Patents

Literature

106results about How to "Reduce crack width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

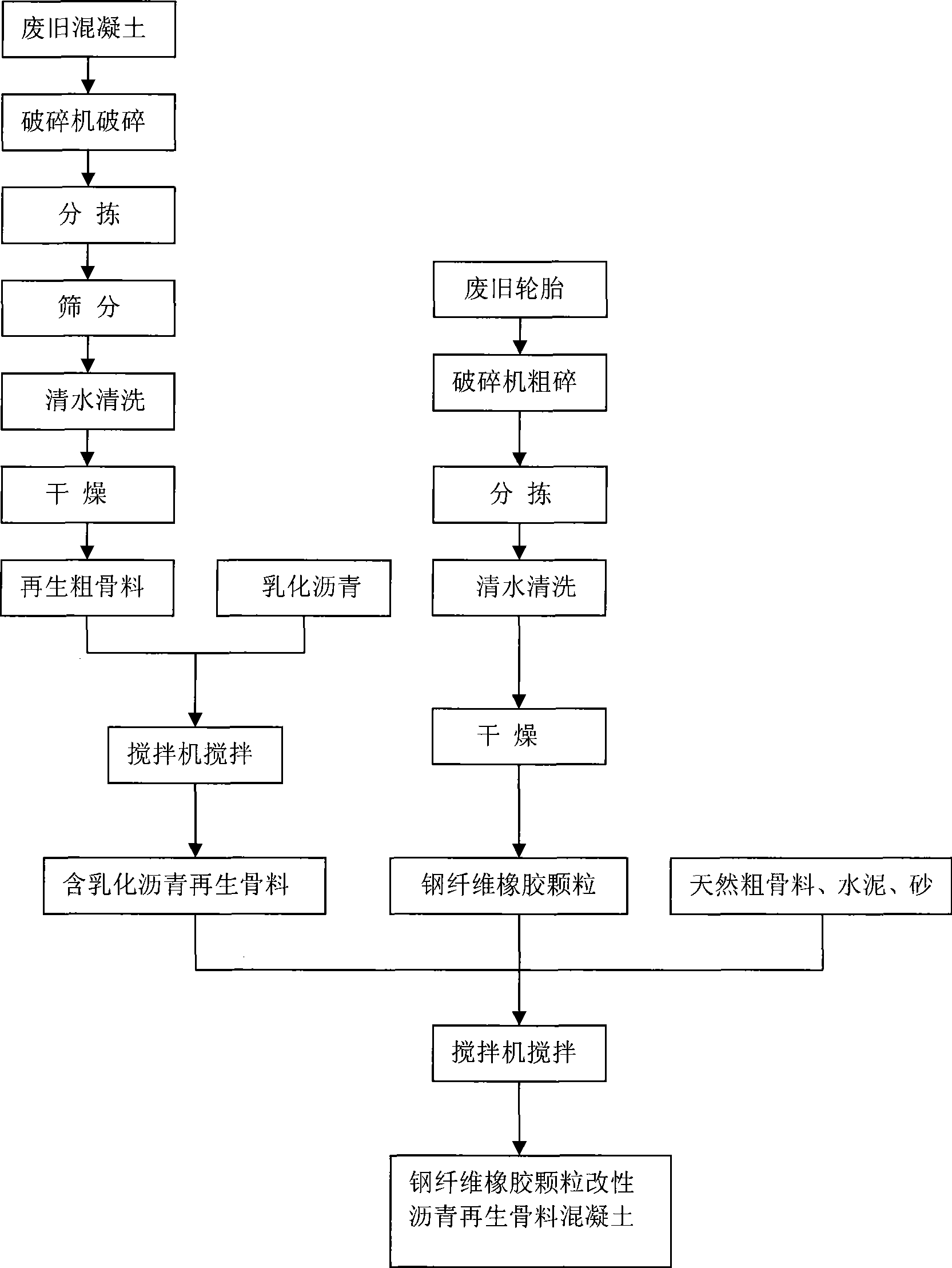

Method for regenerating aggregate concrete from steel fibre rubber granule modified asphalt

InactiveCN101381216AHigh dampingIncrease frictionSolid waste managementCrack resistanceEnergy absorption

The invention discloses a method for preparing steel fiber rubber particle modified asphalt recycled aggregate concrete. In the method, waste concrete is subjected to crushing, separating, screening, washing and drying to obtain the recycled aggregate, and the recycled aggregate is stirred with emulsified asphalt until the emulsified asphalt is covered on the surface of the recycled aggregate; waste tire is subjected to coarse crushing, separating, washing and drying to obtain the steel fiber rubber particle; and the recycled aggregate containing the emulsified asphalt, steel fiber rubber particles, natural aggregate, cement, sand and water are stirred according to certain ratio to obtain the steel fiber rubber particle modified asphalt recycled aggregate concrete. In the invention, the waste tire is subjected to crushing process to produce the steel fiber rubber, and the crack resistance, the heat preservation capability and the energy absorption and noise reduction capability of the asphalt recycled aggregate concrete are effectively improved by the modification of the steel fiber rubber; and the material is a circular economy building material, and by producing the material, the environmental pollution is reduced, and the performance of the material can be improved under the condition of not increasing cost.

Owner:GUANGDONG UNIV OF TECH

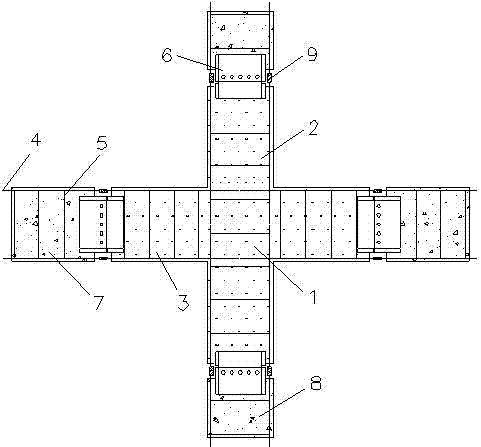

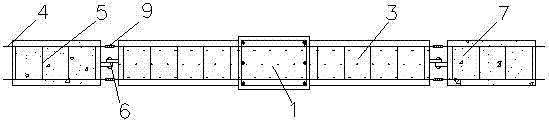

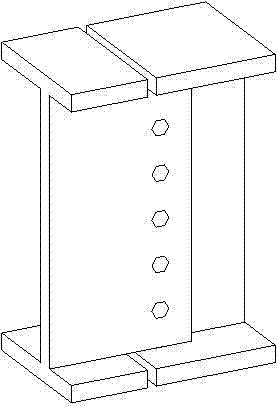

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

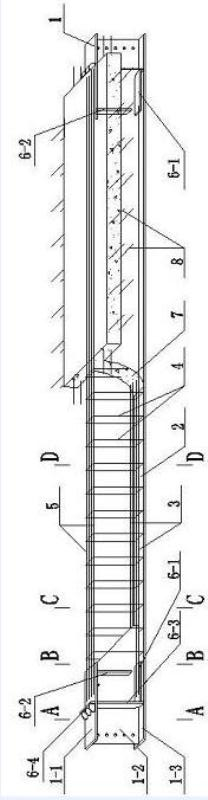

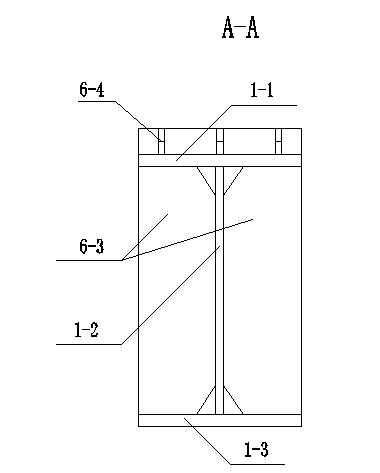

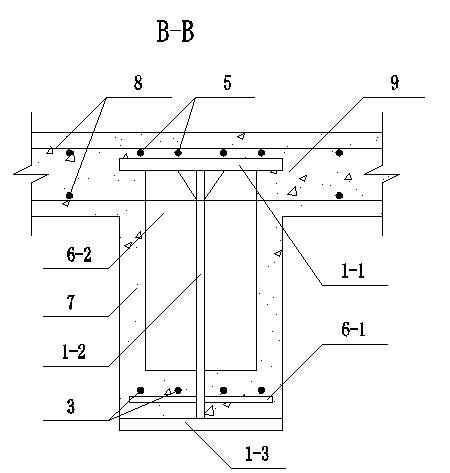

Cast-in-place steel-concrete composite beam

ActiveCN101845871AFast constructionFast integrityLoad-supporting elementsFloor slabReinforced concrete

The invention discloses a cast-in-place steel-concrete composite beam, which relates to a composite beam. The cast-in-place steel-concrete composite beam solves the problems that a reinforced concrete beam and a column connection node in the existing steel structure and the existing steel-concrete composite structure have complex structures and are difficult to construct, the problems that a common composite beam has a large steel consumption and a high structure manufacturing cost, and the problems that a composite beam of which the publication number is CN101215855 is complex in operation and is inconvenient to construct when connected with a reinforced concrete wall column, and has low bearing capacity, small rigidity, weak spanning capacity, large fracture width for tensile region concrete and small application range. Bottom flanges of two I-shaped steel beam sections of the cast-in-place steel-concrete composite beam and a tensile region steel plate are made into an integral body; a longitudinal steel plate ribbed stiffener is connected through a fire-resisting longitudinal bar; top flanges of the two I-shaped steel beam sections are connected through a tensile region longitudinal bar; stirrups are uniformly arranged along the longitudinal direction of the fire-resisting longitudinal bar; floor steel bars are paved on a stiffening framework of the composite beam; and concrete is poured on the floor steel bars and the stiffening framework of the composite beam. The cast-in-place steel-concrete composite beam is applied to civil engineering constructions.

