Novel long rod type porcelain composite insulator and manufacturing method thereof

A ceramic composite insulator and a production method are applied in the directions of insulators, electrical components, circuits, etc. to achieve the effects of increasing wall thickness, reducing energy consumption, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

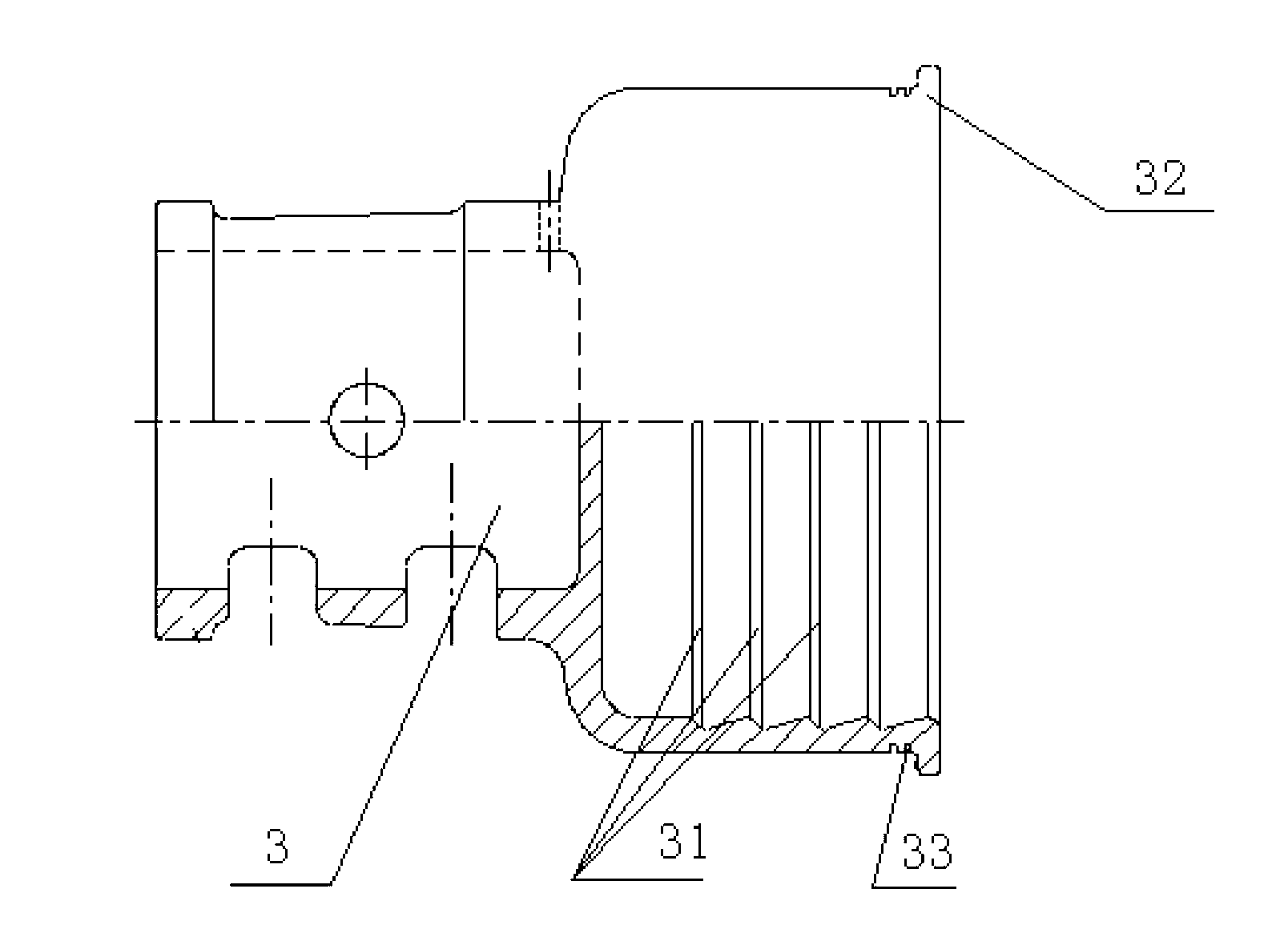

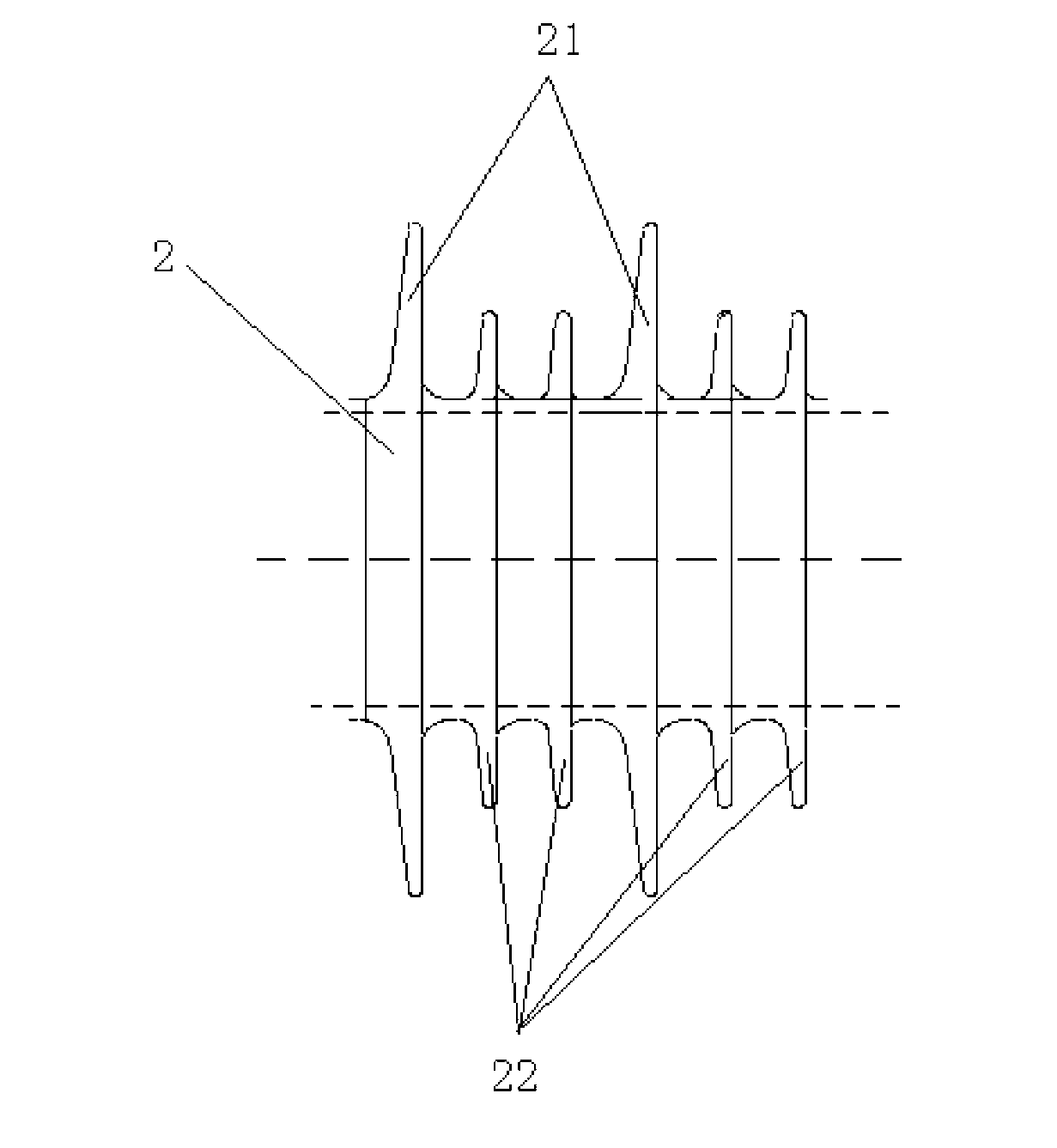

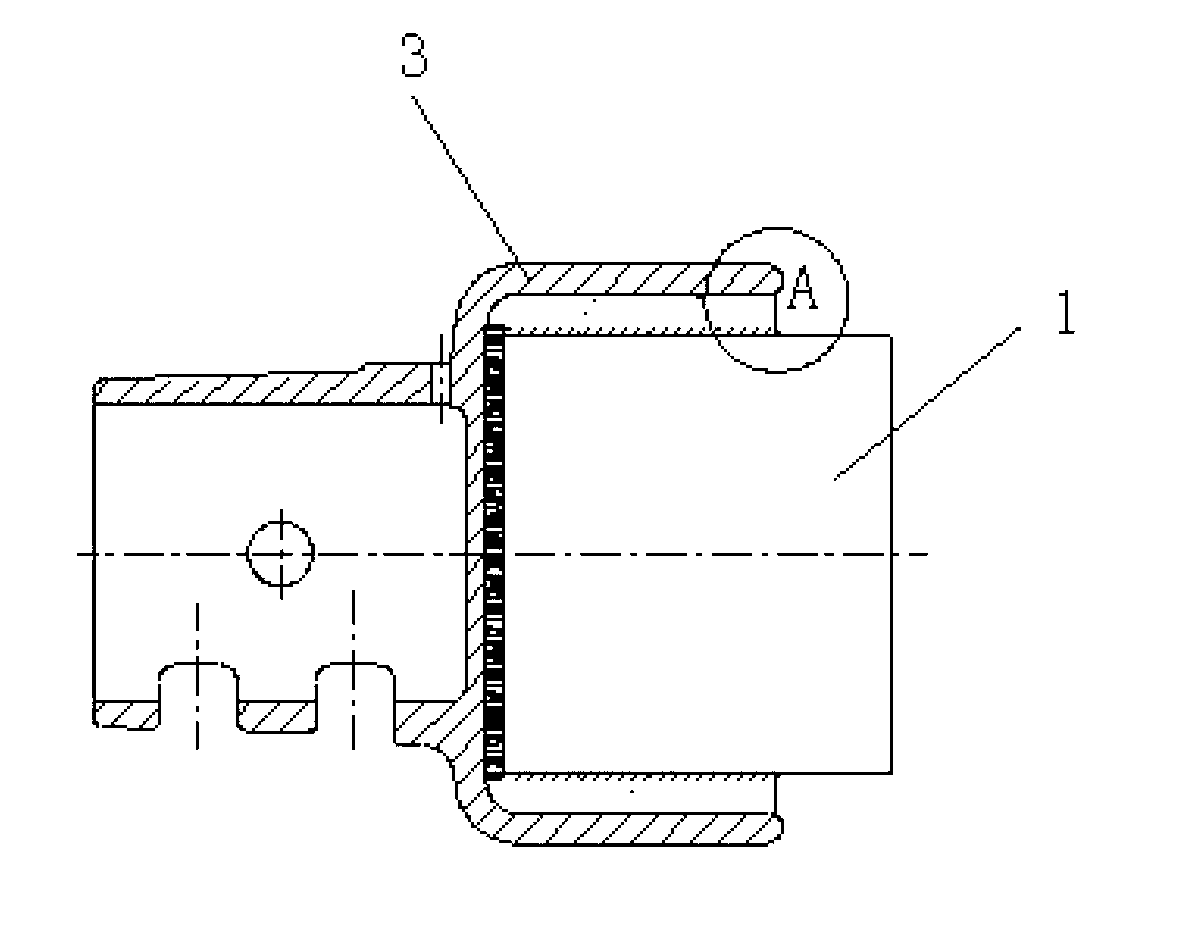

[0034] like Figure 1-2As shown, a new long rod-shaped porcelain composite insulator includes an insulator body 1, an outer insulating shed sheath 2 is provided outside the body 1, and fittings 3 are glued to both ends of the body 1 through glue 4 respectively. , the installation inner hole 31 of each fitting 