Patents

Literature

496results about How to "Improve self-cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass ceramic and metal substrates with a self-cleaning surface, method for the production and use thereof

InactiveUS6872441B2Improve self-cleaningExcellent abrasion resistanceFouling preventionPretreated surfacesRough surfaceGlass-ceramic

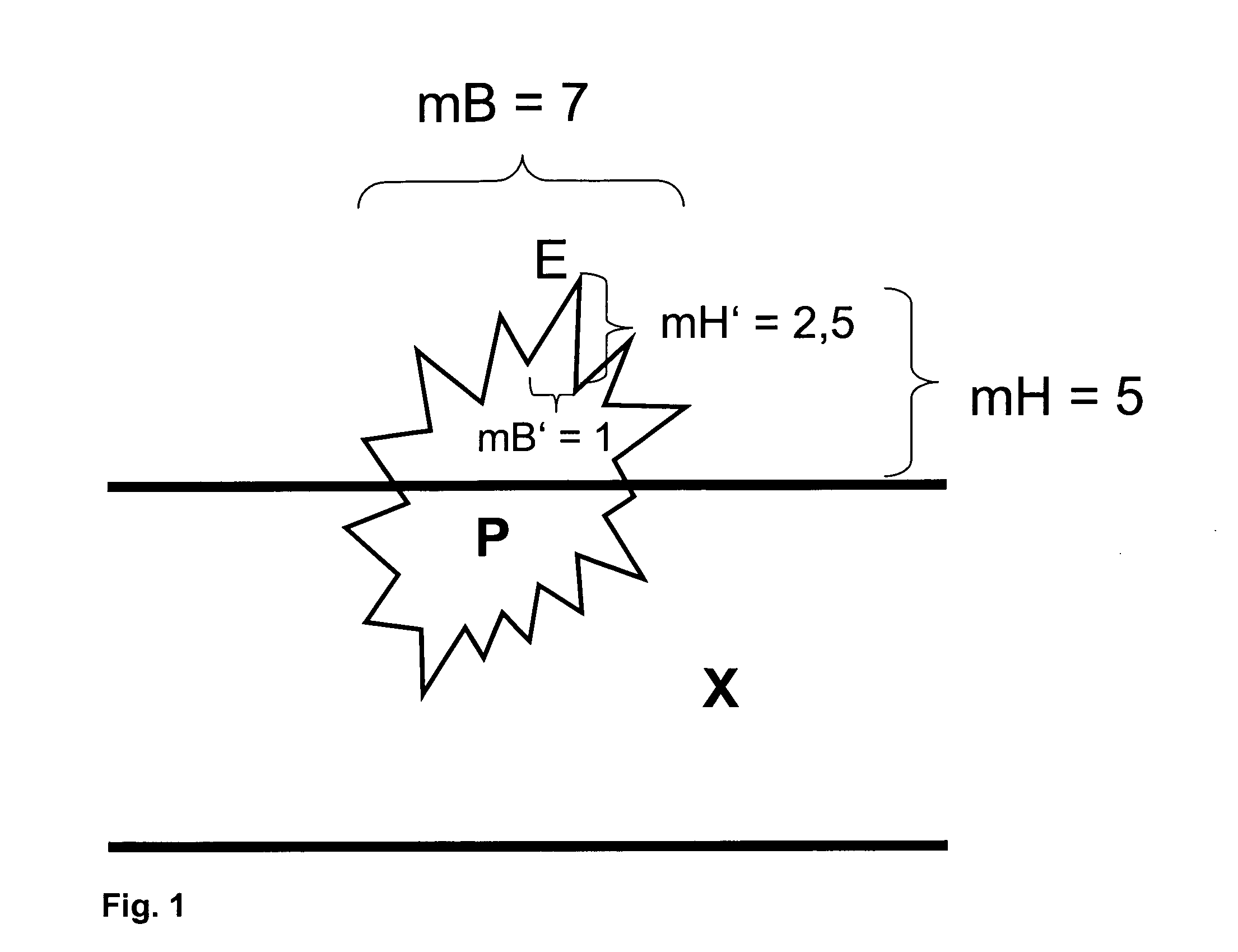

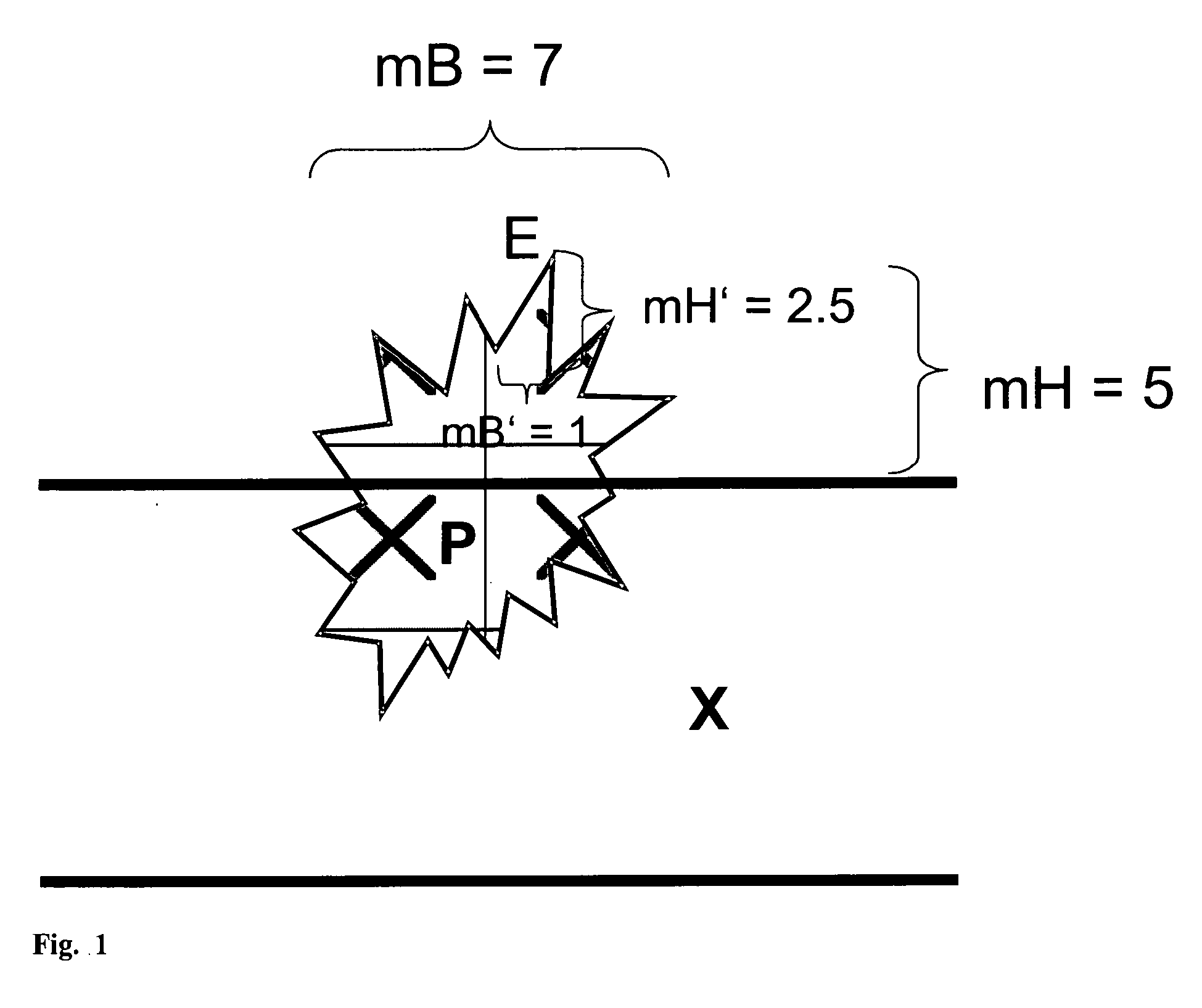

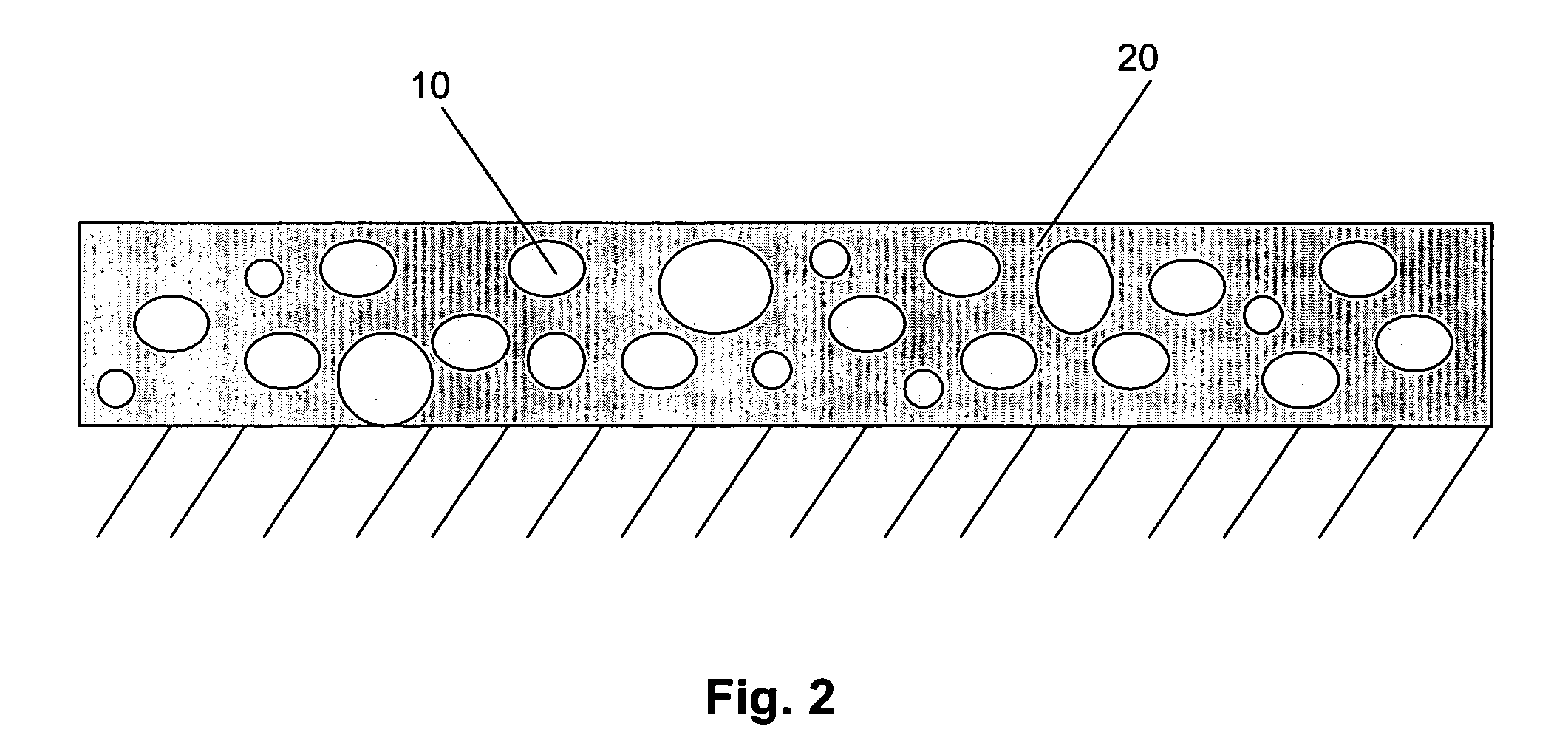

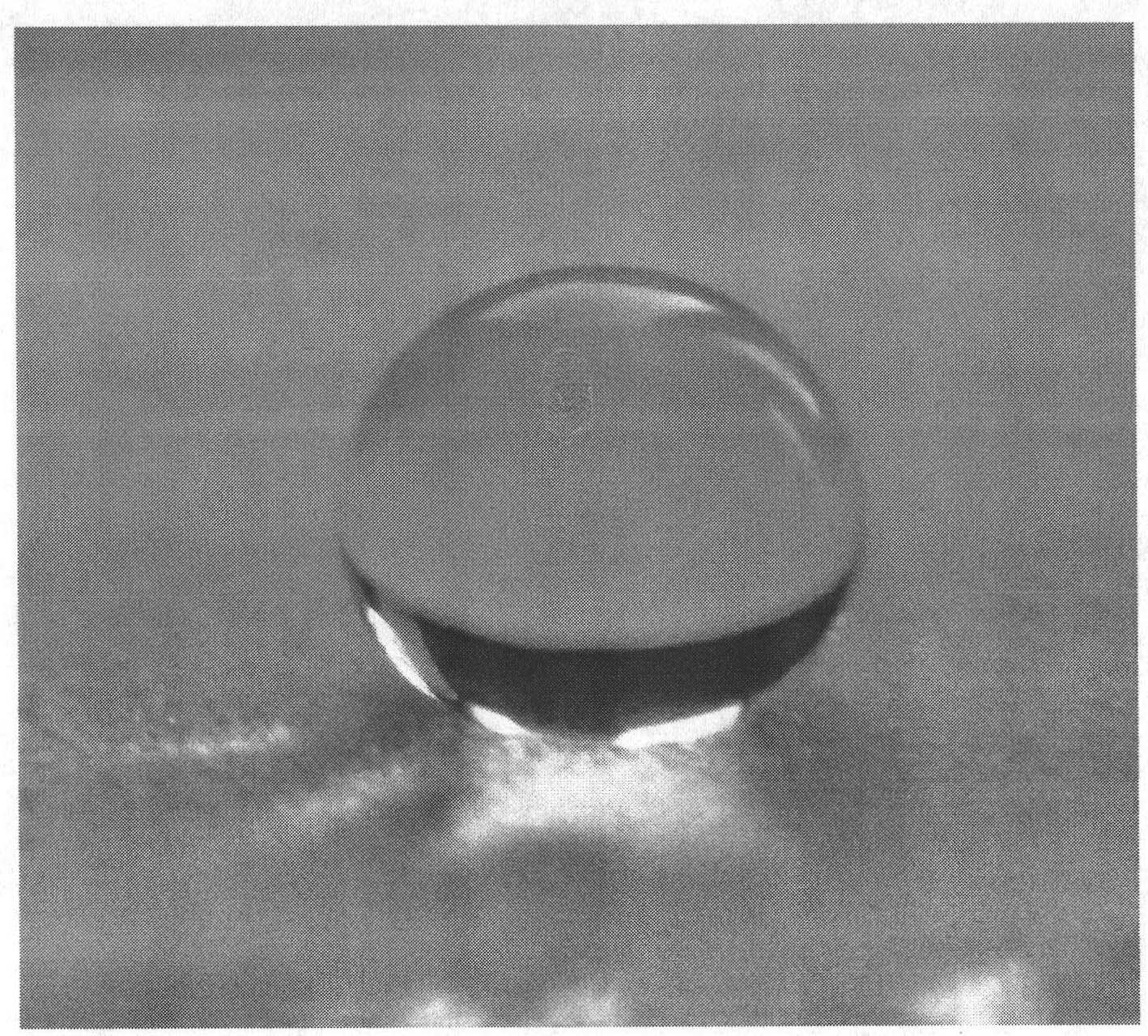

The invention relates to glass, ceramic and metal substrates with at least one self-cleaning surface, comprising a layer with a micro-rough surface structure which is arranged on the substrate and made at least partly hydrophobic. The layer contains a glass flux and structure-forming particles with a mean particle diameter within the 0.1 to 50 μm range; the glass flux and structure-forming particles are present in a volume ratio within the 0.1 to 5 range, and the micro-rough surface structure has a ratio of mean profile height to mean distance between adjacent profile tips within the 0.3 to 10 range.To produce the subject of the invention the substrate is coated with a composition containing a glass flux and structure-forming particles, and the layer is burnt in and made hydrophobic.

Owner:FERRO GMBH

Textile substrates having self-cleaning properties

InactiveUS20060172641A1Simple processImprove the level ofLotus effect fibresSynthetic resin layered productsFiberPolymer science

The present invention relates to a vapor-pervious water-impervious substrate, preferably a fibrous nonwoven web, which can be used in particular as a textile continuous sheet material, for example as an awning or as an inlet in apparel. The substrate according to the present invention may have self-cleaning properties. The substrate according to the present invention is simple to produce in an at least two-step process wherein a coating on the fibers of the substrate is produced in the first step and then hydrophobic particles are applied to the coated fibers by means of an adhesion promoter.

Owner:EVONIK DEGUSSA GMBH

Multi-layer coatings with an inorganic oxide network containing layer and methods for their application

InactiveUS7354650B2Good antifoulingImprove self-cleaningAlkali metal silicate coatingsPretreated surfacesAnti-fogInorganic oxide

Multi-layer coatings are disclosed that include (1) a first layer comprising an inorganic oxide network, and (2) a second layer applied over at least a portion of the first layer, wherein the second layer is deposited from at least one liquid composition that is hydrophilic and includes an essentially completely hydrolyzed organosilicate. Also disclosed are substrates coated with such multi-layer coatings, methods of applying such multi-layer coatings to a substrate and methods for improving the anti-fouling, self-cleaning, easy-to-clean, and / or anti-fogging properties of an article.

