Efficient sunshade double-color tent material

A tent and high-efficiency technology, applied in the field of tent materials, can solve the problems of inability to completely block sunlight, single color, etc., and achieve the effect of improving anti-peeling performance, anti-peeling performance and life expectancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

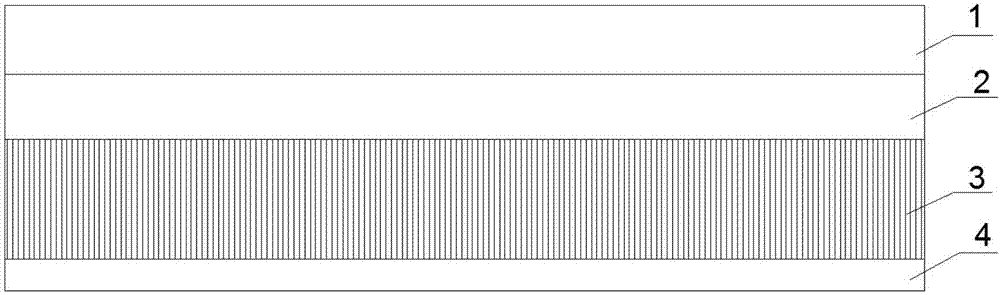

[0029] refer to figure 1 , a high-efficiency sun-shading two-color tent material, the tent material sequentially includes PVC white film 1, PVC black shading film 2, base fabric 3, PVC red film 4 from top to bottom, and the tent material passes through the following Prepared in steps: After the base fabric is double-faced with sizing, after drying and heating, it is laminated with the preheated PVC white film, PVC black shading film, and PVC red film synchronously, and then coiled after embossing and trimming. have to;

[0030] Wherein, the base fabric adopts a high-strength polyester woven fabric with a linear density of 1000D×1000D and a fabric density of 18×18 threads / inch; the thickness of the PVC white film is 12 silk, and the thickness of the PVC black light-shielding film is 10 silk. The thickness of the PVC red film is 3 filaments;

[0031] The raw material of the PVC white film is: 100 parts by weight of 1300 PVC resin powder, 63 parts by weight of DOTP plasticizer,...

Embodiment 2

[0041] refer to figure 1 , a high-efficiency sun-shading two-color tent material, the tent material sequentially includes PVC white film 1, PVC black shading film 2, base fabric 3, PVC red film 4 from top to bottom, and the tent material passes through the following Prepared in steps: After the base fabric is double-faced with sizing, after drying and heating, it is laminated with the preheated PVC white film, PVC black shading film, and PVC red film synchronously, and then coiled after embossing and trimming. have to;

[0042] Wherein, the base fabric adopts a high-strength polyester woven fabric with a linear density of 1000D×1000D and a fabric density of 18×18 threads / inch; the thickness of the PVC white film is 12 silk, and the thickness of the PVC black light-shielding film is 10 silk. The thickness of the PVC red film is 3 filaments;

[0043] The PVC white film raw materials are: 100 parts by weight of 1300 PVC resin powder, 55 parts by weight of DOTP plasticizer, 3 part...

Embodiment 3

[0053] refer to figure 1 , a high-efficiency sun-shading two-color tent material, the tent material sequentially includes PVC white film 1, PVC black shading film 2, base fabric 3, PVC red film 4 from top to bottom, and the tent material passes through the following Prepared in steps: After the base fabric is double-faced with sizing, after drying and heating, it is laminated with the preheated PVC white film, PVC black shading film, and PVC red film synchronously, and then coiled after embossing and trimming. have to;

[0054] Wherein, the base fabric adopts a high-strength polyester woven fabric with a linear density of 1000D×1000D and a fabric density of 18×18 threads / inch; the thickness of the PVC white film is 12 silk, and the thickness of the PVC black light-shielding film is 10 silk. The thickness of the PVC red film is 3 filaments;

[0055] The raw material of the PVC white film is: 100 parts by weight of 1300 PVC resin powder, 72 parts by weight of DOTP plasticizer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com