Patents

Literature

93 results about "Progressive collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A building undergoes progressive collapse when a primary structural element fails, resulting in the failure of adjoining structural elements, which in turn causes further structural failure.

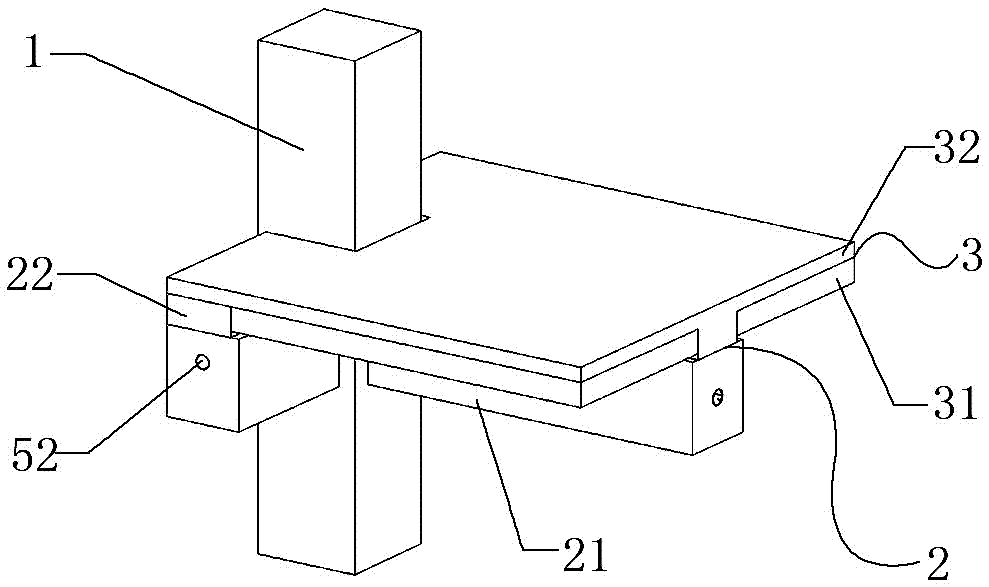

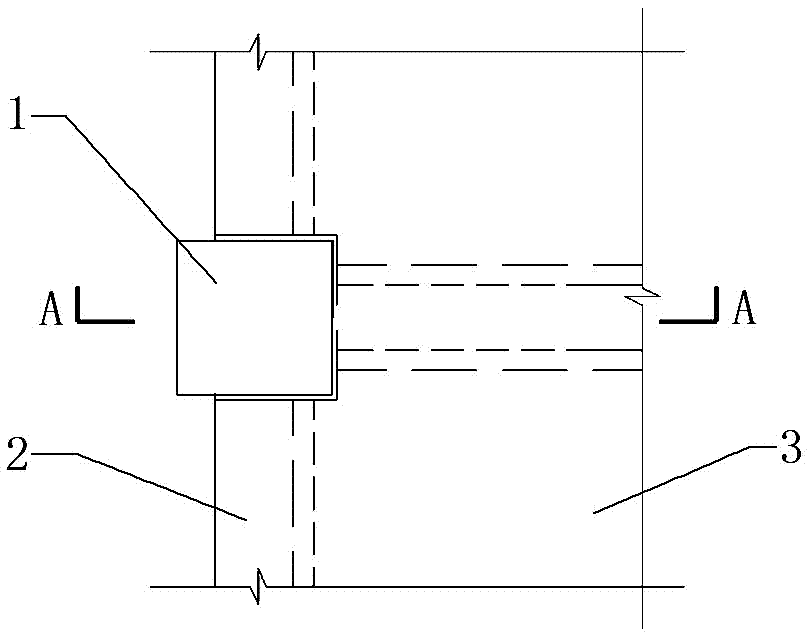

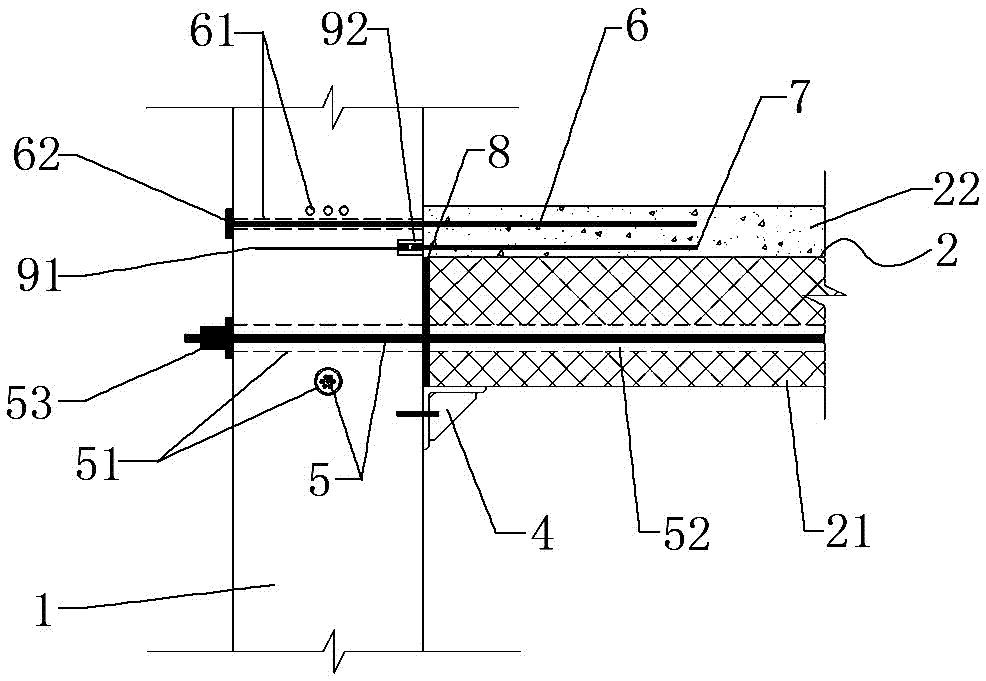

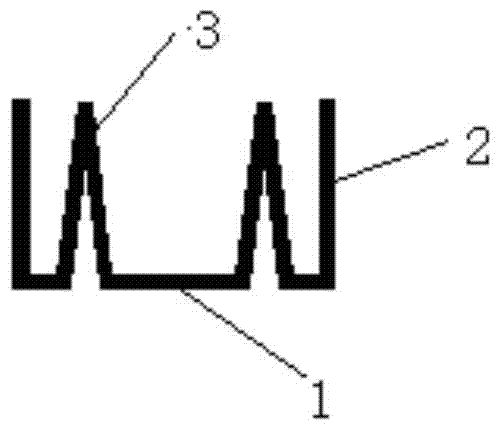

Pre-stressing-force fabricated concrete-frame-joint connecting structure and construction method thereof

PendingCN107165272AImprove integrityImprove energy consumptionGirdersProtective buildings/sheltersFloor slabPre stress

