Patents

Literature

175results about How to "Small loss of prestress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent FRP (Fiber Reinforce Plastic)-concrete composite structure and manufacturing method thereof

The invention discloses an intelligent FRP (Fiber Reinforce Plastic)-concrete composite structure and a manufacturing method of the intelligent FRP-concrete composite structure. The intelligent composite structure comprises an intelligent FRP layer, a reinforced concrete core and an anchoring device, wherein the intelligent FRP layer is formed by carbon fibers or carbon fiber mixed with other fibers and impregnated by resin, and in the composite structure, the intelligent FRP layer both serves as structural material and plays a sensing function. The intelligent FRP layer is wrapped on the stressed side of the reinforced concrete core, certain prestress is applied on the intelligent FRP layer to better play the high strength property of the FRP, and the intelligent FRP layer is connected with the reinforced concrete core through resin adhesion and mechanical connection of anchorage device. The intelligent FRP-concrete composite structure not only has high carrying capacity, self sensing function, excellent corrosion resistance and high durability, but also has strong designability of performance and structure.

Owner:SOUTHEAST UNIV

Construction method of prestressing force stretching high strength composite material and anchoring

A prestress stretch and anchor method for high intensity compound material belongs to the construction of compound material reinforcement or civil engineering structure strengthening especially relates to the technical field of high intensity compound material prestress stretch and anchor to be the simple technology, convenient operation, high reliability, good engineering result, strong adaptability to the engineering structure with light weight, small size, rigid, strong carriage, strong ability of crossover, and widely used in bridge, large crossover industrial workhouses, sheds, docks, underground railways and part mechanical industries such as large scale hoist and transport equipments, ships and lorries.

Owner:重庆达力索缆科技有限公司

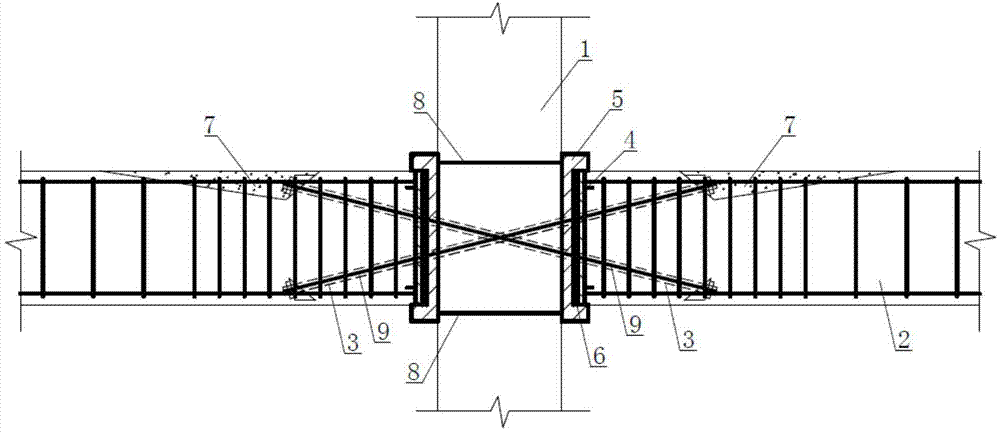

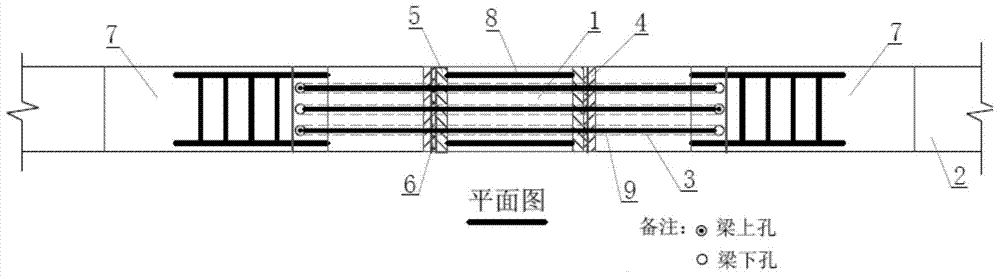

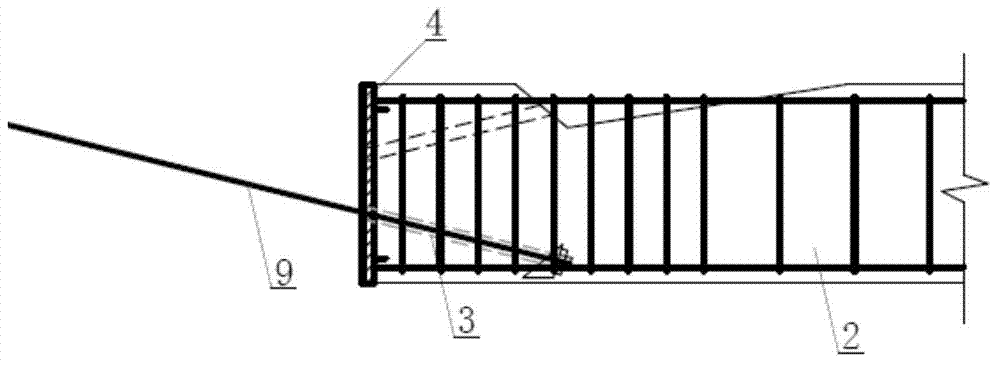

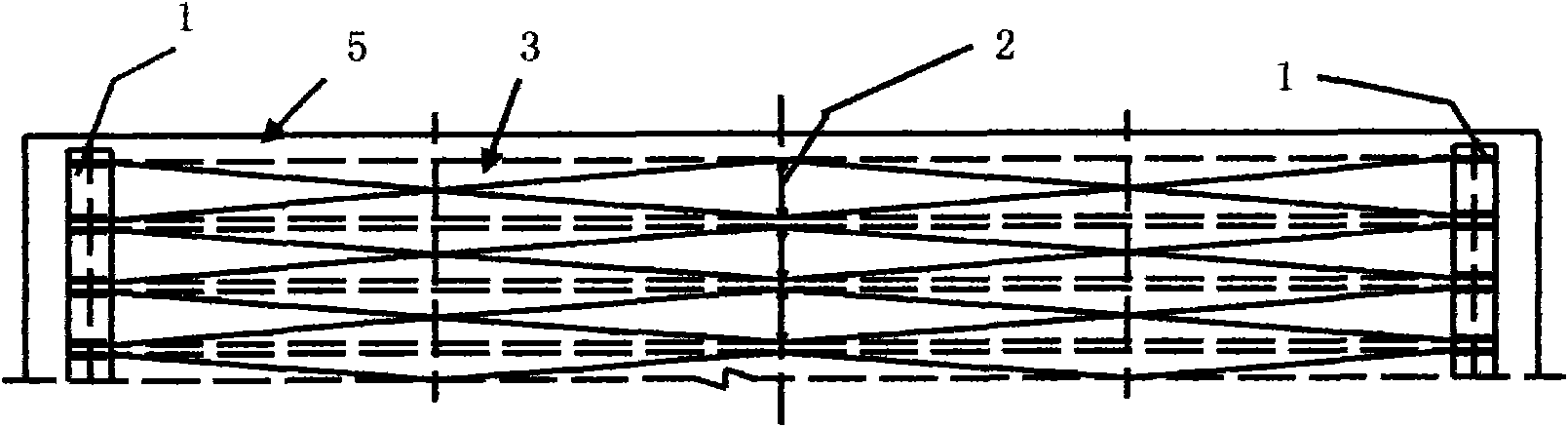

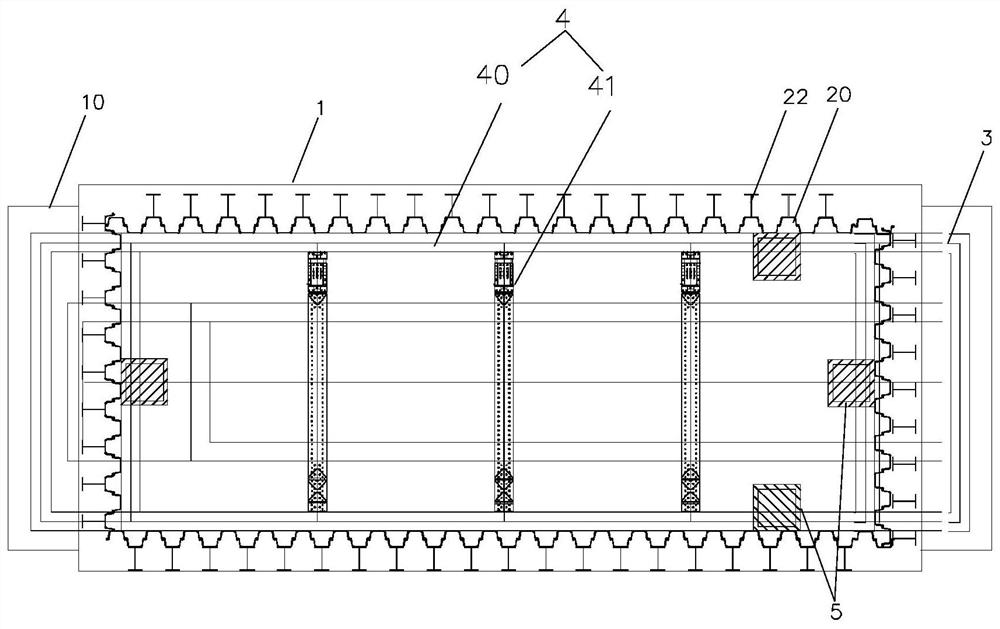

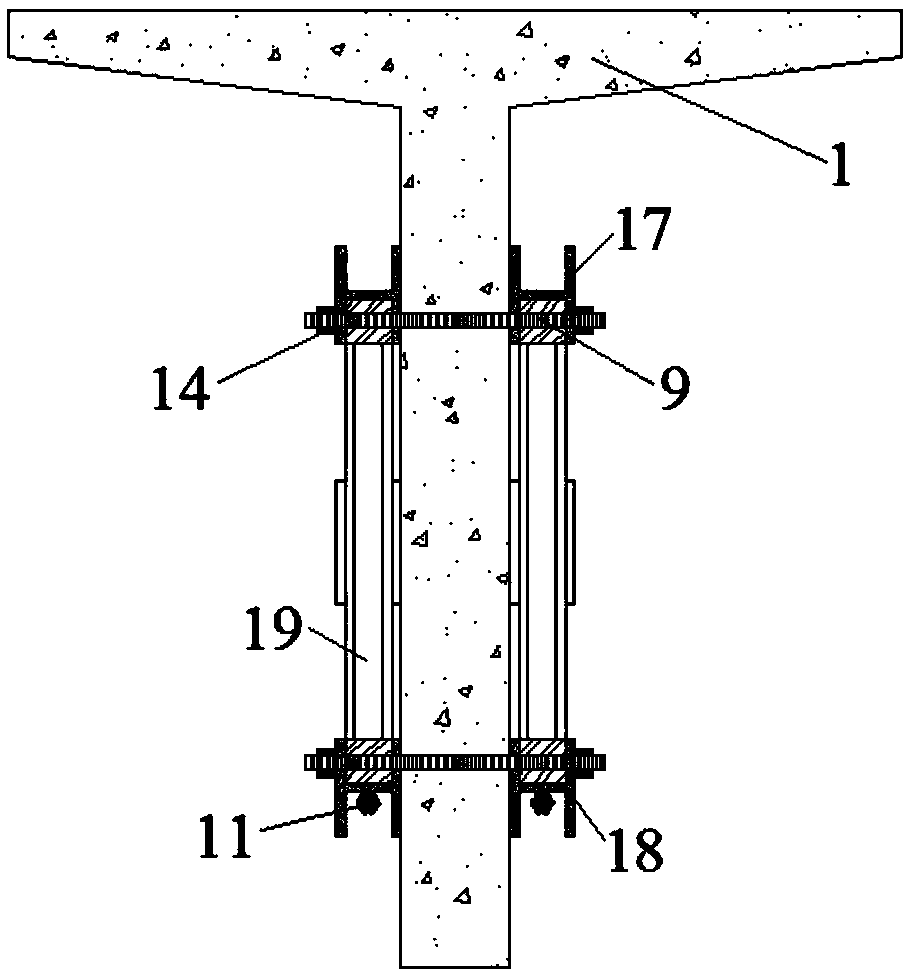

Prestress assembled concrete beam column joint structure and construction method thereof

InactiveCN104727441AArrangement length is shortSmall loss of prestressBuilding constructionsPre stressConcrete beams

The invention relates to a prestress assembled concrete beam column joint structure and a construction method thereof. The prestress assembled concrete beam column joint structure comprises a prefabricated column and a prefabricated beam. The prefabricated beam and the prefabricated column are in prepressing connection through the prestress formed by tensioning prestressed reinforced steel bars. The bottom of the beam end on one side of a joint is connected with the top of the beam end on the other side of the joint through the prestressed reinforced steel bars, and the prestressed reinforced steel bars are symmetrically crossed on a vertical face. When the prefabricated beam is manufactured, the prestressed reinforced steel bars and anchoring parts of the prestressed reinforced steel bars are pre-buried at the bottom of the beam end, prestressed reinforced steel bar pore channels and an anchoring area are reserved in the top of the beam end, and open type stirrups are adopted in the anchoring area. A force transmission steel plate is arranged on the cross section part of the beam end by the way that the cross section part of the beam end is welded with longitudinal bars. Slant prestressed reinforced steel bar pore channels are reserved in a prefabricated column joint area, groove-shaped steel plates are pre-buried on the two sides of the joint of the column, and high damping rubber layers are attached to the insides of the groove-shaped steel plates. In the connecting process, the beam is clamped into channel steel, and the prestressed reinforced steel bars penetrate through a joint core area to the top of the beam end on the other side of the joint and are anchored after being tensioned to be at the designed stress. According to the prestress assembled concrete beam column joint structure and the construction method thereof, assembling construction is convenient, and high shear-bearing capacity, energy-dissipating capacity and self-resetting capacity of the connecting joint can be achieved.

Owner:WUHAN UNIV OF TECH

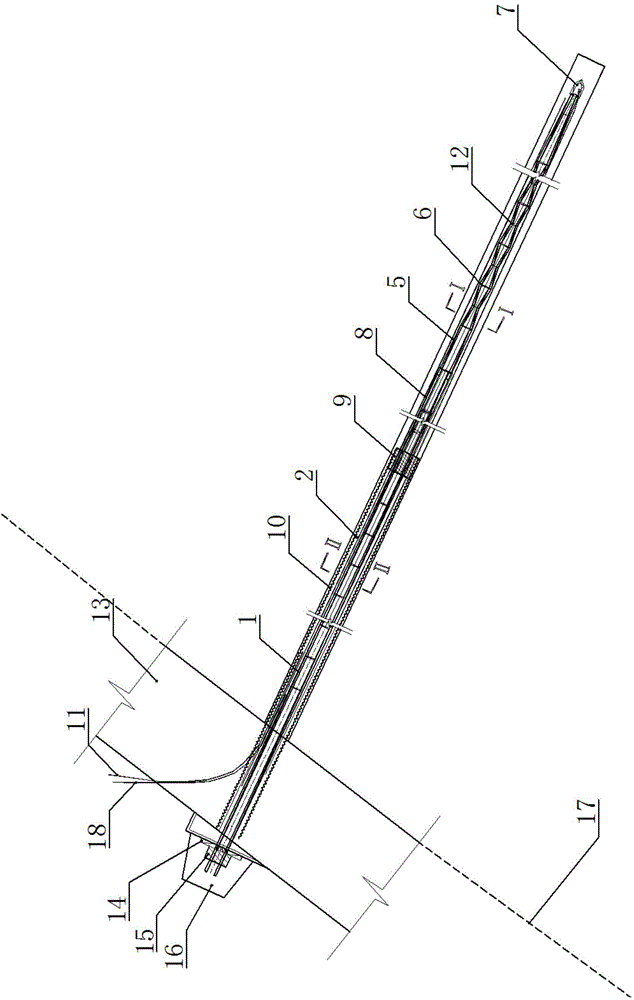

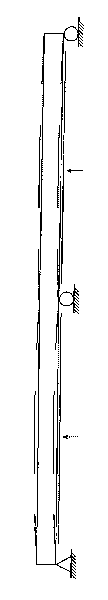

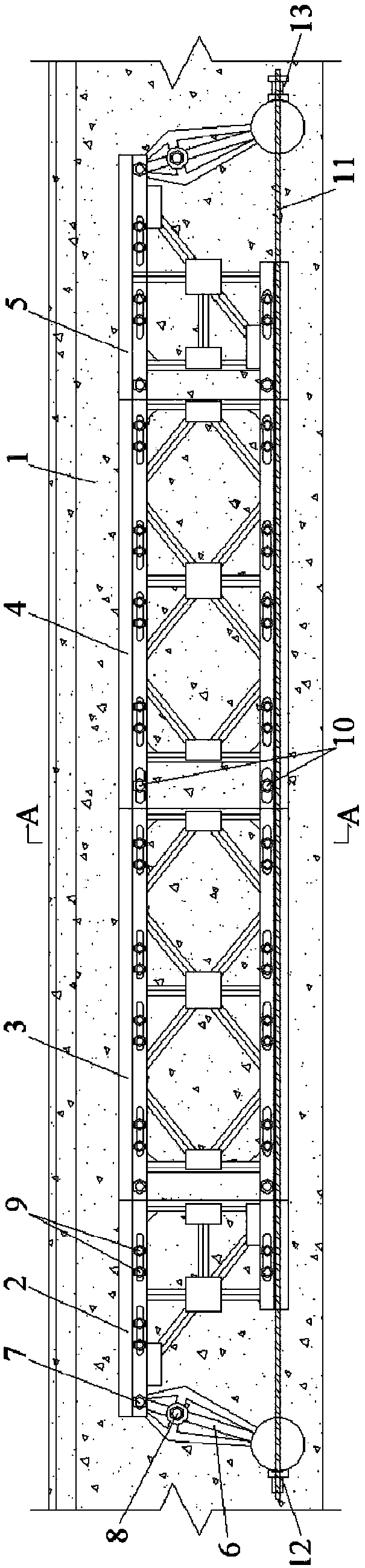

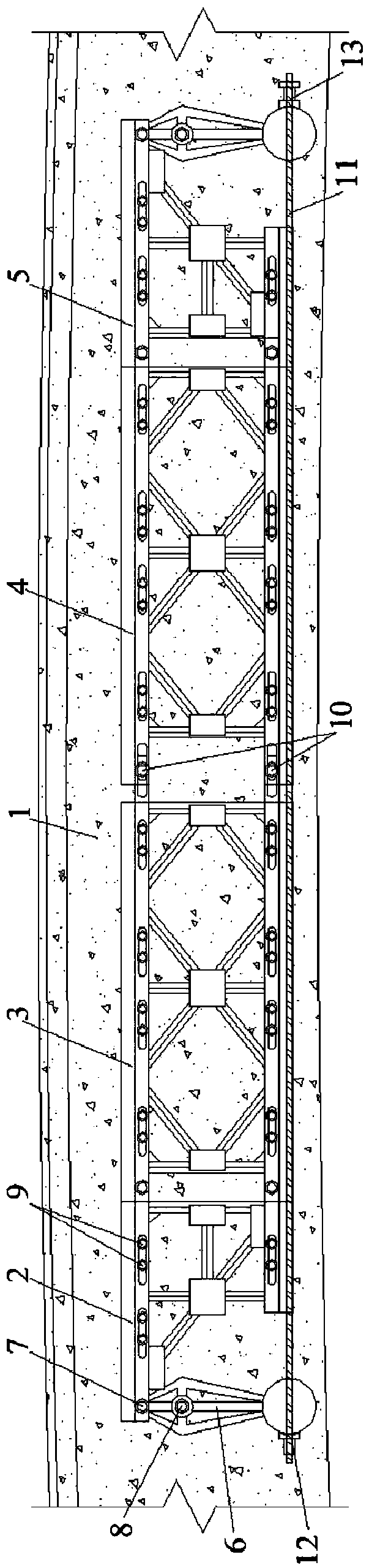

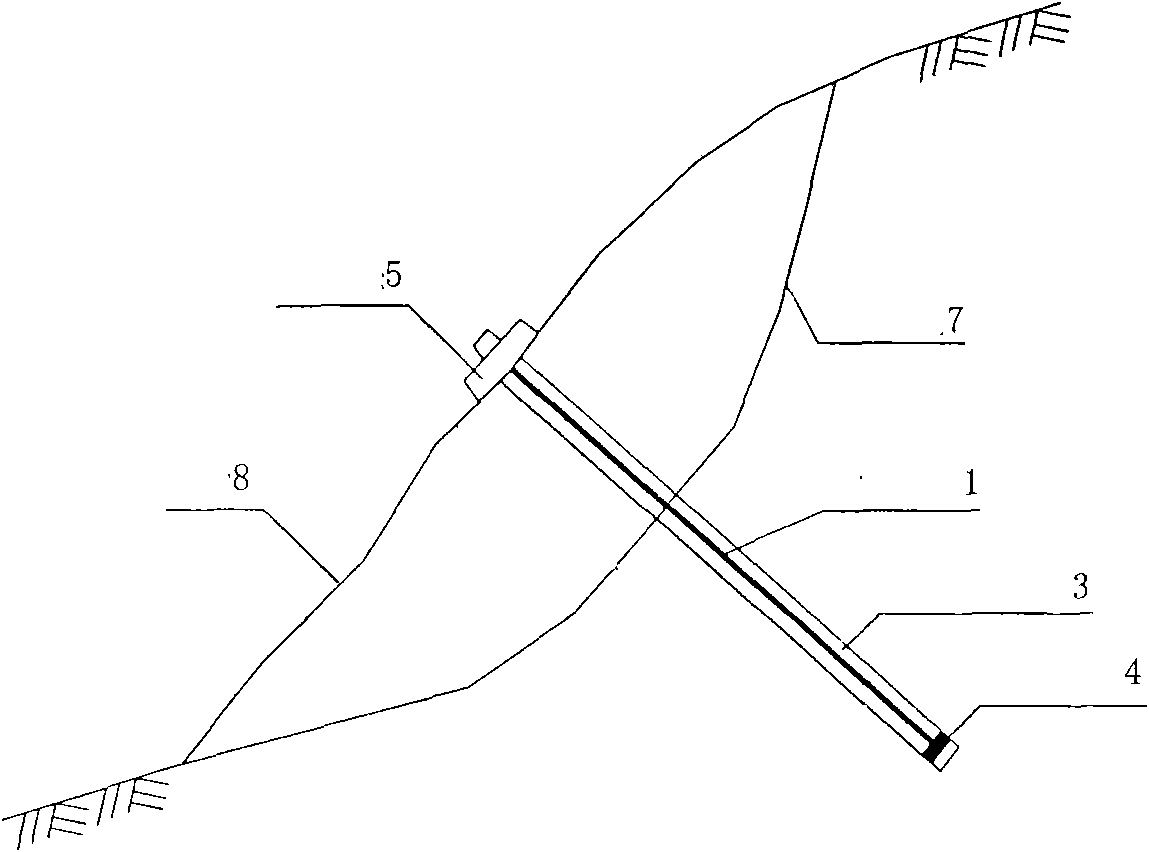

Double-anchoring-section prestress anchor cable structure and constructing method thereof

