Patents

Literature

92results about How to "To achieve the goal of zero emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of recycling valuable metals from arsenic-containing soot

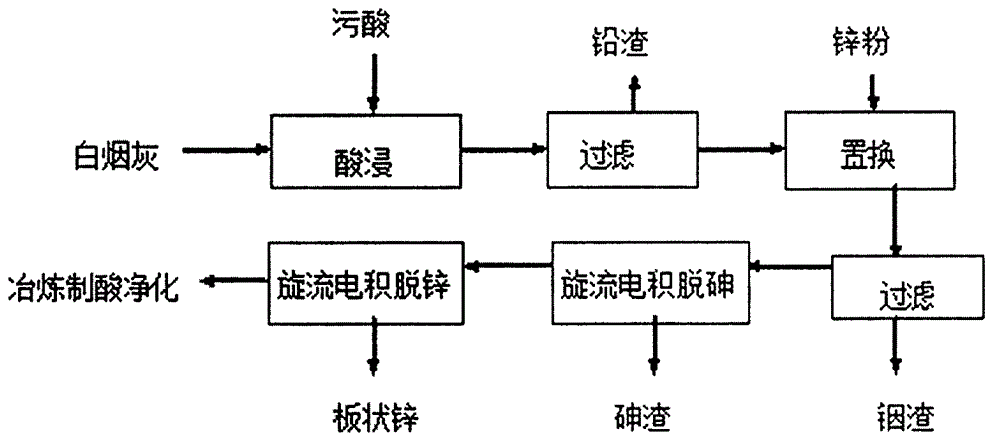

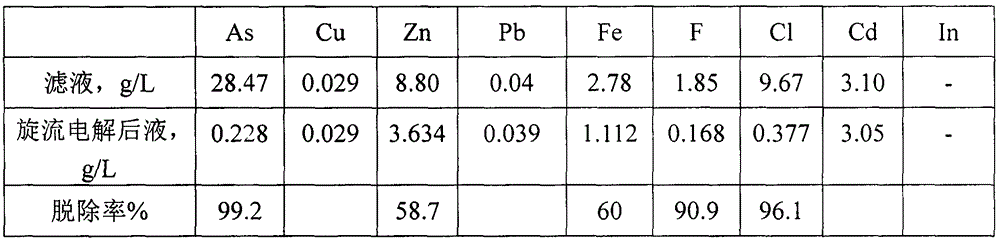

The invention relates to a method of recycling valuable metals from arsenic-containing soot. The method comprises the following steps: (1) mixing acidic wastewater with white soot, controlling the pH value to 2.5-3.0, performing acid leaching at a temperature of 70-80 DEG C, and filtering to obtain leachate and lead slag; (2) replacing indium for the leachate by using zinc powder, and filtering to obtain indium slag; (3) performing rotational-flow electrodeposition arsenic removal and zinc removal on filtrate in sequence to obtain arsenic slag and zinc slag. The method disclosed by the invention can be used for purifying the acidic wastewater to reach a condition for recycling the acidic wastewater to a smelting acid manufacturing and purifying section, so that the treated acidic wastewater can be directly returned to the acid manufacturing and purifying section, and therefore, the gypsum slag is completely removed to truly achieve the purpose of zero emission. Meanwhile, the method disclosed by the invention can also be used for achieving the treatment of white soot and recycling the valuable metals, so that environmental protection and resource comprehensive utilization are achieved.

Owner:五矿铜业(湖南)有限公司 +3

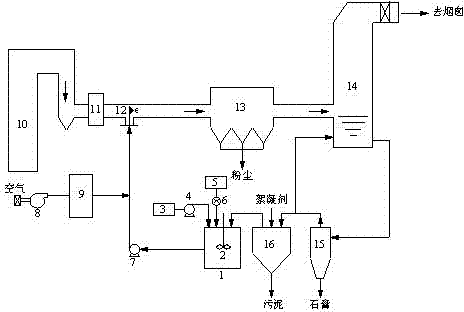

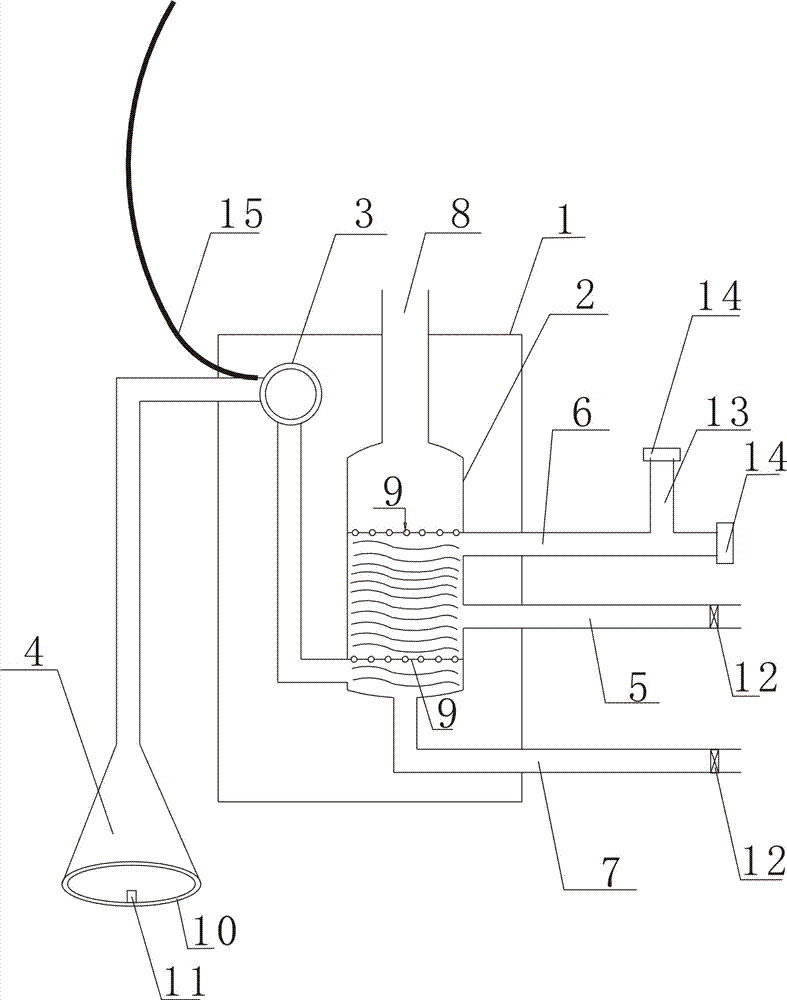

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

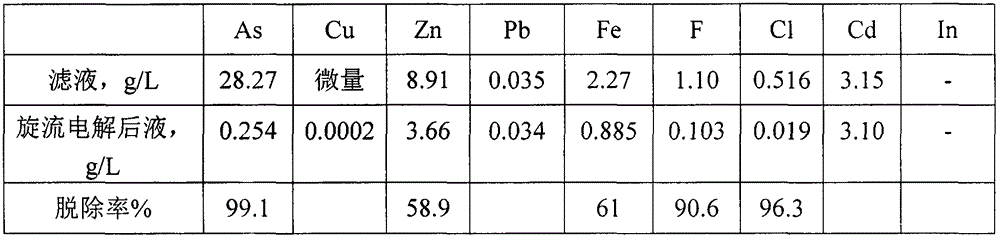

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

Method for directly extracting nickel in acidic chemical nickel plating waste solution

InactiveCN101817607AImprove energy efficiencyEasy to peelWater contaminantsWaste water treatment from metallurgical processLiquid wasteElectrolysis

The invention discloses a method for directly extracting nickel in acidic chemical nickel plating waste solution, and relates to treatment of industrial waste solution. The invention provides the method for directly extracting nickel in the acidic chemical nickel plating waste solution, which can reduce the nickel-containing waste water treatment cost, improve the energy utilization of the nickel and achieve zero discharge of the acidic chemical nickel plating waste solution in place of the traditional chemical method, electro-dialysis method, electrolysis method, RO film separation method, pressure filtering method and the like. The method comprises the following steps of: injecting the acidic chemical nickel plating waste solution into an acidic chemical nickel plating waste solution tank; adding a catalytic reducer and a nickel metal extraction carrier into the acidic chemical nickel plating waste solution tank; depositing nickel ions, which are more than or equal to 97 percent in the acidic chemical nickel plating waste solution, on the nickel metal extraction carrier; and performing RO film reverse osmosis treatment and thermal evaporation treatment on the acidic chemical nickel residue after direct extraction of nickel so as to produce solid waste residue, namely the direct extraction of the nickel in the acidic chemical nickel plating waste solution is finished.

Owner:埃梯星(厦门)电子科技有限公司

Combined absorption analytical method for hydrochloric acid

InactiveCN101214923ANo pollution in the processIncrease relative volatilityChlorine/hydrogen-chloride purificationChemical industryWastewaterEmission standard

The invention relates to a hydrochloride combined absorption and analytic method, which includes the following steps: concentrated hydrochloric acid in a concentrated hydrochloric acid tank enters into a concentrated acid analytic tower through a pump and a double-effect heat exchanger to be analyzed, and partial hydrogen chloride gas is obtained; the no-analyzed dilute hydrochloric acid enters into a dilute acid tank through the double-effect heat exchanger and a cooler; calcium chloride solution in dilute hydrochloric acid and calcium chloride concentration towers goes through a pump, is mixed and enters into a dilute acid tower to be analyzed, the hydrogen chloride gas is obtained; the dilute calcium chloride solution with trace hydrochloride in a dilute hydrochloride analytic tower enters into the calcium chloride concentration tower to be concentrated, waste water within hydrochloride meeting the emission standard is obtained; the concentrated calcium chloride flows back to a calcium chloride preparing tank. The invention improves the recovery rate (99.99 percent) of the hydrogen chloride, reduces the neutralization procedure, resource waste and environmental pollution of the waste water, and can also used together with the processes of the upstream industry.

Owner:XINJIANG TIANYE GRP

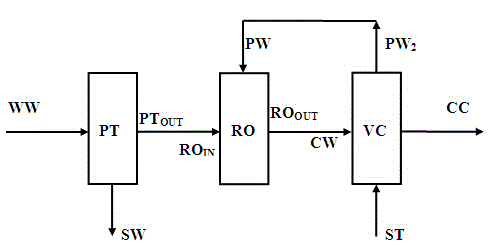

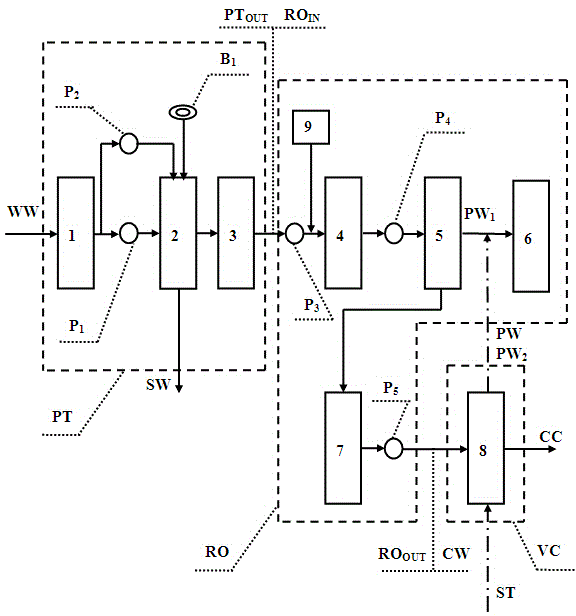

High-salt iron phosphate liquid waste zero-emission treatment device and method

ActiveCN104609631ALow costTo achieve the purpose of emissionGeneral water supply conservationMultistage water/sewage treatmentLiquid wasteEvaporation

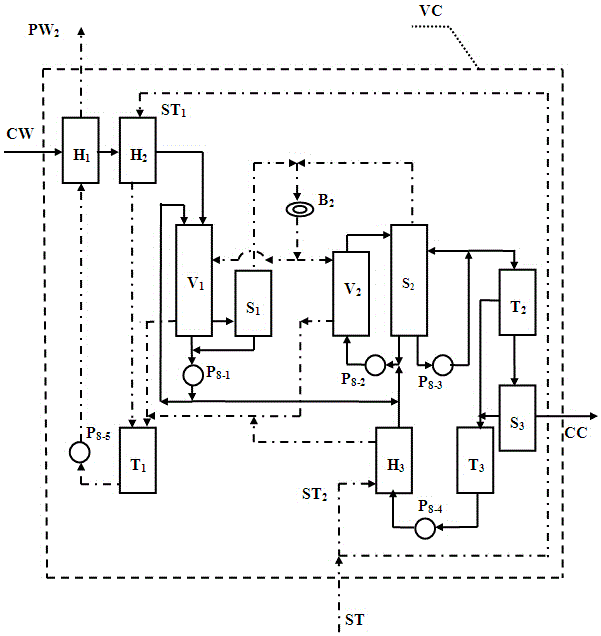

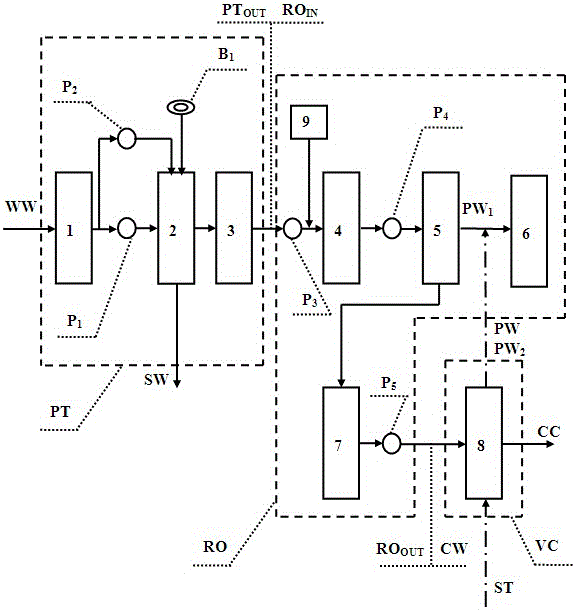

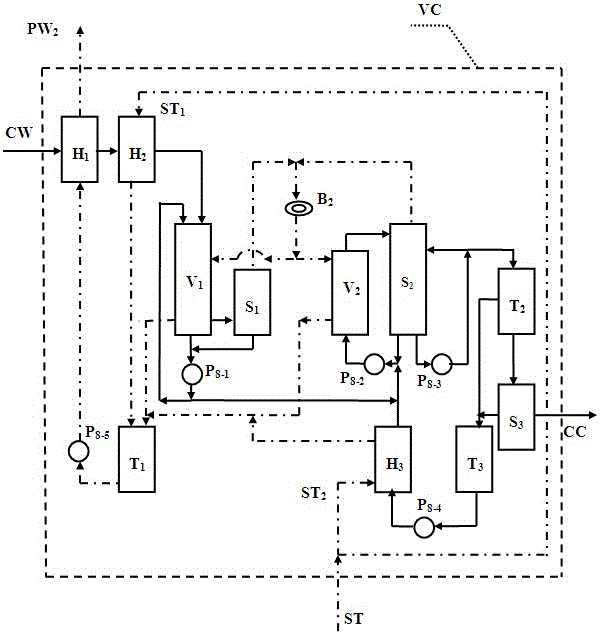

The invention discloses a high-salt iron phosphate liquid waste zero-emission treatment device. The device structurally comprises a pre-treatment (PT) system, a reverse osmosis (RO) treatment system and an evaporative crystallization (VC) treatment system. The high-salt iron phosphate liquid waste zero-emission treatment device has the advantages as follows: the device is designed for high salt of the high-salt iron phosphate liquid waste, the high-salt iron phosphate liquid waste is subjected to pre-treatment to remove part of suspended solids and is subjected to reverse osmosis desalination, concentration reduction and reverse osmosis producing water recycling, reverse osmosis concentrated water is subjected to evaporative crystallization treatment finally, condensate water produced through evaporative crystallization is recycled, waste salt is conveyed outwards, and the purpose of zero liquid emission is achieved. The high-salt iron phosphate liquid waste zero-emission treatment device has the specific advantages as follows: pre-treatment, reverse osmosis and evaporative crystallization are organically combined; 2, the reverse osmosis is adopted for concentration reduction, so that the cost of follow-up evaporative crystallization is reduced; 3, an evaporative crystallization technology combining falling film evaporation and MVR (mechanical vapor recompression) is adopted, energy is saved, the efficiency is high, and the operation cost is reduced; 4, the purposes of water recycling and zero liquid emission are achieved.

