Patents

Literature

116results about How to "Achieve the purpose of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for treating and recycling carbonized wastewater

ActiveCN101428945ASolve processing problemsImprove biochemical propertiesFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processSludgeTreatment design

The invention relates to a coking waste water treatment reuse method and a device thereof. The method comprises the following process steps: 1. strengthening pretreatment; 2. biological treatment; and 3. reuse water treatment. The structure of the method is as follows: electrochemical equipment at the strengthening pretreatment step is connected with a water outlet of an air float and a water inlet of biological treatment; and a water outlet pipe of an MBR water outlet tank at the biological and sludge treatment step is connected in serial with an ozone contact tower, an active carbon filter tower and an RO at the reuse water treatment step. The method has the advantages of providing a novel combination process for the coking waste water, effectively combining the technologies of de-oiling, biochemistry, electrochemistry and membrane, improving the biodegradability of difficultly degraded pollutants by utilizing the electrochemical strengthening pretreatment, strengthening the biochemical treatment by MBR, reasonably designing the reuse treatment of ozone-active carbon-RO, solving the problem of the difficult treatment of coking waste water and achieving the aim of the reuse of the coking waste water.

Owner:上海缘脉环境科技有限公司

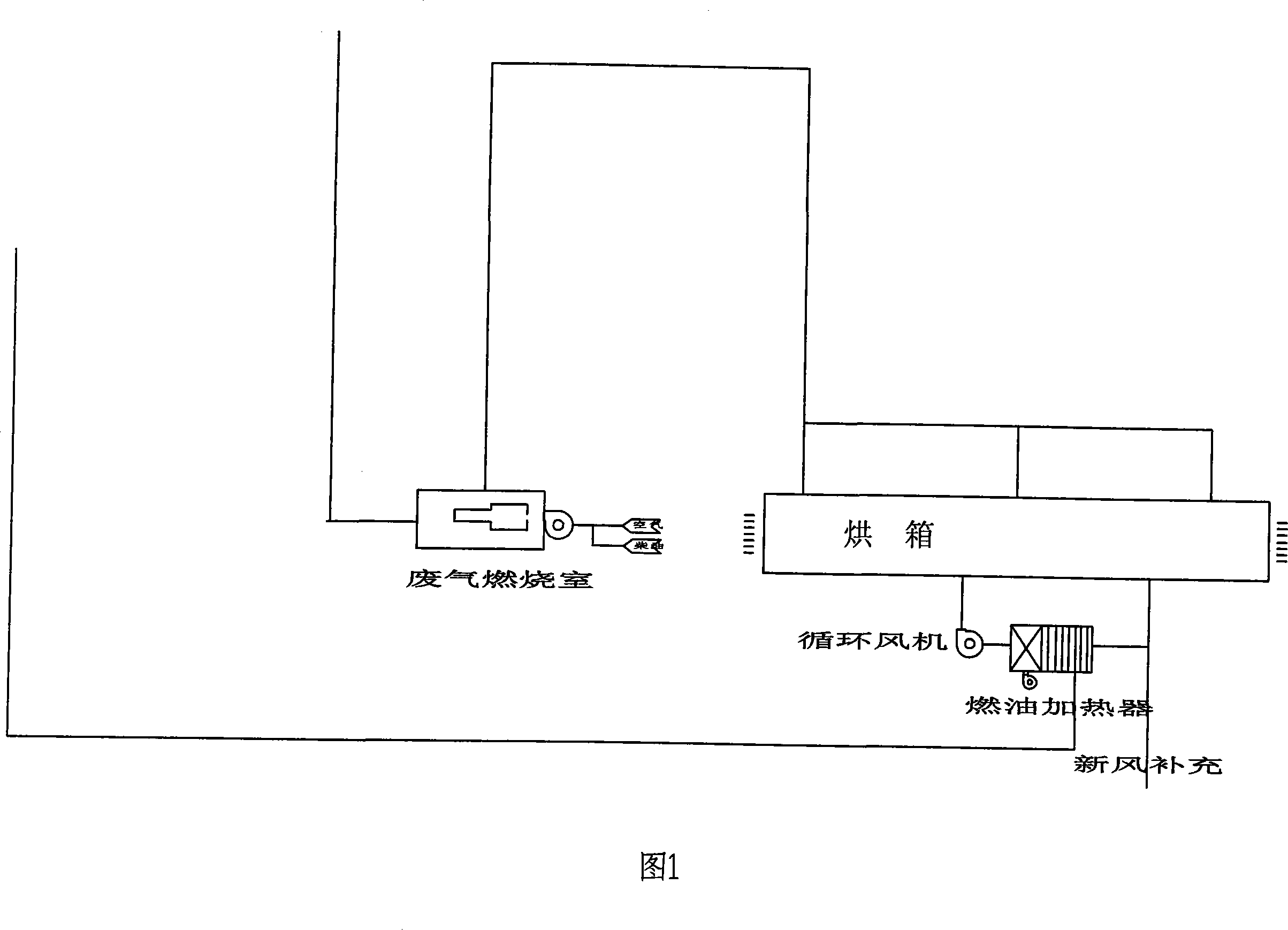

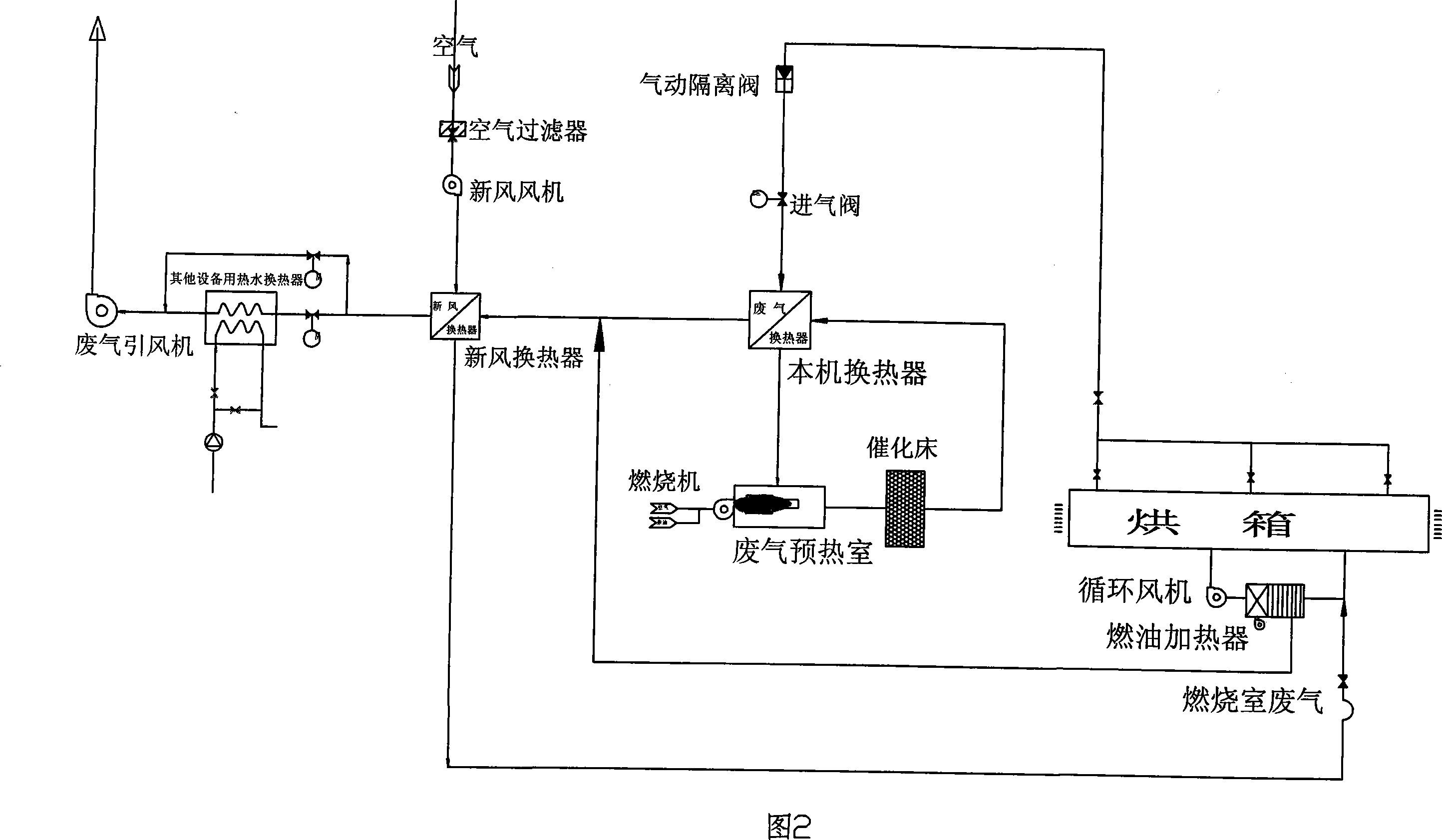

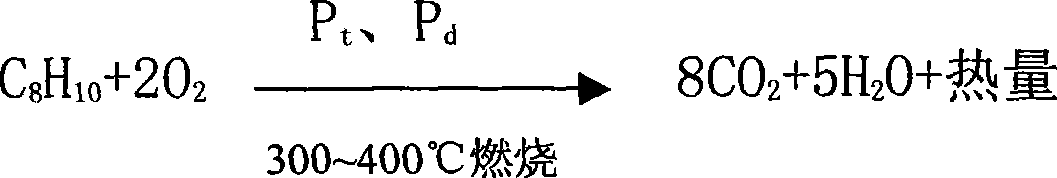

Color-coating waste gas heat recovery method

InactiveCN101162123ACreate pollutionAchieve the purpose of recyclingDrying gas arrangementsIncreasing energy efficiencyRecovery methodOrganic solvent

The invention relates to a method for heat reclaiming colorized painting exhaust gas and mainly solves the problem of air pollution caused by the prior art incapable of treating harmful gas with organic solvent when the colorized painting exhaust gas is heat reclaimed. The invention further solves the technical problems of higher temperature needed by an oven, the need of the additionally heating new wind up to the temperature needed by the oven and great waste of energy. The steps of the invention are as follows: the exhaust gas coming from the oven goes through a local heat interchanger and then is inlet into the local heat interchanger through an exhaust gas preheating chamber and a catalytic bed; the exhaust gas does heat exchange with high temperature catalyzed gas and is heated up to the catalyzing and initiation temperature; the exhaust gas heated up to the catalyzing and initiation temperature enters into the catalytic bed to do catalytic reaction; the high temperature gas after being catalyzed is inlet into a hot water heat interchanger for other devices through a new wind heat interchanger, doing heat exchange with the new wind from an air filter and a new wind blower; the new wind from the air filter and new wind blower is heated by the new wind heat interchanger and then conveyed to a circulated air system of oven.

Owner:HANGZHOU TAIXIN IND

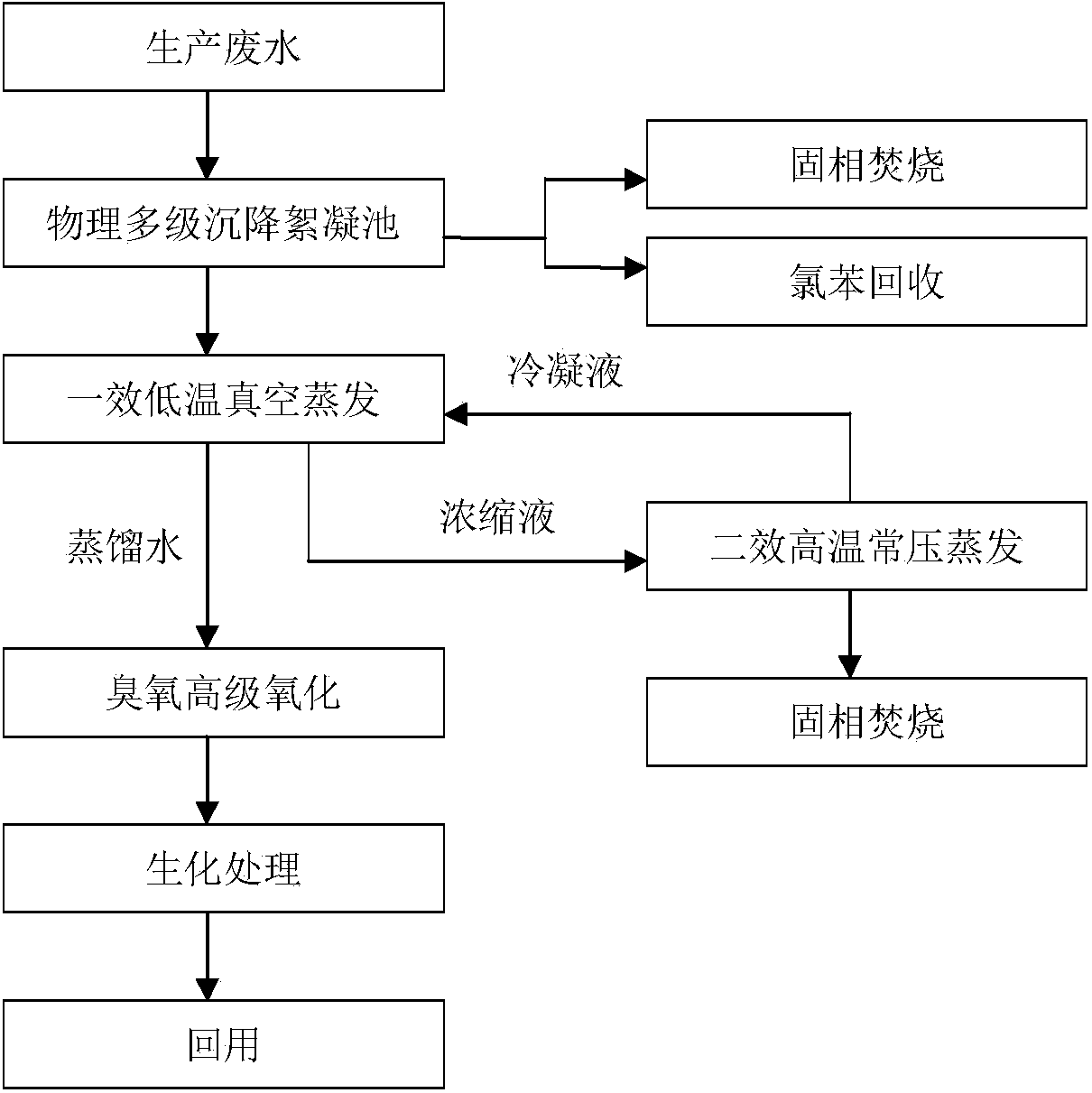

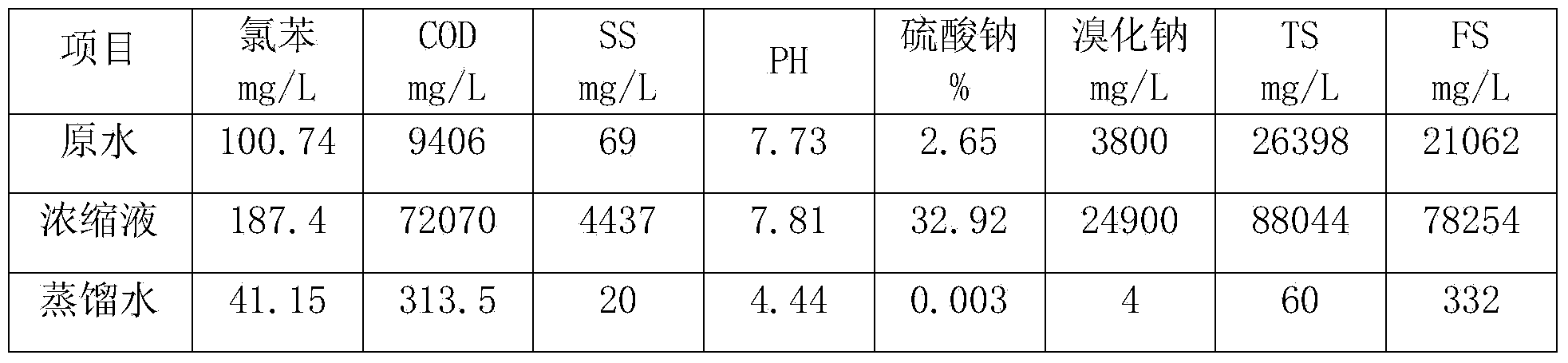

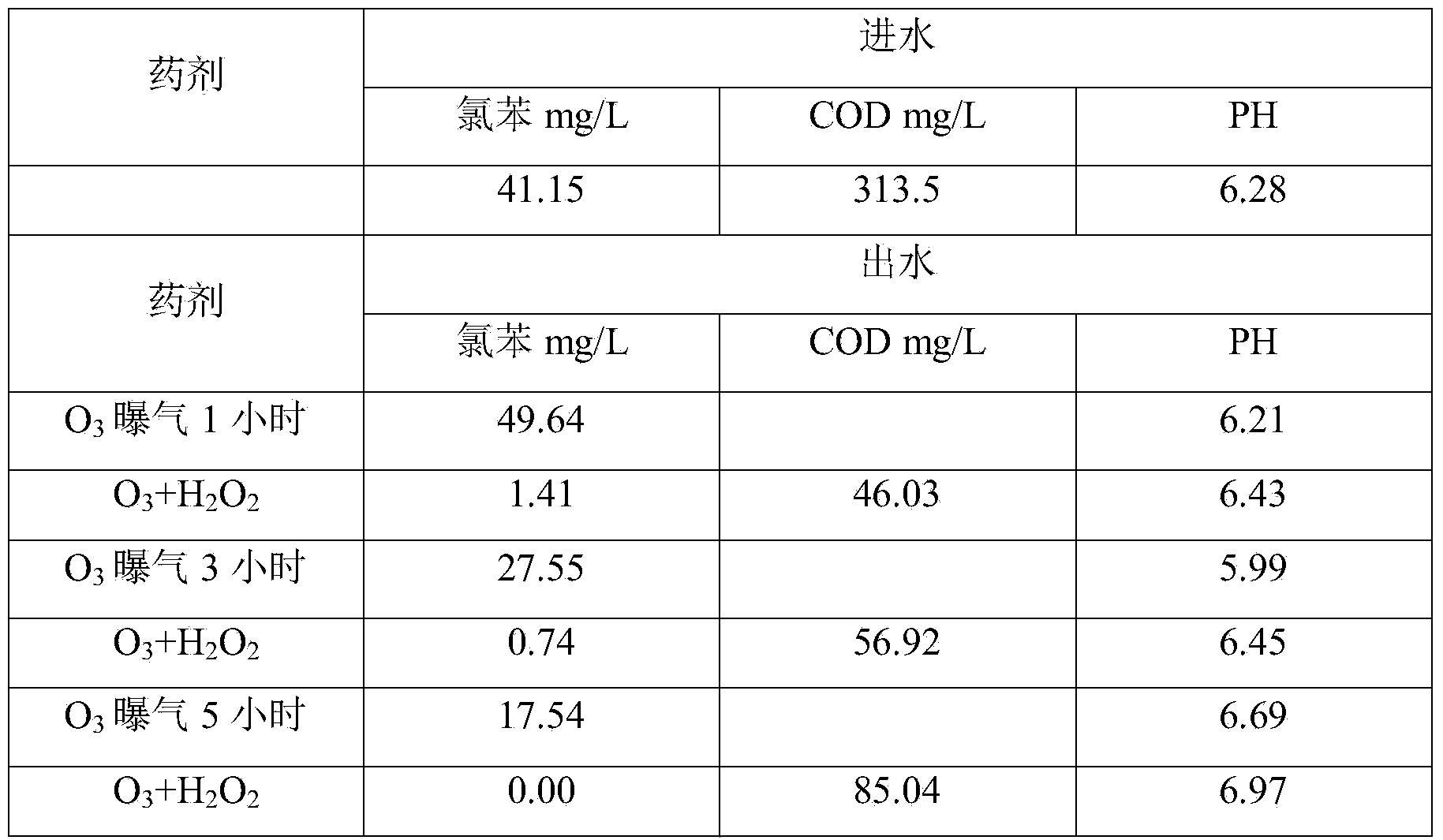

Method for treating and recycling TBBP (tetrabromobisphenol)-A production wastewater

InactiveCN103466894AAchieve removalRealize harmless and up-to-standard dischargeMultistage water/sewage treatmentNature of treatment waterFlocculationChlorobenzene

The invention discloses a method for treating and recycling TBBP (tetrabromobisphenol)-A production wastewater, which comprises the main steps of physical multistage settling, flocculation and recovery, two-effect high / low-temperature evaporative desalination, advanced ozone oxidation and biochemical treatment. According to the invention, the removal of harmful hardly-degradable substances in TBBP-A wastewater is realized, the pH value of wastewater subjected to treatment is neutral, the COD (chemical oxygen demand) can be degraded to below 100 mg / L, and chlorobenzene can be completely decomposed by cutting, thereby reaching reuse and discharge standards, and achieving the purposes of the harmless and up-to-standard discharge of wastewater and the recycling of process water.