Owner:PPG IND OHIO INC

Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

ActiveCN102010636AImprove hydrophobicityExcellent hydrophobic migrationAntifouling/underwater paintsSynthetic resin layered productsResin coatingDibutyltin dilaurate

The invention discloses a normal-temperature cured fluorocarbon resin coating, which consists of the following components in percentage by weight: 35 to 70 percent of tetrafluorochloroethylene-vinyl ester polymer, 5.5 to 12 percent of curing agent, 2 to 10 percent of coupling agent, 1 to 10 percent of pigment, 1 to 30 percent of hydrophobic particles, 0.03 to 3 percent of aid, 20 to 40 percent ofsolvent and 0.001 to 1 percent of catalyst, wherein the coupling agent is fluorosilane with a -CF3 group and a -CF2 group; the aid is a flatting agent, an antifoaming agent and a dispersing agent; the solvent is butyl acetate and methyl isobutyl ketone; the catalyst is dibutyltin dilaurate; and the curing agent is aliphatic diisocyanate. By adopting a specific coating formula, due to the combinedaction of the fluorosilane coupling agent and the hydrophobic particles, the anti-pollution flashover fluorocarbon resin coating has a static contact angle theta of 120 degrees, is excellent in hydrophobic performance and hydrophobic migration property, high in anti-pollution flashover performance, high in coating leveling property, smooth in surface, and high in self-cleanliness, chemicals resistance and hot-water resistance, and has an adhesive force reaching a zero level.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Water fluorine-carbon nanapaint and producing process thereof

A water F-C nano paint is prepared from aqueous vinyl F-C emulsion as filming liquid, nano material as modifier, pigment, filler, assistant and water. Its advantages are smooth surface, high weatherability, self-cleaning power, chemical resistance and durability, and low cost.

Owner:上海开来湿克威防水材料有限公司 +1

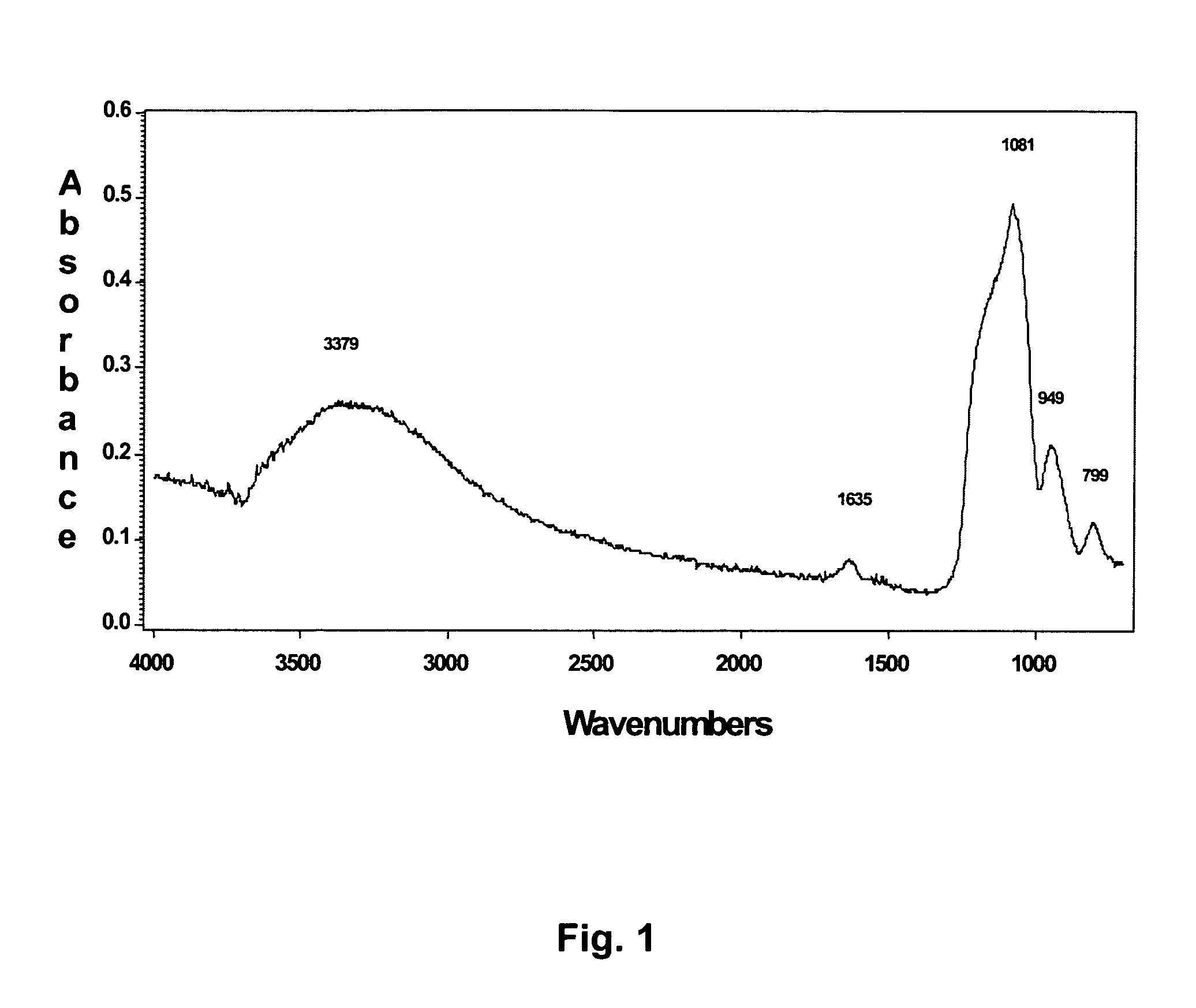

Nano silicon dioxide emulsion, its preparation method and application

InactiveCN1536032AImprove hydrophilicityGood dispersionEmulsion paintsPigment treatment with non-polymer organic compoundsWater basedEmulsion

The present invention discloses a nano silicon dioxide emulsion, its preparation method and application. Said emulsion contains nano silicon dioxide, silane coupling agent, surfactant and water. The described nano silicon dioxide and the described silane coupling agent are combined into a hydrophobic particle, and the described hydrophobic particles are covered with surfactant, and dispersed in the water. Its preparation method includes the following steps: adding water-soluble alcohol into the colloid solution of silicon dioxide in the water, then adding silane coupling agent and adding surfactant and water; another preparation method includes the following steps: adding water-soluble alcohol or aqueous solution of described alcohol into nano silicon dioxide gel, then adding silane coupling agent, surfactant and water. Said emulsion can be directly added into the water-based paint, and can be used for modifying water-based paint and improving various properties of the water-based paint.

Owner:ZHEJIANG YUDA CHEM IND

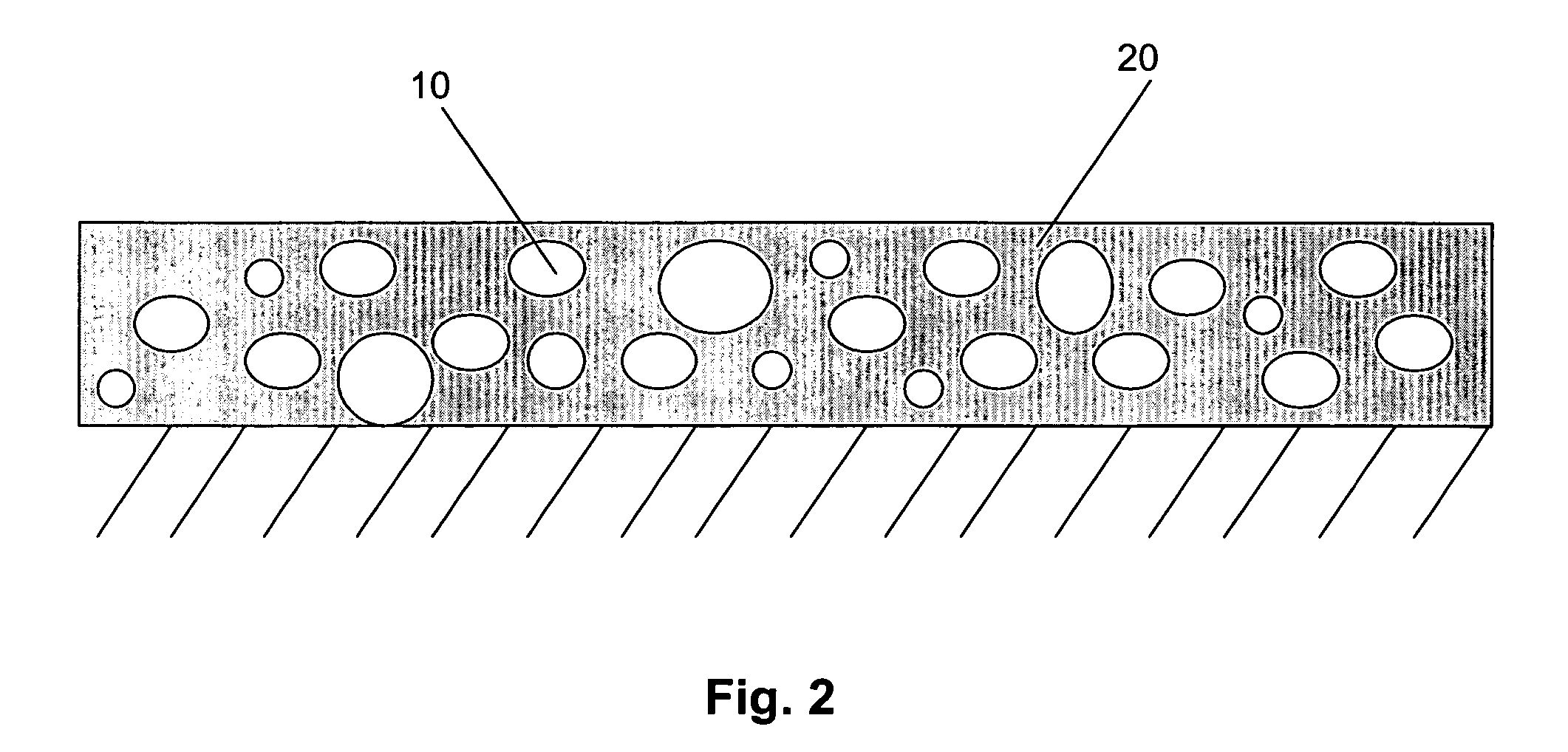

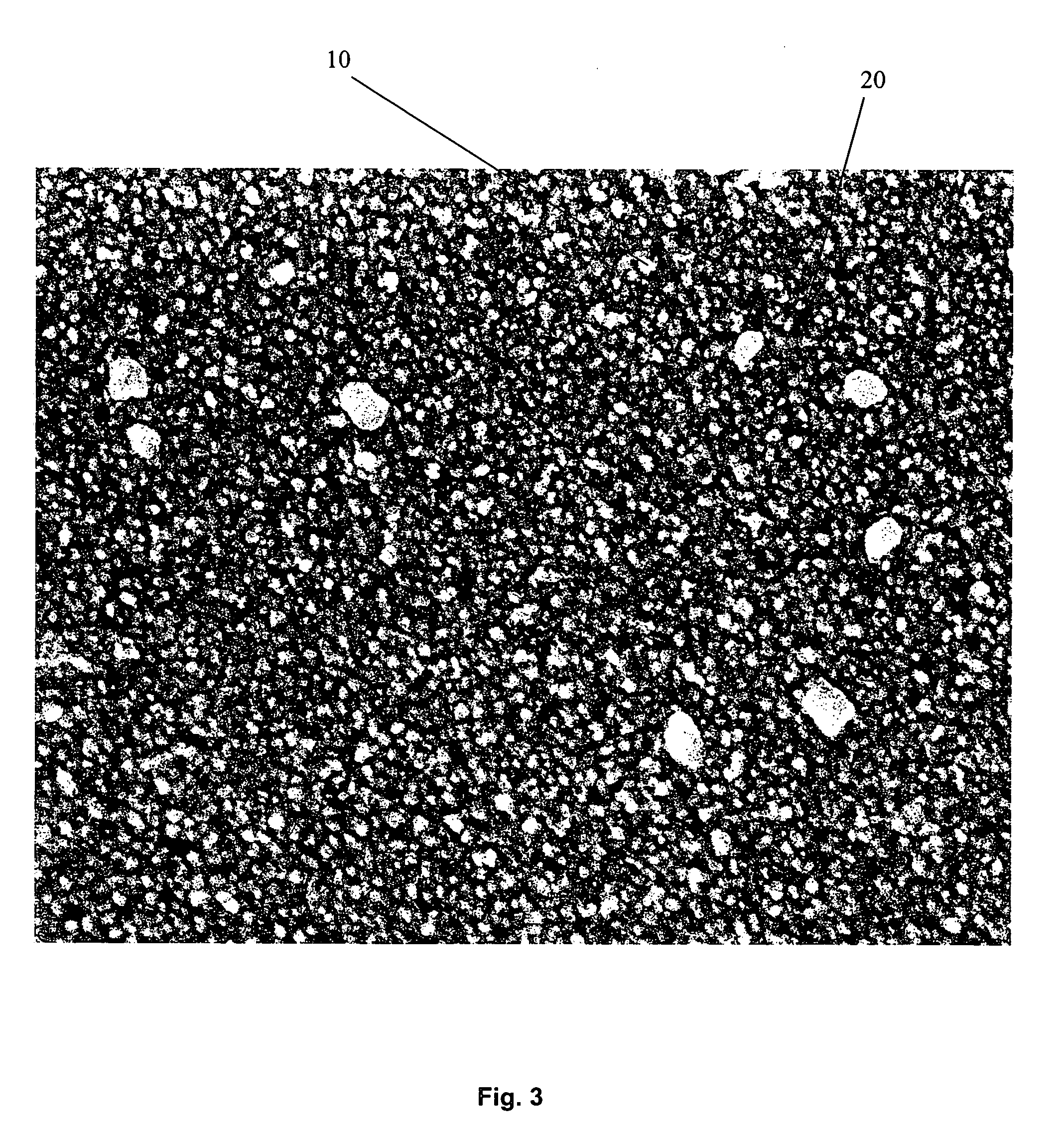

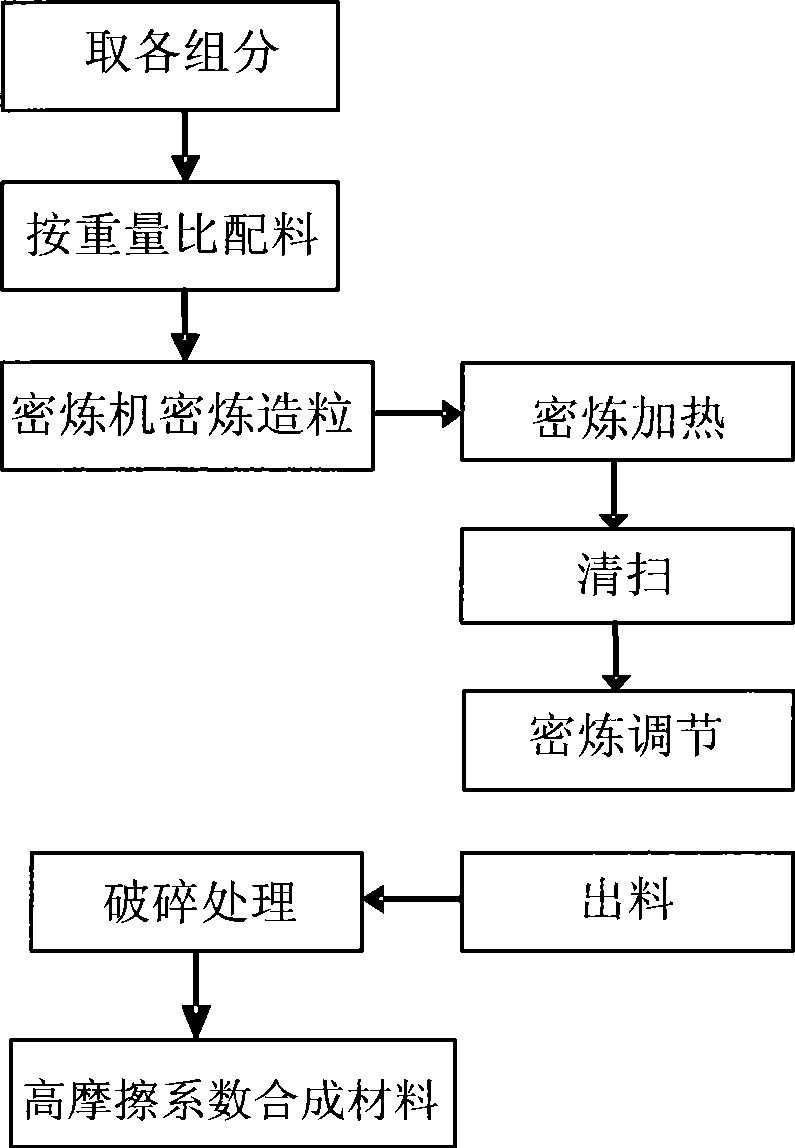

High friction coefficient synthetic materials and preparation method thereof

The invention discloses a high friction coefficient composite material and a manufacturing method thereof, wherein the material is prepared through material sealing and grain-making processing by the following compositions in weight percentage: 8 to 13 percent of butadiene-acrylonitrile rubber, 2 to 10 percent of styrene-butadiene rubber, 5 to 10 percent of cresol methyl-stage phenol-formaldehyde resin modified, 15 to 30 percent of steel fiber, 10 to 15 percent of magnesia, 5 to 10 percent of calcined petroleum coke, 2 to 5 percent of silicon carbide, 10 to 25 percent of mineral fiber, 5 to 10 percent of calcium hydroxide, 10 to 20 percent of barium sulfate, 5 to 10 percent of graphite, 1 to 5 percent of supramoly, 1 to 5 percent of carbon black, 1 to 3 percent of sulfur and 1 to 3 percent of accelerant. The material can be applied in a plurality of situations to prepare friction components, has stable friction performance and good abrasion resistance, effectively inhibits the phenomena of metal inlay, cracking, chip off-falling and so on, reduces the damage on vehicle wheels, has good impact resistance and good weathering resistance, can be used in the environment with large temperature variation for a long time, and has the application characteristics of wide application region and large difference of the regional environment.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

Enhancing the watertightness of textile sheetlike constructions, textile sheetlike constructions thus finished and use thereof

InactiveUS20060141223A1Improve water vapor permeabilityReduce penetrationLiquid surface applicatorsFibre treatmentFiberEngineering

