Patents

Literature

76results about How to "Less welding work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

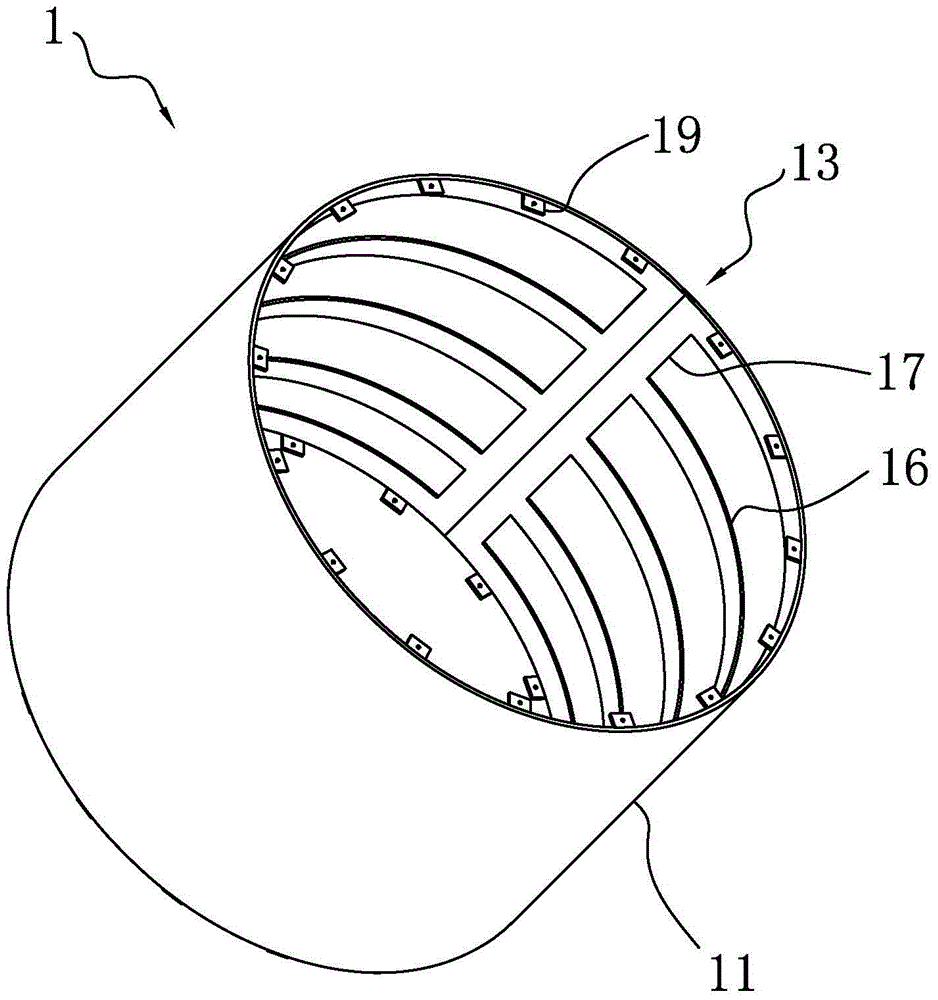

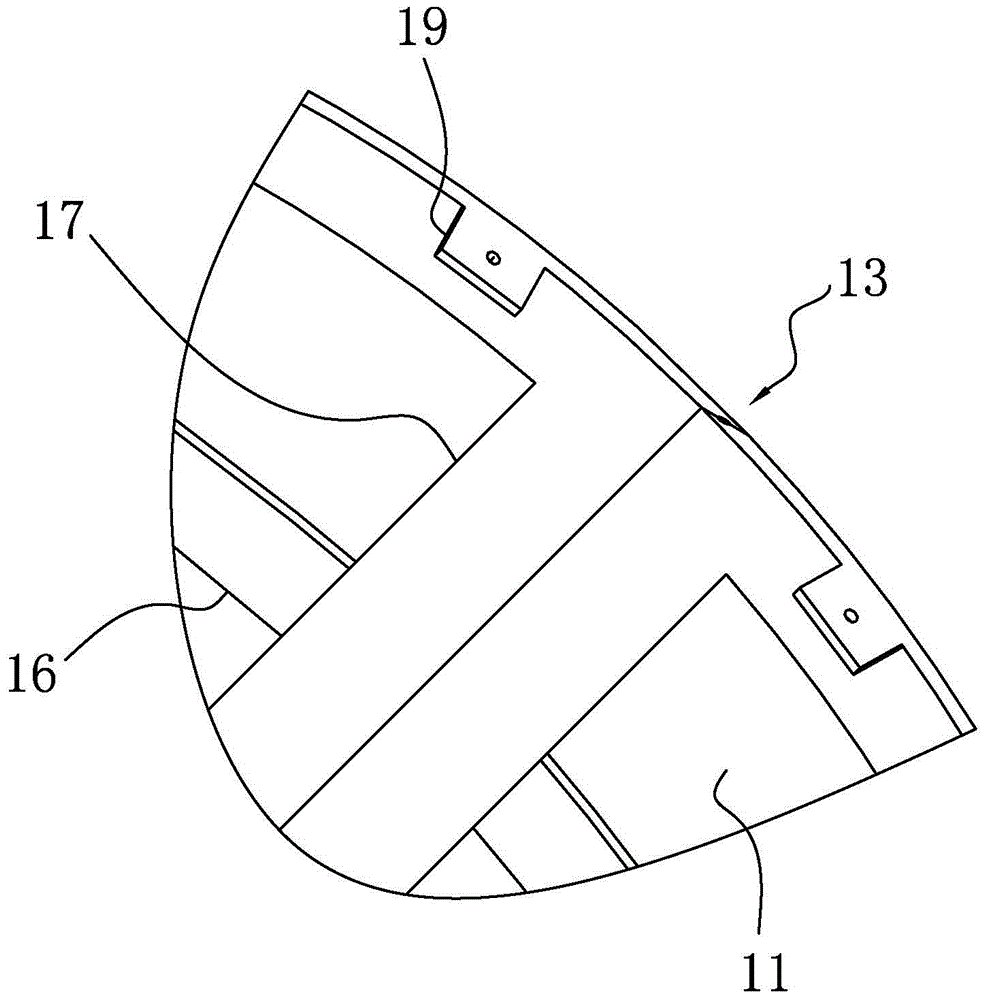

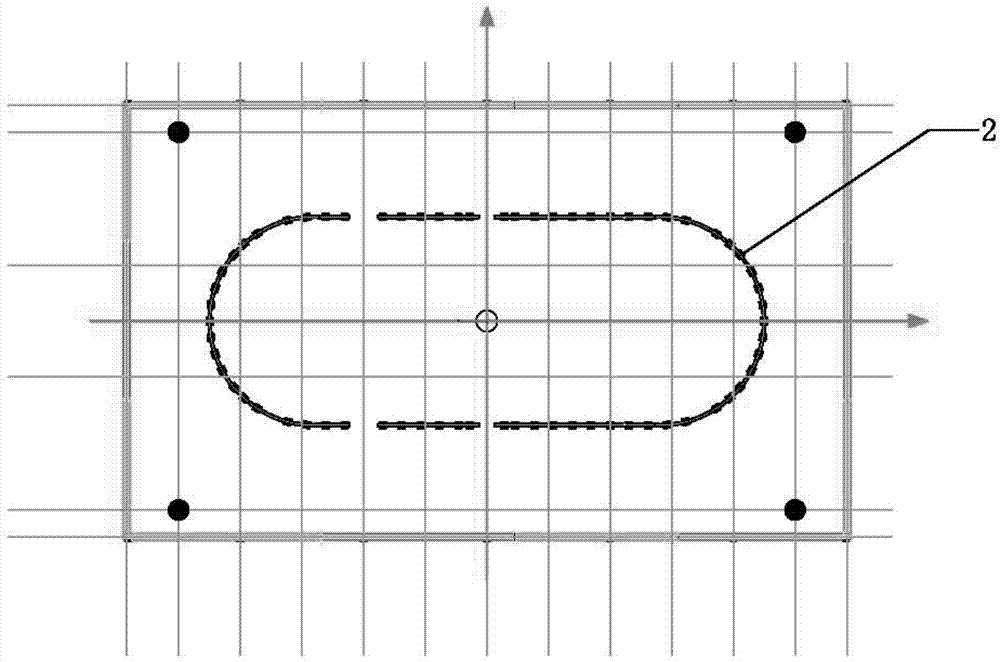

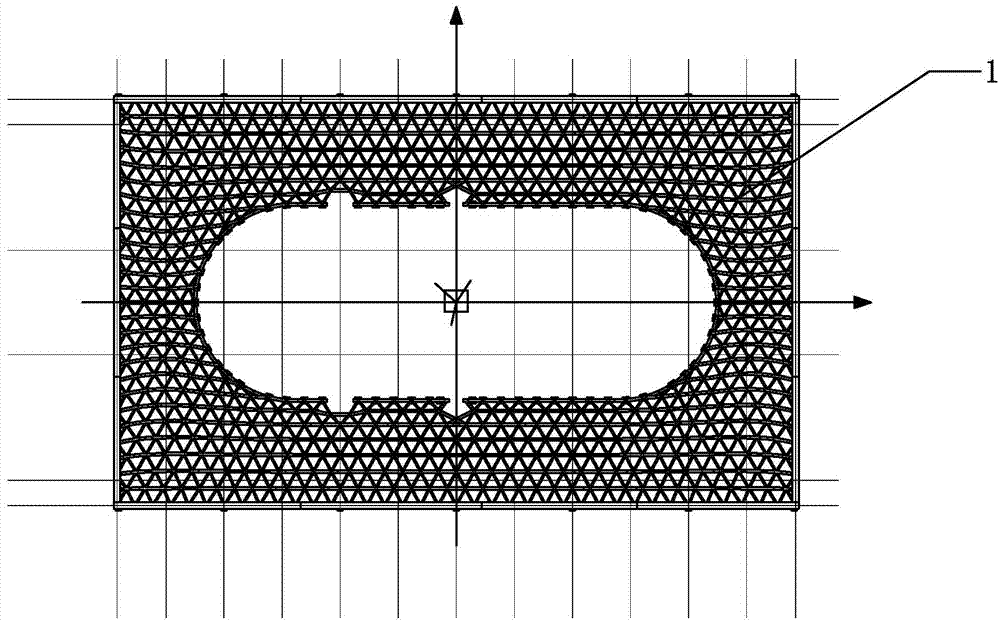

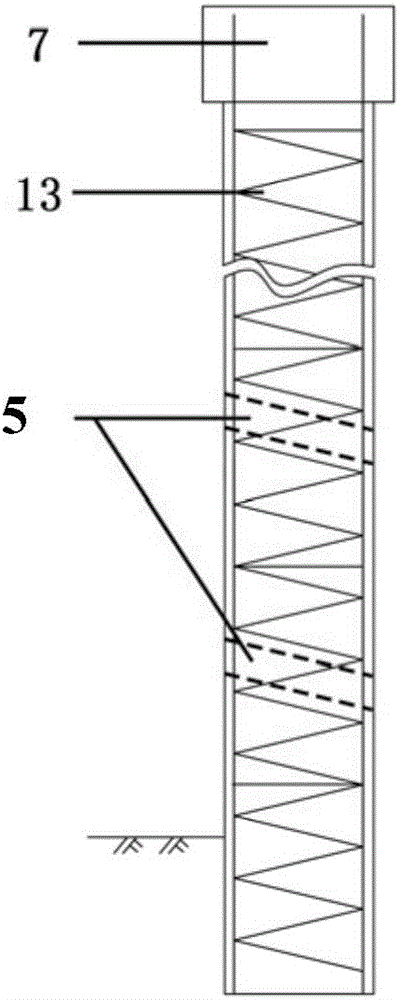

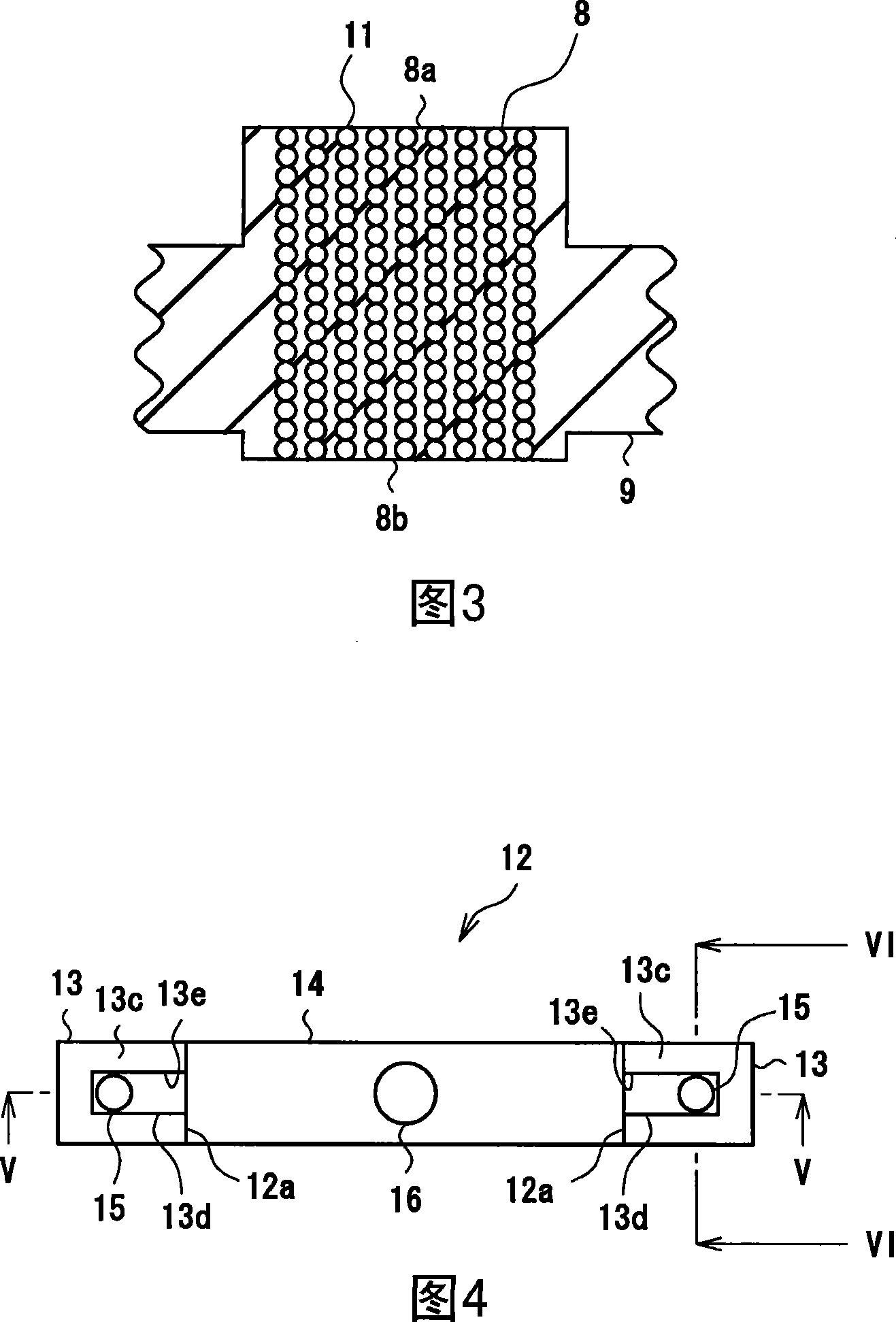

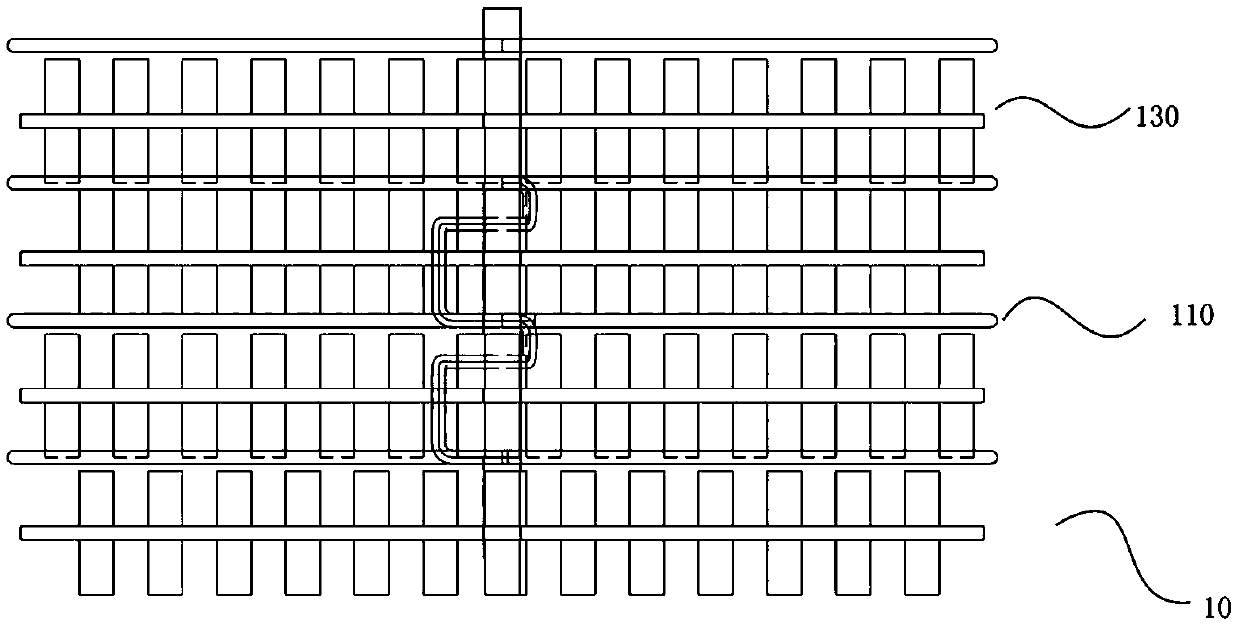

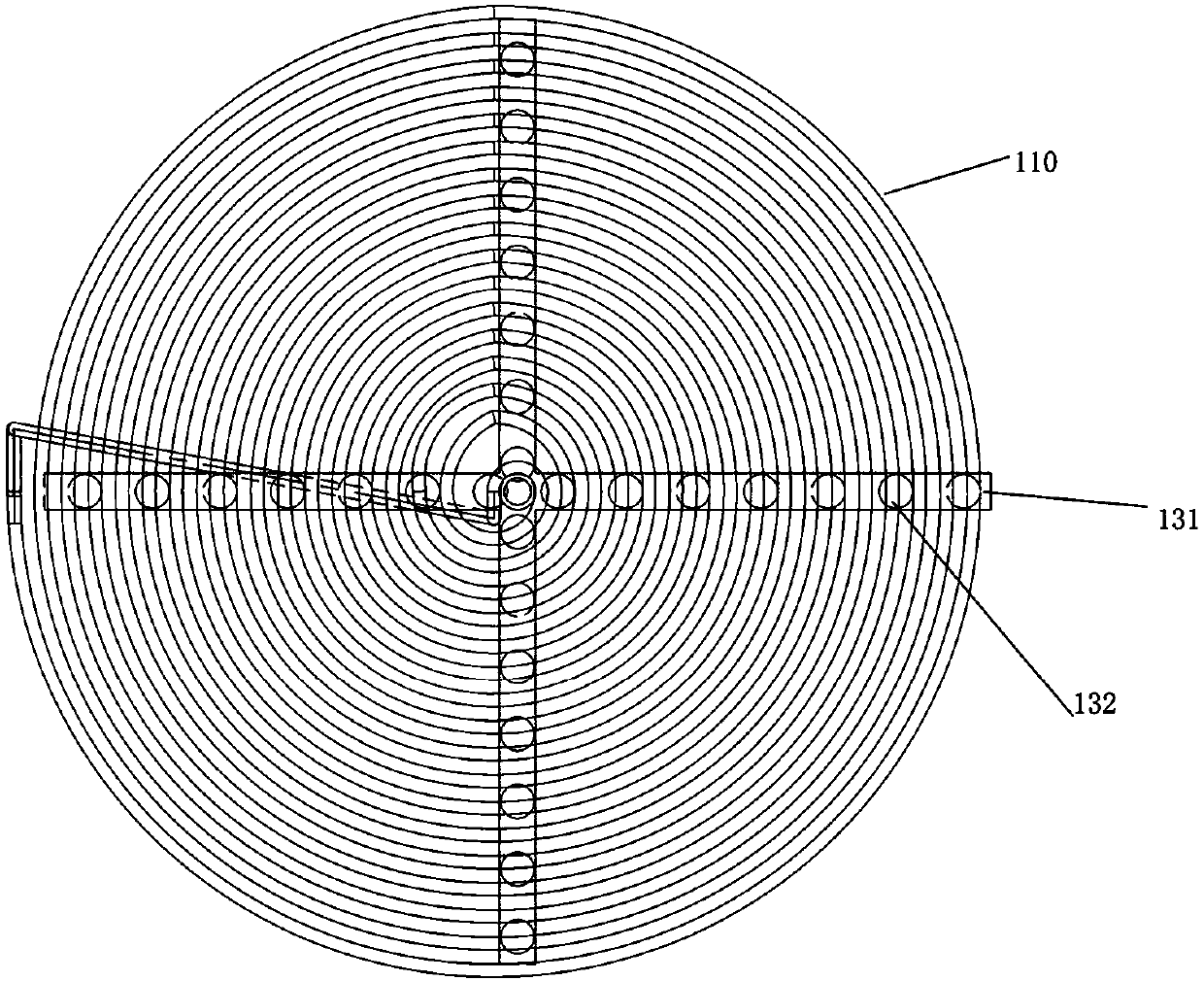

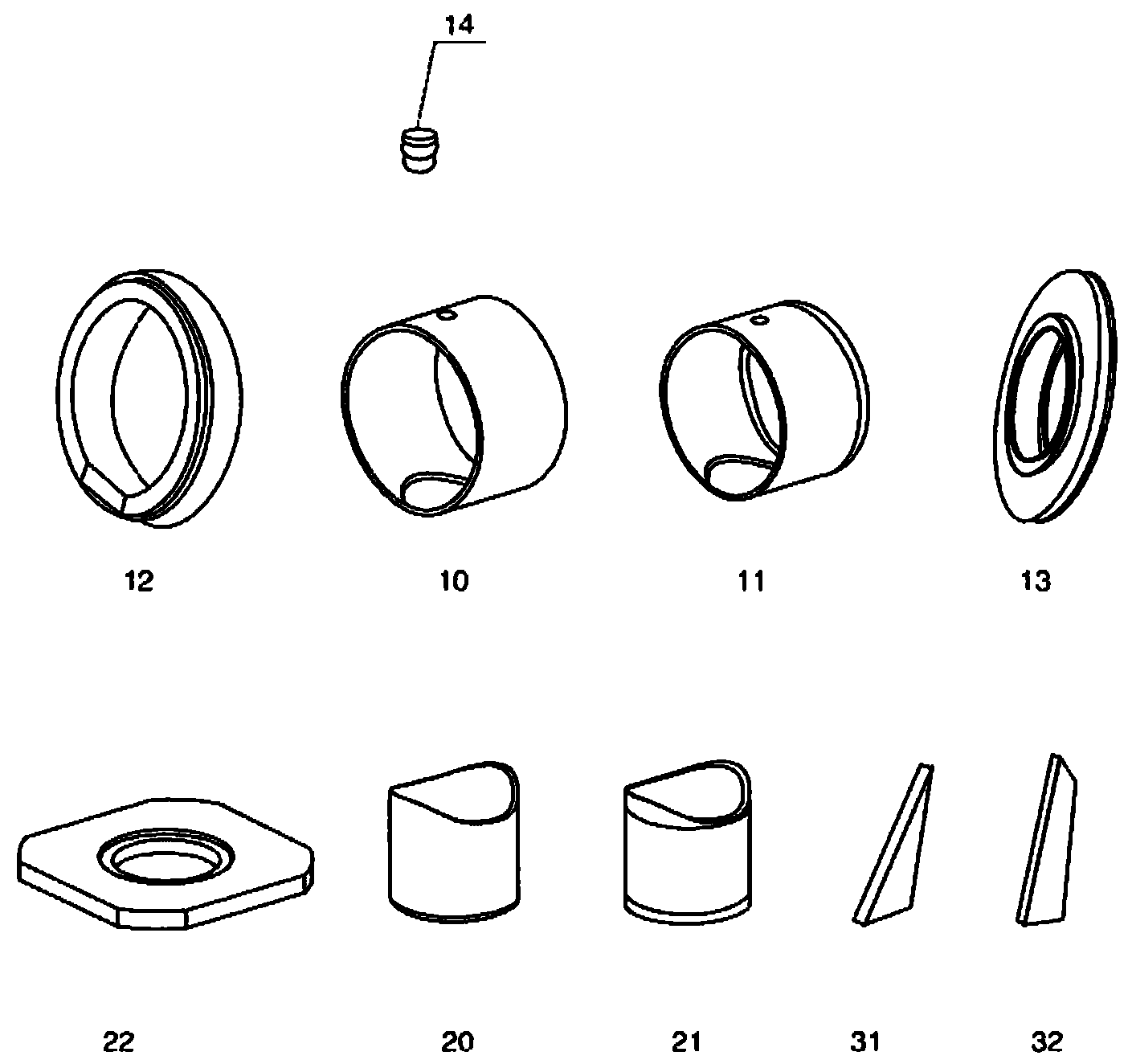

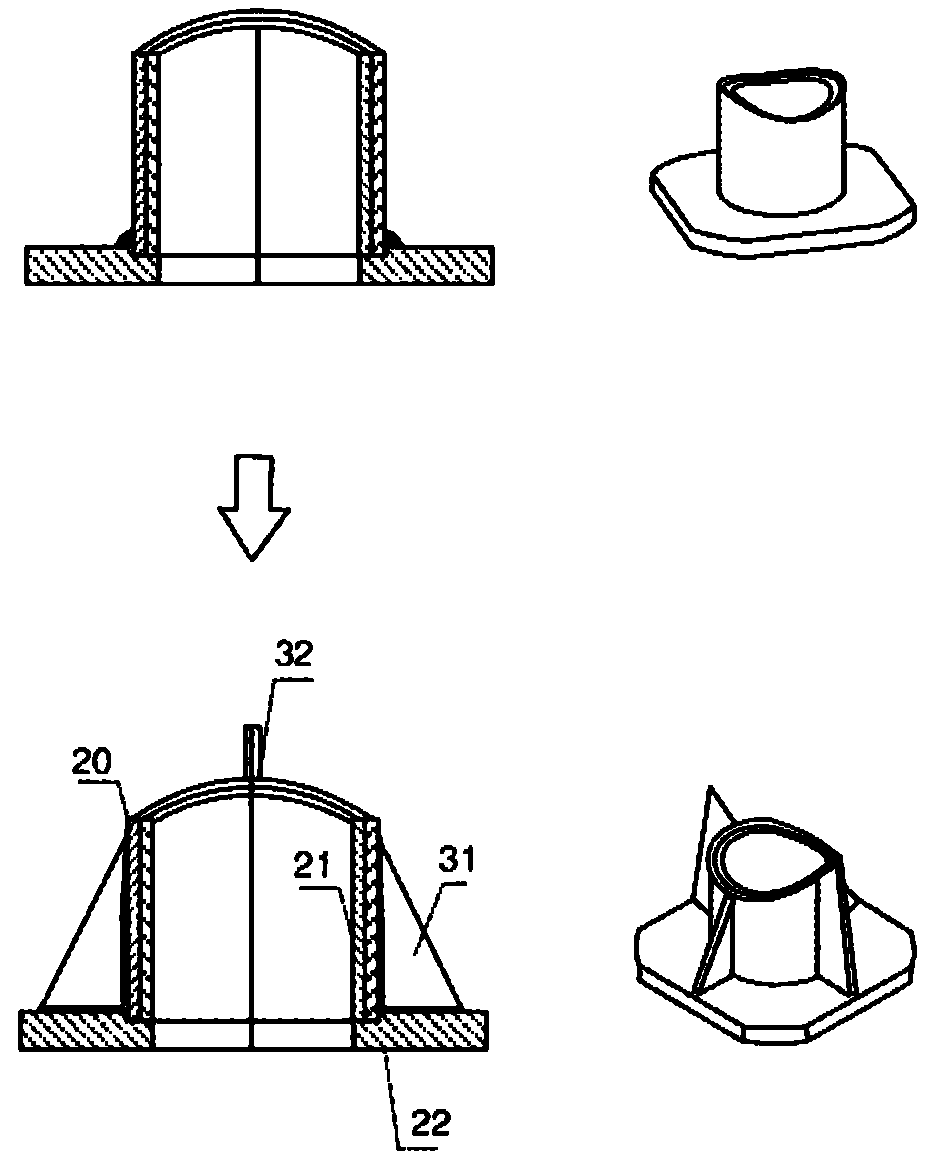

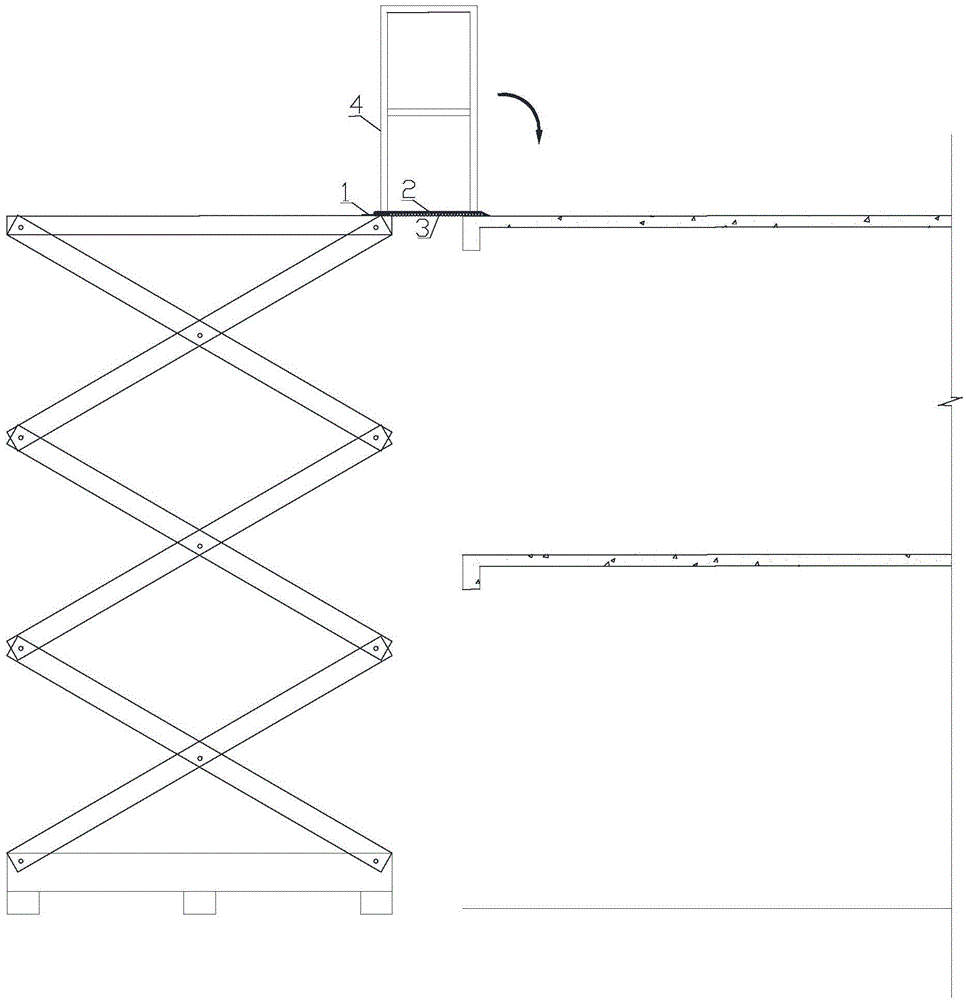

Internal mould, demoulding method thereof, mould for prefabricated concrete tower sections and production method

