Patents

Literature

457results about How to "Low ignition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flameless combustor

InactiveUS6019172AEasy to igniteImprove the level ofApparel holdersInsulationCombustorCombustion chamber

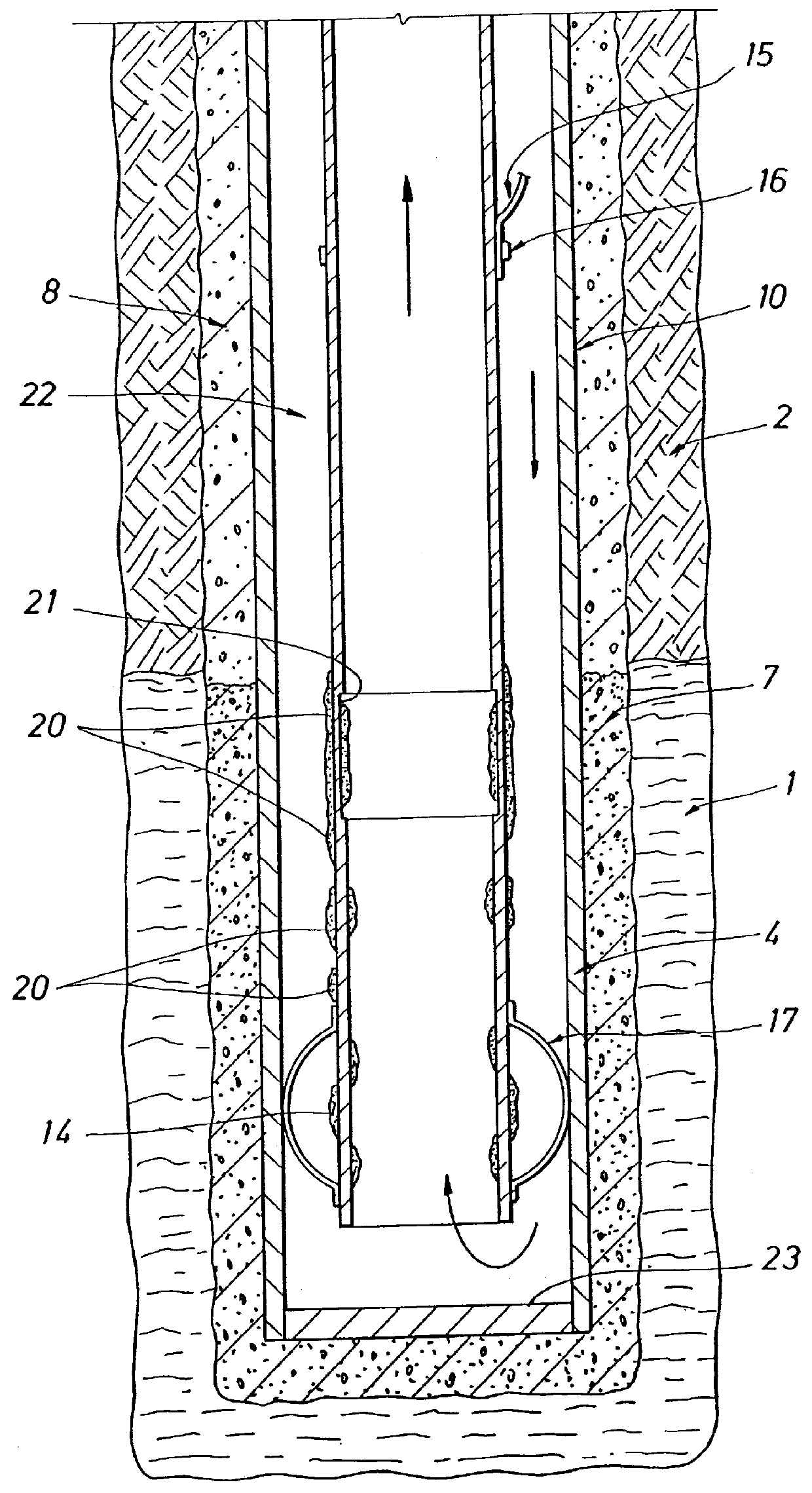

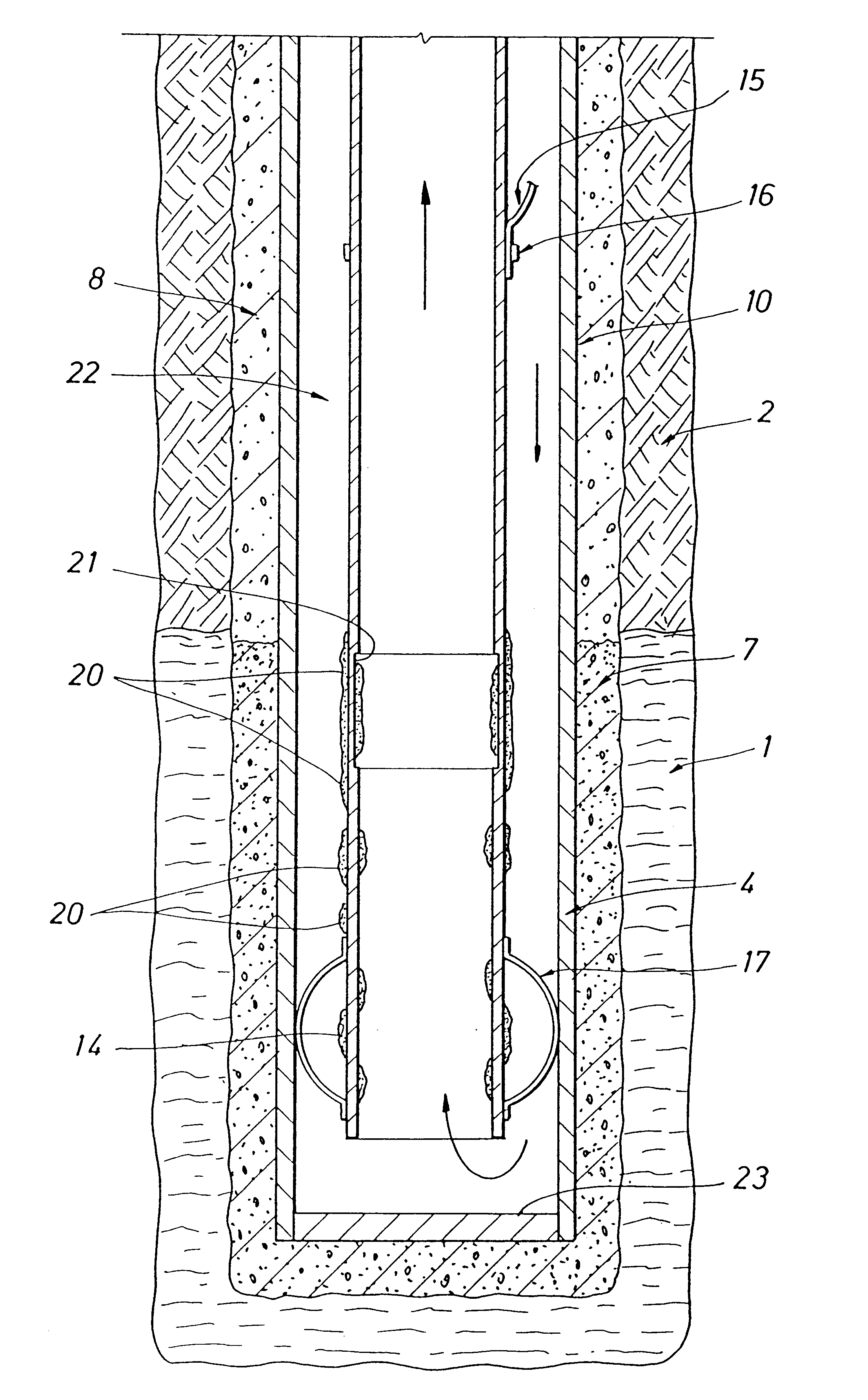

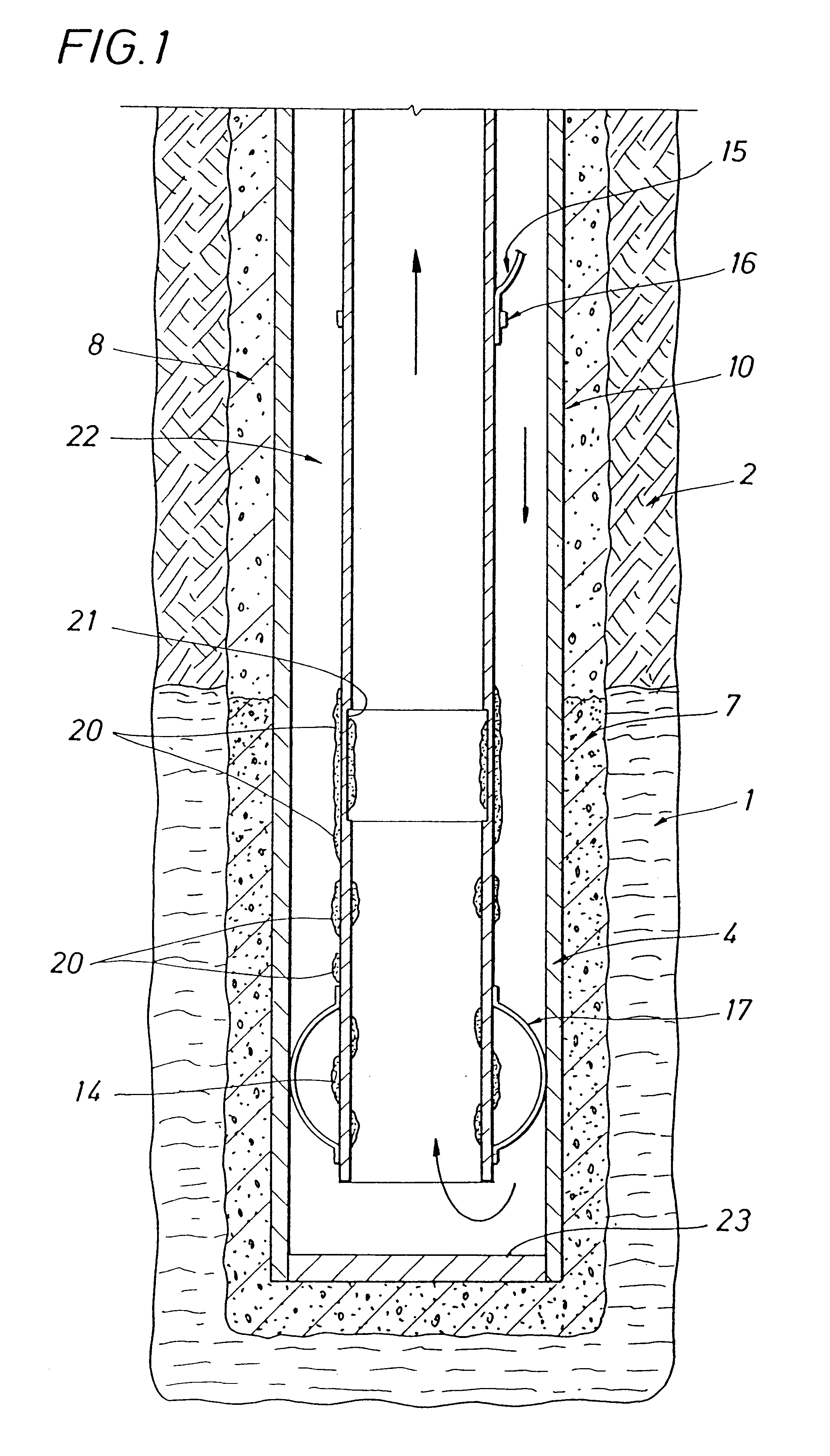

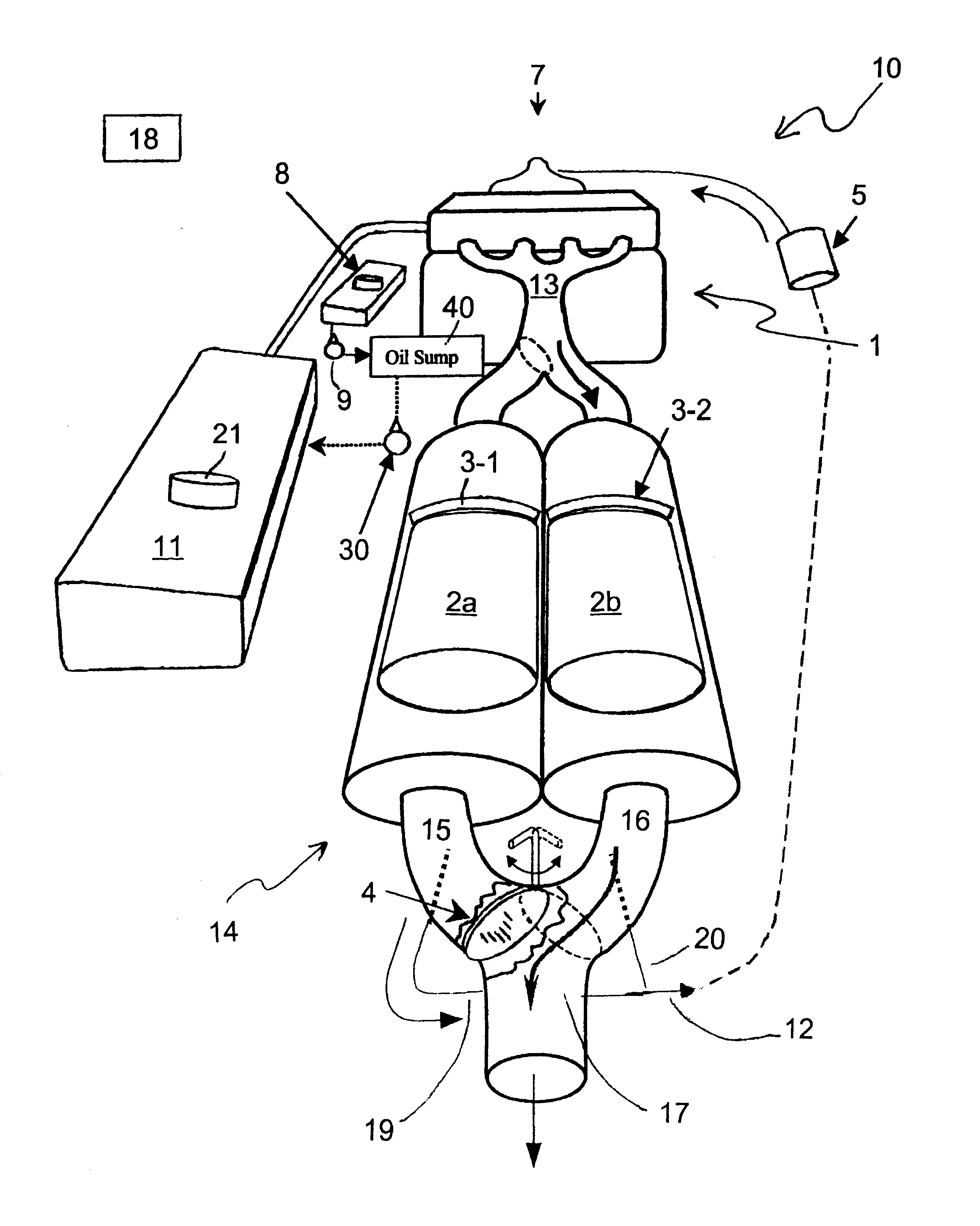

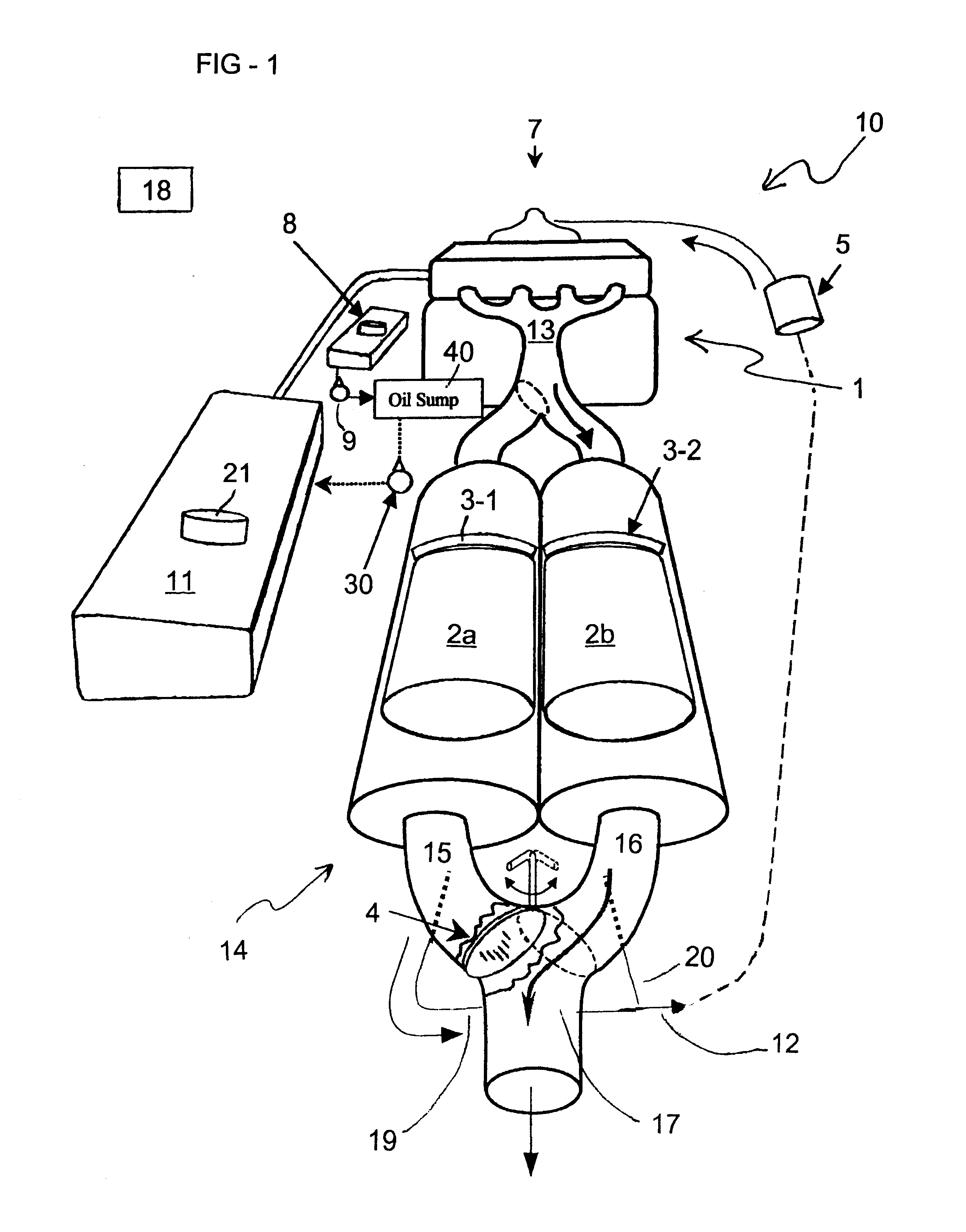

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

Method for ignition of flameless combustor

InactiveUS6269882B1Easy to igniteImprove the level ofApparel holdersIncandescent ignitionCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