3 is zigzag, the end of the outlet end 32 of each fitting 3 is arc-shaped and a rectangular groove 33 is provided outside the end. The structure of the outer shed sheath 2 is that a large umbrella 21 and two small umbrellas 22 are arranged at intervals in sequence, and a large umbrella 21 and two small umbrellas 22 adjacent to each other form a group, and the effective leakage distance of each group of umbrellas is 234mm . The above-mentioned outer shed sheath 2 is a silicone rubber sheath.

[0035] The manufacturing method of the above-mentioned novel long rod-shaped porcelain composite insulator, the method comprises the following steps:

[0036] 1) Fabrication of fi...

Embodiment 2

[0059] Example 2: Basically the same as Example 1, the difference is the base material formula of the porcelain insulator body in step 2), the formula is as follows: 5 parts of black clay, 45 parts of industrial alumina, 10 parts of Zhangcun soil, 20 parts of Jingyang soil 6 parts of Zuoyun soil, 7 parts of Qingcaoling, 11 parts of white clay, 15 parts of feldspar, 5 parts of Ninghai soil, and 5 parts of Xinhui soil.

[0060] Example 2: Basically the same as Example 1, the difference is the base material formula of the porcelain insulator body in step 2), the formula is as follows: 2 parts of black clay, 35 parts of industrial alumina, 5 parts of Zhangcun soil, 8 parts of Jingyang soil 15 parts of Zuoyun soil, 15 parts of Qingcaoling, 20 parts of white clay, 5 parts of feldspar, 1 part of Ninghai soil, and 1 part of Xinhui soil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com