Laminated rotor for high-speed motor

A high-speed motor, laminated technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of motor limit speed restriction, increase, solid rotor iron loss, rotor surface loss, etc., to achieve volume weight and cost reduction , Improve power density and reduce iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

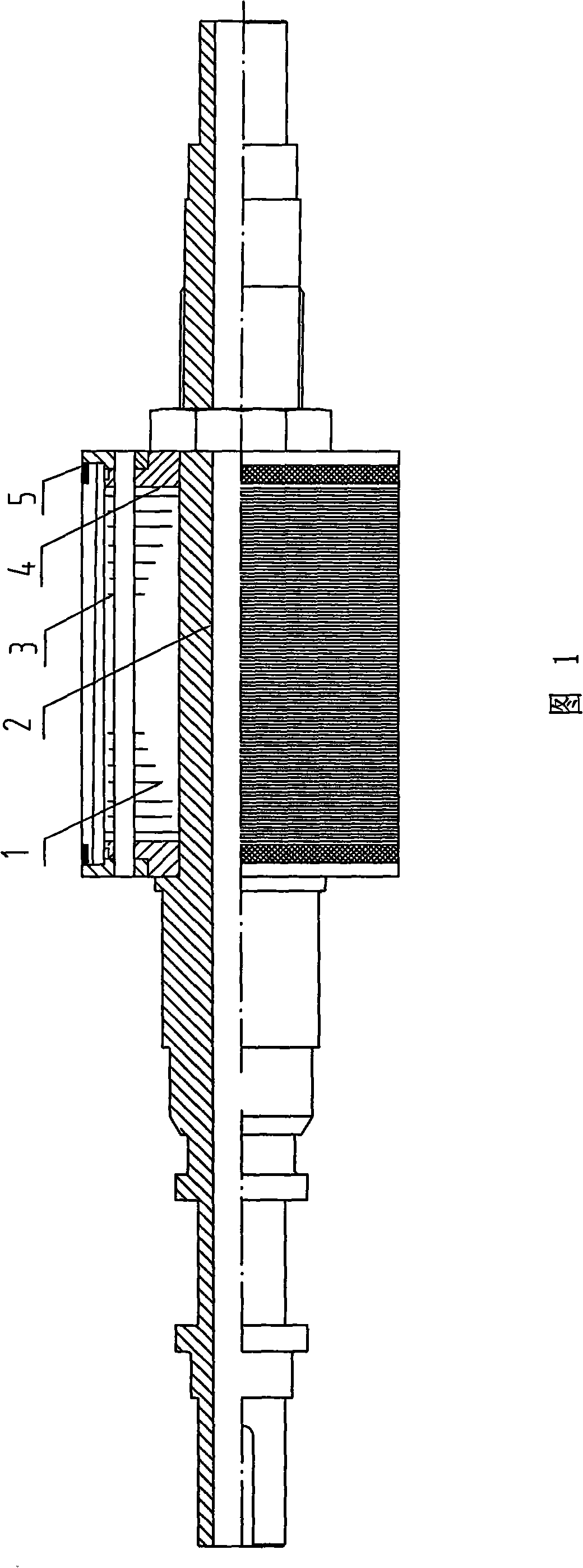

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] With reference to the accompanying drawings, this embodiment includes a lamination 1 made of magnetically permeable silicon steel sheet or a magnetically permeable steel plate, a hollow or solid shaft 2, two ends of the lamination 1 are provided with a pressure plate 4, and the lamination 1 and the pressure plate 4 pass through the pull rod 3 Tensioned into one body, the lamination 1 and the pressure plate 4 are provided with axial ventilation holes and grooves for installing guide bars, and the end of the winding is fixed by a weft-free tape 5; the inner hole of the lamination 1 and the outer diameter of the rotating shaft 2 are interference fit, The interference fit is 0.030-0.033mm. The inner hole of the pressure plate 1 and the outer diameter of the rotating shaft 2 also adopt an interference fit. In the above embodiment, the outer circular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com