Patents

Literature

493results about How to "Simple equipment structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

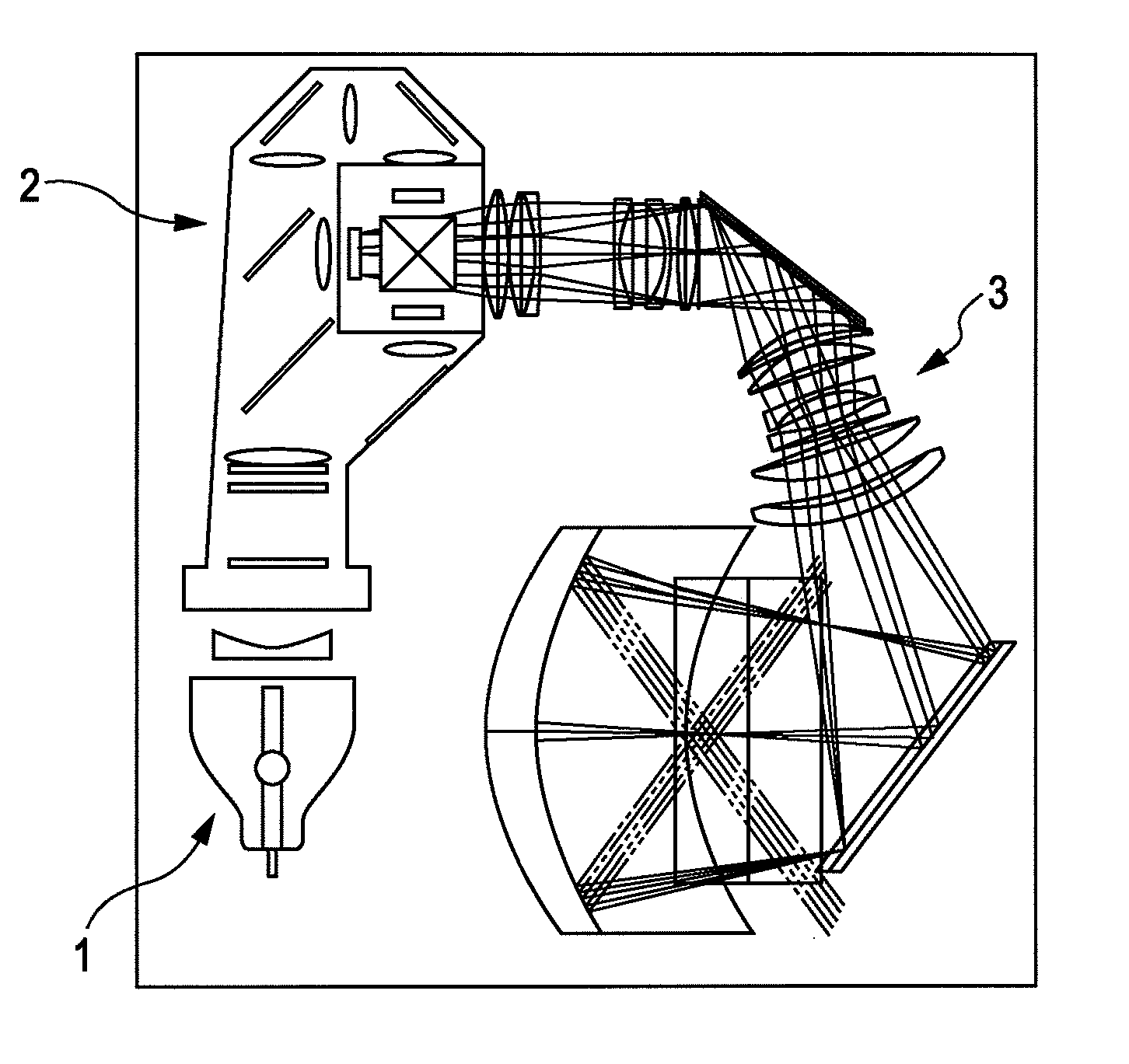

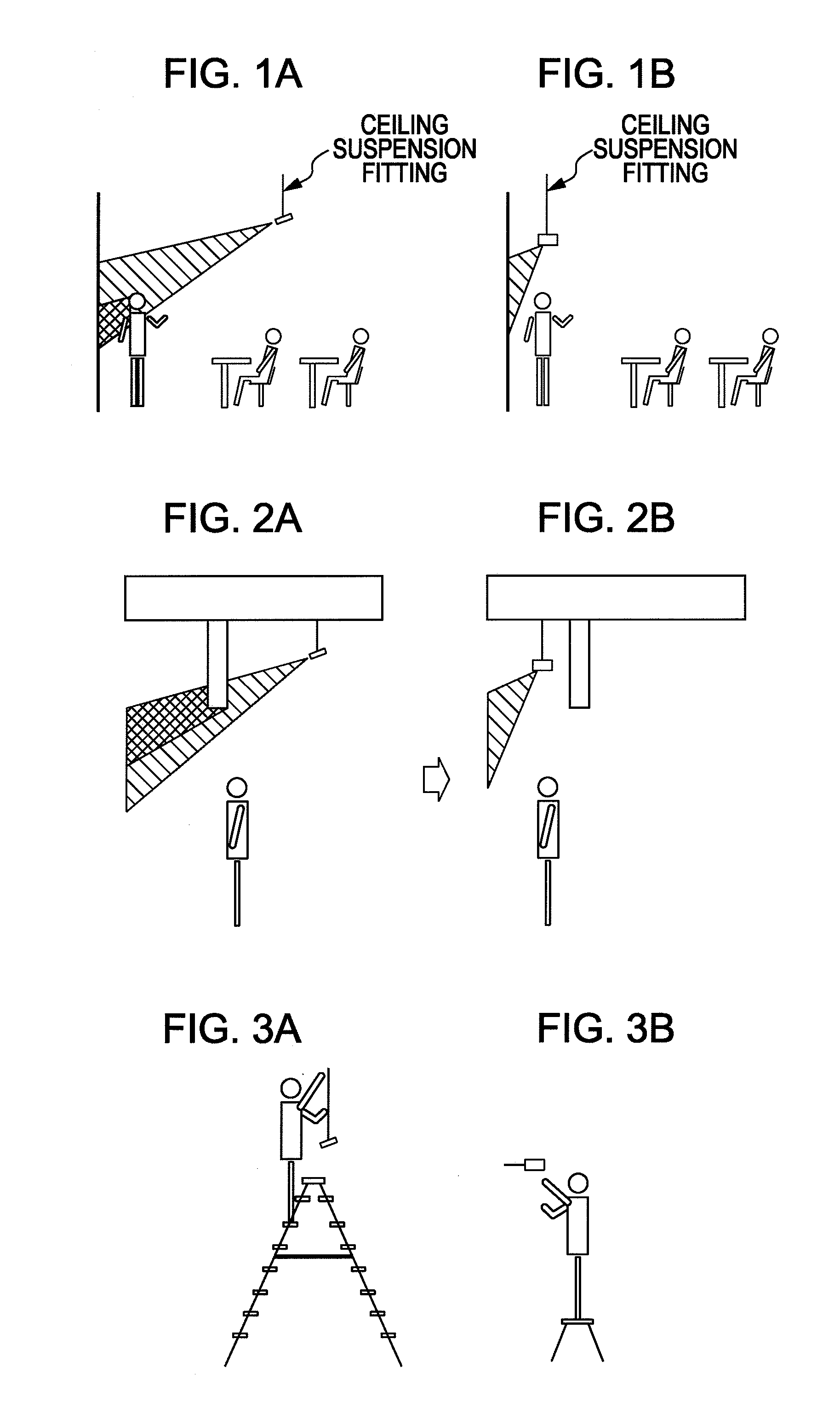

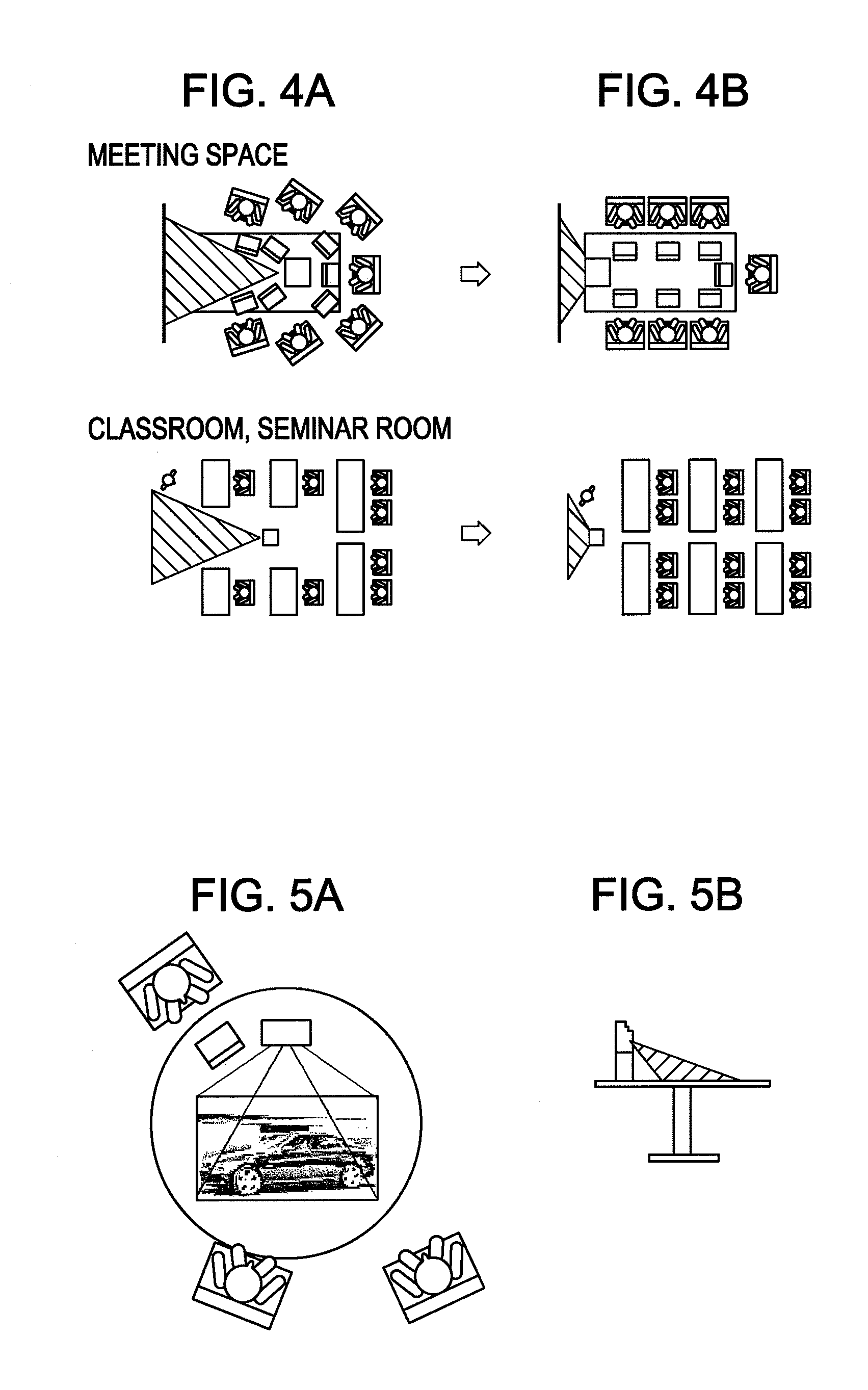

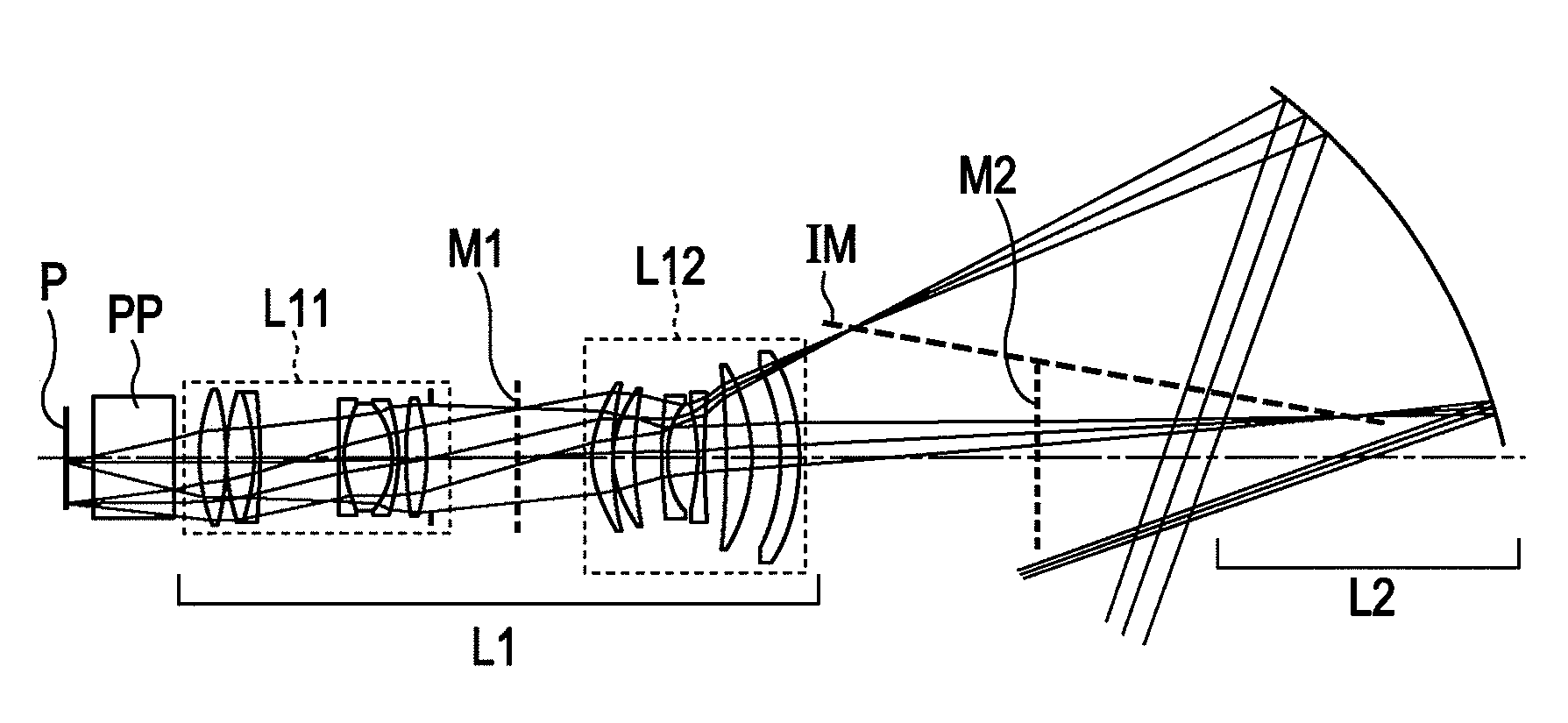

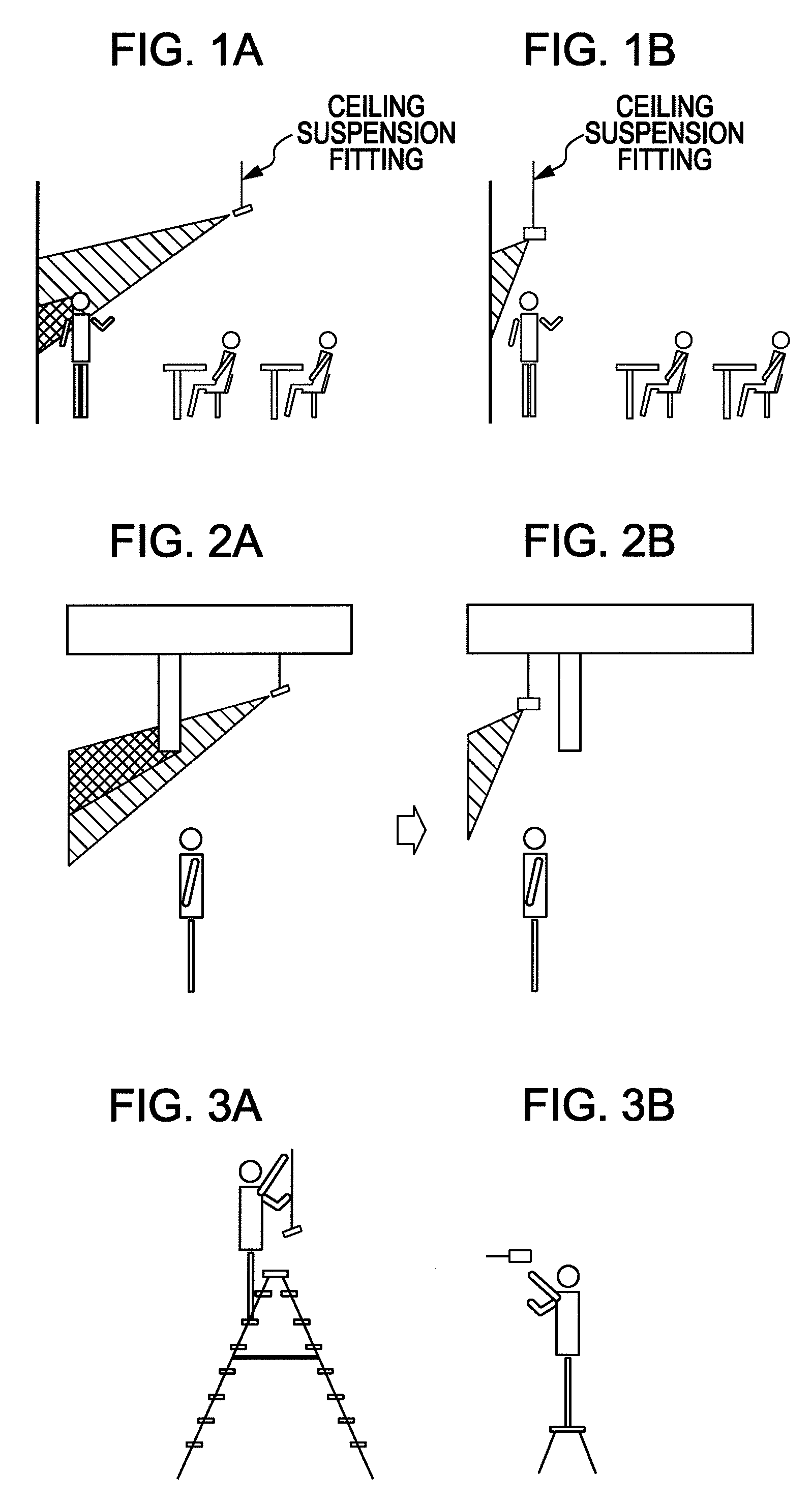

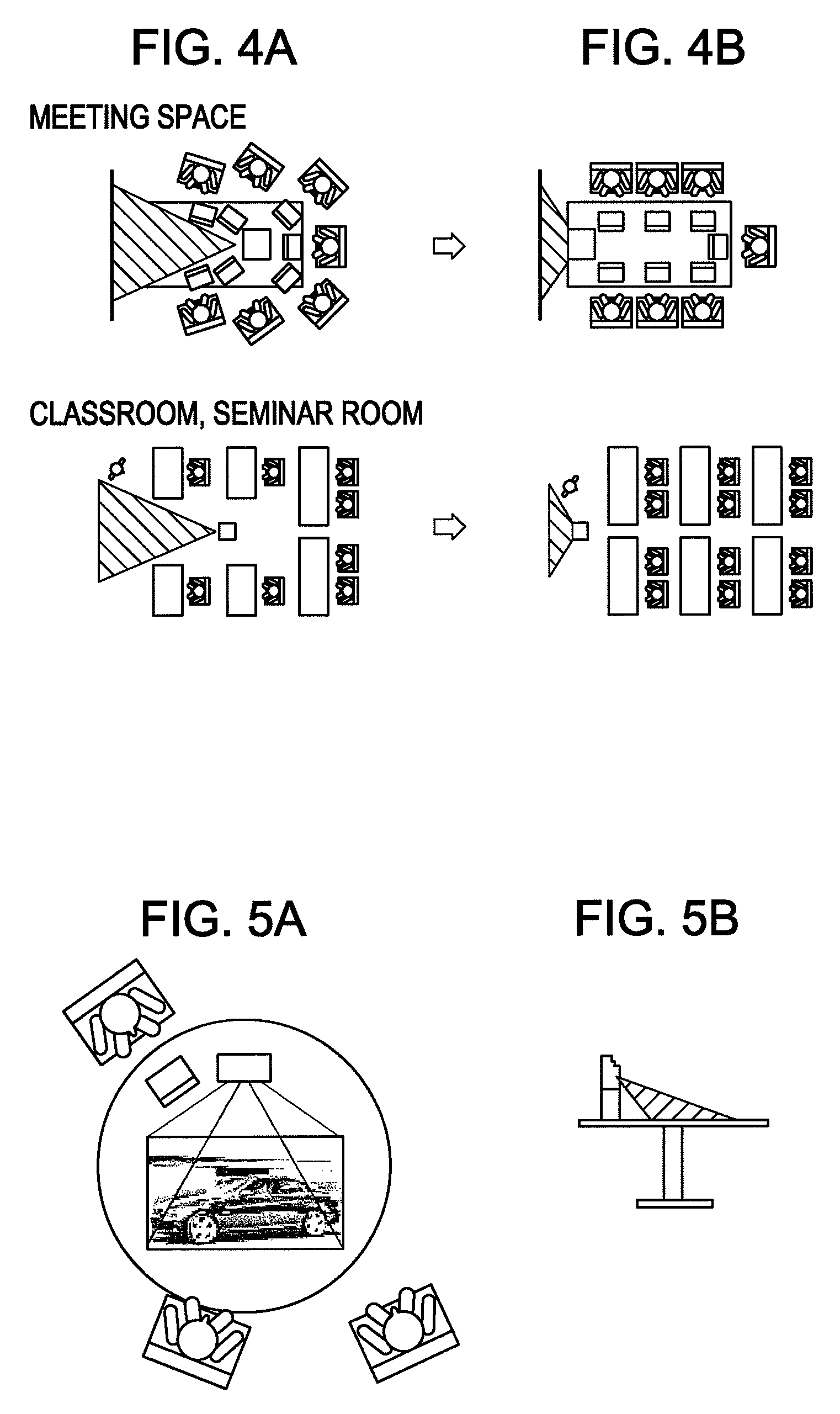

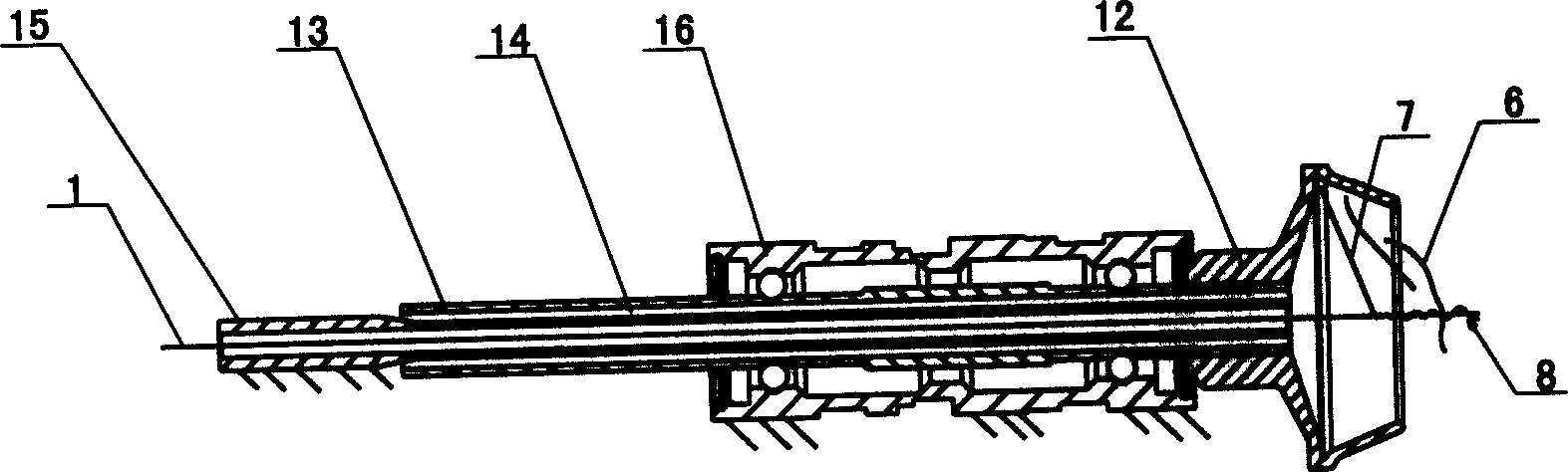

Projection image display device and projection optical system

ActiveUS20100128234A1Simple structureReduce in quantityProjector focusing arrangementCamera focusing arrangementProjection imageProjection optics

A projection image display device includes a light source; an illumination optical system that uniformly irradiates a surface of an image modulating element (primary image surface) with a light beam emitted from the light source; and a projection optical system that performs with respect to a screen (a secondary image surface) extended projection on image information provided at the primary image surface and modulated by the image modulating element. The projection optical system includes a first optical system having a positive refractive power, and a second optical system having a concave reflecting surface. The first optical system has a common optical axis at which all optical components of the first optical system have rotationally symmetric surfaces, and a screen shift function that causes the secondary image surface to be moved by moving at least one of the optical components of the first optical system substantially perpendicularly to the optical axis.

