Patents

Literature

49results about How to "Solve the problem of insufficient strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

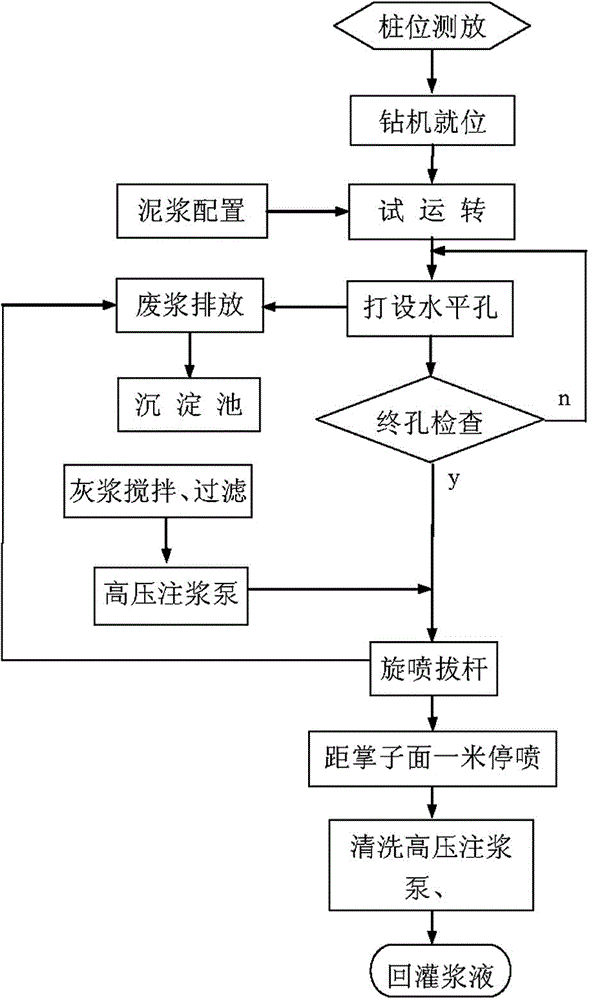

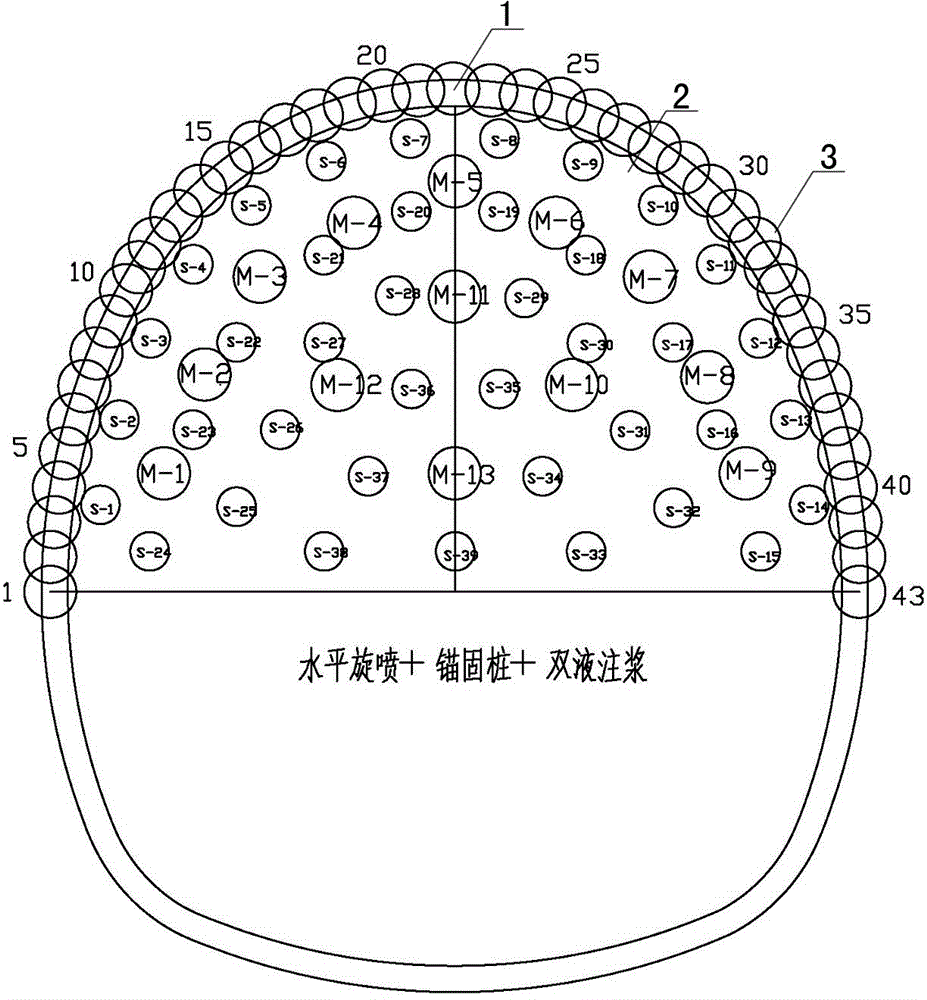

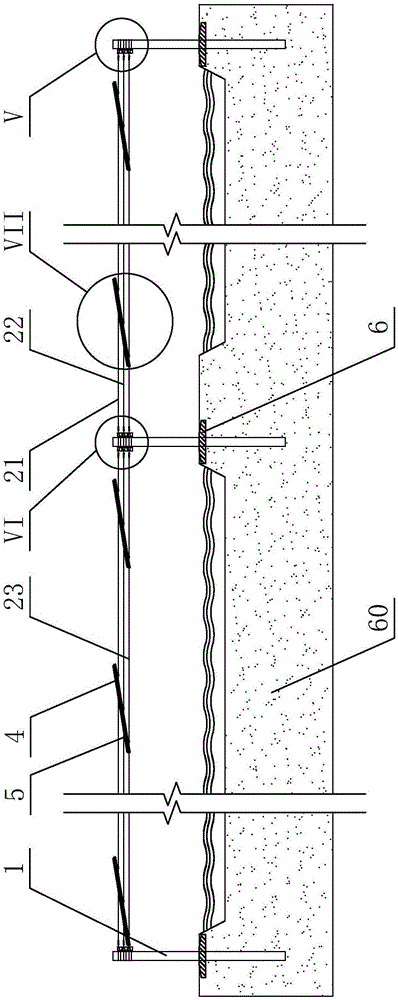

Advanced reinforcing construction method for building tunnel in soft surrounding rock

ActiveCN104453946AAttention to damageImprove permeabilityUnderground chambersTunnel liningPhosphoric acidHigh intensity

An advanced reinforcing construction method for building a tunnel in soft surrounding rock includes the specific steps that first, surveying and lining are performed on the arch top of the tunnel, and piles are positioned; second, through horizontal rotary spraying technology, horizontal rotary spraying pile construction is performed on the arch top of the tunnel; third, a water stopping plug is reinforced on a tunnel face through double-liquid slip casting construction, wherein slurry for double-liquid slip casting is composed of a phosphoric acid solution and a sodium silicate solution. According to the method, horizontal rotary spraying reinforcement is first performed on the arch top of the tunnel and a high-strength reinforced body is formed; double-liquid slip casting construction is performed on the tunnel face for reinforcement, a large-range low-strength reinforced body is formed, the defects of horizontal rotary spraying reinforcement on the arch part are compensated for, a phosphoric acid and sodium silicate slip casting method and a horizontal rotary spraying slip casting method are combined for use so that advantages can be given play to and disadvantages can be avoided, the process is simple, construction efficiency is high, the construction period is shortened, and the method is economical and safe and facilitates project implementation. The method can be widely applied to advanced reinforcing construction for building the tunnel in the soft surrounding rock.

Owner:BEIJING SHOUER ENG TECH

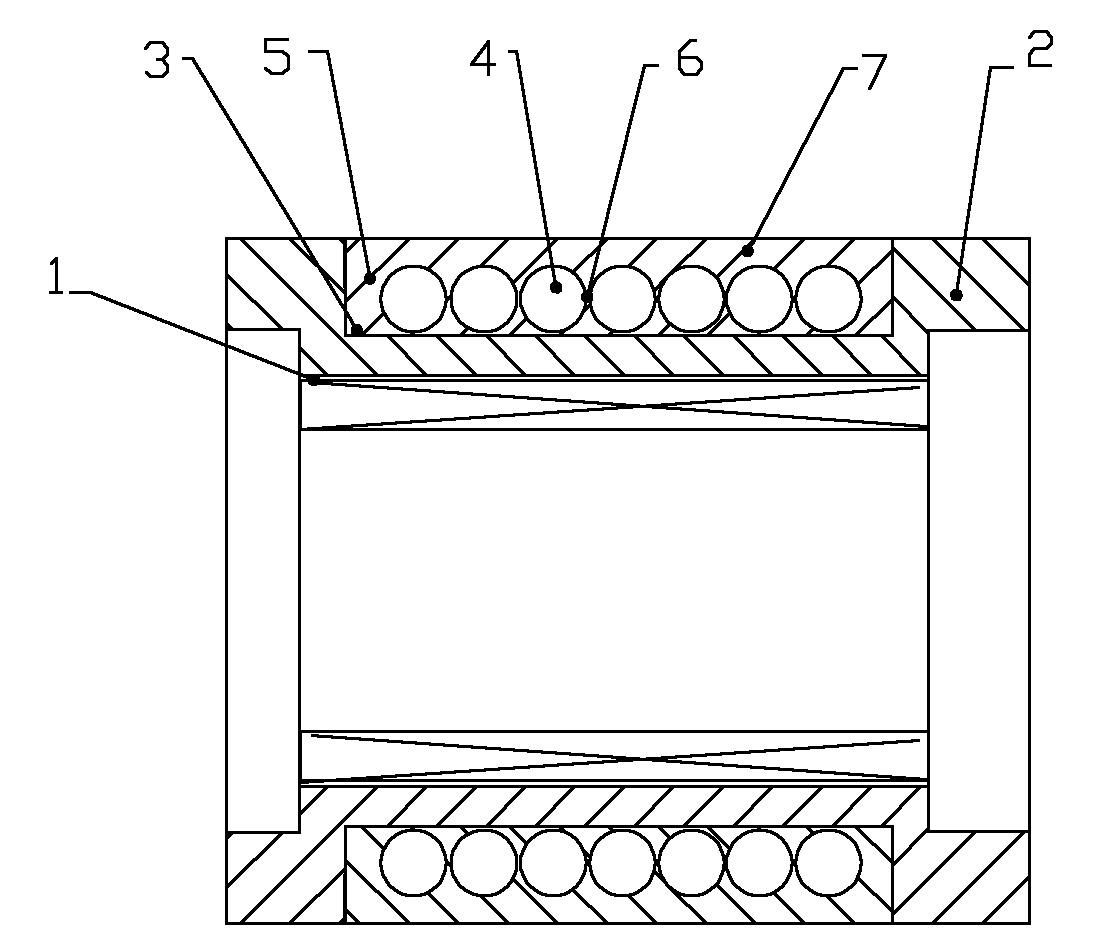

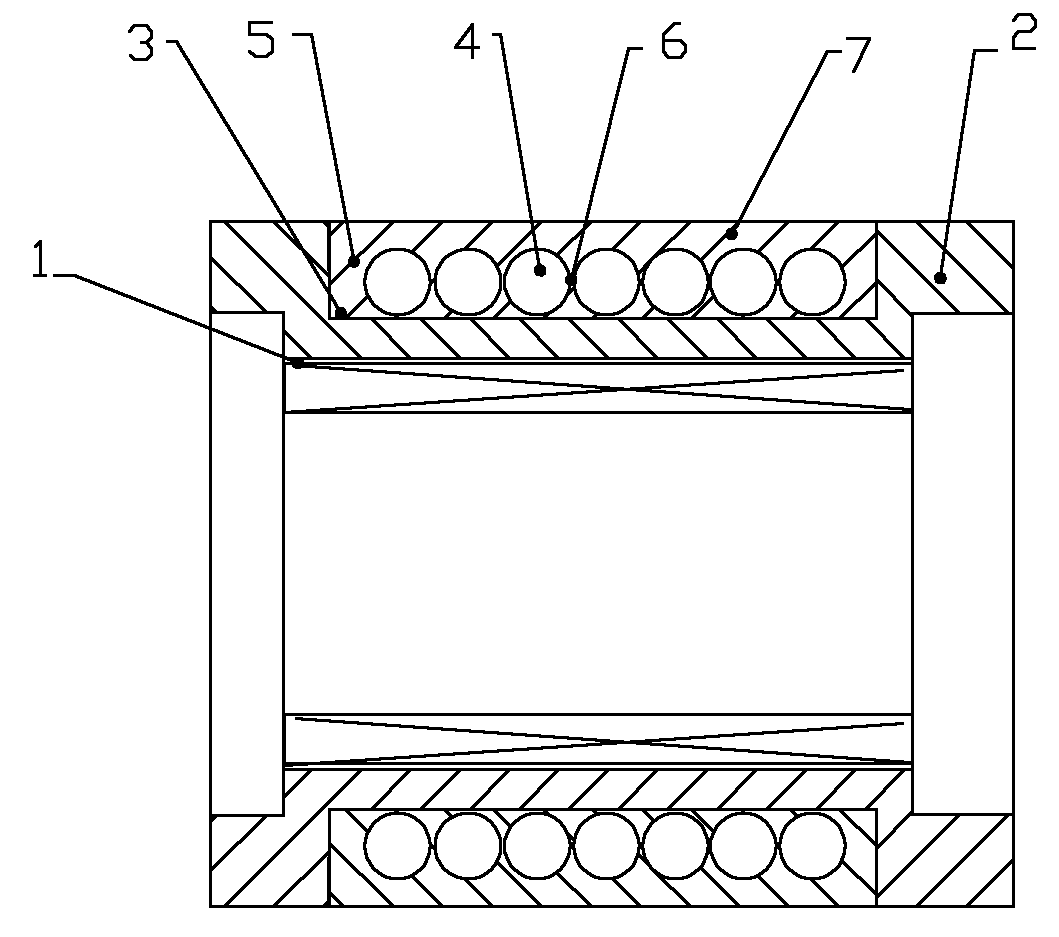

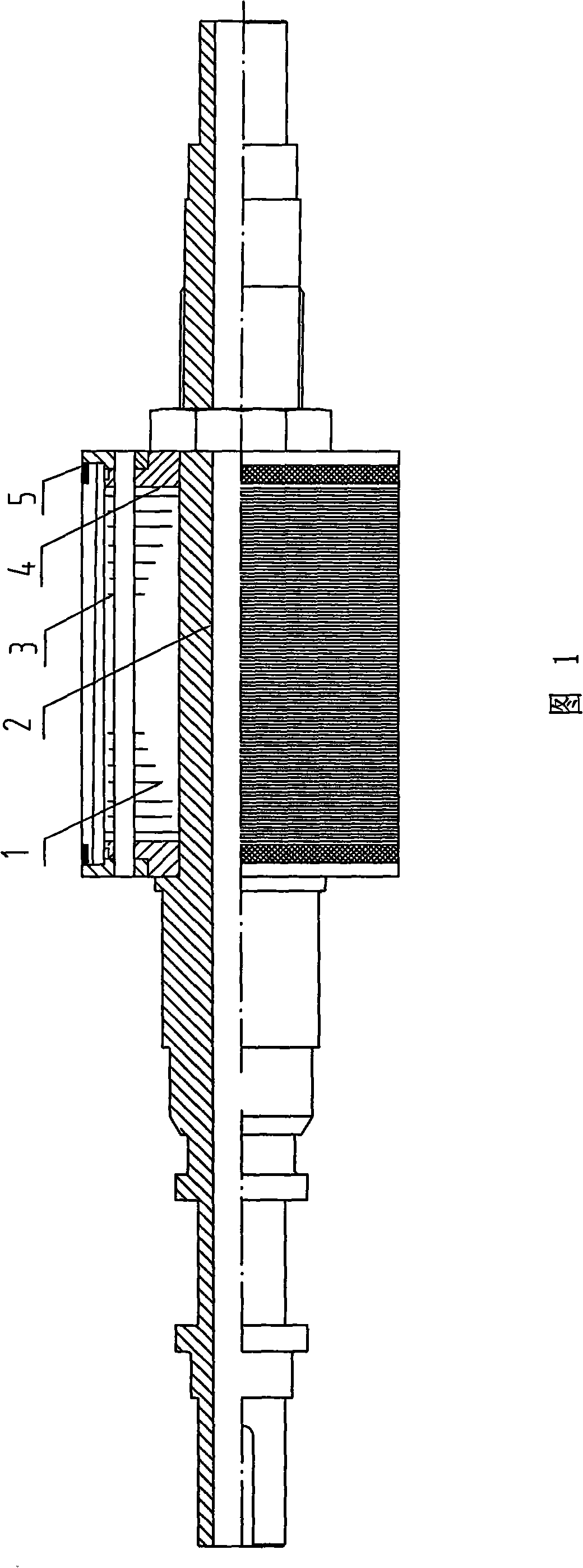

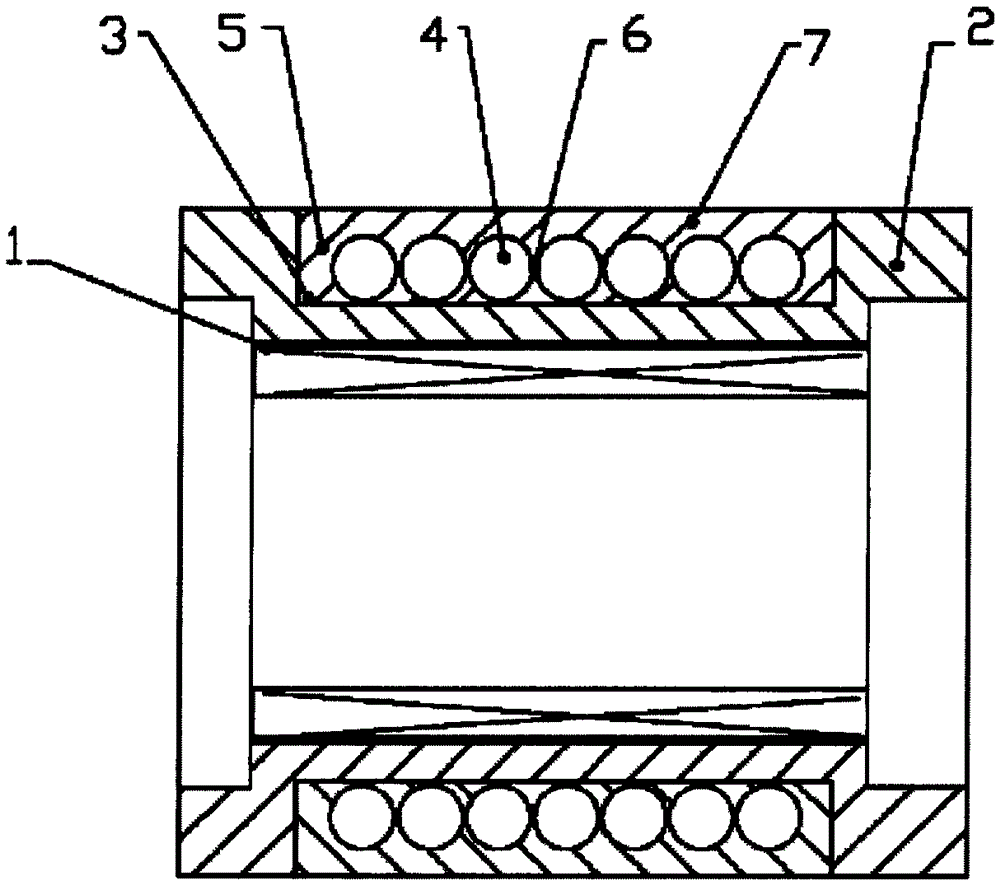

Water cooling method and cooling device for motor

InactiveCN102035306ASolve the problem of insufficient strengthSolve the leakCooling/ventillation arrangementElectric machineryEngineering

The invention discloses a water cooling method for a motor, which has a simple process and high cooling efficiency and is easy to implement, and a cooling device with a simple structure. The method comprises the following steps of: arranging a steel barrel of which the surface wall is provided with a groove on a motor shell; winding a spiral pipe which serves as a water jacket on the groove of the steel barrel; and embedding and casting the water jacket into the groove of the steel barrel by using aluminum alloy. The cooling device comprises the steel barrel which is arranged on the motor shell and a spiral pipe which is wound in the groove of the steel barrel, wherein aluminum alloy casting bodies are arranged on the spiral pipe and between the spiral pipe and the steel barrel.

Owner:JIANGXI SPECIAL ELECTRIC MOTOR CO LTD

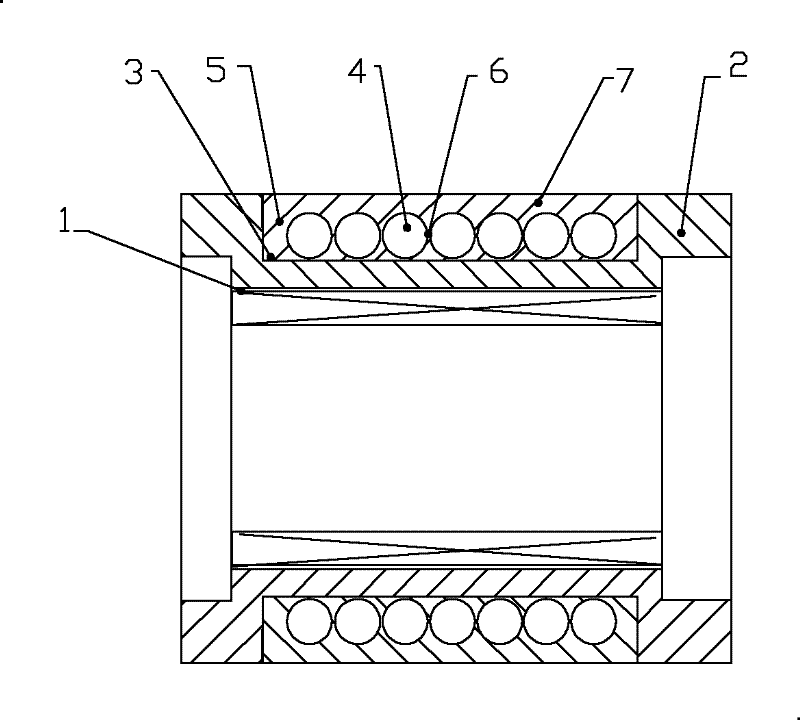

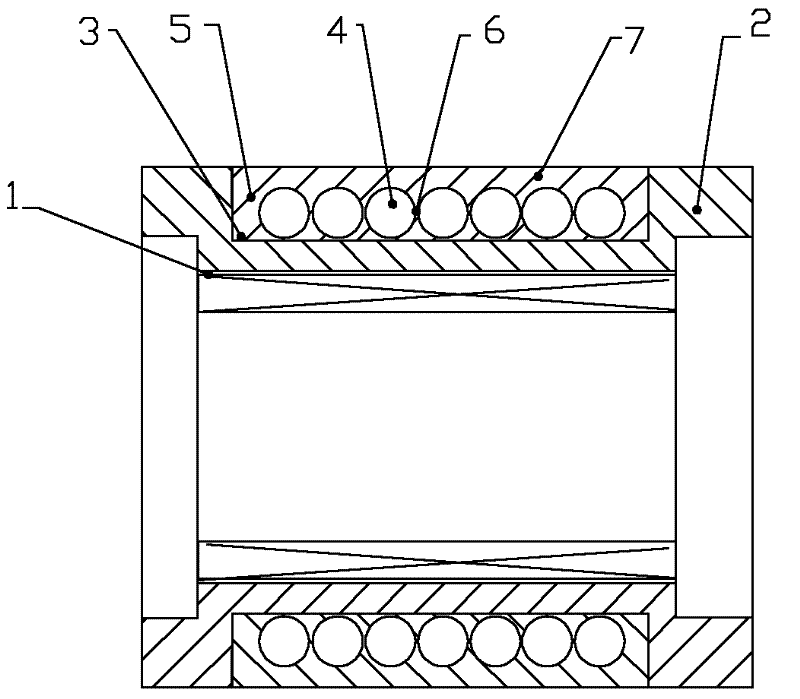

Laminated rotor for high-speed motor

InactiveCN101330232AReduce tangential stressSolve the problem of insufficient strengthWindingsMagnetic circuit rotating partsInterference fitElectrical conductor