Owner:天津长芦汉沽盐场有限责任公司

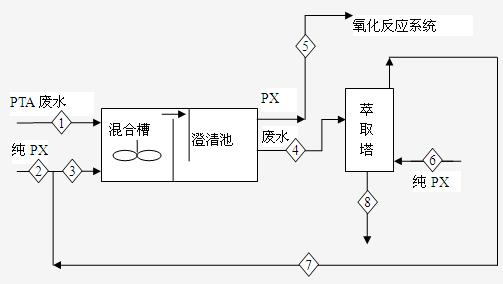

Method for recycling mother solid in PTA-refining wastewater

ActiveCN101941901AAvoid wastingSolve easy blockageMultistage water/sewage treatmentCarboxylic compound separation/purificationRecovery methodSingle stage

The invention discloses a method for recycling mother solid in PTA-refining wastewater, comprises the following steps: mixing PTA-refining wastewater and paraxylene in a prepositioned mixing tank, carrying out single-stage extraction and cooling on the wastewater, dissolving and extracting the solid in mother liquor into a PX phase, returning the extract phase PX discharged from a clarification tank to an oxidizing reaction system, and delivering the wastewater to an extraction tower to be subject to multistage countercurrent extraction; delivering the wastewater discharged from the bottom ofthe extraction tower to be subject to further treatment; and returning the extraction phase discharged from the top of the extraction tower to serve as extract liquor for single-stage extraction. By adopting the method in the invention, most of organic matters, such as p-toluic acid, terephthalic acid and the like in the wastewater can be recycled, thus the purpose of recycling wastes is achieved, and wasting of resources is avoided; and the invention omits the conventional filtering unit, saves the filter cloth-replacing cost, ensures that the extraction tower can operate at appropriate operating temperature, and has the advantages of investment saving, low energy consumption, high resource recovery rate and the like.

Owner:FUZHOU UNIV

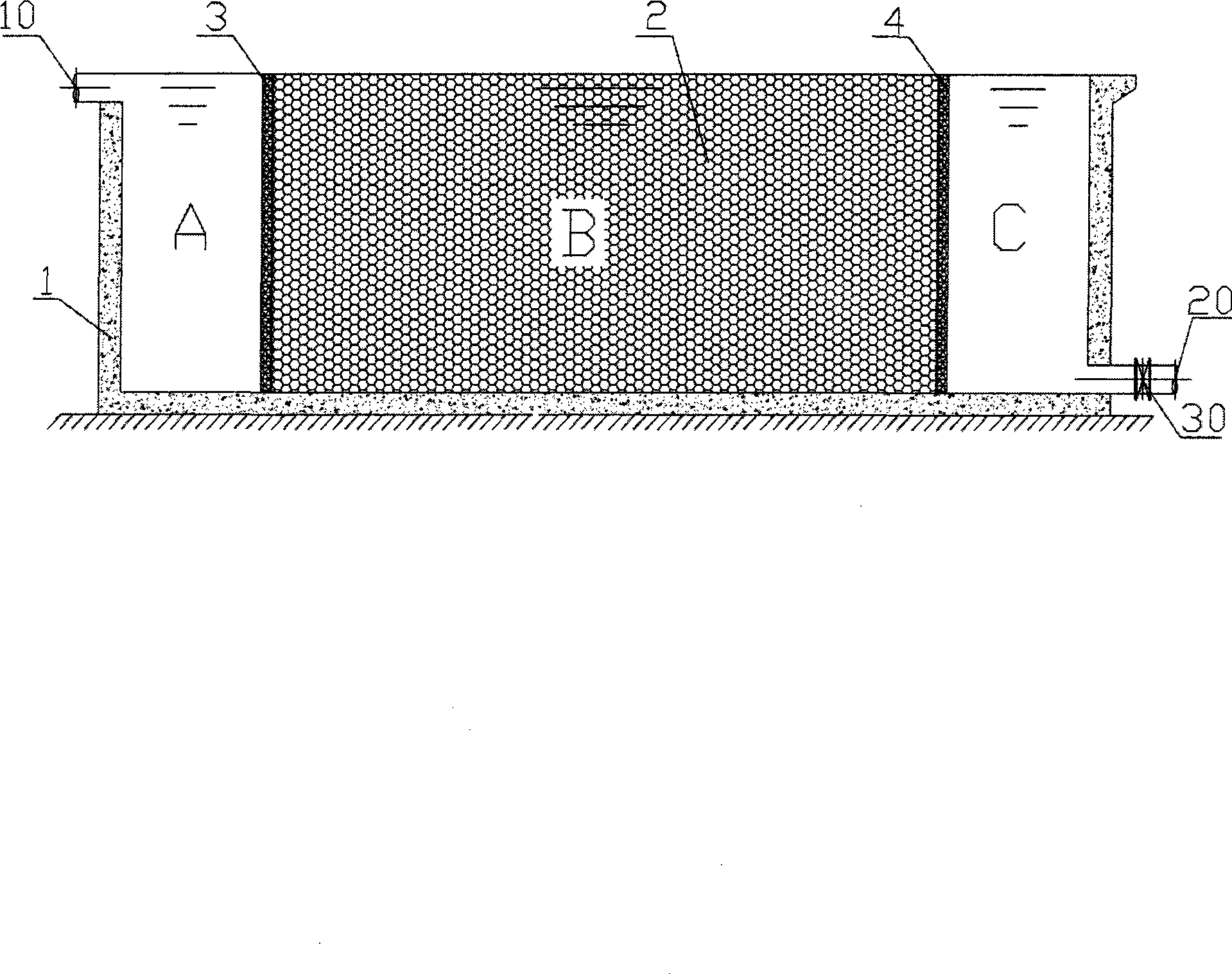

Brine waste water processing reusing device and method

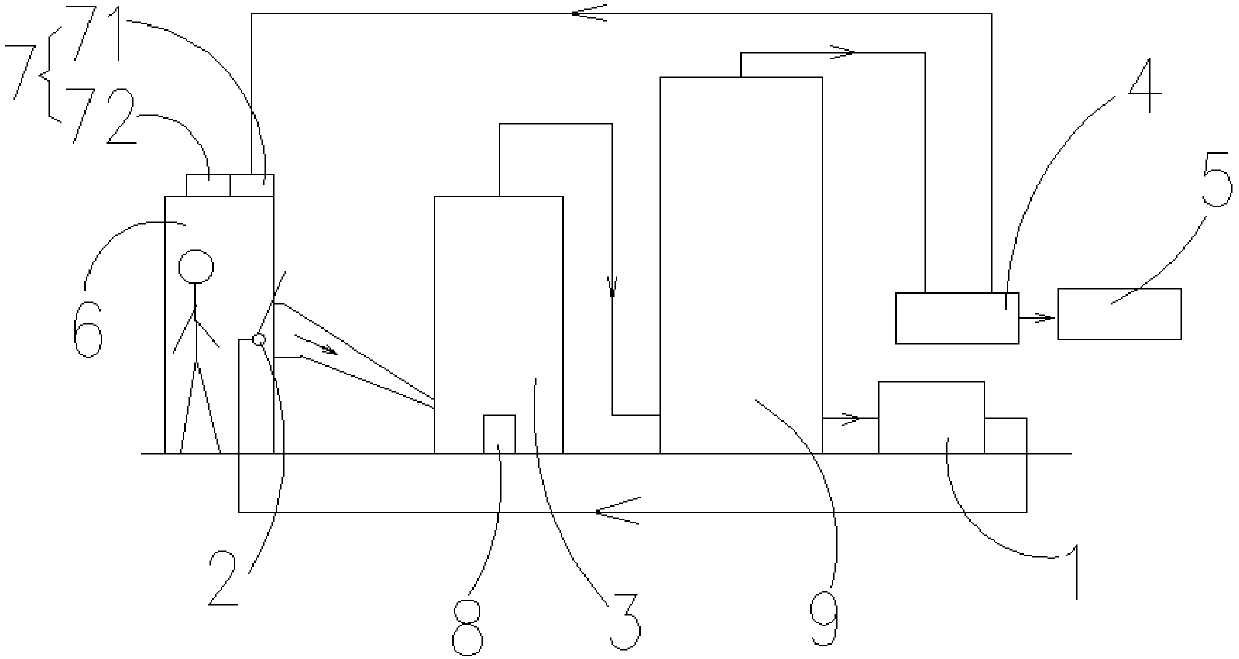

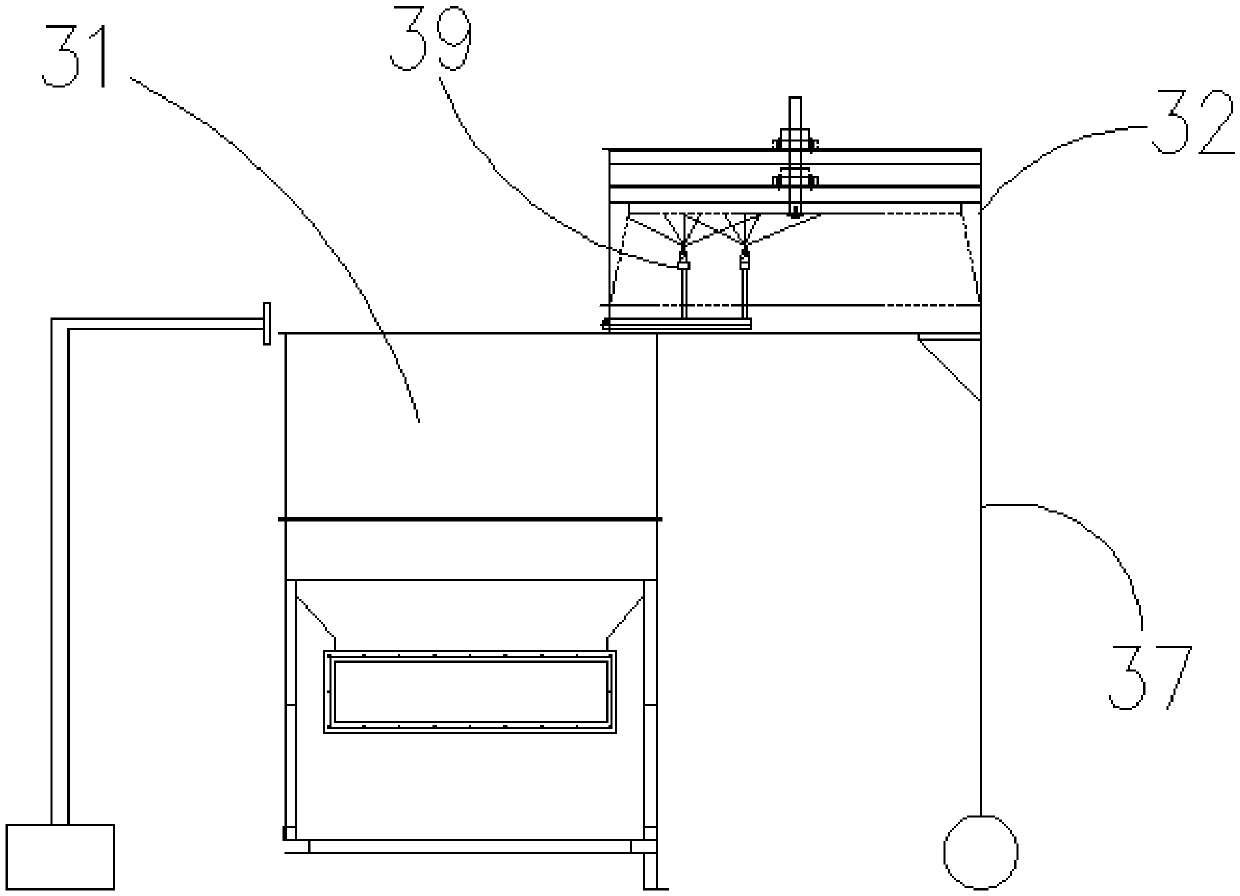

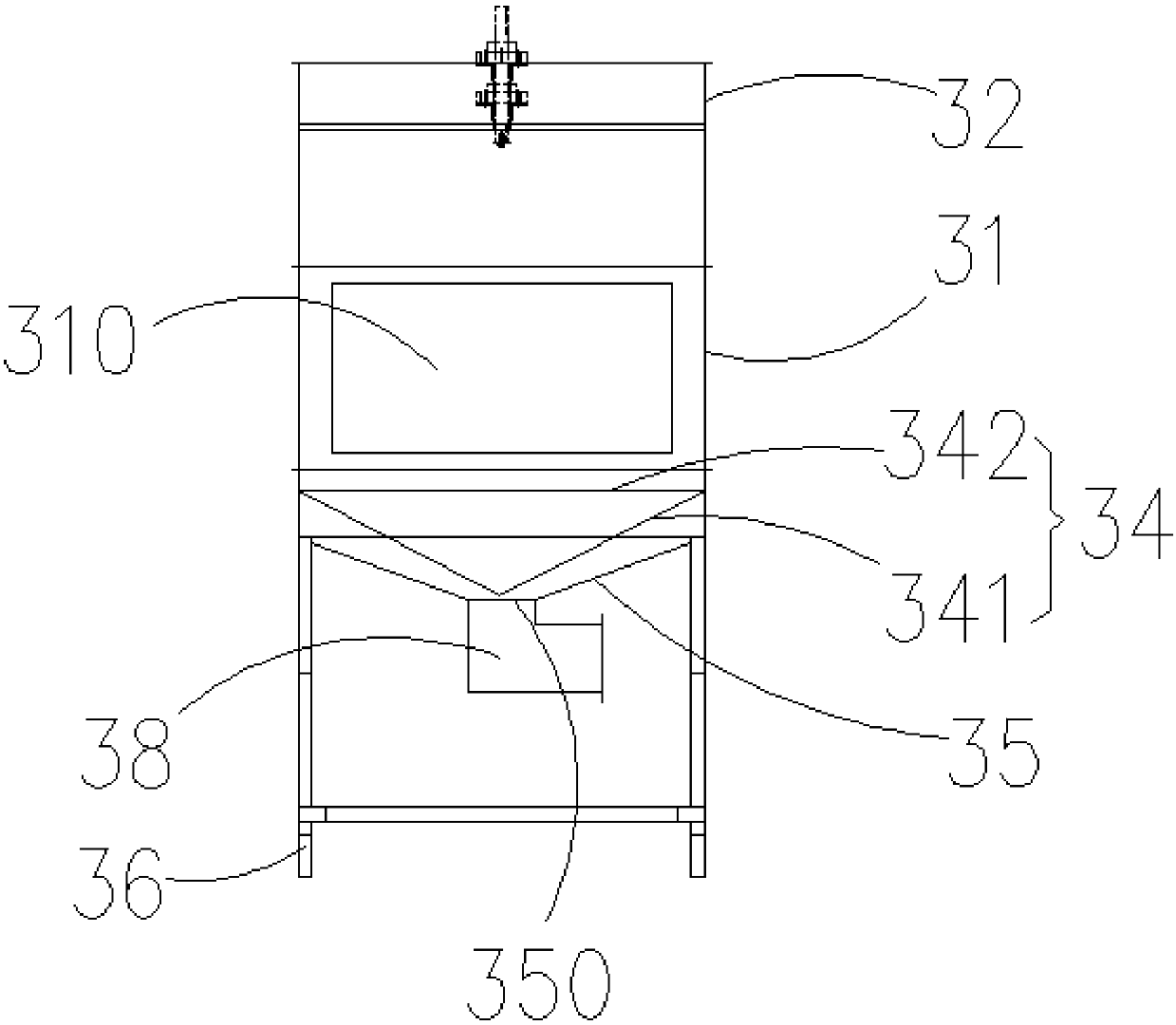

ActiveCN104003569ASolve the hardnessEvaporation energy saving and high efficiencyMultistage water/sewage treatmentUltrafiltrationReverse osmosis

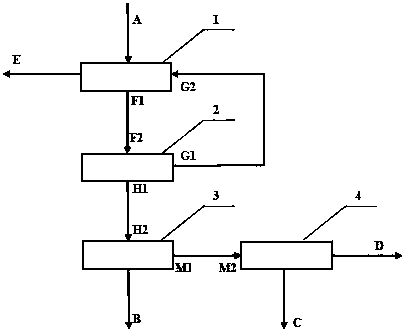

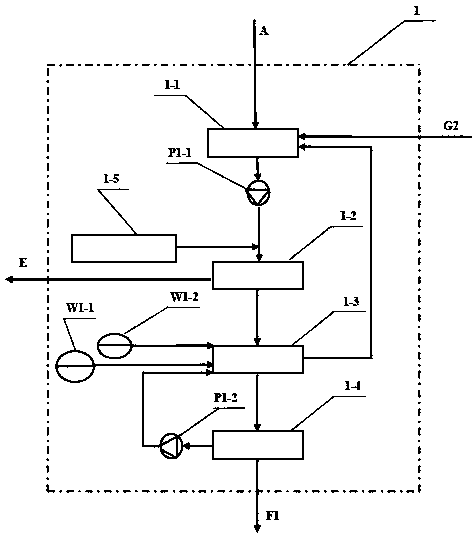

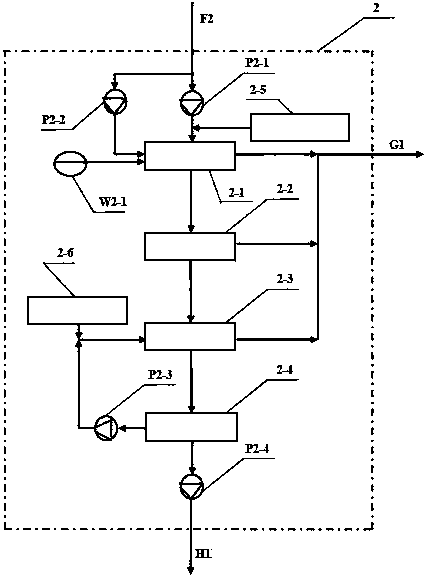

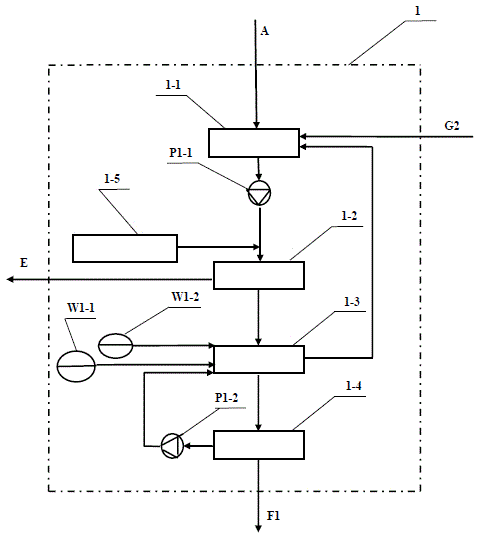

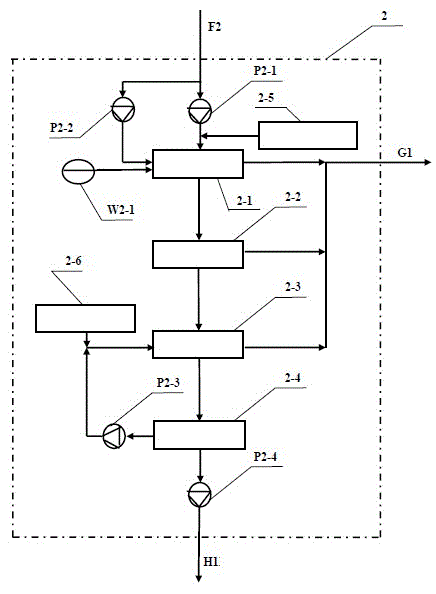

The invention discloses a brine waste water processing reusing device and method. The structure of the device comprises a preprocessing system 1, an ultrafiltration processing system 2, a reverse osmosis processing system 3 and a negative pressure spray evaporation processing system 4. The device has the advantages that the device can be suitable for water draining, circulating water sewage draining, boiler sewage draining, demineralized water station resin regenerating water draining and the like of brine waste water primary treatment; organic pollutants and hardness in brine waste water are removed, and salinity is lowered; (3) the purposes of reusing and zero emission by efficient evaporating on thick water are achieved; (4) preprocessing, ultrafiltration and reverse osmosis are combined organically; (5) rolling type reverse osmosis and flat plate reverse osmosis are combined, and decrement is concentrated to the maximum degree; and (6) energy is saved, efficiency is high in low-temperature negative-pressure spray evaporation, and the purposes of reusing and zero emission are achieved.

