Patents

Literature

60 results about "Fluidized bed combustor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluidized Bed Combustion (FBC) A bed of solid particles is said to be fluidized when the pressurized fluid (liquid or gas) is passed through the medium and causes the solid particles to behave like a fluid under certain conditions. Fluidization causes the transformation of the state of solid particles from static to dynamic.

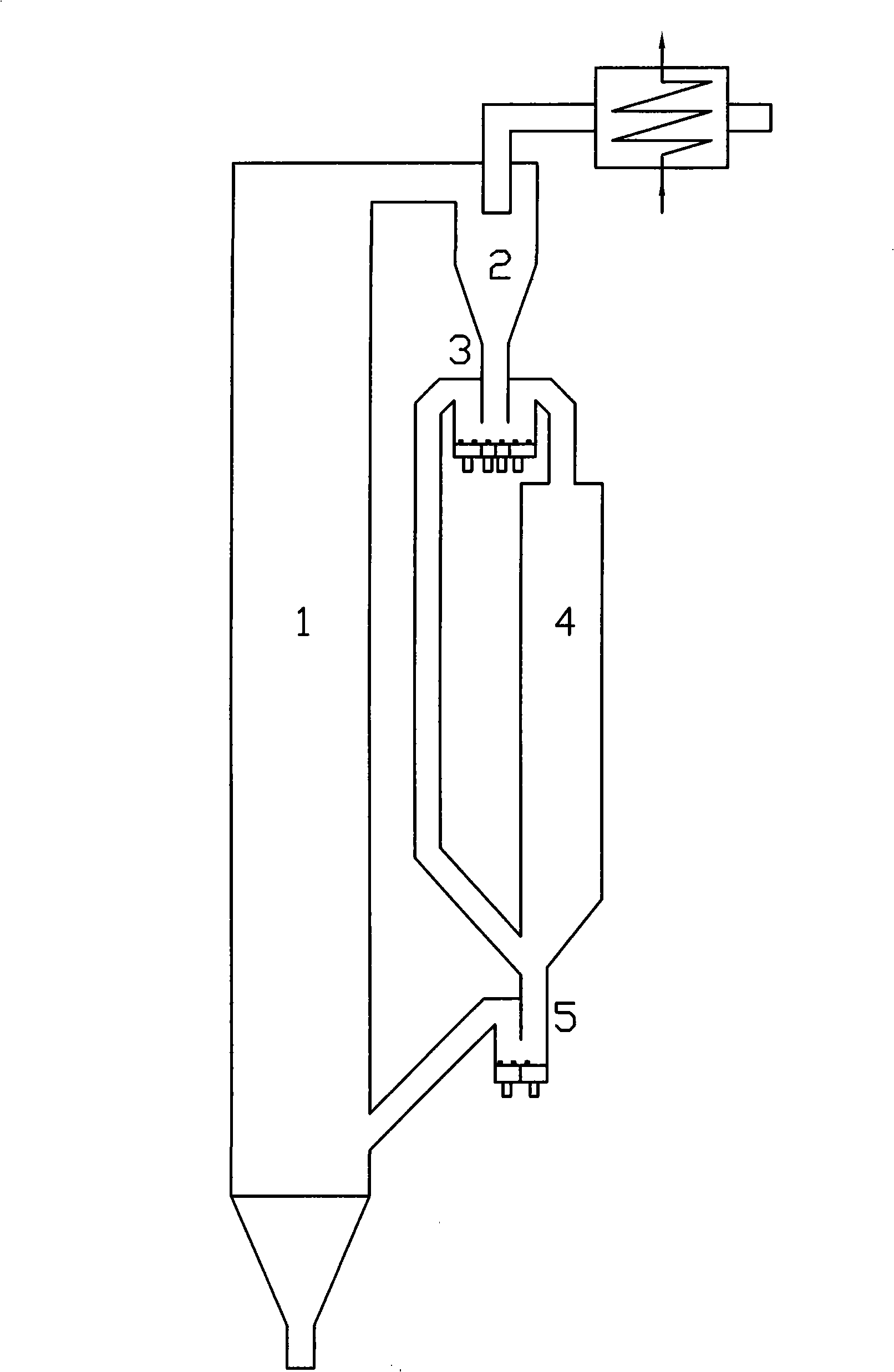

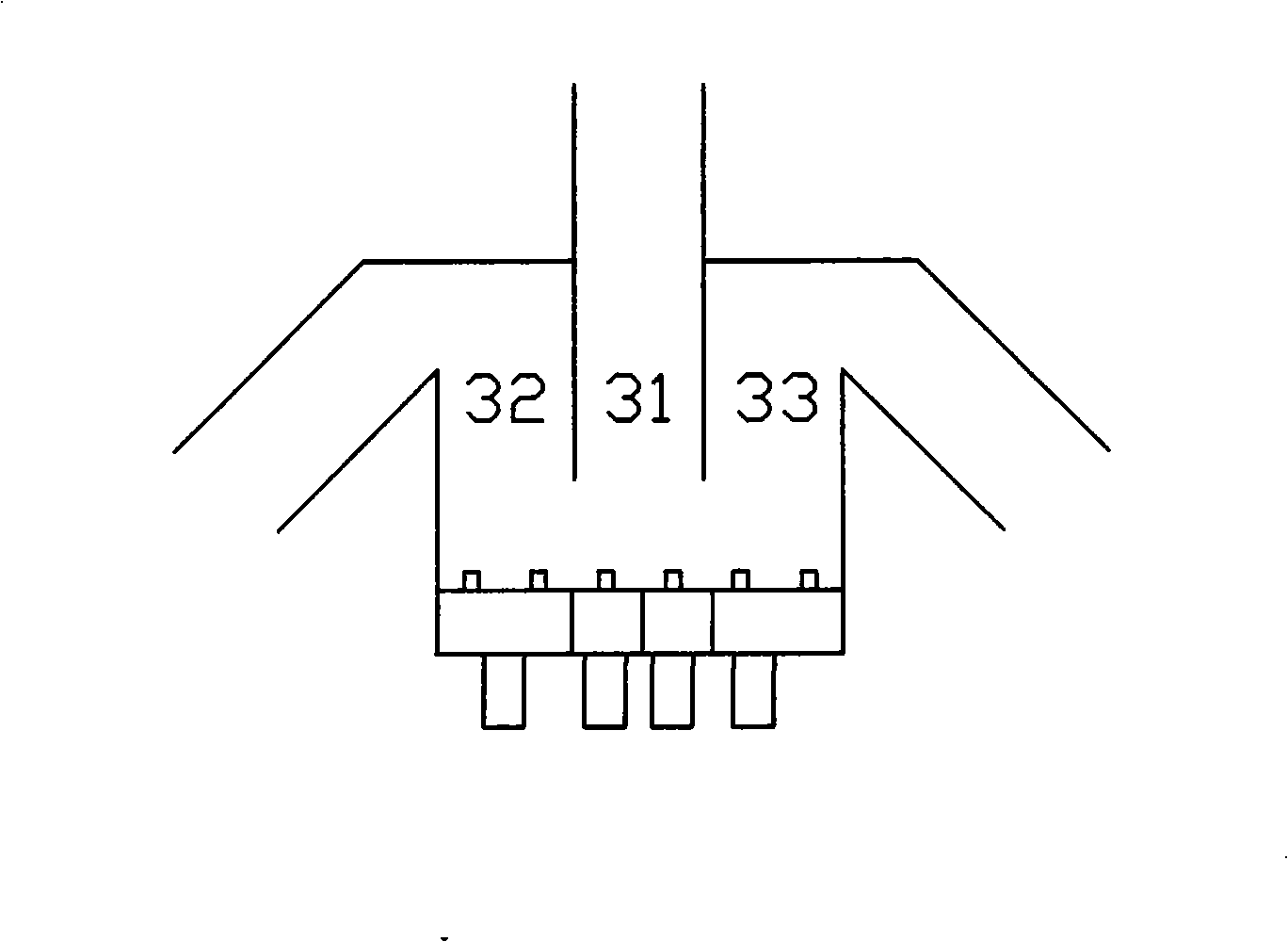

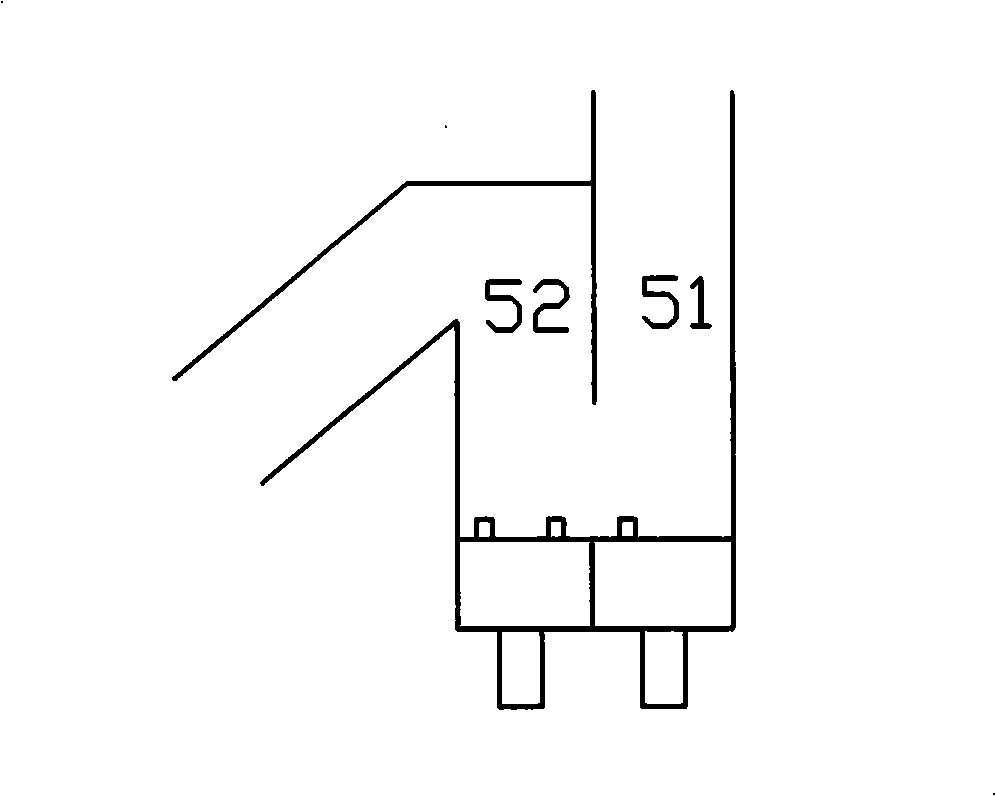

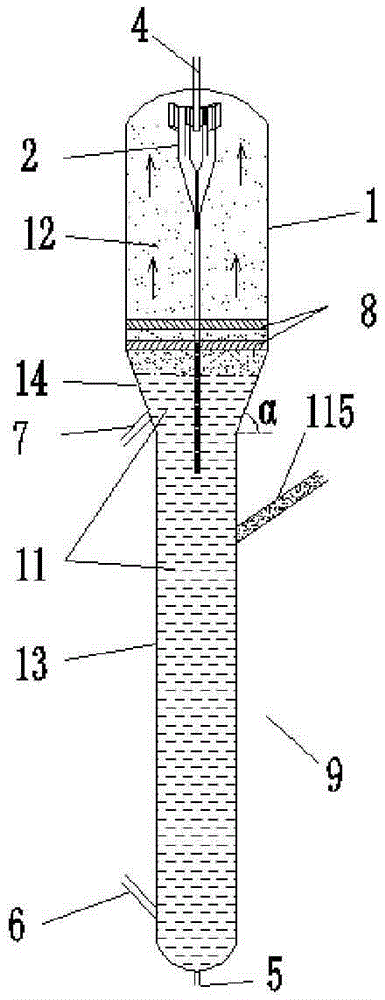

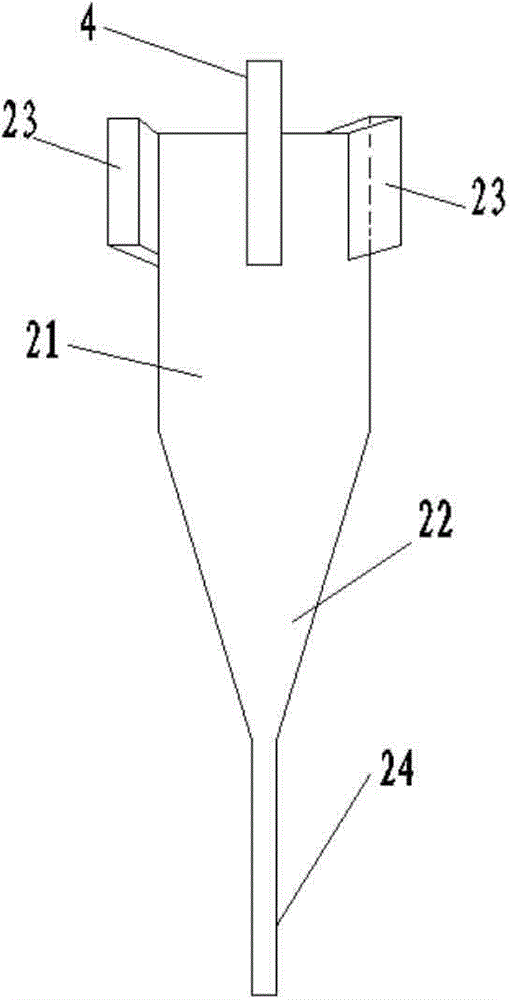

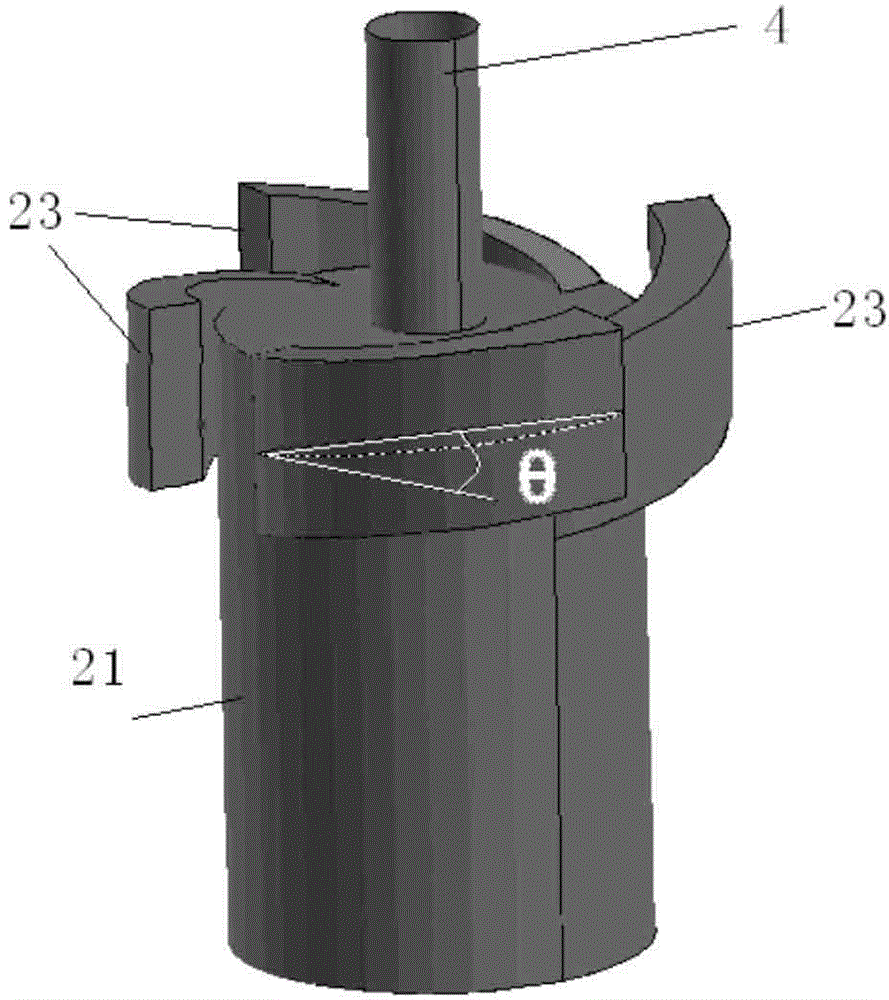

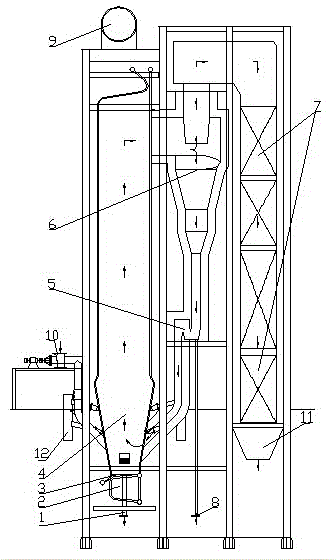

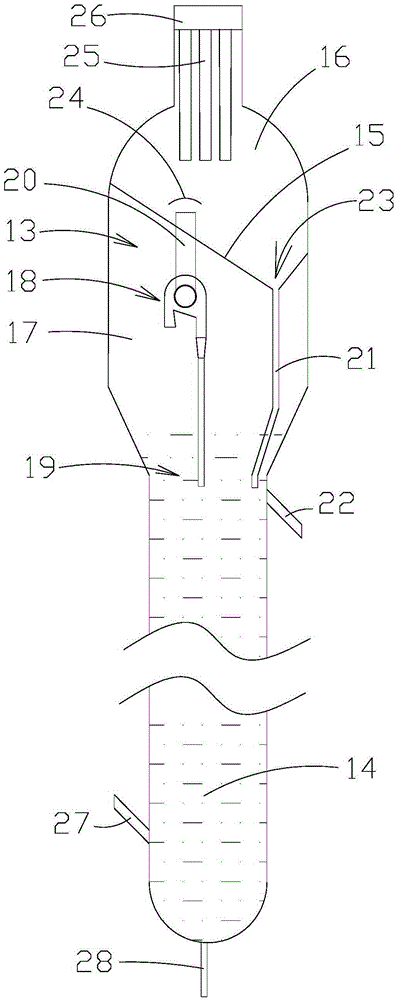

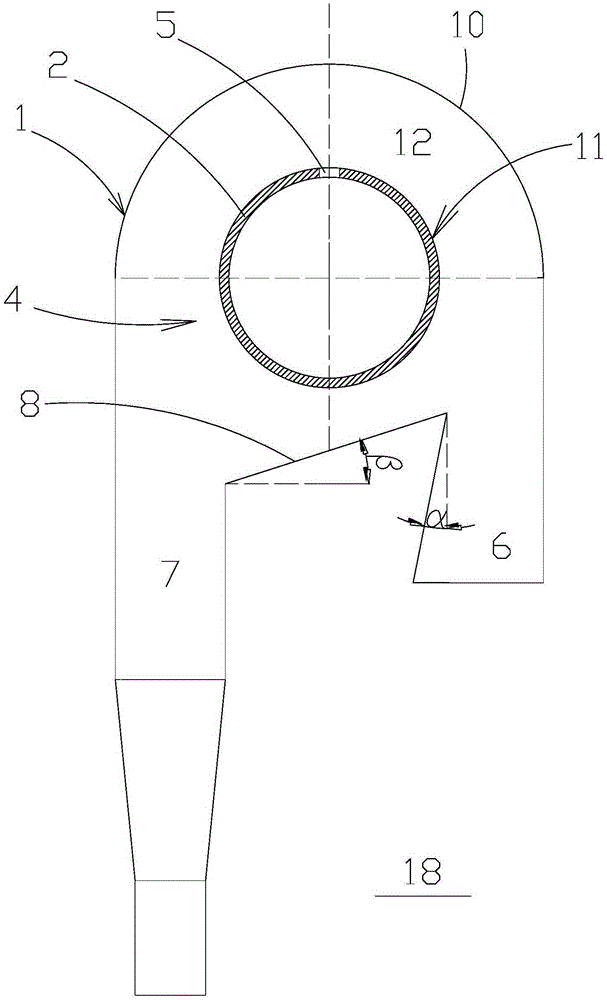

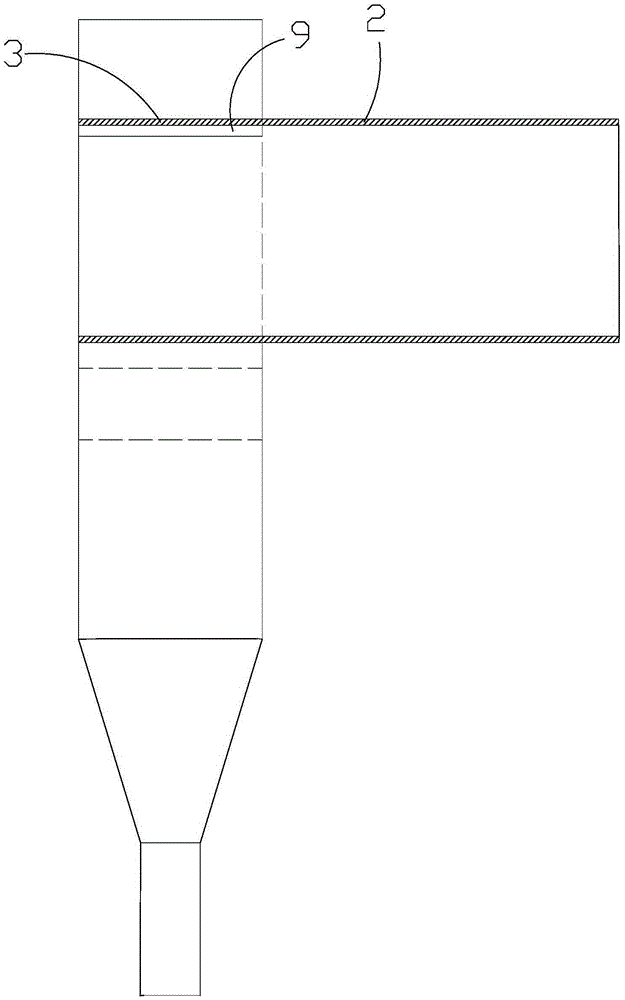

Solid heat carrier rapid pyrolysis method and apparatus

ActiveCN101353582AStable and reliable distributionEasy to control temperatureDirect heating destructive distillationHeat carrierCombustion chamber

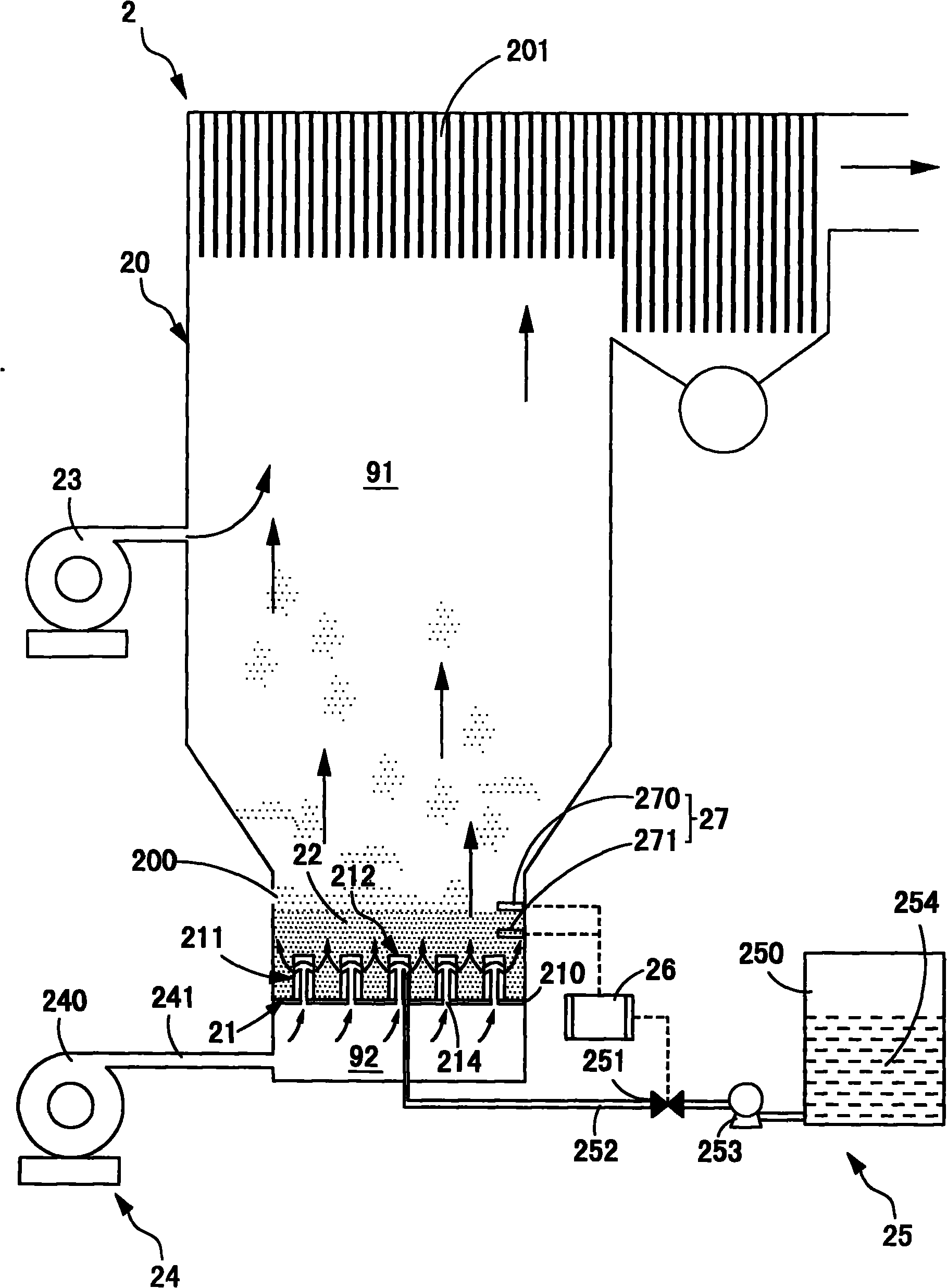

The invention relates to a method and a device for the quick pyrolysis of solid heat carriers; the device comprises a circulating fluidized bed combustor, a cyclone separator, an aerodynamic hot ash distributor, a pyrolysis chamber and a differential bed material return device; fuel is burnt in the circulating fluidized bed combustor, the high-temperature circulation ash of flue gas collected by the cyclone separator is divided into two parts by the hot ash distributor aerodynamically controlled, one part enters the pyrolysis chamber of a moving bed as the solid heat carrier to supply heat for flue pyrolysis, the other part does not enter the pyrolysis chamber but returns to the combustor, together with the semicoke and circulation ash discharged from the bottom of the pyrolysis chamber through the differential bed material return device. The method and the device for the quick pyrolysis of solid heat carrier provided by the invention can distribute the high-temperature circulation ash between combustion and pyrolysis loops stably and reliably, with controllable temperature of the pyrolysis chamber, strengthen the balance capacity between combustion and pyrolysis by virtue of a hot ash cooler, have good adaptability of the flue, and can be used for the pyrolysis of coal, biomass and other carbonaceous refuses.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

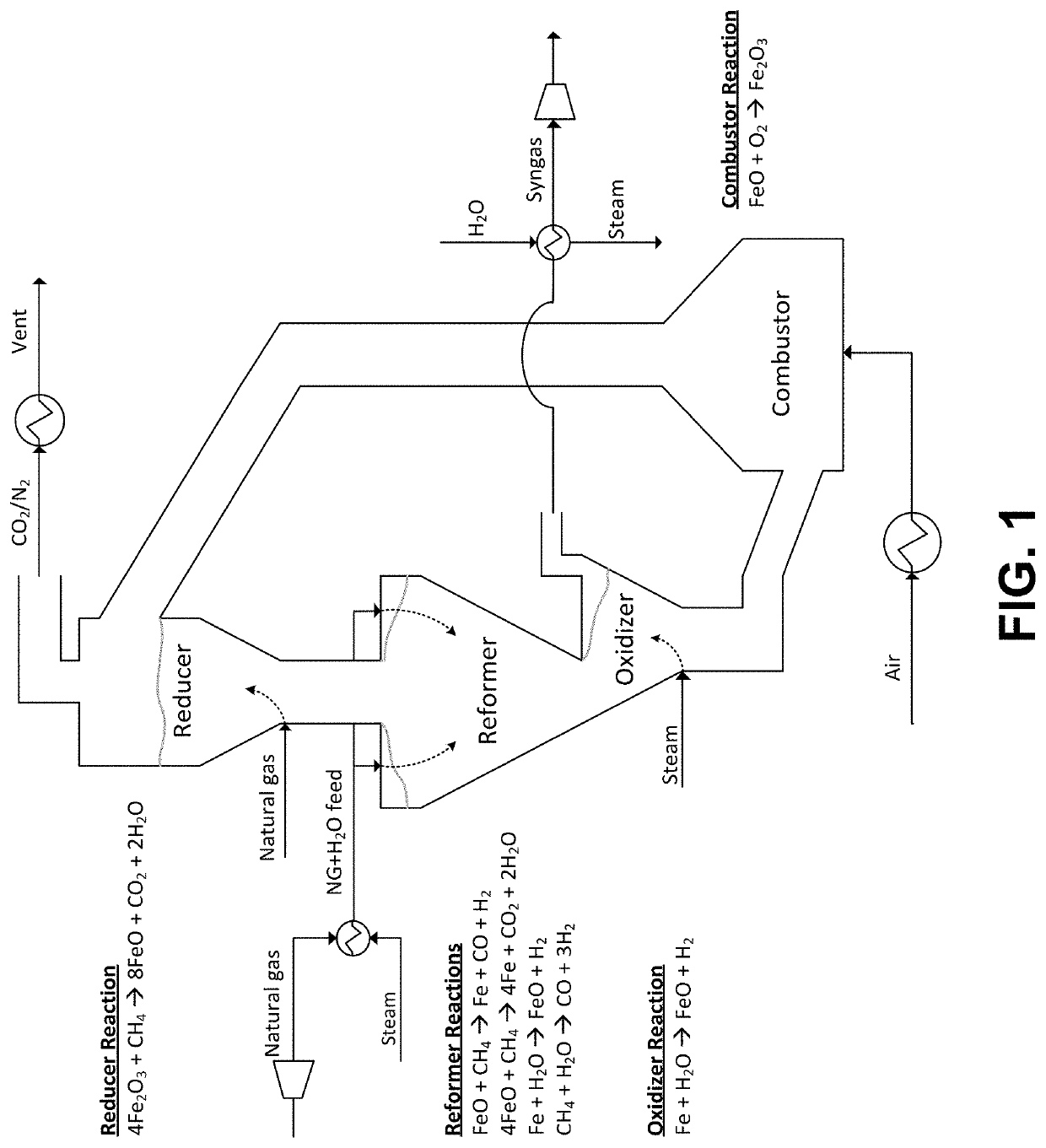

Method for producing synthesis gas by combustible solid waste chemical chain gasification and interconnected fluidized bed reactor

ActiveCN101638590ALower Gasification CostsHigh calorific valueCombined combustion mitigationChemical/physical processesFluidized bedLattice oxygen