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

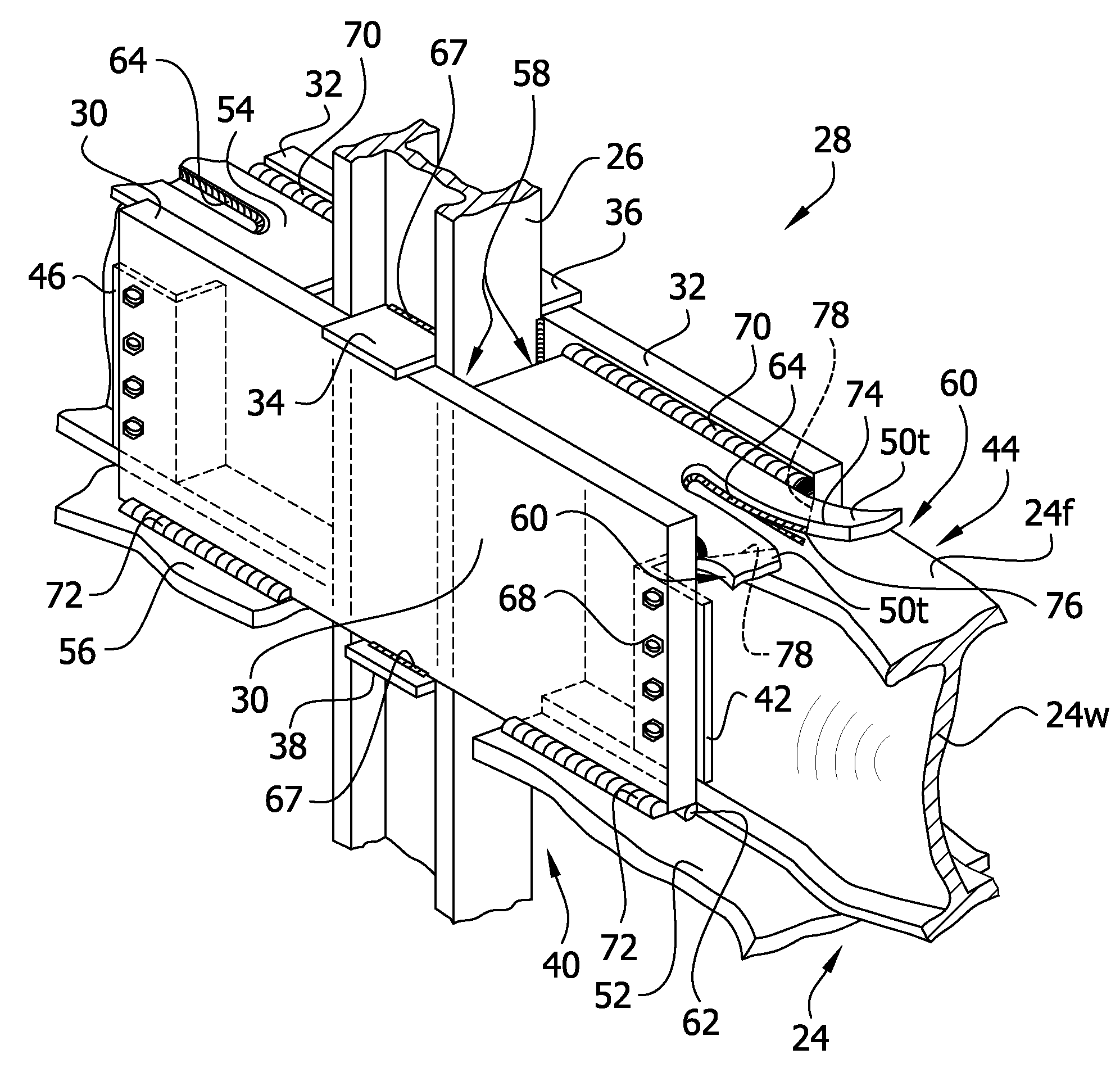

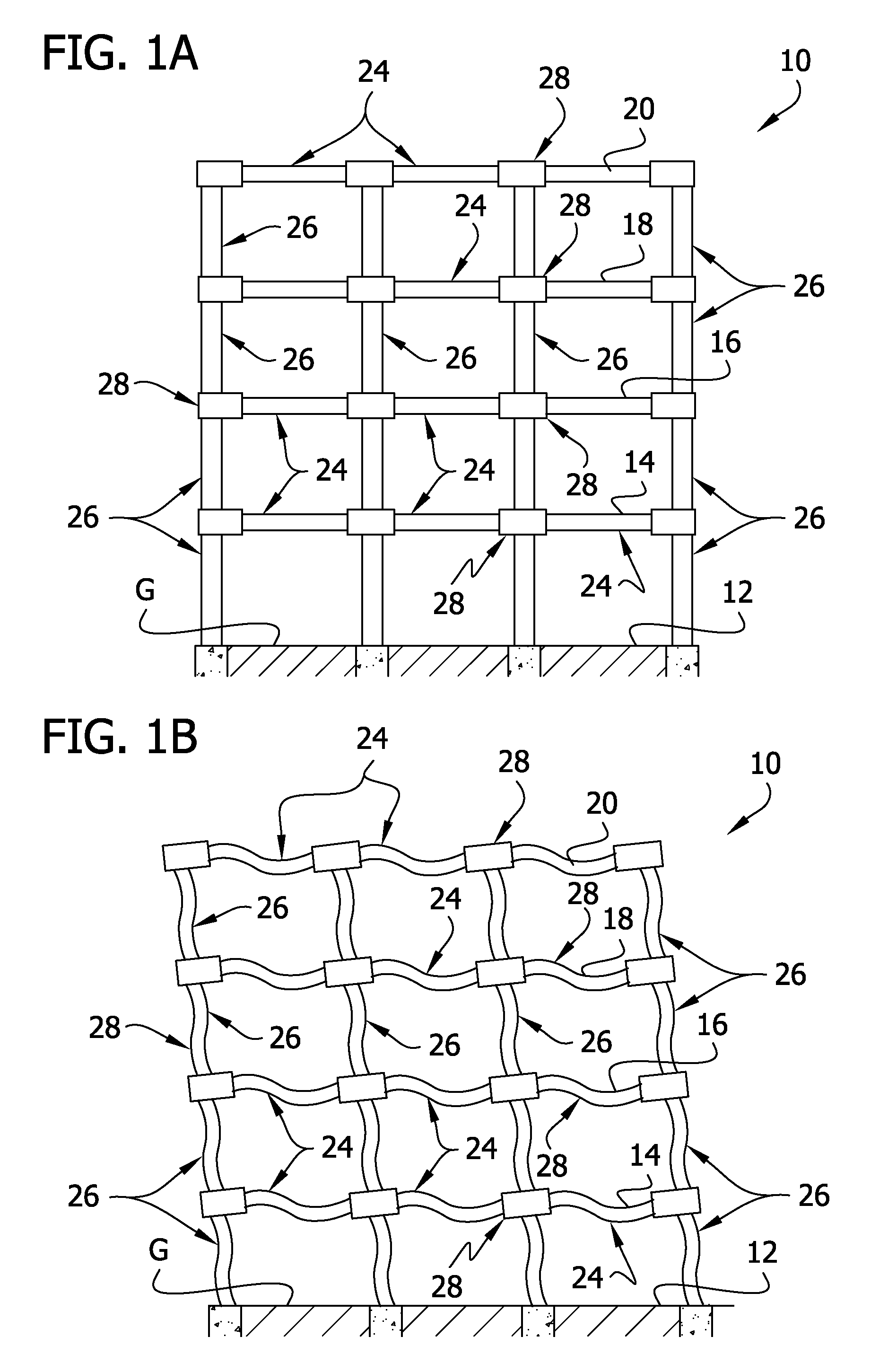

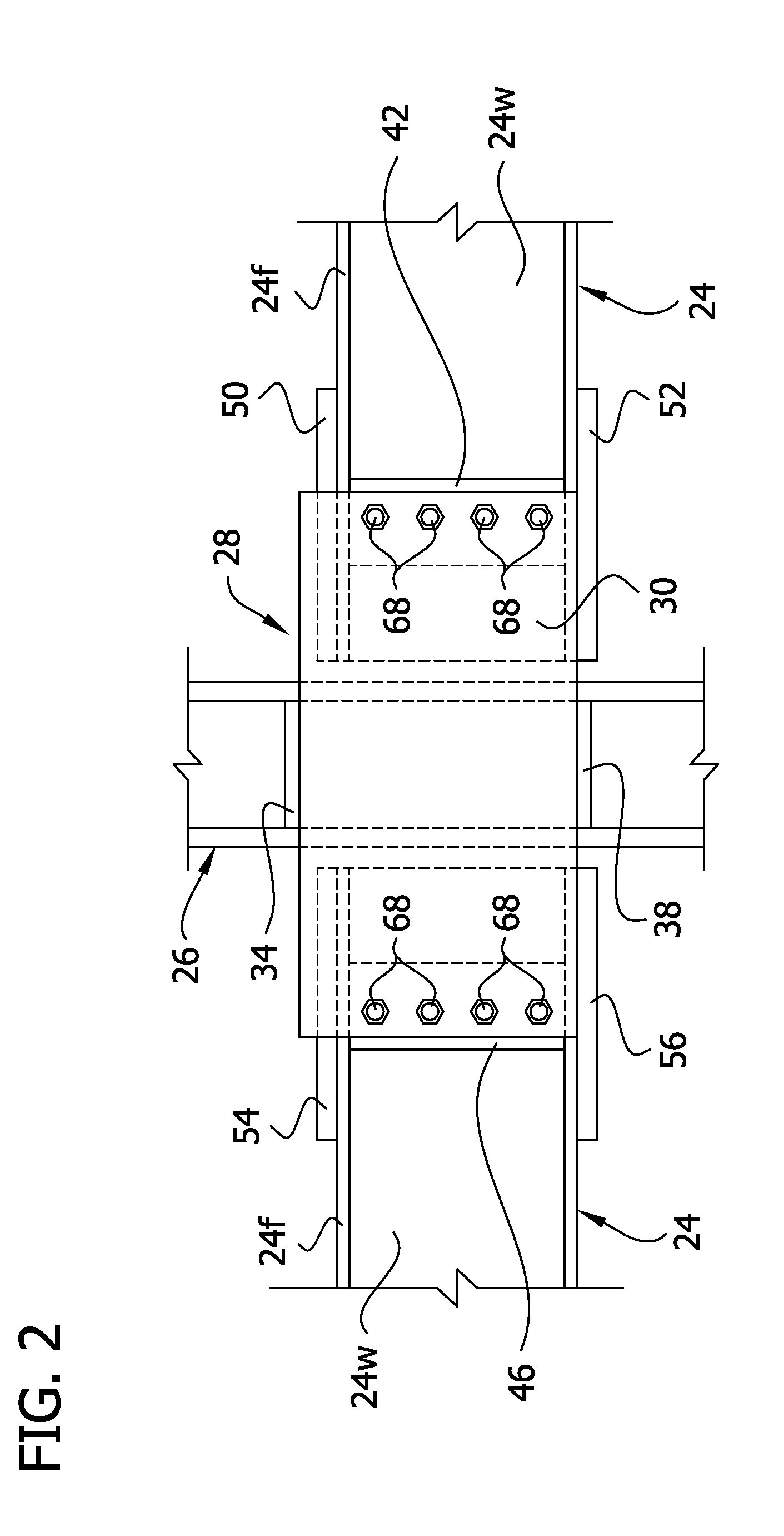

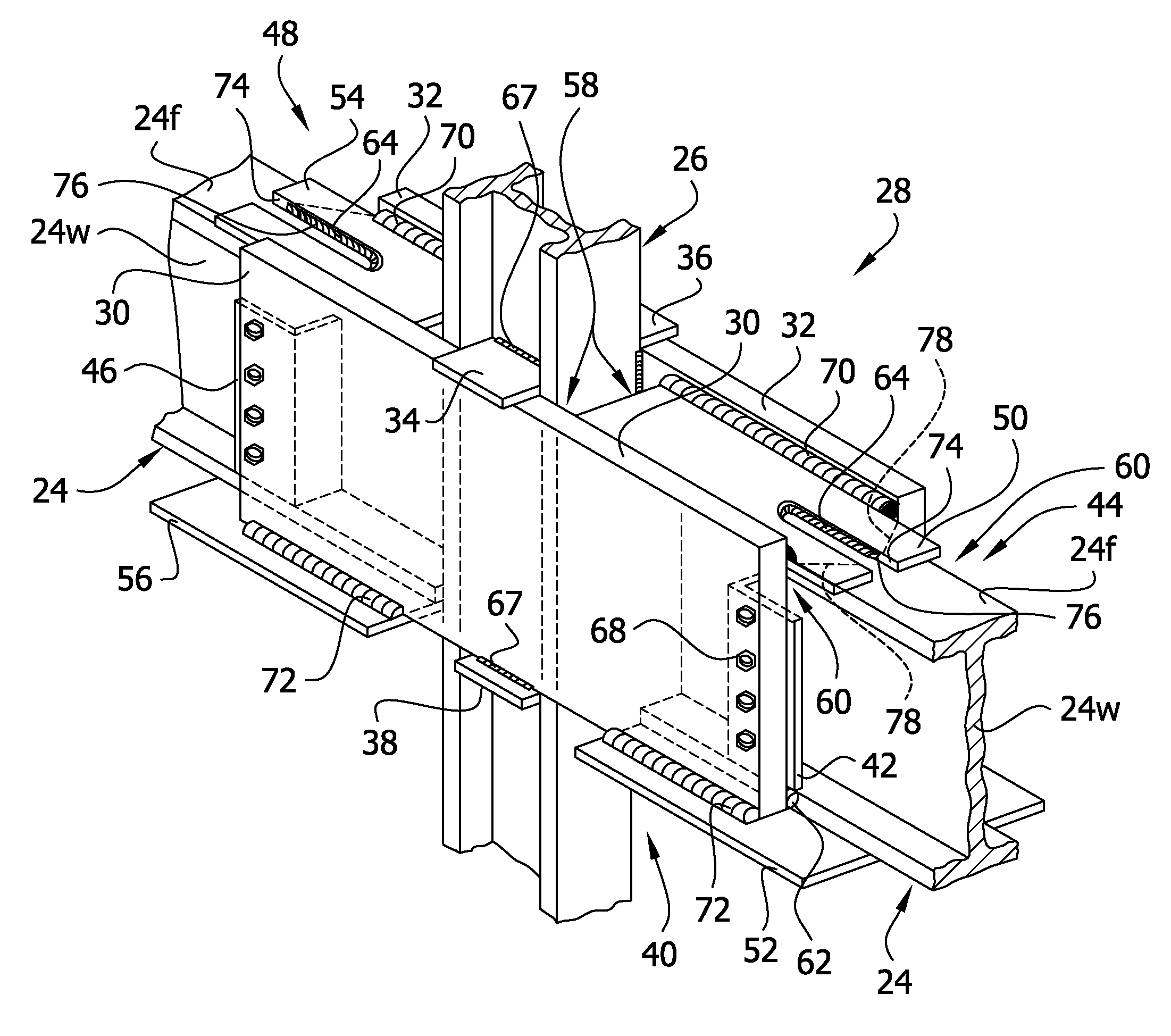

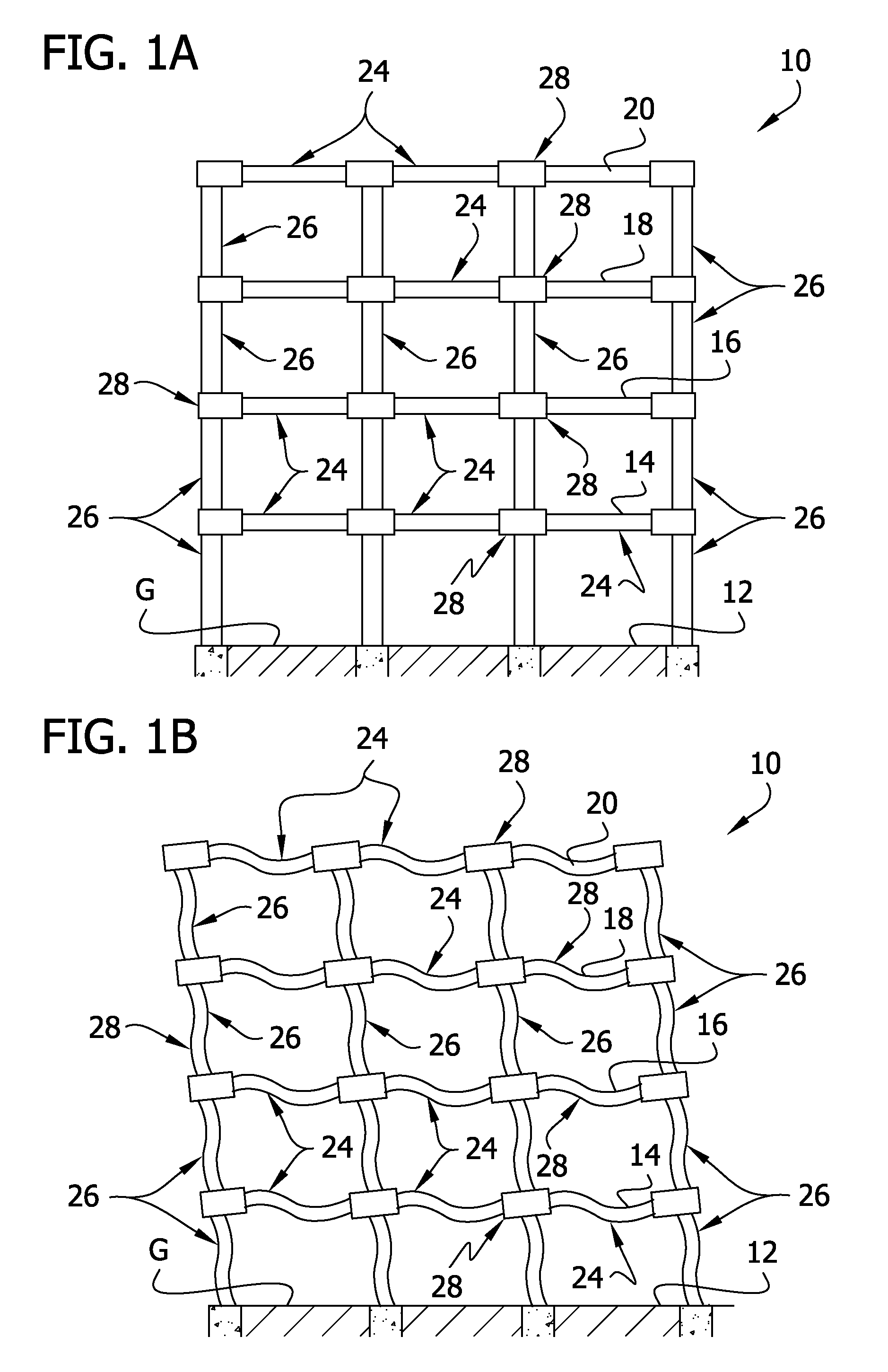

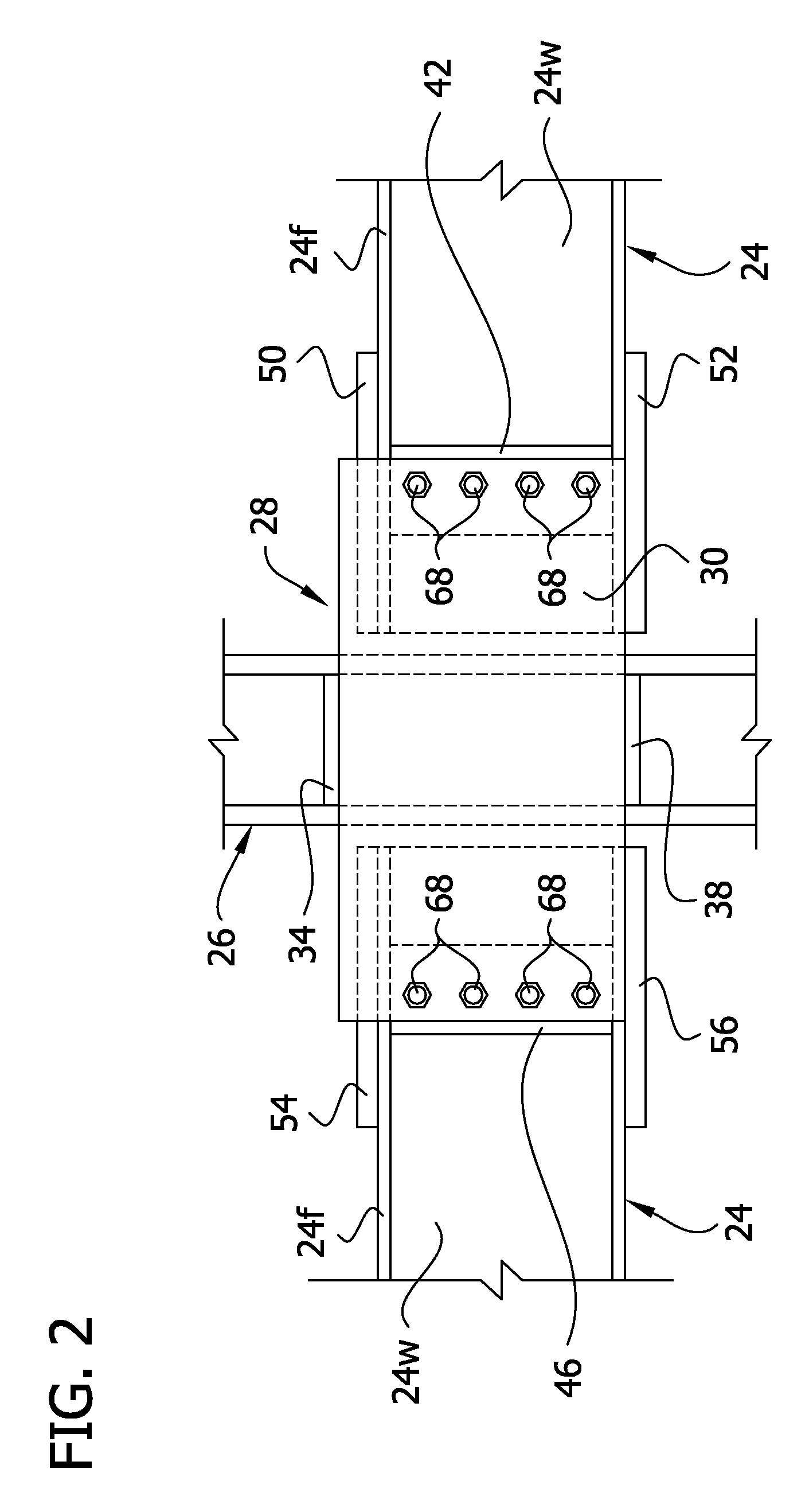

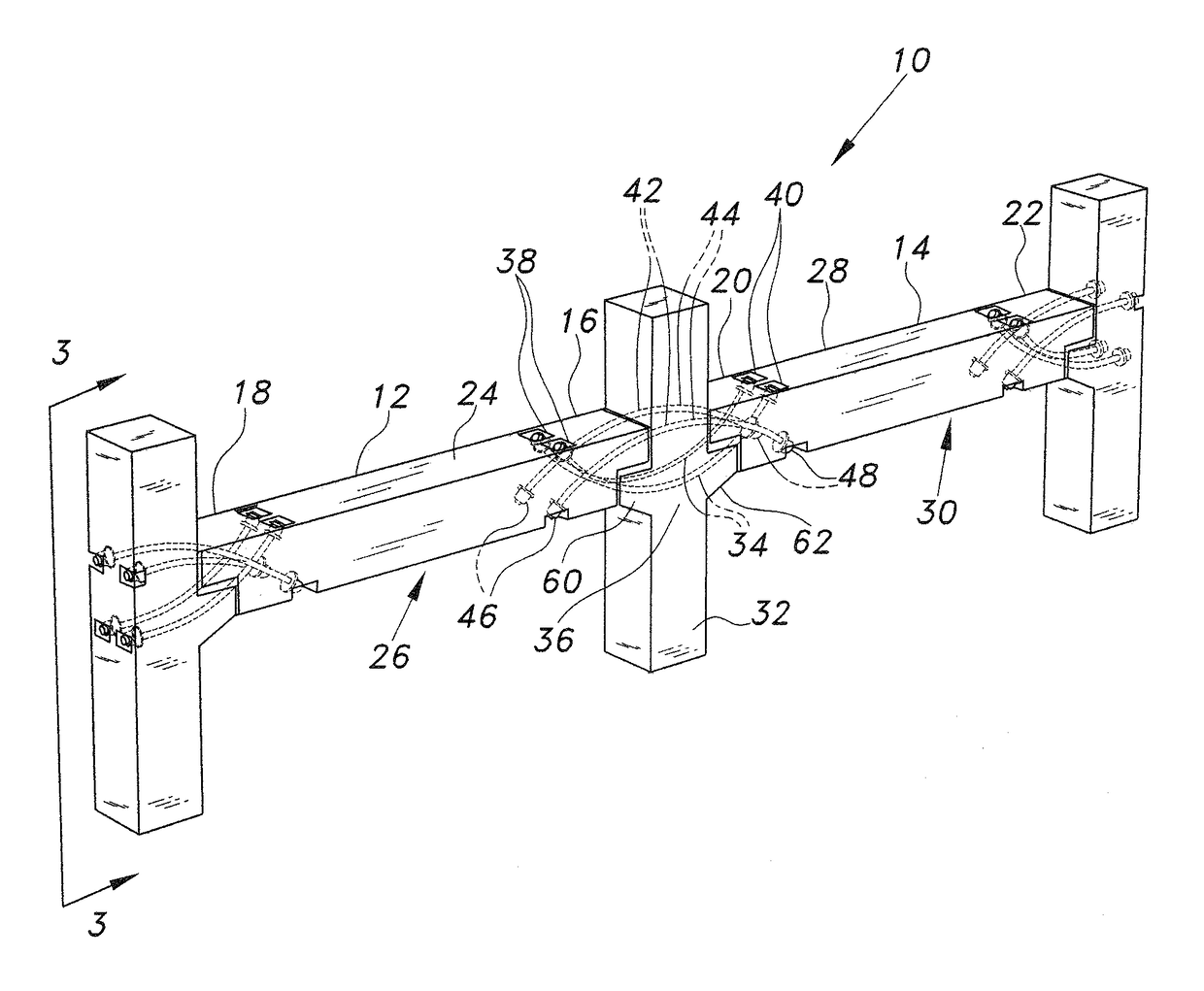

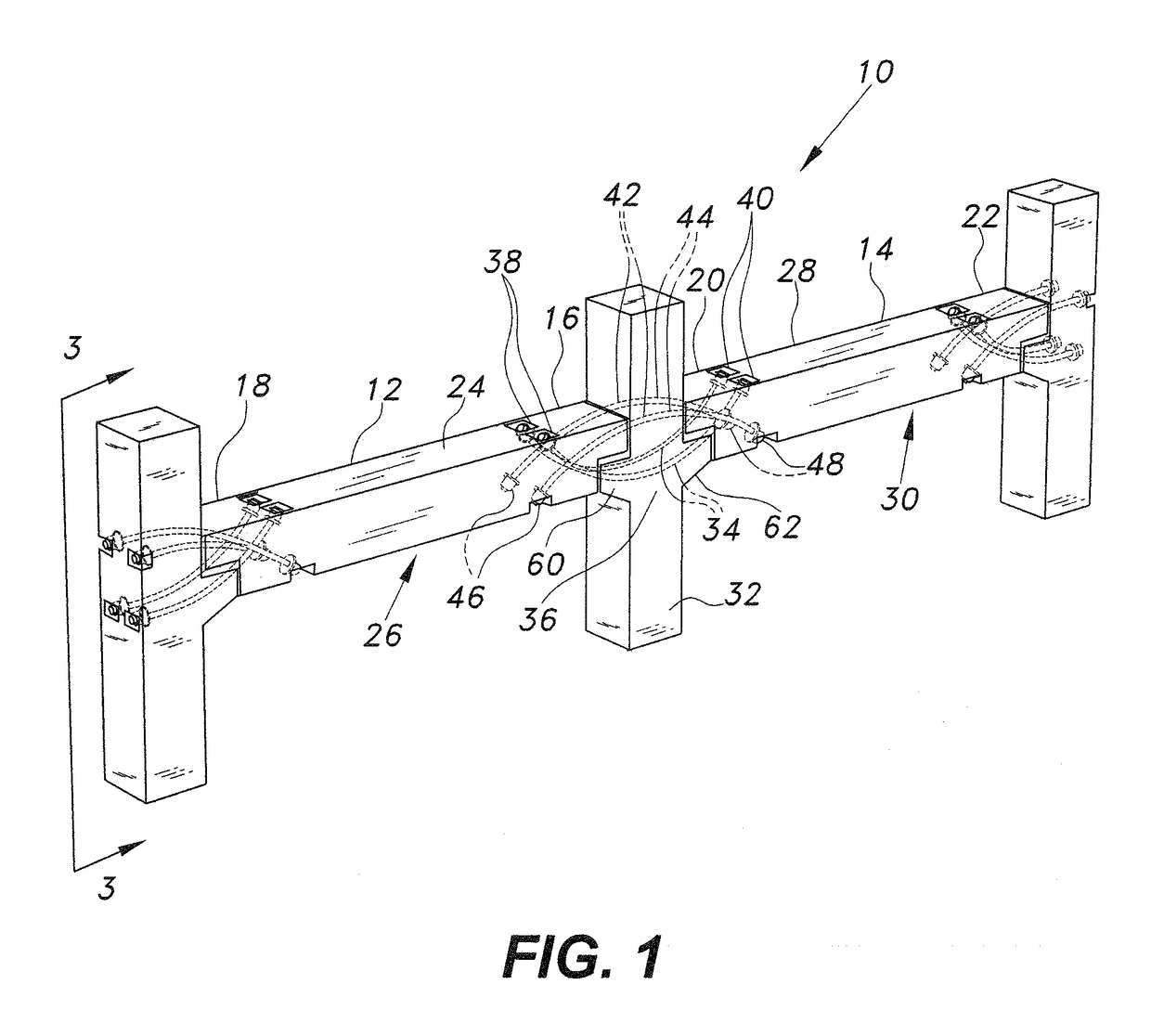

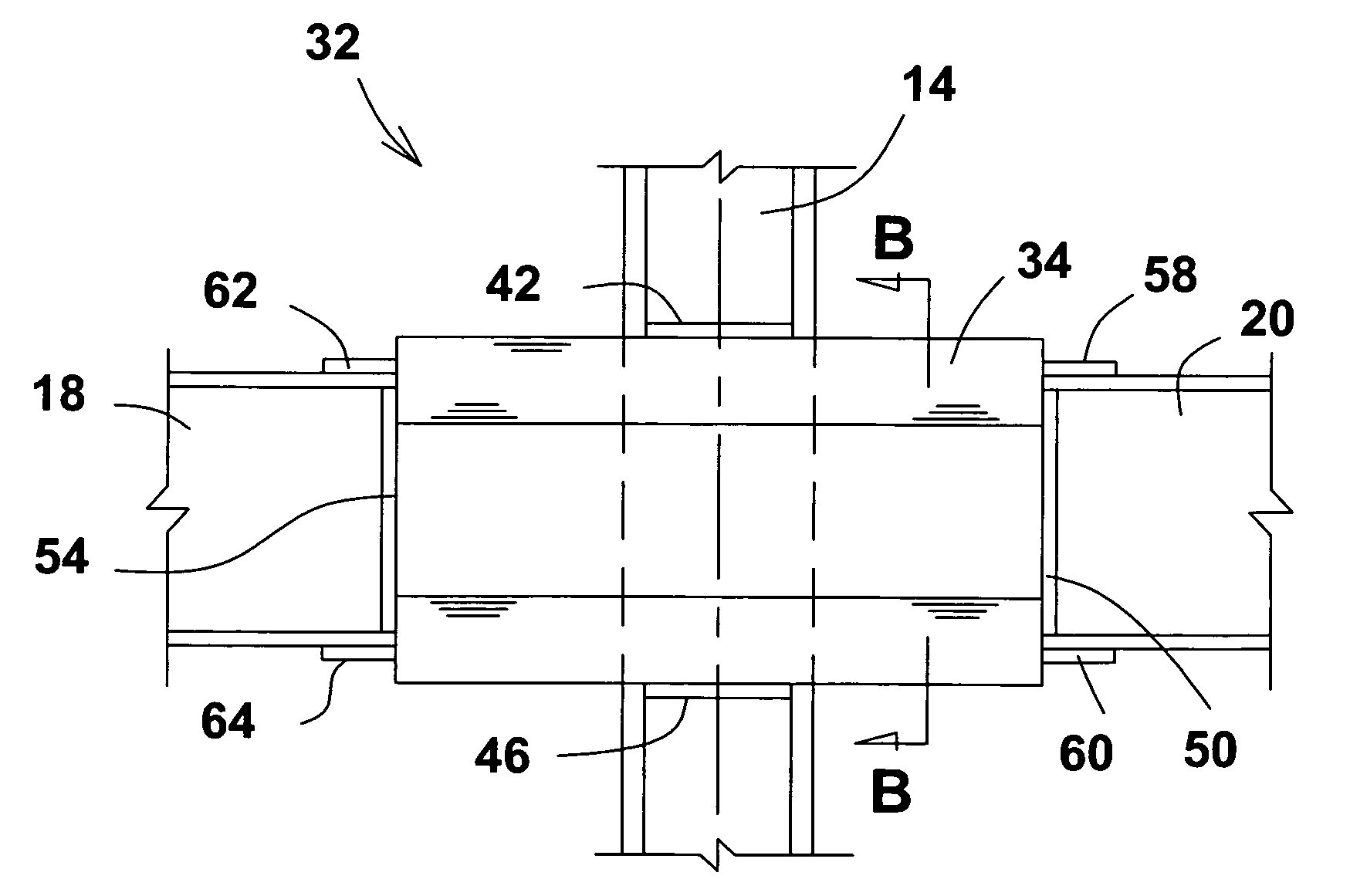

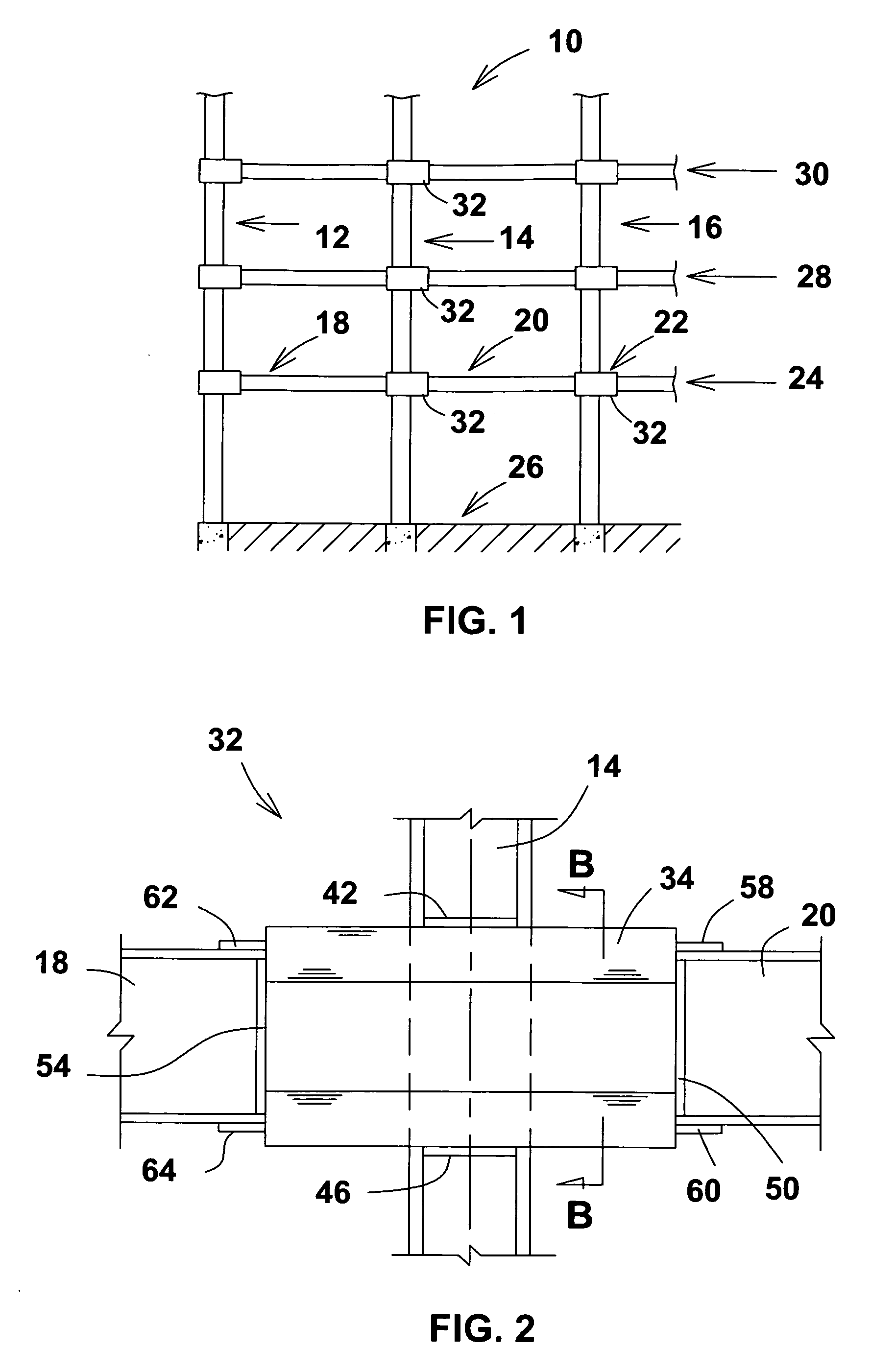

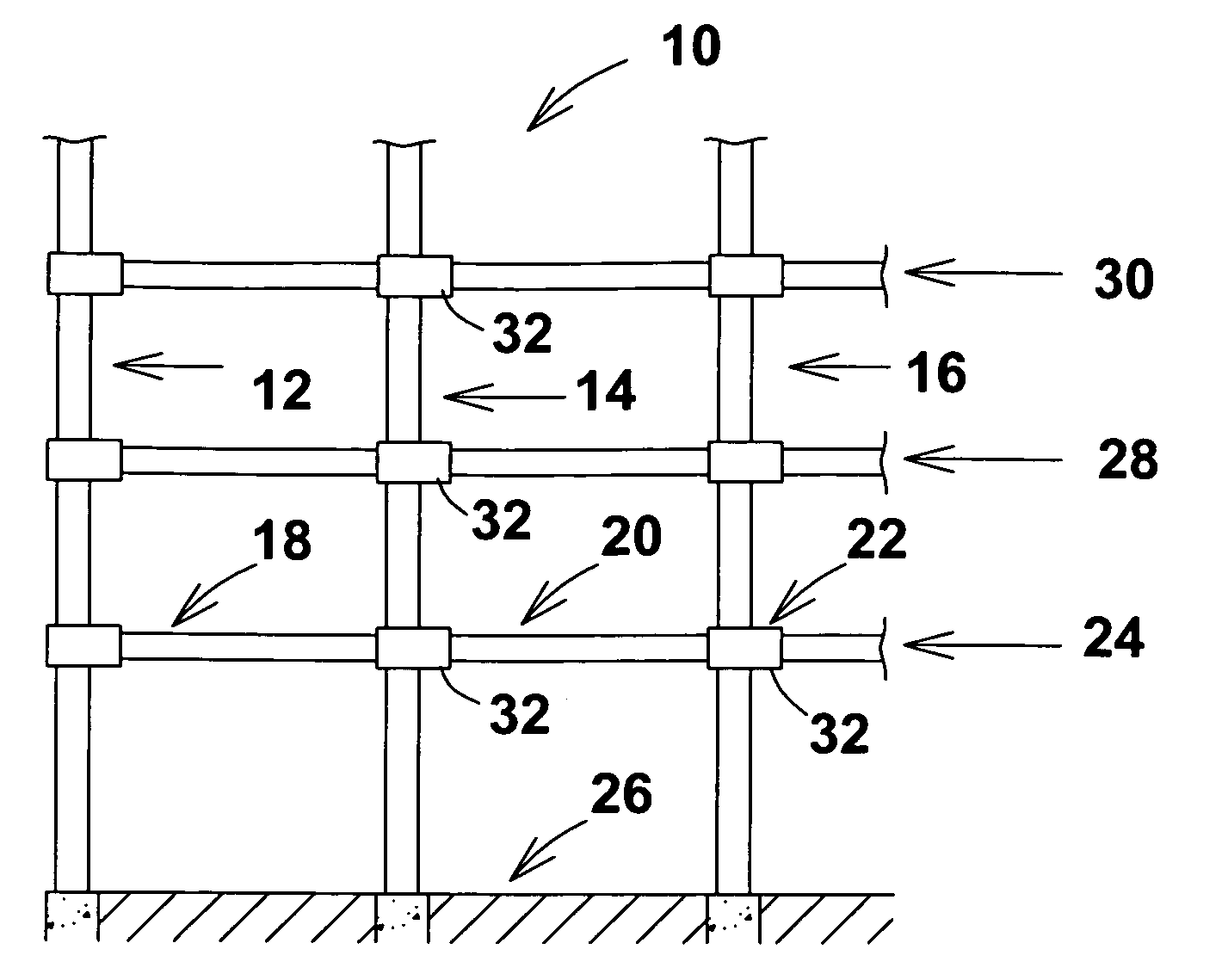

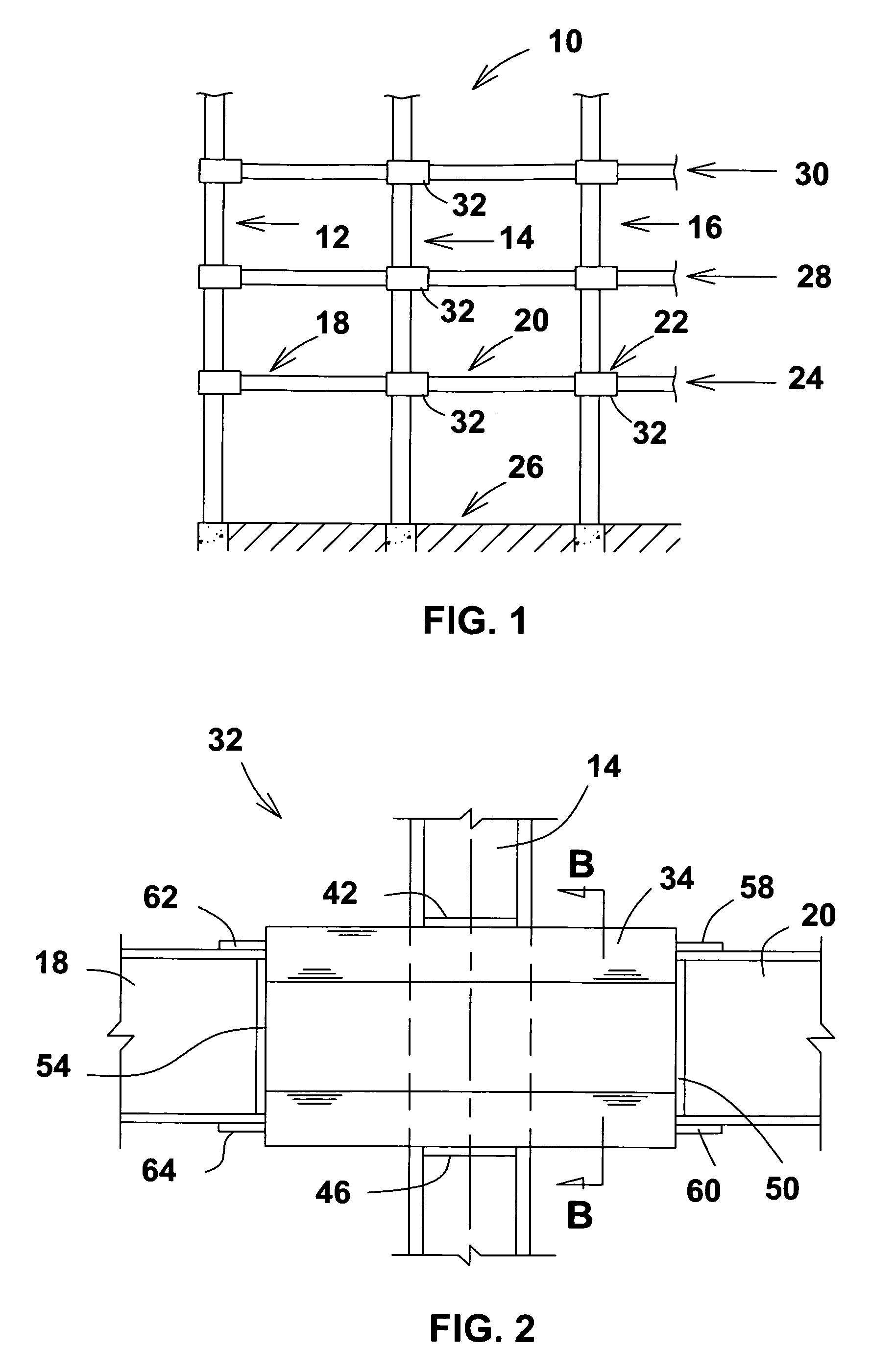

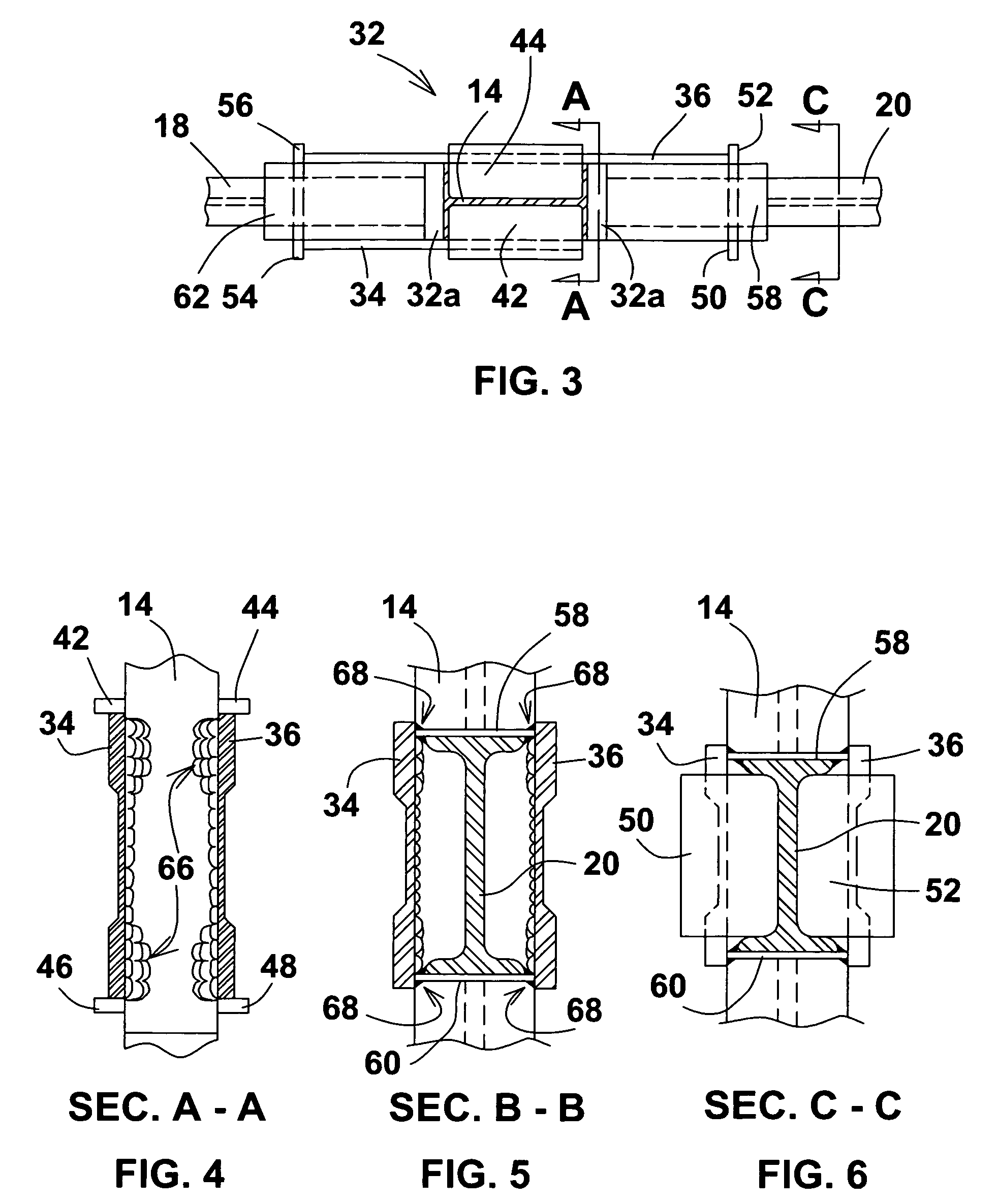

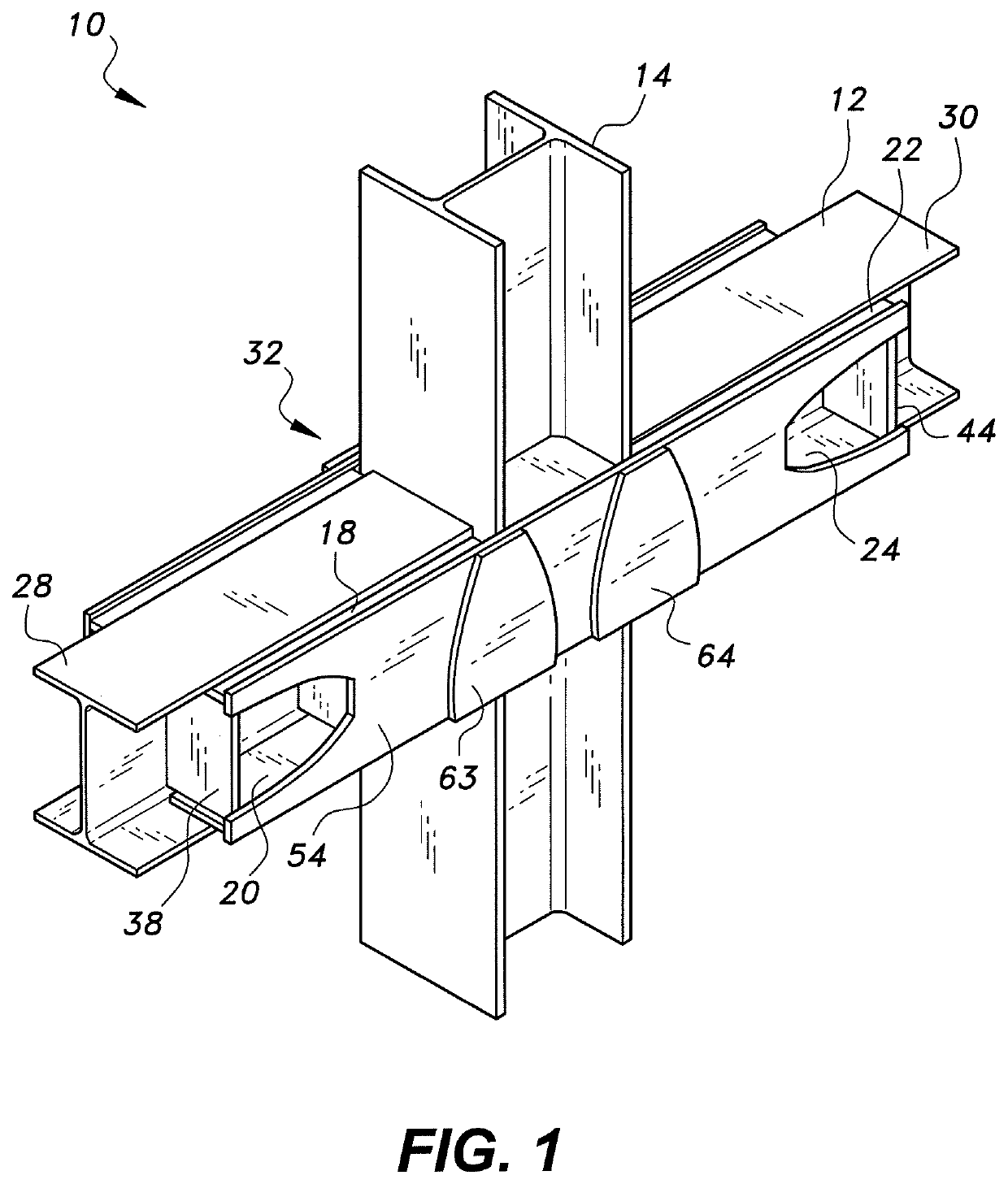

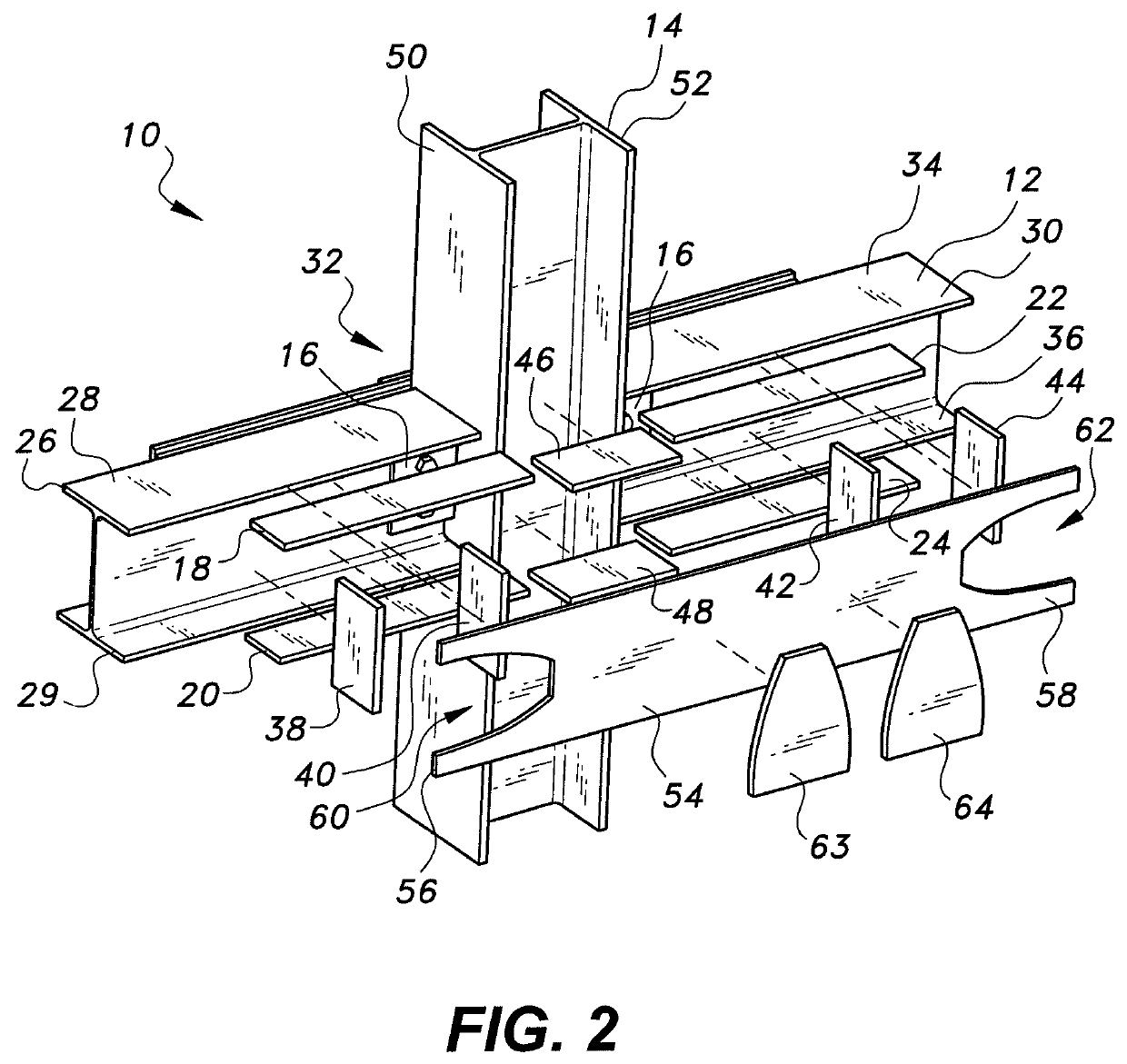

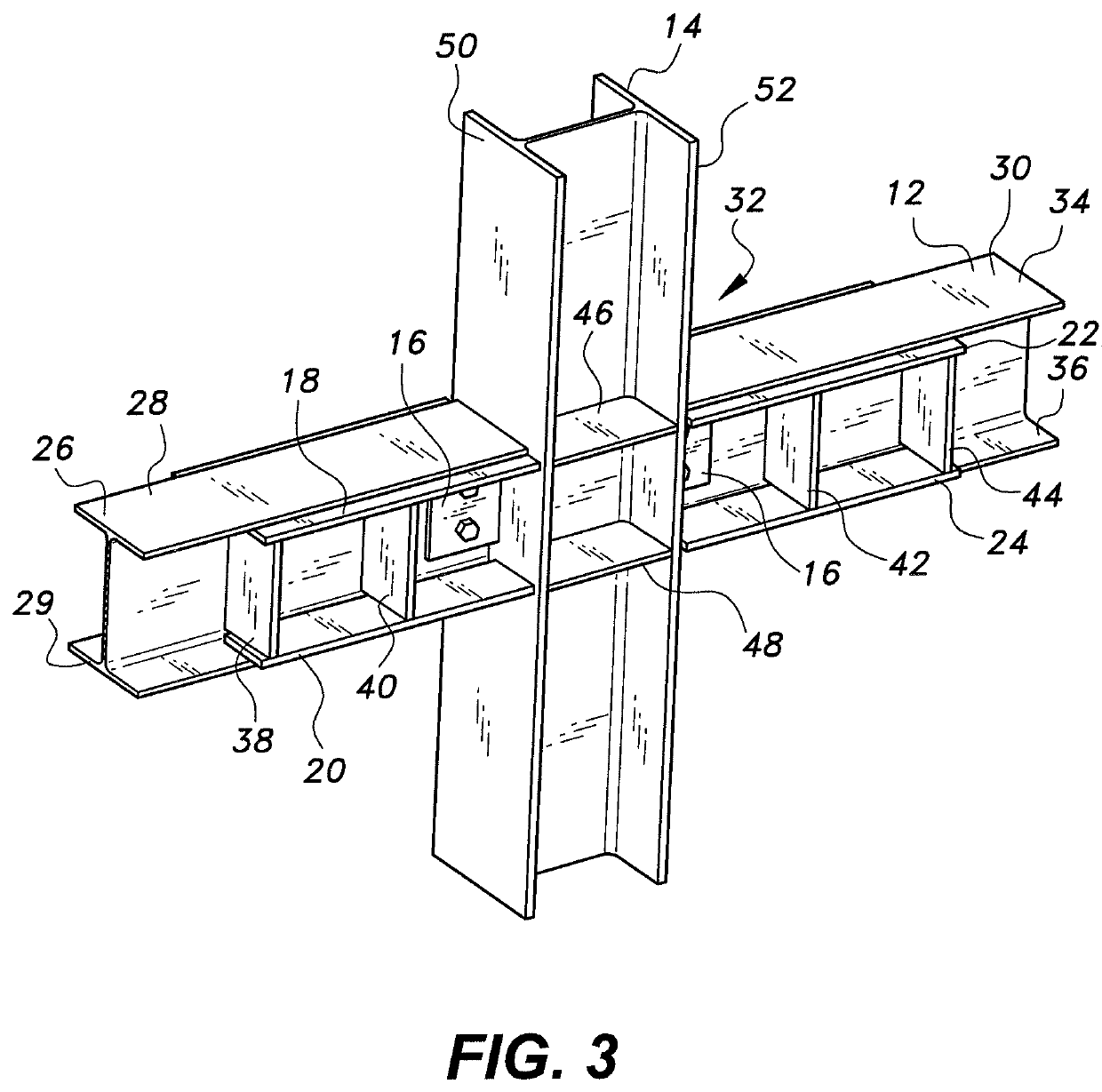

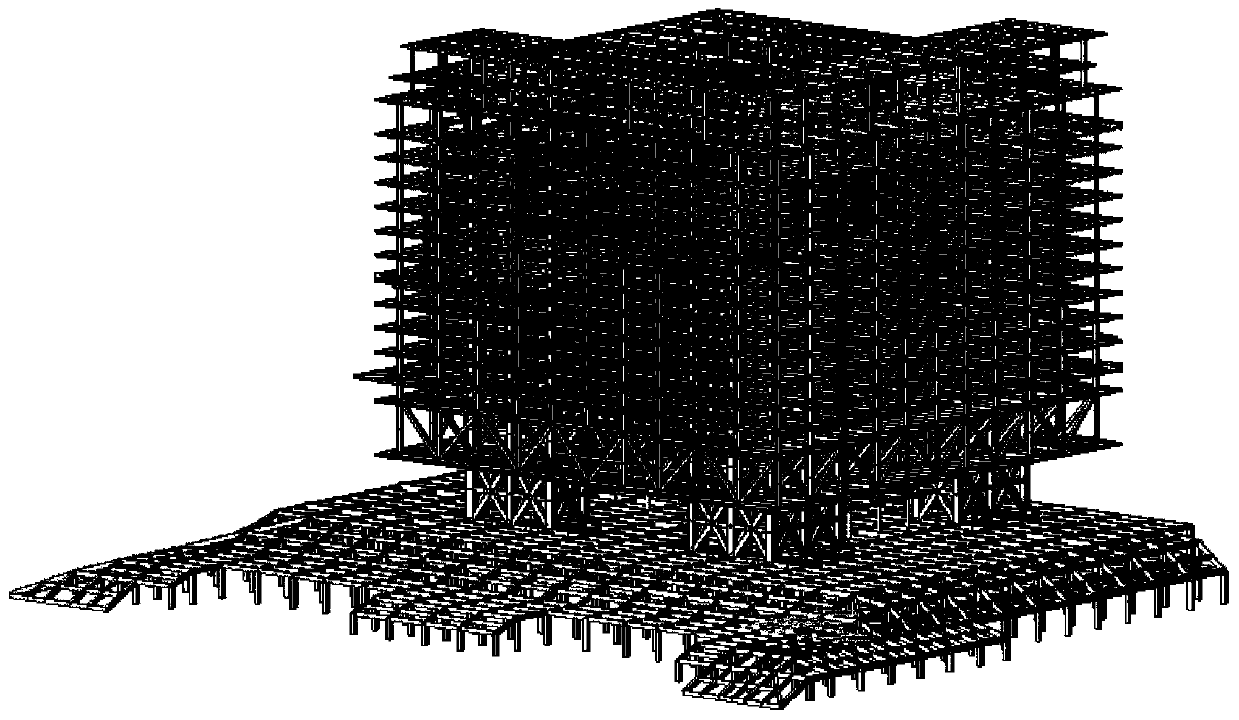

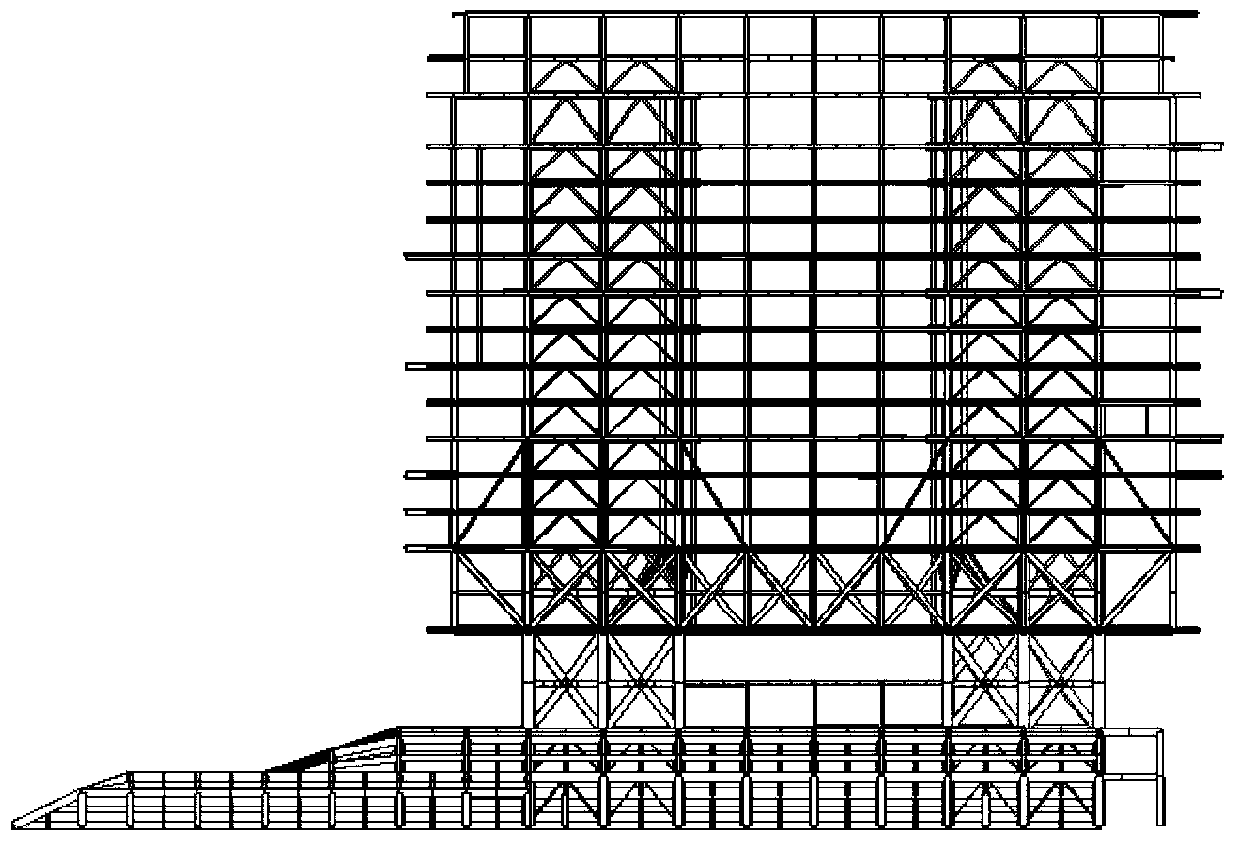

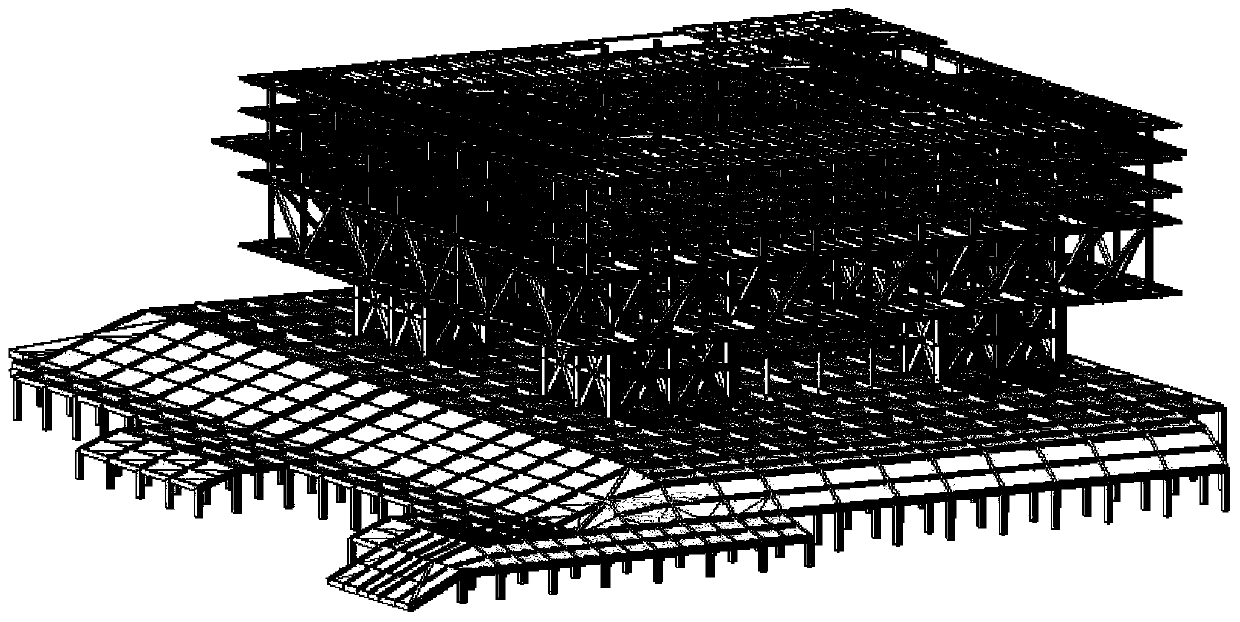

Building Structure, Method of Making, and Components

ActiveUS20110030305A1Preserving building integrityPreserving human lifeStrutsBuilding repairsEngineeringPlastic property

A building framework includes plural column assemblies supporting plural beams supporting floors of the building, with the union of the column assemblies and beams forming beam-to-column (or beam-to-column-to-beam) joint connection assemblies according to this invention. The joint connection assemblies inventively include novel features which remarkably and surprisingly improve the distribution of strain and plastic deformation in the joint connection structure when subjected to extreme load challenges to the building structure (as may occur during earthquake, explosion, progressive collapse load conditions, or massive impact.

Owner:MITEK HLDG INC

Building structure, method of making, and components

A building framework includes plural column assemblies supporting plural beams supporting floors of the building, with the union of the column assemblies and beams forming beam-to-column (or beam-to-column-to-beam) joint connection assemblies according to this invention. The joint connection assemblies inventively include novel features which remarkably and surprisingly improve the distribution of strain and plastic deformation in the joint connection structure when subjected to extreme load challenges to the building structure (as may occur during earthquake, explosion, progressive collapse load conditions, or massive impact.