Owner:安徽森诺膜技术有限公司

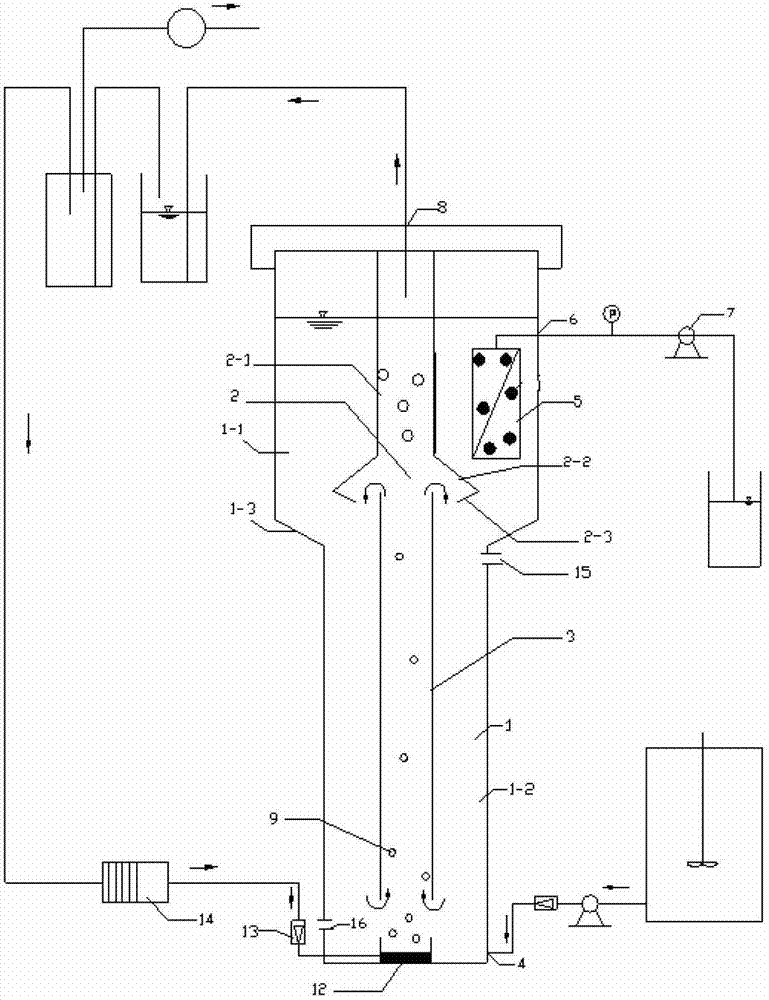

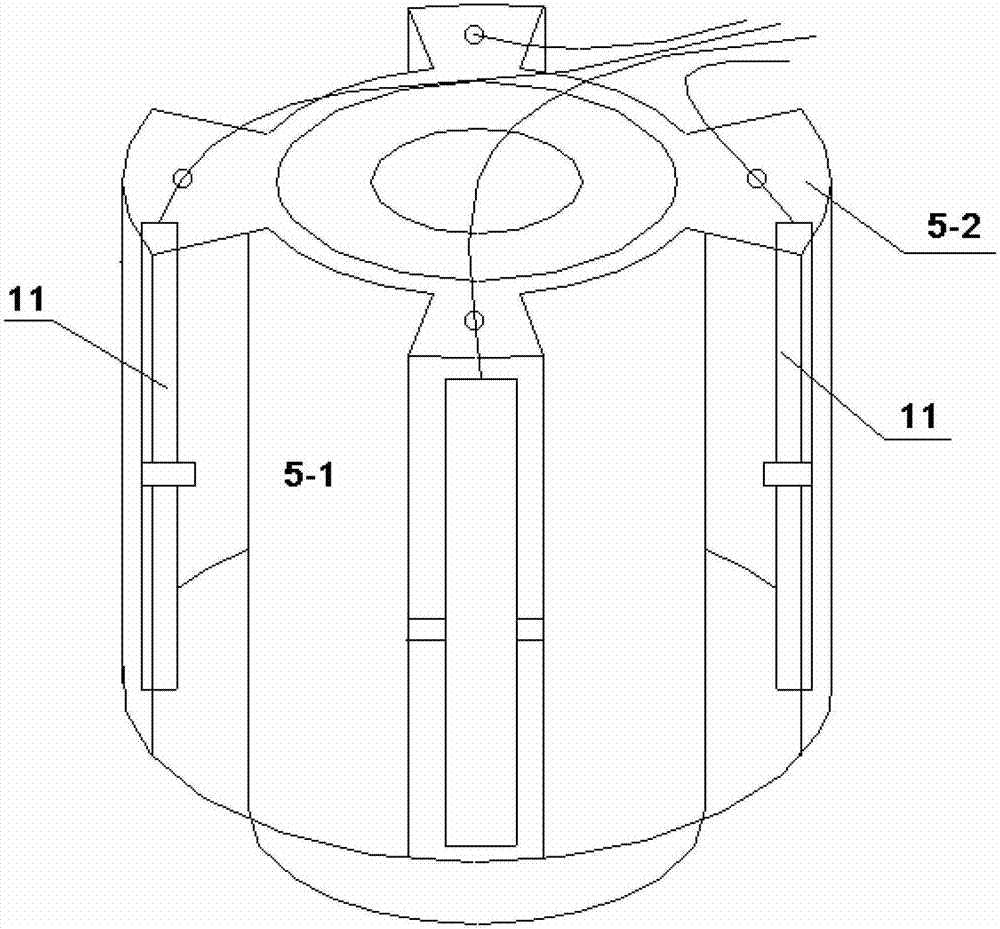

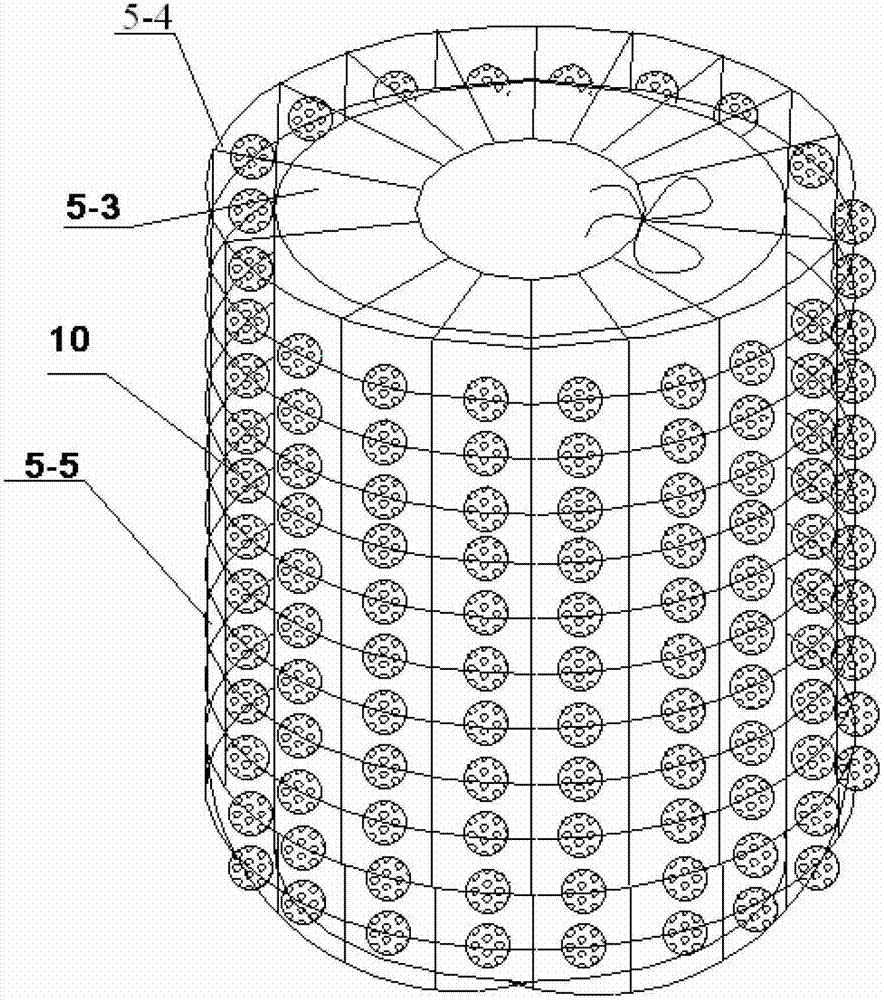

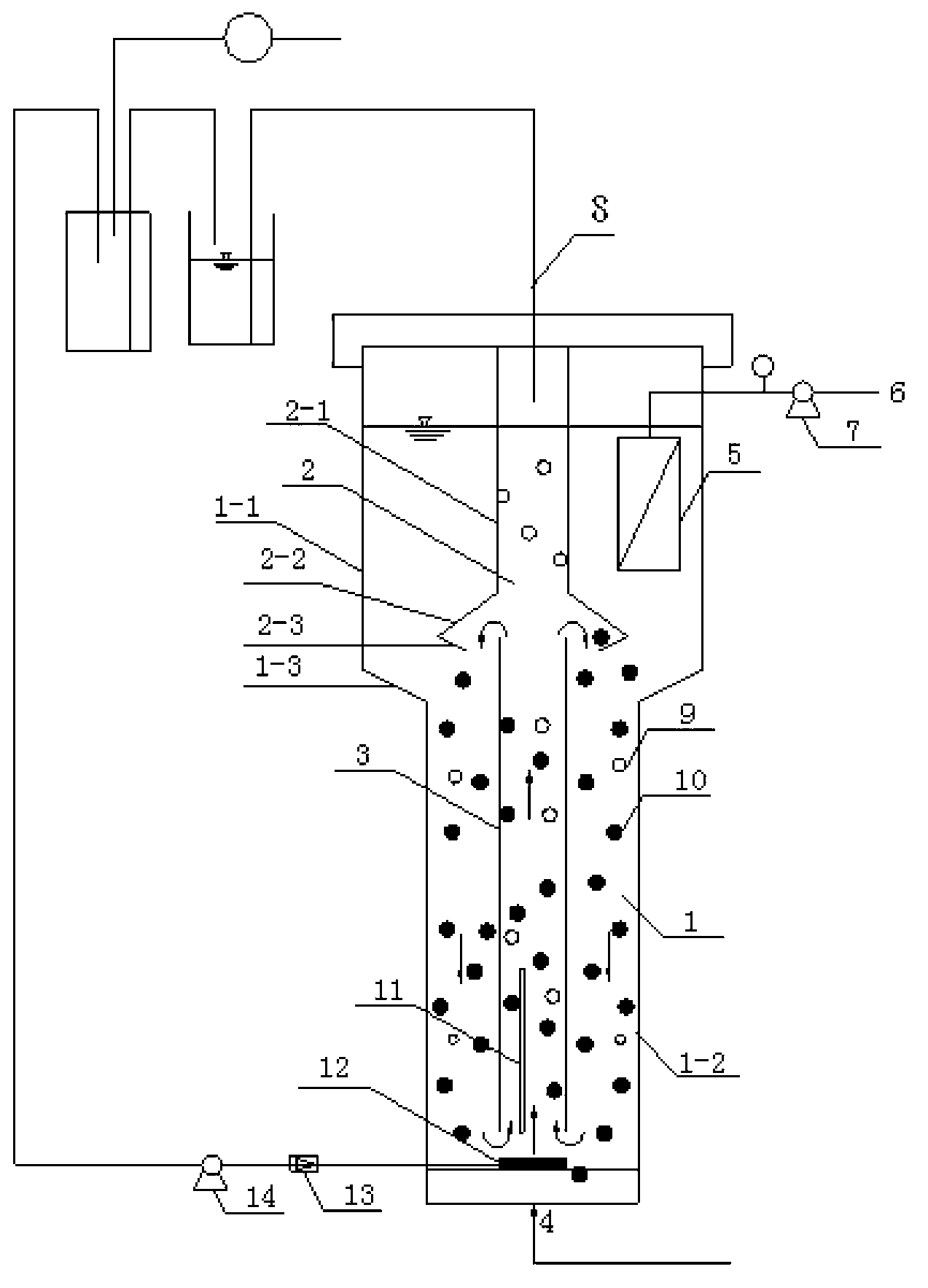

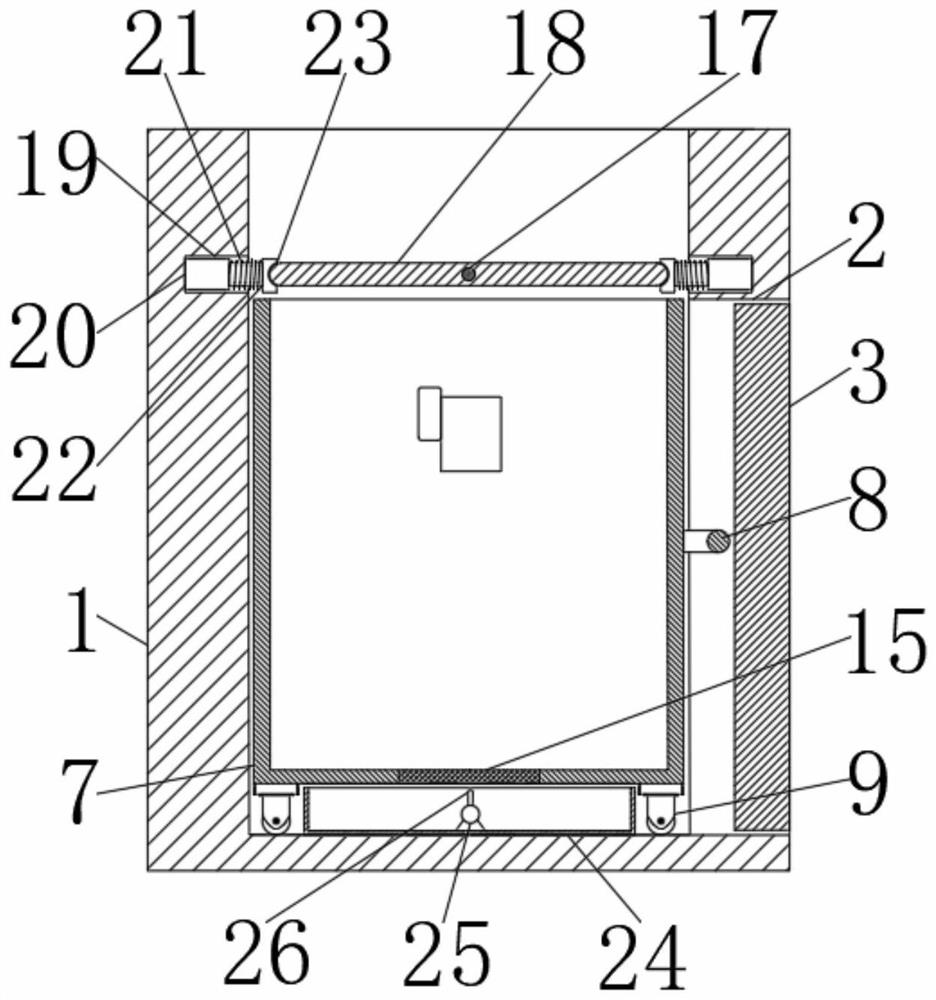

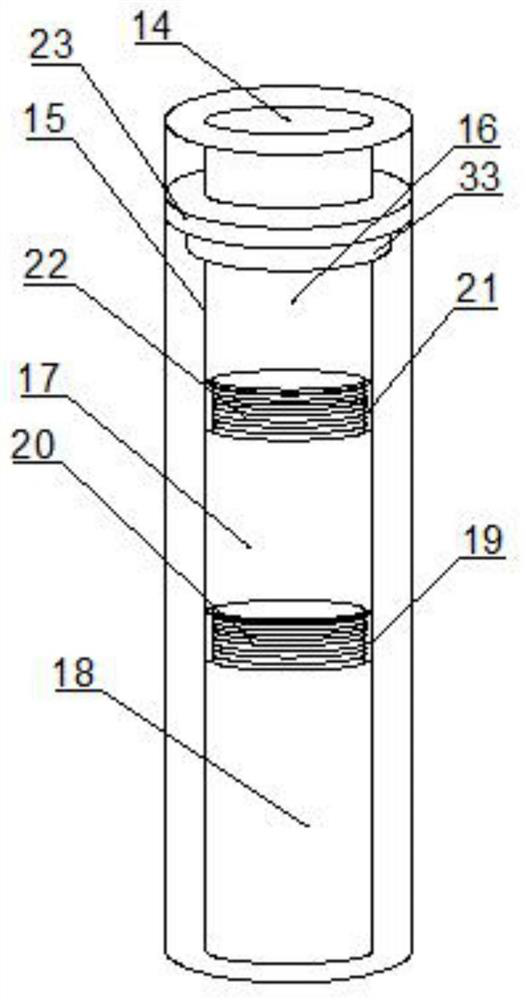

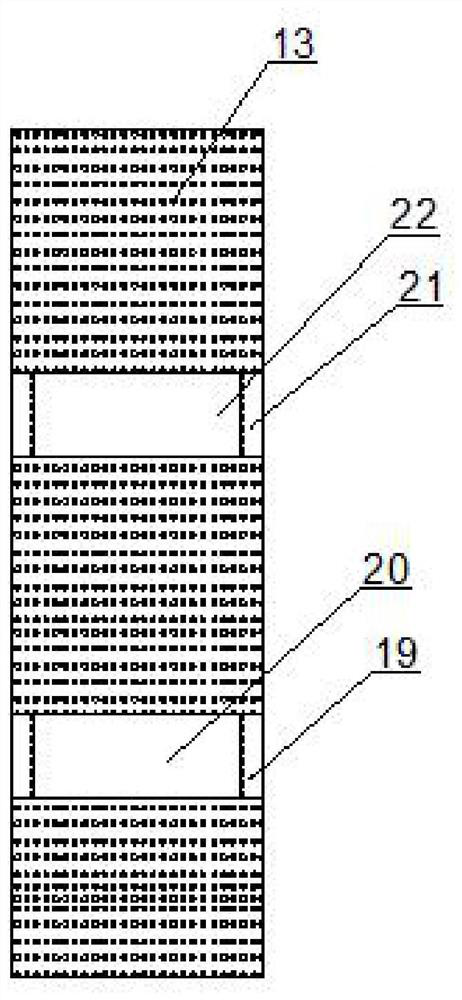

Photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor and working method thereof