The invention provides a laminated rotor used for high-speed motors, which comprises a laminated sheet made from magnetic-permeable silicon steel sheets or magnetic-permeable steel plates and a solid or hollow rotating shaft, wherein press plates are respectively arranged at two ends of the laminated sheet. The laminated sheets are tensioned with the press plates as a whole via a draw bar. Axial air holes are formed on the laminated sheets and the press plates respectively. A groove is formed on the outer circumference of the laminated sheets and used for allowing a winding or a conductor to be embedded therein. The end parts of the winding are fixed by a weftless tape or a steel hoop. The inner hole of the laminated sheets and the outer diameter of the rotating shaft adopt a keyless interference fit. The inner hole of the press plates and the outer diameter of the rotating shaft also adopt a keyless interference fit. The interference value is determined based on the actual interference fit and stress and is different to the products with different specifications. The linear speed of the laminated rotor is as high as more than 200m / s. The iron loss of the rotor is reduced while the rotational speed of the motor is increased, that is, the power density of the motor is increased. Additionally, compared with the solid rotor, the manufacturing time and cost of the laminated rotor are greatly reduced. The laminated rotor is suitable for the high-speed asynchronous motor as well as the high-speed non-salient-pole synchronous motor and the non-commutator direct current motor.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

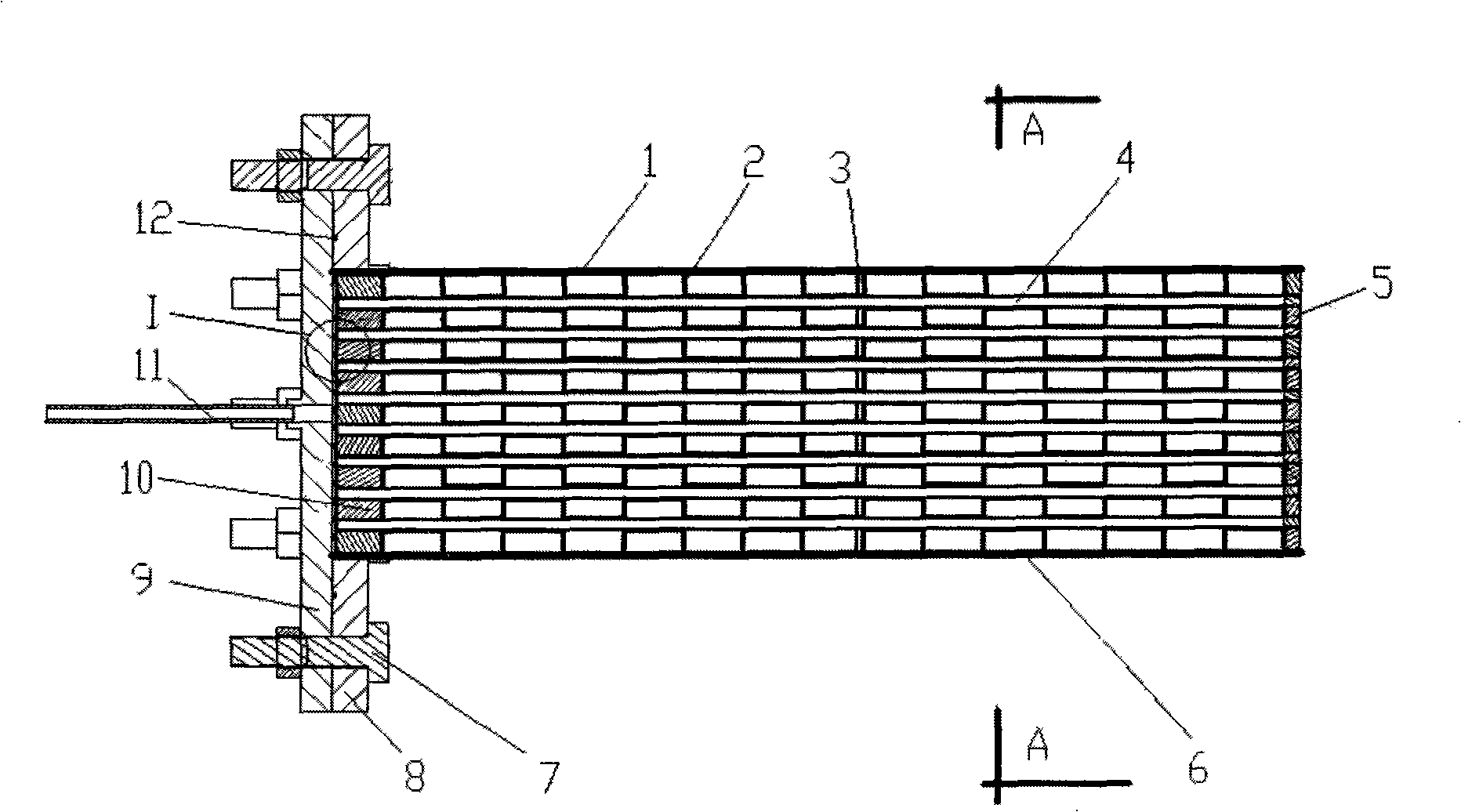

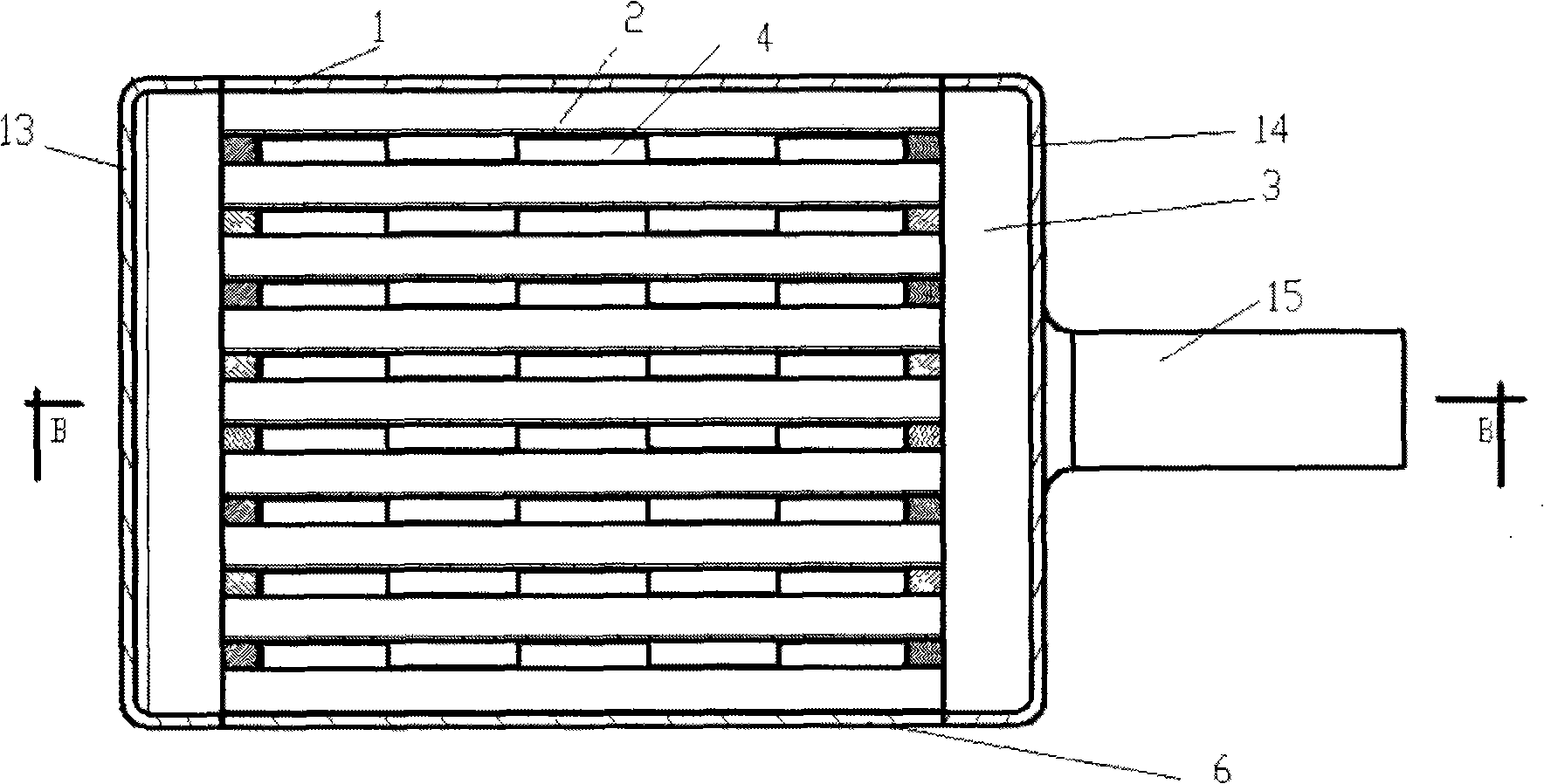

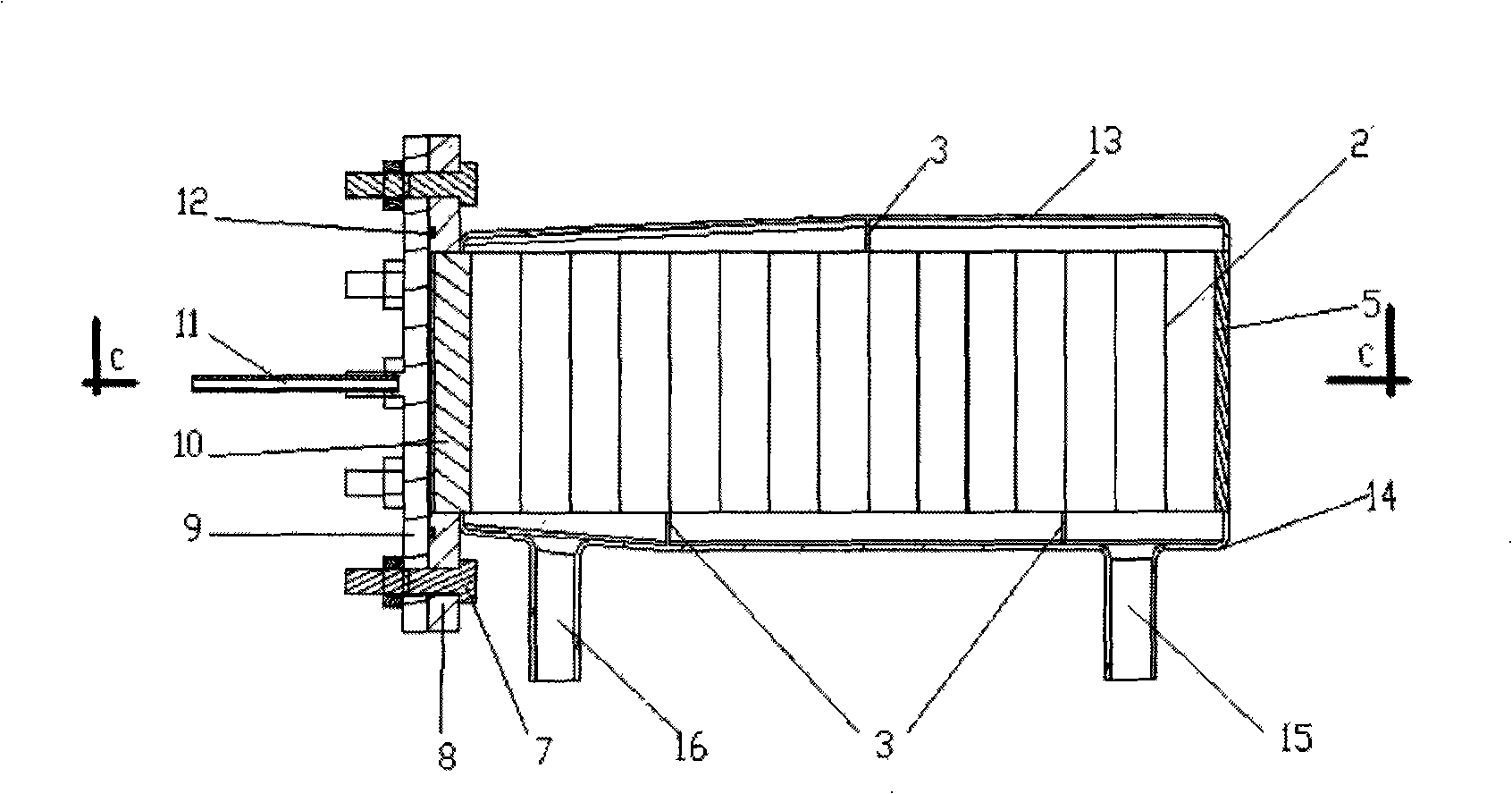

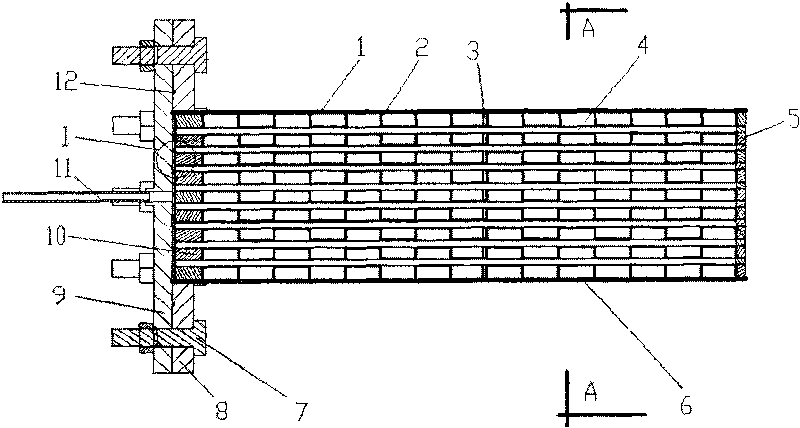

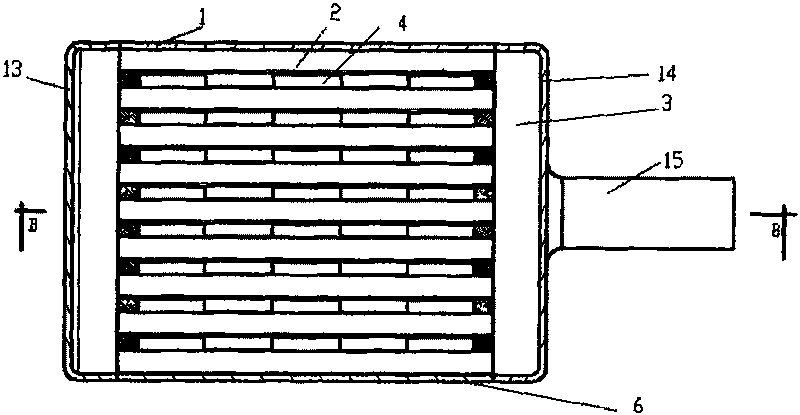

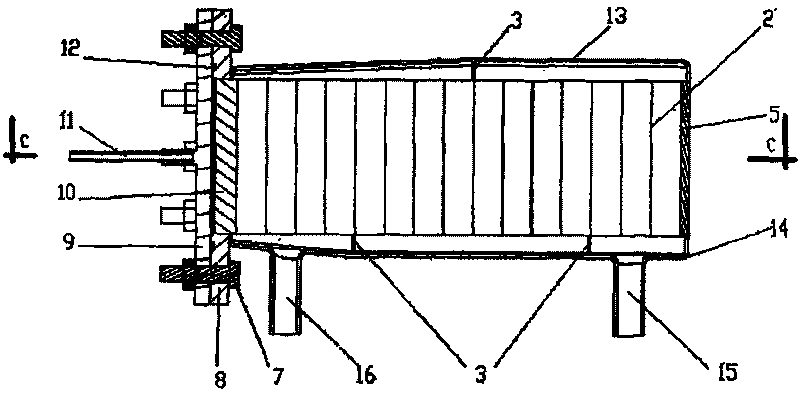

Metal hydrides plate-fin heat exchanger

InactiveCN101307994AIncrease the heat exchange areaImprove effective thermal conductivityStationary plate conduit assembliesThermal conductivityMillipore Filters

Disclosed is a metal hydride plate-fin heat exchanger, which belongs to the industrial heat exchange and energy saving technique field. The invention comprises: an upper cover plate, a fluid path flat tine fin, a spacer plate, reaction bed units, a fluid path tail sealing tape, a lower cover plate, a bolt component, a through hole flanged disc, a blind plate flanged disc, a fluid path head sealing tape, a hydrogen pipe, a fluorine rubber flange gasket, a rear enclosing cover, a front enclosing cover, a liquid inlet, a liquid outlet, a filter sheet gasket and a millipore filter sheet. Each reaction bed unit includes an upper cover plate, a unit tail sealing tape, a unit lateral sealing tape, a lower cover plate and a unit serrate fin. Each reaction bed unit has an open end and is welded with a serrate fin in the inside, thereby the heat exchange area and the effective thermal conductivity are greatly increased, and the intensity of a heat exchange unit can also be ensured under the condition of increasing the heat capacity of the heat exchange unit indistinctively. In addition, filtration and sealing difficulties of metal hydrides are greatly reduced by adopting the structure that all the reaction bed units are connected and fixed on the through hole flanged disc in parallel, meanwhile, the mass transfer capability of hydrogen will not be reduced.