Owner:深圳市华虹清源环保科技有限公司

Recovery method for mother liquor after copper chloride hydroxide production by etching waste liquor

ActiveCN102320703AEfficient recyclingHigh purityMultistage water/sewage treatmentCopper chloridesAmmoniacal nitrogenCopper chloride

The invention discloses a recovery method for mother liquor after copper chloride hydroxide production by etching waste liquor, which is characterized in that the mother liquor of the etching waste liquor after the copper chloride hydroxide production is firstly neutralized, precipitated and filtered, the rest liquor sequentially passes through an ion exchanger filled with ion exchange resin and ion exchange resin fibers, then, the exchange liquor is evaporated, evaporation mother liquor and condensed water are obtained, ammonium chloride is obtained after evaporation mother liquor cooling, and ammonia nitrogen contained in the condensed water is removed through an efficient ammonia nitrogen regeneration reactor. In the second exchange liquor treated by the recovery method, the copper content is less than 5mug / L, and the content of the ammonia nitrogen passing through the efficient ammonia nitrogen regeneration reactor is less than 10mg / L. The etching waste liquor treated by the method has the advantages that copper ions are recovered in the form of copper chloride hydroxide, the ammonia is recovered in the forms of ammonia chloride and ammonia water, the waste water can also reach the industrial application standard to be cyclically utilized, and the goal of zero waste emission is realized.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

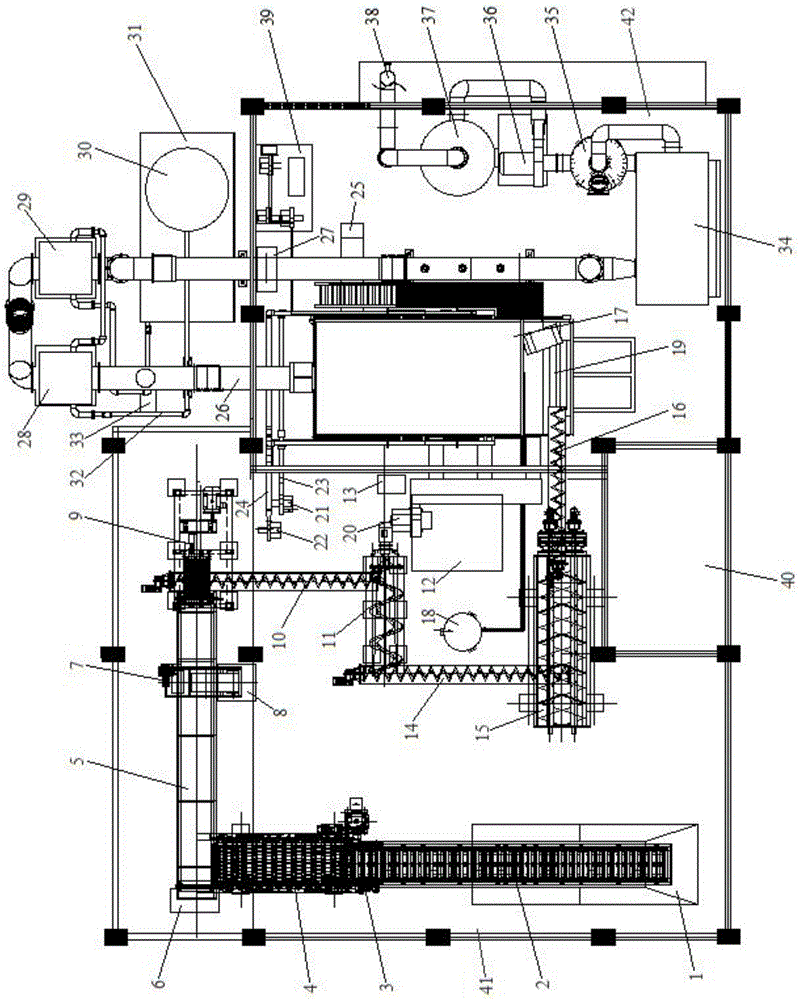

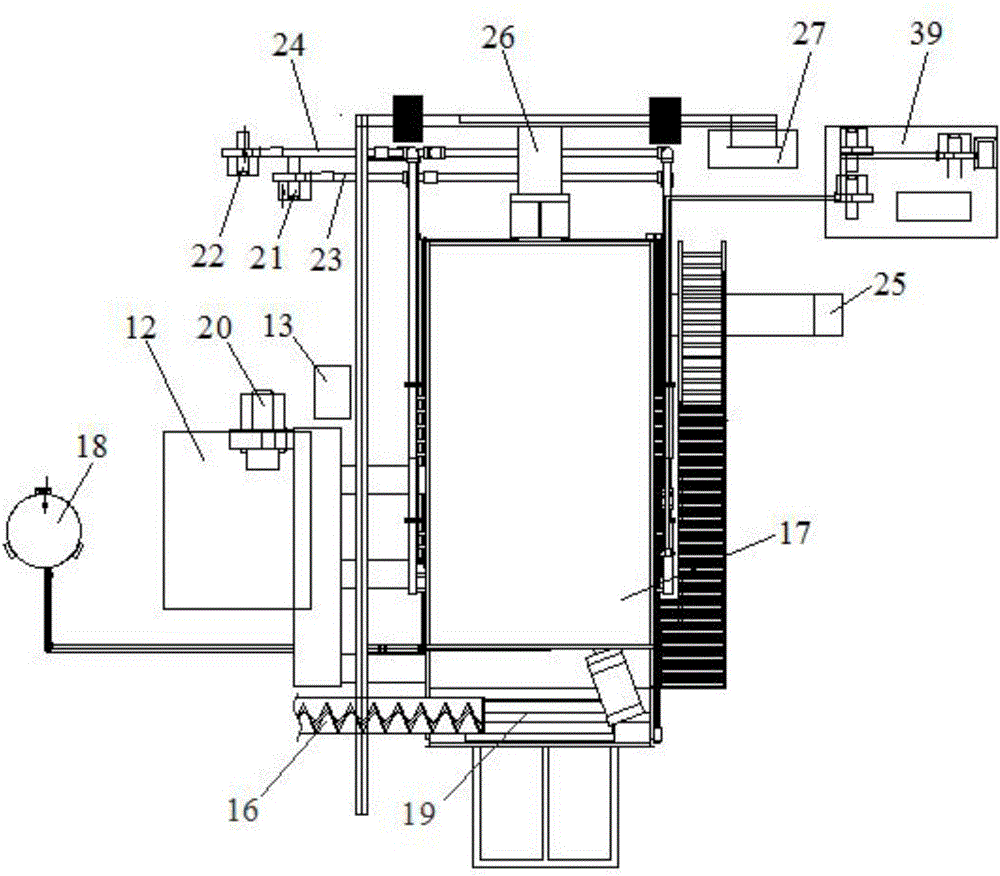

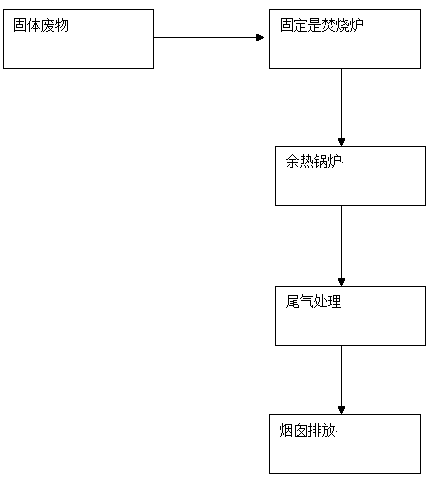

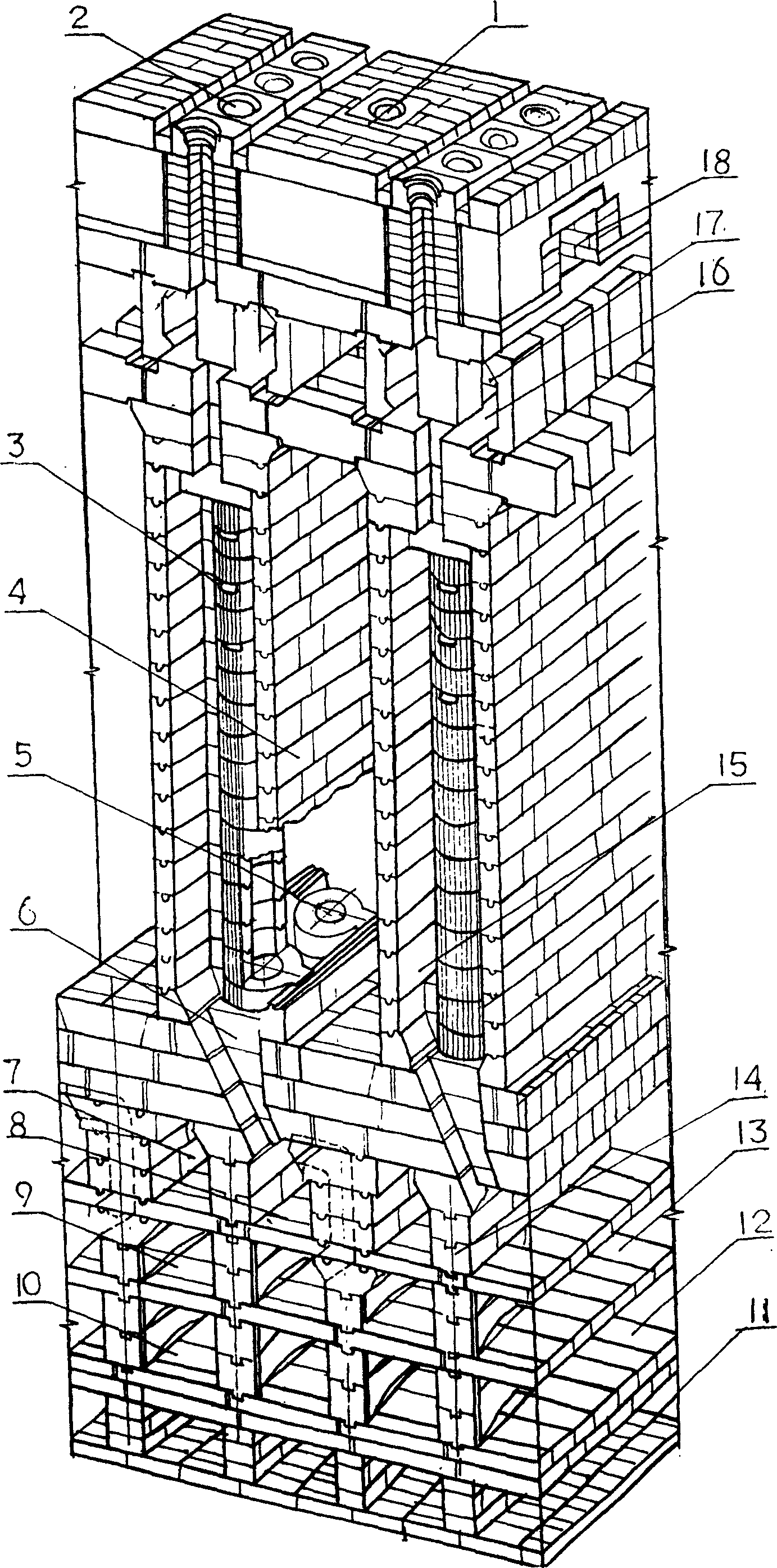

Garbage disposal combustion furnace and garbage disposal system

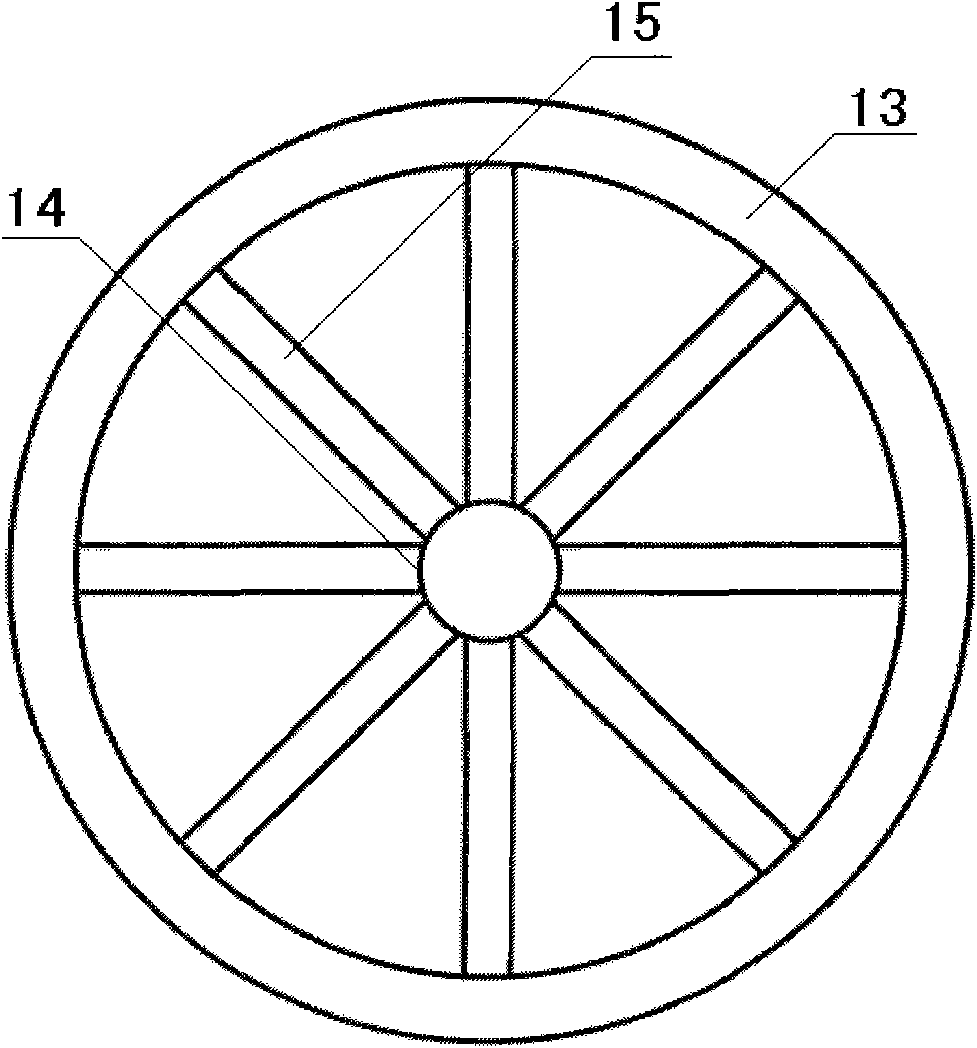

PendingCN107525082AReduce moisture contentTo achieve the goal of zero emissionsCombustion technology mitigationAir/fuel supply for combustionCombustion chamberFlue gas

The invention discloses a garbage disposal combustion furnace and a garbage disposal system. The combustion furnace comprises a furnace body, a blower is arranged on one side of the furnace body to ventilate a fire grate, a first combustion chamber and a second combustion chamber are sequentially arranged above the fire grate, a first secondary blower and a second secondary blower are arranged on the outside of the furnace body to ventilate the first combustion chamber and the second combustion chamber respectively, and full combustion of garbage and flue gas is facilitated. When temperature of the first combustion chamber reaches a preset value, an extraction pump extracts a garbage leachate from a leachate filter tank to spray to the first combustion chamber for gasification disposal, and the purpose of zero discharge of the garbage leachate is achieved; after the garbage is combusted in the first combustion chamber, flue gas enters the second combustion chamber for secondary high-temperature combustion, harmful substances in the flue gas are fully pyrolyzed, the flue gas combusted is disposed through a flue gas disposal part, generation of dioxin can be greatly reduced, and the flue gas finally discharged is allowed to meet the national discharge standard.

