Patents

Literature

276results about How to "Reduce production man-hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid-state lithium ion electrode, solid-state lithium ion battery and preparation method of solid-state lithium ion electrode

InactiveCN103474620ASuitable for continuitySuitable for productivityFinal product manufactureNon-aqueous electrolyte accumulator electrodesSolid state electrolytePowder method

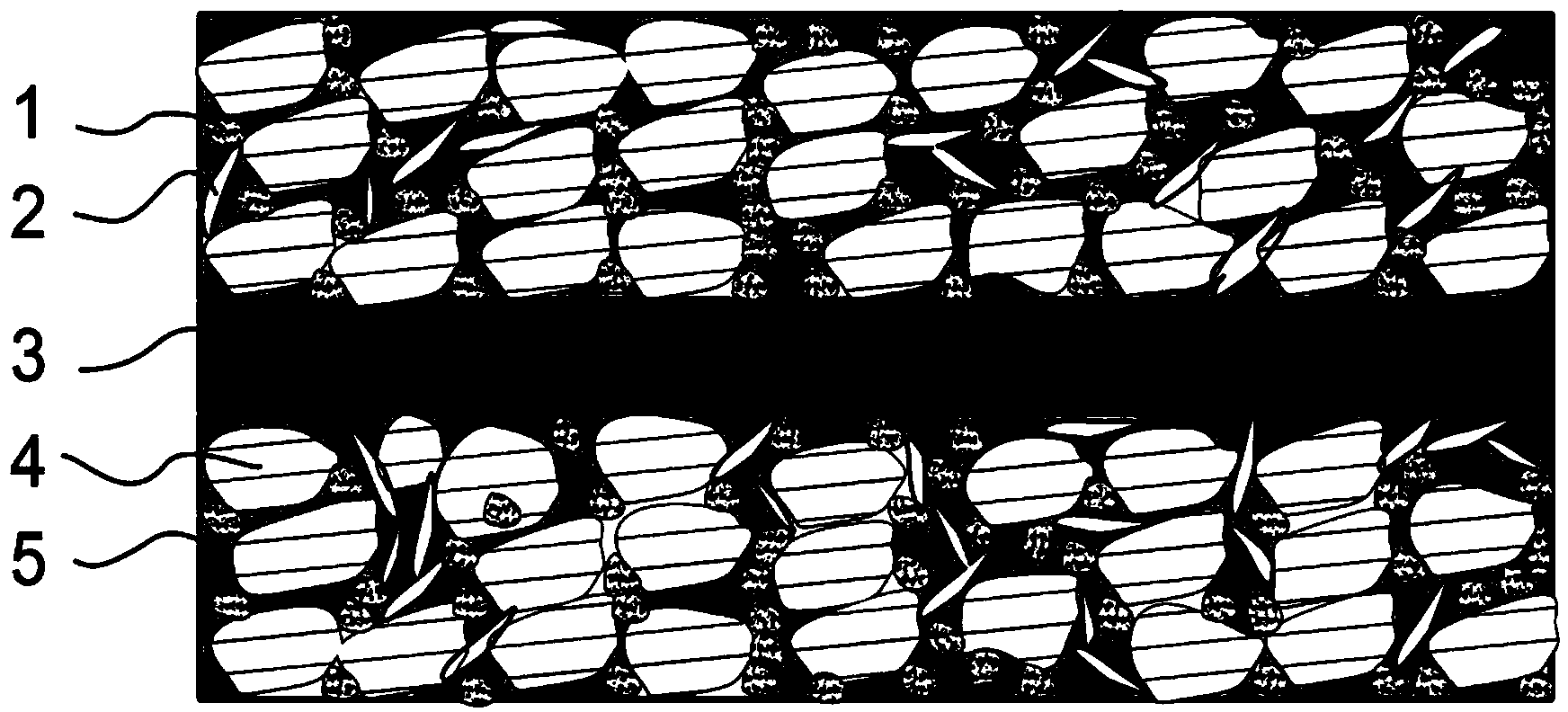

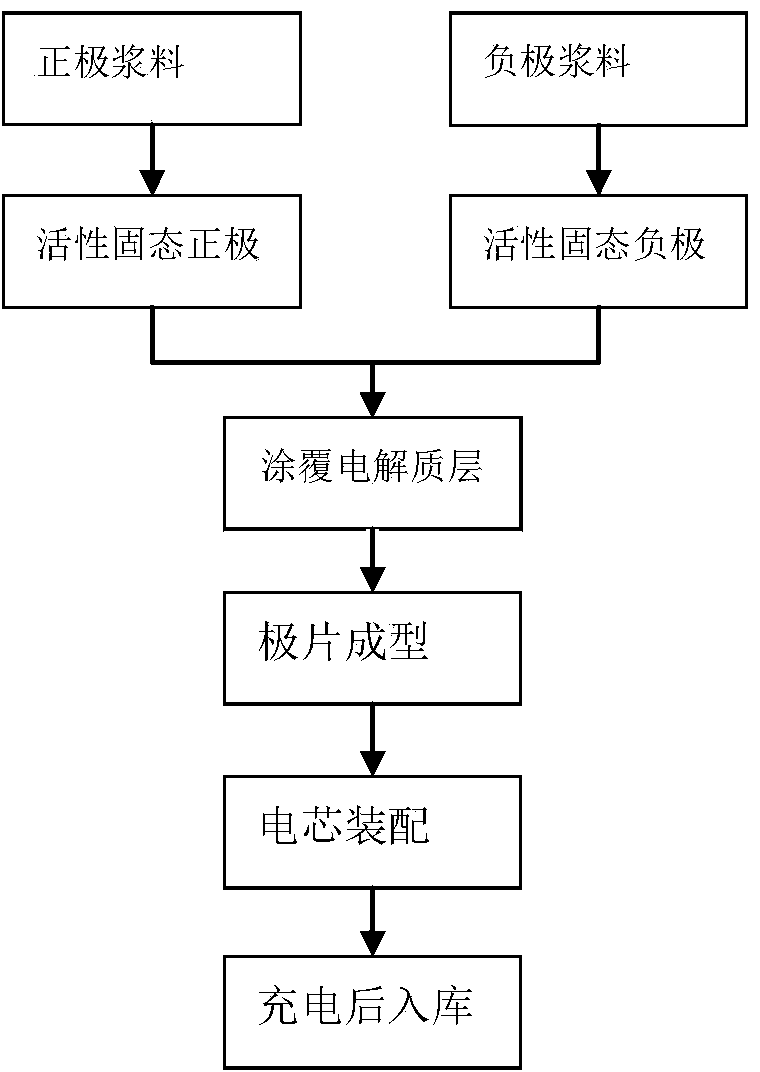

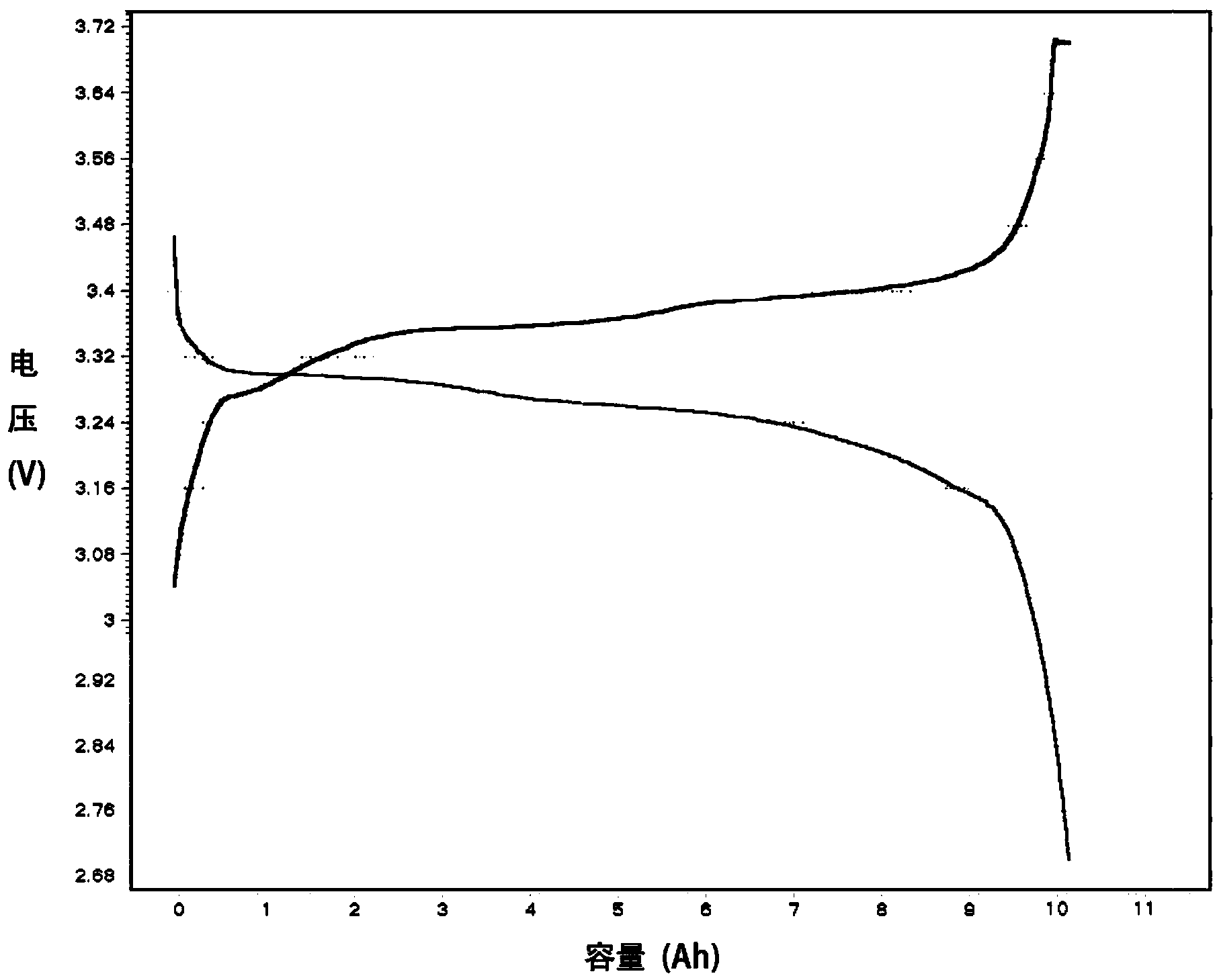

The invention provides a solid-state lithium ion electrode, a solid-state lithium ion battery and a preparation method of the solid-state lithium ion electrode. The solid-state lithium ion battery electrode is composed of a metal current collector, and an active material, a conductive agent, solid electrolyte and a binder, which are attached on the current collector. During the electrode manufacture, the slurry containing the active material and the like is coated on the current collector, the method is suitable for continuous and batch production compared with a deposition method and a compression powder method.

Owner:向勇

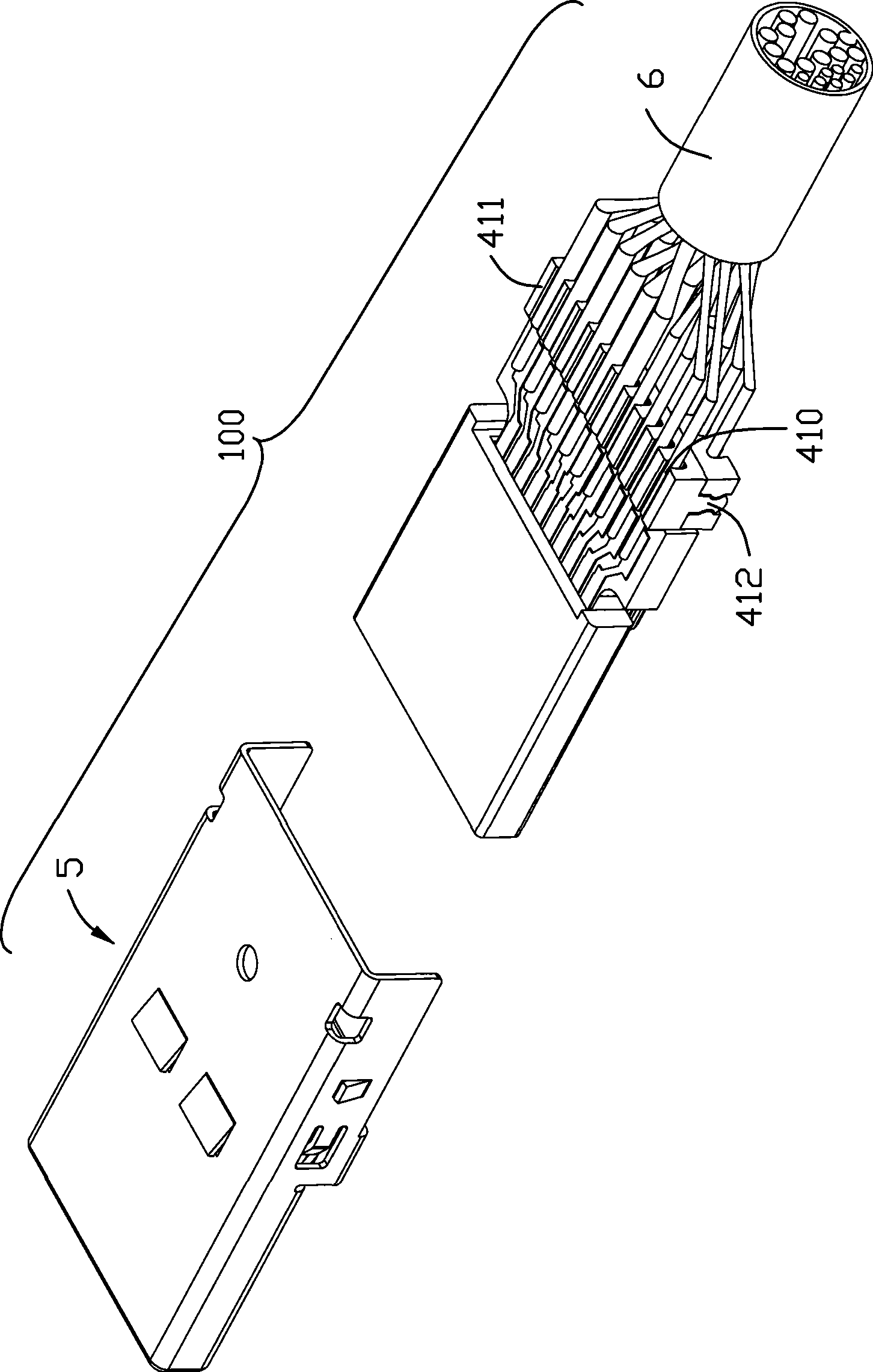

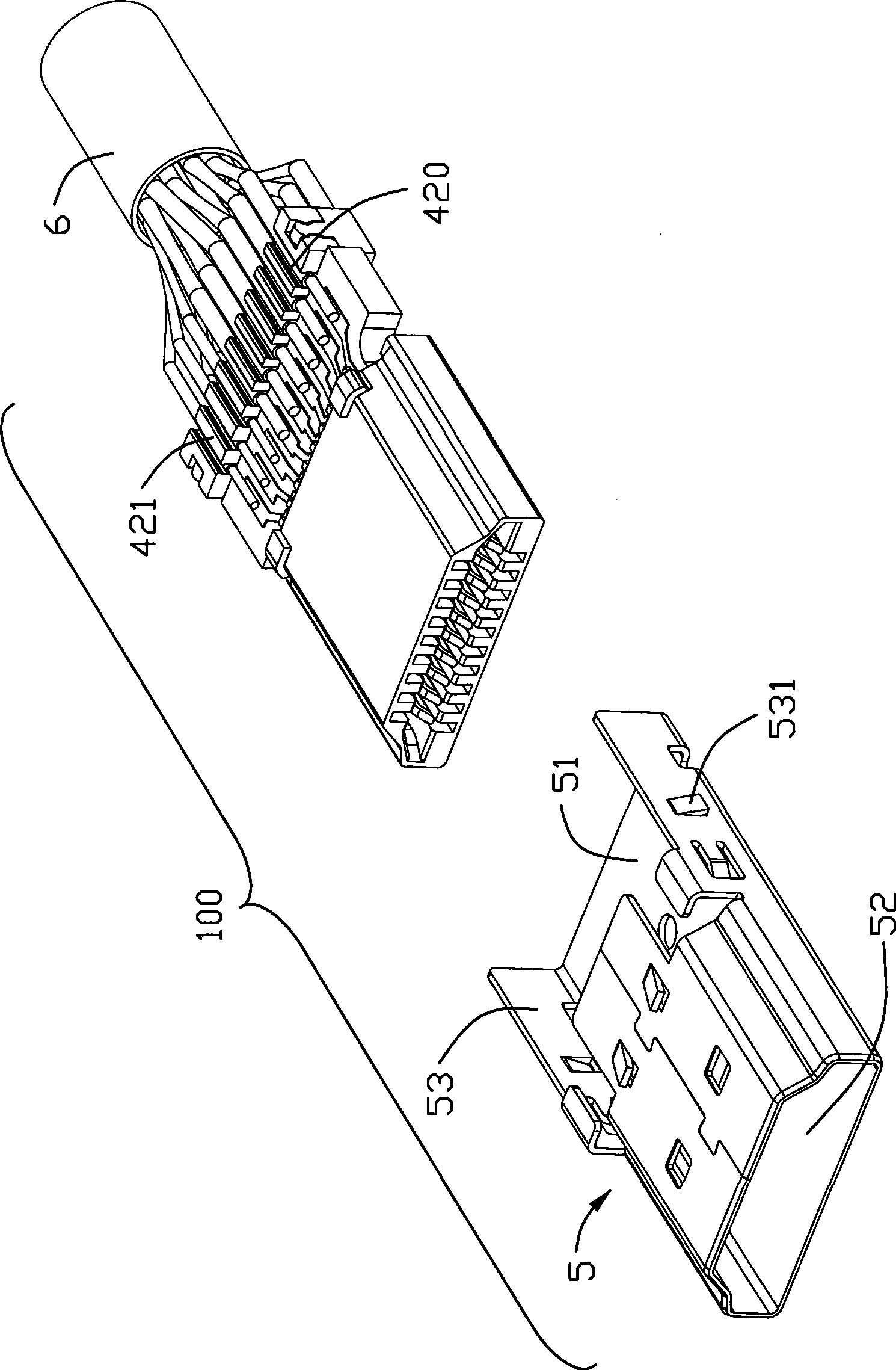

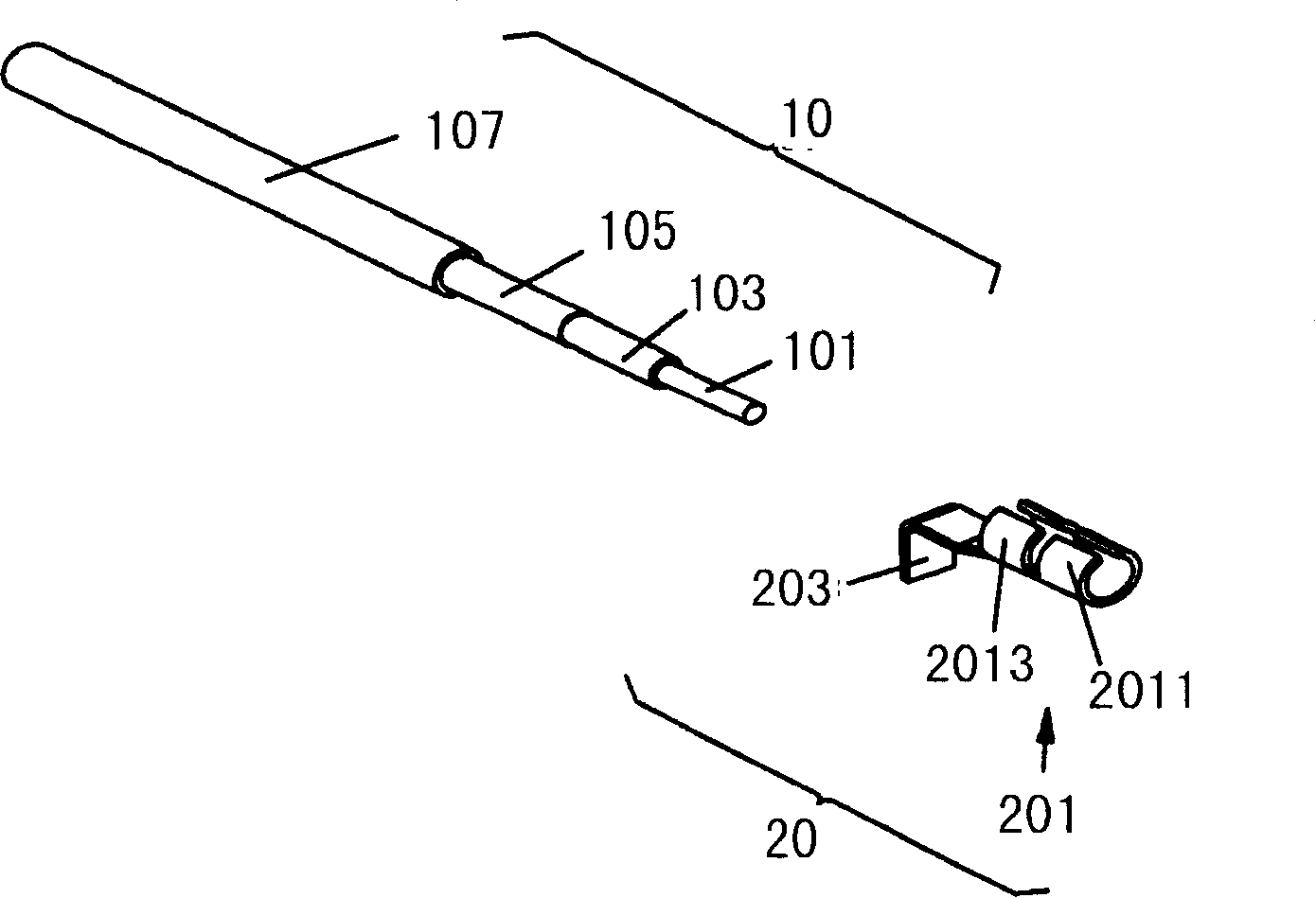

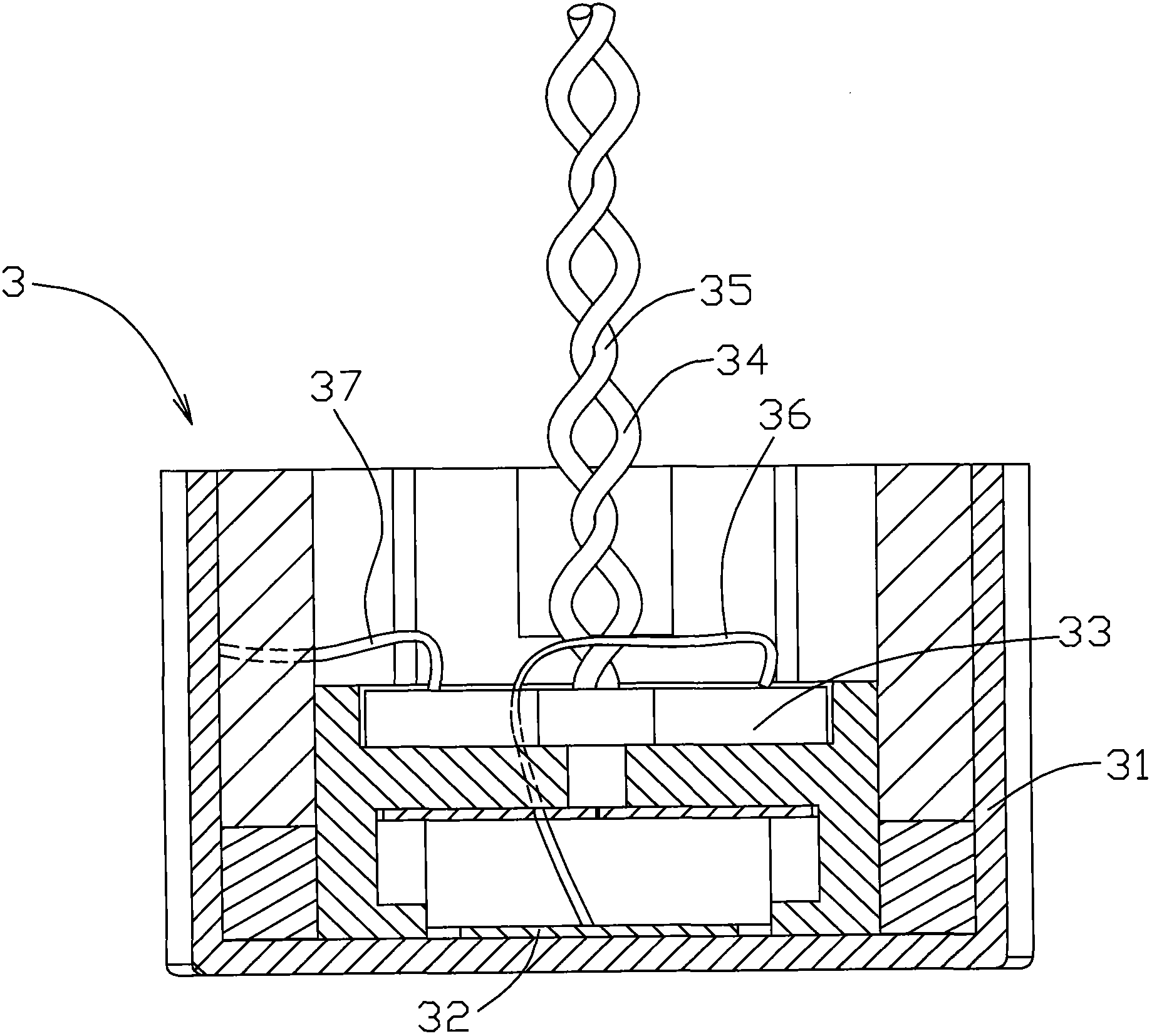

Cable connector assembly and method of making same

InactiveCN101499568ALower the altitudeReduce the overall heightLine/current collector detailsElectrically conductive connectionsEngineeringCable management

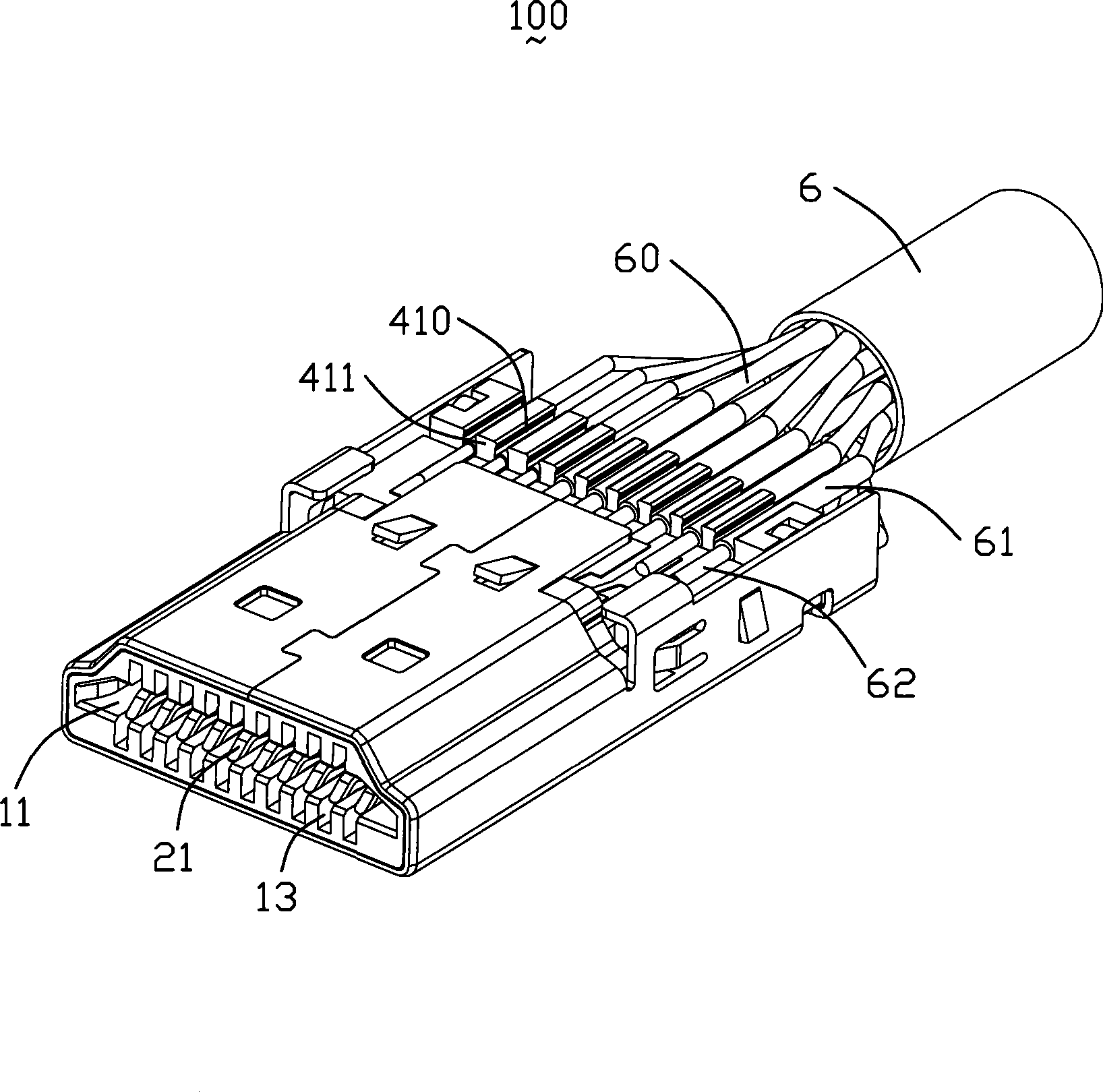

The invention provides a cable connector component and a manufacturing method thereof. The cable connector component comprises an insulation body, a plurality of conductive terminals, a plurality of wire cables and a cable management component. The conductive terminals are fixed on the insulation body and arranged in an upper row and a lower row; the wire cables are electrically connected with the corresponding conductive terminals; and the cable management component is used for arranging wires. The cable management component comprises an upper cable management plate and a lower cable management plate, which can be assembled as whole; the upper surface of the upper cable management plate is provided with a plurality of convex strips which protrude upwards and extend in the wire extension direction, thereby forming a plurality of wire holding grooves which are separated by the convex strips and used for holding and arranging the wires which are electrically connected with the upper rowof conductive terminals. The lower surface of the lower cable management plate is provided with a plurality of convex strips which protrude downwards and extend in the wire extension direction, thereby forming a plurality of wire holding grooves which are separated by the convex strips and used for holding and arranging the wires which are electrically connected with the lower row of conductive terminals. Owning to the structure, the invention can effectively reduce the difficulty in the cable management, reduce the manufacturing time and facilitate the separate removal of the insulation coatings of each layer of wires, and is beneficial to reducing the height of the whole cable management component.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