Owner:SHANGHAI JIAO TONG UNIV

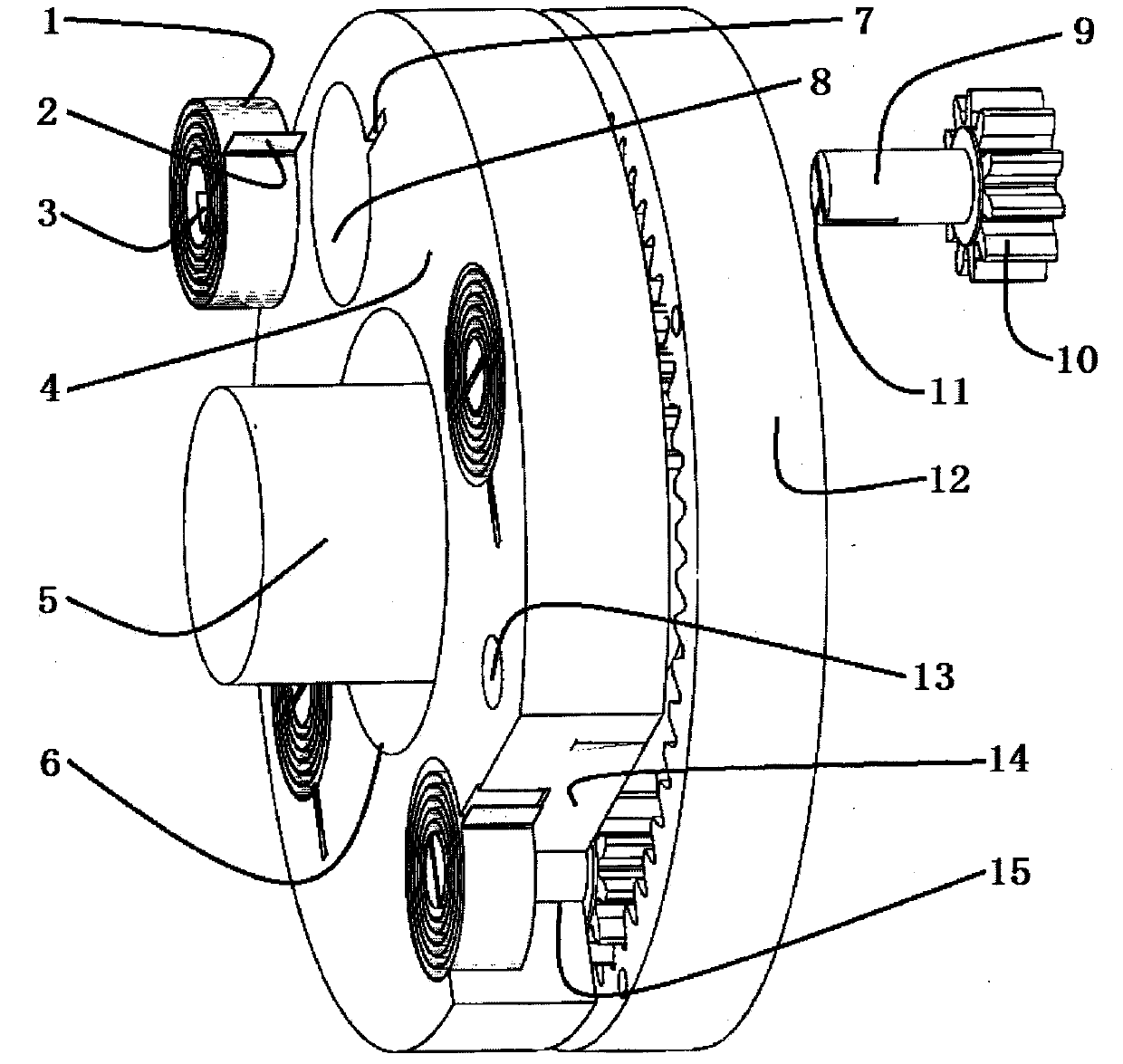

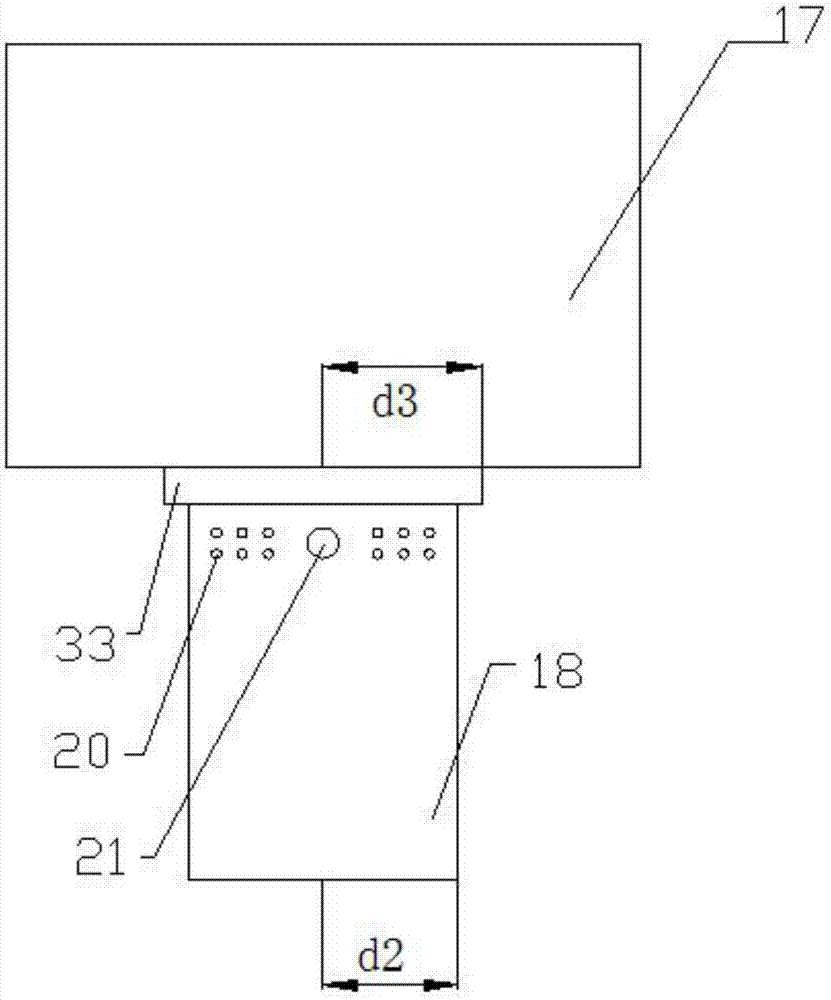

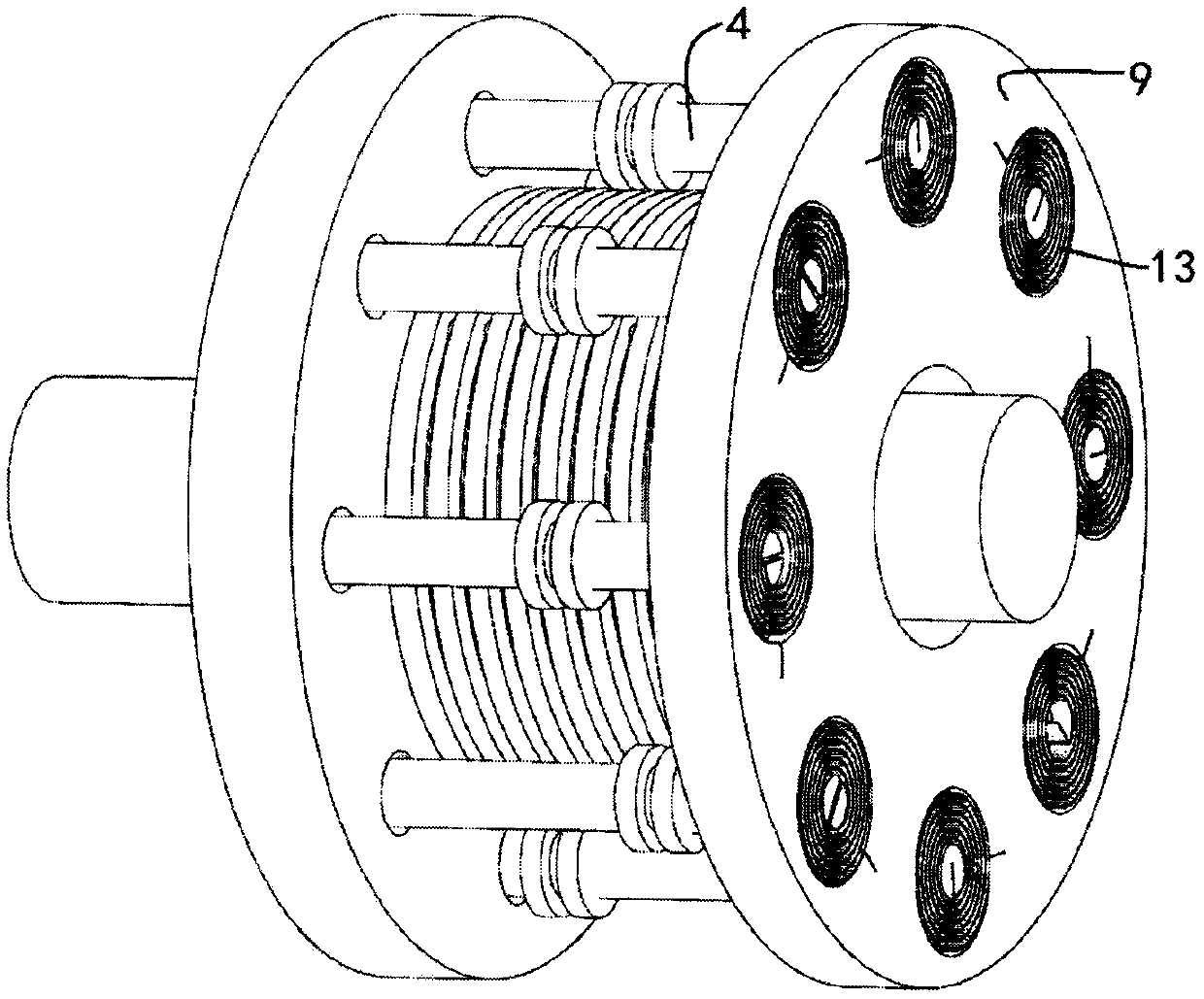

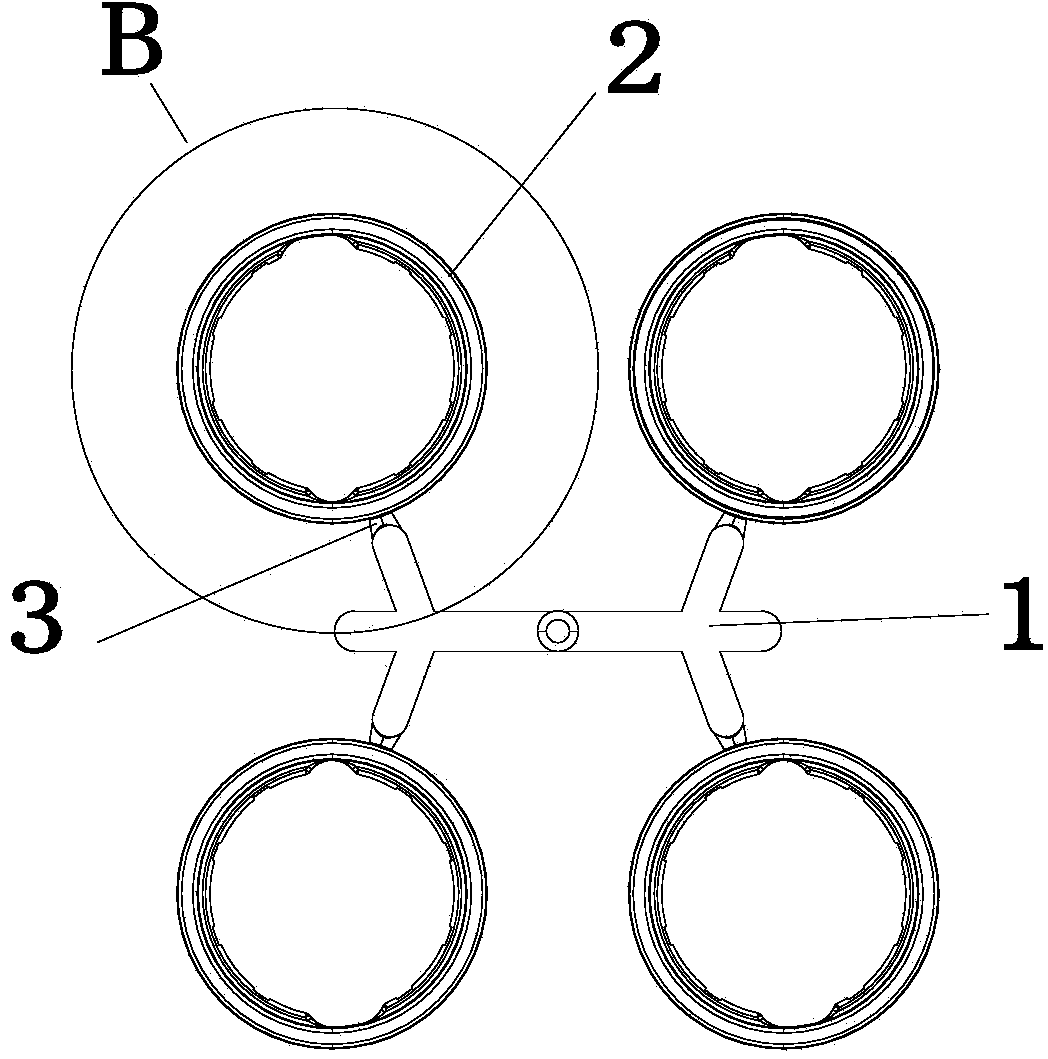

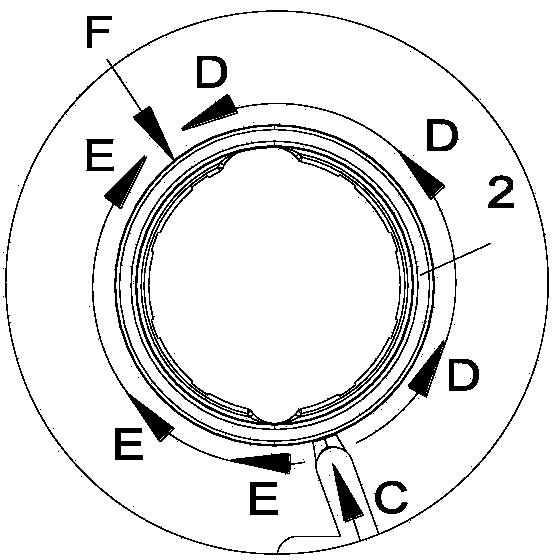

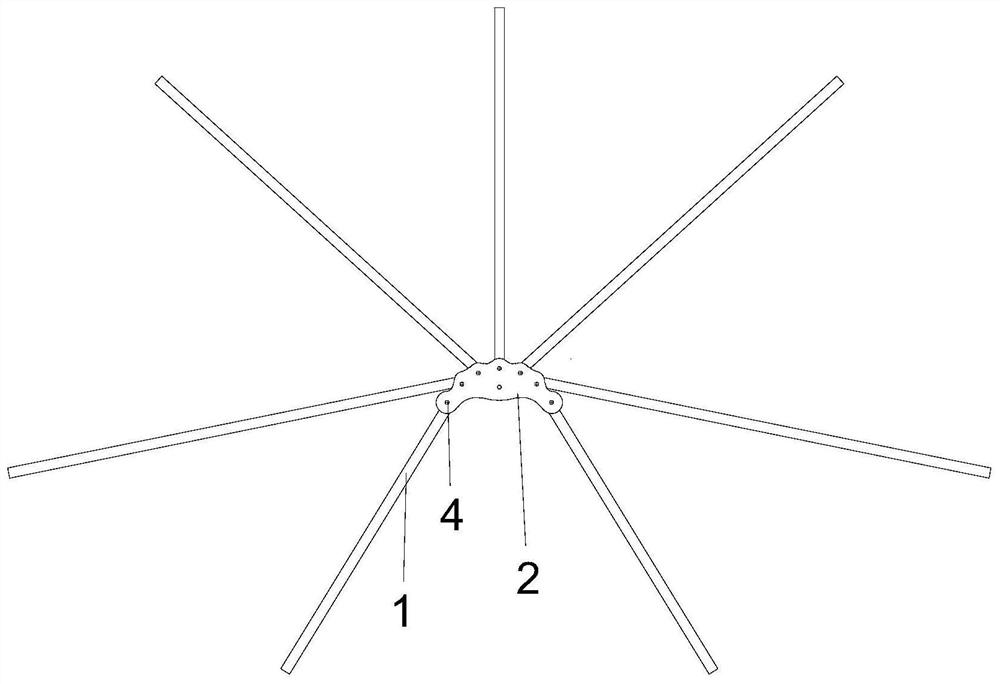

Elastic mechanism used for suspension

PendingCN109532373ASolve the problem of insufficient strengthSmall rotation angleResilient suspensionsGear driveElectric machinery

The invention discloses an elastic mechanism used for a suspension. The elastic mechanism is characterized in that peripheral-distribution power springs and a gear drive mechanism are used, the torqueof the power springs is increased to meet the demand of vehicle suspension elastic elements for torque, the size and the weight of the suspension elastic elements are reduced, and the elastic mechanism is structurally composed of the power springs 1, an installing base plate 4, a planetary gear 10, an inner tooth ring 12 and a motor 20, is suitable for suspensions of passenger vehicles, railway vehicles and engineering vehicles, and is particularly suitable for suspensions of electric automobiles.

Owner:邹务丰

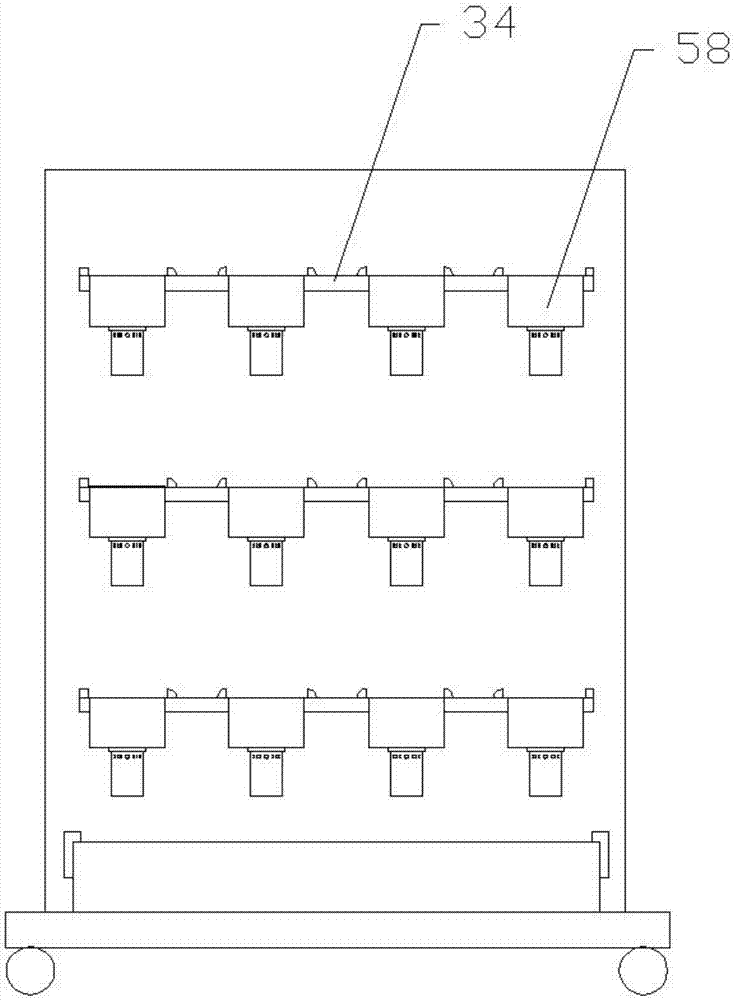

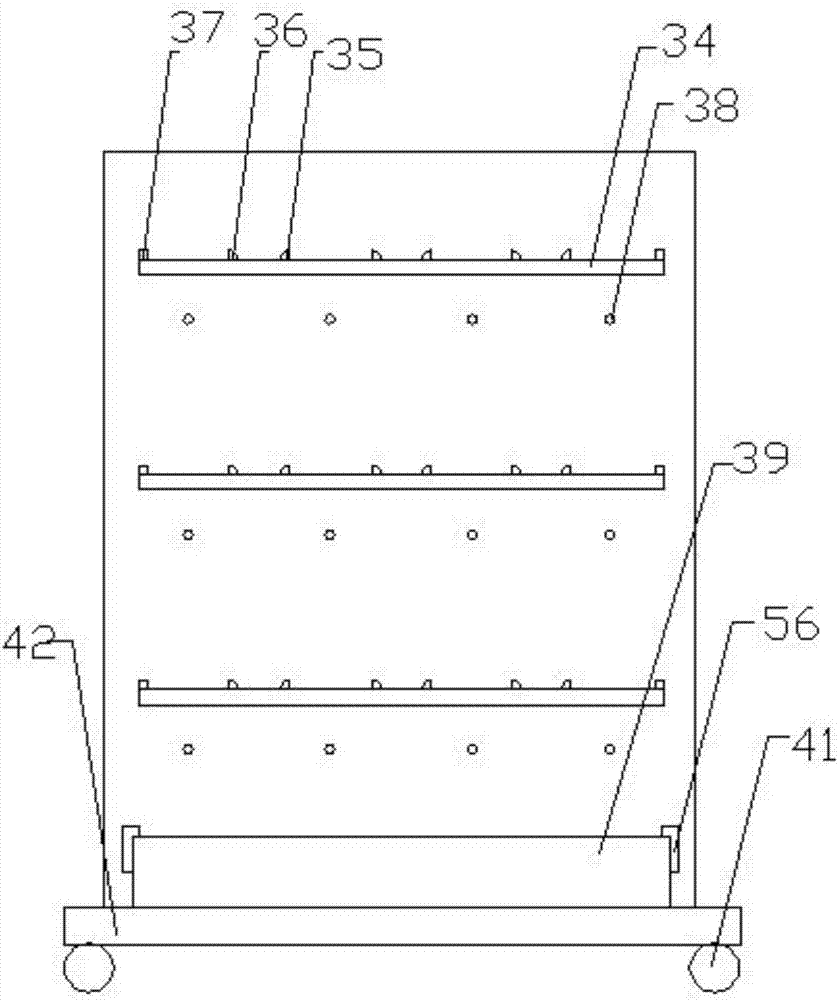

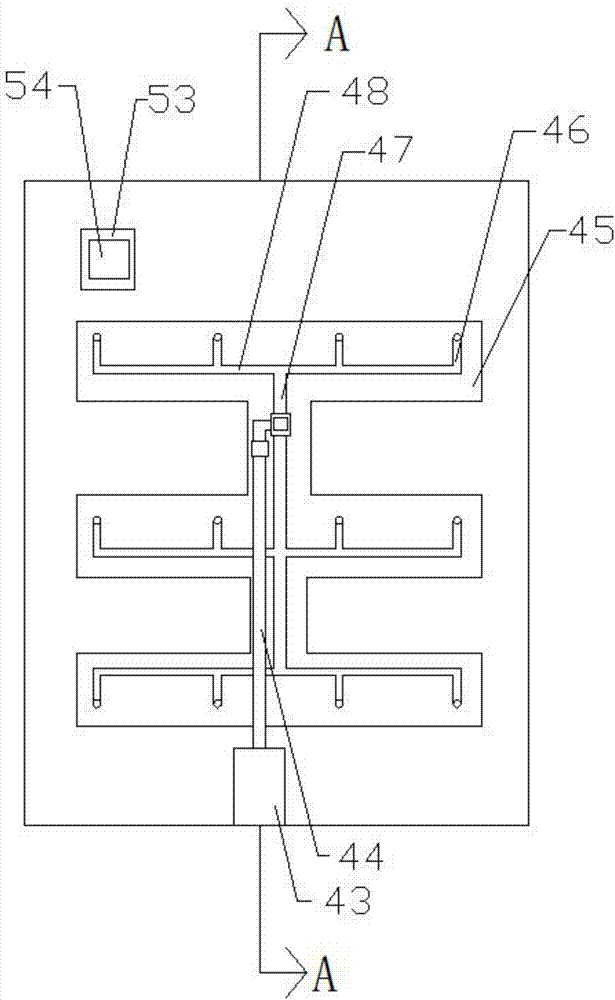

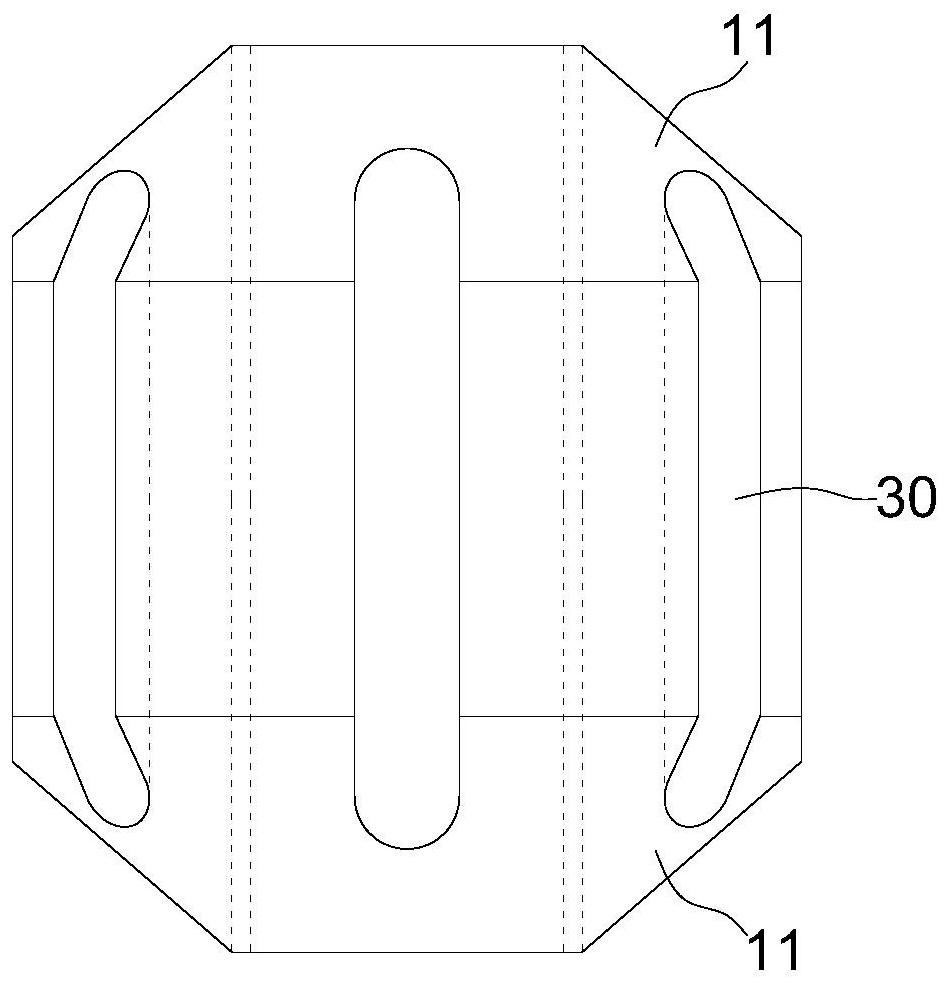

Vertical and combined plant planting frame

ActiveCN107114135ARealize automatic wateringPromote growthSelf-acting watering devicesCultivating equipmentsInter layerWater source

The invention provides a vertical and combined plant planting frame. The plant planting frame comprises a planting frame body, the planting frame body is provided with planting bags, each planting bag is of a three-layer structure, and the middle layer of each planting bag is a support frame; the planting frame body is provided with a plurality of planting bag racks, the planting bag racks are arranged at equal intervals, and each planting bag rack is provided with a first limit block, a second limit block and a third limit block; according to the vertical and combined plant planting frame, when the external connection between a sixth water pipe and a water source is not convenient, water in a water storage tank and water in a third groove can be pumped through a water pump, the water storage tank is located at the lower end of the planting frame body, can collect water which flows out from the planting bags and plays a role of water circulation and re-utilization, the water storage tank is provided with a filter net, and the filter net can filter soil and leaves which fall down; the planting bag racks are provided with the limit blocks, and the limit blocks can play a role of fixing the positions of the planting bags. According to the vertical and combined plant planting frame, various plants can be planted in the planting bags, the combination forms of the plants are diverse, the practicability is high, and the frame is suitable for indoor use.

Owner:FLOWER KING ECO ENG CO LTD

Motor cooling apparatus

InactiveCN106849506ASolve the problem of insufficient strengthSolve the leakCooling/ventillation arrangementSupports/enclosures/casingsEngineeringPre embedding

The invention discloses a water cooling method and a water cooling apparatus for a motor. The water cooling method is simple in process and easy to implement while the water cooling apparatus is simple in structure and high in cooling efficiency. The method comprises the steps of setting a steel cylinder with a groove in the surface wall on the motor shell, winding the groove of the steel cylinder with a spiral pipe to be used as a water leg, and pre-embedding and casting the water leg into the groove of the steel cylinder through aluminum alloy. The cooling apparatus comprises the steel cylinder arranged on the motor shell, and the spiral pipe which is wound in the groove of the steel cylinder, wherein an aluminum alloy casting body is arranged on the upper surface of the spiral pipe and between the spiral pipe and the steel cylinder.

