Novel full-automatic efficient ceramic tile package producing equipment

A production equipment and fully automatic technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of high manufacturing cost, low work efficiency, complex structure, etc., and achieve low manufacturing cost, easy operation, and simple equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

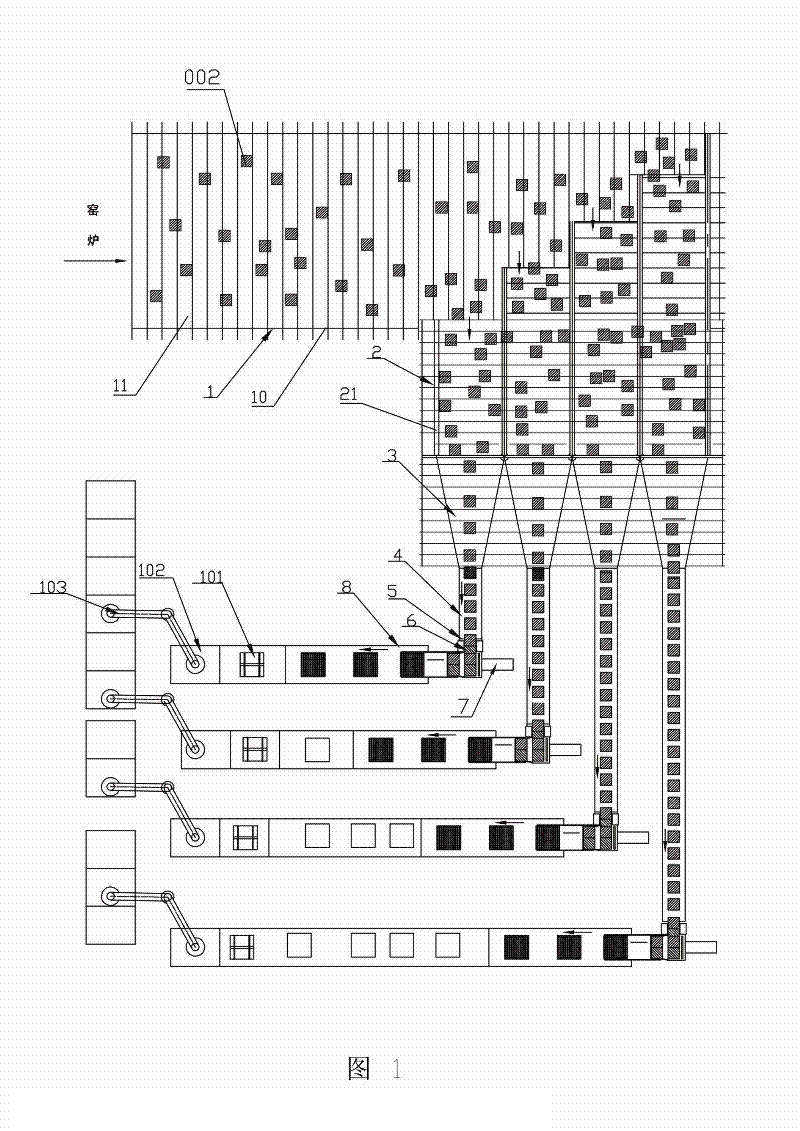

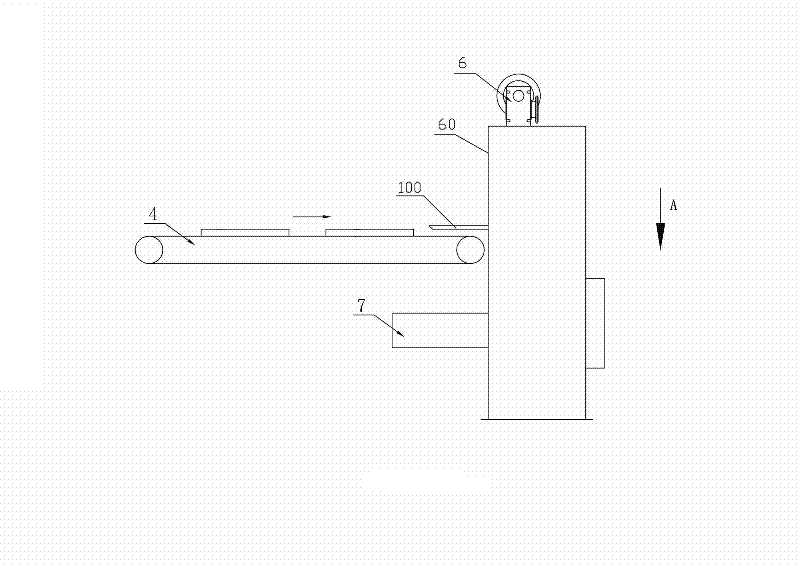

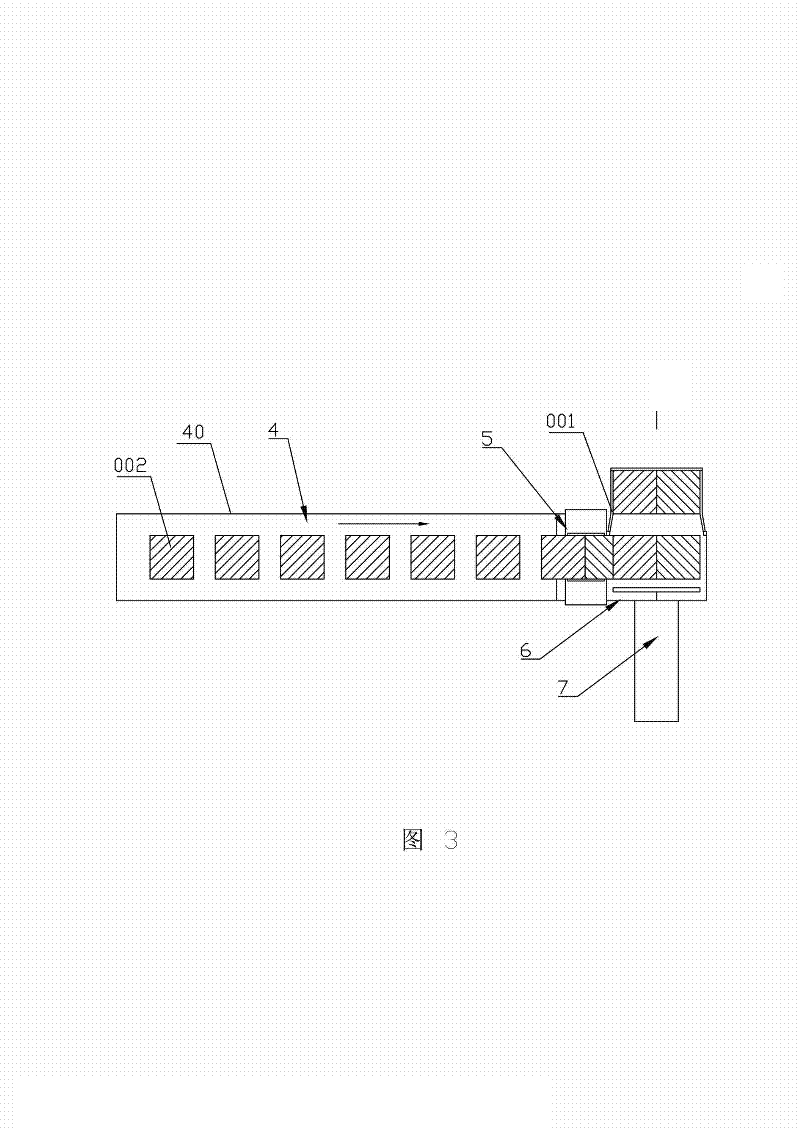

[0043] refer to figure 1 , figure 2 , image 3, a new type of fully automatic and high-efficiency ceramic tile packaging production equipment, including a kiln rear conveyor table 1 through which tiles pass sequentially, an automatic channel diversion mechanism 2, a diversion channel 3, a brick feeding mechanism 4, a brick feeding end transition platform 5, and brick stacking Mechanism 6, Brick Pushing Mechanism 7, Brick Receiving and Turning Box Conveying Mechanism 8, Kiln Rear Conveyor Platform 1, Automatic Channel Diverting Mechanism 2, Brick Feeding Mechanism 4, Brick Stacking Mechanism 6, Brick Pushing Mechanism 7, Brick Receiving and Turning Box Conveying Mechanisms 8 are all connected to a terminal control device;

[0044] The conveying platform 1 behind the kiln comprises a frame 10, a conveying device 11 arranged on the frame 10, and a driving device for driving the conveying device 11, and the driving device is connected with the above-mentioned terminal control d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com