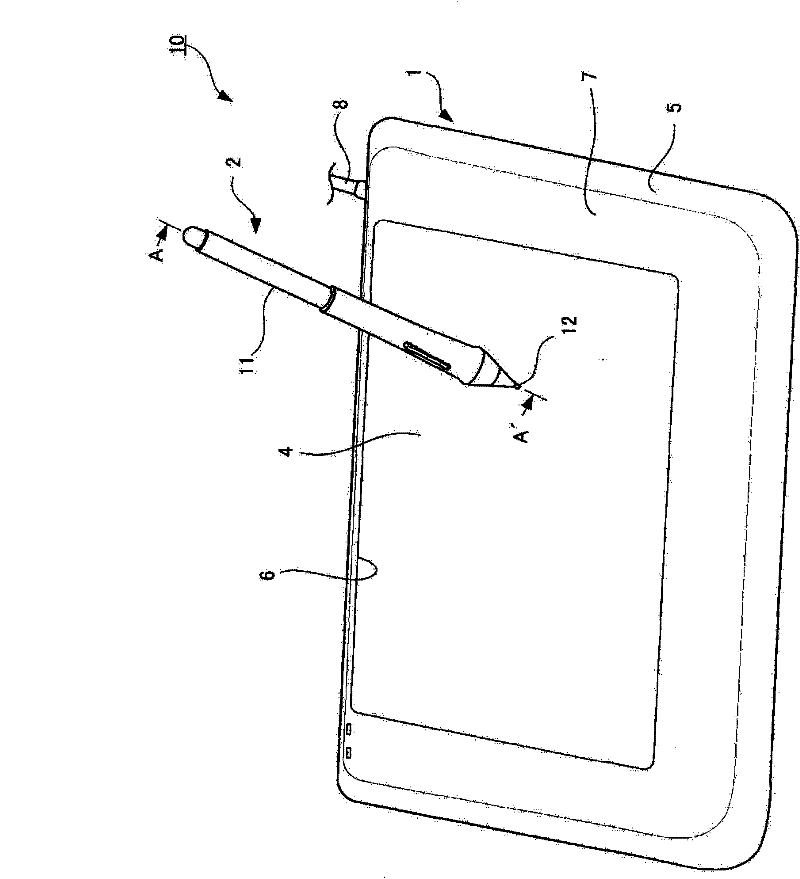

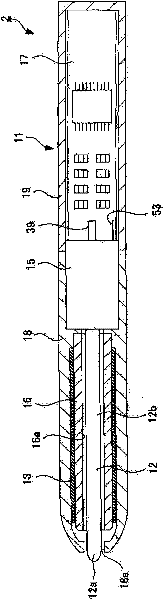

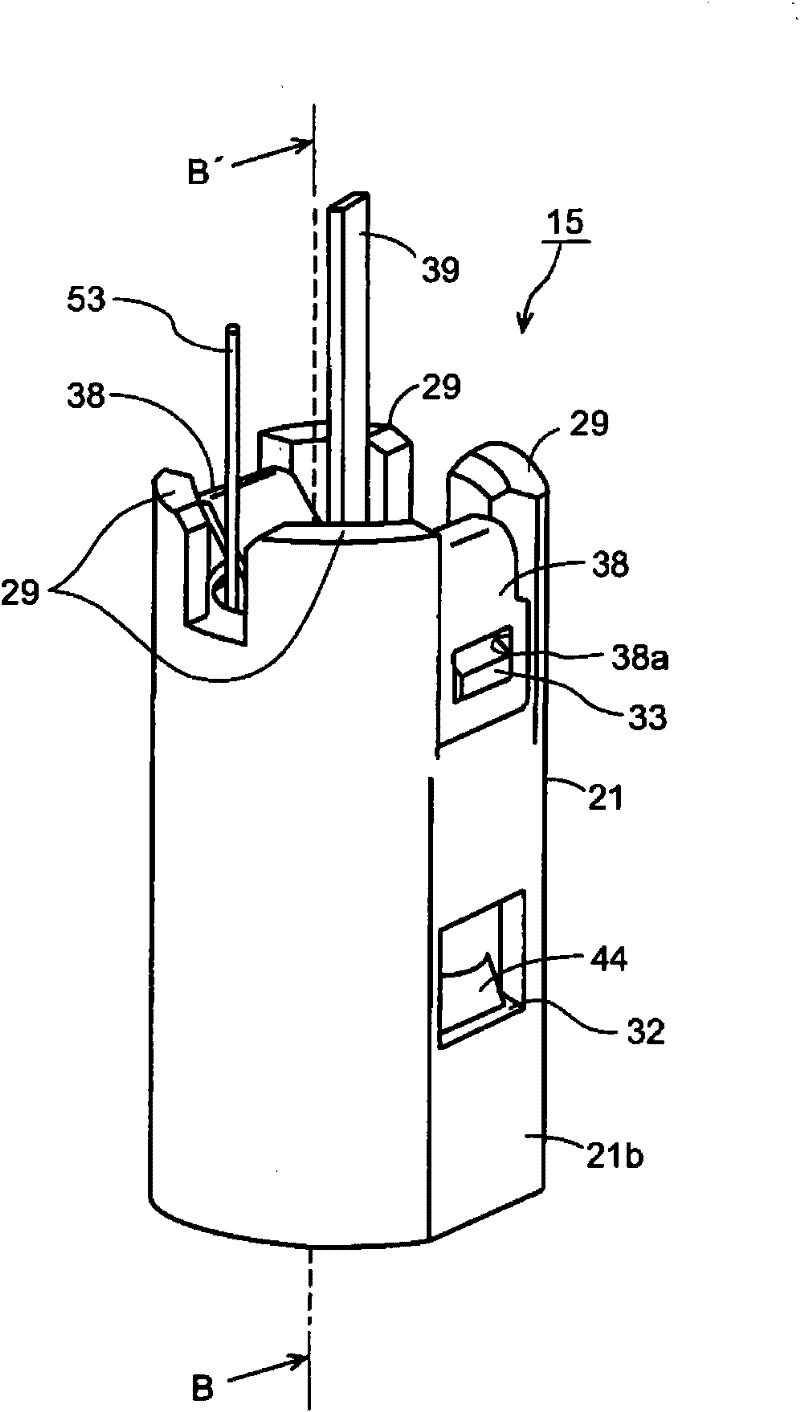

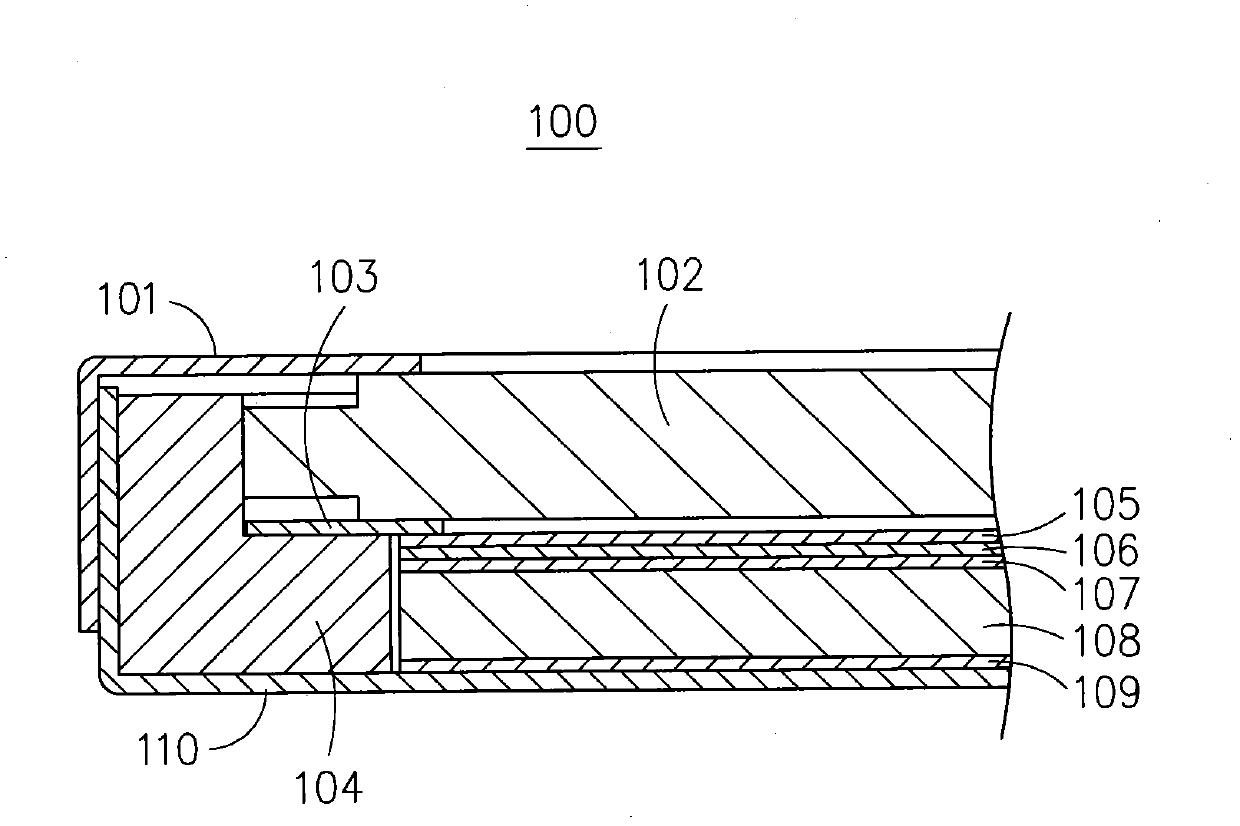

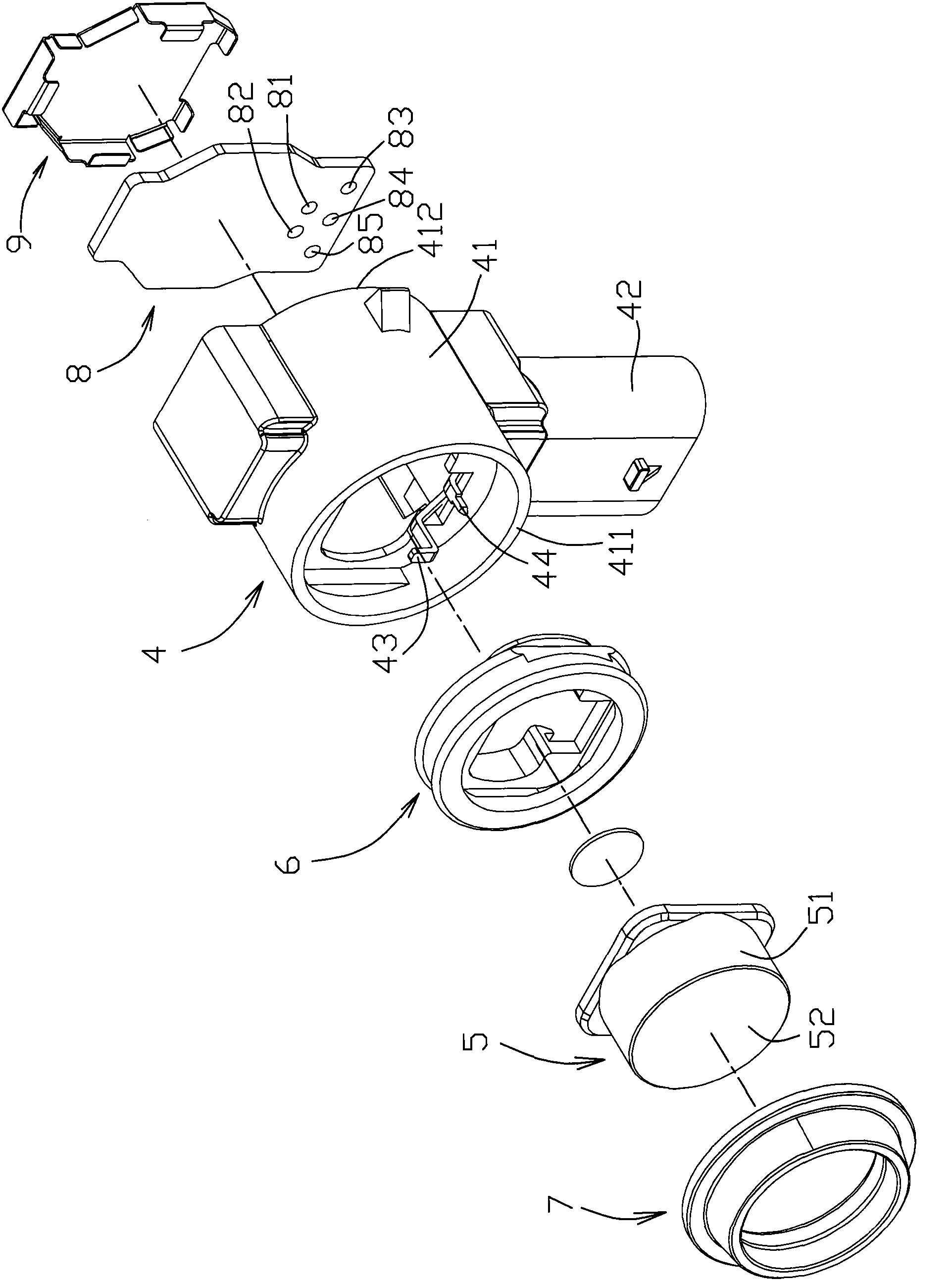

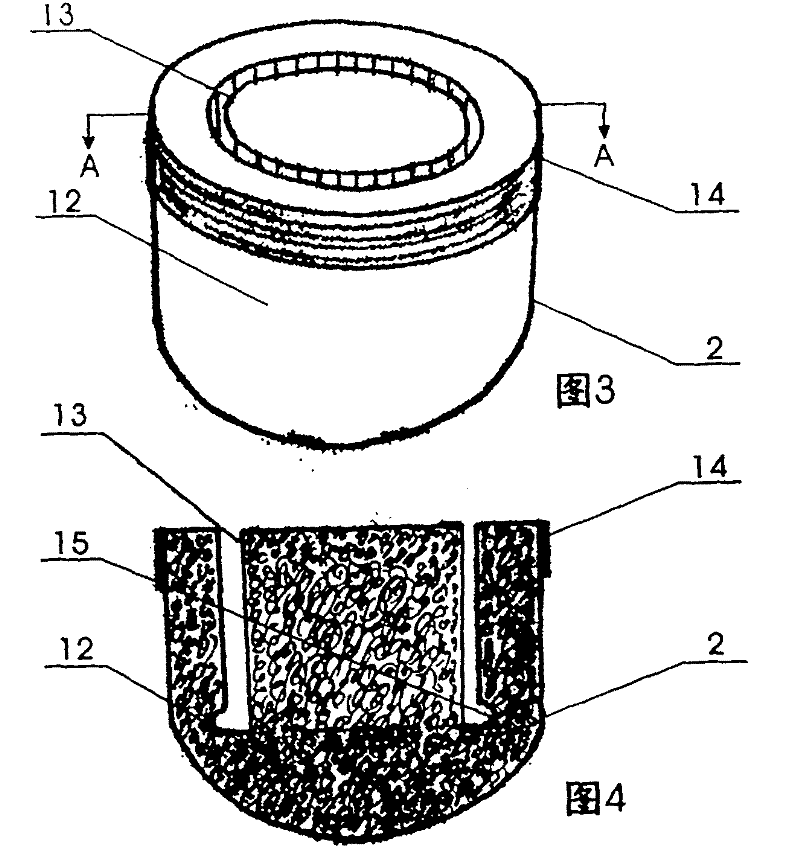

Position pointer, variable capacitor and inputting apparatus

ActiveCN102192760AReduce production man-hoursIncreased durabilityCapacitor with electrode distance variationConverting sensor output electrically/magneticallyDielectricElectricity

Owner:WACOM CO LTD

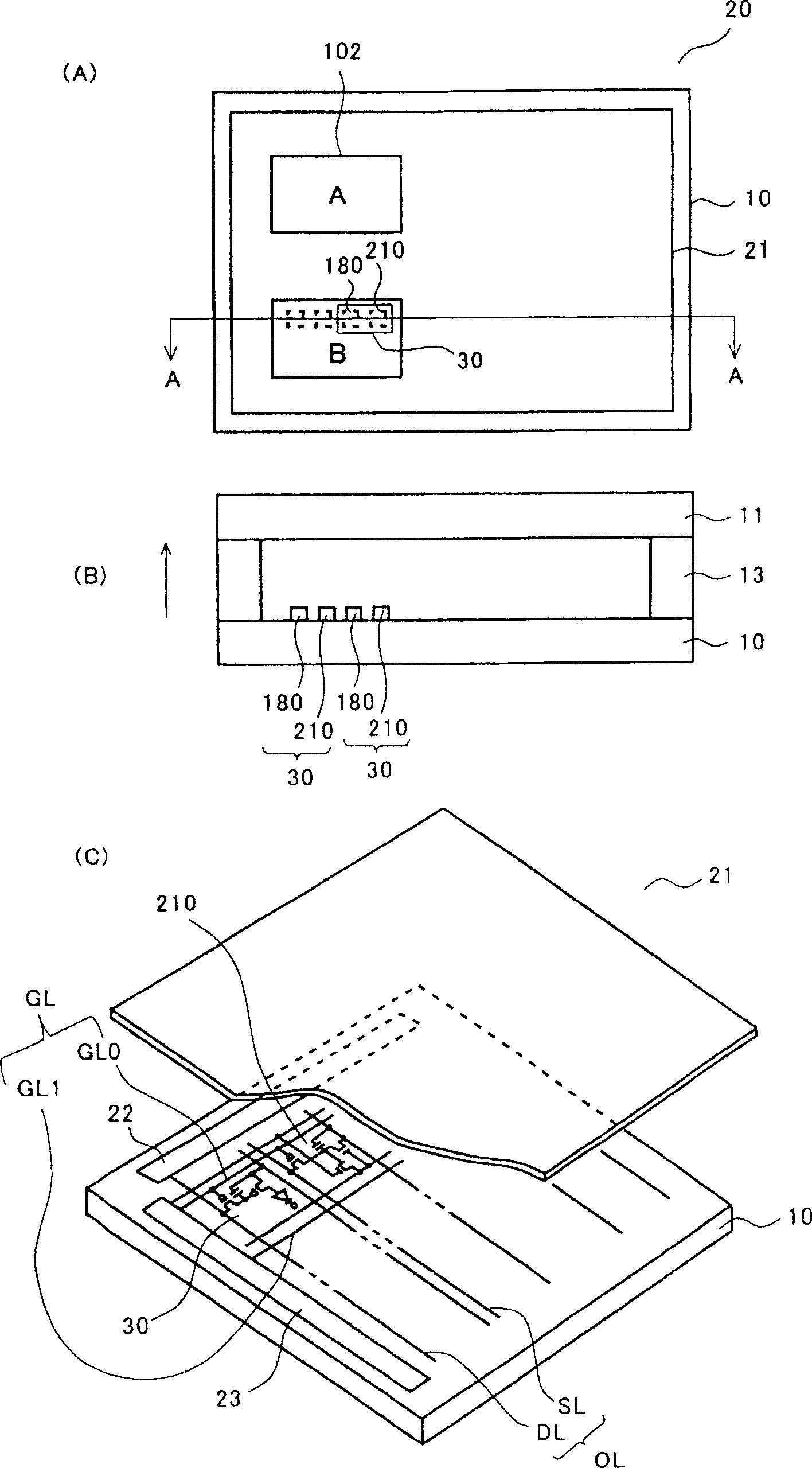

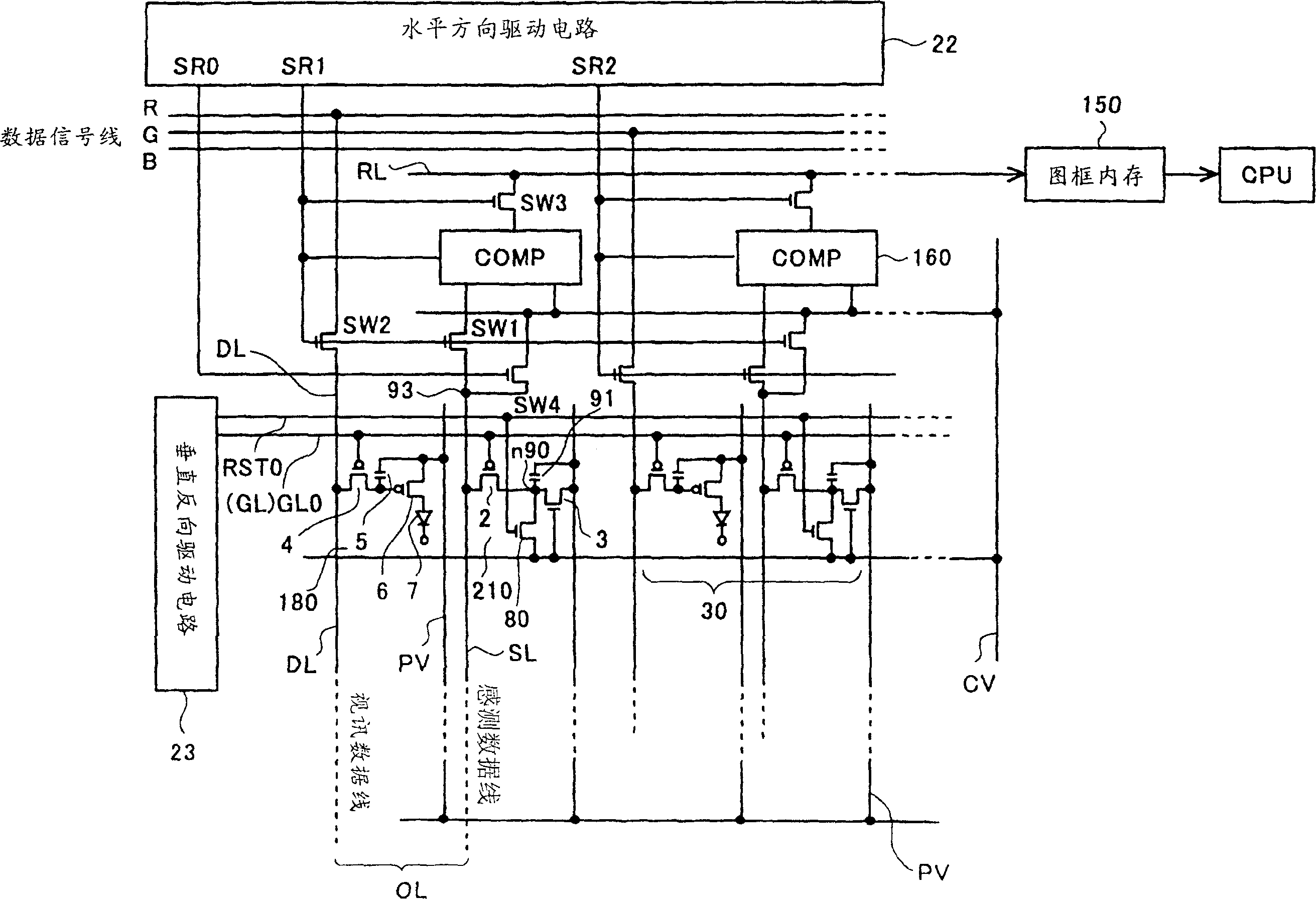

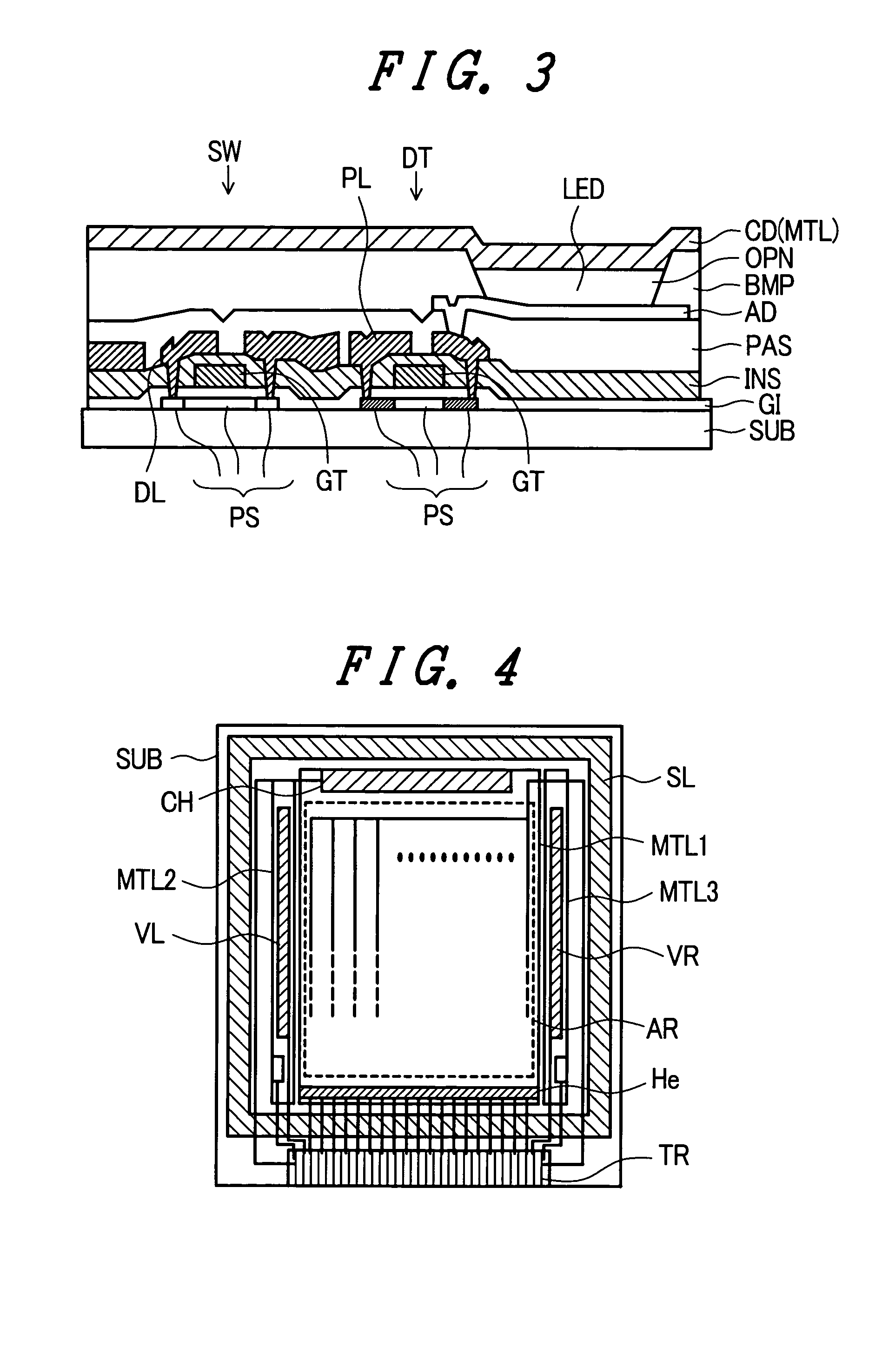

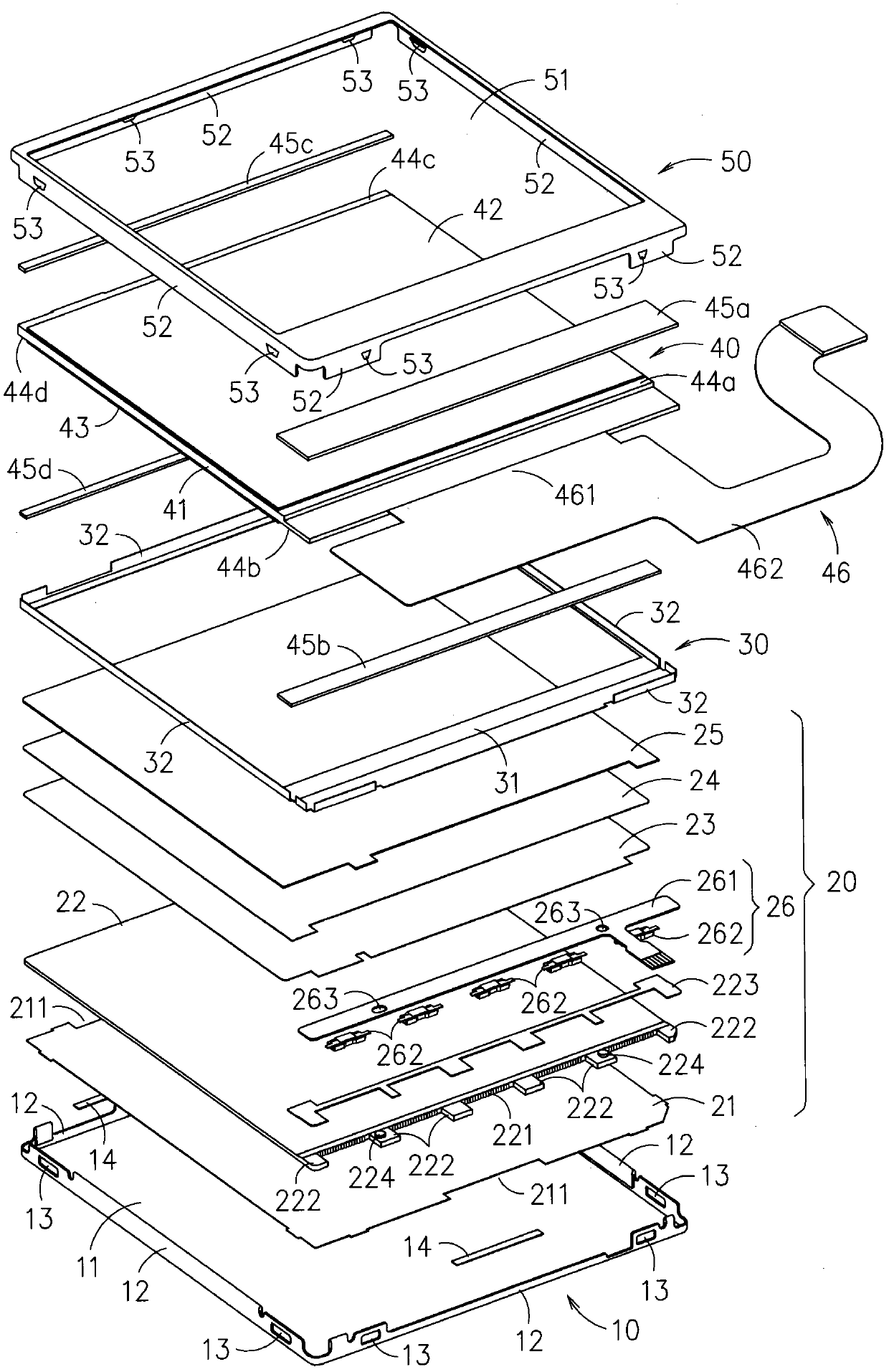

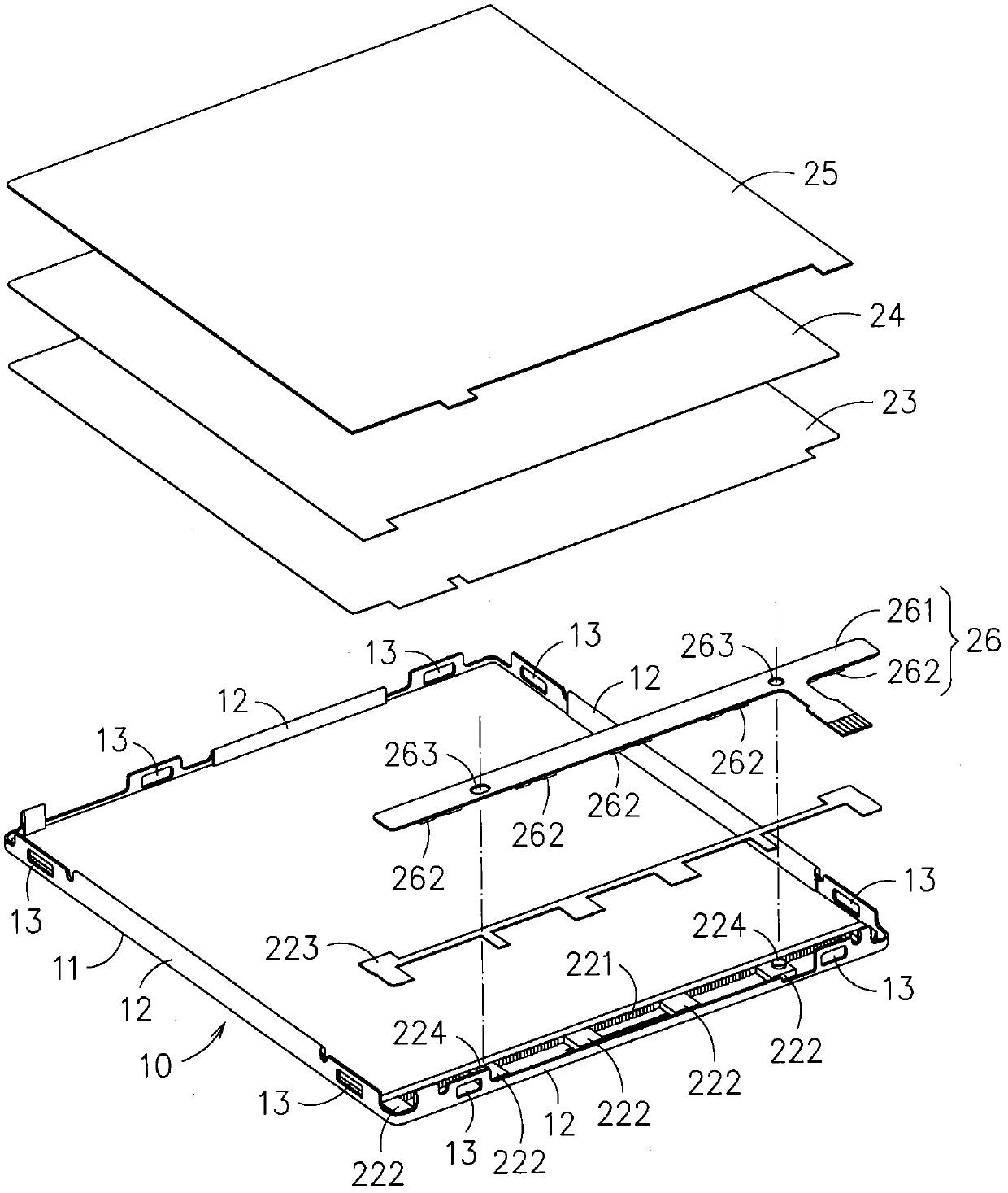

Touch panel

InactiveCN1758197AIncrease the display areaInhibit deteriorationGraph readingMechanical pattern convertionMiniaturizationEngineering

The present invention relates to a touch panel, and a photosensor and the display part are fabricated on the same substrate. Input coordinates are specified by comparing the light quantities among positions (pixels) of contact or non-contact by a finger or the like by using a comparator. This allows TFTs constituting the photosensor to be fabricated on the same substrate in the same process as the pixels, and it is thereby possible to reduce the manufacturing cost and the number of components. A region for disposing a sensor in the outer portion becomes unnecessary, which allows downsizing of the device. Moreover, effective use of the display part is possible because blind spots are eliminated from the display part. It is possible to improve the precision of input recognition and to perform detection uniformly over the entire display part. Furthermore, since the photosensor comprises a photoreceptor circuit capable of adjusting the light-receiving sensitivity, it is possible to achieve uniform light-receiving (detection) sensitivity for the display part.

