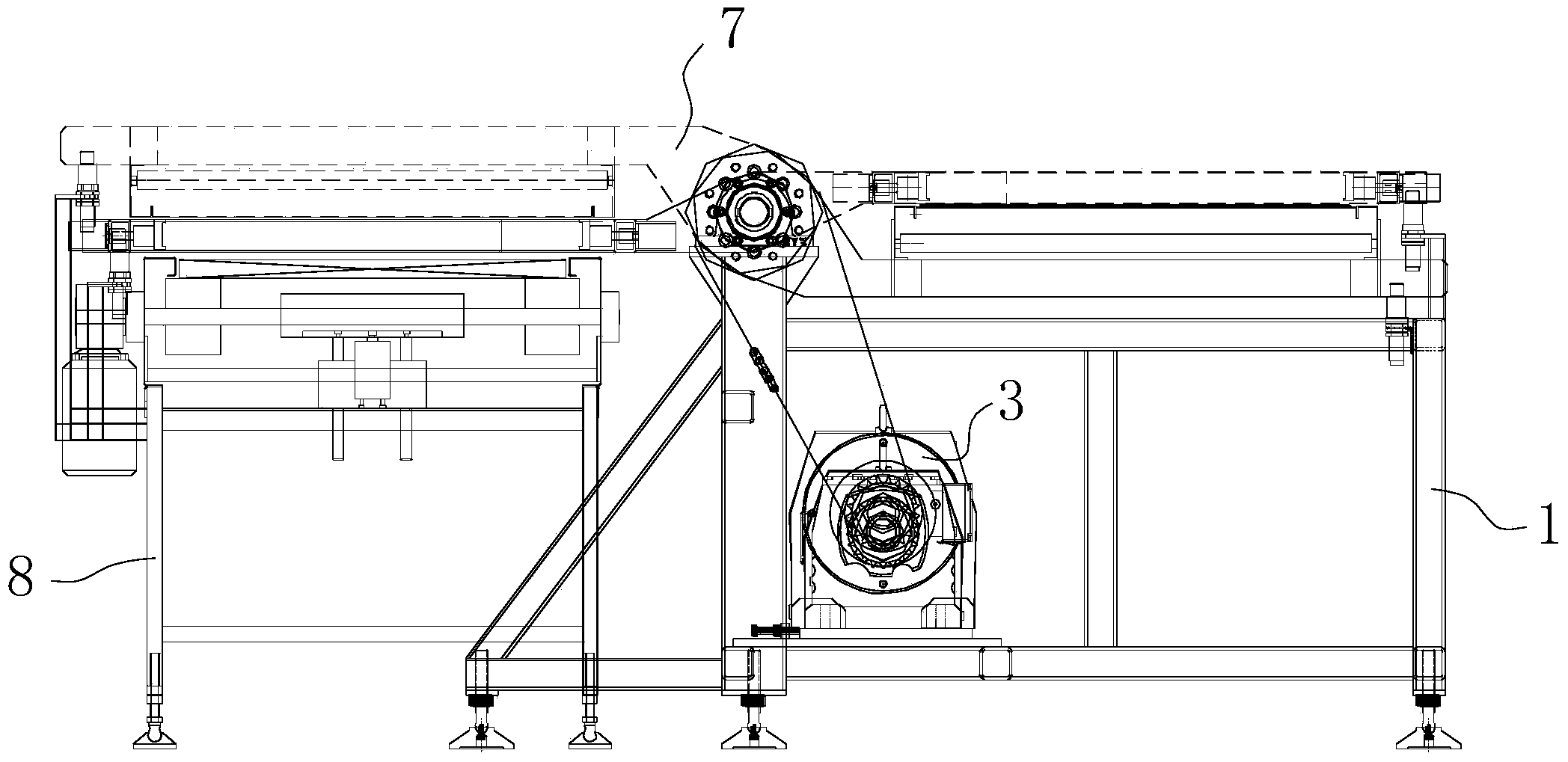

Tray turning and mold stripping machine

The invention discloses a tray turning and mold stripping machine. The tray turning and mold stripping machine comprises a machine frame. The bottom of the machine frame is provided with a first motor and a second motor. The edge of the top of the machine frame is provided with a first rotating shaft and a second rotating shaft. The first rotating shaft is in transmission connection with an output shaft of the first motor through a chain, the second rotating shaft is in transmission connection with an output shaft of the second motor through a chain, and the first rotating shaft is connected with a tray turning mechanism. The tray turning mechanism comprises a clamping air cylinder, a tray clamping board and two tray turning arms. The ends of the two tray turning arms are connected with the first rotating shaft and the second rotating shaft respectively, the tray clamping board is arranged on the tray turning arms, and the clamping air cylinder is arranged on the tray clamping board.

