Effective water-collecting self-cleaning super-amphiphobic coating and preparation method thereof

A super-amphiphobic, self-cleaning technology, applied in the direction of coatings, antifouling/underwater coatings, primers, etc., can solve the problems of difficult preparation and application, poor self-cleaning and anti-oil properties, etc., to facilitate popularization and application, improve dew Droplet nucleation efficiency, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

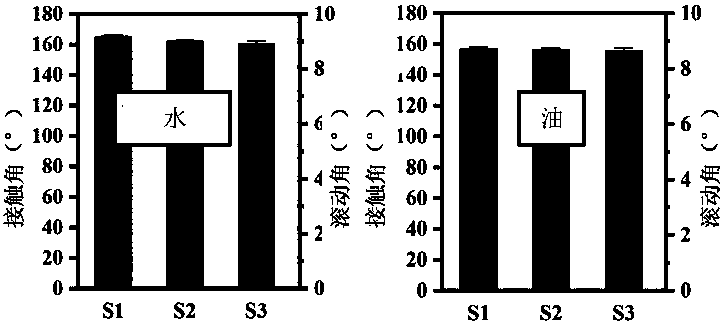

[0039] A method for preparing an efficient water-collecting self-cleaning superamphiphobic coating, the preparation process of which is as follows:

[0040] (1) Super amphiphobic topcoat preparation: 1 volume part of nano silica sol, 2 volume parts of 28 wt.% ammonia water, 6 volume parts of deionized water, 0.1 volume part of tetraethyl orthosilicate, 0.1 volume part of hydrophobic treatment agent Disperse in 60 parts by volume of absolute ethanol, and continuously mechanically stir at 100 rpm for 12 h to obtain a super amphiphobic topcoat, and the hydrophobic treatment agent is fluorosilane.

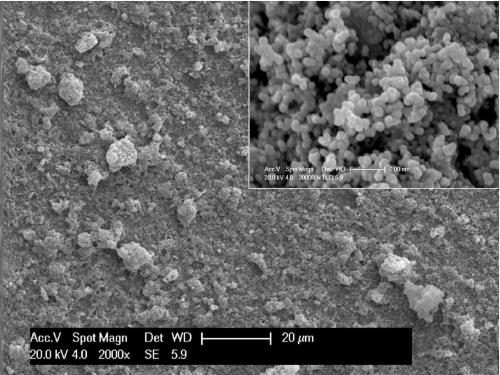

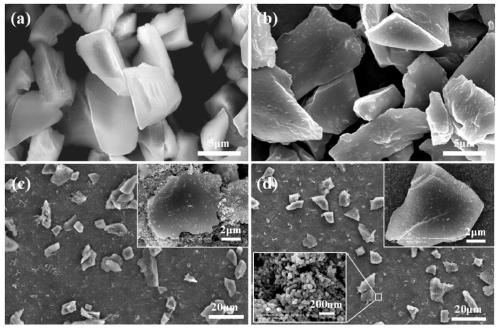

[0041] (2) Preparation of resin-coated particles: Select particles to be coated with a particle size of 3 μm. In this example, the particles to be coated are silicon carbide, and the shape of the silicon carbide particles is a conical structure with a bottom diameter of 5-50 μm , the angle at the top is 4-20°, and the particles are dispersed in absolute ethanol under the state of 100 r...

Embodiment 2

[0046] A method for preparing an efficient water-collecting self-cleaning superamphiphobic coating, the preparation process of which is as follows:

[0047] (1) Super amphiphobic topcoat preparation: 1 volume part of nano silica sol, 2 volume parts of 25 wt.% ammonia water, 6 volume parts of deionized water, 0.1 volume part of tetraethyl orthosilicate, 0.1 volume part of hydrophobic treatment agent Dispersed in 60 parts by volume of absolute ethanol, the hydrophobic treatment agent is fluorosilane, mechanically stirred at 100 rpm for 12 h to obtain a super amphiphobic topcoat;

[0048] (2) Polymer-coated particles: Select the particles to be coated with a particle size of 3-50 μm. In this example, the particles to be coated are molybdenum disulfide, and the shape of the particles is a three-dimensional triangular columnar structure. Disperse the particles in absolute ethanol to obtain a 0.3% mass ratio concentration solution, and then add a hydrophilic polymer to wrap the part...

Embodiment 3

[0052] A method for preparing an efficient water-collecting self-cleaning superamphiphobic coating, the preparation process of which is as follows:

[0053] (1) Superamphiphobic topcoat preparation: 15 parts by volume of nano-silica sol, 10 parts by volume of 28 wt.% ammonia water, 16 parts by volume of deionized water, 1 part by volume of tetraethyl orthosilicate, and 2 parts by volume of hydrophobic treatment agent Dispersed in 100 parts by volume of absolute ethanol, the hydrophobic treatment agent is fluorosilane, mechanically stirred at 300 rpm for 48 h to obtain a super amphiphobic topcoat;

[0054] (2) Polymer-coated particles: select the particles to be coated with a particle size of 3-50 μm, the particles to be coated are copper particles, and the shape of the particles is a pyramid-shaped structure, and the particles are dispersed under mechanical stirring at 300 rpm In absolute ethanol, obtain a 2% mass ratio concentration solution, then add a hydrophilic polymer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com