Patents

Literature

96results about How to "Reduce processing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

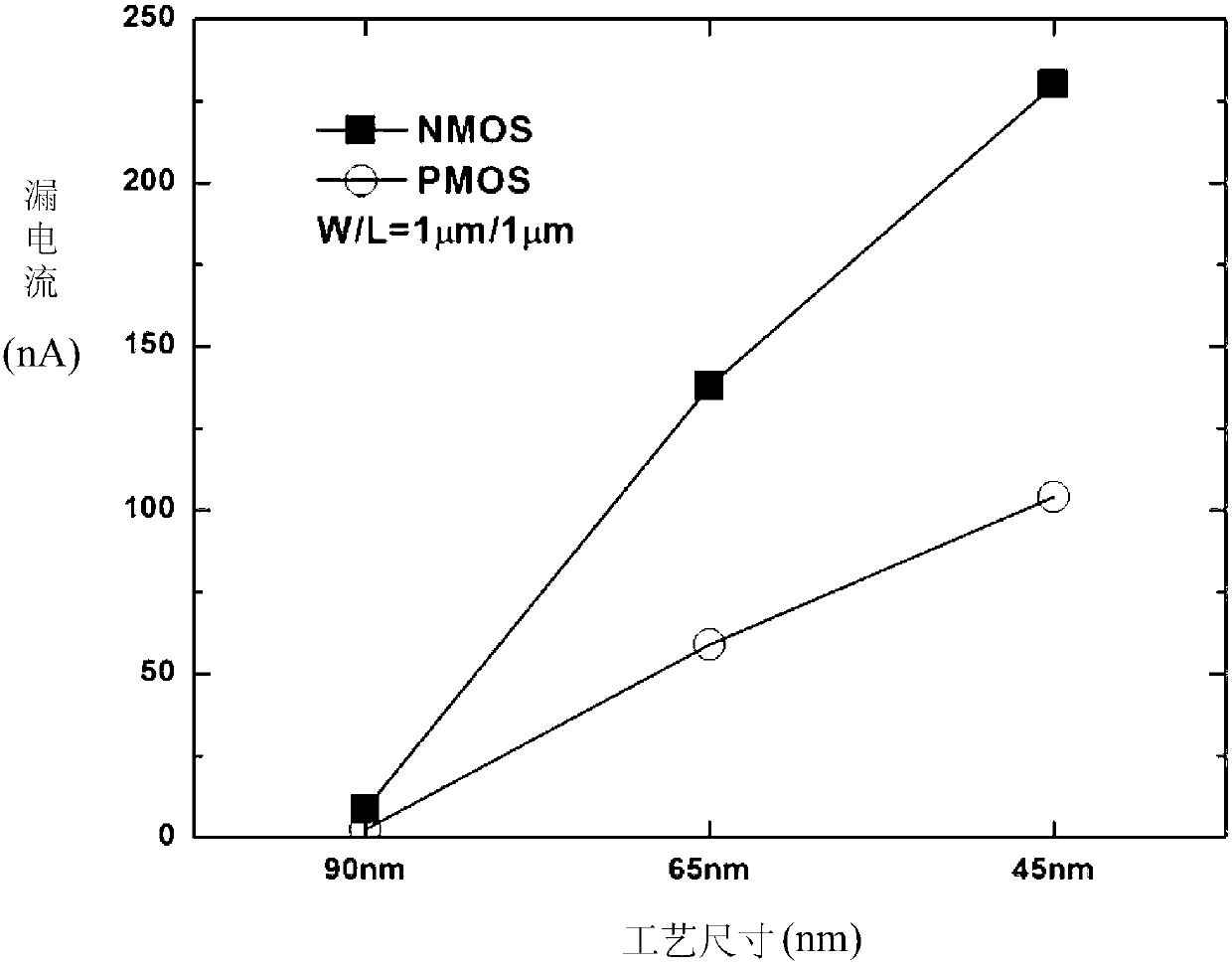

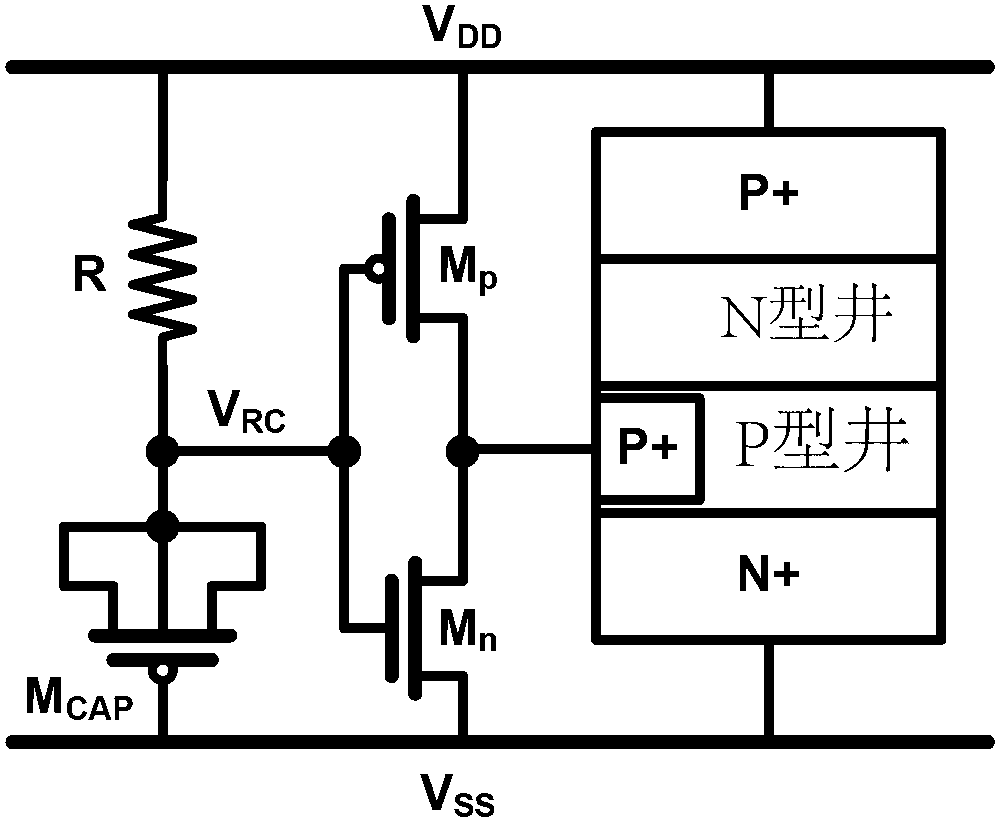

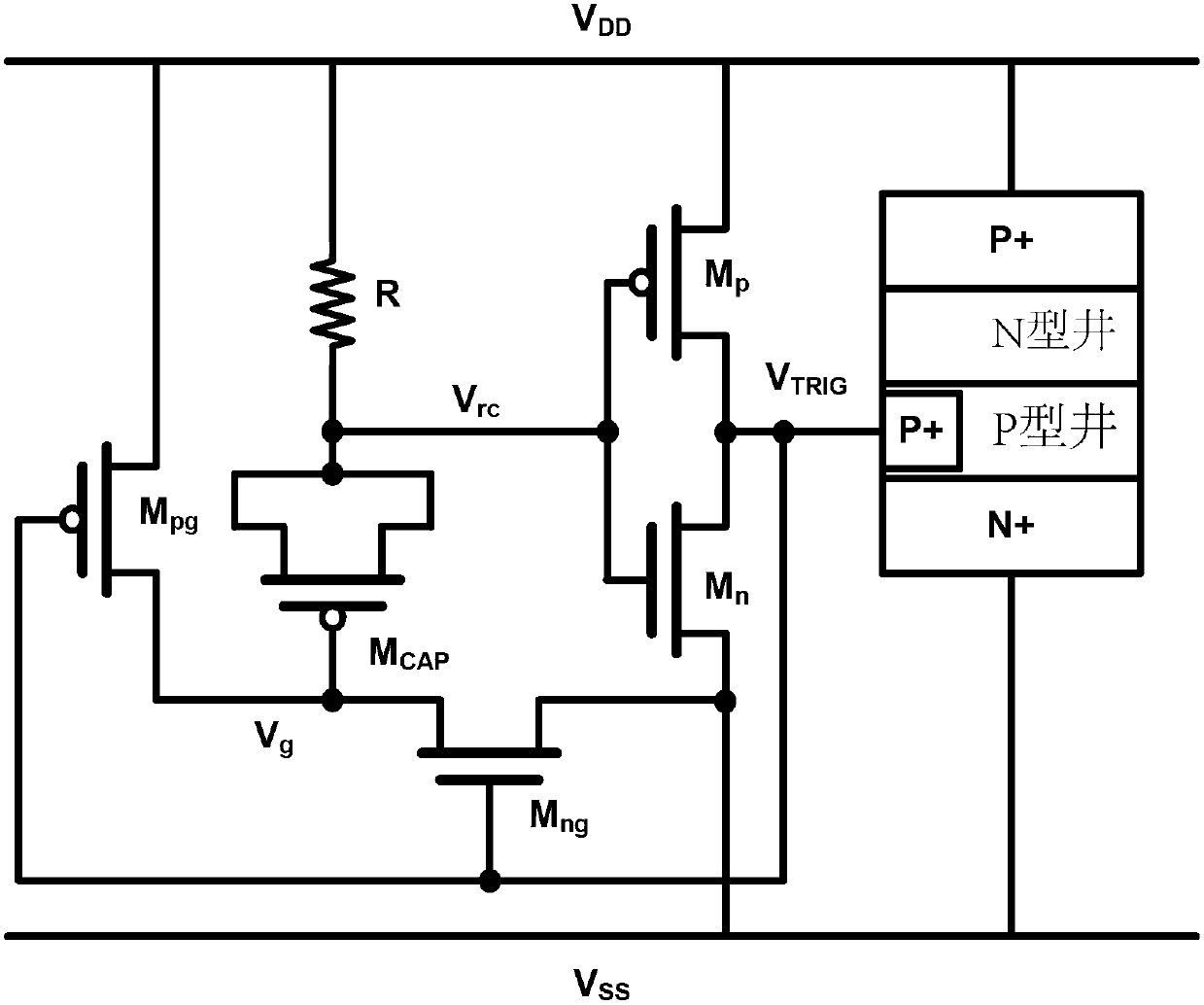

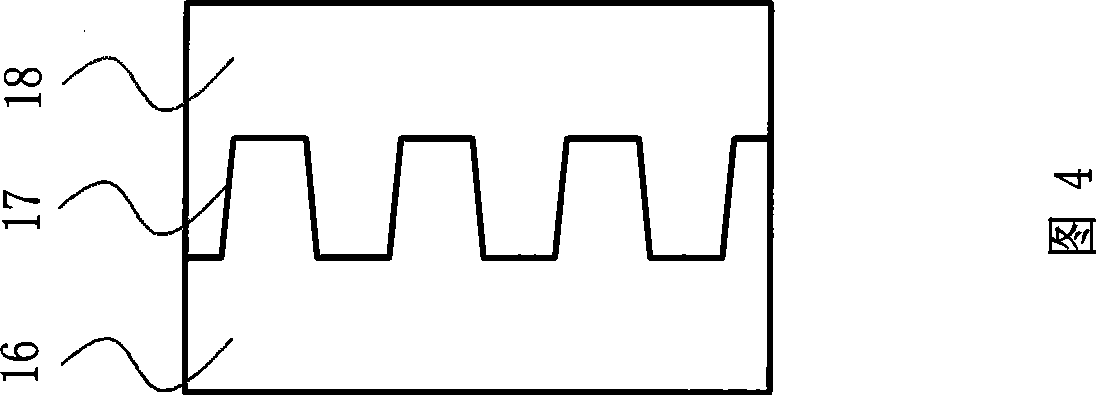

Power strangulation electrostatic discharge protection circuit

ActiveCN103219720AReduce processing areaReduce leakage currentSolid-state devicesEmergency protective arrangements for limiting excess voltage/currentSilicon-controlled rectifierLow voltage

A power strangulation electrostatic discharge protection circuit comprises a silicon control rectifier and a control module, wherein the silicon control rectifier is electrically connected between a high voltage level and a low voltage level to carry a current path. The control module is parallel to the silicon control rectifier, and includes a P-type metal oxide semiconductor field effect transistor, an N-type metal oxide semiconductor field effect transistor, at least one output diode, a resistor, and a breakover serial. The silicon control rectifier can be a P-type or N-type substrate-triggered silicon control rectifier. By using such novel power strangulation electrostatic discharge protection circuit, the leakage current of the circuit can be significantly reduced, and processing area of elements can be eliminated.

Owner:AMAZING MICROELECTRONICS

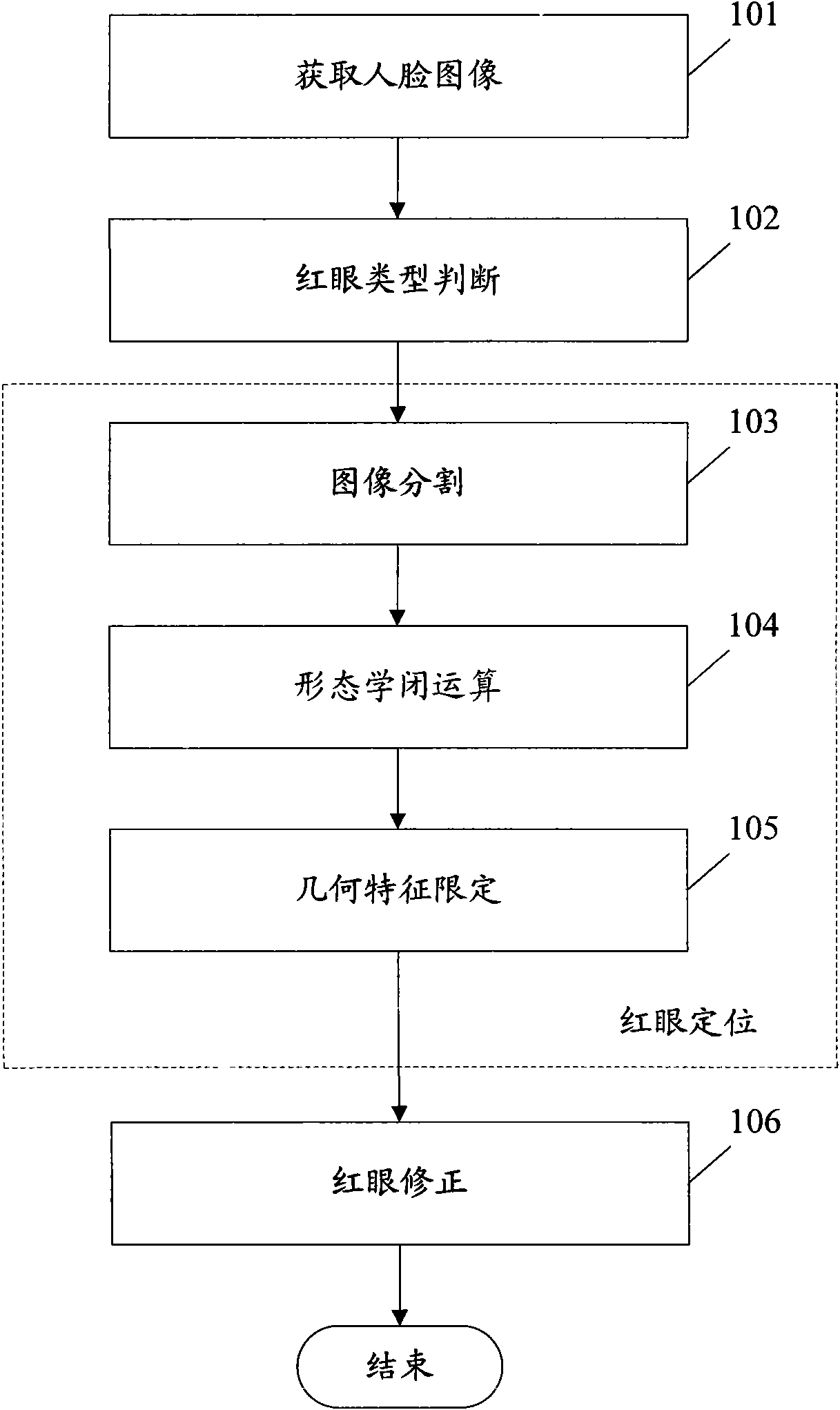

Method for eliminating red eye in image

ActiveCN101620679AProcessing speedReduce processing areaCharacter and pattern recognitionImage segmentationComputer vision

The invention discloses an automatic method for eliminating a red eye, directly utilizing a human face image of a YUV format to eliminate and revise the red eye. A red-eye positioning operation comprises an image dividing step, a closed calculation step and a geometric characteristic limiting step, wherein in the image dividing step, redness division is carried out on an input YUV format drawing by directly utilizing an Y quantity and a V quantity to obtain a binary image of a plurality of communicating regions. For removing an isolating noise point and filling a hole of a division region, closed calculation operation can be carried out on each divided region, and a value of a mask size m is determined through size self-adaptation of the human face image in the invention. In the geometric characteristic limiting step, geometric characteristic detection is carried out on each communicating region in the binary image containing a plurality of communicating regions, and each communicating region which accords with the geometric characteristic of the red eye is determined as a red-eye region; and red-eye revision is carried out on the red-eye region in the human face image. The treatment speed of red-eye elimination can be enhanced by using the invention.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

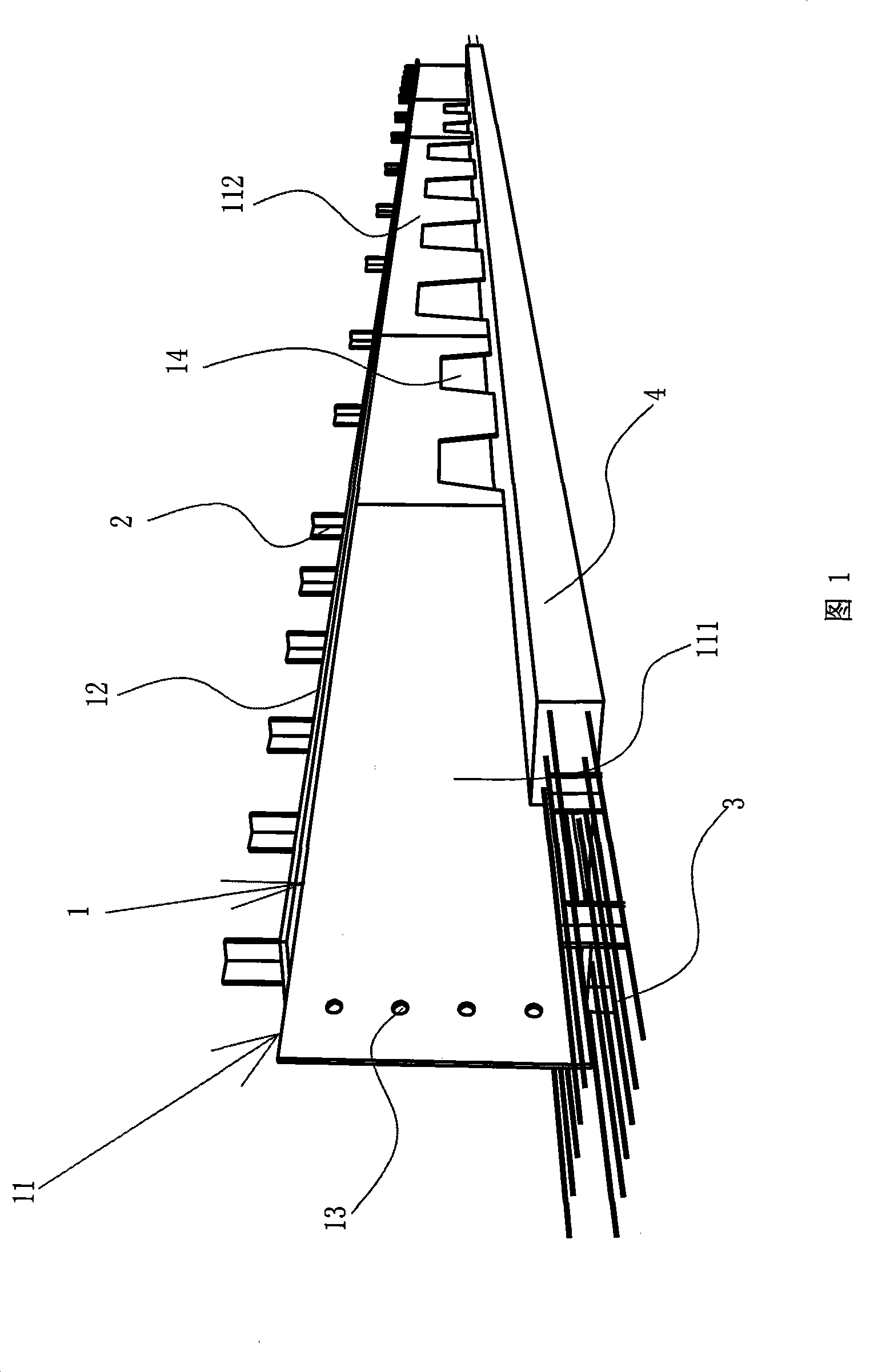

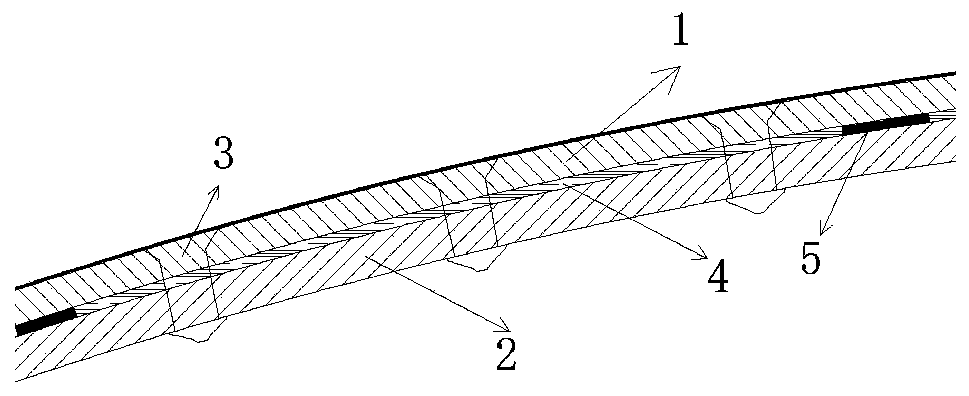

Pretensioned prestressing composite girder and method for producing the same

ActiveCN101418630ASmall beam heightReduce the overall heightLoad-supporting elementsBuilding material handlingShaped beamSheet steel

Provided is a pre-tensioned prestressed composite beam, which is an I-shaped beam composed of H-shaped steel and concrete, the web plate of the H-shaped steel is provided with trapezoidal holes (14) at intervals, the upper flange and the lower flange of the H-shaped steel are welded with shearing nails, the outer periphery of the lower flange is enclosed with concrete to form a steel-concrete lower flange (4), and the inside of the steel-concrete lower flange is embedded with prestressed steel twisted wire by pretensioning method. The manufacturing method of the composite beam is that: a steel plate is cut into two tooth-shaped plates along tooth-shaped line to be respectively as the trapezoidal hole plates of the H-shaped steel flange, the trapezoidal hole plates are welded with steel plates to form the web plate, the web plate is welded with the upper flange and the lower flange to form the H-shaped steel (1) having trapezoidal holes, the H-shaped steel is put on a base surface with the lower flange downward, the two sides of the lower flange are provided with side molds, a stirrup (7) is arranged and steel twisted wires (3) are longitudinally fastened between the two side molds, the steel twisted wire is tensioned to tensioning state, the concrete for enclosing the H-shaped lower flange is poured and tamped between the two side molds, the steel-concrete lower flange (4) is formed after demolding, and the steel twisted wire at tensioning state is loosened after the concrete reached to predetermined strength and is cut off at predetermined position. The invention is suitable for beams of buildings.

Owner:杨峰

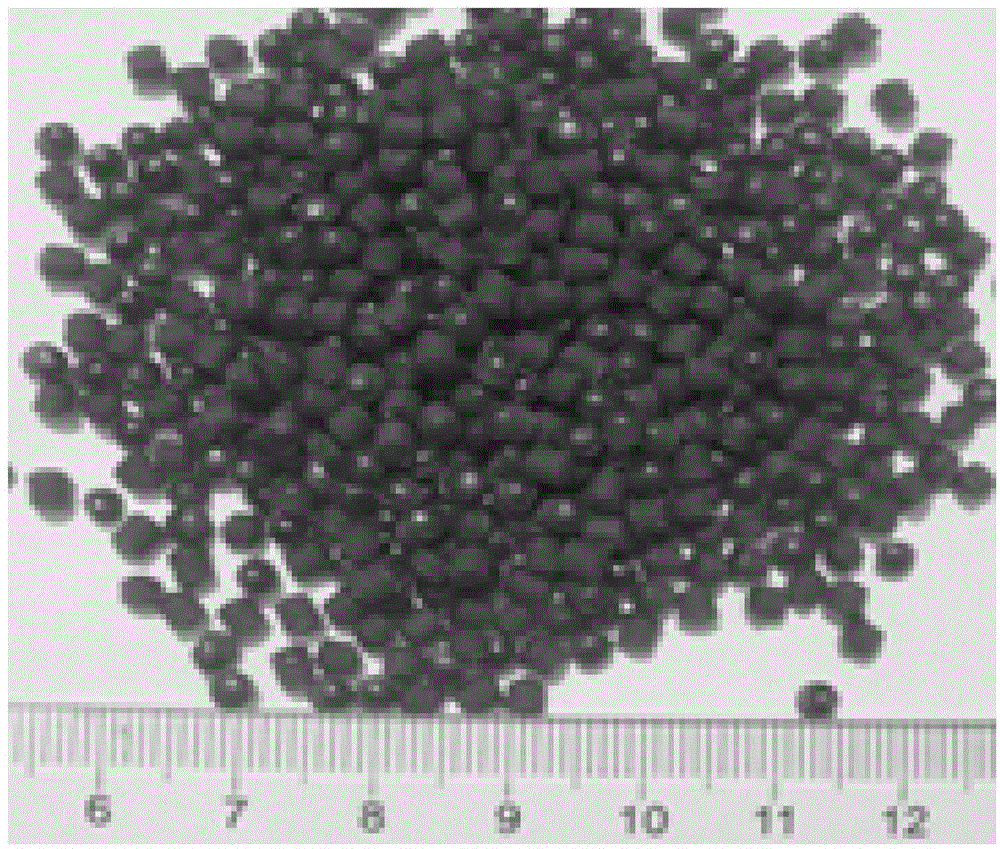

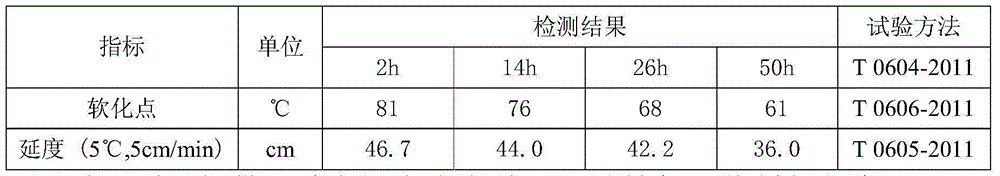

Direct-adding type instant SBS (Styrene Butadiene Styrene) modifier as well as preparation method and application thereof

The invention discloses a direct-adding type instant SBS (Styrene Butadiene Styrene) modifier prepared from the following raw materials in parts by mass: 60-85 parts of SBS, 5-25 parts of ethylene-vinyl acetate copolymer (EVA), 5-10 parts of naphthenic oil, 1-3 parts of a compatilizer and 2-4 parts of an antioxidant. The SBS modifier disclosed by the invention can be directly added into a blending tower (a process for directly adding the modifier into the blending tower is called a 'dry method' according to industry habits) to quickly melt with an aggregate and base asphalt during short-time mixing, thereby achieving micron-scale dispersion and giving play to a modification effect which is the same as that of a wet method.

