Large-diameter sprayer of MOCVD (metal organic chemical vapor deposition) reactor

A spray head and reactor technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of spray head processing, increased manufacturing difficulty, difficulty in spray head cooling, and reduced yield and other problems, to achieve the effect of increasing manufacturing difficulty, improving yield rate, and reducing processing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

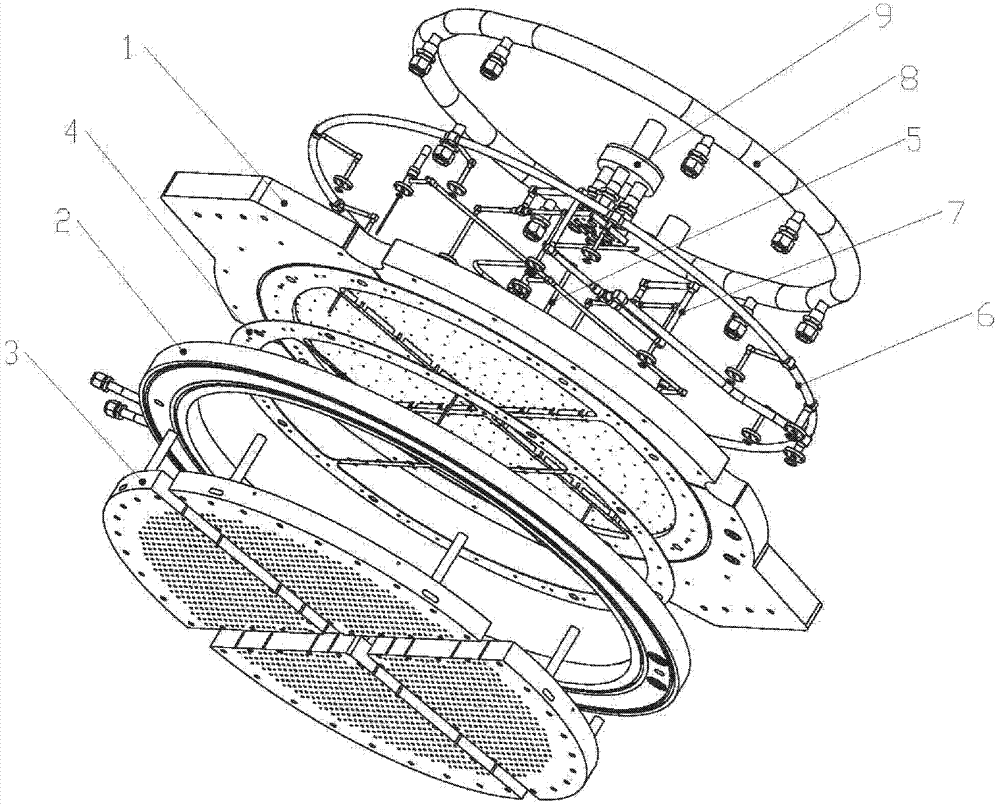

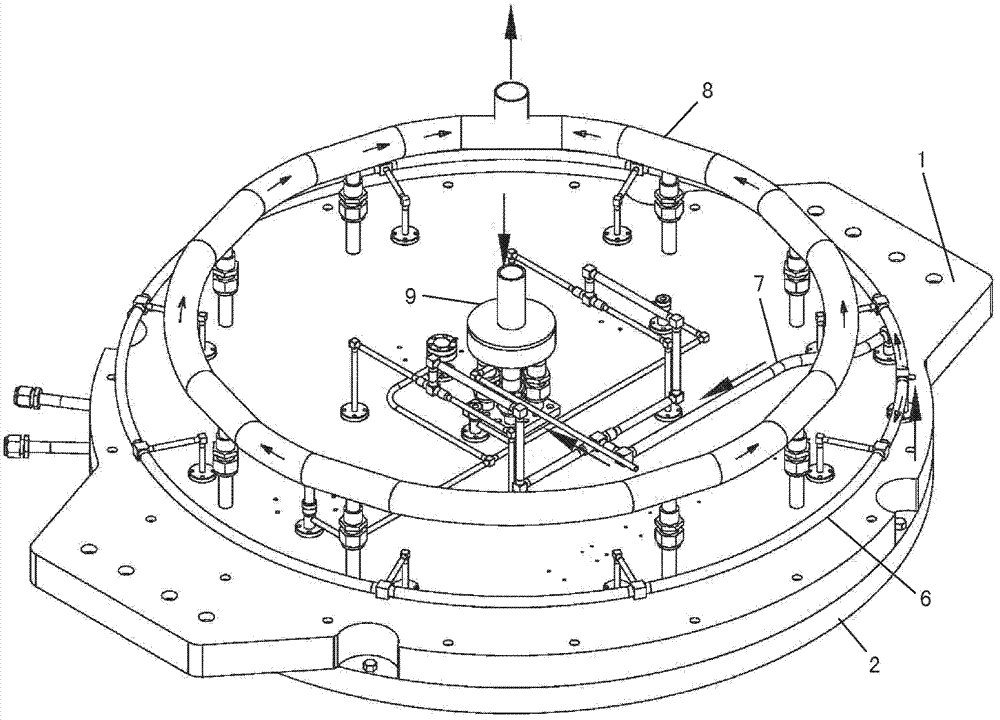

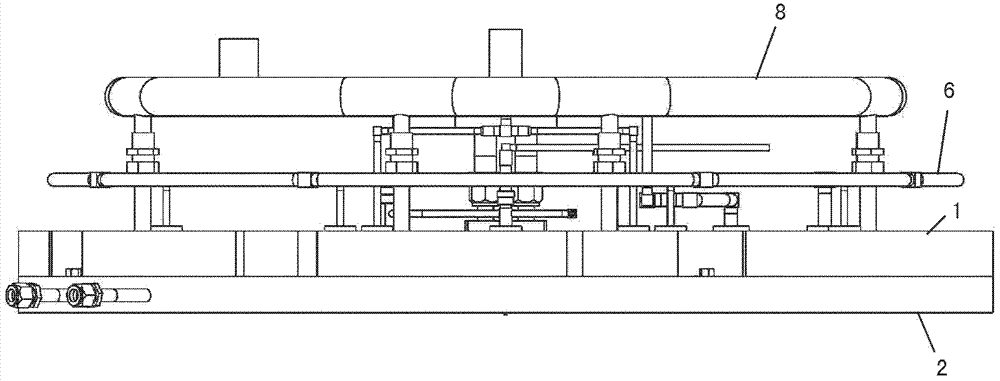

[0050] Figures 1 to 25 A showerhead showing one embodiment of the present invention can be used on a large diameter MOCVD reactor.

[0051] Such as figure 1 As shown, in an embodiment of the present invention, the shower head includes a top assembly 1 , a cooling water ring 2 , and a spray assembly 3 . The top assembly 1, the cooling water ring 2, and the spray assembly 3 will be described respectively below, and then the overall structure of the spray head will be described.

[0052] Such as Figure 9 , Figure 10 , Figure 11As shown, the top assembly 1 includes an upper cover plate 11 and a distribution orifice plate 12 , and the distribution orifice plate 12 is detachably connected to the upper cover plate 11 . The distribution orifice plate 12 includes four equally divided orifice plates 121 , and the four orifice plates 121 have the same structure, and the following description on one orifice plate 121 is also applicable to the other three orifice plates 121 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com