Owner:盛浩铭

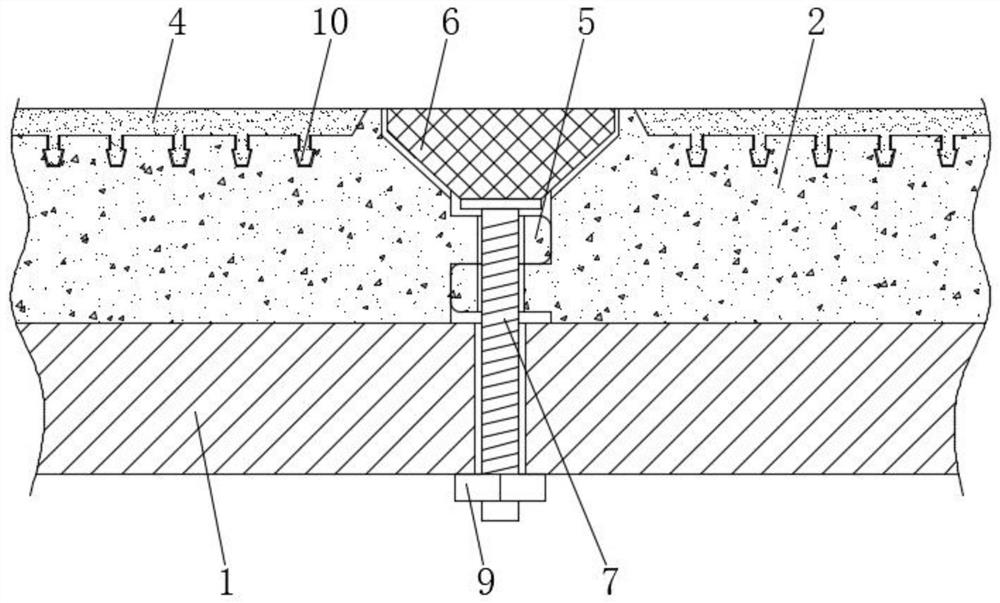

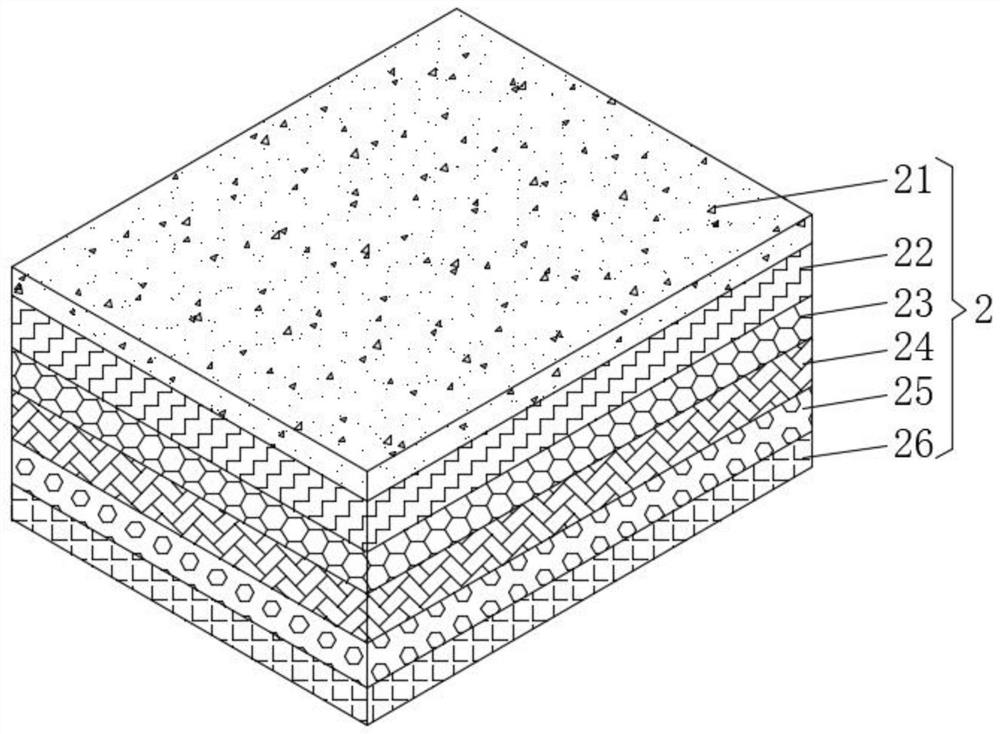

Corrosion-resistant external wall insulation board

InactiveCN112554357AImprove stability and securityEasy to install and fixWallsHeat proofingCorrosion resistantBuilding material

Owner:江苏叙施建筑科技有限公司

High-air-permeability planting bag

ActiveCN107211756ARealize automatic wateringPromote growthSelf-acting watering devicesReceptacle cultivationEngineeringUltimate tensile strength

Owner:FLOWER KING ECO ENG CO LTD

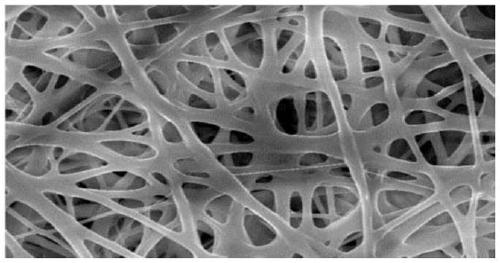

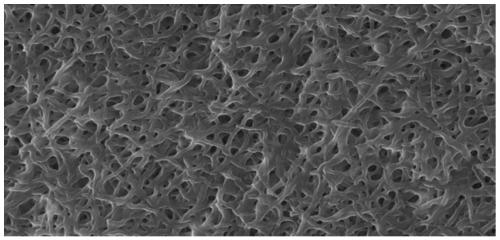

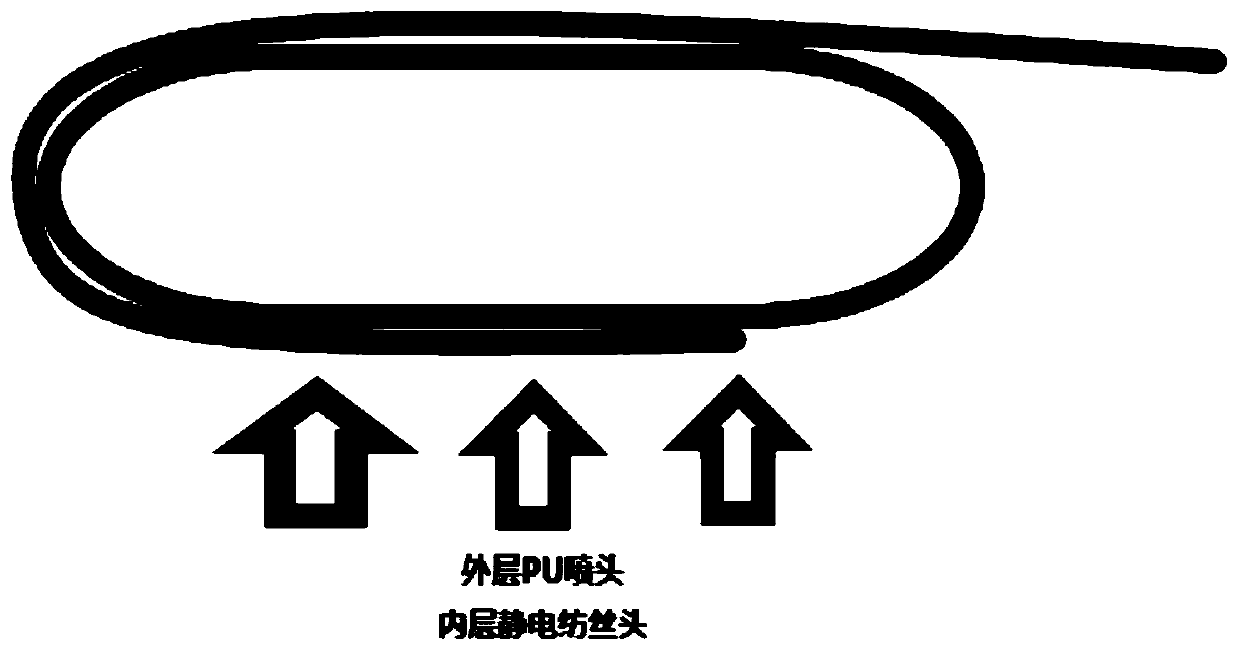

Waterproof and moisture-permeable film and preparation and application thereof

ActiveCN111531994AGood waterproof and moisture permeabilitySolve the problem of low productivitySynthetic resin layered productsLaminationPolymer scienceSpinning

The invention relates to a waterproof and moisture-permeable film and preparation and application thereof. The moisture-permeable film is prepared by the steps that in PU moisture-permeable pulp, polyoxyethylene (PEO) is drawn into superfine fibers through an electrostatic spinning technology and the superfine fibers are implanted therein, water-soluble PEO is dissolved out through water washing after film forming and attaching, microporous channels are formed in the film, and the microporous waterproof and moisture-permeable effects are achieved. Compared with a PU film, the moisture permeability of the novel waterproof and moisture-permeable film is improved by 30%-80%, the strength is improved by 100%-150% compared with an electrostatic spinning film, and the attaching performance and the subsequent processability are better.

Owner:湖州因爱伟大卫生用品有限公司

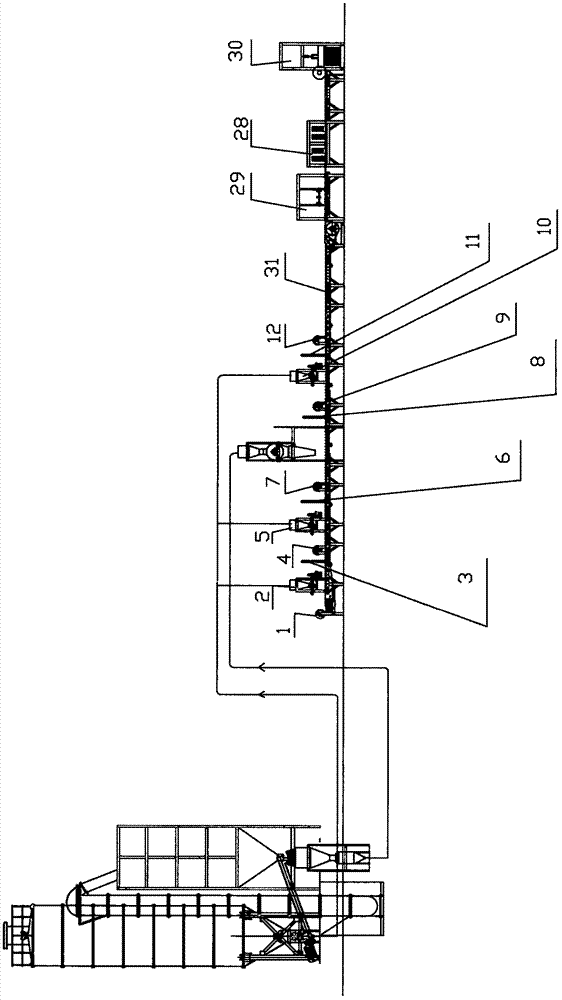

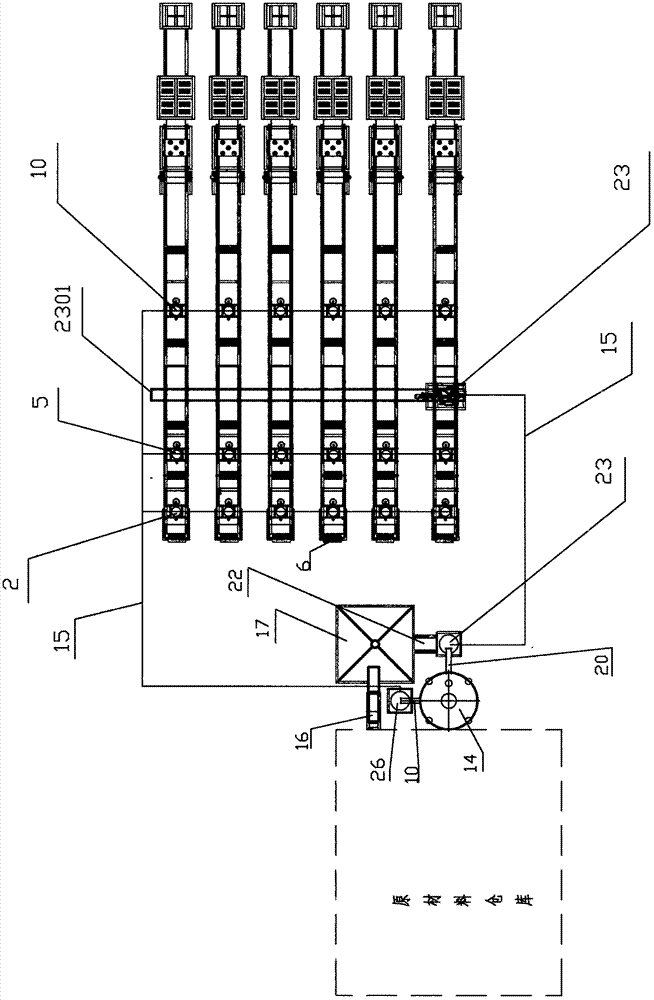

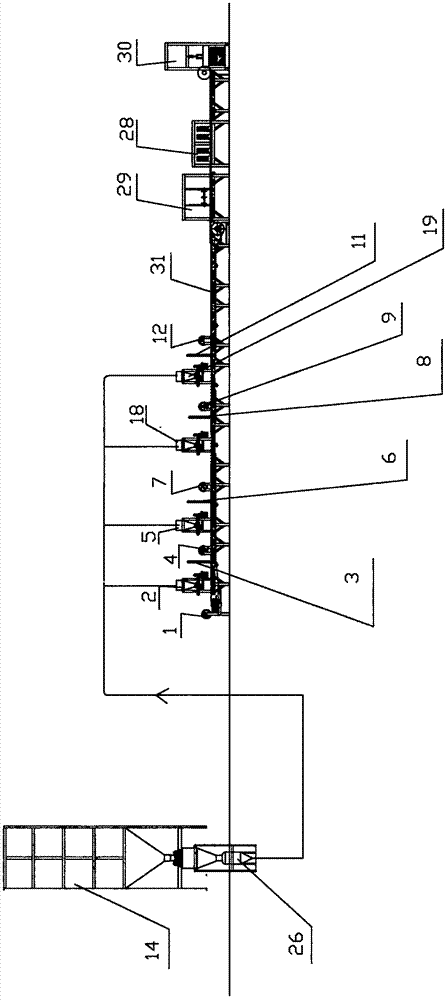

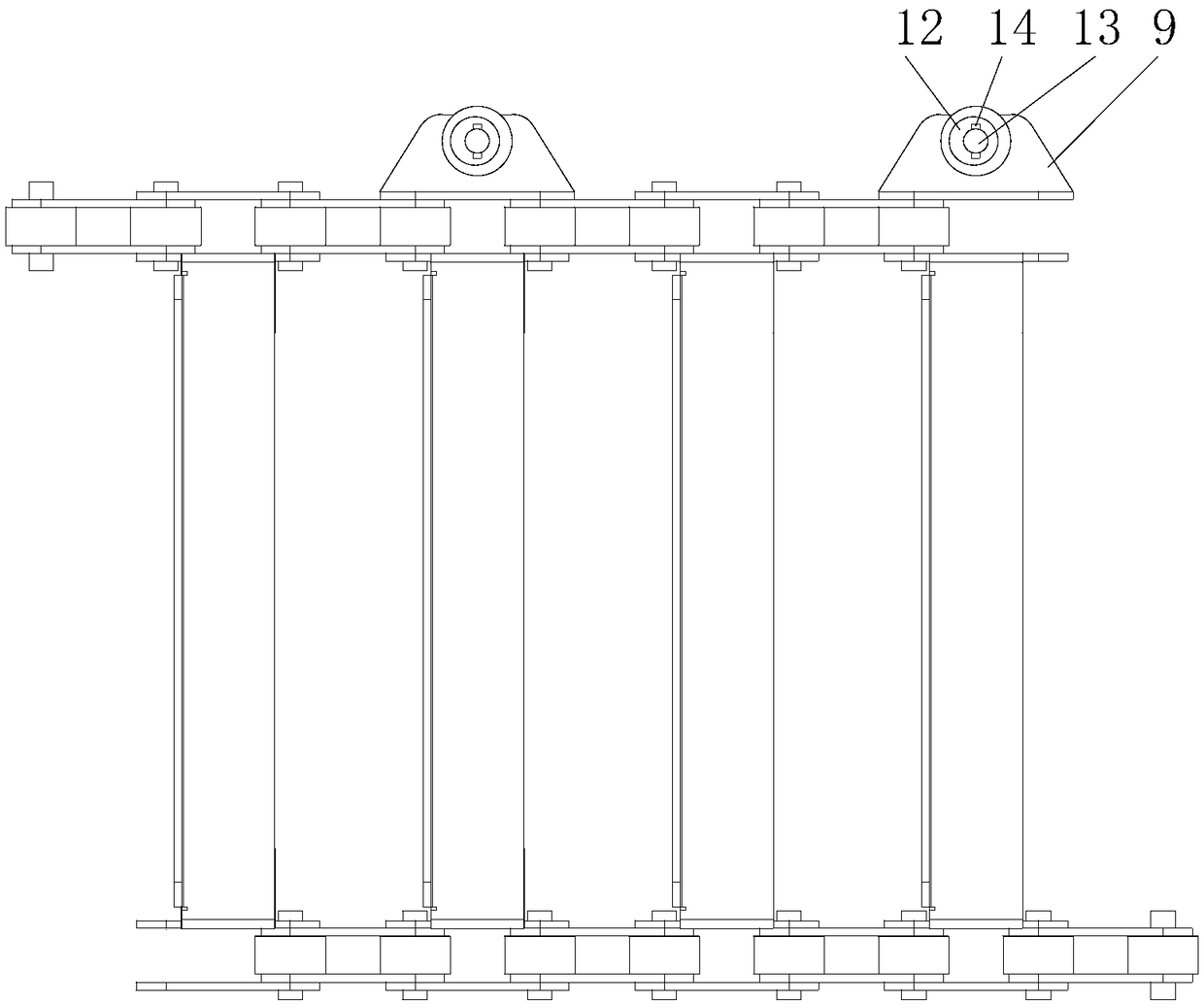

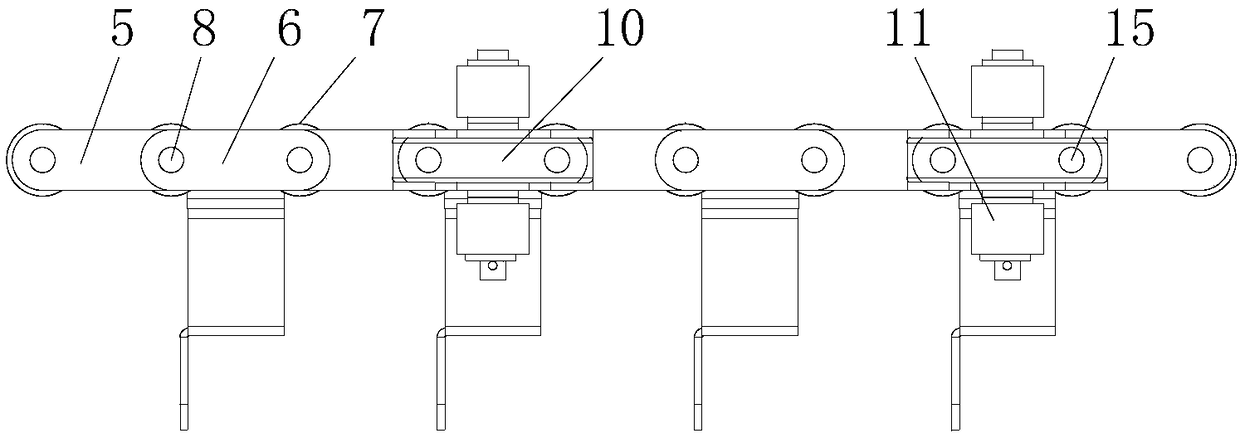

Production line and production method of heat preservation and non-disassembling formwork

InactiveCN107538606AIncrease profitReduce investmentCeramic shaping plantsFeeding arrangmentsProduction lineSlurry

The invention discloses a production line of a heat preservation and non-disassembling formwork. The production line is characterized in that the production line of the heat preservation and non-disassembling formwork is a production line designed and combined together according to capacity requirement, production lines are arranged together, a stirring system is located above a heat preservationslurry moving blanking system to supply materials to the heat preservation slurry moving blanking system. The heat preservation slurry moving blanking system comprises a rack, a rail, a moving blanking hopper and a power system. The rack spans above the combined production line. The moving blanking hopper supplies the materials to the combined single production lines in turn. A cementing materialconveying system communicates with a raw material bin, first material distributing systems, second material distributing systems and third material distributing systems, wherein the first material distributing systems, the second material distributing systems and the third material distributing systems are located on the corresponding single production line. According to the production line of theheat preservation and non-disassembling formwork, the problems that the equipment input is excessive, and equipment is repeatedly built and installed due to the fact that the multiple production lines are needed to be built in order to enlarge the production capacity are solved, and the problems that the product strength is not enough, the product maintenance time is too long, the maintenance equipment investment is high, and a large number of maintenance sites are occupied are solved.