Owner:珠海市云筒环保设备有限公司

Swine fermentation bed and preparation method thereof

The invention relates to a swine fermentation bed and a preparation method thereof. The swine fermentation bed contains a fermentation bed packing and a fermentation bed fungicide, wherein the fermentation bed packing per cubic meter is prepared from, by weight, rice husk 10-15 kg, sawdust 20-25 kg, vinasse 15-20 kg, straw 10-15 kg, rice bran 5-8 kg, corn meal 5-8 kg, rapeseed cake 4-6 kg, tea residues 3-5 kg, sediment 5-8 kg, wormcast 5-8 kg, wormwood 0.3-0.5 kg, Chinese fever vines 0.3-0.5 kg, garlic powder 0.1-0.3 kg and salt 0.5-0.8 kg. The fermentation bed fungicide is indigenous rhizobia, and the usage amount is 0.2-0.3 kg per cubic meter. The fermentation bed prepared by adopting the preparation method is reasonable in composition, straw is laid on the bottom layer of the fermentation bed, the thickness of the packing can be decreased, the temperature of the fermentation bed can be also kept, the Chinese herbal medicines are added to the composition, have the disinfection effect on swine excrement and meanwhile can promote proliferation of beneficial bacteria in swine intestinal tracts to promote growth, the environmental pollution brought by breeding is relieved by adopting the fermentation bed, and the purpose of zero breeding emissions is really achieved.

Owner:ANSHUN DEKANG AGRI & ANIMAL HUSBANDRY CO LTD

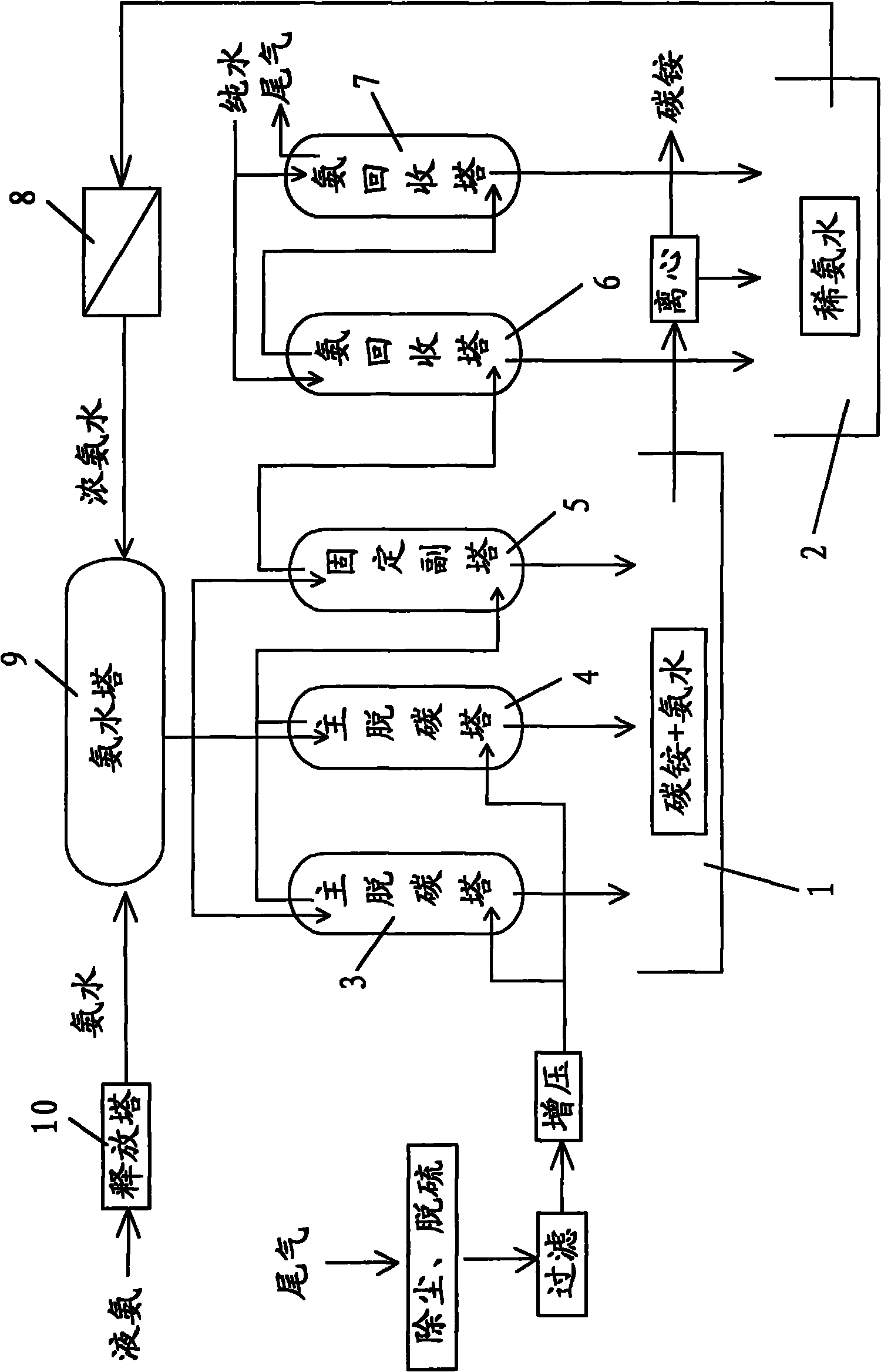

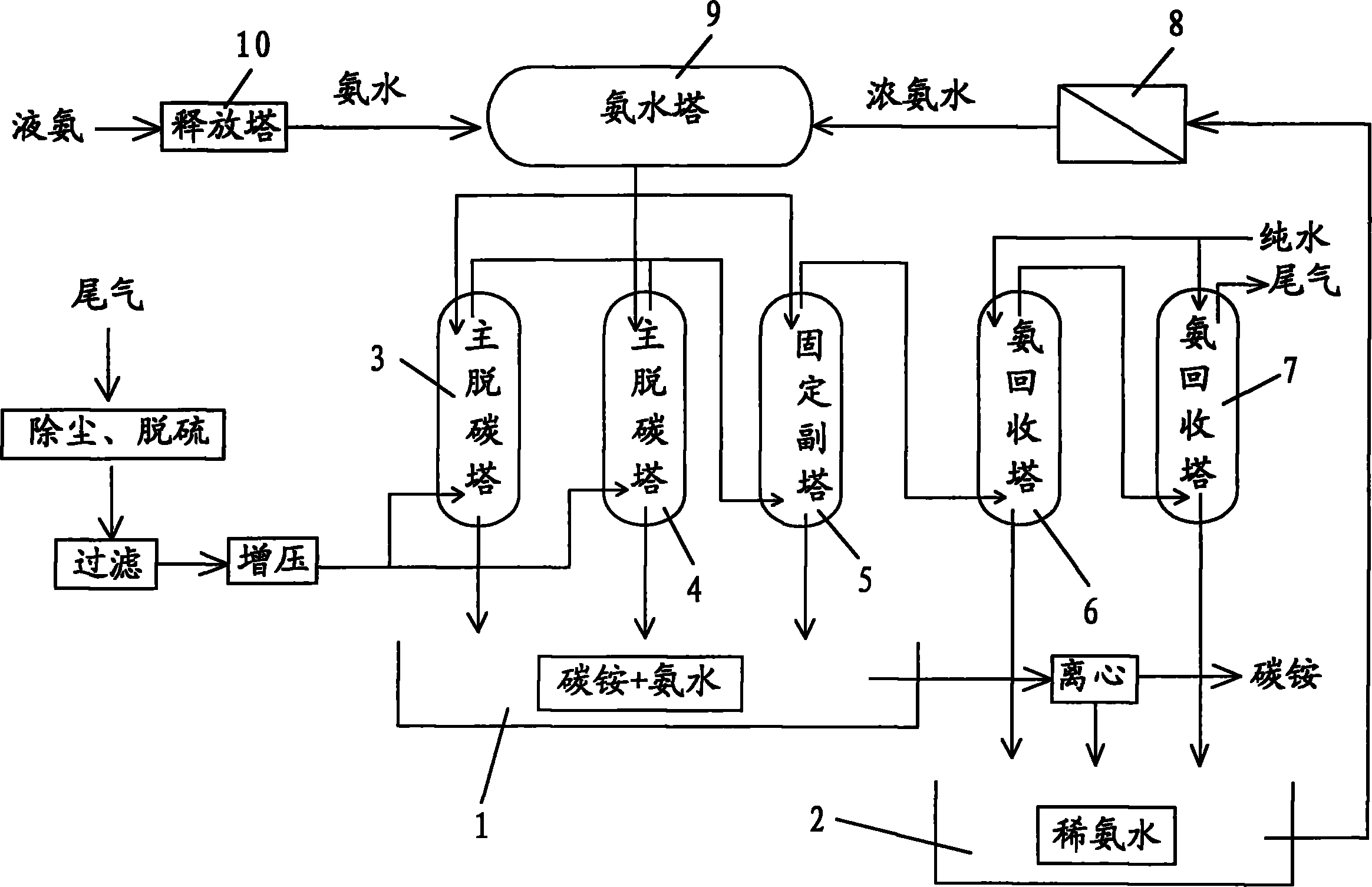

Production method for synthesizing ammonium bicarbonate fertilizer by using CO2 waste gas

InactiveCN101830483AEmission reductionTo achieve the goal of zero emissionsProductsReagentsExhaust gasFertilizer

The invention discloses a production method for synthesizing an ammonium bicarbonate fertilizer by using CO2 waste gas, which comprises the following steps of: using a process which adopts countercurrent contact to prepare the CO2 waste gas and strong ammonia water after tail gas dedusting and desulfurization into ammonium bicarbonate; reclaiming ammonia gas in the previous process step by using an ammonia reclaiming tower; and discharging remaining tail gas into the atmosphere directly, wherein the ammonia water in the process is concentrated in a reverse osmosis system and is used for recycling again. The greenhouse gas CO2 in the method is treated, so the discharge amount of the greenhouse gas is reduced; the generation of the ammonium bicarbonate fertilizer in the production process has economic benefits; and the production method adopts a reverse osmosis technique to concentrate diluted ammonia water and recycle the strong ammonia water and dialysis water so as to fulfill the aim of zero discharge.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

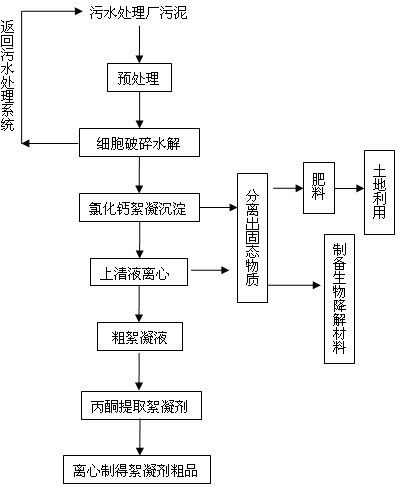

Method for fully recycling sludge

InactiveCN102206025ASolve the problem of sludge treatmentLow costSludge treatmentClimate change adaptationFertilizerChemistry

The invention relates to sewage treatment and solid waste treatment in the environmental engineering field and aims at recycling the excess sludge in a sewage treatment plant. A hydrolyzed solution, which is obtained after the sludge is hydrolyzed, can be used as a flocculating agent which directly flows back for sewage treatment; a calcium chloride solution can be added into the hydrolyzed solution, so that supernatant liquor which contains the biological flocculating agent and bottom sediments which mainly comprise inorganic matters and a small amount of unhydrolyzed organic matters are separated; a crude flocculation solution is obtained by centrifuging the supernatant liquor which contains the flocculating agent; and a flocculating agent crude product can be obtained after the crude flocculation solution reacts with acetone and a reaction product is centrifuged. After being treated, the bottom sediments which mainly comprise the inorganic matters and a small amount of unhydrolyzedorganic matters can be used as a chemical fertilizer. In the invention, after being treated, the sludge is recycled, the purpose of zero sludge discharge is achieved finally, the sludge treatment problem of the sewage treatment plant is thoroughly solved, the cost of water treatment is lowered and the environmental pollution is reduced.

Owner:江苏辉翔环保科技有限公司

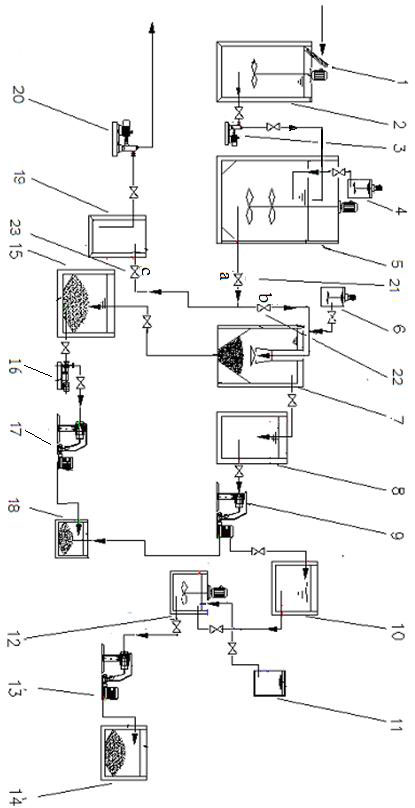

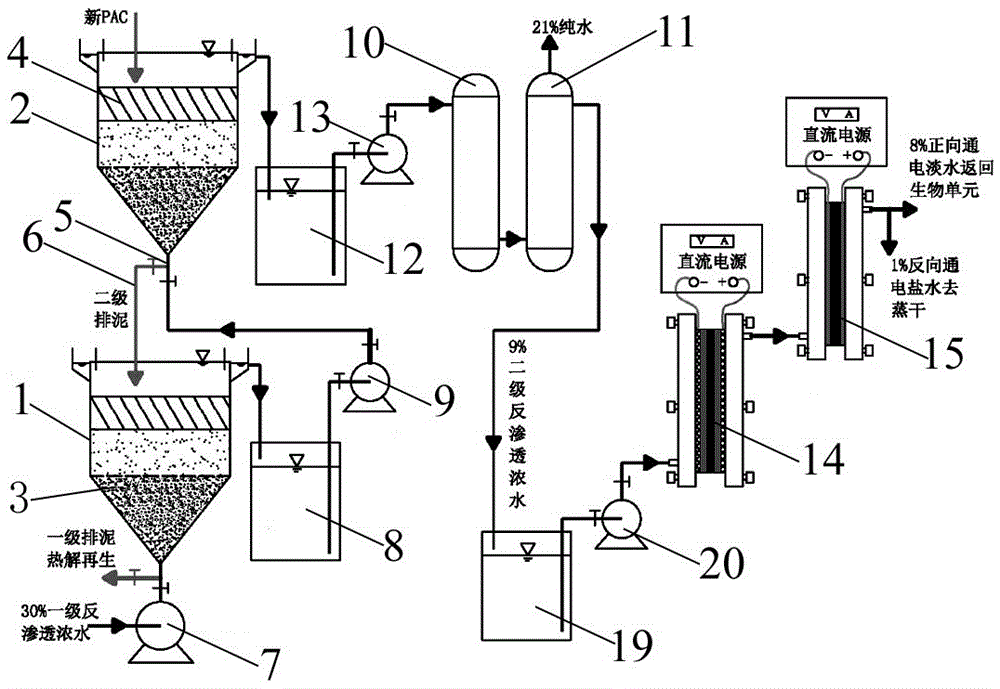

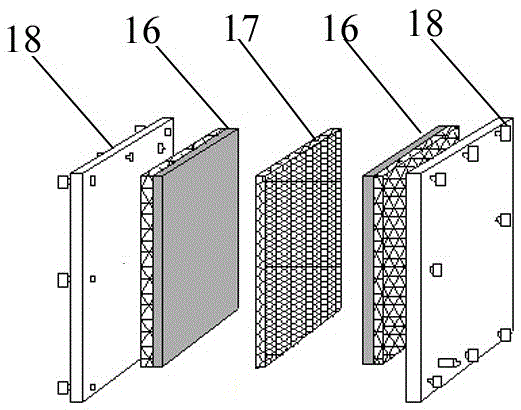

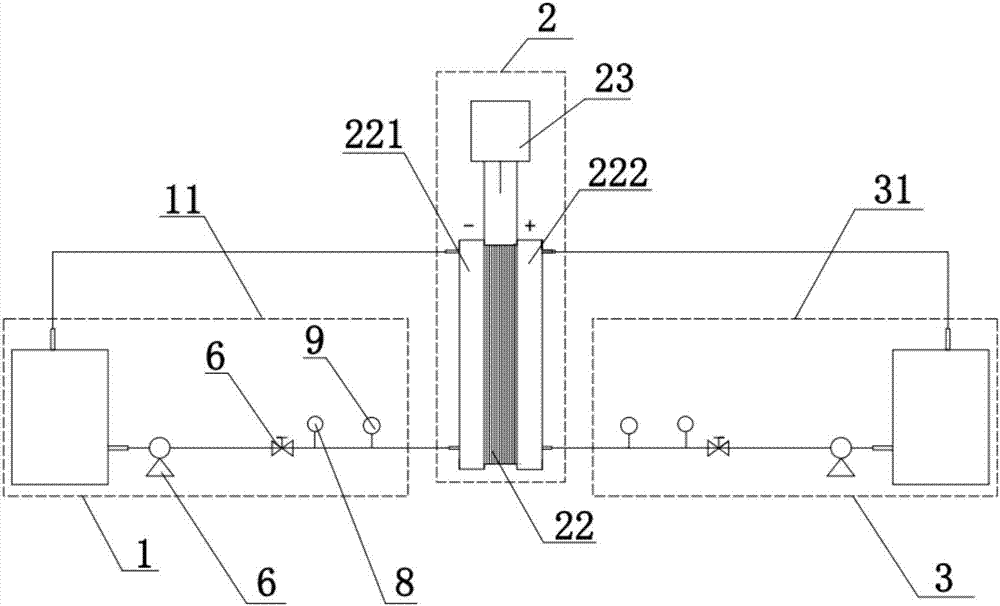

Zero emission treatment method and special treatment system for reverse osmosis concentrated water difficult to decompose