Owner:SANYO ELECTRIC CO LTD

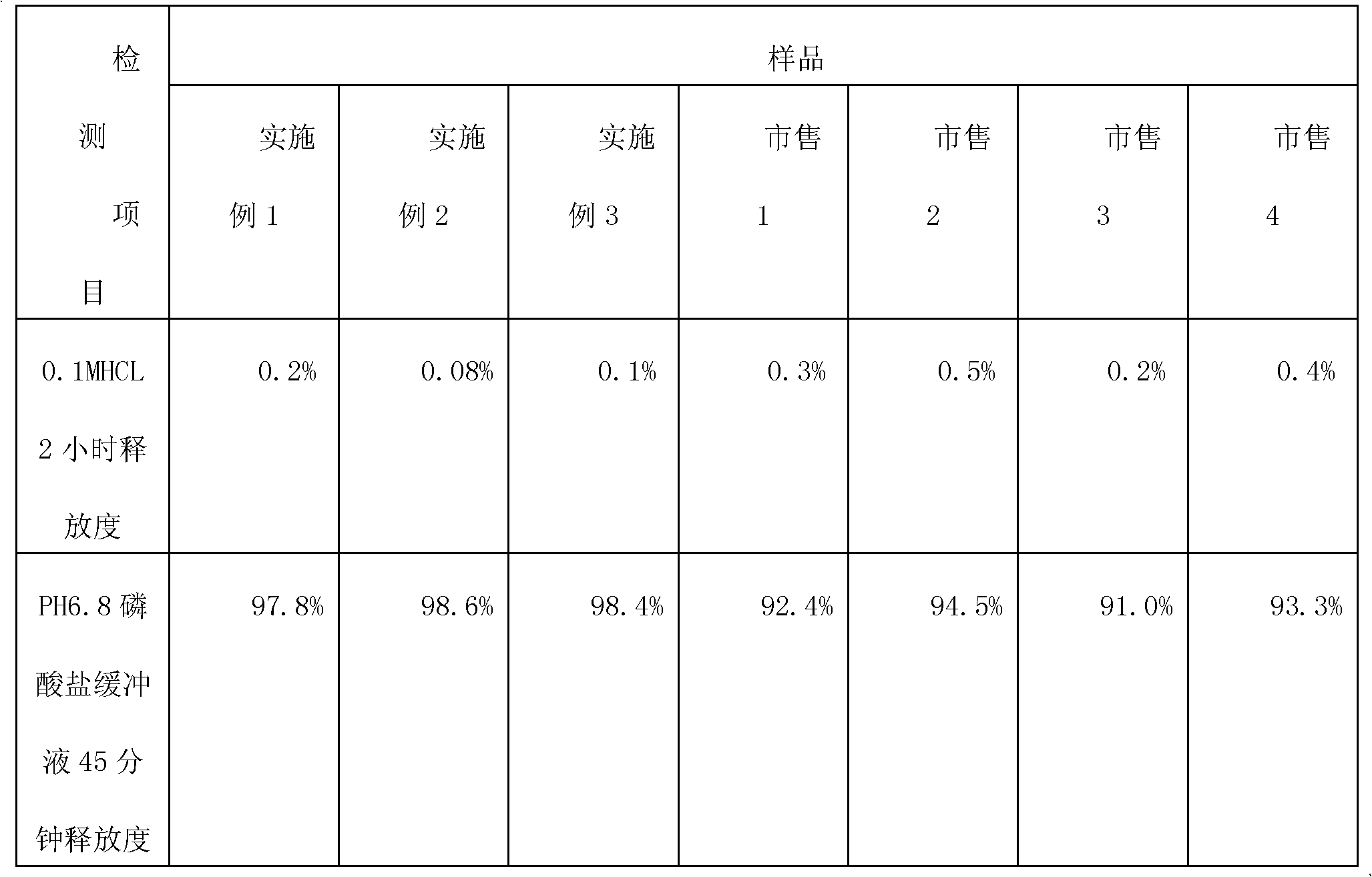

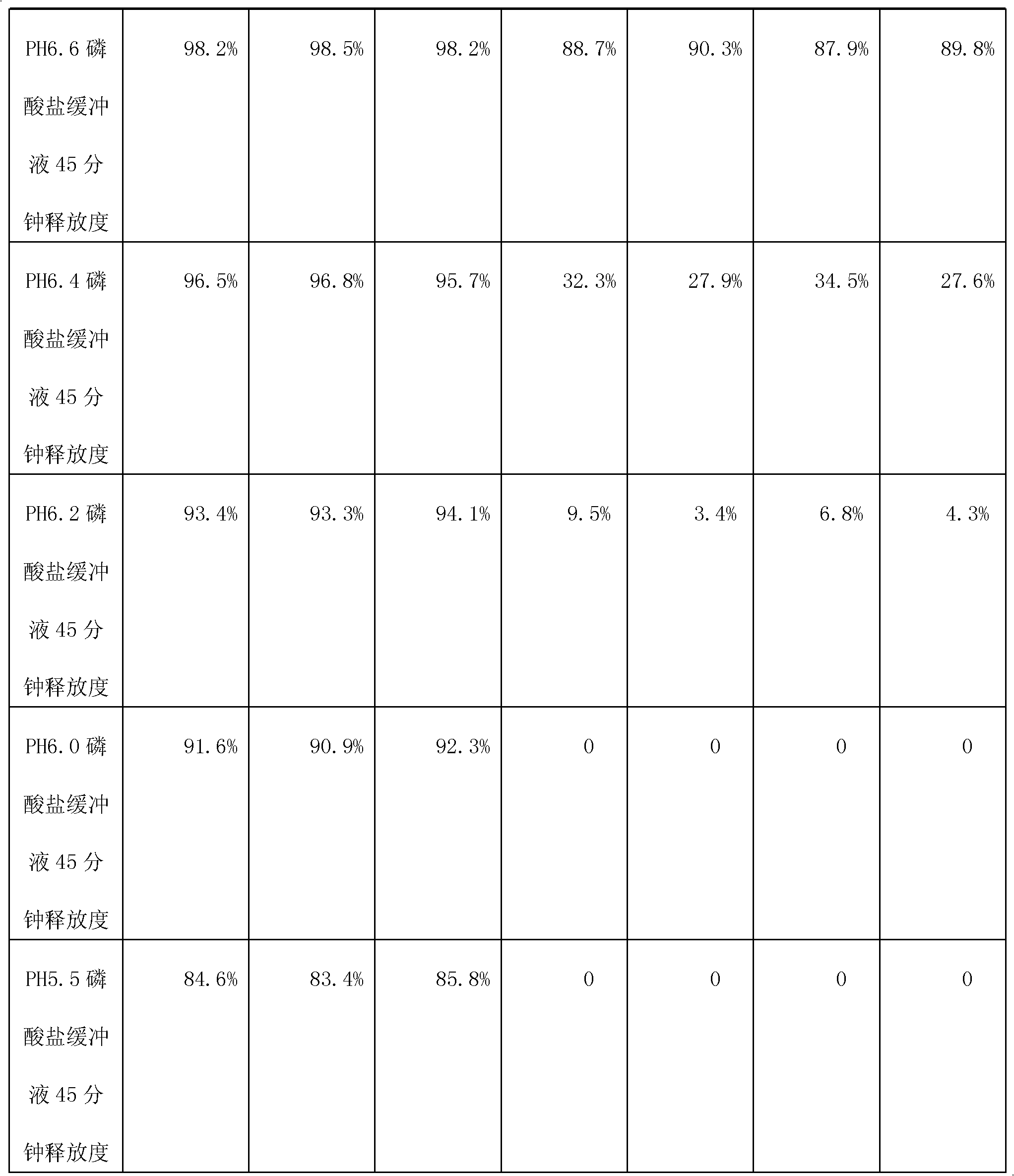

Metformin hydrochloride enteric-coated tablet

InactiveCN102357088AAvoid situations of rapid aggregate denaturationReduce use costOrganic active ingredientsMetabolism disorderManufacturing cost reductionClinical efficacy

The invention discloses a metformin hydrochloride enteric-coated tablet, which comprises a tablet core and an enteric-coated layer. The tablet core is prepared by the following raw materials by weight: 100 parts of metformin hydrochloride, 3-5 parts of povidone K30, 8-12 parts of 75% ethanol water containing 10% povidone K30 and 0.5-1.0 part of magnesium stearate. The enteric-coated layer is prepared by the following raw materials by weight: 100 parts of eudragit L30D-55, 10-30 parts of talcum powder, 2-4 parts of polyethylene glycol 4000, 4-6 parts of 4% sodium hydroxide solution and 80-120 parts of purified water. The preparation process includes the steps of weighing all raw materials according to proportion, preparing the tablet core, preparing enteric-coated solution and then obtaining the metformin hydrochloride enteric-coated tablet. The metformin hydrochloride enteric-coated tablet simplifies preparation technology, effectively reducing manufacture cost, can simultaneously control releasing speed, and effectively guarantees clinical effects of products.

Owner:HEBEI JAMESHILL PHARMA

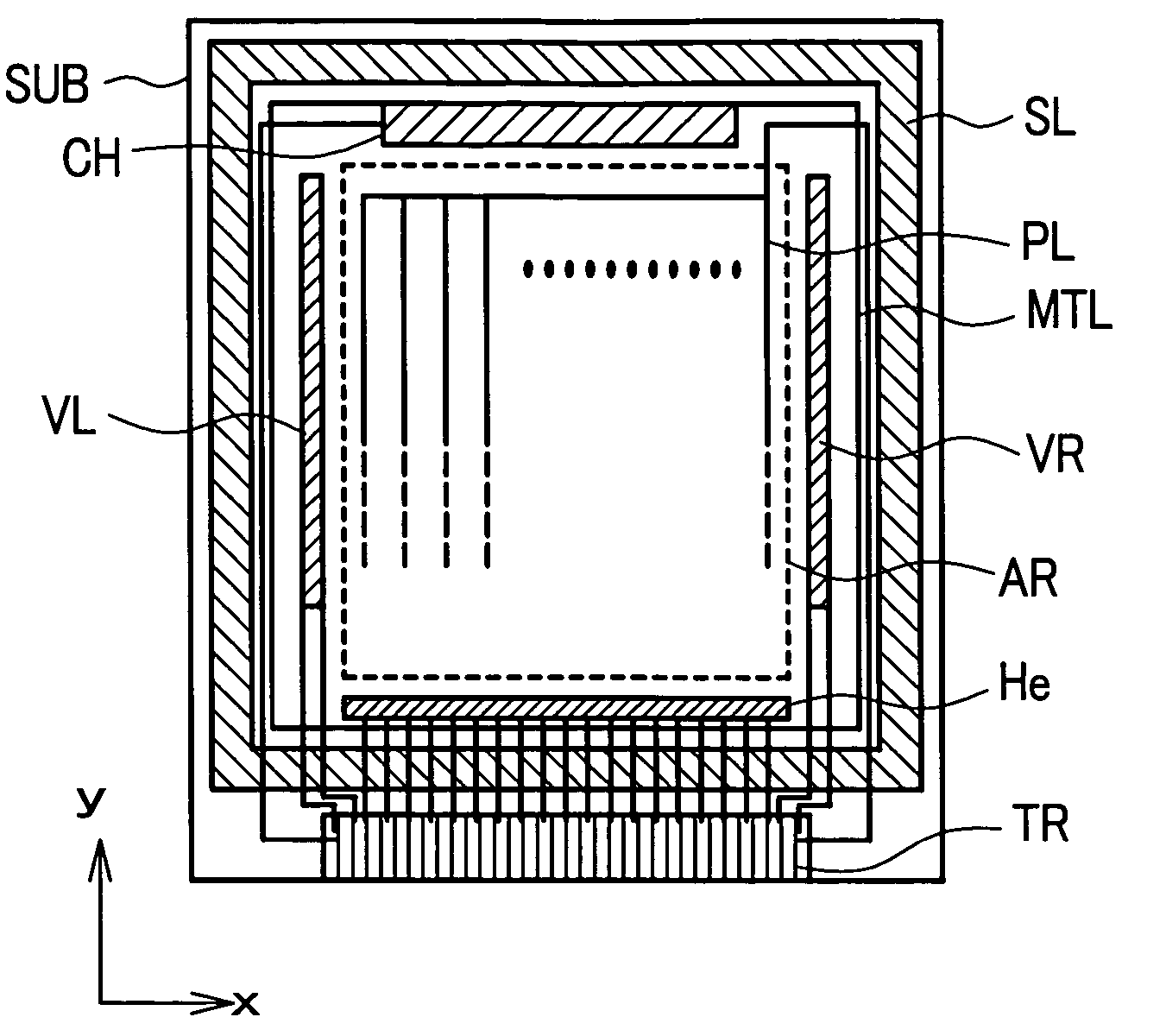

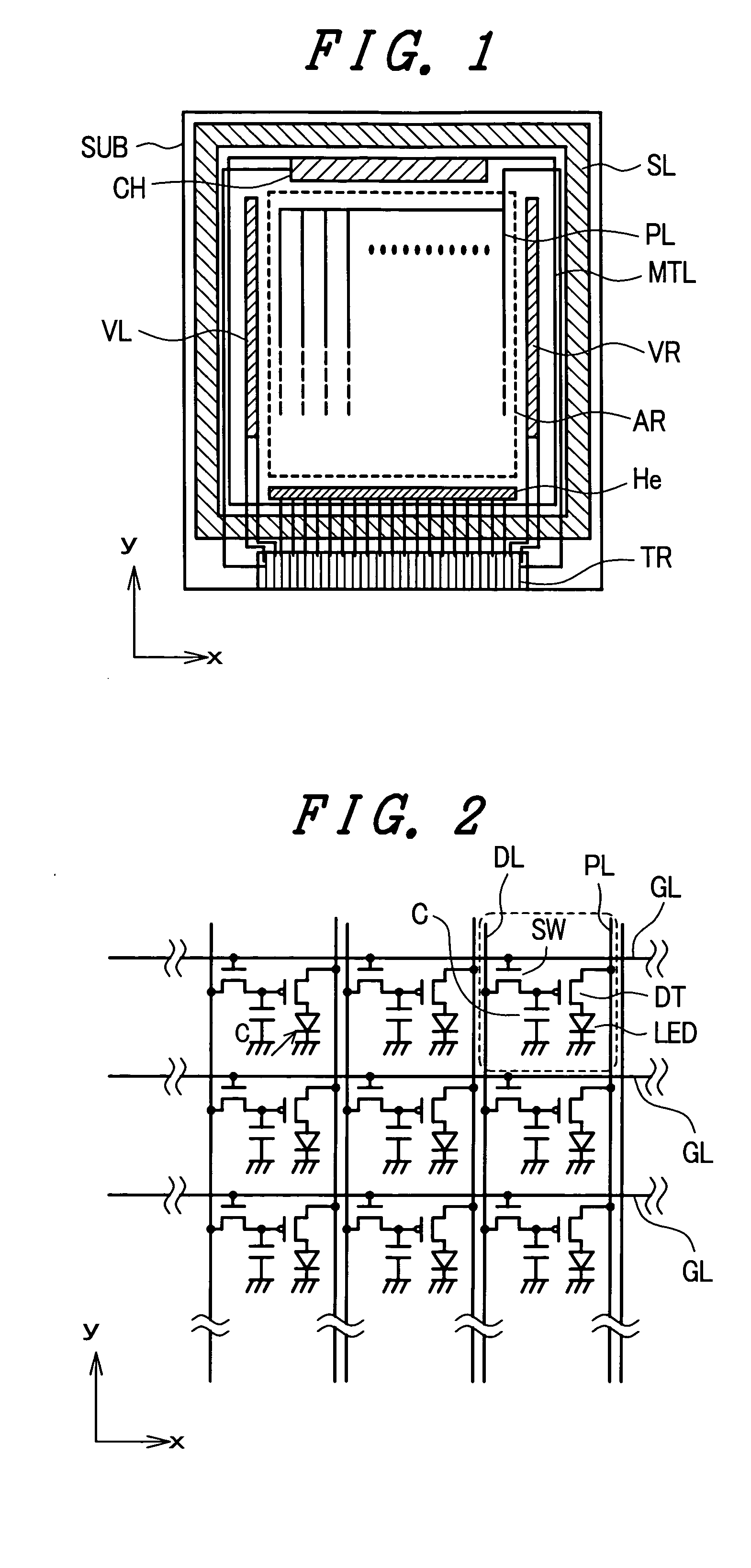

Display device

ActiveUS20050082969A1Give flexibilityReduce parasitic capacitanceDischarge tube luminescnet screensElectroluminescent light sourcesDisplay devicePeripheral

The present invention provides an organic EL display device which imparts the flexibility to the pull-around operation of lines. The organic EL display device is characterized in that the display device includes a display part and a display drive circuit which is formed on a periphery of the display part on a surface of a substrate, wherein the display part includes a plurality of pixels driven by the display drive circuit, each one of the pixels is formed of a stacked body which is constituted of at least one electrode, a light emitting layer and another electrode stacked from the substrate side, another electrodes of respective pixels are electrically connected in common, and a conductive layer which is formed on the same layer and is made of the same material as another electrodes is formed on a region other than the display region in a state that the conductive layer is electrically separated from another electrodes.

Owner:SAMSUNG DISPLAY CO LTD +1

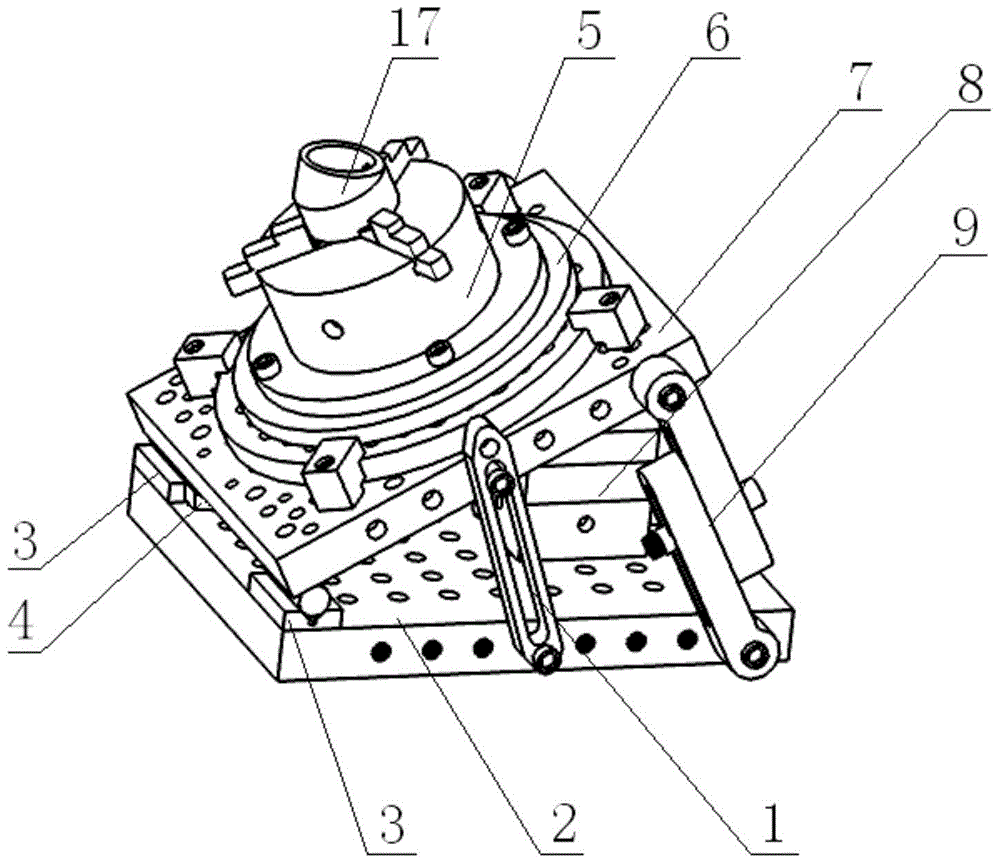

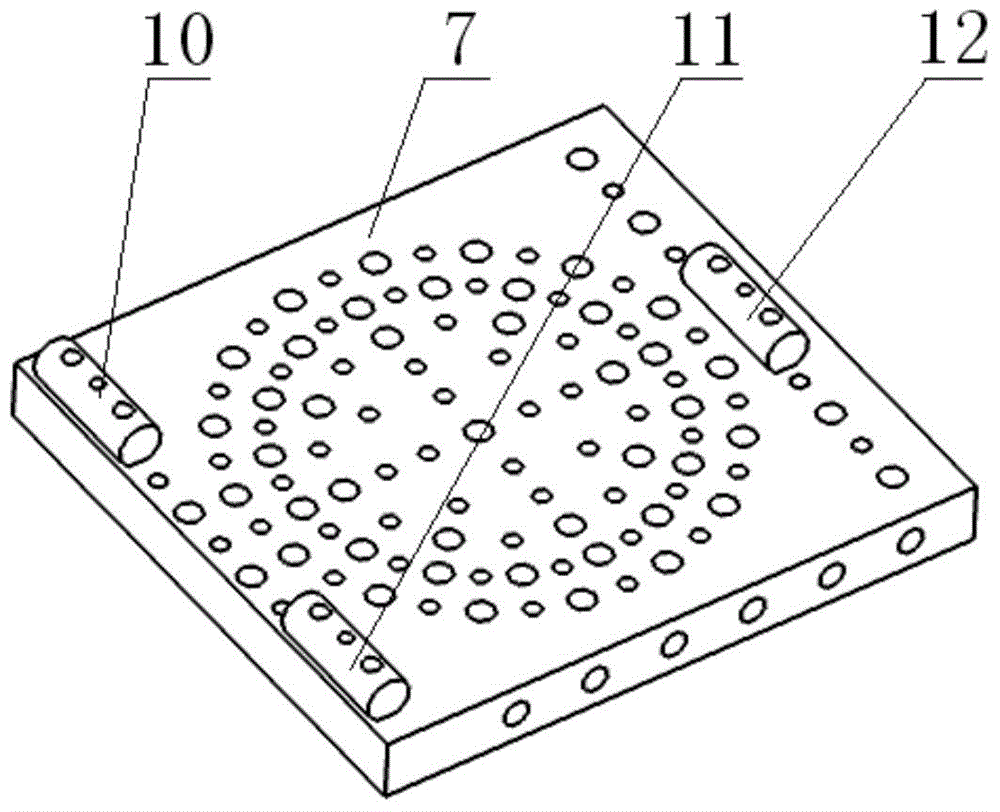

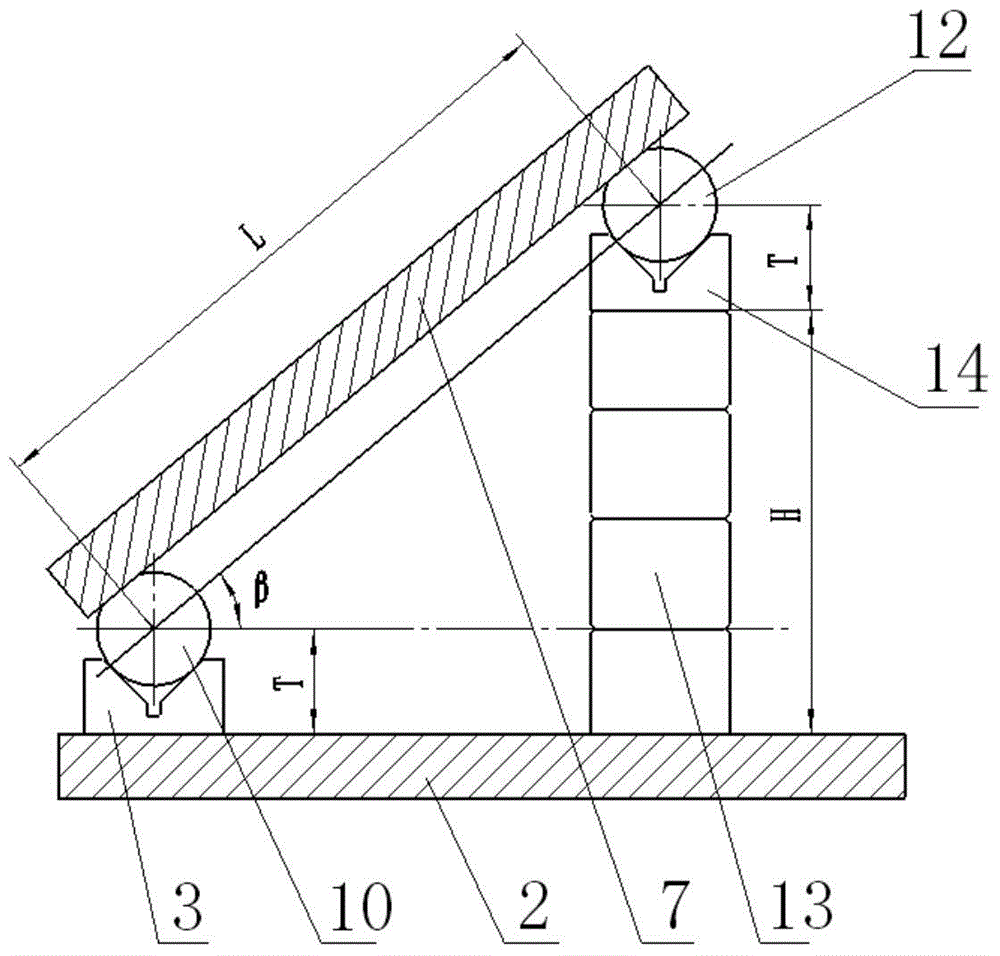

Angle-adjusting numerical control machine tool combined clamp

ActiveCN104668991AHigh precisionReduce production man-hoursChucksPositioning apparatusEngineeringMachine tool

The invention discloses an angle-adjusting numerical control machine tool combined clamp which comprises a lower base plate, an upper base plate, a connecting plate, a support part and a three-jaw chuck. The support part is vertically fixed on the lower base plate. The lower base plate is provided with two identical low-position V-shaped support blocks close to one side. The central lines of the two V-shaped support blocks coincide. The support part comprises a rectangular support element and a high-position V-shaped support block. The high-position V-shaped support block and the low-position V-shaped support blocks are identical in structure. One downward face of the upper base plate is provided with three trimming shafts forming a triangle. The trimming shafts are identical in structure and integrally connected with the upper base plate. The three trimming shafts are respectively located on the two low-position V-shaped support blocks and the high-position V-shaped support block. By the structure, the angle-adjusting numerical control machine tool combined clamp has the advantages that the precision of the clamp is increased greatly, clamp manufacturing time can be reduced, production preparation cycle can be shortened, machining efficiency is increased, and manufacturing cost is lowered.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

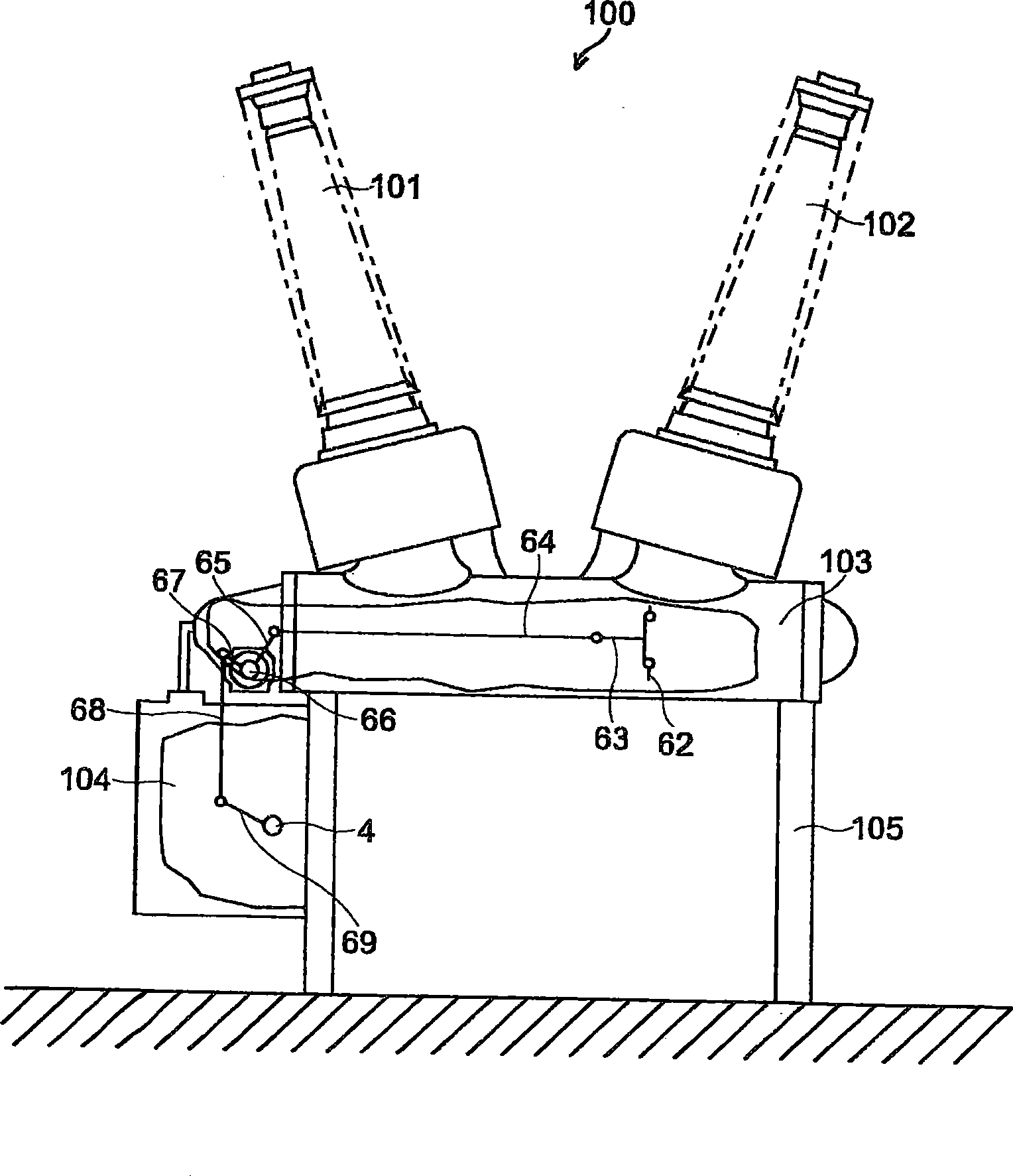

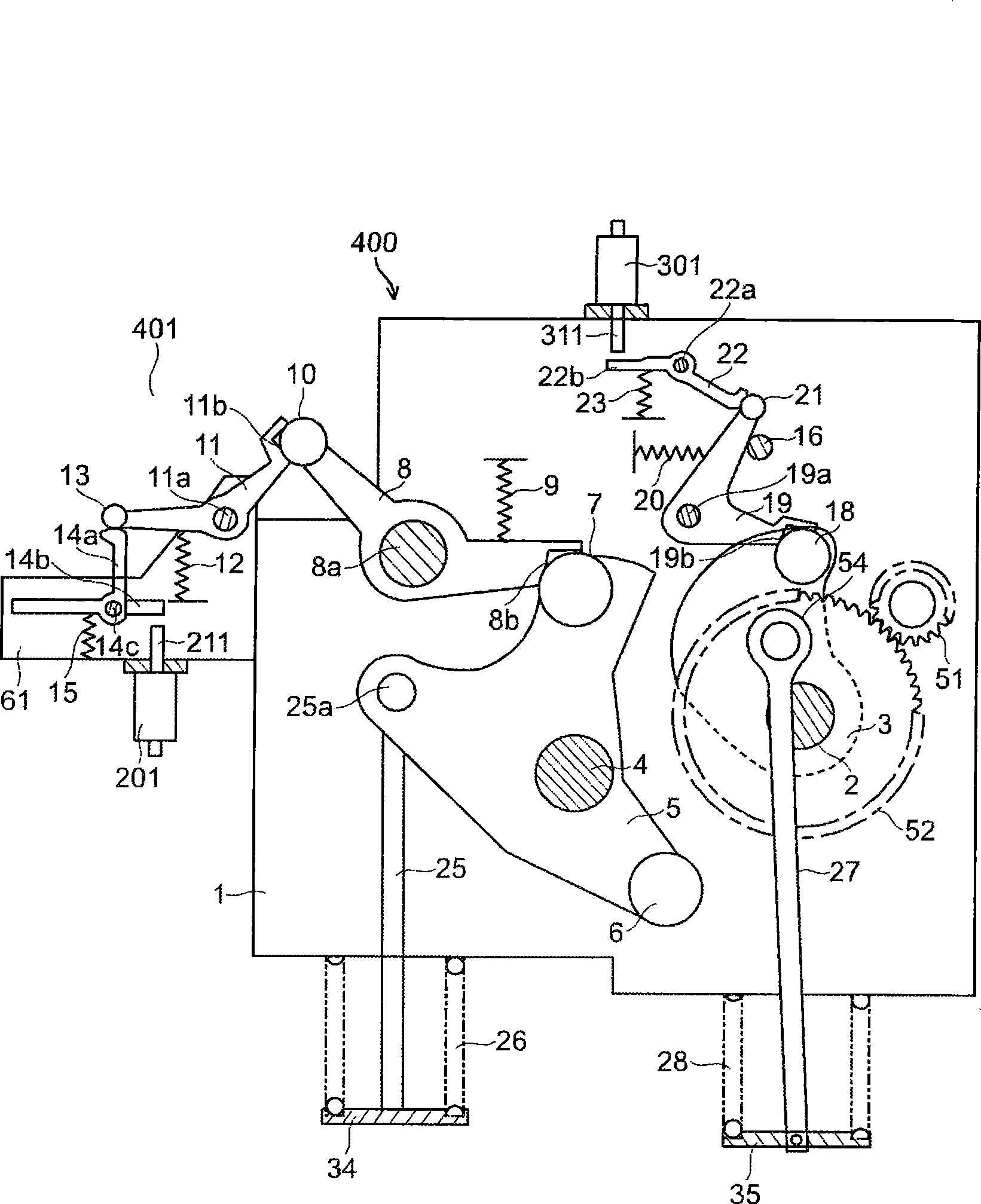

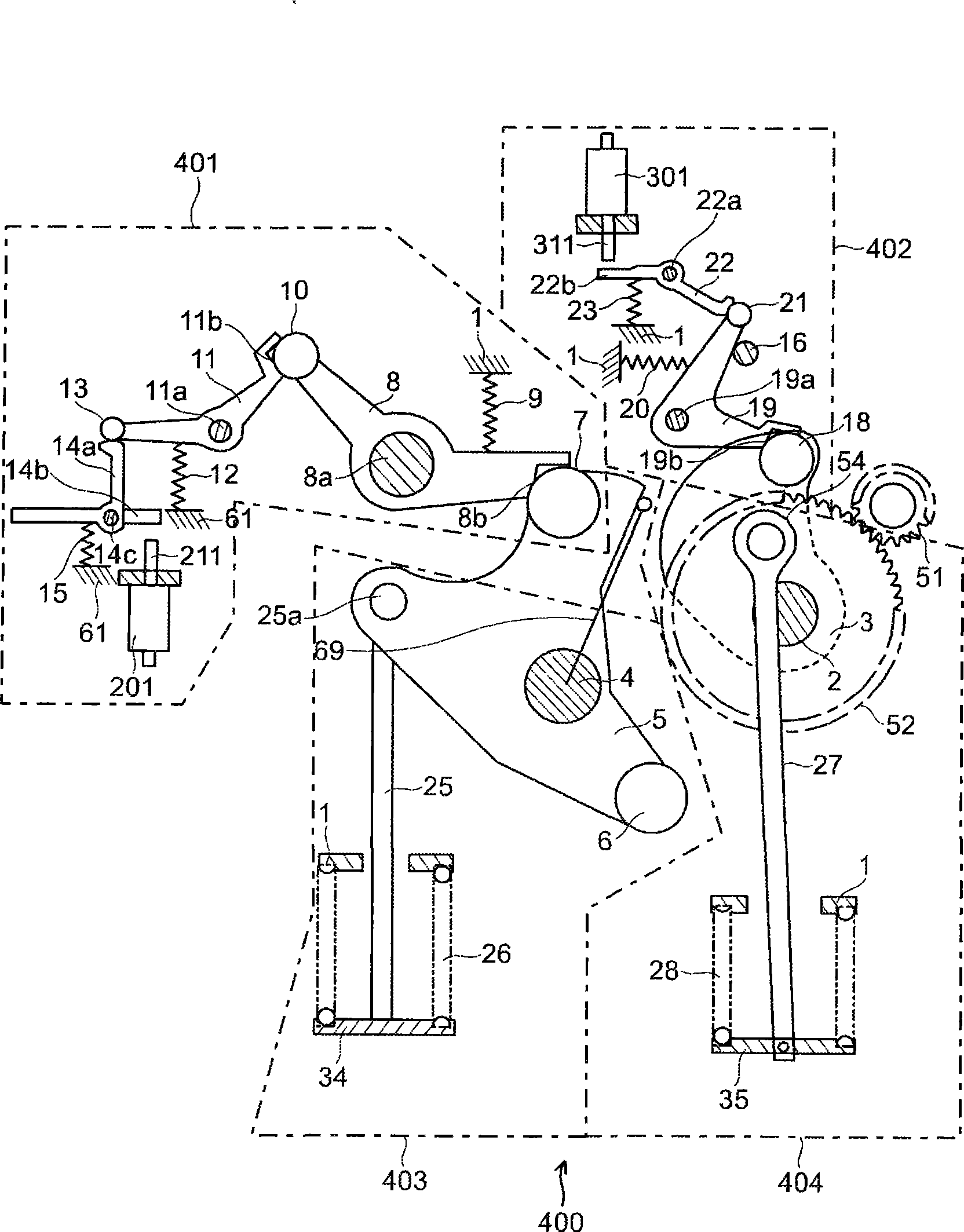

Breaker

InactiveCN101454858ASave preparation timeMeet the requirements of different breaking speedsSwitch power arrangementsHigh-tension/heavy-dress switchesJoystickEngineering

Provided is a breaker, which can match different breaking rate specifications and which is made common and standard in a spring operation mechanism thereby to reduce the number of steps of designing and manufacturing the breaker. This breaker comprises a power transmission mechanism for bringing a movable contact element (63) and a stationary contact element (62) constituting an ON / OFF contact, into and out of contact with each other, a breaking spring (26) for applying a driving force in a direction to release the movable contact element (63) from the stationary contact element (62) through the power transmission mechanism, a latch mechanism for constricting the motion of the power transmission mechanism at a position to hold the biasing state of the breaking spring (26), and a pullout operation unit for releasing the constriction of the power transmission mechanism by the latch mechanism. The pullout operation unit includes activation means and is arranged to confront a first arm of a lever thereby to turn the first arm. The lever includes a second lever arranged to have its leading end retained by the latch mechanism, and is turned to release the constriction of the power transmission mechanism by the latch mechanism. Moreover, the length size from the turning center of the first arm of the lever to the operation axis of the activation means, and the gap between the first arm of the lever and the activation means are different according to the breaking rate specifications.