Owner:GUANGZHOU LINE AUTOMATION EQUIP

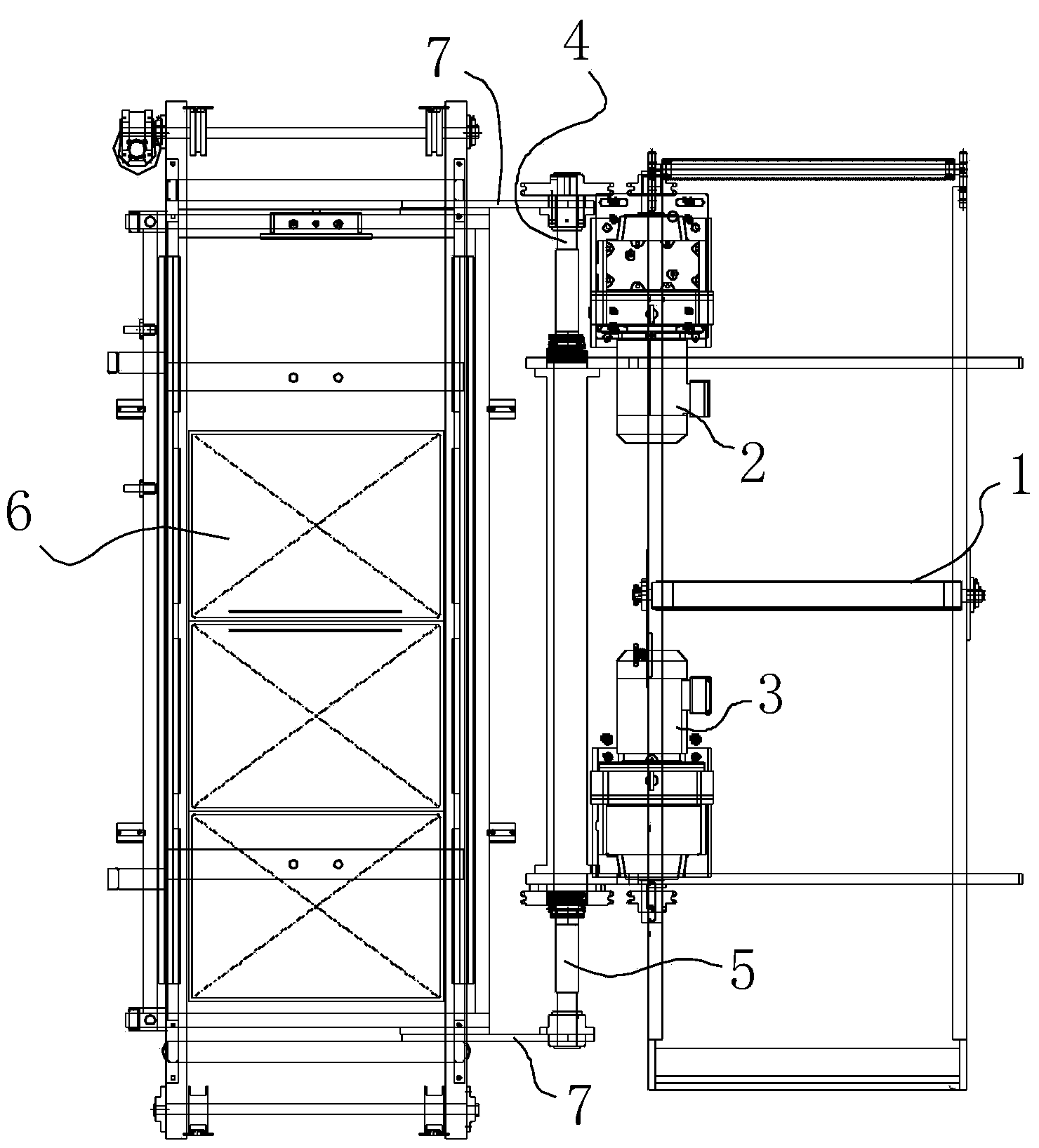

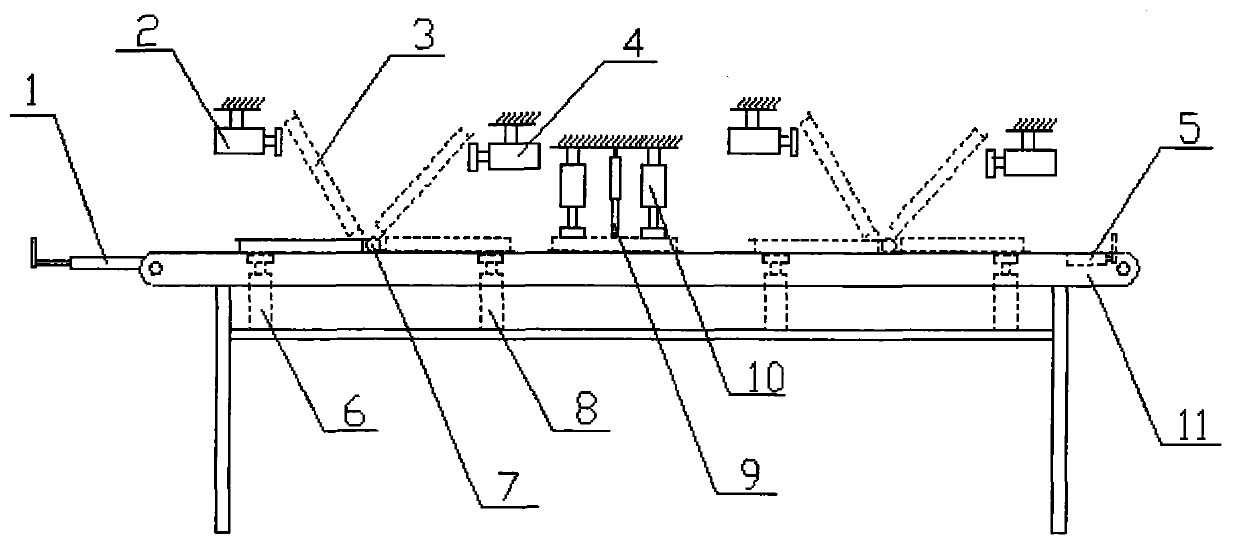

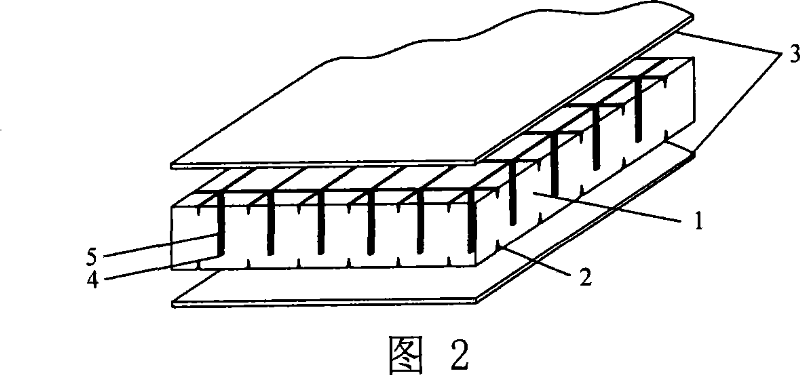

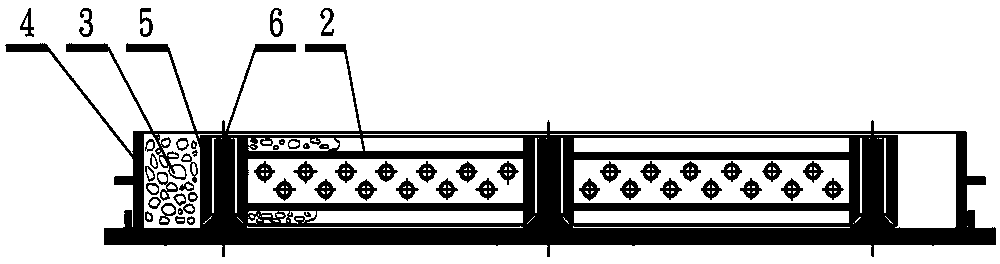

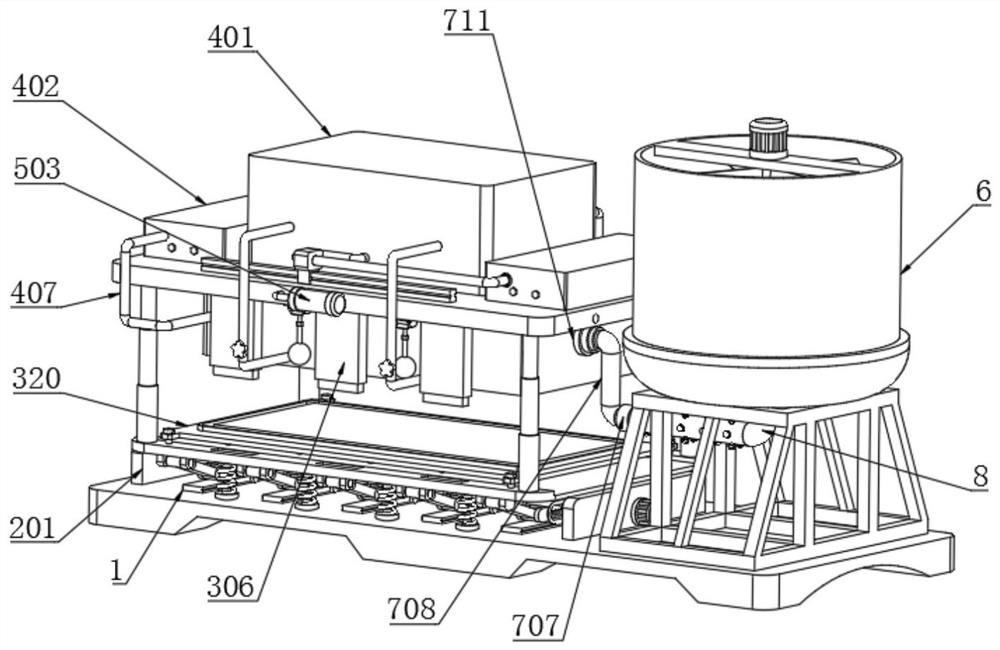

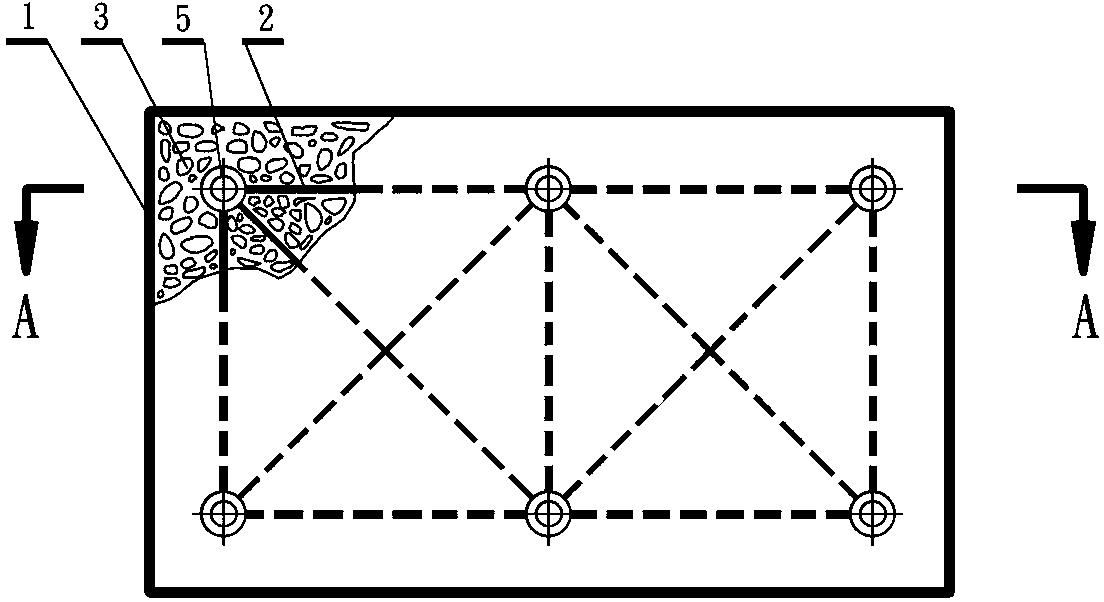

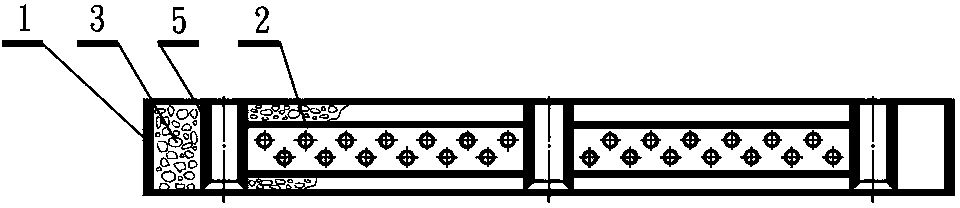

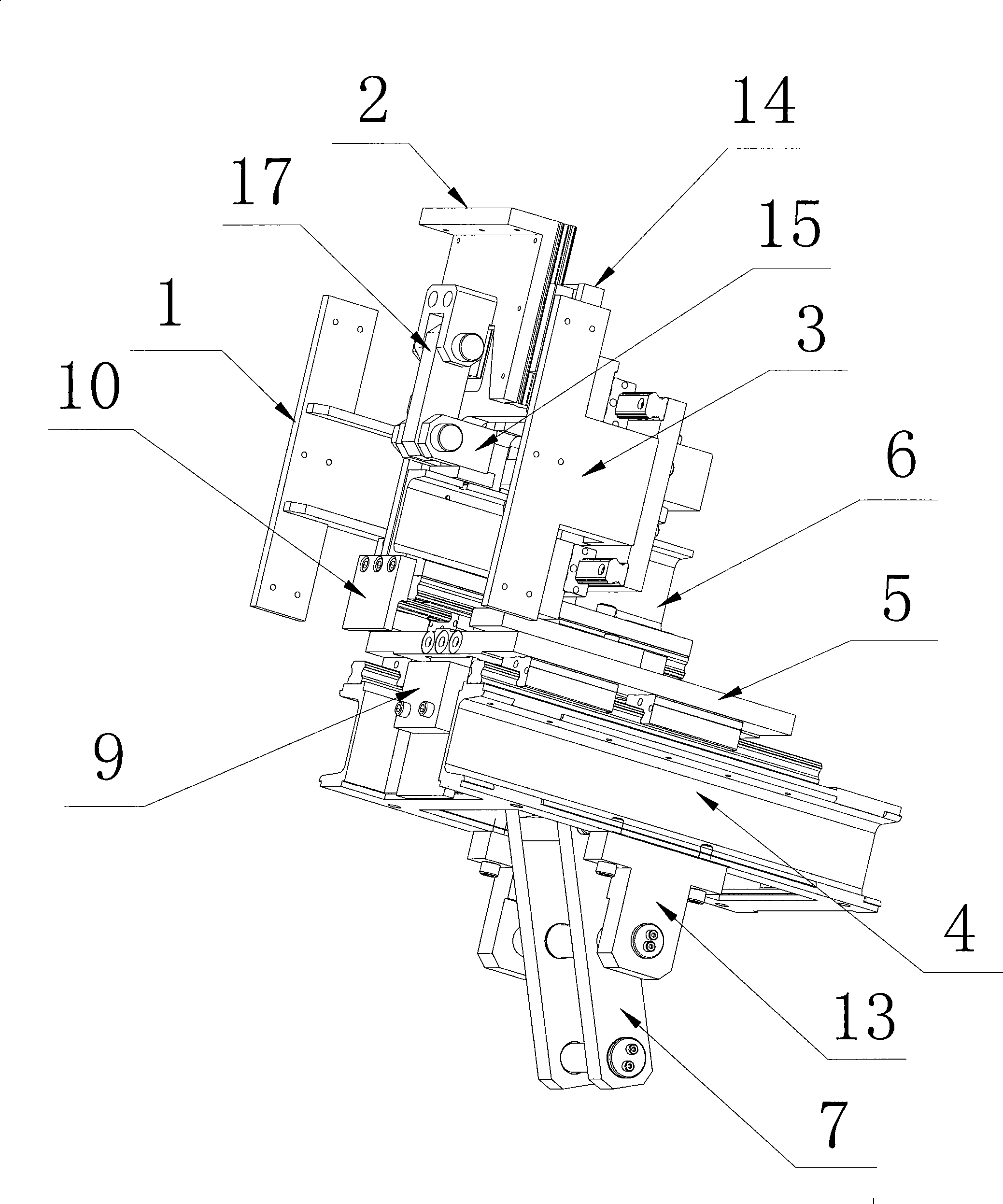

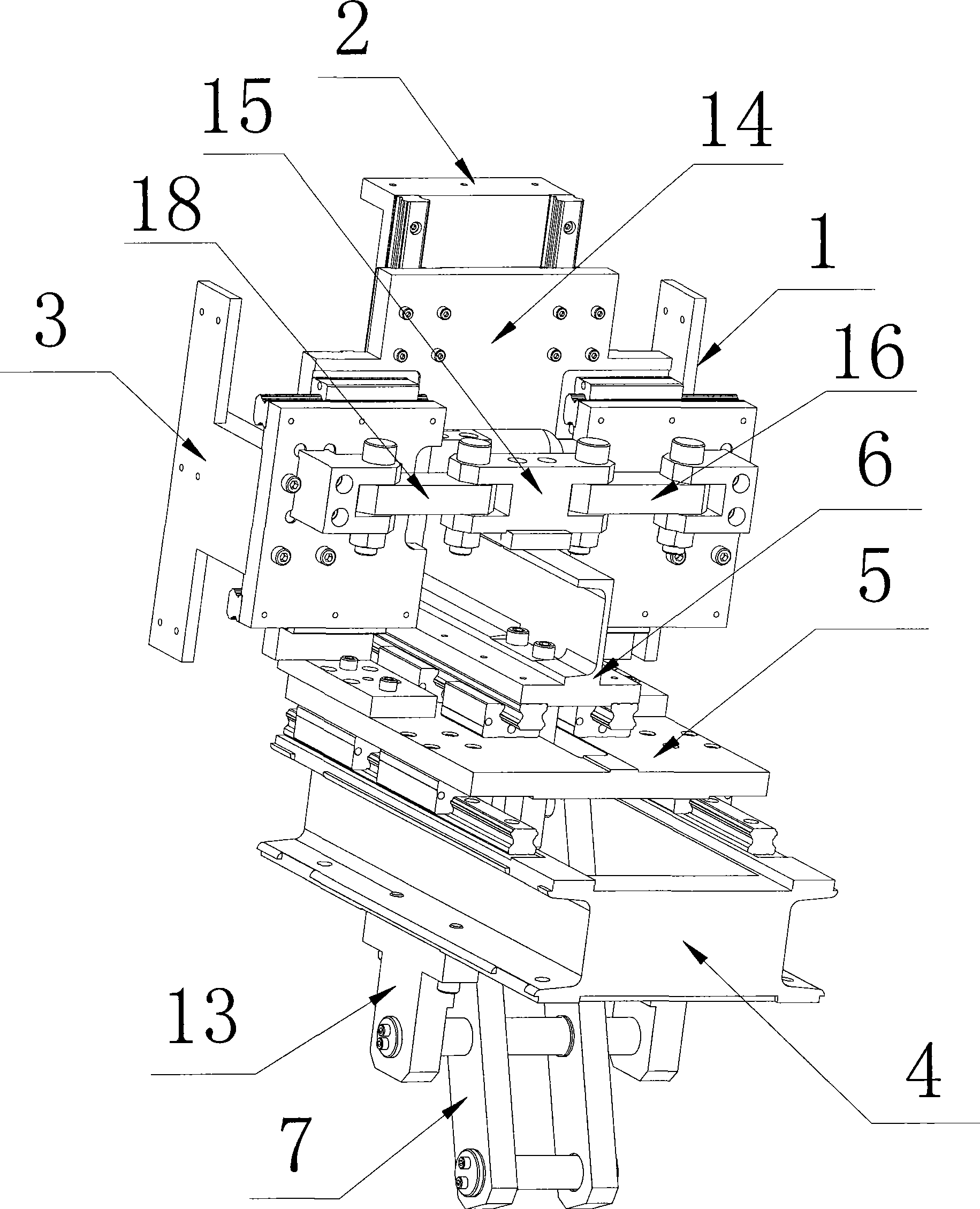

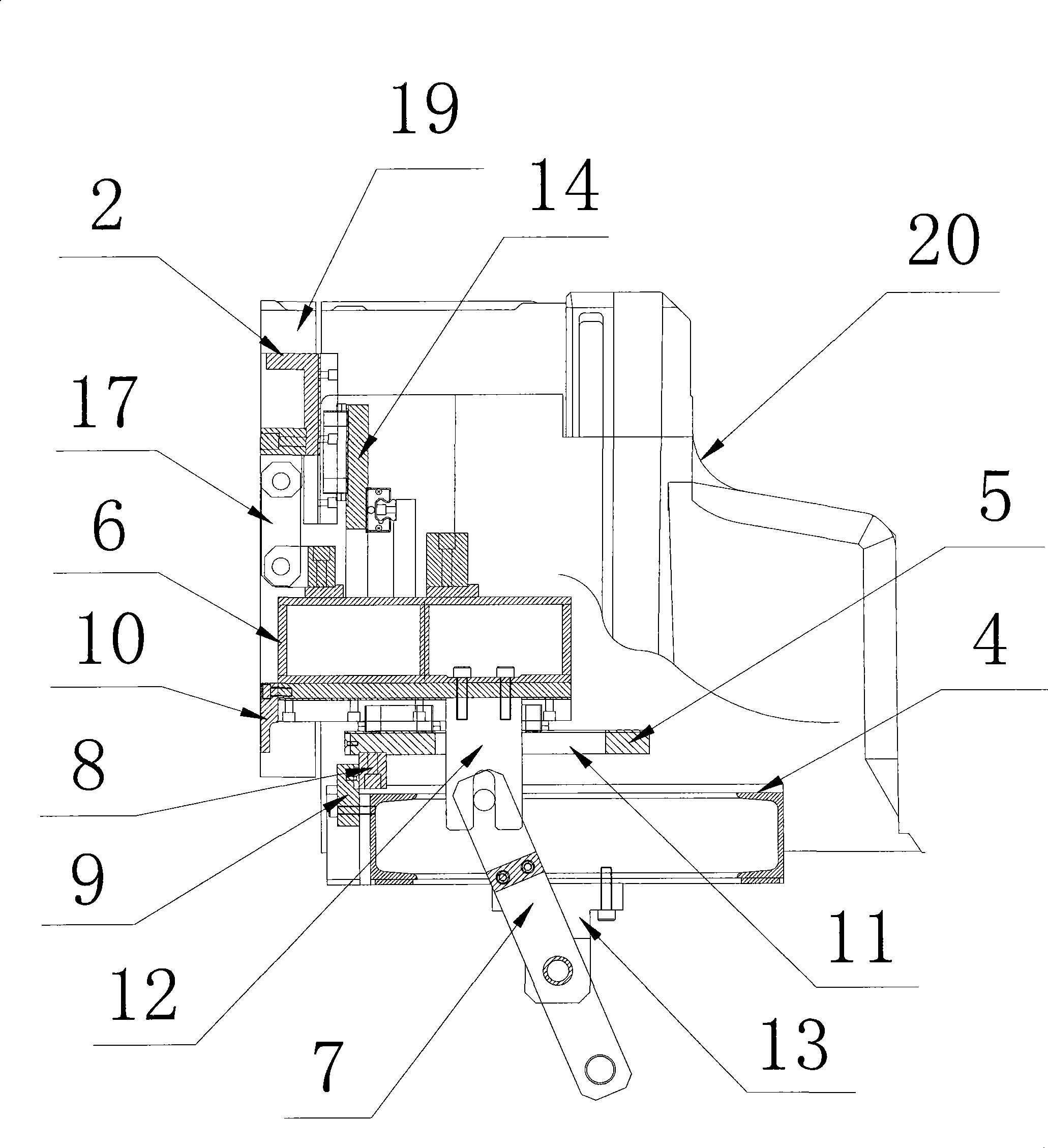

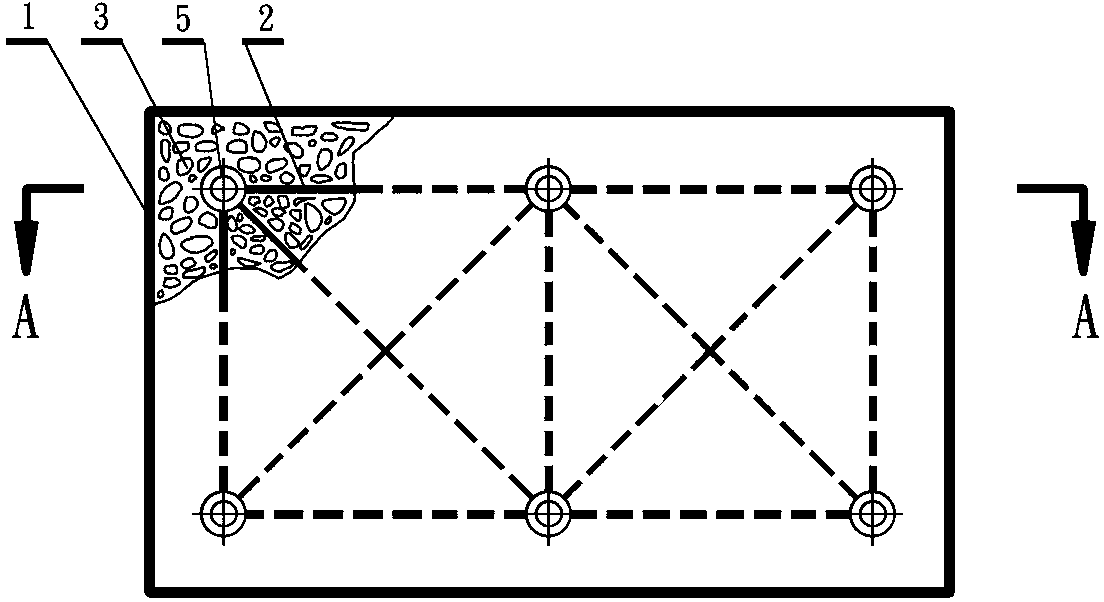

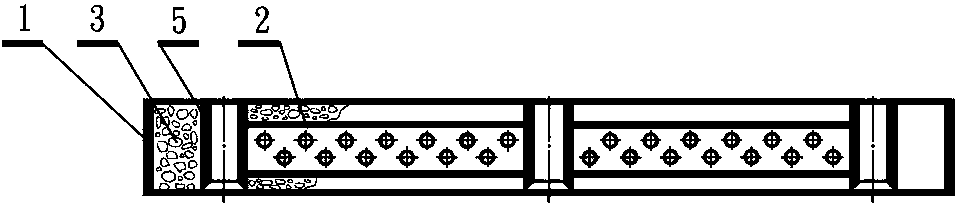

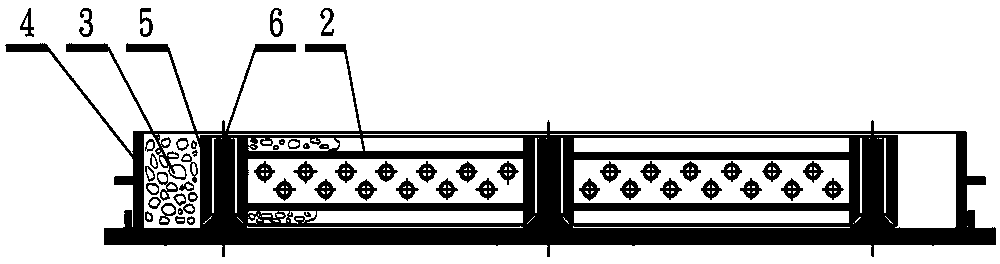

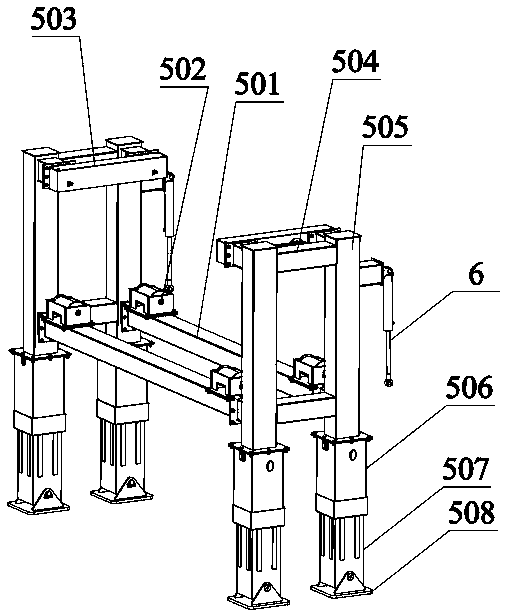

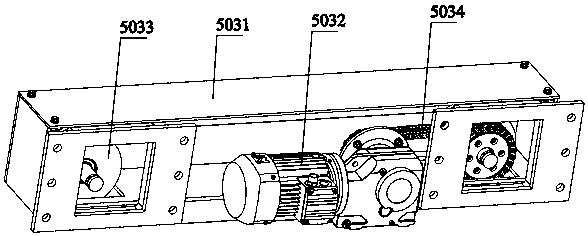

Automatic turnover demolding system in automatic production line for heat-insulating and decoration integrated boards

InactiveCN103216060AFast demoulding speedIncrease production speedDischarging arrangementCovering/liningsProduction lineOutput device

The invention relates to an automatic turnover demolding system in an automatic production line for heat-insulating and decoration integrated boards. In order to greatly improve the demolding efficiency of the automatic production line for the integrated boards, the technical scheme is that the automatic turnover demolding system comprises two sets of 180-degree turnover devices which are arranged on a conveyer belt and a demolding device, and the demolding device is arranged between the two sets of 180-degree turnover devices; each 180-degree turnover device sequentially comprises an input device, a first cylinder, a second cylinder, a retaining device, a third cylinder and a four cylinder according to the running sequence of the production line; the demolding device comprises an air blowing pipe, vibrating and knocking devices and an output device; the devices are respectively provided with an in-position detection device; and under the cooperation between the two sets of 180-degree turnover devices and the demolding device, the automatic demolding of the integrated boards is completed. The automatic turnover demolding system in the automatic production line for the heat-insulating and decoration integrated boards has the advantages that the demolding speed of the integrated boards is greatly improved, the production speed of the integrated boards is improved and the working efficiency is greatly improved.

Owner:牛智勇

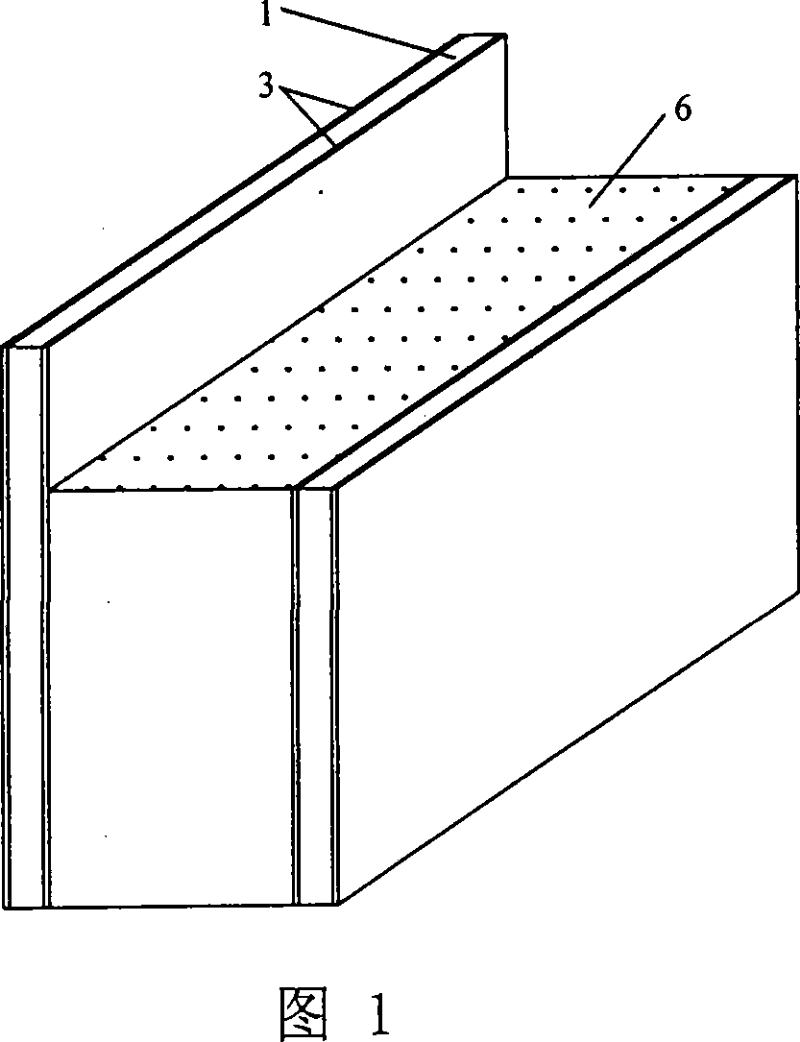

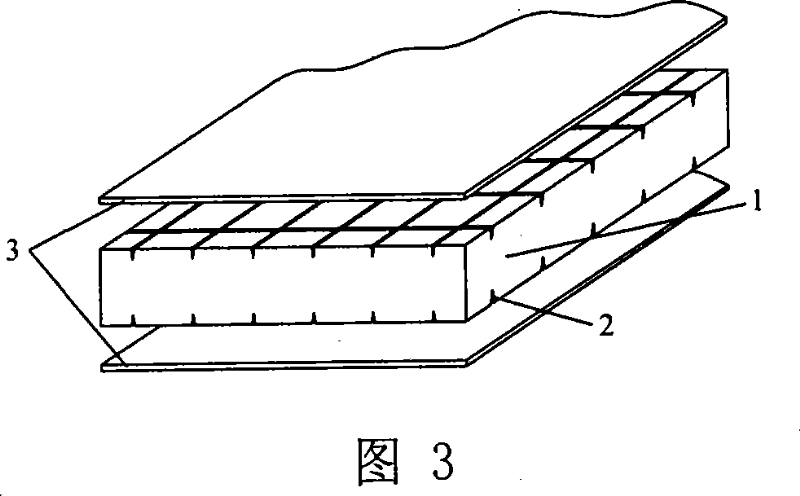

Composite material formwork

InactiveCN101042018AImprove mechanical performanceImprove bonding performanceConstruction materialForming/stuttering elementsFiberMaterials science

The composite material made mold plate comprises the core material, featuring in the slots on the surface of the core material, fiber cloth layer on the top and bottom surface of the core material, setting through holes that stuffed with resin pegs along the thickness direction of the core material at the crossing section of the slots based on requirement. It features in its lightness, high strength, obvious improvement of concrete building speed, not only being able to saving constructing expenses, but also applicable to construction under special conditions.