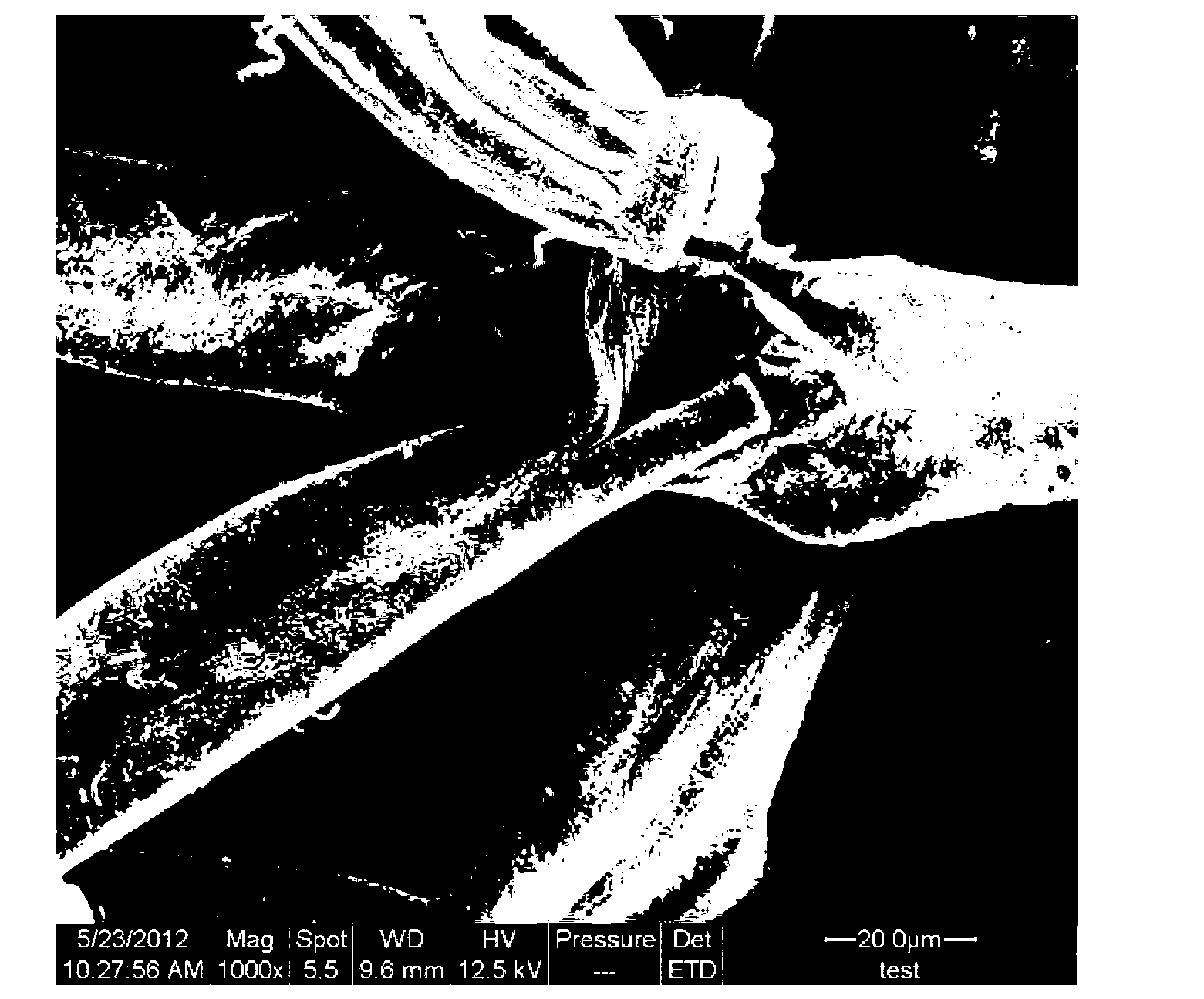

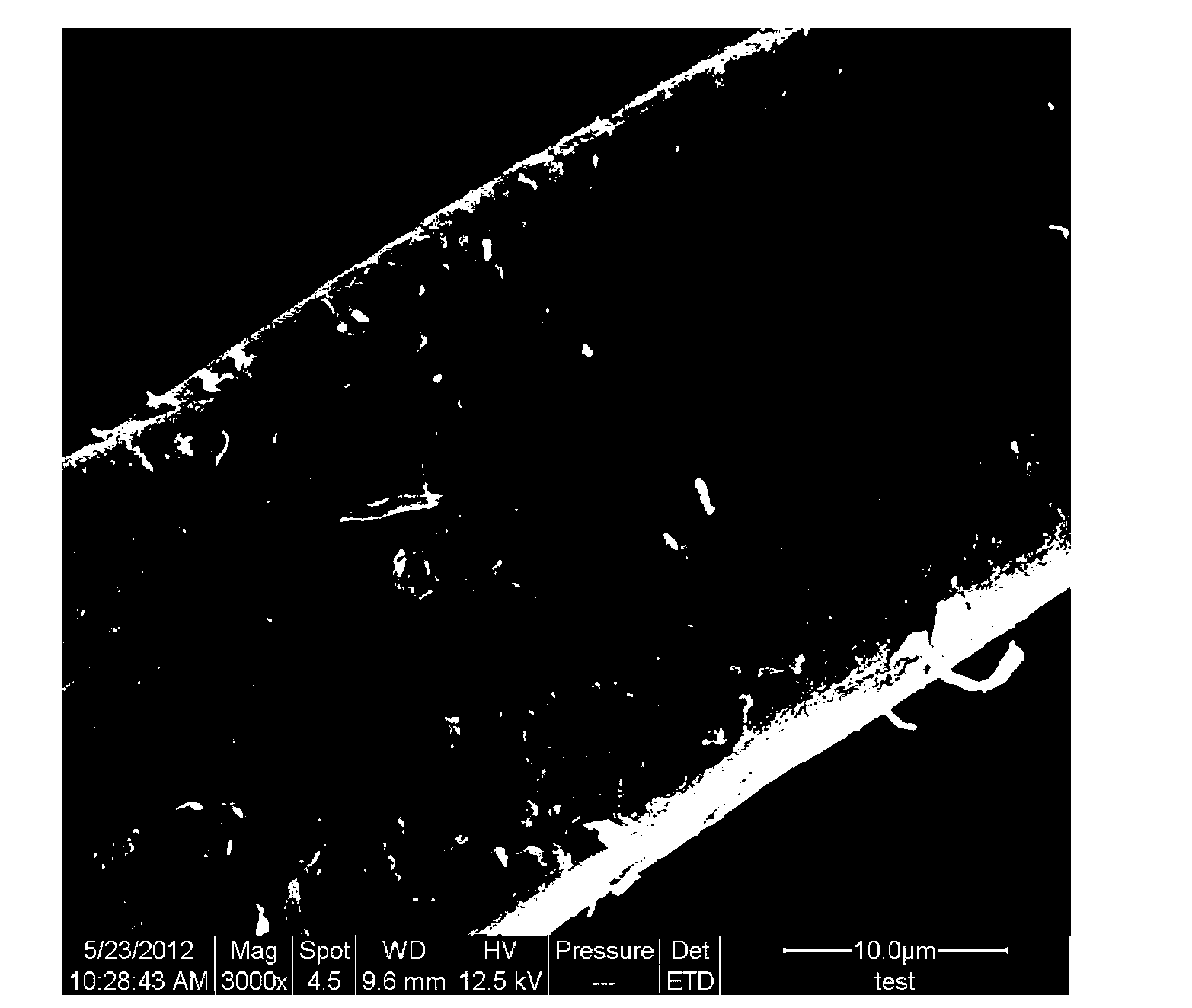

InactiveCN103073150AEasy to handleAchieve the purpose of recyclingWater/sewage treatment by irradiationWaste based fuelFiberPhotocatalytic reaction

The invention relates to a photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor. The photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor comprises a reaction barrel, a gas stripping barrel, a three-phase separator and a membrane assembly, wherein a water inlet pipe and a gas inlet pipe are arranged at the bottom of the reaction barrel; and the membrane assembly is a cylindrical ceramic membrane loaded with nano-titanium dioxide particles, or the membrane assembly is a hollow fiber ultrafiltration membrane of which a light titanium dioxide particle mesh is hung on the outer surface. The invention further discloses a working method of the photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor. An internal-circulation anaerobic treatment technology and a titanium dioxide photocatalytic technology are combined, and advantages of an anaerobic membrane bioreactor and a photocatalytic bioreactor are combined, so that quality of outlet water is obviously improved; and the membrane assembly is arranged at a supernatant part of a three-phase separation zone and doses not directly contact sludge, and nano-titanium dioxide has a photocatalytic effect, so that membrane pollution is greatly reduced, the service life of the membrane assembly is prolonged, and manpower and material resources required in a membrane replacing cycle are reduced.

Owner:SHANDONG UNIV

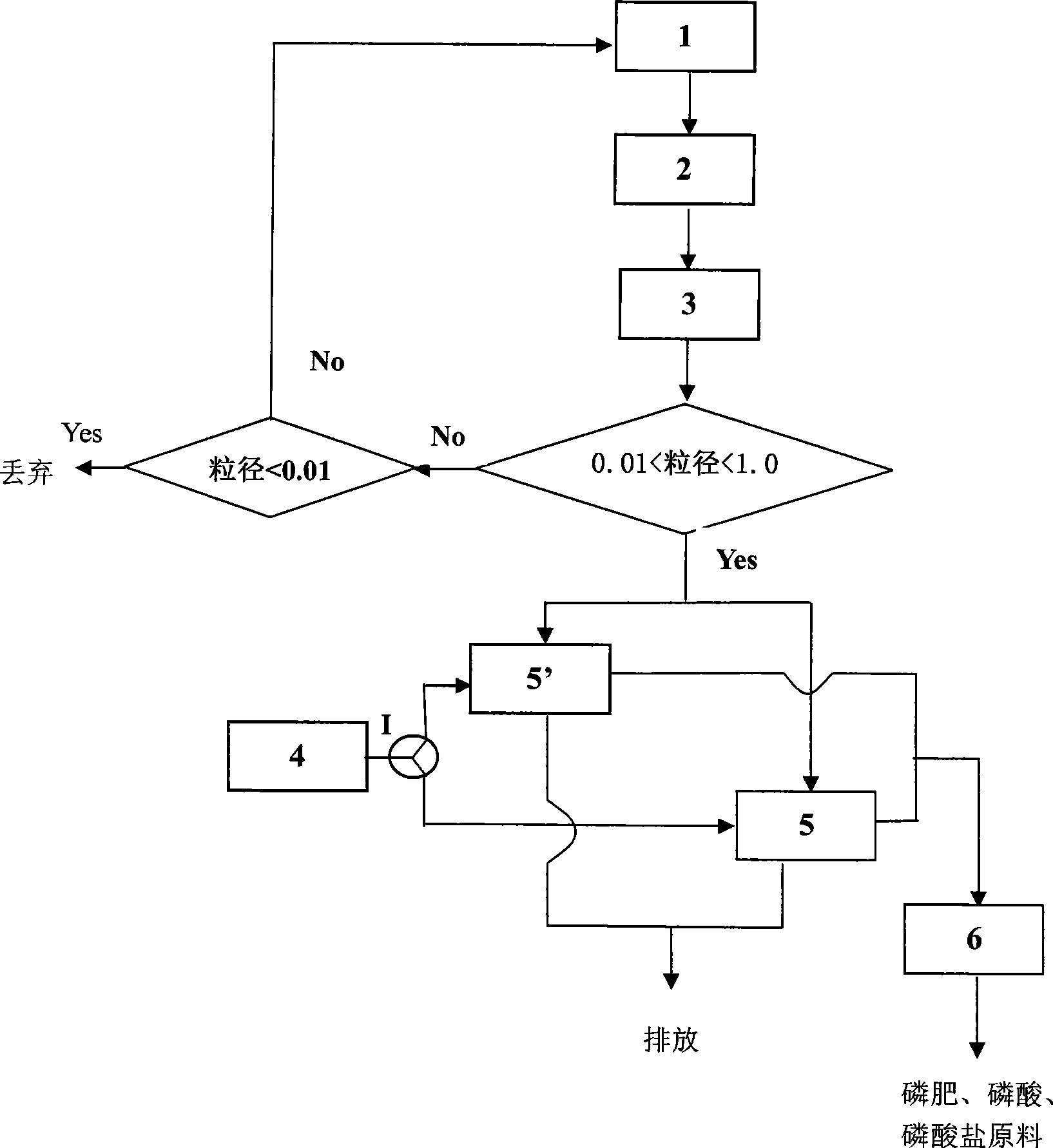

Method for removing phosphor-containing wastewater by using fly ash aerated concrete slag

InactiveCN101475253AAchieve the purpose of recyclingThe process device is simpleWater/sewage treatment by sorptionSlagResource utilization

The invention discloses a method for removing phosphorus in phosphorous wastewater through broken slag of building waste such as waste fly ash aerated concrete blocks. After treatment, the removing rate of the phosphorus can reach over 99 percent. The fly ash aerated concrete blocks are crushed to form the broken slag having the particle diameter of between 0.01 and 1.0 mm; and the broken slag is filled in equipment with a similar sand filter structure to form a phosphorus filter. As fly ash aerated concrete has the property of high-efficiency adsorption to the phosphorous, the phosphorous in the wastewater is continuously adsorbed and removed when the phosphorous wastewater passes through the phosphorus filter; the content of the phosphorus in the adsorbed saturated broken slag reaches as high as 34.85 percent (be equivalent to 79 percent of P2O5); and the broken slag can be used as a slow-release phosphate fertilizer for application or a high-quality raw material for preparing phosphoric acid and phosphate. The method has a simple process and easy implementation, can remove pollution of the phosphorus of the wastewater to environment, can perform resource utilization of the phosphorus in the waste fly ash aerated concrete blocks and the wastewater, uses waste to treat waste, and is environment-friendly.

Owner:深圳龙澄高科技环保股份有限公司

Method for preparing cellulose based dye waste water purification material with waste newspaper

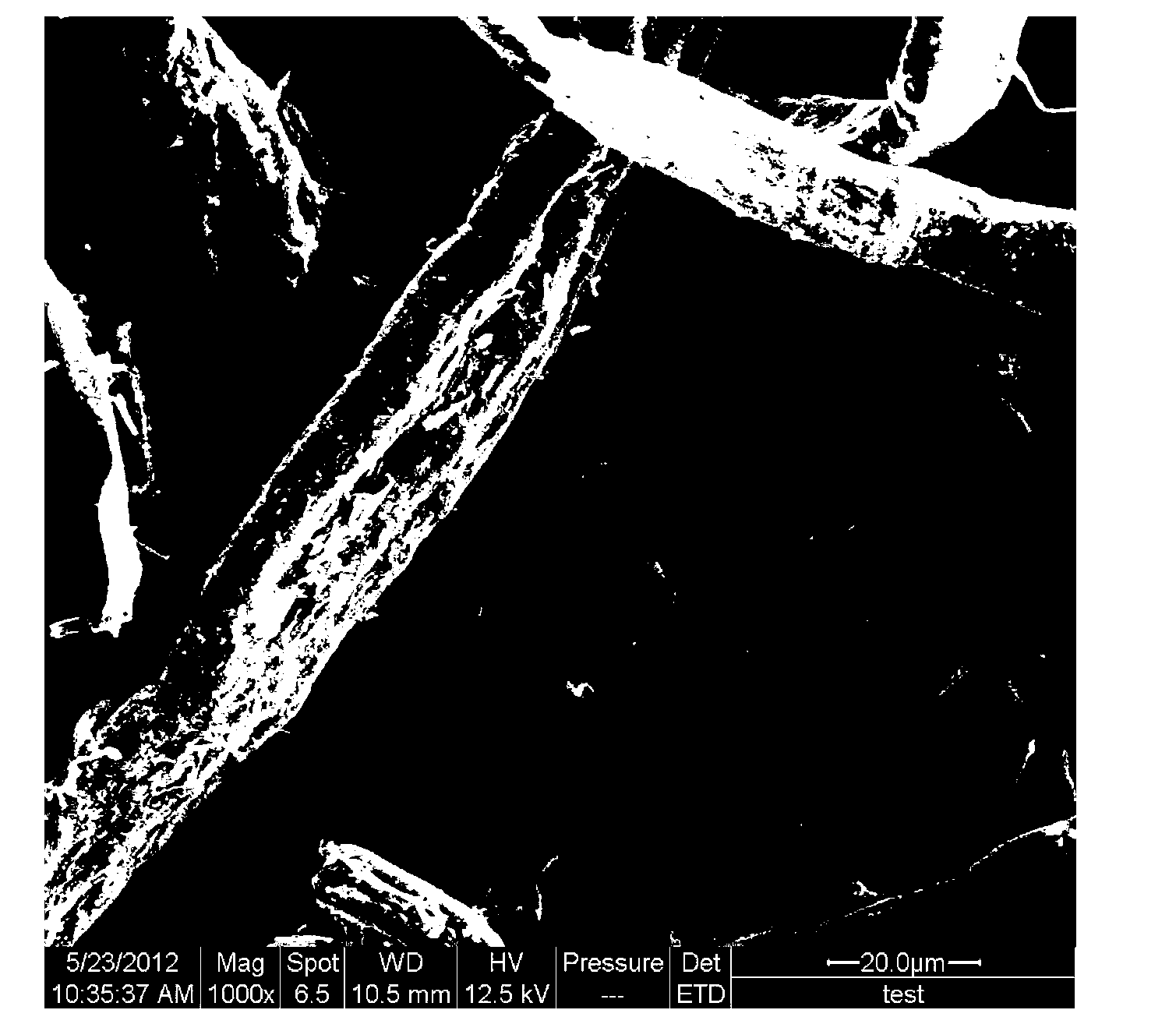

InactiveCN103212379AImprove protectionEfficient use ofOther chemical processesWater/sewage treatment by sorptionCelluloseFiber

The invention relates to a method for preparing a cellulose based dye waste water purification material with waste newspaper, which solves the problems that in the prior art, the existing waste newspaper recycle rate is low, the absorption efficiency of the dye waste water purification material is low, and the process effect of the purification material is not prominent. The method comprises the following steps: mixing and stirring the waste newspaper, Na2Si3 9H2O, H2O2, NaOH and a surfactant to obtain deinked cellulose; washing, drying, crushing and screening the cellulose to obtain waste newspaper fiber; adding a NaOH solution into the waste newspaper fiber, stirring the mixture and filtering out half of the NaOH solution, adding epoxy chloropropane into the remain solution, stirring the solution, filtering out the water, and cleaning the fiber; adding tetramethyl ethylene diamine into the fiber, stirring and filtering the mixture, and cleaning the fiber; adding methyl carbonate into the fiber, stirring and filtering the mixture, and finally cleaning and drying the fiber. The waste newspaper is changed into an environment-friendly cellulose adsorbent which is conducive to environmental protection; the anionic dye solution adsorption efficiency is high, the adsorption capacity is also high, and the absorption effect is obvious.

Owner:NORTHEAST FORESTRY UNIVERSITY

Photocatalytic internal-circulation anaerobic fluidized membrane bioreactor and working method thereof

InactiveCN102936081AEasy to handleAchieve the purpose of recyclingPhysical/chemical process catalystsMultistage water/sewage treatmentUltraviolet lightsPhysical chemistry

The invention relates to a photocatalytic internal-circulation anaerobic fluidized membrane bioreactor which comprises a reaction cylinder, a gas stripping cylinder, a three-phase separator and a membrane element, wherein the bottom of the reaction cylinder is provided with a water inlet pipe and a gas inlet pipe; light-weight granules carrying titanium dioxide are arranged in the reaction cylinder; the inside of the reaction cylinder is axially provided with a marsh gas aeration tray, the gas stripping and the three-phase separator from bottom to top; and an ultraviolet light source is arranged in the gas stripping cylinder. The invention also provides a method for treating wastewater by using the reactor. The invention combines multiple sewage treatment technologies, implements high-efficiency treatment of nondegradable wastewater, achieves the goal of wastewater recycling, and is a high-efficiency practical sewage / wastewater treatment and recycling technique.