Owner:JAPAN AE POWER SYST

Liquid crystal display device

InactiveCN102566091AAvoid light leakageLow costCasings/cabinets/drawers detailsRack/frame constructionCrystallographyLiquid-crystal display

The invention discloses a liquid crystal display device, which comprises a lower frame, a backlight module, a shading adhesive tape, a liquid crystal panel and an upper frame. The backlight module is arranged in the lower frame, the shading adhesive tape consists of a bottom edge and a side edge, the bottom edge is attached to the backlight module, the side edge is attached to a side surface of the lower frame, the liquid crystal panel is arranged on a surface, with the lower frame, of the shading adhesive tape, the edge of a surface of the liquid crystal panel is attached to the bottom edge of the shading adhesive tape, the peripheral edge of the liquid crystal panel is attached to the side edge of the shading adhesive tape, and the upper frame is covered on the liquid crystal panel and combined with the lower frame. The backlight module and the liquid crystal panel are covered and carried by the metal lower frame, the shading adhesive tape with a flanging structure prevents light from leaking, an adhesive frame structure of a traditional liquid crystal display device is omitted, a design trend of light weight, thinness and short and small size of the market is met, material cost and manufacturing working hours are reduced.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

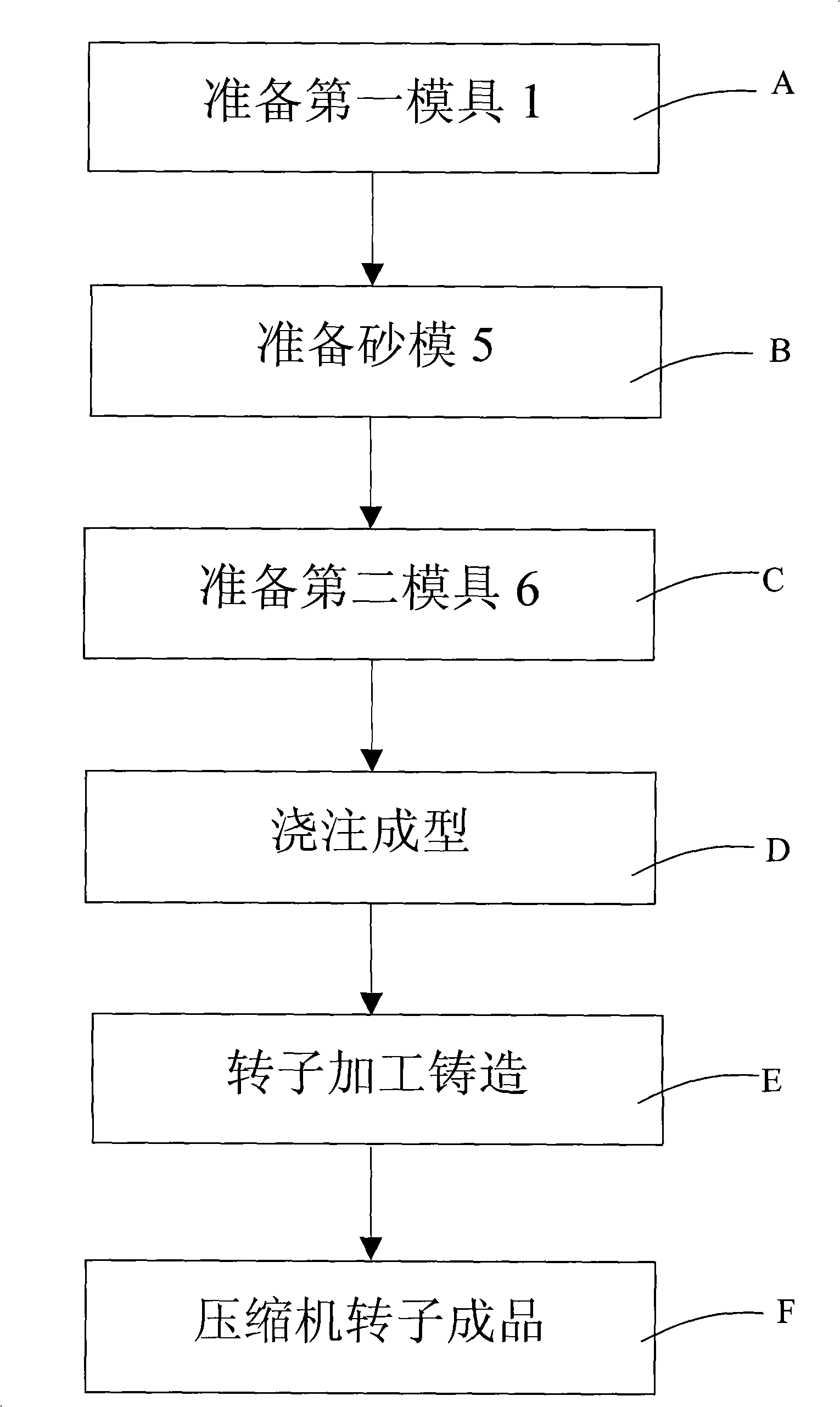

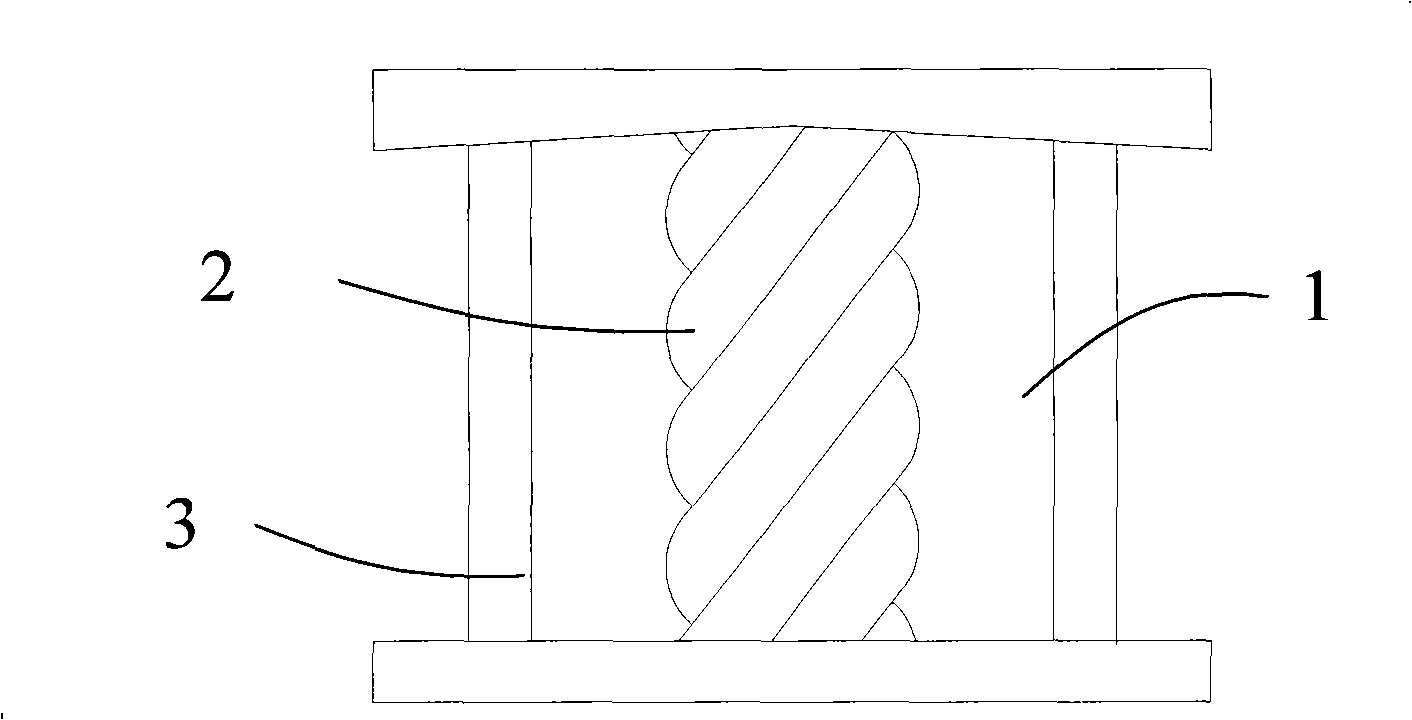

Method for casting and molding spiral rotor of compressor

InactiveCN101342585ASave materialReduce production man-hoursFoundry mouldsFoundry coresComposite material

The present invention relates to a method for casting and forming the helical rotor of a compressor, which is realized through the following steps: preparing a first mould, and a helical part mould is axially arranged inside the first mould; a sand mould is prepared by filling the sand pulp inside the first mould, and after the sand pulp is solidified and formed, the sand mould is formed by removing the mould, and the cast-die cavity of the helical part is arranged inside the sand mould; preparing a second mould: the second mould comprises an upper sand box and a lower sand box, and the sand mould is arranged inside the lower sand box, a molding cavity of a first pivot part and a second pivot part are arranged inside the upper sand box to be fixed and integrated with the upper and the lower sand boxes; pouring and forming: liquid cast-piece material is poured into the cast-die cavity and the molding cavity, and a rotor cast piece that is provided with a helical part and with two ends being respectively connected with the first pivot part and the second pivot part is formed by removing the mould after the cast-piece material is formed; the method of the present invention can save a great amount of materials and can save the manufacturing time.

Owner:SHANGHAI HANBELL PRECISE MASCH CO LTD

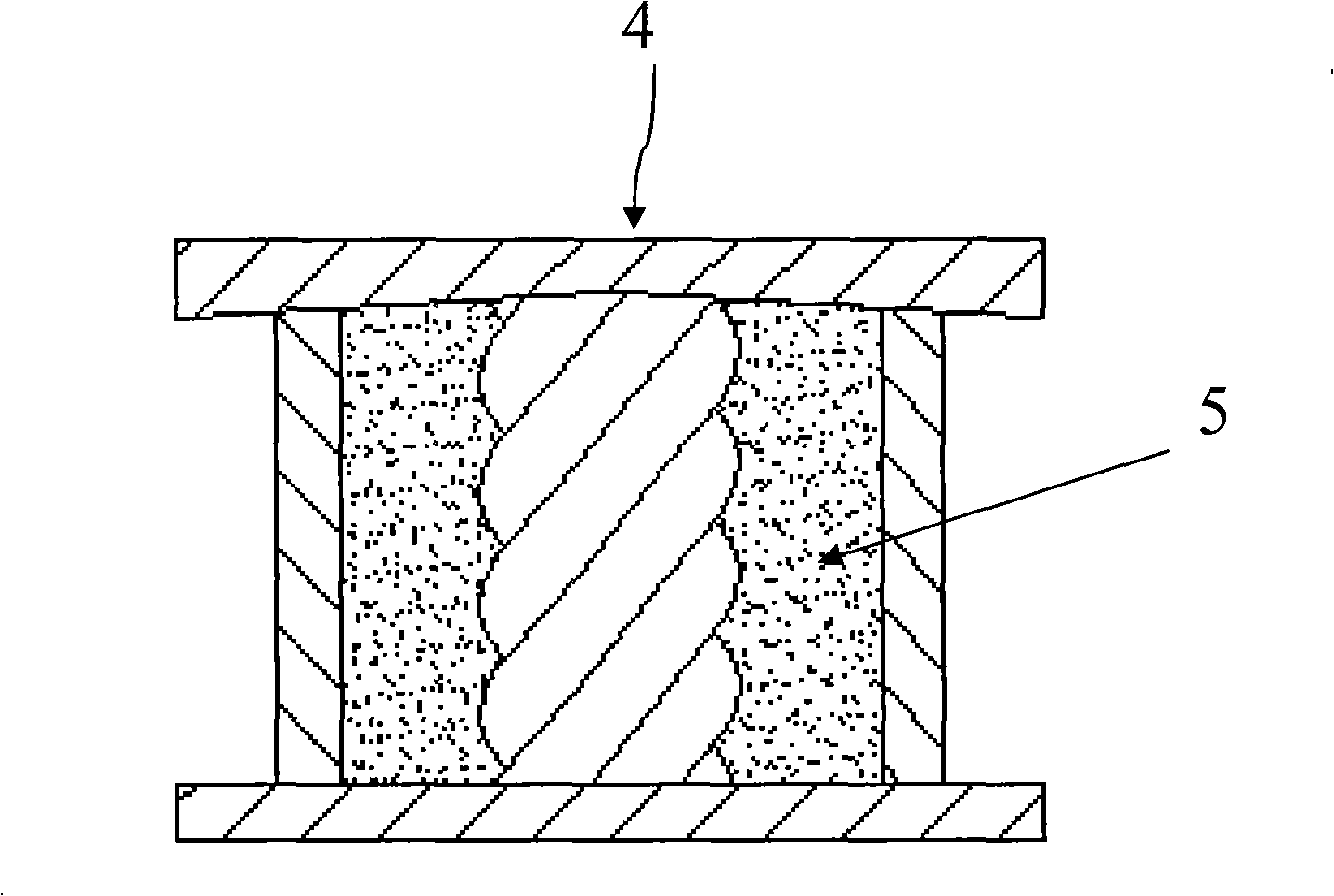

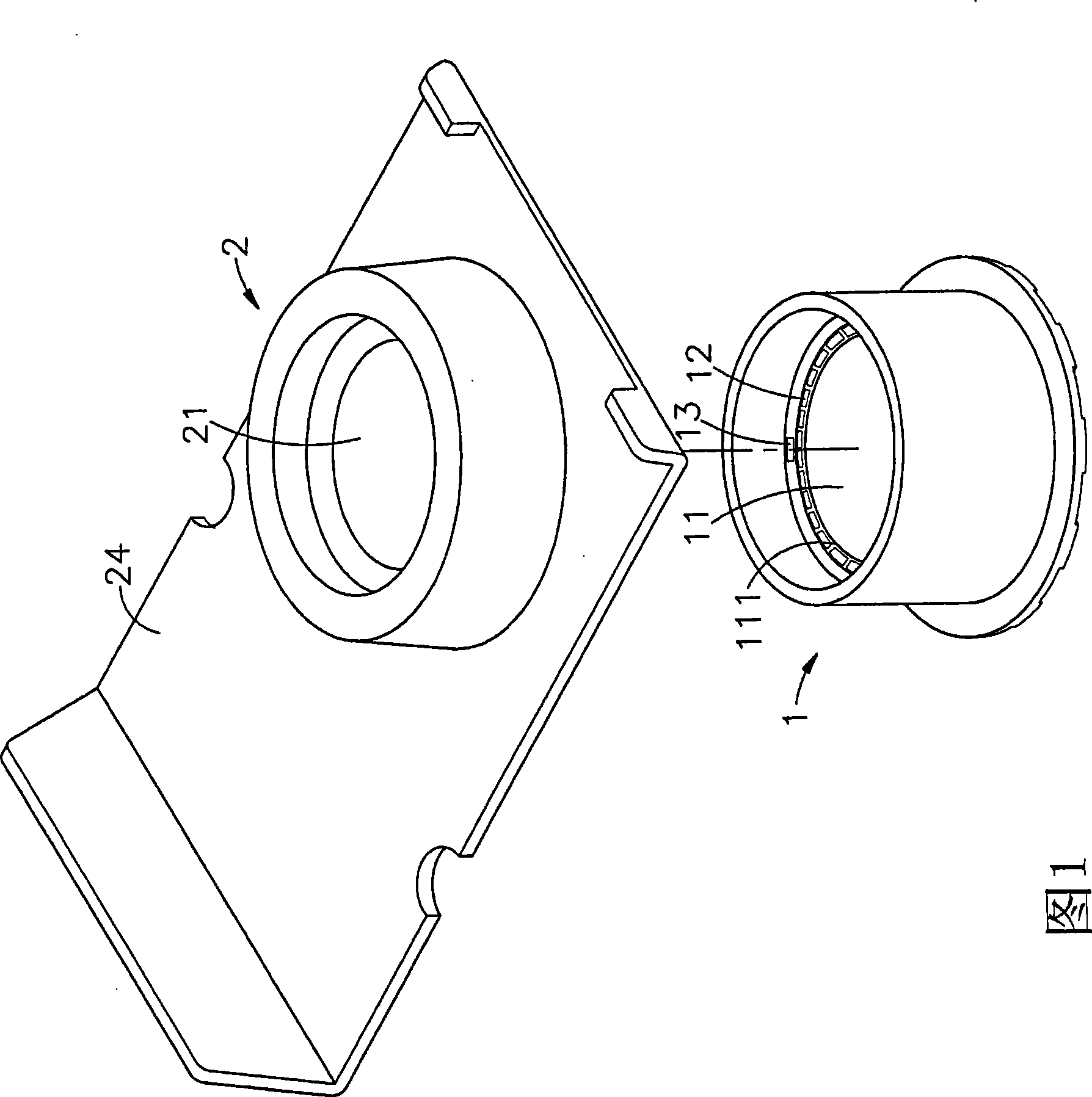

Encapsulating method of large power reactor

InactiveCN101847506AImprove mechanical propertiesImprove water resistanceInductances/transformers/magnets manufactureEpoxyElectrical conductor

The invention relates to an encapsulating method of a large power reactor, which is characterized in that polyurethane encapsulating material is used for pouring a device to be encapsulated. The encapsulating method is mainly suitable for heating and filling air gaps in a multi-conductor wire and cable core or gaps between cable elements with any structure. The polyurethane encapsulating material not only has favorable insulation performance, mechanics property and chemical property of the epoxy resin, but also overcomes the weakness that the epoxy resin is fragile, has poor impact resistance and non-uniform strength at the high temperature and the epoxy resin is fractured at the low temperature; and at the same time, the polyurethane encapsulating material is toxic-free and resists the fire, and is free from containing the composition which is harmful to the human body and the environment.

Owner:INDUCTOTHERM GROUP CHINA

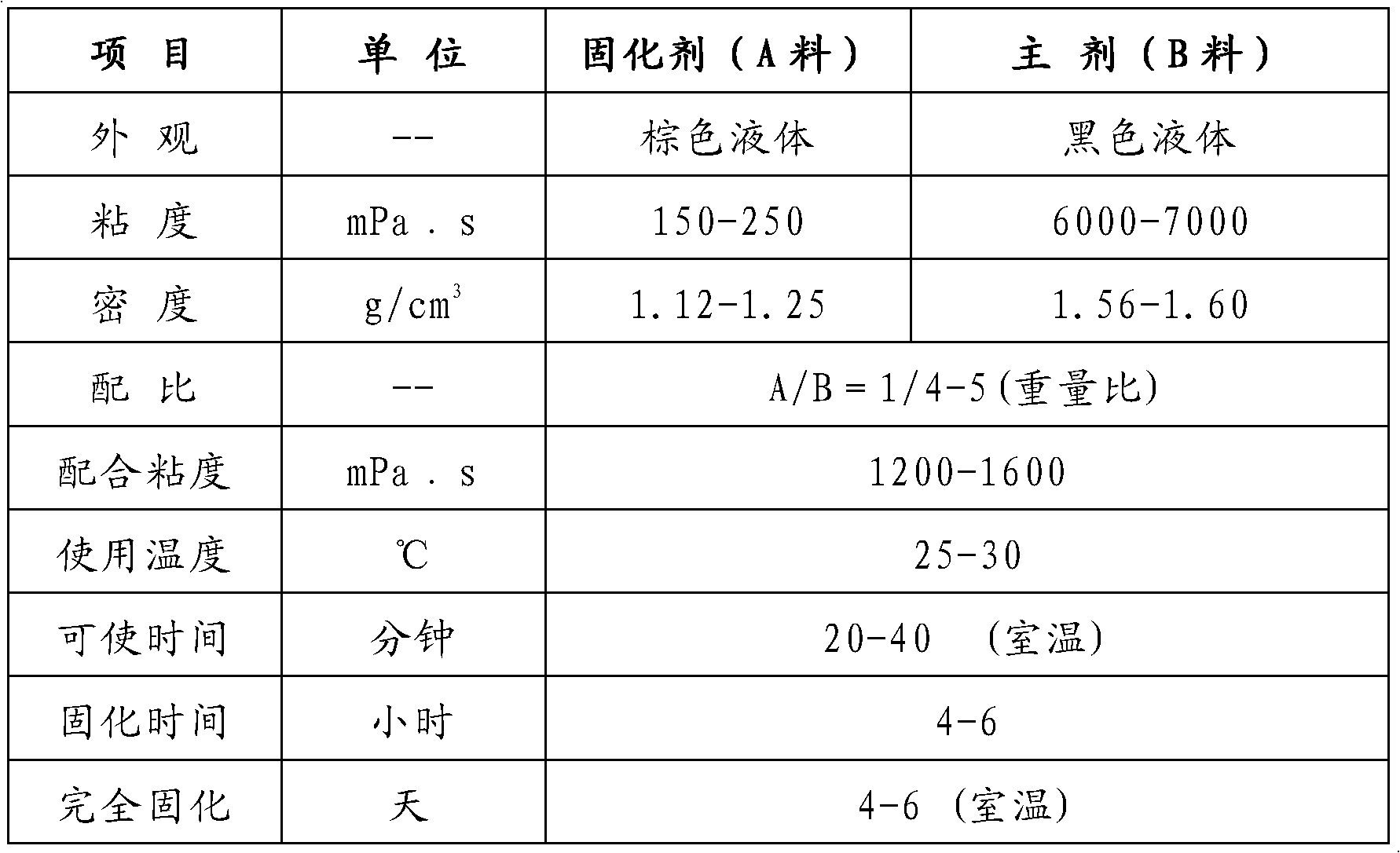

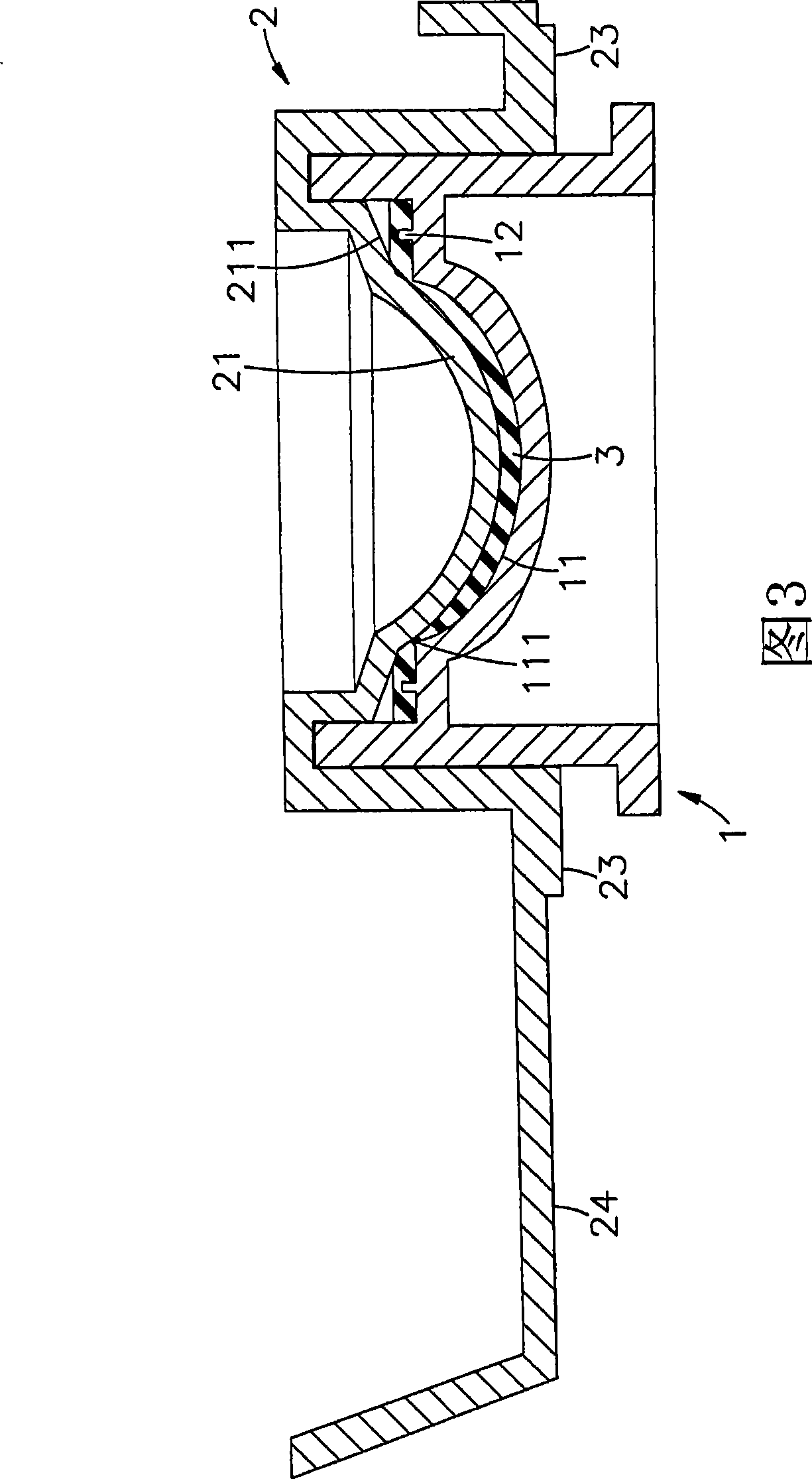

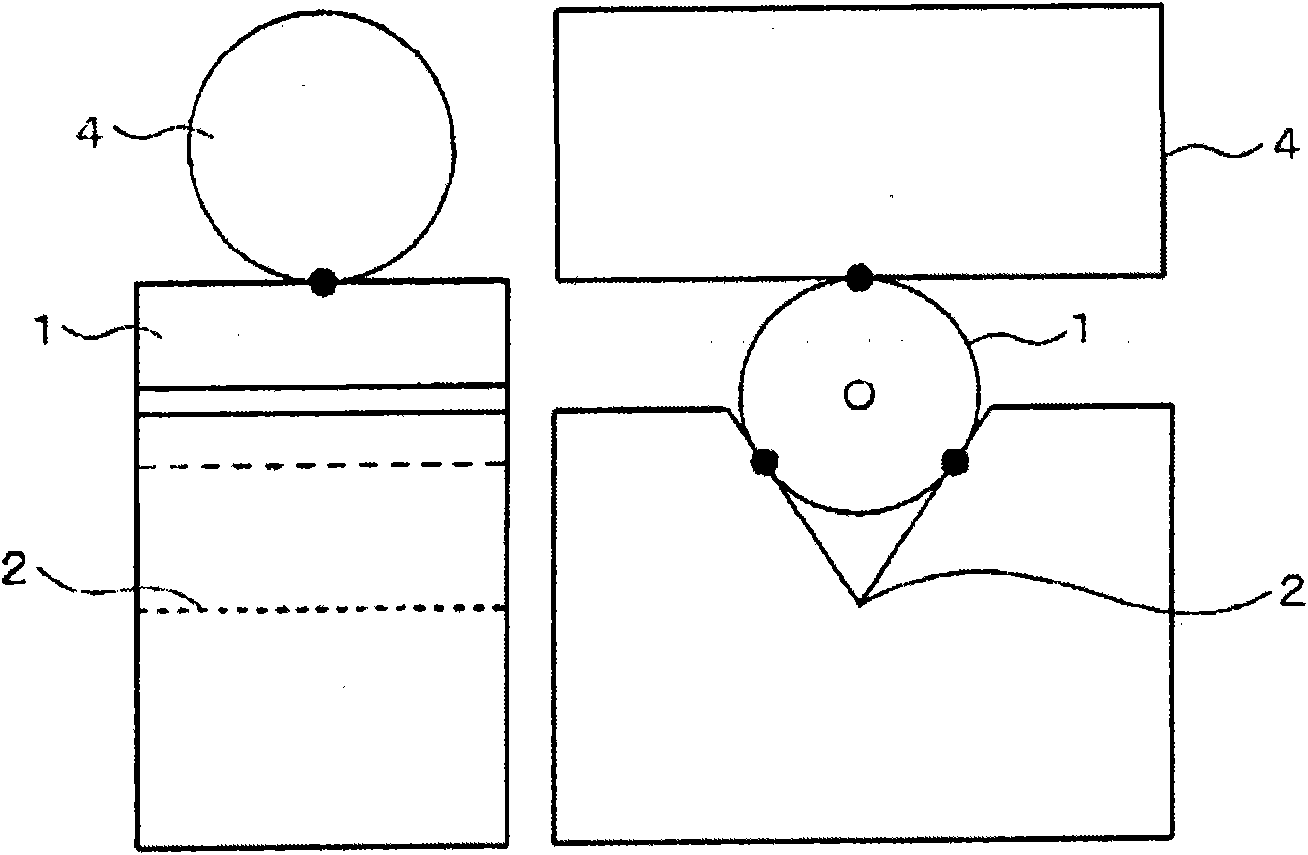

Contact lens molding method and mould

InactiveCN101428477ASimple processShort processOptical articlesUsing protective liquidsManufacturing cost reductionLens plate

The invention relates to a method for shaping contact lenses and a mould, particularly a method which can use simple moulds for forming the contact lenses. The method comprises the following steps: placing the contact lens material in a die cavity of a mould; then, using the mould of an auxiliary appliance to press the lens material in the die cavity; causing the lens material to spread and extend along an arc surface of a die cavity and a mould; pushing excessive materials and overflowing out of the corner cut edge; proving the retained surface at the outer part of the mould for jointing the corner cut edge; removing the excessive materials; solidifying and treating the lens material in the mould; jointing the lens material on the surface of the mould of the auxiliary appliance; shaping glasses of the contact lenses after testing; packaging after injecting buffer solution in the appliance space of the outer part of the mould of an auxiliary appliance; and manufacturing products for selling. The contact lens has the advantages that the manufacturing procedure is simple and fast; and the purposes for saving labor and time, reducing the manufacturing cost, and keeping with the economic effect can be achieved.