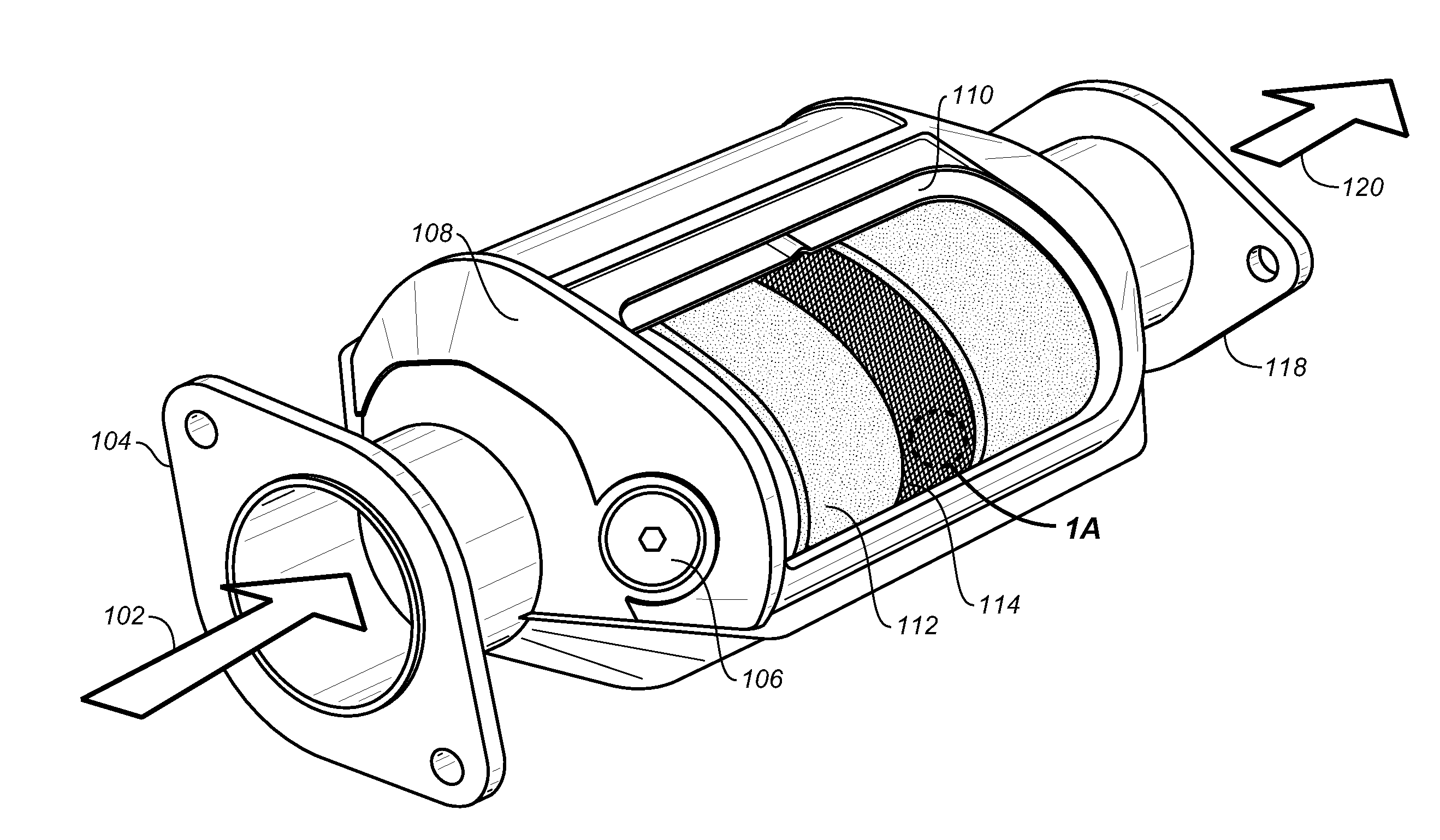

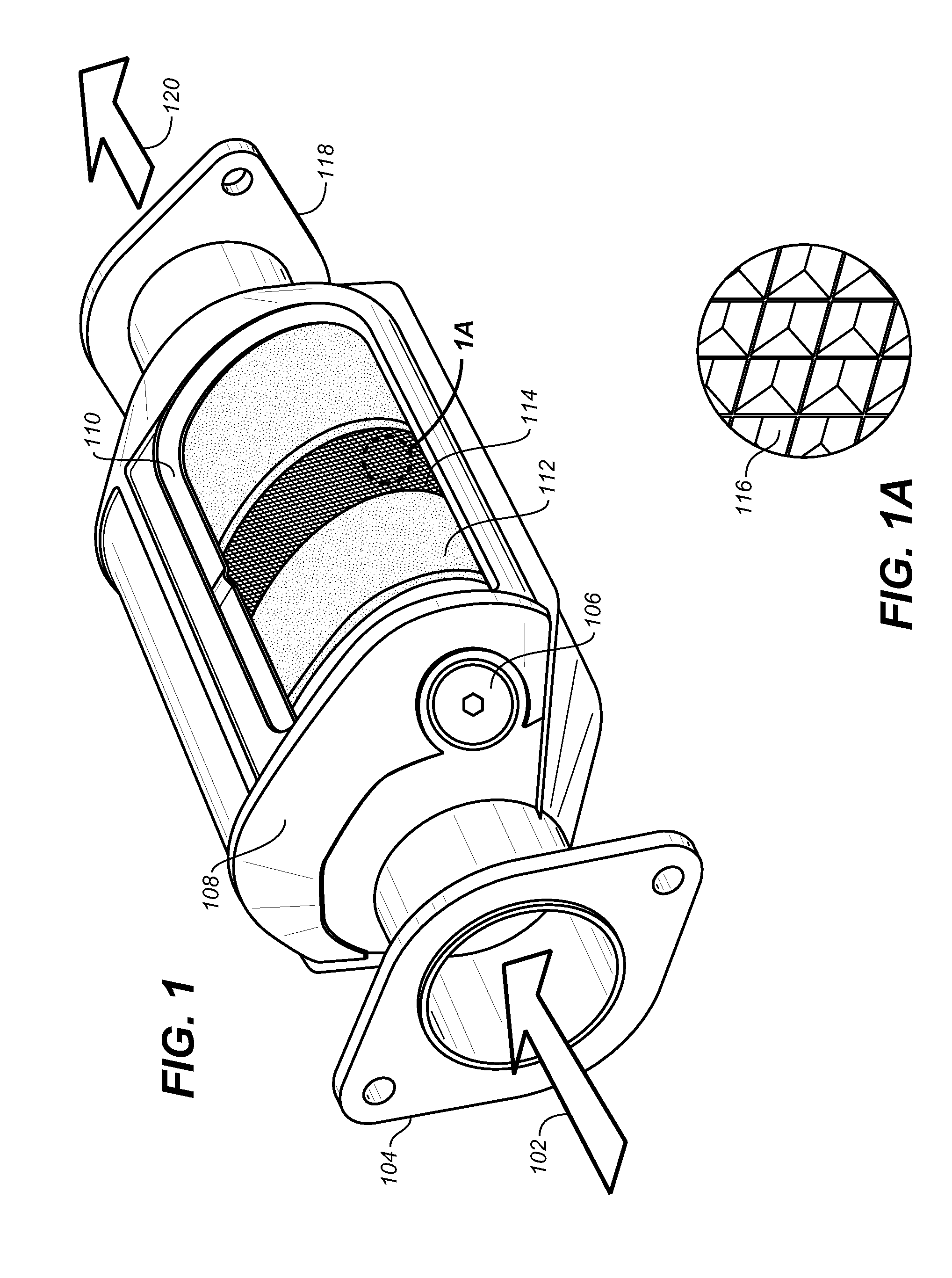

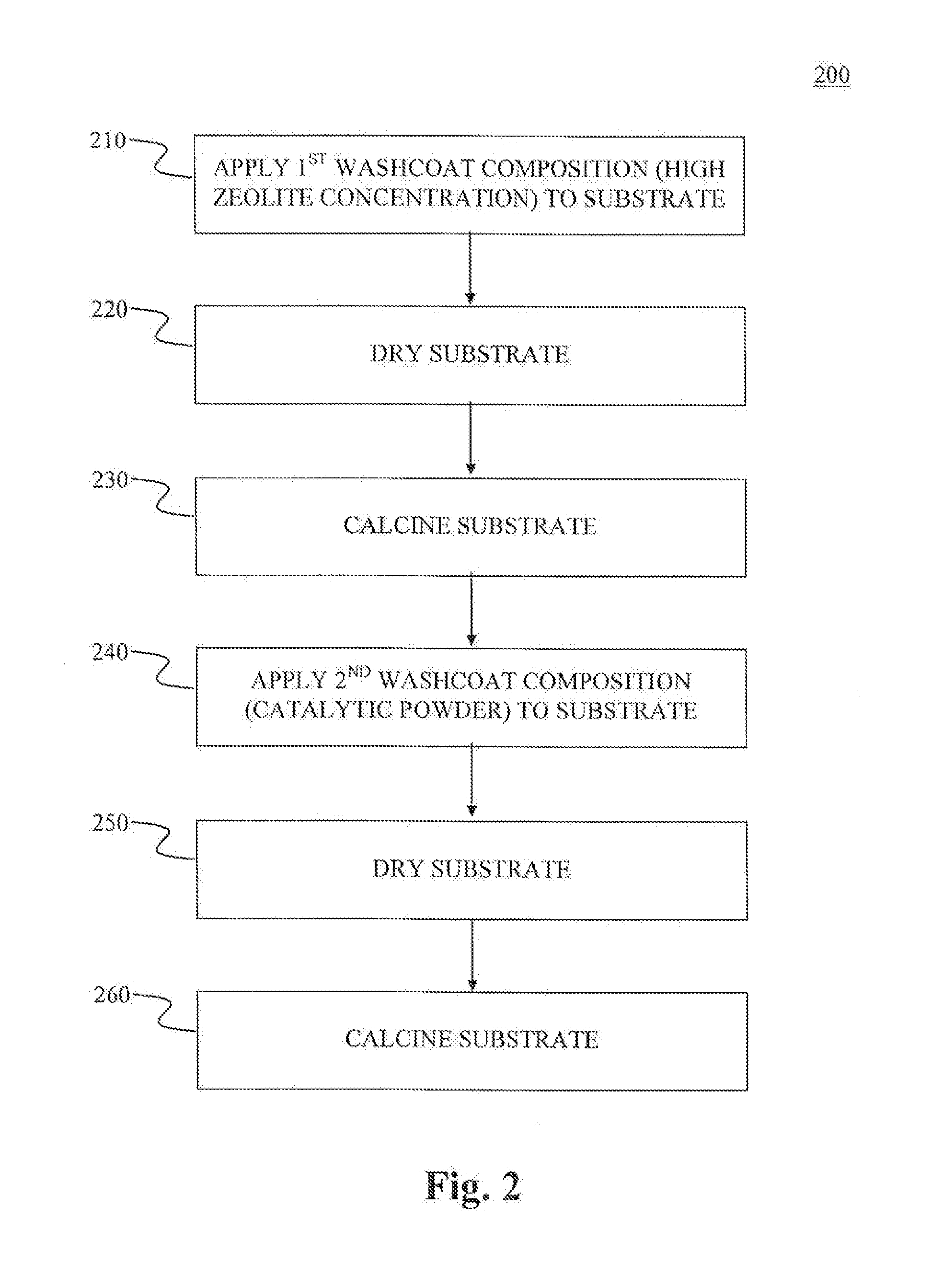

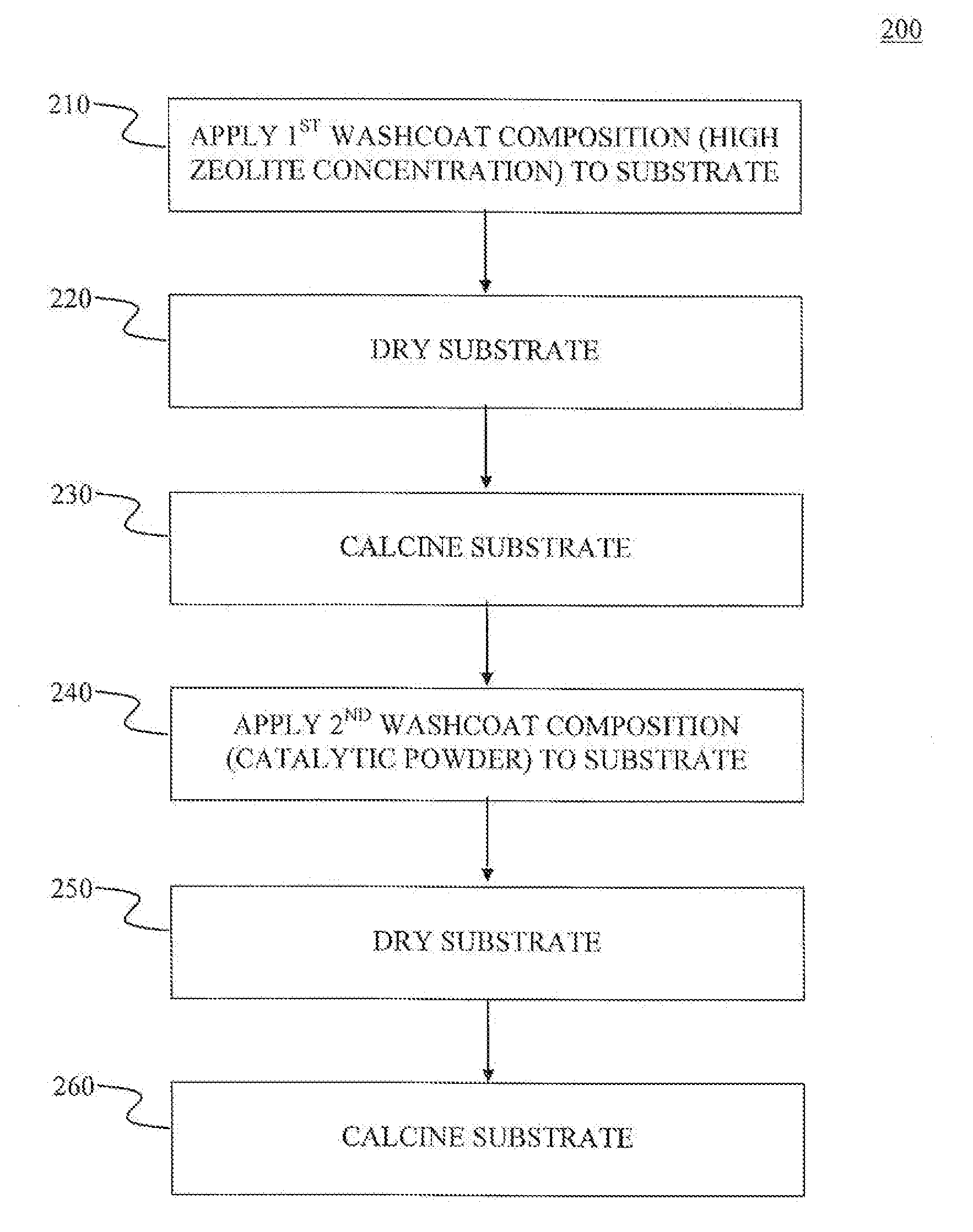

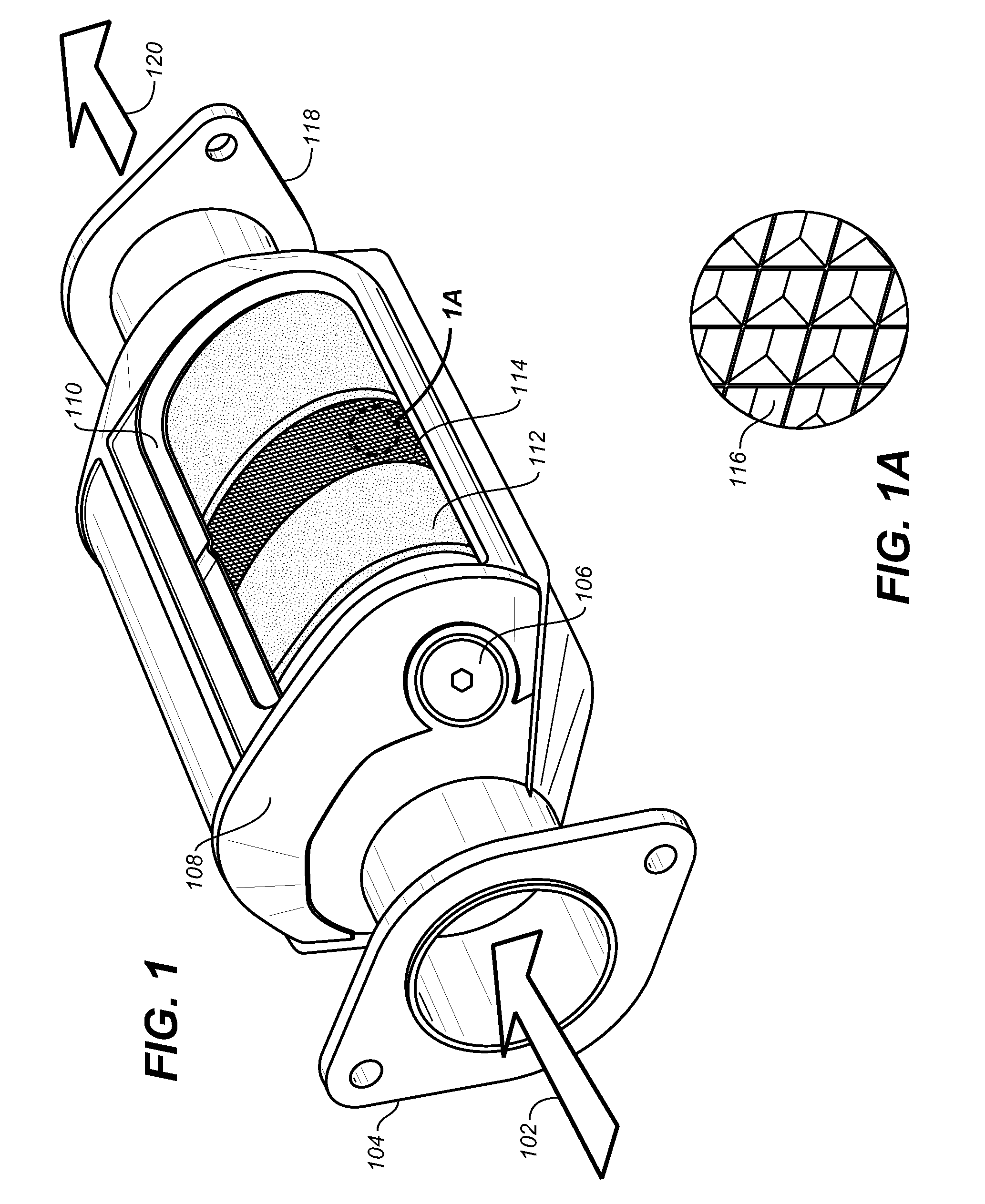

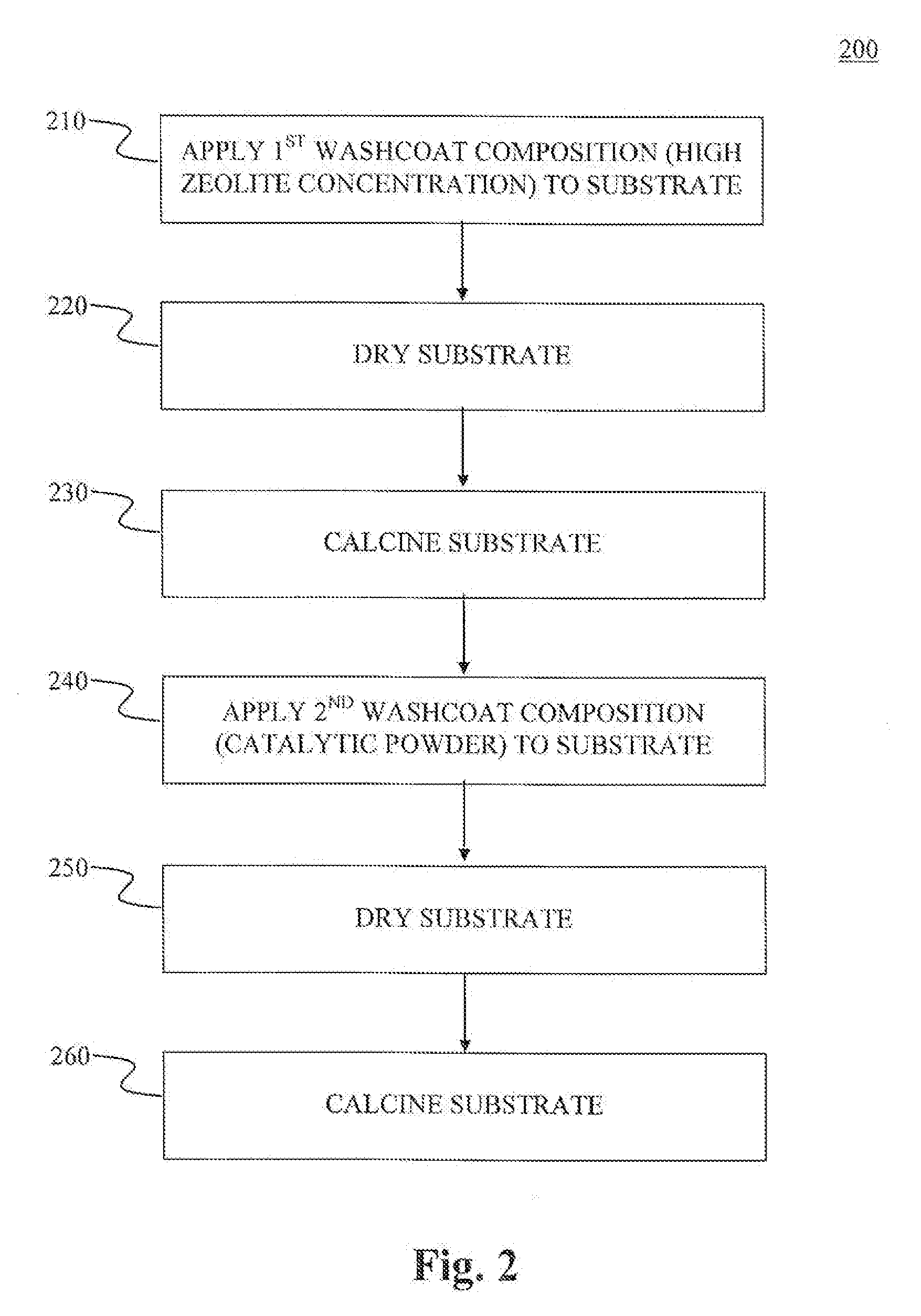

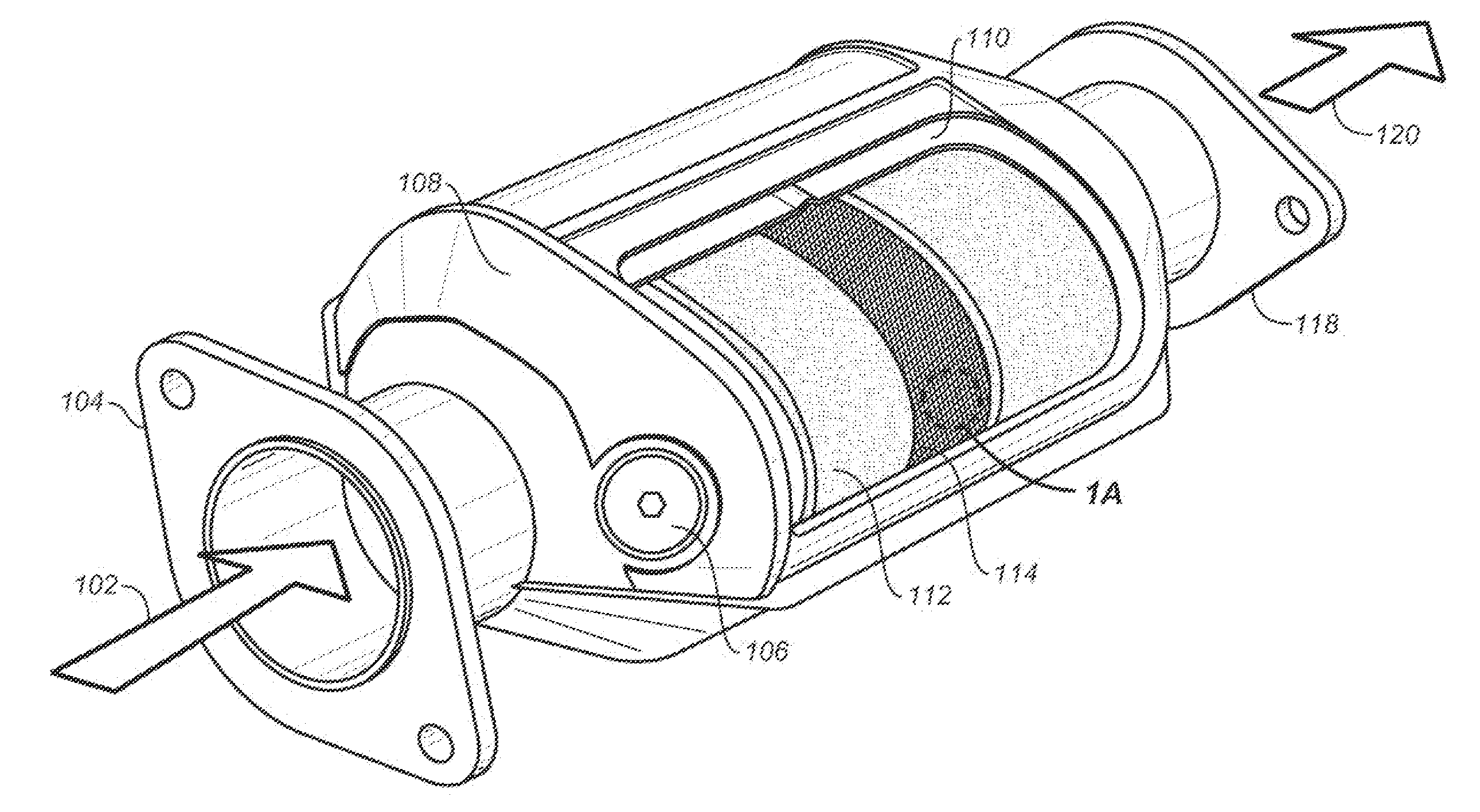

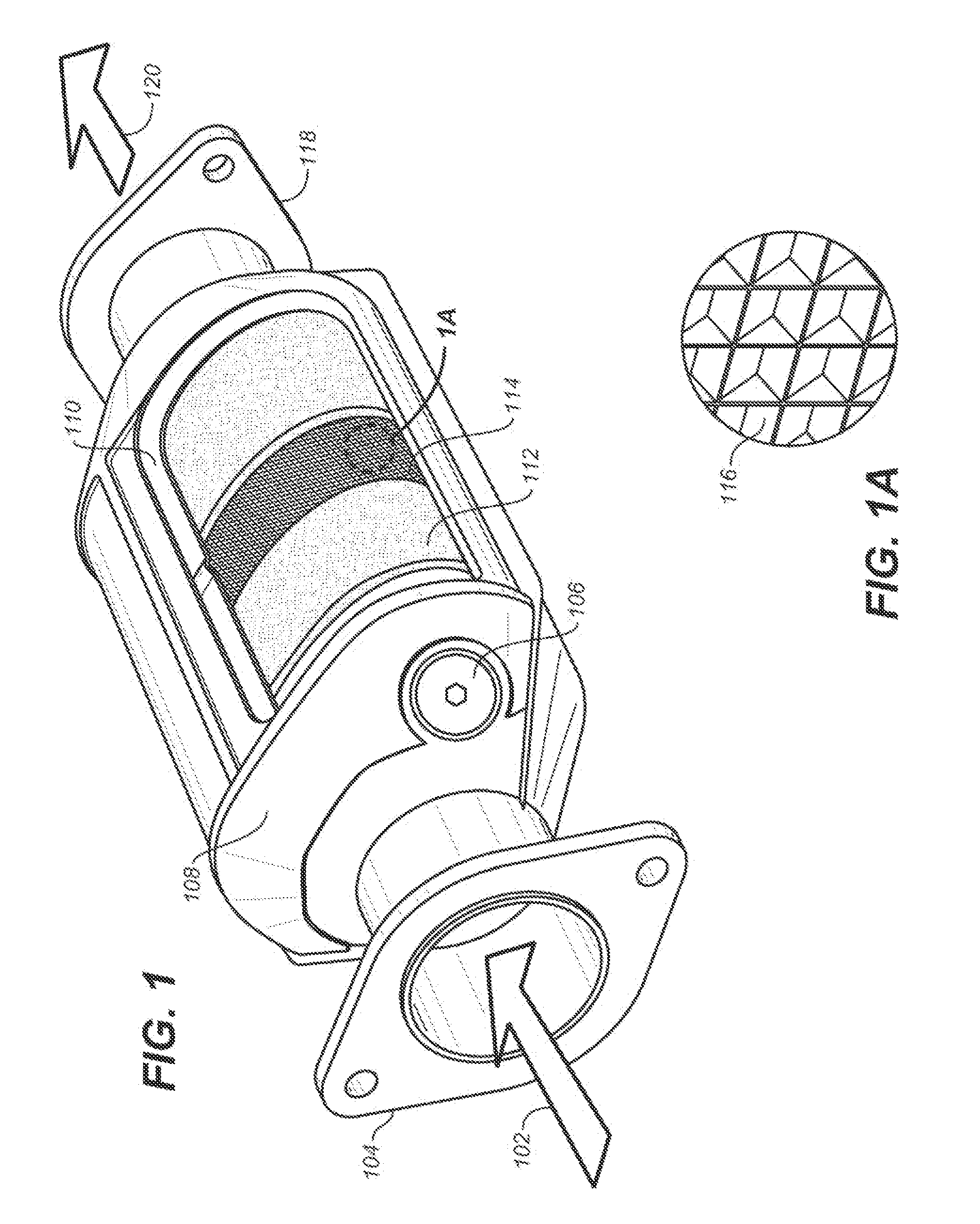

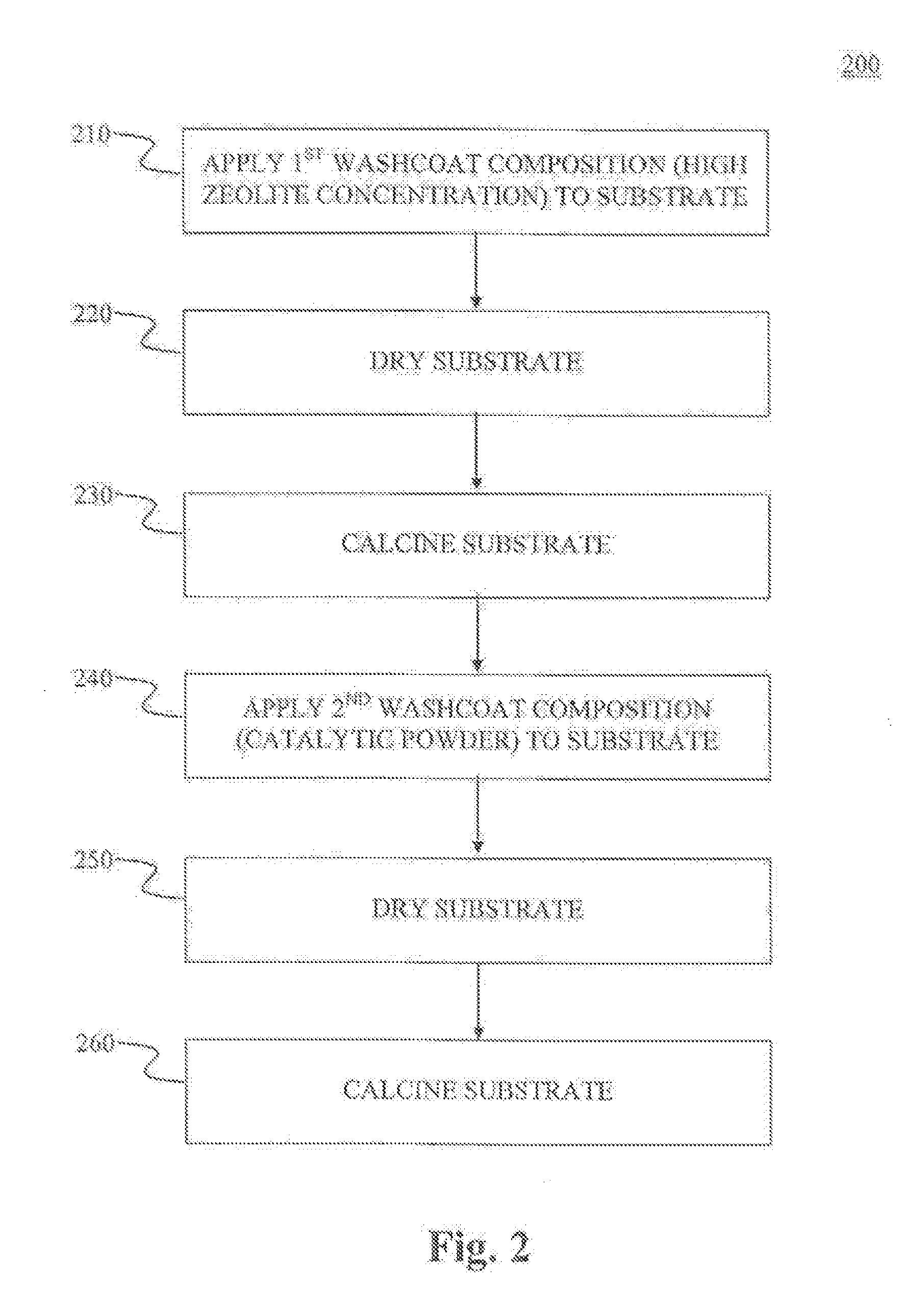

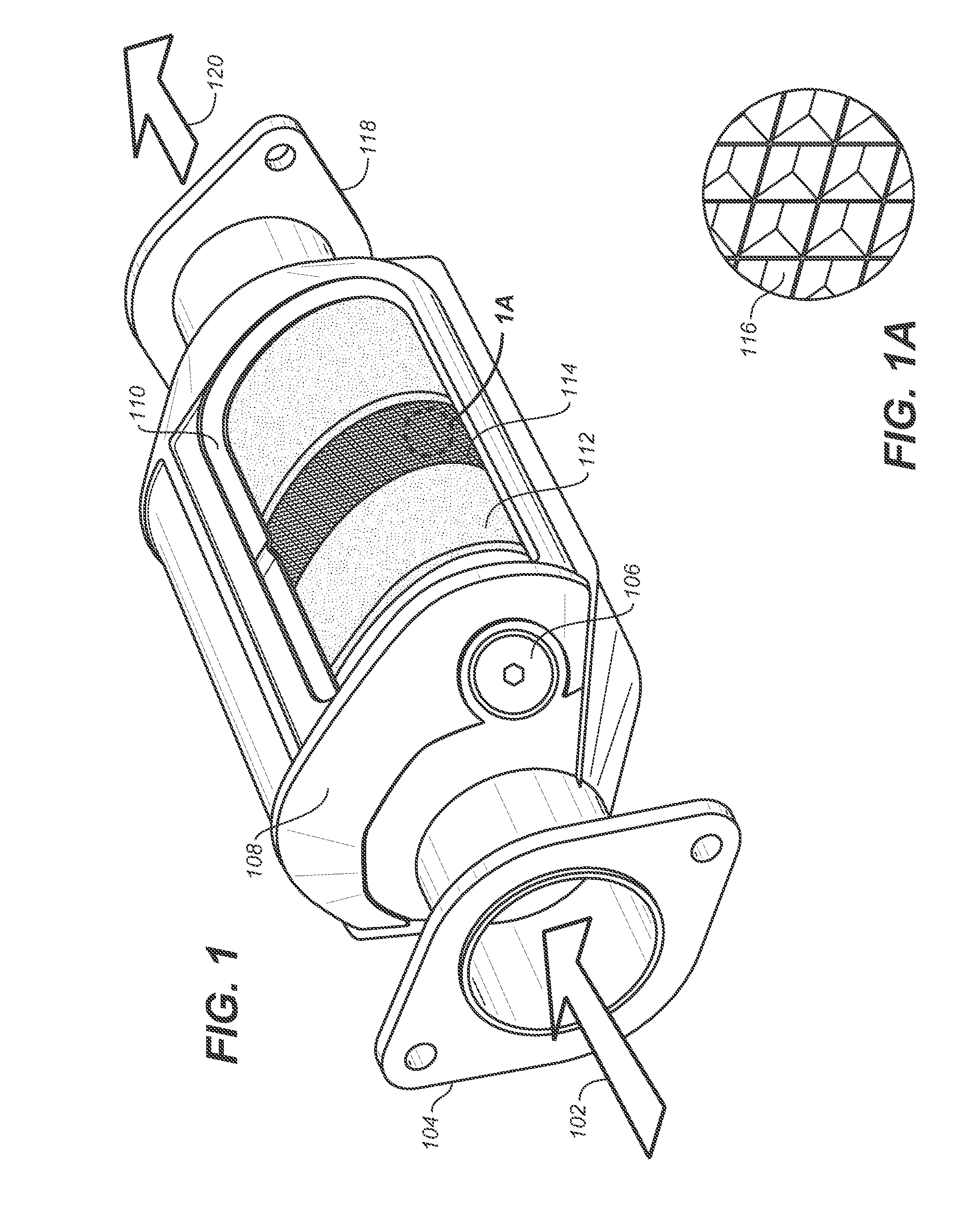

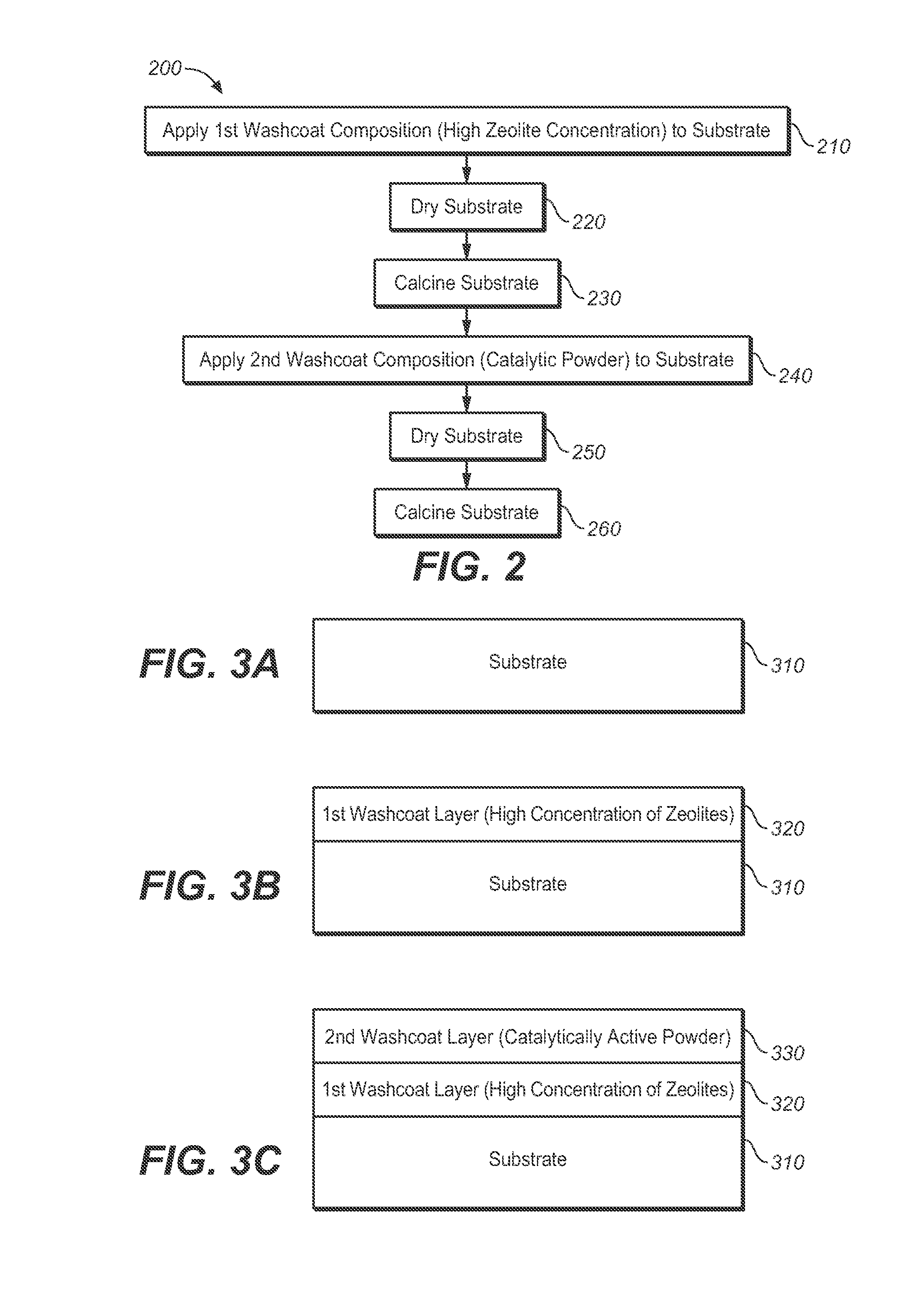

Coated substrates for use in catalysis and catalytic converters and methods of coating substrates with washcoat compositions

ActiveUS20130213018A1Improve performanceReduce emissionCombination devicesNitrogen compoundsChemistryCatalytic transformation

Disclosed are, inter alia, methods of forming coated substrates for use in catalytic converters, as well as washcoat compositions and methods suitable for using in preparation of the coated substrates, and the coated substrates formed thereby. The catalytic material is prepared by a plasma-based method, yielding catalytic material with a lower tendency to migrate on support at high temperatures, and thus less prone to catalyst aging after prolonged use. Also disclosed are catalytic converters using the coated substrates, which have favorable properties as compared to catalytic converters using catalysts deposited on substrates using solution chemistry. Also disclosed are exhaust treatment systems, and vehicles, such as diesel vehicles, particularly light-duty diesel vehicles, using catalytic converters and exhaust treatment systems using the coated substrates.

Owner:SDC MATERIALS +1

Coated substrates for use in catalysis and catalytic converters and methods of coating substrates with washcoat compositions

ActiveUS8679433B2Improve performanceEmission reductionCombination devicesNitrogen compoundsTreatment systemDiesel fuel

Owner:SDC MATERIALS +1

Catalyst for purifying the exhaust gases of diesel engines, and process for the preparation thereof

InactiveUS20010043896A1Increase lytic activityLow ignition temperatureNitrogen compoundsInternal combustion piston enginesIridiumAluminum silicate

A catalyst for purifying the exhaust gases of diesel engines, which catalyst contains at least one zeolite and, additionally, at least one of the support oxides aluminum oxide, silicon dioxide, titanium dioxide and aluminum silicate and at least one of the noble metals platinum, palladium, rhodium and iridium. In this catalyst the atoms of the noble metals have a mean oxidation number of less than +2.5, on average more than 3 metal ligands and less than 3 oxygen ligands and are present on the zeolites and support oxides in the form of crystallites having a mean particle size of from 1 to 6 nm.