Owner:BEIJING ZHONGLU PAVING TECH

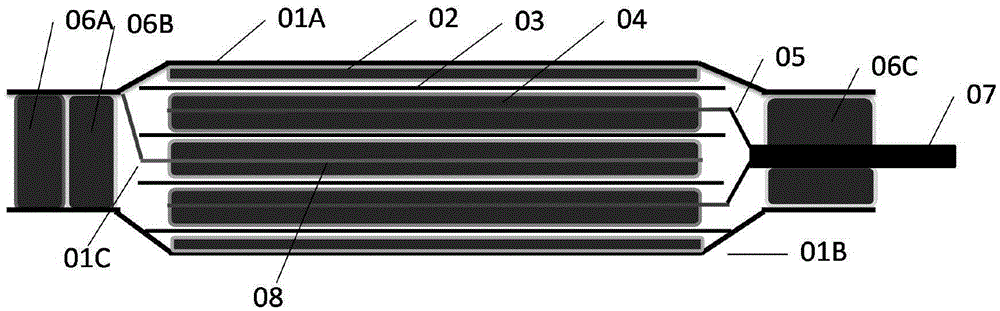

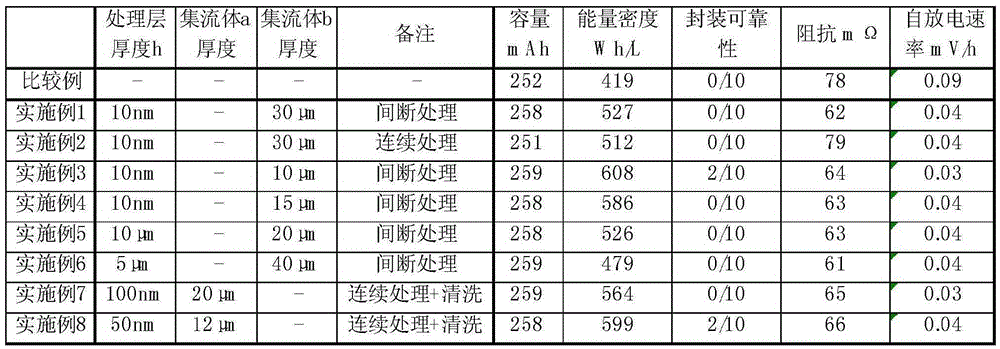

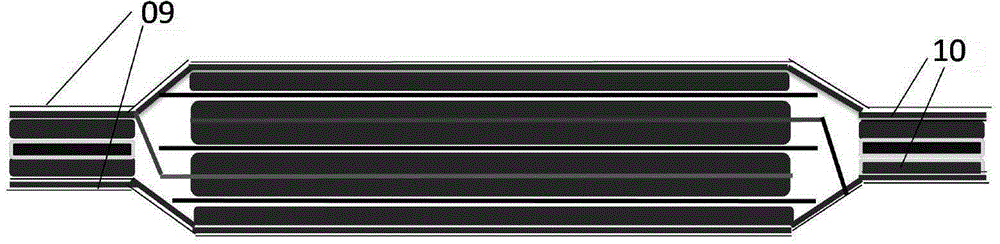

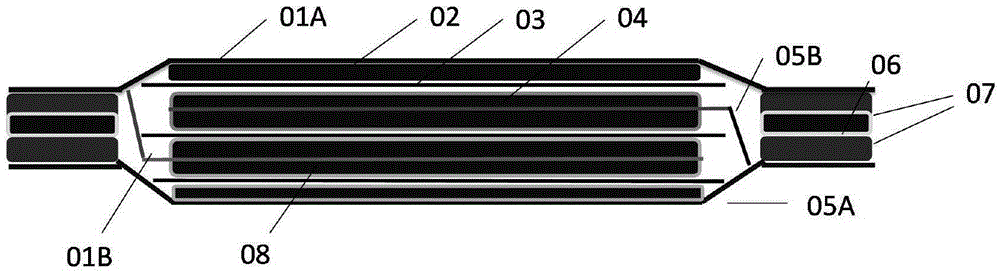

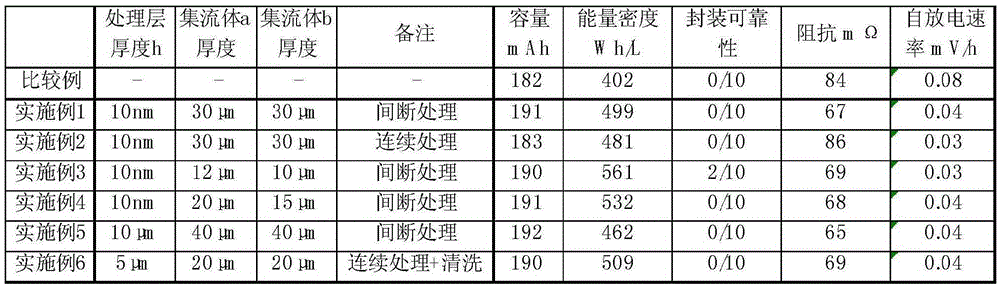

Electrochemical cell and preparation method thereof

ActiveCN105406086AReduce the type and amount of materialsReduce material costsFinal product manufactureElectrode carriers/collectorsBattery energyCurrent collector

The invention belongs to the technical field of flexible devices, and particularly relates to an electrochemical cell. The electrochemical cell comprises positive electrodes, a separator, negative electrodes, an electrolyte and an external packaging structure, wherein the sum n of the number of the positive electrodes and the number of the negative electrodes is an odd number; the external packaging structure at least comprises an positive current collector a and / or a negative current collector b; and the external packaging structure is a tab of the cell. The outermost electrode current collector of the cell serves as the packaging material of the cell and one of the tabs (and thus the cell only needs one special tab), so that the species and using amount of the materials are reduced, and the material cost is reduced; meanwhile, the energy density of the cell is improved; and moreover, in the preparation process, packaging assisted treatment is carried out on the current collector on a sealing side only, so that the problem of packaging reliability can be solved, the treatment cost can be reduced (the using amount of an expensive treating fluid is reduced), and finally the side effects of electrode impedance increase caused by packaging assisted treatment can also be reduced.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

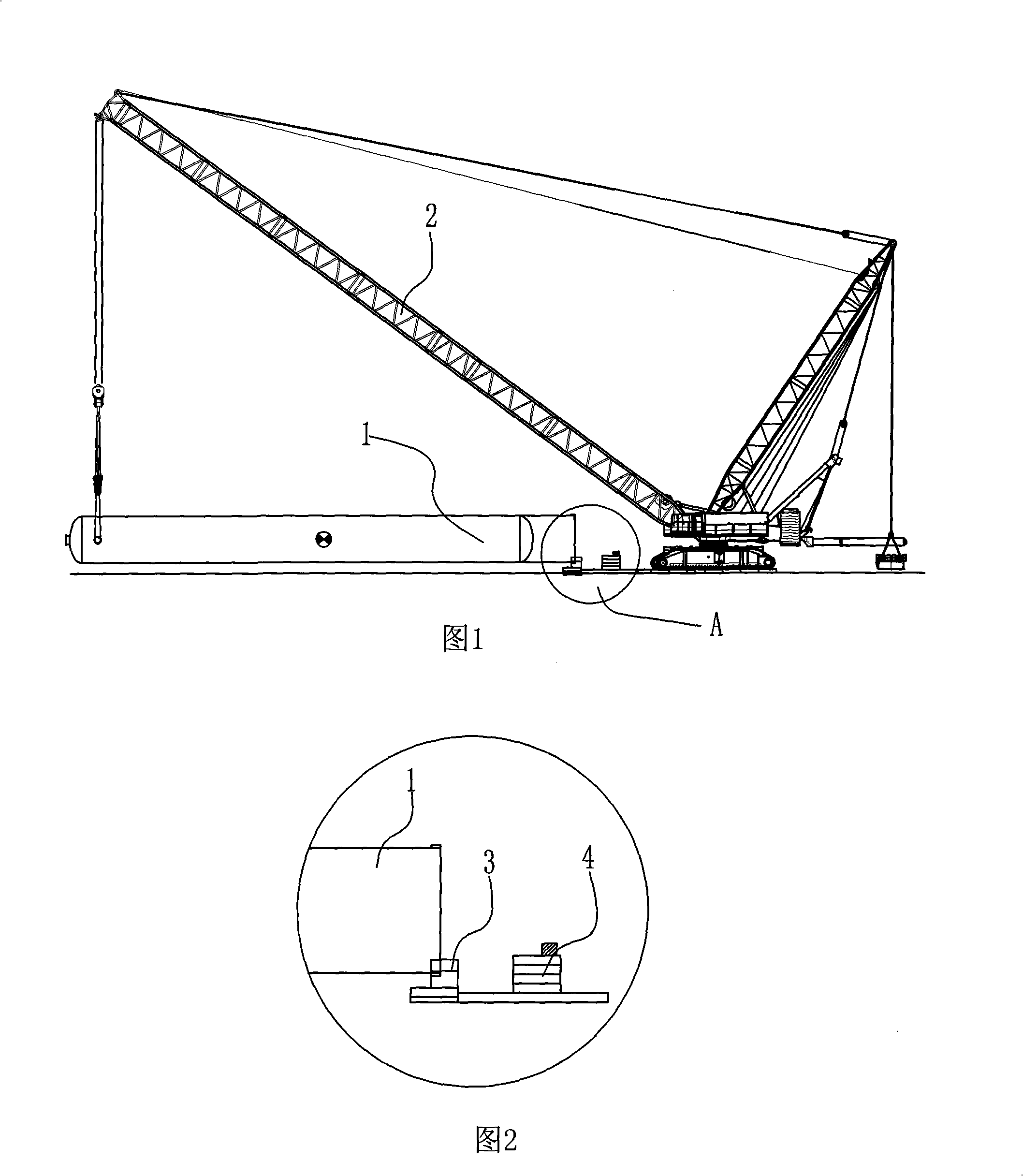

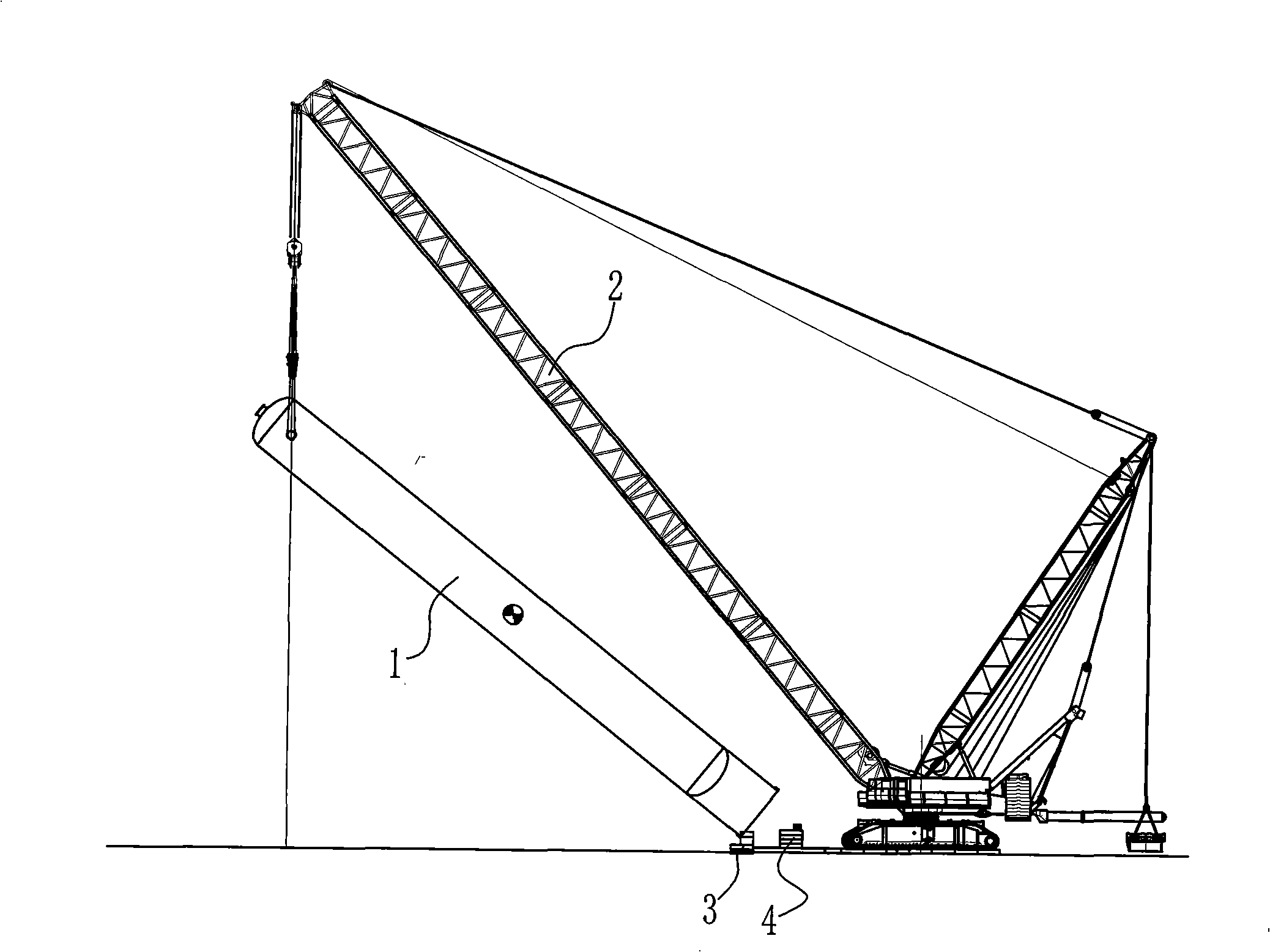

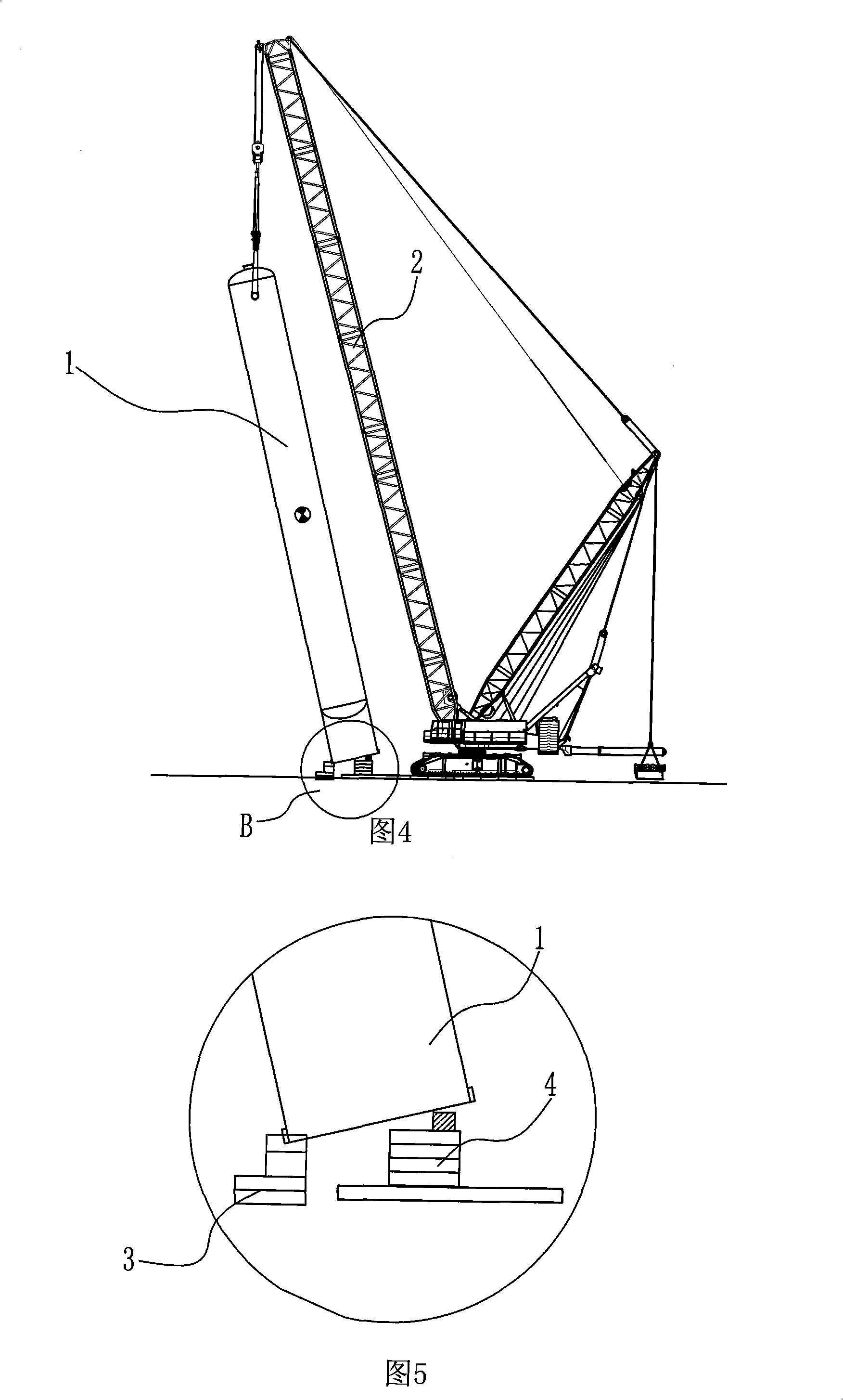

Turning hoisting method for vertical type apparatus

ActiveCN101513974AGood practical valueAvoid defectsLoad-engaging elementsCranesGravity centerIndustrial engineering

The invention relates to a turning hoisting method for the vertical type apparatus, characterized by comprising the following steps: a) the apparatus to be hoisted is unloaded according to the hoisting site condition and the hoisting machine station, and the tail of the apparatus faces to the hoisting machine; b) a rotating shaft system is arranged near to the tail of the apparatus, and a falling preventing device is arranged at the position where the apparatus arrive in the falling preventing angle; c) the lift hook of the hoisting machine is connected with the lifting point of the apparatus, which is located above the center gravity of apparatus; d) the hoisting machine lifts the lift hook and extends the arm rod of the hoisting machine to rotate the apparatus around the rotating shaft system and lift the apparatus step by step: e) the tail of the apparatus contacts with the falling preventing device when the apparatus arrive in the falling preventing angle position, the hoisting machine continuously lifts the lift hook and extends the arm rod of the hoisting machine to rotate the apparatus around the falling preventing device until the apparatus is completely vertical; f) the hoisting machine continuously lifts the lift hook to make the apparatus disengaged from the falling preventing device, the rotating shaft is removed; g) the operation radius of the hoisting machine is adjusted to be the positioning radius, then the apparatus is rotated to the base, the orientation is adjusted to position the apparatus. The hoisting method provided by the invention has no pulley set, no limitation to the lifting point orientation and simple operation.

Owner:SINOPEC NINGBO ENG

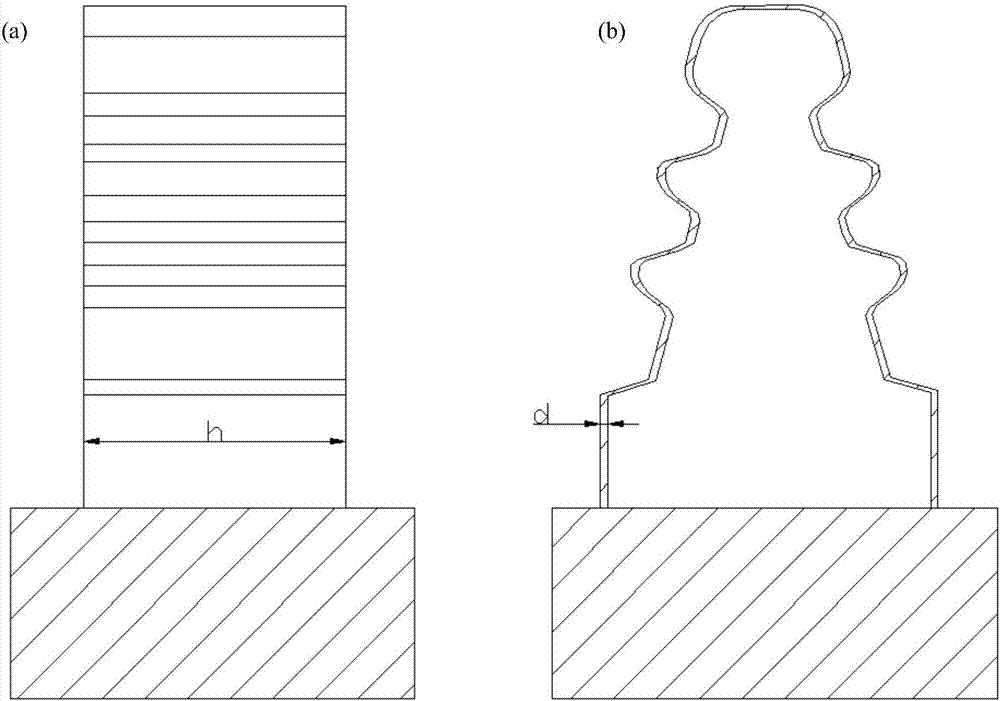

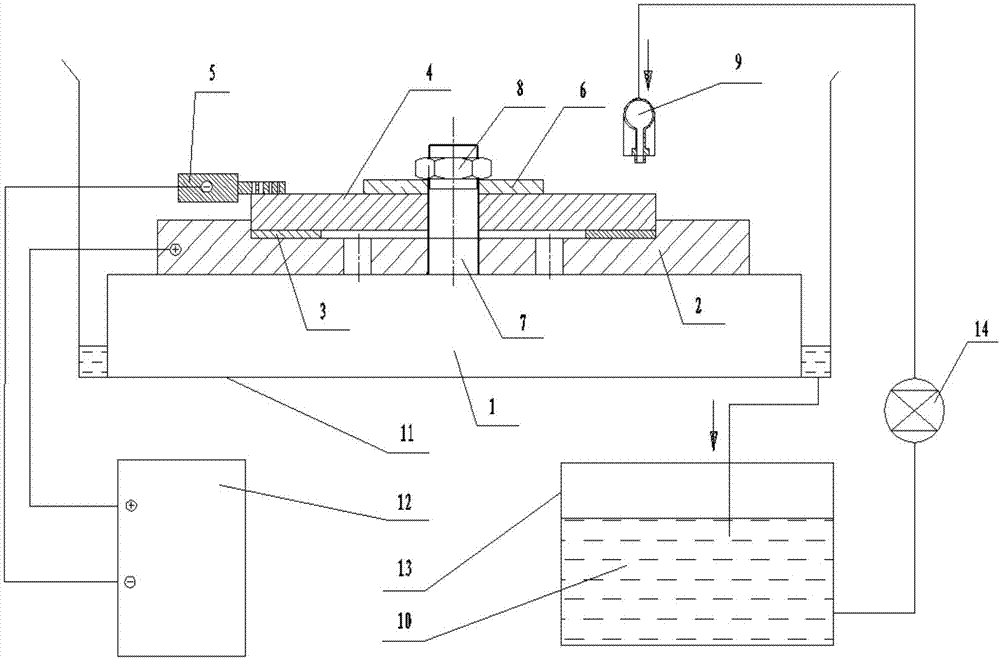

Electrode and machining device and method for electrolytic cutting rapid forming of turbine disc mortise

ActiveCN107962262ASolve technical problems such as high processing precisionReduce labor intensityMachining electrodesMachining working media supply/regenerationElectrolysisEngineering

The invention relates to an electrode and machining device and method for electrolytic cutting rapid forming of a turbine disc mortise, and belongs to the technical field of aero-engine turbine disc mortise electric machining. The electrode is a cutting electrode and is used for serving as a tool cathode on an electrolytic machine tool to carry out rapid cutting forming machining on the turbine disc mortise. The machining device adopting the electrode as the cutting electrode comprises a power source, a work box, a turbine disc part, the cutting electrode, a workpiece clamping and locating system and an electrolyte circulating system. The method adopting the device for cutting machining comprises the steps that equipment is mounted, alignment is carried out, a machining gap is adjusted, cutting machining is carried out, machining parameters are controlled in the machining process, after machining is completed, the turbine disc part is rotated to the next station in an indexing manner,and the process is repeated till electrolytic cutting machining of the whole turbine disc mortise is completed. The method adopts the cutting electrode for electrolytic cutting rapid forming, and through the electrolytic cutting rapid forming machining technological process, high-efficiency and high-quality machining of the turbine disc mortise is completed.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

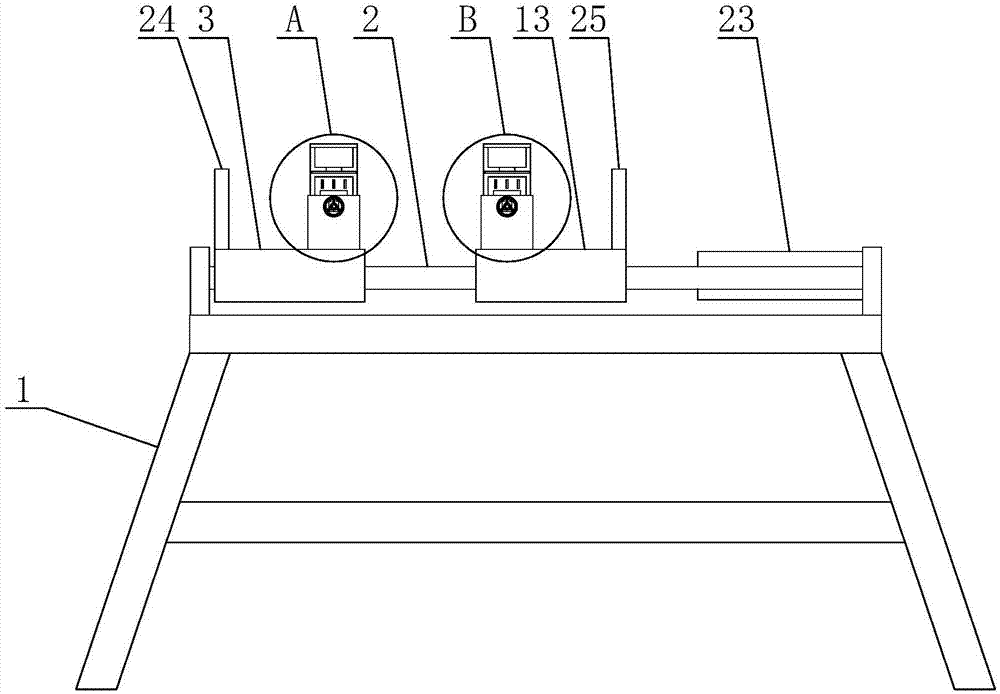

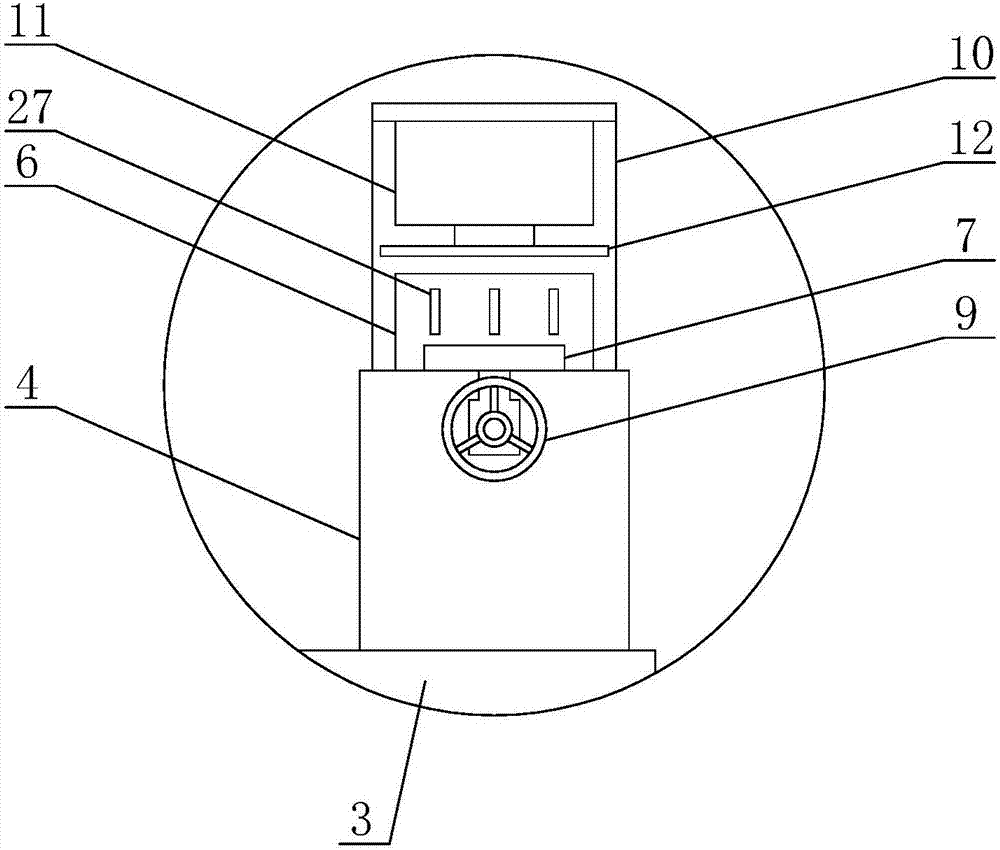

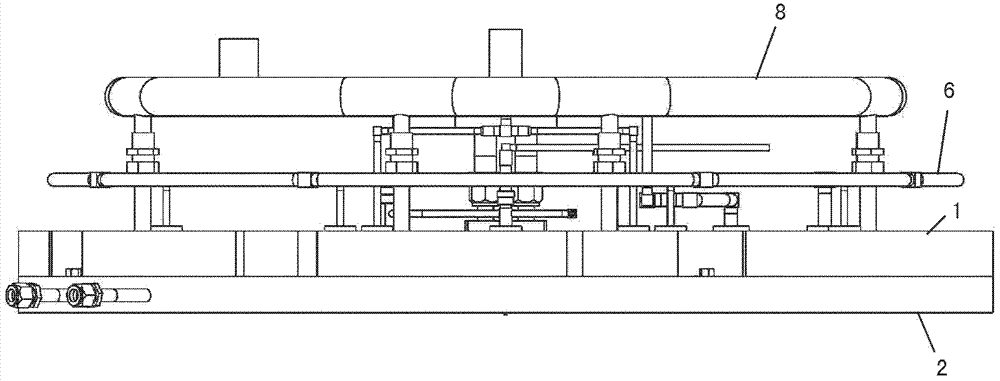

Butt welding machine for constructional engineering

InactiveCN107350711AFast and efficient alignment and clampingGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesRebarBuilding material