Owner:SONY CORP

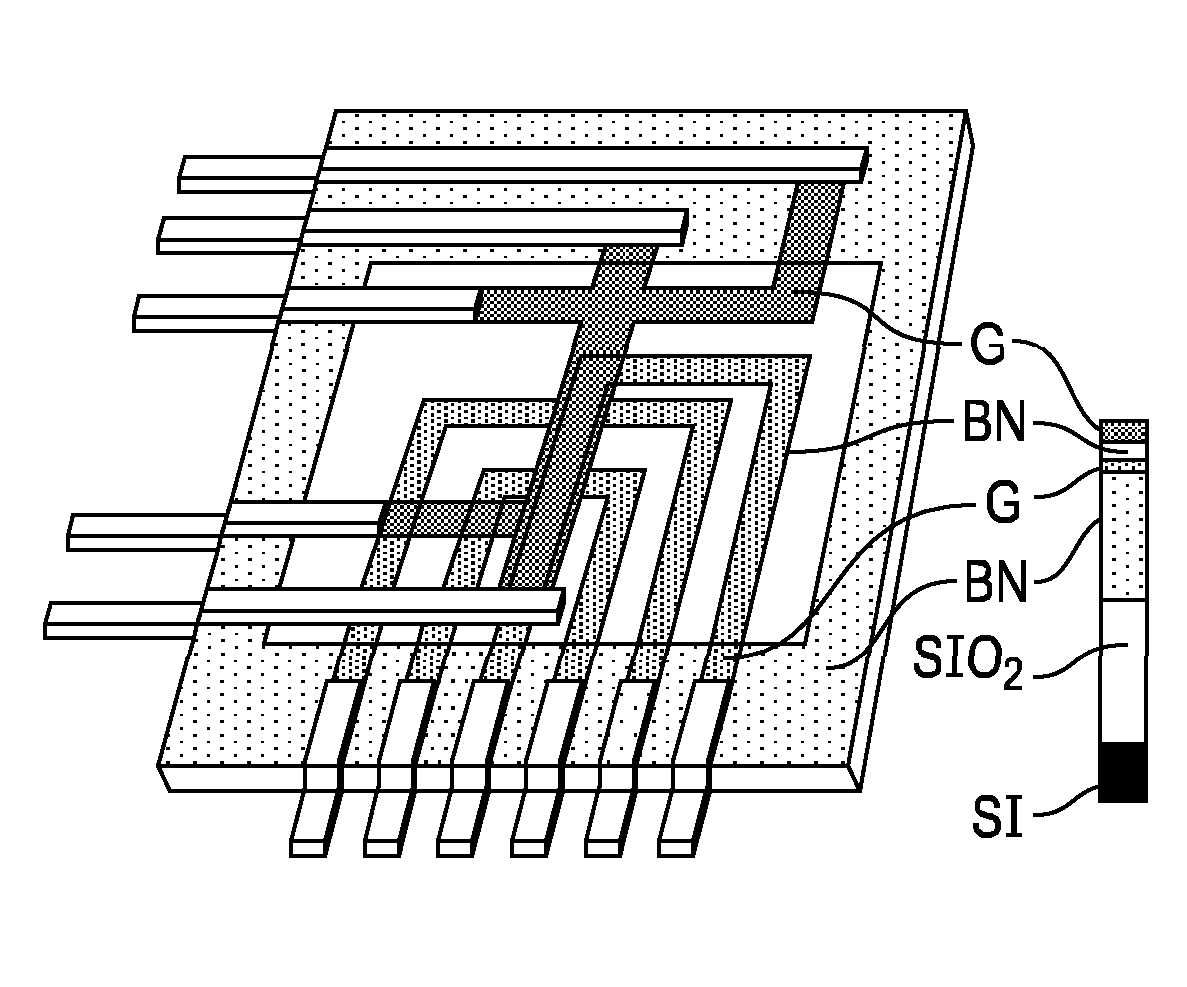

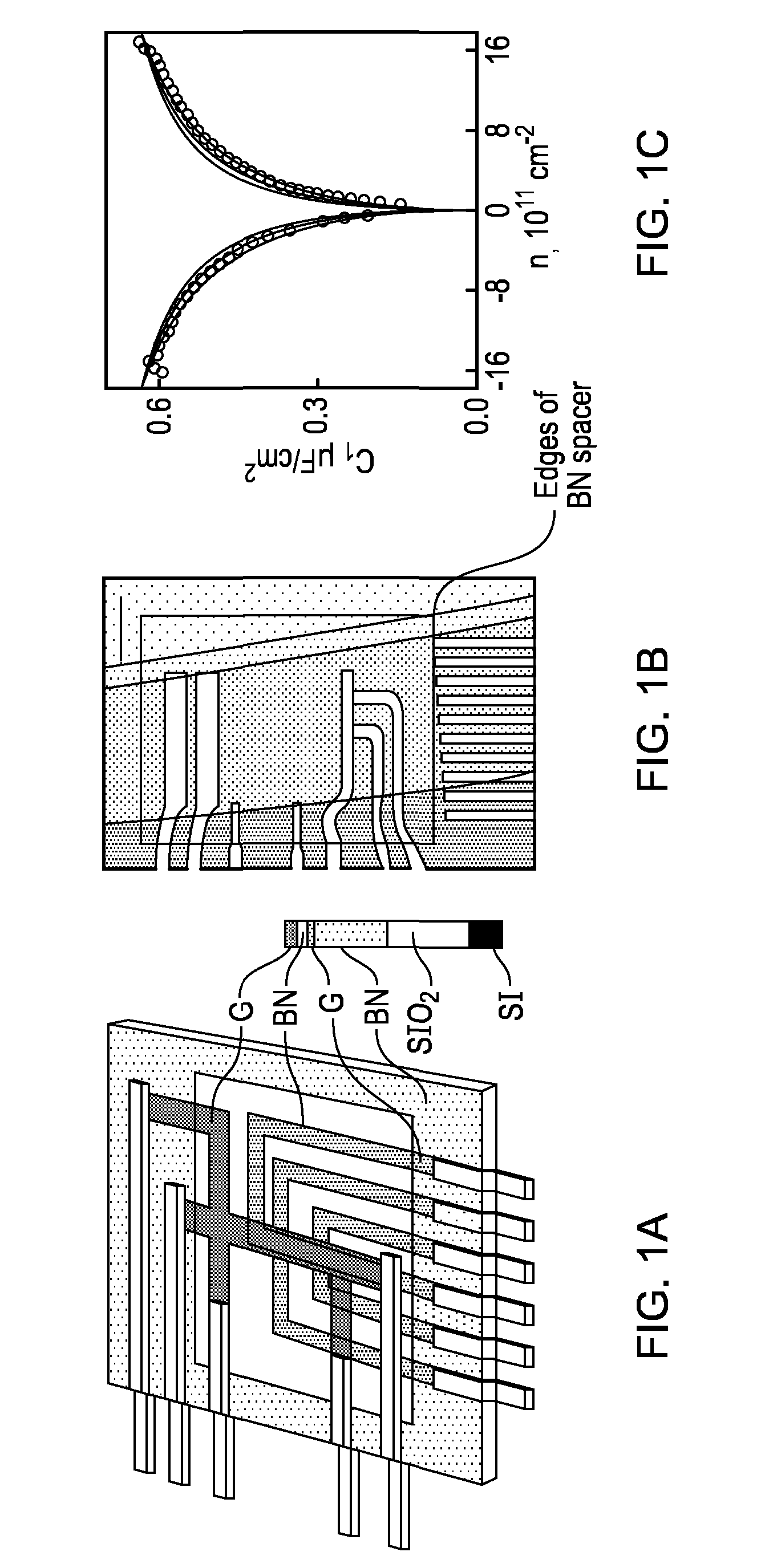

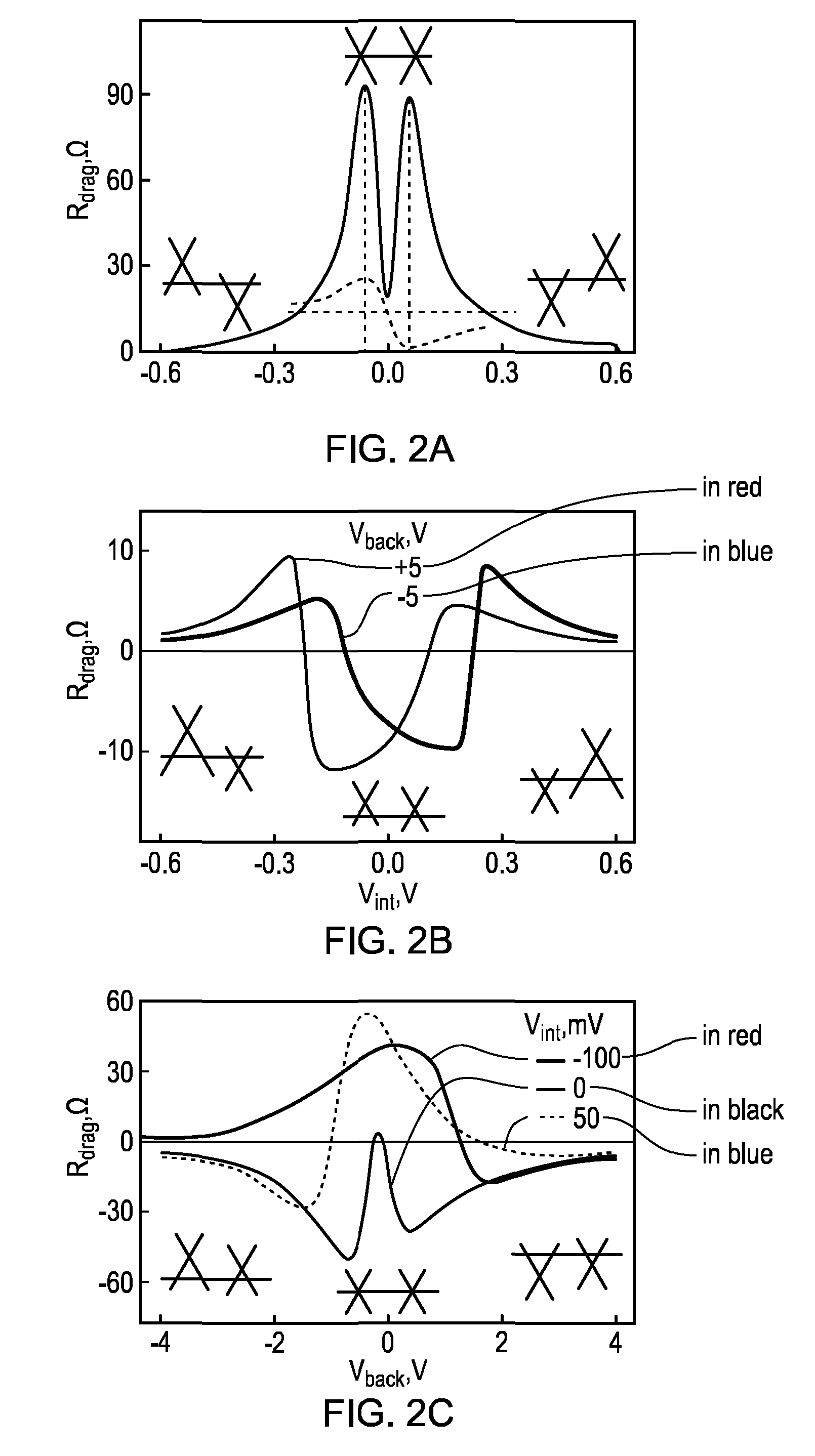

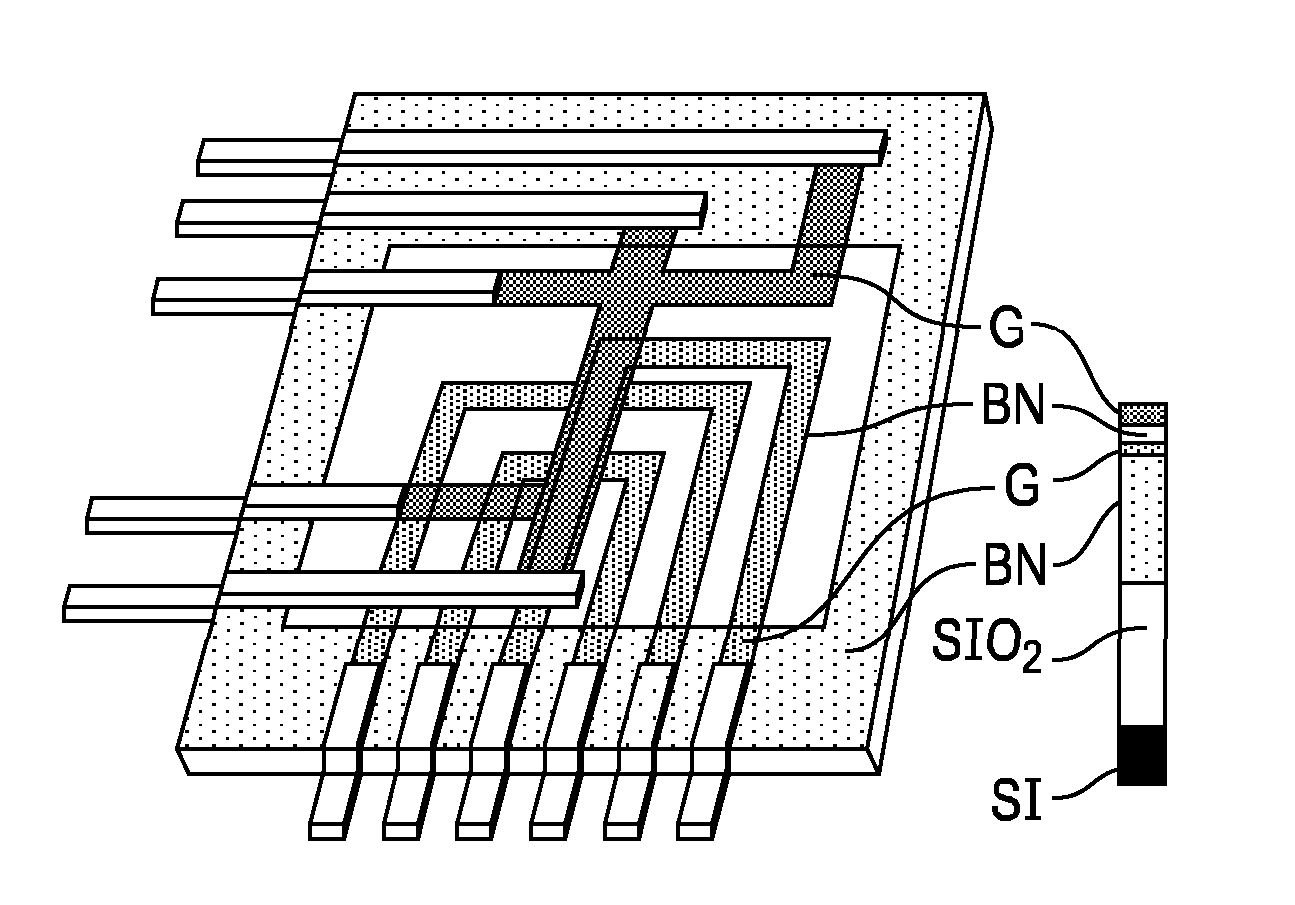

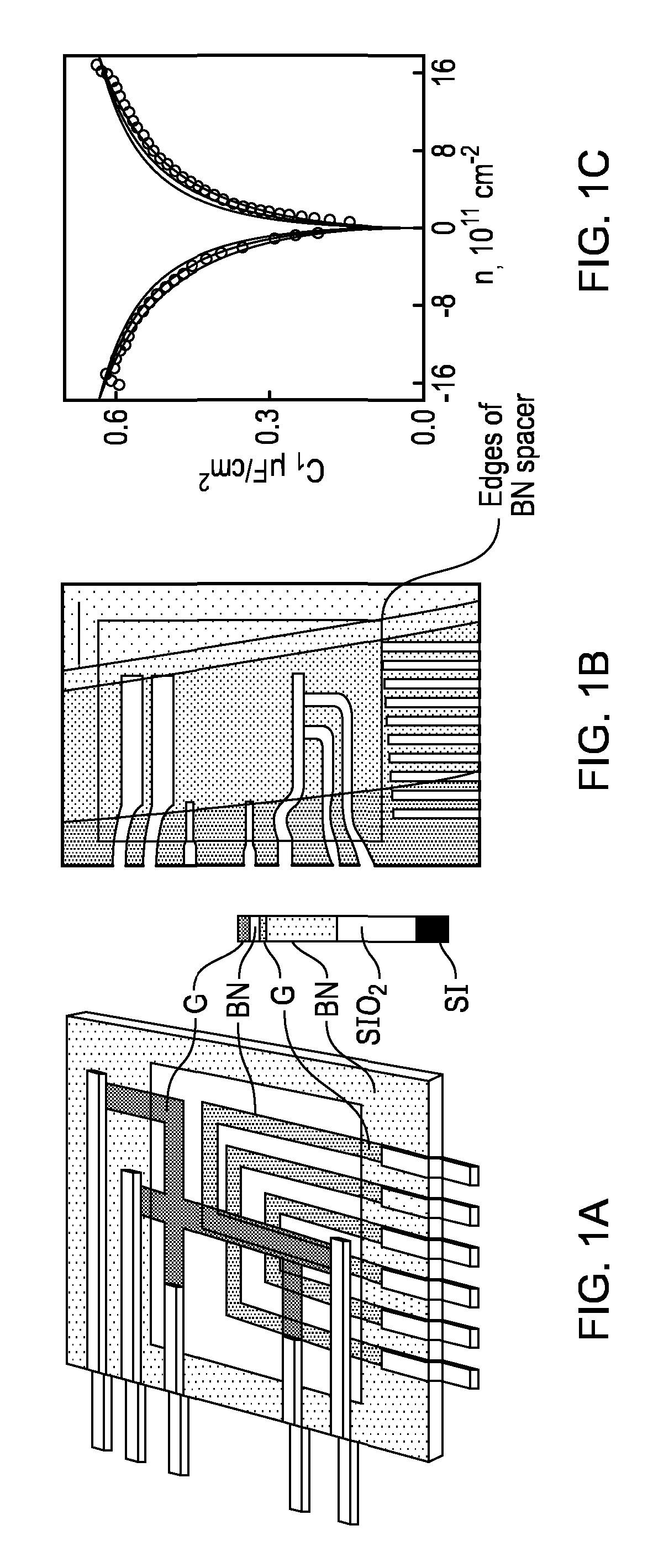

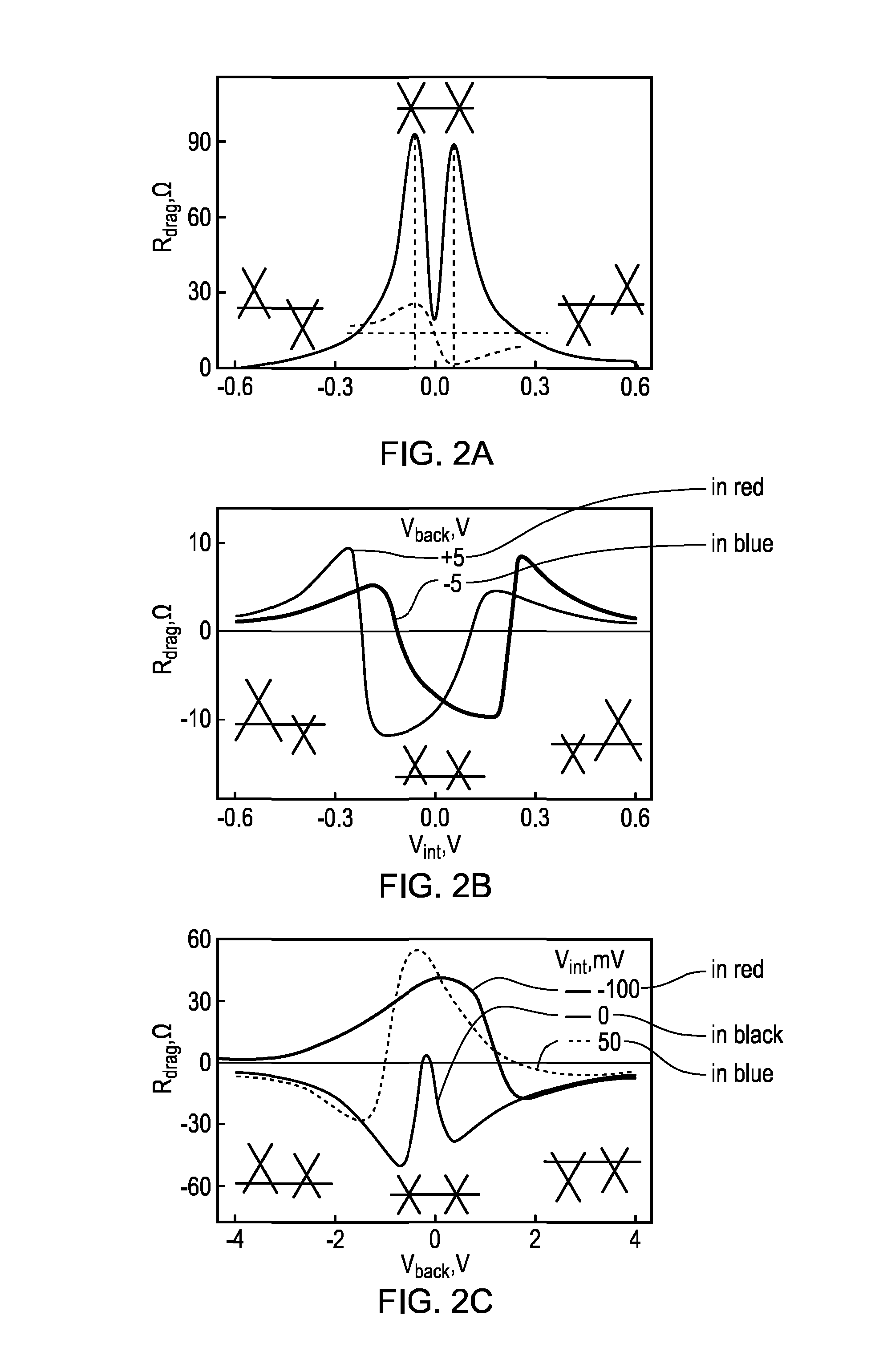

Transistor device and materials for making

ActiveUS20140008616A1Enhances tunnel currentHighSemiconductor/solid-state device manufacturingSemiconductor devicesGrapheneGraphite

This application relates to graphene based heterostructures and transistor devices comprising graphene. The hetero-structures comprise i) a first graphene layer; ii) a spacer layer and iii) a third graphene. The transistors comprise (i) an electrode, the electrode comprising a graphene layer, and (ii) an insulating barrier layer.

