Method for automatically determining adding amount of detergent according to detergent concentration of washing machine

A technology for automatic determination of detergent, applied to the control device of washing machines, other washing machines, washing devices, etc., can solve the problems of changing the dosage of detergent and not being able to automatically determine the concentration of the current detergent, so as to enhance the washing effect and maintain Convenience, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

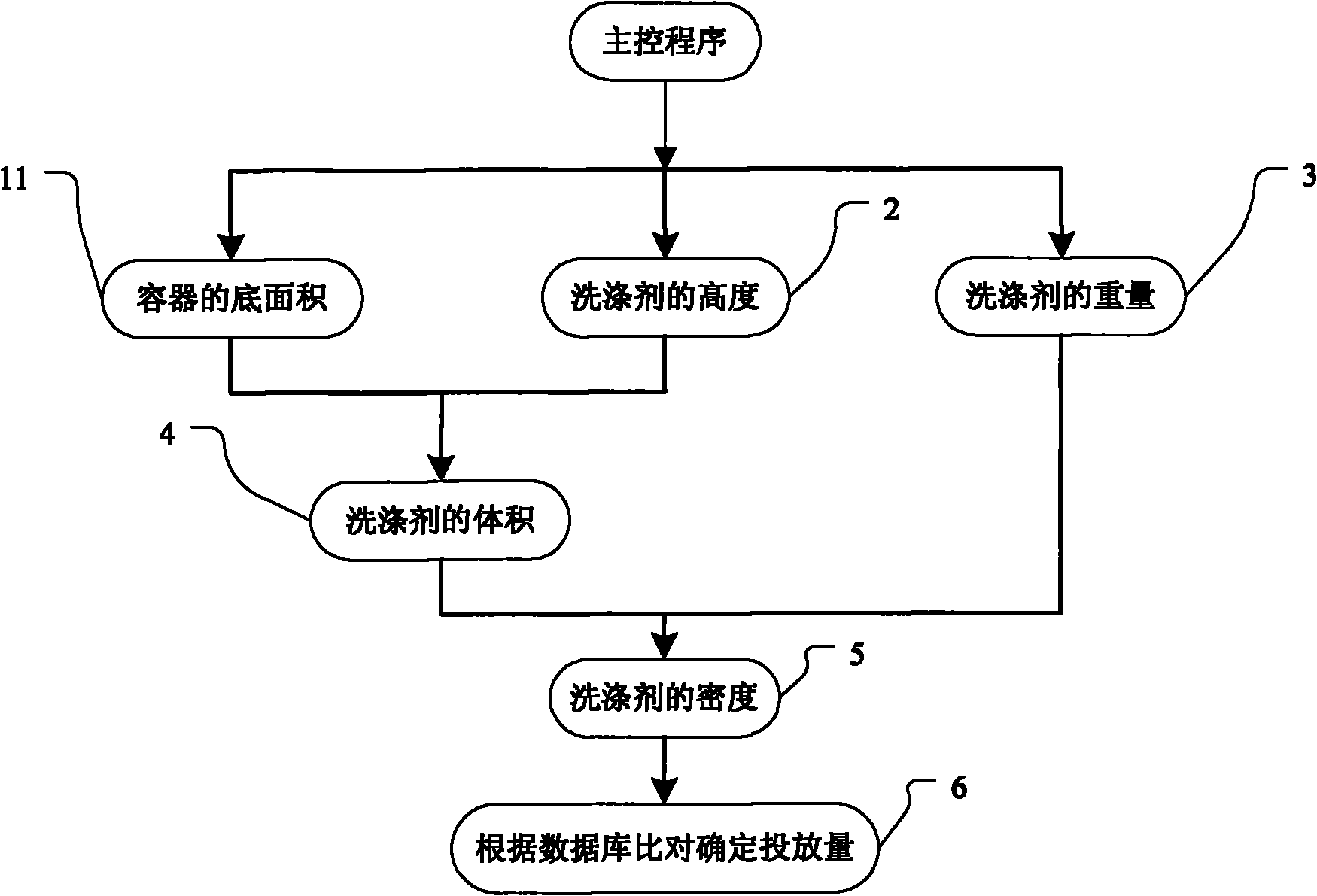

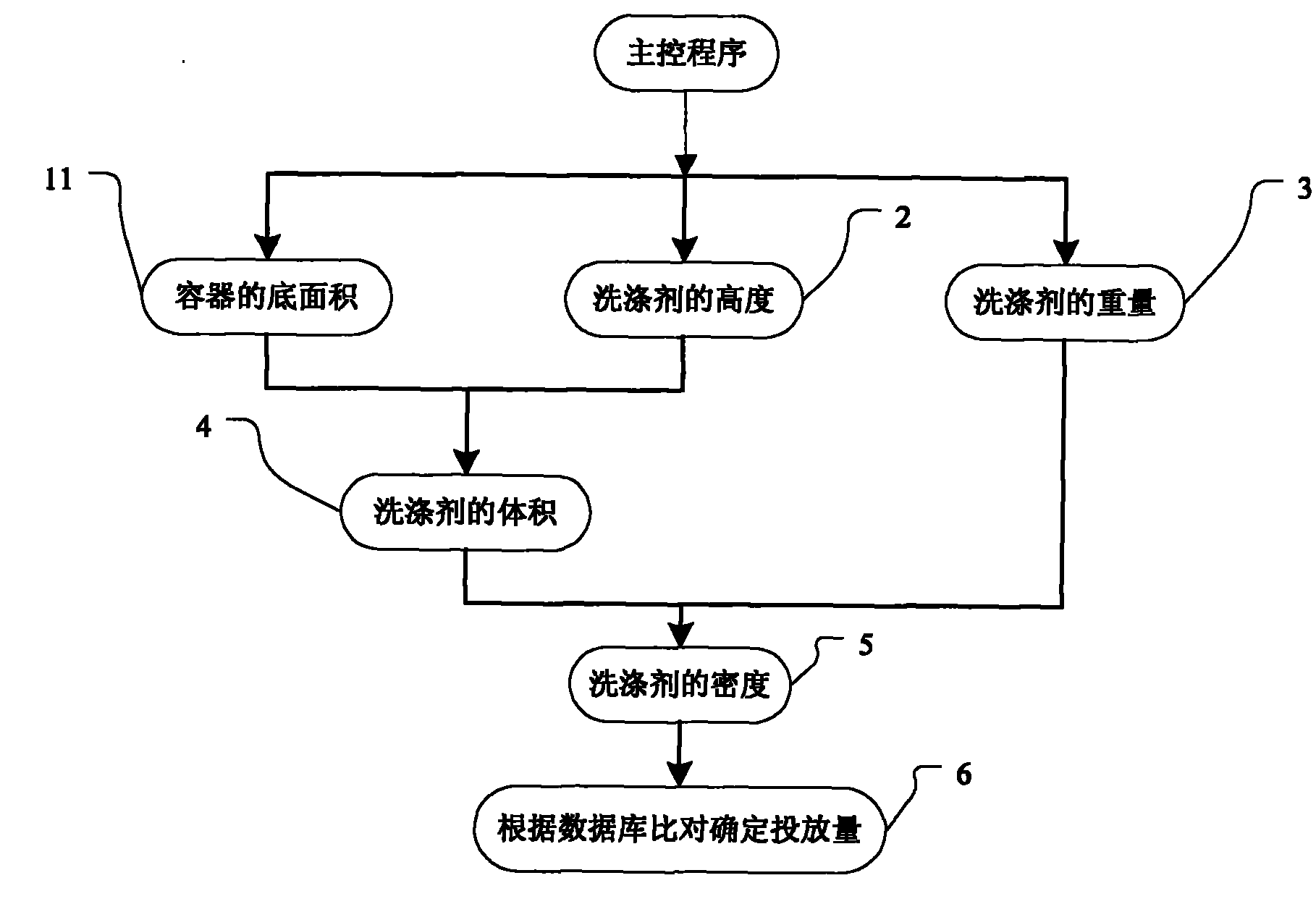

[0039] Embodiment 1: the current container size of detergent is: the bottom area is 20*13.2=264 square centimeters; the height is 7.6 centimeters, so the volume is 264*7.6=2006.4 cubic centimeters=2.0064 liters, when the container is full The volume of the detergent is the volume of the detergent, so the volume of the current detergent is 2.0064 liters. According to the value measured by the weight sensor, the density of the current detergent can be obtained by using ρ=m / v. According to the predetermined corresponding relationship between density and concentration, Determine the concentration of the current detergent and select the corresponding dosage.

Embodiment 2

[0040] Embodiment 2: the size of the detergent container is: the bottom area is 10*10=100 square centimeters, the height is 10 centimeters, and the current volume is 100*10=1000 cubic centimeters=1 liter. The volume is the volume of the detergent, so the volume of the current detergent is 1 liter. According to the value measured by the weight sensor, the density of the current detergent can be obtained by using ρ=m / v. According to the predetermined correspondence between density and concentration, judge Display the concentration of the current detergent and select the corresponding dosage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com