ActiveCN104790393AThe reverse self-locking function generatesReasonable structureBulkheads/pilesEngineeringGrout

The invention discloses a double-anchoring-section prestress anchor cable structure and a constructing method thereof. The double-anchoring-section prestress anchor cable structure comprises an inner anchoring section, a free section, an outer anchoring section and an anchor head part, wherein a steel strand penetrates through the inner anchoring section, the free section, the outer anchoring section and the anchor head part. The portion, located on the inner anchoring section, of the steel strand is attached to one section of the bottom of a drilled hole through a grouting body. The free section is arranged at the upper portion of the inner anchoring section. The anchor head part is arranged outside a drilled hole opening and fixed to the top end of the steel strand. The outer anchoring section is arranged between the upper end of the free section and the drilled hole opening. Grouting is conducted through three steps, the first step of grouting is ended in the middle of the free section B, the inner anchoring section is formed through fracturing grouting in the second step of grouting, and the third step of grouting is conducted on the outer anchoring section C after a grout body of the inner anchoring section reaches the age and the steel strand is stretched. Except that the portion, located on the free section, of the steel stand is free, the portions, located on the inner anchoring section and the outer anchoring section, of the steel strand are both attached to the grout body to form a double-anchoring-section anchor cable with the inner anchoring section and the outer anchoring section. The double-anchoring-section prestress anchor cable structure has the advantages of being advanced in technology, economical, reasonable, rapid in construction and the like, and is a novel slope strengthening technology with prospects.

Owner:铁科检测有限公司

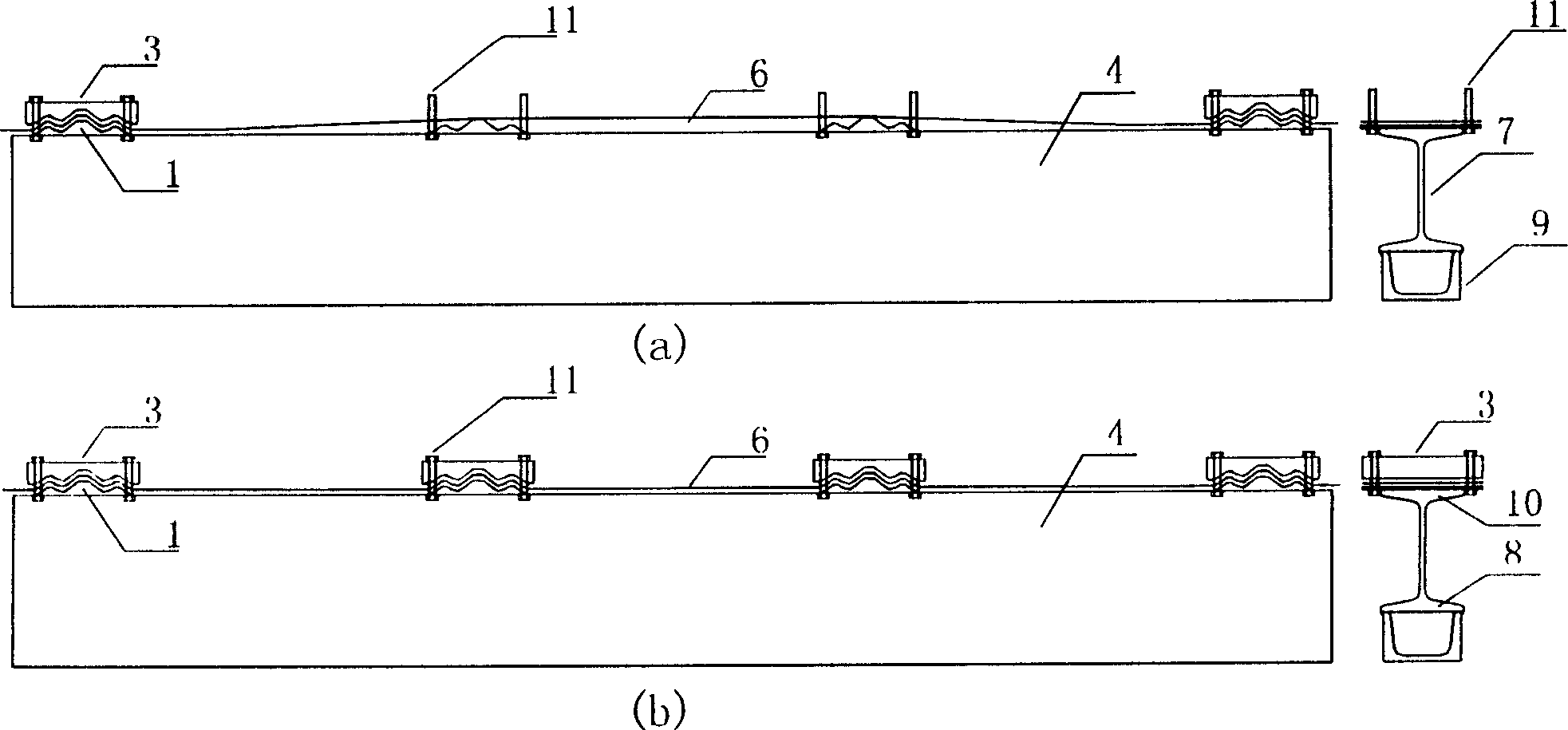

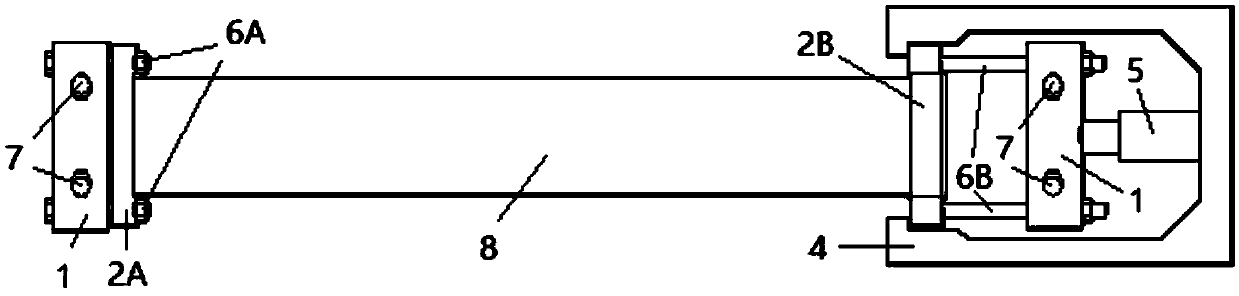

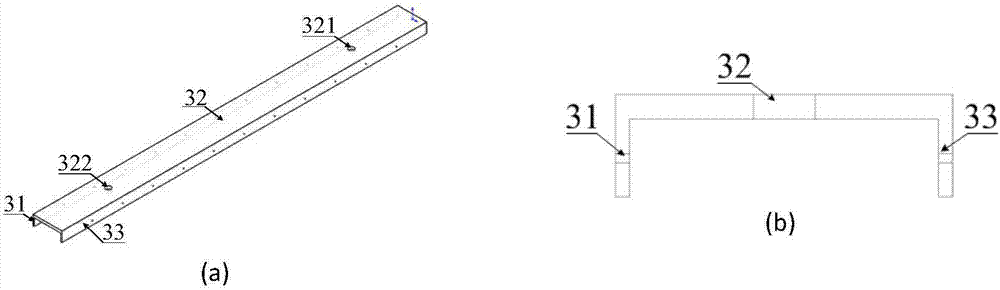

Carbon fiber bar reinforcement device and method for reinforced concrete beam and slab

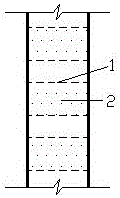

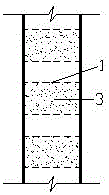

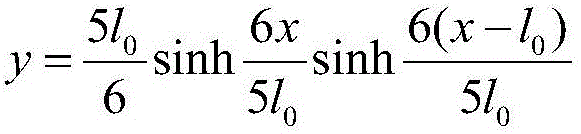

The invention discloses a carbon fiber bar reinforcement device and method for a reinforced concrete beam and a reinforced concrete slab. The carbon fiber bar reinforcement method comprises the following steps: first, assembling a carbon fiber bar and anchorage devices, opening holes in a beam, fixing the anchorage devices to the beam by using chemical anchors, mounting a tensioning device and thecarbon fiber bar onto brackets, tensioning the carbon fiber bar by using a jack, and detaching the mounting brackets after tensioning is completed. The carbon fiber bar is used for reinforcing the reinforced concrete beam, so that the reinforced concrete beam has a smaller area than a carbon fiber plate, the carbon fiber bar reinforcement device and the carbon fiber bar reinforcement method are suitable for beam and slab reinforcement in civil buildings, and during anchorage, less holes need to be opened in an original structure, so that less damage is caused to the structure; the circular carbon fiber bar is directly fixed to supports through nuts, and no connection screw rod is required, so that the length of the anchoring end is short, the prestress loss is less, and the reinforced concrete beam and the reinforced concrete slab can be effectively reinforced; when walls exist at the two ends of the bottom of the beam required to be reinforced, the beam can be reinforced from two sides of the beam; the carbon fiber bar reinforcement device is simple in structure; the reinforcement method is easy to implement; the carbon fiber bar reinforcement device and the carbon fiber bar reinforcement method can be popularized and applied to a variety of occasions where reinforced concrete reinforcement is required.

Owner:NANNING UNIV

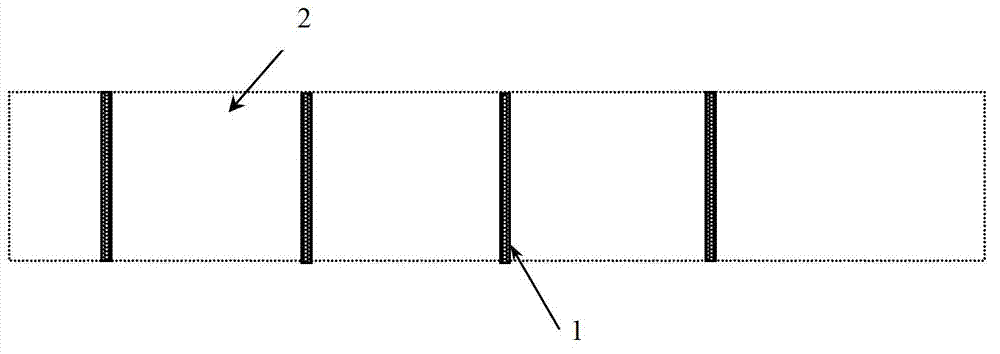

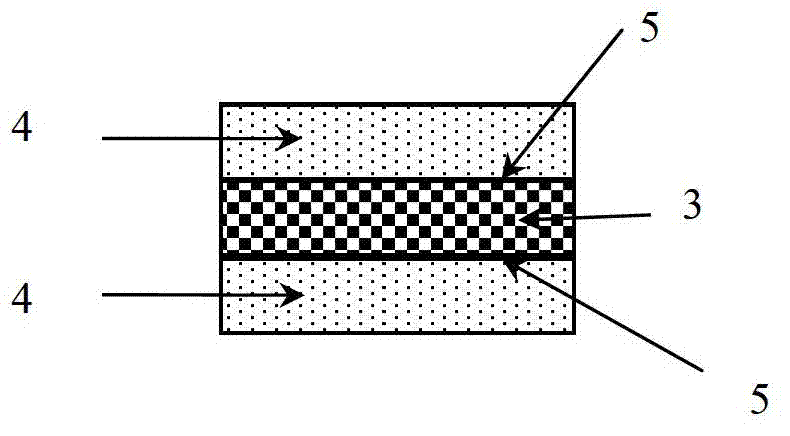

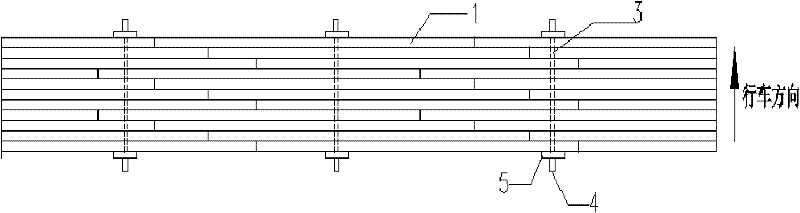

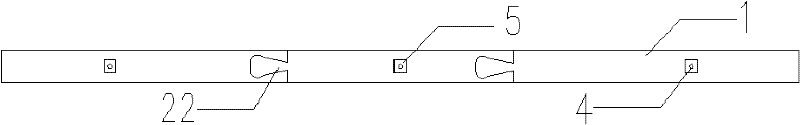

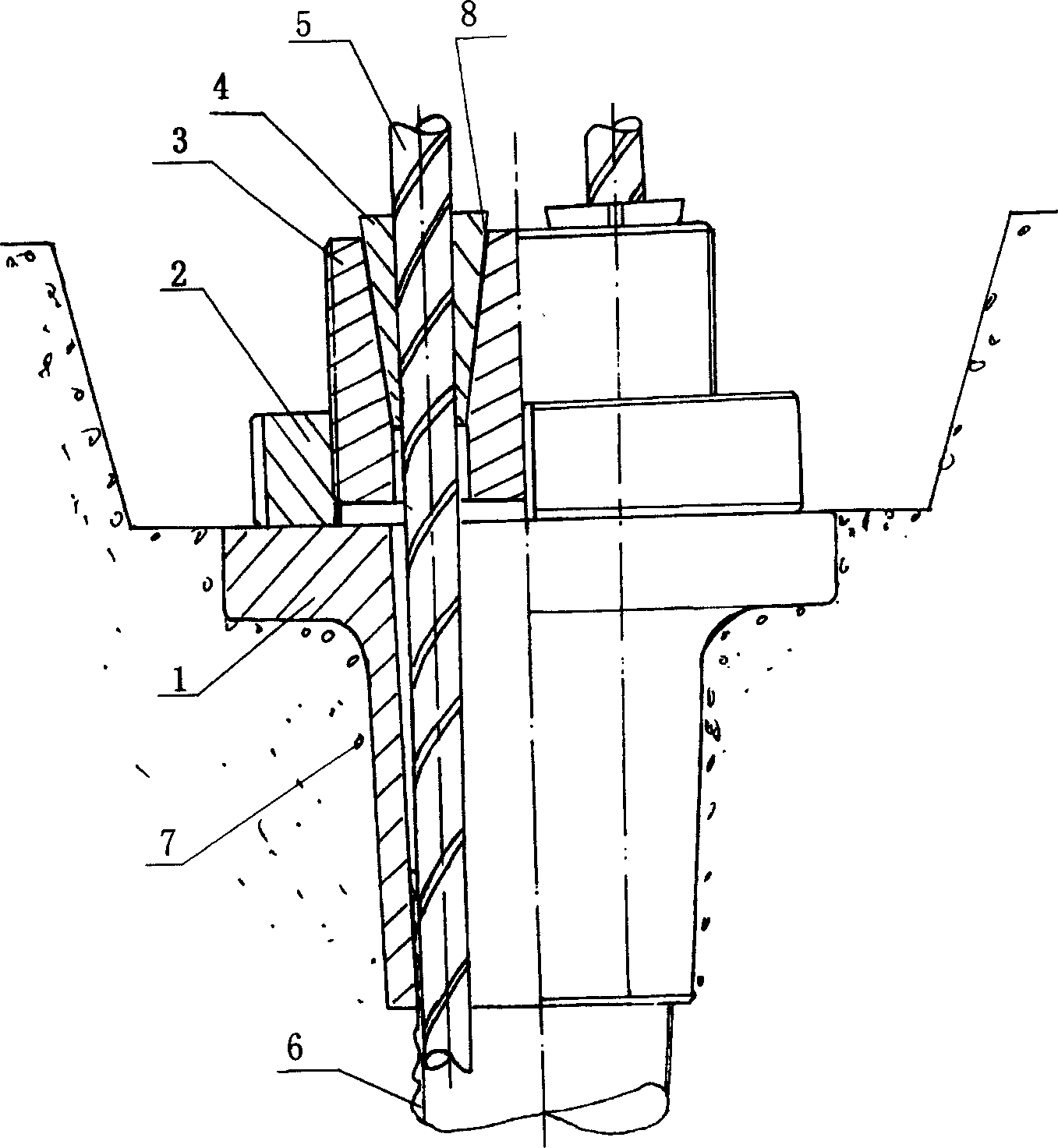

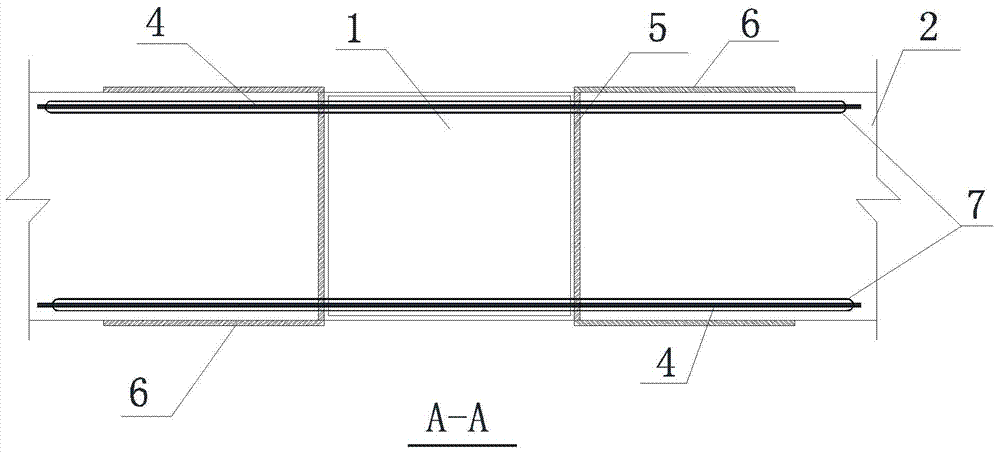

Bamboo bridge deck

InactiveCN102561180AReduce the degree of prestress lossImprove connection strengthBridge structural detailsPre stressSingle plate

The invention discloses a bamboo bridge deck, which comprises prestressed ribs and a plurality of superposed bridge deck sheets, wherein the prestressed ribs penetrate through the bridge deck sheets; two ends of the prestressed ribs penetrate through shim plates and are fixed and tightened by using anchorage devices to constrain the bridge deck sheets; and each bridge deck sheet is formed by sequentially joggling a plurality of single bridge decks made of bamboo veneers end to end, and the joggled parts of the two adjacent bridge deck sheets are staggered. The required width of the bridge deck is achieved in the transverse direction by the method for sequentially joggling the single bridge decks end to end in the cross section width of a bridge. The basic single decks of the bamboo bridge deck can be conveniently prefabricated in a factory and assembled on site to form the bamboo bridge deck; the construction process is simple and fast, and the construction materials are environment-friendly and are easily reclaimed; and the bamboo bridge deck is suitable for a combined structural bridge, and is a bridge deck capable of meeting the using functions and the durability.