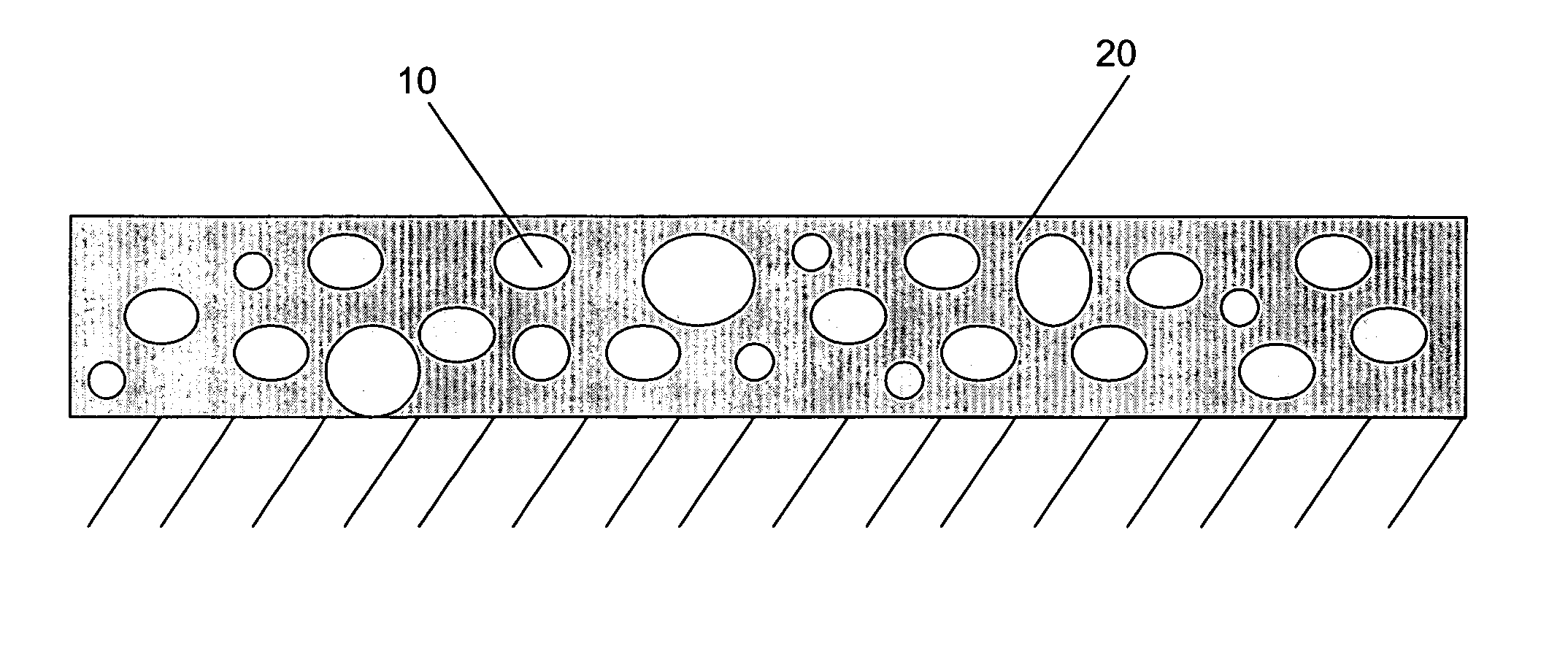

The present invention relates to textile sheetlike constructions having an enhanced watertightness and also to a process for producing them. It was found that, surprisingly, the watertightness of porous textile sheetlike constructions is enhanced when a coating of hydrophobic particles having an average particle size in the range from 0.02 to 100 μm is applied to the surfaces of the fibers. The textile sheetlike constructions can be used for example as textile building materials or for producing tents, umbrellas or the like.

Owner:CARL FREUDENBERG KG PARTIAL INTEREST

Enhancing the watertightness of textile sheetlike constructions, textile sheetlike constructions thus enhanced and use thereof

InactiveUS20060156475A1Simple processWater vapor permeabilityFibre treatmentSynthetic resin layered productsFiberEngineering

The present invention relates to textile sheetlike constructions having an enhanced watertightness and also to a process for producing them. It was found that, surprisingly, the watertightness of porous textile sheetlike constructions is enhanced when a coating of hydrophobic particles having an average particle size in the range from 0.02 to 100 μm is applied to the surfaces of the fibers. The textile sheetlike constructions can be used for example as textile building materials or for producing tents, umbrellas or the like.

Owner:CARL FREUDENBERG KG PARTIAL INTEREST

Multi-layer coatings with an inorganic oxide network containing layer and methods for their application

InactiveUS20050266235A1Good antifoulingImprove self-cleaningAlkali metal silicate coatingsPretreated surfacesAnti-fogInorganic oxide

Multi-layer coatings are disclosed that include (1) a first layer comprising an inorganic oxide network, and (2) a second layer applied over at least a portion of the first layer, wherein the second layer is deposited from at least one liquid composition that is hydrophilic and includes an essentially completely hydrolyzed organosilicate. Also disclosed are substrates coated with such multi-layer coatings, methods of applying such multi-layer coatings to a substrate and methods for improving the anti-fouling, self-cleaning, easy-to-clean, and / or anti-fogging properties of an article.

Owner:PPG IND OHIO INC

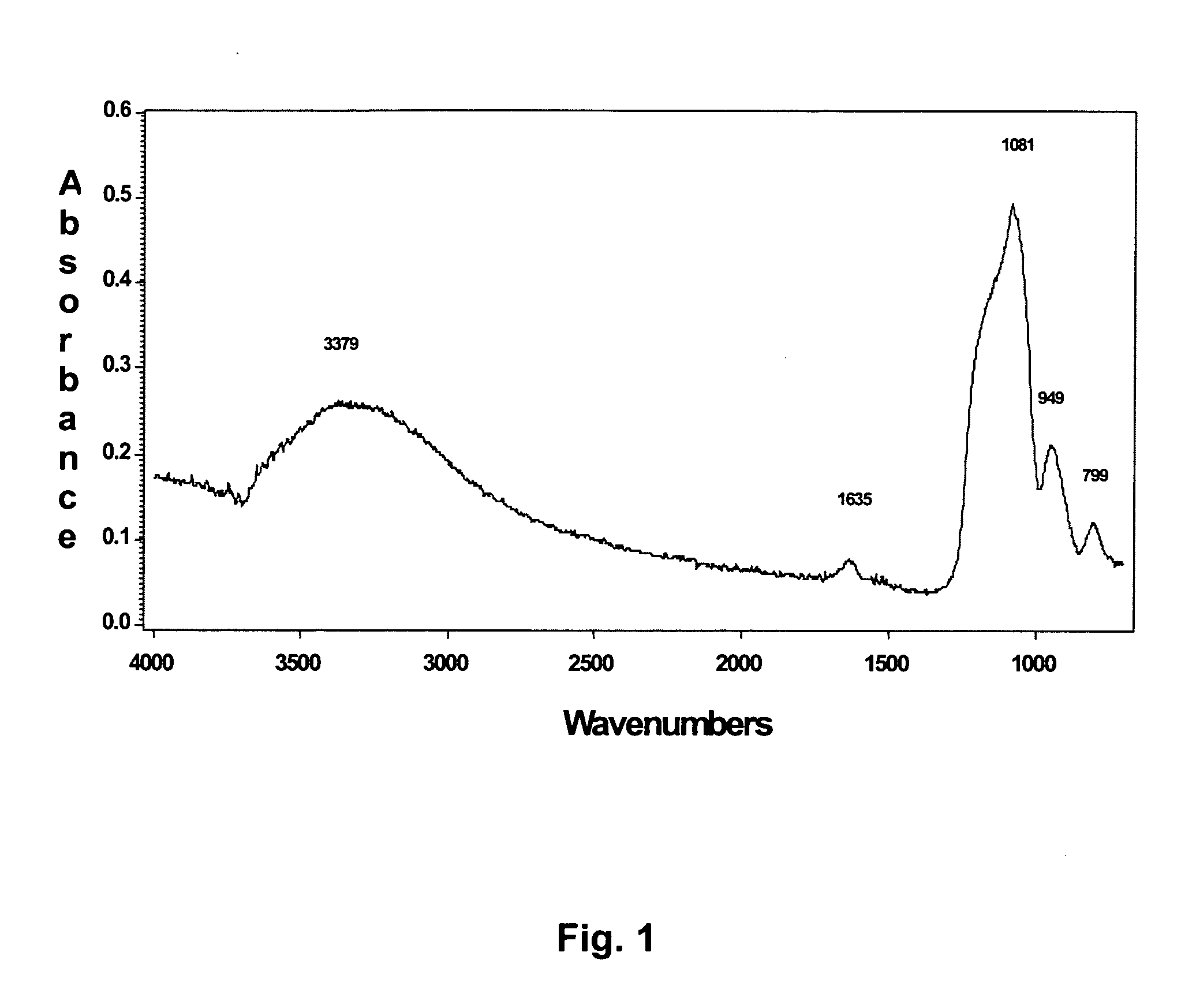

Method for preparing porous silicon dioxide antireflective film with controllable refractive index

The invention provides a method for preparing porous silicon dioxide antireflective film with controllable refractive index, which adopts the method of first base catalysis and then acid catalysis for preparing coating liquid and is suitable for dip coating or spraying process or spin-coating method. Porous silicon dioxide basement film layer is coated on a base plate; and the base plate with porous silicon dioxide basement film layer is processed under high temperature so as to obtain the silicon dioxide film layer. The film layer which is prepared by the invention has the advantages of high hardness, high chemical stability, good self-cleaning capability and broadband antireflection.

Owner:杭州光学精密机械研究所

Cutter bar

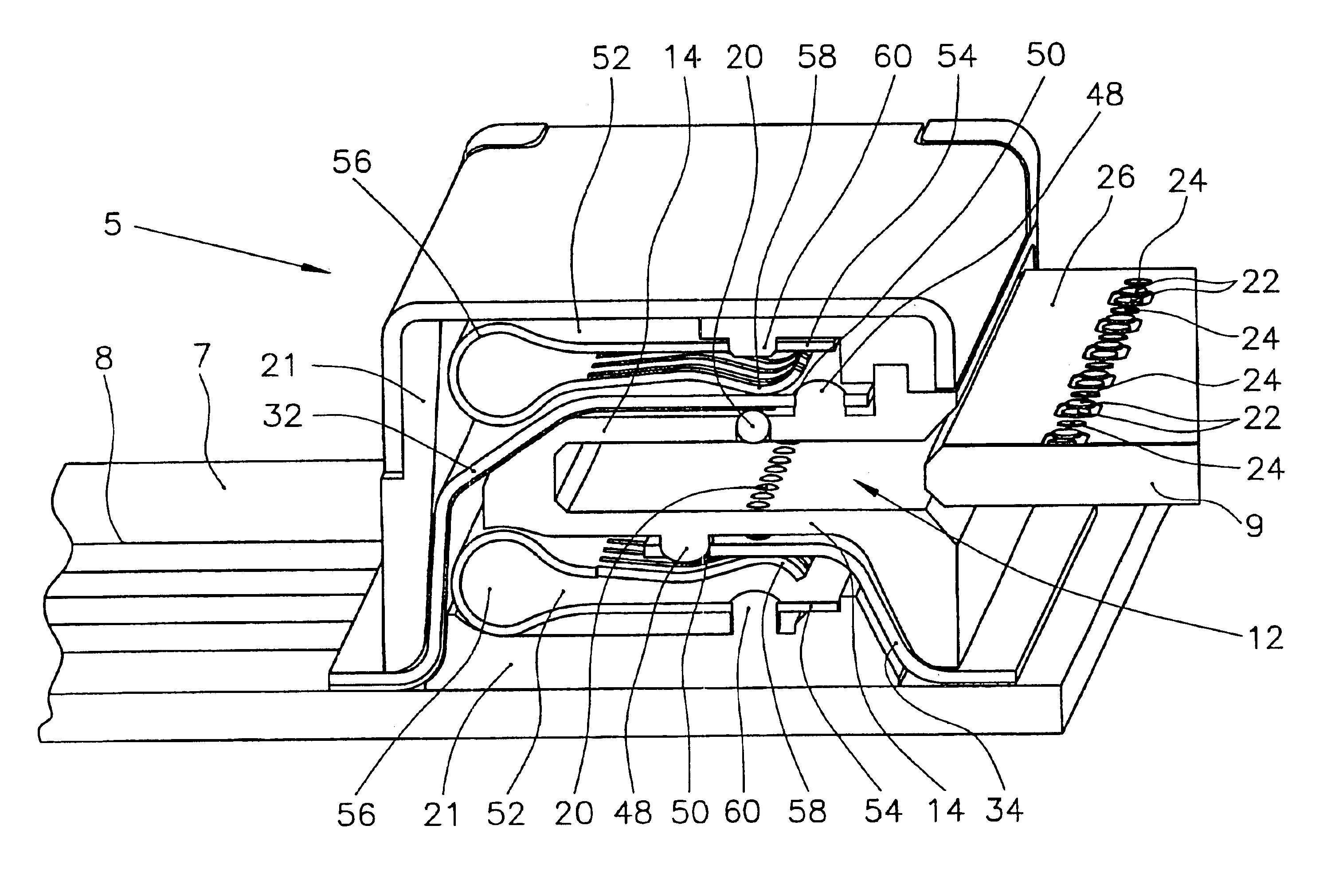

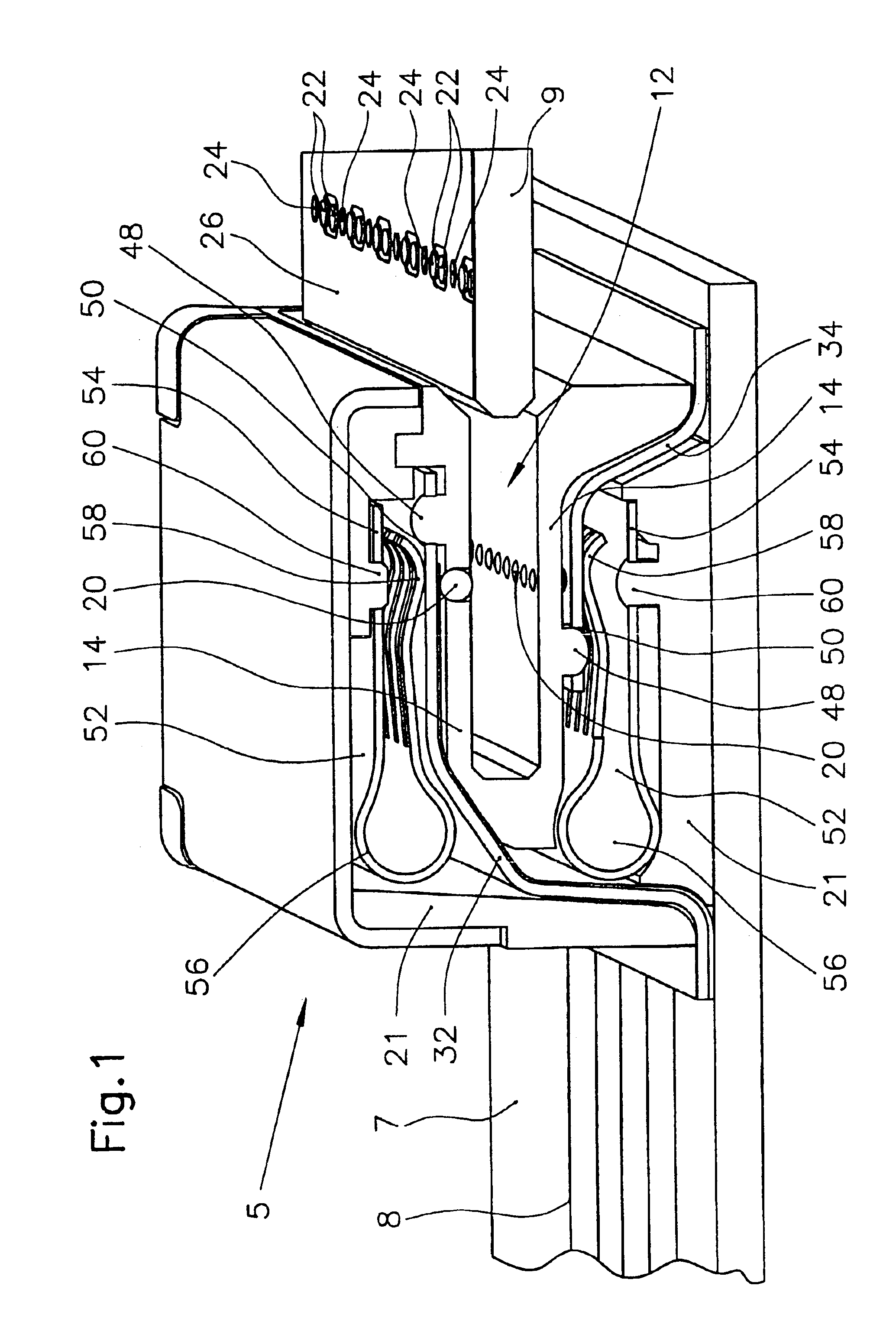

ActiveUS7313903B2Solution to short lifeNo frictional resistance between the knife and the finger barMowersTransverse axisGear wheel