Owner:NANJING UNIV OF TECH

Process for preparing hydrographic transfer printing paper

ActiveCN105735042AImprove smoothnessImprove printing effectCoatings with pigmentsPaper/cardboardAlcoholPolyvinyl alcohol

The invention provides a process of preparing hydrographic transfer printing paper.According to the formula, the hydrographic transfer printing paper is prepared from 20-30 parts of water, 12-20 parts of corn starch, 8-12 parts of potato starch, 5-12 parts of polyvinyl alcohol, 10-15 parts of ethyl alcohol, 4-8 parts of polyvinylpyrrolidone, 2-5 parts of organic titanate and 0.1-0.2 part of nanosilicon dioxide.The process is environmentally friendly and free of pollution, and the surface smoothness is high.

Owner:GUANGDONG SONGYANG RECYCLE RESOURCES

Advanced silica refractory and manufacturing technique thereof

The invention relates to a silicon refractory material with composition proportions of 3.0-1.0 mm and 30 to 55 percent of natural silica, 3.0 to 1.0mm and 0 to 15 percent of waste silica brick particles, 1.0 to 0.09mm and 10 to 25 percent of the natural silica, 3.0 to 1.0 mm and 0 to 15 percent of the waste silica brick particles, 10 to 25 percent of the natural silica plus waste silica brick powder plus calcinations silica less than 0.09mm, 1 to 5 percent of non-aluminum high C3S cement or calcium hydroxide powder, SiO2 no less than 98 percent, 0 to 5 percent of silica micropowder with median particle size D50 no more than 10 Mum, 1 to 5 percent of silica fume with SiO2 no more than 96 percent, 0.05 to 1.0 percent of high-efficiency water reducing agent and 0.03 to 1.0 percent of organic binder; 1 to 2 percent of fluorite, 0 to 6 percent of calcium sulfate, 0 to 4 percent of magnesium sulfate or magnesium oxide are doped as mineralizer. The production process comprises the process that after weighing, mixing and melting, forming and drying, the raw material is roasted as finished products under 1350 to 1460 DEG C for 10 to 36 hours. The invention has the advantages of good forming, rapid demoulding speed and excellent high temperature performance, which is suitable for silicon refractory material for glass manufacture, and large and special shaped silicon dioxide refractory material products.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

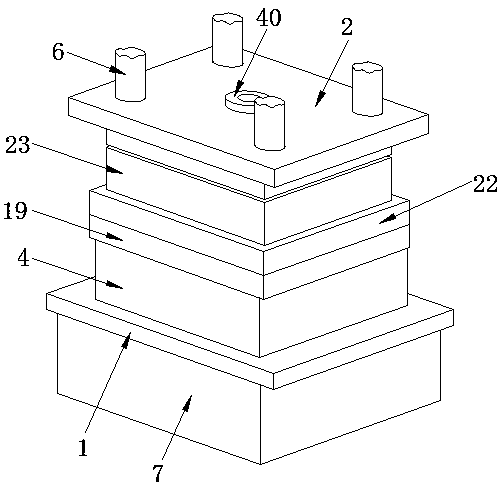

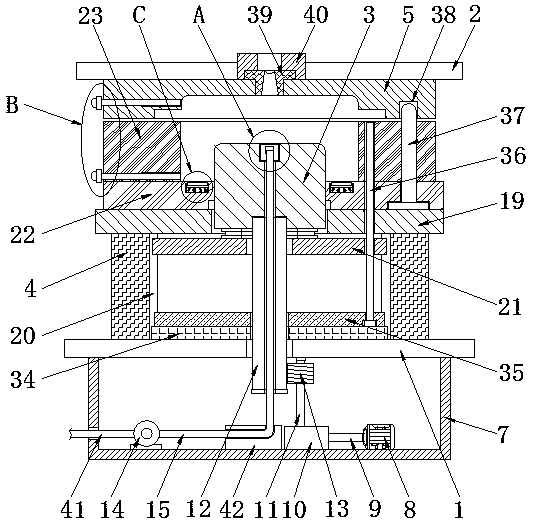

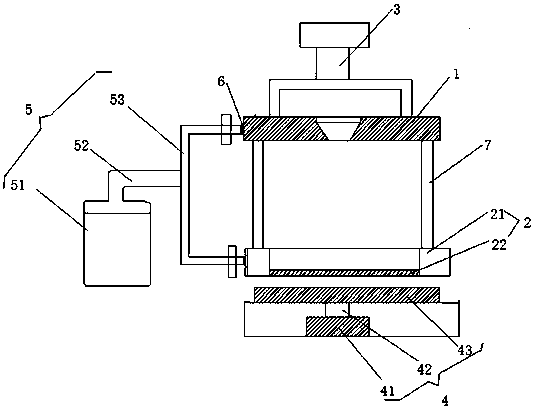

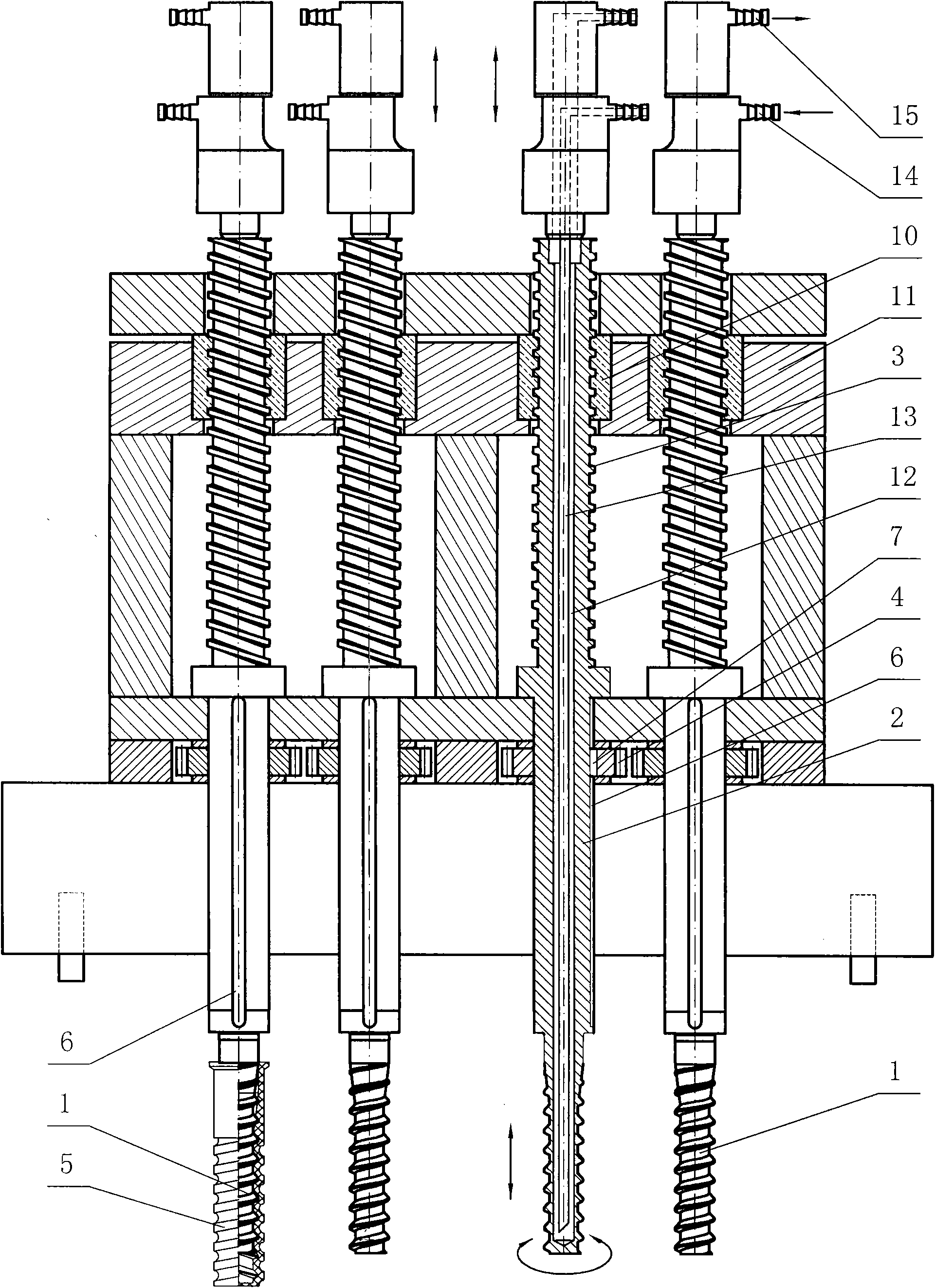

Rotating demoulding type injection mould

InactiveCN110978403AAccelerate the speed of cooling and formingImprove work efficiencyElectric machineryEngineering

The invention discloses a rotating demoulding type injection mould, and relates to the technical field of injection moulds. The rotating demoulding type injection mould comprises a lower mold base, anupper mold base and a male mold, wherein cushion blocks are arranged at two sides of the top of the lower mold base, an upper mold is fixedly connected with the bottom of the upper mold base, a connection post is fixedly connected with the top of the upper mold base, a fixed frame is fixedly connected with the bottom of the lower mold base, a motor is fixedly connected with the right side of thebottom of the inner wall of the fixed frame, and a rotation rod is fixedly connected with one end of an output shaft of the motor. In the rotating demoulding type injection mould, a threaded sleeve can be driven to rotate by working of the motor, so that the male mold is driven to rotate, at the meantime, the male mold moves downwards and smoothly exits from the workpiece, demoulding can be completed instead of manual work, manpower and material resources are saved, and the safety is relatively high; and moreover, the workpiece can be prevented from being damaged during demoulding, the practicability is improved, a cooling liquid can be injected into a mold cavity by working of a water pump, the workpiece moulding speed is accelerated, and the working efficiency is improved.

Owner:赵云凤

Environmental-friendly zeolite acoustic board

InactiveCN103556723AReduce generationImprove closure rateNoise reduction constructionSound proofingFoaming agentThermal insulation

The invention discloses an environmental-friendly zeolite acoustic board. According to the technical scheme, the environmental-friendly zeolite acoustic board is characterized in that a built-in frame is horizontally placed on a die, after each short steel tube in the built-in frame is inserted into the corresponding standing column, zeolite composite foaming agent is poured on the periphery of the built-in frame to allow the built-in frame to be totally embedded inside the zeolite composite foaming agent, and standing, curing, roasting and cooling are performed before the finished environmental-friendly zeolite acoustic board is packaged. The zeolite composite foaming agent comprises activated zeolite powder, attapulgite argil powder, hydrogen peroxide and the like. The cured zeolite composite foaming agent and the built-in frame form an integrity, so that overall strength, bending resistance and actual use effect of the environmental-friendly zeolite acoustic board are improved, sound absorption and noise pollution control effects are enhanced, and functions such as thermal insulation, absorption and air purification are achieved. The environmental-friendly zeolite acoustic board is suitable for being mounted in facilities such as highways, viaducts, city light rails, subways, factories, warehouses and public places.

Owner:许庆华

Mica compound type flame retardant foaming agent

The invention discloses a mica compound type flame retardant foaming agent. The technical scheme is characterized in that the mica compound type flame retardant foaming agent comprises sericite powder, attapulgite potter clay powder provided with an air purifying function, hydrogen peroxide, magnesium hydratefatty alcohol-polyoxyethylene ether sodium sulfate, superfine polyvinyl alcohol powder, simethicone and water. Paste ingredients of the mica compound type flame retardant foaming agent are stirred into the paste, and stirred into a finished product of the mica compound type flame retardant foaming agent. After the mica compound type flame retardant foaming agent is added with water and stirred at a high speed, porous foam slurry is formed, so that a combustible material can be isolated from being contacted with the air quickly, and flame retardance and extinguishment are achieved. A product produced by using the mica compound type flame retardant foaming agent has the flame retardance, thermal insulation and soundproof effects, as well as the air purifying function; and the mica compound type flame retardant foaming agent is suitable for producing a light board, a light wall body and products for flame retardance, extinguishment, and noise damping and reduction.

Owner:新建特阔漂整(南通)有限公司

Environment-friendly red mud acoustic panel

InactiveCN103526849AStrong foaming abilityHigh foaming ratioSound proofingCeramicwareFoaming agentRed mud

The invention discloses an environment-friendly red mud acoustic panel. According to the technical scheme, the environment-friendly red mud acoustic panel is characterized in that a built-in frame is horizontally placed on a die, a red mud composite type foaming agent is poured on the periphery of the built-in frame after short steel tubes in the built-in frame are inserted into stand columns, the built-in frame is completely embedded into the composite type foaming agent, and the finished product of the environment-friendly red mud acoustic panel is obtained through packaging after standing, solidifying, roasting and cooling are conducted. The composite type red mud foaming agent is composed of red mud powder, attapulgite argil powder, hydrogen peroxide and the like. An integral whole is formed through the solidified composite type red mud foaming agent and the built-in frame, and therefore the overall strength, the bending resistance and the actual use effect of the environment-friendly red mud acoustic panel are enhanced, the effect of enhancing sound absorption performance and the effect of controlling noise pollution are improved, and the functions of heat preservation, adsorption and air purification are achieved. The environment-friendly red mud acoustic panel is suitable for being installed in facilities such as highways, viaducts, urban light rails, metros, factories, warehouses and public places.

Owner:北京卯合卯建筑装饰工程设计有限责任公司

Serpentine composite type foaming agent

ActiveCN103253976AImprove adsorption capacityImprove adhesionCeramicwarePolymer scienceFoaming agent

The invention discloses a serpentine composite type foaming agent which adopts the technical scheme that the serpentine composite type foaming agent consists of serpentine powder, attapulgite argil powder with an air purification function, hydrogen peroxide, lauryl dimethyl amine oxide, cocoyl diethanol amine, a silicone polyether emulsion, polyether modified silicone oil and water, and cream ingredients of the serpentine composite type foaming agent are mixed to form cream, and then mixed to form the finished serpentine composite type foaming agent. The serpentine composite type foaming agent has the characteristics that the foaming capacity is high; the foaming expansion rate is high; the foam generation quantity in unit volume is large; foam holes are fine, smooth and uniform, and are not easy to break; the demoulding speed of a product is high; the surface smoothness is good; and the later strength of the product is high. The product produced by the serpentine composite type foaming agent has effects of warm keeping, heat insulation and sound insulation, and has the air purification function, and the serpentine composite type foaming agent is suitable for production of lightweight boards, lightweight walls and silencing and noise reduction products.