The invention provides an internal mould, a demoulding method thereof, a mould for prefabricated concrete tower sections and a production method. The internal mould provided by the invention comprises an internal formwork, both ends of the internal formwork are connected, so that the internal formwork is curved into the shape of a barrel, both ends of the internal formwork are provided with slopes, and the slopes of both ends of the internal formwork are matched with each other and form a demoulding opening. The demoulding method of the internal mould provided by the invention includes the following step: one end, which is located inside the demoulding opening, of the internal formwork is moved simultaneously along the radial direction and tangent direction of the internal mould to get close to the center of the internal mould and extend into the space in the internal formwork. The internal mould provided by the invention can be used for casting a whole ring, the overall elastic deformation of the internal formwork can be conveniently utilized to implement the demoulding and restoration of the internal mould, and a great deal of welding work can be reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

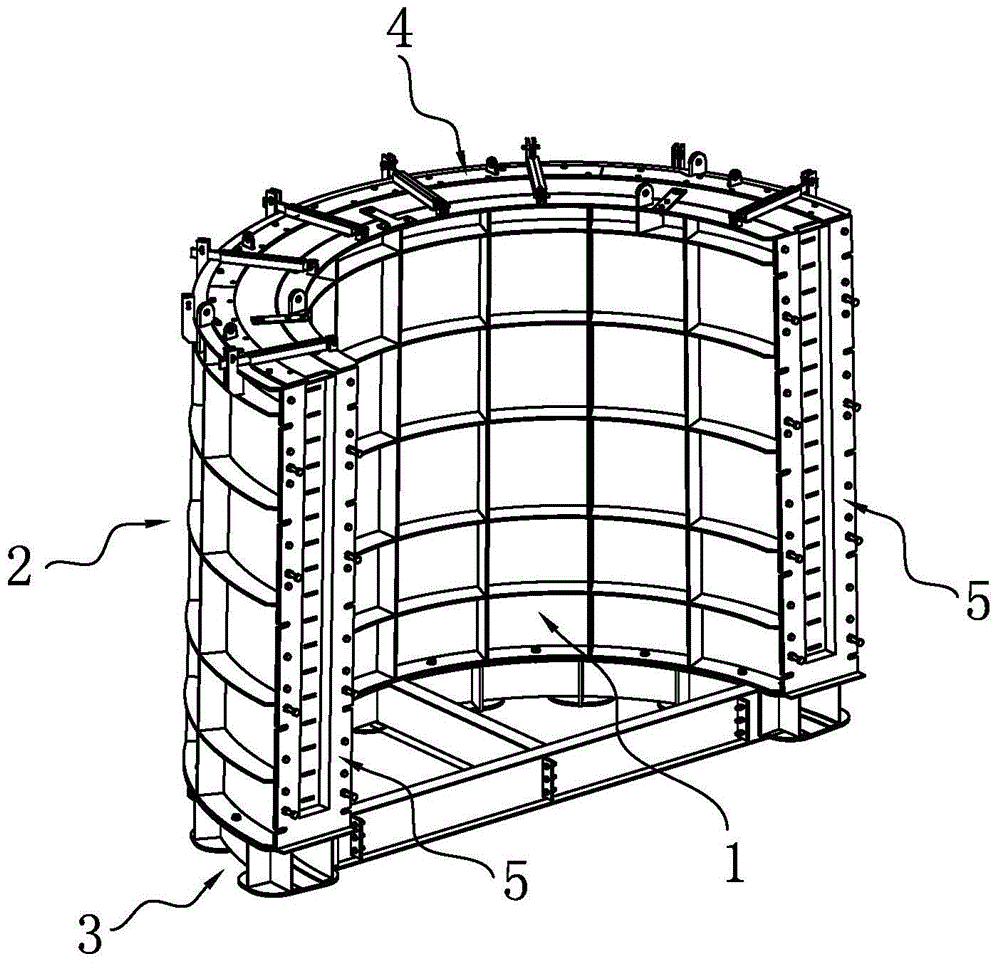

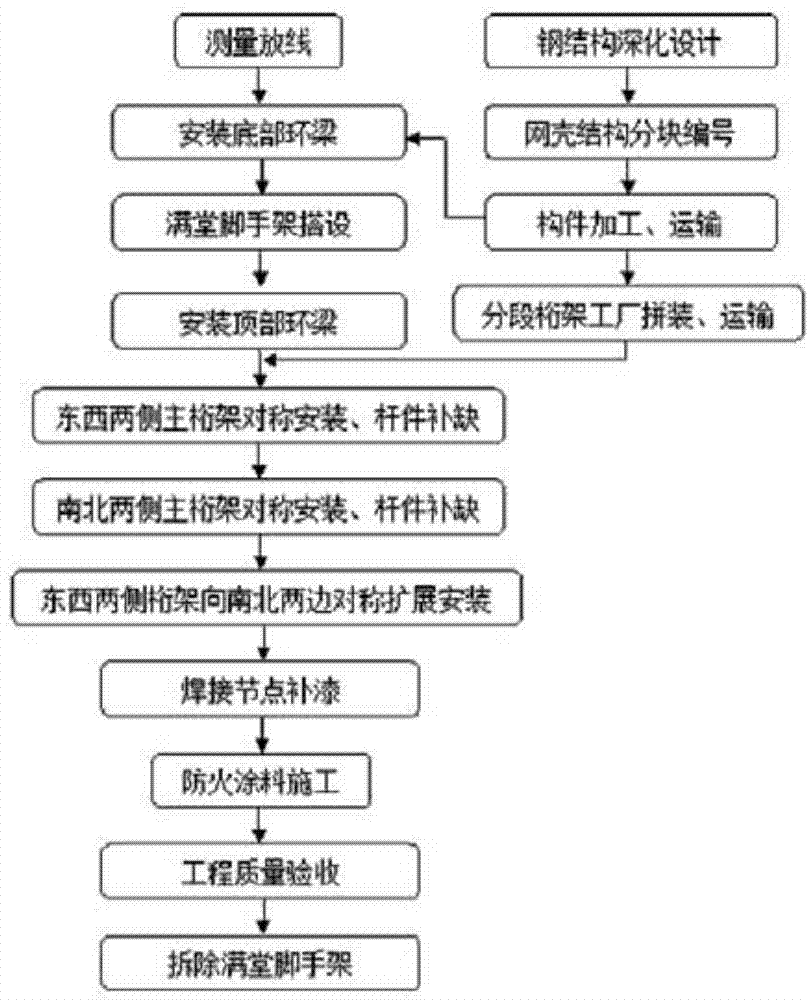

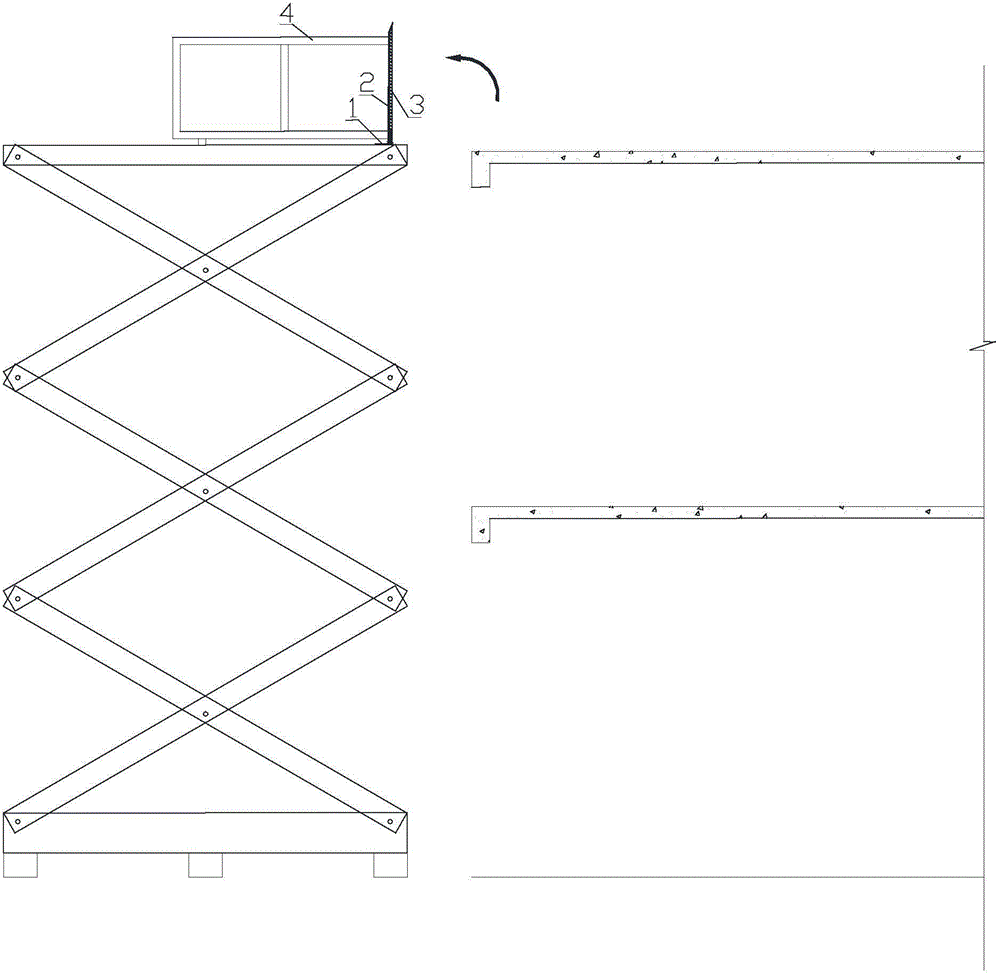

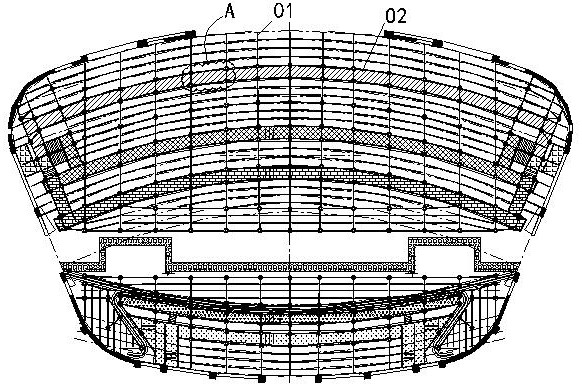

Method for installation construction of roof free-form surface single-layer latticed shell structure of super high-rise building

InactiveCN104727564AReduce direct liftingReduce storage spaceBuilding material handlingSocial benefitsFree form

The invention discloses a method for installation construction of a roof free-form surface single-layer latticed shell structure of a super high-rise building. The roof free-form surface single-layer latticed shell structure comprises a building frame and a latticed shell structure arranged at the top of the building frame. The latticed shell structure comprises a bottom ring beam arranged at the top of the building frame, a top ring beam arranged at the top end of the latticed shell structure and a net-shaped truss arranged between the bottom ring beam and the top ring beam. The method is characterized in that a latticed shell structure installing process comprises the steps of performing measurement and setting out, partitioning the latticed shell structure, installing the latticed shell structure, performing painting make-up on welded nodes, performing fireproof coating construction, performing acceptance of engineering quality and dismantling an all-round scaffold. The method is good in construction quality and quick in speed and has safety in construction and good economic benefits and remarkable social benefits.

Owner:ZHONGYIFENG CONSTR GRP

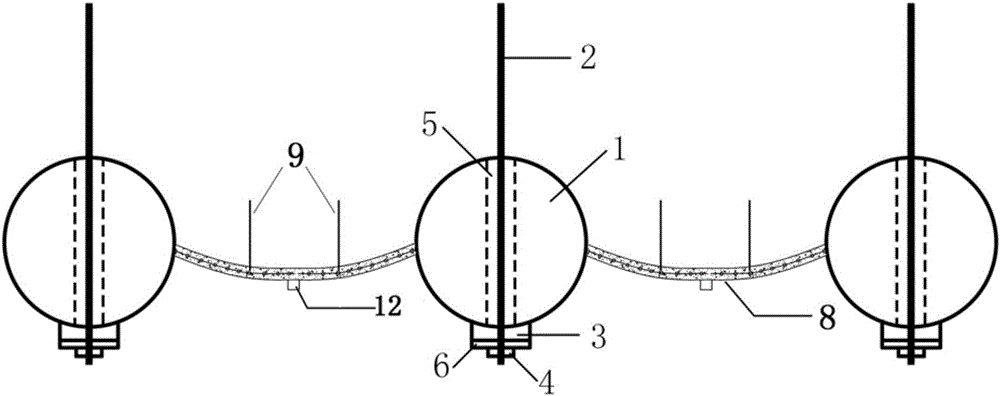

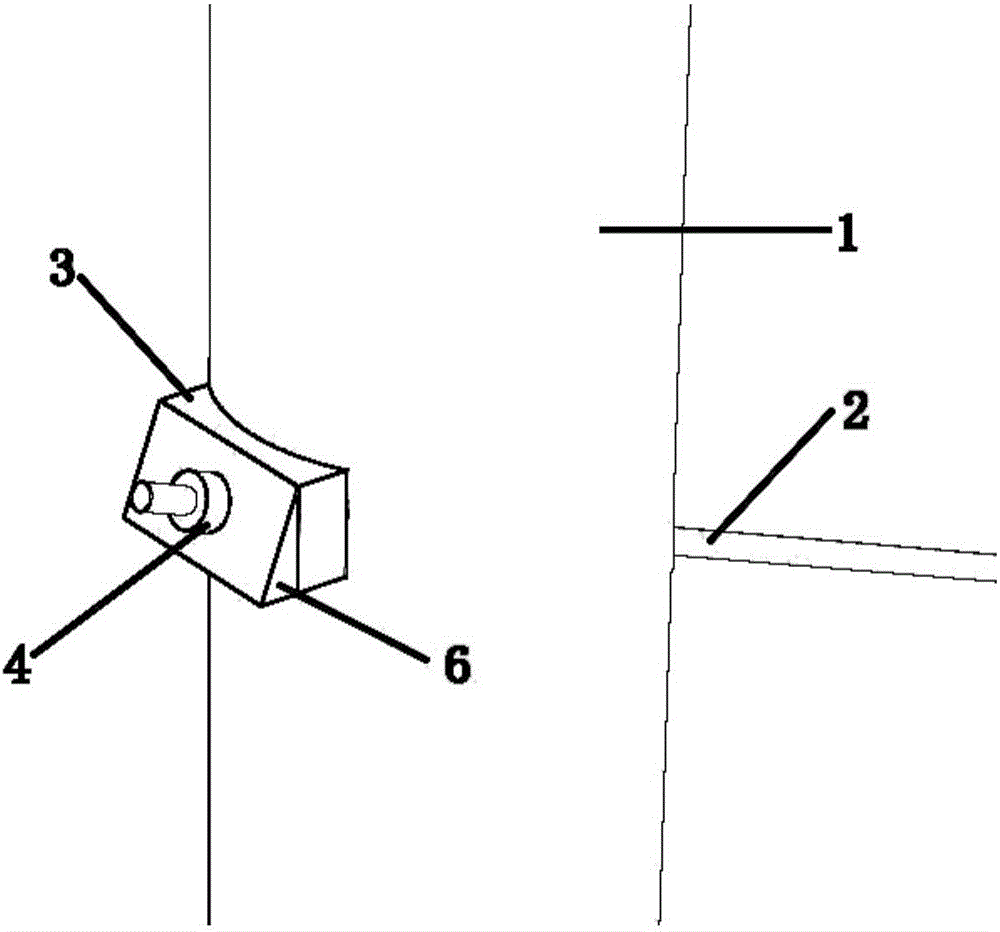

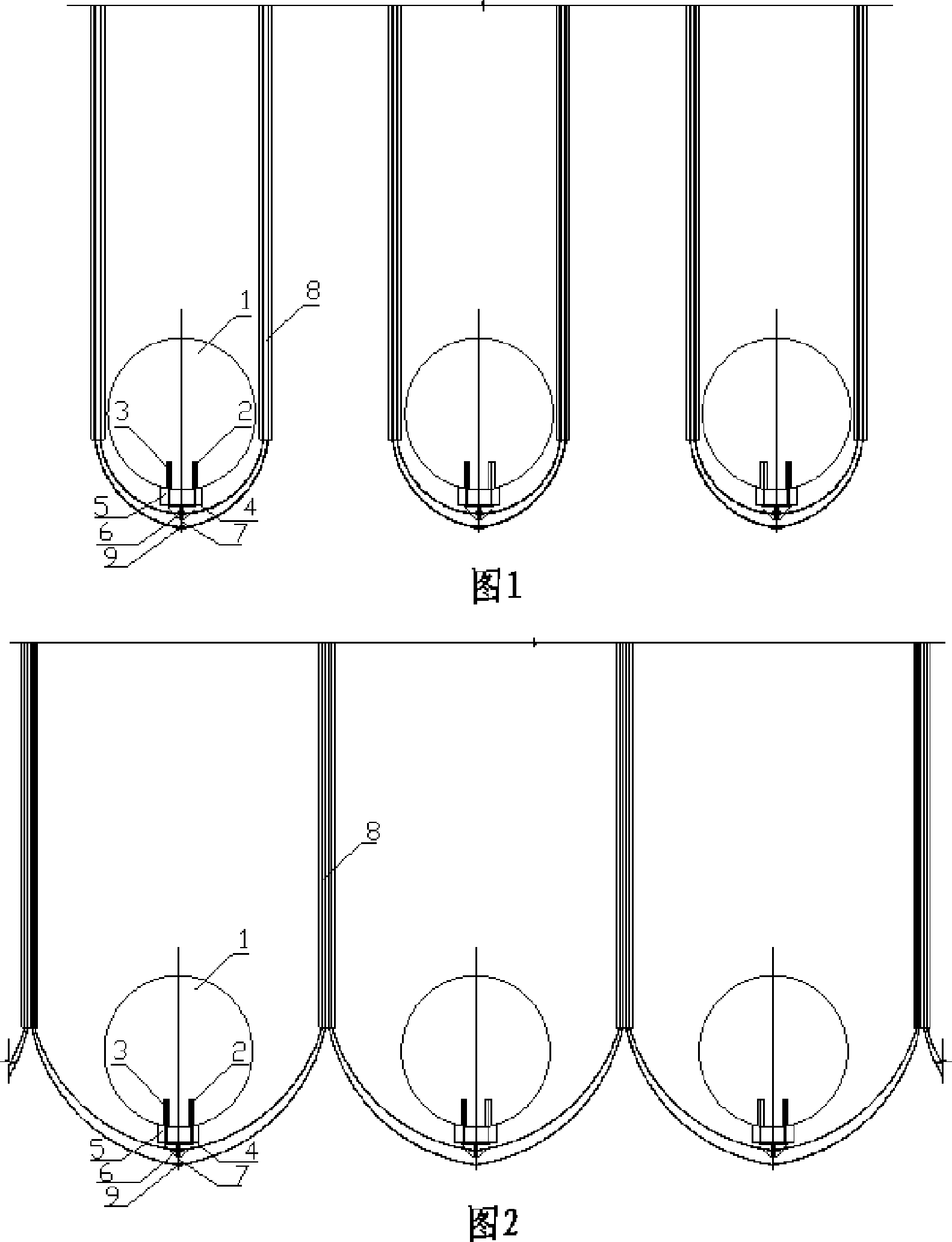

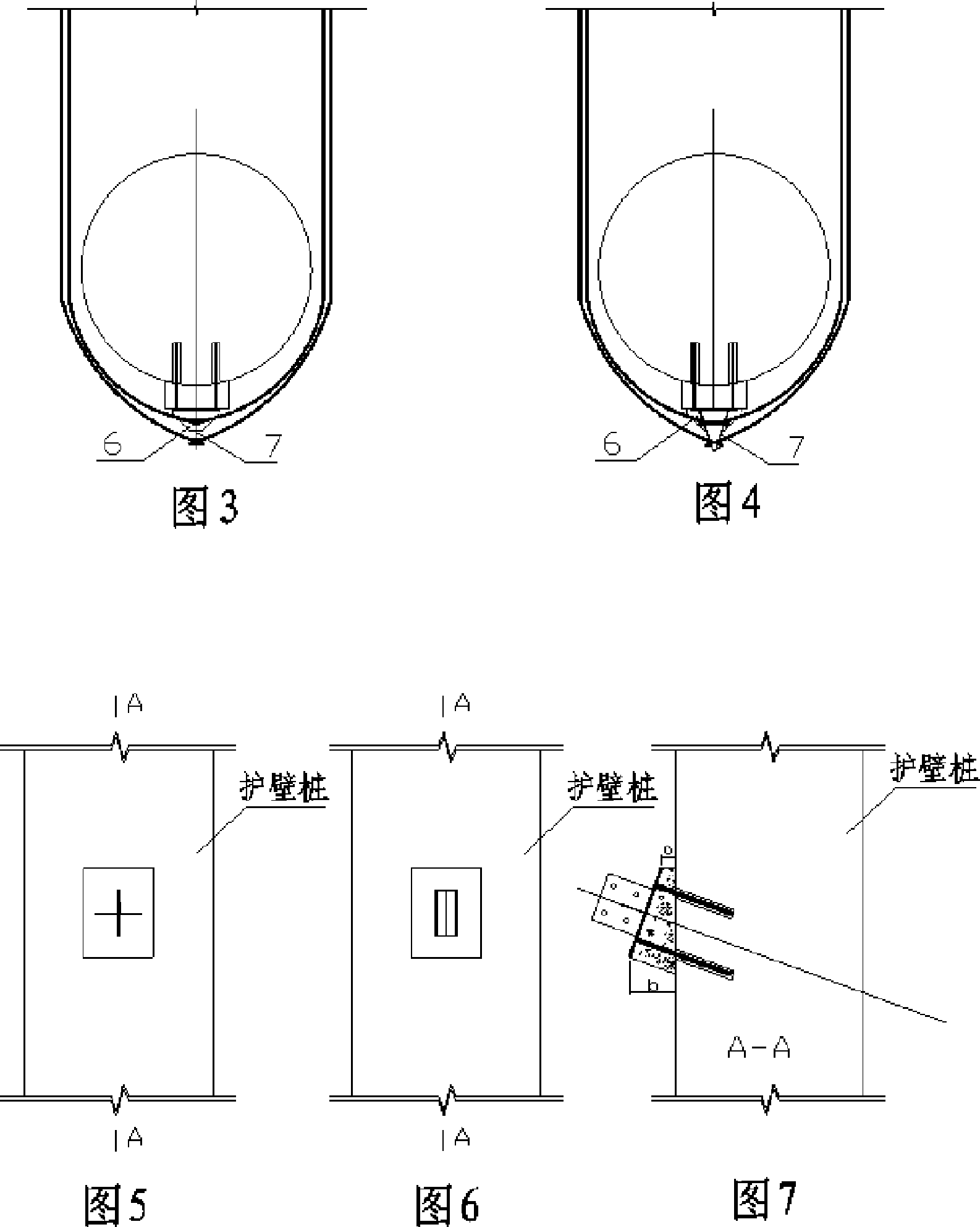

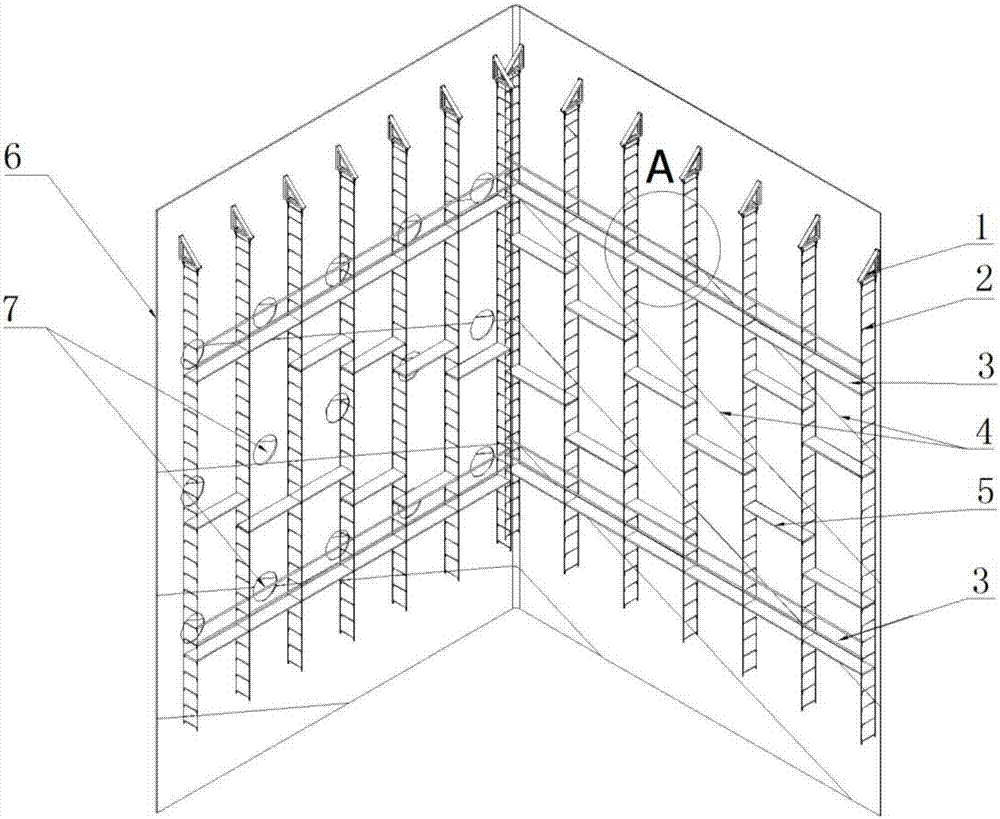

Deep-foundation-pit pile-anchor supporting system with anchor heads arranged on pile bodies and implementing method of system

The invention discloses a deep-foundation-pit pile-anchor supporting system with anchor heads arranged on pile bodies and an implementing method of the system. The supporting system comprises retaining piles, anchor rods, saddle-shaped cushion blocks, anchor devices, PVC pipes, wedges and locking beams; the PVC pipes are arranged inside the retaining piles in advance; inner ends of the anchor rods penetrate through the PVC pipes and are inserted in the foundation pit wall, and outer ends of the anchor rods are fixedly connected with the anchor devices; and included angles being 15-25 degrees are formed between axes of the anchor devices and the horizontal plane and are kept consistent with inclination angles of the anchor rods. Waist beams in a traditional pile-anchor system are canceled, so that the prestress loss caused by deformation of the waist beams is avoided. The force of the anchor rods is directly transferred to the retaining piles, the anchor rods and the retaining piles can be better integrally and synergistically stressed, and a supporting structure is better in integrity, safe and reliable. A lot of connecting batten plates and welding rods are canceled, so that profile steel materials and the electricity consumption are greatly saved. Heavy and dangerous waist beam mounting work is avoided, procedures are simplified, and the construction period is shortened.