Owner:UNICON OPTICAL

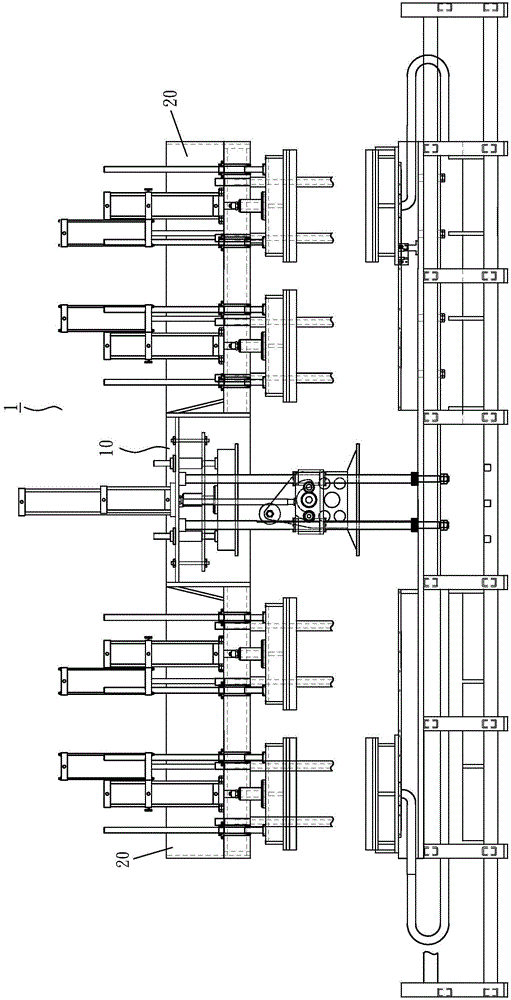

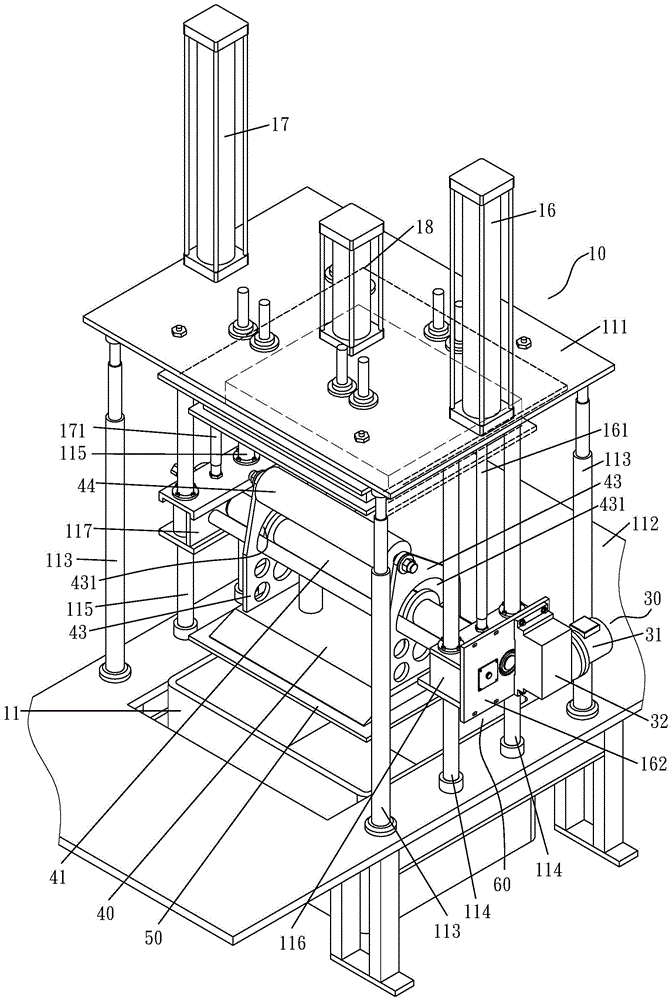

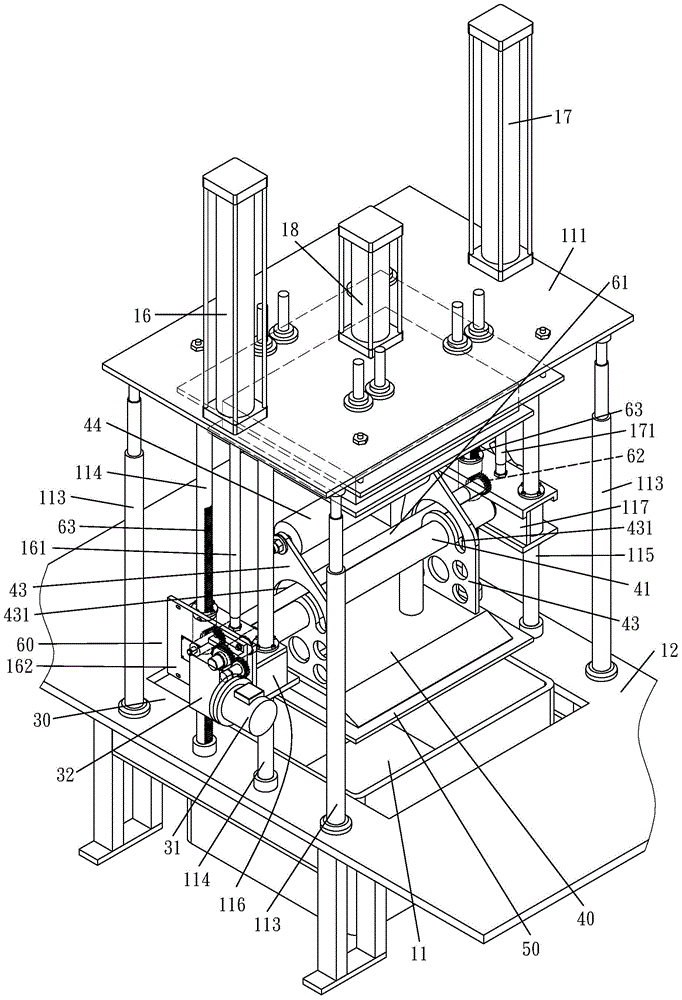

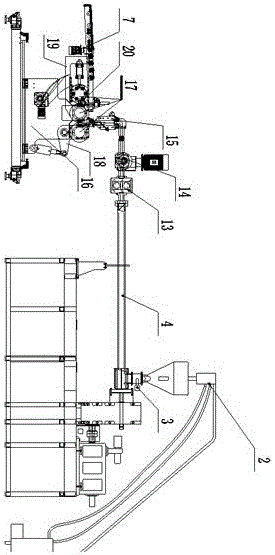

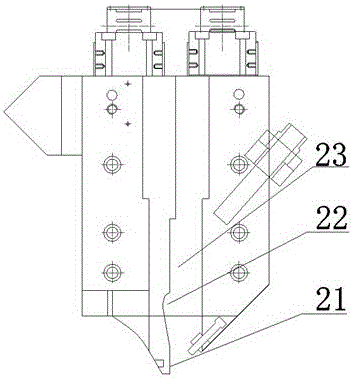

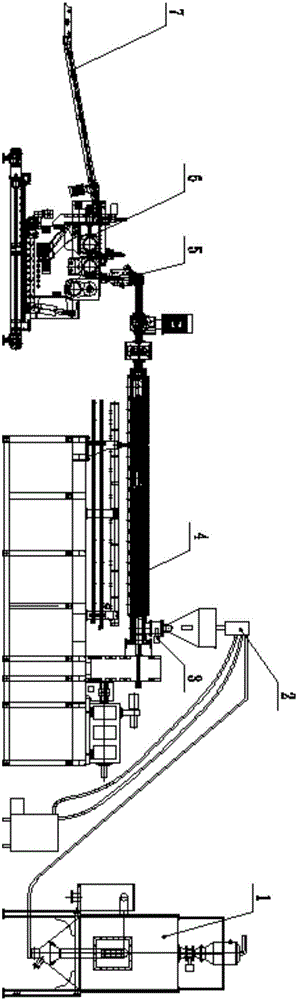

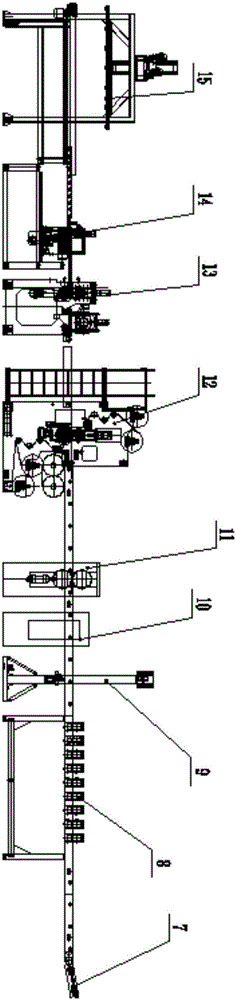

Automatic molding machine for producing pulp moulded products at super small draft angle

ActiveCN104928995AShorten the travel distanceReduce production man-hoursTextiles and paperMan-hourEngineering

The present invention discloses an automatic molding machine for producing pulp moulded products at a super small draft angle, being configured as such that when an overturn means is performing the action of overturning, a centralizing gear of a centralizing means supportively assists in the ascending or descending synchronous movements along a centralizing rack on a centralizing shaft rod so as to enable all shafts to ascend or descend to a defined position in a synchronous and parallel manner, when a pulp absorbing die is conducting up and down movement or overturning movement, due to the supportive assistance between the centralizing gear and the centralizing rack, which will facilitate the realization of a complete and correct die locking as the pulp absorbing die is driven ascended for die locking with an extrusion die, or is driven descended for die locking with a moving die. At the same time, the extrusion die has a descending stroke controlled by a power cylinder body so as to conduct die locking with the ascending pulp absorbing die, which will reduce the move stroke of the pulp die, reduce manufacturing man-hour and manpower, decrease manufacturing cost, and improve qualification rate and excellent quality rate and product competitiveness.

Owner:CHANGZHOU CHENGXIN ENVIRONMENTAL PROTECTION TECH CO LTD

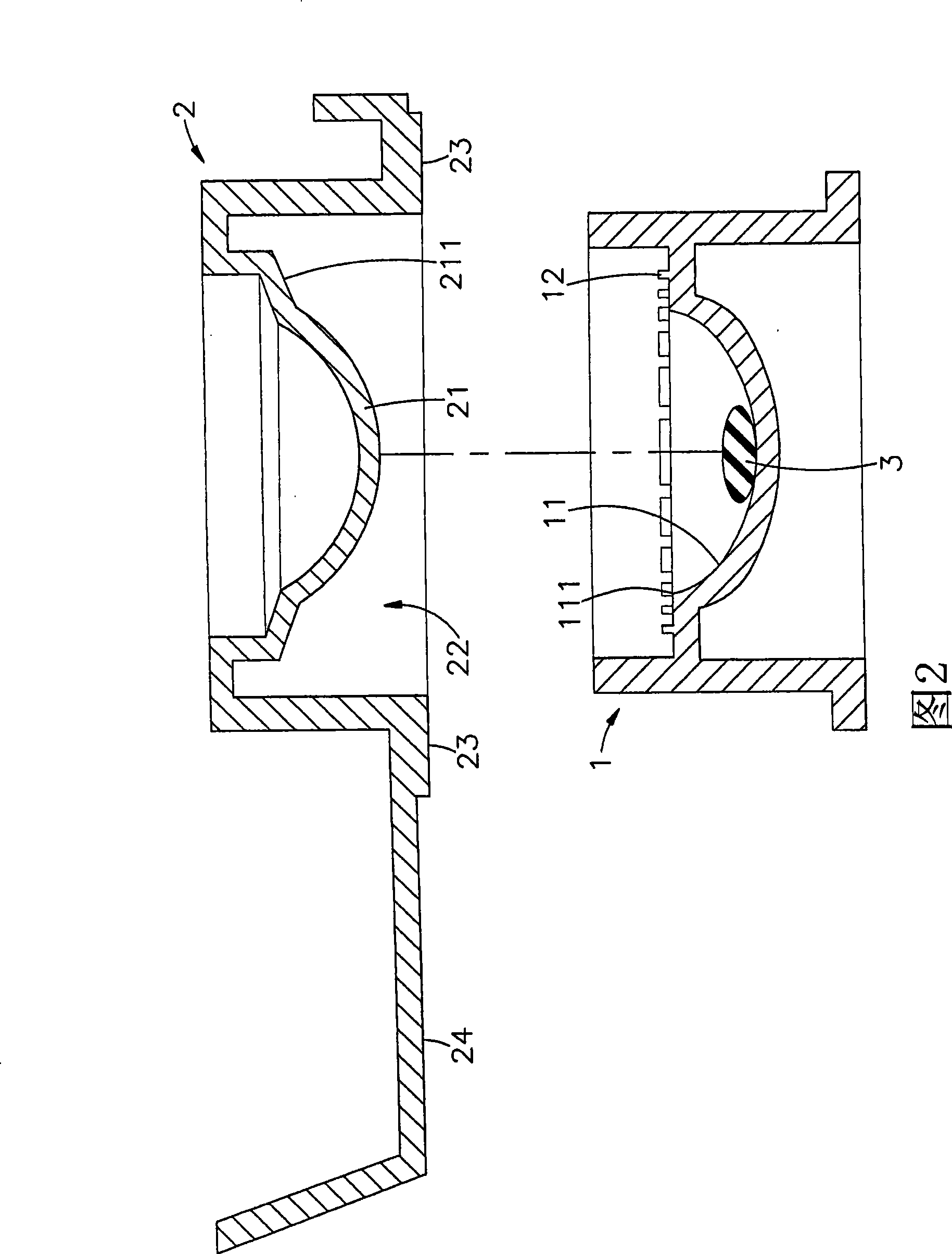

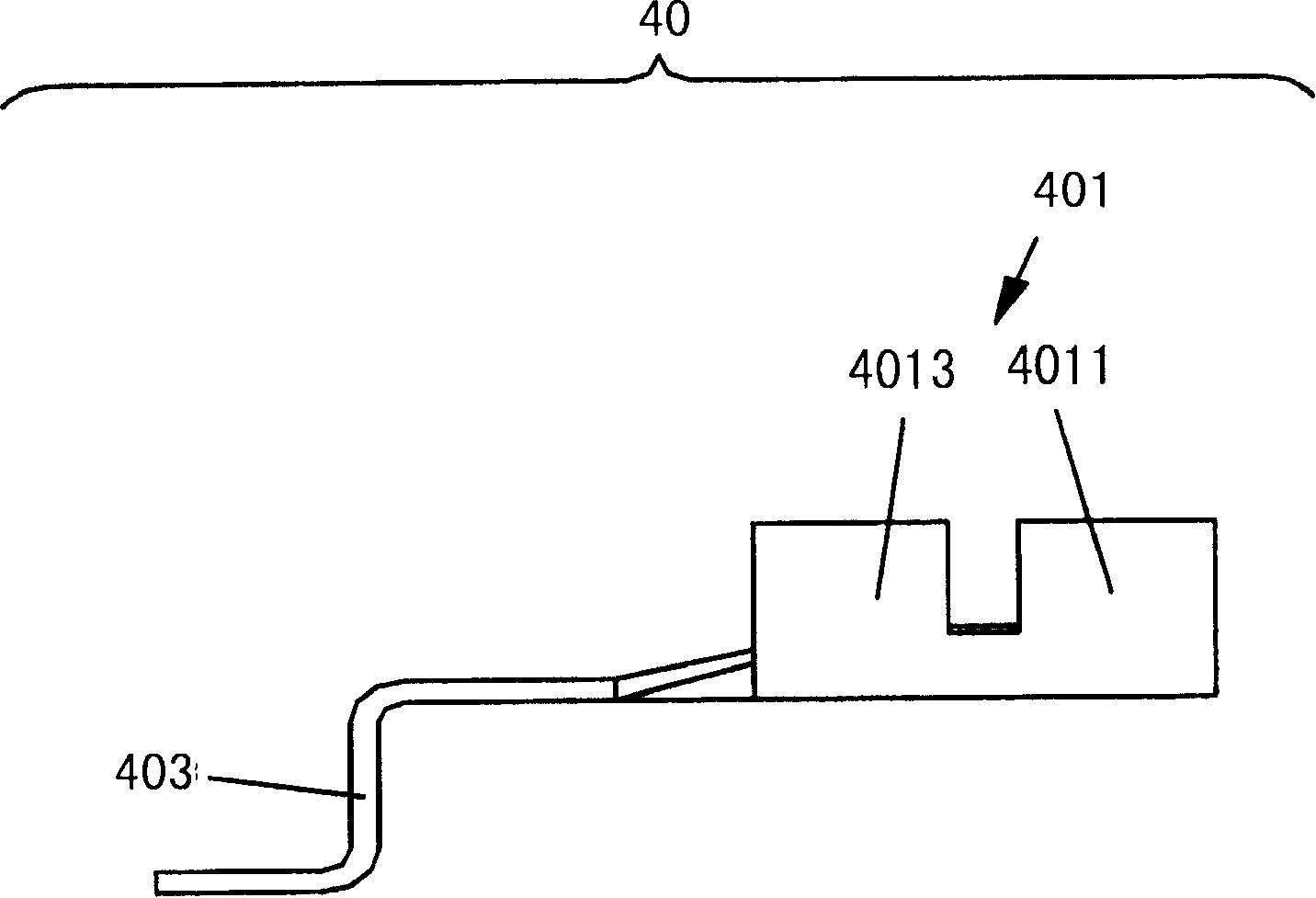

Optical connection structure

An optical connection structure and an optical connection method for achieving translational and rotational positionings in all of the axial direction and directions perpendicular to the axis of an optical fiber by a combination of a small number of components with a small number of optical connection points and simple structures. The optical fiber connection structure comprises an optical fiber,a pressing body with a circular outer cross-section, and an optical member. The optical member includes an optical component, an optical fiber abutment structure, and an optical fiber holding groove.The optical fiber abutment structure is disposed between the optical component and the optical fiber holding groove. The pressing body is disposed perpendicularly to the optical fiber holding groove.The optical fiber is inserted along the optical fiber holding groove until abutting on the optical fiber abutment structure. The pressing member presses the upper surface of the optical fiber toward the bottom of the optical fiber holding groove to optically connect the optical fiber and the optical component.

Owner:RESONAC CORP

Motor rotor and method of manufacturing same

ActiveCN108964310AReduce cogging torqueReduce torque rippleMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineElectrical polarity

The invention relates to a motor rotor and a method of manufacturing the same. The motor rotor (2000) includes a rotor yoke (250) and a plurality of magnetic pole modules (200) disposed on the rotor yoke (250); each magnetic pole module (200) includes a substrate (210), a case (240) and a pair of magnetic pole units (220, 230) with opposite polarities accommodated in an accommodation space formedby the substrate (210) and the case (240); the magnetic pole units (220, 230) in each magnetic pole module (200) are spaced apart from each other by a first distance along the circumferential direction of the rotor yoke (250); and the plurality of magnetic pole modules (200) are mechanically fixed to the rotor yoke (250) through pressing bars (280) and fasteners ( 270). With the motor rotor of themotor rotor of the invention, generator performance (cogging torque and torque ripple), the protection of the magnetic poles, and the mechanical fixation of the magnetic poles can be shared.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

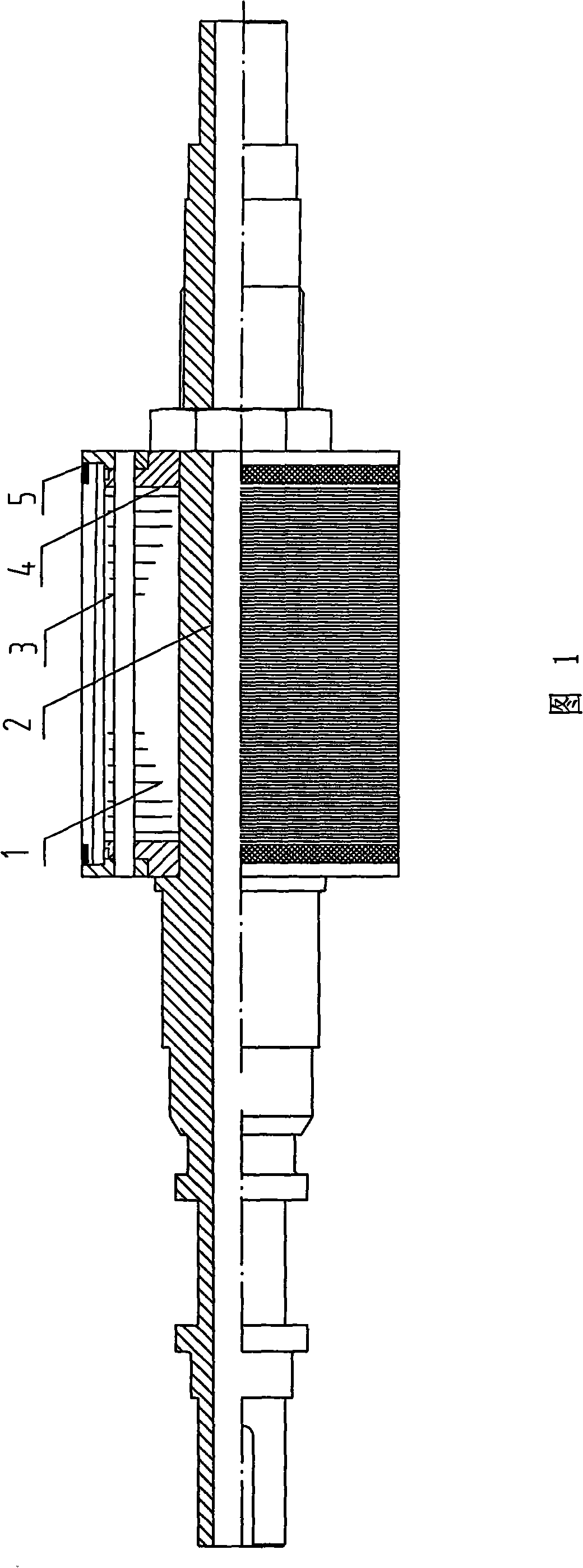

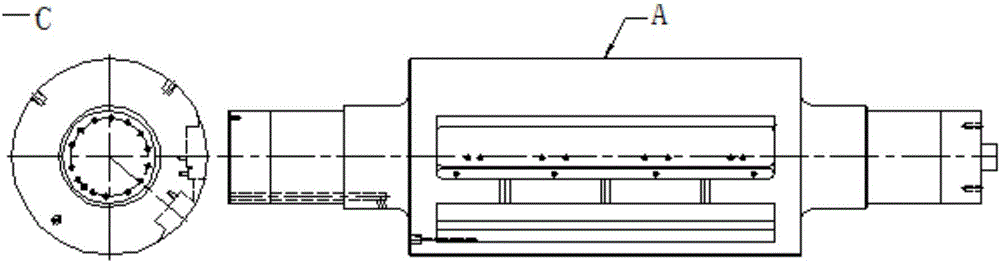

Laminated rotor for high-speed motor

InactiveCN101330232AReduce tangential stressSolve the problem of insufficient strengthWindingsMagnetic circuit rotating partsInterference fitElectrical conductor

The invention provides a laminated rotor used for high-speed motors, which comprises a laminated sheet made from magnetic-permeable silicon steel sheets or magnetic-permeable steel plates and a solid or hollow rotating shaft, wherein press plates are respectively arranged at two ends of the laminated sheet. The laminated sheets are tensioned with the press plates as a whole via a draw bar. Axial air holes are formed on the laminated sheets and the press plates respectively. A groove is formed on the outer circumference of the laminated sheets and used for allowing a winding or a conductor to be embedded therein. The end parts of the winding are fixed by a weftless tape or a steel hoop. The inner hole of the laminated sheets and the outer diameter of the rotating shaft adopt a keyless interference fit. The inner hole of the press plates and the outer diameter of the rotating shaft also adopt a keyless interference fit. The interference value is determined based on the actual interference fit and stress and is different to the products with different specifications. The linear speed of the laminated rotor is as high as more than 200m / s. The iron loss of the rotor is reduced while the rotational speed of the motor is increased, that is, the power density of the motor is increased. Additionally, compared with the solid rotor, the manufacturing time and cost of the laminated rotor are greatly reduced. The laminated rotor is suitable for the high-speed asynchronous motor as well as the high-speed non-salient-pole synchronous motor and the non-commutator direct current motor.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

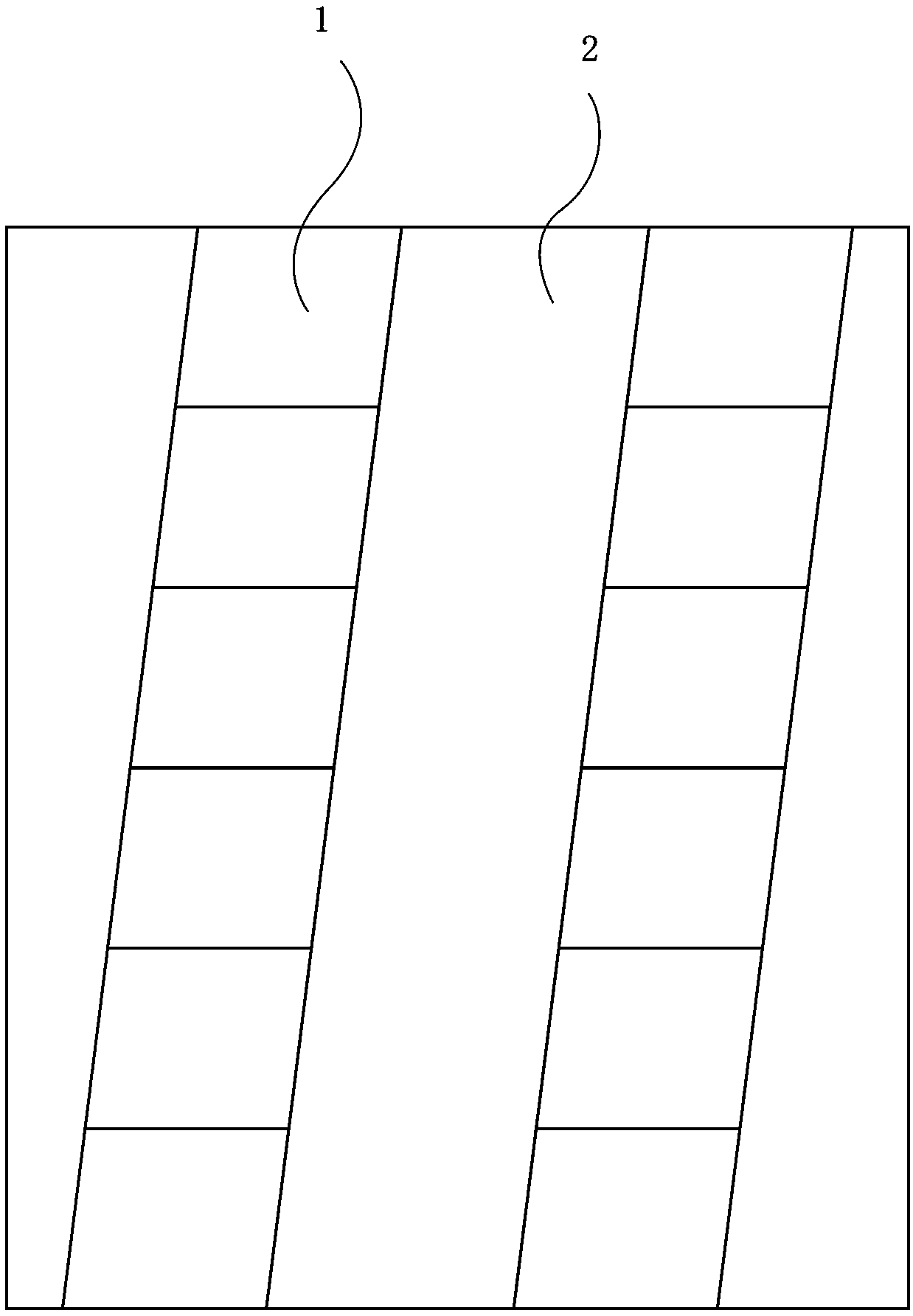

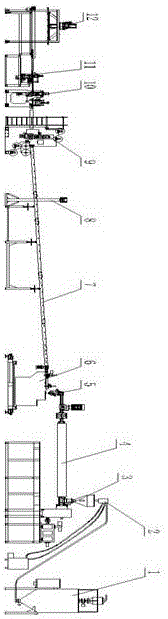

Silk-screen-printing-free light guide plate online production process and production device

InactiveCN106671455ALow costReduce production man-hoursOptical articlesRefractive indexComposite plate

The invention discloses a silk-screen-printing-free light guide plate online production process and production device. During production, an optical granular raw material is prepared by selecting a PMMA, PS, PC, MS, PET or PP material of which the light transmittance is 87-90% and the refractive index is 1.53-1.62; and inorganic silicon or nano barium sulfate is selected as a dispersing agent. The process comprises the following steps: material selection; drying; material supply; hot melting; extrusion calendaring molding; cooling and detection; and film covering, cutting and stacking. By adoption of the silk-screen-printing-free light guide plate online production process and production device provided by the invention, multi-layer optical composite plates of various sizes and materials can be effectively produced; and the production equipment cost and the material requirements are low, the light transmittance and the precision of each finished product are high, and the practical value is very high.

Owner:FUJIAN ZHENGDE OPTOELECTRONICS TECH CO LTD

Online hot pressed composite panel production equipment and production process thereof

InactiveCN106696298ALow costReduce production man-hoursOptical articlesTemperature controlTransmittance

The invention discloses online hot pressed composite panel production equipment which comprises a drier, a dedustor, a distributor, a single screw extruder, a full-automatic multi-layer coextrusion clothes rack die head, a multi-roll calender, a slow cooling rack, a defect detector, a thickness detector, a temperature equalizer, a precise temperature hot press, a traction mulch applicator, an edge cutting traction machine, a transverse cutting machine and a manipulator. A production process of the online hot pressed composite panel comprises the specific steps: S1, material selection; S2, drying; S3, material supply; S4, hot melting; S4, extrusion calendaring forming; S6, cooling and detection; S7, temperature control and hot pressing; and S8, tailoring and stacking. According to the online hot pressed composite panel production equipment and the production process thereof, one material is used and is primarily calendered and formed, so that the manufacturing process is simple, the production efficiency is high, the overall cost is low, the environment is little in influence, and the product is good in transmittance.

Owner:FUJIAN ZHENGDE OPTOELECTRONICS TECH CO LTD

Method for producing molybdenum component for magnetron cathode

InactiveCN101097825AUniform crystallizationGood consistency of densityCold cathode manufactureWire rodMiddle frequency

The invention discloses a method for producing molybdenum element of cathode of magnetron, mainly comprising that first, fills molybdenum powder into a special mould, to be compressed into a molybdenum end cap blank, then sinters the molybdenum end cap blank in inertia gas in a middle-frequency sensitive sinter furnace, while the sinter temperature is between 1650-1800Deg. C, and the sinter time is 2-6h, to obtain an upper molybdenum end cap and a lower molybdenum end cap which bent resistance strength is higher than 35kg / mm2, second, uses laser welding to weld the upper and lower molybdenum end caps respectively with an annular welding sheets together, third, welds the upper molybdenum end cap welded with the annular welding sheet with a central molybdenum lead wire rod together, and welds the lower molybdenum end cap welded with the annular welding sheet with a side molybdenum lead wire rod together. The molybdenum produced by The invention can reduce the fraction defective in welding process, reduce the production time and cost.