Owner:南通中奥车用新材料有限公司

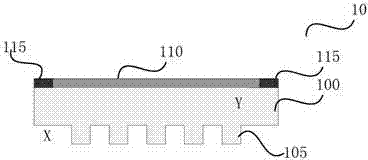

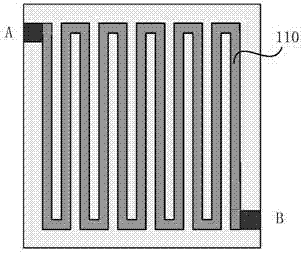

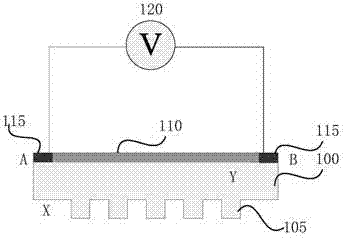

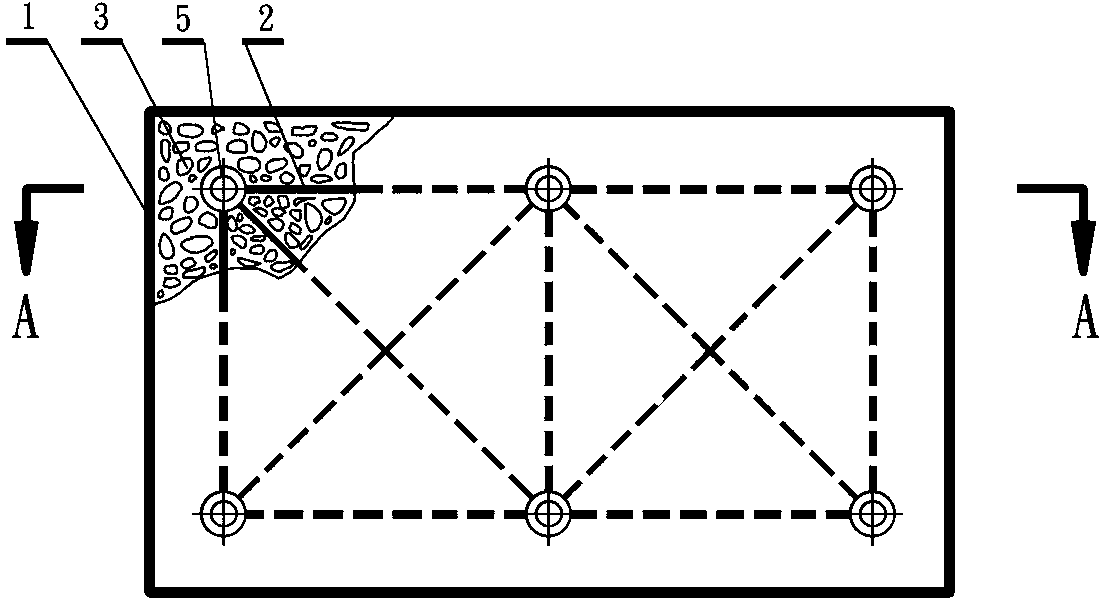

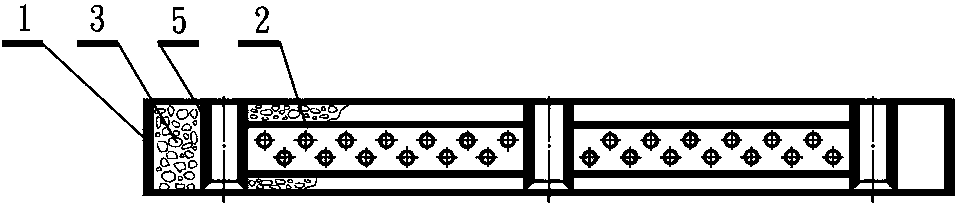

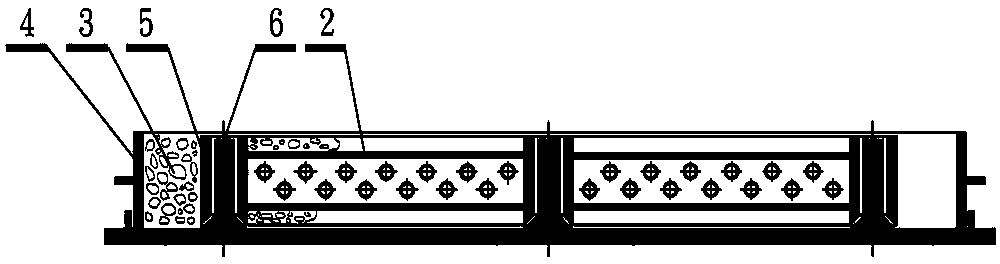

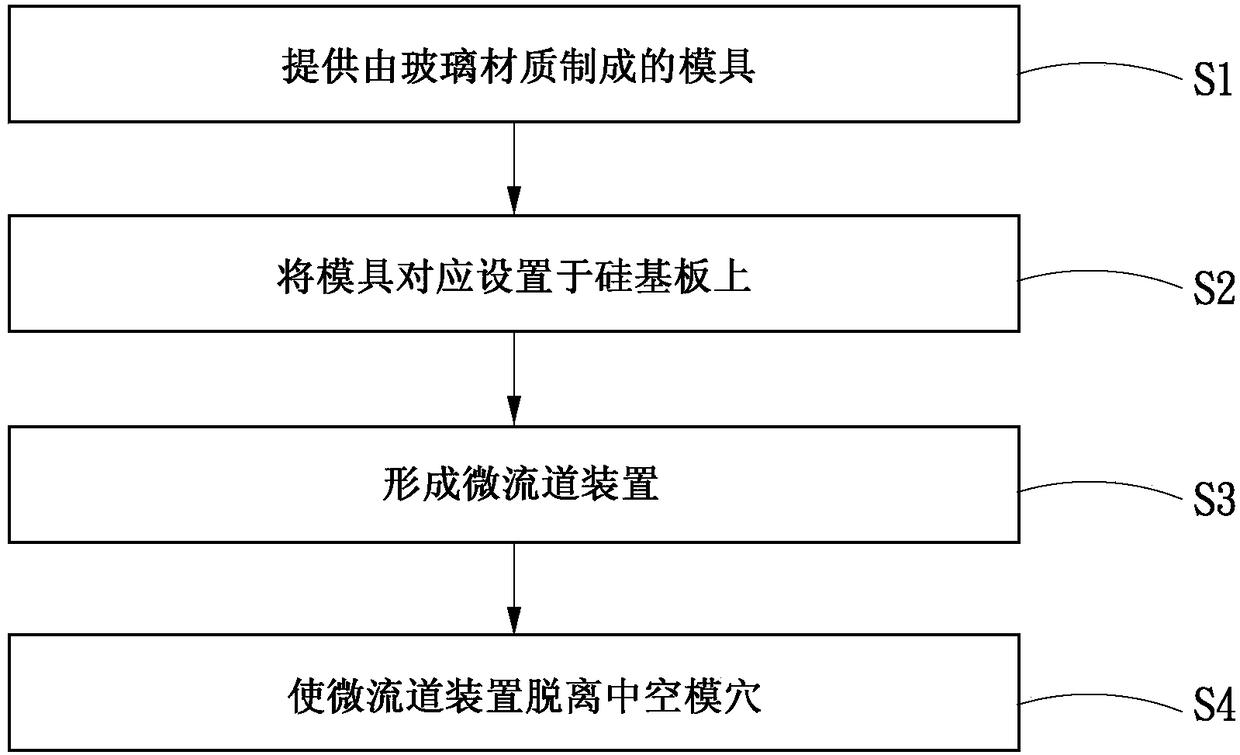

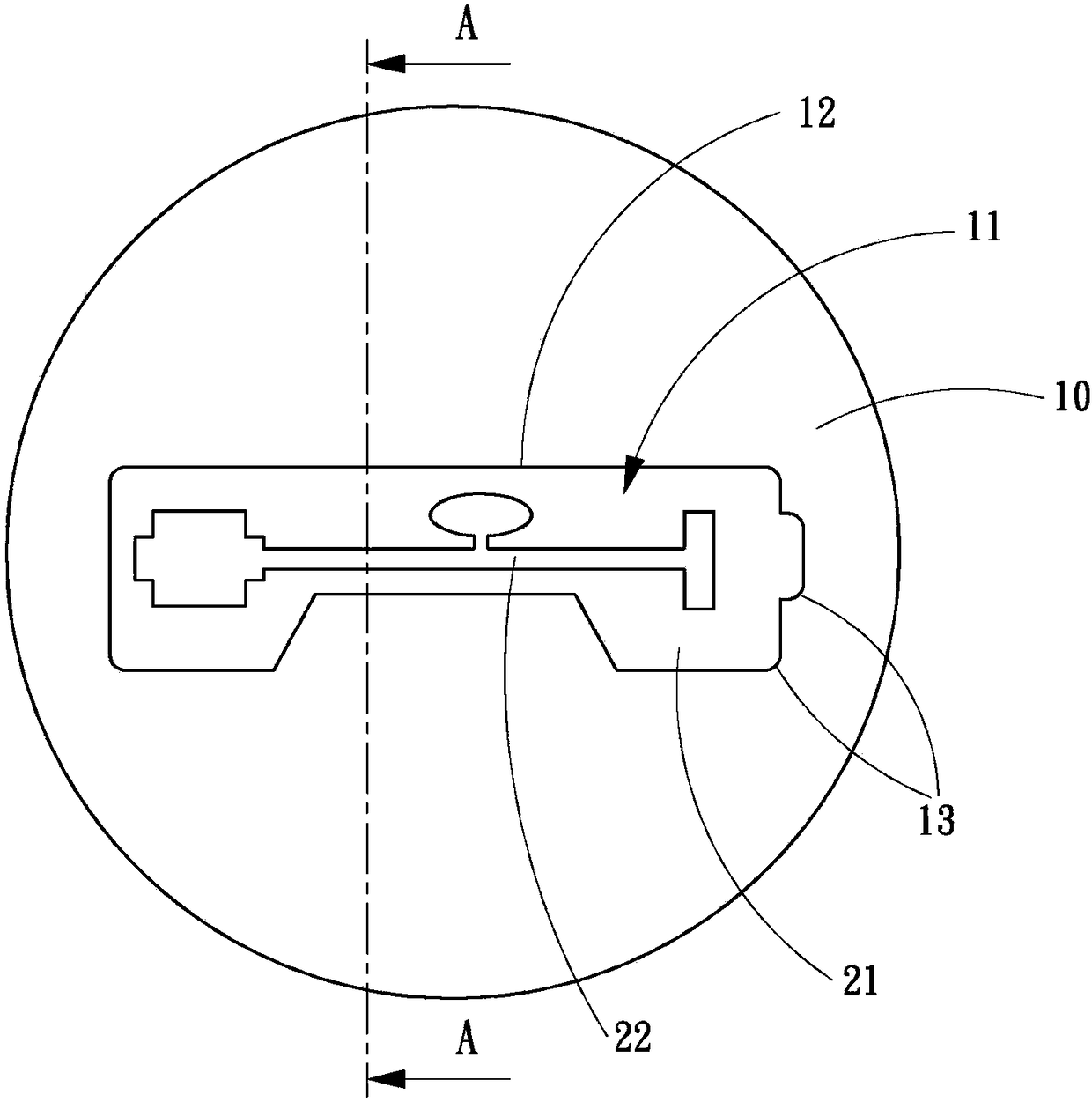

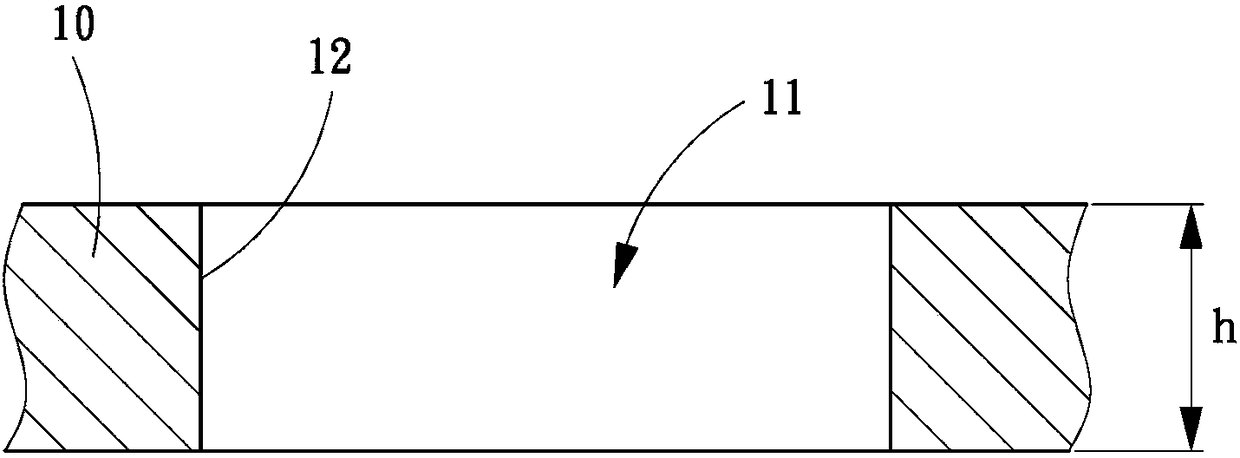

Manufacturing method of microchannel device and the microchannel device

InactiveCN109225086AHigh surface flatnessPrevent overflowChemical/physical/physico-chemical microreactorsPhotomechanical apparatusSuction forceDimethyl siloxane

A manufacturing method of a microchannel device and the microchannel device. A mold made of a glass material is provided. The mold has at least one hollow mold cavity and at least one blocking wall around the hollow mold cavity. The mold is disposed on a silicon substrate, which includes a formation surface corresponding to the hollow mold cavity and a microfluidic male mold protruding from the formation surface. Polydimethylsiloxane (PDMS) is poured into the hollow mold cavity and baked to harden the PDMS to form the microfluidic device. The microfluidic device has a microfluidic structure corresponding to the microfluidic male mold, and a height of a sidewall of the microfluidic device is between 3 mm and 30 mm. With the glass material of the mold, the microfluidic device having a sidewall height greater than 3 mm can be manufactured, preventing an insufficient suction force of a negative pressure.

Owner:TAIWAN CARBON NANO TECHNOLOGY CORPORATION

Unfired sludge foaming acoustical board

InactiveCN103806567AIncrease moisture contentHarm reductionMouldsNoise reduction constructionPublic placeFoaming agent

The invention discloses an unfired sludge foaming acoustical board. According to the technical scheme, the unfired sludge foaming acoustical board is characterized in that a built-in frame is horizontally placed on a mold, after short steel pipes in the built-in frame are inserted into stand columns, sludge cement foaming agent is poured on the periphery of the built-in frame, the built-in frame is totally inlaid in the sludge cement foaming agent, maintenance is performed according to a conventional cement product maintenance method, and packaging is performed to form an unfired sludge foaming acoustical board finished product; the sludge cement foaming agent is prepared from a sludge mixture, high-viscosity attapulgite clay powder, cement and other raw materials; the sludge cement foaming agent and the built-in frame form an integrated whole after the sludge cement foaming agent is cured, and thus the overall strength, the bending resistance and the actual using effect of the unfired sludge foaming acoustical board are improved. The unfired sludge foaming acoustical board not only can be used for effectively controlling noise pollution but also has the functions of heat preservation and air purification and is suitable for being mounted in facilities such as expressways, viaducts, urban light rails, subways, public places and the like.

Owner:许庆华

Pumice composite flame-retardant foaming agent

ActiveCN103288476AReduce burnAchieve flame retardancyCeramicwarePolyvinyl alcoholAluminium hydroxide

The invention discloses a pumice composite flame-retardant foaming agent. The technical scheme of the pumice composite flame-retardant foaming agent has the following key points that the pumice composite flame-retardant foaming agent is composed of pumice powder, attapulgite argil powder having an air purifying function, hydrogen peroxide, aluminium hydroxide, sodium polyoxyethylene fatty alcohol ether sulfate, superfine polyvinyl alcohol powder, simethicone and water; firstly, the paste raw materials of the pumice composite flame-retardant foaming agent are stirred into a paste at first and then the raw materials of the pumice composite flame-retardant foaming agent are stirred into the finished product of the pumice composite flame-retardant foaming agent. A product produced by using the pumice composite flame-retardant foaming agent has the effects of flame retarding, heat preservation, thermal insulation and sound insulation, and also has the air purifying function; and the pumice composite flame-retardant foaming agent is suitable for producing flame-retarding and fire-extinguishing products, light plates, light walls, and sound-attenuating and noise-reducing products.

Owner:顾翔

Injection mould capable of accelerating cooling demoulding of injection molding product and working method of injection mould

PendingCN108081558AFast demoulding speedImprove injection mold release efficiencyCooling channelMaterials science

Owner:太仓朗盛金属制品有限公司

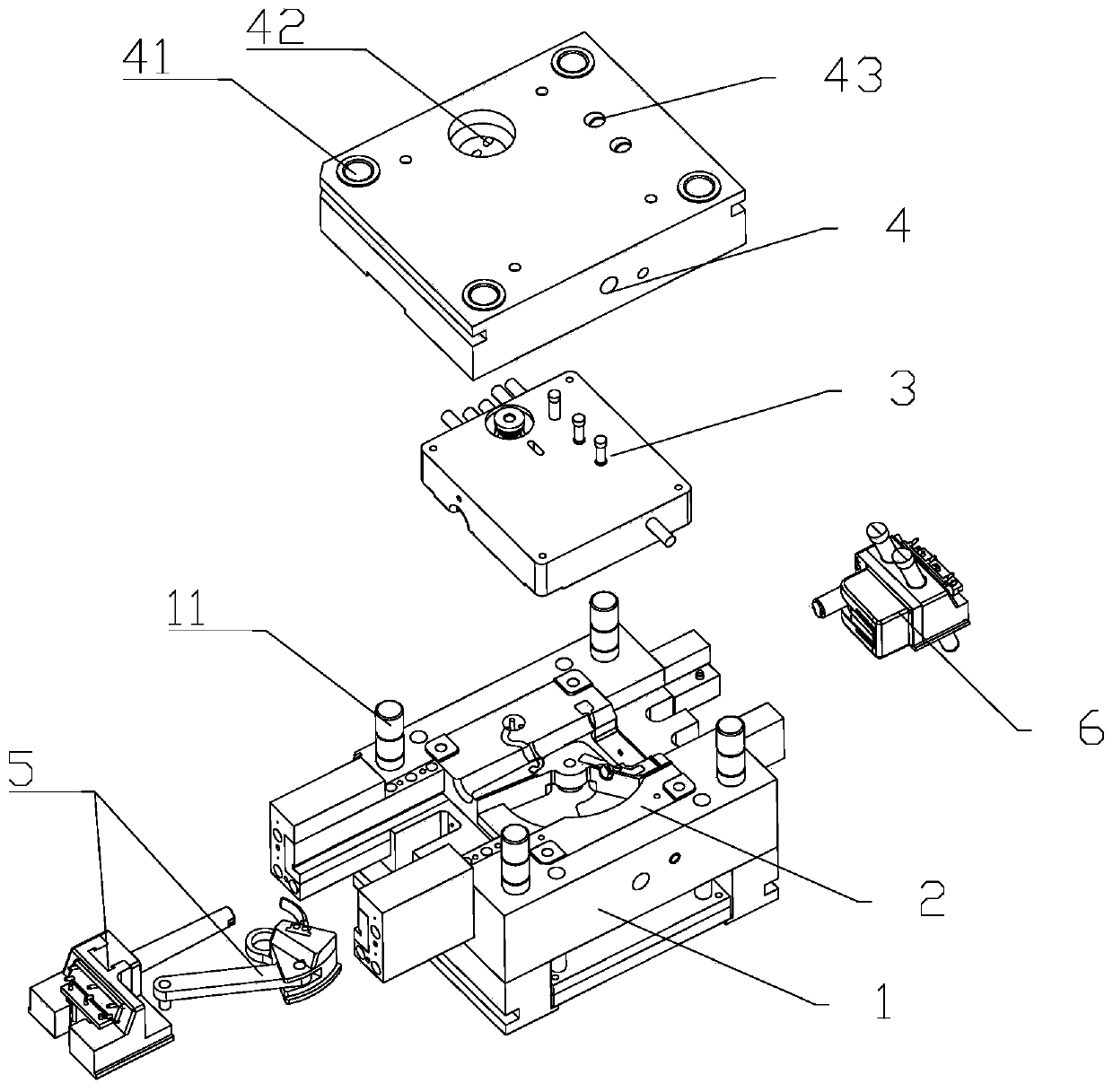

Water faucet forming mould

The invention relates to the technical field of water faucet manufacturing equipment. A water faucet forming mould comprises a lower mould frame, a lower mould core, an upper mould core and an upper mould frame, wherein the lower mould core is fixedly arranged on the lower mould frame; the upper mould core is fixedly arranged on the upper mould frame; a side core-pulling mechanism is arranged on one side of the lower mould frame; an oblique guide pin sliding block mechanism is arranged on the other side of the lower mould frame; the side core-pulling mechanism comprises a direct pushing part and a rotating part; the rotating part and the direct pushing part are hinged; the rotating part is hinged into the lower mould core; the oblique guide pin sliding block mechanism is movably connectedto the other side of the lower mould frame; and the oblique guide pin sliding block mechanism and the lower mould frame form movable connection through an oblique guide pin. According to the water faucet forming mould provided by the invention, the casting dosage is less, so that the waste is reduced; the mould is simple in overall structure and low in cost; through arranging a cooling system, thecooling speed is improved; and the side core-pulling mechanism is driven through a connecting rod, and one movement action and one rotation action are produced at the same time and are associated, sothat the precision for processing every time is high.