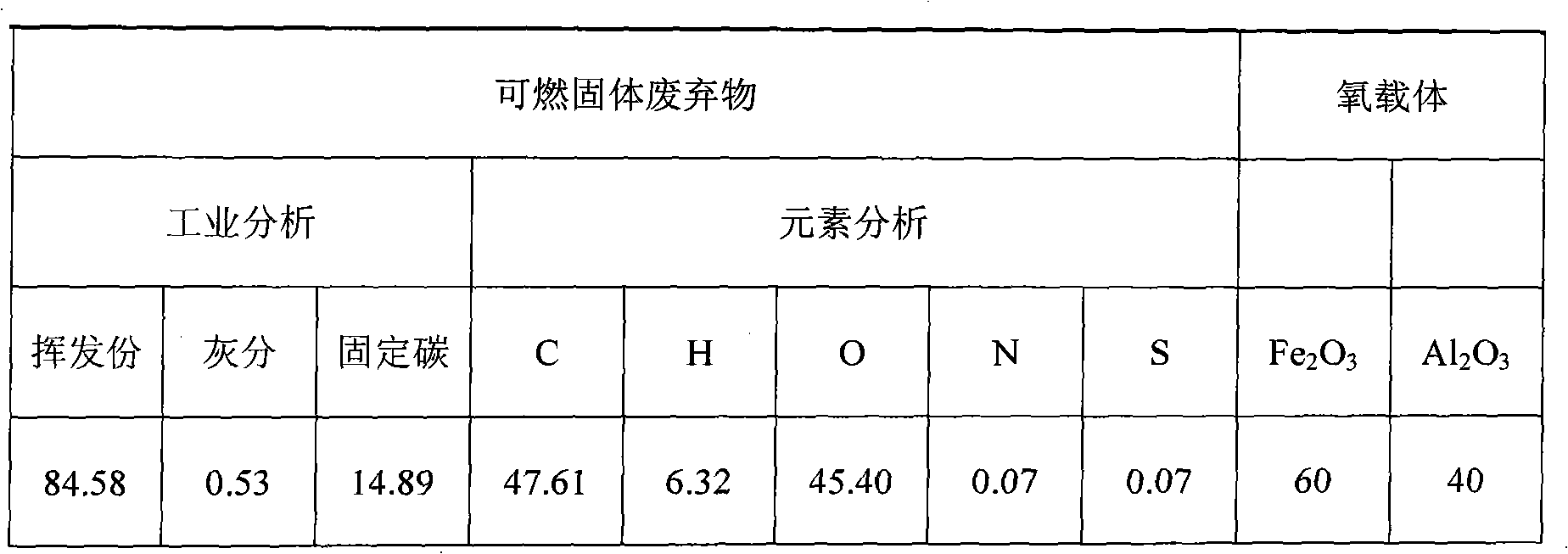

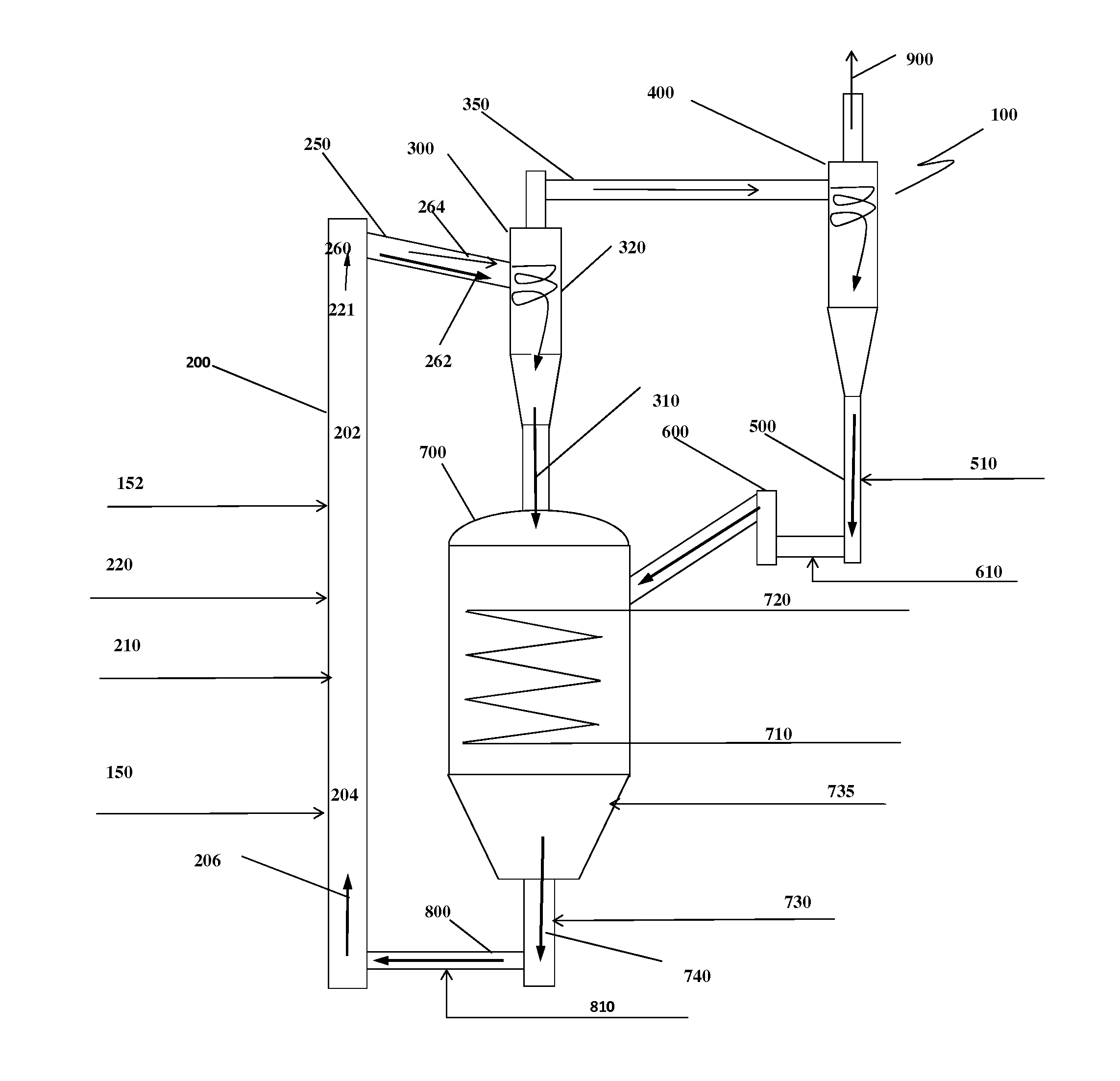

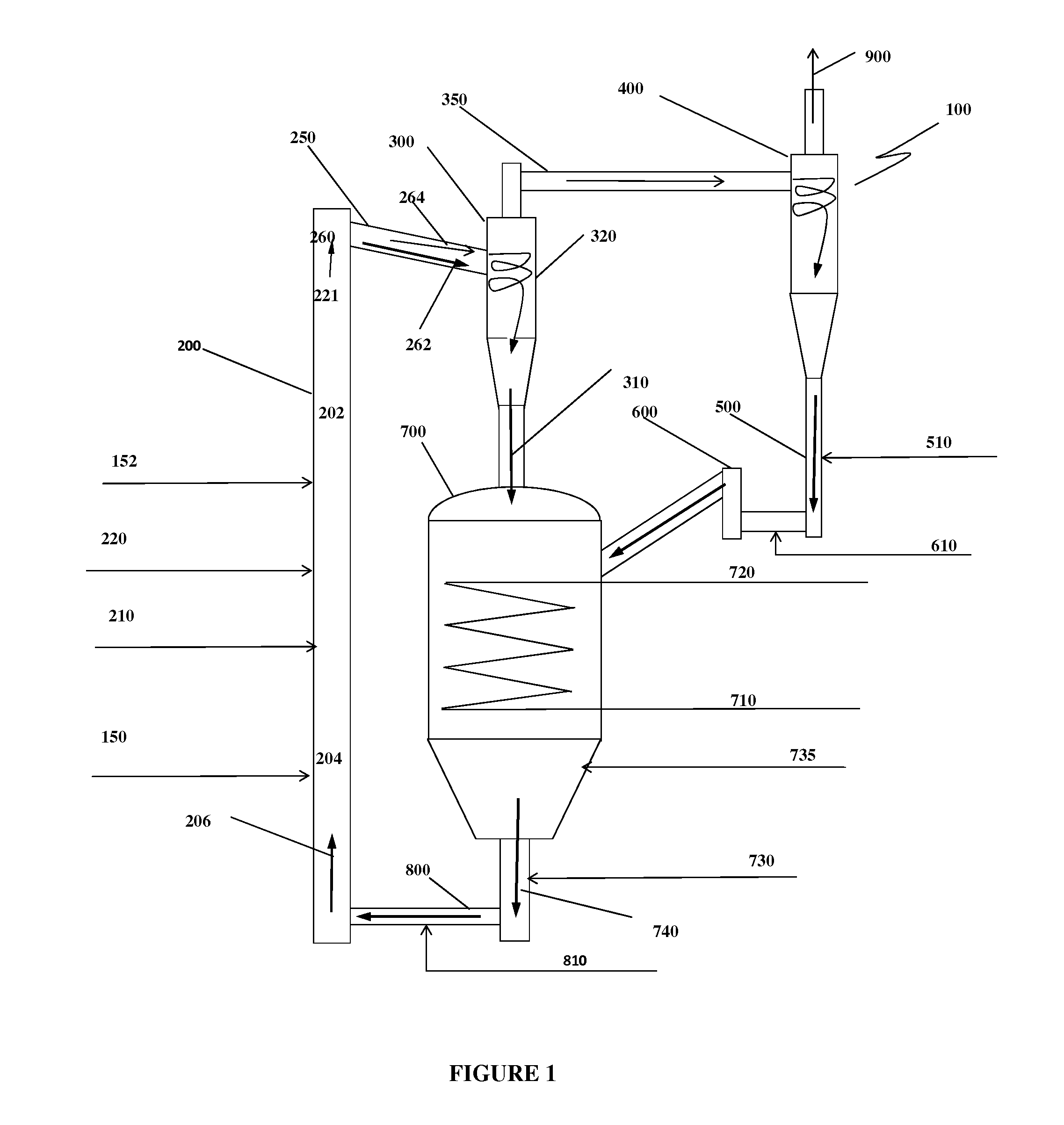

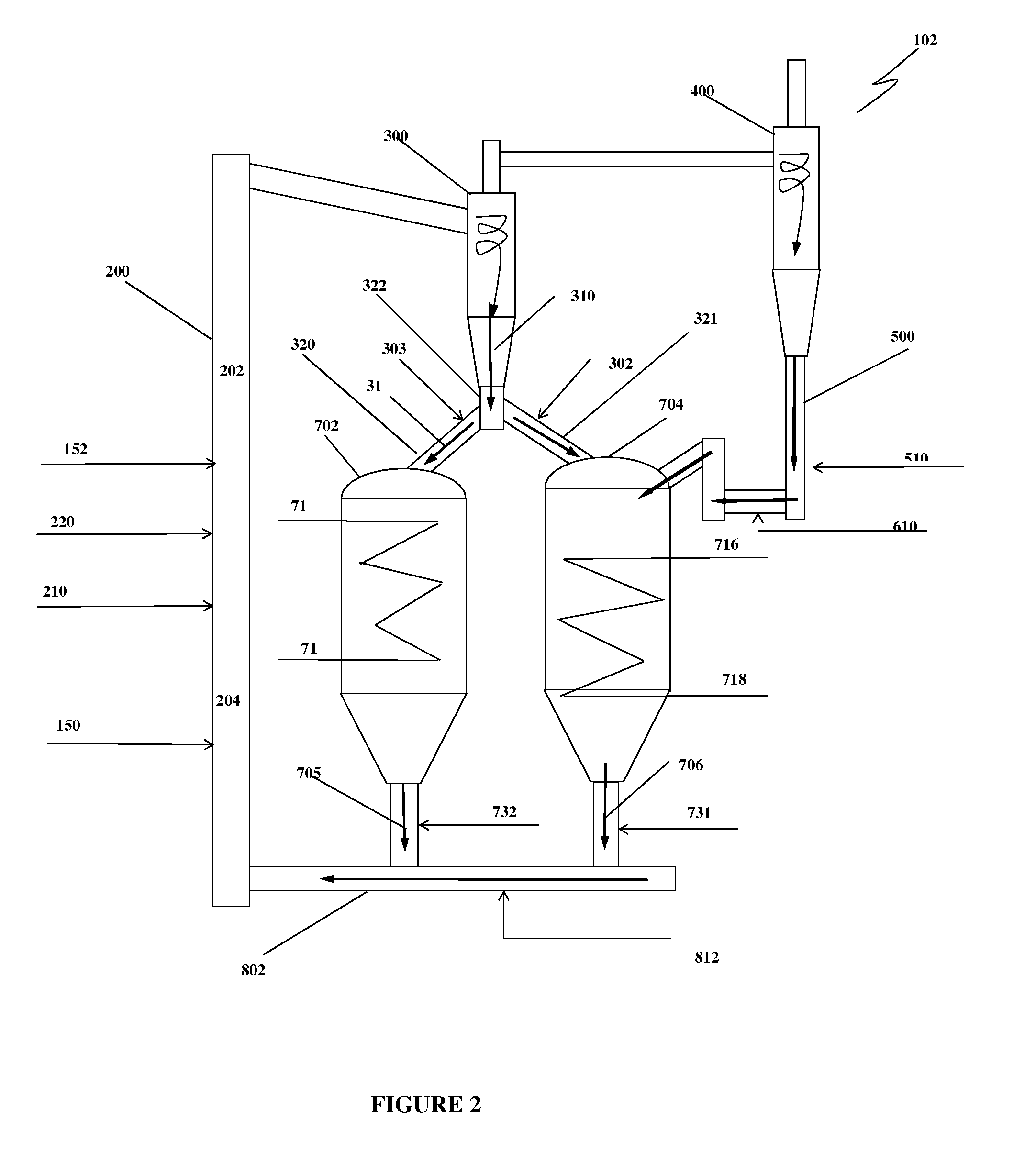

The invention provides a method for producing synthesis gas by combustible solid waste chemical chain gasification and an interconnected fluidized bed reactor. The method is implemented in an interconnected fluidized bed reactor, and the interconnected fluidized bed reactor comprises a fuel reactor and an air reactor communicated with each other internally. The combustible solid waste produces gasification reaction with a carrier of oxygen to produce synthesis gas, and the oxygen element necessary for the gasification of combustible solid waste comes from the lattice oxygen in the carrier component of oxygen; the carrier of oxygen without lattice oxygen is transported to the air reactor, in the air reactor, the carrier of oxygen is re-oxidized by high-temperature air to recovery to latticeoxygen; the carrier of oxygen recovered with lattice oxygen is carried out the air reactor by high-speed air, returns back to the fuel reactor for cycle use and produces gasification reaction with the combustible solid waste again. The invention relates to a high-efficiency combustible solid waste gasification technique breaking the prior art, and the invention can produce high-quality synthesisgas and reduce the contents of tar and carbon deposite during the gasification process.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

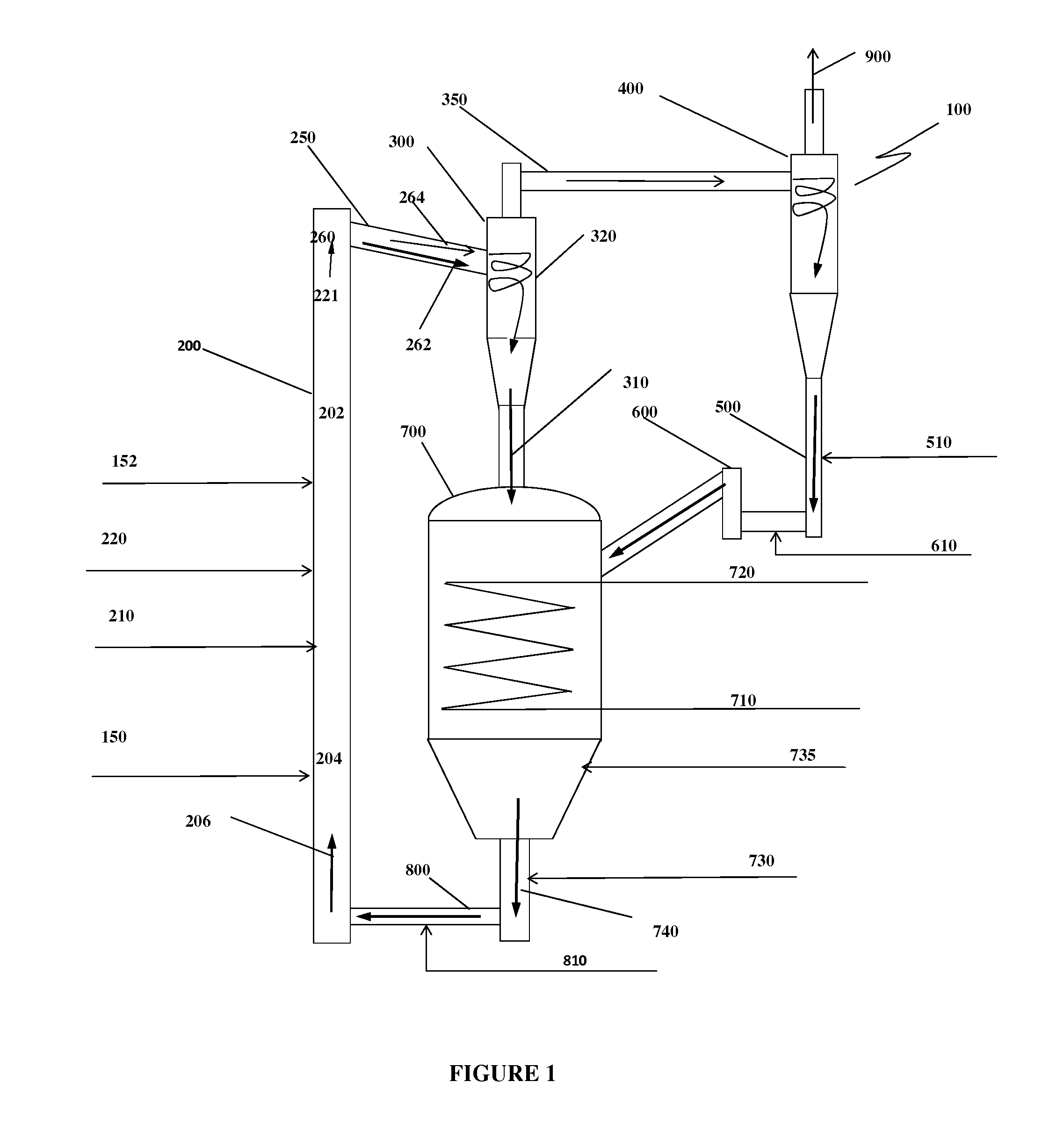

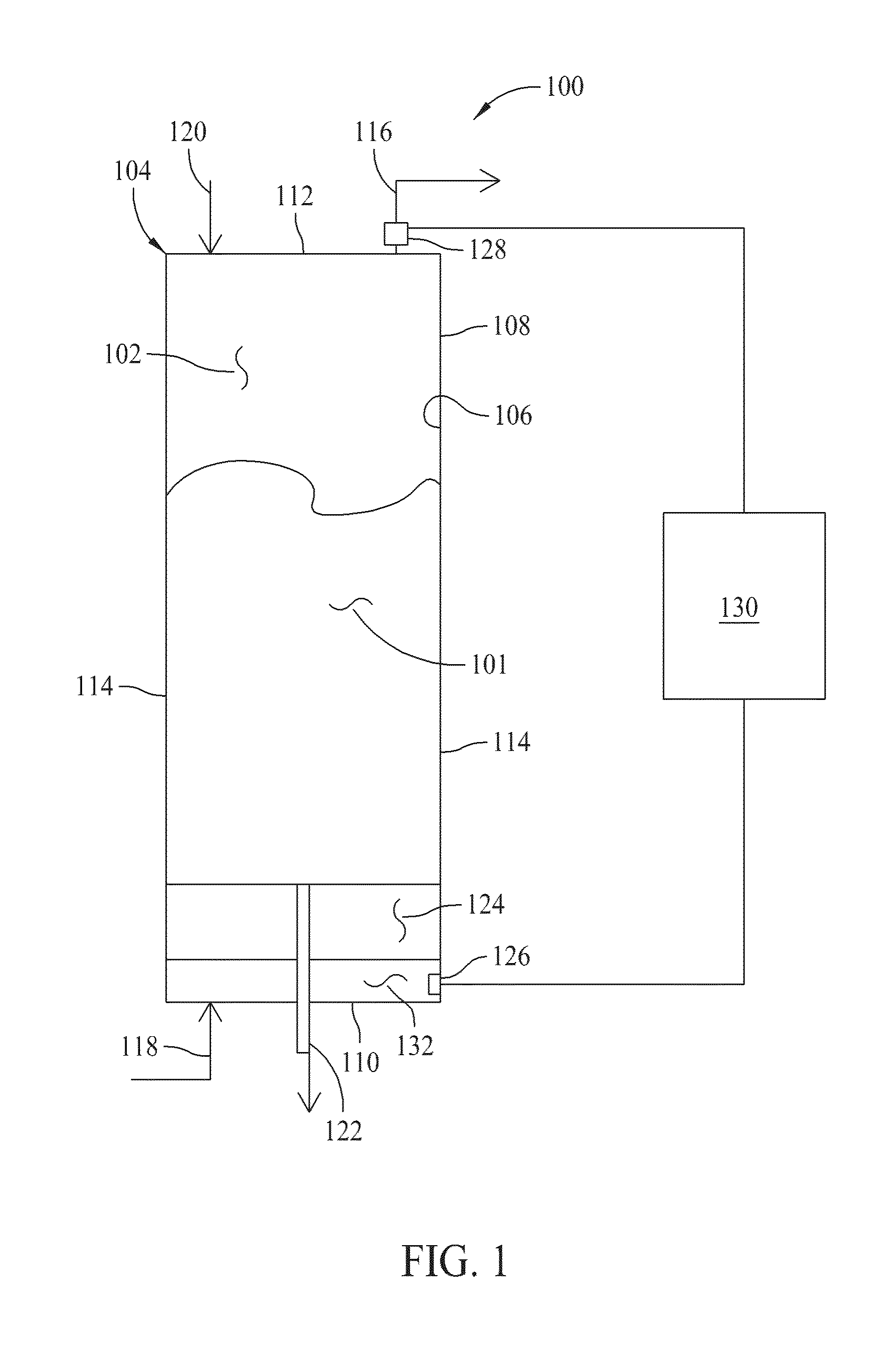

Oxycombustion In Transport Oxy-Combustor

ActiveUS20130055936A1Efficient removalReduce operating costsFluidized bed combustionSteam generation using pressureFlue gasMoisture condensation