Owner:DMC2 DEGUSSA METALS CATALYSTS CERDEC +1

Nano-thermite Well Plug

Owner:CONOCOPHILLIPS CO

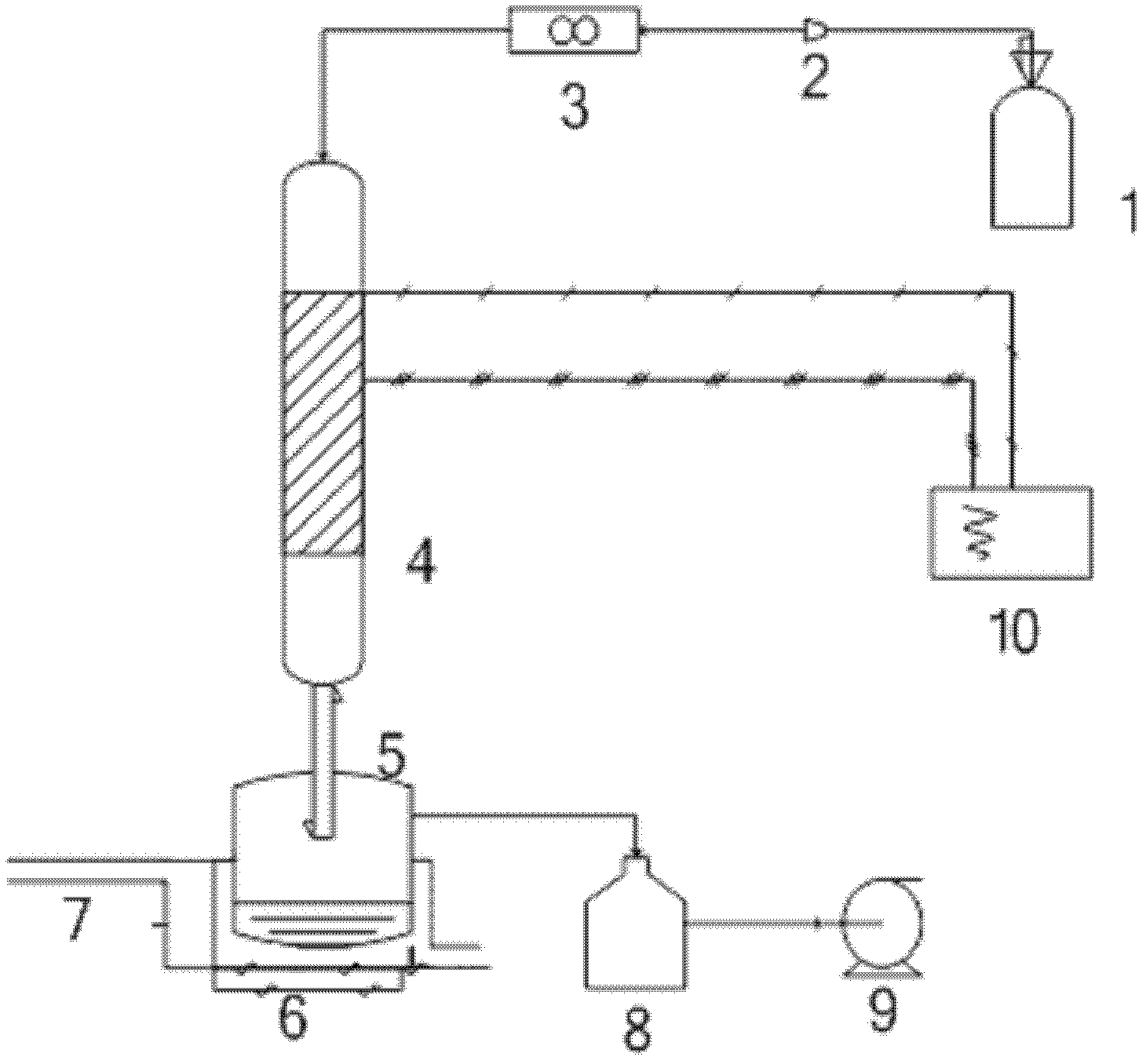

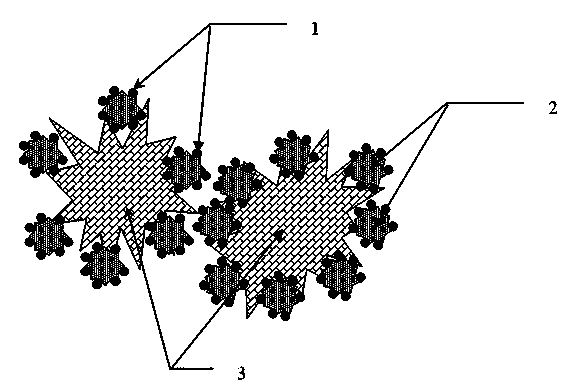

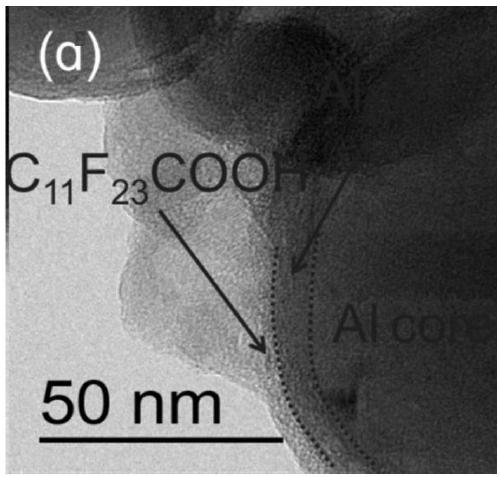

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274ALow ignition temperatureShorter ignition delay timeChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Catalyst for purifying the exhaust gases of diesel engines, and process for the preparation thereof

InactiveUS6685900B2Increase lytic activityLow ignition temperatureNitrogen compoundsInternal combustion piston enginesIridiumAluminum silicate

A catalyst for purifying the exhaust gases of diesel engines, which catalyst contains at least one zeolite and, additionally, at least one of the support oxides aluminum oxide, silicon dioxide, titanium dioxide and aluminum silicate and at least one of the noble metals platinum, palladium, rhodium and iridium. In this catalyst the atoms of the noble metals have a mean oxidation number of less than +2.5, on average more than 3 metal ligands and less than 3 oxygen ligands and are present on the zeolites and support oxides in the form of crystallites having a mean particle size of from 1 to 6 nm.

Owner:DMC2 DEGUSSA METALS CATALYSTS CERDEC +1

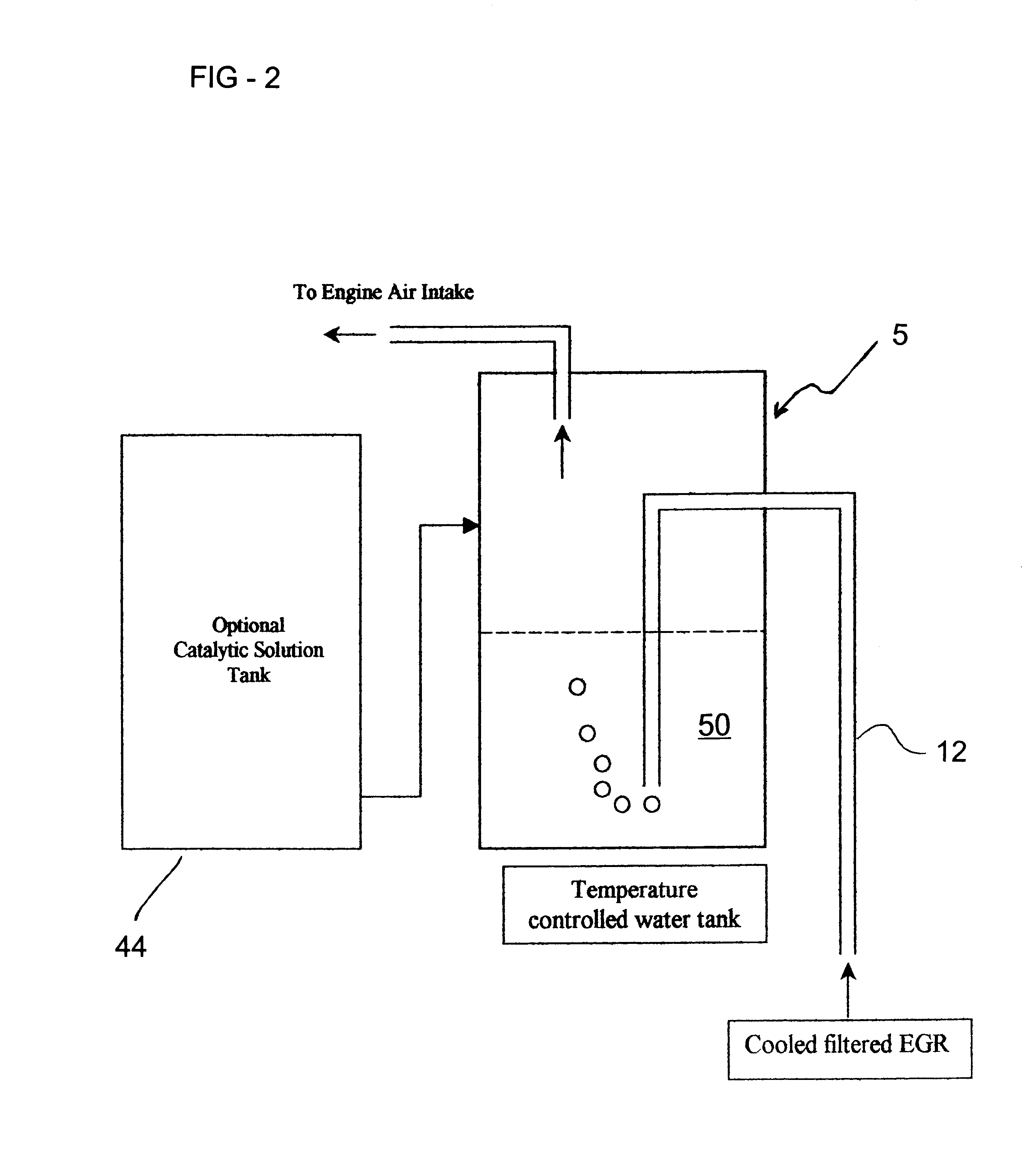

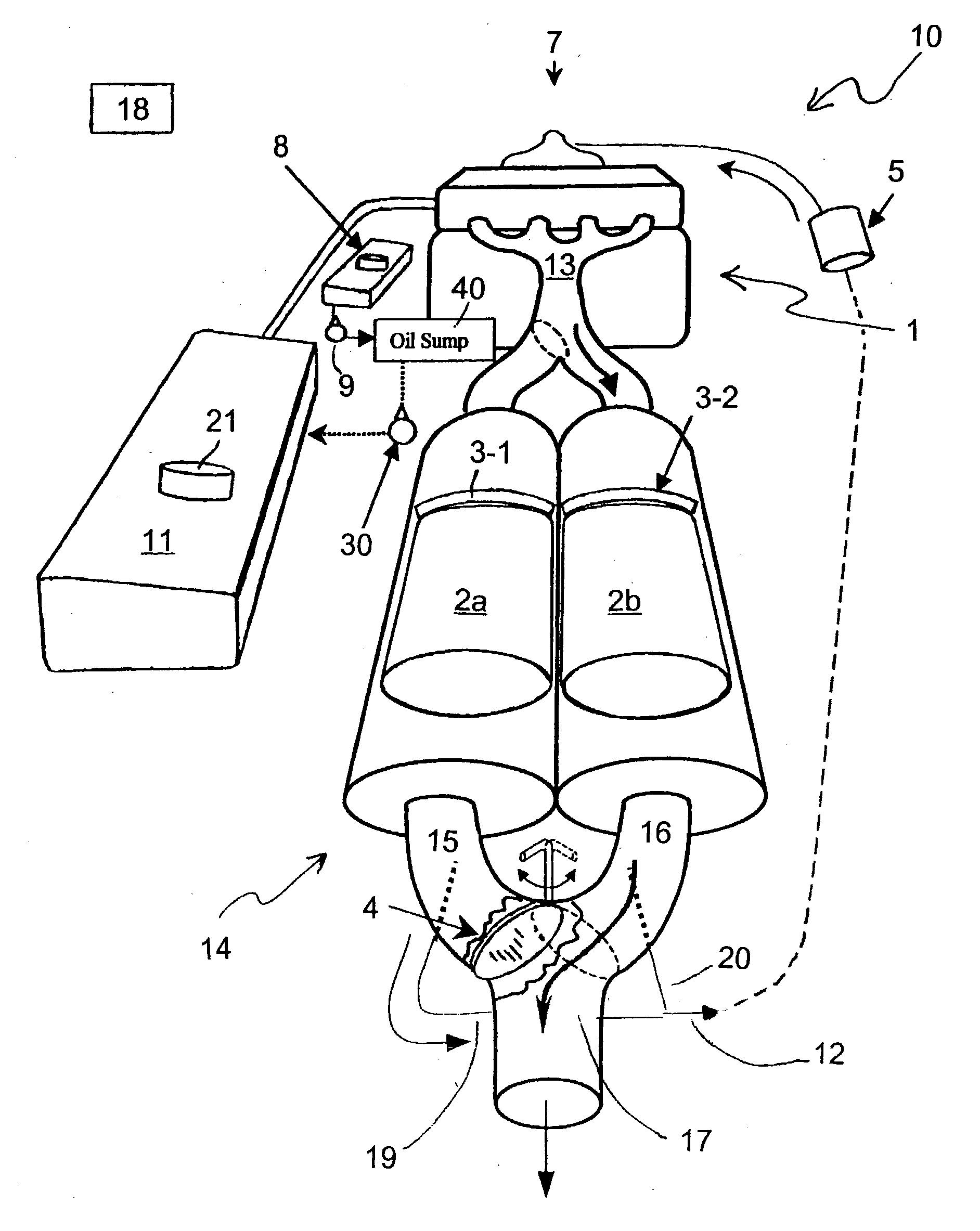

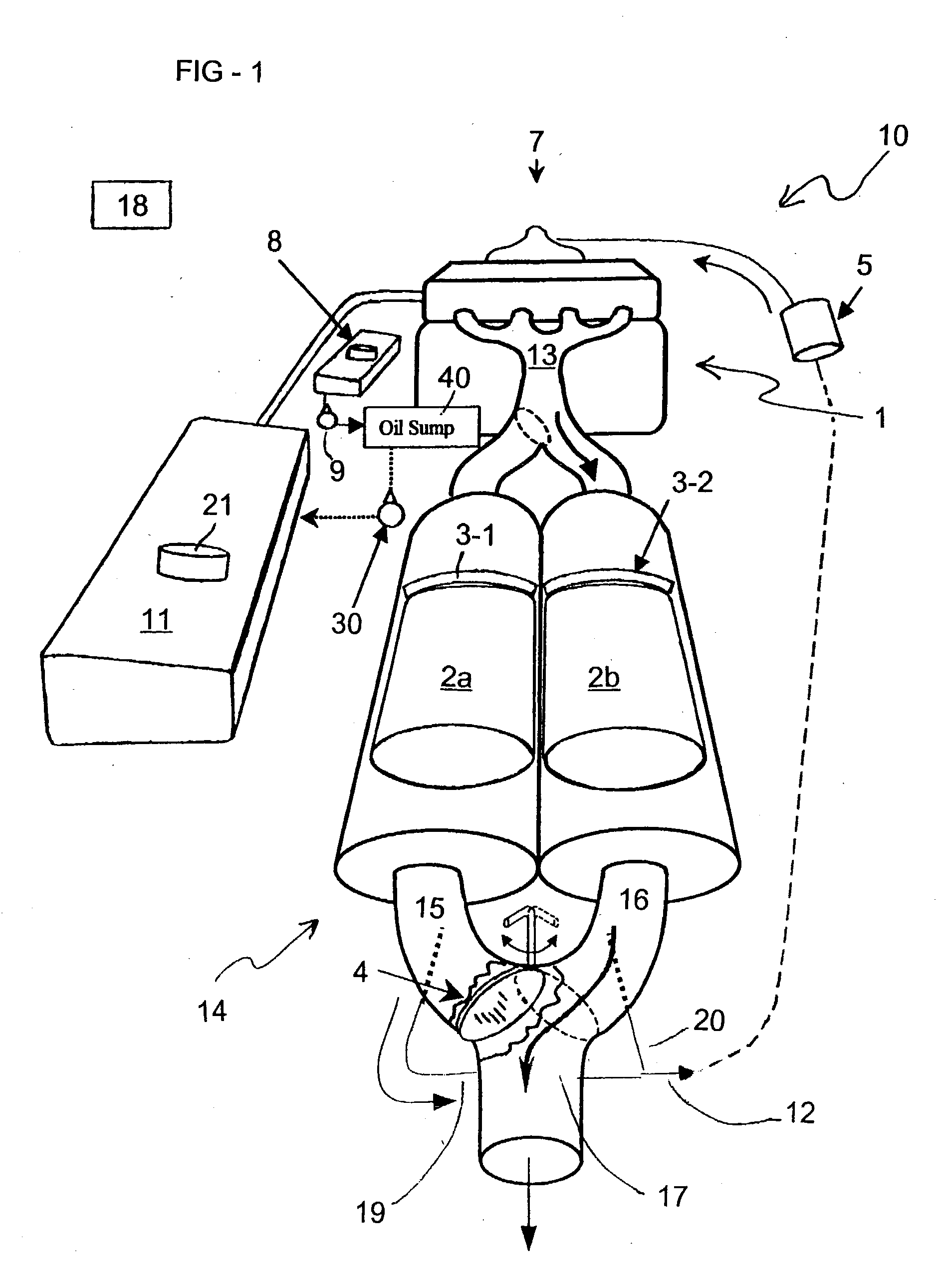

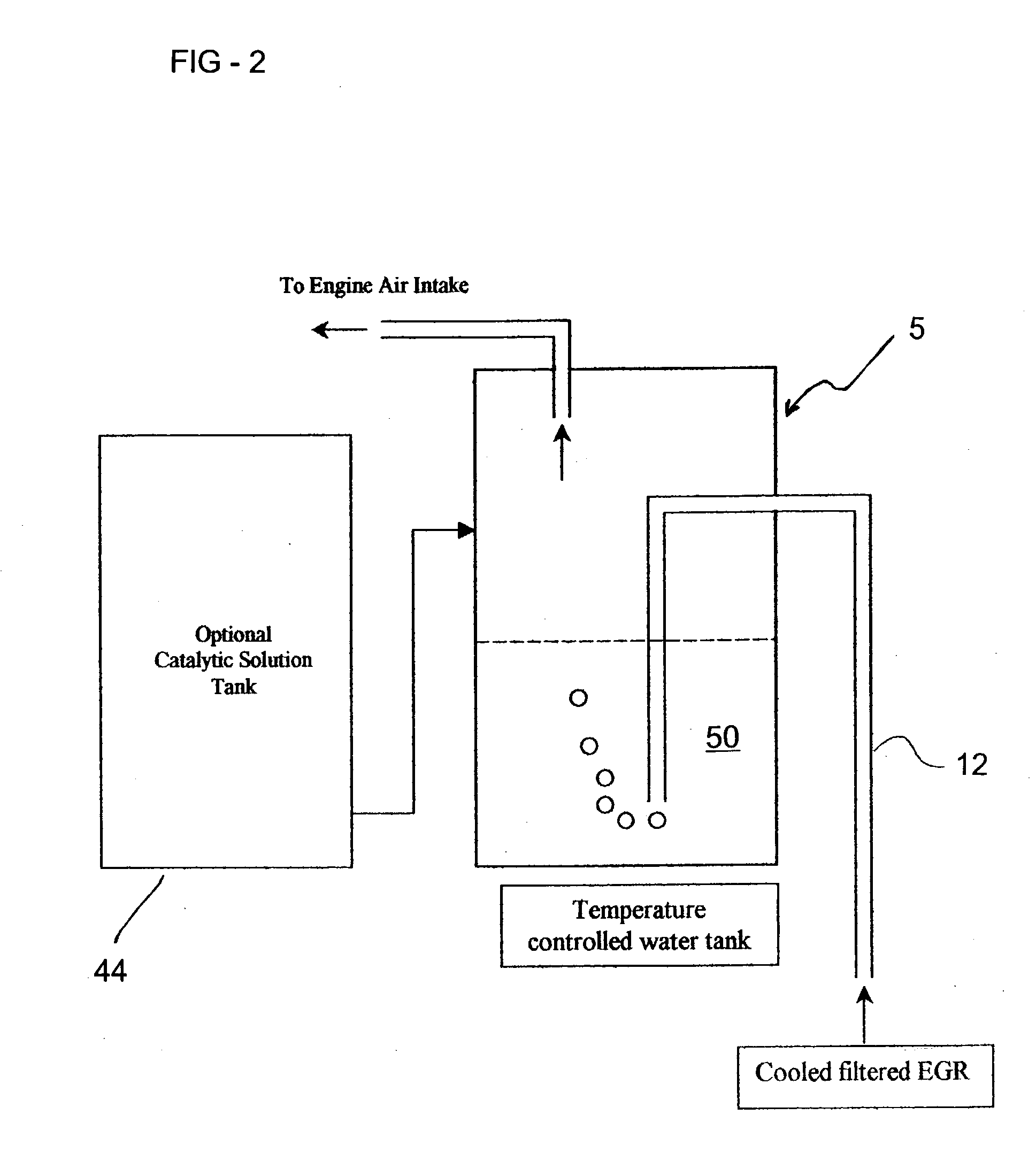

System for and methods of operating diesel engines to reduce harmful exhaust emissions and to improve engine lubrication

InactiveUS6892531B2Promote regenerationAnti-wear propertyInternal combustion piston enginesNon-fuel substance addition to fuelExhaust gas emissionsFuel tank

A Diesel engine anti-wear lubricant oil additive composition that includes organo-metallic compounds of Cu, Ce, etc., is used to catalytically burn-off diesel particulate matter (PM) collected by diesel particulate filter (DPF). A fuel borne catalyst (FBC) of Cu,Ce,Fe etc., required for regenerating the DPF is made by blending a predetermined quantity of used engine oil, removed from the engine crankcase oil system, with fuel in the fuel tank of a diesel engine equipped with DPF and EGR systems. A method of fumigating water and catalytic compounds of Cu, Fe, Ce, etc., into the air-intake system of a diesel engine in the EGR gases from the DPF or air, to reduce both PM and NOx emissions from a diesel engine, with improved engine lubrication performance, is also disclosed.