Owner:DALIAN JIAOTONG UNIVERSITY

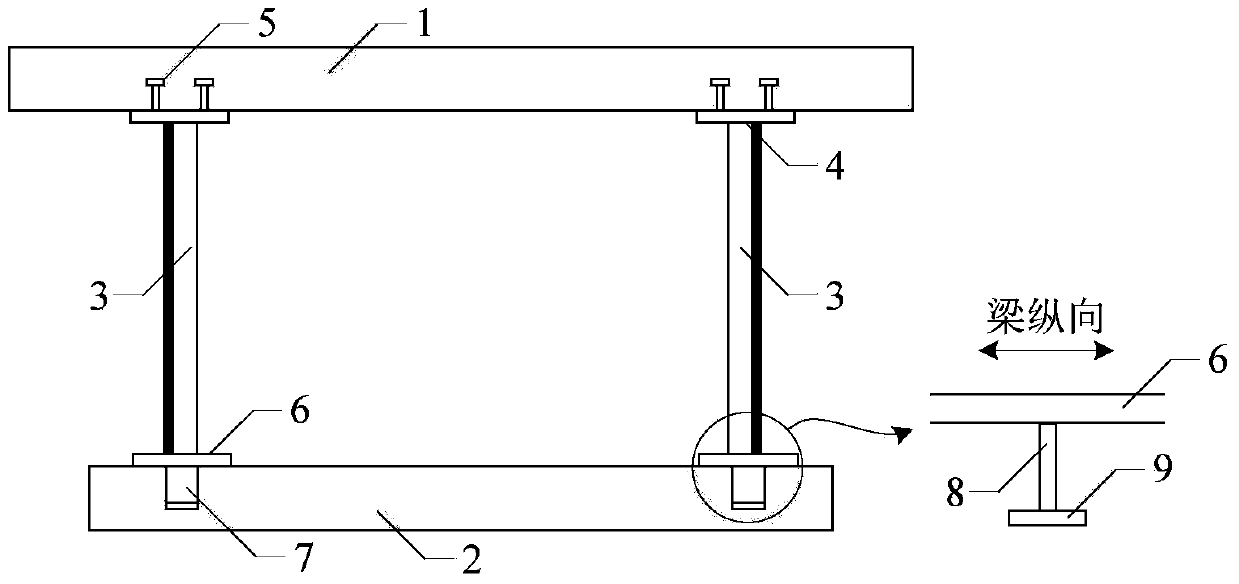

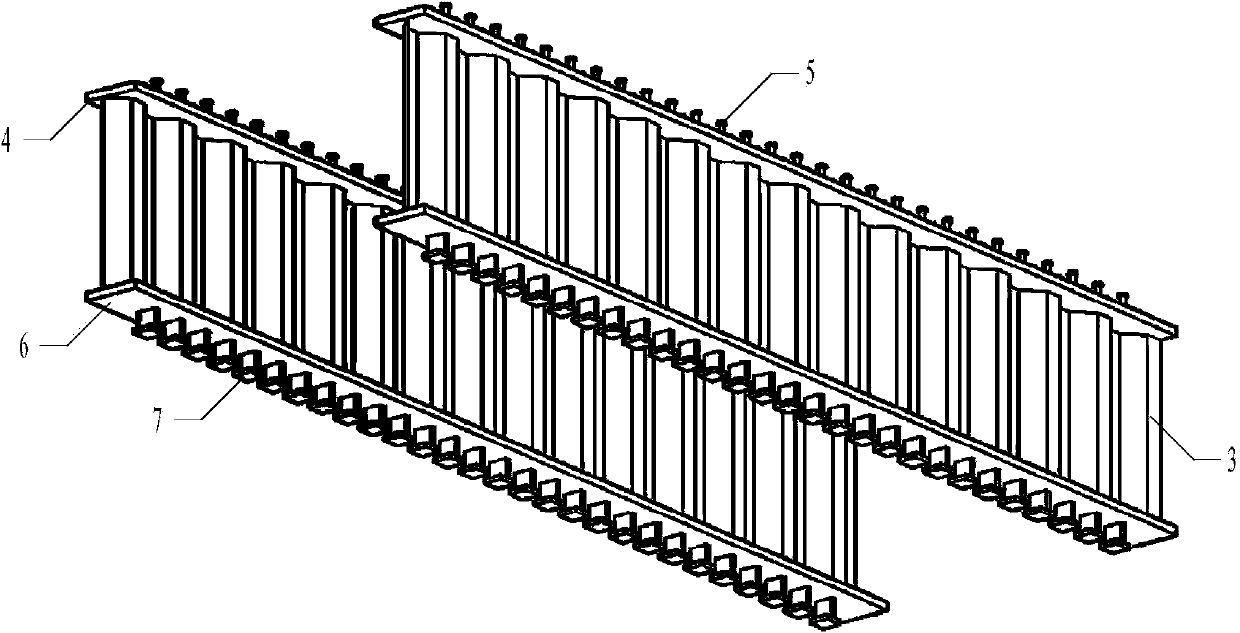

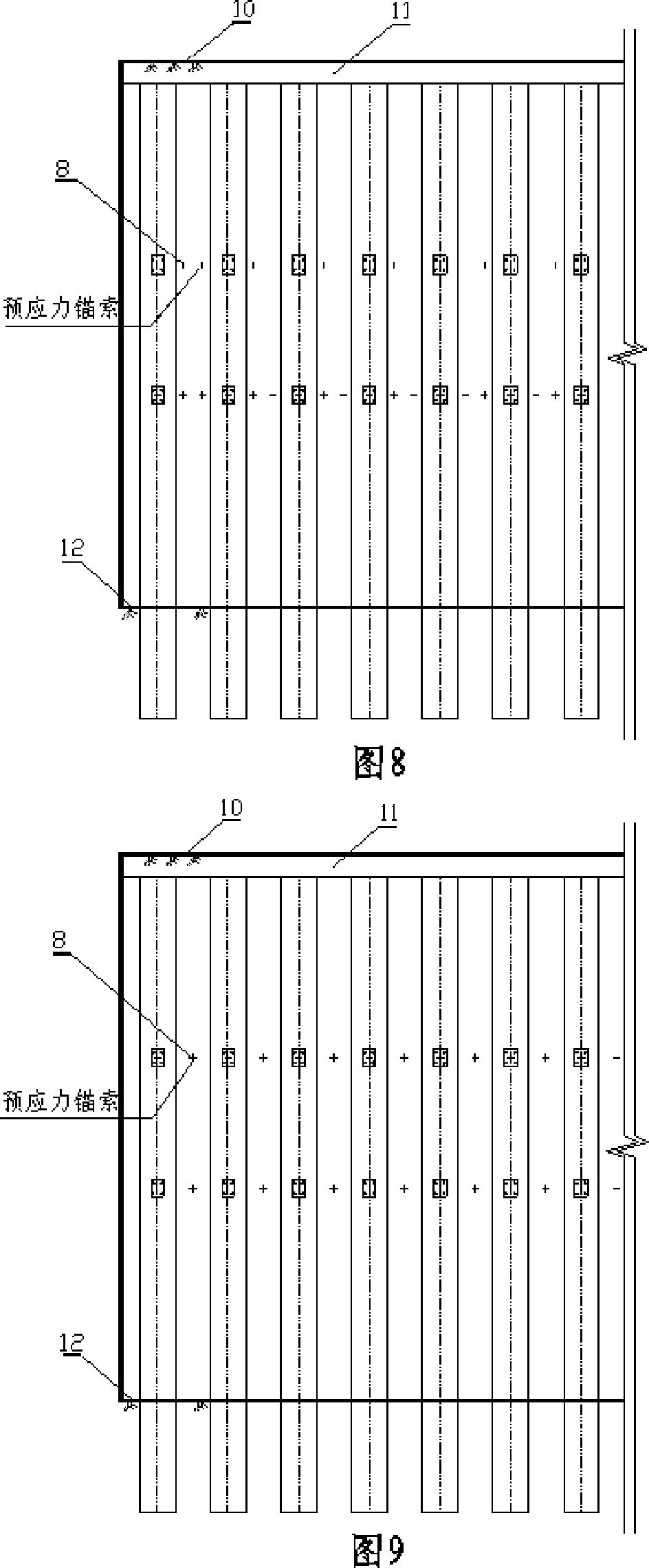

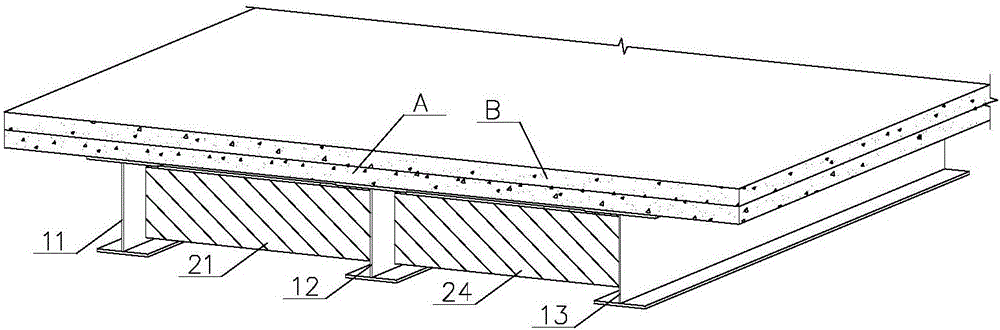

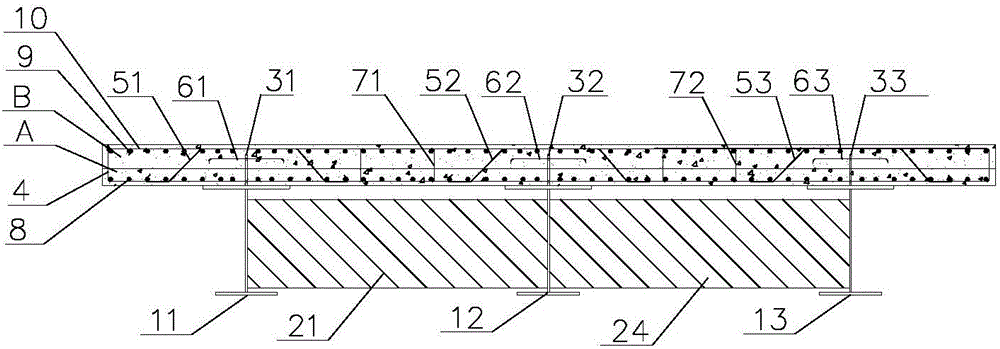

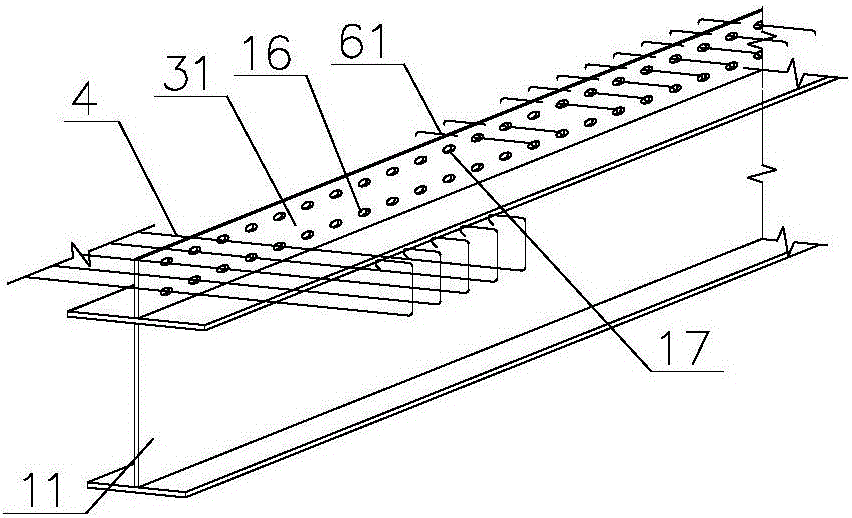

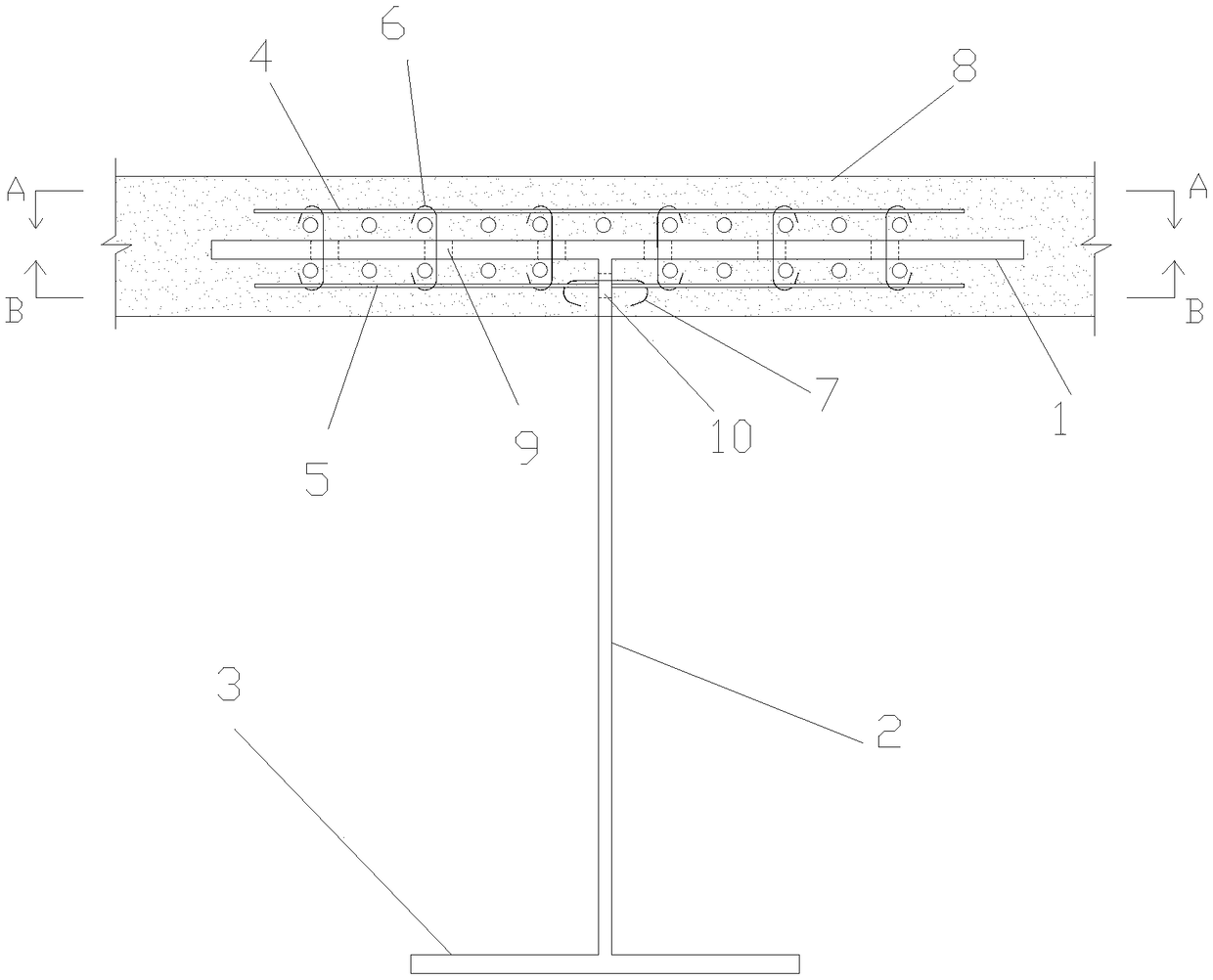

Novel prefabricated type steel-concrete composite beam bridge upper structure and manufacturing technology thereof

InactiveCN106120532AReduce quality problemsReduce fatigueBridge structural detailsBridge materialsManufacturing technologyConcrete beams

The invention provides a novel prefabricated type steel-concrete composite beam bridge upper structure comprising main steel beams, transverse connecting steel beams, metal connecting pieces and prefabricated reinforced concrete bridge deck slabs. The main steel beams are arranged according the shape of a bridge. The webs of the adjacent main steel beams are connected through the transverse connecting steel beams. The upper flanges of the main steel beams are provided with the metal connecting pieces. The prefabricated reinforced concrete bridge deck slabs are laid on the upper flanges of the main steel beams and provided with preformed holes used for grouting of grouting materials after the bridge deck slabs are well installed. The metal connecting pieces are located in the preformed holes. The invention further provides a manufacturing technology of the novel prefabricated type steel-concrete composite beam bridge upper structure. By the adoption of the novel prefabricated type steel-concrete composite beam bridge upper structure and the manufacturing technology of the novel prefabricated type steel-concrete composite beam bridge upper structure, damaged medium and small span concrete beam bridges can be rapidly replaced, the structure safety is good, the construction period is short, the cost is low, and the durability is good.

Owner:宁波金蛟龙重工钢构有限公司

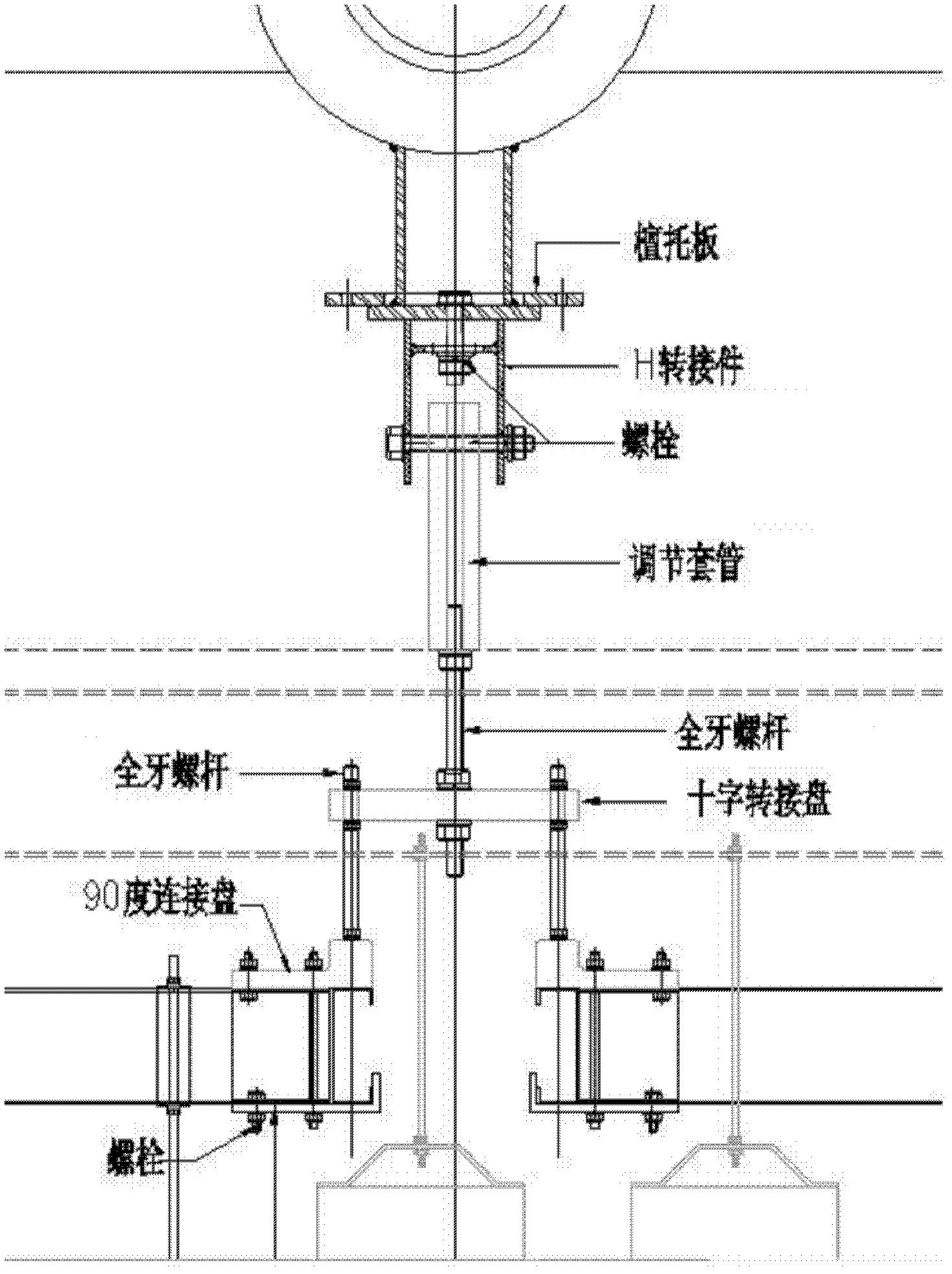

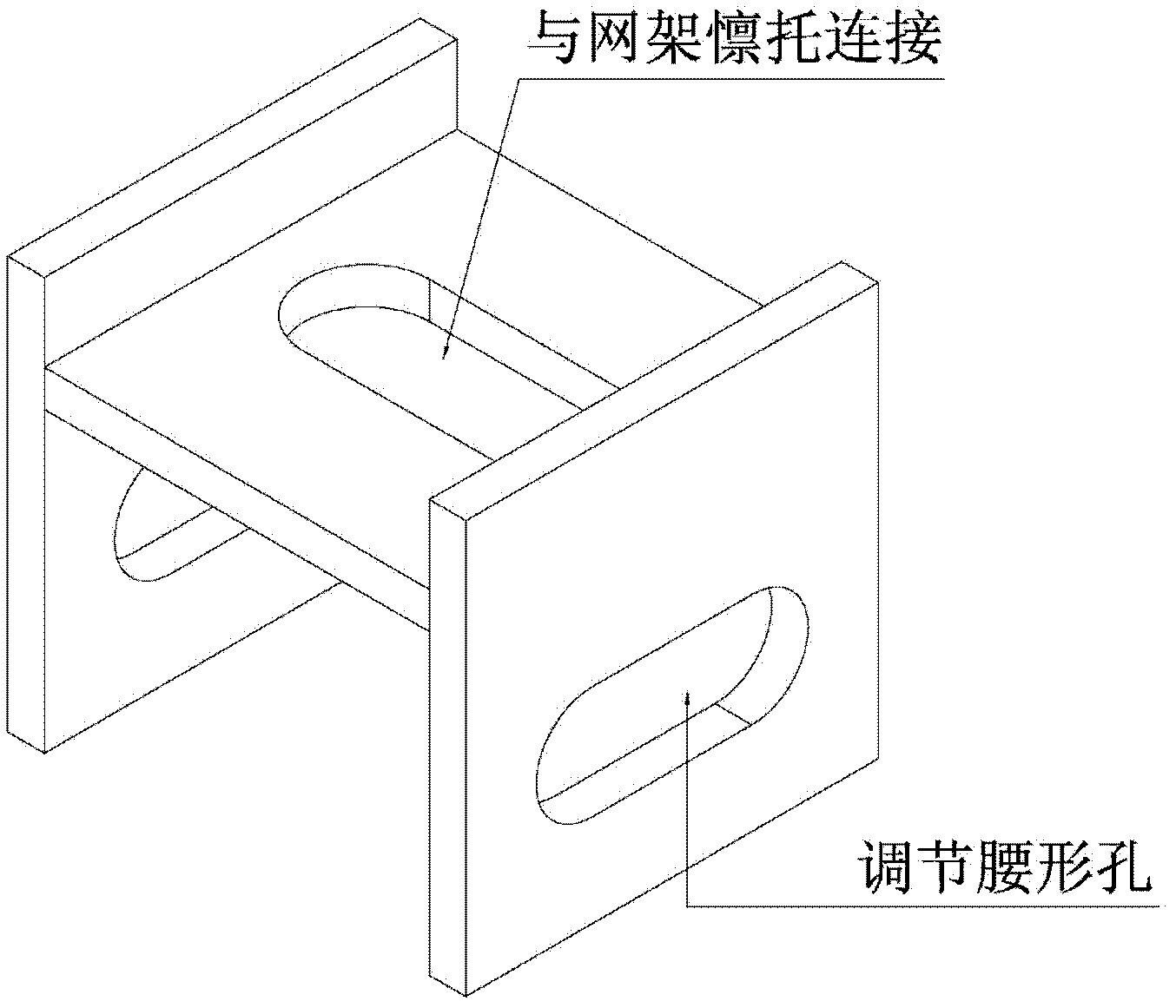

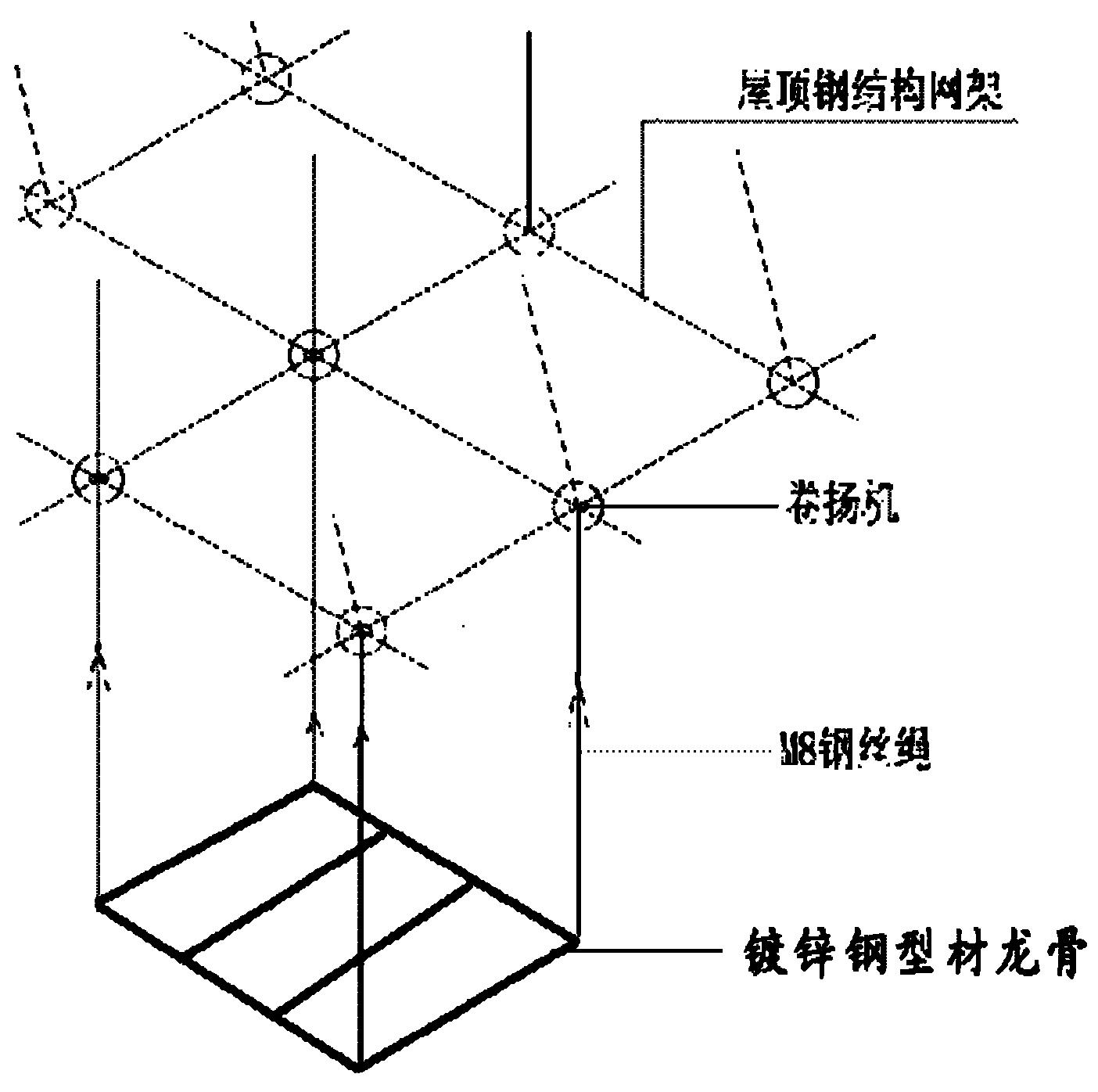

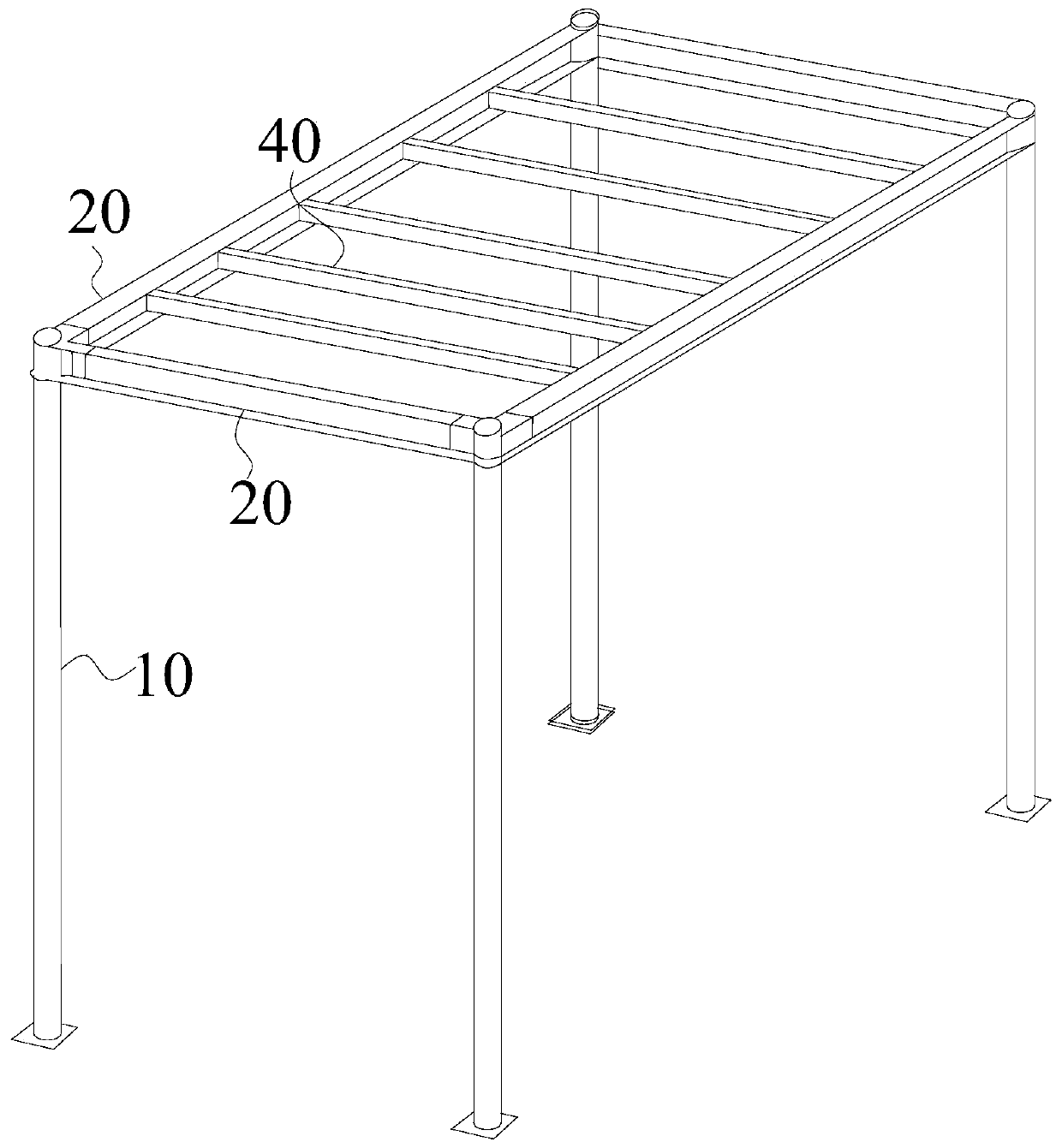

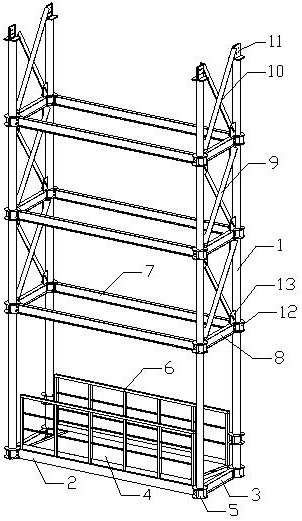

Assembled type unit framework installing method

ActiveCN102995907AReduce investmentImprove installation work efficiencyBuilding material handlingEconomic benefitsEngineering

The invention discloses an assembled type unit framework installing method which is characterized by comprising the following four steps of: measuring, paying off and positioning; installing a seamless steel tube lifting piece; installing an assembled type unit framework; and installing an aluminum panel. According to the assembled type unit framework installing method, the assembled type unit framework is wholly lifted and installed, so that the welding working is greatly reduced, the on-site manufacturing time is saved, the efficiency in large-span high altitude suspended ceiling installation working is improved, and the difficulty in vertical transportation is greatly reduced; by adopting a reversed installation process, the whole installation process is rapider and more convenient, and the erection and the detachment of a scaffold are avoided, so that time is greatly saved for construction on the ground, the labor investment is reduced, the cost is saved, and significant economic benefits are achieved; and moreover, the structure is more solid, the influence from the load of an adjacent region is small, the overall stress is more uniform, and the structure is safer; and meanwhile by utilizing the method, aspects such as on-site civilized construction, security production, construction quality and the like are all well ensured.

Owner:中建八局装饰工程有限公司

Lower flange anti-pulling composite box girder with corrugated steel webs and construction method

InactiveCN103741584AImprove structural performanceGood for long termBridge erection/assemblySheet steelRebar

The invention relates to a lower flange anti-pulling composite box girder with corrugated steel webs and a construction method of the composite box girder, and belongs to the technical field of bridge structures. The composite box girder comprises an upper flange concrete slab, a lower flange concrete slab, the corrugated steel webs, upper flange steel plates, lower flange steel plates and connectors, the corrugated steel webs are connected with the upper flange steel plates and the lower flange steel plates, the lower flange concrete slab is integrated with the lower flange steel plates through the connectors welded on the lower portions of the lower flange steel plates, and the upper flange concrete slab is integrated with the upper flange steel plates through the stud connectors welded on the upper portions of the upper flange steel plates. The composite box girder is characterized in that the connectors on the lower portions of the lower flange steel plates are T-shaped connectors comprising T-shaped connector webs and T-shaped connector top plates. Without increasing steel dosage, the composite box girder solves the problems that reinforcing meshes in a traditional corrugated steel web lower flange concrete slab with PBL connectors, particularly, transverse reinforcements are difficultly constructed, and construction quality is difficultly ensured.

Owner:TSINGHUA UNIV

Connecting structure for use in piled anchor supporting system and its construction method

InactiveCN1970893AGood synergyImprove integrityExcavationsBulkheads/pilesSupporting systemArchitectural engineering

The invention relates to a connecting structure for pile-anchor supporting system and the implementation method, belonging to base foundation engineering technology. The invention contains three parts that the first part comprises drilling hole, anchorage bars and cement mortar, in which steel bar inserts into the drilling hole on the retaining pile and cement mortar is jetted to anchor the steel bar; the second part comprises concrete and pre-buried steel plate, after support framework the wedge is formed by jetted concrete, steel bar and steel plate; the third part comprises connecting steel plate and stiffener. When it is implemented in detail the first step is locating steel bar, chiseling hole, planting reinforcing bar, jetting cement mortar to anchor; the second step is welding the pre-buried steel plate and anchorage bar, forming wedge by cast-in-place concrete; the final step is welding the connecting steel bar and stiffener on the pre-buried steel plate. The invention is provided with safe and reliable supporting system, low cost, short engineering period. Because steel middle beam is canceled, a mass of steel material is saved so as to decrease engineering cost is greatly, simplify construction procedure and shorten the construction period.