Owner:SHANDONG UNIV

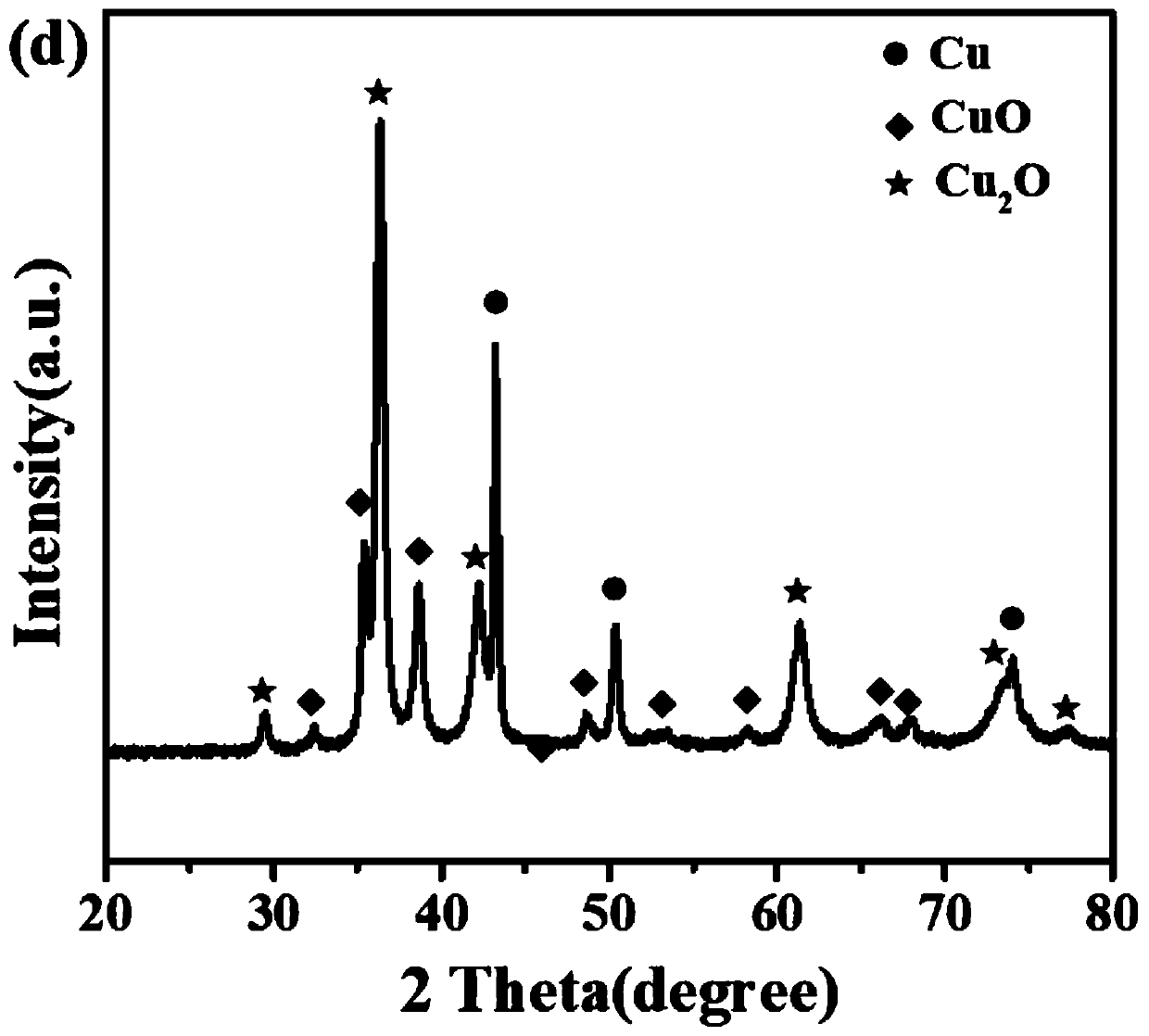

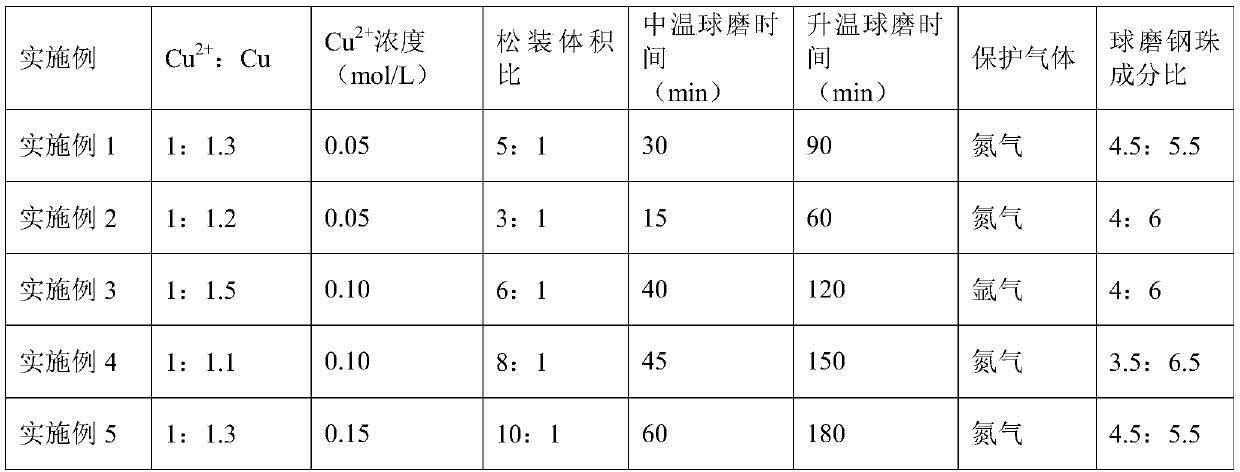

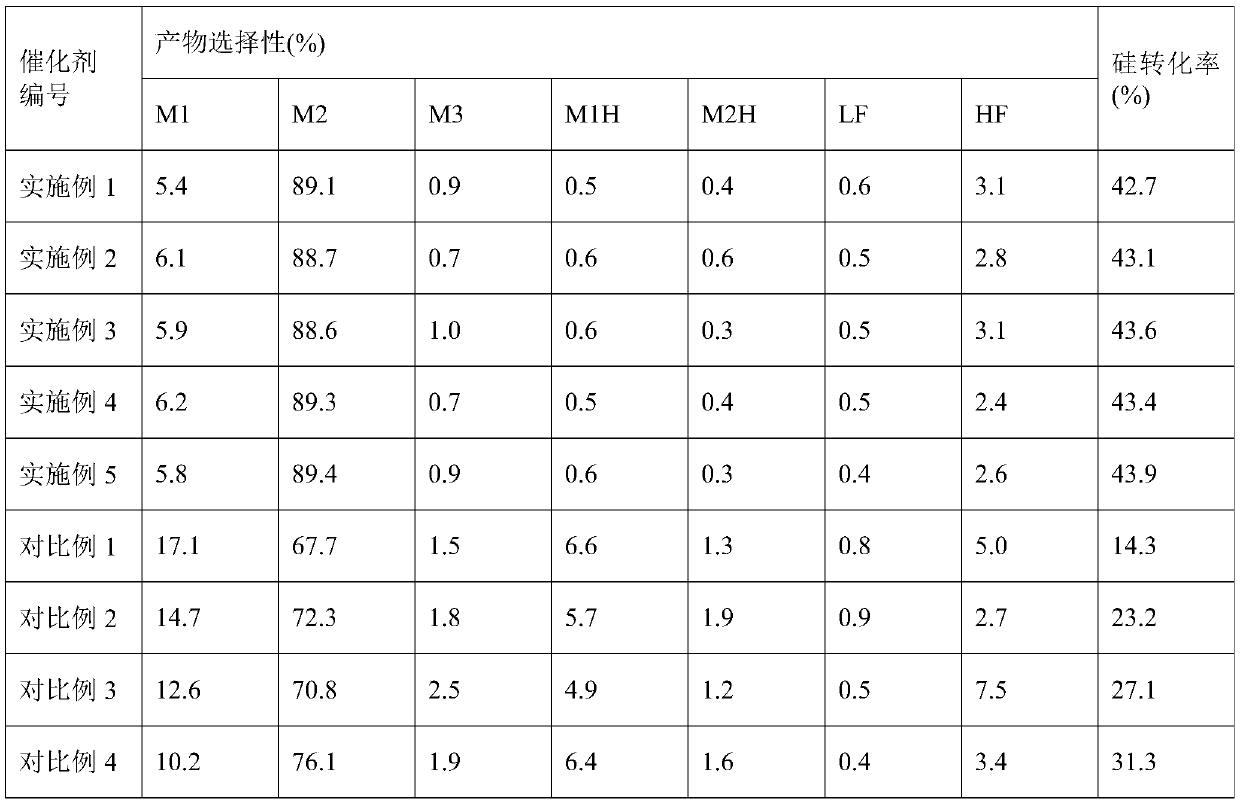

Preparation method of ternary copper catalyst with high specific surface area

ActiveCN110773177AIncrease profitAchieve recyclingGroup 4/14 element organic compoundsCatalyst activation/preparationPtru catalystMetallurgy

The invention relates to the field of copper catalysts, particularly to a preparation method of a ternary copper catalyst with a high specific surface area. The method comprises:1) adding excessive metal copper micro-powder into a copper solution, reacting for a certain time, adding an alkali liquor to adjust the pH value so as to separate out precipitate, filtering, and separating to obtain solidparticles; 2) introducing a protective gas into a ball mill to form a protective atmosphere, placing the obtained solid particles and an acidic auxiliary agent into the ball mill, and carrying out medium-temperature ball milling to obtain an intermediate; and 3) keeping the protective atmosphere, and continuously carrying out heating and ball-milling on the intermediate to obtain the ternary copper catalyst with the high specific surface area. According to the invention, the prepared ternary copper catalyst has extremely high specific surface area so as to achieve excellent catalytic effect.

Owner:安徽德诠新材料科技有限公司

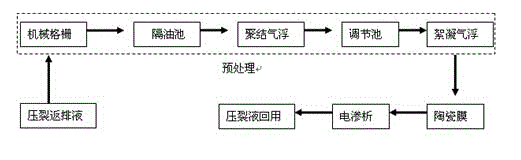

Unconventional oil field exploration and development fracturing flowback fluid reuse treatment method

InactiveCN105668864AReduce turbidityReduce salinityWaste water treatment from quariesMultistage water/sewage treatmentTurbidityWater quality

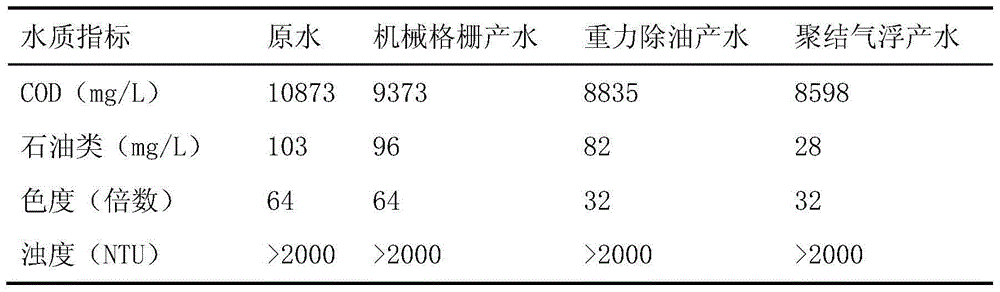

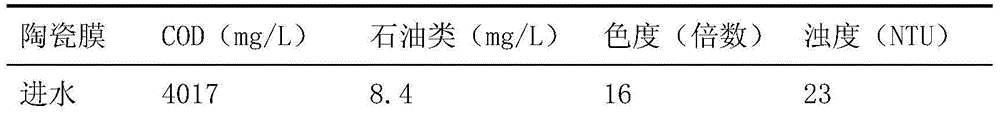

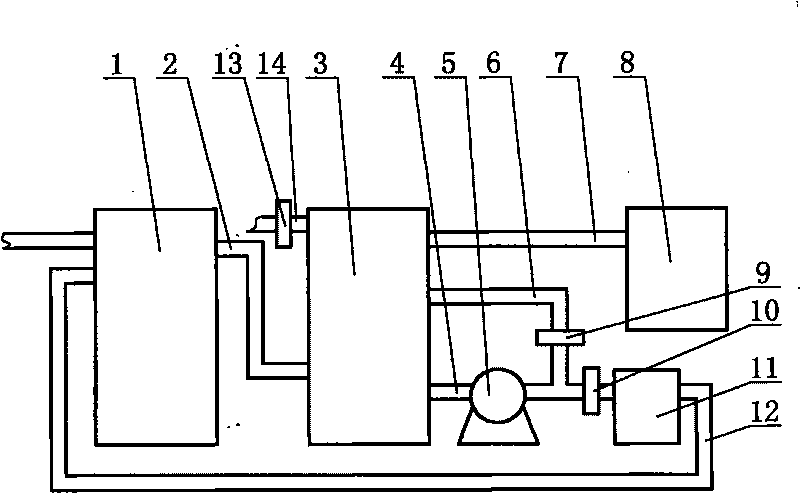

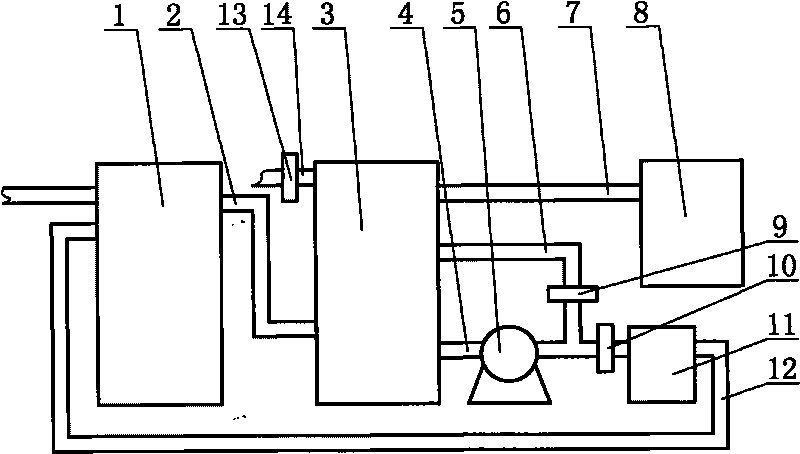

The present invention provides an unconventional oil field exploration and development fracturing flowback fluid reuse treatment method. The treatment method includes the following specific steps: pretreatment, ceramic membrane microfiltration treatment and electrodialysis treatment. The pretreatment section uses processing steps of mechanical grid, oil separator, coalescence and flotation, conditioning tank, and flocculation and flotation, effectively removes chunks of contaminant, particle suspended solids and oil in various forms, etc. in water body, mitigates the ceramic microfiltration membrane operating load, and ensures a smooth and efficient operation of the ceramic microfiltration membrane. The ceramic membrane microfiltration can ensure a stable water quality of the produced water, effectively reduce turbidity and oil content in the water body, further improve the water quality, and delay the pollution trends of electrodialysis device. The electrodialysis technology uses the operation of the electrodialysis device to treat the treated pressure flowback fluid in a light chamber and a concentrated chamber of the device, so as to significantly reduces water body mineralization and achieves the purpose of reuse.

Owner:CHINA PETROLEUM & CHEM CORP +1

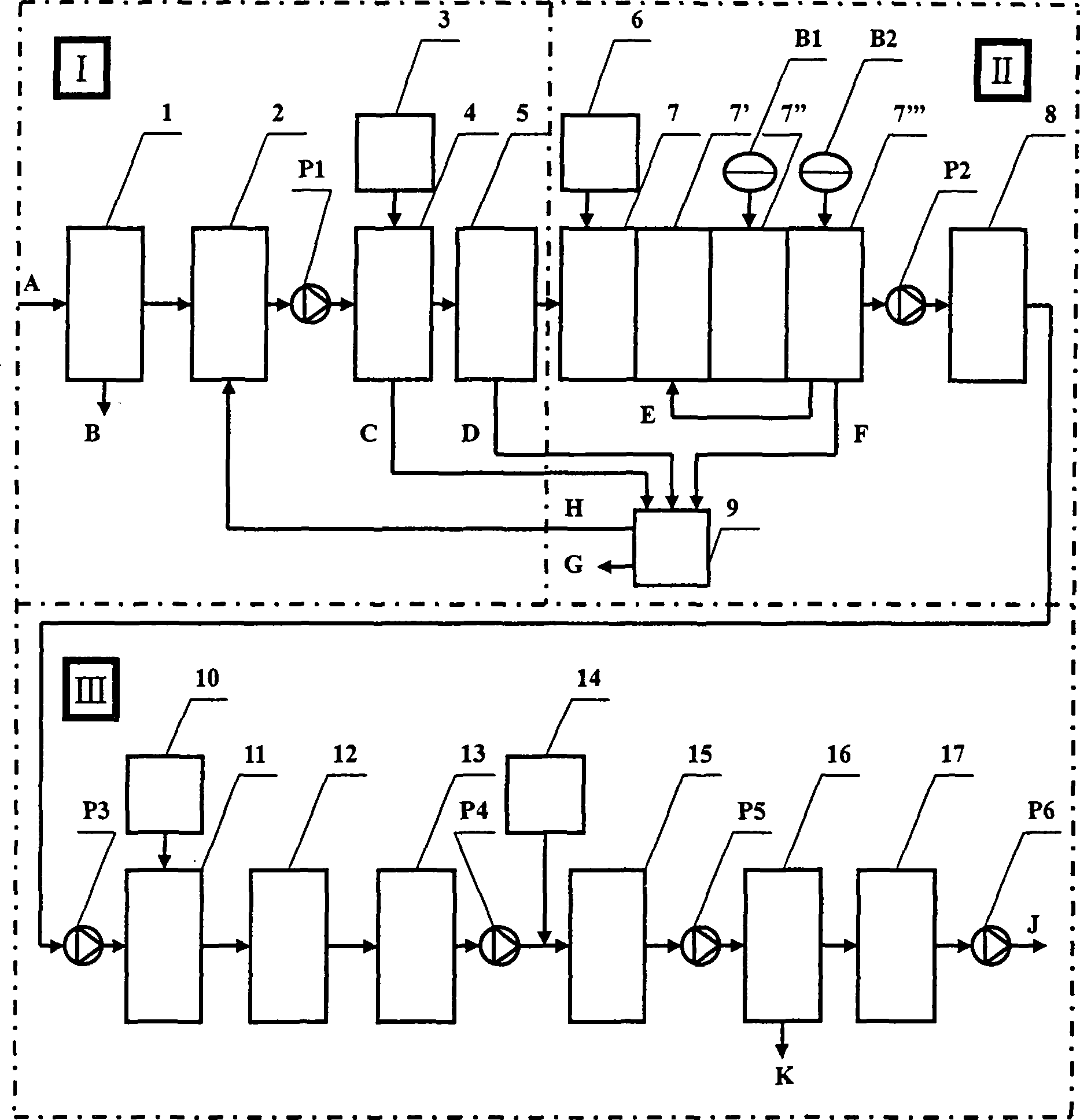

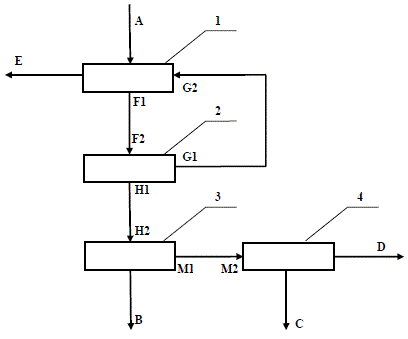

Process for recovering organic matters in hydrogen chloride gas and equipment used by same

InactiveCN101721886ASimple and reasonable processIntroduction to Process StepsDispersed particle separationChemistryHydrogen chloride

The invention discloses process for recovering organic matters in hydrogen chloride gas and equipment used by same. The process comprises the following steps of: (1) inputting mixed gas generated by a methane chloride generation device into an organic matter absorption tower, importing methane chlorides into the organic matter absorption tower as an absorbent to absorb the mixed gas, blending organic matters in the mixed gas in the methane chlorides and exhausting hydrogen chloride gas in the mixed gas; and (2) conveying the hydrogen chloride gas exhausted from the organic matter absorption tower to a hydrogen chloride absorber and absorbing the hydrogen chloride gas in the hydrogen chloride absorber by adopting hydrochloric acid. The invention has the advantages that the organic matters in the mixed gas are absorbed, thereby achieving the purpose of recycling the organic matters in the hydrogen chloride, and the process flow is compact and reasonable. Compared with the prior art, the invention has simple process steps and can greatly reduce the cost, and the like.

Owner:聊城鲁西氯甲烷化工有限公司

Multi-path recycling method for wastewater produced in acid-making with smelting gas

ActiveCN107512813AReliable operationLow running costSulfur compoundsTreatment involving filtrationChemistryHeavy metals

The invention discloses a multi-path recycling method for wastewater produced in acid-making with smelting gas, which belongs to the technical field of chemical engineering. The method comprises the steps of firstly performing discharging reduction on the acid wastewater by an internal circulation concentration method of a purification system, treating the acid wastewater by a process of primary vulcanization, neutralization and secondary vulcanization to remove heavy metals, arsenic, sulfuric acid, iron and zinc in the acid water in sequence, according to market demand, producing magnesium sulfate heptahydrate by cooling crystallization, and preparing sulfuric acid solution by evaporation concentration, thus realizing the ultimate goal of zero acid wastewater discharging. The process flow is reliable and can be used for recycling the acid water in two different ways; operating cost is low, new produced waste quantity is small, multiple products can be produced for generating profit, slag generated in different stages has different utilization values, and the aim of multi-path recycling of the acid wastewater is truly realized.

Owner:JINCHUAN GROUP LIMITED

Waste white clay recovery and utilization method

ActiveCN109908881ARelaxed process conditionsReduce manufacturing costCombustible gas purificationFilter regenerationSolid phasesChemistry

The invention discloses a waste white clay recovery and utilization method, which comprises: carrying out mixing treatment on waste white clay and water, and separating the obtained material through standing to obtain three layers of a solid phase, a water phase and an oil phase; carrying out mixing treatment on the obtained solid phase and a treating agent, standing, removing the uppermost layermaterial, and further carrying out solid-liquid separation to obtain filtrate and waste white clay; and washing the waste white clay, and drying to obtain regenerated white clay. According to the present invention, with the method, oil, colloid and asphaltene can be separated from the waste white clay while the structure of the white clay is not damaged so as to conveniently achieve the subsequentregeneration and reuse of the white clay, other pollutions are not generated during the treatment, and the activity of regenerated white clay is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and tower for quickly precipitating papermaking sewage

