Method for fully recycling sludge

A technology of resource utilization and sludge, applied in the direction of chemical instruments and methods, sludge treatment, sewage/sludge fertilizer, etc., can solve the problems of sludge discharge, sewage treatment plant surplus, etc., to reduce environmental pollution, reduce costs, The effect of solving the problem of sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

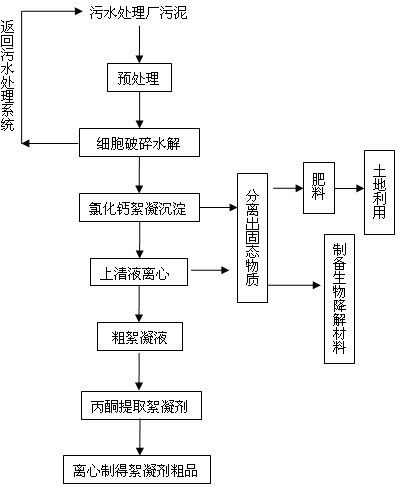

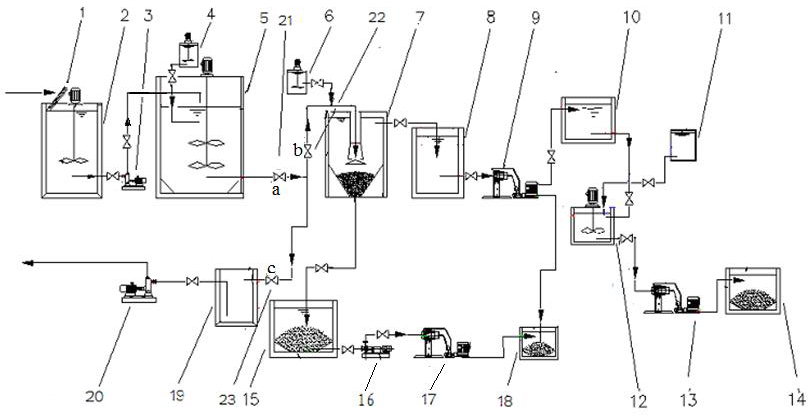

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] The excess sludge treatment mode of most sewage treatment plants is that after the excess sludge is concentrated in the sewage plant, the sludge is dehydrated to a moisture content of about 80% by mechanical dehydration, and then transported outside for landfill, composting or incineration. , this mode not only increases the sludge transportation cost, the cost is high, and it is easy to produce secondary pollution. The process of the invention can be applied to new construction or reconstruction of on-site sludge treatment facilities in sewage treatment plants, and can also be used in sludge treatment plants.

[0018] Such as figure 1 As shown, the equipment of the present invention is: mechanical screen 1, sludge regulating tank 2, sludge lifting pump 3, sludge hydrolysis dosing system 4, sludge hydrolysis reaction tank 5, cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com