Owner:DALIAN UNIV OF TECH

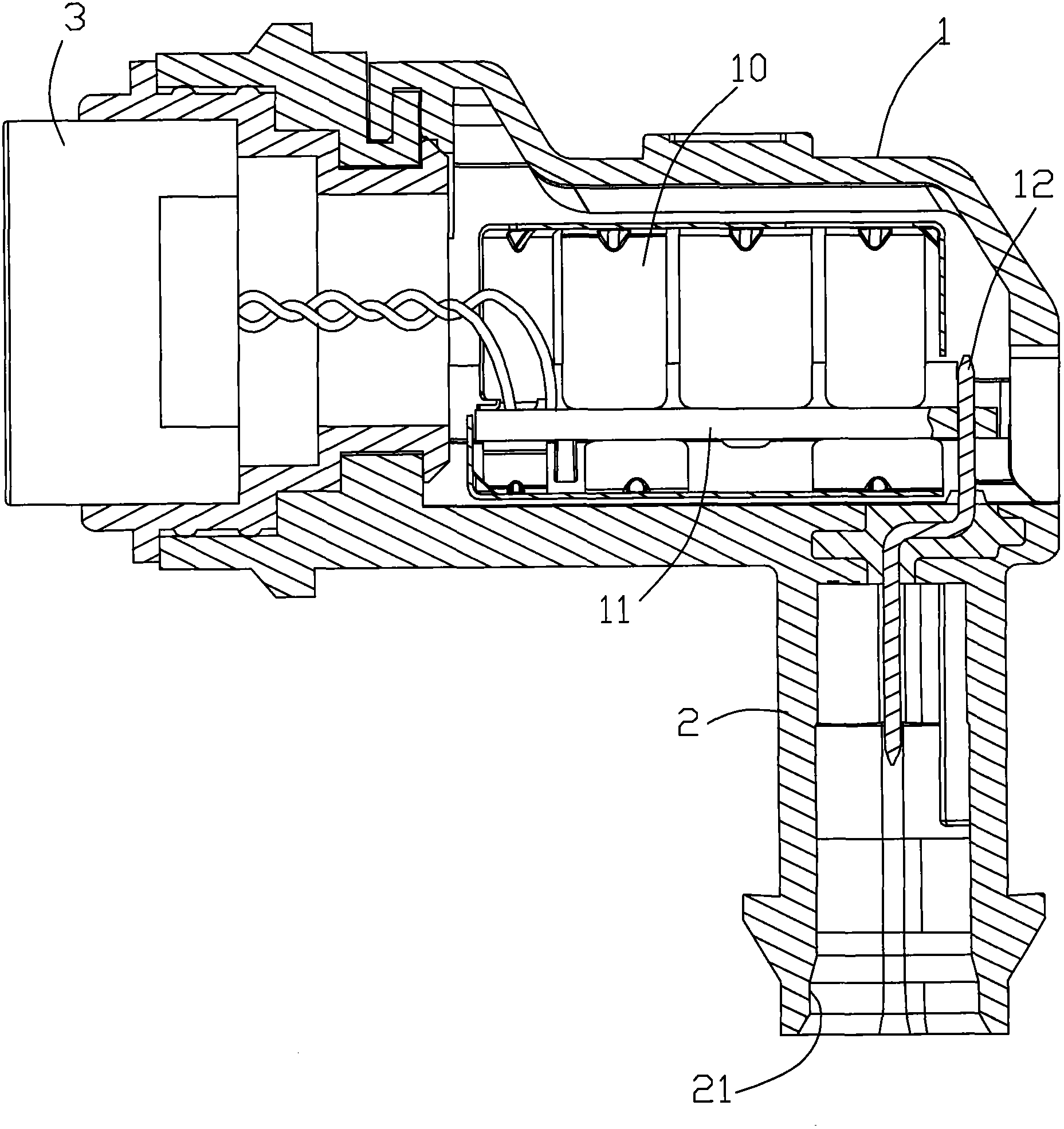

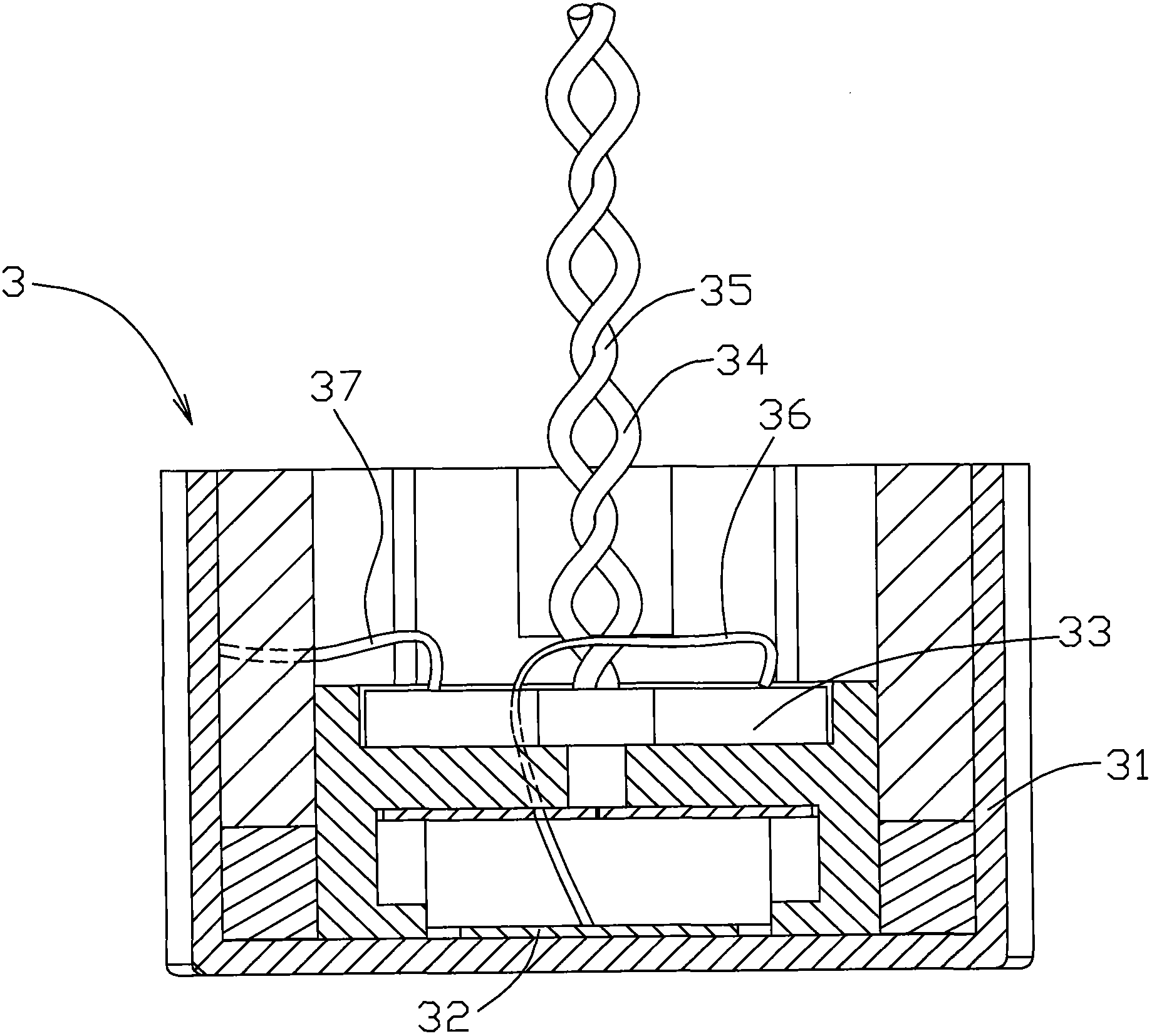

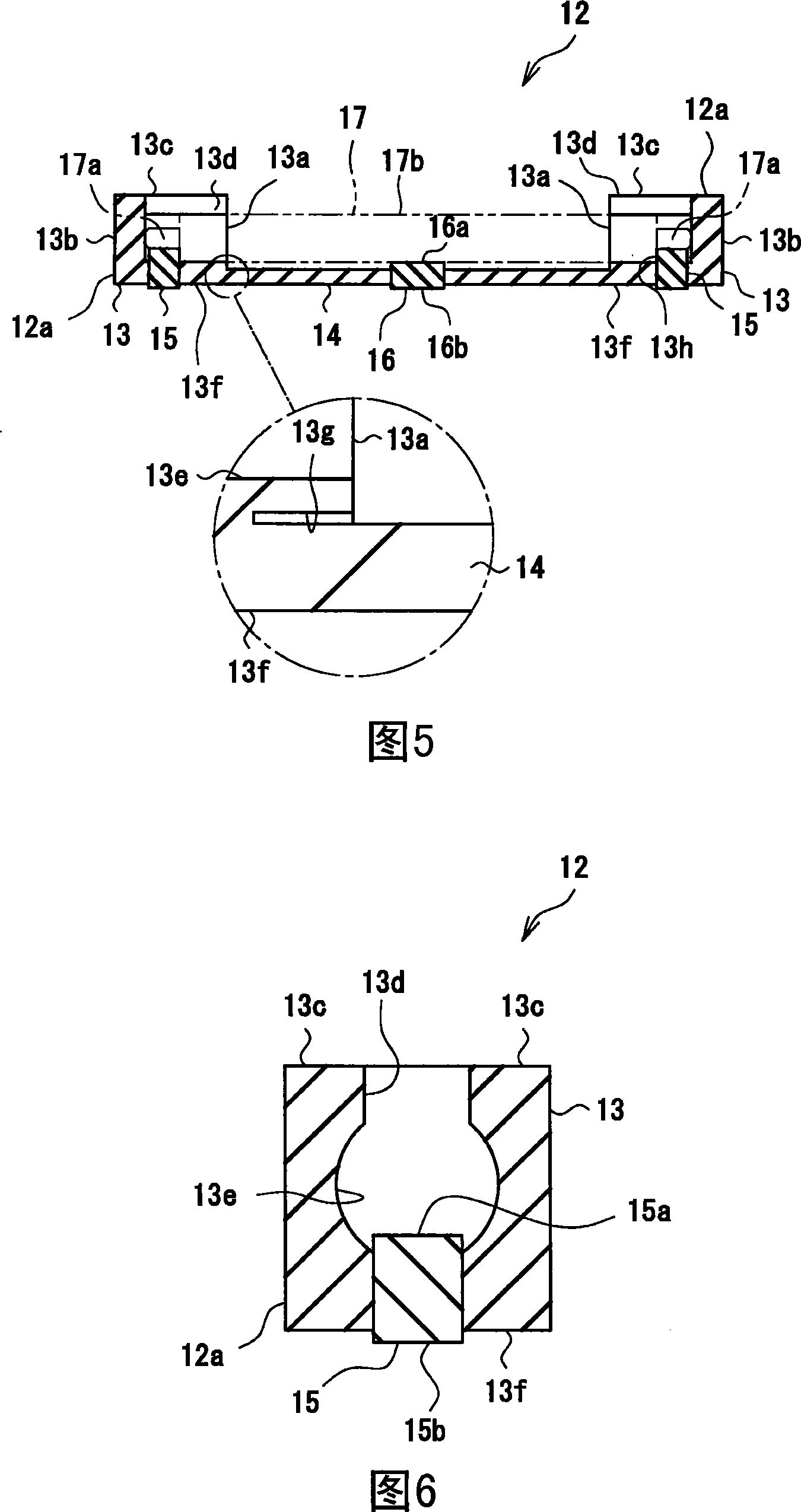

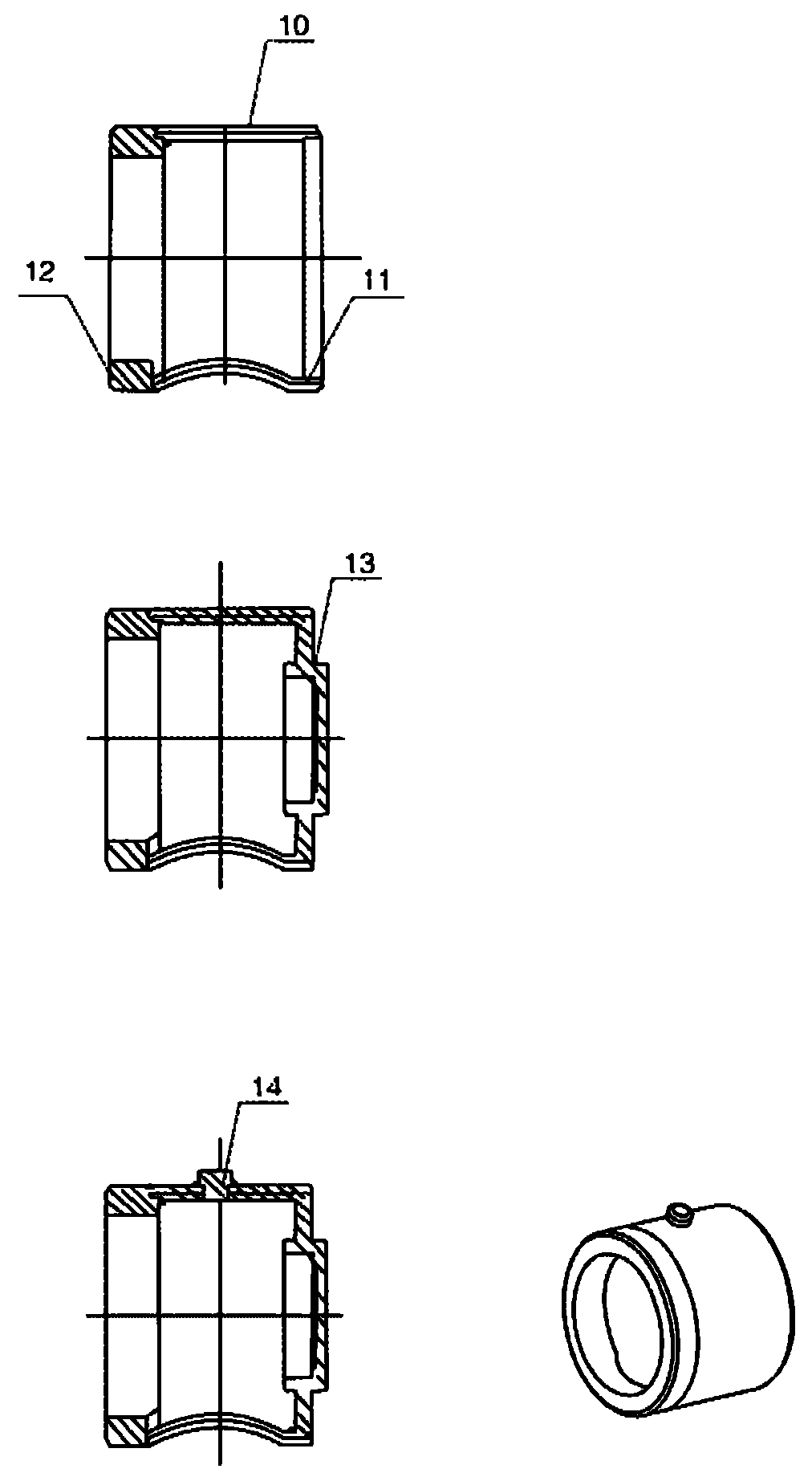

Ultrasonic sensor device

InactiveCN103256950ALess welding workReliable electrical connectionConverting sensor ouput using wave/particle radiationUltrasonic sensorEngineering

The utility model discloses an ultrasonic sensor device, which comprises a hollow shell, a connecting tube part connected with the hollow shell, five pins, a sensor and a circuit board, wherein one end of each pin is positioned at a first opening of the hollow shell, the other ends of two pins are positioned at a second opening of the hollow shell, and the other end of the other three pins are extended into the connecting tube part and positioned at a third opening of the connecting tube part; the sensor is provided with an opening, and the side wall of the sensor is provided with a ground wire hole; the sensor is fixed at the second opening of the hollow shell, so that the other end of one of the pins extended to the second opening extends into the opening and is electrically connected with a piezoelectric patch, and the other end of the other pin extended to the second opening is inserted into the ground wire hole; and the circuit board is arranged on the first opening of the hollow shell and electrically connected with one end of each pin.

Owner:TUNG THIH ELECTRONICS

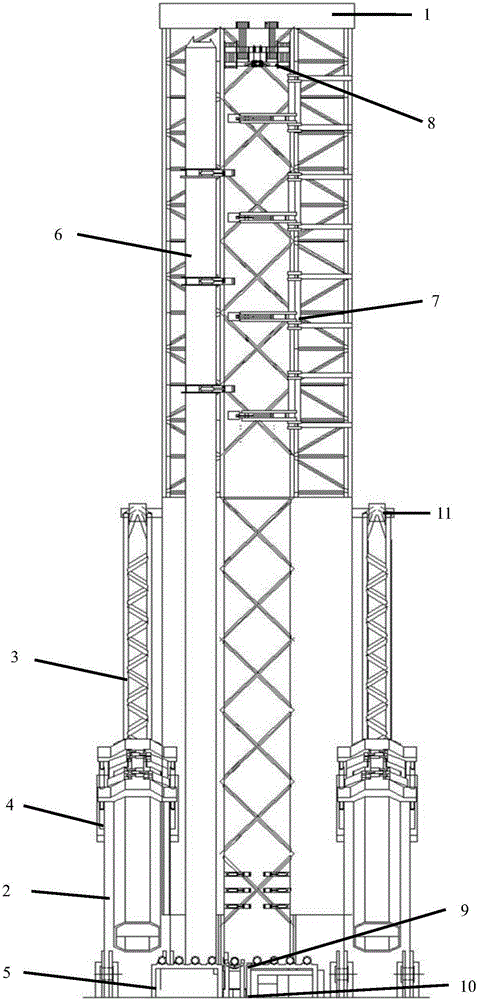

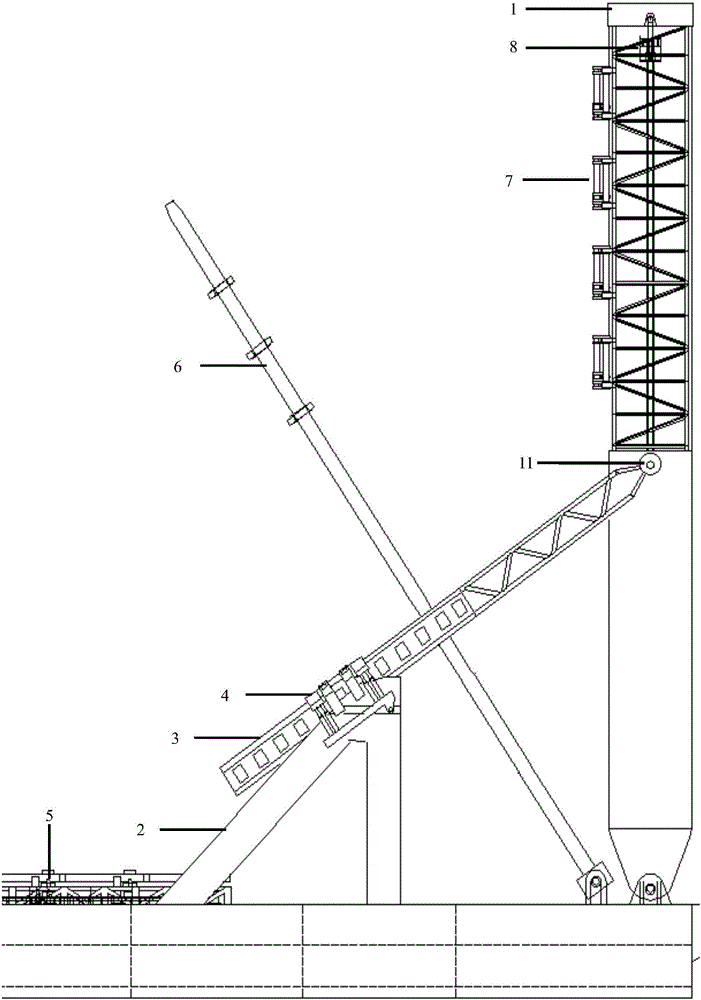

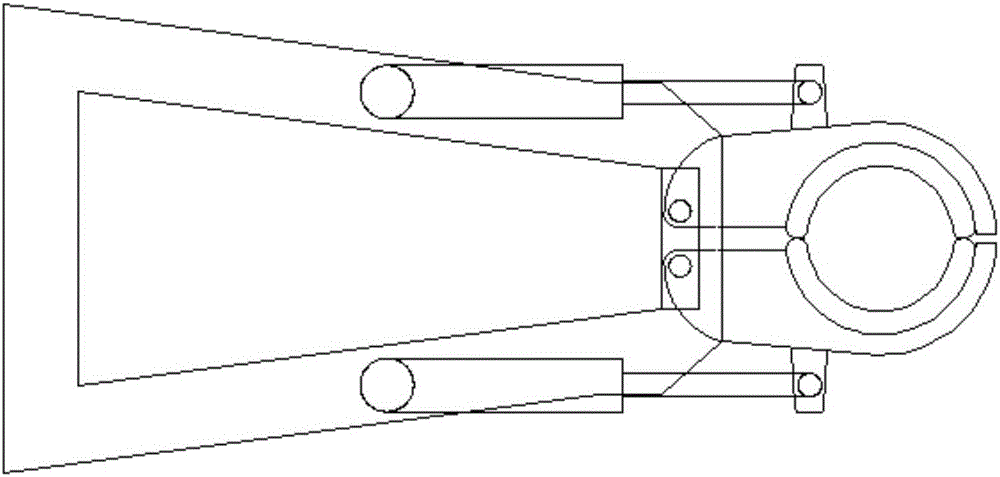

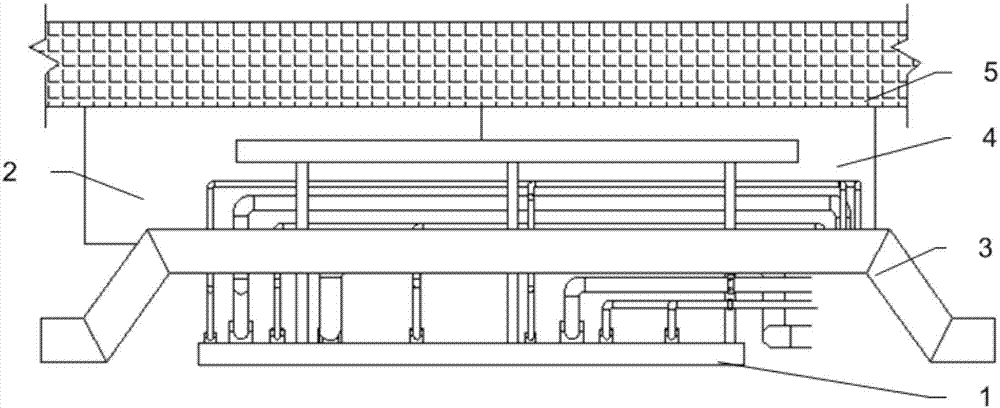

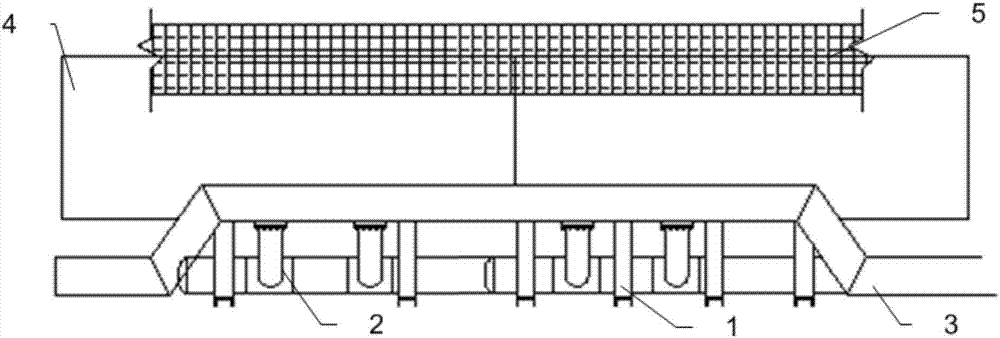

Deep-water quick J-type laying system

ActiveCN105757340ALaying speed is fastImprove efficiencyPipe laying and repairHydraulic cylinderLoading arm

The invention provides a deep-water quick J-type laying system, comprising a laying column, a laying column angle adjusting system, a J-type laying segment conveying system, and J-type laying related equipment. The laying column angle adjusting system mainly comprises an A-shaped frame, an angle adjuster and a hydraulic cylinder, the J-type laying segment conveying system comprises a horizontal conveying system, a loading arm, a rotating arm and an elevator; the J-type laying related equipment generally comprises a centering unit, a welding station and a moving platform. It is possible to provide a 1*4 node (one 4-node segment is laid on the laying tower, and each 4-node segment is 48.8 m in length) laying mode at the premise of controlled height of the laying tower, and by optimizing equipment structure and layout, the laying speed is 80.2% higher than typical J-lay speed of 1.5 km / d and laying cost is reduced.

Owner:哈尔滨航沣科技开发有限公司

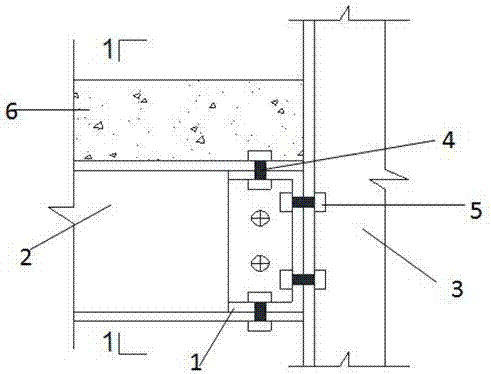

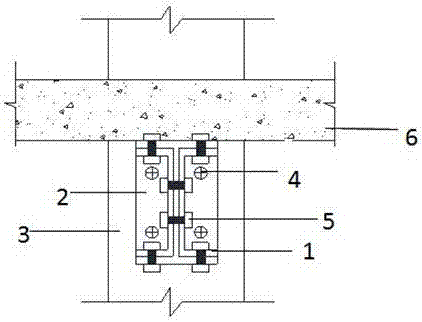

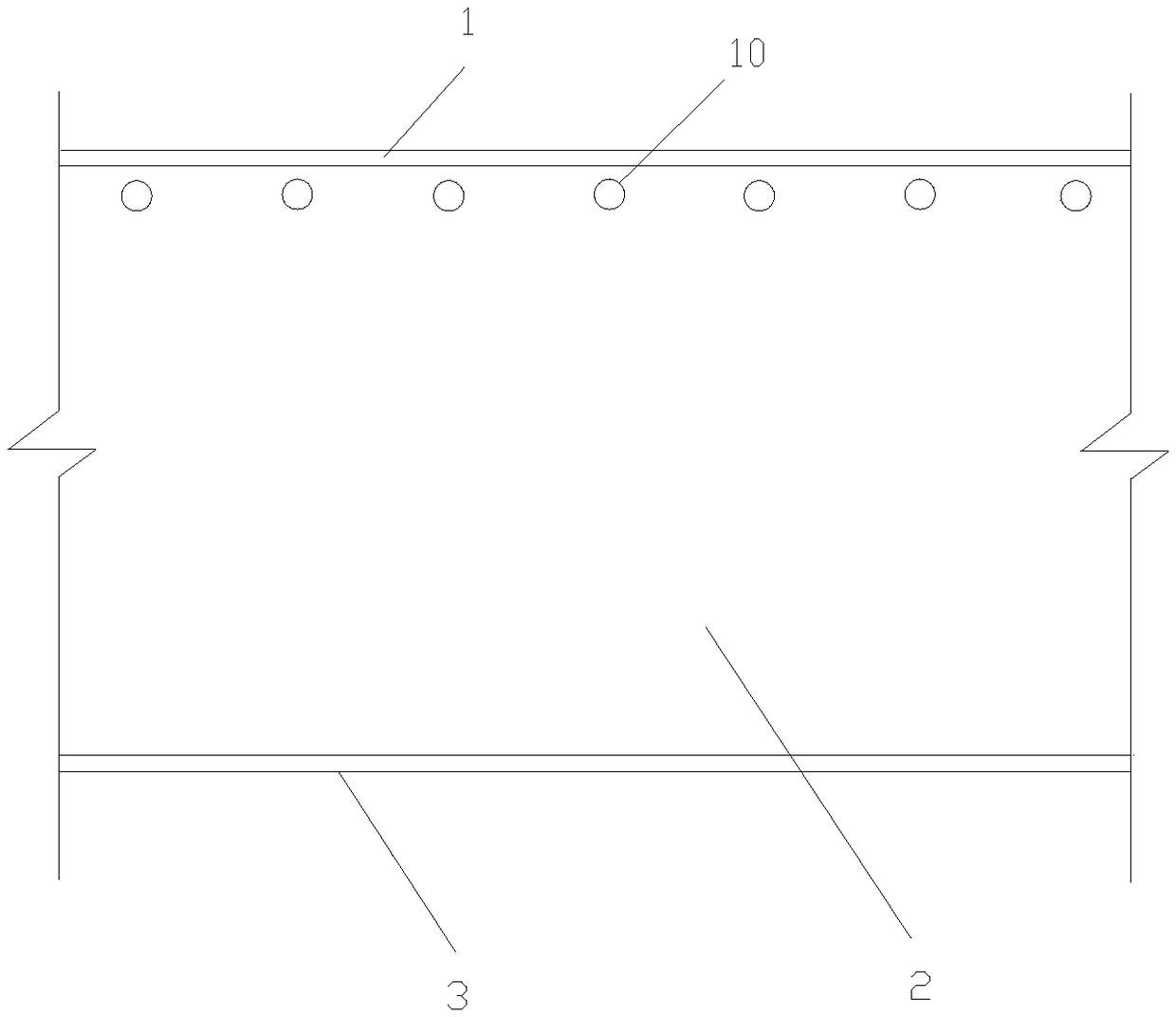

Prefabricated assembly type bolted connection reinforced concrete box-girder

InactiveCN106869404AImprove assembly efficiencyWork lessLoad-supporting elementsPrecast concreteMaterials science

A prefabricated assembly type bolted connection reinforced concrete box-girder comprises a prefabricated concrete slab, a steel beam, embedded bolts, an embedded thin-wall steel plate, embedded steel plates and a butt weld. Firstly, the steel beam and the prefabricated concrete slab are connected through the bolts embedded in the midspan of the prefabricated slab, the bearing capacity of a joint is improved, and the progressive collapse resistance of a structure is facilitated. Secondly, the embedded steel plates embedded at the two ends of the slab can be connected through the butt weld, the two adjacent plates are connected to resist hogging moment of a support part of the structure, and the integrity of the structure is improved. According to the assembly type steel beam, industrialized production is achieved, on-site fast assembly is achieved, the effect that concrete is poured on site is avoided, the construction efficiency is improved, and the environment pollution is reduced. Meanwhile, by the adoption of the assembly type structure system, the detachment and replacement functions of a member can be achieved, and the energy-saving and environment-friendly idea of the building is achieved.

Owner:XIJING UNIV

Off-line assembling and quick installing method for pipelines of confined space

InactiveCN107237923AImprove efficiencyOptimizing processPipe laying and repairGas pipelineConfined space

The invention provides an off-line assembling and quick installing method for pipelines of a confined space, and aims at reducing the confined space pipeline installing and welding difficulty, changing a conventional technological procedure, shortening the construction period and improving the production efficiency. The method is characterized by comprising the steps that 1, the pipeline installing positions, varieties, number and areas are determined according to a pipeline installing drawing; 2, the pipelines in the confined space are manufactured into a frame type pipe network according to relevant data in a manufacturing field; 3, the frame type pipe network is installed on corresponding parts by being divided into a plurality of portions or integrally installed on the corresponding parts before a structure or a platform or equipment is hoisted; 4, the equipment with the frame type pipe network is installed in position; and 5, the tail-end pipeline of the frame type pipe network is connected with a medium pipeline. According to the new technology, the construction procedure that the pipelines are prefabricated and assembled in advance and then assembled on the equipment in an off-line mode to be installed together with the equipment is adopted, therefore, the construction time in the confined space is correspondingly shortened, and the quality and the installing precision are improved.

