Prestressed carbon cloth reinforced tensioner

A carbon fiber cloth and prestressing technology, which is applied in the field of devices for stretching carbon fiber cloth to components, can solve the problems that cannot be solved by carbon fiber cloth stretching equipment, difficult anchoring of clip-type anchors, and the breaking of tows one by one. Light weight, small prestress loss, convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

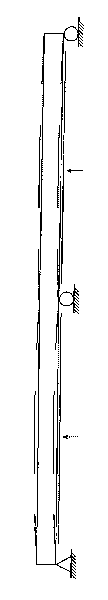

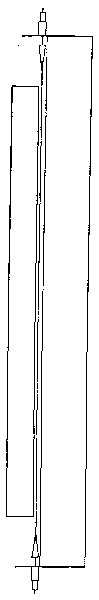

[0043] The main body of the present invention includes two reaction force frames 1, and their structure is as Figure 11 As shown, it is made of 10mm steel plate, and the two reaction force frames 1 are connected and fixed on both sides of the component 13 with fastening bolts 2 . Such as Figure 4 As shown, a supporting device 3 is installed on the reaction force frame 1 for realizing the steering of the carbon fiber cloth 12 . The anchorage of the fixed end of the carbon fiber cloth 12 can be directly pasted on the concrete member 13 with structural glue. After the structural glue is cured, the end of the carbon fiber cloth is naturally anchored. Concrete Structure Technology" regulations CECS146: 2003 in the relevant provisions and related documents to determine. The other end of the carbon fiber cloth 12 bypasses the supporting device 3 and is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com