Patents

Literature

212results about How to "Reduce light transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

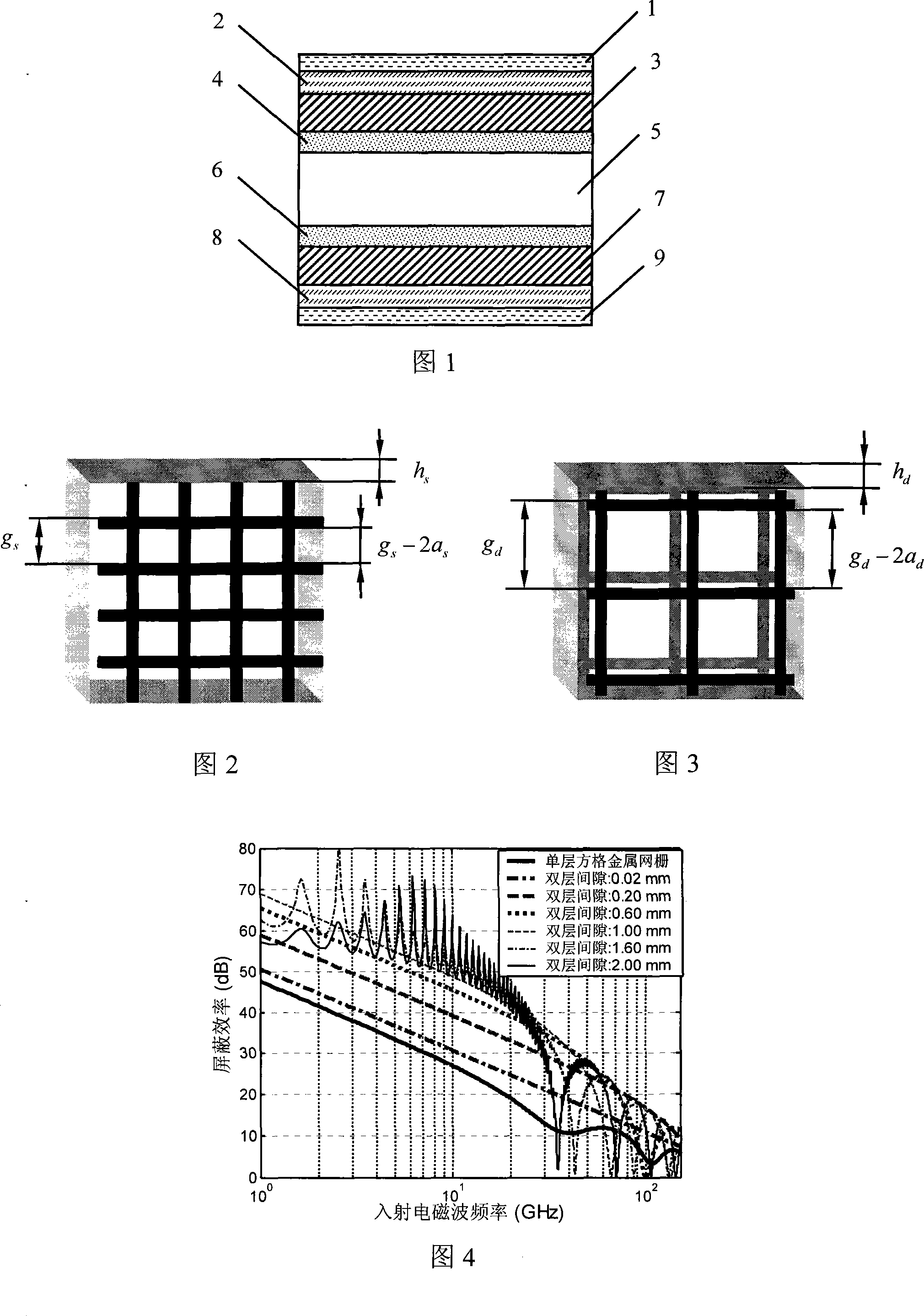

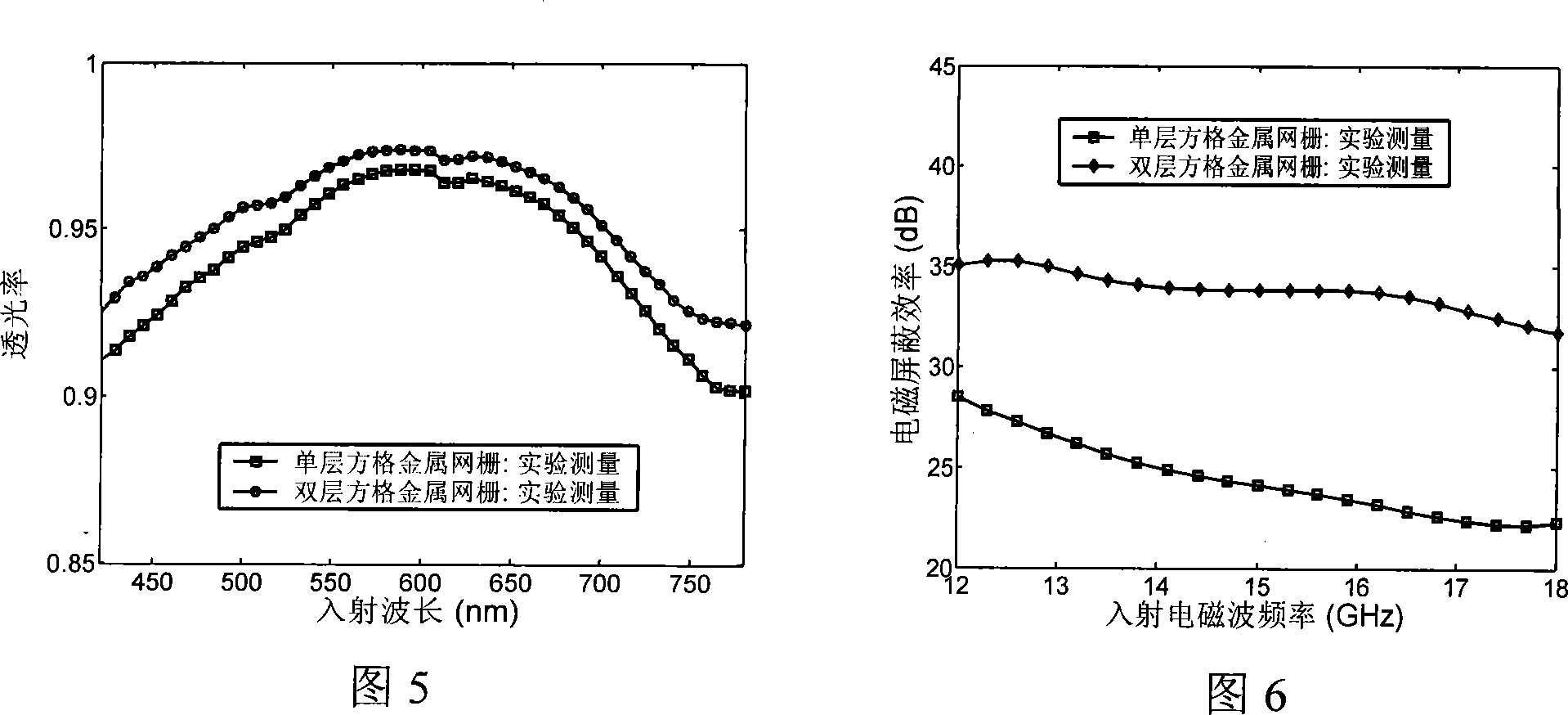

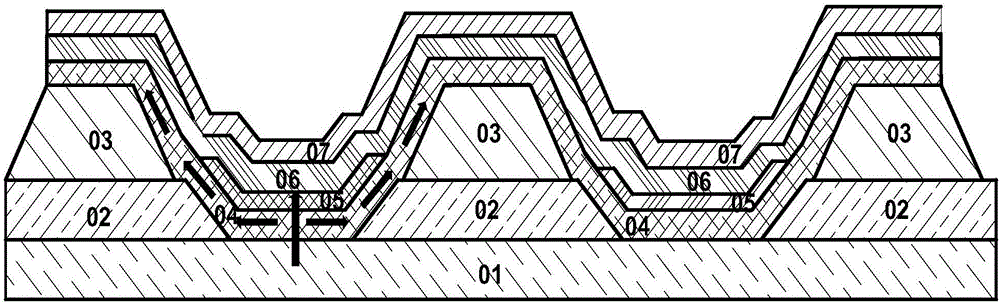

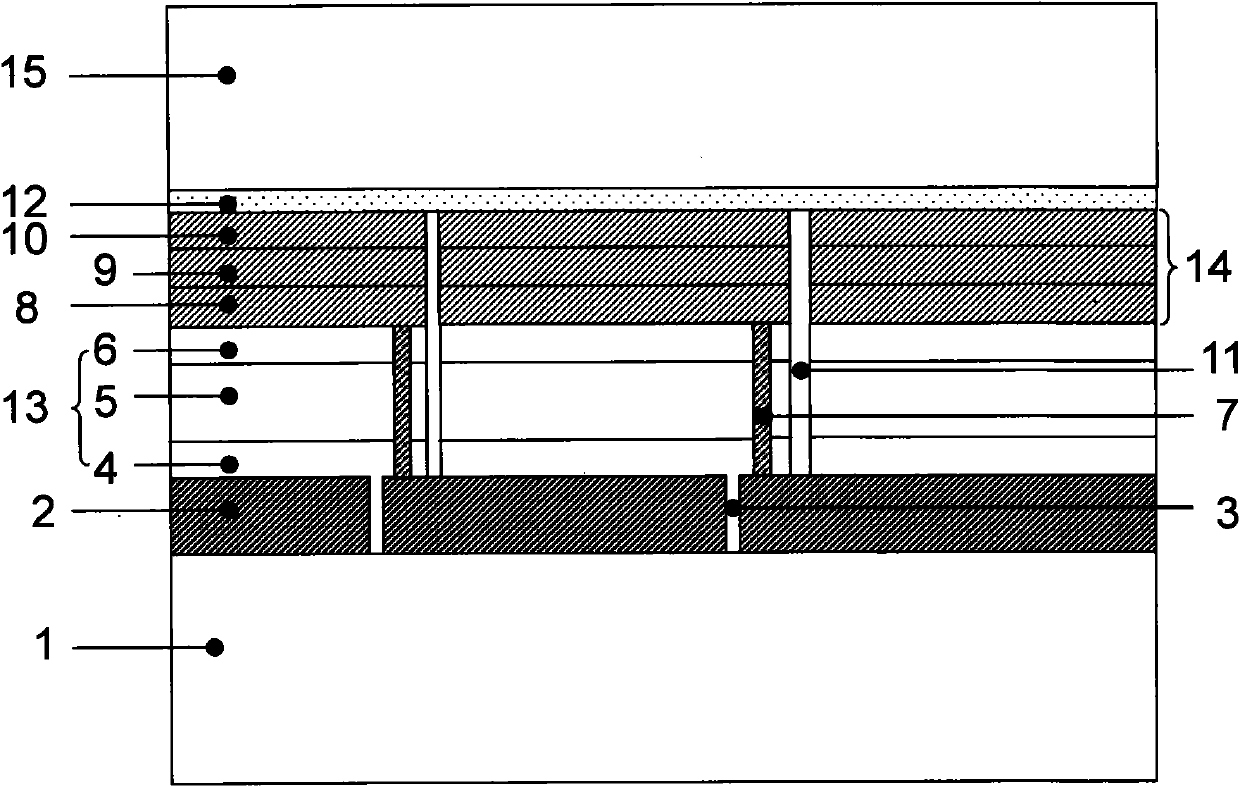

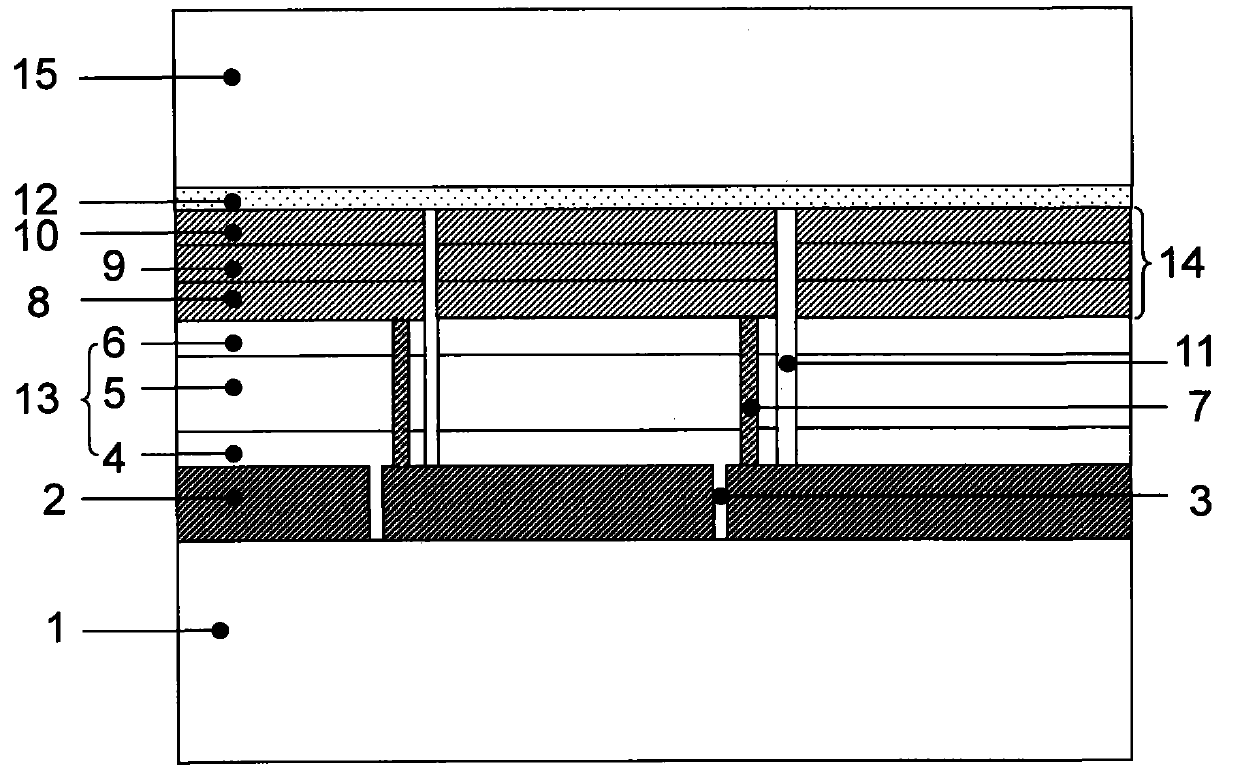

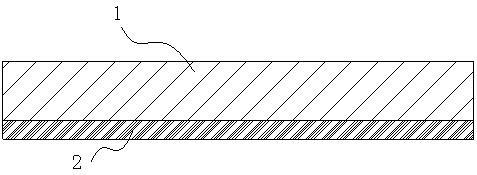

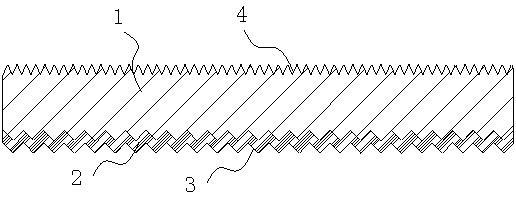

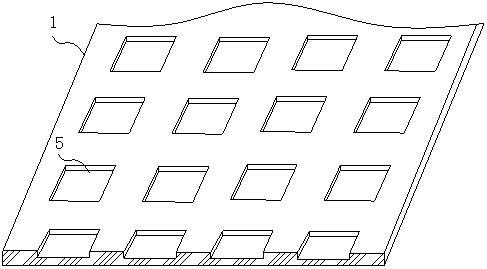

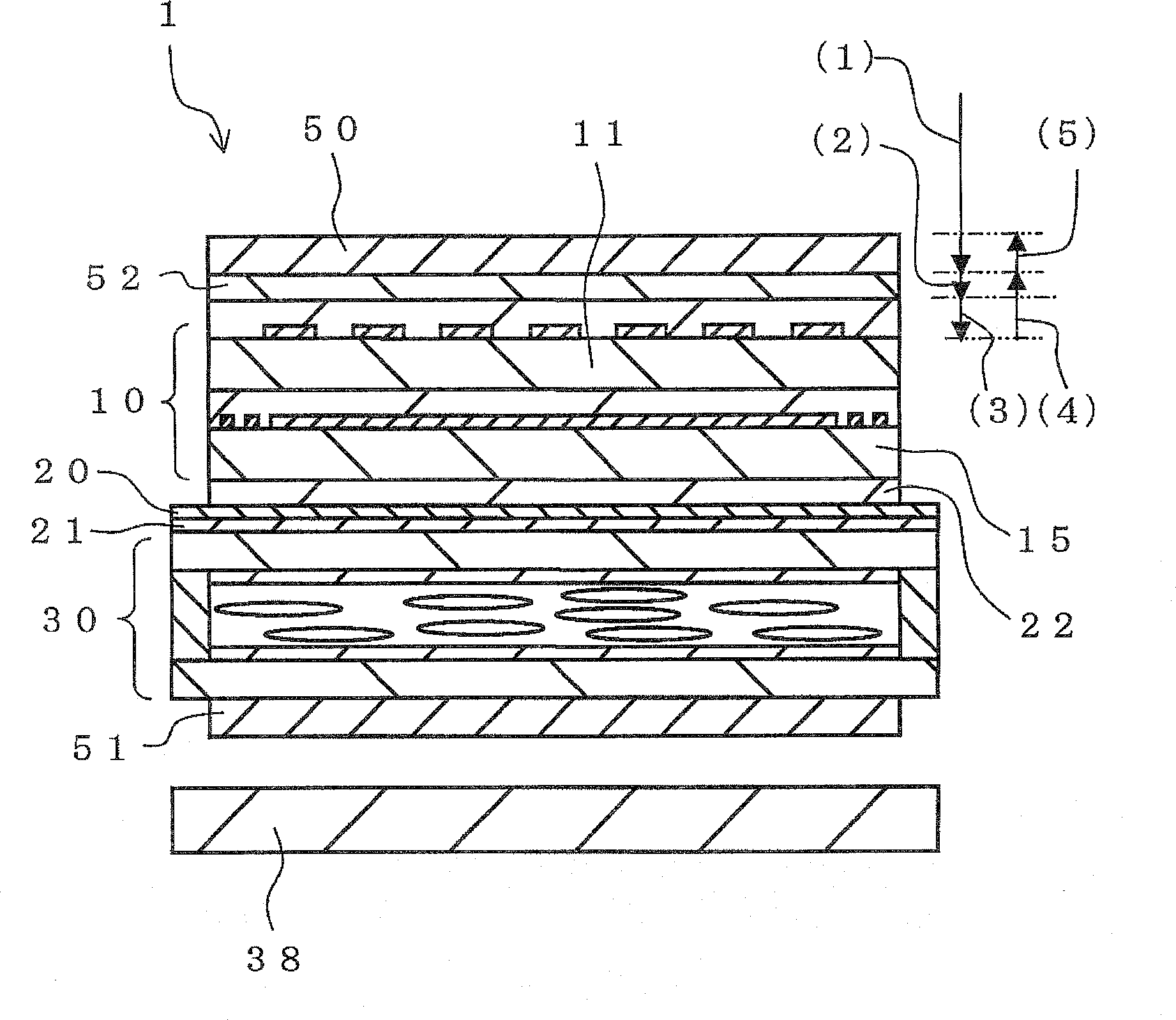

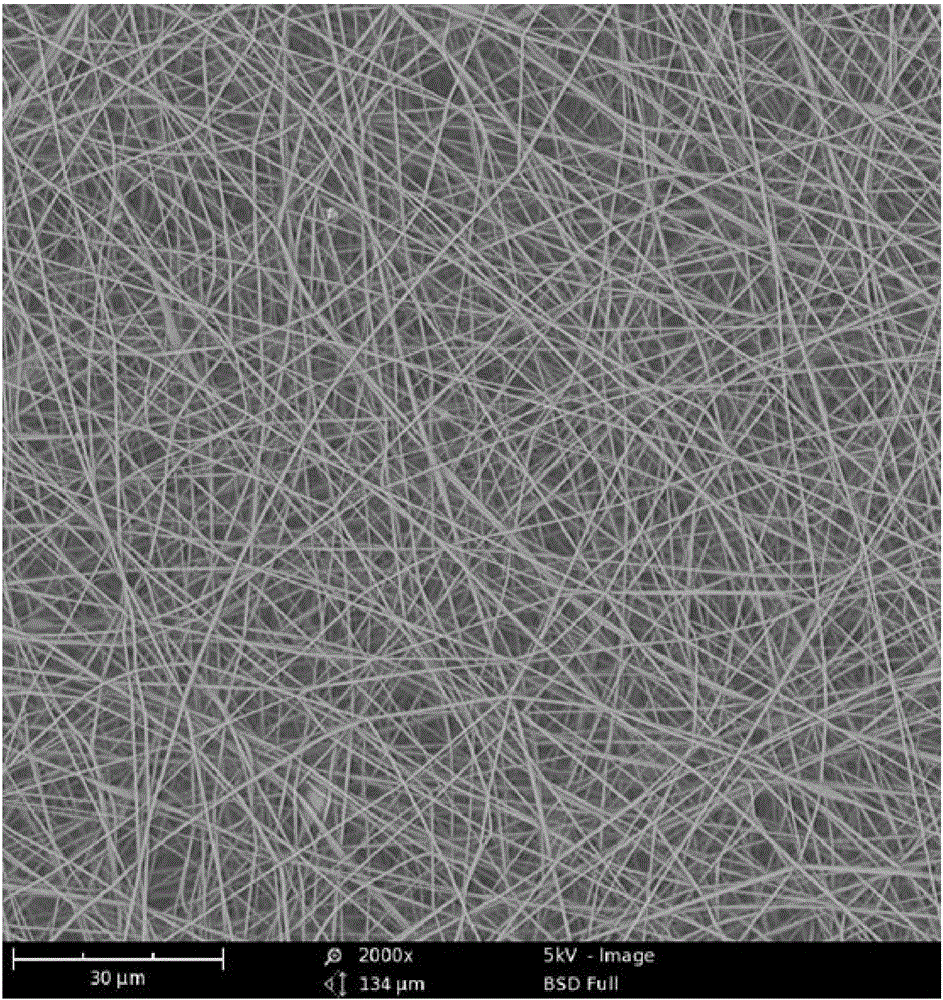

Electromagnetic shielding optical window with double-layer pane metal gridding structure

ActiveCN101222840AHigh shielding efficiencyWide shielding bandMagnetic/electric field screeningUnderlayOptical transmittance

The invention relates to an electromagnetic shielding optical window with a two-double pane metal grating structure and belongs to the optical transparent piece electromagnetic shielding technical field; the electromagnetic shielding optical window is formed by placing two layers of pane metal gratings or metal silk screens with the same structure parameters on two sides of the optical window or a transparent underlay in parallel; a side length of a pane of the two-double pane metal grating is greater than two times of a side length of a pane of the prior monolayer pane metal grating; the space between two layers of pane metal gratings is two to four times of the side length of the pane; compared with the prior monolayer pane metal grating, the optical window adopting the two-double pane metal grating structure does not reduce light transmittance, substantially improves the shielding efficiency of microwaves and millimeter waves, solves the problems that the high light transmittance and strong electromagnetic shielding efficiency can not simultaneously considered in the prior optical window electromagnetic shielding technology and is suitable for electromagnetic shielding in aerospace equipment, security facilities, medical diagnostic instruments and other military and civil optical transparent pieces.

Owner:HARBIN INST OF TECH

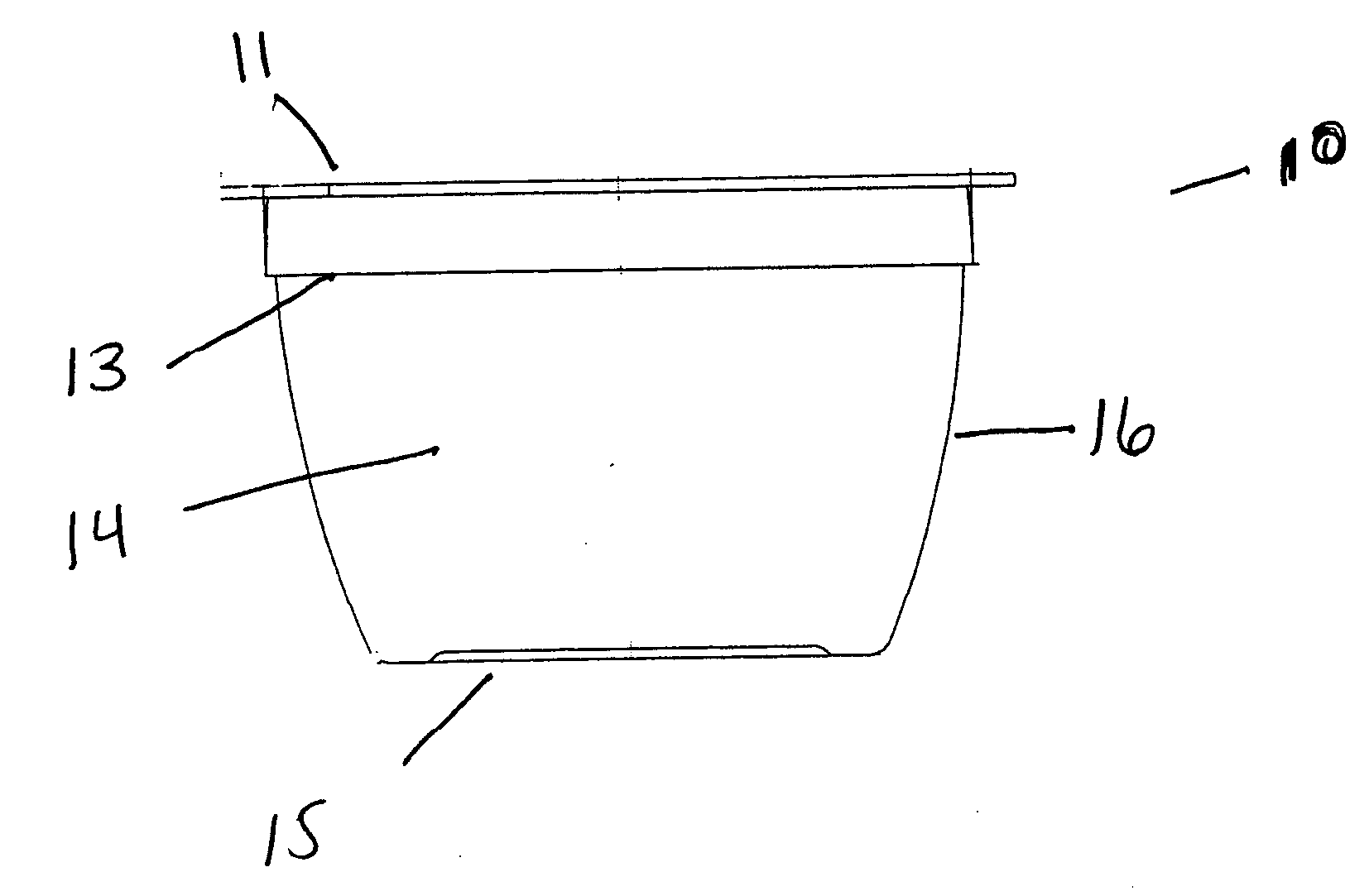

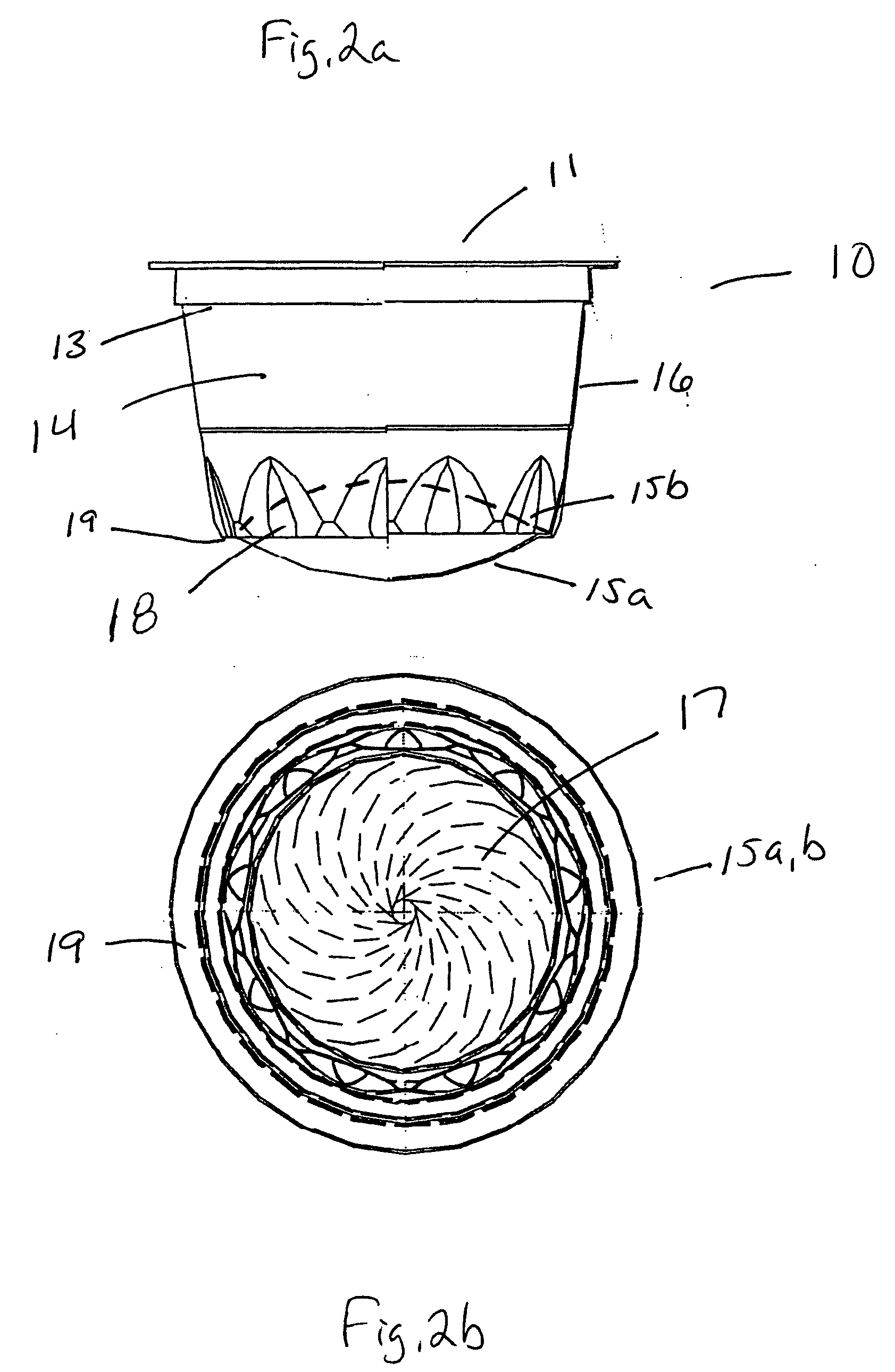

Container for hot fill food packaging applications

A plastic container suitable for hot-fill food packaging applications is disclosed which is characterized by walls of proportionately decreasing thickness from the mouth of the container to a predetermined collapsible point. The wall thickness is designed such that the container walls will collapse, or deform, only at the collapsible point during cooling after hot-filling of food product or during transportation of the container between locations of varying altitudes and pressures. The container preferably collapses in the base area such that the collapse is not visible to the consumer and also the collapse does not affect stability of the container while in use or during loading and storage. The container of the invention is advantageous in that it requires less plastic material to form than other known hot-fill containers, and also can be formed out of any suitable food-grade plastic material or by any process.

