Preparation method of straw micro-nano cellulose

A technology of micro-nano cellulose and straw, which is applied in fiber raw material processing, textiles and paper making, etc. It can solve the problems of many nano-cellulose operations and low aspect ratio of rod-shaped nano-cellulose, and achieve easy operation and high mechanical strength. High, good biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

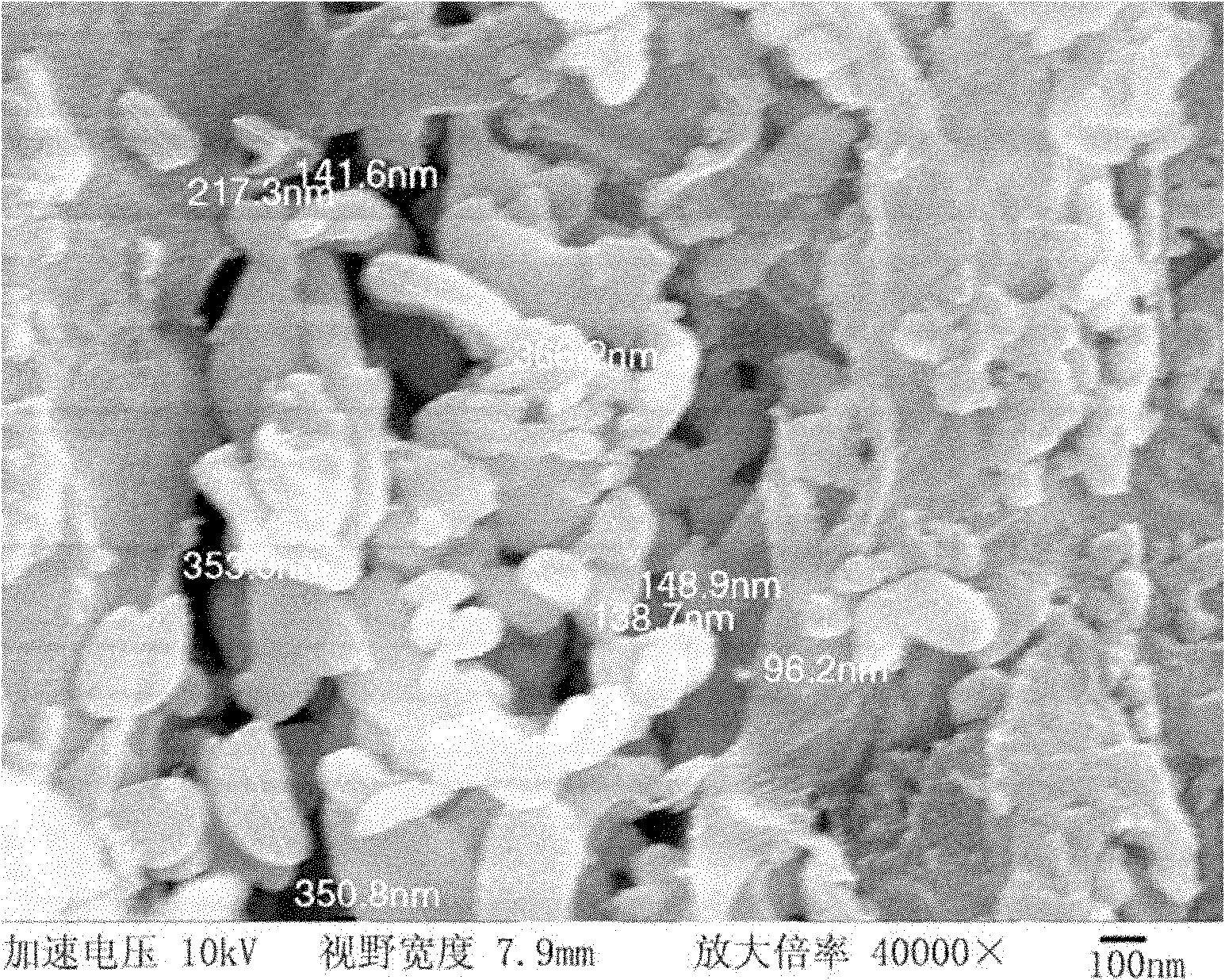

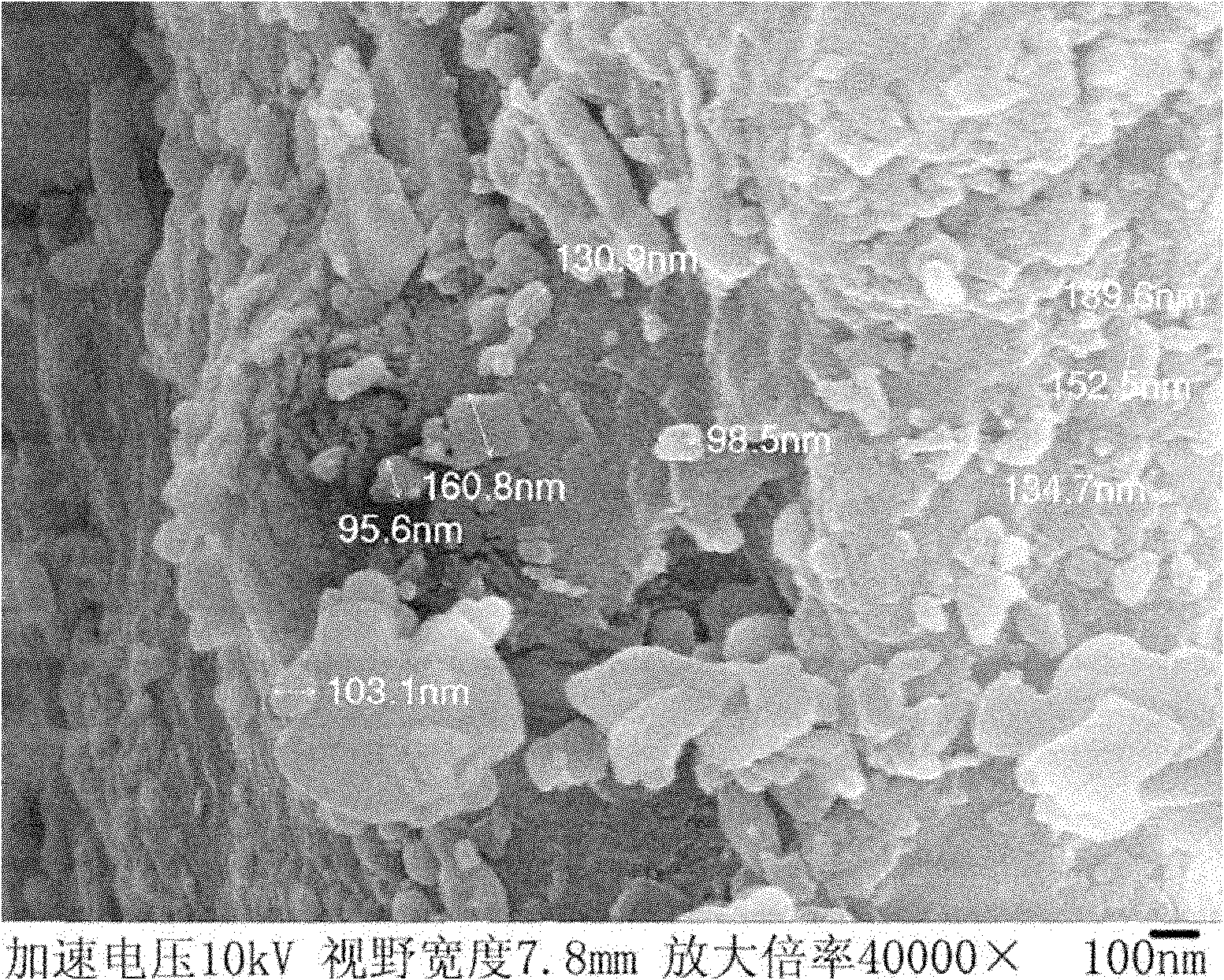

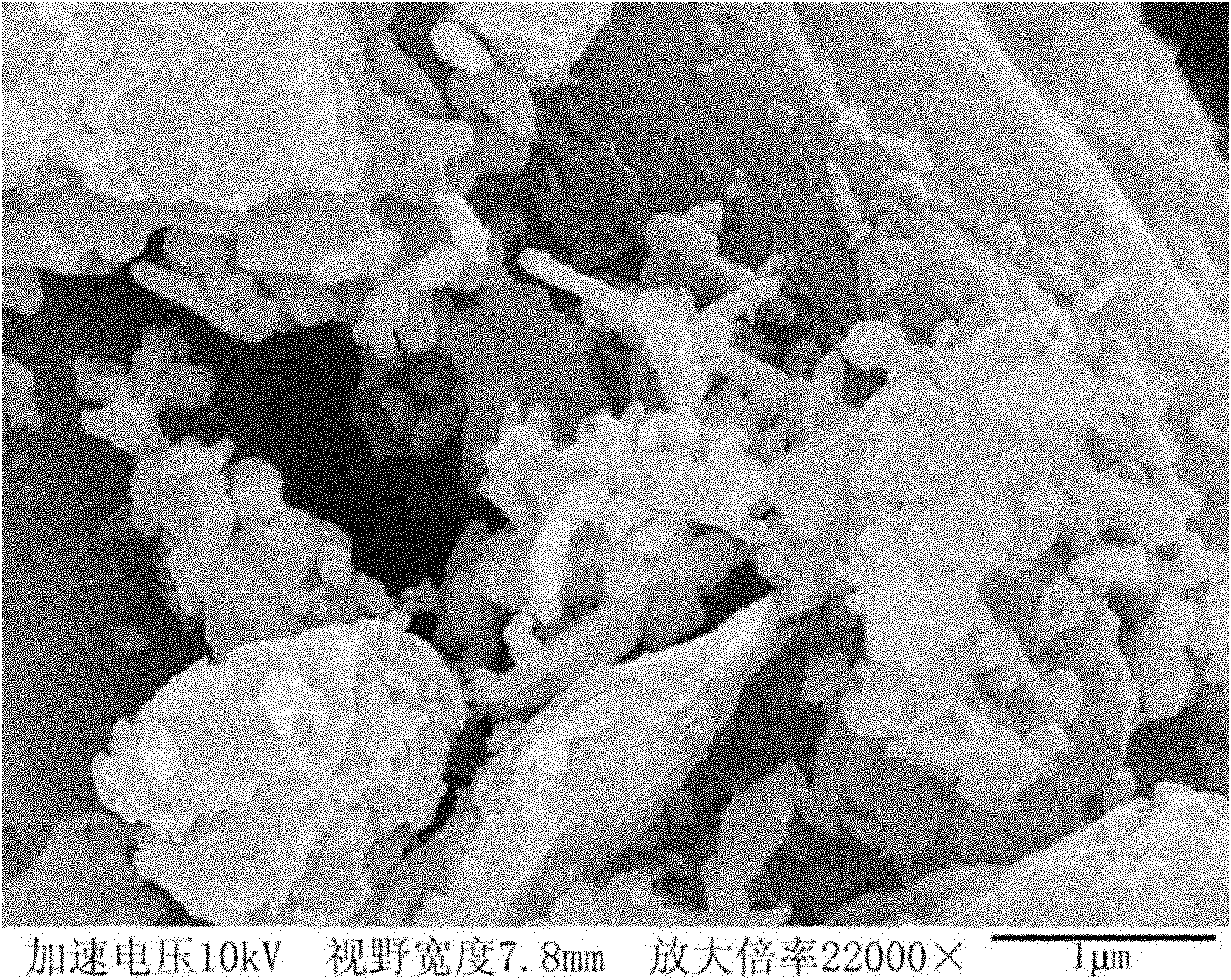

[0016] Specific embodiment 1: The preparation method of straw micro-nano cellulose in this embodiment is carried out according to the following steps: 1. Cooking: cut the straw short, place