Owner:HARBIN INST OF TECH

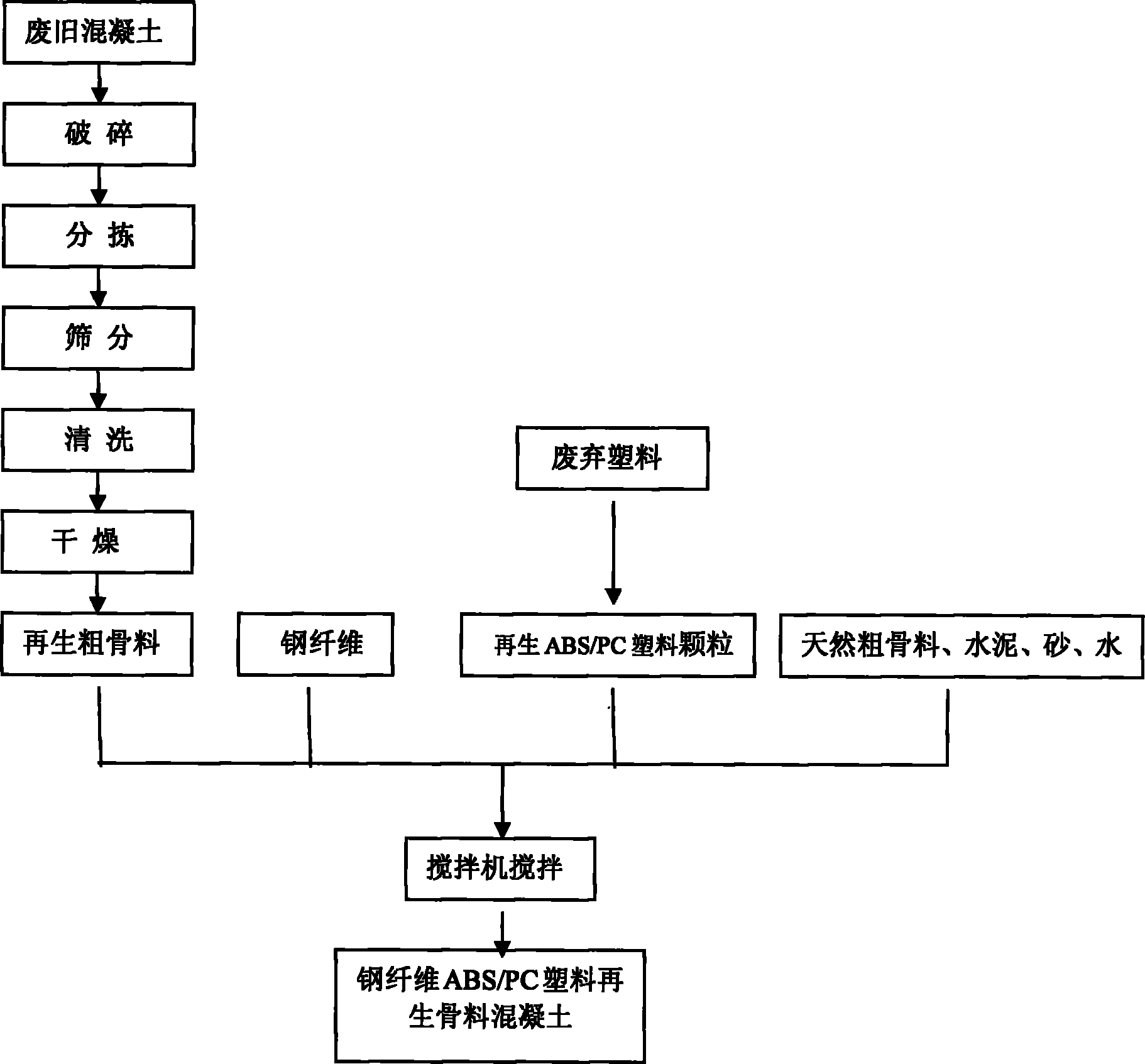

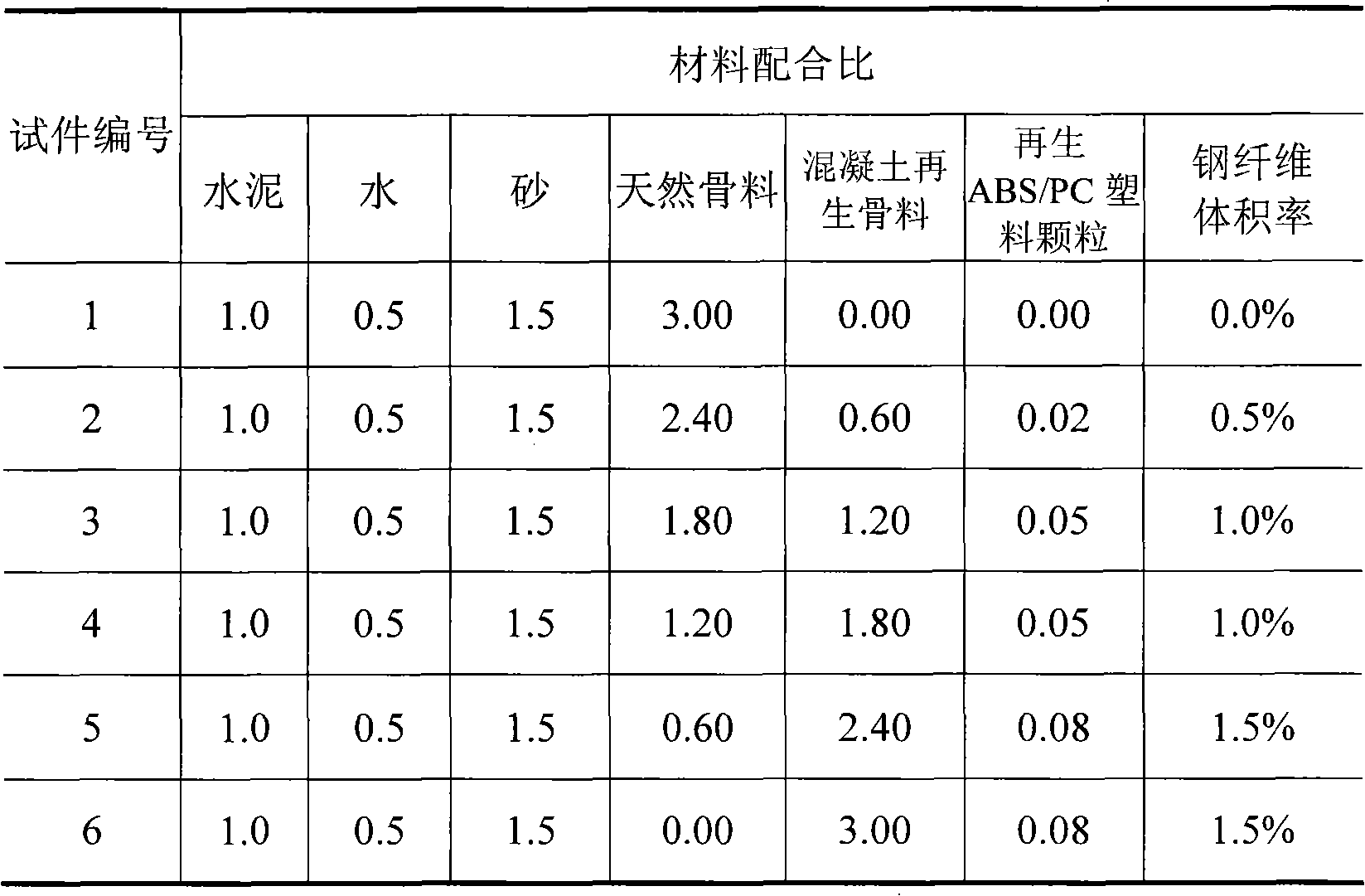

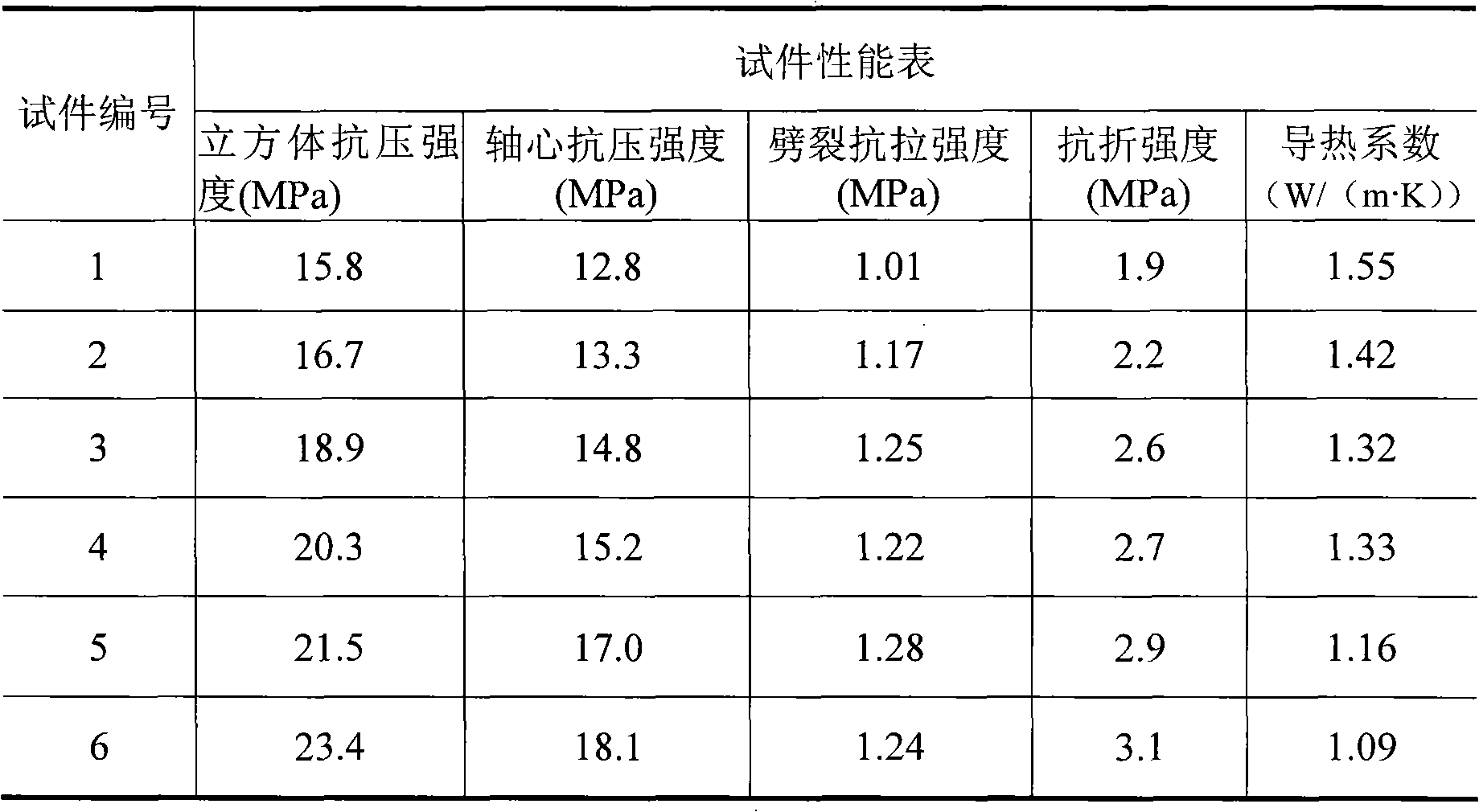

Preparation method for steel fiber ABS/PC plastic reclaimed aggregate concrete

ActiveCN101830029AHigh dampingIncrease frictionSolid waste managementCeramic shaping apparatusThermal insulationCompressive strength

The invention discloses a preparation method for steel fiber ABS / PC plastic reclaimed aggregate concrete, which comprises the following steps of smashing, separating, sieving, cleaning and drying waste building concrete to obtain reclaimed concrete aggregate; smashing waste ABS / PC plastics to obtain reclaimed ABS / PC plastic particles; and then stirring steel fibers, reclaimed ABS / PC plastic particles, reclaimed concrete aggregate, natural coarse aggregate, sand, cement and water in proportion. The toughness, rupture strength, compression strength, impact resistance and other properties of the reclaimed aggregate concrete can be effectively improved by steel fiber modification; the reclaimed ABS / PC plastic particles can improve the anti-cracking performance, thermal insulation performance, wear-resisting performance and compression strength of the concrete; and the production of the material can reduce the environment pollution and improve the performance of the material without increasing cost.

Owner:GUANGDONG DIANBAI CONSTR GRP

Road slope silt curing agent and preparation method thereof

The invention relates to a road slope silt curing agent and a preparation method thereof. The road slope silt is prepared from the following components in percentage by weight: 50-90% of silt and 10-50% of a curing agent, wherein the curing agent is prepared from the following components in percentage by weight: 40-70% of cement, 10-30% of coal ash, 5-10% of an expanding agent, 0.5-4% of a high polymer, 0.1-2% of a super plasticizer, 1-3% of an early strength agent, 0.001-0.1% of a retarder, 0.01-1% of a thickener, 0.1-3% of fibers and the balance of grass seeds. According to the curing agent provided by the invention, the expanding agent and fibers are introduced. Compared with a curing agent in the prior art, the road slope silt curing agent has the advantages that the shrinkage rate of cured sandy soil is reduced by 40%, so that the crack resistance of a curing body is improved. A pore structure can be controlled, so as to provide a growing space for plants. By adopting low-grade coal ash, turning waste into wealth and environmental friendliness are facilitated.

Owner:JIANGSU DINGTAI ENG MATERIAL

Modified coarse aggregate, fiber nano recycled concrete prepared from modified coarse aggregate and preparation method of fiber nano recycled concrete

The invention belongs to the technical field of building materials, and particularly relates to a modified coarse aggregate with improved performance, excellent-performance fiber nano recycled concrete prepared from the modified coarse aggregate and a preparation method of the fiber nano recycled concrete. The preparation method includes the following steps that waste concrete test blocks and waste sintered bricks are crushed and screened to obtain a recycled coarse aggregate, and the recycled coarse aggregate is dried after being soaked with a nano silica sol to obtain a modified concrete coarse aggregate and a modified brick coarse aggregate; water, cement, fine aggregate, the modified concrete coarse aggregate, the modified brick coarse aggregate and polyvinyl alcohol fiber are preparedin proportion; the modified brick coarse aggregate, the modified concrete coarse aggregate, the cement and the fine aggregate are put into a stirrer and pre-stirred, the polyvinyl alcohol fiber is evenly dispersed and added, and dry mixing is carried out; water and a water reducer are sequentially added into the stirrer and stirred until the mixture is evenly mixed. Construction waste is effectively utilized to prepare the recycled concrete with certain performance indexes.

Owner:ZHENGZHOU UNIV

Self-repairing anti-shrink cement based composite material

The invention discloses a self-repairing anti-shrink cement based composite material which comprises the following components in parts by weight: 400-800 parts of cement, 200-600 parts of waste, 400-1000 parts of sand, 264-528 parts of water, 10-70 parts of fiber, 4-10 parts of additive and polymer emulsion which accounts for 5%-10% of the gross weight of the cement. The self-repairing anti-shrink cement based composite material has good anti-shrink performance, impermeability and durability. When having a crack, the material can realize a self-repairing function under field conditions, and can be used as restorative materials for retaining walls, road mat coats, concrete pipelines, oil and gas pipelines, dams and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

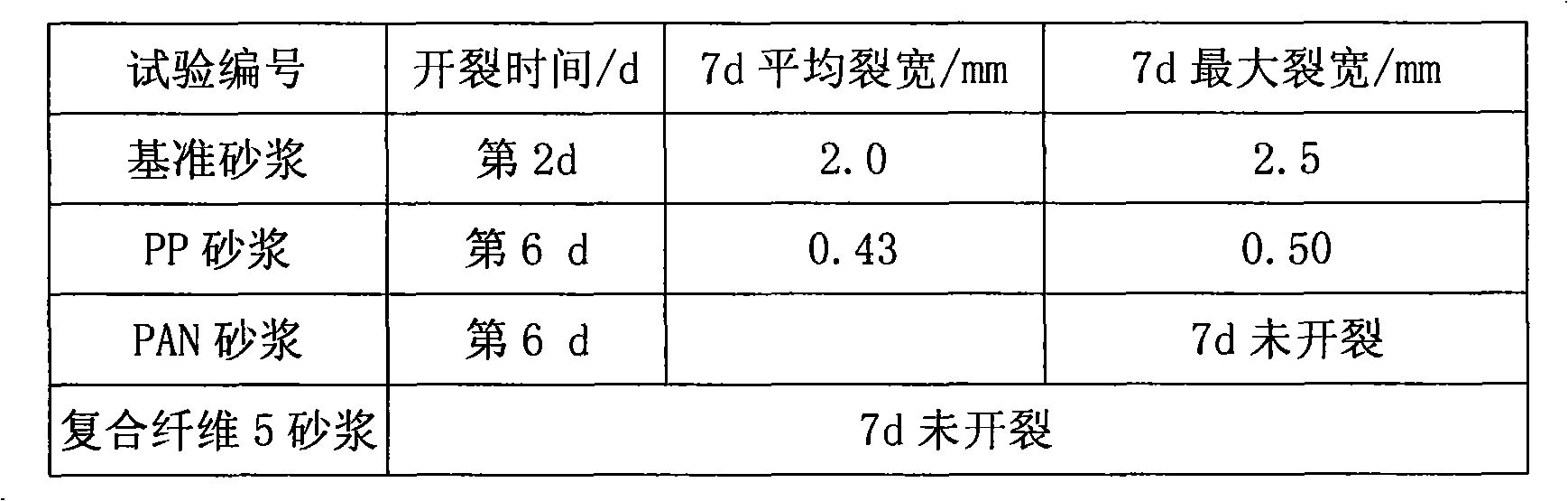

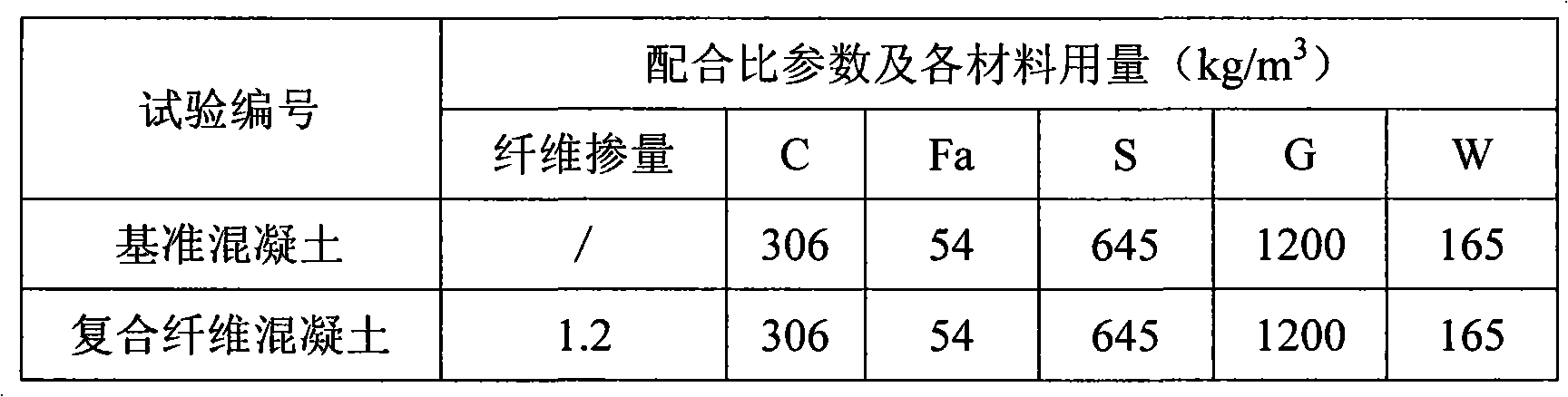

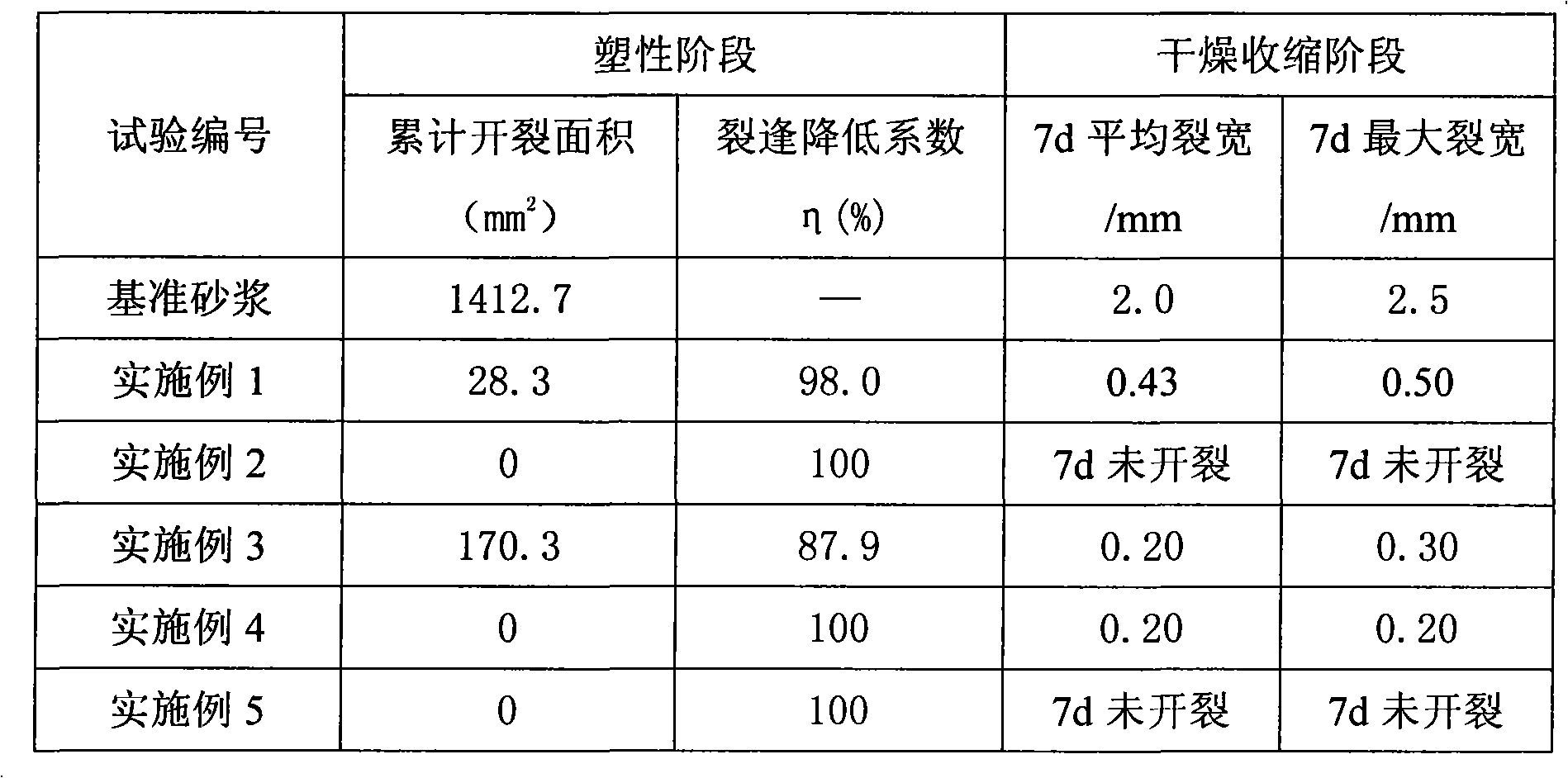

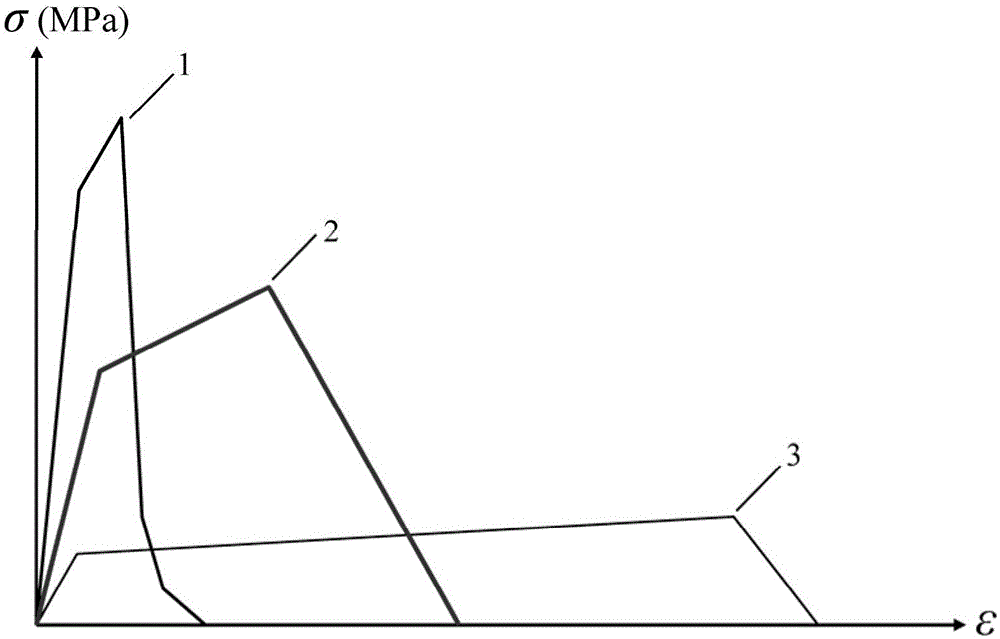

Composite fiber for whole time anti-cracking for concrete

The invention relates to duplex fiber used for resisting cracking of concrete throughout the course. The duplex fiber is prepared with the following synthetic fiber by weight: 15 to 50 percent of a high strength and high modulus synthetic fiber, 20 to 40 percent of a medium strength and medium modulus synthetic fiber, 20 to 45 percent of a low strength and low modulus synthetic fiber. The duplex fiber is prepared with fibers of different length, different elastic modulus and different strength of extension through compounding, thus forming a low strength and low modulus, medium strength and medium modulus, high strength and high modulus compound system. In this way, the duplex fiber not only has the advantages of various individual filaments but also has the superimposed effect of compounding of various fibers. Accordingly, the duplex fiber has synergistic actions in different periods when concrete is coagulated and hardened, which not only can prevent the plastic cracking of concrete, but also can effectively control the cracks during the hardening of concrete. In addition, the duplex fiber can effectively improve the toughness and the malleability of the concrete so that the durability of the concrete is significantly improved.

