Powder metallurgy preparation method of carbon nanotube reinforced aluminum alloy composite material

A technology of carbon nanotubes and composite materials, applied in the field of metal matrix composite materials, can solve the problems of reducing the reinforcing effect of carbon nanotubes, damage to the structure of carbon nanotubes, strict requirements on the preparation environment, etc. Conducive to large-scale production, reliable and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

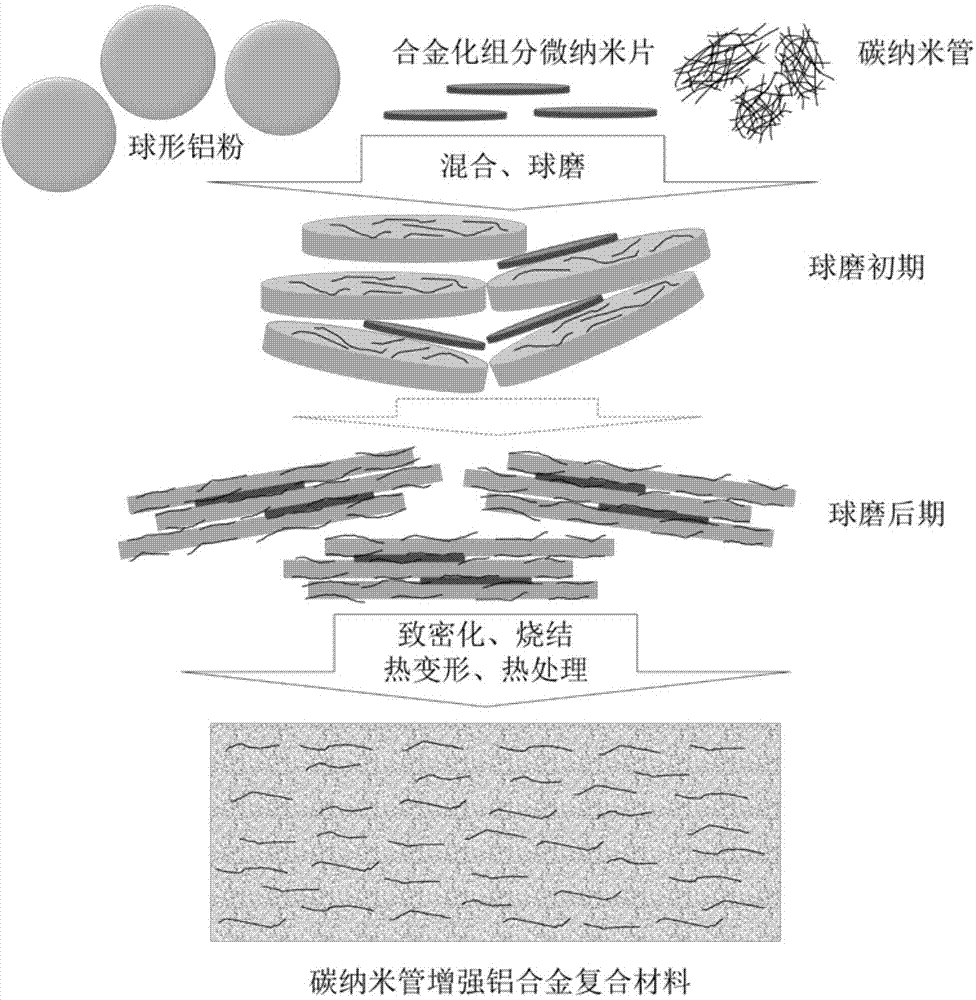

Method used

Image

Examples

Embodiment 1

[0039] Carbon nanotube reinforced aluminum-copper alloy (containing 3wt.% carbon nanotubes and 4wt.% copper)

[0040] Take 50g of 40μm pure copper powder and place it in a planetary ball mill, use water as a solvent, add 4g of imidazoline as a ball milling process control agent, use stainless steel balls as a ball milling medium, the ball to material ratio is 20:1, and ball mill at a speed of 426 rpm After 10 hours, the flake copper powder was obtained after suction filtration and drying. The flake diameter was about 5 μm, the flake thickness was about 500 nm, and the aspect ratio was about 10.