it in the steel inner barrel of the autoclave, add delignification reagent, and the temperature of the reactor 159~166℃, heating and cooking for 40~60min; 2. Soaking and washing: Take out the boiled straw in the steel inner barrel, soak it in tap water for 12-16 hours; Sewn vibrating separation screen to obtain crude fiber; 4. Bleaching: add NaClO to the obtained crude fiber 2 , glacial acetic acid and distilled water, heat in a microwave oven with a power of 600W for 30-45min, and add NaClO every 10-15min 2 5. Hydrolysis and ultrasonic treatment: add sulfuric acid solution with a mass concentration of 50% to 60% to the solid, stir and hydrolyze in a water bath at 40 to 45 ° C for 1 to 5 hours, and then 6. Add sodium bicarbonate to adjust the pH value to 6-7, then wash with distilled water...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the delignification reagent added in step 1 is Na 3 PO 4 ·12H 2 O, anthraquinone and ethanol solution with a concentration of 45% by mass, add 1.5-1.6g Na per gram of straw 3 PO 4 ·12H 2 O, 0.0005 g of anthraquinone and 10 to 15 mL of an ethanol solution with a mass percentage concentration of 45%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the delignification reagent added in step 1 is Na 3 PO 4 ·12H 2 O, anthraquinone and tap water, add 3-3.2g Na per gram of straw 3 PO 4 ·12H 2 O, 0.001 g of anthraquinone and 10 to 14 mL of tap water. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com