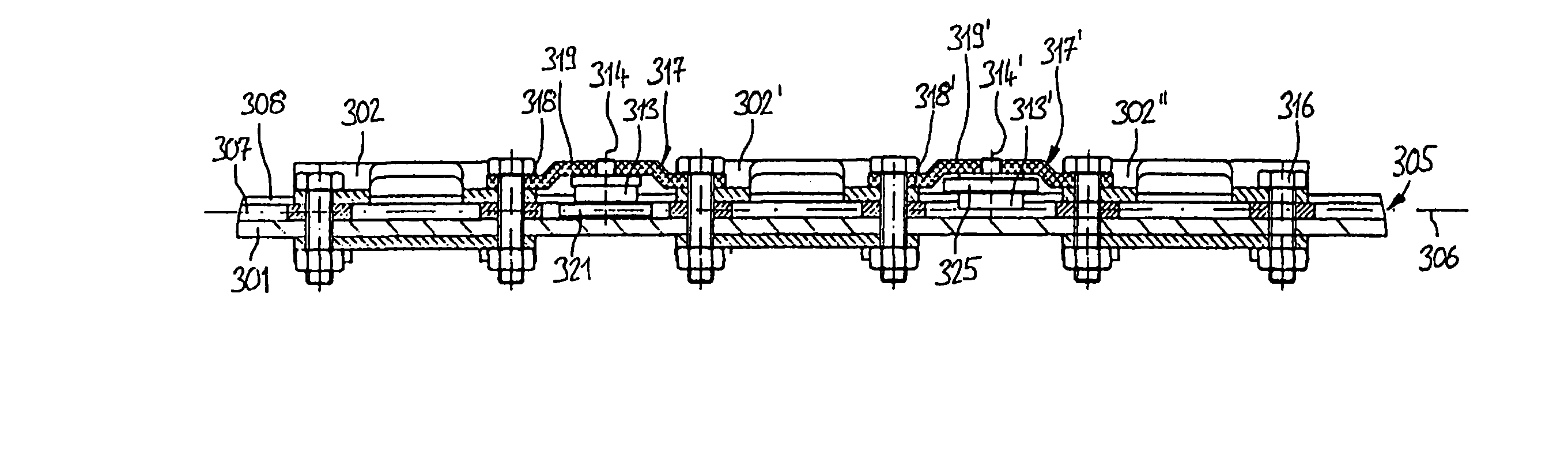

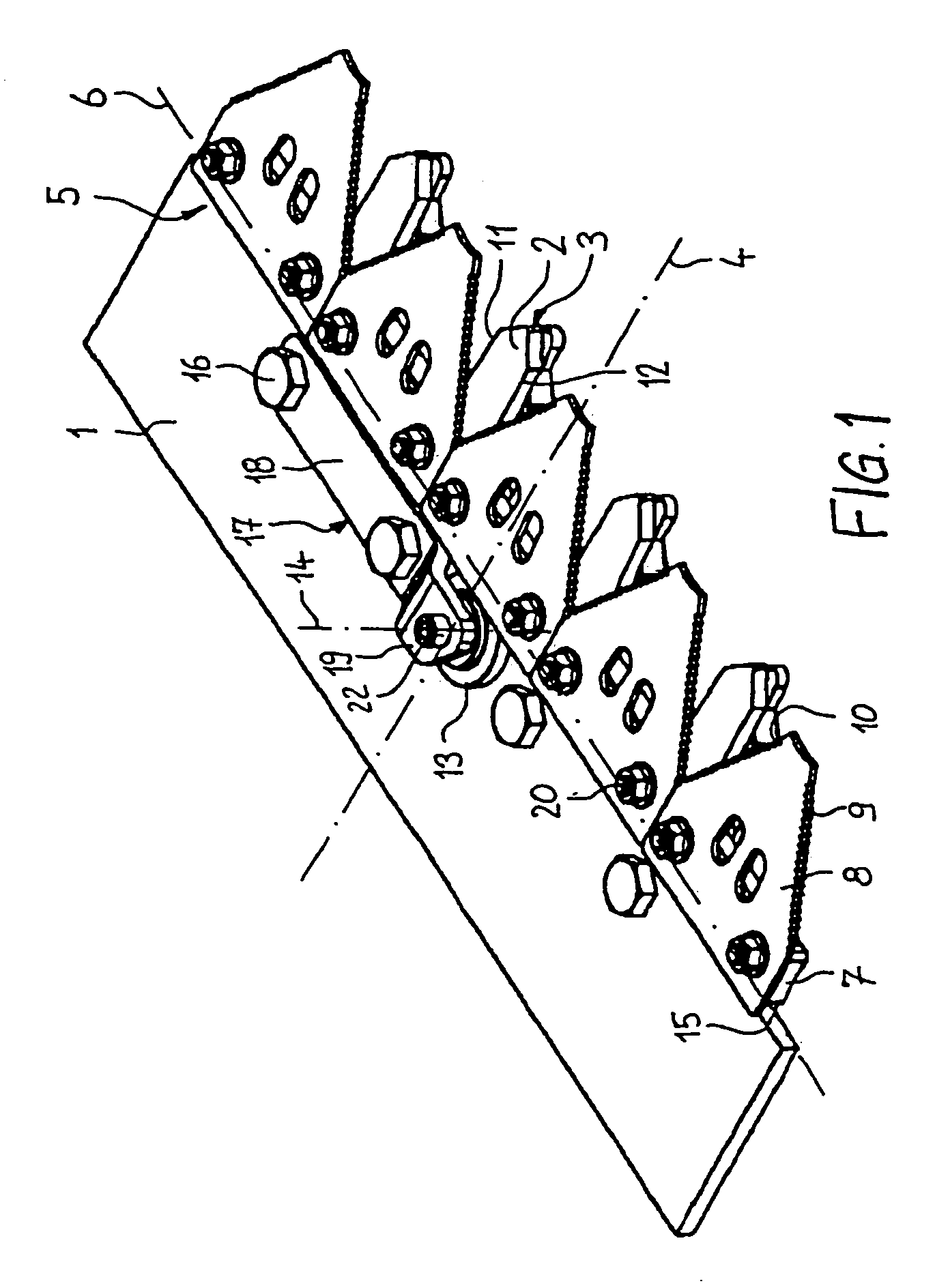

The invention relates to a reciprocating cutting bar for the cutting gear of an agricultural machine, comprising a longitudinal axis (4) along which the reciprocating cutting bar may be moved in a working direction for crop cutting, a finger bar (1), cutting fingers (2), which are fixed to the finger bar (1), each forming counter cutters (11), a knife (5) with a knife bar (7), having knife blades (8) fixed to the knife bar (7) which each have cutters (9), whereby the knife (5) is made to oscillate relative to the finger bar (1) along a transverse axis (6), which is arranged horizontally and perpendicular to the longitudinal axis (4), rollers (13), by means of which the knife (5) is supported against the finger bar (1) to the rear when viewed in the working direction. The rollers (13) are each mounted to rotate on a roller holder (17) and the roller holders (17) are fixed to the finger bar (1).