Owner:UNIV OF MANCHESTER

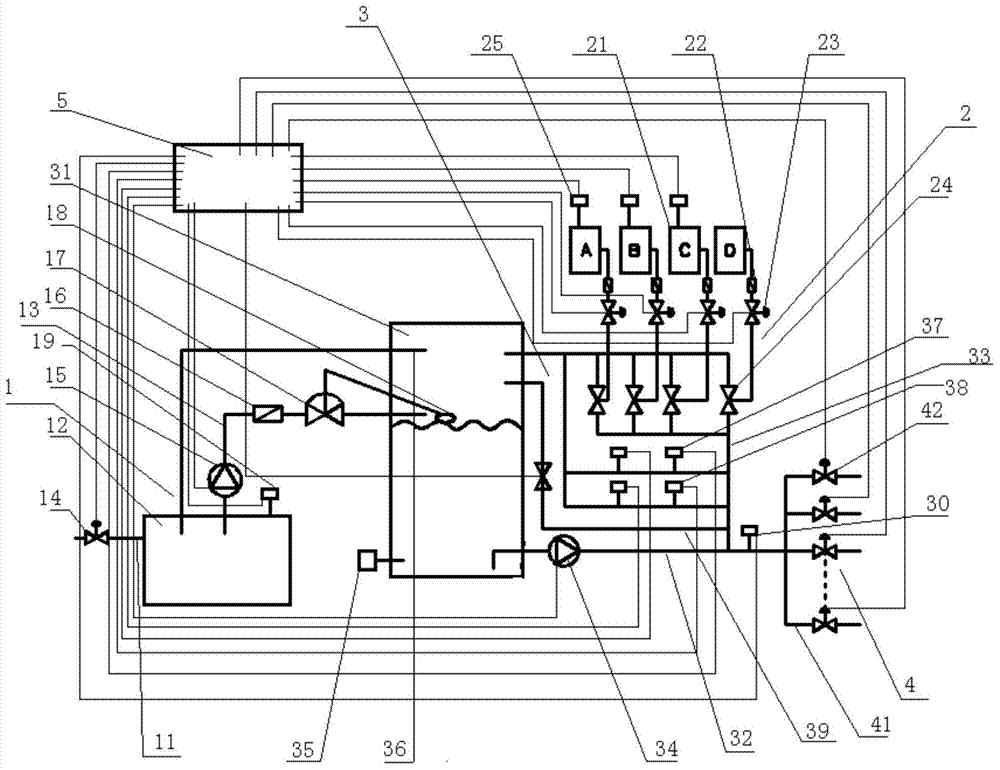

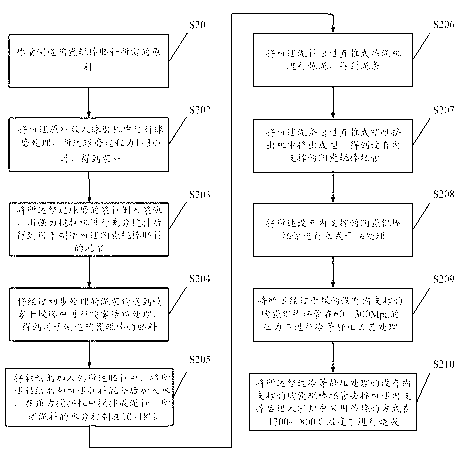

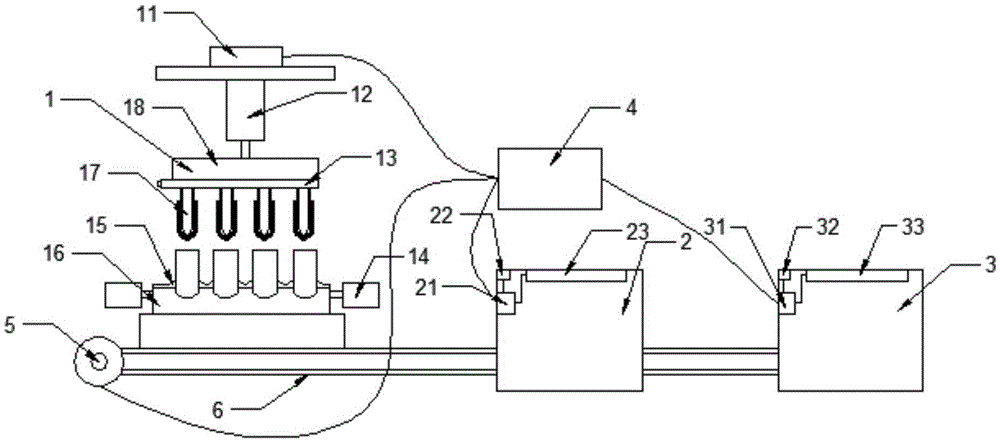

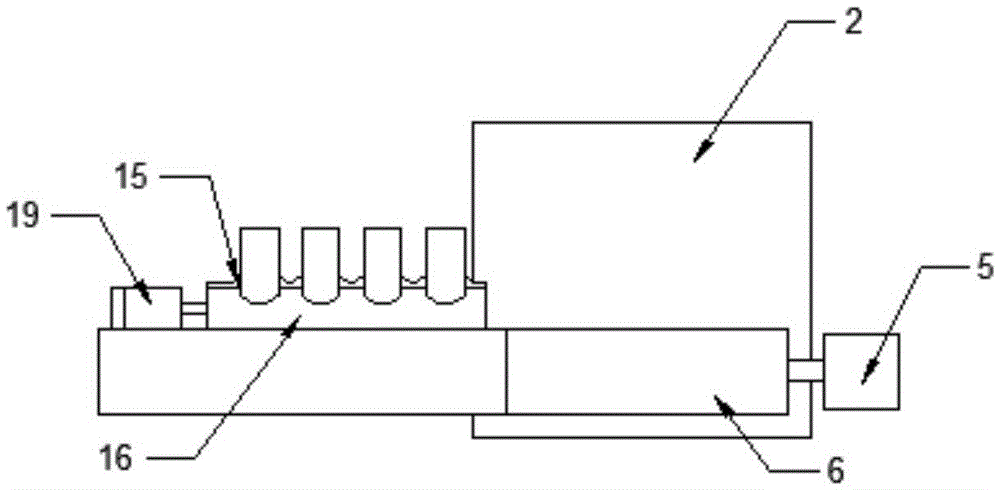

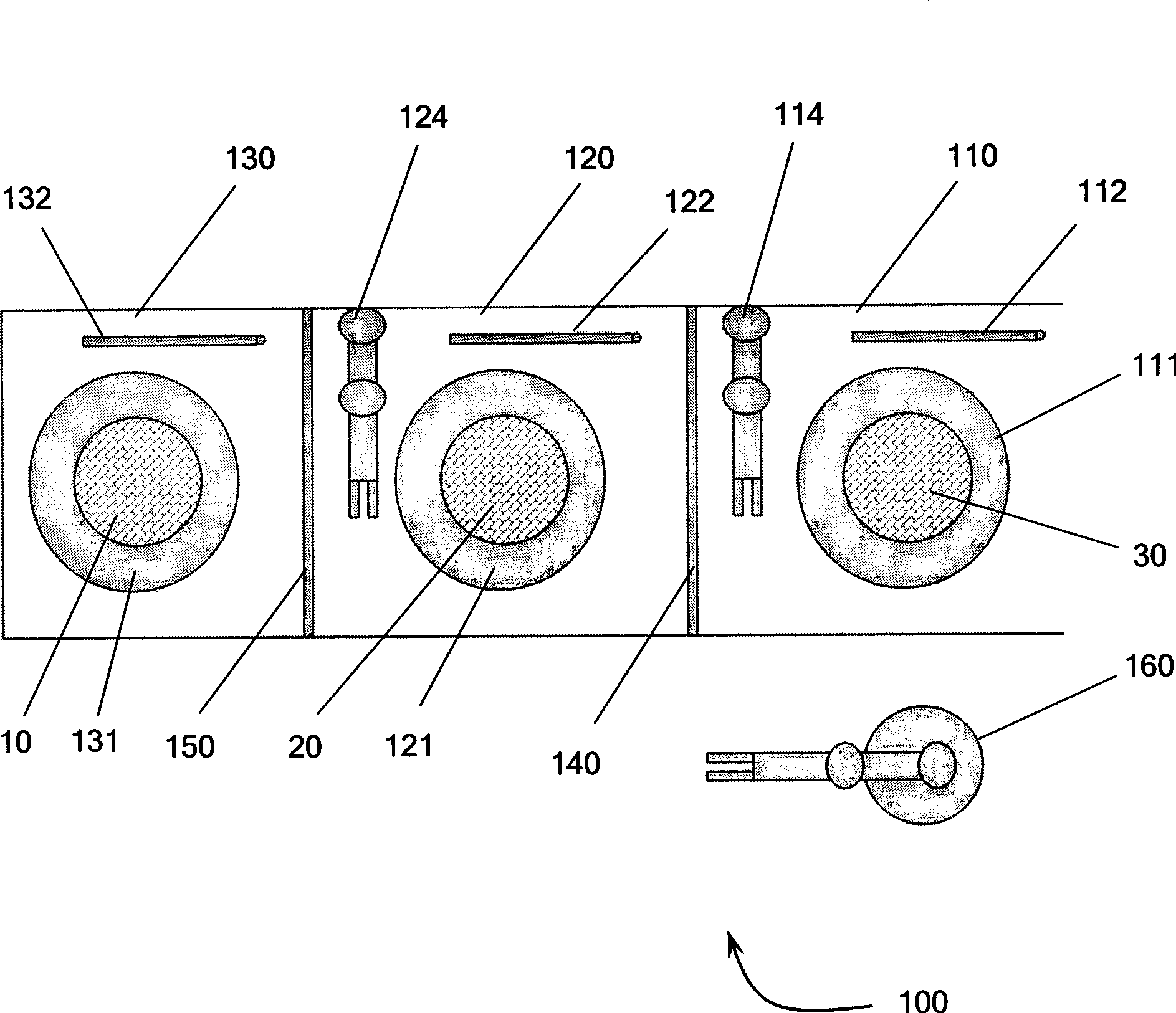

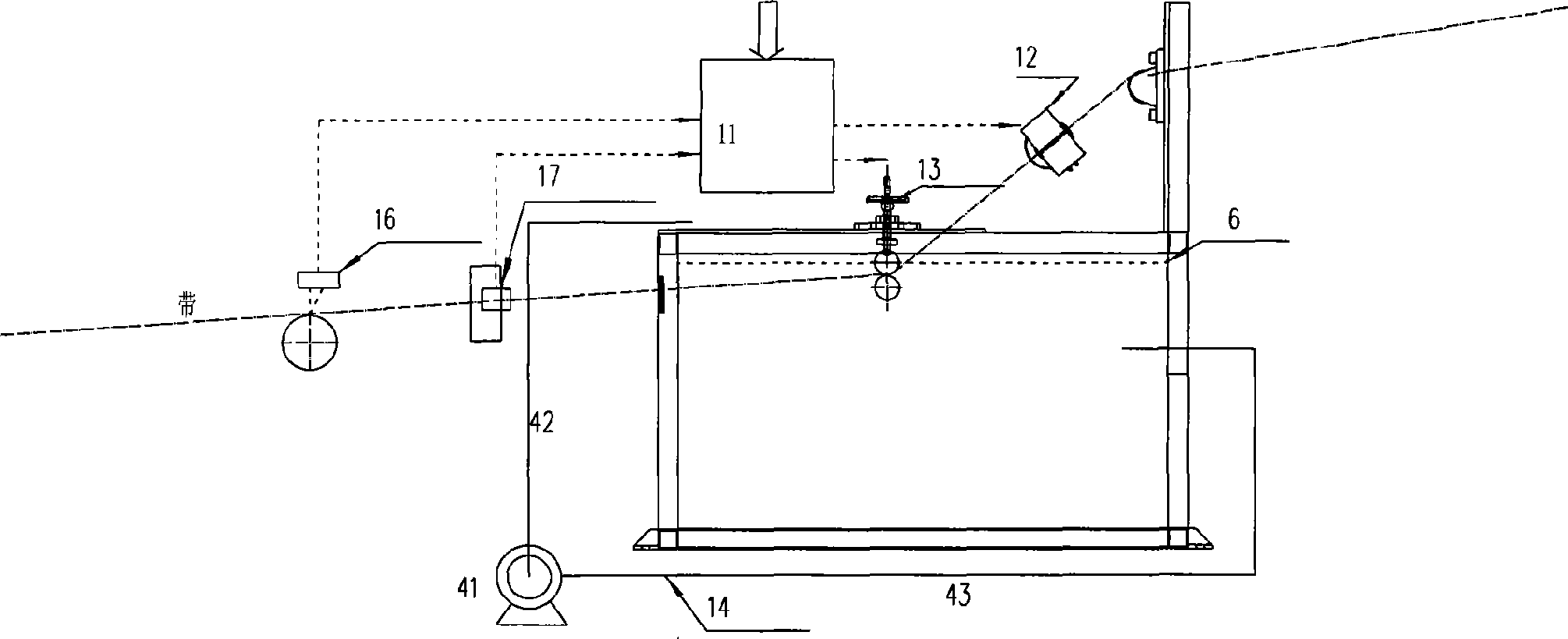

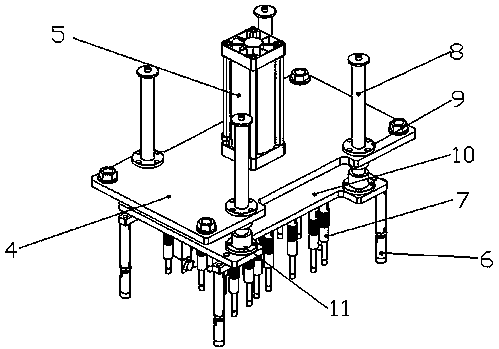

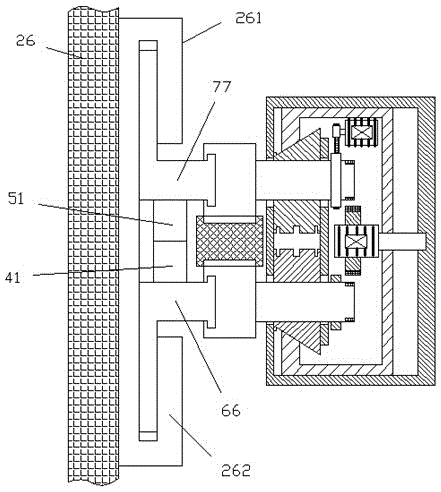

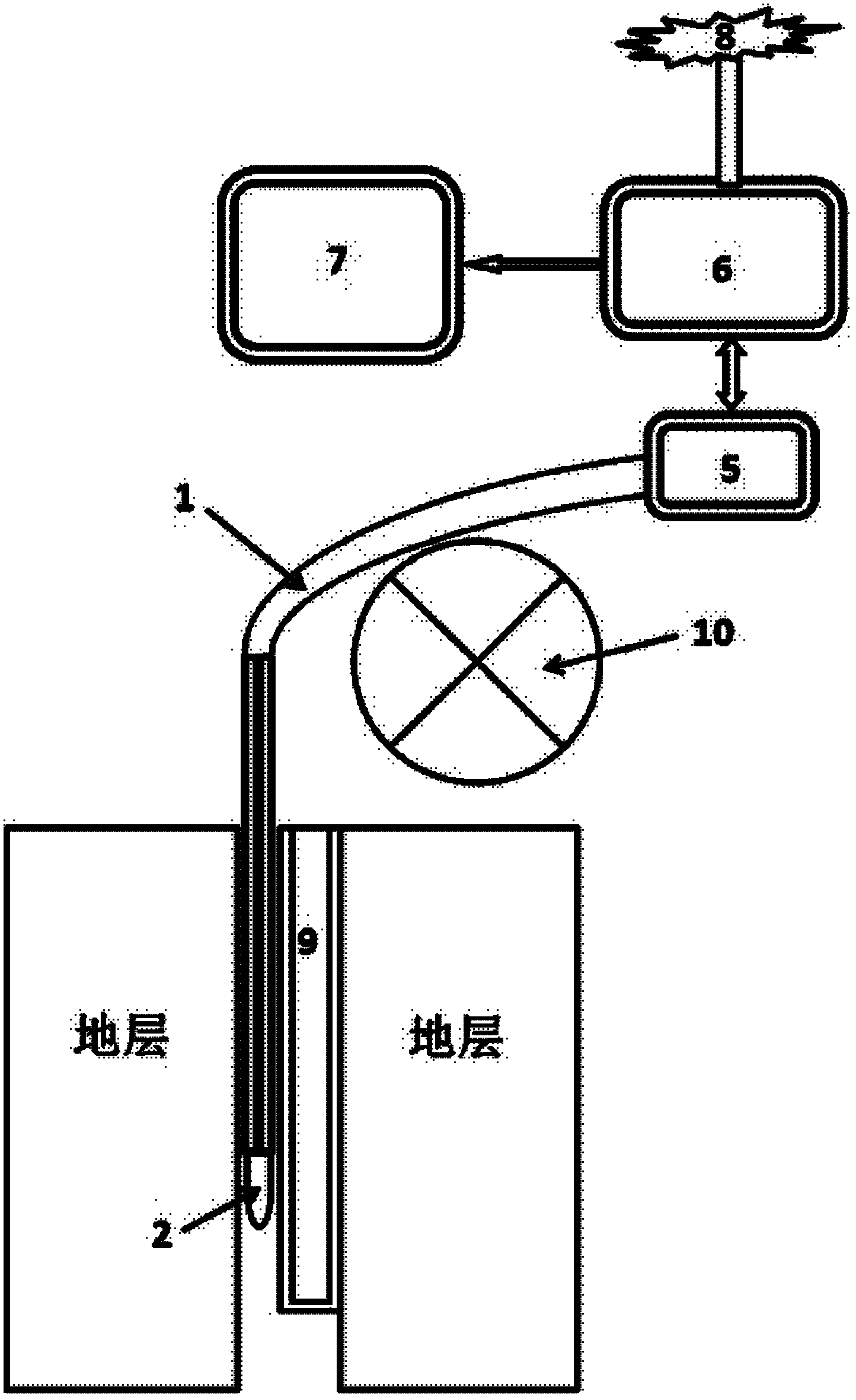

Multiple-irrigation-area automatic irrigation and fertilizer application device control equipment

InactiveCN103535245ASimple equipment structureLow costClimate change adaptationWatering devicesFertilizerAgriculture

The invention provides multiple-irrigation-area automatic irrigation and fertilizer application device control equipment which comprises a water feeding device, a water complementing device, a fertilizer sucking device, a mixing device, an irrigation and fertilizer application device and a control device. The water feeding device, the water complementing device and the fertilizer sucking device are respectively connected with the mixing device, the irrigation and fertilizer application device is connected with the mixing device, and the control device is respectively connected with the water complementing device, the fertilizer sucking device, the mixing device and the irrigation and fertilizer application device, receives a detection signal and outputs a control signal. The equipment is simple in structure, low in cost, convenient to use and capable of monitoring water feeding, fertilization matching and pressure adjustment in the irrigation and fertilizer application procedure when multiple irrigation areas are automatically irrigated through the equipment, meanwhile, the equipment can automatically adjust system output pressure of irrigation and fertilizer application, guarantee consistency of nutrition ingredients of a nutrient solution and target values and guarantee precision of fertilization matching, and the equipment can be applied to soilless cultivation, drop irrigation and micro irrigation systems in modernized glass greenhouses, sunlight greenhouses, plastic greenhouses and other agricultural facilities.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

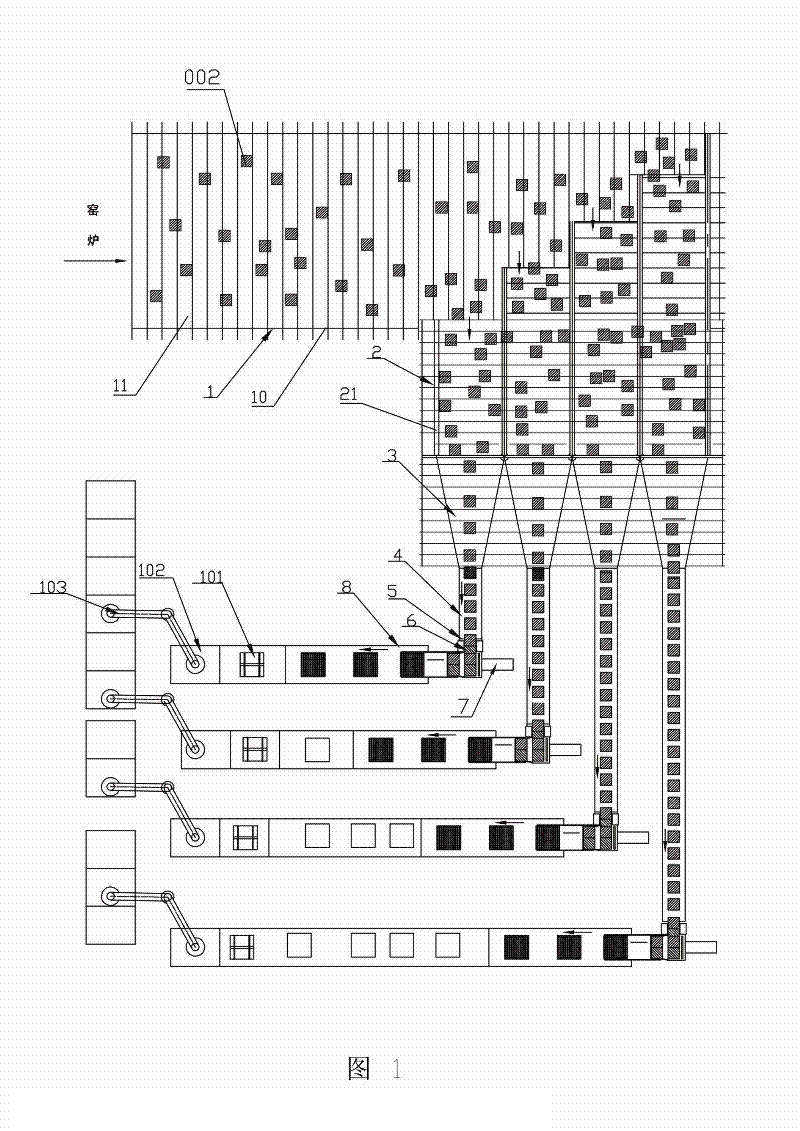

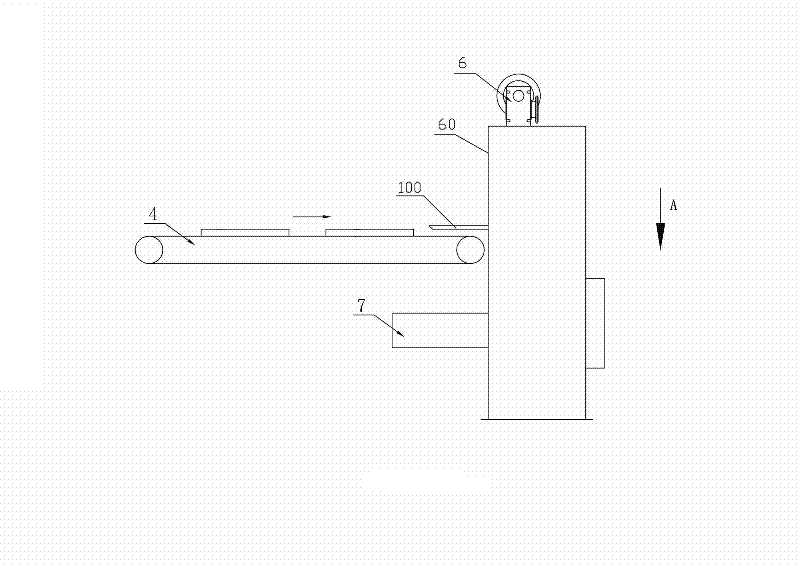

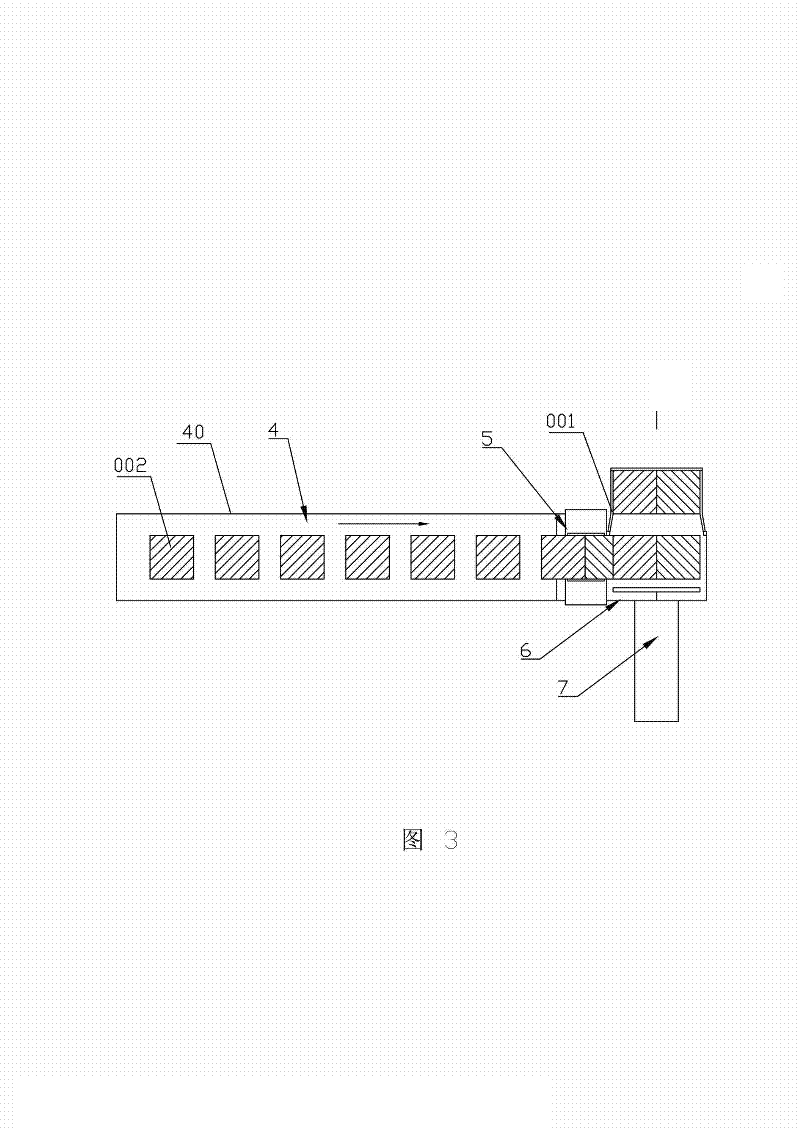

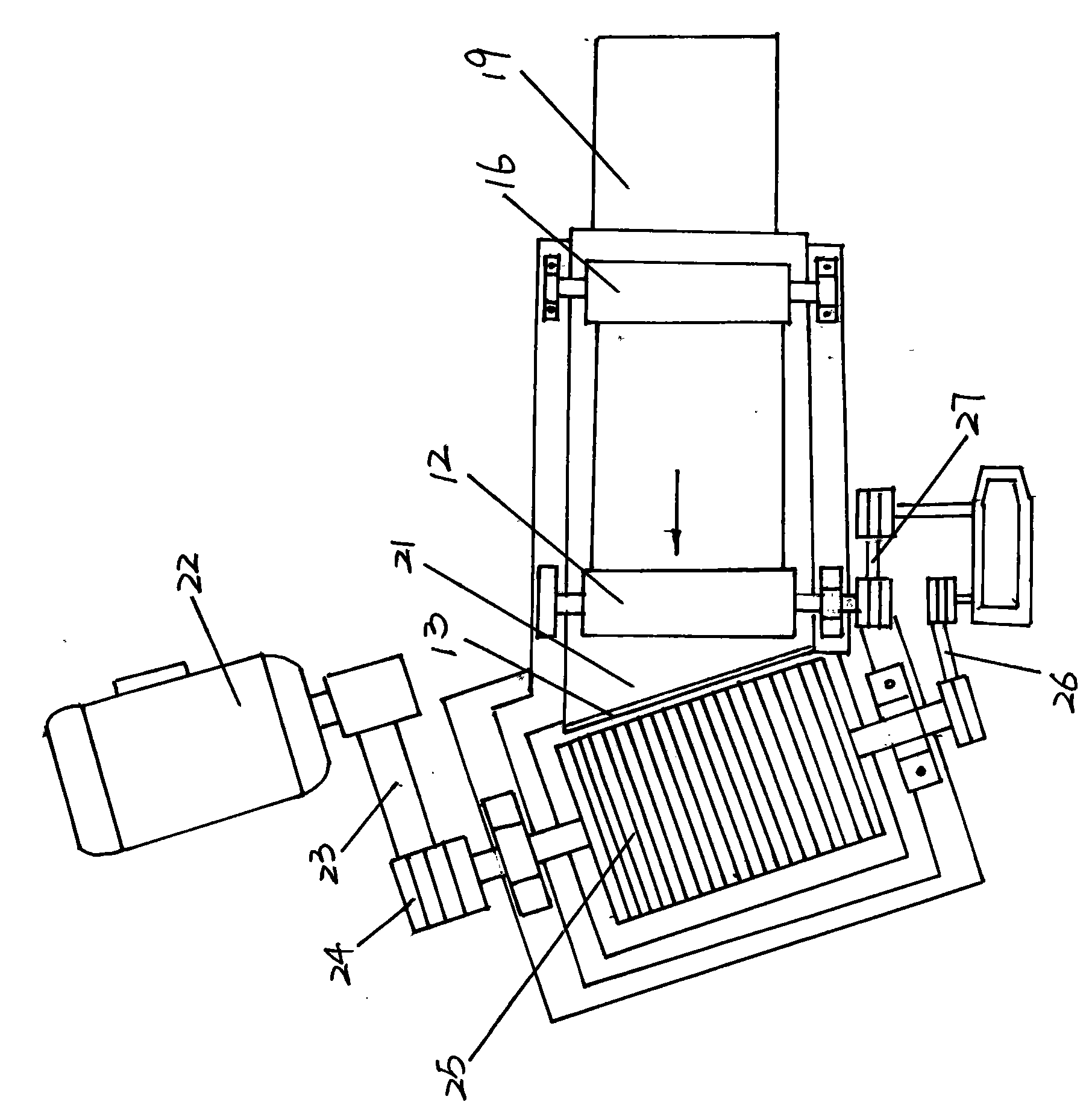

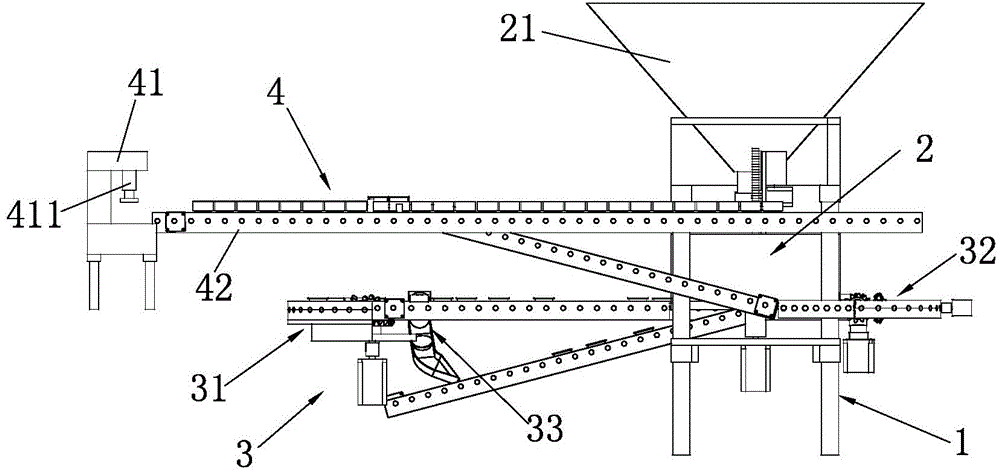

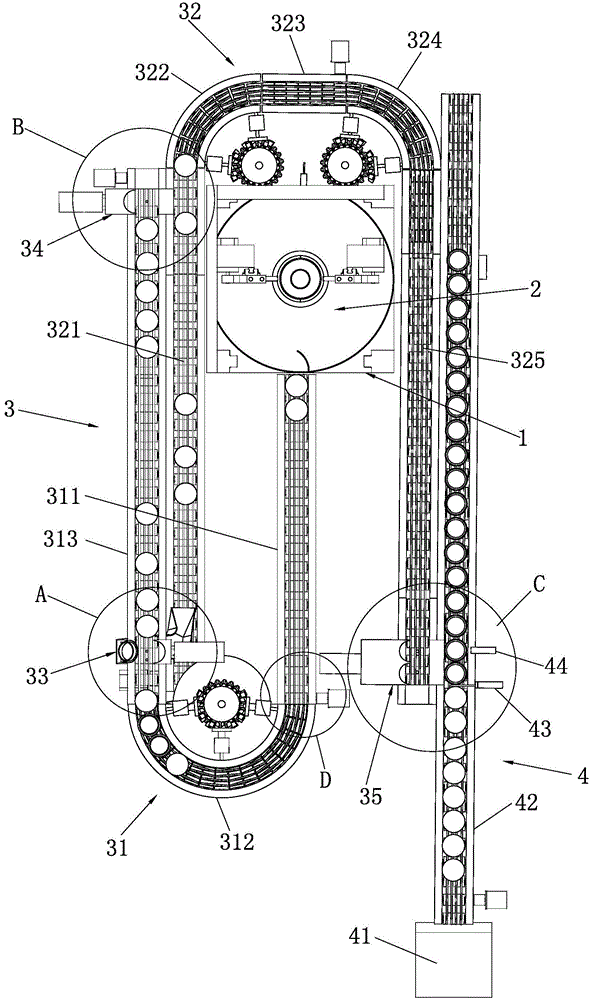

Novel full-automatic efficient ceramic tile package producing equipment

InactiveCN102241284ASimple equipment structureSimple and efficient operationPackaging automatic controlCeramic tilesEngineering

The invention provides novel full-automatic efficient ceramic tile package producing equipment. Through a conveying table behind a kiln, an automatic track lining mechanism, a division channel, a tile feed conveying mechanism, a tile stacking mechanism, a tile pushing mechanism, a tile receiving turnover conveying mechanism, an automatic carton sealing mechanism, an automatic code spraying mechanism, an automatic stacking machine and the like, the equipment can realize operations of automatic track lining division of ceramic tiles output by the kiln, stacking, cartoning, turnover, carton lifting and conveying, automatic carton sealing, automatic code spraying, automatic carrying and stacking and the like. The production line equipment has a simple structure, and is simple and convenient to operate, convenient to maintain, low in manufacturing cost and cheap; the equipment not only can be used for packing large-specification ceramic tiles, but also can be used for packing the ceramic tiles of various specifications such as relatively small-specification ceramic tiles and the like, is not only suitable for online ceramic tile package, but also suitable for offline ceramic tile package, especially suitable for automatically packing the ceramic tiles of different specifications on the same production line; and moreover, the equipment is widely applicable, convenient, practical, efficient and fast.

Owner:NANAN XINJIE MACHINERY

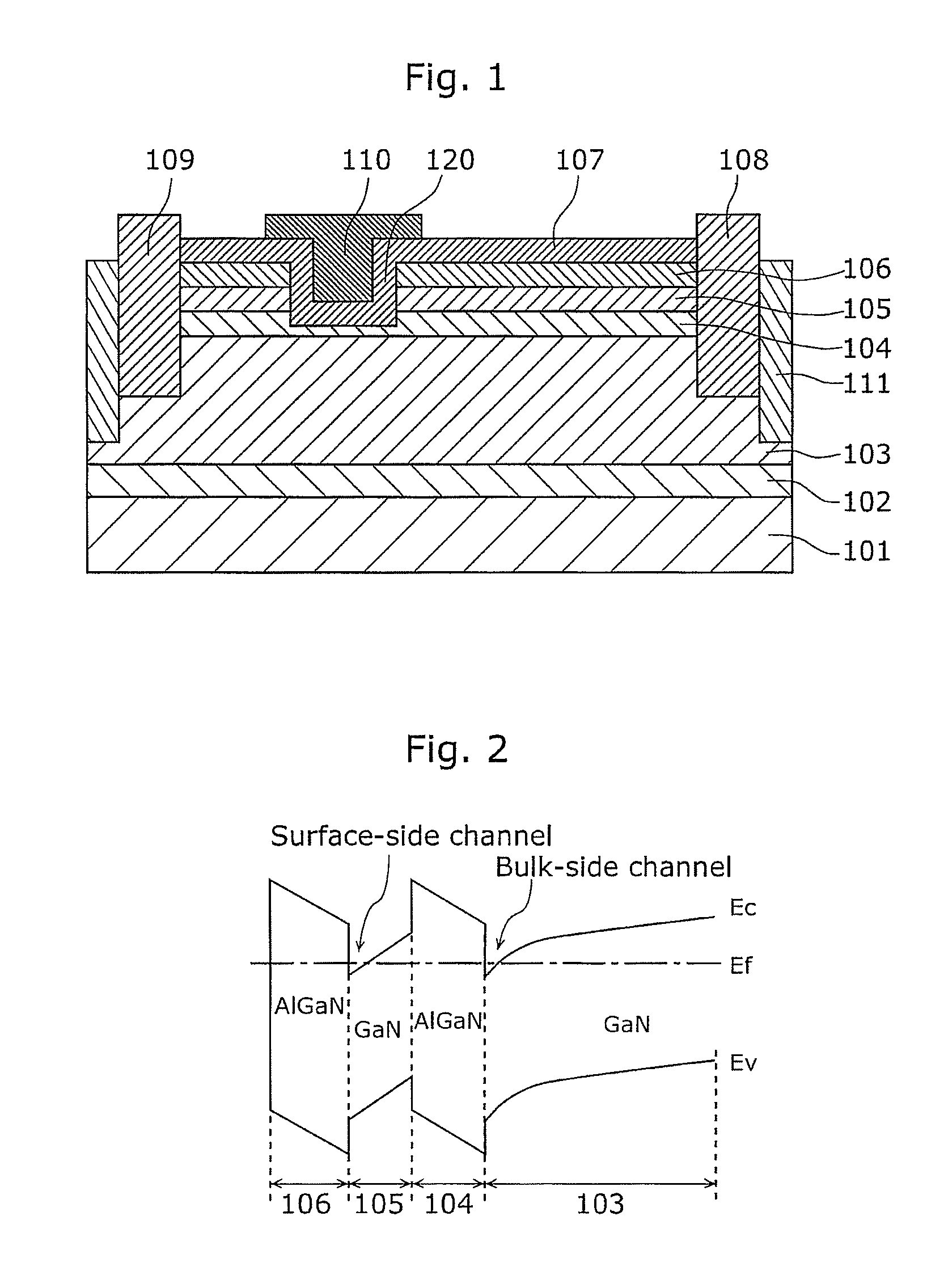

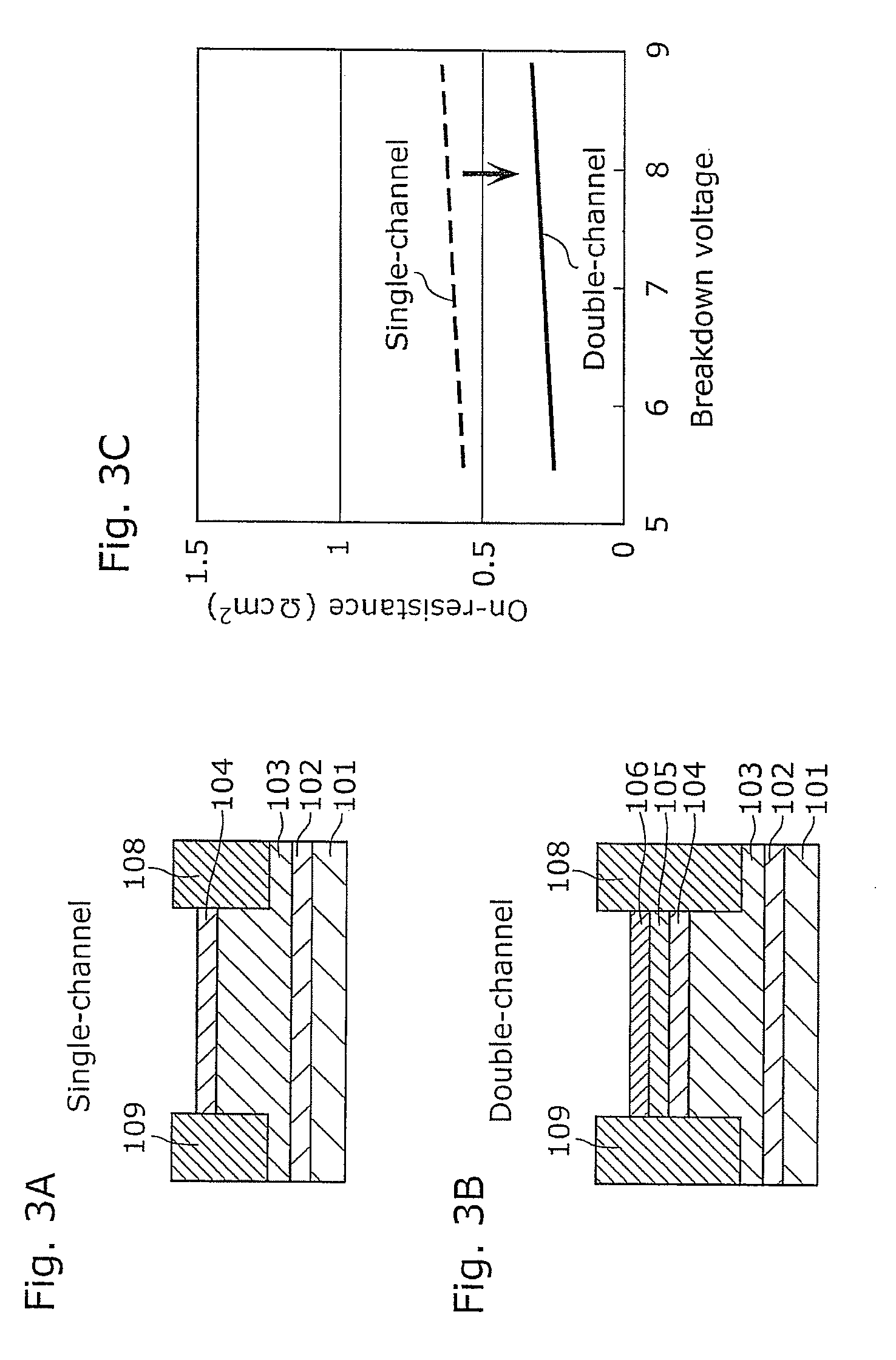

Field-effect transistor

InactiveUS20110227132A1Reduce exposureReduce contact resistanceSemiconductor devicesHeterojunctionField-effect transistor

The present invention has as an object to provide a FET having low on-resistance. The FET according to the present invention includes: first nitride semiconductor layer; a second nitride semiconductor layer formed on the first nitride semiconductor layer and having a higher band gap energy than the first nitride semiconductor layer; a third nitride semiconductor layer formed on the second nitride semiconductor layer; a fourth nitride semiconductor layer formed on the third nitride semiconductor layer and having a higher band gap energy than the third nitride semiconductor layer. A channel is formed in a heterojunction interface between the first nitride semiconductor layer and the second nitride semiconductor layer.