ActiveCN106186458ASimple structureReduce processing costsGeneral water supply conservationMultistage water/sewage treatmentUltrafiltrationReverse osmosis

The invention relates to a zero emission treatment method for reverse osmosis concentrated water difficult to decompose. The method comprises the following steps: (a) creation of a treatment system; (b) adsorbing treatment by using an activated carbon filter bed; (c) filtering treatment by using an ultrafiltration component and a second-level reverse osmosis component; (d) electric treatment by using an electrocatalytic oxidation module and a capacitive deionization module; the reverse osmosis concentrated water difficult to decompose is finally treated into fresh water and strong brine, the fresh water is recycled, the strong brine is evaporated to dryness, so that the purpose of zero emission is fulfilled. Meanwhile, the invention further discloses a special treatment system using the treatment method. The special treatment system is simple in structure; the treatment method is easy in operation; the treatment cost is low, and the purification efficiency is high; the reverse osmosis concentrated water difficult to decompose, especially waste water from a petrochemical enterprise, is completely purified to achieve zero emission; the popularization and application of the treatment method and the special treatment system on a large scale has a very high social benefit.

Owner:HEBEI UNIVERSITY

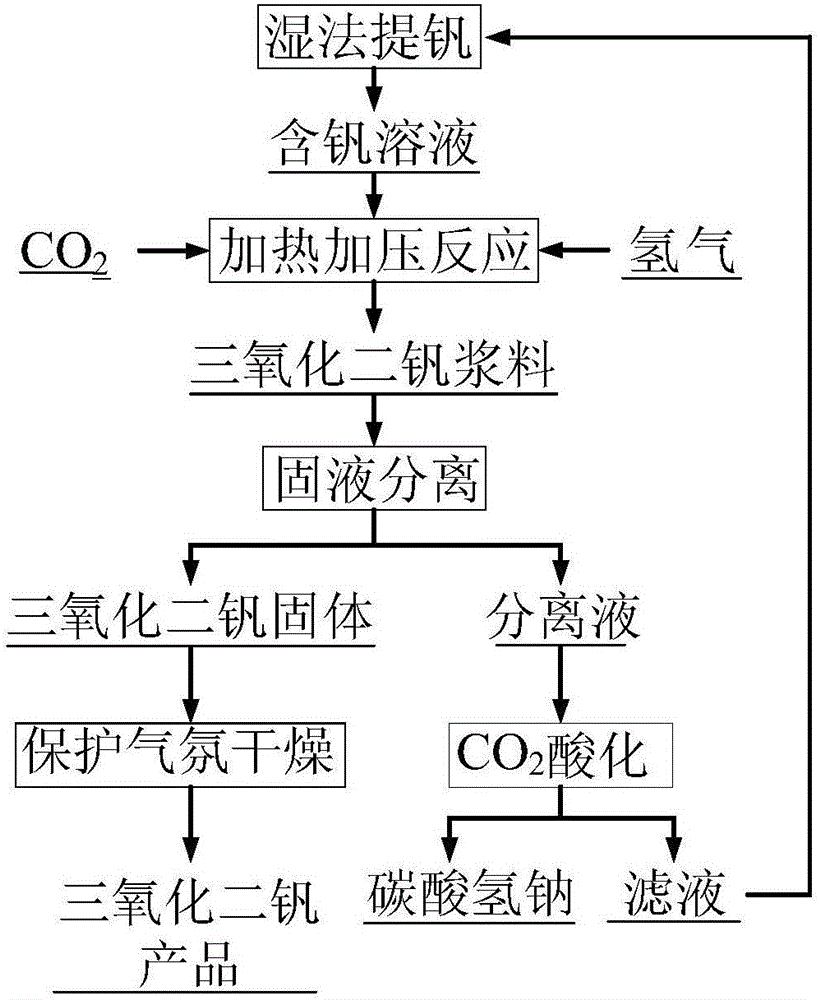

Method for preparing vanadium trioxide from vanadium-containing solution

InactiveCN107434259ALower pHHigh reactivityVanadium oxidesAlkali metal carbonatesHydrogenPhysical chemistry

The invention relates to a method for preparing vanadium trioxide from a vanadium-containing solution. The method comprises the steps of introducing CO2 and H2 into the vanadium-containing solution, carrying out a reaction under heated and pressurized conditions, and carrying out solid-liquid separation after the reaction is completed, thereby obtaining solid vanadium trioxide and a separated solution. According to the method disclosed by the invention, the gas mixture of CO2 and H2 is adopted to react with the vanadium-containing solution, so that the technical problem that a reduction reaction is difficult to carry out due to the fact that sodium hydroxide is produced in a hydrogen gas reduction process of vanadate is solved; the efficiency of reduction of the vanadate is increased, and the vanadium trioxide product with the purity higher than 99% is obtained; and meanwhile, the generation of ammonia nitrogen wastewater is effectively avoided, the cyclic utilization of water resources is achieved, and the aim of zero wastewater emission is achieved. The method has the characteristics of short process flow, high production efficiency, high-end product, environment-friendliness, low cost and the like and is applicable to industrialized popularization.

Owner:HEBEI IRON AND STEEL

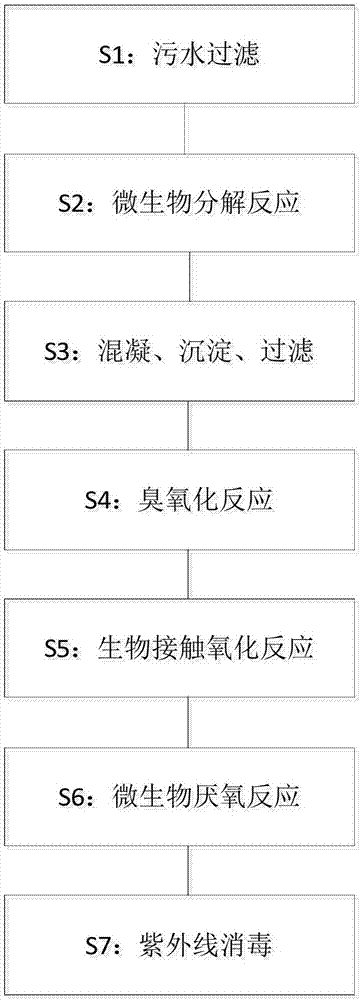

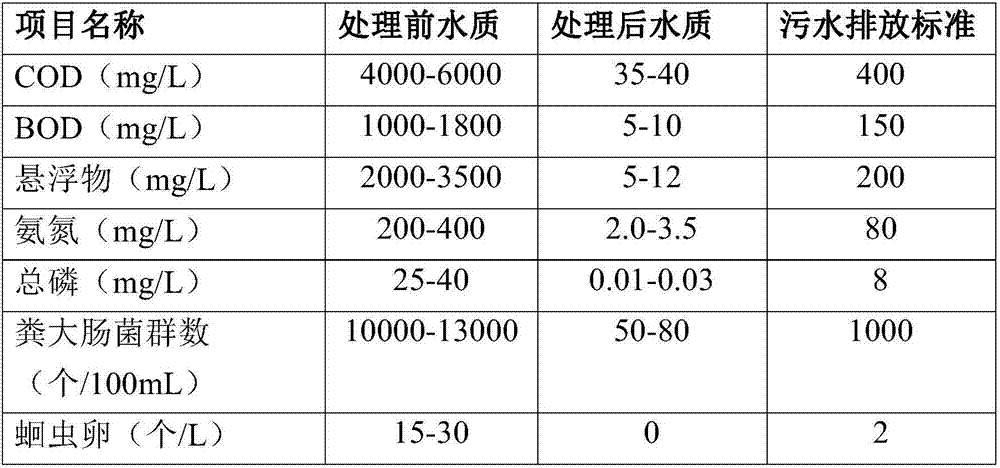

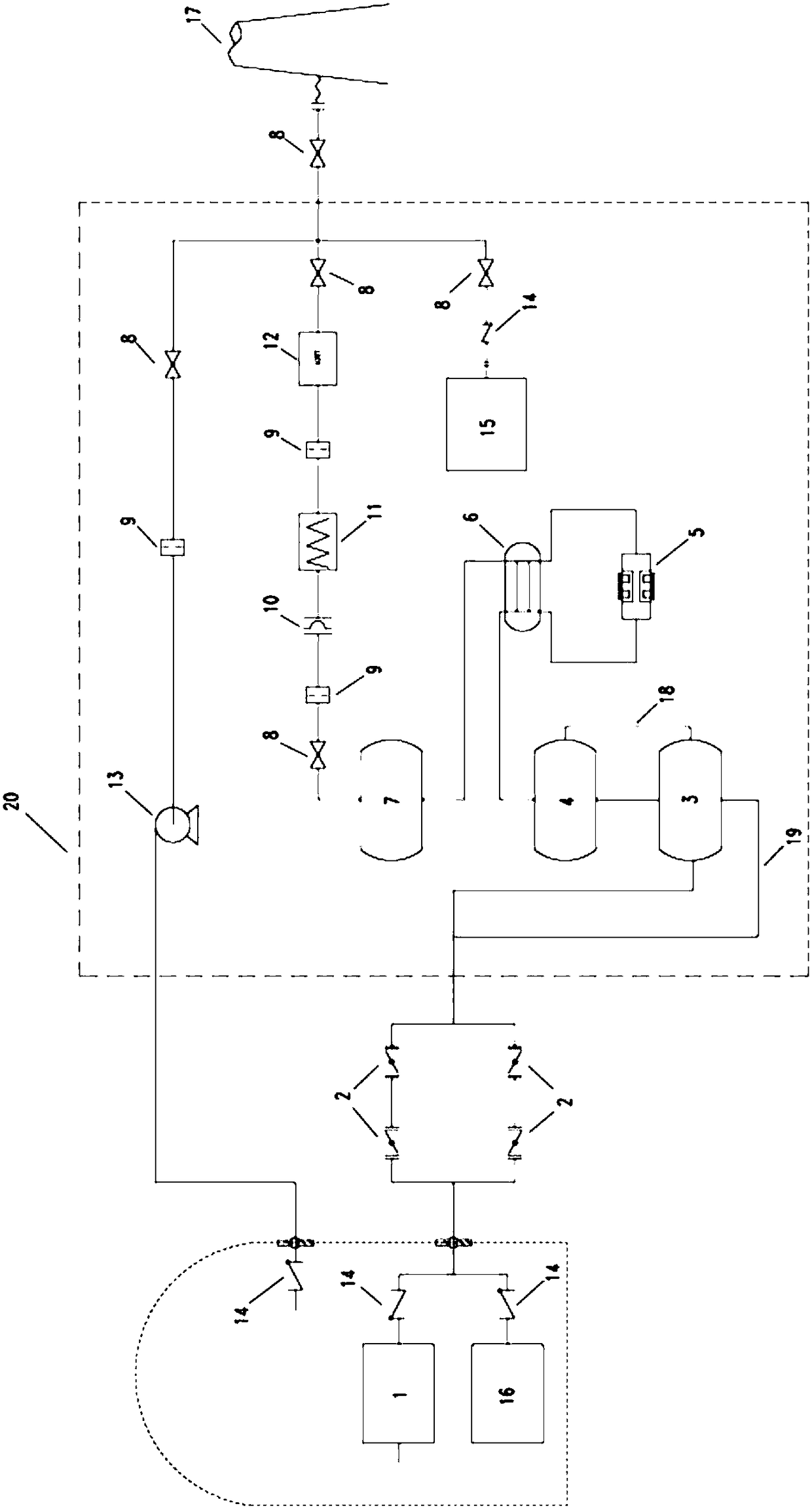

Cold region livestock and poultry breeding sewage treatment method

InactiveCN107473541ASolve pollutionAchieving processing powerTreatment using aerobic processesWater/sewage treatment by irradiationMicroorganismDecomposition

The invention discloses a cold region livestock and poultry breeding sewage treatment method. The cold region livestock and poultry breeding sewage treatment method comprises following steps: S1, sewage is delivered through a filtering basin, wherein filtering is carried out at a water inlet, a middle part, and a water outlet of the filtering basin using a filter screen; S2, after filtering, low temperature decomposition microorganism colonies are added into water for 3 to 5 days of reaction; S3, the processed water is subjected to coagulation, deposition, and filtering treatment; S4, after coagulation and filtering treatment, the water is delivered into an ozone reaction device, ozone is added for 4 to 5min of ozonization; S5, after ozonization, the processed water is delivered into a biological contact oxidation pond for 0.5 to 1h of biological contact oxidation; and S6, the water processed via biological contact oxidation is delivered into an anaerobic pond, is heated to 15 to 20 DEG C with solar energy, low temperature decomposition microorganism colonies are added at the same time, and the water is subjected to reaction for 5 to 7 days; and S7, disinfection is carried out using an ultraviolet ray sterilizer so as to obtain water for up-to-standard discharge. The cold region livestock and poultry breeding sewage treatment method is simple, is high in efficiency and low in cost, and is capable of solving water pollution problems caused by livestock and poultry breeding.

Owner:YANBIAN UNIV

Containment vessel pressure relieving, filtering, and discharging comprehensive system

ActiveCN108062984AEffective protectionAchieving zero emissionsNuclear energy generationEmergency protection arrangementsExhaust fumesMetal fibers

The invention relates to a containment vessel pressure relieving, filtering, and discharging comprehensive system. The system comprises a discharge pipeline for discharging air in a containment vessel. A first metal fiber filter is arranged on the section, which is in the containment vessel, of the discharge pipeline. After the discharge pipeline is leaded out from the containment vessel, the discharge pipeline penetrates an isolating valve of the containment vessel and is connected to a Venturi water washing filter. After the discharged air is filtered by the Venturi water washing filter, discharged air enters a second metal fiber filter. Condensate formed in the second metal fiber filter is returned to the Venturi water washing filter by a condensate returning pipeline. The air outlet end of the second metal fiber filter is connected to a silver-zeolite filter through a preheating loop. The air outlet end of the silver-zeolite filter is connected to a rupture disk. A downstream pipeline of the rupture disk is connected to a chimney of a nuclear power plant through a discharge isolating valve; or the downstream pipeline is returned to the interior of the containment vessel throughan air returning pipeline or is connected to a waste gas storage device. The system can guarantee the integrity of a containment vessel after a severe accident and ensures that no radioactive substance is discharged to the atmosphere and no person is damaged.