Owner:顾进跃

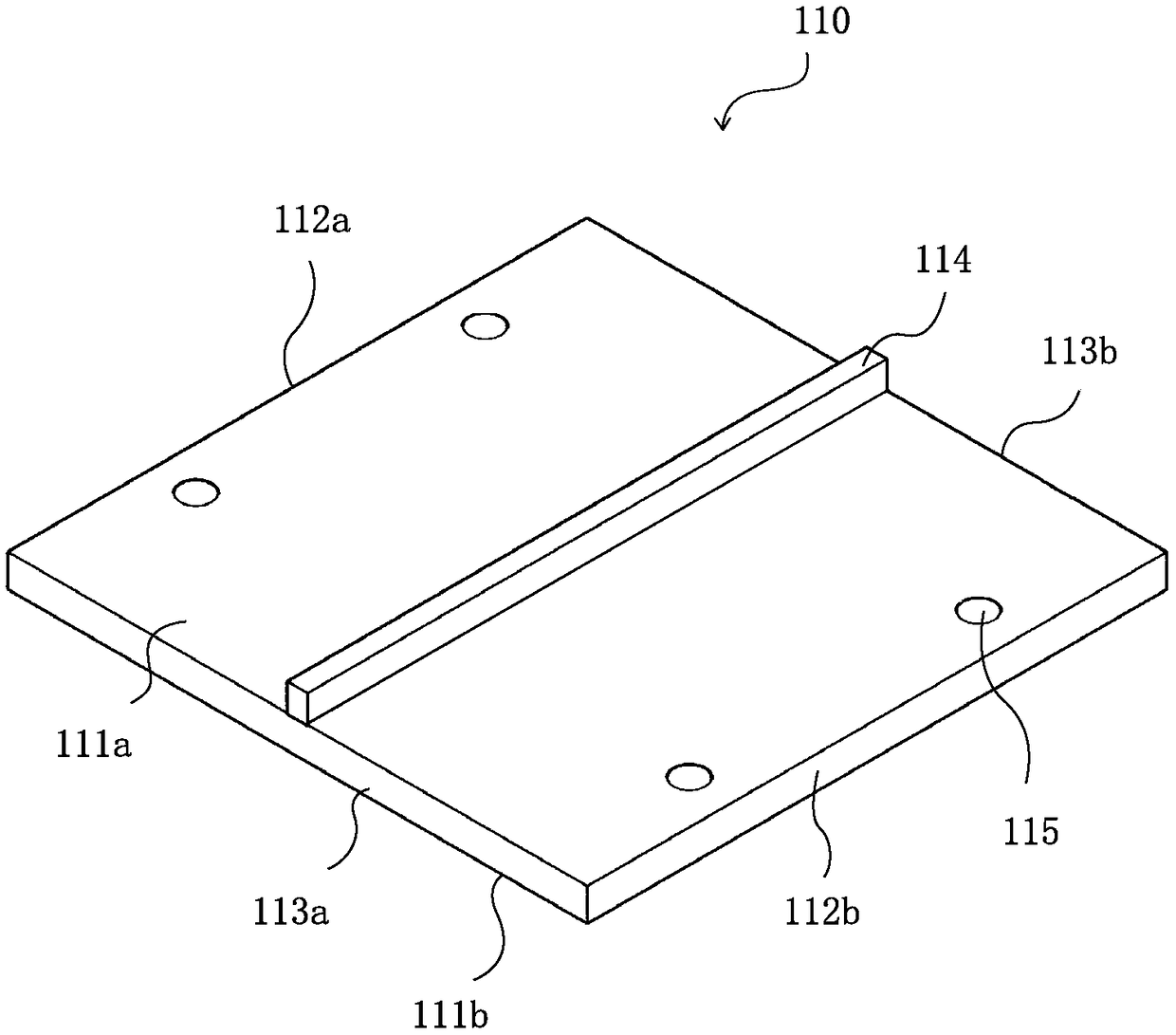

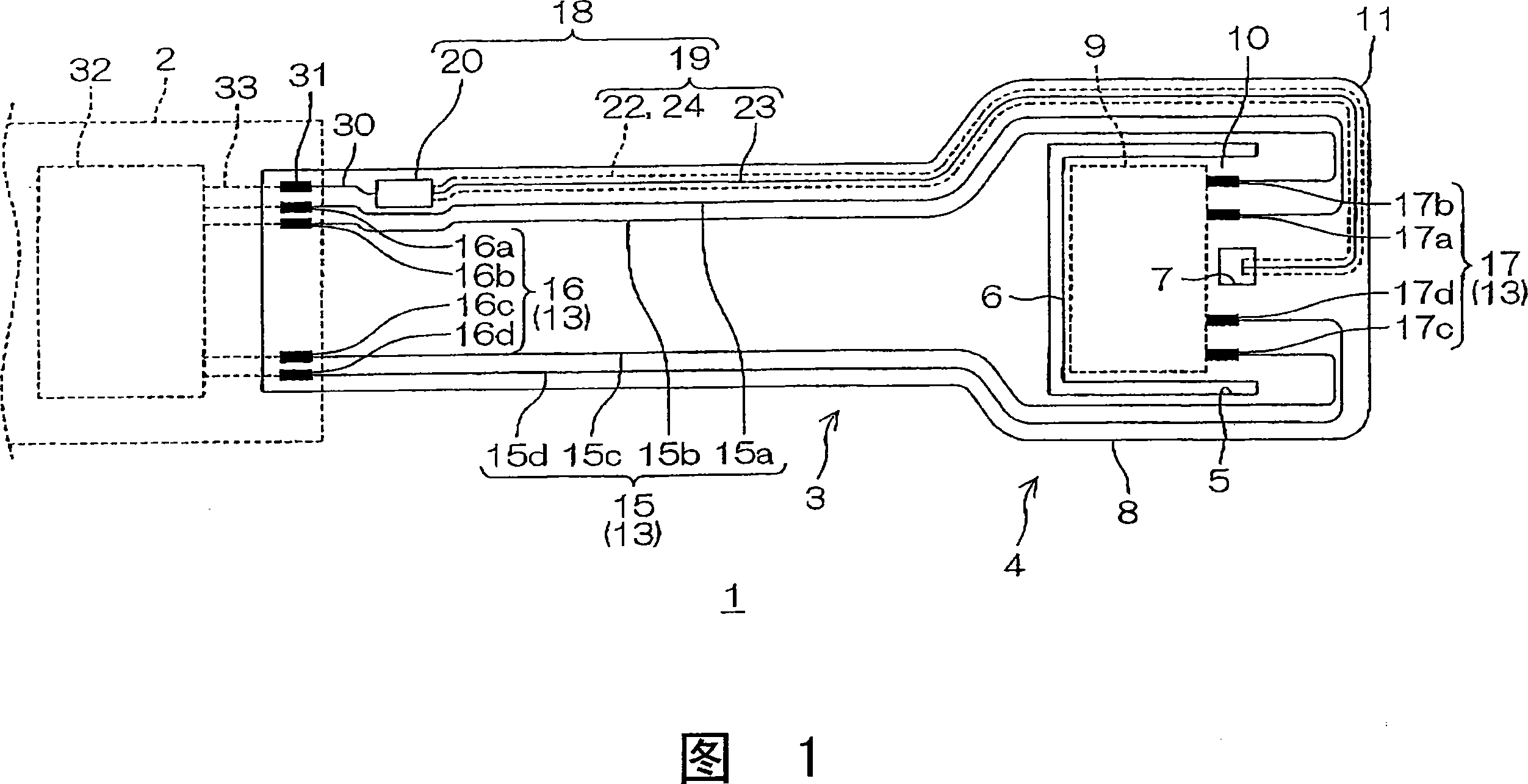

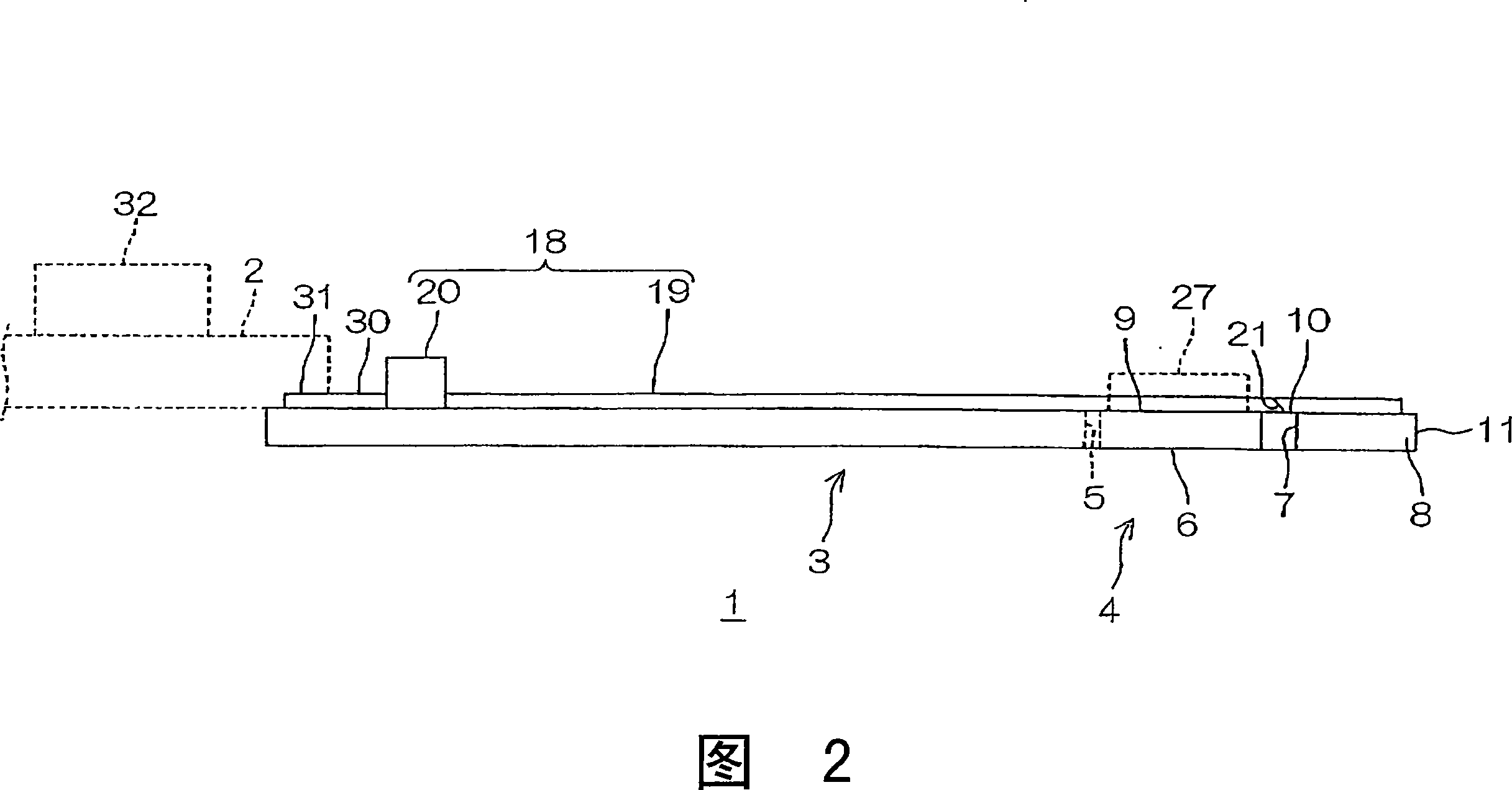

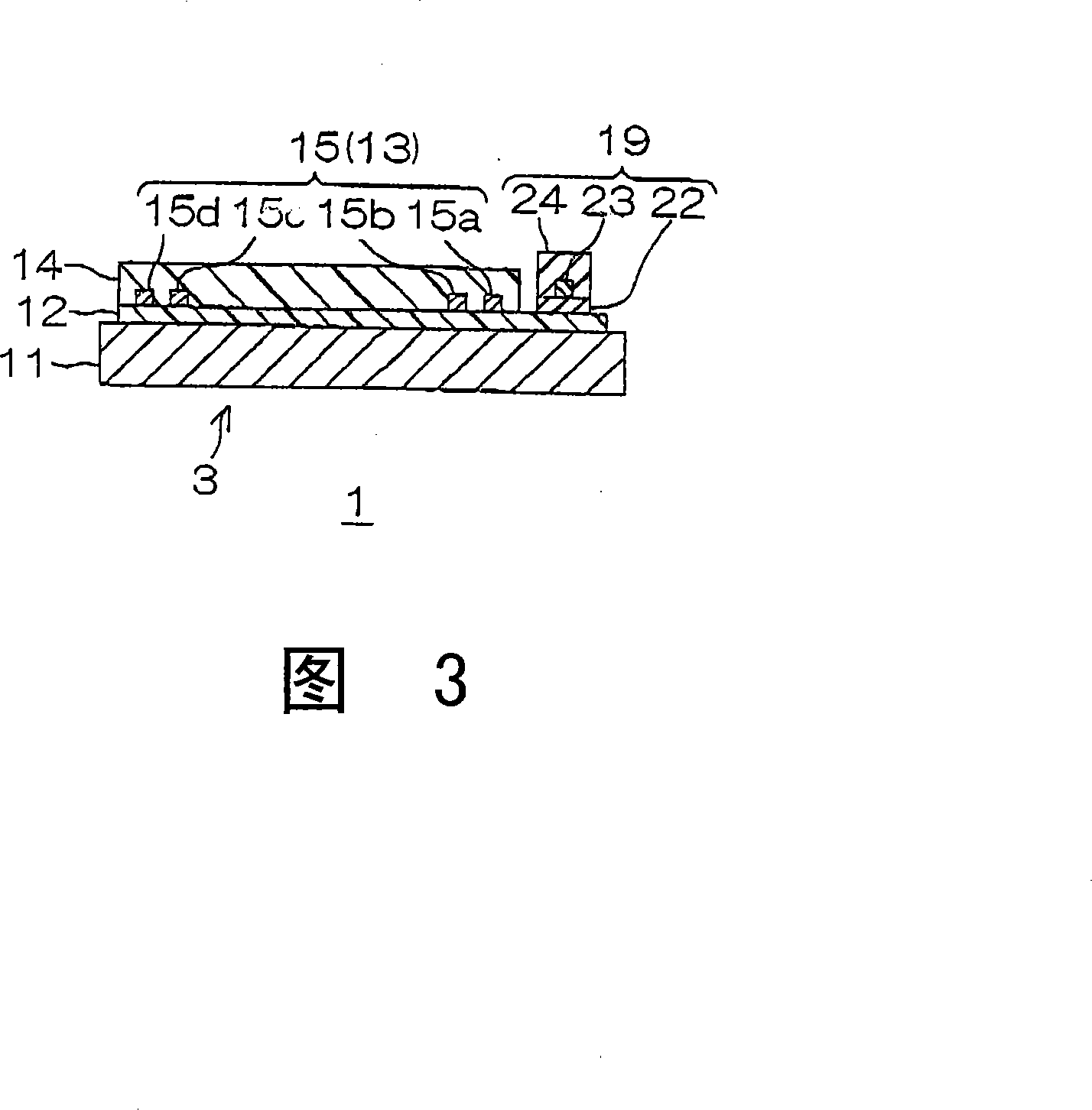

Suspension board with circuit and producing method thereof

ActiveCN101188113AImprove manufacturing efficiencyLow manufacturing costArm with optical waveguideLight beam reproducingEngineeringElectrical conductor

A suspension board with circuit includes a metal supporting board, an insulating base layer formed on the metal supporting board, a conductive pattern formed on the insulating base layer, an insulating cover layer formed on the insulating base layer so as to cover the conductive pattern, and an optical waveguide.

Owner:NITTO DENKO CORP

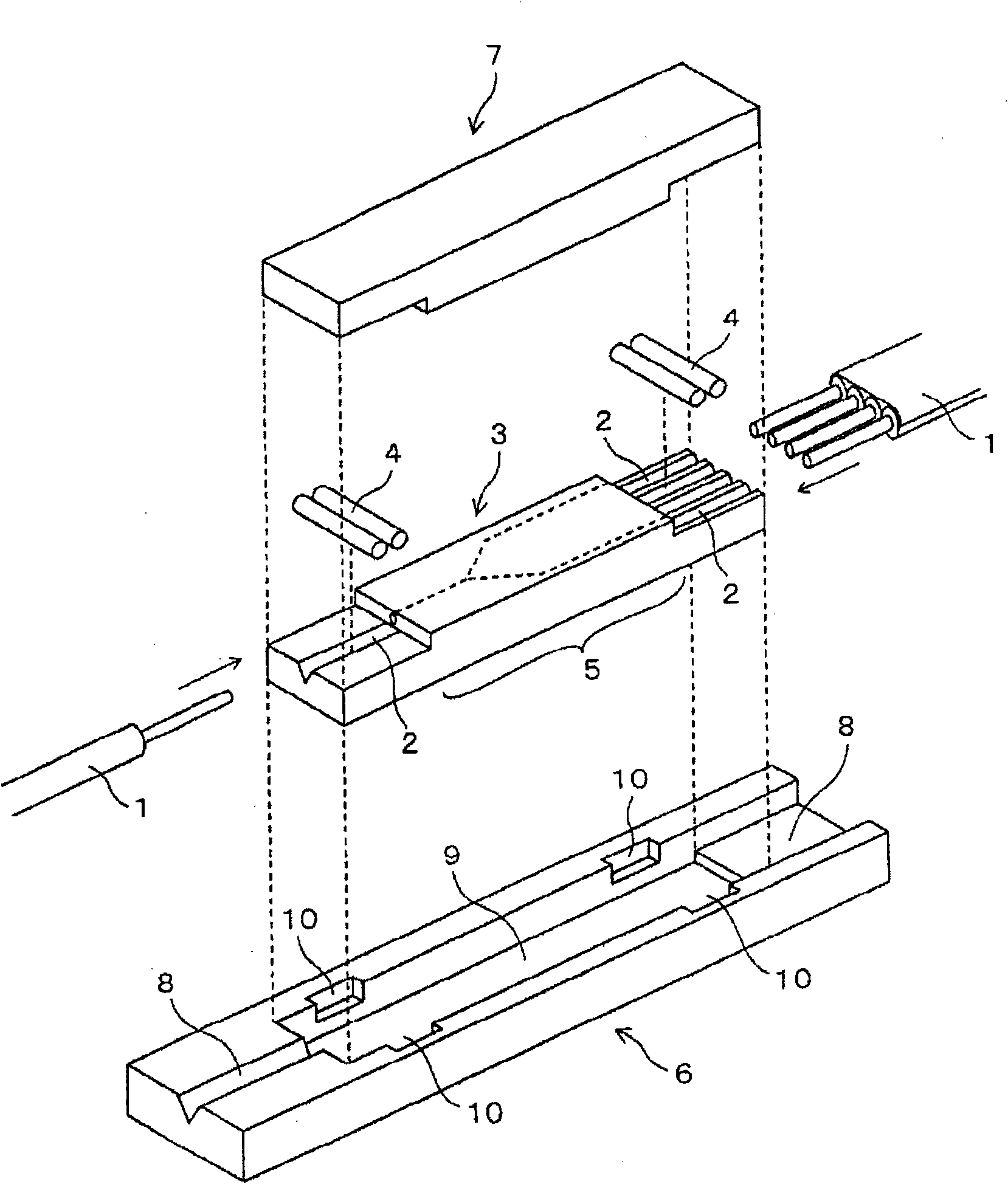

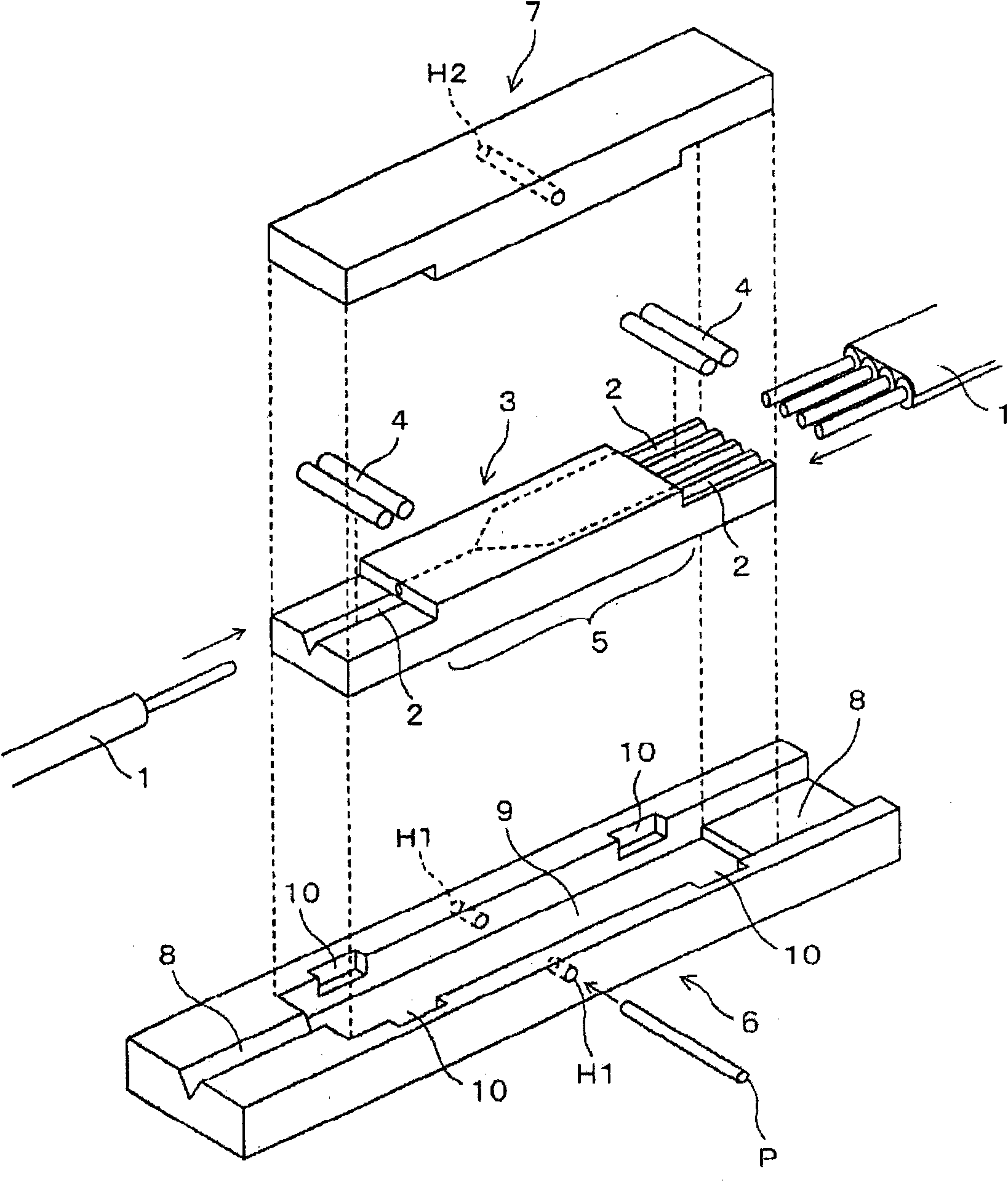

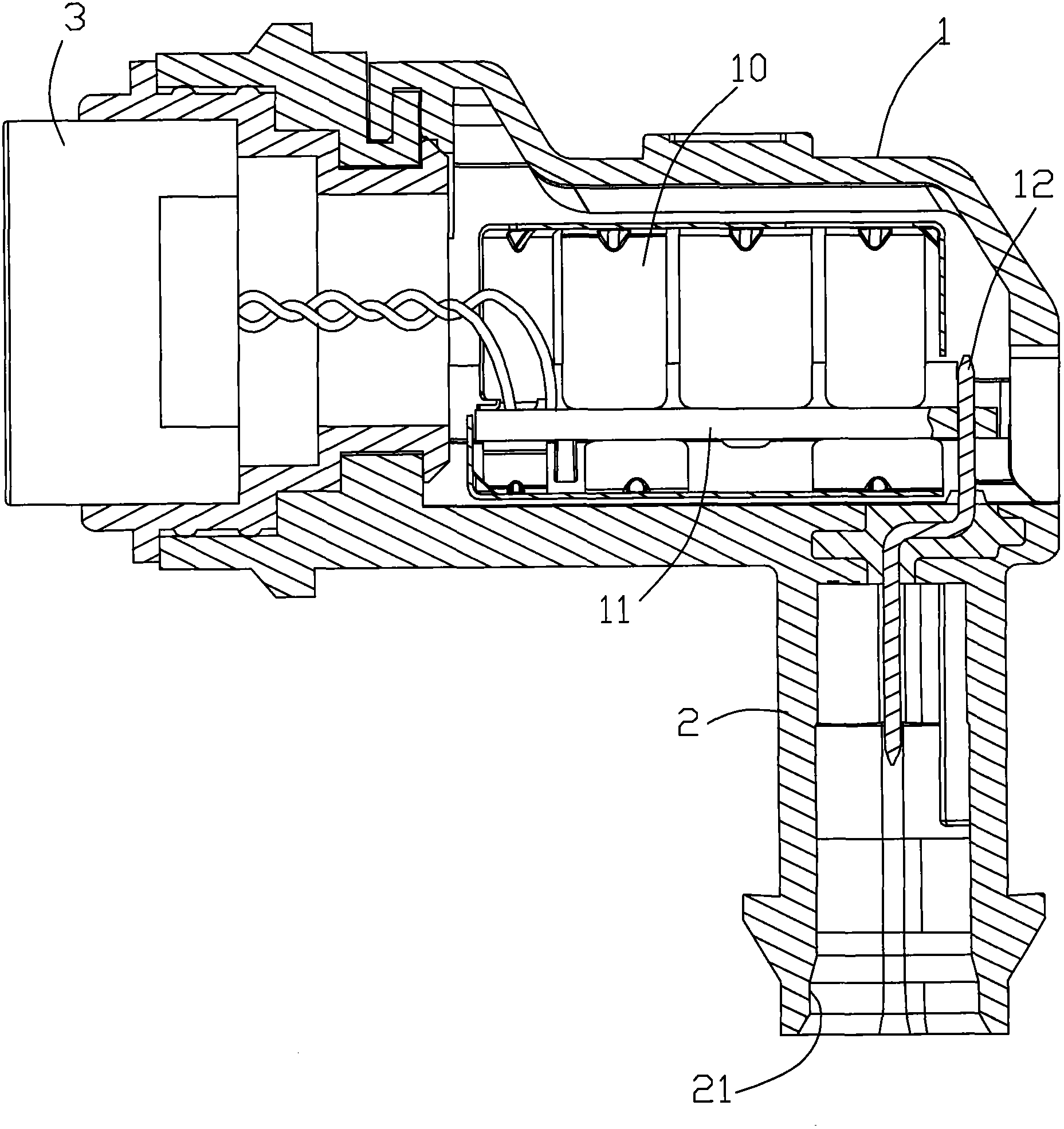

Apparatus and method for fixing coaxial cable yarn in aerial device

InactiveCN101207232AAvoid destructionImprove production yieldAntenna supports/mountingsConnections effected by permanent deformationYarnCoaxial cable

The invention relates to a device for fixing a coaxial cable in an antenna device and the method thereof. The coaxial cable is firstly combined in advance with the fixing device, and then the coaxial cable with the fixing device is arranged on basis material with the antenna device, and the fixing device and the ground plane on the basis material are finally welded to realize electrical property connection, the direct welding of the coaxial cable is avoided in order not to damage the structure of the coaxial cable due to the high temperature; therefore, the product yield rate of the antenna device is increased, and the manufacturing cost is reduced.

Owner:连展科技电子(昆山)有限公司

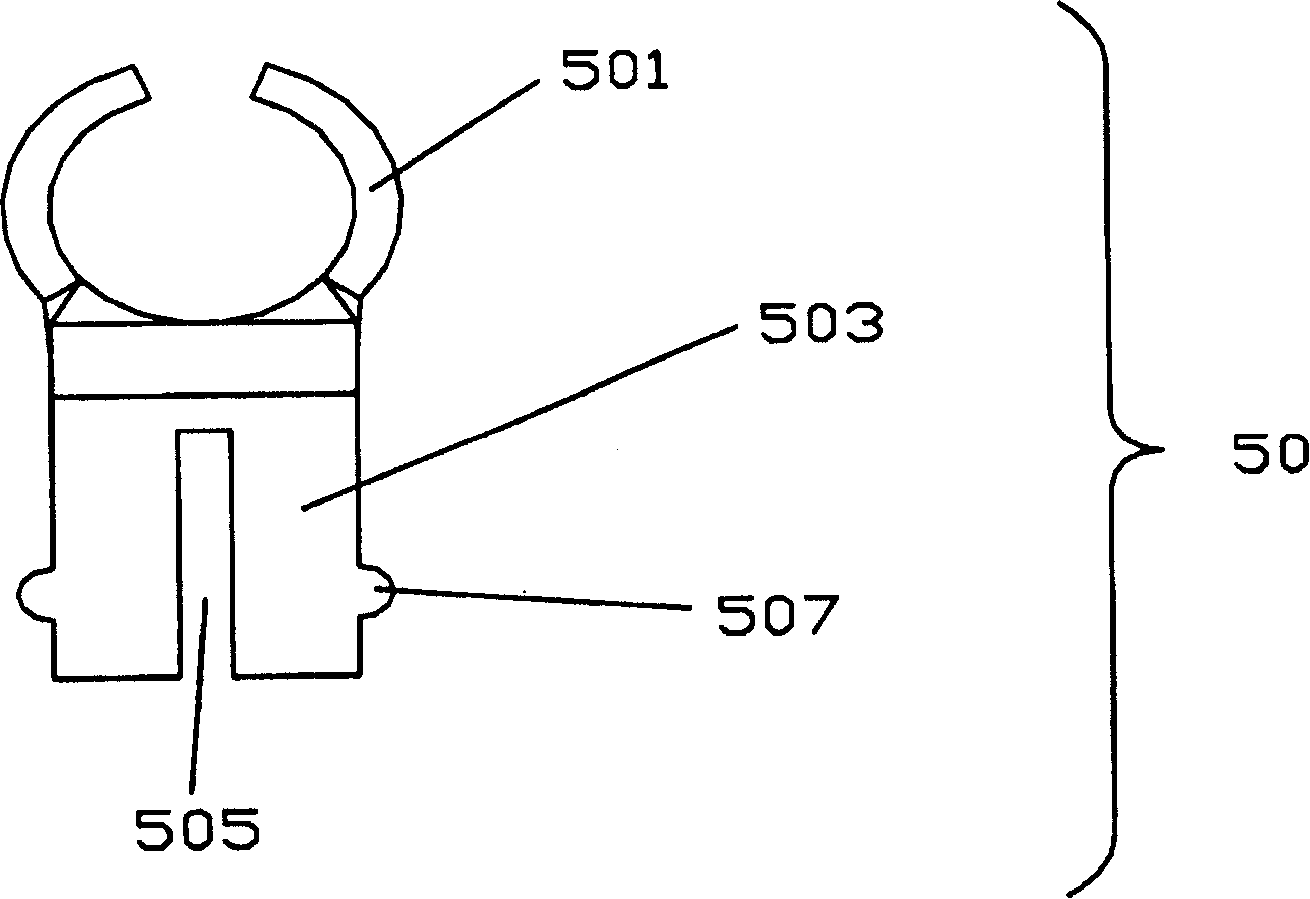

Ultrasonic sensor device

InactiveCN103256950ALess welding workReliable electrical connectionConverting sensor ouput using wave/particle radiationUltrasonic sensorEngineering

The utility model discloses an ultrasonic sensor device, which comprises a hollow shell, a connecting tube part connected with the hollow shell, five pins, a sensor and a circuit board, wherein one end of each pin is positioned at a first opening of the hollow shell, the other ends of two pins are positioned at a second opening of the hollow shell, and the other end of the other three pins are extended into the connecting tube part and positioned at a third opening of the connecting tube part; the sensor is provided with an opening, and the side wall of the sensor is provided with a ground wire hole; the sensor is fixed at the second opening of the hollow shell, so that the other end of one of the pins extended to the second opening extends into the opening and is electrically connected with a piezoelectric patch, and the other end of the other pin extended to the second opening is inserted into the ground wire hole; and the circuit board is arranged on the first opening of the hollow shell and electrically connected with one end of each pin.

Owner:TUNG THIH ELECTRONICS

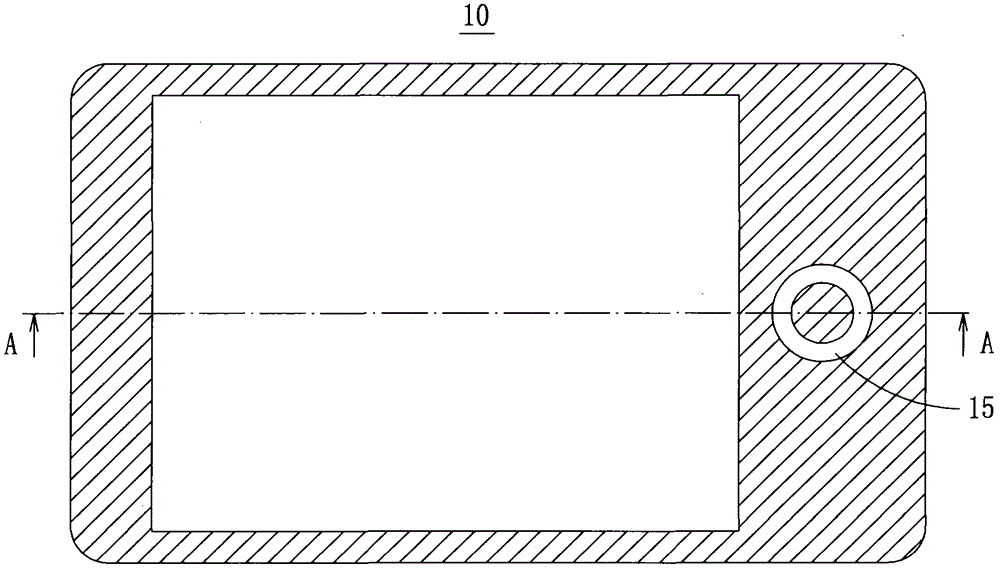

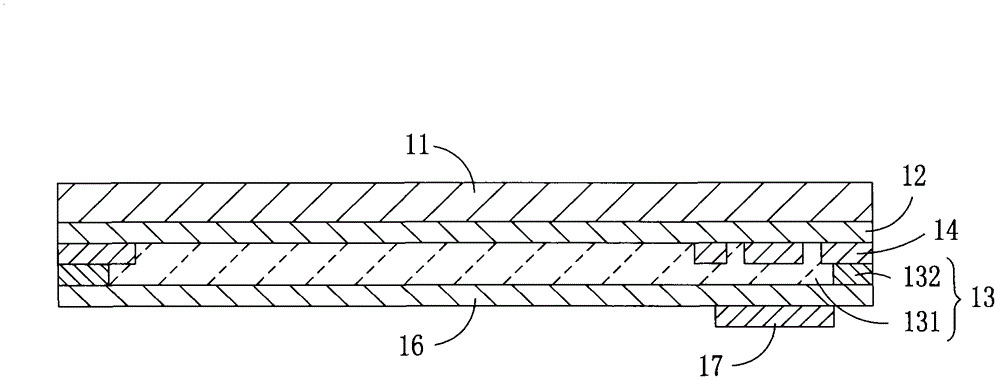

Touch panel structure and manufacture method thereof

InactiveCN103064544AReduce manufacturing costReduce production man-hoursInput/output processes for data processingComputer scienceTouch panel

The invention relates to a touch panel structure and a manufacture method thereof. The touch panel structure comprises a substrate, a decoration layer, a touch control unit and at least one first ink layer, wherein the decoration layer and the touch control unit is arranged on one side of the substrate, the decoration layer is clamped between the touch control unit and the substrate, the decoration layer is provided with a visual area and at least on patter arrangement area, the touch control unit comprises a transparent sensing element extending to be covered on the pattern arrangement area, the first ink layers are arranged on the touch control unit and provided with at least one pattern, and the first ink layers correspond to the pattern arrangement area. Thus, cost and labor hours for forming patterns of the touch panel are reduced.

