Paint mist interceptor of paint spraying energy saving and emission reduction system

An energy-saving and emission-reduction, interceptor technology, applied in the direction of spraying device, can solve the problems of waste paint emission, personnel health impact, etc., to achieve the effect of energy-saving and emission-reduction paint recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

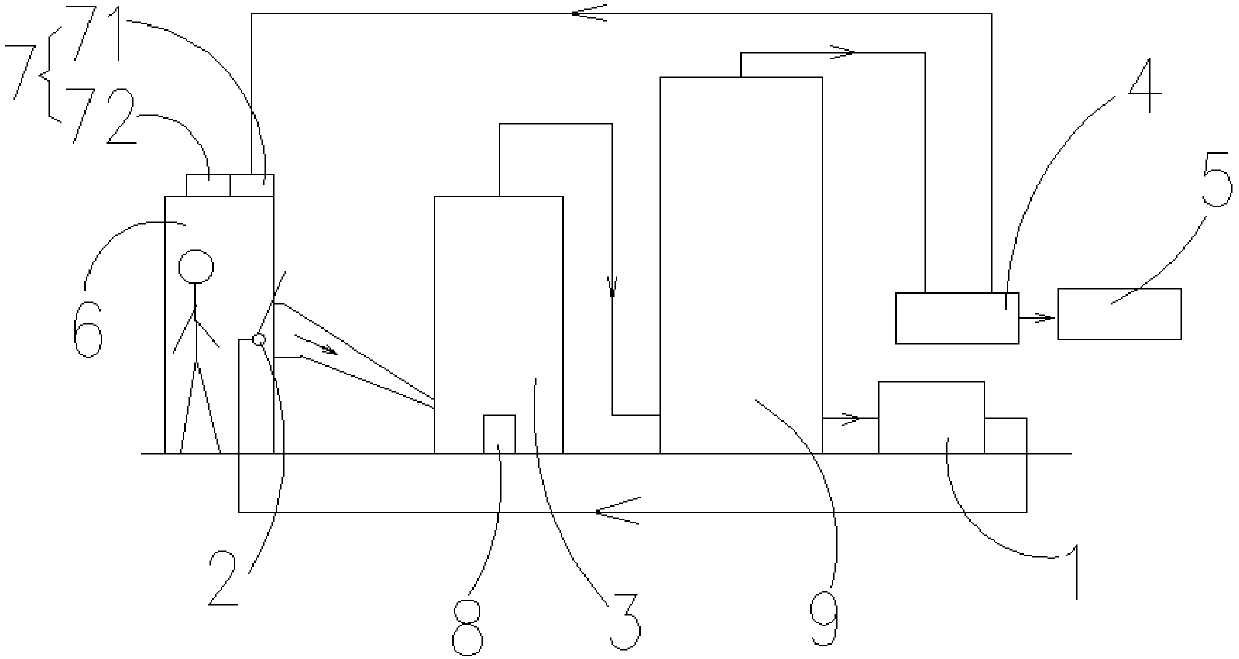

[0033] Please refer to figure 1 , The paint spraying energy saving and emission reduction system of the present invention includes an air compressor 1 , a paint spraying gun 2 , a paint mist interceptor 3 , an induced draft fan 4 and a purification system 5 . The airtight connection between the output end of the air compressor 1 and the inlet end of the paint spray gun 2 and between the outlet end of the paint spray gun 2 and the input end of the paint mist interceptor 3 is realized through a closed channel. The input end of the induced draft fan 4 and the output end of the paint mist interceptor 3 are connected through an exhaust gas storage barrel 9 . The output end of the paint mist interceptor 3 is connected to the exhaust gas storage barrel 9 from the bottom of the exhaust gas storage barrel 9 , and the input end of the induced draft fan 4 is connected to the exhaust gas storage barrel 9 from the top of the exhaust gas storage barrel 9 . The output end of the induced dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com