Owner:CHINA MCC20 GRP CORP

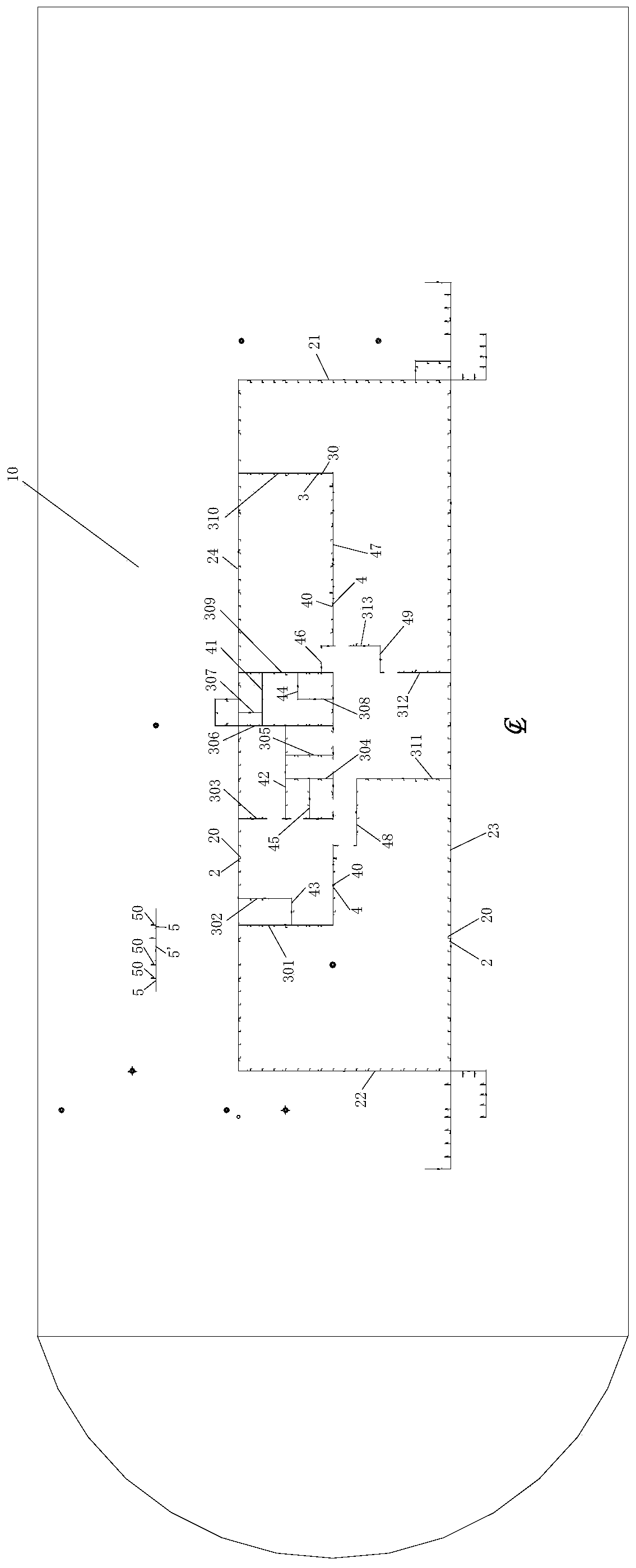

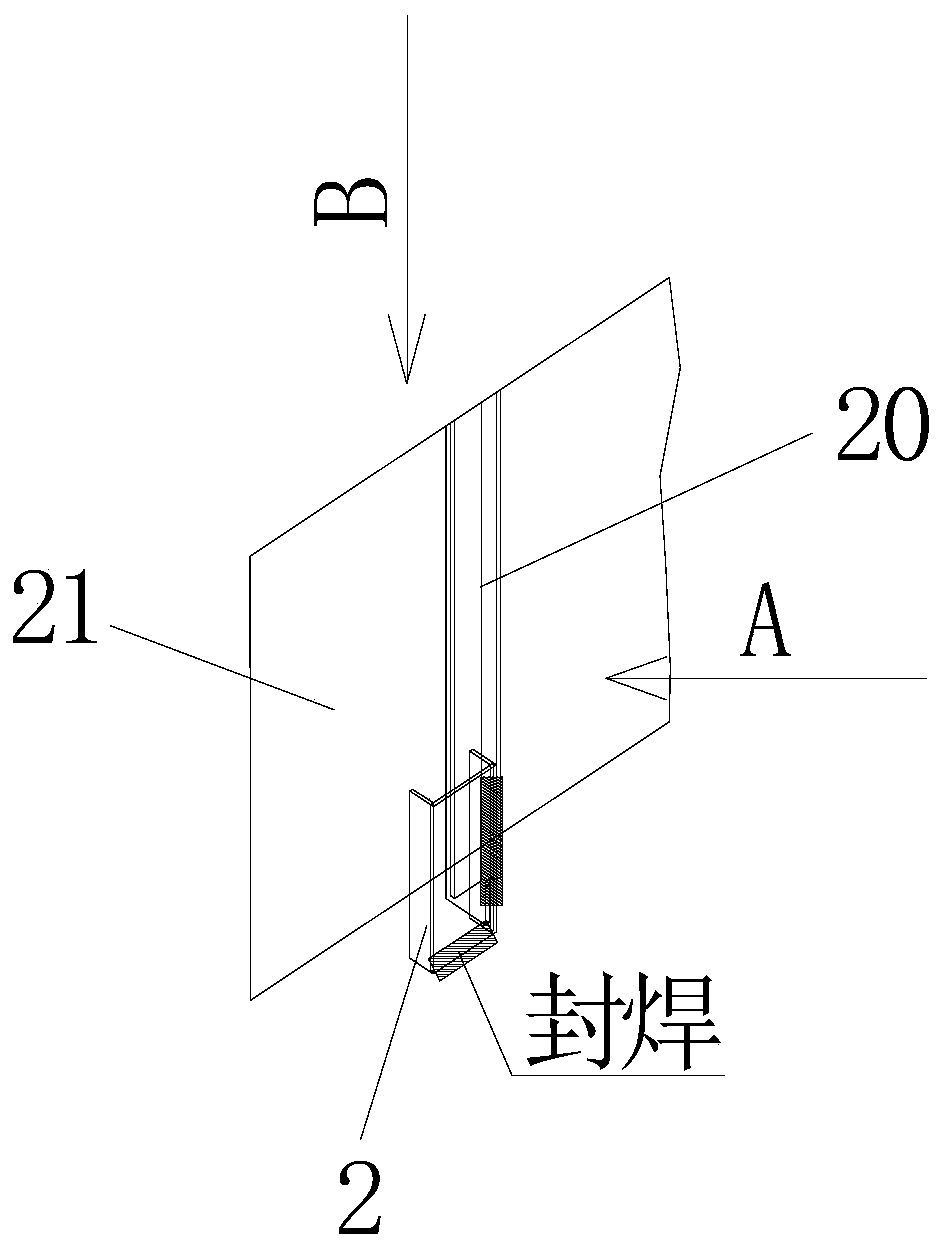

Sea bond structure for FPSOsuperstructure total segment during lightering

ActiveCN110304208ASave materialLow costVessel superstructuresAccommodation for deck loadsEngineeringUpper floor

The invention discloses a sea bond structure for FPSO superstructure total segment during lightering. The sea bond structure comprises a lighter, a superstructure total section, a plurality of wall enclosing sea binding members, a plurality of longitudinal sea binding members, a plurality of transverse sea binding members and two outer wall sea binding members. The superstructure total section comprises an enclosing wall, an inner wall and an outer wall, wherein the enclosing wall comprises a larboard enclosing wall, a starboard enclosing wall, a bow enclosing wall and a stern enclosing wall;the inner wall comprises a first to a thirteenth longitudinal inner walls and a first to a ninth transverse inner walls; and one surface of the outer wall is provided with outer wall vertical stiffeners at intervals. The superstructure total section is hoisted on the deck of the lighter in a manner that the starboard enclosing wall is towards the bow of the lighter, and the stern enclosing wall istowards the starboard of the lighter, and a sixth transverse inner wall is superposed with the central line of the hull of the lighter. The enclosing sea binding members, the longitudinal sea bindingmembers, the transverse sea binding members and the outer wall sea binding members are of channel steel with the length equal to 500 mm. The sea bond structure has the advantages that materials are saved, the manpower, time and cost can be reduced and requirements on transportation safety can be met.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

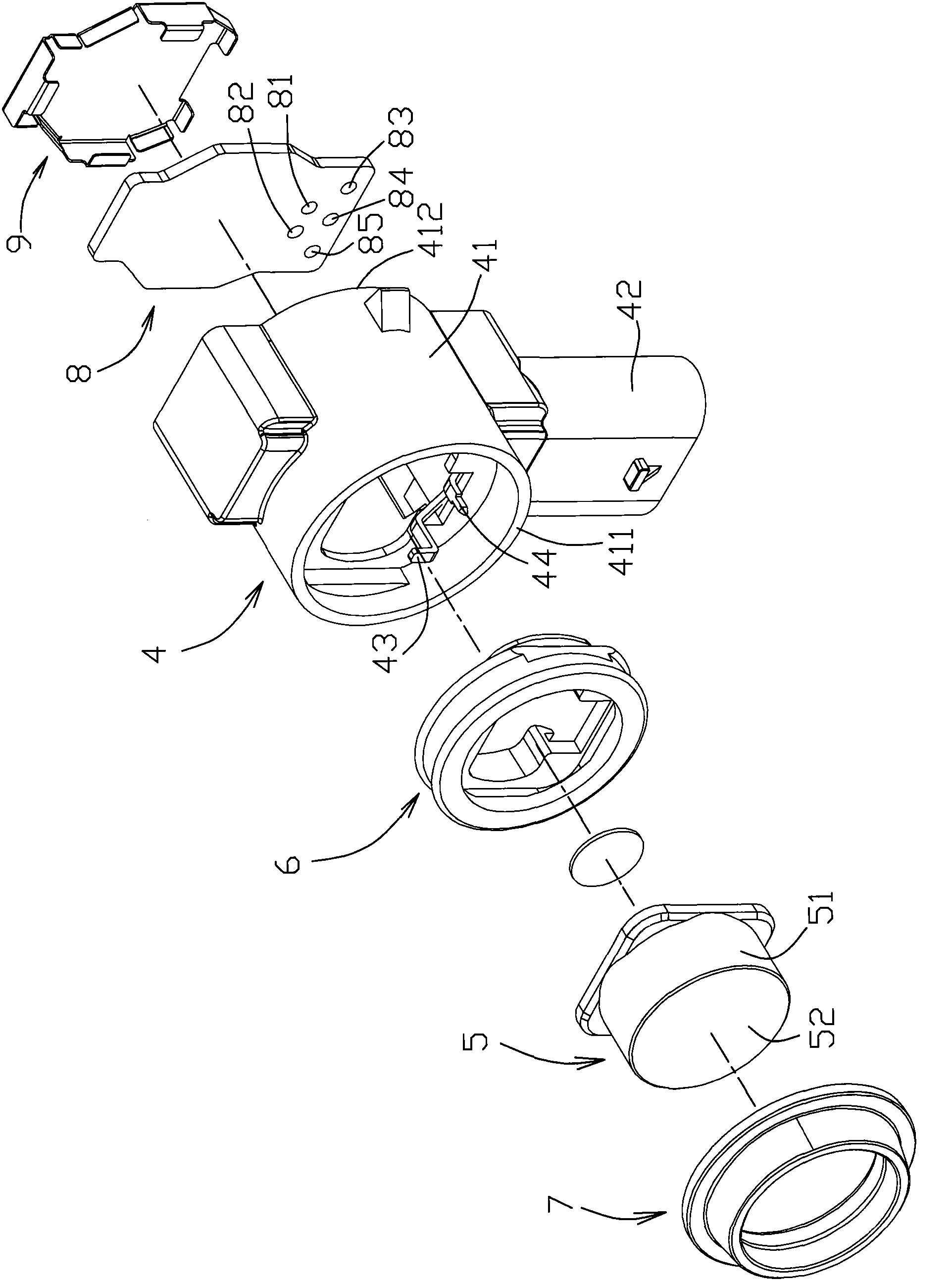

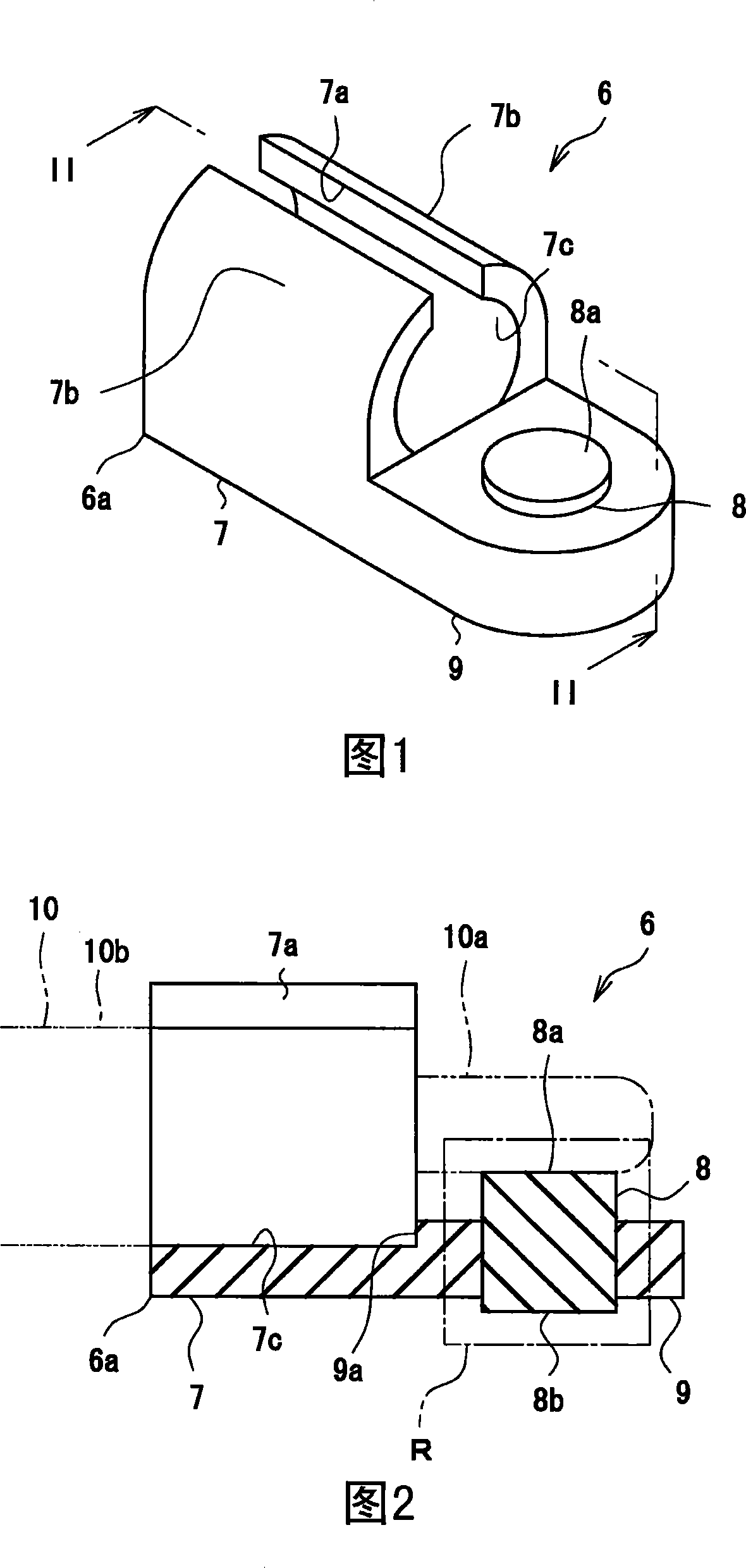

Discharge tube connector

InactiveCN101210669AWon't hurtFirmly connectedElectric discharge tubesElectric circuit arrangementsManufacturing cost reductionElastomer

The present invention provides a discharge tube connector which suppresses the occurrence of a damage of a discharge tube at the time of installation and can be easily installed. An end electrode (10a) of the discharge tube (10) and a board electrode on a circuit board can be electrically connected with each other through a conductive connection portion (8) without using lead wires, so a damage such as a crack and the like, of a light-emitting portion (10b) of the discharge tube (10) can be avoided. When a holding portion (6a) is made of a rubber-like elastic material, the conductive connection portion (8) has rubber-like elasticity, so the conductive connection portion (8) can be pressed between the end electrode (10a) and the board electrode on the circuit board to conductively connect the end electrode (10a) with the board electrode. Therefore, the soldering operation can be omitted. Thus, installation does not take time, so a manufacturing cost can be reduced.

Owner:POLYMATECH CO LTD

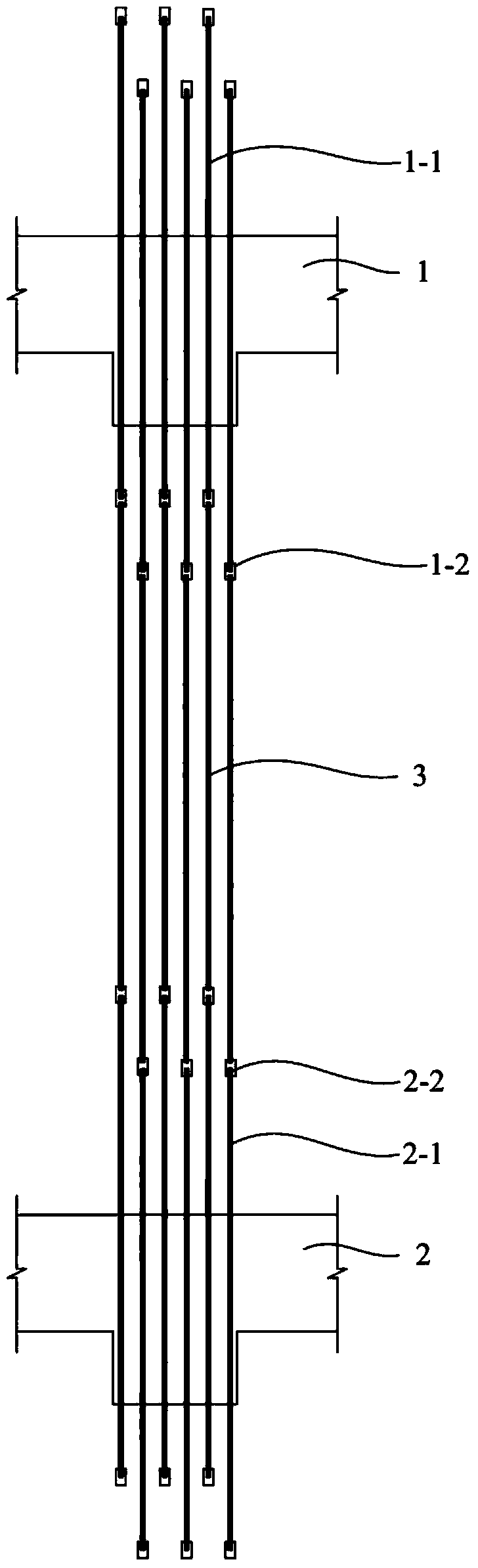

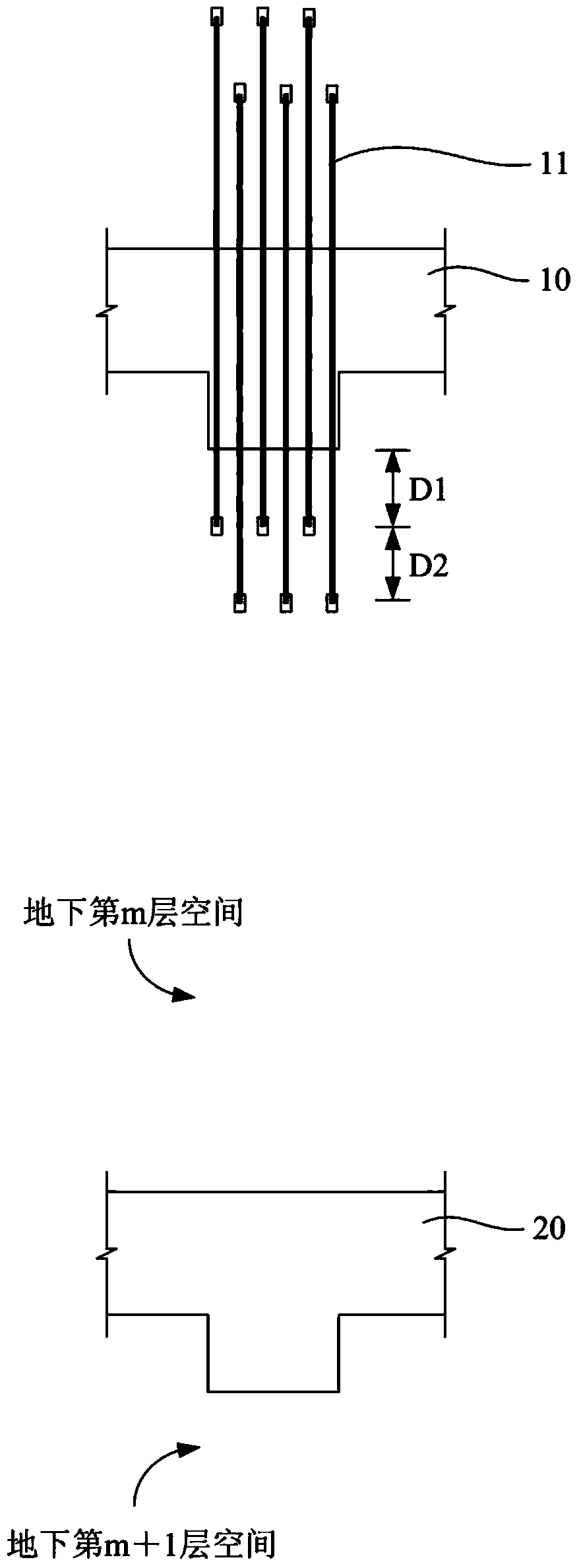

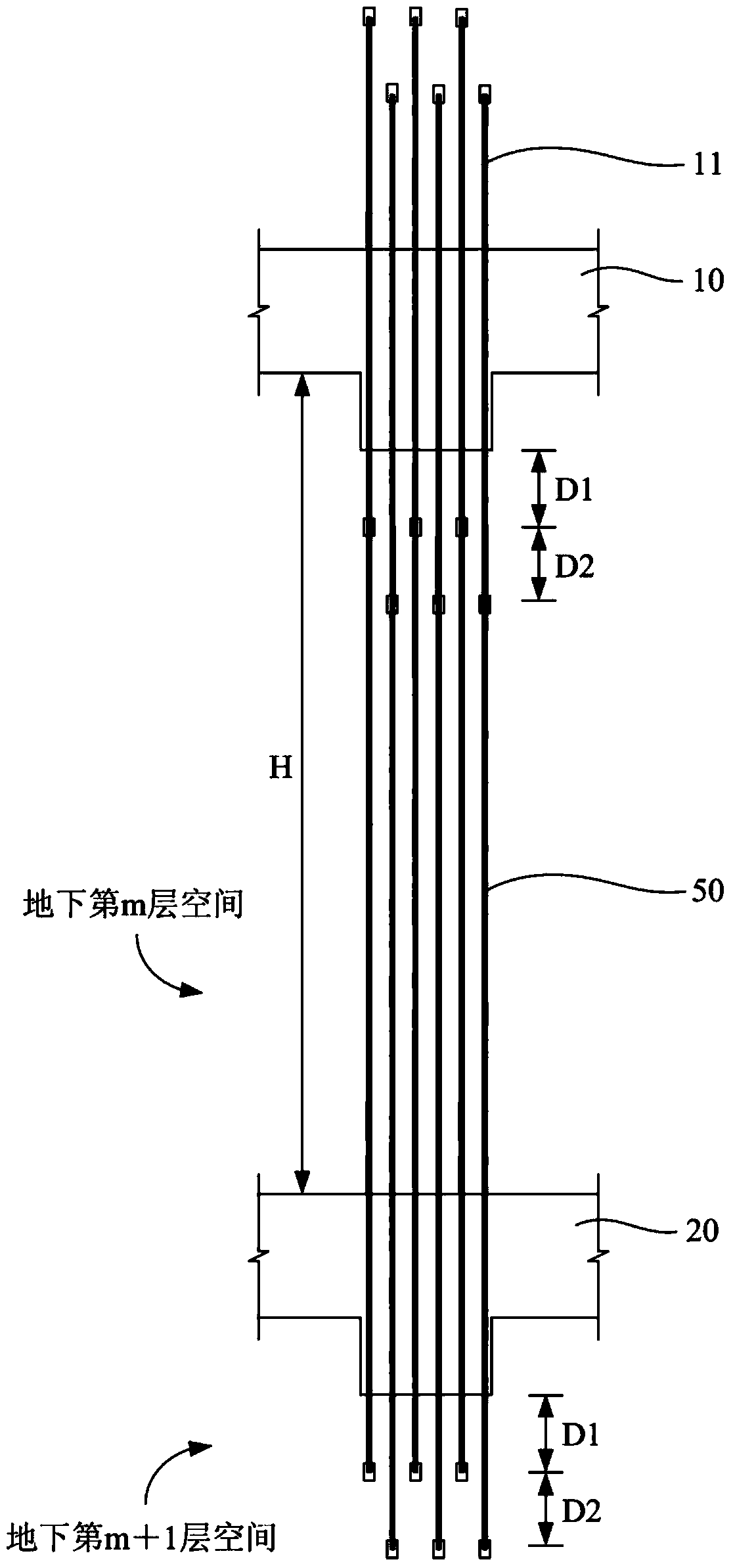

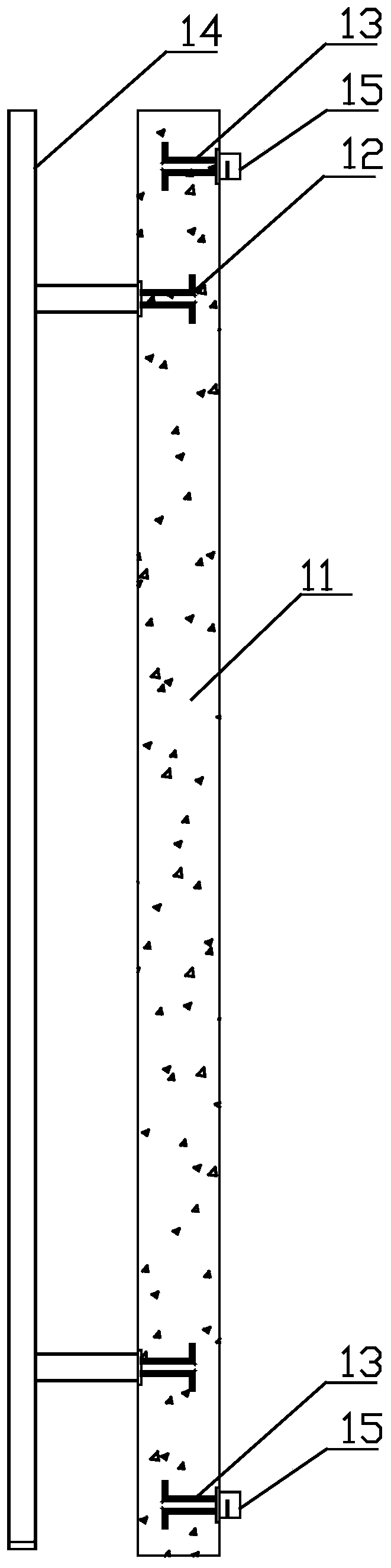

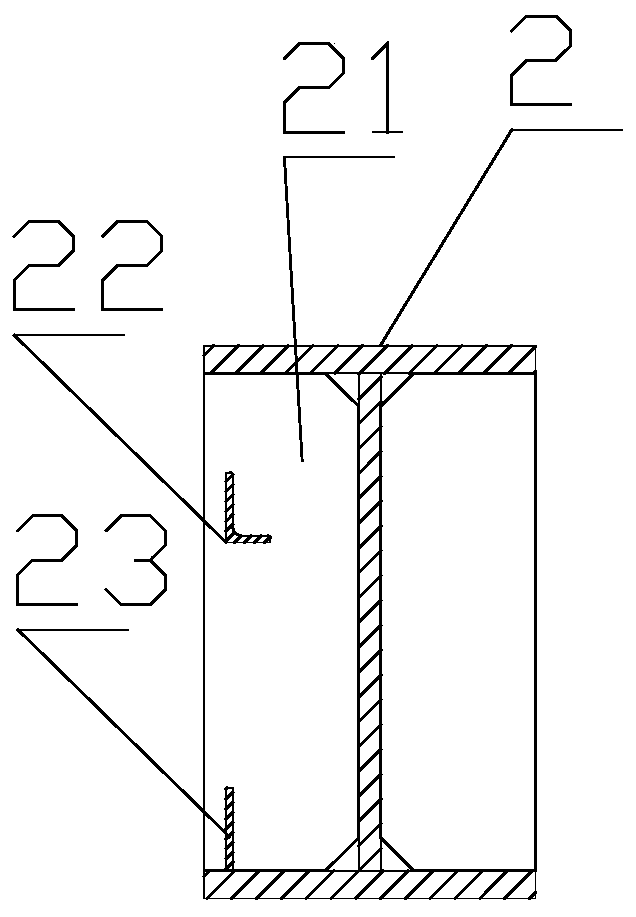

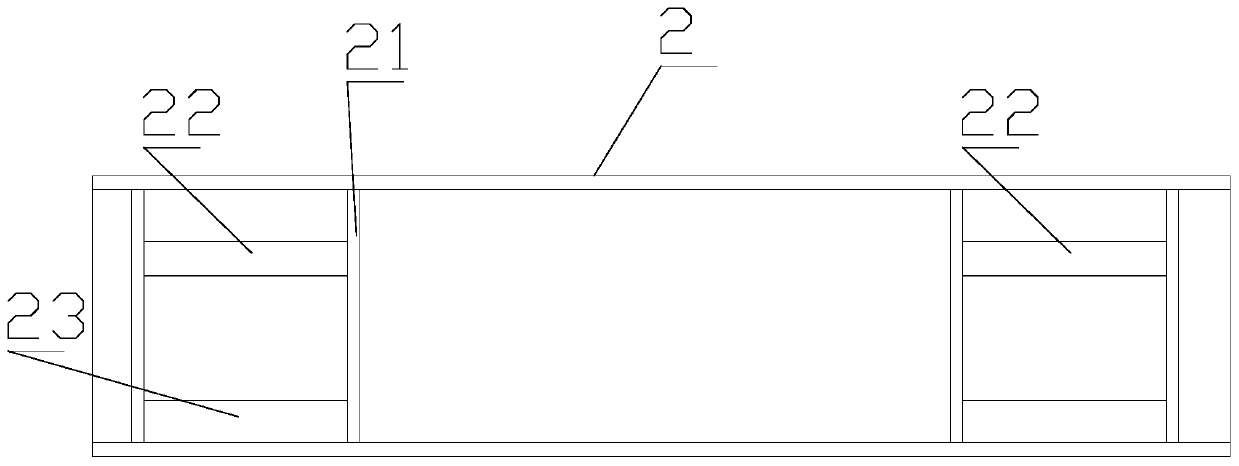

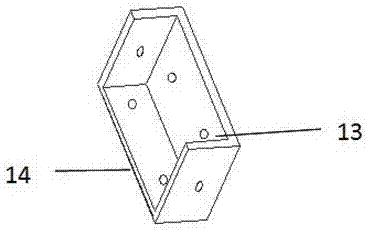

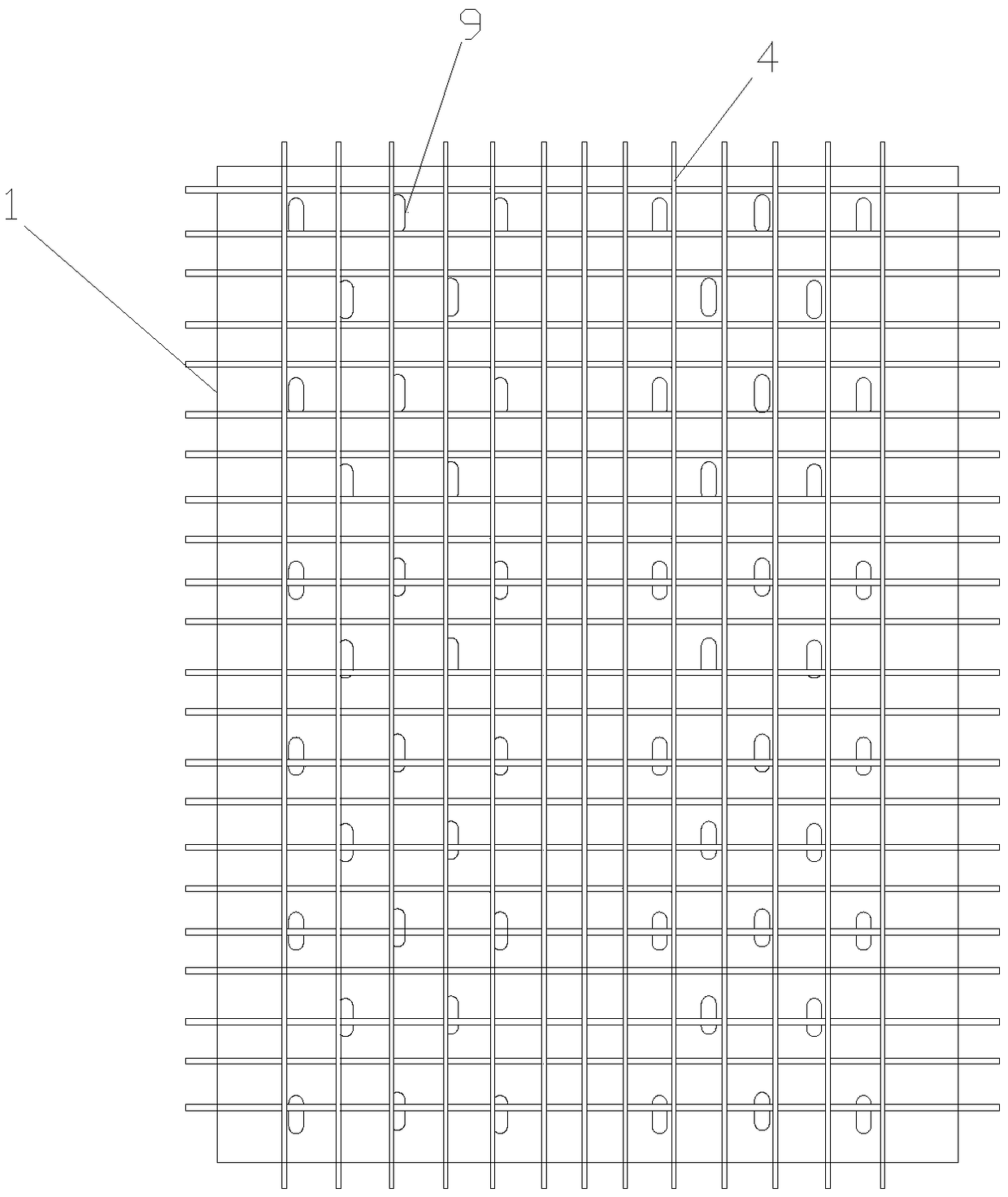

Cylindrical reinforcing steel bar connecting method and connecting structure in reverse building method