Owner:PHOENIX CAPITAL

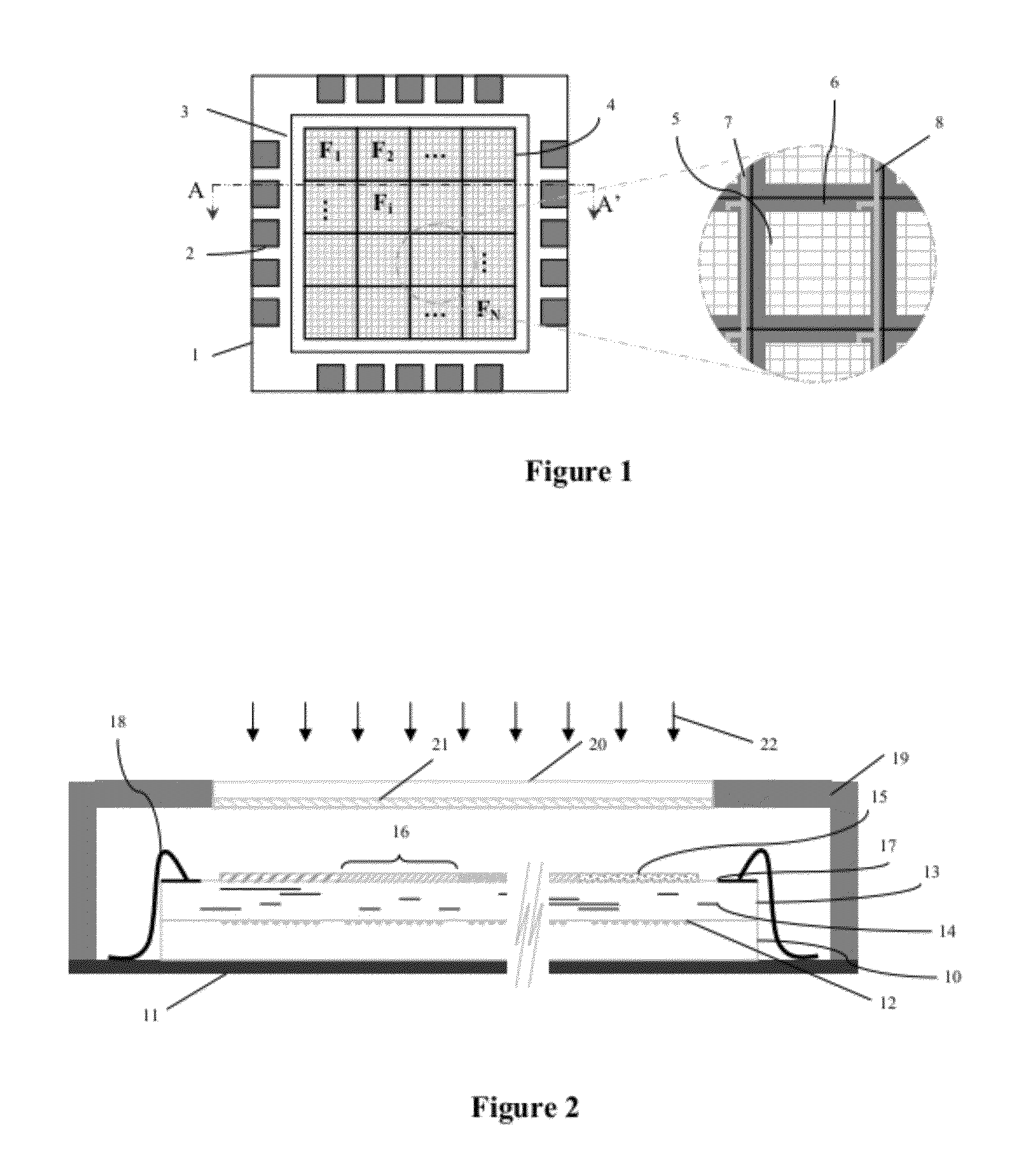

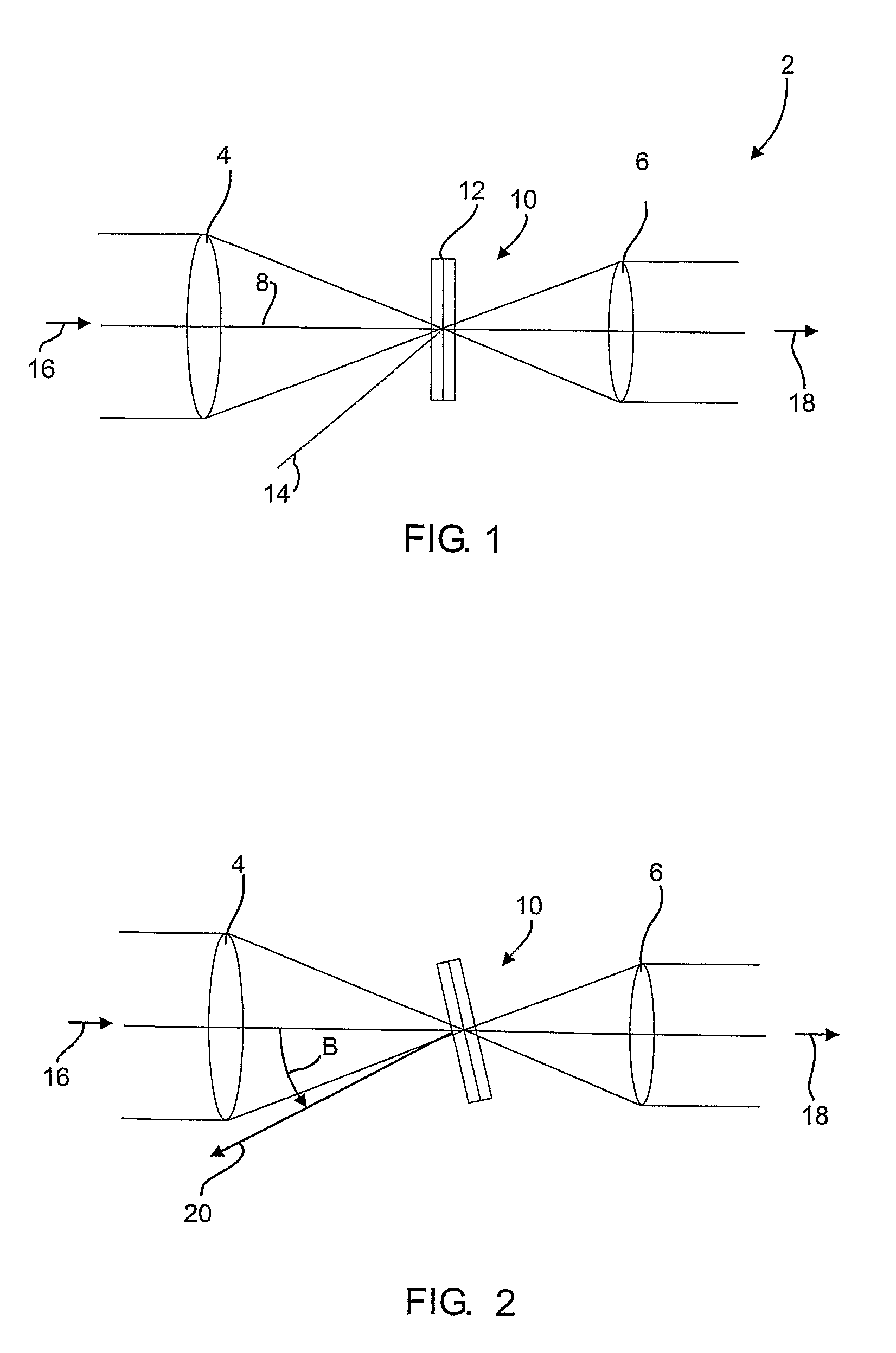

Integrated cytometric sensor system and method

InactiveUS20120156714A1Increase dynamic rangeLow dynamic range , sensitivity and specificityBioreactor/fermenter combinationsBiological substance pretreatmentsForward scatterOpto electronic

Owner:RADISENS DIAGNOSTICS

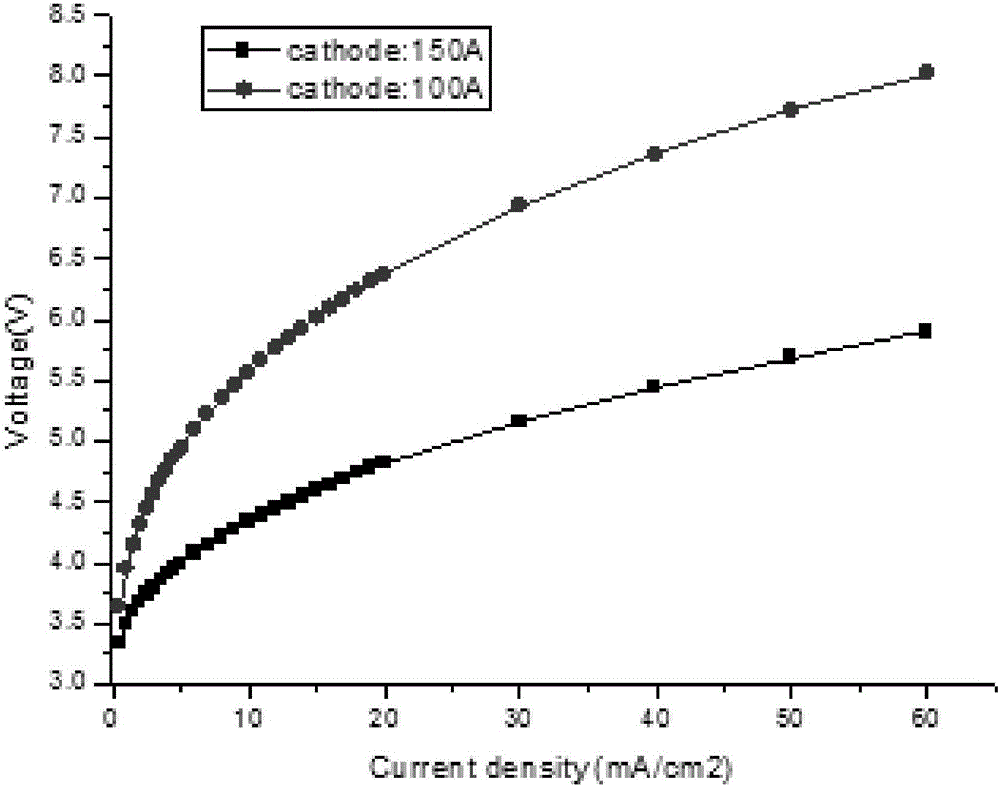

OLED (organic light-emitting diode) display device and manufacture method thereof

ActiveCN106449726ALower resistanceReduce voltage dropSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The application discloses an OLED (organic light-emitting diode) display device and a manufacture method thereof; the OLED display device comprises a substrate, an anode layer, a pixel definition layer, a hole injection layer, a hole transport layer, a light-emitting layer, an electronic transport layer, an electronic injection layer, spacer pillars, passivating pillars positioned on the spacer pillars, and a cathode layer, wherein conductive pillars are electrically connected to the cathode layer. By electrically connecting the conductive pillars to the cathode layer, it is equivalent that a conductive resistor is connected parallelly to the cathode layer, resistance of the cathode layer is decreased, voltage drop of the cathode layer is decreased accordingly, and the OLED display device can provide more uniform displaying at the premise of not increasing the thickness of the cathode layer or decreasing the light transmittance of the cathode layer. With the presence of the passivating pillars, lateral leaking current between adjacent light-emitting pixels is decreased, the problem of brightness possessing by pixels is avoided, color mixing rate is deceased, and product yield is increased.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

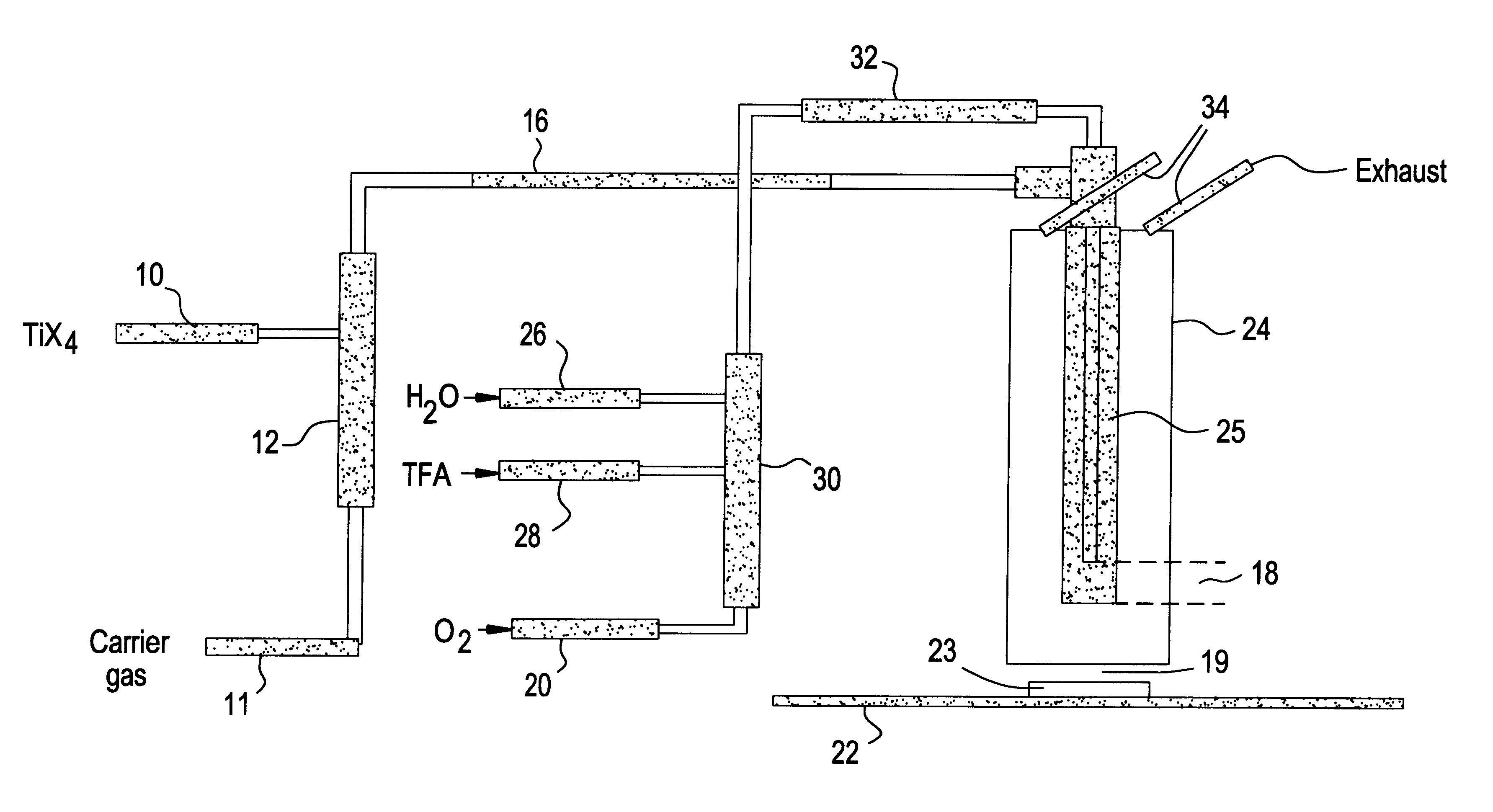

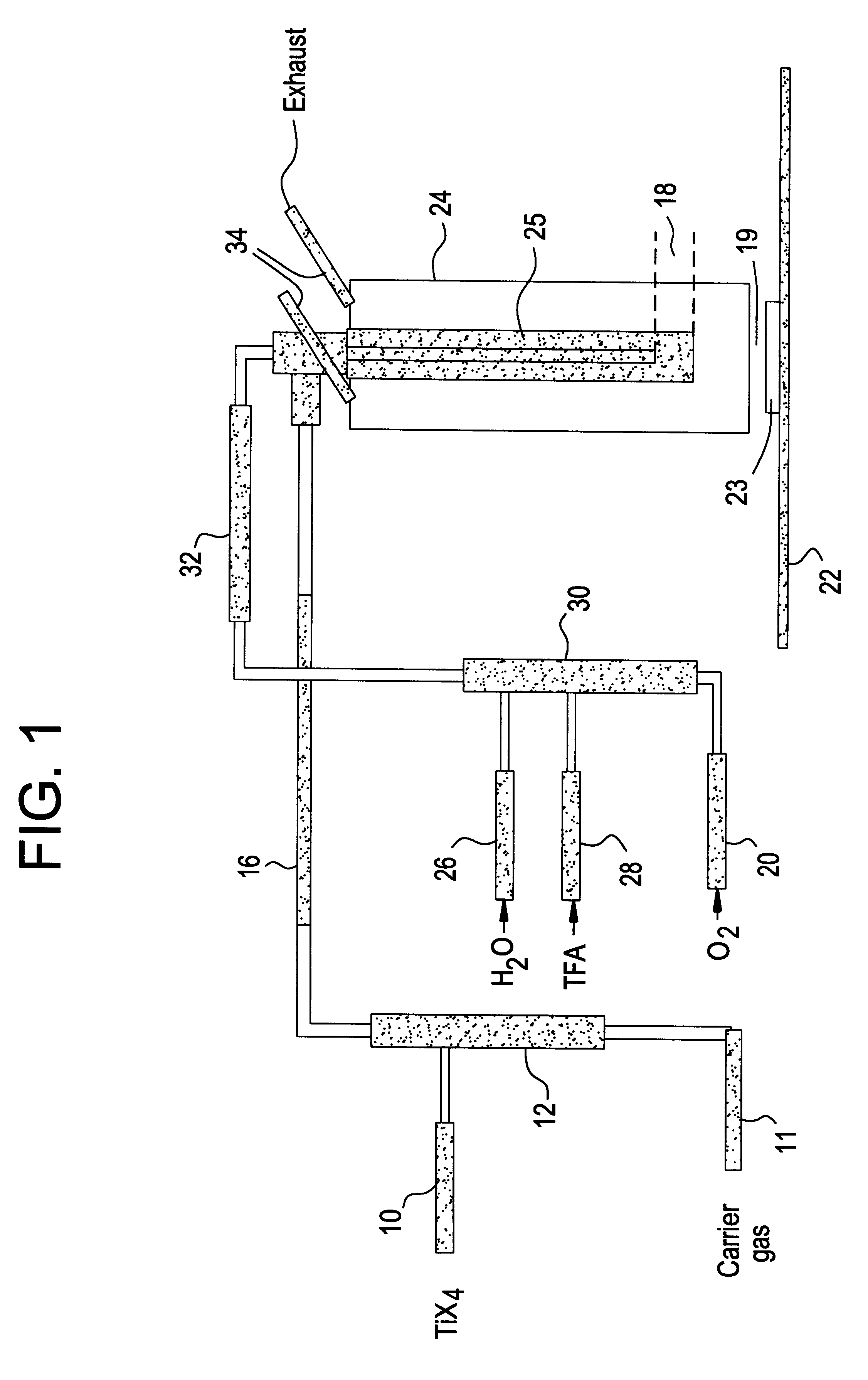

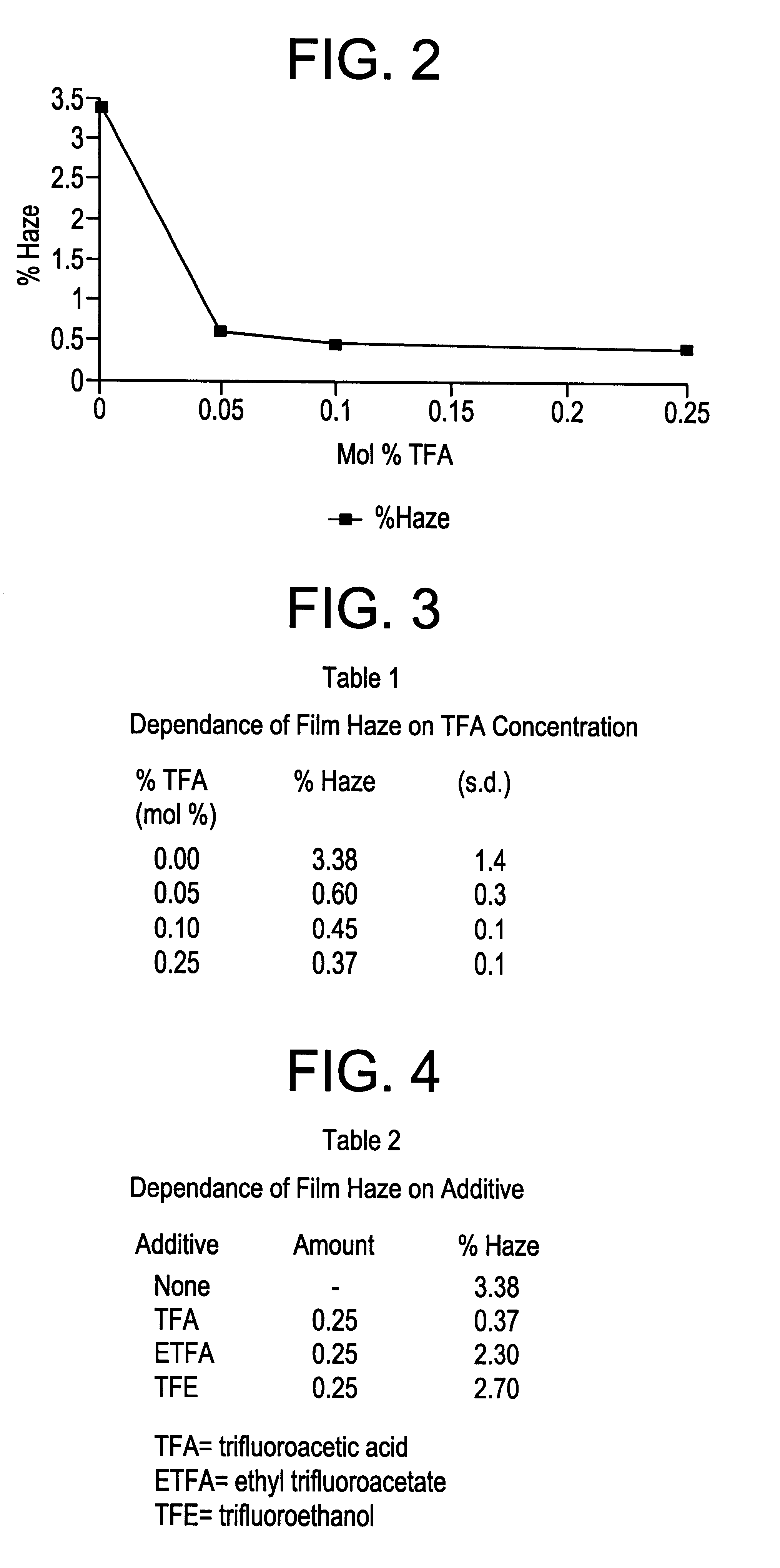

Preparation of fluorine modified, low haze, titanium dioxide films

InactiveUS6268019B1Improve propertiesDegradation of optical propertySpecial surfacesChemical vapor deposition coatingGas phaseRefractive index

The present invention concerns the deposition of fluorine modified, titanium dioxide films (TiO2) onto hot glass by atmospheric pressure chemical vapor deposition (APCVD) using TiCl4 vapor. The invention is also suitable for depositing other metallic oxide films from their metallic halides such as SnCl4, GeCl4, and VCl4. The present invention provides a process that deposits a novel, fluorine modified, titanium dioxide film (TiO2) onto hot glass by atmospheric pressure chemical vapor deposition using TiCl4 vapor. The process uses injection of TiCl4 into a hot, nonoxygen containing carrier gas and blends the carrier gas and TiCl4 vapor with an oxygen containing gas stream containing a haze reducing quantity of a fluorine containing compound before contacting a surface of hot glass with the blended mixture. The process is capable of depositing a fluorine modified, TiO2 film at deposition rates exceeding 900 Å per second. The crystalline phase of the fluorine modified film is essentially anatase. The film has a haze of less then 1% and a refractive index of greater than or equal to about 2.48. Also provided is an apparatus for practicing the process and a novel coated glass.