The invention discloses a butt welding machine for constructional engineering, and mainly relates to the technical field of constructional engineering equipment. The butt welding machine comprises a machine frame; a guide column is horizontally arranged at the top of the machine frame; a fixed base is arranged at one end of the guide column; a first supporting base is arranged at the top of the fixed base; a plurality of first V-shaped grooves are formed in the top of the first supporting base; a first positioning check block is arranged at one end of the first supporting base; a first clamping block is arranged on the first supporting base; a second supporting base is arranged at the top of a movable base; second V-shaped grooves are formed in the second supporting base; a second positioning check block is arranged at one end of the second supporting base; a second clamping block is arranged on the second supporting base; and a propelling oil cylinder is arranged on one side, far away from the fixed base, of the movable base. The butt welding machine has the advantages that building materials such as reinforcing steel bars or square tubes to be welded can be rapidly and effectively aligned and clamped, the positioning precision can be guaranteed, the time occupied by welding preparation work can be shortened, and the working efficiency can be improved.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

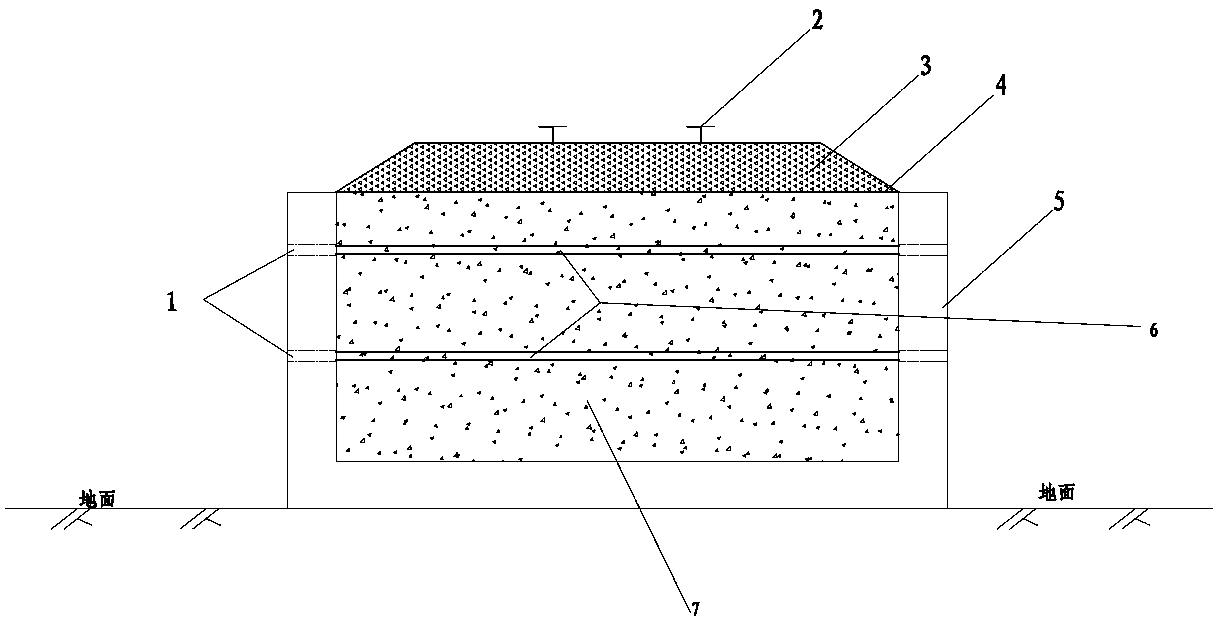

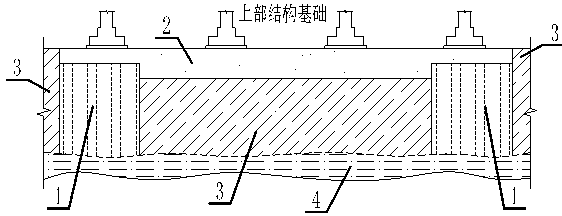

Railway roadbed structure for reducing roadbed settlement deformation through opposite-pulling rib U-shaped groove

The invention relates to a railway roadbed structure for reducing roadbed settlement deformation through an opposite-pulling rib U-shaped groove. The U-shaped reinforced concrete groove with an upwardnotch is formed in the bottom and filled with a roadbed stacking and filling material, the top of the roadbed stacking and filling material is flush with the top edge of the U-shaped reinforced concrete groove and provided with railway ballast, and a railway track structure is arranged above the railway ballast; and opposite-pulling ribs are transversely arranged in the U-shaped reinforced concrete groove, and the two ends of each opposite-pulling rib extend out of the U-shaped reinforced concrete groove. On the one hand, lateral deformation of a roadbed body is greatly restrained through theU-shaped opposite-pulling reinforced concrete groove, roadbed body stuffing is stacked and filled or concrete is poured within the limited space with lateral confinement, and roadbed body settlementis controlled to a great degree; and on the other hand, the occupied width of the bottom of a roadbed is greatly reduced, and plenty of requisition land and plenty of foundation treatment area are saved.

Owner:XIAN RAILWAY SURVEY & DESIGN INST CO LTD

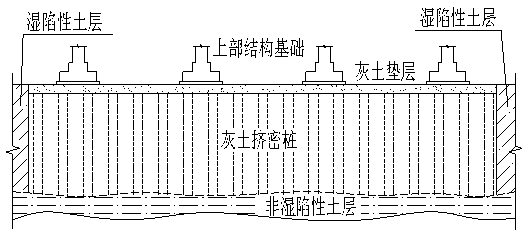

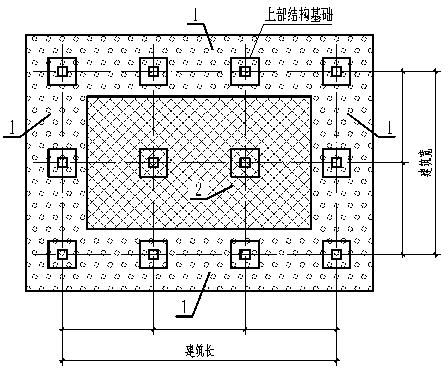

Impermeable type lime-soil compaction pile composite manual foundation

InactiveCN103161175AReduce processing areaReduce processing depthProtective foundationLoessWater layer

The invention discloses an impermeable type lime-soil compaction pile composite manual foundation. A lime-soil compaction pile impermeable layer (1) is arranged on the periphery of a collapsibility soil layer (3) which is in a construction foundation range, a lime-soil impermeable layer (2) is arranged on the upper side of the collapsibility soil layer (3) and at the top of the lime-soil compaction pile (1); wherein the lime-soil compaction pile impermeable layer (1) and the lime-soil impermeable layer (2) can form an impermeable outer shell and the impermeable outer shell is shaped like a reversed Chinese character 'ao'. The bottom of the lime-soil compaction pile impermeable layer (1) is a non-collapsibility soil layer. The impermeable layer is arranged at the top and on the periphery of the foundation in the construction foundation range and water can be prevented from entering into a collapsibility loess layer. Collapsibility can not be conducted to the foundation and the security of upper architectural structures can be guaranteed. The impermeable type lime-soil compaction pile composite manual foundation can relatively reduce the area and the depth of foundation treatment. Construction cost is low. Treatment expense is saved and construction period is shortened.

Owner:GUIYANG AL-MG DESIGN & RES INST

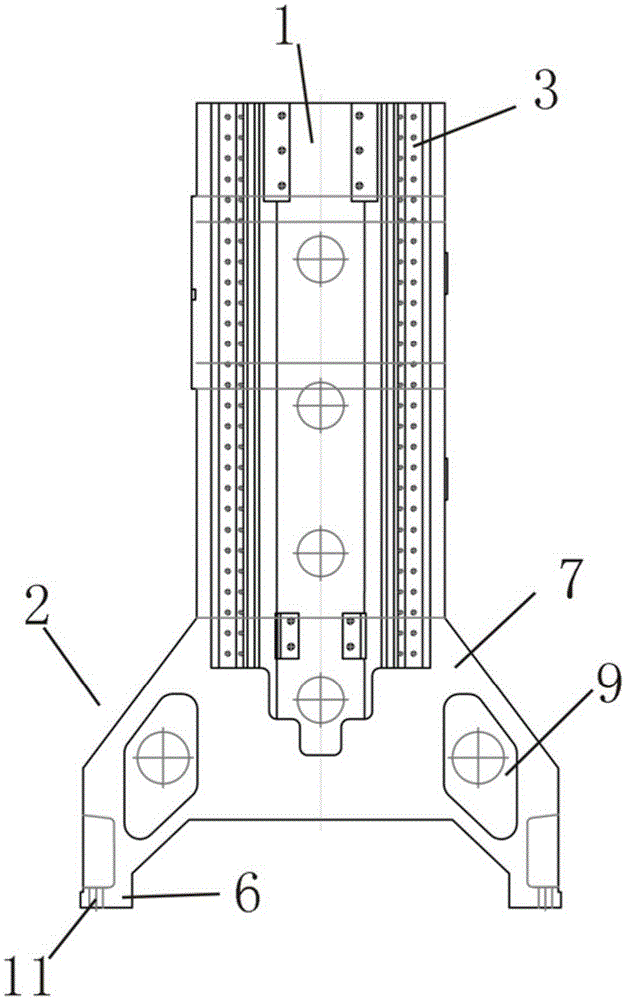

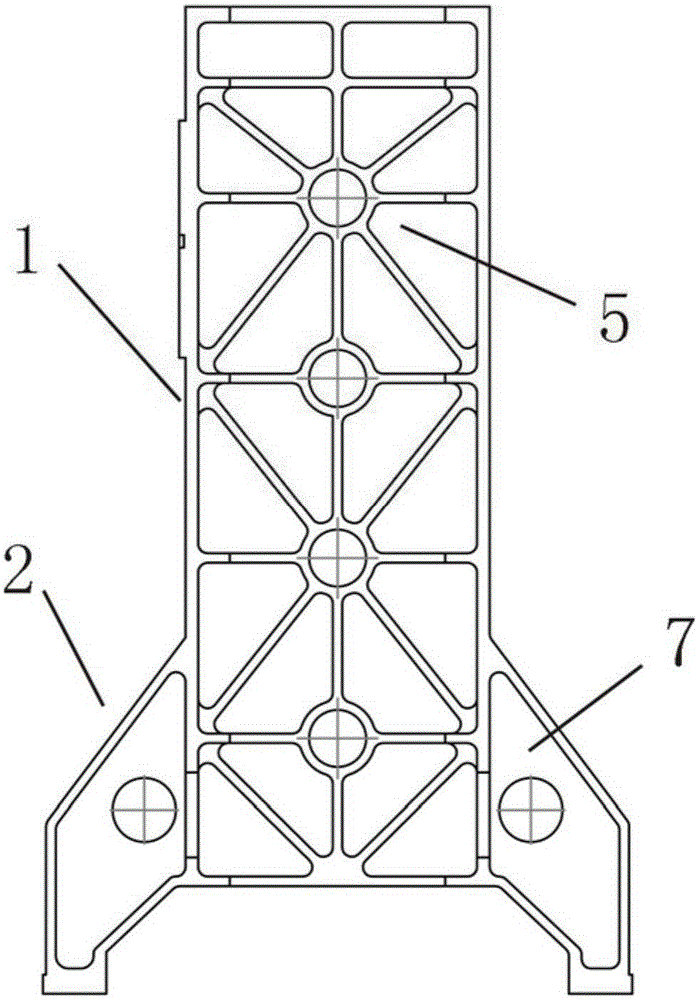

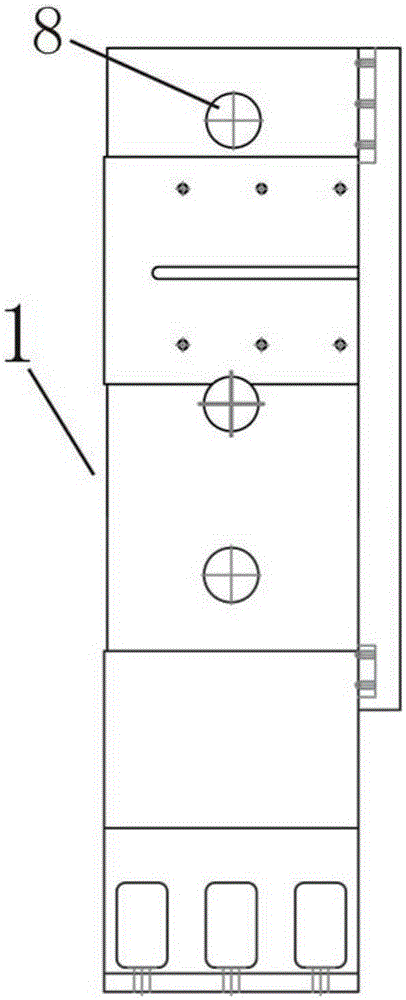

Machine tool stand column

InactiveCN105196068AImprove structural strengthImprove carrying capacityLarge fixed membersCarrying capacityChinese characters

The invention discloses a machine tool stand column. The machine tool stand column comprises a column body, a base, linear rails which are arranged on one side of the exterior of the column body and used for connecting a machine tool spindle head and a top used for fixing a counterweight stretcher, a guide chain and a balancing weight; the interior of the column body is provided with a cavity and reinforcing ribs shaped like a Chinese character 'mi'; the base comprises connecting parts used for connecting a machine tool pedestal and a base body arranged between the column body and the connecting parts; the base body symmetrically extends from the two sides of the lower portion of the column body. The machine tool stand column is high in structural strength, large in carrying capacity, high in stability, low in stand column cost, small in machining area and capable of effectively reducing vibration generated when a machine tool machines a workpiece.

Owner:苏州金凡球墨铸铁有限公司

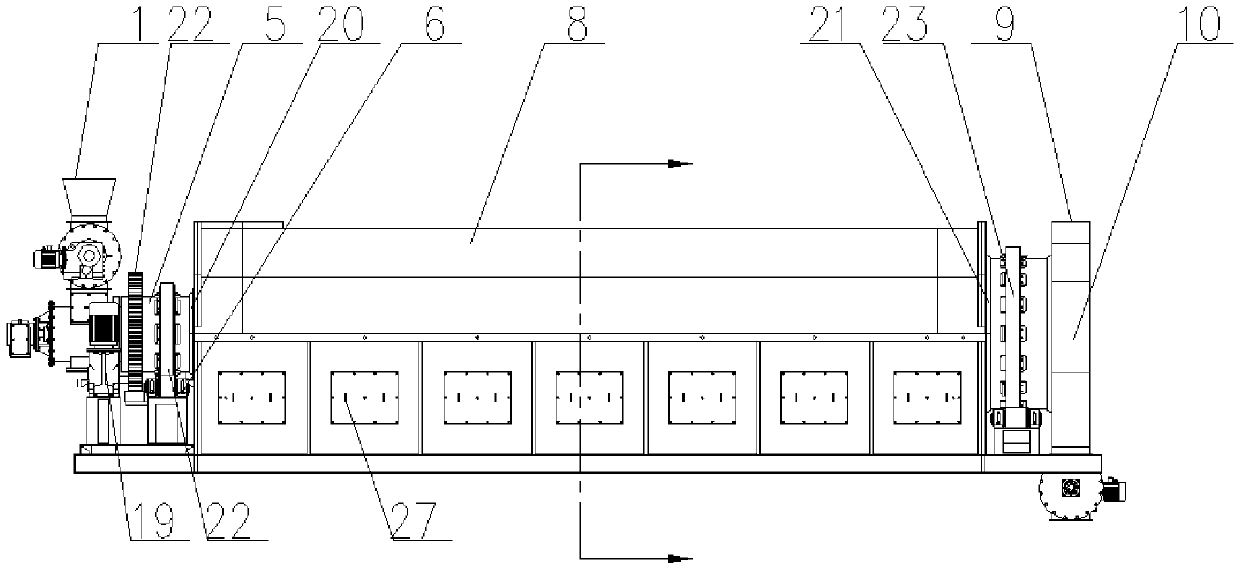

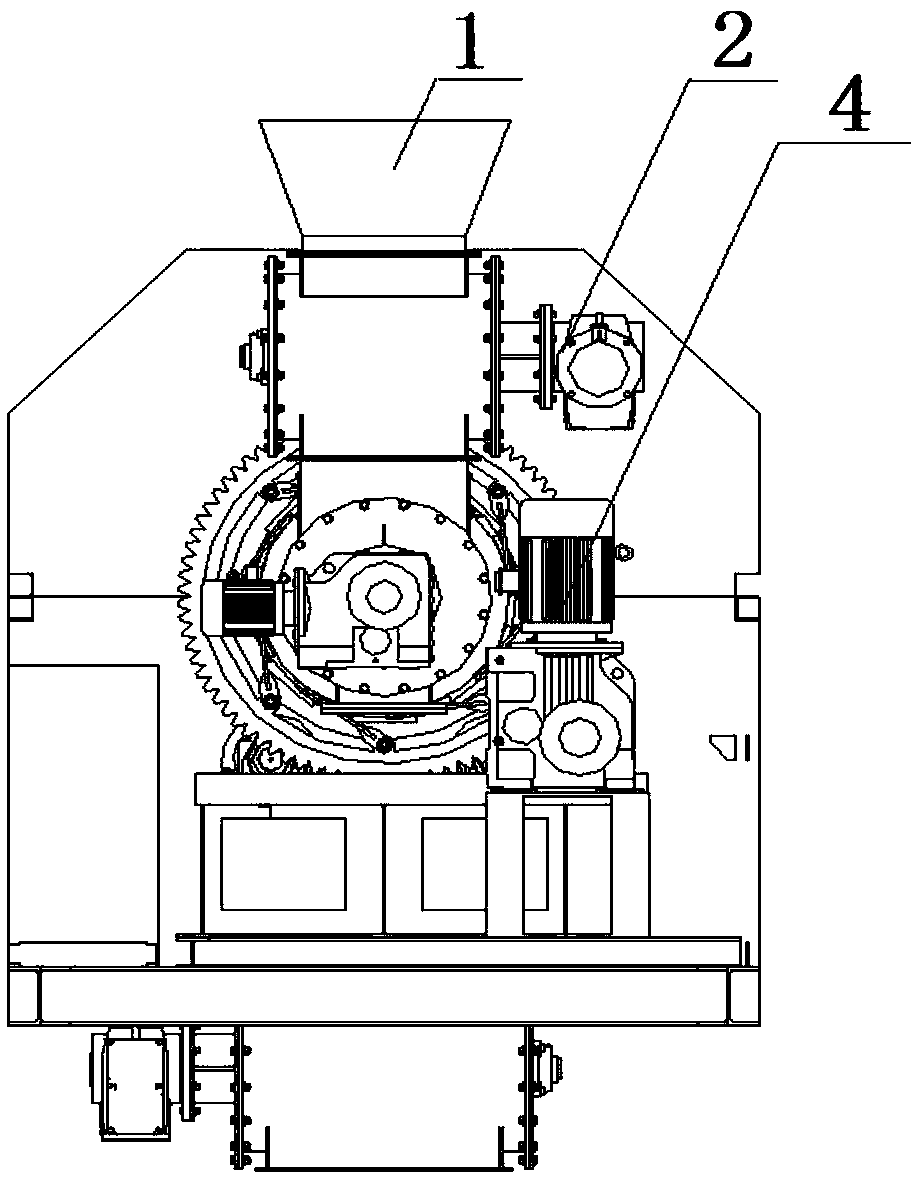

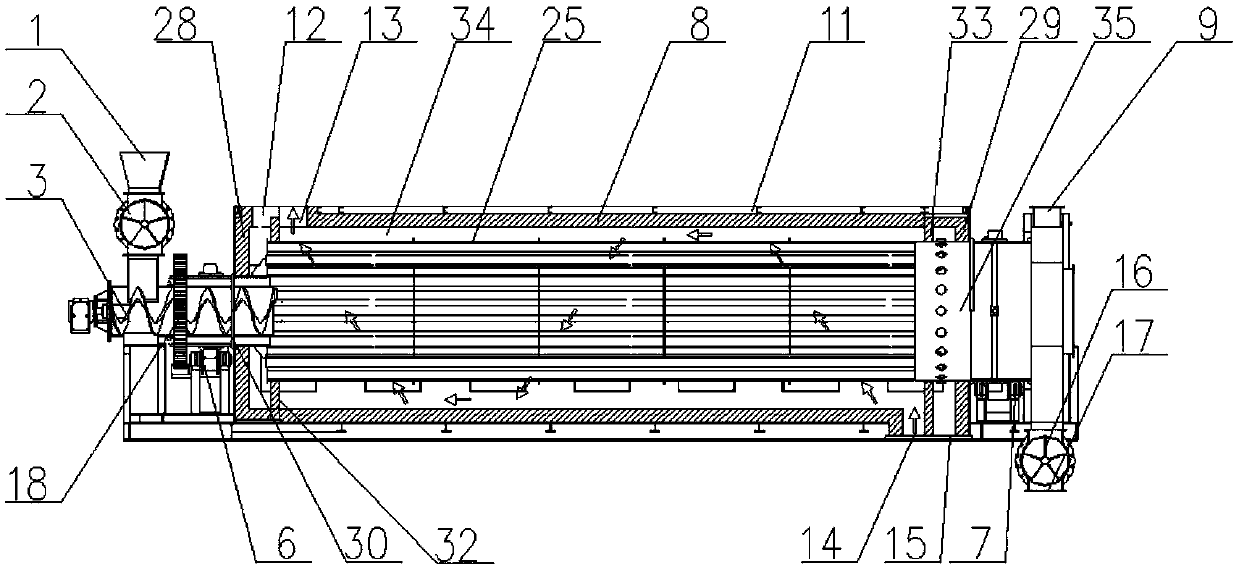

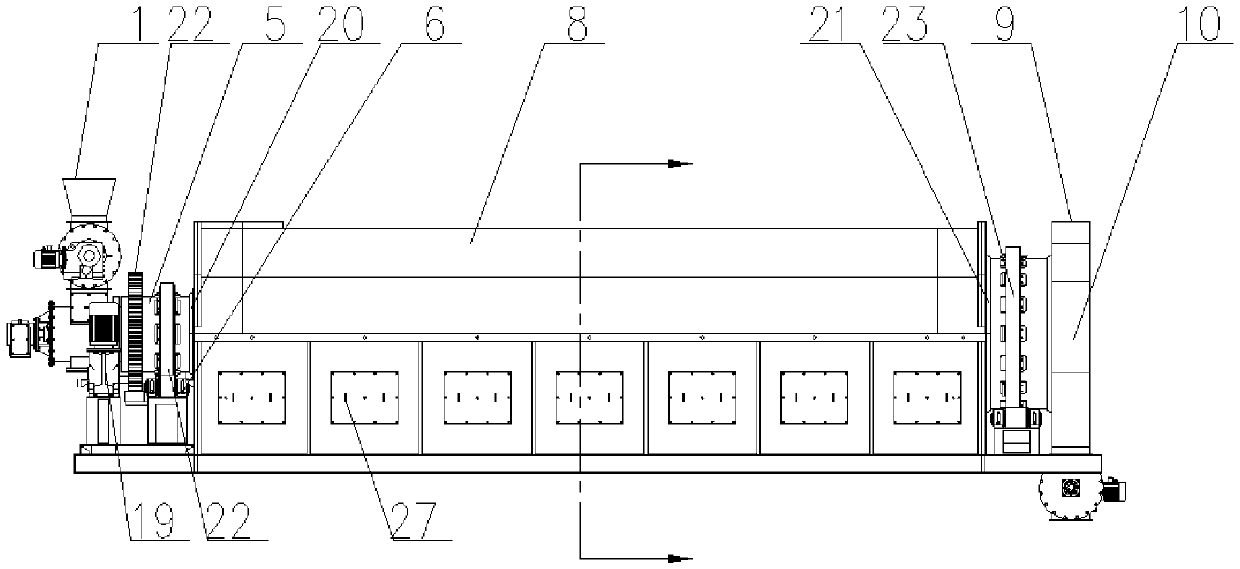

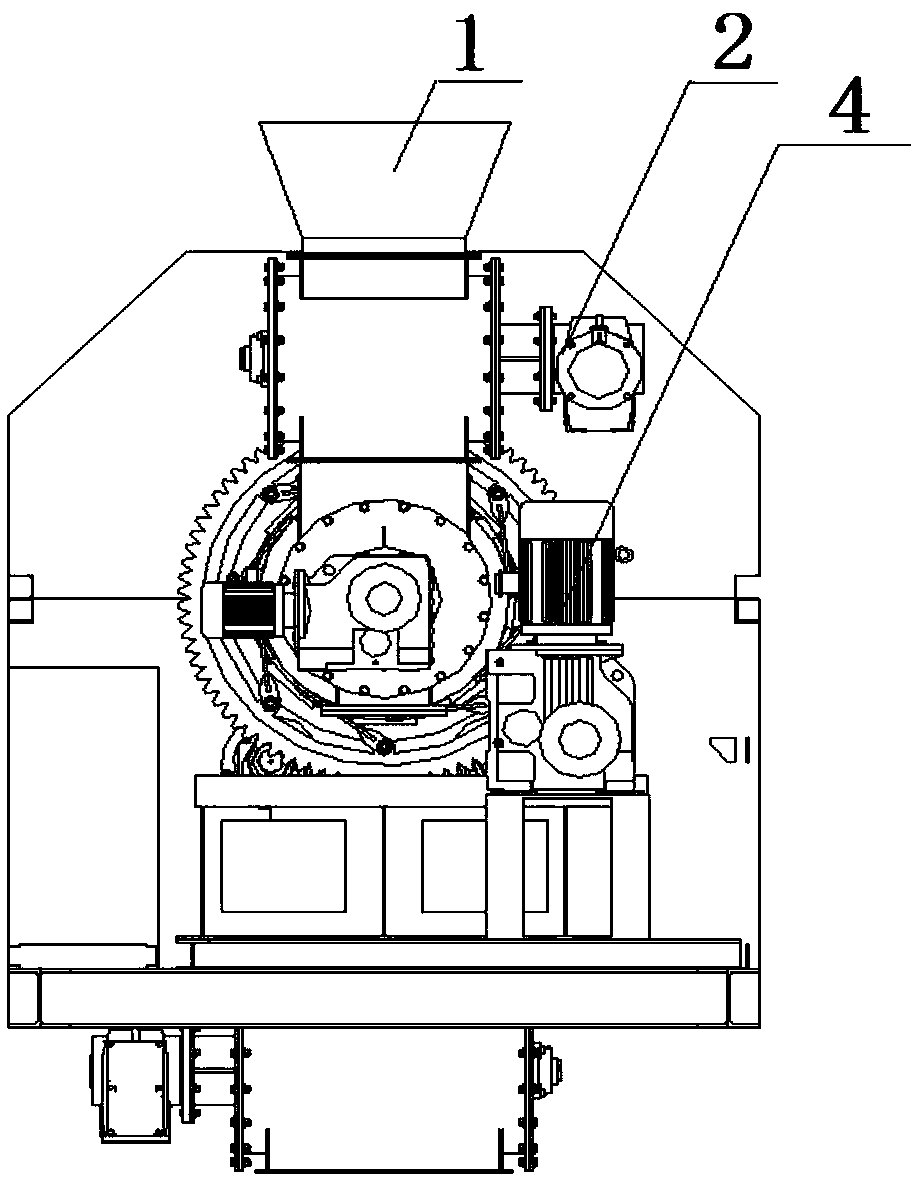

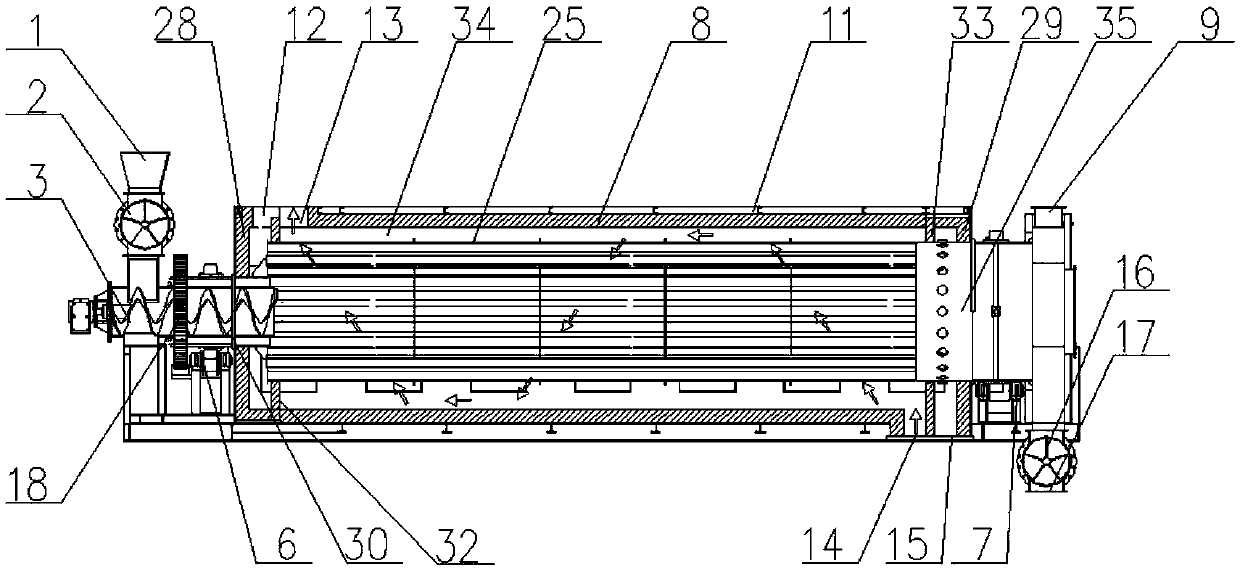

Heat transfer strengthened external heat rotary type organic polluted soil thermal desorption device

ActiveCN109570217ALarge amount of processingReduce processing areaContaminated soil reclamationEngineeringThermal desorption

The invention discloses a heat transfer strengthened external heat rotary type organic polluted soil thermal desorption device and belongs to the technical field of polluted soil restoration. The heattransfer strengthened external heat rotary type organic polluted soil thermal desorption device comprises a raw soil feeding device, a rotary external heat type reactor and a purified soil discharging device. The heat transfer strengthened external heat rotary type organic polluted soil thermal desorption device can achieve larger processing capacity and a smaller processing area under the condition of identical unit processing energy consumption.