Owner:RIM JULIUS J

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

Prepn and application of catalyst for eliminating HCN-containing waste gas

InactiveCN1416950AGive full play to the catalytic advantagesLow costDispersed particle separationCatalyst activation/preparationTarProcess engineering

The catalyst for eliminating HCN-containing waste gas is prepared via dissolving H2PtCl6.6H2O in H2O, impregnating Al2O3 carrier in H2PtCl.6H2O solution, drying calcinating and reduction. When it is used, the catalyst is loaded in reactor furnace, the temperature in the furnace is raised to 250-450 deg.c mixed gas contg. HCN, NH3, tar and air is introduced into the reactor furnace to eliminate waste gas via catalytic burning. The present invention has the advantages of simple preparation process, low cost and simple operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Coated substrates for use in catalysis and catalytic converters and methods of coating substrates with washcoat compositions

InactiveUS20140243187A1Improve performanceEmission reductionGas treatmentMolecular sieve catalystsCatalytic transformationConverters

Owner:SDC MATERIALS +1

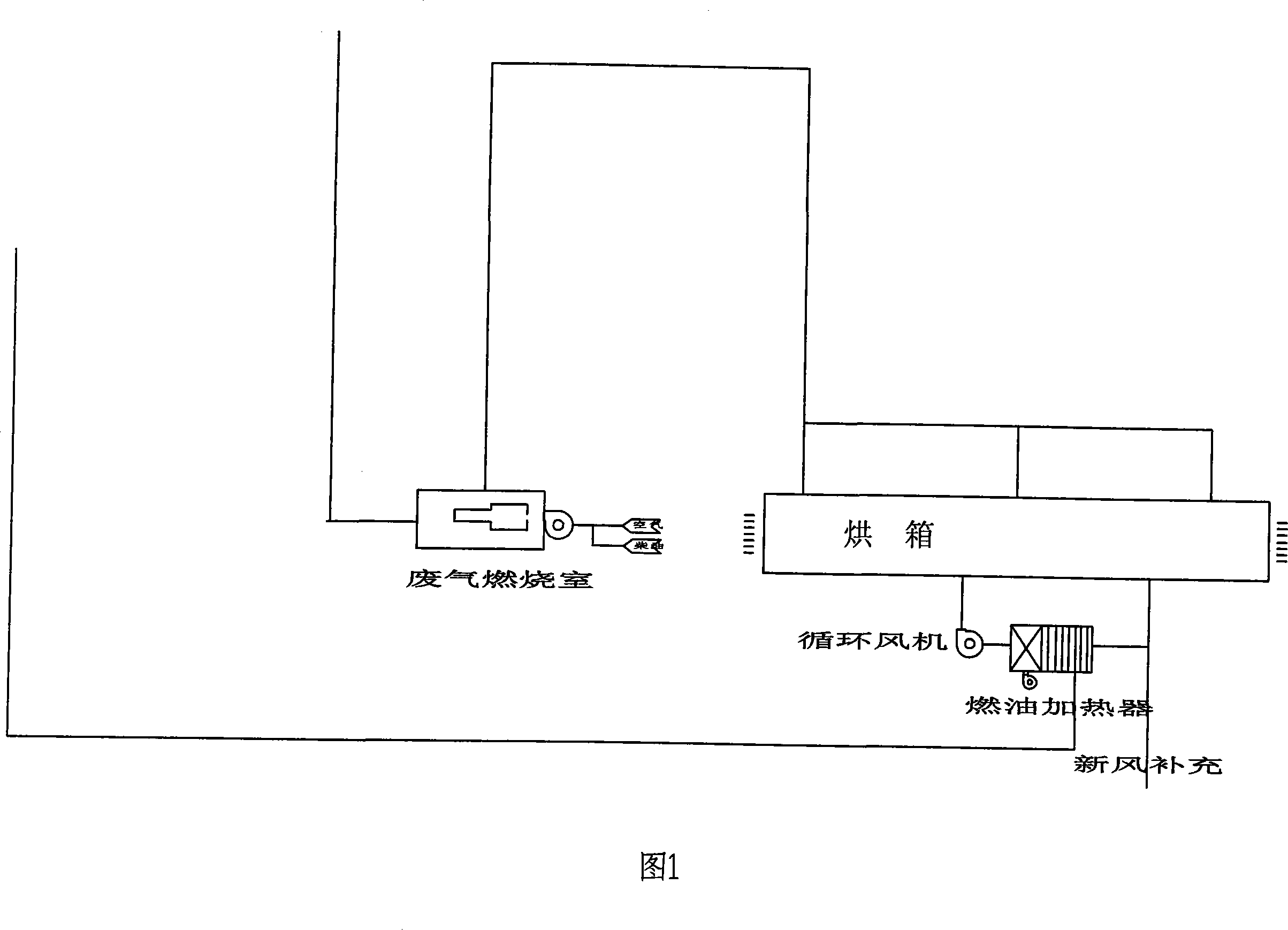

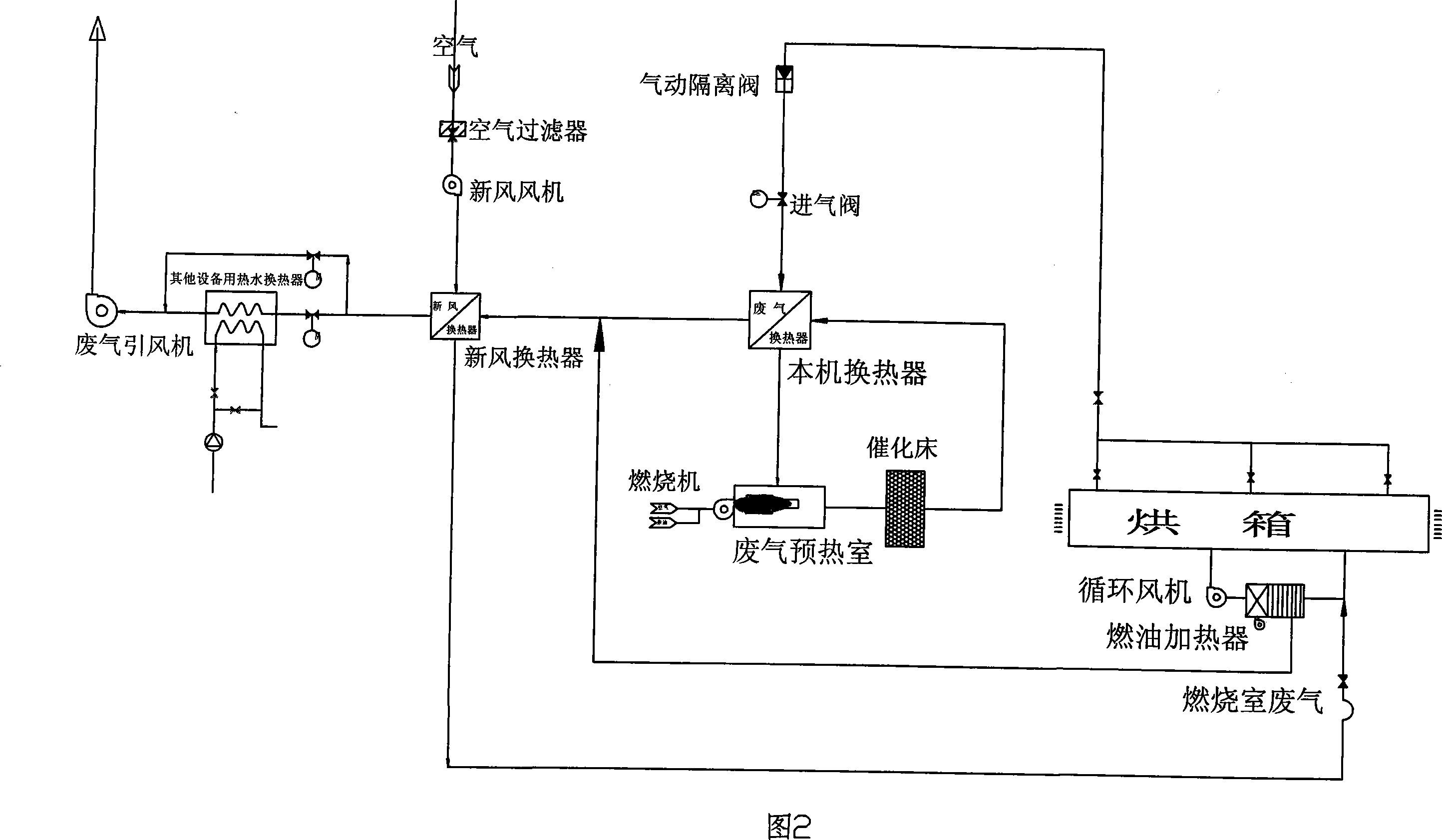

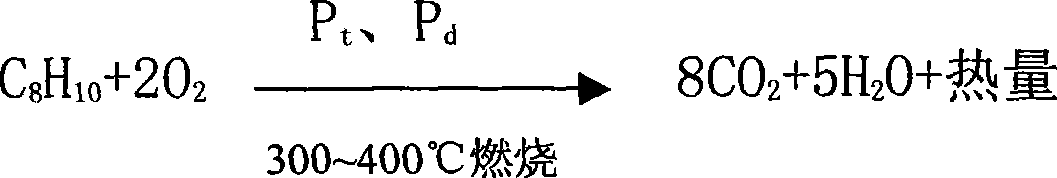

Color-coating waste gas heat recovery method

InactiveCN101162123ACreate pollutionAchieve the purpose of recyclingDrying gas arrangementsIncreasing energy efficiencyRecovery methodOrganic solvent

The invention relates to a method for heat reclaiming colorized painting exhaust gas and mainly solves the problem of air pollution caused by the prior art incapable of treating harmful gas with organic solvent when the colorized painting exhaust gas is heat reclaimed. The invention further solves the technical problems of higher temperature needed by an oven, the need of the additionally heating new wind up to the temperature needed by the oven and great waste of energy. The steps of the invention are as follows: the exhaust gas coming from the oven goes through a local heat interchanger and then is inlet into the local heat interchanger through an exhaust gas preheating chamber and a catalytic bed; the exhaust gas does heat exchange with high temperature catalyzed gas and is heated up to the catalyzing and initiation temperature; the exhaust gas heated up to the catalyzing and initiation temperature enters into the catalytic bed to do catalytic reaction; the high temperature gas after being catalyzed is inlet into a hot water heat interchanger for other devices through a new wind heat interchanger, doing heat exchange with the new wind from an air filter and a new wind blower; the new wind from the air filter and new wind blower is heated by the new wind heat interchanger and then conveyed to a circulated air system of oven.

Owner:HANGZHOU TAIXIN IND

Washcoats and coated substrates for catalytic converters and methods of making and using same

ActiveUS20150093312A1Low ignition temperatureImprove performanceNitrogen compoundsInternal combustion piston enginesTreatment systemDiesel fuel

Disclosed are, inter alia, methods of forming coated substrates for use in catalytic converters, as well as washcoat compositions and methods suitable for using in preparation of the coated substrates, and the coated substrates formed thereby, which in some cases use iron-exchanged zeolite particles that provide enhanced performance such as lower light-off temperatures and lower pollutant levels in exhaust gases. The catalytic material is prepared by a plasma-based method, yielding catalytic material with a lower tendency to migrate on support at high temperatures, and thus less prone to catalyst aging after prolonged use. Also disclosed are catalytic converters using the coated substrates, which have favorable properties as compared to catalytic converters using catalysts deposited on substrates using solution chemistry. Also disclosed are exhaust treatment systems, and vehicles, such as diesel vehicles, particularly light-duty diesel vehicles, using catalytic converters and exhaust treatment systems using the coated substrates.

Owner:UMICORE AG & CO KG +1

System for and methods of operating diesel engines to reduce harmful exhaust emissions and to improve engine lubrication

InactiveUS20040194454A1Facilitates DPF regenerationAnti-wear propertyInternal combustion piston enginesNon-fuel substance addition to fuelOil additiveExhaust gas emissions

A Diesel engine anti-wear lubricant oil additive composition that includes organo-metallic compounds of Cu, Ce, etc., is used to catalytically bum-off diesel particulate matter (PM) collected by diesel particulate filter (DPF). A fuel borne catalyst (FBC) of Cu,Ce,Fe etc., required for regenerating the DPF is made by blending a predetermined quantity of used engine oil, removed from the engine crankcase oil system, with fuel in the fuel tank of a diesel engine equipped with DPF and EGR systems. A method of fumigating water and catalytic compounds of Cu, Fe, Ce, etc., into the air-intake system of a diesel engine in the EGR gases from the DPF or air, to reduce both PM and NOx emissions from a diesel engine, with improved engine lubrication performance, is also disclosed.

Owner:RIM JULIUS J

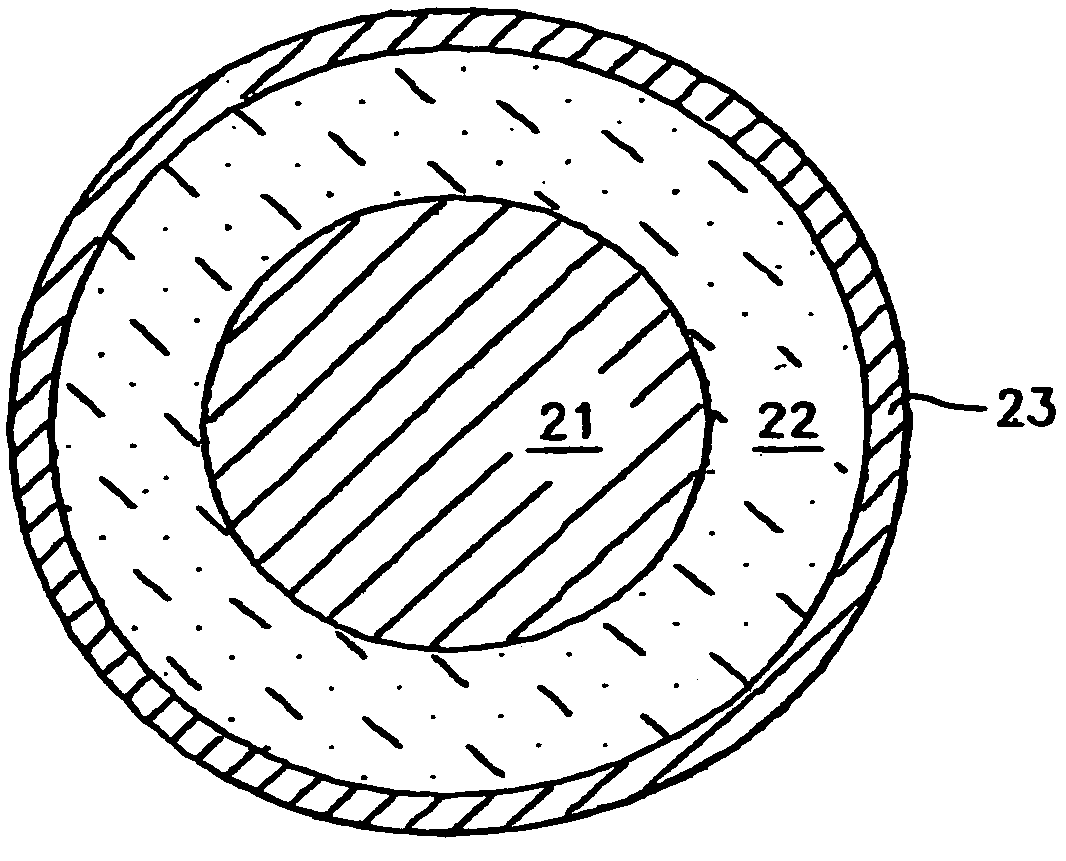

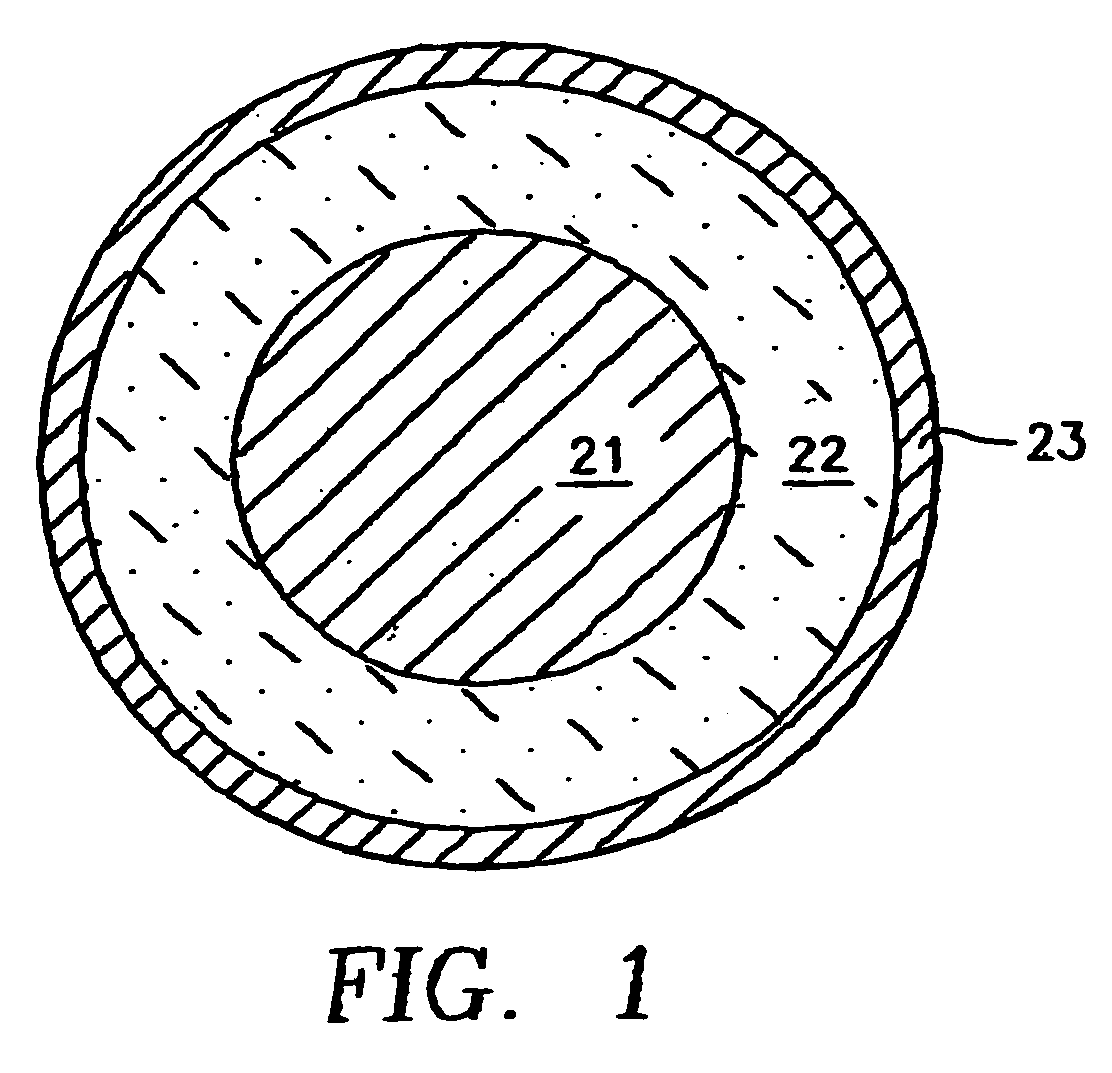

Advanced thermobaric explosive compositions

InactiveUS6955732B1Promote combustionIncrease pressureNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPlasticizerSolid fuel

The invention disclosed herein relates to an explosive capable of enhanced combustion efficiently capable of sustaining a high pressure over a period of time in a confined environment, such as an air tight room or a cave, where oxygen may be in limited supply. An embodiment of the present invention is a metal composite that combines a binder, a reactive metal and an oxidizer. In another embodiment, a plasticizer and a catalyst are added. In another embodiment of the present invention, a solid fuel-air explosive (SFAE) having an annular construction is used. In a typical annular construction, a cylindrical shell of SFAE surrounds the cylindrically shaped high explosive. The SFAE includes at least one of reactive metal and metal composite. In addition, the metal composite is formed from at least one reactive metal, at least one binder and an oxidizer.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