Owner:SOUTHEAST UNIV

Secondary tensile prestressed anchorage

The invention relates to a twice spreading prestressing force anchor tool that can make the middle or short prestressing force tendon take twice spreading. The invention is made up of sole plate, bearing nut, anchor circle and clamping piece. That can anchor fix 1-20 prestressing steel strand and high intension steel bundle. It can be widely used for anchor fixing the prestressing force tendon of road and bridge, railway girder, and so on.

Owner:万国强 +1

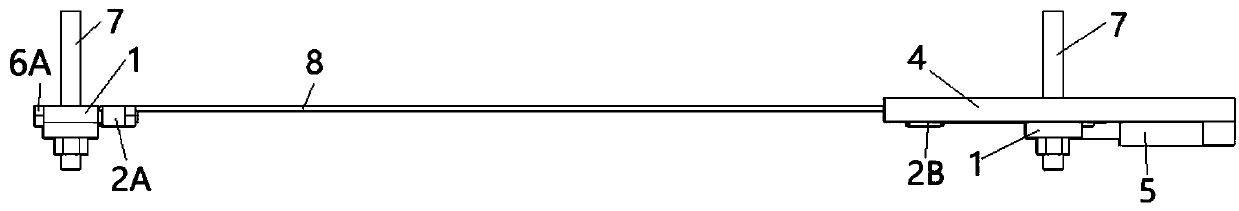

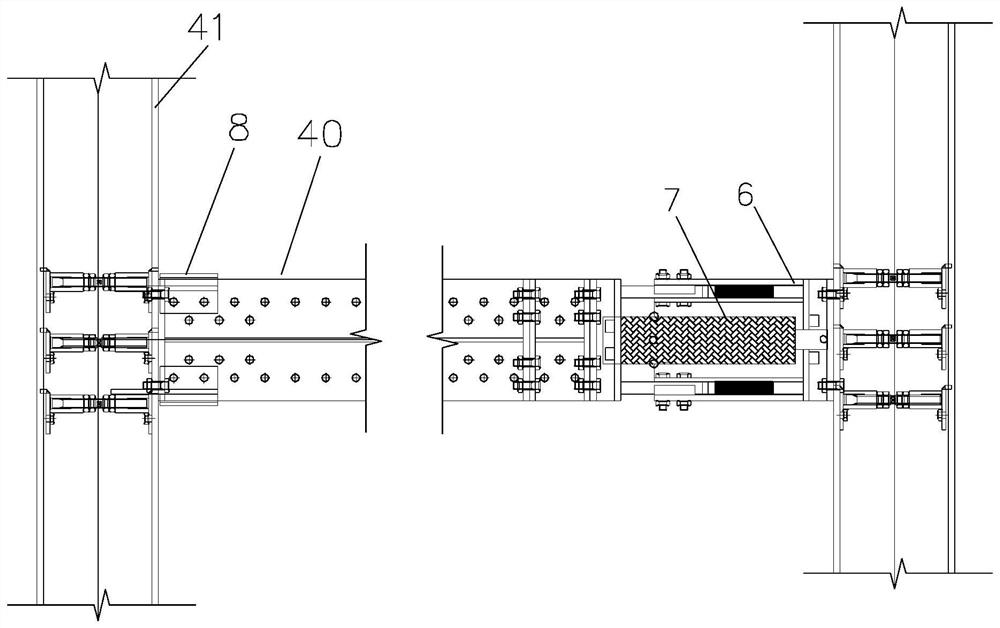

Tensioning and anchoring device for prestressed fiber cloth reinforced beams and construction method of device

ActiveCN108843037APrevent slippageImprove anchoring efficiencyBuilding repairsBuilding material handlingFiberPre stress

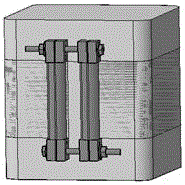

The invention discloses a tensioning and anchoring device for prestressed fiber cloth reinforced beams and a construction method of the device. The device comprises fixed supports, a fixed end anchorage device, a tensioning end anchorage device, clamping pieces, short anchoring screws, long anchoring screws, chemical bolts, fiber cloth, a prestress application frame and a jack, wherein the fixed supports, the fixed end anchorage device and the tensioning end anchorage device are cuboid; the fixed supports are fixed with a to-be-reinforced beam through the chemical bolts; the fixed end anchorage device and the tensioning end anchorage device are connected with the fixed supports through the short anchoring screws and the long anchoring screws respectively; a rectangular through seam allowing the fiber cloth to pass is formed in the fixed end anchorage device; wedge-shaped holes allowing insertion of the clamping pieces are formed in the tensioning end anchorage device, and the clampingpieces are wedged into the wedge-shaped holes, so that clamping of the fiber cloth is realized. The construction method comprises steps as follows: firstly, the anchorage devices are mounted, then thefixed supports are assembled and the anchorage devices are fixed, finally, the prestress application frame and the jack are mounted, and tensioning and anchoring are implemented. The device is reasonable and simple in structure and convenient to operate and can be reused, and the applied prestress is large.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Cable support node connecting device

InactiveCN101881050ASmall turning angleReduce the adverse effects of bending stiffnessBuilding reinforcementsUltimate tensile strengthMotherboard

The invention relates to a cable support node connecting device. The device comprises a cable body and a connecting device, wherein the connecting device comprises a node main plate, node upper plates, a vertical connecting plate, a node lower cover plate, clamping plates and a lug plate; the node upper plates, the vertical connecting plate and the node lower cover plate are connected into a cavity through a centre shaft; a bearing is sleeved on the centre shaft; both ends of the node main plate are provided with the node upper plates; both sides of the node lower cover plate are provided with the clamping plates; the cable body passes through the internal space of the connecting device and is tangent to the bearing; the centre shaft fixes the bearing and the cable body inside the connecting device through pre-tightening force of bolts; and the clamping plates are fixedly connected with the node upper plates through the bolts and are used for clamping or fixing the cable body passing through from the middle part. The node connecting device has the characteristics of simple structure, clear force transmission, reasonable stress, strong bearing capacity and the like. The device can fully exert material strength, effectively transmit steel cable force, reduce stress amplitudes, reduce prestress loss caused by friction and improve integral bearing capacity and stability of the structure.

Owner:BEIJING UNIV OF TECH

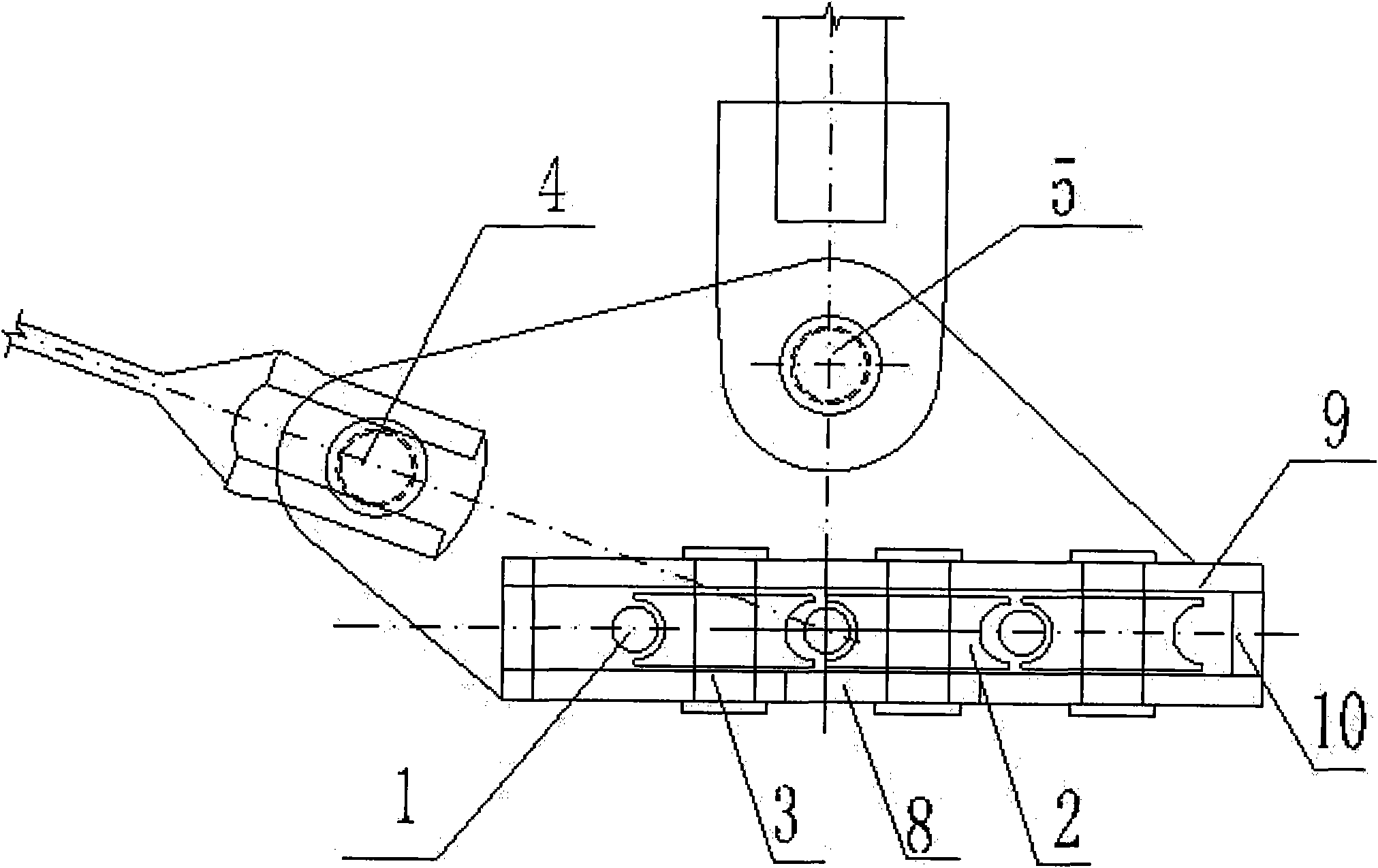

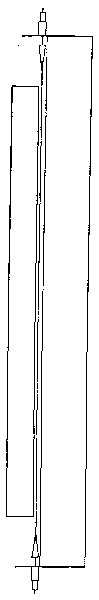

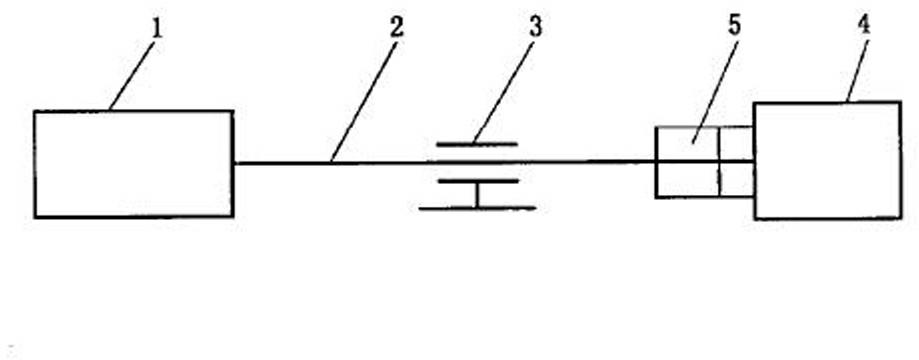

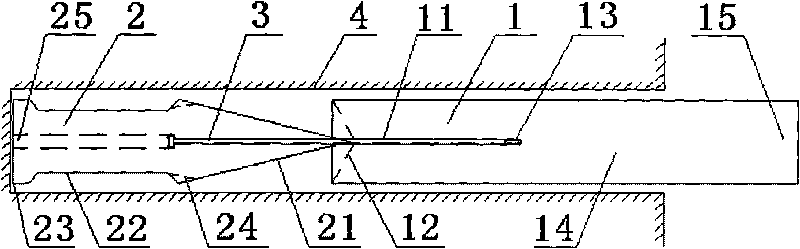

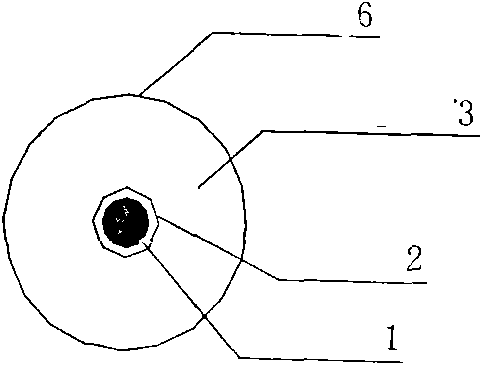

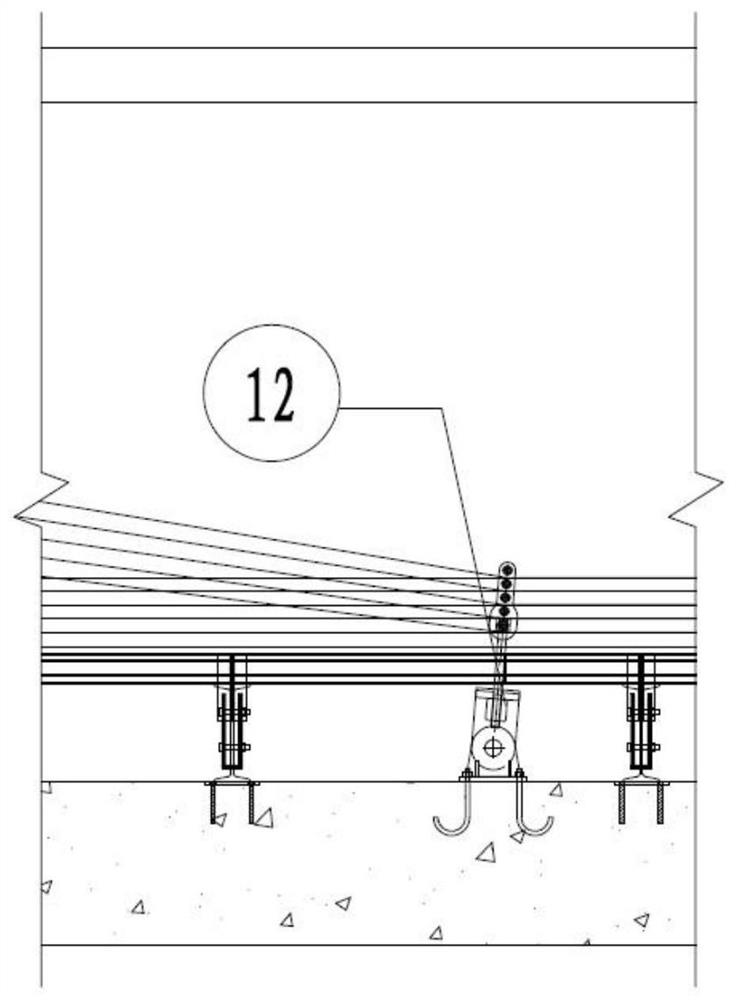

Prestressed carbon cloth reinforced tensioner

InactiveCN101713253AEasy to assemble and disassembleImprove adaptabilityBuilding material handlingUniversal jointEngineering

The invention relates to a prestressed carbon cloth reinforced tensioner which is characterized by comprising two counterforce racks (1), wherein the two counterforce racks (1) are fixed to both sides of a component (13) through bolts; the counterforce racks (1) are provided with a supporting device (3); one end of carbon cloth (12) is connected with an anchorage device (5) after bypassing the supporting device (3); the anchorage device (5) is connected with one end of a universal joint (6); the other end of the universal joint (6) is connected with a pull rod (10); the pull rod (10) is provided with a lifting jack (9), and a fixing nut (7) and a tension nut (11) which are respectively positioned on both sides of the lifting jack (9); and the fixing nut (7) is positioned on the outer side of a backing board between the two counterforce racks (1). The invention has the advantages of convenient assembly and disassembly, favorable adaptability, simple operation, accurate tensioning control and little prestressing loss, is especially suitable for engineering constructions and can enhance the engineering efficiency.

Owner:江苏省苏科建设技术发展有限公司

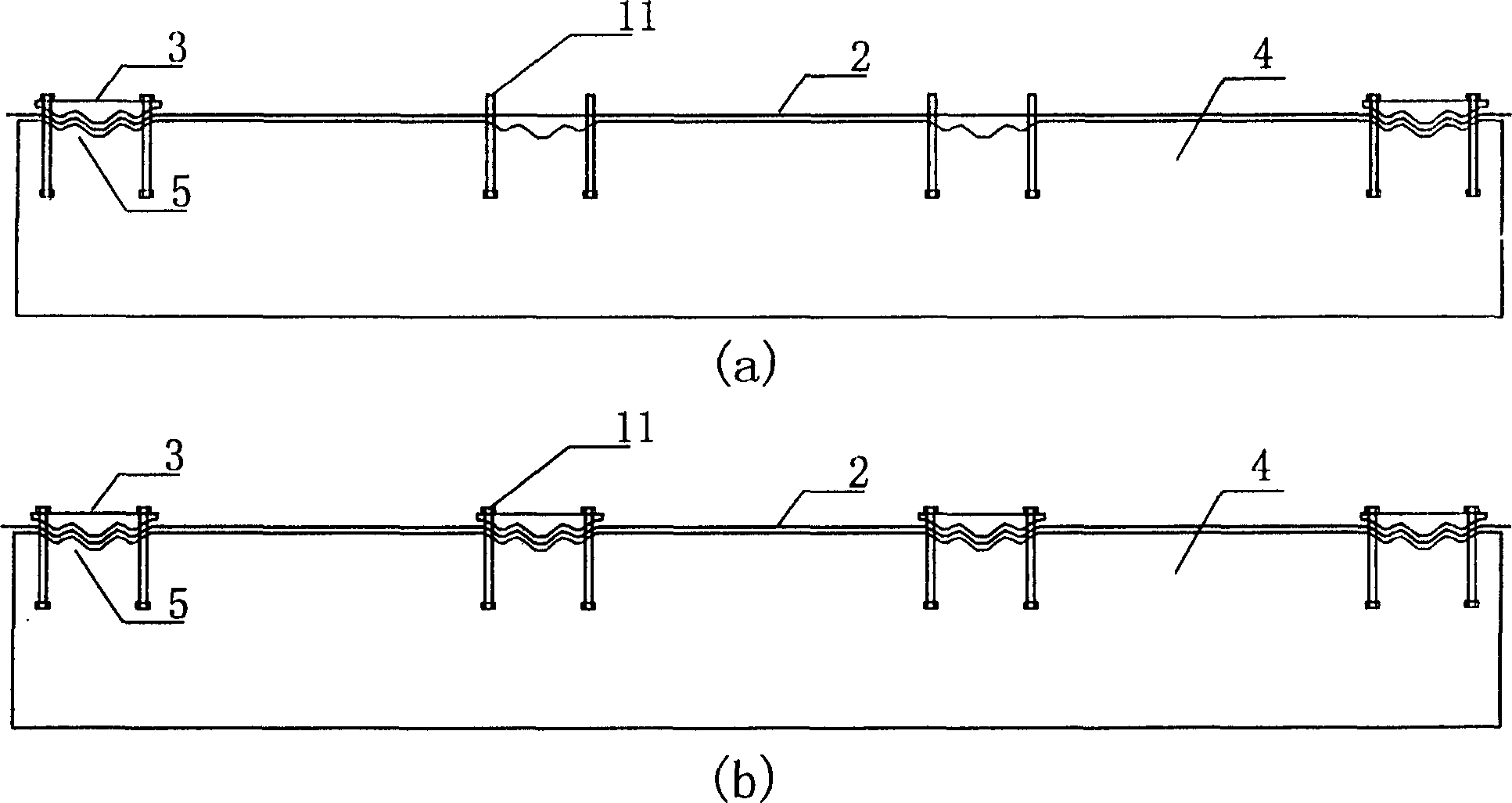

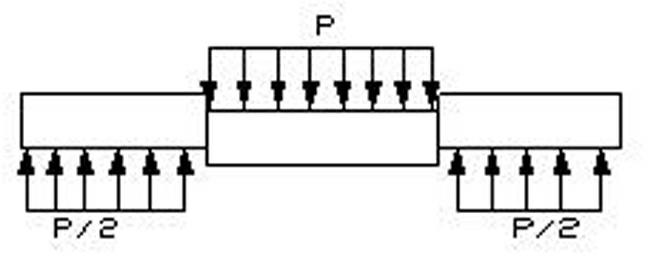

Method for reinforcing bonded prestressing force of transversely tensioning epoxy coating reinforcing steel bar of concrete beam slab

InactiveCN101929131AOptimize layoutReduce dependenceBuilding repairsBridge erection/assemblyPre stressConcrete beams

The invention relates to a method for reinforcing a bonded prestressing force of a transversely tensioning epoxy coating reinforcing steel bar of a concrete beam slab, which relates to the reinforcement of reinforced concrete and prestressed concrete bridges and is suitable for the reinforcement of house buildings and other building structures. In a prestressing force reinforcing technique of the invention, a novel transversely tensioning corrosion-resistant epoxy coating reinforcing steel bar is used for substituting for a longitudinally tensioning high-strength steel strand or common hot-rolled reinforcing steel bar and a transversely clamping device is used for substituting transverse tensioning for longitudinal tensioning, so that low-cost composite mortar or concrete can be used for substituting for high-cost high-performance tensile composite mortar or polymer mortar to perform a structure treatment and construction process, and the problems of low utilization efficiency of materials, high reinforcing cost and inconvenient reinforcing construction are solved.

