Long-span bi-prestressed superposed framework, floor system and construction method

A construction method and prestressing technology, applied in floors, building components, buildings, etc., can solve problems such as difficulty in component production, transportation, hoisting and on-site installation, increase the weight of prefabricated components themselves, and achieve efficient production and mechanized operation. Resistance to continuous collapse, effect of reducing section size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

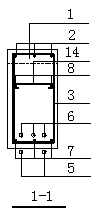

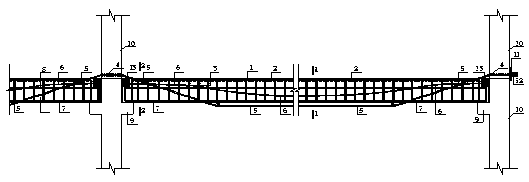

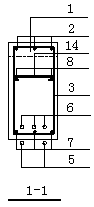

[0061] Embodiment 1, a large-span double prestressed composite concrete frame, including prefabricated columns with corbels, said prefabricated columns support composite beams, said composite beams include two parts, the first part is factory-made pre-tensioned or Post-tensioned prestressed prefabricated part, this part can bear the self-weight of prefabricated components, construction load and part of the load to set up ordinary steel bars and prestressed tendons; the second part is the part of cast-in-place composite concrete and external prestressed tendons Tension anchorage, this part can consider the remaining load of the prefabricated part to configure external prestressed tendons.

[0062] In this example, if Figure 7-12 , The prestressed tendons of the prestressed prefabricated part adopt the pretensioning method, and are completed in batches in the factory according to the construction technology of the pretensioning method, and the prestressed tendons are made of hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com