Owner:湖南晨熙绿色建筑产业有限公司

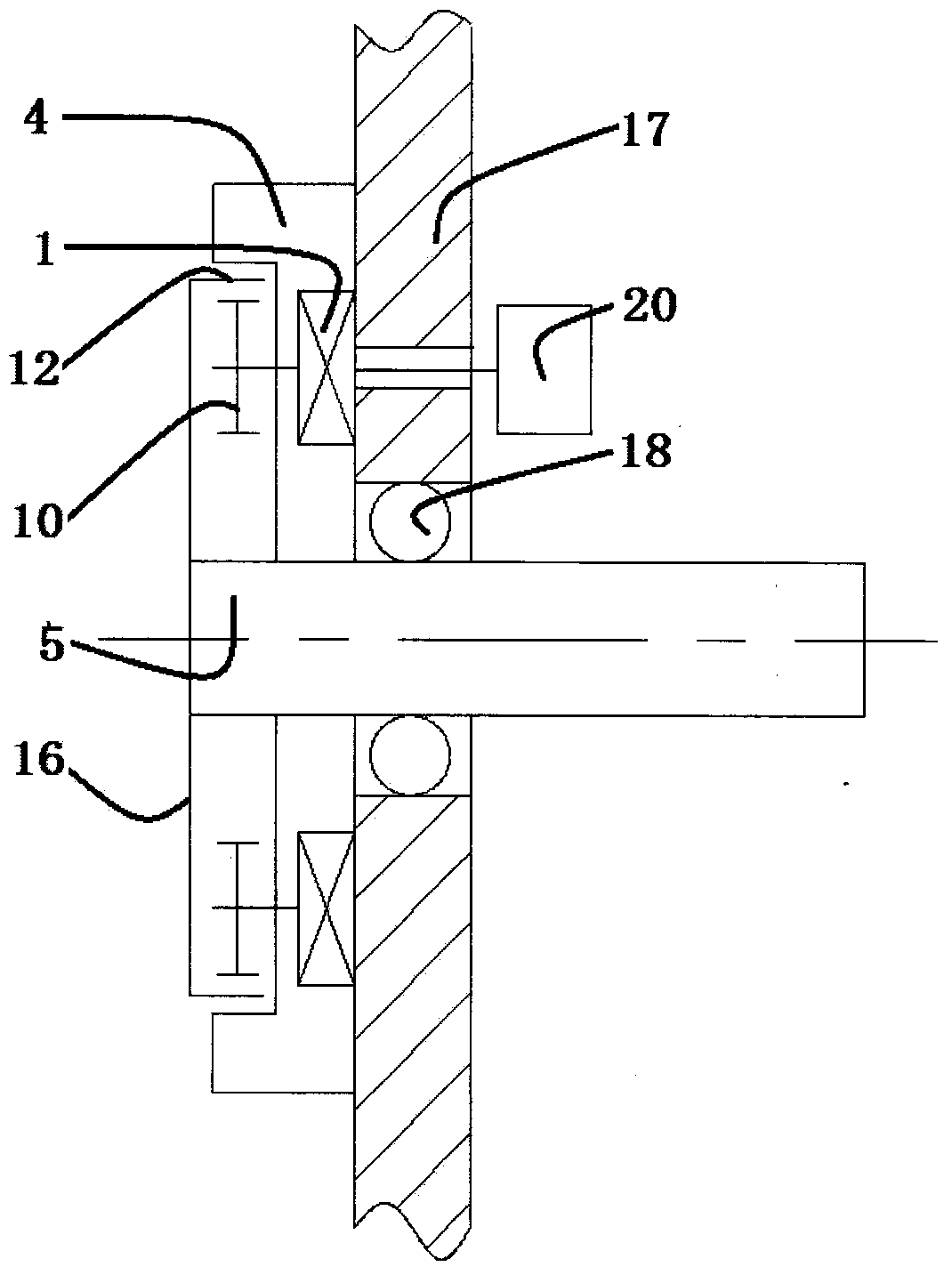

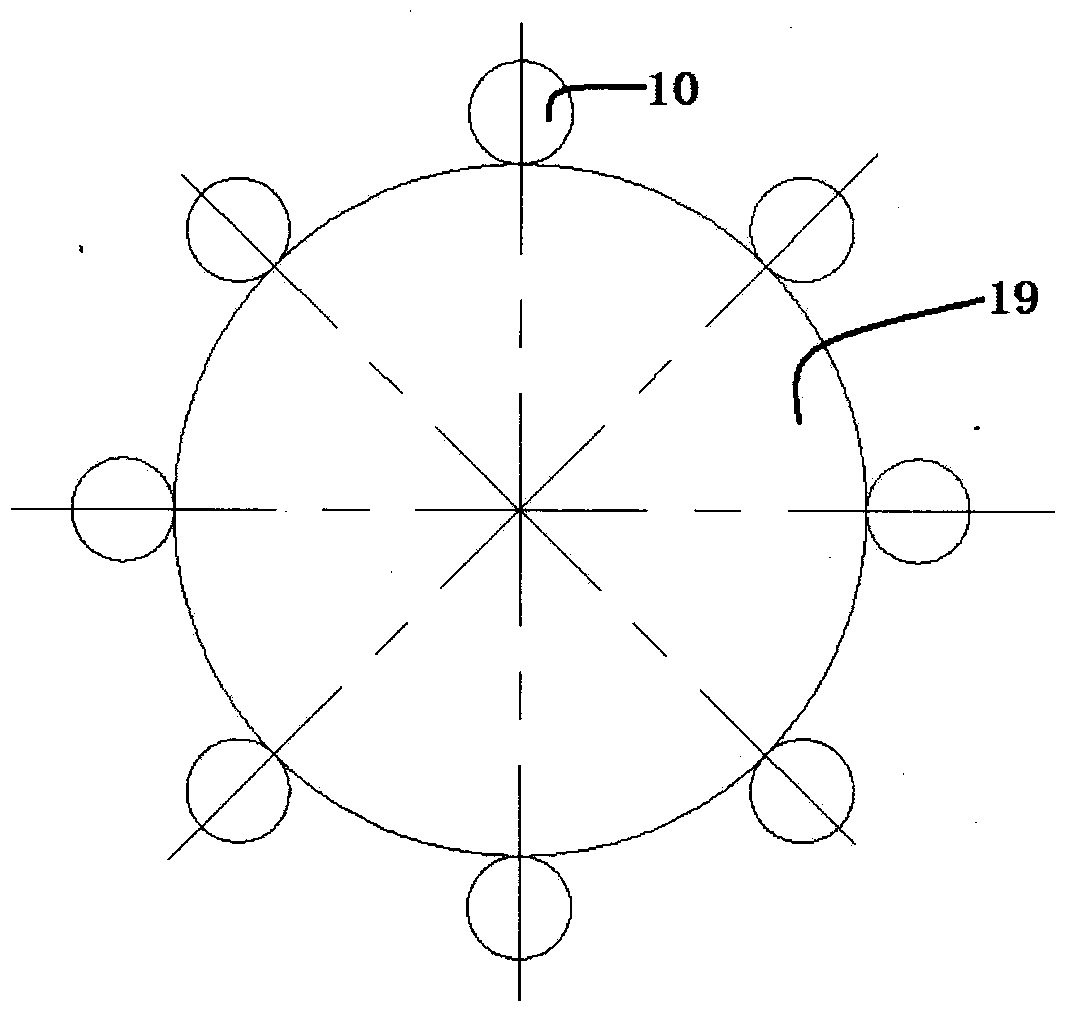

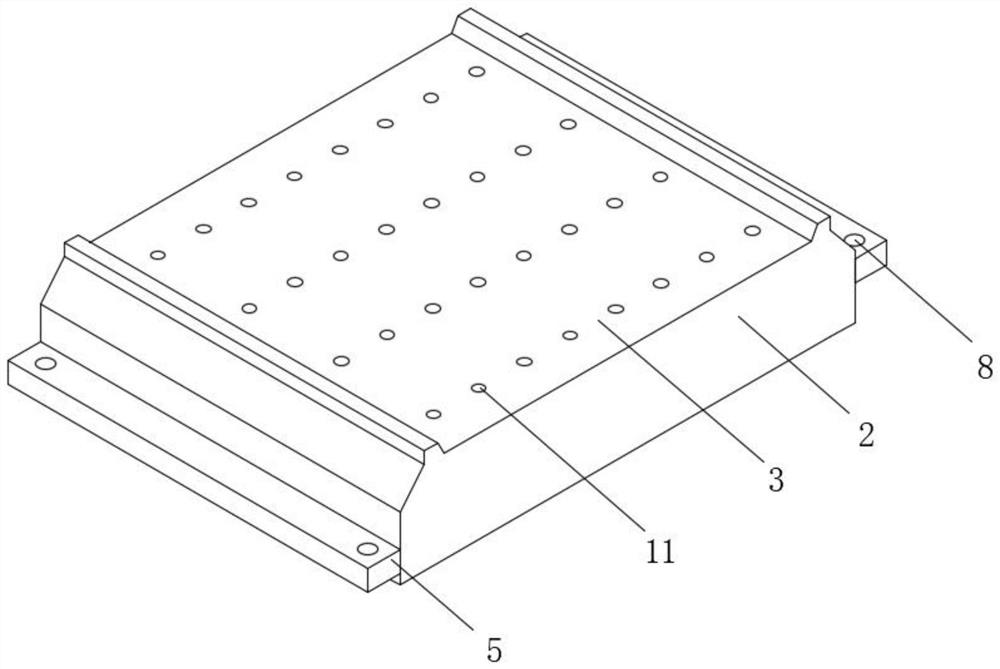

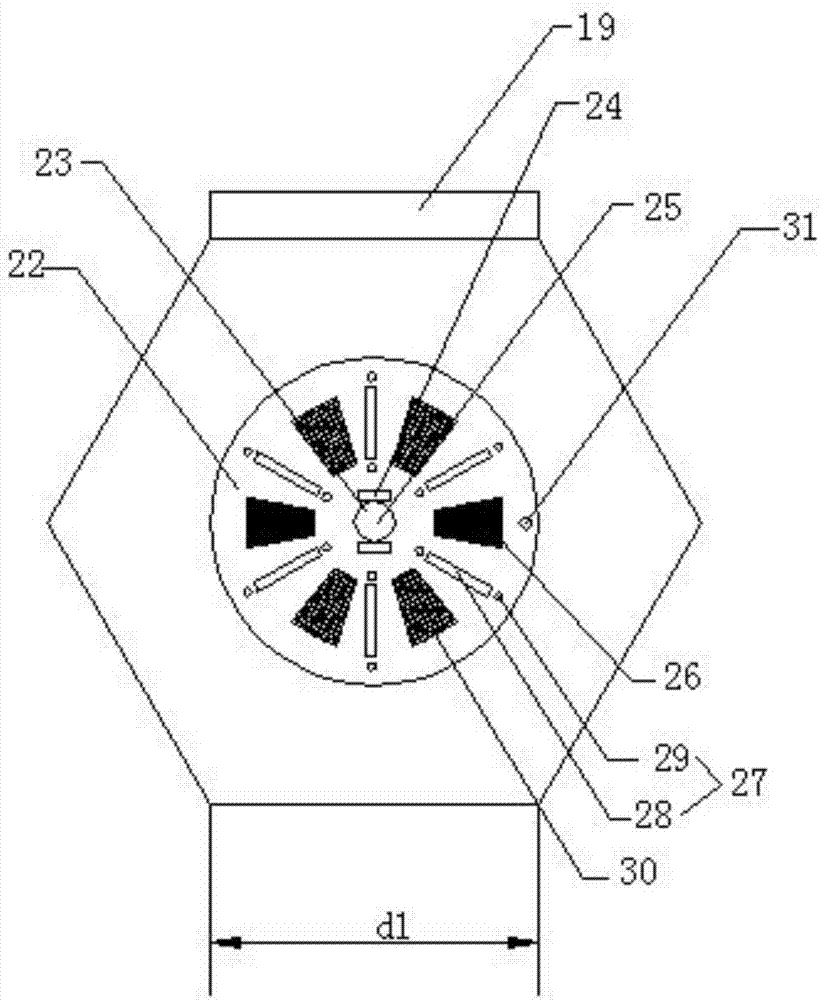

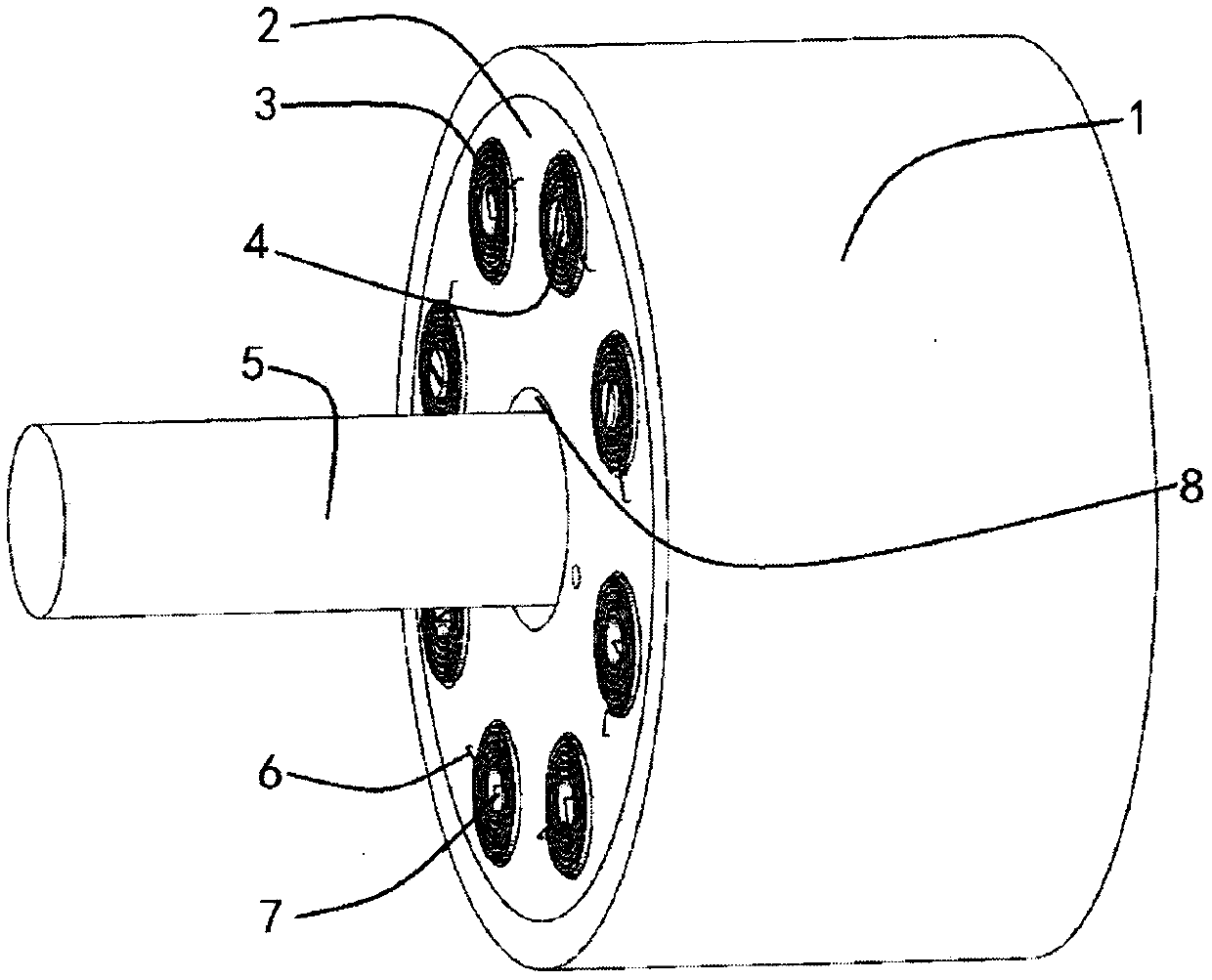

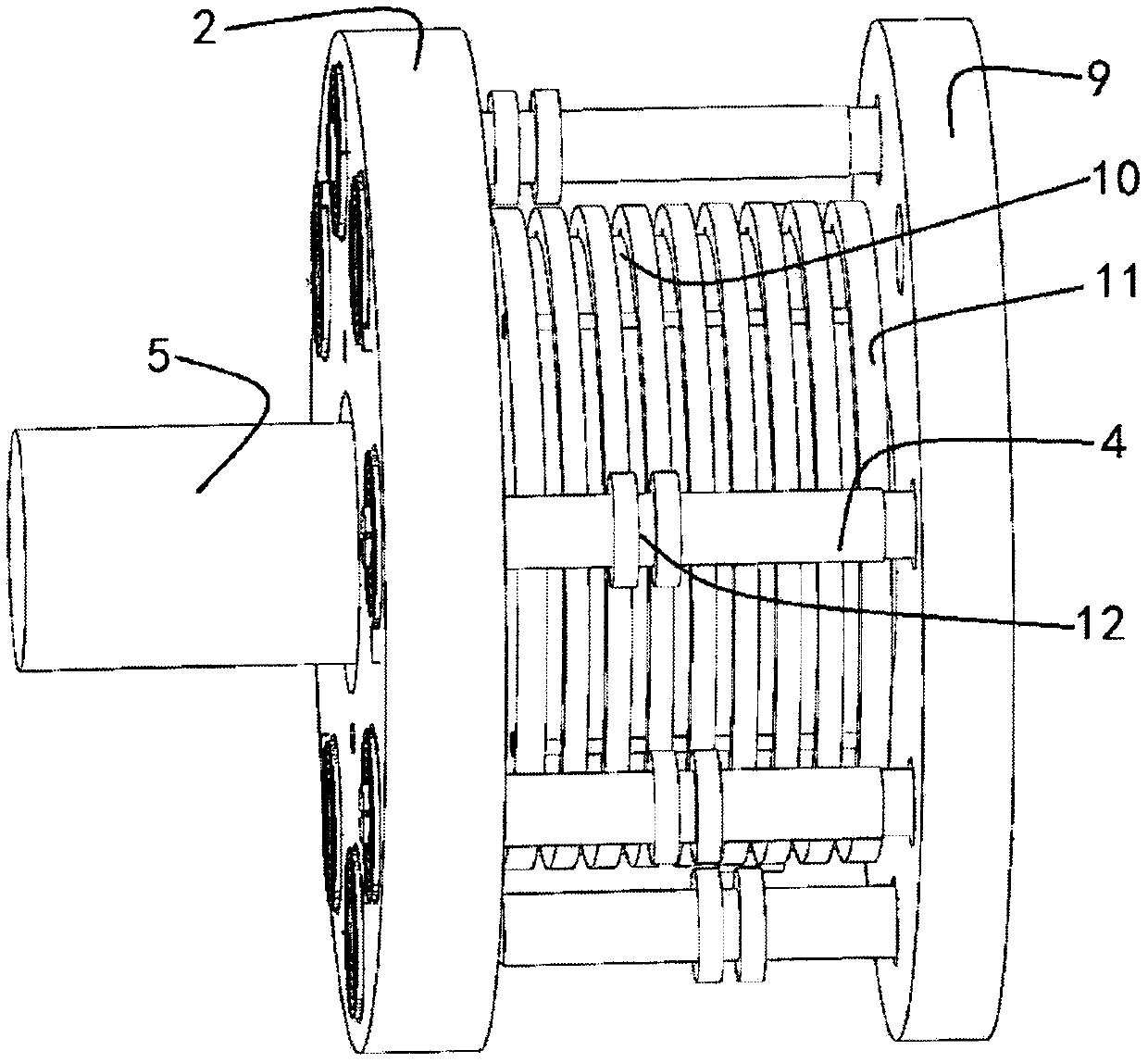

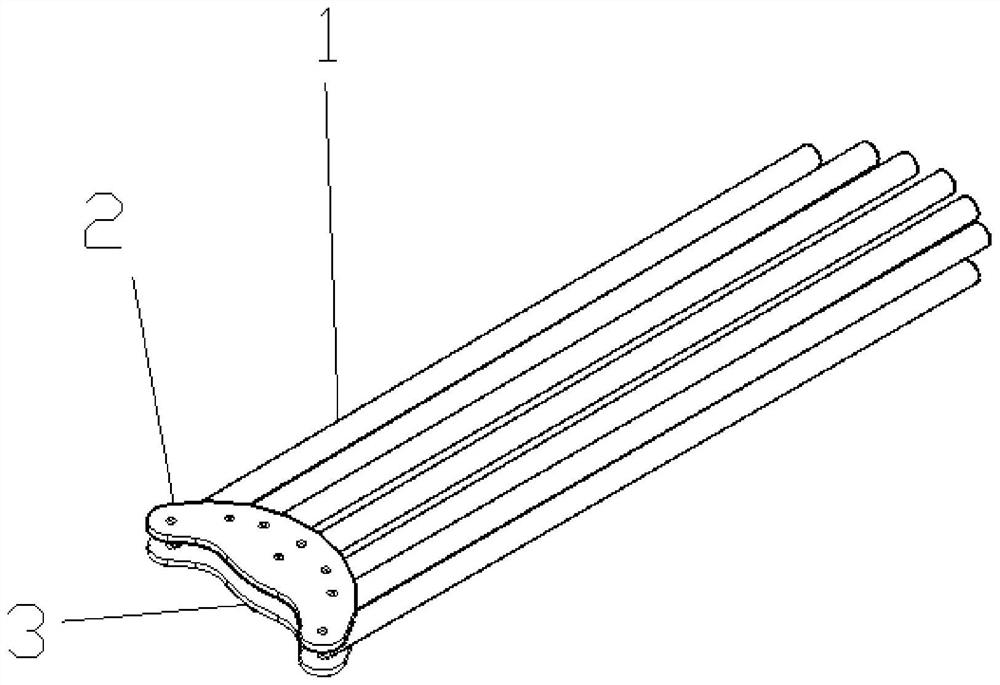

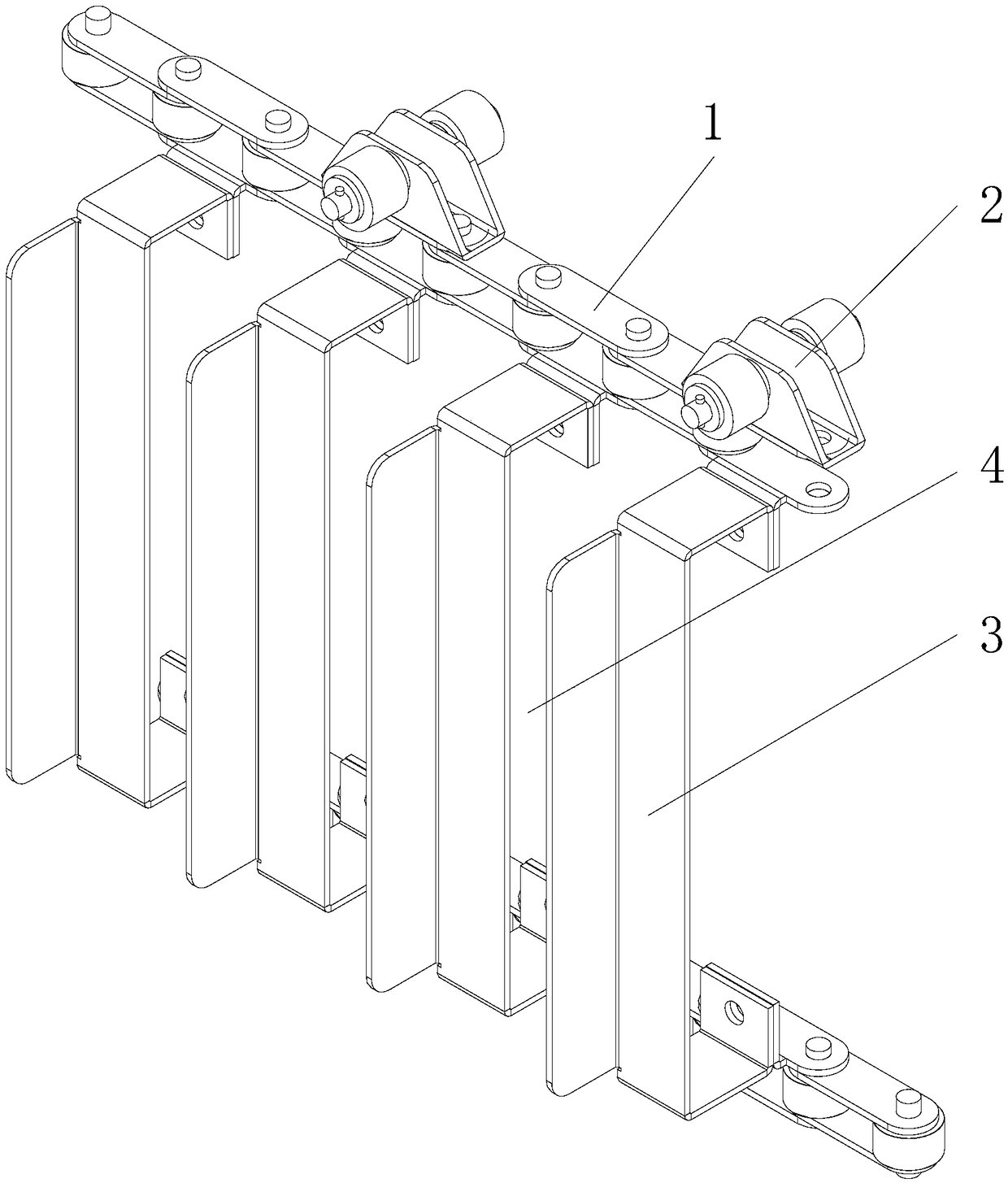

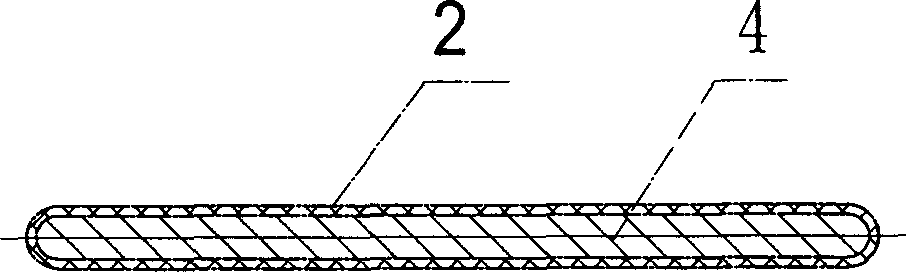

Coil spring combined elastic mechanism through rope transmission

ActiveCN110873140ASolve the problem of insufficient strengthSmall rotation angleSprings/dampers functional characteristicsMultiple spring combinationsClassical mechanicsCoil spring

The invention relates to a coil spring combined elastic mechanism through rope transmission. The mechanism has a function meeting the torque requirements required by vehicle suspension elastic elements through amplifying the torque of a coil spring as well as a function of changing stiffness, and can be applicable to suspension use for passenger vehicles, rail vehicles and engineering vehicles aswell as weight balancing use for a mechanical arm, and is also used as an energy storage mechanism for a vehicle short-period traction or launch device. The specific structure of the mechanism is composed of a first side plate 2, a second side plate 9, an outer cylinder 1, a steel wire rope shaft 4, a left-side coil spring 3, a right-side coil spring 13, an output steel wire rope groove cylinder 11, an output connecting shaft 5, two disc bevel gears 19, a small bevel gear 20, a small worm wheel 21, a worm 25 and a motor 26, and is particularly suitable for suspension use of electric automobiles.

