Manufacturing method of microchannel device and the microchannel device

A manufacturing method and technology of micro-channels, which are applied in fluid controllers, chemical instruments and methods, and photoplate-making processes on patterned surfaces, etc., can solve the problem of insufficient side wall height of polydimethylsiloxane micro-channels, Insufficient negative pressure suction and other problems, to avoid damage, prevent insufficient negative pressure suction, and increase manufacturing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Relating to the detailed description and technical contents of the present invention, it is now described as follows with regard to the accompanying drawings:

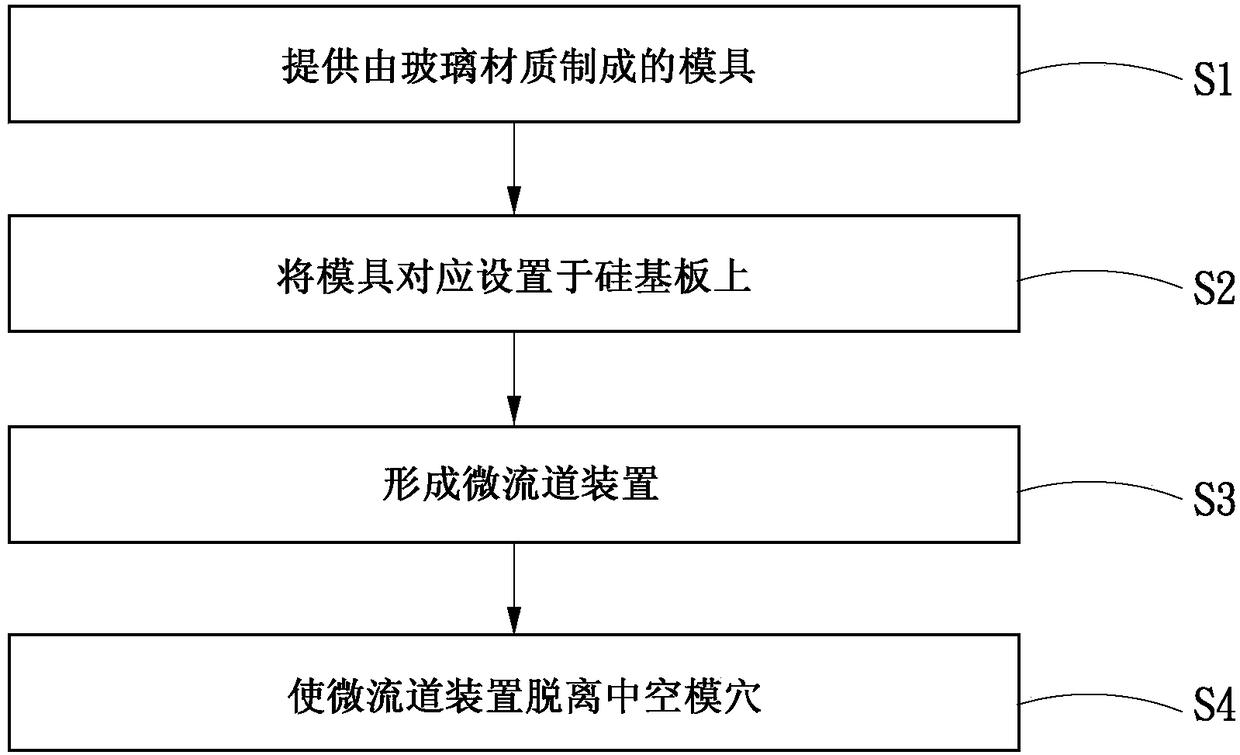

[0023] see Figure 1 to Figure 4 As shown, the present invention is a method of manufacturing a micro-channel device and its structure. The micro-channel device 40 has a micro-channel structure 41 and its side wall height is between 3 millimeters and 30 millimeters, and its manufacture The method includes the following steps:

