A kind of drilling method of porous copper ingot for niobium-three-tin superconducting wire

A technology of superconducting wire and drilling method, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. It can solve the problems of small spacing and poor deformation of core wires, and achieve reduction in quantity, Improve the effect of poor deformation and optimize distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1, select an oxygen-free copper rod with a diameter of Φ200mm, and saw and cut it to obtain an oxygen-free copper ingot with a length of 300mm;

[0022] In step 2, the oxygen-free copper ingot obtained in step 1 is clamped on a lathe, and the end surface is processed to be smooth. Use the method of deep hole drilling to drill 2 layers of through holes from one end, the diameter of the innermost layer is Φ14mm, and the diameter of the outermost layer is Φ25mm, and the number of holes in each layer is the same as 20, which are radially distributed.

Embodiment 2

[0024] Step 1, select an oxygen-free copper rod with a diameter of Φ250mm, and cut it to obtain an oxygen-free copper ingot with a length of 800mm;

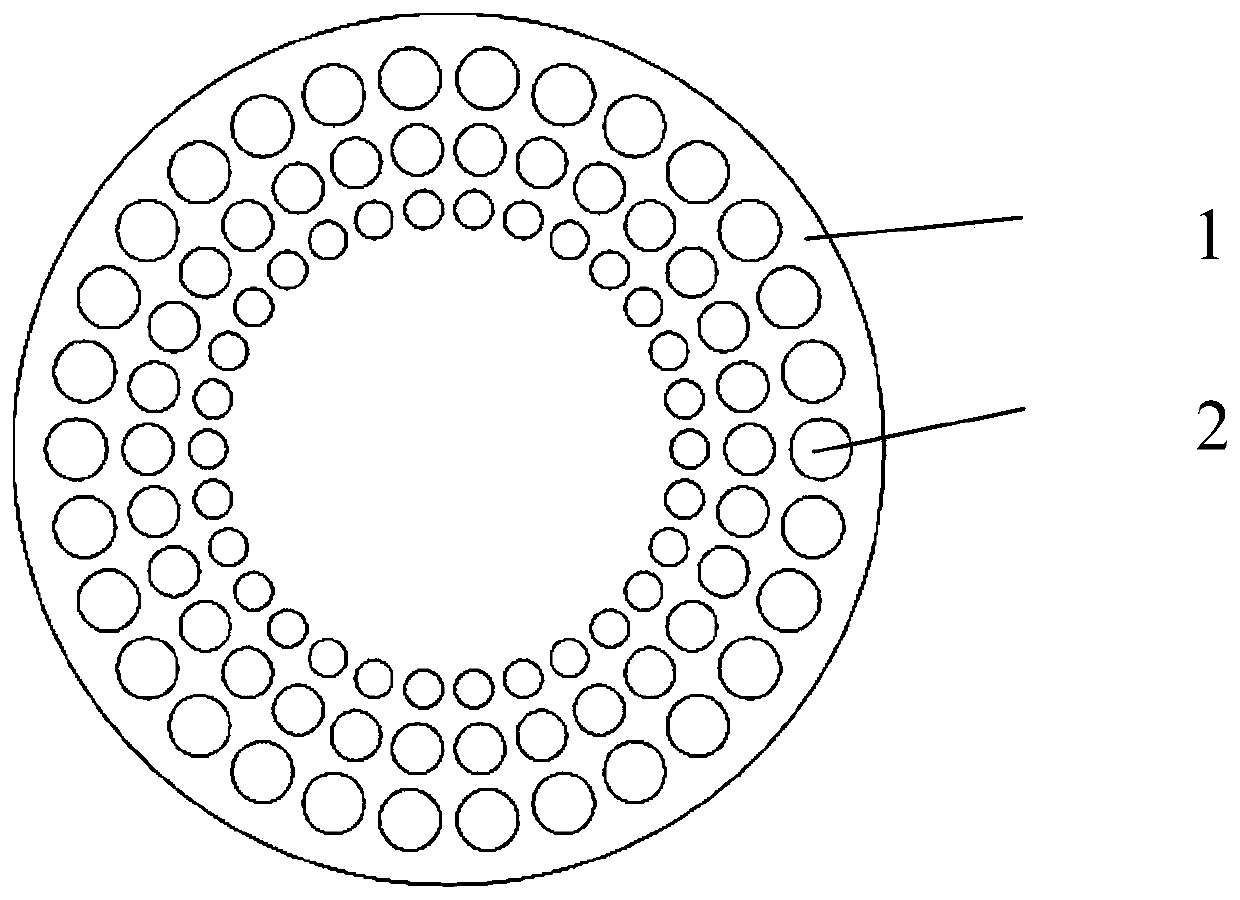

[0025] In step 2, the oxygen-free copper ingot obtained in step 1 is clamped on a lathe, and the end surface is processed to be smooth. Use the method of deep hole drilling to drill 3 layers of through holes from one end, the diameter of the innermost layer is Φ10mm, the diameter of the outermost layer is Φ20mm, and the number of holes in each layer is the same as 30, which are radially distributed. The cross-section of the prepared porous copper ingot, such as figure 1 shown.

Embodiment 3

[0027] Step 1, select an oxygen-free copper rod with a diameter of Φ300mm, and cut it to obtain an oxygen-free copper ingot with a length of 500mm;

[0028] In step 2, the oxygen-free copper ingot obtained in step 1 is clamped on a lathe, and the end surface is processed to be smooth. Use deep hole drilling method to drill 4 layers of through holes from one end, the diameter of the innermost layer is Φ8mm, the diameter of the outermost layer is Φ15mm, the number of holes in each layer is the same as 50, and they are radially distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com