Owner:东莞市新亿隆弹簧有限公司

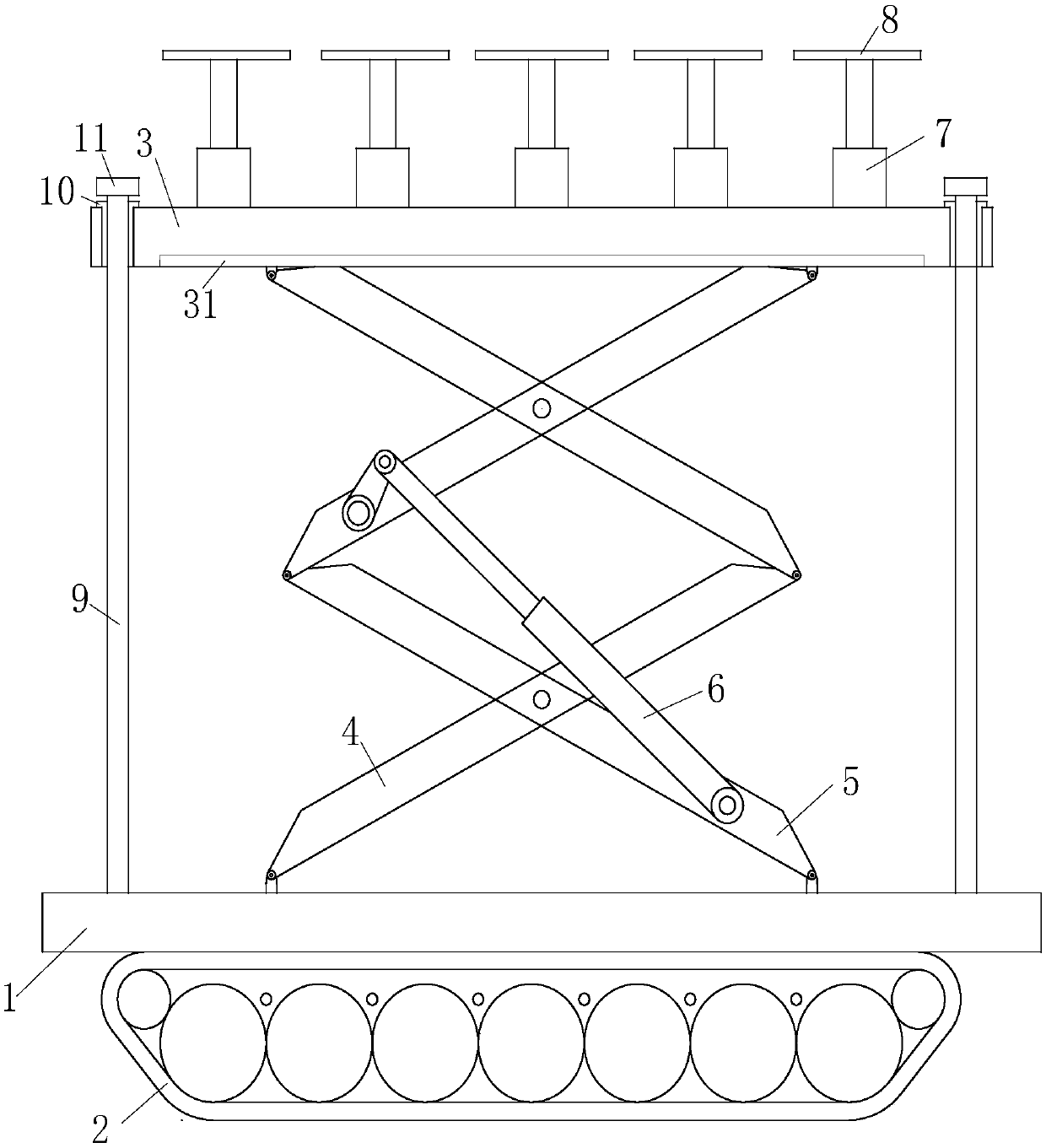

Mining drivage shielding support for coal mine

The invention relates to the technical field of supports, in particular to a mining drivage shielding support for coal mine. The mining drivage shielding support for coal mine comprises a base, a topbeam and a crawler device. One ends of multiple first fulcrum rods are hinged to the left side of the base, one ends of multiple second fulcrum rods are hinged to the right side of the base, the middles of the first fulcrum rods and the second fulcrum rods are hinged, the other ends of the first fulcrum rods are hinged to one ends of the second fulcrum rods above the first fulcrum rods, one ends of the second fulcrum rods are hinged to one ends of the first fulcrum rods above the second fulcrum rods, and the middles of the first fulcrum rods above the second fulcrum rods and the second fulcrumrods are hinged. The mining drivage shielding support has the advantages of being simple in structure, convenient and safe to operate, good in supporting performance, easy to apply and popularize andthe like, puking accidents can be effectively avoided, the safety of the coal mining operation is guaranteed, a roof is not likely to deviate during supporting through guide rods, first hydraulic cylinders are evenly arranged at intervals, it can be effectively avoided that several portions are stressed excessively, the top beam is not prone to deformation, and supporting is firm and safe.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

Plastic mold with automatically separated material overflow structure

ActiveCN104354273ASolve the automatic separation problemSolve the problem of insufficient strengthMANDRILSeparation problem

The invention discloses a plastic mold with an automatically separated material overflow structure. A cavity is communicated with a runner through a single-side pouring gate; plastic in the runner enters the cavity after being divided into two strands from the single-side pouring gate and then is gathered at the tail filling end; the plastic mold further comprises the material overflow structure arranged at the tail filling end and a material overflow mandril of the material overflow structure; the material overflow structure comprises a convex boss and a concave boss; the convex boss comprises a material overflow cavity communicated with the cavity; a reverse tunnel gate is formed in one end of the material overflow cavity and is connected with the tail filling end of the cavity; the other end of the material overflow cavity is communicated with a balance pipe; the length of the balance pipe is equal to that of the reverse tunnel gate; a mandril hole is formed between the reverse tunnel gate and the balance pipe; the length of the mandril hole is equal to that of the balance pipe; the material overflow mandril is fixed on a thimble fixing plate. According to the plastic mold, the problem that the product intensity is low because of a dissolving trace is effectively solved, and the problems existing in automatic separation of the material overflow structure are solved.

Owner:NINGBO TIANLONG ELECTRONICS

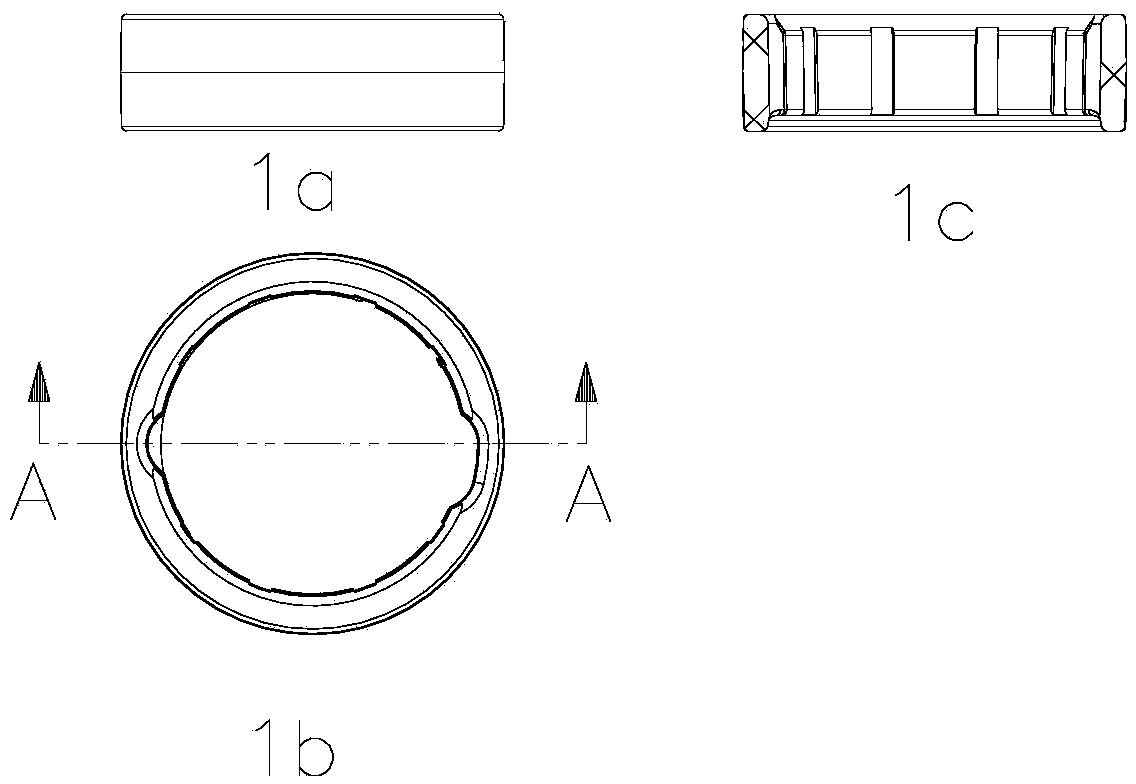

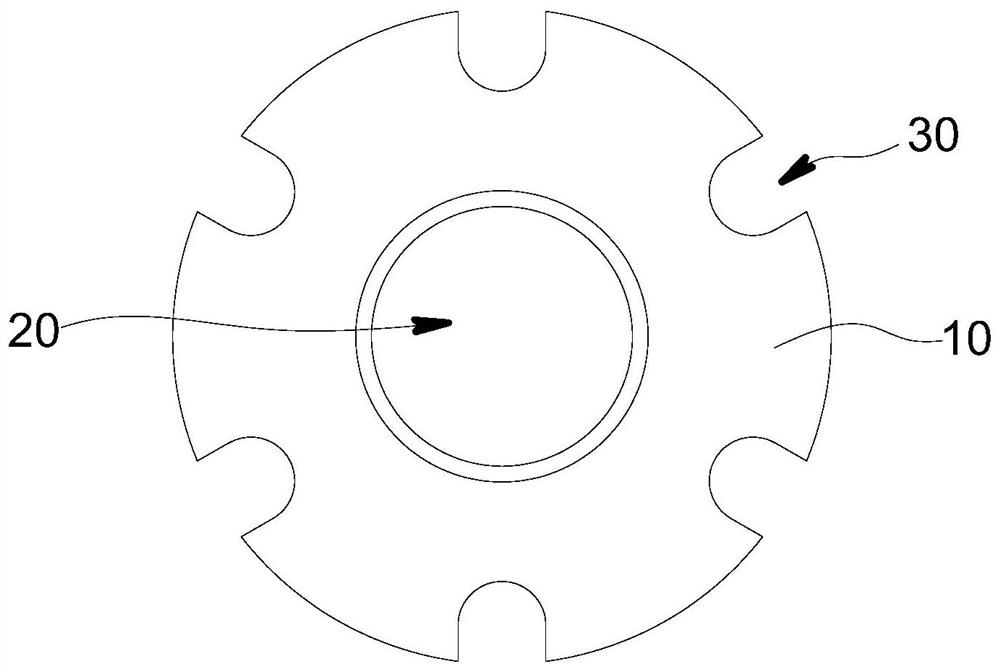

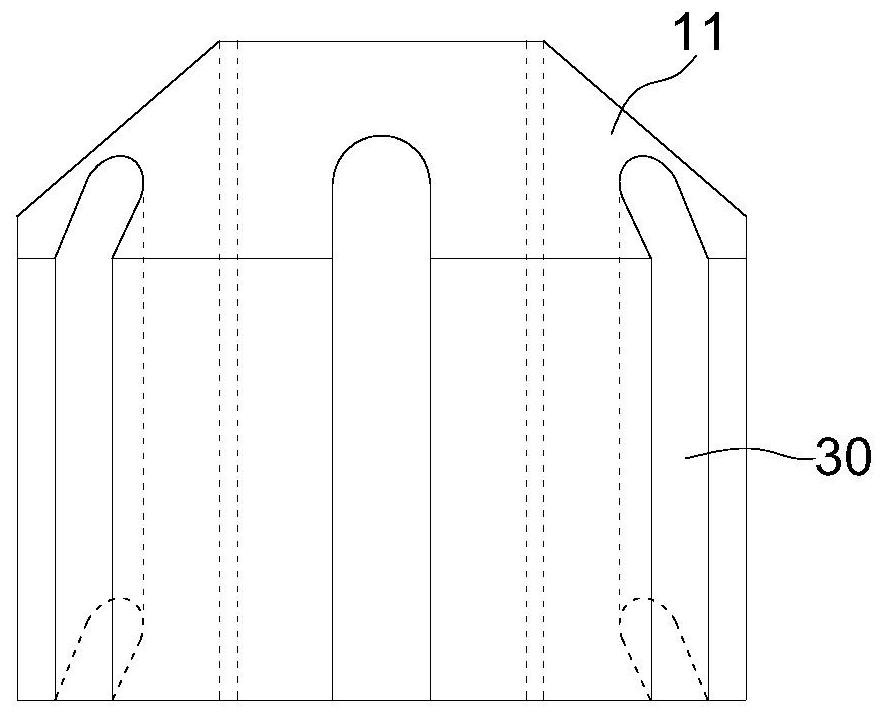

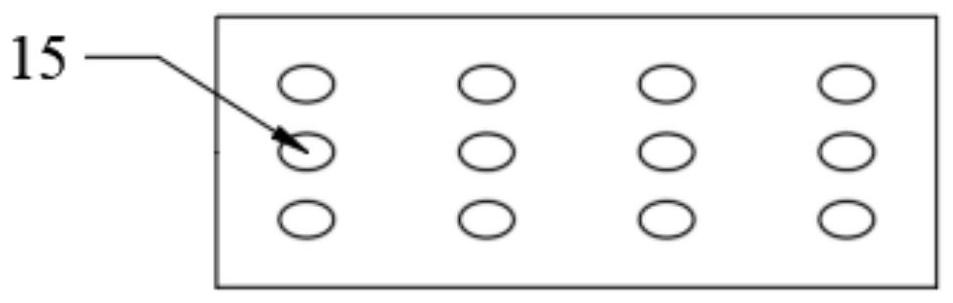

Constructed wetland filler and preparation method thereof

PendingCN113354098ALight weightPromote growth and reproductionBiological water/sewage treatmentConstructed wetlandMicroorganism

The invention discloses a constructed wetland filler which comprises a through hole penetrating through a body. The through hole and the body are coaxially arranged. The peripheral side surface of the body is concave and / or convex. The filler is prepared by mixing and pressing main raw materials including clinker, building slag, a strong caking agent and water according to a ratio. Through the concave and / or convex outer edge of the body, the contact area between the body and the outside is greatly increased, the attachment area of the body is enlarged, the number of microorganisms in unit area is increased, and then the sewage purification capacity of the constructed wetland is improved.

Owner:HUNAN YIJING ENVIRONMENTAL PROTECTION TECH CO LTD

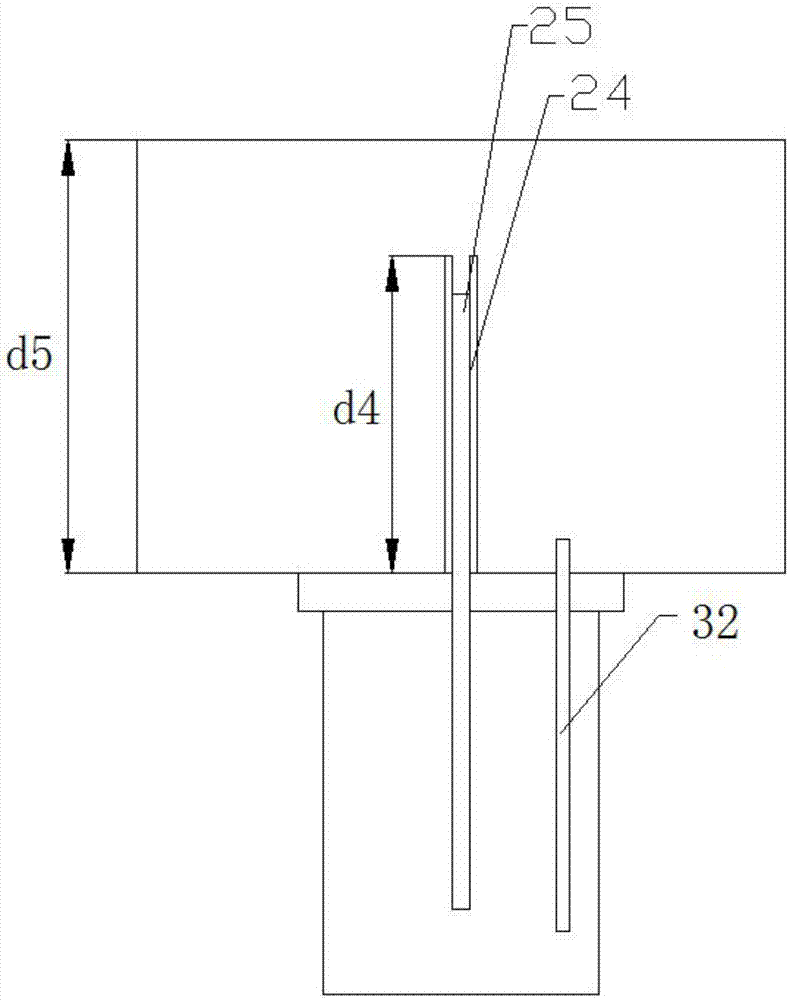

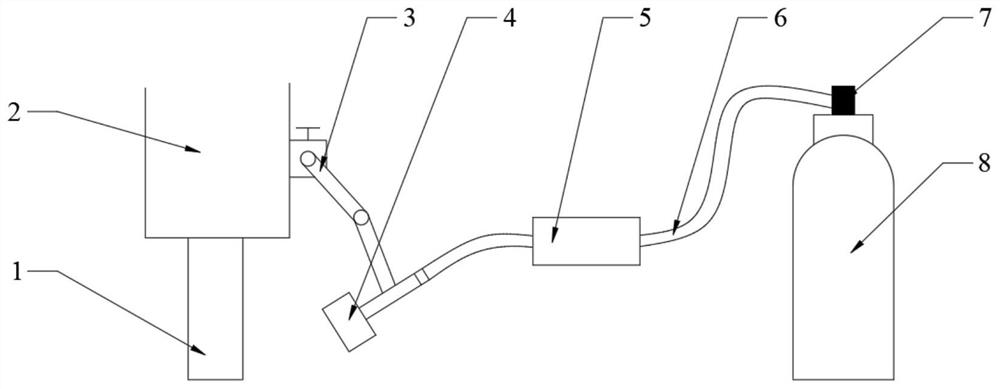

Frozen sand mold printing low-temperature nozzle gas follow-up scanning device

PendingCN114558995ASolve the problem of curingInadequate when resolvingAdditive manufacturing apparatusDomestic cooling apparatusEngineeringNitrogen gas

The invention relates to a low-temperature nozzle gas follow-up scanning device for frozen sand mold printing. The low-temperature nozzle gas follow-up scanning device comprises a printing nozzle, a rack for installing the printing nozzle, a gas nozzle, a fixing support of the gas nozzle, a gas supply pipe and a high-pressure nitrogen supply device. A straight gas inlet pipe is arranged at the upper end of the gas nozzle to be connected with the fixed bracket; an air flow channel is arranged in the straight air inlet pipe and is used for conveying air; an air pipe joint is arranged on the straight air inlet pipe and is connected with the air supply pipe; the high-pressure nitrogen supply device comprises a nitrogen tank and a high-pressure valve arranged at an outlet of the nitrogen tank; a nitrogen accommodating cavity communicated with the gas flow channel is formed in the gas nozzle; and a plurality of nozzles are uniformly distributed at the lower end of the gas spray head and are communicated with the nitrogen accommodating cavity through a gas spraying channel. According to the method, freezing of micro-droplets in the frozen sand mold printing forming process is enhanced, so that the overall strength of the frozen printing sand mold is improved, the frozen sand mold is prevented from collapsing in advance during pouring, and meanwhile, the performance of the obtained casting is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

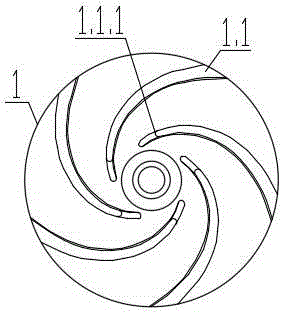

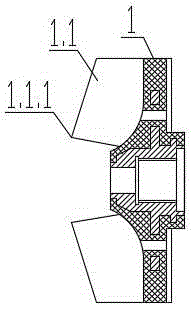

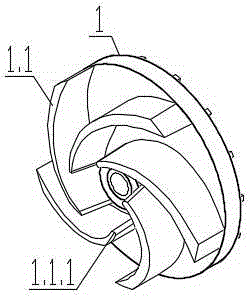

Semi-open plastic impeller for lining plastic corrosion prevention pump

InactiveCN105179305AImprove efficiencyLow running costSpecific fluid pumpsPump componentsImpellerSemi open

A semi-open plastic impeller for a lining plastic corrosion prevention pump comprises an impeller center plate and a plurality of longitudinally-bent cylinder blades which are circumferentially arranged on the impeller center plate at intervals in a radial manner. The upper end points and the lower end points of the vertical end faces of the ends, located at a suction port of the corrosion prevention pump, of the cylinder blades move in the opposite directions of the horizontal plane, and the cylinder blades are distorted in the radial direction to form distorted blades. An opening ring is arranged at the attack angles of the suction ports of the distorted blades. The diameter of the opening ring is equal to the diameter of a circle defined by attack angles of the multiple distorted blades, and the bottom end of the opening ring is fixedly connected with the attack angles of the distorted blades. The parts, located on the periphery of the opening ring, of the distorted blades are in an open state. The problems that torsion resistance of the impeller is large, and a metal pressing mold is difficult to demould are solved, and the defect that due to thin plastic impeller blades, the blade strength is insufficient can be overcome. Meanwhile, the defect that the flow of a closed type plastic impeller cannot be adjusted can be overcome. Power consumption is small, manufacturing is easy, and cost is saved.

Owner:宜兴市宙斯泵业有限公司

Preparation method of high-strength hollow polypropylene fibers

InactiveCN112941653ASolve the problem of insufficient strengthImprove stabilityHollow filament manufactureMonocomponent polyolefin artificial filamentHollow fibreCellulose

The invention belongs to the field of non-woven fabric, and particularly relates to a preparation method of high-strength hollow polypropylene fibers. The preparation method includes the following steps: step 1, adding ethyl cellulose into absolute ethyl alcohol, performing ultrasonic dispersion to dissolve, then adding ammonium carbonate, and uniformly stirring to form turbid liquid; step 2, adding polypropylene into toluene, carrying out ultrasonic dispersion to form a stable dissolved solution, and then carrying out low-temperature ultrasonic dispersion on phenyl trichlorosilane to form a mixed solution; step 3, carrying out reduced pressure distillation on the mixed solution for 30-60 minutes to form a viscous solution; and then carrying out constant-temperature spinning by taking the viscous liquid as a shell layer solution and the turbid liquid as a core layer solution, and standing to form prefabricated cellosilk; and step 4, carrying out constant-temperature illumination standing treatment on the prefabricated cellosilk to form the hollow cellosilk.

Owner:WUXI YOUJIA NON WOVEN TECH

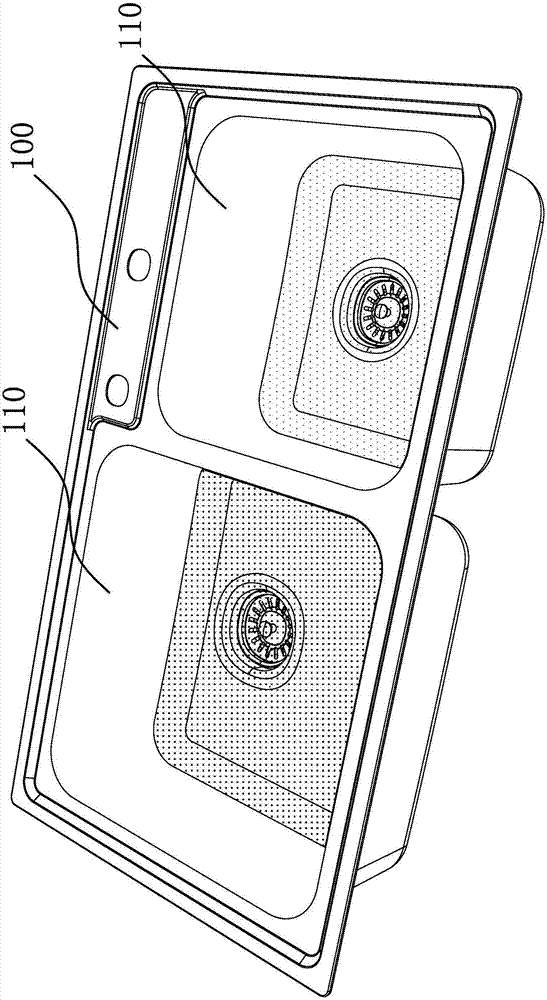

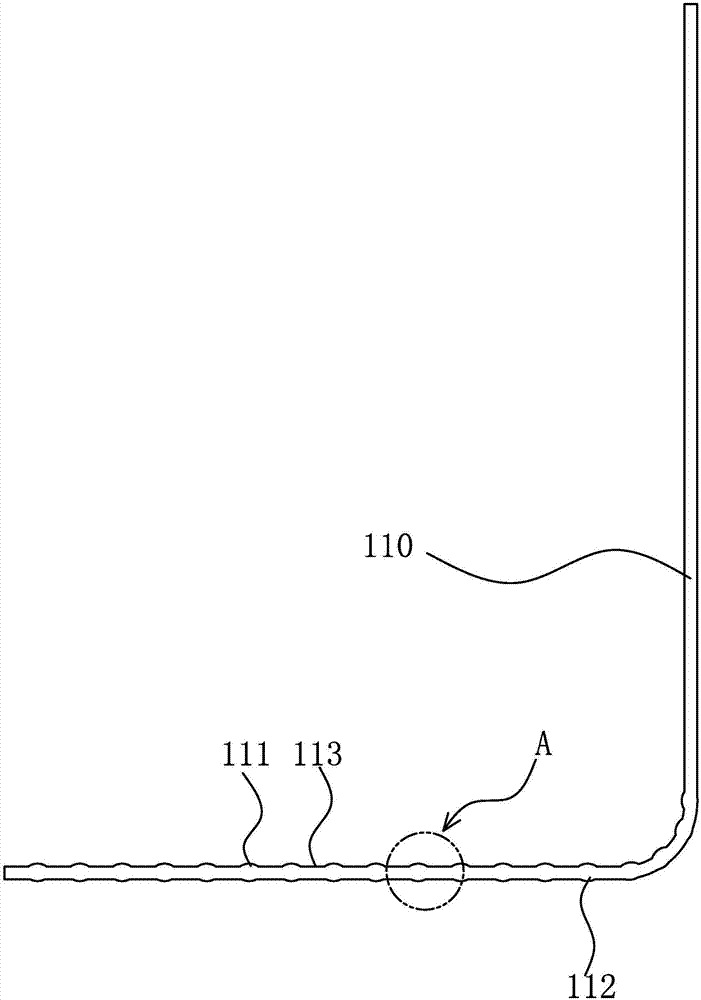

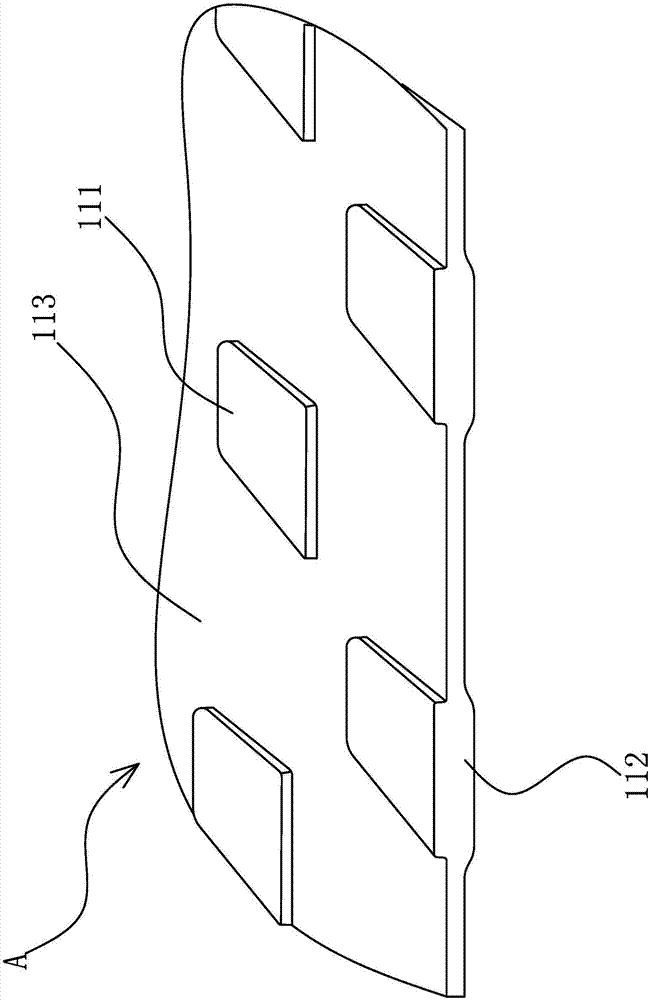

Water channel

InactiveCN106869260AMaintain aestheticsChange the acoustic structureDomestic plumbingEngineeringWater channel

The invention provides a water channel which comprises a channel body, wherein at least one washing channel is formed in the channel body, and an upper bump and a lower bump are separately formed in two side faces of the bottom of each of the washing channels and the chambered edge of each of the washing channels. As the upper bumps are formed on the upper surfaces of the bottoms of the water channels and the chambered edges, surfaces which are inconsistent in thickness are formed in the bottom of the channel, so that the problem of insufficient strength as a bottom metal plate is thin as the water channel is stretched is solved, and meanwhile, the acoustic structure of the bottom of the water channel is changed. The water channel has the anti-noise function when a faucet discharges water or tableware falls into the water channel, and the problem that the conventional water channel which is used is easily scratched by tableware such as a ceramic bowl and a metal article on the surface of the bottom is solved as the upper bumps are formed in the bottom of the water channel, and the bottom of the water channel is kept attractive.

