Treatment system and treatment method for aerospace propellant wastewater

A wastewater treatment system, aerospace technology, applied in multi-stage water treatment, water/sewage treatment, special compound water treatment, etc., can solve problems such as high inorganic content, difficult treatment, intermittent generation of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

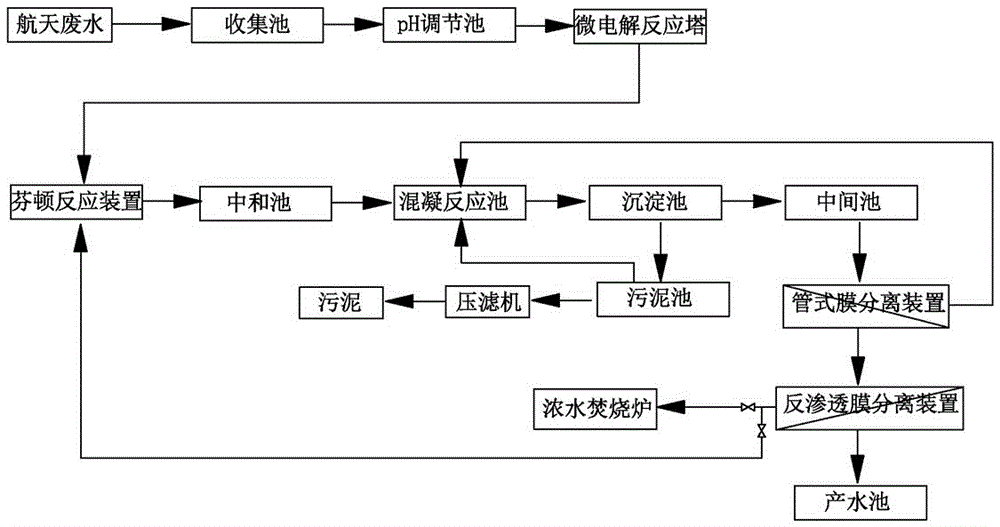

[0035] use figure 1 The process route of the system, aerospace propellant wastewater COD=20900mg / L, pH=0.43, salt content 7.3%, water body color is dark blue, opaque, wastewater contains oximes, oximes, hydrazine, oxalic acid di Pollutants such as ethyl oxalohydrazide, after step 1 pH adjustment and micro-electrolysis reaction, the COD = 11791mg / L, the pH value is 3.55, and the salt content is 4.71%; after the Fenton reaction, the COD = 4791mg / L , and after subsequent coagulation precipitation, neutralization, tubular ultrafiltration and reverse osmosis separation, the product water COD=43mg / L, pH=7.8, no oximes, oximes, hydrazine, diethyl oxalate were detected Pollutants such as oxalodihydrazide meet the requirements for reuse.

Embodiment 2

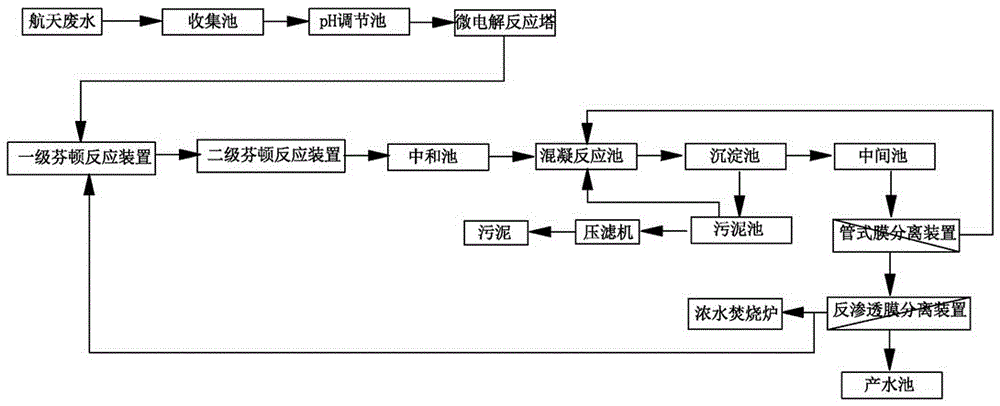

[0037] use figure 2 The process route of the shown system, its difference with embodiment 1 is, passed through 2 grades of Fenton reaction devices, and what the first grade Fenton reaction device adopts is swirl mixing Fenton reaction device; The secondary Fenton reaction device is Photoelectric Fenton reaction device using gas diffusion electrodes. Its water inflow and the previous process are all the same as in Example 1. What the product water adopts through the first-stage Fenton reaction device is a swirl mixing Fenton reaction device, and the COD is=4878mg / L, and then through the second-stage Fenton reaction device. After using the photoelectric Fenton reaction device with gas diffusion electrodes, the COD is = 2769mg / L. After subsequent coagulation precipitation, neutralization, tubular ultrafiltration and reverse osmosis separation, the reverse osmosis produced water COD = 33mg / L, pH = 7.5 , No oximes, oximes, hydrazine, diethyl oxalate oxalyl dihydrazide and other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com