Owner:MITEK HLDG INC

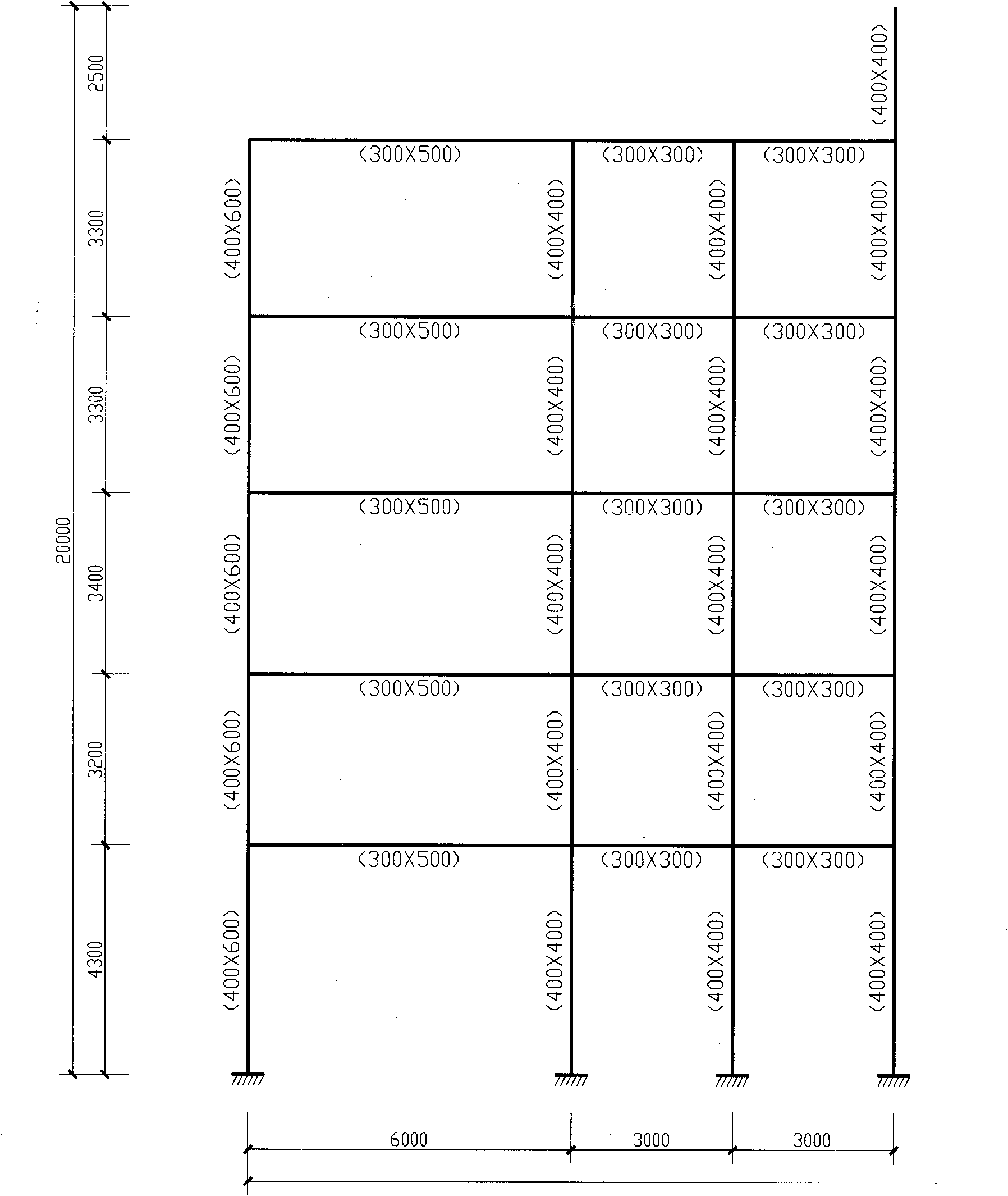

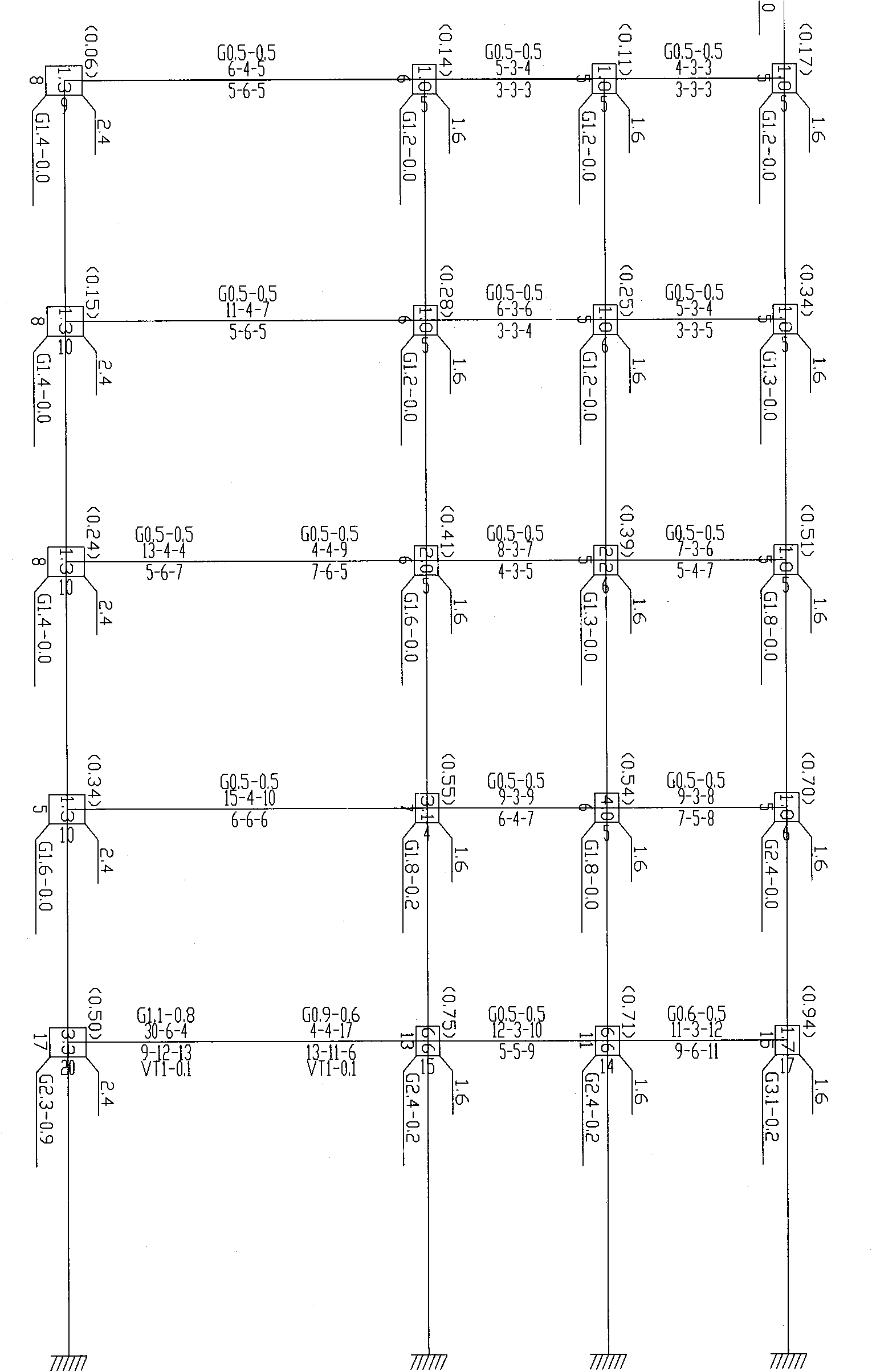

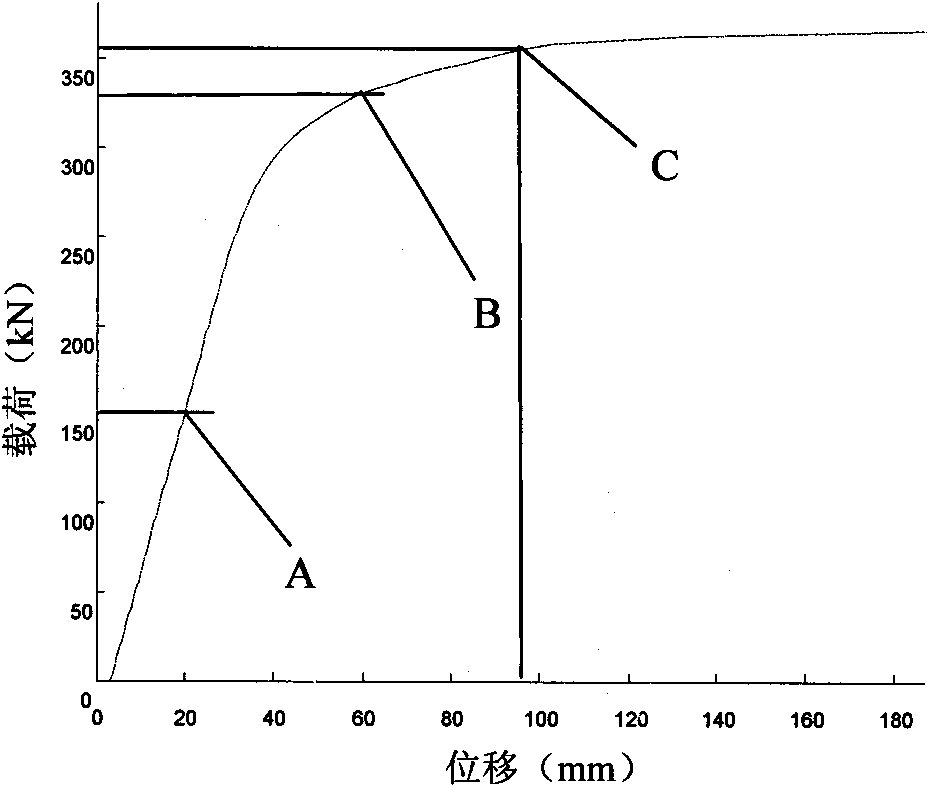

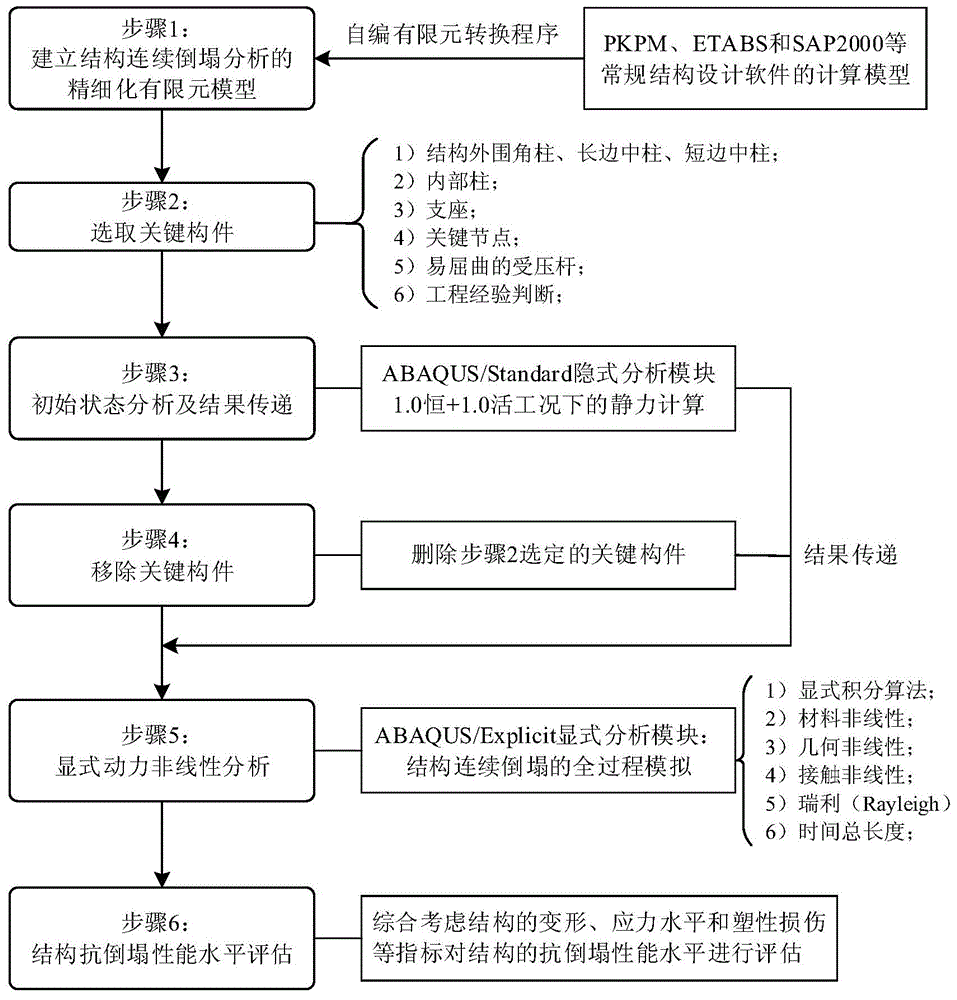

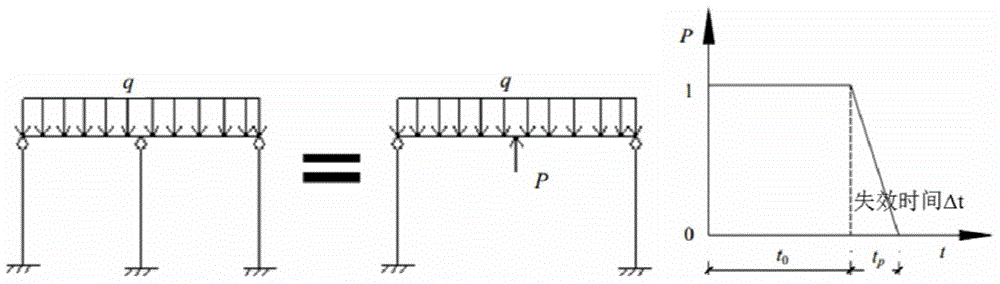

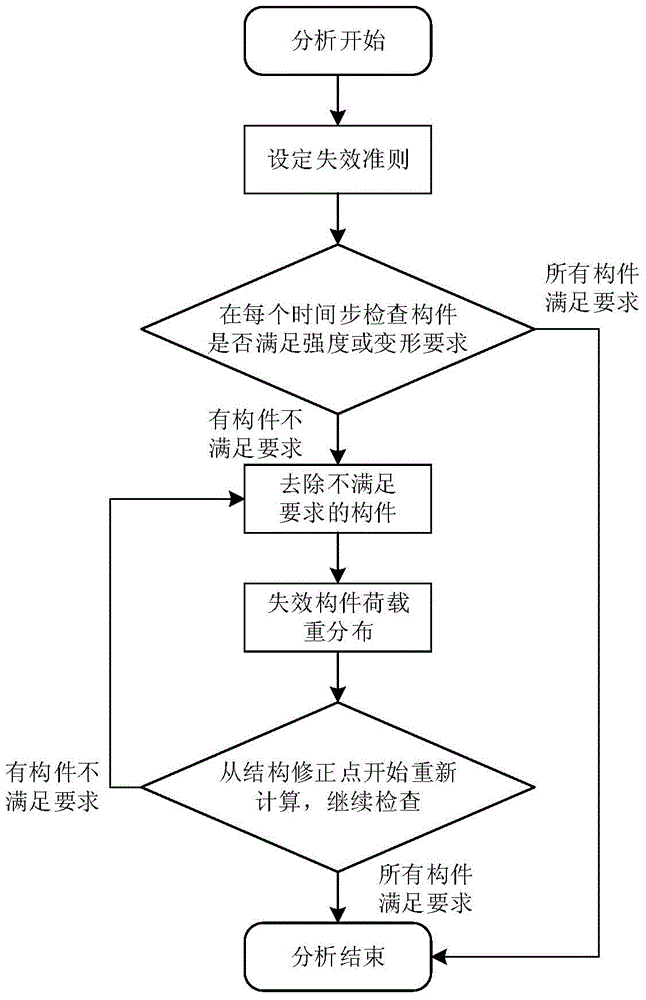

Method for designing progressive collapse-resisting frame structure

InactiveCN101851962AVerify validityEasy for quantitative analysisSpecial data processing applicationsShock proofingOperabilityGeometrically nonlinear

The invention provides a method for designing a progressive collapse-resisting frame structure, relating to an architecture structure design method. The invention provides a simple, easy and high reliable method for designing the progressive collapse-resisting frame structure, and comprises a design method of progressive collapse resistance due to earthquake action and a design method of progressive collapse resistance due to human accidents. The invention is characterized in that analysis and calculation on static nonlinear collapse for a plane frame are carried out by using a limited unit method according to the characteristic of collapse of the frame structure and in view of geometrically nonlinear influence under the conditions of nonlinear and large displacement of materials; carrying out collapse-resisting analysis on the two progressive collapses to provide design methods with progressive collapse resistance, wherein the design methods are suitable for the background of design specifications of China, have operability of engineering application, and comprise the design method of progressive collapse resistance due to earthquake action and the design method of progressive collapse resistance due to human accidents.

Owner:厦门合立道工程设计集团股份有限公司

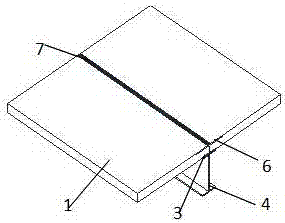

Precast reinforced concrete construction elements with pre-stressing connectors

The precast reinforced concrete construction elements with pre-stressing connectors provide beam-column connections which are post-tensioned through a combination of active and passive pre-stressing tendons. The active pre-stressing tendons improve the efficiency and effectiveness of the beam-column connections under service loads, as well as during application of external forces and stresses, such as during earthquakes. The passive pre-stressing tendons are lightly pre-stressed and only become effective during progressive collapse of the building. Specifically, the passive pre-stressing tendons become stressed only during downward movement of a joint due to the loss / damage of a column, thus providing resistance against further downward movement of the joint and thereby resisting the progressive collapse.

Owner:KING SAUD UNIVERSITY

Method for analyzing anti-progressive collapse performance of large-span spatial structure

InactiveCN104820731AFast modelingImprove work efficiencySpecial data processing applicationsSpatial structureEngineering

The invention discloses a method for analyzing an anti-progressive collapse performance of a large-span spatial structure. The method can be applied to analysis of the anti-progressive collapse capacity of the structure after failure of damaged local members of a building structure due to explosion, car collision, earthquake and so on. The method takes failure time of the members, geometric nonlinearity, material nonlinearity and conditions of rupture, contact, collision and so on into account in analysis, and also takes the inertia and dynamic effect of the structure due to member failure into account, thereby simulating the anti-progressive collapse performance of the structure more accurately.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

Steel-frame building and method of making

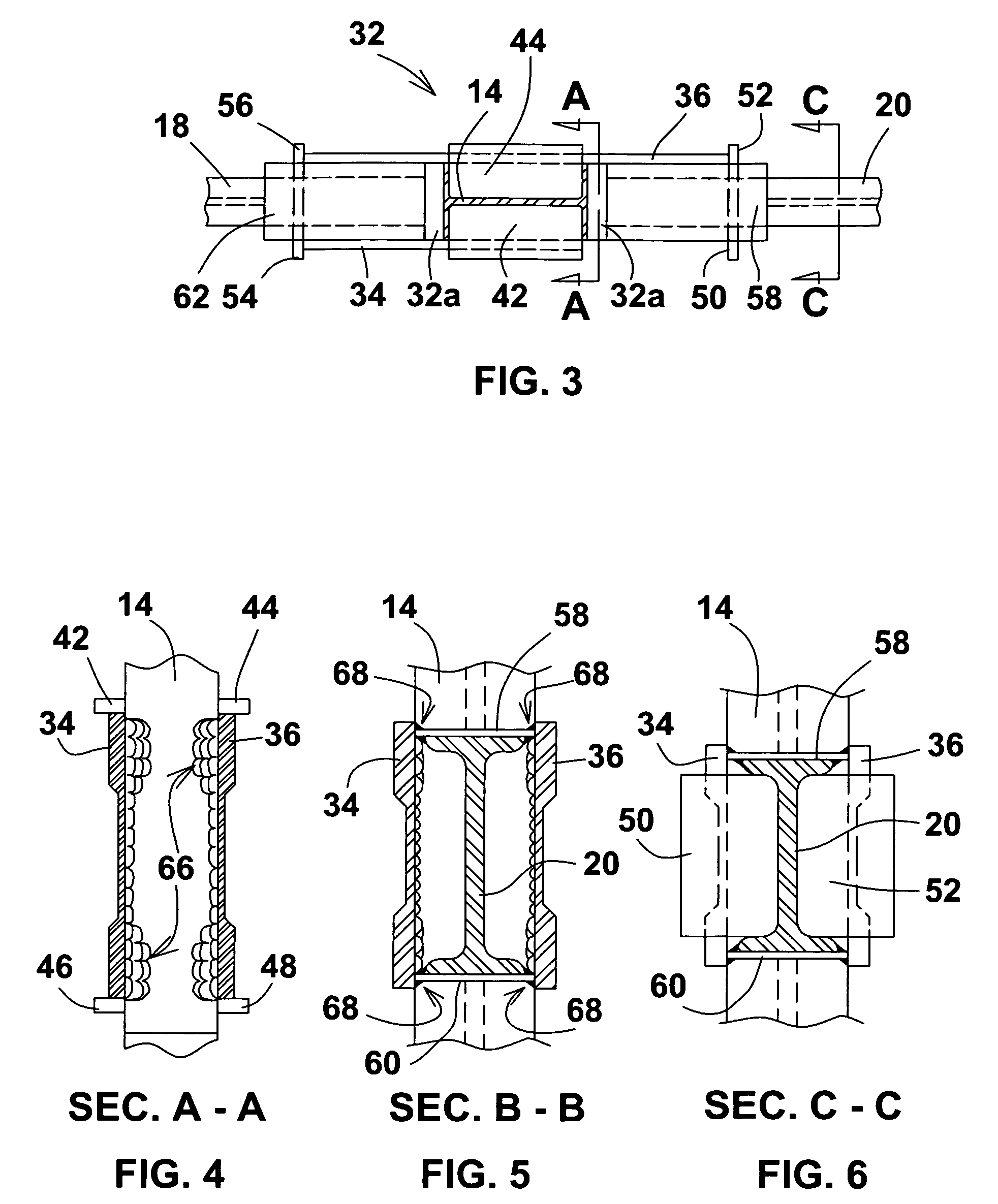

ActiveUS20100043316A1Reduce harmMoment-resisting connectionHuman health protectionLoad-supporting elementsBlast effectsEngineering

An improved building structure and method for making steel frame buildings includes a beam-to-column or beams-to-column joint or connection which is most preferably shop fabricated (as opposed to on-site fabrication) and which offers a considerable savings in both steel requirements (i.e., material savings) and labor to make the joint connection. Also, because material utilization is improved in the connection, the new structure is more resistant to damage by seismic events (i.e., earthquake), by severe weather, and to damage from blast effects (i.e., terrorist attack or accident), than was the prior technology. The improved building structure also mitigates against progressive collapse of the building.

Owner:MITEK HLDG INC

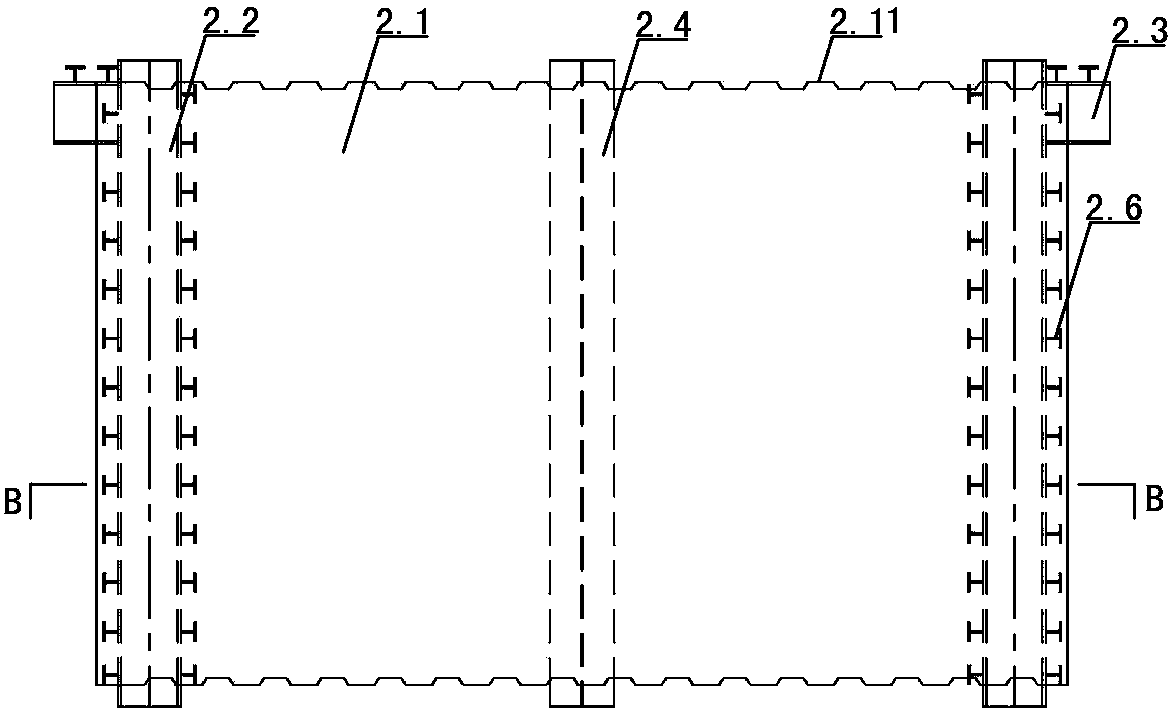

Assembly-type T-shaped mixed coupled wall and construction method thereof

Disclosed are an assembly-type T-shaped mixed coupled wall and a construction method thereof. The assembly-type T-shaped mixed coupled wall comprises a first wall unit and a second wall unit which are connected together perpendicularly and form a T shape. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type T-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved, building operating requirements can be met conveniently, and assembly procedures can be simplified conveniently; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Steel-frame building and method of making

Owner:MITEK HLDG INC

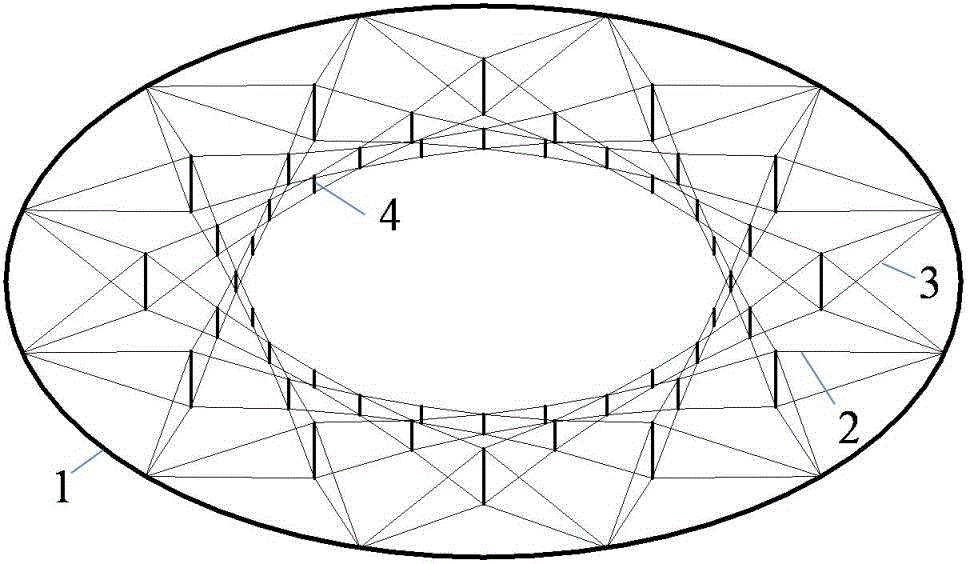

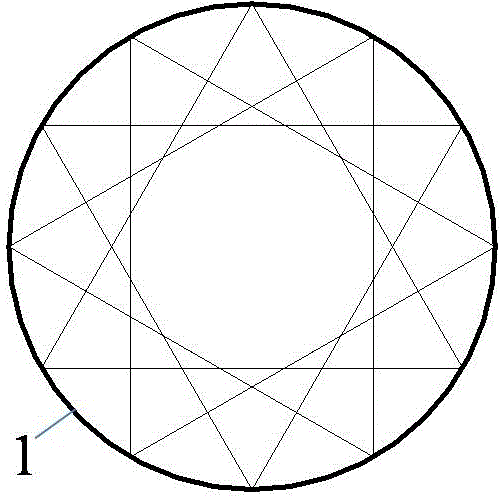

Circular cross cable truss structure

InactiveCN105926850ABeautiful buildingReasonable structural stressGirdersJoistsEngineeringStructural engineering

Owner:SHANDONG JIANZHU UNIV

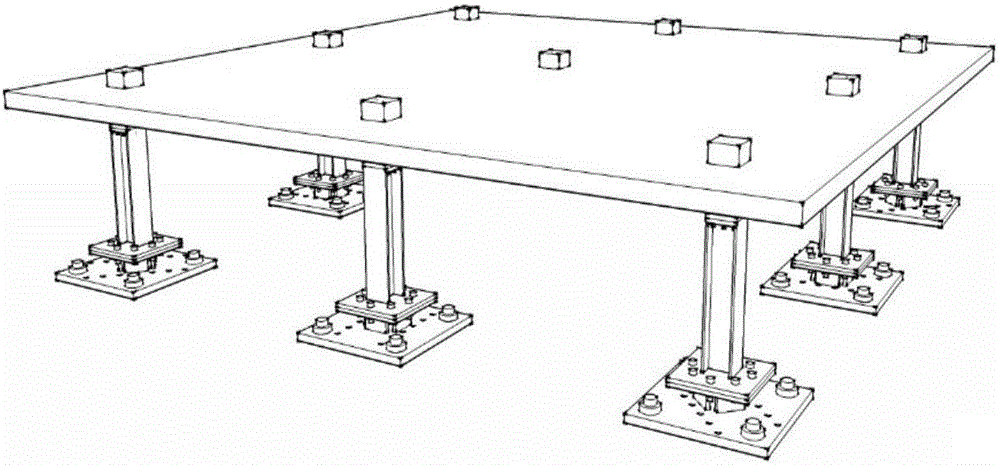

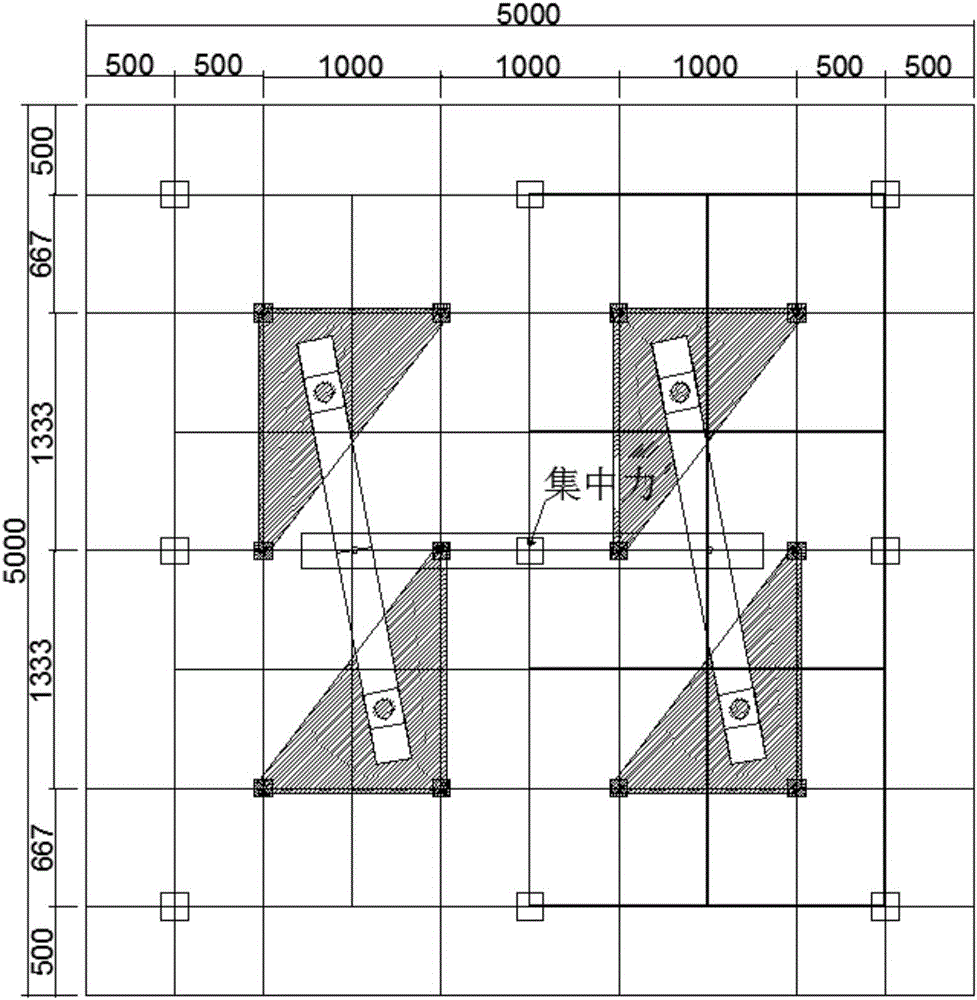

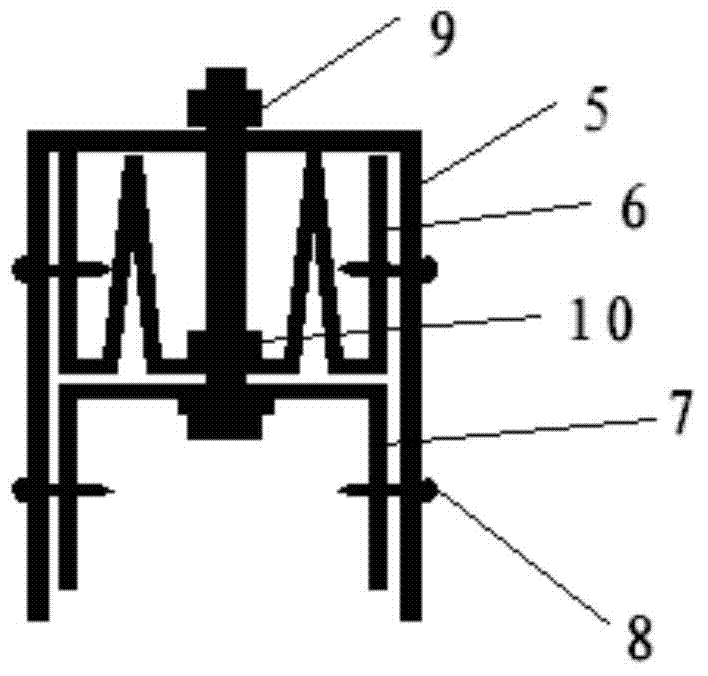

Device and method for testing progressive collapse performances of concrete plate-column structure

ActiveCN106383039ASave spaceWide range of applicationsStructural/machines measurementPlate columnEngineering

The invention relates to a device and method for testing the progressive collapse performances of a concrete plate-column structure. The progressive collapse of the structure is the progressive collapse, caused by a local damage failure caused by an incidental load, of a member connected with a failure damaged member, and finally may cause the overall collapse of a building structure or the collapse damage in a larger range relative to the initial local damage, thereby causing a large number of casualties and a great deal of financial loss. Therefore, the design of the progressive collapse performance of the structure is important. The device and method are used for carrying out the testing of the progressive collapse performances of the plate-column structure, and carry out the research of the distribution conditions of internal forces when the plate-column structure is caused by the accidental load to be partially invalid. The device and method carries out the design of the progressive collapse of the plate-column structure based on the internal force redistribution, and guarantees that the plate-column structure has the capability of resisting the progressive collapse under certain safety and reliability conditions.