Owner:PANASONIC CORP

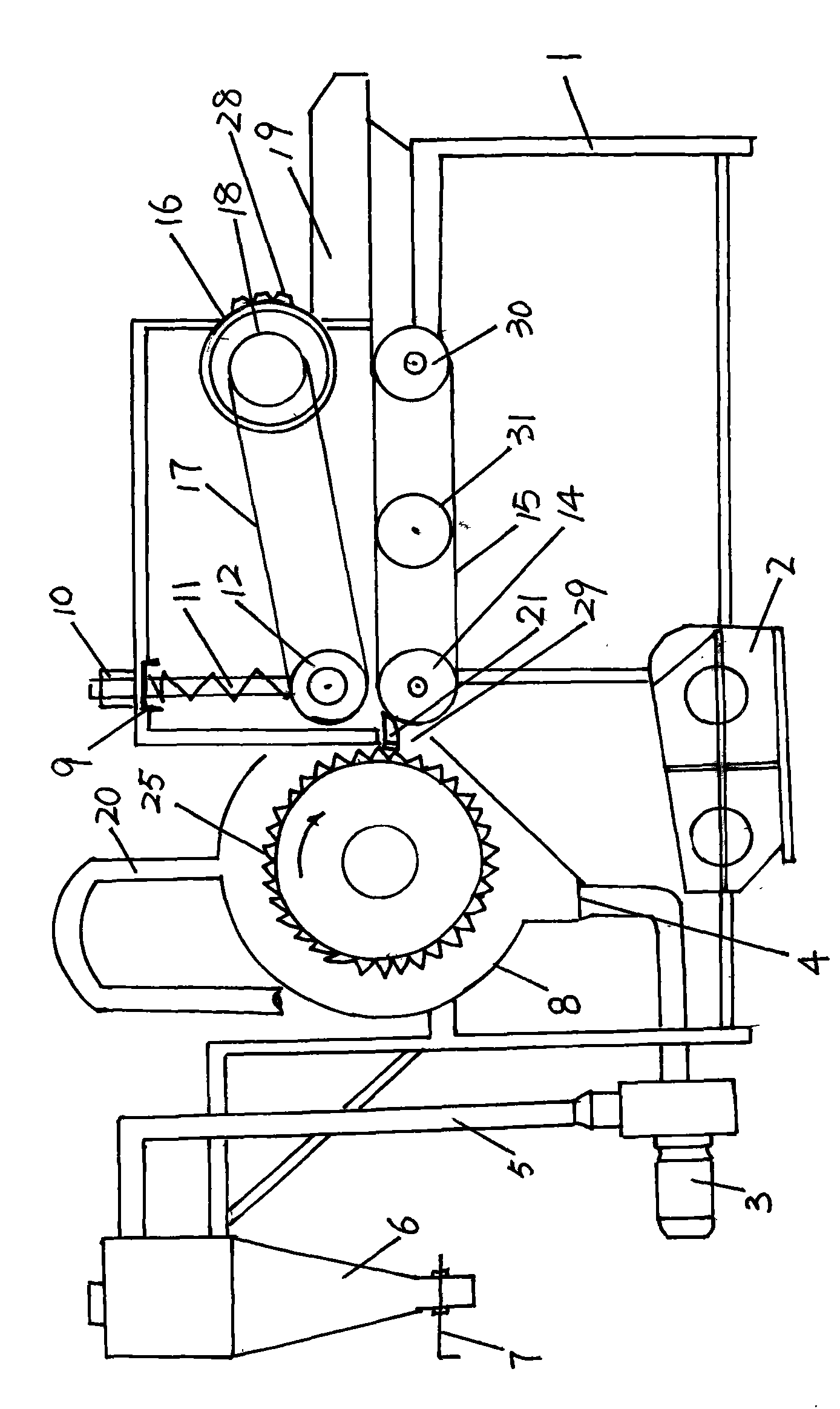

Device for finely crushing biomass

InactiveCN101579650ASimple equipment structureLow costGrain treatmentsBiomassEnvironmental resistance

The invention belongs to the technical field of a biomass crushing machine, in particular relates to a device for finely crushing biomass suitable for branches and straws, and solves the problem that the prior device for crushing biomass discharges rough material and has high energy consumption and low yield. The device for finely crushing biomass comprises a bracket assembly, a feeding mechanism and a crushing mechanism. The crushing mechanism comprises a strip hard stationary knife and a movable knife combined knife roll with the axial line in parallel with knife-edge line of the hard stationary knife. The included angle between the knife-edge line of the hard stationary knife and the feeding direction of the feeding mechanism is 20-30 degrees. The invention has the beneficial effects that 1, the device has a simple structure, low manufacturing cost and convenient maintenance; 2, the device has strong applicability and is capable of crushing all straws and finely discharging material once only no matter the straws are dry or wet; 3, the device is environment-friendly, saves energy and has high yield, and the cutter has long service life.

Owner:周忠信 +2

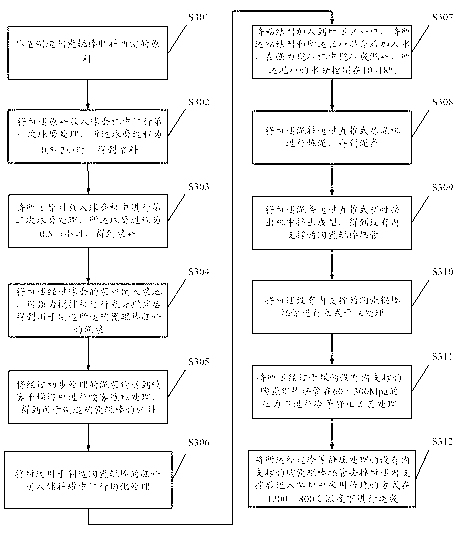

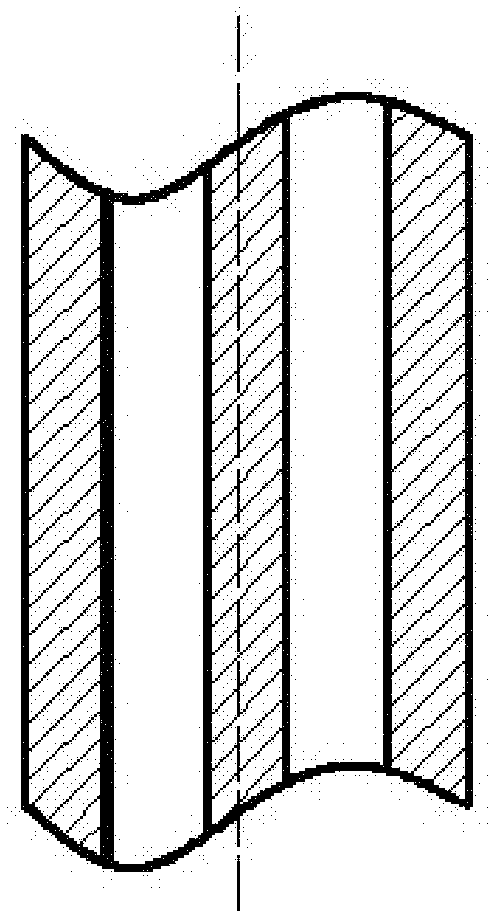

Preparation process of ceramic roller rod

The invention discloses a preparation process of a ceramic roller rod. The preparation process comprises the following steps of: atomizing and prilling on primarily-treated slurry; adding a binder, mixing, then adding water, and mixing in a into pug into a powerful mixer, wherein the water content of the pug is 10-18%; refining the pug through a direct pushing-type pug refining machine, and obtaining pug stripes; enabling the pug stripes to conduct extrusion molding through a direct pushing-type plastic extruder, and obtaining ceramic roller rod blank tubes provided with inner supports; conducting vertical type drying treatment on the ceramic roller rod blank tubes; conducting isostatic cool pressing process treatment on the ceramic roller rod blank tubes at the pressure of 60-300Mpa; and removing the inner supports of the ceramic roller rod blank tubes, putting the ceramic roller rod blank tubes into a kiln, and burning by a hanging and burning mode at the temperature of 1200-1800 DEG C. By means of preparation process, the prepared ceramic roller rod is high in density, high in flexure strength, big in load capacity and good in appearance regulation degree.

Owner:广东金刚新材料有限公司 +1

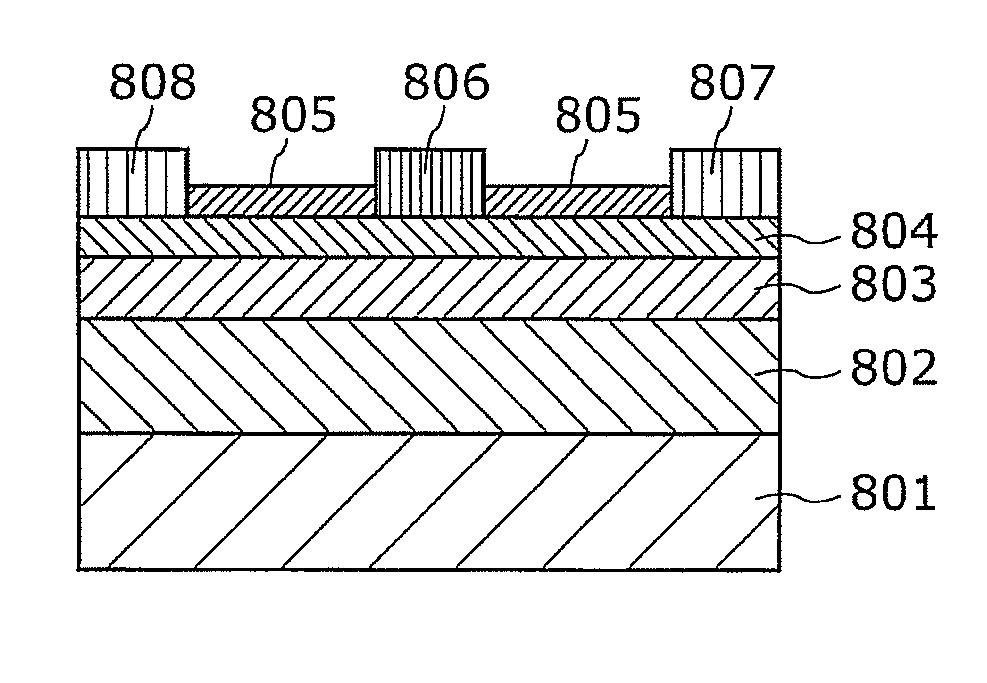

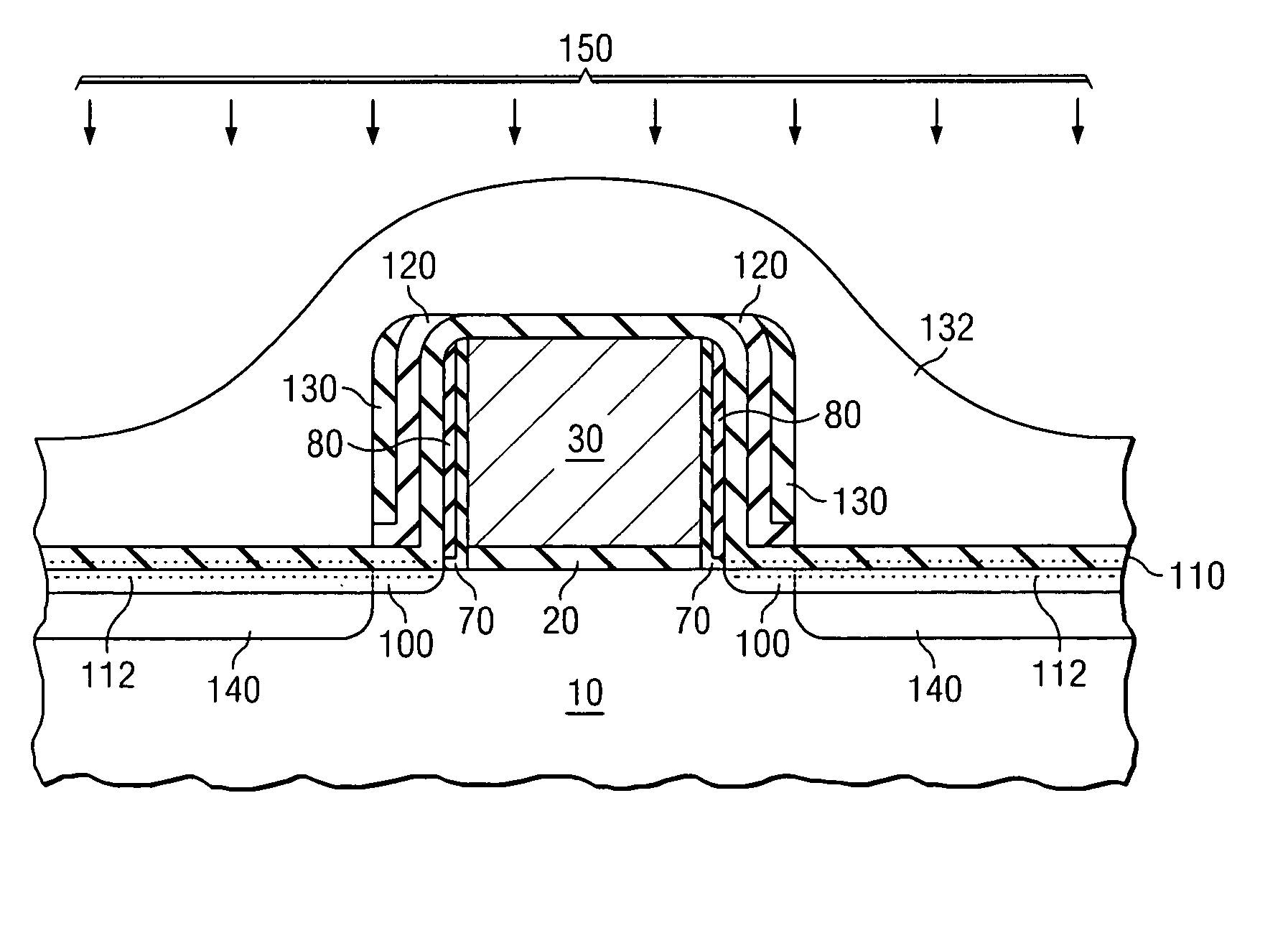

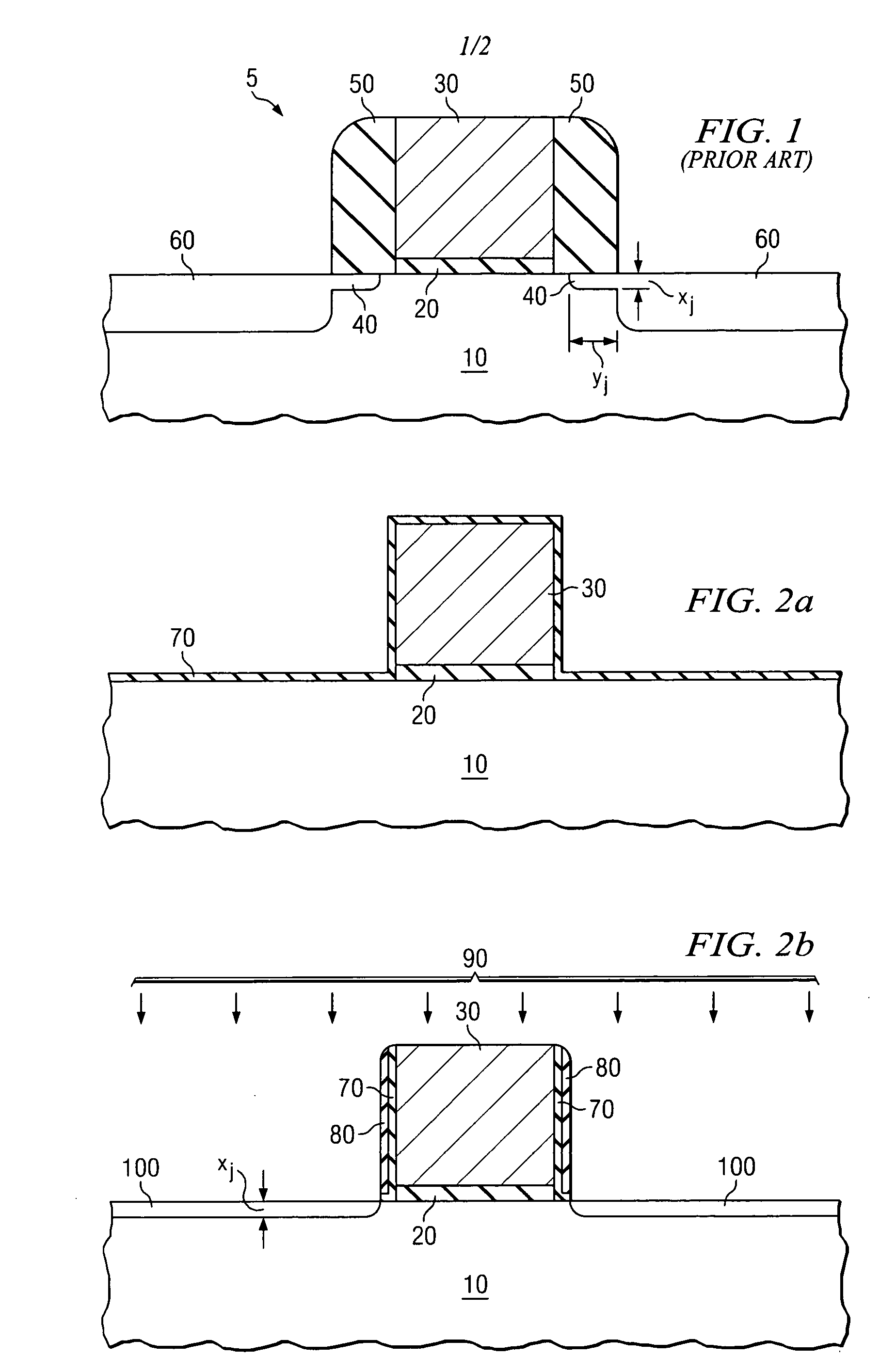

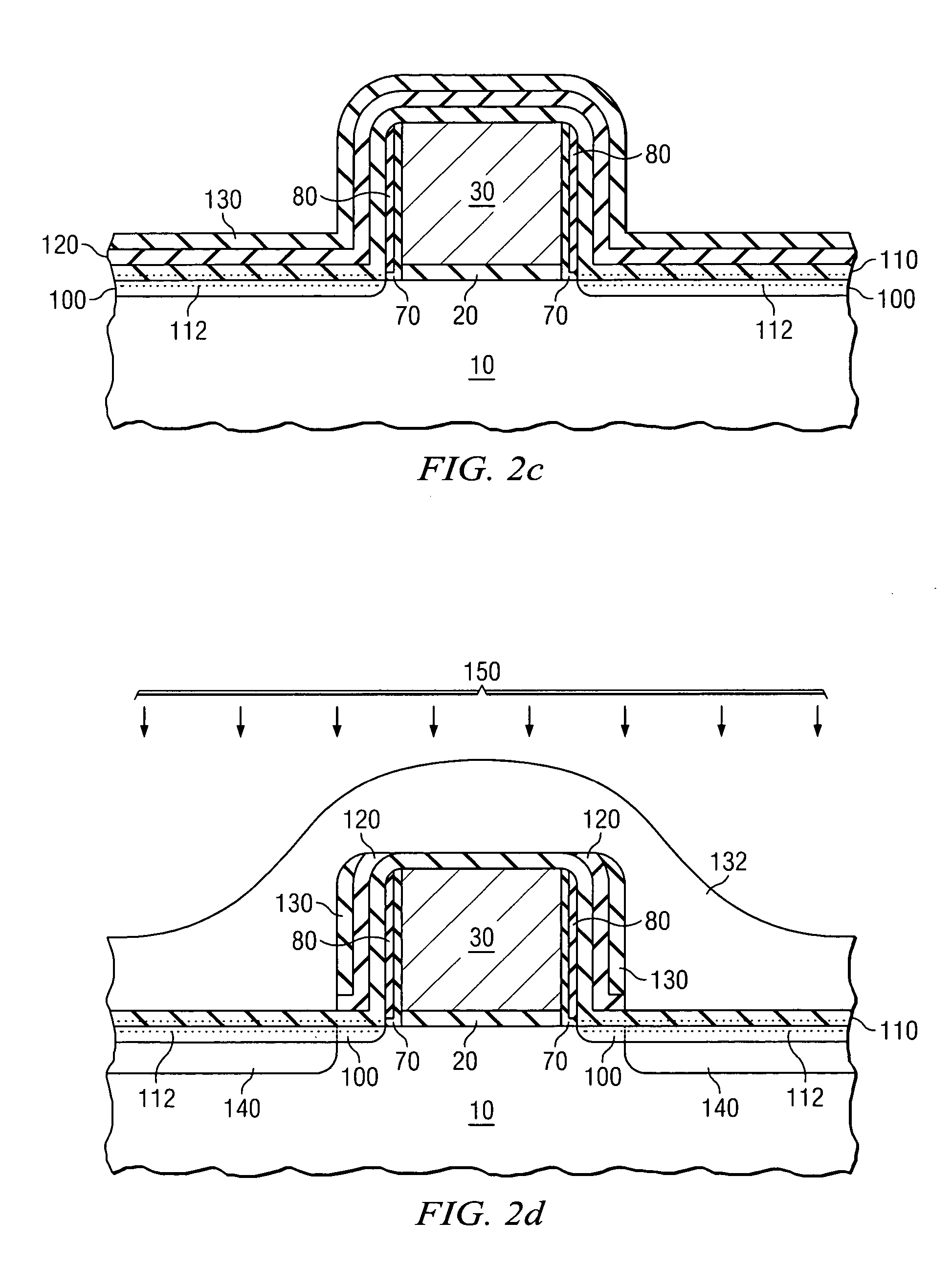

CMOS transistors and methods of forming same

InactiveUS20050059260A1Easy to operateEasy to optimizeTransistorSemiconductor/solid-state device manufacturingCMOSDriving current

The present invention teaches the formation of CMOS transistors using interfacial nitrogen at the interface between the lightly doped extension regions and an overlying insulating layer in combination with a capping layer of silicon nitride, both prior to the final source / drain anneal. Doses and energies may be increased for the P-channel lightly-doped drain, source and drain regions. The resulting transistors exhibit desirably high drive current and low off-state leakage current and overlap capacitance.

Owner:TEXAS INSTR INC

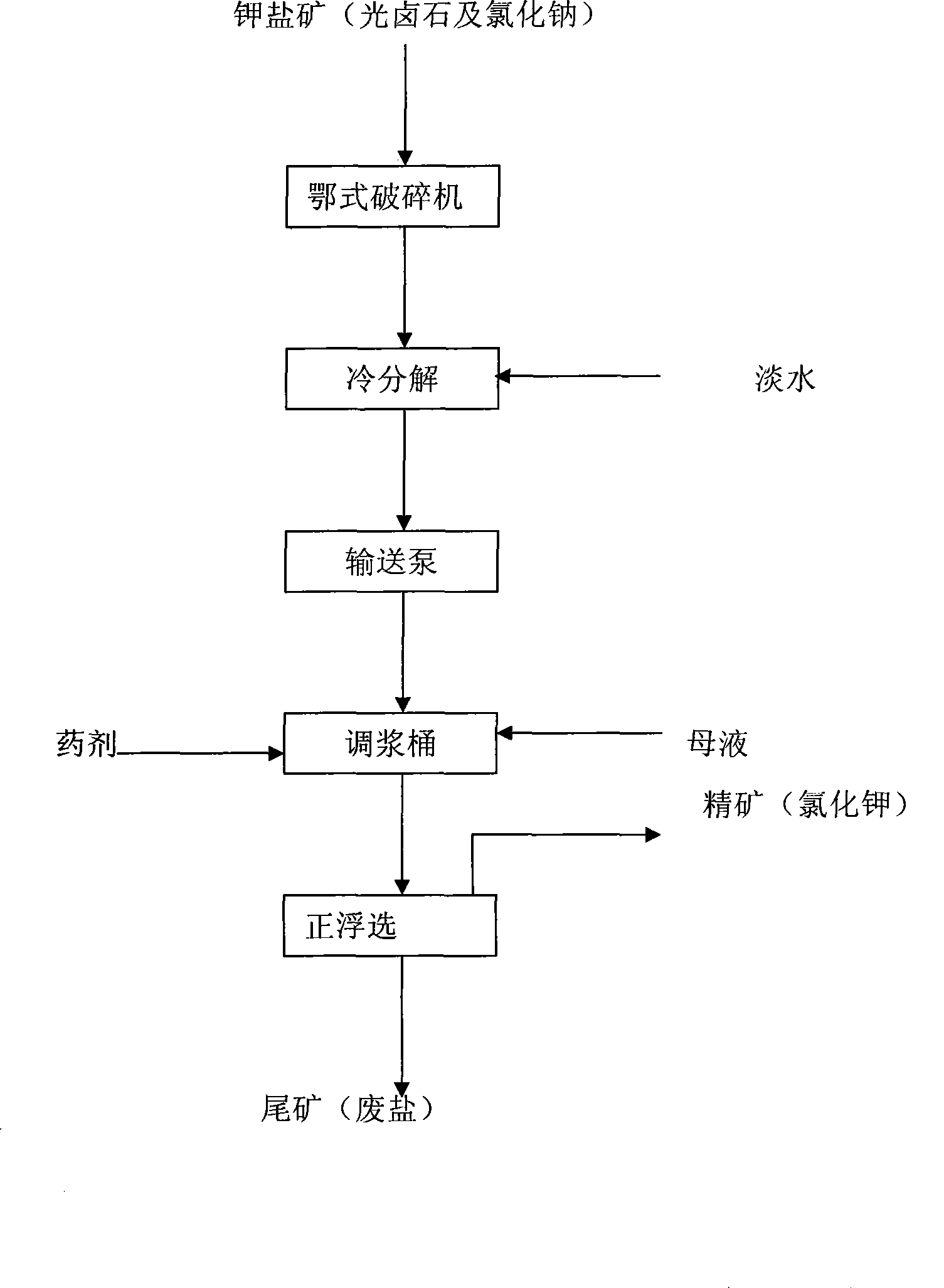

Method for flotation of potassium chloride from potassium salt mine

ActiveCN101474598ASimple equipment structureLarge amount of processingFlotationChemical industryAutomatic control

The invention relates to a method for the floatation of potassium chloride in a sylvite mine, and a method for producing the product of chemical industry, in particular to a novel floatation method for extracting the potassium chloride from the sylvite mine. The method of the invention mainly comprises the following steps: a. the sylvite mine is pulverized and graded, the particle size of the pulverized mine rages from 3 to 8mm, and the pulverized mine is processed by the operation of cooling decomposition by being added with sweet water; b. mine slurry obtained in the step a is led into a mineralization slot and is added with the saturated mother solution of potassium chloride, sodium chloride and magnesium chloride as well as a positive floating agent; and the mine slurry, the saturated mother solution and the positive floating agent are completely mixed to control the concentration of the mine slurry to be from 20 to 40 percent; c. the mine slurry obtained in the step b is led into a flotation separation device to obtain the potassium chloride by the positive floatation; and d. particles fallen to the bottom of a flotation column are milltailings, particles which are discharged from the flotation column and are caused to float to the top end of the flotation column are potassium chloride particles, and the particles are collected to be concentrated, filtered and dried. The method has the advantages of simple and stable process, easier automatic control, favorable flotation effect, low agent consumption and production cost, etc.