Owner:南京派尼尔科技实业有限公司

Cement-based composite material for steel box girder bridge deck, as well as preparation and pavement thereof

ActiveCN103449786AImprove toughnessLimit extensionBridge erection/assemblyBridge materialsEpoxyBridge deck

The invention relates to a cement-based composite material for pavement of a steel box girder bridge deck, as well as a preparation method and a pavement method thereof. The invention aims at providing a lightweight and high-toughness cement-based composite material which is suitable for pavement of larger-span steel box girder bridge decks, and the cement-based composite material comprises the following components in parts by weight: 849-881 parts of cement, 339-425 parts of quartz sand, 215-273 parts of pottery sand, 100-226 parts of fly ash, 30-56 parts of silica fume, 275-295 parts of water, 10-13 parts of water reducing agent, 40-80 parts of steel fiber, 6.5-13 parts of organic fiber and 20-30 parts of epoxy resin. Through material optimization, the durability of a bridge deck paving layer is improved, the overall dead weight is reduced, the cost of a project is simultaneously saved, and the cement-based composite material is suitable for pavement of the larger-span steel box girder bridge decks.

Owner:WUHAN UNIV OF TECH

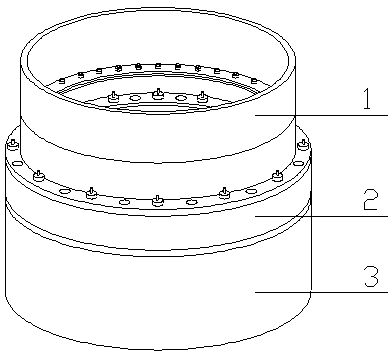

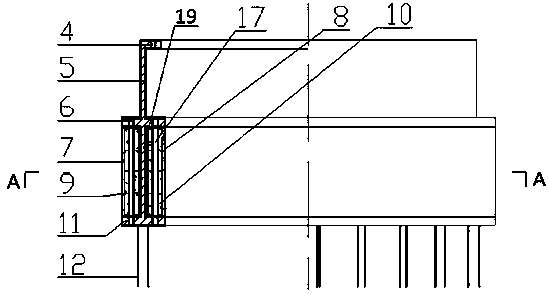

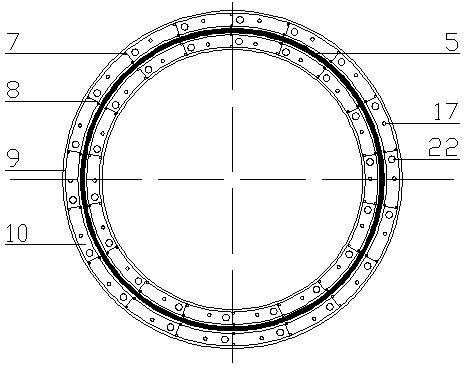

Connection device of prestress concrete and steel combination wind power generation tower

ActiveCN103994034AUniform stress distributionAvoid uneven distributionWind energy generationWind motor componentsTension stressWind force

The invention relates to a connection device of a prestress concrete and steel combination wind power generation tower. The lower surface of a lower connection flange is provided with anchor bars connected with a concrete tower section. The connection device is further provided with prestress application components, a tension anchor flange and the lower connection flange are respectively and uniformly provided with flange holes for the prestress application components to pass, and the flange holes of the tension anchor flange are the same as those of the lower connection flange in quantity and correspond to the flange holes of the lower connection flange in a one-to-one mode in the vertical direction. The prestress application components sequentially penetrate through the flange holes of the anchor flange and the flange holes of the lower connection flange and penetrate through the concrete tower section on the lower portion. The top ends of the prestress application components are anchored on the top face of a lower section connection steel cylinder through anchorage devices after the prestress application components are tensioned. Concrete is poured between the tension anchor flange and the lower connection flange to form a prestress concrete structure. Due to the connection mode, the concrete on the flange connection section is uniformly stressed, stress concentration is reduced, the tensile stress level of the concrete is improved, and the situation that the concrete cracks is avoided.

Owner:HUNAN UNIV

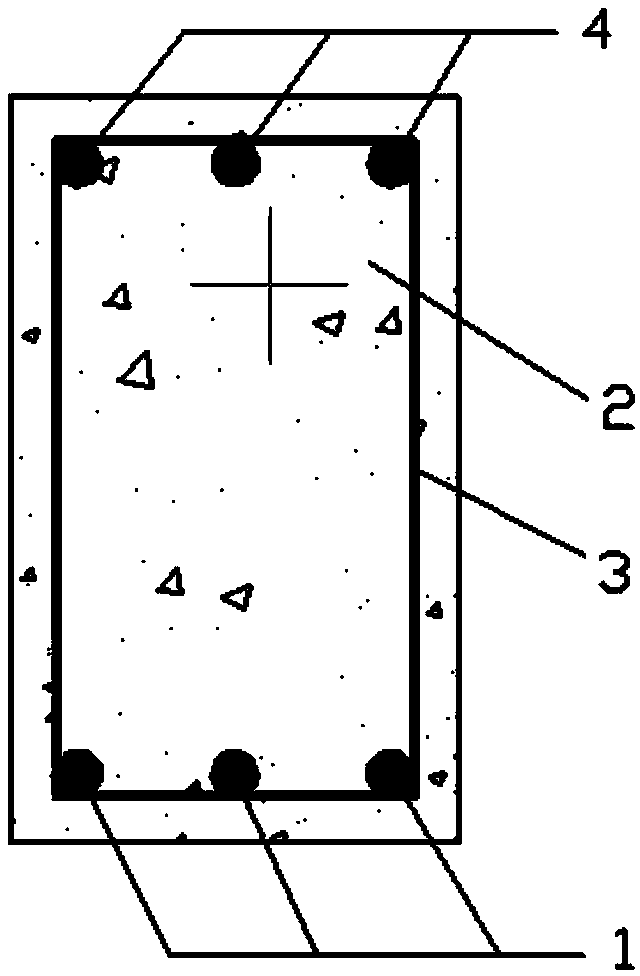

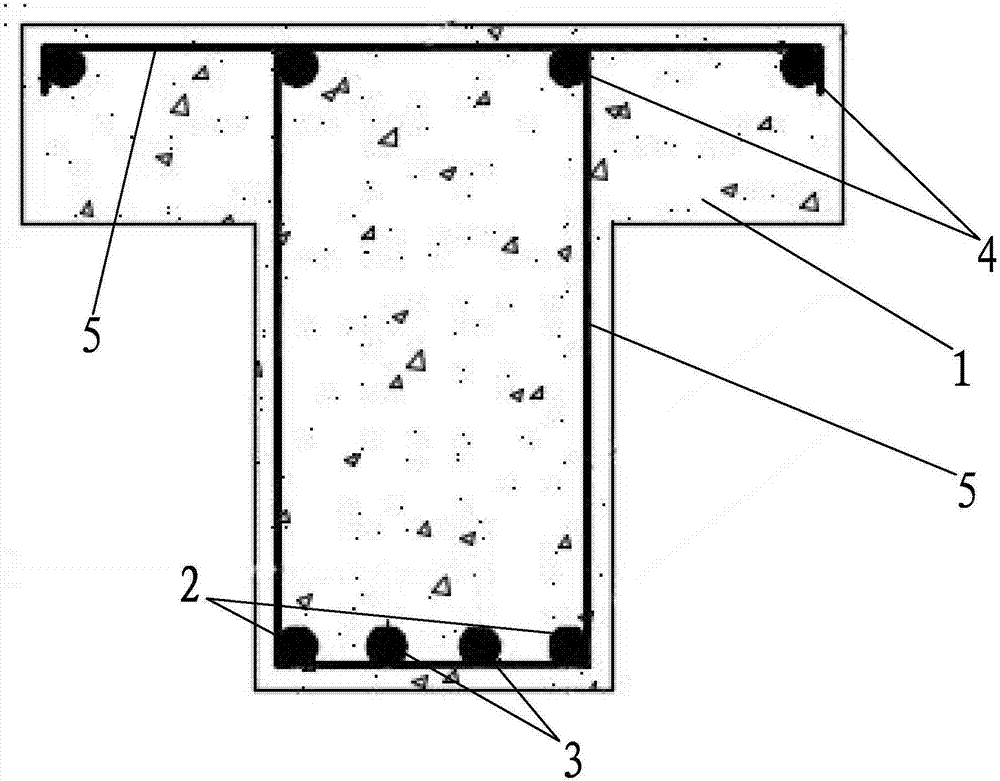

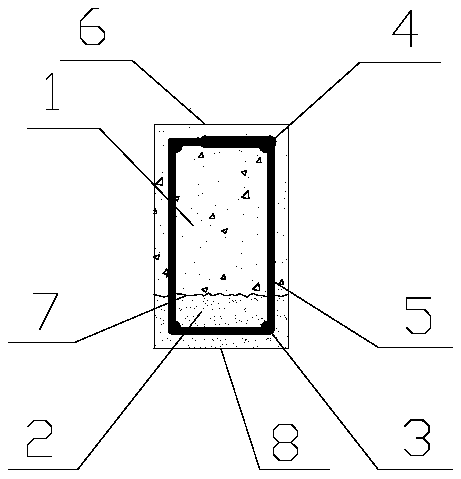

FRP (Fiber Reinforced Plastic) bar and fiber high-strength concrete beam component

The invention relates to an FRP (Fiber Reinforced Plastic) bar and fiber high-strength concrete beam component. The FRP (Fiber Reinforced Plastic) bar and fiber high-strength concrete beam component comprises fiber high-strength concrete and an FRP bar framework cast in the fiber high-strength concrete, wherein the cross section of the beam component is solid rectangular, hollow rectangular, T-shaped or box-shaped; for the solid rectangular or hollow rectangular cross section, the FRP bar framework consists of longitudinal strained FRP bars, FRP stirrup bars and longitudinal erected FRP bars, and the longitudinal strained FRP bars and the longitudinal erected FRP bars are attached to the inner sides of the FRP stirrup bars and bundled together; for the T-shaped cross section and the box-shaped cross section, the FRP bar framework consists of longitudinal strained FRP bars, FRP stirrup bars, erected FRP bars, girder web distributed FRP bars and top plate stressed FRP bars, the longitudinal strained FRP bars are attached to the inner sides of the FRP stirrup bars, the distributed FRP bars are attached to the inner sides of the FRP stirrup bars, the erected FRP bars are attached to the inner sides of the top plate stressed FRP bars, and the top plate stressed FRP bars are connected with the FRP stirrup bars to form effective connection.

Owner:ZHENGZHOU UNIV

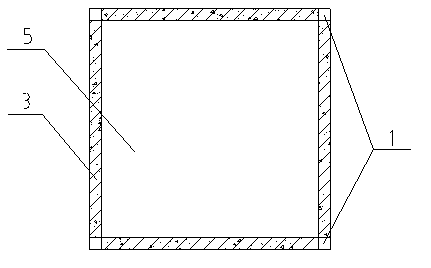

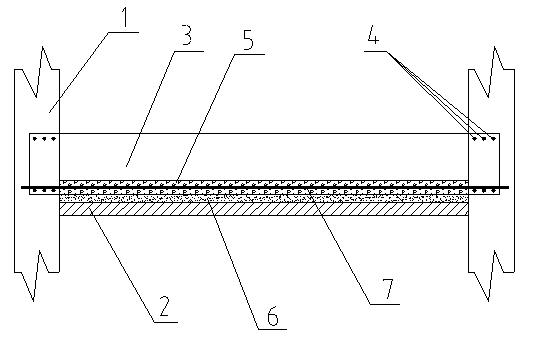

Preparation method of reinforced concrete beam with demounting-free textile reinforced concrete (TRC) bottom mould

ActiveCN102814861AProtect the environmentOvercoming weightCeramic shaping apparatusFiberglass meshGlass fiber

The invention discloses a preparation method of a reinforced concrete beam with a demounting-free textile reinforced concrete (TRC) bottom mould, which relates to a long strip-shaped structural member for bearing. The preparation method comprises the following steps of: A, manufacturing a textile fleece reinforced concrete board: determining the size of the TRC board, and constructing a common steel mouldboard for the TRC board or customizing the steel mouldboard of the required size according to the size of the TRC board, preparing the textile glass fleece, mixing the concrete prepared according to the mass rate, grouting the concrete in the constructed common steel mouldboard or the customized steel mouldboard, paving the textile glass fleece, maintaining, and demounting the mould; and B, manufacturing the concrete beam with the demounting-free TRC bottom mould: constructing a common steel mouldboard for the TRC board or customizing the steel mouldboard of the required size according to the size of the TRC board, reinforcing bars, grouting the concrete, maintaining, and demounting the mould. The TRC board manufactured by using the method disclosed by the invention replaces the current wood mouldboard, the bamboo plywood mouldboard or the steel mouldboard, so that the defects that the current wood mouldboard, the bamboo plywood mouldboard or the steel mouldboard is not environmental-protection, is large in weight, high in price and low in construction efficiency, and can easily cause the conditions that the reinforcing steel bars cannot be accurately positioned and the surface of the member is not smooth after the mould is demounted, and the like can be overcome.

Owner:HEBEI UNIV OF TECH

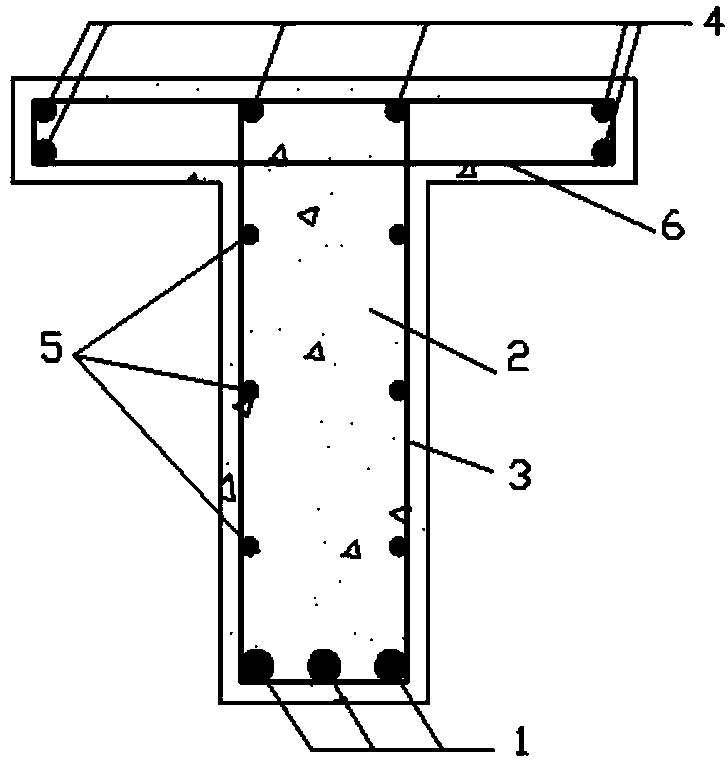

Novel earthquake damage control system for thin-wall hollow pier

InactiveCN104674649AReduce residual displacementReduce widthBridge structural detailsBridge erection/assemblyPre stressTorsional strength

The invention discloses a novel earthquake damage control system for a thin-wall hollow pier. The novel earthquake damage control system comprises a pier base, a thin-wall hollow pier, high-tenacity fiber-enhanced cement-based composite material expanded sections, an unbonded prestressed tendon and steel energy consumption elements, wherein the thin-wall hollow pier is arranged on the upper end surface of the pier base, so that the torsional strength and the energy-dissipating capacity of the thin-wall pier are improved. The high-tenacity fiber-enhanced cement-based composite material expanded sections are arranged on the inner side and the outer side of the lower part of thin-wall hollow pier; a series of steel energy consumption elements are arranged in the thin-wall hollow pier along the pier height; the lower part of the unbonded prestressed tendon is anchored on the pier base; and the upper part of the unbonded prestressed tendon is anchored at the center of the first steel energy consumption element from bottom to top. By virtue of the unbonded prestressed tendon, the self-resetting capacity of the pier after the earthquake is provided; and the crack width of the pier after the earthquake is reduced. By virtue of the high-tenacity fiber-enhanced cement-based composite material expanded sections, the axis-compression ratio of the bottom section of the thin-wall hollow pier is reduced; the shear-bearing capacity and the anti-bending capacity of the thin-wall hollow pier are increased; and the steel energy consumption elements can be arranged as rapid exchange components, so that the repairability after the earthquake is increased.