Owner:杨立夸

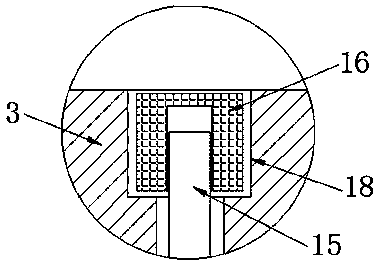

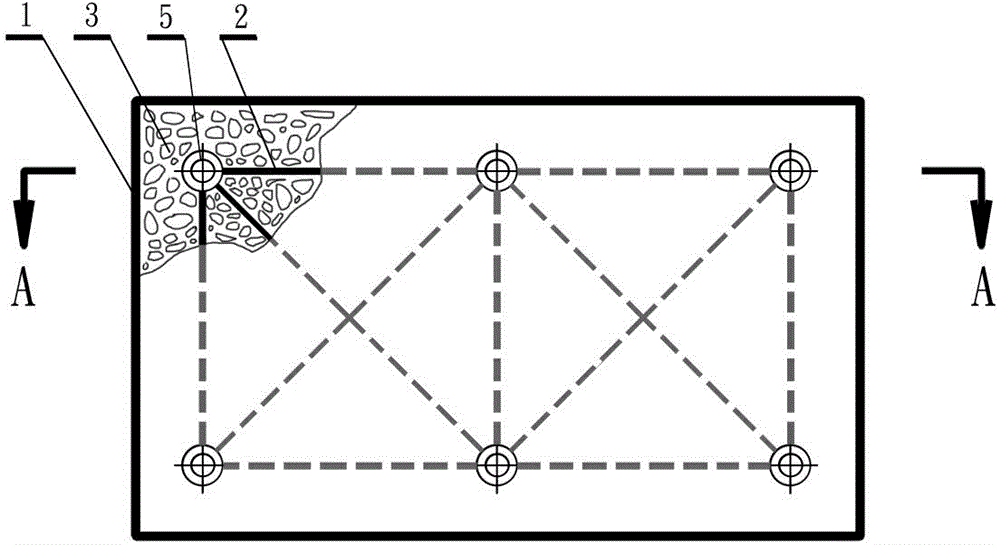

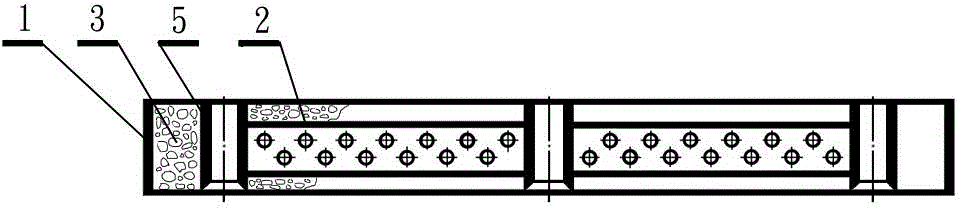

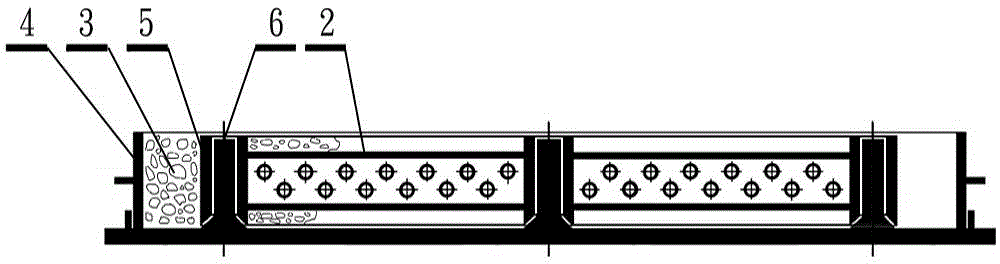

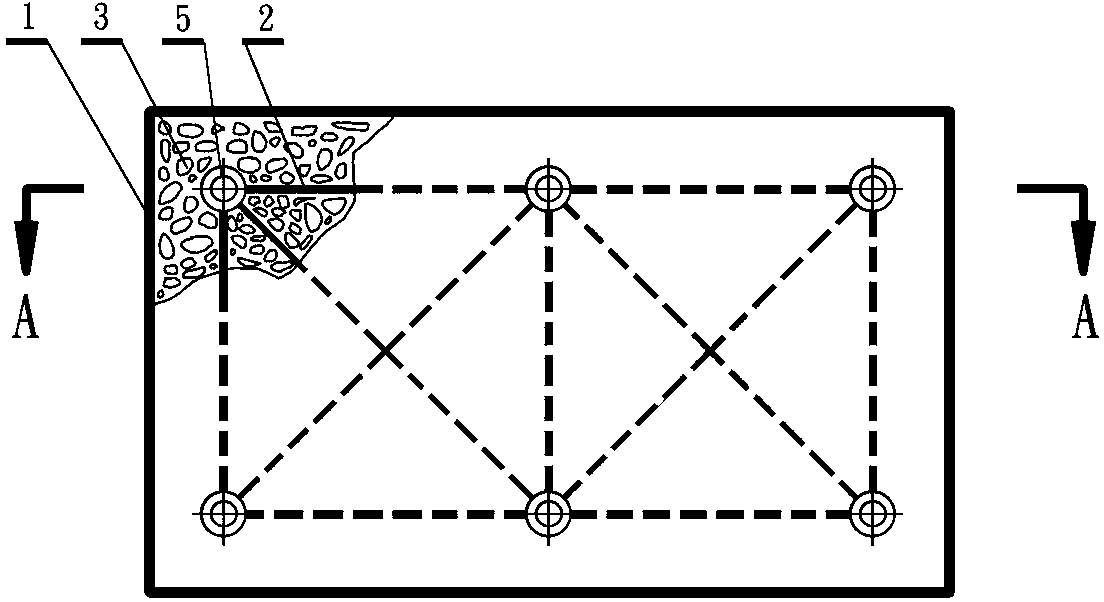

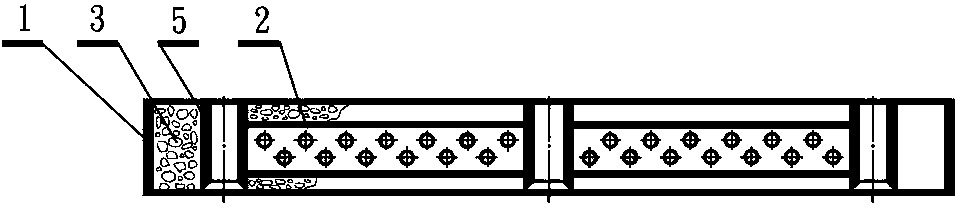

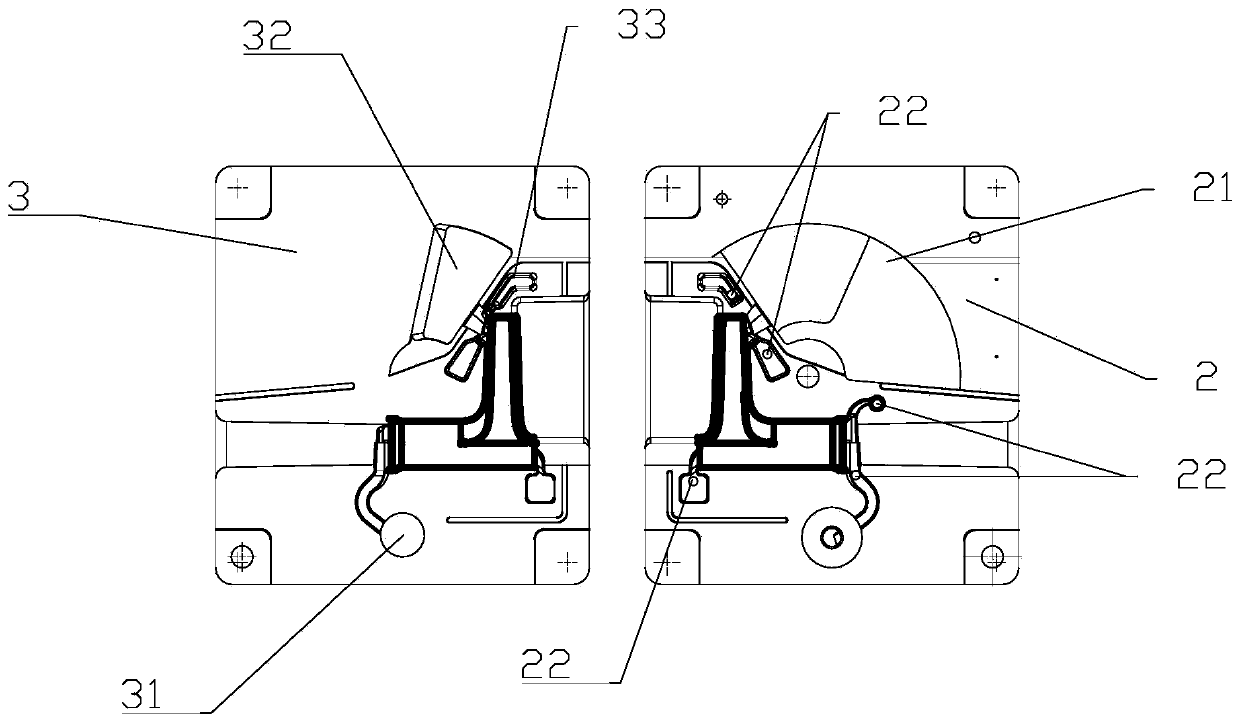

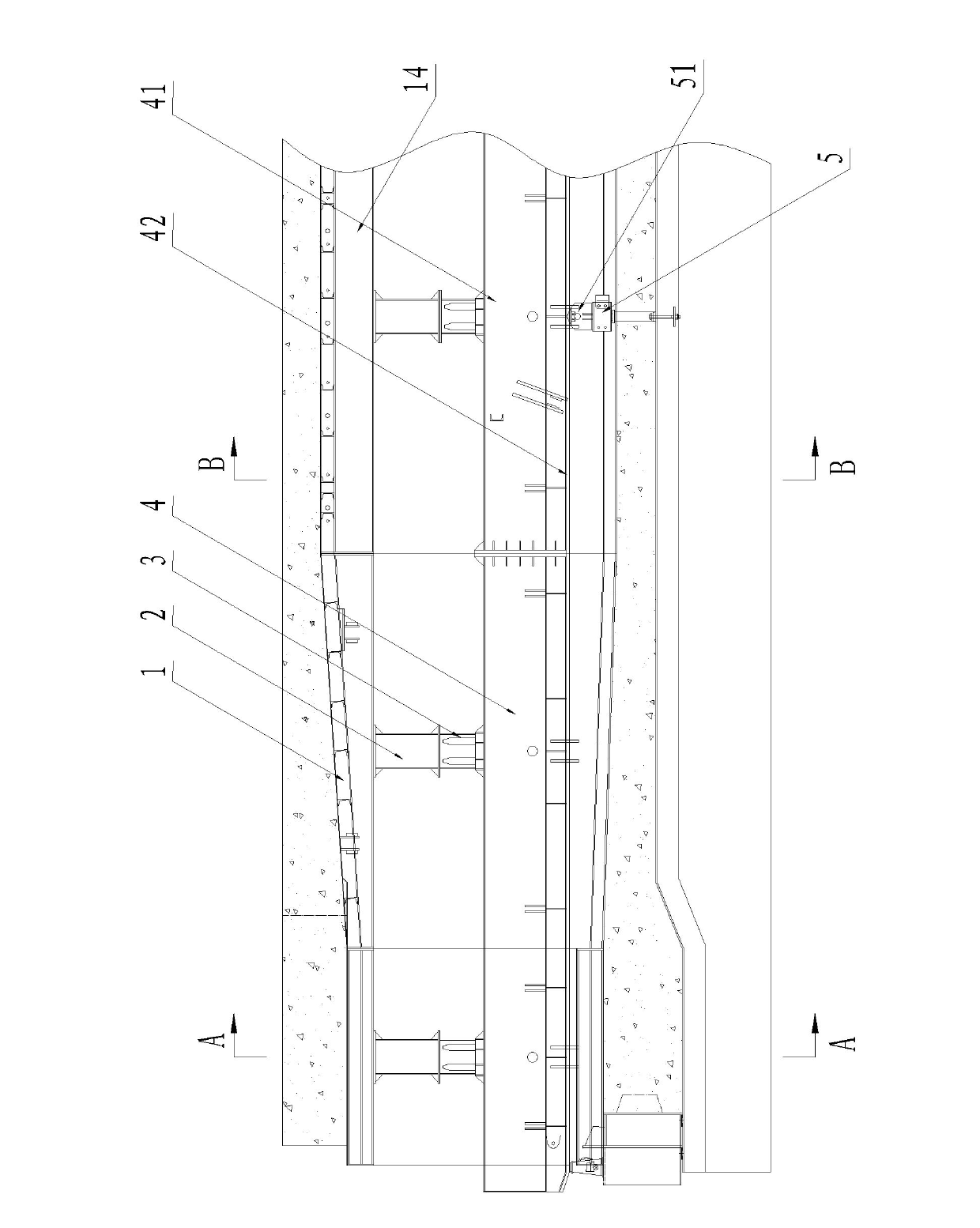

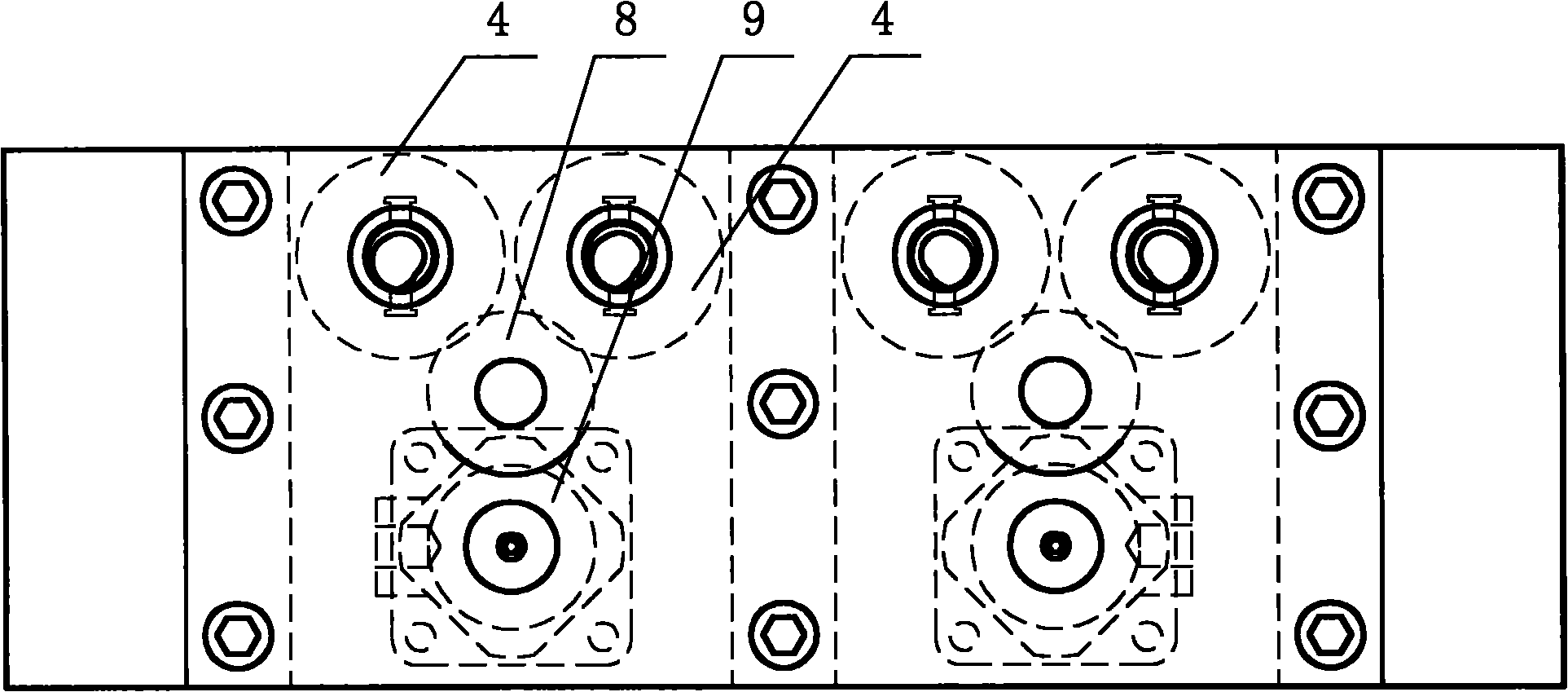

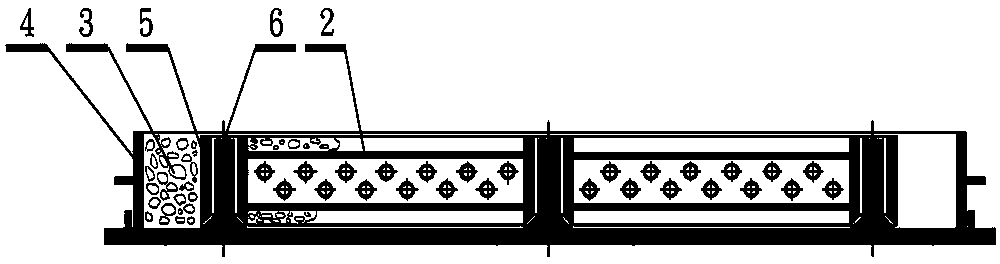

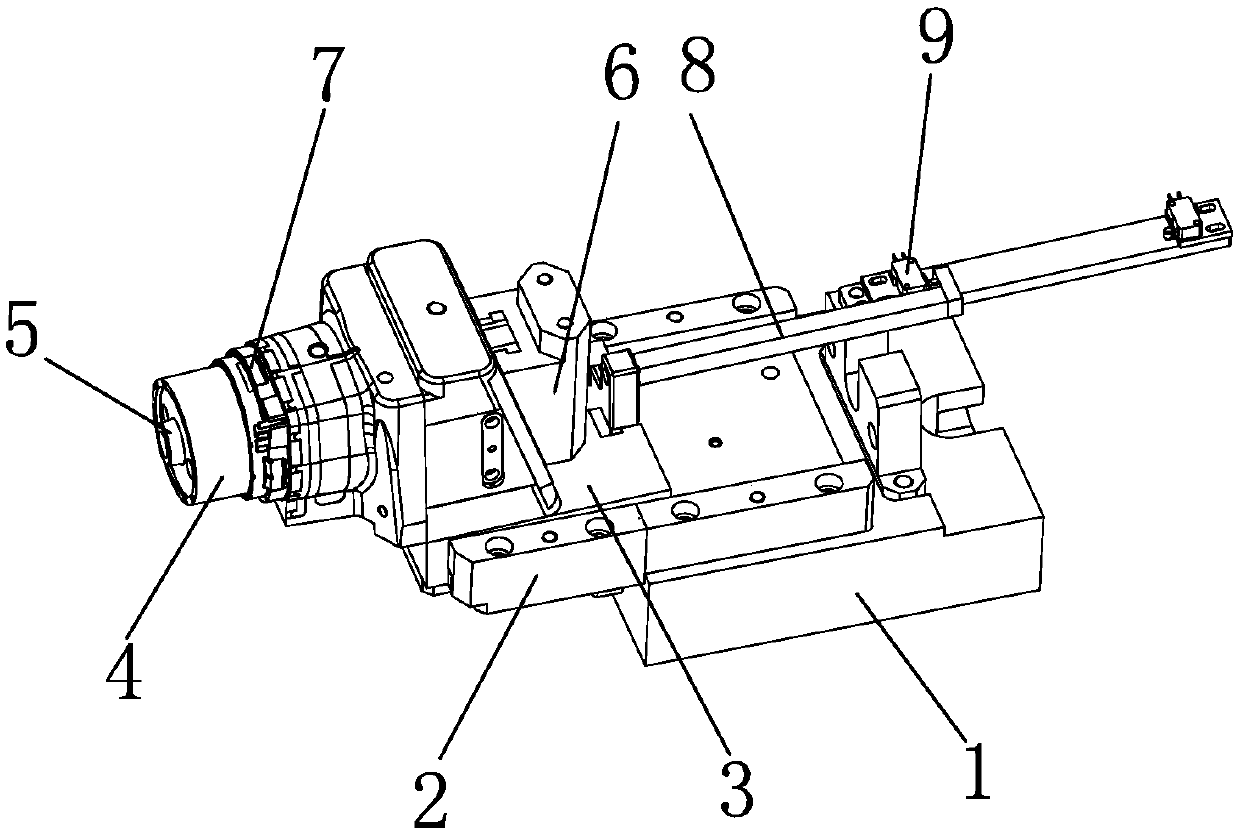

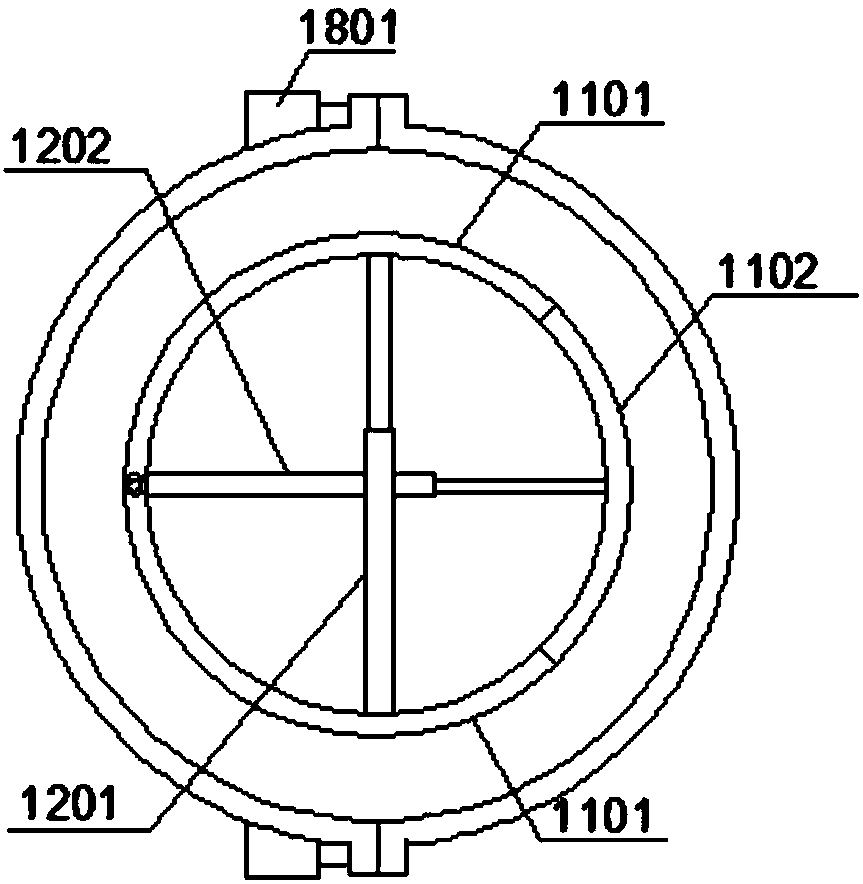

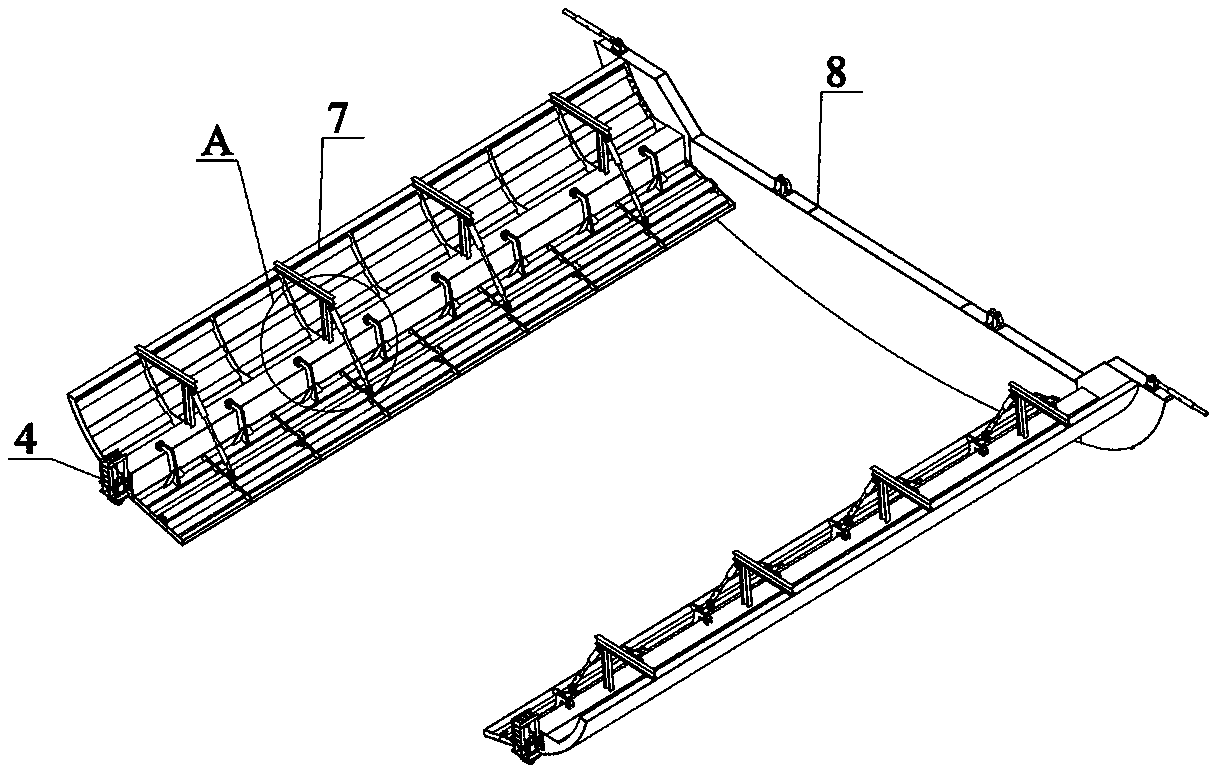

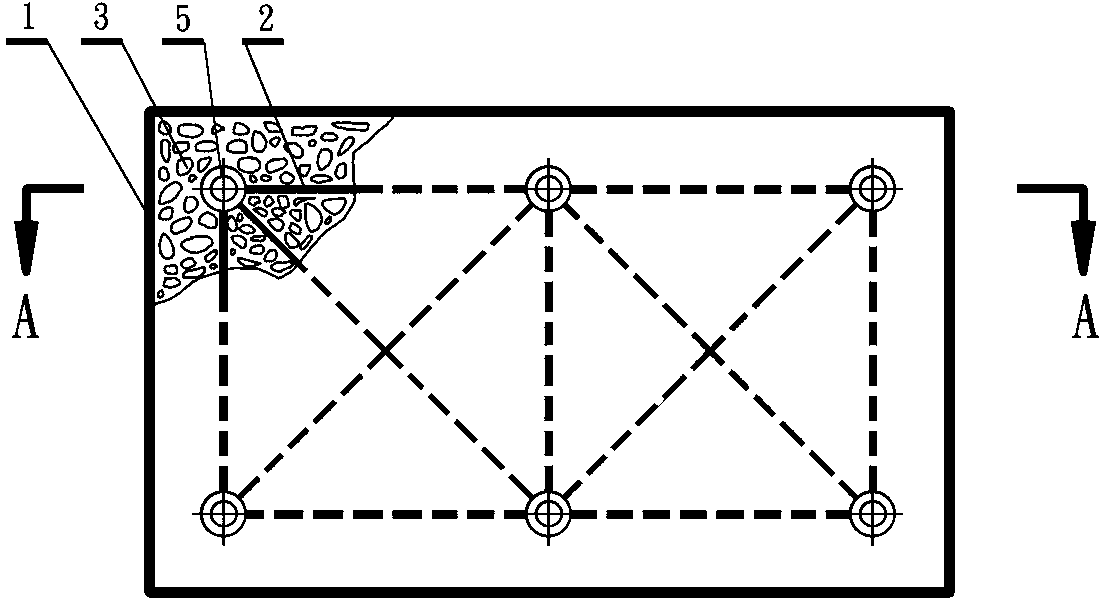

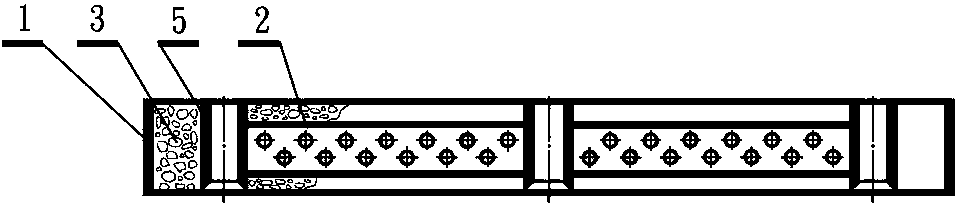

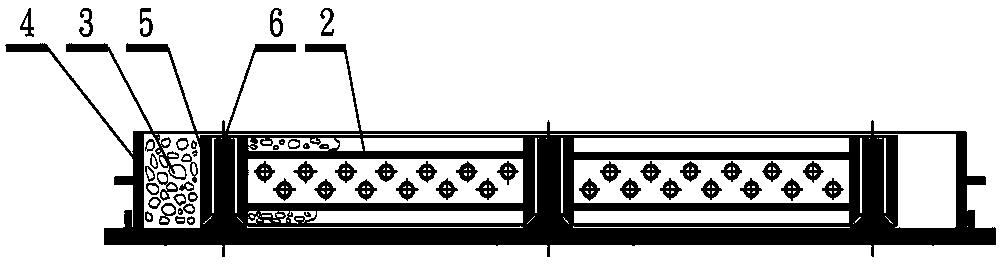

Combined box girder hydraulic internal mould

ActiveCN102001127AImprove molding qualityFast demoulding speedCeramic shaping apparatusEngineeringIdler-wheel

The invention discloses a combined box girder hydraulic internal mold which comprises a template, a guide post, a main beam and a supporting base, wherein the template is connected with the guide post through a regulating post, the main beam is internally provided with a guide sleeve, the bottom of the main beam is provided with a guide rail, the guide post is arranged in the guide sleeve and can slide in the guide sleeve, a reverse idler wheel is arranged on the supporting base, and the main beam is placed on the reverse idler wheel through the guide rail and can slide on the reverse idler wheel for dragging the internal mould out of a beam body. The guide rail is arranged on the main beam, thus the step of additionally paving a mould transferring rail is reduced, and the working efficiency is improved. Meanwhile, different mould collecting modes are adopted for templates on different positions, which ensures that each section of template can meet the