Owner:HARBIN INST OF TECH

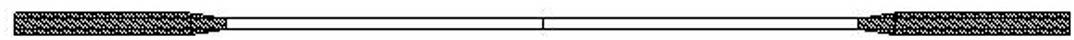

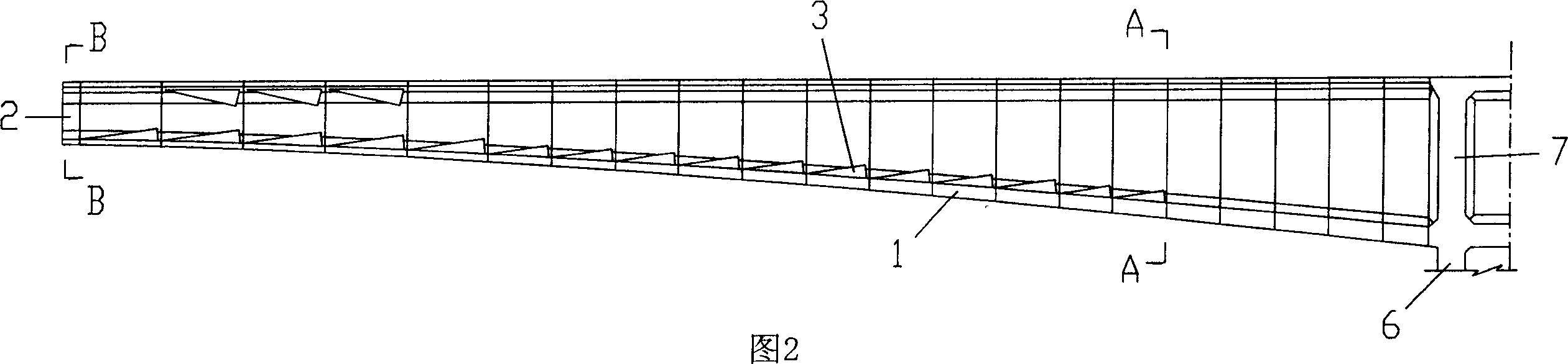

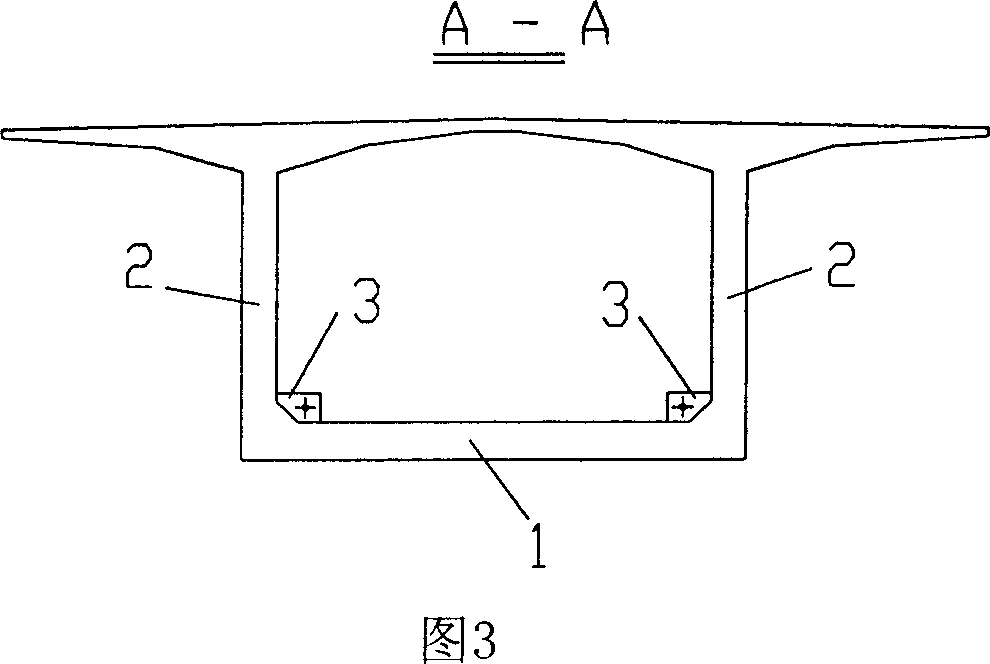

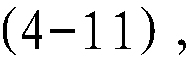

Corrugated steel web pre-flex assembled groove shape beam and manufacturing method thereof

InactiveCN101691737AEasy to manufactureIncreased complexityBridge erection/assemblyBridge materialsStress conditionsSheet steel

The invention discloses a corrugated steel web pre-flex assembled groove shape beam and a manufacturing method thereof. The assembled groove shape beam comprises a corrugated steel webs (1) located at two sides of the assembled groove shape beam, primary concrete bad plate (5) cast at the periphery of a lower flange steel plate (3), and a secondary concrete cast at the periphery of an upper flange steel plate (2) or connected with the upper flange steel plate (2) by a shear connecting piece (4), the upper parts of the corrugated steel webs (1) are connected with the upper flange steel plate (2), the lower parts of the corrugated steel webs (1) are connected with the lower flange steel plate (3), and the formed cross section is a groove shape structural beam. The assembled groove shape beam solves the problems of the complex stress condition of plate-beam joint position of common prestress concrete groove shape beam, the easy cracking of concrete, the complex structure of reinforcing bars of the plate-beam joint position and high construction difficulty, high requirements for construction technology and condition, the large occupied area of on-site casting construction, the long construction period, etc.

Owner:SOUTHEAST UNIV

Precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection

ActiveCN103924680AGuaranteed reliabilityReduce weakening effectBuilding constructionsSheet steelReinforced concrete

The invention relates to a precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection and belongs to the technical field of building structures. The precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection comprises a square-rectangular concrete-filled steel tube column, a reinforced concrete beam, prestressed bars, steel plates, and steel channels. Both the square-rectangular concrete-filled steel tube column and the reinforced concrete beam are precast. The parts, corresponding to the beam section, of the square-rectangular concrete-filled steel tube column and the precast reinforced concrete beam are provided with ducts in which metal bellows are embedded. The steel plates are welded at the connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam. The steel channels are welded on the square-rectangular concrete-filled steel tube column. Ordinary rebars and unbonded prestressed rebars are passed through the metal bellows, and the prestressed rebars are tensioned so that the beam and the column are integrated. The precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection has the advantages that construction speed is high, the field welding process is not required, joint connection reliability is guaranteed, seismic performance is good, and the joint has promising application prospect.

Owner:宝嘉智能科技(南通)有限公司

Foundation pit groove steel sheet pile profile steel supporting system and construction method

PendingCN112627190AShort construction periodReduce riskExcavationsBulkheads/pilesSupporting systemPurlin

The invention discloses a foundation pit groove steel sheet pile profile steel supporting system and a construction method. The supporting system comprises enclosure structures laid along the inner side wall of a foundation pit groove, an upper supporting structure arranged at the two ends of the opening of the foundation pit groove in a crossing mode and fixed to the side walls of the upper ends of the enclosure structures, and a plurality of lower supporting structures arranged below the opening and above the bottom of the foundation pit groove, and the two ends of the lower supporting structure are connected with the enclosure structures arranged on the two sides in the foundation pit groove; and the lower supporting structure comprises lower steel enclosing purlins and lower profile steel supporting beams, the multiple layers of lower steel enclosing purlins are arranged on the enclosure structures, the lower steel enclosing purlins are connected to the surfaces of the enclosure structures through bolts in the surrounding direction of the inner side wall of the foundation pit groove, and the multiple lower profile steel supporting beams which are parallel to one another are arranged in the width direction of the foundation pit groove. By means of the construction method, prestress can be effectively applied to the supporting system when the excavation depth of the foundation pit groove is large, deformation of the foundation pit groove can be better prevented, and it is guaranteed that the whole supporting system is evenly stressed.

Owner:广西建工集团第一安装工程有限公司

Method for reinforcing bridge by external transverse prestressing tendons

InactiveCN103276674AEasy to stretchReduce the impactBridge erection/assemblyBridge strengtheningPre stressEngineering

The invention belongs to a method for reinforcing a bridge by external transverse prestressing tendons. The method is characterized in that finish-rolled deformed steel bars are used as the transverse prestressing tendons, the tensioning ends and the fixing ends of the transverse prestressing tendons are cone anchors. The finish-rolled deformed steel bars are used as the transverse prestressing tendons, so that influences of vehicle load and bridge vibration on anchoring effect are reduced; the tensioning ends and the fixing ends are the cone anchors, so that loss of prestress is reduced effectively; loss of prestress of the finish-rolled deformed steel bars in an operation period is low; and meanwhile, the finish-rolled deformed steel bars can be tensioned quite conveniently, are simple in structure and high in practicality, and has high popularization and application value.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Production method of prestressed concrete corrugated sheet pile

The invention relates to a production method of a prestressed concrete corrugated sheet pile. The method is characterized by including: preparing concrete mixture; producing reinforcement cages; die-filling; prestress tensioning; concrete pouring and vibration forming; prestress tension releasing and die removing; conveying the overall die to an assembling pedestal, using a special automatic opening-closing device to open the lateral die so as to take out a finished sheet pile, cleaning the dies, apply demolding agent, and turning to the next production procedure; examining and putting into storage. The production method is high in production efficiency and low in energy consumption, work environments are improved, labor intensity of workers is lowered, and the products are stable in quality, high in safety coefficient and good in mechanical performance.