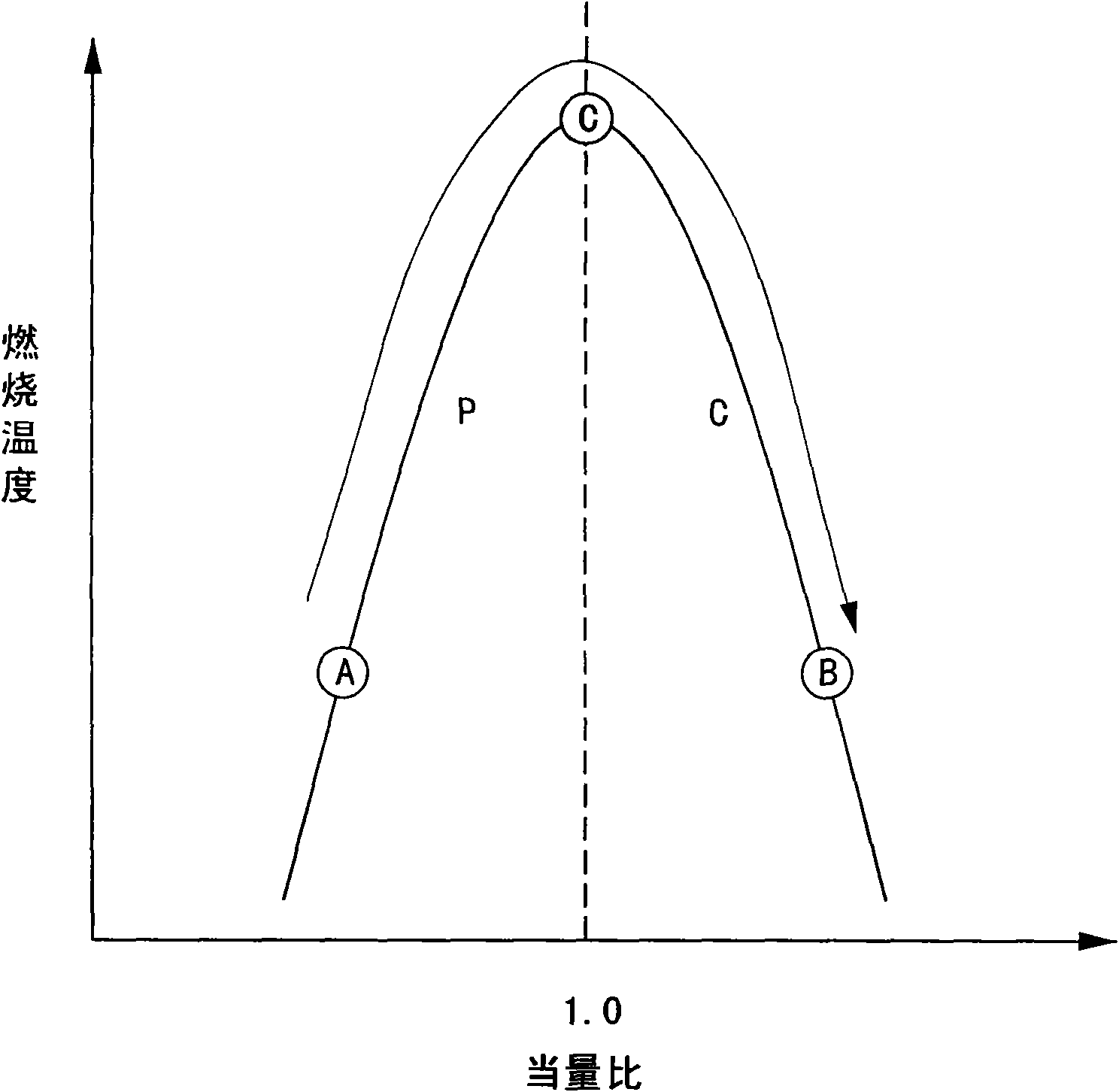

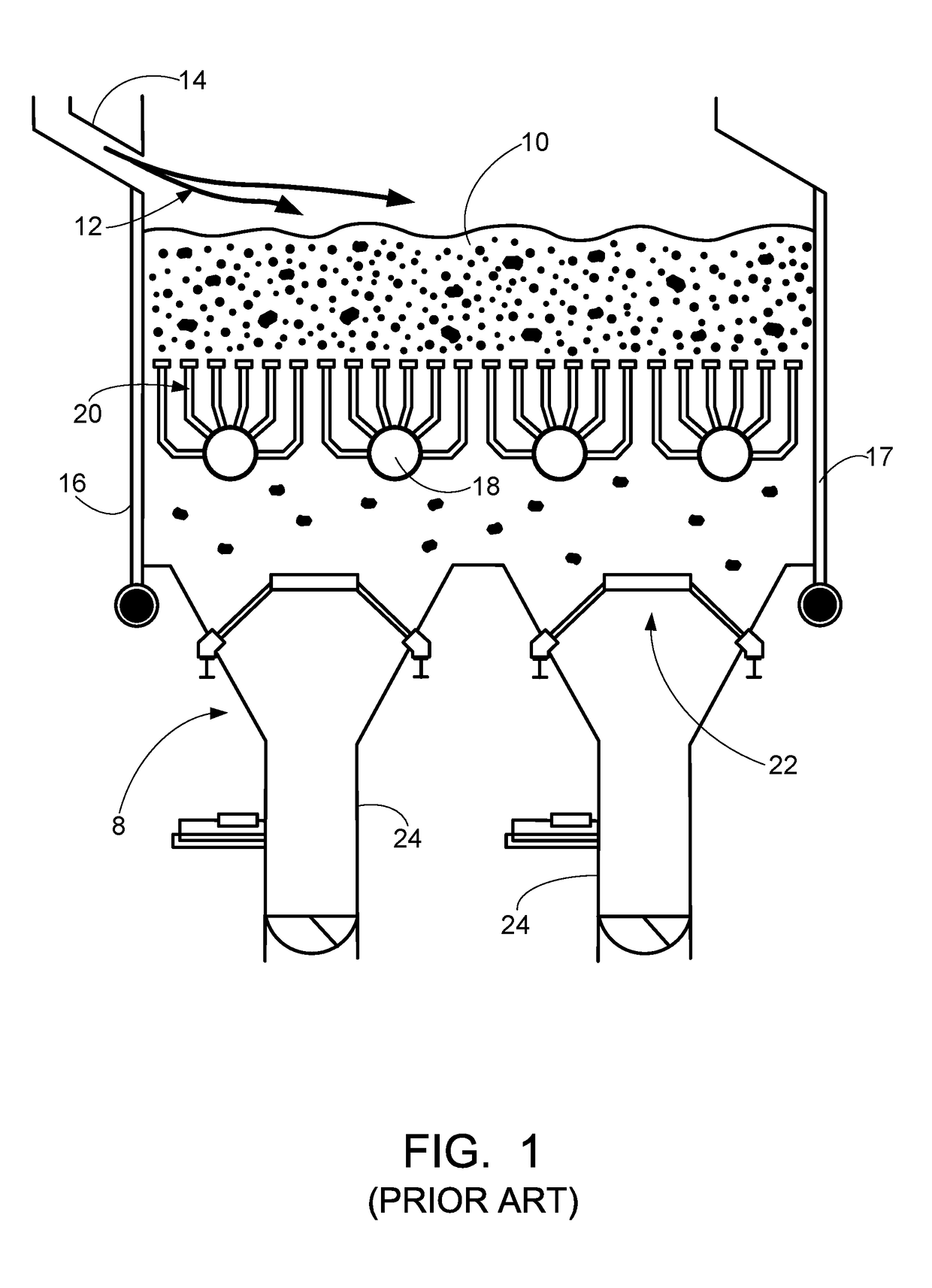

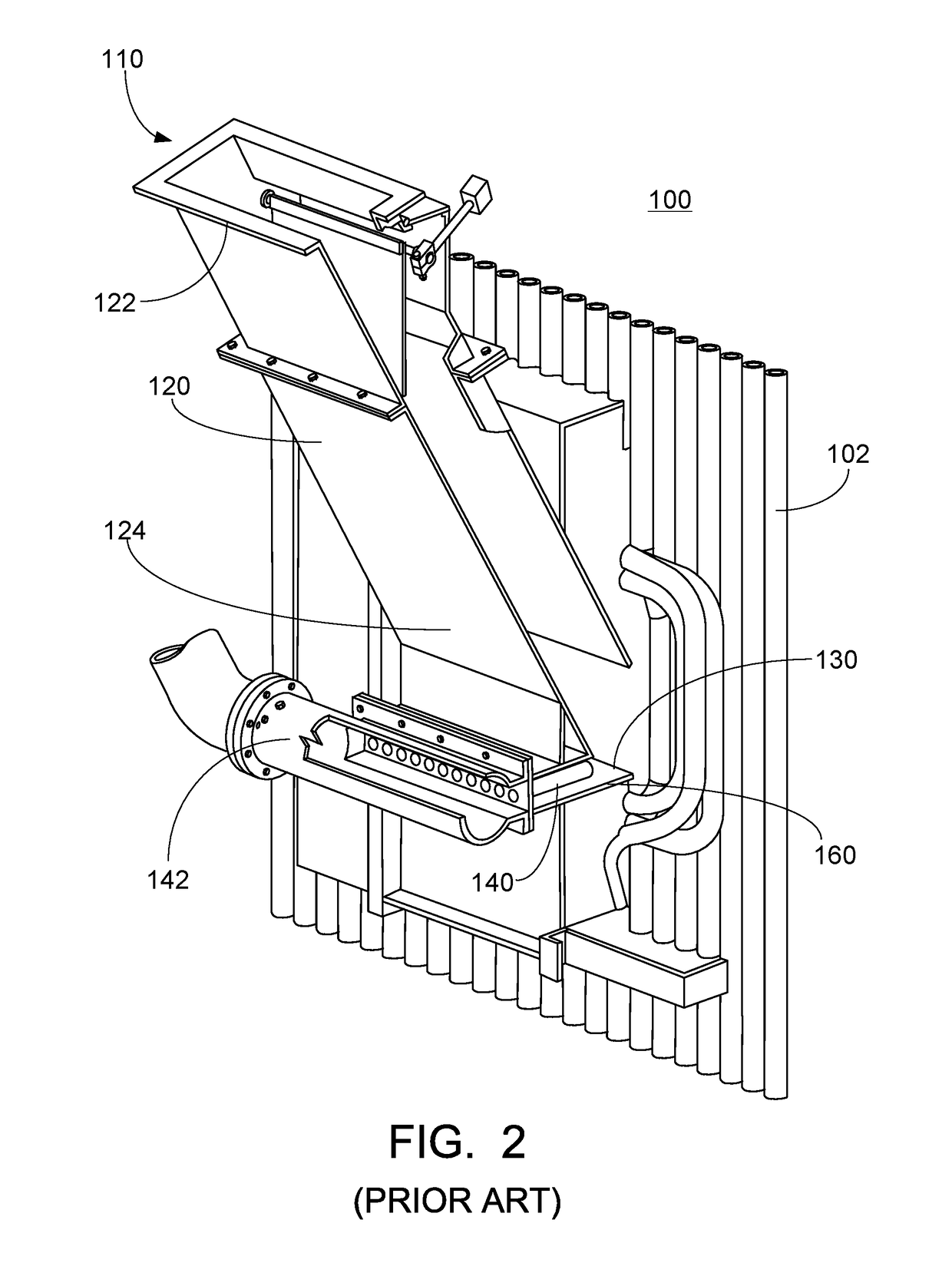

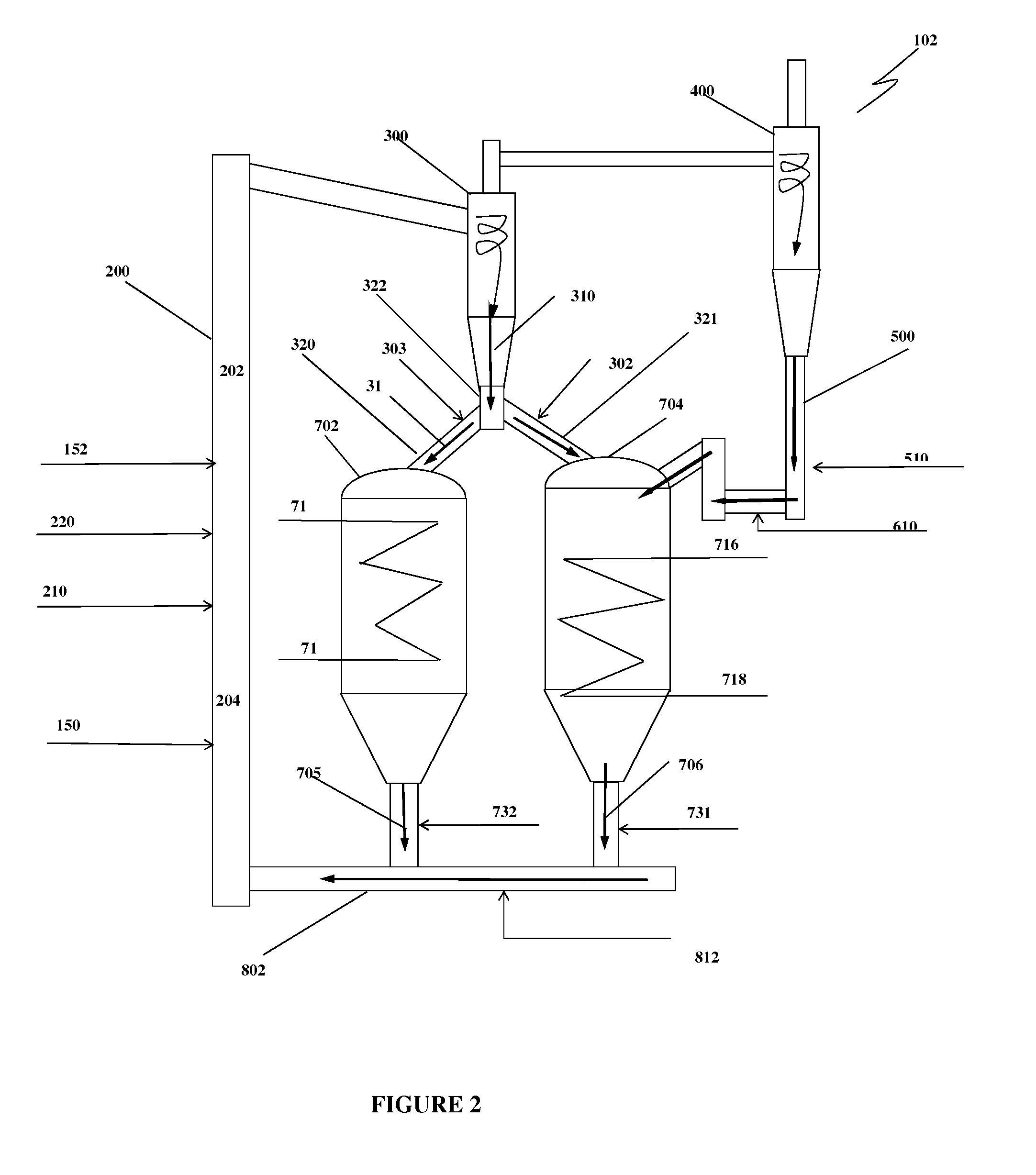

A pressurized transport oxy-combustor with different configurations is disclosed. Substantially pure oxygen is fed to the transport oxy-combustor under pressure to combust fossil fuels, generating steam for power generation. The end product is the flue gas containing substantially pure CO2 after moisture condensation. The low excess oxygen necessary to achieve complete combustion in the combustor is scavenged by adding another fuel so that substantially all oxygen fed to the combustor is completely consumed. The capability to operate the transport oxy-combustor as a circulating fluidized bed combustor at very high solids circulation rates makes it unnecessary to use recycled CO2 or flue gas as a means to moderate and control the combustion temperature. The temperature in the combustor is effectively controlled by relatively cooler circulating solids that enter the combustion zone. A small amount of CO2 is recycled for aeration and to convey solids fuel to the combustor.

Owner:THE SOUTHERN CO

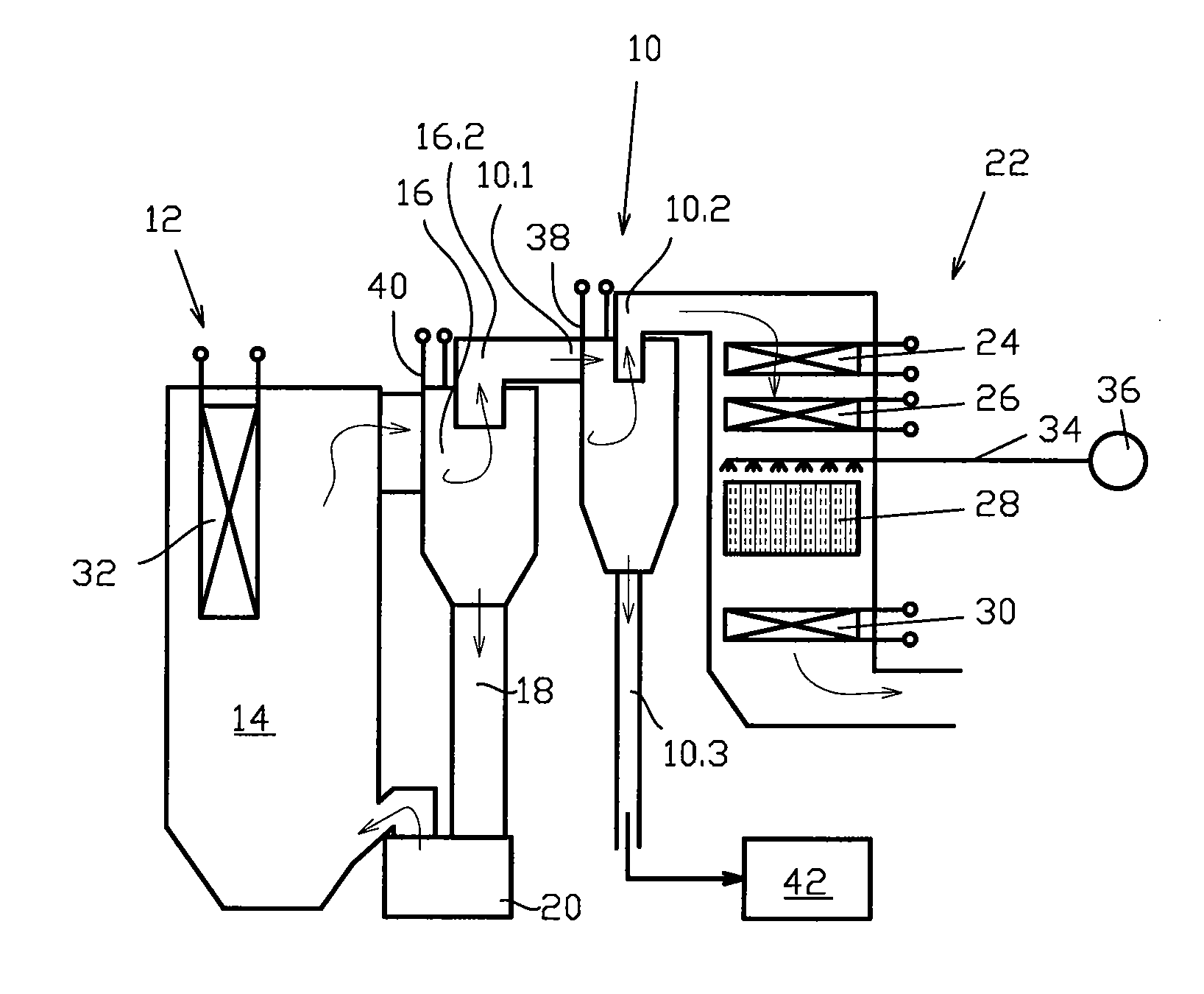

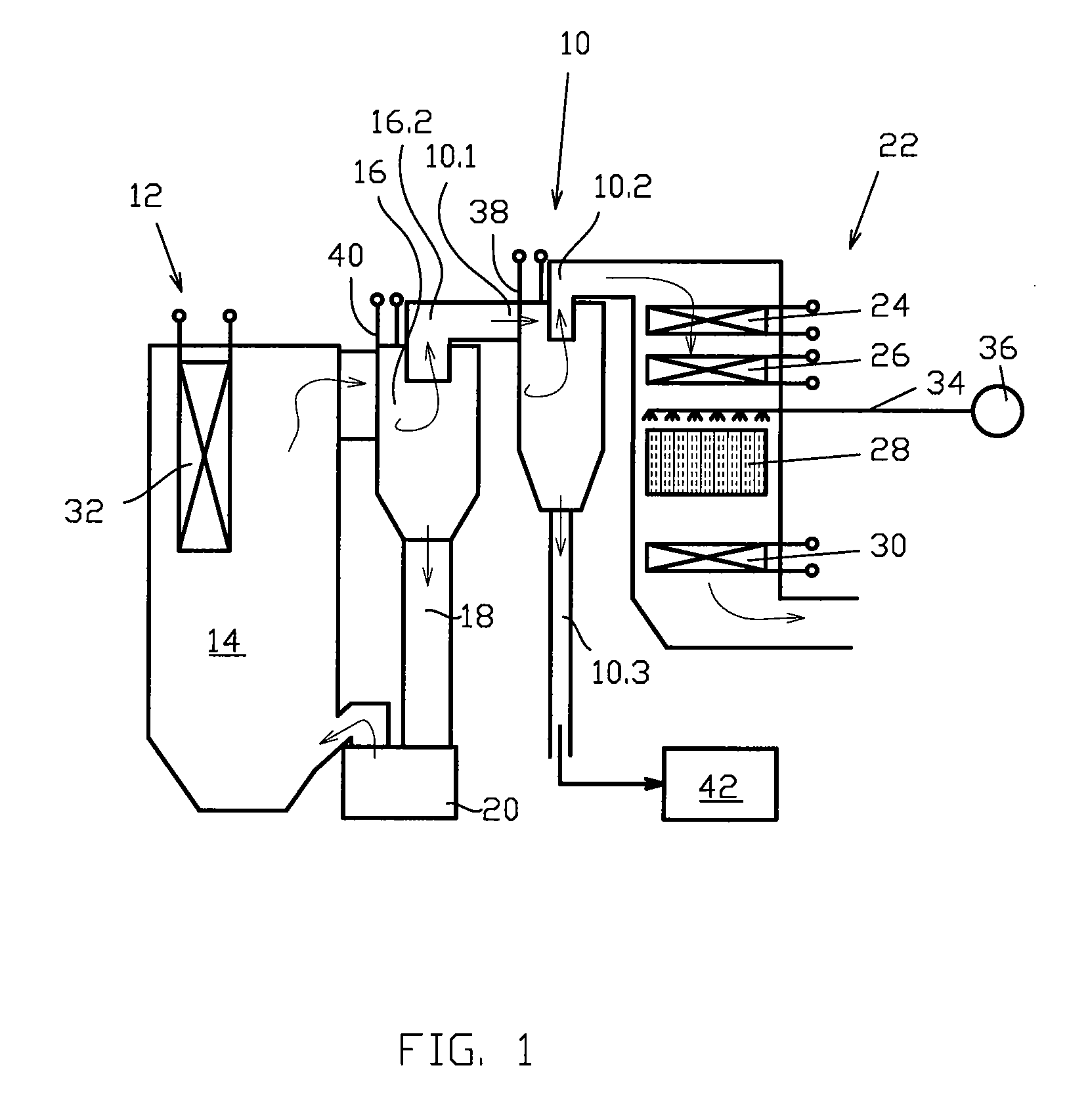

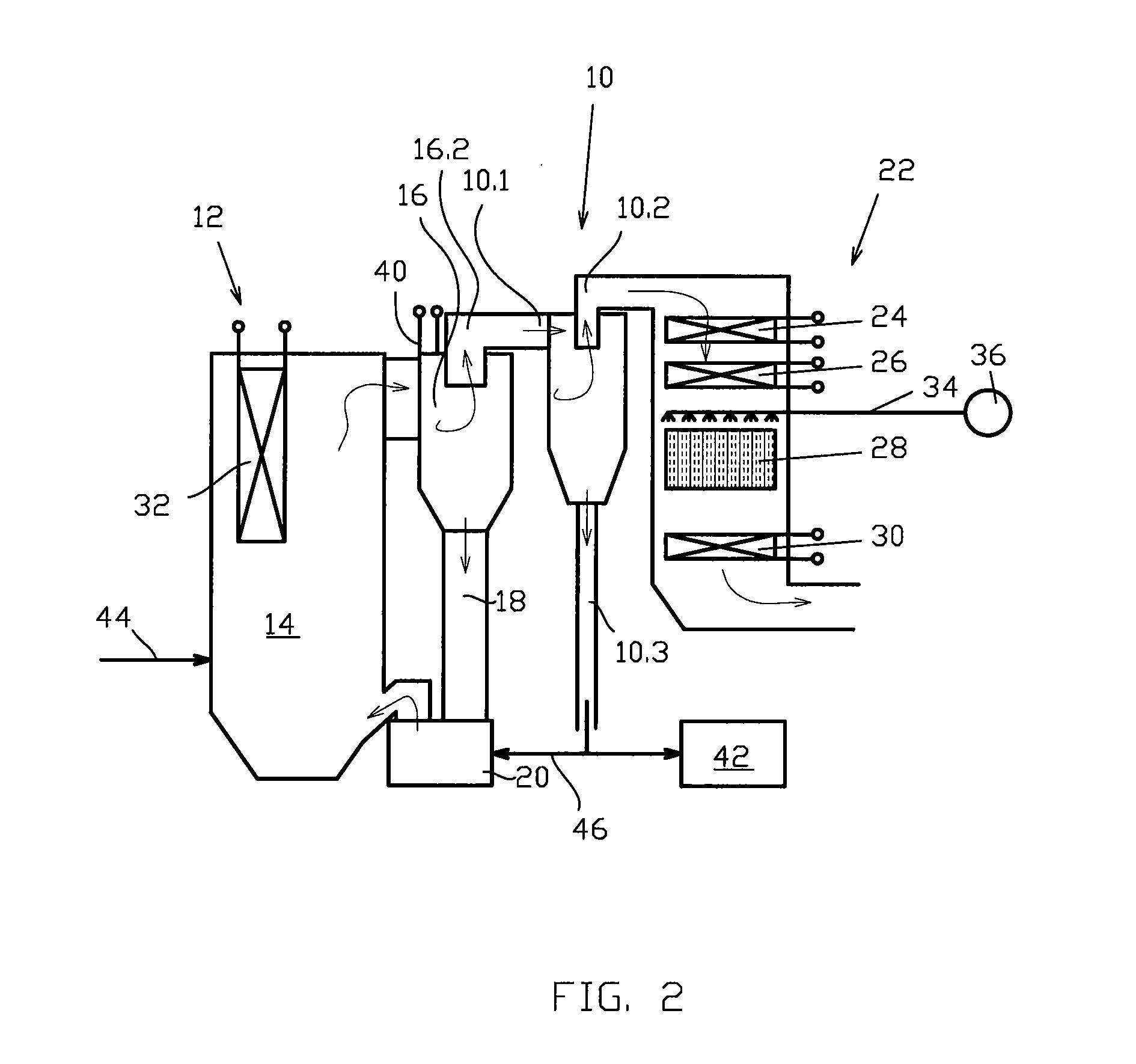

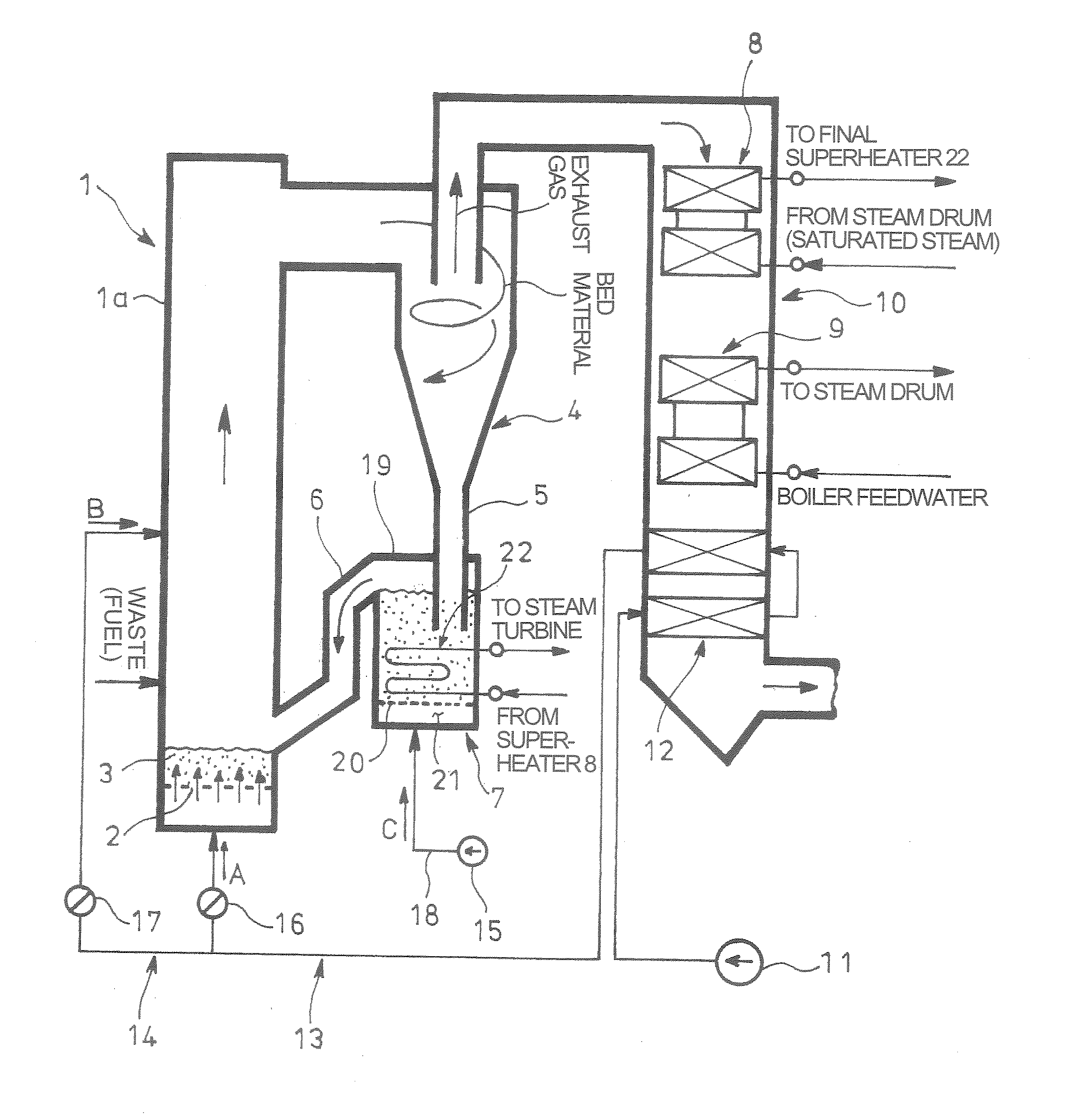

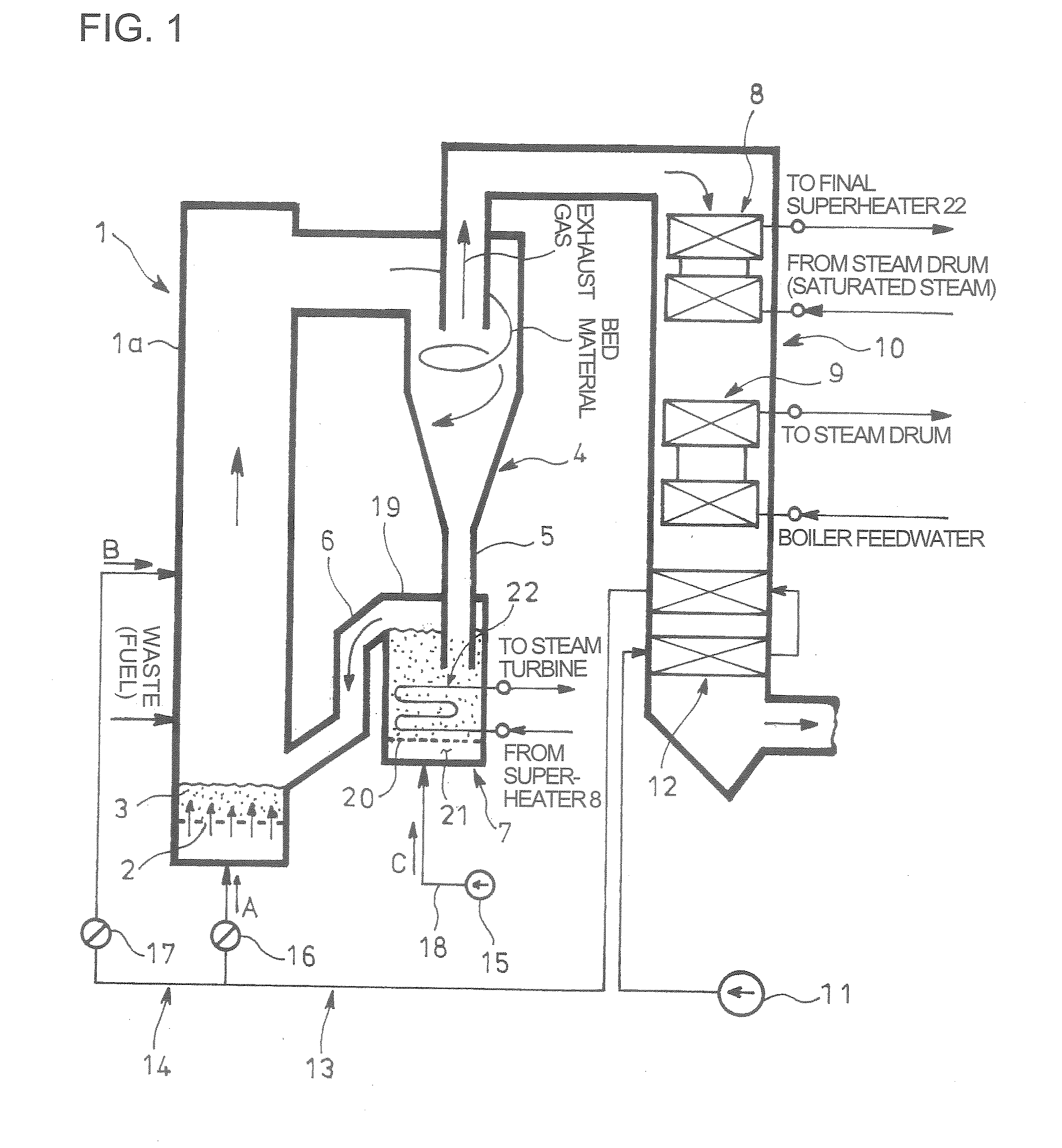

Circulating Fluidized Bed Combustor and a Method of Operating a Circulating Fluidized Bed Combustor

InactiveUS20110265697A1Reduce the amount requiredGuaranteed uptimeFluidized bed combustionEmission preventionCombustion chamberSolid particle

A circulating fluidized bed combustor arrangement includes (a) a circulating fluidized bed reactor in which (i) a combustion chamber combusts a fuel material in a suspension of solid particles of a circulating fluidized bed, (ii) a first cyclone separator arrangement receives a mixture of gases and solid particles from the combustion chamber for separating a first fraction of the solid particles from the exhaust gases, and (iii) a solid particle return system connected to the first cyclone separator returns separated solid particles to the combustion chamber, (b) a heat transfer section including a water / steam heat exchanger section arranged after the first cyclone separator arrangement in the exhaust gas flow path, (c) a heat recovery device provided in connection with the combustion chamber, the first cyclone separator arrangement and the heat transfer section being arranged for recovering heat resulting from the combustion process in the combustion chamber, (d) a selective catalytic reduction system arranged in the exhaust gas flow path, after the heat transfer section, for removing NOx from the exhaust gas, (e) a device for injecting NOx reducing agent into the exhaust gases upstream of the selective catalytic reduction system, and (f) a second cyclone separator arrangement provided downstream of the first cyclone separator arrangement and upstream of the heat transfer section, in which a second fraction of the solid particles is separated form the exhaust gases.

Owner:FOSTER WHEELER NORTH AMERICA CORP

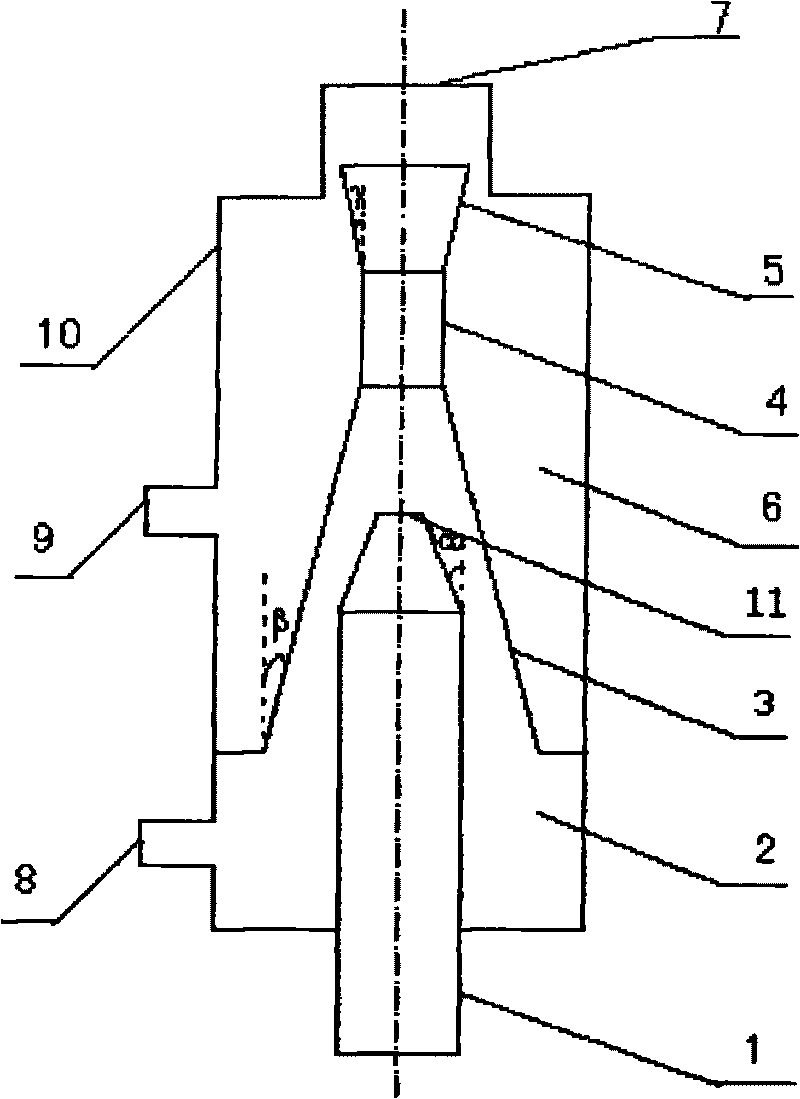

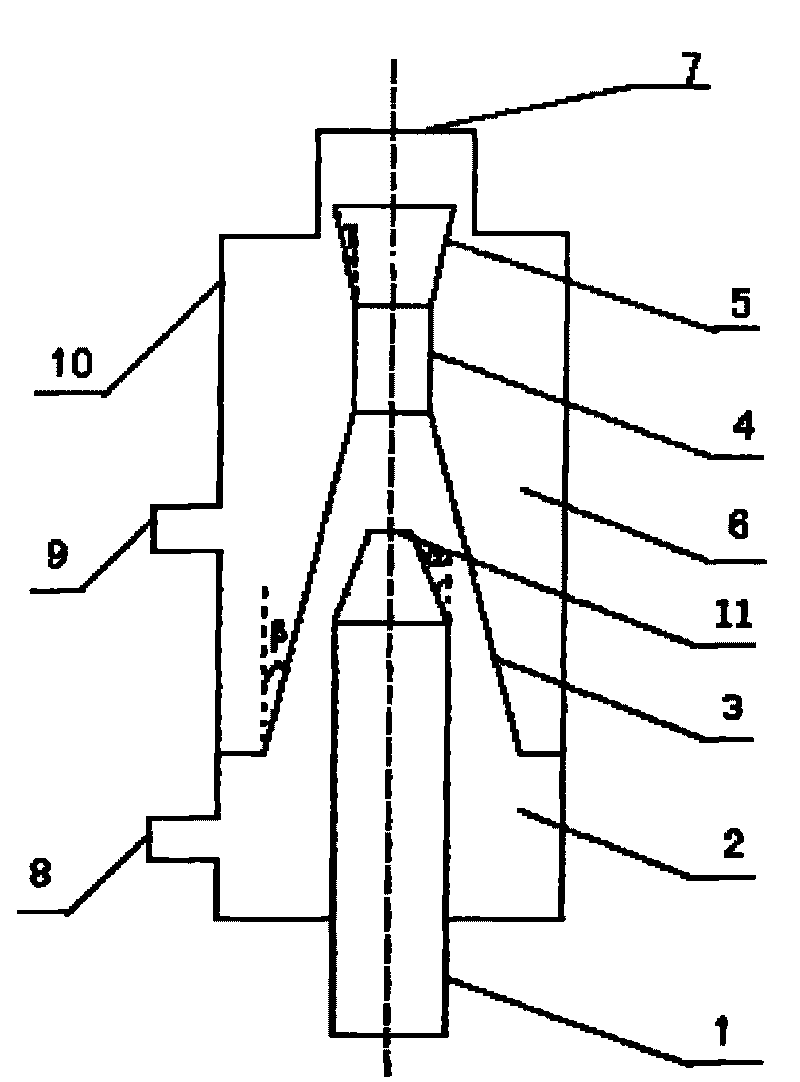

Portable nozzle and fluidized bed reactor with same

ActiveCN101721959AGood gas-liquid mixing effectLess investmentChemical/physical/physico-chemical nozzle-type rreactorsSolid phasesFluidized bed combustor