Owner:NANJING UNIV OF TECH +2

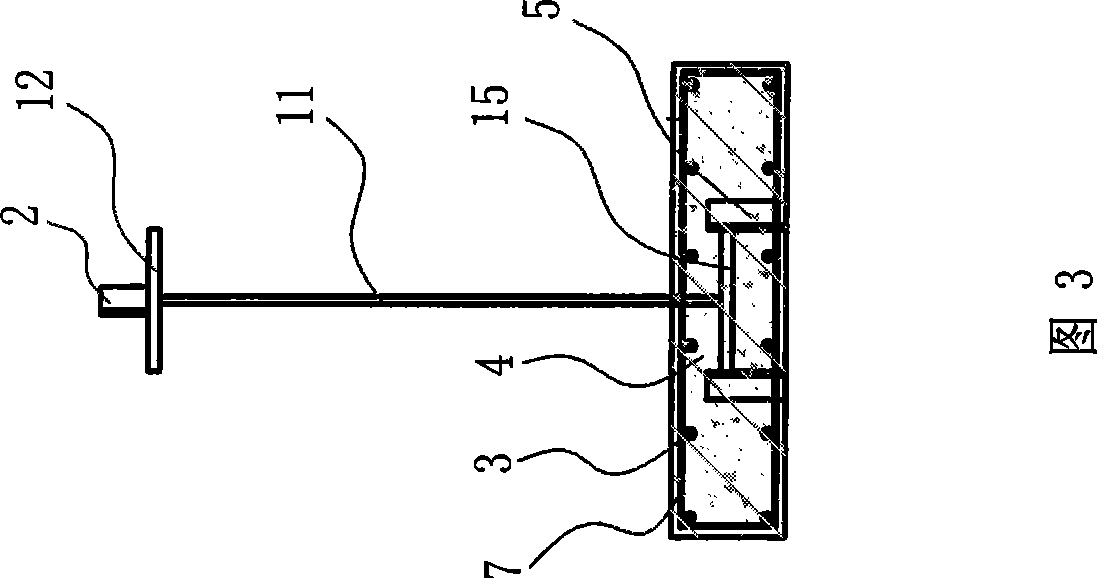

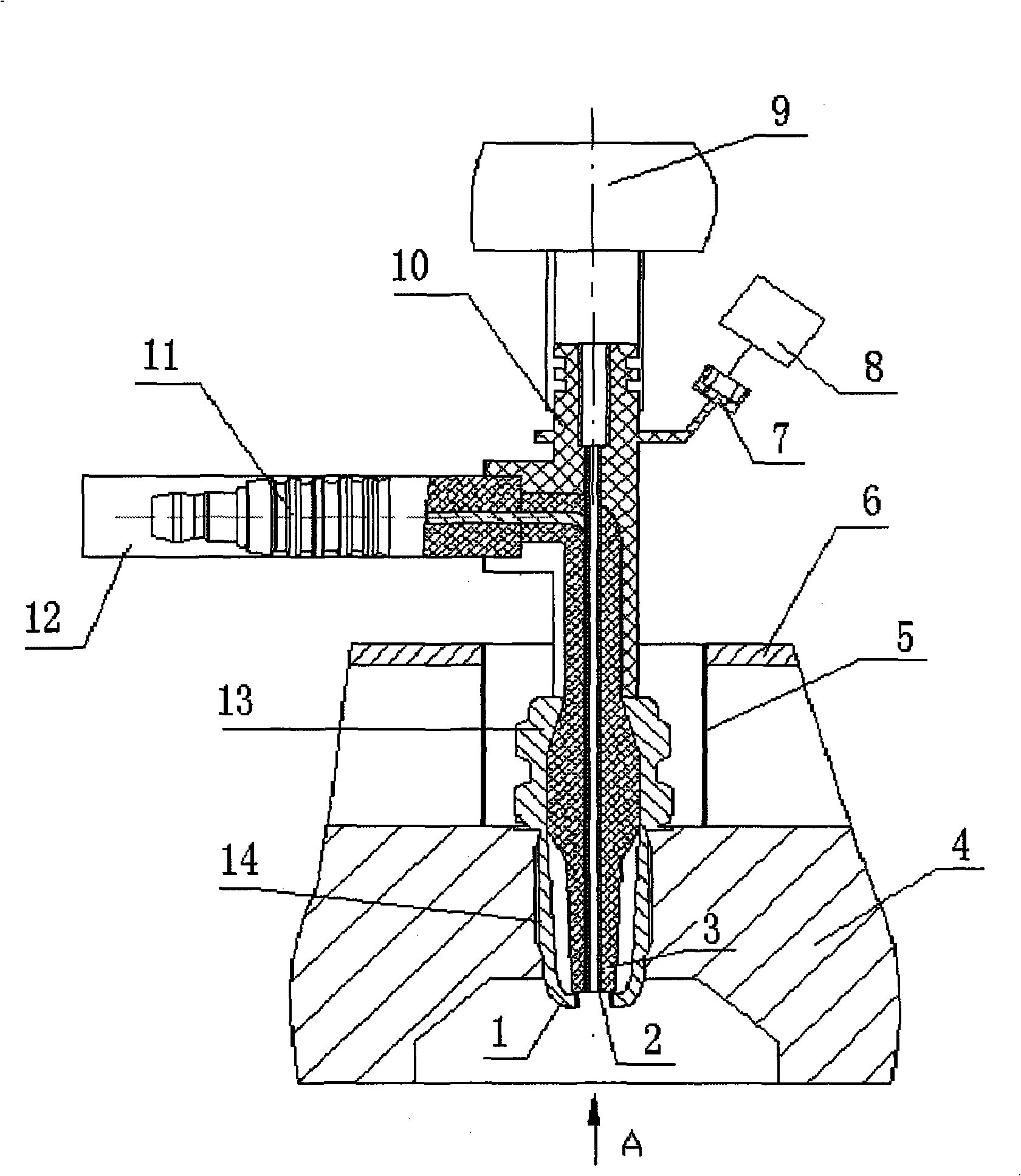

Oil spouting ignition apparatus

The invention discloses an oil injection lighter, which comprises an oil rail (9), a cylinder cover (4), a fuel oil injector (10) and a spark plug (11), wherein, the spark plug (11) comprises a central electrode (2) and an insulator by which the central electrode (2) is coated; the fuel oil injector (10) and the spark plug (11) are integrated into a whole; the lower part of the fuel oil injector (10) is overlapped with the lower part of the spark plug (11); an included angle is formed between the upper part of the fuel oil injector (10) and the upper part of the spark plug (11); and the central electrode (2) on the lower part of the spark plug (11) is provided with a squirt hole (15) which is extended into a combustion chamber. The oil injection lighter adopts the structure that two independent important parts - the fuel oil injector and the spark plug of the prior engine are integrated into a part, thereby reducing the number of parts, being favorable for arrangement of an inlet pipe, the oil rail and the fuel oil injector, reducing the cost of the engine, and having a compact structure, good emission performance of the engine and low oil consumption of the engine.

Owner:CHERY AUTOMOBILE CO LTD

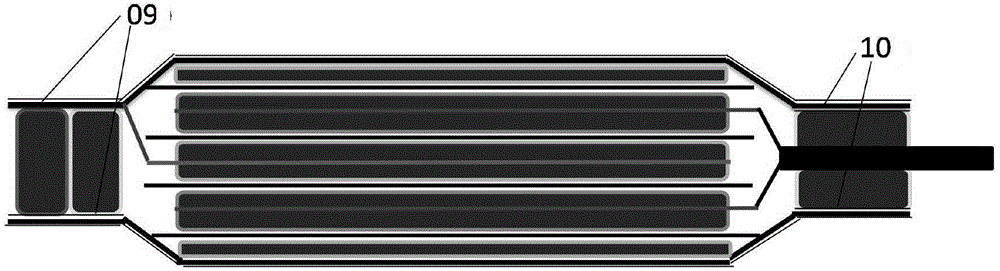

Electrochemical battery and preparation method thereof

InactiveCN105390628AIncrease energy densityReduce typesElectrode manufacturing processesSmall-sized cells cases/jacketsSide effectPositive current

The invention belongs to the technical field of flexible devices, and particularly relates to an electrochemical battery. The electrochemical battery comprises positive electrodes, an isolating membrane, negative electrodes, an electrolyte and an outer package structure, wherein the sum n of the number of the positive electrodes and the number of the negative electrodes is an even number; the outer package structure at least comprises a positive current collector a or / and a negative current collector b; and the outer package structure is a positive tab and a negative tab of a battery core respectively. The electrode current collectors at the outmost layer demonstrate the functions of the package material of the battery and the battery tabs; the variety and the comsumption of materials are reduced; the material cost is reduced; meanwhile the energy density of the battery is improved; and in the preparation process, only the current collectors on the seal edge are subjected to packaging assistant treatment, so that the problems of the package reliability can be solved; the treatment cost can be reduced (the consumption of an expensive treating fluid is reduced); and finally the side effect of an electrode impedance increase caused by the packaging assistant treatment can also be reduced.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

External thermal rotary organic contaminated soil thermal desorption device with inner tube bundle

ActiveCN109622587ALarge amount of processingReduce processing areaContaminated soil reclamationSoil remediationEngineering

The invention discloses an external thermal rotary organic contaminated soil thermal desorption device with an inner tube bundle, and belongs to the technical field of soil remediation of contaminatedsites. The device comprises a raw earth feeding device, a rotary external thermal reactor and a pure soil discharging device. The external thermal rotary organic contaminated soil thermal desorptiondevice with a heat transfer enhancement function has a larger processing capacity and a smaller processing area in the case of the same unit processing energy consumption.

Owner:NANJING UNIV OF TECH +2

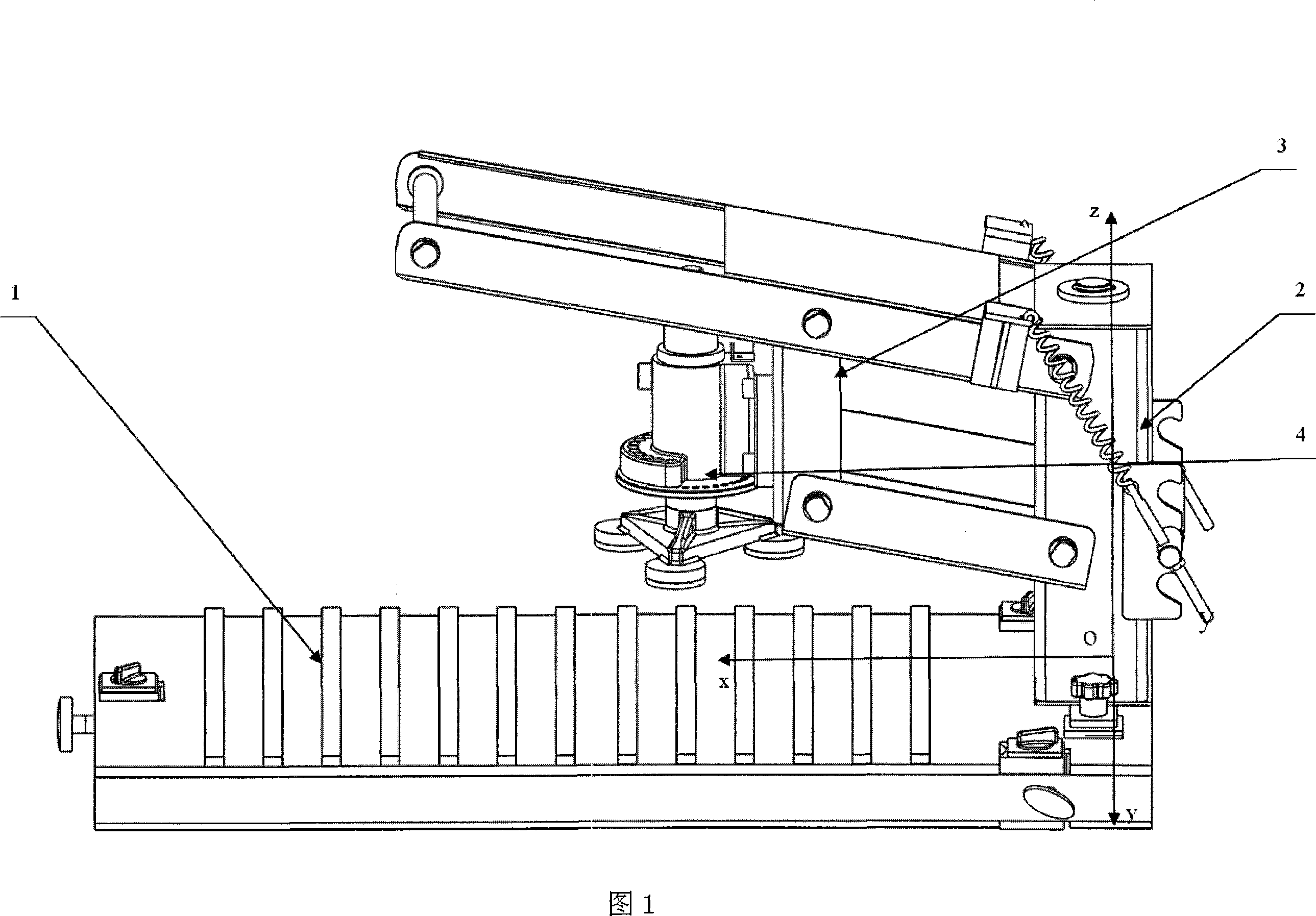

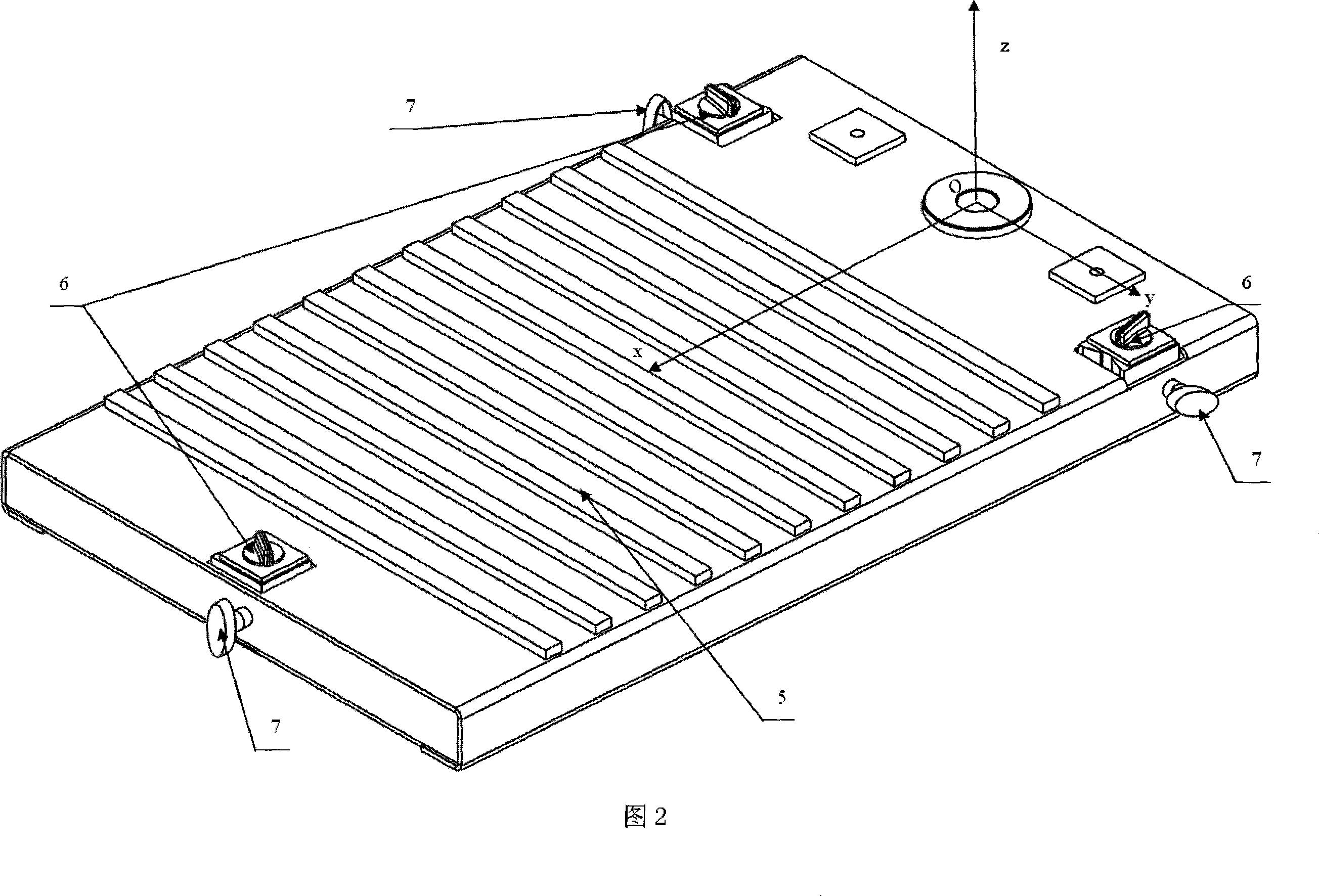

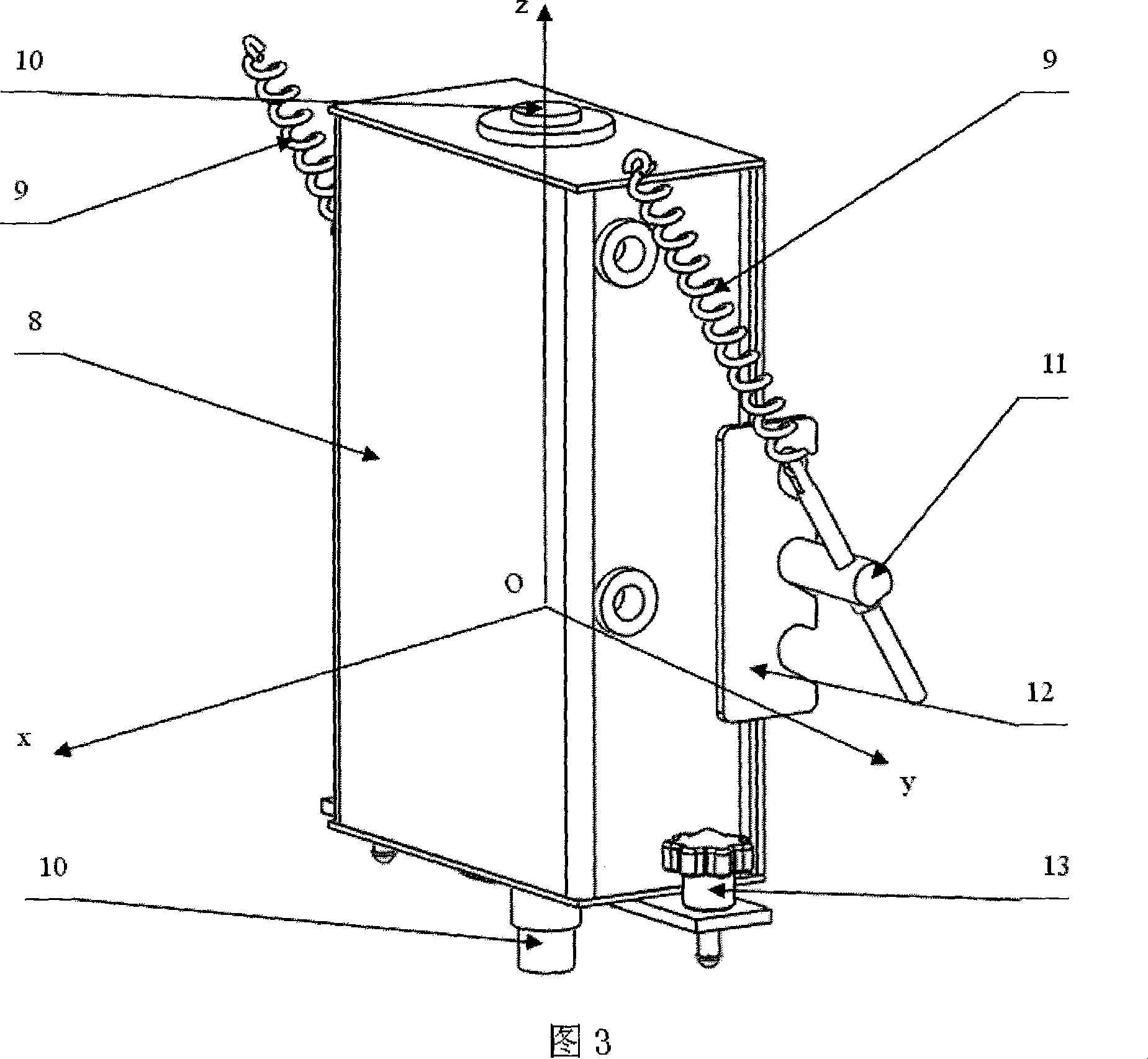

Calibrating apparatus for portable vehicle four-wheel position finder rotation angle disk

InactiveCN101246088AQuick clampingReduce weightVehicle wheel testingEngineeringMechanical engineering

Owner:JILIN UNIV

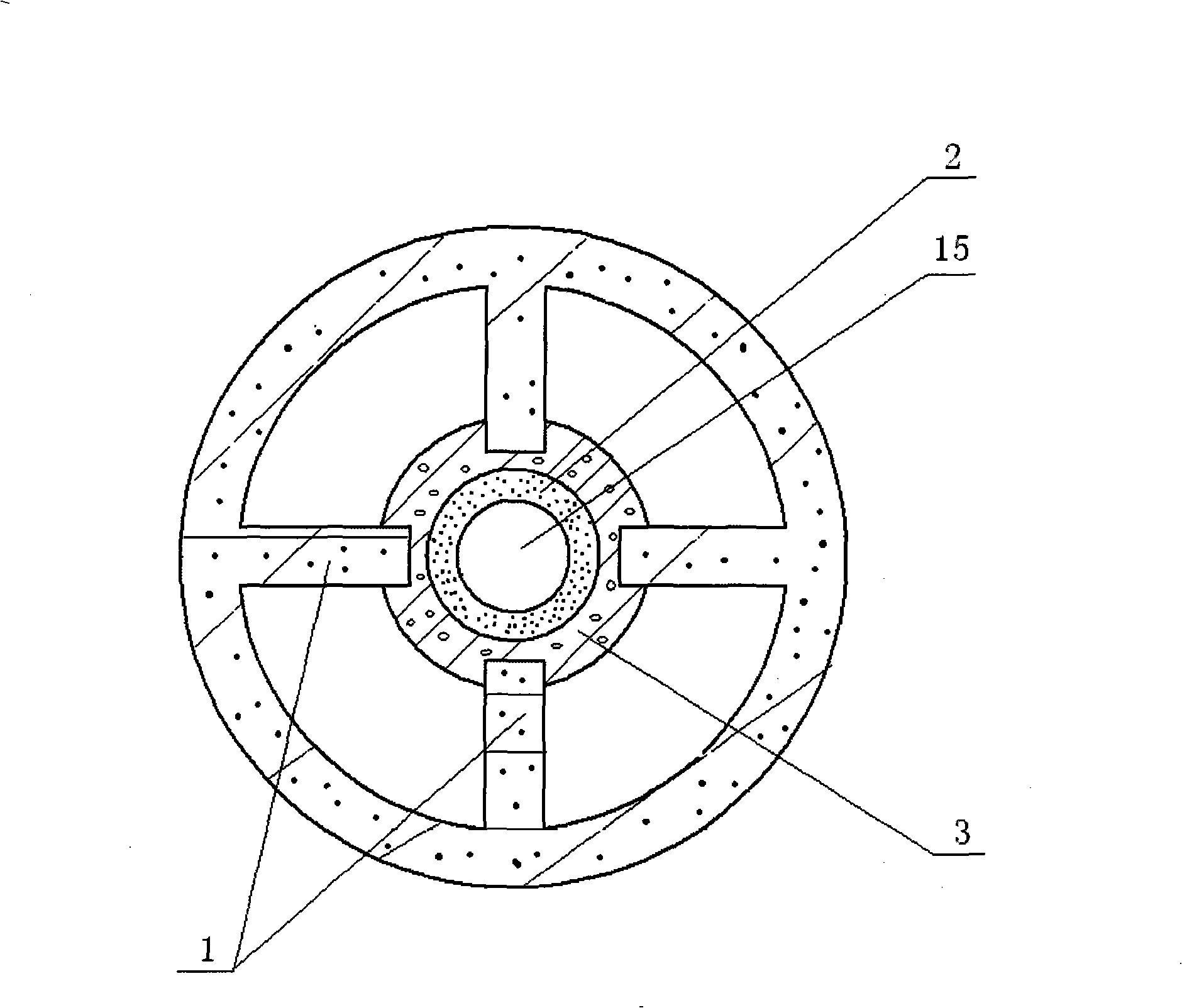

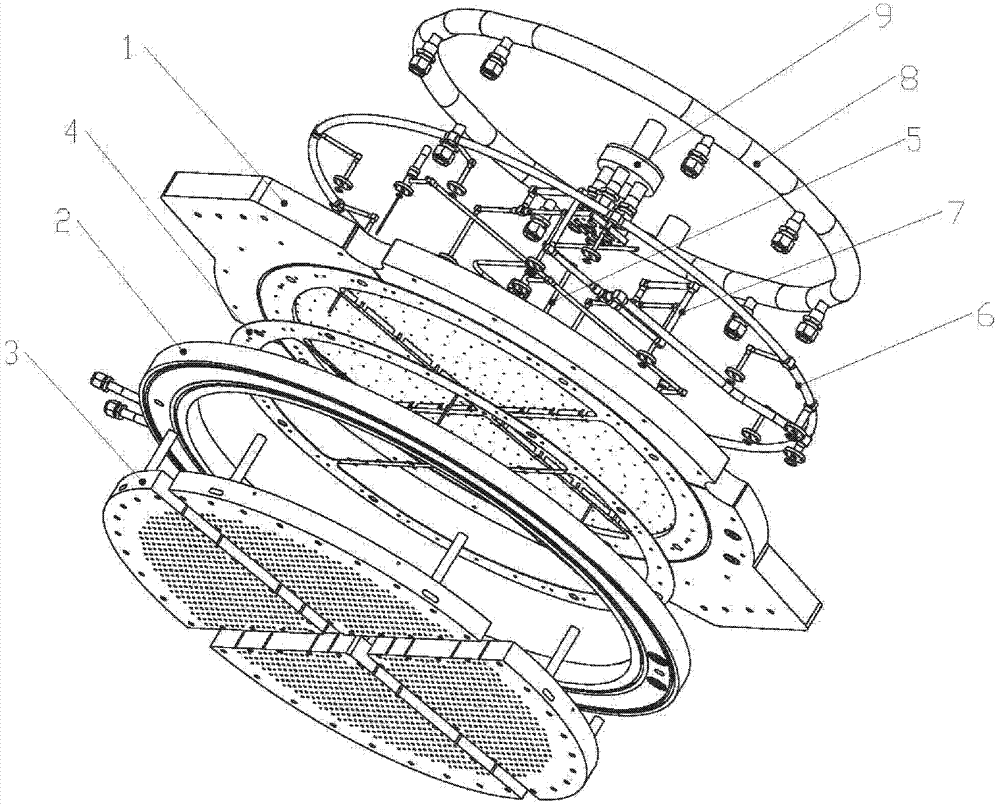

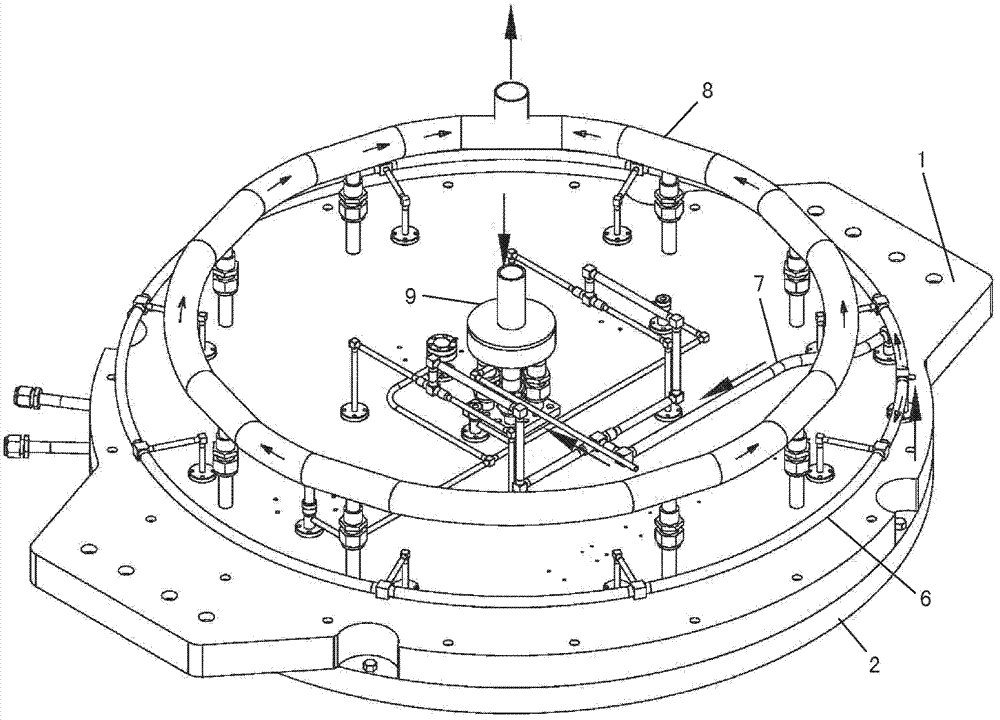

Large-diameter sprayer of MOCVD (metal organic chemical vapor deposition) reactor

ActiveCN102953050AIncrease hole spacingReduce processing areaChemical vapor deposition coatingSprayerMetal

The invention aims to provide a large-diameter sprayer of an MOCVD (metal organic chemical vapor deposition) reactor. Processing difficulty of the sprayer cannot be evidently increased with increase of the diameter. The large-diameter sprayer of the MOCVD reactor comprises an III-group cavity, a V-group cavity and a cooling water cavity, and is characterized in that the III-group cavity, the V-group cavity and the cooling water cavity are respectively divided into N cavities, the N is a natural number larger than or equal to 2, and each cavity is a single body.