Owner:CHINA NUCLEAR POWER ENG CO LTD

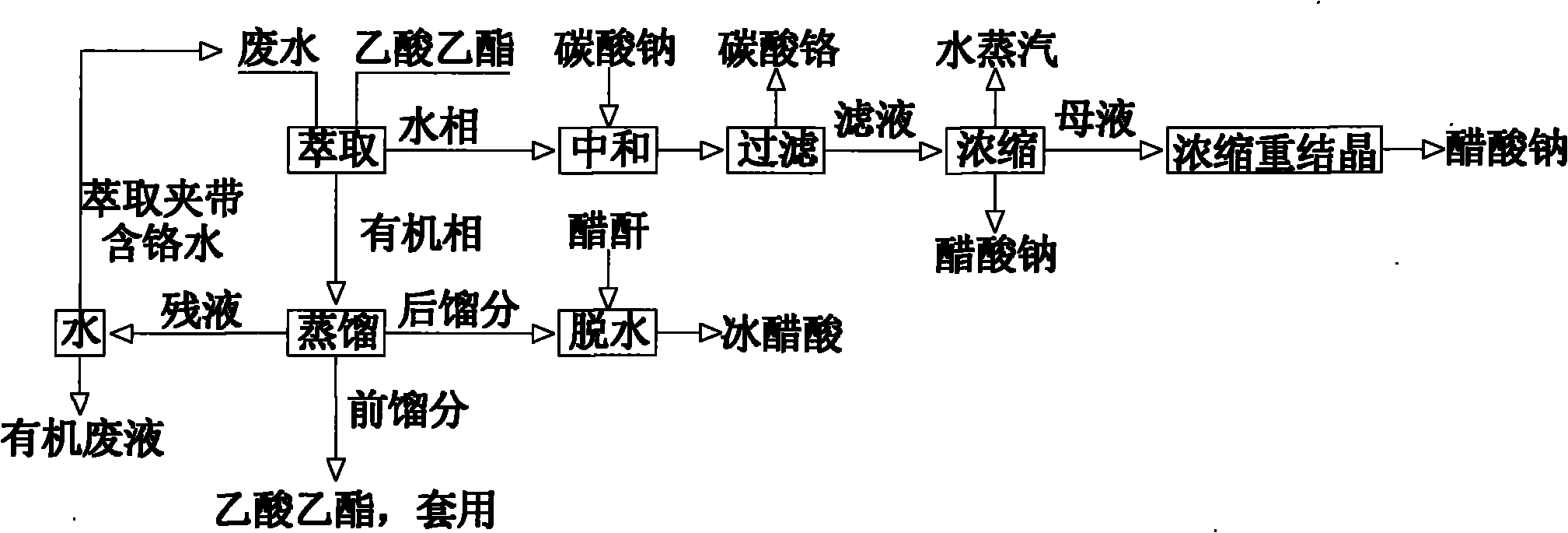

Method for controlling and recycling waste water containing acetic acid and chromium

InactiveCN101955274AIncrease concentrationReduce energy consumptionMultistage water/sewage treatmentCarboxylic acid salt preparationAcetic acidSodium acetate

The invention relates to a method for controlling and recycling waste water containing acetic acid and chromium, belonging to the chemical field. The method solves the pollution of acid-chromium waste water produced in the production process of diene, simultaneously recycles sodium acetate and glacial acetic acid, is used for circular production, obtains chromium salt capable of being applied in the market and does not generate new waste water pollution.

Owner:湘西自治州奥瑞克医药化工有限责任公司

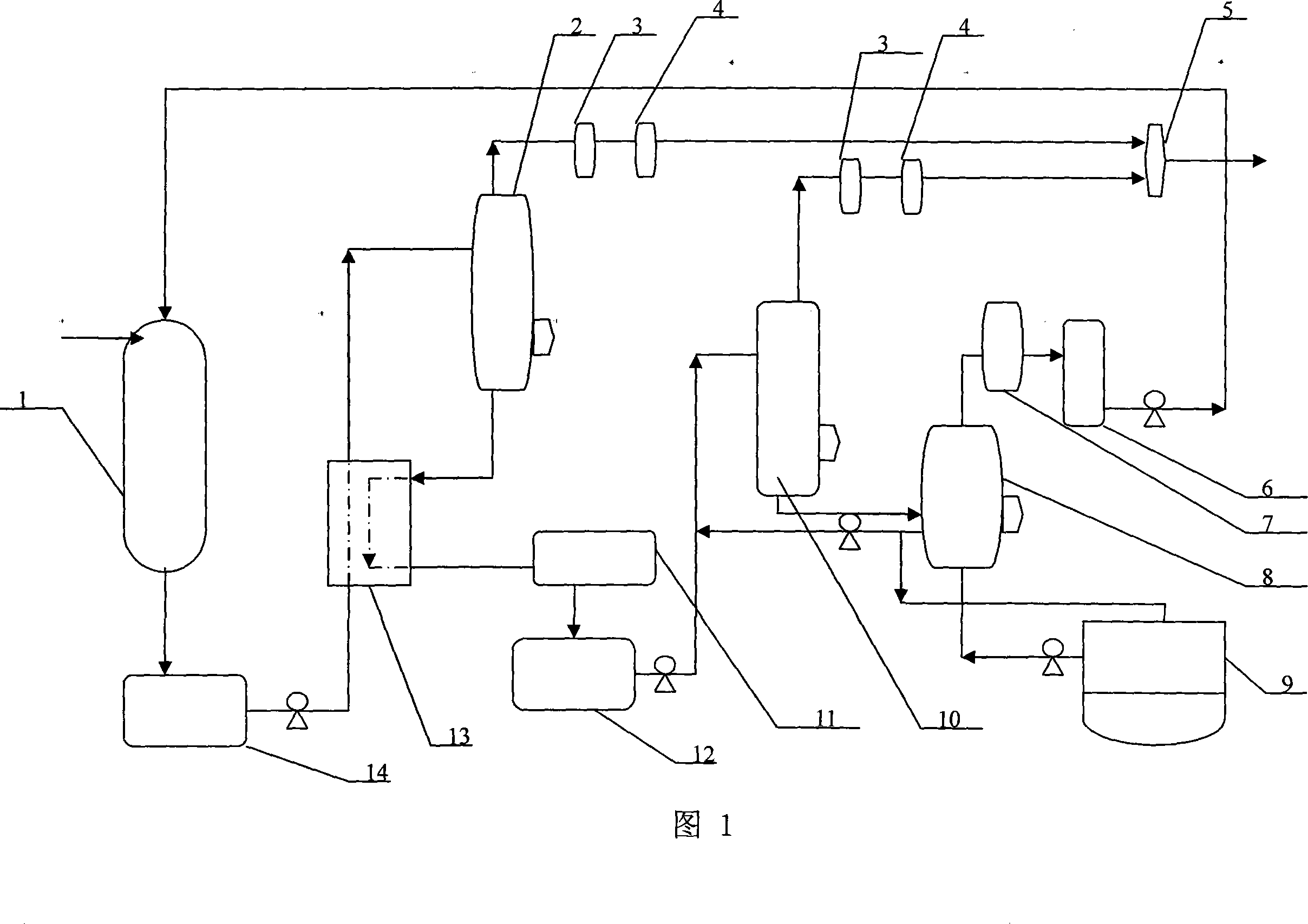

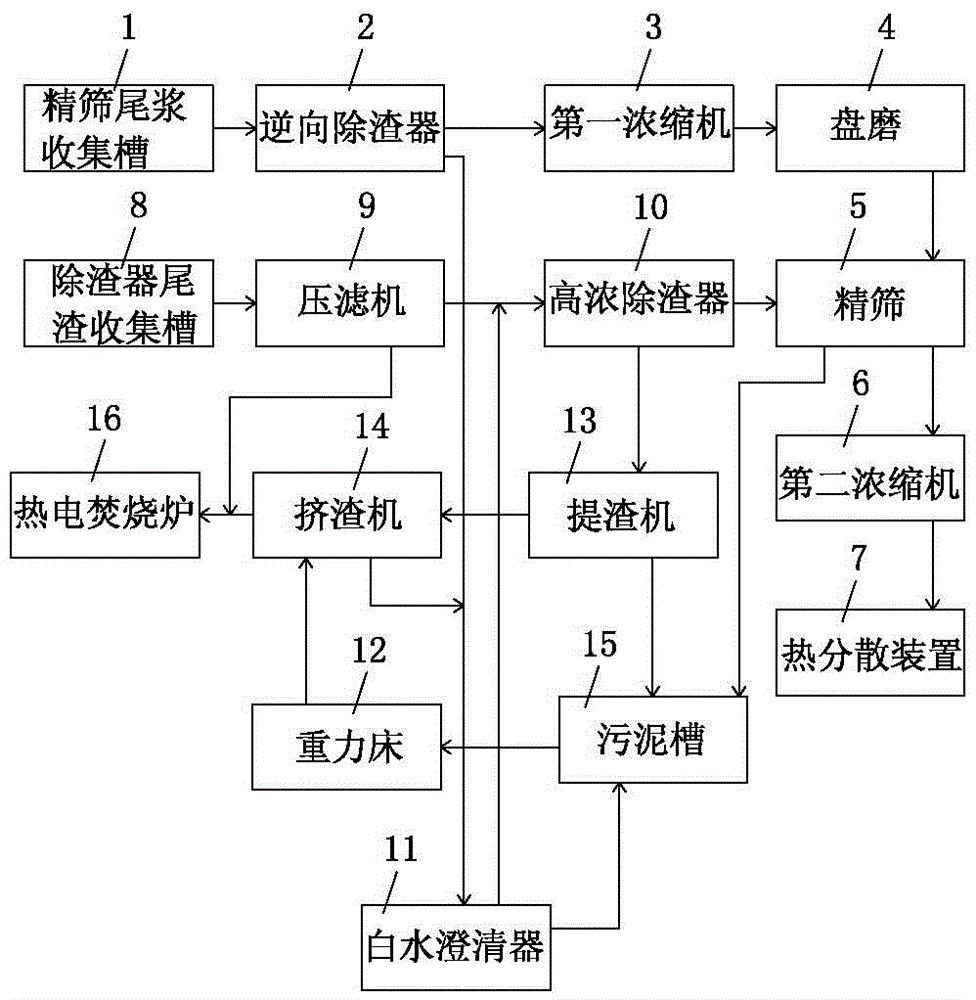

Pulp residue treating and recycling system

ActiveCN106592315AReduce churnReduce organic contentMachine wet endPulp beating/refining methodsHigh concentrationSludge

The invention relates to the technical field of papermaking and particularly relates to a pulp residue treating and recycling system. The system comprises a fine screen tail slurry collecting tank, a reverse residue separator, a first concentrator, a disc mill, a fine screen, a second concentrator, a thermal dispersion device, a residue separator tailing collecting tank, a press filter, a high-concentration residue separator, a white water clarifier, a gravity bed, a residue extracting machine, a residue squeezing machine, a sludge sump and a pyroelectric incinerator. According to the pulp residue treating and recycling system, un-dispersed fiber bundles in residue separator tailings and fine screen tail slurry can be scattered and dispersed again, and lightweight bubbles can be separated; and meanwhile, non-fibrous components such as sand and fine ashes can be further separated from the residue separator tailings and the fine screen tail slurry, so that the pulp residue treating and recycling system has the advantages that fiber loss can be reduced, the content of organic matters in discharged sewage is reduced, the sewage treatment load is reduced greatly, and finally, the energy-saving and environment-friendly social benefits are achieved.

Owner:DONGGUAN NINE DRAGONS PAPER IND

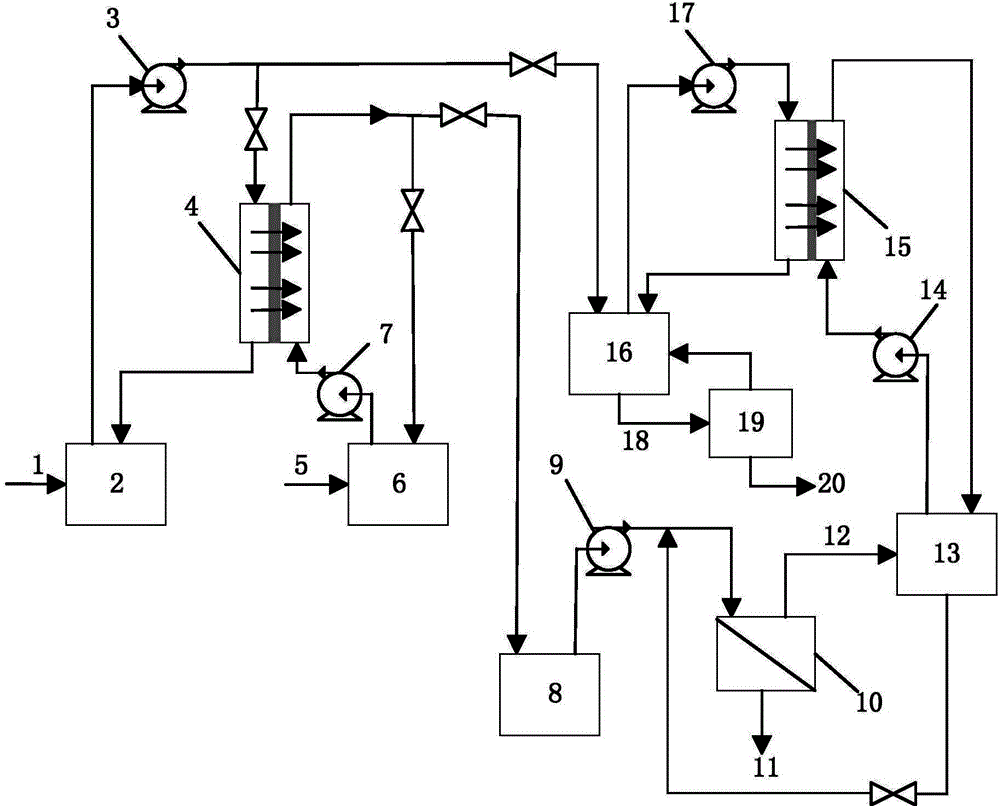

Multi-path recycling method for wastewater produced in acid-making with smelting gas

ActiveCN107512813AReliable operationLow running costSulfur compoundsTreatment involving filtrationChemistryHeavy metals

The invention discloses a multi-path recycling method for wastewater produced in acid-making with smelting gas, which belongs to the technical field of chemical engineering. The method comprises the steps of firstly performing discharging reduction on the acid wastewater by an internal circulation concentration method of a purification system, treating the acid wastewater by a process of primary vulcanization, neutralization and secondary vulcanization to remove heavy metals, arsenic, sulfuric acid, iron and zinc in the acid water in sequence, according to market demand, producing magnesium sulfate heptahydrate by cooling crystallization, and preparing sulfuric acid solution by evaporation concentration, thus realizing the ultimate goal of zero acid wastewater discharging. The process flow is reliable and can be used for recycling the acid water in two different ways; operating cost is low, new produced waste quantity is small, multiple products can be produced for generating profit, slag generated in different stages has different utilization values, and the aim of multi-path recycling of the acid wastewater is truly realized.

