Composite film, its preparation method and composite material

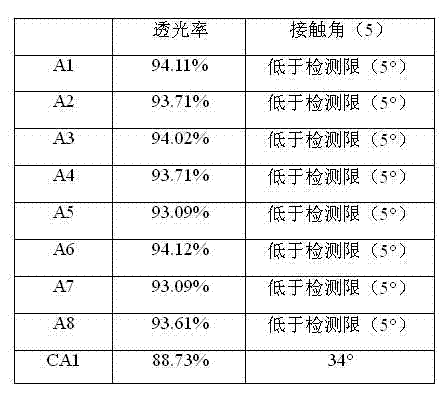

A composite film and film technology, which is applied in the field of composite film and its preparation and composite materials, can solve the problems of low gloss rate and low self-cleaning ability, and achieve the effect of high light transmittance and long-lasting self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a kind of preparation method of above-mentioned thin film, and this method comprises the following steps:

[0029] The method includes the following steps:

[0030] S1. Preparation of SiO 2 sol

[0031] SS1 Mix ethyl orthosilicate and hydrated absolute ethanol and stir to form a mixed solution; wherein, the molar ratio of each substance is: ethyl orthosilicate: water: absolute ethanol=1:3-5:35-45 , and then adjust the pH value to 2-4 with acid, and age with stirring;

[0032] SS2 adjusts the pH of the mixed solution in step SS1 to 8-10 with alkali, and ages to form a sol;

[0033] SS3 adjust the pH value of the sol in step S2 to 2-4 with acid to obtain acidic SiO 2 Sol;

[0034] S2, preparation of TiO 2 sol

[0035] Mix tetrabutyl titanate, water, acetylacetone and absolute ethanol and stir evenly, TiO 2 The molar ratio of each substance in the sol is tetrabutyl titanate: water: acetylacetone: absolute ethanol = 1: 2-3: 0.5-1.5: 16-2...

Embodiment 1

[0057] S1, preparation of SiO2 sol

[0058] SS1 Mix ethyl orthosilicate and hydrated absolute ethanol and stir to form a mixed solution; among them, the molar ratio of each substance is: ethyl orthosilicate: water: absolute ethanol = 1:4:40, and then use hydrochloric acid Adjust the pH value to 3, stir for 4 hours, and age for 24 hours;

[0059] SS2 adjusts the pH of the mixed solution in step SS1 to 9 with sodium hydroxide, and ages for 24 hours to form a sol;

[0060] SS3 adjusting the pH value of the sol in step S2 to 3 with hydrochloric acid to obtain an acidic SiO2 sol;

[0061] S2, prepare TiO2 sol

[0062] Mix tetrabutyl titanate, water, acetylacetone and absolute ethanol and stir evenly. The molar ratio of each substance in the TiO2 sol is tetrabutyl titanate: water: acetylacetone: absolute ethanol = 1: 2.5: 1: 18, then adjust the pH value to 4 with hydrochloric acid, stir for 2 hours, and age for 24 hours;

[0063] S3, prepare SiO2-TiO2 composite sol

[0064] Whi...

Embodiment 2

[0071] Prepare the composite film A2 loaded on the substrate according to the method of Example 1, the difference is: in the nitrogen-doped N-SiO2-TiO2 composite sol, the content of titanium dioxide is 16mol, the content of silicon dioxide is 64mol, and the content of urea is 10mol; based on the total mass of the nitrogen-doped N-SiO2-TiO2 composite sol, the content of the surfactant is 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com