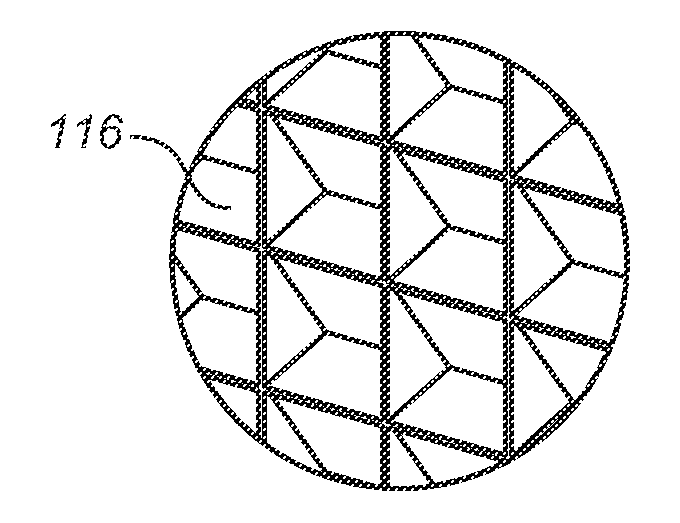

Thin wall cordierite carrier for ceramic honeycomb catalyst and method for preparing the same

InactiveCN1827217AEasy alignmentSmall expansion coefficientCatalyst carriersCeramicwarePorosityCordierite

The invention relates to the improvement on the ceramic beehive catalyst carrier, especially providing a ceramic beehive catalyst carrier with high mechanical strength and lower expansion parameter and preparing method. The invention is characterized in that: said beehive catalyst carrier is the alumina micro powder in 12-15%WT whose average particle diameter is less than 2 micron; the sheet kaolin and / or clay micro powder in 43-47% whose average particle diameter is less than 2 micron, the sheet steatite micro powder in 33-37% whose average particle diameter is 5-15 micron, and the fuse quartz in 6-12% whose average particle diameter is less than 2 micron to be mixed, molded and baked to attain the cordierite whose total amount is 92-96%, wherein, the Al203, MgO and SiO2 are each in 36-37%, 13.0-14.0% and 50-52%. The invention adds surface active agent in the mixture when in preparation. The prepared beehive cordierite total amount with 600 hole / square inch can reach 92-96%, the expansion parameter can reach 0.8X10-6 / Deg. C (800Deg. C to room temperature), and the factor of porosity can reach 39-40%. The invention can reduce the ignition temperature 25-40Deg. C, and reduce the tail gas discharge of nitrogen oxygen compound and carbon monoxide of vehicle 5-10% to meet the demand of Europe III standard.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY +1

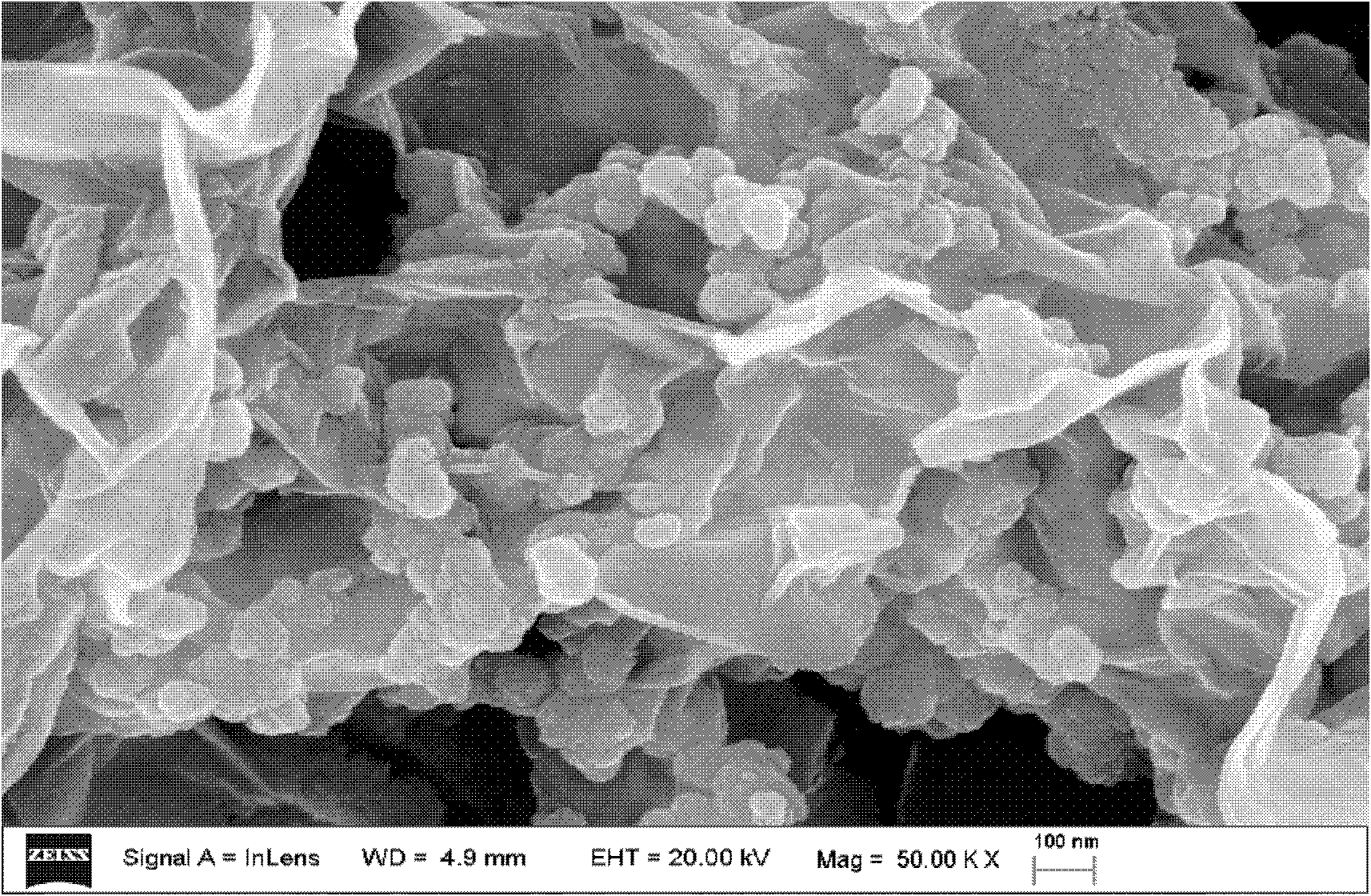

Catalyst for tail gas purification and preparation method thereof

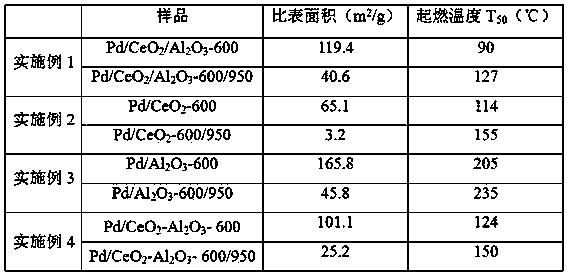

InactiveCN103464152AGood dispersionImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCerium(IV) oxide

The invention provides a catalyst for tail gas purification and a preparation method of the catalyst for tail gas purification. The catalyst for tail gas purification comprises an alumina supporter, cerium dioxide borne on alumina and a precious metal active component borne on the surface of the cerium dioxide. The alumina supporter and the cerium dioxide are prepared according to the sediment hydrothermal method. The precious metal active component is borne according to the hydrothermal in-situ reduction sediment method. According to the catalyst for tail gas purification, the interaction between the cerium dioxide and a precious metal species is strong, the cerium dioxide supporter can generate more oxygen vacancies, oxygen molecules are activated and converted into a reactive oxygen species, and therefore the activity of catalytic oxidation is improved. Interspersion and mutual contact are conducted between the alumina and the cerium dioxide, the mutual insulation function is achieved, sintering with the single cerium oxide serving as a supporter can be avoided, and the thermal stability of the alumina at a high temperature is remarkably improved.

Owner:FUZHOU UNIV

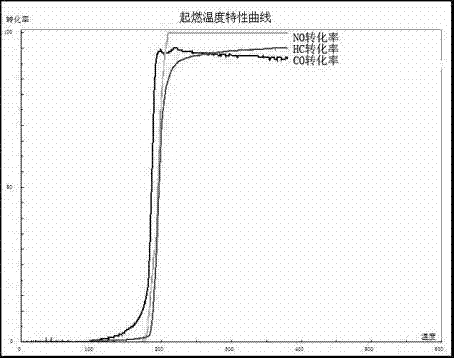

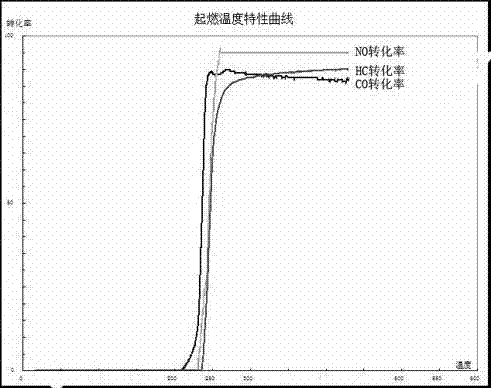

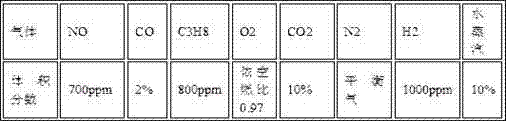

Internal combustion engine tail gas purifying ternary catalyst and preparation method thereof

InactiveCN103877975AImprove conversion efficiencyLow ignition temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCordierite

The invention relates to the field of internal combustion engine tail gas treatment, in particular to a ternary catalyst for purifying the tail gas of an internal combustion engine and a preparation method thereof. The preparation method is characterized in that cordierite ceramic honeycomb is used as a carrier, precious metals such as platinum, palladium and rhodium are adopted as active components, the bottom layer catalyst contains the palladium active component with the active component concentration of 0.1 to 6g / L, the content of cerium of a cerium-containing oxygen storage material is 15-30 percent by weight, the top catalyst contains palladium and / or rhodium active component with the concentration of 0.01 to 0.6g / L, the content of cerium of the cerium-containing oxygen storage material is 40 to 80 percent by weight, a heat-resisting oxide is aluminum oxide consisting of gamma-aluminum oxide or theta-aluminum oxide, the aluminum oxide is stabilized by 3 to 8 percent by weight of lanthanum, the specific surface area is 120 to 300 m<2> / g, the weight ratio of the aluminum oxide to cerium-containing oxygen storage material to additive is 100: (40-80): (11-30). By adopting the catalyst based on the technical scheme, the conversion efficiency of the pollutants in tail gas of the internal combustion engine is high, the ignition temperature is lower, and the thermal stability in high temperature is high.

Owner:CHONGQING TONGQING ENVIRONMENTAL PROTECTION TECH

Composite catalyst used for catalytic combustion of organic waste gas as well as preparation method and application thereof

ActiveCN102240560ALow ignition temperatureReduce manufacturing costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCouplingActive component

The invention discloses a composite catalyst used for catalytic combustion of organic waste gas as well as a preparation method and an application thereof, belonging to the technical field of catalysts. The composite catalyst is a Pt-Pd / Cu-Mn-Zn-Fe / transition layer / cordierite catalyst, macroporous high-sticky composite pseudo boehmite is taken as a second carrier, namely transition rubber, any two of La, Y, Ce and Zr are selected as assistants, non-precious metals such as Cu, Mn, Zn and Fe and precious metals Pd and Pt are taken as active components, wherein the second carrier and the assistants form the transition layer. The preparation method comprises the following steps of: carrying out acid treatment on the cordierite honeycomb ceramic surface and loading the transition layer, then loading the non-precious metal elements Cu, Mn, Zn and Fe by adopting an immersion method, and then sequentially loading the precious metals Pd and Pt by adopting a precipitation-thermal adsorption coupling method. By adopting the invention, sulphur poisoning of the catalyst can be prevented, the life of the catalyst can be prolonged, and the production cost of the catalyst can be reduced.

Owner:BEIJING UNIV OF CHEM TECH

Double layer noble metal active component catalyst and preparing method thereof

InactiveCN101224424AMeet high temperature aging resistanceLow ignition temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentNitrogen oxide

The invention provides a dual-layer noble metal active component catalyst, wherein the active component is distributed in lamination, and a dual-layer coating method is adopted to separate the active components of noble metal and lead the active components to stay on different layers to play individual functions fully. Not only the resistance to aging at high temperature of catalyst can be satisfied but also the catalytic reduction ability of nitrogen oxide under lean-burn condition can be improved and the ignition temperature of the catalyst can be reduced, thus greatly improving the utilization of active component.