Owner:YUNNAN CHEM RES INST

Transistor device and materials for making

ActiveUS9318591B2Improve conductivityLow densitySemiconductor/solid-state device manufacturingSemiconductor devicesGrapheneMaterials science

This application relates to graphene based heterostructures and transistor devices comprising graphene. The hetero-structures comprise i) a first graphene layer; ii) a spacer layer and iii) a third graphene. The transistors comprise (i) an electrode, the electrode comprising a graphene layer, and (ii) an insulating barrier layer.

Owner:UNIV OF MANCHESTER

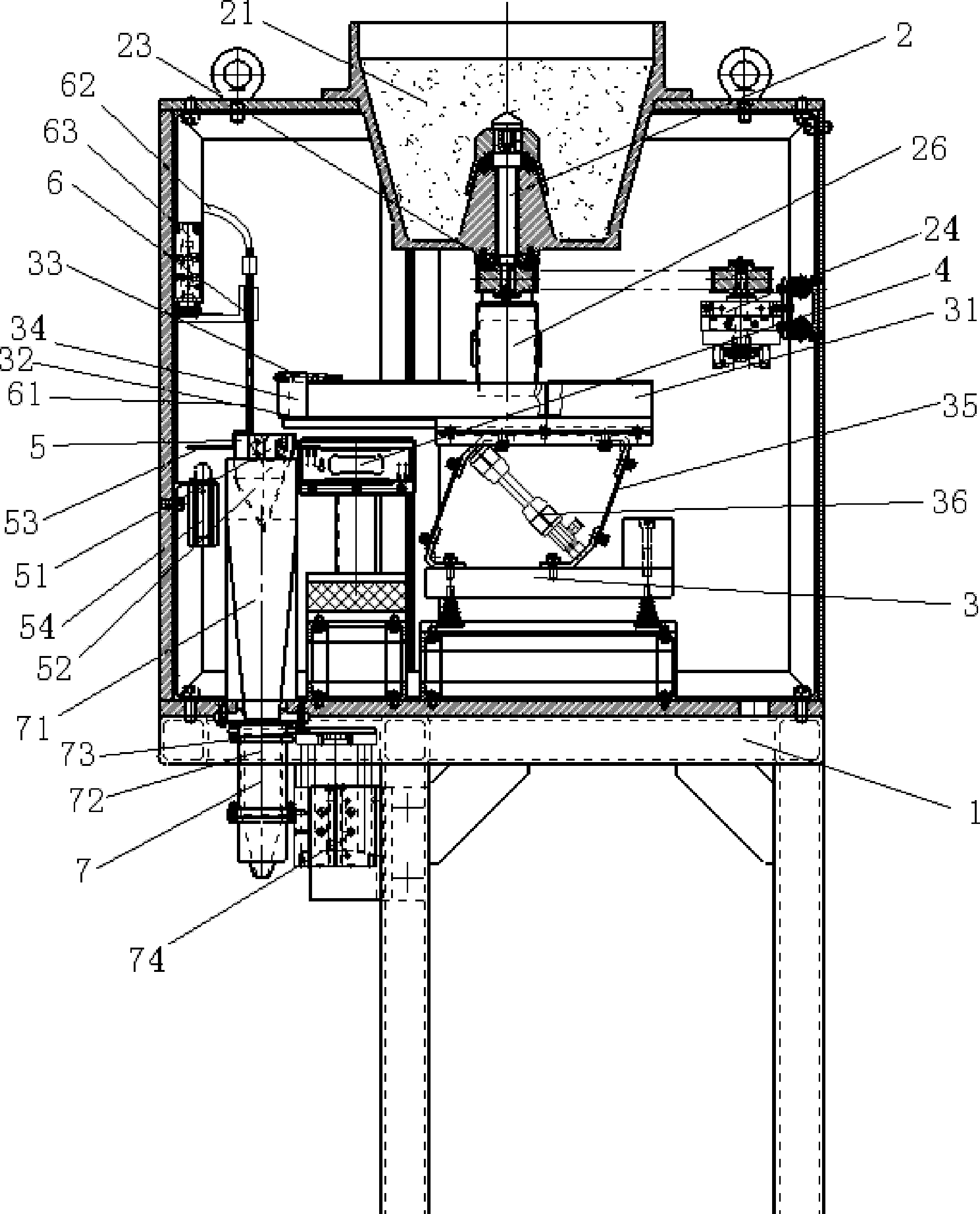

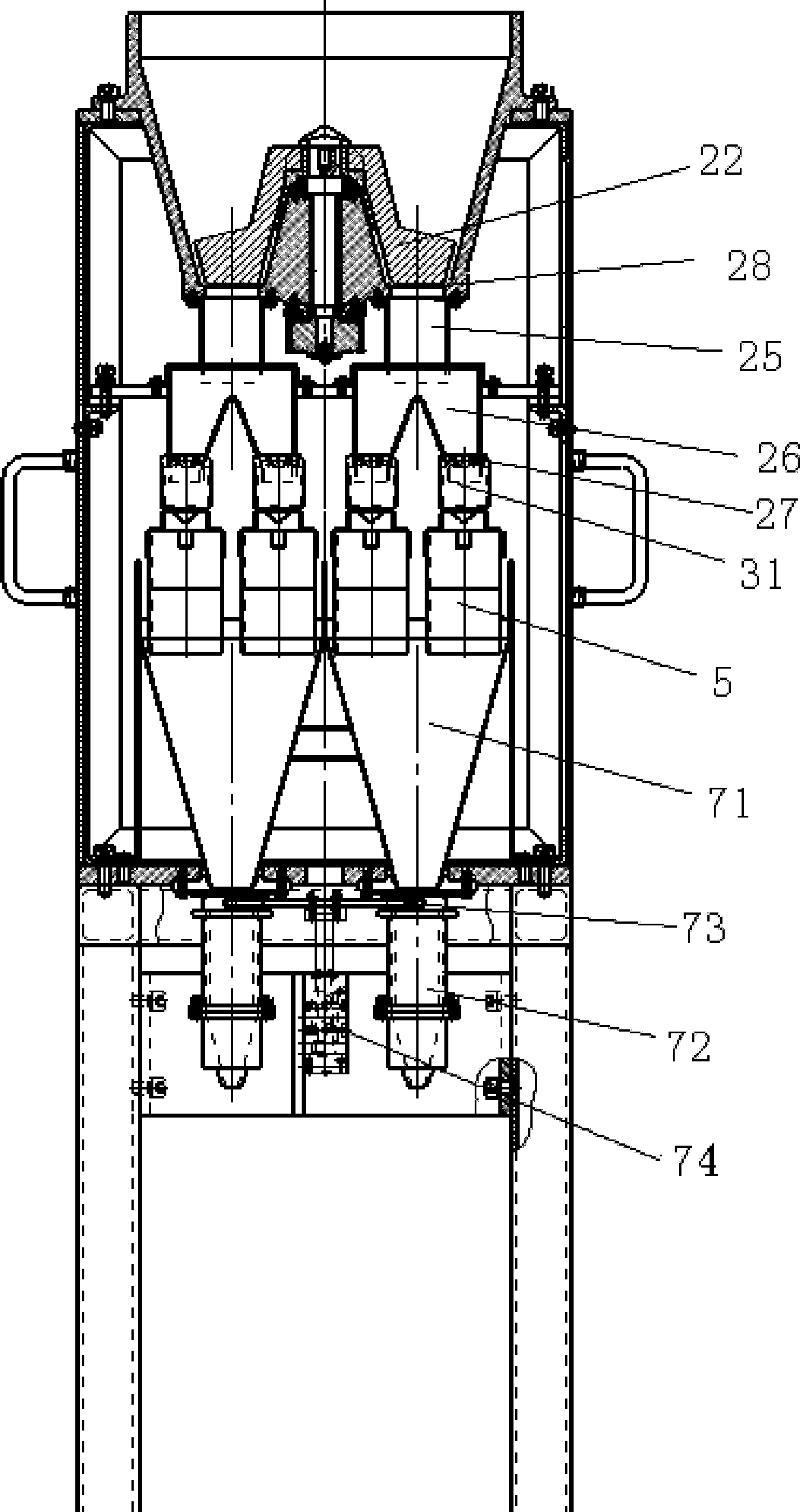

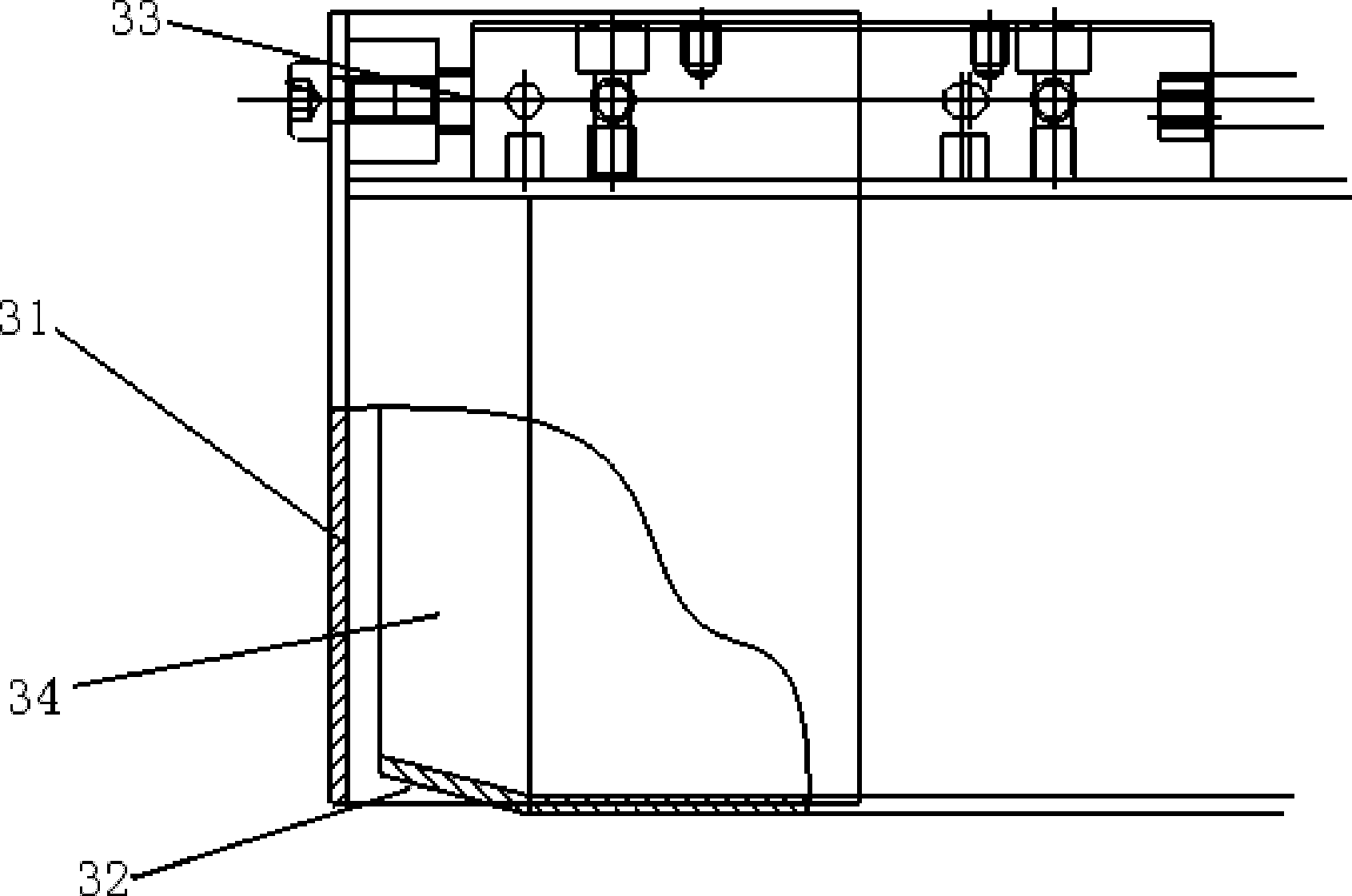

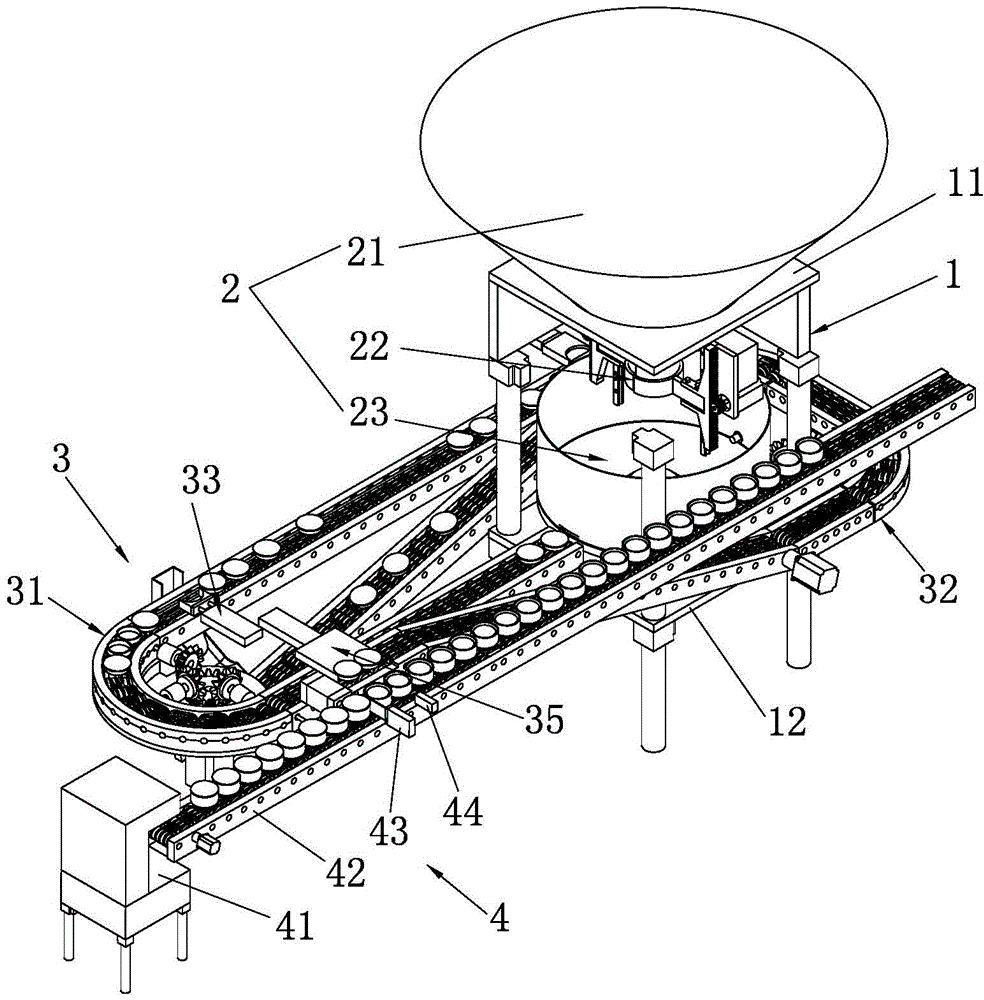

Medicine weighing and loading machine and use method thereof

ActiveCN102616393ASimple equipment structureSimple operating deviceSolid materialMedicineDust collector

The invention relates to a medicine weighing and loading machine and a use method thereof. The medicine weighing and loading machine is characterized in that the medicine weighing and loading machine comprises a stand, a medicine storage device, vibration conveying devices, weighing sensors, a weighing hopper, a vacuum sucking device, a medicine injecting device and a computer control system, wherein the medicine storage device comprises a medicine cabin, a medicine stirring plate, a driving device, a swing air cylinder and two distribution troughs, wherein each vibration conveying device comprises a medicine conveying trough, an adjusting air cylinder, a controlled baffle and a vibrator connected with the stand through two spring plates; the number of the weighing sensors is the same as that of the medicine conveying troughs; the weighing hopper comprises a fixed hopper, a movable hopper, an opening rod and an opening air cylinder; the vacuum sucking device comprises a suction tube, a dust collector and a lifting air cylinder; the medicine injecting device comprises two medicine injecting cylinders, a lifting cylinder, a connecting rod and a telescopic air cylinder; and the swingair cylinder, the vibrator, the adjusting air cylinder, the weighing sensors, the opening air cylinder, the lifting air cylinder and the telescopic air cylinder are respectively connected with the computer control system. The medicine weighing and loading machine disclosed by the invention can be widely applied to the metering and producing processes of medicine and dangerous goods industries.

Owner:廊坊智通机器人系统有限公司

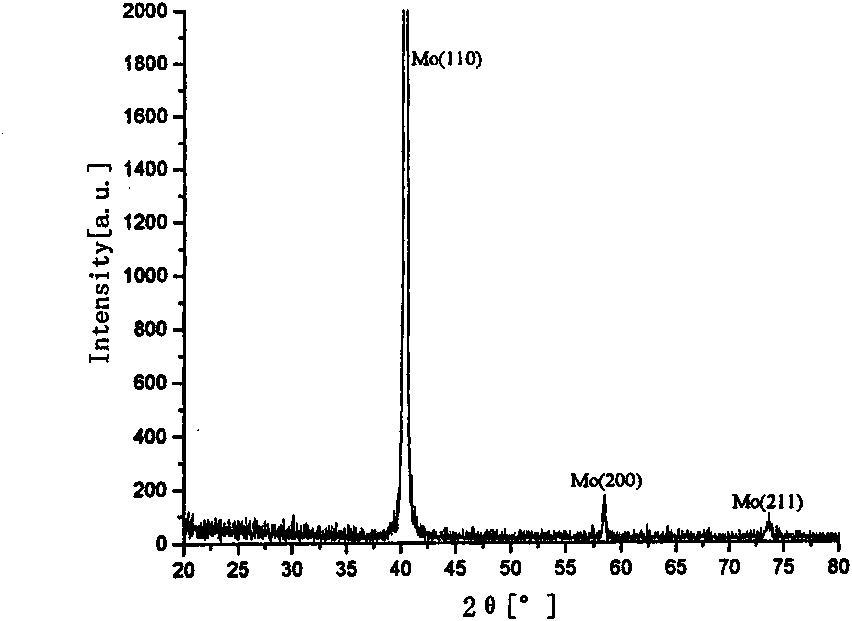

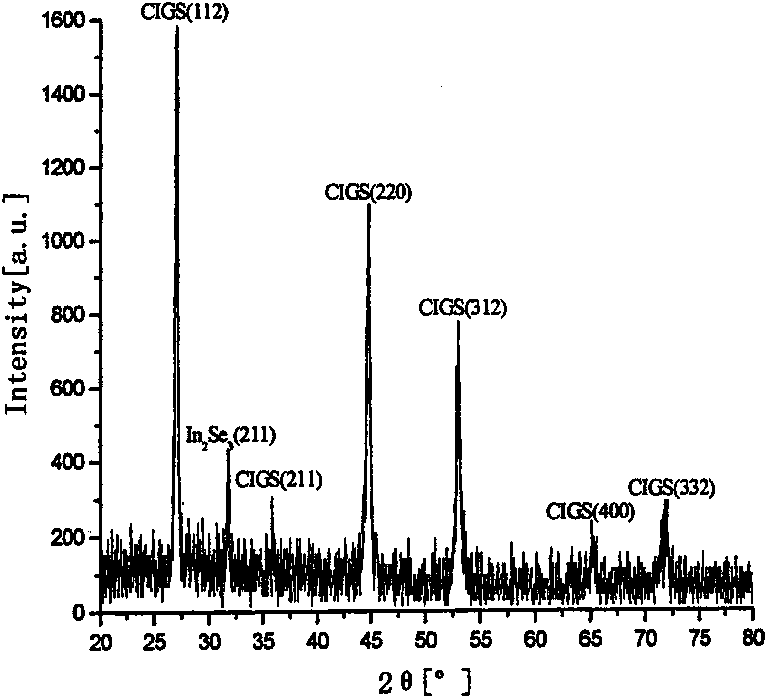

Method for preparing light absorption layer of CuInSe2 (CIS) based thin film solar cell

InactiveCN101661971ASimple equipment structureIncrease productivityFinal product manufactureVacuum evaporation coatingReduction rateArgon

The invention relates to a method for preparing a light absorption layer of CuInSe2(CIS) based thin film solar cell. The method includes the following steps: firstly, sputtering Mo electrodes requiredfor preparing the CIS radical thin film solar cell on a soda glass substrate; then sputtering on the Mo electrodes by taking CuIn0.7Ga0.3Se2.2 as target to obtain a CuIn0.7Ga0.3Se2.0 (CIGS) thin filmin deposited status; subsequently conducting heat treatment on the CIGS thin film in deposited status: filling argon in a vacuum cavity to 100Pa, heating up the CIGS thin film in deposited status atthe heating rate of 20-40 DEG C / min to 450-550 DEG C, preserving the heat for 15min, then reducing the temperature to 350 DEG C at the temperature reduction rate of 20-40 DEG C / min, cooling to the room temperature with a furnace and obtaining the light absorption layer of CuInSe2 radical thin film solar cell CIGS.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

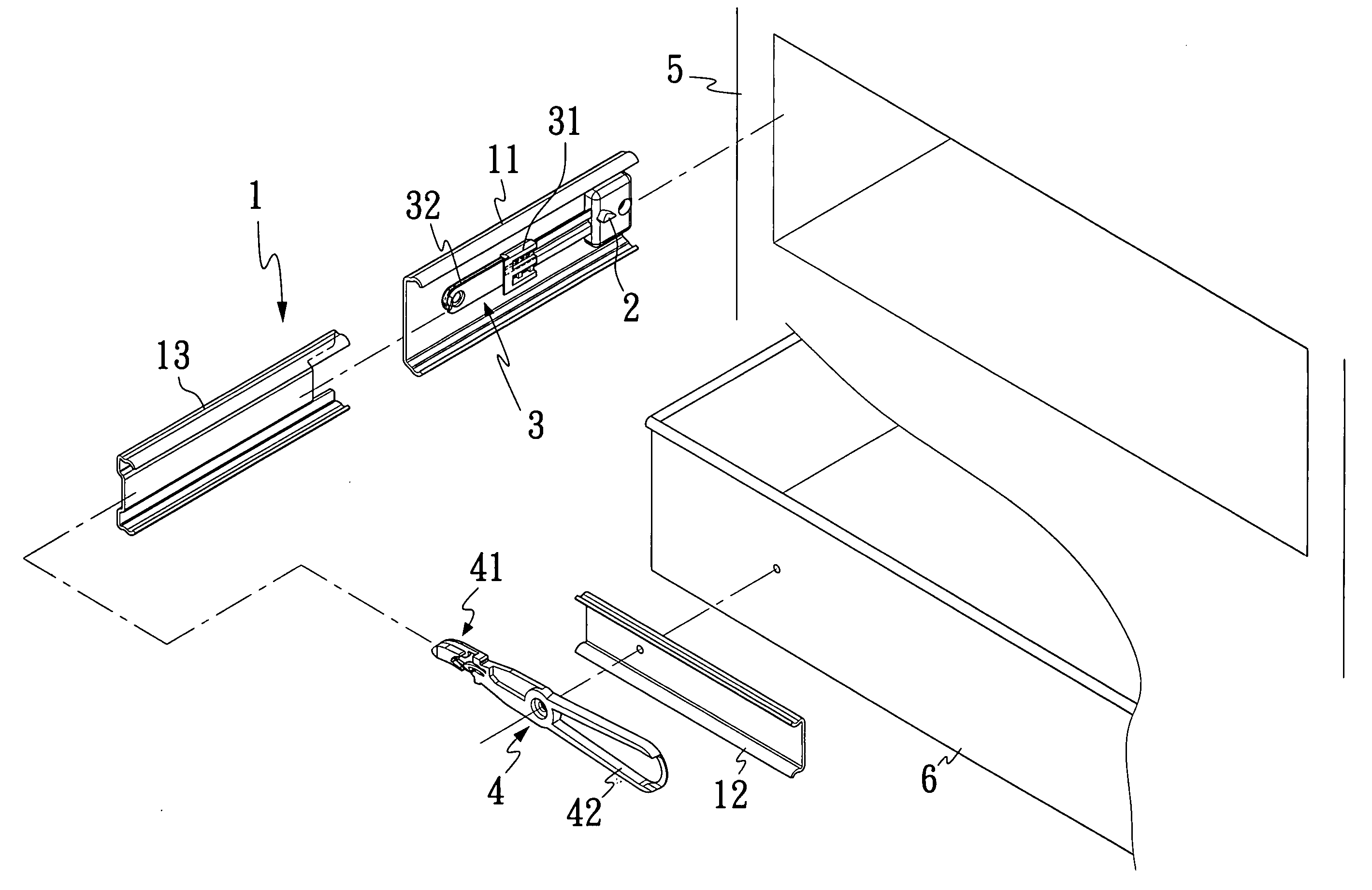

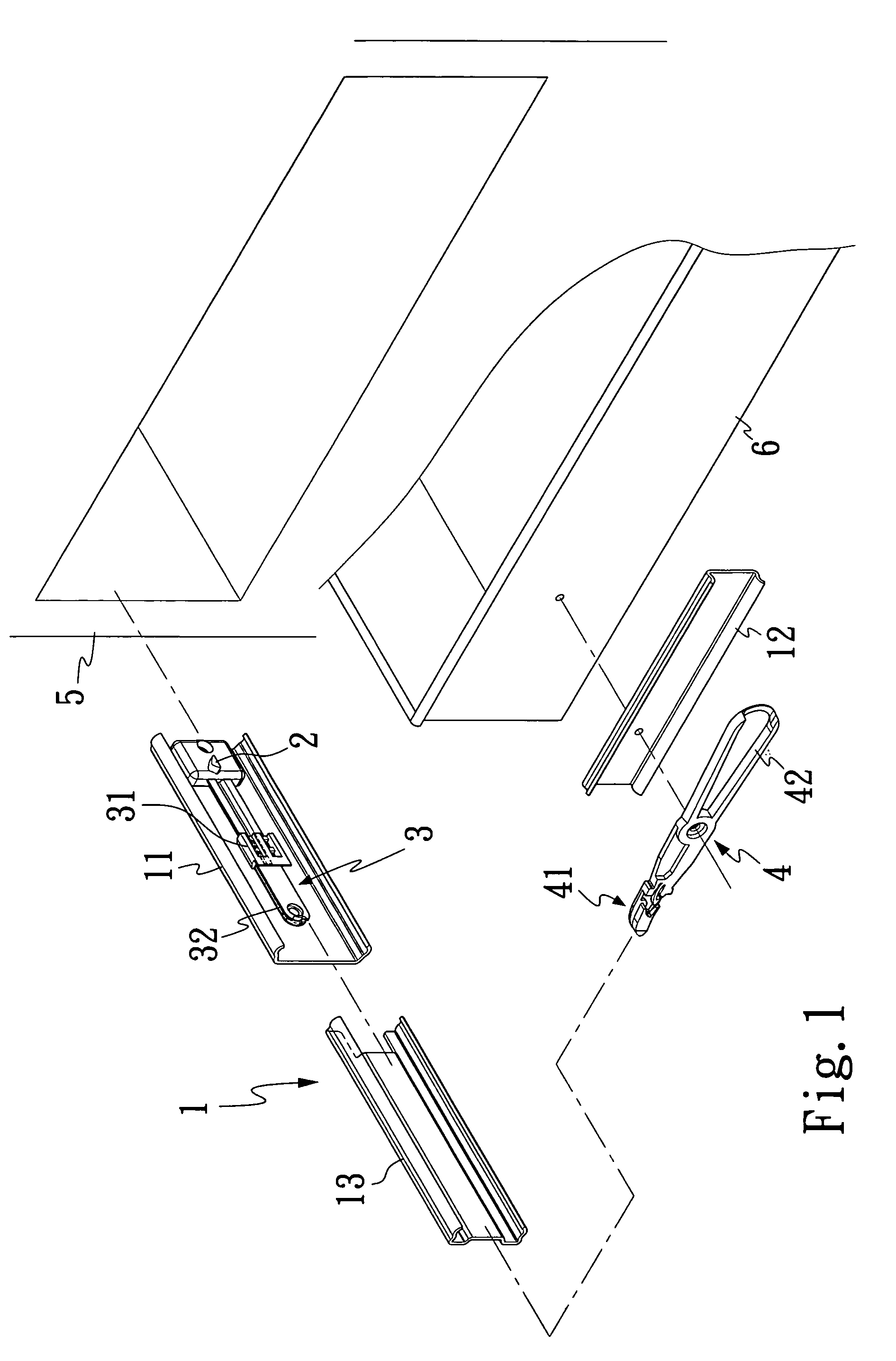

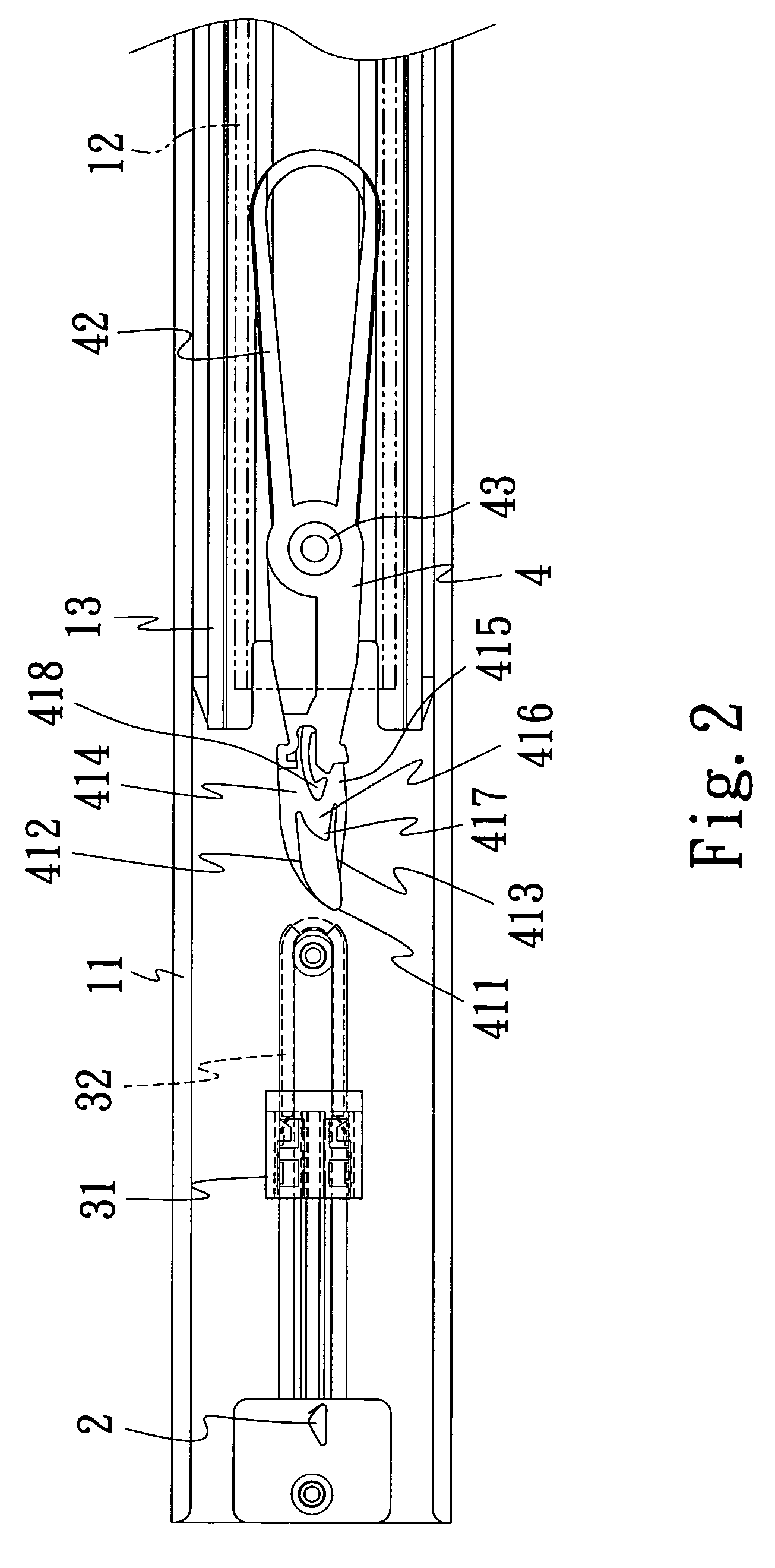

Locking device of sliding drawer

InactiveUS7413270B2Simple designEasily slid in/out of a cabinet bodyDrawersFittingRestoring forceEngineering