Owner:张武 +1

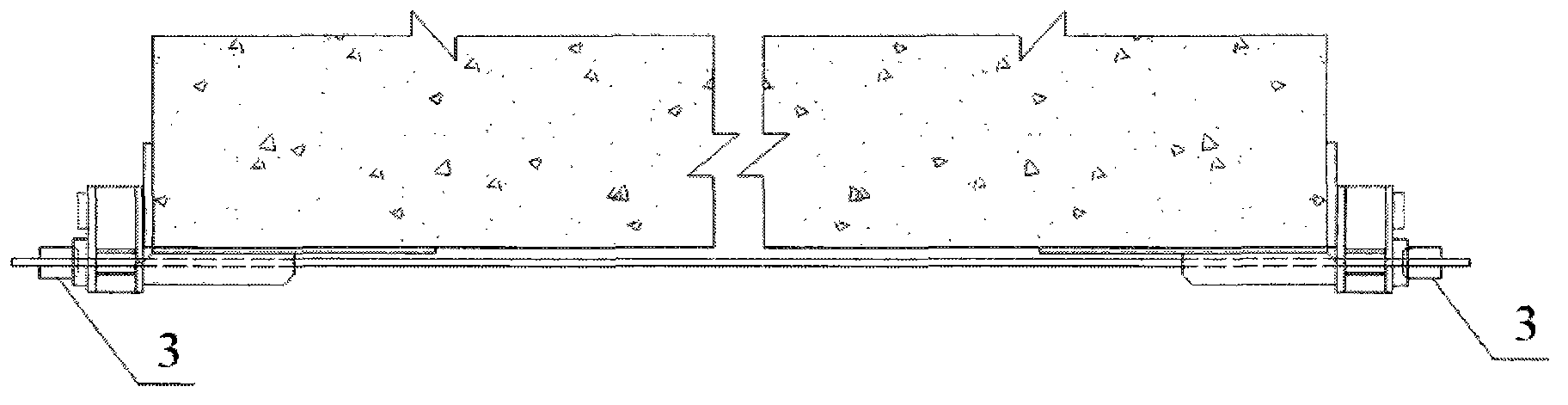

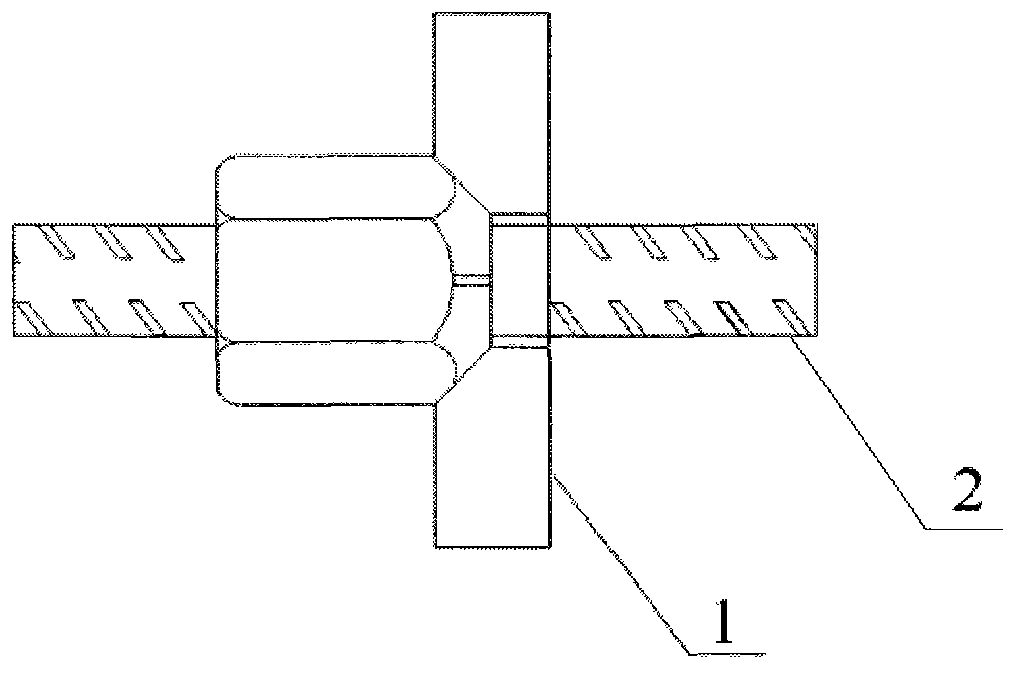

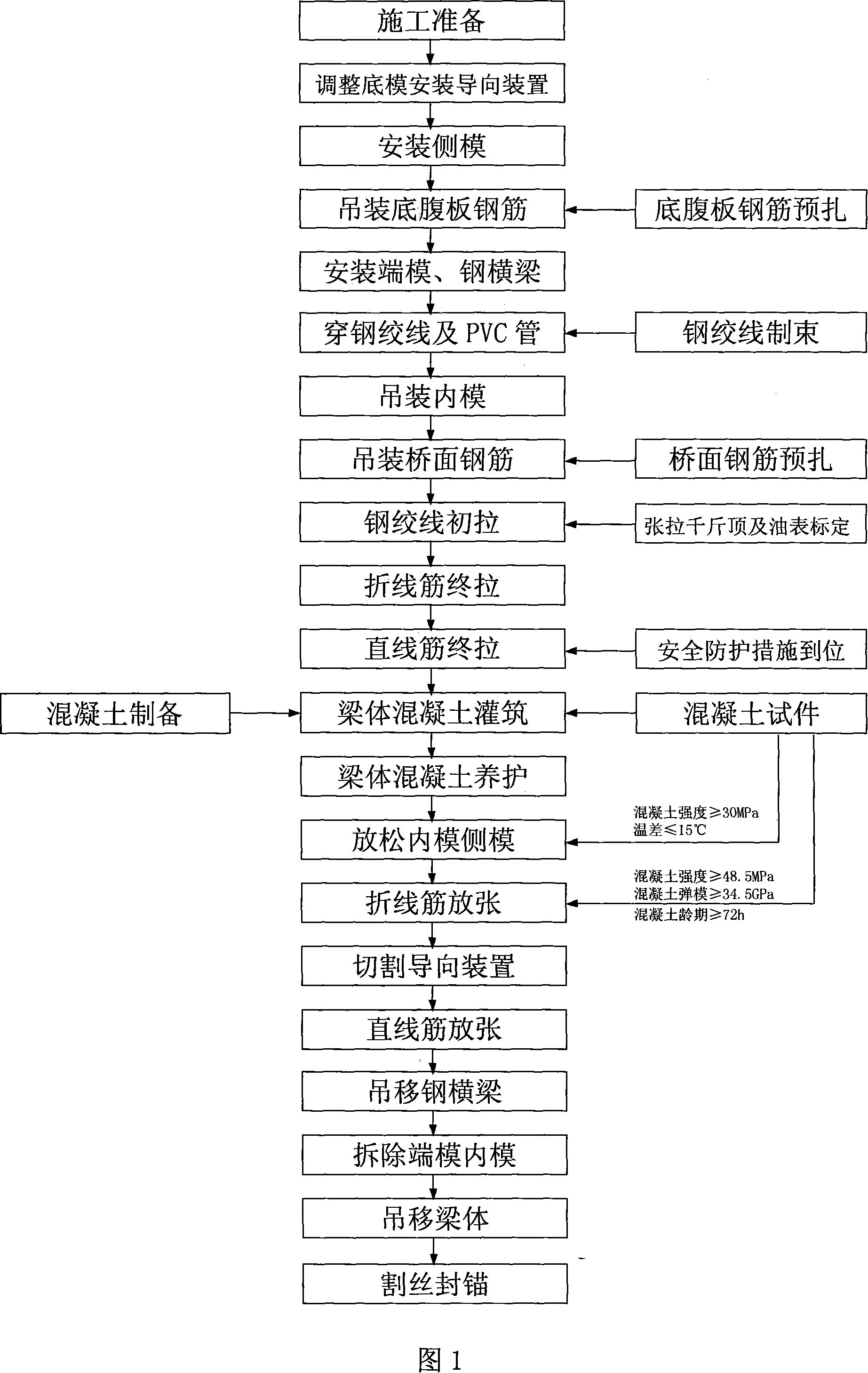

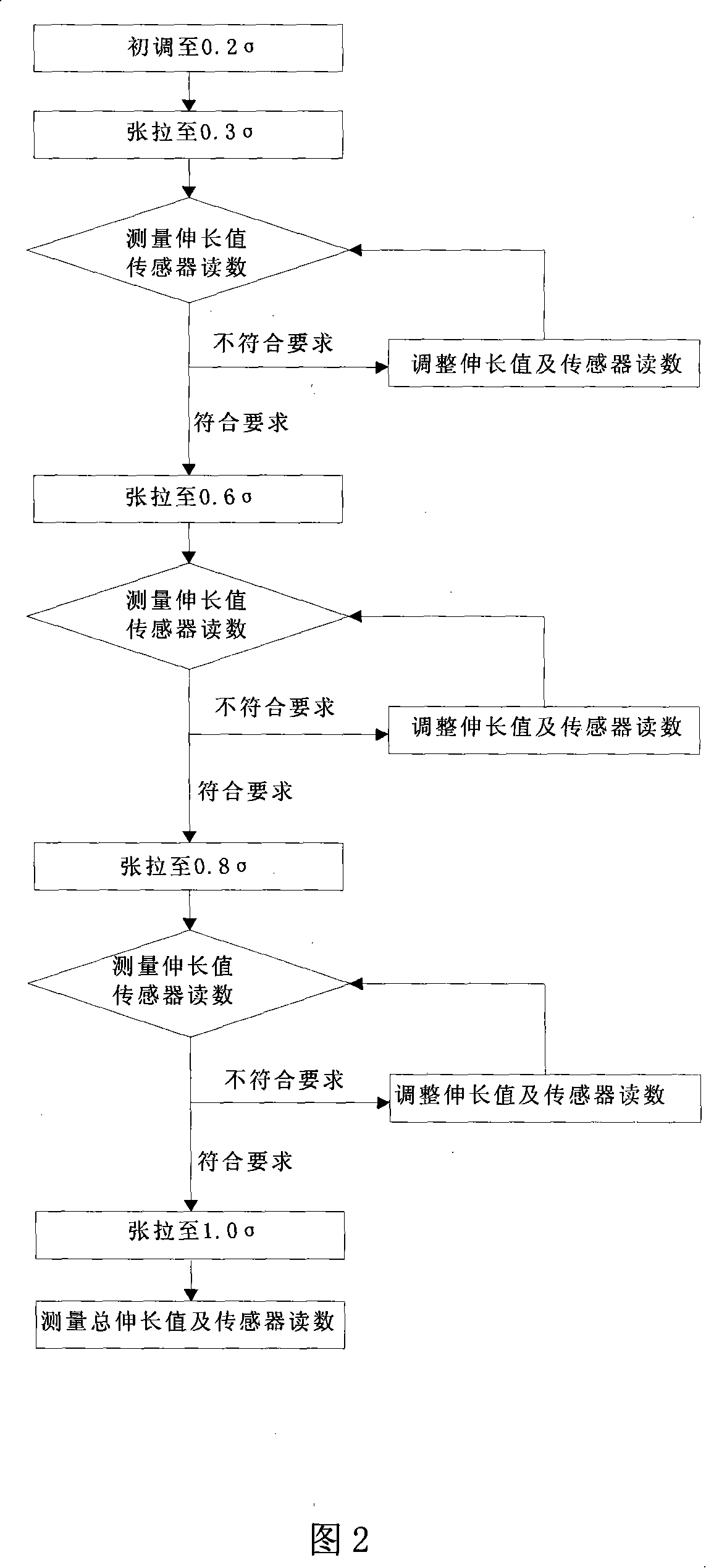

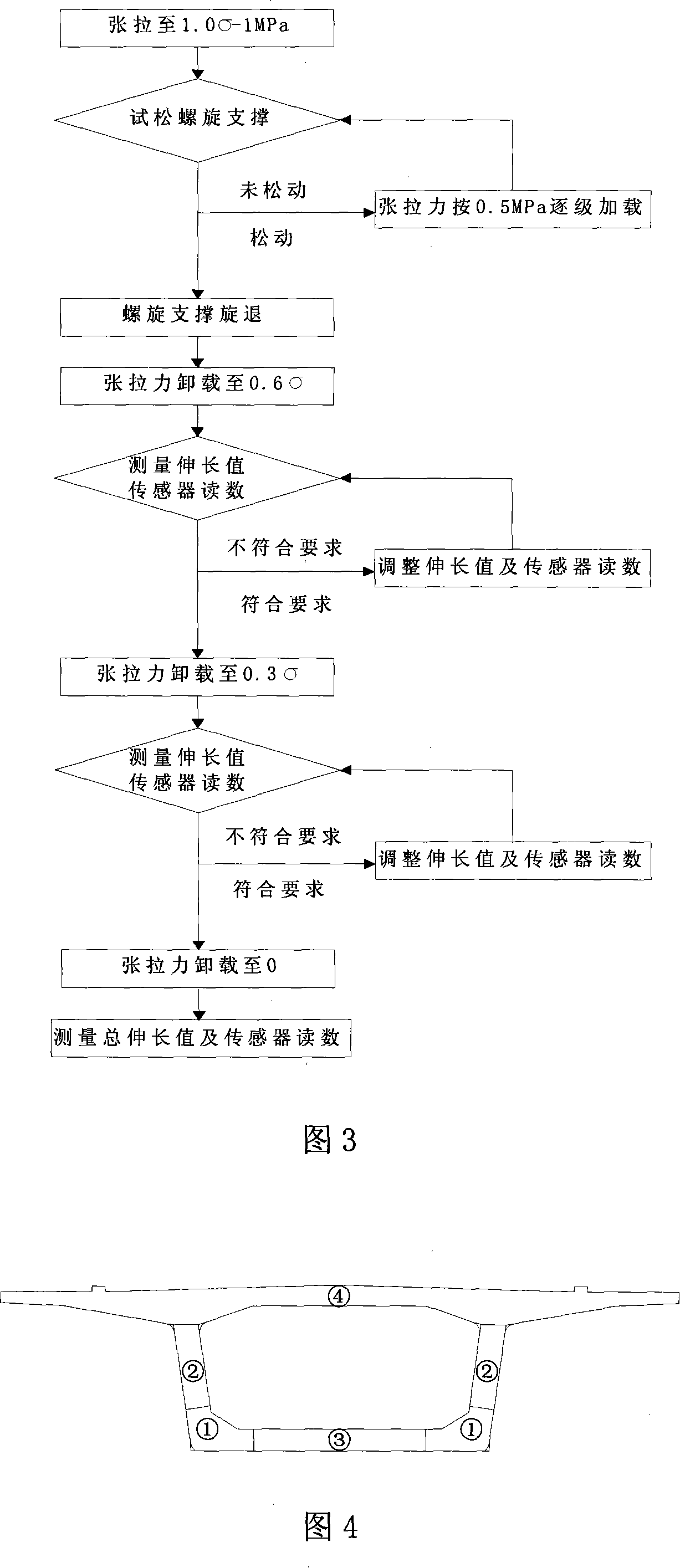

Pretensioned beam whole opening prefabricated construction method

InactiveCN101125440AMeet the needs of prefabricated constructionEven by forceMouldsEngineeringBox girder

The present invention discloses a monolithic prefabricated construction method of pretensioned beam, the main working procedures of which comprise: construction preparation, bottom die adjustment, guide device and lateral die installation, hoisting bottom web reinforcement, end die and steel beam installation, threading steel strand and PVC pipe, hoisting internal die and deck reinforcement, firstly pulling of steel strand, finally pulling of broken line reinforcement, finally pulling of straight line reinforcement, grider concrete packing, grider concrete maintenance, loosening internal and lateral dies, broke line extension, cutting guide device, straight line reinforcement extension, hoisting steel beam, end and internal dies removal, hoisting grider, cutting wire and sealing anchor, etc. The construction method adopts straight line and broken line reinforcements, which is able to meet the demand of prefabricated construction of bridge with 32m / 900t big span and large tonnage; at the same time, the construction method selects tension and extension technique of 52000kN large tonnage tensioning force, which ensures that the grider has balanced stress, and improves the tension and extension efficiency and security, etc.

Owner:CHINA RAILWAY HI TECH IND CORP LTD

Glass fiber reinforced plastic engineering anchor rod and manufacturing method thereof

The invention relates to the field of engineering building materials, belongs to the category of new materials, and in particular relates to a glass fiber reinforced plastic (FRP) engineering anchor rod and a manufacturing method thereof. The invention is characterized in that: raw materials mainly comprise glass fibers, resins and additives, wherein the glass fibers account for 70 to 85 weight percent of the raw materials. The invention has the advantages that: the FRP material has the advantages of light weight, high strength, corrosion resistance, capacity of being easily cut, insulativity (not conducting electricity or magnetism), flame retardancy, low-temperature resistance, fatigue resistance and the like; the anchor rod can locally replace steel bars according to the characteristics of the FRP material so as to fulfill the aim of saving steel and labor cost, the labor efficiency can be greatly improved, and the cost is saved; the anchor rod can be applied to environments with serious corrosion of corrosive media for a long time, can maintain the strength and service life, and meet the requirement of structure durability; the anchor rod can be applied to structure with special requirements; and prestress loss due to concrete creep and shrinkage can be reduced, and the prestress loss due to prestressed reinforcing steel loosening can be reduced.

Owner:CHINA RAILWAY SHANGHAI DESIGN INST GRP

Pre-stressing carbon fiber cloth reinforcement reinforced concrete column construction method

ActiveCN105888277AReduce frictionIncrease the effective prestressBuilding repairsReinforced concrete columnFiber

The invention discloses a pre-stressing carbon fiber cloth reinforcement reinforced concrete column construction method. The method comprises the steps: performing chamfering, surface polishing and hole filling treatments on a to-be-reinforced concrete column, and coating the surface of a pre-designed to-be-reinforced part with epoxy, thereby achieving a function of reducing surface friction force between carbon fiber cloth and concrete after the epoxy is solidified, and effectively transferring a pre-stressing force; meanwhile, in order to prevent the edge of the carbon fiber cloth from running before covering, adhering a transparent adhesive tape on the surface of the carbon fiber cloth; clamping the carbon fiber cloth by utilizing self-locking type anchorage clamping pieces, winding the carbon fiber cloth around the covered concrete column, and screwing a screw rod by utilizing a spanner to apply a pre-stressing force; after the pre-stressing force is up to a preset size, and re-coating the surface of the carbon fiber cloth with a layer of epoxy, thereby preventing individual fibers of the carbon fiber cloth from generating breaking and running situations, and ensuring the integral stress. The pre-stressing carbon fiber cloth reinforcement reinforced concrete column construction method has the advantages that the concept is novel, construction steps are clear, simple and practical, and a high-strength function of the carbon fiber cloth is fully exerted, so that the reinforcement effect is integrally improved, and the method is convenient to popularize and apply.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