Owner:SCHUMACHER GUSTAV

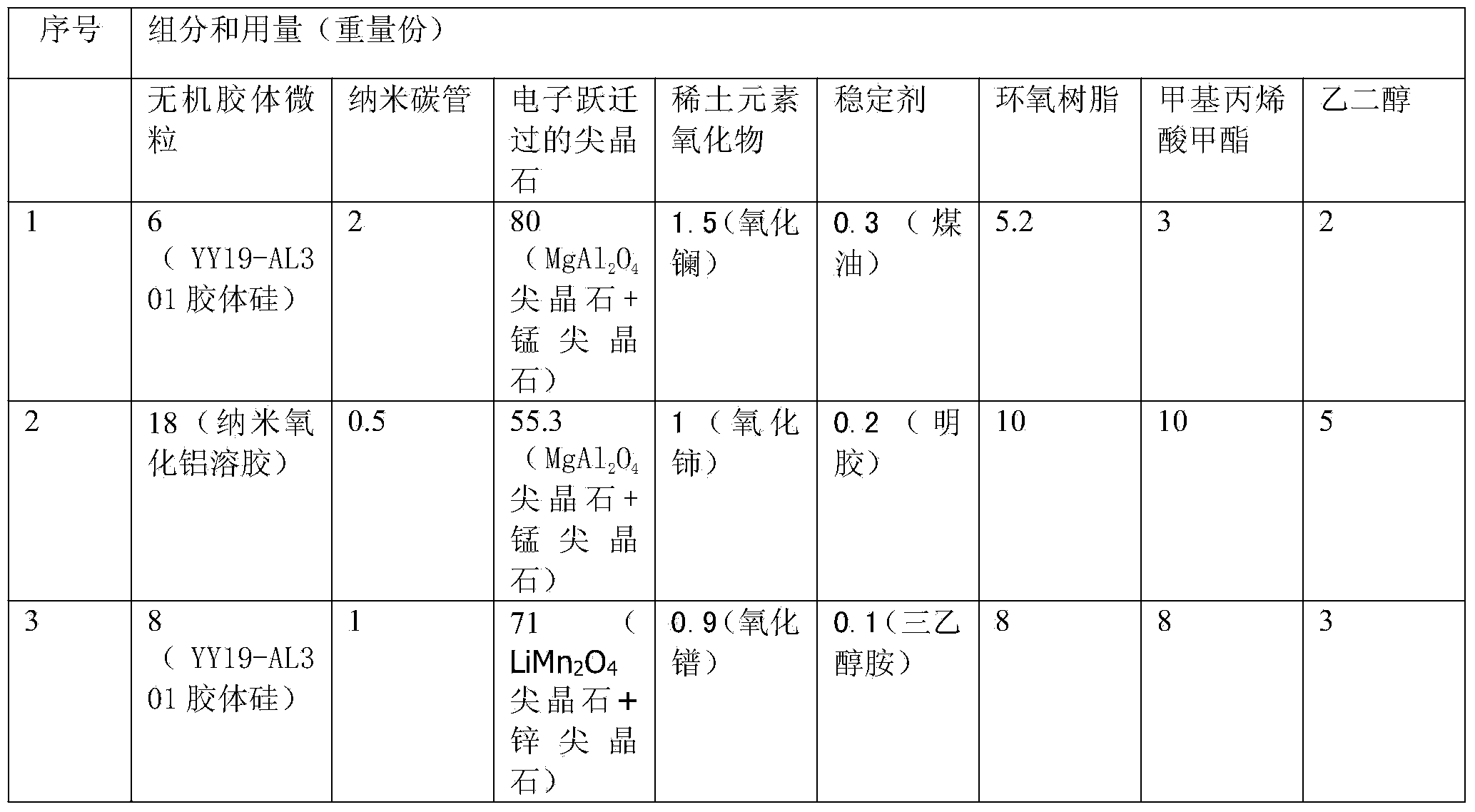

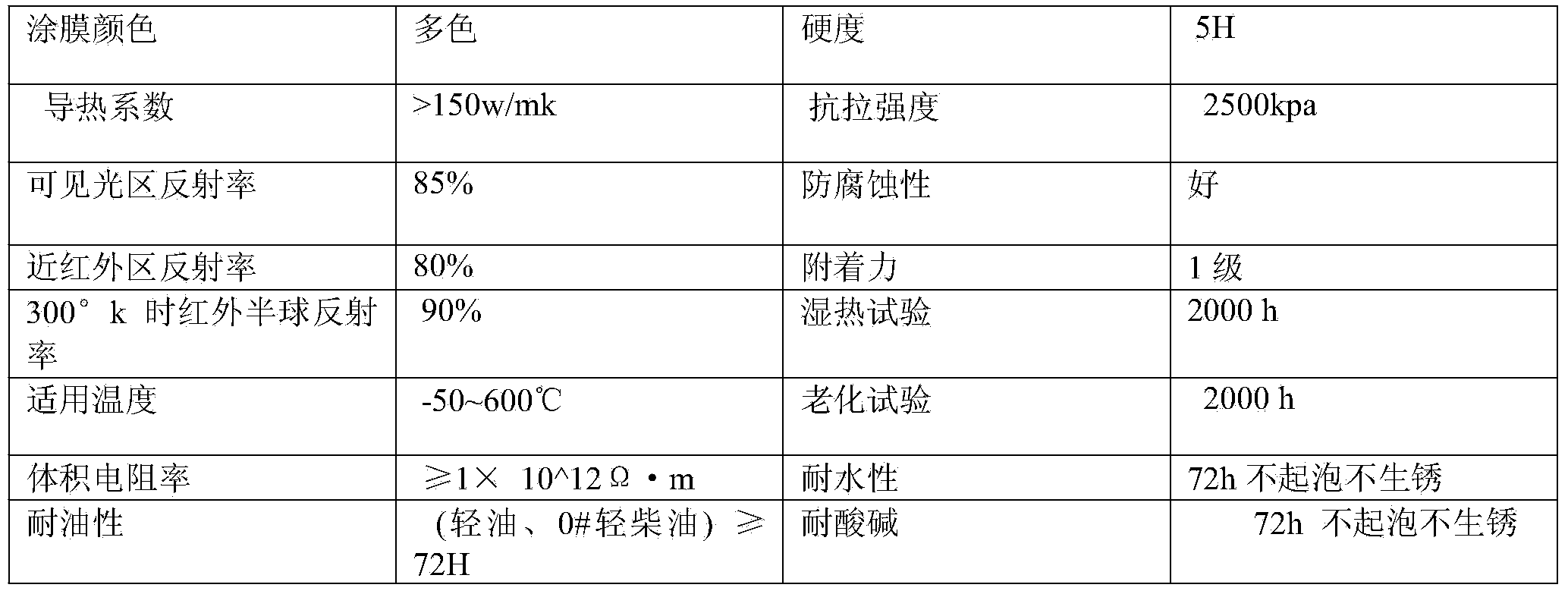

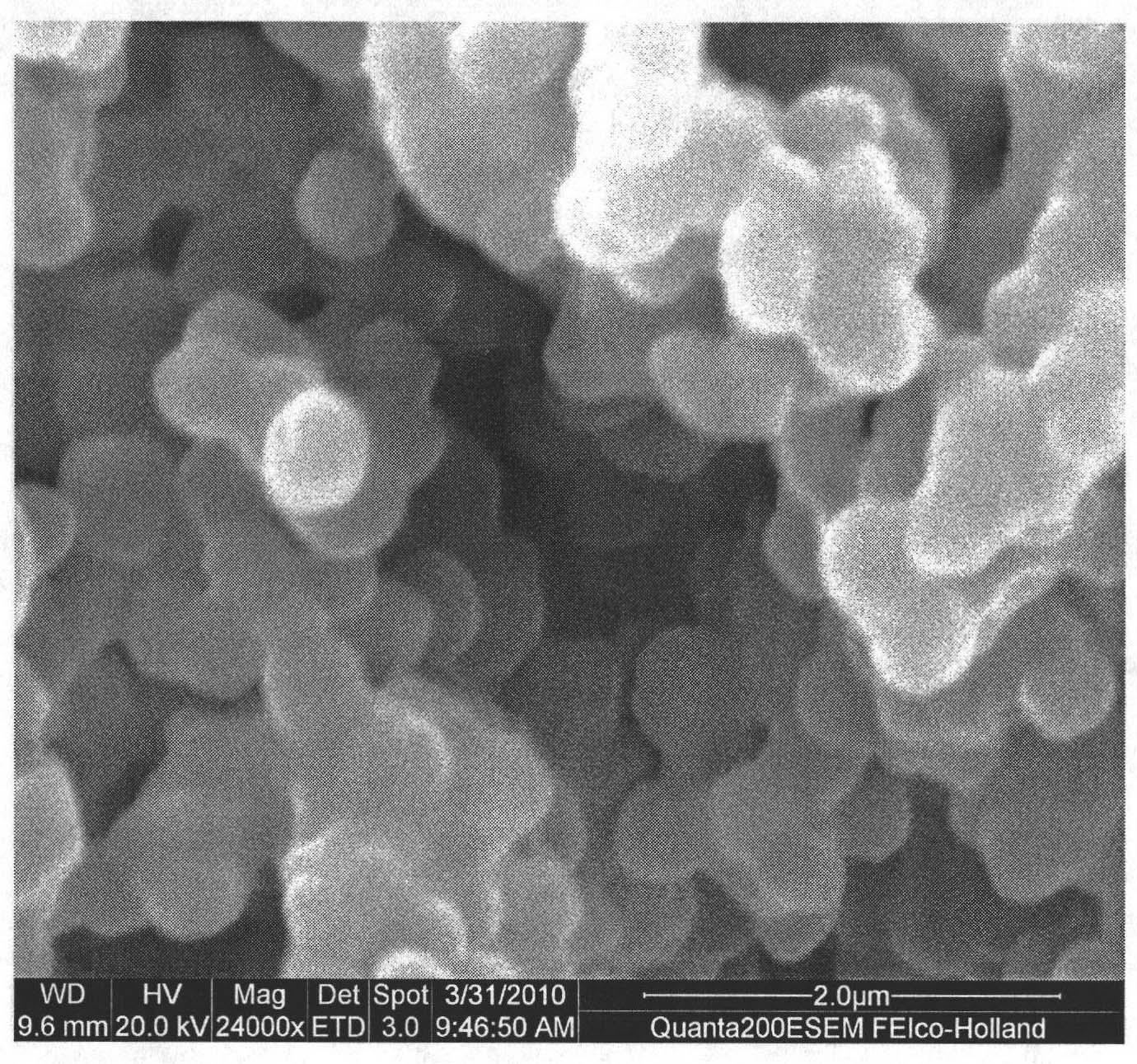

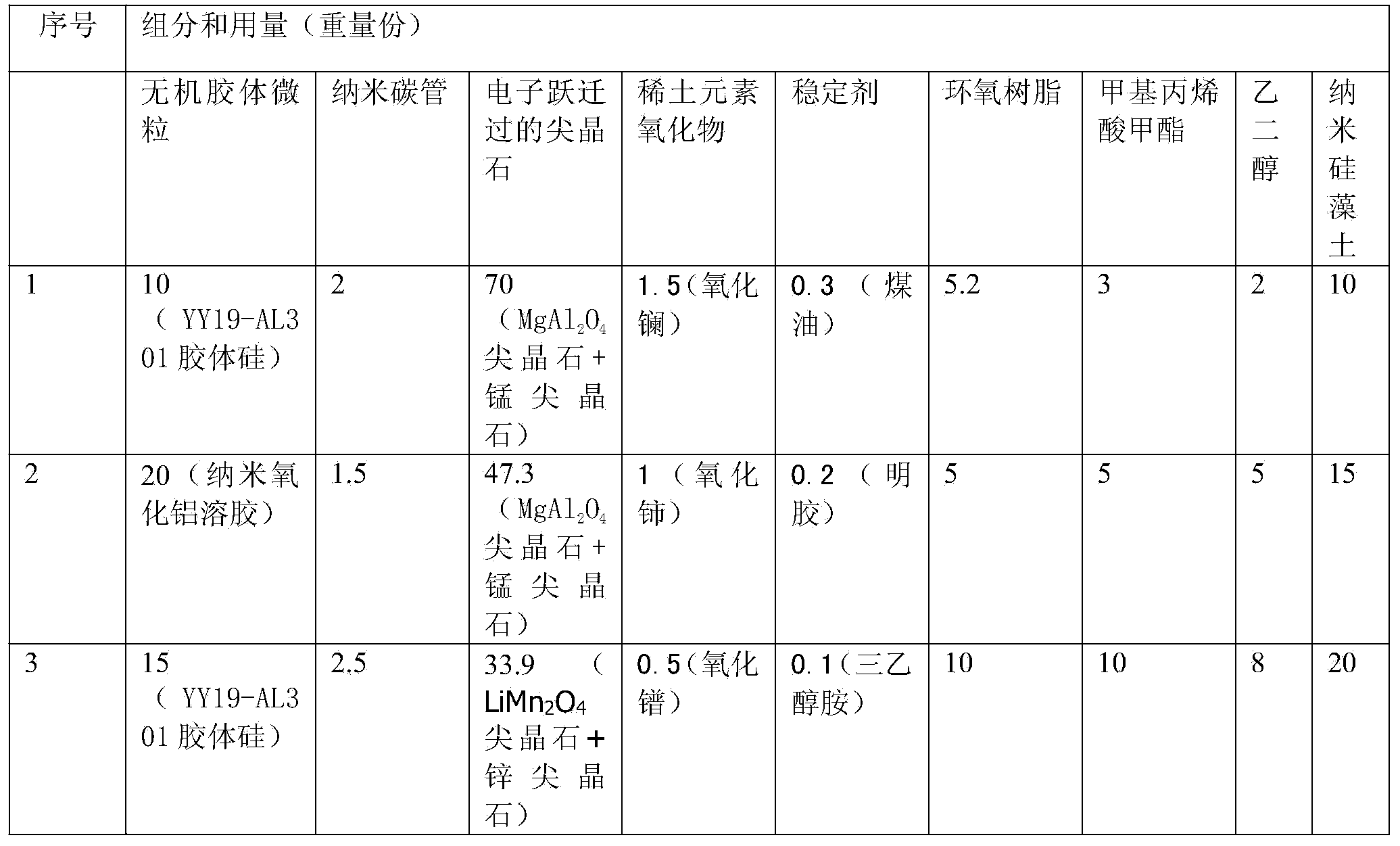

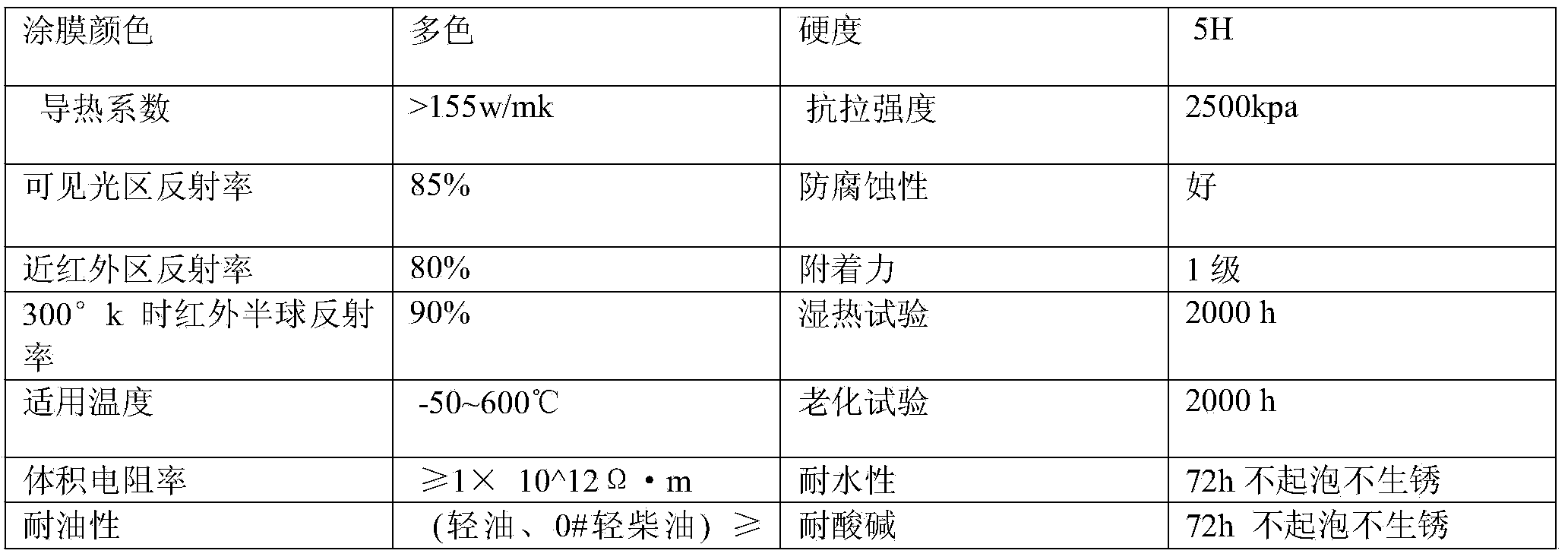

Coating for cooling surface of light-emitting diode (LED) radiator

ActiveCN103965671AGood self-cleaningEasy constructionReflecting/signal paintsRare-earth elementCorrosion

The invention discloses a coating for cooling the surface of a light-emitting diode (LED) radiator. The coating is characterized by being prepared from the following components in parts by weight: 6-20 parts of inorganic colloidal particle, 0.5-2 parts of carbon nano-tube, 15-80 parts of electron transition spinel, 0.05-2 parts of rare-earth element oxide, 0.1-0.3 parts of stabilizer, 3-10 parts of epoxy resin, 3-10 parts of methyl methacrylate and 2-5 parts of ethylene glycol. The coating has obvious heat dissipating and cooling effects, is not affected by surrounding medium when taking the cooling effect, can be used in a vacuum environment, also has the advantages of good self-cleaning property, corrosion resistance, waterproofness, fire retardancy, insulativity, and acid and alkali resistance, and convenient construction when taking a radiation cooling effect.

Owner:NINGBO AISHI ELECTRIC EQUIP

Method for preparing styrene grafted silicon dioxide superhydrophobic thin film

The invention discloses a method for preparing a styrene grafted silicon dioxide superhydrophobic thin film, which comprises: firstly, adding tetraethoxysilane into mixed solution of a catalyst and an alcohol solvent to obtain nano silicon dioxide spheres by reaction; secondly, adding the nano silicon oxide spheres into the alcohol solvent, and adding a silane coupling agent and the catalyst to obtain vinyl modified nano silicon oxide spheres; and finally, adding the vinyl modified nano silicon oxide spheres into a benzene or ketone organic solvent, adding an initiator and a styrene monomer in turn to obtain the styrene grafted silicon dioxide spheres, dispersing the styrene grafted silicon dioxide under ultrasonic waves, and preparing the styrene grafted silicon dioxide by using an organic or inorganic material as a substrate and by a coating method. The preparation process is simple and high in repeatability, the cost is low, and the promotion is more convenient.

Owner:QILU UNIV OF TECH

Thermal insulative coating and preparing method thereof

InactiveCN1583895AIsolated conductionGood weather resistanceFireproof paintsPetrochemicalMaterials science

The sun-proof coating of a kind of heat insulation and method of preparing, are suitable for various kinds of vehicles, shipping, all kinds of pots in the petrochemical industry, the trough, the appearance of the pipeline, and the outer walls of all kinds of buildings, the covering, the appearance of the tarpaulin insulates against heat, decorate and scribble to decorate using; Insulate against heat sun-proof coating join 1-30% of the hollow ceramic thermal insulator in invention this, form one pre -pressing vacuum layer things surface put to paint, a very ettective one isolate the sun ray radiation hot and heat radiation of air conduct, differ by with temperature not external inside not painting by object that put 4-8deg.C, great reduction energy very consume, the heat insulation coating of this invention has the good one and is able to bear the waiting, wearability is waterproof, since clean.

Owner:吕艺

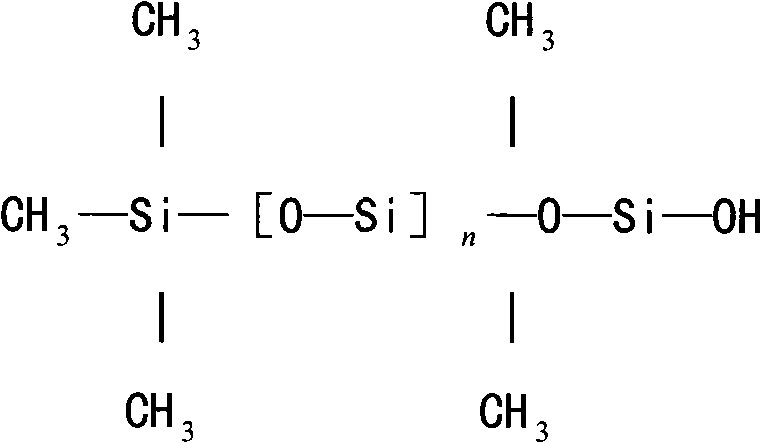

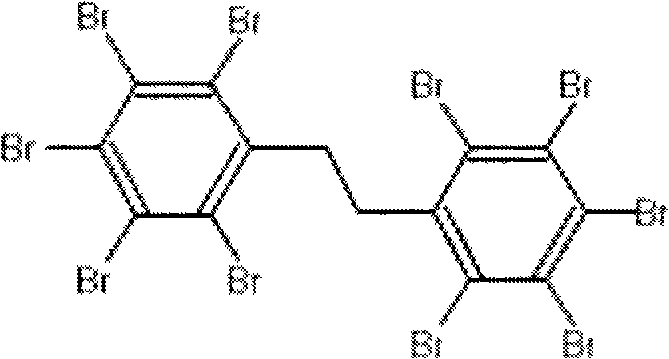

Nanometer enhanced type fluorosilicone rubber long-acting anti-fouling flashing coating

ActiveCN101338159AIncreased hydrophobic migration speedIncreased durability of hydrophobic migrationAntifouling/underwater paintsPaints with biocidesInsulation layerElectric power system

The invention provides a nanometer strengthening fluoride silicone rubber long-acting anti fouling and flashing coating material (nano PRTV coating material) which is used on an external insulation layer of a power system high pressure transmission and transformation device. The coating is composed of the following compositions (weight portion) of 20-40 percent of hydroxyl-fluoride containing polysiloxane, 2-5 percent of small molecular siloxane, 1-6 percent of cross linker, 0.02-1 percent of catalyst, 2-6 percent of nano silicon dioxide, 4-6 percent of decabromodiphenyl ethane, 1-2 percent of pigment and 30-50 percent of solvent. The coating provided by the invention is provided with perfect flame retardancy, solvent resistance, oil resistance, high and low temperature resistance and good self-cleaning performance. The surface of the coating material is smoother than dirt flash preventing coating material. Compared with the dirt flash preventing coating material, the coating material of the invention is greatly improved in aspects of hydrophobic migration speed, proportionality, sustainability, etc. Once filming can be realized. With the service life of more than 20 years, the coating material can be used permanently.

Owner:XIAN TAIPING ELECTRONICS TECH & DEVCO

Method for preparing polytetrafluoroethylene spatial structure building film material

The invention relates to a producing method of a teflon spatial structure membrane comprising following steps: fiberglass cloth low temperature genapping treatment, fiberglass cloth bottom layer dipping treatment, structure layer dipping treatment, surface layer dipping treatment and sintering treatment. Low temperature high speed genapping, multitime coating low-temperature treatment, and once hyperthermia flash sintering effectively reduce tensile strength descending caused by high-sintering treatment. Since fiberglass cloth is used as backing material, dipping treatment is not needed to be performed on the fiberglass yarn, the procedure is simplified to facilitate the production thereof, and shortcomings in prior art are overcome which are modified fiberglass yarn weaving difficulty and intensity and plasticity descending caused by multitime sintering. The teflon spatial structure membrane produced by using the invented method has a bottom layer, a structure layer and a surface layer, is provided with high pulling-against intensity, high tearing-against intensity, anti-aging property, good flexibility, good light-admitting quality and a long service life, and can be used widely in air stations, gymnasiums, exhibition halls, large-scale factory buildings and factory building warehouses.

Owner:JIANGSU VEIK TECH & MATERIALS CO LTD

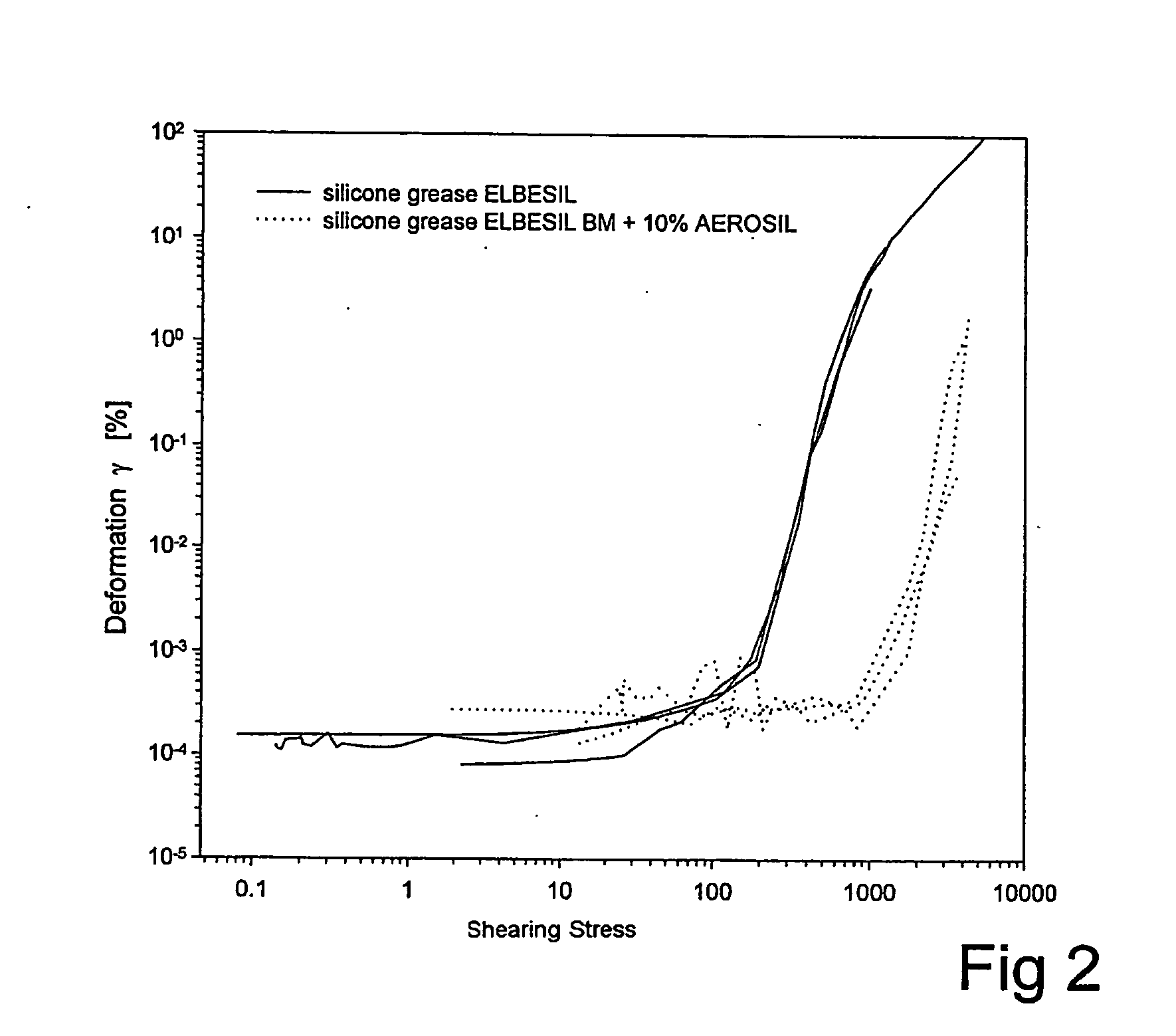

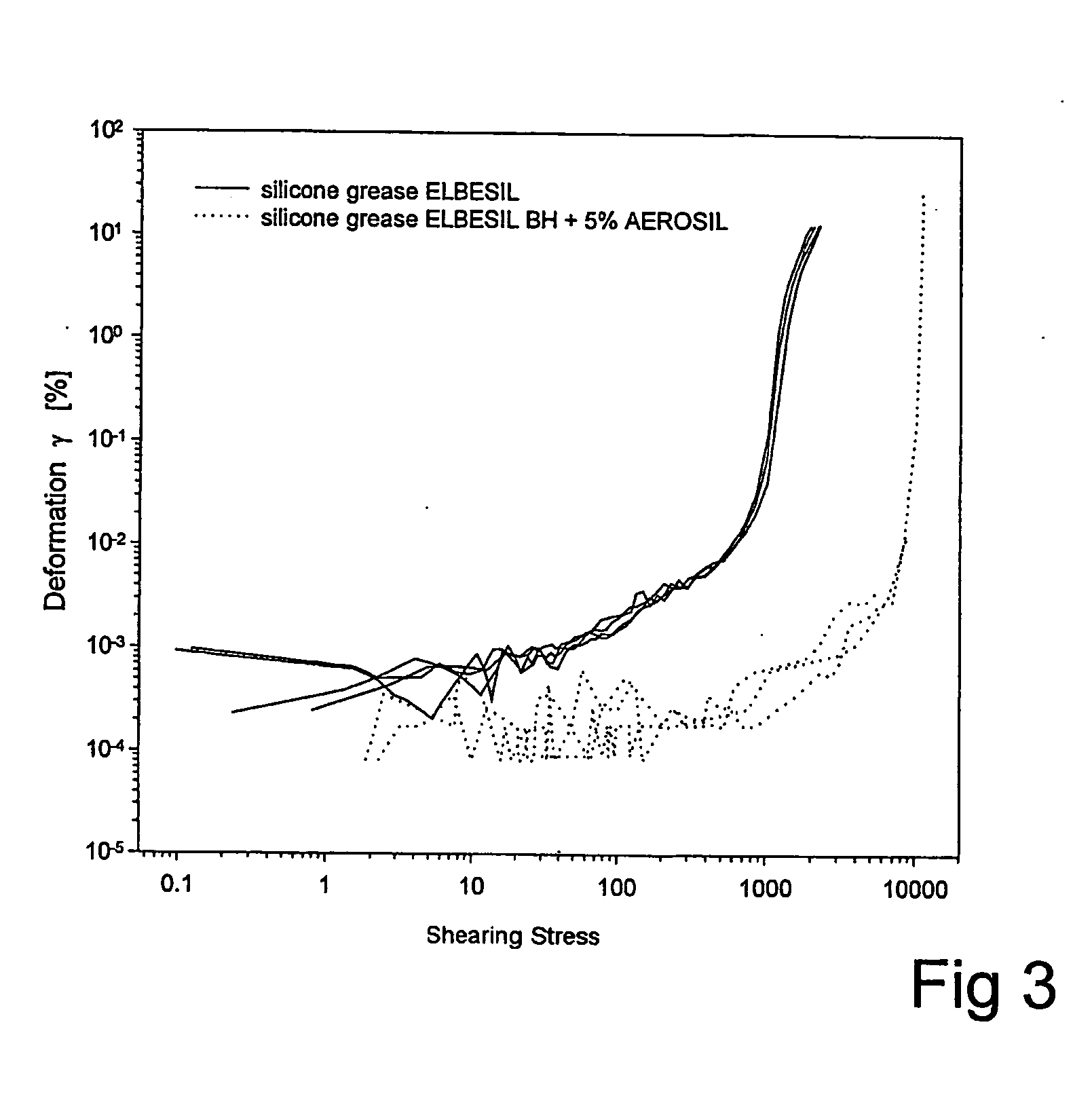

Viscoelastic coating paste for protecting against macrofouling and method for producing a coating