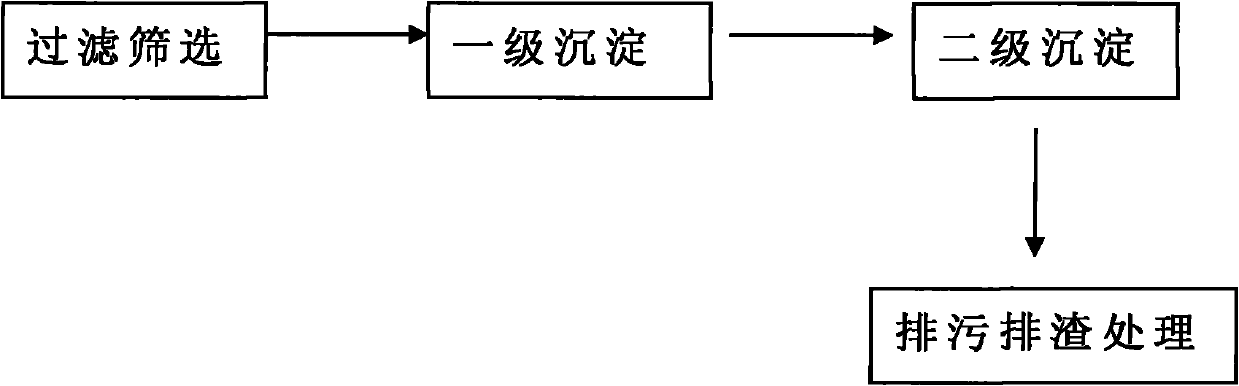

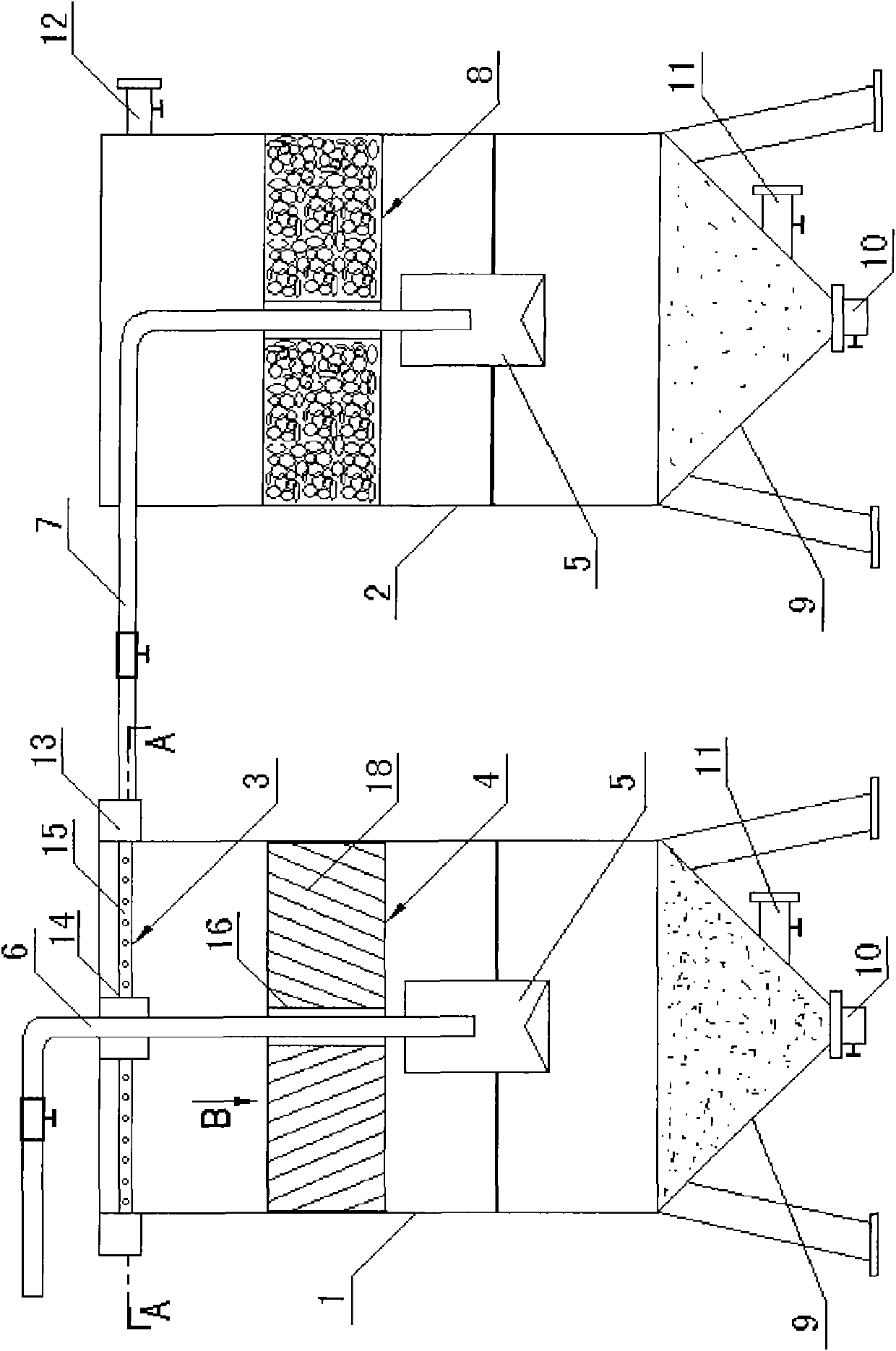

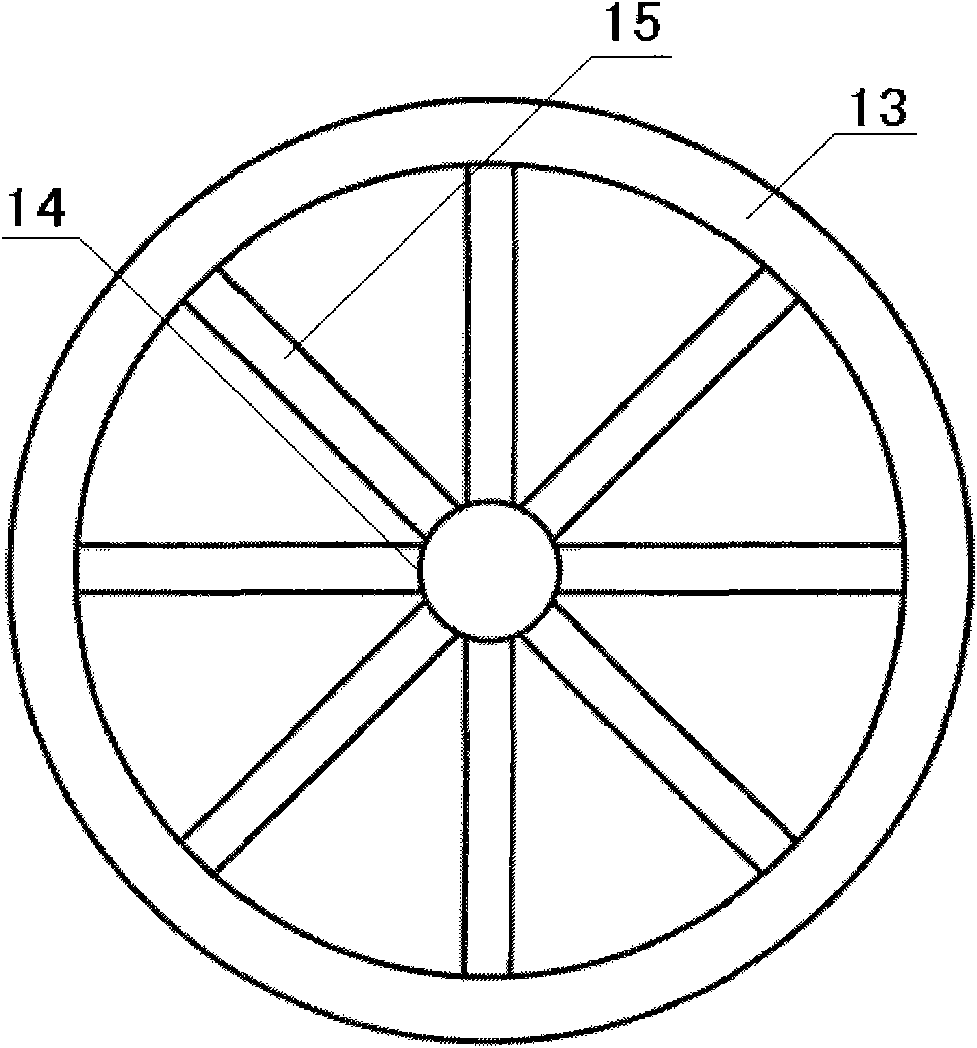

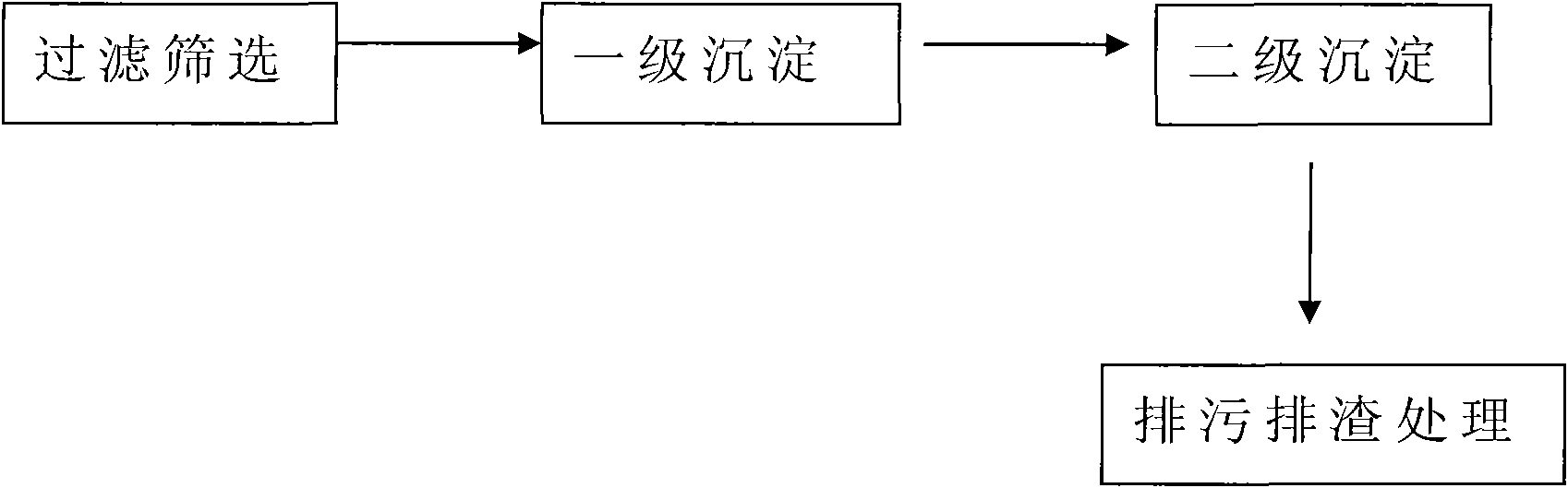

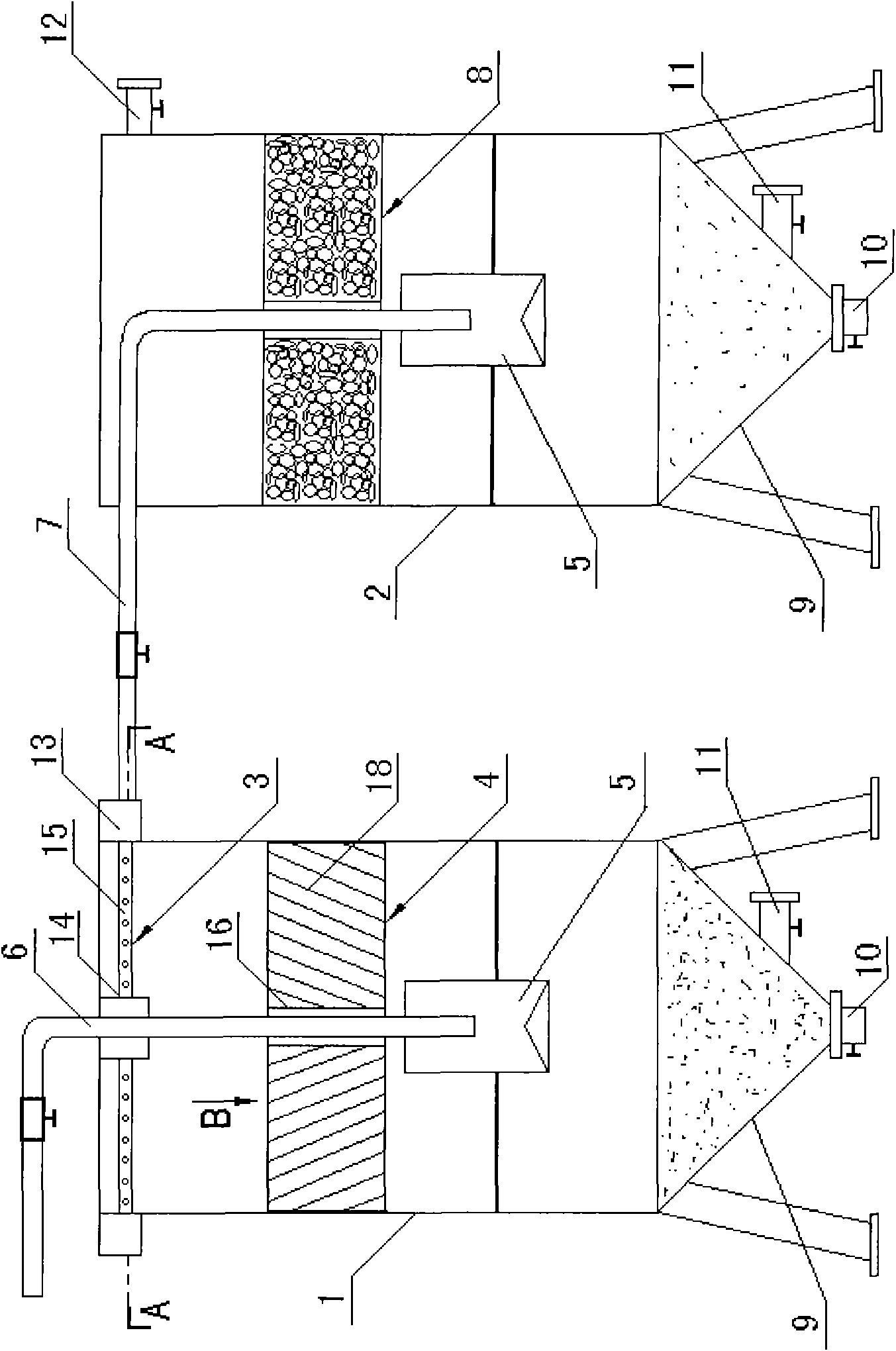

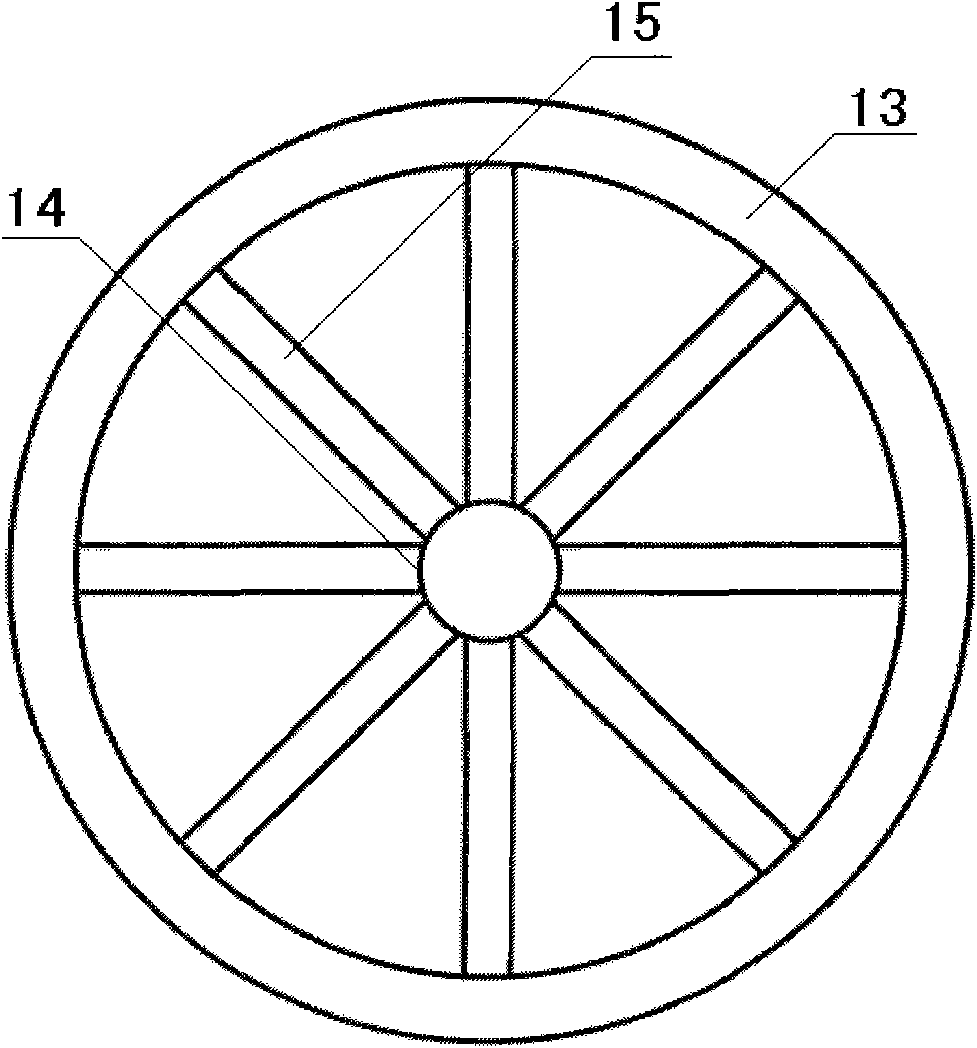

InactiveCN102198967AGood effectTo achieve the goal of zero emissionsWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationSlagPapermaking

The invention relates to a method for treating papermaking sewage, in particular to a method and a tower for quickly precipitating the papermaking sewage. The papermaking sewage of small papermaking enterprises is treated by a two-stage quick precipitation method through synergy of a radial water outlet device, an inclined plate precipitation device, a buffer slot and a spherical filtering filler layer on the quick precipitation tower and process steps of filtering and screening, first-stage precipitation, second-stage precipitation, sewage and slag removal and the like; and the process technology is reasonable, equipment has a simple structure, and the aims of treating papermaking industrial pollution, saving energy and reducing emission can be fulfilled.

Owner:梨树县郭家店汇泉造纸机械厂

Dye-sensitized solar cell for recovering energy from sewage

ActiveCN103762086AIncrease electron yieldAccelerates the process of degrading organic pollutantsLight-sensitive devicesGeneral water supply conservationIonPhysics

The invention discloses a dye-sensitized solar cell for recovering energy from sewage. According to the dye-sensitized solar cell for recovering the energy from the sewage, a chirality TiO2 nanotube with the Ag / AgCl load serves as the anode, a P / TiO2-Pt electrode serves as the cathode, and the dye-sensitized solar cell is formed in the mode that the chirality TiO2 nanotube with the Ag / AgCl load, the P / TiO2-Pt electrode and an externally-connected circuit are connected. According to the dye-sensitized solar cell for recovering the energy from the sewage, due to the fact that the chirality TiO2 nanotube serves as the anode, the surface plasma resonance effect of the chirality TiO2 nanotube is improved, and the oxidation effect of the anode on organic pollutants is improved; the organic matter on the anode loses electrons to carry out an oxidation reaction so as to generate matter such as H2O and CO2, the electrons are obtained by the cathode, a reduction reaction is carried out, and heavy metal ions such as copper ions are reduced to generate H2. According to the dye-sensitized solar cell for recovering the energy from the sewage, the degradation effect of a fuel cell on the organic matter is improved, the energy is recovered from the sewage, safety and high efficiency are achieved, and harmful substances are not generated.

Owner:HOHAI UNIV

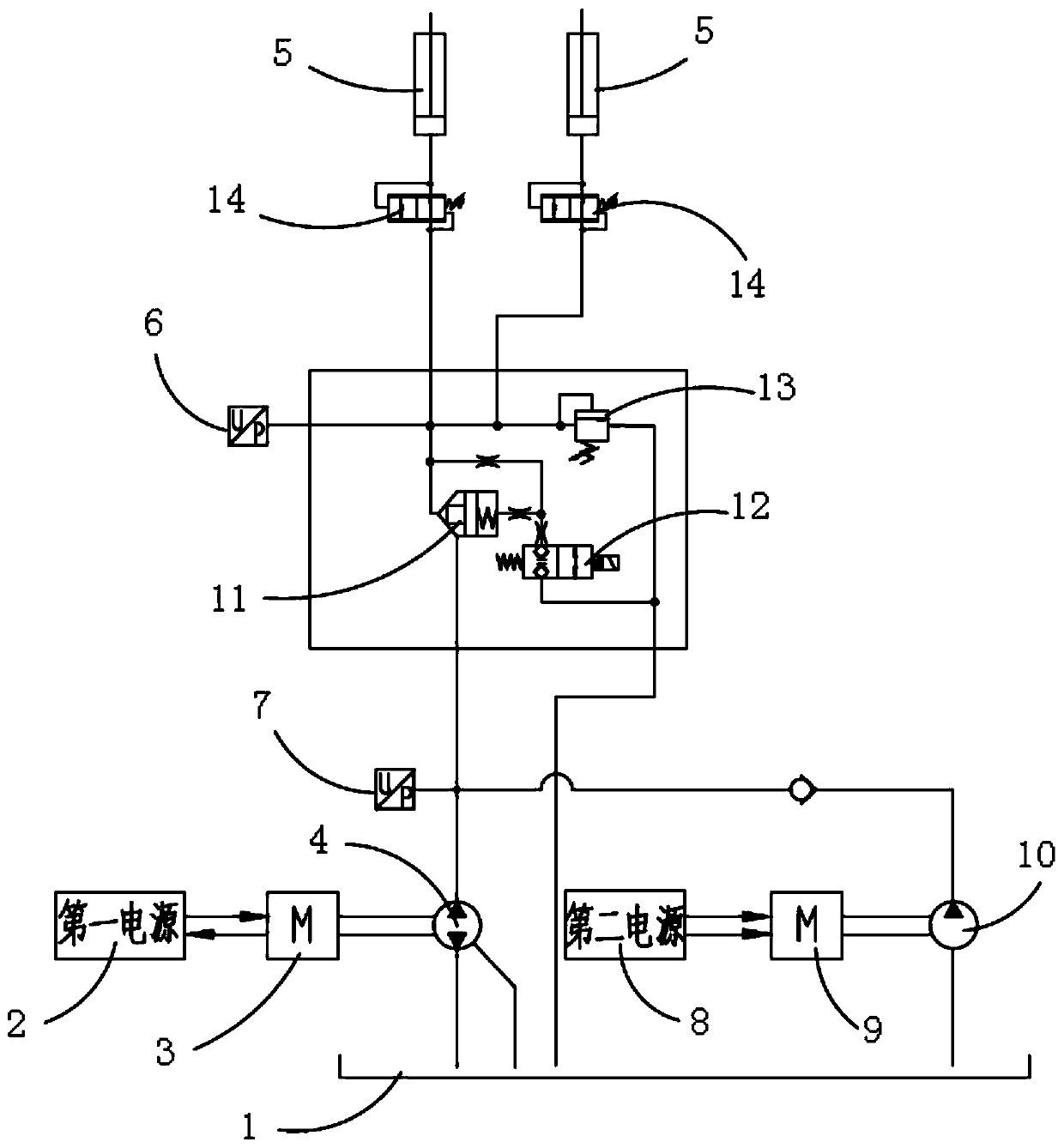

Potential energy recovery system and control method thereof

PendingCN110966151AAchieve the purpose of recyclingReduce lossesServomotorsServometer circuitsElectric machineElectrical connection

The invention relates to the technical field of equipment with a potential energy recovery function, in particular to a potential energy recovery system and a control method thereof. The potential energy recovery system comprises an oil tank, a first power supply, a first motor, a motor, a lifting oil cylinder and a controller, the first power supply is a storage battery, the first motor can be switched between a motor mode and a generator mode, and the lifting oil cylinder is used for driving lifting components to lift; the storage battery is electrically connected with the first motor, the first motor is connected with the motor, the first connector of the motor communicates with the lifting oil cylinder through a valve assembly, and the second connector of the motor communicates with anoil tank; a first pressure sensor is installed between the valve assembly and the lifting oil cylinder, a second pressure sensor is installed between the motor and the valve assembly, and the first pressure sensor, the second pressure sensor, the valve assembly and the first motor are all electrically connected with the controller. The control method is applied to the potential energy recovery system. According to the potential energy recovery system and the control method thereof, the energy conversion efficiency is high.