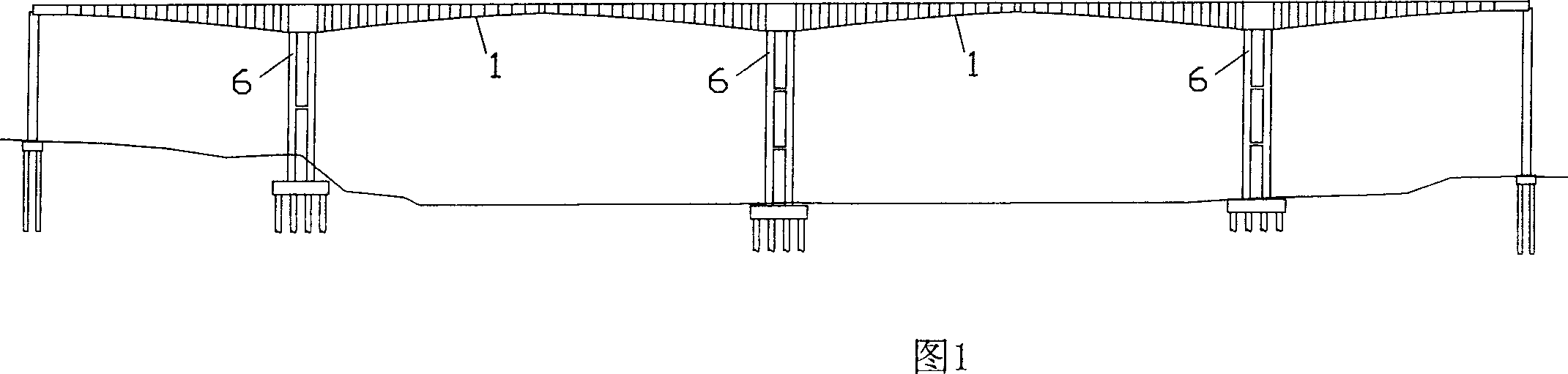

Baseboard cable horizontal arrangement prestress concrete variable cross-section box girder bridge and construction method thereof

InactiveCN1974930ASolve the problem that the radial force increases continuously with the spanEliminate radial forceBridge erection/assemblyBridge materialsBaseboardPre stress

The present invention belongs to the field of civil engineering bridge technology, and relates to a baseplate ropes horizontally-arranged prestressed concrete non-uniform box beam bridge. It is characterized by that in the position of midspan baseplate which is correspondent to the beam height in the box beam interior a horizontal anchor plate is set longitudinally, said horizontal anchor plate and box beam baseplate are combined into one body, the thickness of said horizontal anchor plate is identical to that of midspan baseplate, the baseplate ropes are arranged in the horizontal anchor plate interior, and said horizontal anchor plate and box beam can be cast in-situ together. Said invention can raise durability of the bridge and can greatly raise crossing capacity of said bridge.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

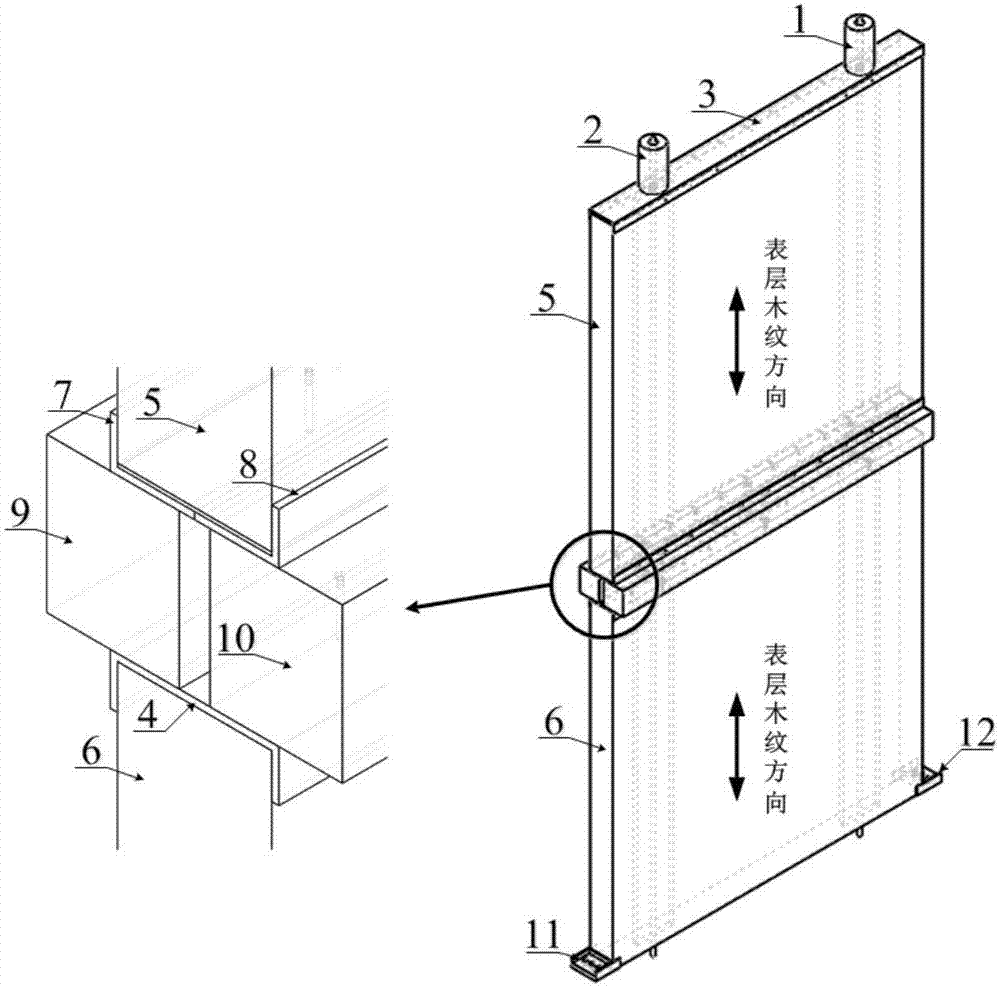

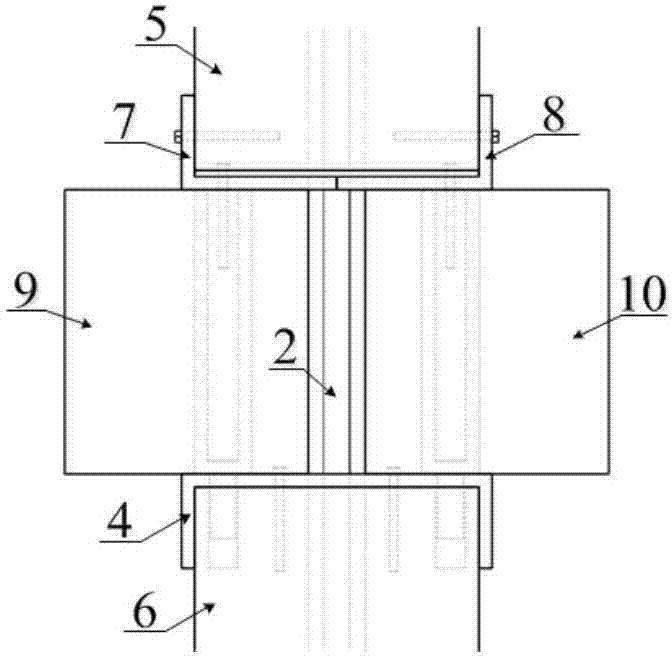

Assembling prestress orthogonal laminated wood shear wall

ActiveCN107574953AIn line with the structural design conceptImprove lateral force resistanceWallsProtective buildings/sheltersPre stressSelf recovery

The invention discloses an assembling prestress orthogonal laminated wood shear wall. The assembling prestress orthogonal laminated wood shear wall comprises bond-free prestress bars, bearing beams, CLT wall plates, slab supporting frames and limiting steel components. The two limiting steel components are connected with a base. The CLT wall plates on the lower layer tightly abut against the basethrough the bond-free prestress bars. The bearing beams on the lower layer are connected with the CLT wall plates on the lower layer. The slab supporting frames on the lower layer are connected with the CLT wall plates on the lower layer and then put on the top of the bearing beams on the lower layer. The CLT wall plates on the upper layer are connected with the two slab supporting frames on the lower layer. The bearing beams on the upper layer are connected with the CLT wall plates on the upper layer. The two bond-free prestress bars penetrate through the CLT wall plates on the upper layer and the lower layer. The CLT shear wall has high initial rigidity, high ultimate bearing capacity and a certain self-recovery characteristic under lateral loads after the bond-free prestress bars are applied, and the common damage mode of weak joints and strong components of a common CLT shear wall is avoided. The assembling prestress orthogonal laminated wood shear wall is high in assembling degree, and prestress loss caused when CLT slabs have big creep deformation under the band stress action can be reduced obviously due to the arrangement of the slab supporting frames on the lower layer.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

BIM-based No.0 block longitudinal prestressed pipeline positioning construction method

InactiveCN111576235APrecise positioningReduced durabilityGeometric CADBridge erection/assemblySupporting systemPre stress

The invention discloses a BIM-based No.0 block longitudinal prestressed pipeline positioning construction method. The method mainly comprises the steps of BIM modeling, support system installation, bottom die template installation and support prepressing, steel bar binding and prestressed pipeline installation, No.0 block end die template installation and adjustment and concrete pouring and maintenance. According to the method, the BIM technology is adopted to simulate the positions of the No.0 block prestressed pipeline and the reinforcing steel bars, the collision points are checked, the positions of the reinforcing steel bars can be optimized and adjusted in advance, accurate positioning of the prestressed pipeline is ensured, and the technical problems that the prestressed pipeline hole position structure is not straight, positioning precision is poor and construction efficiency is low are solved.

Owner:HENAN NO 1 CONSTR ENG GRP

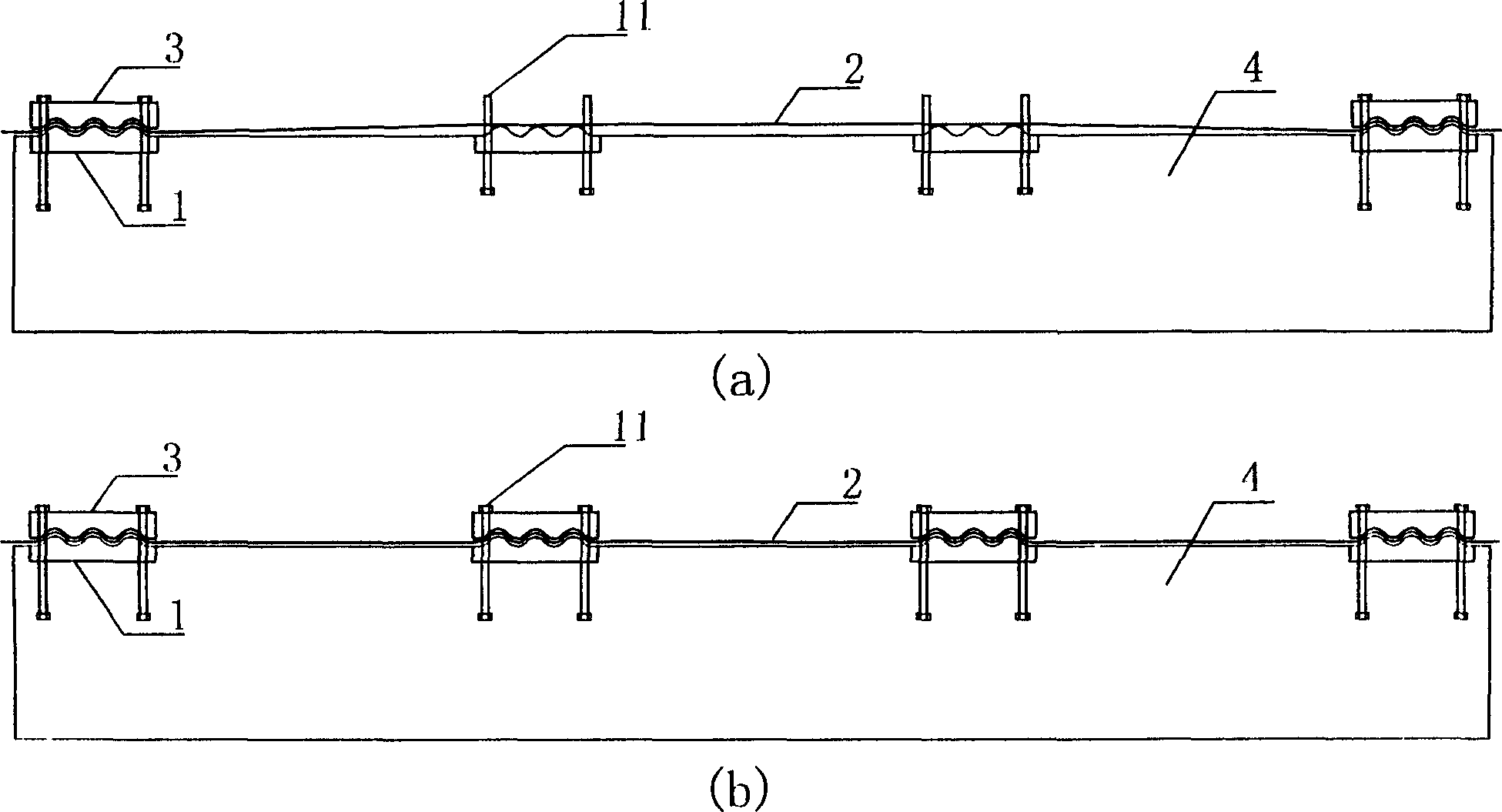

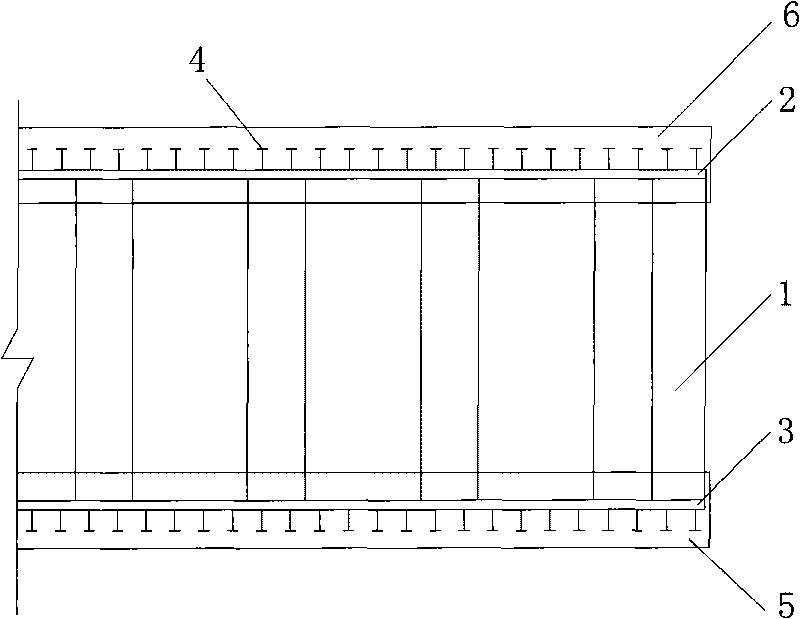

Prestress Bailey beam for reinforcement and construction method thereof

ActiveCN108103965AForce is simple and clearIncrease weightBuilding repairsBridge erection/assemblyPre stressBunches