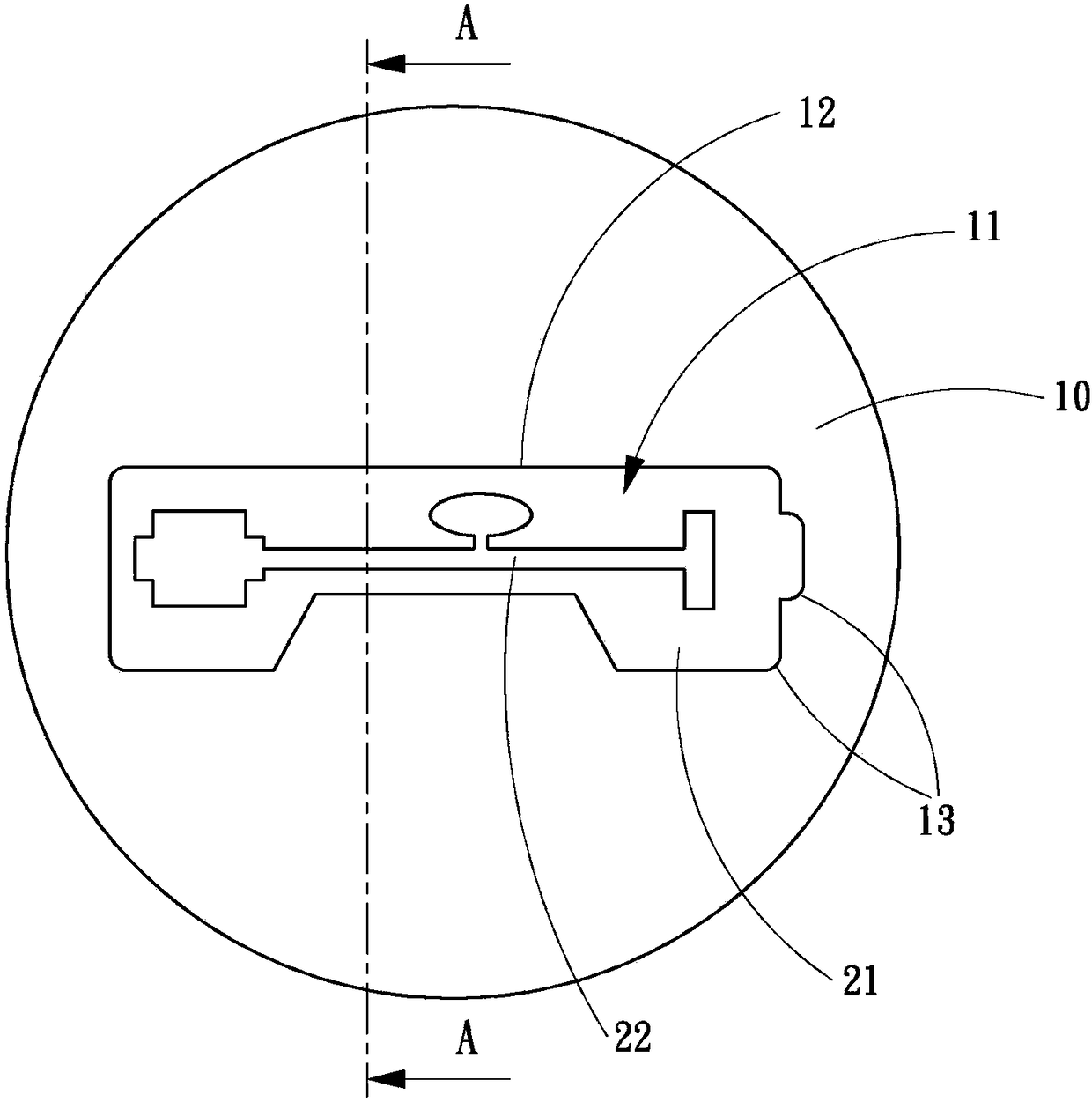

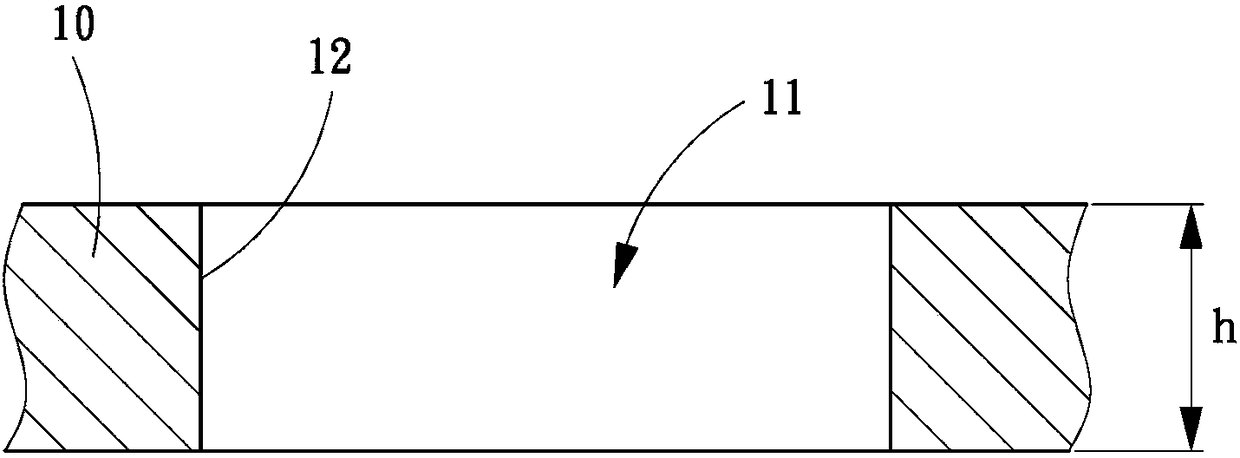

[0024] S1: if Figure 3A As shown, a mold 10 is provided, the mold 10 is made of glass material, and has a hollow mold cavity 11 and a retaining wall 12 surrounding the hollow mold cavity 11, and the retaining wall 12 has a thickness of not less than 3 mm the height h.

[0025] Wherein, the manufacturing method of the mold may be to use laser processing to process the glass to form the mold 10, so that the mold 10 has the hollow mold cavity 11 and the retaining wall surrounding the hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com