Owner:SANY MARINE HEAVY IND

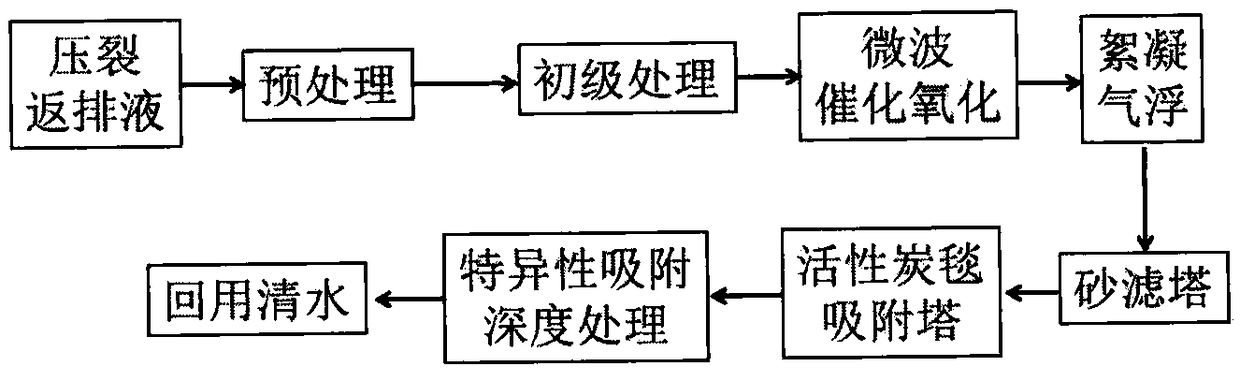

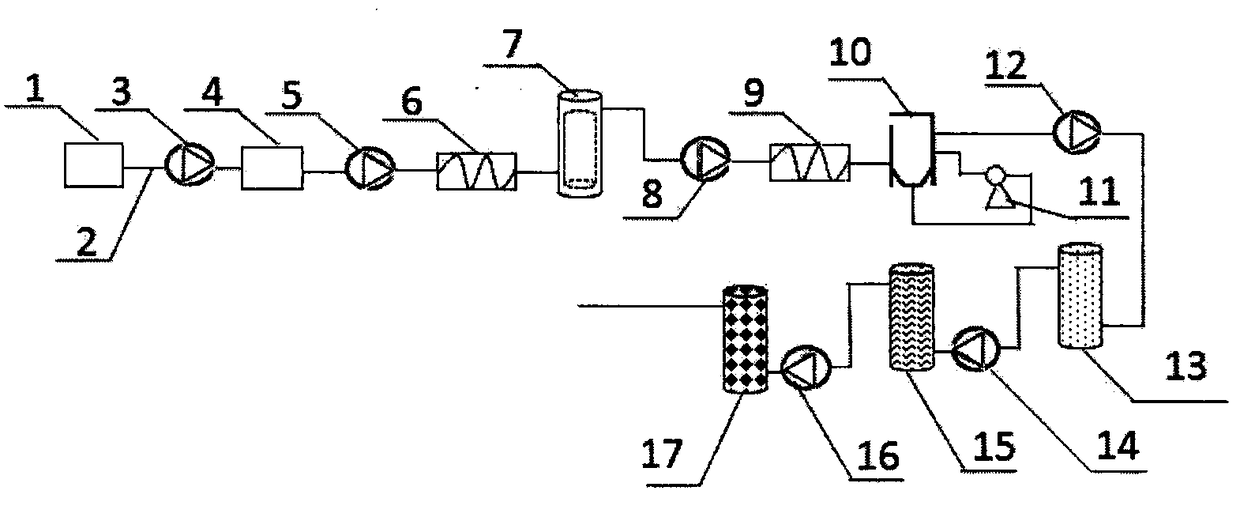

Fracturing flow-back fluid treatment method

PendingCN109455854AOperableImprove processing efficiencyWaste water treatment from quariesTreatment involving filtrationCatalytic oxidationFracturing fluid

The invention relates to a fracturing flow-back fluid treatment method. A device involved in the method comprises a water pretreatment reactor, a pipeline, a first water pump, a primary treatment reactor, a second water pump, a first dosing mixer, a microwave reactor, a third water pump, a second dosing mixer, an air-floating device, a dissolved air pump, a fourth water pump, a sand filtering tower, a fifth water pump, an activated carbon adsorption tower, a sixth water pump and a specific resin adsorption tower, fracturing flow-back fluids are treated by the steps of pretreatment, primary treatment, microwave catalytic oxidation, flocculating air-floating, filtration by the sand filtering tower, adsorption by the activated carbon adsorption tower, specific adsorption deep treatment and the like, harmful impurities in the fracturing flow-back fluids are removed, various standard requirements of preparing water for fracturing fluids again are met, and the method is used for preparing the fracturing fluids. Refined recycling treatment of the fracturing flow-back fluids is realized, the method is simple in operation and strong in adaptability, reuse rate reaches 95% or more, the technical problem of difficulty in reuse of the fracturing flow-back fluid is fundamentally solved, and the goals of efficiency increase, energy conservation, water conservation and environmental protection are achieved.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

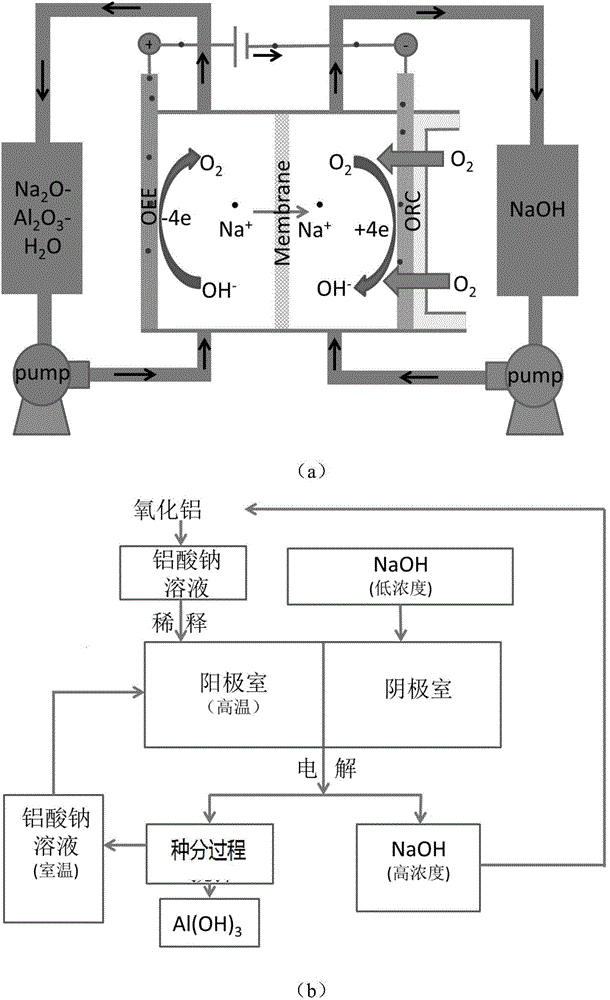

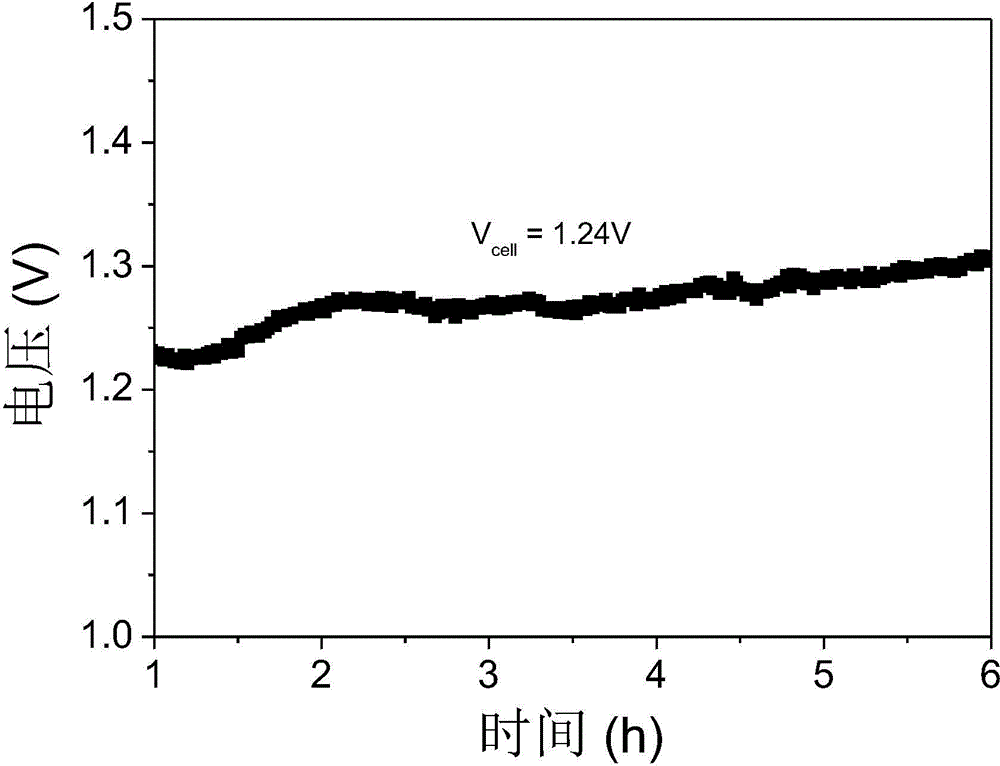

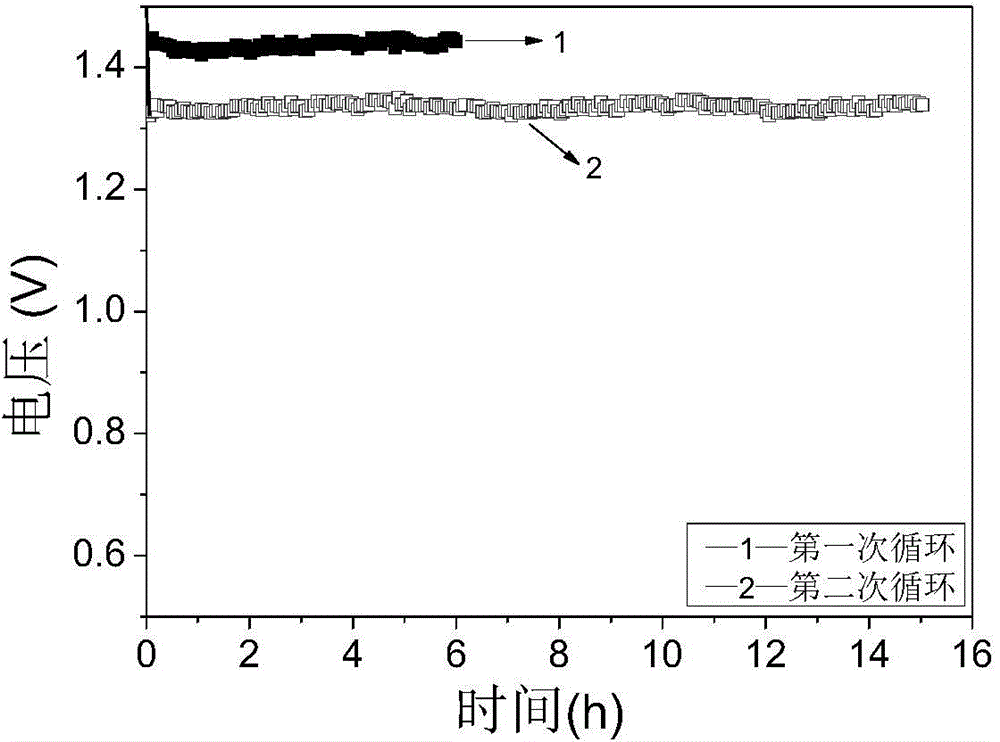

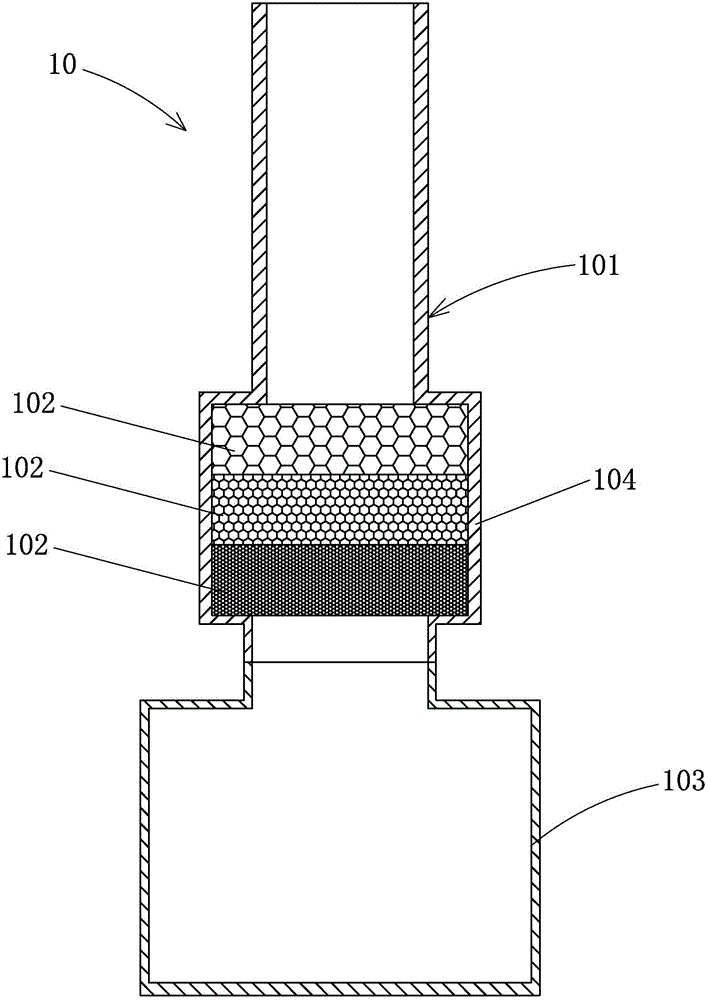

Method for preparing aluminum oxide by circularly and continuously electrolyzing sodium aluminate solution

ActiveCN106283098AIncrease alkalinityImprove dissolution efficiencyElectrolysis componentsIon-exchange membranesChemistry

The invention provides a method for preparing aluminum oxide by circularly and continuously electrolyzing a sodium aluminate solution, and belongs to the technical field of production of aluminum oxide. The method for preparing the aluminum oxide by circularly and continuously electrolyzing the sodium aluminate solution comprises the steps that the sodium aluminate solution and a diluted NaOH solution are guided into an anode chamber and a cathode chamber separated by an ion exchange membrane correspondingly, the NaOH solution is subjected to reductive electrolysis on the cathode while the sodium aluminate solution is oxidized on the anode, and seed precipitation is conducted on an electrolyte, obtained after electrolysis, in the anode chamber, so that aluminum hydroxide is separated out, and electrolysis can be conducted again after solid-liquid separation; and the high-concentration NaoH solution, obtained through electrolysis, in the cathode chamber can be used for the leaching process of the aluminum oxide. According to the method for preparing the aluminum oxide by circularly and continuously electrolyzing the sodium aluminate solution, a hug seed precipitation tank is not needed, seed crystals do not need to be added, the decomposition rate is increased while energy is saved, and meanwhile, the high-concentration alkaline solution which can be used for leaching of the aluminum oxide is obtained.

Owner:内蒙古瑞达泰丰化工有限责任公司

Method for preparing mixed rare earth carbonate by using mixed precipitant in sulphuric acid system

InactiveCN107760867AReduce outputReduce the temperatureProcess efficiency improvementAmmonium sulfateChemistry

The invention discloses a method for preparing mixed rare earth carbonate by using a mixed precipitant in a sulphuric acid system. The method comprises the following steps: with continuous stirring, mixing ammonium bicarbonate and industrial-grade ammonia water in the molar ratio of 5.6:4.4-10:1, and adding water at 15-30 DEG C to enable the concentration of the mixed precipitant to be 3 to 7 mol / L; placing the mixed precipitant and a seed crystal into a reaction tank, wherein the seed crystal is the mixed rare earth carbonate which is produced by taking mixed sulphuric acid rare earth solution as a raw material; with continuous stirring, controlling the temperature of the solution in the reaction tank to be 20-50 DEG C, and slowly adding the mixed sulphuric acid rare earth solution into the reaction tank, wherein the adding time is 2 to 6 hours, and the using amount enables the pH of the solution equal to be 6.5-7; after the ending of precipitating, aging for 0.5-2 hours at the temperature of 30-50 DEG C with stirring; filtering and washing a precipitant to obtain the mixed rare earth carbonate and ammonium sulphate-containing precipitation wastewater. According to the method, theoutput quantity of the precipitation wastewater can be reduced.

Owner:CHINA NORTHERN RARE EARTH (GROUP) HIGH TECH CO LTD

Zirconium alloy melting and casting method

A zirconium alloy melting and casting method comprises the following steps: 1, carrying out primary melting: carrying out sampling analysis on components of a zirconium alloy ingot to determine needed alloy elements; 2, carrying out secondary melting: adjusting alloy components, and stirring to make components of zirconium alloy melt uniform; 3, preparing a purifying technology through preheating a filtering medium-embedded runner to 1000-1200DEG C, and preparing an ingot casting die through cleaning the surface of the ingot casting die to realize no adhesion of impurities or oil stains; and 4, casting and purifying: pouring the molten zirconium alloy melt into the runner, allowing the zirconium alloy melt to go through the filtering medium in order to make impurities in the alloy melt intercepted and adsorbed by the filtering medium and clean zirconium alloy melt to enter the ingot casting die, and cooling to form a cast ingot. The method has the advantages of simple operation, low energy consumption and good purification effect.