InactiveCN103711132APrevent foundation pit from upliftingReduce welding workloadExcavationsRebarBuilding material

The invention provides a cylindrical reinforcing steel bar connecting method and connecting structure in a reverse building method, and relates to the technical field of site manufacturing of building materials or building components. The problems that an existing cylindrical inserting bar is multiple in connecting welding spot, the plasticity of steel bars is lowered, the brittleness of the steel bars is enhanced, welding workloads are large, and the consumption of steel is large are solved. The cylindrical reinforcing steel bar connecting method comprises the steps that first, cylindrical inserting bars are reserved in a cross beam in the underground mth layer of space; second, connecting steel bars are machined; third, the top ends of the connecting steel bars are fixedly connected with the cylindrical inserting bars in the underground mth layer of space, and the bottom ends of the connecting steel bars penetrate through a cross beam in the underground (m+1)th layer of space to enter the inside space; fourth, the second step and the third step are repeatedly executed to form cylindrical steel bars in the underground (m+1) layer of space, in this way, circulation is conducted to form cylindrical steel bars in the underground (m+n)th layer of space, and the m and the n are integers larger than or equal to one. The connecting structure comprises a plurality of connecting steel bars, the top ends of the connecting steel bars are fixedly connected with the cylindrical inserting bars in the cross beam in the underground mth layer of space, the bottom ends of the connecting steel bars penetrate through the cross beam in the underground (m+1)th layer of space to enter the inside space in the underground (m+1)th layer.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

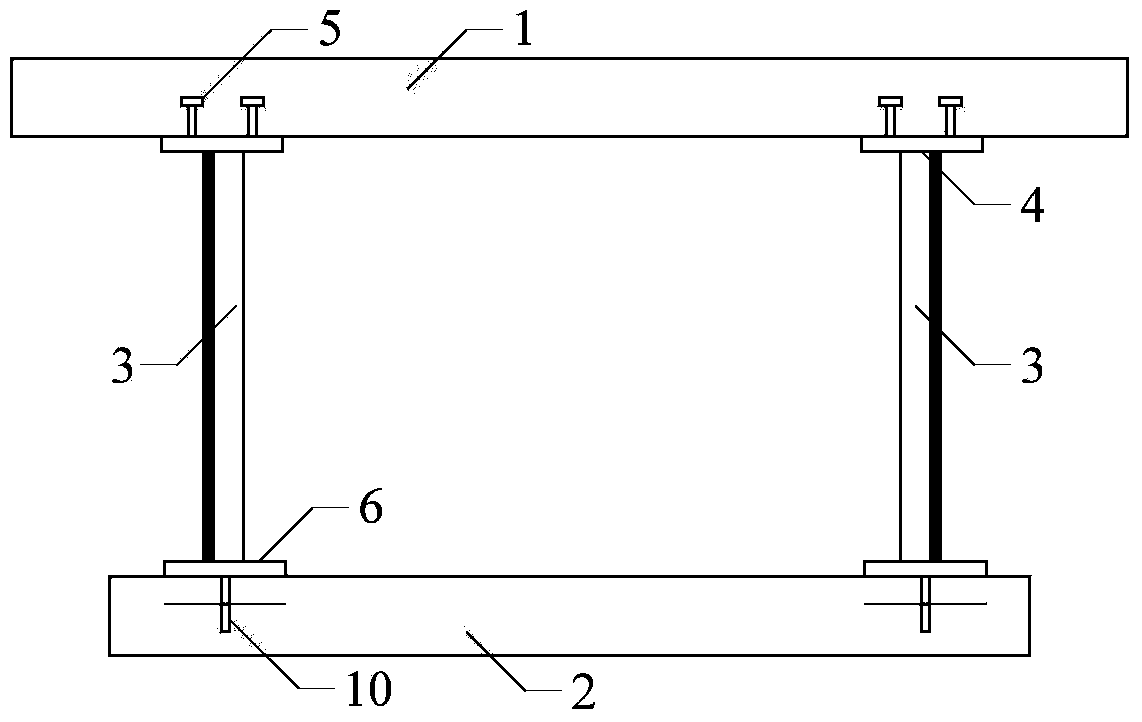

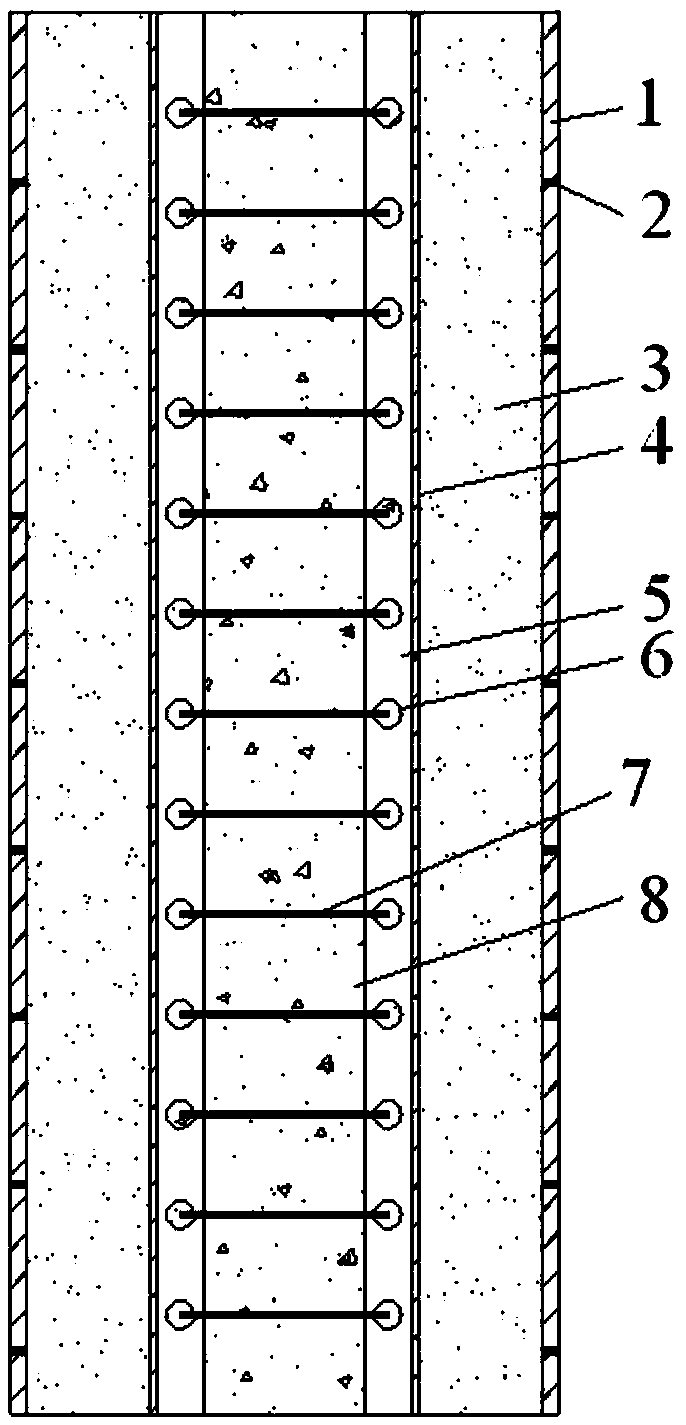

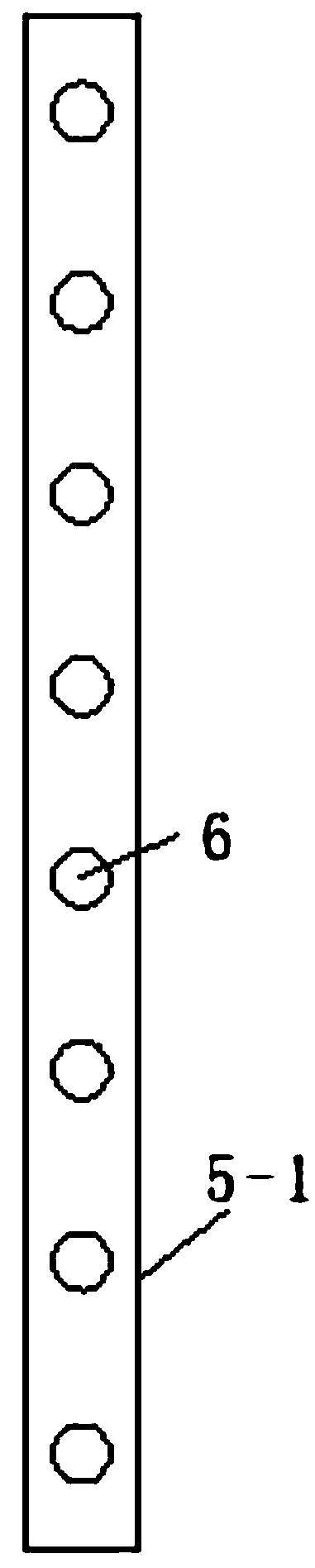

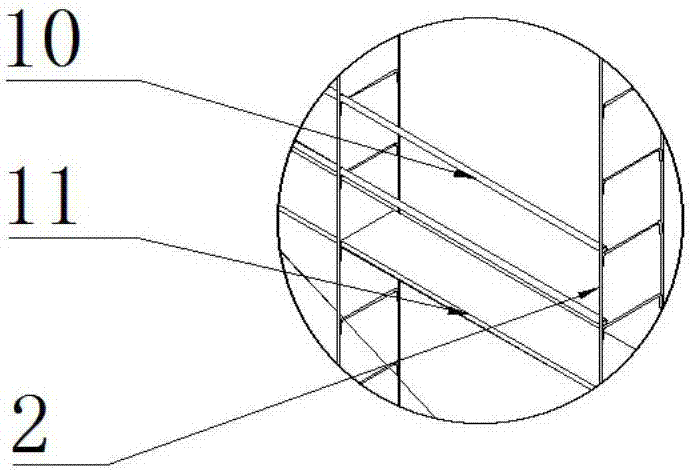

Assembled type steel structure concrete external wall panel and node and construction method of node

PendingCN110777994ALess welding workReduce high-altitude welding operationsWallsKeelArchitectural engineering

The invention discloses an assembled type steel structure concrete external wall panel and a node and a construction method of the node. The method comprises the following steps of 1) preparing the assembly node in an assembled type steel structure steel beam; 2) preparing the light-weight concrete external wall panel with a hook embedded part and a curtain wall main keel embedded part; 3) weldinga curtain wall main keel and the curtain wall main keel embedded part, a hook and the hook embedded part; and 4) hanging the light-weight concrete external wall panel with the curtain wall main keelon a fixed clamping plate and a fixed angle steel. According to the assembled type steel structure hook type light-weight concrete external wall panel with the composite curtain wall main keel, the on-site welding operation is less, the high-altitude welding operations is reduced, the full assembly of the construction is realized, at the same time, compared with the traditional connection method,the structure is simple, the installation speed is greatly increased, the construction efficiency is high, and the bearing capacity is greatly improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

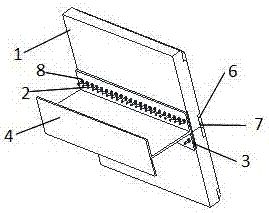

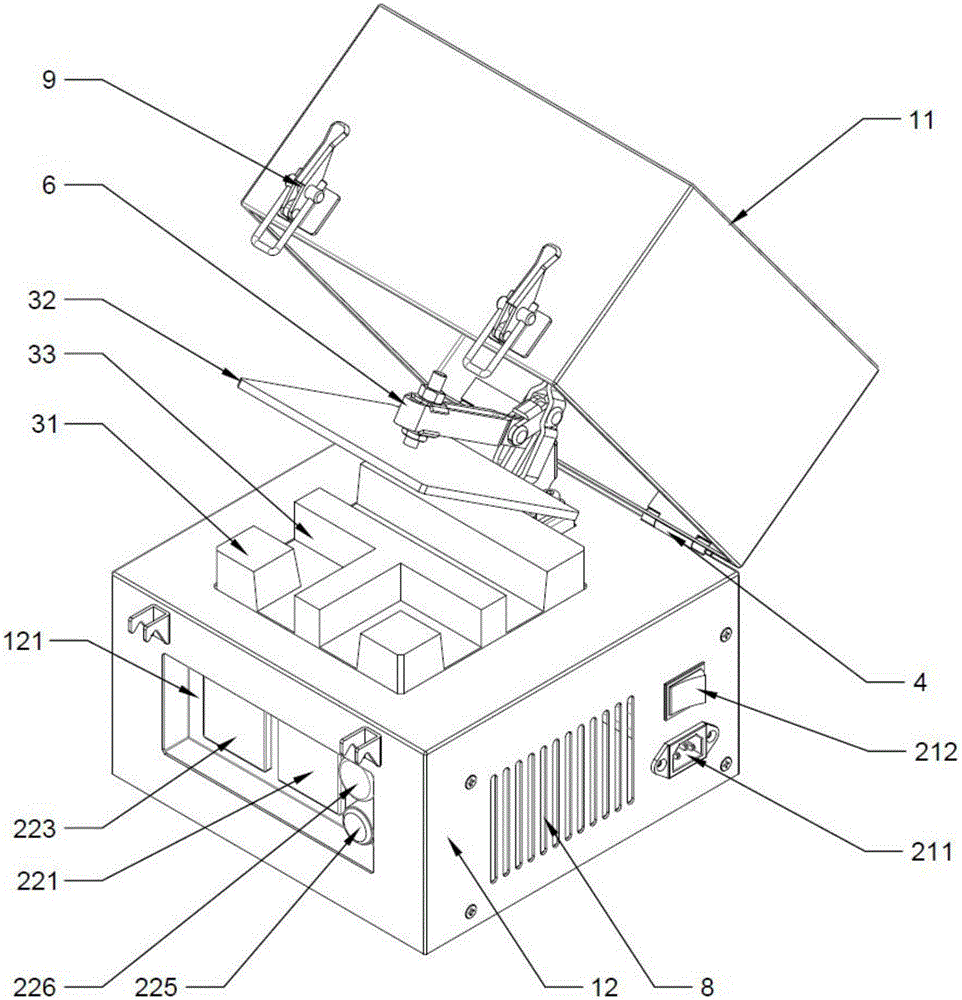

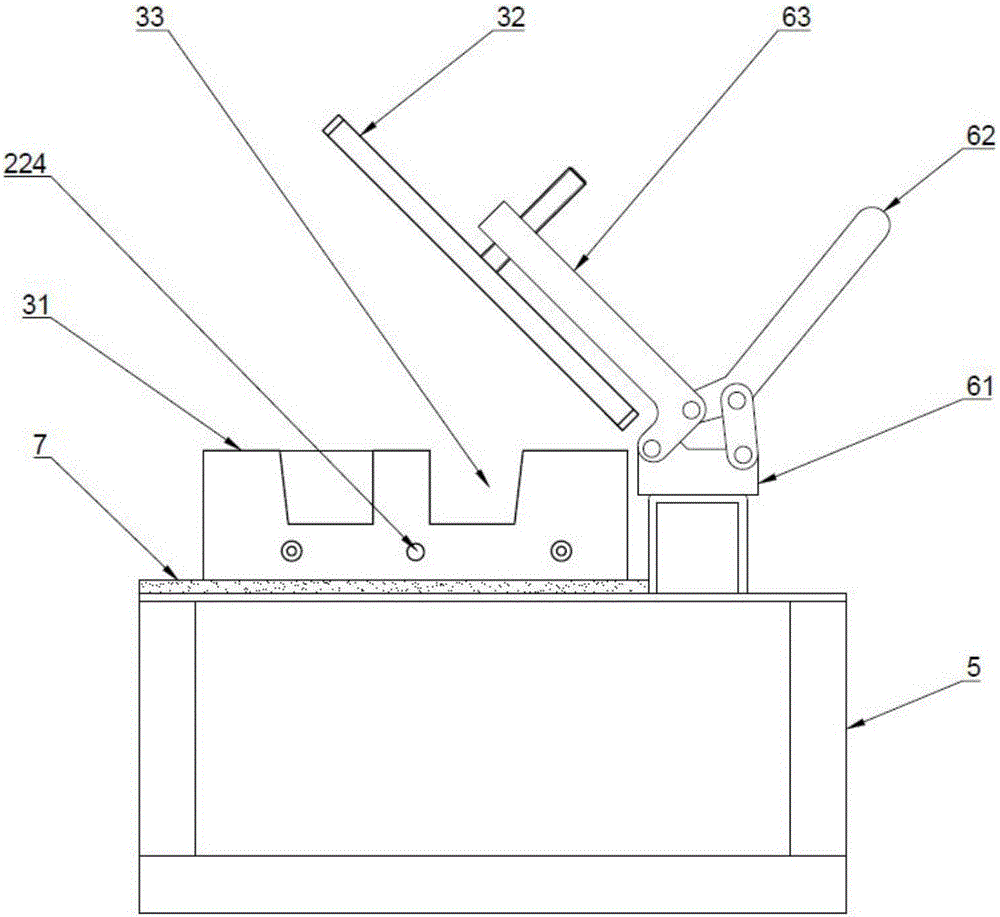

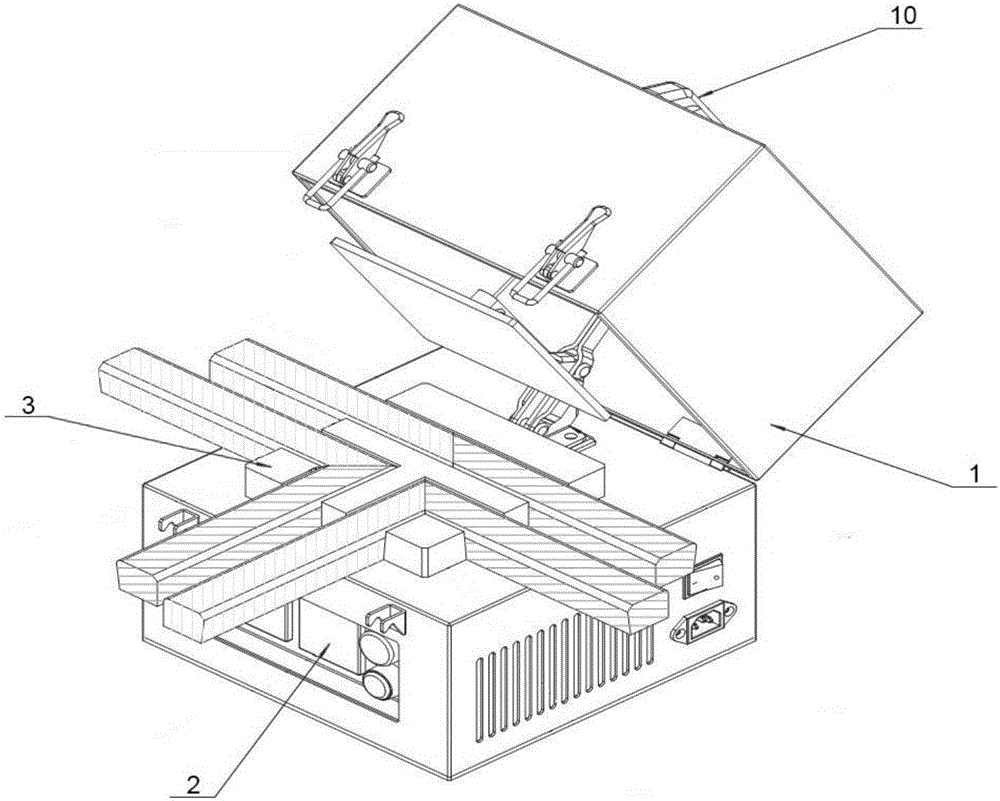

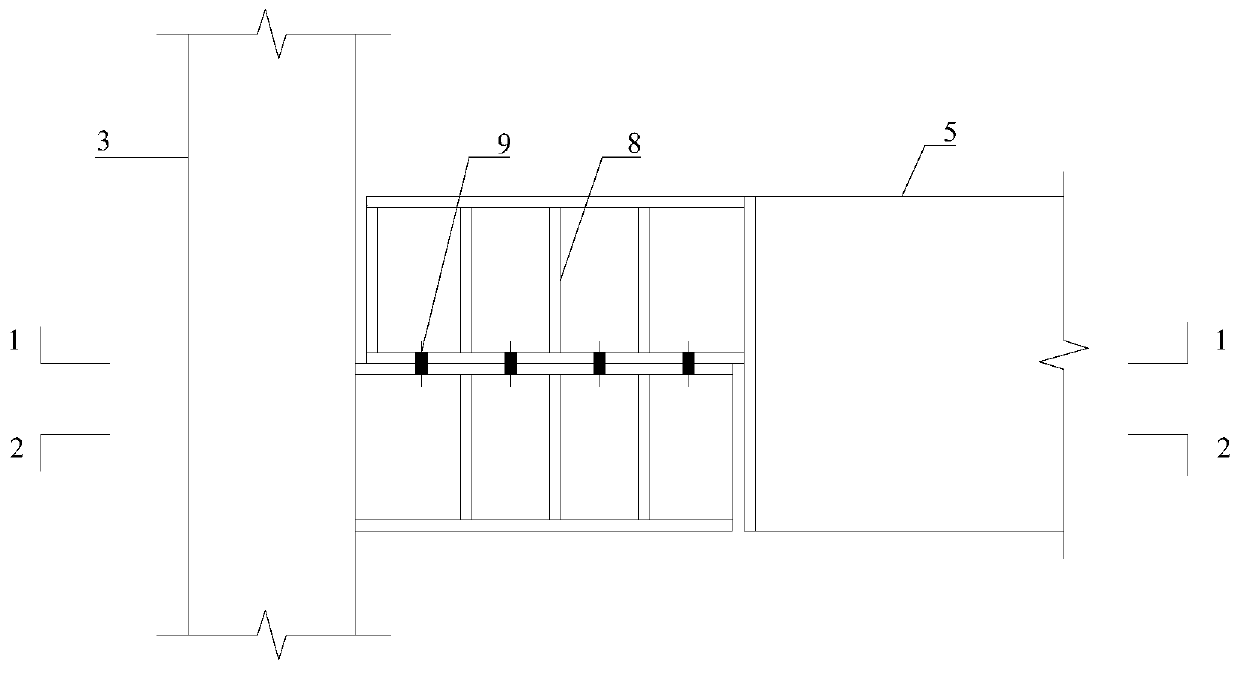

Portable thermal vulcanizing welding machine

ActiveCN106426962AIncrease power consumptionReduce power consumptionDomestic articlesControl systemEngineering

The invention provides a portable thermal vulcanizing welding machine, and relates to the technical field of a civil defense door sealing. The portable thermal vulcanizing welding machine comprises a shell body; the shell body is internally provided with a control system and a welding mechanism; the control system is connected with the welding mechanism, and the shell body includes an upper shell body and a lower shell body; one side of the upper shell body is hinged with one side of the lower shell body through a hinge, and a bottom frame is arranged in the lower shell body; the welding mechanism includes a lower template and an upper template covered on the lower template; the lower template is placed on the bottom frame, and at least one groove body with opened two ends is arranged on the lower template, and the upper template is fixedly arranged on the bottom frame through a horizontal rapid clamp. The portable thermal vulcanizing welding machine is small in volume, low in power consumption, and low in purchasing and using cost, and convenient to use at different places; the machine can be used in the factory, and also taken to the work site to perform the abutting and repair of the sealing glue strips.