Owner:ATOCHEM OF NORTH AMERICA INC

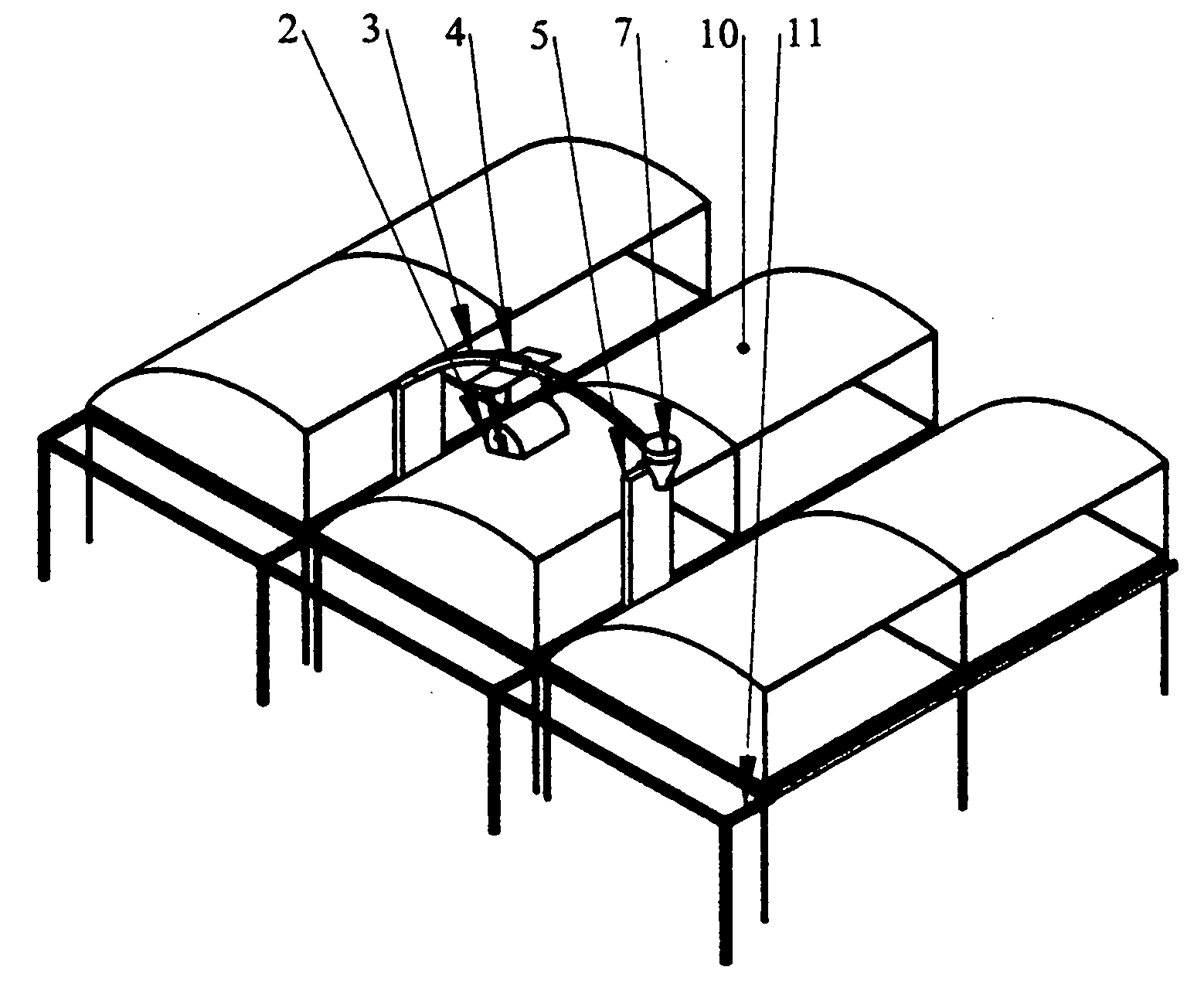

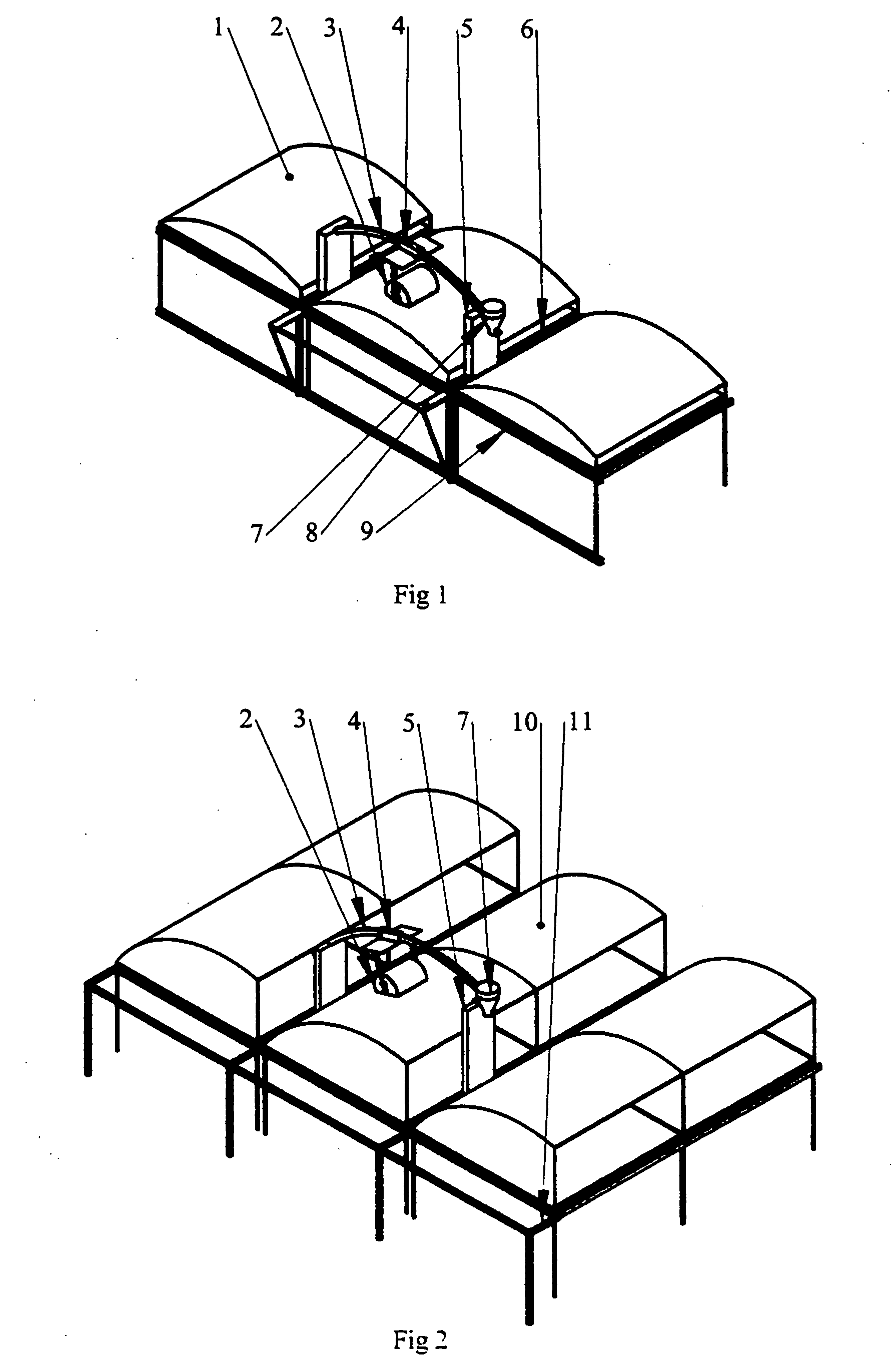

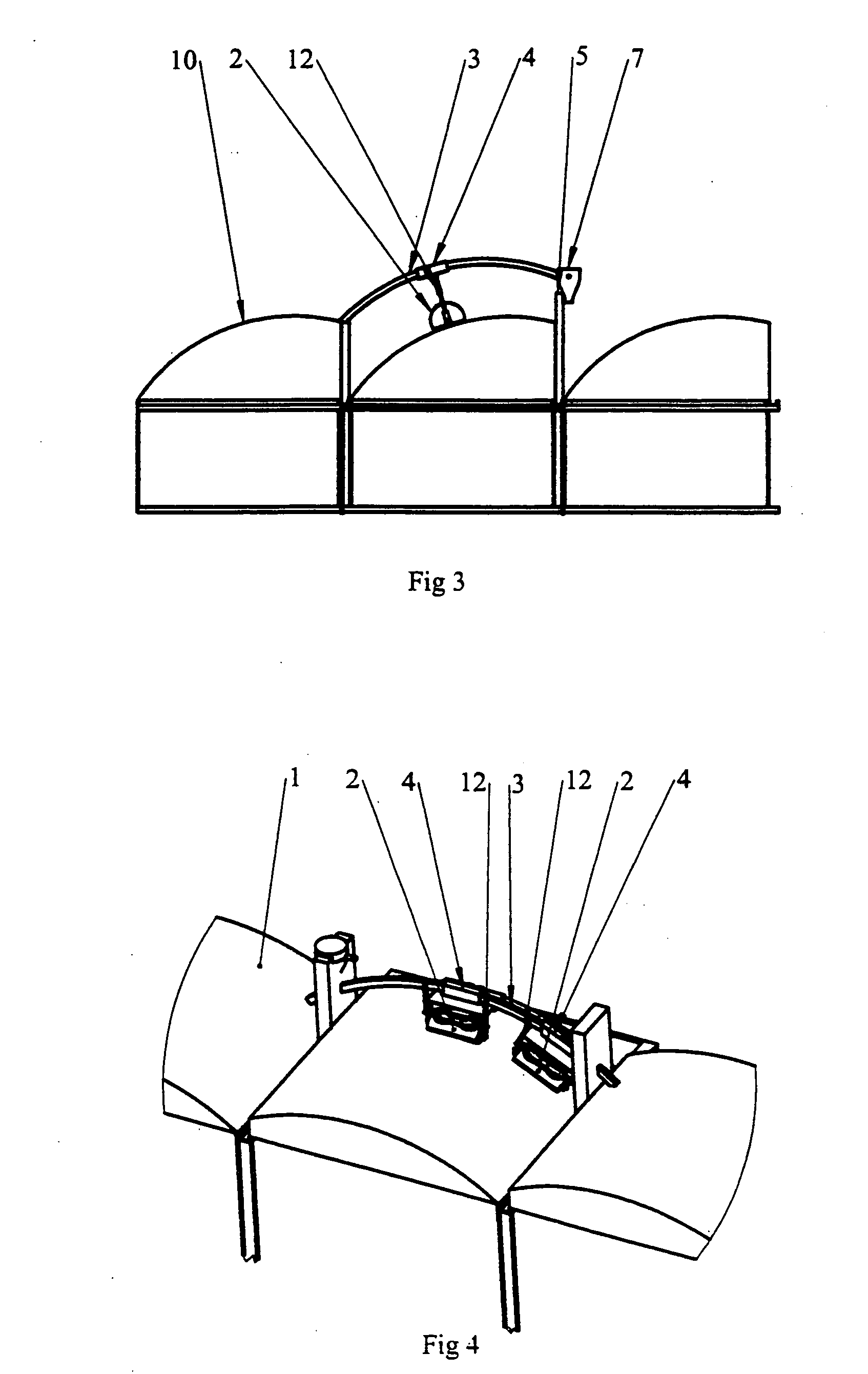

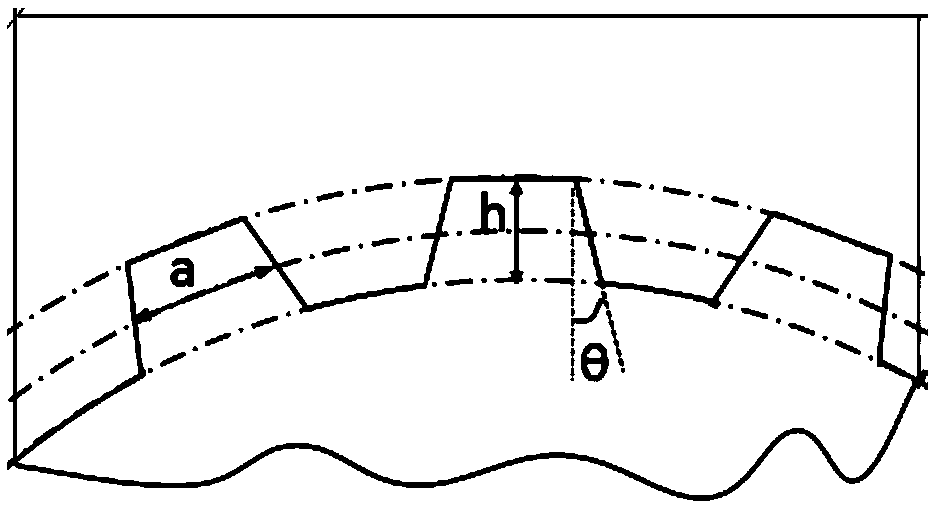

Method of cleaning greenhouse roofs

InactiveUS20060118136A1Avoid damageReduce light transmissionLiquid processingCarpet cleanersGreenhouseCivil engineering

The invention provides a method of cleaning greenhouse roofs mechanically to remove the accumulation of dust and grit. The method comprises at least one dust cleaning device moving over a soft roof The cleaning device is controlled to follow the irregular surface of the soft roof with limited pressure to avoid damage. The invention also provides a dust-cleaning system to remove dust and grit from the soft roof.

Owner:MANOR GEDELYAHU

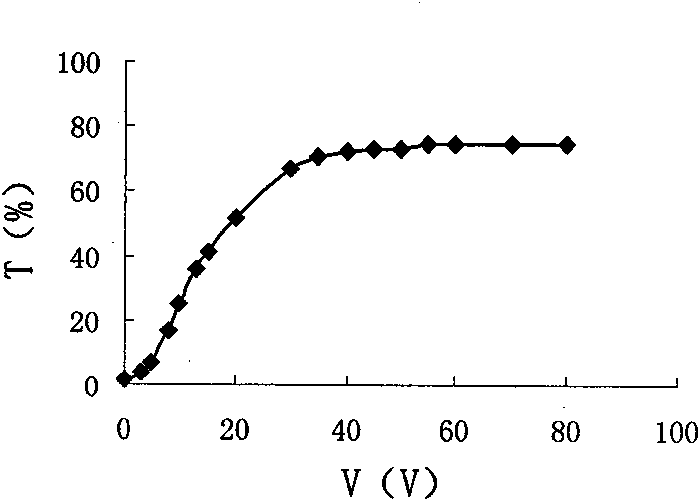

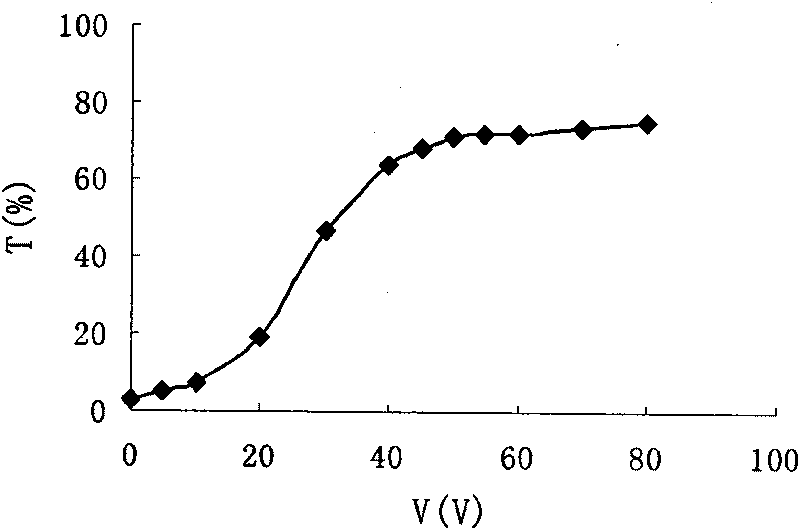

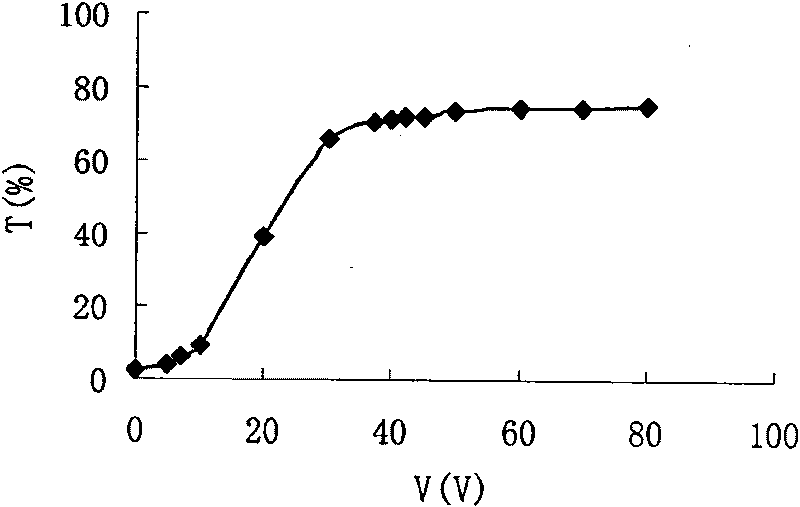

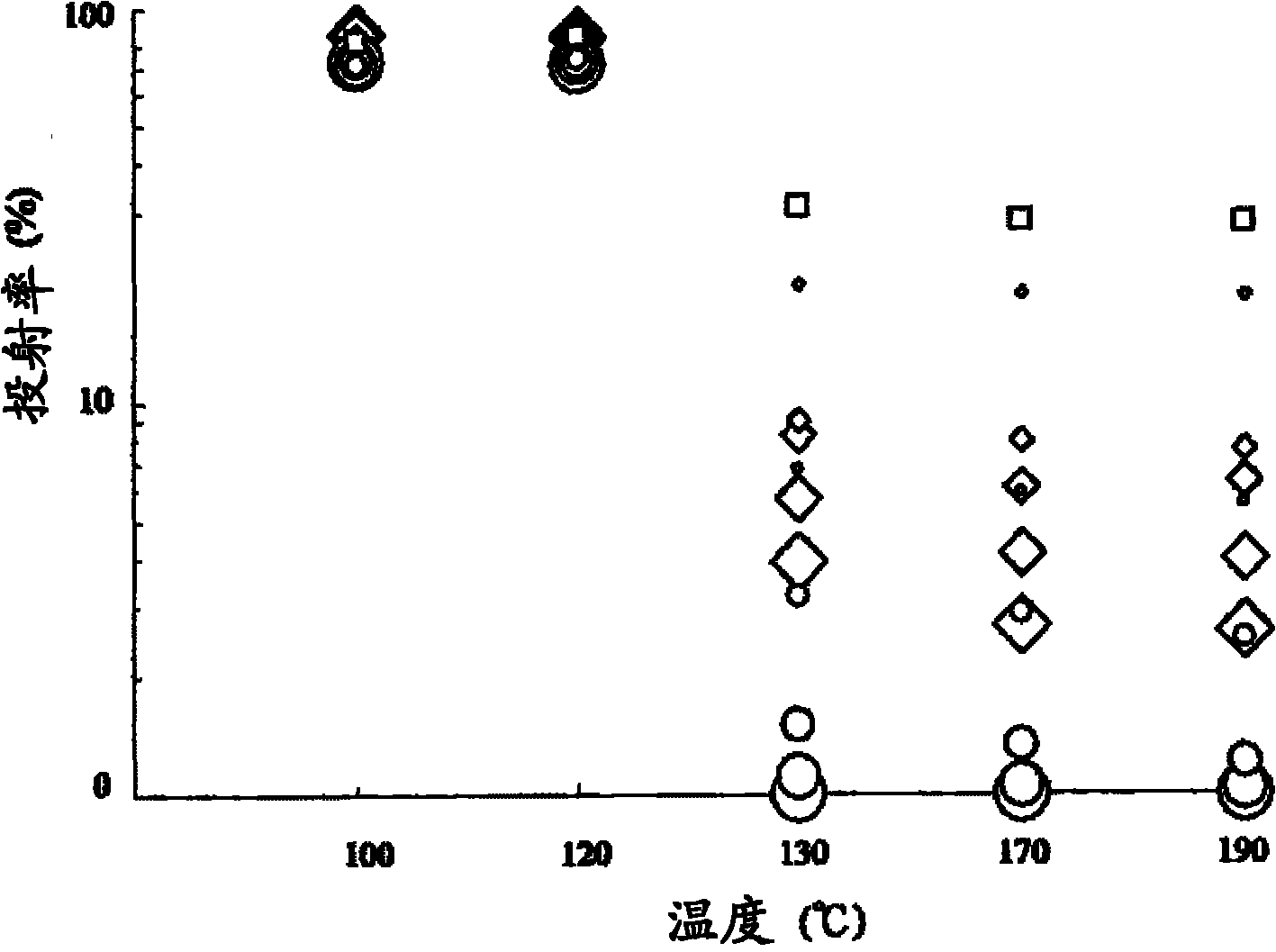

Polymer dispersed liquid crystal material and method for preparing liquid crystal films from same

ActiveCN101717647AReduce the driving voltageIncrease the driving voltageLiquid crystal compositionsNon-linear opticsPolyesterPolymer science

The invention discloses a polymer dispersed liquid crystal material and a method for preparing liquid crystal thin films from the same, which belongs to the technical field of liquid crystal application. Thin films prepared can be widely applied in liquid crystal display, intelligent glass and other related fields. A polymer dispersed liquid crystal composition comprises 20 to 80 parts by weight of polymer monomer, 1 to 10 parts by weight of photoinitiator, 20 to 70 parts by weight of oligomer and 0.1 to 10 parts by weight of polymerization inhibitor, wherein the oligomer is at least one of epoxy acrylate oligomer, urethane acrylate oligomer, polyester acrylate oligomer, polyether acrylate oligomer and unsaturated polyester oligomer, and the polymer monomer is at least one of monofunctional-group (methyl) acrylate monomer, bifunctional-group (methyl) acrylate monomer and high-functional-group acrylate monomer with three or more functional groups. A PDLC thin film prepared from the mixture provided by the invention has high contrast, low driving voltage and good stability.

Owner:青岛诚志光电科技有限公司

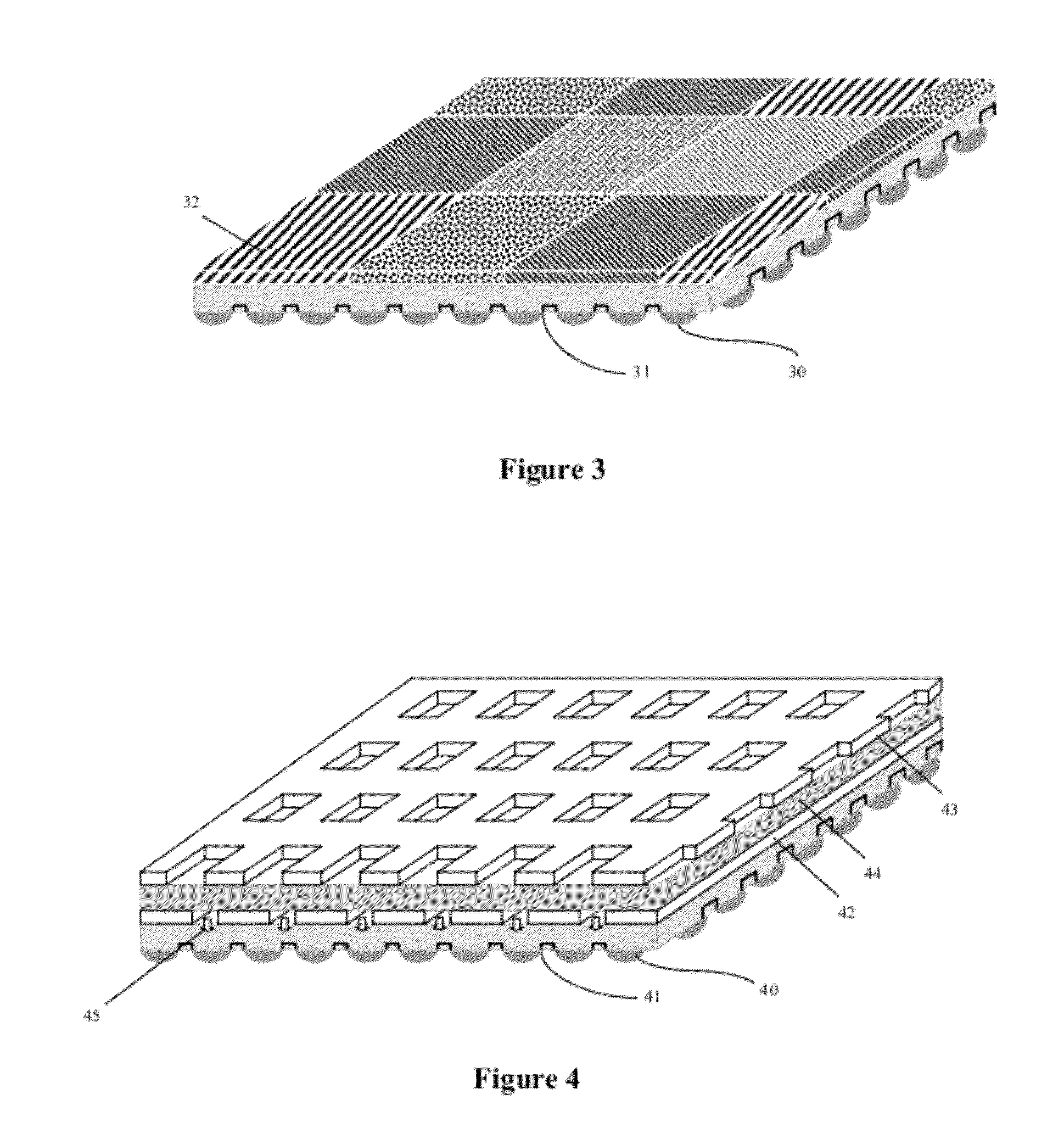

Method for manufacturing transparent thin-film solar cell component

InactiveCN101908582AReduce light transmissionGood light transmissionFinal product manufactureSemiconductor devicesTransmittanceTransparent conducting film

The invention discloses a method for manufacturing a transparent thin-film solar cell component. The method comprises a process of manufacturing a transparent substrate, a first electrode layer, a photoelectric translating cell area and a back electrode layer and is characterized in that the back electrode layer is made from a high-permeability and high-conductivity transparent conducting film, wherein the conducting film consists of a first layer of transparent conducting sull, a metal film and a second layer of transparent conducting sull, which are sequentially deposited on the photoelectric translating cell area. The thickness of the metal film is only 5 to 30nm, so the metal film has good light transmittance. Compared with the prior art, the method has the advantages of simple manufacturing process, low cost of raw materials and good light transmittance, is suitable for mass production and has very wide market prospect.

Owner:通用光伏能源(烟台)有限公司

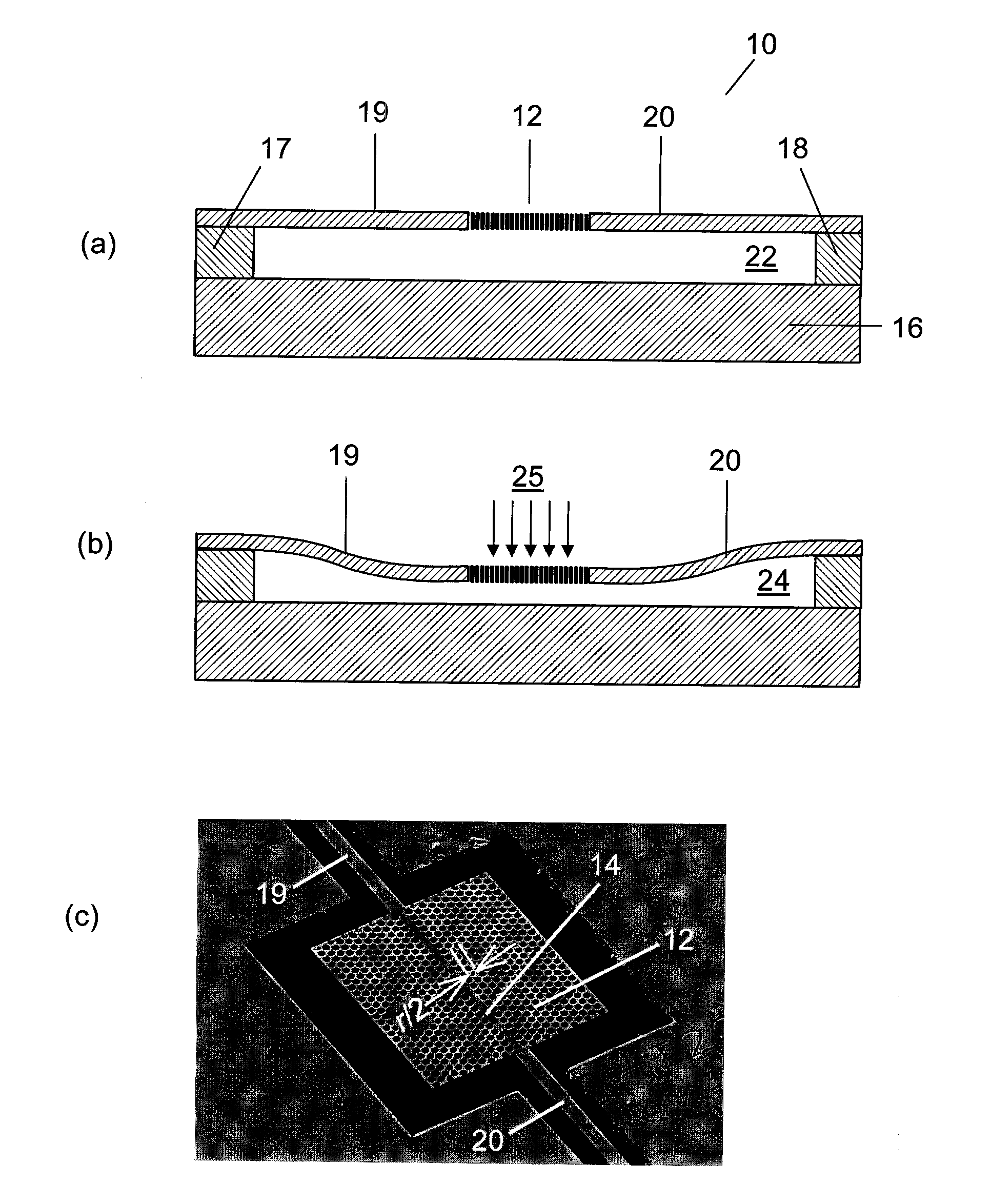

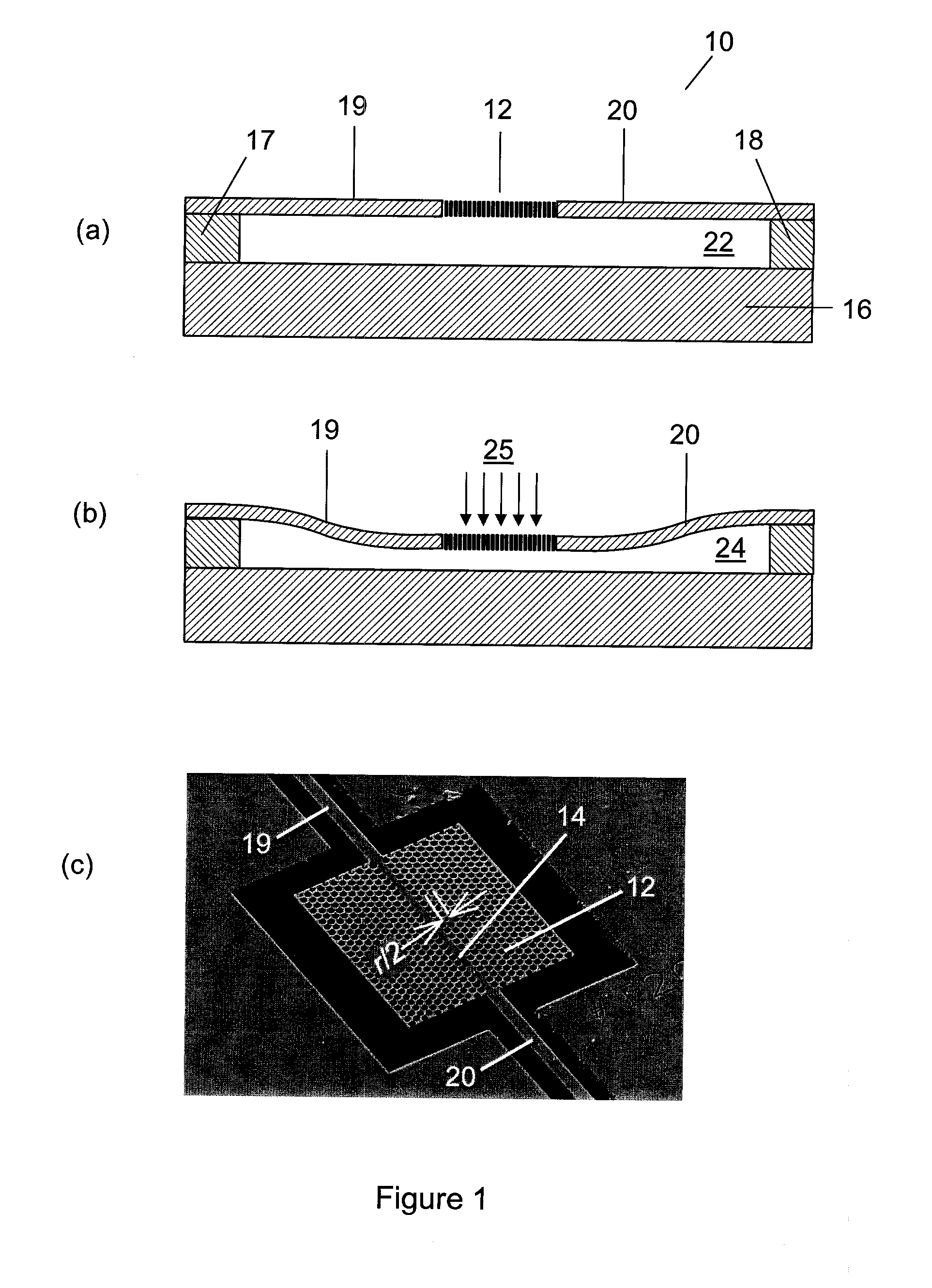

Photonic crystal pressure sensor

InactiveUS20120096956A1Reduce light transmissionIncrease evanescent couplingFluid pressure measurement by electric/magnetic elementsForce measurementPhotonic crystalSmall form factor

The present invention provides a microscale pressure sensor that exhibits high sensitivity in a small form factor. The sensor is a bridged device in which a photonic crystal waveguide, surrounded by a photonic crystal slab, is suspended over a dielectric substrate. Under applied pressure, the photonic crystal waveguide is deflected toward the substrate, causing a decrease in optical transmission across the waveguide due to the coupling of the evanescent field of the guided mode to the dielectric substrate. In a preferred embodiment, the waveguide is coupled to a photonic crystal microcavity, which increases evanescent coupling.

