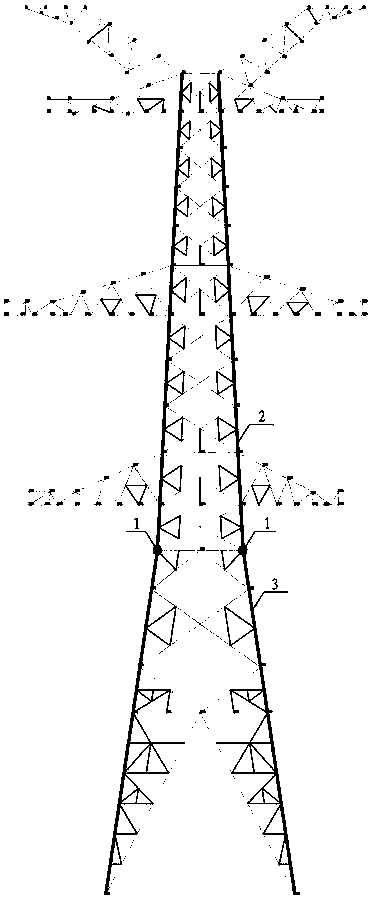

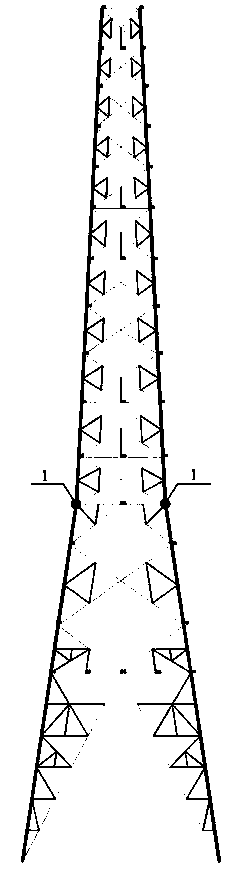

Variable slope joint for section of non-filler plate four-piece combined angle steel of power transmission tower

A technology for transmission towers and angle steel sections, applied in towers, building types, buildings, etc., can solve the problems of low safety performance reserves at variable slope points, inconvenient processing and construction, and large welding workload, etc., to improve rigidity and safety performance, Convenience of construction and the effect of reducing welding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0045] Investigating the current production and construction of the four-combination angle steel, it is found that the large number of fill plates of the four-combination angle steel tower is the main reason for the heavy weight of the tower, the large amount of welding, and the inconvenience of processing and construction. Consider the many effects of fill. Aiming at the deficiencies of the previous models, the present invention adopts direct contact connection of four-combination angle steels, and adopts internal cladding steel to strengthen the node stiffness at the slope change, which greatly improves the safety performance of the joints. The plate effectively reduces the weight of the slope-changing nodes and the whole tower, reduces the welding work, facilitates processing and constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com