Owner:DALIAN MARITIME UNIVERSITY

PVA fiber reinforced cement-based composite material

InactiveCN105906261ALow costReduce cement consumptionSolid waste managementClimate change adaptationStress concentrationNatural resource

The invention discloses a PVA fiber reinforced cement-based composite material, which is composed of the following ingredients (by weight): 11.8-26.8 parts of cement, 32.2-47.2 parts of flyash, 20.8-21.5 parts of river sand, 0.53-0.54 part of a water reducing agent, 0.03 part of an antifoaming agent, 0.03 part of a thickening agent, 1.24-1.25 parts of fiber and 17.7-17.9 parts of water. By replacing cement in the PVA fiber reinforced cement-based composite material with high volume of flyash, wastes are changed into valuable things, cost is reduced, CO2 emission is minimized, and lots of natural resources and energy are saved. In addition, crack width and natural air shrinkage of the PVA fiber reinforced cement-based composite material are reduced, long-term durability of the structure is enhanced, stress concentration degree of crack tip is weakened, fiber crack-retarding mechanism is fully performed, and flexural toughness of the fiber reinforced cement-based composite material is enhanced.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

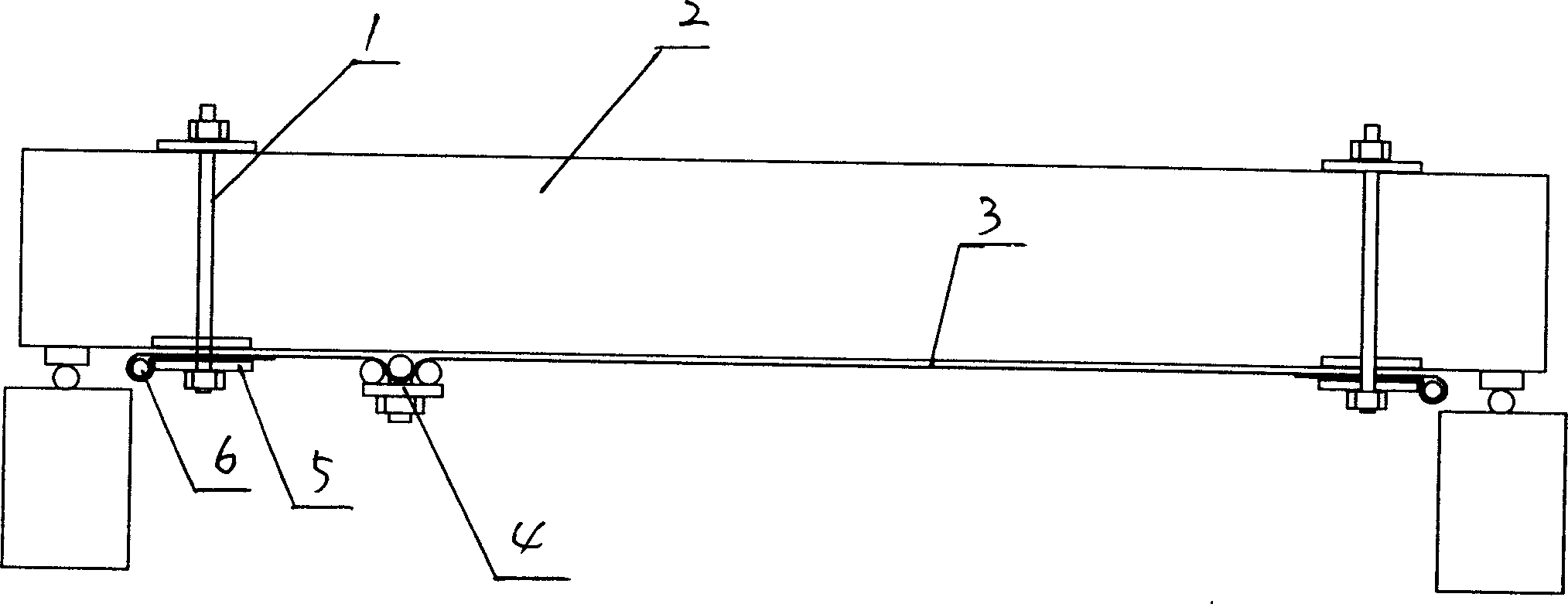

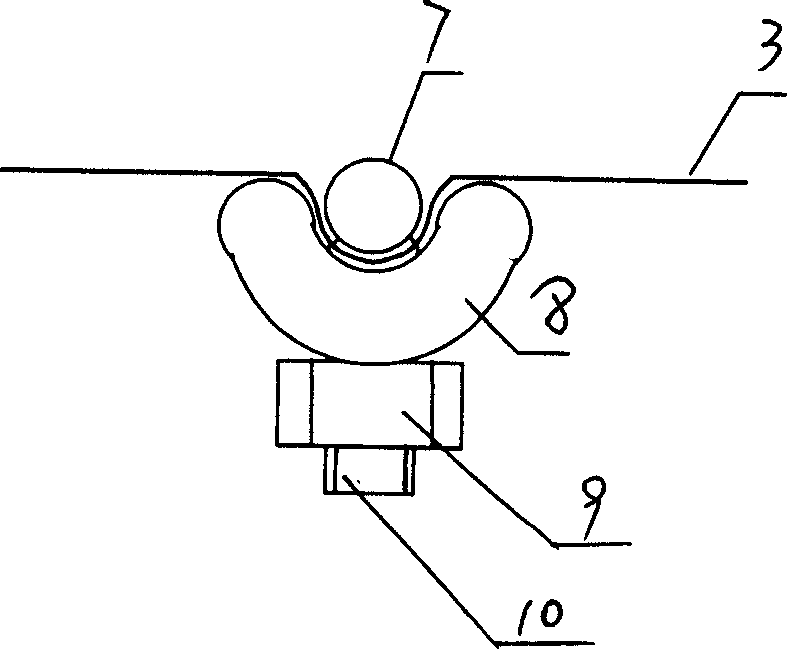

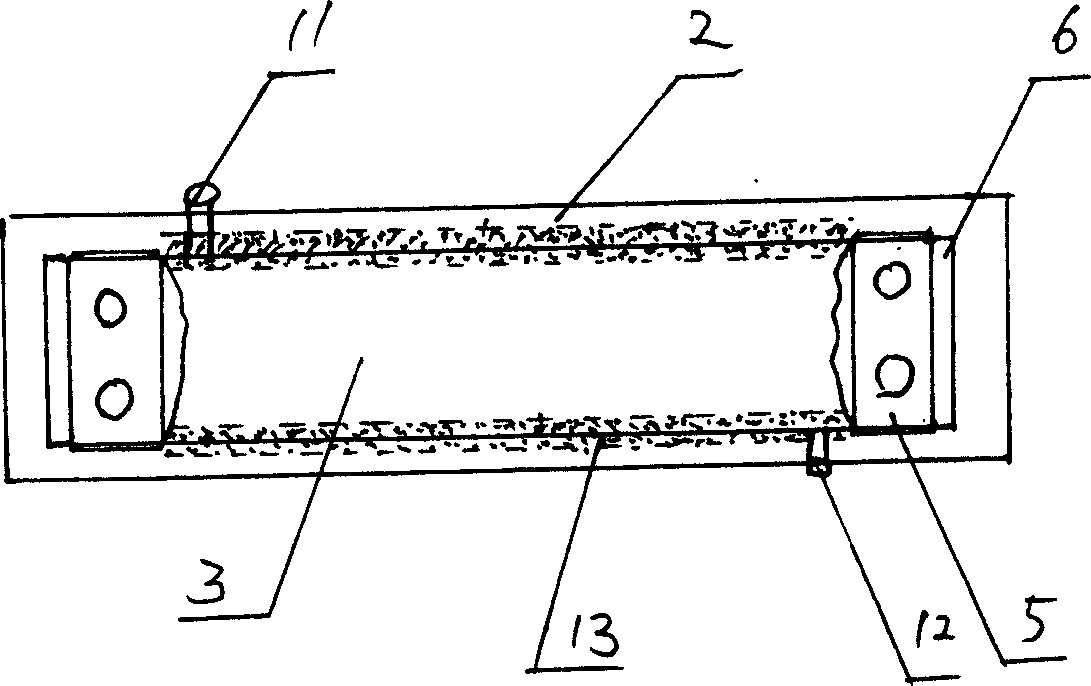

Method for strengthening construction unit using high strength fibre cloth

InactiveCN1693623ADisadvantages of changing reinforcementRealize unloadingBuilding reinforcementsFiberSheet steel

This invention discloses is a method of using high intensity fiber cloth for strengthening member. The cloth is anchored to the two ends of member after it is flattened. Then horizontal strain is done through horizontal stretching equipment between the two anchor ends. The anchor method is that the end of the cloth is rolled through a steel roller and then retraced, and it is nipped between two steel boards with the cloth, then they are fixed at end of consolidated pieces through high tensile bolt. Binding coat can be painted on member surface, then anchor and stretching is done before the glue of the binding coat doesn't solidify. Also using rubber belt to seal fiber cloth edge and member after anchor and stretching is done, compound lining hole is set at one end, and vent hole is set at the other end, structure glue is injected between fiber cloth and members through the hole. Stiffness and ultimate strength of the consolidated structure member can be increased by using the method in this invention, and the deformation in application stage can be recovered or part recovered and crack width of structure members can be reduced.

Owner:田安国

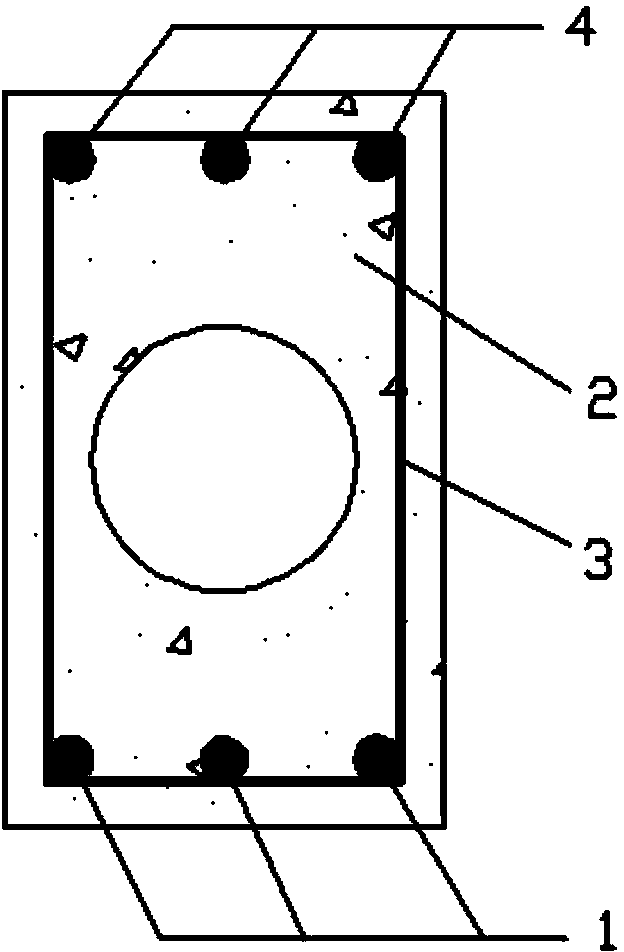

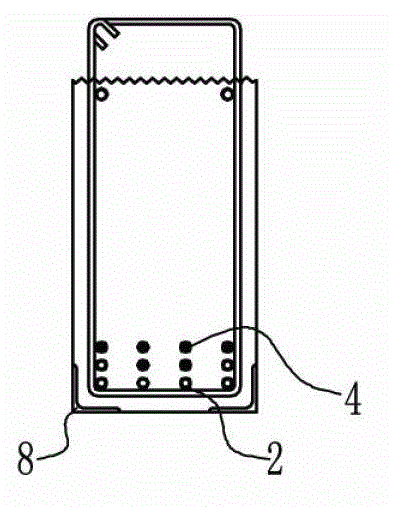

Assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and manufacturing method thereof

ActiveCN110318495AGive Full Play to the "Hoop Effect"Give full play to the "ring effect"MouldsClimate change adaptationConcrete beamsLong term durability

The invention discloses an assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and a manufacturing method thereof. The assembled permanent formwork overlapped FRPrib seawater sea sand recycled concrete beam comprises a prefabricated assembled permanent formwork and an FRP rib seawater sea sand recycled concrete beam. The prefabricated assembled permanent formwork is formed by assembling corer strip assembly blocks, first panels, second panels and positioning connecting parts, and the formwork is manufactured from an engineering cement-based composite (ECC)and a fiber woven mesh. The FRP rib seawater sea sand recycled concrete beam comprises seawater sea sand recycled concrete poured into the prefabricated assembled permanent formwork and an FRP rib framework fixedly arranged in the seawater sea sand recycled concrete. As the TRE formwork and the FRP rib seawater sea sand recycled concrete are compounded, the engineering manufacturing cost of the formwork is effectively reduced, the ductility of the FRP rib seawater sea sand recycled concrete beam is improved, the long-time durability of FRP ribs is guaranteed, and meanwhile the problems that an existing integral formwork is large in occupied space and not easy to transport are solved.

Owner:CHINA UNIV OF MINING & TECH

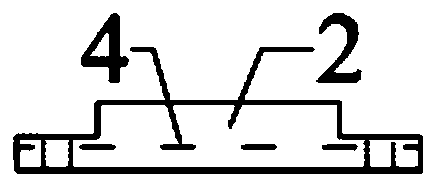

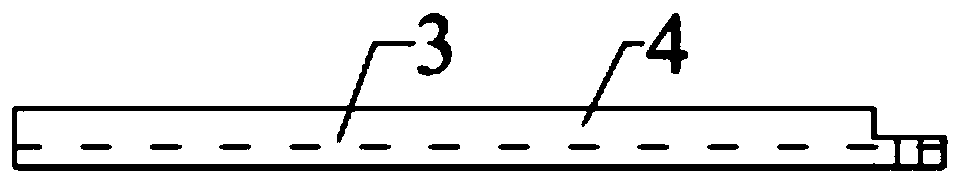

Uplift pile mixed connection structure

ActiveCN105756054AEfficient deliverySolve the problem of impact resistanceBulkheads/pilesAdhesiveStructural engineering

The invention discloses an uplift pile mixed connection structure which comprises a pile head protective sleeve I, a pile head protective sleeve II and a plug connector. The plug connector comprises a first sleeve-shaped fixed positioning sleeve and a second sleeve-shaped fixed positioning sleeve. A clamping piece is arranged in the first fixed positioning sleeve. A plug connection piece is arranged in the second fixed positioning sleeve. The plug connection piece can be inserted into the first fixed positioning sleeve and limited on the clamping piece, and therefore the first pile head protective sleeve and the second pile head protective sleeve can be fixedly connected in a butted mode. Both the first fixed positioning sleeve and the second fixed positioning sleeve are connected with main reinforcement bars and fixedly combined with the pile head protective sleeves through screws. When the uplift pile mixed connection structure is subjected to tensile force, the plug connector effectively connects the upper and lower main reinforcement bars, butt connection of the upper and lower main reinforcing bars on the same axis is achieved, inner stress is effectively transferred, meanwhile, the butted connection faces of the pile head protective sleeve I and the pile head protective sleeve II are in butted connection through a steel adhesive, the uplift resistance is further improved, and the purposes of impact resistance of a pile head end face and shear resistance and corrosion resistance of the connector are thoroughly achieved.