Owner:UNIV OF WESTERN ONTARIO

Anti-fogging preservative film

ActiveCN102675722AAvoid water dropletsReduce bond strengthFlexible coversWrappersLinear low-density polyethyleneAdditive ingredient

The invention discloses an anti-fogging preservative film, which can be in a single-layer structure and is mixed by the following ingredients in percentage by weight: 0.2-3% of anti-fogging agent, 42-99.6% of LLDPE (Linear low density polyethylene), 0-50% of MLLDPE (Metallocene linear low density polyethylene) and 0.2-5% of tackifier. The anti-fogging preservative film also can be in an A / B type double-layer structure and is composed of 10% of layer A and 90% of layer B in percentage by weight, or is composed of 20% of layer A and 80% of layer B, or is composed of 30% of layer A and 70% of layer B. The anti-fogging preservative film also can be in an A / B / C three-layer structure and is composed of 10% of layer A, 80% of layer B and 10% of layer C in parentage by weight, or is composed of 20% of layer A, 60% of layer B and 20% of layer C or is composed of 30% of layer A, 40% of layer B and 30% of layer C. No matter the anti-fogging preservative film is in the single-layer structure, the double-layer structure and the three-layer coextrusion structure, the preservative film has an anti-fogging effect because the antifogging agent is added into the raw material so as to avoid generating fog on the surface of the preservative film, which is convenient for consumers to clearly see the preserved commodity.

Owner:XIAMEN JUFU PLASTIC PRODS

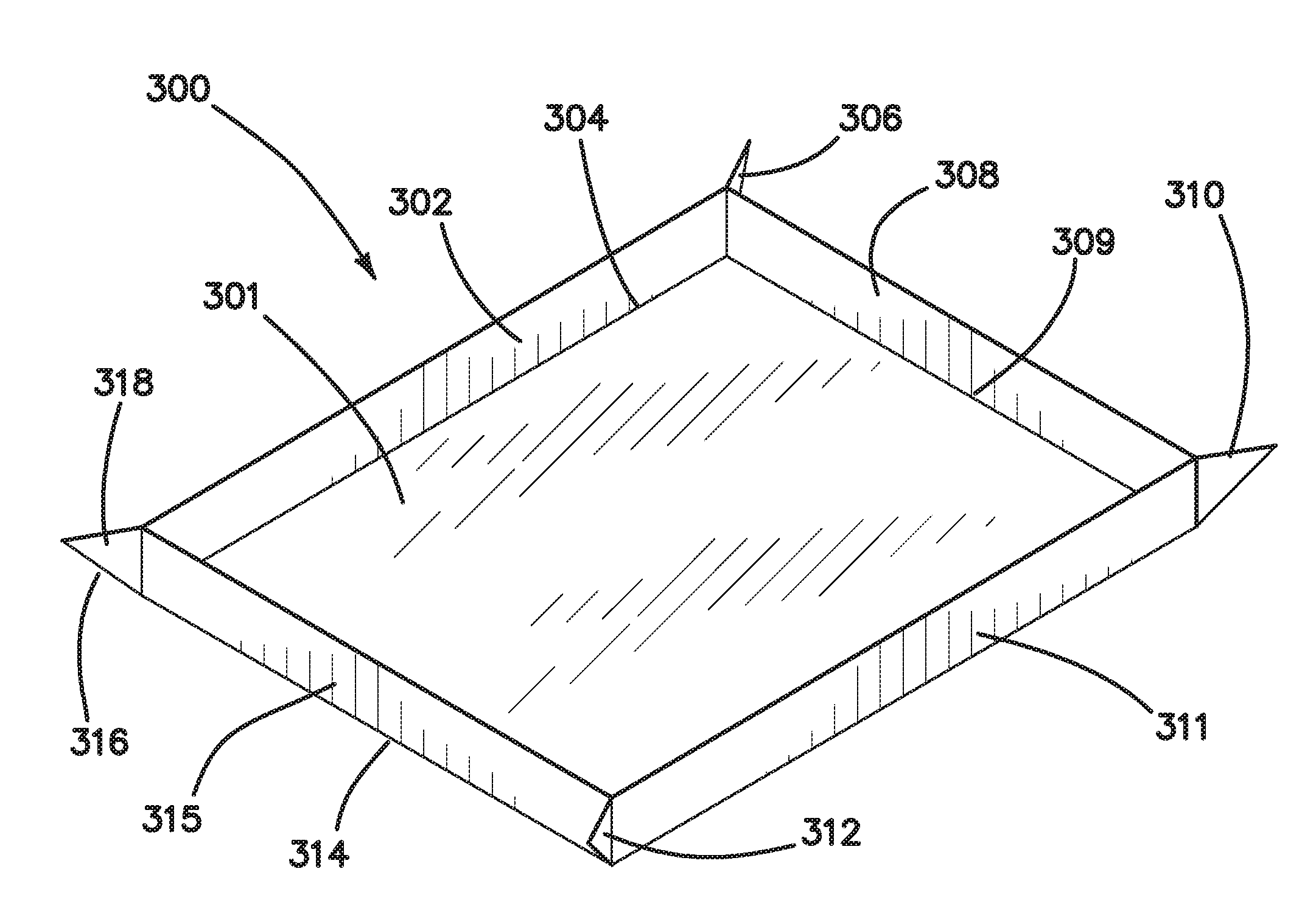

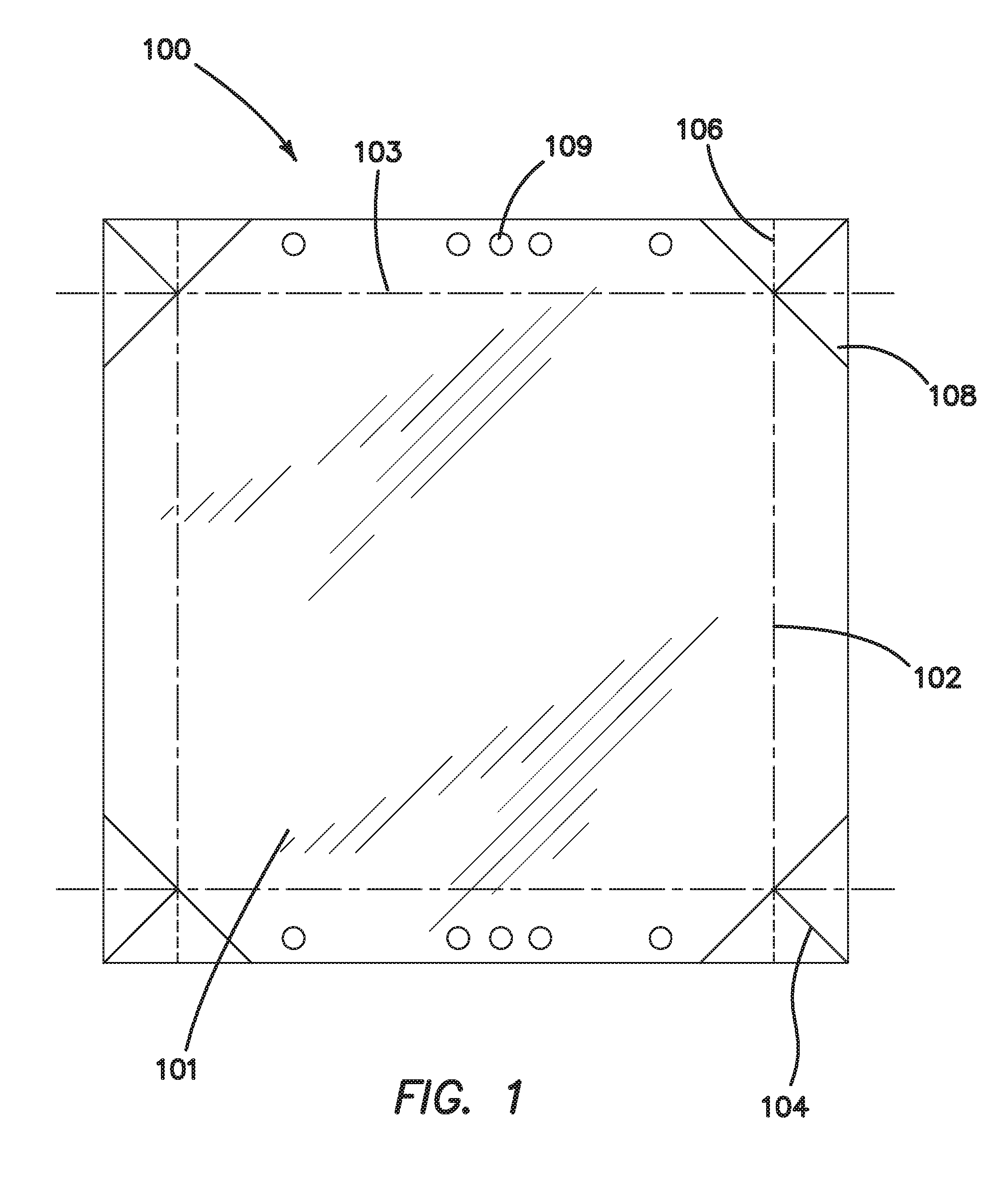

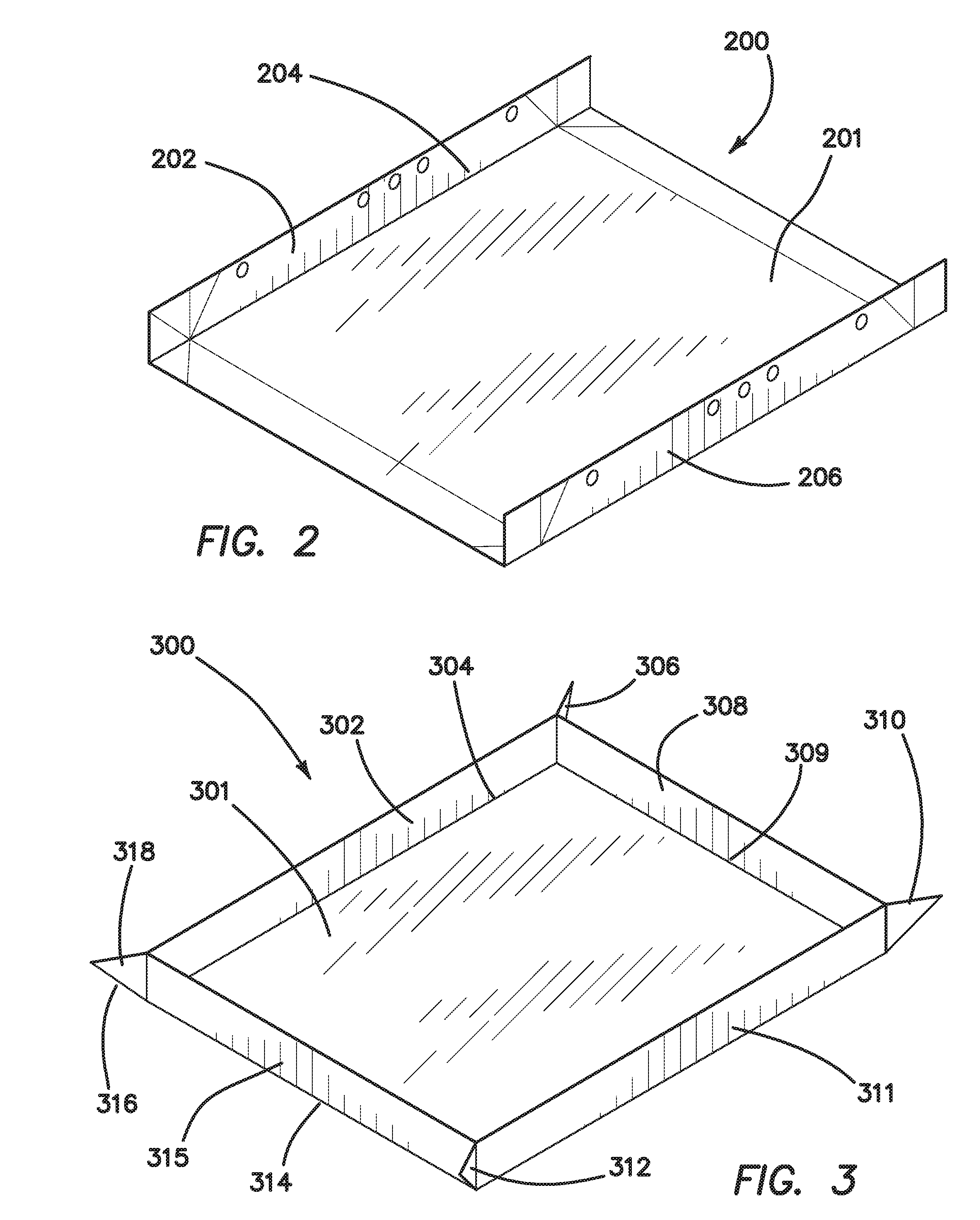

Release liner/layer, system and method of using the same with additive manufacturing

InactiveUS20160176112A1Easy to removeEasy to replaceManufacturing platforms/substratesLayered productsPolyolefinThermoforming

Release liner forming structures and methods of making and using the same. The methods of making the release liner include thermoforming and sheet bending. The flexible release liner may be used in conjunction with a rigid, transparent supporting surface. The release liner may be developed from a flexible sheet formed into a deformable resin fluid vat. A release layer, and additional structure if desired, can be formed of or include plastic, such as polyolefin or fluoropolymer. In some instances, the polyolefin is, or includes, polymethylpentene or a fluropolymer is fluorinated ethylene propylene. The optical and other properties of the release layer can be altered with treatments and other materials to, for example, reduce over-penetration of a light beam or deform a release layer.

Owner:FULL SPECTRUM LASER

Corneal crosslinking methodology using custom etched contact lenses

InactiveUS20120065572A1Rigidity is increased and stabilizedReduce areaElectrotherapyEye treatmentMedicineUltraviolet

An improved methodology for the treatment of corneal abnormalities involving the application of a crosslinking solution, such as riboflavin, to the surface of the cornea followed by exposure to UV light such that the rigidity of the cornea is increased and stabilized, the method improved by providing a transparent contact lens that is selectively etched to create areas on the lens that either preclude or reduce penetration of UV light, thereby eliminating or reducing crosslinking for areas of the cornea that do not require stabilization while allowing penetration of UV light to areas of the cornea that do require stabilization.

Owner:LEWIS SCOTT E +3

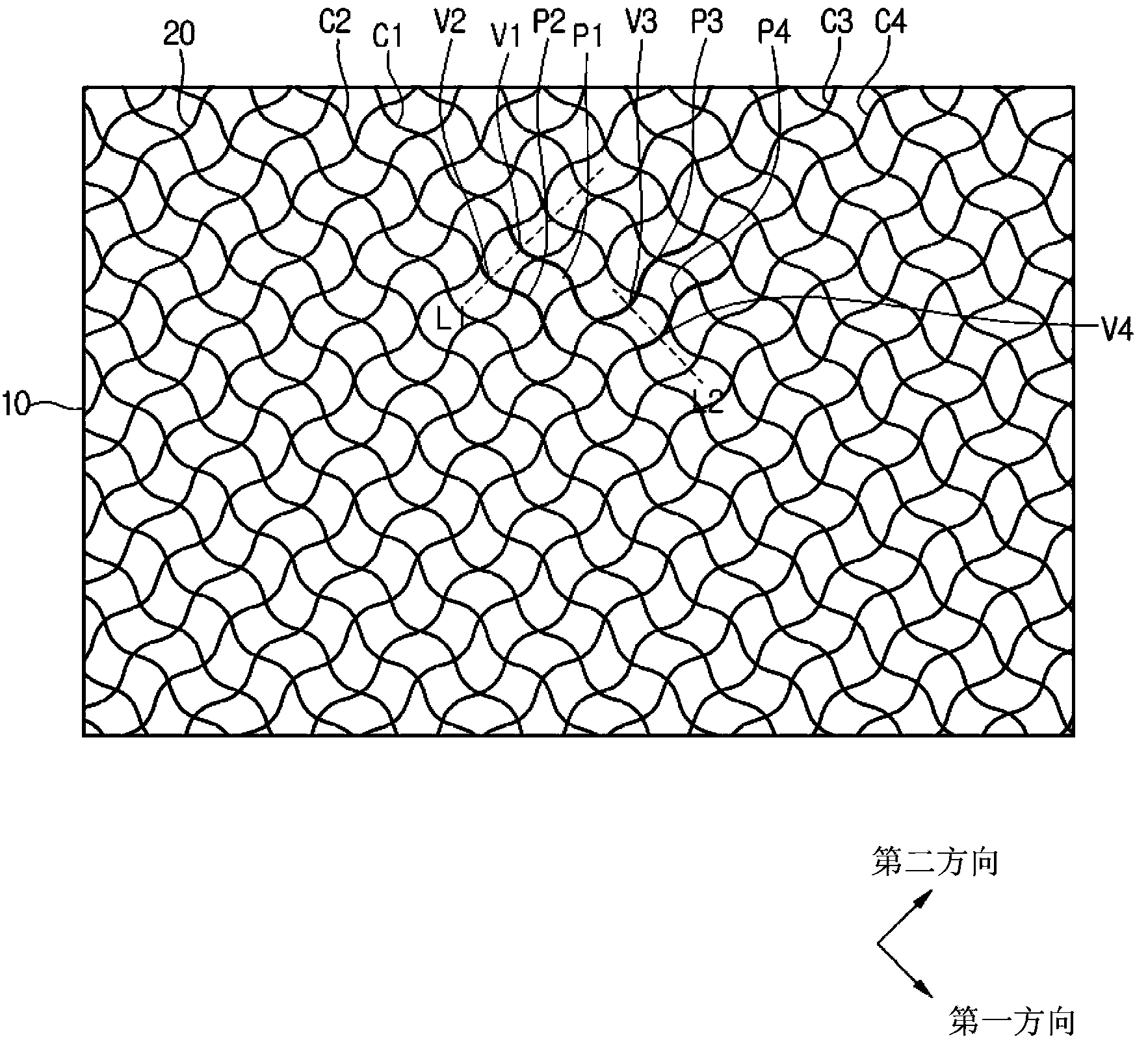

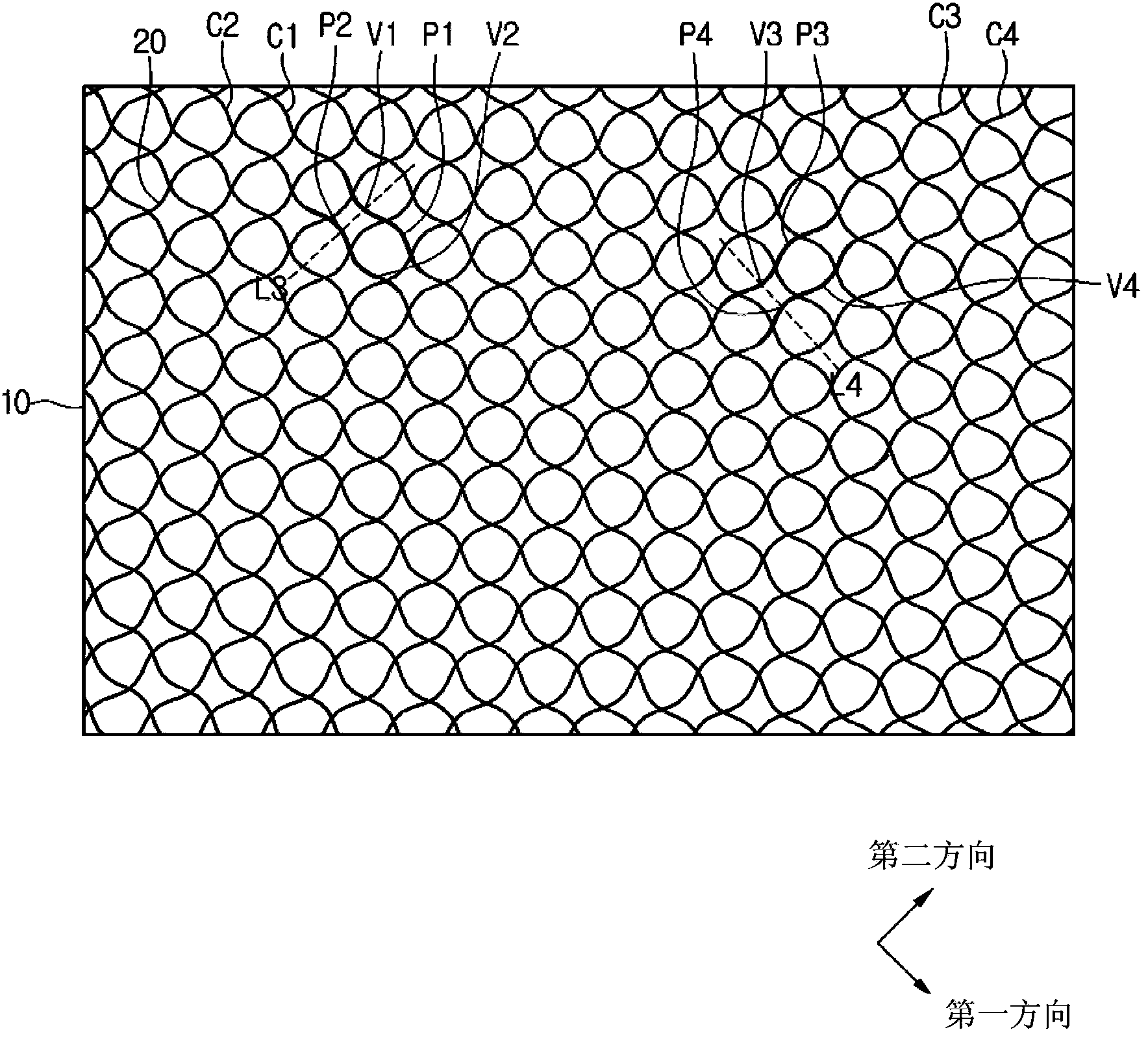

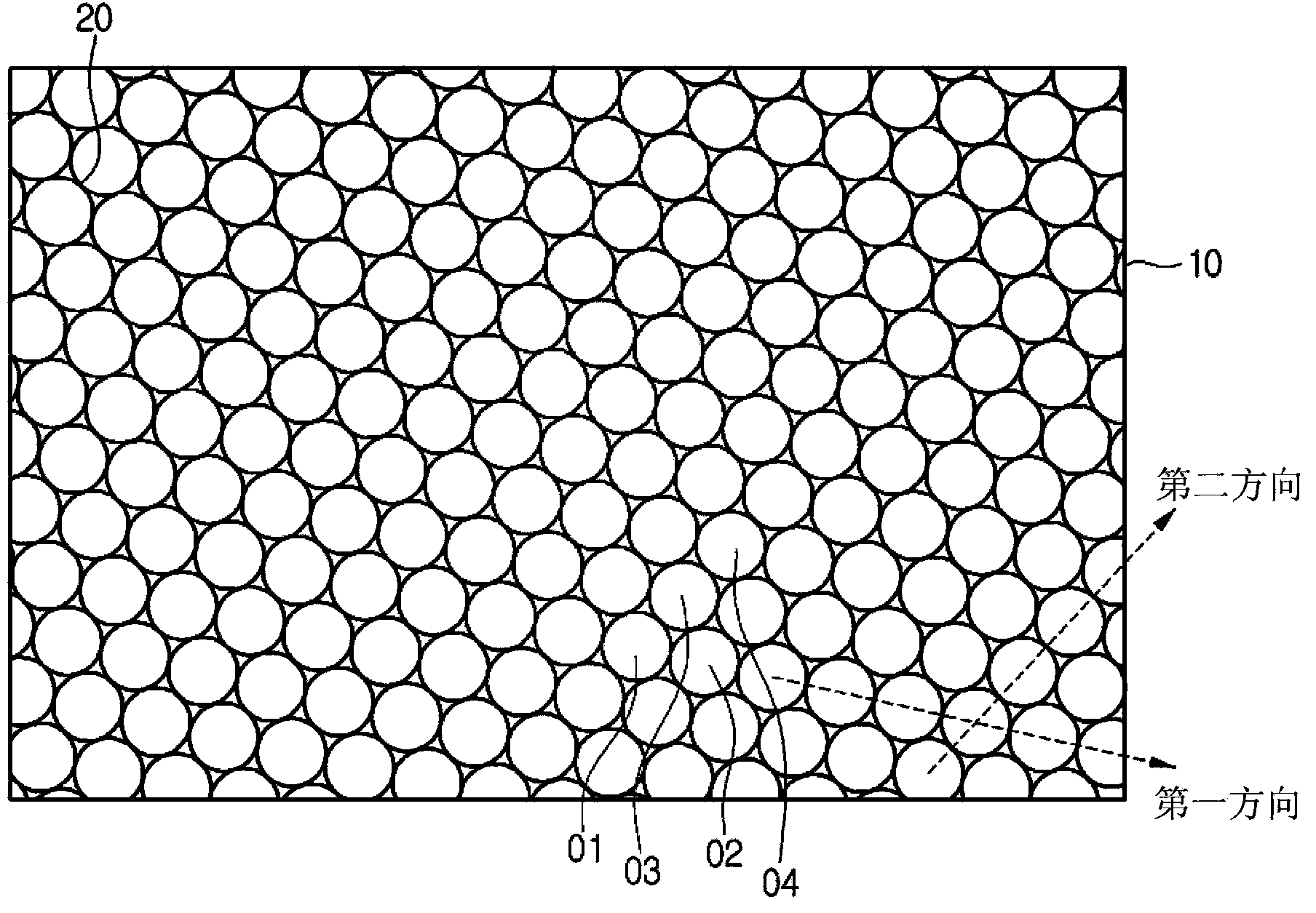

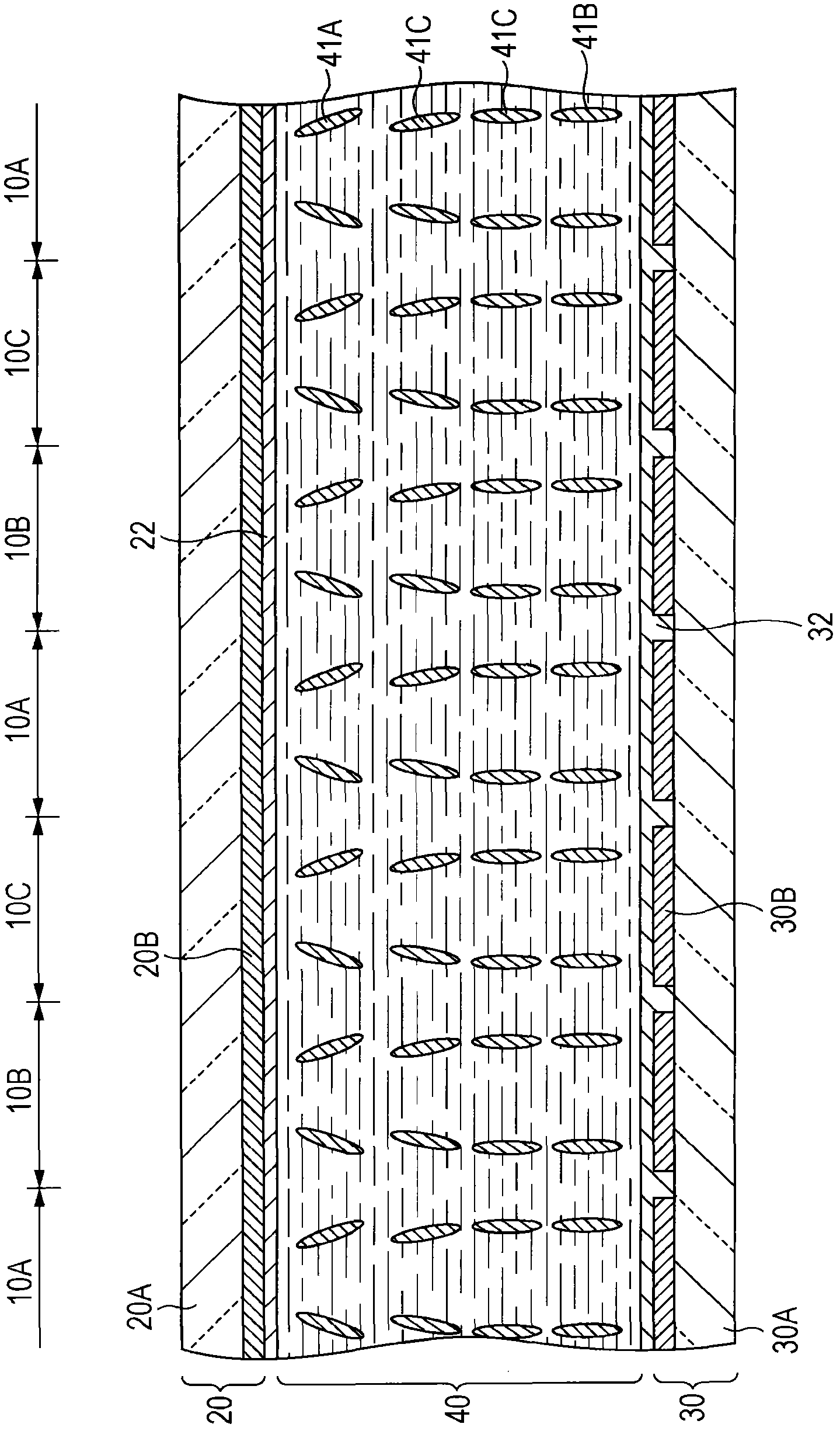

Electrode member and touch screen including the same

ActiveCN103389843APrevent Moire phenomenonMoire phenomenon overcomePrinted circuitsInput/output processes for data processingEngineeringMesh grid

