Novel prefabricated assembled type combined joint

A technology of prefabricated assembly and combination of nodes, applied in the direction of building and building structure, can solve the problems of slow construction efficiency, difficult construction, environmental pollution, etc., to achieve the effect of convenient construction, improve construction efficiency, and reduce welding work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing.

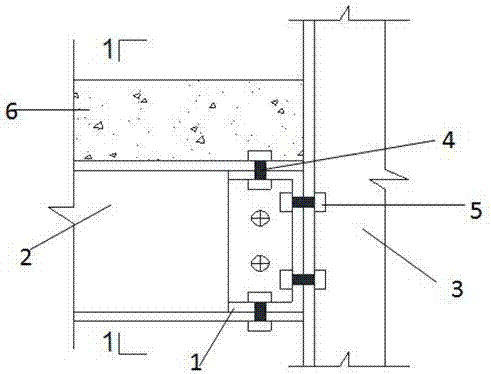

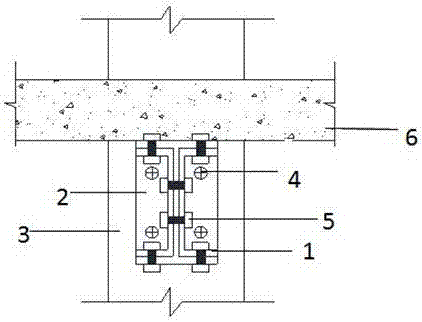

[0020] Such as figure 1 , 2 , 3, 4, and 5, a new type of prefabricated composite node, including fastener 1, fastener 1 is used to connect steel beam 2 and steel column 3, and steel beam 2 and steel column 3 reserve holes in corresponding positions , reserved holes for placing high-strength bolts 4, fixed by nuts 5, pre-embedded shear bolts 7 and thin-walled steel plates 8 on both sides of the lower part of the precast concrete slab 6 in contact with the steel beam 2, and reserved holes on the steel beam 2 It is used to place the shear bolts 7, and the embedded parts 9 are embedded on both sides of the upper part of the precast concrete slab 6, and the embedded parts 9 on two adjacent precast concrete slabs 6 are welded with butt welds 10.

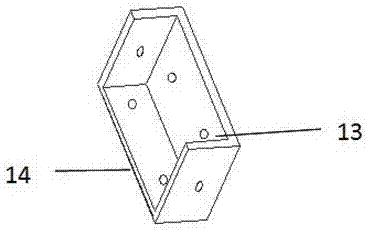

[0021] The fastener 1 is made by welding the channel steel 13 and the steel plate 14, and holes should be reserved at positions corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com