Owner:天海钢棒(张家港)有限公司

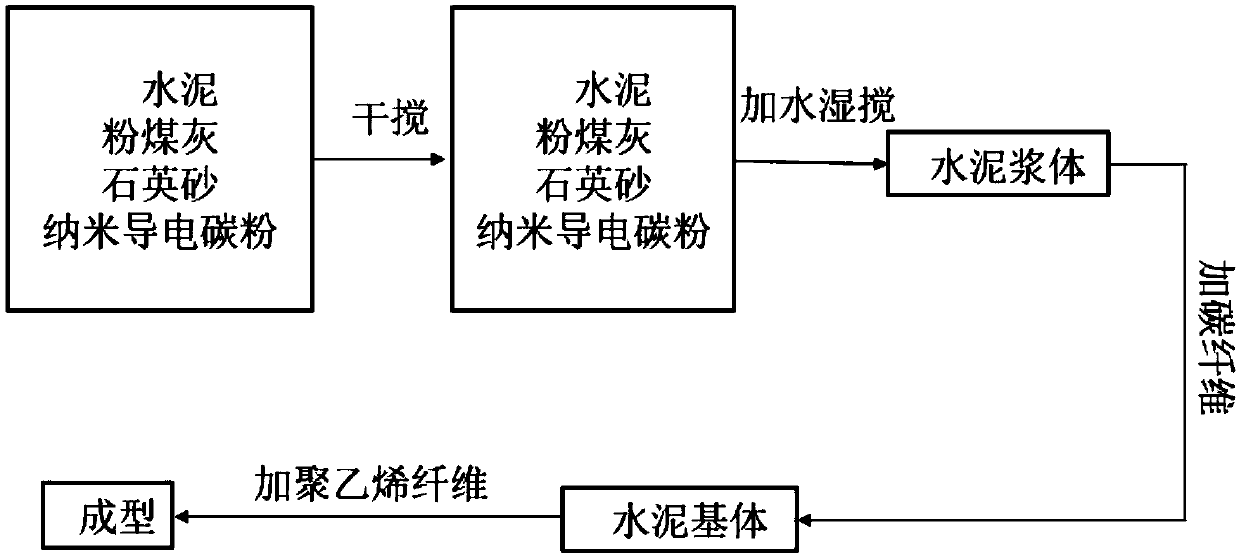

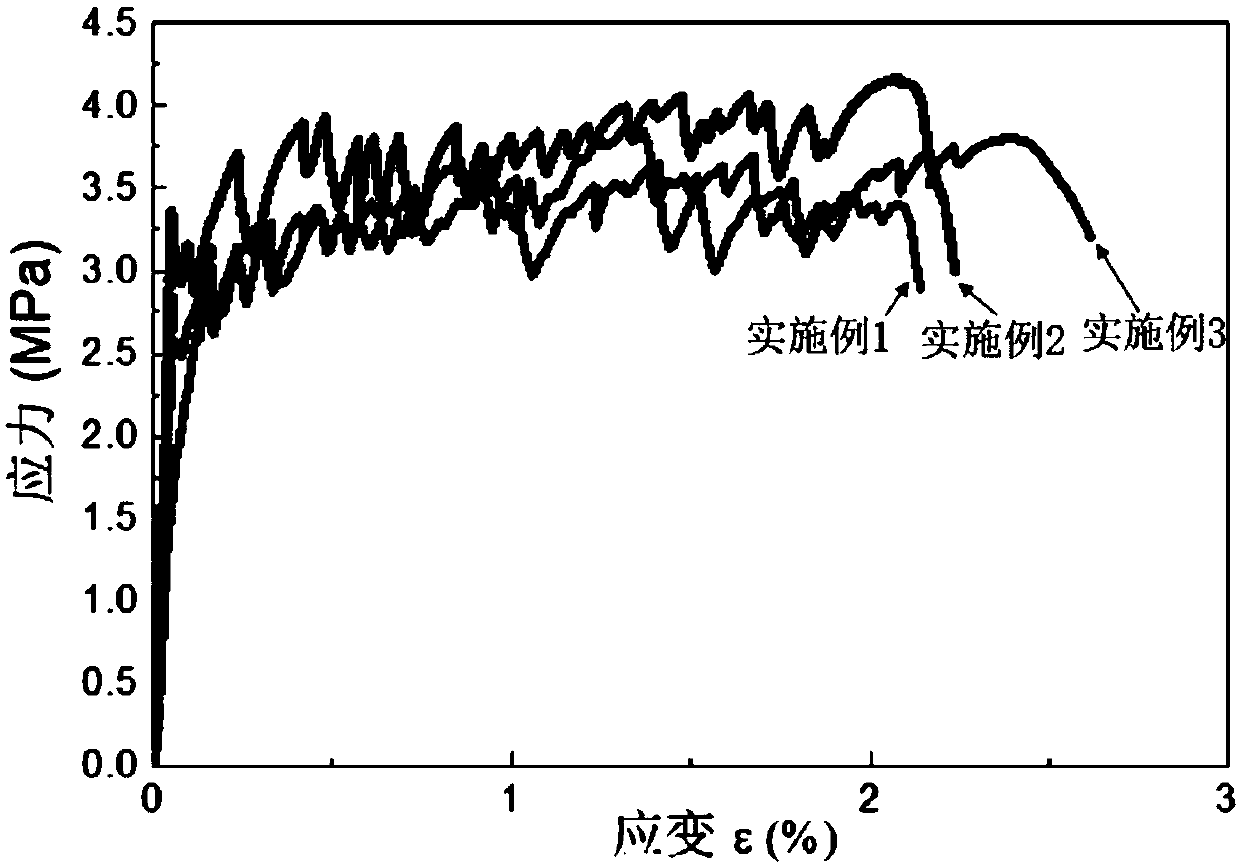

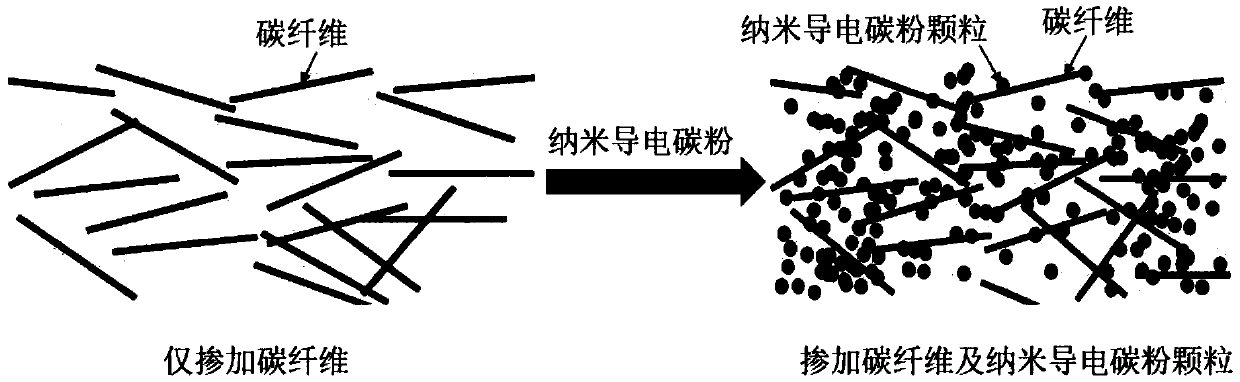

Conductive super high ductility cement-based composite material and preparation method thereof

The invention discloses a conductive super high ductility cement-based composite material and a preparation method thereof. The cement-based composite material is prepared from, by weight, 40-45 partsof cement, 15-20 parts of a fly ash, 10-15 parts of quartz sand, 3-5 parts of nano-conductive carbon powder, polyethylene fiber with a volume fraction of1.5%-2% and a carbon fiber with a volume fraction of 0.5%-1%. The preparation method comprises the steps of 1) weighing each raw material according to a ratio; 2) dry-mixing the cement, the fly ash, the quartz sand and the nano-conductive carbonpowder, and adding water for wet-stirring to form cement matrix; 3) adding the carbon fiber and the polyethylene fiber to the cement matrix, uniformly stirring, and obtaining the conductive super highductility cement-based composite material after injection molding and mold release curing. The cement-based composite material has both high electrical conductivity and crack control capability, andis suitable for snowmelt de-icing on road surfaces.

Owner:SOUTHEAST UNIV +1

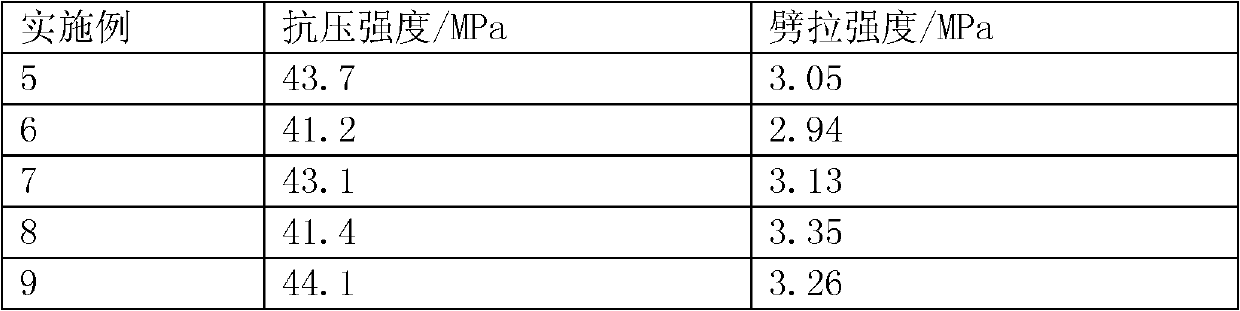

High-strength concrete composite material and preparation method thereof

The invention discloses a high-strength concrete composite material which comprises the following components in parts by weight: 100 parts of cement, 1-5 parts of fiber, 2-20 parts of silica fume, 1-20 parts of coal ash, 1-10 parts of composite rare earth, 10-20 parts of magnesium silicate granules, 140-200 parts of sand, 140-200 parts of macadam and 30-50 parts of water. The product is high in anti-cracking ability and small in loaded crack width and has long-term durability. Moreover, the interaction of composite concrete is improved, the material performance is far higher than basic performance of common concrete, main indexes of the concrete are obviously improved, a temperature crack is avoided, and the strength, freezing resistance and anti-permeability of the concrete are guaranteed.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