Owner:BEIJING UNIV OF TECH

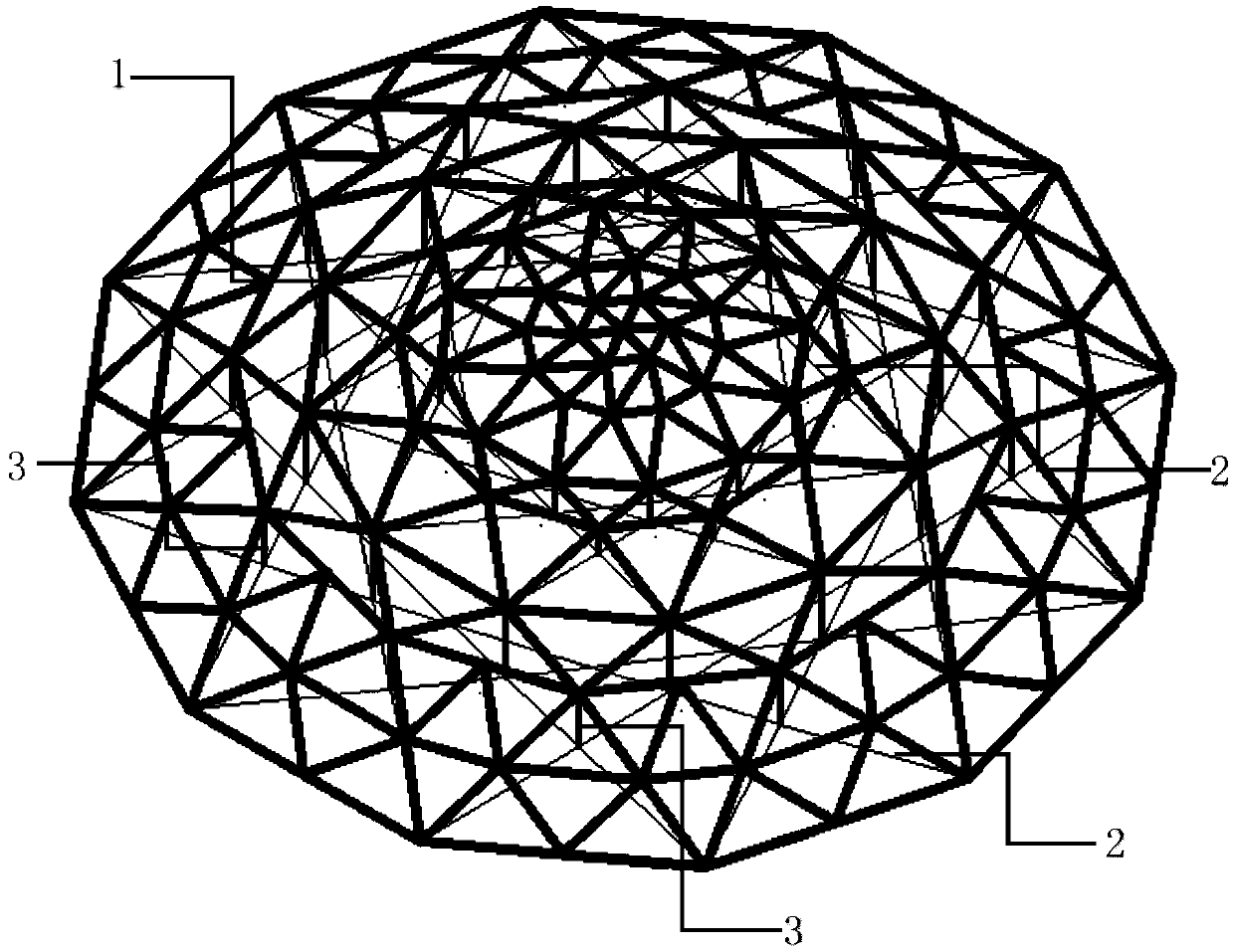

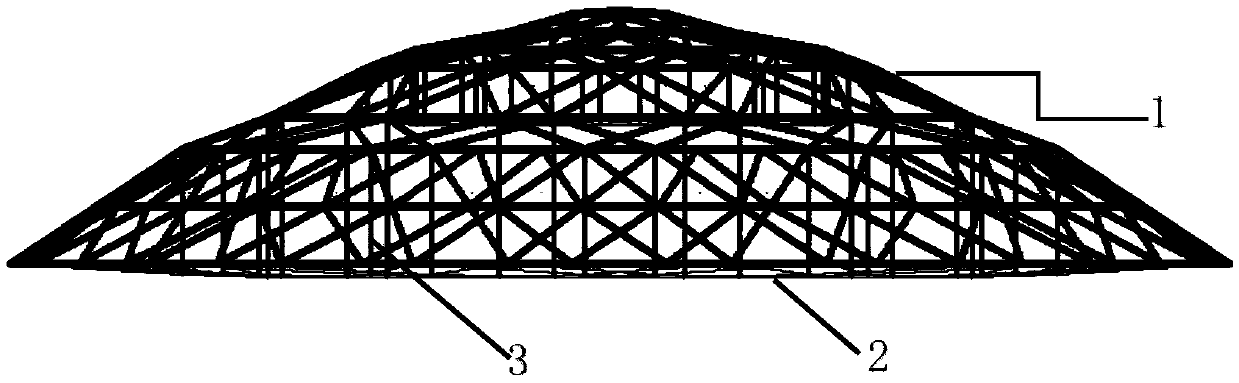

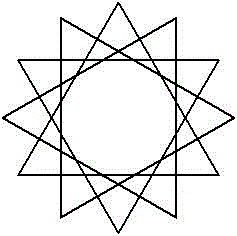

Rotary intersection cable system supporting dome structure

ActiveCN105507477ANovel structureStrong resistance to progressive collapseBuilding roofsSpatial structureStructural engineering

The invention discloses a rotary intersection cable system supporting dome structure, and belongs to the field of large-span spatial structures. The rotary intersection cable system supporting dome structure is composed of an upper reticulated shell, lower rotary intersection cable systems and vertical supporting rods. The lower rotary intersection cable systems are of an annular structure defined by a plurality of cable intersected dispersing points. The vertical upper ends of the vertical supporting rods are connected with the upper reticulated shell, and the lower ends of the vertical supporting rods are connected with the lower rotary intersection cable systems. The upper end of each vertical supporting rod is connected with a corresponding reticulated intersection in the upper reticulated shell, and the lower end of each vertical supporting rod is connected with the cable cross portion of the corresponding lower rotary intersection cable system. According to the rotary intersection cable system supporting dome structure, the rotary intersection cable systems and the vertical supporting rods have good space stress performance, the upper reticulated shell is supported, the stress mechanisms of the reticulated shell structure is changed, and horizontal thrust generated by the reticulated shell structure is reduced. The rotary intersection cable system supporting dome structure has the advantages of being novel in structural style, reasonable in structure stress, high in progressive collapse resisting capacity, attractive in building appearance and the like, is convenient to manufacture and mount, and has high practical significance.

Owner:BEIJING UNIV OF TECH

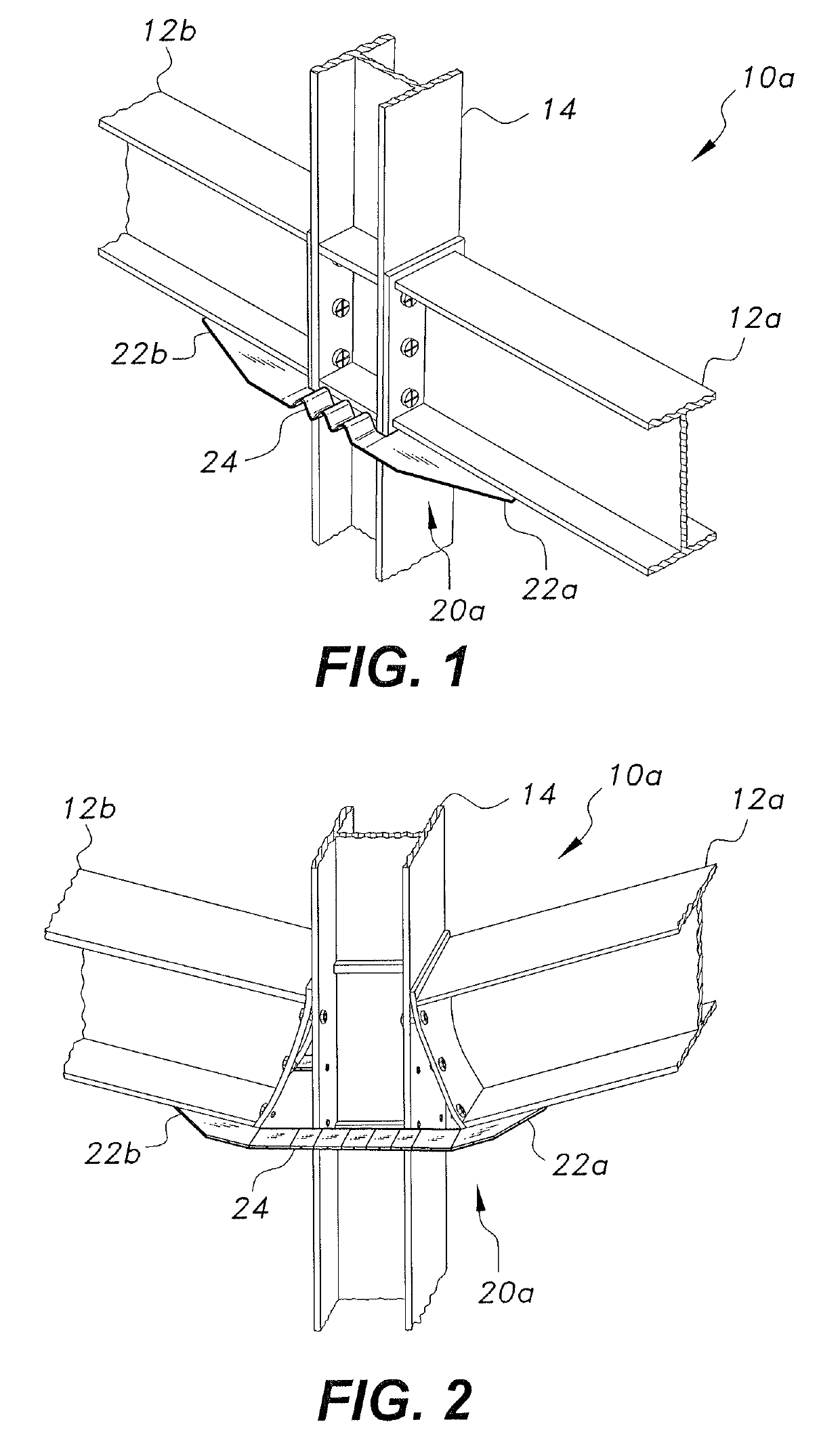

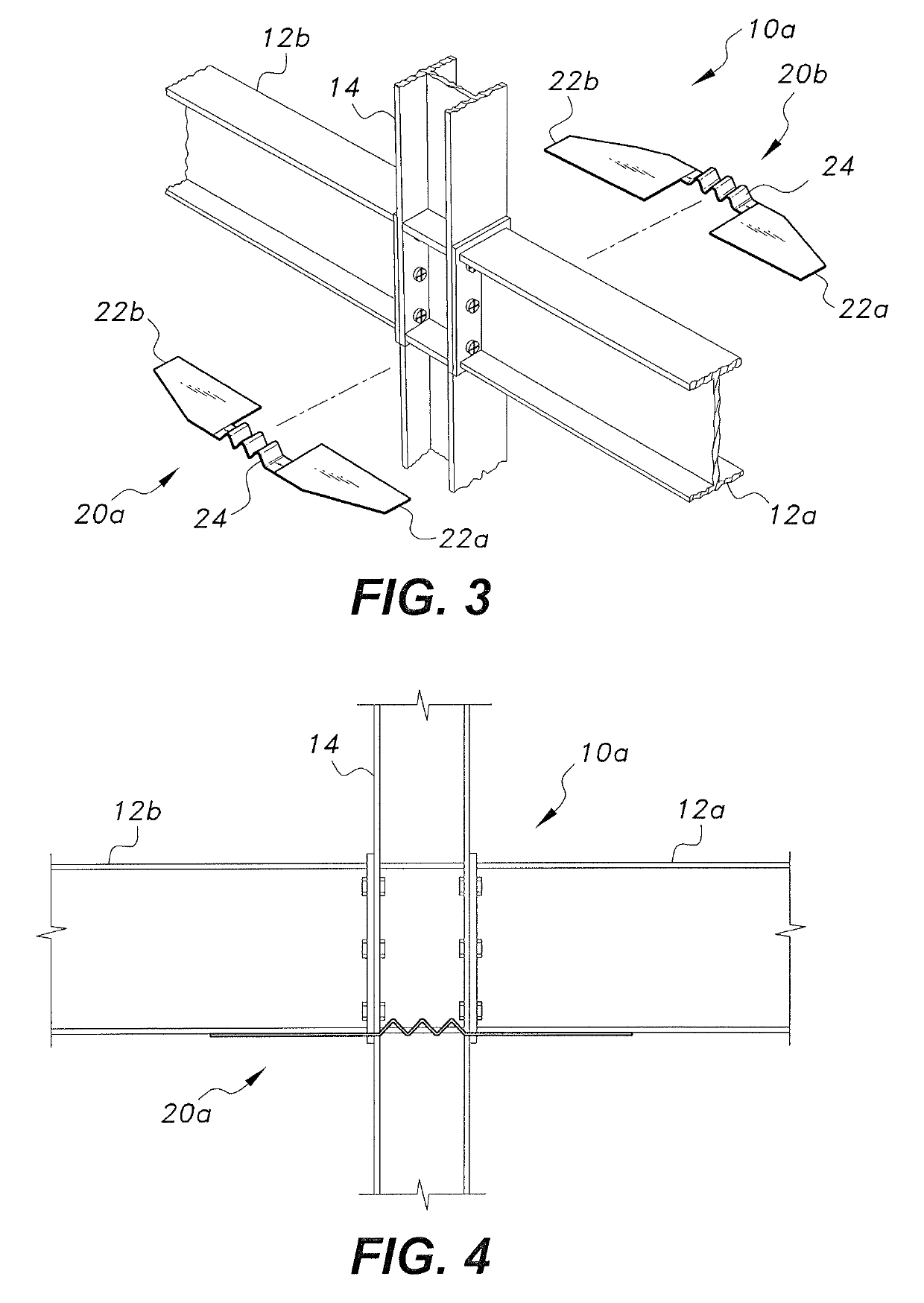

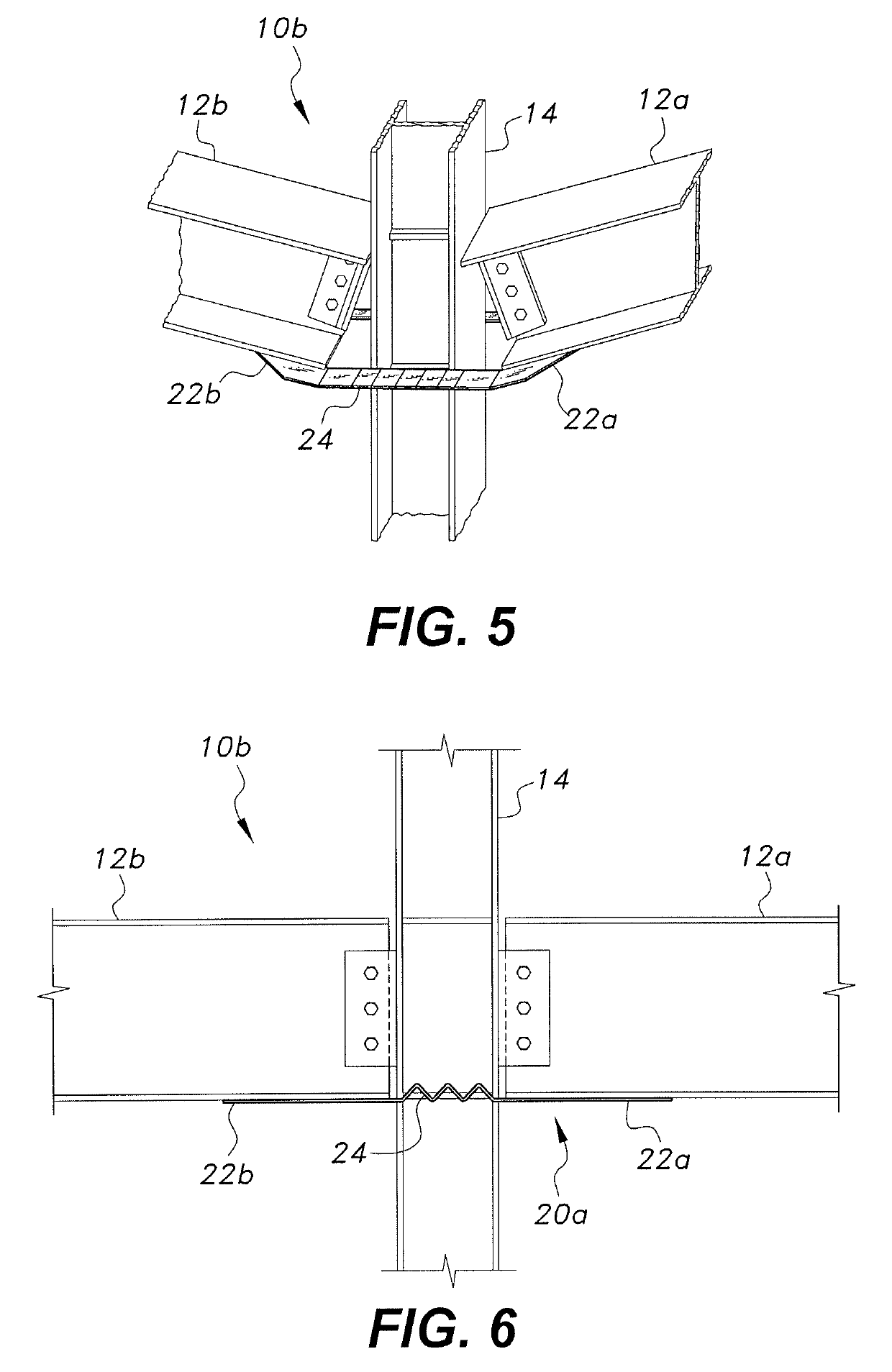

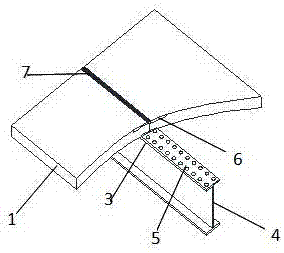

Strengthening system for beam-column connection in steel frame buildings to resist progressive collapse

ActiveUS10415230B1Simple and fast to construct and demountableEasy to repair/replaceProtective buildings/sheltersShock proofingBlast loadUpper joint

The strengthening system for beam-column connections in steel frame buildings to resist progressive collapse helps to mitigate progressive collapse in the event of accidental column loss by using a system of rippled steel plates reinforcing the beam-column connection. Various configurations of rippled steel plates are provided to connect in-plane and transverse beams at a joint. In the event of severe damage caused to a column of a steel framed building, the upper joints of the damaged column undergo downward movement. The rippled plates at the joint straighten during the initial downward movement, and resist further downward movement after complete straightening of the ripples. This helps in the development of catenary action in steel beams. The proposed system is simple, fast to construct, demountable, and easy to repair / replace after damage caused by blast loads.

Owner:KING SAUD UNIVERSITY

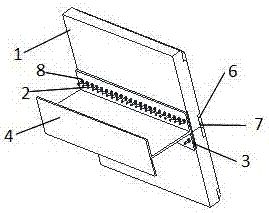

Reinforced joint for beam-column connection

ActiveUS10900215B1Improve the immunityBuilding constructionsProtective buildings/sheltersSteel frameJoint (building)

The reinforced joint for a beam-column connection is provided for improving the resistance of steel-framed buildings against progressive collapse. Flange stiffening plates reinforce flanges of structural beams, with beam web stiffeners being attached to and extending between the flange stiffening plates. Additional column web stiffeners are attached to and extend between flanges of a structural column. A longitudinal cover stiffening plate is attached to the column stiffeners and the flange stiffening plates, extending across the joint and at least partially covering the beam web stiffeners. The reinforced joint between the structural beams and the structural column develops catenary action in the structural beams in the event of collapse.

Owner:KING SAUD UNIVERSITY

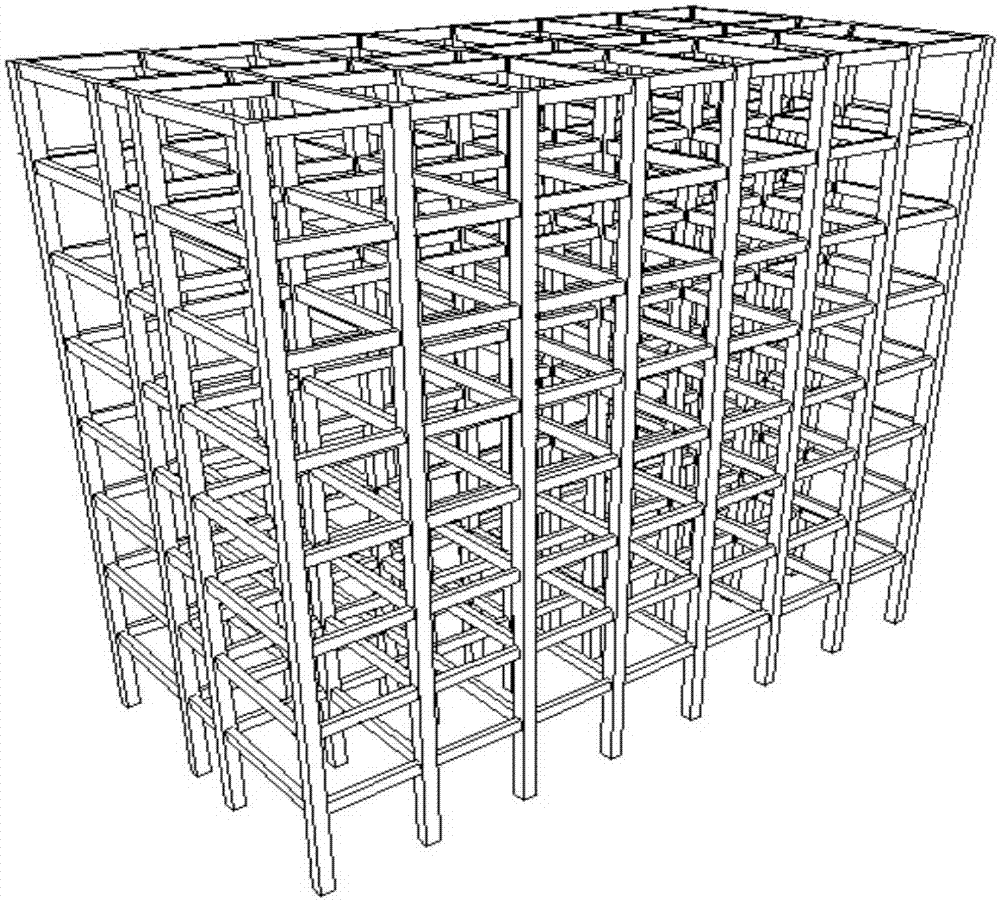

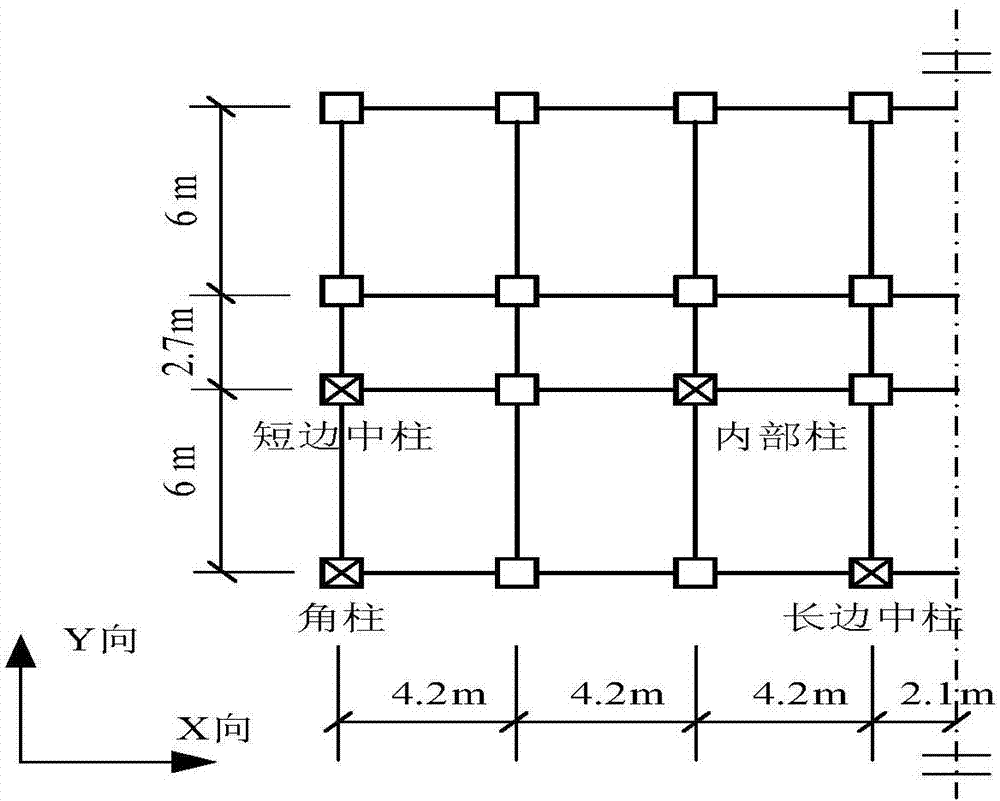

Design method for increasing progressive collapse resistance of RC frame structure