Owner:HANGZHOU SILAN AZURE

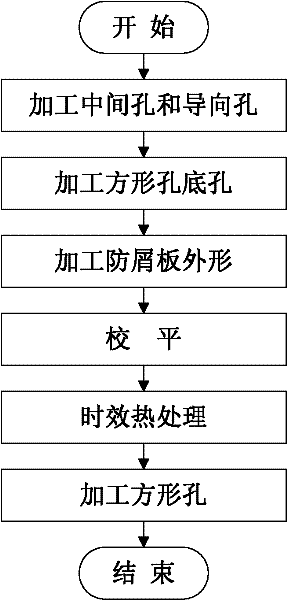

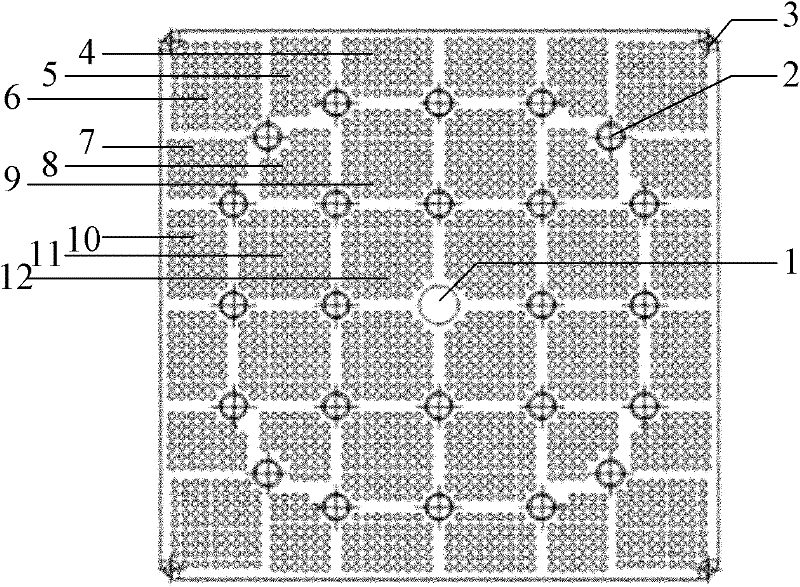

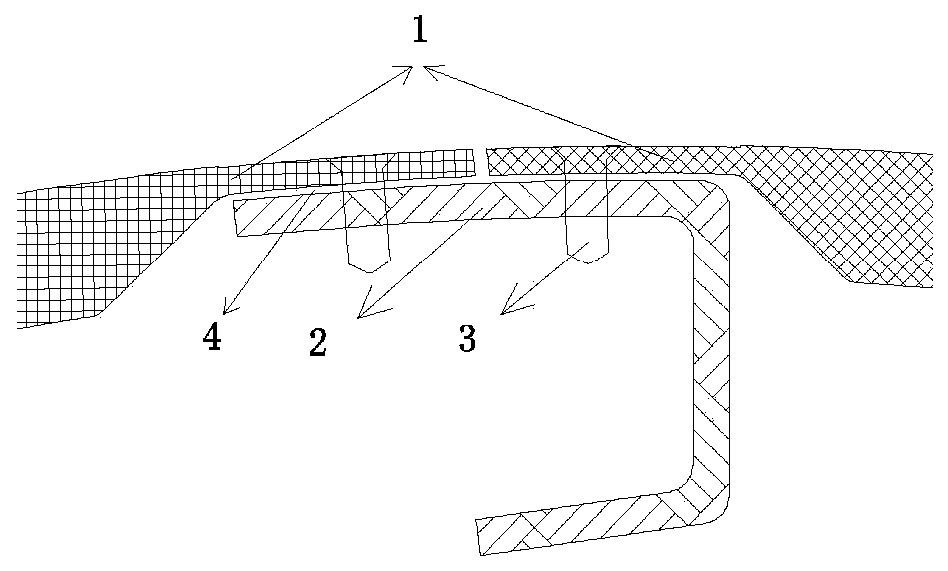

Manufacturing method for chip-resistant plate of lower tube seat

The invention belongs to the technical field of chip-resistant plates, and particularly relates to a manufacturing method for a chip-resistant plate of a lower tube seat. The technical scheme of the invention comprises the following steps of: processing a middle hole and a guide hole; processing a bottom square hole; processing the appearance of the chip-resistant plate; leveling; performing ageing treatment; and processing a square hole. Due to the adoption of the manufacturing method, the technical problems of high local electrode loss and low working efficiency caused by frequent secondary discharge since an electrical erosion product is difficult to discharge in time in the conventional chip-resistant plate are solved. According to the invention, the processing area of an electric spark machine tool is reduced by 80 percent, the electrical erosion product is discharged in time, and high local electrode loss caused by frequent secondary discharge is avoided; and moreover, the square hole is processed by adopting a combined electrode, so that replacement of an electrode is avoided, maintenance is facilitated, and working efficiency is greatly increased.

Owner:CNNC JIANZHONG NUCLEAR FUEL

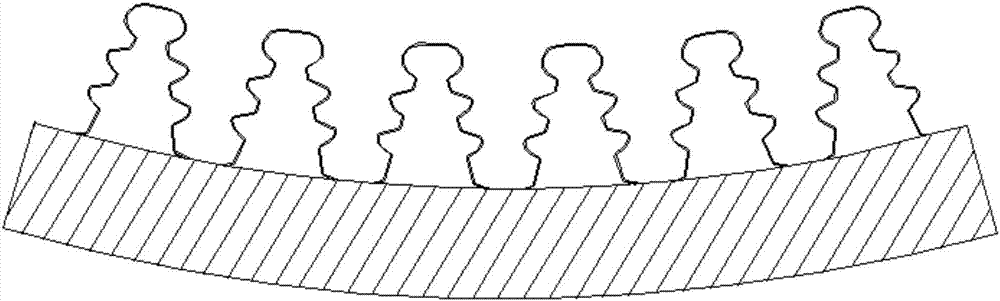

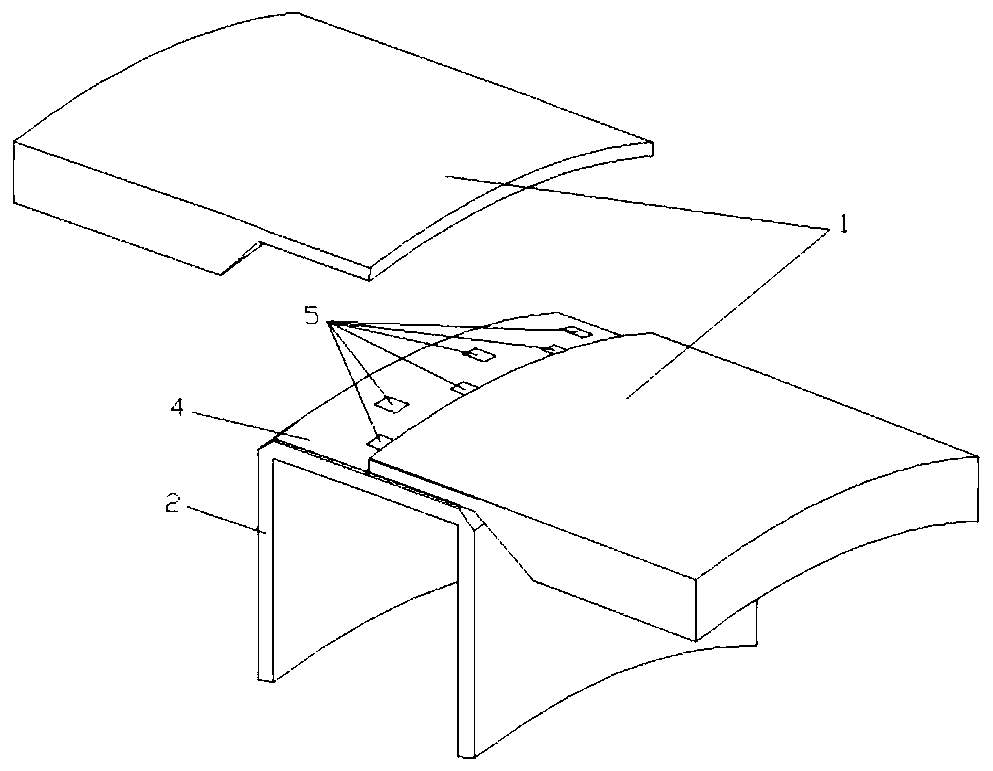

Curved surface composite material connecting structure, forming method and rail vehicle

ActiveCN111452395AReduce processing difficultyReduce difficultyAxle-box lubricationDomestic articlesComposite materialCompositermes

The invention relates to the field of composite materials, and provides a curved surface composite material connecting structure, a forming method and a rail vehicle. The curved surface composite material connecting structure comprises a pair of composite material curved surface skins and a connecting beam, wherein the pair of composite material curved surface skins is spliced on the outer surfaceof the connecting beam; the curved surface composite material connecting structure further comprises a plurality of thickening sheets which are fixedly arranged on the bonding surface of each composite material curved surface skin correspondingly; the plurality of thickening sheets are arranged on the bonding surface of each composite material curved surface skin at intervals; the bonding surfaceof each composite material curved surface skin is in contact with the outer surface of the connecting beam through the thickening sheets; a gap is formed between each composite material curved surface skin and the outer surface of the connecting beam; and the gaps are filled with adhesive layers. According to the curved surface composite material connecting structure, the forming method and the rail vehicle, the machining, connecting and assembling difficulty of the whole composite material connecting structure can be reduced, so that the structure is firmer when the composite material curvedsurface skin is bonded with the connecting beam.

Owner:CRRC QINGDAO SIFANG CO LTD

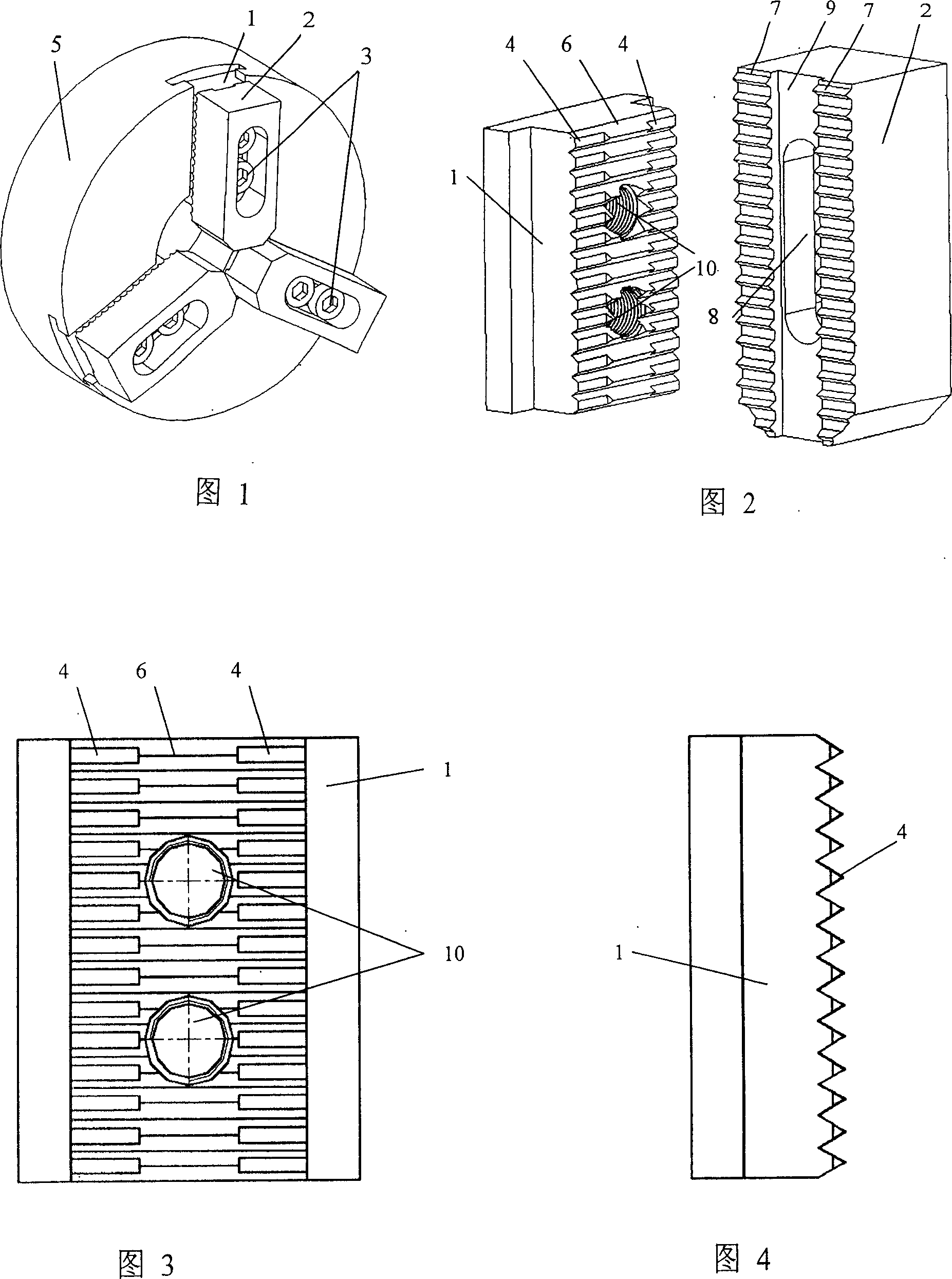

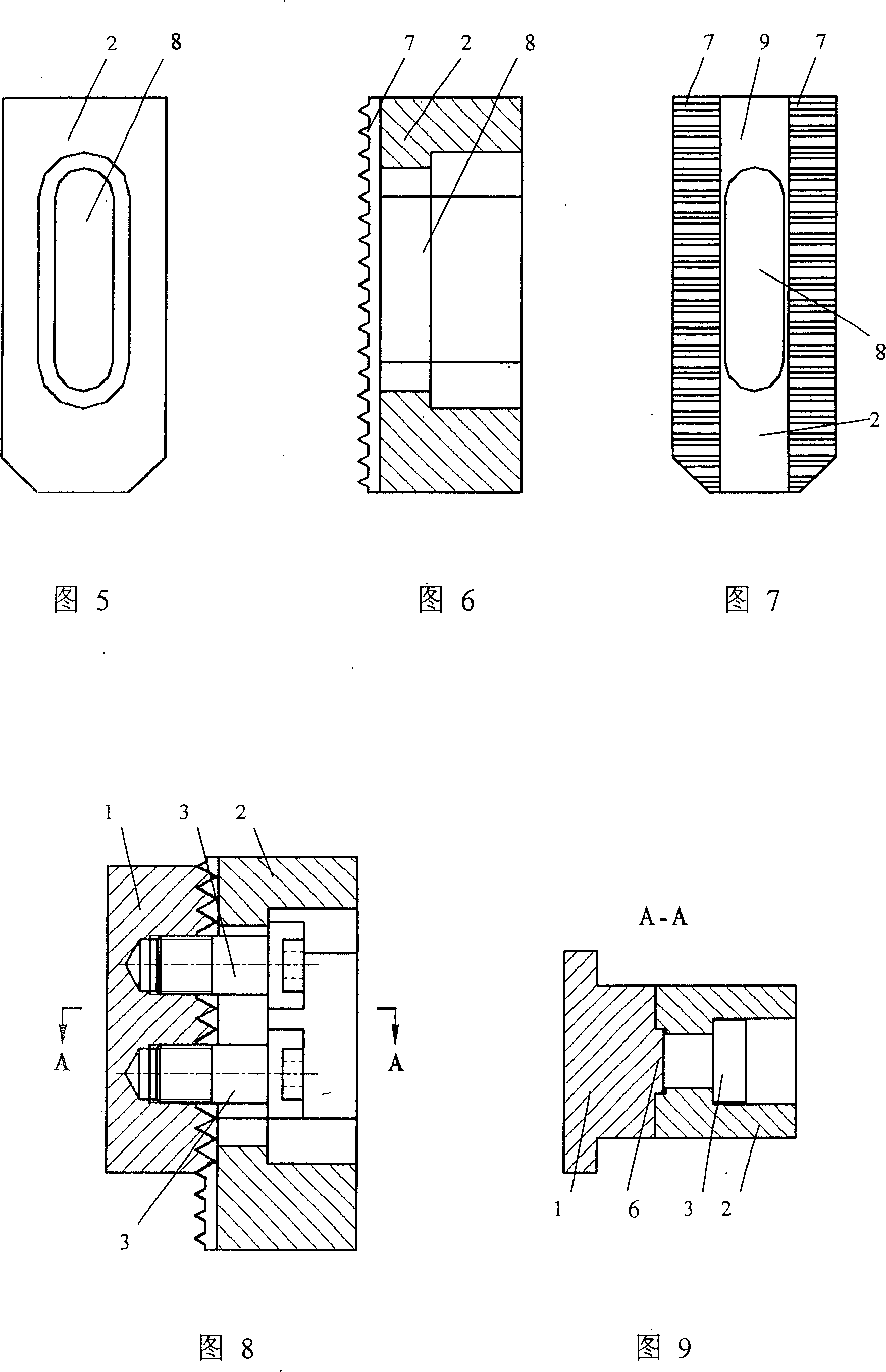

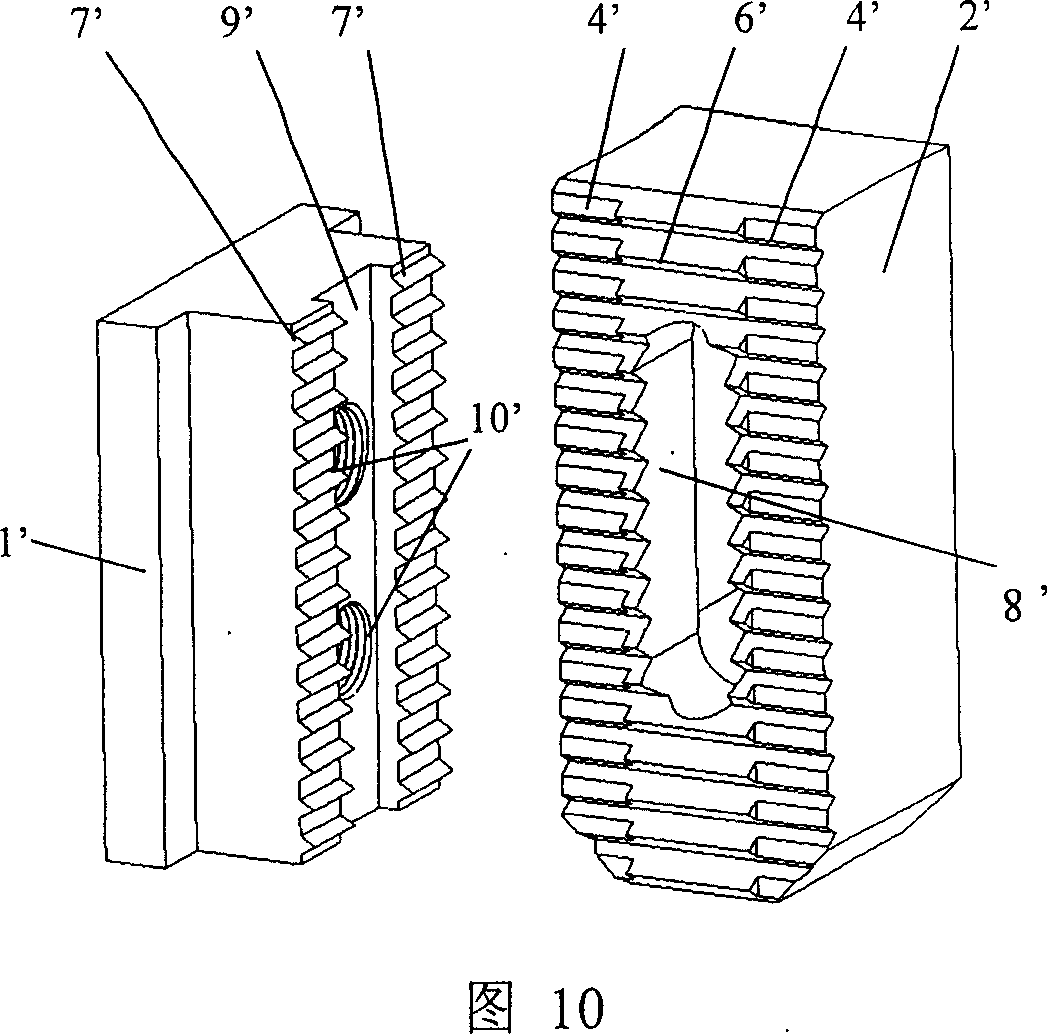

Jack catch for clamping workpiece or cutting tool

A clamping jaw for claming workpiece or cutting tool is composed of a basic jaw with triangular teeth whose tooth top has both truncated sides to become trapezoidal side teeth and the screw hole at the position of triangular teeth, and a high jaw with triangular teeth and trapezoidal tooth spaces for matching with the trapezoidal side teeth of basic jaw, transverse locating slot on the tooth and waist hole.