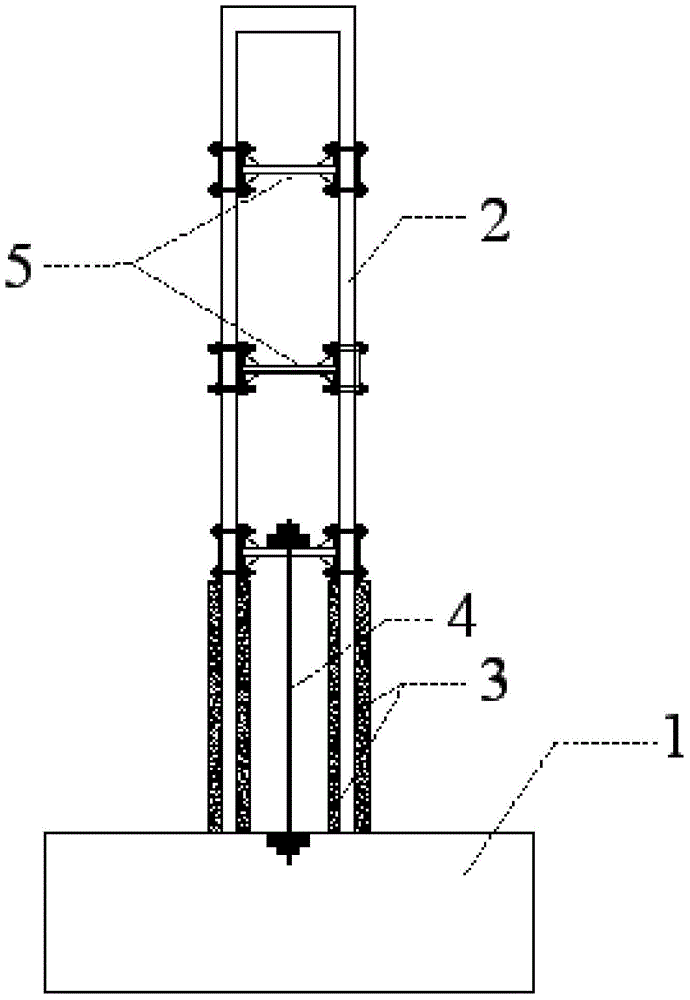

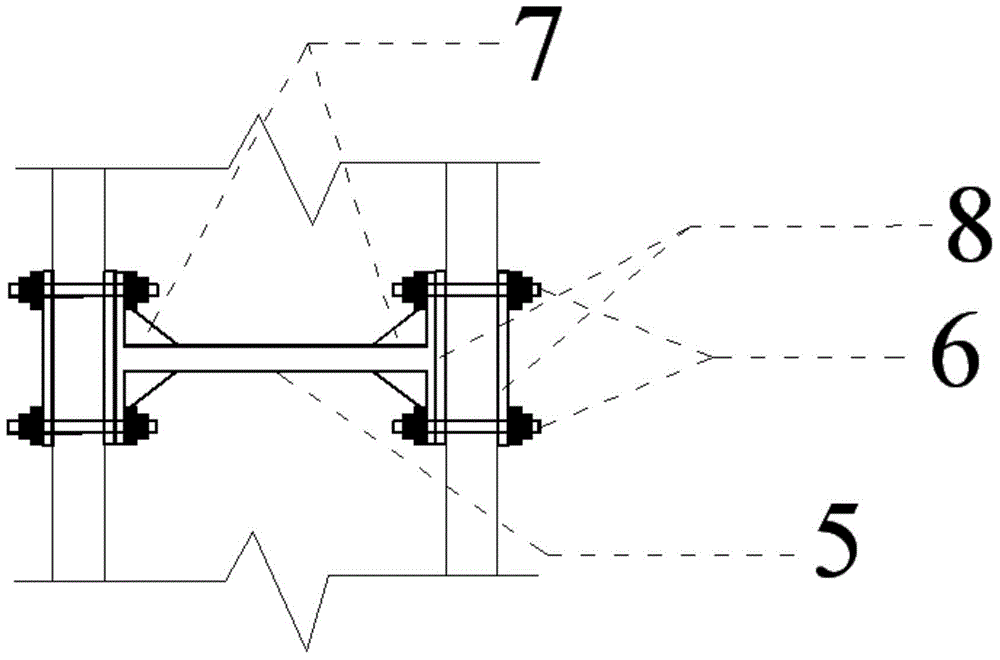

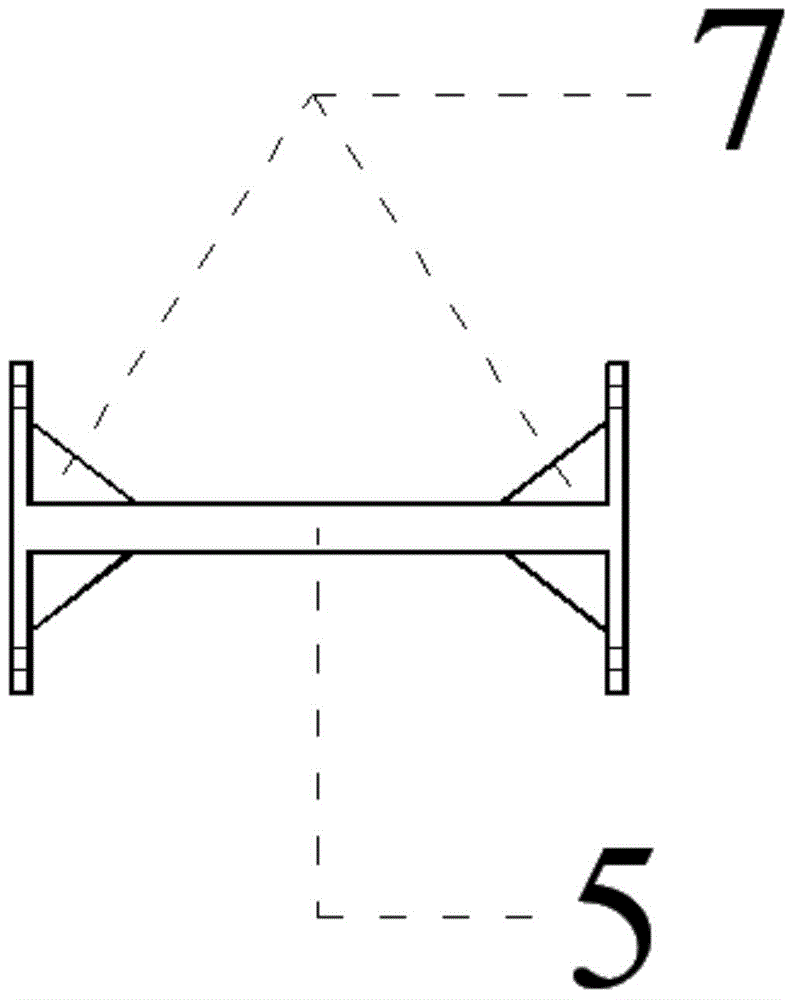

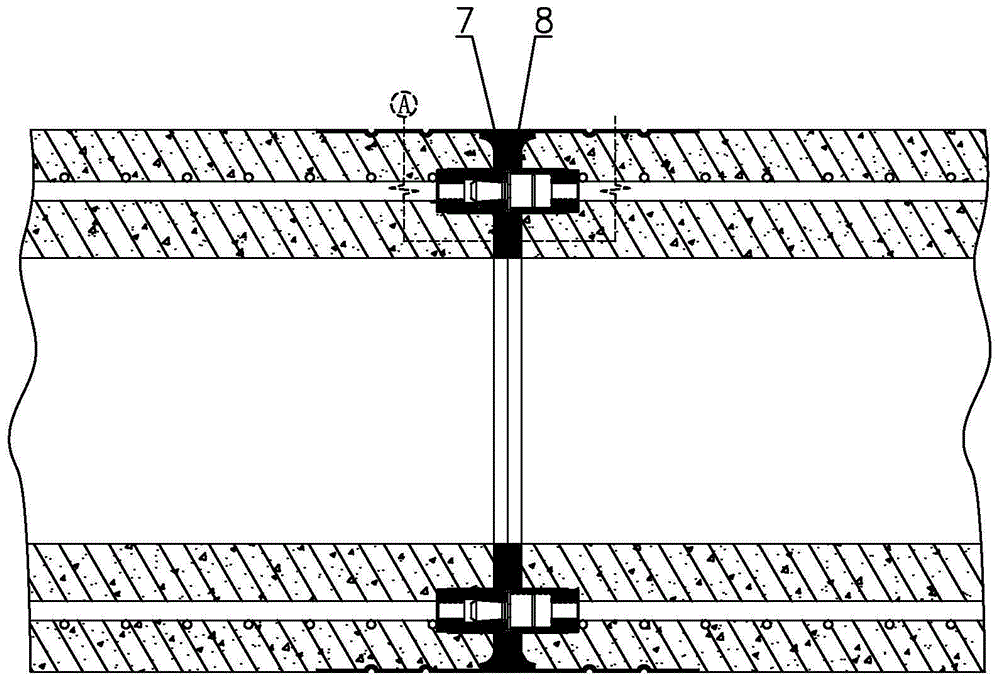

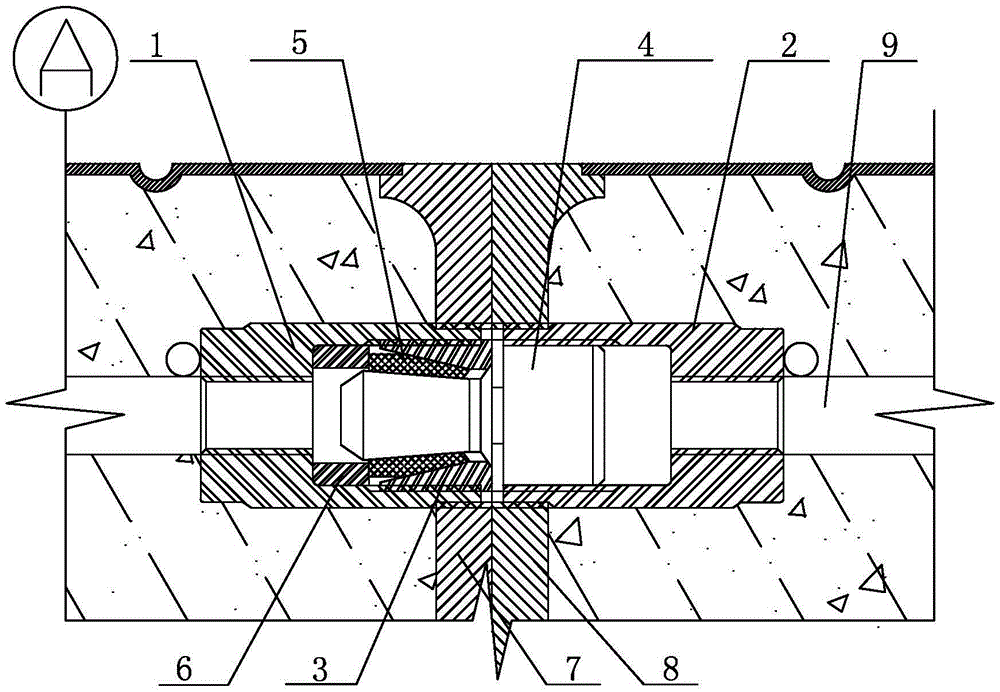

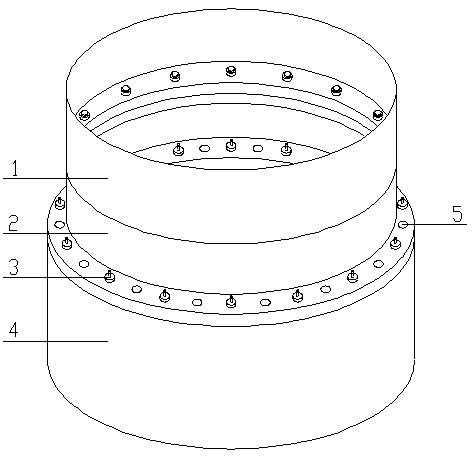

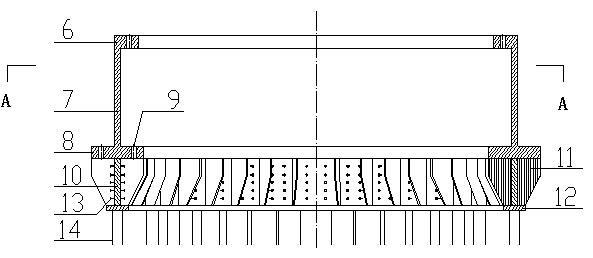

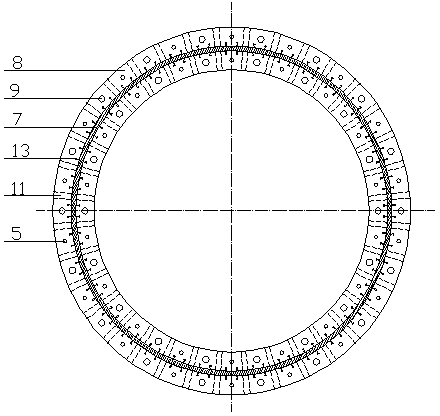

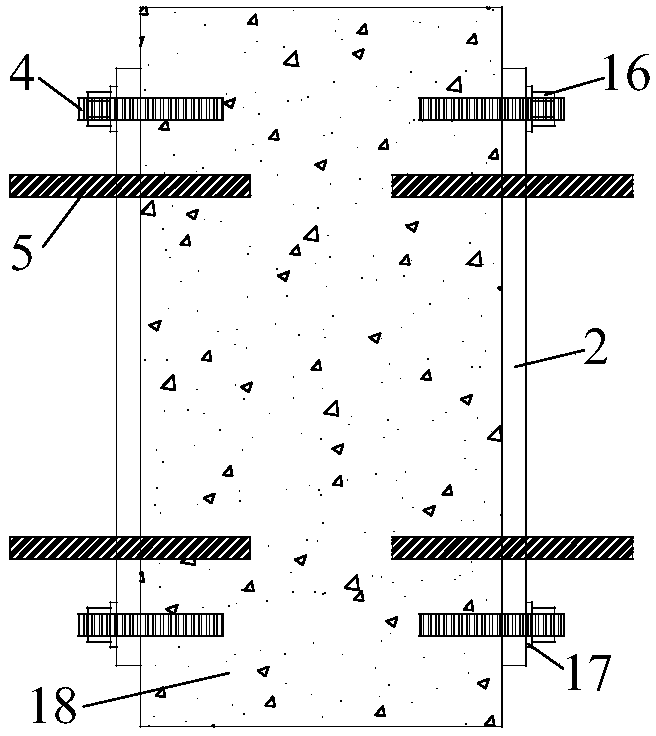

Anchored ribbed type connecting device for prestressed concrete and steel tower section of wind power combined tower

ActiveCN104005919AImprove securityIncreased durabilityWind energy generationWind motor componentsElectricityPre stress

The invention relates to an anchored ribbed type connecting device for prestressed concrete and a steel tower section of a wind power combined tower. The top end of an upper connecting steel cylinder section is connected with the upper steel tower section through a connecting mechanism. A lower connecting flange plate is installed between the upper connecting steel cylinder section and a lower connecting steel cylinder section. The upper connecting steel cylinder section and the lower connecting steel cylinder section are both located on a middle annular surface between the outer annular surface and the inner annular surface of the lower connecting flange plate. A horizontal annular plate is installed on the bottom surface of the lower connecting steel cylinder section. A prestress exerting component is further arranged in the lower connecting steel cylinder section and a lower concrete tower section. A plurality of radial stiffening plates are arranged on the inner side and the outer side of the lower connecting steel cylinder section. According to the an anchored ribbed type connecting device for prestressed concrete and the steel tower section of the wind power combined tower, due to the fact that prestress is exerted on the concrete, it is guaranteed that the concrete tower section is in the vertically pressed state, and the concrete is prevented from being cracked; in addition, due to the fact that the design of the connecting sections is improved, the connection performance between the connecting sections and the concrete is improved, and the width of cracks of the concrete tower section is effectively controlled.

Owner:HUNAN UNIV

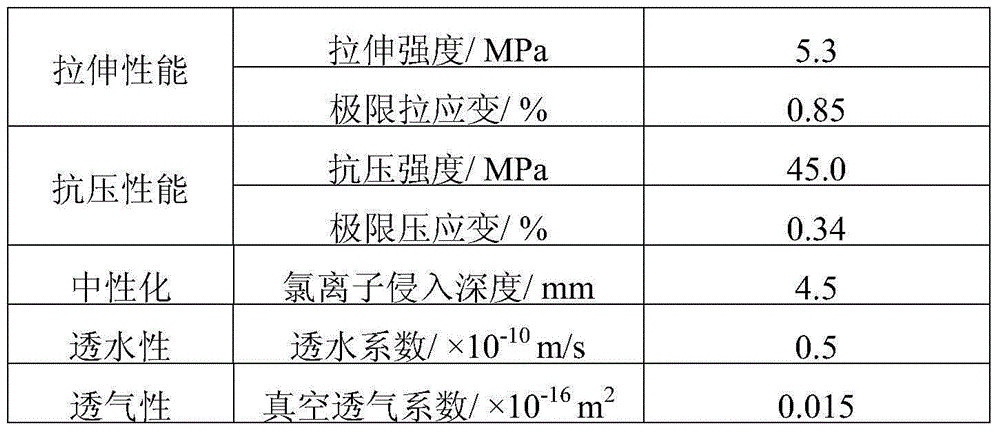

Fiber reinforced cement based composite material for reinforcing reinforced concrete structure

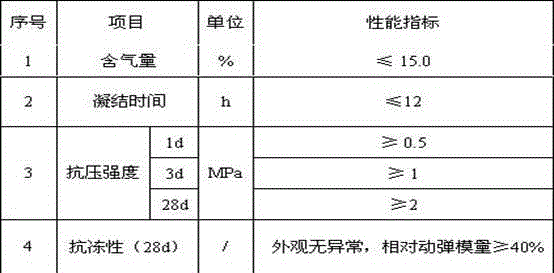

ActiveCN105060779AAchieve stacking densificationImprove corrosion resistanceSelf-healingMaterial Design

The invention relates to a high-performance fiber reinforced cement based composite material for reinforcing a cracked reinforced concrete structure under severe environments, and belongs to the technical field of building materials. The composite material is formed by mixing cement, silica powder, swelling agent, water reducing agent, fine sand, fiber and water, wherein the total mass percentage of cement, silica powder, swelling agent, water reducing agent, fine sand and fiber is 77.6% to 88.0%, and the mass percentage of water is 12.0% to 22.4%. The composite material designed by the invention has higher elasticity modulus, higher tensile strength and compression strength, higher self-healing capacity and low permeability. The material is reasonable in component design, simple in construction and maintenance and convenient for large-scale application.

Owner:NANJING FORESTRY UNIV

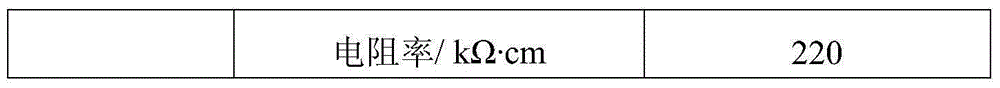

Anti-cracking protective mortar for roof waterproof layer

The invention discloses anti-cracking protective mortar for a roof waterproof layer, which solves the problems that the conventional roof waterproof layer is high in brittleness, easy to crack and poor in durability. The anti-cracking protective mortar consists cement, fly ash, silica fume, sand, polyvinyl alcohol (PVA) fiber and water, wherein in percentage by mass, the ratio of the cement, the fly ash, the silica fume, the sand to the water is 1: 0.9: 0.1: 0.76: 0.58; and based on the total volume after the cement, the fly ash, the silica fume, the sand and the water is mixed uniformly, the volume of the PVA fiber is 1.5 percent. The anti-cracking protective mortar has the characteristics of high strength, high ductility, durability and good anti-cracking performance, and can effectively prevent tearing of the waterproof layer due to temperature stress, improve and ensure the waterproof performance and the anti-penetrability performance of a roof, also improve the durability of the roof waterproof layer and prolong the service life of the roof waterproof layer.

Owner:西安五和新材料科技集团股份有限公司

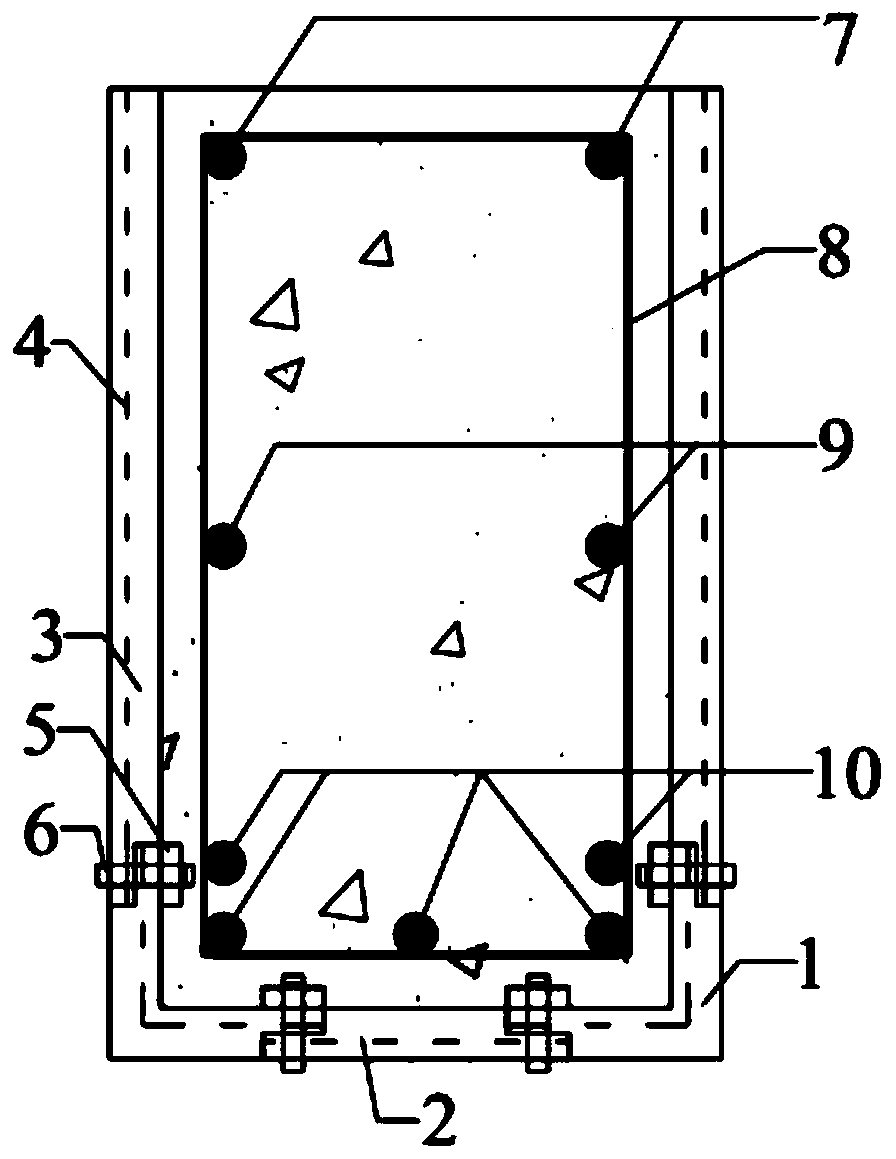

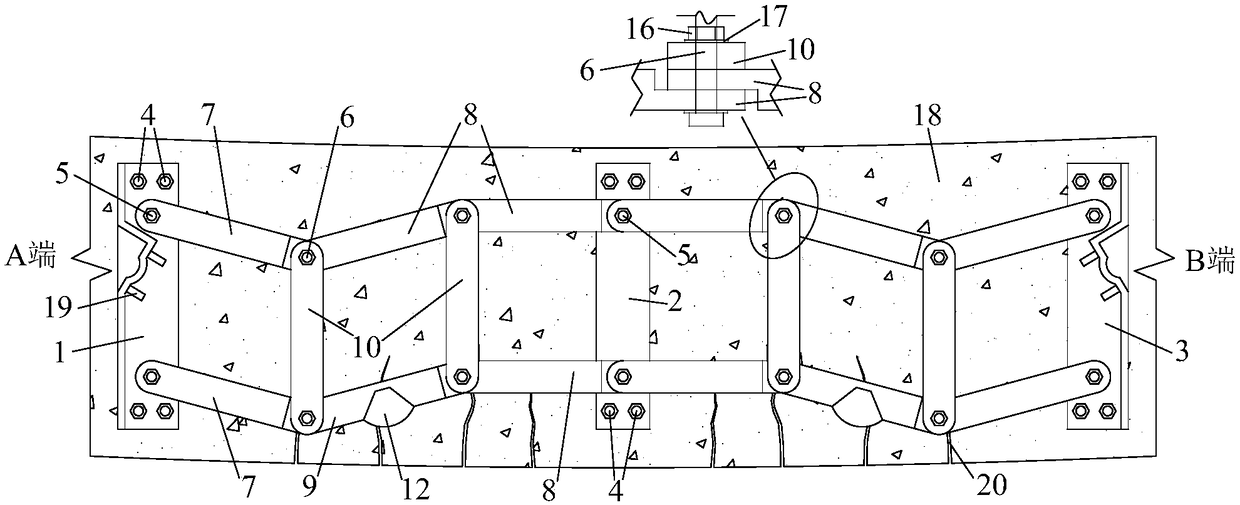

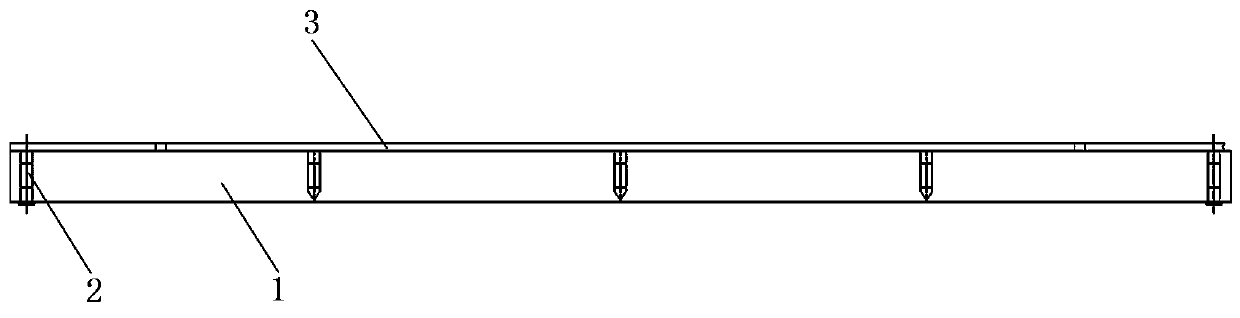

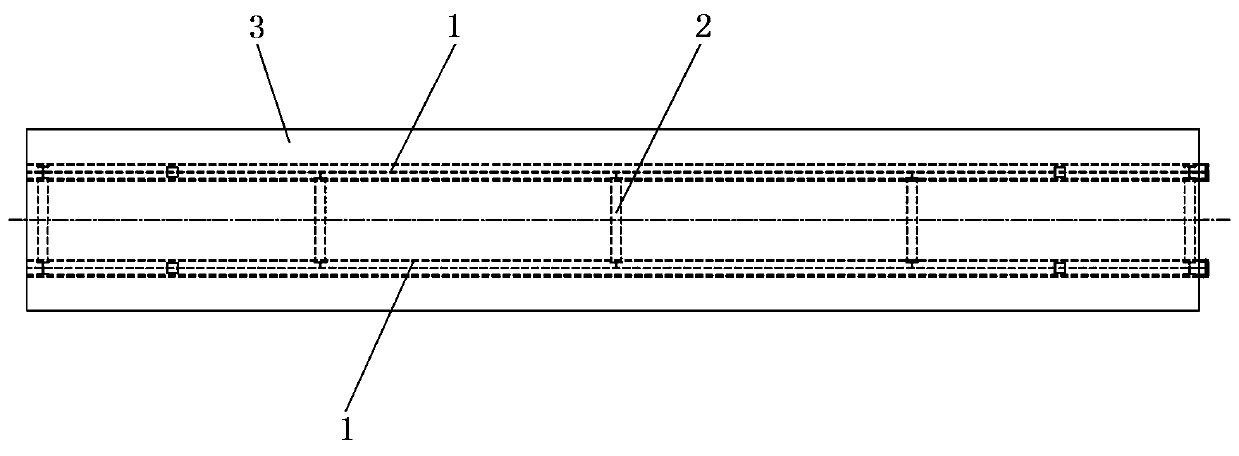

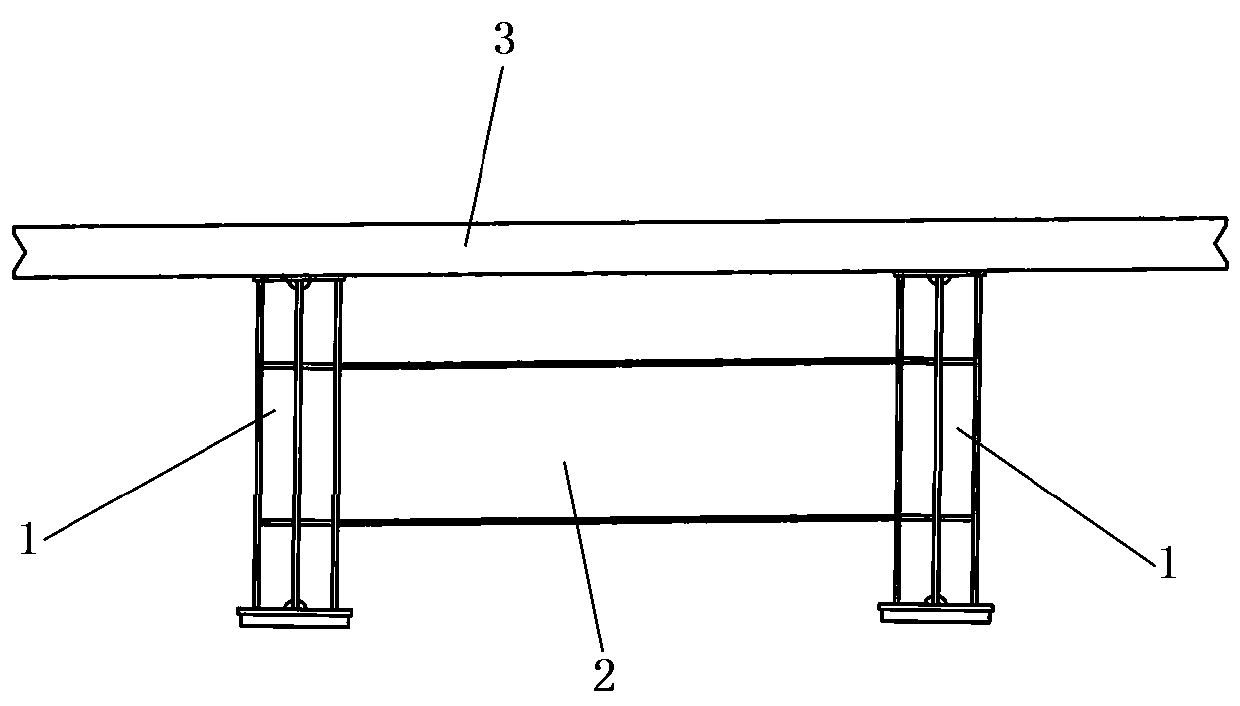

Assembled prestressed truss for reinforcement and construction method thereof

ActiveCN108193607AIncrease stiffnessEnhanced anchorage systemBuilding repairsBridge erection/assemblySteel platesBending moment

