Fitting method of blade surface data

A technology of surface data and airfoil profile, which is applied in the field of aero-engine manufacturing, can solve problems such as inability to meet accuracy, and achieve the effects of improving forming quality, improving precision forging technology, and uniform allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

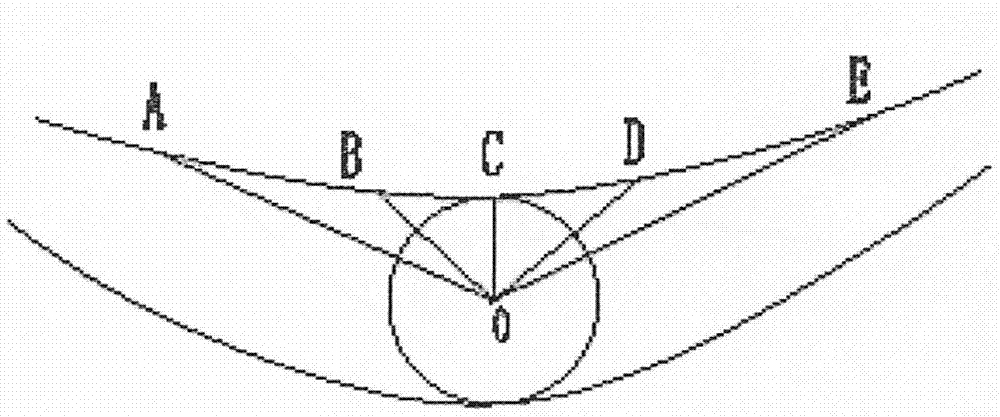

[0022] Such as figure 1 As shown, the method of determining the center and radius of the intake and exhaust edges is:

[0023] Fit a suitable circle according to the dense points given in the design drawing, and set the center of one of the circles as (x oj ,y oj ), the radius is r j ,(j=1,2,n 0 ), the coordinates of each point on the edge are (x i ,y i ) (i=1,2...,n), then the edge circle that is relatively close to each point must meet the following conditions:

[0024] min 1 ≤ j ≤ n 0 { Σ i = 1 n | ( x i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com