An improved locking device of sliding drawer comprises a sliding rail and a locking device, when the sliding drawer is pushed back to a cabinet body, the locking device is initiated when a second sliding track moves along the sliding rail towards a direction of the cabinet body. When one of the circumferential parts of the locking device comes into contact with a protruding portion of a first sliding track, an attaching portion is rotated around the rotating shaft at a rotation center thereby biasing a flexible part of the locking device and generating a first restoring force, a flexible device of the first sliding track is triggered by the second sliding track to generate a second restoring force, when the protruding portion is inserted through the trench and seated within the arc-shaped structure, the first restoring force of the flexible device is released such that the drawer is now locked within the cabinet body.

Owner:NAN JUEN INT CO LTD

Automatic test tube washing machine

InactiveCN105414132ASimple equipment structureReduce labor intensityHollow article cleaningElectric machineryTesting tubes

The invention provides an automatic test tube washing machine which comprises a washing module, a drying module, a disinfecting module, a main controller, a conveying motor and a conveying belt, wherein a washing controller, a drying controller, a disinfecting controller and the conveying motor are connected with the main controller electrically and respectively. The test tube washing machine is suitable for washing various test tubes; the structure of the machine is simple; the labor intensity is reduced and the washing is clean; washing, drying and disinfecting are finished together; time is saved; and the problem that chemical reagents contaminate human bodies is also avoided.

Owner:TIANJIN ELITES LAB ENG CO LTD

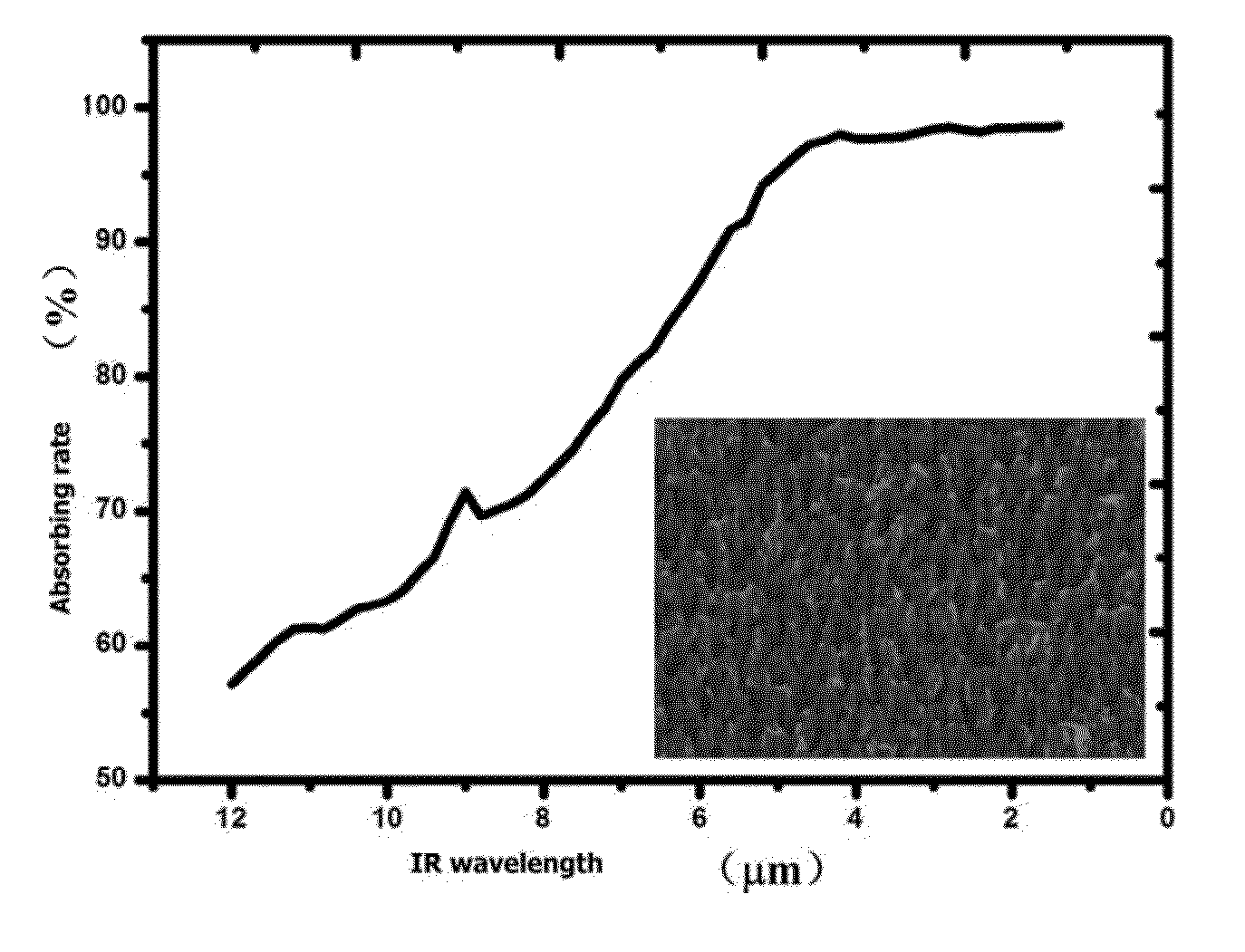

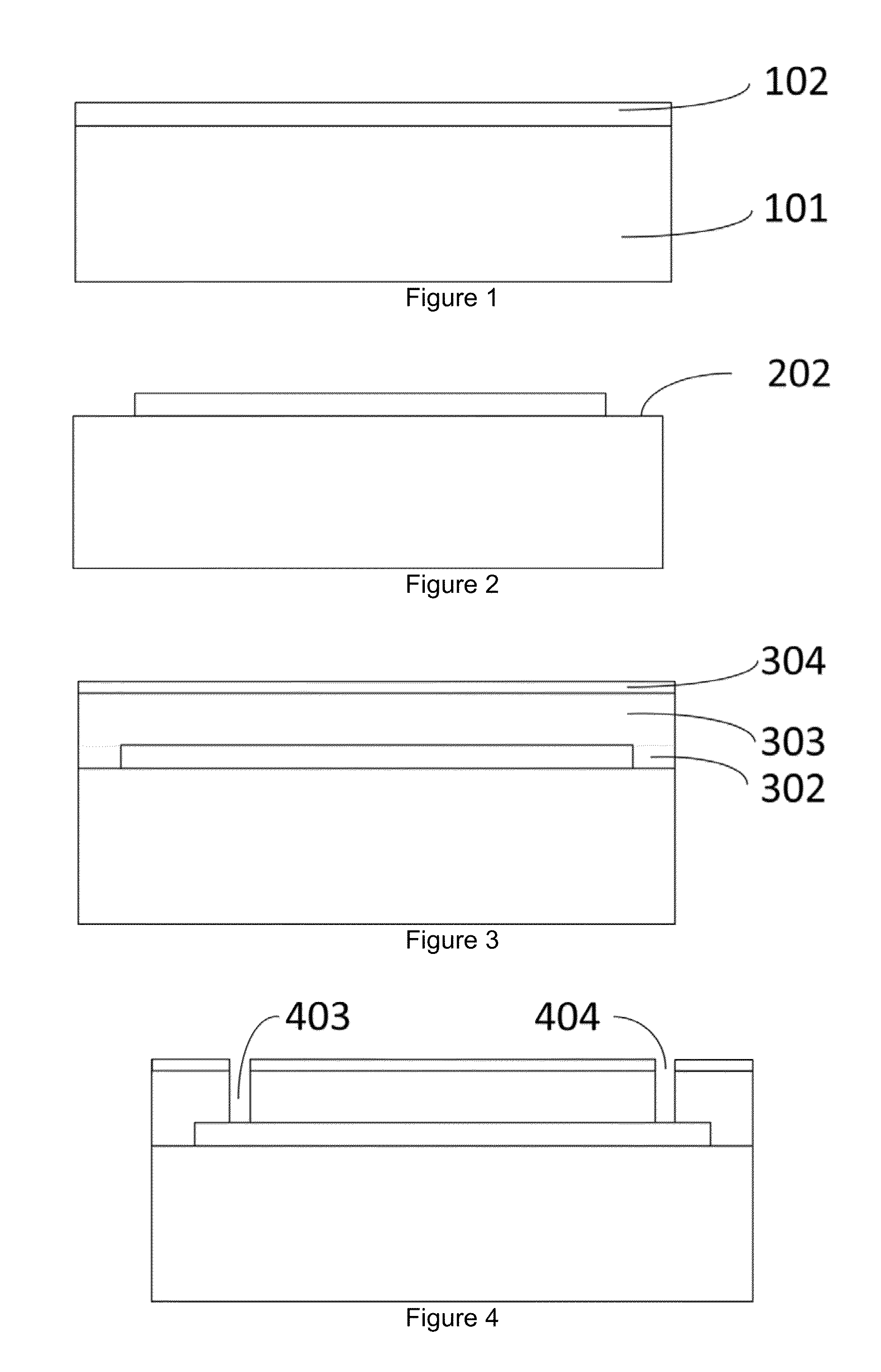

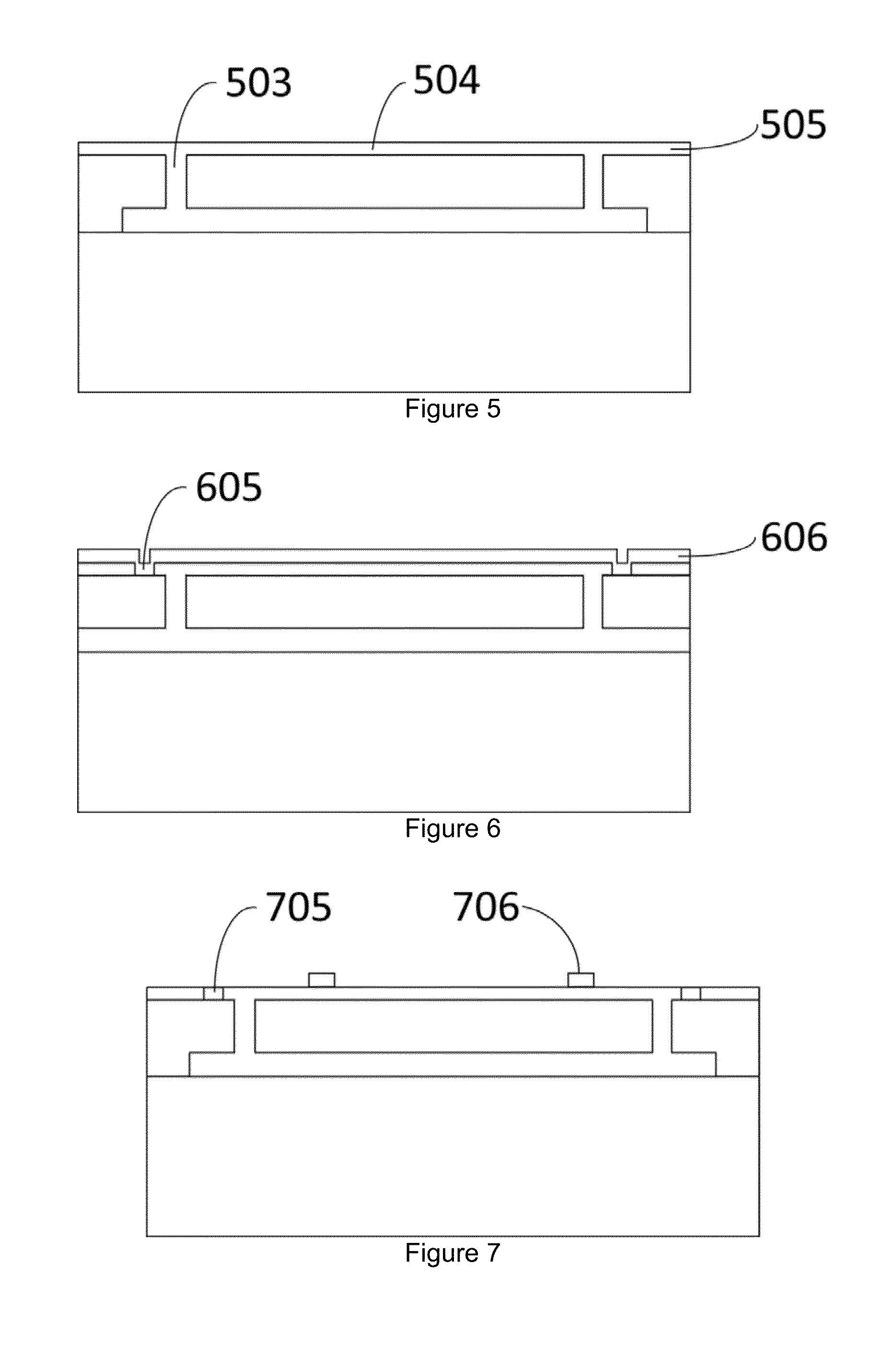

Structure and fabrication method of a high performance MEMS thermopile ir detector

ActiveUS20150137304A1Good process compatibilitySimple equipment structureSolid-state devicesSemiconductor/solid-state device manufacturingThermal isolationThermopile

The invention involves structure and fabrication method of a high performance IR detector. The structure comprises a substrate; a releasing barrier band on the substrate; a thermal isolation chamber constructed by the releasing barrier band; a black silicon-based IR absorber located right above the thermal isolation chamber and the black silicon-based IR absorber is set on the releasing barrier band; a number of thermocouples are set around the lateral sides of the black silicon-based IR absorber. The thermopiles around the black silicon-based IR absorber are electrically connected in series. The cold junctions of the thermopile are connected to the substrate through the first thermal-conductive-electrical-isolated structures as well as the heat conductor under the first thermal-conductive-electrical-isolated structures. The hot junctions of the thermopile are in contact with the IR absorber through the second thermal-conductive-electrical-isolated structures, and the second thermal-conductive-electrical-isolated structures are located above the releasing barrier band. The structure of such detector is simple, and it is easy to implement and can also be monolithicly integrated. Such detector has high responsivity and detection rate, and is CMOS-compatible, thus can be used widely in a safe and reliable manner.

Owner:ZHONGKE FUTURE OF CHIP MICROELECTRONICS TECH CHENGDU CO LTD

Cleaning equipment of semiconductor silicon chip and cleaning method thereof

InactiveCN101533760AGuaranteed capacitySimple equipment structureSemiconductor/solid-state device manufacturingCleaning using gasesSilicon chipProcess engineering

The invention discloses cleaning equipment of a semiconductor silicon chip and a cleaning method thereof. The cleaning equipment comprises a plurality of process cavities which are connected in series, lift separators, rotatable platforms, mechanical arms and cleaning cantilevers, wherein the lift separators are arranged among a plurality of process cavities; the rotatable platforms are arranged in the plurality process cavities for supporting the silicon chip; the mechanical arms are arranged in the plurality of process cavities for conveying the silicon chip among the plurality of process cavities; the cleaning cantilevers are arranged in the plurality of process cavities, and are provided with nozzles which are connected with cleaning agent feed pipelines and inert gas feed pipelines; each process cavity is subjected to different cleaning steps, and is provided with the cleaning agent feed pipeline and the inert gas feed pipeline required by different cleaning steps, thereby greatly simplifying the equipment structure, reducing equipment cost, and improving production efficiency.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

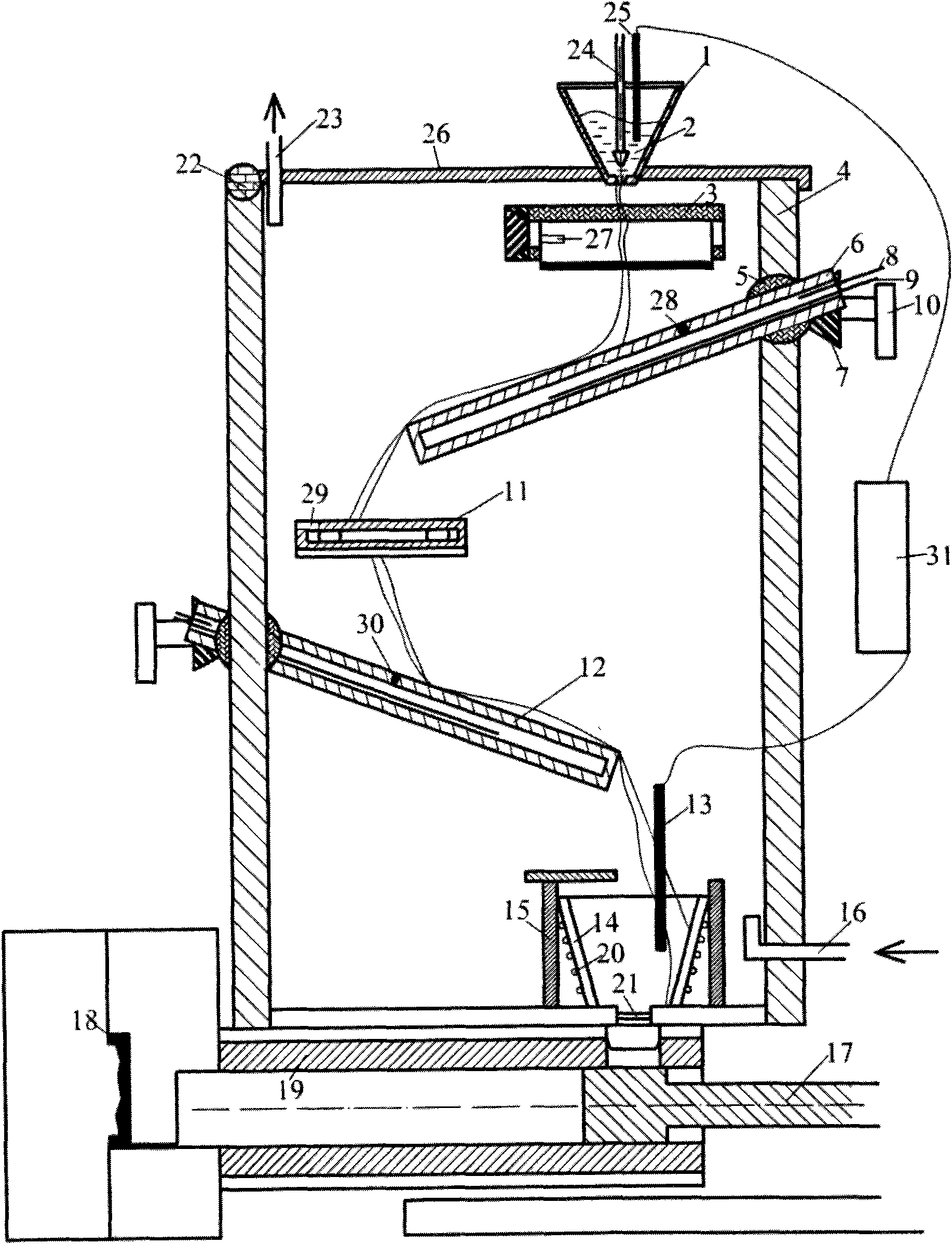

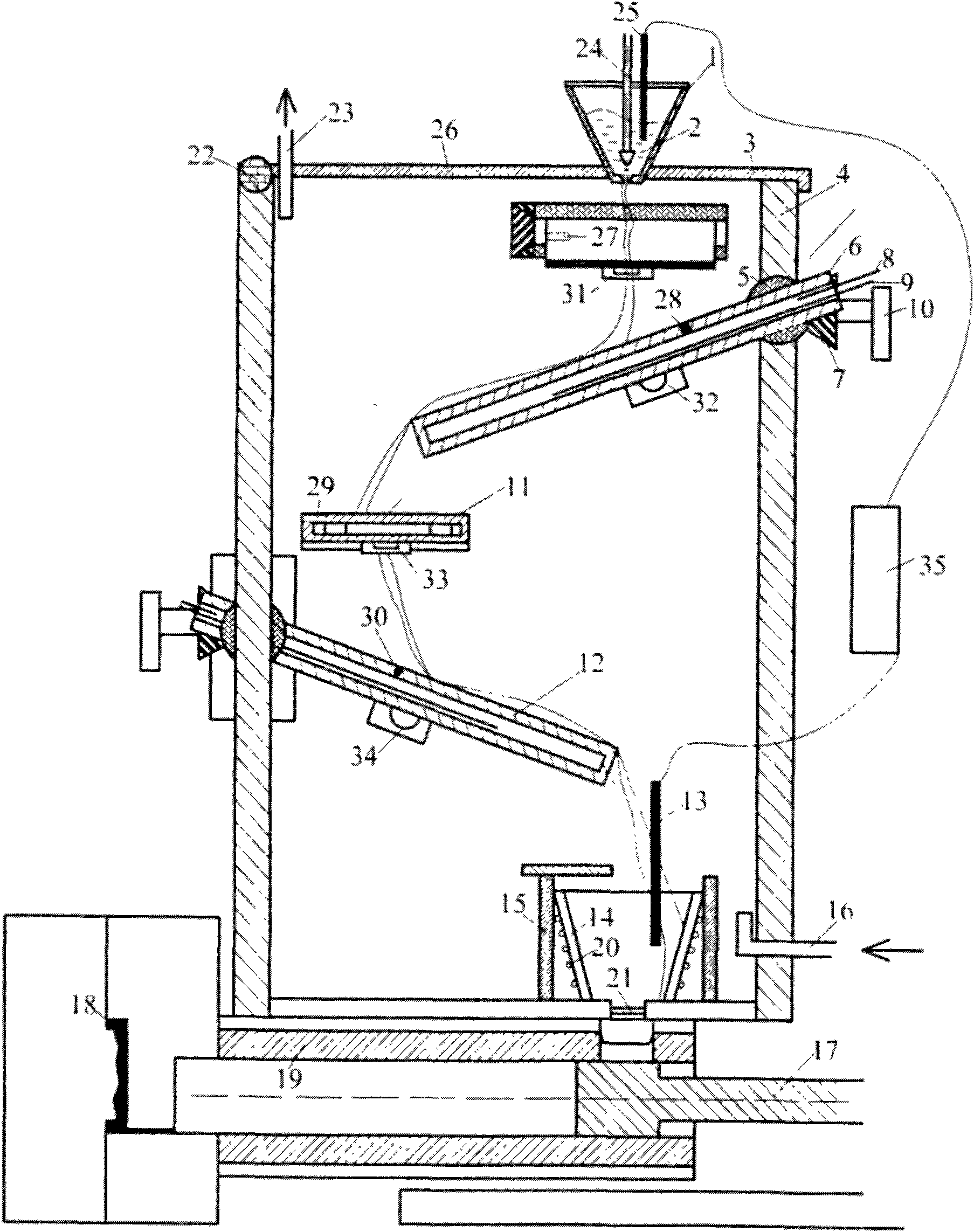

Semi-solid rheological molding device for metal part

The invention relates to a semi-solid rheological molding device for a metal part. The semi-solid rheological molding device is characterized by consisting of a pouring system, a fusant cooling system, a cooling plate adjusting mechanism, a size insulation system, a structure supporting and sealing system, a multichannel temperature monitoring system, an inert gas protection system and a die-casting system. The semi-solid rheological molding device solves the problem that size is difficult to store and transport in the semi-solid rheological molding process, and realizes the integration of semi-solid rheological pulping and molding; the device has a simple and compact structure, saves the space and does not need to make any improvement on the prior die-casting equipment; and a pulping process is simple, has a short flow, is convenient to monitor, can effectively protect gas, prevent oxidation, improve the quality of a fusant, and reduce factors influencing heat exchange of the system, is favorable for controlling the thermal balance of the system and improving the precision and the stability of temperature control, reduces thermal loss, is favorable for energy conservation and consumption reduction, and is in particular suitable for small-and-medium-sized enterprises. The semi-solid rheological molding device has wide application prospect including semi-solid blanking and rheological die-casting of aluminum alloy, magnesium alloy and tin alloy.

Owner:KUNMING UNIV OF SCI & TECH

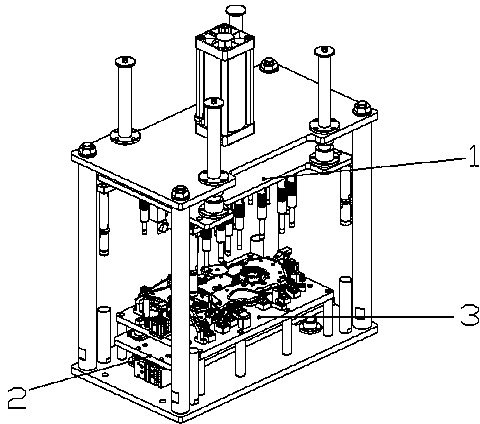

Automatic bottom cap mounting machine

ActiveCN104828760ASimple equipment structureEasy to operateFlanged caps applicationConveyor partsEngineeringMaterial supply

The invention provides an automatic bottom cap mounting machine. The automatic bottom cap mounting machine comprises a machine frame and a control mechanism, wherein a first flat plate and a second flat plate which are arranged up and down in a spaced manner and are used for mounting components are arranged on the machine frame; the control mechanism is used for controlling the operating of the overall automatic bottom cap mounting machine; the automatic bottom cap mounting machine further comprises a material supply device which is used for storing and automatically releasing bottom caps, a cap arranging device which is used for arranging the bottom caps, and a cap compressing device which is used for compressing the bottom caps to bottle bodies, wherein the feeding end of the cap arranging device is connected with the material supply device; the discharge end of the cap arranging device is connected with the cap compressing device. The automatic bottom cap mounting machine is simple in structure, easy to operate, low in manufacturing cost, long in service life and easy to maintain and repair; the production cost and the labor intensity of a worker can be effectively reduced; the cap arranging and compressing effects are good; the production efficiency is greatly improved.