Owner:WINTEK CHINA TECH LTD +1

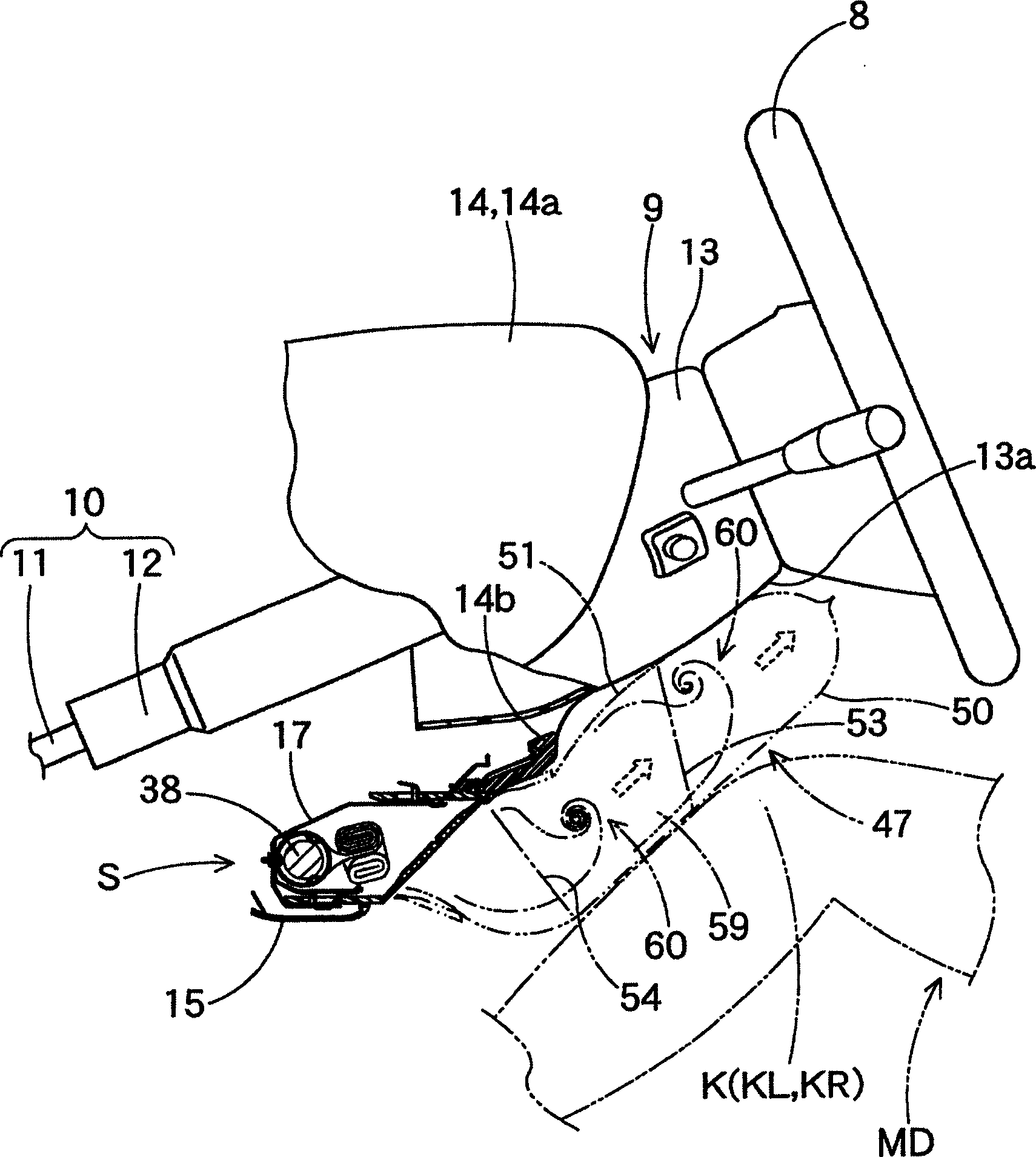

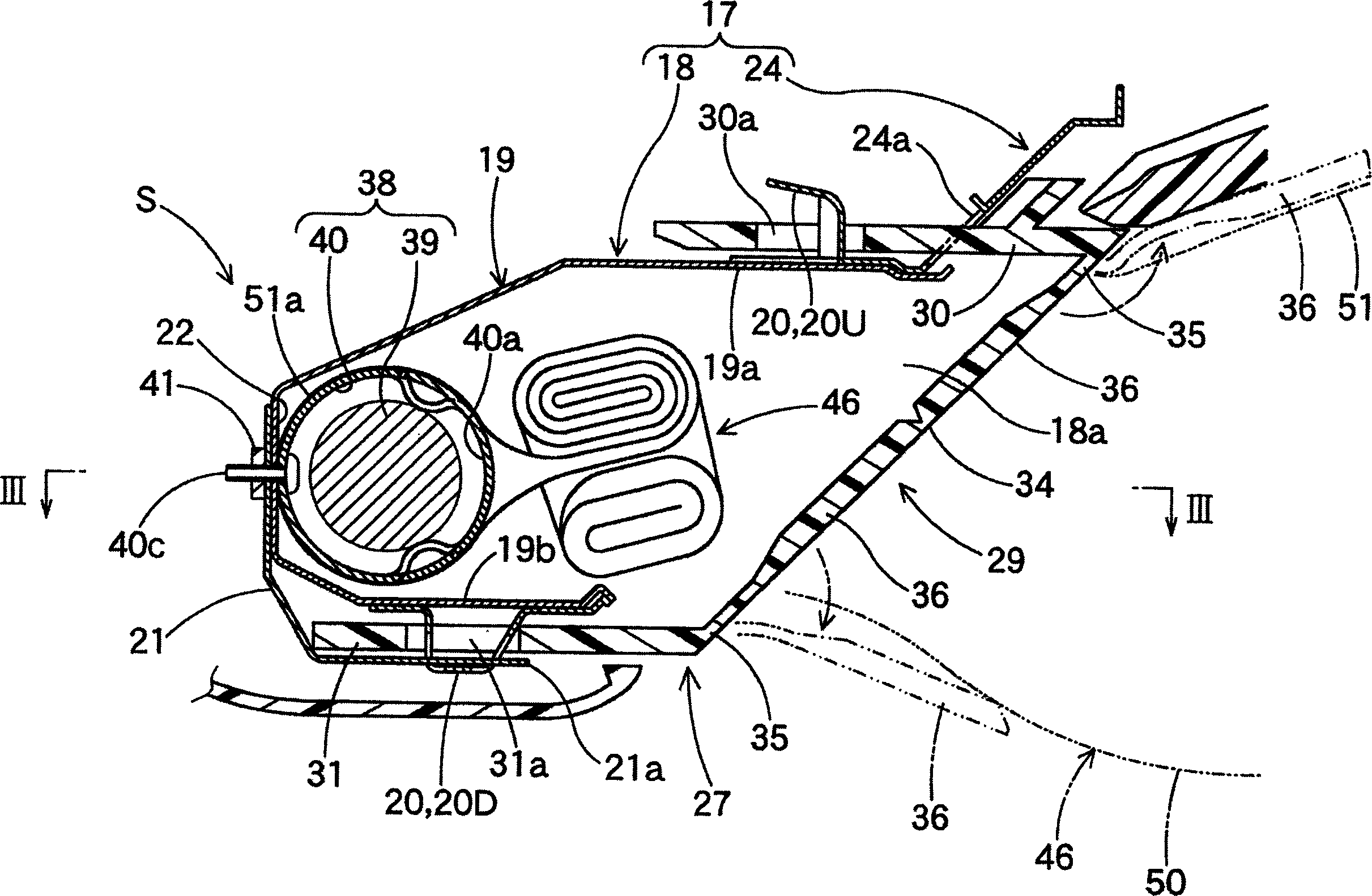

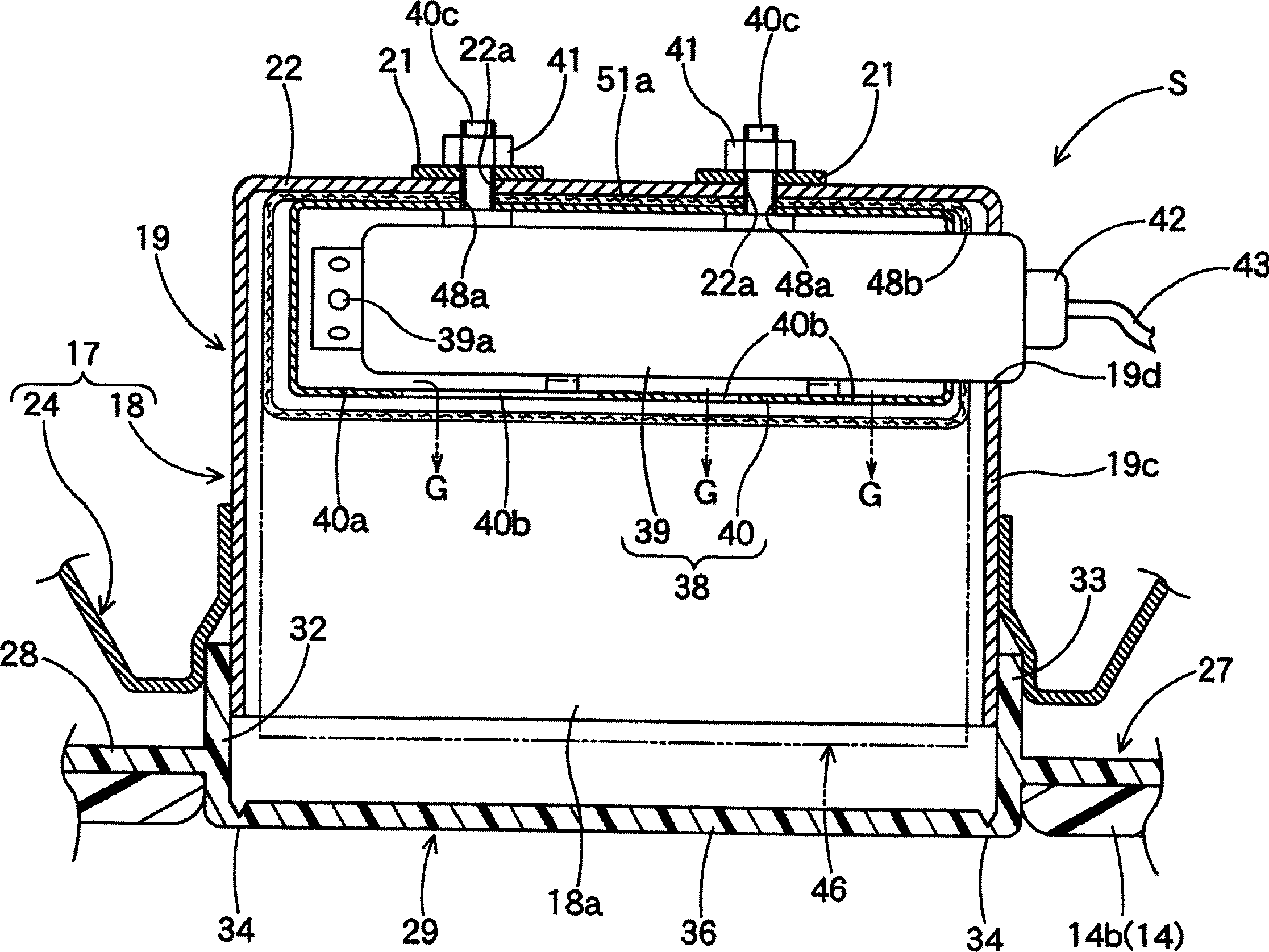

Airbag for protecting knee

InactiveCN1796188AReduce production man-hoursLow costPedestrian/occupant safety arrangementEngineeringAirbag

The present invention relates to an air bag for protecting knee portion of passenger. Said air bag can be folded, and can be received in the front side of knee portion of the passenger taken seat. Said air bag includes said air bag main body and tie band, and said air bag main body contains air channel and air flowing hole. Said invention also provides the concrete structure of said air bag main body and its application method.

Owner:TOYODA GOSEI CO LTD

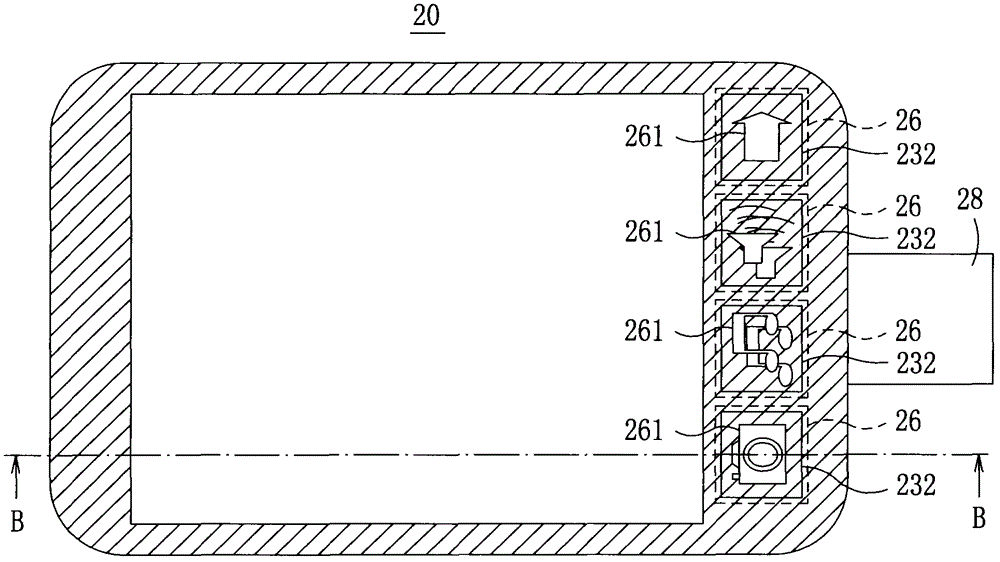

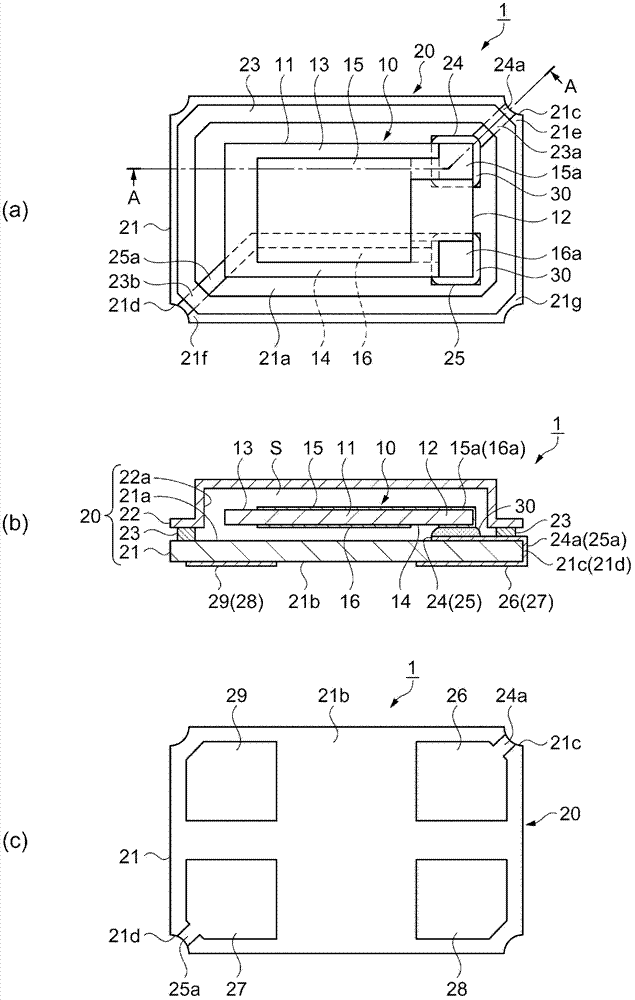

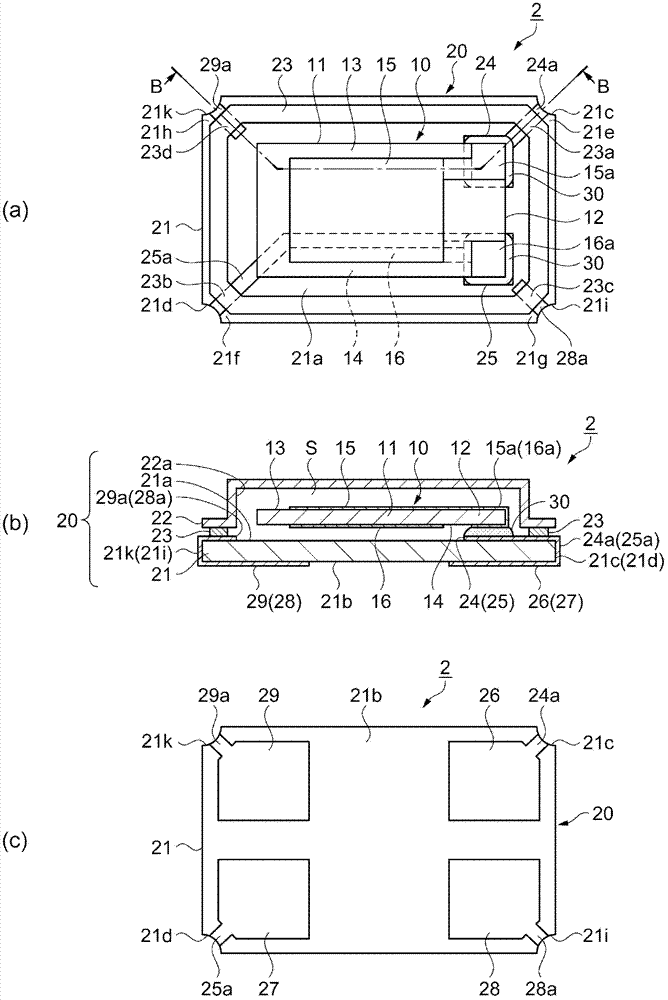

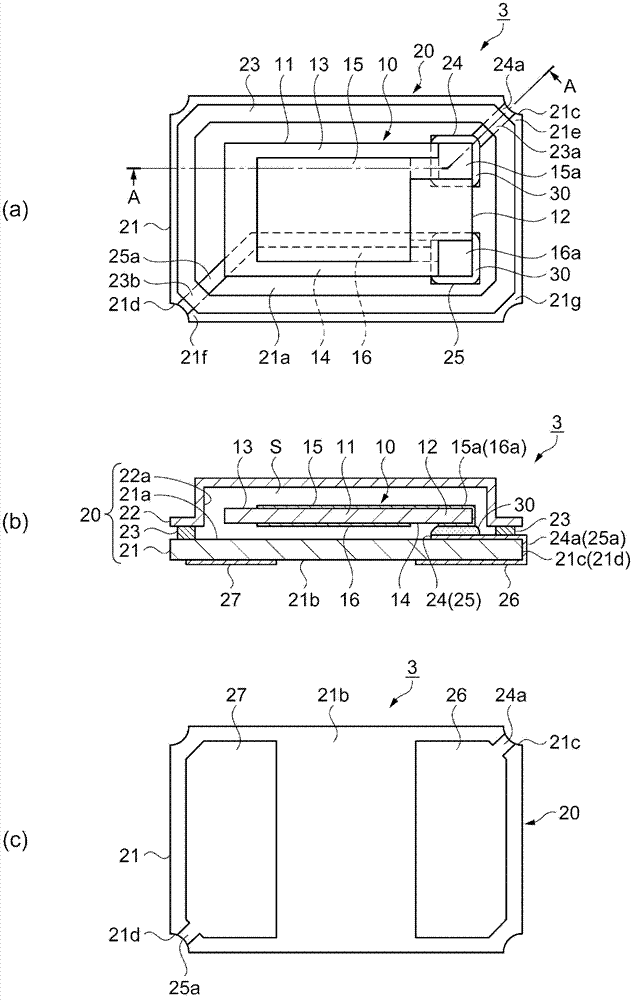

Base substrate, resonator, oscillator, and electronic device

ActiveCN102739185AReduce production man-hoursLow costImpedence networksSemiconductor/solid-state device detailsEngineeringAlloy

The invention provides a base substrate, a resonator, an oscillator, and an electronic device, which guarantees tightness and realizes low cost. A package (20) of a quartz resonator (1) includes a tabular base substrate (21), a base material of which is a single layer, a lid section (22) that has a recess (22a) and covers the base substrate (21), and a bonding material (23) provided over the entire periphery of one principal plane (21a) of the base substrate (21) and including low-melting glass for bonding the base substrate (21) and the lid section (22). Internal electrodes (24, 25) are provided on the one principal plane (21a) of the base substrate (21). External electrodes (26, 27, 28, 29) are provided on the other principal plane (21b) of the base substrate (21). A wire (24a) contains an Ag-Pd alloy having a glass component and crosses the bonding material (23) on the one principal plane (21a).

Owner:SEIKO EPSON CORP

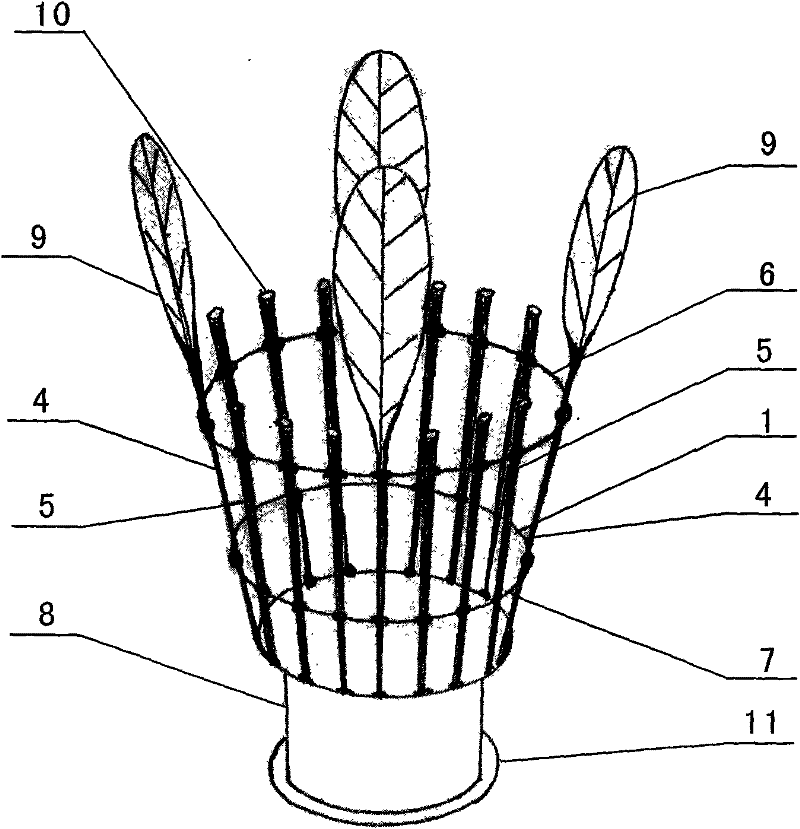

Badminton

InactiveCN102527008AReduce production man-hoursGreat increase in work efficiencySport apparatusEngineeringPlastic materials

The invention discloses badminton, and particularly relates to badminton which is formed by combining detachable feathers, a badminton head and a connecting frame with the artificial feathers, wherein the connecting frame with the artificial feathers consists of vertical stems with the artificial feathers, vertical stems with feather implanting holes, connecting ribs and a badminton head clamping base, and is machined by using a high-strength plastic material; the detachable feathers comprise feather leaves and feather roots at lower ends and can be manufactured by natural feathers or non-natural materials artificially; and the badminton head comprises an outer badminton head body and a clamping base hole. According to the badminton manufactured by the technology, complex processes can be saved, the production efficiency can be improved, and the cost can be reduced; the sizes, shapes and weights of the badminton are consistent, and the motion performance of the badminton is improved; and particularly, the phenomena of the breakage of feather leaves and feather stems and looseness of weaved strings in the conventional badminton are reduced obviously, the service life of the badminton is prolonged, and the cost performance is improved.

Owner:欧明华

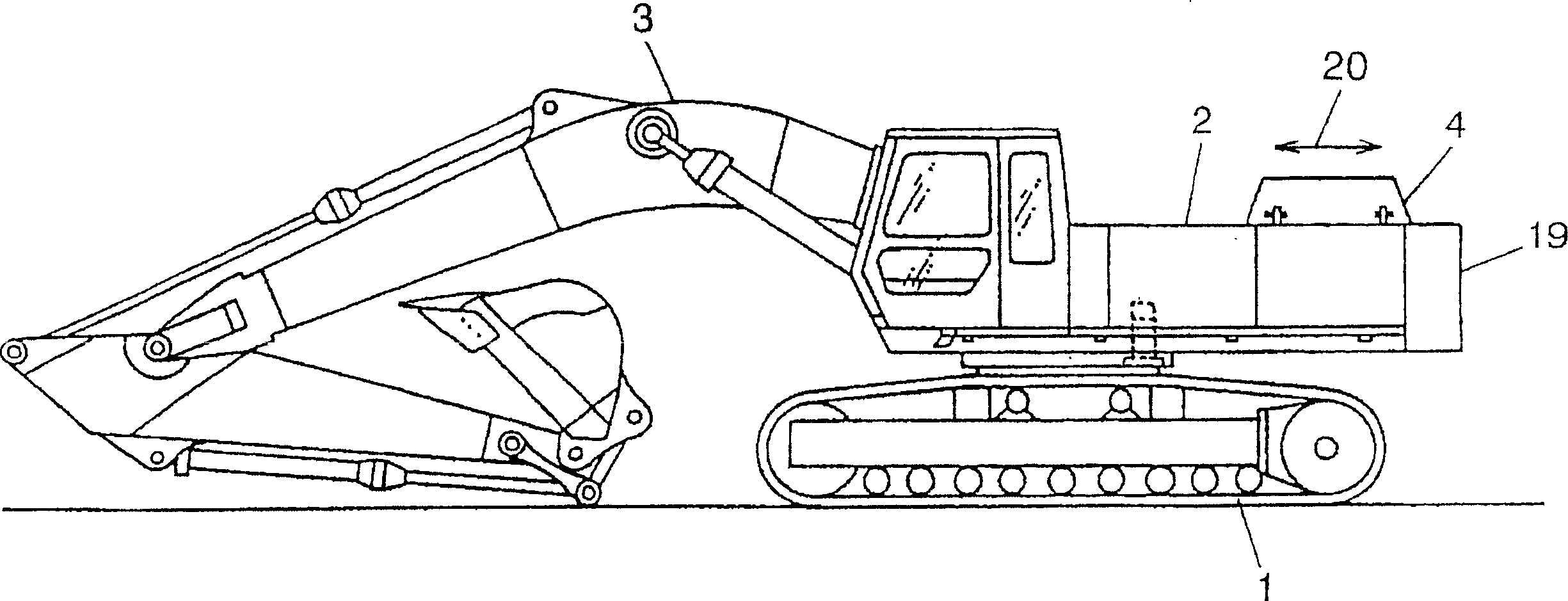

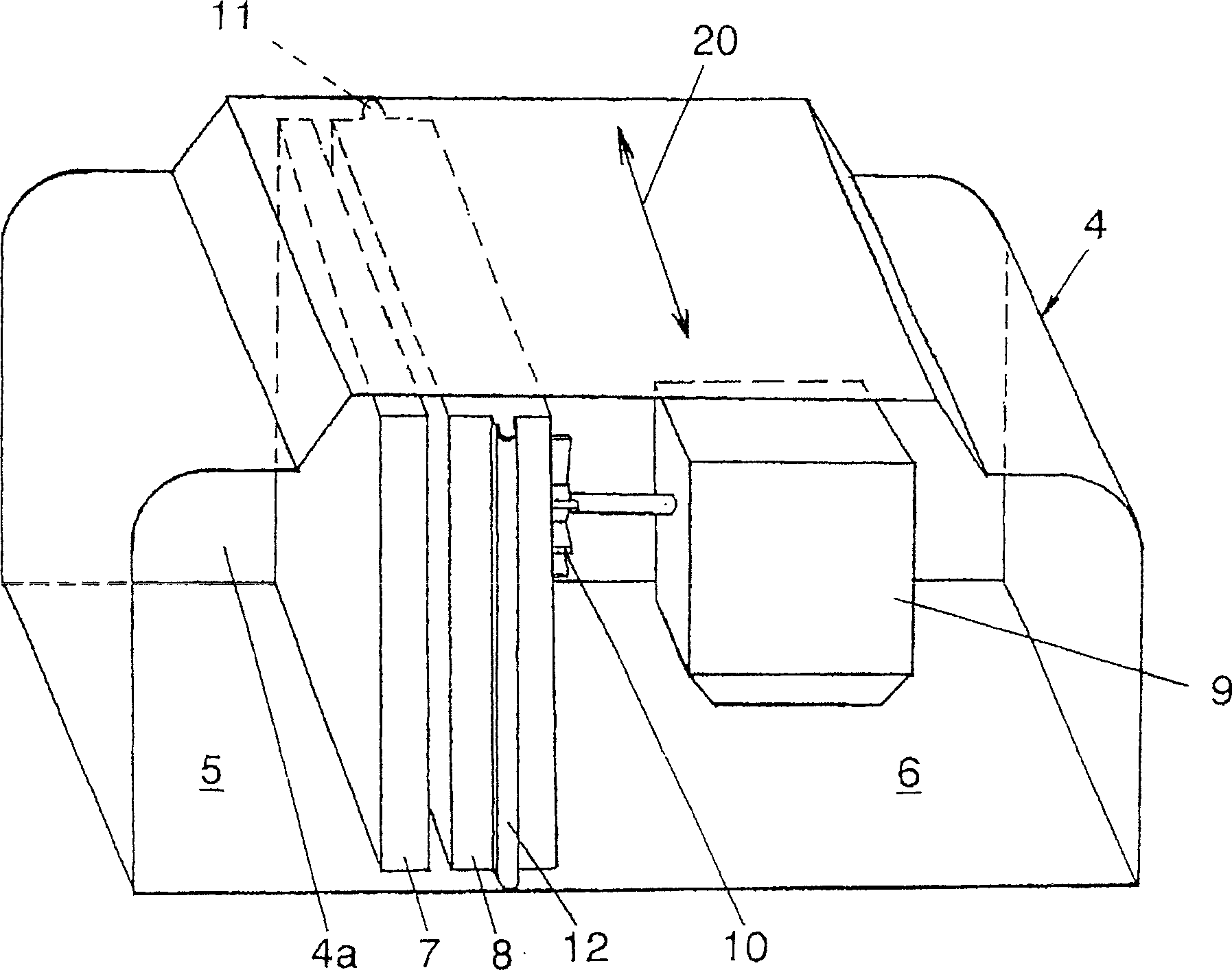

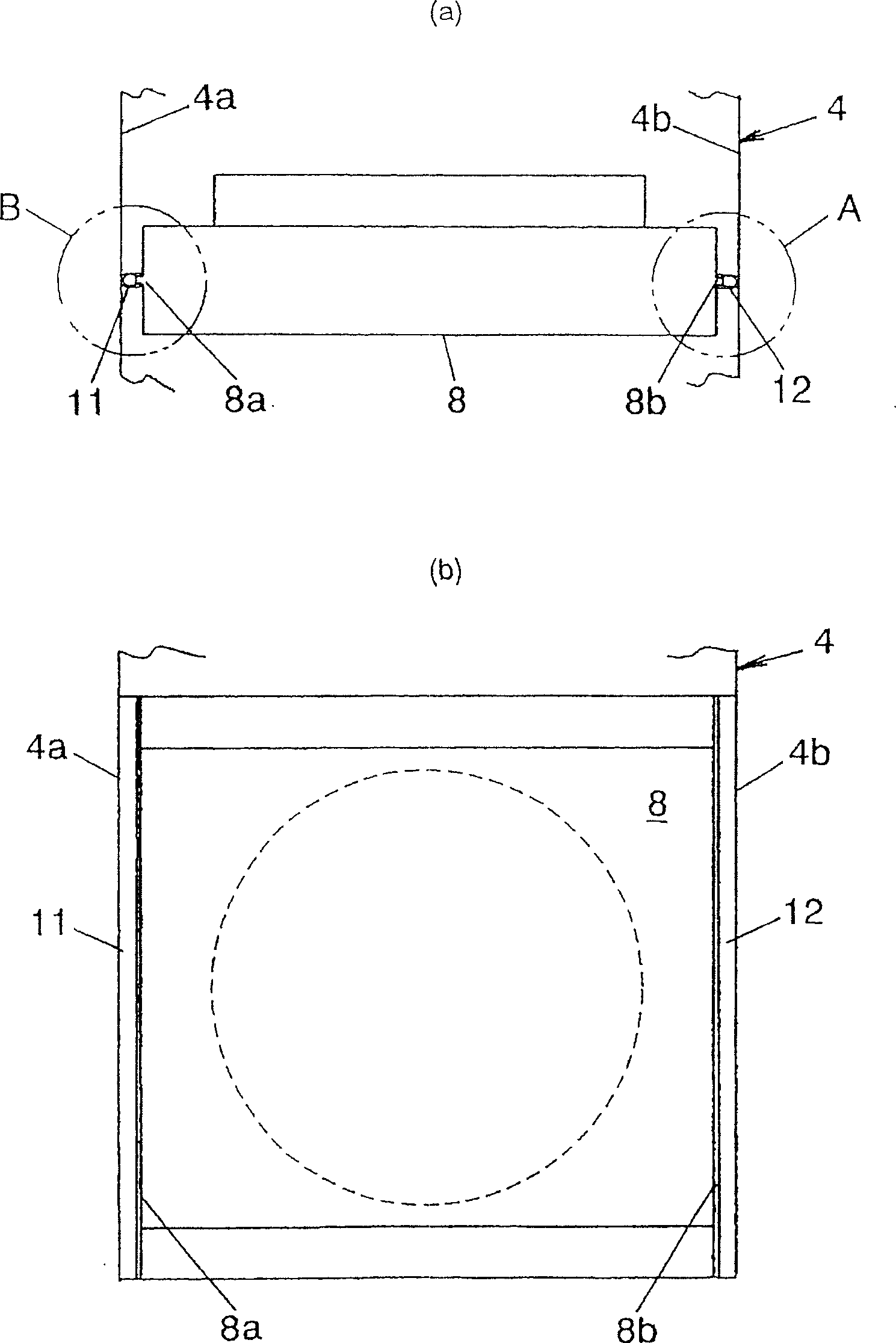

Engineering machinery cooling device collocating structure

InactiveCN1690379AReduce the number of partsReduce production man-hoursLiquid coolingSoil-shifting machines/dredgersEngineeringEngine room

This inveniton provides a cooling device disposition structure of a construction machine, decreasing the number of parts and reducing the disposition space of a heat exchanger. In this structure, a cooling device including an oil cooler 7, a radiator 8 and a cooling fan 10 for cooling the oil cooler 7 and the radiator 8 is disposed in a revolving structure 2 of a hydraulic shovel. The radiator 8 is disposed so that both side parts of the radiator 8 are respectively opposite to a front wall member 4a and a rear wall member 4b which are members constituting an engine room 4. A first projecting part 8a and a second projecting part 8b are formed on both side parts of the radiator, respectively, and a first seal member 11 sealing a gap between the first projecting part 8a and the front wall member 4a and a second seal member 12 sealing a gap between the second projecting part 8b and the rear wall member 4b are provided.