Owner:LG INNOTEK CO LTD

Master batch composition, compound board and preparation method of compound board, and refrigeration plant

InactiveCN103113703AReduce light transmissionImprove anti-photooxidative aging functionPolyolefinEngineering

The invention discloses a master batch composition, a compound board and a preparation method of the compound board, and a refrigeration plant. The master batch composition comprises 20-40 parts by weight of a matrix resin which is selected from HIPS (High Impact Polystyrene), 30-50 parts by weight of a flexibilizer which is selected from at least one of SBS (Styrene-Butadiene-Styrene), butadiene styrene rubber, naphthenic oil, PE-g-PS (Polythene-g-Polystyrene), POE-g-PS (Polyolefin-g-Polystyrene), EPDM-g-PS (Ethylene-Propylene-Diene Monomer-g-Polystyrene), 3-20 parts by weight of pigment, 0-10 parts by weight of a brightener, 0-3 parts by weight of an anti-light and oxygen ageing agent and 5-20 parts by weight of an antistatic agent. Thus, the master batch composition can effectively prepare a liner and can further increase the strength of the surface of the liner, increase the anti-cracking ability and particularly the resistance to chemical corrosions such as oils, cleaning agents and the like, increase the weather resistance and the surface gloss and increase the antistatic and dirt-proof functions, so that the liner is easier to clean.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

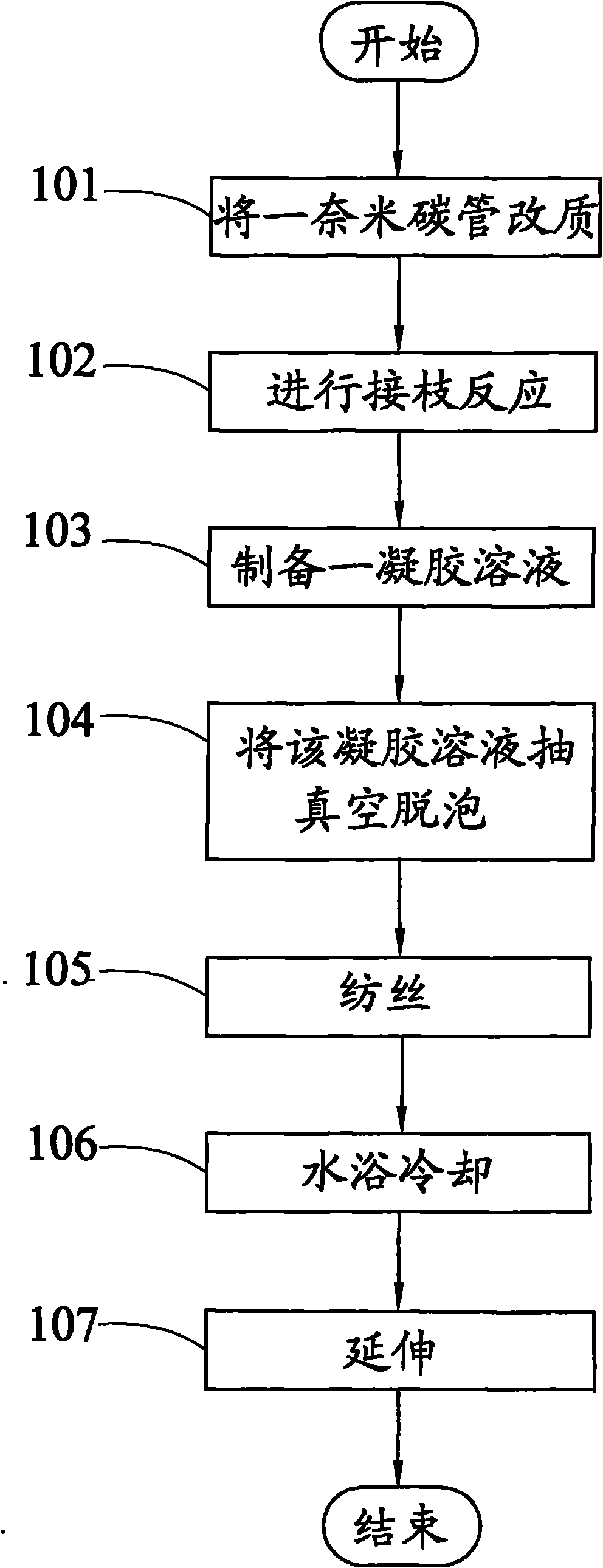

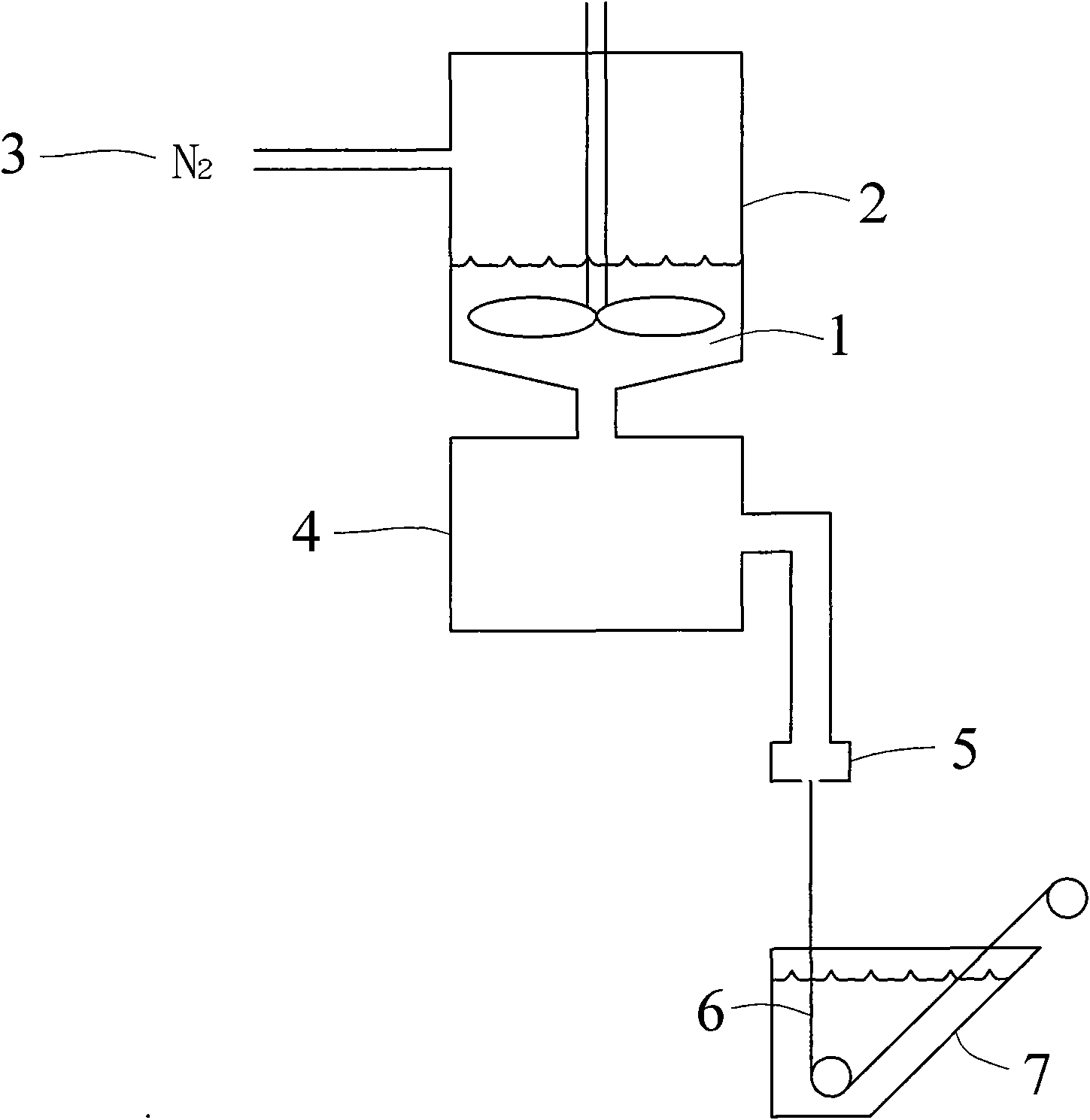

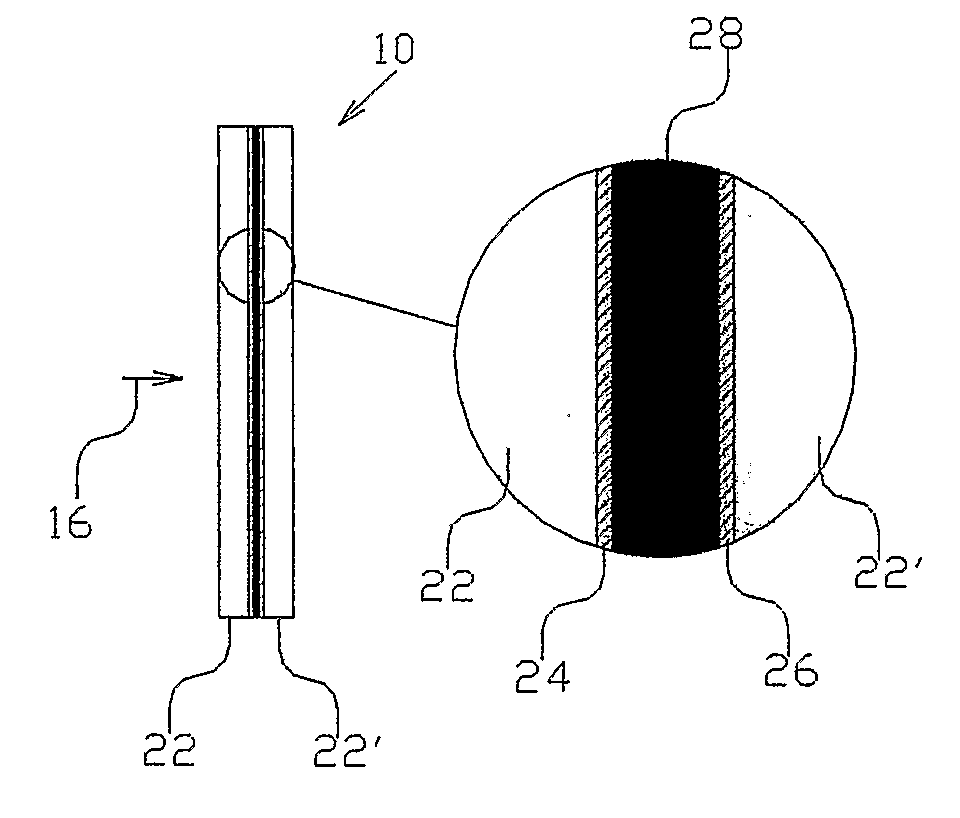

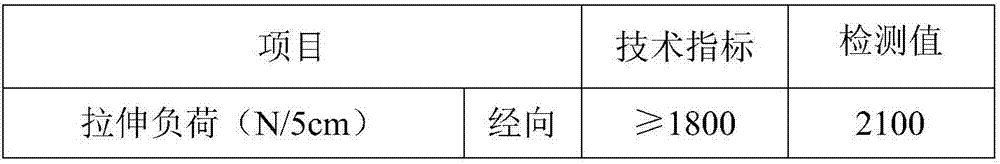

Ultra-high molecular weight polyethylene (UHMPE) and nano-inorganic substance composite material and manufacturing method of high-performance fiber thereof

InactiveCN101988221AHigh fiber strengthLess frizzMelt spinning methodsMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses an ultra-high molecular weight polyethylene (UHMPE) and nano-inorganic substance composite material and a manufacturing method of high-performance fiber thereof, belonging to the field of a composite material.The manufacturing method of the composite material comprises the following steps: preparing UHMPE and a nano-inorganic substance, such as attapulgite, a carbon nanotube, sepiolite, wollastonite, montmorillonite and the like into gel solution; in the case of light transmittance close to zero under certain concentration, heating the gel solution for dissolving; and vacuumizing, defoaming, spinning with different spinneret boards containing various spinneret angles as well as feed length and discharge length, carrying out air-quenching, carrying out aqueous-phase curing, performing multi-segment temperature change extension and the like to finally obtain the composite material for the ultra-high strength fiber the light transmittance of which is close to zero. The obtained composite material can increase the strength and modulus of UHMPE fiber and solve the defects of the UHMPE fiber, such as high crimp, high creep, light transmittance and the like.

Owner:叶正涛 +1

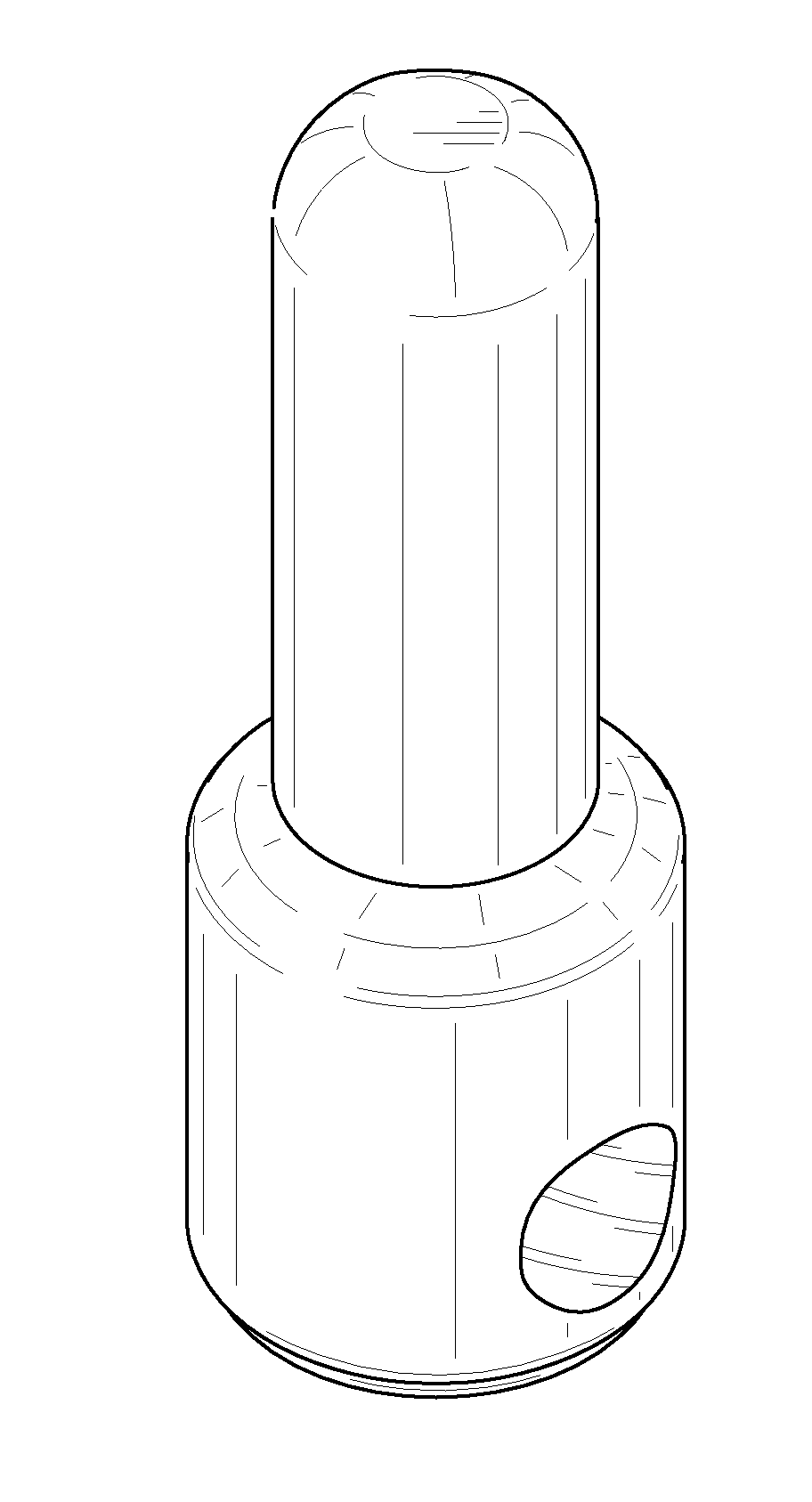

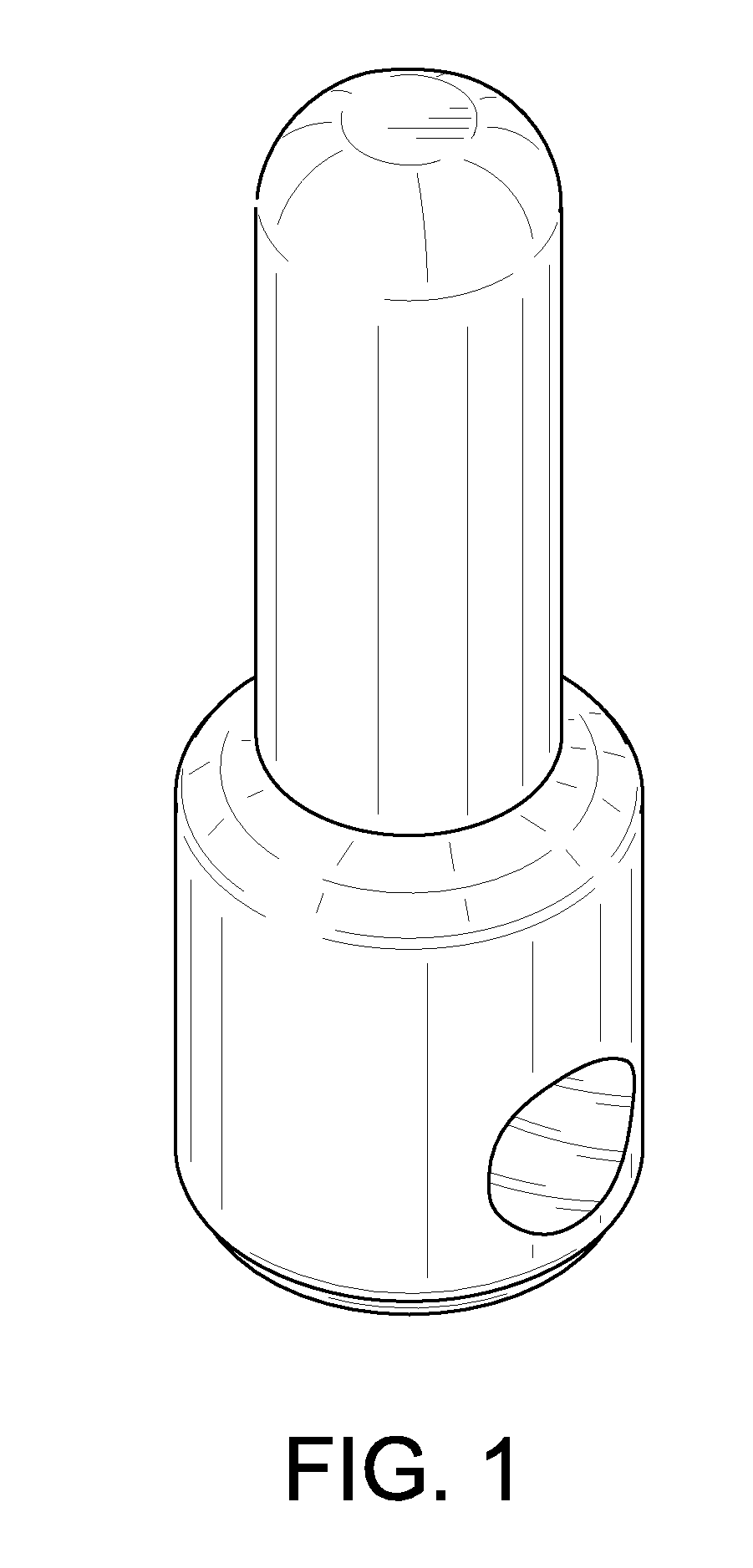

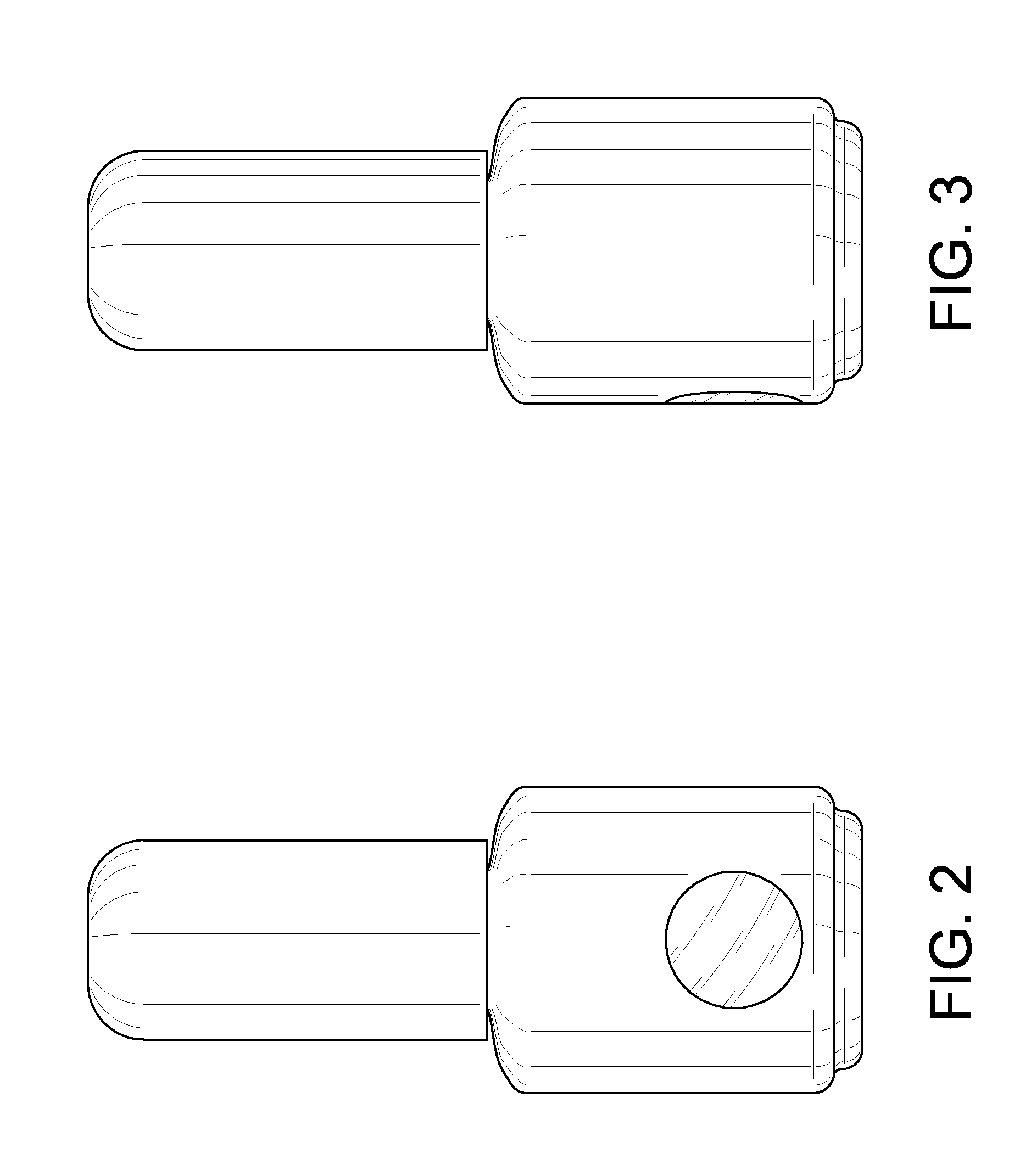

Package for colored products

ActiveUS20110120907A1Reduce light transmittanceSensitive to lightClosure with auxillary devicesOther accessoriesEngineeringBottle

Disclosed are packages including transparent containers such as bottles and jars comprising a coating that reduces transmission of light through the container. The containers further comprise a product viewing area or window through which the product is visible to a consumer or purchaser. The containers are disclosed as being useful for protecting photo-sensitive products while allowing the color of those products to be displayed to the user.

Owner:NAIL ALLIANCE

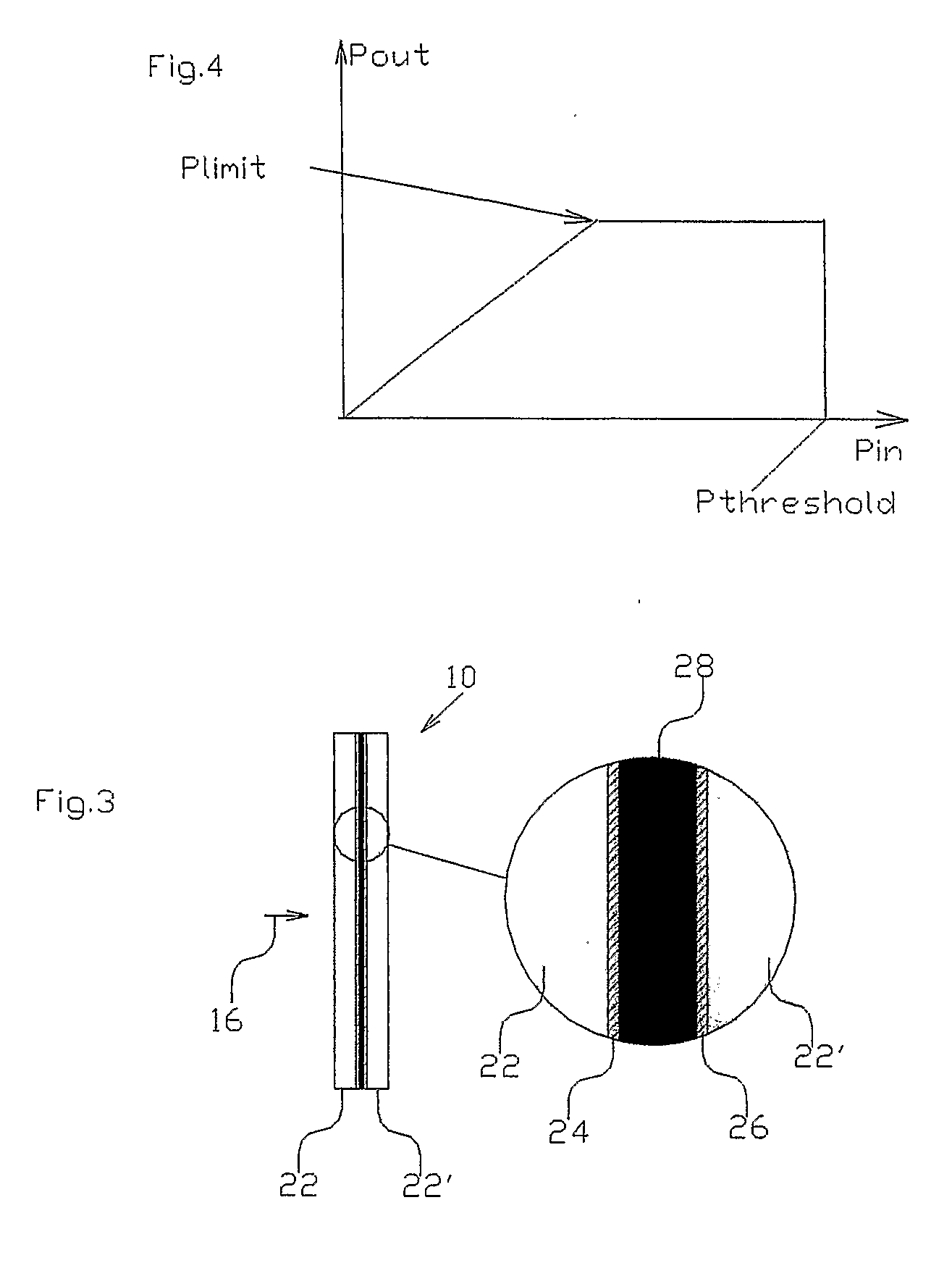

Optical power limiting and switching combined device and a method for protecting imaging and non-imaging sensors

InactiveUS20090207478A1Enhance electric field strengthReduce light transmissionOptical devices for laserNon-linear opticsOptical powerPower level

An optical power limiting and switching device comprises at least one plate made of transparent dielectric material, and a thin limiting solid mixture coated on one side of the plate. Upon being exposed to an optical power beam having a power level exceeding a predetermined limit power, the layer of solid mixture limits the power transmission by scattering out part of the impinging energy. When the power increases to the damage threshold, the solid mixture forms a plasma or catastrophic breakdown, damaging the solid mixture material and thereby rendering the portion of the plate surface under the impinging beam opaque to light.