Owner:NINGBO OULIN IND CO LTD

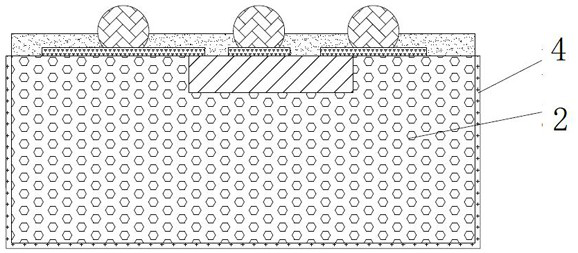

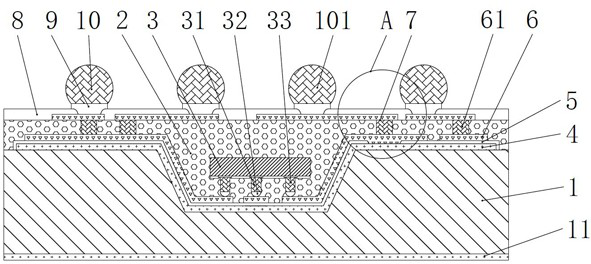

Fan-out packaging structure with electromagnetic shielding function and packaging method

PendingCN114566489AHigh strengthLow costSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

The invention relates to a fan-out packaging structure with an electromagnetic shielding function, which comprises a wafer, a cavity arranged on the wafer, and a metal shielding layer, a repassivation layer, a first rewiring layer, a metal bump arranged on the first rewiring layer, a chip and a metal bump arranged on the chip which are sequentially arranged on the surface of the wafer and the cavity, the cavity, the chip, the first rewiring layer, the metal bumps and the like form a plastic package body, the second rewiring layer, the PI protection layer, the UBM layer and the solder balls are sequentially arranged on the surface of the plastic package body, and the metal heat dissipation layer is arranged on the lower surface of the wafer. The invention further provides a packaging method of the fan-out type packaging structure with the electromagnetic shielding function. According to the fan-out type packaging structure and the packaging method, the packaging efficiency is high, the electromagnetic shielding effect is good, the structure is stable, and heat dissipation is easy.

Owner:ZHUHAI PEOPLES HOSPITAL GUANGDONG PROVINCE

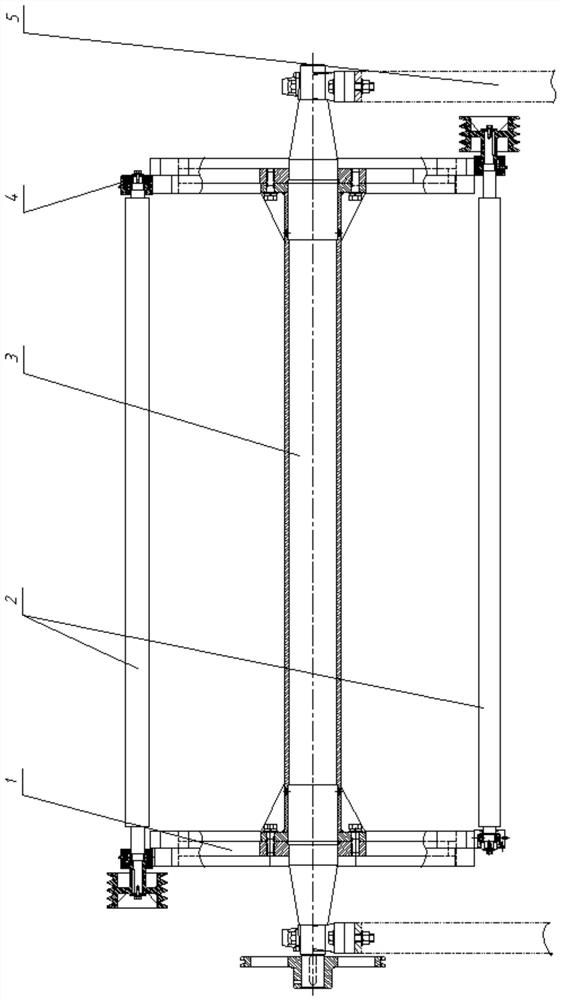

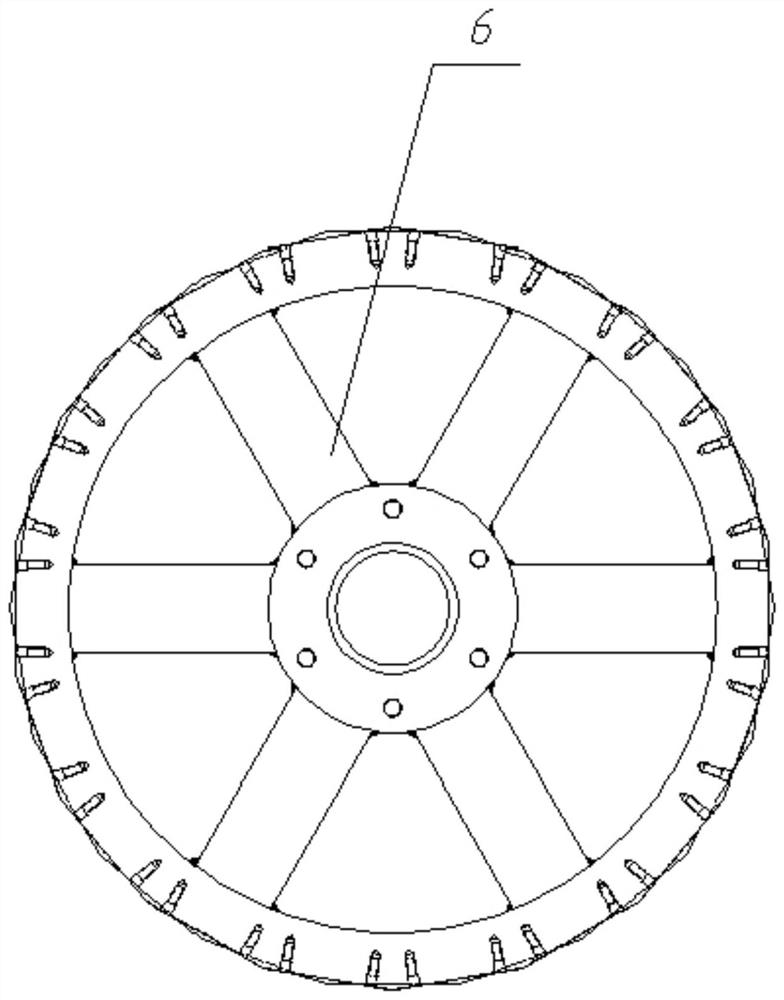

A magnetic pole connection structure of a high-speed pumped storage unit

ActiveCN104868632BAvoid the phenomenon of easy strainSolve the problem of insufficient strengthWindingsMagnetic polesCopper

A magnetic pole connection structure for a high-speed pumped-storage unit, which includes a U-shaped connector, the U-shaped connector includes hard copper connecting pieces (3) on both sides and a middle one for connecting two hard copper connecting pieces (3) ), the hard copper connecting pieces (3) on both sides of the U-shaped connecting piece are respectively connected to the adjacent magnetic pole lead-out wires (1) of the generator motor in the pumped storage unit. The magnetic pole connection structure of the high-speed pumped water storage unit of the present invention adopts a clever U-shaped soft connection and a radial fixing method of the chute in the design of the magnetic pole connection. It eliminates the phenomenon that the U-shaped hard connection is easy to strain, and resolves the problem of insufficient strength of the U-shaped soft connection. At the same time, it also strengthens the U-shaped connection and eliminates the hidden danger of the U-shaped connection being thrown out.

Owner:STATE GRID CORP OF CHINA +2

Detachable folding tent framework

PendingCN111852173AAchieve replacementSolve the problem of insufficient strengthTents/canopiesStructural engineeringMechanical engineering

Owner:郑生锐

High-speed raising machine raising assembly

ActiveCN111910379BSolve the problem of insufficient strengthImprove stabilityRougheningMachineDISC assembly

Owner:LIANYUNGANG CHUNJIANG MACHINERY

Metal hydrides plate-fin heat exchanger

InactiveCN101307994BIncrease the heat exchange areaImprove effective thermal conductivityStationary plate conduit assembliesFiltrationEngineering

Disclosed is a metal hydride plate-fin heat exchanger, which belongs to the industrial heat exchange and energy saving technique field. The invention comprises: an upper cover plate, a fluid path flattine fin, a spacer plate, reaction bed units, a fluid path tail sealing tape, a lower cover plate, a bolt component, a through hole flanged disc, a blind plate flanged disc, a fluid path head sealingtape, a hydrogen pipe, a fluorine rubber flange gasket, a rear enclosing cover, a front enclosing cover, a liquid inlet, a liquid outlet, a filter sheet gasket and a millipore filter sheet. Each reaction bed unit includes an upper cover plate, a unit tail sealing tape, a unit lateral sealing tape, a lower cover plate and a unit serrate fin. Each reaction bed unit has an open end and is welded with a serrate fin in the inside, thereby the heat exchange area and the effective thermal conductivity are greatly increased, and the intensity of a heat exchange unit can also be ensured under the condition of increasing the heat capacity of the heat exchange unit indistinctively. In addition, filtration and sealing difficulties of metal hydrides are greatly reduced by adopting the structure that all the reaction bed units are connected and fixed on the through hole flanged disc in parallel, meanwhile, the mass transfer capability of hydrogen will not be reduced.

Owner:SHANGHAI JIAO TONG UNIV

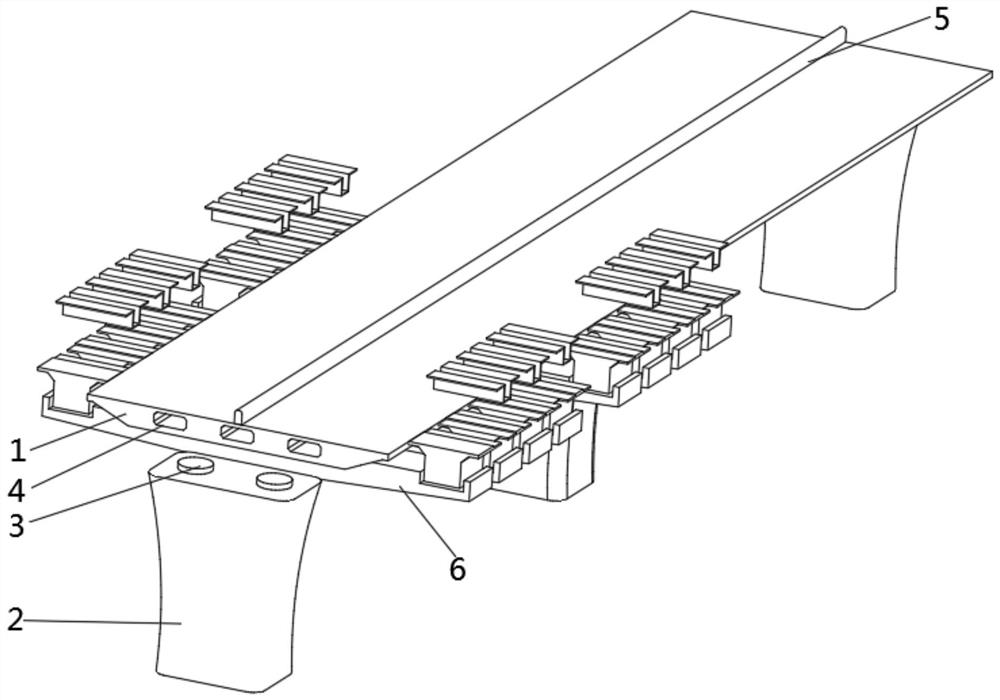

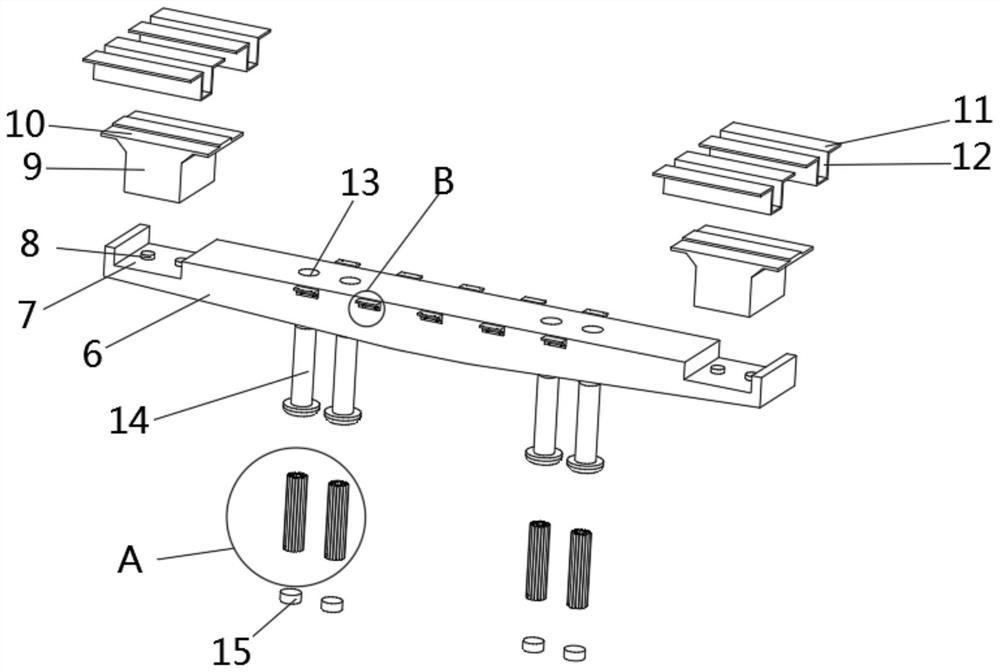

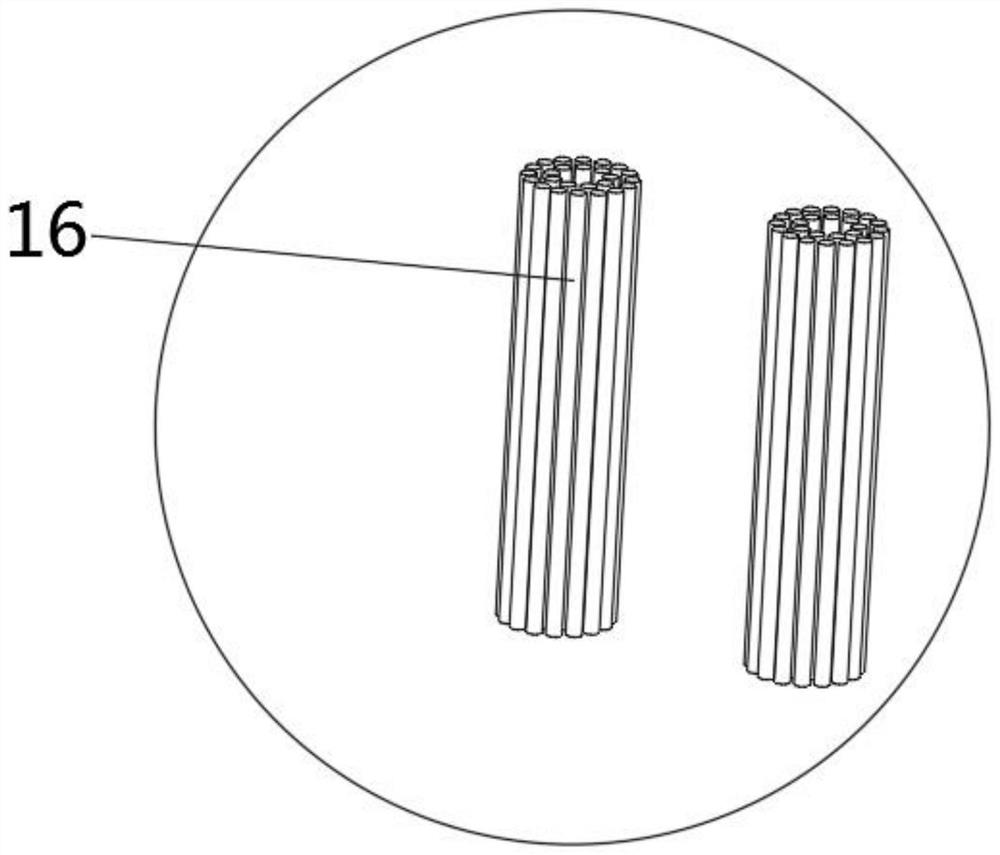

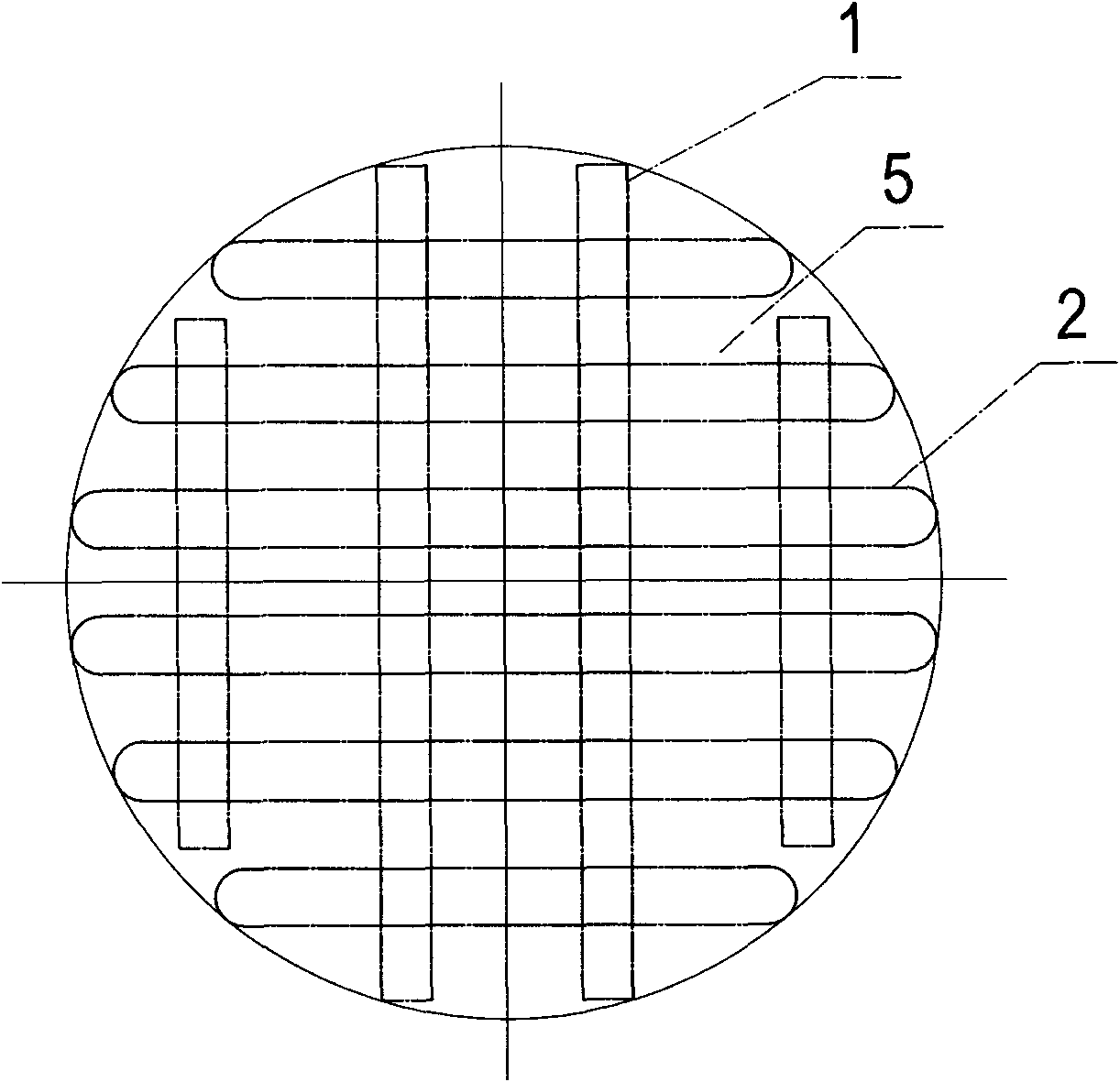

Structure for widening bridge by additionally arranging steel bent caps on pier tops

InactiveCN112502056AHigh strengthSolve the problem of insufficient strengthBridge erection/assemblyBridge strengtheningRebarPier

The invention discloses a structure for widening bridge by additionally arranging steel bent caps on pier tops. The structure comprises a bridge body, a second screw hole is formed in the lower end face of the bridge body, a broadening beam is arranged below the bridge body, side opening grooves are formed in the left side and the right side of the upper end face of the broadening beam, second buffer seats are fixedly connected with the upper end faces of the side opening grooves, a connecting beam is arranged above the second buffer seats, a communicating block is arranged above the connecting beam, an upper opening groove is formed in the upper end face of the communicating block, first screw holes are formed in the upper end face of the broadening beam, a main bolt is arranged below each first screw hole, a reinforcing steel bar is arranged below each main bolt, and plugging cement paste is arranged below each reinforcing steel bar. By arranging the widening beam, the first screw holes, the second screw holes, the reinforcing steel bars, the main bolts and the plugging cement paste, the action that the widening beam is connected with the lower end face of the bridge body and then the reinforcing steel bars are inserted into the first screw holes to be plugged through the plugging cement paste can be completed, and the effect of reinforcing connection and fastening of the widening beam is achieved.