ActiveCN103924663AImprove structural collapse resistance requirementsBuilding constructionsNatural disasterEngineering

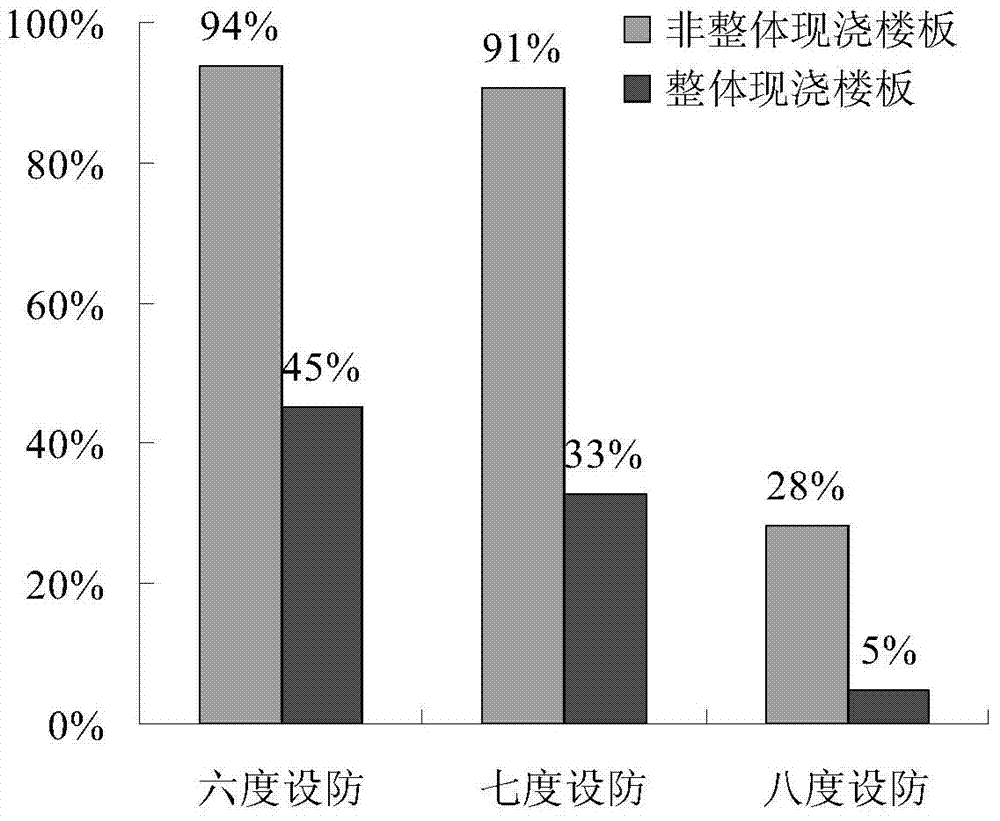

The invention relates to a design method for increasing progressive collapse resistance of an RC frame structure and belongs to the field of natural disaster prevention and reduction of building structures. Progressive collapse resistance of a structure refers to the capability, for resisting local destruction, of an overall structural system. Under the initial local destructive effects of different parts of the structural system, collapse responses are different, however, the progressive collapse resistance as the feature of the overall structural system should be irrelevant to specific initial destructions, and the method is provided aiming at the limitation in measuring the progressive collapse resistance of the overall structural system. Collapse proportionality coefficient and structural bearing capacity safety coefficient are built on the analysis of all typical local initial destructions and irrelevant to specific initial destructions, and accordingly the progressive collapse resistance of the whole structure can be reflected. When the two coefficients are used to analyze the progressive collapse resistance of an eight-storey concrete frame structure, the collapse resistance of the structure designed based on the coefficients is increased evidently.

Owner:BEIJING UNIV OF TECH

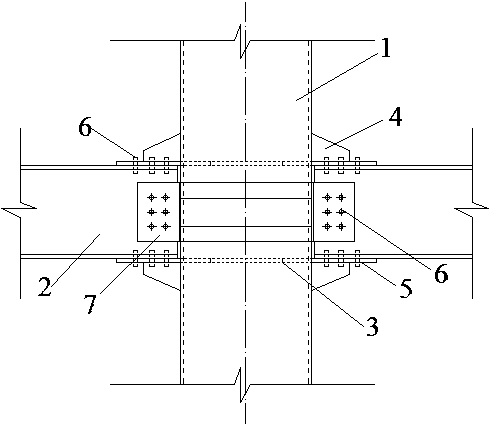

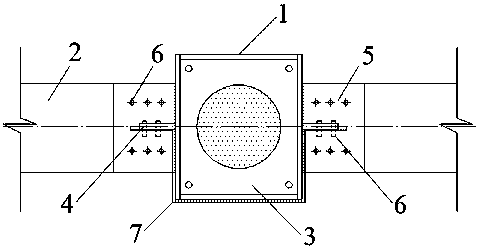

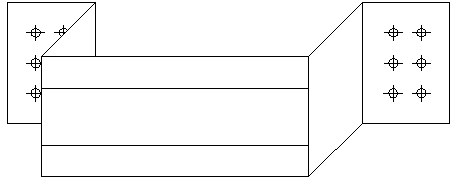

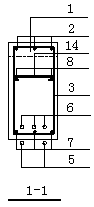

Concrete-filled square steel tube and steel beam semi-rigid reinforcing joint for preventing progressive collapse

InactiveCN103526950AWithout destroying the integrityImprove continuityBuilding repairsSteel tubeBeam column

The invention discloses a concrete-filled square steel tube and steel beam semi-rigid reinforcing joint for preventing progressive collapse. The joint comprise a concrete-filled square steel tube column and an I-shaped steel beam. Internal partitions and reinforcing plates are respectively disposed inside and outside the square steel tube walls corresponding to the upper flange and the lower flange of the steel beam. A U-shaped steel connecting plate winds around the square steel tube column wall and is fixed with I-shaped steel beam webs on two sides of the column through high-strength bolts. The beam columns are connected through the U-shaped steel connecting plate and the high-strength bolts. The U-shaped steel connecting plate is also used as a vertical joint connecting plate. The internal partitions under impact load can avoid local buckling of square steel tube column walls. The reinforcing plates can increase joint end bending resistance. The joint is reasonable in structure, uncontinuous beams are integrated while column continuity is also considered, structural integrity and joint ductility are increased, dynamic effect during partial component failure is relieved, and progressive collapse preventing capability is increased.

Owner:SHANDONG UNIV OF SCI & TECH

Progressive collapse preventing design method for failure of prestressed cables in string tensioning structure of building system

ActiveCN104213635AImprove playbackReasonable and light structureExtraordinary structuresSpecial data processing applicationsPre stressEngineering

The invention discloses a progressive collapse preventing design method for failure of prestressed cables in a string tensioning structure of a building system. The method comprises the following steps of step (1) establishing an analysis model, and obtaining the original state and response of the string tensioning structure; step (2) selecting a concrete prestressed cable to carry out failure processing, and then carrying out response analysis on a massive structure; step (3) carrying out failure processing on the prestressed cables one by one, and carrying out response analysis on the failed structures one by one; repeating the step (2) to obtain the collapse state and the response of the string tensioning structure of each prestressed cable at the failure state; step (4) carrying out progressive collapse preventing design of the string tensioning structure. The method can effectively prevent the occurrence of progressive collapse of the string tensioning structure when any prestressed cable is failed, and can ensure the stability of the massive structure of the string tensioning structure.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

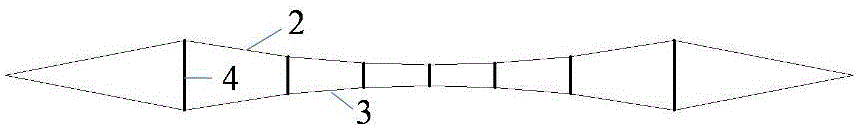

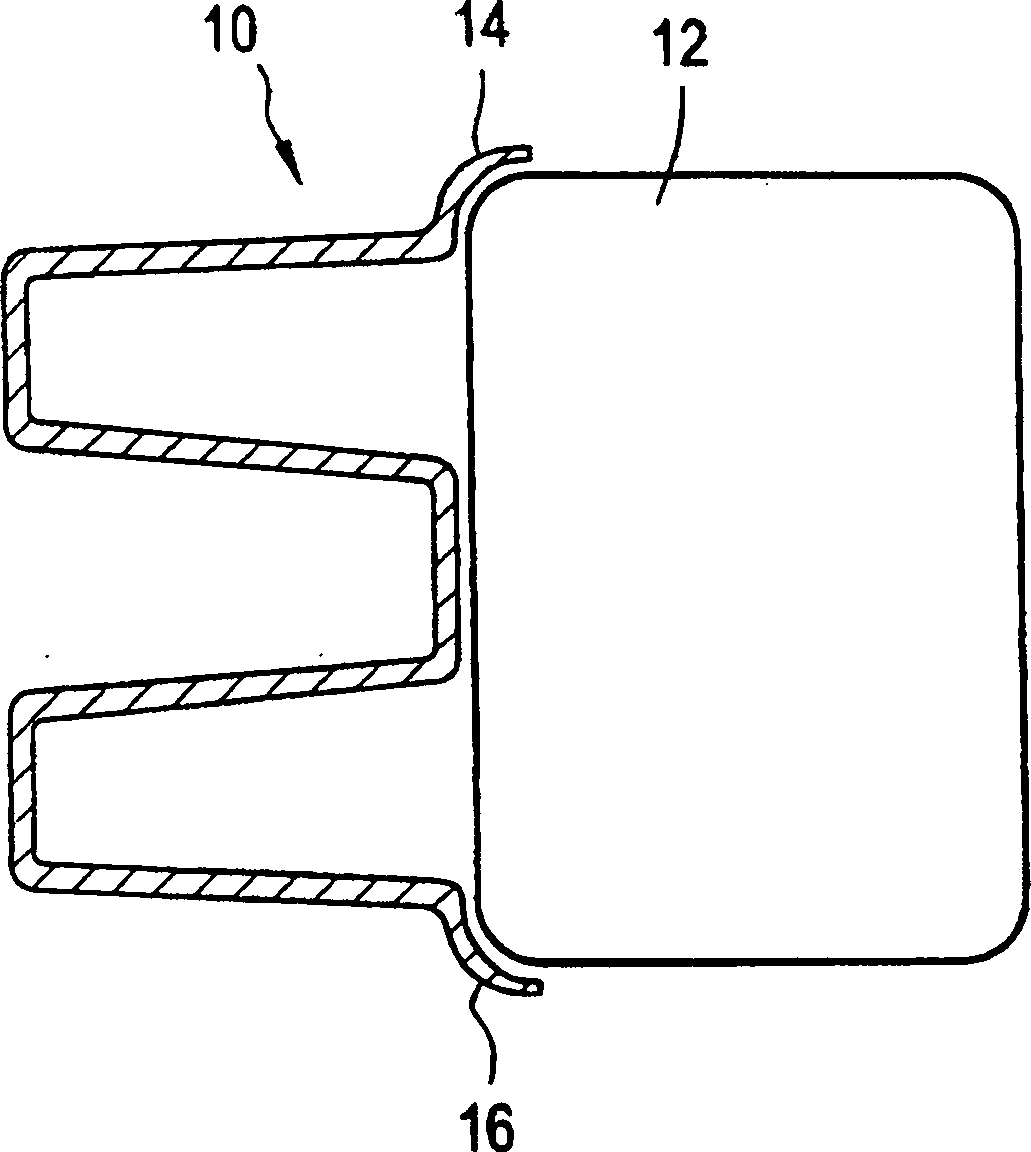

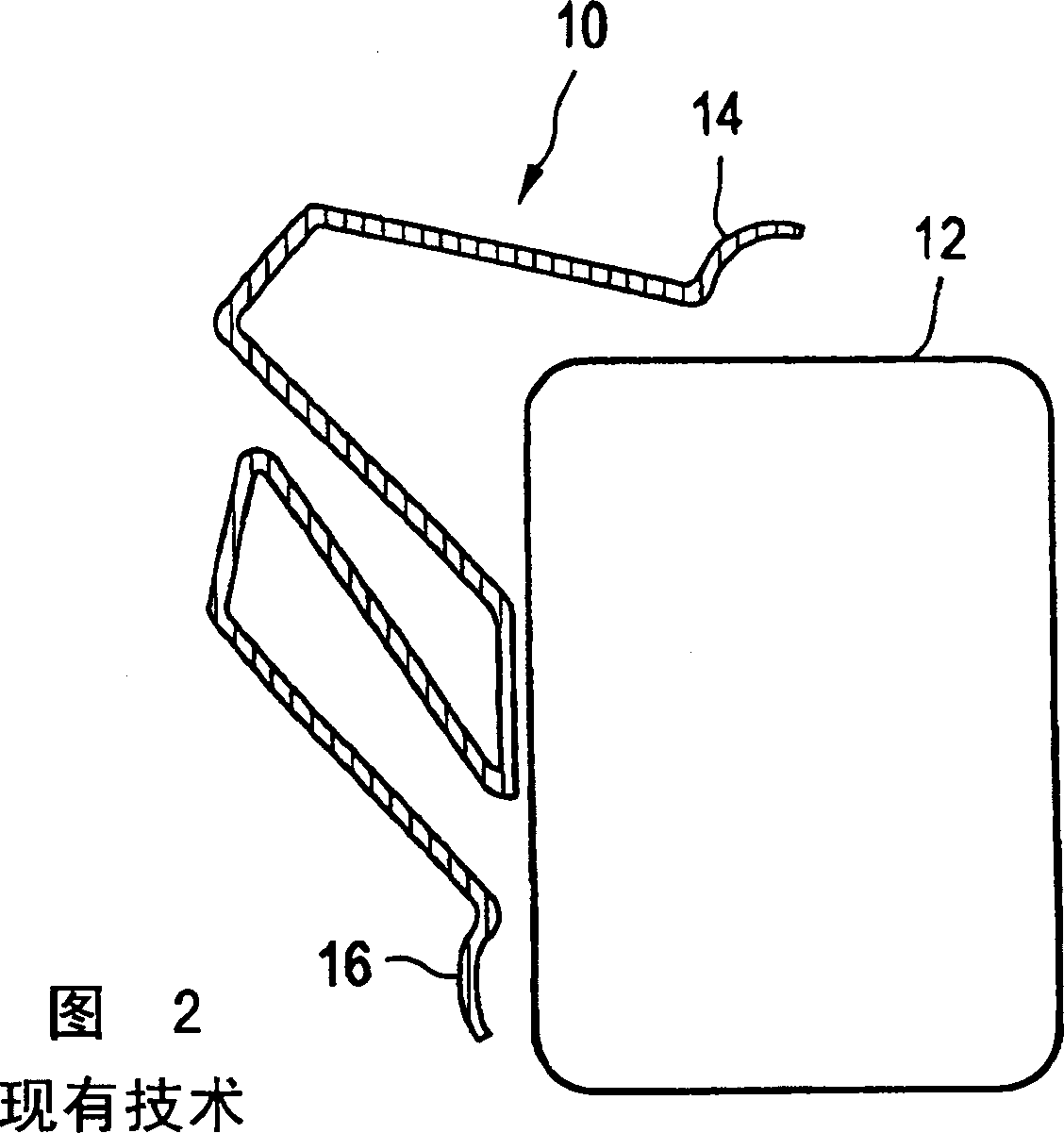

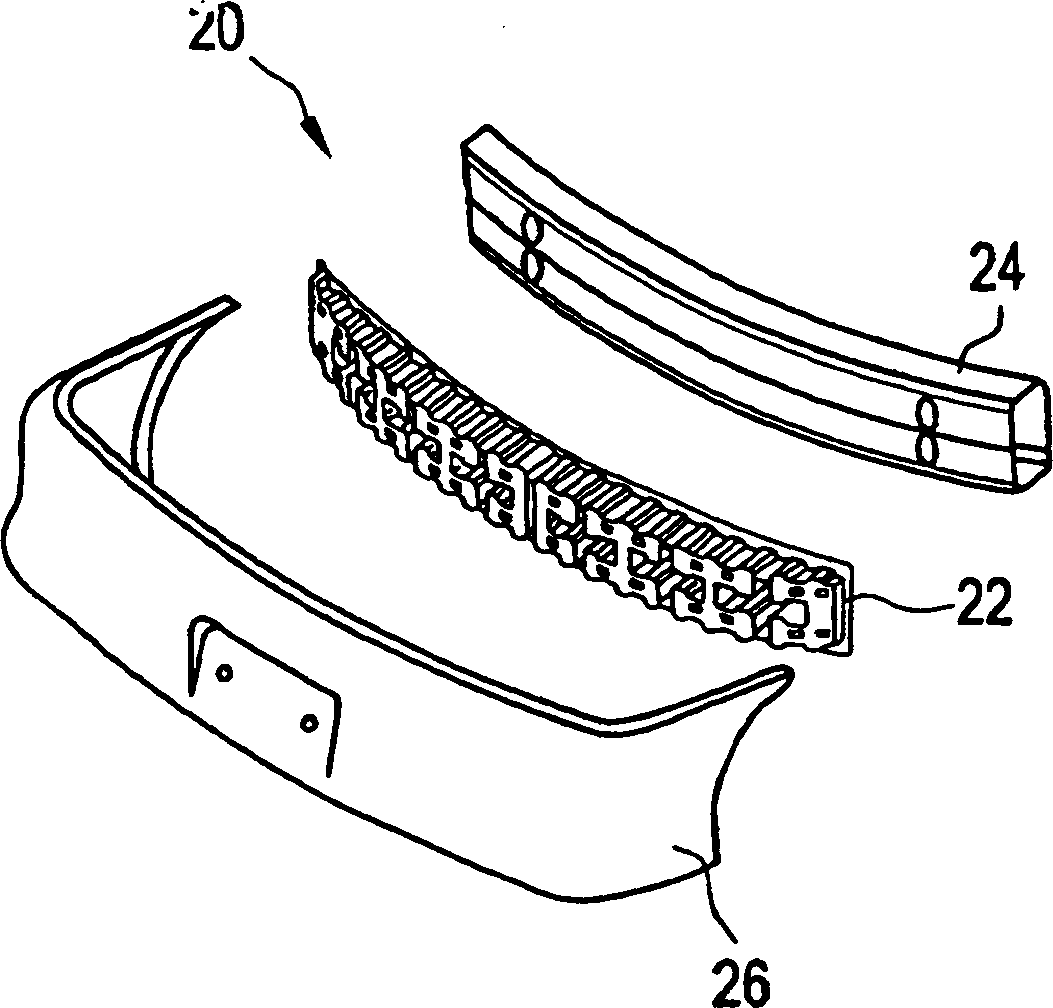

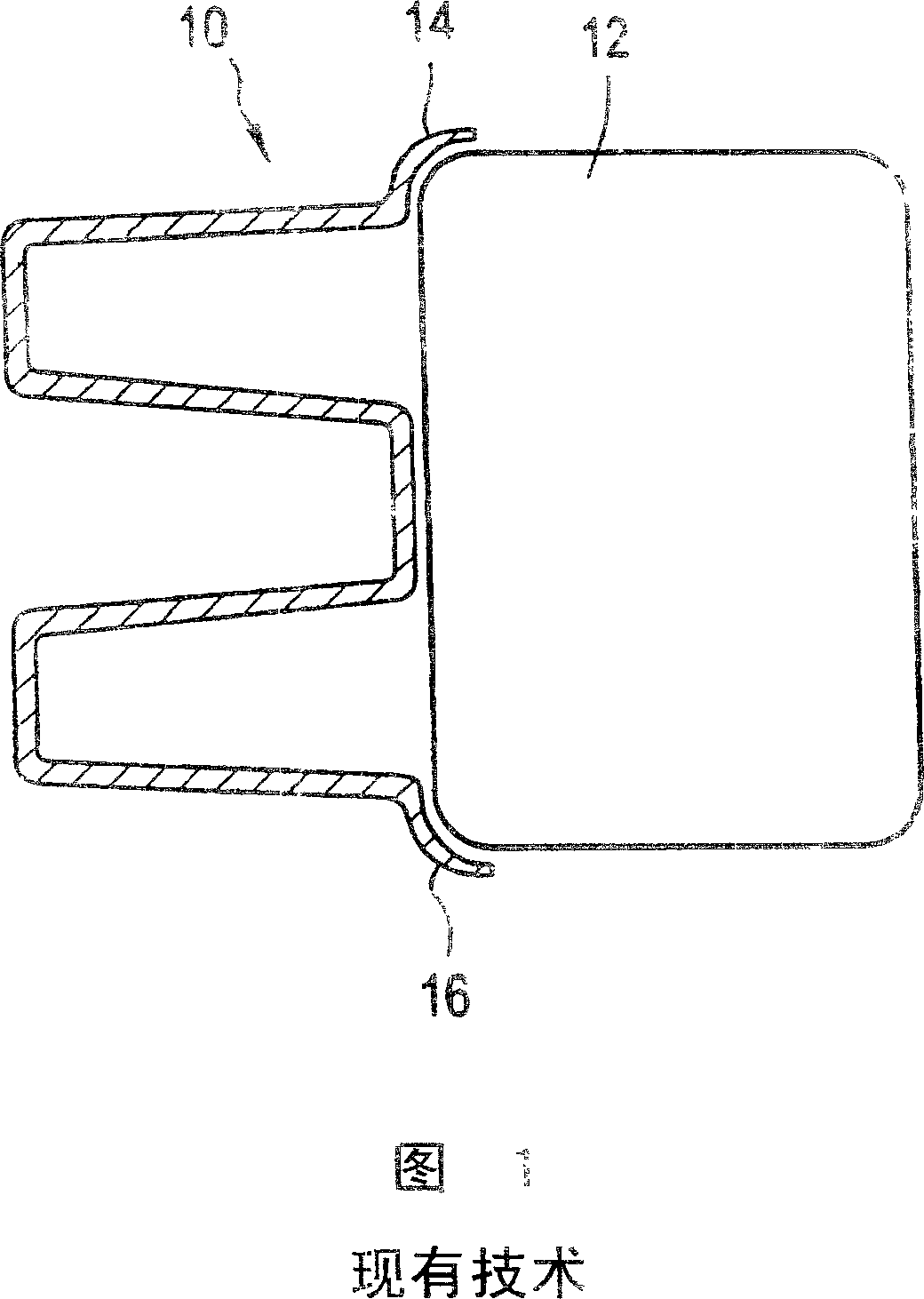

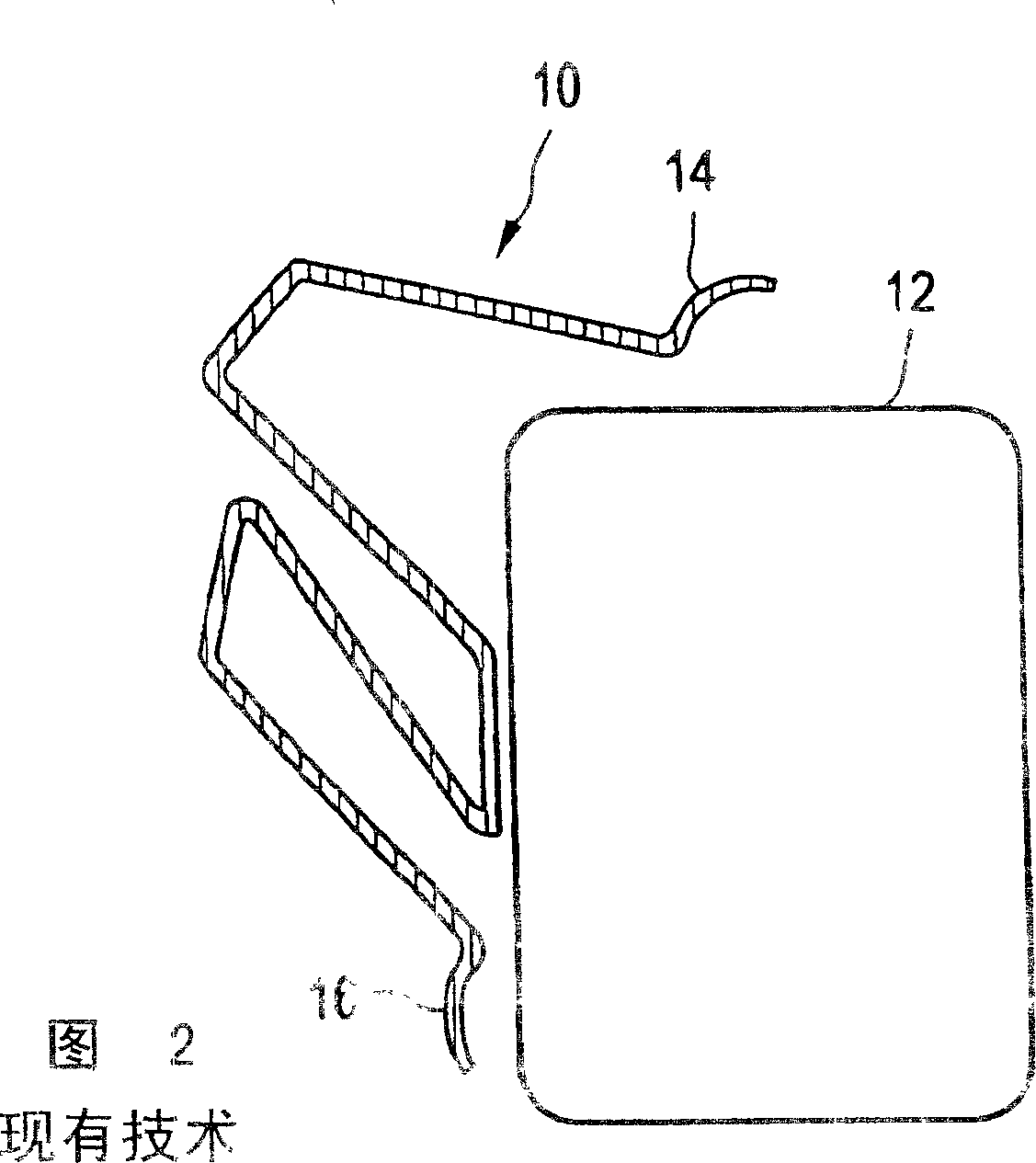

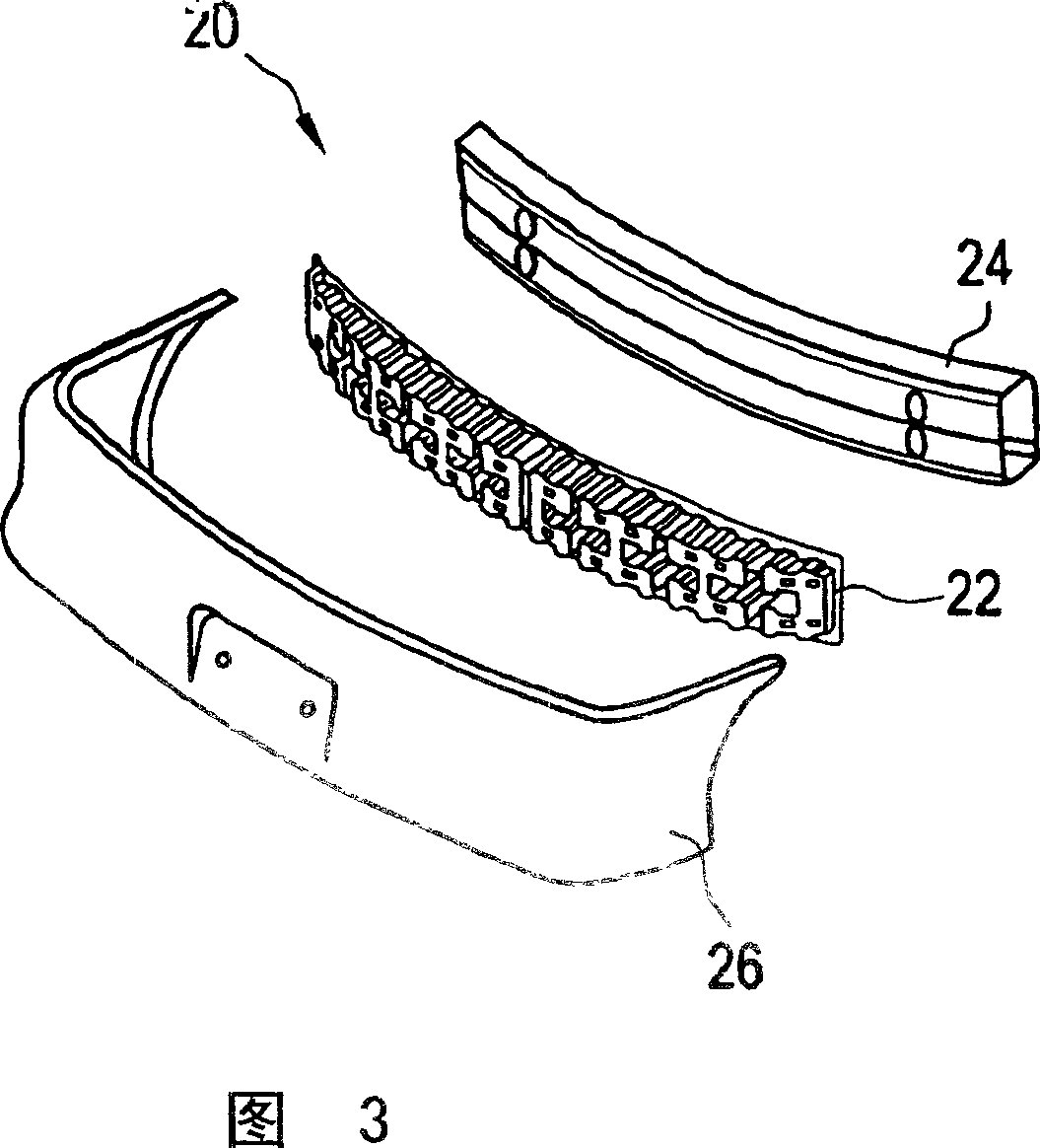

Energy absorber system for attachment to vehicle

An energy absorbing system (20) for a vehicle includes an eleongated energy absorber (22) including a flanged frame (32, 34) for attachement to a reinforcing beam (24) and a body (44) including a plurality of spaced apart tunable cruch boxes (54) capable of deformation and progressive collapse upon impact for absorbing the energy of impact.