Owner:ZHEJIANG UNIV

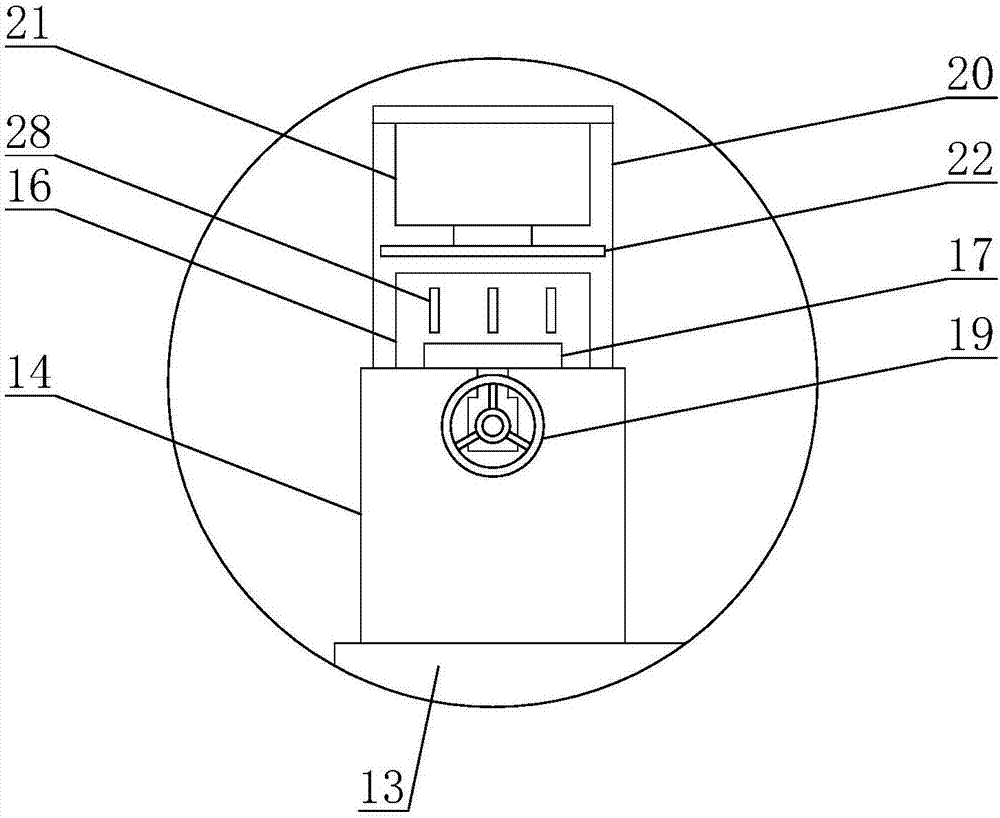

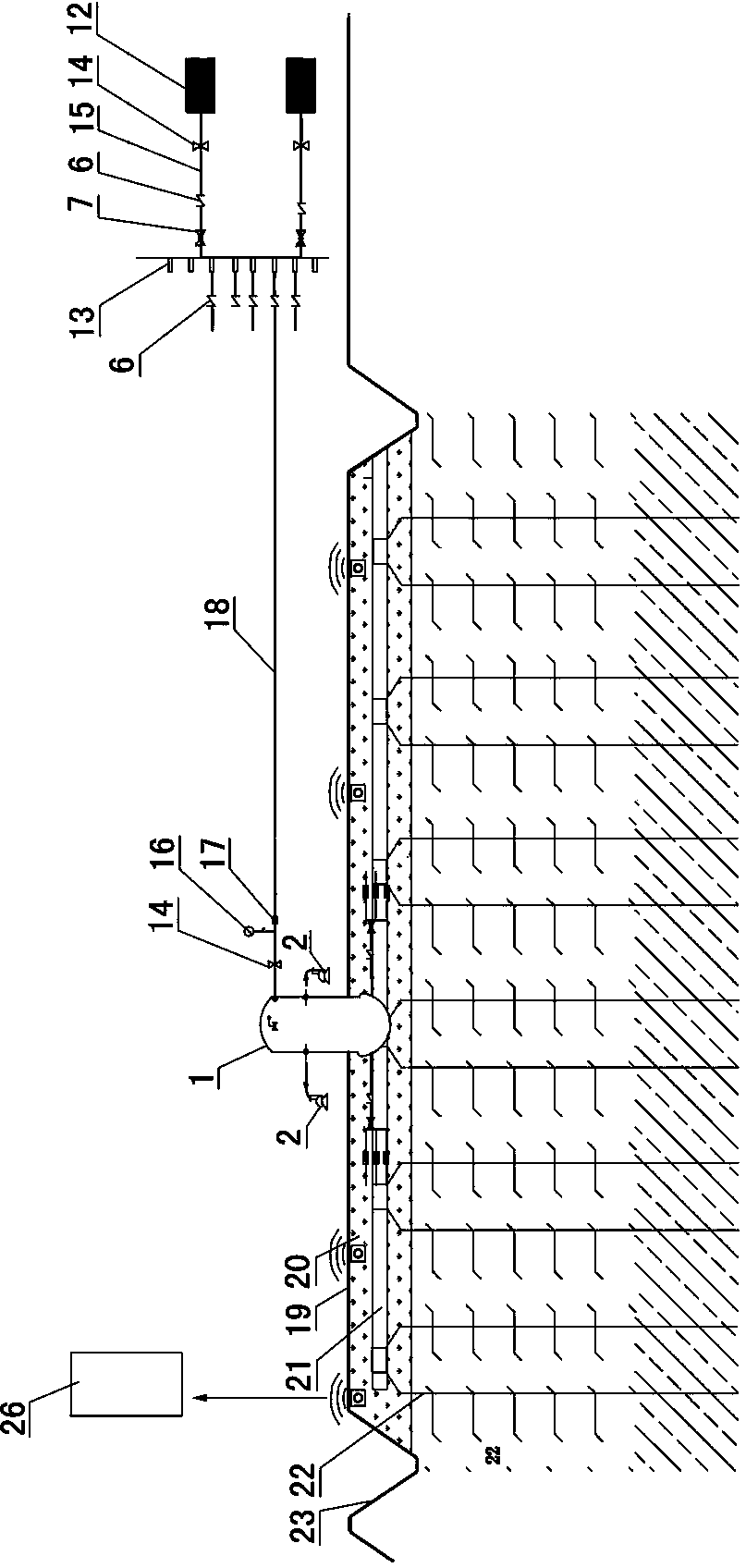

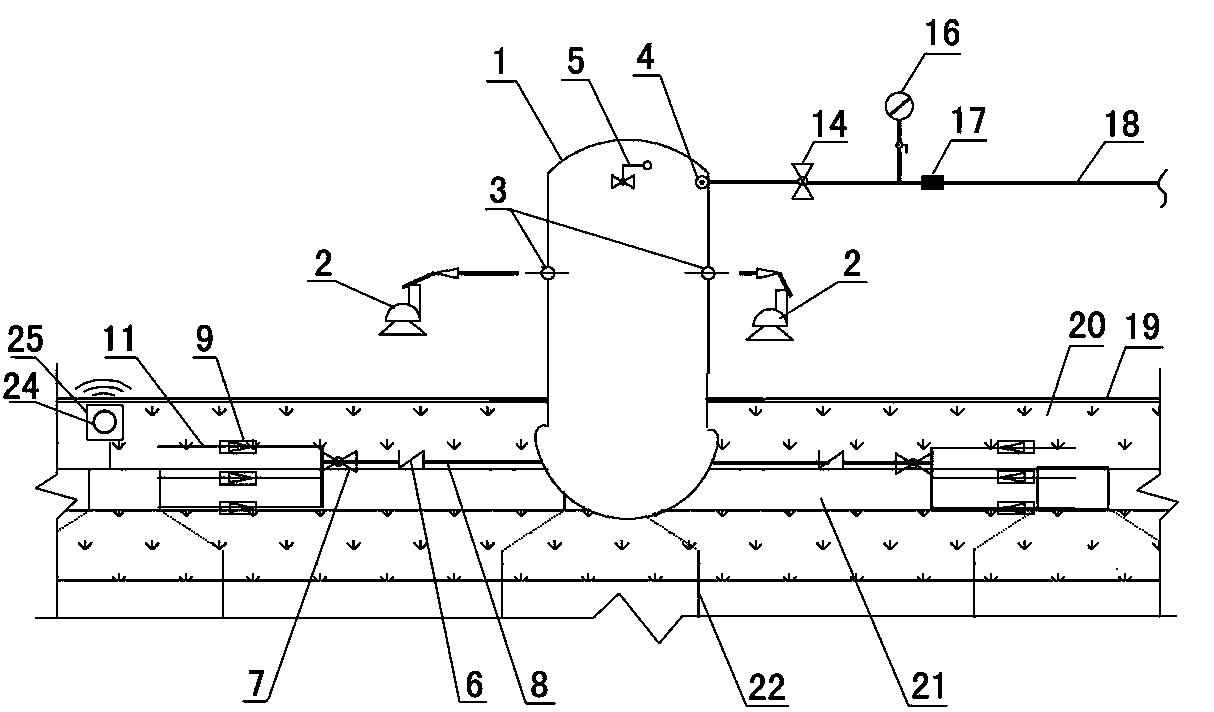

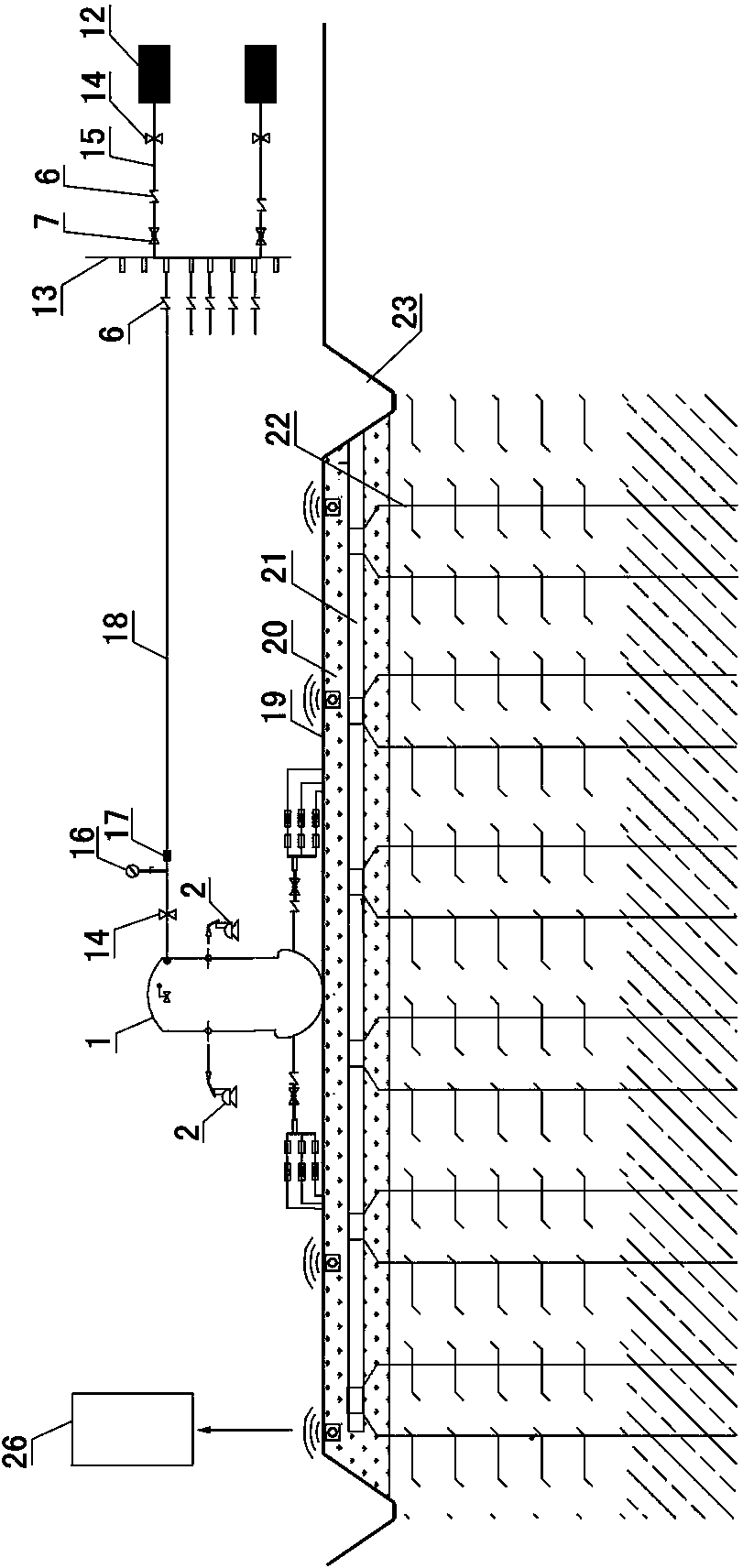

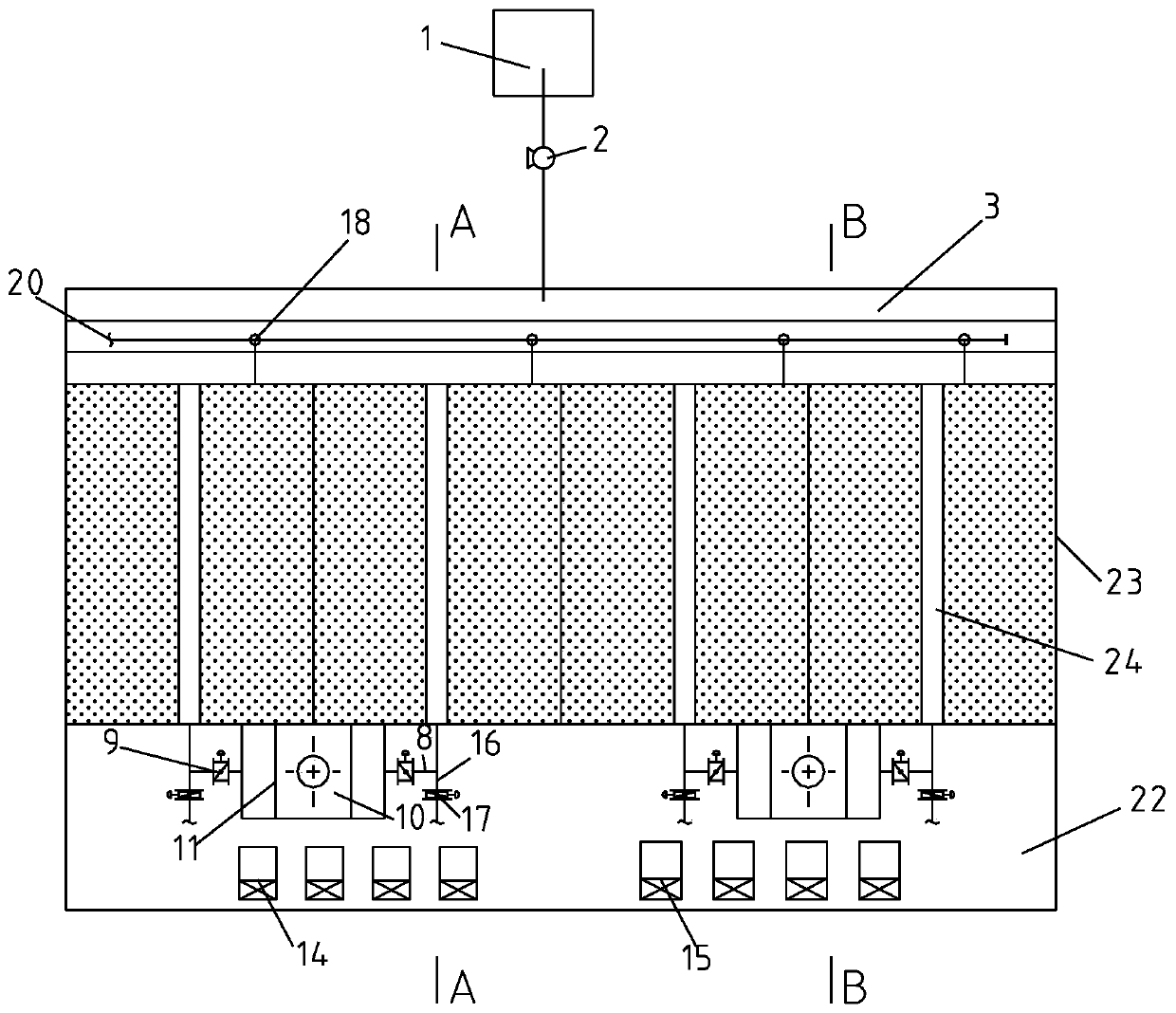

Oversized-area efficient energy-saving vacuumizing soft foundation treatment system and construction method

InactiveCN103866756AReduce usageEfficient constructionSoil preservationWater storage tankPressure data

The invention provides an oversized-area efficient energy-saving vacuumizing soft foundation treatment system and a construction method. The system is composed of a vacuumizing device, a gas-liquid separation device, a water collection device and an automatic vacuum data transmission device. The automatic vacuum data transmission device is composed of a vacuum data signal sensor, an automatic vacuum data transmitter and a vacuum data receiver. The vacuum data signal sensor is composed of a pressure induction module and a pressure data collection module. The vacuum data receiver is composed of a wireless signal receiving module and a display module. According to the system, the mode that data are monitored by a worker everyday is changed into the mode that data are automatically transmitted and monitored and technicalization and automation of the construction technique and management are facilitated; the structure that a jet pump and a water storage tank are designed in a split mode is adopted in the gas-liquid separation device, so that the system is transported, repaired and replaced in a soft foundation conveniently, and the defect that the traditional vacuum preloading technology is large in power consumption is overcome by the system.

Owner:河北晟港工程技术有限公司 +1

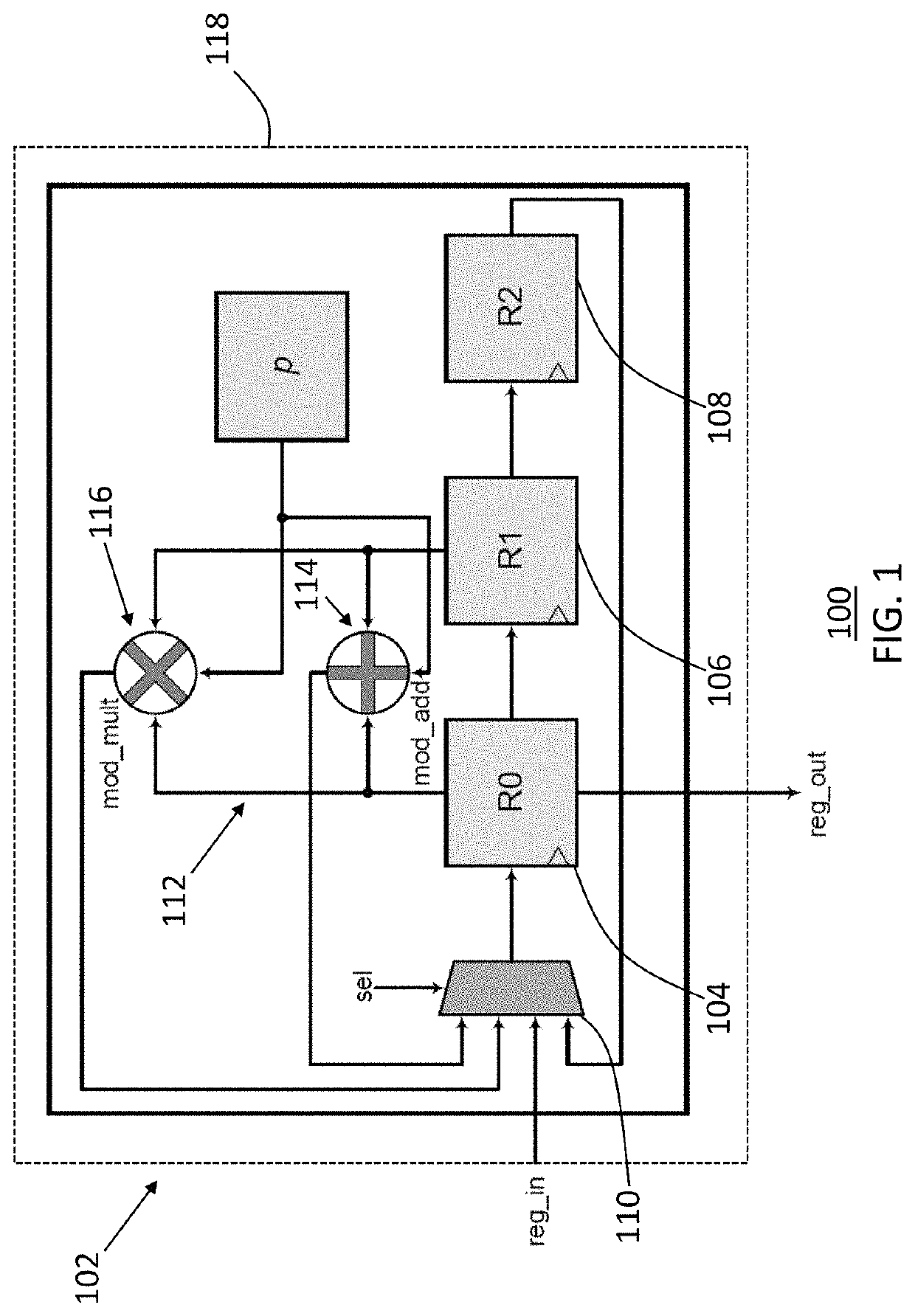

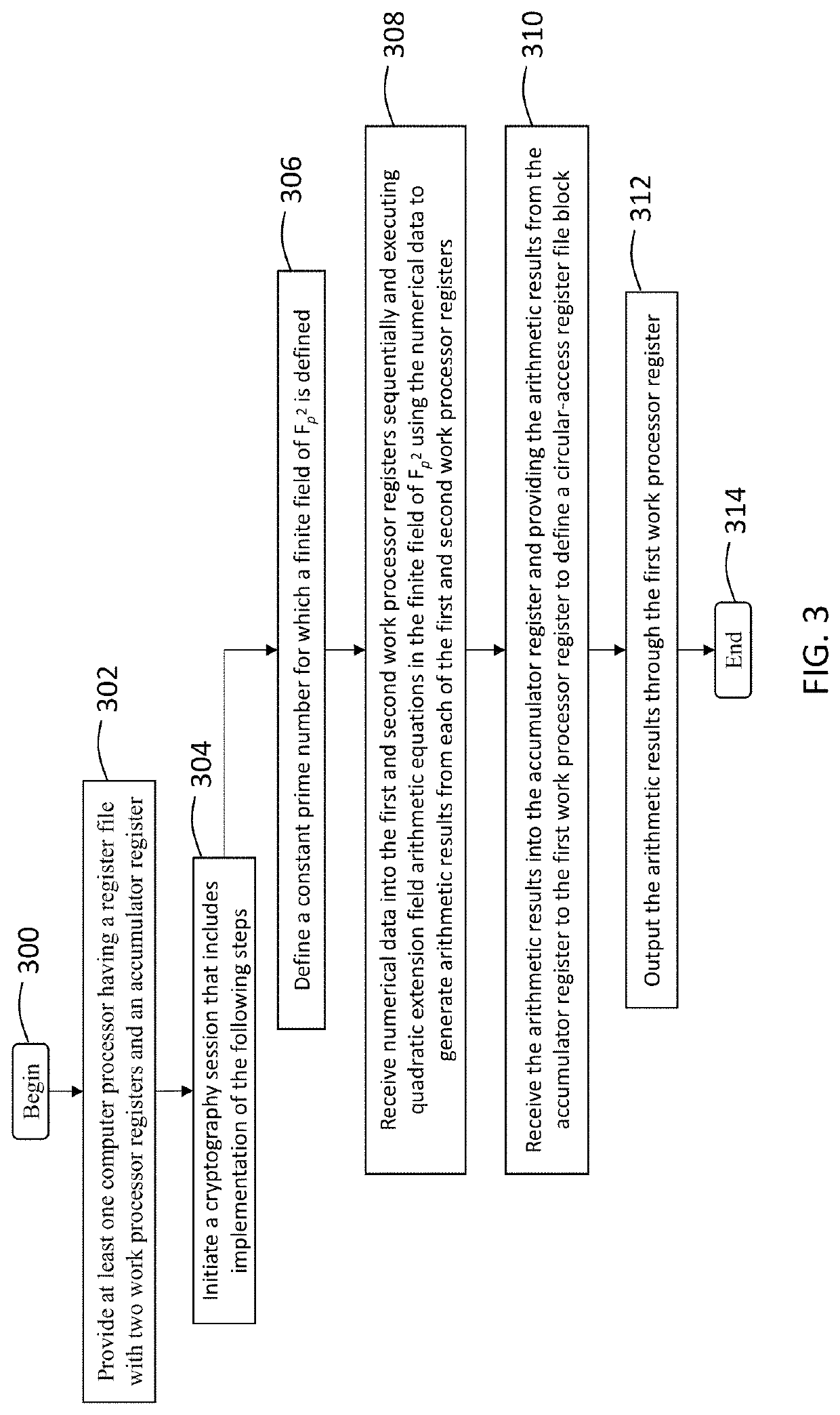

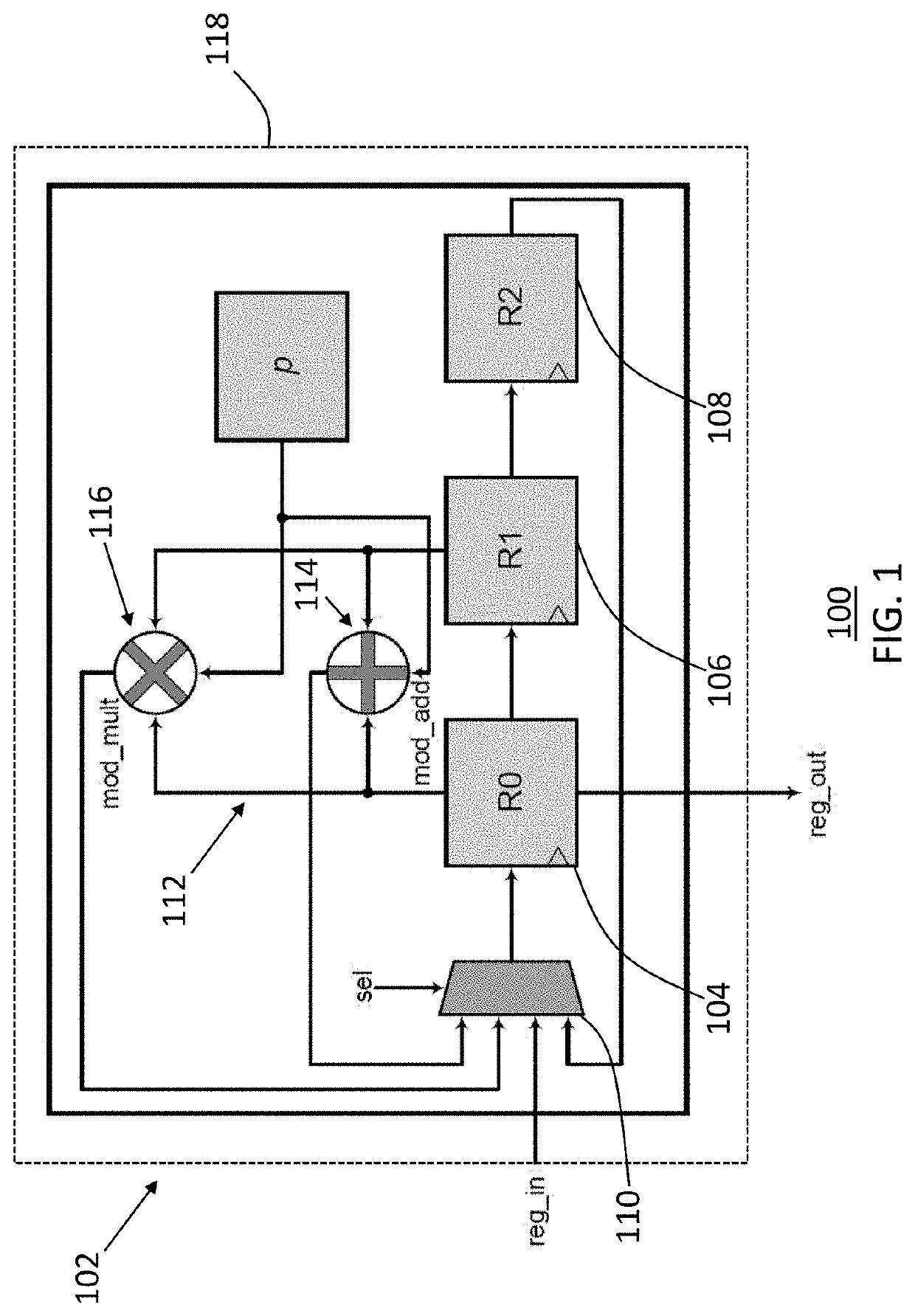

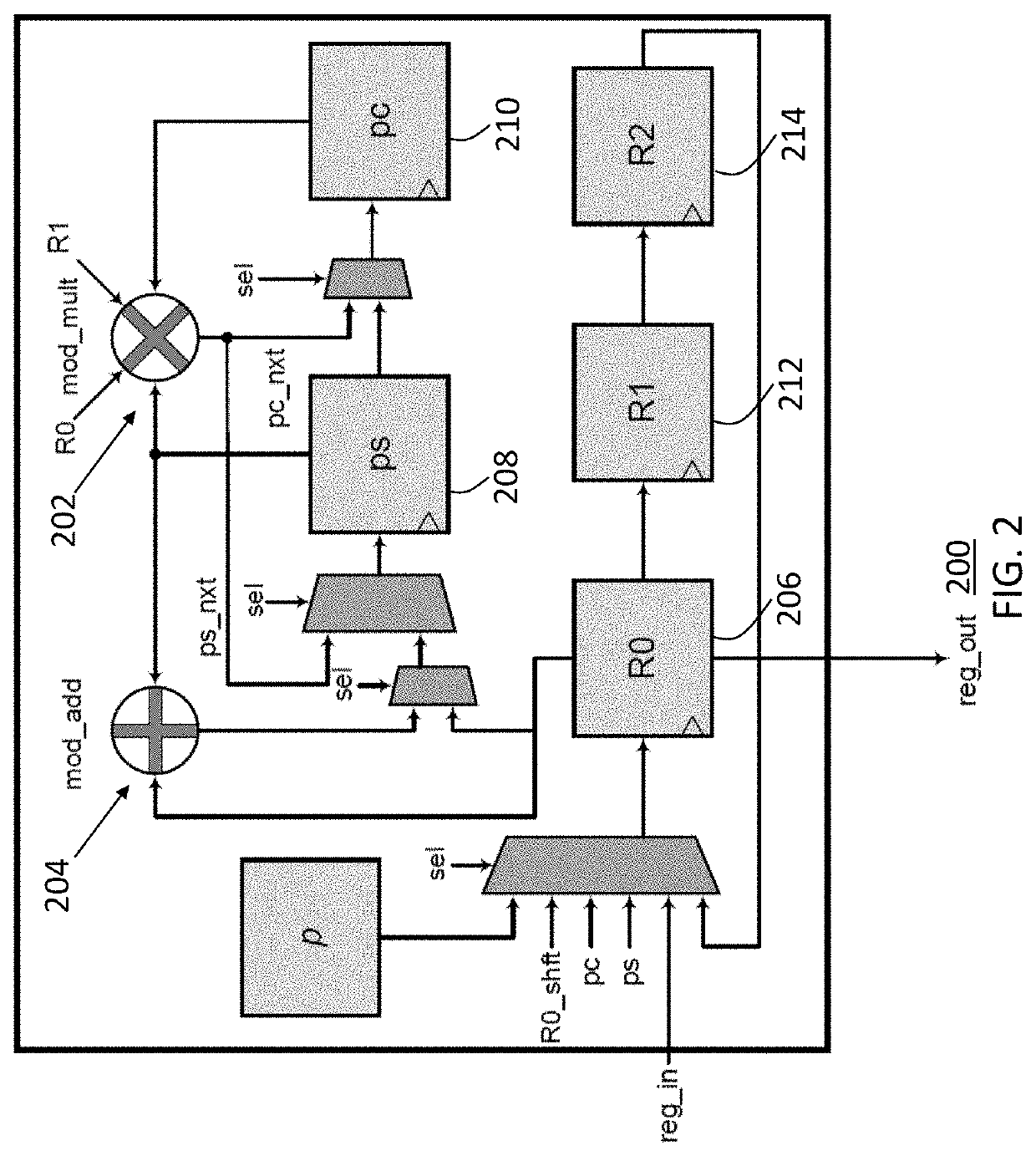

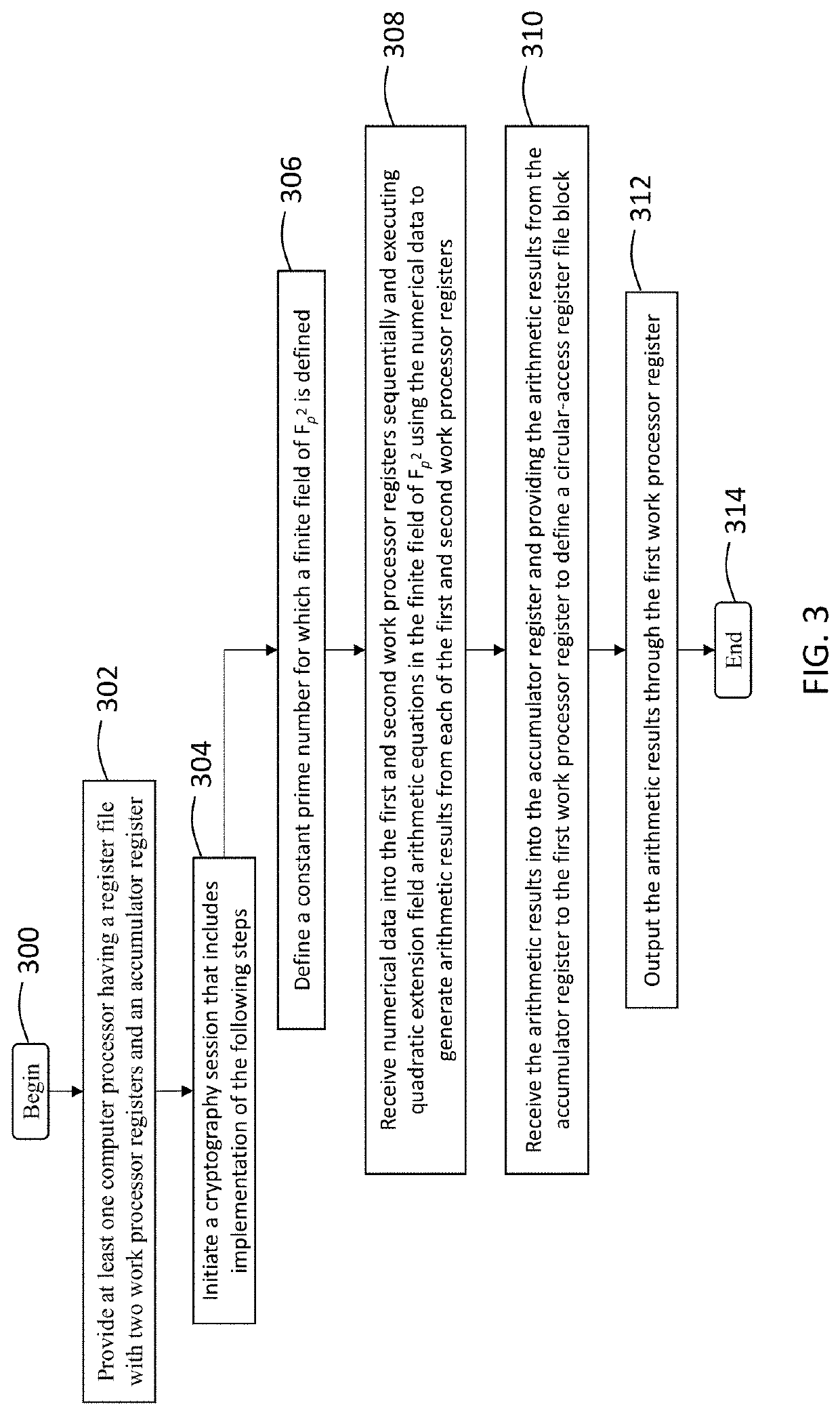

Efficient architecture and method for arithmetic computations in post-quantum cryptography

ActiveUS11165578B1Reducing processing footprintReduce necessary power and energyKey distribution for secure communicationPublic key for secure communicationComputer architectureCryptosystem

A computer processing system for reducing a processing footprint in cryptosystems utilizing quadratic extension field arithmetic such as pairing-based cryptography, elliptic curve cryptography, code-based cryptography and post-quantum elliptic curve cryptography that includes at least one computer processor having a register file with three processor registers operably configured to implement quadratic extension field arithmetic equations in a finite field of Fp2 and a multiplexer operably configured to selectively shift from each of the three processor registers in sequential order to generate modular additional results and modular multiplication results from the three processor registers.