The invention discloses a portable nozzle and a fluidized bed reactor with the same, and belongs to the field of petro-chemical machinery. The portable nozzle takes oil of which partial pressure is higher than reaction pressure as power; and then the oil flows into a venture tube through the nozzle to form a draft which carries the hot oil to circulate. The portable nozzle of the invention is applied to the fluidized bed reactor, can completely satisfy a large amount of circulation liquid phases needed by good gas-liquid distribution and normal solid-phase fluidization in a hydrogenation process of a fluidized bed by using together with a fluidized bed catalyst with a relatively small grain size and a specially designed tree-phase separator, is more in favour of a reaction process, homogenizes bed layer temperature and achieves better catalyst fluidization effect and gas-liquid distribution effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

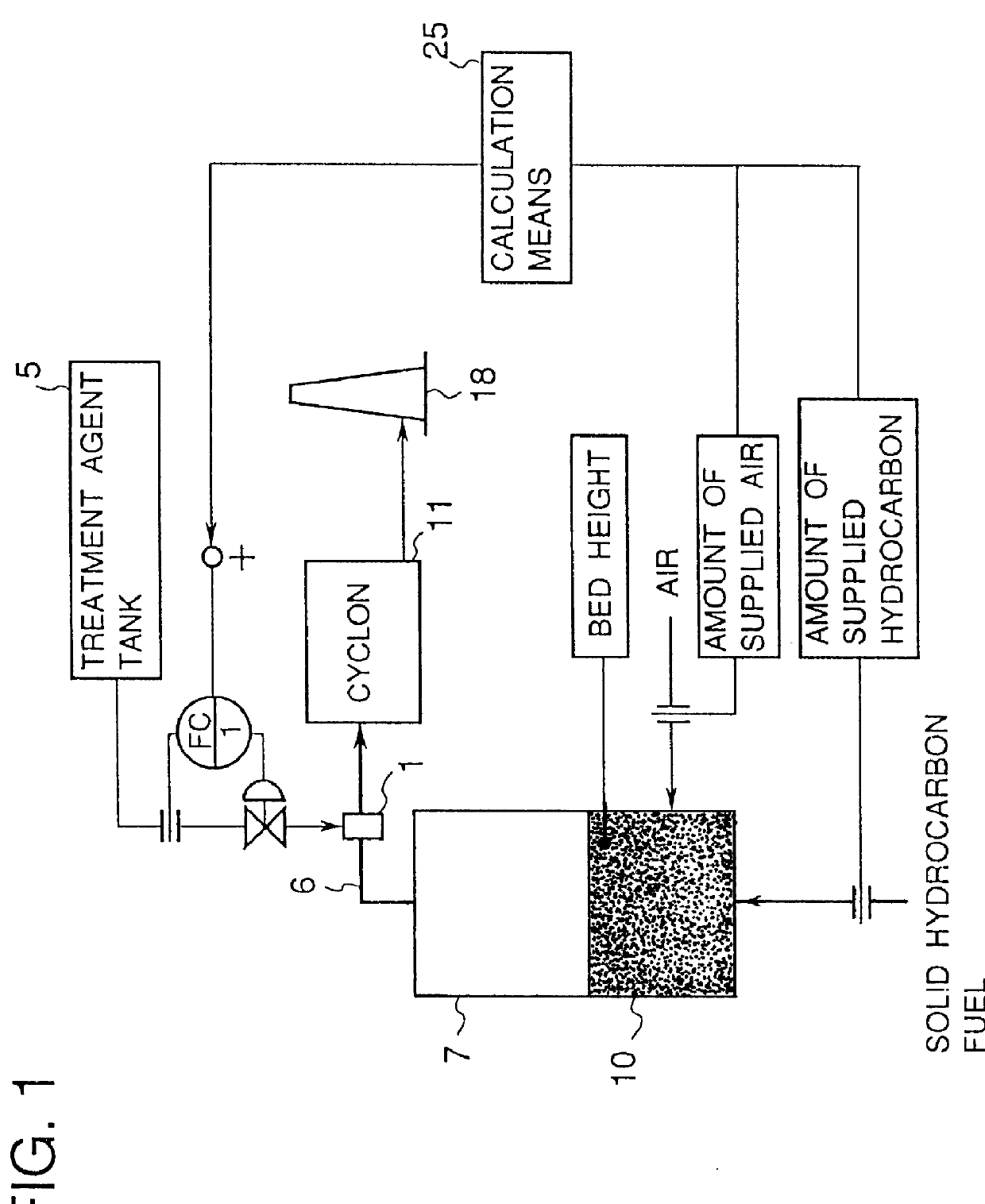

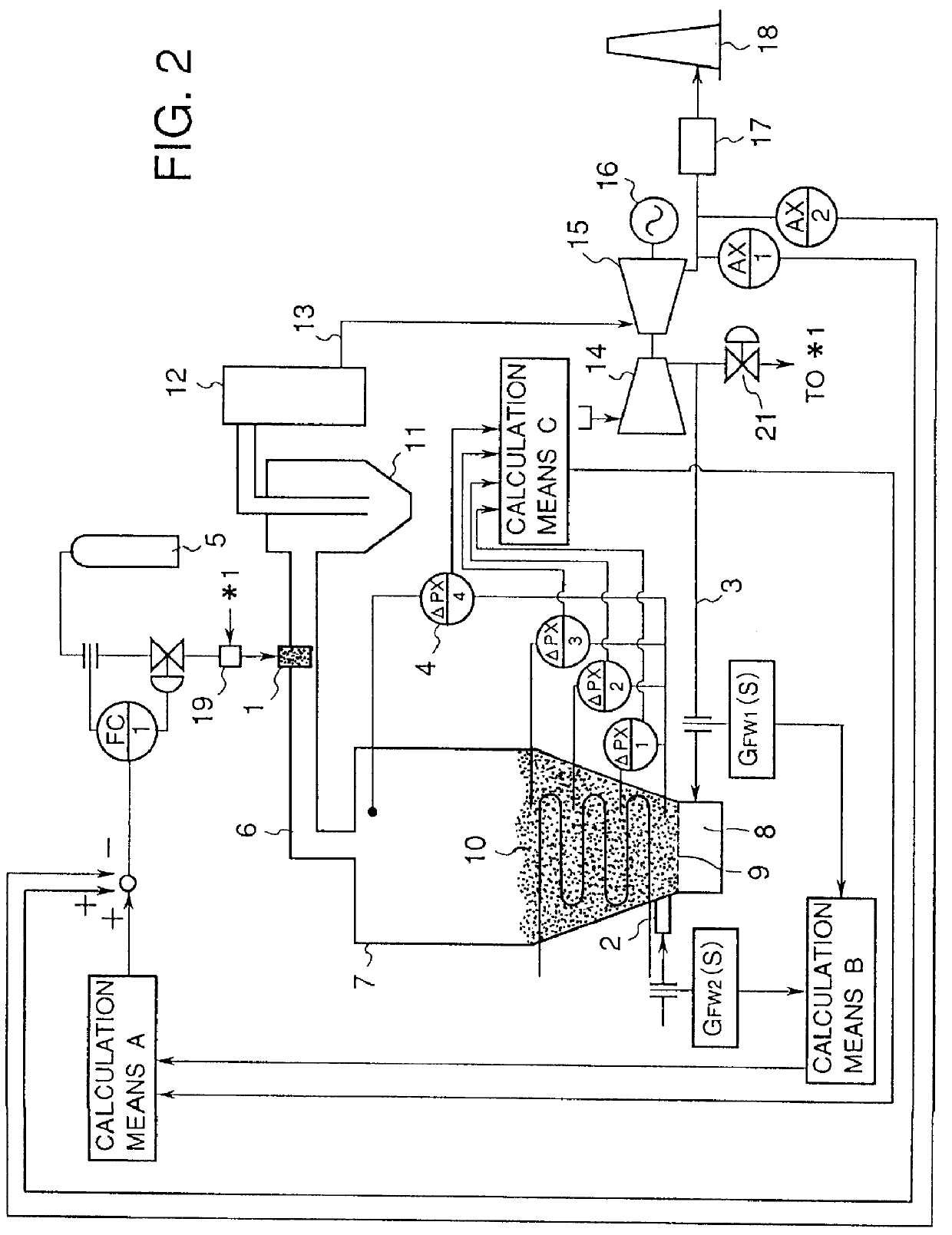

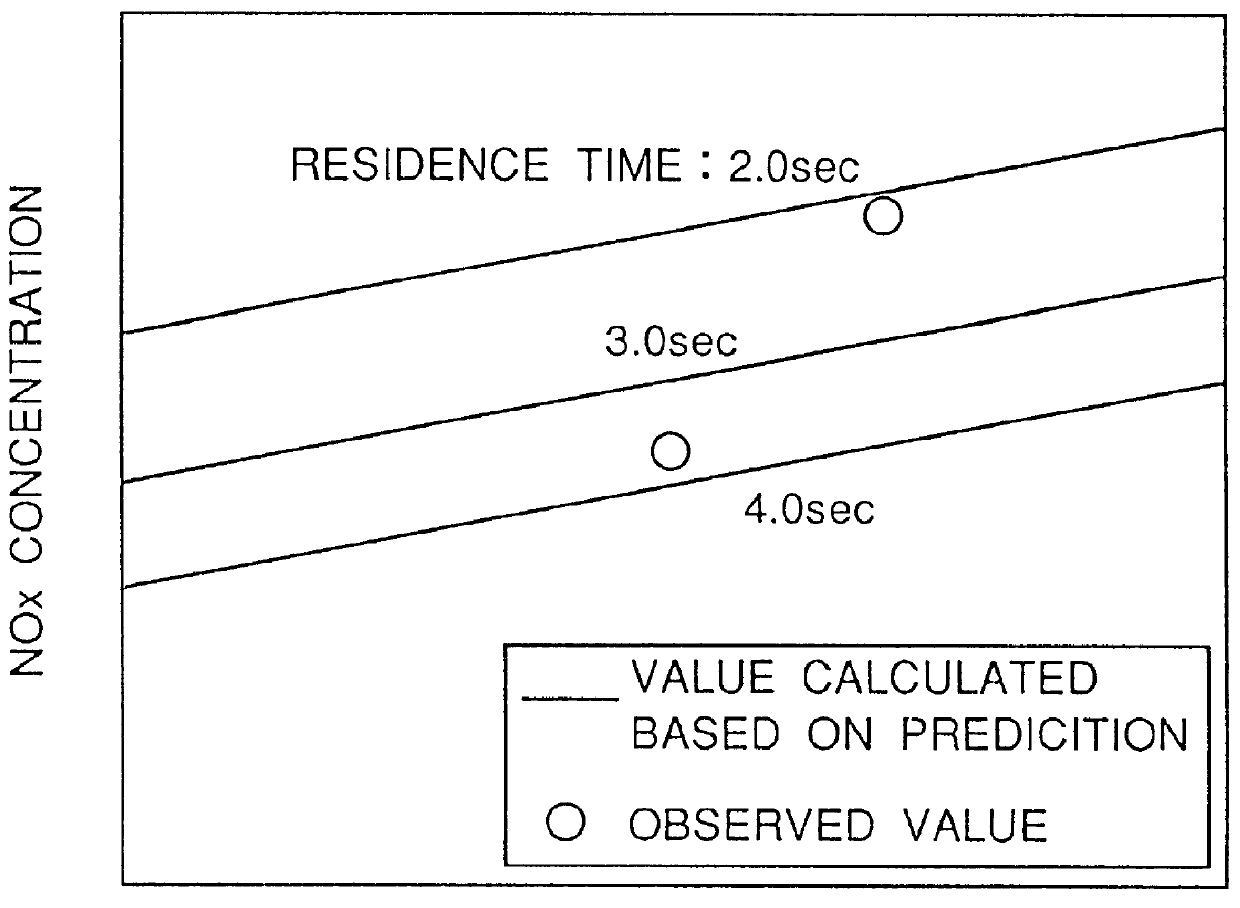

Method of predicting and controlling harmful oxide and apparatus therefor

The present invention provides a method and an apparatus for predicting and calculating an amount of harmful oxide such as NOx contained in an exhaust gas from a reference concentration of harmful oxide, which is previously determined by a type of fuel supplied to a fluidized bed combustor, an amount of change of an air ratio and an amount of change of a gas residence time to the conditions of a specific air ratio and gas residence time in the combustor, and injecting a treatment agent such as NH3 in an amount optimum to the predicted amount into an exhaust gas. With this arrangement, an amount of harmful oxide in the exhaust gas can be securely lowered to a target value.

Owner:HITACHI LTD

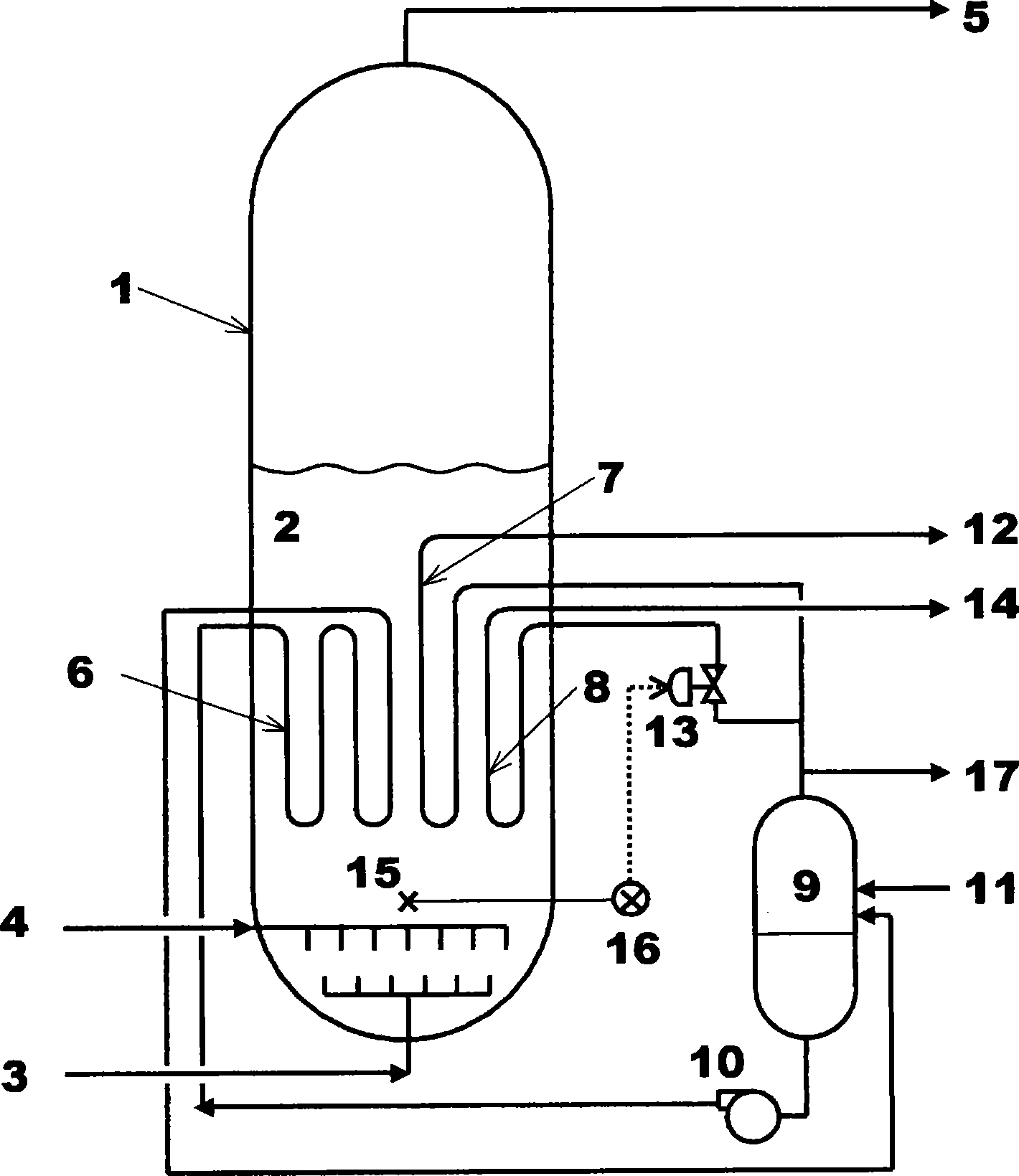

Temperature control method of fluidized bed reactor

ActiveCN101507907ATemperature controlTemperatue controlChemical/physical processesTemperature controlFluidized bed

The invention provides a temperature control method, which can more precisely control the temperature in a fluidized bed reactor when the fluidized bed reactor is used for implementing gas-phase exothermal reaction. The method for controlling the temperature when the fluidized bed reactor which is provided with a general heat extraction pipe, a heat extraction adjusting pipe and a temperature detector is used for implementing the gas-phase exothermal reaction comprises the following steps: (i) performing heat extraction through the general heat extraction pipe, and simultaneously detecting the temperature of the fluidized bed reactor through the temperature detector; and (ii) converting the heat extraction capacity of the heat extraction adjusting pipe from less than 10 percent of the adjustable range FS to more than 90 percent or from more than 90 percent to less than 10 percent at the average change rate of more than 0.1 FS per minute when the detected temperature deviates from the set temperature so as to adjust the temperature of the fluidized bed reactor to the set temperature.

Owner:ASAHI KASEI KK

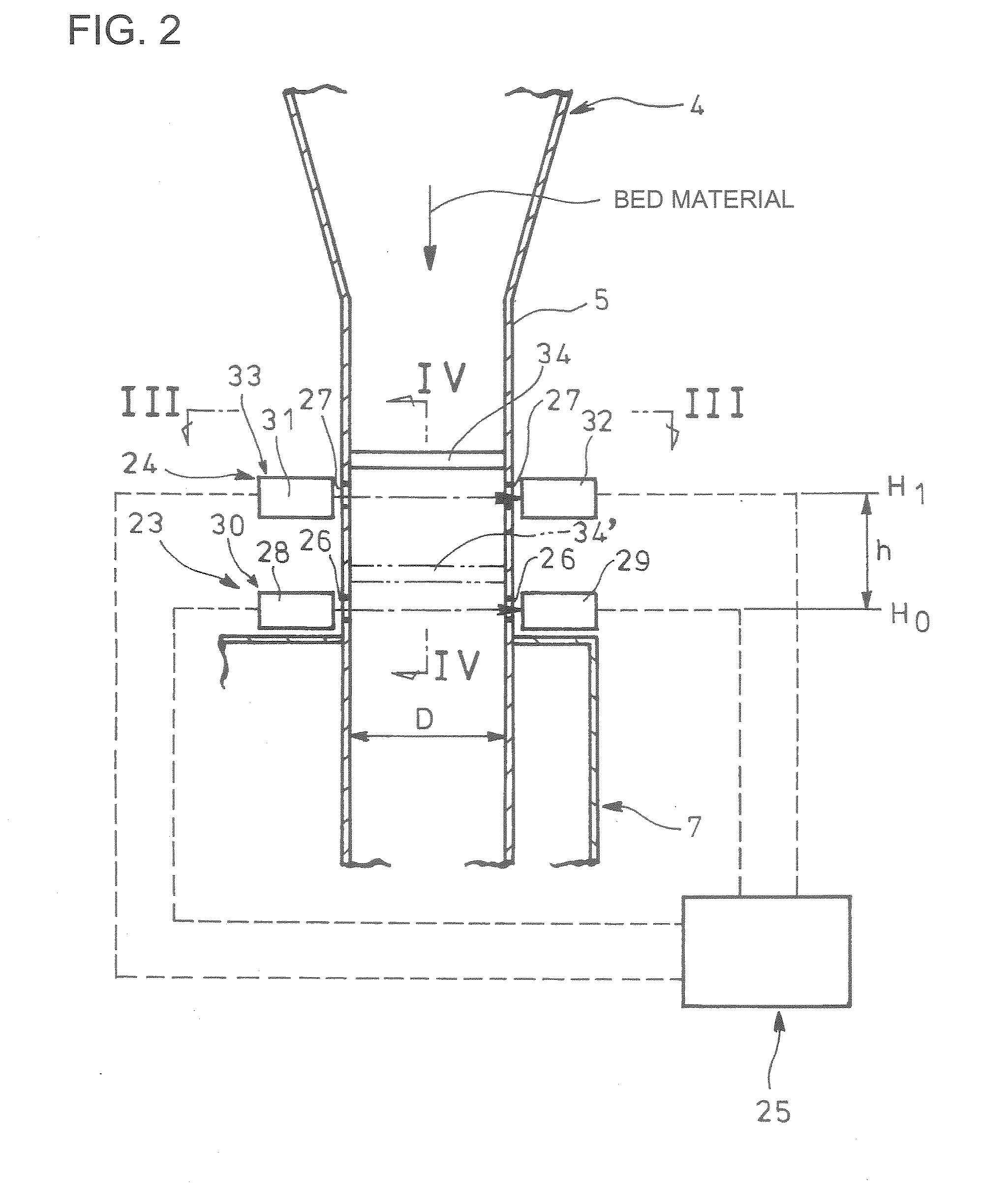

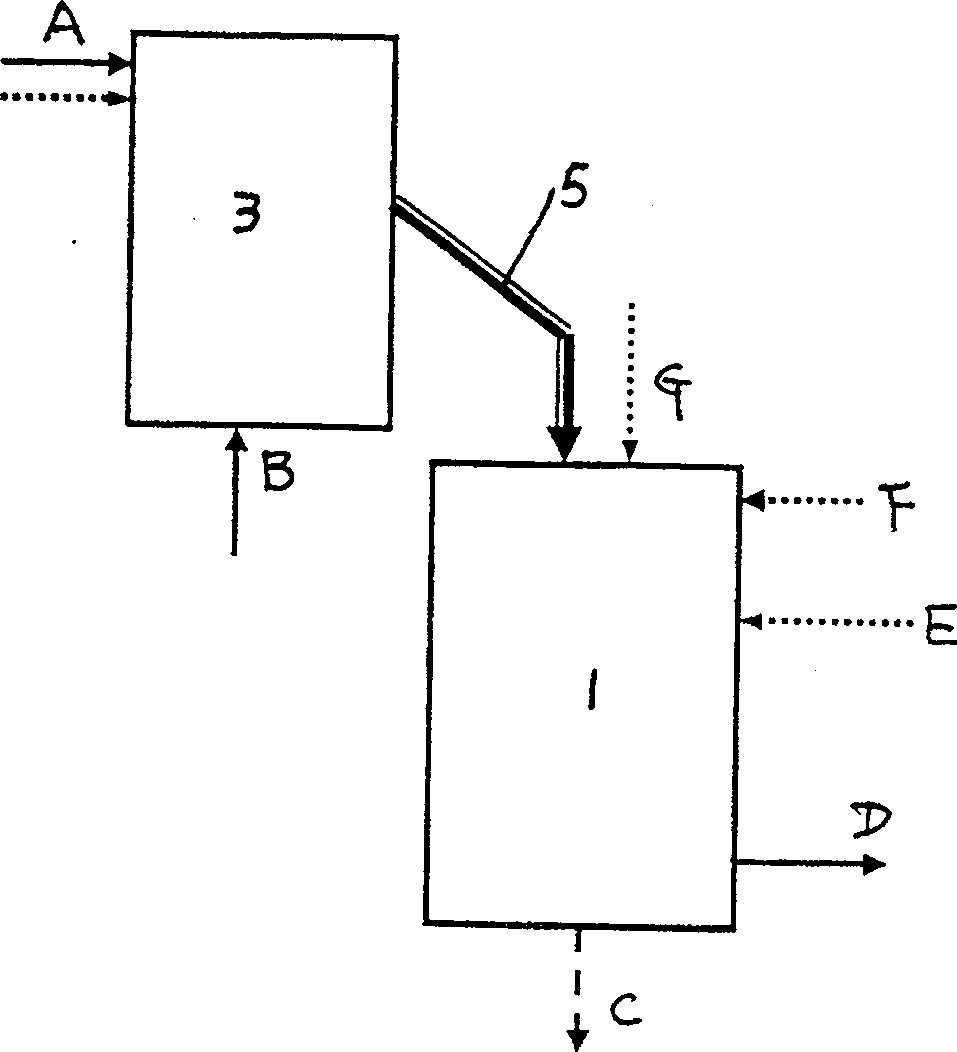

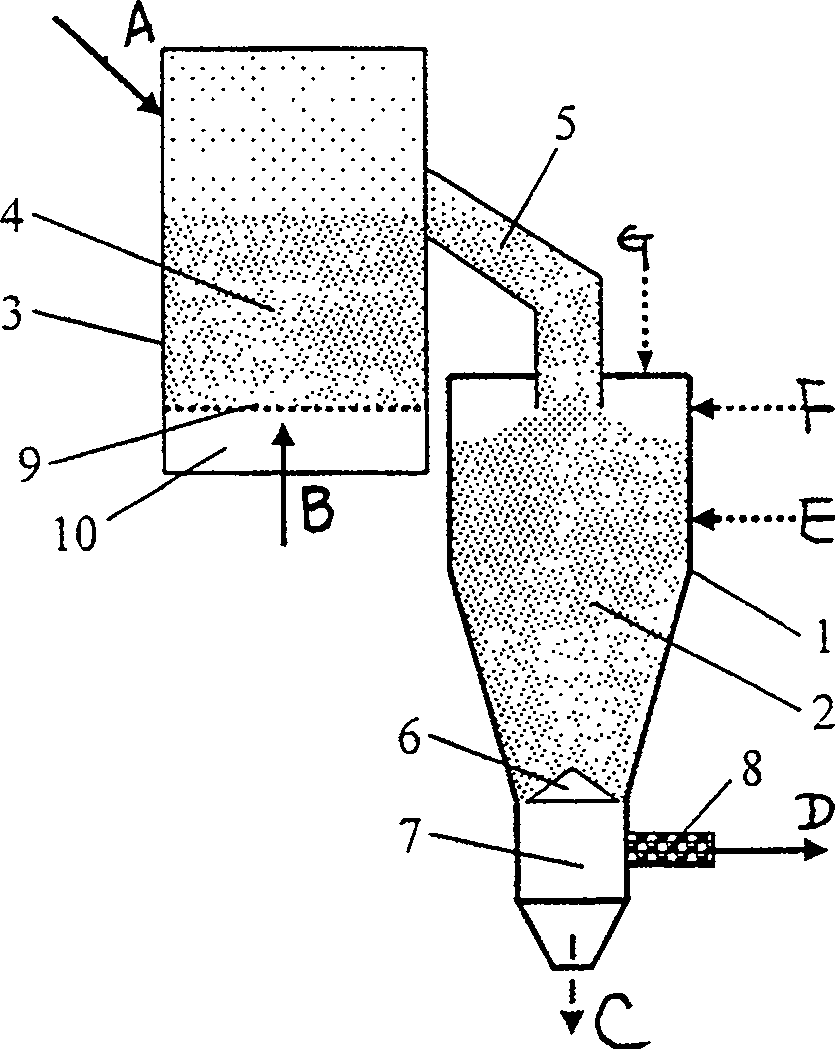

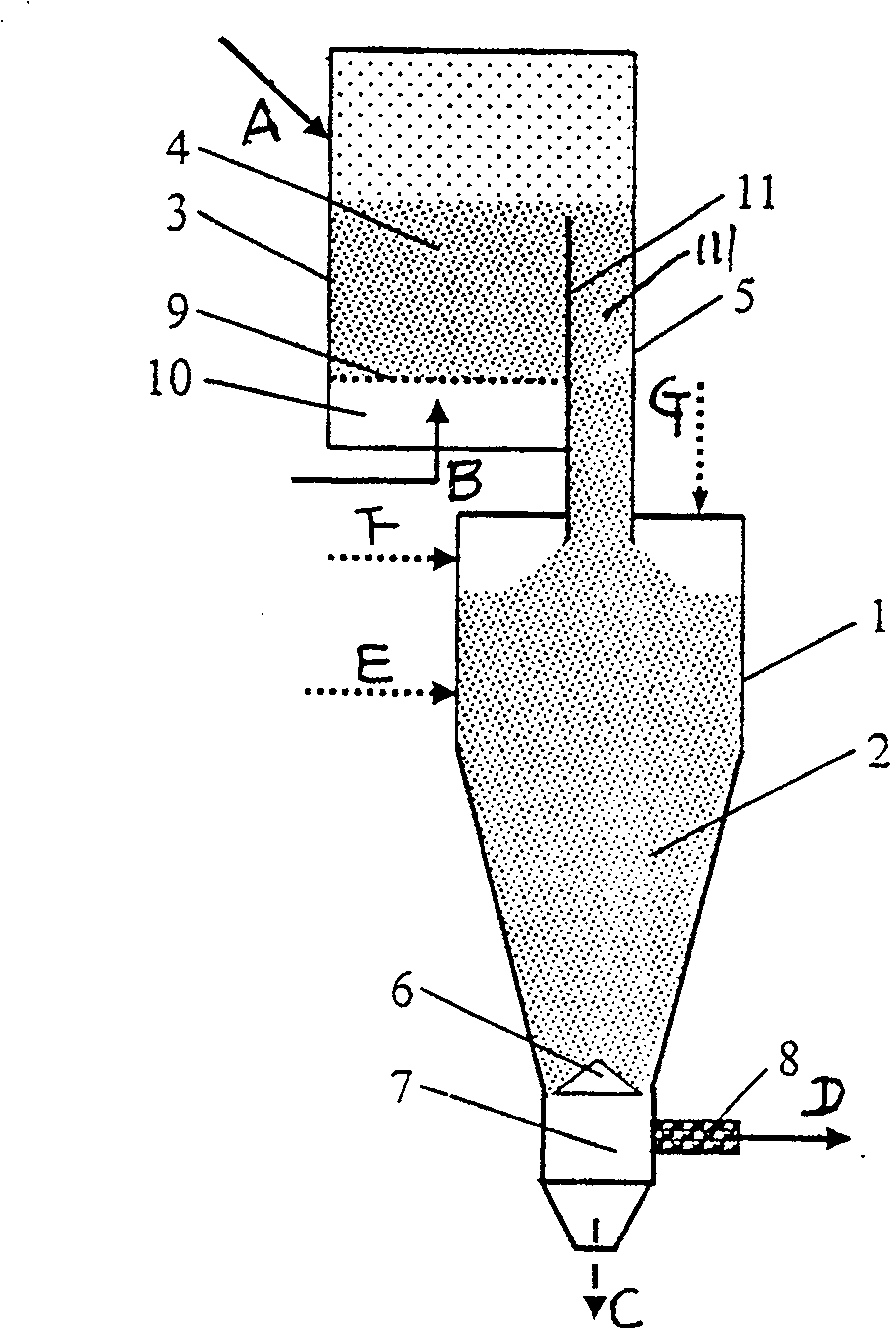

Method and Device For Measuring Circulation Quantity of Bed Material in Circulating Fluidized Bed Combustor

