Method and tower for quickly precipitating papermaking sewage

A technology of papermaking sewage and sedimentation method, which is applied in the direction of flocculation/sedimentation water/sewage treatment, waste water treatment in processing, etc. It can solve problems such as hindering production development, small scale of enterprises, serious problems, etc., and achieve fast inclined plate sedimentation and advection work Smooth, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

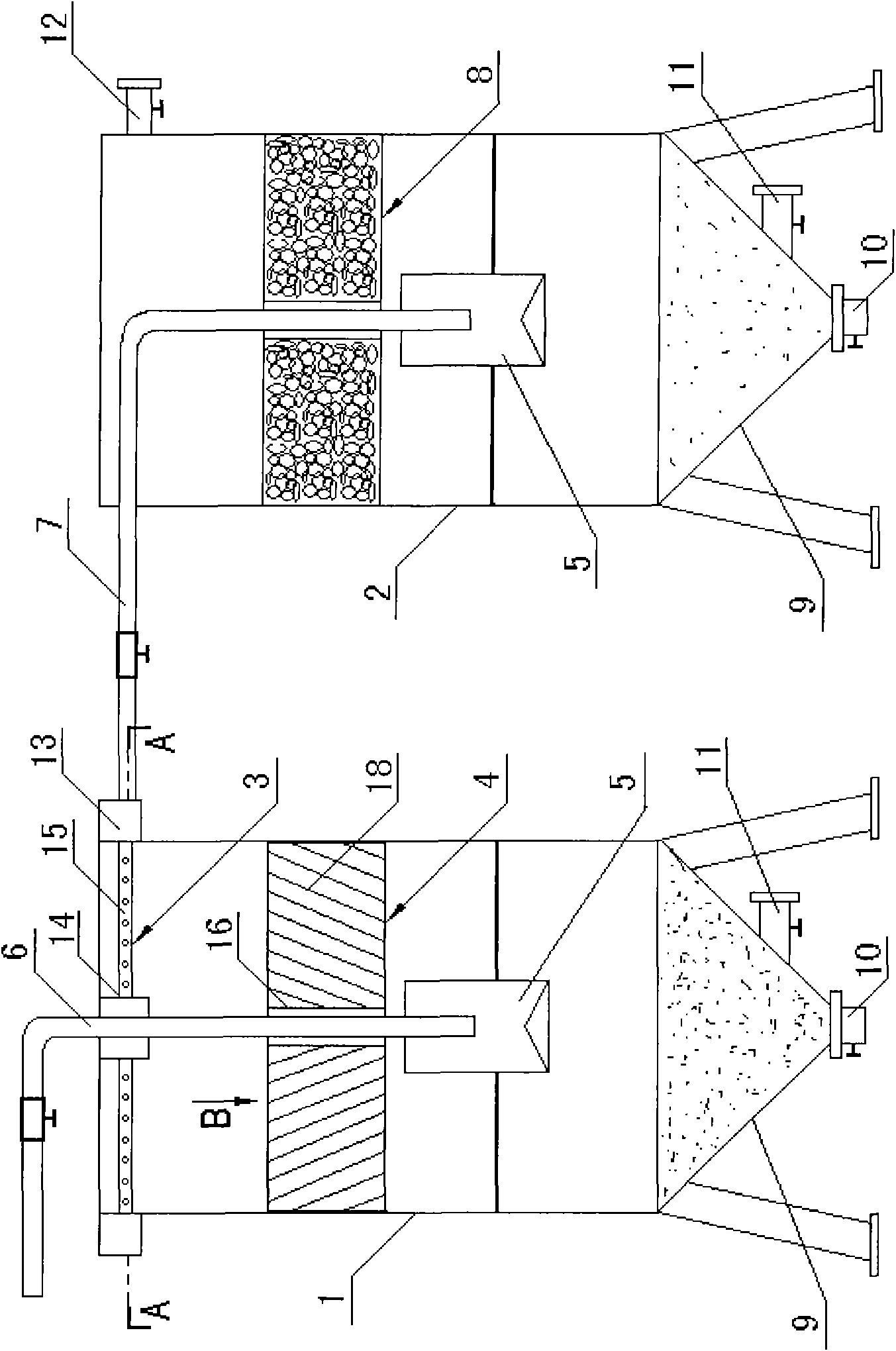

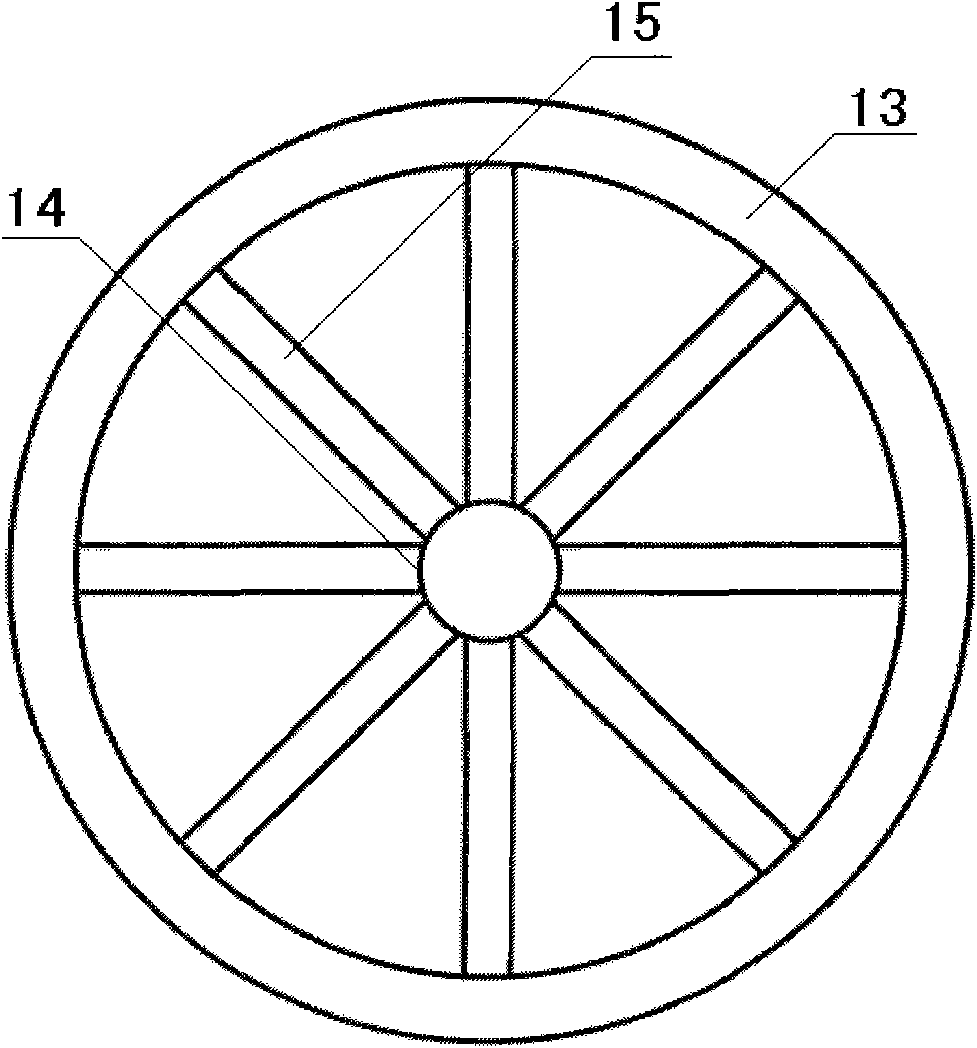

[0042] attached by figure 2 As shown: the sedimentation tower includes the main body of the first-level sedimentation tower 1, the main body of the second-level sedimentation tower 2, the radial water outlet device 3, the inclined plate sedimentation device 4, the buffer tank 5, the sewage inlet pipe 6, the primary water outlet pipe 7, and spherical filter packing Layer 8, the main body 1 of the primary sedimentation tower and the main body 2 of the secondary sedimentation tower are independently arranged side by side, connected through the primary clear water pipe 7, the radial water outlet device 3 is arranged on the upper end of the main body 1 of the primary sedimentation tower, and the inclined plate sedimentation device 4 is set in the middle of the main body 1 of the first-stage sedimentation tower, and the sewage inlet pipe 6 passes through the top of the main body 1 of the first-stage sedimentation tower, and passes through the central hole of the radial water outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com