The invention discloses an assembled prestressed truss for reinforcement and a construction method thereof. The truss is composed of anchoring angle steel, an anchoring steel plate, a chord member, aweb member, prestressed tendons and anchors. The components of the truss are all prefabricated in a factory and assembled on site through bolts, and the prestressed tendons are anchored at both ends of a truss body. The truss body can be deformed in a prestressed tensioning process to ensure that a prestressing force is effectively applied to reinforced components to achieve the effects of reducing downward deflection and closing seams. After tensioning is completed, the truss body is fixed through inclined rods to enable the inclined rods to serve as force frameworks, the truss body bears bending moments and shear forces together with the components, the stiffness of the components is enhanced, meanwhile an anchoring system of the prestressed tendons is enhanced, and the effect of reducing the prestressing loss is achieved. The truss for reinforcement adopts an assembly concept, the construction is convenient, the traffic is not needed to be interrupted, large hoisting equipment is not needed, the construction period is short, and the advantages of two reinforcement methods of the truss and external prestressing are fully utilized. The truss has wide application in the field of concrete structure reinforcement.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

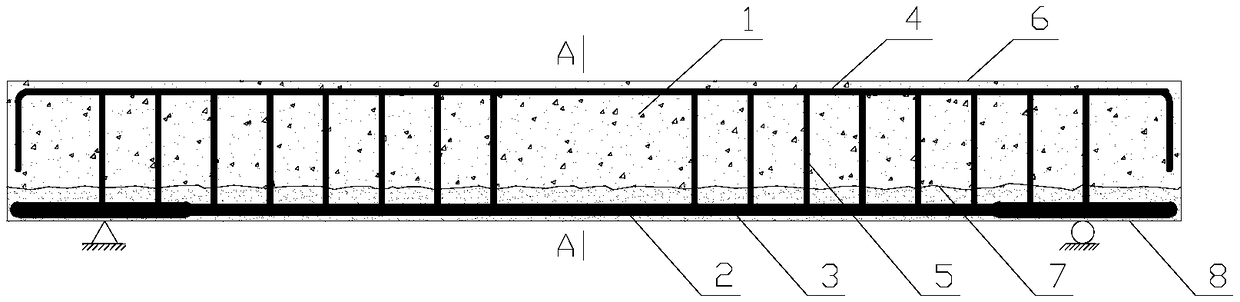

Anti-seismic prestressed precast beam

The invention relates to an anti-seismic prestressed precast beam. The anti-seismic prestressed precast beam comprises a beam body, a prestressed steel stranded wire which is buried in the beam body as a main bar, a stirrup and an additional bar, and is characterized in that the stirrup extends out of the upper surface of the beam body by a certain length, the part of the steel stranded wire is sheathed with a sleeve with a certain length at the end part of the beam body, the sleeve is buried in the end part of the beam body, the additional bar is buried in the lower part of the end part of the beam body, and the additional bar extends out of the end part of the beam body for the certain length. The U-shaped additional anti-cracking steel bar is buried at the end of the beam, and the steel bar has good anchoring performance in the beam and can effectively control the width of a crack at the root part of the beam; and simultaneously, the energy-consuming capability at the end of the beam is improved, so that the anti-seismic performance problem of the prestressed beam can be thoroughly solved.

Owner:杨众 +1

Reinforcing method and reinforcing structure of improvement of original construction floor structure

ActiveCN103161322AReduce the stress level of the original structureReduce deformationBuilding repairsRebarStress level

The invention discloses a reinforcing method and a reinforcing structure of an improvement of an original construction floor structure. Reverse arm beams are additionally arranged among original pillar net structures of an original building. Overhead layers are arranged between the reversed arm beams and the original construction floor structure. The reverse arm beams are connected with the original pillar net structures by planting rebars. And then non-adhesion prestress base plate construction is performed on the reverse arm beams. Loads of horizontal components of the original structure are transferred to the additionally arranged structures so as to reduce stress levels of the original structure and reduce deformation of the original structure. The width of a fracture is narrower and even zero. A complete load bearing structure system is formed by additionally arranged beam plates so as to effectively change use functions of the building. Pipes and lines are convenient to lay in the overhead layer so as to increase an effective use space. As reinforcement construction is performed on the floor of variated functions, daily use of the original building is not affected.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC

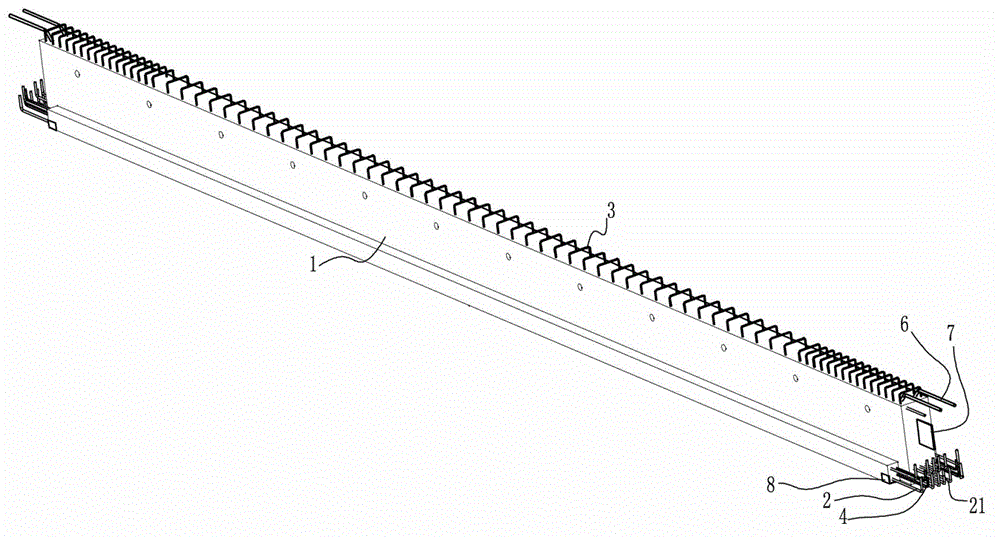

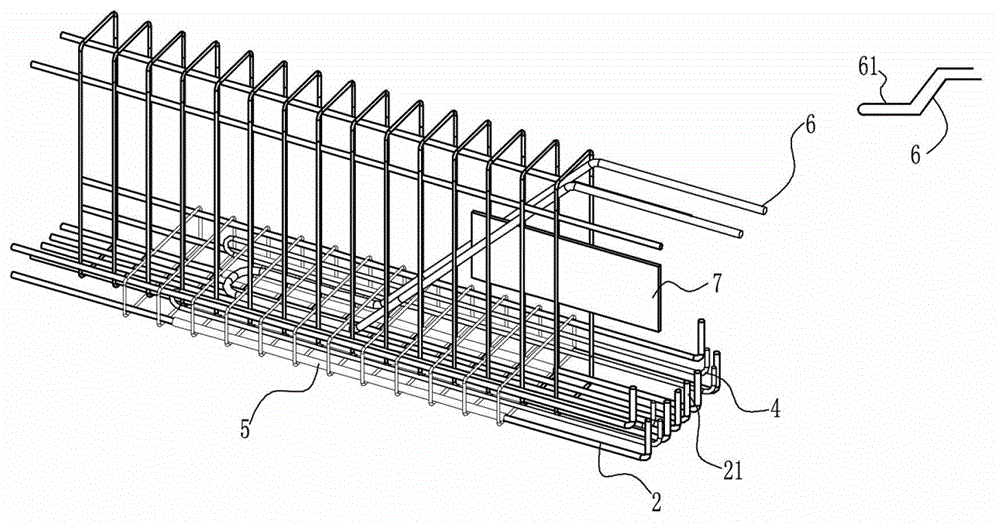

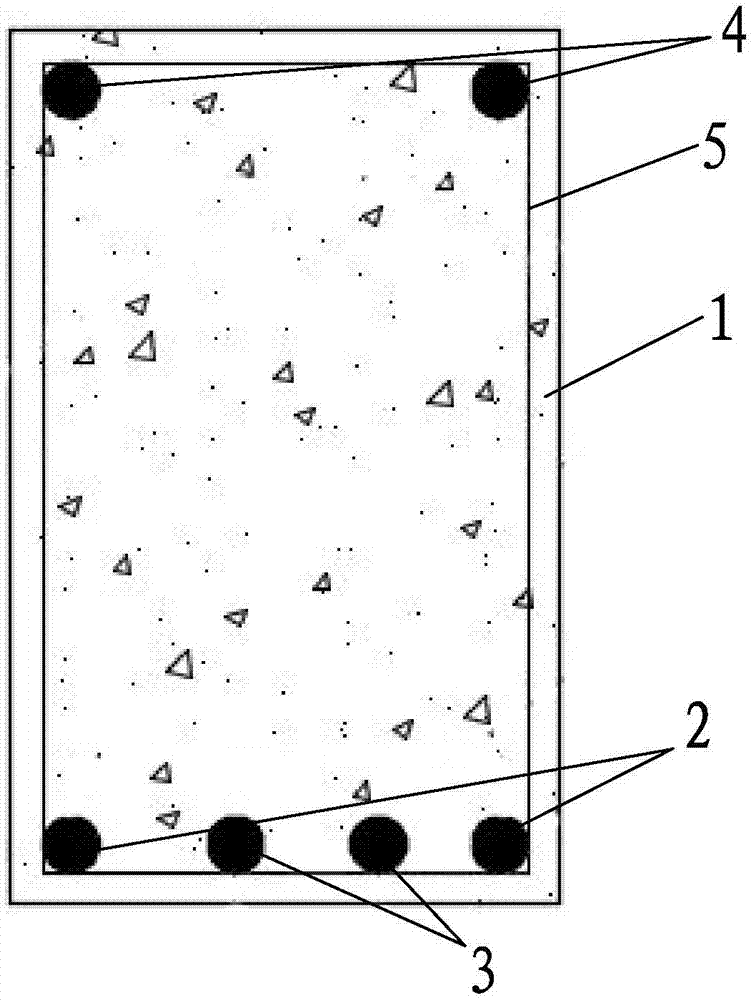

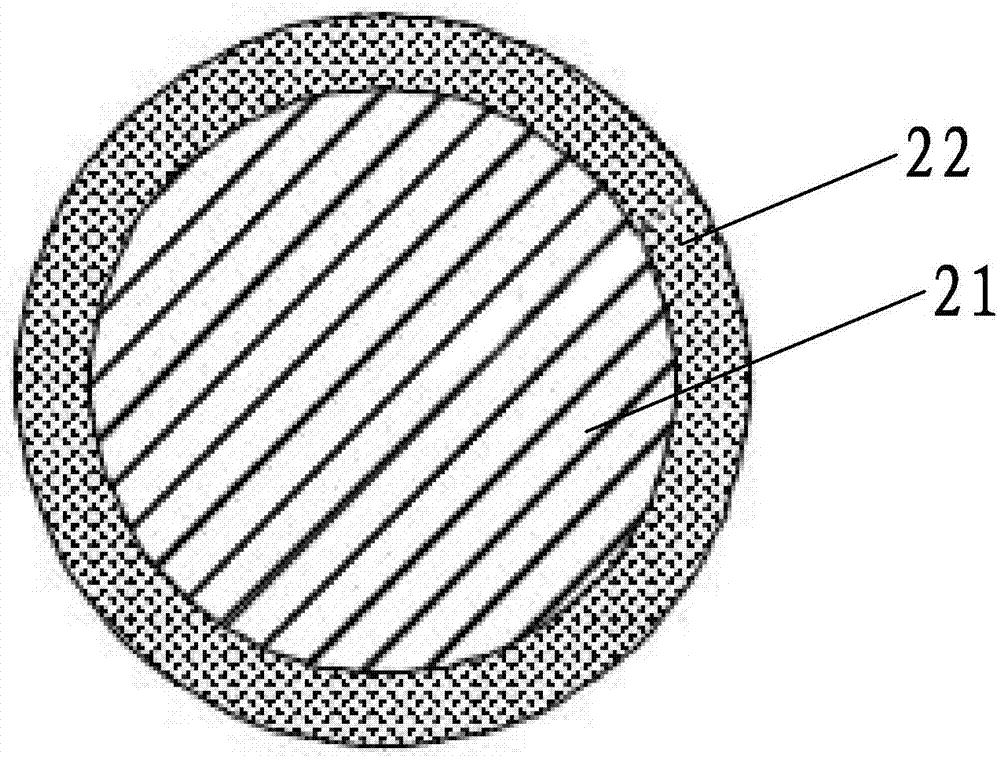

Sea sand concrete beam with mixed reinforcements of fiber reinforced plastics (FRP)-steel composite bars and FRP bars and construction method thereof

The invention discloses a sea sand concrete beam with mixed reinforcements of fiber reinforced plastics (FRP)-steel composite bars and FRP bars. The sea sand concrete beam comprises sea sand concrete, the FRP-steel composite bars, the FRP bars, erection bars and a plurality of stirrups, wherein the FRP-steel composite bars, the FRP bars, the erection bars and the stirrups are fixedly arranged in the sea sand concrete. The FRP-steel composite bars and the FRP bars are arranged at the lower end of the sea sand concrete, and the erection bars are arranged at the upper end of the sea sand concrete. The lengths of the FRP-steel composite bars and the FRP bars are arranged along the length of the sea sand concrete. The stirrups are evenly and fixedly connected to the outer surfaces of the FRP-steel composite bars, the FRP bars and the erection bars in a bound mode in the direction of the lengths of the FRP-steel composite bars and the erection bars. The FRP-steel composite bars comprise steel bars and FRP fiber cloth, wherein the outer surfaces of the steel bars are wrapped with the FRP fiber cloth. The FRP fiber cloth is bonded with the sea sand concrete. The invention further discloses a construction method of the sea sand concrete beam with the mixed reinforcements of the fiber reinforced plastics (FRP)-steel composite bars and the FRP bars. According to the sea sand concrete beam with the mixed reinforcements of the fiber reinforced plastics (FRP)-steel composite bars and the FRP bars and the construction method thereof, sea sand does not need to be subjected to desalting treatment, the strength is high, and the bearing property is good.