requirement for mould collection. The invention has the characteristics of convenience for operation and use, good forming quality of a box girder, high demoulding speed, high production efficiency and the like, and is suitable for designing various types of box girder internal moulds.

Owner:湖南五新智能科技股份有限公司

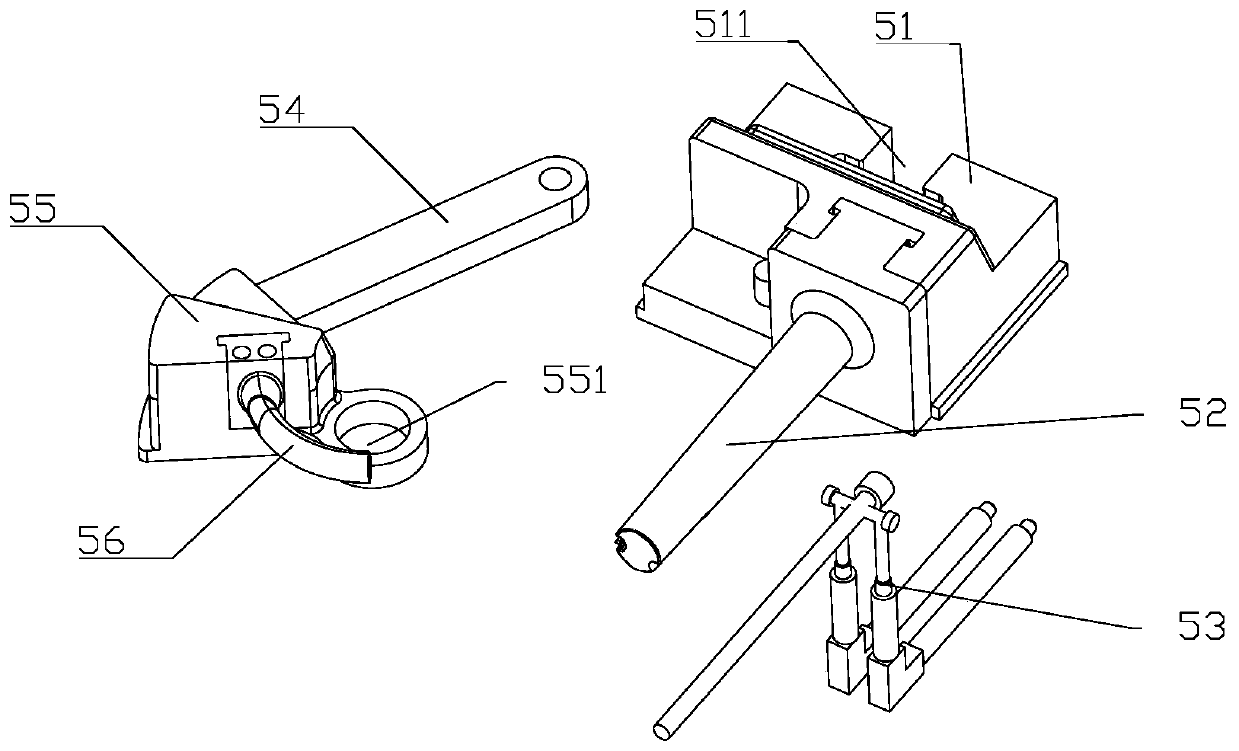

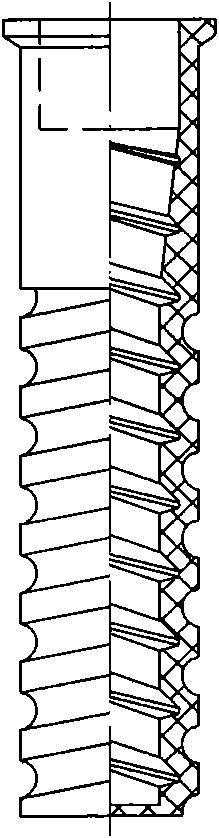

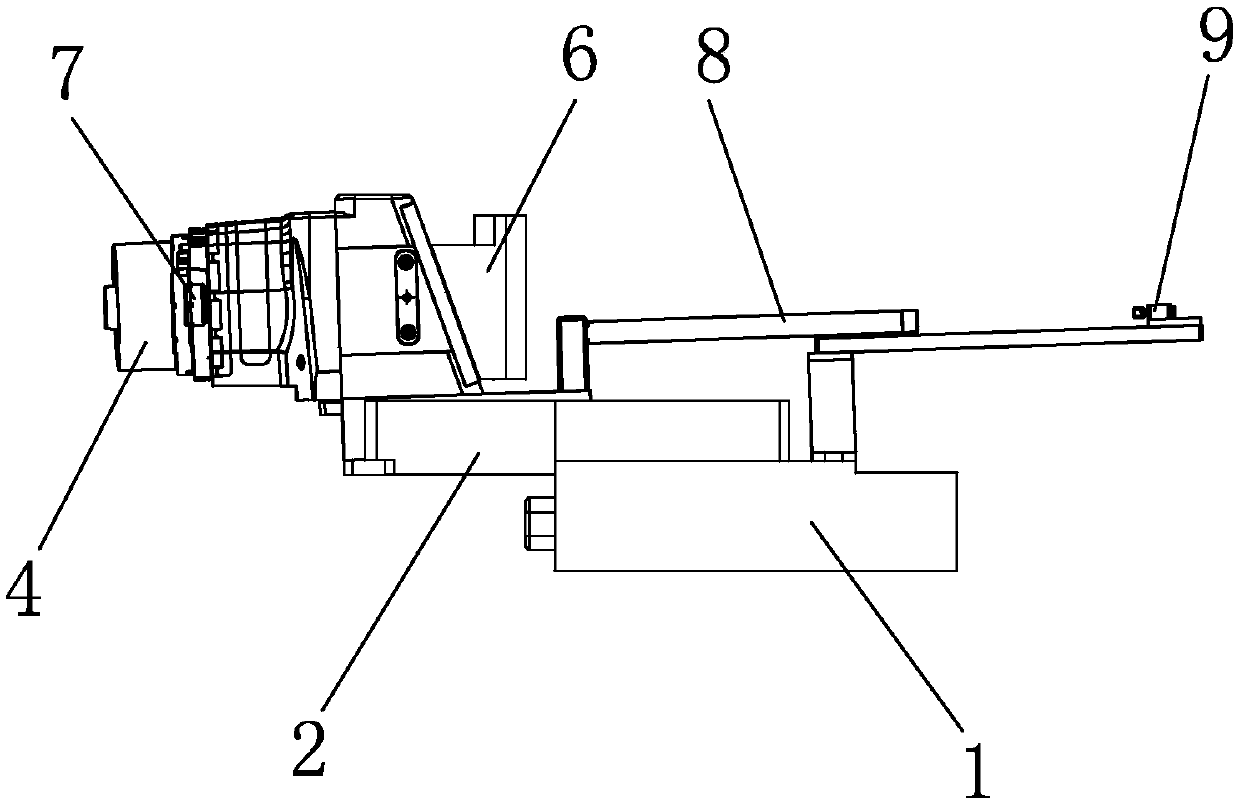

Automatic sleeve demoulding mechanism

The invention discloses an automatic sleeve demoulding mechanism, and aims to provide the automatic sleeve demoulding mechanism, which has the characteristics of simple structure, convenient manufacture and use, continuous production, and rapidness. The automatic demoulding mechanism comprises a mandril and is characterized in that: the mandril is provided with a connecting shaft and a screw which are connected with the mandril integrally; a gear is sleeved on the connecting shaft; the connecting shaft is provided with a key slot which is greater than the depth of the inner hole of the sleeve; the gear is connected with the connecting shaft through a key arranged in the key slot; the connecting shaft and the gear are moved relative to the axial direction; the gear is engaged with a rotary drive gear; a nut which is matched with the screw is screwed on the screw to form a screw pair structure; and the gear and the nut are respectively fixed on a machine frame. The automatic demoulding mechanism has the characteristics of ingenious design, novel structure, high demoulding speed, high quality, and high demoulding efficiency when the drive gear is engaged with a plurality of groups of automatic sleeve demoulding mechanisms, and is suitable for injection-molding, machining and demoulding of large-batch sleeves.