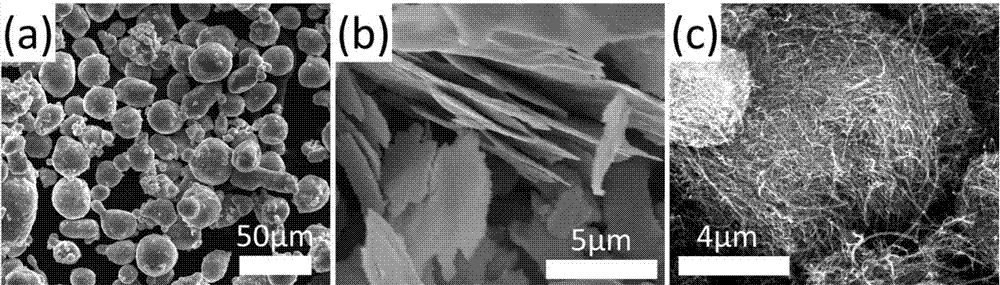

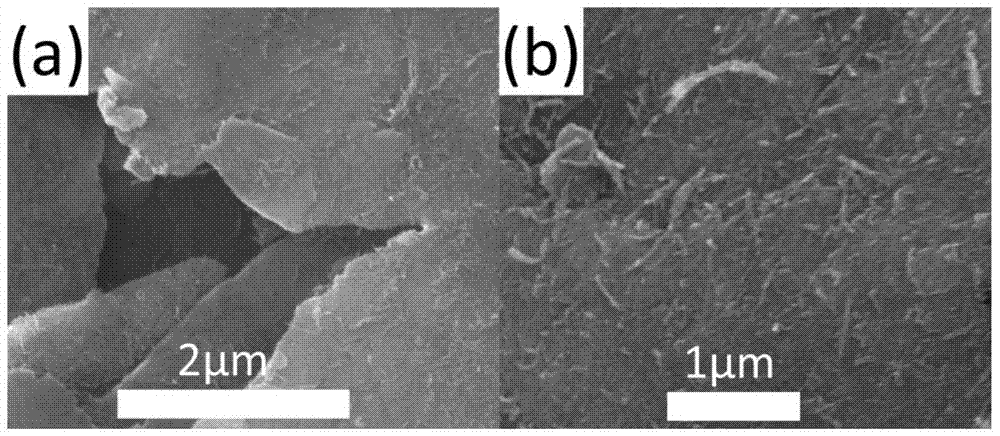

[0041] Get 93g30μm pure aluminum powder, 4g above-mentioned flake copper powder and 3g carbon nanotube, as figure 2 Shown is its scanning electron micrograph, where: figure 2 (a) is spherical aluminum powder, figure 2 (b) is flake copper powder, figure 2 In (c) is the raw material carbon nanotubes, from figure 2 In (c), it can be seen that the carbon nanotubes initially agglo...

Embodiment 2

[0050] Carbon nanotube reinforced aluminum-zinc-magnesium-copper-silicon alloy (containing carbon nanotubes 1wt.%, zinc 9wt.%, magnesium 2wt.%, copper 2.5wt.%)

[0051] Using 40 μm pure zinc powder as the zinc source, 50 g of zinc powder was placed in a planetary ball mill, under the protection of argon, stainless steel balls were used as the ball milling medium, the ball-to-material ratio was 10:1, and the ball milled at a speed of 426 rpm for 8 hours. The flaky zinc powder was obtained, with a sheet diameter of about 3 μm, a sheet thickness of about 200 nm, and an aspect ratio of about 15.

[0052] Using 10μm 5083 aluminum powder (containing 4wt.% magnesium) as the magnesium source, take 100g of 5083 aluminum powder and place it in a stirring ball mill and add 1.5g of stearic acid. Under the protection of argon, use stainless steel balls as the ball milling medium, and the ball-to-material ratio is 20:1, ball milled at 426 rpm for 2 hours to obtain flake 5083 aluminum powder...

Embodiment 3

[0058] Carbon nanotube reinforced aluminum-copper-magnesium alloy (containing carbon nanotubes 2wt.%, copper 2wt.%, magnesium 0.5wt.%)

[0059] Prepare flake copper powder and flake 5083 powder according to the method in embodiment 1 and embodiment 2, take 83.5g100μm spherical pure aluminum powder, 2g flake copper powder, 12.5g flake 5083 powder and 2g carbon nanotube according to the design ratio , placed in a stirring ball mill, under the protection of argon, using stainless steel balls as the ball milling medium, the ball-to-material ratio is 20:1, milling at a speed of 352 rpm for 3 hours, and then milling at a speed of 426 rpm for 1 hour , to prepare carbon nanotube / metal composite powder.

[0060]The above-mentioned composite powder was sintered by vacuum hot pressing at 575°C and 100 MPa for 2 hours to form a green body with a diameter of 40 mm, and then kept in a vacuum extrusion furnace at 460°C for 1 hour and then extruded at an extrusion ratio of 16:1 and an extrusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com