Owner:KILOLAMBDA TECH

Photoluminescent wafer as well as preparation method and application thereof

InactiveCN102140690ALattice integrityReduce surface recombinationPolycrystalline material growthSolid-state devicesRare-earth elementWafering

The invention relates to the manufacturing field of light emitting diodes (LED), in particular to a photoluminescent wafer for the LED as well as preparation method and application thereof. The photoluminescent wafer is a slice-shaped crystal in a garnet structure with a general formula of A3B5O12 without doping any resins and other bonding agents, the thickness of the photoluminescent wafer is not less than 20 um, and the size of the crystal particle is not less than 10 um; moreover, the photoluminescent wafer comprises a first element A, a second element B and an active element, wherein thefirst element A is at least one of rare-earth elements Y, Lu, La, Gd or Sm; the second element B is at least one of the elements Al, Ga or In; and the active element is at least one of the rare-earthelements Ce, Pr, Tb and Dy. The photoluminescent wafer has the characteristics of high light emitting efficiency and good light emitting uniformity; the light transmission of the light emitting layercan not be reduced by light adsorption of the bonding agent; and the surface of the photoluminescent wafer is easy for people to carry out various optical treatments.

Owner:ZHEJIANG SHENDU LIGHTING

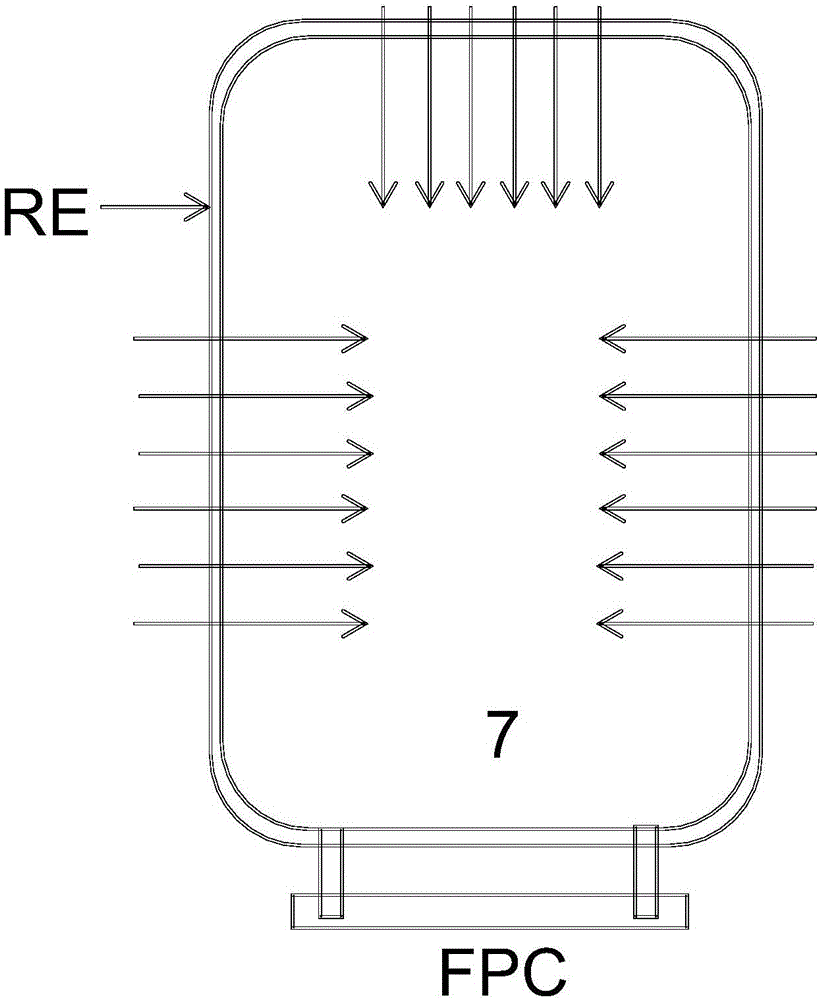

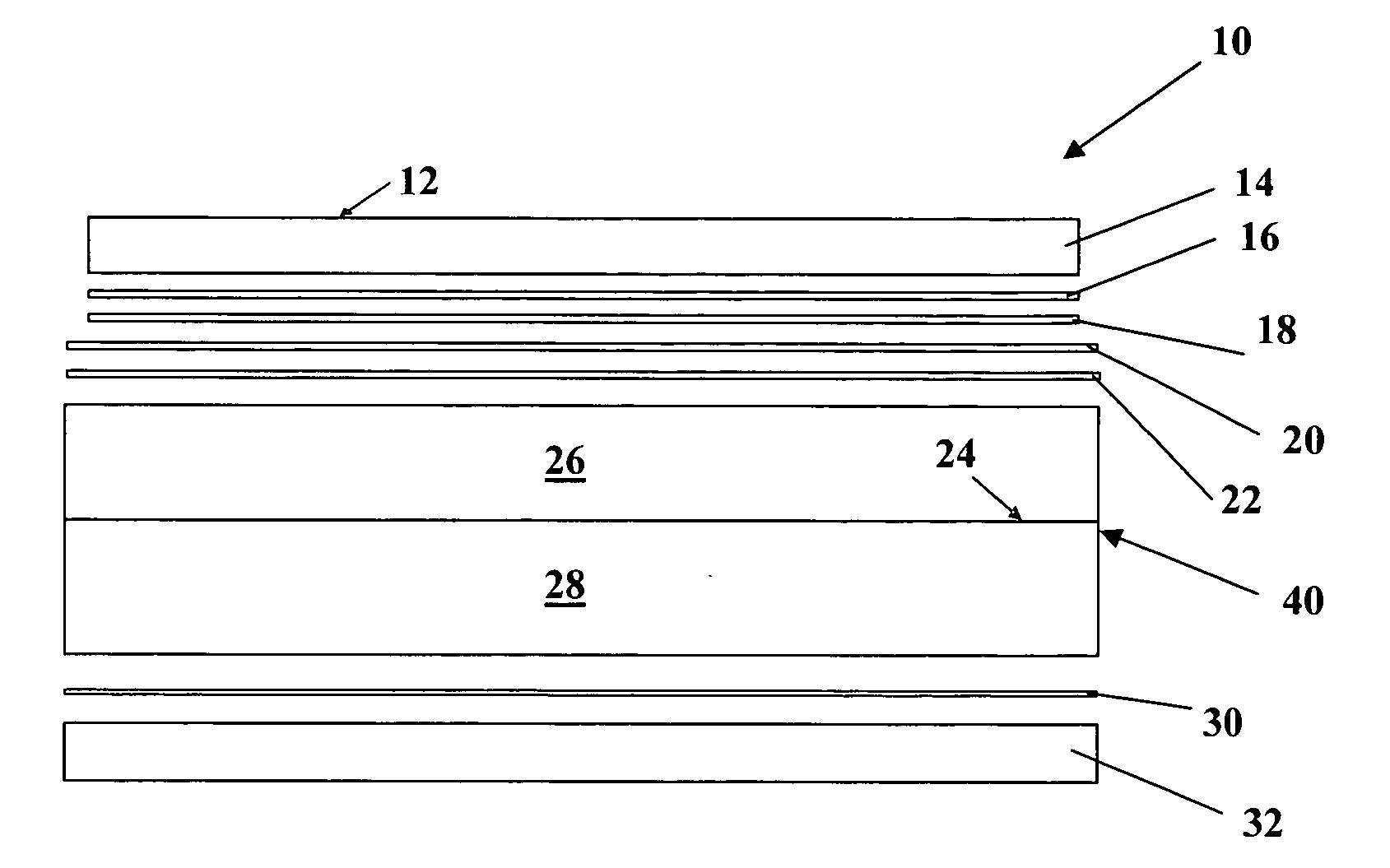

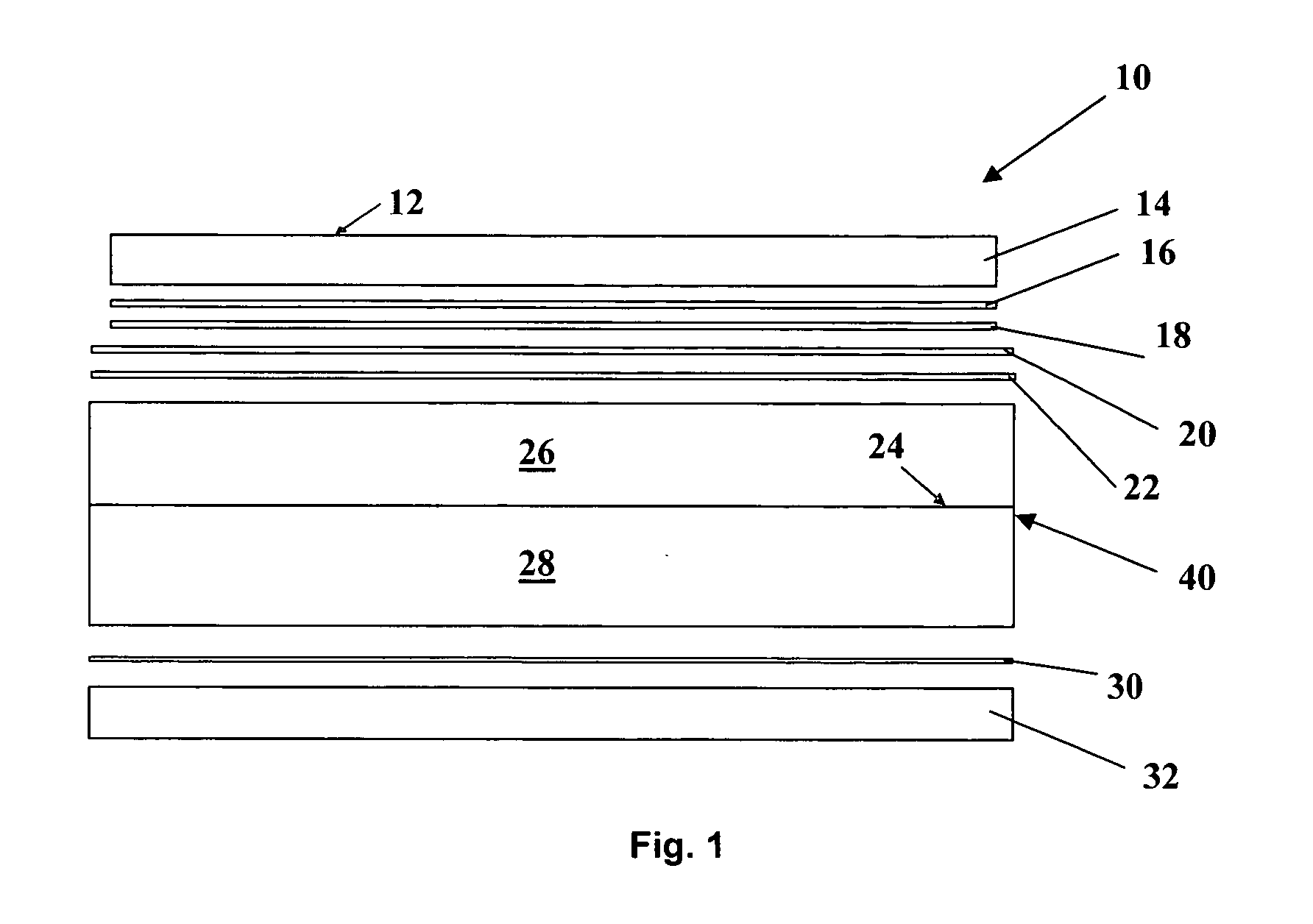

Flat panel display with external integral heater

ActiveUS20080291386A1Weight increaseReduce light transmissionNon-linear opticsLiquid-crystal displayIndium tin oxide

A flat panel display has an optically-transparent electrically-conductive layer, especially an indium tin oxide layer, directly formed on an outer front surface of a liquid crystal display (LCD) assembly having a front plate, a rear plate, and a layer of liquid crystal material interposed between said front and rear plates. The optically-transparent electrically-conductive layer is preferably uniform and functions as an integral heater when connected to a direct current power source.

Owner:AMERICAN PANEL CORP INC

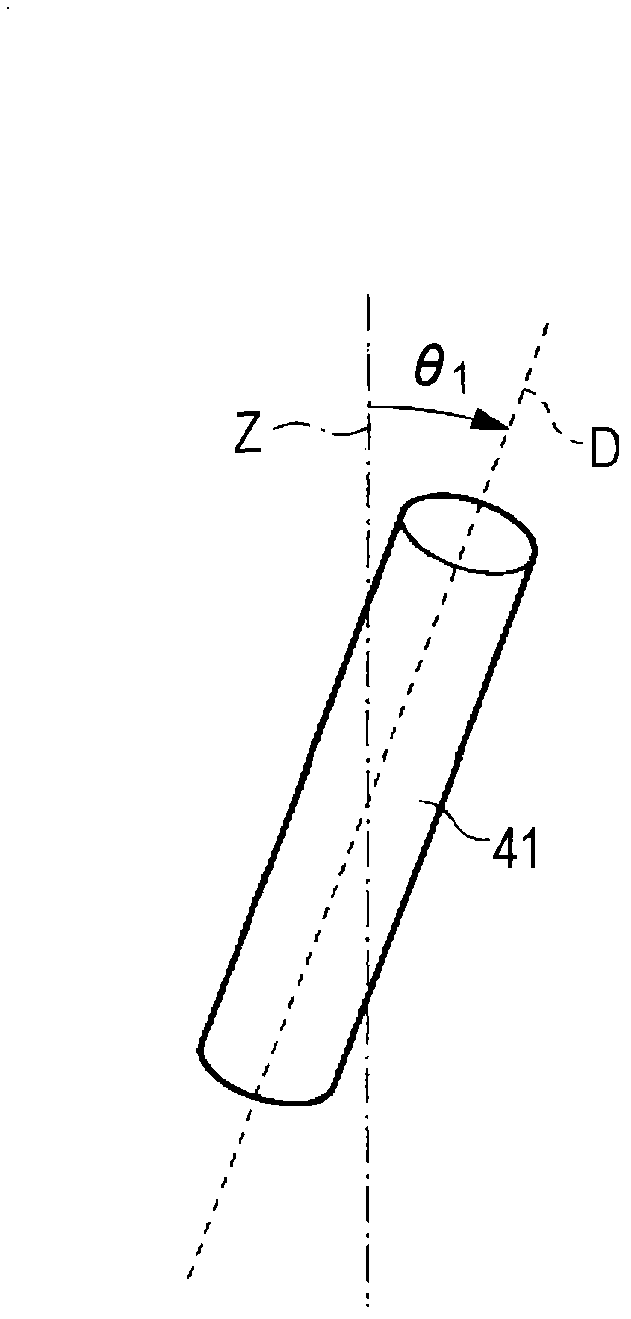

Liquid crystal display device and manufacturing method thereof

ActiveCN102650767AFavorable display characteristicsQuick responseAdhesivesNon-linear opticsCross-linkSide chain

A liquid crystal display device includes a liquid crystal display element including a first alignment film and a second alignment film and a liquid crystal layer that is provided between the first alignment film and the second alignment film, wherein the first alignment film includes a compound in which a polymer compound that includes a cross-linked functional group or a polymerized functional group as a side chain is cross-linked or polymerized, the second alignment film includes the same compound as the compound that configures the first alignment film, and the formation and processing of the second alignment film is different from the formation and processing of the first alignment film and when a pretilt angle of the liquid crystal molecules which is conferred by the first alignment film is [theta]1 and a pretilt angle of the liquid crystal molecules which is conferred by the second alignment film is [theta]2, [theta]1>[theta]2.

Owner:SONY CORP

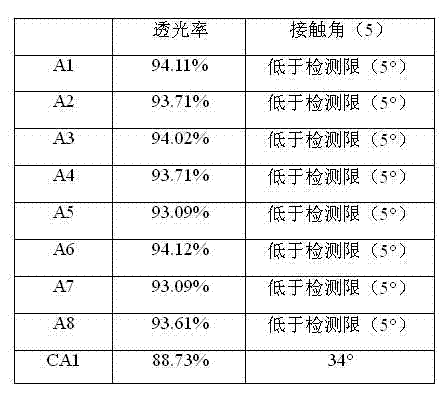

Composite film, its preparation method and composite material

ActiveCN102898035AImprove self-cleaning abilityImprove anti-reflection effectComposite filmTransmittance

The invention provides a composite film containing titanium dioxide and silicon dioxide, wherein the titanium dioxide is nitrogen doped titanium dioxide. In terms of the total mole number of the film, the titanium dioxide accounts for 9.8-49.8 mole percent, the silicon dioxide accounts for 44.8-88.2 mole percent, and the nitrogen element accounts for 0.4-2 mole percent. Being spherical, the silicon dioxide has an average particle size of 80-100nm. The invention also provides a preparation method of the thin film and a composite material containing the film. The film provided in the invention has high light transmittance and a strong self-cleaning ability.

Owner:BYD CO LTD

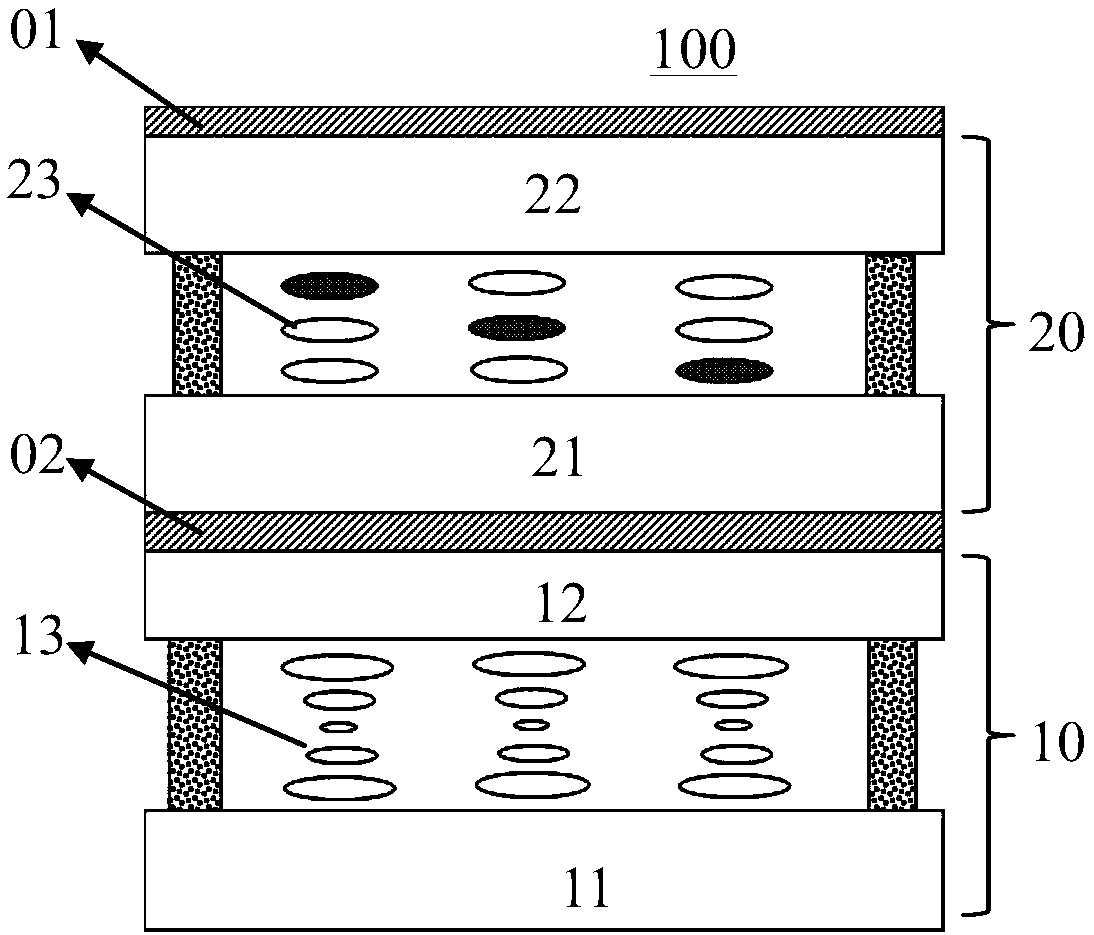

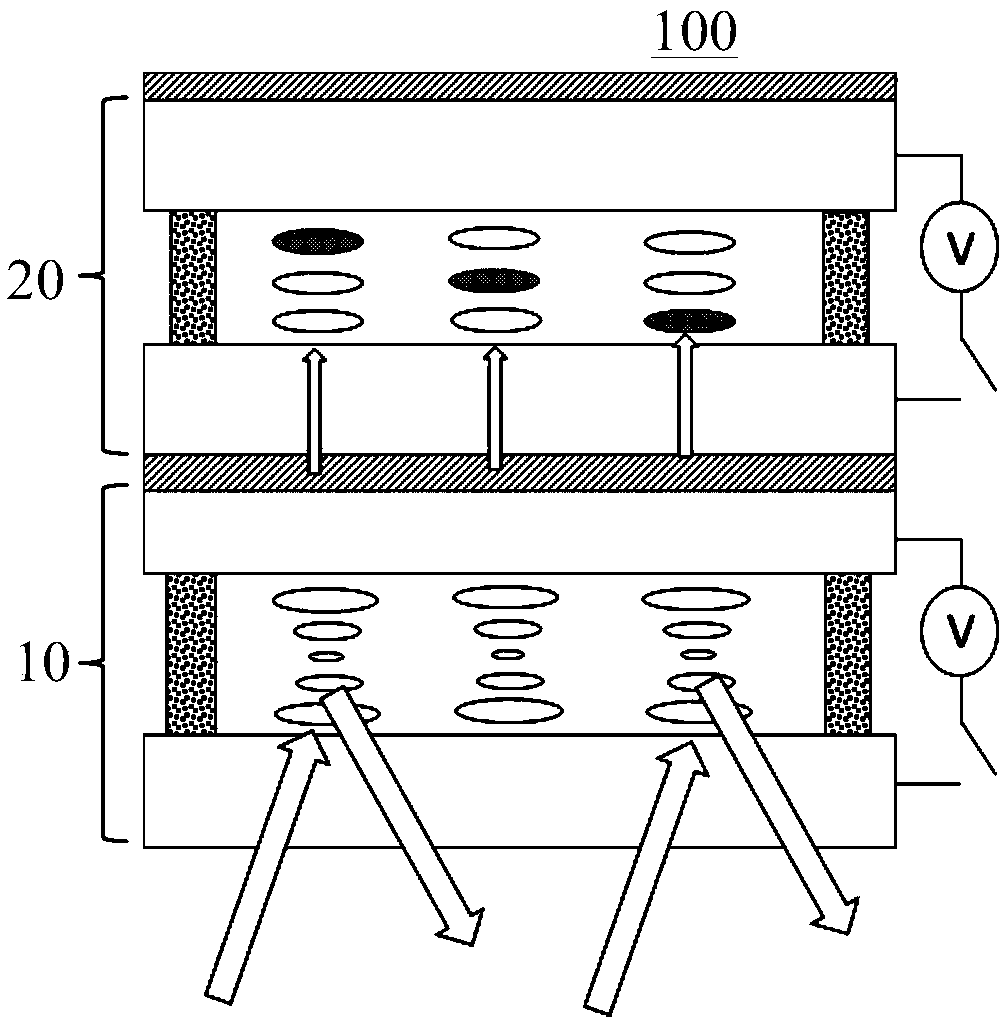

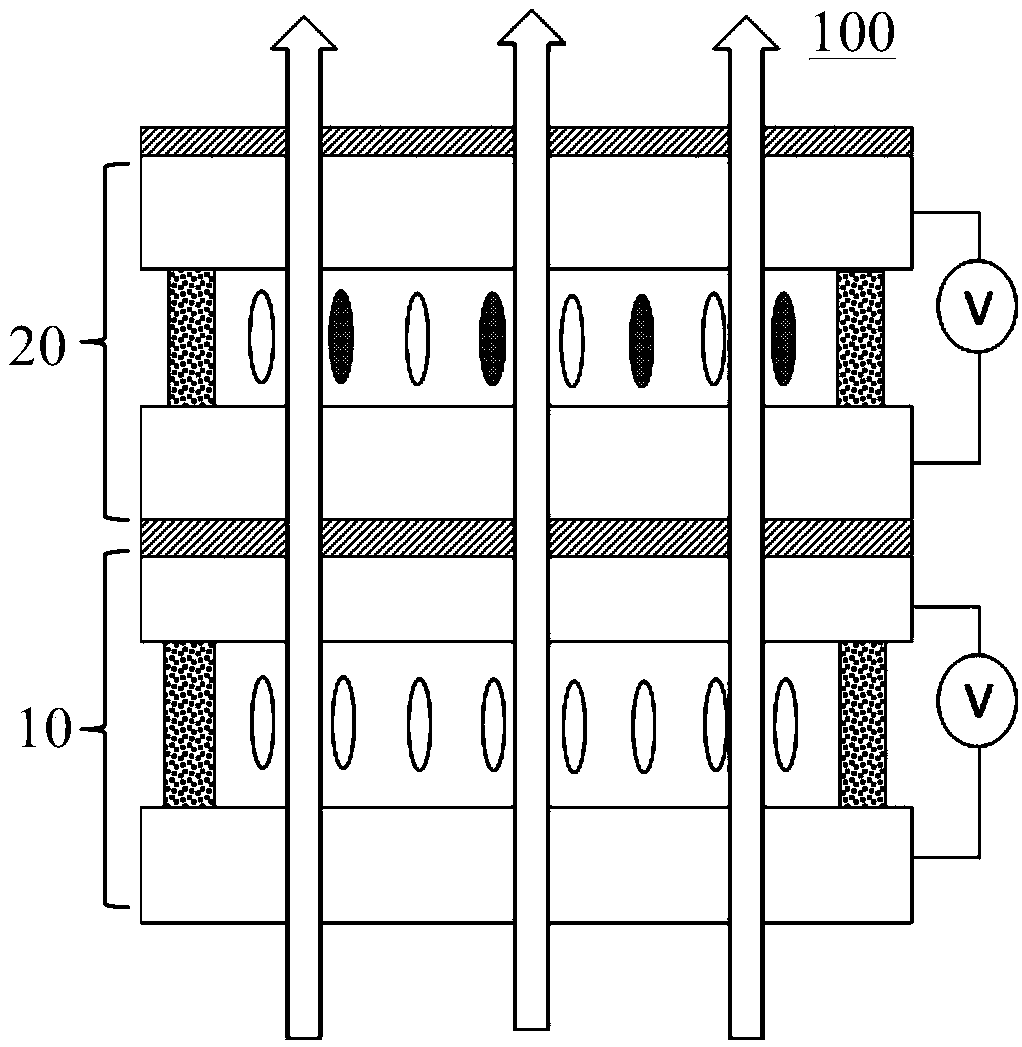

Liquid crystal device and 3D printing system

ActiveCN108919552AStrong reflexesReduce light transmissionAdditive manufacturing apparatus3D object support structuresBlock effectEngineering

The invention provides a liquid crystal device and a 3D printing system. The liquid crystal device comprises a first liquid crystal box and a second liquid crystal box which are parallel to each otherand arranged in an overlapped mode. The first liquid crystal box is a bi-stable liquid crystal box. Through the strong reflection ability of the first liquid crystal box on light under the powered-off condition and the blocking effect of the second liquid crystal box on the light under the powered-off condition, the light transmissivity is decreased jointly, the black state is generated, the transmissivity of the black state is decreased, thus the contrast ratio of the liquid crystal device can be increased, and the printing accuracy of the 3D printing system can be improved.