Owner:GEM YEAR IND

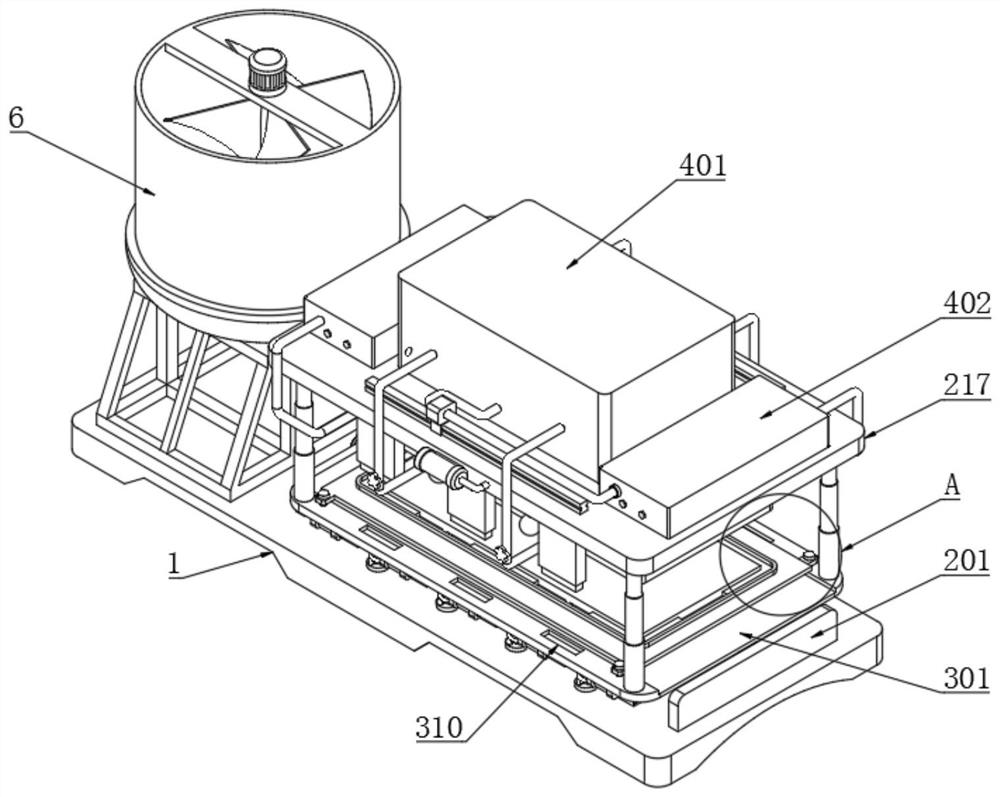

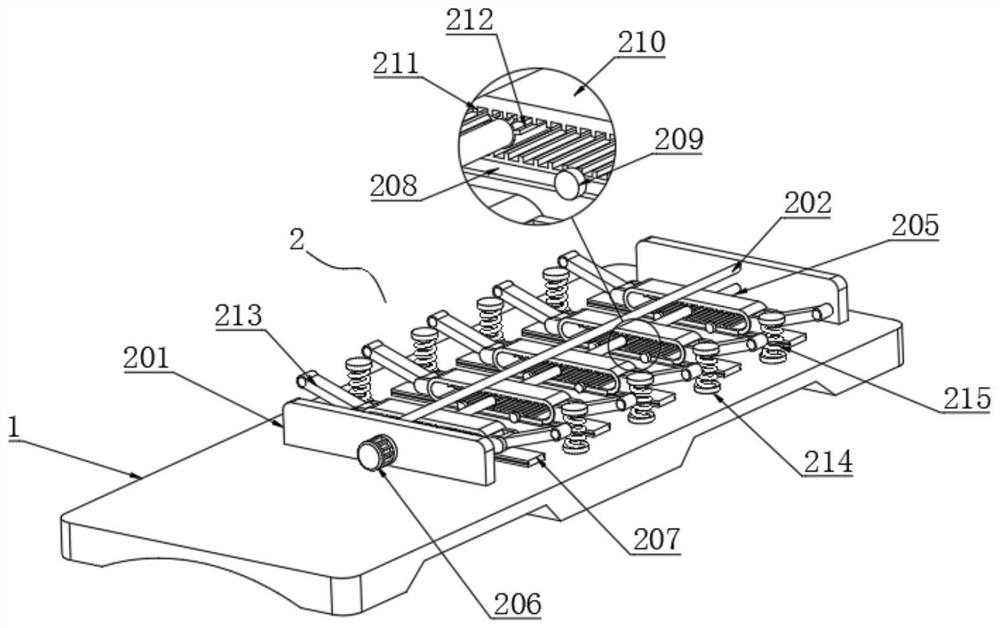

Energy-saving and heat-preservation type preparation equipment for concrete blocks

InactiveCN112692957AImprove uniformityReduce gapDischarging arrangementFeeding arrangmentsElectric machineGear wheel

The invention discloses energy-saving heat preservation type preparation equipment for concrete blocks. The equipment comprises a bottom plate, wherein a stirring tank is fixedly connected to the side position of the top end of the bottom plate, a discharging pipe is fixedly connected to the bottom end of the stirring tank, a vibration stirring mechanism is fixedly connected to the position, corresponding to one side of the stirring tank, of the top end of the bottom plate, and the vibration stirring mechanism comprises a fixed plate, a rotating rod, a rotating block, a shaking plate, a rotating shaft, a rotating motor, a sliding plate and a limit plate. The equipment is scientific and reasonable in structure and safe and convenient in use; the vibration stirring mechanism is arranged, and the rotating shaft is driven by the rotating motor to rotate, so that the rotating shaft drives a gear to rotate, and the gear is matched with a cam through the arrangement of a sector gear; and an incomplete gear mechanism is formed to drive a moving frame to repeatedly slide, the shaking plate is pushed through cooperation of a rotating plate and rotates and swings along the rotating rod, concrete in a mold is stirred, and the uniformity of the concrete in the mold is improved.

Owner:韦海强

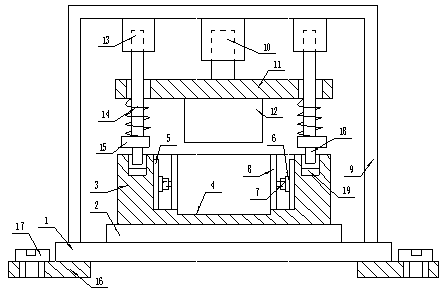

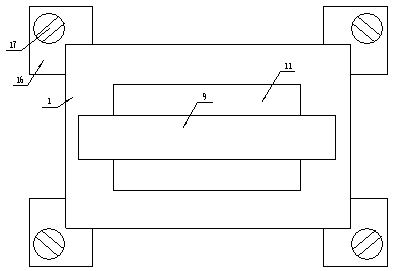

Buffer stamping and shaping die convenient for rapid demolding

InactiveCN107649587AFast demoulding speedImprove buffering effectShaping toolsStructural engineeringElectric control

The invention discloses a buffer stamping and shaping die convenient for fast demoulding. The buffer stamping and shaping die comprises a rectangular fixing base, and the upper surface of the rectangular fixing base is fixedly connected with a lower mold base; a lower die body is fixedly connected to the center position of the upper surface of the lower die base, and a concave model cavity is machined in the center position of the upper surface of the lower die body; a pair of strip-shaped sliding grooves are machined on the surface of the two sides in the concave model cavity, a vertical sliding rail is fixedly connected to the inner side surface of each strip-shaped sliding groove, each vertical sliding rail is provided with an electric control trolley, an electric control telescopic cross rod with a telescopic end in a horizontal direction is fixedly connected to the side surface of each electric control trolley, and the telescopic end of each electric control telescopic cross rod is fixedly connected with a strip-shaped extrusion plate matched with each of the strip-shaped sliding grooves; and the upper surface of the rectangular fixing base is fixedly connected with a door type fixing frame. The buffer stamping and shaping die has the beneficial effects of being simple in structure, and high in practicability.

Owner:TIANJIN XINYUAN HONGDA TECH CO LTD

Unburned zeolite foam sound-absorbing board

InactiveCN103556746AHigh strengthImprove bending resistanceNoise reduction constructionSound proofingThermal insulationMaterials science

The invention discloses an unburned zeolite foam sound-absorbing board. The technical scheme is characterized in that an internal frame is flatly placed on a mould, after short steel tubes in the internal frame are inserted into columns, a zeolite cement foaming agent is poured on the periphery of the internal frame, the internal frame is totally inlaid in the inside of the zeolite cement foaming agent, curing is carried out according to a conventional cement product curing method, and packaging is performed to form an unburned zeolite foam sound-absorbing board finished product. The zeolite cement foaming agent is composed of raw material such as zeolite, high-viscosity attapulgite clay powder and cement. The zeolite cement foaming agent is integrated with the internal frame into a whole after curing, so that integral strength, bending resistance capacity and actual use effect of the unburned zeolite foam sound-absorbing board are improved. The unburned zeolite foam sound-absorbing board can not only effectively control noise pollution but also has functions in thermal insulation and air purification; besides, the unburned zeolite foam sound-absorbing board is suitable for being mounted in facilities such as highways, viaducts, urban light rails, subways and public places.

Owner:张连重

Novel injection mold for inverse buckle demolding

InactiveCN109605684ASimple and reasonable structureReduce manufacturing costDomestic articlesSlide plateInjection moulding

The invention discloses a novel injection mold for inverse buckle demolding. The novel injection mold comprises a movable mold body and a fixed mold body and further comprises an inclined guide block,a mounting seat, a sliding table, a sliding plate, a driving cylinder and a mold core. The sliding table and the driving cylinder are fixedly arranged on the mounting seat. A linear chute is formed in the sliding table. The sliding plate is movably clamped in the linear chute. The driving cylinder is connected with the sliding plate. The mold core is installed on the sliding plate. A hollow cavity is formed in the mold core, and a core column is arranged in the cavity. The front end of the core column is of a conical structure, and sliding rails are arranged at the front end of the core column. A movable insert is movably clamped to each sliding rail. The movable inserts penetrate through the inside of the mold core in the radial direction of the core column. A T-shaped groove is formed in the inclined guide block. The tail end of the core column is movably clamped in the T-shaped groove. According to the novel injection mold, the movable inserts are arranged on the mold core and matched with the core column in the mold core, so that inverse buckle demolding of a pipe opening of a shell of an air filter element device is ingeniously realized, the production efficiency is high, thedemolding speed is high, the injection molding quality is good, the yield is high, and the use effect is good.

Owner:苏州希尔林机械科技有限公司

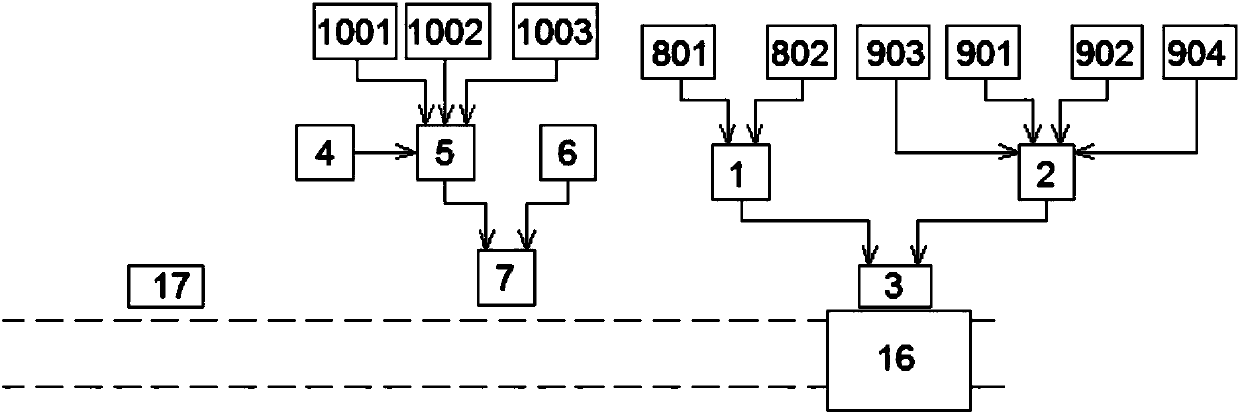

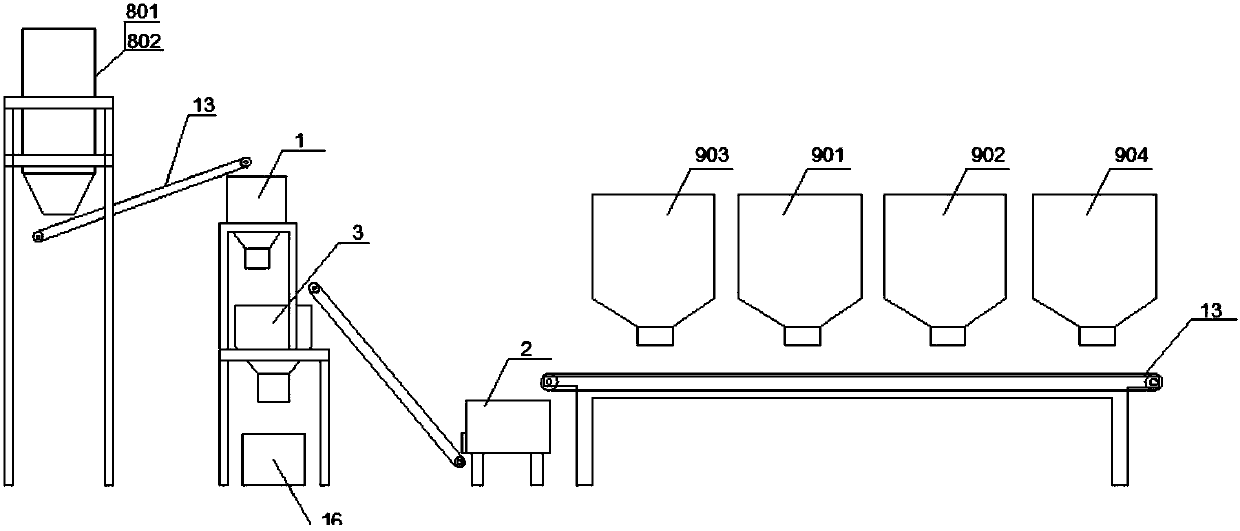

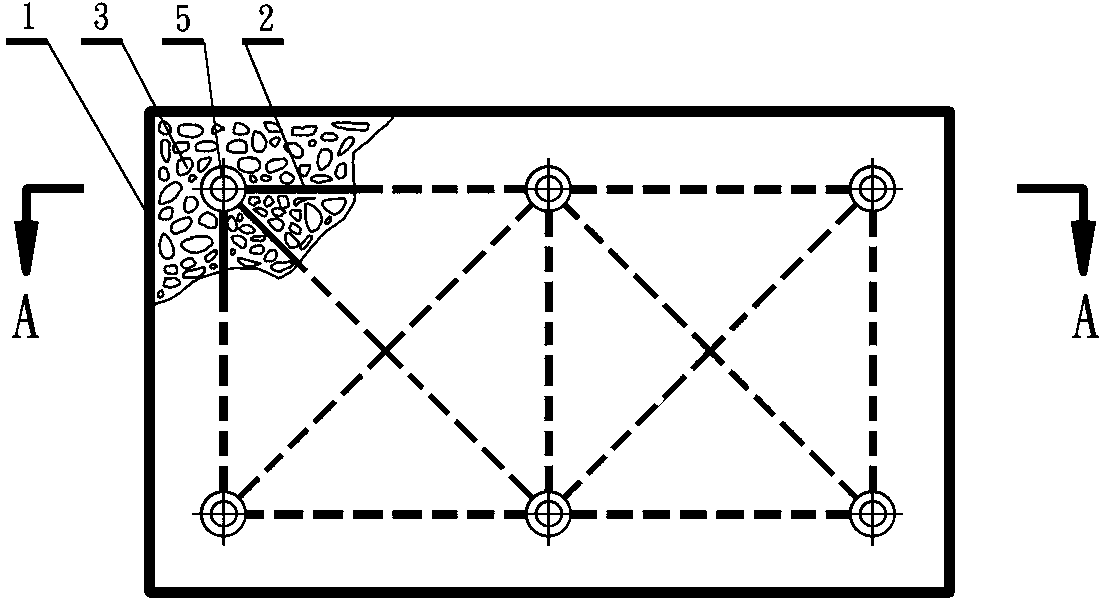

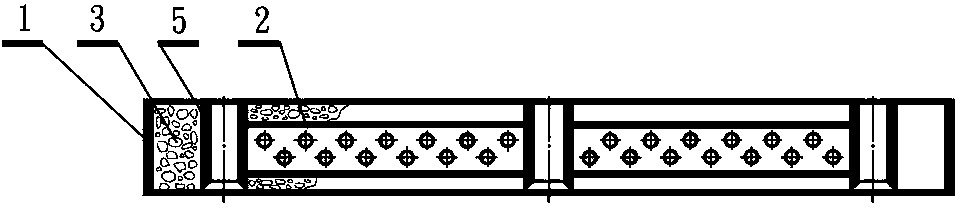

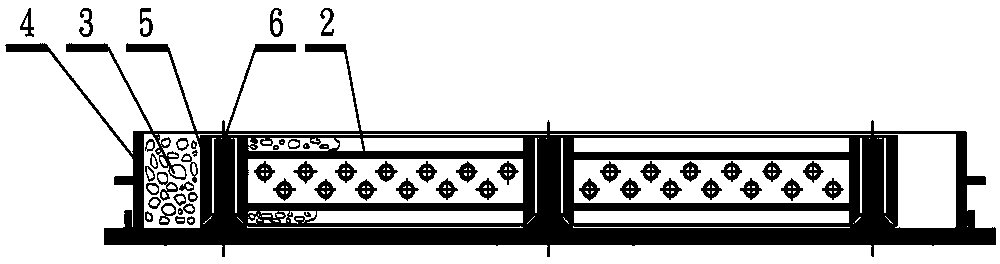

Polymer concrete pipe production line

ActiveCN107599274AImprove adhesionNot prone to adhesionTubular articlesProduction linePolymer concrete

The invention relates to a polymer concrete pipe production line. The polymer concrete pipe production line comprises an aggregate feeding mechanism, a liquid material feeding mechanism, a material mixing mechanism and a pouring mechanism; the input end of the material mixing mechanism is connected with the output end of the aggregate feeding mechanism and the output end of the liquid material feeding mechanism, and the output end of the material mixing mechanism is connected with the input end of the pouring mechanism; the aggregate feeding mechanism comprises a first mixing machine and a second mixing machine which are arranged in parallel, the output ends of the first mixing machine and the second mixing machine are connected with the input end of a third mixing machine, the input end of the first mixing machine is connected with a coarse material bin, and the input end of the second mixing machine is connected with a powdery material bin; the liquid material feeding mechanism comprises an auxiliary tank, a resin tank, a transferring tank, an ingredient tank and a mixing tank, the output ends of the auxiliary tank and the resin tank are connected with the input end of the transferring tank, and the output ends of the transferring tank and the ingredient tank are connected with the input end of the mixing tank; and the pouring mechanism comprises a pouring die and a driving mechanism of the pouring die, and a movable hopper is arranged among the output end of the third mixing machine, the output end of the mixing tank and the input end of the pouring die.