Owner:JINCHUAN GROUP LIMITED

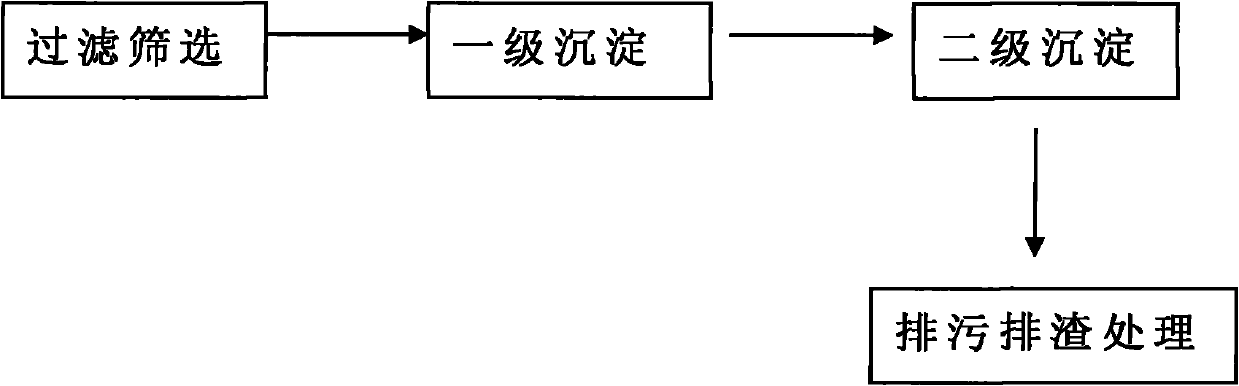

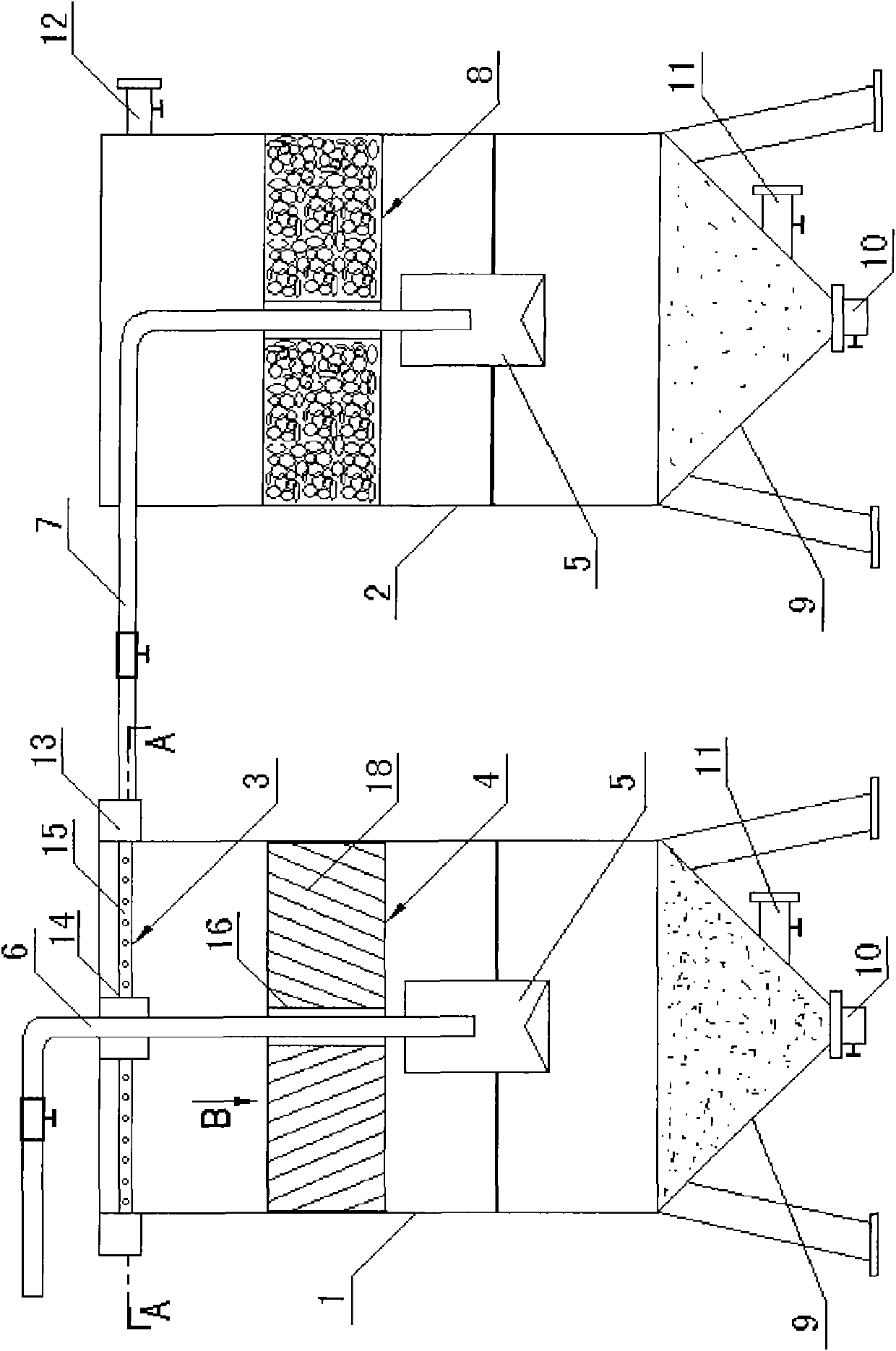

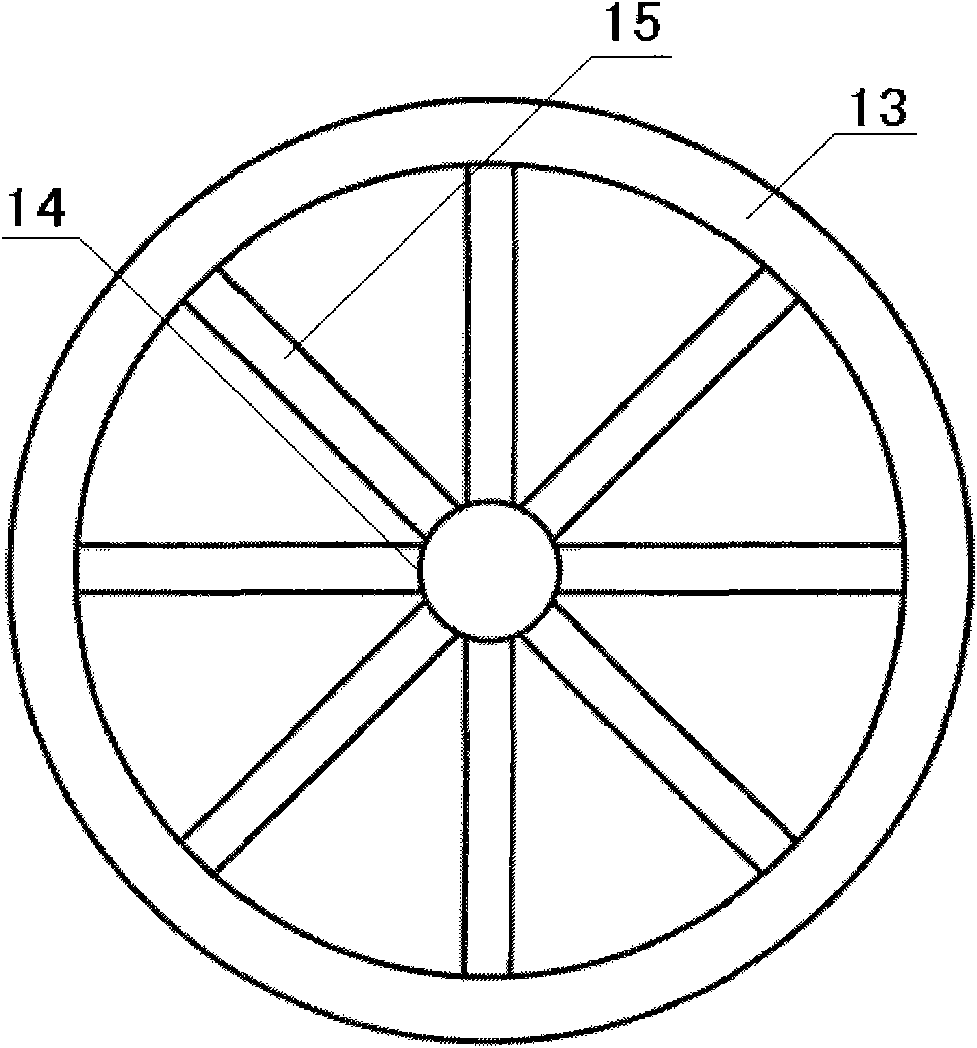

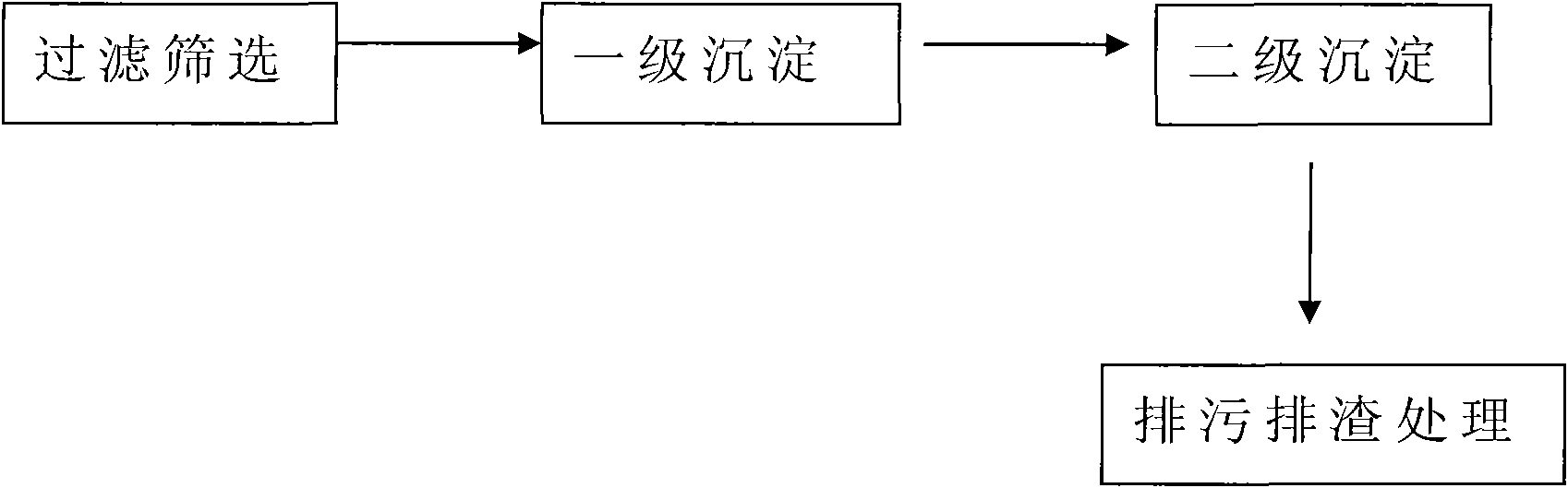

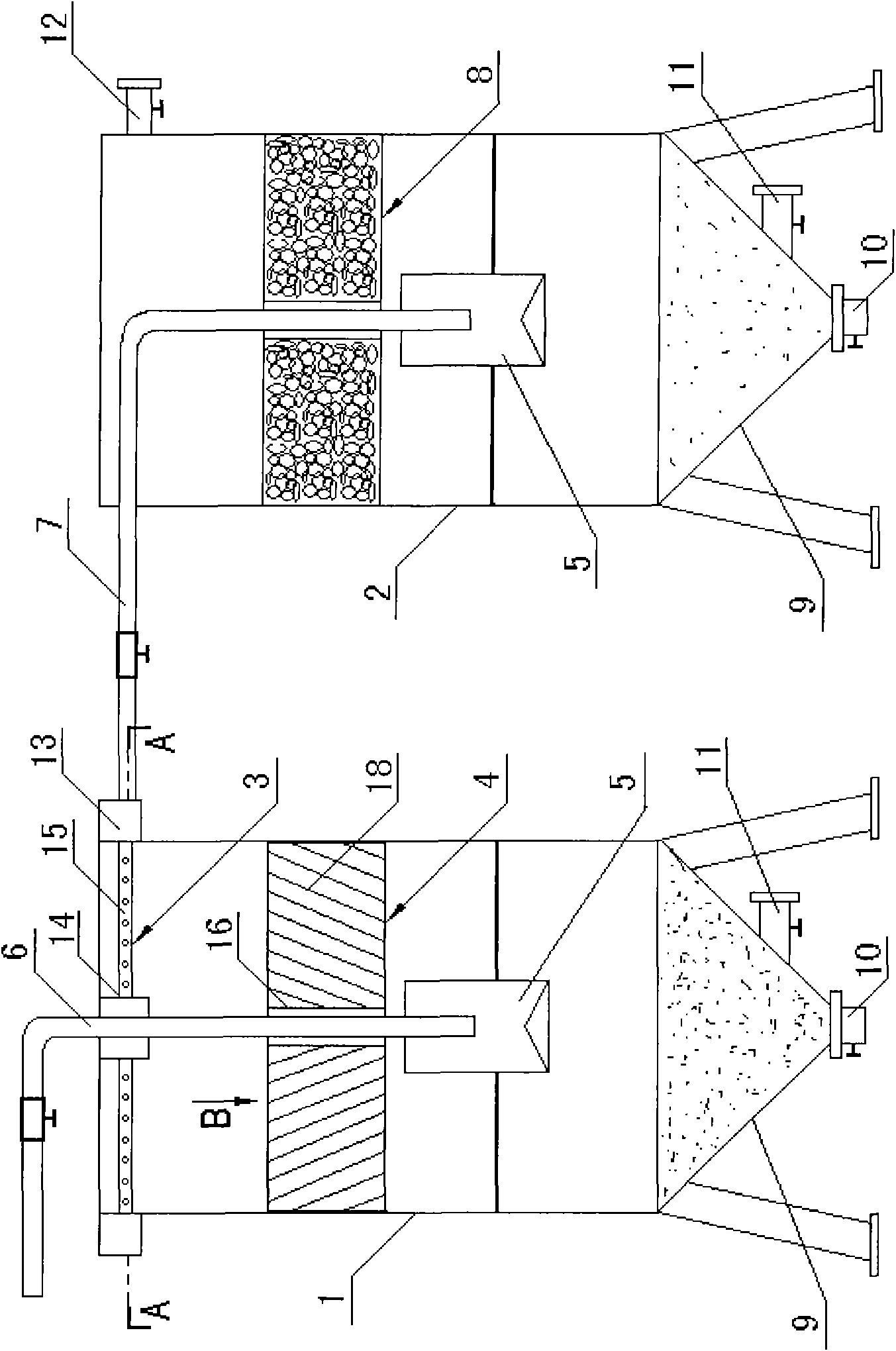

Method and tower for quickly precipitating papermaking sewage

InactiveCN102198967AGood effectTo achieve the goal of zero emissionsWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationSlagPapermaking

The invention relates to a method for treating papermaking sewage, in particular to a method and a tower for quickly precipitating the papermaking sewage. The papermaking sewage of small papermaking enterprises is treated by a two-stage quick precipitation method through synergy of a radial water outlet device, an inclined plate precipitation device, a buffer slot and a spherical filtering filler layer on the quick precipitation tower and process steps of filtering and screening, first-stage precipitation, second-stage precipitation, sewage and slag removal and the like; and the process technology is reasonable, equipment has a simple structure, and the aims of treating papermaking industrial pollution, saving energy and reducing emission can be fulfilled.

Owner:梨树县郭家店汇泉造纸机械厂

Environment-friendly fermentation bed and preparation method thereof

InactiveCN107864888AMaintain humidityNormal humidityBird housingsEnvironmental engineeringMechanical engineering

The invention discloses an environment-friendly fermentation bed, comprising a feed trough arranged on the ground, and packing placed in the feed trough, wherein a plurality of drainage channels are arranged at the lower end of the feed trough, and discharge outlets communicated with the drainage channels are formed in the bottom of the feed trough; a plurality of air supply pipes and exhaust pipes are respectively arranged at the bottom of an inner cavity of the feed trough, and are arranged at intervals; the ends, extending out of the outer side of the feed trough, of the plurality of air supply pipes are separately provided with an air feeder; the ends, extending out of the outer side of the feed trough, of the plurality of exhaust pipes are separately provided with an exhaust fan. Themoisture, discharged into the packing, in feces is discharged into the drainage channels through the discharge outlets; the air feeder sends the outdoor gas into the packing for drying the packing inthe air, so that the normal humidity of the packing is maintained; the exhaust pipes exhaust the ammonia gas which can not react with the packing in time in the packing and breeding houses by means ofthe exhaust fans, so that the normal environment inside the breeding houses can be guaranteed. The environment-friendly fermentation bed provided by the invention is simple in technology and suitablefor large-area popularization and use.