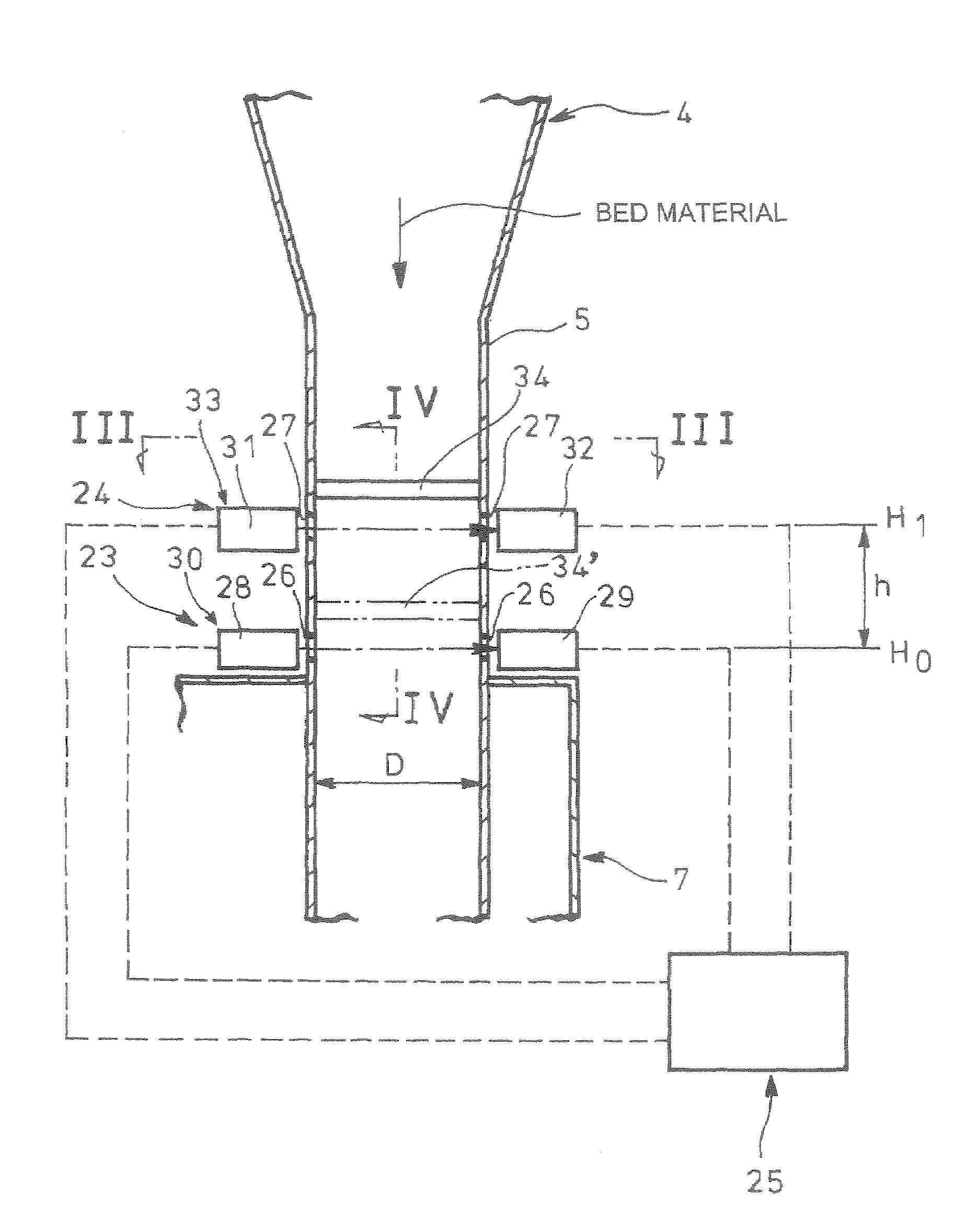

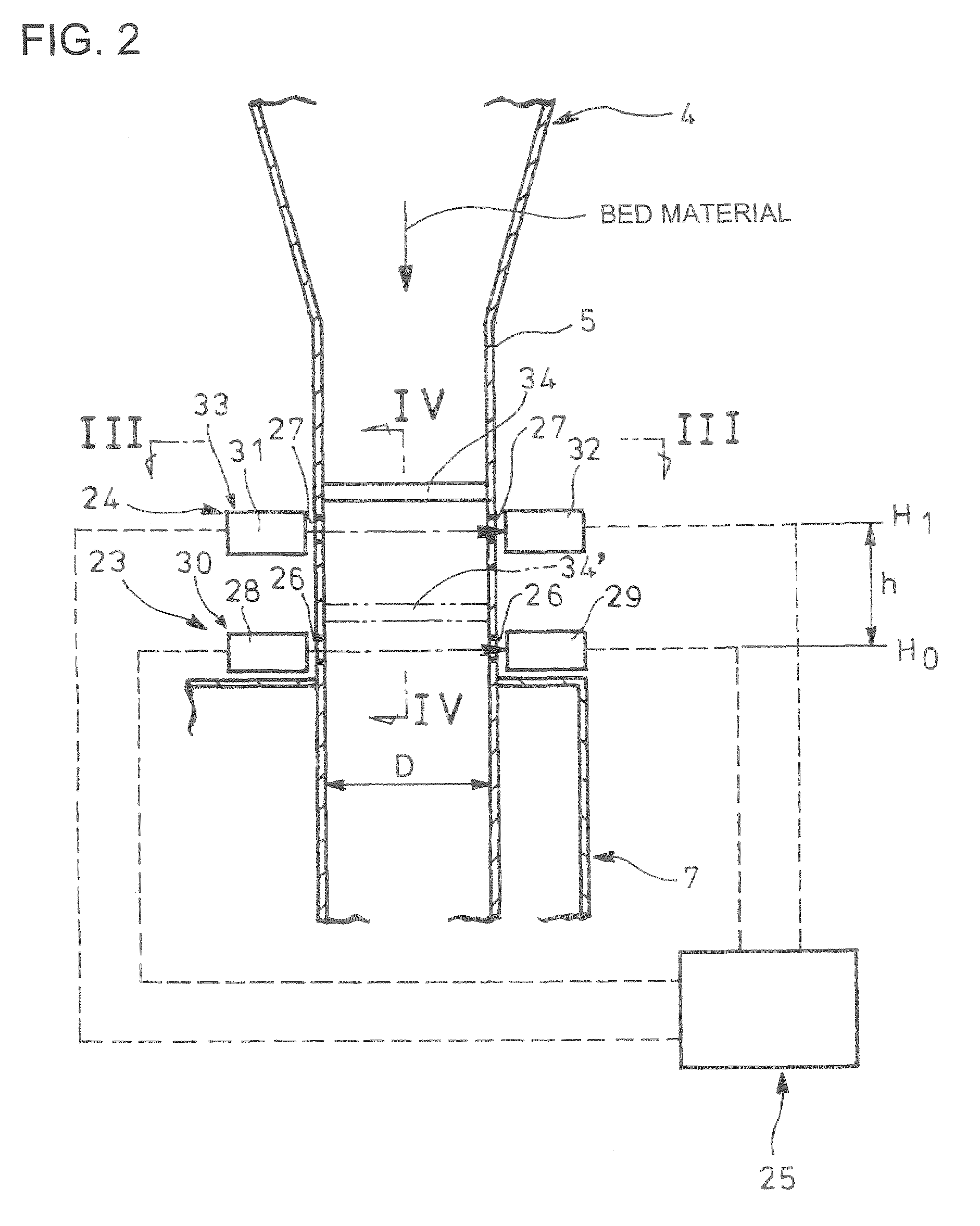

ActiveUS20080153048A1Good effectImprove accuracyFluidized bed combustionWater circulationCombustion chamberEngineering

In order to quantitatively evaluate actual circulation quantity of bed material extremely simply and to enhance accuracy of comparison of results of thermal balance examined through simulation or the like with actual operation results, time is measured which is required for bed material in a downcomer 5 to reach an upper predetermined height H1 from a lower reference height H0 during stopped feeding of fluidizing air to an external heat exchanger 7; a flow rate of the bed material as circulation quantity is determined from the time and an accumulated amount of the bed material based on an inner diameter D of the downcomer 5.

Owner:IHI CORP

Fluidized bed reactor and application thereof

ActiveCN104587911AStable long-term operationReduce suspended concentrationHydrocarbon oils refiningChemical/physical processesGas solidFluidized bed

The invention provides a fluidized bed reactor and application thereof. The fluidized bed reactor comprises a reactor main body with sealed top, at least one spiral-flow type gas-solid separator, and a gas guide pipe; the upper part at a straight tube zone of the spiral-flow type gas-solid separator is provided with at least two guiding air intake channels along the tangential direction, and the contour of each guiding air intake channel is a spiral curve. The fluidized bed reactor is capable of effectively reducing suspension concentration of a catalyst fine powder in a settlement space, timely transferring the catalyst fine powder generated in the reaction process out of the reaction system, avoiding accumulation of the catalyst fine powder in the fluidized bed reactor, and enabling the reaction apparatus to stably operate for a long time and obtain good and stable reaction effect. The spiral-flow type gas-solid separator in the fluidized bed reactor generates small wearing on a catalyst particle, and is capable of obviously reducing catalyst consumption and reducing operation cost of the apparatus especially when being used as a reactor for adsorption desulphurization.

Owner:CHINA PETROLEUM & CHEM CORP +1

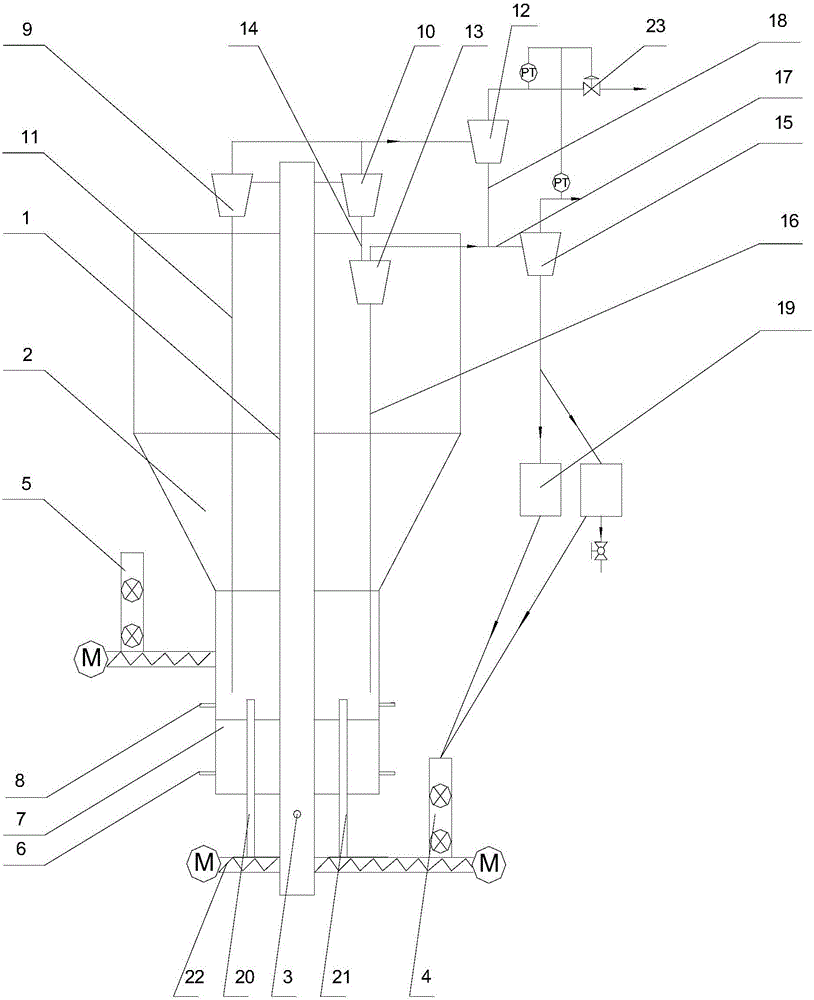

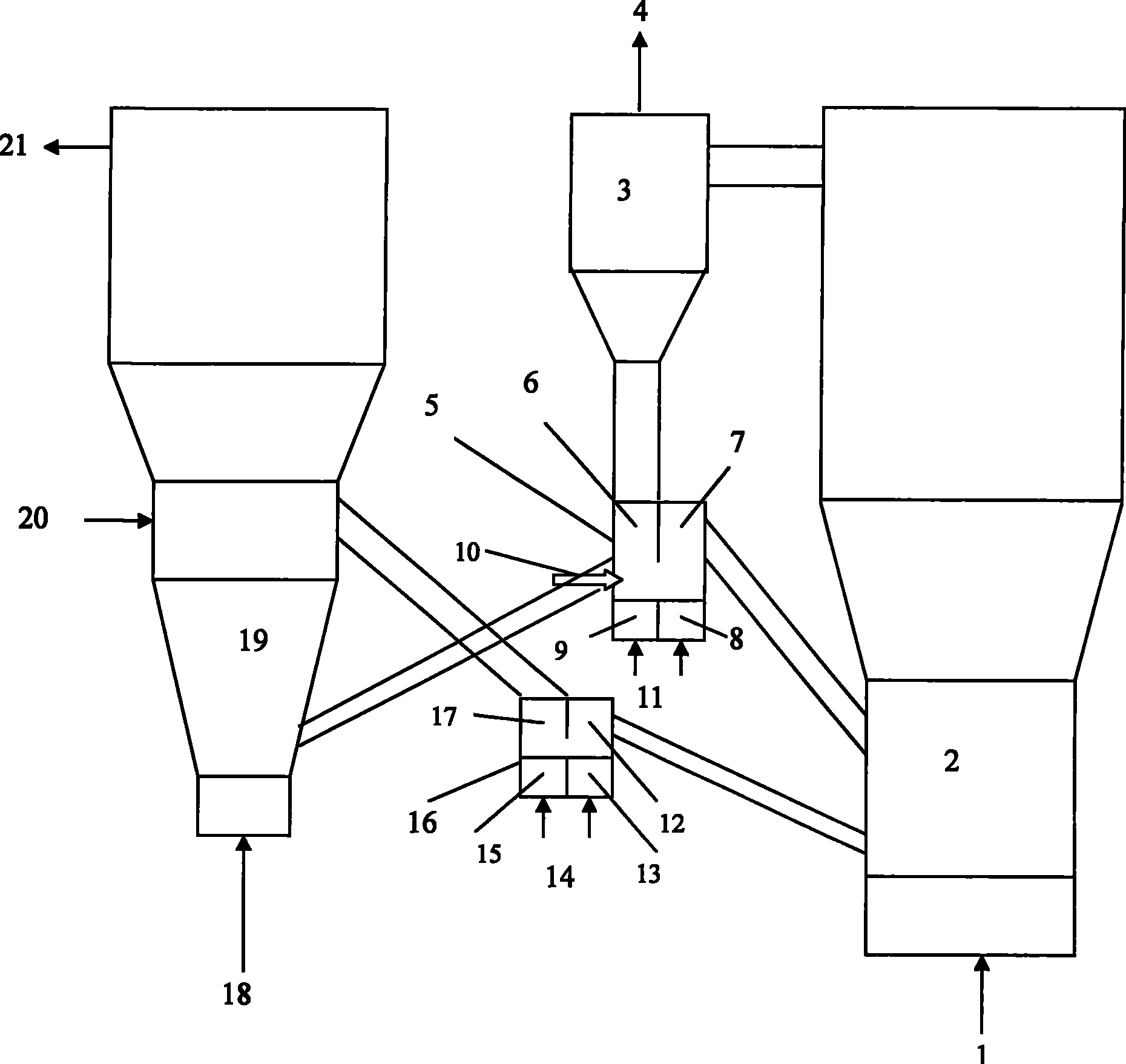

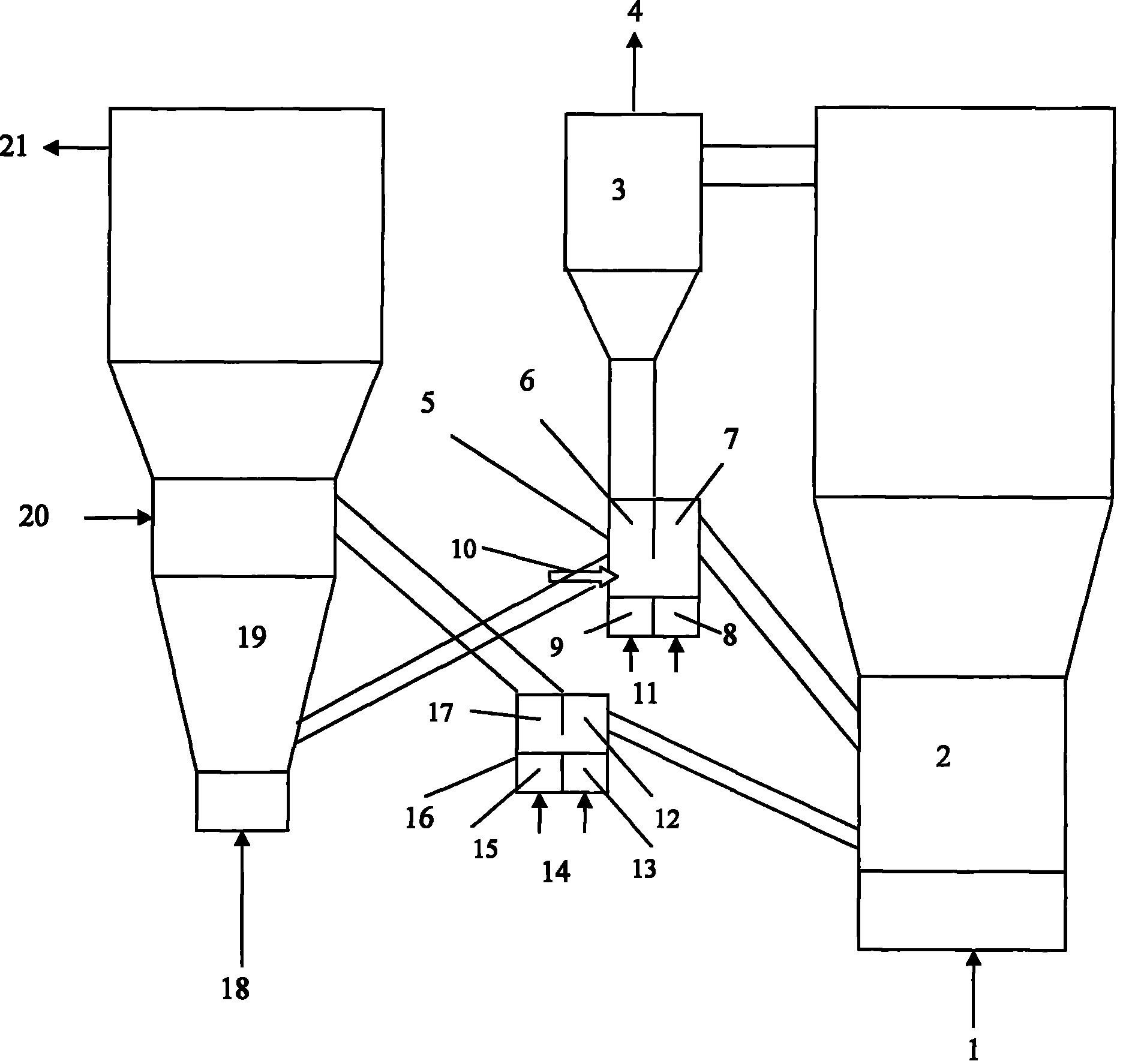

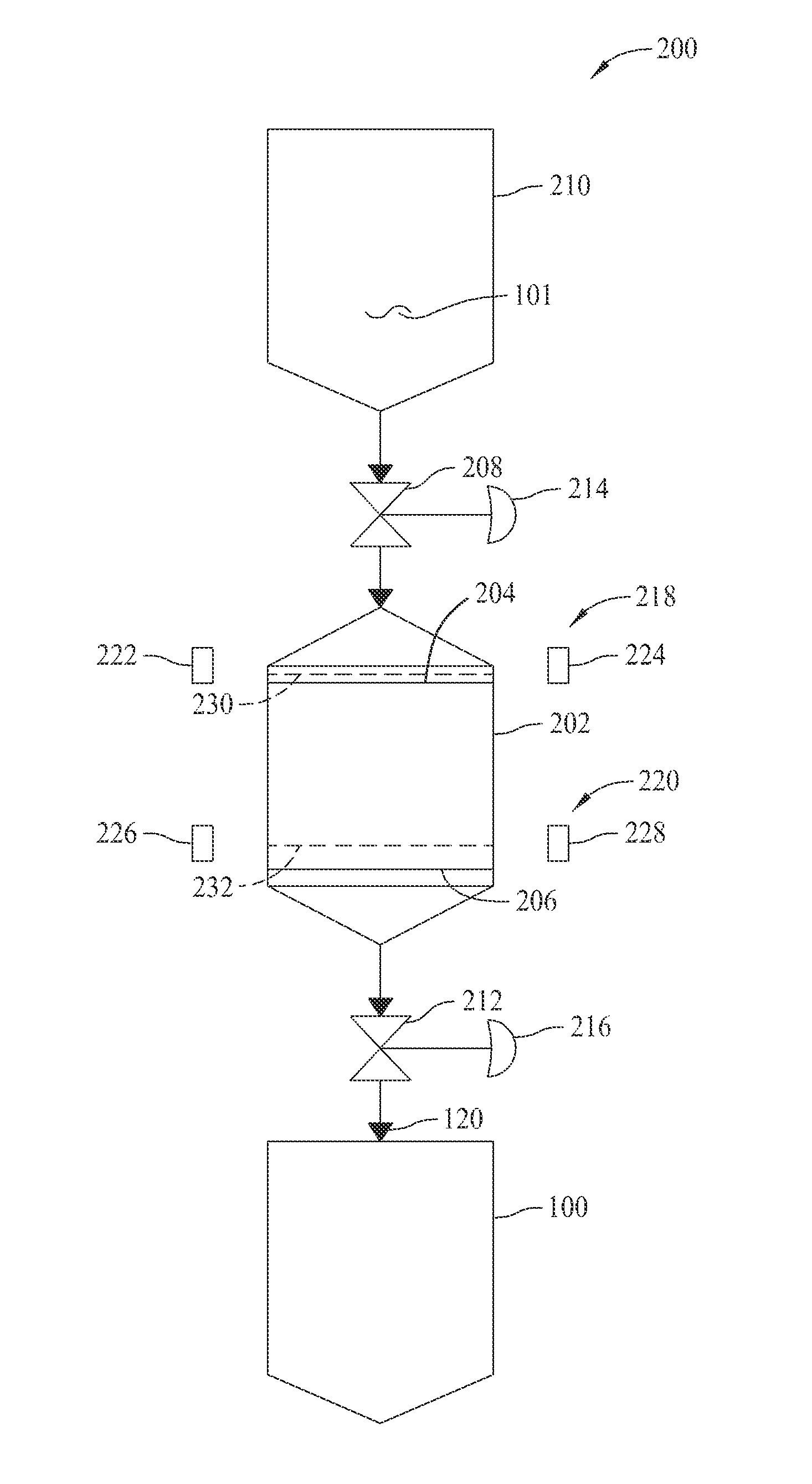

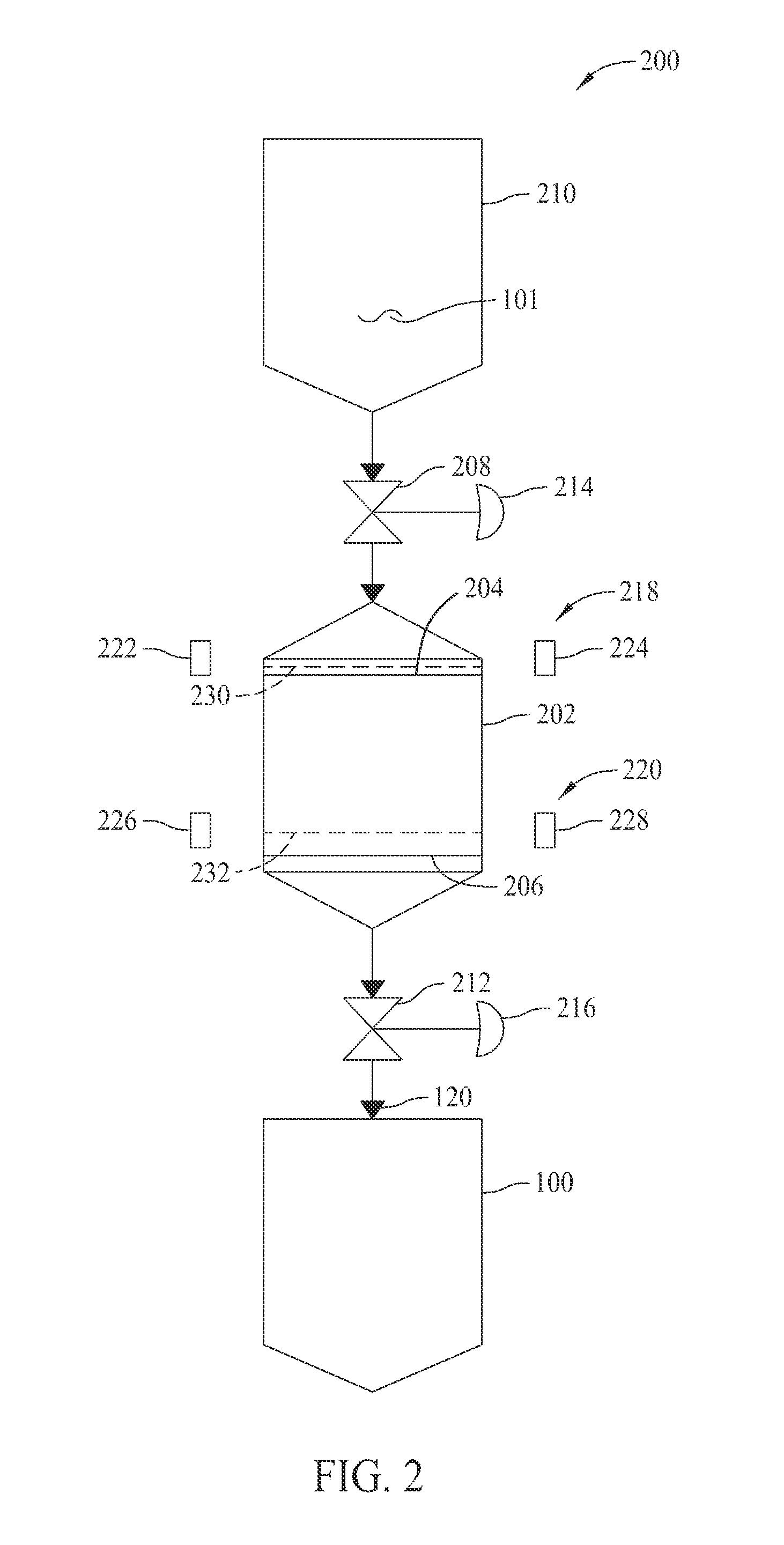

Biomass double fluidized bed indirect gasification system and control method thereof

ActiveCN105018154AHigh calorific valueAvoid backmixingGranular/pulverulent flues gasificationWater vaporNitrogen gas

The invention relates to a biomass double fluidized bed indirect gasification system and its control method. Double fluidized beds interact to realize combustion and indirect gasification so as to prepare a high-quality biomass syngas. The system provided by the invention comprises a fluidized-bed combustor and its secondary cyclone separator, a fluidized-bed gasifier and a second cyclone separator, a combustor air injection system, a combustor bed material feeding system, a gasifier vapor injection system, a gasifier biomass feeding system, a gasifier and combustor bed material circulatory system, a bed material recovery system, a combustor and a gasifier pressure control system. By the internal and external circulating double fluidized bed indirect gasifier, nitrogen in the air is naturally separated from the syngas. Through improvement of structure design of a reactor, mixed use of different bed materials, a bed material circular flow system and improvement of the gas-solid mixing level, gasification efficiency is raised, calorific value of the syngas is increased, tar content is reduced, and high-quality syngas is prepared.

Owner:代建军

Decarburization method of coal gangue and circulating fluidized bed mineral separating boiler

InactiveCN104100967AHigh thermal efficiencyGuaranteed carbon contentFluidized bed combustionClinker productionEngineeringCalcination

A decarburization method of coal gangue and a circulating fluidized bed mineral separating boiler. The decarburization method comprises the following steps: (1), crushed and dried coal gangue is placed in a fluidized bed combustor of a fluidized bed boiler to be combusted, heat is transferred to the boiler wall by high-temperature flue gas generated by the combustion of the coal gangue, so that the temperature of the boiler furnace is improved to 850 to 950 DEG C, and the coal gangue is combusted completely to be further decarburized; (2), the high-temperature flue gas generated by the combustion of the coal gangue is separated through a cyclone separator, so that vanadium in the coal gangue can be extracted by stage in the form of vanadium pentoxide according to the graded distribution of the furnace pressure of the fluidized bed; the invention further provides the fluidized bed mineral separating boiler. According to the invention, electricity generation, supply of heat, calcination and efficient and integrated mineral separation can be achieved, the coal gangue can be decarburized till 2% of residual carbon, and the heat efficiency of the fluidized bed mineral separating boiler is improved by 5% above.

Owner:HUNAN CHANGHONG BOILER

Iso-denseness seaweed biomass circulating fluid bed burn processing method

InactiveCN101182925ARaise the slagging temperatureAvoid high temperature slaggingFluidized bed combustionIncinerator apparatusCombustion chamberSlag

The invention relates to a differential density circulating fluidized bed combustion method for treating seaweed biomaterial, which adopts the mixture of quartz sand and limestone to constitute the medium of the differential density circulating fluidized bed and feeds seaweed grains or slices into the fluidized bed for combustion. The seaweed is broken and abraded during the combustion, and fine particles are brought into a dilute-phase region on the upper part for combustion from a dense-phase region by hot smoke and air. The large seaweed grains and the medium, which are brought out and are abraded incompletely, are separated and caught by a separating burnout feedback device arranged at the outlet of a fluidized bed combustor, and then return to the dense-phase region on the lower part of the combustor to realize circular combustion. Accordingly, the combustion efficiency is improved and the medium loss is reduced. The combustion temperature of the fluidized bed is controlled between 650 DEG C and 950 DEG C; the generation of heat NOX is controlled and the seaweed is prevented from forming slag inside the fluidized bed. The cinder generated after combustion is used to manufacture agricultural fertilizer. The heat generated in combustion provides heat as a heater after the heating working medium or provides power source for a steam turbine to produce kinetic energy which can push the dynamo to generate power.