Owner:山东土大力管道工程有限公司

Environmental-friendly flyash acoustic board

ActiveCN103556737AStrong foaming abilityHigh foaming ratioNoise reduction constructionSound proofingFoaming agentThermal insulation

The invention discloses an environmental-friendly flyash acoustic board. According to the technical scheme, the environmental-friendly flyash acoustic board is characterized in that a built-in frame is horizontally placed on a die, after each short steel tube in the built-in frame is inserted into the corresponding standing column, flyash composite foaming agent is poured on the periphery of the built-in frame to allow the built-in frame to be totally embedded inside the flyash composite foaming agent, and standing, curing, roasting and cooling are performed before the finished environmental-friendly flyash acoustic board is packaged. The flyash composite foaming agent comprises flyash, attapulgite argil powder, hydrogen peroxide and the like. The cured flyash composite foaming agent and the built-in frame form an integrity, so that overall strength, bending resistance and actual use effect of the environmental-friendly flyash acoustic board are improved, sound absorption and noise pollution control effects are enhanced, and functions such as thermal insulation, absorption and air purification are achieved. The environmental-friendly flyash acoustic board is suitable for being mounted in facilities such as highways, viaducts, city light rails, subways, factories, warehouses and public places.

Owner:浙江龙鹰光电科技有限公司

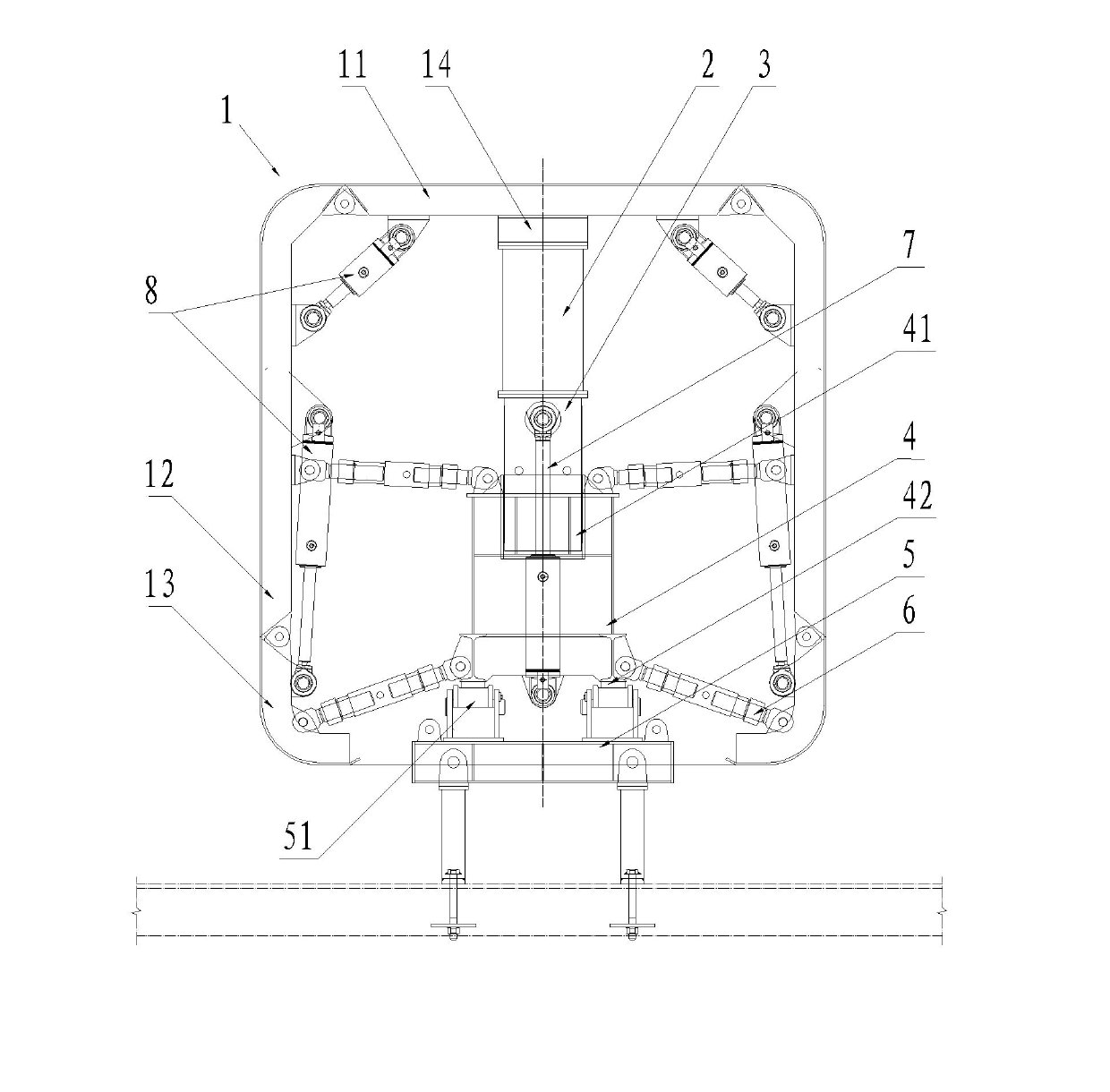

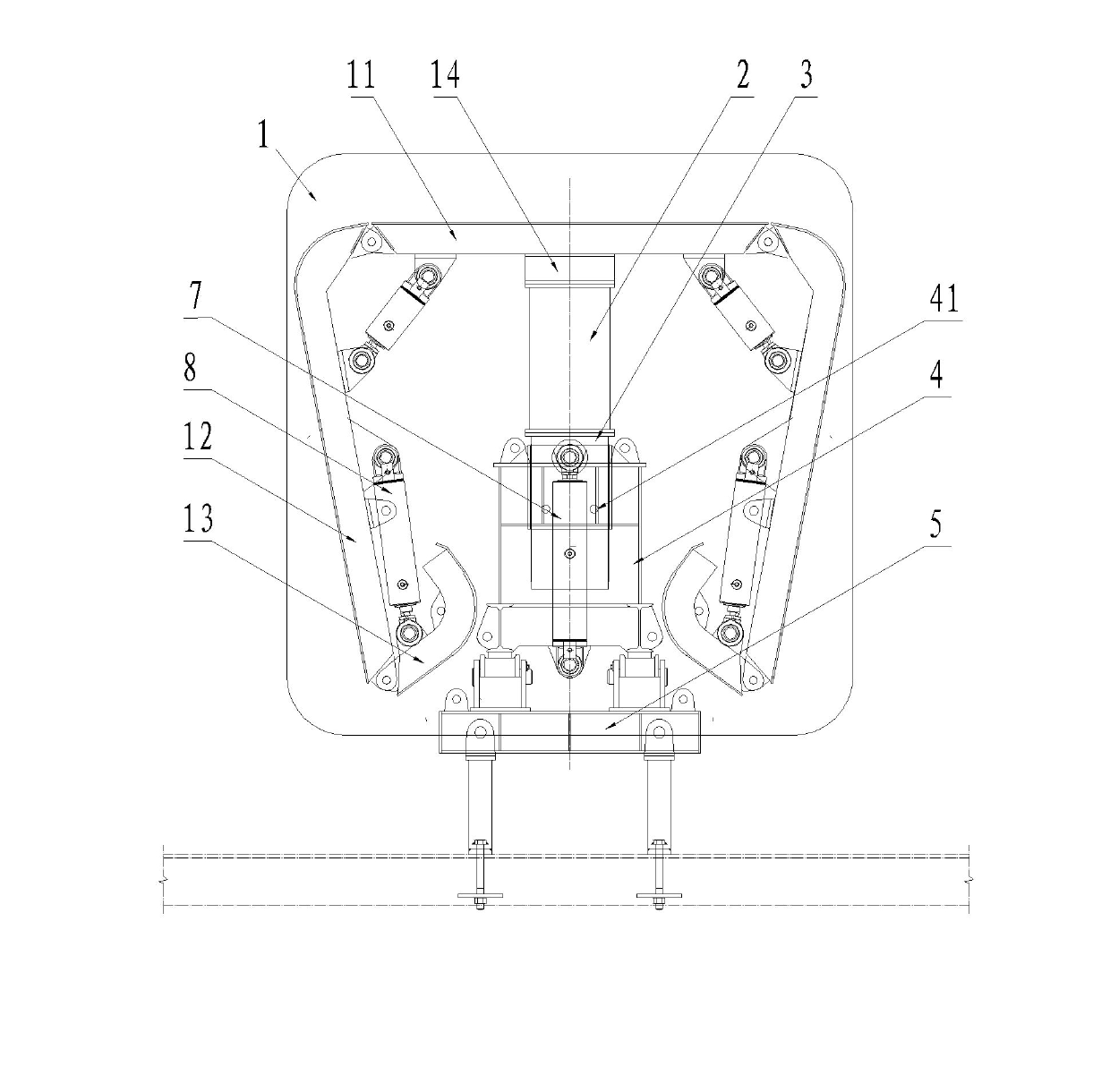

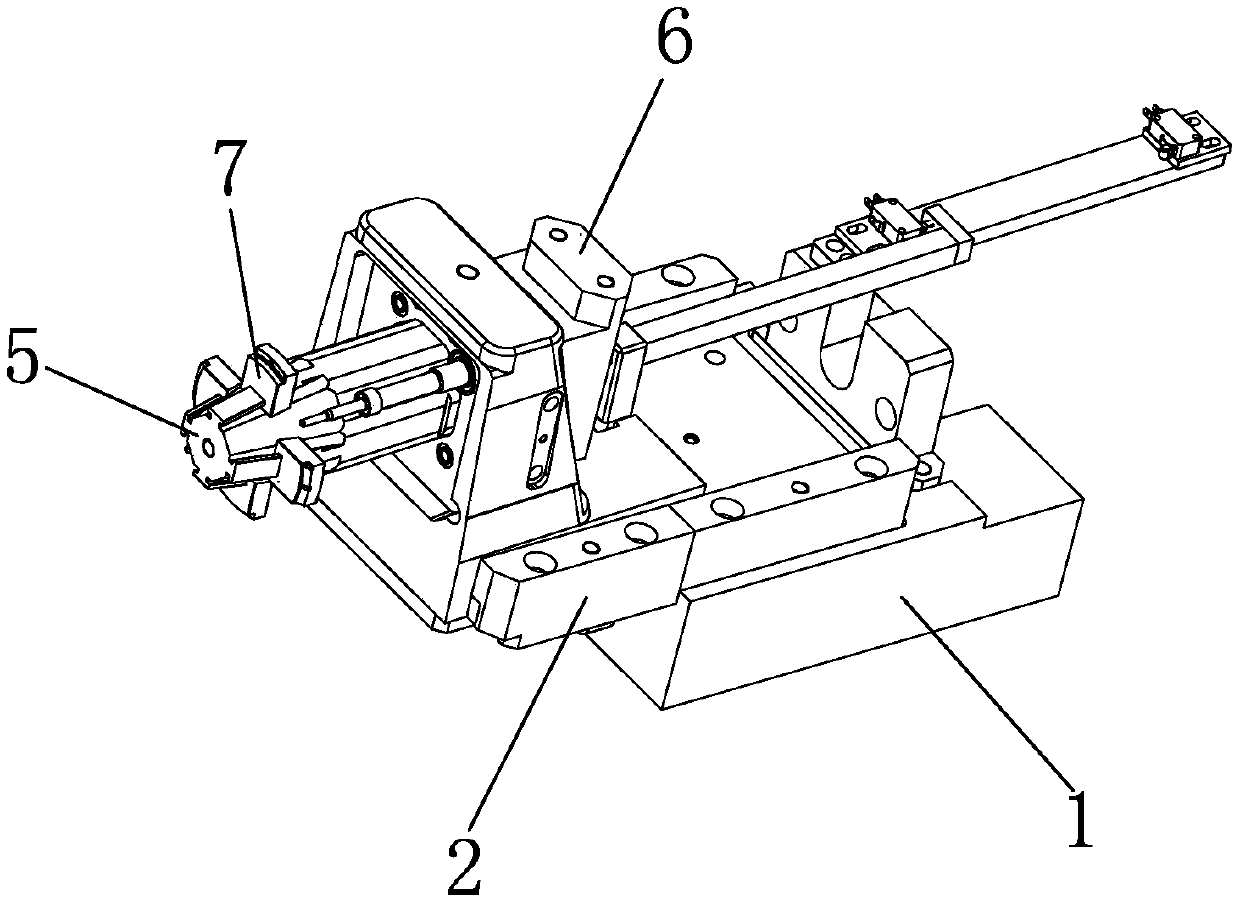

Supporting and positioning device for refrigerator foaming internal mold

InactiveCN101476810AFast demoulding speedIncrease productivityDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses a device for supporting and positioning a refrigerator foaming internal mold, which comprises a translation mechanism and a linkage support mechanism arranged on the translation mechanism, wherein the linkage support mechanism comprises a slider mechanism provided with a left ejector block, an upper ejector block and a right ejector block, and a link mechanism connected with the slider mechanism and the translation mechanism for driving the three ejector blocks to move. The device for supporting and positioning the refrigerator foaming internal mold can be opened in the refrigerator foaming internal mold to support and position the refrigerator foaming internal mold, and can be shrunk rapidly after finishing foaming to be taken out successfully from the refrigerator foaming internal mold, thereby speeding up the demoulding of the refrigerator foaming internal mold. Compared with the prior wood neutron for supporting and positioning the refrigerator foaming internal mold, the device is obviously more favorable for improving the production efficiency of the refrigerator foaming technology.

Owner:昆山市三建模具机械有限公司

Environmental-friendly attapulgite acoustical board

InactiveCN103526848AImprove adsorption capacityImprove adhesionSound proofingCeramicwareFoaming agentProcess engineering

The invention discloses an environmental-friendly attapulgite acoustical board. The key points of the technical scheme are that a built-in framework is flatly arranged on a die, a short steel tube in the built-in frame is inserted into a stand column, an attapulgite compound foaming agent is poured at the periphery of the built-in framework, the built-in framework is completely embedded in the compound foaming agent to stand, be cured, be roasted and be cooled, and the built-in framework is packed to form a finished product of the environmental-friendly attapulgite acoustical board. The attapulgite compound foaming agent solidifies to be integrated with the built-in framework. A semi-finished product of the environmental-friendly attapulgite acoustical board is roasted to greatly improve the whole strength, the bending resistance and the actual using effects of the environmental-friendly attapulgite acoustical board. Thus, the effects of sound absorption and noise pollution control are enhanced. The environmental-friendly attapulgite acoustical board further has the thermal-insulation, absorption and air-purifying functions. The environmental-friendly attapulgite acoustical board is suitable for being installed in facilities of highways, viaducts, urban light rails, subways, factories, warehouses, public places and the like.

Owner:许庆华

Self-propelled trestle trolley for inverted arch trestle trolley

InactiveCN111535148ASave assemblySave demolitionUnderground chambersTravelling bridgesArchitectural engineeringStructural engineering

The invention provides a self-propelled trestle trolley for an inverted arch trestle trolley. After an inverted arch formwork system is installed at a time, the inverted arch formwork system can be dragged by a trestle trolley to achieve inverted arch operation construction of a whole tunnel with the same section, formwork assembling and disassembling are omitted, full-automatic mechanical controlmoving and positioning are adopted, labor intensity of workers is greatly reduced, labor cost is saved, and construction efficiency and construction quality are improved; and meanwhile, the invertedarch formwork system is detachably connected with the trestle trolley, a separation mode is simple, the inverted arch formwork can be ensured not to interfere with construction of other procedures inthe procedures of inverted arch excavation, wire-tie and the like, and control is flexible and convenient.

Owner:李军

Foamed light cement board

InactiveCN107572918AWith sound insulationEnvironmentally friendlyCeramicwareManufacturing technologyCement board

The invention discloses a foamed light cement board, and belongs to the technical field of production of foamed cement boards. The foamed light cement board is formed by adding a cement foaming agentinto a cement slurry, stirring, pouring into a mould and curing, wherein the cement slurry comprises the following components in parts by mass: 25-35 parts of acid cement, 10-15 parts of sodium polyacrylate, 10-25 parts of calcium chloride, 5-10 parts of sodium hydrogen carbonate, 5-15 parts of magnesium oxide, 5-8 parts of sodium dodecyl benzenesulfonate, 3-5 parts of disodium ethylenediaminetetraacetate, 10-15 parts of quartz sand and 5-9 parts of sodium pyrophosphate; the cement foaming agent comprises the following components in parts by mass: 25-80 parts of a composite cement foaming agent paste, 10-35 parts of hydrogen peroxide, 1-5 parts of polyether-modified silicone oil and 10-45 parts of water. Compared with the prior art, the foamed light cement board has the advantage as follows: the problem that the conventional foamed cement board has a poor foaming capability can be solved.

Owner:南丹县住房和城乡建设局

Environment-friendly medical-stone sound-absorbing plate

InactiveCN103526845AStrong foaming abilityHigh foaming ratioSound proofingCeramicwareFoaming agentEngineering

The invention discloses an environment-friendly medical-stone sound-absorbing plate. According to the technical scheme, an internal framework is flatly placed on a die, after a short steel tube in the internal framework is inserted into a stand column, composite medical-stone foaming agents are poured on the periphery of the internal framework, the internal framework is totally embedded in the composite foaming agents, and after standing curing processing, roasting and cooling, the internal framework and the composite foaming agents are packaged to form an environment-friendly medical-stone sound-absorbing plate finished product. The composite medical-stone foaming agents include medical-stone powder, attapulgite pot clay powder, hydrogen peroxide and the like. After being cured, the composite medical-stone foaming agents and the internal framework form an integrated whole, the integral strength, the anti-bending capacity and the actual use effects of the environment-friendly medical-stone sound-absorbing plate are improved, the effects of improving sound-absorbing capacity and noise pollution controlling capacity are achieved, and the functions of temperature preservation, adsorption and air purifying are achieved. The environment-friendly medical-stone sound-absorbing plate is suitable for being used for highways, viaducts, urban light rails, metros, factories, warehouses, public places and other facilities.

Owner:许庆华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com