The invention discloses a prestress Bailey beam for reinforcement and a construction method thereof. The Bailey beam is composed of Bailey sheets, reinforcing rods, bolts, anchoring bolts, prestress bunches and anchoring tools. Each component of the Bailey beam is prefabricated in a factory and then assembled and hoisted on site; the prestress bunches are placed in lower chords of a Bailey beam body and fixedly anchored on the reinforcing rods at both ends. The Bailey beam can slide towards the two ends in a prestress expansion process and are integrally lifted up; meanwhile, a pre-pressure isperformed on the lower brim to achieve the functions of reversely arching the structure, closing cracks and reducing downward warping; after expansion is completed, by fixing filling pieces, sealingsteel plates and injecting solidified bodies for sealing, the prestress bunches and the Bailey beam body form a whole part to bear force, and not only is the waste of the prestress reduced, but also the durability of the prestress bunches is improved. The Bailey beam carries out power transmission based on the lever principle, and the advantages of the Bailey beam and external prestress are fullyutilized; through assembled-type construction, splicing is simple, the construction period is short, there is no need to interrupt the traffic, and the prestress Bailey beam and the construction method thereof can be widely applied to the field of concrete structure reinforcement.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

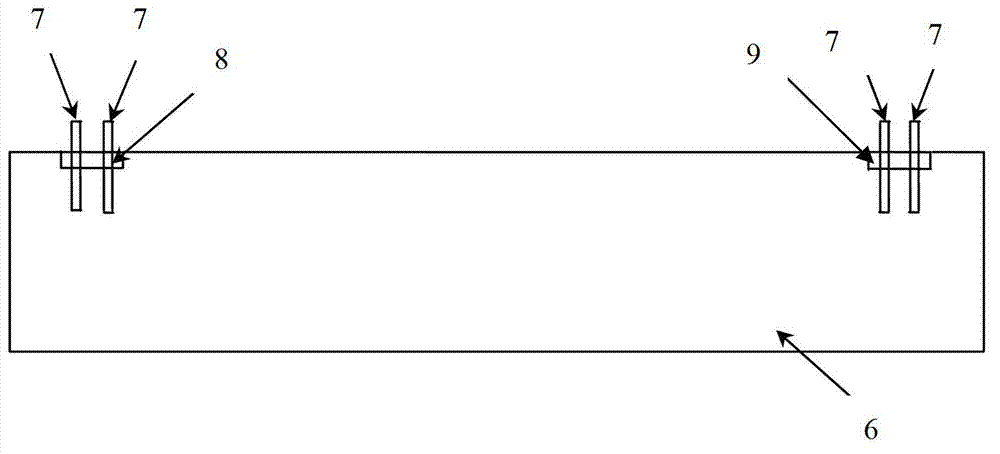

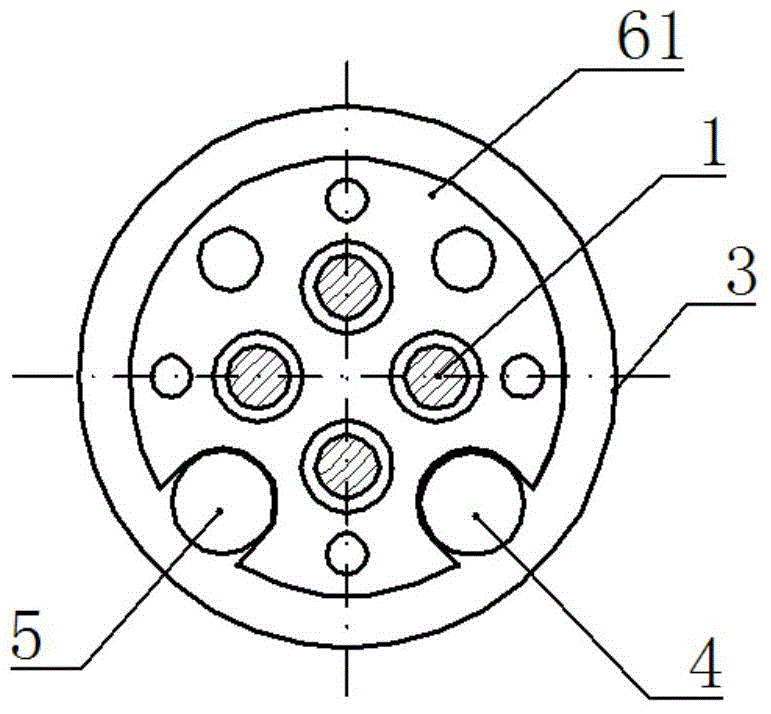

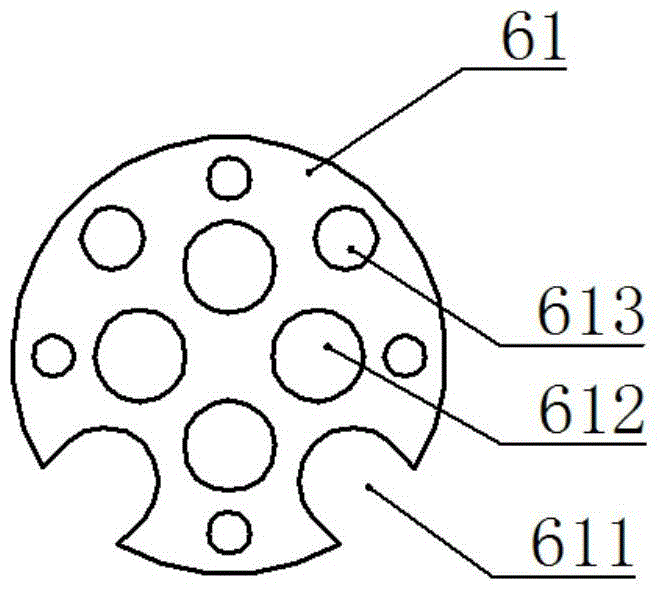

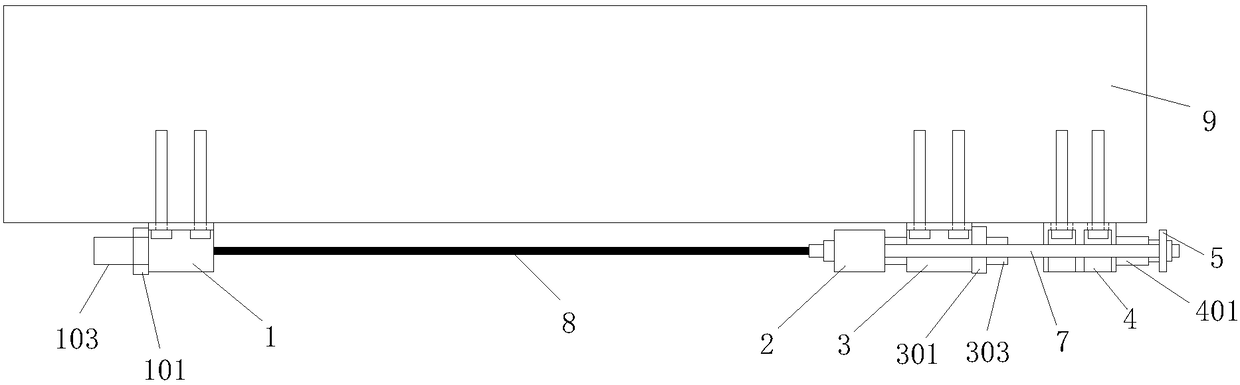

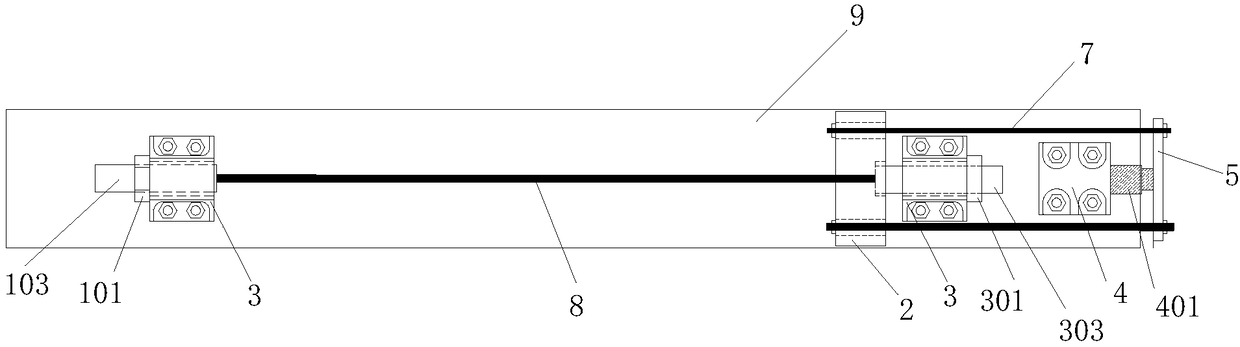

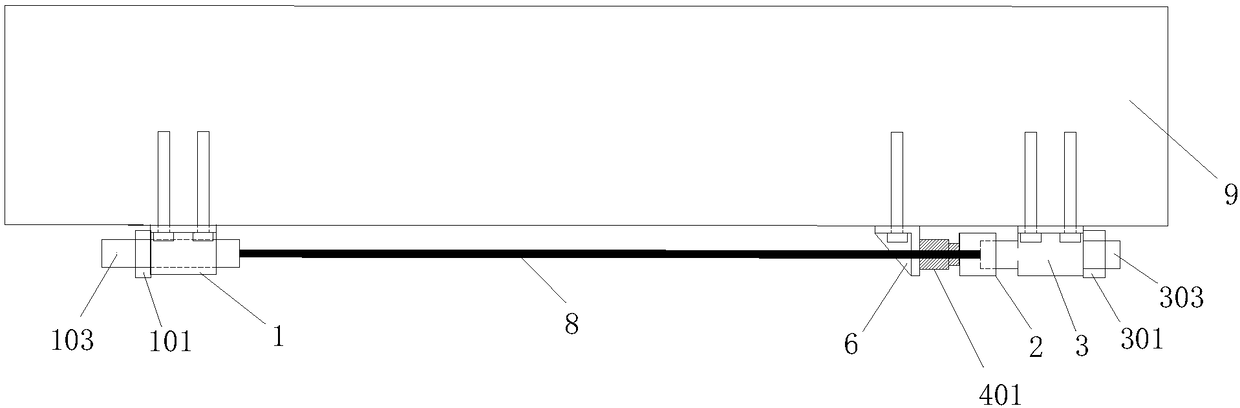

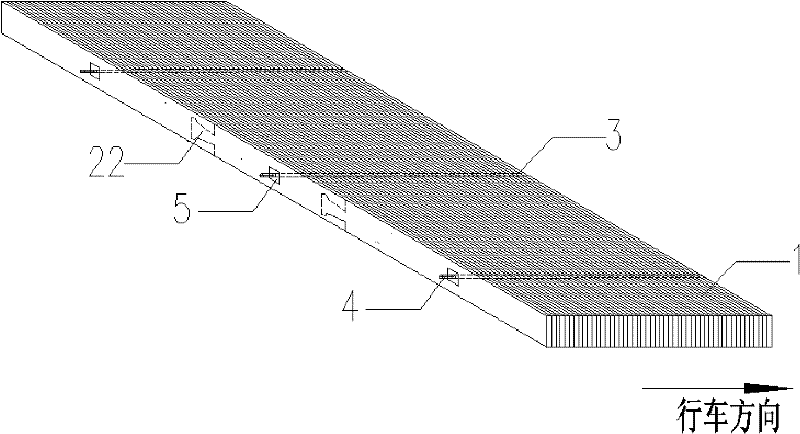

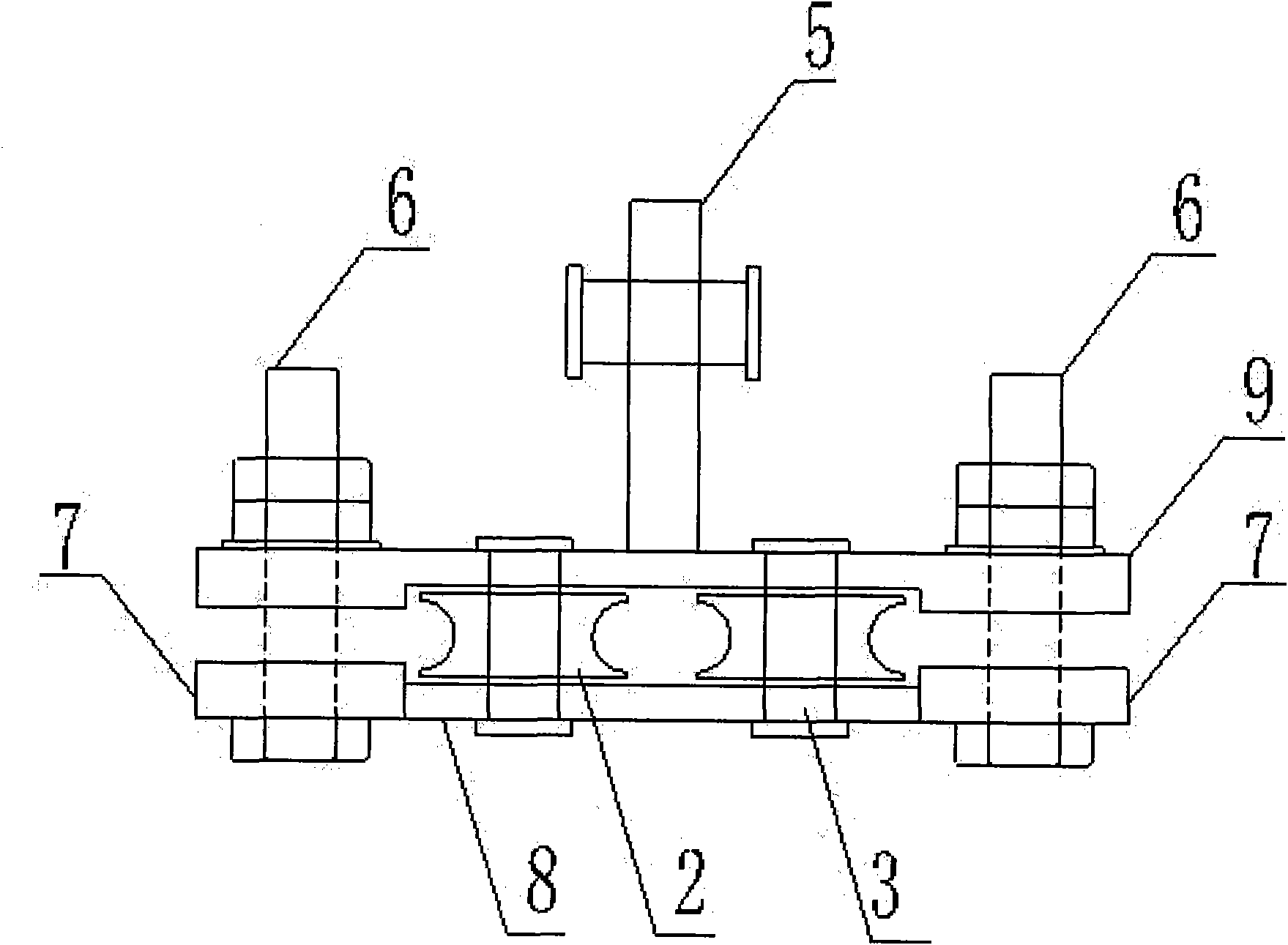

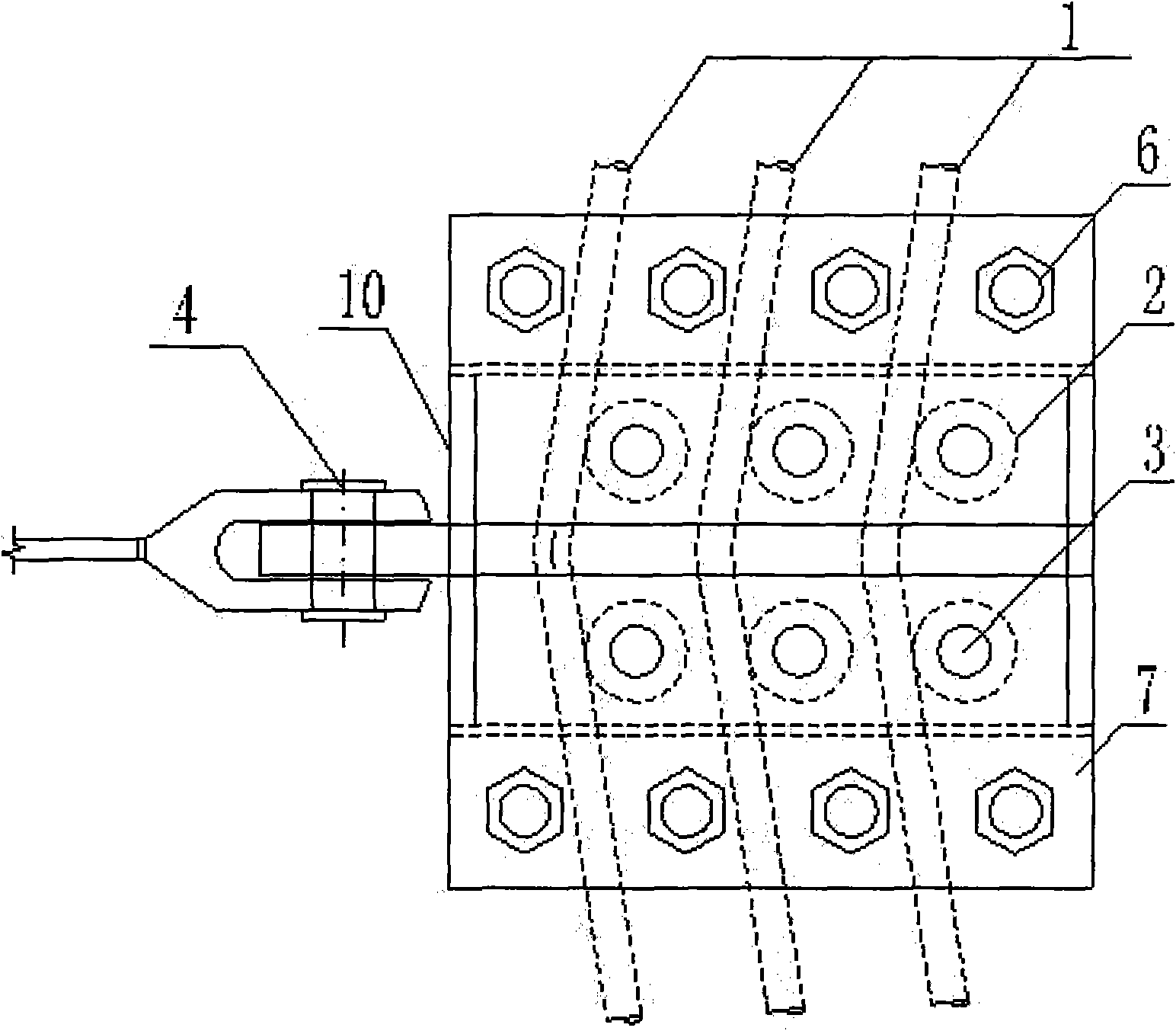

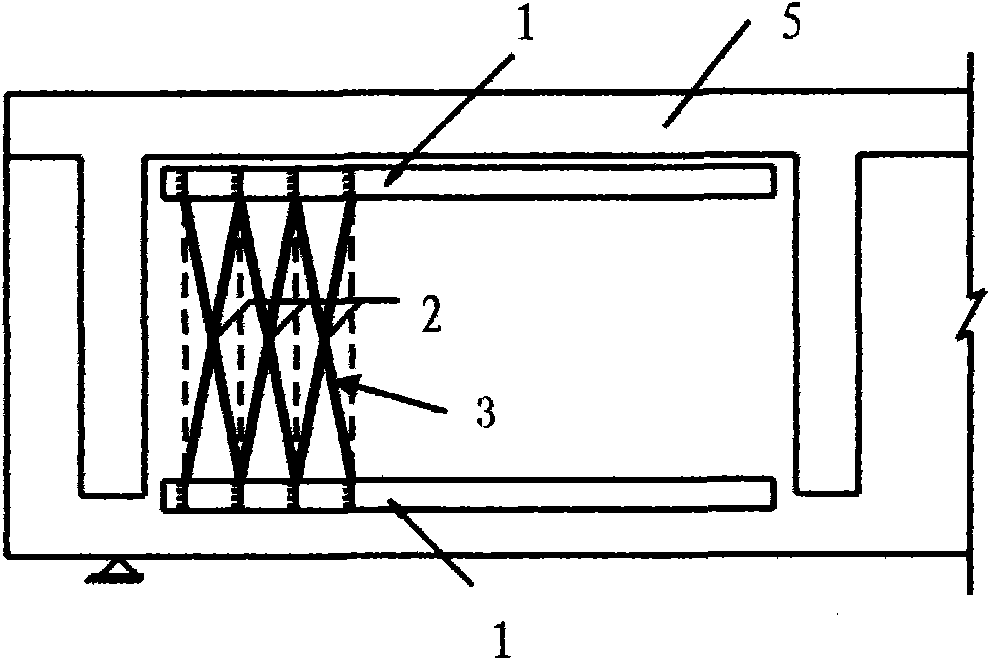

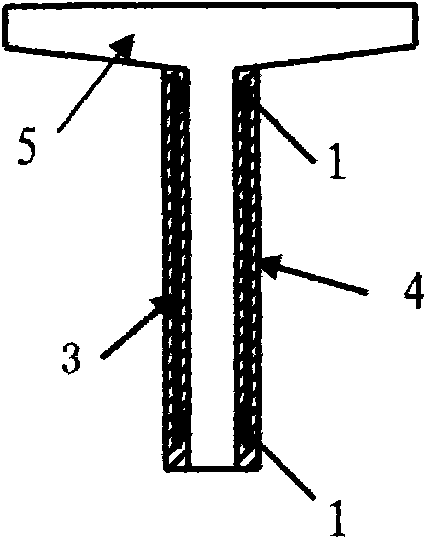

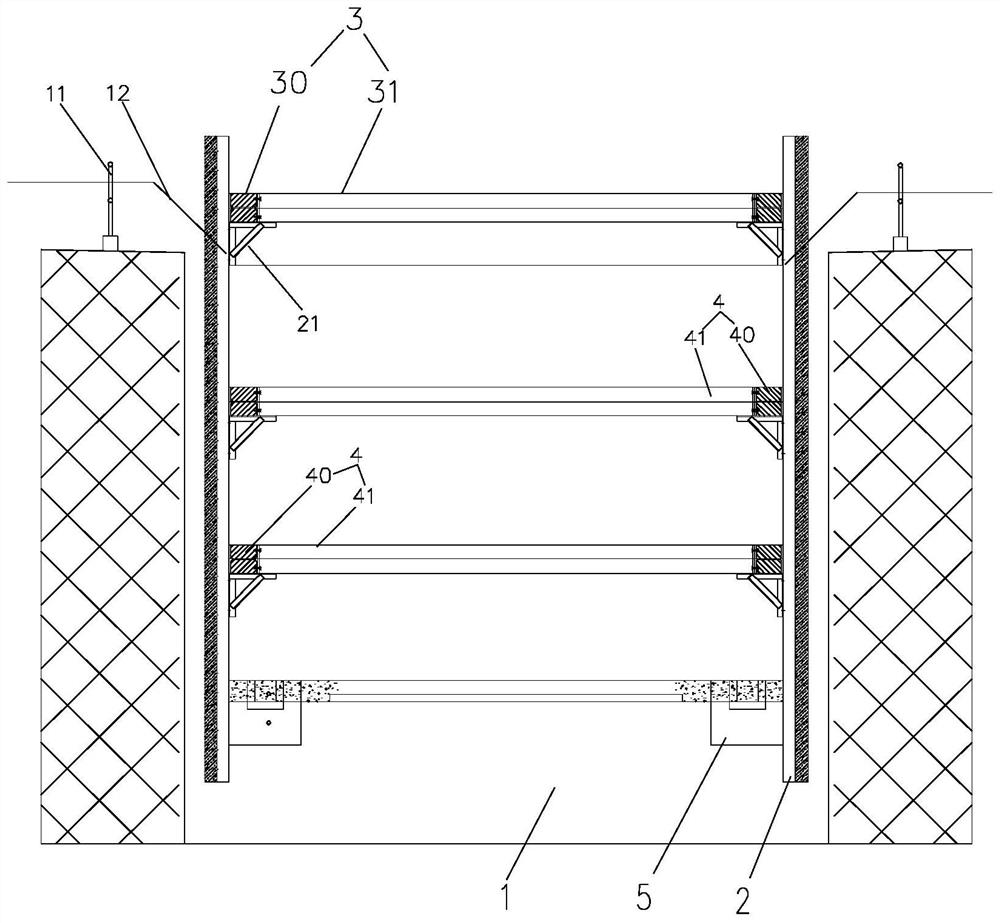

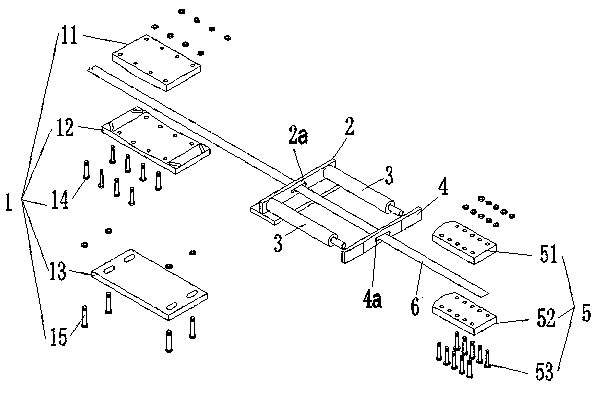

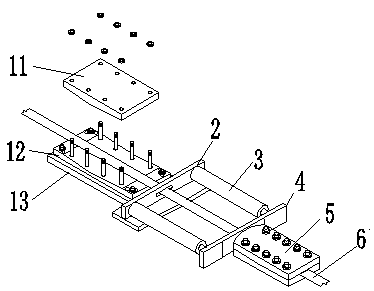

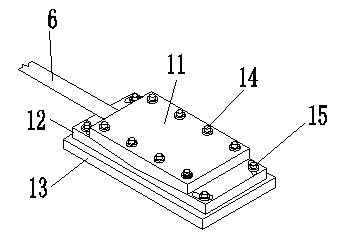

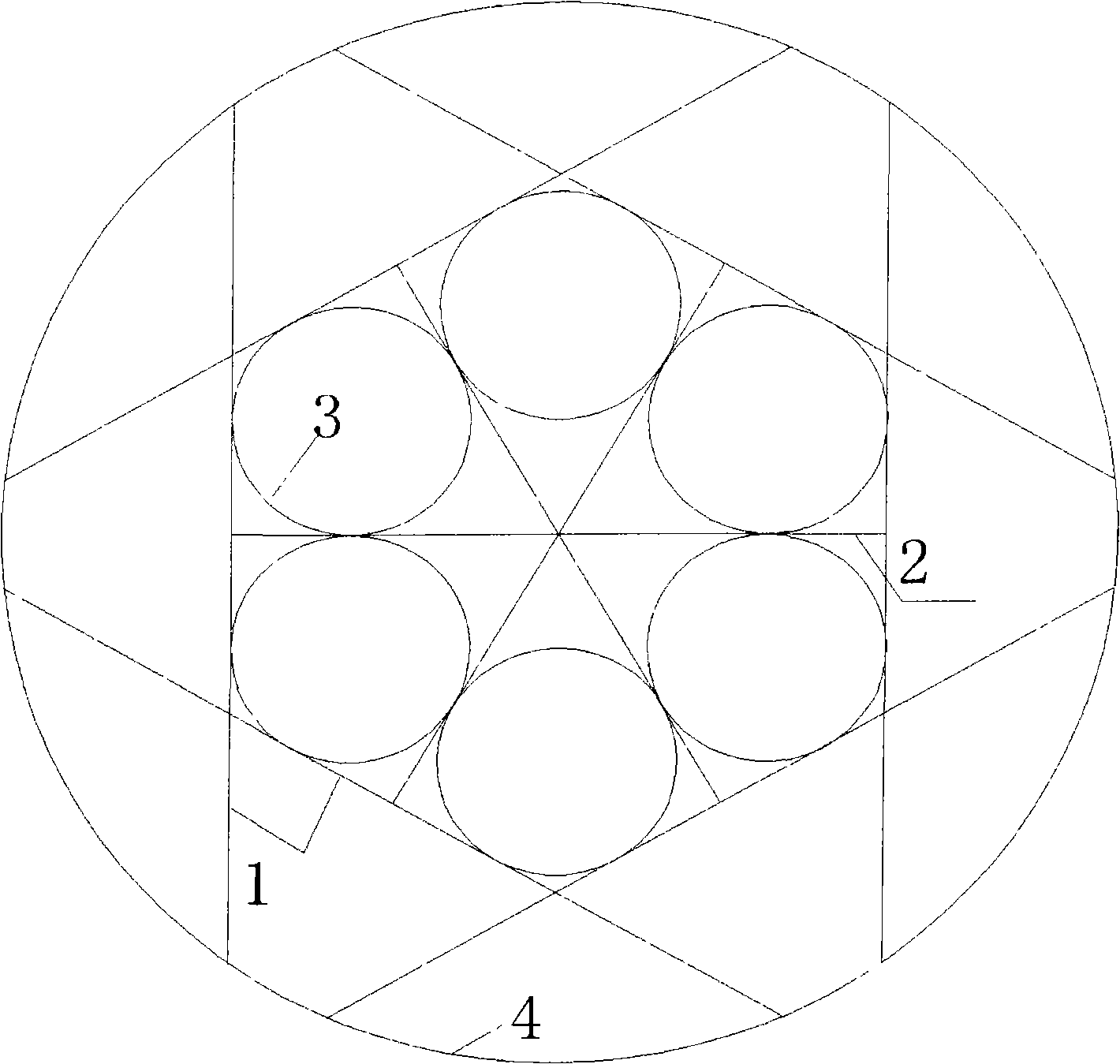

Tensional anchoring system for secondary clamping of prestressed sheets

InactiveCN103075014ASmall loss of prestressNo warping stressBuilding repairsBuilding material handlingPre stressHigh stress

The invention discloses a tensional anchoring system for the secondary clamping of prestressed sheets. The tensional anchoring system comprises an anchoring anchorage device combination (1), a tensional pressure bearing block (2), a horizontal jack (3), a tensional support block (4) and a tensional anchorage device combination (5), wherein the anchoring anchorage device combination (1) comprises an upper anchoring clamp plate (11), a lower anchoring clamp plate (12), permanent clamp bolts and nuts (14) and a force transmitting bolt (15), and the tensional anchorage device combination (5) comprises an upper tensional clamp plate (51), a lower tensional clamp plate (52) and tensional clamp bolts and nuts (53). The system has the advantages that the tensional components and the anchoring components are completely separated, and the permanent components are simple; and under the condition of having automatic centering, tensioning and directional anchoring functions, the system can tension and anchor high-stress and large-tonnage prestressed sheets and ensure that prestress losses cannot be produced by anchorage devices in the use process.