Owner:TIANMA MICRO ELECTRONICS

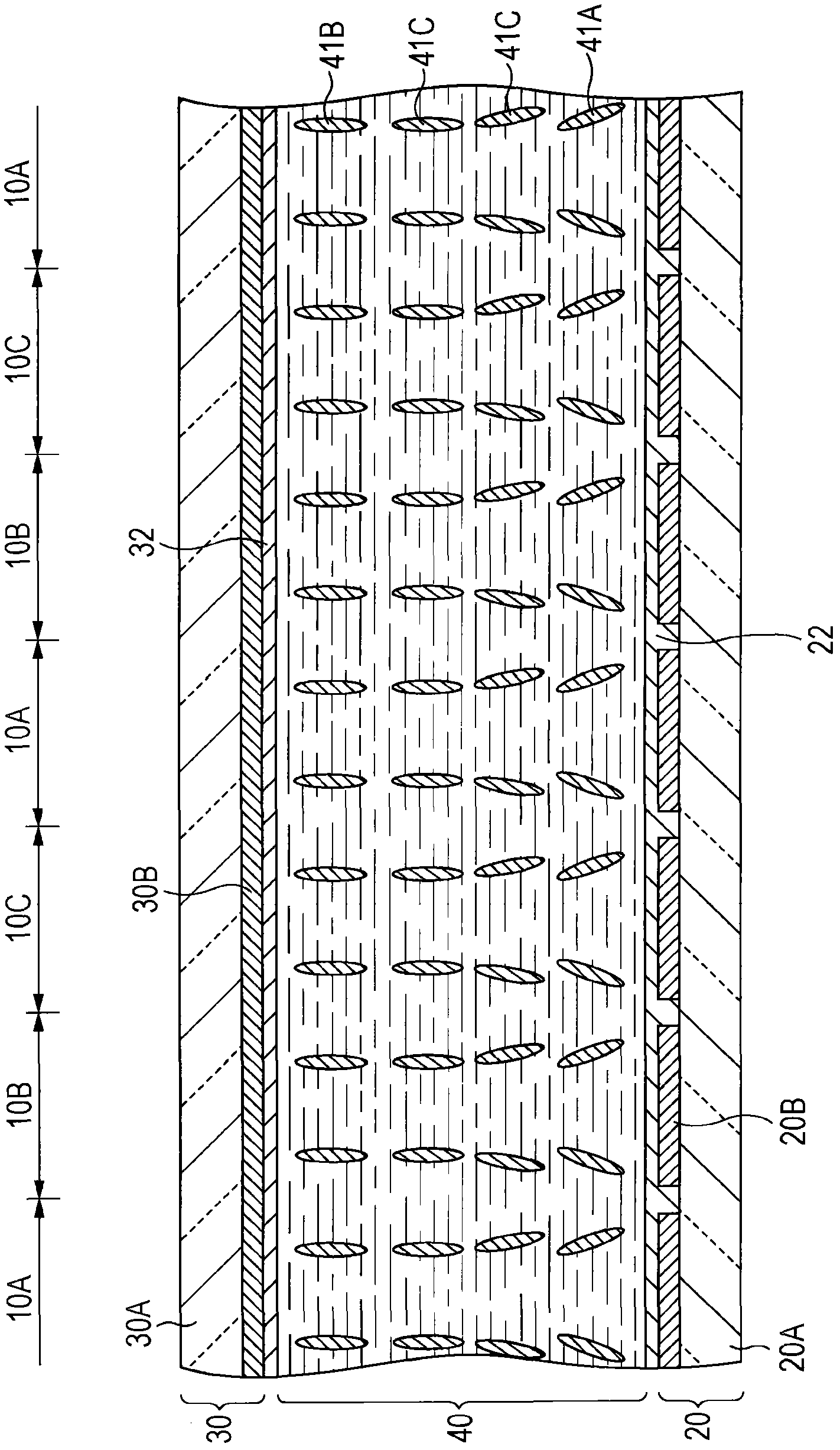

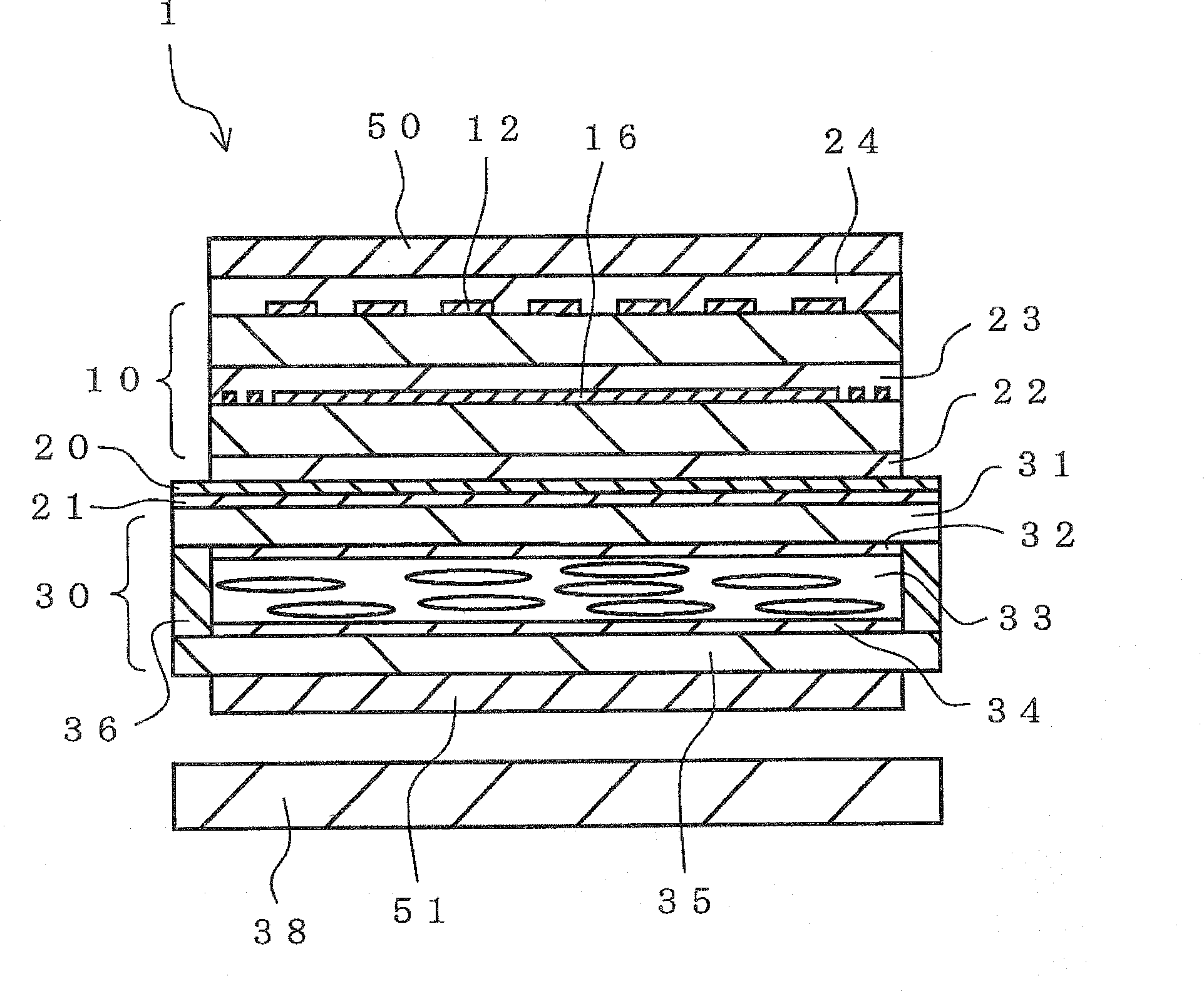

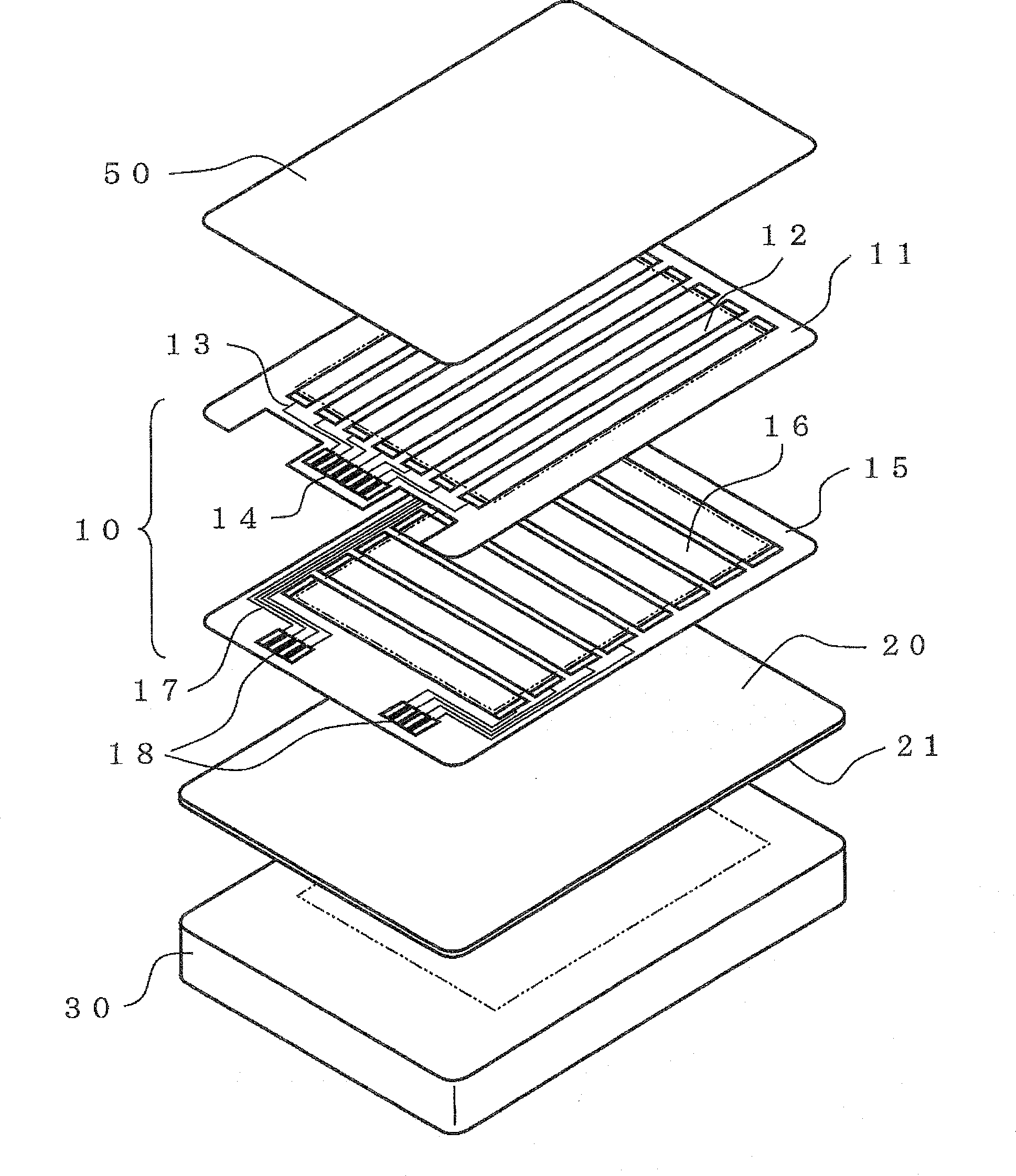

Touch panel integrated display device and method for manufacturing same

InactiveCN102880334ASuppress electromagnetic noiseSuppression of thinningStatic indicating devicesAdhesivesDisplay deviceEngineering

The present invention provides a touch panel integrated display device and a method for manufacturing the same that can suppress electromagnetic noise from a display panel, reduce the device thickness, and lower the manufacturing costs. A method for manufacturing a touch panel integrated display device (1) including a touch panel (10) and a display panel (30) that are integrally stacked, with a light-transmissive sticky layer (22) interposed therebetween, includes the steps of (a) forming a transparent conductive layer (20) by transfer onto a display surface of the display panel (30), with an adhesive layer (21) interposed therebetween, by using a transferable film having the adhesive layer (21)and the transparent conductive layer (20); (b) stacking a polarizing layer (50) on one surface of the touch panel (10), the one surface being an input surface of the touch panel; and (c) bonding the transparent conductive layer (20) formed on the display surface of the display panel (30) to the other surface of the touch panel (10), with the sticky layer (22) interposed therebetween.

Owner:ALPS ALPINE CO LTD

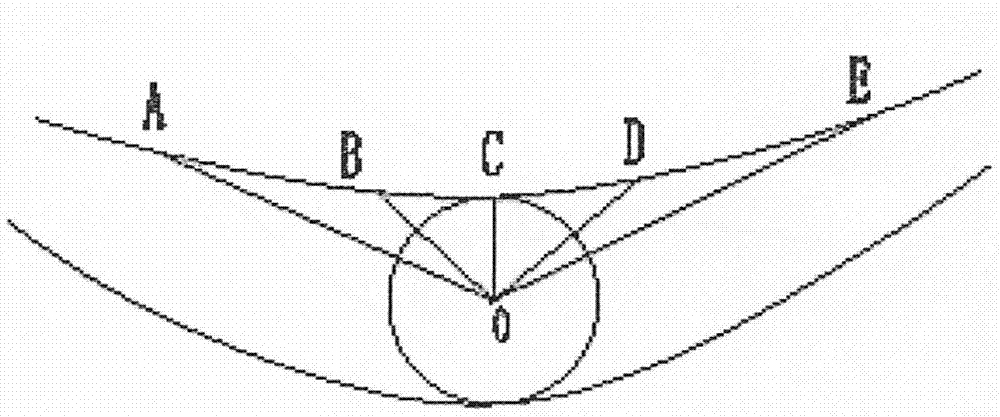

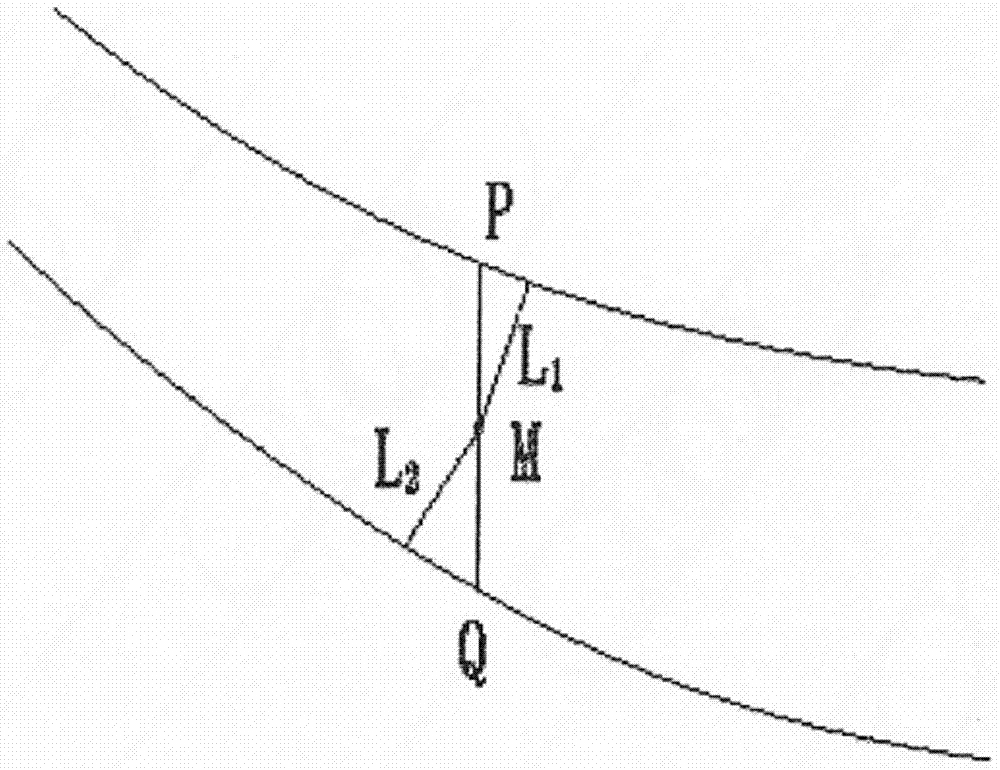

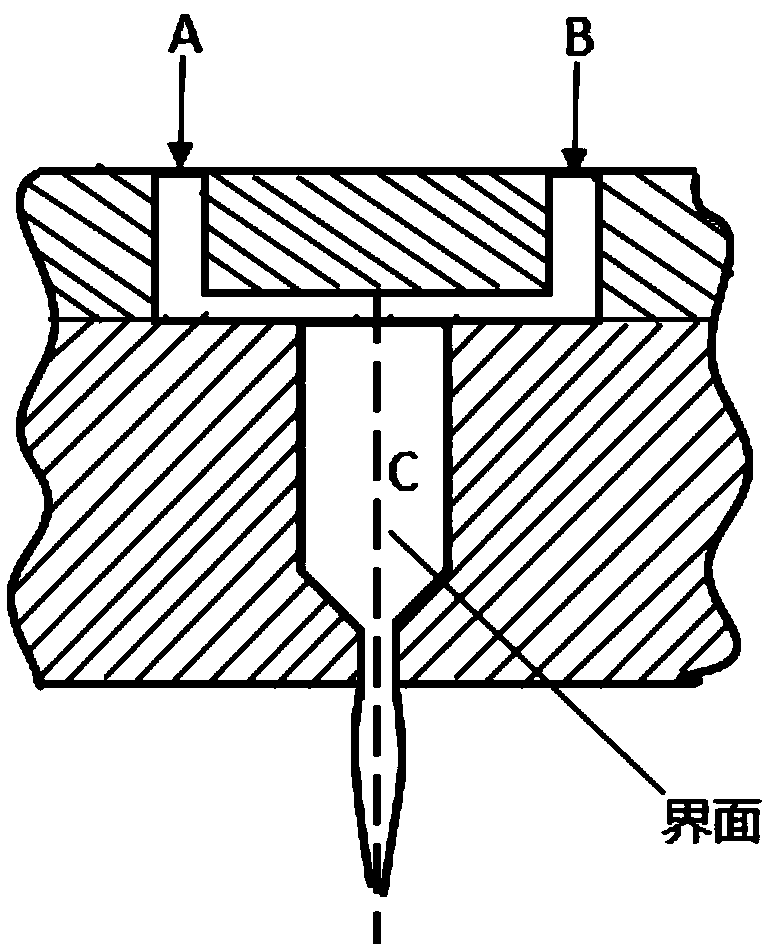

Fitting method of blade surface data

InactiveCN103577635AReduce duplicationReduce computing timeSpecial data processing applicationsEngineeringSolid surface

The invention discloses a fitting method of blade surface data. The method comprises the steps of the fixing of centers and radiuses of intake and exhaust sides, the fixing of arcs in polynomial fitting blade body surface and blade surface, and the fixing of the maximum thickness value of the blade body surface. According to the method,The repeated computing amount and the computing time of designers are greatly reduced, the computation of the blade surface data is enabled to be accomplished in seconds, the whole bade development time is shortened by one third, the data accuracy and the jig design accuracy of blade surfaces are improved, the precision forging technology is improved, and the requirements of modern digital machining equipment are met. Blades machined through the fitting method is smooth in solid surfaces, the phenomenon of back which usually occurs in traditional blade bodies manually adjusted can not occur, the blade body profile line of a blade forge piece designed on the basis of the surface is smooth, a final die cavity is not required to be repeatedly repaired, and the forming quality of the blade forge piece is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

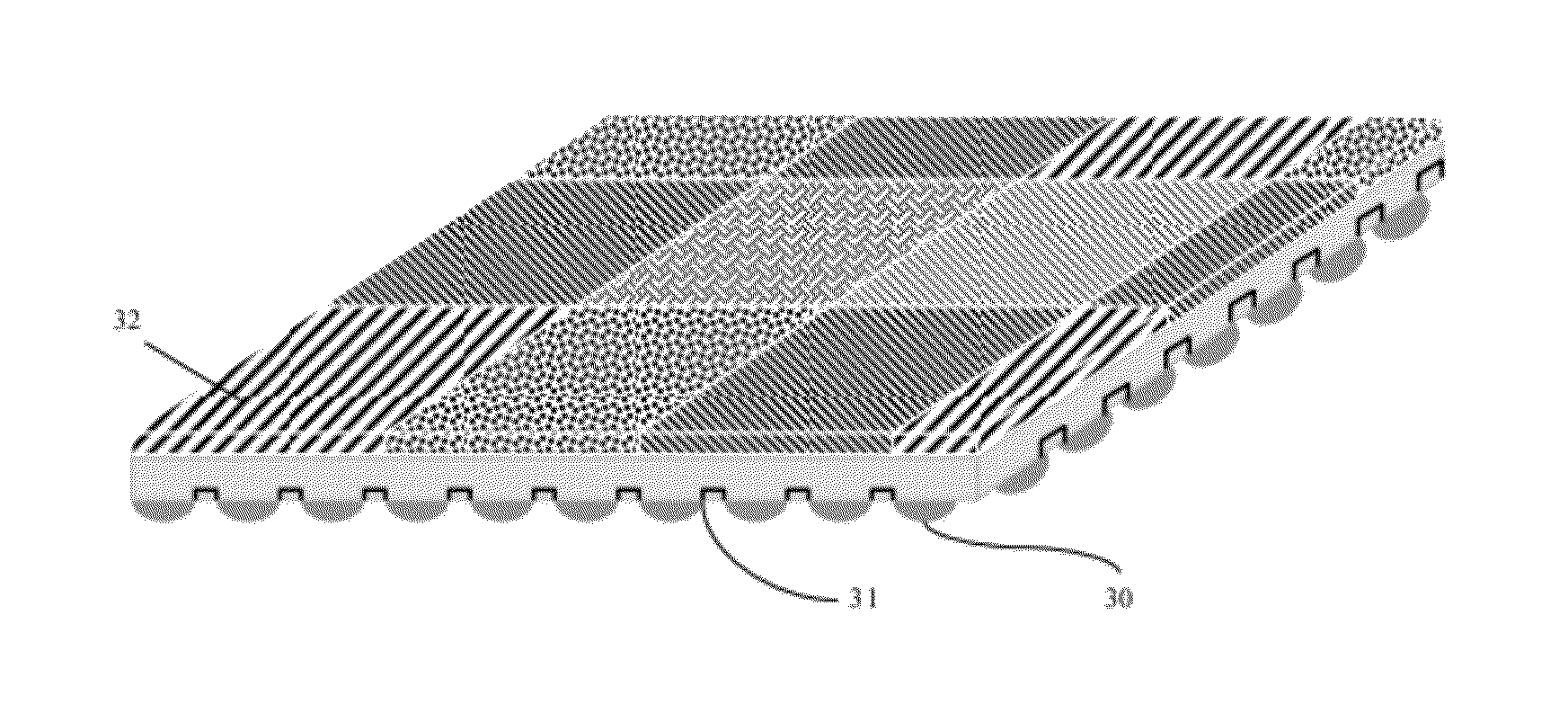

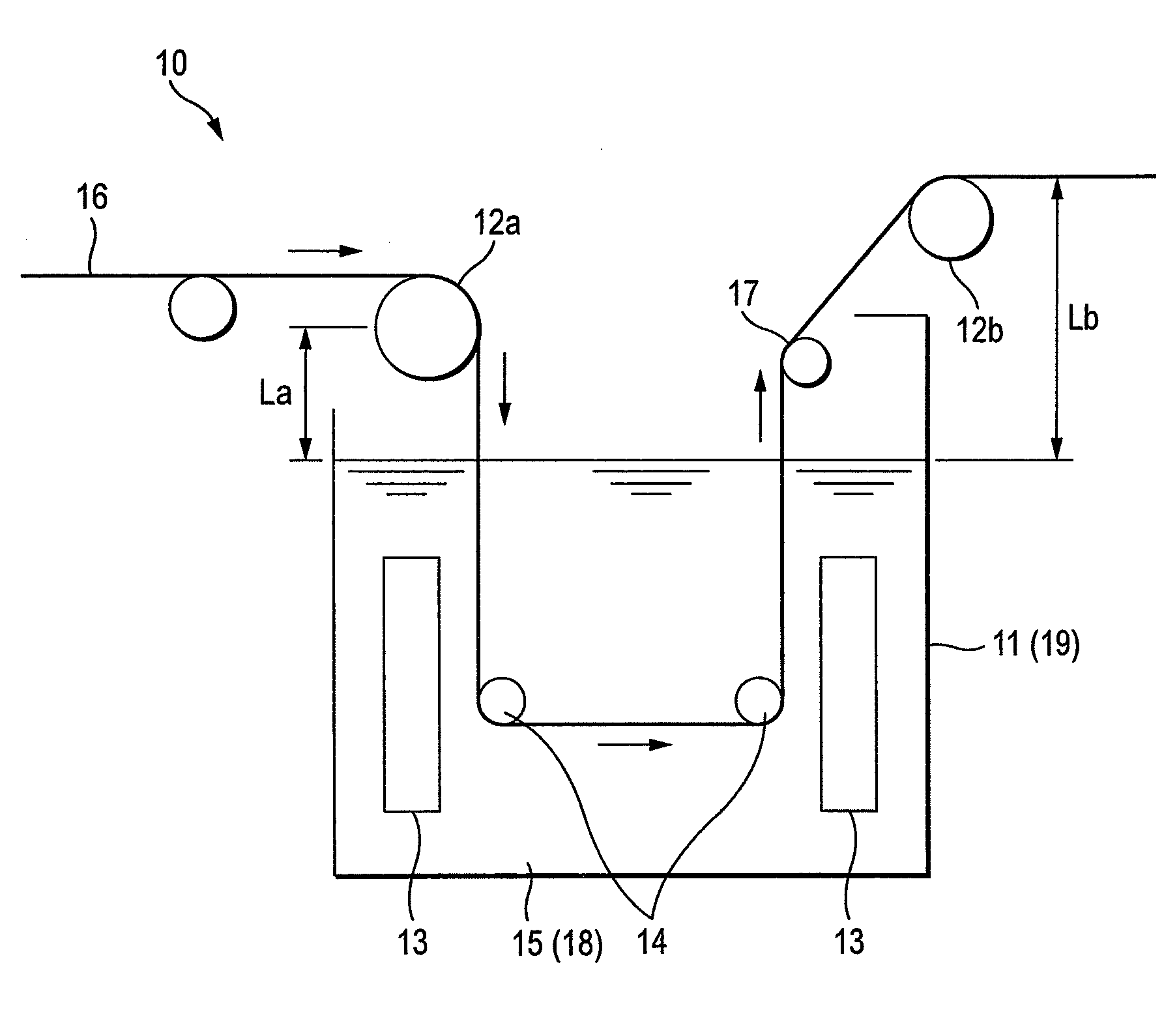

Conductive film and manufacturing method thereof, and transparent electromagnetic shielding film

ActiveUS20100170710A1Forming the conductive metal layer inexpensively and easilyReduce light transmissionMagnetic/electric field screeningPhotoprinting processesMass ratioAlloy

An electromagnetic shielding film for plasma display which is excellent in electromagnetic shielding characteristics for effectively shielding electromagnetic waves, near infrared rays, stray light, external light, and the like and even when stored under a wet heat condition, is small in change of color tint and good in adhesion, with a blackening layer hardly peeled away, is provided by a transparent electromagnetic shielding film including a transparent support having thereon a conductive metal layer in a pattern-like state having an electromagnetic shielding ability and having a surface covered by a blackening layer, with the blackening layer made of an alloy of nickel and zinc in a nickel / zinc mass ratio of from 0.5 to 50.

Owner:FUJIFILM CORP

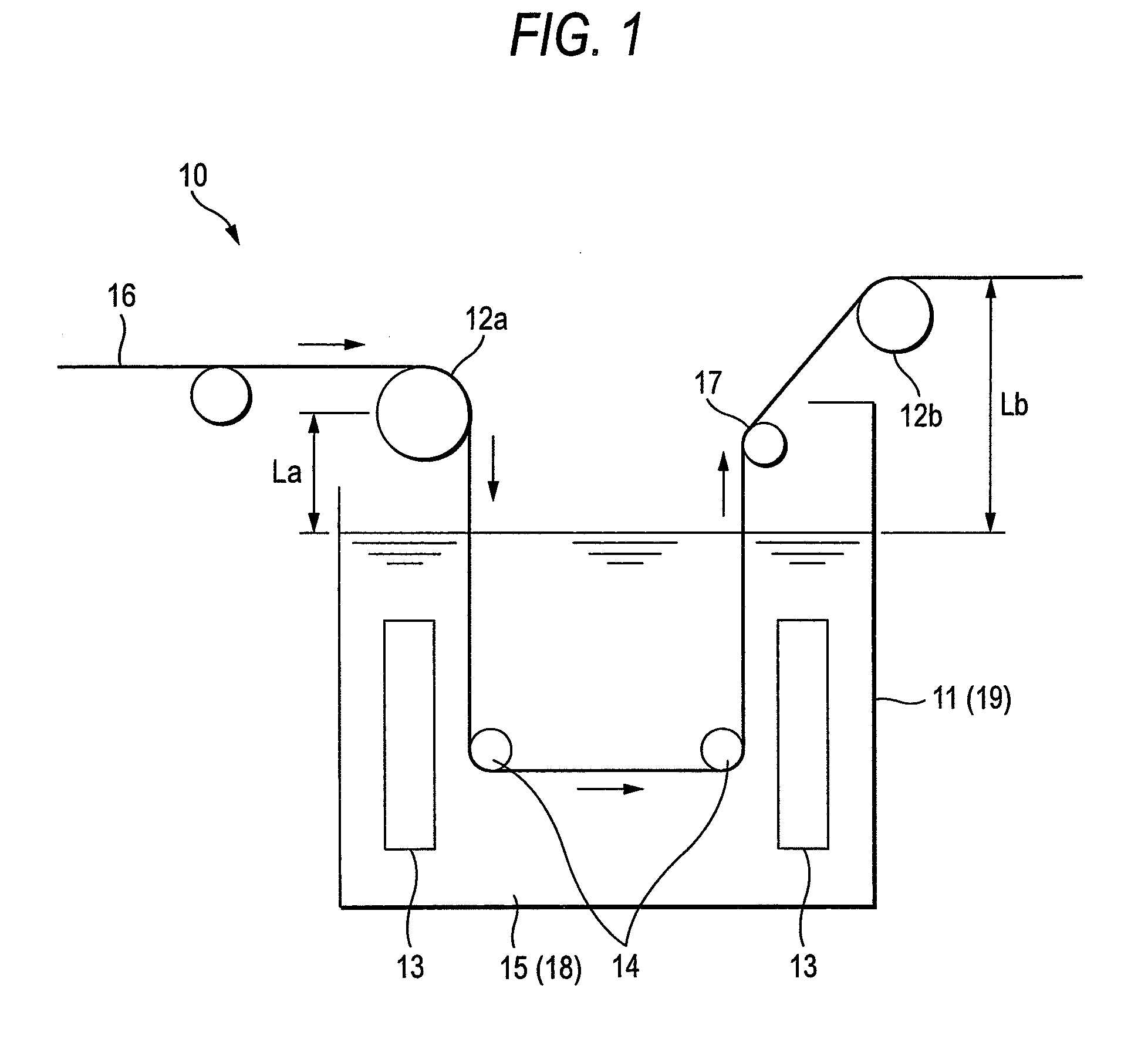

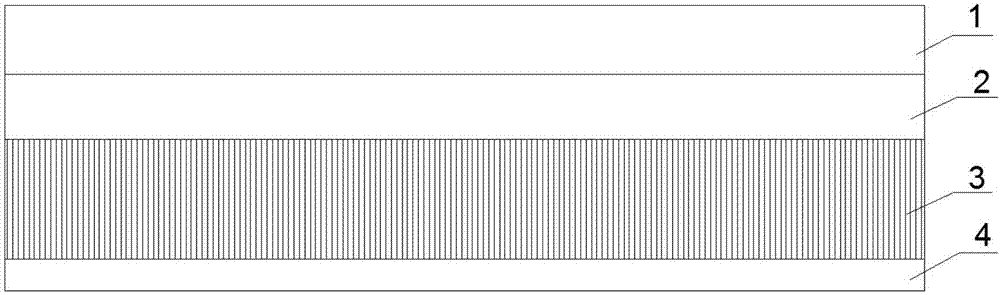

Anti-haze window gauze and preparation method thereof

InactiveCN106639844AGood anti-smog effectImprove control efficiencySynthetic resin layered productsInsect protectionFiltrationNanofiber

The invention discloses an anti-haze window gauze and a preparation method thereof. The widow gauze comprises in sequence a receiving layer, a gel layer, a polymer nanofiber layer and a protection layer which are four layers. The receiving layer is made by metal net, non-woven fabric or woven fabric. The receiving layer is glued to the polymer nanofiber layer through the gel layer. The thickness of the polymer nanofiber layer is 0.1-100 millimeter. The mesh diameter is 50-2000 nanometers. The protection layer is non-woven fabric and woven fabric. The anti-haze window gauzepossesses good anti-haze effect. The cleaning rate of PM2.5 is as high as more than 99%. The air permeation and light transmission are excellent. The window gauze is anti-wearing and anti-scraping, has an enduring PM2.5 filtration effect. The invention further provides a preparation method of the anti-haze window gauze. The method can use the nanofiber prepared by using various methods in the prior art as the material for the production of the anti-haze gauze.

