Assembled prestressed truss for reinforcement and construction method thereof

A prestressed, prefabricated technology, applied in bridge reinforcement, erection/assembly of bridges, building maintenance, etc., can solve the problems of long interruption of traffic during construction period, complicated construction process, and increase of structural self-weight, etc., to achieve short construction period, The effect of clear force and reduction of prestress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

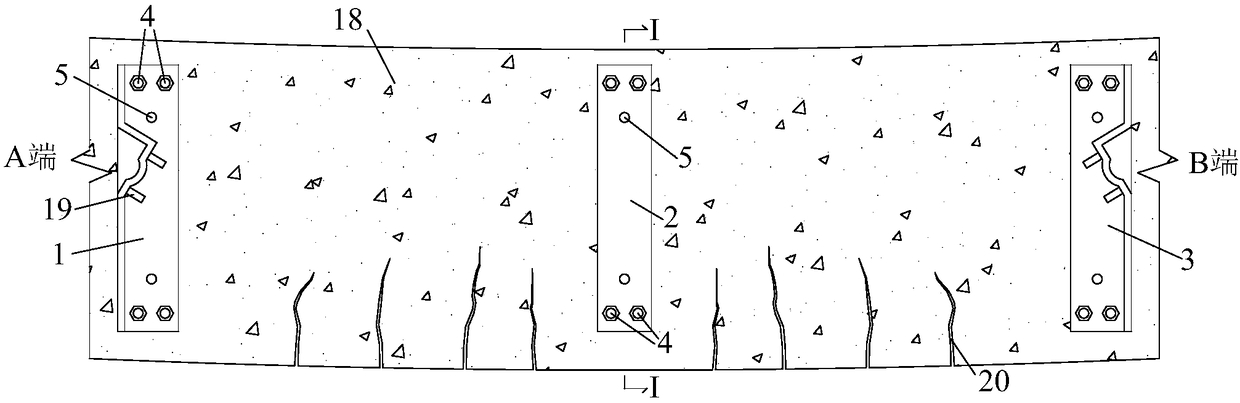

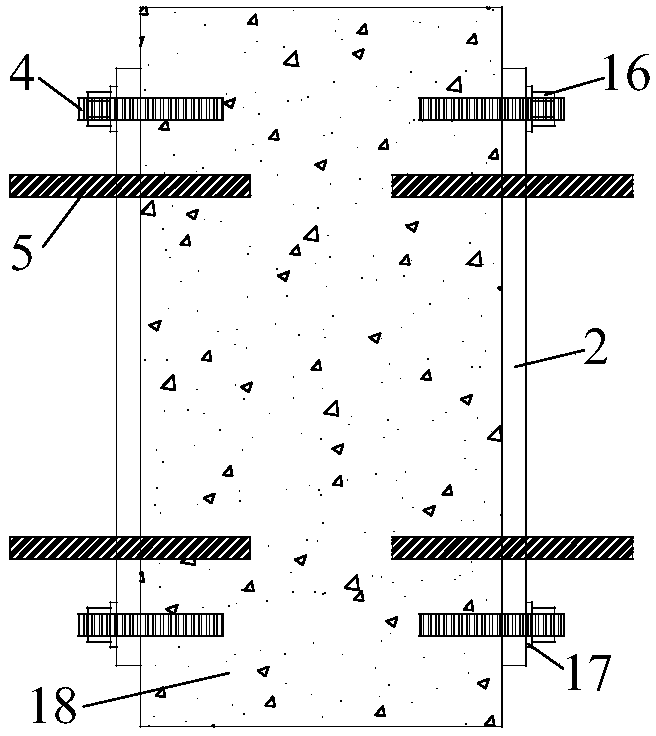

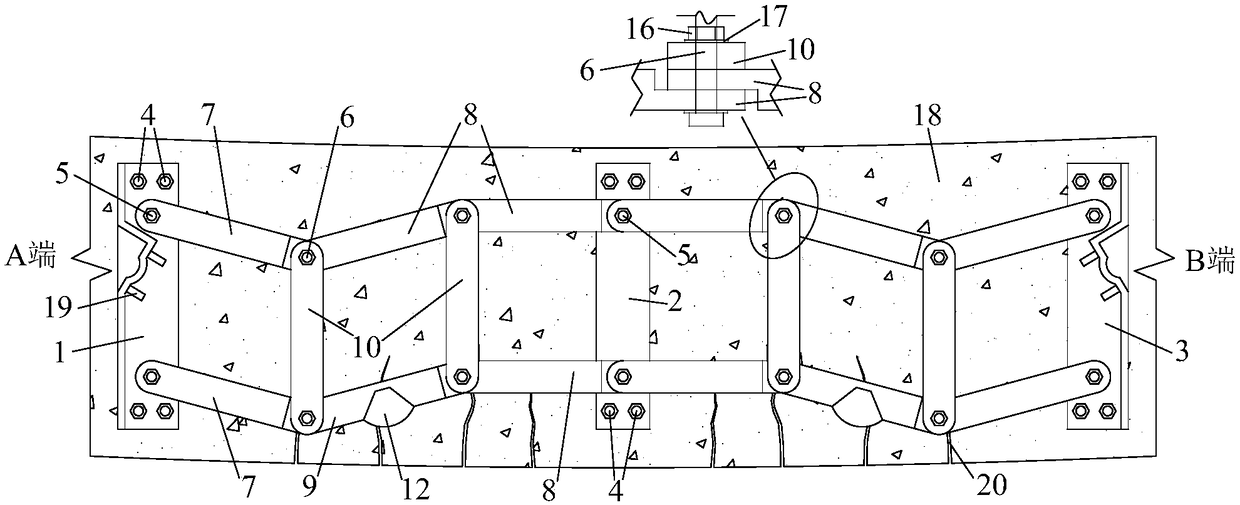

[0036] see Figure 1 to Figure 7 , This embodiment includes anchoring steel plates, A-end anchoring angle steel, B-end anchoring angle steel, upper chord, lower chord, web, anchorage and prestressed tendon. The anchor steel plate is fixed on the concrete member, and the anchor angle steel at the A end and the anchor angle steel at the B end are fixed on the concrete member symmetrically with the anchor steel plate as a symmetrical axis. The A-end anchor angle steel and the B-end anchor angle steel both include a bottom steel plate and a vertical steel plate. The A-end anchor angle steel and the B-end anchor angle steel used in this embodiment are symmetrical structures for the convenience of processing. In actual use, only It is necessary to ensure that the structure of the bottom steel plate and the vertical steel plate is used. One side of the bottom steel plate is in contact with the concrete member, and the vertical steel plate is vertically arranged on the surface of the...

Embodiment 2

[0053] see Figure 8 , the two ends of each slanting rod in this embodiment are also connected to the joints of the adjacent connecting rods in the upper chord and the lower chord, but the difference from Embodiment 1 is that each slanting rod in this embodiment is not They are connected end to end, but are arranged in parallel on both sides of the anchoring steel plate, and the two oblique rods connected to the anchoring steel plate share a joint. Other structures of this embodiment are the same as those of Embodiment 1.

[0054] The setting of the above slanting rods is only an example adopted in this embodiment. In actual use, as long as the two ends of each slanting rod are also connected to the joints of the adjacent connecting rods in the upper chord and the lower chord, the principle can be Correspondingly make the deformation of various arrangements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com