Owner:HITACHI CONSTR MASCH CO LTD

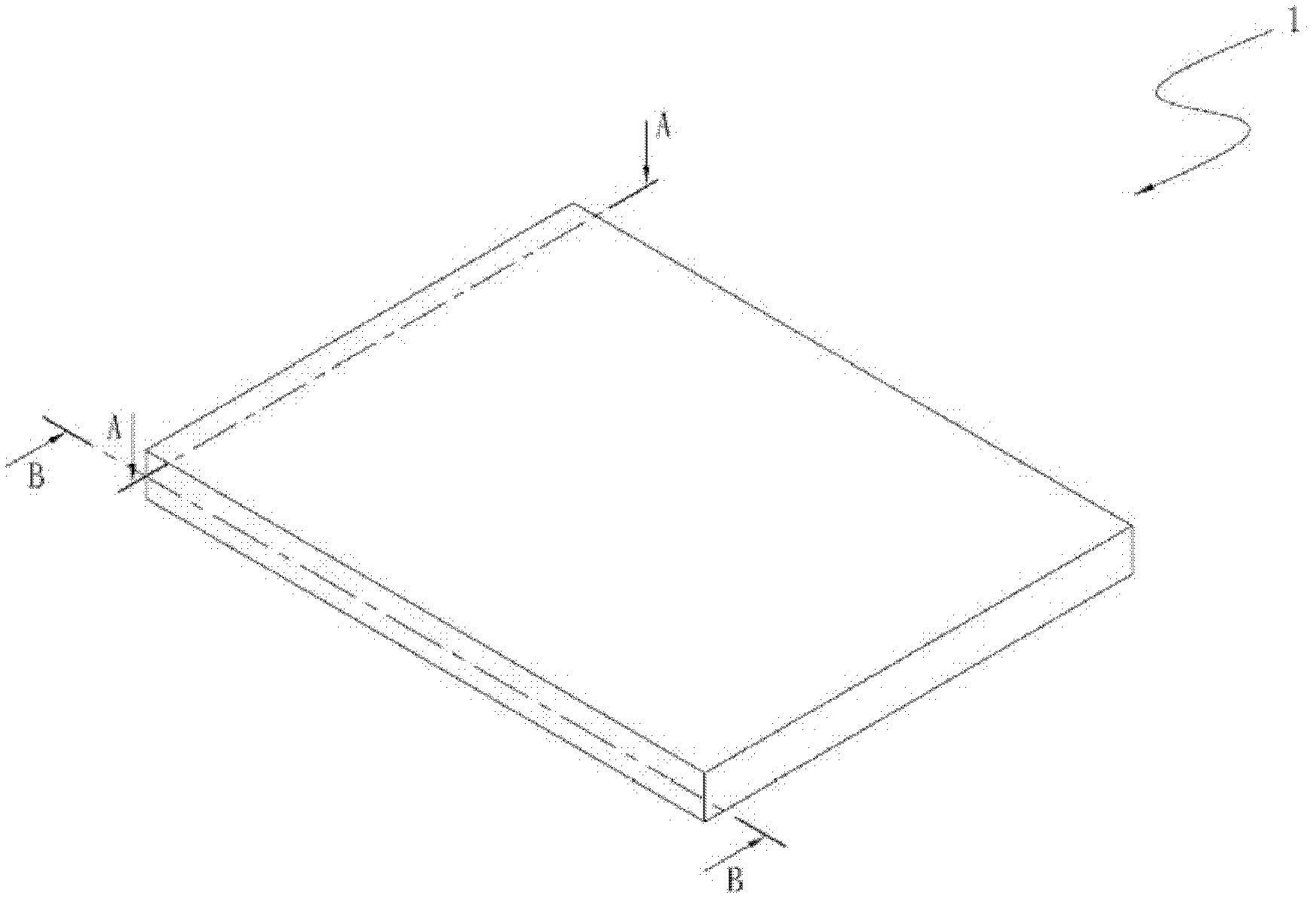

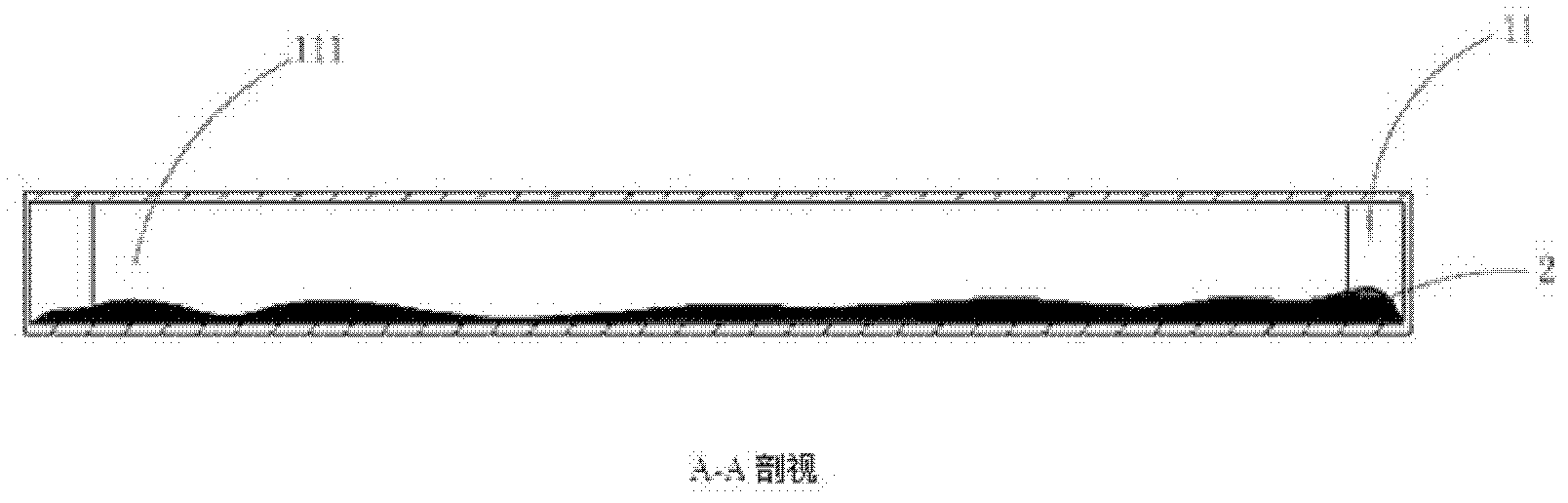

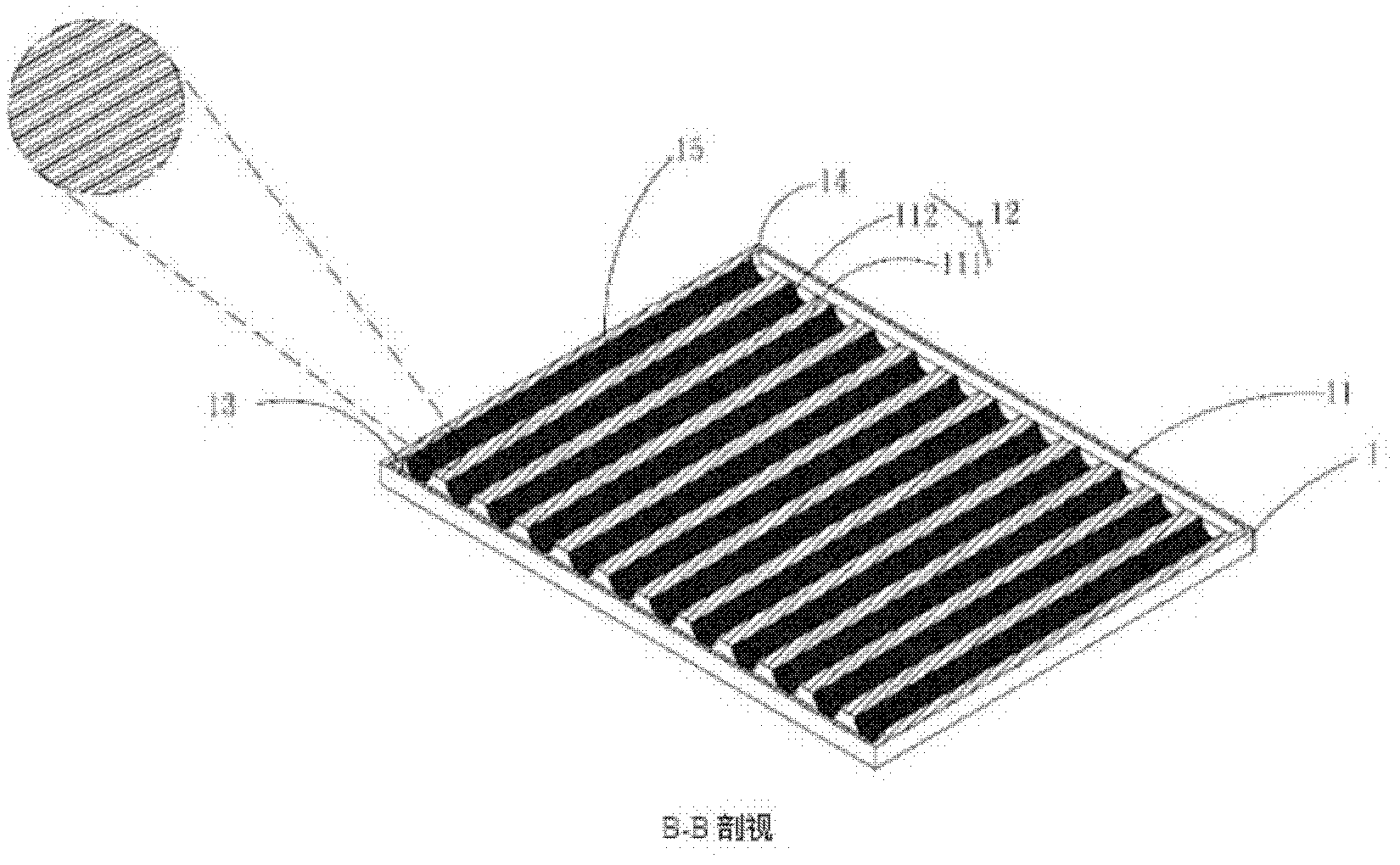

Temperature-uniformizing plate structure and manufacturing method for temperature-uniformizing plate

InactiveCN102878844AIncrease vapor-liquid circulationImprove heat transfer efficiencyIndirect heat exchangersWorking fluidEngineering

The invention discloses a temperature-uniformizing plate structure and a manufacturing method for the temperature-uniformizing plate. The temperature-uniformizing plate structure comprises a body, wherein the body is provided with a plurality of flow guide bodies and working fluid; at least one flow channel is formed among the flow guide bodies, and the flow channel and the flow guide bodies define a flow guide area together; and the two ends of the flow guide area are respectively connected with a first convection area and a second convection area and are communicated with the flow channel. The temperature-uniformizing plate structure is characterized in that the body is formed by extruding according to the invention, and the internal flow channel is formed when the external body is formed, so that the labor hour is reduced greatly and the cost is saved.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

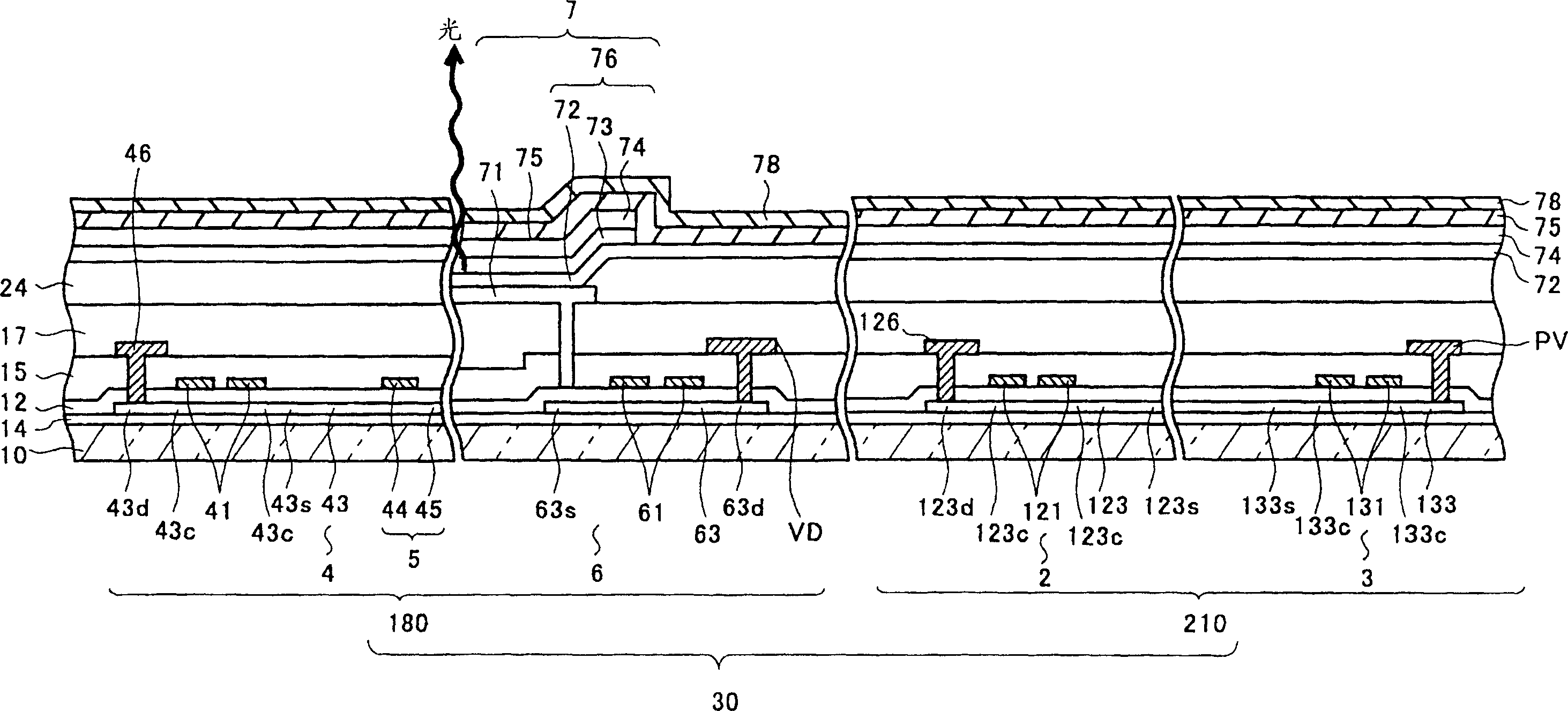

Display device and fabrication method thereof

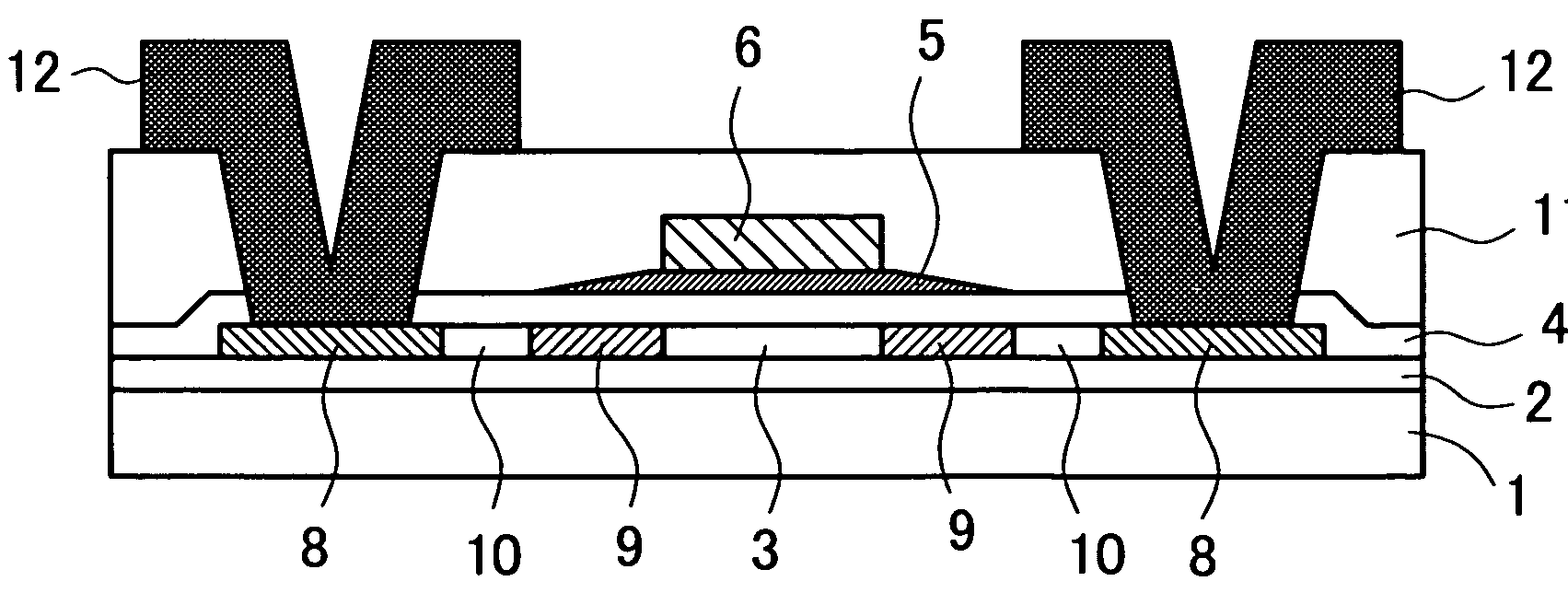

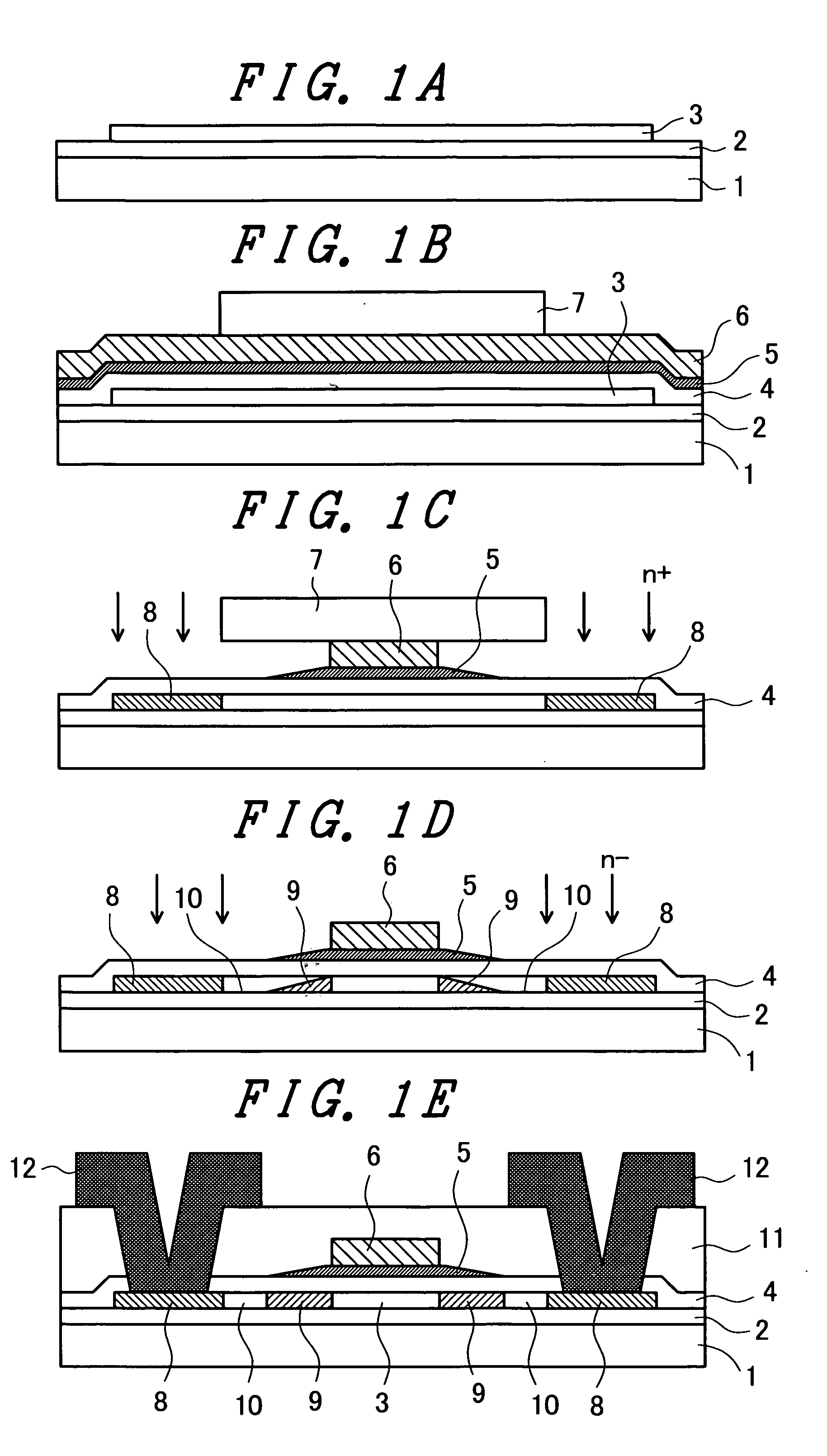

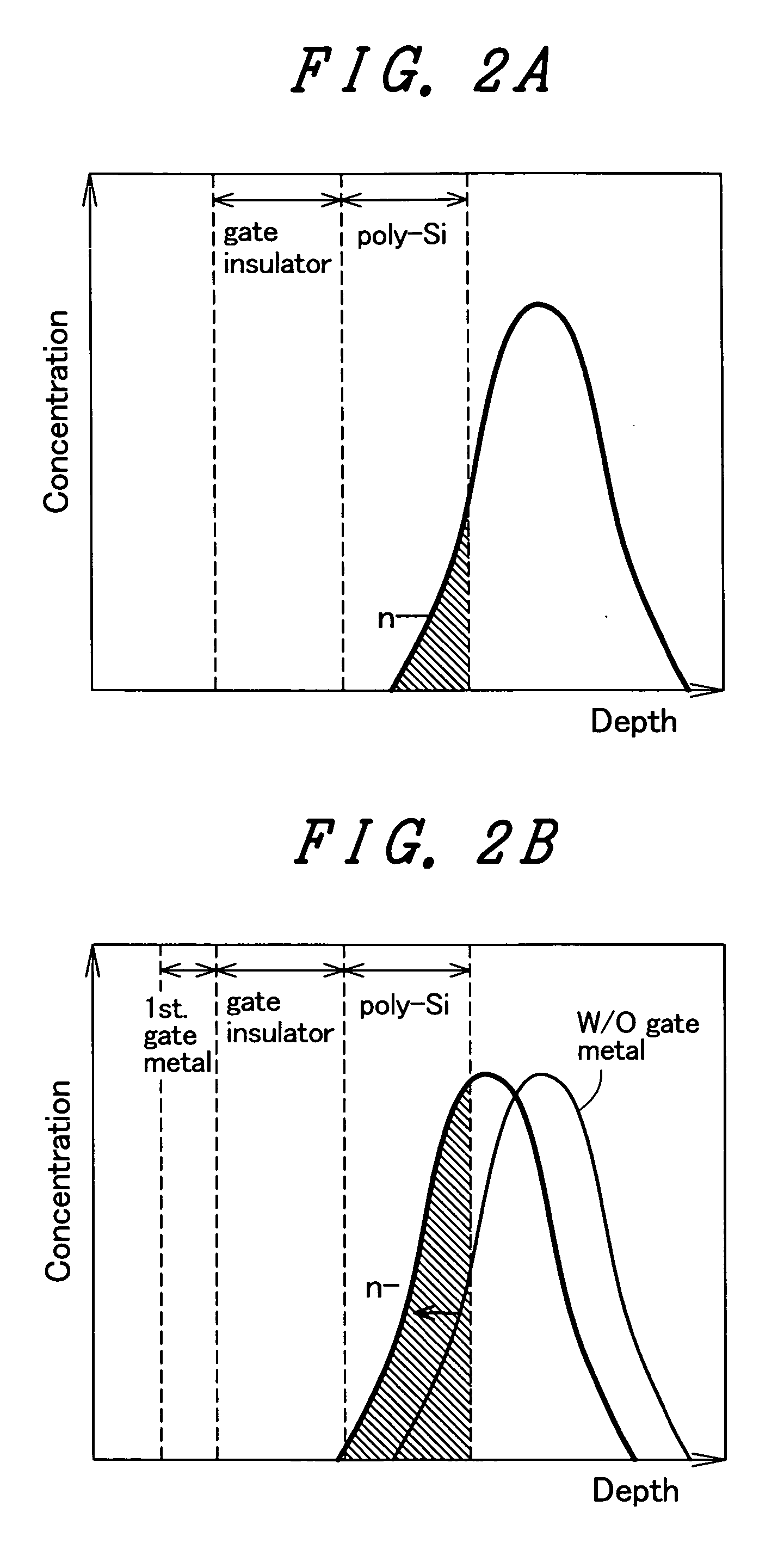

ActiveUS20070108449A1Reduce production man-hoursFabrication can be reducedSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The present invention provides a fabrication method of a display device which aims at the reduction of fabricating man-hours. In a fabrication method of a display device having a thin film transistor in which a gate electrode includes a first gate electrode and a second gate electrode which is overlapped to the first gate electrode and has a size thereof in the channel direction set smaller than the corresponding size of the first gate electrode, the semiconductor layer includes a channel region which is overlapped to the second gate electrode, a first impurity region which is overlapped to the first gate electrode and is formed outside the second gate electrode, a second impurity region which is formed outside the gate electrode, and a third conductive impurity region which is formed outside the gate electrode and the second impurity region, the first impurity region, the second impurity region and the third impurity region are respectively formed of the same conductive type, the impurity concentration of the first impurity region is lower than the impurity concentration of the third impurity region, and the impurity concentration of the second impurity region is lower than the impurity concentration of the first impurity region, impurities are collectively implanted into both of the first and second impurity regions such that the impurities are implanted into the first impurity region by way of the first gate electrode and the impurities are implanted into the second impurity region such that a peak position of the impurity concentration in the depth direction is positioned below the semiconductor layer thus lowering the impurity concentration of the second impurity region than the impurity concentration of the first impurity region.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

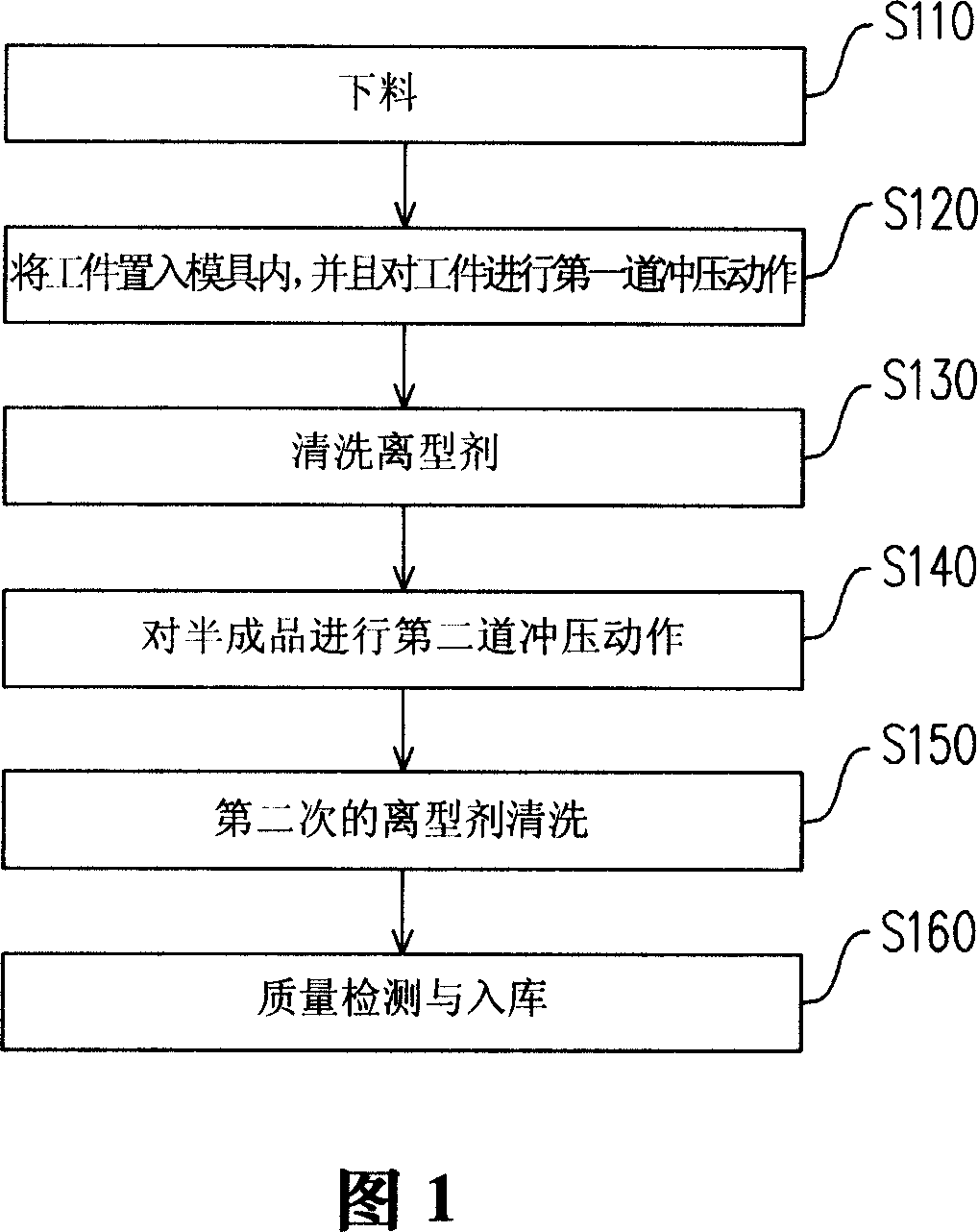

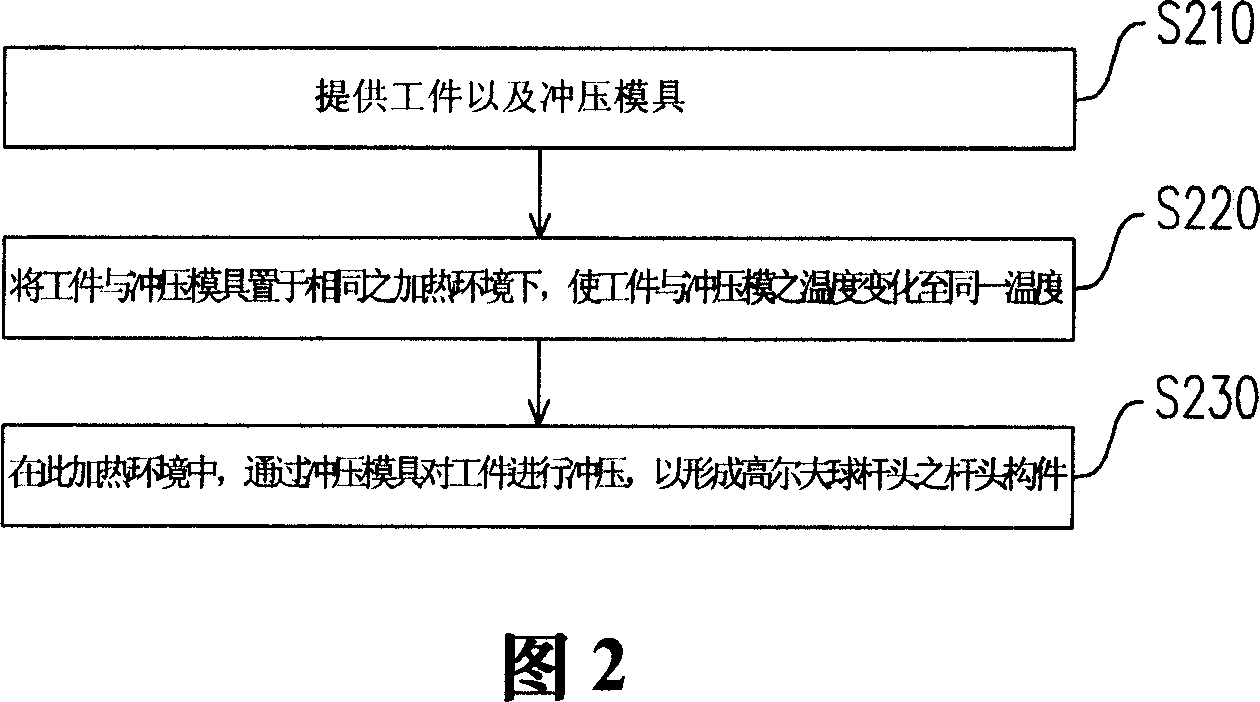

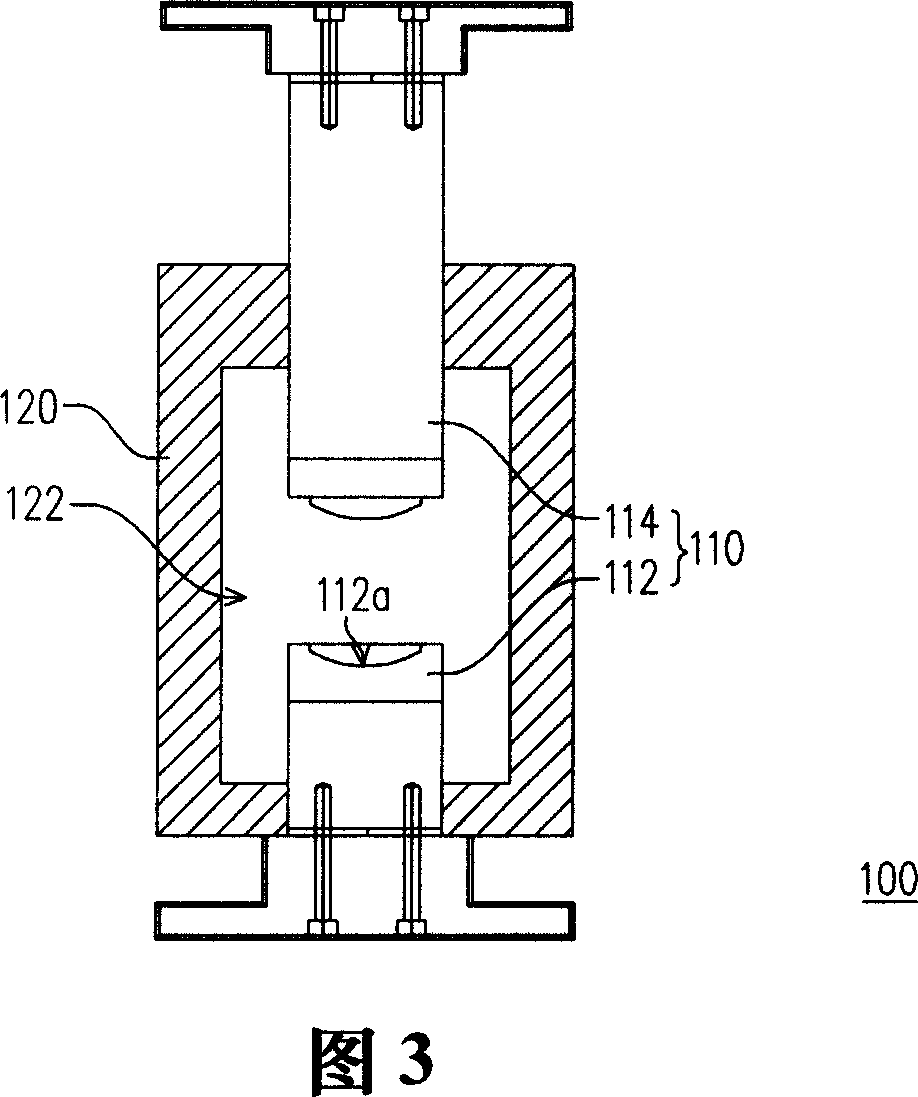

Golf club head component and punch table of producing said club head component and the method thereof

InactiveCN101032871AImprove the problem of residual stressReduce punching timesMetal-working apparatusGolf clubsEngineeringGolf club

The process of making member for golf club head includes the following steps: providing workpiece and punching die; heating the workpiece and the punching die simultaneously in the same temperature; and punching the workpiece in the punching die in the heating environment to form the member for golf club head. In addition, the present invention proposes also the punch for making the golf club head member. The golf club head member has the advantages of stable shape and no residual machining stress.

Owner:FUSHENG IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com