Owner:谢绍良

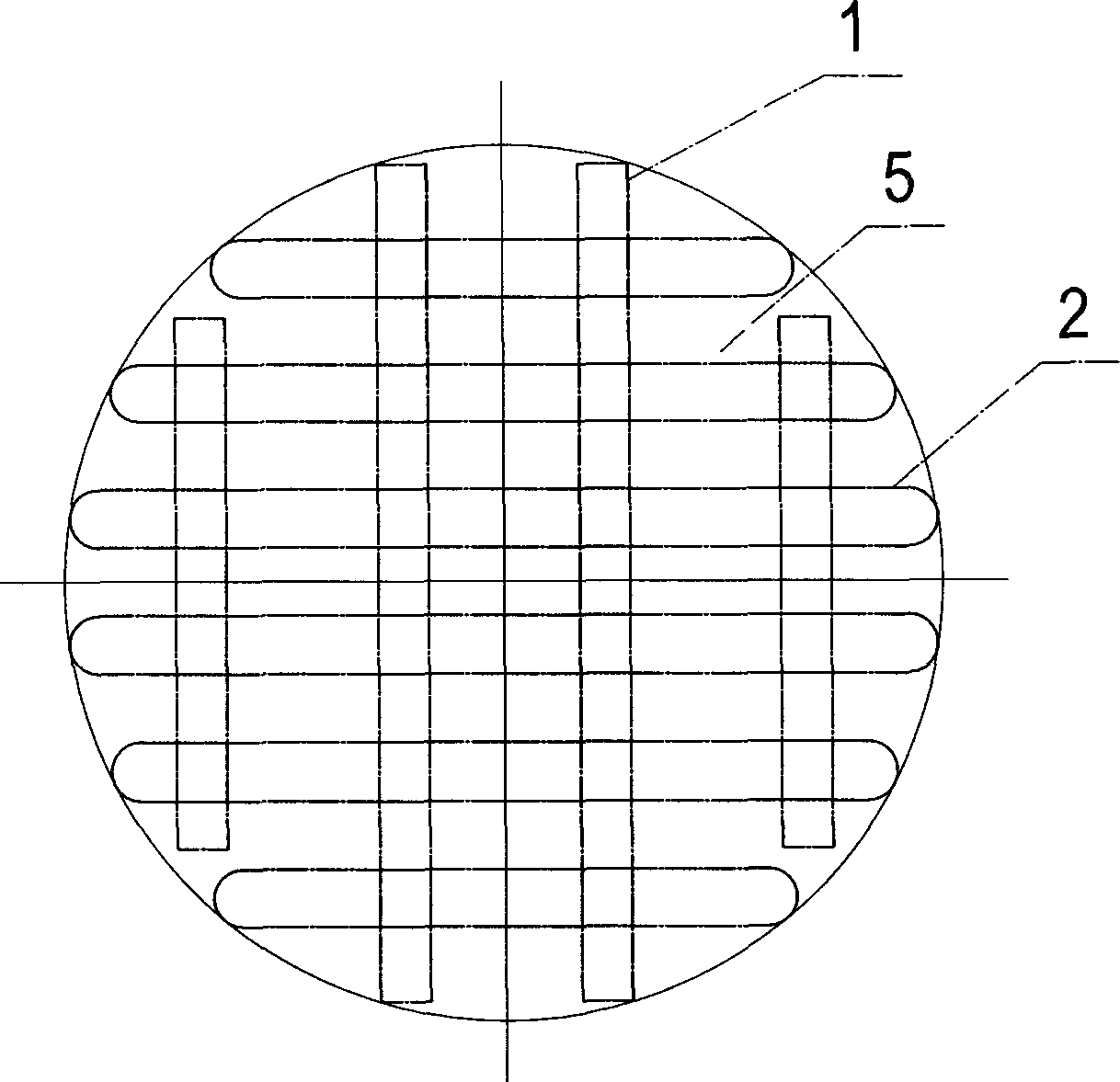

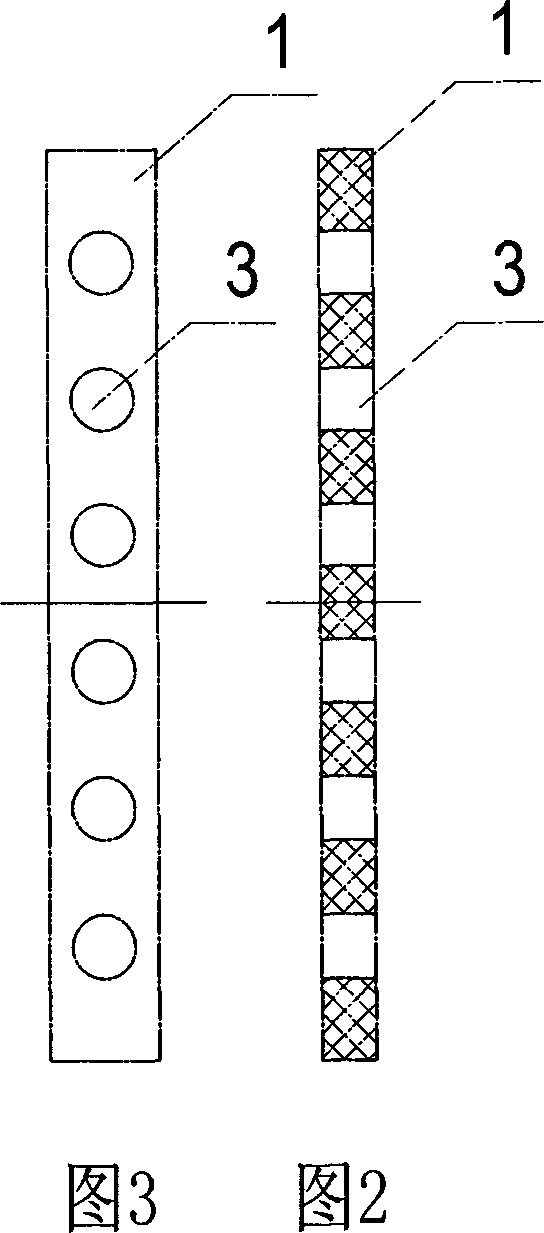

Polytetrafluoroethylene porous grid and its manufacturing method

ActiveCN102278589ASolve the problem of insufficient strengthHigh strengthElongated constructional elementsManufacturing gridEngineering

The invention relates to a polytetrafluoroethylene porous grid plate and a manufacturing method thereof. The grid plate is formed by combining a plurality of polytetrafluoroethylene square bars and a plurality of polytetrafluoroethylene round bars in an interpenetration way, wherein the lateral surfaces of the polytetrafluoroethylene square bars are provided with a plurality of round holes, and the round holes and the outer diameters of the polytetrafluoroethylene round bars are mutually matched. According to the manufacturing method, grid plates of different shapes can be combined as required; and the manufactured grid plate has the advantages of high strength, simple structure, convenience for manufacturing, short production time, less PTFE (polytetrafluoroethylene) raw material consumption, low manufacturing cost, and the like.

Owner:温州赵氟隆有限公司

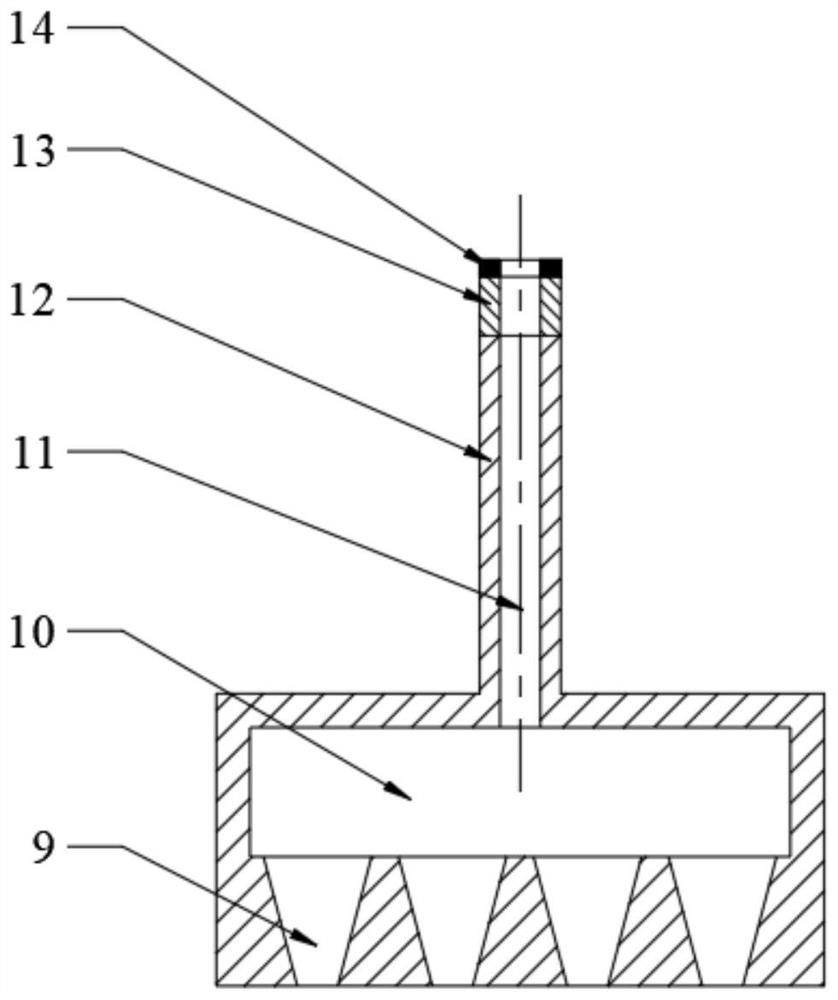

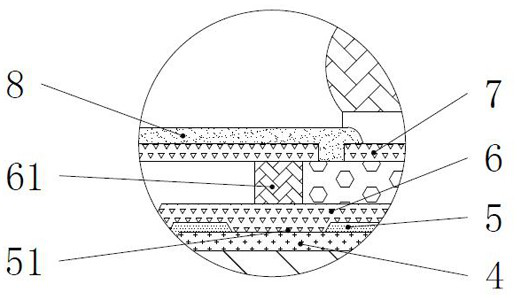

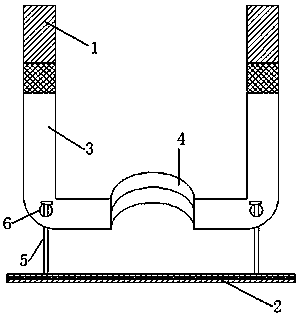

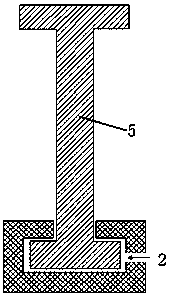

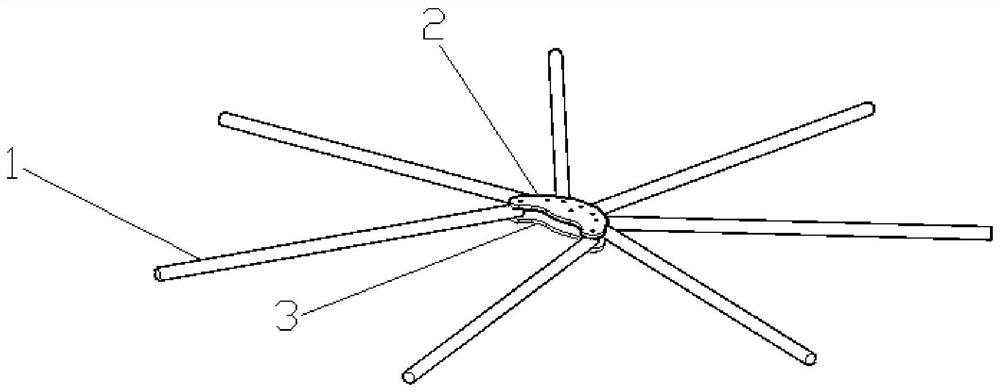

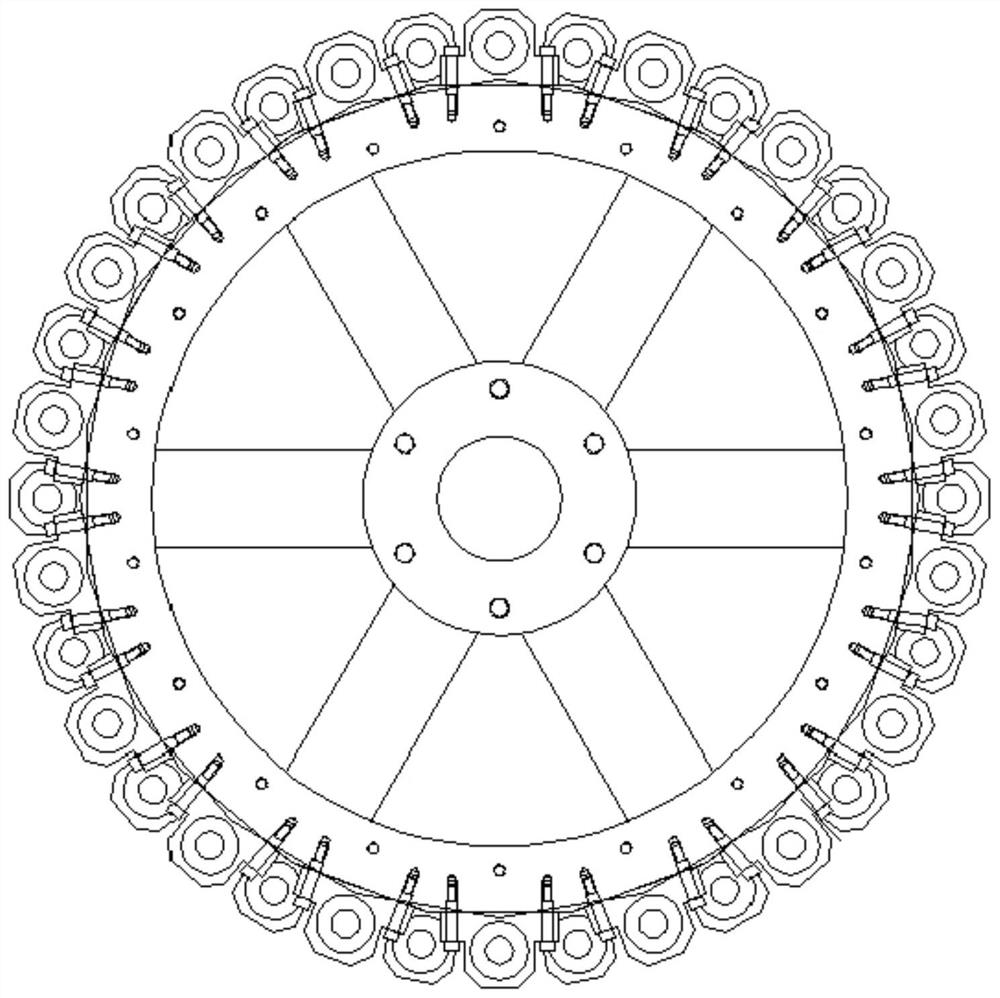

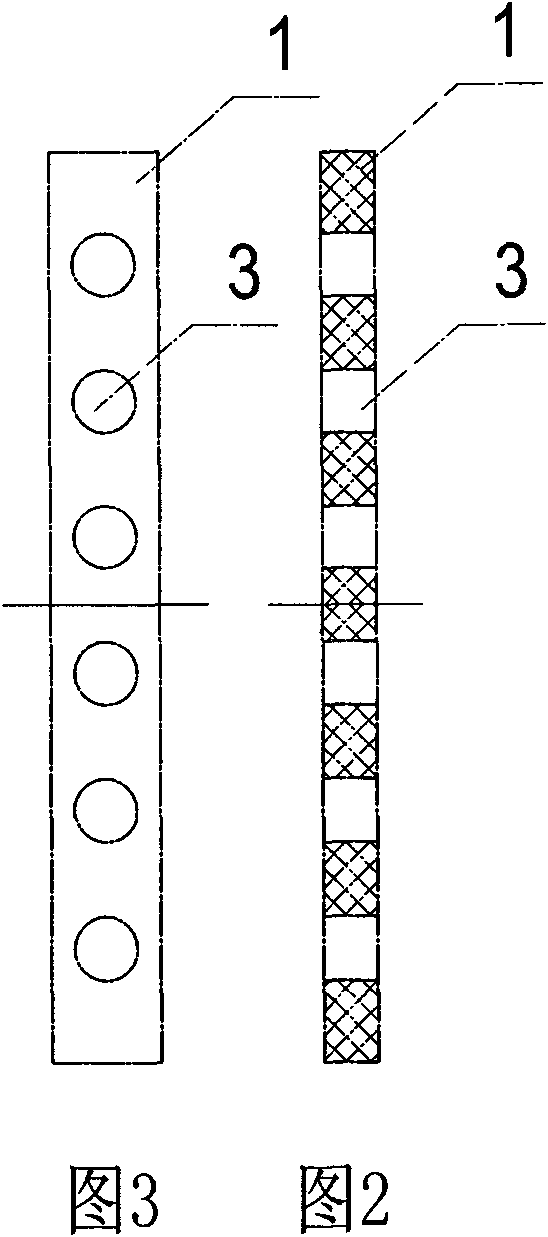

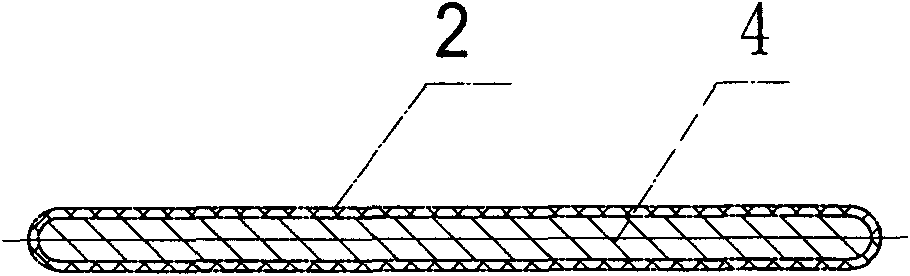

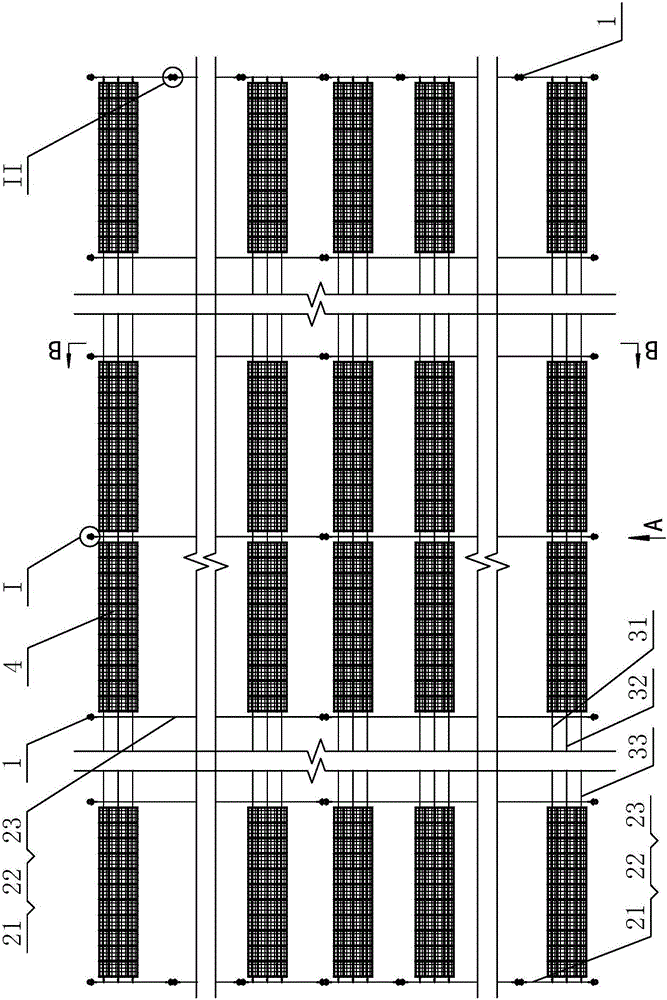

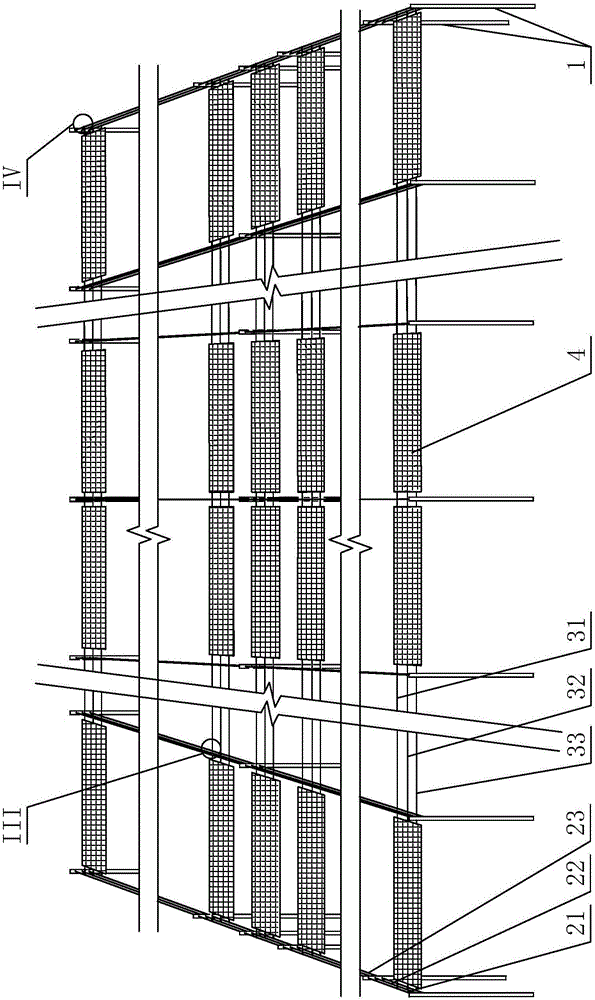

Prefabricated erect column pile anti-settlement chuck and solar photovoltaic flexible support system

ActiveCN106026867ASave materialImprove anti-settling effectPhotovoltaic supportsPhotovoltaic energy generationSupporting systemSupport system

The invention discloses a prefabricated erect column pile anti-settlement chuck and a solar photovoltaic flexible support system comprising the prefabricated erect column pile anti-settlement chuck. The prefabricated erect column pile anti-settlement chuck comprises a hoop configured to circumferentially enclasp a prefabricated erect column pile (1), reinforcements (66) fixedly connected with the hoop to form a grid structure, and the concrete (67) that coats the reinforcements (66) to form the main body and the outer shape of the chuck. The hoop comprises two semicircular hoop bodies (61), installation lug plates (62) connected with the two side edges of the hoop bodies (61), a reinforcing rib (63) connected with the hoop bodies (61) and the installation lug plates (62), and a double-head screw (64) for relatively and fixedly connecting the installation lug plates (62) of the two matched hoop bodies (61). The anti-settlement chuck is embedded in the ground along with the prefabricated erect column pile (1). The prefabricated erect column pile anti-settlement chuck and the solar photovoltaic flexible support system comprising the prefabricated erect column pile anti-settlement chuck are widely applied to the prefabricated column pile and solar photovoltaic field.

Owner:珠海横琴博信能源建设有限公司 +2

Water cooling method and cooling device for motor

InactiveCN102035306BSolve the problem of insufficient strengthSolve the leakCooling/ventillation arrangementWater jacketCooling efficiency

The invention discloses a water cooling method for a motor, which has a simple process and high cooling efficiency and is easy to implement, and a cooling device with a simple structure. The method comprises the following steps of: arranging a steel barrel of which the surface wall is provided with a groove on a motor shell; winding a spiral pipe which serves as a water jacket on the groove of the steel barrel; and embedding and casting the water jacket into the groove of the steel barrel by using aluminum alloy. The cooling device comprises the steel barrel which is arranged on the motor shell and a spiral pipe which is wound in the groove of the steel barrel, wherein aluminum alloy casting bodies are arranged on the spiral pipe and between the spiral pipe and the steel barrel.

Owner:JIANGXI SPECIAL ELECTRIC MOTOR CO LTD

Special chain plate for feeding frame cleaning machine

The invention discloses a special chain plate for a feeding frame cleaning machine. The special chain plate comprises a chain. The chain is fixedly provided with a plurality of operation rolling wheels. Insertion groove plates are fixedly arranged on the side face of the front end of the chain. Insertion groove parts correspond to the operation rolling wheels in position in a one-to-one mode. Feeding frame grooves are formed between the insertion groove plates. According to the special chain plate for the feeding frame cleaning machine, by arranging the chain, the operation rolling wheels andthe feeding frame insertion grooves, the good impact performance, tensile strength, impact capacity and fatigue performance are achieved, meanwhile, the effects of bending transmission and conveying are achieved, and the problems of poor flexibility of high strength chains and insufficient strength of side bending chains are solved.

Owner:昆山通莱五金机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com