Containment vessel pressure relieving, filtering, and discharging comprehensive system

A containment and comprehensive technology, applied in the field of containment pressure relief filtration and discharge comprehensive system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

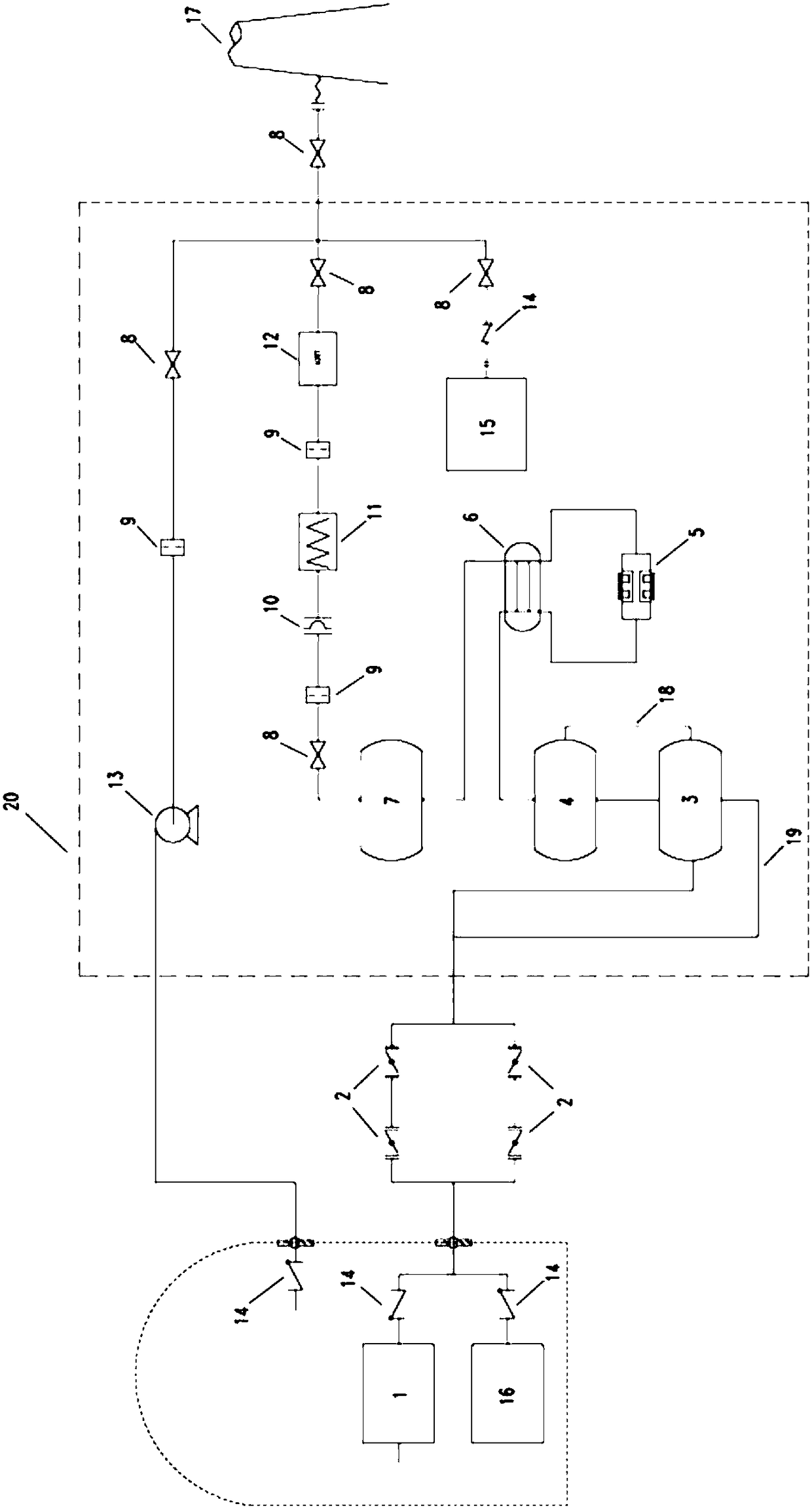

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] In the event of a severe accident in a nuclear power plant, a large amount of radioactive gas will be produced in the containment, and if released into the environment, it will cause adverse nuclear safety consequences to personnel and the environment. The research of the present invention starts from understanding the mass-energy release and containment performance and behavior in the long-term stage after the severe accident of the PWR nuclear power plant, and carries out technical exploration and program research of zero discharge after the severe accident. Through the study of several technical means for containment depressurization and collection and filtration of emissions, analyze their reality and possibility, develop system and core equipment design combinations, and carry out research and trial production and performance verification. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com