Owner:SHANGHAI JIAO TONG UNIV

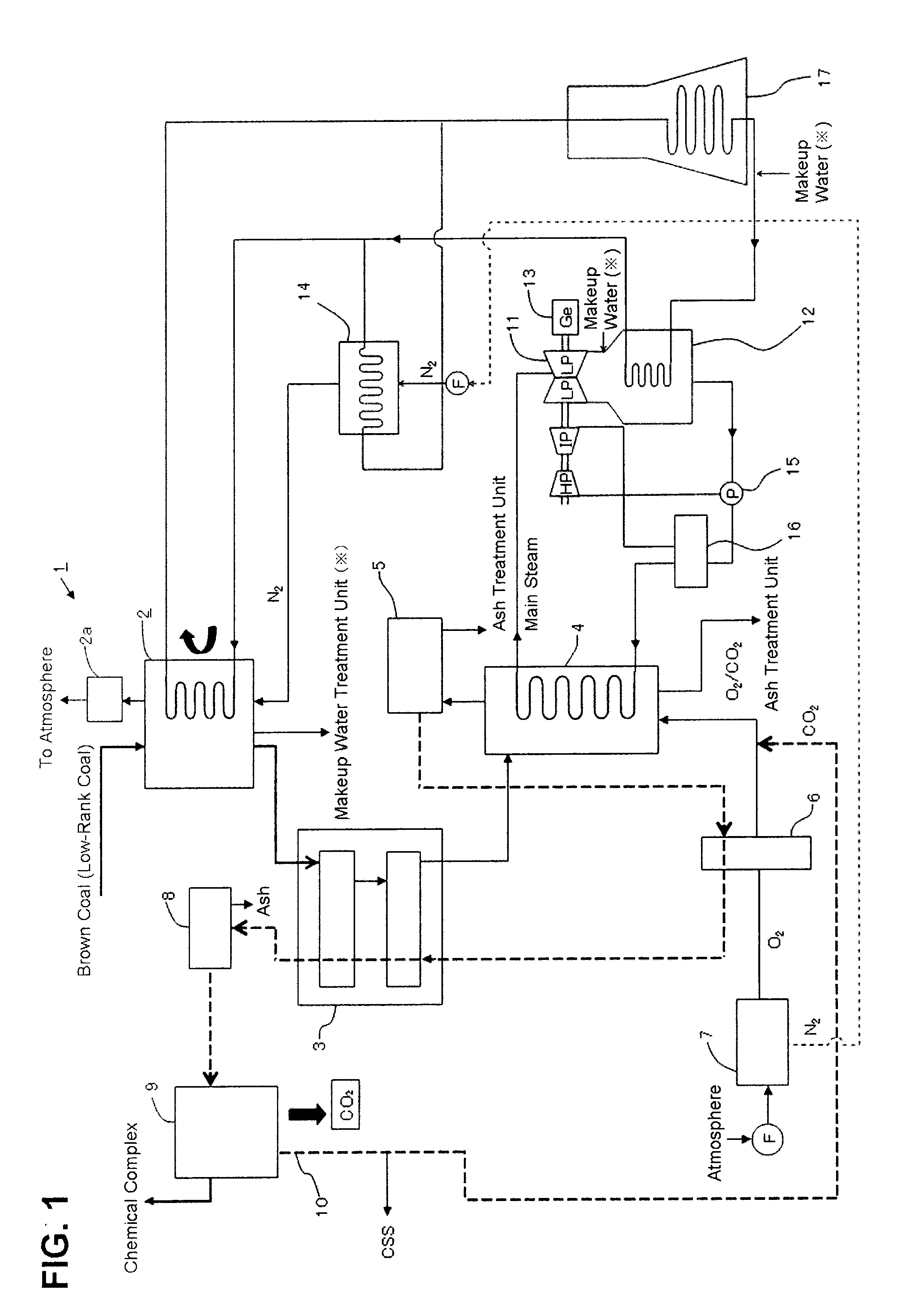

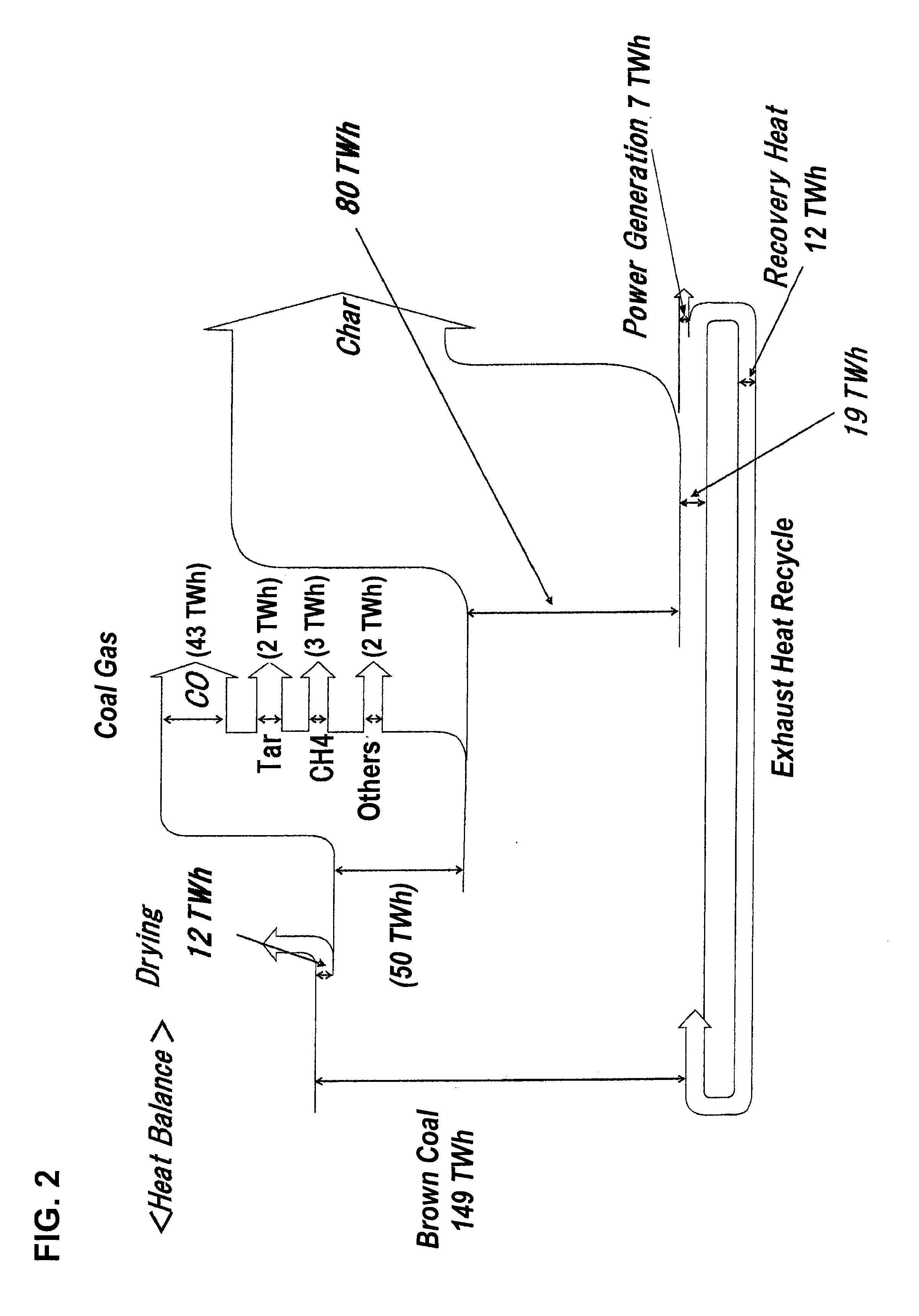

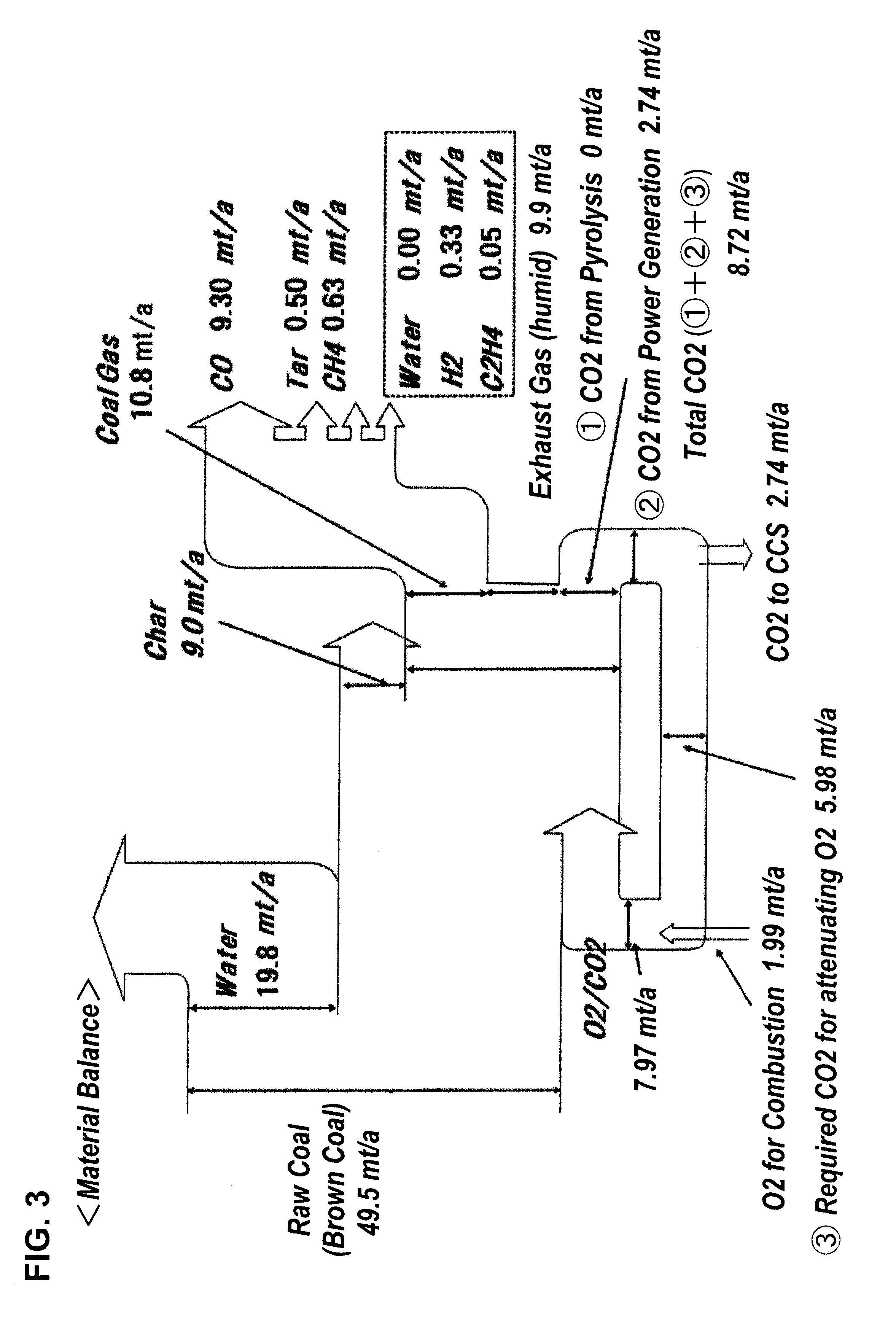

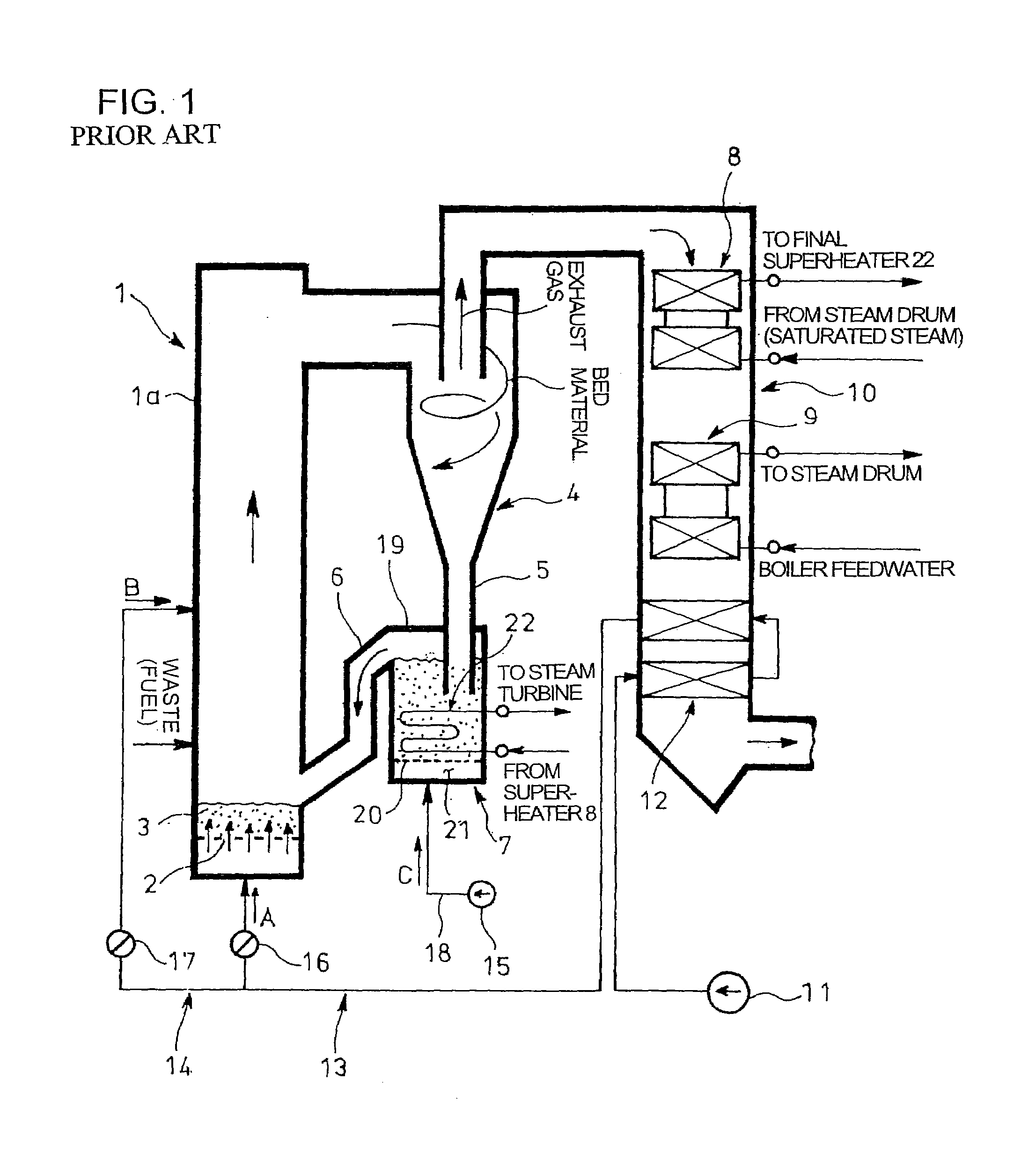

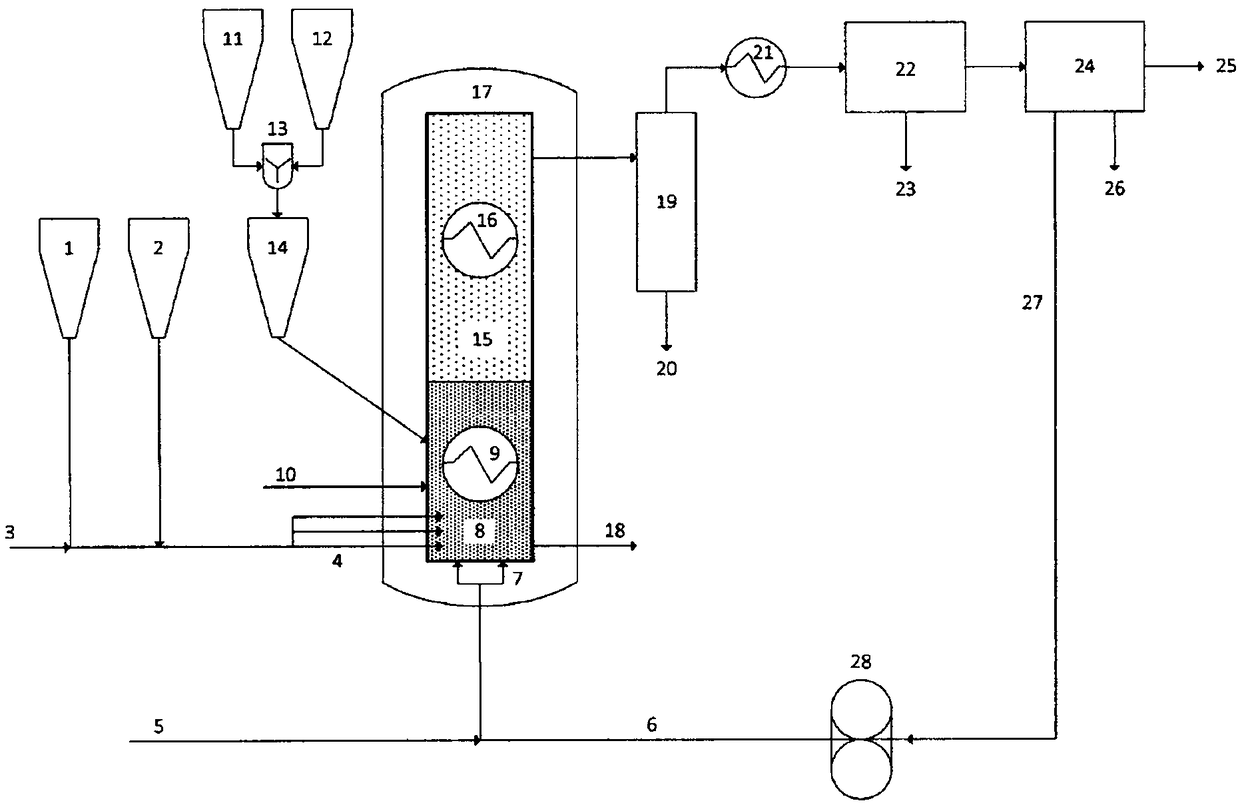

Complex system for utilizing coal in manufacture of char and raw material gas and electric power generation

ActiveUS20140030155A1Increase moisture contentReduce heatSolid fuelsGasification processes detailsMoistureElectric power

Most of the abundant naturally occurring low rank coal, which has a high moisture content and a high oxygen content, is transported with poor efficiency; utilized for heating with degraded thermal efficiency because of the loss of heat due to sensible heat for heating moisture and latent heat for vaporizing moisture; and utilized in existing coal combustion facilities with difficulty due to a high volatile component content. A complex system of the present invention for utilizing coal for manufacture of char and raw material gas and electric power generation is adopted to include: a drying unit for drying low rank coal of a high moisture content; a reformer for reforming the low rank coal that has been dried in the drying unit; a fluidized bed combustor for employing, as a fuel, the reformed coal obtained in the reformer; a producer gas supply pipe for supplying a combustion exhaust gas from the fluidized bed combustor as a pyrolytic and gasifying agent to the reformer; and a catalyst reforming unit for reforming a volatile component and the producer gas obtained from the low rank coal reformed in the reformer.

Owner:KYUSHU ELECTRIC POWER CO INC +1

Fluidized bed reactor

ActiveCN106606999AReduce suspensionChemical/physical processesHydrocarbon oils treatmentFluidized bedProcess engineering

The invention discloses a fluidized bed reactor. The inner space of the main body of the fluidized bed reactor comprises a settlement zone and a reaction zone from top to bottom. An inclined separation body is hermetically arranged in the settlement zone and divides the settlement zone into an upper chamber and a lower chamber. The upper chamber is provided with a gas outlet. A gas-solid separation device is arranged in the lower chamber. A gas-solid mixed phase inlet section and a particle outlet section of the gas-solid separation device are located in the lower chamber. An exhaust pipe of the gas-solid separation device passes is communicated with the upper chamber through a gas delivery pipe passing through the separation body. The upper chamber is communicated with a return pipe which passes through the separation body and can stretch into a dense bed. The fluidized bed reactor can timely convey separated fine catalyst particles into the dense bed of the reactor so that the amount of the suspended catalyst particles in the settlement zone of the fluidized bed reactor is significantly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

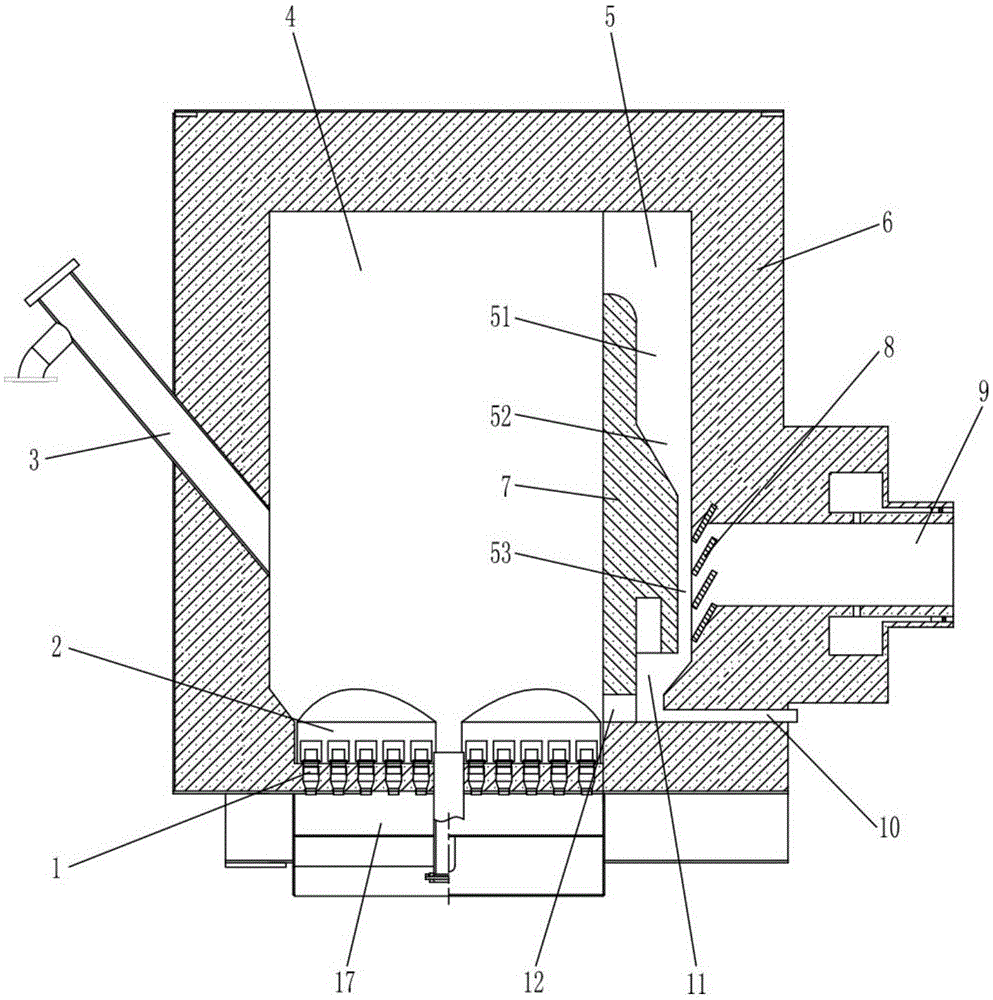

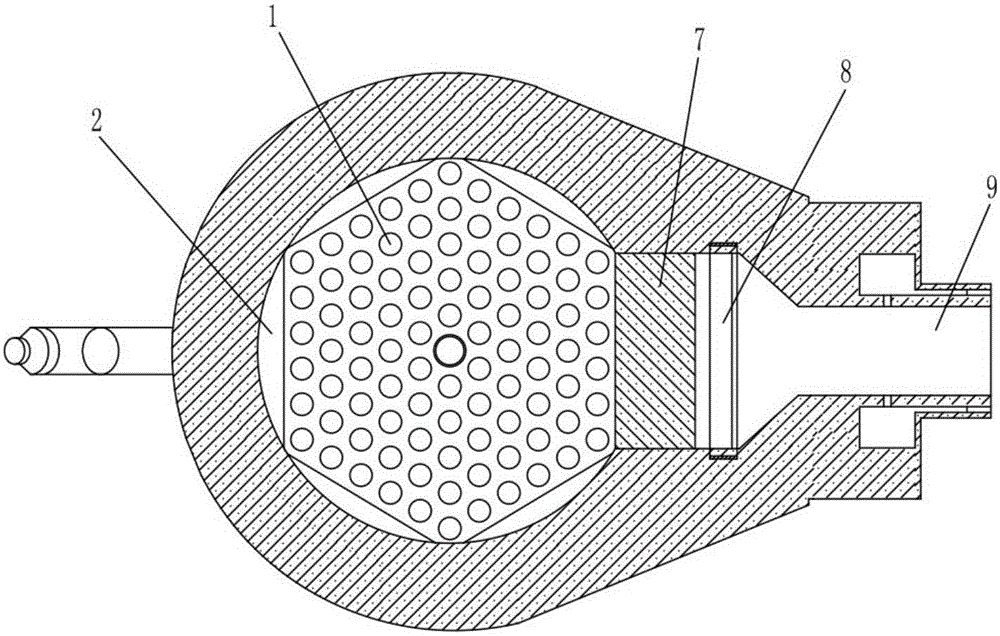

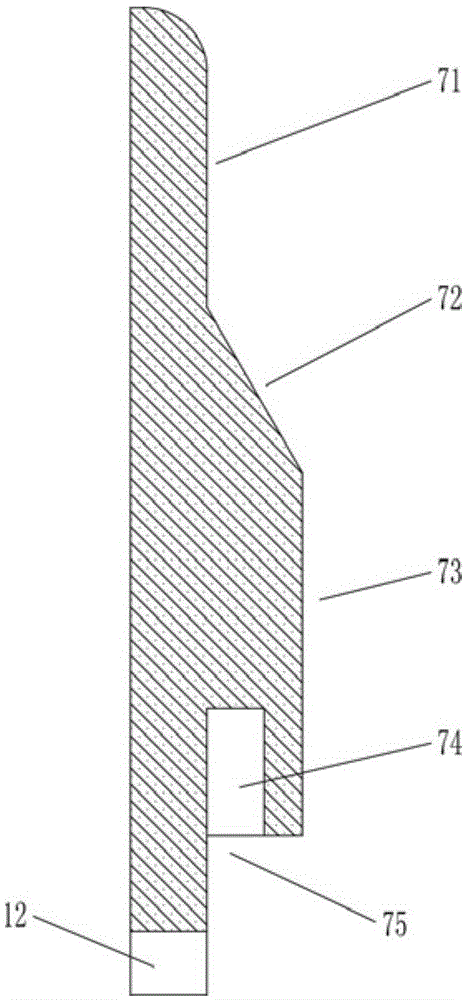

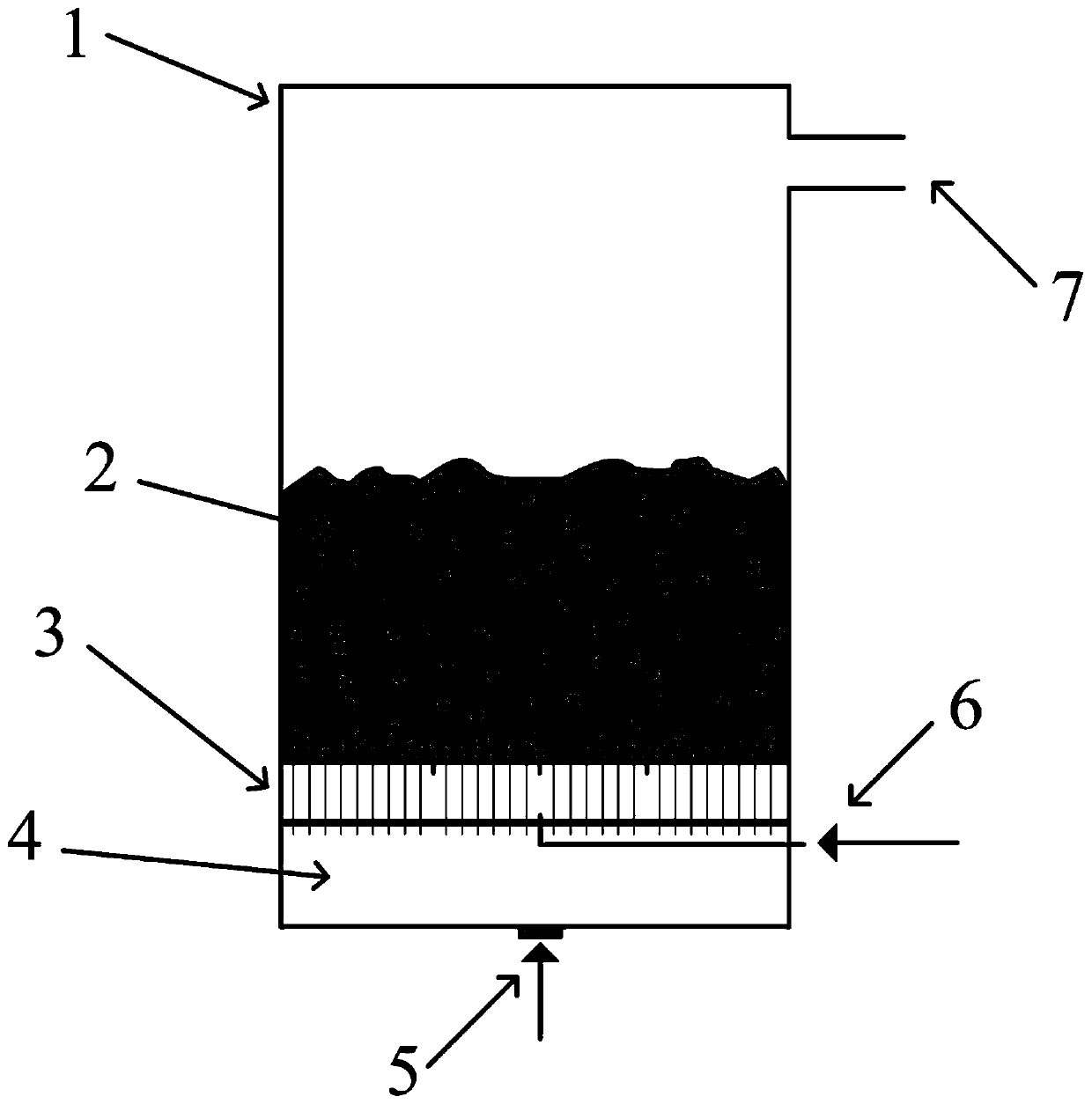

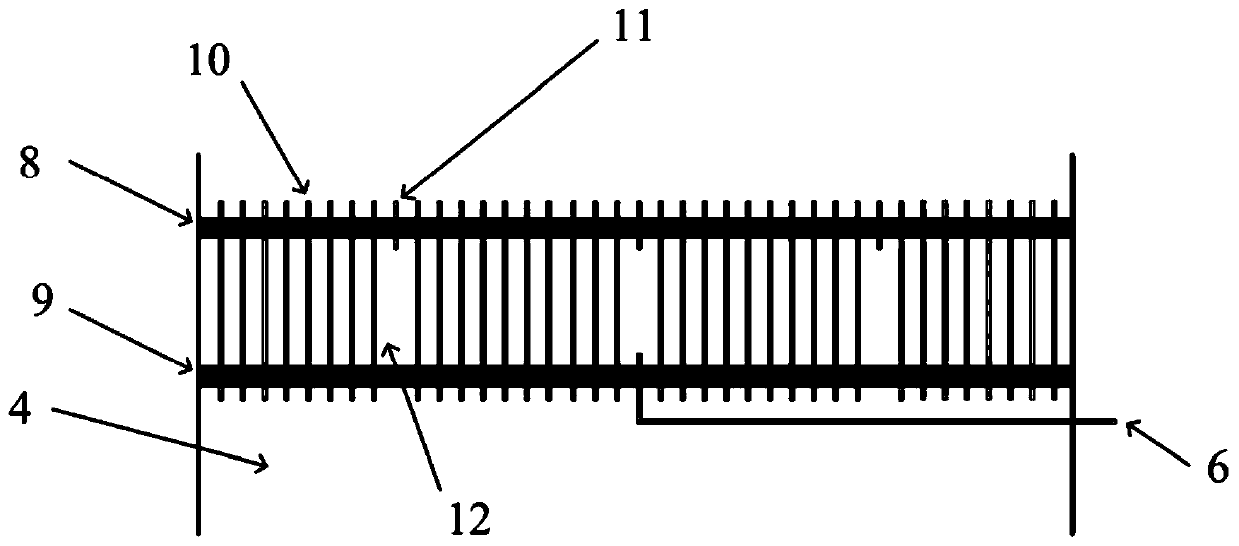

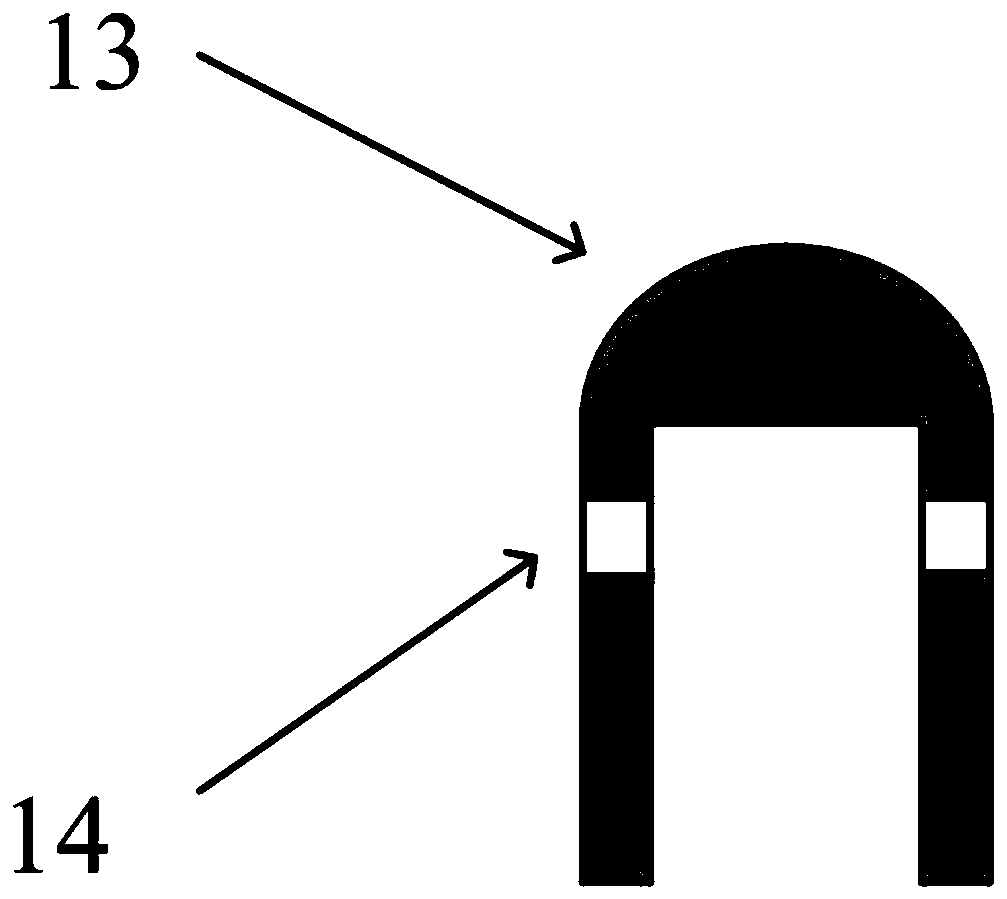

Fluidized bed combustion furnace and control method thereof

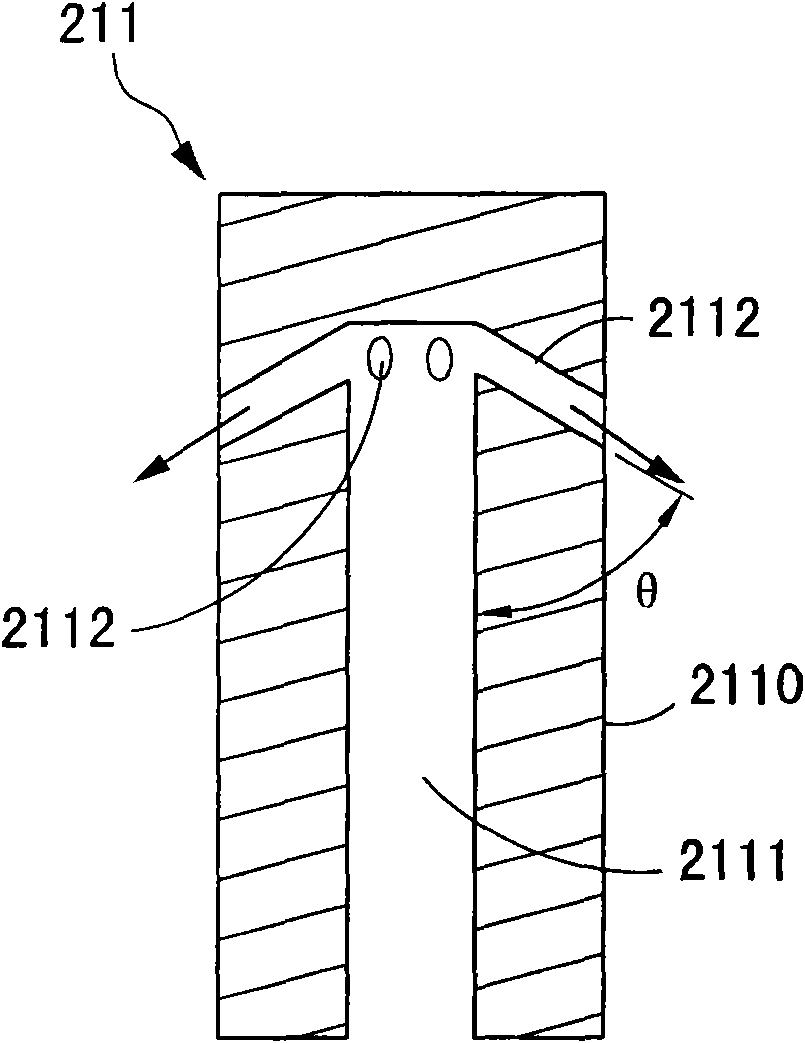

ActiveCN102042587AEasy to operateFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringDistributor

The invention provides a fluidized bed combustion furnace and a control method thereof. The fluidized bed combustion furnace is characterized in that: a gas distributor is arranged in the furnace body, a first air distribution head and a second air distribution head are arranged on the gas distributor, and each of the first air distribution head and the second air distribution head can supply a fluidized gas to a bed material, wherein the second air distribution head can supply liquid to the bed material. The control method is characterized in that: whether the liquid is injected to the bed material by the second air distribution head is determined according to the temperature of the bed material during loading or unloading of the fluidized bed combustion furnace so as to absorb heat in the bed material to reduce the temperature of the bed material, prevent the bed material from being burnt due to over high temperature and stabilize the operation of the fluidized bed combustion furnace.

Owner:IND TECH RES INST

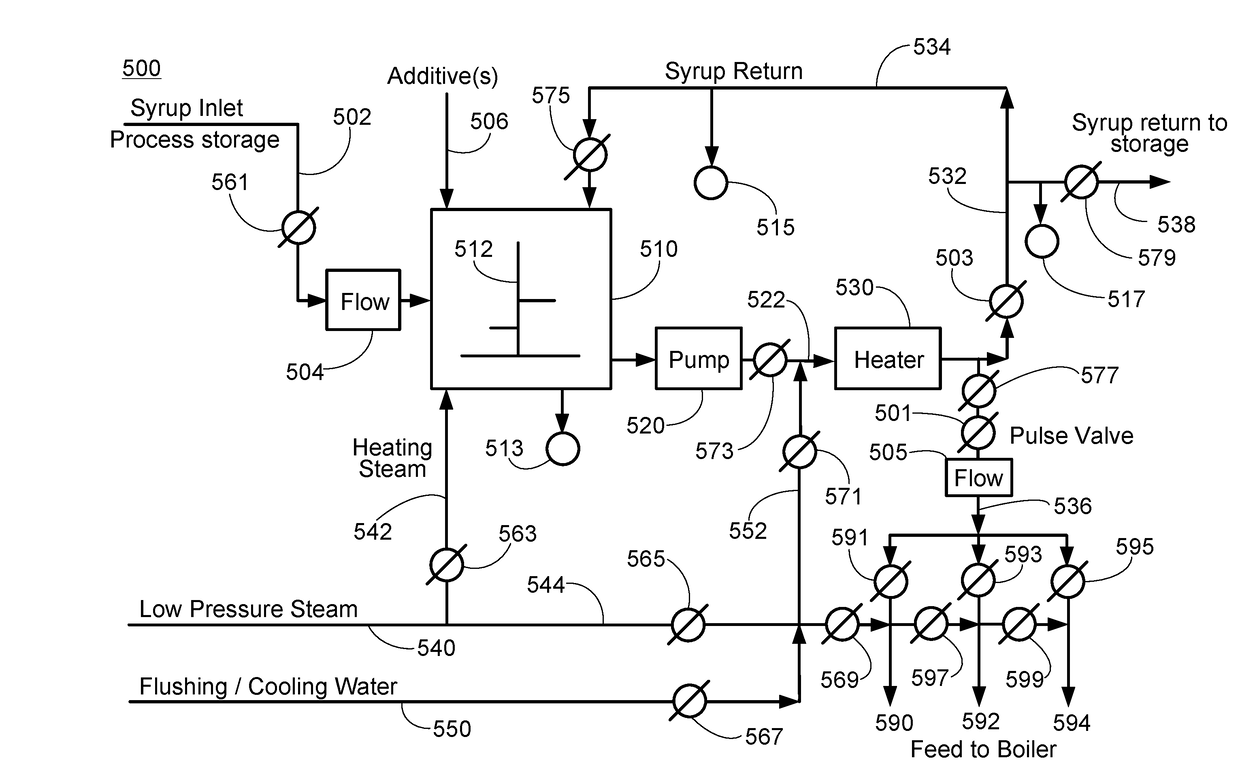

Methods of generating energy from cellulosic biofuel waste

Energy is generated from cellulosic biofuel waste streams, specifically a lignin filter cake and a waste syrup, by combusting these waste products in a fluidized bed combustor under specified conditions. The heat and steam generated can be used to generate electricity and / or in cellulosic biofuel production processes.

Owner:THE BABCOCK & WILCOX CO

Method and device for measuring circulation quantity of bed material in circulating fluidized bed combustor

ActiveUS7562641B2Good effectImprove accuracyFluidized bed combustionWater circulationCombustion chamberEngineering

In order to quantitatively evaluate actual circulation quantity of bed material extremely simply and to enhance accuracy of comparison of results of thermal balance examined through simulation or the like with actual operation results, time is measured which is required for bed material in a downcomer 5 to reach an upper predetermined height H1 from a lower reference height H0 during stopped feeding of fluidizing air to an external heat exchanger 7; a flow rate of the bed material as circulation quantity is determined from the time and an accumulated amount of the bed material based on an inner diameter D of the downcomer 5.

Owner:IHI CORP

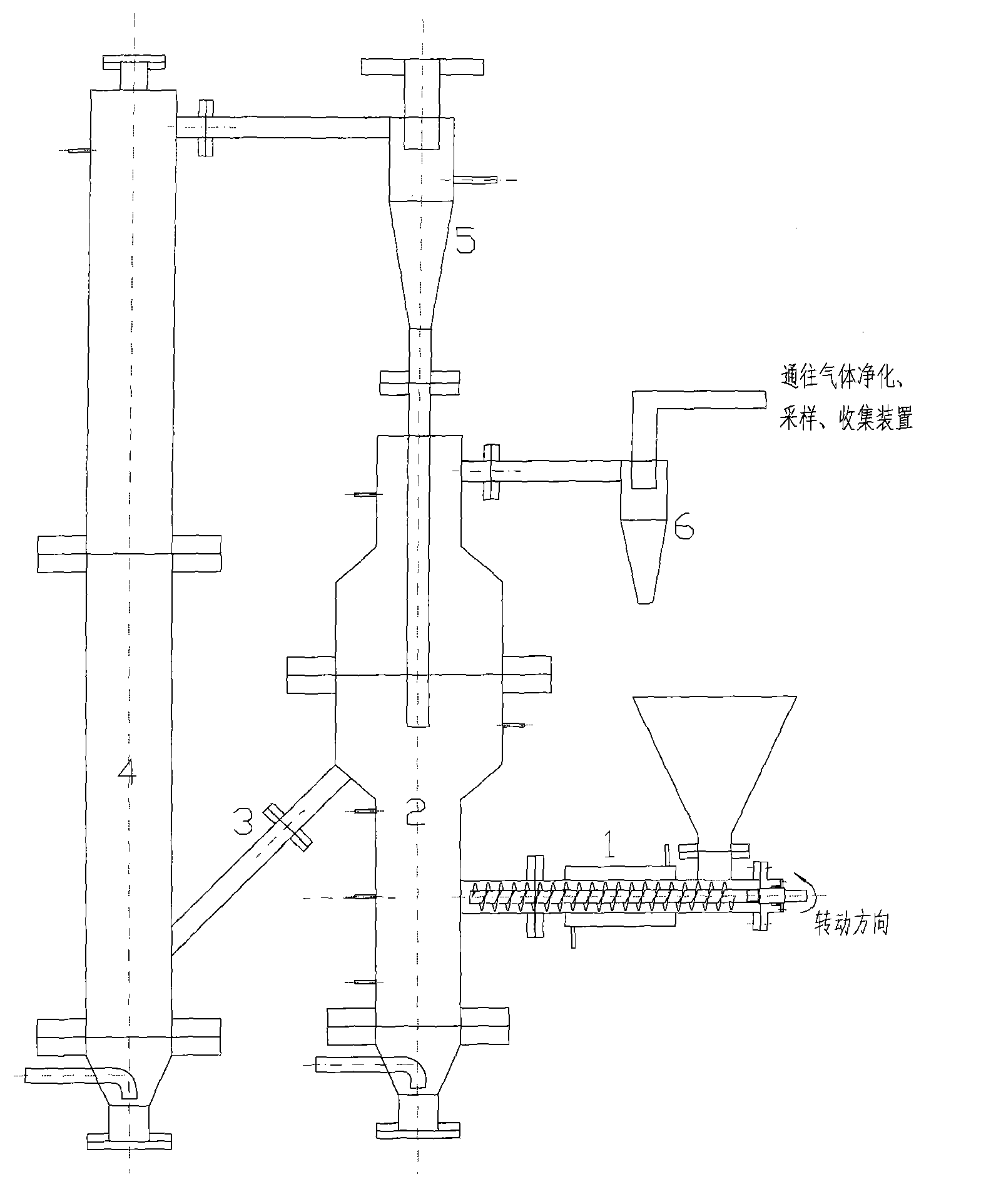

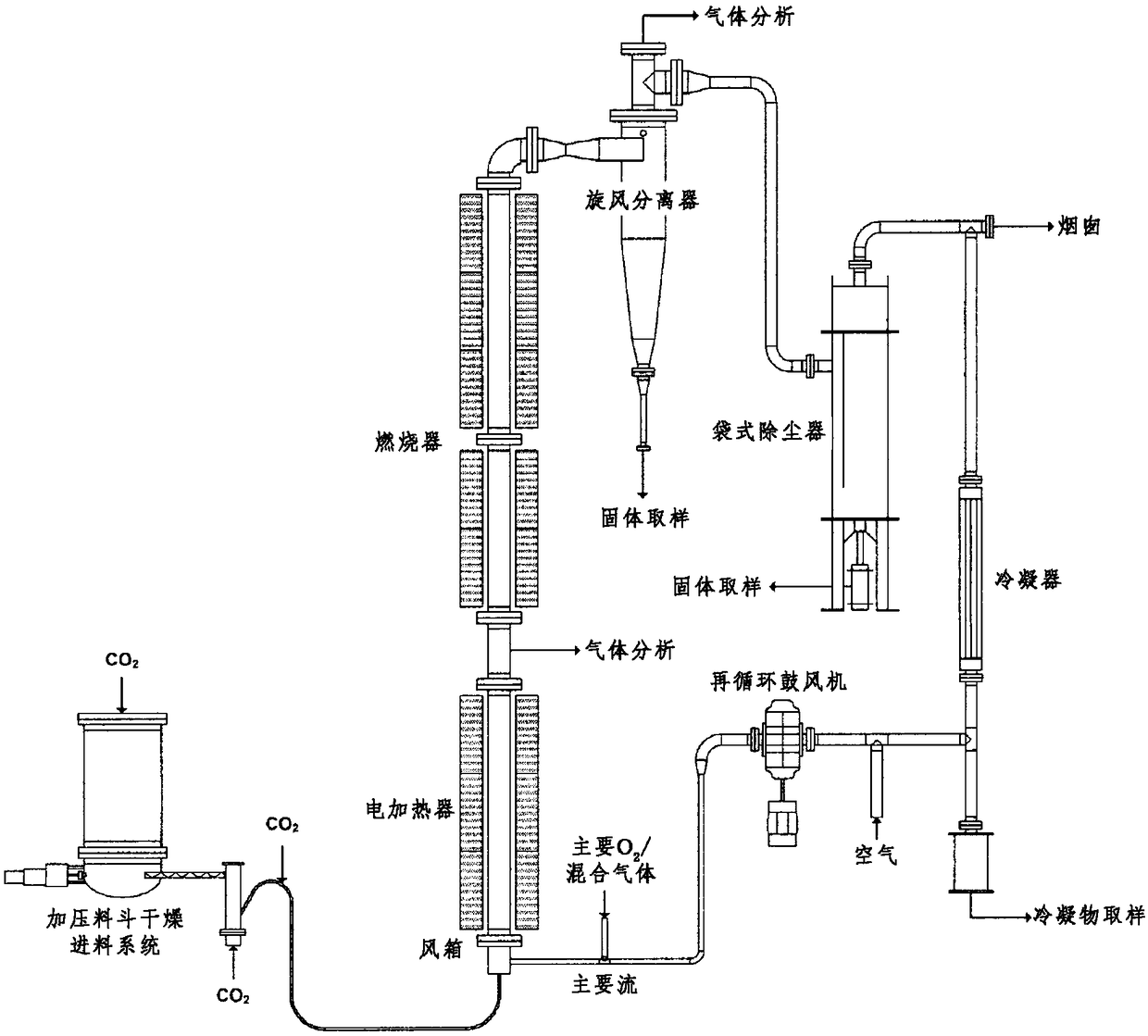

Bottom feed type gas method and equipment for preparing gas with no tar products through oxygendeficient fluid bed combustion

InactiveCN100543116CAccelerate modification/decomposition reactionSimple equipment structureBulk chemical productionGranular/pulverulent flues gasificationFluidized bedFixed bed

This invention relates to downdraft gasification method and equipment for preparing tar-free product gas by oxygen-deficient fluidized burning. The equipment comprised a front fluidized bed burner, a downdraft fixed bed gasifier set lower than the burner, a transporting pipe for carbocoal and semi-finished gas connecting the burner and the gasifying furnace, a fuel inlet and an oxidant inlet. The method comprised: (1) adding fuel through the fuel inlet of the fluidized bed burner, and performing oxygen-deficient fluidized burning with oxidant added through the oxidant inlet at the bottom of the fluidized bed burner to obtain carbocoal and semi-finished gas containing tar, and (2) sending the unseparated carbooal and semi-finished gas containing tar to a down-draft fixed bed gasifier at a high temperature to gasify the carbocoal, and modifying and cracking the tar introduced by the semi-finished gas by the catalytic activity of high-temperature carbocoal to obtain the product gas with tar. The equipment has such advantages as simple structure, easy operation and high gasifying efficiency, and is suitable for a wide variety of fuels and can produce product gas without tar.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

System and method for oxygen carrier assisted oxy-fired fluidized bed combustion

ActiveCN109073213ALow fluidization velocityFluidized bed combustionMaintainance of heating chambersSorbentProcess engineering

An oxygen fired fluidized bed combustor system (Oxy-FBC) is provided. The system provides means of producing a nearly pure stream of carbon dioxide for storage at high efficiency by controlling the oxygen content within certain regions of the combustor to control the rate of heat release allowing efficient transfer of heat from the combustor to the boiler tubes while avoiding excessively high temperatures that will cause ash melting, and simultaneously remove sulphur from the combustor via sorbents such as limestone and dolomite. The system utilizes a coarse oxygen carrier bed material to distribute heat and oxygen throughout an Oxy-FBC, while injecting fine sulphur sorbent that will continuously be removed from the bed.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

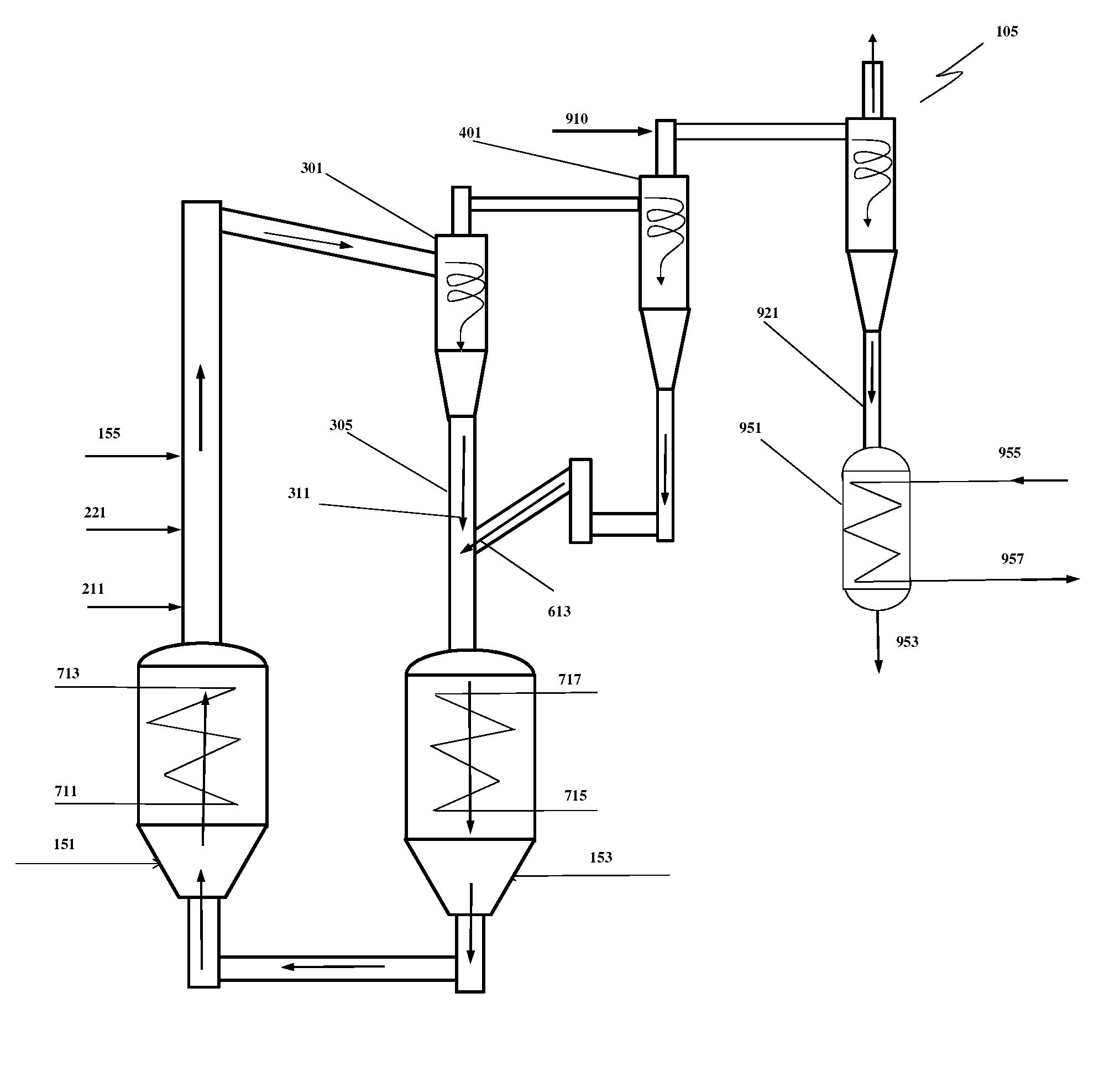

Oxycombustion in transport oxy-combustor

ActiveUS8689709B2Increase conversionsLarge specific surface areaFluidized bed combustionSteam generation using pressureMoisture condensationFlue gas

A pressurized transport oxy-combustor with different configurations is disclosed. Substantially pure oxygen is fed to the transport oxy-combustor under pressure to combust fossil fuels, generating steam for power generation. The end product is the flue gas containing substantially pure CO2 after moisture condensation. The low excess oxygen necessary to achieve complete combustion in the combustor is scavenged by adding another fuel so that substantially all oxygen fed to the combustor is completely consumed. The capability to operate the transport oxy-combustor as a circulating fluidized bed combustor at very high solids circulation rates makes it unnecessary to use recycled CO2 or flue gas as a means to moderate and control the combustion temperature. The temperature in the combustor is effectively controlled by relatively cooler circulating solids that enter the combustion zone. A small amount of CO2 is recycled for aeration and to convey solids fuel to the combustor.

Owner:THE SOUTHERN CO

Recycling process for waste furnace slag in fluidized bed boiler combustion system

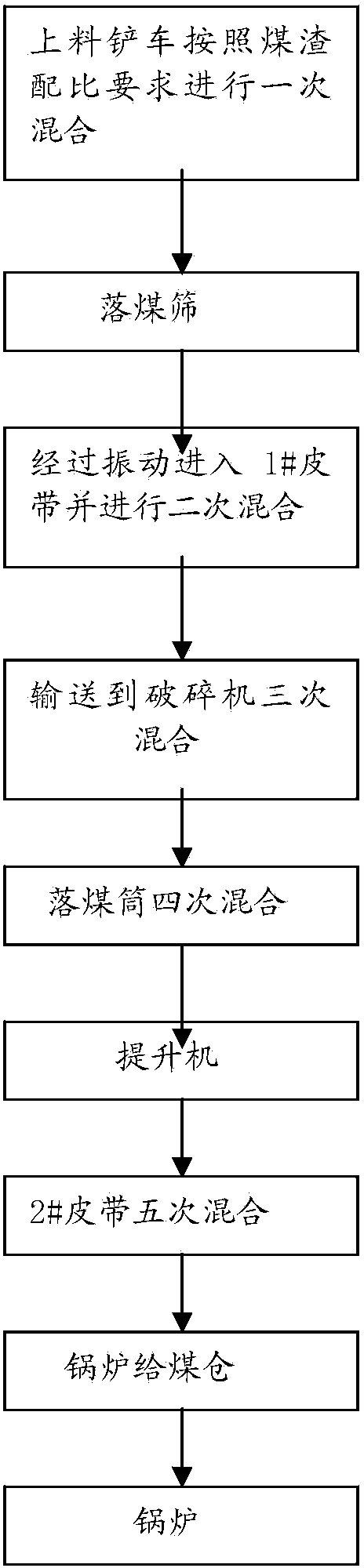

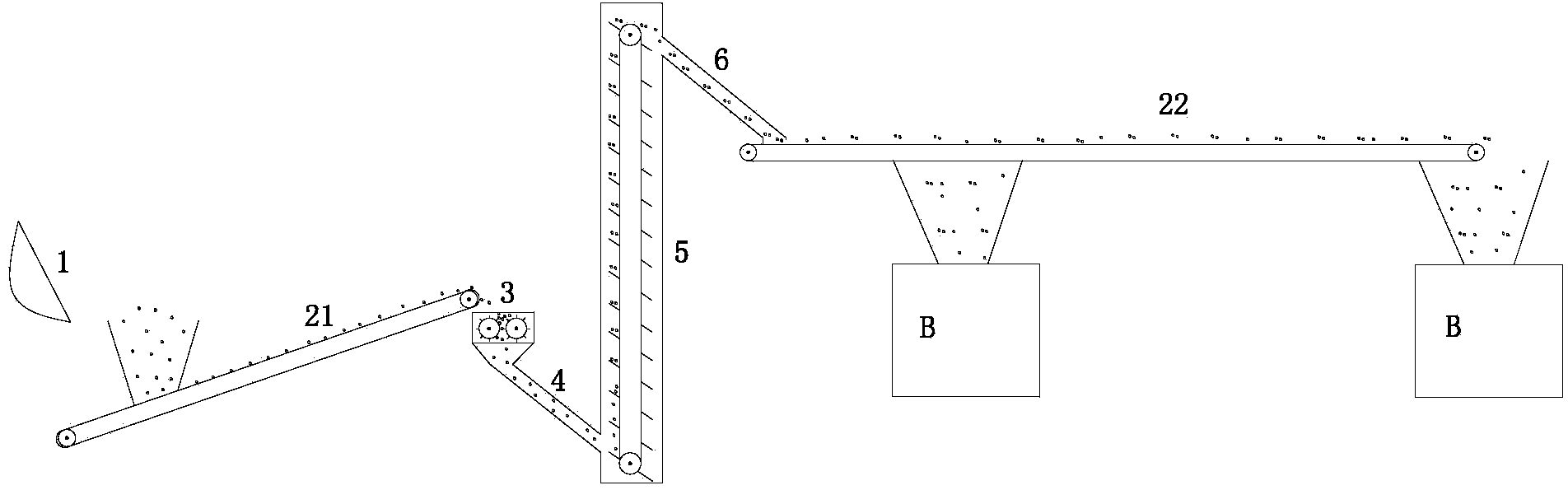

ActiveCN103411212AReduce pollutionReduce wasteFluidized bed combustionApparatus for fluidised bed combustionCombustion systemSlag

The invention relates to a process method and equipment for recycling waste furnace slag in a fluidized bed boiler combustion system. The process method comprises the following steps of (1) analyzing the low caloric value of the waste furnace slag, and judging the combustibility of the waste furnace slag; (2) uniformly proportioning and mixing coal and the combustible waste furnace slag as required, and loading materials to a circulating fluidized bed loading system; (3) setting parameters such as primary air openness, current, induced air openness, the air pressure of an air chamber, primary air amount, primary air pressure and the smoke pressure of an induced air inlet according to the different thicknesses of backing materials; and (4) combusting a coal slag mixture in a circulating fluidized bed boiler according to the parameters which are set in the step (3). By the adoption of the process method for recycling the waste furnace slag in the fluidized bed boiler combustion system and the fluidized bed boiler system corresponding to the process, a great number of coal resources can be saved, the environmental pollution is alleviated, the resource wasting is reduced, the benefit is improved, waste materials are changed into profitable materials, and energy conservation and emission reduction are realized.

Owner:太原钢铁(集团)有限公司

Low-nitrogen fluidized bed combustor for biomass

InactiveCN105090941AImprove combustion efficiencyBurn fullyFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberFlue gas

The invention discloses a low-nitrogen fluidized bed combustor for biomass. A feed opening and a flame nozzle are formed in the side wall of an inner chamber of a furnace body, and an air distribution plate and a partition wall are arranged at the bottom of the inner chamber. The inner chamber is divided into a combustion chamber and a flue through the partition wall, the combustion chamber is used as a combustion area, and the flue is used for settling solid particles. The upper part of the combustion chamber is communicated with a flue inlet, a through hole is formed in the bottom of the partition wall, and the combustion chamber is communicated with the flue. According to the inner chamber structure with the air distribution plate, the flue and the through hole, when flue gas passes through the flue, solid bodies in the flue gas settles under the action of dead weight, and precipitates are circulated to the combustion chamber for combusting utilization through the through hole. The combustion mode of a circulating fluidized bed is realized, the combustion efficiency is high, and the effective effects of sufficient combustion without coking and effective settling without ash deposition are realized.