Owner:全恩懋

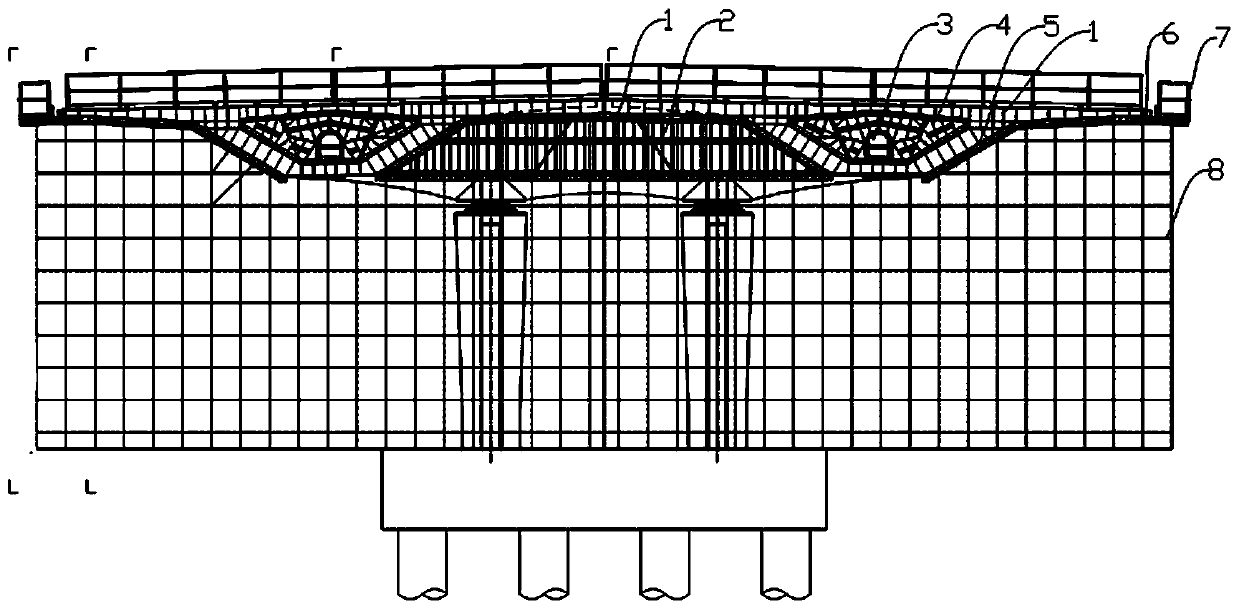

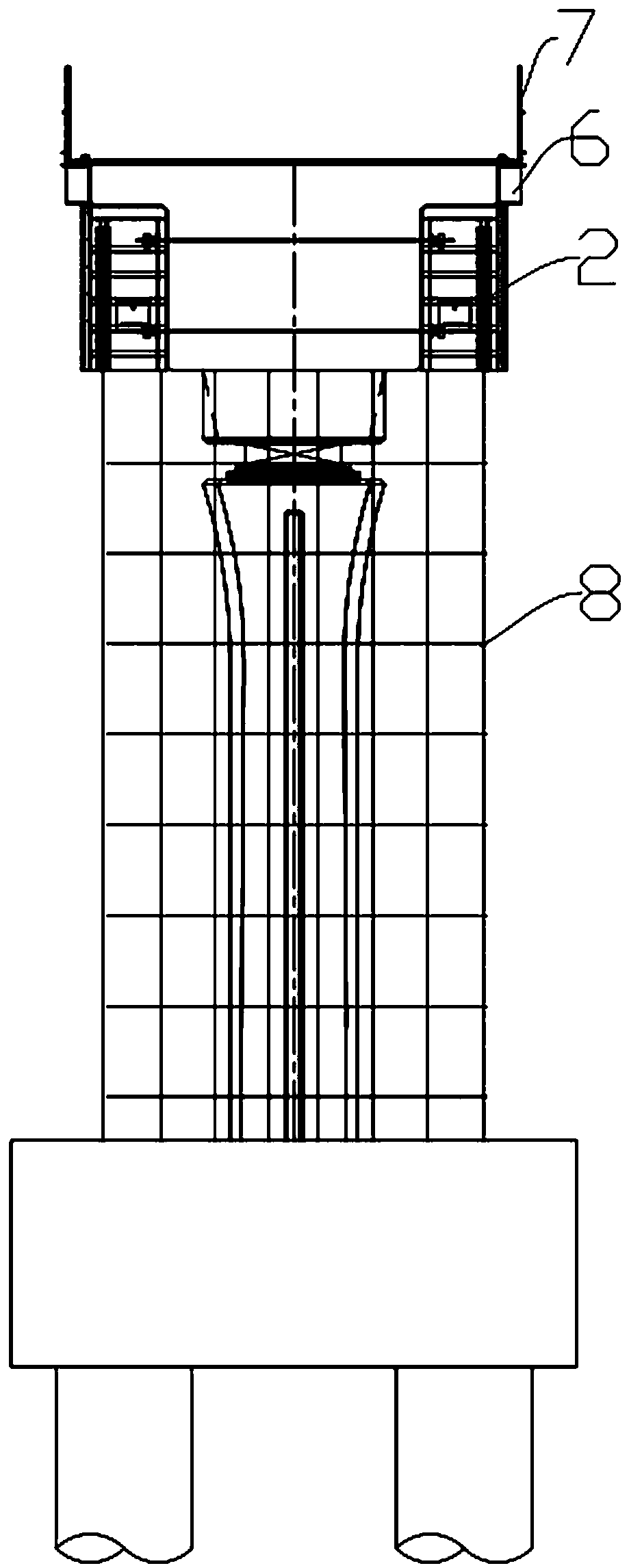

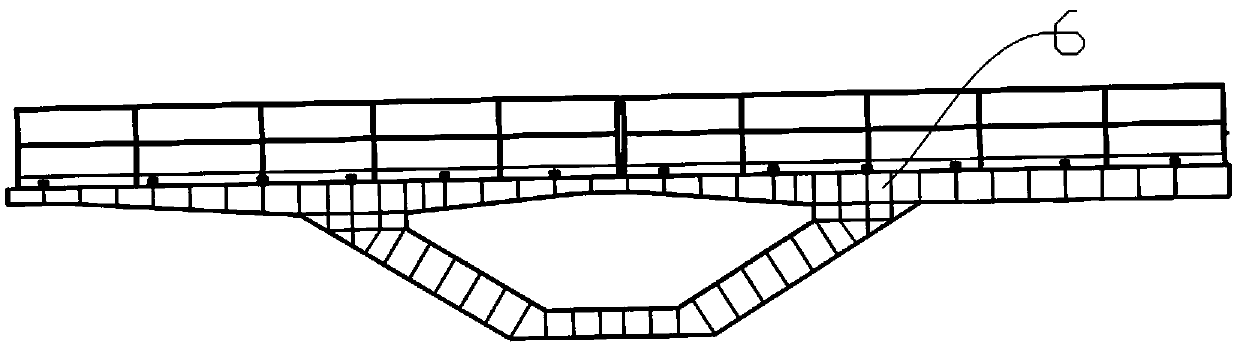

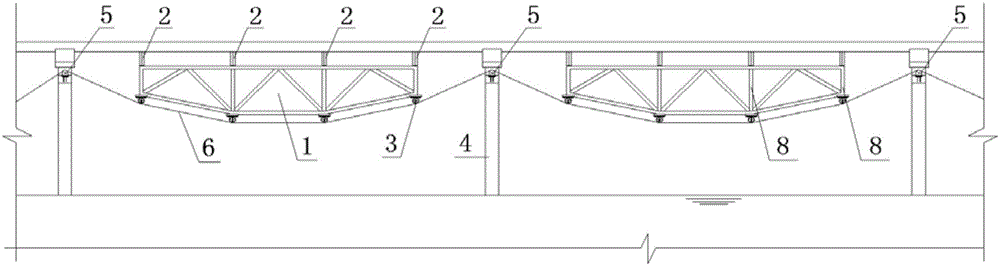

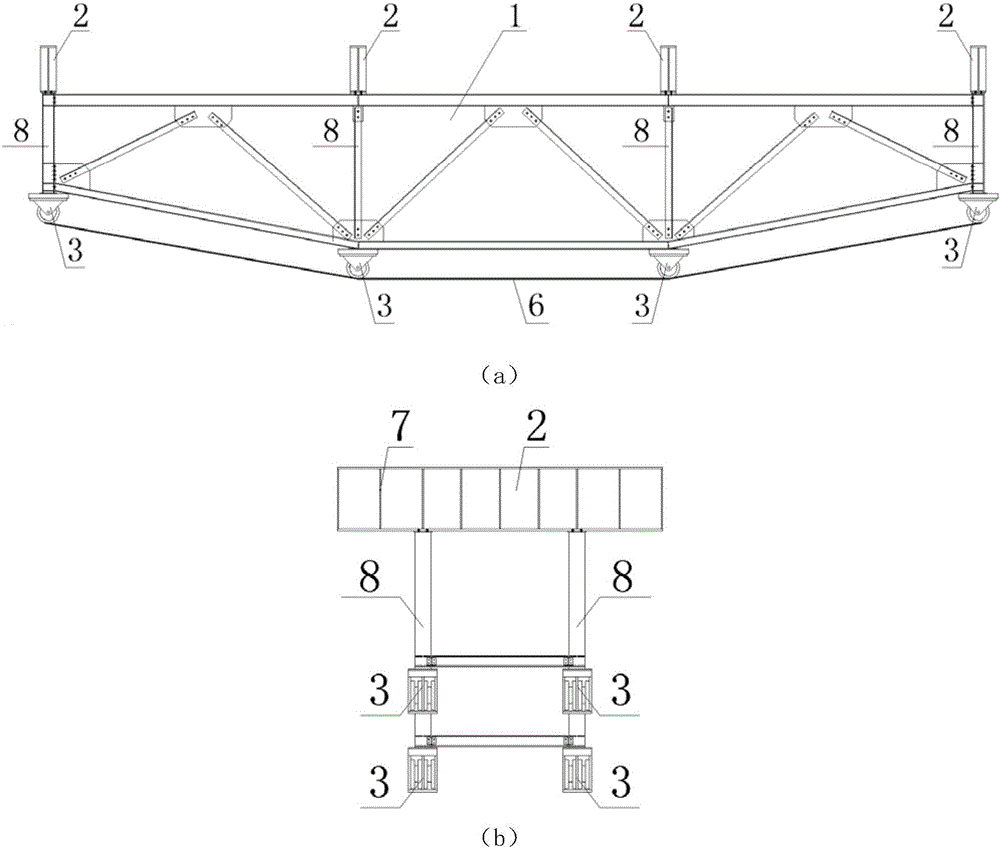

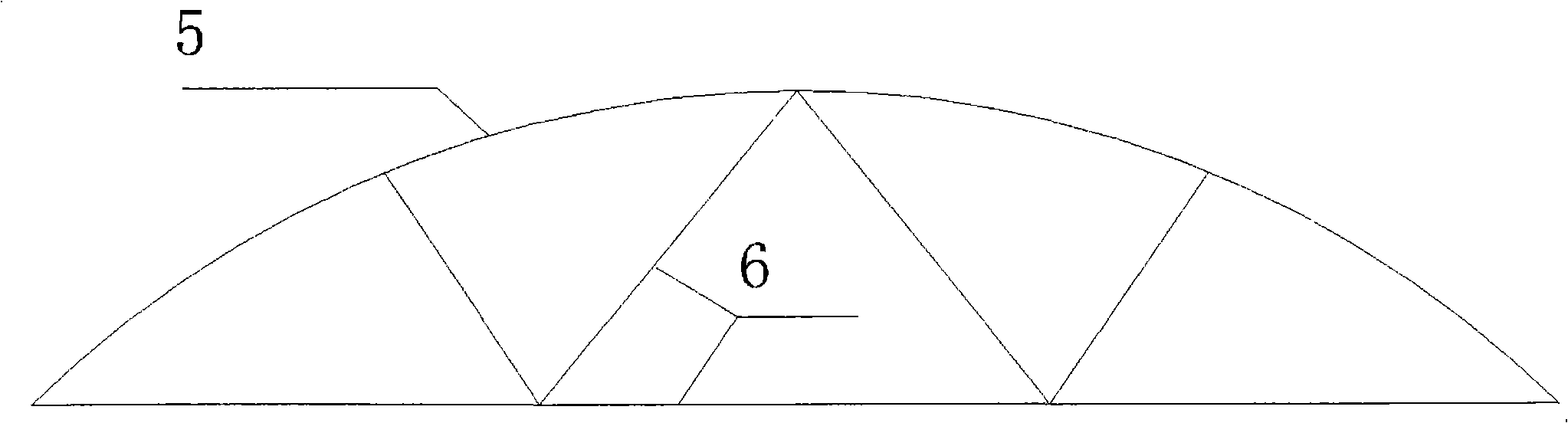

Variable-height cable-truss bridge reinforcing structure system

ActiveCN106567344ASignificant liftUniform jacking forceBridge erection/assemblyBridge strengtheningNet forcePre stress

The invention discloses a variable-height cable-truss bridge reinforcing structure system. The system comprises five parts including a prestress wire, a truss, a distributing beam, steering sliding wheels and a force transmission sliding wheel; the steering sliding wheels are fixed to the upper portion of a bridge pier, the inversed force transmission sliding wheel is fixed to the bottom of the truss, and the distributing beam is placed on the top; and the prestress wire sequentially penetrates the steering sliding wheels and the force transmission sliding wheel for connecting the fixed end and the stretching end on the two sides of an overall bridge, and therefore the distributing beam abuts against the lower surface of a top bridge plate. the prestress wire form upward resultant force at the bottom of the truss, and the resultant force is transmitted by the truss to the bridge face plate to form jacking force. The lengths of vertical web members of the truss are in bilateral symmetry, the vertical web members on the outmost sides are shortest, and the best reinforcing effect is achieved. By means of the above manner, the dead load of the bridge plate can be partially offset, the bearing capacity and the rigidity of the structure are effectively improved, and the aim of reinforcing the bridge is achieved.

Owner:ZHEJIANG UNIV

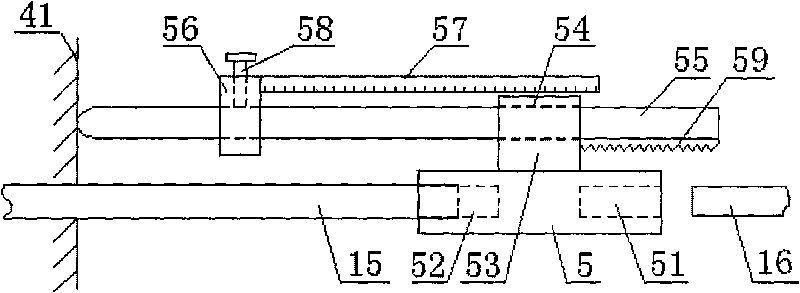

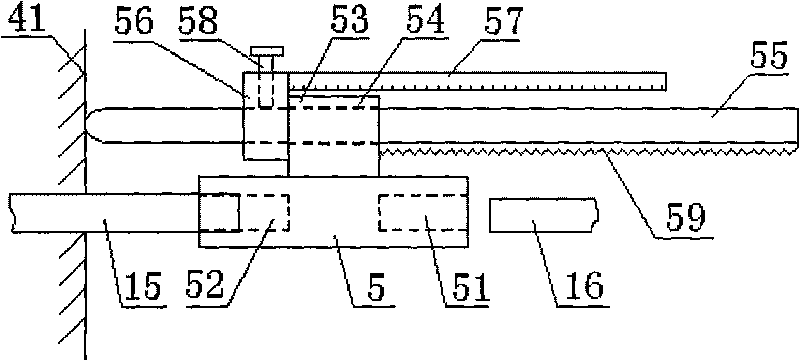

Construction method for installing support rapidly by using rear chambering self-locking anchor rod

ActiveCN101705831AQuick installationQuality is easy to controlAnchoring boltsSelf lockingEngineering

A construction method for installing a support rapidly by using a rear chambering self-locking anchor rod comprises the following steps: A. removing residues in an anchor hole (4) by using high pressure air; B. inserting the rear chambering self-locking anchor rod in the bottom of the anchor hole (4); and installing a rear chambering anchor rod installer at the external part of the anchor hole (4); C. calibrating the sliding distance of a sliding bar base (53) of the rear chambering anchor rod installer on a sliding bar (55); D. installing a drill rod (16) on an air pick, inserting the drill rod (16) into the rear chambering anchor rod installer, starting the air pick, propelling the anchor rod to the bottom part of the anchor hole (4), and until the anchor rod is propelled to the final point of the calibrated distance, stopping the air pick, and disassembling the rear chambering anchor rod installer; and E. installing a cushion block at the exposing end (15) of the anchor rod body and locking the cushion block by nuts. The method is convenient for mechanized construction, has high installation speed, large anchoring force and stable anchoring quality, is convenient for monitoring and detection, good in adaption on the obliquely arranged anchor rod, and provides feasible implementation specifications for the wide application of the rear chambering self-locking anchor rod.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Pressure-type carbon fiber prestressing force anchor cable land-sliding control structure

InactiveCN101624828ALight in massEasy to transportExcavationsBulkheads/pilesCarbon fibersFiber bundle

The invention relates to a pressure-type carbon fiber prestressing force anchor cable land-sliding control structure, comprising an anchor cable which is composed of carbon fiber bundles with more than 3500Mpa of tensile strength, and a polrvinyl chloride sleeve is wrapped at the outer side of the carbon fiber bundles, cement mortar is poured at the outer side of the polrvinyl chloride sleeve, an anchor cable bore is arranged at the outer side of the cement mortar, and a bearing steel plate is arranged at the end part of the carbon fiber bundles. The structure has the characteristics of light weight, high tensile strength, corrosion resistance and long service life.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Construction method for special structure layer of cone bottom wheat-immersion

InactiveCN101294420AGuaranteed StrengthGuaranteed stabilitySpecial buildingExtraordinary structuresFalseworkShaped beam

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

Design method for unbonded prestress and steel-concrete combined reinforcement of concrete box girder

ActiveCN106120574AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSteel jacketPre stress

The invention discloses a design method for unbonded prestress and steel-concrete combined reinforcement of a concrete box girder. The design method comprises the following steps of I, determining a combined reinforcing structure: determining the unbonded prestress and steel plate-concrete combined structure of the box girder to be reinforced wherein the combined reinforcing structure comprises a steel jacket box formed by a base steel pate, two longitudinal side steel plates and two end part plugging steel plates, and a plurality of unbonded prestressed reinforcing bars are arranged in the steel jacket box; II, determining structural parameters for reinforcing the front box girder; and III, determining structural parameters of the combined reinforcing structure in the process comprising the following steps of initializing the parameters, calculating theoretical maximum thickness of the reinforcing steel plates, determining the thickness of the reinforcing steel plates and the thickness of concrete, and determining the height of the longitudinal side steel plates and the width of the base steel plate. The method disclosed by the invention is simple in steps, reasonable in design, convenient to realize, and good in using effect, the structural parameters of the combined reinforcing structure of a bridge can be simply, conveniently and quickly determined, and the designed combined reinforcing structure of the bridge is economical and practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

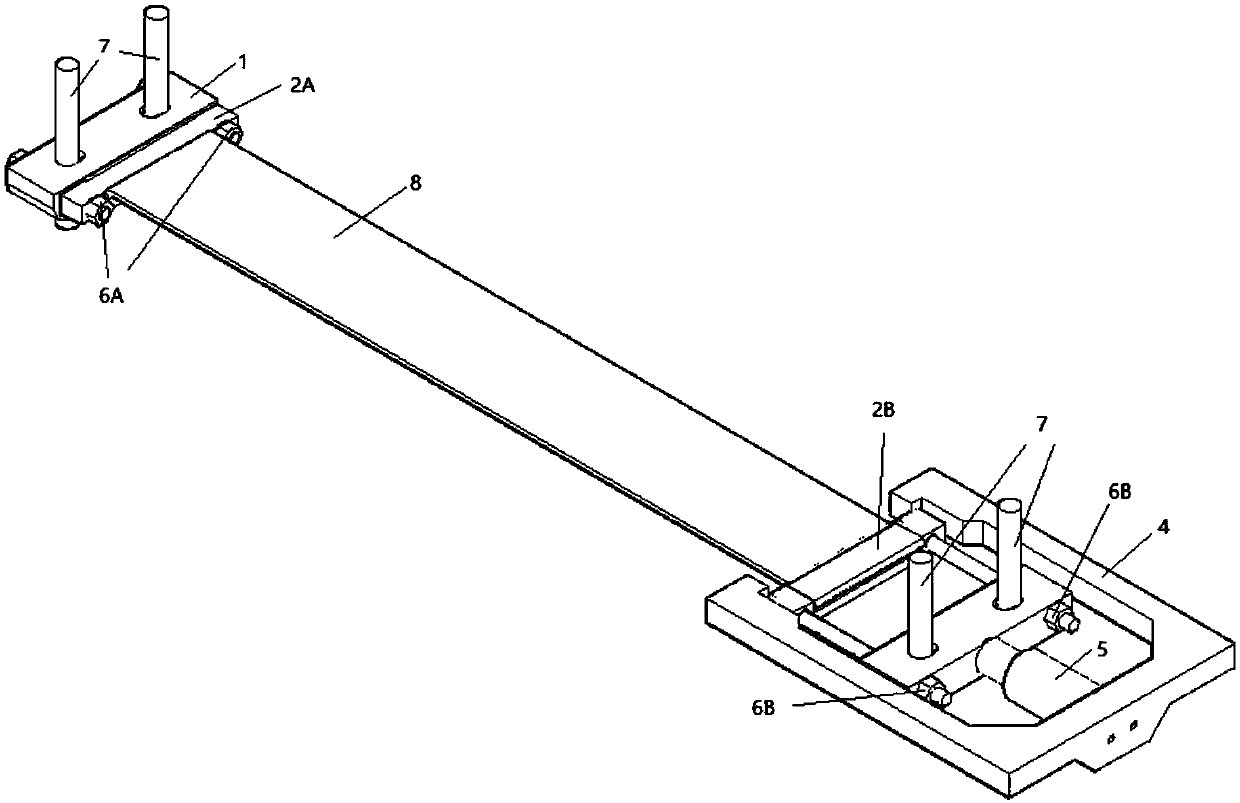

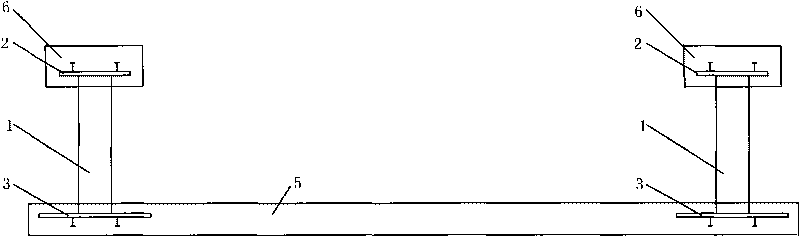

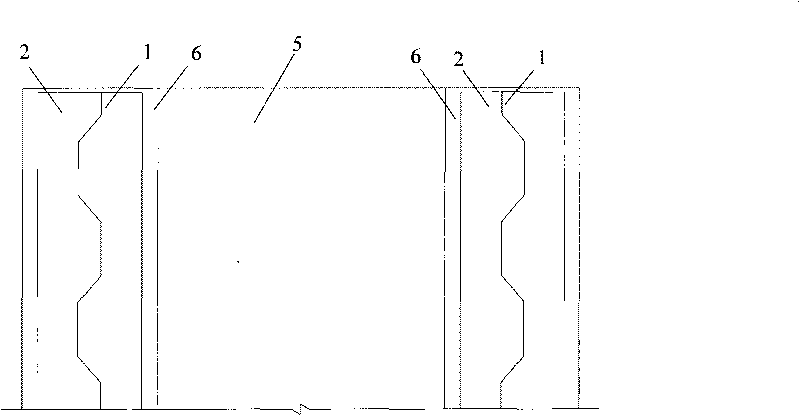

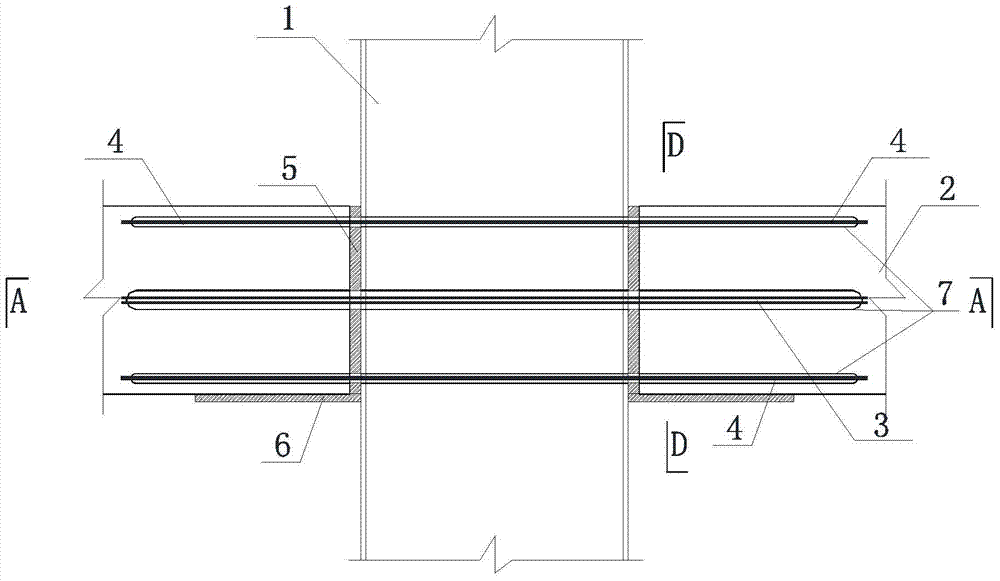

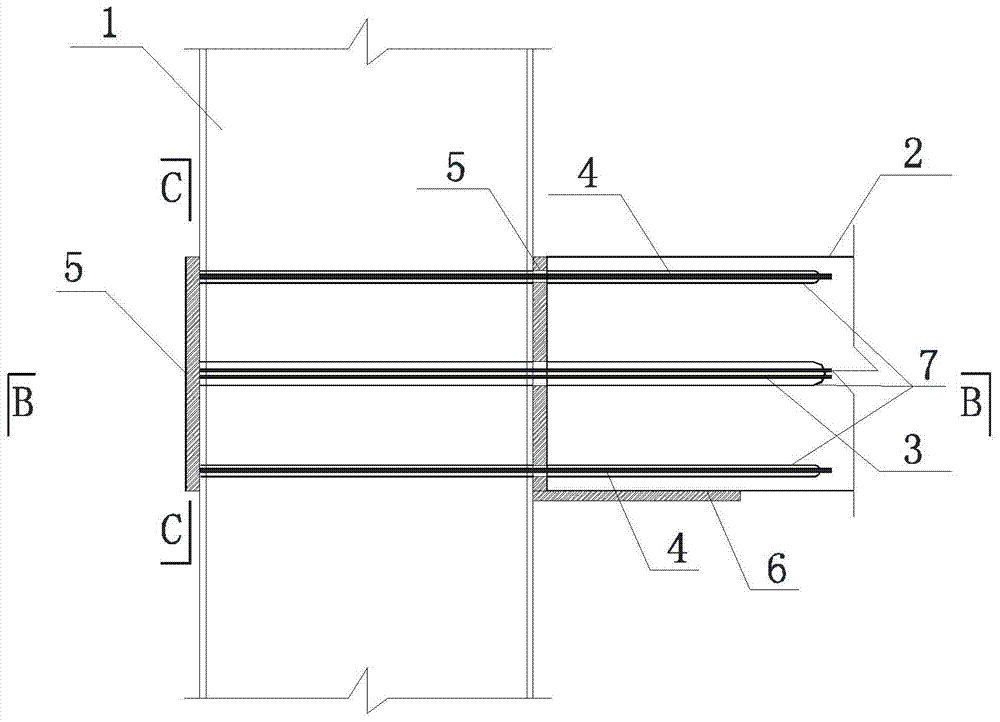

Pre-tensioning precast beam plate stressing bed structure

The invention discloses a pre-tensioning precast beam plate stressing bed structure. The pre-tensioning precast beam plate stressing bed structure comprises first stressing anchor ends, a spread foundation, bottom die frames, benders, second bogies and second stressing anchor ends. The structure is a pile column type structure, horizontal tension of prestress steel strands is transmitted through the spread foundation, the overturning moment of a stressing end is borne by pipe piles below the spread foundation, and the upward pulling force of the benders is also counteracted by the dead weightof the spread foundation, so that the using amount of pedestal concrete and steel is saved to the maximum extent; according to the structure, two beams can be precast at the same time by stressing thesteel strands once, so that the stressing frequency can be reduced, the beam plate construction efficiency can be improved, the investment of the pipe piles at the stressing end can be reduced, and the occupied area of a site can be reduced; pulleys of a first bogie and the second bogies adopt roller inner sleeve bearings, so that the prestress loss of the steel strands is effectively reduced; and a reaction wall, an inclined strut, an anchoring trolley and the bogies are all of steel structures, so that secondary use in tectonic stress field transformation can be achieved on the premise thatthe strength and rigidity of the reaction wall, the inclined strut, the anchoring trolley and the bogies are guaranteed.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com