Owner:PQSECURE TECH LLC

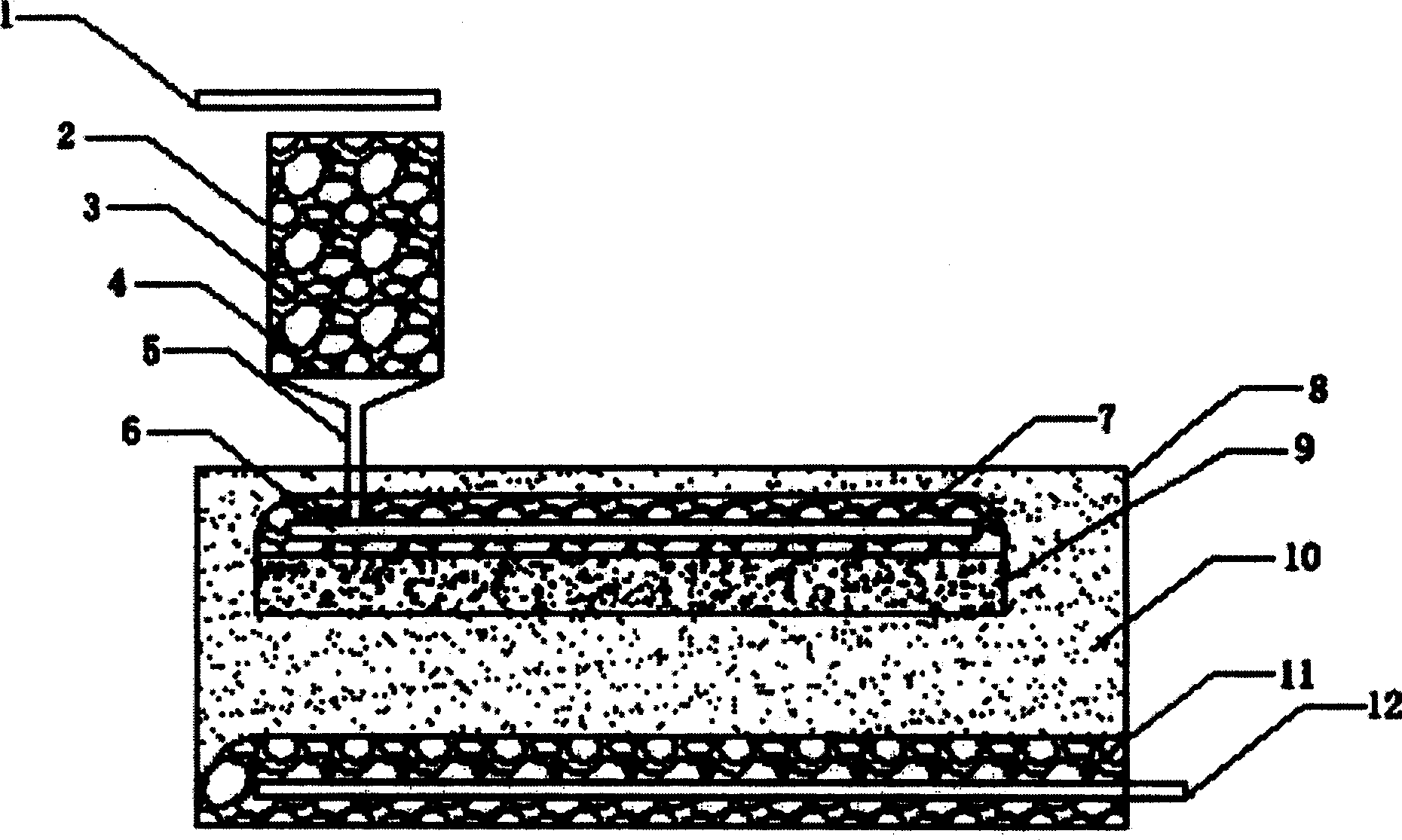

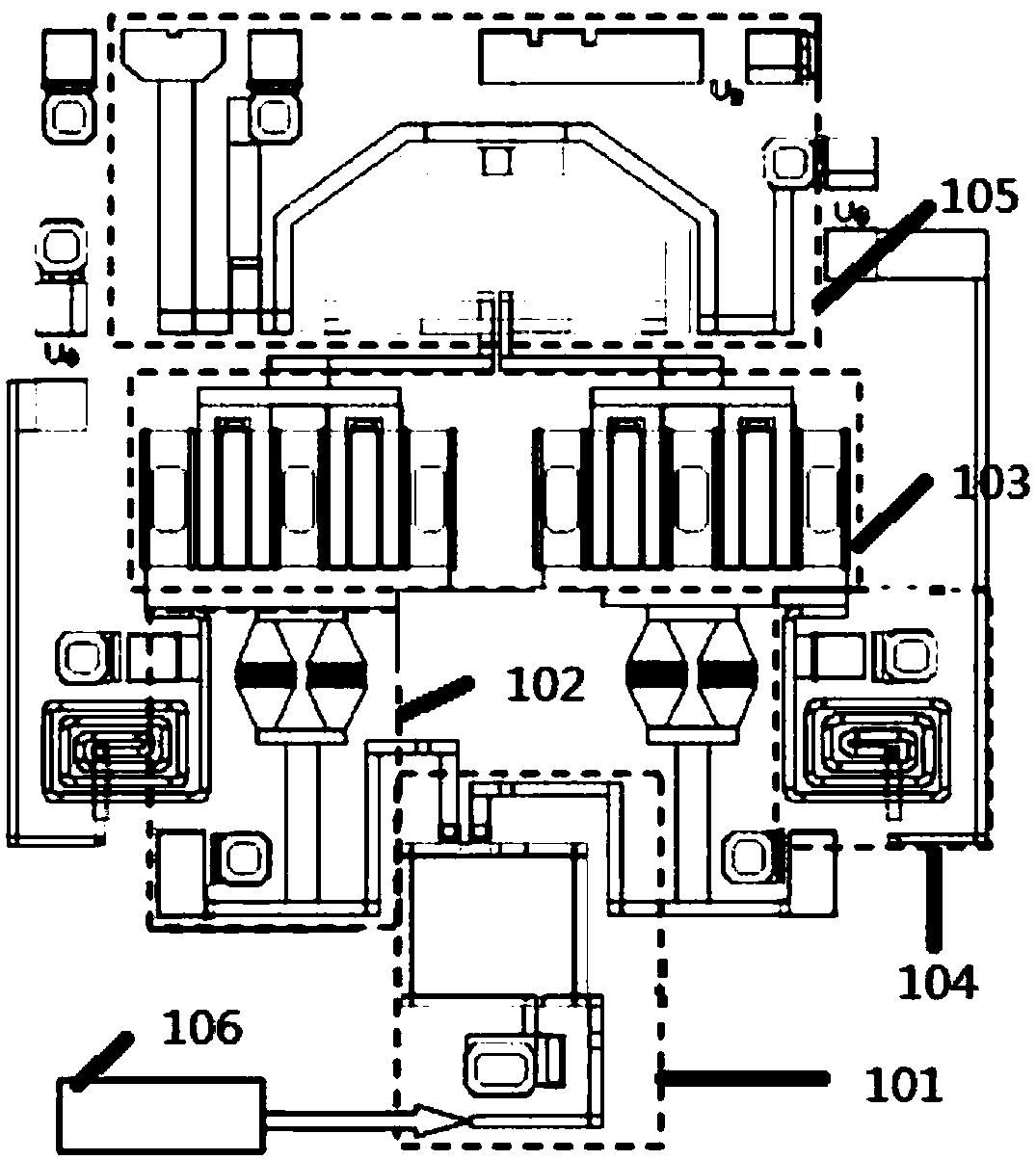

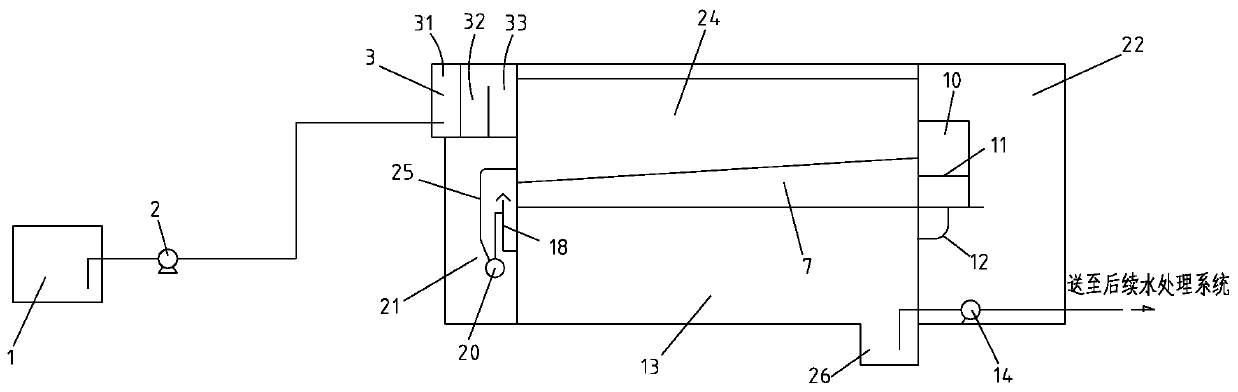

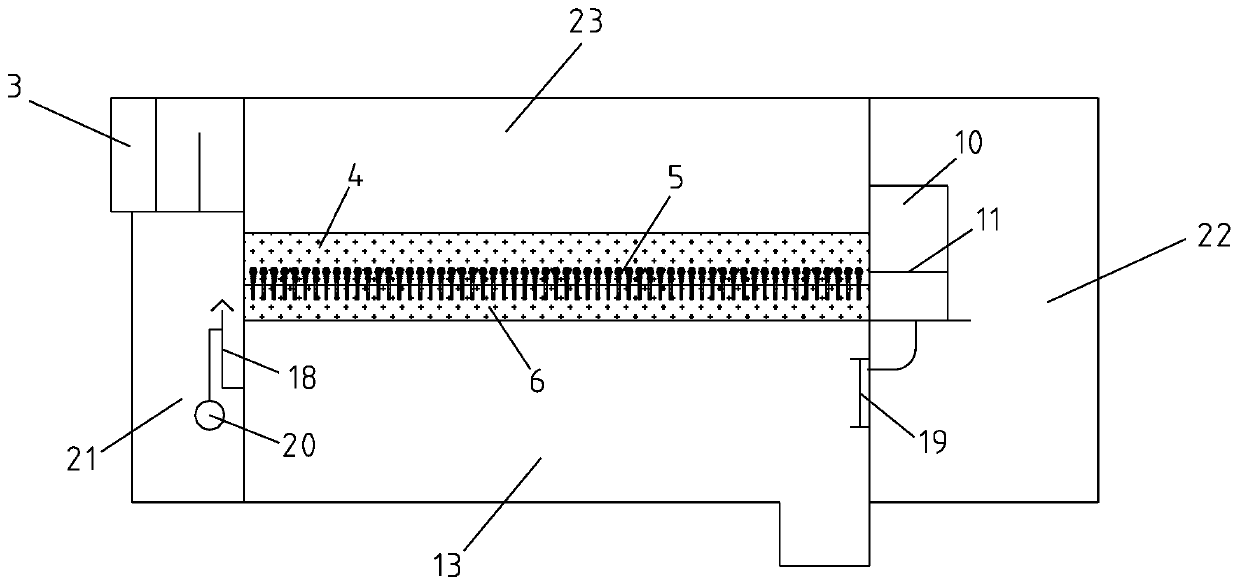

Integrated sewage treating apparatus combining biological filter tower and underground percolation

InactiveCN1272261CReduce processing areaImprove denitrification efficiencyTreatment using aerobic processesTreatment with anaerobic digestion processesFiltrationBiological filter

The integrated sewage treating apparatus consists of two parts of ground trickling filtration tower and underground percolation system. The trickling filtration tower with ventilation port has filled stuffing as the biological film growth carrier, water distributing plate in the top, isolating net in the bottom and water outlet pipe connected to the water distributing pipe in the underground percolation system. The underground percolation system has water outlet pipe buried in the bottom gravel layer, anaerobic tank buried in the upper soil, and underground percolating water distributing pipe buried in the gravel layer in the upper part of the anaerobic tank. In the trickling filtration tower, the sewage has most ammonia nitrogen converted into nitrate nitrogen and most of BOD degraded; in the underground anaerobic tank, the residual suspended grains are intercepted and nitrate nitrogen is denitrified; and the sewage is further percolated and deep treated.

Owner:SHANGHAI JIAOTONG UNIV

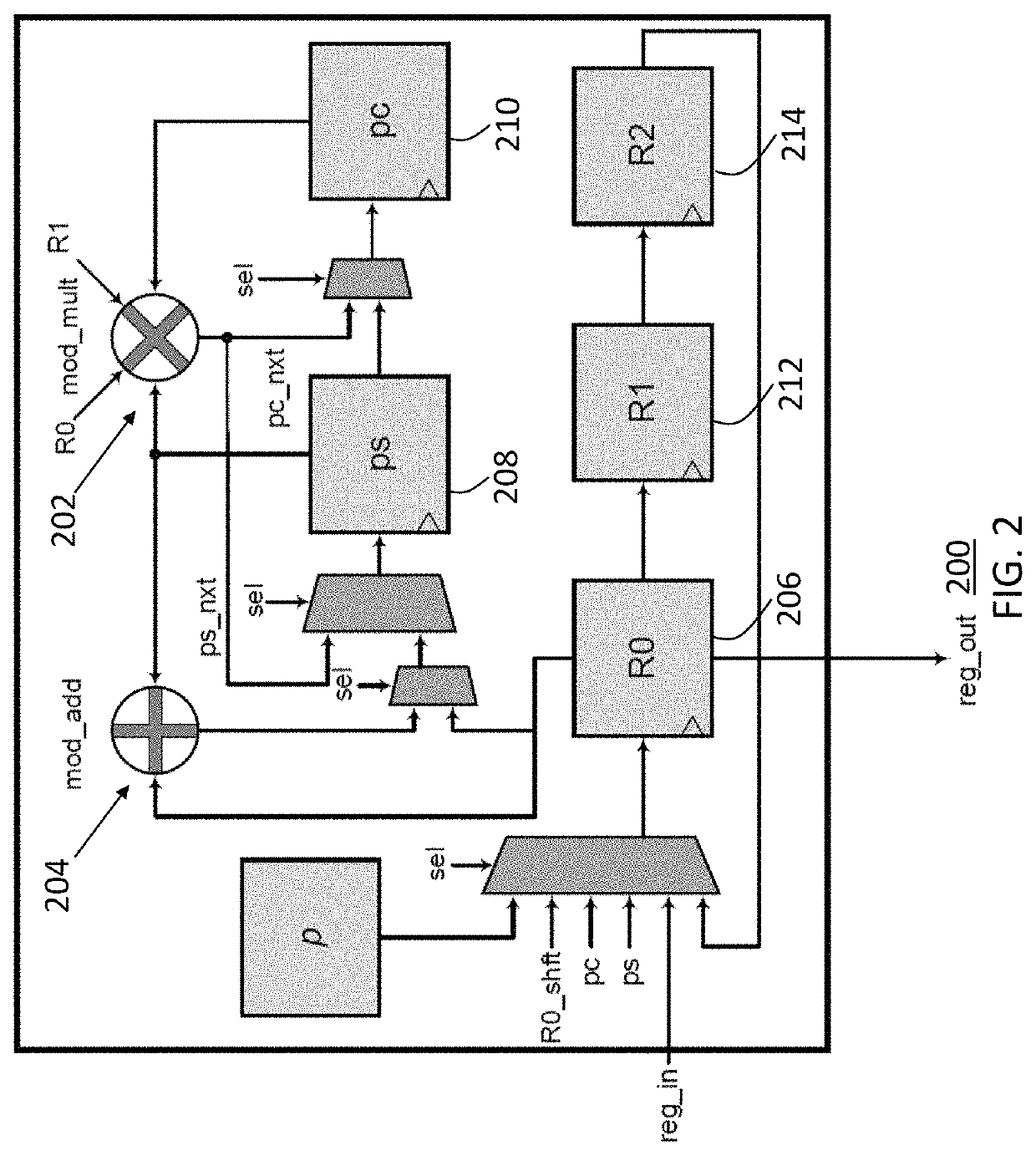

Efficient architecture and method for arithmetic computations in post-quantum cryptography

ActiveUS20210320796A1Reducing processing footprintReduce necessary power and energyKey distribution for secure communicationPublic key for secure communicationComputer architectureCryptosystem

A computer processing system for reducing a processing footprint in cryptosystems utilizing quadratic extension field arithmetic such as pairing-based cryptography, elliptic curve cryptography, code-based cryptography and post-quantum elliptic curve cryptography that includes at least one computer processor having a register file with three processor registers operably configured to implement quadratic extension field arithmetic equations in a finite field of Fp2 and a multiplexer operably configured to selectively shift from each of the three processor registers in sequential order to generate modular additional results and modular multiplication results from the three processor registers.

Owner:PQSECURE TECH LLC

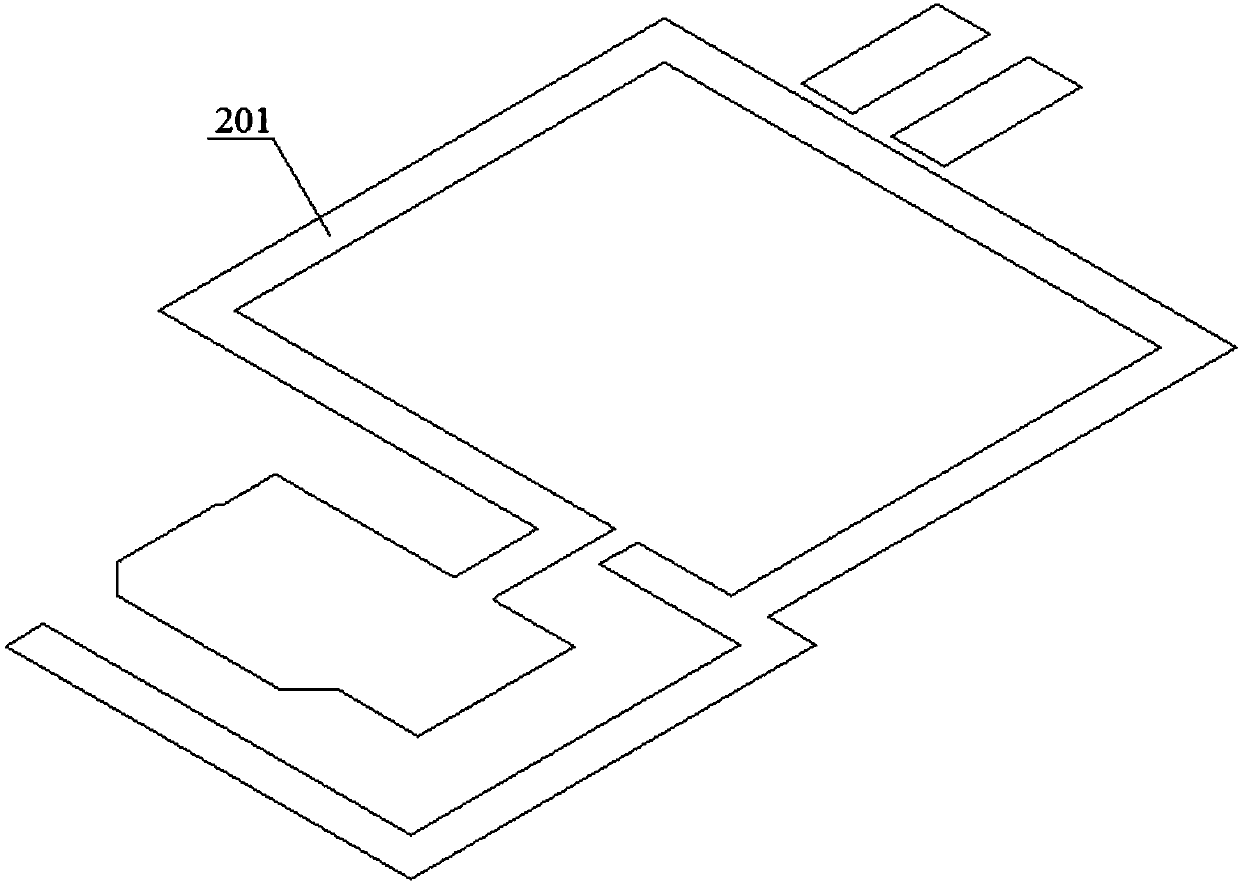

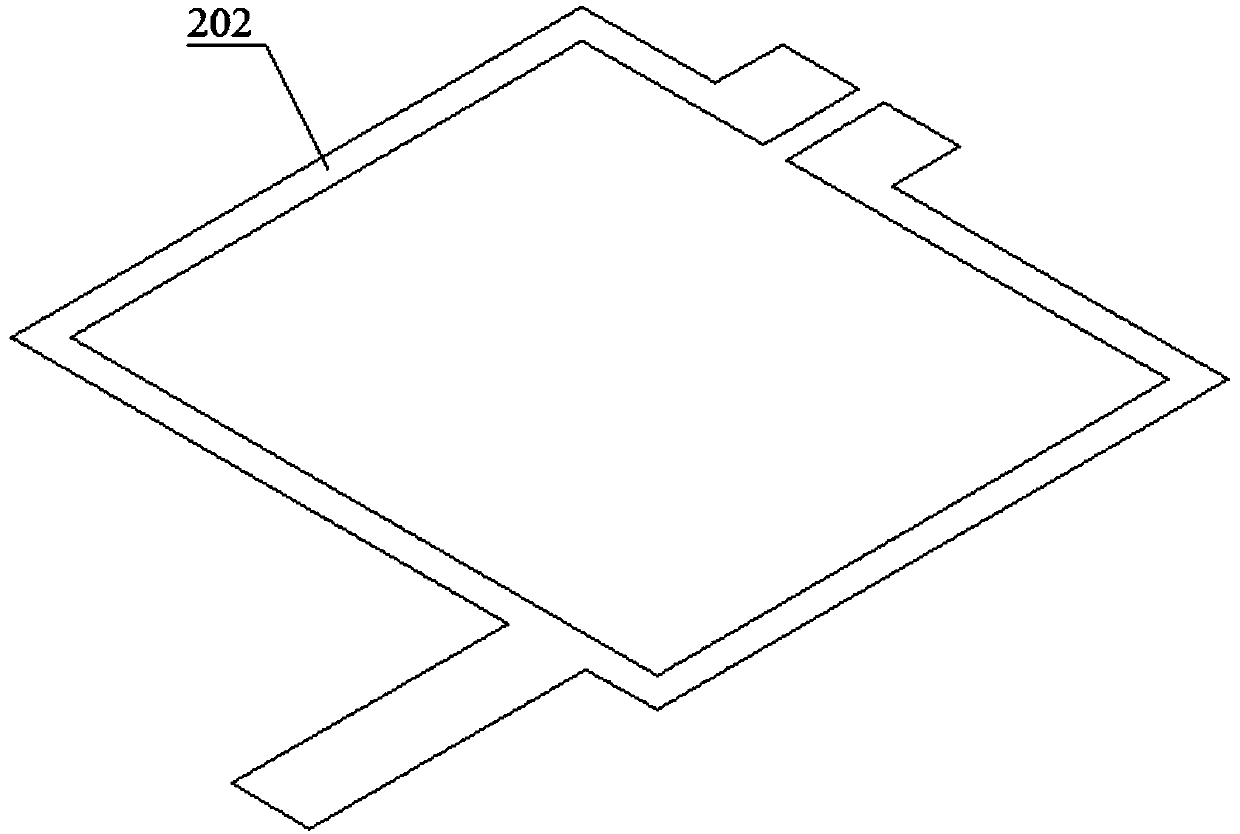

Differential amplifier

InactiveCN107743684AReduce processing areaAvoid lossSemiconductor/solid-state device detailsRF amplifierDifferential amplifierOperating frequency

A differential amplifier, comprising a previous-stage drive level (106), an input balun (101), a matching network (102), a differential transistor pair (103), a bias network (104) and an output balun(105). An output end of the previous-stage drive level (106) is connected to an input end (203) of the input balun (101). An output end (205) of the input balun (101) is connected to an input end of the matching network (102), an output end of the matching network (102) is connected to an input end of the differential transistor pair (103) and the bias network (104), and an output end of the differential transistor pair (103) is connected to the output balun (105). The input balun (101) is a single-turn stacked transformer. The output balun (105) is a planar transformer with a full inner-frameand a half outer-frame. The input balun of the differential amplifier is a single-turn stacked transformer, and the output balun has a structure with a full inner-frame and a half outer-frame, so that the differential amplifier takes up less space, and has low loss, high operating frequency and better power amplifier efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

V-shaped filter tank with produced water tanks arranged below filter tanks and working method thereof

PendingCN110860115AEnsure safetyGuaranteed three-dimensional arrangementStationary filtering element filtersWater storageWater treatment system

The invention relates to a V-shaped filter tank with produced water tanks arranged below filter tanks and a working method thereof. A water storage chamber is arranged at the bottom of each filter tank body, and filter heads are arranged on a filter plate between the water storage chamber and a filter material; drainage grooves are arranged between the filter tank bodies, and gas-water chambers are arranged at the bottoms of the drainage grooves; the water storage chambers are communicated with the gas-water chambers through a plurality of holes on the side wall; produced water tanks are arranged below the filter tanks; water outlet wells and water supply pumps are arranged outside the filter tanks at the water outlet ends; the gas-water chambers are communicated with the produced water chambers through the water outlet wells, and the produced water tanks are connected to a subsequent water treatment system through a water outlet pipeline. According to the invention, the produced watertanks of the V-shaped filter tank are arranged below the filter tanks, the overall floor space is reduced, and the investment is low; through effluent weirs and corresponding communicating pipes, theeffluent water of the filter tanks can be conveyed into the produced water tanks below by means of gravity, and water supply pumps, backwashing water pumps and other equipment can be placed in a pumproom concentratedly, thus guaranteeing the function of the filter tanks, and not increasing the floor area.