Owner:北京英泰世纪环境科技有限公司

Reducing NOx emissions with a staged catalyst

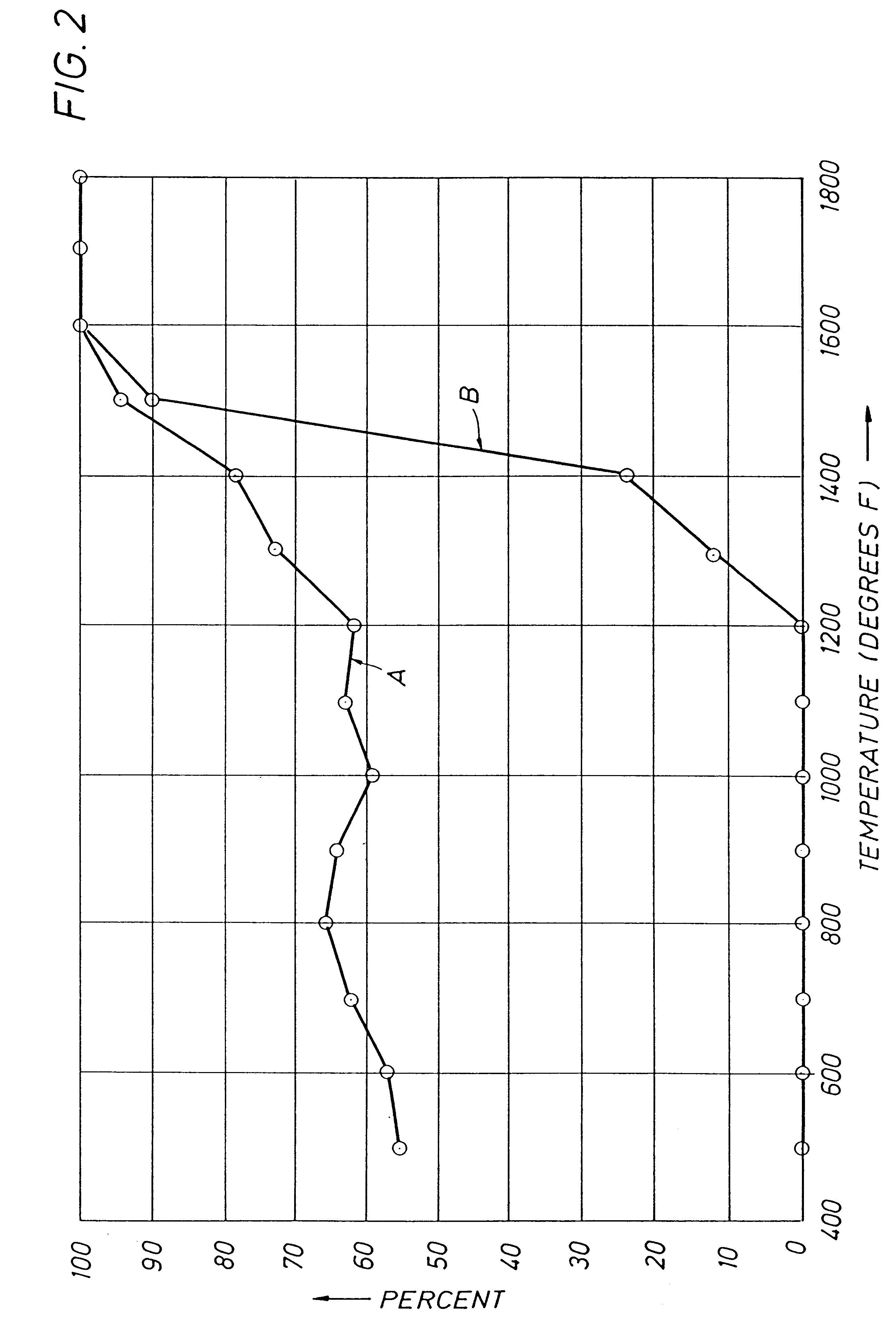

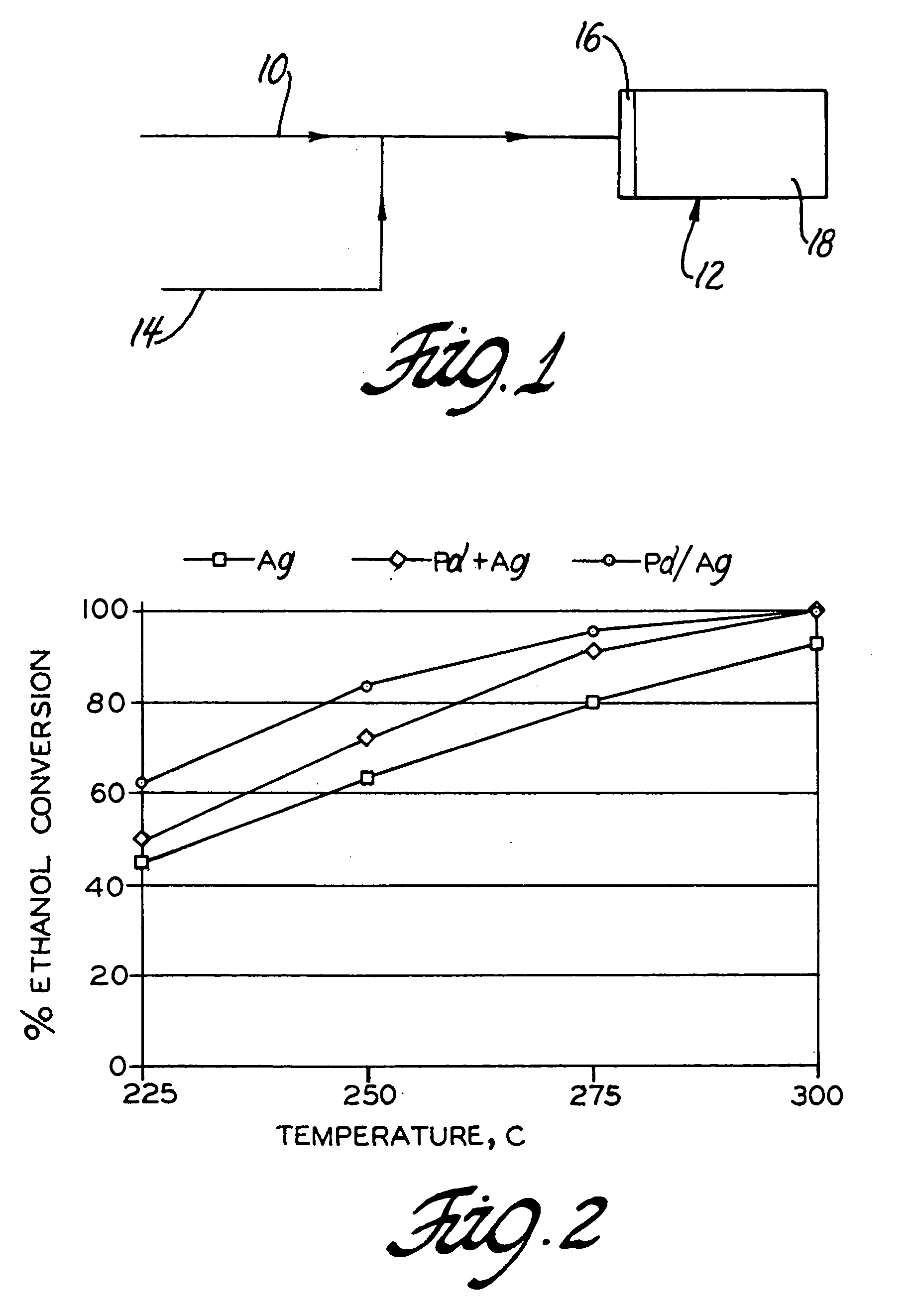

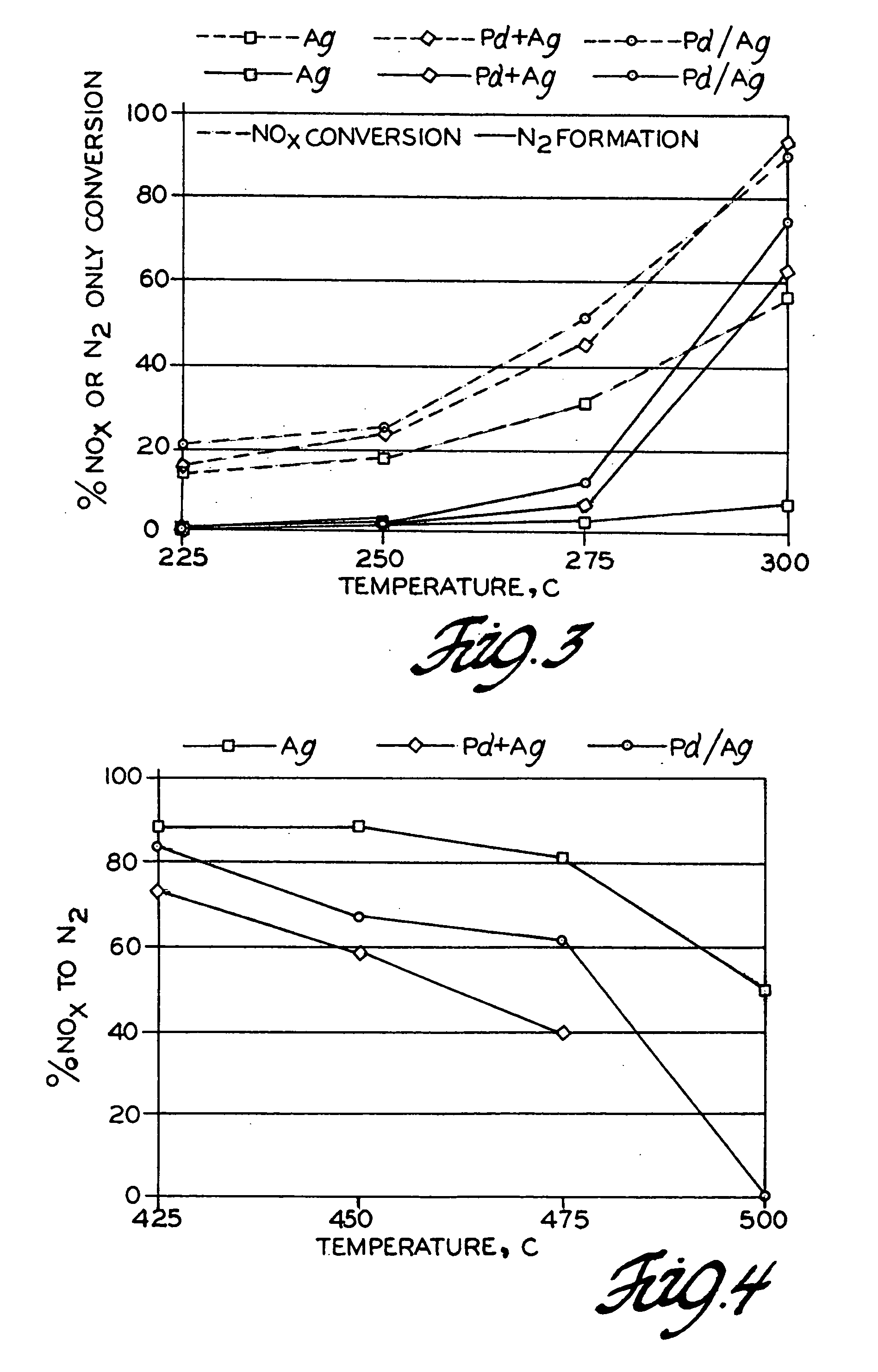

ActiveUS20060075742A1Improve performanceLow ignition temperatureCombination devicesNitrogen compoundsHydrocotyle bowlesioidesNitrogen

The conversion of NOx to nitrogen in the exhaust of a lean burn engine using a hydrocarbon assisted-selective catalytic reduction system is benefited by a two-stage oxidation catalyst-reduction catalyst SCR reactor. The character and quantity of the oxidation catalyst is managed to just activate the hydrocarbon reductant at low temperatures (but not fully burn it at high temperatures) to increase its NOx reduction efficiency as the exhaust then contacts the larger reduction catalyst stage of the two-stage reactor.

Owner:GM GLOBAL TECH OPERATIONS LLC

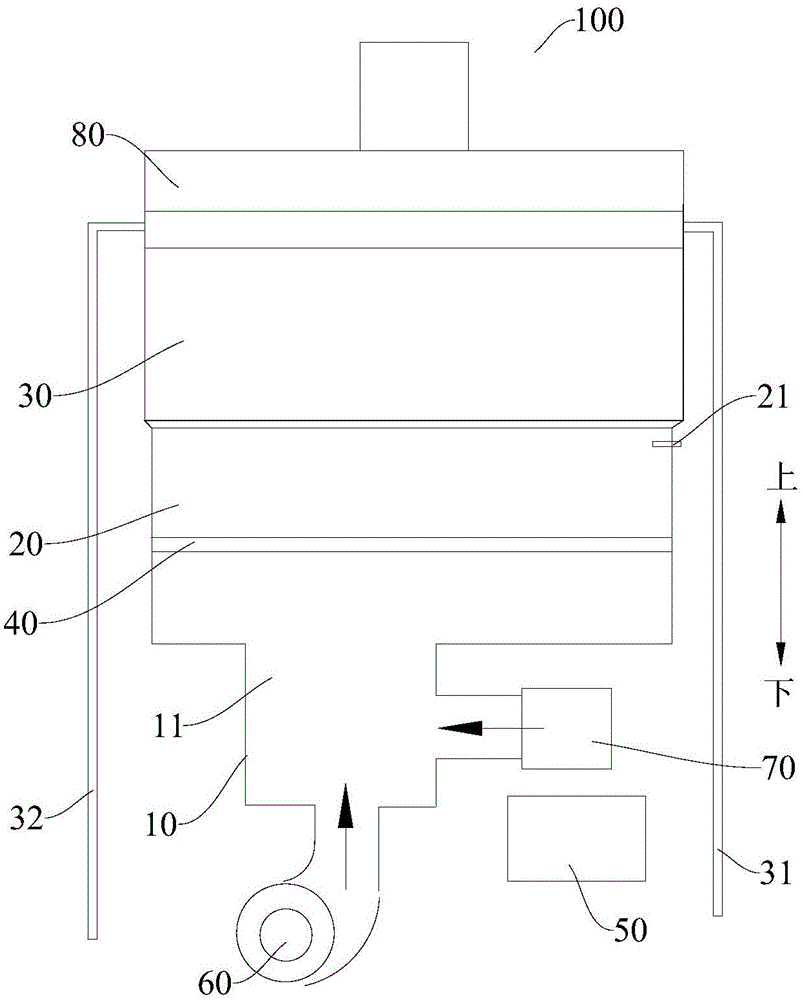

Gas water heater

InactiveCN105841340ASimple structureEasy to assemble and disassembleWater heatersGaseous fuel burnerReaction rateProcess engineering

The invention discloses a gas water heater. The gas water heater comprises a pre-mixing cavity shell, a combustor, a heat exchanger, a pre-heating disc and controller; a mixing cavity is limited in the pre-mixing cavity shell, and the pre-mixing cavity shell is provided with a gas inlet, an air inlet and a mixed gas outlet which are communicated with the mixing cavity; the combustor is communicated with the mixed gas outlet, and a catalyst for catalyzing the combustor to carry out smokeless catalytic combustion is arranged in the combustor; the heat exchanger is connected with the combustor so as to absorb heat generated by combusting of the combustor and is provided with a water inlet and a water outlet; the pre-heating disc is connected with the combustor so as to preheat the combustor; and the controller is connected with the pre-heating disc so as to control heating temperature of the pre-heating disc. According to the gas water heater, the reaction rate of fuel can be improved, the utilization rate of the fuel is improved, generation of harmful gas can be avoided, the fuel can be subject to flameless catalytic combustion in the combustor, generation of the harmful gas is greatly reduced, and use is safe and environment-friendly.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

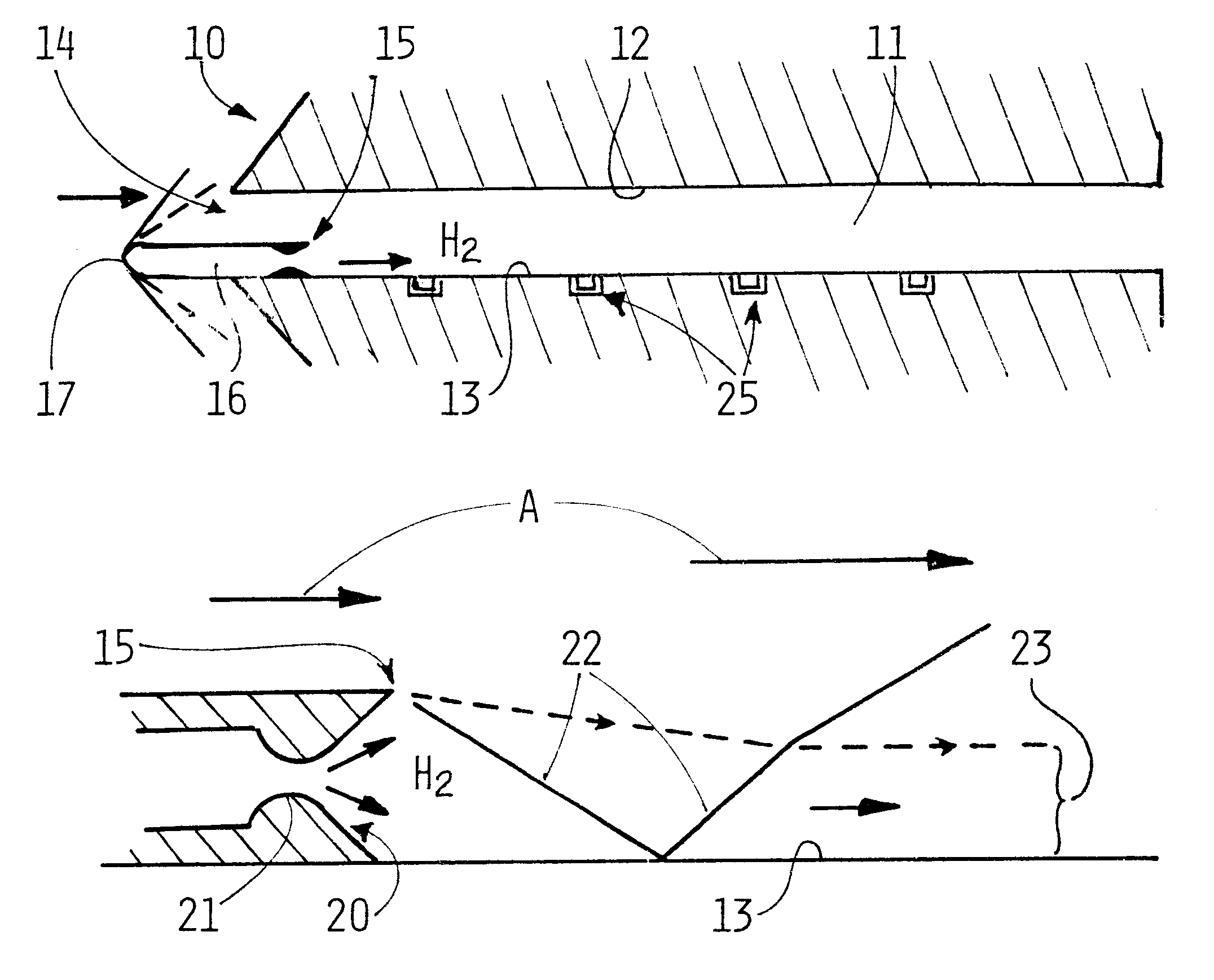

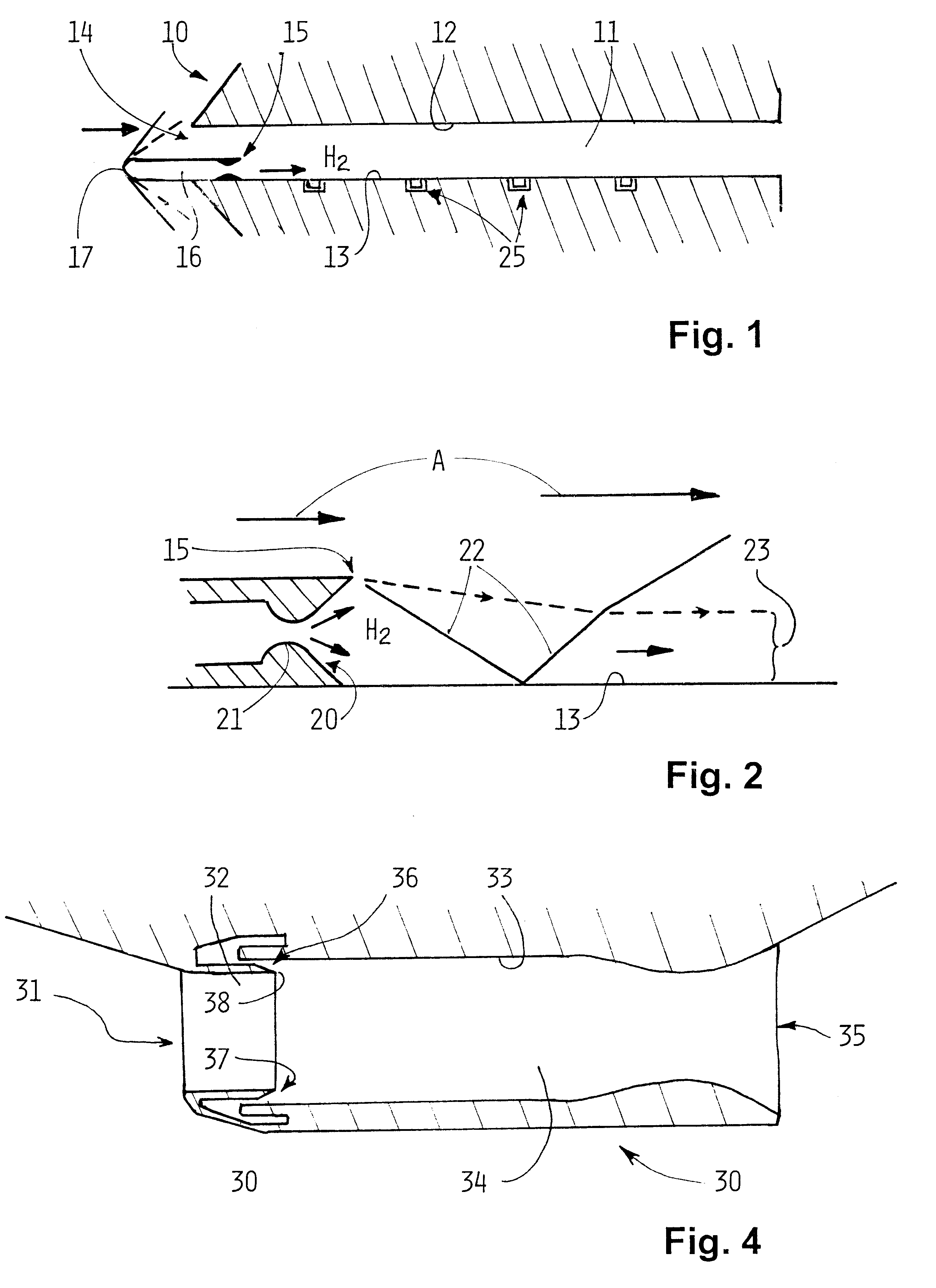

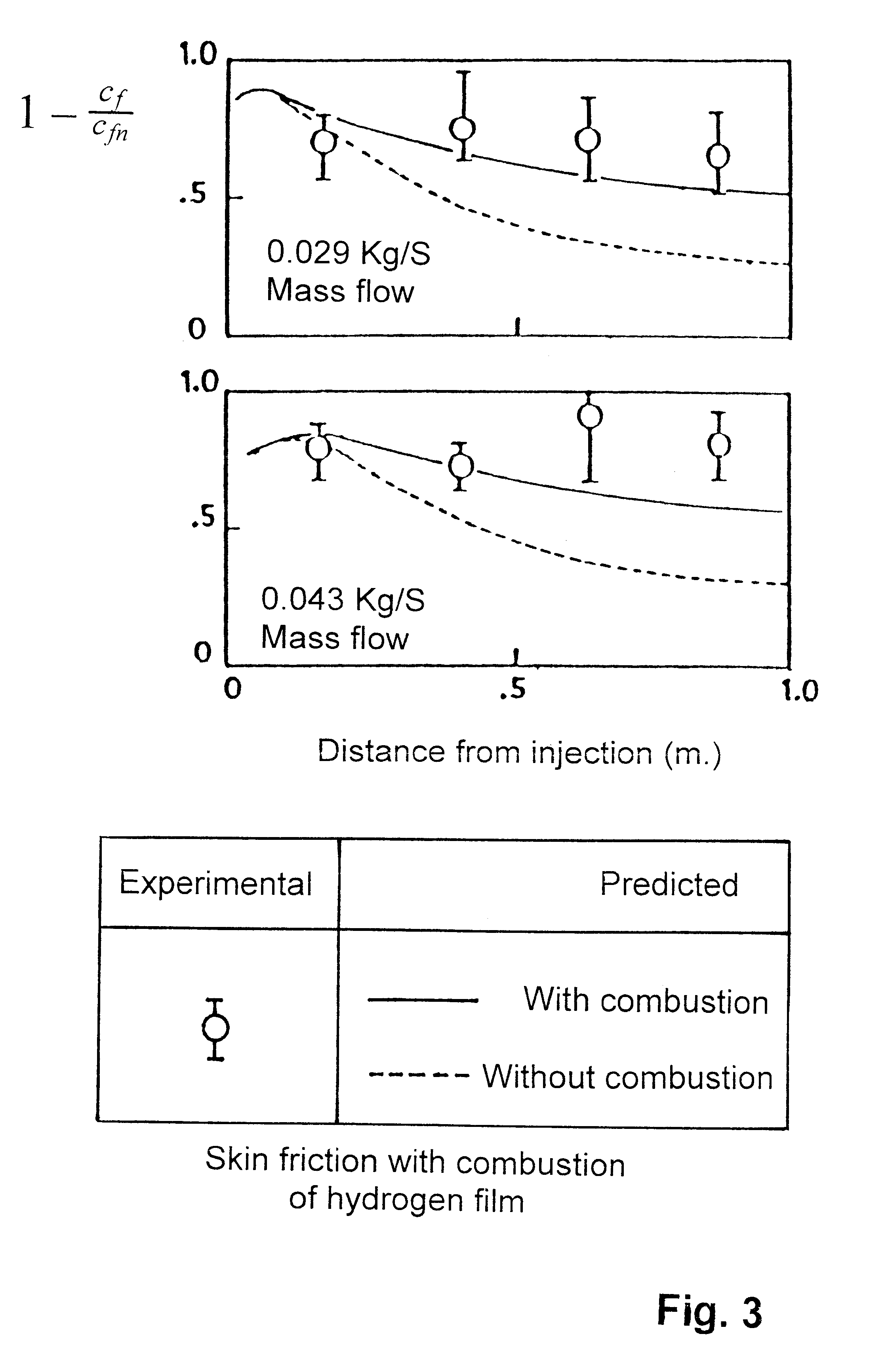

Reducing skin friction drag

InactiveUS6532728B1Reduce skin friction dragReduce frictionCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberEngineering

The skin friction drag acting on a surface of an article travelling at high speed such as a vehicle at supersonic or particularly hypersonic speed can be reduced by introducing a fuel into the boundary layer under conditions of the fuel introduction to ensure combustion in the boundary layer. The fuel is injected through orifice(s) or a slot provided at the surface so that the fuel enters the passing fluid with a major component of the direction of injection being parallel to the local flow direction. The fuel is injected at supersonic speed, e.g. at a speed of about Mach 1.5 or higher. The invention is applicable to scramjet engines with the fuel being injected around the entire internal circumference of the wall of the scramjet engine, upstream of the commencement of the combustion chamber.

