Decarburization method of coal gangue and circulating fluidized bed mineral separating boiler

A circulating fluidized bed and coal gangue technology, applied in fluidized bed combustion equipment, combustion methods, steam boilers, etc., can solve the problems of high carbon content in ash and slag, achieve good activity, high calcination efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

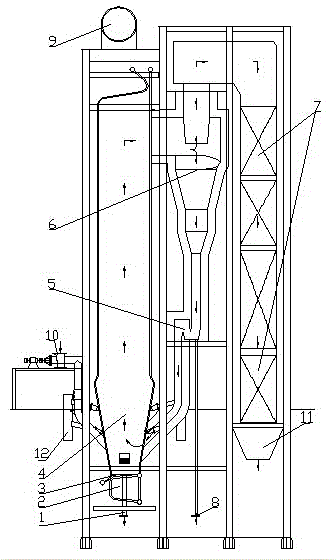

[0026] like figure 1 Shown: a circulating fluidized bed beneficiation boiler, including a furnace 4, a drum 9 is installed above the furnace 4; the bottom side of the furnace 4 is externally connected with a feeder 10 and an air inlet device 12 blowing toward the furnace; The feeder 10 leads to the fluidized bed combustion chamber 3 at the lower part of the furnace 4 through the pipeline; the water-cooled air chamber 2 and the slag discharge port 1 are arranged below the fluidized bed combustion chamber 3; the flue gas at the outlet of the furnace 4 rises and enters the cyclone separator 6. The flue gas at the outlet of the cyclone separator 6 rises and turns through the horizontal flue to the tail shaft flue; the shaft flue is provided with a tail heating surface 7 and a tail flue 11 in sequence; the cyclone separator 6 is arranged below the horizontal flue ; The lower outlet of the cyclone separator 6 is connected to the return channel 5; the beginning of the return channel ...

Embodiment 2

[0033] A coal gangue decarbonization method, comprising the following steps:

[0034] (1) Put the crushed and dried coal gangue in the fluidized bed combustion chamber 3 of the fluidized bed boiler for combustion. The high-temperature flue gas transfers heat to the furnace wall, and the heat transferred to the furnace wall increases the temperature of the furnace 4 to 850~950°C, so that the coal gangue can be fully burned and decarbonized; the oxygen source required for the coal gangue to fully burn is provided by the tail The air preheater in the heating surface 7 heats the wind in the natural state sent by the air inlet device 12 into hot air, and the hot air is divided into two parts and enters the air inlet device 12 and the water-cooled air chamber 2 to provide sufficient fuel for the coal gangue to fully burn. enough oxygen;

[0035](2) The high-temperature flue gas produced after coal gangue combustion is separated by the cyclone separator 6, and the vanadium in the co...

Embodiment 3

[0040] The difference between this embodiment and Embodiment 1 is that the feeder 10 is a belt feeder; the cyclone separator 6 is a water-cooled cyclone separator with material legs.

[0041] The water outlet pipeline of the drum 9 is connected to the water-cooled water inlet of the water-cooled cyclone separator with the material leg;

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com