Owner:盐城耀晖人防防护设备科技有限公司

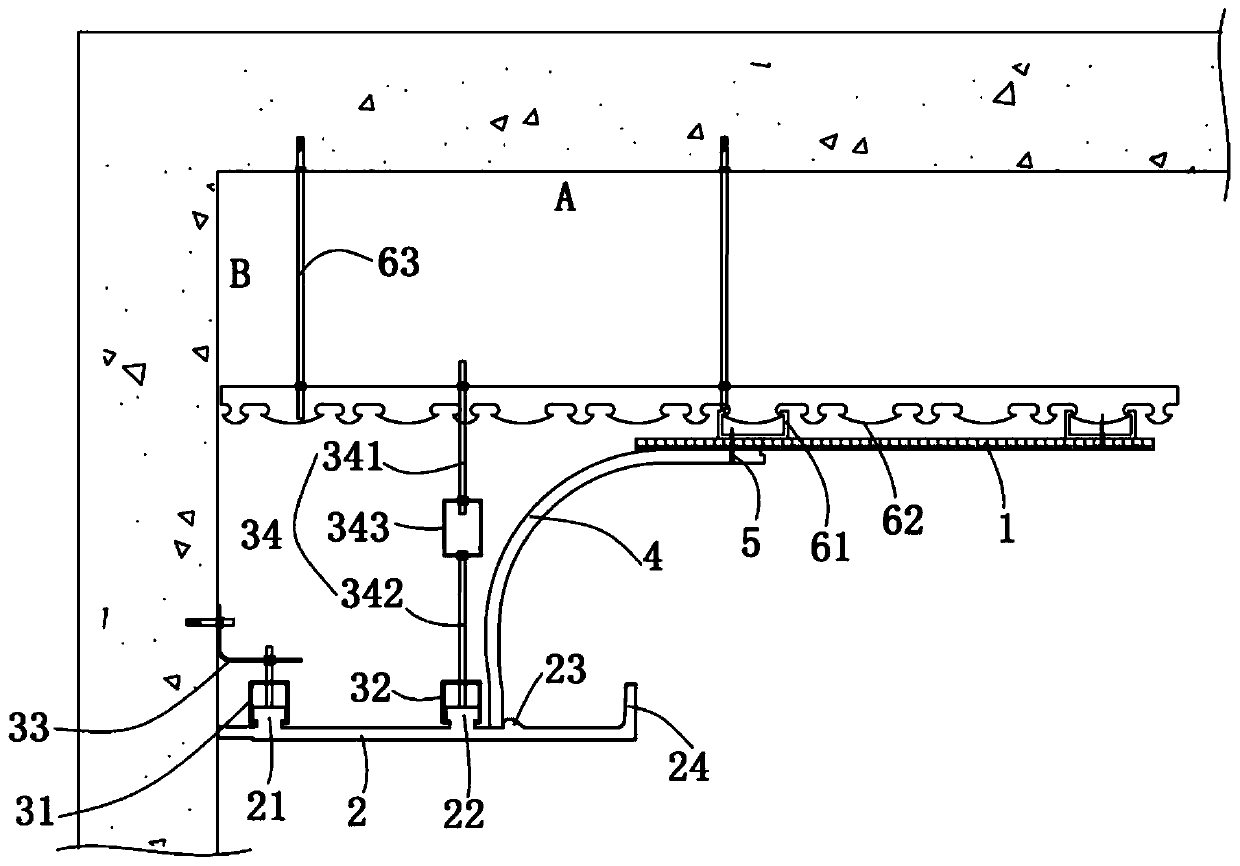

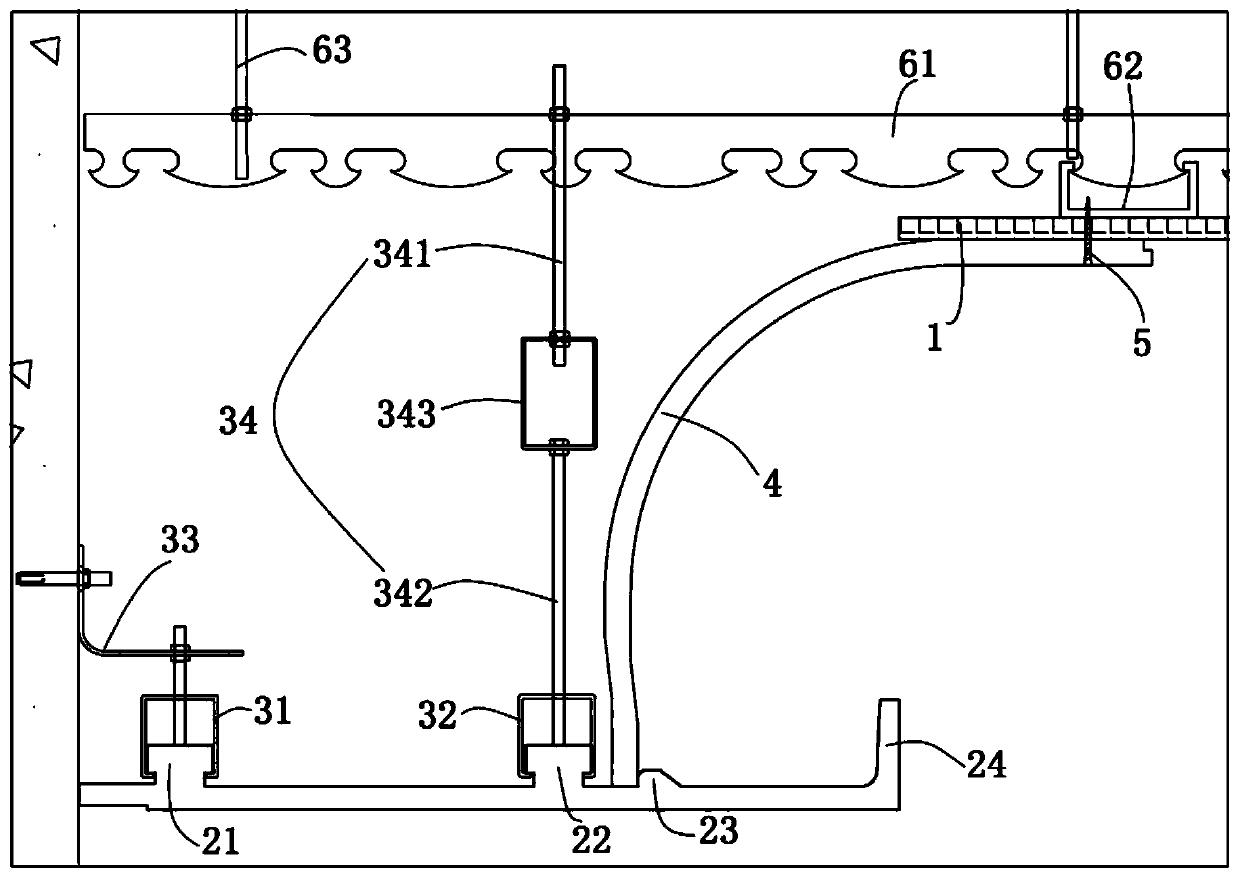

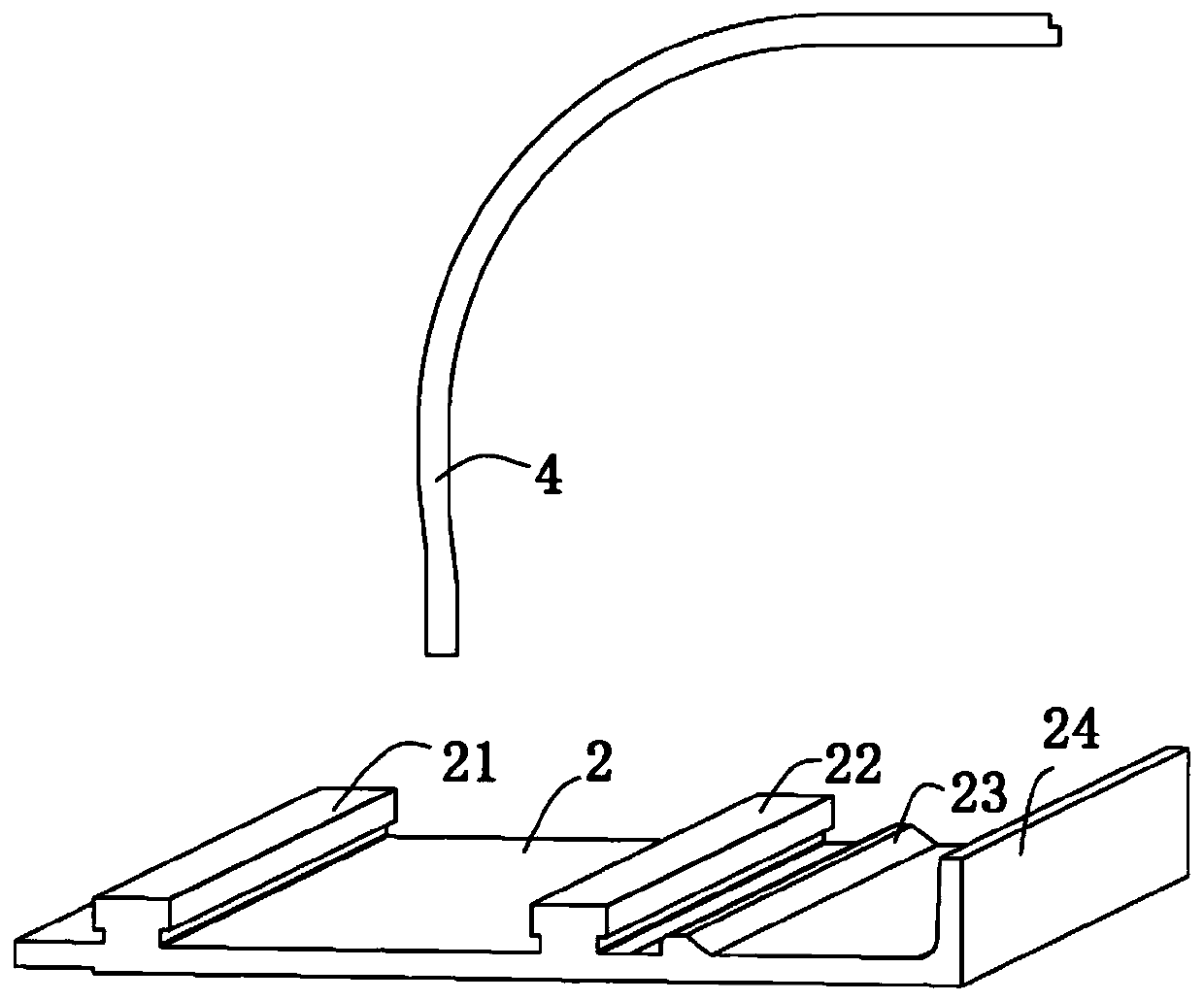

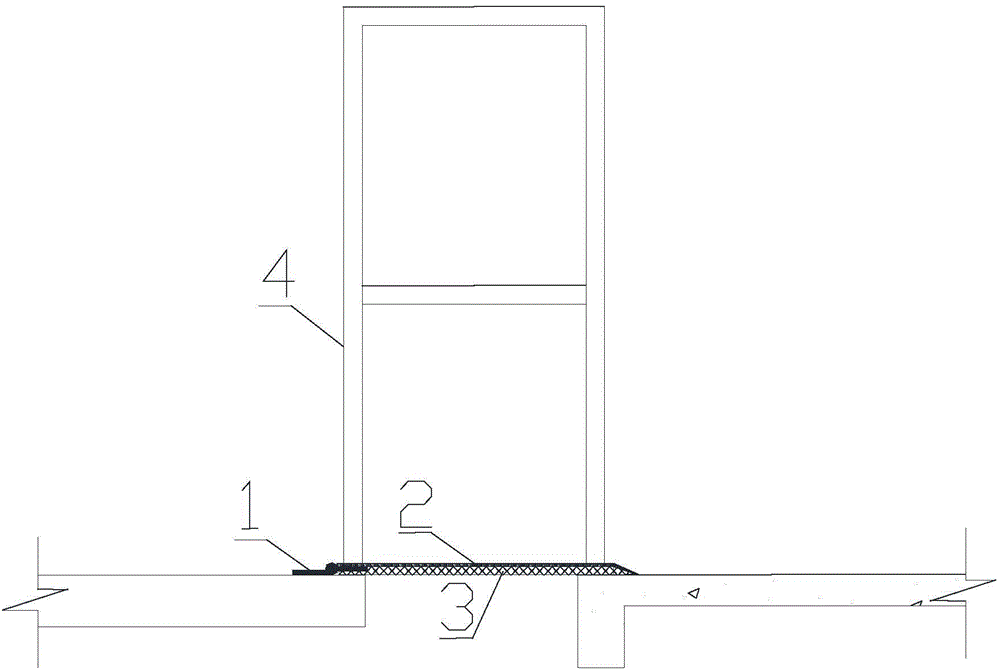

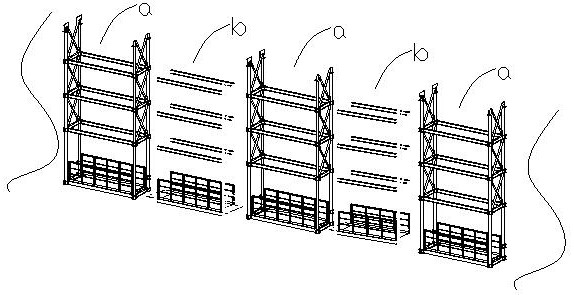

Assembled composite structure system and implementation method thereof

InactiveCN111021532AImprove integrityLess welding workWallsFloorsReinforced concreteArchitectural engineering

The invention discloses an assembled composite structure system and an implementation method thereof. L-shaped truss steel columns are adopted as bearing components and transverse anti-bending components in the vertical direction of the system, the bearing components and the transverse anti-bending components are welded to embedded parts in a foundation on site, and the L-shaped truss steel columns can reach a stable state without temporary supporting after being welded. The L-shaped truss steel column is provided with an outwards-extending beam section in the horizontal direction, and the prefabricated steel beam and the truss column are connected through high-strength bolts at the outwards-extending beam section. Prefabricated reinforced concrete laminated slabs are adopted for floors, and concrete surface layers are cast in place after the prefabricated reinforced concrete laminated slabs are connected with steel beams through studs on site. The external wall body of the system adopts an external hanging type prefabricated wall plate so that the field external decoration work is omitted. The building industrialization degree can be improved, the labor intensity of workers can bereduced, the product quality is easy to control, the building assembly industrialization requirement can be met and the system an be widely applied to the assembled building structures.

Owner:JIANGNAN UNIV

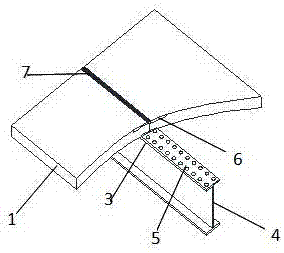

Variable slope joint for section of non-filler plate four-piece combined angle steel of power transmission tower

The invention discloses a variable slope joint for a section of non-filler plate four-piece combined angle steel of a power transmission tower. The variable slope joint comprises a pedestal plate and upper and lower shoe plates, and is provided with inner covering angle steel and the non-filler plate four-piece combined angle steel, wherein an end part of each non-filler plate four-piece combined angle steel is aligned with an end part of the lower shoe plate; the inner covering angle steel is arranged on the outer sides of the non-filler plate four-piece combined angle steel and the lower shoe plate; the upper section of the inner covering angle steel is connected with the lower shoe plate; the lower section of the inner covering angle steel is connected with the non-filler plate four-piece combined angle steel; the mounting direction of the inner covering angle steel is consistent with the non-filler plate four-piece combined angle steel on the lower part in direction. According to the structure provided by the invention, the filler plate required by a conventional connection mode is not required to be arranged for a four-piece angle steel member while the rigidity and the safety of the variable slope joint are improved, the weight of the entire tower is effectively reduced, the welding workload is reduced, the machining and the construction are convenient, the construction period is shortened, the engineering cost is saved, and the joint has certain economy.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

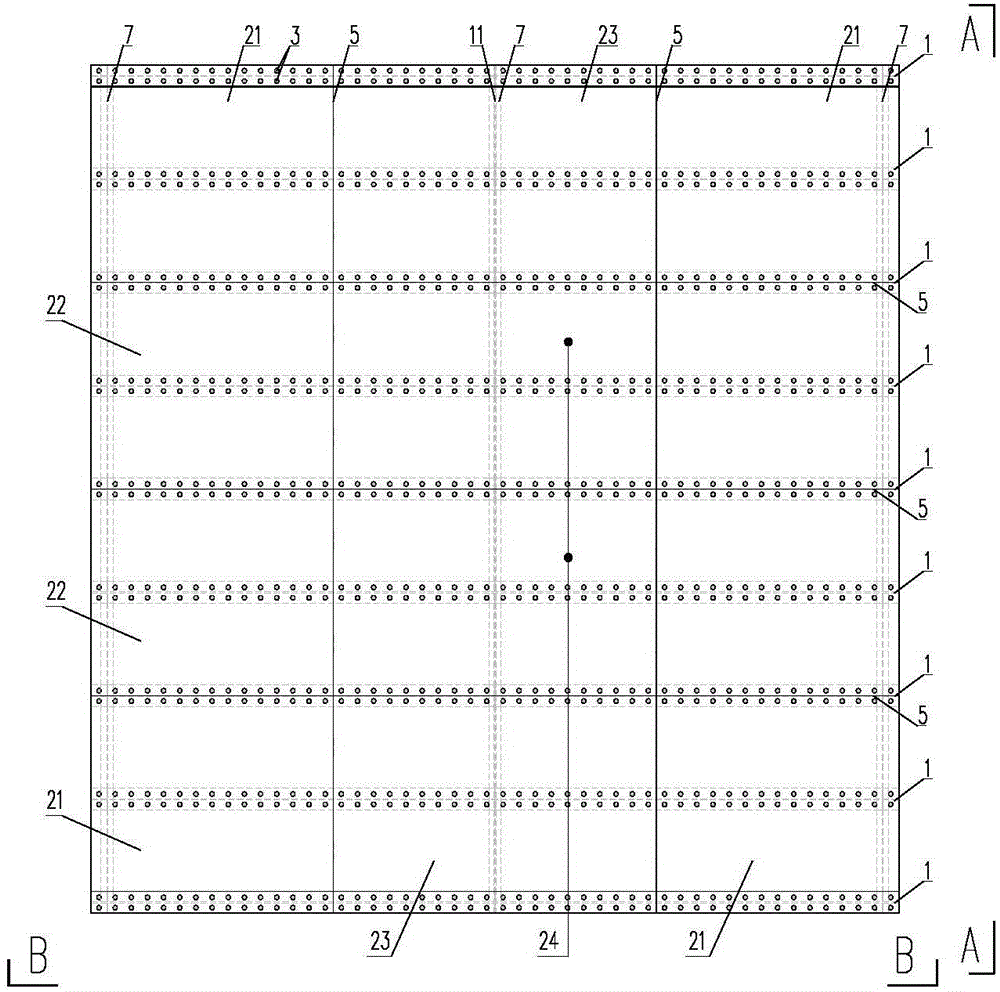

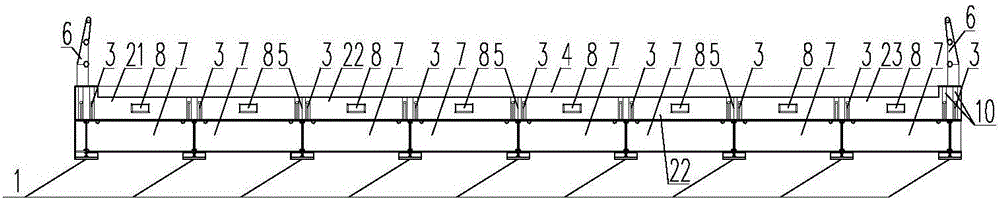

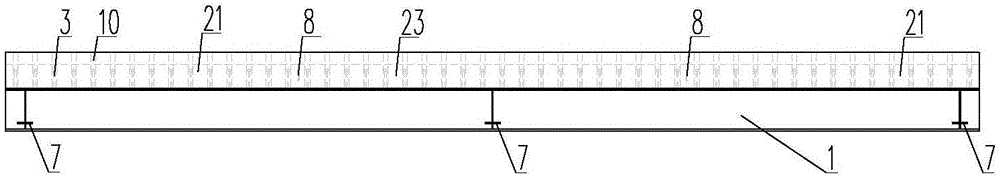

Steel-concrete partially-prefabricated composite beam structure using layered perforated plate connecting piece and manufacturing process thereof

ActiveCN105887648AShorten the construction periodEase traffic pressureBridge erection/assemblyBridge materialsComposite beamsSuperstructure

The invention relates to a steel-concrete partially-prefabricated composite beam structure using layered perforated plate connecting pieces. The steel-concrete partially-prefabricated composite beam structure using the layered perforated plate connecting pieces comprises steel main beams, transverse connecting steel plates, perforated plate connecting pieces, prefabricated portion slabs and cast-in-situ portion slabs, wherein the perforated plate connecting pieces are arranged on upper flanges of the steel main beams, an upper row of openings and a lower row of openings are formed in the perforated plate connecting pieces, the transverse connecting steel plates are connected between webs of adjacent steel main beams, the prefabricated portion slabs are located on the upper flanges of the steel main beams, the perforated plate connecting pieces are exposed out of the prefabricated portion slabs, the lower row of openings are located in the prefabricated portion slab, the upper row of openings are located above the prefabricated portion slabs, the cast-in-situ portion slabs are located on the prefabricated portion slabs, and the upper row of openings are located in the cast-in-situ portion slabs. The invention further provides a manufacturing process of a steel-concrete partially-prefabricated composite beam structure using layered perforated plate connecting pieces. The steel-concrete partially-prefabricated composite beam structure using the layered perforated plate connecting pieces and the manufacturing process have the advantages that the replacement time of a bridge superstructure can be greatly reduced, the construction period is shortened and the urban traffic pressure is greatly relieved; and the mass of the bridge superstructure is reduced.

Owner:宁波万泰建设工程有限公司

Reinforced steel frame for buildings

InactiveCN109826317AImprove reinforcementImprove stabilityBuilding constructionsSteel frameHigh intensity

The invention discloses a reinforced steel frame for buildings. The reinforced steel frame comprises a plurality of columns, a plurality of H-shaped main beams, connectors, connecting sleeves and high-strength bolts; the columns are connected with the main beams through the connectors to form a steel frame body; each connector comprises a main connecting body and a lateral connecting plate, wherein each main connecting body is provided with a through hole, each column penetrates through the corresponding through hole, and each H-shaped lateral connecting plate is arranged on the lateral extending part of the corresponding main connector; the two opposite sides of each H-shaped connecting sleeve are provided with a first opening and a second opening; the end, away from the corresponding main connecting body, of each lateral connecting plate penetrates into the corresponding connecting sleeve through the corresponding first opening and is connected with the connecting sleeve through thecorresponding high-strength bolt. The main beams penetrate into the connecting sleeves through the second openings and are connected with the connecting sleeves through the corresponding high-strengthbolts. The reinforced steel frame for buildings is firm in structural connection and detachable for application on a transition site.

Owner:广东华工大建筑工程有限公司

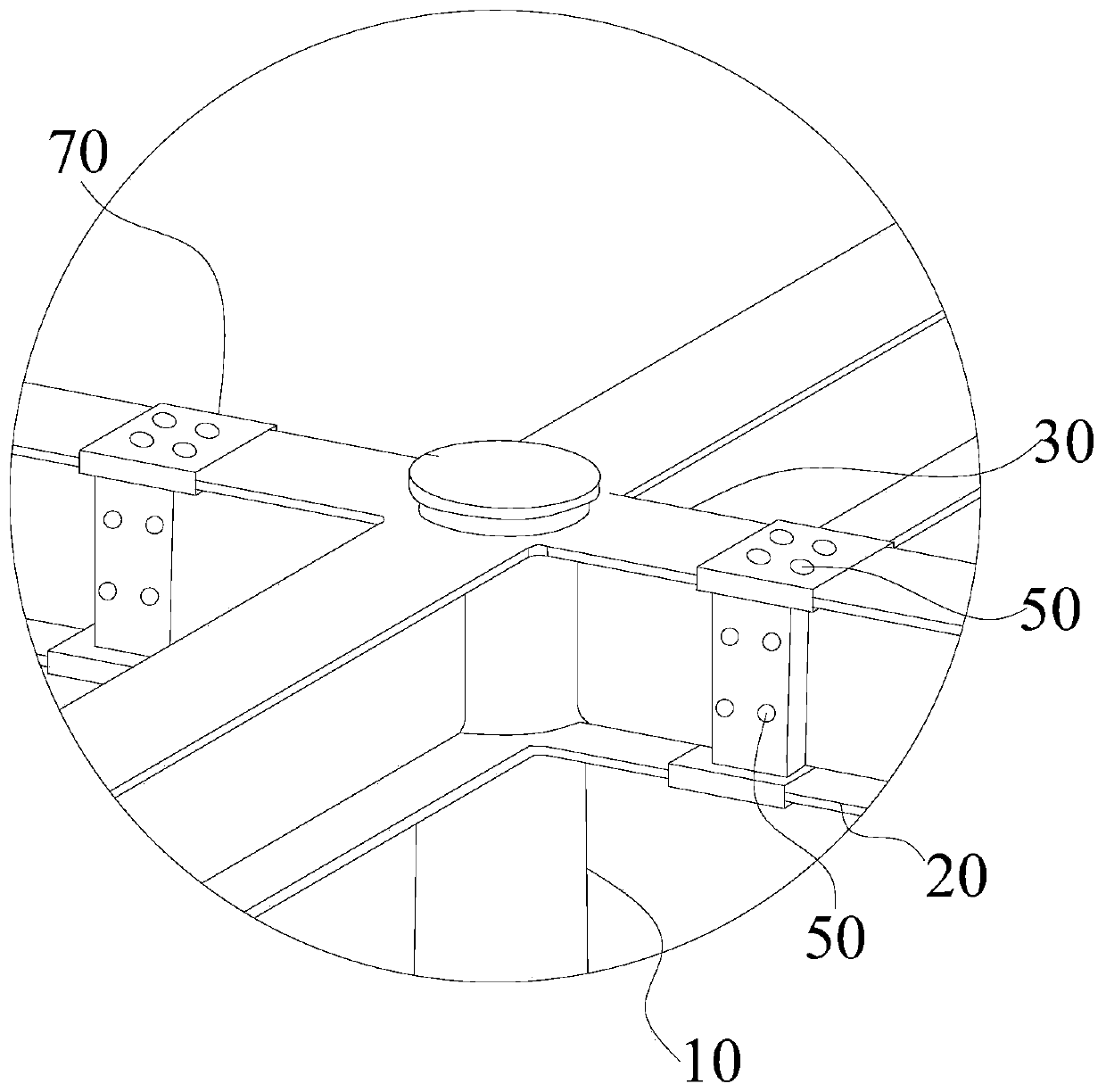

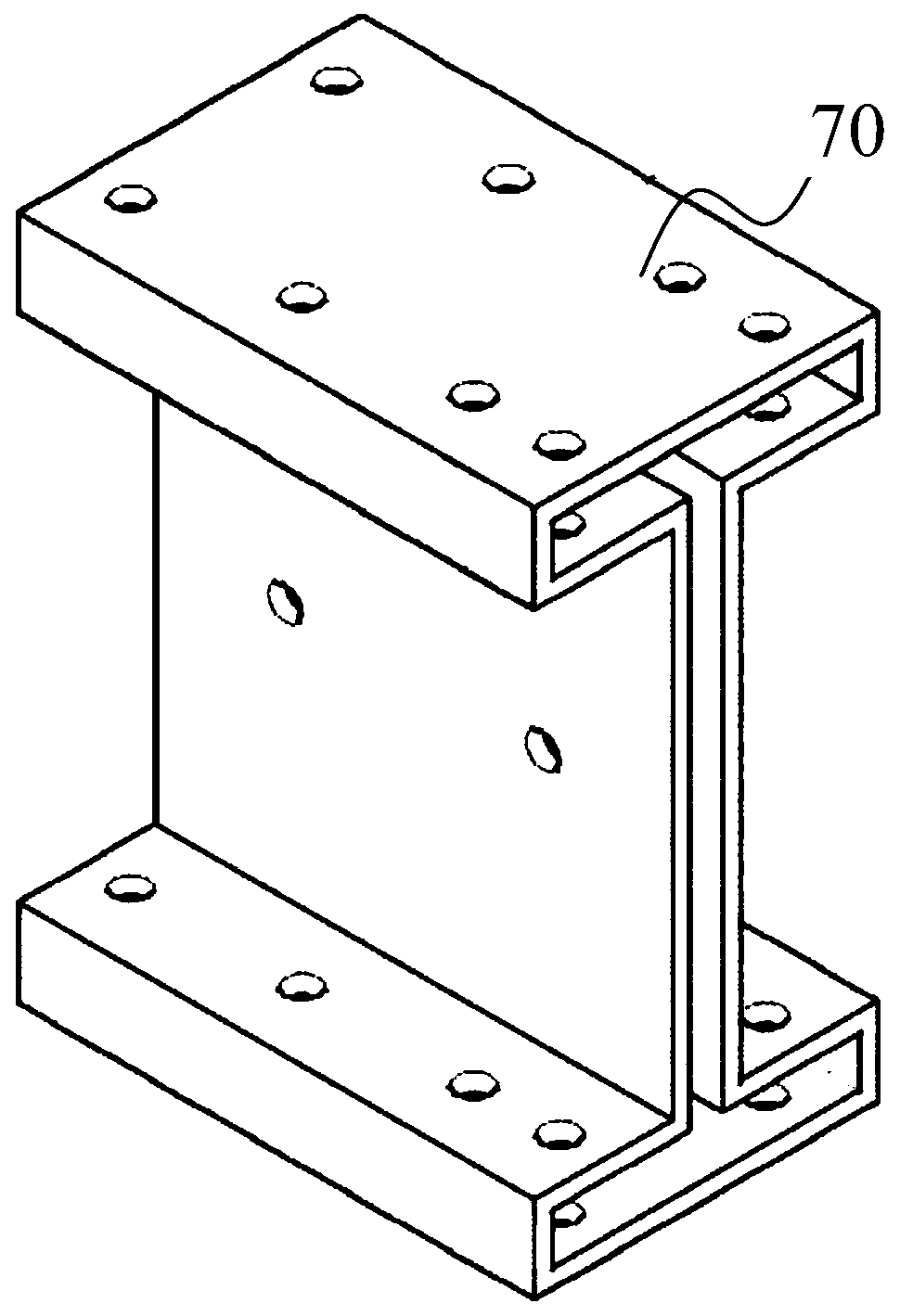

Novel prefabricated assembled type combined joint

InactiveCN106869336AReduce on-site welding workImprove construction efficiencyBuilding constructionsShock resistanceSteel columns

A novel assembly type combined joint mainly comprises a buckling piece, a steel beam, a steel column, high-strength bolts, an embedded thin-wall steel plate, embedded parts and a butt weld. Firstly, the steel beam and the steel column are connected through the buckling piece and the high-strength bolts, the rotation capacity of the combined joint is improved, thus, the pressure arch effect can be better formed though a structure under the action of impact loads, the catenary action can be achieved better, and the shock resistance and the progressive collapse of the structure are improved. Secondly, the steel beam and the prefabricated concrete slab are connected through shearing bolts embedded in the midspan of the prefabricated slab, and the shearing resistance of the joint is improved. Thirdly, the embedded parts embedded in the two ends of the slab can be connected through the butt weld, the two adjacent slabs are connected so that the hogging moment of a support part of the structure can be resisted, and the integrity of the structure is improved. According to the assembly type combined joint, industrialized production is achieved, on-site fast assembly is achieved, the effect that concrete is poured on site is avoided, the construction efficiency is improved, and the environment pollution is reduced.

Owner:XIJING UNIV

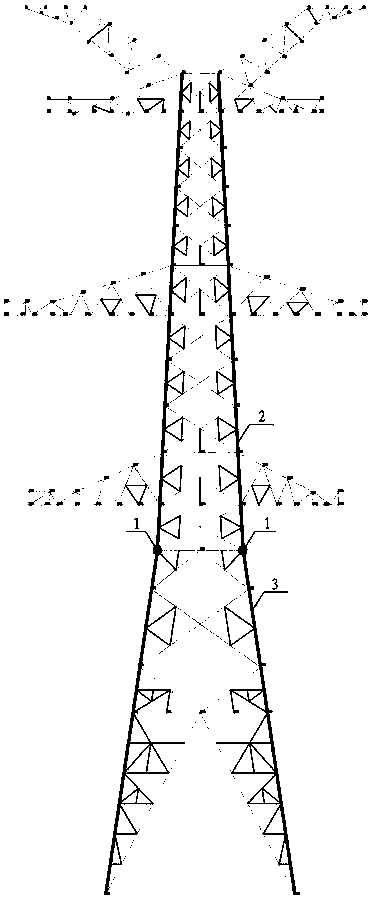

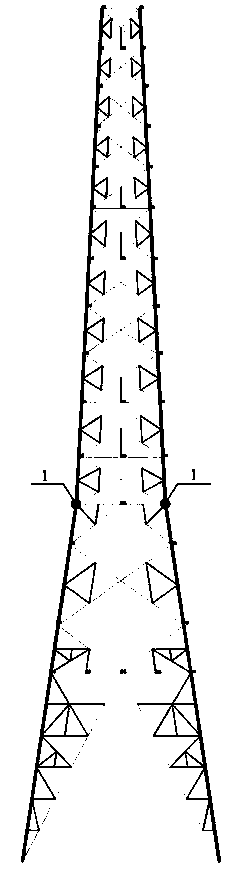

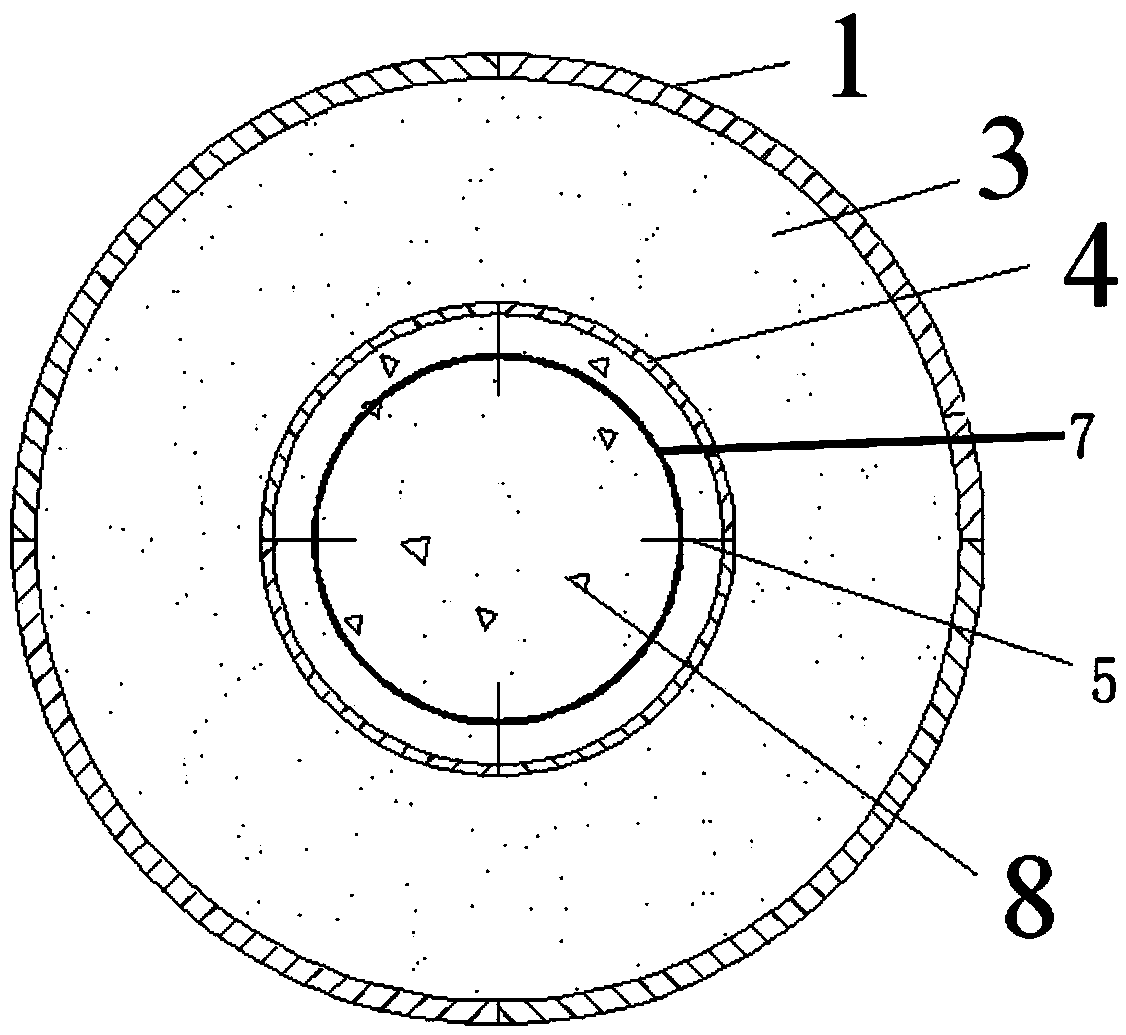

Power transmission tower and power transmission tower supporting pillar

InactiveCN110409903AImprove stress resistanceImprove tensile propertiesTowersTransmission towerAdhesive

The invention relates to a power transmission tower and a power transmission tower supporting pillar. The power transmission tower comprises a tower body which is vertically arranged, and cross arms horizontally arranged on the top of the tower body. A supporting pillar is lengthways arranged at the bottom of the tower body. The supporting pillar comprises adhesives which are arranged radially from inside to outside, a reinforcing frame and an outer layer pipe. Mortar is arranged between the outer wall of the reinforcing frame and the inner wall of the outer layer pipe. The power transmissiontower supporting pillar combines the stress characteristics of the two materials, gives full play to the characteristic of a steel and concrete composite structure, and has the high pressure bearing capacity; and the capacity of the reinforcing frame and the outer layer pipe for local buckling local can be effectively enhanced, the lamellar tearing problem caused when thick steel plates are adopted is avoided, the problems in the process of processing or making the reinforcing frame and the outer layer pipe are smoothly solved, the production technology is simple, and the production cost is low.