InactiveUS20060144286A1Improve antifouling performanceConvenient coatingFireproof paintsAntifouling/underwater paintsWall shearMacroscopic scale

A non-toxic anti-fouling coating paste having a rheologic switching behavior based on a flow point, which can be set to the hydrodynamic and biological environmental conditions of a submarine component to be protected and which is between 5 Pa and 2,000 Pa above the wall shearing stress of the unfouled component to form a substrate which prevents colonization by marine fouling organisms.

Owner:CGGVERITAS SERVICES HLDG U S +1

Heat cooking apparatus and self-cleaning material and producing method thereof

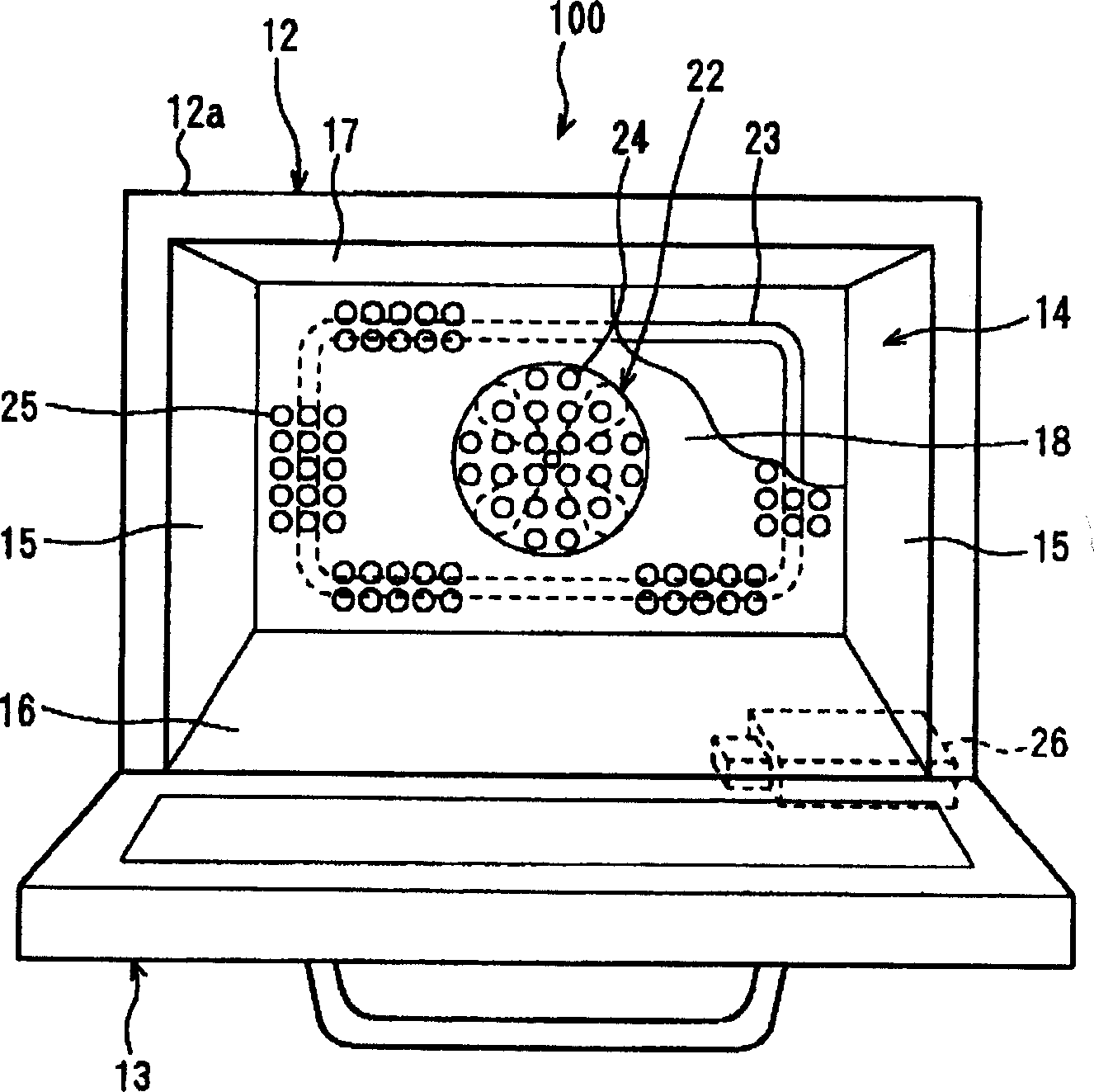

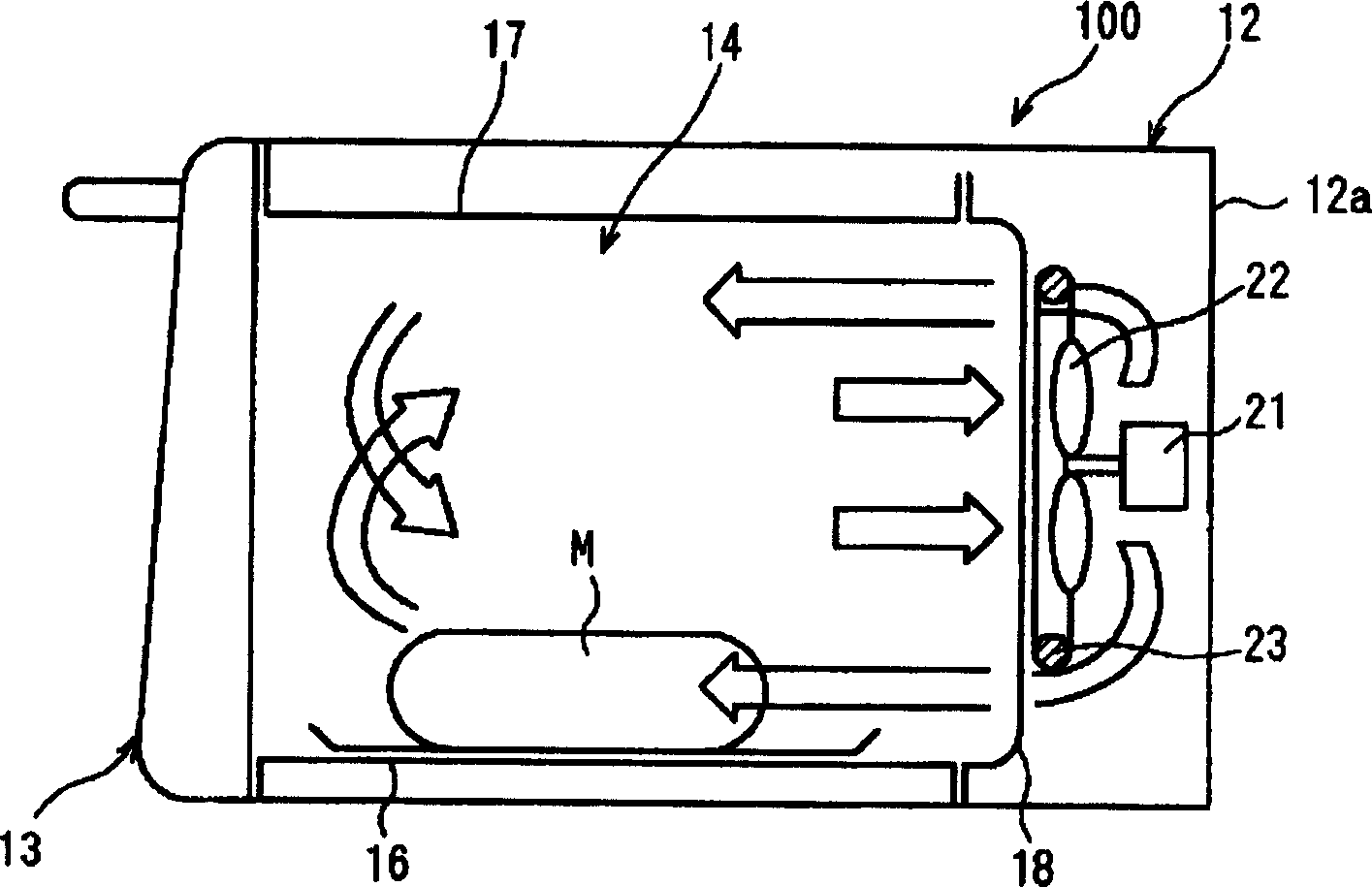

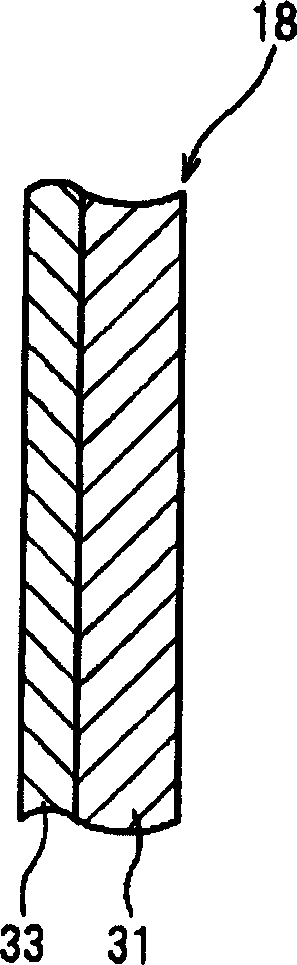

InactiveCN1487240AReduce capacityReduce consumptionSelf-cleaning stoves/rangesLighting and heating apparatusConvection heaterMethods of production

A convection heater (23) is disposed along a back surface of a rear face plate (18) which is comprised of a stainless steel plate that forms a heating chamber (14). On a back side of the rear face plate (18), disposed is a circulation fan (22) by which, air in the heating chamber (14) is sucked from air intake use through-holes into the back side, and after it is heated by the convection heater (23), it is returned from air blowing use through-holes to the heating chamber. On a surface of an inner side of the heating chamber (14) of the rear face plate (18), a self-cleaning layer is formed by dissolving a self-cleaning material which oxide-decomposes and removes accreted dirt at high temperature into a porcelain enamel glaze and by applying and bake-sticking.

Owner:PANASONIC CORP

Transparent heat insulation coating with nanoparticles and preparation method thereof

The invention discloses a transparent heat insulation coating with nanoparticles and a preparation method thereof; the preparation method comprises the following steps: adding nanoscale powder slurry of aluminum oxide, silicon oxide, titanium oxide, zinc oxide, cerium oxide, iron oxide, ATO and the like in water-based acrylic emulsion, adjusting the pH value to 5.5-9.0, stirring with a machine for 30-60min while adding defoaming agent, dispersant and flatting agent, then stirring with a high speed stirrer for 20-40min and finally performing ultrasonic vibration for 30-60min to obtain the transparent heat insulation coating. The invention has low cost and simple production process, after the coating is coated to form a film, the film has good transmission of light and outstanding heat-shielding performance; the coating has better self-cleaning ability, good durability and good washing resistance and brushing resistance; and the film has long life, good stability and simple maintenance.