Owner:スンナテクノロジーズシャンハイカンパニーリミテッド

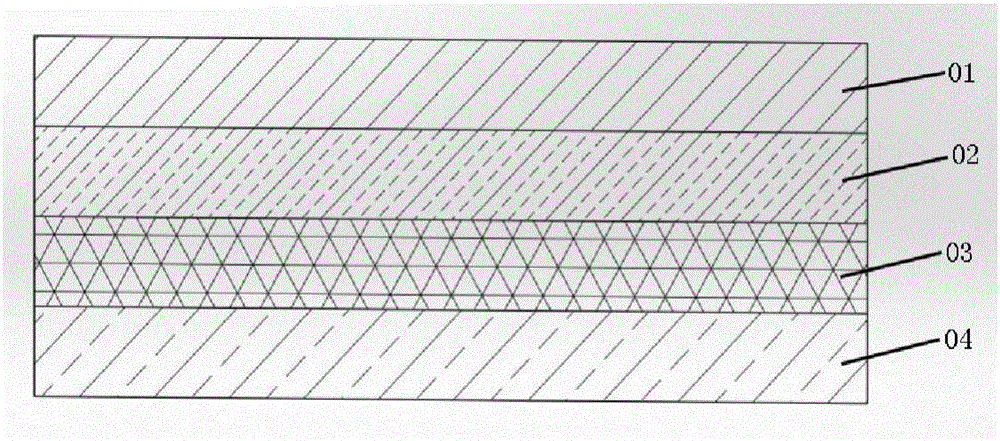

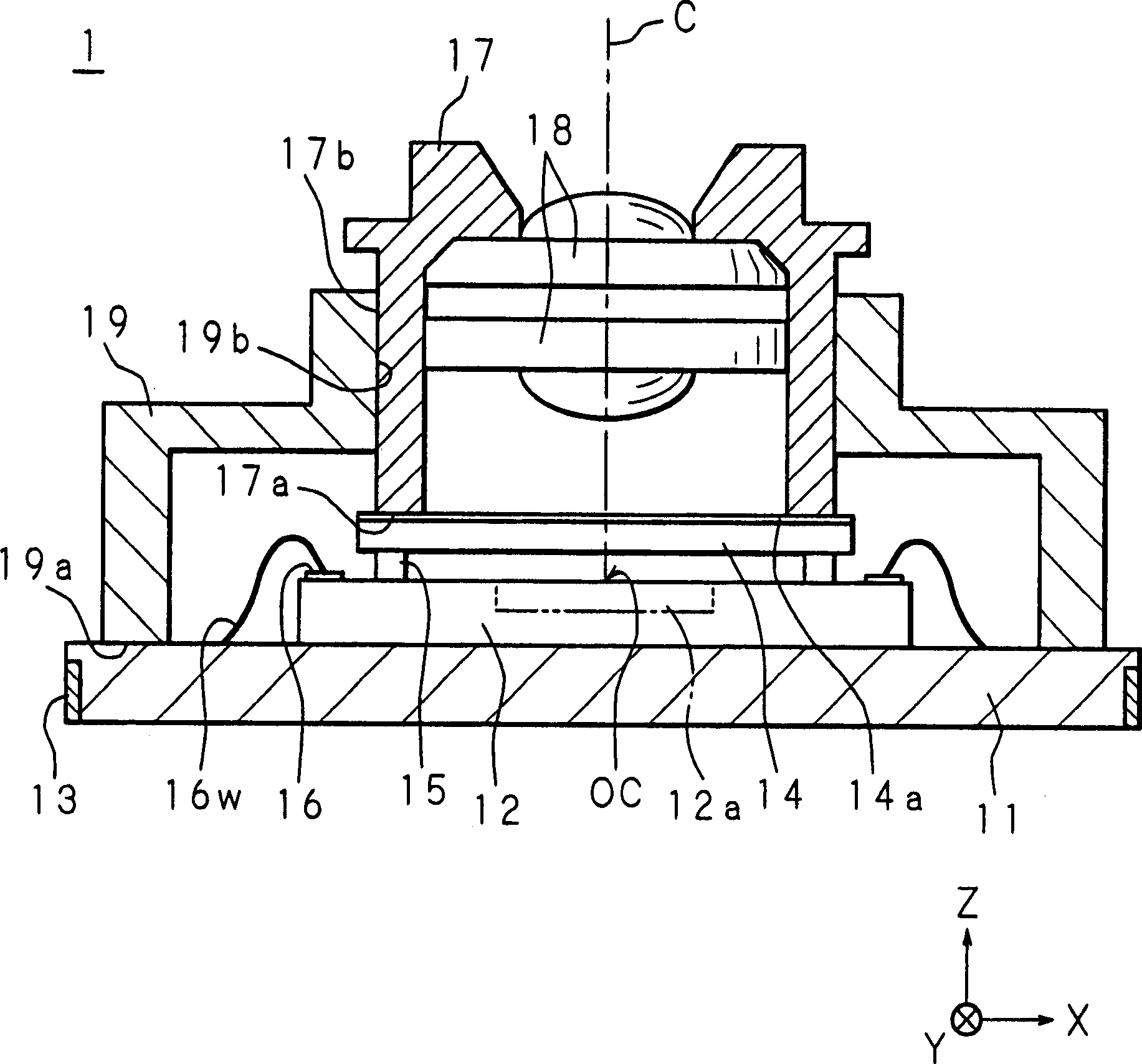

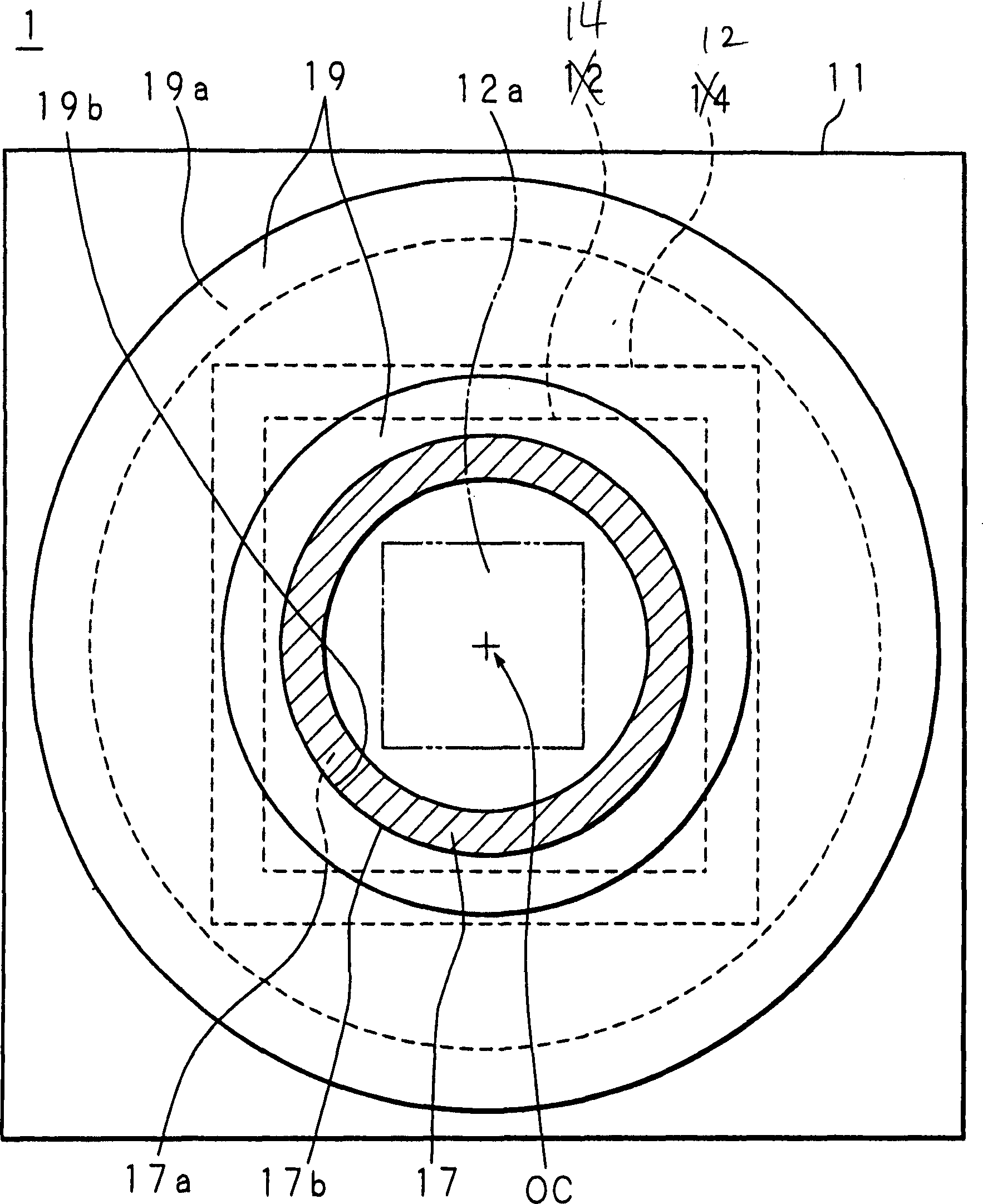

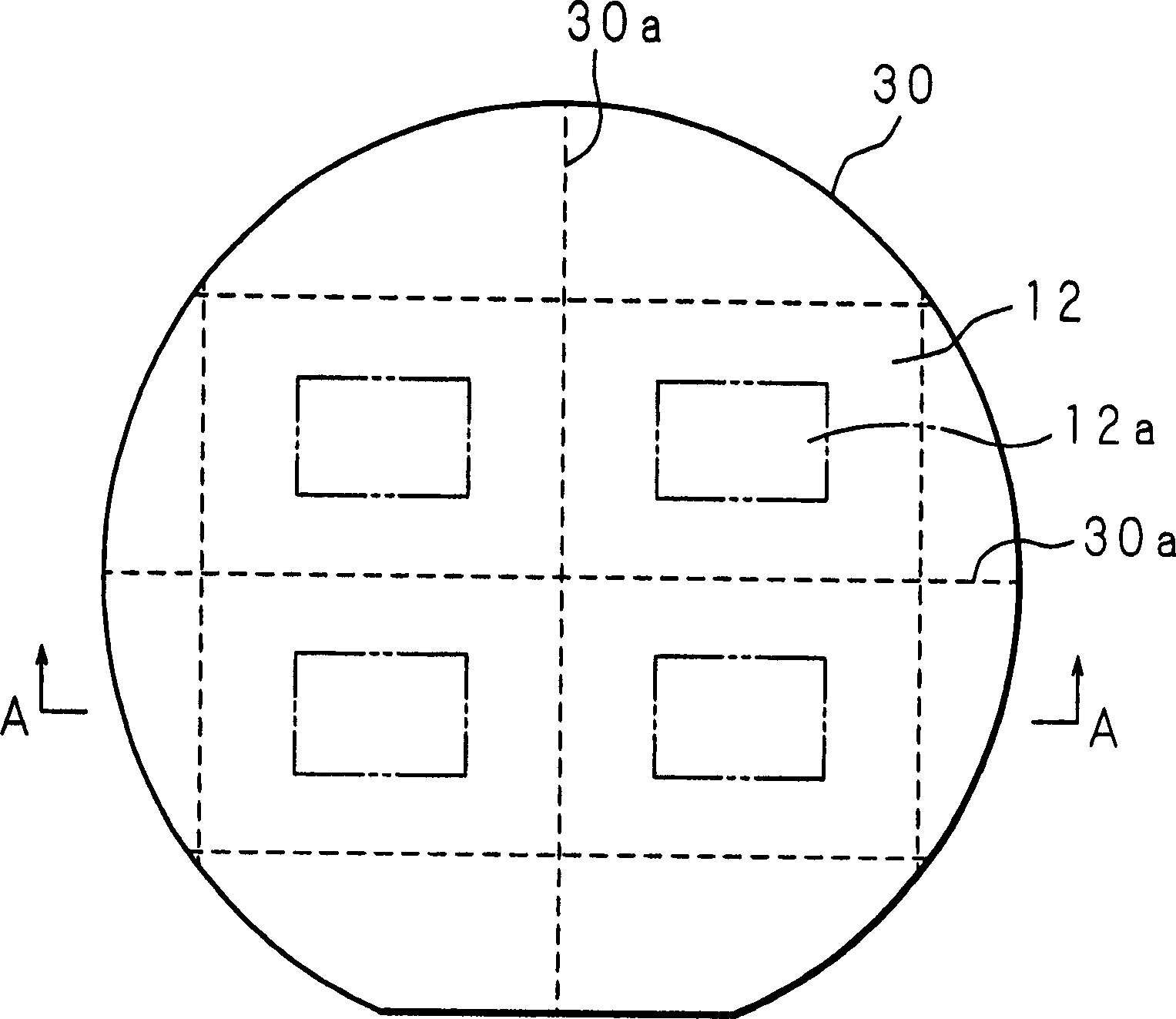

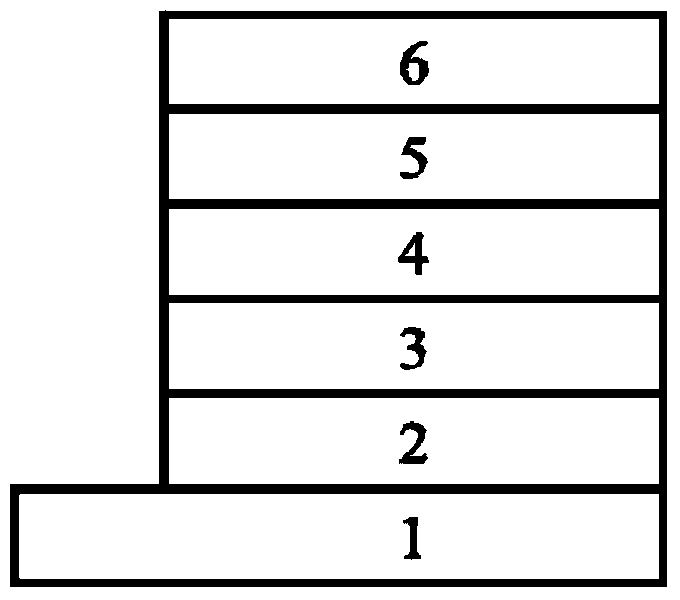

Image pickup module and manufacturing method of image pickup module

InactiveCN1783953AReliable focusReduce manufacturing costTelevision system detailsSolid-state devicesEngineeringMethod of images

The camera module (1) of the present invention is provided with a tubular cover (19) and a lens holder (17). The cover (19) is fixed (bonded) to the substrate (11) with its legs (19a) in contact with the surface of the substrate (11). Moreover, the lens holder (17) is inserted into the inner surface (19b) of the cover (19), the lens holder (17) is in contact with the transparent plate (14) at its foot (17a) and its outer surface (17b) is in contact with the inner surface of the cover In the state, the outer surface (17b) of the lens holder (17) is fixed (bonded) on the inner surface (19b) of the cover (19). A lens (18) guiding the path of incident light to the light receiving portion (12a) of the imaging element (12) is fixed at a predetermined position on the lens holder (17).

Owner:SHARP KK

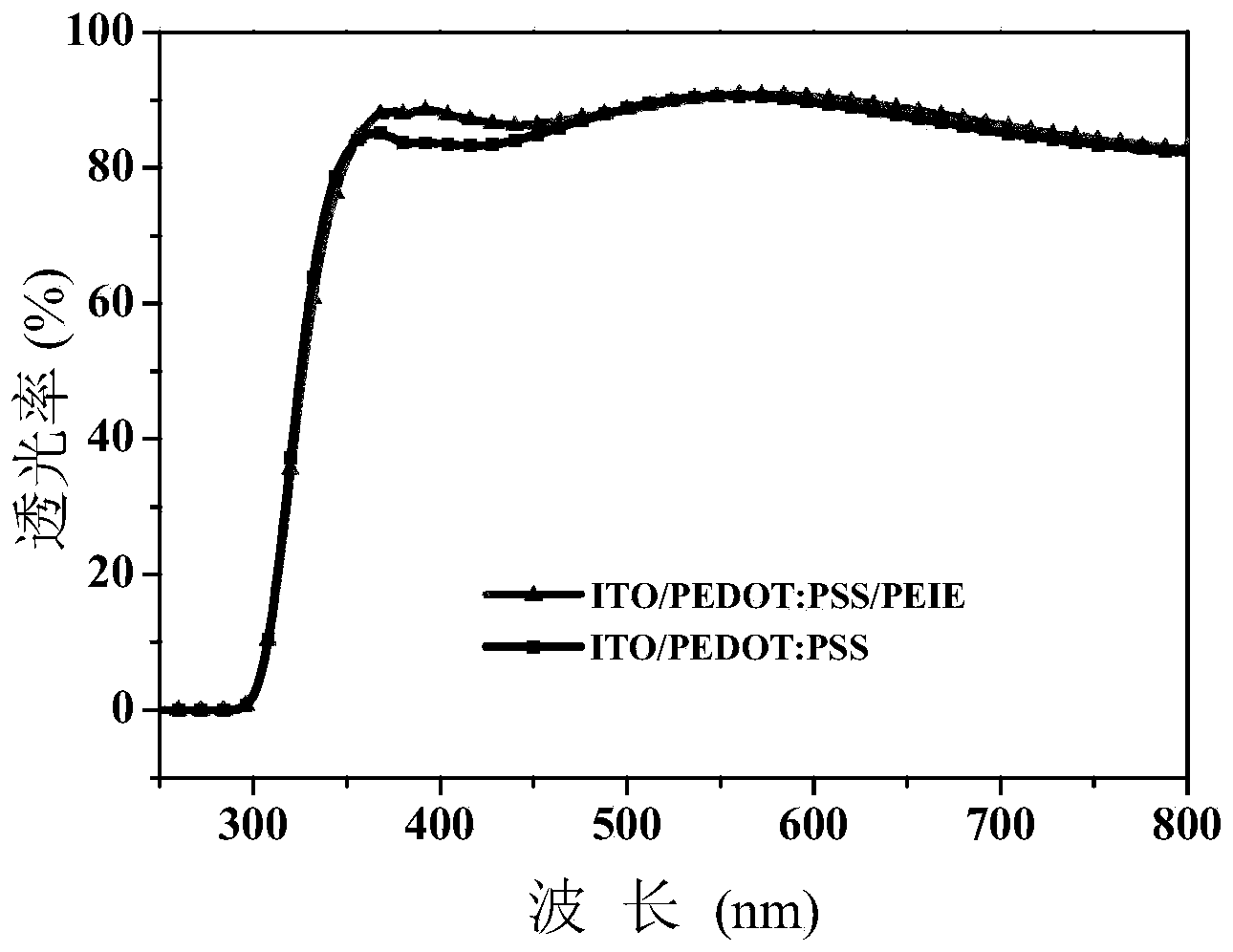

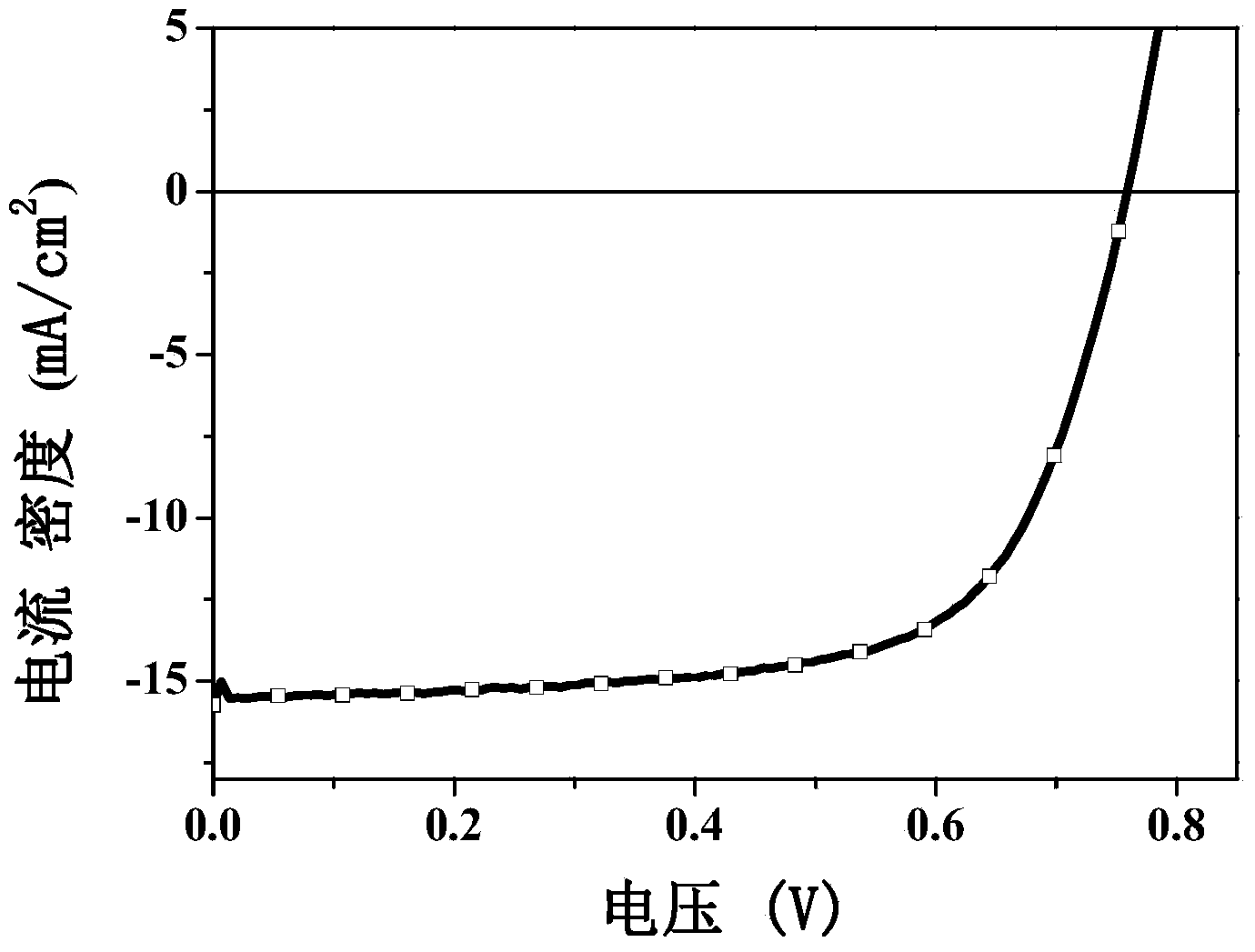

Organic solar cell and preparation method thereof

InactiveCN104393175AReduce corrosionImprove stabilityFinal product manufactureSolid-state devicesOrganic solar cellHole transport layer

The invention relates to an organic solar cell and a preparation method thereof. The organic solar cell consists of a transparent substrate, a cathode, an electron transport layer, an optical activation layer, a hole transport layer, an anode and is characterized in that the electron transport layer includes a modification layer and a PEDOT:PSS layer; and the modification layer is made from a material containing amino. According to the preparation method of the electron transport layer, a PEDOT:PSS solution is paved on the surface of the cathode cleaned clearly, and spinning and coating and spin-dry processing are carried out and then annealing is carried out; and the modification layer material solution coating is carried out in a spinning mode and is drying in a spinning mode and then annealing is carried out, thereby obtaining the electron transport layer. According to the invention, the surface of the PEDOT:PSS film is coated with the modification layer material containing amino in a spinning mode, thereby reducing the PEDOT:PSS work function; and thus the energy level relation between all layers is met, so that the PEDOT:PSS layer can be converted into the state beneficial to electron transport. With the alkaline modification layer containing amino, the acid PEDOT:PSS layer can be neutralized, thereby reducing corrosion to the ITO and hygroscopicity and improving stability. Flexible reel-to-reel commercial production of the organic solar cell can be realized well based on normal-temperature preparation. Moreover, the operation is simple; the manufacturing cost is low; and the production efficiency is high.

Owner:NANCHANG UNIV

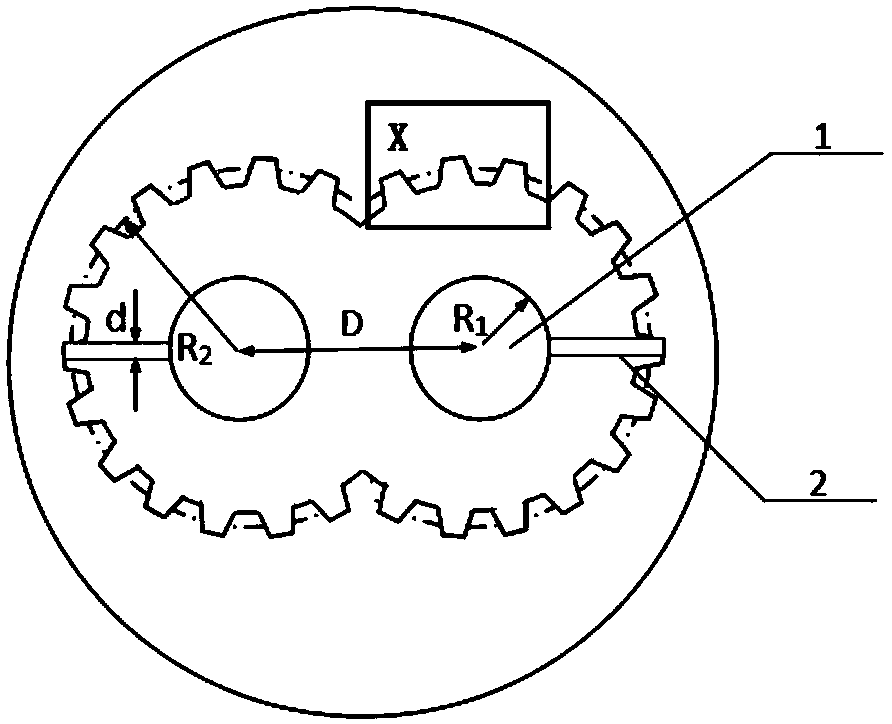

Gear-shaped parallel composite elastic fiber and preparation method thereof

ActiveCN109208095AImprove cohesionGood shape retentionHollow filament manufactureMelt spinning methodsElastomerCo extrusion

The invention relates to a gear-shaped parallel composite elastic fiber and a preparation method thereof. The preparation method comprises the steps of carrying out melt spinning on a component A anda component B through a composite spinning assembly to obtain a gear-shaped parallel composite elastic fiber, wherein main materials of the component A and the component B are respectively an elastomer and a non-elastomer, the composite spinning assembly is internally provided with two melt flow channels and a co-extrusion flow channel, and the component A and the component B get into the co-extrusion flow channel respectively through the two melt flow channels and are then extruded from a spinneret orifice. The outer edge of the cross section of the spinneret orifice is composed of double C,wherein the endpoints of the double C are mutually connected, the double C or one of the double C are / is a non-smooth curve, and the shape is identical to the edge of an outer gear. The prepared fiberis composed of a part A and a part B, wherein the part A and / or the part B are / is added with an anti-ultraviolet material and / or functional particles. The gear-shaped parallel composite elastic fiberis good in shape-keeping performance, anti-perspective performance and anti-ultraviolet performance, and the preparation method is simple.

Owner:DONGHUA UNIV

Efficient sunshade double-color tent material

InactiveCN107325444AImprove practicalityImprove shadingSynthetic resin layered productsLight resistant fibresPolyvinyl chlorideEngineering

The invention relates to an efficient sunshade double-color tent material. The tent material sequentially comprises a white polyvinyl chloride (PVC) film, a black PVC lightproof film, base cloth and a PVC bottom film from top to bottom; the tent material is prepared by the following steps: starching the double sides of the base cloth, drying and heating; then, synchronously sticking the base cloth together with the preheated white PVC film, the black PVC lightproof film and the PVC bottom film; embossing, trimming and reeling. The efficient sunshade double-color tent material provided by the invention has the characteristic of being used at the both sides; the white PVC film has good ink absorption, thus being used for jet drawing; the black PVC lightproof film has excellent lightproof property, thus being capable of preventing the transmission of sunlight and ultraviolet rays and further effectively achieving the effects of sun-shading and heat insulation; the red PVC film is obtained by adding pigment and calendaring molding, thus having good color fastness to water and color fastness to sunlight. After the technology of synchronously sticking the three films and the one piece of cloth is adopted, the processing flow is simplified, the production efficiency is improved, and the stripping fastness is more reliable.

Owner:浙江明士达股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com