Owner:广东和力百分百粤西生产基地有限公司

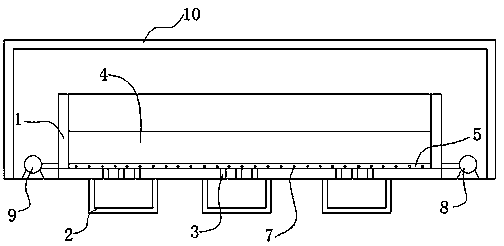

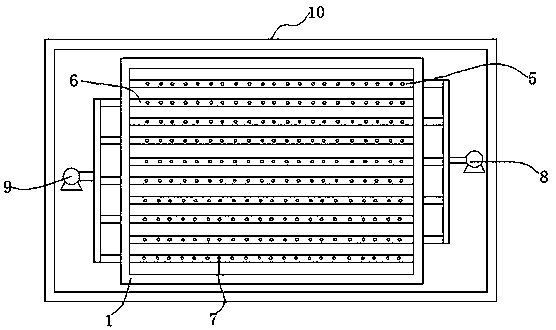

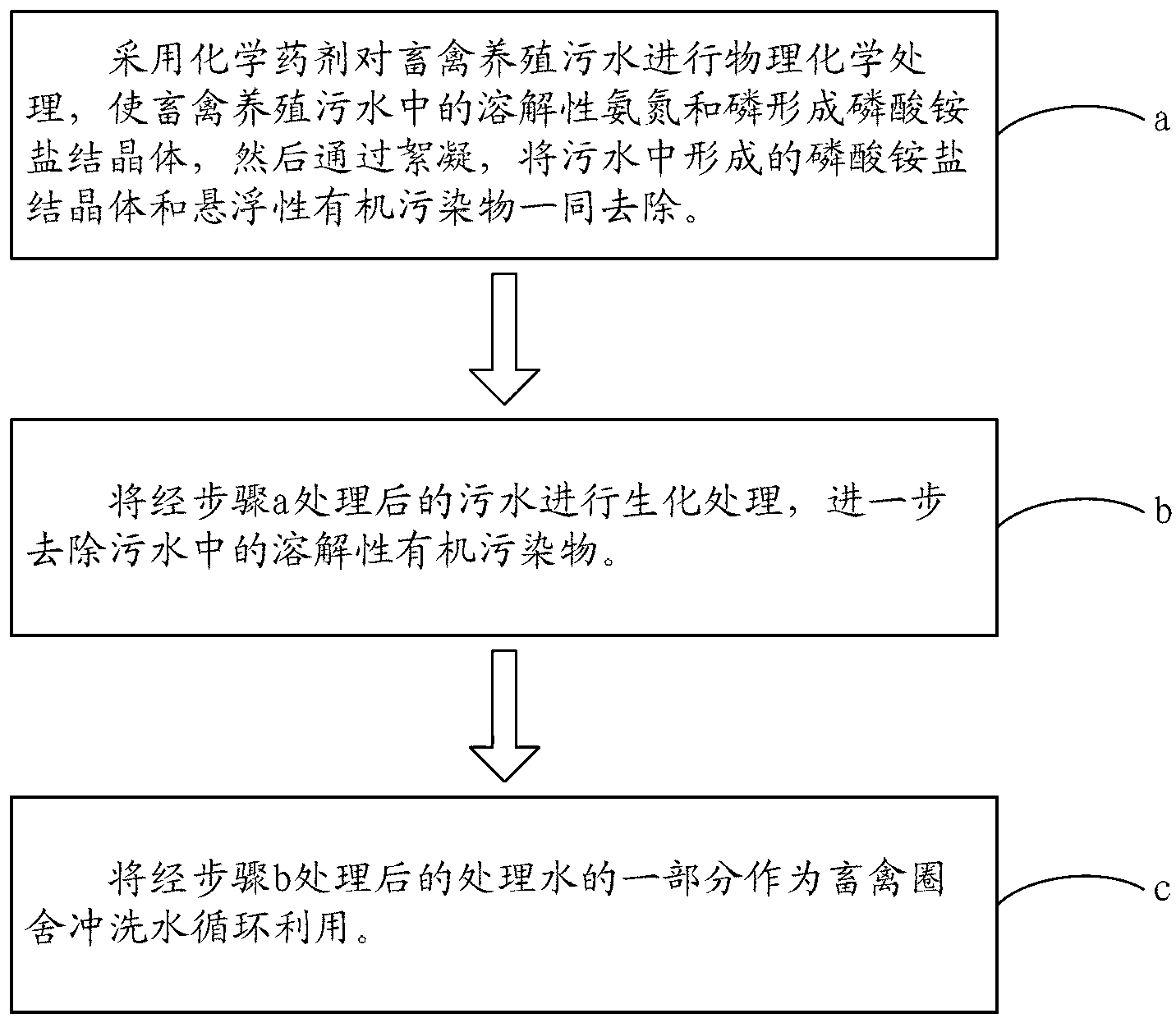

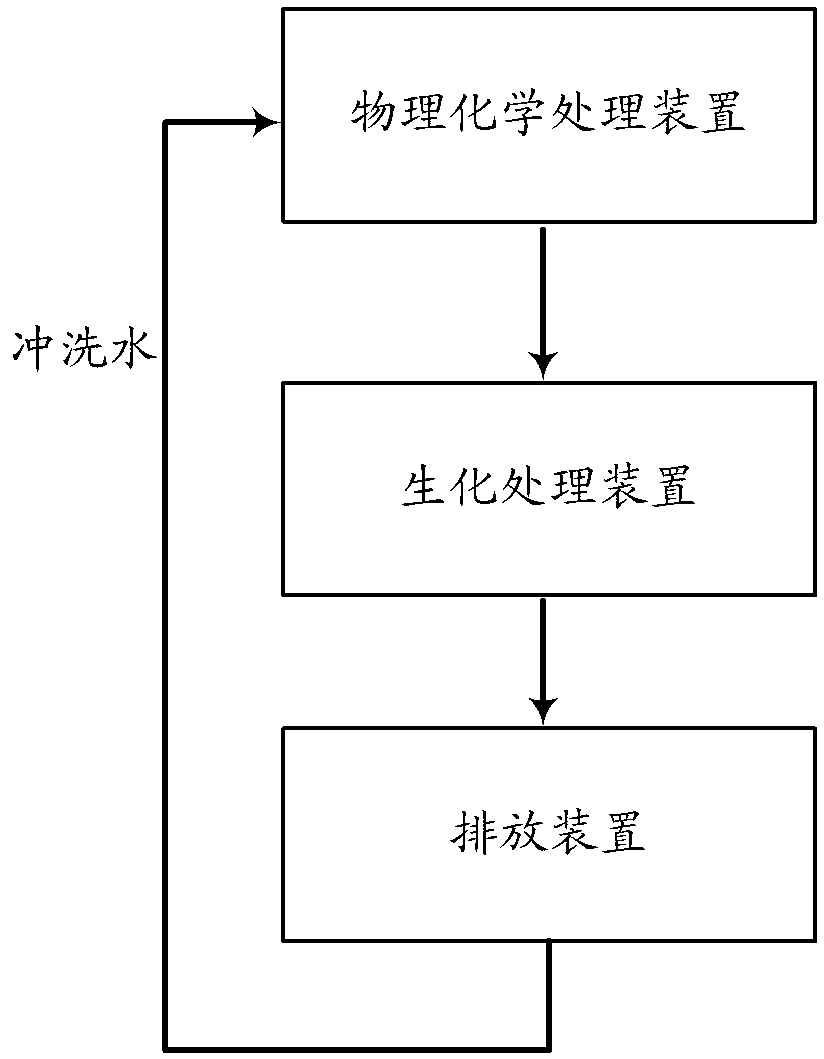

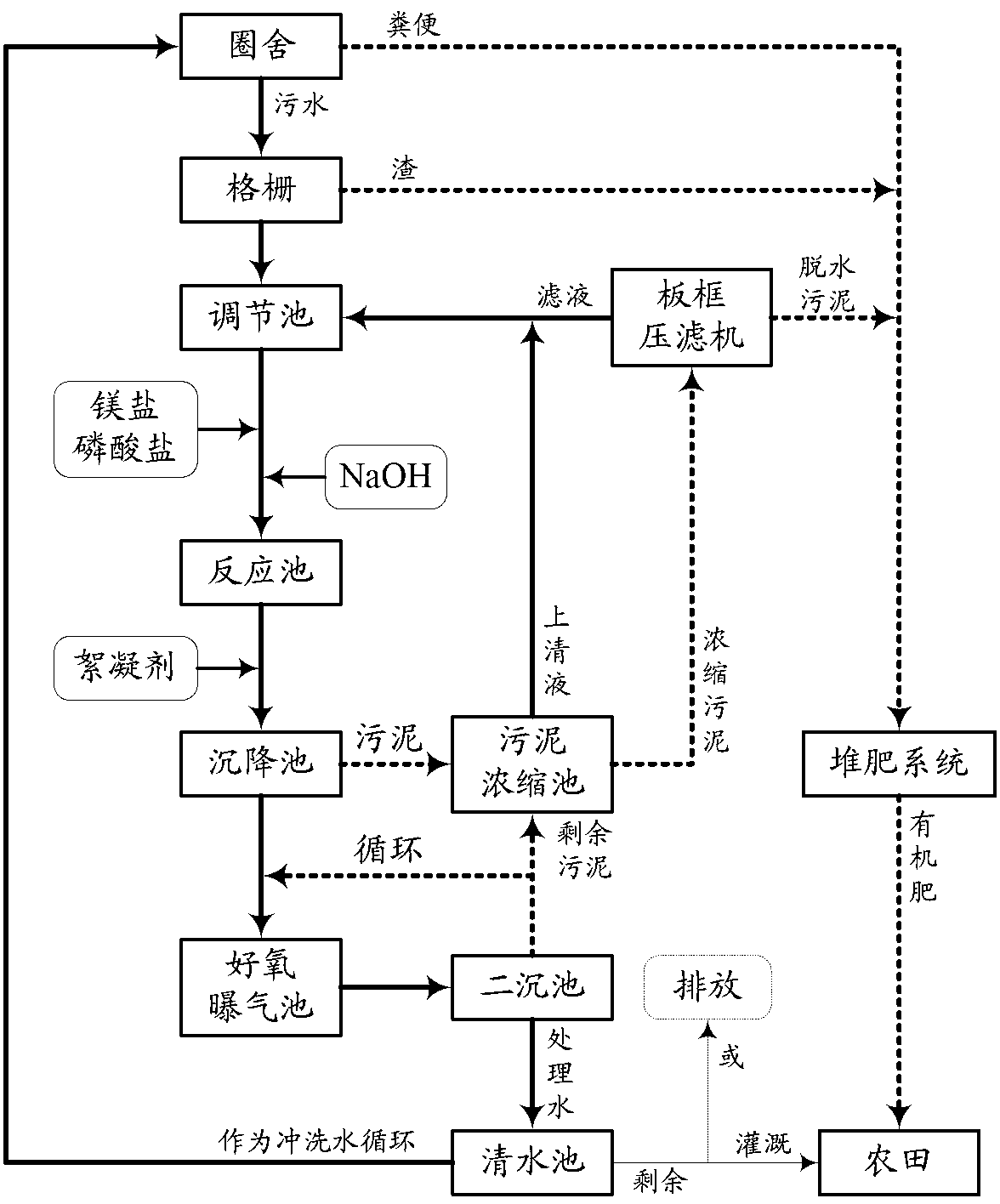

Large-scale livestock breeding sewage treatment method and equipment

InactiveCN103172217AEfficient use ofReduce pollutionSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentPhosphoric acidBiology

The invention provides a large-scale livestock breeding sewage treatment method. The large-scale livestock breeding sewage treatment method comprises the following steps of: step a. carrying out physicochemical treatment on livestock breeding sewage by adopting a chemical agent, so that soluble ammonia nitrogen and phosphorus in the livestock breeding sewage form ammonium phosphate crystals, then removing the ammonium phosphate crystals formed in the sewage and suspended organic pollutants together through flocculation; step b. carrying out biochemical treatment on the sewage treated in the step a, and further removing soluble organic pollutants in the sewage; and step c. using a part of treating water treated in the step b as flushing water for colony houses of livestock, thus realizing the cyclic utilization of sewage. The invention also provides large-scale livestock breeding sewage treatment equipment. The large-scale livestock breeding sewage treatment equipment provided by the invention can be used for preventing pollution caused by livestock sewage breeding and realizing recycle processing and cyclic utilization of breeding sewage.

Owner:吉林市环境保护科学研究院

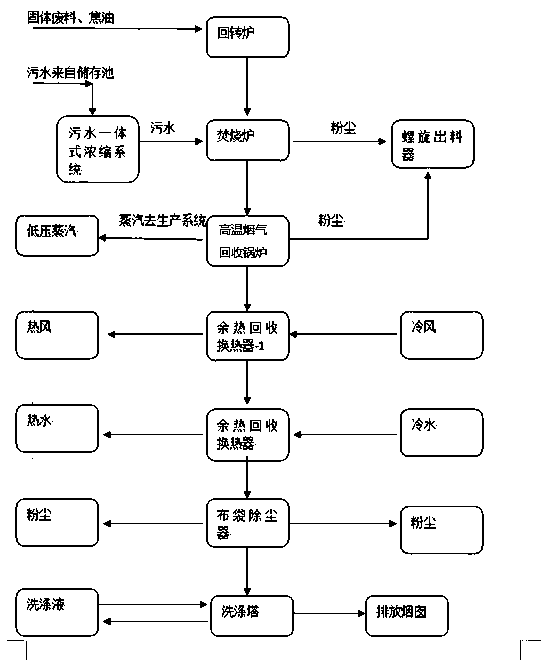

Industrial waste treatment technology and device thereof

PendingCN108726614ANo energy consumptionNo addedWater/sewage treatment by heatingIncinerator apparatusHigh concentrationToxic industrial waste

The invention discloses an industrial waste treatment technology and a device thereof. A method comprises the steps that hazardous waste of tar and the like is subjected to incineration, high-concentration high-salinity sewage is subjected to incineration, the two segments of incineration are combined to form a secondary complete incineration system, hazardous pollutants are removed, and the solidhazardous waste is treated when sewage incineration is conducted; meanwhile, high-temperature waste heat and medium-temperature waste heat are recycled, so that the sewage treatment cost is reduced;an integrated sewage concentration system is adopted, so that the sewage incineration quantity is reduced by 40%-60%, the sewage treatment cost can be saved by 30% or above, the direct cost of sewageincineration is reduced, whole system energy consumption is low, and sewage treatment recycling is achieved.

Owner:PINGYUAN ZHONGDE TAIXING ENVIRONMENTAL PROTECTIONTECH & EQUIP CO LTD

Probiotic fermentation bed for breeding livestock and poultry

InactiveCN104620996ASolve pollutionRapid and effective degradationBio-organic fraction processingFood processingWater sourceAntibiotic Y

The invention relates to an ecological cultivation method with health care fermented feed matched with a probiotic fermentation bed. The method includes the steps that first, probiotic fermentation is carried out, wherein the probiotic fermentation comprises anaerobic fermentation of anaerobes and aerobic fermentation of aerobic microorganisms; second, the probiotic fermentation bed is prepared, wherein various raw materials for preparing the material of the fermentation bed are evenly mixed so as to obtain organic bedding, bacterium solution is inoculated for fermentation, and the organic bedding contains saw dust, rice husks, bran and first compound Chinese herbal medicine; third, the fermented feed contains corn, bean pulp, vitamins, microelements, mineral substances, amino acids, other additives, second compound Chinese herbal medicine and the like, and microorganisms are added into the feed components for fermentation. The ecological cultivation method has the advantages that water can be purified, and hidden danger to health of hogs caused by a water source is blocked; the using amount of the microelements is reduced, resources are saved, emissions are reduced, and the environment is protected; no antibiotics or residue exists, and food safety and human health are guaranteed; the Chinese herbal medicines have the functions of being resistant to disease and promoting growth and can replace antibiotics.