Owner:广州迪森热能设备有限公司

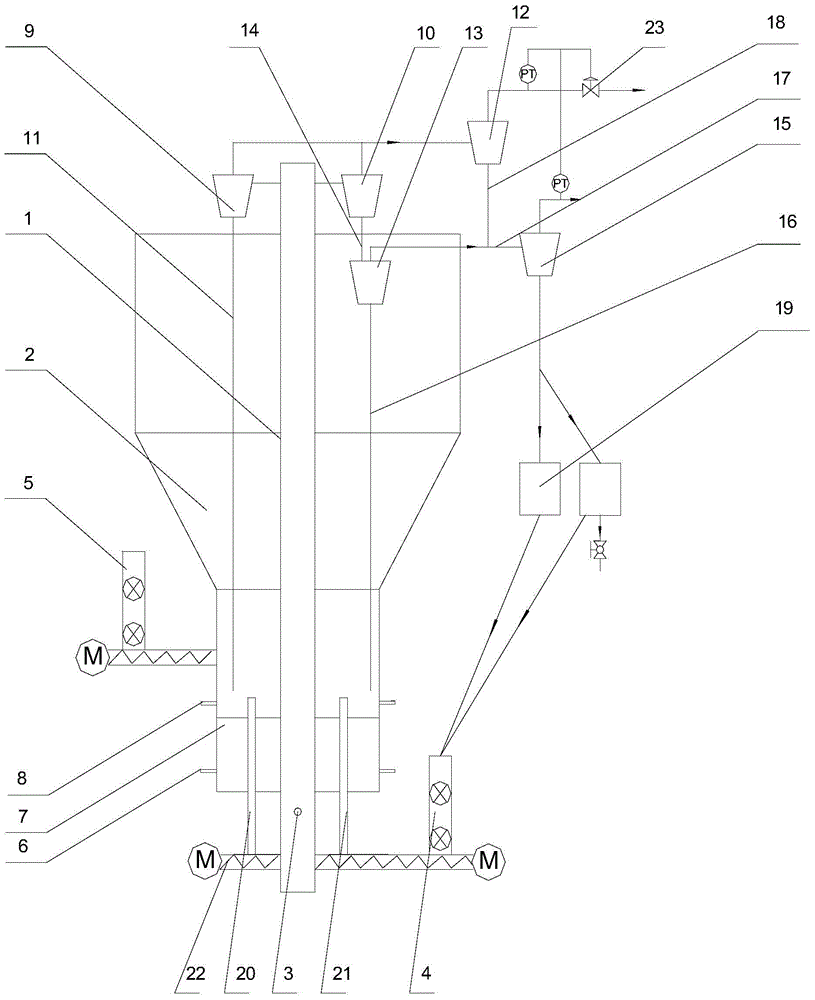

Circulating system of combustion gasification materiel for double fluidized bed

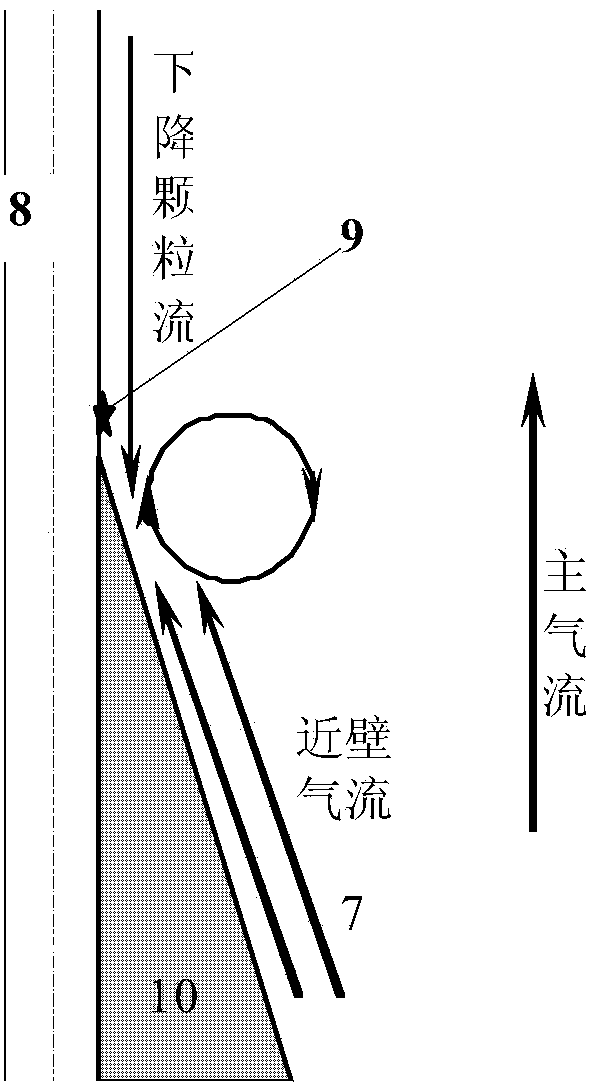

ActiveCN101255987BReasonable useControl operating temperatureFluidized bed combustionApparatus for fluidised bed combustionFluidized bed gasifierEngineering

The present invention discloses a double fluidized beds combustion-gasification material circulating system comprising a fluidized bed gasification furnace and a circulating fluidized bed combustion furnace; the middle portion of the fluidized bed gasification furnace is connected with a material charging chamber of a material returning chamber, and then is connected with the lower portion of the circulating fluidized bed combustion furnace through a material discharging chamber of the material returning device; the upper portion of the circulating fluidized bed is connected to a material charging chamber of a bi-directional material control device through a hyperthermia separator, then is divided into two paths, one path is connected with the lower portion of the fluidized bed gasification furnace through a hyperthermia conical valve on the side surface of the material charging chamber of the bi-directional material control chamber, and the other path is connected with the lower portion of the circulating fluidized bed combustion furnace through the material returning chamber of the bi-directional material control chamber. The circulating fluidized bed combustion furnace and the fluidized bed gasification furnace are combined tightly to implement gasification, combustion, classification and conversion of coal in one set of system, which leads to highly efficiency conversion of coal; the inventive system is also can be used broadly in combustion, gasification, catalysis and regeneration processes.

Owner:ZHEJIANG UNIV +1

Fluidized bed combustion device for ammonia gas, power generation system and combustion method of ammonia gas

InactiveCN111322610AFire stableUniform temperatureFluidized bed combustionGas turbine plantsFlame propagationFlue gas

The invention relates to the technical field of combustion devices for ammonia gas, and provides a fluidized bed combustion device for ammonia gas, a power generation system and a combustion method ofthe ammonia gas. The combustion device comprises fluidized bed combustor shell, a fluidized bed layer, an air distributing plate, a pumping chamber, a combustion-supporting gas inlet, a fuel gas inlet pipe and a flue gas exhaust port; the air distributing plate is wholly mounted at the lower part of the fluidized bed combustor shell, and the fluidized bed layer is arranged on the upper surface ofthe air distributing plate; the pumping chamber is located below the air distributing plate; the combustion-supporting gas inlet is formed in the pumping chamber; the fuel gas inlet pipe is fixed onthe air distributing plate and communicates with an inner cavity of the air distributing plate; and the flue gas exhaust port is formed in the upper part of the fluidized bed combustor shell. According to the designed fluidized bed combustion device, the problems of has high firing energy, high flame propagation velocity, narrow firing concentration range and unstability of ammonia gas combustionare solved thoroughly. Therefore, the power generation system can successfully use the ammonia gas as fuel, and the remarkable carbon dioxide emission reducing effect is realized.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

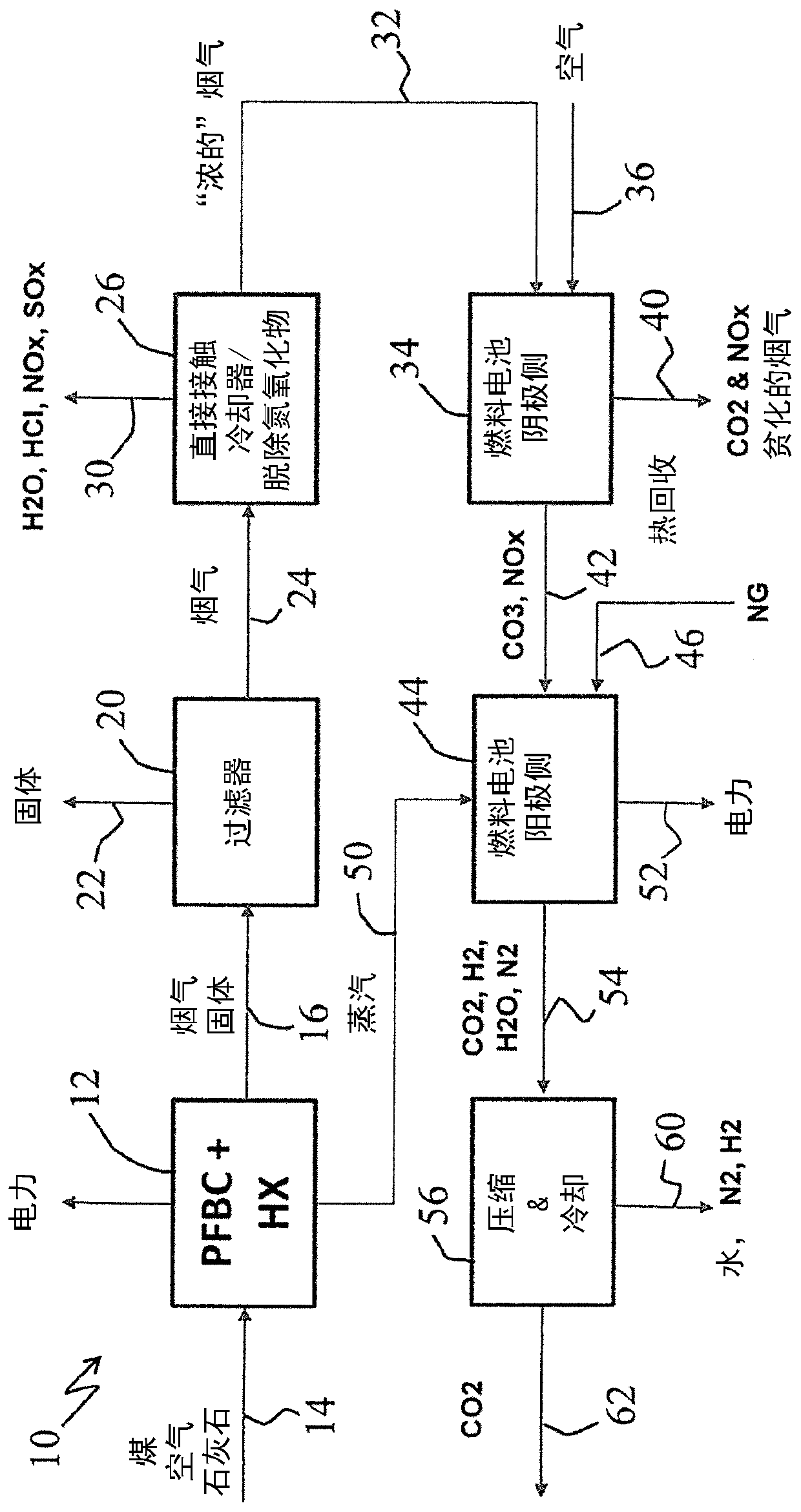

Pressurized fluidized bed combustor with fuel cell carbon dioxide capture

Systems and methods for generating electricity that combine a pressurized fluidized bed combustor (PFBC) and a molten carbonate fuel cell (MCFC) to provide a 2 A low-cost solution for captured power generation. Introducing a solid fuel into a pressurized fluidized bed combustor to generate steam, first electricity and CO containing 2 smoke. Combining air, natural gas, at least a portion of steam and at least a portion containing CO 2 The flue gas is introduced into the molten carbonate fuel cell to generate a second electricity and mainly contains CO 2 output stream. The pressurized fluidized bed combustor may desirably be air fired and the solid fuel introduced therein may desirably be in finely divided form.

Owner:GAS TECH INST

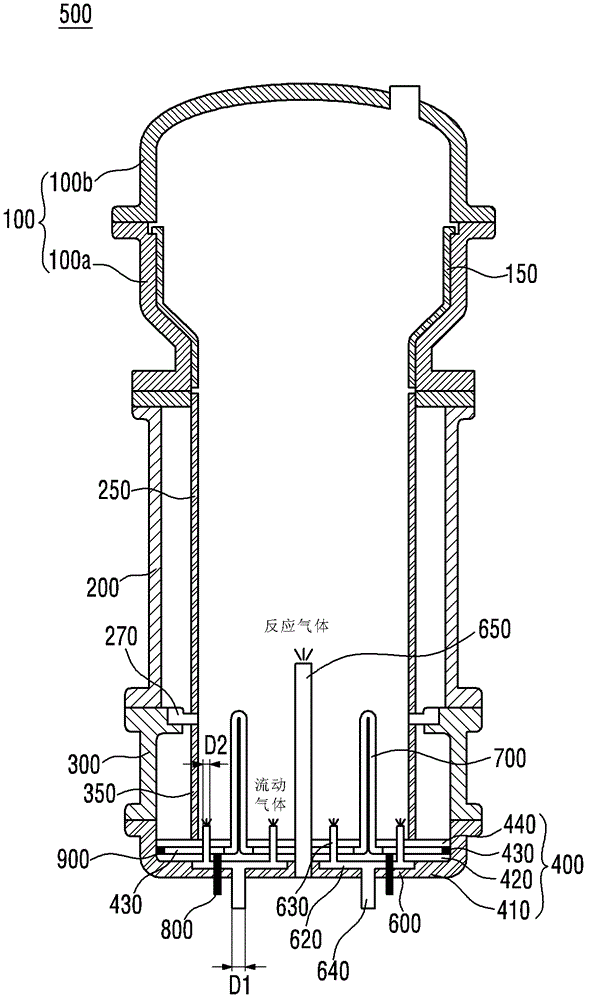

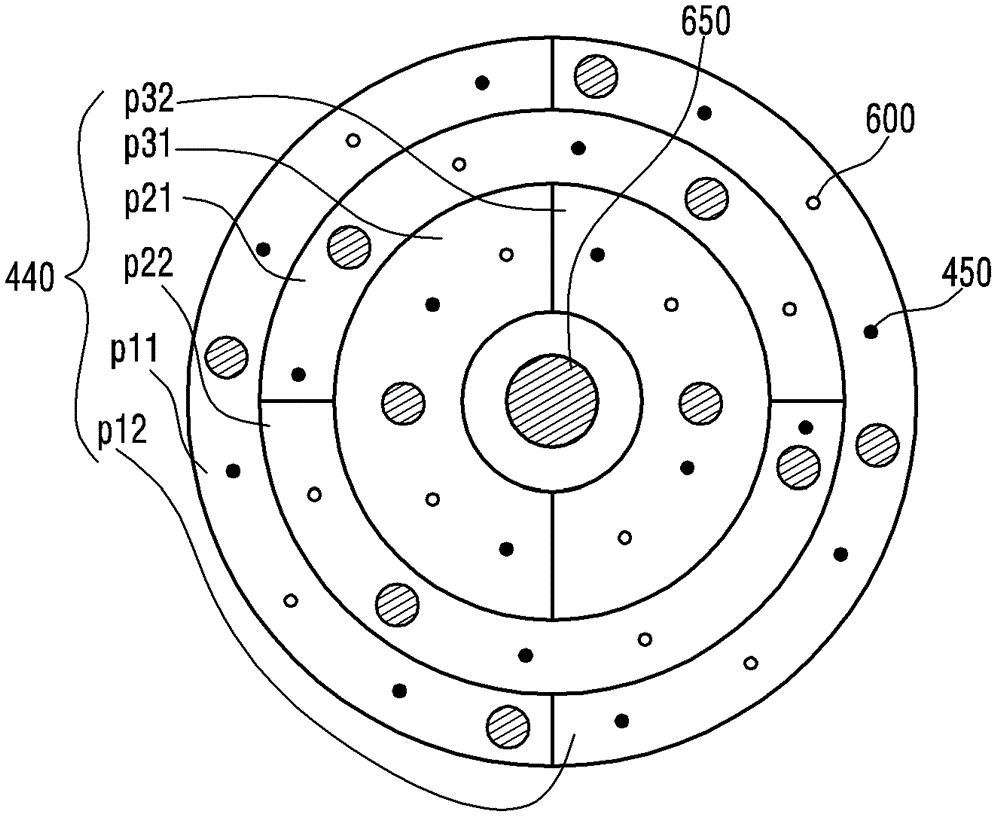

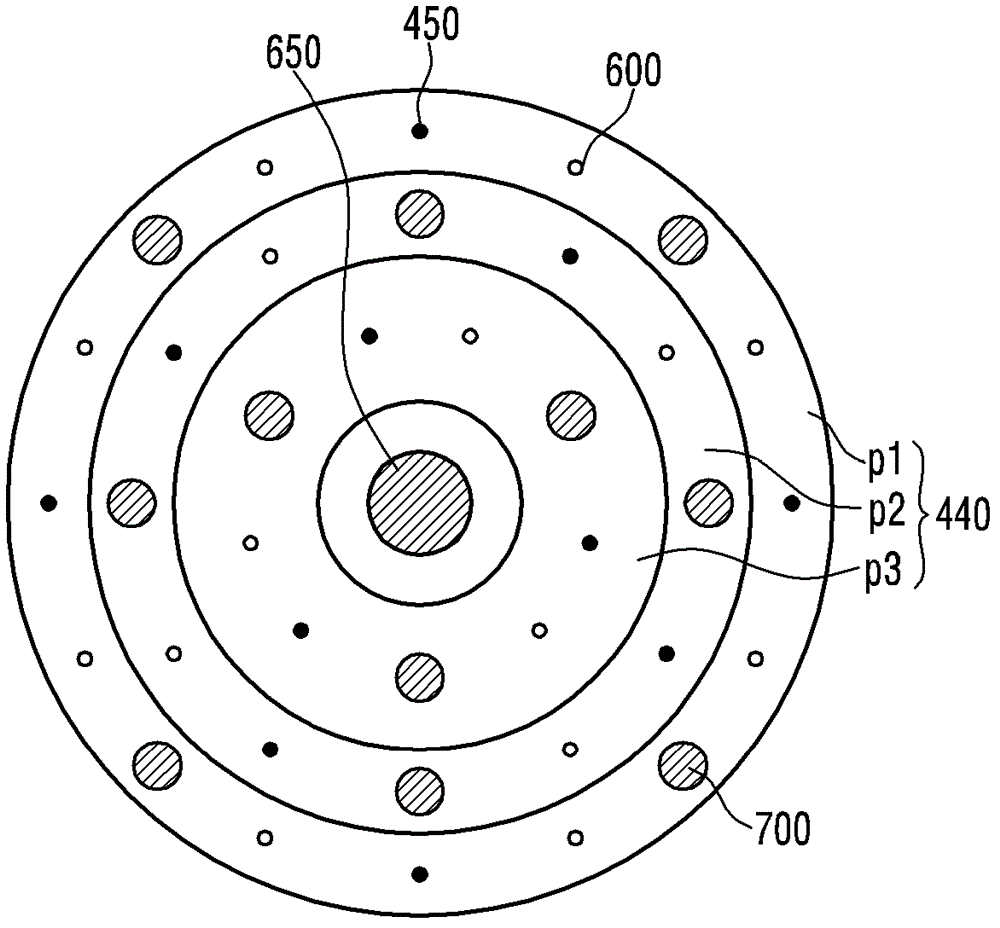

Fluidized bed reactor

InactiveCN102744021AEasy to assembleEasy to installPolycrystalline material growthSiliconFluidized bedProcess engineering

A fluidized bed reactor is disclosed. The fluidized bed reactor includes a reaction pipe,a flowing-gas supply unit configured to supply flowing gas to an internal space of the reaction pipe by controlling the supply of the flowing gas independently,and a reaction gas supply unit configured to supply reaction gas to the internal space of the reaction pipe.

Owner:SILICONVALUE

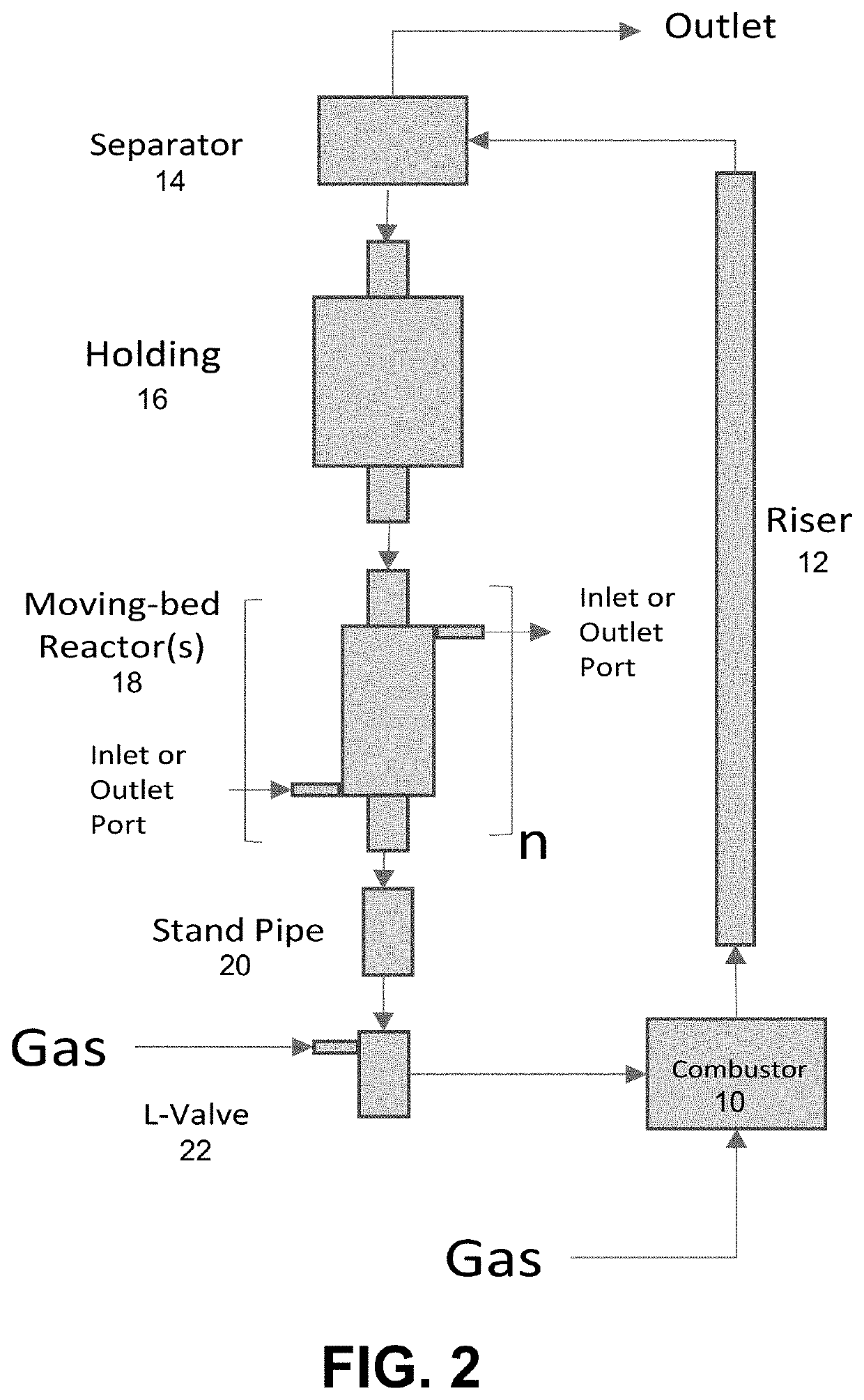

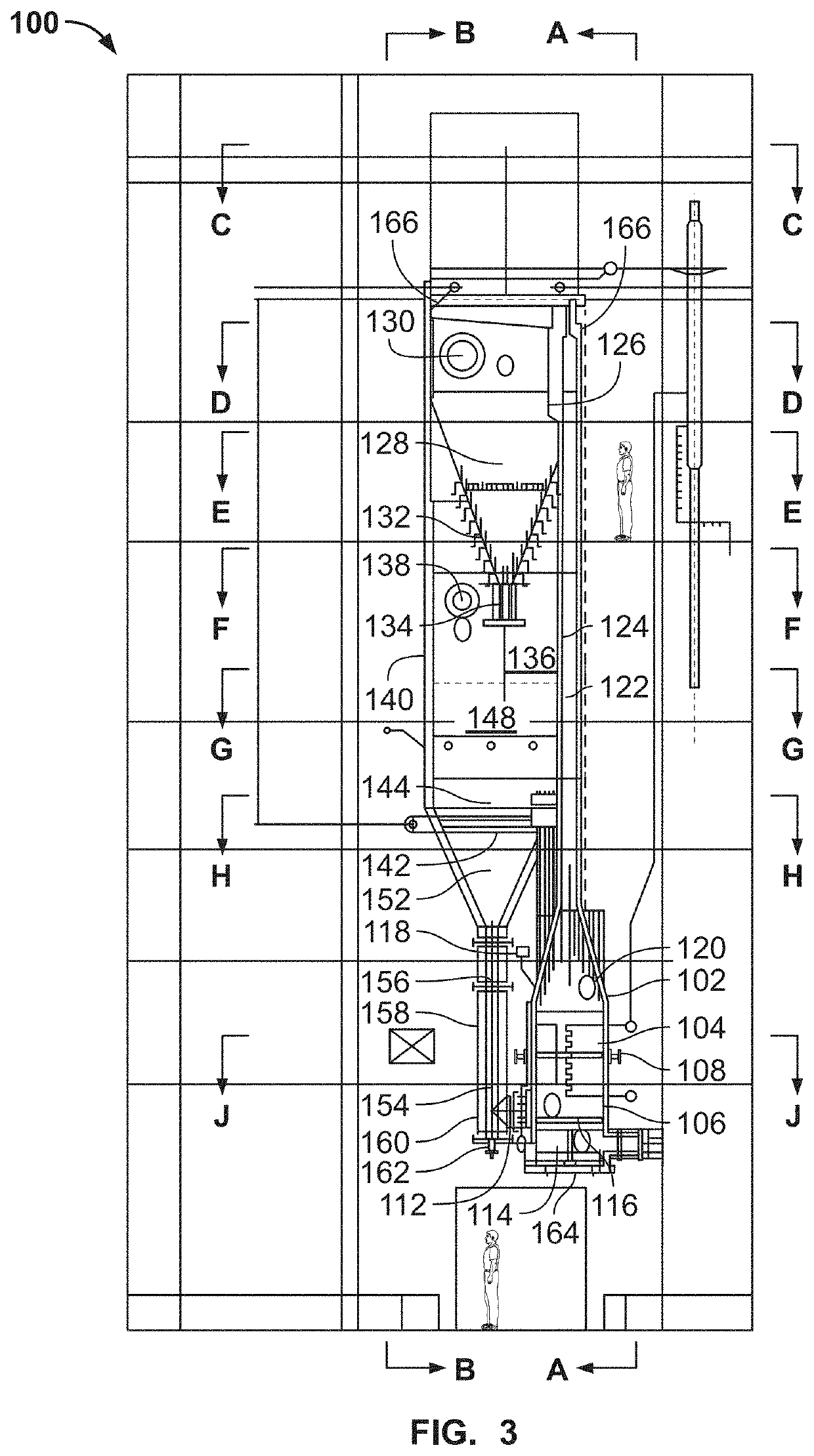

Apparatus for enclosing a chemical looping process

The present invention relates generally to an apparatus for housing a chemical looping process comprising of at least one fluidized-bed combustor reactor, at least one entrained riser, at least one particle separator, optionally at least one particle holding reactor, at least one moving-bed reactor, at least one standpipe, at least one L-valve system for solid flow control and interconnecting sections.

Owner:THE BABCOCK & WILCOX CO

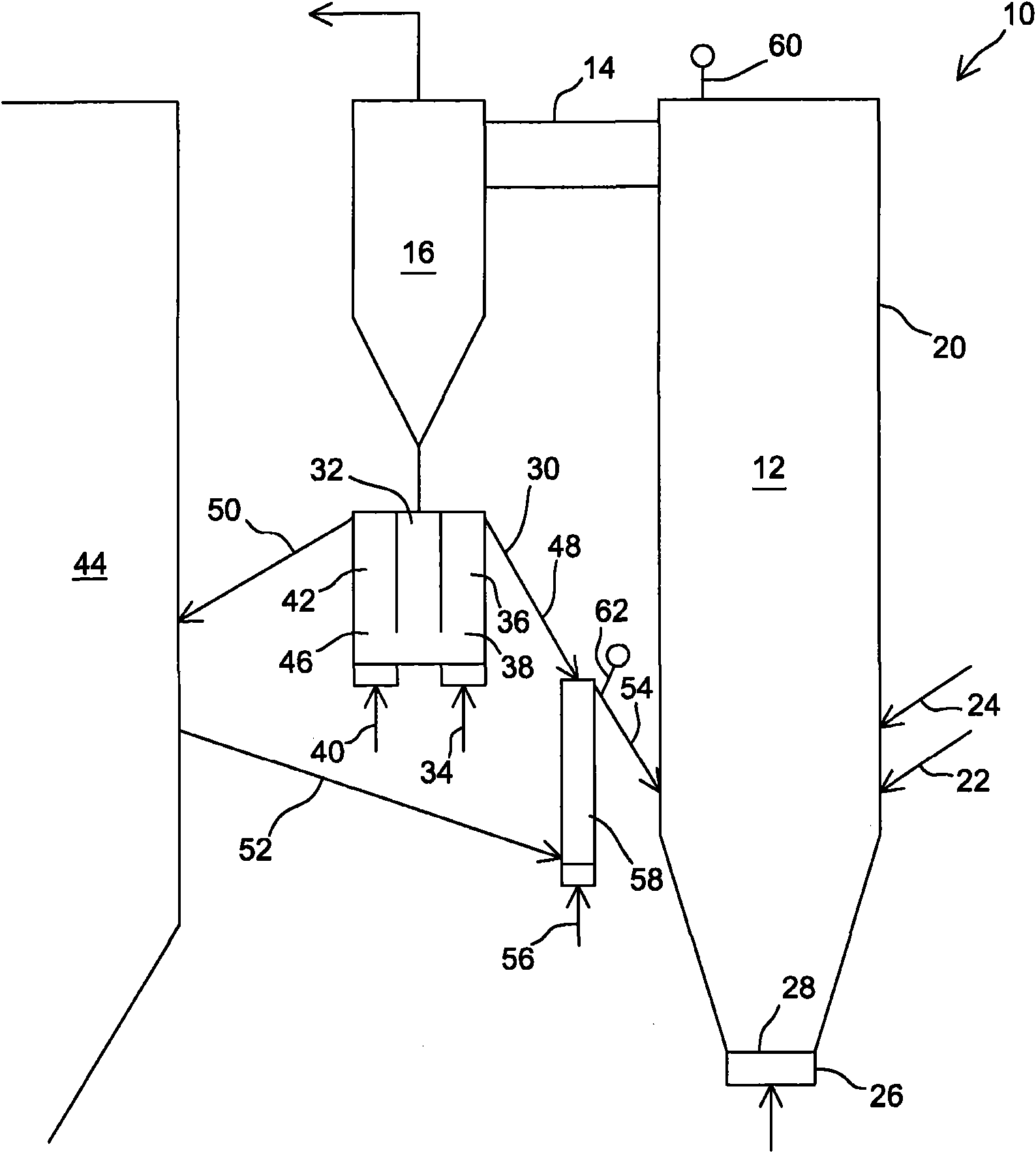

Method of and apparatus for controlling the temperature of a fluidized bed reactor

InactiveCN101646486AFluidized bed combustionDirect heating destructive distillationFluidized bedEngineering

Method of and apparatus for controlling the temperature of a fluidized bed reactor (10), comprising separator means (16) for separating first solid particles from the fluidized bed reactor; a return duct (30) for returning a first portion of the first solid particles to the fluidized bed reactor; a discharge duct (50) for the discharge of a second portion of the first solid particles and an inletduct (52) for transferring second solid particles from a second fluidized bed reactor to said fluidized bed reactor, in which the return duct (30) and the inlet duct (52) share a common end 10 portion (54) for transferring a mixture of solid particles, formed of the first portion of the first solid particles and the second solid particles, to the fluidized bed reactor (10). Said apparatus also preferably comprises a fluidized mixing device (58) for mixing the first portion of the solid particles and the second solid particles with each other.

Owner:A AHLSTROM CORP

Systems and methods for particle size determination and control in a fluidized bed reactor

Owner:CORNER STAR LTD

Biomass double fluidized bed indirect gasification system and its control method

ActiveCN105018154BHigh calorific valueAvoid backmixingGranular/pulverulent flues gasificationWater vaporNitrogen gas

The invention relates to a biomass double fluidized bed indirect gasification system and its control method. Double fluidized beds interact to realize combustion and indirect gasification so as to prepare a high-quality biomass syngas. The system provided by the invention comprises a fluidized-bed combustor and its secondary cyclone separator, a fluidized-bed gasifier and a second cyclone separator, a combustor air injection system, a combustor bed material feeding system, a gasifier vapor injection system, a gasifier biomass feeding system, a gasifier and combustor bed material circulatory system, a bed material recovery system, a combustor and a gasifier pressure control system. By the internal and external circulating double fluidized bed indirect gasifier, nitrogen in the air is naturally separated from the syngas. Through improvement of structure design of a reactor, mixed use of different bed materials, a bed material circular flow system and improvement of the gas-solid mixing level, gasification efficiency is raised, calorific value of the syngas is increased, tar content is reduced, and high-quality syngas is prepared.

Owner:代建军

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com