Owner:黎源

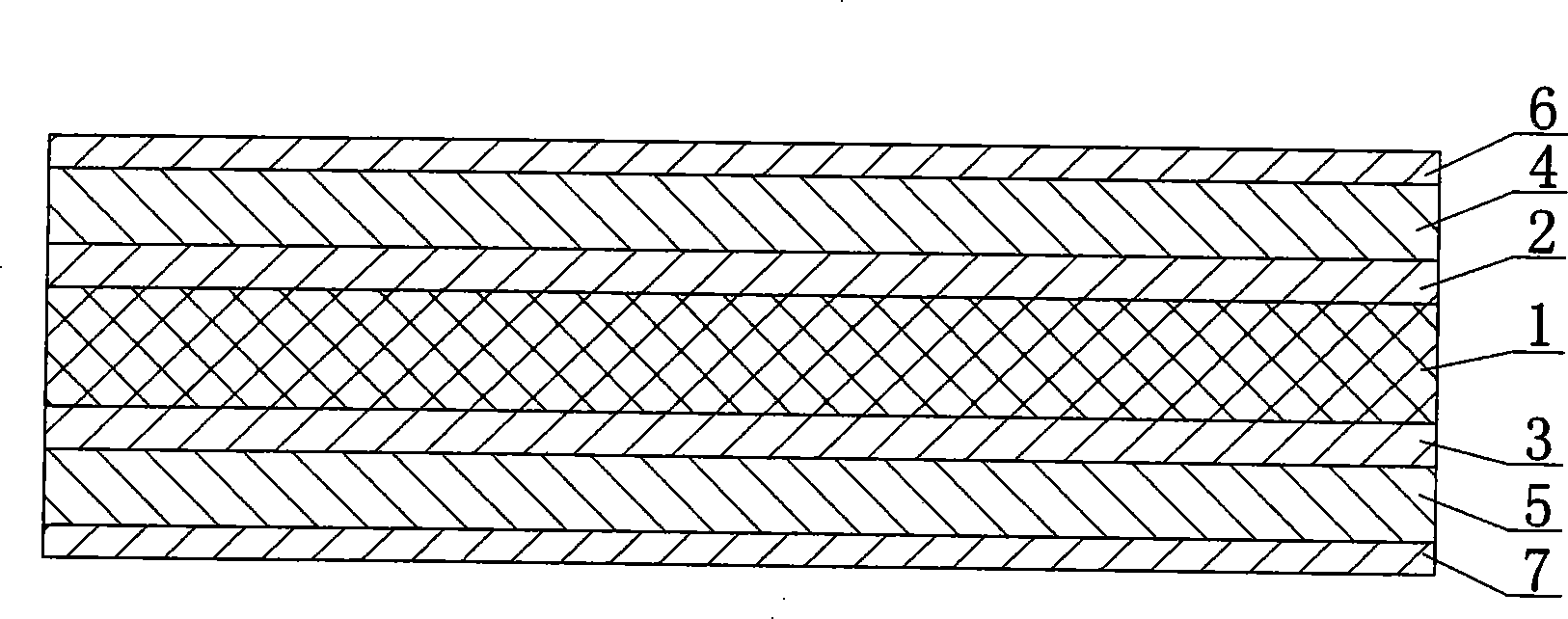

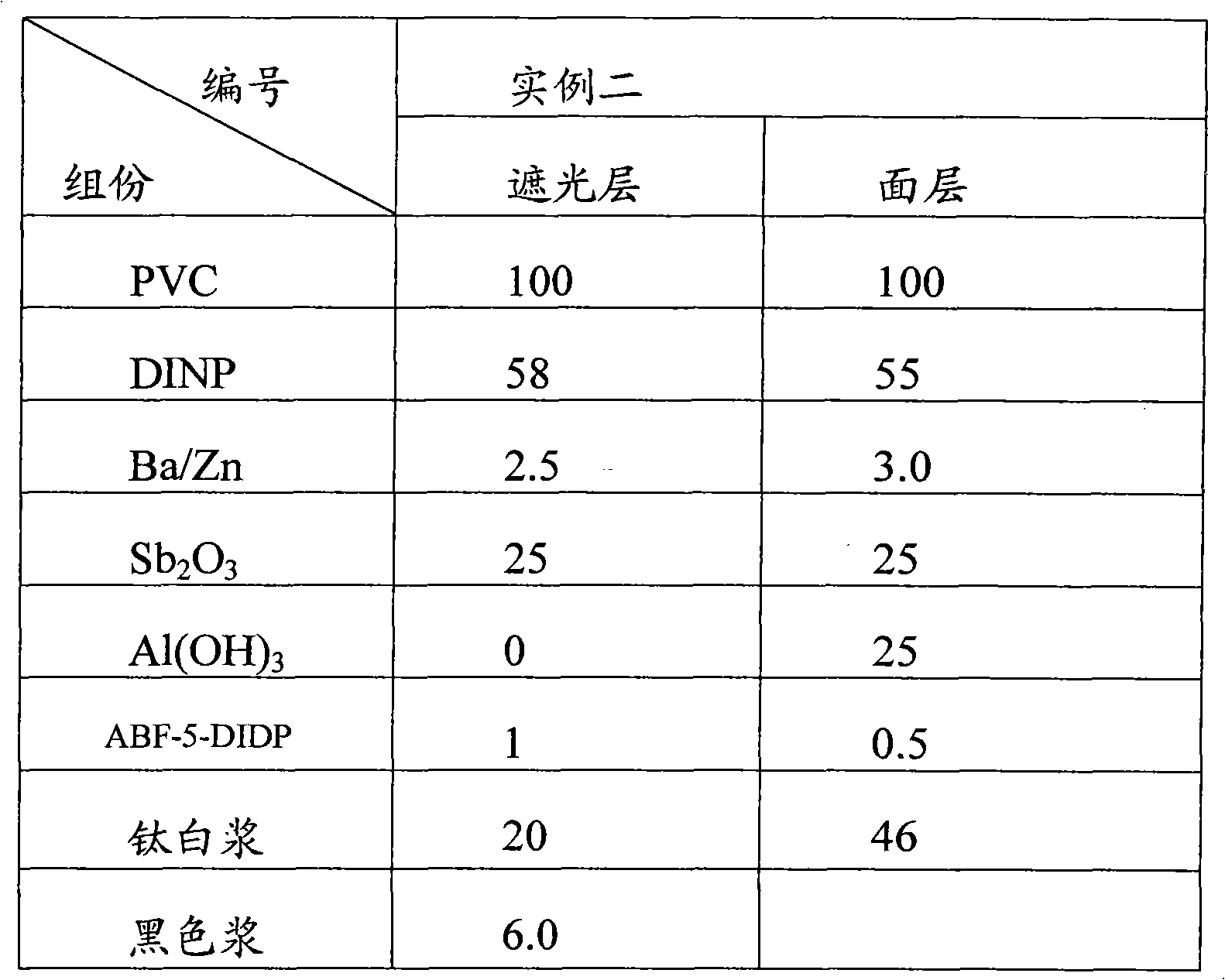

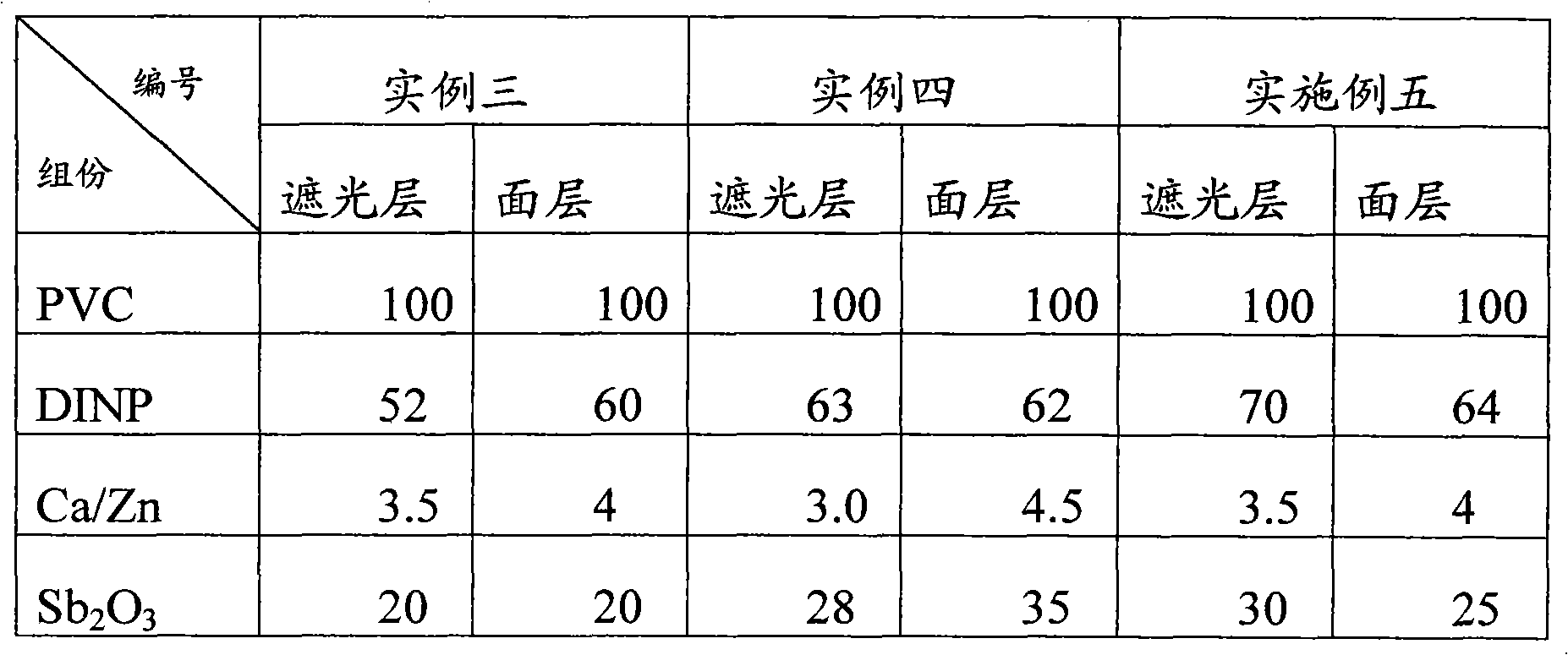

PVC coating tent material

InactiveCN101818589AGood shading effectImprove self-cleaningSynthetic resin layered productsTents/canopiesCoatingSelf cleaning

The invention relates to a PVC coating tent material. The invention is characterized in that the PVC coating tent material comprises substrate layers and PVC coatings coated on the surfaces of the substrate layers, and the tent material is provided with a front side and a back side, wherein the PVC coating on the front side comprises a front-side shading layer, a front-side main shading layer and a front-side facing layer which are orderly arranged from the substrate layer to the outside, the front-side shading layer and the front-side main shading layer are formed by coating opaque paint twice; the PVC coating on the back side comprises a back-side bottom layer and a back-side facing layer from the substrate to the outside; and the surface of the facing layer of the PVC coating is provided with a surface treatment layer. By coating the shading layer on the front side twice, a continuous shading layer can be formed, thereby achieving the excellent shading effect, and improving the yield. By coating both the front side and the back side twice with surface treatment paint, the quantity of the surface treatment paint can be ensured, thereby achieving the better self-cleaning effect. Besides, the invention realizes the free use of the tent material even without distinguishing the front side and the back side in use.

Owner:FOSHAN GAOMING YILONG PLASTICS & RUBBER IND

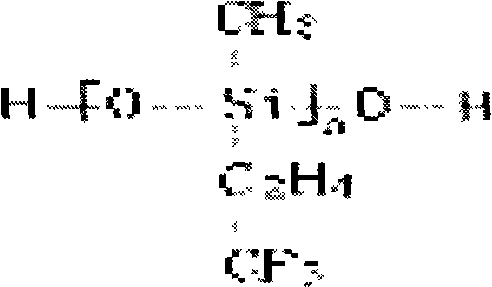

Synthesis of photo-cured fluorosilicone polymer and preparation method of photo-cured fluorosilicone polymer coating

ActiveCN103936996AShort curing timeImprove performancePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceSide chain

The invention discloses a preparation method of a photo-cured fluorosilicone polymer. The photo-cured fluorosilicone polymer is a fluorosilicone polymer with light sensitivity, which is prepared by respective hydrosilylation of hydrogen-containing polysiloxane with fluorine-containing olefins and an olefin bifunctional reactive diluent. The photo-cured fluorosilicone polymer is used for preparing a photo-cured fluorosilicone composite coating. The structural formula of the photo-cured fluorosilicone polymer is shown in a formula (I) in the specification, wherein Rf is a fluorine-containing group, R is an alkylene-containing light sensitive group, x is 10-100, y is 10-30, z is 5-20, x accounts for 60-80% of the total quantity, and y+z accounts for 20-40% of the total quantity. The fluorine-containing group and the light-cured active group are introduced to side chains of the polysiloxane through hydrosilylation. Compared with a polycondensation method, the preparation method is relatively simple and has relatively high yield. After the synthesized light sensitive fluorosilicone polymer is fully mixed with a reactive diluent, a plasticizer, stuffing, a photoinitiator and the like, the fluorosilicone coating is formed by curing in ultraviolet light; the fluorosilicone coating has excellent performances such as high-temperature resistance, hydrophobicity and oleophobicity, antifouling property and weather resistance and can be applied to the fields of high and new technologies such as electronics and electrics, chemical engineering, automobiles and the like.

Owner:江苏矽时代材料科技有限公司

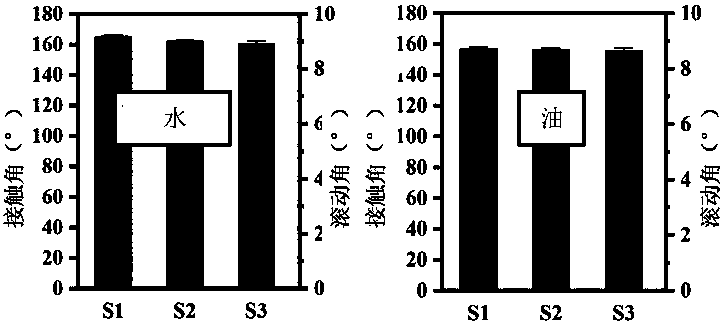

Effective water-collecting self-cleaning super-amphiphobic coating and preparation method thereof

ActiveCN110041741AEnhanced condensation characteristicsImprove dew drop nucleation efficiencyAntifouling/underwater paintsPaints with biocidesMicro nanoCoated surface

The invention relates to an effective water-collecting self-cleaning super-amphiphobic coating and a preparation method thereof and belongs to the field of preparation of ultra-infiltration functionalcoating materials. A multilevel micro-nano coarse structure coating layer with a combination of nanometer porous structure and hydrophilic microparticle structure is formed on the surface of the coating. The preparation method comprises the following steps: firstly, adding a chained aqueous silica sol after alkalization into a volatile organic solution, and then performing hydrophobic modification on the surface, thereby acquiring a super-amphiphobic finishing coat; coating micron particles with a hydrophilic polymer, hybridizing the micron particles with the super-amphiphobic finishing coat,coating on a bottom surface and drying, thereby acquiring a super-amphiphobic hybridized coating surface. The coating has an excellent condensation reinforcing dew formation effect, an excellent water drop self-repelling bouncing desorption effect and an efficient water mist collecting effect, has a super-hydrophobic and super-oleophobic super-amphiphobic characteristic, shows excellent self-cleaning and anti-oil properties, is widely applied to the fields of self-cleaning, water mist collection, desalination, condensation heat exchange, and the like, is simple in equipment and process, is easy for operation and is suitable for large-scale preparation and production.