Owner:SABIC GLOBAL TECH BV

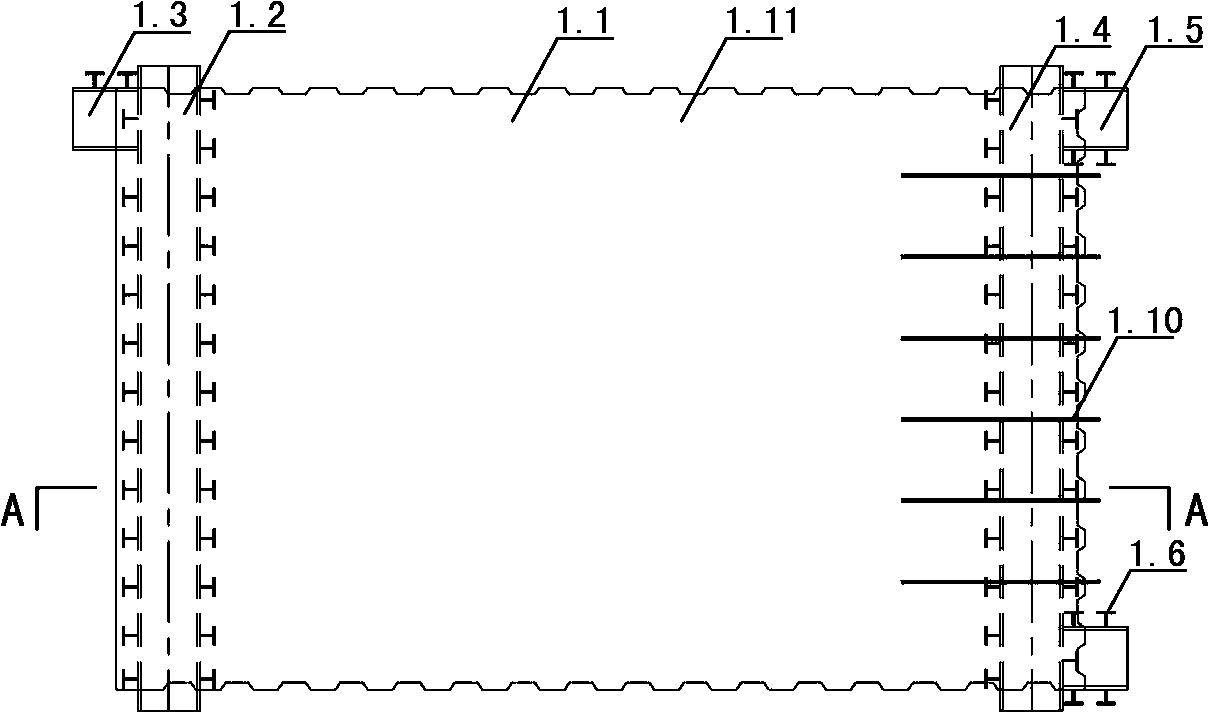

Assembly-type cross-shaped mixed coupled wall and construction method thereof

InactiveCN104032855AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type cross-shaped mixed coupled wall and a construction method thereof. The assembly-type cross-shaped mixed coupled wall comprises first wall units and a second wall unit which are connected together perpendicularly and form a cross shape. The first wall units are symmetrically distributed on the two sides of the second wall unit, the first wall units and the second wall unit are all prefabricated parts, and the first wall units and the second wall unit are connected through joint post-pouring belts. According to the assembly-type cross-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

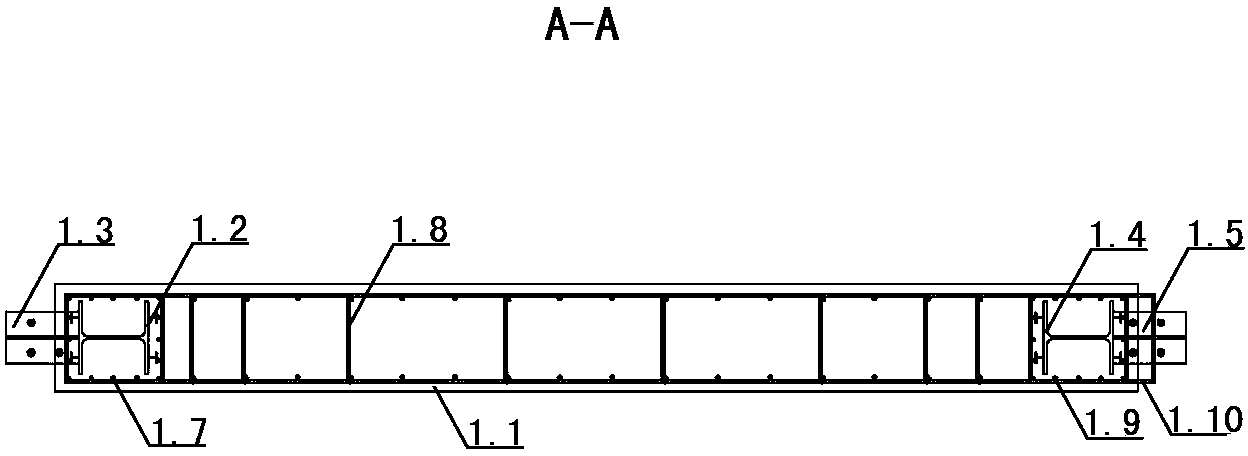

Assembly-type L-shaped mixed coupled wall and construction method thereof

Disclosed are an assembly-type L-shaped mixed coupled wall and a construction method thereof. The assembly-type L-shaped mixed coupled wall comprises a first wall unit and a second wall unit which are connected together perpendicularly and form an L shape. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type L-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved, building operating requirements can be met conveniently, and assembly procedures can be simplified conveniently; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

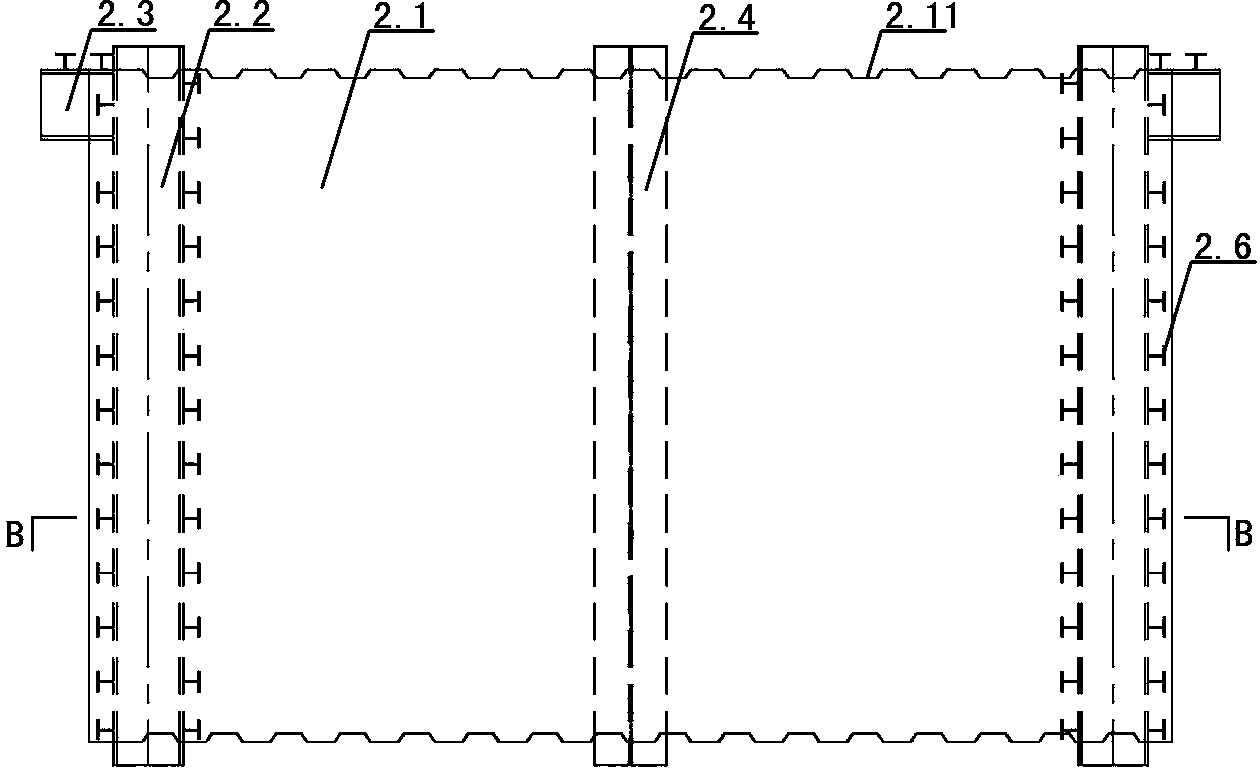

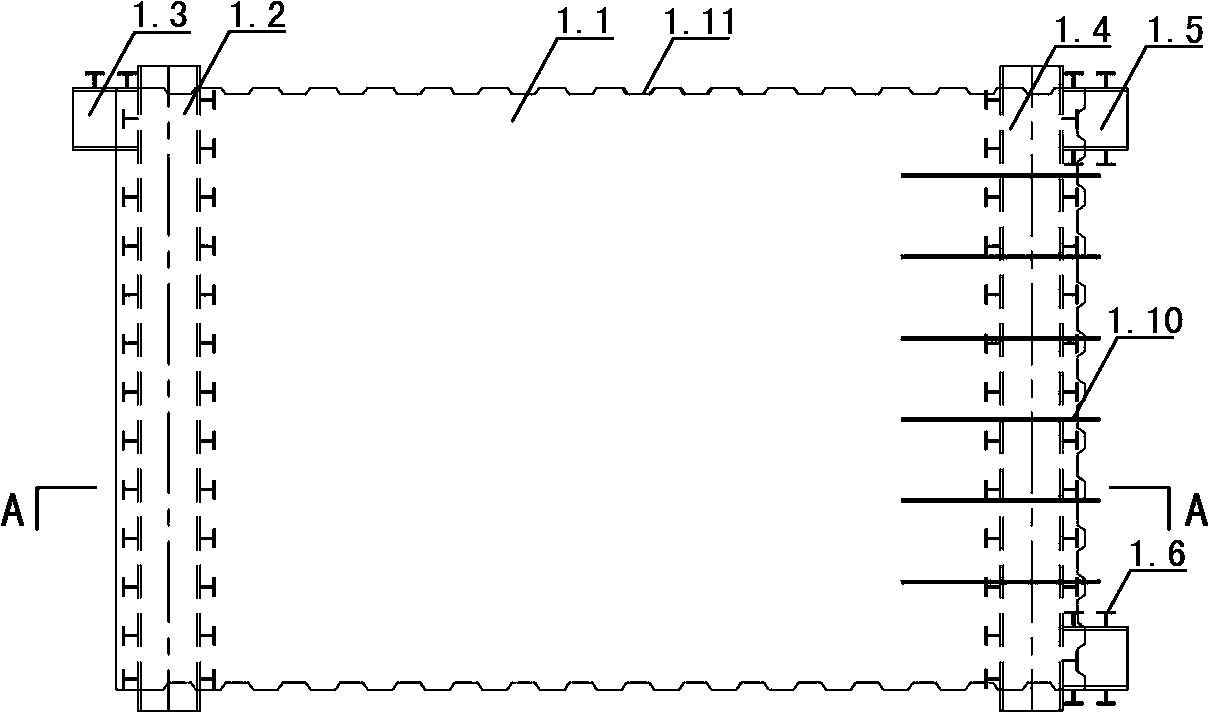

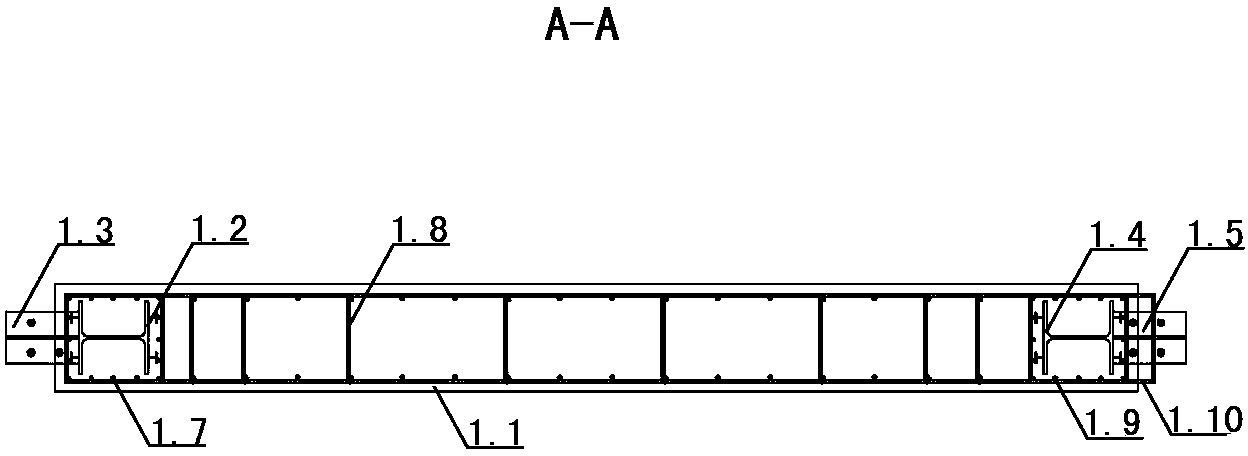

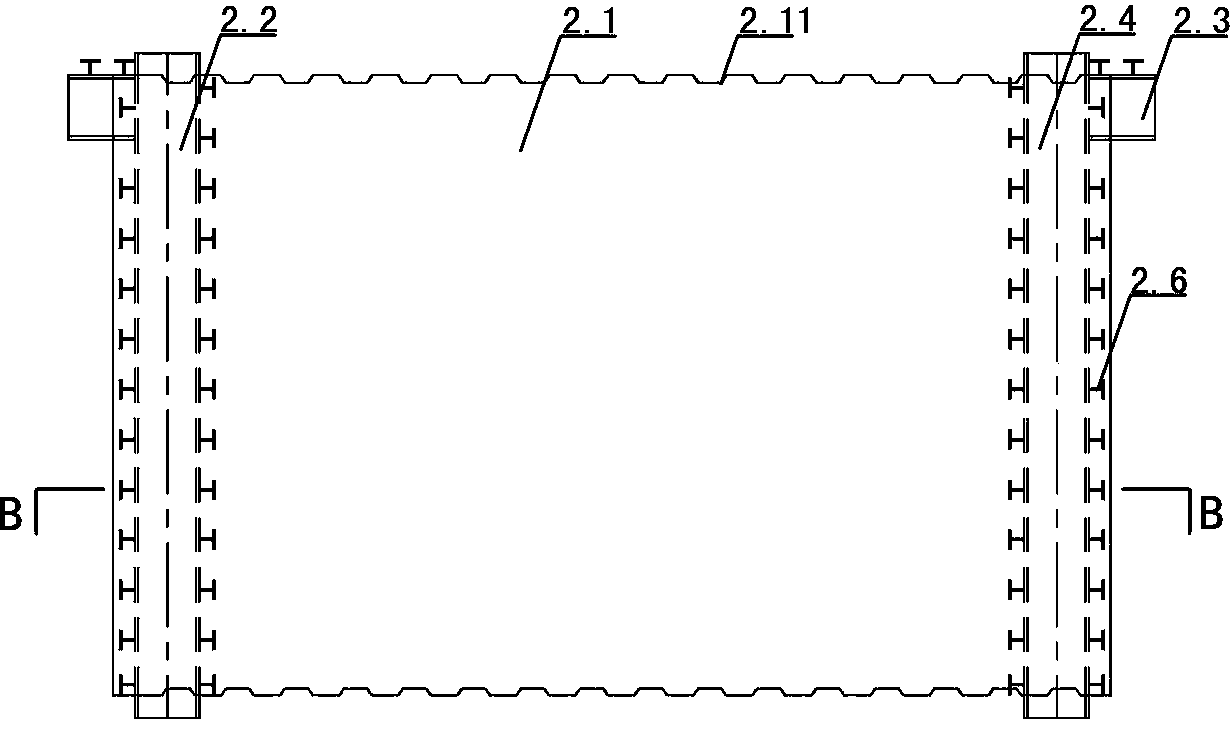

Prefabricated assembly type bolted connection reinforced concrete box-girder

InactiveCN106869404AImprove assembly efficiencyWork lessLoad-supporting elementsPrecast concreteMaterials science

A prefabricated assembly type bolted connection reinforced concrete box-girder comprises a prefabricated concrete slab, a steel beam, embedded bolts, an embedded thin-wall steel plate, embedded steel plates and a butt weld. Firstly, the steel beam and the prefabricated concrete slab are connected through the bolts embedded in the midspan of the prefabricated slab, the bearing capacity of a joint is improved, and the progressive collapse resistance of a structure is facilitated. Secondly, the embedded steel plates embedded at the two ends of the slab can be connected through the butt weld, the two adjacent plates are connected to resist hogging moment of a support part of the structure, and the integrity of the structure is improved. According to the assembly type steel beam, industrialized production is achieved, on-site fast assembly is achieved, the effect that concrete is poured on site is avoided, the construction efficiency is improved, and the environment pollution is reduced. Meanwhile, by the adoption of the assembly type structure system, the detachment and replacement functions of a member can be achieved, and the energy-saving and environment-friendly idea of the building is achieved.

Owner:XIJING UNIV

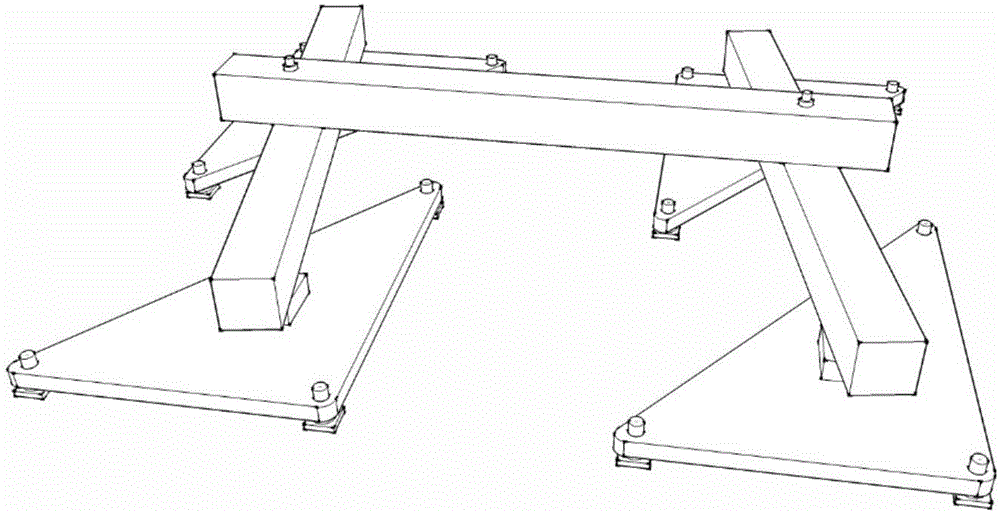

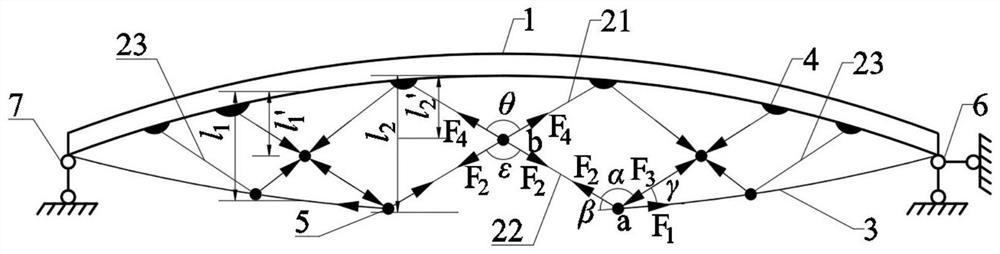

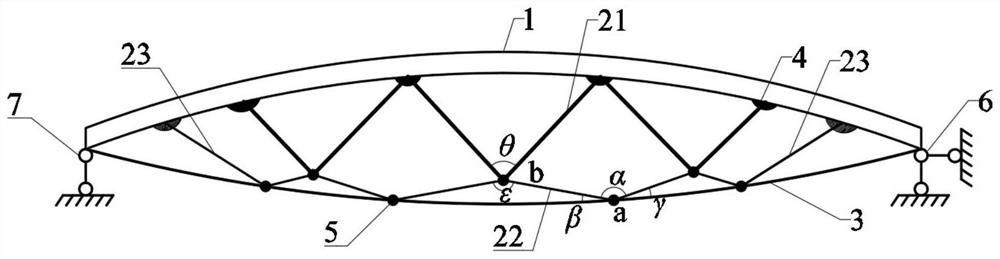

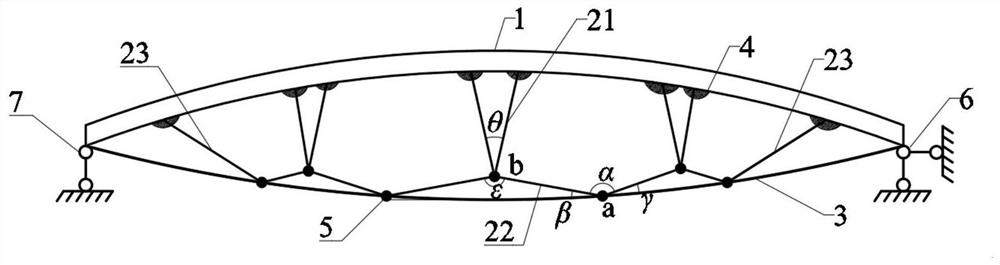

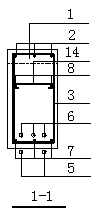

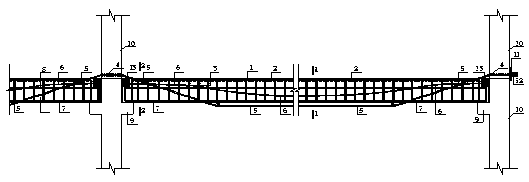

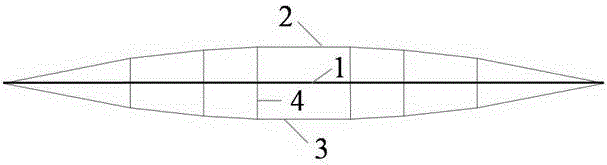

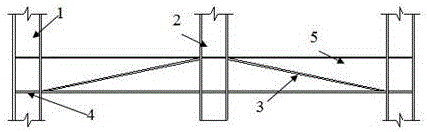

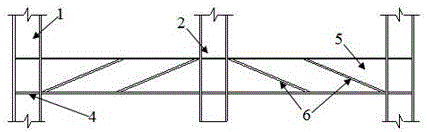

Beam string structure with high progressive collapse resistance performance and implementation method of beam string structure

PendingCN111636623AOvercoming the problem of insufficient redundancyIncrease redundancyGirdersJoistsStructural engineeringMechanical engineering

The invention discloses a beam string structure with high progressive collapse resistance performance and an implementation method of beam string structure. The beam string structure involves an upperbeam string and a lower inhaul cable, wherein a plurality of first joints are arranged on the upper beam string, a plurality of second joints are arranged on the lower inhaul cable, a plurality of third joints are arranged in the space between the upper beam string and the lower inhaul cable, four inclined supporting rods are arranged on each third joint, and the four inclined supporting rods areconnected to the two adjacent first joints on the upper beam string and the two adjacent second joints on the lower inhaul cable correspondingly. Compared with a traditional beam string structure, the beam string structure forms a standby force transmission path through the inclined supporting rods after the cable is broken, the structure can be effectively prevented from collapsing, meanwhile the supporting rod redundancy is increased, a prestress clamp at each second joint can effectively control the prestress loss of the lower inhaul cable in the service period, and the beam string structure with the high progressive collapse resistance performance and the implementation method of the beam string structure are simple in structure, easy to implement and suitable for being applied to practical engineering.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

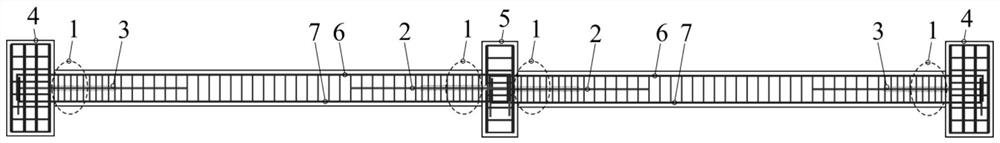

Long-span bi-prestressed superposed framework, floor system and construction method

The invention relates to a long-span bi-prestressed superposed framework, a floor system and a construction method. The long-span bi-prestressed superposed framework comprises a prefabricated pillar with a bracket, wherein the prefabricated pillar supports a superposed beam; the superposed beam comprises two parts; the first part is a factory-made pre-tensioned or post-tensioned prestressed prefabricated part; the second part is a tensioned anchorage part formed by cast-in-place superposed partial concrete and external prestressed bars. According to the long-span bi-prestressed superposed framework, during application of a long-span assembled structure, the cross-sectional size of a prefabricated component can be reduced, and requirements for production, transportation and installation aremet; a pre-tension method can realize efficient production and mechanical operation of the prefabricated component; application of the external prestressed bars and anchoring of supporting componentscan improve the overall anti-seismic property of the structure; the progressive collapse resistance of the structure can be enhanced; efficient utilization of a design and construction integration prestressing technology can be realized; the requirements of the building industry for an assembled development tendency in an ultralong span and overweight load public buildings in the future can be met.