Owner:SHEN ZHEN TOP LINK TECH CO LTD

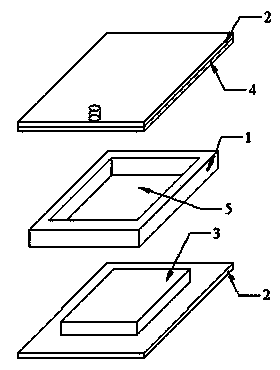

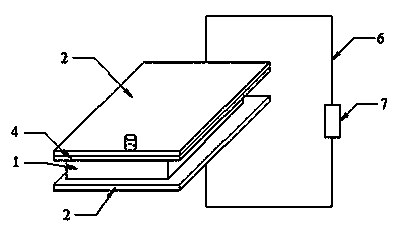

Planar fiber leftover material recycling and reusing method

InactiveCN111809276AAchieve the purpose of recyclingImprove performanceSevering textilesTextile disintegration and recoveryFiberProcess engineering

The invention discloses a planar fiber leftover material recycling and reusing method and relates to the planar fiber recycling field. By the adoption of the planar fiber leftover material recycling and reusing method, for multiple kinds of planar fiber leftover materials, the integrated technology of cutting the planar fiber leftover materials into fiber sheet materials of a fixed length in a linkage manner, conducting fiber dispersing machining and recycling to form a short fiber material which is loose and fluffy and has a certain length, machining the short fiber material into fiber non-woven felt, fiber punched felt, fiber felt prepreg, SMC, BMC and other products can be adopted. The planar fiber leftover material recycling and reusing method is high in production efficiency and capable of achieving large-scale production, the recycled short fiber is used for manufacturing punched fiber felt or non-punched fiber felt, and the performance of the punched felt or non-punched fiber felt is better than that of the same type of products and is approximate to that of a brand new fiber product. The recycled raw materials are wide in source, and low in cost, the planar fiber leftover material recycling and reusing method is suitable for weaving manners of multiple kinds of raw material fabric, the requirement for the raw materials is low, and cost is saved beneficially.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

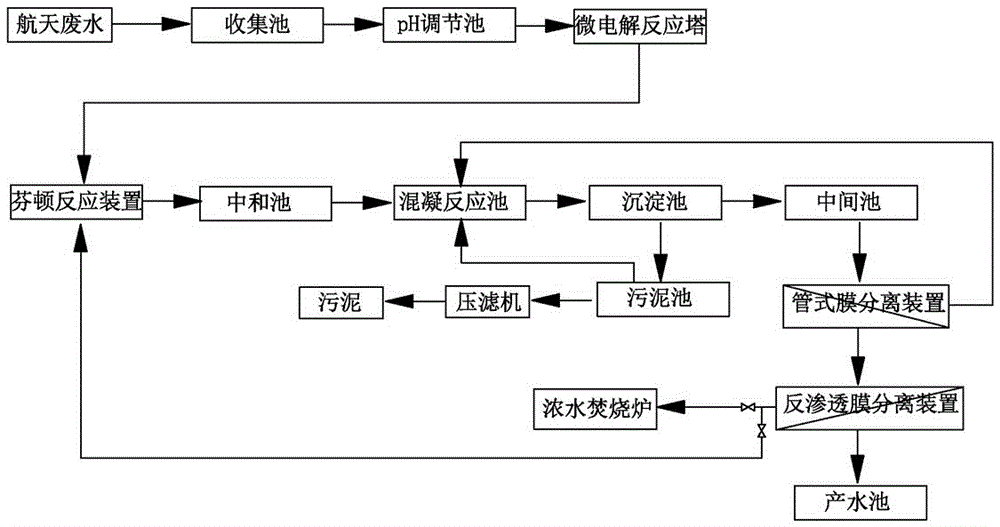

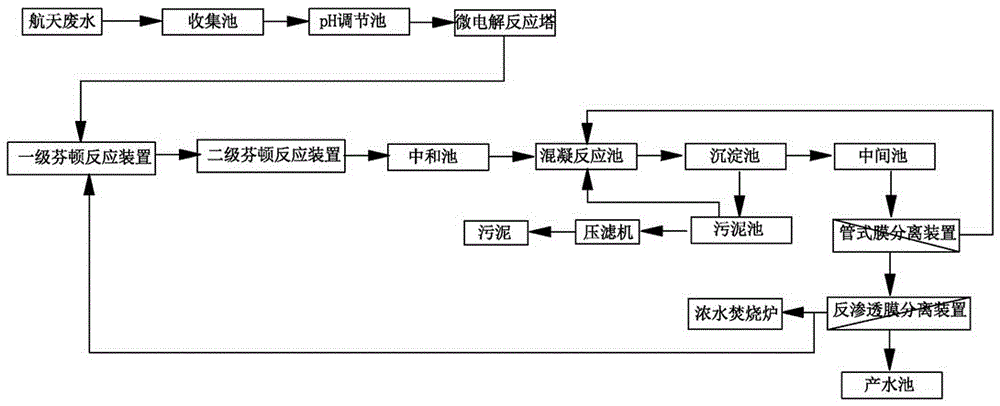

Treatment system and treatment method for aerospace propellant wastewater

PendingCN106477788AAchieve the purpose of recyclingSludge treatment by de-watering/drying/thickeningWater treatment compoundsElectrolysisSludge

The invention discloses a treatment system for aerospace propellant wastewater. The treatment system is characterized by comprising a pH (potential of Hydrogen) regulation pond, a micro-electrolysis reaction tower, a Fenton reaction device, a neutralization pond, a coagulation reaction pond and a settling pond, wherein the pH regulation pond, the micro-electrolysis reaction tower, the Fenton reaction device, the neutralization pond, the coagulation reaction pond and the settling pond are connected in sequence through pipelines; a sludge outlet of the settling pond is connected with a sludge pond and a pressure filter in sequence through pipelines; a supernatant fluid outlet of the sludge pond is connected with the coagulation reaction pond through a pipeline; a supernatant fluid outlet of the settling pond is connected with an intermediate water pond and a tubular membrane separation device in sequence through pipelines; a yielding water outlet of the tubular membrane separation device is connected with a reverse osmosis membrane separation device; a concentrated water outlet of the tubular membrane separation device is connected with the coagulation reaction pond; a yielding water outlet of the reverse osmosis membrane separation device is connected with a yielding water pond; a concentrated water outlet of the reverse osmosis membrane separation device is connected with a concentrated water combustion furnace and the Fenton reaction device in sequence through pipelines respectively. The invention also discloses a treatment method for the aerospace propellant wastewater. By using the treatment system and the treatment method which are provided by the invention, most pollutants in the wastewater can be removed; the purpose of recycling the wastewater is achieved.

Owner:厦门科滤膜技术有限公司

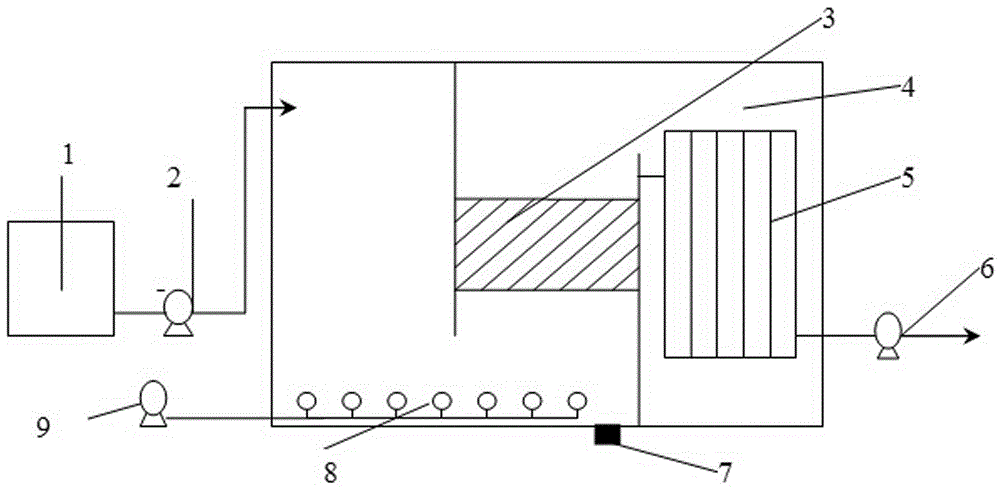

Integrated membrane bioreactor for recycling schoolyard wastewater

InactiveCN106219742ASave resourcesReduce pollutionBiological treatment apparatusSustainable biological treatmentEconomic benefitsEngineering

The invention discloses an integrated membrane bioreactor for recycling schoolyard wastewater. The integrated membrane bioreactor comprises a water inlet tank, a water inlet pump, an inclined plate, a membrane bioreactor, a membrane component, a sucking pump, a sludge discharge hole and an aerator, wherein the water inlet tank is connected with the water inlet of the membrane bioreactor via the water inlet pump; the sludge discharge hole is formed in the bottom of the membrane bioreactor; the inclined plate, the membrane component and the aerator are arranged inside the membrane bioreactor; the aerator is arranged at the bottom of the membrane bioreactor; the inclined plate is positioned on the water inlet side of the membrane bioreactor; the membrane component is positioned on the water outlet side of the membrane bioreactor and is connected with the sucking pump. As the integrated membrane bioreactor is organically combined with schoolyard wastewater, not only is schoolyard wastewater effectively treated, but also treated water can be recycled for toile flushing, greening and the like, and environmental benefits and economic benefits of urban pollution treatment, energy conservation and emission reduction and pollutant recycling and reuse are increased to a very large extent.

Owner:曹雯雯

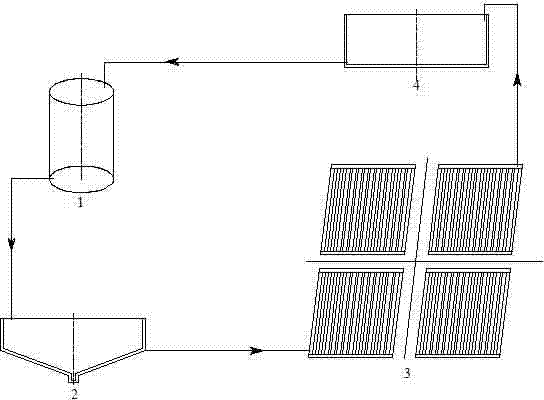

Method for treating and reusing Haematococcus pluvialis large-scale culture wastewater

ActiveCN103087921AAchieve the purpose of recyclingEfficient removalBioreactor/fermenter combinationsBiological substance pretreatmentsHaematococcusWastewater

The invention provides a method for treating and reusing Haematococcus pluvialis large-scale culture wastewater. The method utilizes the heat sensitivity characteristic of the growth inhibitors in the Haematococcus pluvialis large-scale culture wastewater and adopts a technology of precipitation after heating to remove the growth inhibitors, so the recycle of the wastewater is realized. The invention simultaneously provides a method for realizing the treatment and the reuse of the Haematococcus pluvialis large-scale culture wastewater. The device which adopts a large solar apparatus to heat the wastewater has the advantages of energy saving, environmental protection, low cost, and strong maneuverability.

Owner:SHANDONG ANALYSIS & TEST CENT

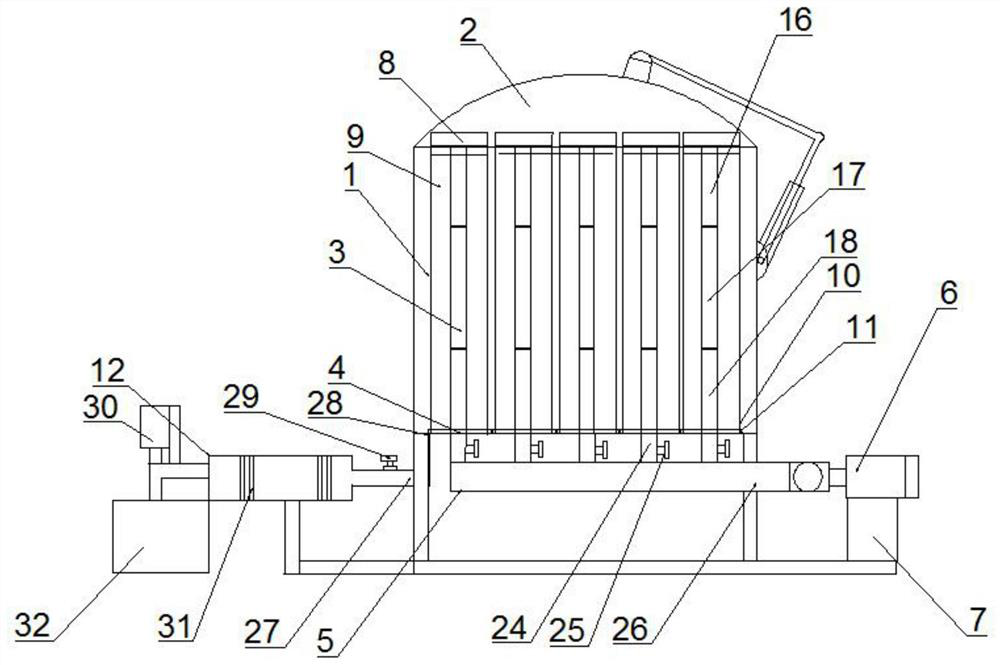

Paint mist interceptor of paint spraying energy saving and emission reduction system

InactiveCN107755151AAchieve the purpose of recyclingRealize energy savingSpraying apparatusWaste management

The invention provides a paint mist interceptor of a paint spraying energy saving and emission reduction system. The paint mist interceptor comprises a barrel. The upper end of the barrel is providedwith an opening which communicates with a paint mist waste gas exhaust device. The paint mist waste gas exhaust device can transversely move relative to the barrel. A plurality of axial-flow type fanblades capable of rotating are transversely arranged in the paint mist waste gas exhaust device. The fan blades are scattered in a strip shape. A tapered air plate is arranged on the lower portion ofthe barrel. The air plate is provided with a tapered wall and a taper port at the upper portion of the tapered wall. The taper port of the air plate faces the fan blades. The tapered wall of the air plate is provided with a plurality of air holes. A center sunken type paint collector is arranged below the air plate. A discharge port is formed in the center of the bottom of the paint collector andcommunicates with an air inlet. By adopting the paint mist interceptor, the purpose of energy saving, emission reduction and paint recovery are achieved.

Owner:HUANSIN ENVIRONMENTAL ENG KUSN

Salt wastewater treatment and reuse device and method thereof

ActiveCN104003569BSolve the hardnessEvaporation energy saving and high efficiencyMultistage water/sewage treatmentUltrafiltrationReverse osmosis

Owner:安徽森诺膜技术有限公司

Intelligent garbage can capable of achieving automatic cleaning, sterilizing and disinfecting

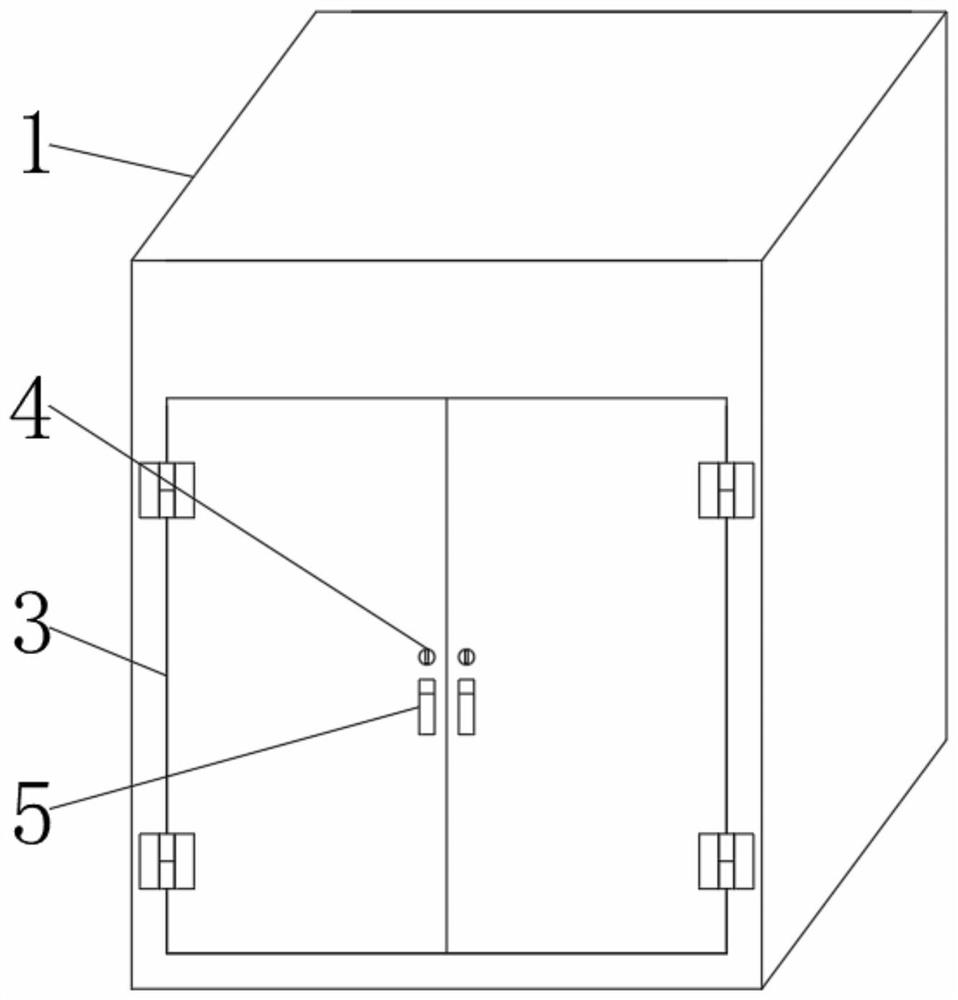

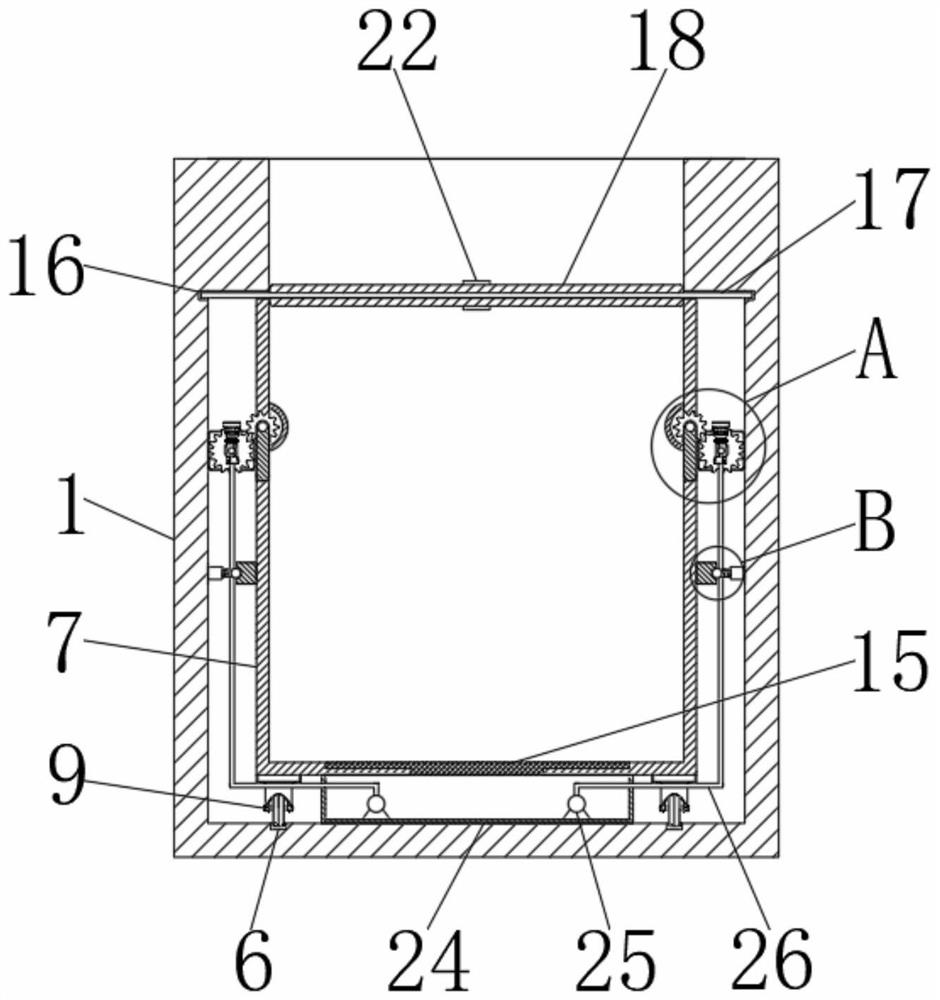

PendingCN111646051AEasy to removeEasy to handleRefuse receptaclesRefuse cleaningGear wheelElectric machinery

The invention discloses an intelligent garbage can capable of achieving automatic cleaning, sterilizing and disinfecting. The intelligent garbage can comprises a garbage can shell, a rotating door, afirst handle, a garbage can body, a second handle, a universal wheel, a first telescopic rod, a limiting ball, a filter screen, a cover plate, a second telescopic rod, a second limiting block, a watertank, a water pump, a water conveying pipe, a high-pressure water gun, a motor, a driving gear, a driven gear and a rotating plate. According to the intelligent garbage can capable of achieving automatic cleaning, sterilizing and disinfecting, through the matching of the water tank, the water pump, the water conveying pipe, the high-pressure water gun, the motor, the driving gear, the driven gearand the rotating plate, the structure is simple, using is convenient, the high-pressure water gun is driven by the motor to spray water, the purpose of full range automatic cleaning of the inner partof the garbage can is achieved, by adding a disinfectant in the water tank, the purpose of sterilization and disinfection in the garbage can is achieved, and through the matching of the filter screen, the water pump and the water conveying pipe, the purpose of water circulation in the water tank is achieved.

Owner:DALIAN JIAOTONG UNIVERSITY

Center-rod-adjustable high-temperature and high-pressure dyeing machine and using method thereof

PendingCN112011924AGuaranteed dyeing effectUniform dyeingTextile treatment machine arrangementsTextile treatment carriersYarnEngineering

The invention discloses a center-rod-adjustable high-temperature and high-pressure dyeing machine. The dyeing machine comprises a high-pressure cylinder and a cylinder cover, a plurality of adjustingdyeing cylinders are mounted in the high-pressure cylinder; the adjusting dyeing cylinders are welded to the bottom end face of the high-pressure cylinder. A plurality of circulating holes are formedin the bottom end surface of the high-pressure cylinder; the circulating holes communicating with inner holes of the dyeing cylinders; the lower ends of the plurality of circulating holes are connected with a circulating device; the circulating device is connected to a circulating pump; the circulating pump is fixed on a support at the lower end of the high-pressure cylinder; an outer cylinder seat is arranged on the cylinder cover; the outer cylinder seat is connected with an outer cylinder; the outer cylinder is arranged on the outer side of the dyeing barrel; and an outer cylinder threadedsleeve is arranged on the bottom end surface. According to the center-rod-adjustable high-temperature and high-pressure dyeing machine, the use of a dyeing agent can be reduced, the yarn dyeing amountof customers with different requirements on customized dyes is increased, and the requirements of the customers on the customized amount of samples are met, so that the strain capacity for differentcustomer requirements is improved.

Owner:李有双

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com