Owner:SOUTHEAST UNIV

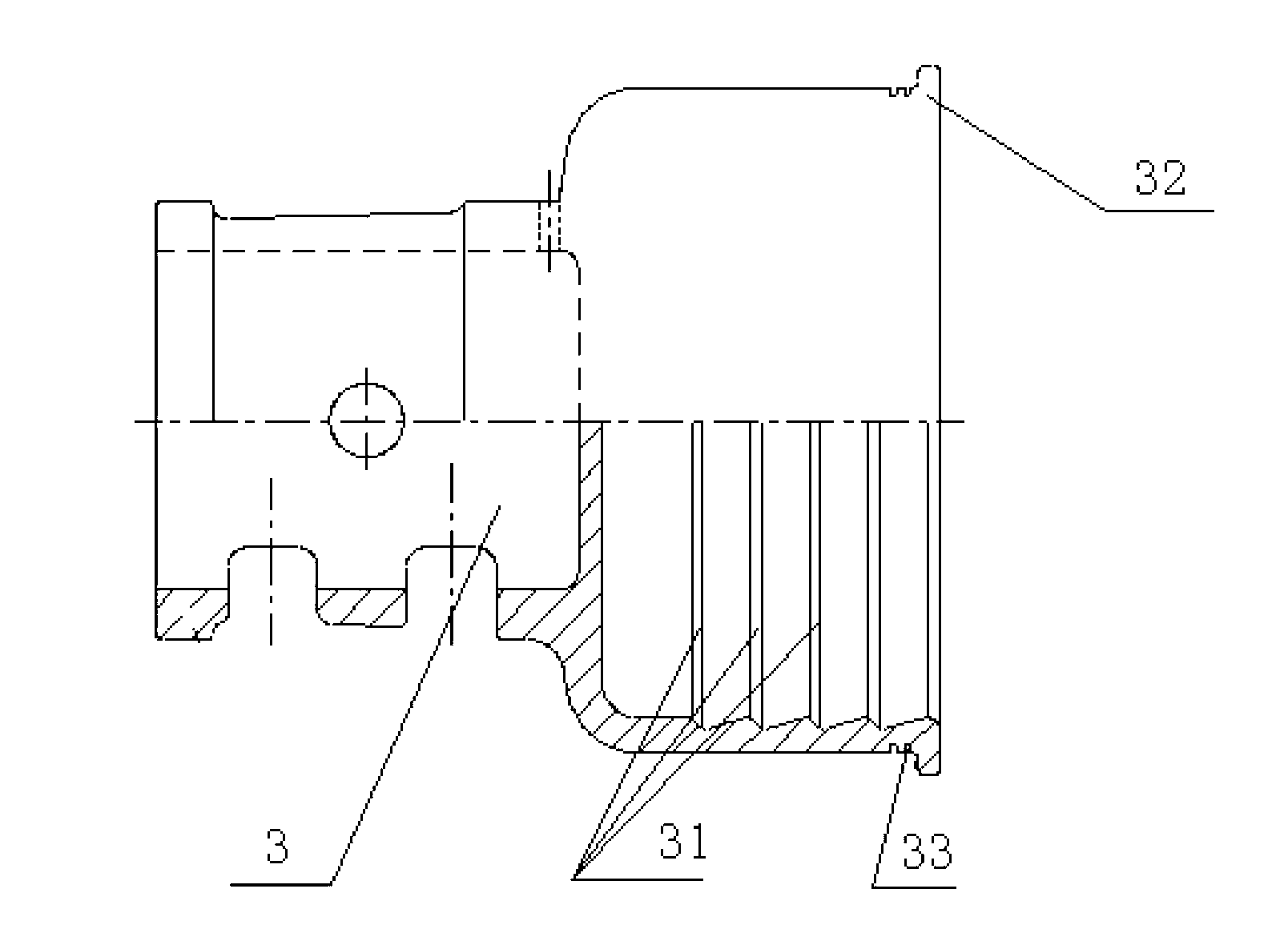

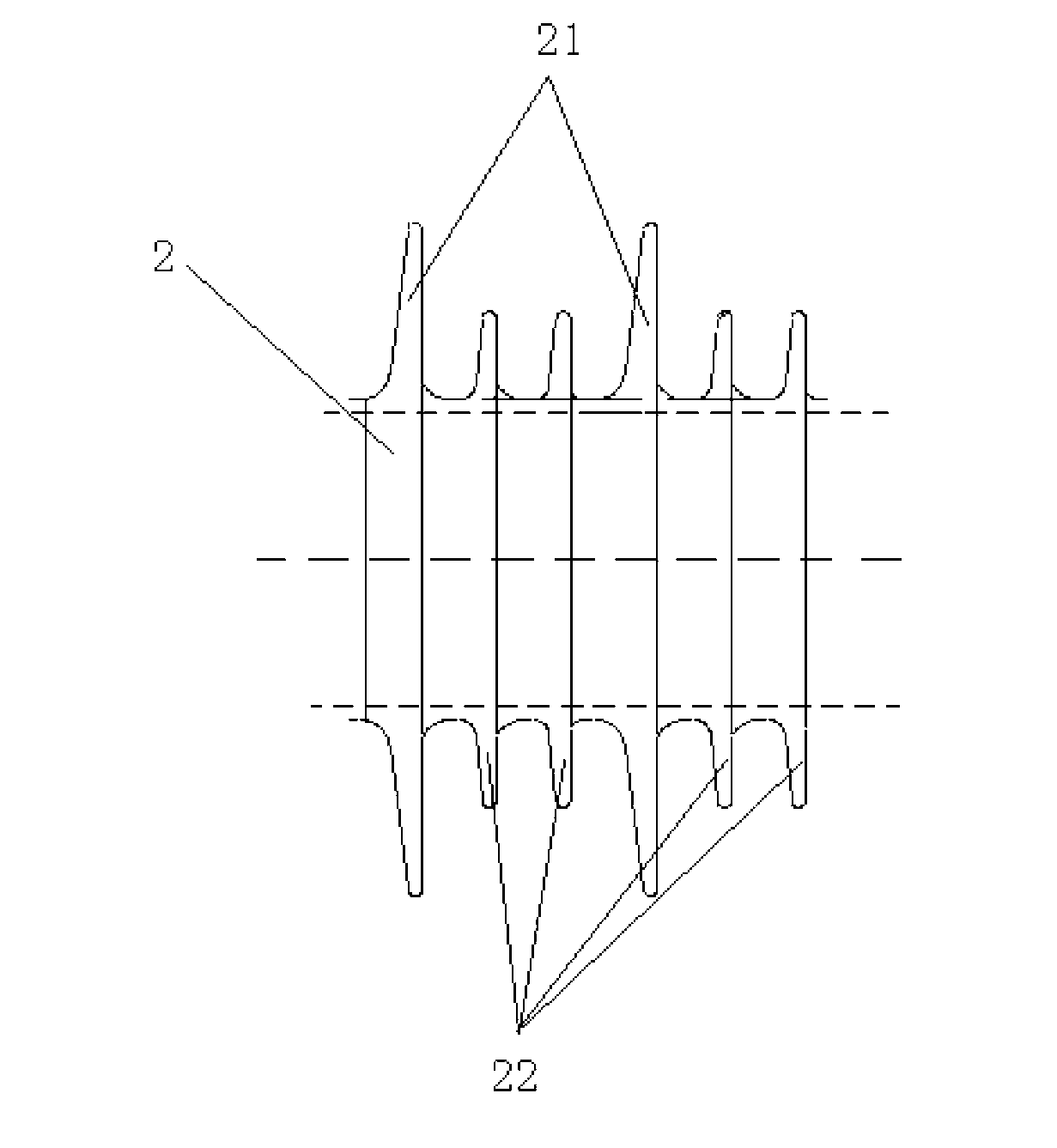

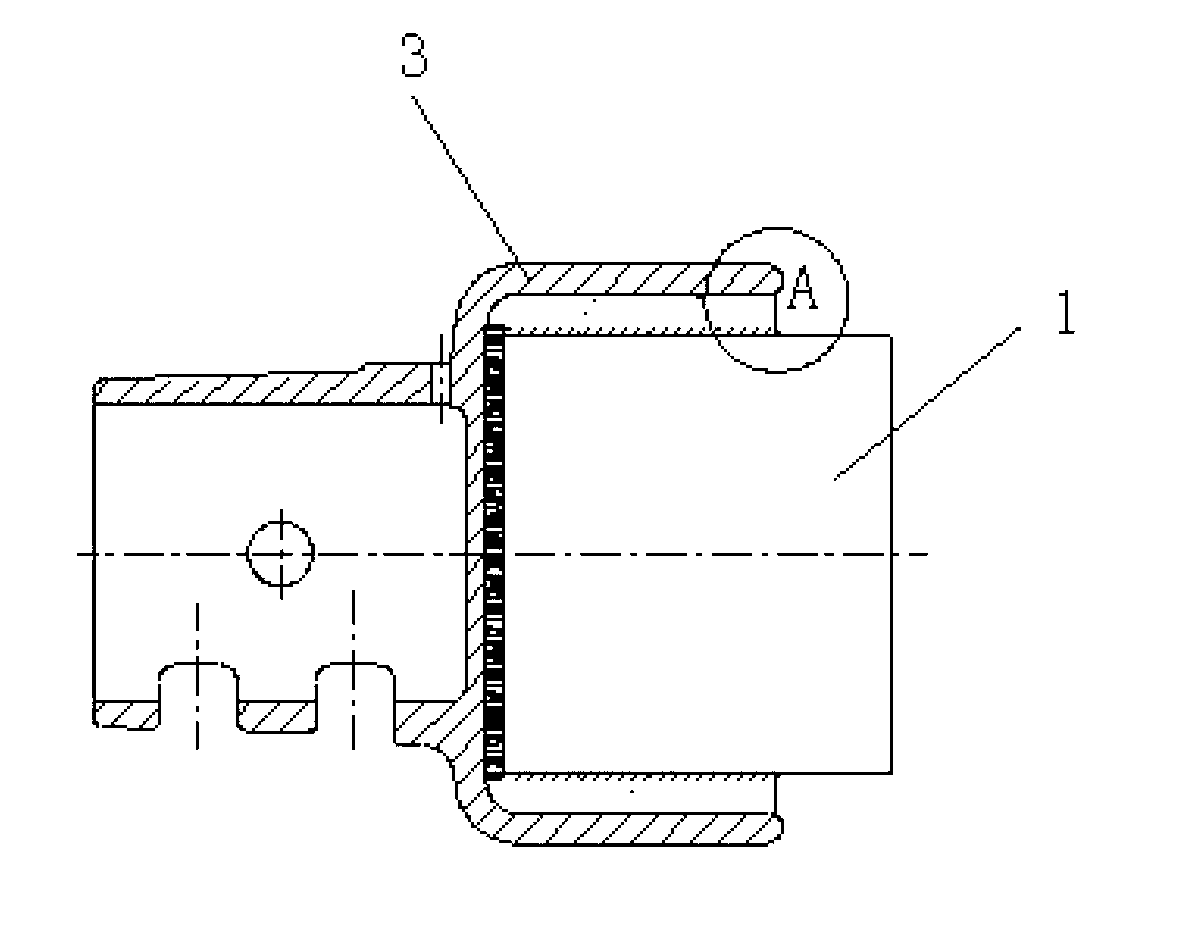

Novel long rod type porcelain composite insulator and manufacturing method thereof

ActiveCN103165247AImprove pass rateHigh mechanical strengthInsulatorsComposite insulatorsEngineering

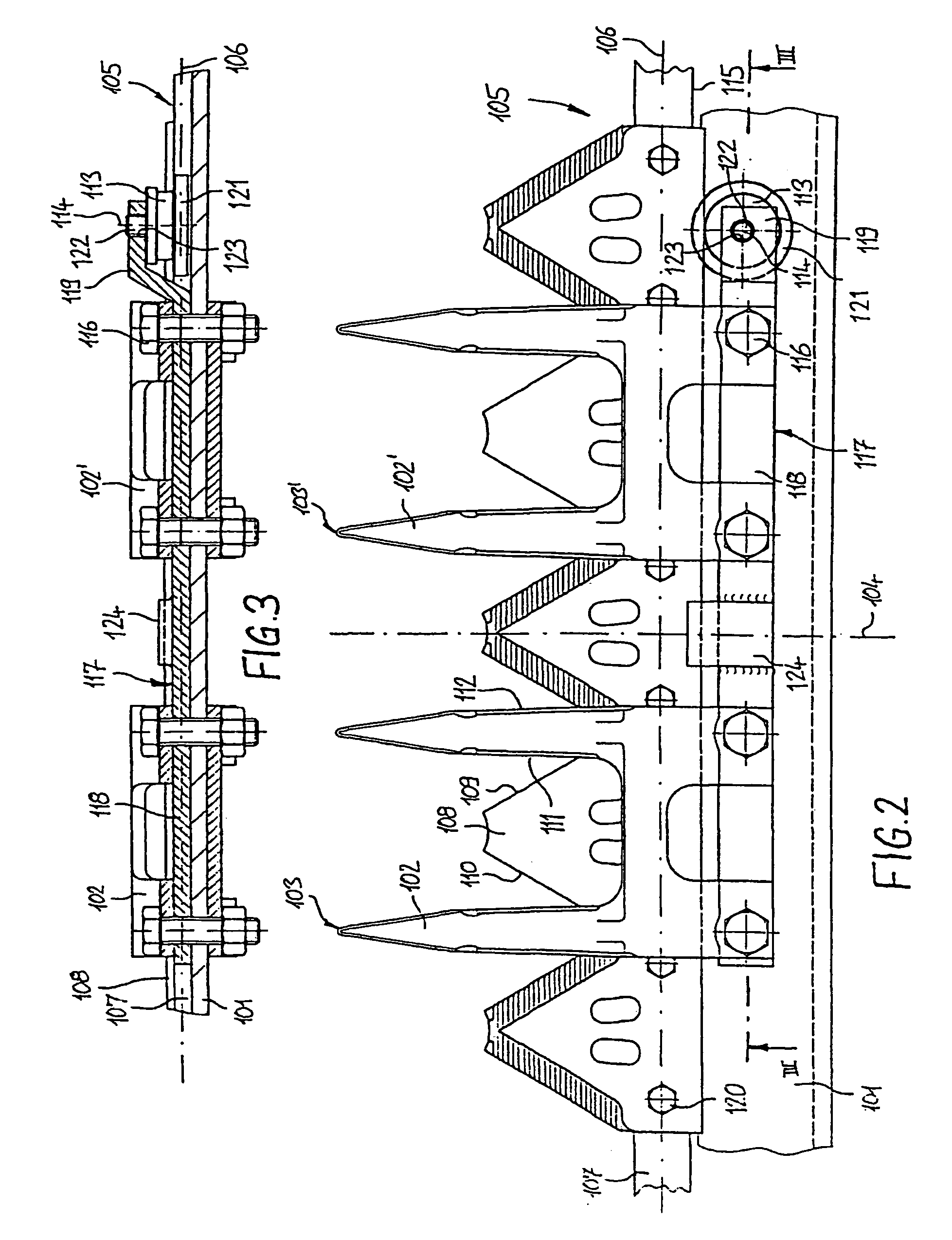

The invention discloses a novel long rod type porcelain composite insulator. The long rod type porcelain composite insulator comprises an insulator body, wherein an outer insulating umbrella skirt sheath is arranged outside the insulator body; hardware fittings are cemented at two ends of the body; a mounting inner hole of each hardware fitting is in a sawtooth shape; and the outlet end of each hardware fitting is in a circular arc shape, and a rectangular groove is formed outside the outlet end. Due to the adoption of reasonable structural design and high-quality production raw materials and the selection of an advanced manufacturing process, the long rod type porcelain composite insulator has high electromechanical properties. According to the long rod type porcelain composite insulator, high-temperature vulcanized silicon rubber is used as the outer insulating umbrella skirt sheath, high-strength ceramic is used as internal insulation, and the end fittings are cemented by using high-strength silicates through a amplitude varying process to manufacture the porcelain composite insulator. By the porcelain composite insulator, the accidents of brittle failure and string breakage can be avoided, and the problem of external insulation pollution flashover of the porcelain insulator is solved, so that the long rod type porcelain composite insulator is high in mechanical and electrical properties and is suitable for various extremely severe work conditions.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

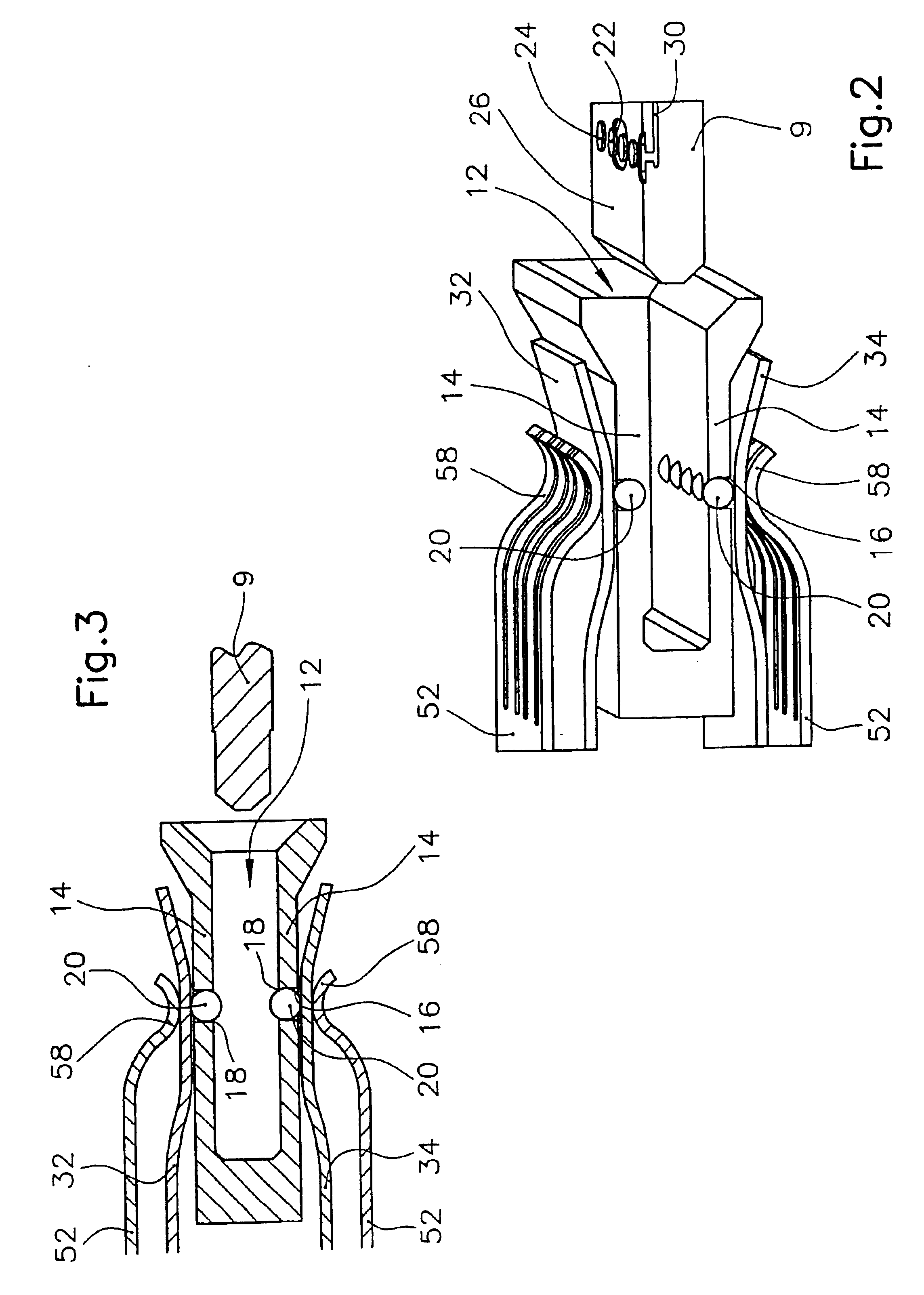

Connector with movable contact elements

InactiveUS6857908B2Easy to produceImprove self-cleaningRotary current collectorTwo-part coupling devicesElectrical conductorContact element

A connector for receiving a plug-in card comprises a carrier which defines a receiving space for the plug-in card, at least one guide hole which is formed in the carrier and which opens in the receiving space, a contact element which is movably arranged in the guide hole, a spring which urges the contact element towards the receiving space, and a conductor path which is electrically connected with the contact element.

Owner:HARTING ELEKTRO OPTISCHE BAUTEILE

Bus with heat radiation function

InactiveCN102446578AImprove self-cleaningImprove anti-corrosion performanceInsulated cablesInsulated conductorsElectrical conductorRadiation temperature

The invention discloses a bus with a heat radiation function, which comprises a bus conductor (1), wherein a heat radiation layer (2) which is formed by heat radiation coating is coated on the outer part of the bus conductor (1), and the heat radiation coating forming the heat radiation layer (2) is formed by a nanometer material having high visible light and near infrared reflection rate, high thermal infrared transmission rate, high temperature stability, good physical performance, good chemical performance and good construction performance, so the high-efficient radiation temperature reduction and heat insulation can be realized.

Owner:CHANGSHU TONGRUN SWITCHGEAR FACTORY CO LTD

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

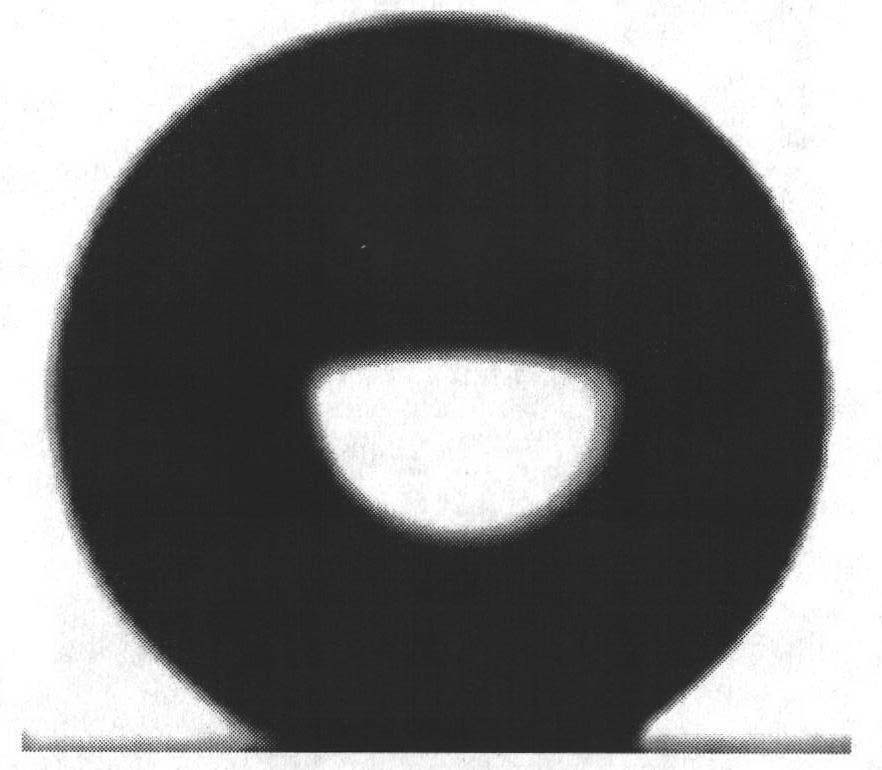

Paint with strong adhesion for cooling surface for LED (light emitting diode) radiator

ActiveCN103965672AImprove self-cleaningImprove anti-corrosion performanceReflecting/signal paintsRare-earth elementEpoxy

The invention discloses paint with strong adhesion for cooling the surface for an LED (light emitting diode) radiator. The paint is characterized by being prepared from the following components in parts by weight: 10-25 parts of inorganic colloidal particles, 1-3 parts of carbon nano-tube, 25-90 parts of electron transited spinel, 0.05-1.5 parts of rare earth oxide, 0.1-0.5 part of a stabilizing agent, 3-15 parts of epoxy resin, 2-10 parts of methyl methacrylate, 10-25 parts of nano- diatomite and 2-10 parts of ethylene glycol. The paint has remarkable heat dissipating and cooling effects, is not influenced by peripheral media, can be used in a vacuum environment, plays a role in radiating and cooling, and has the advantages of good self-cleaning performance, corrosion resistance, water resistance, flame retardance, insulating performance and acid-alkali resistance, and is convenient to construct.

Owner:NINGBO AISHI ELECTRIC EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com