Owner:UNIV OF JINAN

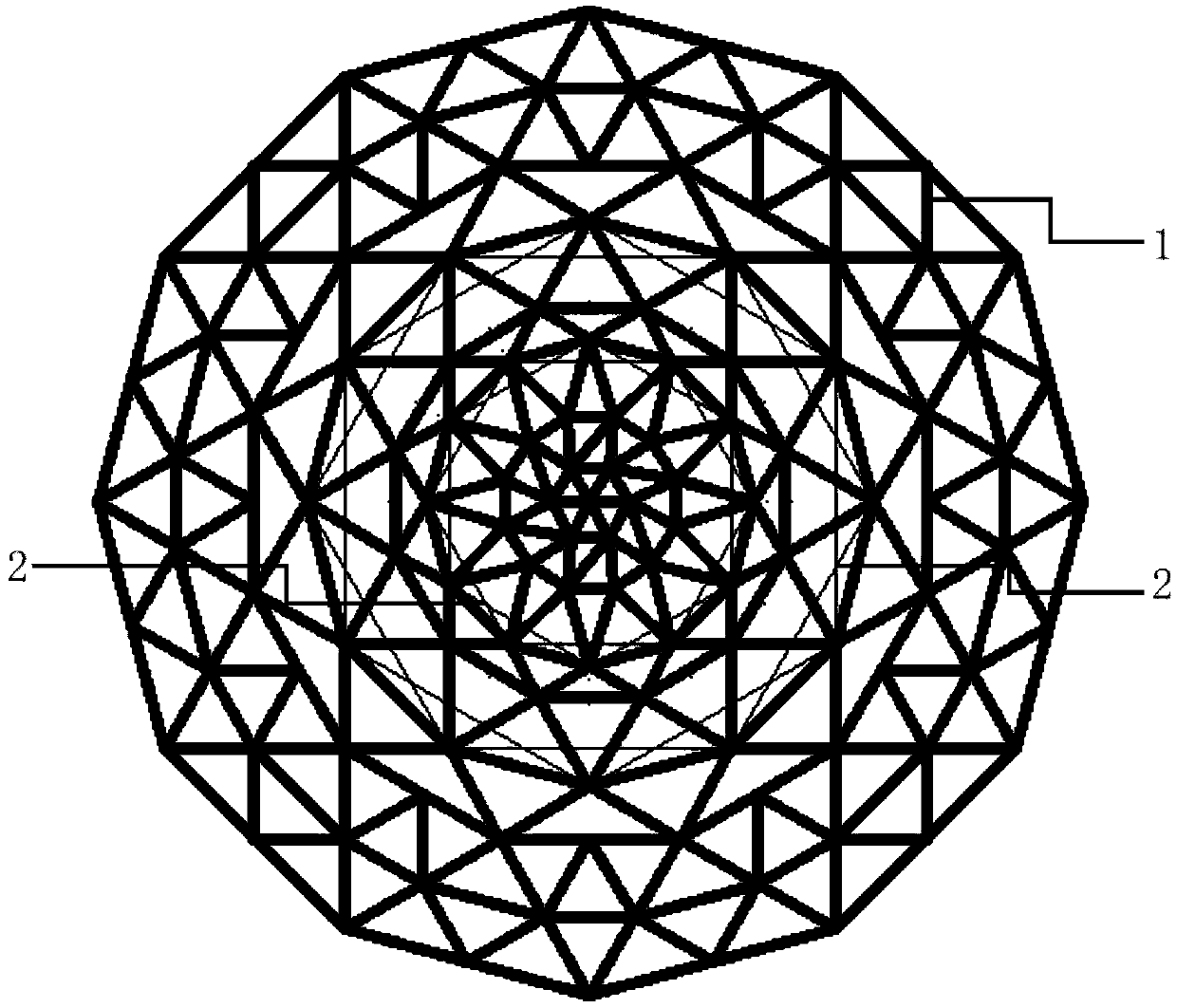

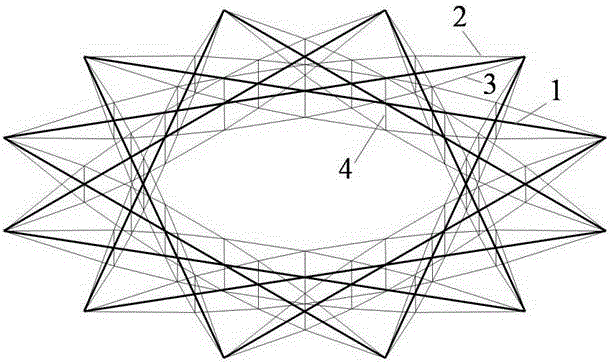

Rotary intersection self-balanced cable truss structure

InactiveCN106088440ABeautiful buildingReasonable structural stressBuilding roofsEnergy absorptionStructural stress

A rotary intersection self-balanced cable truss structure is formed by mutual crossing combination of multi-truss one-way self-balanced cable trusses. The middle of the structure is open, and a roof is arranged on the periphery of the structure. Each one-way self-balanced cable truss is composed of a middle beam or truss, an upper string cable, a lower string cable and a support rod, wherein the upper end and lower end of the support rod are connected with the middle beam or truss and the upper string cable or the lower string cable respectively, the support rod is a round tube, rectangular tube or multi-arm lattice type support rod, and the support rod is hinged to the middle beam or truss and the upper string cable or the lower string cable. The structure has the advantages that an architectural image is attractive, structural stress is reasonable, wind resistance and energy absorption capacity are high, end reaction is small, progressive collapse resistance is high, and machining, manufacturing and installation are easy.

Owner:SHANDONG JIANZHU UNIV

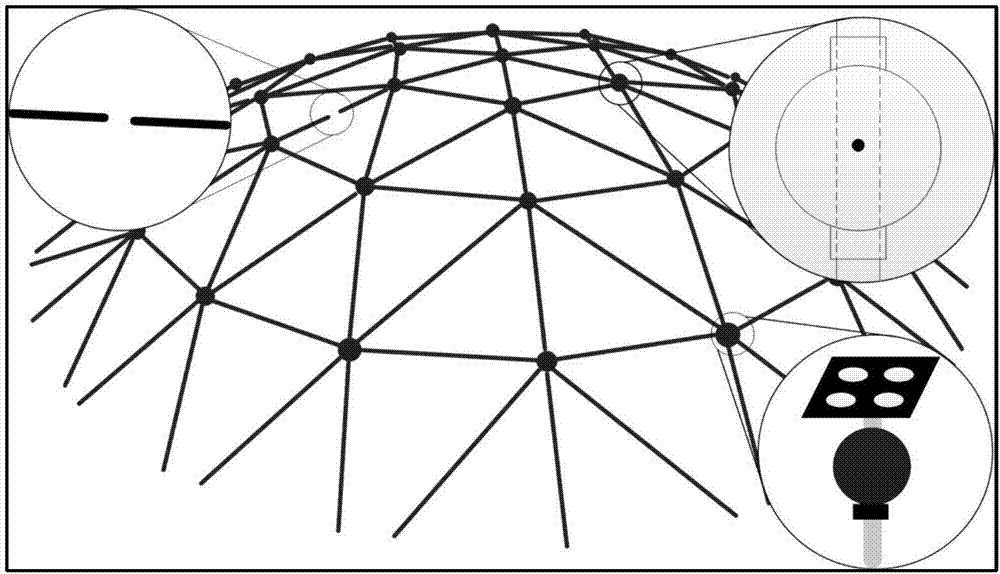

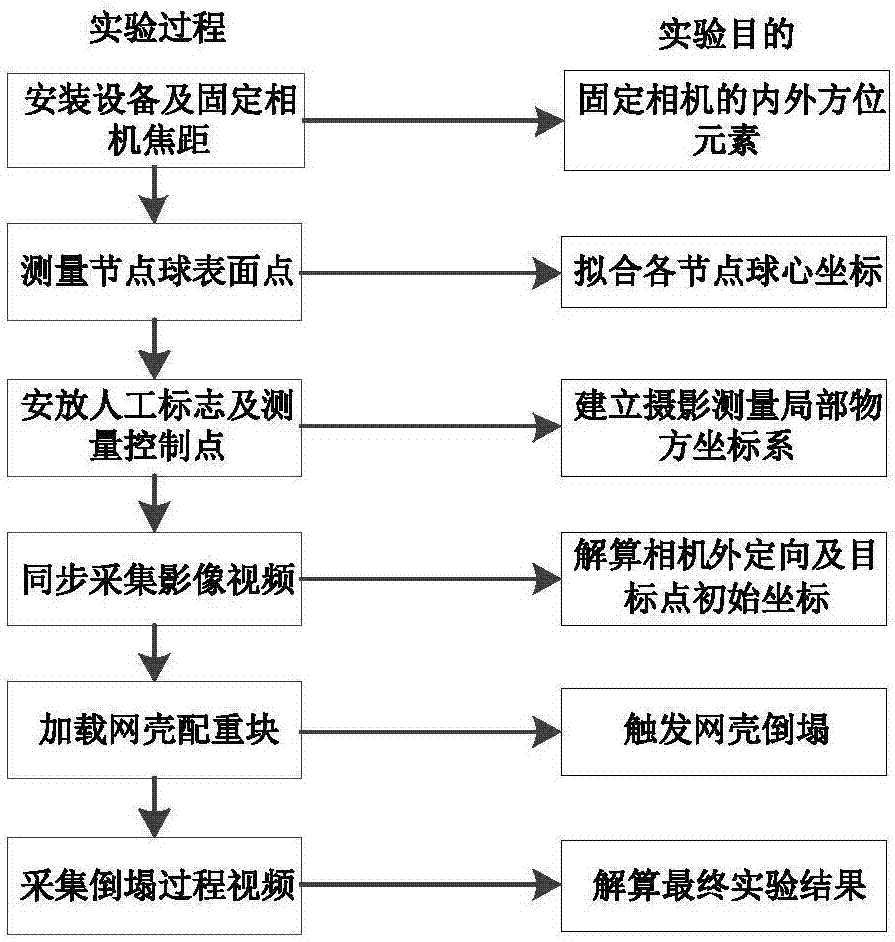

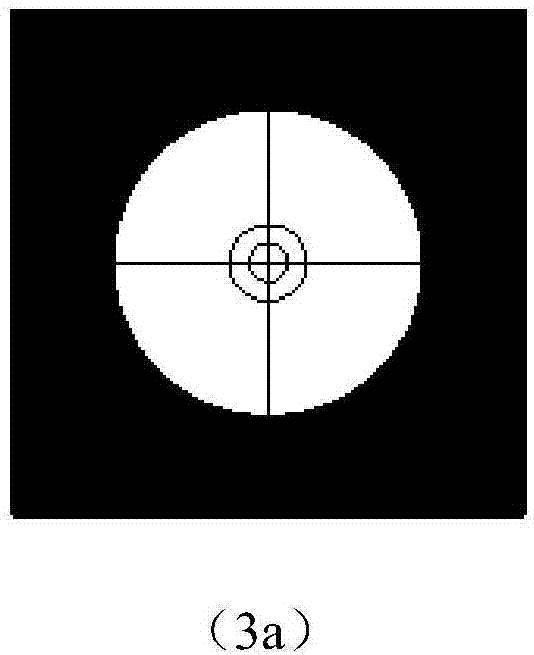

High-speed video measurement method for progressive collapse of latticed shell structure

The invention relates to a high-speed video measurement method for progressive collapse of a latticed shell structure. The high-speed video measurement method includes the steps of (1), arranging multiple high-speed cameras above a latticed shell model; (2), performing spherical-surface fitting to obtain initial three-dimensional coordinates of the center of sphere of each spherical node; (3), building a local object space coordinate system and distributing target point marks corresponding to the spherical nodes on the latticed shell model; (4), acquiring elements of exterior orientation of the cameras, the initial three-dimensional coordinates of the target point marks, and establishing fixed spatial relationship between the marks and the spherical nodes; (5), starting a latticed shell breaking device to realize progressive collapse of the latticed shell, and synchronously acquiring the image data about the collapse of the latticed shell through the high-speed cameras; (6), acquiring three-dimensional coordinates of the target point marks corresponding to centers of spheres of the spherical nodes, and carrying out coordinate conversion to obtain the three-dimensional coordinates of the center of sphere of each spherical node to finally obtain three-dimensional time history displacement of the center of the sphere of the spherical node. Compared with the prior art, the high-speed video measurement method has the advantages of high convenience in measurement of spherical center coordinates in a non-contact way, high precision, high frequency and the like.

Owner:TONGJI UNIV

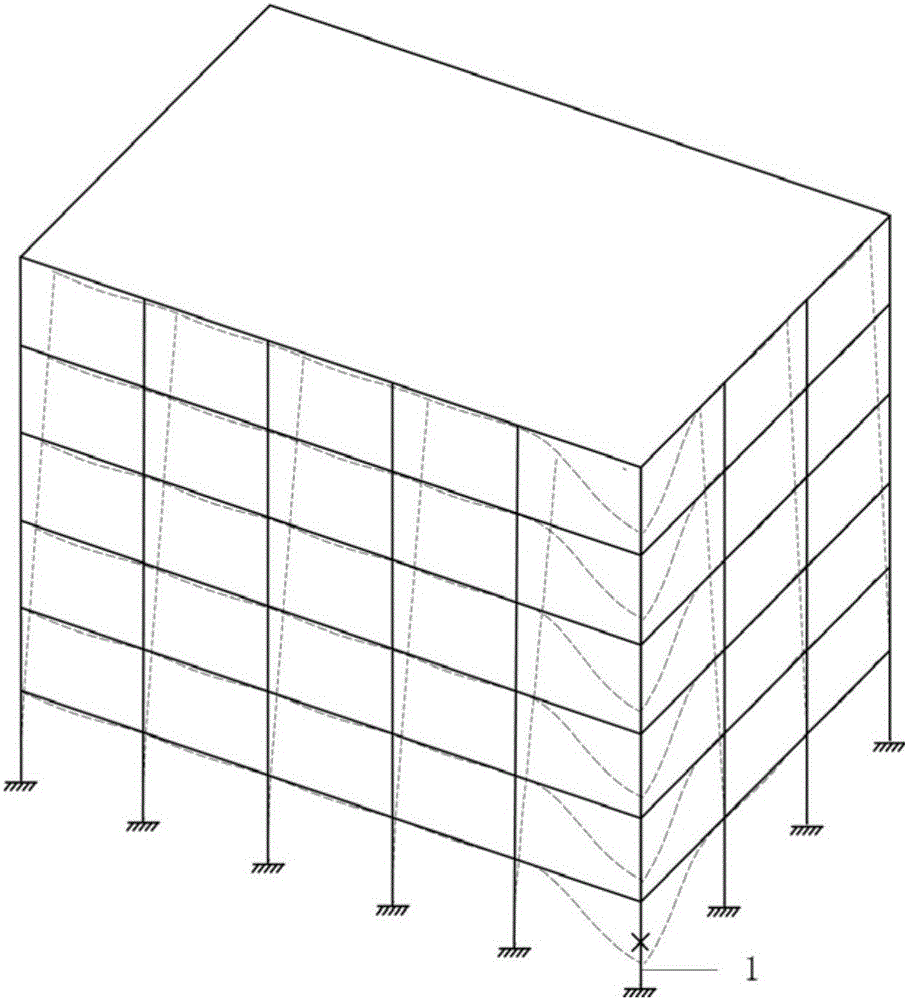

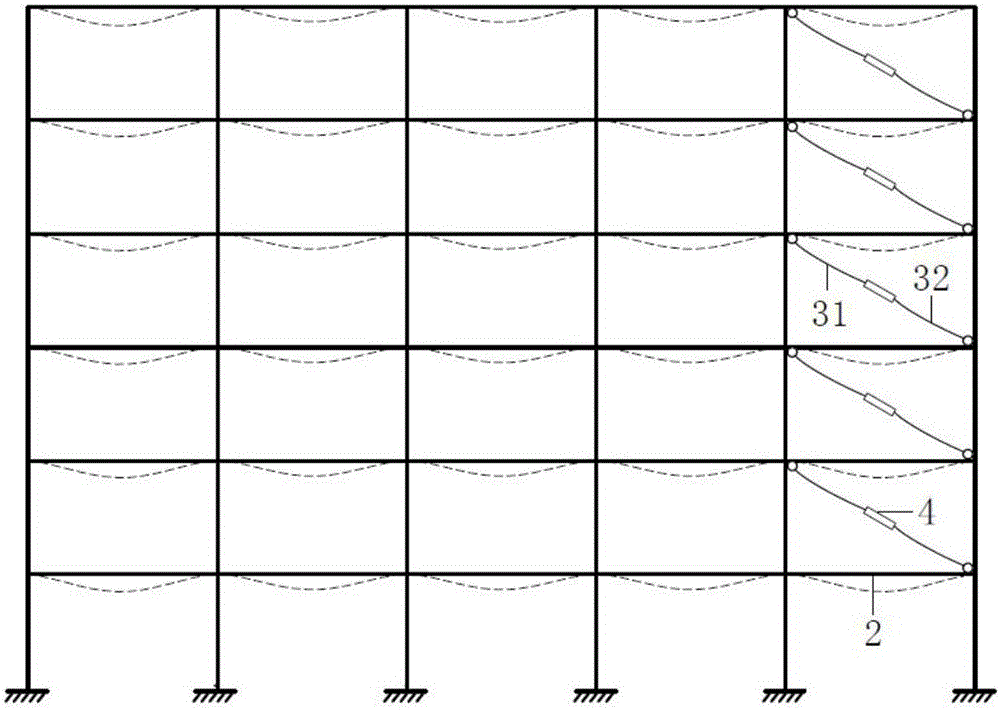

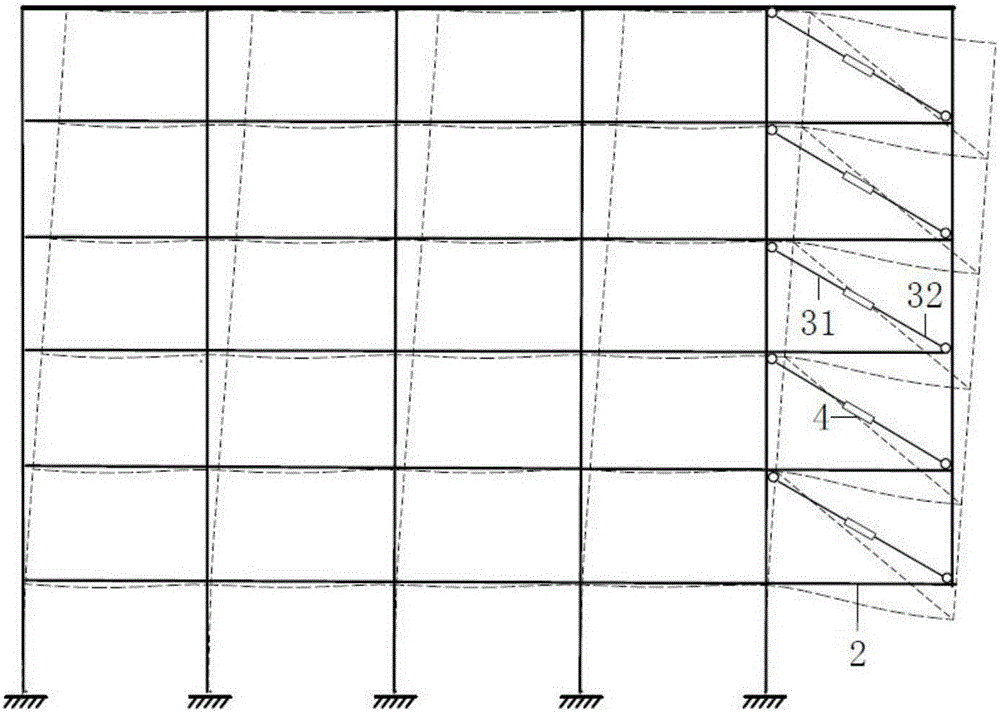

Strengthening method for resisting progressive collapse through steel frame structure

ActiveCN106593006ASimple design and installationLow costBuilding repairsSteel columnsProgressive collapse

The invention provides a strengthening method for resisting progressive collapse through a steel frame structure. Through the design method for resisting progressive collapse in the standard, the position of a key pillar is determined. After the key pillar is chosen and determined, the key pillar is assumed as a destroyed steel pillar, and single oblique ribs or double oblique ribs are additionally arranged on joist steel of the two sides of the destroyed steel pillar. The pressure arching effect of the key pillar position is reinforced, and the redundancy degree and the progressive collapse resistance property of a newly-built building are improved. Or after a weak pillar or a destroyed pillar is known through exploration and observation, the weak pillar or the destroyed pillar is assumed as the destroyed steel pillar. According to the arrangement conditions of building components and site conditions of construction, the single oblique ribs or the double oblique ribs are chosen for strengthening, and strengthening for progressive collapse resistance is achieved. The strengthening method for resisting progressive collapse through the steel frame structure is simple in design and mounting and good in economic benefits. Oblique ribs and regular stress components are not superimposed, so that the strengthening method for resisting progressive collapse through the steel frame structure is applied to a newly-built structure, strengthening reconstruction of an existing structure, a full welding beam pillar joint point, and an end plate connecting beam pillar joint point.

Owner:XIJING UNIV

Connecting unit capable of preventing structure progressive collapse after corner post failure and using method thereof

InactiveCN106049688AIncrease ultimate strengthImprove the state of stressBuilding repairsEngineeringPost failure

Owner:TONGJI UNIV

Progressive collapse resistant cold-formed thin-walled profile combined wall and quick field mounting method thereof

The invention discloses a progressive collapse resistant cold-formed thin-walled profile combined wall and quick field mounting method thereof. An upper guide rail is a combined guide rail composed of a conventional U-shaped cold-formed thin-walled steel keel, a ribbed web U-shaped cold-formed thin-walled steel keel and an outer-framing U-shaped cold-formed thin-walled steel keel. A lower guide rail is a conventional U-shaped cold-formed thin-walled steel keel. A wall pillar is a C-shaped cold-formed thin-walled steel keel. The upper guide rail can effectively transmit vertical load, thus a cold-formed thin-walled steel floor beam need not be aligned with the keel pillars of the combined wall, and flexibility of a structural arrangement scheme of a cold-formed thin-walled steel house is improved; meanwhile, when the certain keel pillar of the combined wall is destructed due to earthquake, fire or the like, the upper load of the pillars can still be transmitted to the other wall pillars through the upper guide rail, progressive collapse of the combined wall is avoided, and structural safety and reliability is improved.

Owner:SOUTHEAST UNIV

Energy absorber system for attachment to vehicle

An energy absorbing system (20) for a vehicle includes an eleongated energy absorber (22) including a flanged frame (32, 34) for attachement to a reinforcing beam (24) and a body (44) including a plurality of spaced apart tunable cruch boxes (54) capable of deformation and progressive collapse upon impact for absorbing the energy of impact.

Owner:SABIC GLOBAL TECH BV

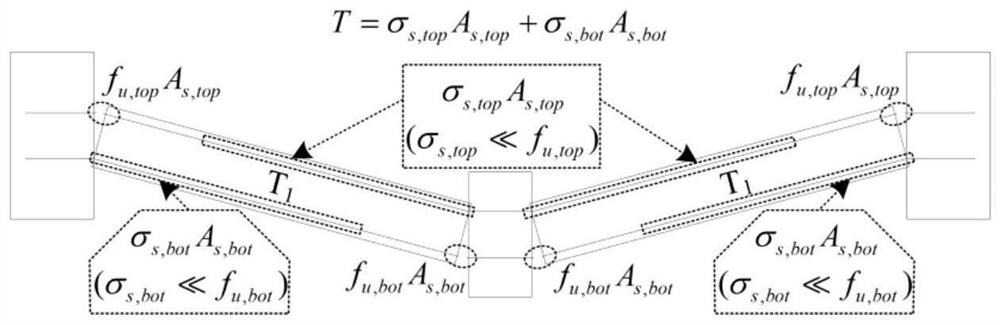

Design method for progressive collapse resistance of structure and ultimate bearing capacity calculation method

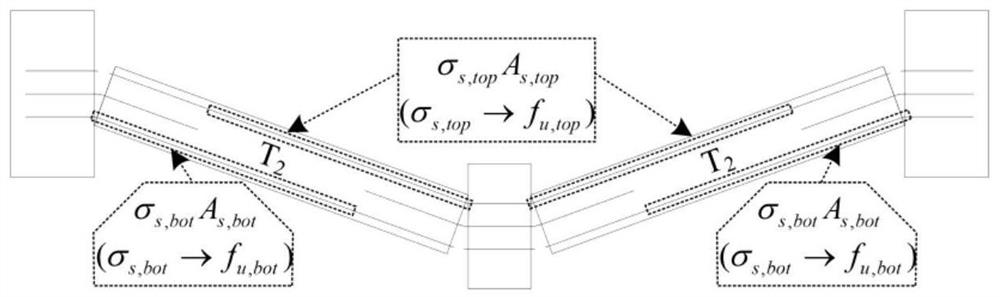

PendingCN114036602AImprove ultimate turning abilityMaximize your ultimate pullGeometric CADGirdersPolyolefinRebar

According to the method capable of improving the progressive collapse resistance of the structure, the limit rotation capacity of a beam end is improved, so that the tensile property of a longitudinal bar outside a strain concentration area is fully utilized, and the effect of a catenary is more completely exerted. Longitudinal short steel bars partially debonded with concrete are additionally arranged in a near-beam end area, and the short steel bars are arranged at the half-height position of a beam section, so that resistance continues to be provided after longitudinal bars at the top of a near-side column beam end or longitudinal bars at the bottom of a near-middle column beam end are broken, and continuous collapse of the structure is prevented. Local debonding of the longitudinal short steel bars and the concrete is achieved by wrapping the surfaces of the short steel bars with thermal polycondensation olefin pipes. The invention further provides an ultimate bearing capacity calculation method of the beam-column structure additionally provided with the short steel bars at the half-height position of the beam section. The progressive collapse resistance design technology provided by the invention has the advantages that the practice is easy, the anti-seismic property of the structure is not obviously influenced, and the economical efficiency is good; and the given ultimate bearing capacity analysis model has the characteristics of simplicity and accuracy.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com