Owner:CHINA ELECTRIC POWER RES INST +2

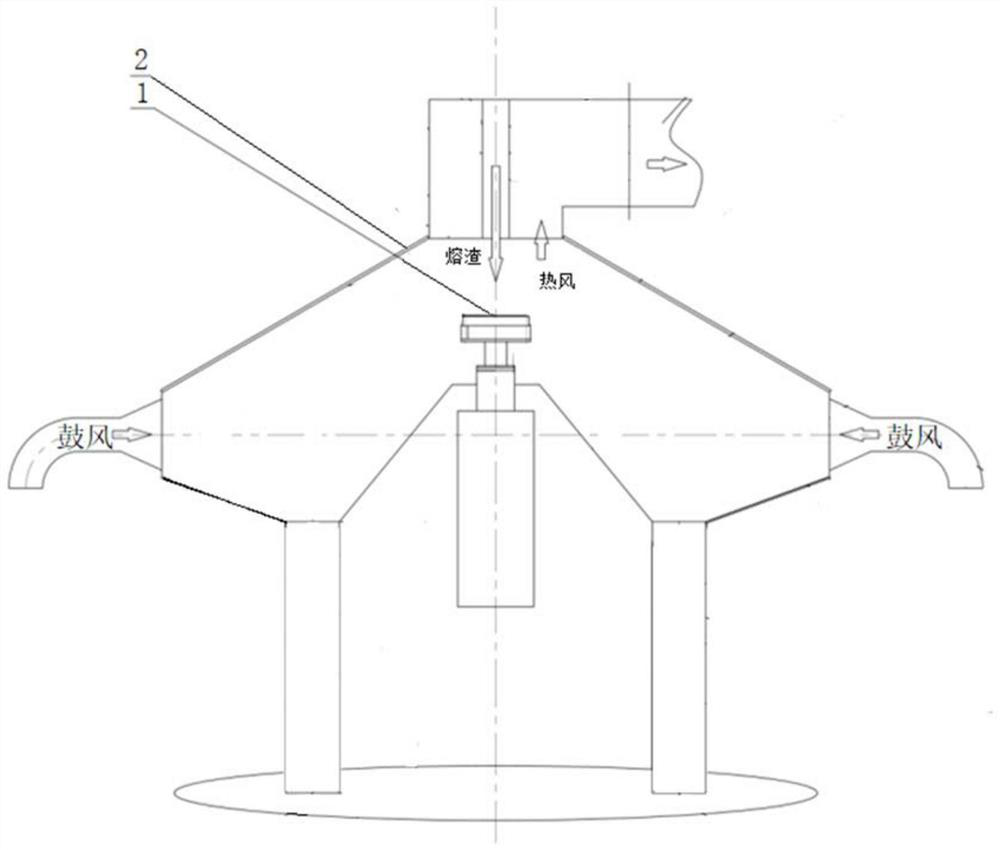

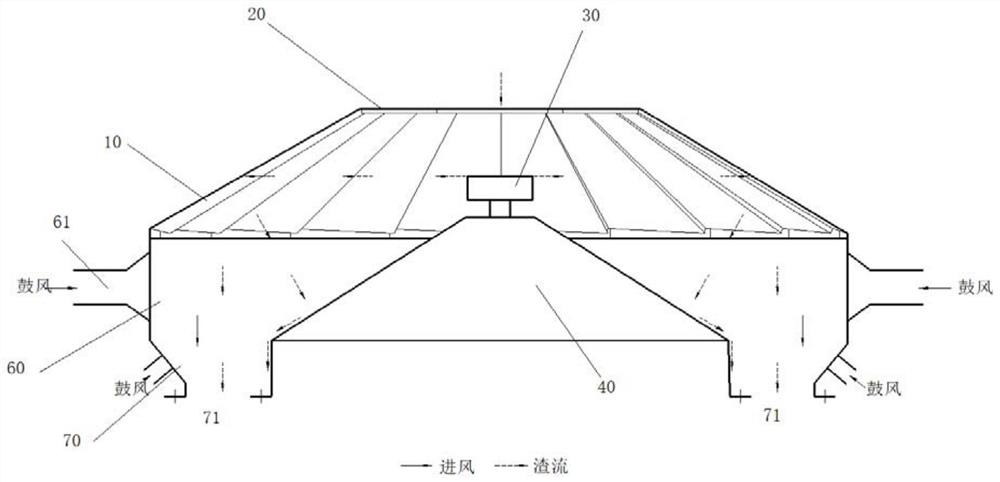

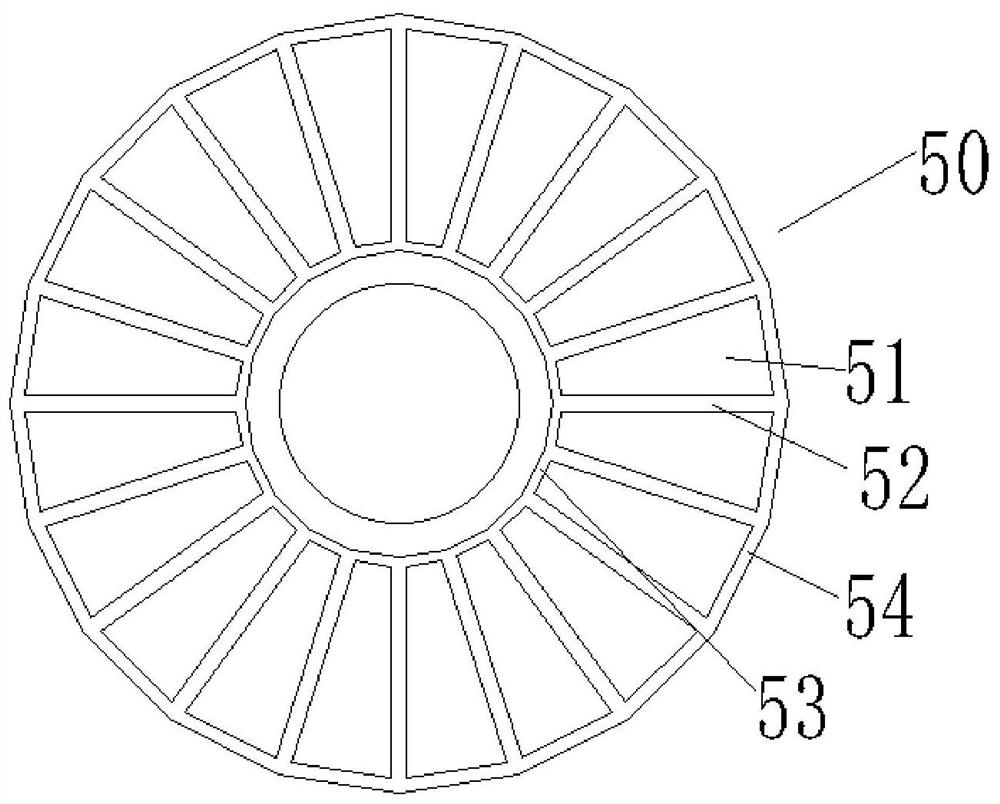

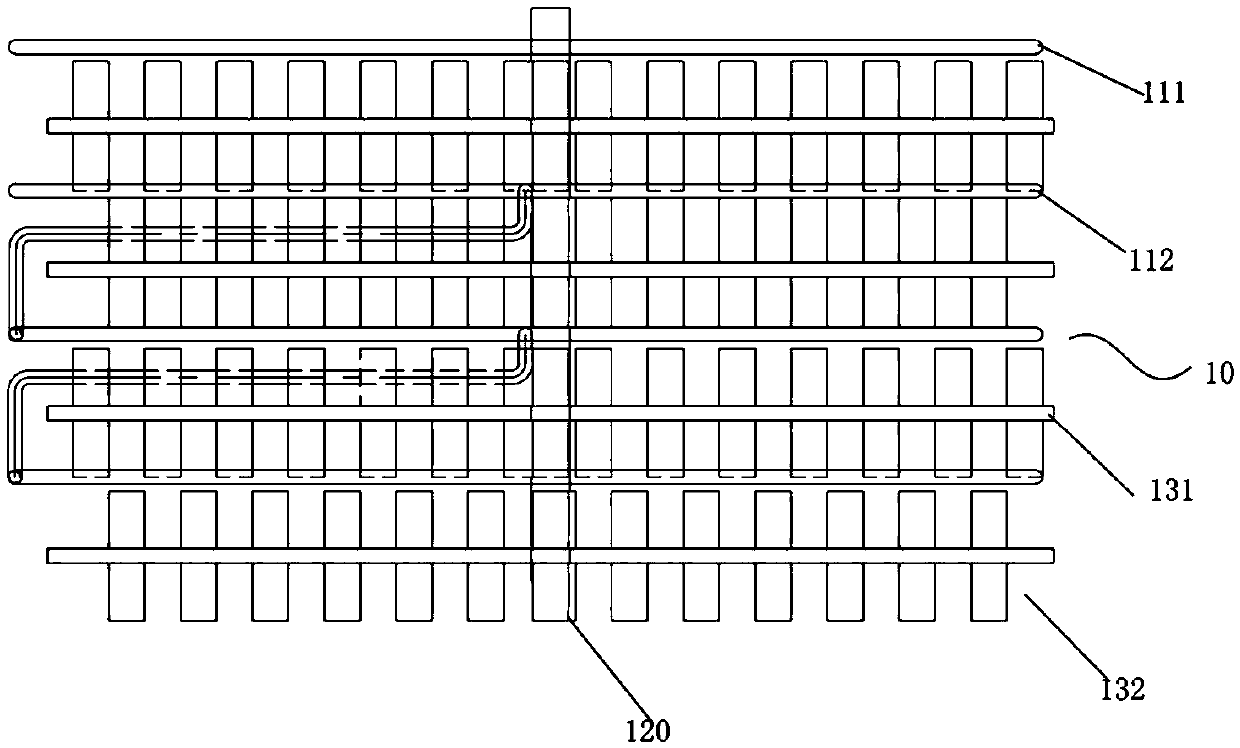

Granulating chamber of granulating device

ActiveCN113913568AAvoid high-altitude welding operationsLess welding workRecycling and recovery technologiesPhysicsSlag (welding)

The invention discloses a granulating chamber of a granulating device. The granulating chamber comprises a water-cooling top plate, an upper cone, an inner cone, a middle ring section and a lower cone, the upper cone is in an annular frustum shape, the inner cone is conical, the upper cone and the inner cone are coaxially arranged at intervals up and down, the lower cone surrounds the outer side of the inner cone, and a discharging opening for discharging granulated slag is connected between the lower cone and the inner cone. The middle ring section is arranged between the lower cone and the upper cone, an annular space for slag granulating is formed among the upper cone, the inner cone, the lower cone and the middle ring section, the water-cooling top plate is in closed connection with the top end of the upper cone, an opening for slag to enter the granulating chamber is formed in the center of the water-cooling top plate, and a granulating disc extends upwards from the top of the inner cone. The top end of the granulating disc is provided with a disc surface used for bearing the slag, the granulating disc is driven by a driving mechanism to rotate, and the middle ring section is provided with a first blower nozzle used for feeding first cooling air into the granulating chamber. According to the granulating chamber of the granulating device, the slag adhesion phenomenon of the upper cone manufactured by welding during dry granulating can be avoided.

Owner:北京中冶设备研究设计总院有限公司

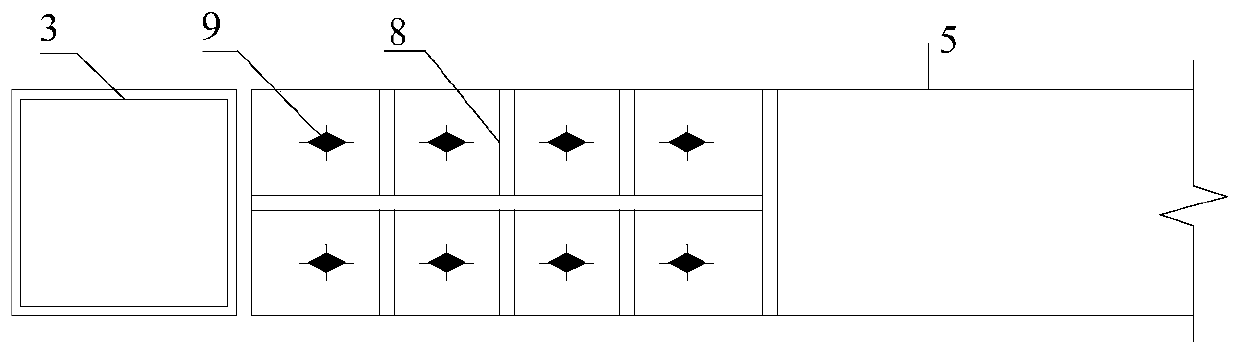

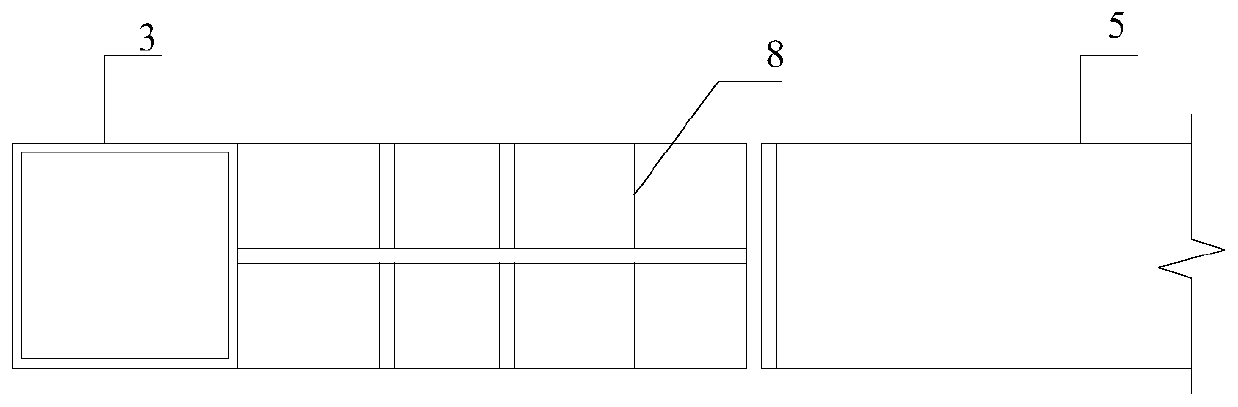

Heat exchange coil pipe, heat exchange coil pipe group and evaporative condenser

PendingCN109579375AIncrease flow resistanceImprove heat transfer effectCleaning heat-transfer devicesEvaporators/condensersEngineeringRefrigerant

The invention discloses a heat exchange coil pipe. The heat exchange coil pipe comprises at least two serially-connected spiral heat exchange coil pipes and rotary shafts penetrating through the centers of the spiral heat exchange coil pipes, wherein the spiral heat exchange coil pipes are formed by winding metal pipes, and arranged in a layered manner in the extension direction of the central axis of the heat exchange coil pipe; and a cleaning mechanism used for cleaning the surfaces of the spiral heat exchange coil pipes and connected with the rotary shafts is arranged between the adjacent spiral heat exchange coil pipes. According to the heat exchange coil pipe, the heat exchange efficiency of the heat exchange pipe is increased, and descaling treatment can be effectively carried out onthe heat exchange pipe at any time. During working of the bottom and the middle heat exchange pipe part of an evaporative condenser comprising the heat exchange coil pipe, cooling water is attached to a brush and capable of making up heat exchange non-uniform to a certain extent, so that the problem of scaling of the cooling water on the heat exchange pipe is effectively solved; and in a runningprocess of a unit, because the heat exchange pipe is approximately circular, the flowing direction of a refrigerant in the heat exchange pipe is always changed, and the circulation resistance of the refrigerant is increased, so that the heat exchange effect of the condenser is further improved.

Owner:南京恒标斯瑞冷冻机械制造有限公司

Method for manufacturing gear case

The invention discloses a method for manufacturing a gear case. The method include following manufacturing steps: firstly, selecting carbon steel plates for blanking to form components; secondly, subjecting the components to roughing, sheet-metal working and vibratory aging treatment; thirdly, assembling and welding the components to respectively form a case body and a case seat and welding the case body on the case seat; fourthly, subjecting the welded case body and the case seat to vibration polishing for removing stress; fifthly, cleaning the surfaces of the case body and the case seat; and finally, subjecting the case body to finishing such as boring, face cutting, drilling and tapping. The gear case manufactured by the method has the advantages of uniformity in wall thickness, freeness of internal air holes and shrinkage cavities, good mechanical performance and long service life. Compared with existing casting methods for the gear case, the method for manufacturing the gear case has the advantages that time and consumable cost of raw materials and auxiliary materials can be saved while manpower can be reduced greatly, and accordingly production efficiency is improved.

Owner:浙江昌亨机械集团股份有限公司

Non-welding connector steel-concrete composite girder and construction method thereof

ActiveCN109338899AReasonable structural designEasy constructionClimate change adaptationBridge structural detailsBridge deckEngineering

The invention discloses a non-welding connector steel-concrete composite girder and a construction method thereof. The steel-concrete composite girder comprises multiple bridge segments, and each bridge segment comprises a steel girder structure, a steel mesh mechanism and a UHPC bridge deck arranged on the steel girder structure, wherein the steel girder structure comprises a base plate, a top plate and a web; the steel mesh mechanisms are arranged on the upper sides and the lower sides of the steel girder top plates and connected through vertical reinforcements penetrating through the steelgirder top plates, and the steel girder top plates, the steel mesh mechanisms and the vertical reinforcements are all wrapped by the UHPC bridge decks. The construction method for the construction process of each bridge segment comprises the following steps of 1, steel girder structure installation; 2, steel mesh mechanism installation; 3, UHPC bridge deck formation; 4, all construction process performing by repeating the steps from first to third multiple times. Accordingly, by means of the vertical reinforcements, shearing force between the bridge decks and the steel girder top plates is transmitted, people do not need to weld shearing force connectors to the top plates, construction is simplified, and environmental protection is facilitated.

Owner:XIAN UNIV OF SCI & TECH

Integrally-hoisted reflector lamp trough system

PendingCN111188449AReduce construction costsShorten construction timeCeilingsLight fasteningsEngineeringStructural engineering

The invention provides an integrally-hoisted reflector lamp trough system. The system comprises a gypsum board, a lamp trough bottom plate, and an arc-shaped reflector, wherein the gypsum board is hoisted below the indoor top face of a building, the lamp trough bottom plate is arranged below the gypsum board, a first side of the lamp trough bottom plate is connected with the indoor side face, a first clamping strip and a second clamping strip which are arranged at an interval are arranged on the lamp trough bottom plate in a protruding mode, a first U-shaped hanging piece and a second U-shapedhanging piece are connected to the first clamping strip and the second clamping strip in a clamped mode respectively, the first U-shaped hanging piece is fixed to the indoor side face through a firstconnecting piece, the second U-shaped hanging piece is fixed to the indoor top face through a second connecting piece, the arc-shaped reflector is provided with a first edge and a second edge which are opposite to each other, the first edge is arranged on the lamp trough bottom plate, and the second edge extends upwards and is fixed to the side, away from the indoor side face, of the arc-shaped reflector together with the gypsum board. According to the integrally-hoisted reflector lamp trough system, a base layer is free of being manufactured, on-site overall hoisting is achieved, the construction cost is reduced, the construction time is shortened, and the construction quality is guaranteed.

Owner:中建八局装饰工程有限公司

Rapid docking platform and building method thereof

InactiveCN104555845ASmall footprintIncrease stiffnessLifting devicesMaterials scienceStandardization

The invention relates to a rapid docking platform and a building method thereof; the rapid docking platform comprises a steel hinge, a riffled plate, a profile steel, and protective barriers; the steel hinge is fixed on a movable platform base; the riffled plate is fixed with the steel hinge; the riffled plat is respectively integrally welded with the profile steel and the protective barriers. The building method comprises the following steps: (1) fixing one side of the steel hinge on the movable platform by means of embedding, welding or bolting; (2) determining lengths and width of the riffled plate and the profile steel based on the gap between the movable platform and the fixed platform as well as the sizes of the movable platform and the fixed platform, making the docking platform by means of welding; (3) respectively installing the protective barriers on the left and right sides of the docking platform; (4) fixing the docking platform with the other side of the steel hinge. The rapid docking platform enables to seamlessly dock two independent platforms, and avoids temporarily building a moving channel. The rapid docking platform is reasonable in design, simple and convenient in manufacturing. The rapid docking platform can be used as a standard and finalization configuration of docking platform; and the rapid docking platform can be reused, thereby reducing the cost; the rapid docking platform has a good application foreground.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

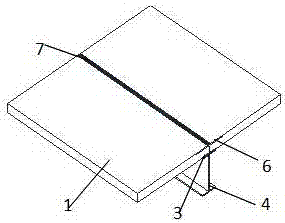

Mounting structure for roof trusses and arc-shaped multilayer berm and construction method of berm

PendingCN111852041ALess welding workTake advantage ofBuilding material handlingShaping building partsSpare partParallelogram

The invention discloses a mounting structure for roof trusses and an arc-shaped multilayer berm and a construction method of the berm. The berm stretches across the plurality of roof trusses and is suspended on lower strings of the roof trusses, a berm unit is formed between every two adjacent roof trusses, the whole berm is formed by connecting the plurality of berm units in series, each berm unit comprises four hanging rods, the lower ends of every four hanging rods are connected through two walkway longitudinal beams and two walkway cross beams to form a parallelogram frame, and walkway plates are arranged inside the parallelogram frames. The construction method of the berm comprises the steps that the whole arc-shaped berm is divided into a plurality of hoist units and spare part unitsaccording to the distance between every two adjacent roof trusses, each spare part unit is located between the two corresponding hoist units, and then the steps of prefabricating semi-finished products in a factory, splicing the hoist units outside a span, hoisting the hoist units outside the span, and splicing the spare part units inside the span are adopted to complete the construction of the arc-shaped multi-layer berm. According to the construction method, the working efficiency is improved, and the hoisted hoist units are used as an operating platform, so that the construction cost is saved.

Owner:中冶建工集团重庆钢结构有限公司

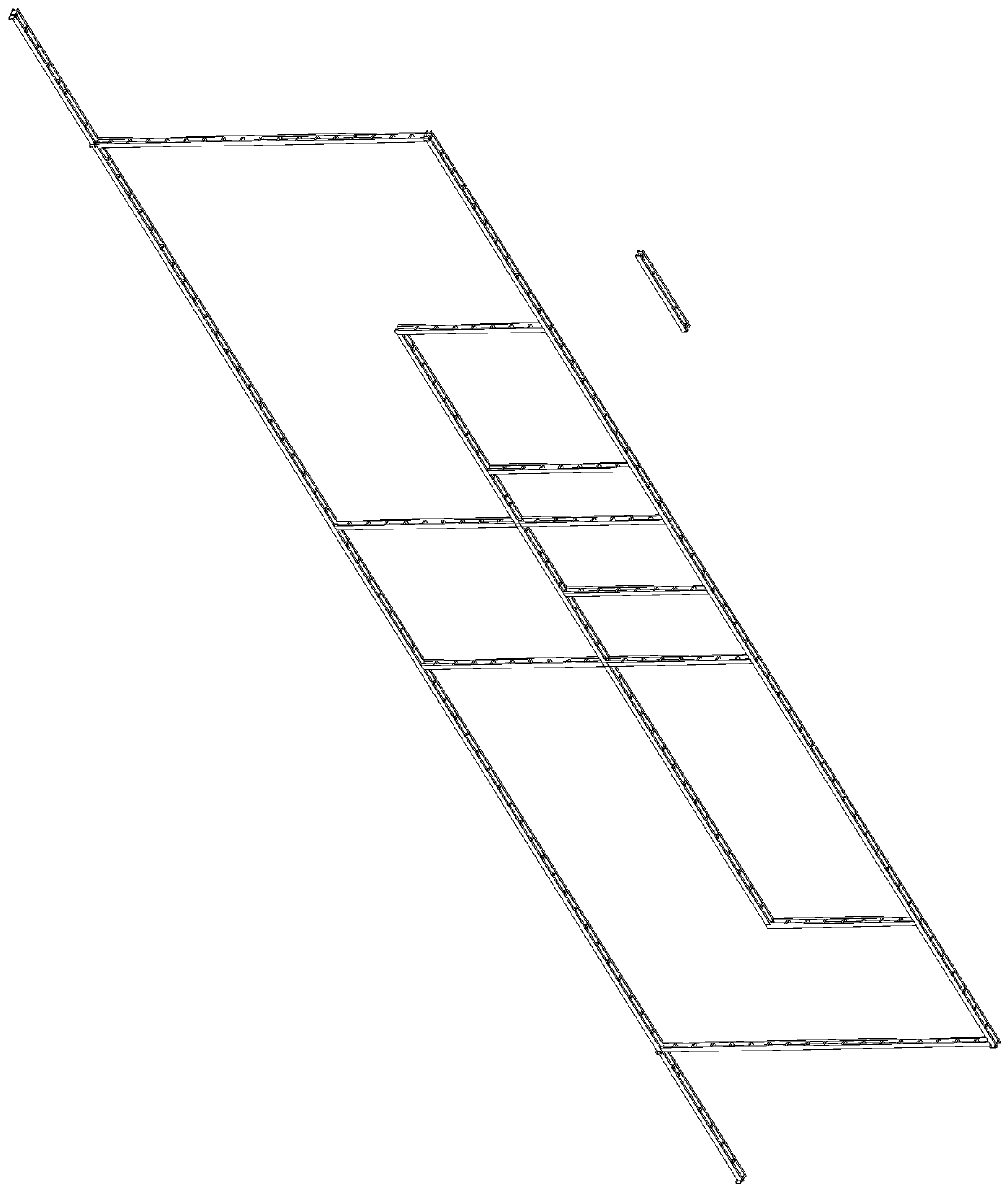

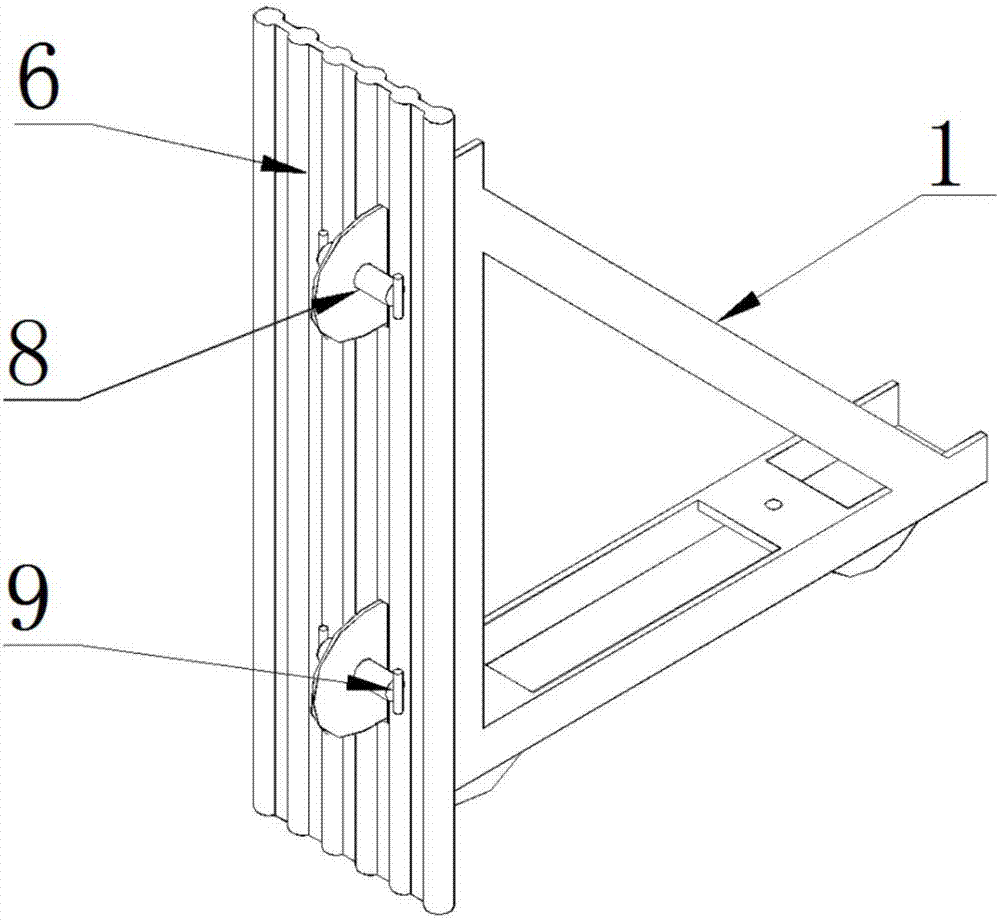

Hanging ladder type scaffold for mounting water-cooled wall spiral section and its erection method

PendingCN107217830ALess grinding workLess welding workBuilding support scaffoldsFalseworkEconomic benefits

The invention discloses a hanging ladder type scaffold for installing a water-cooled wall spiral section and its erection method. The hanging ladder type scaffold comprises a plurality of bearing brackets and an annular channel; a climbing ladder is arranged correspondingly below each force bearing bracket; the erection method thereof includes steps of confirming overall length of the climbing ladders according to the height of the water-cooled wall spiral section; hanging the lower part along the upper part of the climbing ladders through a climbing ladder hook; hanging the climbing ladder and erecting a scaffold board and a protective railing along with the mounting of a water-cooled wall; carrying out construction by operators at the construction position nearby through the annular channel. Compared with the conventional erection methods, the method greatly decreases the cutting, polishing or welding work of a rooting point, and reduces the pipe injury by cutting and other quality risks while reducing the long-time overhead safety operation risk caused by erecting of an all-around scaffold; through replacing the conventional all-around scaffold by the hanging ladder type scaffold, the amount of turnover materials in use is greatly reduced, and the labor investment in erection and dismounting is reduced; besides, the economic benefit is significant.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com