Owner:QUANZHOU HUASHUO IND

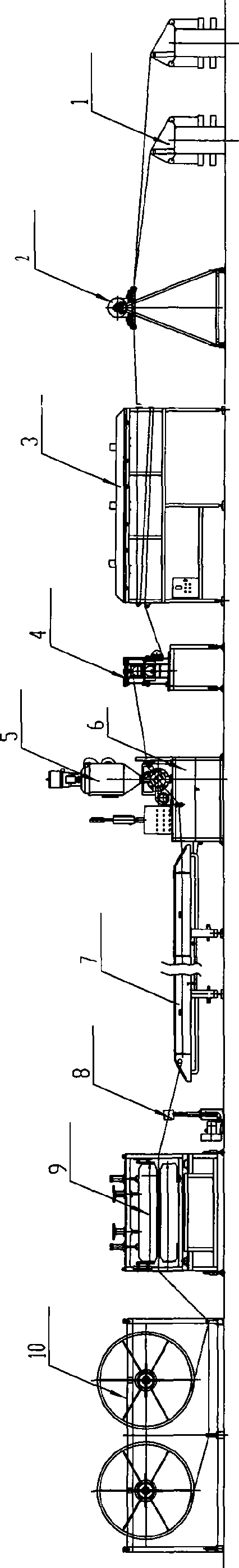

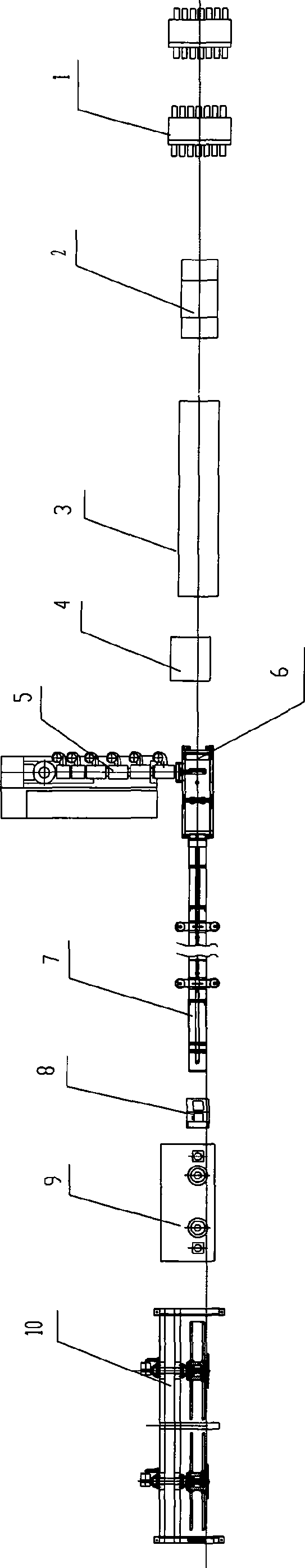

Technique and equipment for producing reinforcing band

The invention relates to a process and a device for manufacturing a reinforcing band. The process comprises the following steps: (1) fiber spindles or steel wires are regularly arranged to be fiber bundles or steel wire bundles by a payoff rack; (2) each fiber bundle or steel wire bundle passes through a tension controller, the tensions and the positions of the fiber bundles or steel wire bundles in row are adjusted and controlled, the tension of the fiber bundles or steel wire bundles is retained under the action of a fiber bundle or steel wire bundle hauling machine, and the fiber bundles and the steel wire bundle are arranged equidistantly; (3) the equidistantly arranged fiber bundles or steel wire bundles are dried by a dryer; (4) an extruder covers a layer of uniform plastic among the equidistantly arranged fiber bundles or steel wire bundles and on the periphery of the equidistantly arranged fiber bundles or steel wire bundles through a plastic extruding mould to form a thin long-strip-shaped plastic covered band; (5) the plastic covered band is cooled for molding through a formation guiding device and a first cooling water tank; (6) the plastic covered band is further cooled and dried for molding by an air cooler; (7) the cooled and dried plastic covered band carries out tension control, so the reinforcing band is obtained; and (8) the reinforcing band is stored, cut and coiled by a band storage coiling device. The process is simple and practical; and the device has simple structure, good controlling performance and stable and reliable operation.

Owner:GUANGZHOU ADVANCE TECH

Projection image display device and projection optical system for performing extended projection

ActiveUS8292438B2Well formedReduce brightnessProjector focusing arrangementCamera focusing arrangementOptical axisProjection image

A projection image display device includes a light source; an illumination optical system that uniformly irradiates a surface of an image modulating element (primary image surface) with a light beam emitted from the light source; and a projection optical system that performs with respect to a screen (a secondary image surface) extended projection on image information provided at the primary image surface and modulated by the image modulating element. The projection optical system includes a first optical system having a positive refractive power, and a second optical system having a concave reflecting surface. The first optical system has a common optical axis at which all optical components of the first optical system have rotationally symmetric surfaces, and a screen shift function that causes the secondary image surface to be moved by moving at least one of the optical components of the first optical system substantially perpendicularly to the optical axis.

Owner:SONY CORP

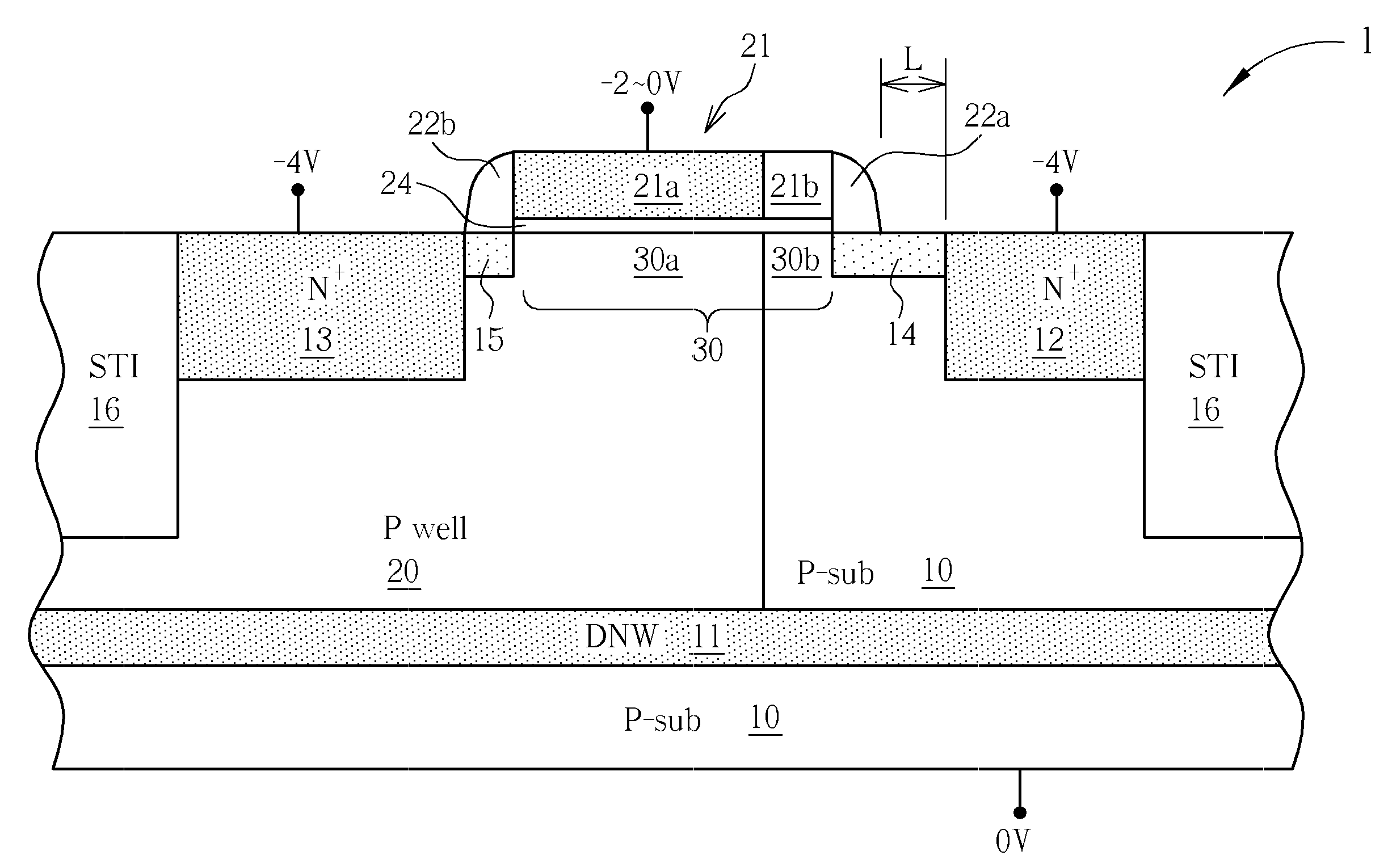

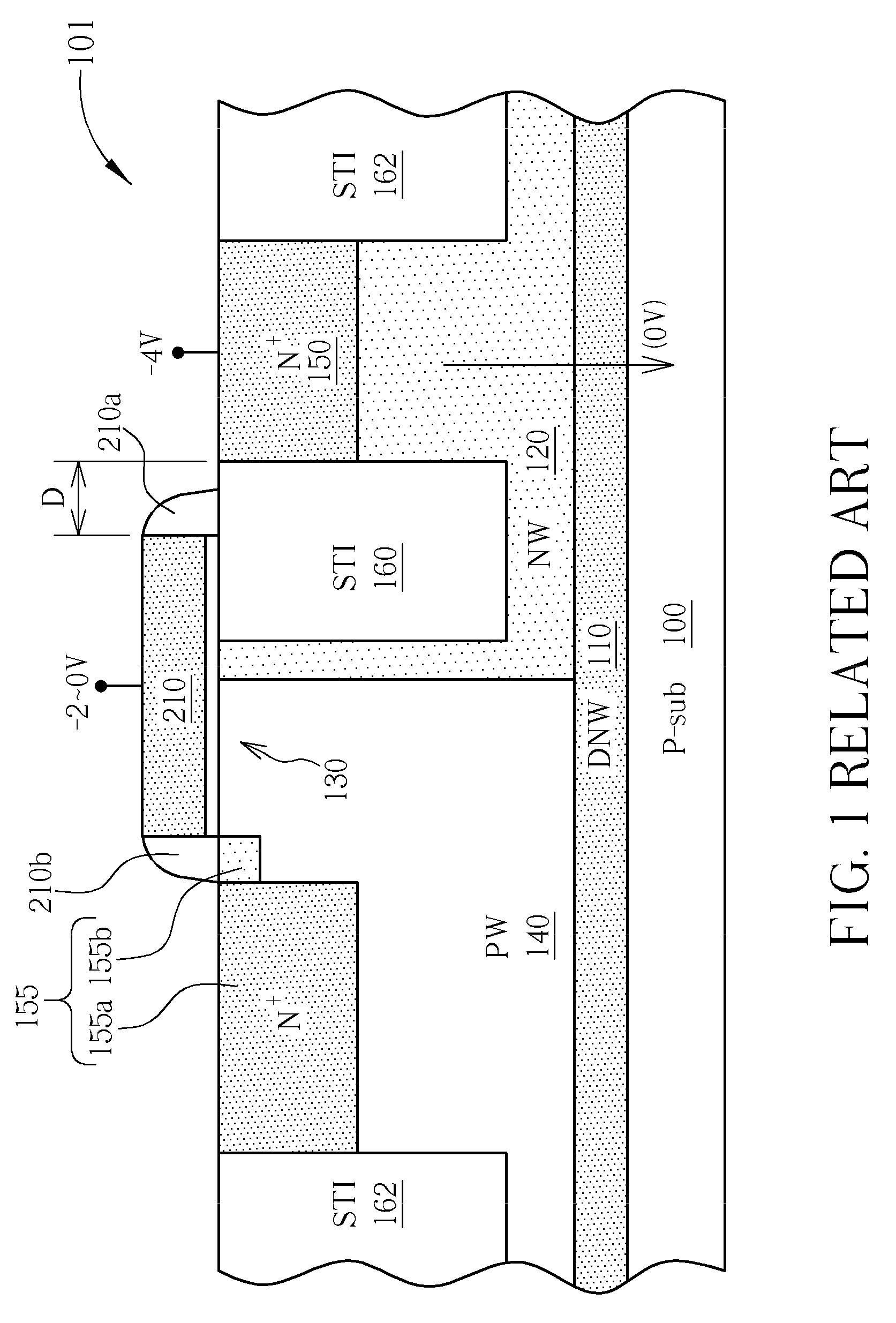

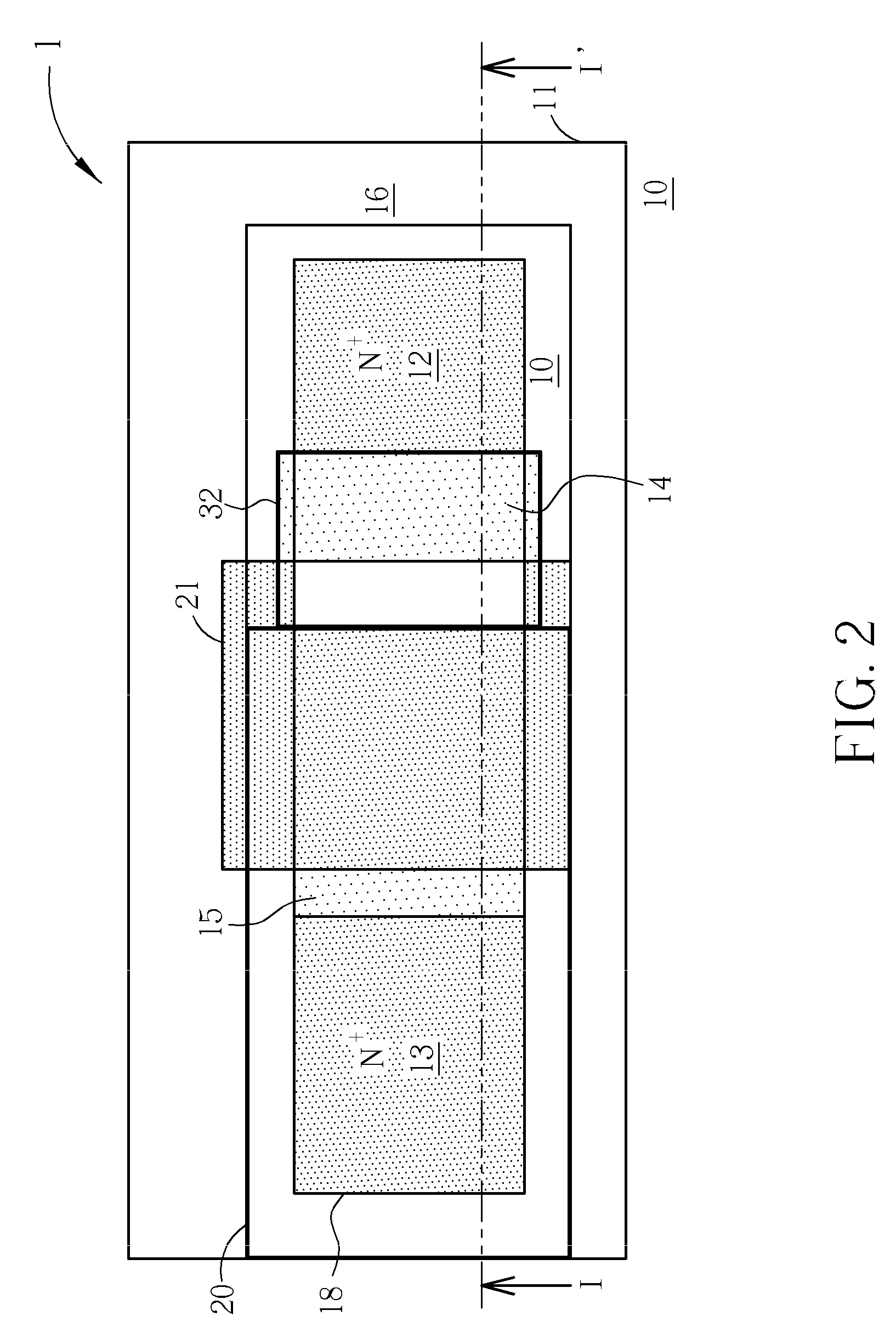

High-voltage metal-oxide-semiconductor device

InactiveUS20100164018A1Simple equipment structureExtension of timeSemiconductor/solid-state device manufacturingSemiconductor devicesHigh pressureSemiconductor

A high-voltage MOS transistor includes a gate overlying an active area of a semiconductor substrate; a drain doping region pulled back away from an edge of the gate by a distance L; a first lightly doped region between the gate and the drain doping region; a source doping region in a first ion well; and a second lightly doped region between the gate and the source doping region.

Owner:MEDIATEK INC

Method for eliminating impurities of lead, zinc from nickel solution

InactiveCN101050487ASimple equipment structureEasy to operatePhotography auxillary processesOther chemical processesIonLead zinc

This invention relates to a method for removing Pb2+ and Zn2+ impurities from Ni electrolyte during Ni production. The method utilizes a weak-alkaline anion exchange resin with primary amine groups ((R3N) +OH-) to adsorb Pb2+ and Zn2+ in the Ni electrolyte. The method alternately performs adsorption, elution and regeneration. Adsorption is performed in a packed moving bed, while elution and regeneration are performed in a fluidized bed. The packed moving bed / fluidized bed apparatus has such advantages as simple structure, easy operation, and little resin abrasion. The method can accelerate the exchange between the resin and trace elements, and can easily elute Pb2+ and Zn2+ impurities in Ni electrolyte.

Owner:JINCHUAN GROUP LIMITED

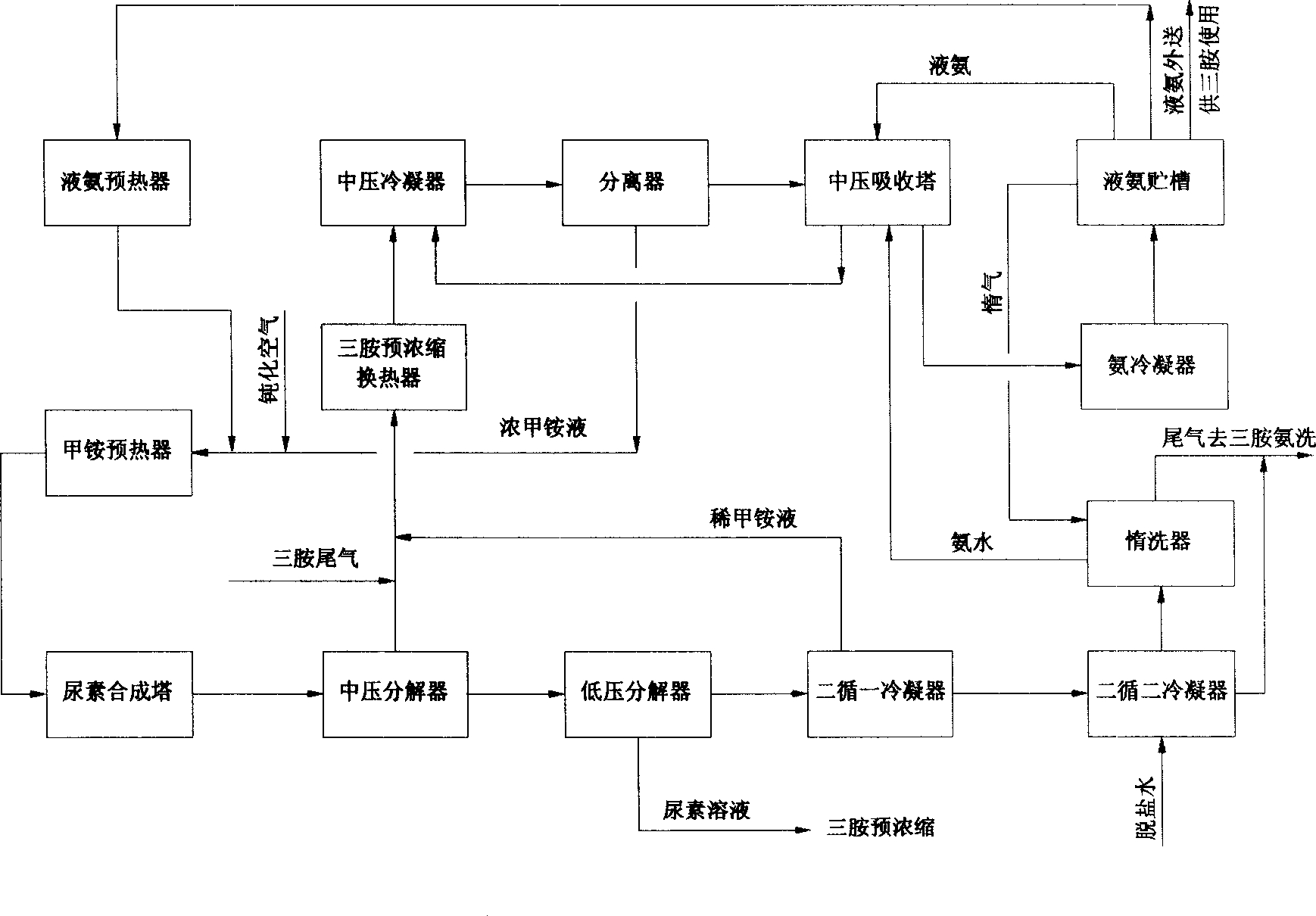

Process of directly preparing urea by tripoly cyanamide

InactiveCN100999486AAdaptableReliable Instrument ControlUrea derivatives preparationOrganic compound preparationDecompositionProcess configuration

This invention relates to a urea preparation methods which directly use melamine assembly end gas, including high pressure synthesis, midst-low-pressure decomposition, condensing pressure, low pressure condensate recovery steps. First absorbing and condensing melamine assembly end gas (composition: NH3: 40 to 45%; CO2: 35 to 40%, and the rest of H2O) into ammonio liquid; and then mix ammonio liquid with liquid ammonia and passive air as raw materials of urea synthesis; at last to preheat this mixture to 180 ~ 195 deg C, and sent into tower of urea synthesis of high-pressure, generate urea solution.

Owner:EAST CHINA ENG SCI & TECH +1

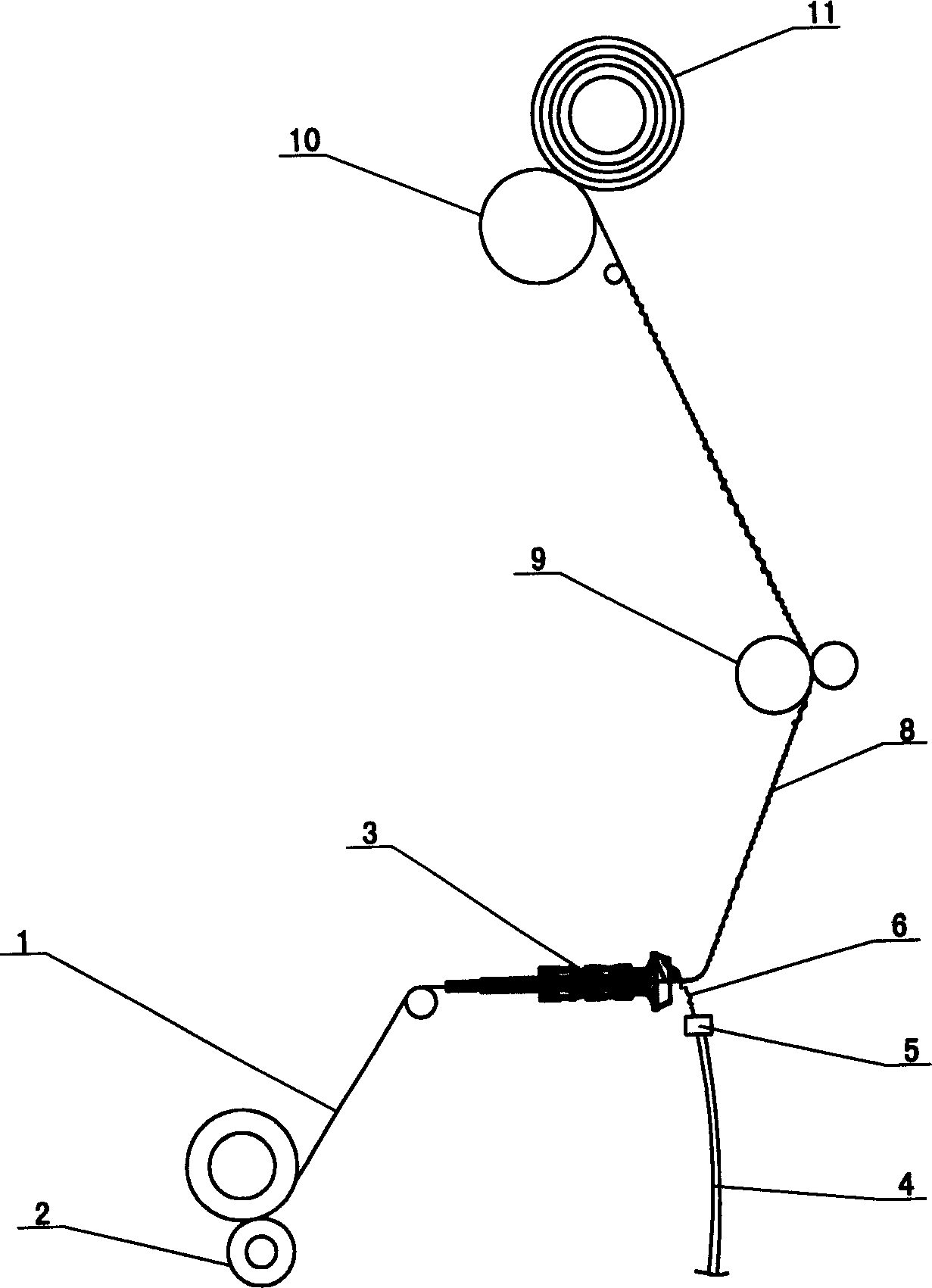

Prestressed carbon cloth reinforced tensioner

InactiveCN101713253AEasy to assemble and disassembleImprove adaptabilityBuilding material handlingUniversal jointEngineering

The invention relates to a prestressed carbon cloth reinforced tensioner which is characterized by comprising two counterforce racks (1), wherein the two counterforce racks (1) are fixed to both sides of a component (13) through bolts; the counterforce racks (1) are provided with a supporting device (3); one end of carbon cloth (12) is connected with an anchorage device (5) after bypassing the supporting device (3); the anchorage device (5) is connected with one end of a universal joint (6); the other end of the universal joint (6) is connected with a pull rod (10); the pull rod (10) is provided with a lifting jack (9), and a fixing nut (7) and a tension nut (11) which are respectively positioned on both sides of the lifting jack (9); and the fixing nut (7) is positioned on the outer side of a backing board between the two counterforce racks (1). The invention has the advantages of convenient assembly and disassembly, favorable adaptability, simple operation, accurate tensioning control and little prestressing loss, is especially suitable for engineering constructions and can enhance the engineering efficiency.