Owner:GUANGDONG UNIV OF TECH

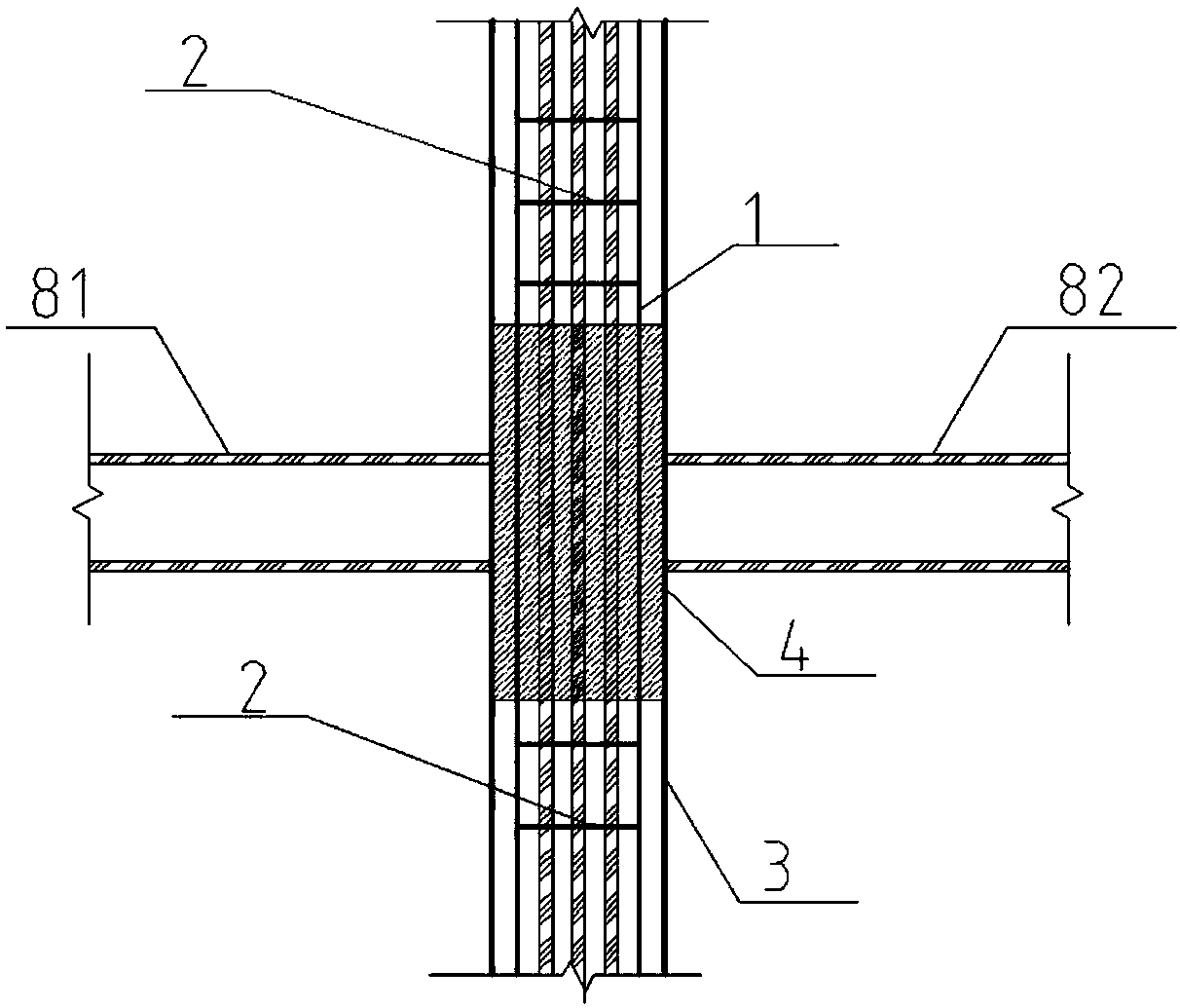

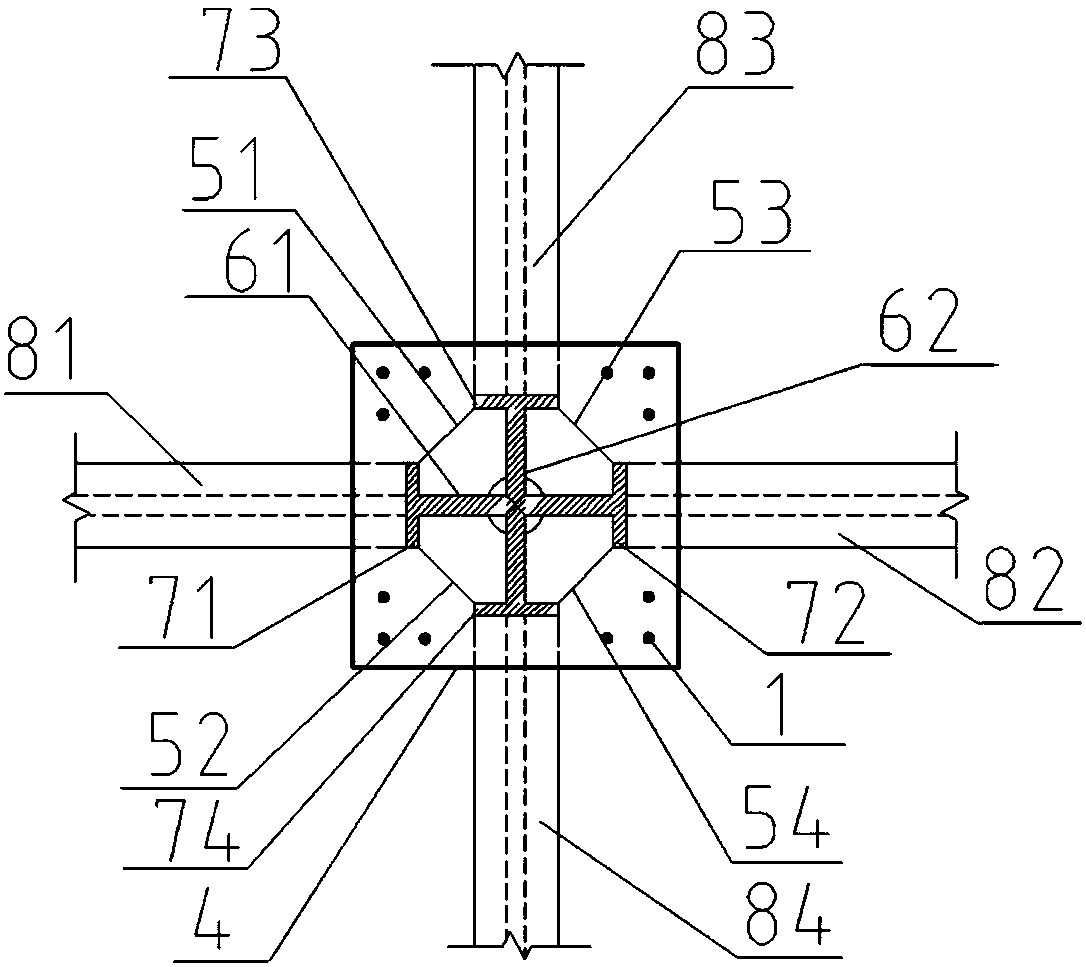

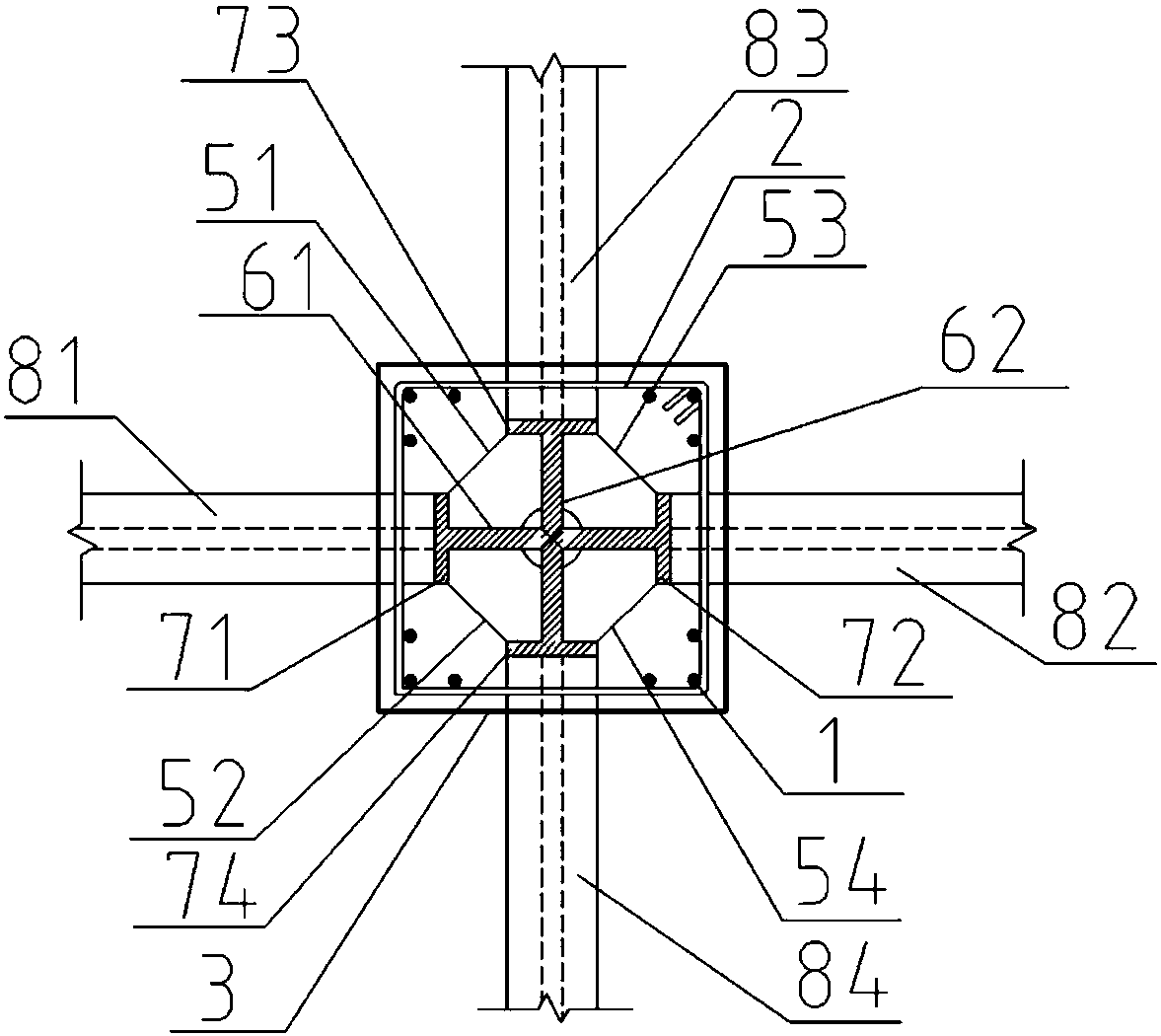

Steel reinforced concrete column-steel beam joint locally adopting fiber reinforced concrete

PendingCN107842107AAvoid brittle failureIncreased shear capacityProtective buildings/sheltersShock proofingReinforced concrete columnMetallurgy

The invention discloses a steel reinforced concrete column-steel beam joint locally adopting fiber reinforced concrete. The steel reinforced concrete column-steel beam joint comprises core profile steel, the fiber reinforced concrete, a first steel beam, a second steel beam, a third steel beam and a fourth steel beam; the core profile steel comprises a first profile steel web and a second profilesteel web which are welded to form cross-shaped profile steel, the two ends of the first profile steel web are correspondingly provided with a first profile steel flange and a second profile steel flange, and the two ends of the second profile steel web are correspondingly provided with a third profile steel flange and a fourth profile steel flange; and the first profile steel flange, the second profile steel flange, the third profile steel flange and the fourth profile steel flange are correspondingly connected with the first steel beam, the second steel beam, the third steel beam and the fourth steel beam. The steel reinforced concrete column-steel beam joint locally adopting the fiber reinforced concrete has the characteristics that the fiber reinforced concrete is adopted at a joint core zone, the using amount of stirrups in the core zone can be reduced or even eliminated, the shear resistance capacity of the joint, the rotating capability of the joint and the energy dissipation capability can be remarkably improved, and meanwhile, construction complexity is reduced.

Owner:CHANGAN UNIV

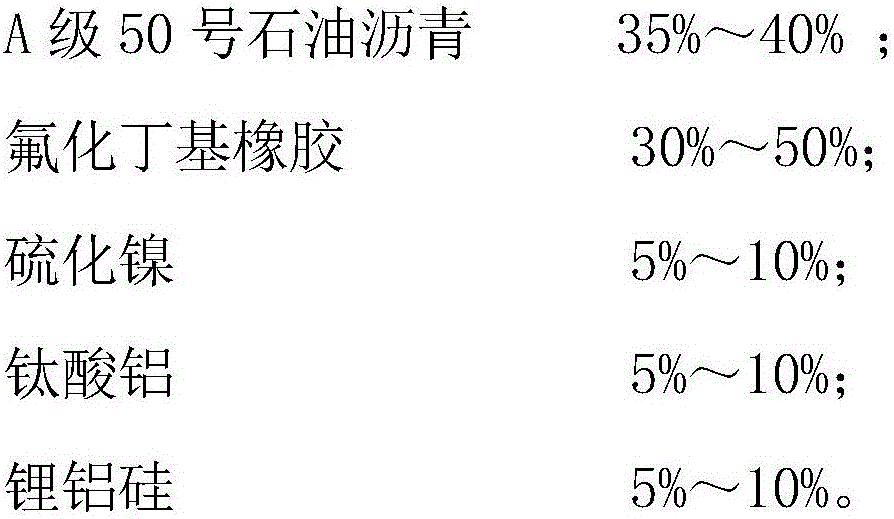

Heat-contraction and cold-expansion pavement crack repairing agent and production process thereof

The invention relates to a heat-contraction and cold-expansion pavement crack repairing agent and a production process thereof. The pavement crack repairing agent is prepared from 35 percent to 40 percent of A-grade No. 50 petroleum asphalt, 30 percent to 50 percent of butyl rubber fluoride, 5 percent to 10 percent of nickel sulfide, 5 percent to 10 percent of aluminium titanate and 5 percent to 10 percent of lithium aluminum silicate. The pavement crack repairing agent provided by the invention can be contracted by heat and expanded by cold along with the change of air temperature, and the expansion rate and the contraction rate are respectively 30 percent or above, so that the pavement crack repairing agent can meet the requirement on heat-expansion and cold-contraction of a road. The pavement crack repairing agent provided by the invention is high in stickiness, firm to bond, and long in service life, the manufacturing process of the pavement crack repairing agent provided by the invention is simple, and the pavement crack repairing agent is suitable to be volume-produced.

Owner:HEBEI ROAD & BRIDGE GROUP

Quickly-installed steel-concrete combined beam bridge and construction method thereof

PendingCN110863417ASimplify construction stepsThe connection quality is stable and controllableBridge structural detailsBridge materialsArchitectural engineeringBridge deck

The invention discloses a quickly-installed steel-concrete combined beam bridge and a construction method thereof. The steel-concrete combined beam bridge comprises steel-concrete combined beams, andannular lap-joint steel bars are arranged on the four edges of each concrete bridge deck; and cut-through steel bars penetrate into the annular lap-joint steel bars between every two adjacent concretebridge decks, longitudinal and transverse wet joints are poured with high-performance concrete, and bottom plates of the longitudinal adjacent steel beams are connected through splicing steel platesand high-strength bolts. The construction method mainly comprises the steps that the steel-concrete combined beams are prefabricated and hoisted in places; and the cut-through steel bars penetrate into the annular lap-joint steel bars of the transverse and longitudinal adjacent concrete bridge decks, the transverse and longitudinal wet joints are poured with the high-performance concrete, and thebottom plates of the longitudinal adjacent steel beams are connected through the splicing steel plates and the high-strength bolts. The quickly-installed steel-concrete combined beam bridge and the construction method thereof have the advantages that industrialized production is achieved, and the beam quality is reliable; traditional time-consuming and labor-consuming steel bar welding connectionfor the longitudinal and transverse joints among the concrete bridge decks is abandoned; and construction is convenient and fast, and little influence is generated on existing traffic.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

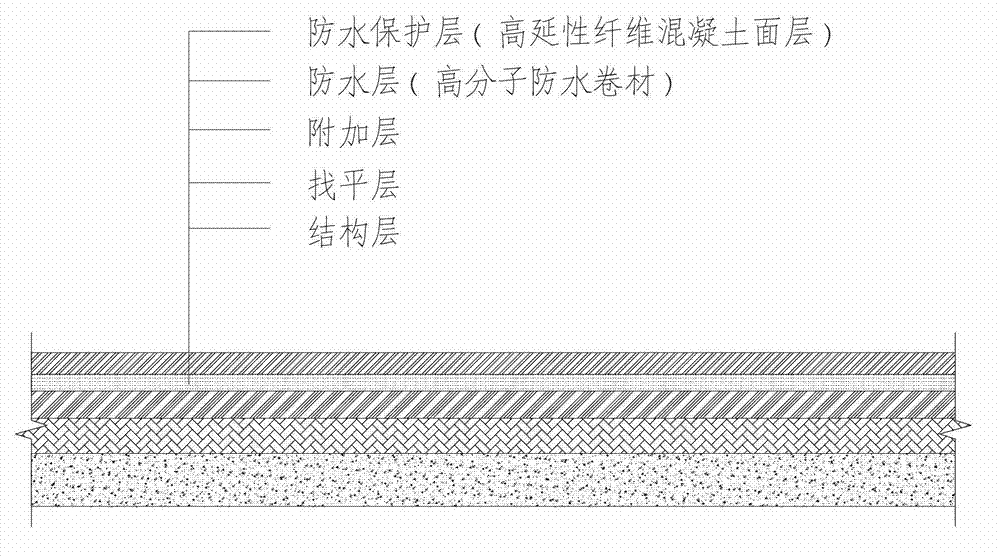

FRP rib seawater sea sand-ultra high ductile cementitious composites (UHDCC) composite beam and construction method thereof

InactiveCN108824696AImprove bending resistanceImprove distributionGirdersJoistsConcrete beamsCementitious composite

The invention relates to an FRP rib seawater sea sand-ultra high ductile cementitious composites ( UHDCC) composite beam and a construction method thereof. The composite beam comprises a beam body anda FRP rib skeleton arranged in the beam body, wherein the FRP rib skeleton comprises FRP tensile longitudinal ribs, FRP erecting ribs and FRP stirrups, and the FRP tensile longitudinal ribs and the FRP erecting ribs are distributed in the direction of the beam body. The FRP stirrups are disposed between the FRP tensile longitudinal ribs and the FRP erecting ribs and connected with the FRP tensilelongitudinal ribs and the FRP erecting ribs. The beam body comprises a seawater sea sand concrete layer made of seawater sea sand concrete and a composite material layer made of ultra-high ductile cementitious composites, and the FRP tensile longitudinal ribs are located in the composite material layer. Compared with the prior art, the bottom of a seawater sea sand concrete beam is replaced by the composite material layer made of the ultra-high ductile cementitious composites, the bending resistance of the FRP rib seawater sea sand beam and the distribution form of cracks in the beam can be improved, and the crack width is reduced.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com