Owner:鞍钢集团工程技术有限公司

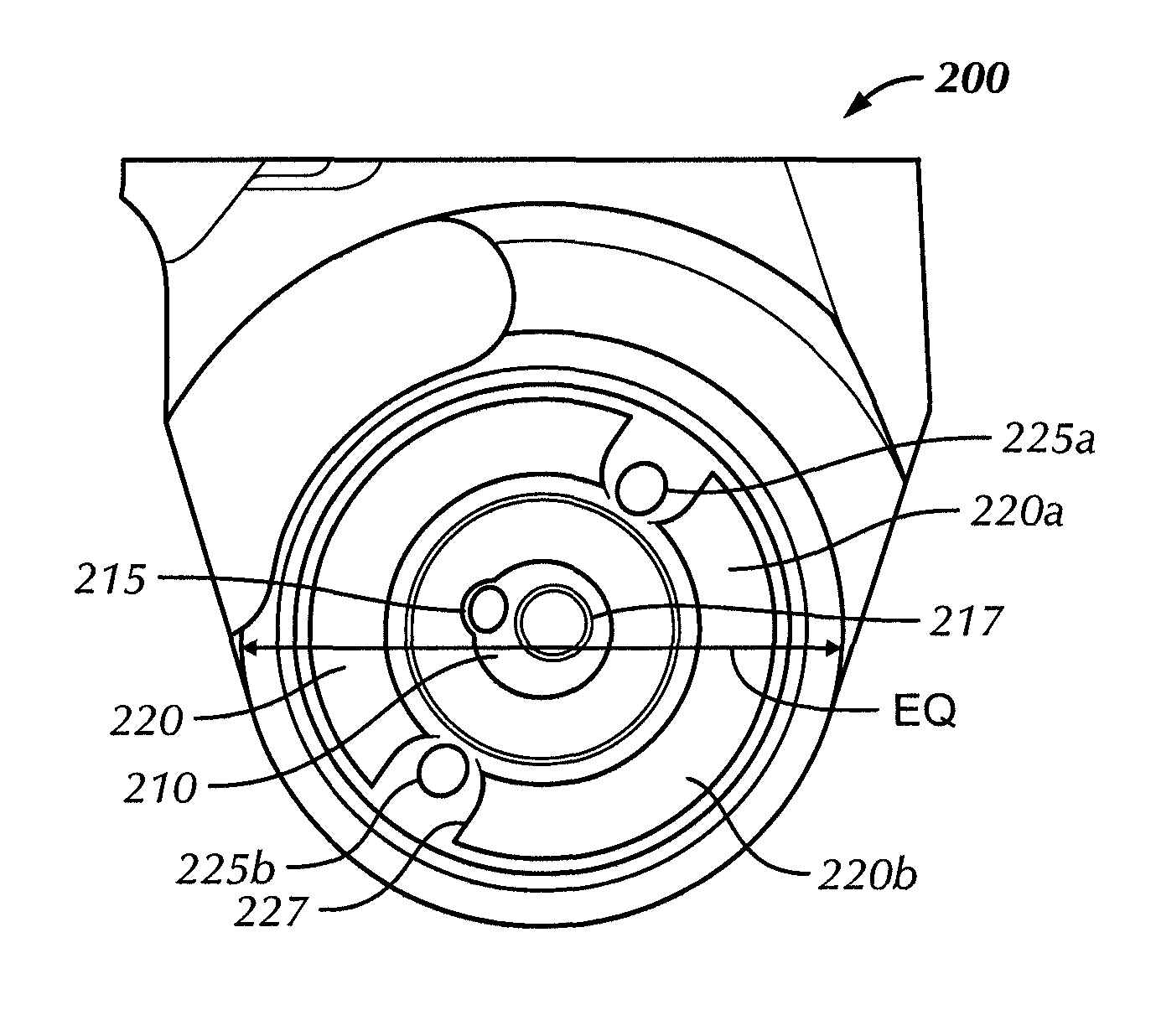

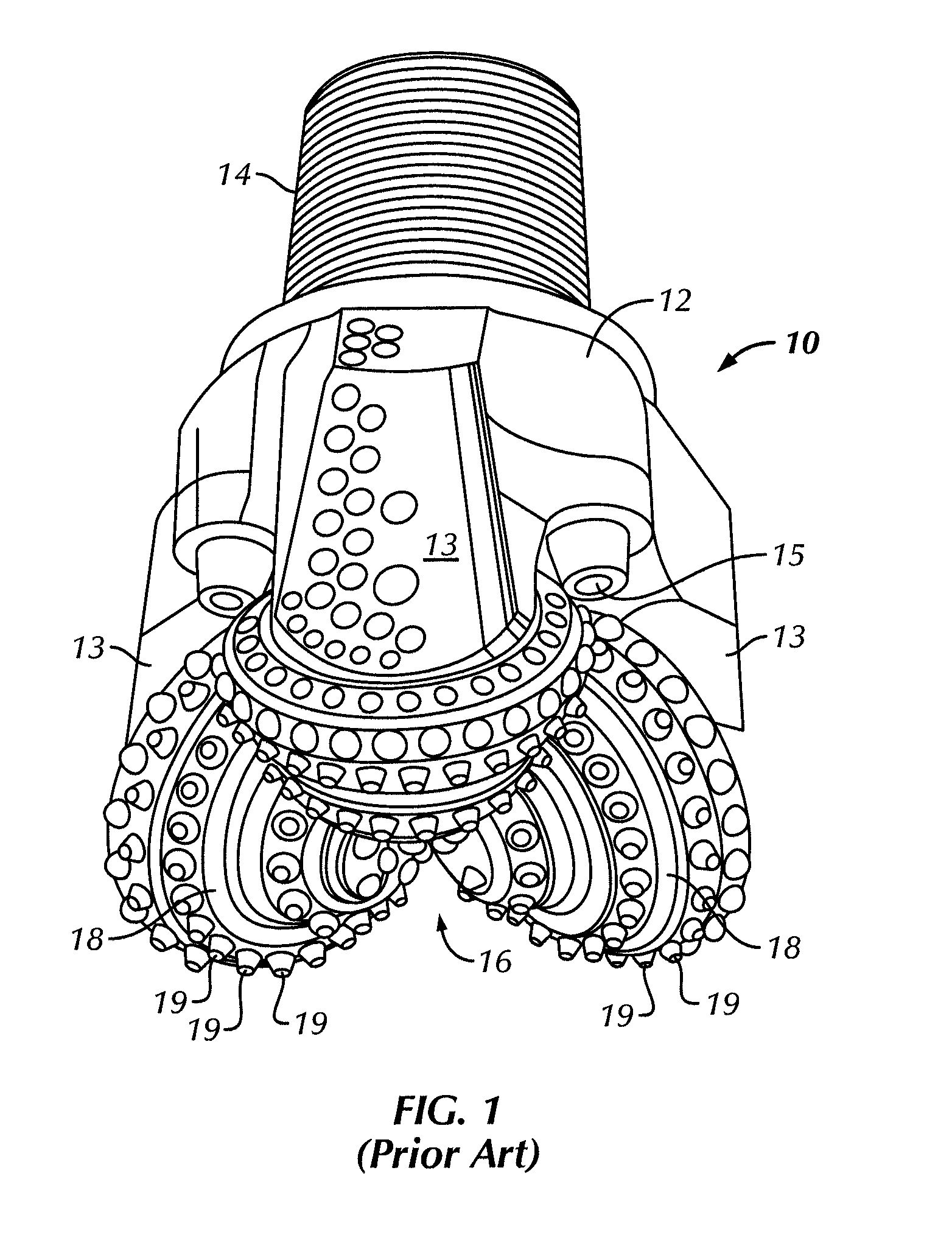

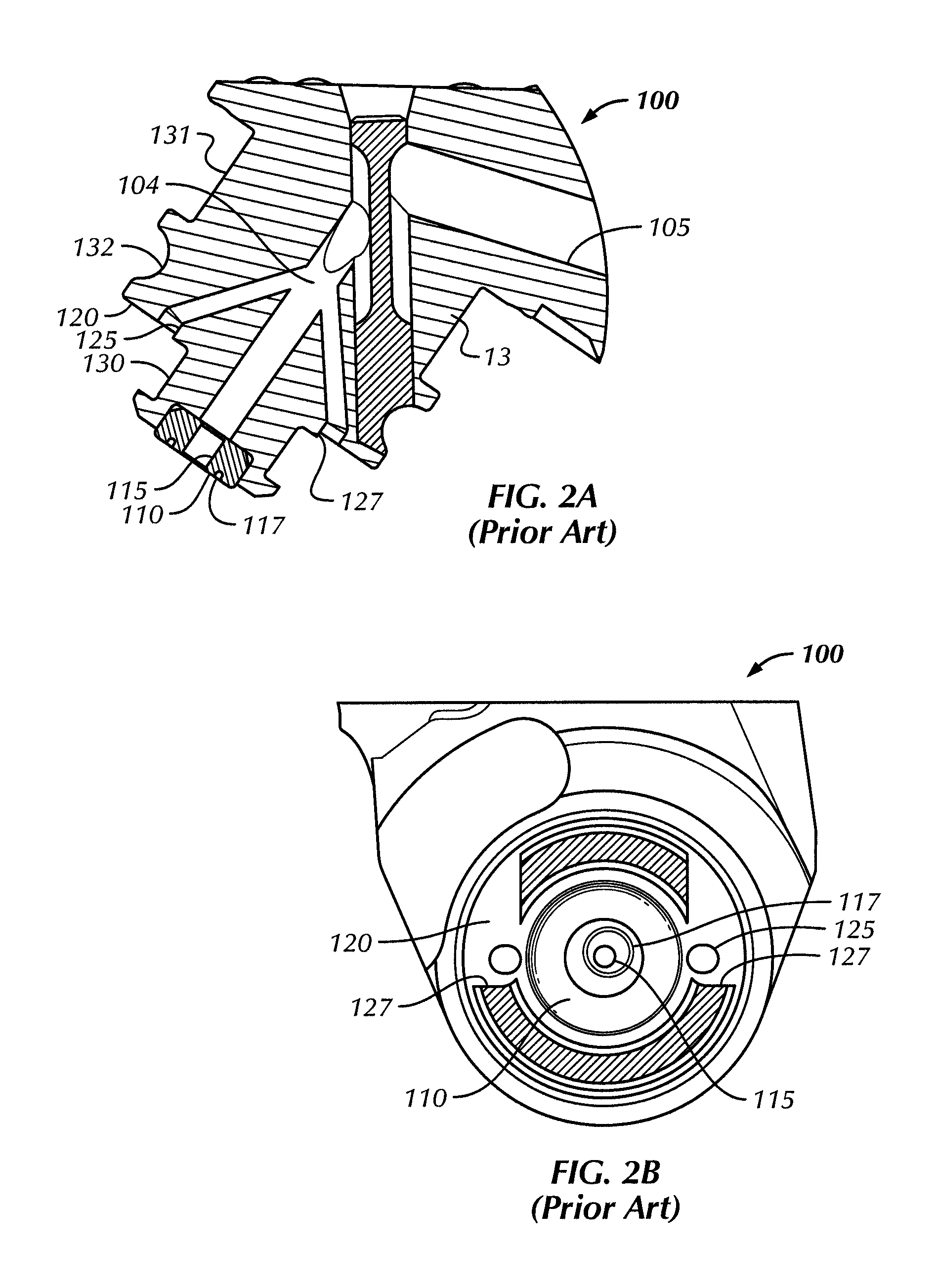

Air circulation ports in rotary rock bit journal bearing

ActiveUS8337085B2Optimizing the efficiency of a journal bearingReduce processing areaDrill bitsConstructionsThrust bearingBearing surface

A thrust bearing system for a roller cone rock bit includes at least one roller cone disposed on a leg having an air channel therethrough, the thrust bearing system including a primary thrust bearing surface on the leg configured to contact a corresponding primary bearing surface on the roller cone, wherein the primary thrust bearing surface on the leg includes at least one air circulation port in fluid communication with the air channel. The thrust bearing system further includes a secondary thrust bearing surface on the leg configured to contact a corresponding secondary bearing surface on the roller cone, wherein the secondary thrust bearing surface on the leg includes at least two air circulation ports located at specified locations in the secondary bearing surface and in communication with the air channel, and wherein a first circulation port is located in an upper half of the secondary thrust bearing surface and a second circulation port is located in a lower half of the secondary thrust bearing surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

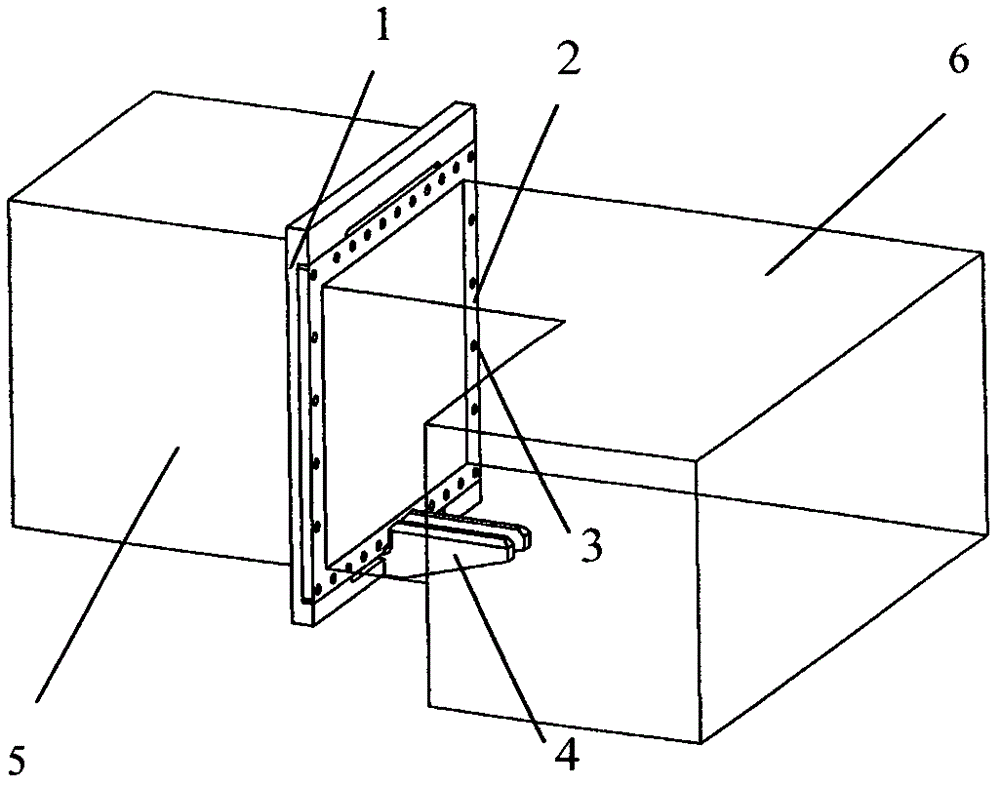

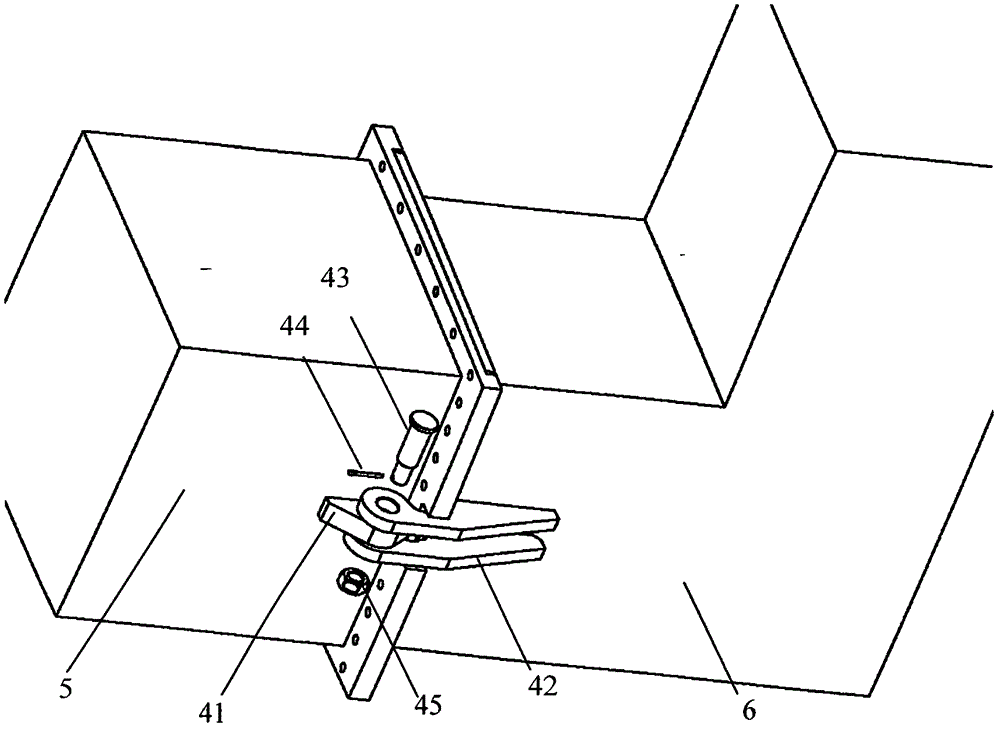

Shear-stress-resisting flange butt joint device

ActiveCN106438602AImprove connection reliabilityReduce processing areaSecuring devicesFastenerEngineering

The invention provides a shear-stress-resisting flange butt joint device. The device comprises a flange plate I, a flange plate II, bolt fasteners, a safety device, a connecting body and a connecting body. The flange plate I and the flange plate II are square plates in shape. Opening grooves are formed in the lower middle portions of the flange plate I and the flange plate II. A transversely-through groove is formed in the middle of the butt joint face of the flange plate I and the flange plate II. The height of the groove is consistent with the height of the flange plate II. The depth of the groove is consistent with the thickness of the flange plate II. The groove is in clearance fit with the flange plate II. Bolt connecting holes are formed in the peripheral edges of the flange plate I and the flange plate II. The flange plate I is welded to the end face of the corresponding connecting body, and the flange plate II is welded to the end face of the corresponding connecting body. The flange plate II is embedded in the groove in the flange plate I and is fastened through the bolt fasteners, and the connecting bodies are in butt joint. After the flange connecting structure of the shear-stress-resisting flange butt joint device is adopted, the connecting face is allowed to bear large shear force, bolts are protected, and the connecting reliability is improved.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

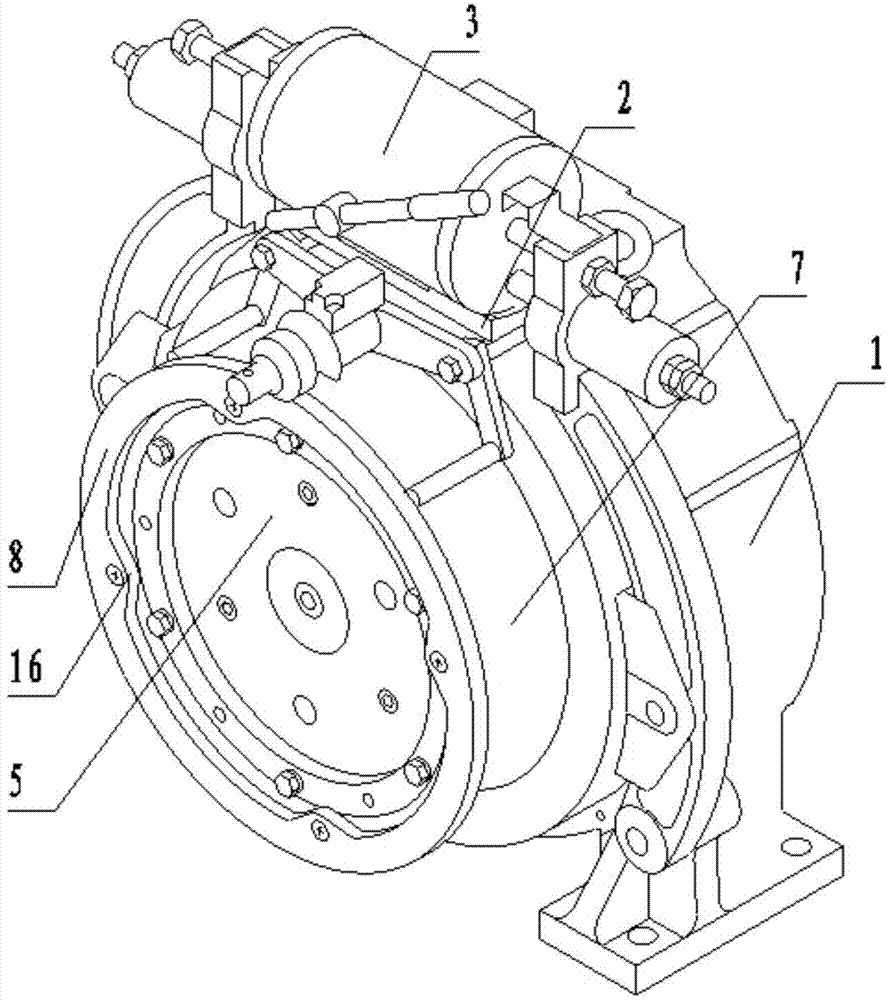

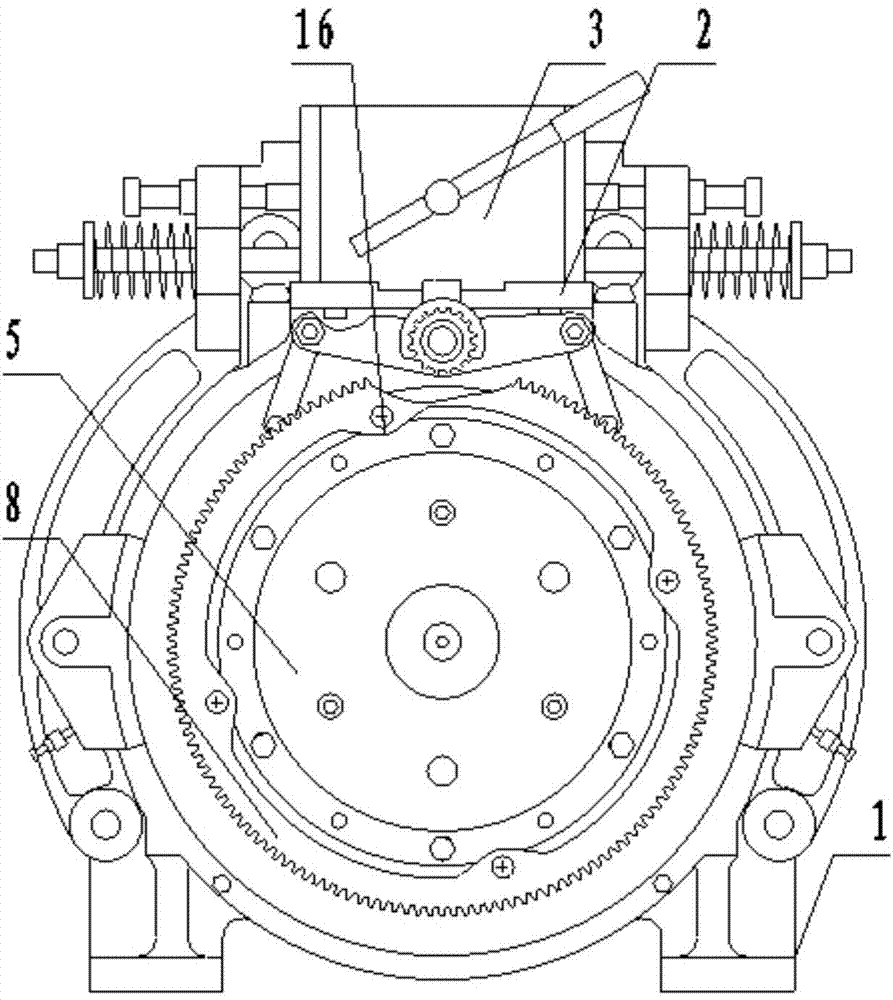

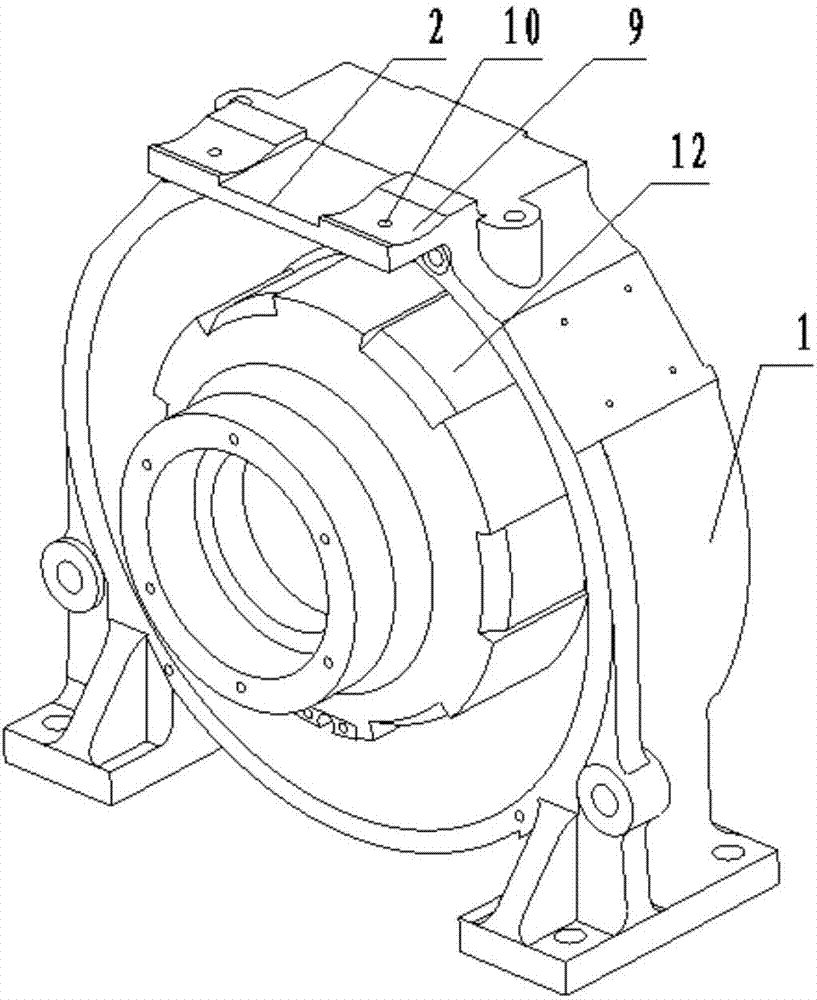

Elevator traction machine and method for improving comprehensive performance thereof

ActiveCN104495583AHigh strengthEasy to installManufacturing dynamo-electric machinesMechanical energy handlingStator coilUltimate tensile strength

The invention discloses an elevator traction machine and a method for improving the comprehensive performance thereof. The method for improving the comprehensive performance of the elevator traction machine includes forming a connecting seat by the aid of a bending forming process and forming arc-shaped mounting grooves for mounting a brake; constraining a stator coil by the aid of grooves and positioning pins when the stator coil rotates; fastening magnetic steel by the aid of bosses and a magnetic steel pressing component; connecting a gear ring onto a traction sheave by the aid of a seam and lugs. The elevator traction machine which is constructed by the aid of the method comprises a base (1). The brake (3) is connected to the top of the base (1) by the connecting seat (2); the stator coil (4) is arranged in the base (1), and a rotor yoke (5) is arranged between the stator coil (4) and the base (1); the magnetic steel (6) is arranged in the rotor yoke (5), and the gear ring (8) is connected to the outside of the rotor yoke (5) by the traction sheave (7). The elevator traction machine and the method have the advantages that the brake can be conveniently fixed, the stator coil can be prevented from rotating, the magnetic steel is convenient to detach and replace, the magnetic steel fastening stability can be improved, and the elevator traction machine is high in integral strength and low in machining cost.

Owner:YIDA EXPRESS ELEVATOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com