Owner:BEIJING HUAMU GREAT EXPLOIT SCI & TECH +1

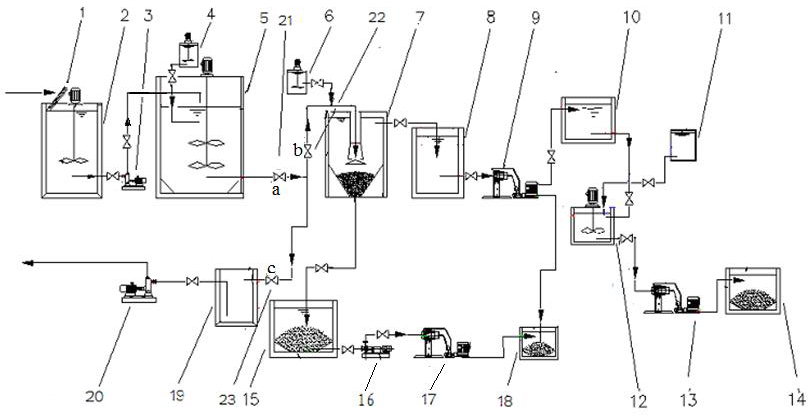

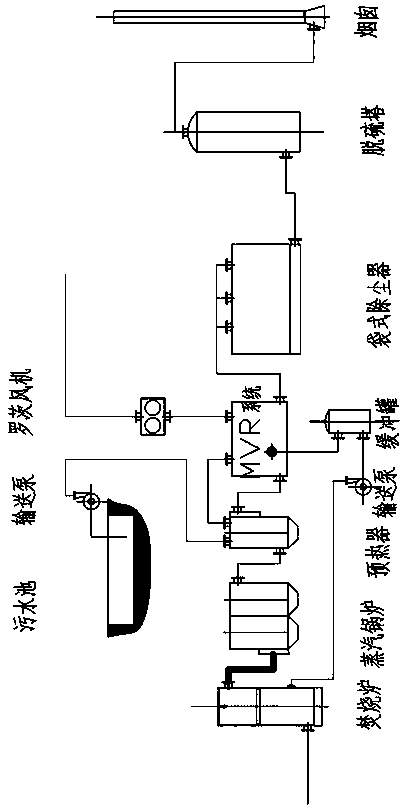

Zero release device of high-salt high-ammonia-nitrogen waste water

ActiveCN104609616AAchieving zero emissionsSolve processing problemsWater contaminantsWater/sewage treatment bu osmosis/dialysisWater qualityWater resources

The invention provides a zero release device of high-salt high-ammonia-nitrogen waste water. The zero release device is mainly used for solving problems of conventional devices that discharge standards are not reached, and water resource recovery rate is low in high-salt high-ammonia-nitrogen waste water treatment. The zero release device is a membrane coupling device, and mainly comprises a membrane absorption unit, a nanofiltration unit, a forward osmosis unit, and a cooling crystallization unit; the membrane absorption unit is connected with the nanofiltration unit, the nanofiltration unit is connected with the forward osmosis unit, the forward osmosis unit is connected with the membrane absorption unit and the cooling crystallization unit, and a plurality of circulation loops are formed via connection of the units. The zero release device is easy for operation, and is easy for realization. The zero release device can be used for solving processing problems of high-salt high-ammonia-nitrogen waste water effectively, water recovery rate is high, and quality of obtained water is high. The zero release device is used for circulating condensation of high-salt high-ammonia-nitrogen waste water, almost no concentrated water is discharged, and recovery of water resource of high-salt high-ammonia-nitrogen waste water is realized as far as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

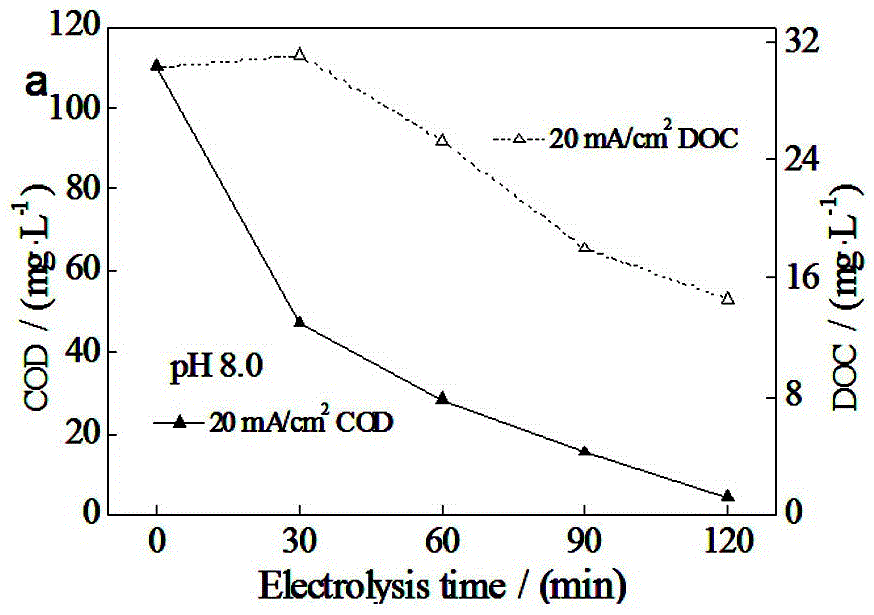

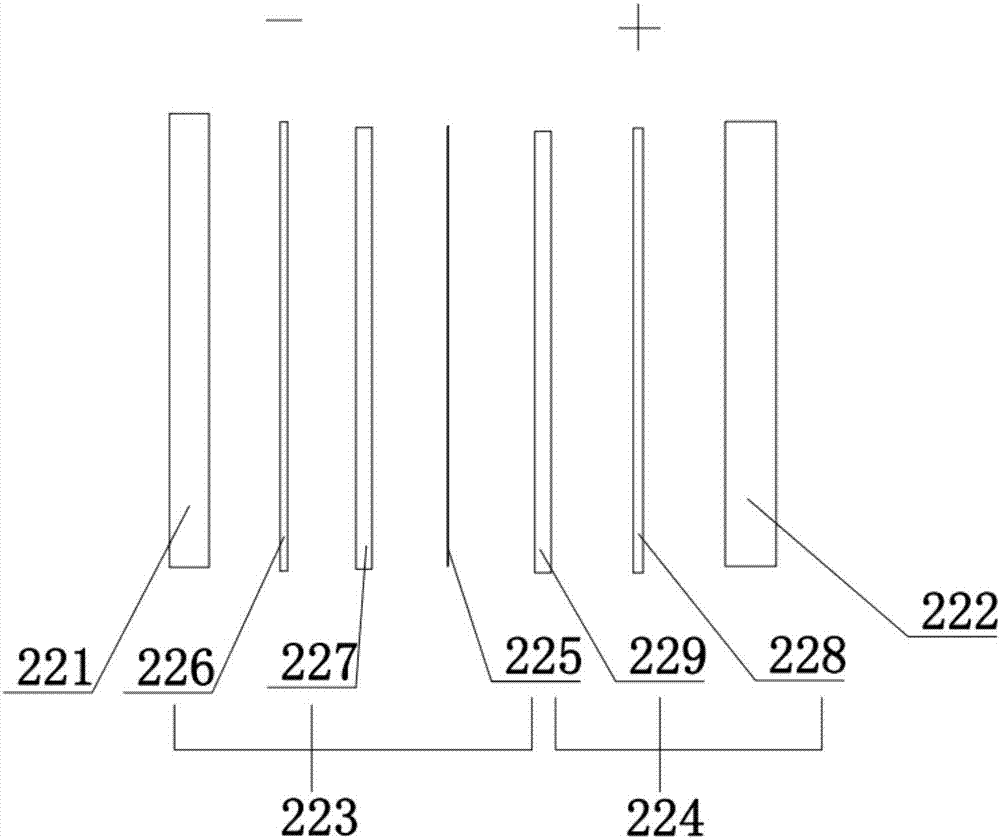

Zero-discharge recycling treatment device for wastewater with high salinity and high organic substance content

PendingCN107055703ATo achieve the goal of zero emissionsEfficient degradationElectrolysis componentsWater/sewage treatment by oxidationChemical oxygen demandRedox

The invention relates to a zero-discharge recycling treatment device for wastewater with high salinity and high organic substance content, relates to the technical field of treatment of high-salinity wastewater and solve the technical problems that treatment is large in investment and high in operation cost and cannot realize expected purification effect in the prior art. The zero-discharge recycling treatment device for wastewater with high salinity and high organic substance content comprises a cathode chamber circulating unit, a recycling module and an anode chamber circulating unit, wherein wastewater entering the recycling module can be subjected to a redox reaction by means of a membrane stack in the recycling module, so that the chemical oxygen demand can be reduced, and organic substances in the wastewater can be degraded effectively; besides, salts in wastewater can be recycled well by means of electrochemical principles, and zero-discharge recycling is realized.

Owner:ZIBO GERUI WATER TREATMENT ENG

Lampblack depuration machine

InactiveCN103084023AWill not polluteTo achieve the goal of zero emissionsUsing liquid separation agentNosocomial infectious diseasePollution

The invention relates to a lampblack depuration machine comprising a housing. A water container is arranged in the housing. The water container is connected to a blower through a pipe. The blower is connected to a lampblack hood through a pipe. The water container is connected to a water inlet pipe and a water overflow pipe which is positioned above the water inlet pipe. A waste discharge pipe is arranged on the bottom of the water container. An exhaust vent is arranged on the upper part of the water container. With the lampblack depuration machine provided by the invention, environment pollution caused by lampblack and dust is solved, and harmful gas zero discharge is realized. The lampblack depuration machine can be widely applied in domestic kitchens and catering operating rooms of restaurants, hotels, and canteens. The lampblack depuration machine can also be used in factories and hospital infectious disease areas.

Owner:王绍坤

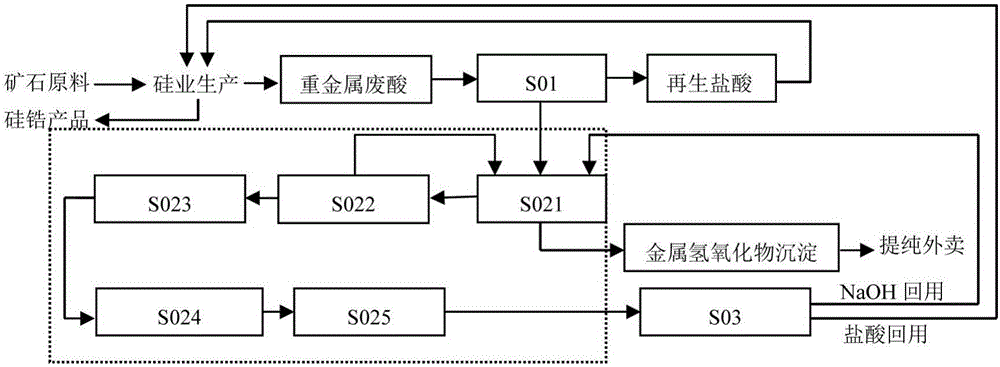

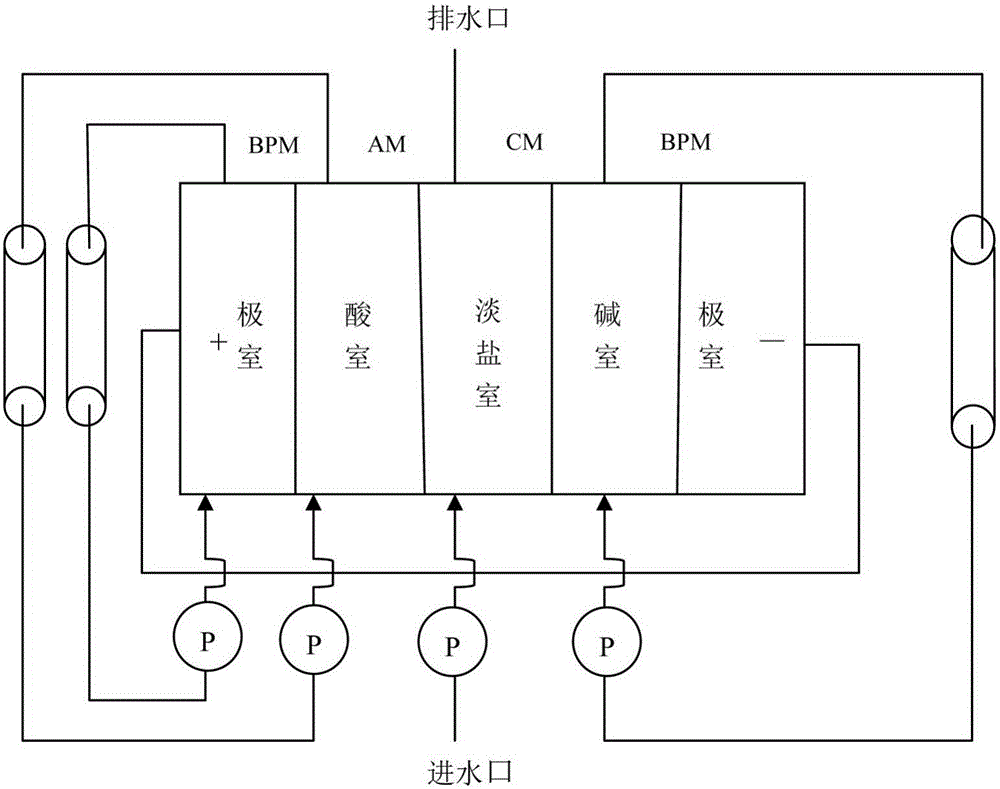

Rare earth heavy metal waste liquid treatment method

ActiveCN106277482ATo achieve the goal of zero emissionsPlay a protective effectWater contaminantsWater/sewage treatment by ion-exchangeLiquid wastePhysical chemistry

The invention provides a rare earth heavy metal waste liquid treatment method, relates to the field of wastewater treatment, and aims at providing a clean production method for achieving heavy metal wastewater zero discharging. The rare earth heavy metal waste liquid treatment method comprises the following steps of 01 diffusing dialysis; 02 pretreatment, wherein pretreatment comprises the following steps of 021 alkali neutralization, 022 nanofiltration and separation, 023 SS adsorption, 024 Na resin softening and 025 homogeneous electrodialysis; 03 bipolar membrane electrodialysis.

Owner:BEIJING TINGRUN MEMBRANE TECH DEV

Ecological pig breeding fermentation bed and management method of thereof

The invention discloses an ecological pig breeding fermentation bed and a management method of thereof. The fermentation bed is characterized in that the fermentation bed is of a four-layer structureand sequentially comprises an activated carbon and quick lime layer, a plant straw, saw dust and livestock salt layer, a wormwood, saw dust, wood dust and fermentation bacterium layer and a bran, sawdust and fermentation bacterium layer from bottom to top, fermentation bacterium solution is regularly sprayed, and the surface layer of the fermentation bed are furbished. According to the fermentation bed, excrement such as feces and urine of pigs can be effectively treated and decomposed, growing environments of the pigs are improved, the problems of soil pollution and air pollution of the feces and the urine of pigs are effectively solved, odor in the breeding process of the pigs is removed, injurious insect and harmful bacteria are restrained, gaskets and excrement can be decomposed intonutrient substances such as sugar, protein, organic acid and microorganisms by beneficial flora, disease resistance of the pigs can be enhanced, healthy growth of the pigs is facilitated, zero emission is achieved in the pig breeding process, and economic values of a pig farm are improved.

Owner:宁德生隆农业科技有限公司

Heat transfer room type heat recovery coke-oven

ActiveCN1242024CContinuous and stable heatingImprove lateral heating uniformityCoke ovensCombustion chamberExhaust fumes

The invention discloses a novel cell-type coking furnace, wherein the coal is subjected to destructive distillation in charring chamber, most of the obtained coal gas enters horizontal gas channel, and is divided to adjacent blast chambers through the coal gas distribution hole, the rest is distributed to each blast chamber. The dedusted thermal waste gas can be used by exhaust-heat boiler to produce steam power generation.

Owner:程相魁

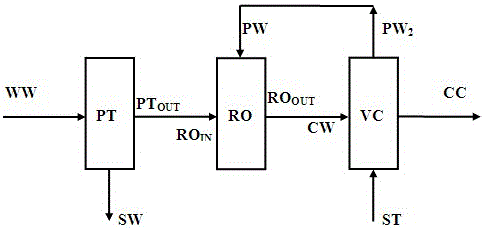

Zero-discharge treatment device and method for ferric phosphate high-salt waste liquid

ActiveCN104609631BLow costTo achieve the purpose of emissionGeneral water supply conservationMultistage water/sewage treatmentLiquid wasteSalt-wasting

The invention is a zero-discharge treatment device for ferric phosphate high-salt waste liquid, and its structure includes a pretreatment system (PT), a reverse osmosis treatment system (RO), and an evaporation crystallization treatment system (VC). Advantages, the present invention is designed for the high salinity of ferric phosphate high-salt waste liquid. The ferric phosphate high-salt waste liquid is firstly treated to remove part of the suspended matter, and then desalted by reverse osmosis, concentrated and reduced, and the water produced by reverse osmosis is reused , The reverse osmosis concentrated water is finally treated by evaporation and crystallization, the condensed water from evaporation and crystallization is reused, and the waste salt is transported outside to achieve the purpose of zero liquid discharge. The specific advantages are: ① organically combine pretreatment, reverse osmosis, and evaporation crystallization; ② use reverse osmosis to concentrate and reduce weight, and reduce the cost of subsequent evaporation crystallization; ③ use falling film evaporation combined with MVR (steam mechanical recompression) Advanced evaporation and crystallization technology, energy-saving and high-efficiency, reducing operating costs ④ It not only achieves water reuse, but also achieves the purpose of zero liquid discharge.

Owner:深圳市华虹清源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com