Owner:江苏省苏科建设技术发展有限公司

Full-automatic bolt press fitting equipment

ActiveCN103801928ASimple equipment structureEasy to operateMetal working apparatusProduction rateEngineering

Owner:NANTONG GUANGYE AUTOMATION SYST ENG

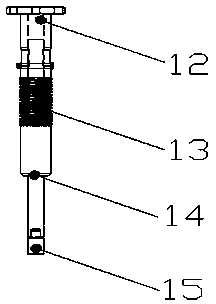

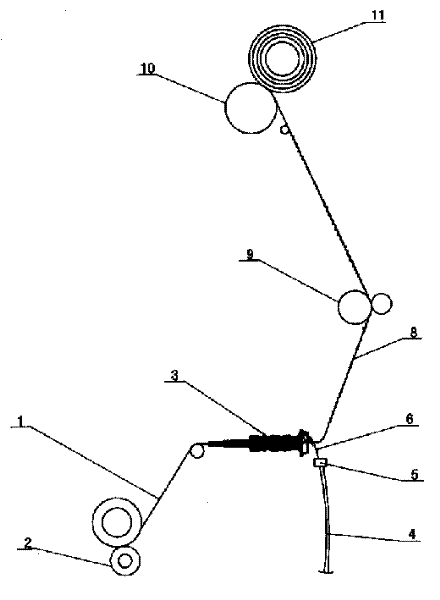

Coated yarn spinning method and apparatus

InactiveCN1468989ASimple equipment structureIngenious ideaContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

Owner:浙江日发控股集团有限公司

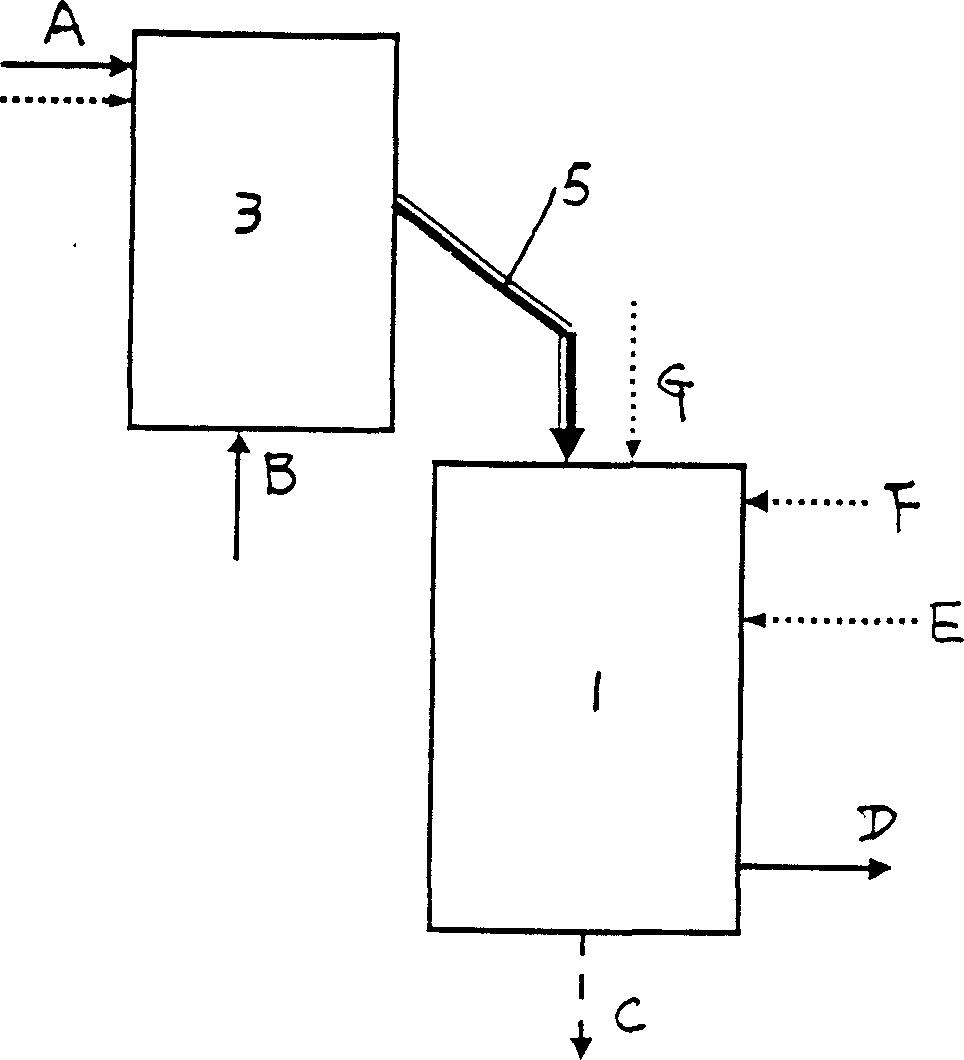

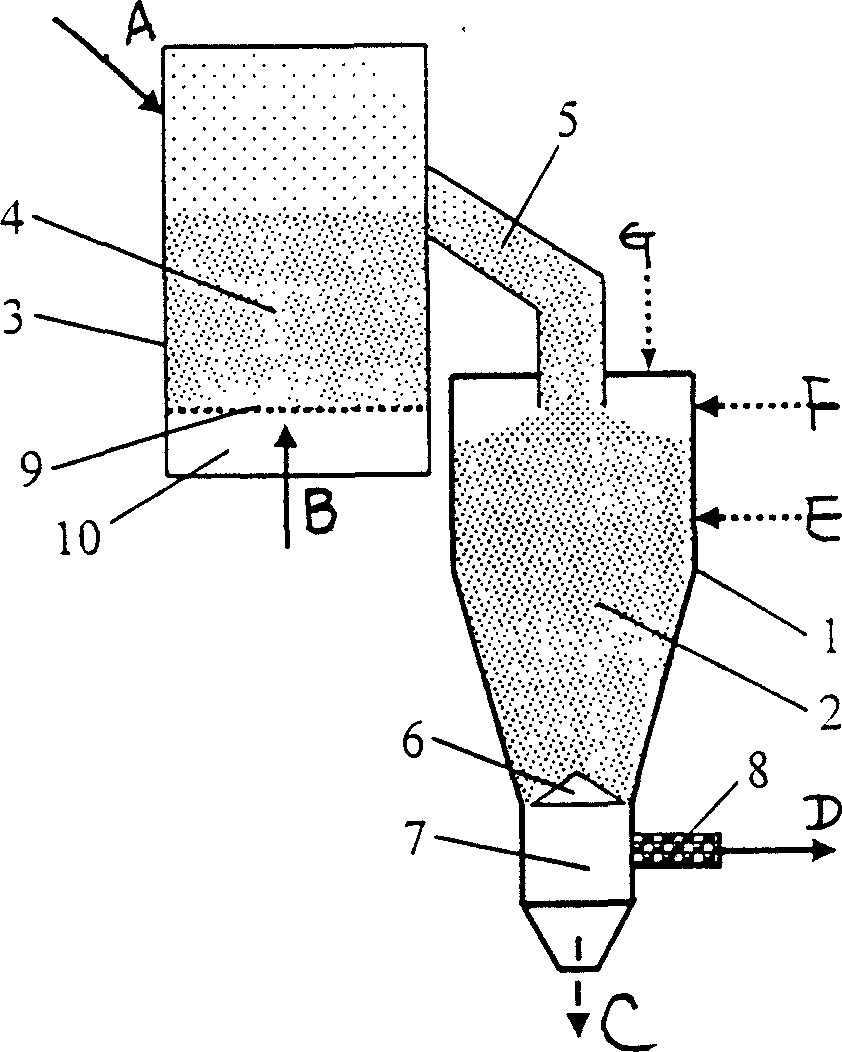

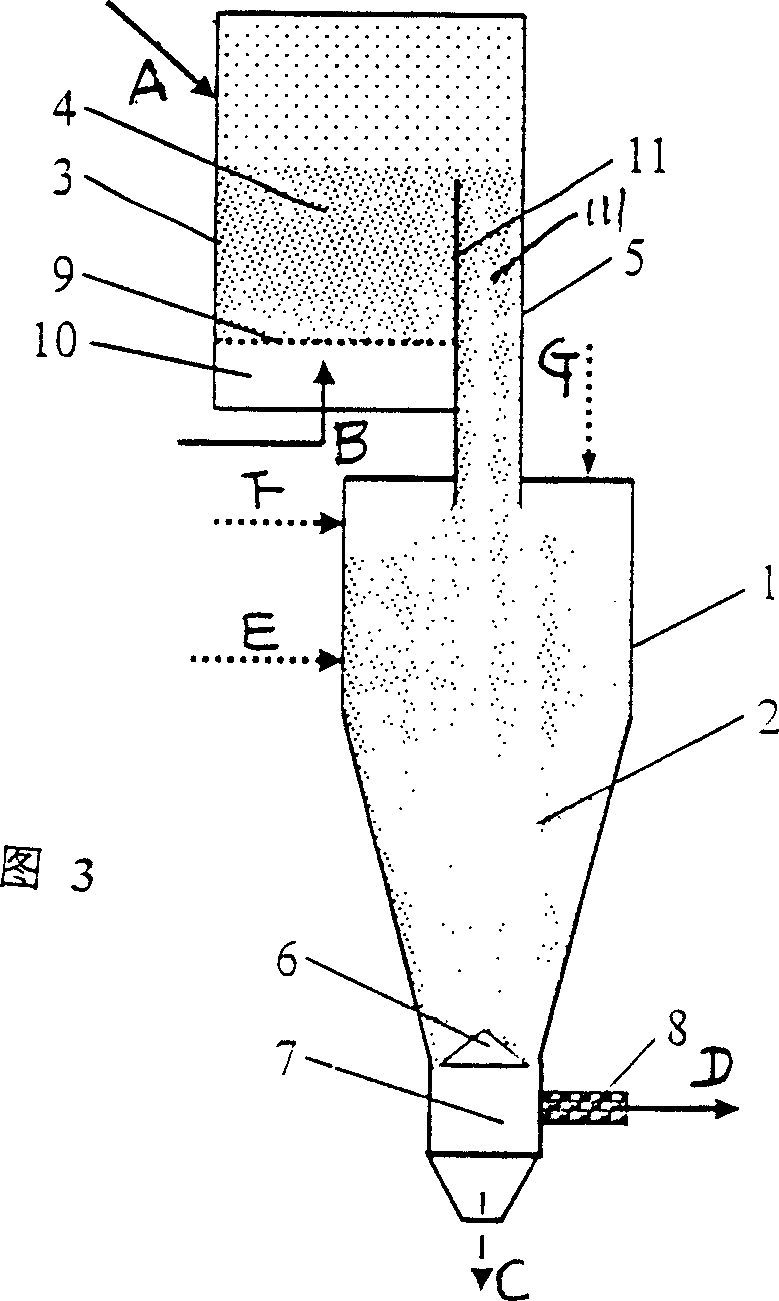

Bottom feed type gas method and equipment for preparing gas with no tar products through oxygendeficient fluid bed combustion

InactiveCN1916123AAccelerate modification/decomposition reactionSimple equipment structureBulk chemical productionGranular/pulverulent flues gasificationTarFluidized bed combustor

This invention relates to downdraft gasification method and equipment for preparing tar-free product gas by oxygen-deficient fluidized burning. The equipment comprised a front fluidized bed burner, a downdraft fixed bed gasifier set lower than the burner, a transporting pipe for carbocoal and semi-finished gas connecting the burner and the gasifying furnace, a fuel inlet and an oxidant inlet. The method comprised: (1) adding fuel through the fuel inlet of the fluidized bed burner, and performing oxygen-deficient fluidized burning with oxidant added through the oxidant inlet at the bottom of the fluidized bed burner to obtain carbocoal and semi-finished gas containing tar, and (2) sending the unseparated carbooal and semi-finished gas containing tar to a down-draft fixed bed gasifier at a high temperature to gasify the carbocoal, and modifying and cracking the tar introduced by the semi-finished gas by the catalytic activity of high-temperature carbocoal to obtain the product gas with tar. The equipment has such advantages as simple structure, easy operation and high gasifying efficiency, and is suitable for a wide variety of fuels and can produce product gas without tar.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

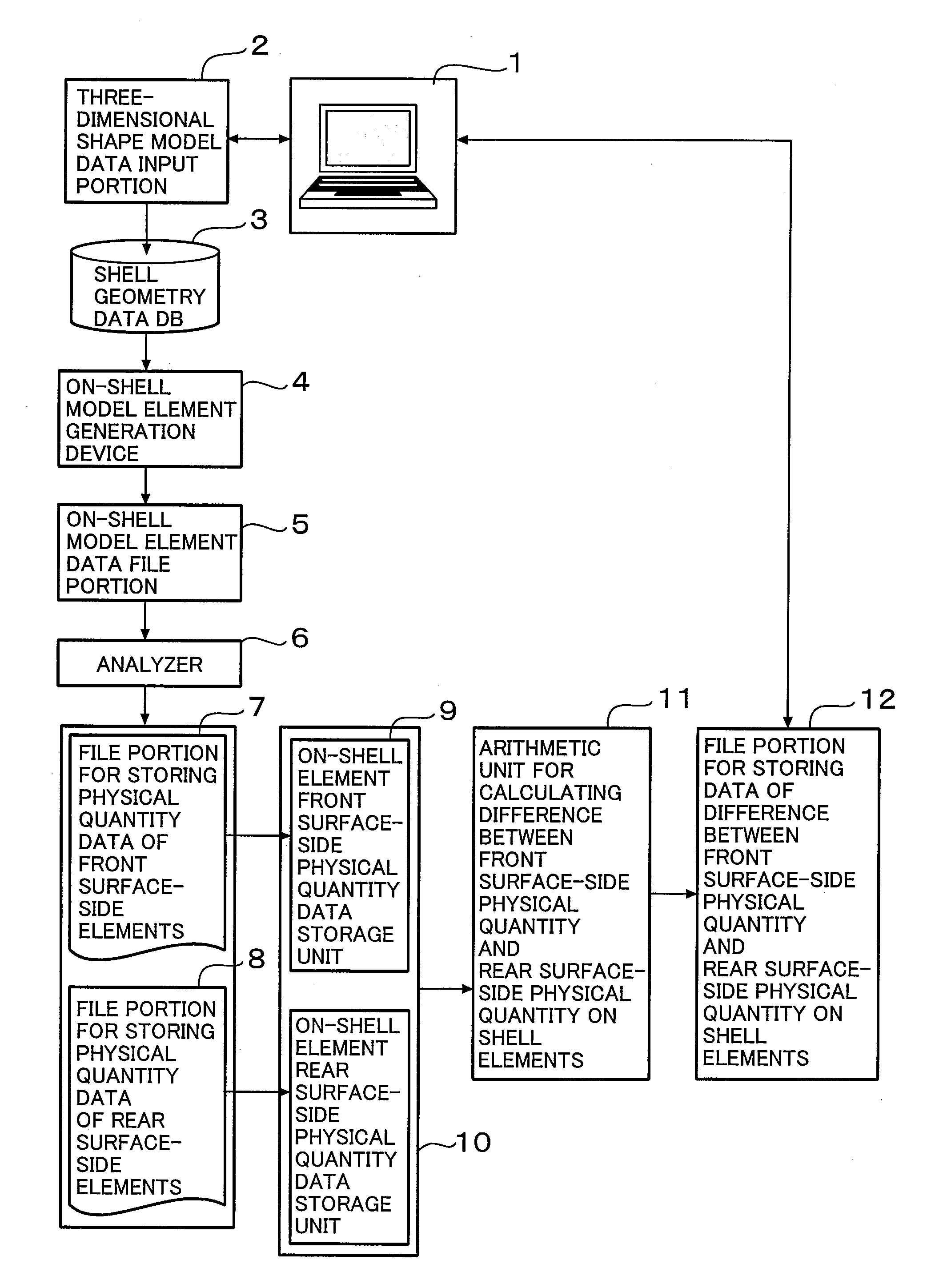

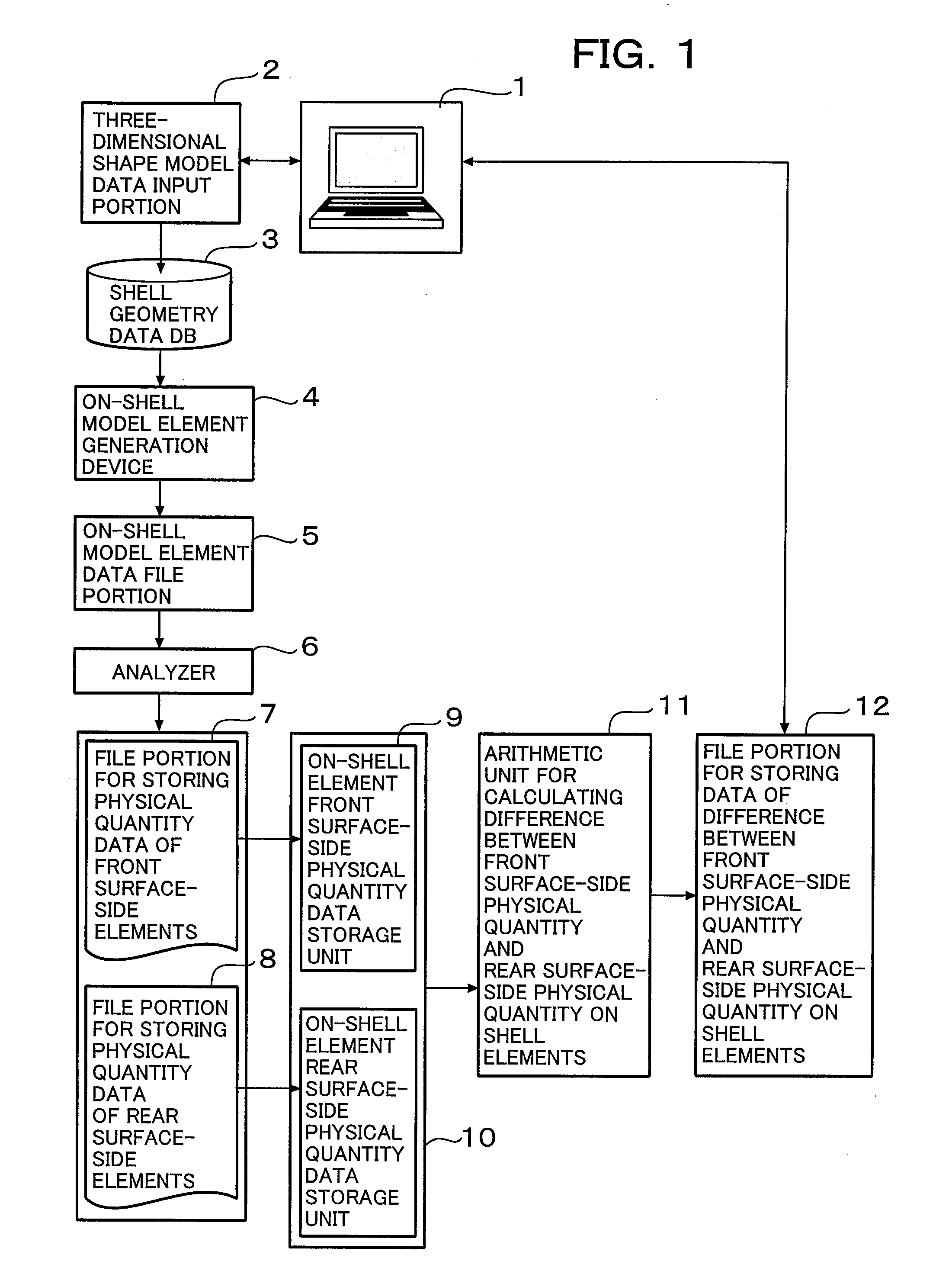

Numerical analysis data evaluation apparatus and thermal fluid pressure data evaluation apparatus using the same

InactiveUS20110098987A1Reduce riskImproved device structureDesign optimisation/simulationAnalogue computers for heat flowThree dimensional shapeSHELL model

A numerical analysis data evaluation apparatus includes: a shell generation model which converts a three-dimensional shape model into a three-dimensional shell model so that a thickness on an analysis model becomes zero; a front surface-side physical quantity projector and a rear surface-side physical quantity projector which interpolate physical quantities of front surface-side elements and physical quantities of rear surface-side elements of the three-dimensional shape model obtained as a result of the numerical analysis in on-shell model element data obtained by spatially discretizing the three-dimensional shell model, and project the physical quantities on front surface-side physical quantities and rear surface-side physical quantities of on-shell elements; an on-shell element front surface-side physical quantity data storage unit; an on-shell element rear surface-side physical quantity data storage unit; and an arithmetic unit which calculates differences between the front surface-side physical quantities and the rear surface-side physical quantities of the on-shell elements.

Owner:HITACHI LTD

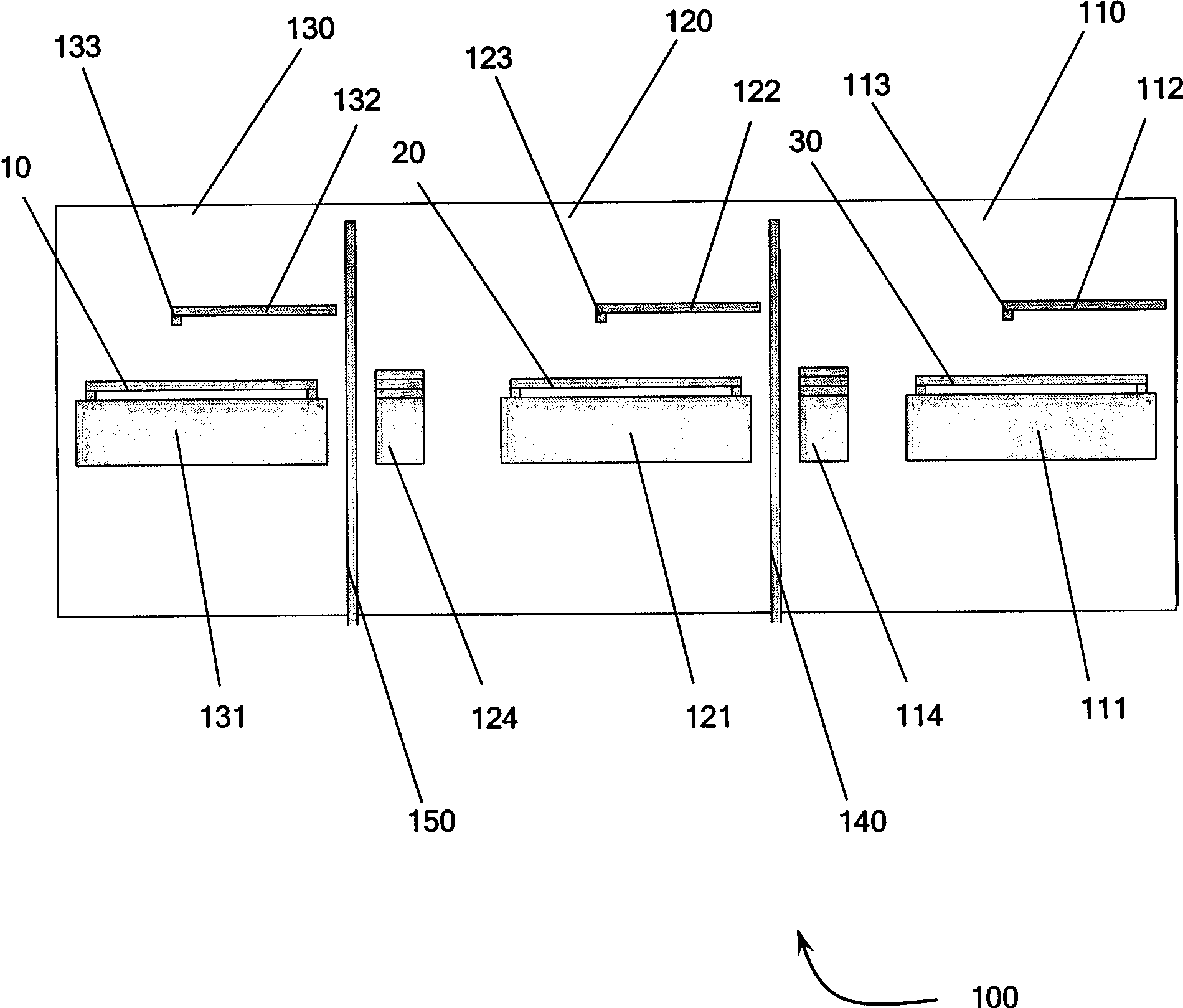

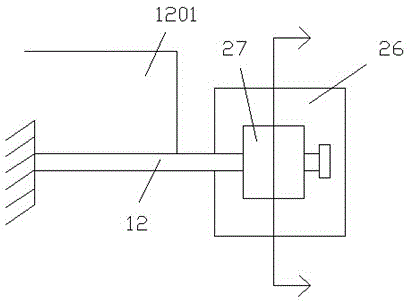

Installing assembly provided with radiator fan and applied to LED display device

InactiveCN105090714AReliable structureSimple equipment structureStands/trestlesIdentification meansComputer fanCantilever

An installing assembly provided with a radiator fan and applied to an LED display device comprises a rail beam (12), a lower idler wheel (13), an upper idler wheel (14), an LED display device installing and connecting part (261) and a driving box (27). The rail beam is fixed to a building (1201), extends outwards in a cantilever manner and is provided with an upper rail groove (120) and a lower rail groove (120); the lower idler wheel and the upper idler wheel can roll in the two rail grooves (120); and the LED display device installing and connecting part and the driving box are respectively connected to the two sides of the lower idler wheel (13) and the two sides of the upper idler wheel (14).

Owner:YIWU CITY GECE COMMODITY

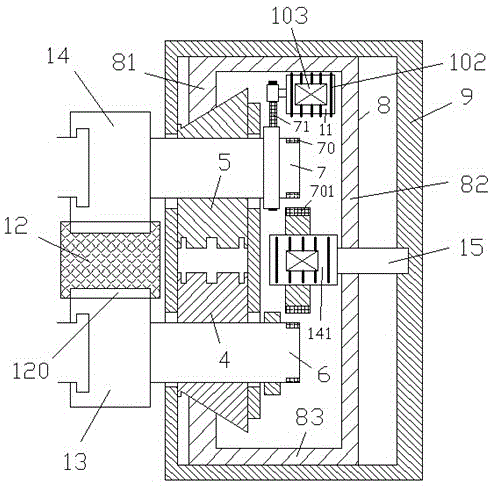

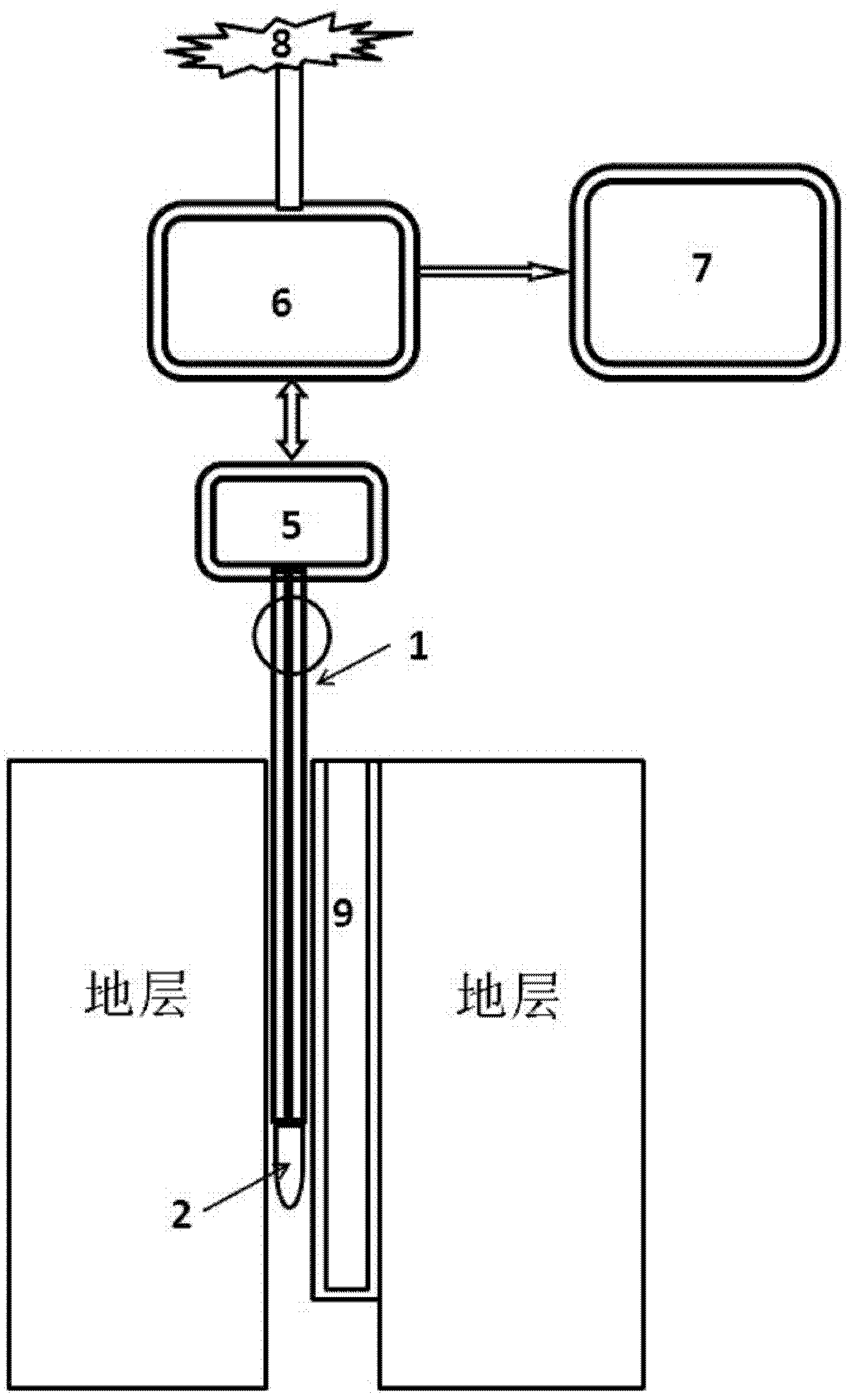

System for continuously monitoring temperature and pressure during steam injection and soaking process

ActiveCN102206995ASimple process structureSimple equipment structureSurveyTemperature stressMonitoring temperature

The invention discloses a system for continuously monitoring temperature and pressure during steam injection and soaking process. The system comprises an armoured cable (1), a pressure and temperature sensor (2), a ground data processor (5) and a ground controller (6). The armoured cable (1) comprises a pair of capillaries (3 and 4), namely a temperature measuring capillary (3) and a pressure measuring capillary (4). Both the two capillaries are filled with a high-temperature pressure conductive medium. Both the aboveground end parts of the two capillaries are connected with the ground data processor (5). Both the underground end parts of the two capillaries are exposed outside the armoured cable (1). Underground pressure is conducted to the pressure measuring capillary (4) through a clean pipe at the underground end part of the pressure measuring capillary (4). The underground end part of the temperature measuring capillary (3) is communicated with the pressure and temperature sensor(2). The ground data processor (5) is used for amplifying and conditioning two pressure signals transmitted by the pressure measuring capillary (4) and the temperature measuring capillary (3) and sending to the ground controller (6) so as to correct the two pressure signals into pressure and temperature engineering values of an underground oil layer.

Owner:河南省科学院同位素研究所有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com