Owner:QUEENSLAND UNIV OF

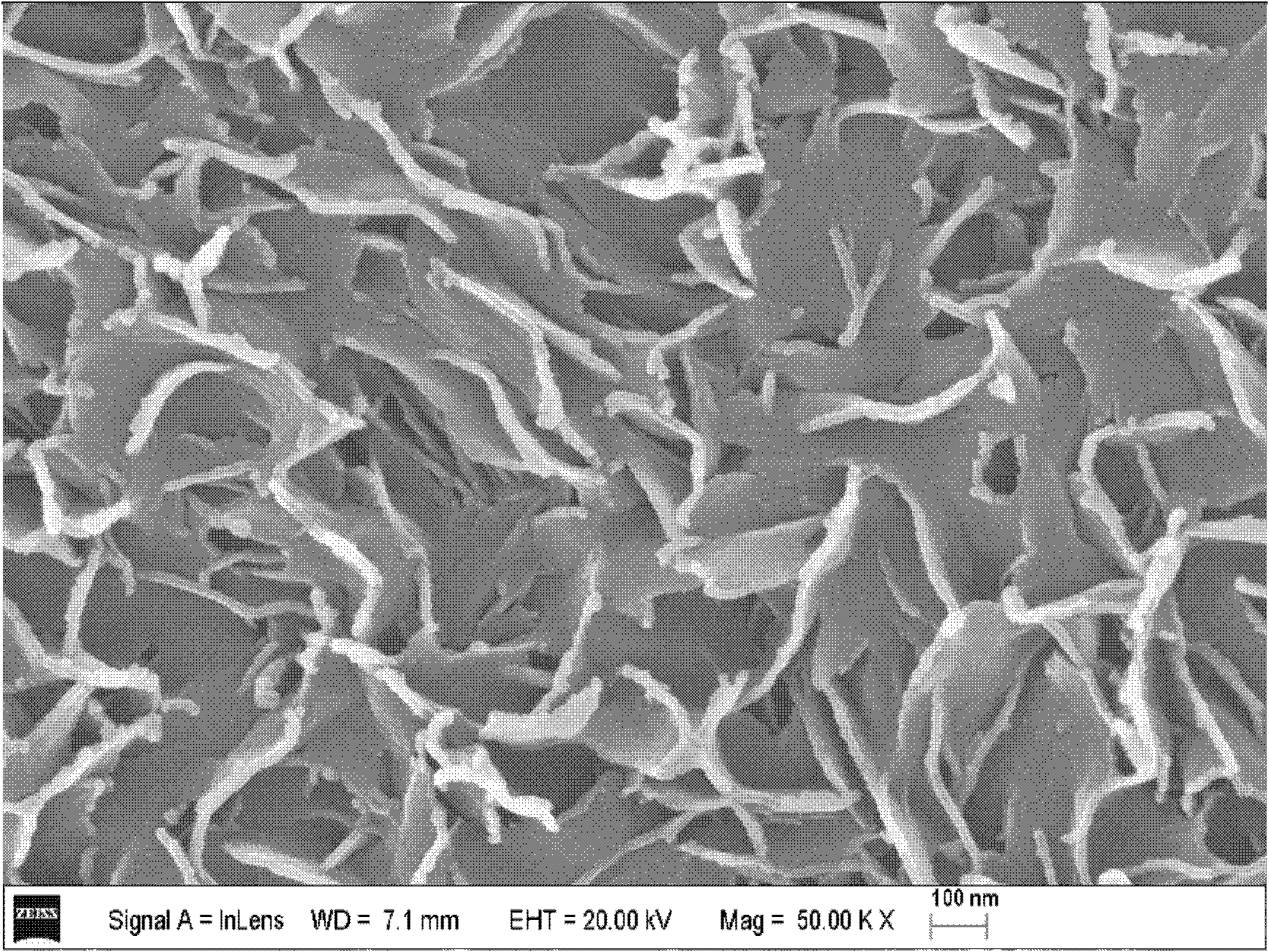

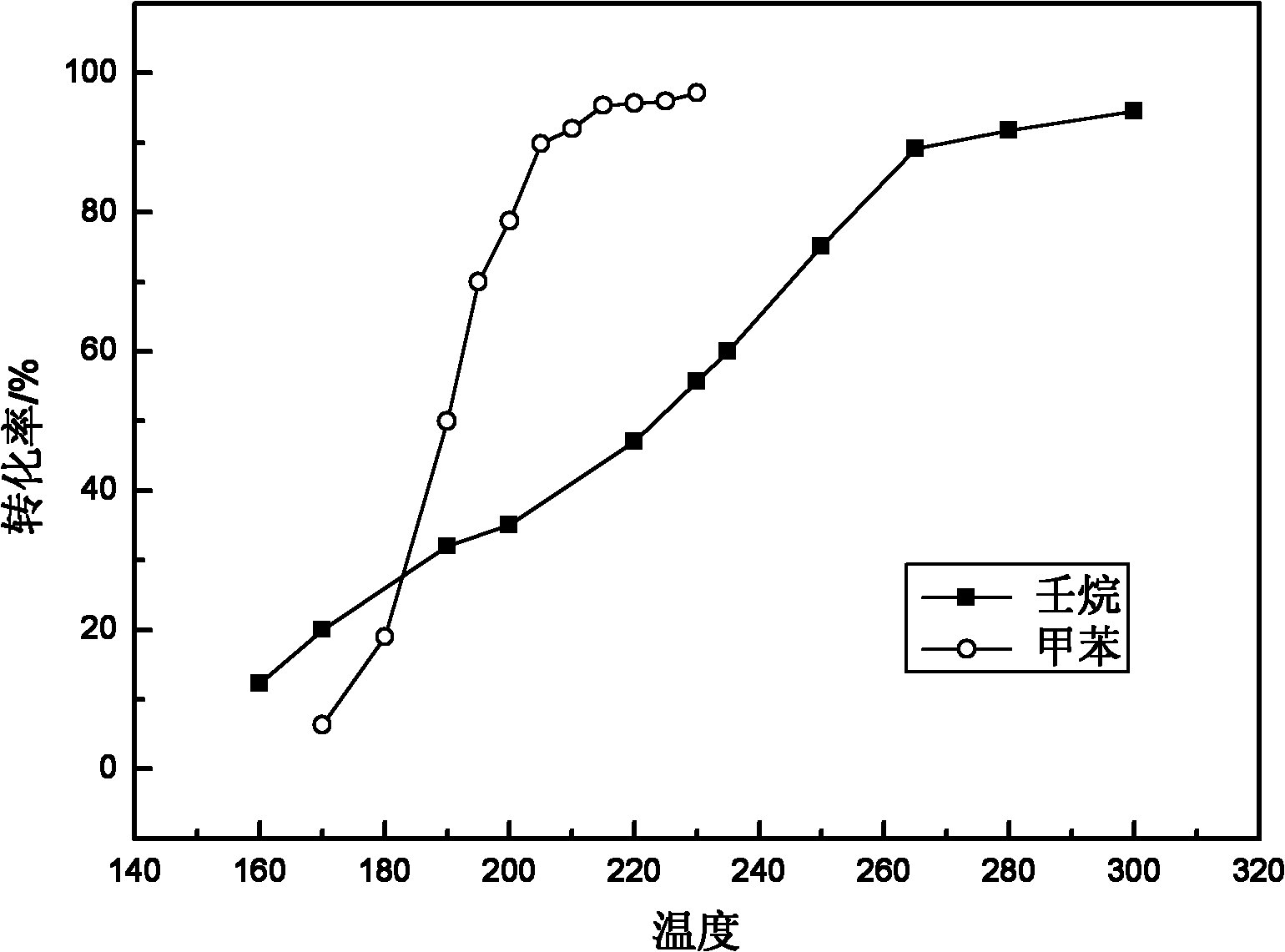

Nickel-palladium integral type catalyst for purification of volatile organic pollutant and preparation method

InactiveCN1768934AImprove high temperature resistanceImprove catalytic purification effectDispersed particle separationCatalyst activation/preparationPalladium catalystCerium

The invention discloses a nickel-palladium integrated catalyst used for purifying volatile organic contaminant and its relative preparing method. The inventive catalyst uses the cordierite cellular ceramic material with high pore capacity as carrier, the cerium zirconium solid solution, rare-earth oxide and aluminum oxide as coating, the palladium-nickel metallic oxide as catalysis activator. The invention also provides the method for preparing said catalyst. The invention has better catalysis and purifying property to volatile organic contaminant, while it can reduce the combustion initiation temperature of toluene to 200-205Deg. C, and it has better high-temperature resistance, while the best using temperature can reach 1000Deg. C, and the service life can last more than 2 years. The invention adds nickel with lower price into catalysis active component to reduce the cost of palladium, and its property is better than palladium catalyst.

Owner:EAST CHINA UNIV OF SCI & TECH

Concentrated phase high-temperature oxygen-enriched oilless ignition combustion apparatus

ActiveCN101424398ALow ignition energyLow ignition temperaturePilot flame ignitersPulverulent fuel combustion burnersOil freeOxygen delivery

The invention relates to a dense-phase high-temperature oxygen-enriched oil-free ignition combustion device, which solves the defects that the prior art is high in energy consumption, unstable in fire, low in combustion intensity, easily worn in equipment and narrow in the adaptation range to coal types. The device comprises an ignition pulverized-coal nozzle which is arranged in the center of a shell. An outer port of the ignition pulverized-coal nozzle and an ignition chamber are connected with a central shaft, and an inner port of the ignition pulverized-coal nozzle is communicated with an ejection opening of an ignition device, wherein the ignition device comprises a pulverized-coal conveying pipe the inside of which is provided with an oxygen conveying pipe; an outlet of the pulverized-coal conveying pipe and a gas outlet of the oxygen conveying pipe are communicated with the inner port of the ignition pulverized-coal nozzle respectively so as to form the ejection opening; and a heating system is arranged outside the pulverized-coal conveying pipe the inside of which is provided with the oxygen conveying pipe. The device has the advantages of low energy consumption, stable reliable fire, high combustion intensity, equipment not easy to wear and wide adaptation range to coal types.

Owner:郑平安

Preparation method of composite metal oxide catalyst for catalytic decomposition for VOCs (Volatile Organic Compounds)

InactiveCN107442106ASimple methodLow costGas treatmentDispersed particle separationCatalytic decompositionCatalytic oxidation

The invention discloses a preparation method of a composite metal oxide catalyst for the catalytic decomposition of VOCs (Volatile Organic Compounds). Nano powder TiO2 is used as a carrier; after a composite metal oxide layer is formed, transition metal salt is added; the composite metal oxide catalyst with multiple active components is formed after heat treatment. The composite metal oxide catalyst has higher catalytic oxidation capacity (more than 98 percent) for ester and benzene organic matters at a low ignition temperature (300 DEG C). The catalyst is prepared by adopting a normal-temperature precipitation method; the method is simple and convenient. The composite metal oxide catalyst does not contain a noble metal element, and is low in cost. The composite metal oxide catalyst is prepared by adopting a two-step precipitation method to ensure that Ce is closely in contact with the TiO2; a solid solution is conveniently formed during roasting; the composite metal oxide catalyst has favorable oxygen supply capacity. Finally, loaded transition metal elements are uniformly distributed on the surface of the catalyst; the adsorption on molecules of the VOCs is facilitated; an active site is provided; the catalytic capacity is increased. The obtained catalyst is used for oxidizing the VOCs into CO2 and H2O, has advantages of high catalytic conversion rate, low ignition temperature, high stability, low price and the like, and has favorable application value and prospect.

Owner:南通斐腾新材料科技有限公司

Noble metal monolithic catalyst for purifying organic waste gas and preparation method thereof

InactiveCN101811046ASimple processReduce manufacturing costDispersed particle separationCatalyst activation/preparationManganeseCordierite

The invention provides a noble metal monolithic catalyst for purifying organic waste gas and a preparation method thereof. The catalyst is a noble metal monolithic catalyst which uses cordierite ceramic pretreated by dilute nitric acid as a carrier and is loaded with zirconium-manganese mixed oxide serving as a first coating layer and a noble metal palladium active ingredient serving as a second coating layer. The method for preparing the catalyst comprises the following steps of: acidifying the carrier by adopting the dilute nitric acid to increase the specific surface area and the surface coarseness of the carrier, soaking and roasting a precursor loaded with zirconium and manganese serving as the first coating layer, and soaking a precursor loaded with noble metal palladium serving as the second coating layer of the main active ingredient. The catalyst has uniformly-loaded active ingredients, high catalytic performance, little using amount and low cost of noble metal, easy popularization, high catalytic combustion removal efficiency of triphenyl, polycyclic aromatic hydrocarbon and other organic waste gas and low ignition temperature and can be widely applied to the purification treatment of industrial organic waste gas.

Owner:SOUTH CHINA UNIV OF TECH

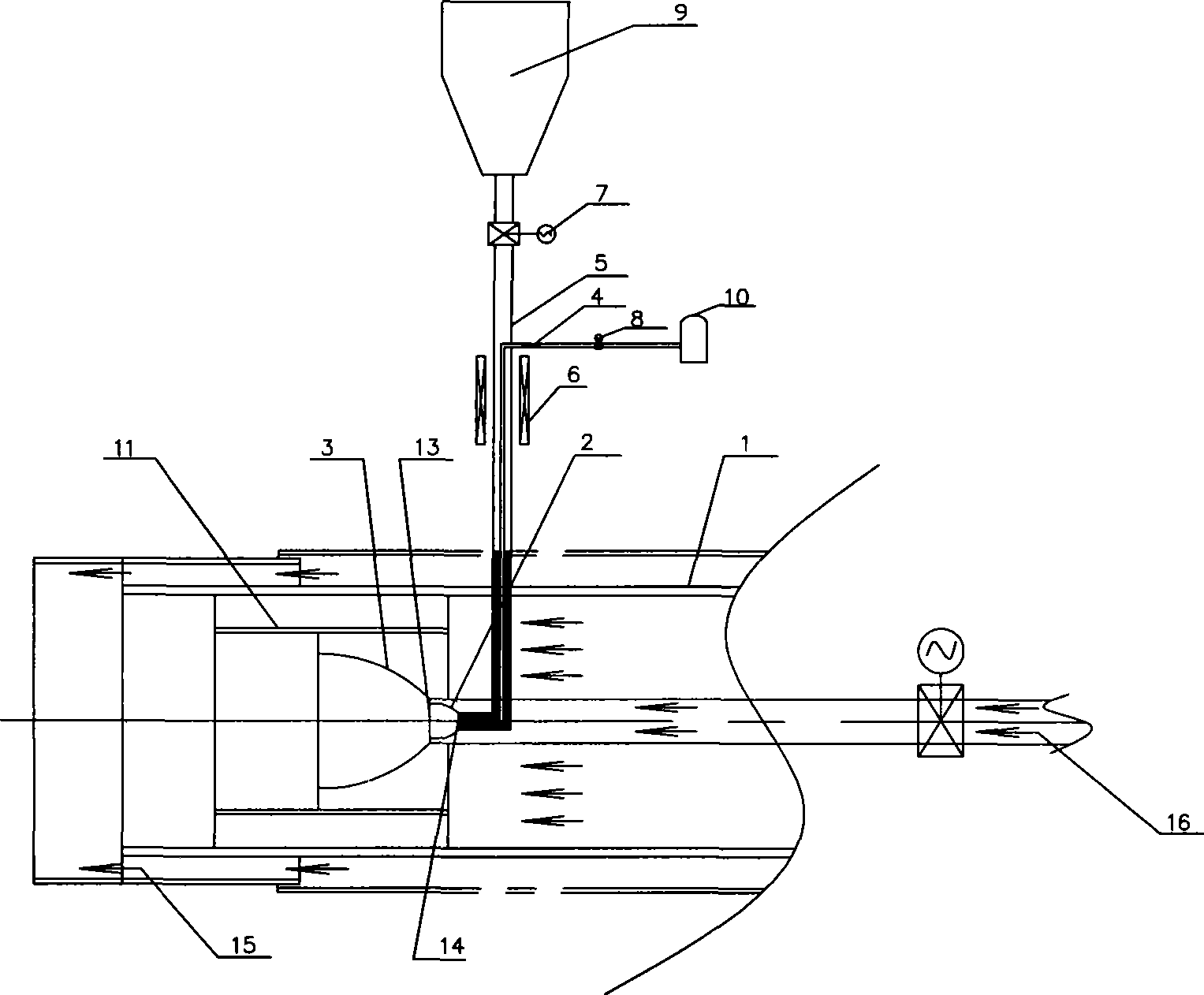

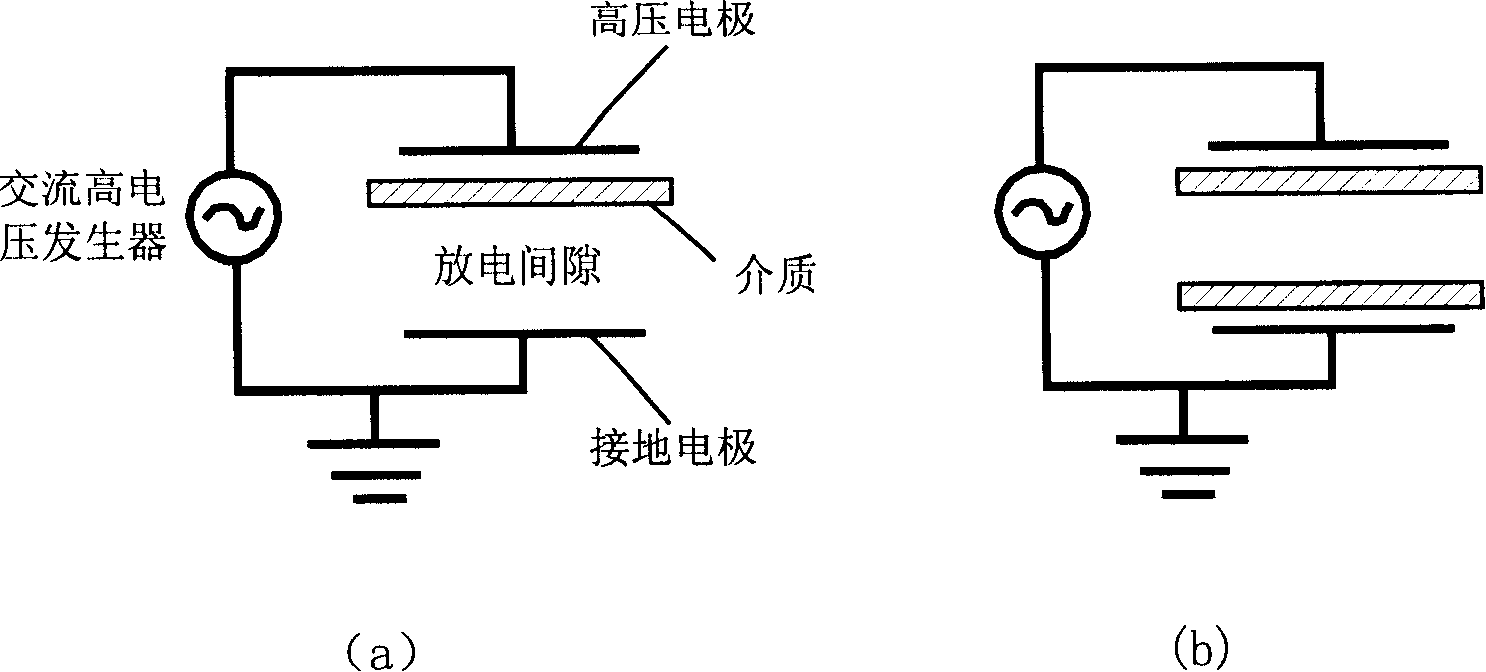

Low-temperature plasma non-hot point fire steadying flame device

InactiveCN101158321ALow ignition temperatureShorten ignition timeRocket engine plantsVoltage amplitudeCombustion chamber

The invention provides a low-temperature plasma no-heat ignition flame stabilization device which adopts the low-temperature plasma to cause the flammable mixed gas to produce a plurality of free radicals and active components such as electrons and hydroniums, etc. to implement large-volume igniting flammable mixed gas, belonging to aeronautics and astronautics power thrust system field. The invention consists of a high pressure powers supply 1, a high pressure electrode 2, an air inlet hole 3, an air inlet seat 4, a retaining medium 5, a low voltage electrode 6, a rectifier 7 and a combustion chamber 8; the high voltage electrode 2 is hermetically connected with the air inlet seat 4 and is connected with a high voltage electrode 1; the air inlet hole 3 is provided with openings on the air inlet seat 4; the interior of the air inlet seat 4 is hermetically connected with the retaining medium 5; the external wall of the rectifier 7 is tightly close to the internal wall of the retaining medium 5; the upstream is the high voltage electrode 1 and the downstream is the combustion room 8 which is hermetically connected with the retaining medium 5. The invention can implement large-volume ignition, reduces the voltage amplitude to large extent, has simple structure and reliable system, and is an ignition device with extremely developmental prospect used by the aeronautics and astronautics and industrial combustion systems.

Owner:TSINGHUA UNIV

Aluminum powder surface self-activation method

InactiveCN109293463APrevent reoxidationRapid responseExplosive ingredient compoundingIgnition delayAluminium powder

The invention discloses an aluminum powder surface self-activation method. The method includes steps: adding aluminum powder into an anhydrous solvent, mixing, and stirring to disperse uniformly to form aluminum powder dispersion liquid; dissolving organic fluoride into a solvent to form organic fluorine solution, adding the organic fluorine solution into the aluminum powder dispersion liquid by acertain rate, and stirring to volatilize the solvent in which the organic fluoride is dissolved at a certain temperature, so that organic fluoride is slowly separated out by crystallization on the aluminum powder surface to form a compact surface activation layer; centrifugally separating to remove the solvent, washing, and performing vacuum drying at 60 DEG C to obtain organic fluorine surface self-activated aluminum powder. By forming of the organic fluorine self-activation layer on the aluminum powder surface, the aluminum powder ignition temperature can be effectively lowered while ignition delay time is shortened, combustion efficiency of aluminum powder in oxidants is improved while the energy releasing rate is increased, and the organic fluorine surface activation layer is effective in aluminum powder oxidation, so that stability is improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com